Track teaching and planning method of master-slave mode multi-robot cooperative system

A multi-robot, master robot technology, applied in the field of industrial robots and flexible manufacturing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

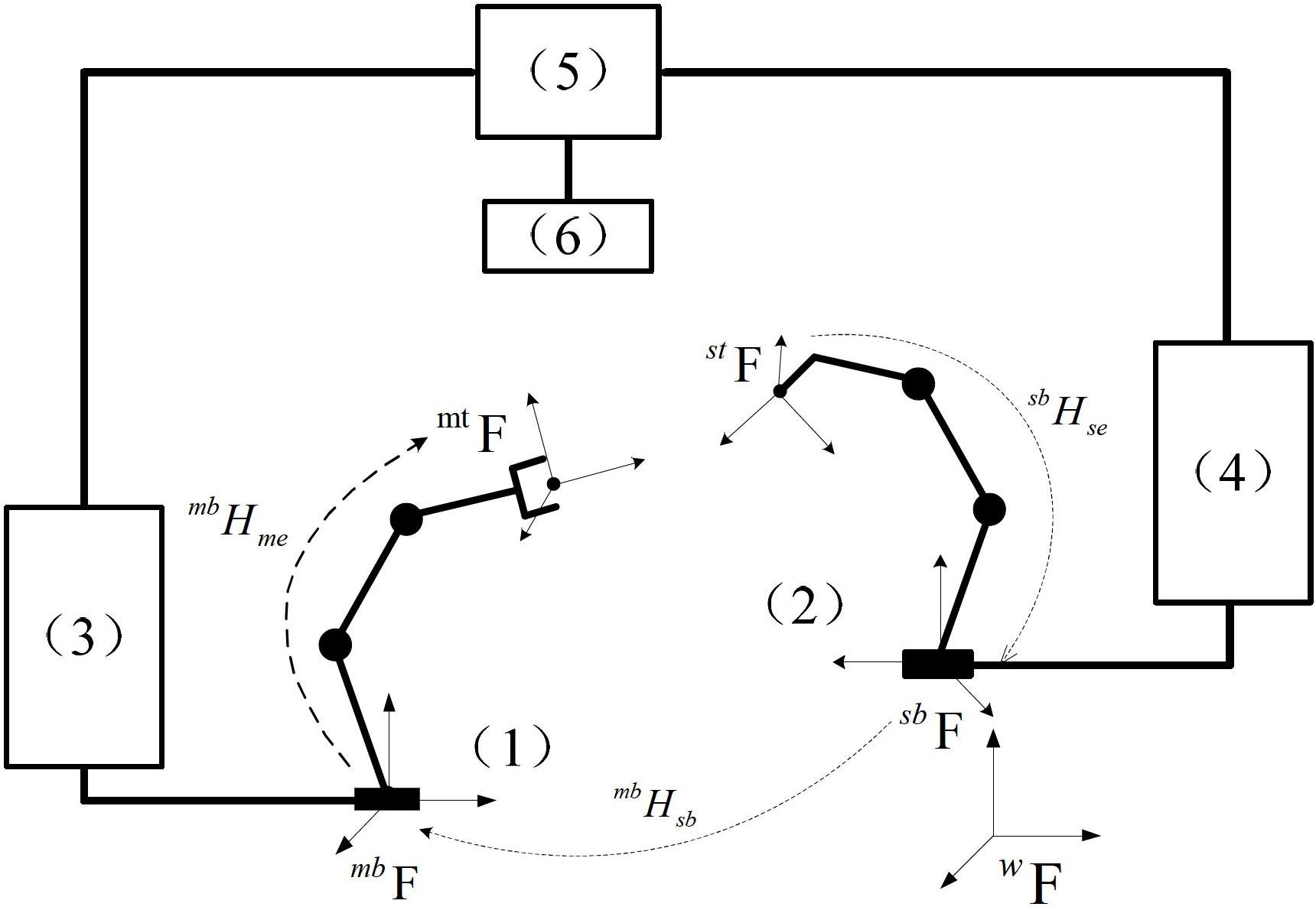

[0061] The hardware basis of the present invention is attached figure 1 As shown, a master robot 1 and a slave robot 2, in the figure is the base coordinate system of the main robot, is the tool hand coordinate system of the main robot, is from the base coordinate system of the robot, is from the robot tool hand coordinate system, The homogeneous transformation matrix from the main robot tool hand coordinate system to the main robot base coordinate system, is the homogeneous transformation matrix from the robot tool hand coordinate system to the robot base coordinate system, is the homogeneous transformation matrix from the robot base coordinate system to the main robot base coordinate system. There can be multiple slave robots during use, and only one slave robot is used for illustration here. When there are multiple slave robots, a sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com