Welding seam automatic tracking method for large-sized complex box-shaped structural part

A technology of automatic tracking and structural parts, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unable to guarantee the quality of welding seam, unable to adapt to the requirements of unified tracking in the narrow space of box-shaped squares, etc. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1-7 As shown in , a method for real-time automatic tracking of weld seams for large and complex box-shaped structural parts adopts the following steps:

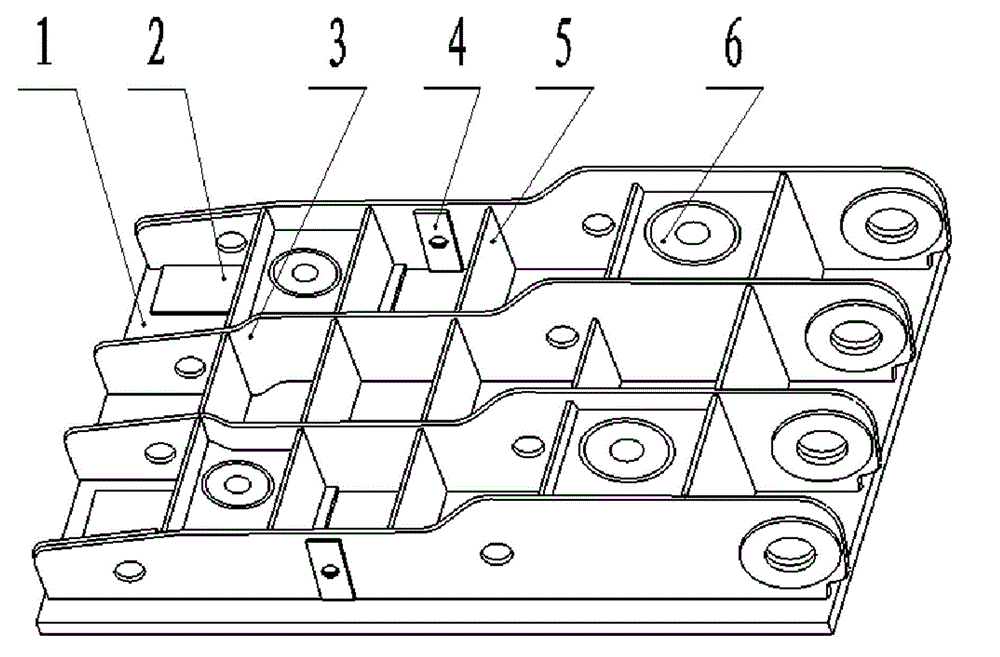

[0029] ①, (refer to figure 1 ) Assemble the flat plate 1, backing plate 2, curved plate 3, pasting plate 4, straight plate 5 and functional components 6 into a grid structure according to the production requirements of large and complex box-shaped structural parts.

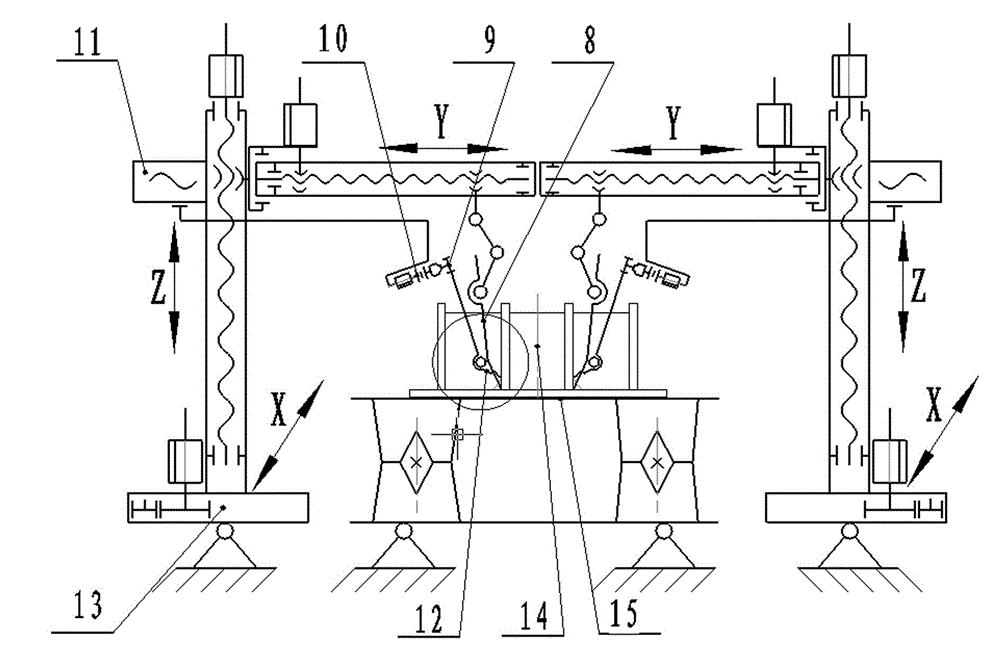

[0030] ②, (refer to image 3 ) Place the assembled large complex box-shaped grid structure 14 on the automatic welding station 15, start the inner cavity automatic welding equipment 13, and the welding torch 8 configured on it automatically finds the starting point of the weld according to the preset welding program; Simultaneously, the swinging striker 12 installed at the end of the welding torch begins to swing obliquely repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com