Workpiece clamping clamp and wire spool welder using same

A winding reel and welding machine technology, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of manual placement, inaccurate workpiece positioning, etc., achieve simple structure, accurate and reliable movement, and ensure automatic and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

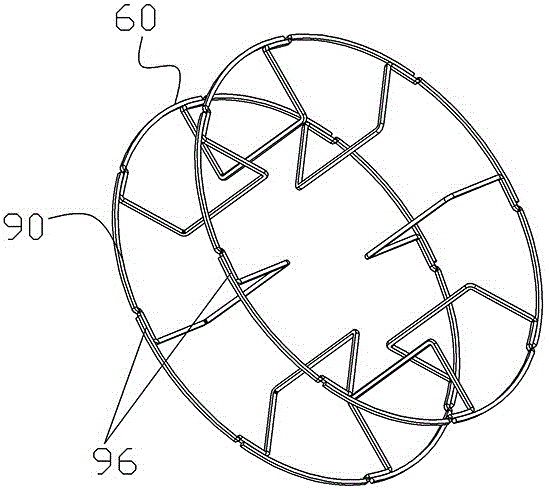

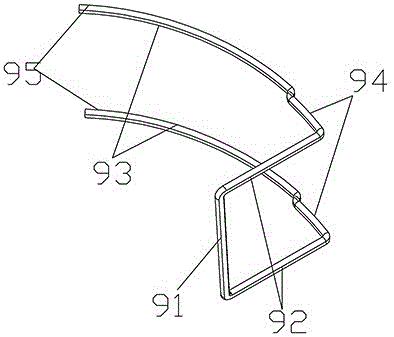

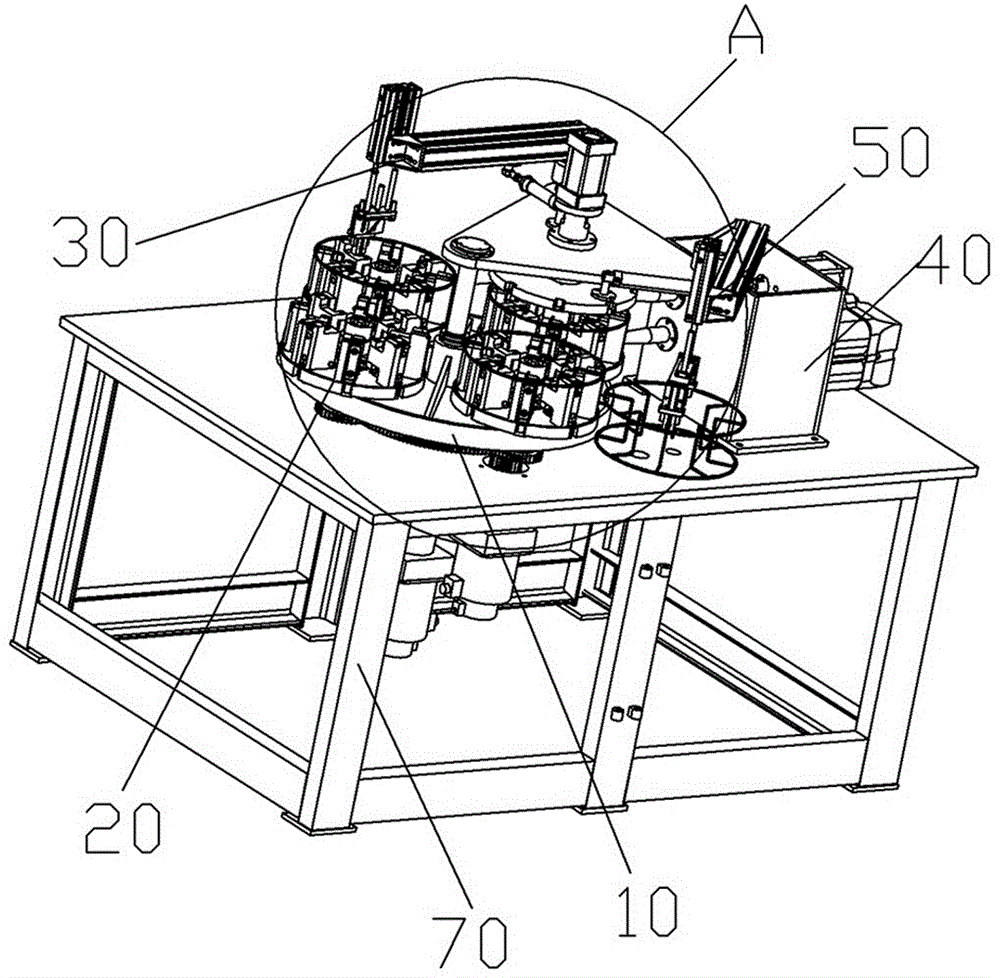

[0043] Such as image 3 to figure 1 As shown in 8, an embodiment of a winding reel welding machine, the welding machine in this embodiment can be used for welding assembly Such as figure 1 , figure 2 Shown is a spool 60 for winding welding wire.

[0044] The welding machine provided in this embodiment includes a frame 70, on which a planetary gear train transmission mechanism 100, a clamping fixture 20 for clamping each component unit 90 of the winding reel, and an upper part for loading the component unit 96 are arranged on the frame 70. Material device 30, welding device 40, and feeding device 50.

[0045] The welding machine provided in this embodiment drives the clamping fixture through four stations successively through the planetary gear transmission mechanism 100, which are respectively the preparation station, the loading station, the welding station and the blanking station. The positions are evenly distributed along the circumferential direction. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com