Preparation method of large-size sintered silicon carbide wear-resistant pipeline

A technology for sintered silicon carbide and wear-resistant pipes, which is applied in the direction of manufacturing tools, molds, ceramic molding cores, etc., and can solve the problem of low yield of sintered silicon carbide wear-resistant pipes, difficulty in meeting production and application requirements, mold size and grouting Unsuitable control of quantity and other problems, to achieve the effect of reasonable structure, change of production process, and promotion of green body formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a large-size sintered silicon carbide wear-resistant pipe, specifically comprising the following steps:

[0045] 1. Processing of production drawings:

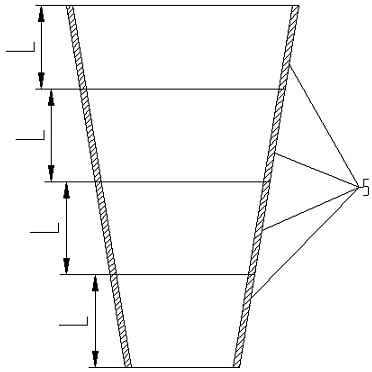

[0046]According to the axial length of the silicon carbide wear-resistant pipe product to be produced, the silicon carbide wear-resistant pipe is divided into a plurality of production units 5 evenly along its axial direction from bottom to top, and each production unit 5 is numbered. The length L of the unit 5 is less than or equal to 100 mm, and then the production size of each production unit 5 is calculated according to the product structure and parameters of the silicon carbide wear-resistant pipe.

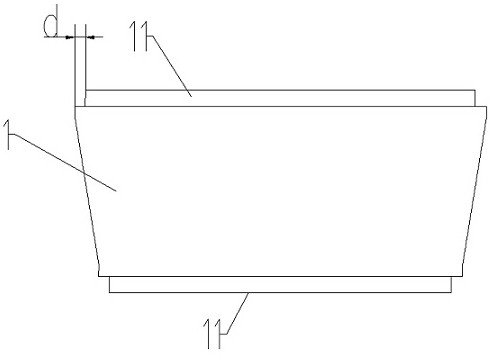

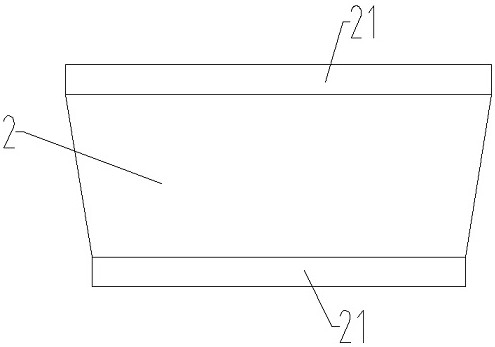

[0047] Such as figure 2 Shown: 2. Make the outer bottom mold:

[0048] Make the outer bottom mold 1 according to the outer surface size of each production unit 5 in the above step 1, the overall outer surface structure of the outer bottom mold 1 matches the overall outer surface shape of the c...

Embodiment 2

[0101] A method for preparing a large-size sintered silicon carbide wear-resistant pipe, specifically comprising the following steps:

[0102] 1. Processing of production drawings:

[0103] According to the axial length of the silicon carbide wear-resistant pipe product to be produced, the silicon carbide wear-resistant pipe is divided into a plurality of production units 5 evenly along its axial direction from bottom to top, and each production unit 5 is numbered. The length L of the unit 5 is 75 mm, and then the production size of each production unit 5 is calculated according to the product structure and parameters of the silicon carbide wear-resistant pipe.

[0104] 2. Make the outer bottom mold: use epoxy resin, and make the outer bottom mold 1 according to the outer surface size of each production unit 5 in the above step 1, the outer surface diameter of the outer bottom mold 1 is greater than or equal to the corresponding production unit 5 The diameter of the outer sur...

Embodiment 3

[0139] A method for preparing a large-size sintered silicon carbide wear-resistant pipe, specifically comprising the following steps:

[0140] 1. Processing of production drawings:

[0141] According to the axial length of the silicon carbide wear-resistant pipe product to be produced, the silicon carbide wear-resistant pipe is divided into a plurality of production units 5 evenly along its axial direction from bottom to top, and each production unit 5 is numbered. The length L of the unit 5 is 85 mm, and then the production size of each production unit 5 is calculated according to the product structure and parameters of the silicon carbide wear-resistant pipe.

[0142] 2. Make the outer bottom mold: use aluminum alloy, and make the outer bottom mold 1 according to the outer surface size of each production unit 5 in the above step 1, the outer surface diameter of the outer bottom mold 1 is greater than or equal to the corresponding production unit 5 The outer surface diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com