Patents

Literature

68 results about "Production drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production drawings (sometimes called working drawings) are complete sets of drawings that detail the manufacturing and assembly of products (as distinct from engineering drawings prepared by and/or for production engineers whose task is to decide how best to manufacture the products).

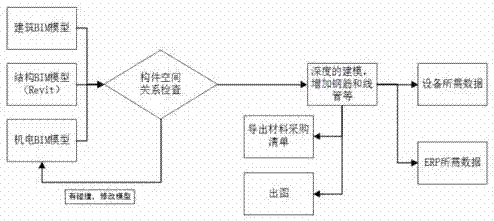

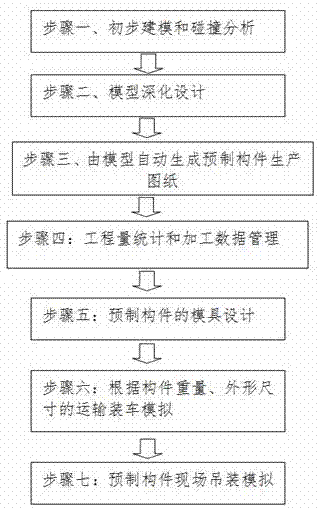

Assembled building deepening design method based on BII software

ActiveCN107967399AImprove accuracyImprove efficiencyGeometric CADSpecial data processing applicationsProduction drawingCollision analysis

The invention provides an assembled building deepening design method based on BII software. The assembled building deepening design method comprises the following steps of 1, conducting preliminary modeling and collision analysis; 2, conducting model deepening design; 3, automatically generating member production drawing through a model; 4, conducting engineering amount statistics and processing data management; 5, designing a mold of a prefabricated member; 6, conducting transportation vehicle-loading simulating and optimizing according to the member weight and the profile size; 7, conductingfield hoisting and simulating of the prefabricated member, and optimizing the hoisting sequence. Aiming at defects of an existing prefabricated member deepening design method, it is adopted that firstly, a three-dimensional model is modeled before deepening design drawing is drawn, a three-dimensional examination method is adopted, after the space conflict relation between the prefabricated member is excluded, the drawing is generated, a large amount of modification of the drawing is avoided, parts in the model all have the accurate three-dimensional size, material information and member subordination relationship, a member material list can be generated simply by conveying the information, and thus an accurate and efficient effect is achieved.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

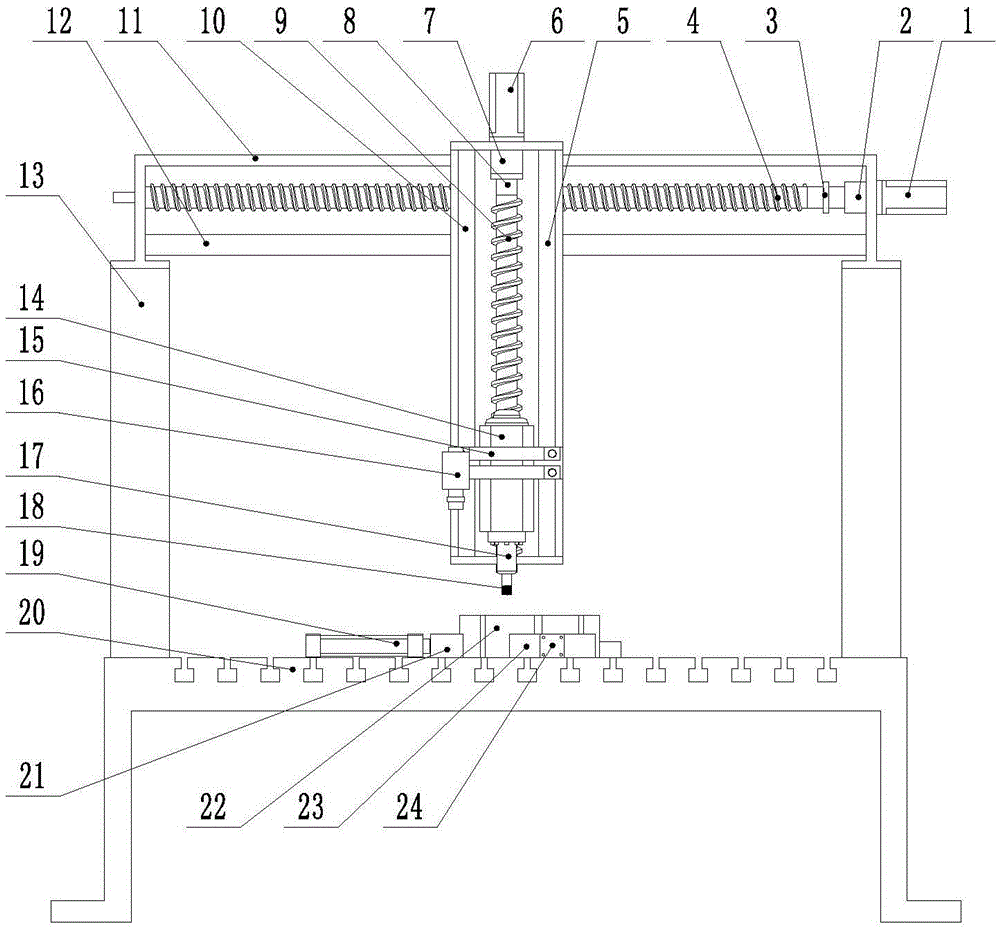

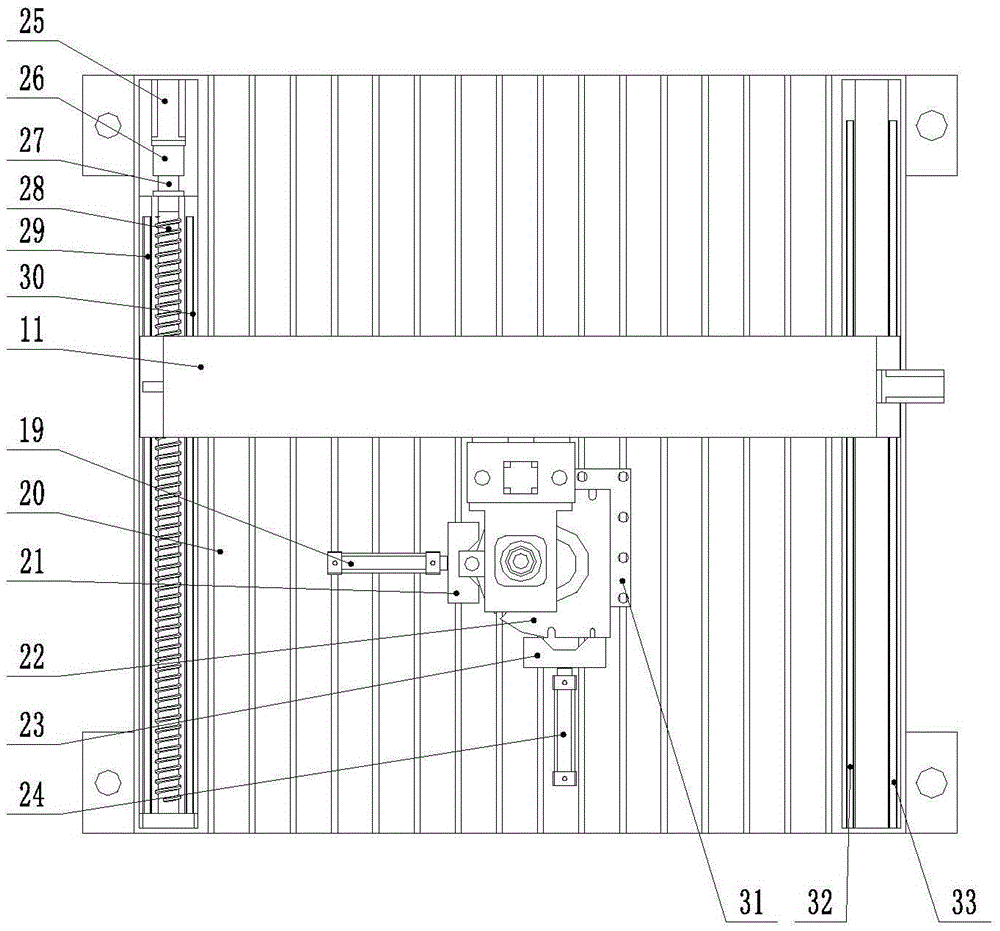

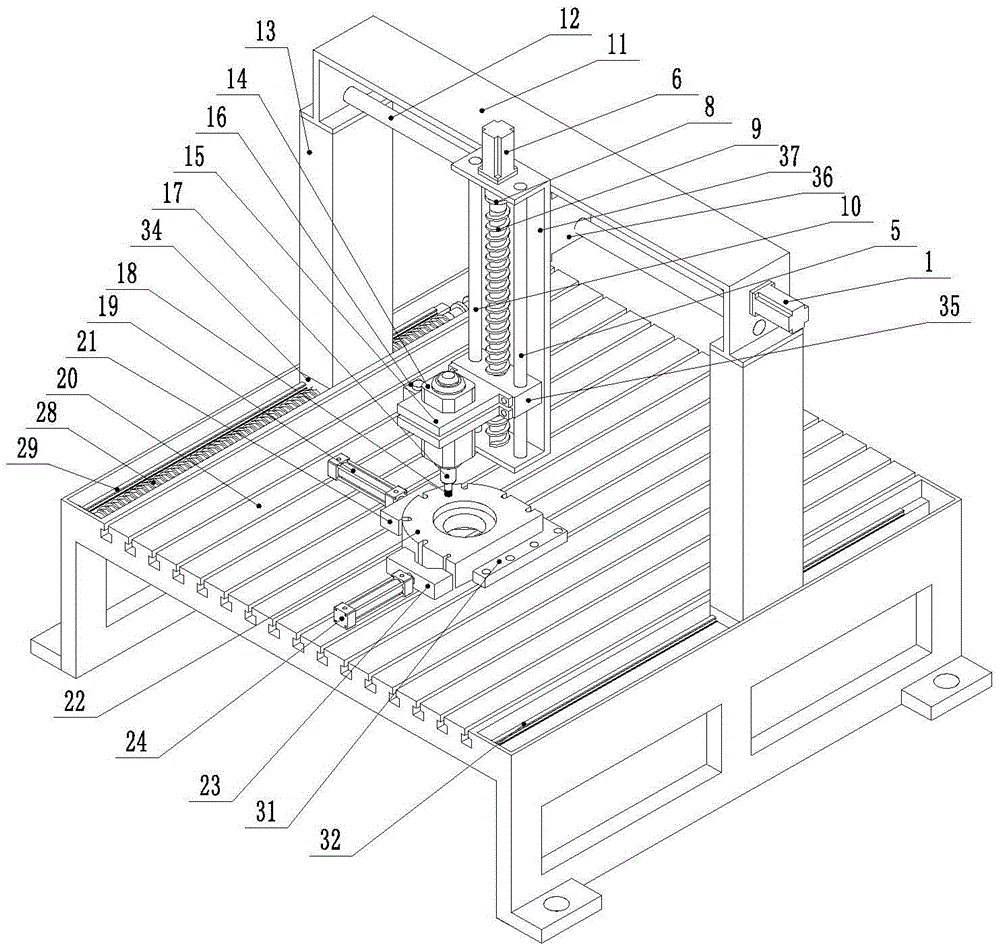

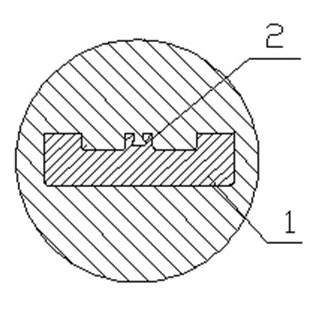

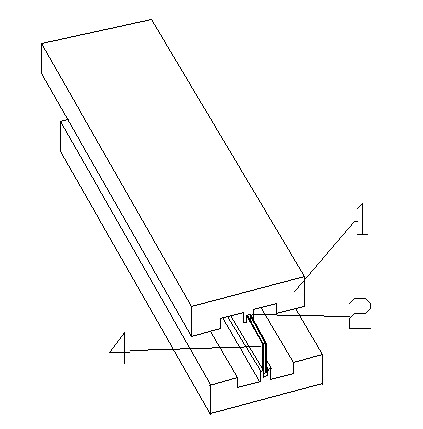

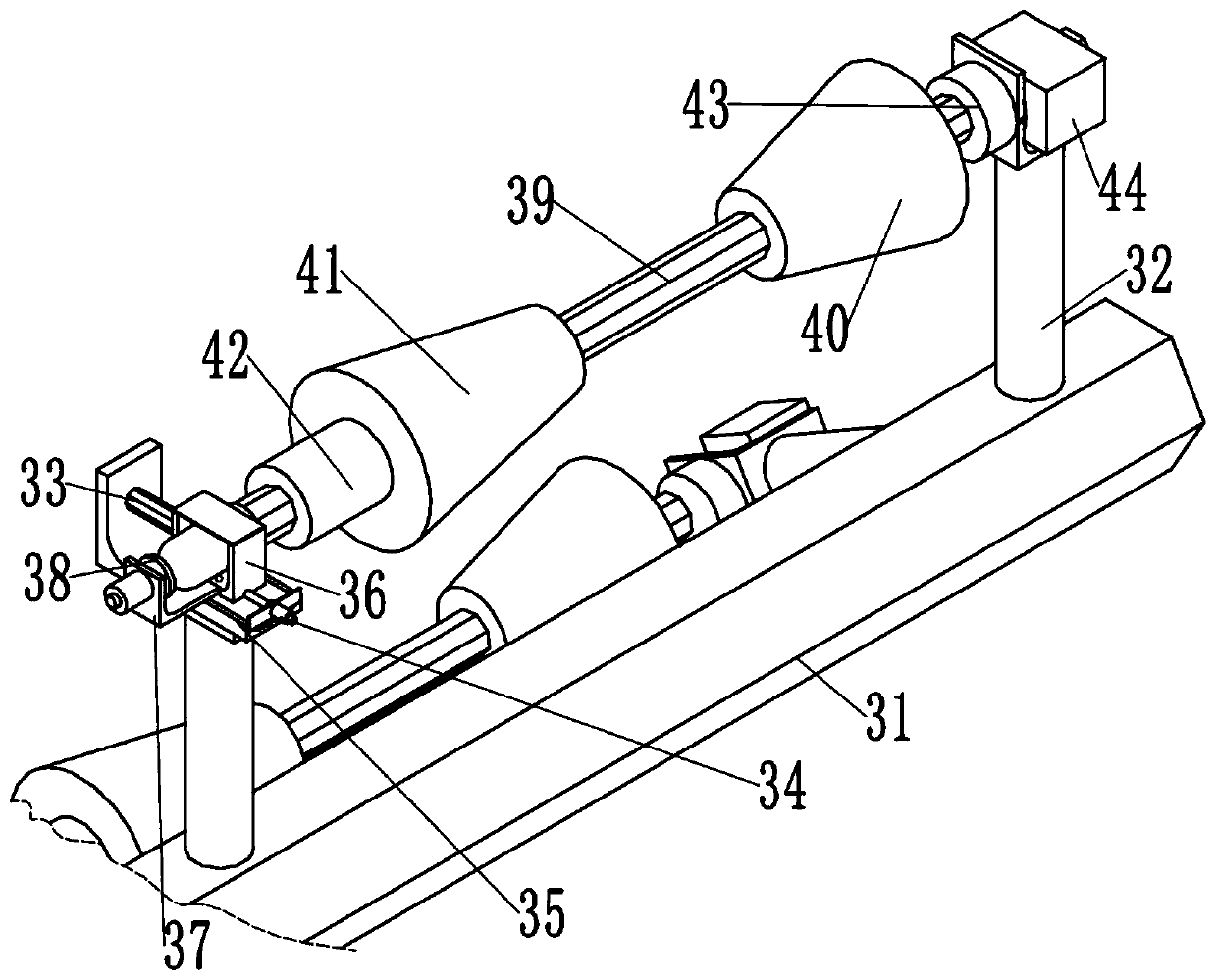

Workpiece clamping structure for grinding tool, and tracking type casting edging machine and method

InactiveCN105598777ASo as not to damageImprove uneven lightingEdge grinding machinesGrinding wheel securing apparatusProduction drawingControl system

The invention discloses a workpiece clamping structure for a grinding tool, and a tracking type casting edging machine and method. The workpiece clamping structure comprises a workbench, the workbench is provided with a plurality of positioning devices, at least one positioning device comprises a cylinder and a clamping block, and the clamping blocks clamp or leave a workpiece to be machined, under the action of cylinder piston rods. The tracking type casting edging machine comprises a bed, a moving mechanism, a grinding head assembly, the above-mentioned workpiece clamping structure, an industrial camera, a visual recognition system and a control system. The edging machine can quickly grind flash and burrs on a casting according to the requirements of a production drawing and the shape and size of the casting, without programming and equipment adjusting during casting replacement, the production efficiency is high, and machining error is small.

Owner:UNIV OF JINAN

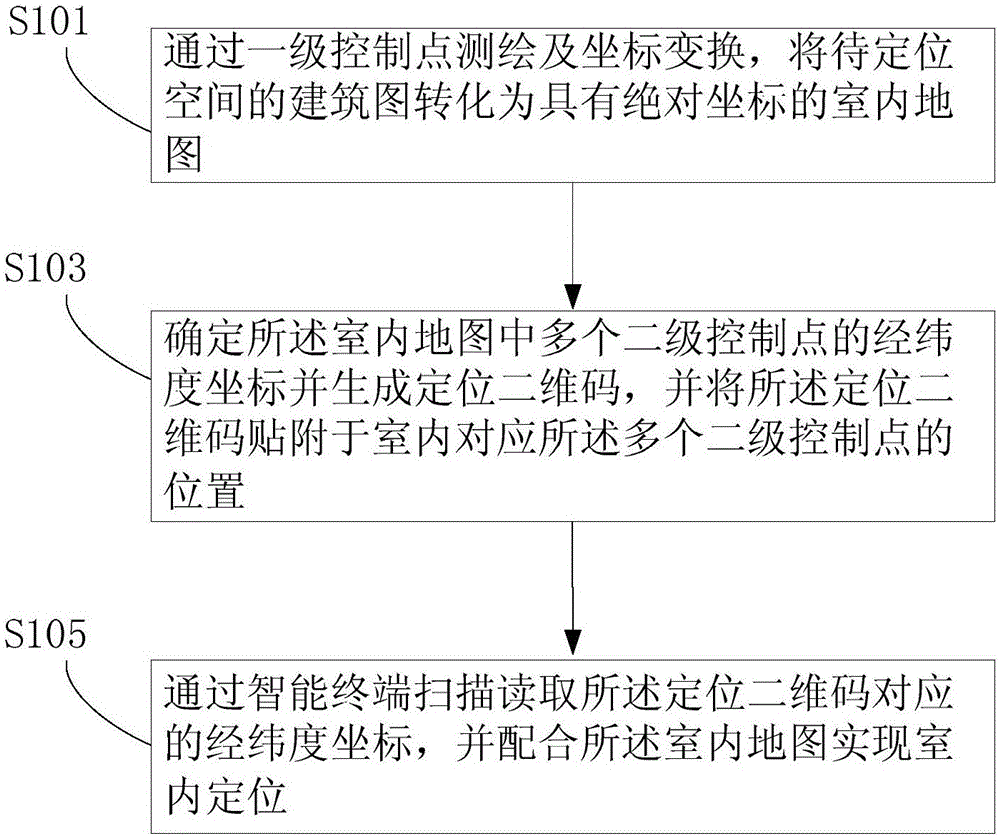

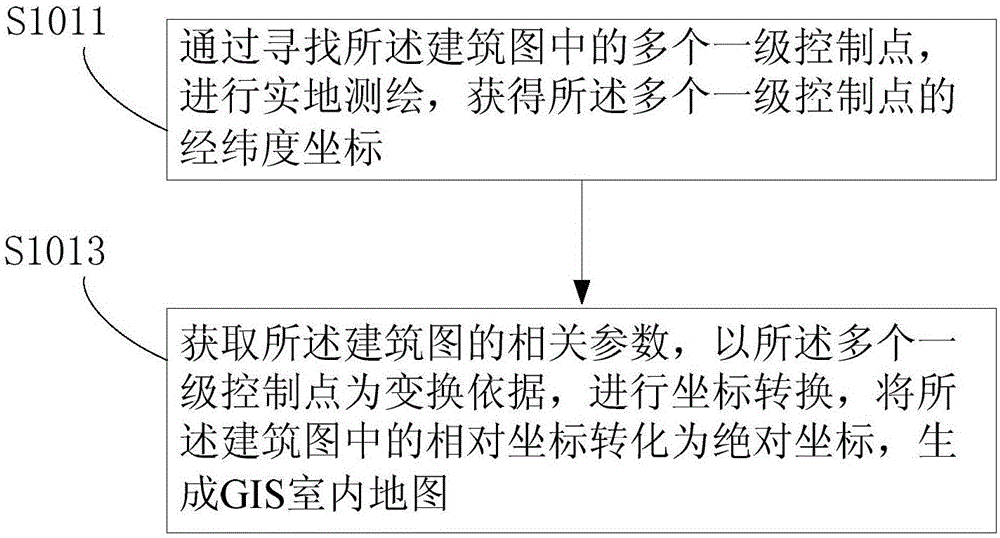

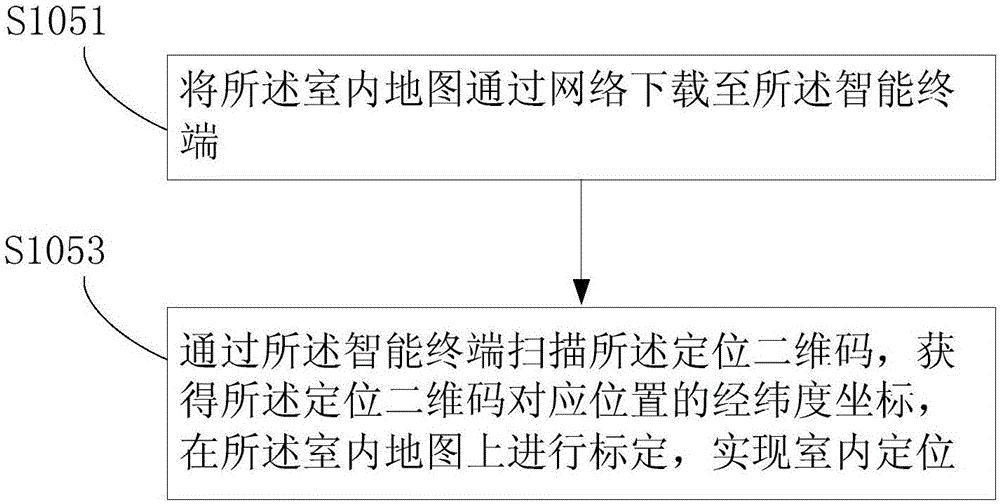

Indoor positioning method and system

InactiveCN105115506AReduce work intensityLow costNavigational calculation instrumentsProduction drawingLongitude

The invention provides an indoor positioning method. The method comprises the following steps: S101: an architectural drawing (a design drawing, a production drawing, an effect picture and the like) of a space to be positioned is converted into an indoor map with an absolute coordinate through first-grade control point plotting and coordinate transformation; S103: latitude and longitude coordinates of multiple second-grade control points in the indoor map are determined, positioning two dimensional codes are generated, and the positioning two dimensional codes are attached to positions corresponding to the multiple second-grade control points indoors; S105: the latitude and longitude coordinates corresponding to the positioning two dimensional codes are scanned and read through an intelligent terminal, and indoor positioning is achieved in cooperation with the indoor map. The invention provides an indoor positioning system. The provided indoor positioning method converts the architectural drawing into an indoor map through coordinate transformation, the working intensity of manual plotting is lowered effectively, and the working efficiency is raised. In addition, indoor positioning is carried out by utilization of two dimensional codes on this basis, the method is simple and convenient, and the cost can be lowered effectively.

Owner:SHENZHEN INST OF ADVANCED TECH

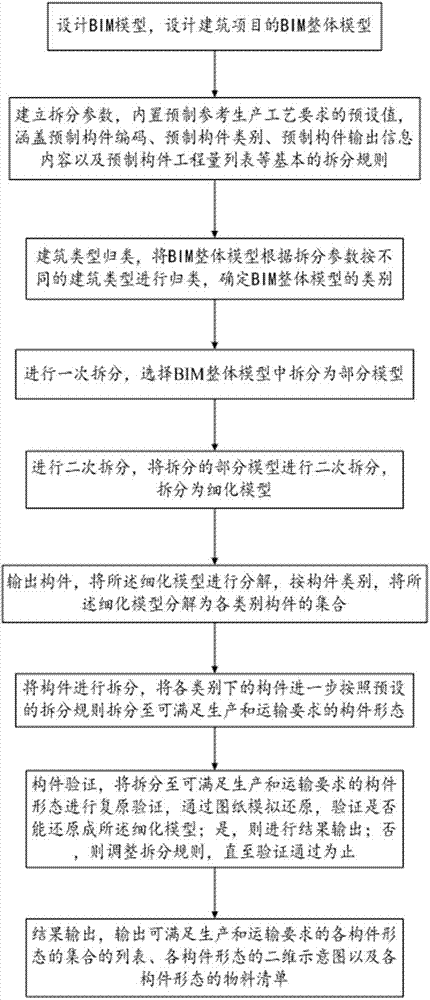

Automatic prefabricated part splitting method based on BIM and computing device

InactiveCN107545120ARealize the purpose of one-key split designImprove accuracySpecial data processing applicationsProduction drawingComputer science

The invention provides an automatic prefabricated part splitting method based on BIM and a computing device. The method comprises the steps that an overall BIM of a building project is designed, splitting parameters are built, and splitting rules for the number, the classification, the output information content and the project amount of a prefabricated part are made according to the preset splitting parameters; the overall BIM is classified according to the splitting parameters, and a building type is determined, so that mistakes are prevented from being made in the subsequent splitting process; the overall BIM is split into refined models step by step through two-time splitting, and in the subsequent part verification process, only part of models need to be verified, and the overall model does not need to be verified, so that the work efficiency is improved; the overall BIM is decomposed into a set of various parts and split into the minimum units meeting the production manufacturingand transporting requirements, and the part shapes are subjected to restoration verification, so that splitting errors are avoided; a production drawing of the part shapes is directly output, and theaim of one-key splitting design of the prefabricated part is achieved with the combination of the splitting requirements of the prefabricated part. Therefore, the accuracy and the efficiency for designing the drawing of the prefabricated part based on the BIM are improved.

Owner:CSCEC STRAIT CONSTR & DEV +1

Engineering project division method capable of quickly and accurately carrying out valuation

ActiveCN107301527AFast and Accurate ValuationFast and Accurate VerificationOffice automationSpecial data processing applicationsProduction drawingConstruction management

The invention relates to an engineering project division method capable of quickly and accurately carrying out valuation, and belongs to the field of engineering project management. Engineering project composition entity materials are subjected to classification and division, and the "quantity" and the "price" of the division contain all factors including a structure position, engineering materials, a construction scheme, construction management and the like; a coupling algorithm and a database corresponding to the "quantity" and "quantity" as well as the "quantity" and "price" of the traditional division of the same type of finished engineering project in a place where the engineering project entity material division and engineering projects are positioned are established, and the automatic mathematical statistics and the intelligent data mining of the "price" of the entity material division are realized; the engineering project preliminarily designs an estimate budget and a production drawing budget to carry out comparison and verification on the measurement value of the "price", practical generation values including bid price, settlement price, final settlement price and the like in bidding and tendering and the statistic value of the "price" to realize the utilization and the verification of the "price" in a basic construction whole process including the estimation value in a decision stage, the measurement value in a design stage, the practical value in a construction stage and the like, the "quantity" of an entity (material) subitem is automatically realized by a BIM (Building Information Modeling) model, and the quick and accurate valuation of the engineering project is realized.

Owner:KUNMING UNIV OF SCI & TECH

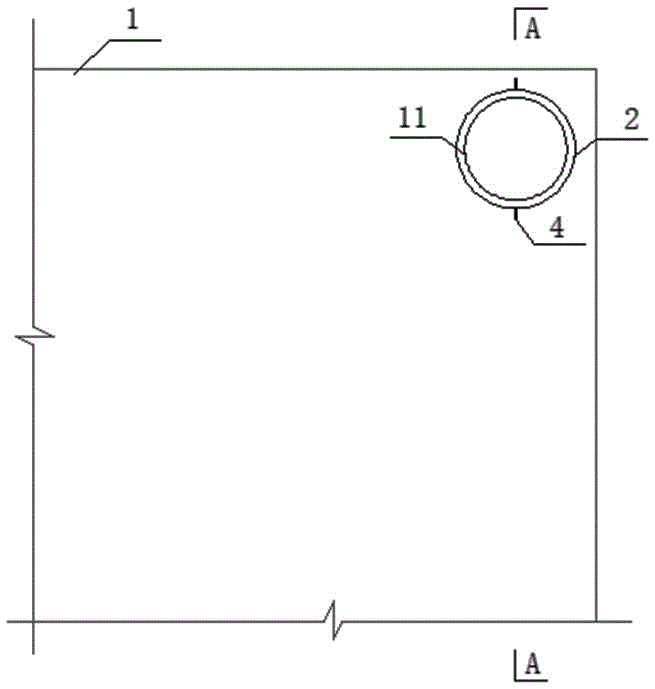

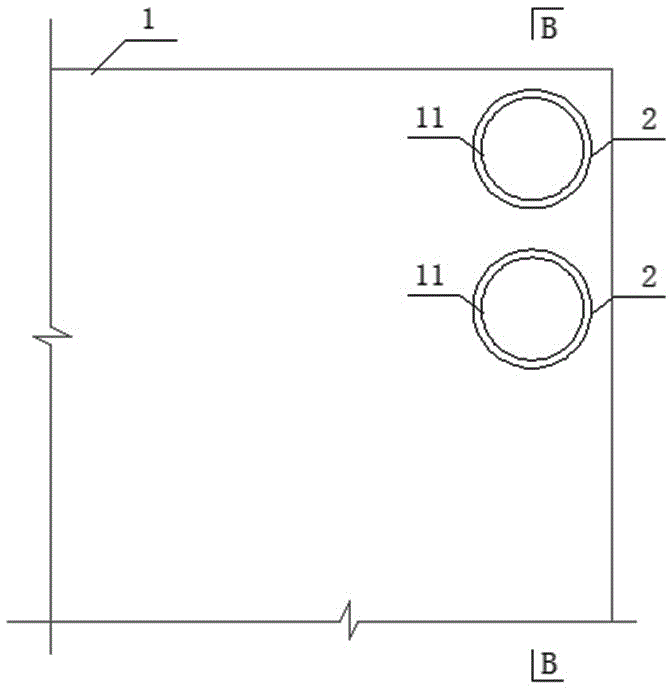

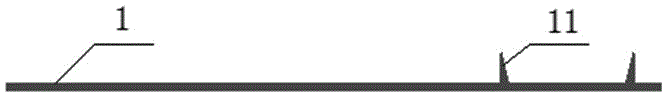

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

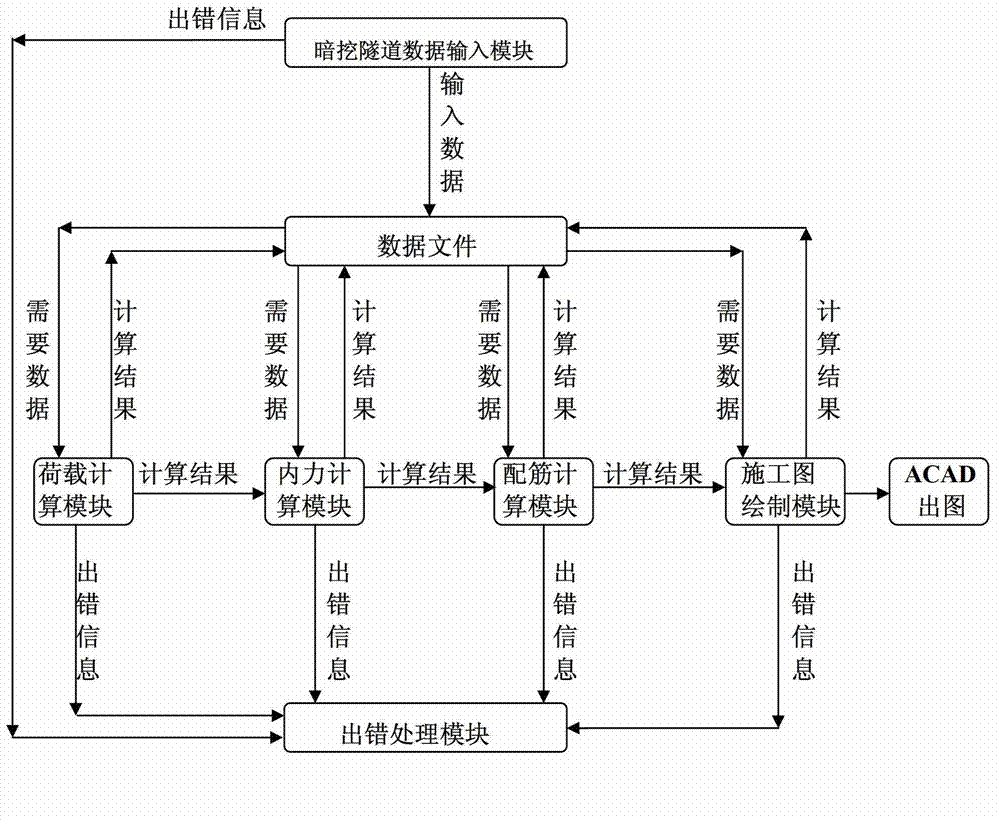

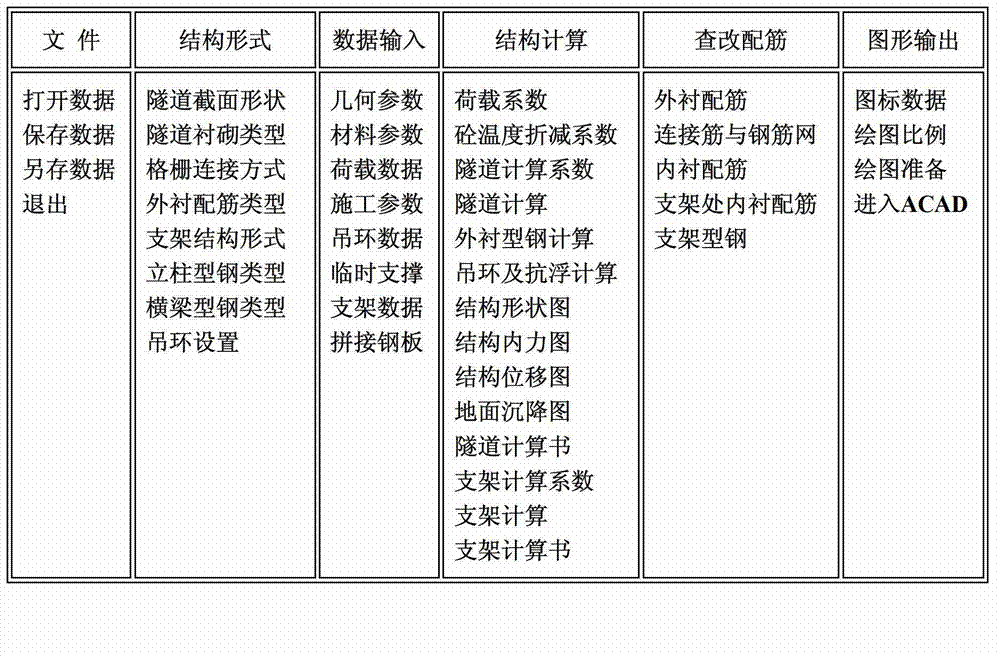

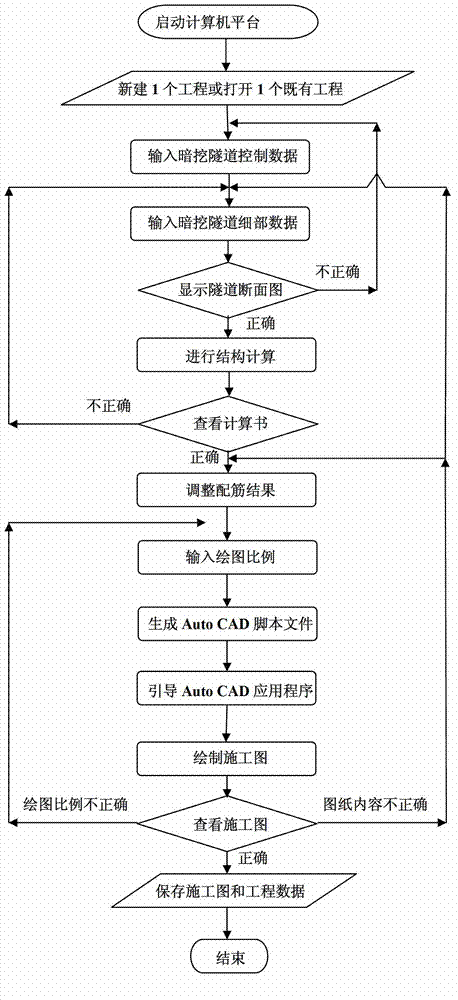

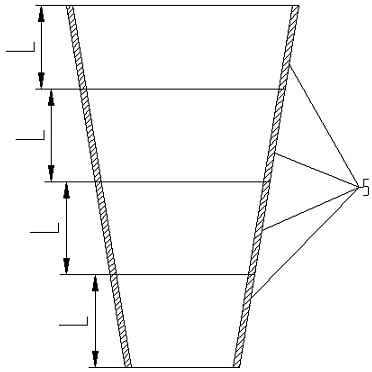

Data processing method for heat engineering shallow tunnel structure and Computer-Aided Design (CAD) system

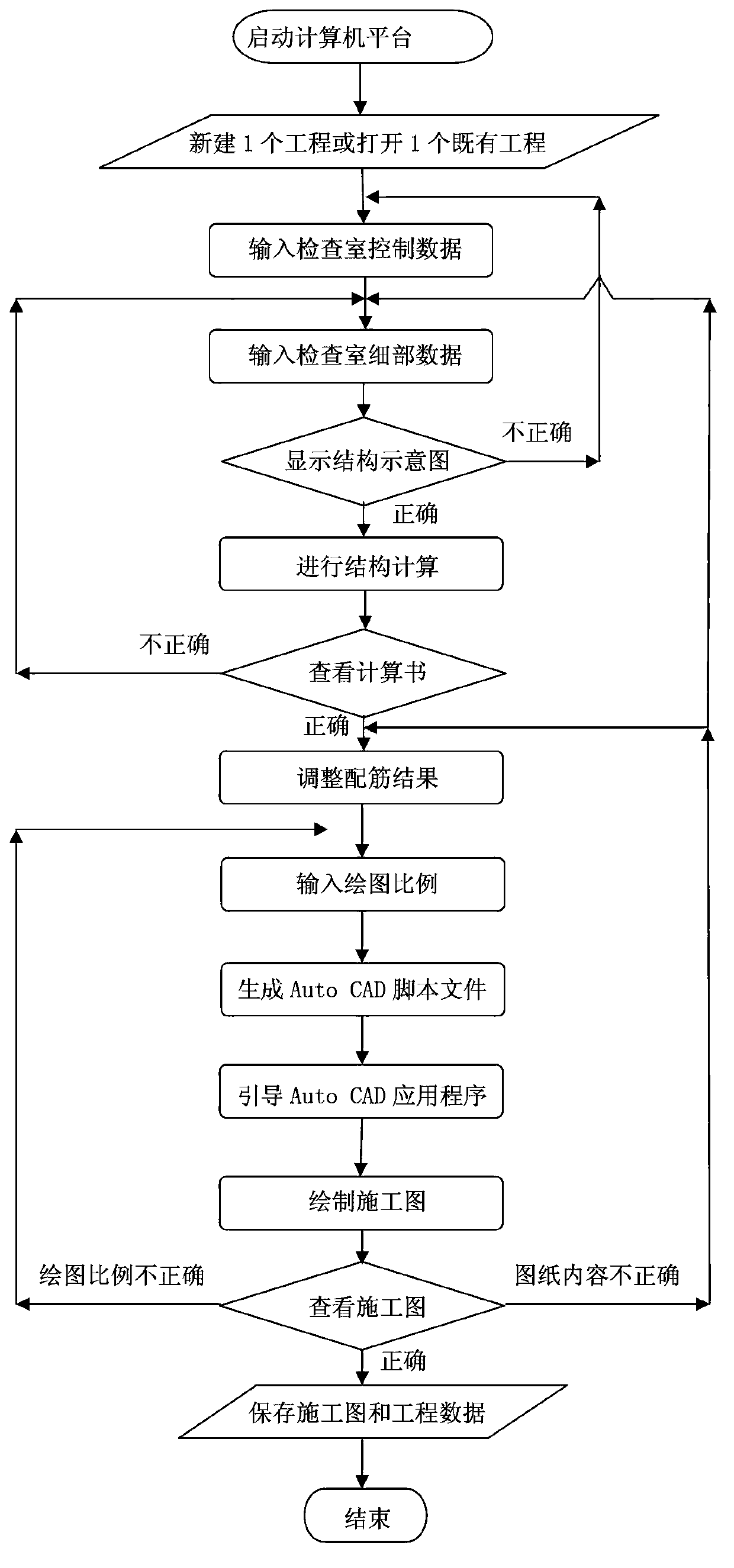

ActiveCN103093050AImprove drawing efficiencySpeed up the construction cycleSpecial data processing applicationsComputer Aided DesignStructure chart

The invention discloses a data processing method for a heat engineering shallow tunnel structure and a computer-aided design (CAD) system. The data processing method for the heat engineering shallow tunnel structure and the CAD system are beneficial for shortening a construction cycle of a shallow tunnel and guaranteeing the construction quality of the shallow tunnel. The data processing method for the heat engineering shallow tunnel structure is characterized by including the following steps: (1) building a new shallow tunnel project template or opening an existing shallow tunnel project template on a computer platform, (2) inputting shallow tunnel structure data selected or determined by a designer, (3) displaying a shallow tunnel structure chart according to the shallow tunnel structure data, judging the correctness of the shallow tunnel structure data according to the shallow tunnel structure chart, (4) conducting structural calculation of the shallow tunnel determined by the shallow tunnel structure data, (5) repeating the step (2)-(4) until obtaining results complying with a design requirement if the computed results of the structure fail to comply with the design requirement, (6) and determining or drawing a shallow tunnel production drawing according to the results complying with the design requirement, and inputting the shallow tunnel production drawing through the Auto CAD.

Owner:BEIJING TEZE HEATING PROJECT DESIGN +1

Manufacturing method of knotless screen printing plate suitable for SE solar battery piece printing

InactiveCN109940974AImprove photoelectric conversion efficiencyScreen printersScreen printingProduction drawing

The invention provides a manufacturing method of a knotless screen suitable for SE solar battery piece printing. According to the manufacturing method, the knotless screen printing plate and the SE solar battery are perfectly combined, the advantages of the solar battery piece are brought into full play, the photoelectric conversion efficiency of the battery piece is better improved, after the prefabricated semi-finished product is free of the knotless screen printing plate, the digital comparison of the scanning screen printing plate image and the actual etching groove drawing paper is carried out, a production drawing corresponding to the overlapping part of the screen mesh and the etching groove on the screen is obtained, and then the laser cutting equipment is used for removing the screen mesh on the semi-finished mesh-free screen printing plate according to a production drawing used for cutting, so as to obtain a corresponding knotless screen printing plate.

Owner:昆山良品丝印器材有限公司

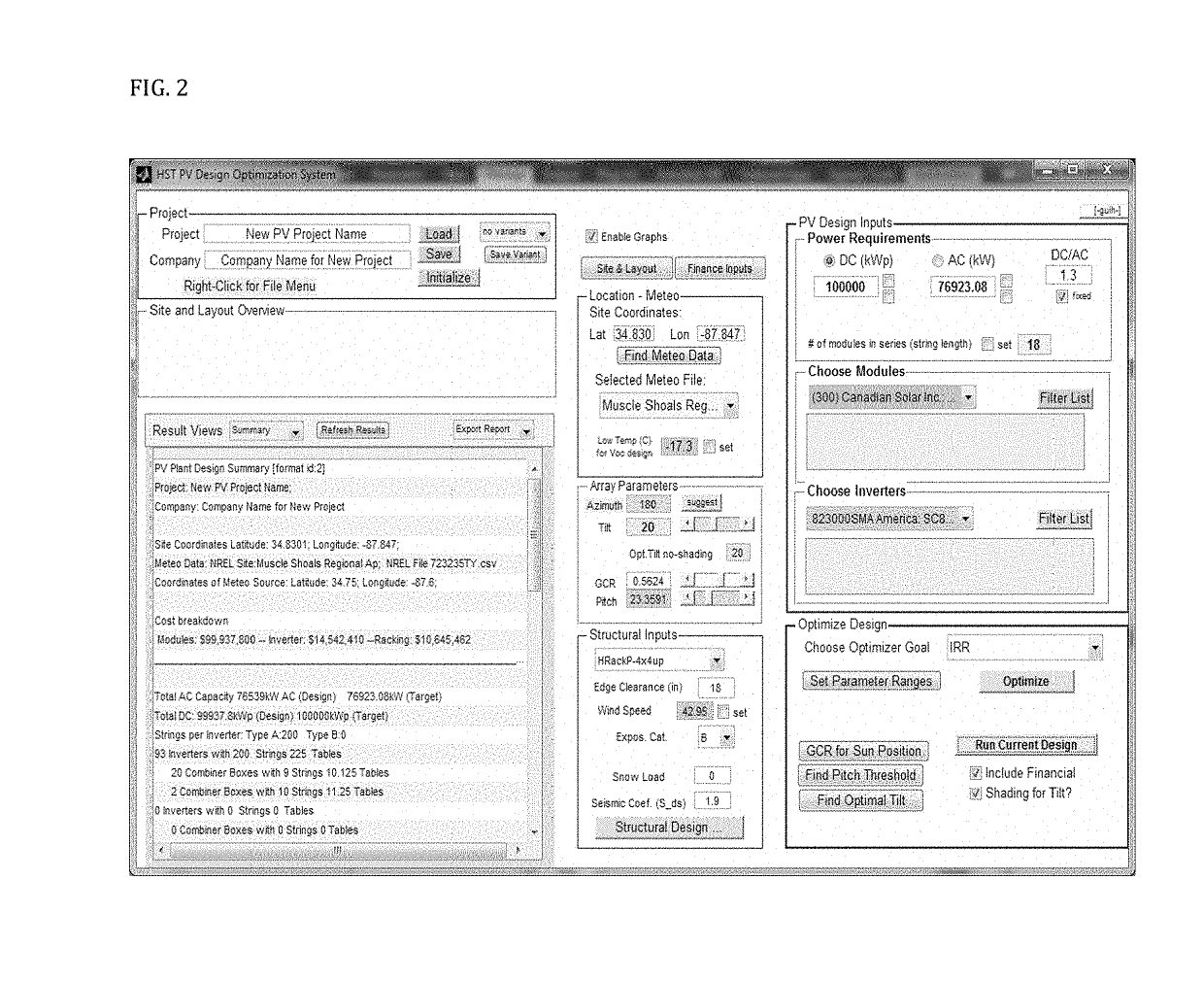

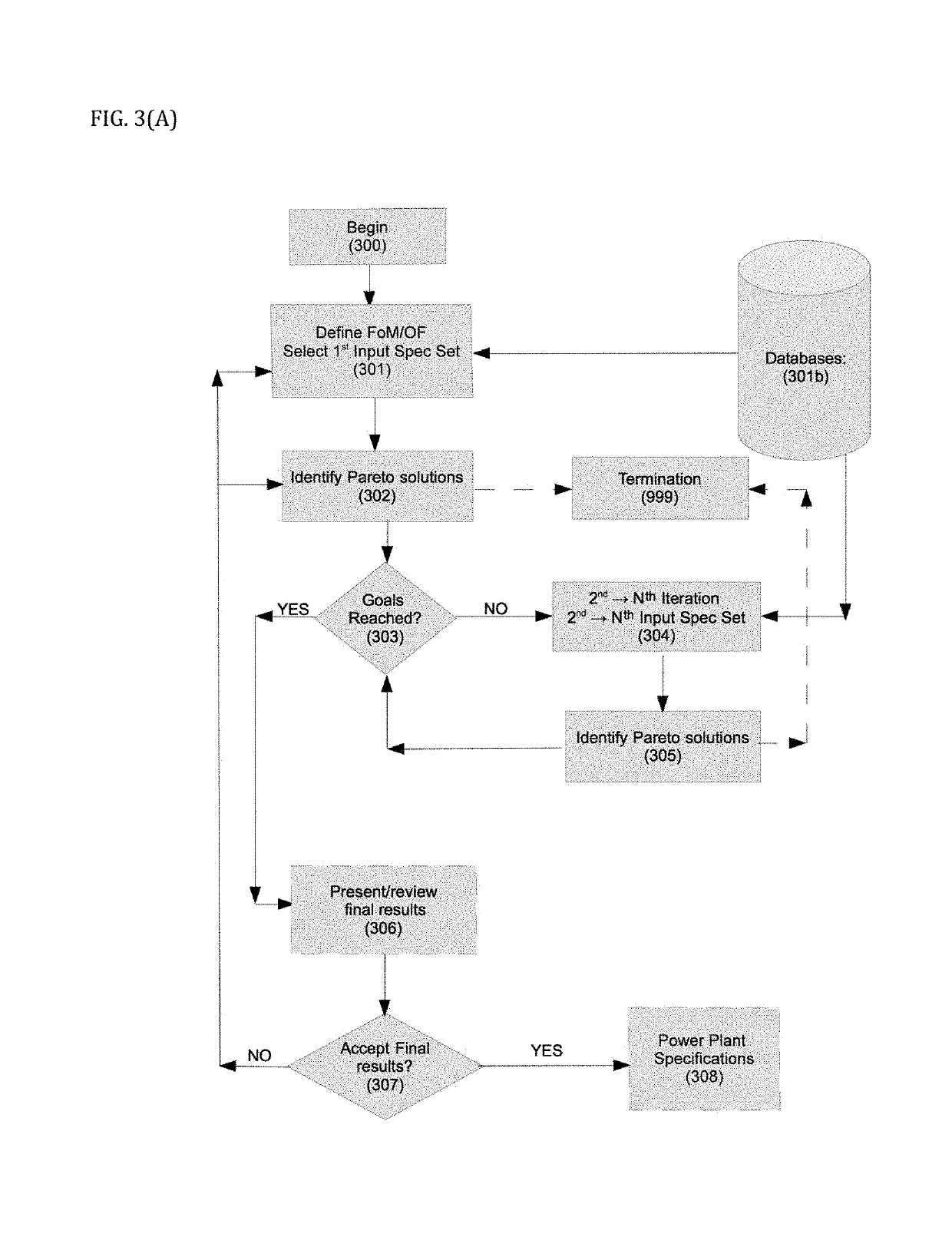

System and methods for solar photovoltaic array engineering

ActiveUS10289757B2Low costMaximizing overall rate of returnGeometric CADPhotovoltaic supportsSystems designBill of materials

The present application concerns automated optimization, customization or production methods for the design of a solar photovoltaic array, involving one or more or all components in a photovoltaic array, in which the products include system designs, production drawings, permitting and construction drawings, layouts for the mechanical and electrical systems, bill of materials and financial return analyses of such a photovoltaic array.

Owner:HST SOLAR FARMS

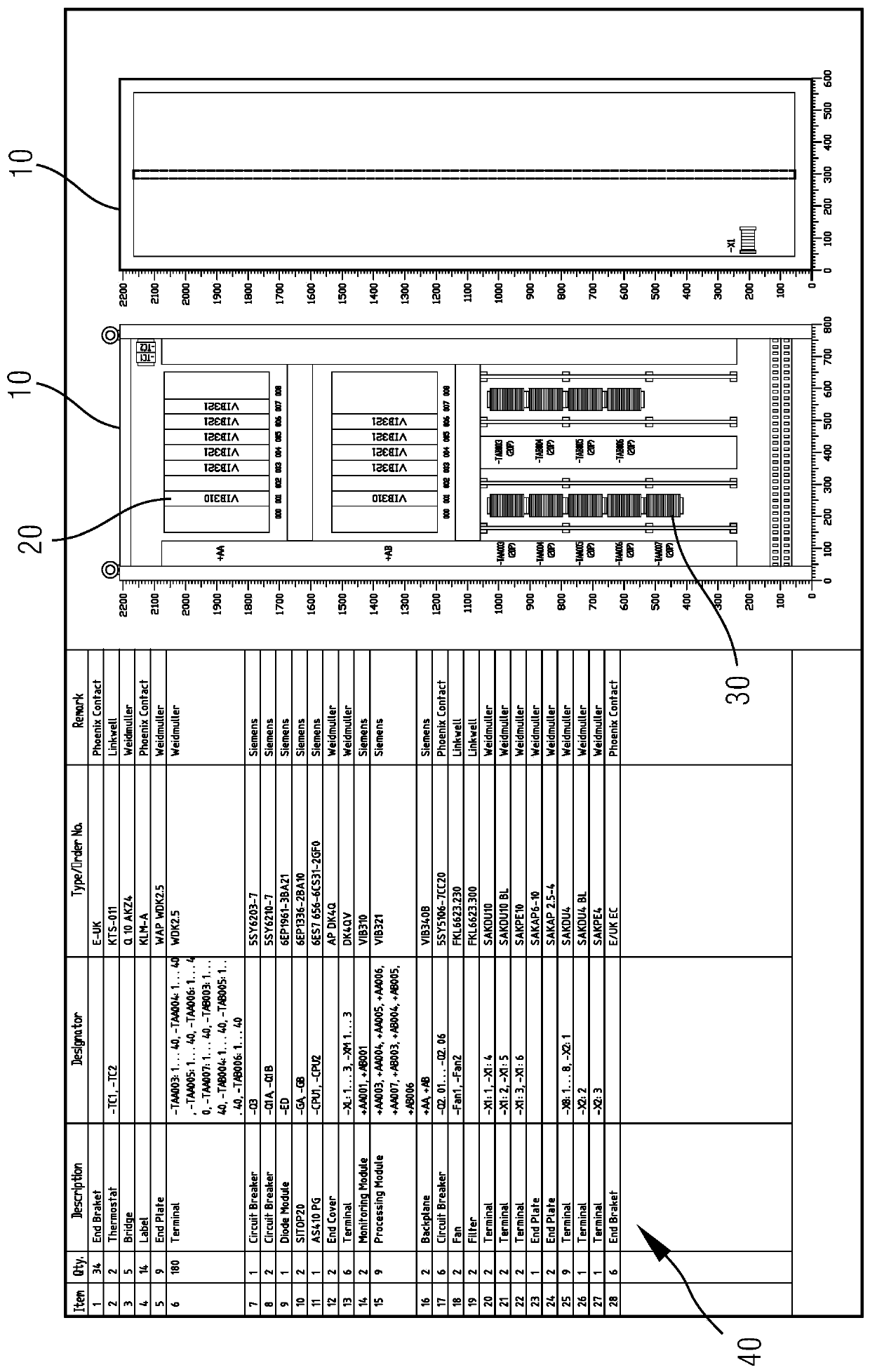

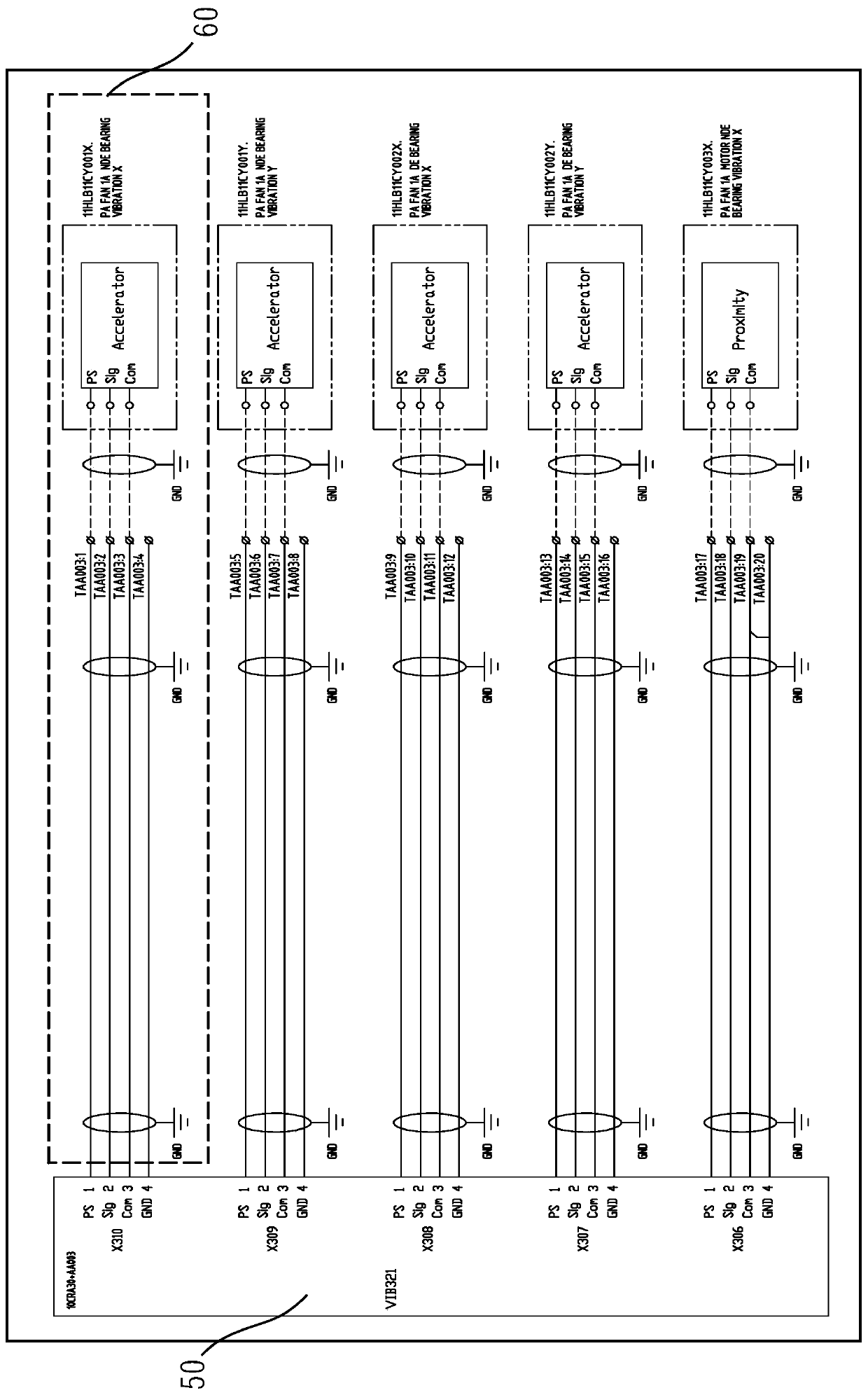

Method for generating a production drawing of a distributed control system

PendingCN110175363AIncrease productivityDesign optimisation/simulationLogisticsGraphicsProgram instruction

The invention discloses a method for generating a production drawing of a distributed control system. The method comprises the following steps of: drawing a drawing template through AutoCAD; drawing acomponent graph through AutoCAD, packaging the component graph and the corresponding component attribute information into a component graph block representing a component, and storing the component graph block in the drawing template; importing the equipment measuring point list into a database program; importing the reference coordinate table of the image block into a database program, and generating an image block arrangement coordinate table comprising the coordinates of the component image block and the attribute information of the component according to the equipment measuring point list; and enabling the AutoCAD connection data program to obtain a graph block arrangement coordinate table, and inserts the component graph blocks into a drawing template according to the graph block arrangement coordinate table through a program instruction to generate a drawing file. According to the method, AutoCAD can be used for automatically generating the production drawings in batches, and the production efficiency is improved.

Owner:SIEMENS POWER PLANT AUTOMATION

Method for controlling product quality according to standards

ActiveCN103455845AGuarantee the quality of managementData processing applicationsSpecial data processing applicationsProduction drawingQuality control

A method for controlling product quality according to standards is used for performing strict standard control when a design department of an enterprise provides production drawings for use of front-line workers and performing strict production drawing aging management when a production department carries out production, and a quality testing department carries out detailed comparison and verification of products, the production drawings and standard contents. According to the method for controlling the product quality according to the standards, components and parts serve as a unit for standard data management; when the standards are altered, designers can timely adjust and alter the production drawings, and production people can carry out management on the data accuracy of the production drawings in the producing process so that correspondence between the production drawings of a production front line and the standards can be ensured; when performing quality testing on the products, quality control personnel can accurately acquire the standards corresponding to the tested products and can perform quality testing on the products according to the latest standards; therefore, implementing of the standards can be ensured, and the product quality is guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

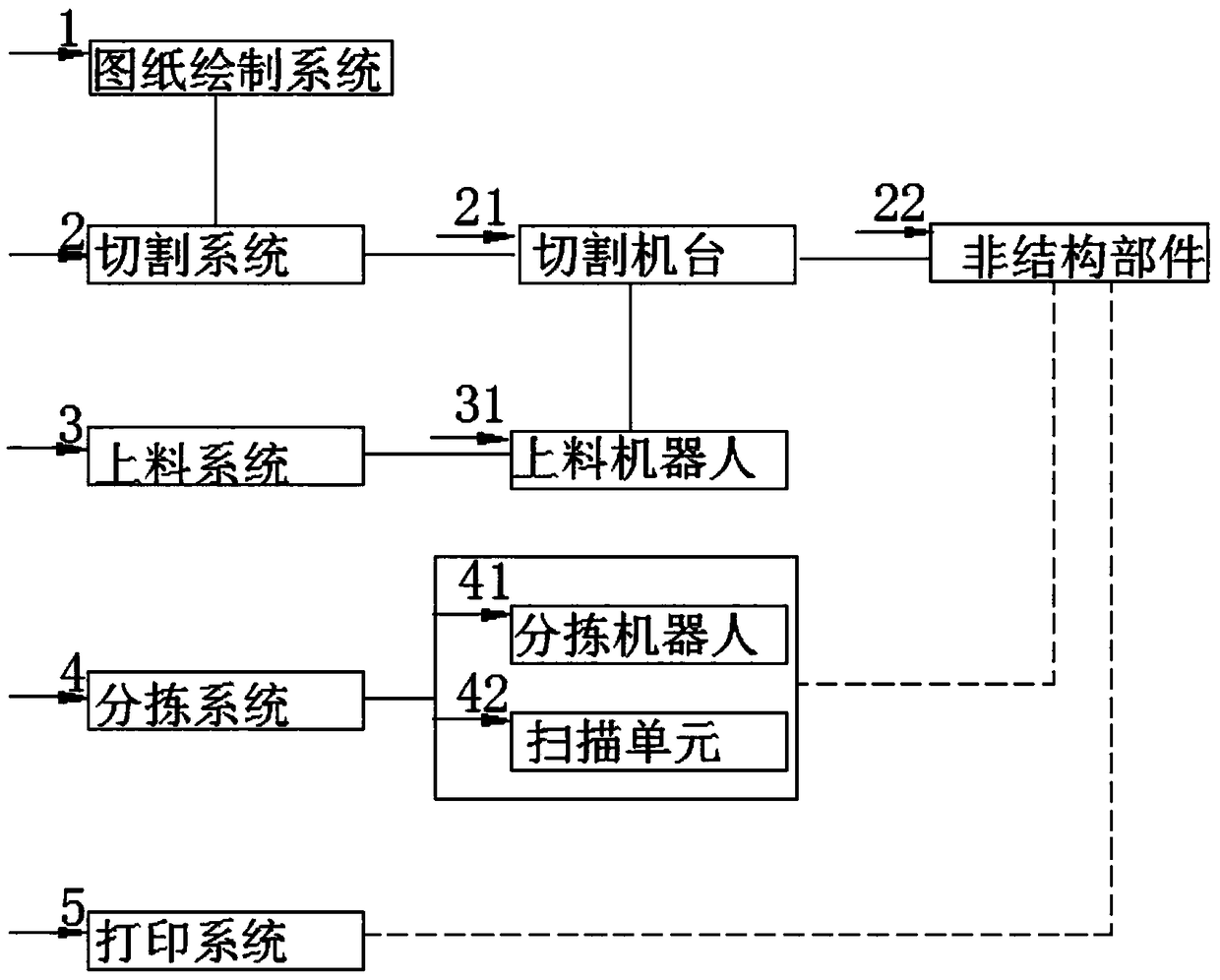

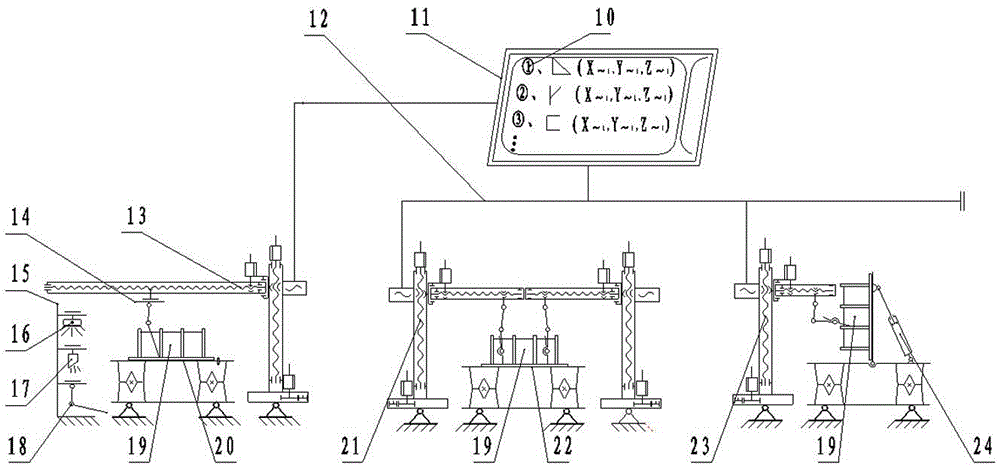

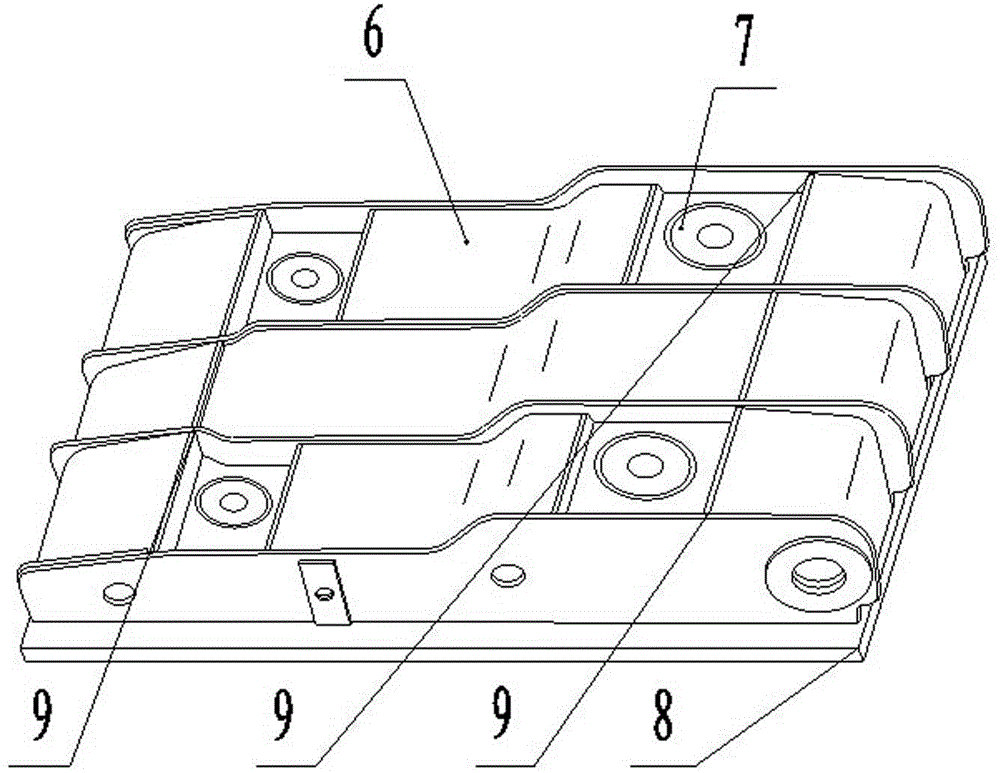

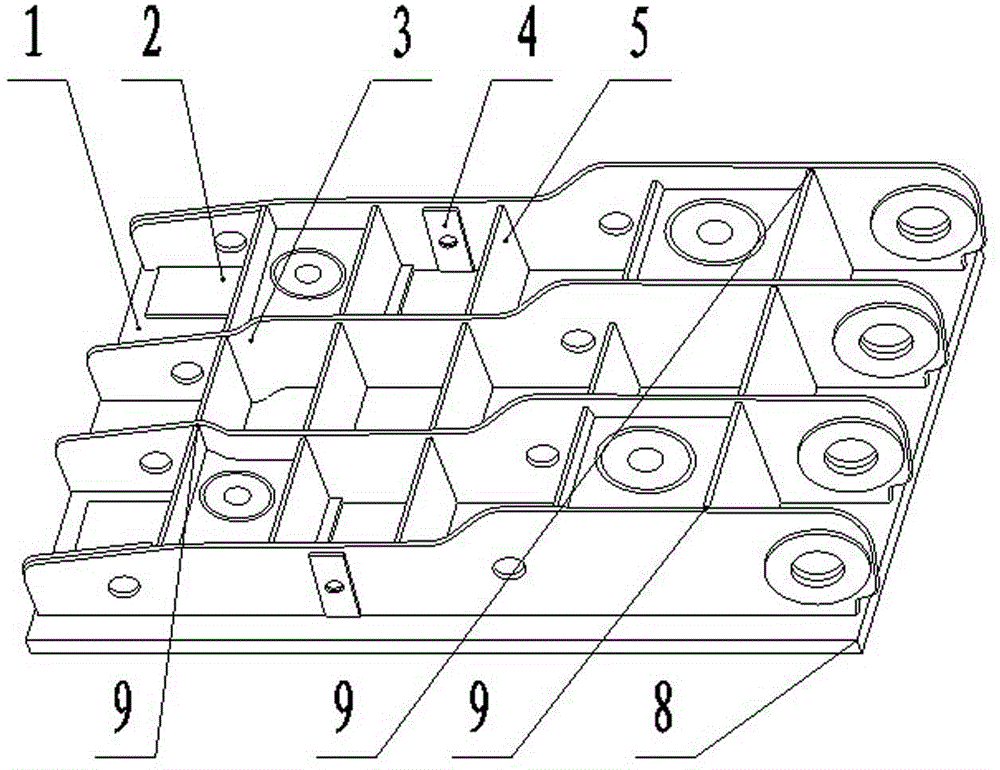

Machining system of unstructured component

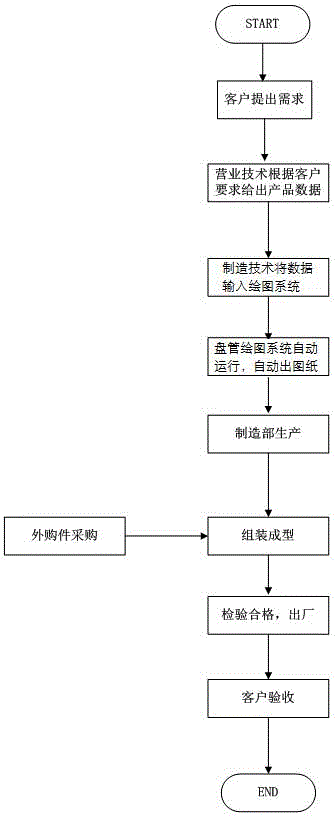

InactiveCN109483066AImprove consistencyEasy to place an orderSortingLaser beam welding apparatusCustomer requirementsProduction drawing

The invention discloses a machining system of an unstructured component. The machining system comprises a drawing system and a cutting system. The cutting system is used for determining cutting schemes of each unstructured component based on production drawings and component tables. A cutting machine table is used for cutting a plate into unstructured components based on the cutting schemes. A feeding system is used for conveying the plate onto the cutting machine table. A sorting system is used for determining orders of each unstructured component by identifying a unique identity, and sortingthe unstructured components out based on identifying results. A sorting robot adopts mechanical arms to sort each unstructured component out. The rejection rate can be reduced, waste is reduced, corresponding optional packages can be set up for customers to choose based on customer requirements, order making and using of the market department are facilitated, the time of repeated selection is greatly shortened, and working efficiency is improved.

Owner:宁波欧尼克科技有限公司

Method for controlling production through standards

ActiveCN103389698AAvoid non-complianceGuaranteed matchTotal factory controlProgramme total factory controlProduction lineProduction drawing

Disclosed is a method for controlling production through standards. The method comprises a basic standard data acquisition step, a standard data management step, a design data management step and a production drawing management step. In the standard data management step, affected products in a standard production, change, replacing and being replaced and dying out life cycle of enterprises are managed. In the design data management step, designers of design departments of enterprises are reminded according to data changes in the standard data management step at the design stage of production drawings provided through design terminals. In the production drawing management step, standard numbers are searched according to part drawing numbers or names of production drawings on production lines, and the searched standard numbers are compared with the standard numbers on the production drawings. According to the method for controlling production through standards, standard data management is performed with parts as units, and standard implementation can be guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

Production process of thermoplastic elastomer rail pad

ActiveCN103753754AAmazing resilienceExcellent toughnessCoatingsThermoplastic elastomerProduction drawing

The invention provides a production process of a thermoplastic elastomer rail pad, and belongs to the technical field of railway fittings. The production process comprises the following steps: (1) drying raw materials, namely, adding rubber to a dryer to dry for at least two hours under drying temperature of 110 to 130 DEG C; (2) injection molding, namely, performing injection molding through an injection molding machine, adding the dried raw material to a material barrel of the injection molding machine for heating, and then closing a die, injecting, maintaining the pressure, cooling, and opening the die to finish injection molding; (3) cutting nozzles, namely, moving the product subjected to injection molding from a die cavity, and removing burr through a nozzle cutting machine so as to meet the requirements of a production drawing and product technology; and (4) examining and testing, namely, warehousing qualified thermoplastic elastomer rail pads. With the adoption of the production process, the produced thermoplastic elastomer rail pad is stable in structure, small in plastic change, and small in elastic deformation under heavy load, reaches 300 to 500kN / mm of static stiffness, has service life longer than that of a steel rail, realizes stable line and driving safety, and also enables the reduction of the cost of repair and maintenance.

Owner:浙江中元铁路配件有限公司

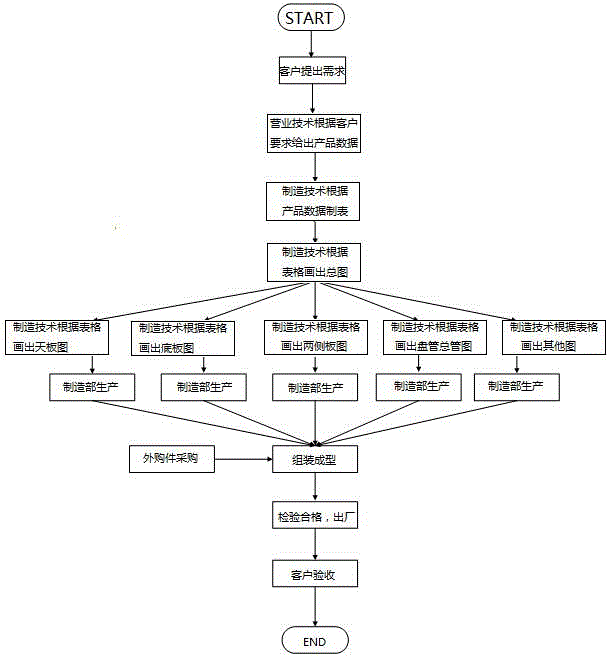

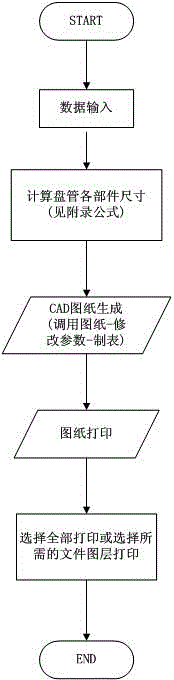

Method for automatically drawing standard fan coil manufacturing drawings

InactiveCN104820742AIncrease production capacityEnhance the imageSpecial data processing applicationsComputer Aided DesignProduction drawing

The invention discloses a method for automatically drawing standard fan coil manufacturing drawings. The method comprises the following specific steps: collecting existing drawing, establishing a database; inputting condition parameters, computing the size of each component of a coil, generating and printing drawings, judging and computing the size of each component of the coil through a preset formula during computation of the size of each component of the coil, and performing command guidance for CAD (Computer-Aided Design) based on the size; and calling corresponding standard machine drawings through a drawing system to establish temporary drawings, replacing sheet metal total size and pipe diameter hole data, drawing tables in the drawings through the command guidance, summarizing filled condition parameters, and automatically making CAD manufacturing drawings. Manufacturing of all drawings including a general production drawing, a ceiling drawing, a bottom plate drawing, a drawing of two side plates, a water outlet drawing, a coil main pipe drawing and the like is finished automatically by inputting given condition parameters, so that the labor force is greatly reduced; the working efficiency is increased; the enterprise capacity is increased; the error rate is reduced; the delivery period of a user is shortened; and the corporate image is improved.

Owner:王文谦

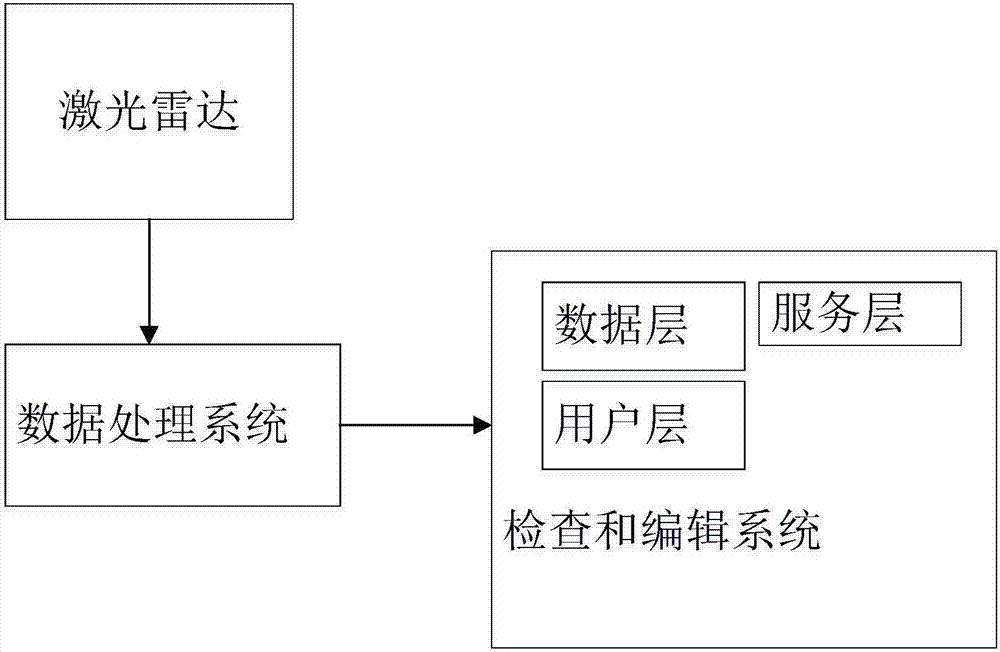

Automatic generation system of ground line data

PendingCN107085219AImprove the efficiency of survey designReduce cost of measurementElectromagnetic wave reradiationData modelingProduction drawing

The invention provides an automatic generation system of ground line data. The system comprises a laser radar, a data processing system and a checking and editing system; the laser radar obtains point cloud data of a ground line; the data processing system processes the obtained point cloud data, carries out data modeling and elevation interpolation according to ground type points in the point cloud data to obtain the ground line; and the checking and editing system drafts the obtained ground line in a visual graph environment, checks the edits the generated ground line visually by overlapping LiDAR point cloud and DOM data, and generates ground line data finally. The system can extract the designed ground line rapidly and automatically, and integrate laser radar measurement with road production drawing design; and in an area with many structures, the ground line generated by the system reflects real land surface information of micro-landforms more accurately compared with that via a digital-analog interpolation method.

Owner:SHANGHAI HUACE NAVIGATION TECH

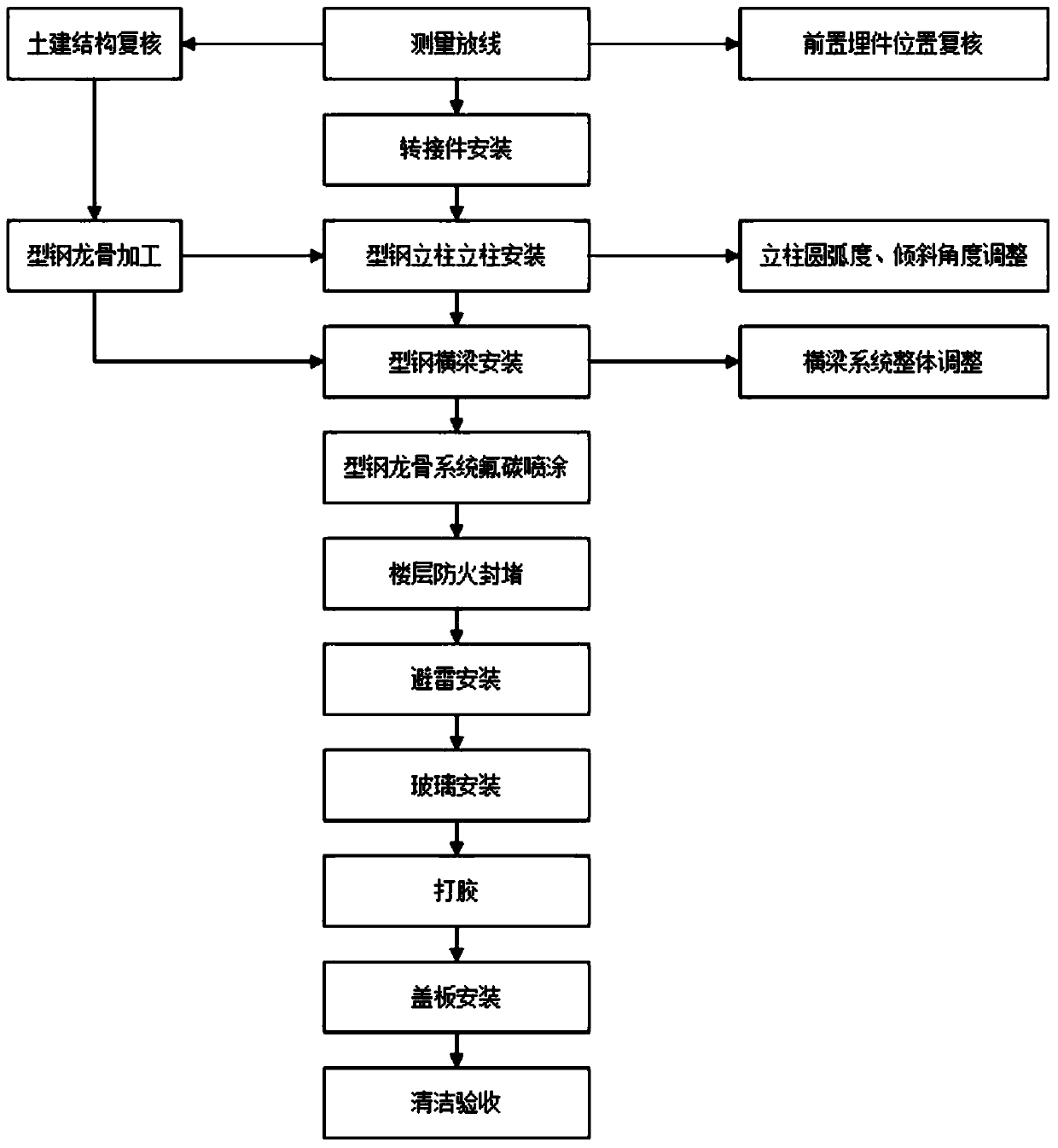

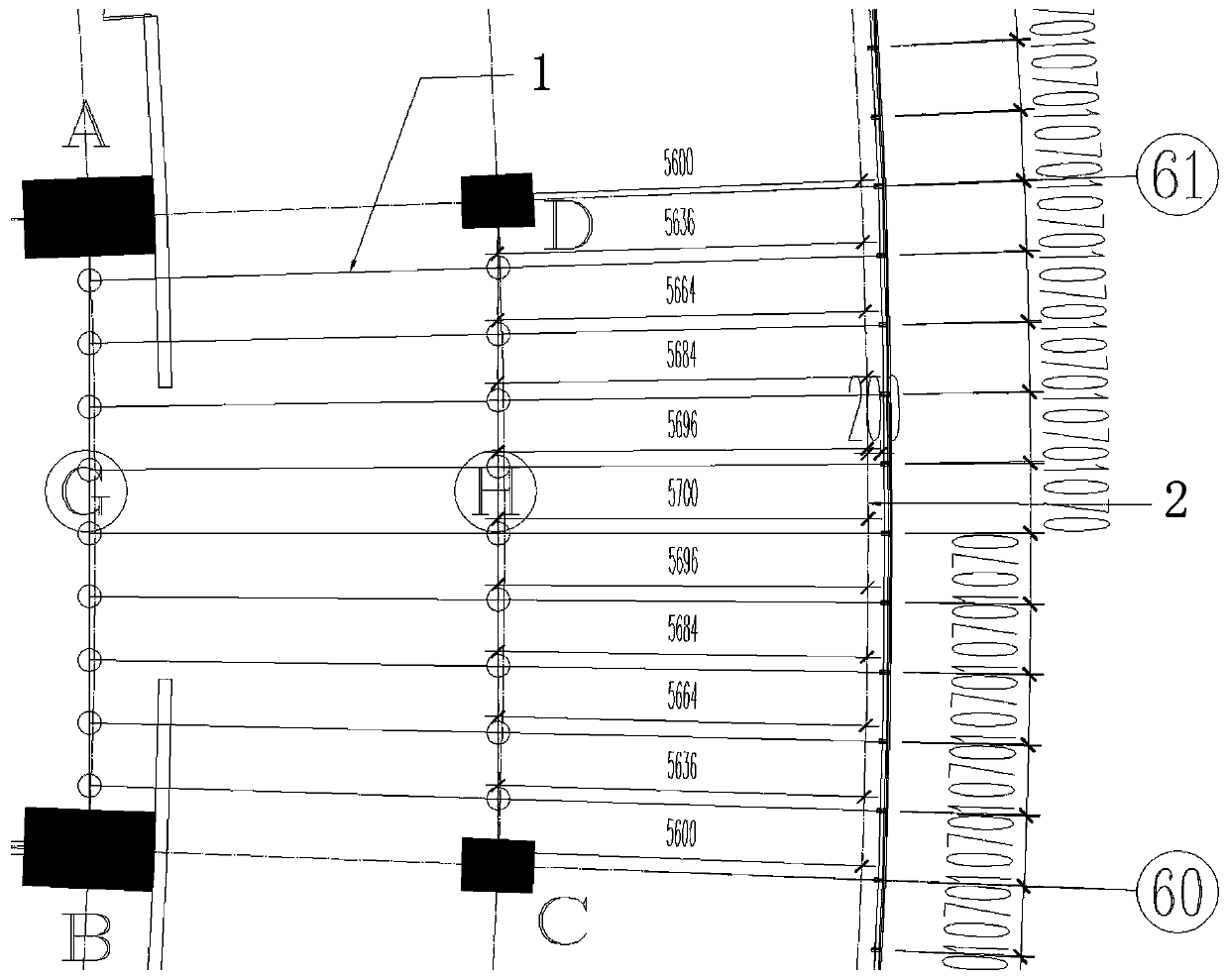

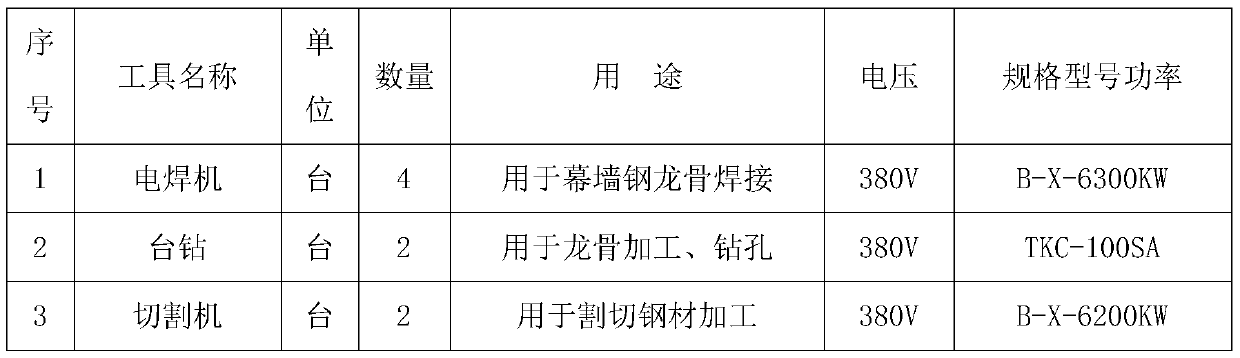

Construction method of longspan deformed steel joist glass curtain wall

The invention discloses a construction method of a longspan deformed steel joist glass curtain wall, and belongs to the technical field of building construction. The implementation manner of the method comprises the following steps that according to a curtain wall design production drawing and field measurement, a radial grid locating line and an annular depth control line of the arc curtain wallare confirmed, and the locating points of stand columns are confirmed; after the locating points of the stand columns are corrected and re-checked and have no error, structural steel joint stand columns are mounted; after the stand columns are mounted, the arc degree, the inclination degree and the up-and-down straightness of the stand columns are checked and adjusted, and it is ensured that the highest points of top double curve arcs are on the same arc and the same elevation; after the stand columns are mounted, cross beams are located through a glass grid, structural steel joist cross beamsare mounted, one ends of the cross beams and the stand columns are welded, and the other ends of the cross beams are hinged to the stand columns; and after the cross beams and the stand columns are mounted and checking is carried out, full welding and fixing are achieved, and locating of a keel system is finished. According to the method, the construction problems about precision control over locating and inclination angles and radians of curtain wall type straightness joint systems and the like can be effectively solved, and therefore construction efficiency is improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

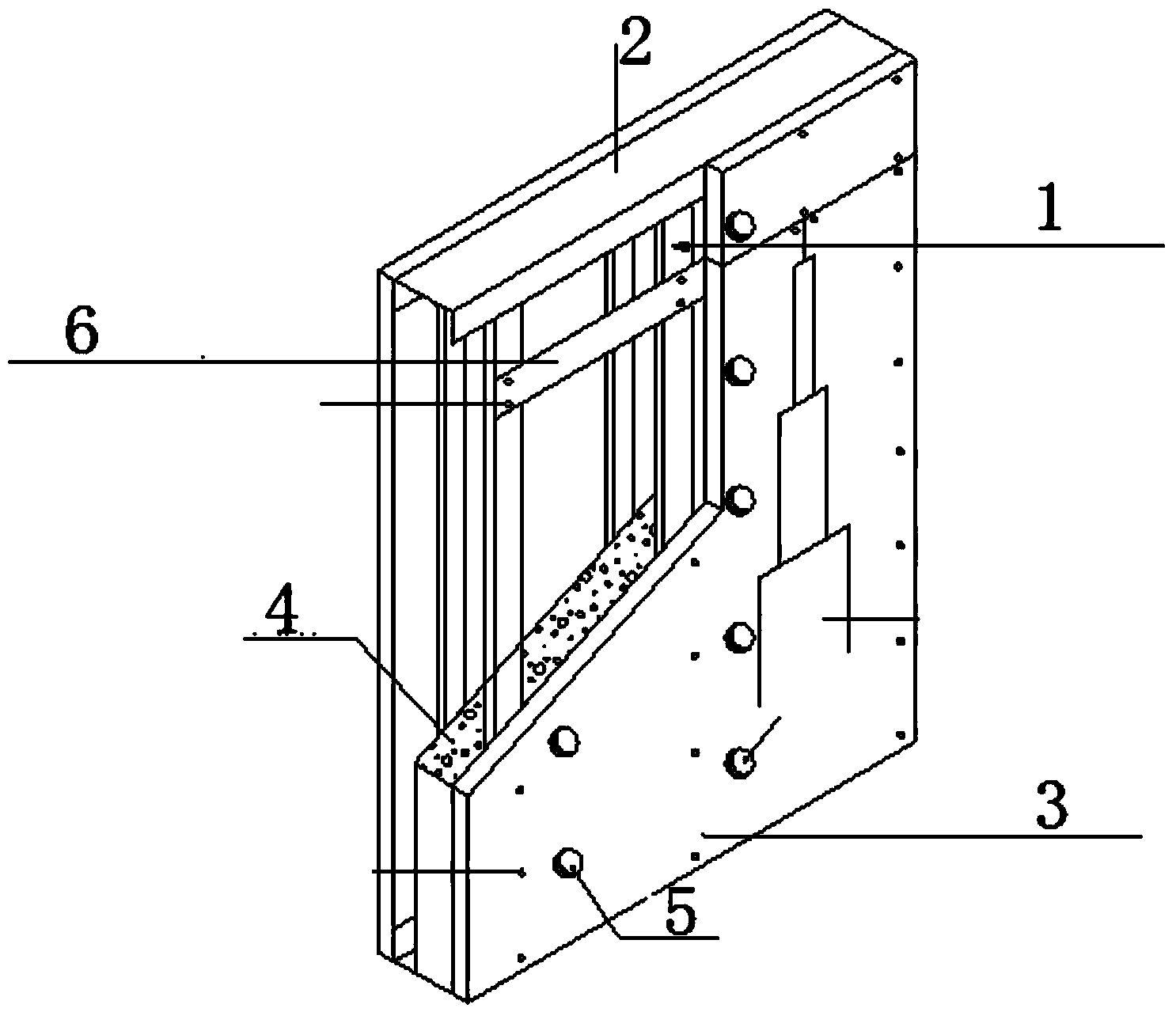

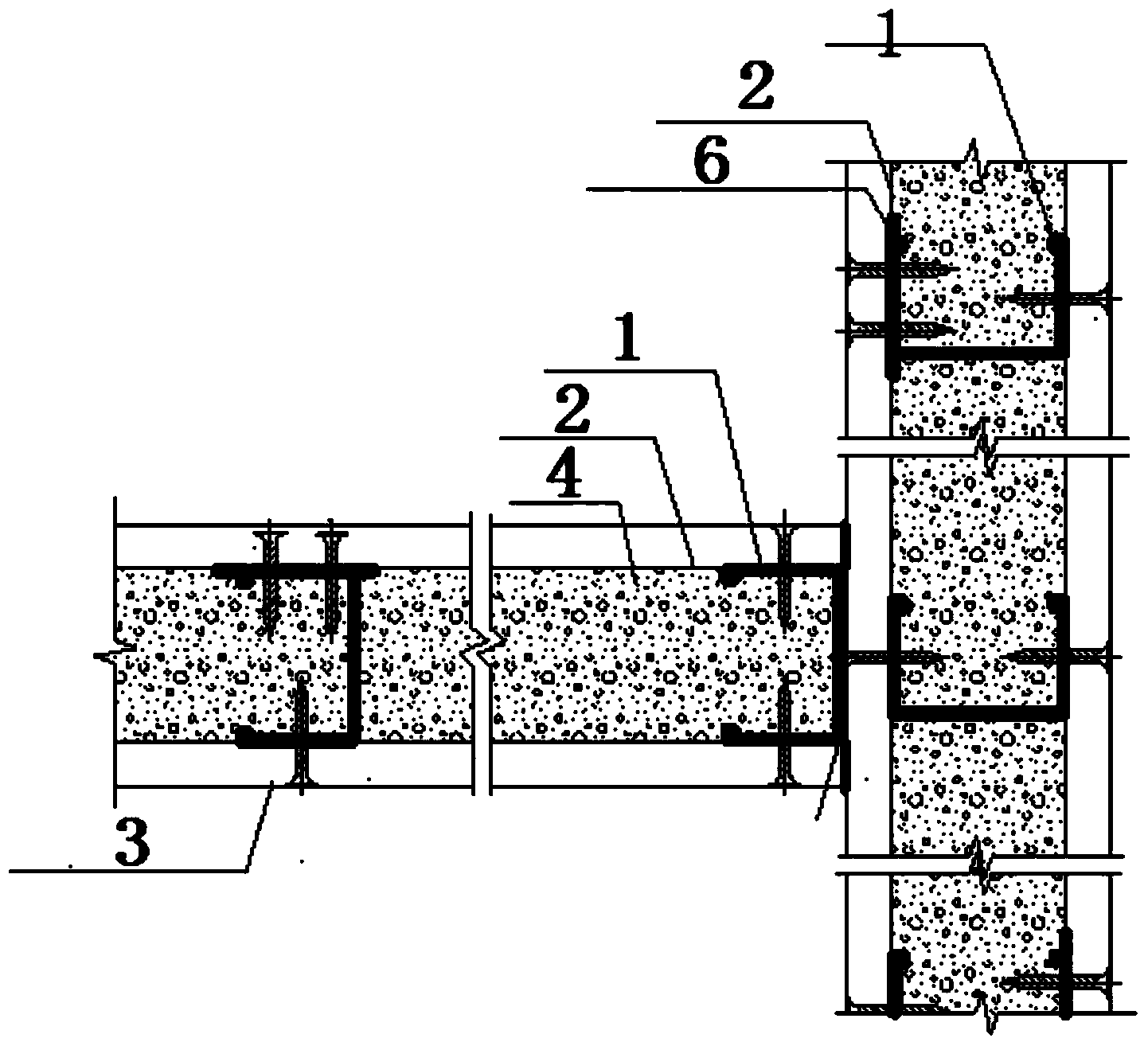

Construction method for integrally grouting wall by lightweight concrete through CCA board

The invention discloses a construction method for integrally grouting a wall by lightweight concrete through a CCA board. The method comprises the following steps: a) firstly lofting according to a design drawing and the instructions of a production drawing approved by field engineers; b) sleeving a vertical keel into an upper keel and a lower keel according to the space of 400mm after the upper keel and the lower keel are fixed; c) directly fixing the two sides of a door frame and a framework by screws, and horizontally fixing the door frame by the unit of a household; d) fixing the CCA board by self-tapping screws according to the space of 5cm at the altitude below 30cm of the ground; e) grouting lightweight concrete; f) directly brushing clean water on chamfer parts by a paint brush, and caulking before the water is evaporated or absorbed; rapidly scraping caulk to positions where the caulking is required.

Owner:ZHONGTIAN CONSTR GROUP

Heating index evaluation method and system for turbine machine room in million kilowatt unit nuclear power station

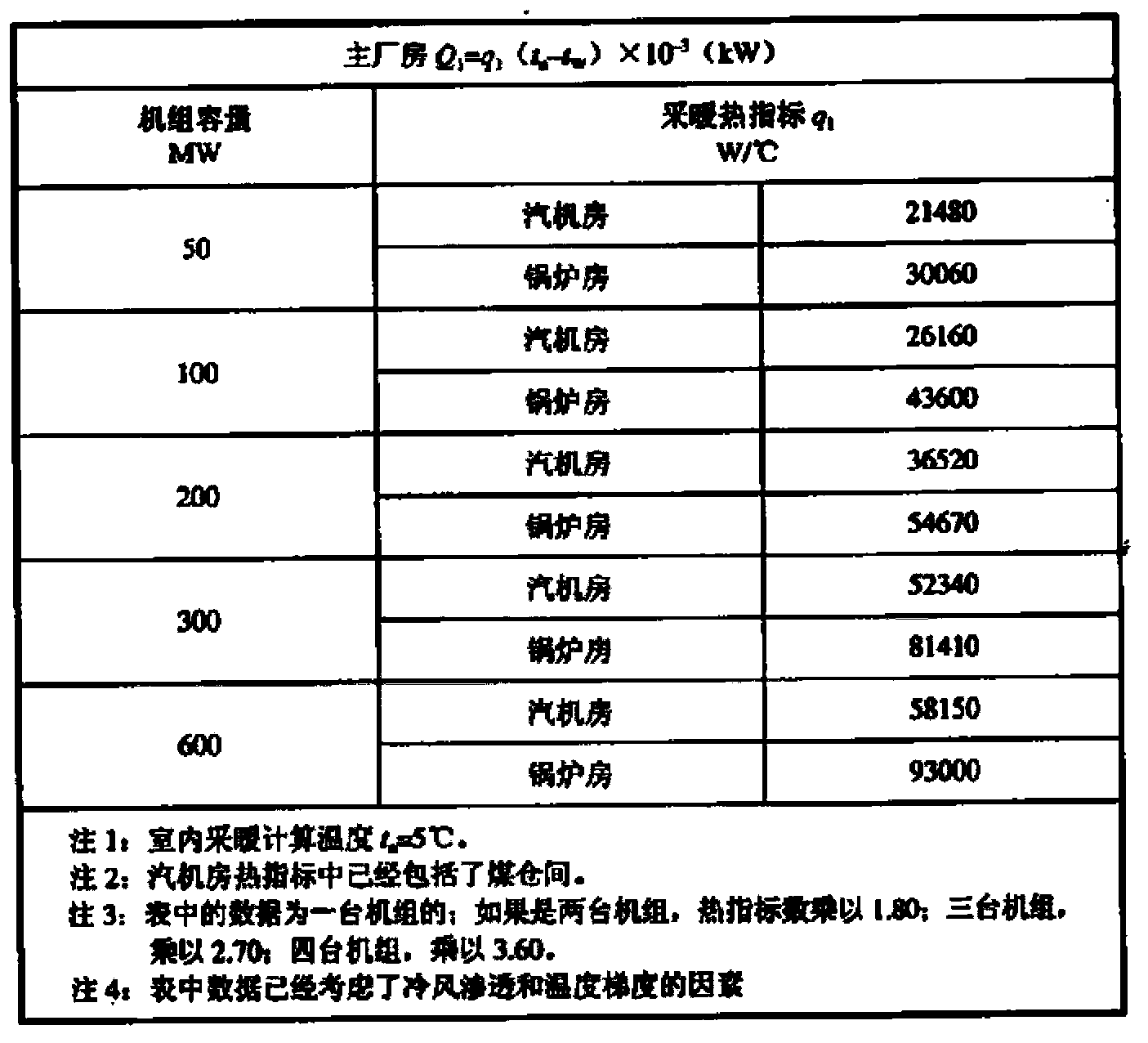

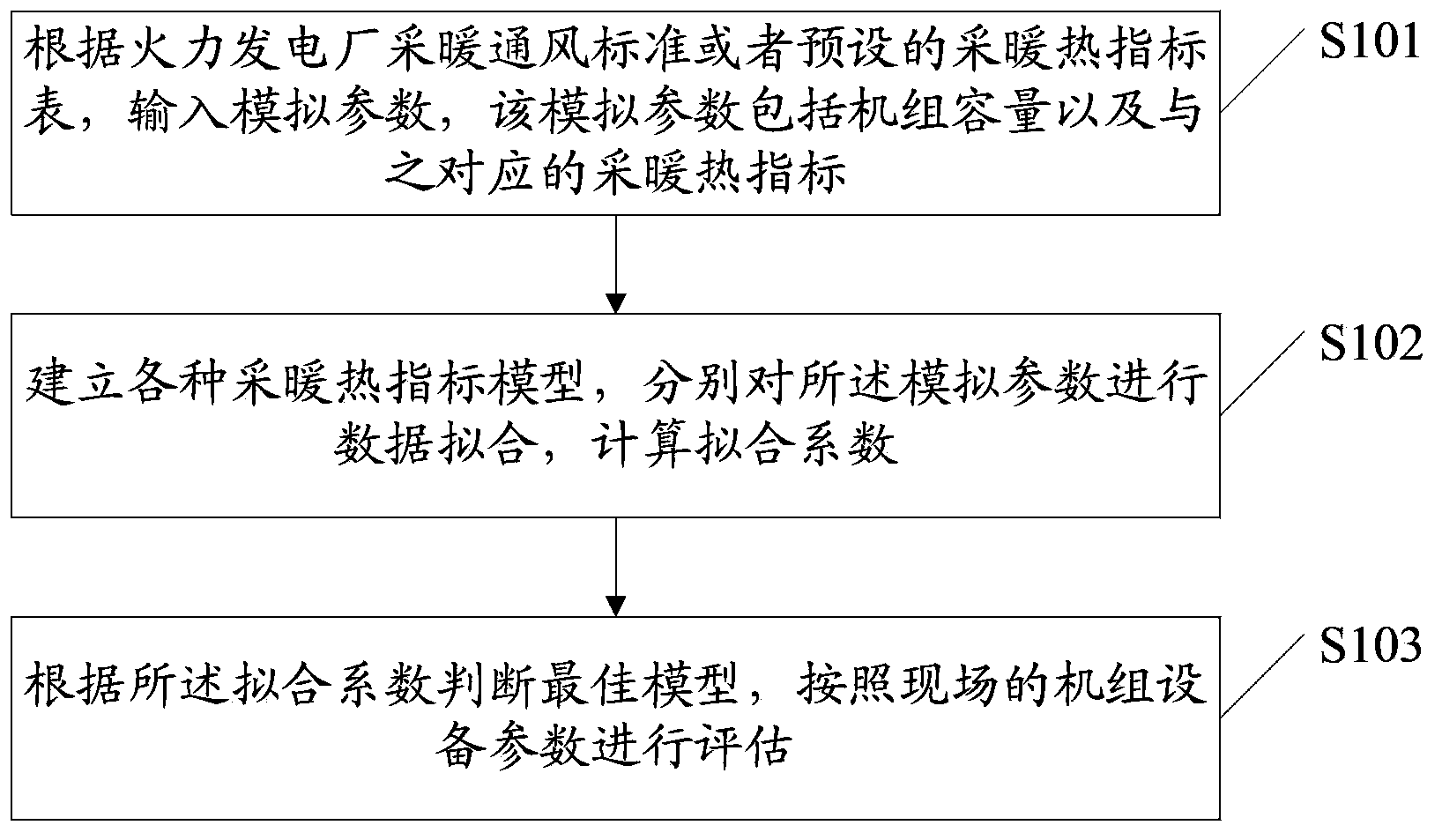

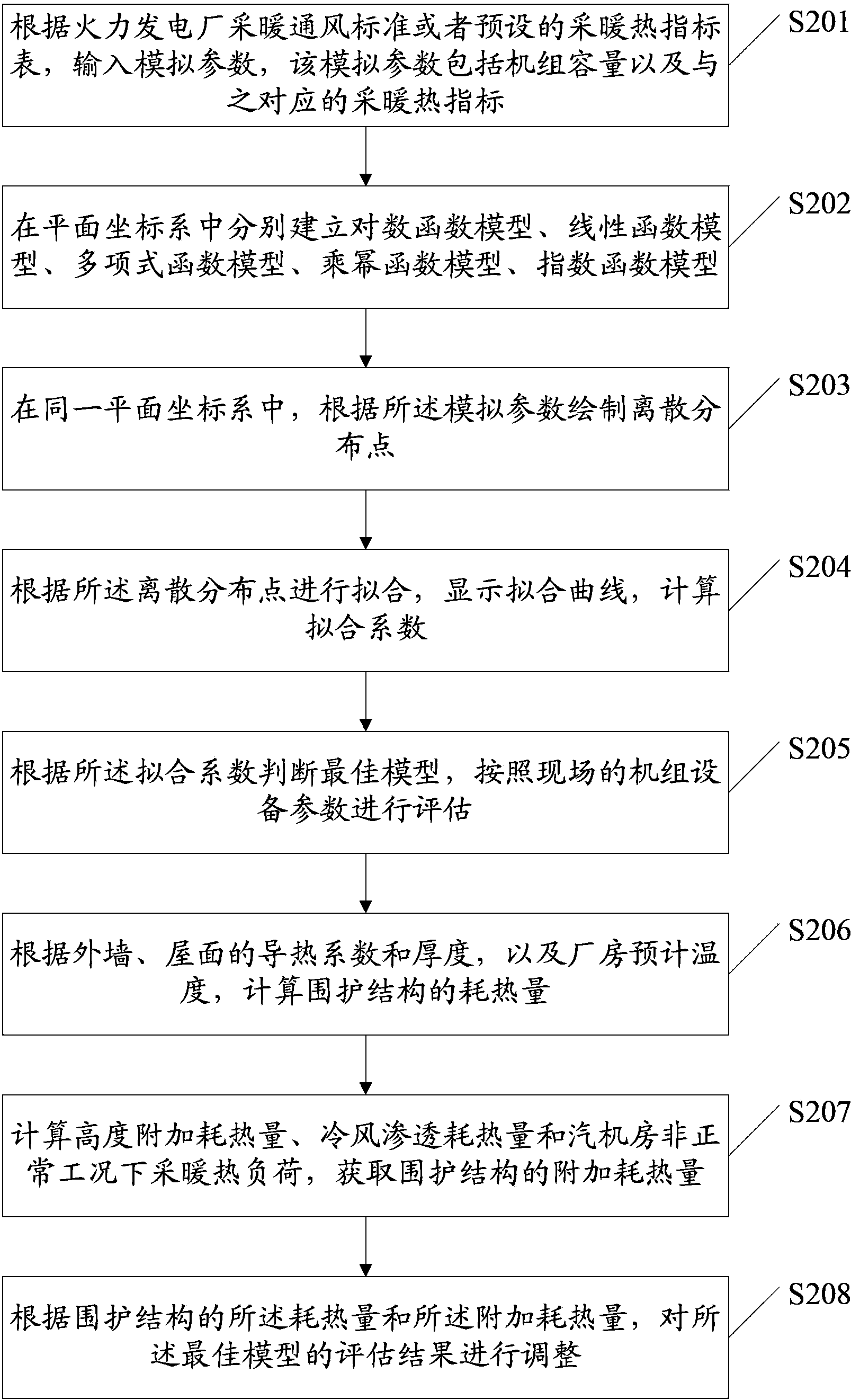

InactiveCN103353903AAvoid cumbersome calculationsSpecial data processing applicationsInformation technology support systemHeat indexNuclear power

The invention discloses a heating index evaluation method and system for a turbine machine room in a million kilowatt unit nuclear power station. The method comprises the following steps: inputting a simulation parameter according to a heating and ventilation standard of a thermal power plant or a preset heating index table, and the simulation parameter comprises the unit capacity and a heating index corresponding to the unit capacity; building various heating index modules, conducting data fitting to the simulation parameters respectively, and computing the fitting coefficient; judging the best module according to the fitting coefficient, and conducting evaluation according to the field unite equipment parameter. Through the adoption of the method and system provided by the invention, tedious computing of a production drawing is overcome, heating evaluation is realized fast and conveniently, and the technique blanking is filled.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Preparation method of large-size sintered silicon carbide wear-resistant pipeline

PendingCN111908933APromote formationSolve the problem of easy crackingMouldsCeramic shaping coresCarbide siliconProduction drawing

The invention discloses a preparation method of a large-size sintered silicon carbide wear-resistant pipeline, which comprises the following steps: earlier-stage molding, slurry mixing and slip casting, later-stage sintering and earlier-stage molding. The method specifically comprises the following steps that (1) a production drawing is processed, (2) an outer bottom die is manufactured, (3) an inner bottom die is manufactured, (4) the outer bottom die is used for manufacturing the production outer die, (5) a production inner die is manufactured, and (6) the production inner die is used for manufacturing the inner die. After the sizes of the production units are obtained after a drawing is analyzed, production is conducted according to the production units, then splicing is conducted, andthe large-size sintered silicon carbide abrasion-resistant pipeline can be obtained. The method is simple in overall process, the content of the dispersing agent and the content of the binding agent are increased in the slurry, blank forming can be promoted, and therefore the problem that a large-size pipeline is prone to cracking is solved. According to the technology, a traditional production process is completely changed, a two-mold-opening structure is adopted, and a positioning assembly and a sliding block assembly structure are additionally arranged on the mold, so that green body forming and demolding can be assisted, and use is convenient.

Owner:山东中鹏特种陶瓷有限公司

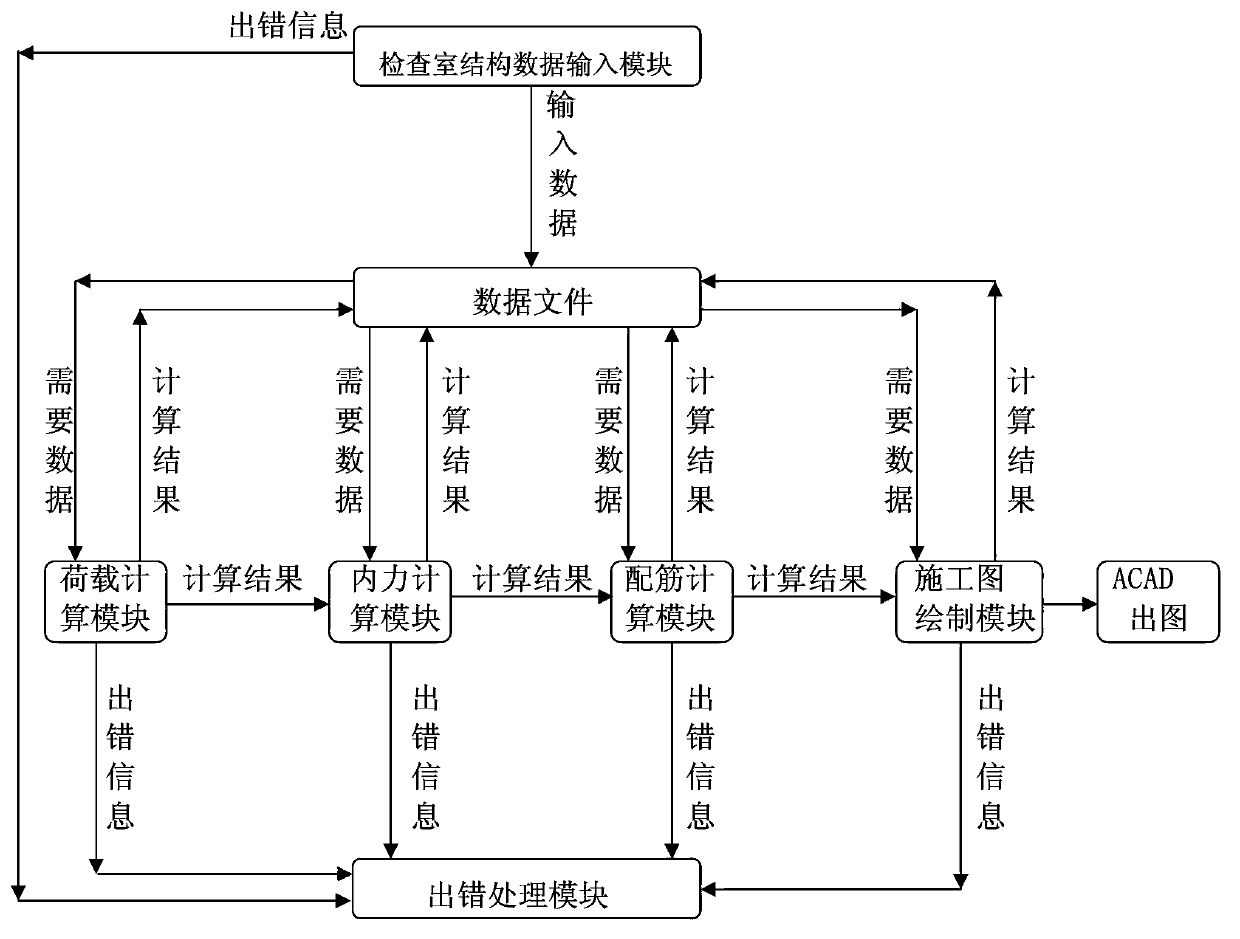

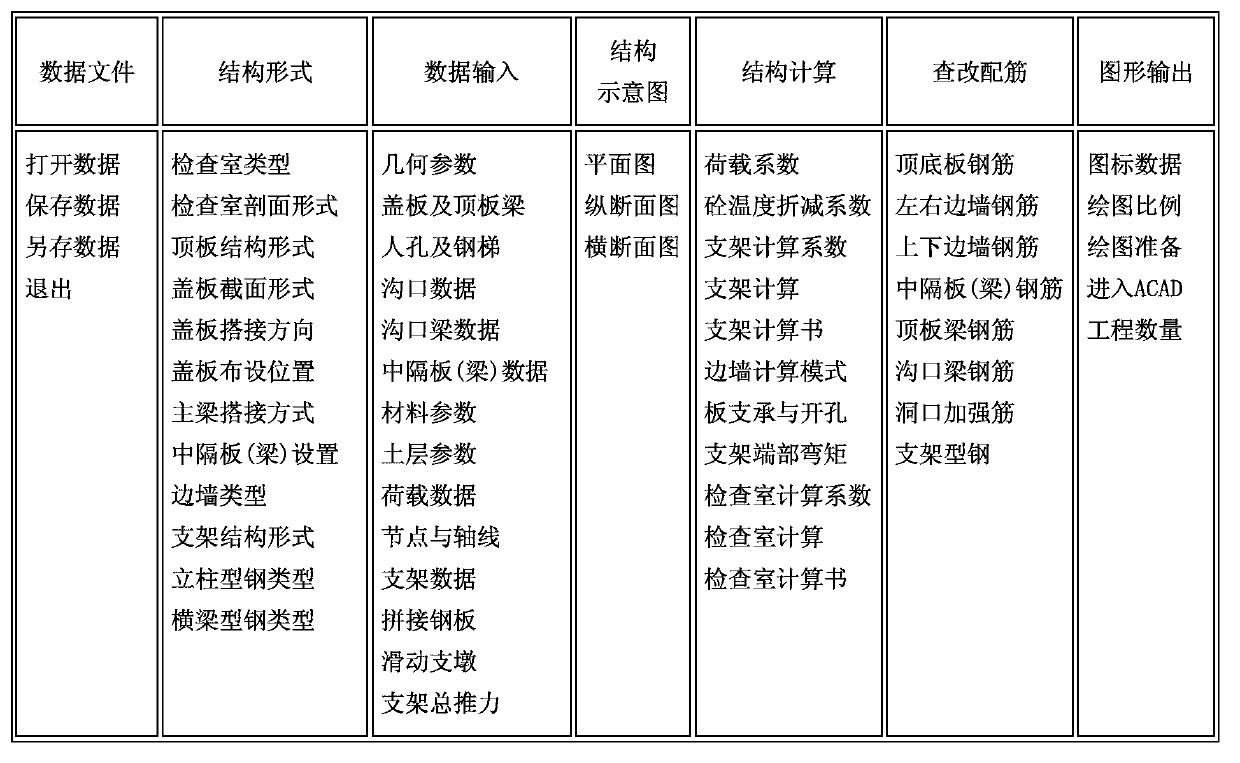

Data processing method of thermal examination chamber and computer aided design system of thermal examination chamber

ActiveCN103106297ASpeed up the construction cycleShort construction periodSpecial data processing applicationsComputer Aided DesignProduction drawing

A data processing method of a thermal examination chamber and a computer aided design system of the thermal examination chamber are beneficial to reducing the construction period of the thermal examination chamber and guaranteeing the construction quality of the thermal examination chamber. The data processing method of the thermal examination chamber and the computer aided design system of the thermal examination chamber are characterized by comprising steps: (1) building a new thermal examination chamber on a computer platform or opening an existing thermal examination chamber project template; (2) inputting thermal examination chamber structure data ensured or selected by a designer; (3) displaying a thermal examination chamber structure chart, judging the input correctness of the thermal examination chamber structure data; (4) conducting structural calculation; (5) if computed results of the computed results do not comply with the design requirement, repeating step (2) to (4) until the computed results of the computed results complying with the design requirement are got; (6) confirming or drawing a thermal examination chamber production drawing according to the computed results complying with the design requirement, and outputting the thermal examination chamber production drawing in the AutoCAD by using script files generated.

Owner:BEIJING TEZE HEATING PROJECT DESIGN +1

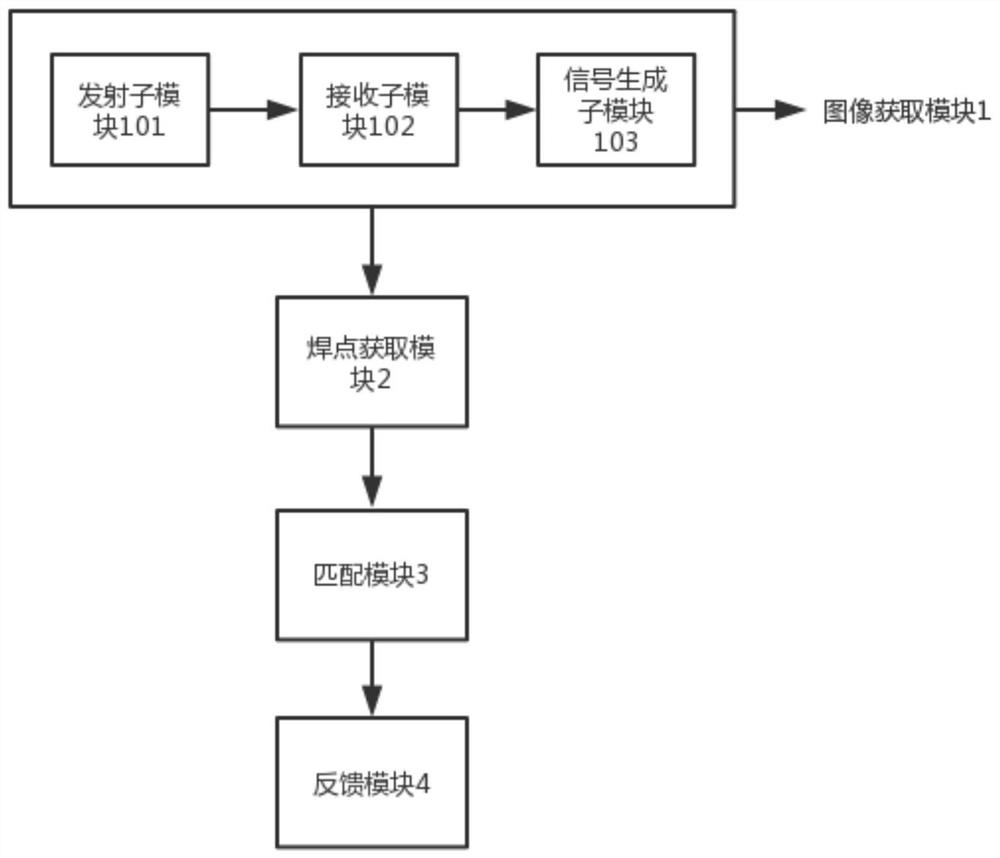

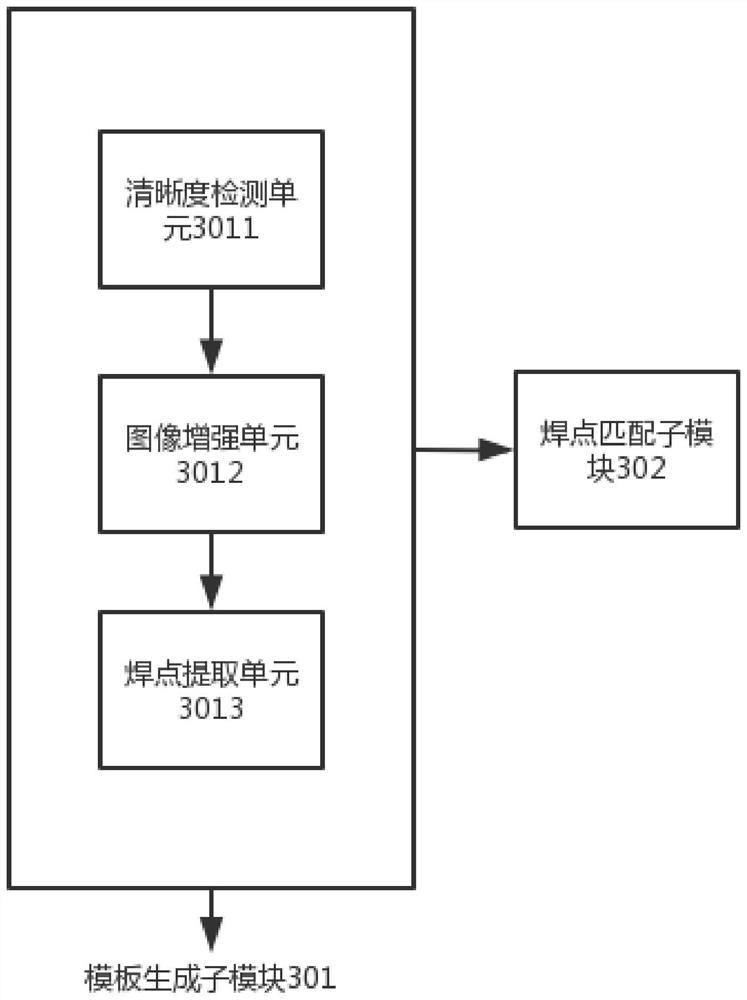

Welding spot detection device and method for cylindrical battery cap

The invention provides a welding spot detection device and method for a cylindrical battery cap. The device comprises an image obtaining module which is used for obtaining a welding spot image of the cylindrical battery cap; a welding spot acquisition module which is used for detecting welding spots in the welding spot image based on a multi-feature welding spot template to obtain welding spot quality information; a matching module which is used for matching the welding spot quality information with welding spot standard information of a standard welding spot template corresponding to an actual production drawing, and sending a corresponding result to a feedback module when the welding spot quality information is not matched with the welding spot standard information; and the feedback module which is used for feeding back the result to a user terminal. The method can solve the problem that the number of welding spots which are complex in supplied material and excessively different from a template is not matched completely when the welding spots are matched.

Owner:GUANGDONG AOPUTE TECH CO LTD

Special-shaped copper bar for hydroelectric generator and its processing technology and application

InactiveCN102290124AEasy to findReduce uneven size and uneven sizeSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesCopper conductorHigh rate

The invention relates to a special-shaped copper bar, in particular to a special-shaped copper bar for the straight line part copper wire of a hydroelectric generator rotor, as well as its processing technology and application. The cross-section of the copper bar is "E" type, and the two copper bars are riveted into a double-hole hollow wire, which can achieve the effect of rapid water cooling. The invention adopts extrusion and cold drawing forming technology for production, has good electrical conductivity, high dimensional accuracy, fast water cooling, simple processing method, high yield and low cost, greatly reduces labor time and improves efficiency.

Owner:济南宝世达实业发展有限公司

Method for controlling design according to standards

ActiveCN103455870AAvoid requirements that do not conform to the content of the corresponding standardEnsure implementationResourcesManufacturing computing systemsProduction drawingData acquisition

A method for controlling design according to standards comprises the following steps: basic standard data collection, standard data management and design data management. The basic standard data collection refers to collecting and systemizing drawings of products of an enterprise, drawings of parts used by the products and corresponding standard information through a standard management device. The standard data management refers to managing the products affected by the life cycle of producing, altering, replacing, being replaced and dying out of the standards of the enterprise. The design data management refers to reminding designers according to data changes in the step of standard data management in the design stage that a design department of the enterprise provides production drawings through a design device. According to the method for controlling the design according to the standards, parts serve as a unit for standard data management, and implementing of the standards can be ensured ever since the design stage.

Owner:CHINA HANGFA SOUTH IND CO LTD

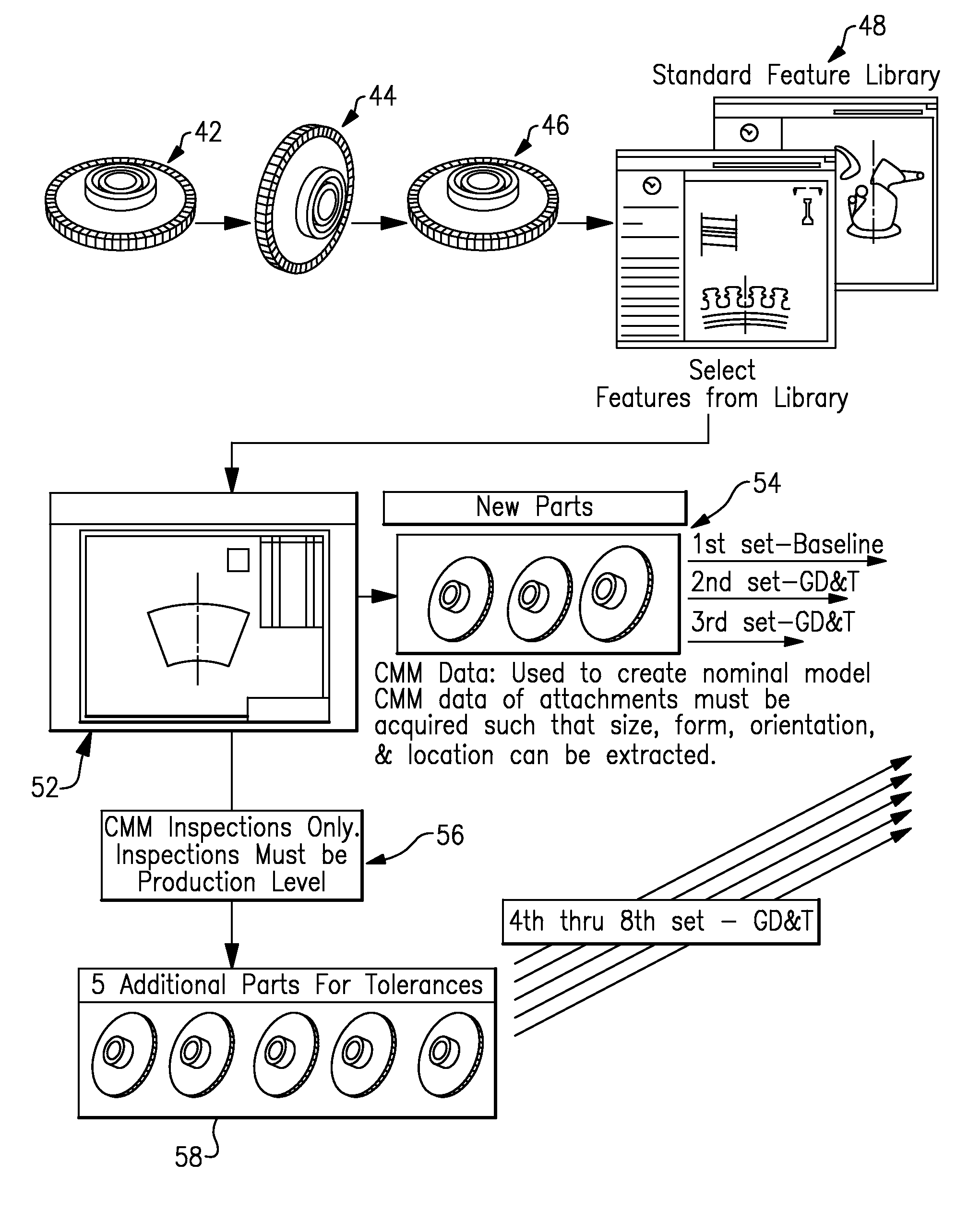

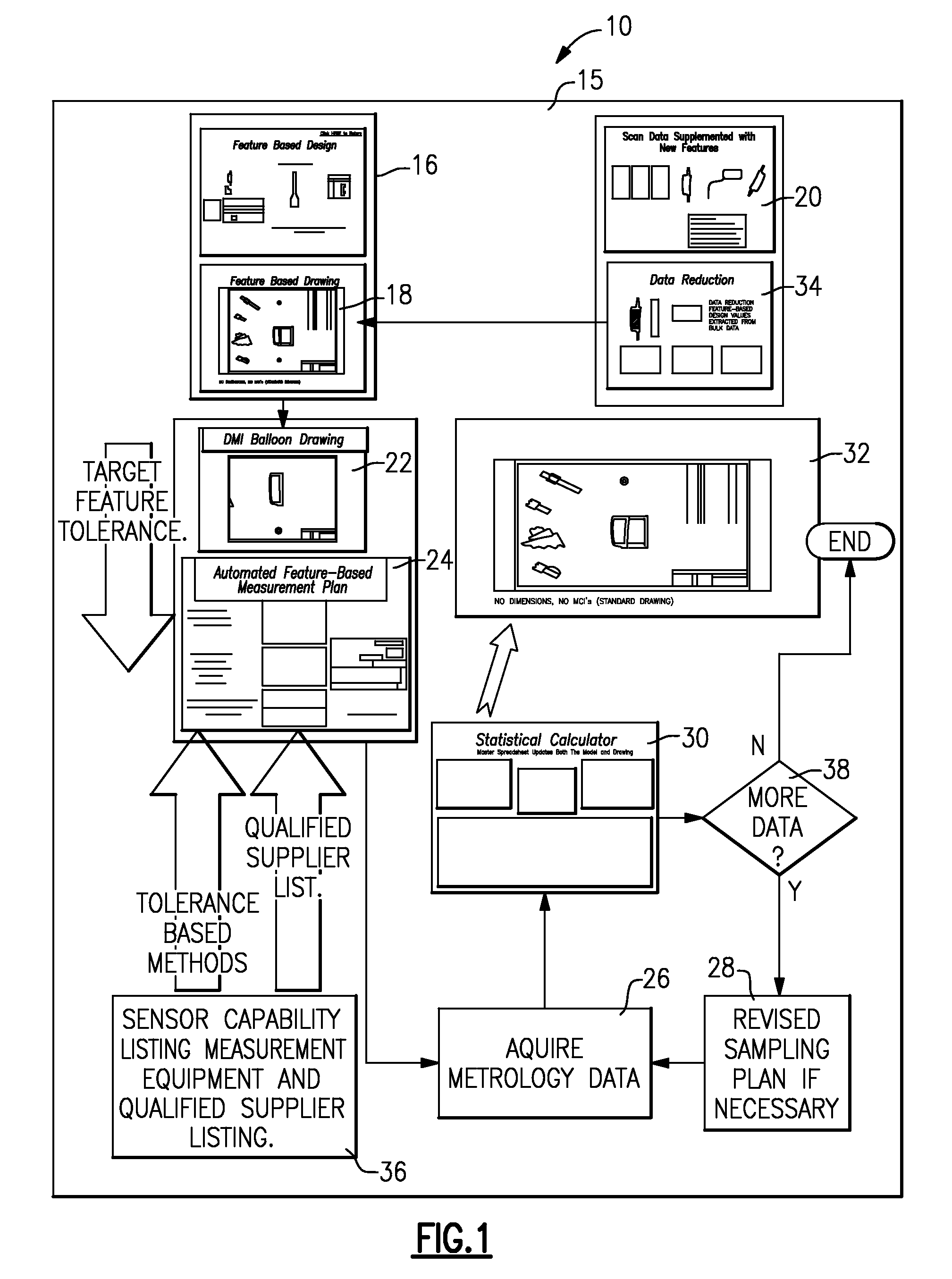

Measurement data management system

InactiveUS20100161287A1Shorten the timeEffective distributionDigital computer detailsUsing electrical meansProduction drawingData management

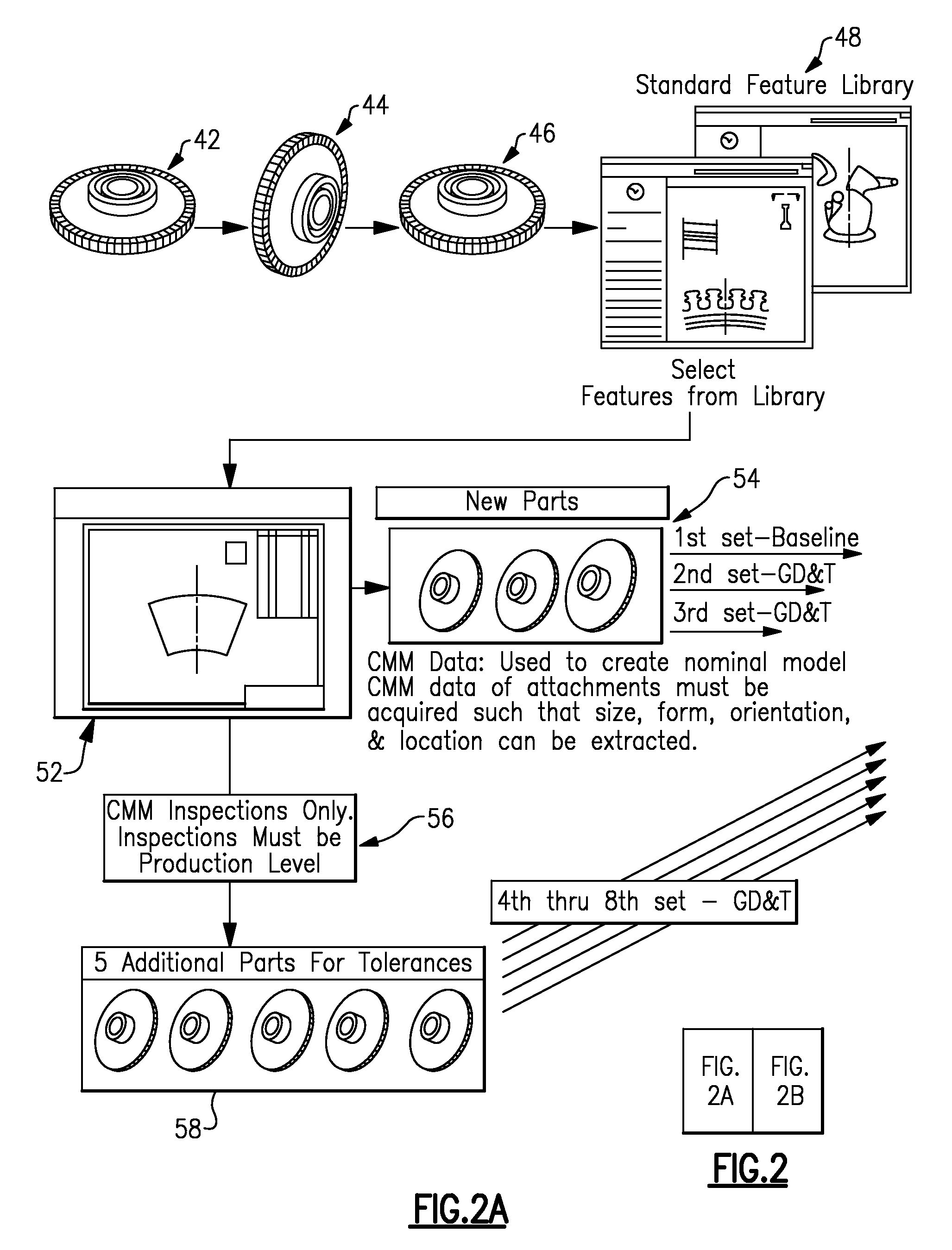

A system and process for managing measurement data and generating production and engineering drawings from measurements obtained from a sample population parts to generates and parametrically update engineering and production drawings from measurement data of actual parts. The system and process provides efficient allocation of measurement resources to generate engineering drawings and models. The resources are allocated in a manner that eliminates and reduce time required for producing and generating usable engineering models and drawings.

Owner:UNITED TECH CORP

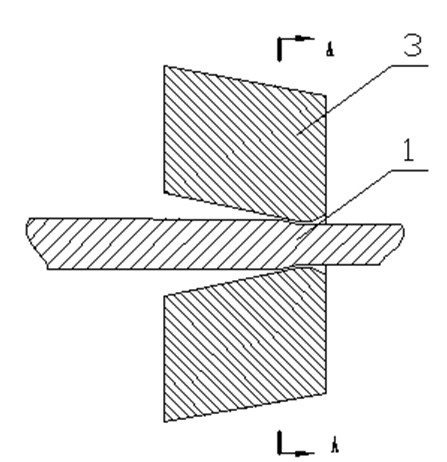

Offline detecting type automatic welding method used for large-scale complex box type structural member

ActiveCN104889533AIncreased Online UtilizationOvercoming the problem of poor welding strengthArc welding apparatusProduction drawingEngineering

The invention specifically discloses an offline detecting type automatic welding method used for a large-scale complex box type structural member. The problem of relatively poor welding intensity of an existing large-scale complex box type structural member which adopts a manual teaching mode is solved. The large-scale complex box type structural member is assembled and shaped according to a production drawing of the large-scale complex box type structural member; a three-coordinates measuring system is adopted to measure, record and sequentially store the track of each welding seam; all the welding seam information formed by detection of the three-coordinates measuring system is stored in an automatic welding equipment control center and is numbered; the welding seam information is taken based on the number of a work-piece for automatic welding until the welding of all the welding seams of the structural member is finished. The offline detecting type automatic welding method used for the large-scale complex box type structural member is suitable for welding in small and narrow space of box type square grids and uniform tracking requirements on multiple welding seam forms, and completely eradicates the phenomenon that the discontinuity point similar fitting track of manual teaching cannot guarantee the welding seam forming quality.

Owner:SHANXI PINGYANG IND MACHINERY

Construction method of glass magnesium board

InactiveCN105672595AThe construction method is simple and fastNo crackCovering/liningsCoatingsSurface layerProduction drawing

The invention discloses a construction method of a glass magnesium board. The construction method comprises the following steps: (1) mounting of a keel: mounting the keel on a wall surface covered with a glass magnesium board according to the requirements of a design drawing or production drawing, and performing leveling treatment on the keel; (2) mounting of the glass magnesium board: fixing the glass magnesium board on the keel, banding the edges of the glass magnesium board, reserving gaps at the edge banding lines, and sealing with silica gel; (3) brushing the surface of the glass magnesium board with an interface agent, and plastering or making a decorative surface layer. The construction method of the glass magnesium board is simple, convenient and fast, glass magnesium board seams do not crack, and the wall surface is more aesthetically pleasing.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Intelligent manufacturing platform of customized panel furniture

PendingCN111399467AAccurate collectionAccurate data displayTotal factory controlProgramme total factory controlProduction drawingSmart manufacturing

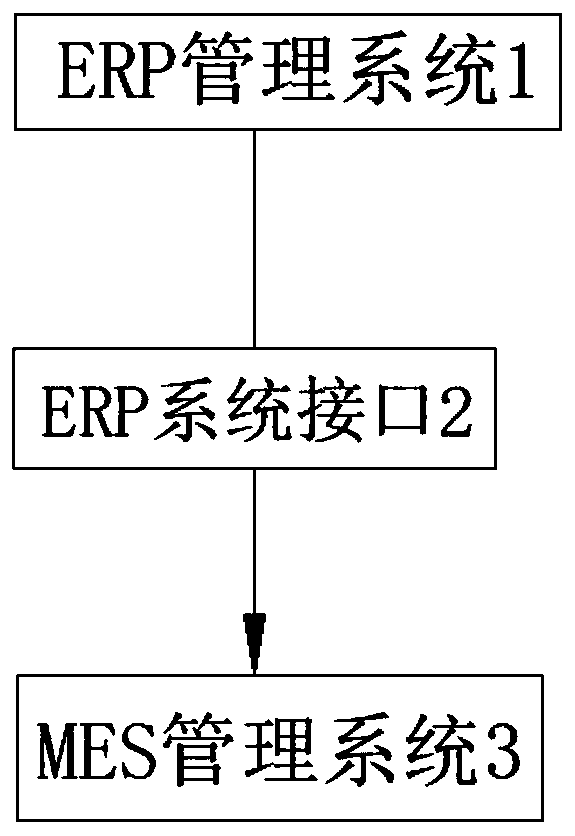

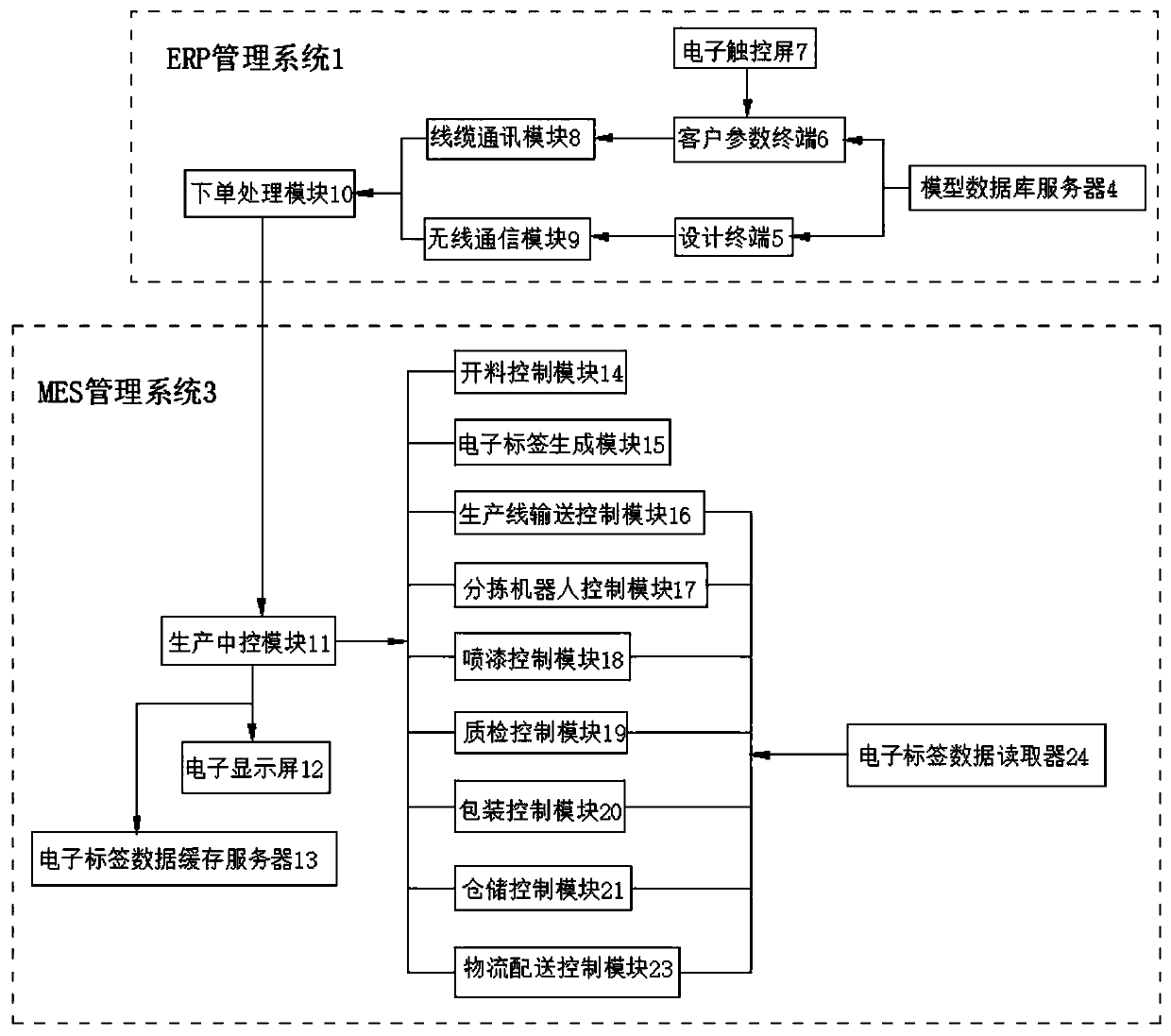

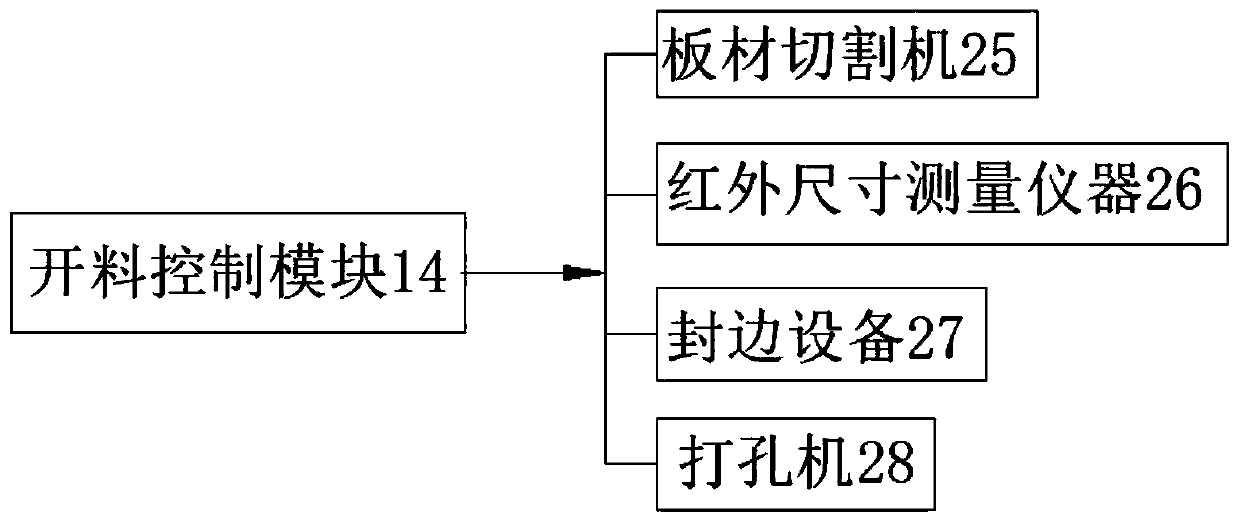

The invention relates to the technical field of intelligent manufacturing and further discloses an intelligent manufacturing platform of customized panel furniture. The platform comprises an ERP management system and an MES management system. The ERP management system generates customized production tasks and production drawings, orders are processed, and data are transmitted to the MES managementsystem through an ERP system interface. The MES management system comprises a production central control module, the production tasks and requirements are analyzed, and all production procedures arecontrolled based on the production central control module and a flexible production line. The MES management system further comprises an electronic tag generation module, an electronic tag data cacheserver and an electronic tag data reader, and production state information and management data can be obtained by scanning production tags in time. By arranging an ERP and MES collaborative managementsystem, intelligent manufacturing and process management of the customized panel furniture are achieved, and by arranging the electronic tags for real-time storage, production state information and management data are obtained, and production process flow tracking and tracing management are achieved.

Owner:SHANDONG JIAOTONG UNIV

Drawing file digital informatization management system and management method

ActiveCN111309998AReasonable designLow costTypewritersOffice automationNumerical controlInformatization

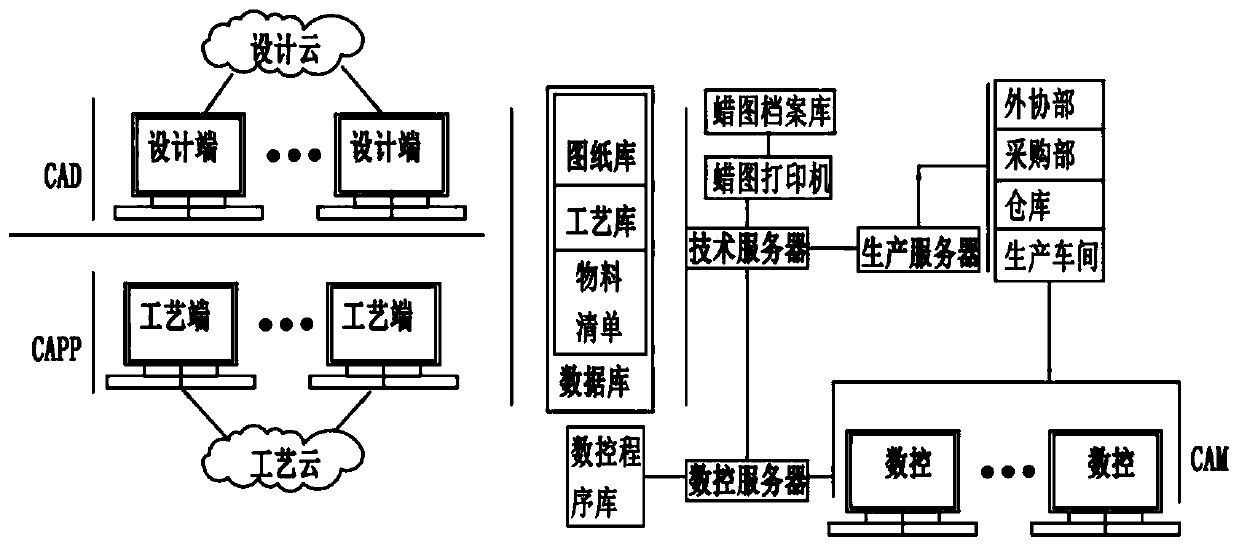

The invention relates to a drawing archive digital informatization management system and management method, and the system comprises a design end which carries out the modeling of a design product andthe drawing of a production drawing based on industrial design software, and carries out the utilization of each design end computer through design cloud; the process end which is used for simulatingthe production and manufacturing process of the designed product based on process compiling software, compiling a production process and utilizing computers of all the process ends through process cloud; the database is provided with an electronic drawing imported by the design end and stores process data and a product physical list imported by the process end; the technology server which servesas an upper computer of the design end and the process end and is connected with the database; the numerical control server which stores digital electric programming of each machine tool and is connected with a numerical control programming library and a technical server through a network or hardware; the device is reasonable in design, compact in structure and convenient to use.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

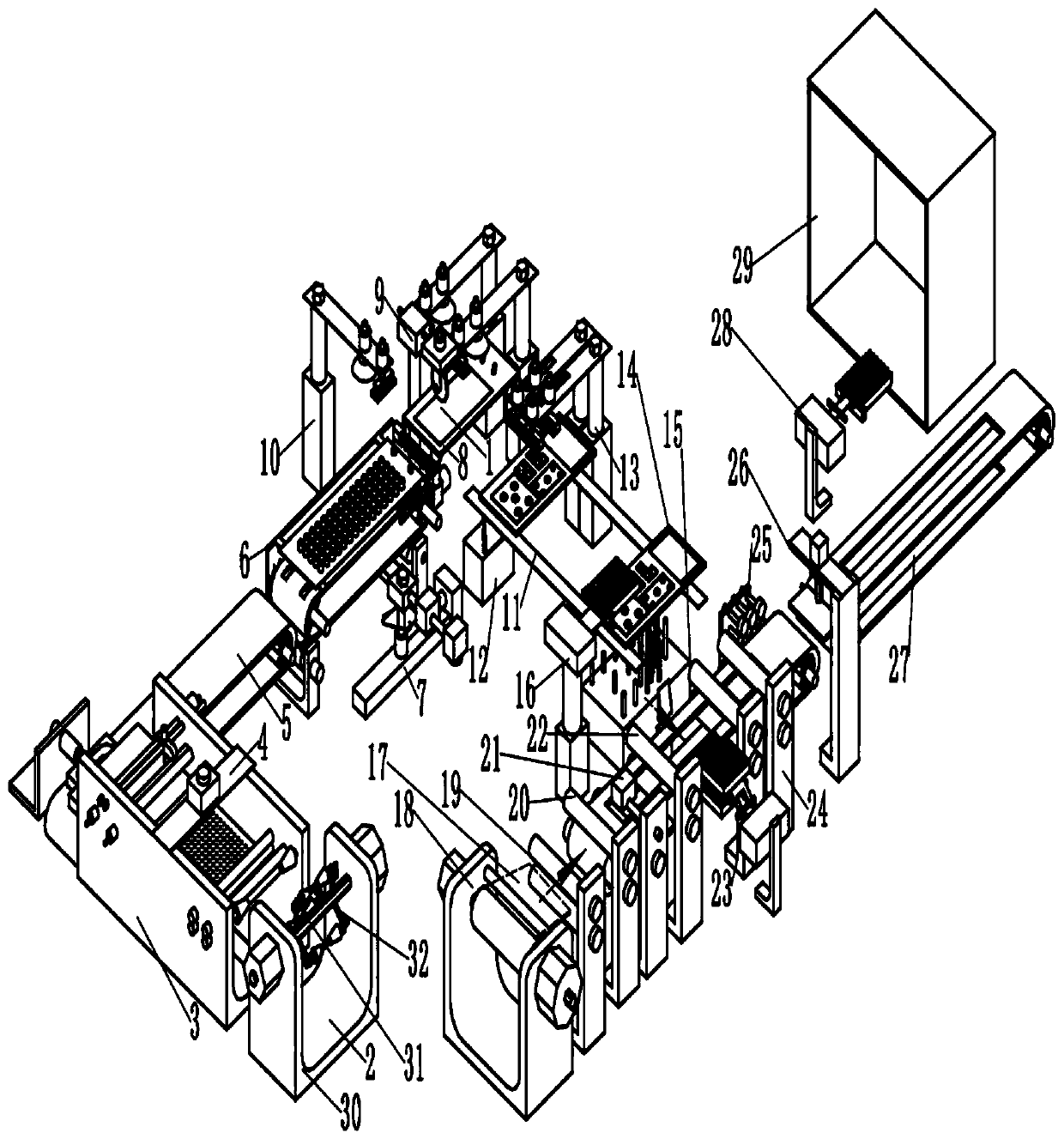

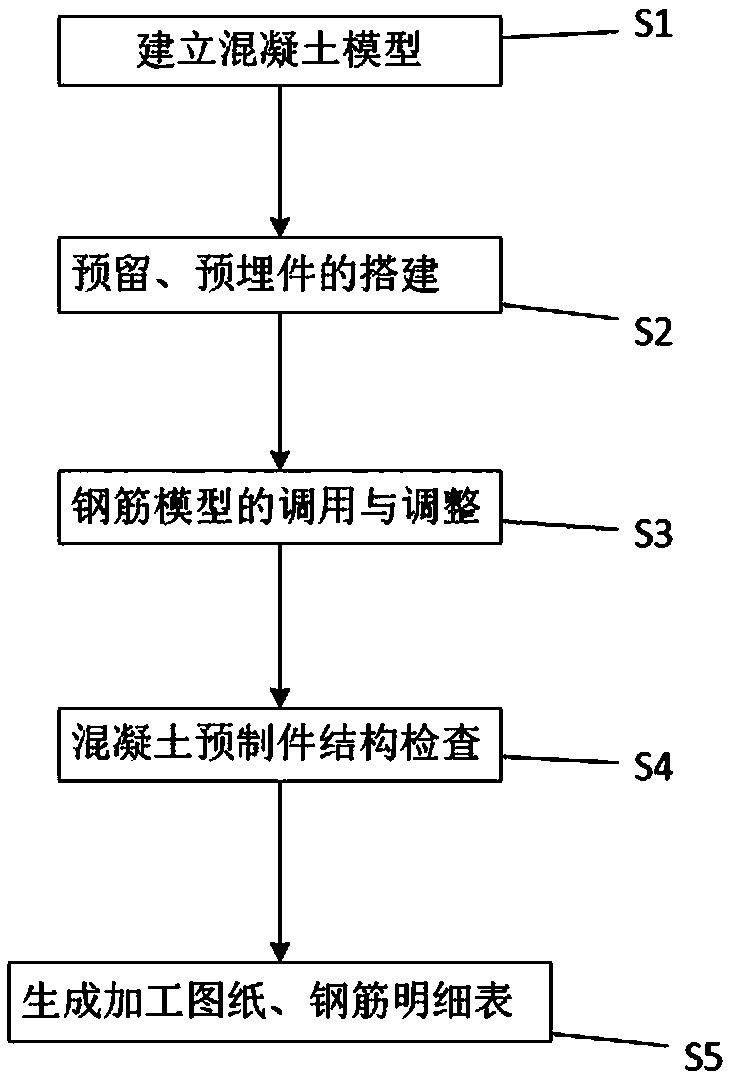

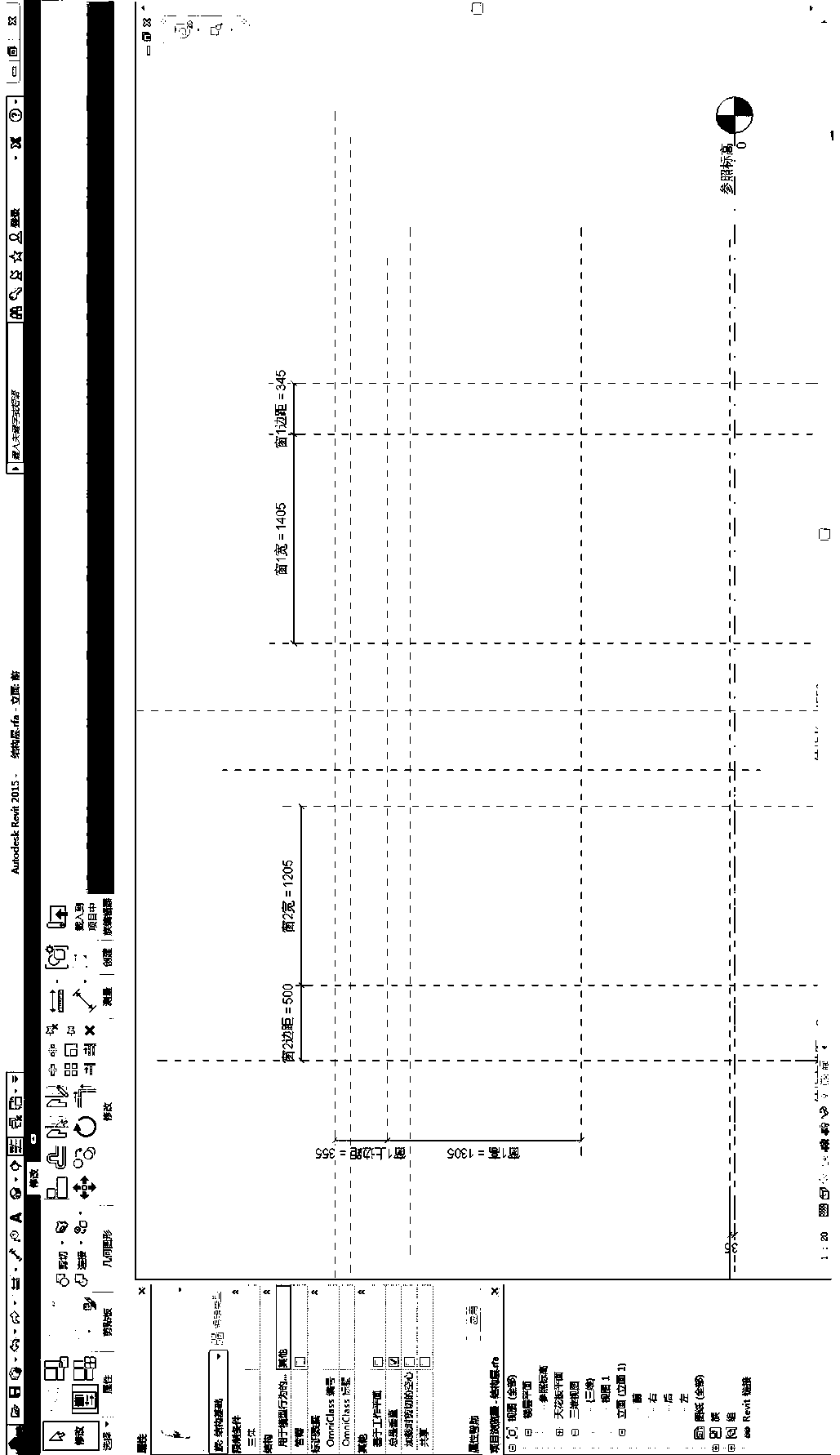

A detailed design method of concrete prefabricated parts based on revit

ActiveCN105550386BImprove the efficiency of detailed designEnable smart designSpecial data processing applicationsIntelligent designProduction drawing

The invention discloses a method for deepening the design of concrete prefabricated parts based on Revit, which includes the following steps: firstly, building a concrete model; then, constructing reserved and embedded parts; then, calling and adjusting the steel bar model; and then, prefabricating concrete Check the structure of the parts; finally, generate processing drawings and steel bar schedules. The concrete prefabricated part deepening design method provided by the present invention independently develops the steel bar family file according to the national standard of the steel bar; adopts the family nesting design method, and associates the steel bar with the structural wall nesting to realize intelligent design; can automatically generate steel bar shape parameters The steel bar schedule with model information improves the efficiency of detailed design of concrete prefabricated parts.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com