Collaborative robot safety control method based on vision

A safety control and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of high cost of force sensors, the environment that does not consider the presence of people, and the cost increase of collaborative robots, so as to promote application promotion and versatility Good, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

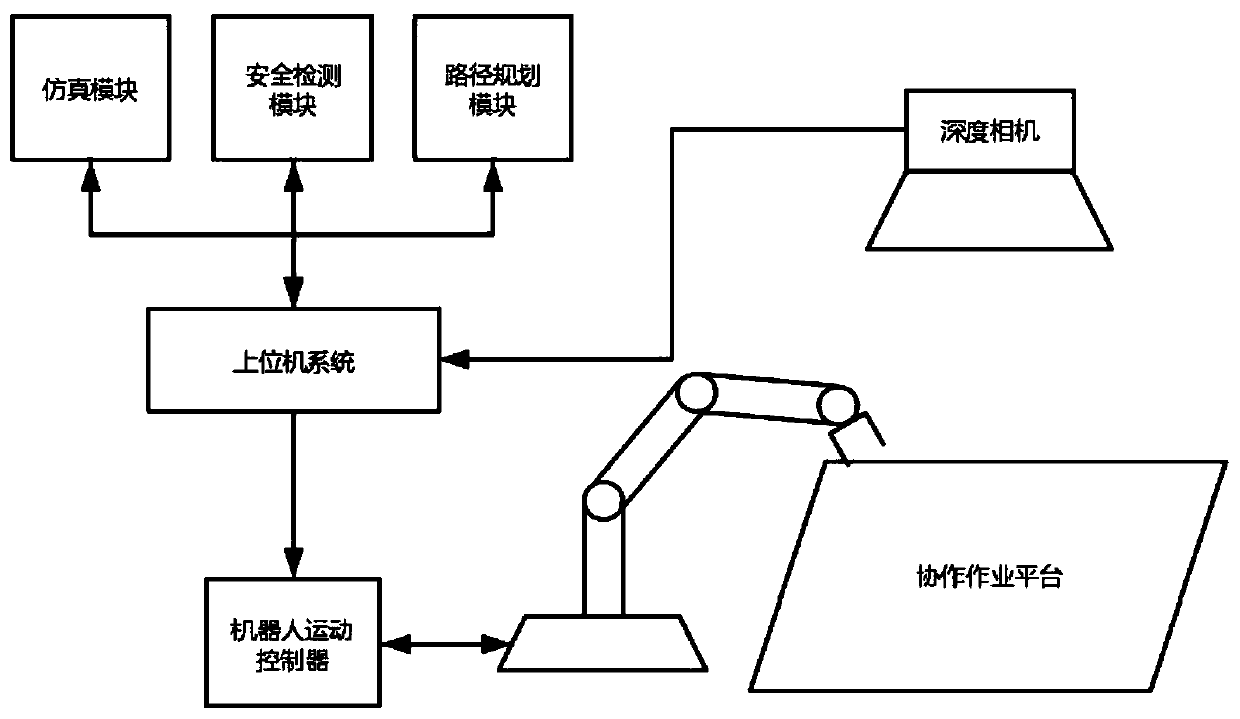

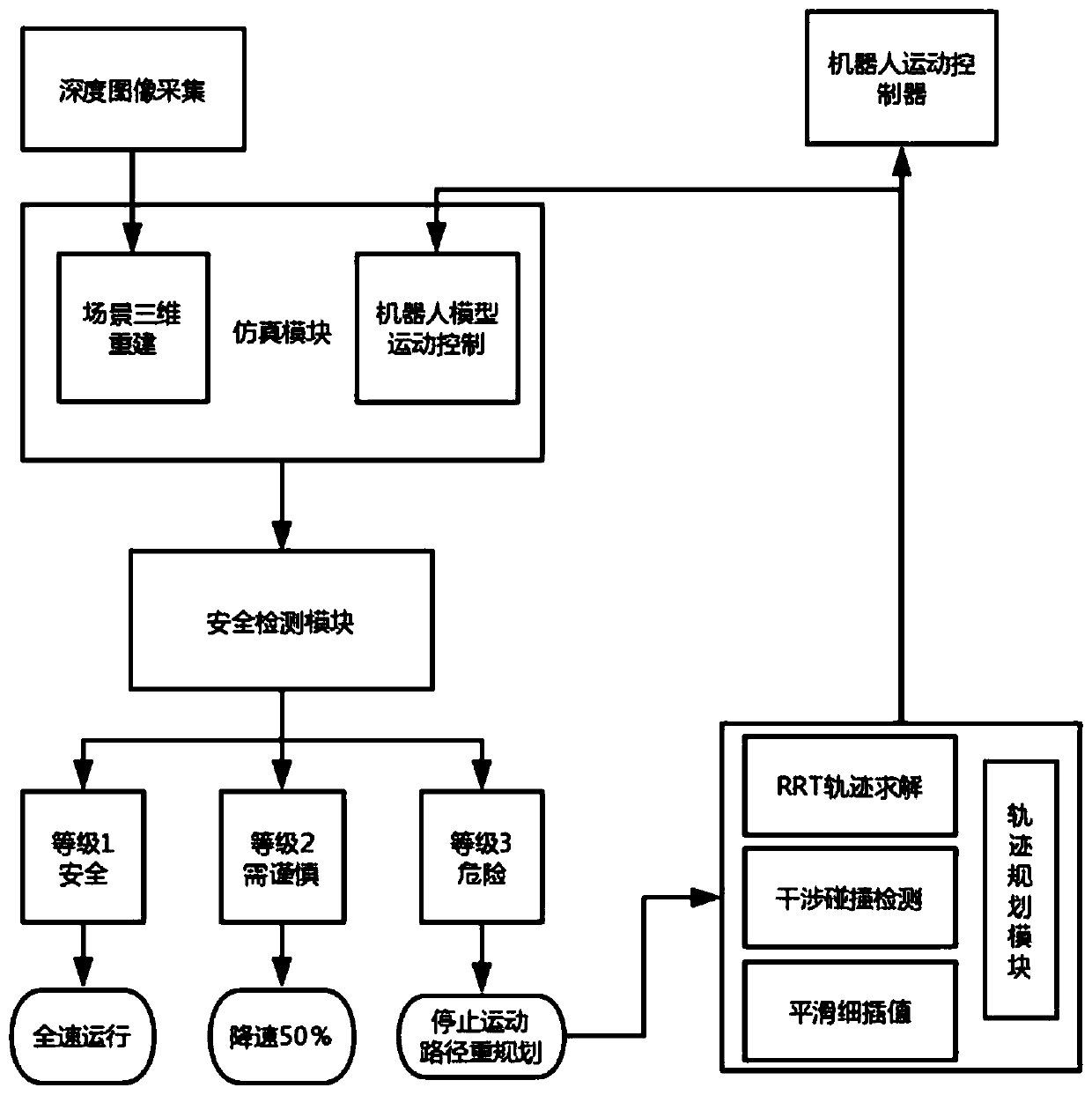

[0033] refer to figure 1, the applicable implementation routine of this method includes: a depth vision sensor, an industrial robot and its motion controller, and a host computer. Among them, the depth vision sensor is installed on the upper side of the collaborative operation scene, and the field of vision covers the collaborator, the robot arm, and the work area, and the depth vision information is sent to the host computer through the network cable interface. As the actual control object of the industrial robot, its motion controller receives the path points sent by the host computer and performs fine interpolation and joint space conversion to control the robot to move according to the planned trajectory. The method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com