Offline detecting type automatic welding method used for large-scale complex box type structural member

An automatic welding and box-shaped structure technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor welding strength and other problems, and achieve the effect of eliminating the phenomenon of welding seam forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

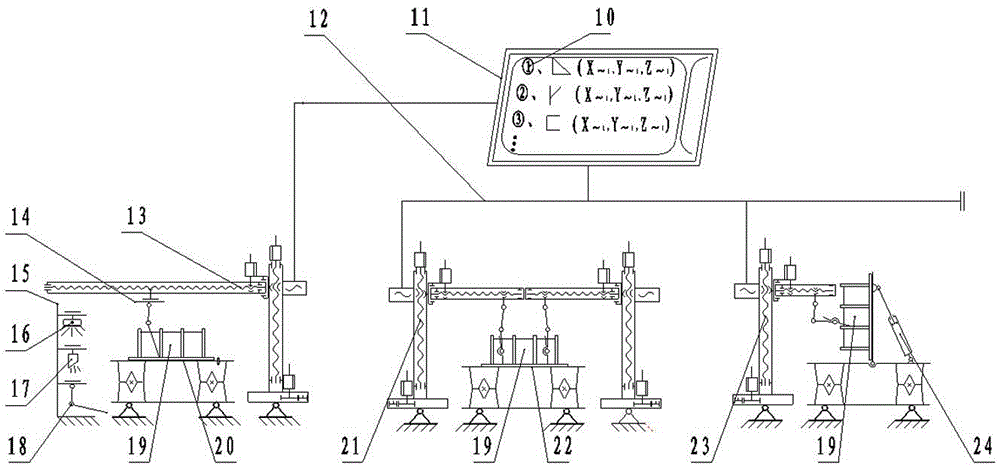

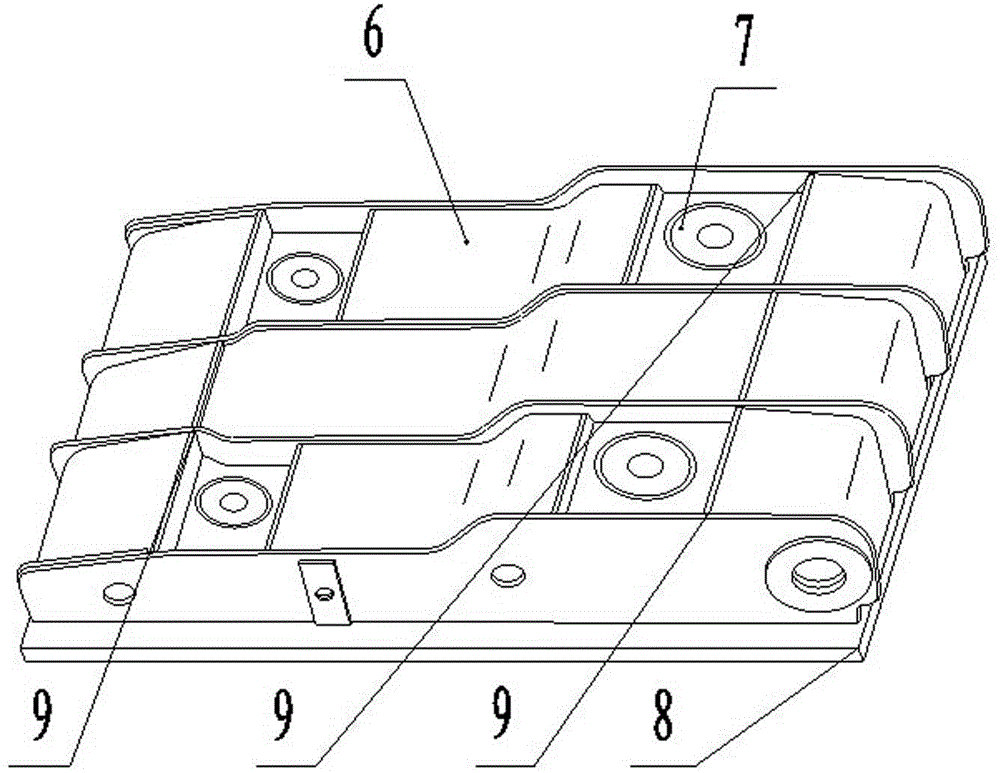

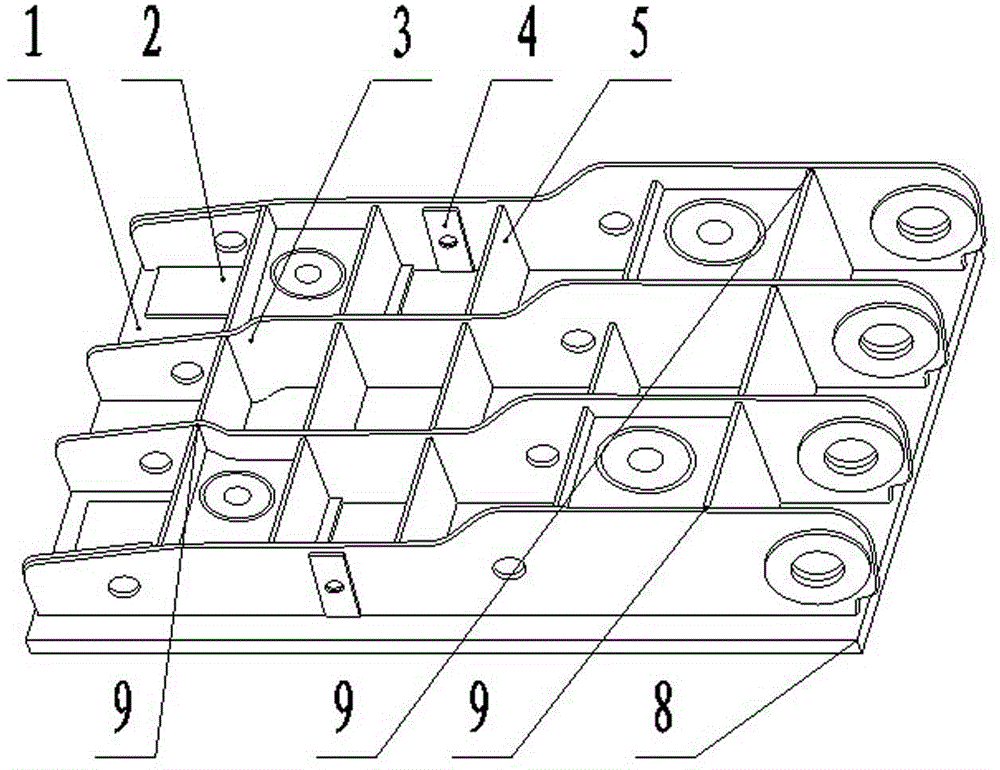

[0015] An off-line detection type automatic welding method for large and complex box-shaped structural parts, which adopts the following steps: a. According to the production drawings of large and complex box-shaped structural parts 19, the flat plate 1, backing plate 2, and curved plate 3 contained in it are , pasting plate 4, straight plate 5, cover plate 6 and functional parts 7 are assembled and formed; b, the large and complex box-shaped structural part 19 assembled and formed is placed on the automatic measurement station 20, and the three-coordinate measurement on the top of the automatic measurement station 20 The system 13 grabs the contact-type continuous measuring instrument 18 from the measuring instrument storage library 15 through the quick-change joint 14, constructs the real workpiece Cartesian coordinate system 8 with the flat plate 1 as the reference, and constructs the real object Cartesian coordinate system 8 in the three-dimensional direction of the large an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com