Patents

Literature

708results about How to "Realize automatic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

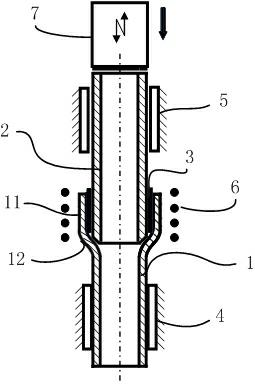

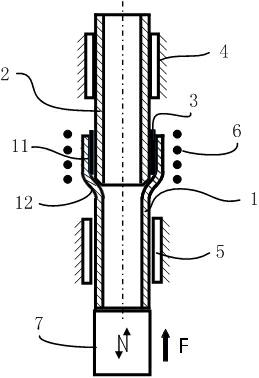

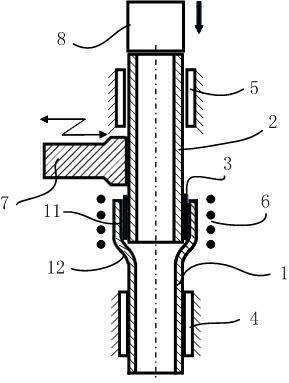

Method for brazing copper aluminum tubes without aid of brazing flux

InactiveCN102581414AReduce porosityImprove air tightnessSoldering apparatusWelding/soldering/cutting articlesSlag (welding)Weld seam

The invention discloses a method for brazing copper aluminum tubes without the aid of brazing flux. The method includes the steps: firstly, expanding one end of optional one of the copper aluminum tubes into a socket by a thermal expansion method, manufacturing a brazing alloy plate into a brazing thin tube by a stamping method, and placing the brazing thin tube into the socket; secondly, inserting one end of another welded tube into the brazing thin tube, and tightly abutting the end opening of the welded tube to the bottom of the socket to form close fit; and thirdly, assembling the brazing thin tube and the welded tube on a welding fixture, performing local induction heating for joints, and applying proper welding pressure and ultrasonic vibration. The method can be used for brazing the thin-wall copper aluminum tubes without the brazing flux, fusion lines are long, welding seams are compact, slag inclusion is avoided, the air tightness and the bonding strength of the joints are greatly improved, reliability is high, welding time is short, and great production and use values are achieved.

Owner:李明雨 +1

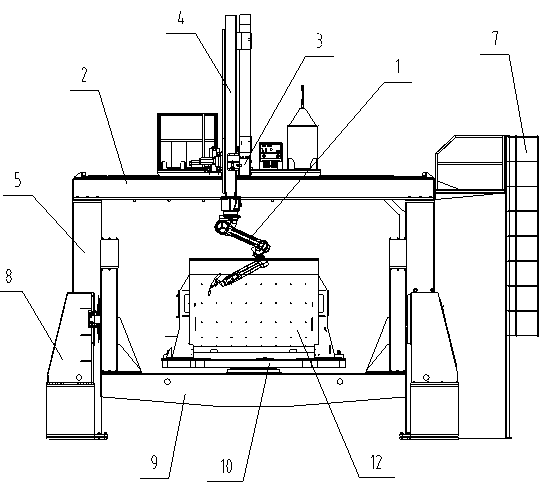

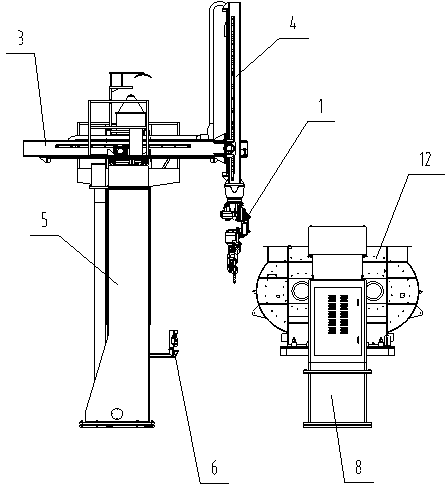

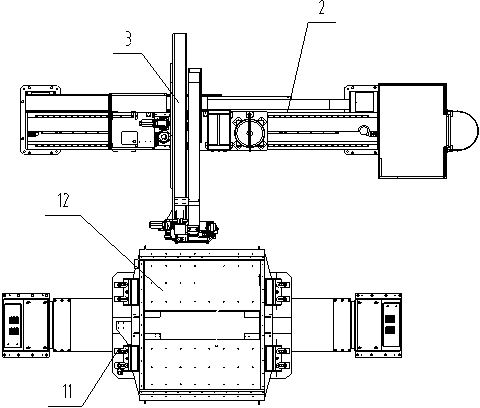

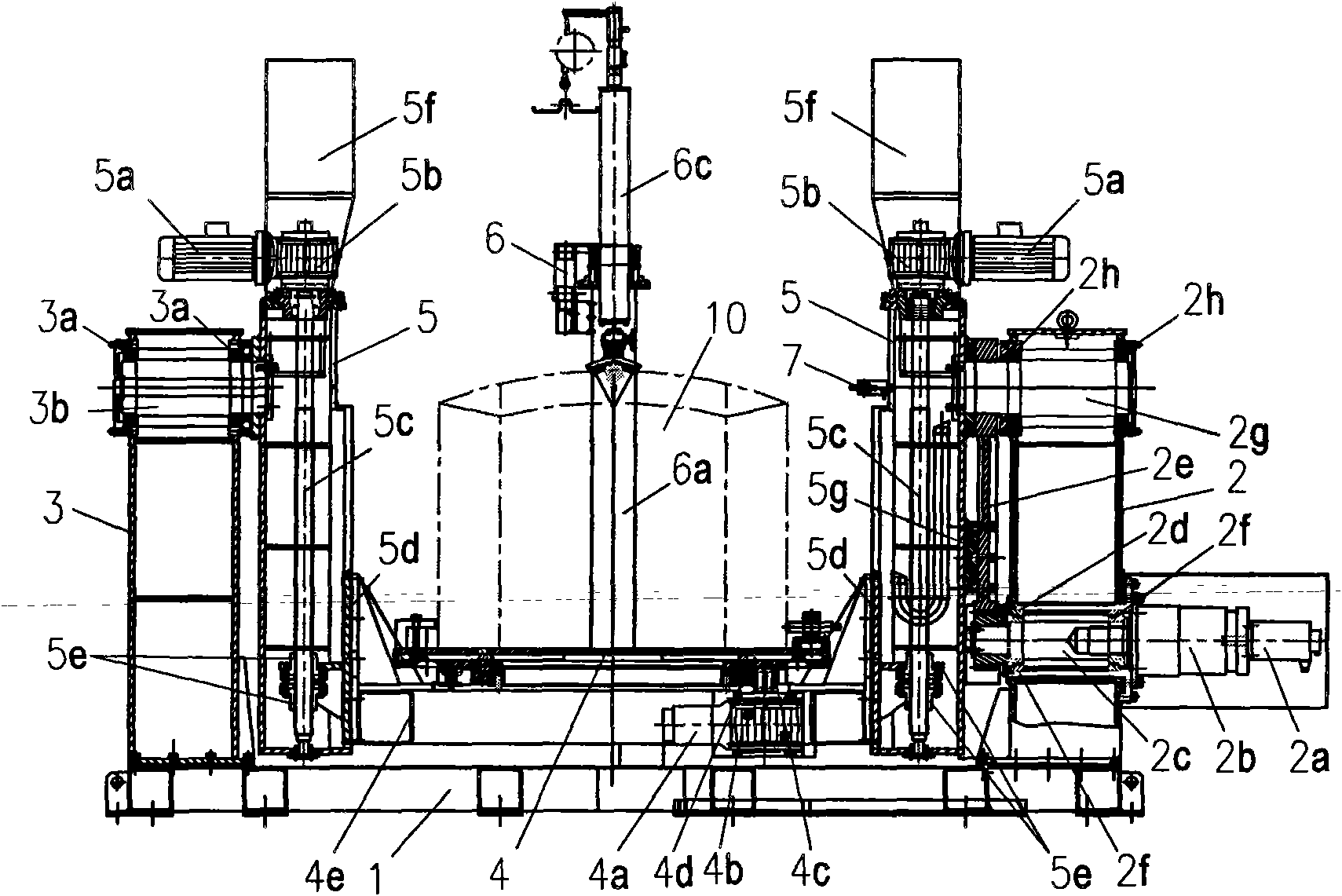

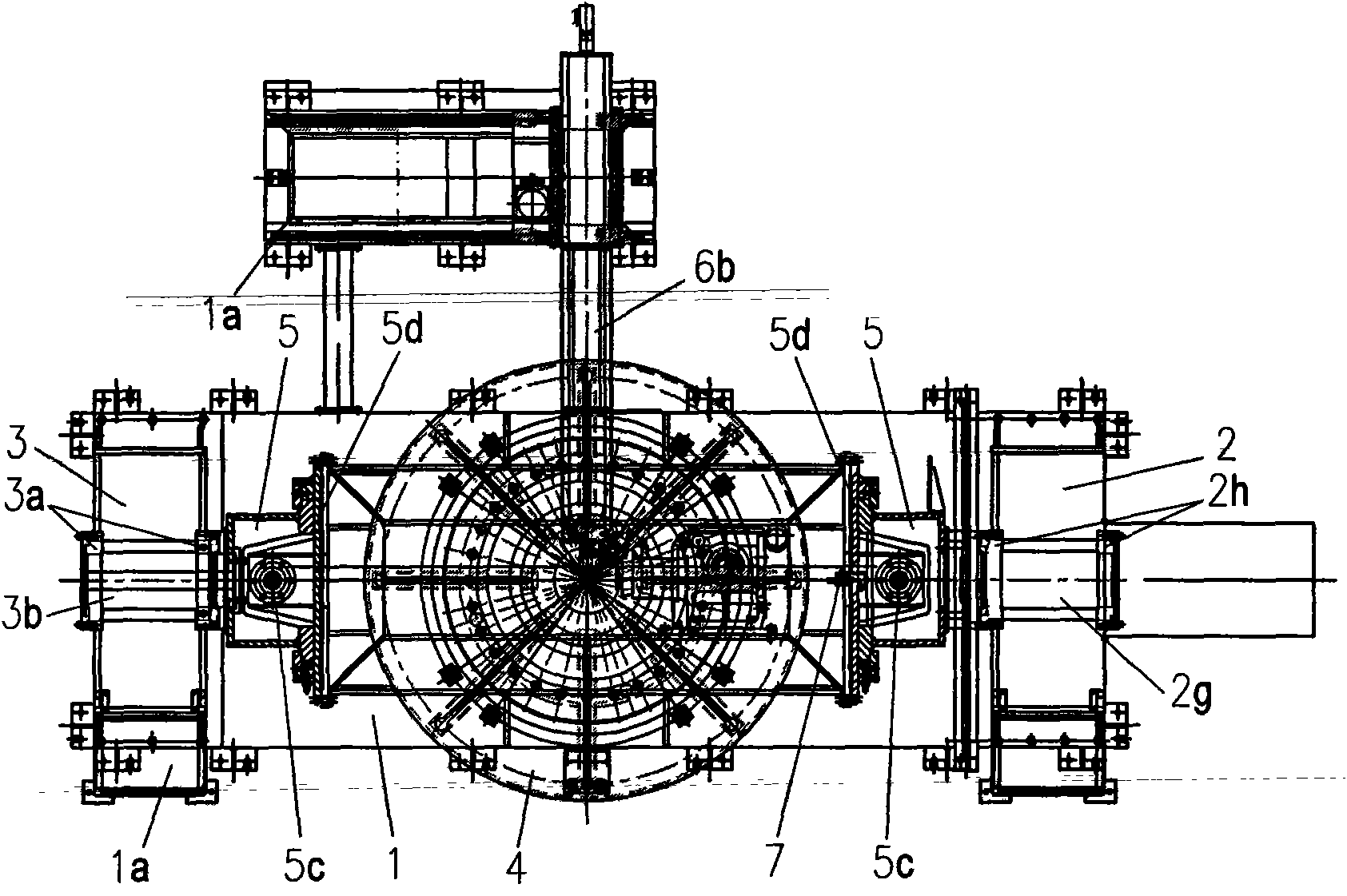

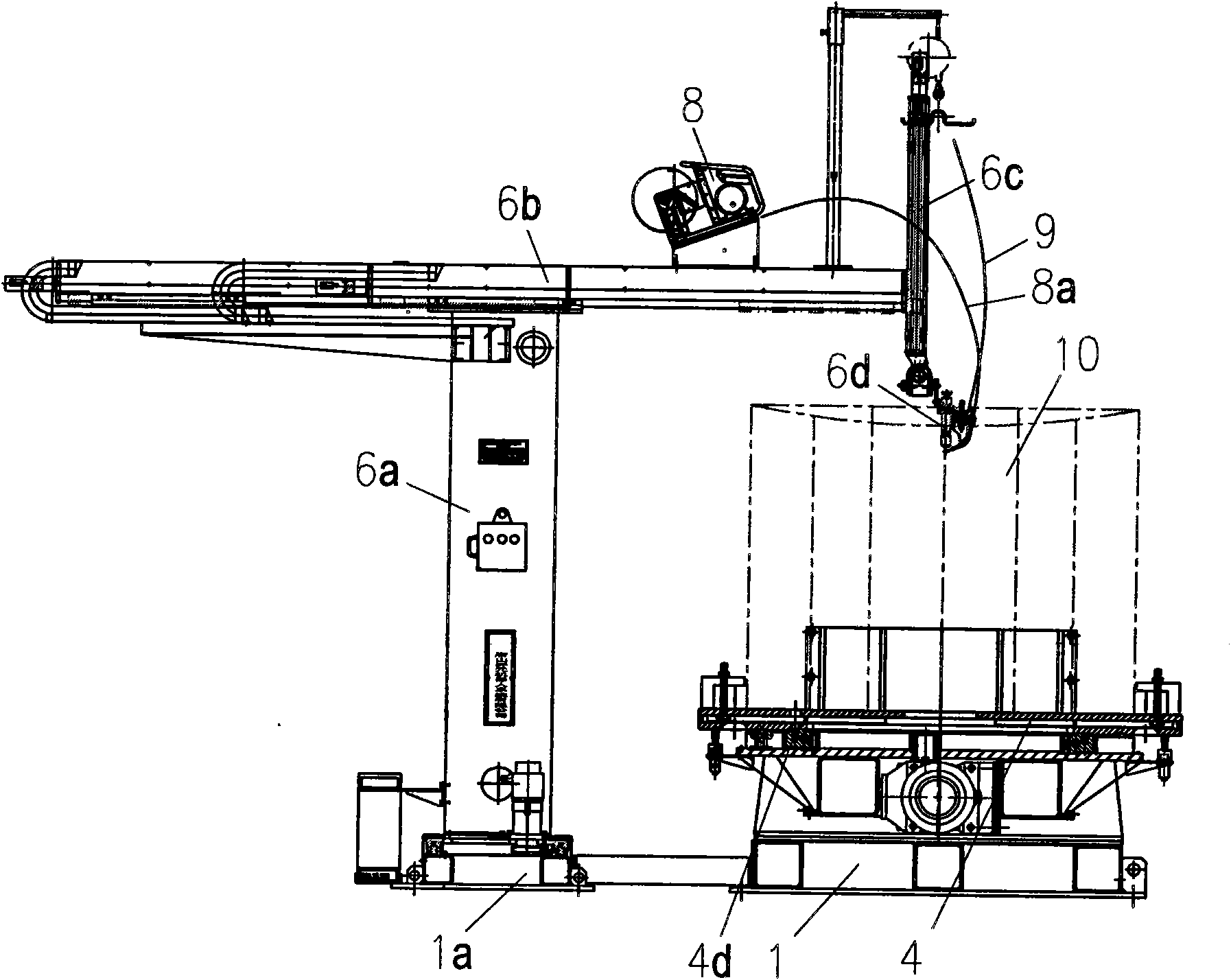

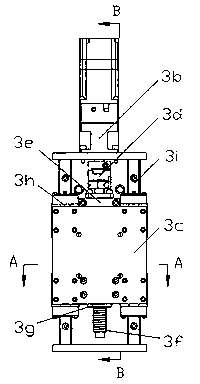

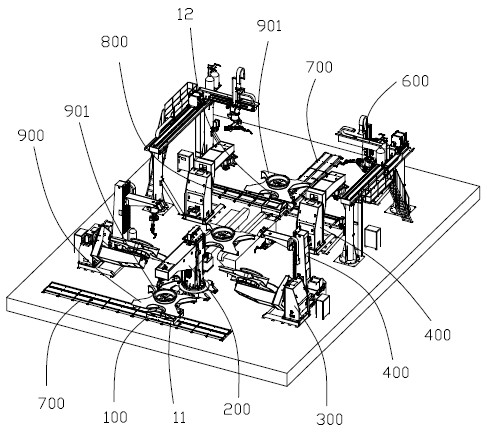

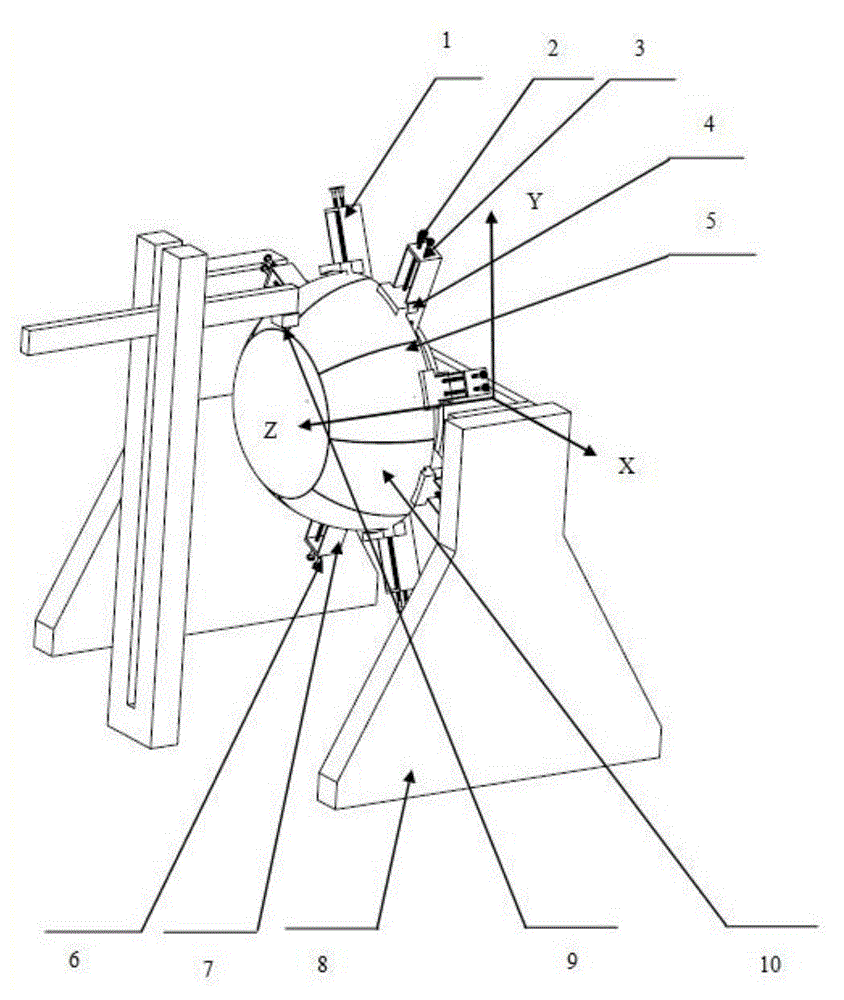

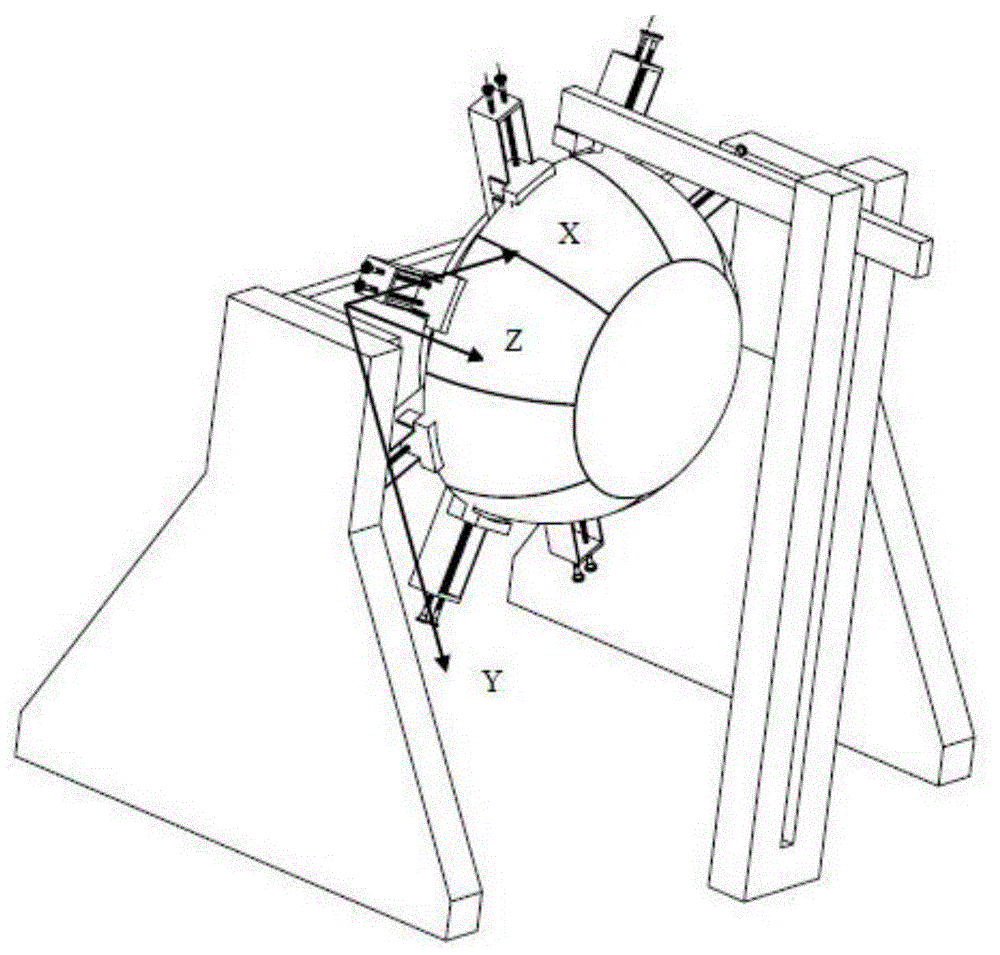

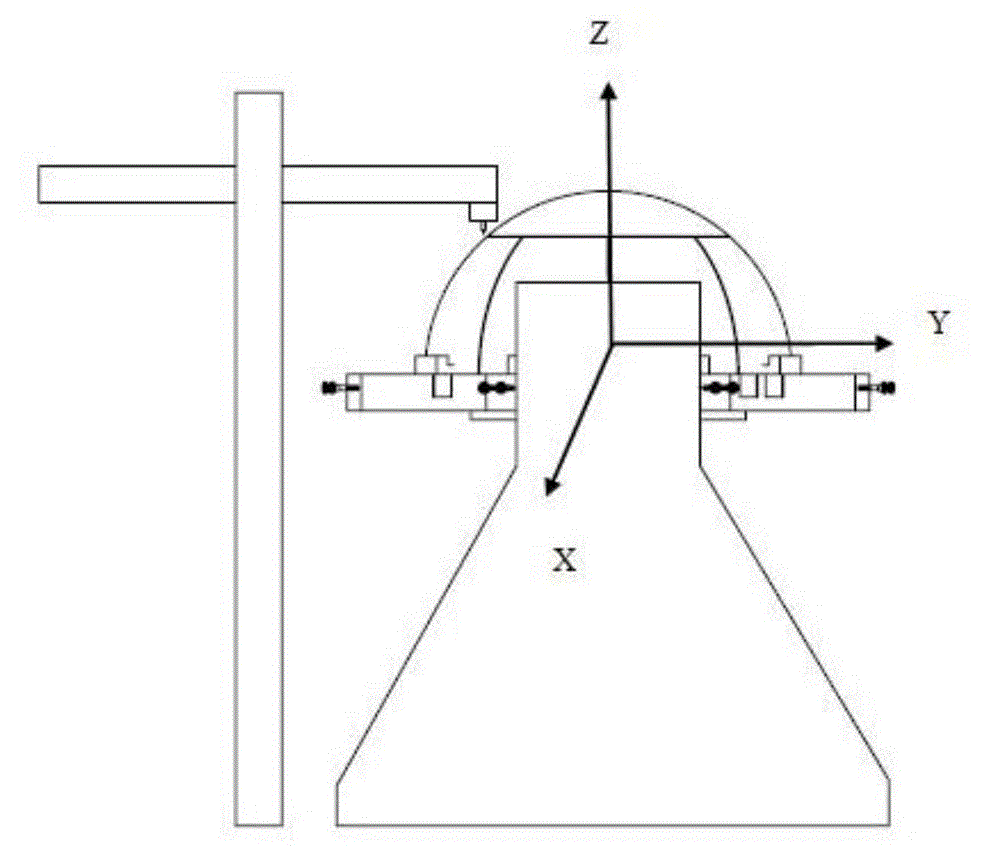

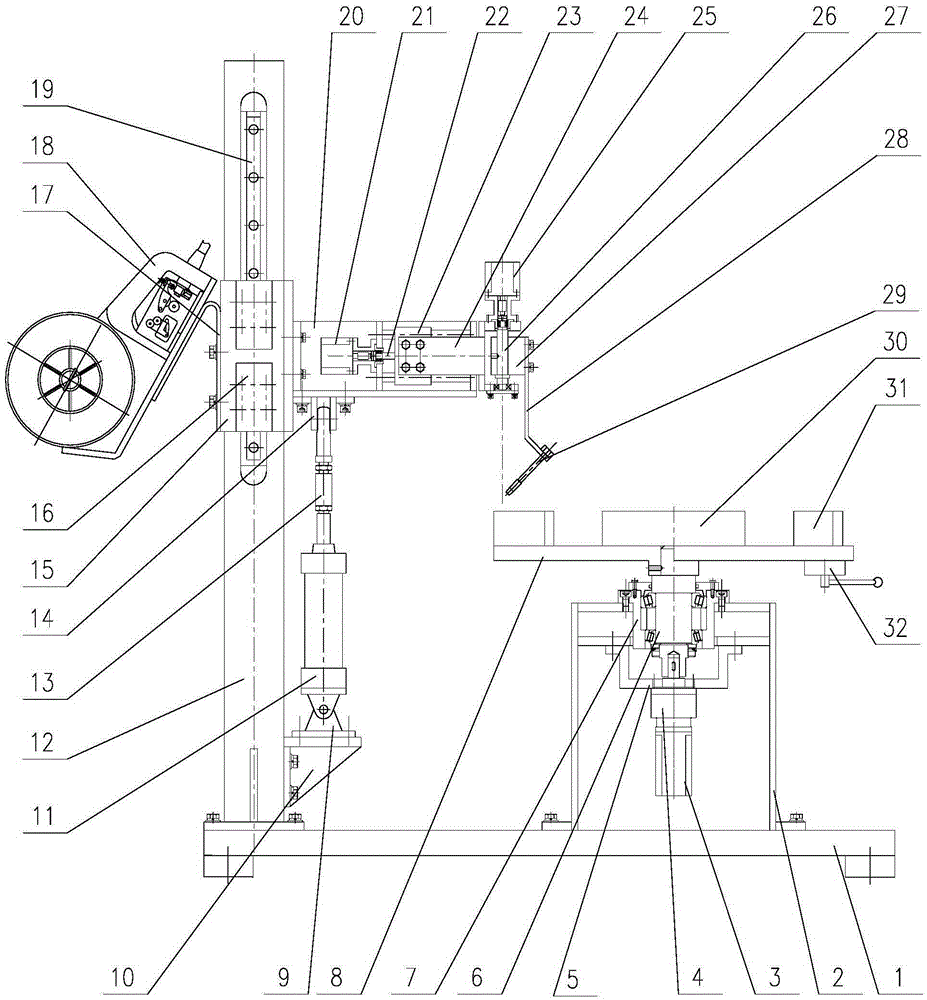

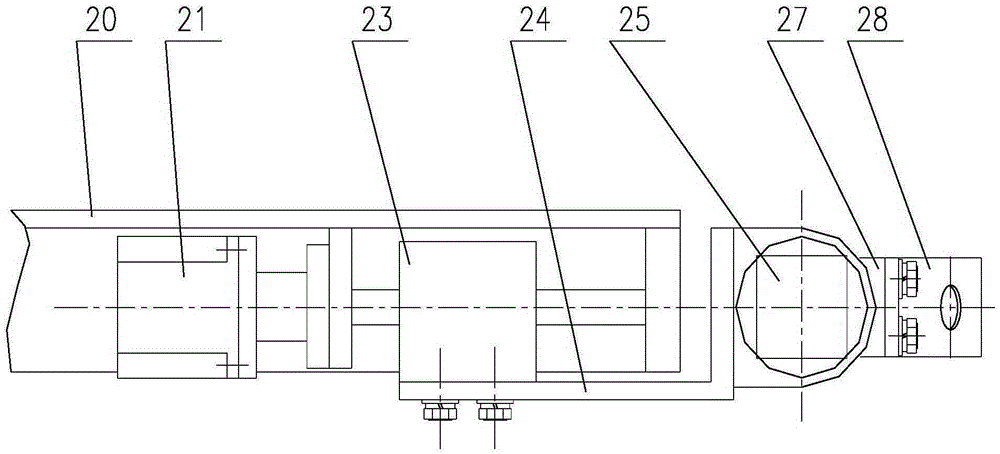

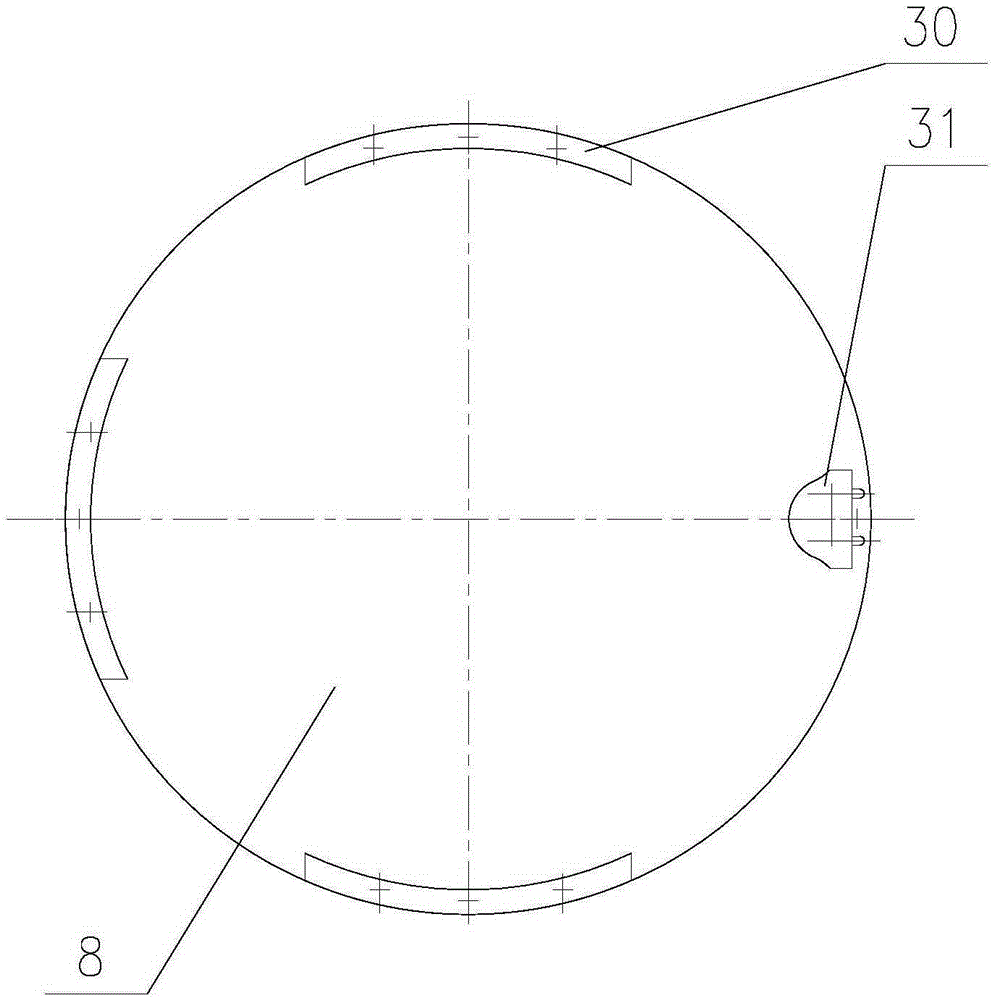

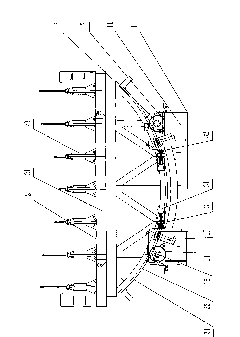

Robot welding workstation for cylinder body

InactiveCN103170707AImprove accessibilityReduce volumeWelding/cutting auxillary devicesElectrode supporting devicesOperation modeWorkstation

The invention discloses a robot welding workstation for a cylinder body. The robot welding workstation for the cylinder body comprises an arc welding robot, a welding positioner and a movable sliding table. The movable sliding table mainly comprises a shaft X, a shaft Y and a shaft Z, wherein the shaft X, the shaft Y and the shaft Z are perpendicular to one another, the shaft X and the shaft Y are horizontally arranged, the shaft Z is vertically arranged, two ends of the bottom portion of the shaft X are connected with upright columns, the top portion of the shaft X is connected with the shaft Y in a sliding mode, and one end portion of the shaft Y is connected with the shaft Z in a sliding mode. The arc welding robot is mounted at the bottom end of the shaft Z, and the welding positioner is arranged beside the movable sliding table and corresponds to the arc welding robot. The robot welding workstation for the cylinder body has the advantages that a traditional manual welding operation mode is replaced, automatic welding of the cylinder body of a stirring machine is realized, and welding efficiency and welding quality are improved.

Owner:成都佳士科技有限公司

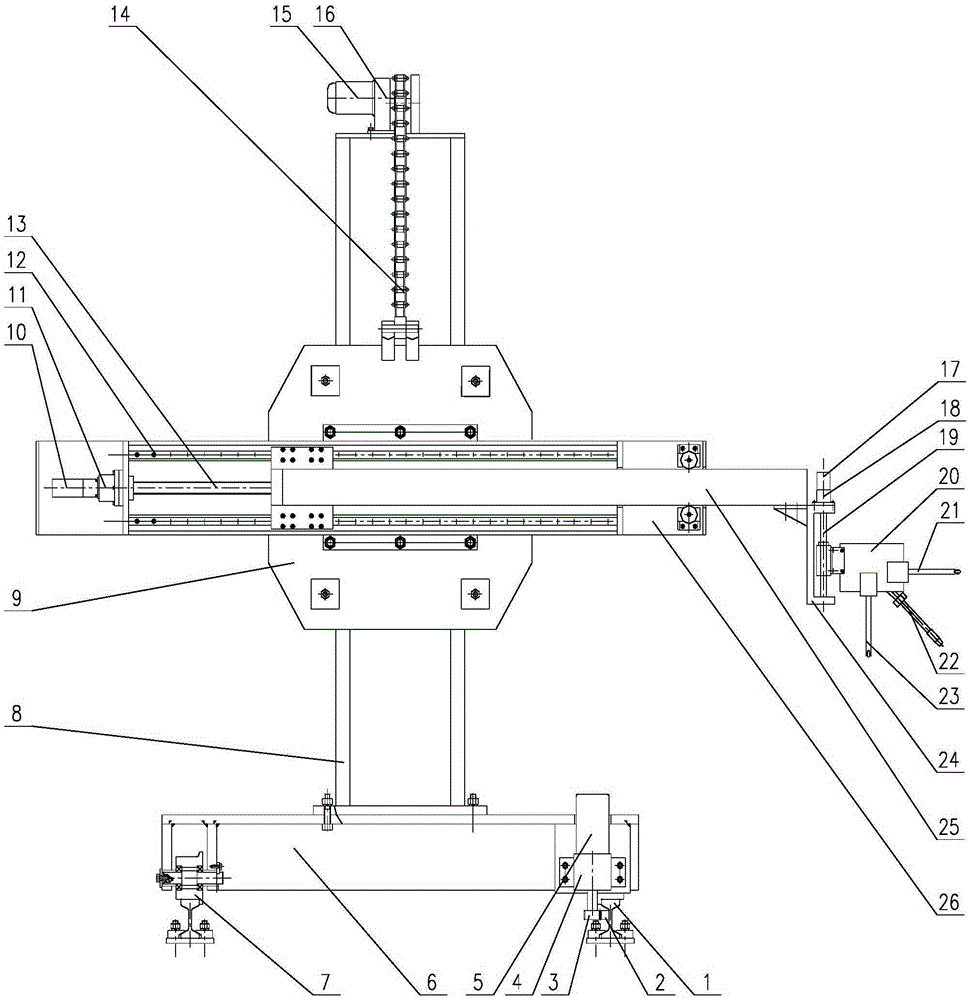

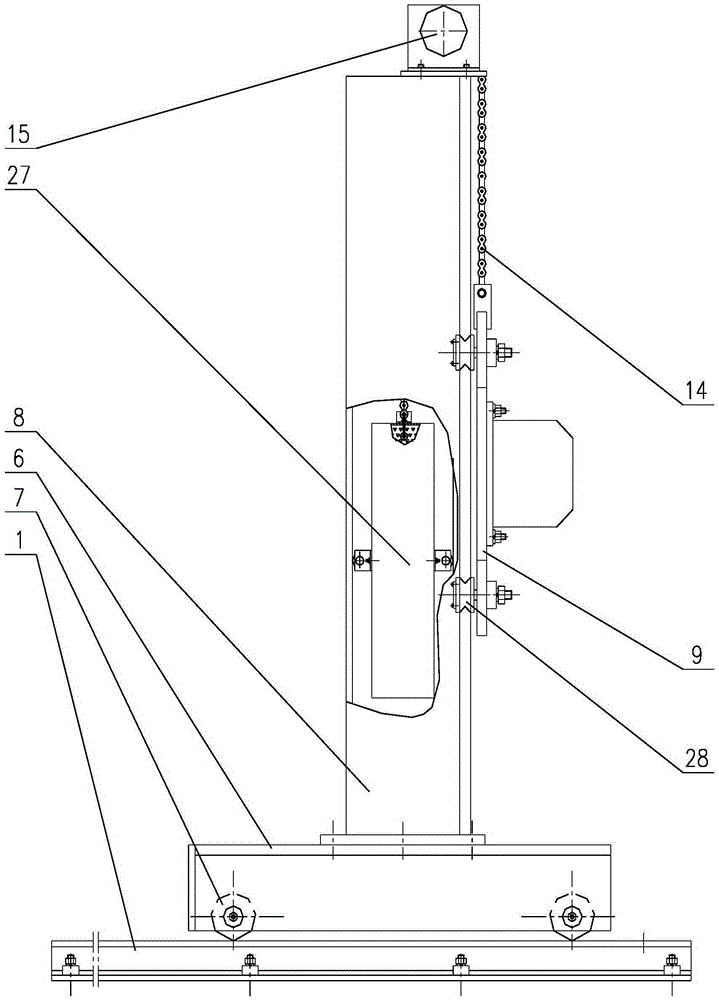

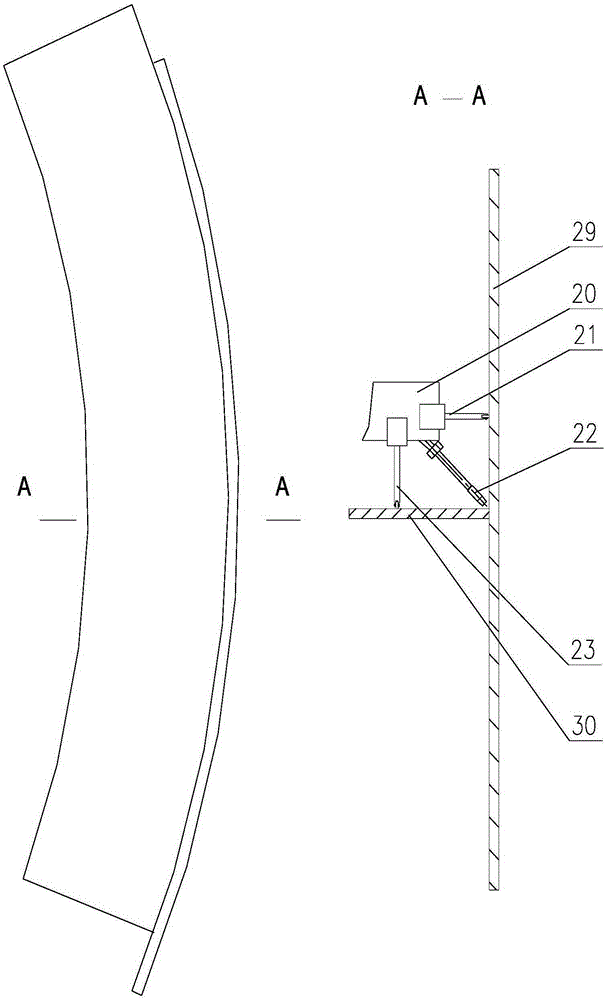

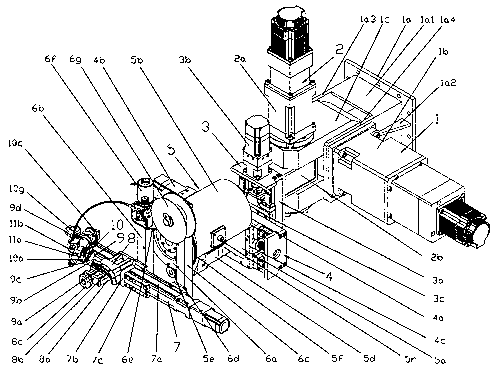

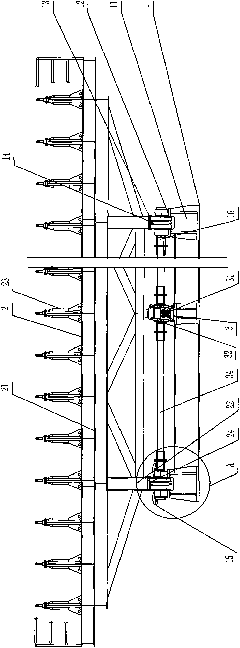

Oil tank shell inner rib plate welding equipment

InactiveCN105234606AHigh control precisionRealize automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesControl systemControl engineering

The invention provides oil tank shell inner rib plate welding equipment and belongs to the field of automatic welding equipment. The welding equipment is composed of a longitudinal guide rail, a base, stand columns, a sliding plate, a cross beam, a telescopic arm and a welding mechanism. In the welding process, a touch type displacement sensor collects the relative distance between a welding gun and a shell and the distance between the welding gun and an inner rib plate in real time, a control system controls a transverse servo motor to drive the telescopic arm to move in the horizontal direction and controls a vertical servo motor to drive an installing plate to move in the vertical direction, the relative position between the welding gun and the shell and the relative position between the welding gun and the inner rib plate are kept unchanged, the welding track is not influenced by errors of a work-piece clamping position, automation of the process of welding the inner rib plate of the oil tank shell is achieved, and welding quality and welding efficiency are improved easily.

Owner:SHANDONG JIANZHU UNIV

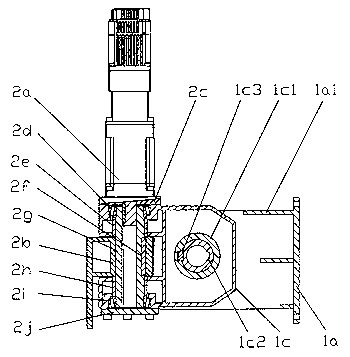

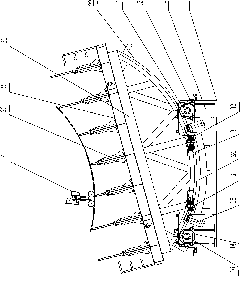

Automatic bead welding equipment of saddle-shaped pipe joint surface with conical table and welding method thereof

InactiveCN101804493AAchieve horizontal displacementConsistent weld beadWelding accessoriesEngineeringLinkage concept

The invention relates to automatic bead welding equipment of a saddle-shaped pipe joint surface with a conical table and a welding method thereof, belonging to the technical field of automatic welding equipment and welding methods. The equipment comprises a station regulating device, an automatic welding gun manipulator, a laser positioner and an electrical control device. When the equipment works, the electrical control device controls the station regulating device and the automatic welding gun manipulator to be dynamically matched to complete the bead welding of an anti-corrosive layer of the saddle-shaped pipe joint surface with the conical table. The invention has the advantages that the electrical control device controls five-shaft linkage so that the end surface of the bead welding position of a workpiece is in a horizontal state; due to the adoption of a hot wire TIG (Tungsten Inert Gas) welding process and a horizontal continuous welding, the automatic bead welding equipment has good welding quality; the automatic bead welding equipment completely realizes automatic welding, reduces the polishing quantity of the bead welding surface and improves the utilization rate of a welding material; and voltage is added between a wire-feeding conducting nozzle and the workpiece through adopting a hot wire technique so that current flows through a welding wire between the wire-feeding conducting nozzle and the workpiece to heat the welding wire, and then the absorption of the welding wire for the heat quantity of an electric arc is reduced, thereby improving the welding efficiency.

Owner:CHINA FIRST HEAVY IND +1

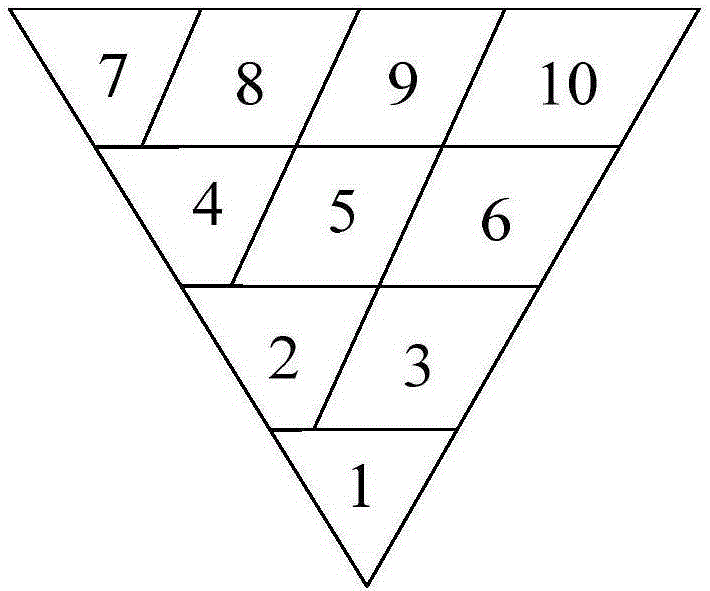

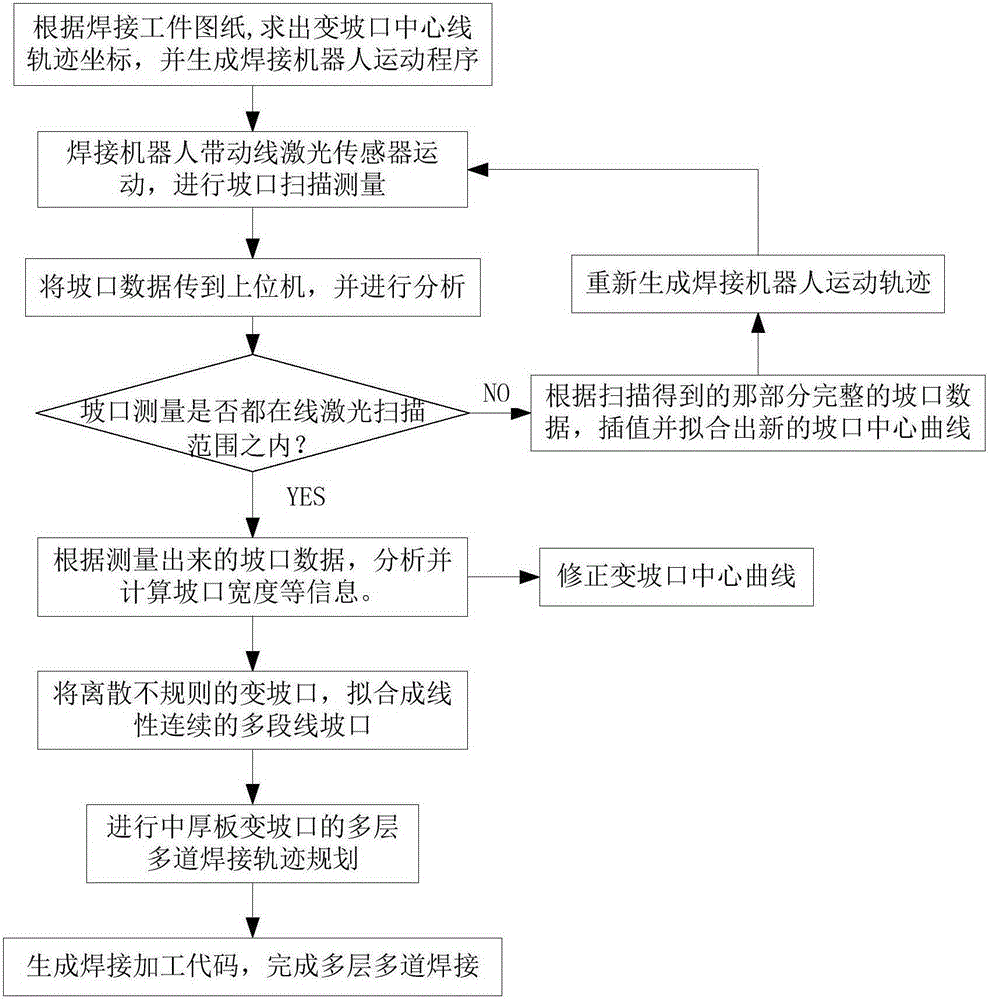

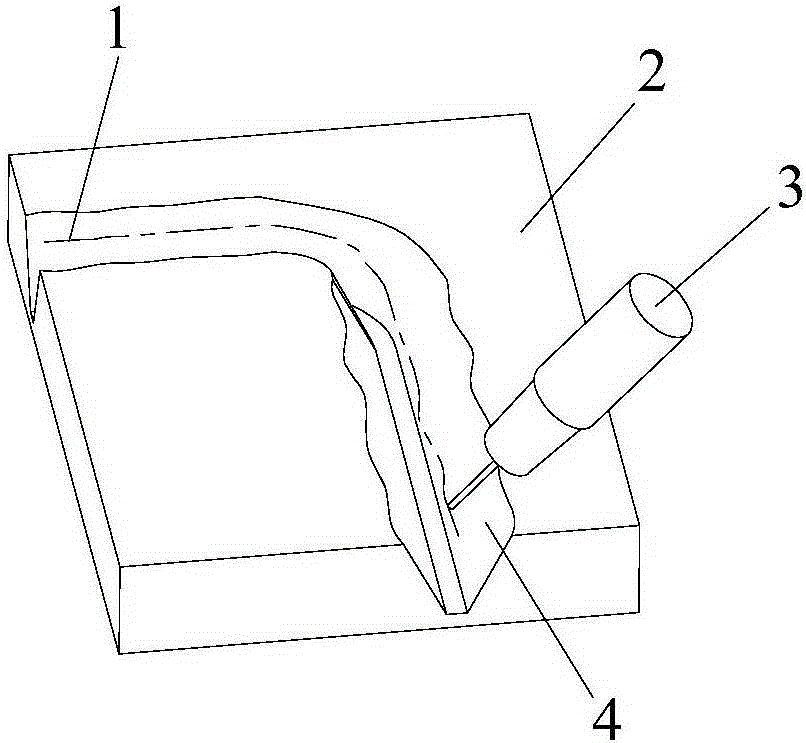

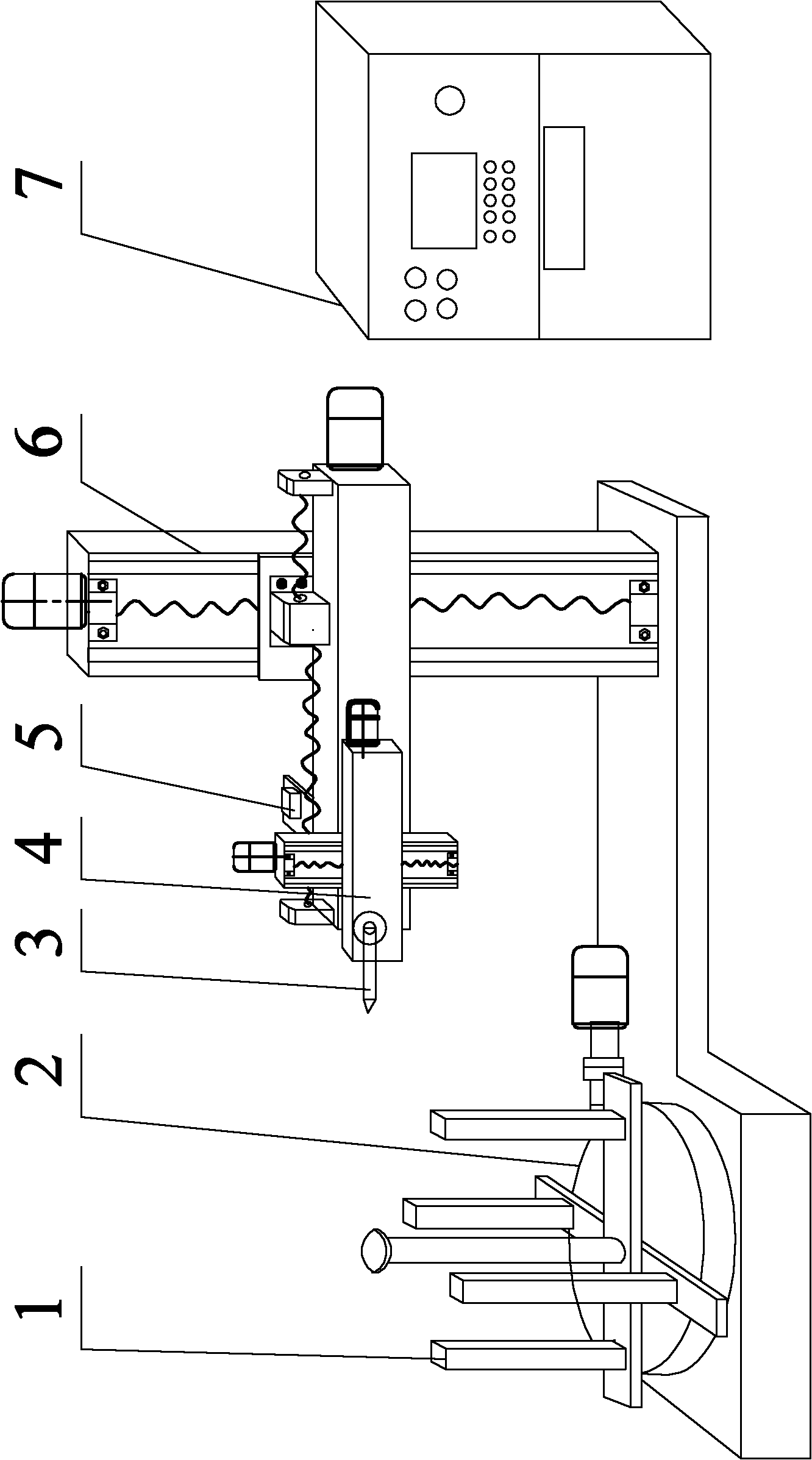

Multilayer and multipass welding track planning method for variable-groove-width heavy and medium plates

ActiveCN105171289ARealize automatic weldingMeet the needs of actual weldingWelding/cutting auxillary devicesAuxillary welding devicesLaser sensorPhysics

The invention discloses a multilayer and multipass welding track planning method for variable-groove-width heavy and medium plates. A line laser sensor is used for carrying out groove scanning and measuring on variable-groove-width heavy and medium plate welding parts; variable groove information is collected according to certain sampling frequency; then key information extraction and data processing are carried out on collected grooves, a variable groove center curve is finished, and irregularly-discrete variable groove data points are fitted into multiple linearly-continuous line segments; and finally according to multilayer and multipass welding parameters of the heavy and medium plates, the variable groove center curve and the fitted multi-line-segment groove data are combined, and multilayer and multipass welding track planning of the variable-groove-width heavy and medium plates is completed. The method can be used for welding track planning of variable-groove-width welding parts and is simple, good universality and high practicality are achieved, and good application prospects are achieved.

Owner:XIAMEN UNIV OF TECH

Turbine cylinder block sealing surface repairing process

The invention relates to the field of steam turbines, in particular to a turbine cylinder block sealing surface repairing process. According to the turbine cylinder block sealing surface repairing process, adopted cold metal transition (CMT) welding is an MIG / MAG additive manufacturing technique, and the process is used for repairing the turbine cylinder block sealing surface. According to turbinecylinder block materials including P265GH and medium high temperature and high pressure steam, Ni-based alloy welding wire Ni-Cr-Mo is selected as an additive manufacturing material. According to theturbine cylinder block sealing surface repairing process, cold metal transition (CMT) additive manufacturing is used for repairing the sealing surface, operation is easy, the efficiency is high, andthe bonding force is better.

Owner:浙江翰德圣智能再制造技术有限公司

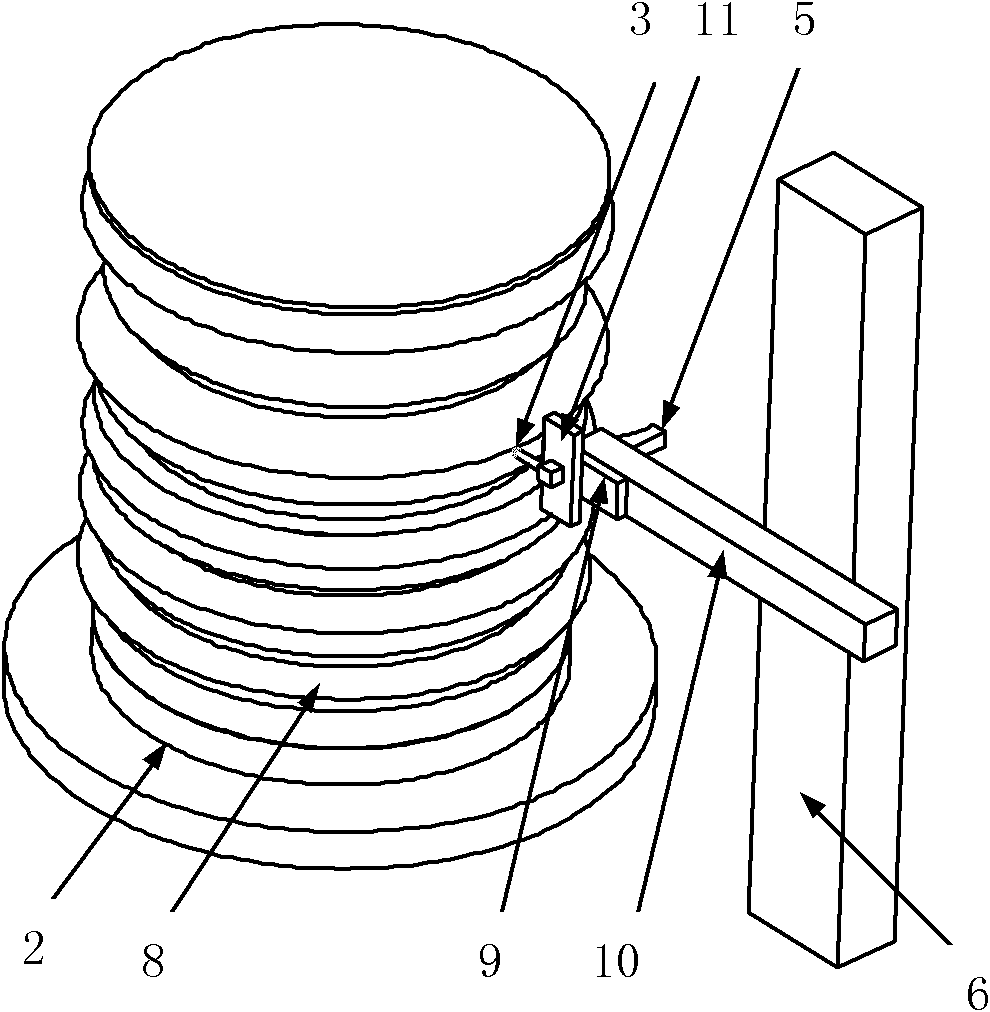

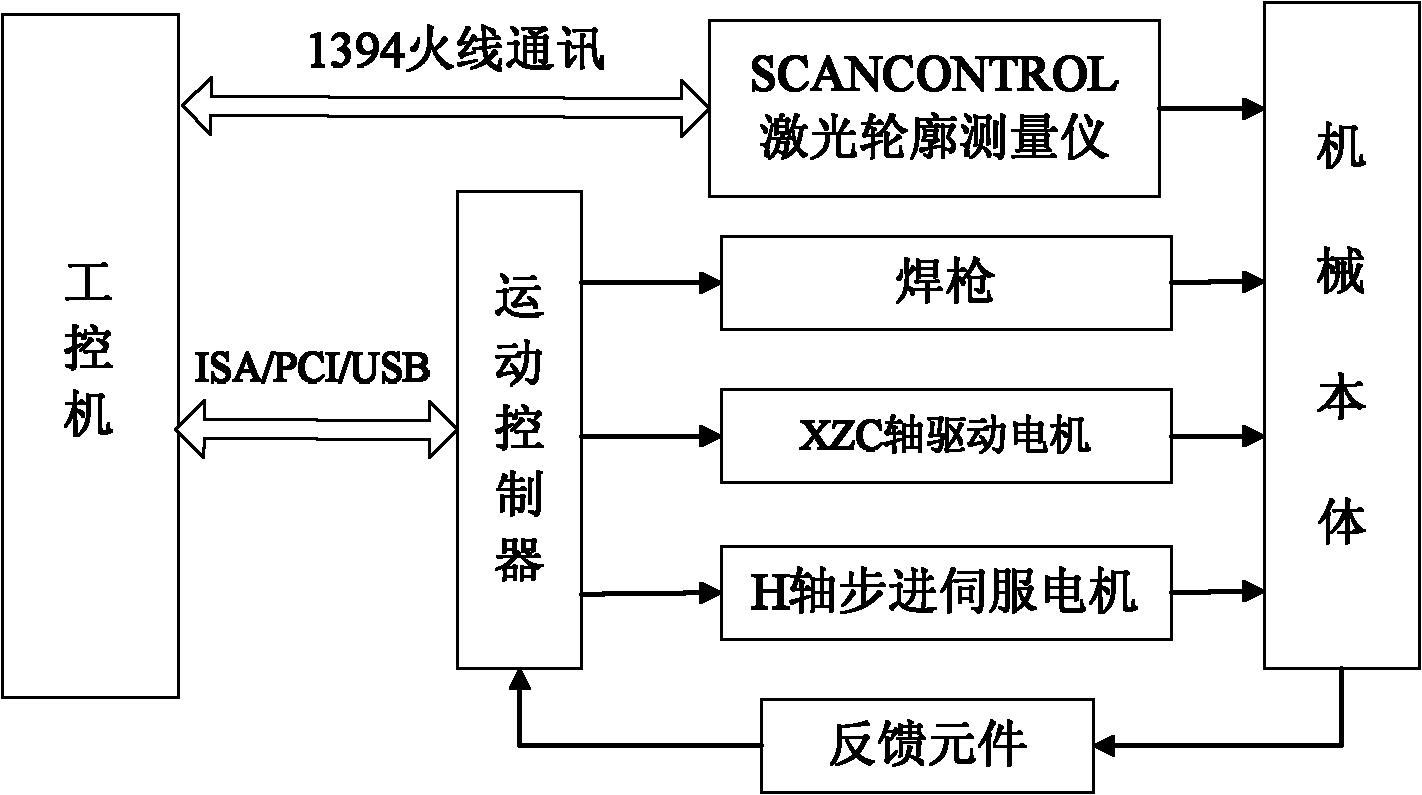

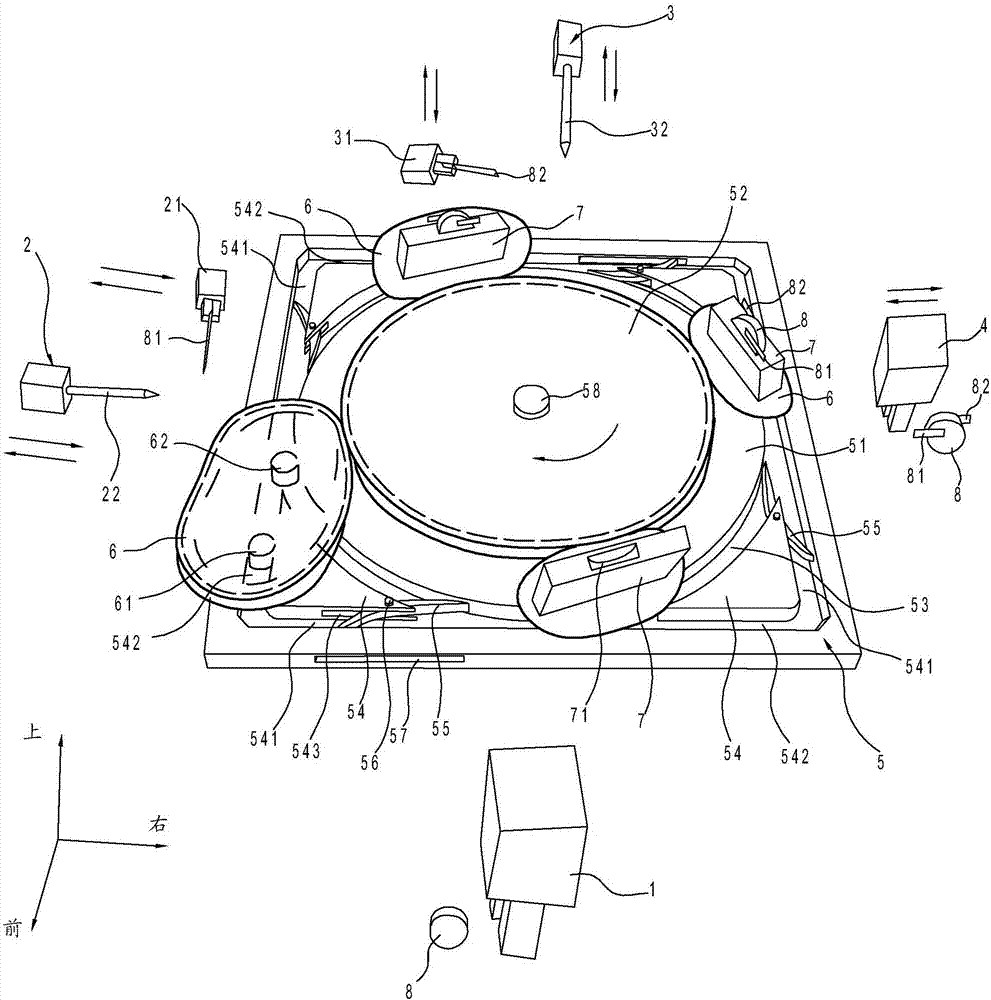

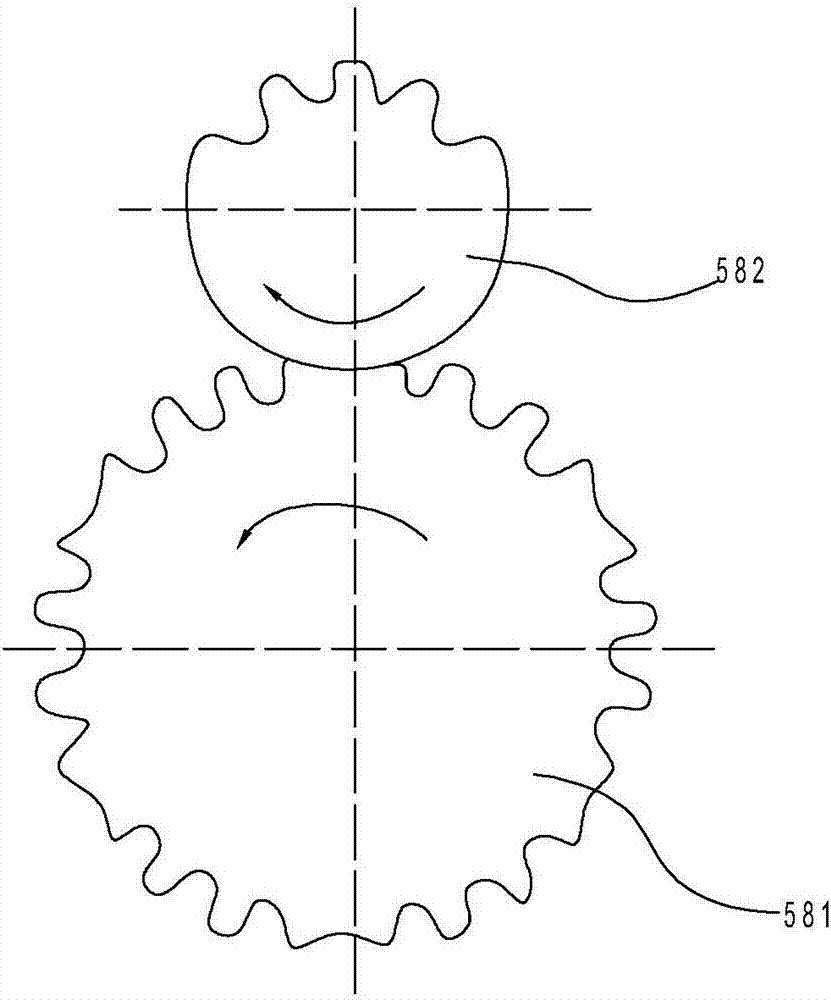

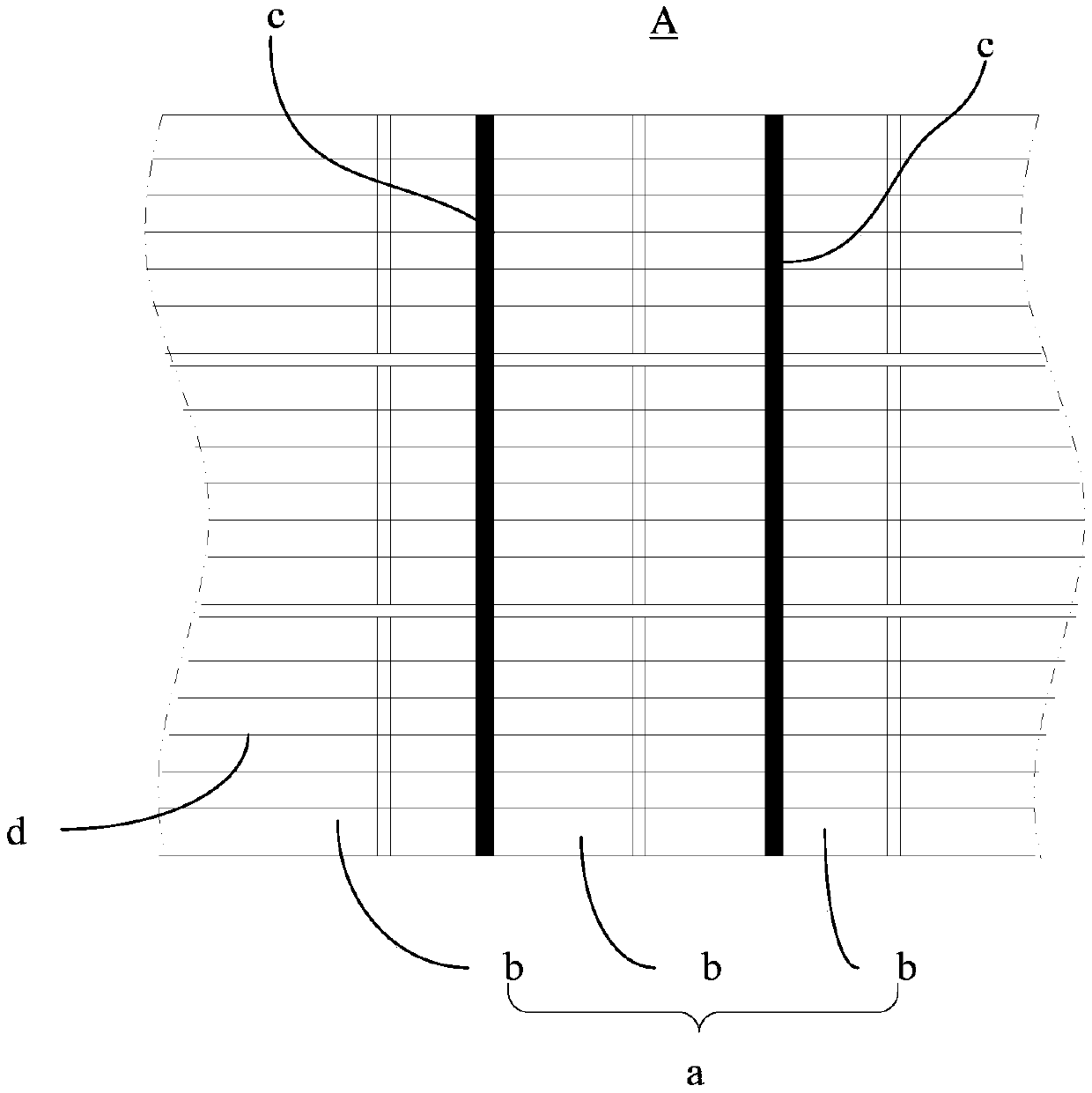

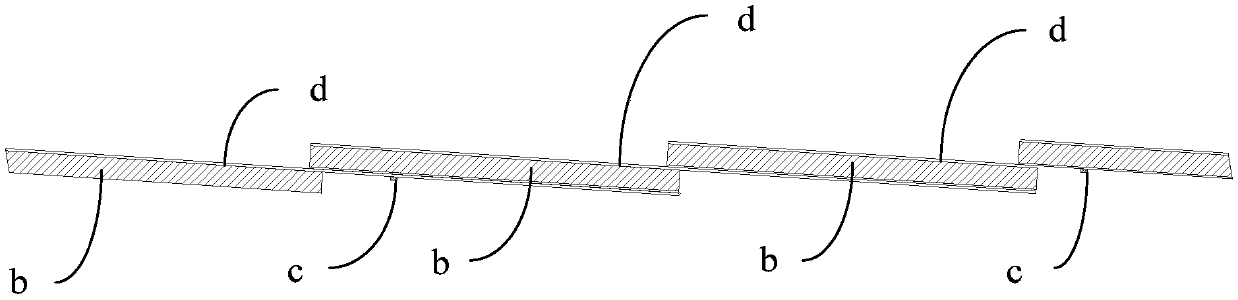

Automatic corrugated pipe welding equipment for transformer and welding method thereof

InactiveCN102485401ARealize automatic weldingIncrease productivityArc welding apparatusNumerical controlMeasuring instrument

The invention relates to automatic corrugated pipe welding equipment for a transformer and a welding method thereof, and belongs to the welding technical field of a corrugated pipe for a transformer. The automatic corrugated pipe welding equipment for the transformer comprises a rotary workbench, a two-dimensional numerical control platform, a laser outline measuring instrument, an R axis, a welding machine tool and a control system; the rotary workbench is fixed on the workbench surface of the machine tool; one end of the R axis is arranged on the welding machine tool body in a sliding way, and both sides of the other end of the R axis are respectively provided with the laser outline measuring instrument and the two-dimensional numerical control platform which slides along the R axis; a welding torch is connected onto the two-dimensional numerical control platform in a sliding way; the laser of the laser outline measuring instrument is in parallel with the axis of the welding torch; the rotary workbench, the two-dimensional numerical control platform and the welding machine tool body are respectively connected with the controller of the control system through motors; and the laser outline measuring instrument is connected with the industrial computer of the control system. The automatic corrugated pipe welding equipment for the transformer and the welding method thereof solvethe difficult problem of the manual welding of a large thin-wall corrugated pipe, reduce the labor intensity of a welder, improve the production efficiency, and simultaneously ensure the uniformity and the stability of the welding quality.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

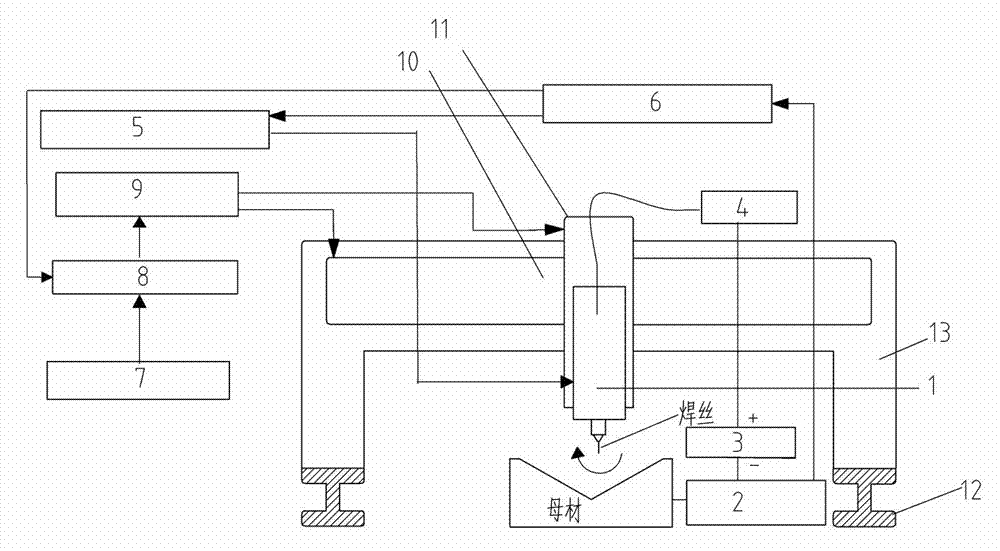

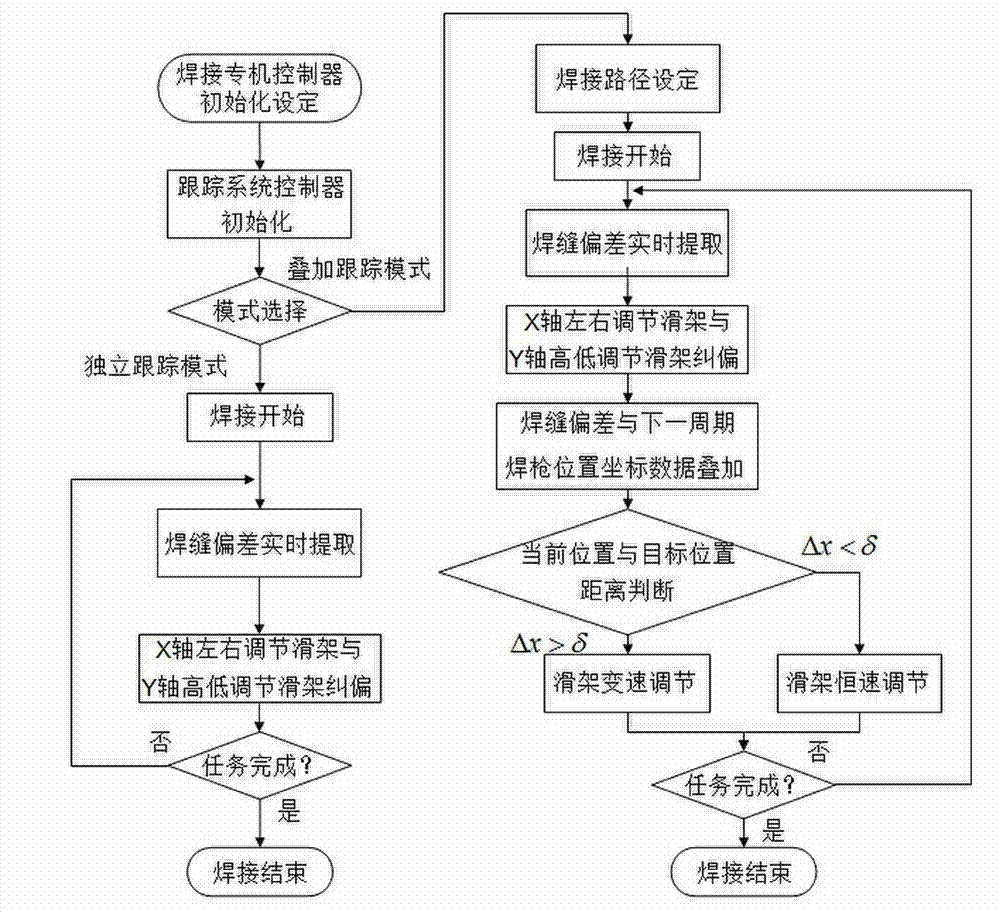

Automatic welding control method and system based on dual-mode real-time welding seam tracking

ActiveCN103567606ARealize automatic weldingImprove stabilityArc welding apparatusPolygonal lineDual mode

The invention discloses an automatic welding control method and system based on dual-mode real-time welding seam tracking, and mainly solves the technical problems of difficulty in automatic welding, low welding seam tracking precision and the like in a conventional space welding seam with a complex track. According to the technical scheme, the automatic welding control method and system based on dual-mode real-time welding seam tracking is proposed in combination with the characteristics of an electric arc sensing type real-time welding seam tracking system and a digital control type special welding machine system. According to the invention, the rotary electric arc sensing type welding seam tracking system is organically combined with the digital control type special welding machine system, the processing and assembly errors of workpieces and the position and size change of the welding seam caused by thermal deformation during welding are effectively compensated, and automatic tracking of the space welding seam with the complex track, especially a curved welding seam with high bending degree and a welding seam with a large-angle fold line is realized.

Owner:XIANGTAN UNIV

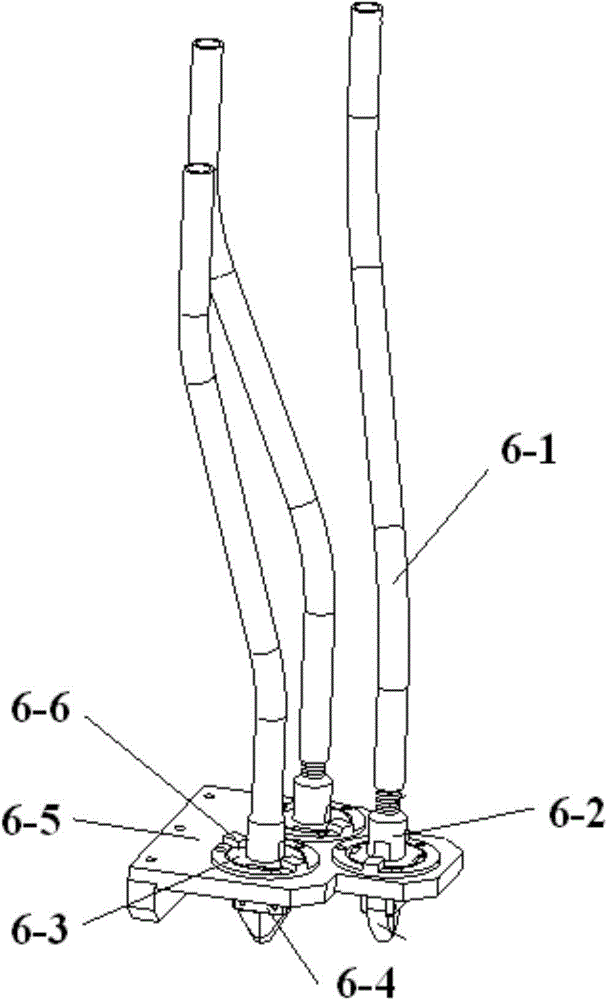

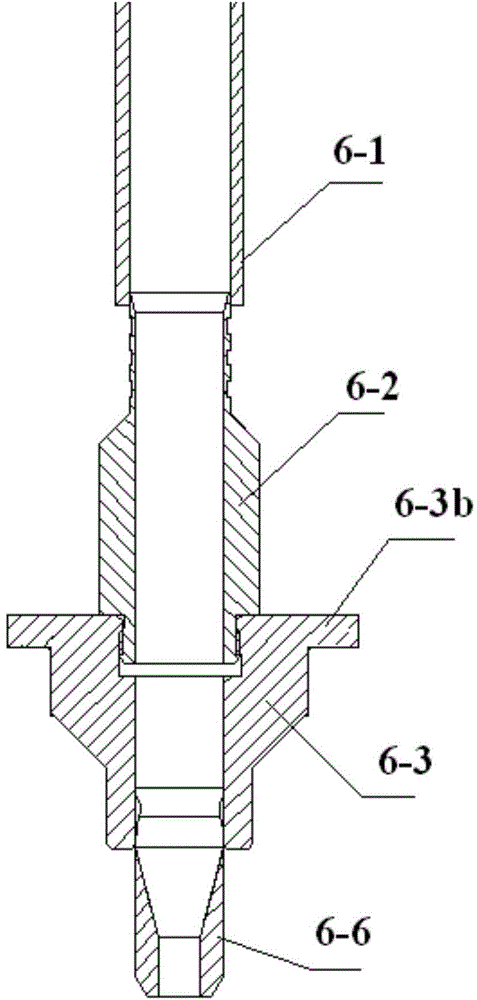

Flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and welding method thereof

InactiveCN102825368AExcellent surfacing qualityEasy post-weld processingArc welding apparatusElectrical controlElectric control

The invention provides a flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and a welding method thereof, belonging to the technical field of automatic welding equipments and welding methods. The automatic welding equipment mainly comprises a position regulation mechanism and a TIG rotary welding head, wherein the TIG rotary welding head is used for regulating a surface welding position of a flange sealing groove through the position regulation mechanism. An electric control device is used for setting parameters such as welding current, a wire feed speed, a welding speed and arc voltage control according to the circumferential position located by the welding head and a cycle of 12 preset partitions so as to carry out welding control. The rotational radius of the welding head can be automatically changed inwards or outwards according to set width after a cycle of welding is finished, so that surface welding in the flange sealing groove is realized, and surface welding on the side surface of the flange sealing groove is carried out after an angle of a welding gun is changed until one end surface is piled up. The surface welding surface is smooth, so that the problems of cutter beating and long processing time in the process of processing the flange sealing groove by manual surface welding at a later stage are avoided, surface welding quality is superior to quality of manual surface welding, and the problem that a product is repaired due to defects after manual surface welding is reduced.

Owner:CHINA FIRST HEAVY IND +1

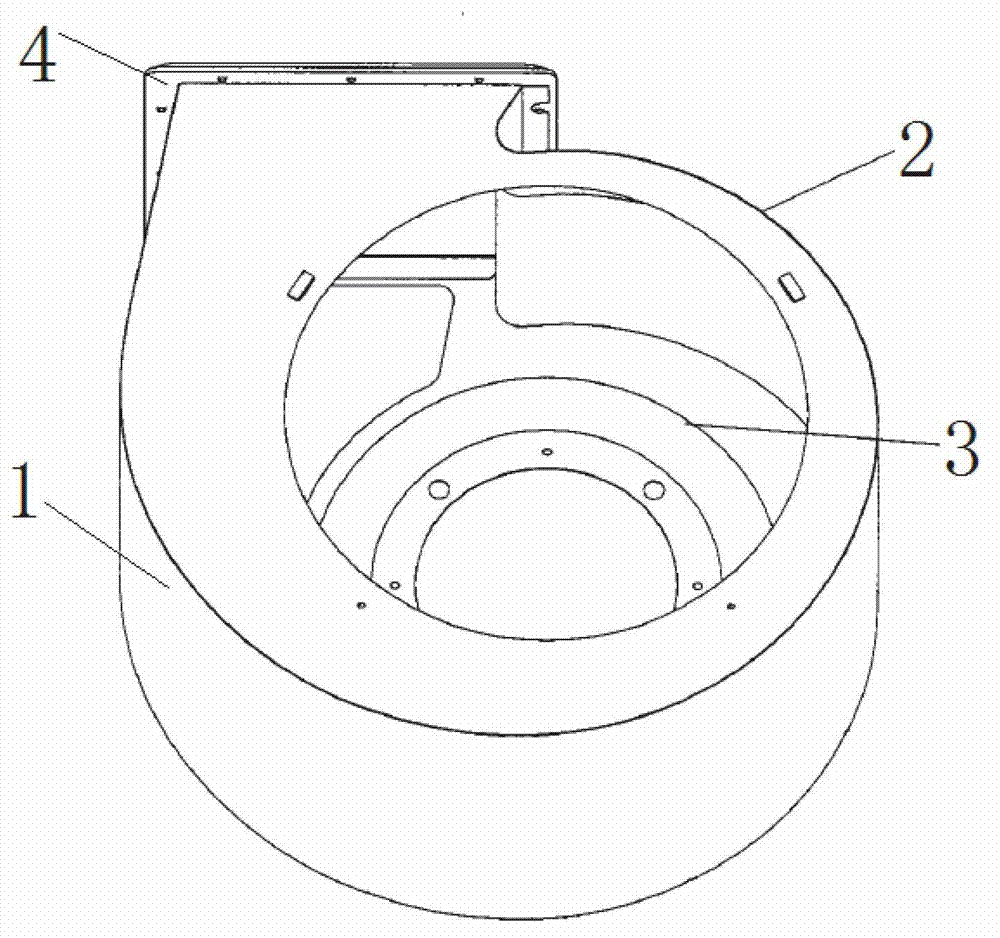

Welding processing device and welding method of extractor hood volute

ActiveCN103028831ARealize automatic weldingReduce difficultyWelding/cutting auxillary devicesAuxillary welding devicesScratchingFlange

The invention discloses a welding processing device and a welding method of an extractor hood volute. The volute comprises a coaming, a top plate, a bottom plate and a flange plate. The welding processing device comprises a welding robot, a top plate welding fixture, a bottom plate welding fixture and a flange plate welding fixture, wherein on the top plate welding fixture, the welding robot is used for welding and connecting the top plate with the coaming, on the bottom welding fixture, the welding robot is used for welding and connecting the bottom plate with the coaming, and on the flange plate welding fixture, the welding robot is used for welding and connecting the flange plate with the coaming. Compared with the prior art, the welding processing device and the welding method have the advantages of realizing automatic welding of the volute by adopting the welding robot and the welding fixtures, avoiding the interference of human factors, reducing the difficulty of volute welding, improving the welding quality, being good in sealing property of the welded volute, being capable of eliminating an ash scratching or glue scratching procedure, simplifying the welding process and increasing the welding efficiency.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

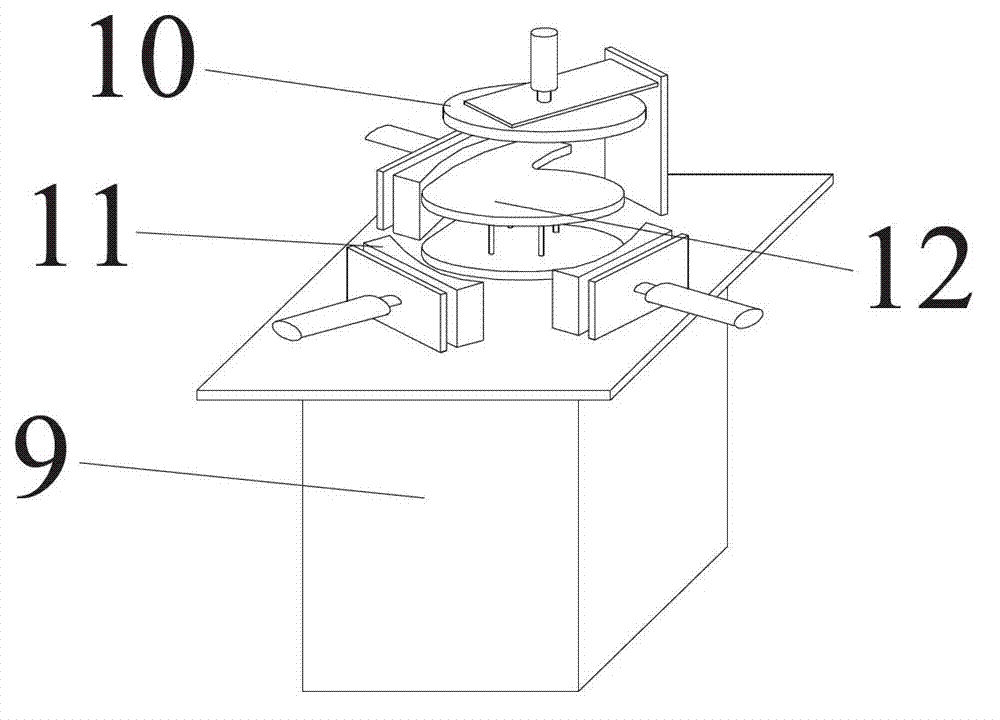

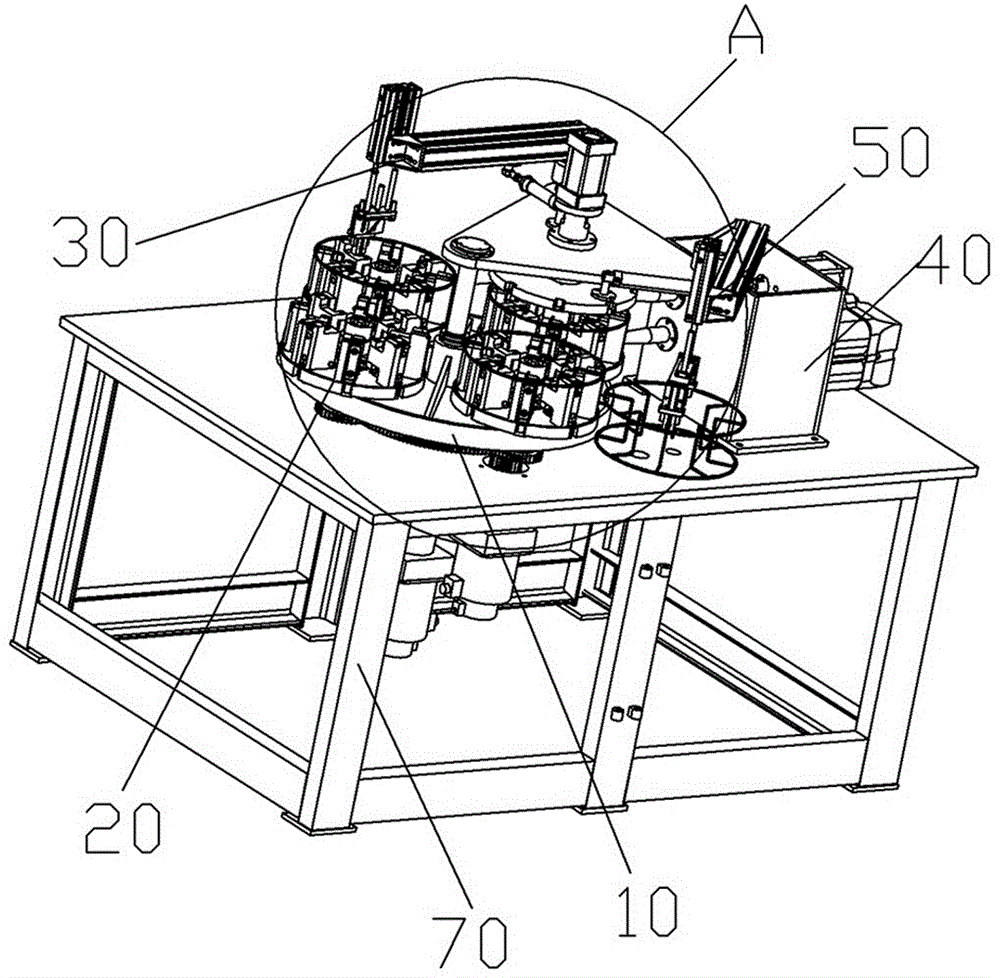

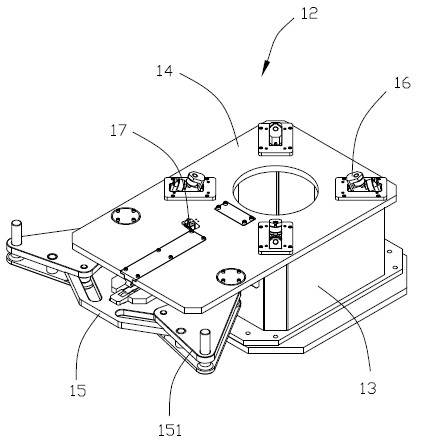

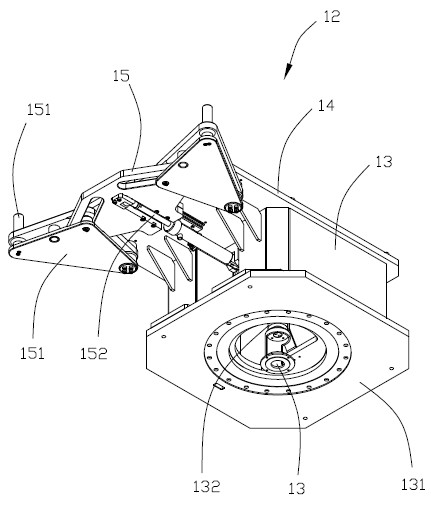

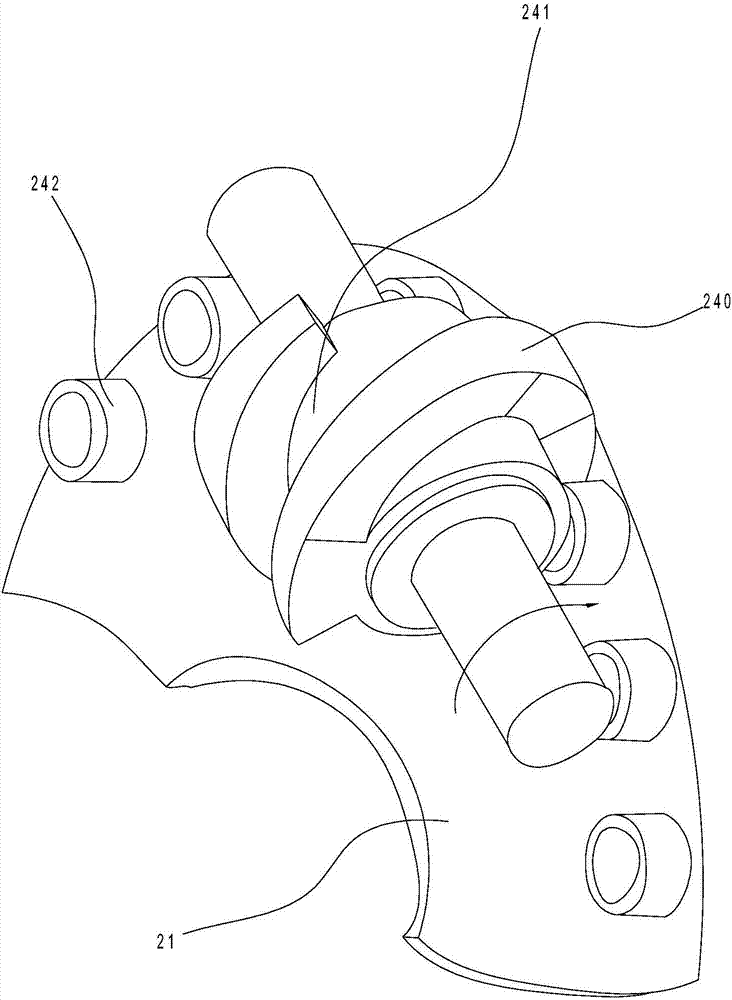

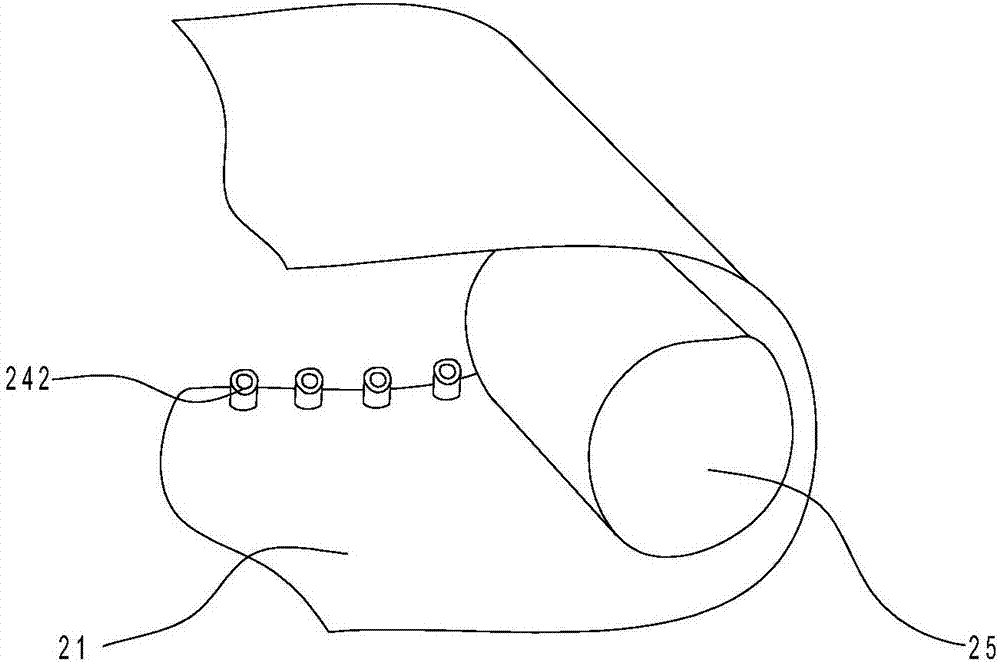

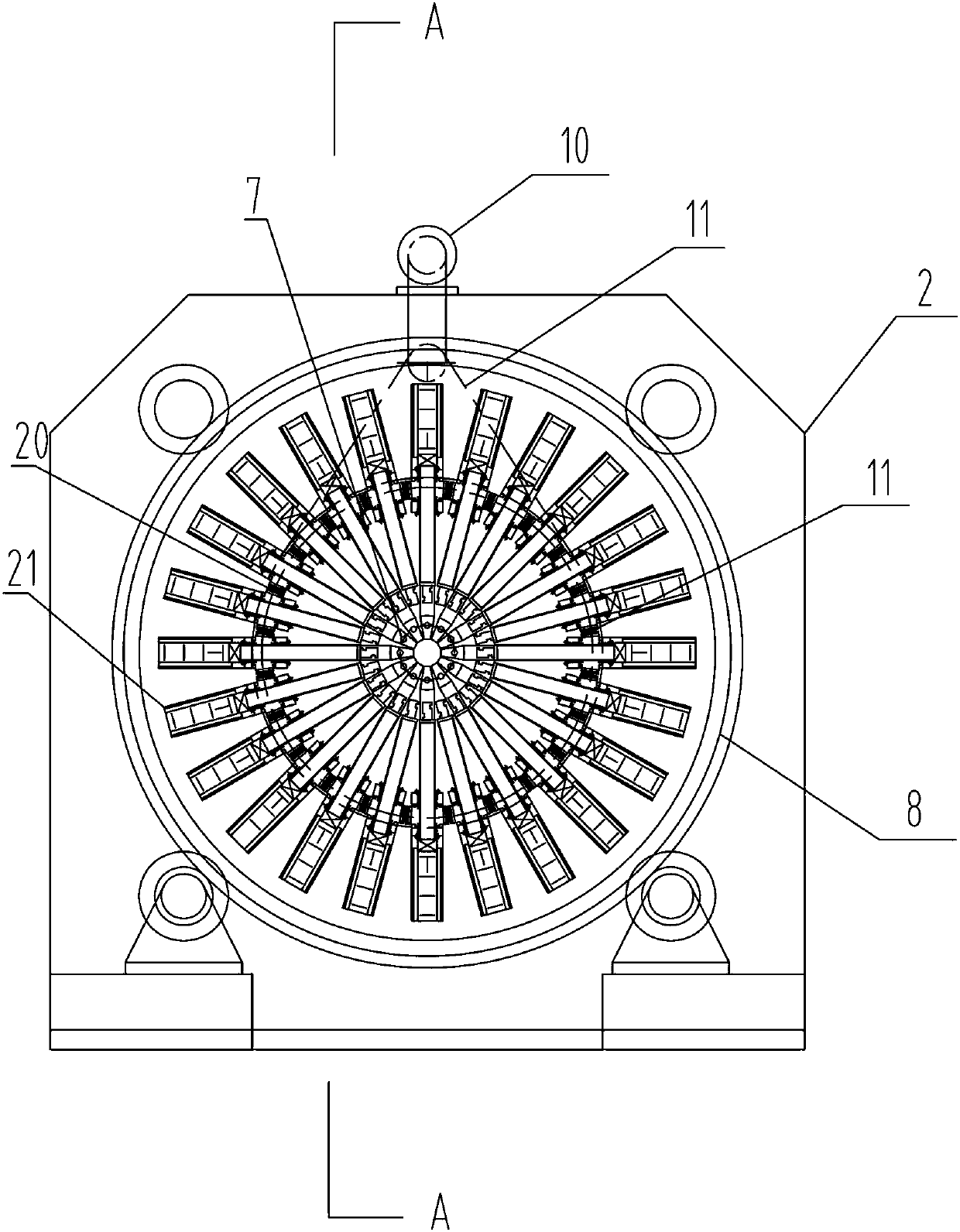

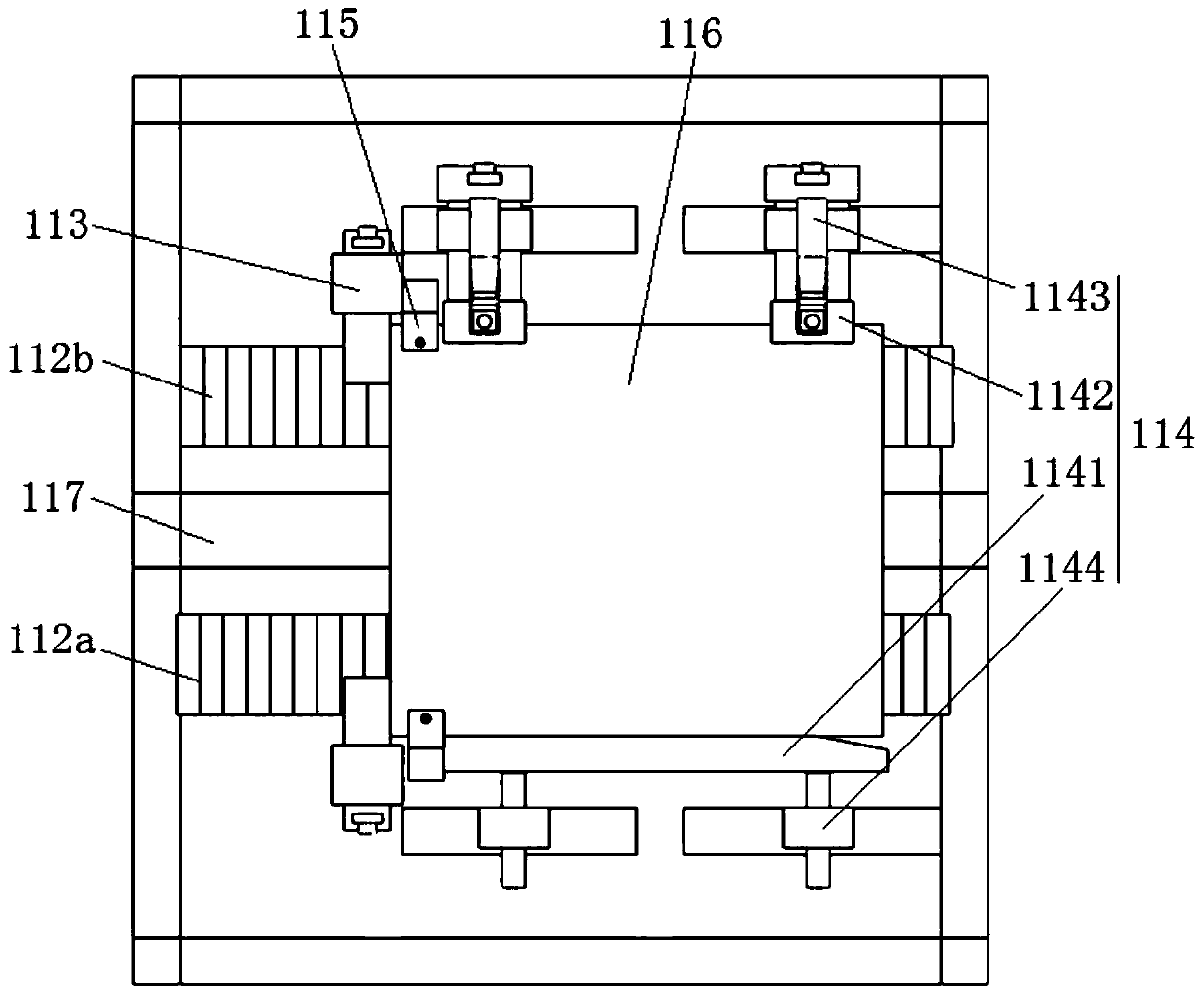

Workpiece clamping clamp and wire spool welder using same

ActiveCN104985369ARealize automatic and accurate positioningEnsure automatic and accurate positioningWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

The invention provides a workpiece clamping clamp and a wire spool welder using same. The welder comprises a clamping clamp, wherein a circumferential datum plane is arranged on a positioning base of the clamping clamp; a plurality of clamping assemblies are arranged on the clamping clamp; each clamping assembly can reciprocate in a guiding mode along the circumference; a clamping block of each clamping assembly is driven by a clamping drive mechanism to close to clamp the constitutional units when each clamping assembly moves towards the corresponding circumferential datum plane, and to open when each clamping assembly moves away from the corresponding circumferential datum plane; and each clamping assembly is provided with a fixed station on reciprocating motion stroke, so that an arc-shaped part of each constitutional unit is resisted against the corresponding circumferential datum plane when each clamping assembly moves to the fixed station. When the constitutional units are clamped and fixed by the clamping assemblies, the arc-shaped parts of the constitutional units are further directly resisted against and fixed on the circumferential datum plane by the clamping assembly which moves towards the circumferential datum plane, so that automatic and accurate positioning of each constitutional unit is finally guaranteed.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

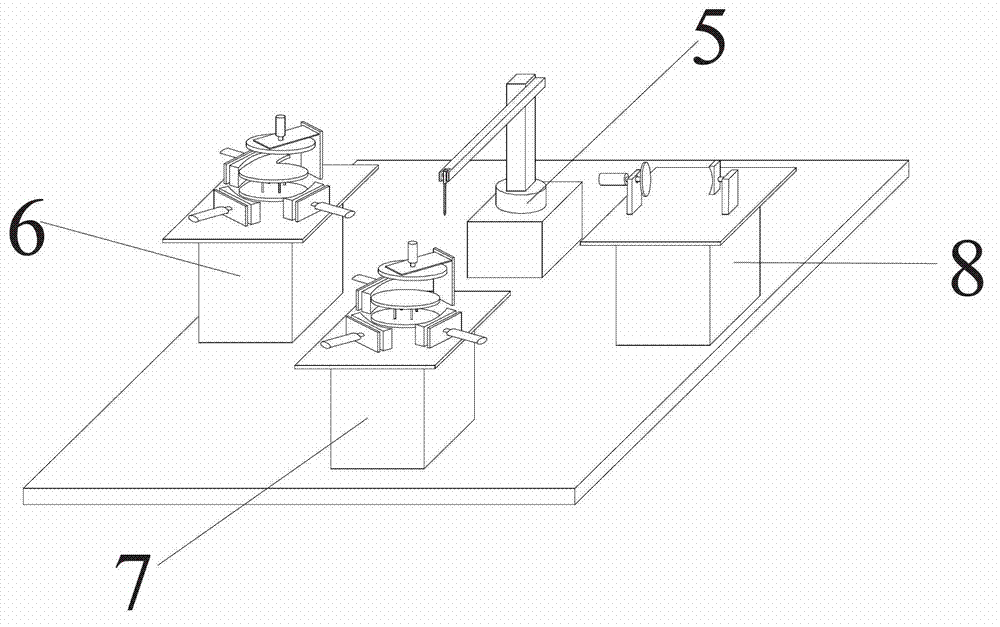

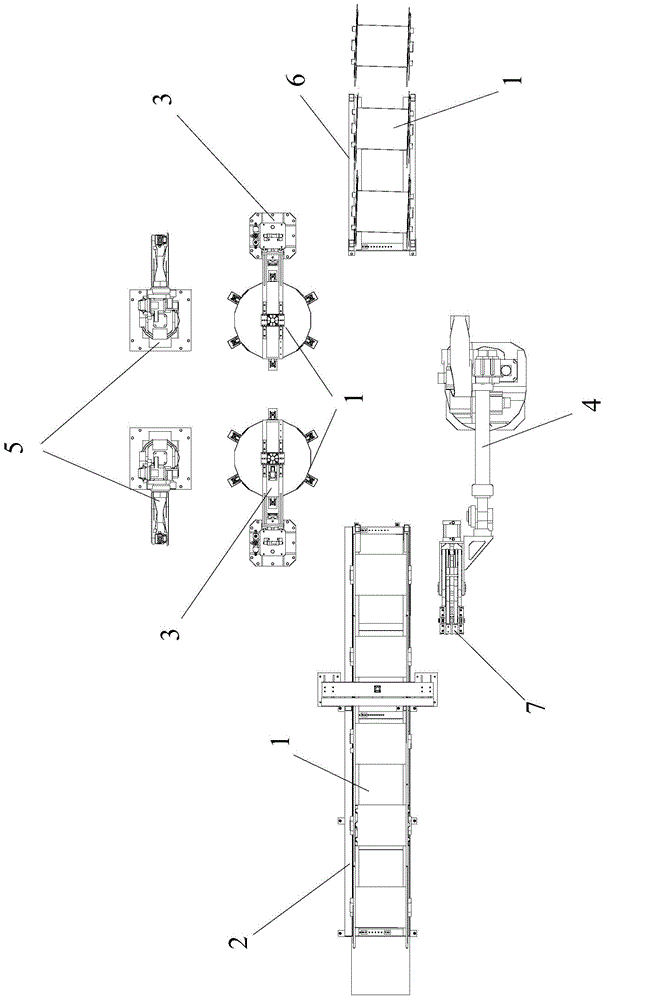

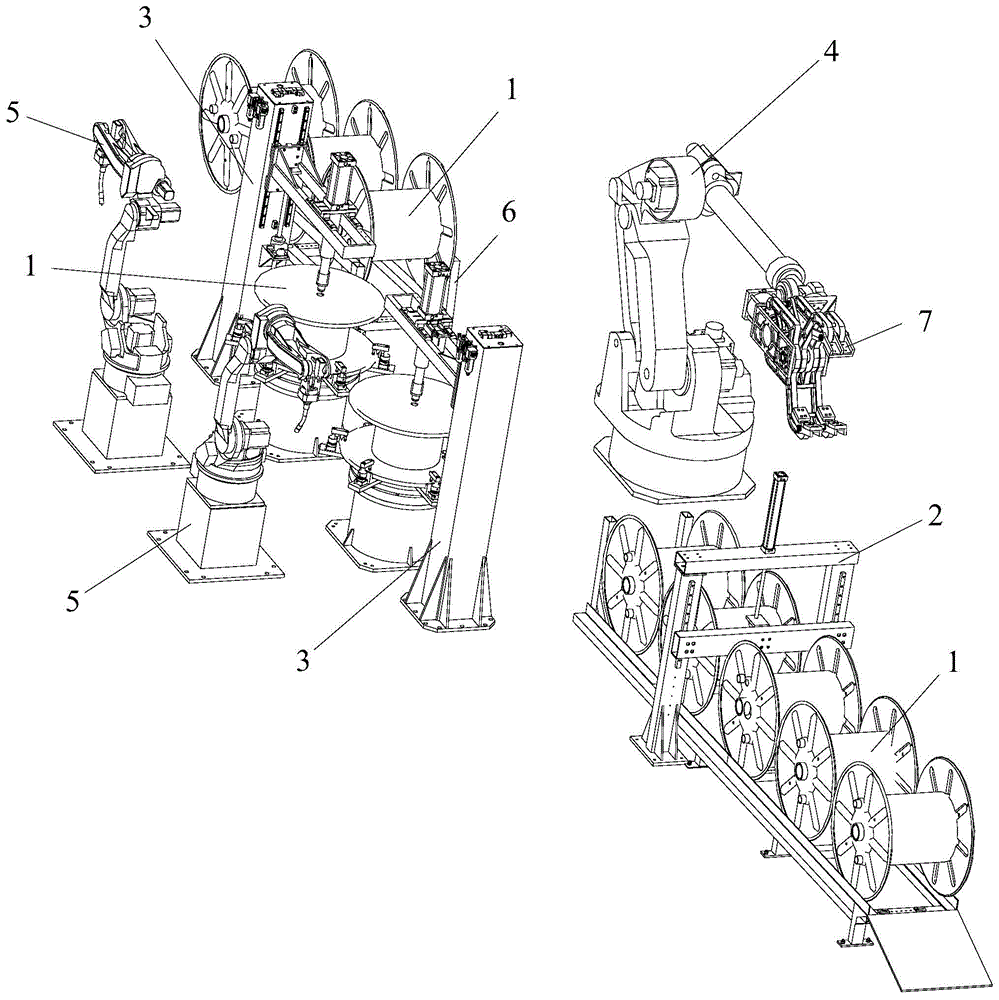

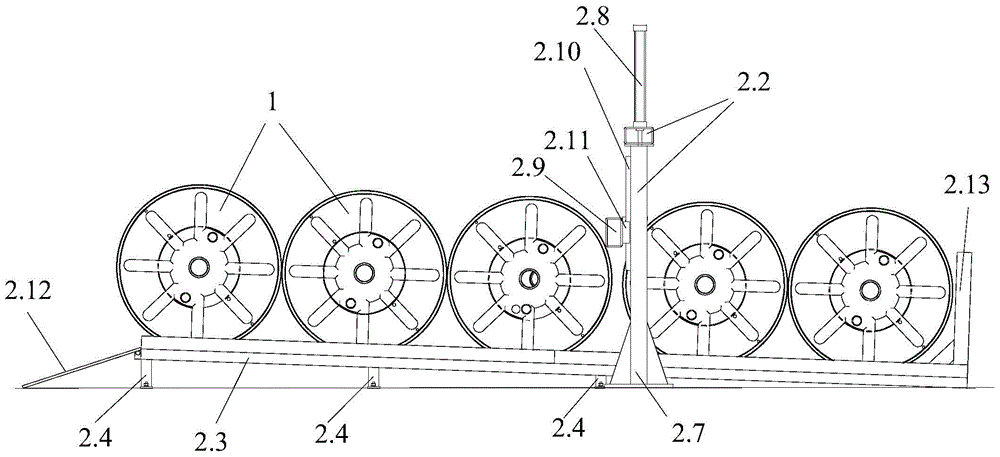

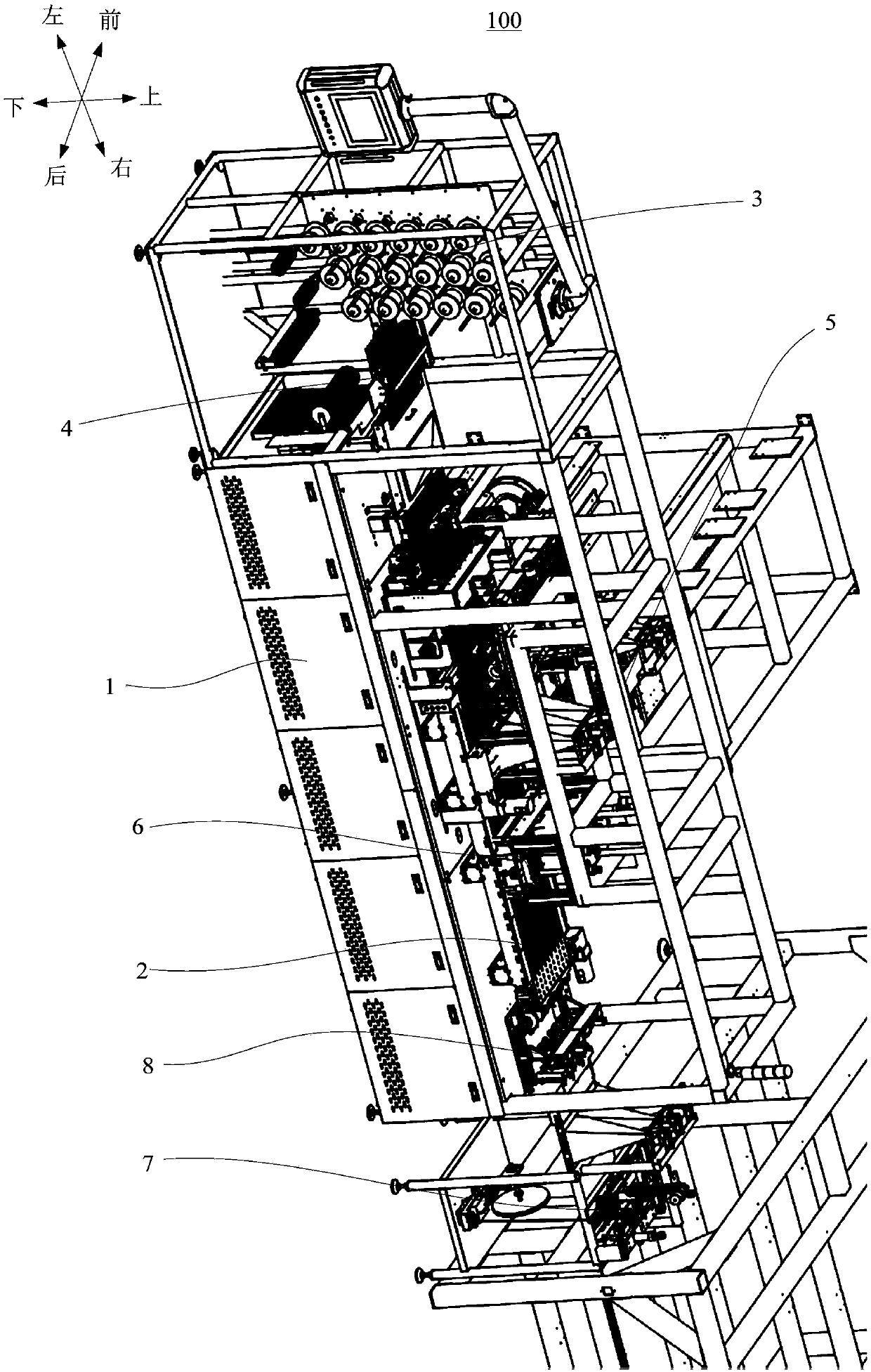

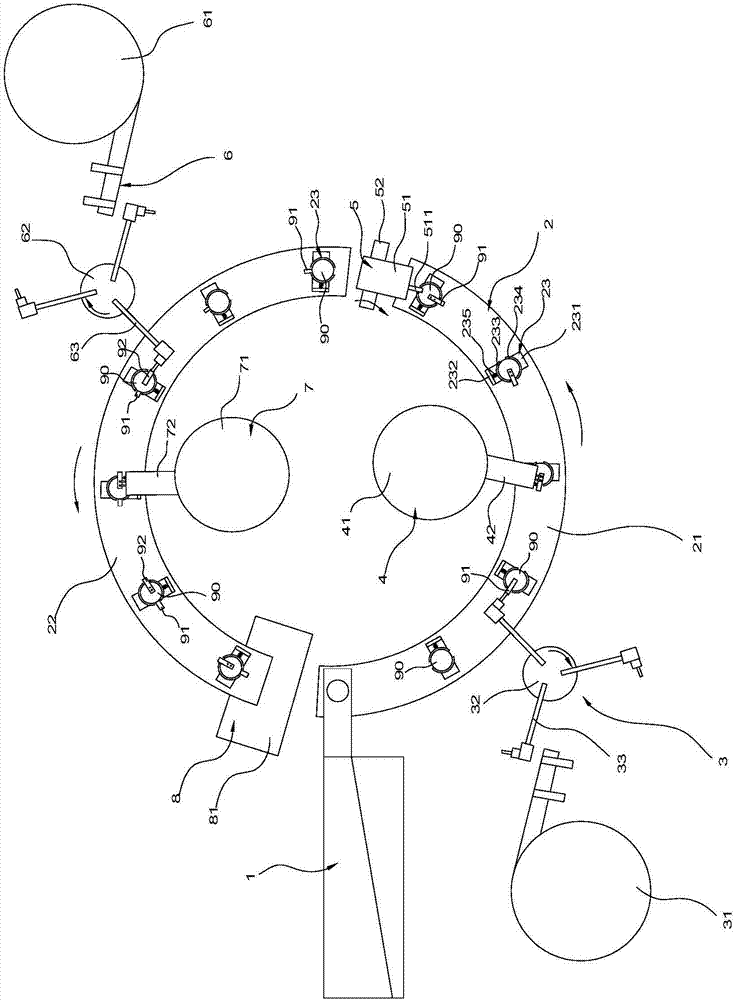

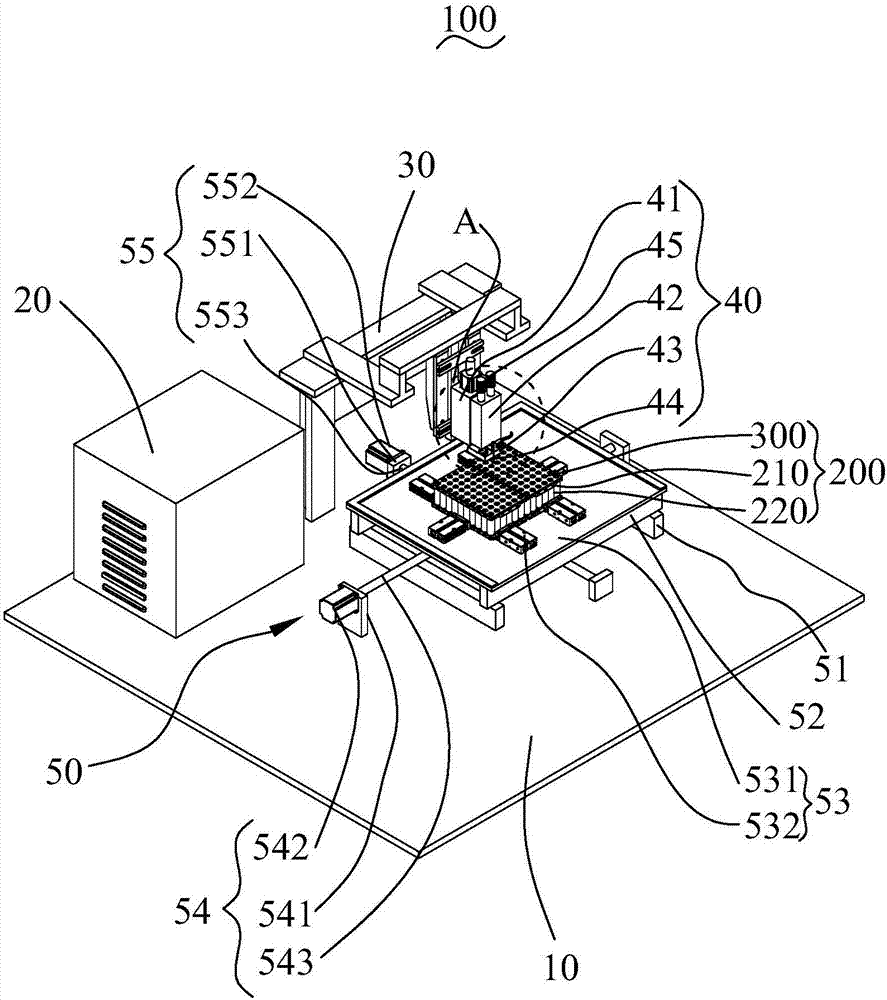

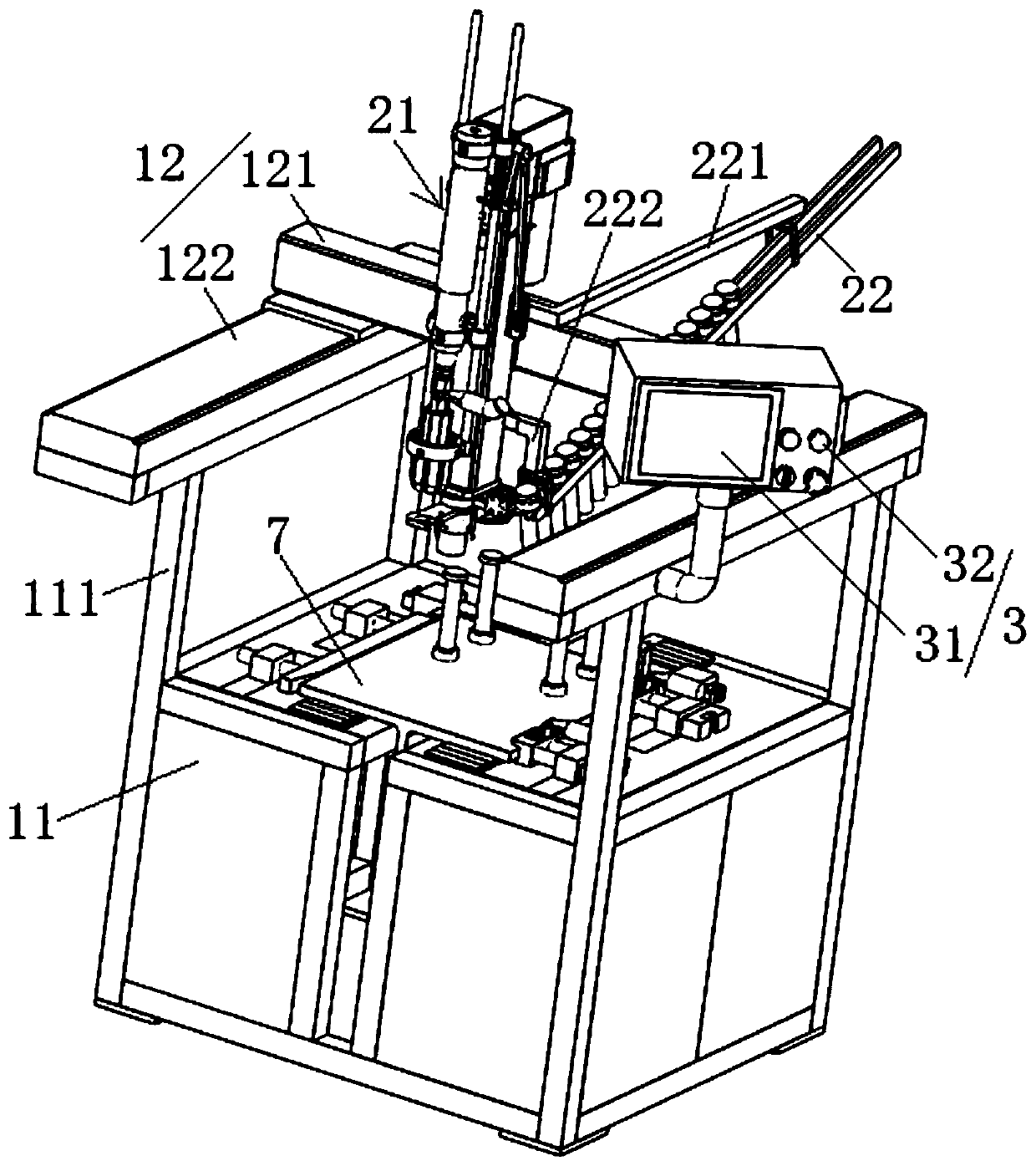

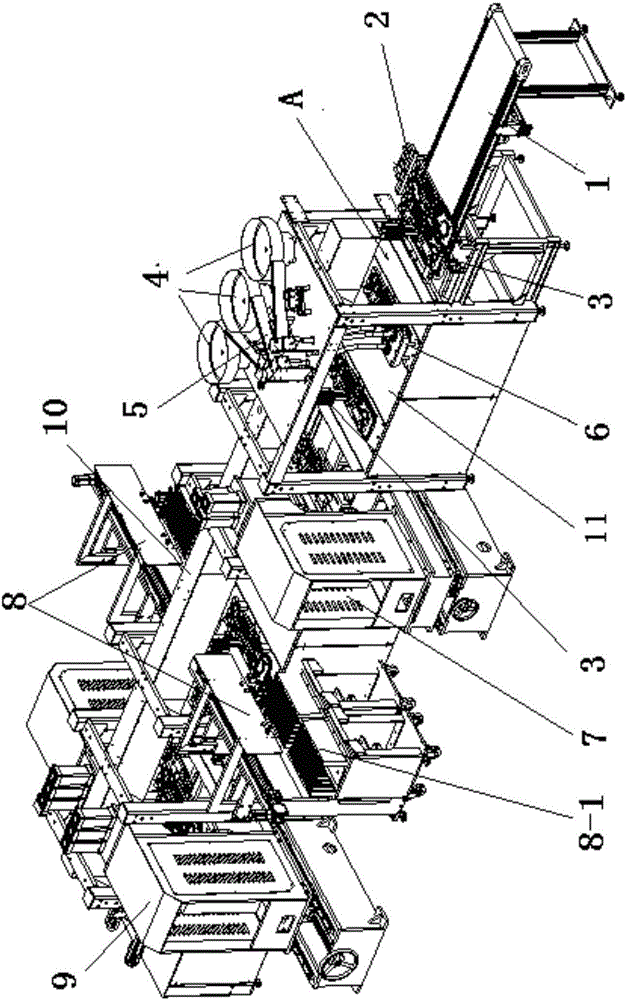

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

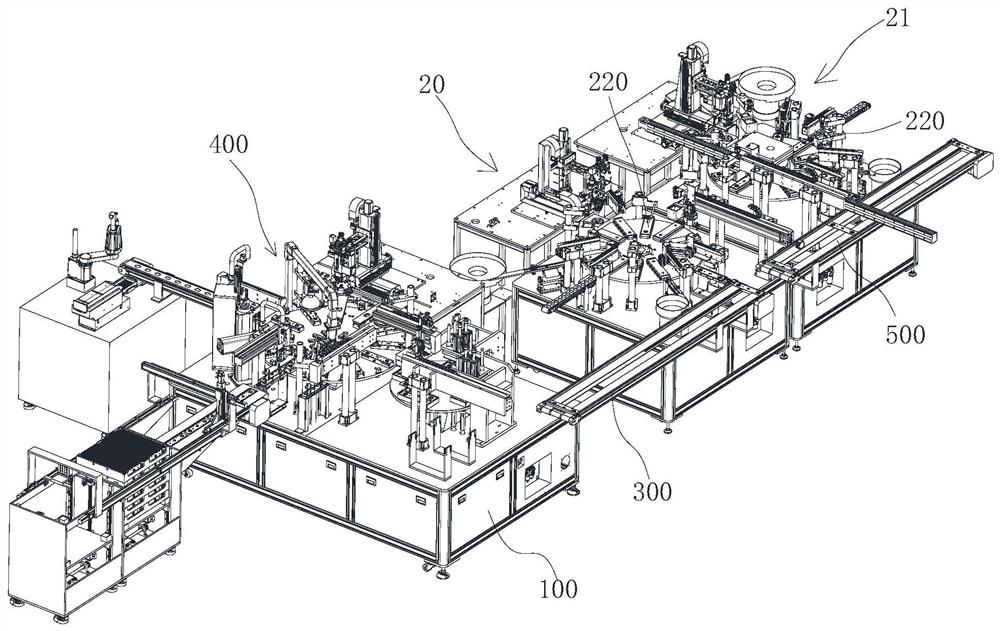

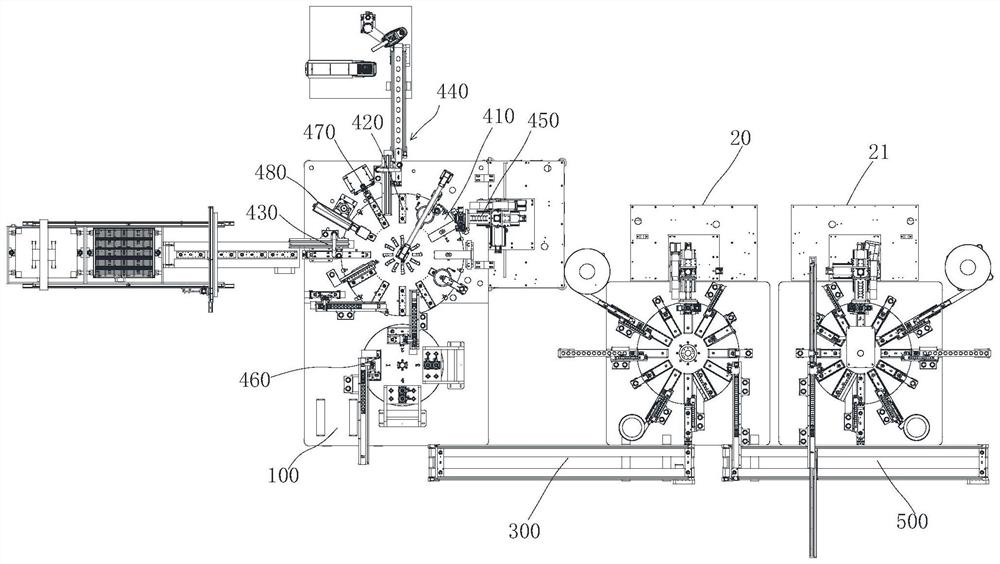

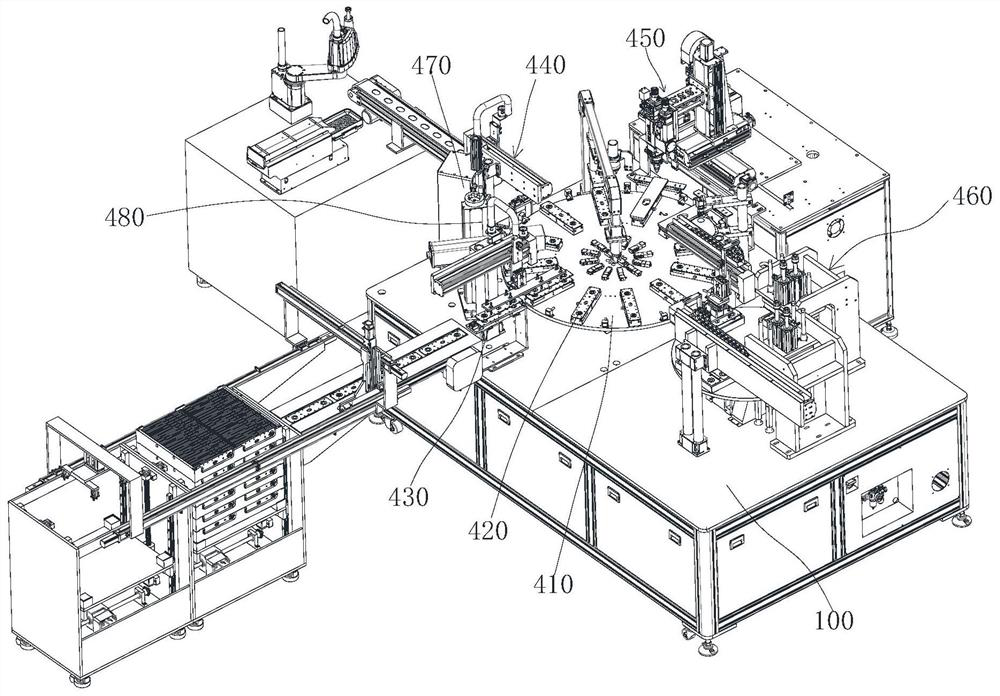

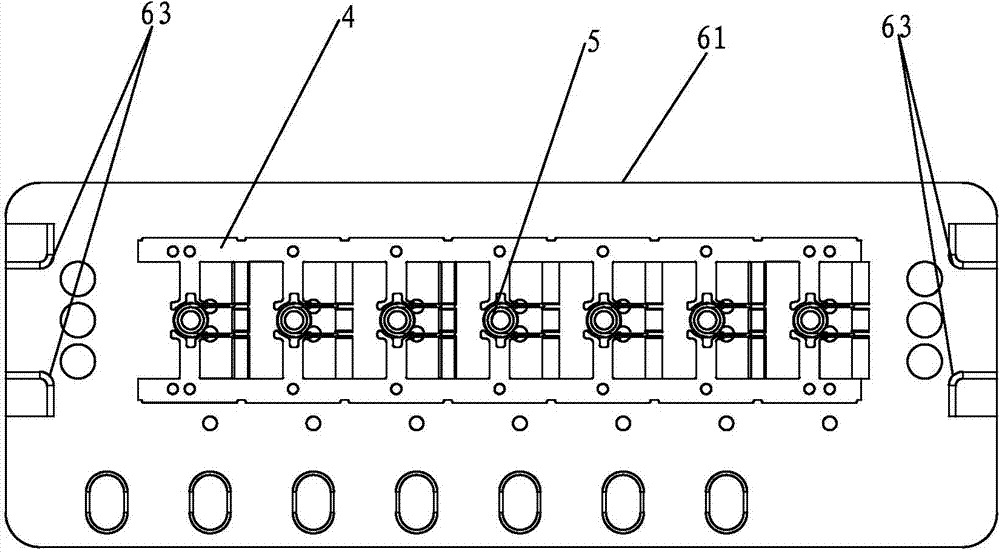

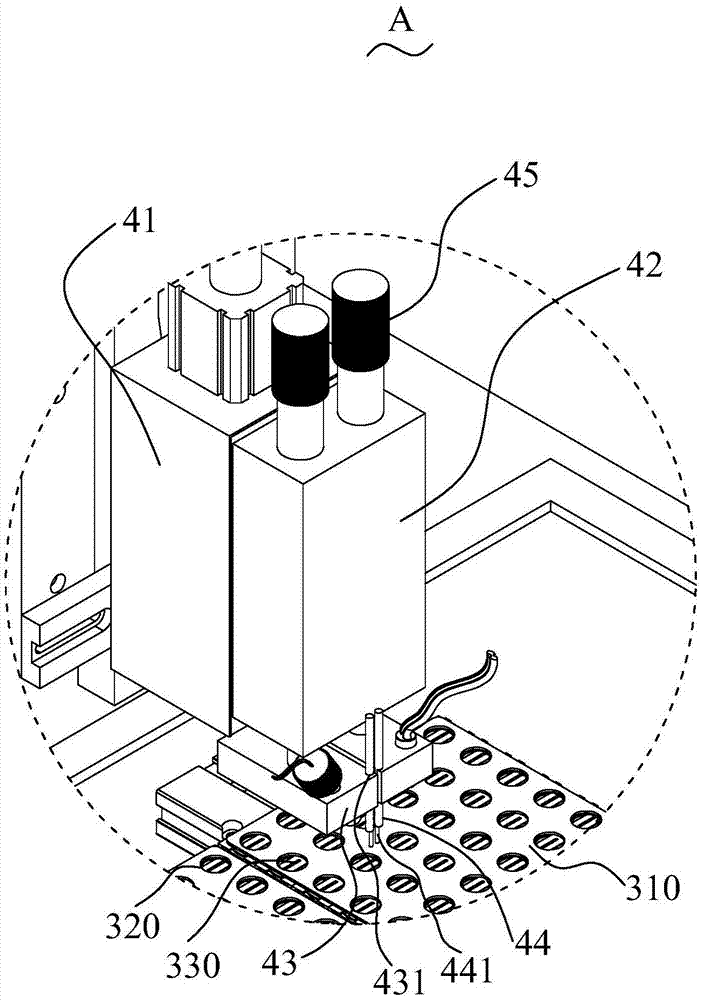

Aluminum shell battery cover plate assembling all-in-one machine

PendingCN112397760ARealize automatic weldingImprove efficiencyPrimary cell manufactureAssembling battery machinesElectrical batteryEngineering

The invention belongs to the technical field of automatic machinery, and particularly relates to an aluminum shell battery cover plate assembling all-in-one machine which comprises a rack, an explosion-proof valve welding device, a first pole column assembling machine, a second pole column assembling machine, a first transferring mechanism and a second transferring mechanism. The explosion-proof valve welding device, the first pole assembly machine and the second pole assembly machine are sequentially arranged on the rack; the first pole assembly machine and the second pole assembly machine are respectively used for the positive electrode welding and negative electrode welding of a battery cover plate; the first transferring mechanism is arranged between the explosion-proof valve welding device and the first pole assembly machine, and the second transferring mechanism is arranged between the first pole assembly machine and the second pole assembly machine; and the positioning dies in the first pole assembly machine and the second pole assembly machine are respectively provided with the positioning bosses. After the explosion-proof valve is welded to the battery cover plate, the battery cover plate is conveyed to the first pole assembly machine through the first conveying mechanism to weld the positive electrode of the battery cover plate, and the battery cover plate is conveyedto the second pole assembly machine through the second conveying mechanism to weld the negative electrode.

Owner:东莞市钜升智能机械有限公司

X frame automatic welding system

InactiveCN102672373AEasy to weldRealize automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an X frame automatic welding system which comprises a first feeding trolley, a carrying robot, a first positioning machine, a first welding robot, a second feeding trolley, a second positioning machine, a second welding robot and a control device, wherein the carrying robot is used for automatically picking up an X frame from the first feeding trolley; the first positioning machine is used for receiving the X frame picked up by the carrying robot; the first welding robot is used for carrying out first welding on the X frame on the first positioning machine; the second feeding trolley is used for receiving the X frame which is picked up by the carrying robot and is welded on the first positioning machine; the second positioning machine is used for picking up the X frame on the second feeding trolley and overturning the X frame; the second welding robot is used for carrying out second welding on the X frame overturned on the second positioning machine; and the control device is used for controlling the feeding trolleys, the carrying robots, the positioning machines and the welding robots to work. Therefore, according to the X frame automatic welding system disclosed by the invention, the integral automatic welding production line of X frame welding can be implemented and the production efficiency is improved.

Owner:HUAHENG WELDING

Automatic end socket welding method of automatic welding device based on large-curved-surface end socket welding

InactiveCN104014945AEasy assembly, positioning and clampingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesBall screwEngineering

The invention discloses an automatic end socket welding method of an automatic welding device based on large-curved-surface end socket welding. The device comprises a support base plate, a ball screw, a group of rolling bearings, an external locating block, an internal locating block, a rotary handle, a calibrated scale, a welding positioner, and a welding head realizing automatic welding, and the end socket comprises a plurality of claw end sockets and a segment. The method is characterized by comprising following steps of end socket fixation, welding of external welding line, welding of internal welding line, and annealing heat treatment. The method can be used for automatic welding of large end sockets of various sizes, thus lowering labor intensity of workers, shortening the manufacturing cycle of products, and lowering production cost.

Owner:NANJING INST OF TECH

Full-automatic laser welding method and full-automatic laser welding device

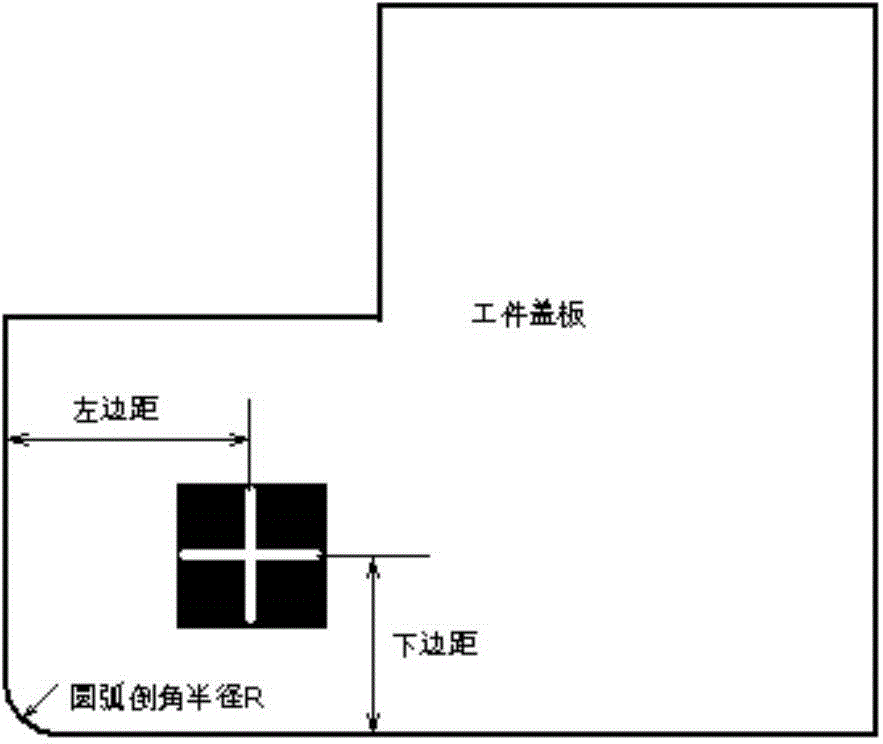

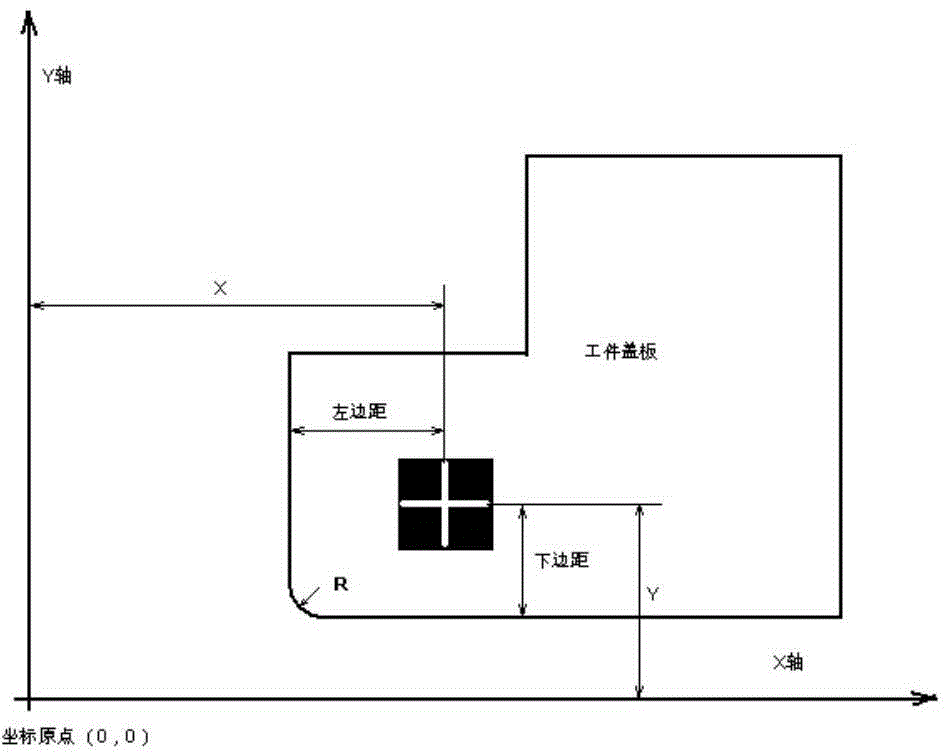

InactiveCN104400217ARealize automatic weldingRealize fully automatic laser weldingLaser beam welding apparatusWeld seamEngineering

The invention provides a full-automatic laser welding method and a full-automatic laser welding device. The method is divided into a preparatory stage and a welding stage. The preparatory stage comprises the following steps: storing track information of to-be-welded welding seams into a computer; marking any one or multiple positions in a pick-up head photographing range which includes a to-be-welded region; setting a welding seam search region based on marks by taking the marks as reference. The welding stage comprises the following steps: collecting image information; searching the mark quantity and position information in images; performing linear detection to obtain the position and angle information of the welding seams and finally generating the actual position and outline tracks of the welding seams. The method can be used for realizing full-automatic laser welding, not only is automatic welding of straight welding seams realized, but also the automatic welding of random welding seam tracks such as circular arcs and curves is realized, to-be-welded workpieces are positioned without fixtures, multiple workpieces on the top of a workbench can be randomly placed each time and automatic welding is realized; track welding can be realized without special mechanical parts.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

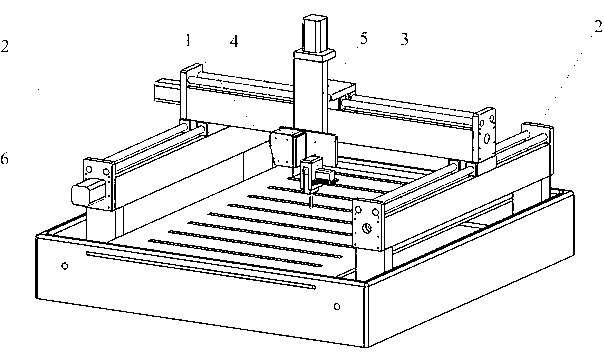

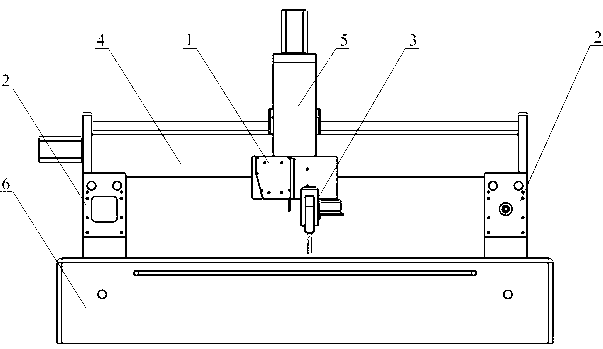

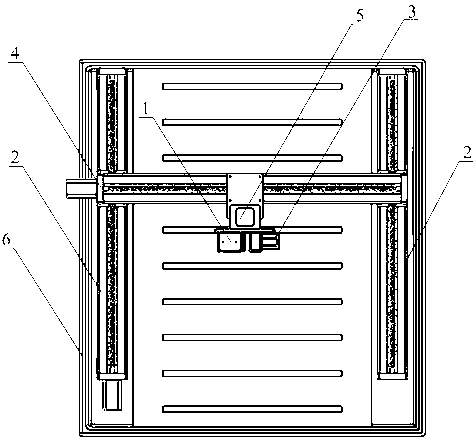

Object shelf tray self-adaptation welding device based on laser vision

InactiveCN103273233AHigh precisionRealize automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses an object shelf tray self-adaptation welding device based on laser vision. The welding device comprises a base, two first axis moving devices arranged on the base in parallel, a second axis moving device arranged perpendicular to the first axis moving devices, a vertical axis moving device arranged on the second axis moving device, a laser vision sensor and a welding gun gesture mechanism. The laser vision sensor and the welding gun gesture mechanism are arranged abreast at the bottom end of the vertical axis moving device. Two ends of the second axis moving device are connected with the first axis moving devices. The laser vision sensor collects a welding gap image and stores the image to a computer through an image collection card, the computer processes the image to obtain the welding gap position, and a motion control card is utilized to control a welding gun walking device to conduct welding accurately. The self-adaptation welding device is high in self adaptability, capable of accurately recognizing the welding gap position of an object shelf tray, high in expandability, low in cost, simple and efficient to control and high in reliability.

Owner:SOUTHEAST UNIV

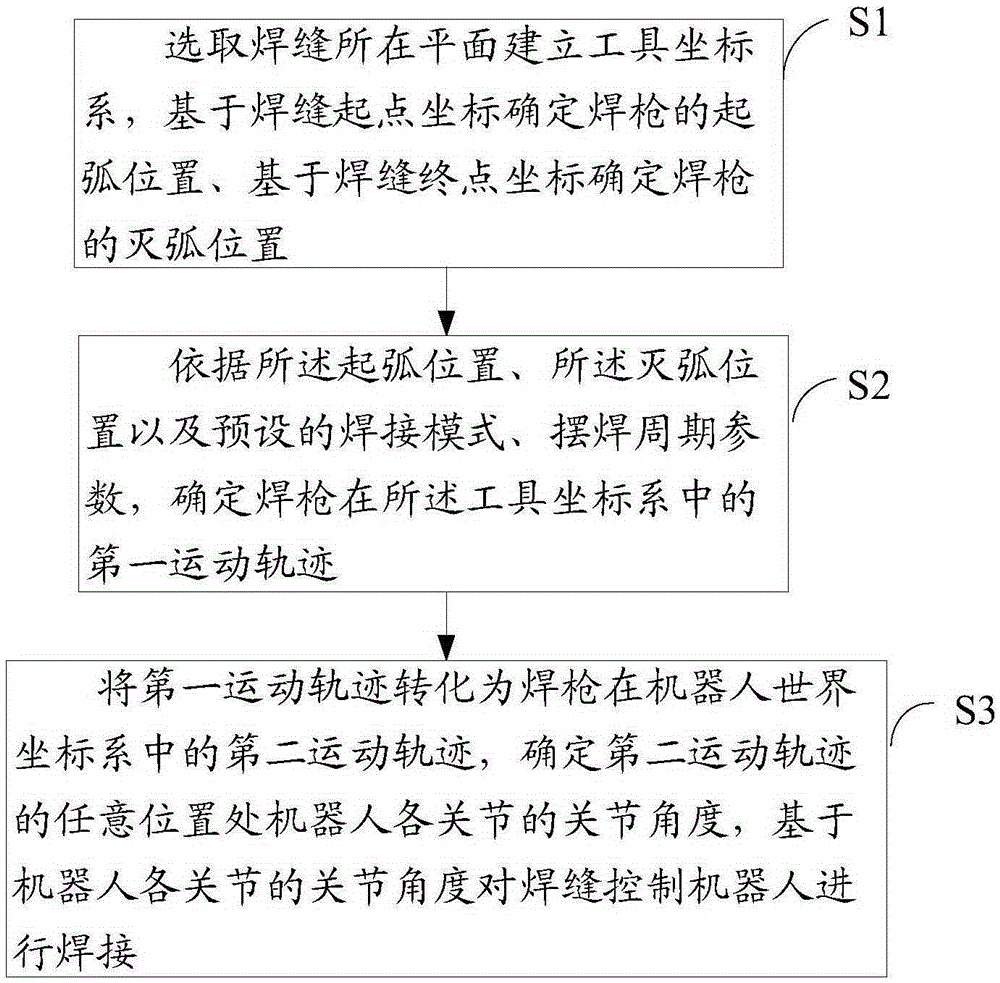

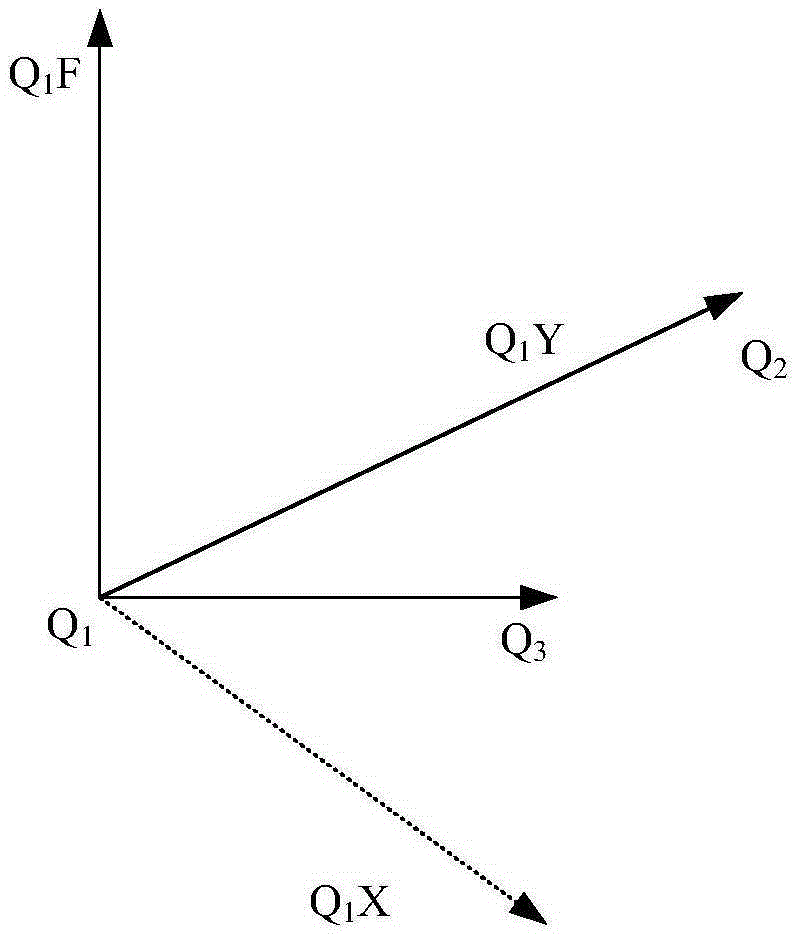

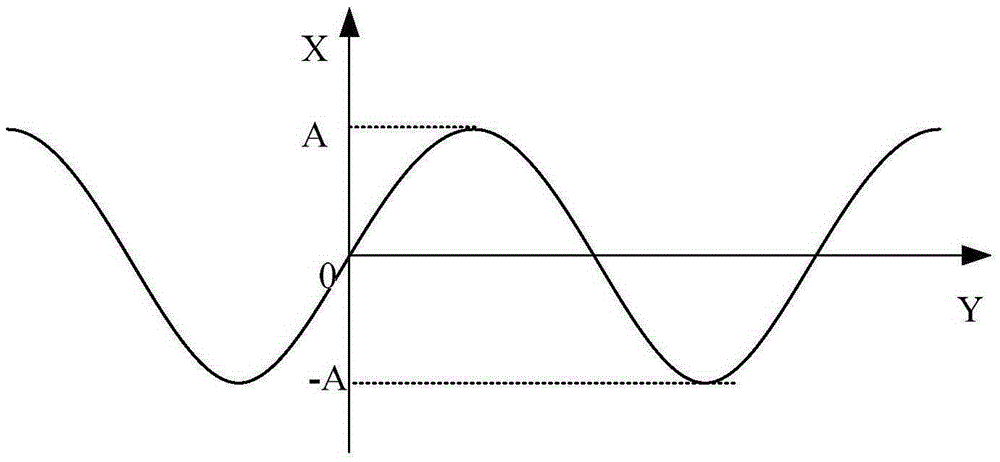

Motion control method of robot in oscillatory arc welding of marine T-shaped sections

InactiveCN105252110ARealize automatic weldingImprove welding efficiencyArc welding apparatusSimulationMotion control

The invention discloses a motion control method of a robot in oscillatory arc welding of marine T-shaped sections. The motion control method comprises the steps of establishing a tool coordinate system on the plane where a weld joint is located, determining the arc striking position of a welding gun on the basis of the starting point coordinates of the weld joint and determining the arc extinguishing position of the welding gun on the basis of the end point coordinates of the weld joint; determining a first motion trail of the welding gun in the tool coordinate system according to the arc striking position, the arc extinguishing position, the preset welding mode and the preset oscillatory welding period parameters; converting the first motion trail into a second motion trail of the welding gun in a robot world coordinate system, determining the joint angles of joints of the robot on any position of the second motion trail, and controlling the robot to weld the weld joint on the basis of the joint angles of the joints of the robot. According to the motion control method, the motion trail of the robot and the welding gun can be accurately controlled in oscillatory arc welding, downward welding and vertical position welding of the marine T-shaped sections can be automatically achieved, the welding efficiency is high, the safety is high, and the application range is wide.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

Automatic welding device

ActiveCN103567693AEnsure consistencyRealize automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesHigh volume manufacturingEngineering

The invention discloses an automatic welding device. A copper belt and a coil are placed on a jig lower cover in a locating mode in advance, a jig upper cover is covered, then tray jigs are placed in a ball clip in an overlapping mode through a guiding stand column of the ball clip, a material pushing air cylinder works, a pushing rod extends out, a tray jig on the lowest bottom of the ball clip is pushed to a welding position of a track, the material pushing air cylinder retracts the pushing rod, other tray jigs in the ball clip slide downwards correspondingly through self gravity, an electric welding head of a spot welder body carries out spot welding on the corresponding positions on the copper belt and the coil on each tray jig in sequence, automatic welding is achieved, consistency of welding quality is guaranteed, production efficiency is improved, and large-batch production can be carried out.

Owner:和瑞电子(中山)有限公司

Plasma welding robot

PendingCN110722259ALarge rotation angleGuaranteed stabilityPlasma welding apparatusAutomotive engineeringWeld bead

The invention discloses a plasma welding robot. The plasma welding robot comprises rails, a welding car and a plasma power supply; the car is provided with a drive walking mechanism and a bracket thereof, welding gun angle and position adjusting mechanisms and a welding gun bracket; the walking mechanism controls motions in an X-axle rail direction and a Y-axle rail perpendicular direction; the angle adjusting mechanism is provided with an angle sensor for realizing the angle rotating adjustment of a R-axle welding gun; the welding gun position adjusting mechanism provides the position adjustment in Z-axle front and back directions and AVC-axle welding gun firepower line directions; a laser tracking sensor controls the position adjustment of ZX-axle laser points deviated from welding linesfront and back; three contact sensors are arranged on the car; two are used for judging curved surface positions to control the car to walk and to adjust the angle of the welding gun; and one is usedfor measuring local deformation of plates to realize automatic arc height adjustment. The plasma welding robot adopts quickly installed guide rails to realize automatic welding of all-position stainless steel corrugated plate joints through control of a six-axle linkage robot and a welding line laser automatic tracking system by a PLC.

Owner:ZHEJIANG JINHUA JUNENG ELECTRONICS TECH

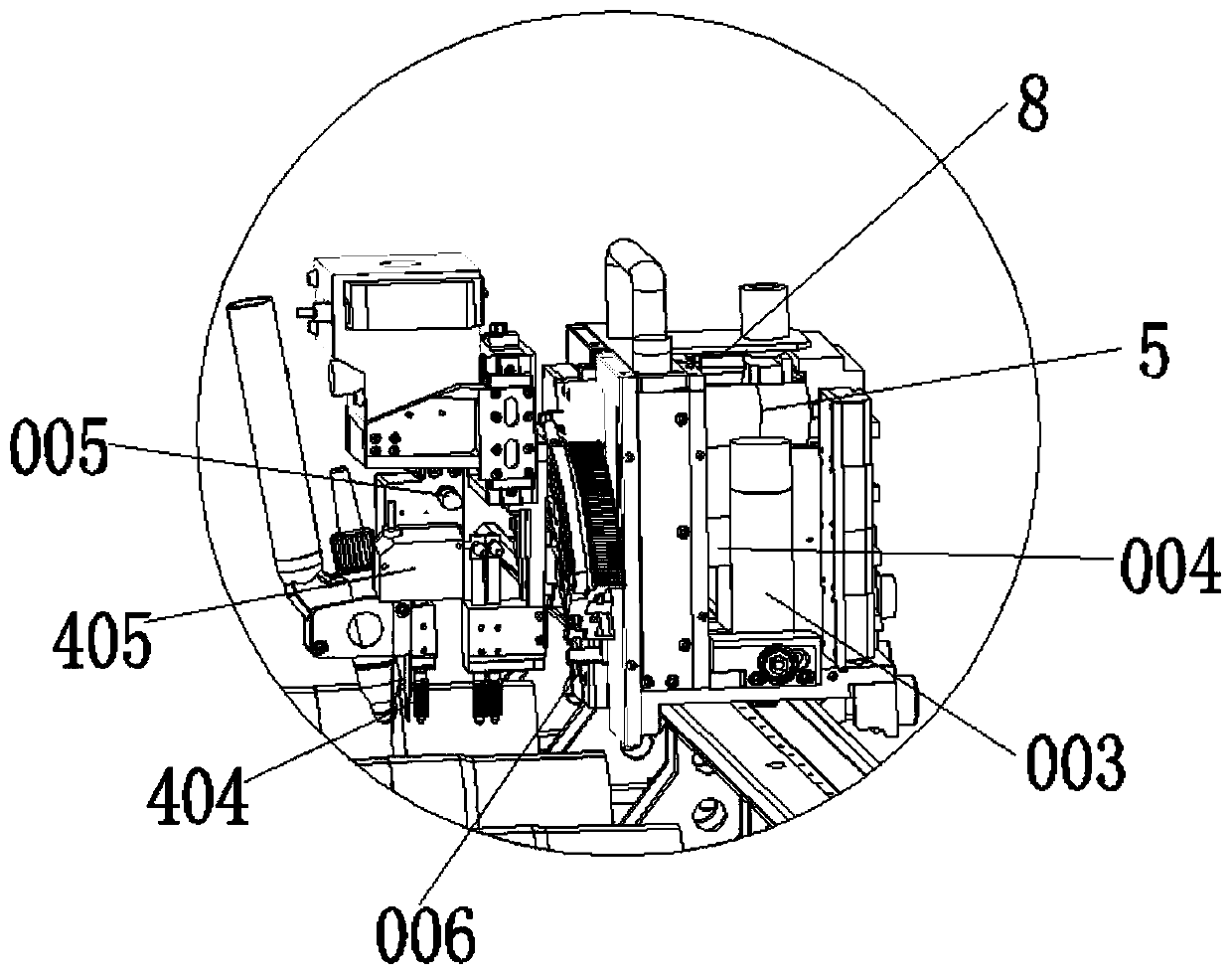

Direct spot welding device and method of button lithium battery

ActiveCN107262927ARealize automatic weldingImprove welding efficiencyAssembling battery machinesFinal product manufactureEngineeringHolding tank

The invention discloses a direct spot welding device and method of a button lithium battery. The spot welding device comprises a spot welding disk which is provided with a center gear, an annular slide track and four triangular bosses as well as a plurality of elliptical gears engaged with the center gear, and the spot welding disk is externally provided with a feeding manipulator, a first leg feeding and welding mechanism, a second leg feeding and welding mechanism and a discharge manipulator; the method comprises the steps that the elliptical gears are driven by the center gear to rotate around the center gear circumferentially, and the position of accommodation plates on the elliptical gears changes when the elliptical gears pass through each triangular boss; a battery body is placed in a holding tank through the feeding manipulator, and one side, relative to the battery body, of the first leg feeding and welding mechanism is welded with a first leg; and the other side, relative to the battery body, of the second leg feeding and welding mechanism is welded with a second leg, and the battery body is discharged by the discharge manipulator upon completion of welding of the legs at both sides.

Owner:启东新亚电子科技有限公司

Solar cell welding machine

PendingCN109623218ARealize automatic weldingClosely arrangedFinal product manufactureWelding/cutting auxillary devicesCell interconnectionWelding

The invention discloses a solar cell welding machine. The solar cell welding machine comprises a machine base, a conveying assembly, a first welding strip feeding device, a second welding strip feeding device, a cell feeding and discharging device, an interconnection welding device and a confluence welding device; the machine base is provided with a cell paving station, a waiting station, an interconnection welding station and a confluence welding station; the conveying assembly conveys a plurality of solar cells to the interconnection welding station via the cell paving station successively;the first welding strip feeding device conveys a first welding strip to the cell paving station; the second welding strip feeding device conveys a plurality of second welding strips to the waiting station and the cell paving station; the cell feeding and discharging device conveys solar cells to the cell paving station; the interconnection welding device welds and forms a plurality of interconnected solar cell strings; and the confluence welding device welds and forms a cell interconnection plate. Simultaneous welding of the multiple solar cell strings and automatic welding of the solar cell interconnection plate are achieved, the production efficiency is improved, and the conversion efficiency of a photovoltaic module is improved.

Owner:WUHAN SUNIC INTELLIGENT EQUIP MFG CO LTD

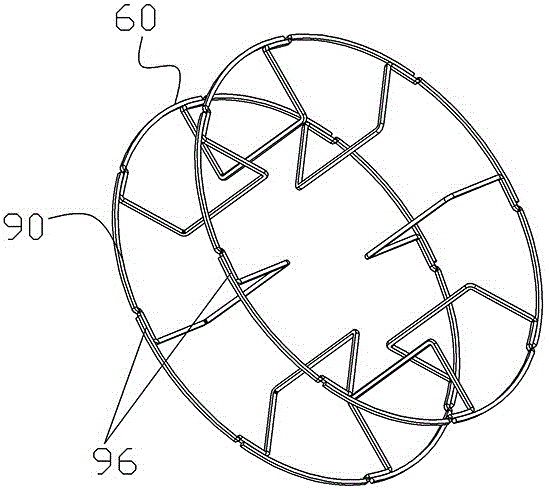

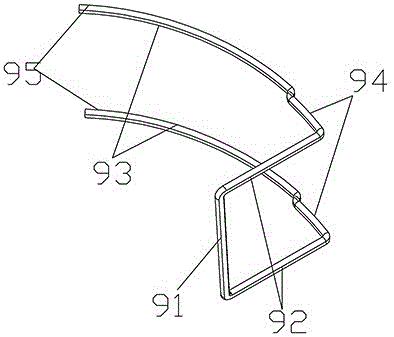

Automatic spot welding machine of button-shaped lithium batteries and automatic spot welding method

ActiveCN107150173ARealize automatic weldingImprove welding efficiencyMetal working apparatusLaser beam welding apparatusSpot weldingLithium battery

The invention discloses an automatic spot welding machine of button-shaped lithium batteries and a method. The spot welding machine comprises a battery body loading mechanism for conveying battery bodies to a welding station, a semicircular conveying mechanism for oppositely arranging one set of intermittently conveyed battery bodies, a first welding leg welding mechanism for welding first welding legs, a second welding leg welding mechanism for welding second welding legs, an overturning mechanism connected between the tail end of one semicircular conveying belt and the head end of the other circular conveying belt for overturning the battery bodies, a first welding leg loading mechanism, a second welding leg loading mechanism and a battery body unloading mechanism. The method comprises the following steps: the battery body loading mechanism conveys the battery bodies to the head end of one semicircular conveying belt; the first welding leg loading mechanism conveys the first welding legs into an annular clamping base; the first welding leg welding mechanism welds the first welding legs; the overturning mechanism overturns the battery bodies by 180 degrees; and the second welding leg welding mechanism welds the second welding legs.

Owner:盐城柏达电气科技有限公司

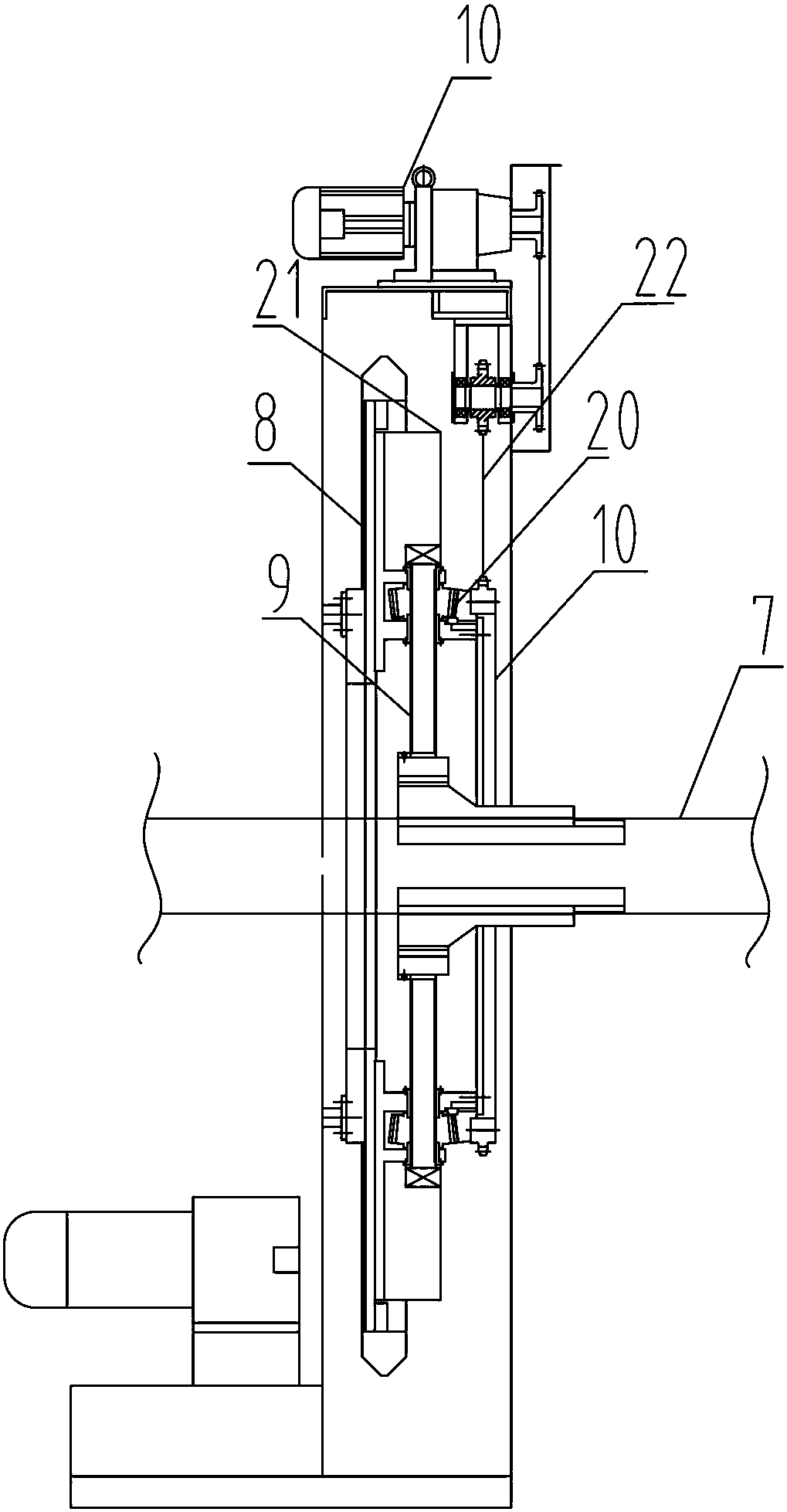

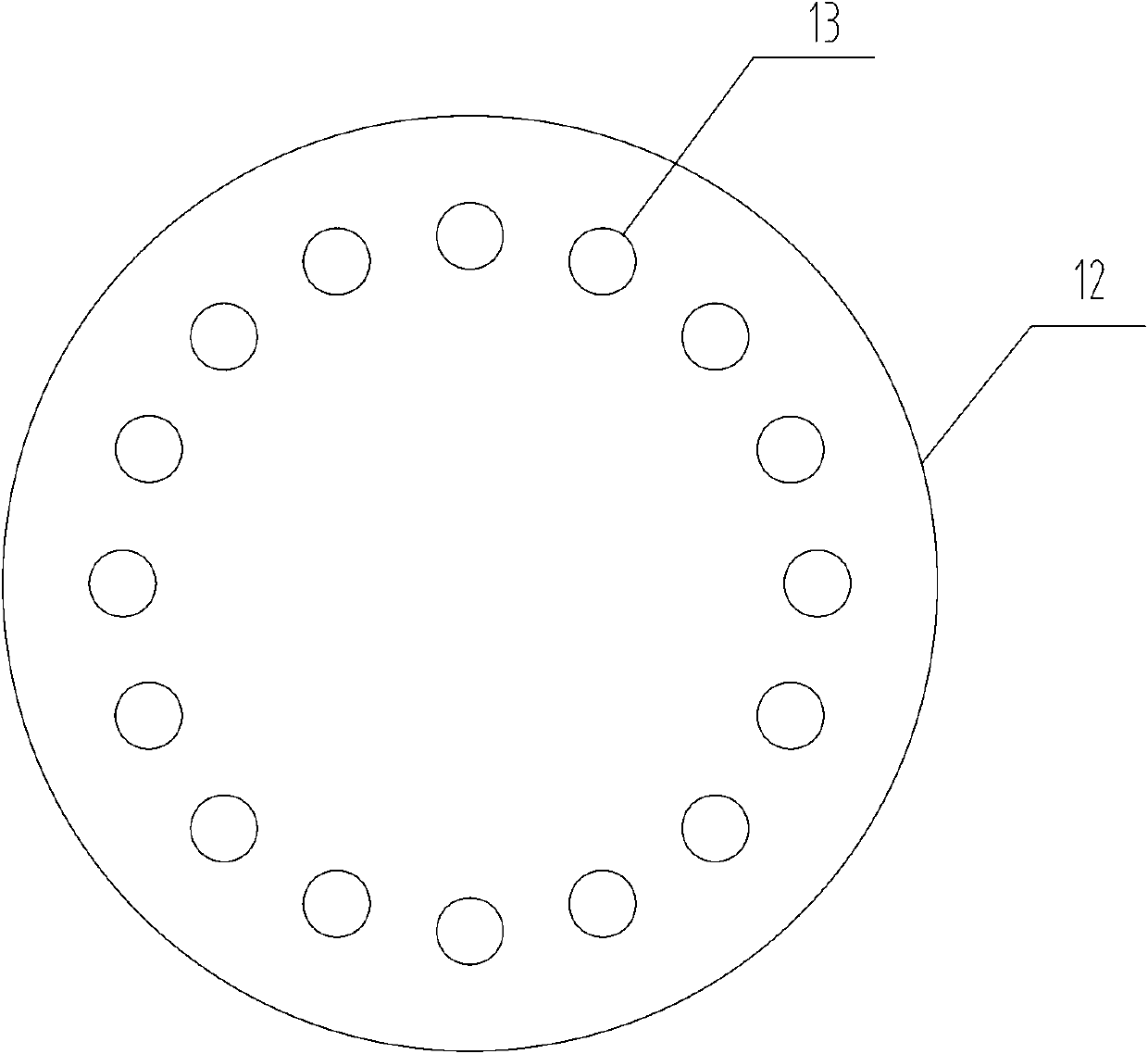

Automatic welding and forming machine of tapered pole reinforcing cage

InactiveCN102989934ARealize automatic weldingStable supportMeshed-ring wire networkResistance welding apparatusMolding machineStructural engineering

The invention relates to an automatic welding and forming machine of a tapered pole reinforcing cage. The automatic welding and forming machine comprises a material frame, a reinforcing cage forming mechanism and a movable rotary mechanism, which are arranged on a bottom bracket, wherein the movable rotary mechanism comprises a first driving device and a locating disc driven by the first driving device, and a main reinforcement locating hole capable of passing through the reinforcing cage is formed in the locating disc; the reinforcing cage forming mechanism comprises a second driving device and a rotary disc driven by the second driving device, a main reinforcement locating device capable of passing through the reinforcing cage is formed in the rotary disc, and the rotary disc and the locating disc rotate synchronously; and a welding device is arranged on one side of the reinforcing cage forming mechanism. The forming machine of the tapered pole reinforcing cage disclosed by the invention has the advantages of being capable of implementing automatic welding and improving the working efficiency.

Owner:YICHANG HAITIAN ULTRASONIC TECH

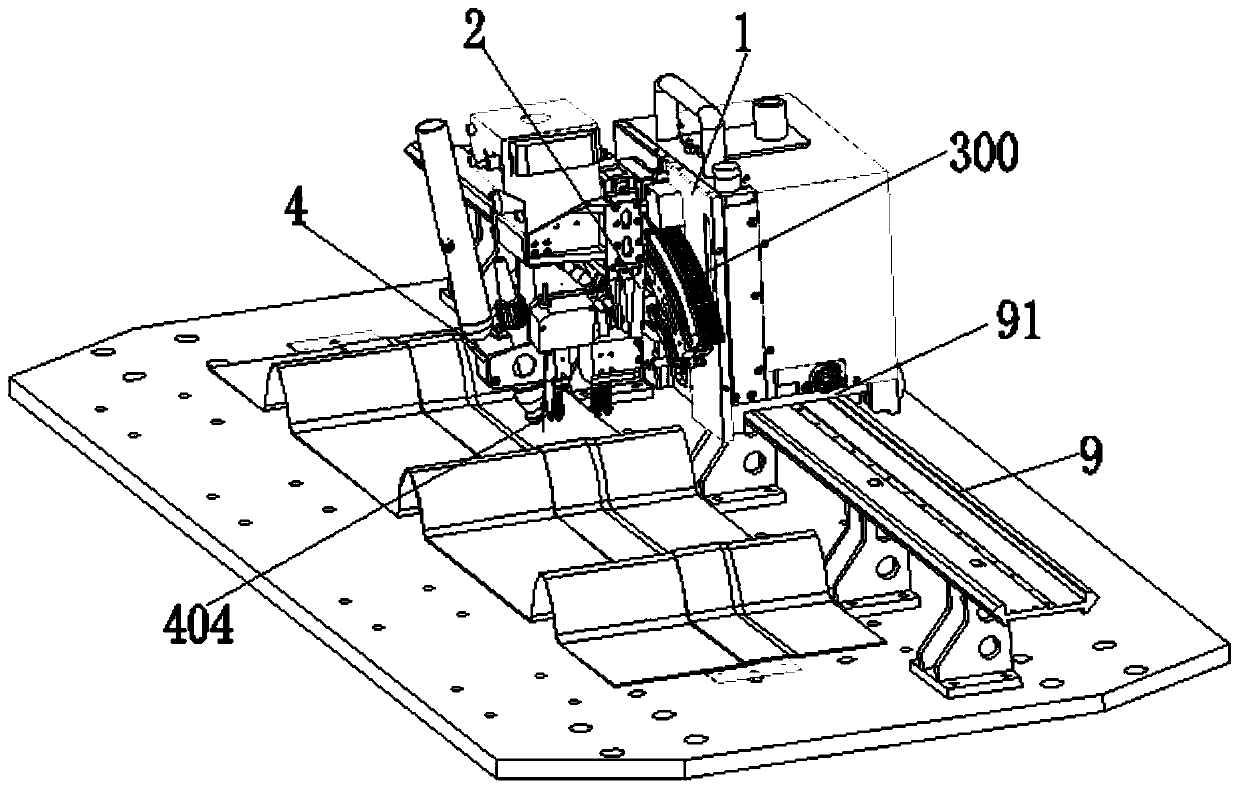

Welding device for battery module

InactiveCN107262866ADoes not affect rust resistanceEasy to disassemble and separateAssembling battery machinesFinal product manufactureEngineeringSoldering

The invention provides a welding device for a battery module. The welding device is used for welding the battery module. The welding device for the battery module comprises a base, a welding mechanism and a moving mechanism; the welding mechanism comprises a driving part, a first sliding block, two second sliding blocks and two welding needles; the driving part is used for driving the first sliding block to slide relative to the driving part; the two second sliding blocks are arranged on one side of the first sliding block side by side, are close to the moving mechanism and can move in the direction of being close to or far away from the moving mechanism under driving of the first sliding block; the battery module is installed on the moving mechanism, enables a bus board to face the welding needles and can move in the first direction and the second direction relative to the base under driving of the moving mechanism; the two welding needles are installed on the two sliding blocks respectively and release alternating currents to melt solder when the welding needles are connected with the bus board in a butted mode, and then the bus board and a plurality of single batteries are welded. According to the welding device for the battery module, the defects existing in electric resistance welding and manual soldering are overcome.

Owner:伍伟东 +1

Ship double bottom block assembly welding technology

InactiveCN102848091ARealize automatic weldingSmall structural deformationWelding apparatusAgricultural engineeringDouble bottom

The invention discloses a ship double bottom block assembly welding technology. The ship double bottom block assembly welding technology comprises the following steps of: presetting corresponding tire holders of the double bottom, marking a seam line mark on each tire holder, and starting to assemble external plates corresponding to the seam line marks on the tire holders, and welding the external plates; marking vertical and horizontal framework mounting lines on the external plates, and mounting a middle bottom girder; assembling vertical and horizontal frameworks at corresponding positions of the vertical and horizontal framework mounting lines, welding a front pressurizing row, welding the seam between the frameworks and the seam between the frameworks and the external plates, then, detaching the pressurizing row, correcting deformation, and fitting out block by block; hoisting inner bottom plates on the vertical and horizontal frameworks, marking block assembly locating lines on the inner bottom plates, and welding flying rings block by block; hoisting and turning over the blocks, placing the blocks on a platform, and welding the seams between the vertical and horizontal frameworks and the inner base plates, and the sealing run of the external bottom plates. With the adoption of the technology provided by the invention, the ship double bottom assembly efficiency is high, and the welding quality is good.

Owner:世纪华海(福建)船舶重工有限公司

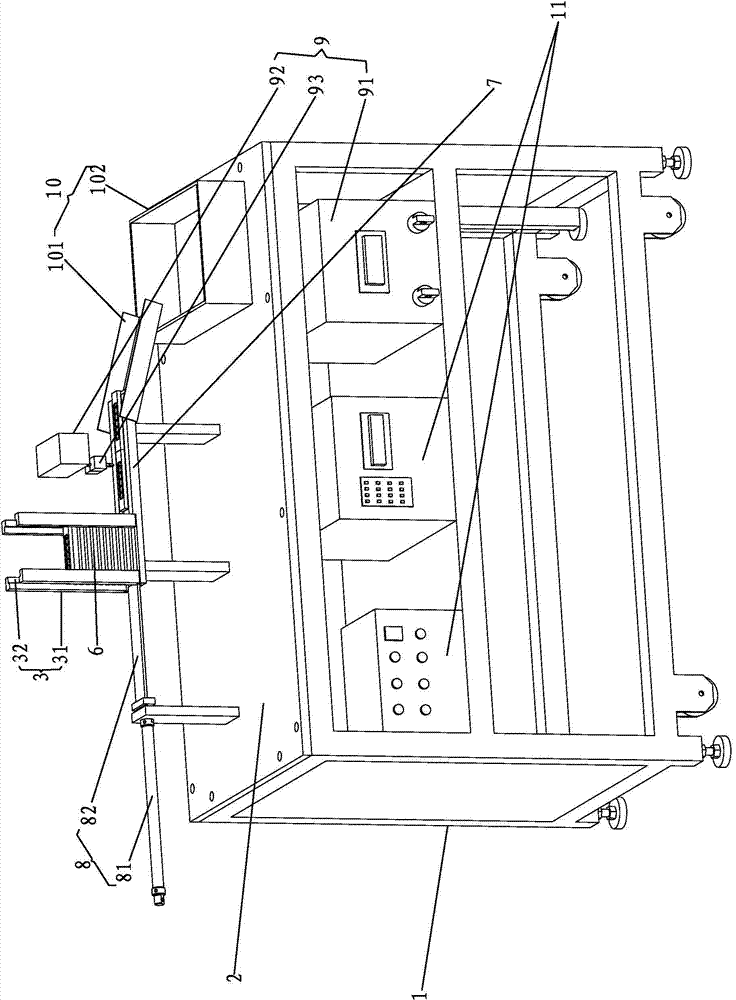

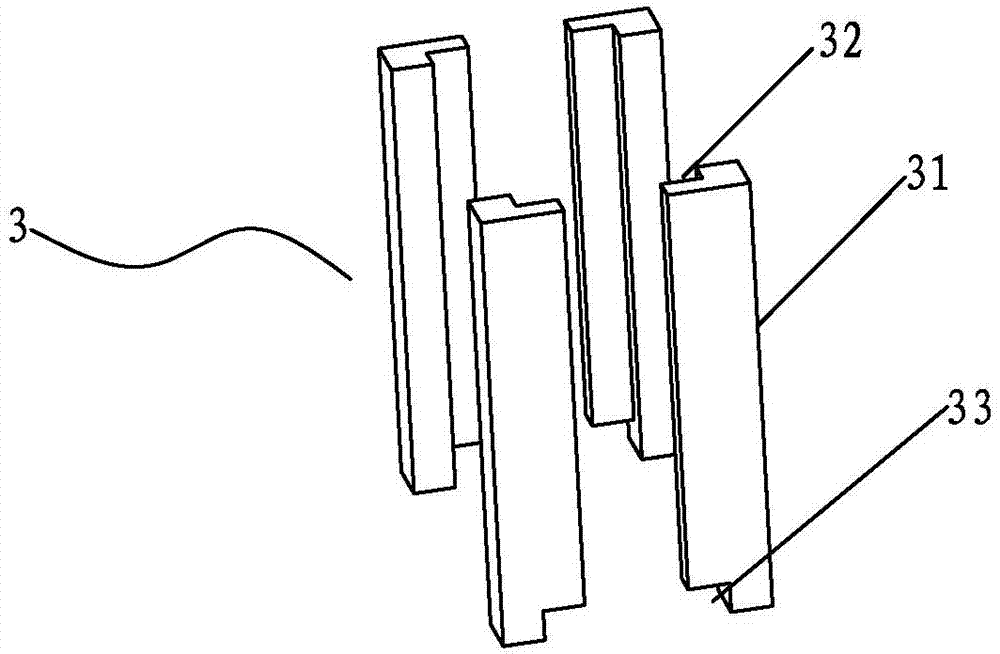

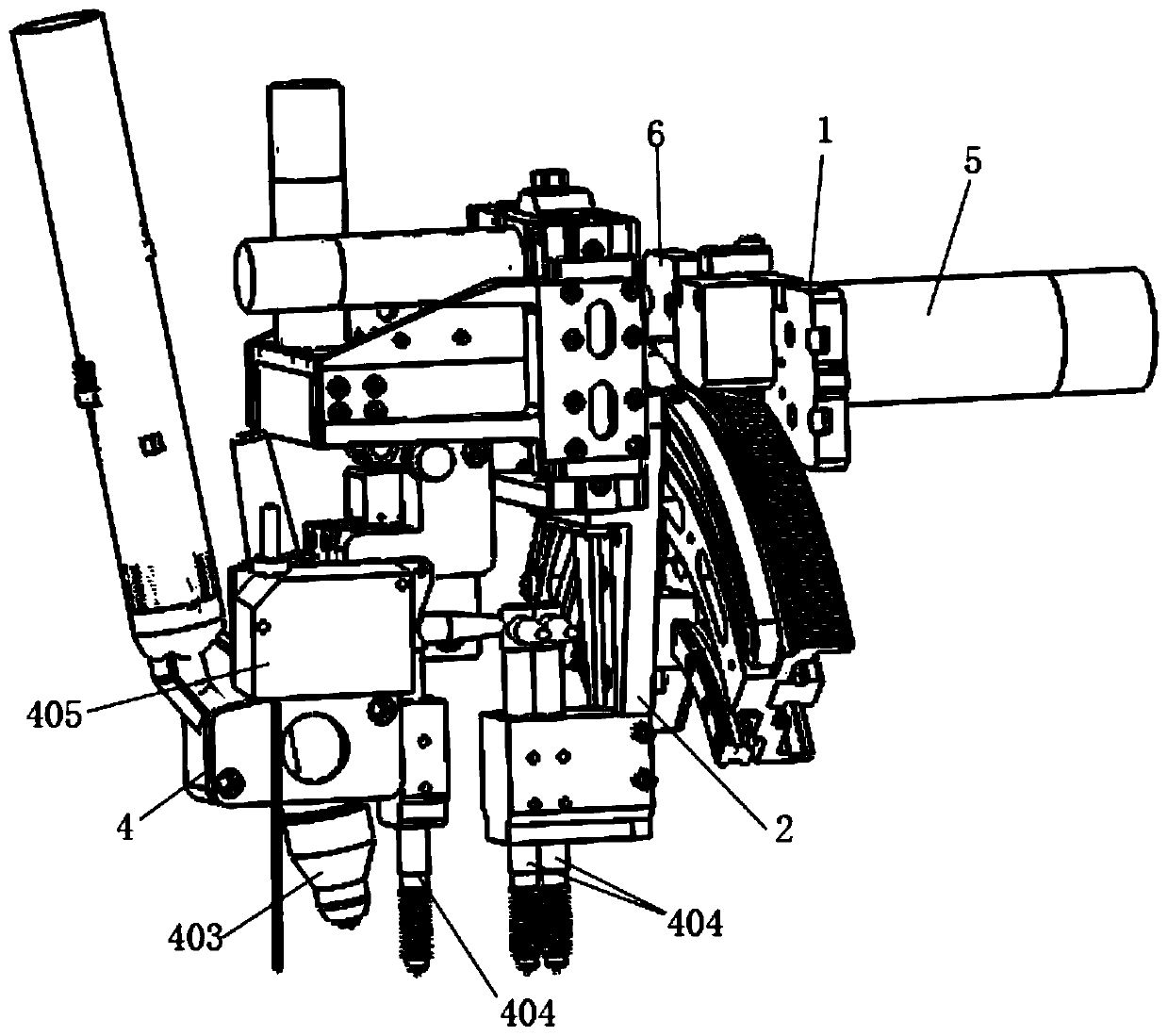

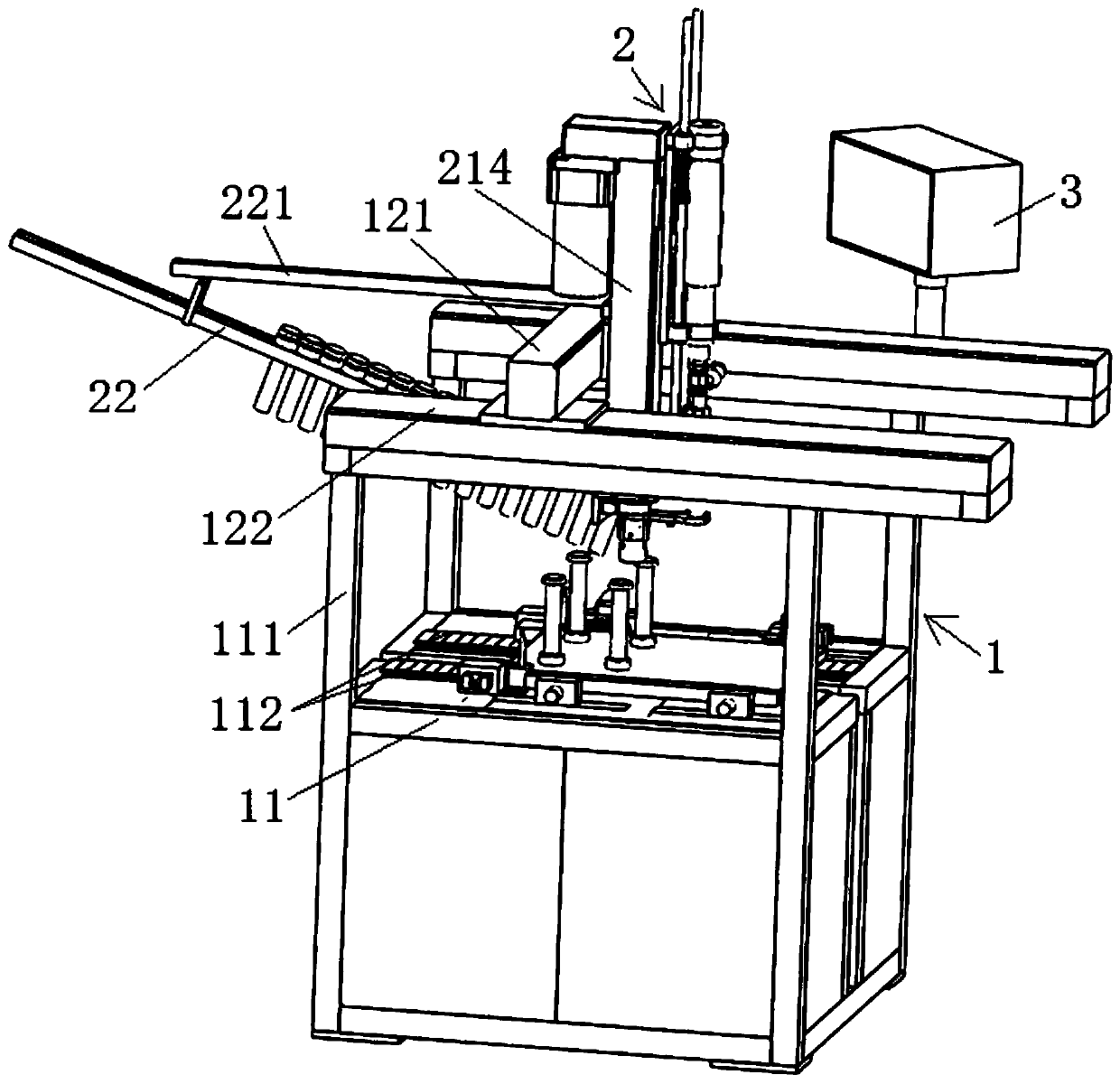

Device for achieving automatic welding of T-shaped stud on embedded part

PendingCN110238577AHigh degree of automationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention discloses a device for achieving automatic welding of a T-shaped stud on an embedded part. The device comprises a welding platform and an automatic welding mechanism. The welding platform comprises a cabinet type worktable and a double-axis movement support. The automatic welding mechanism comprises an automatic welding gun, a material clamp, a material putting assembly and a material receiving and sending assembly. The automatic welding gun comprises a welding gun body, a welding gun body fixing plate, a lifting sliding block and a perpendicular lifting mechanism. The material putting assembly comprises a material blocking rod which is arranged at the discharging end of the material clamp in a penetrating manner and can achieve telescopic motion. The material receiving and sending assembly comprises a receiving and sending clamp and a receiving and sending motor. A U-shaped material receiving groove with an opening facing the material clamp is formed in one end of the receiving and sending clamp, the other end of the receiving and sending clamp is connected to an output shaft of the receiving and sending motor in a sleeving manner, and the receiving and sending motor is fixed to the bottom of the perpendicular lifting mechanism. By means of the device, automatic welding of the T-shaped stud on the embedded part is achieved for the first time, the automation degree is high, in addition, the labor intensity of welding workers can be obviously lowered, the welding efficiency is high, and the welding quality can be ensured.

Owner:浙江上势自动焊接科技有限公司

Automatic welding device for agricultural vehicle balance weight

InactiveCN105234607ARealize two-axis interpolation motionRealize automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention discloses an automatic welding device for an agricultural vehicle balance weight and belongs to the field of automatic welding equipment. The device is composed of a base, a working table, a stand column, a lifting beam and a welding gun swing mechanism. During welding, a welding gun is driven by a horizontal motor to move in the radial direction, a rotary motor drives the working able to rotate, two-dimensional interpolation motion in a polar coordinate system is achieved, the welding gun swing mechanism drives the welding gun to rotate along the axis of a swing shaft to enable the projection of the axis of the welding gun on the welding path surface to be always perpendicular to the tangential direction of the welding path during welding, welding attitude retentivity is high, and welding quality and welding efficiency are improved.

Owner:SHANDONG JIANZHU UNIV

Automatic welding device of curved plate

ActiveCN101823191ARealize automatic weldingImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld lineRoller chain

The invention discloses an automatic welding device of a curved plate, comprising a roller base, a rotary assembly jig, a drive unit, a welding trolley and a control system, wherein, the roller base is composed of a base, four axle bases, a support roller and a sprocket wheel, the axle bases are arranged on four corners of the base, and the support roller and the sprocket wheel are axially arranged on a support shaft; the rotary assembly jig is composed of a welding platform and circular arc tracks, wherein, the two circular arc tracks are arranged on the bottom of the welding platform in parallel, and a roller chain is arranged along the circular arc tracks; the drive unit is composed of a servo motor, a reduction box and a transmission shaft, wherein, the reduction box drives the sprocket wheel by the transmission shaft; the welding trolley is arranged on the curved plate; the control system is composed of a monitoring tracker and a programmable controller; and the welding platform is tangent to the outer diameter of the support roller of the base by the two circular arc tracks, and the sprocket wheel is meshed with the roller chain. The automatic welding device can ensure that a bent segmented welding line still keeps in a horizontal status in the welding process to automatically weld the curved panel, obviously improve the welding quality of a boat deck and effectively improve the production efficiency of shipbuilding industry.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Automatic air conditioner base bolt and base foot welding production system

InactiveCN104858579ARealize automatic weldingSave human effortWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterial resources

The invention discloses an automatic air conditioner base bolt and base foot welding production system which comprises a conveying belt and a rack matched with the conveying belt. An air conditioner base plate feeding station, a screw feeding station, a screw welding station, a base foot feeding station and a base foot welding station are sequentially arranged on the rack in the air conditioner base plate machining direction, positioning templates are arranged on the stations, and station manipulators are installed on the rack. The automatic air conditioner base bolt and base foot welding production system is characterized in that the air conditioner base plate feeding station comprises a conveying belt and a correction device; the screw feeding station comprises a vibratory selecting machine, a screw distributor and an automatic bolt feeding device; the screw welding station comprises a screw welding machine; the base foot feeding station comprises an automatic base foot feeding device and a moving feeding trolley; the base foot welding station comprises a base foot double-end welding machine. The automatic air conditioner base bolt and base foot welding production system completely achieves automatic air conditioner base bolt and base foot welding, and the whole system enables labors to be saved, overcomes the shortcoming that the quality of an existing air conditioner base plate cannot be ensured and has the advantages of being capable of saving manpower and material resources, high in production process and free of insufficient solder.

Owner:武汉市博达自动焊接设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com