Patents

Literature

158results about How to "Accurate clamping and positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

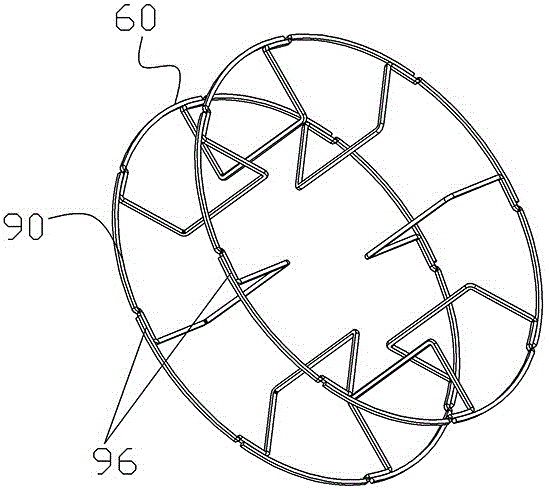

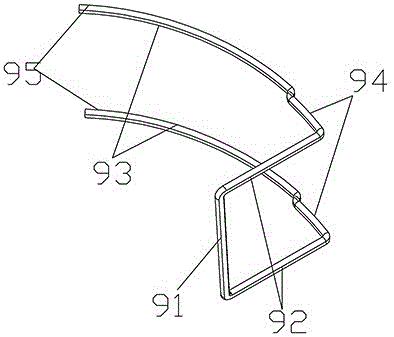

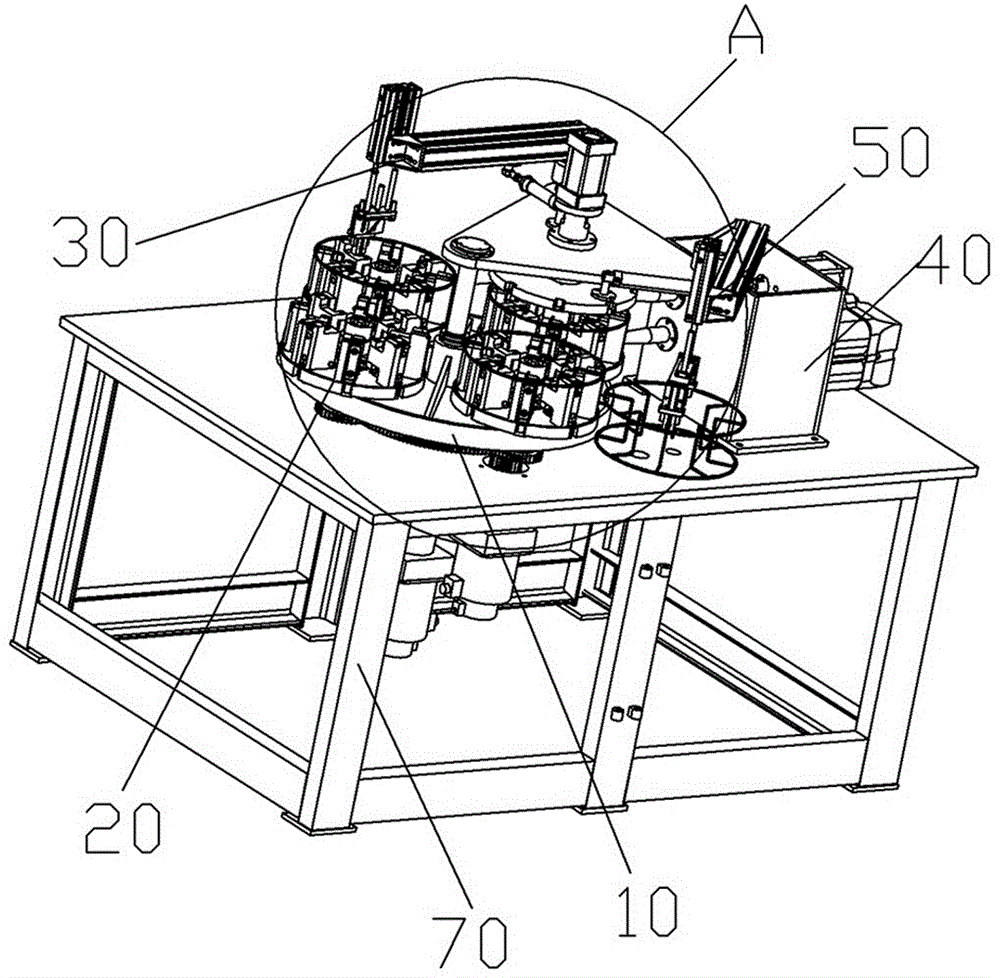

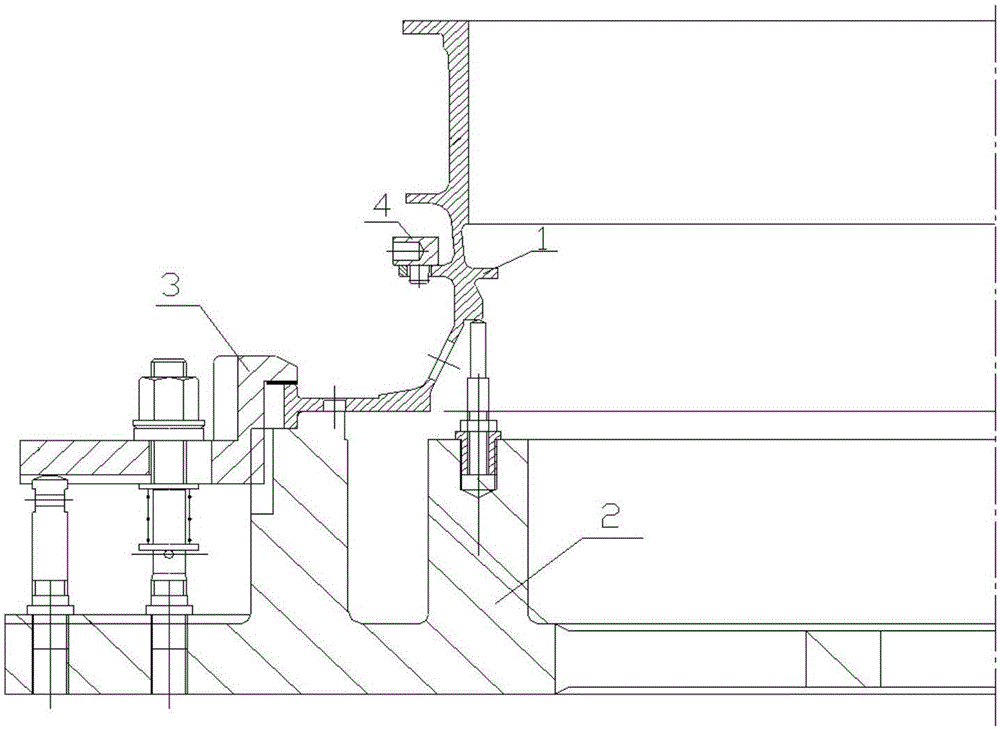

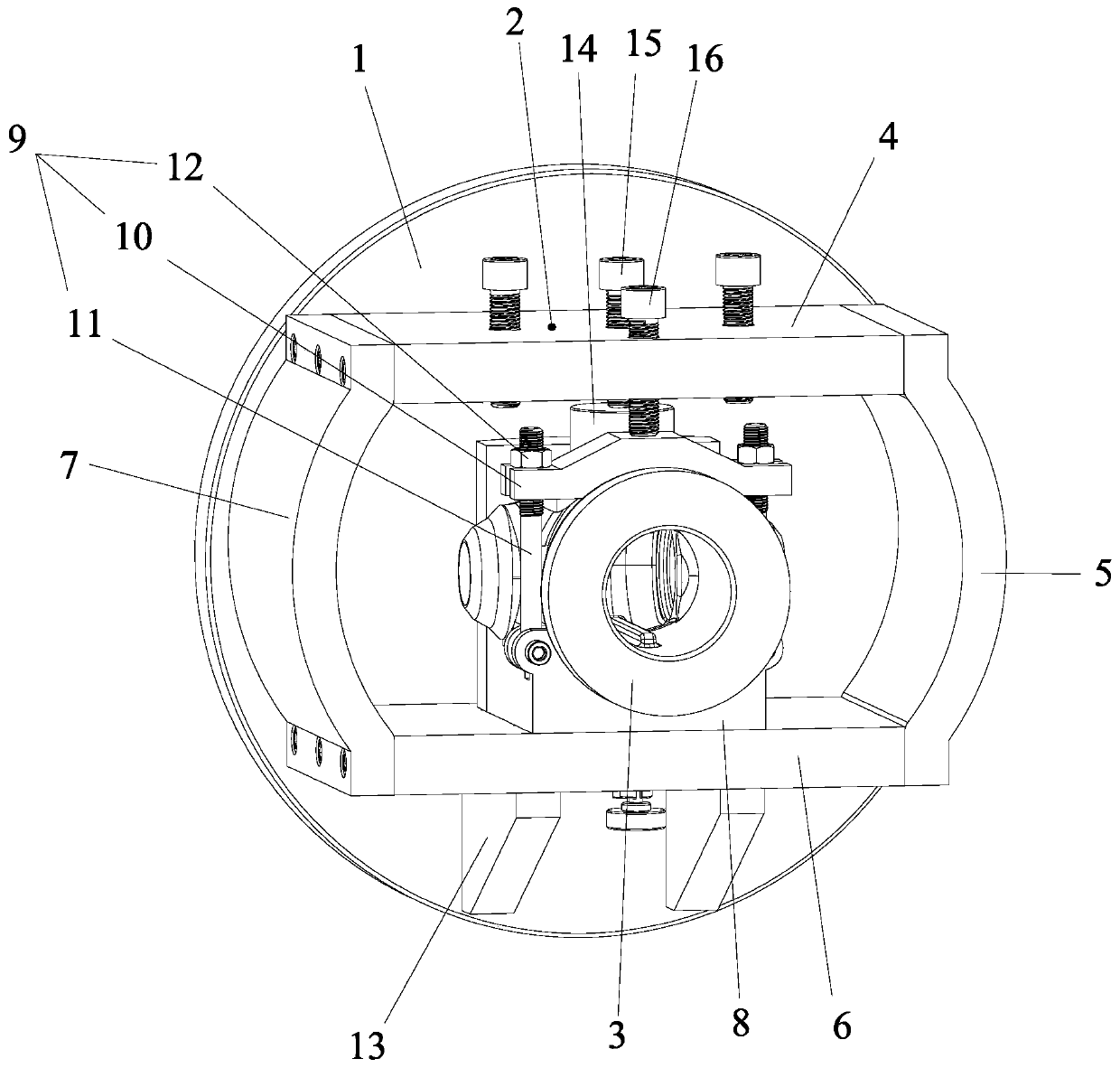

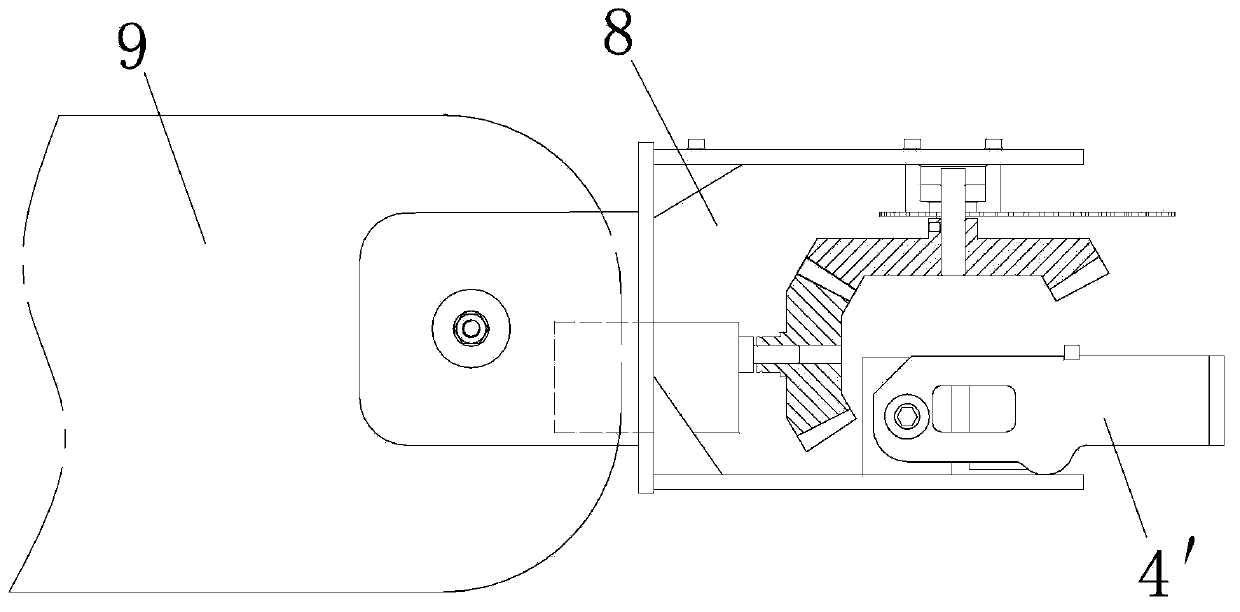

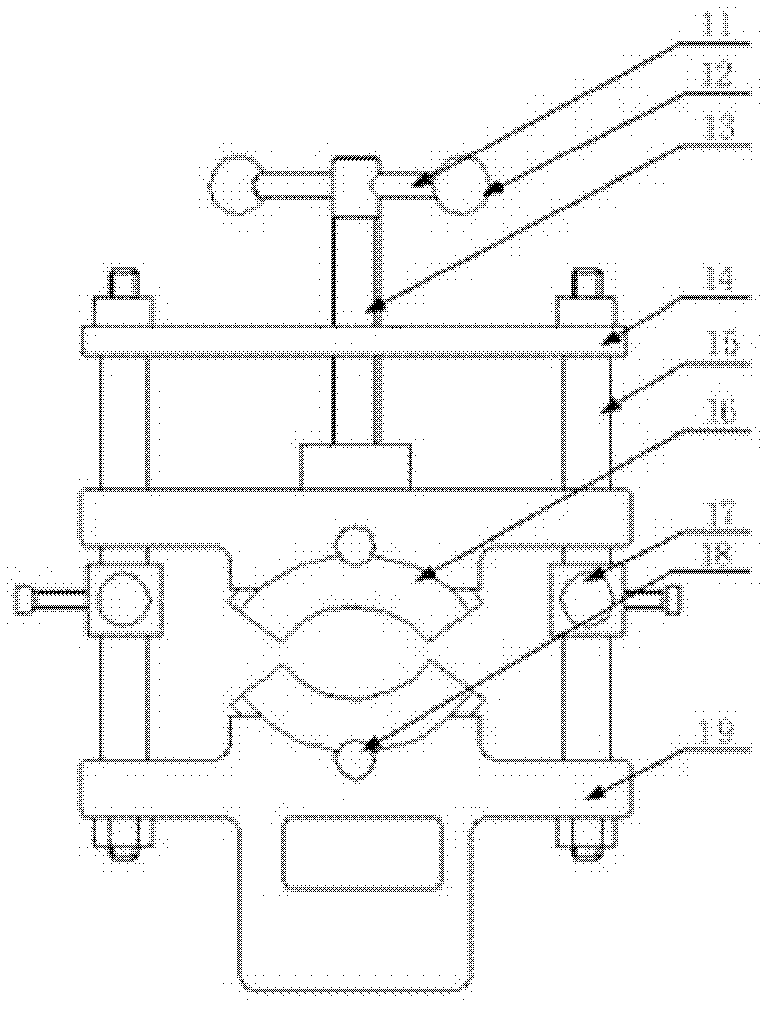

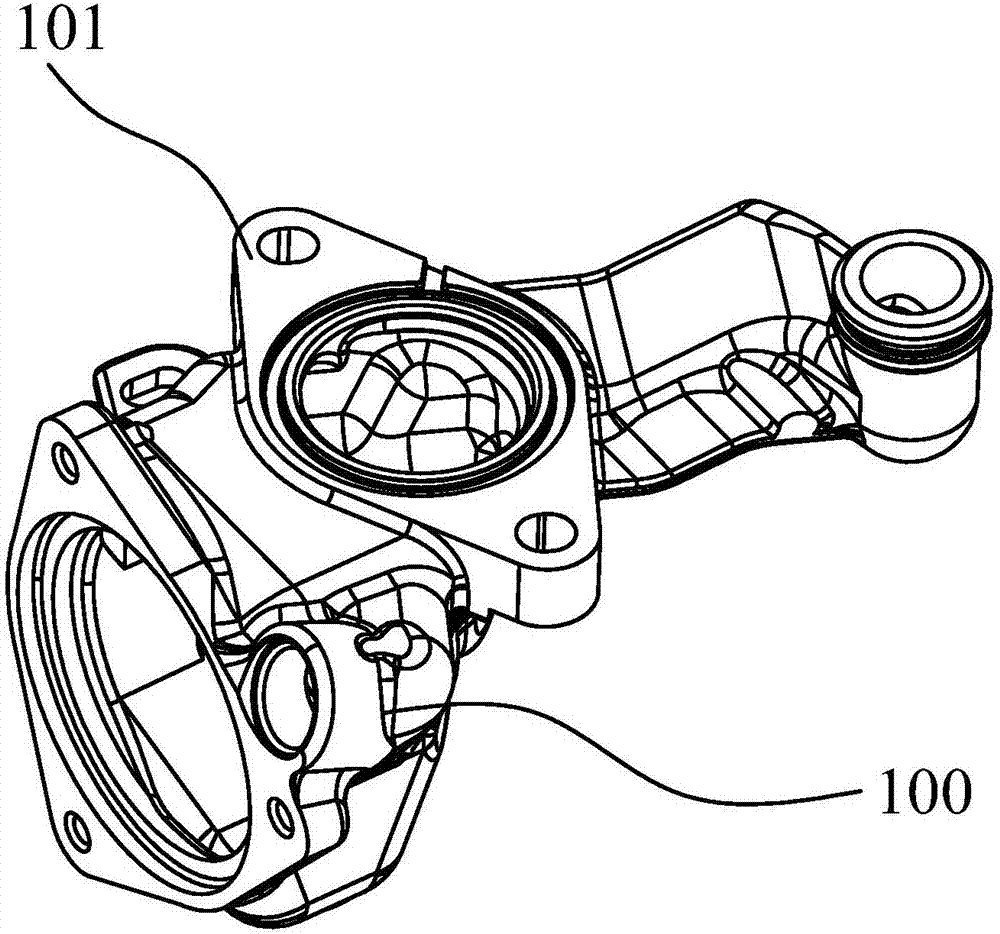

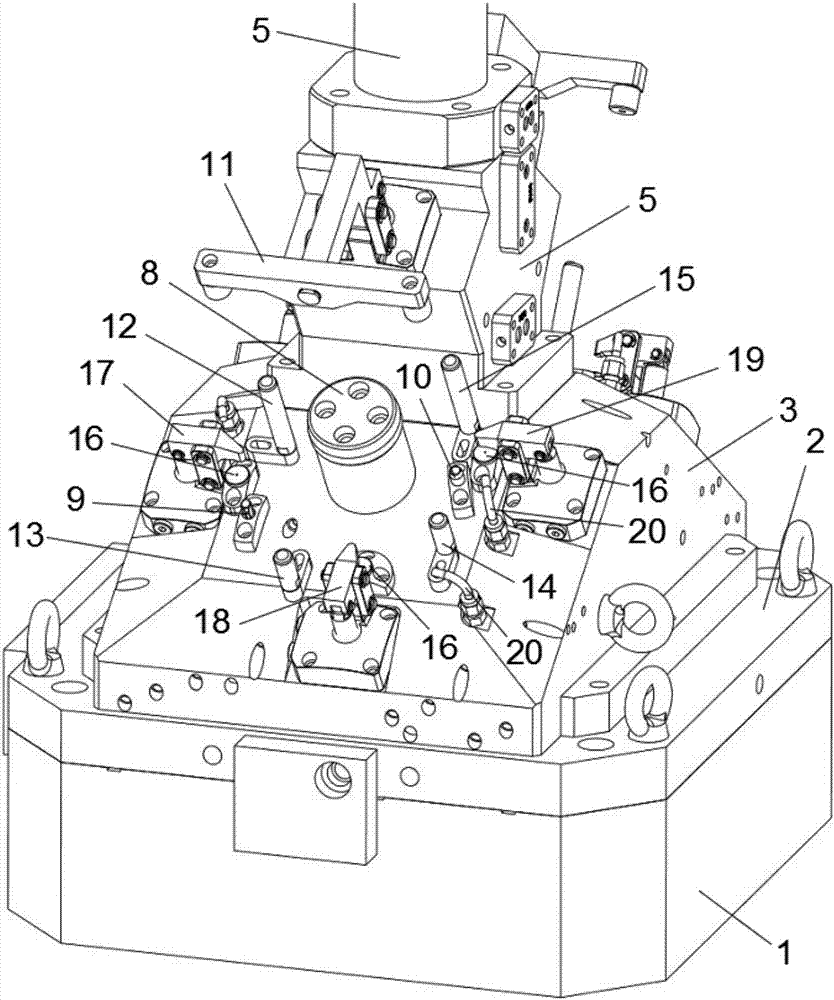

Workpiece clamping clamp and wire spool welder using same

ActiveCN104985369ARealize automatic and accurate positioningEnsure automatic and accurate positioningWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

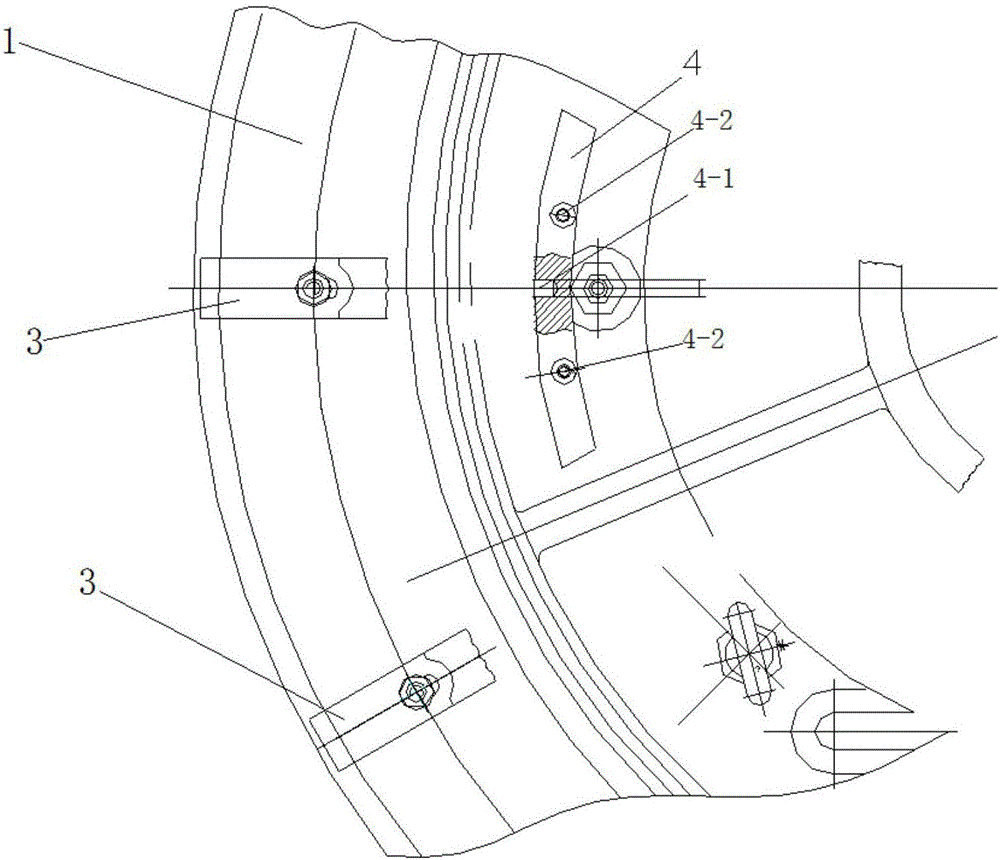

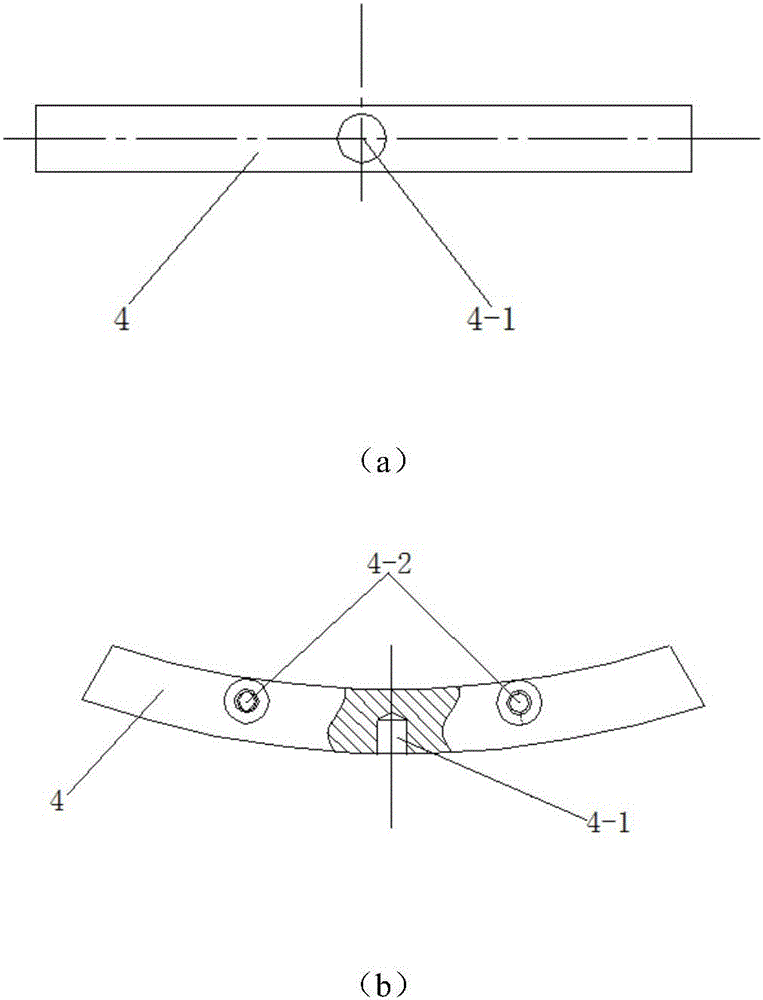

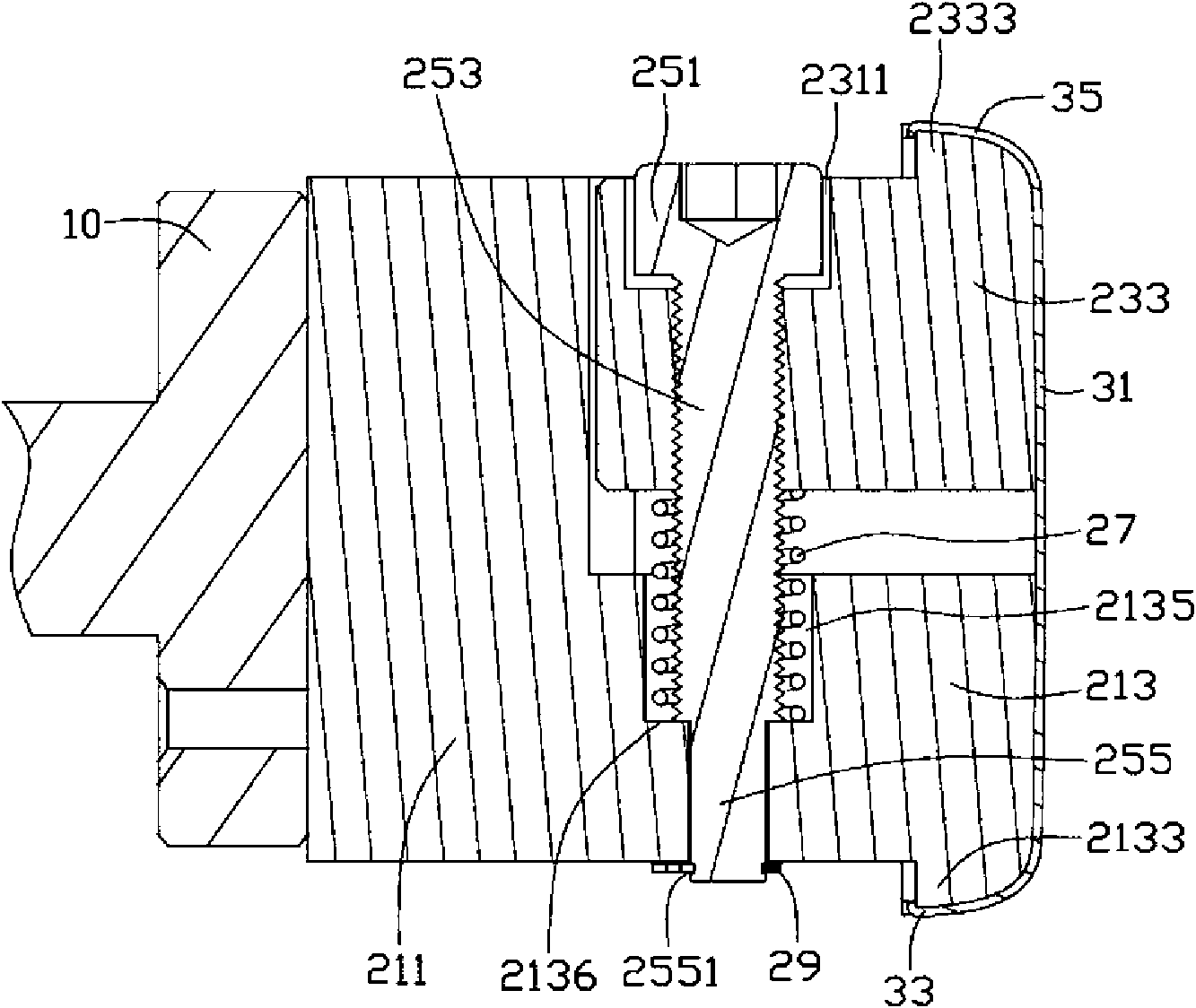

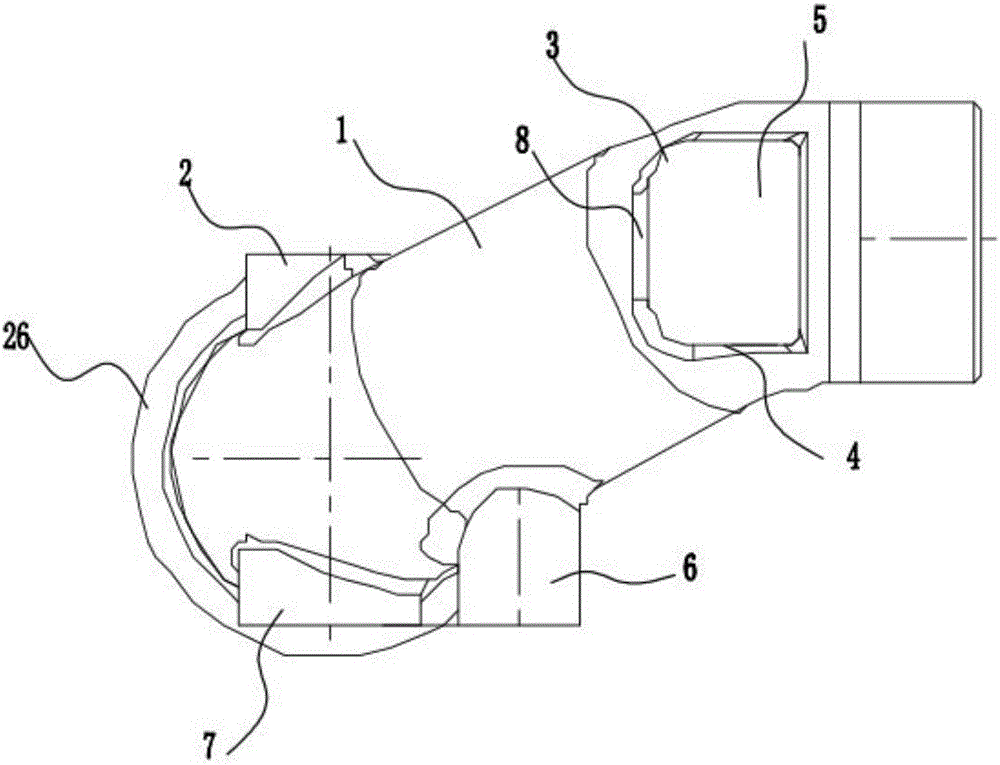

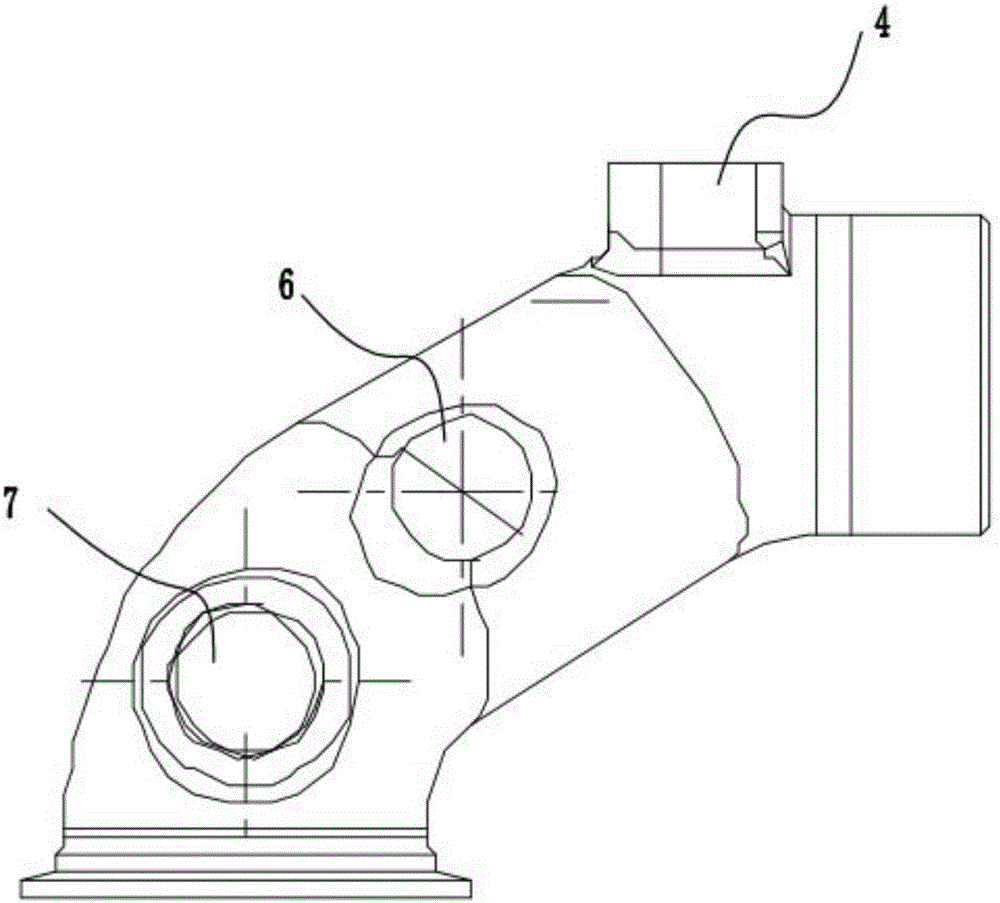

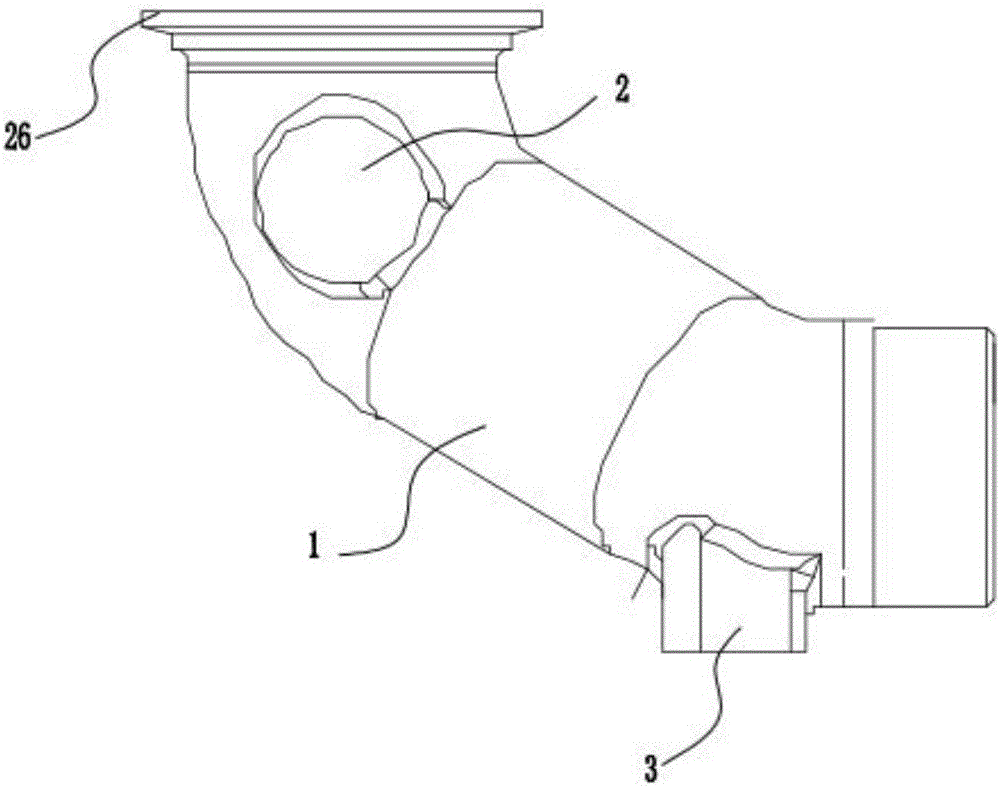

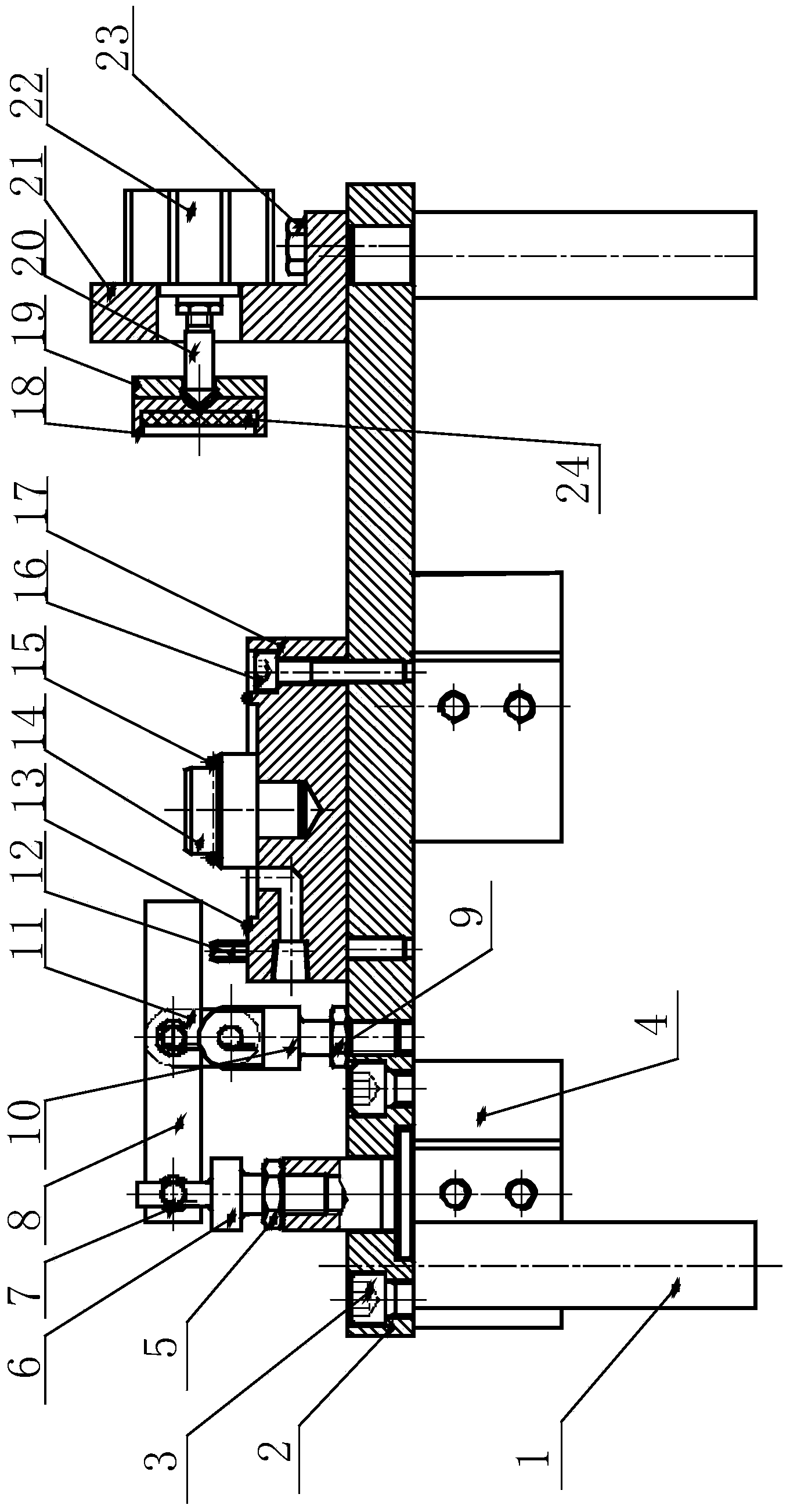

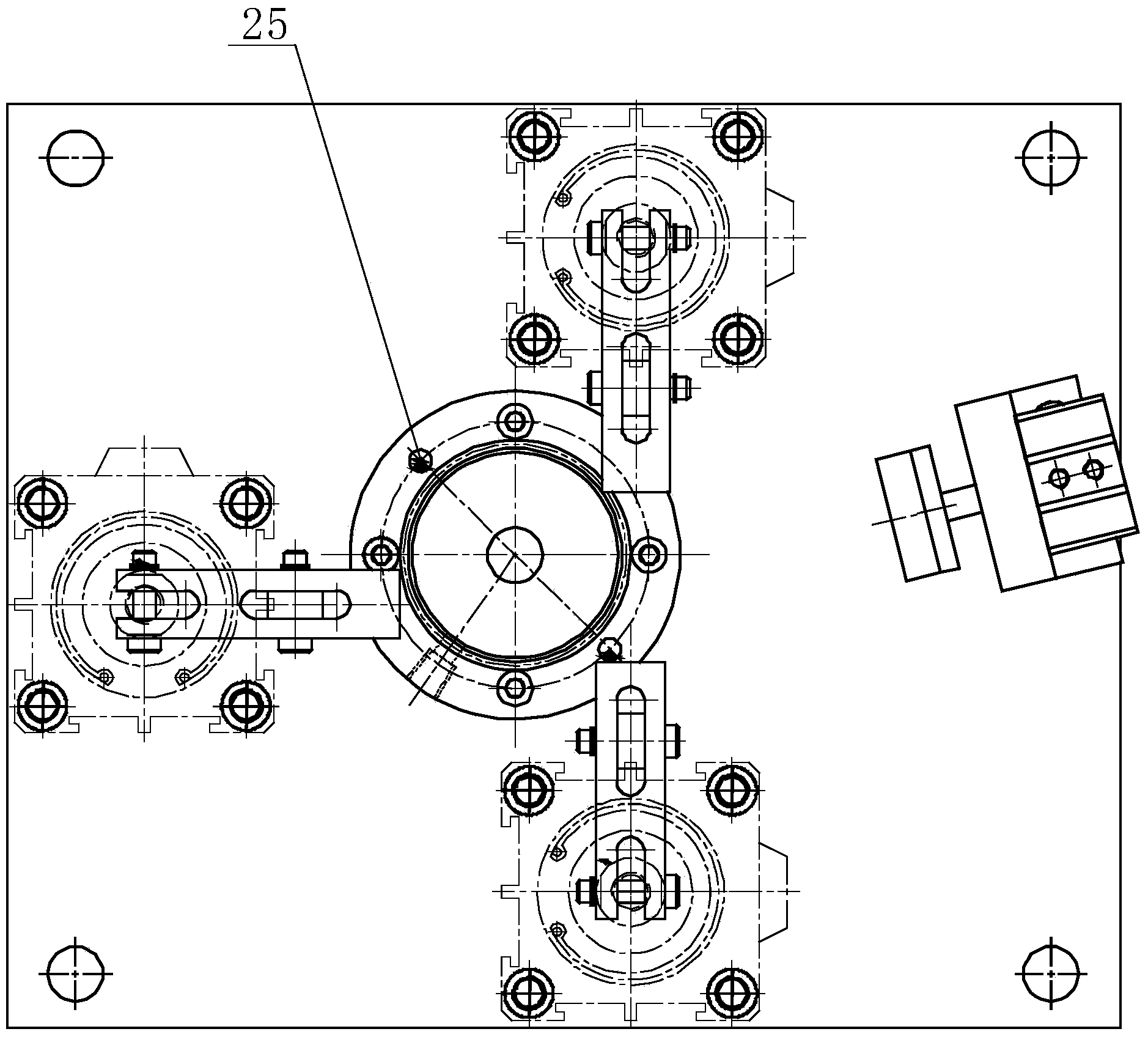

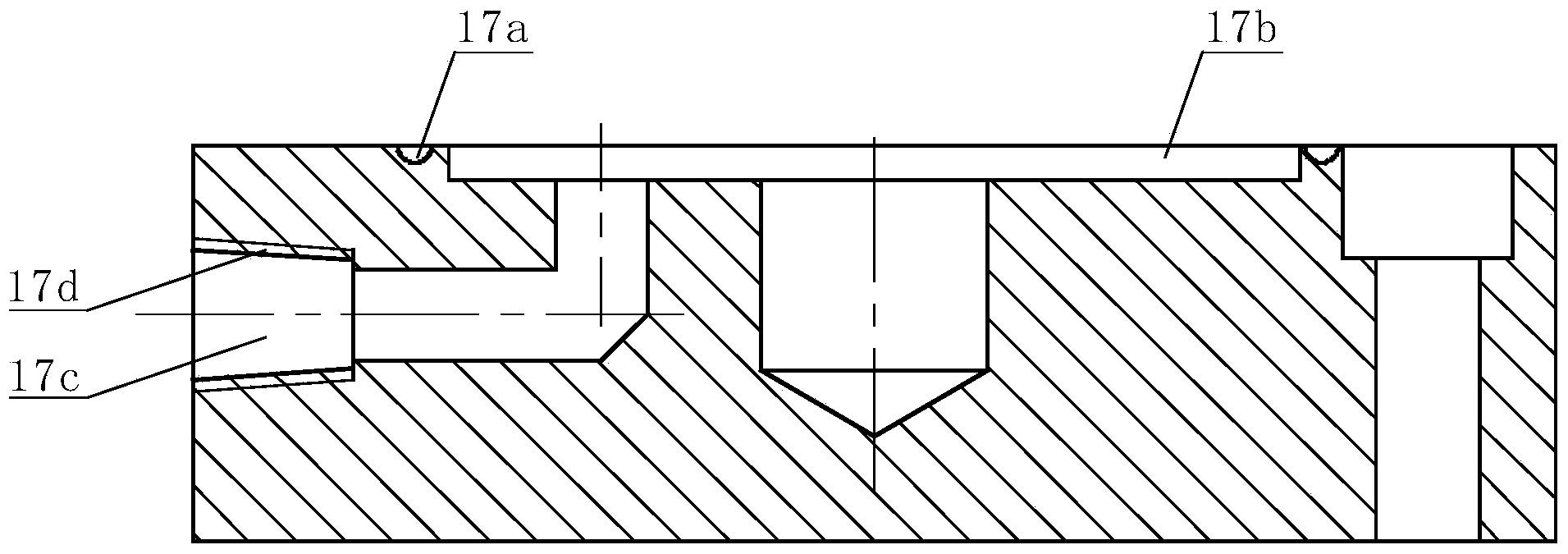

The invention provides a workpiece clamping clamp and a wire spool welder using same. The welder comprises a clamping clamp, wherein a circumferential datum plane is arranged on a positioning base of the clamping clamp; a plurality of clamping assemblies are arranged on the clamping clamp; each clamping assembly can reciprocate in a guiding mode along the circumference; a clamping block of each clamping assembly is driven by a clamping drive mechanism to close to clamp the constitutional units when each clamping assembly moves towards the corresponding circumferential datum plane, and to open when each clamping assembly moves away from the corresponding circumferential datum plane; and each clamping assembly is provided with a fixed station on reciprocating motion stroke, so that an arc-shaped part of each constitutional unit is resisted against the corresponding circumferential datum plane when each clamping assembly moves to the fixed station. When the constitutional units are clamped and fixed by the clamping assemblies, the arc-shaped parts of the constitutional units are further directly resisted against and fixed on the circumferential datum plane by the clamping assembly which moves towards the circumferential datum plane, so that automatic and accurate positioning of each constitutional unit is finally guaranteed.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Part angle alignment method and clamp thereof

ActiveCN106271801ASuitable for processingEasy to operatePositioning apparatusMetal-working holdersProcess alignmentEngineering

The invention discloses a part angle alignment method and a clamp thereof. The method comprises the steps that a process alignment block is firstly manufactured according to the structure of a part, a process alignment hole and mounting holes are machined in the process alignment block, and the process alignment hole or an angular straightening face is machined at the zero-degree position of the clamp; then the clamp is mounted on a machine tool, the process alignment hole or the angular straightening face on the clamp is aligned, the zero-degree angular position is set, and the clamp is pressed; the part is mounted on the clamp and pressed; then the process alignment block is mounted on the part through the process alignment hole and the mounting holes in the process alignment block; finally, a dial indicator is used for metering to straighten the angular straightening face on the clamp and align the alignment hole in the clamp to determine the zero-degree position, the process hole in the part or the process alignment hole in the process alignment block is aligned, the zero-degree angular position of the part is determined, and the zero-degree position of the machine tool is determined. The method is simple in operation process, reasonable in step and accurate in alignment, and by directly aligning an angular alignment locating hole in a locating block, the method is convenient to use and suitable for machining of batched parts.

Owner:AECC AVIATION POWER CO LTD

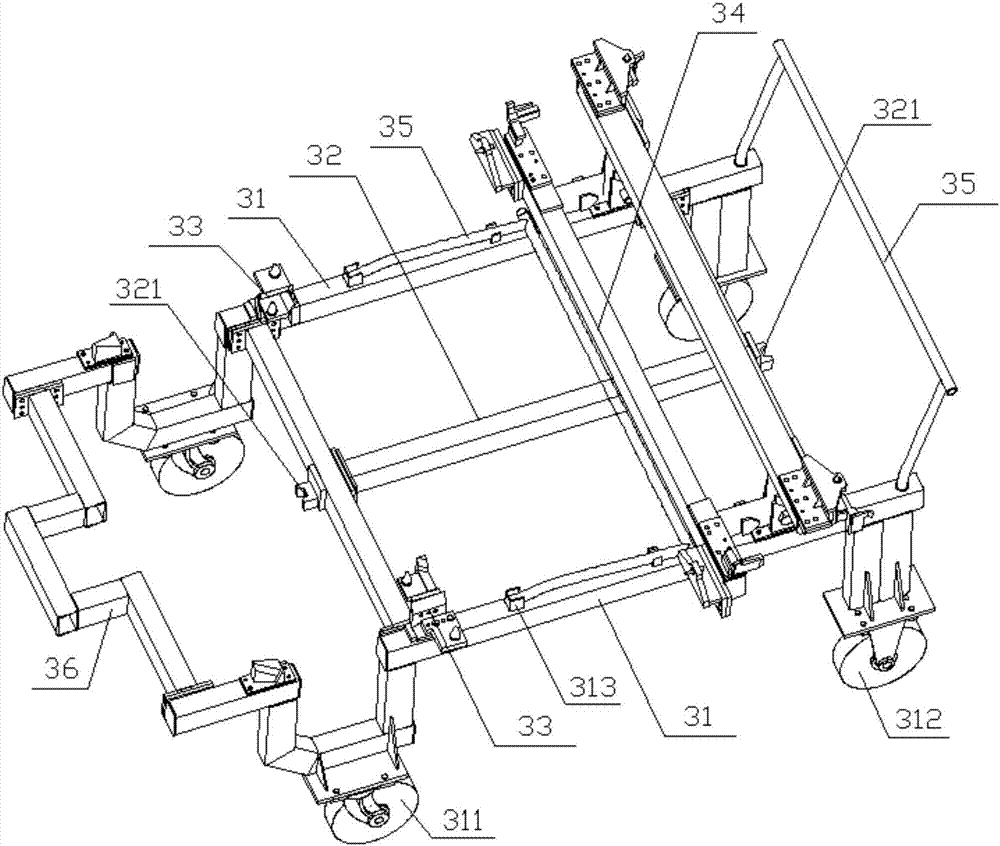

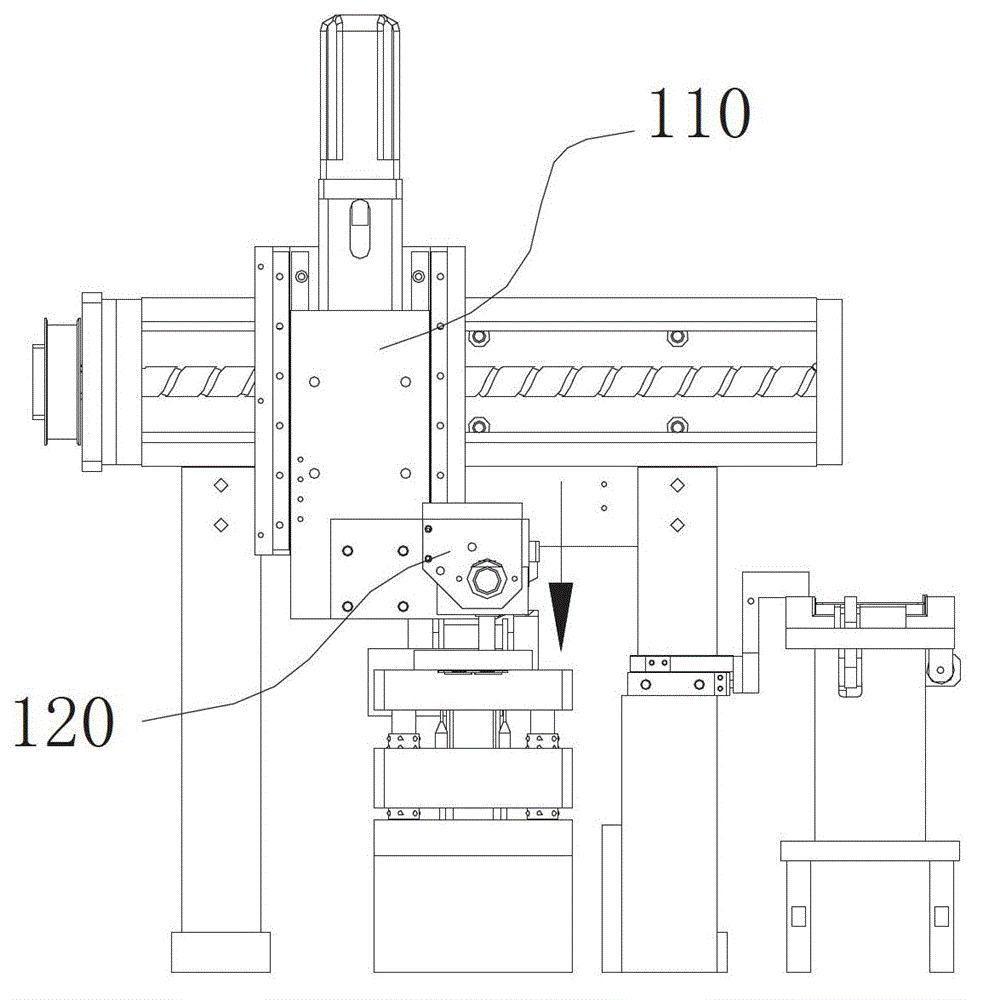

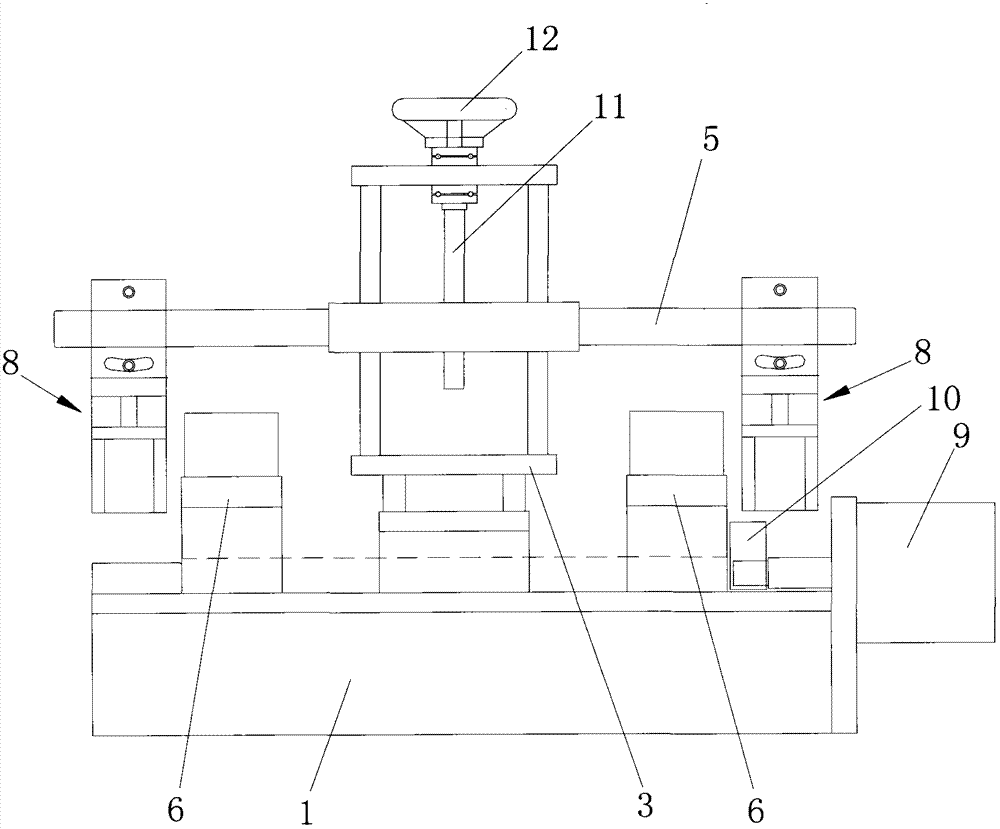

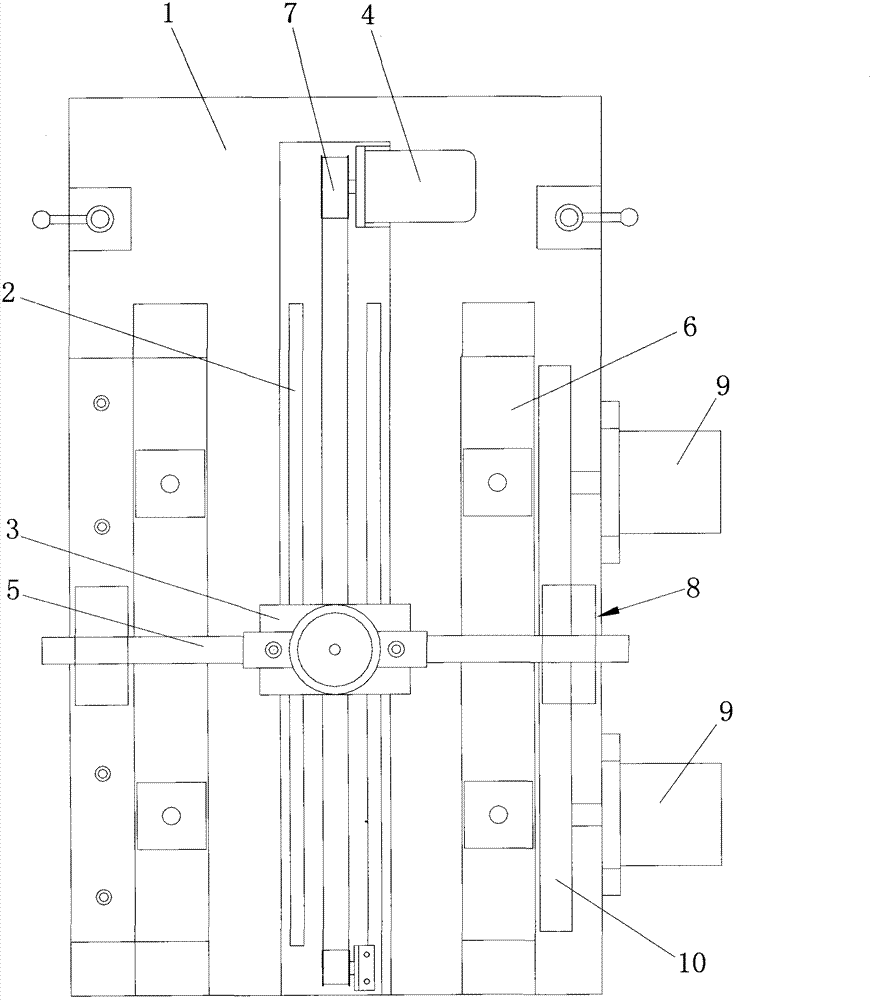

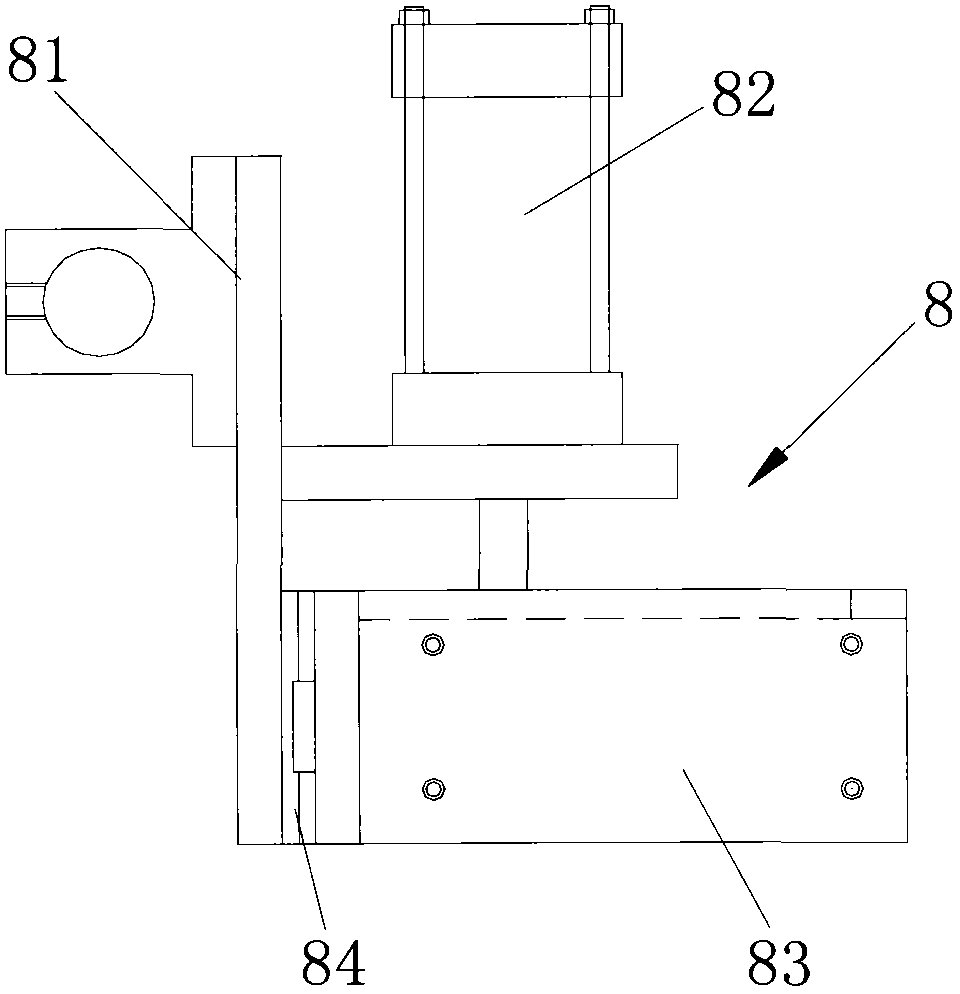

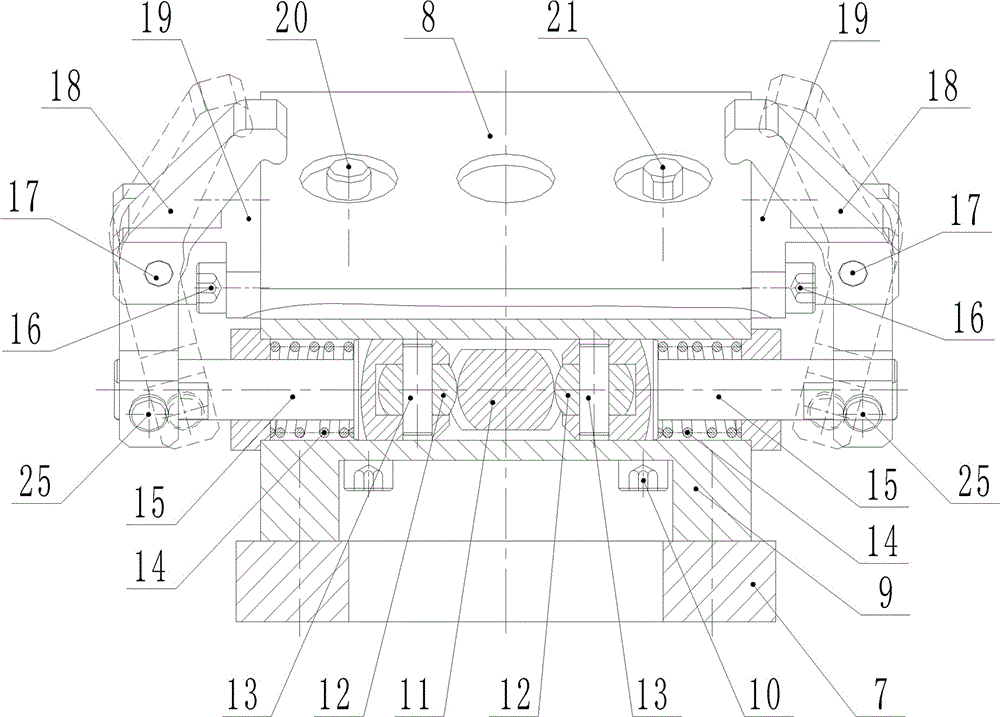

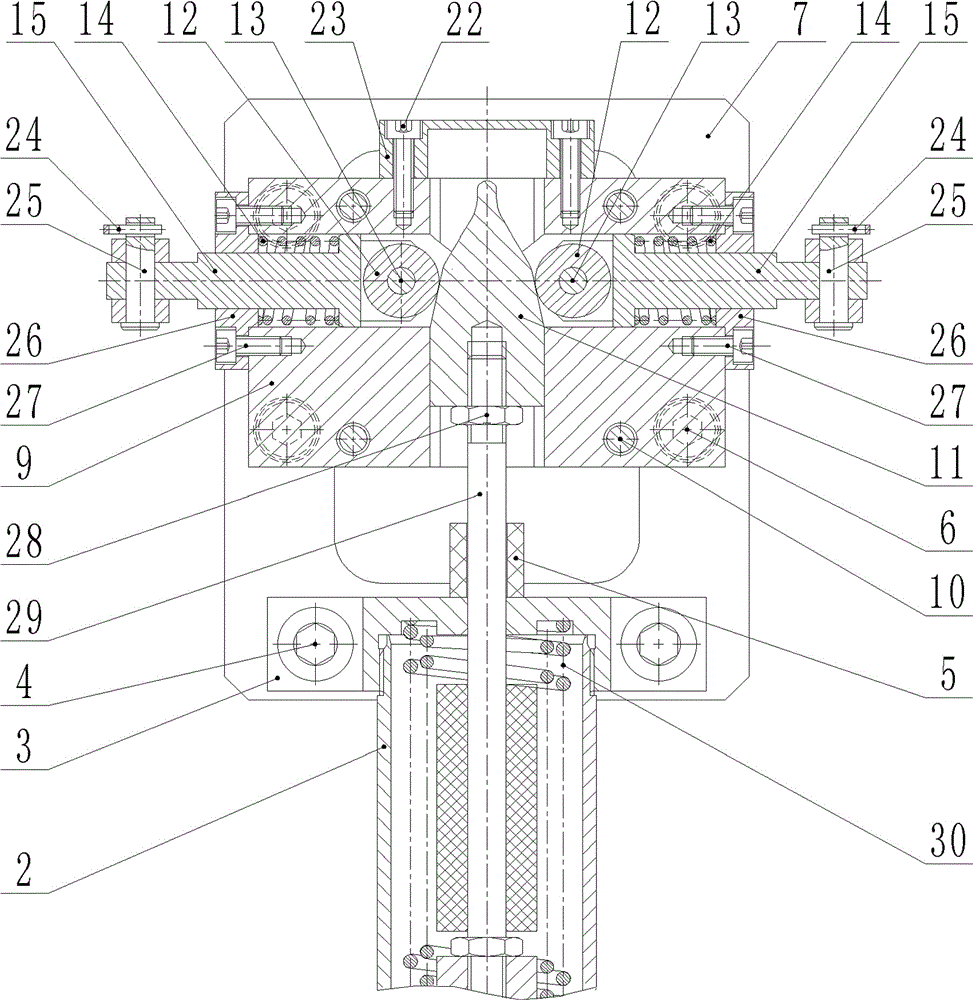

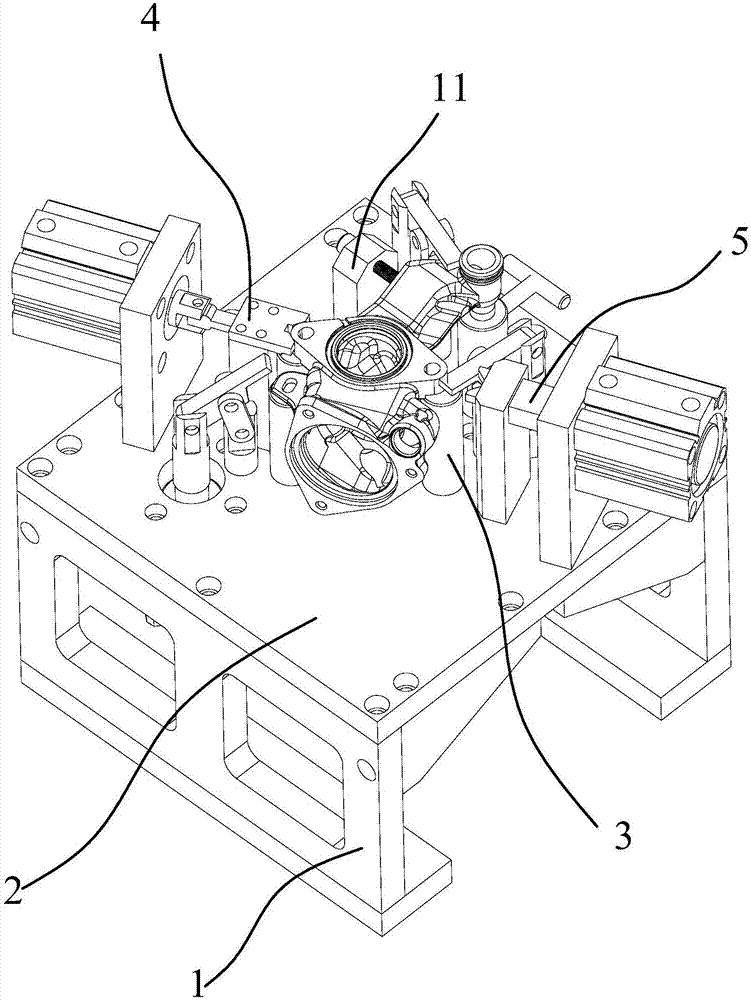

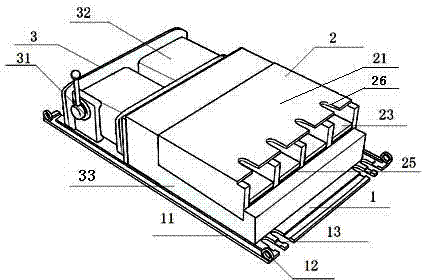

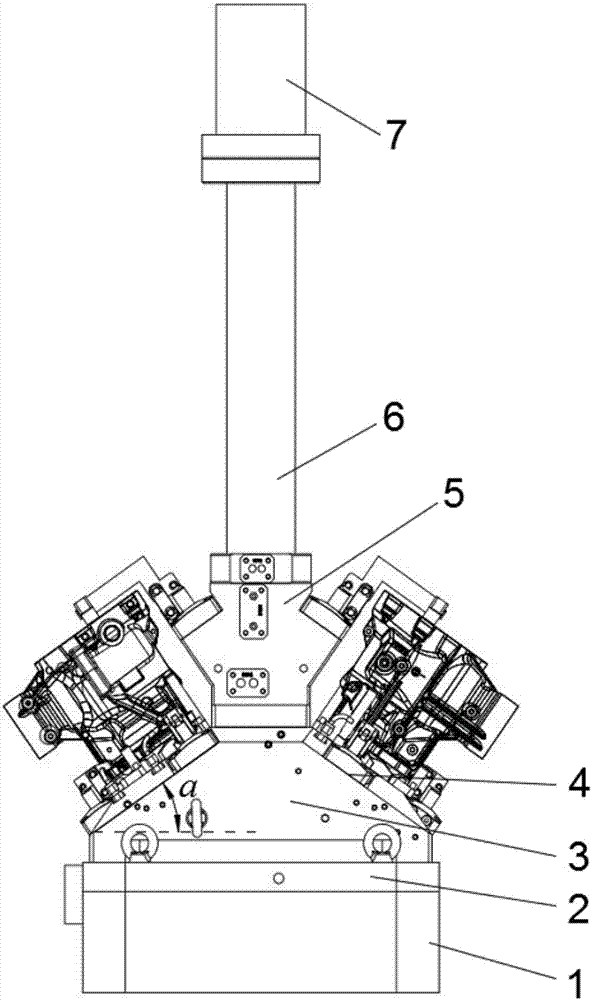

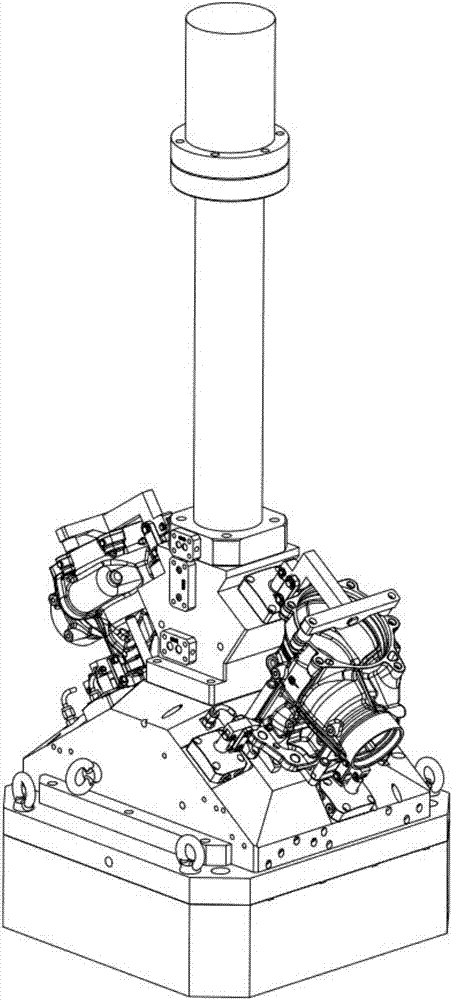

Tool for welding white car bodies by robot

ActiveCN107309587APrecision weldingHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesRobot weldingIndustrial engineering

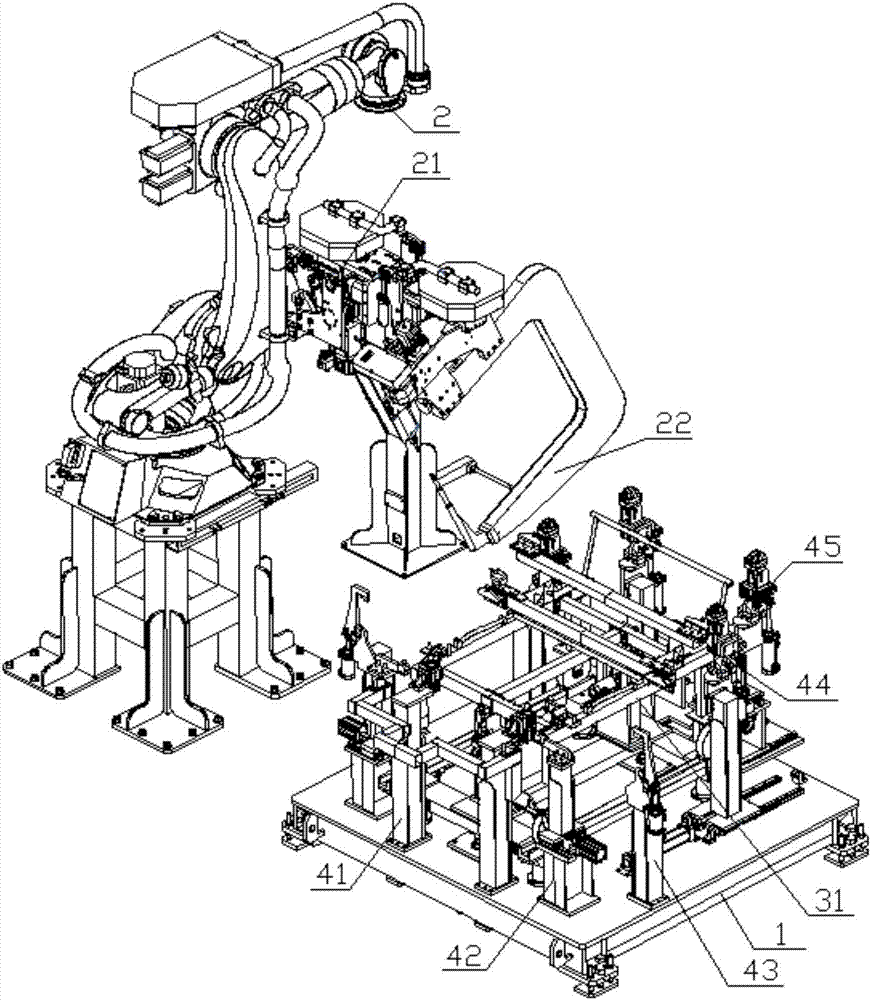

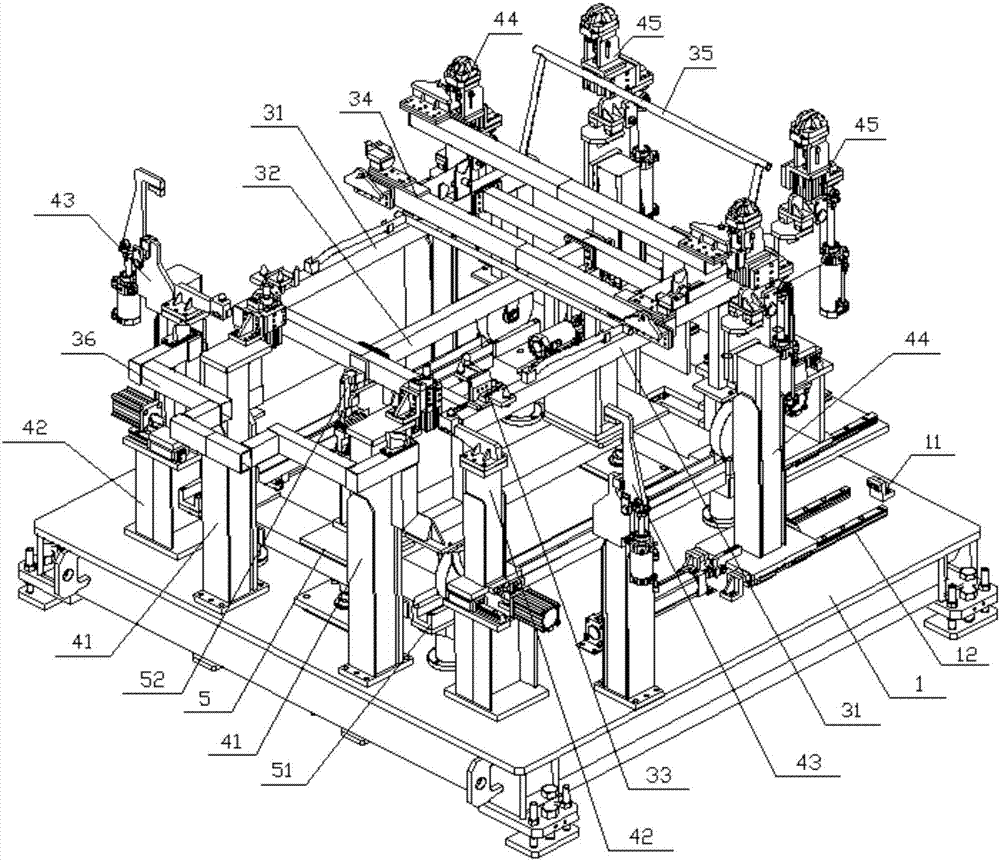

The invention relates to the technical field of car bodies welding equipment, in particular to a tool for adapting to welding of white car bodies of multiple car types by a robot. The tool comprises a base, a lifting device, and a trolley for positioned conveying of the white car bodies; the base is provided with a positioning and clamping device for positioning and clamping the white car bodies; the white car bodies are placed on the trolley; the trolley is supported on the lifting device; and through lifting by the lifting device, the white car bodies enter or leave from a clamping position of the positioning and clamping device. The tool has the following beneficial effects: transfer and positioning of the white car bodies are realized through matching between the trolley and the lifting device; and the white car bodies are sent in an appointed position, so that the robot can accurately weld the white car bodies, the positioning precision is improved, the labor intensity is reduced, and the production efficiency is improved.

Owner:QINGLING MOTORS GRP +1

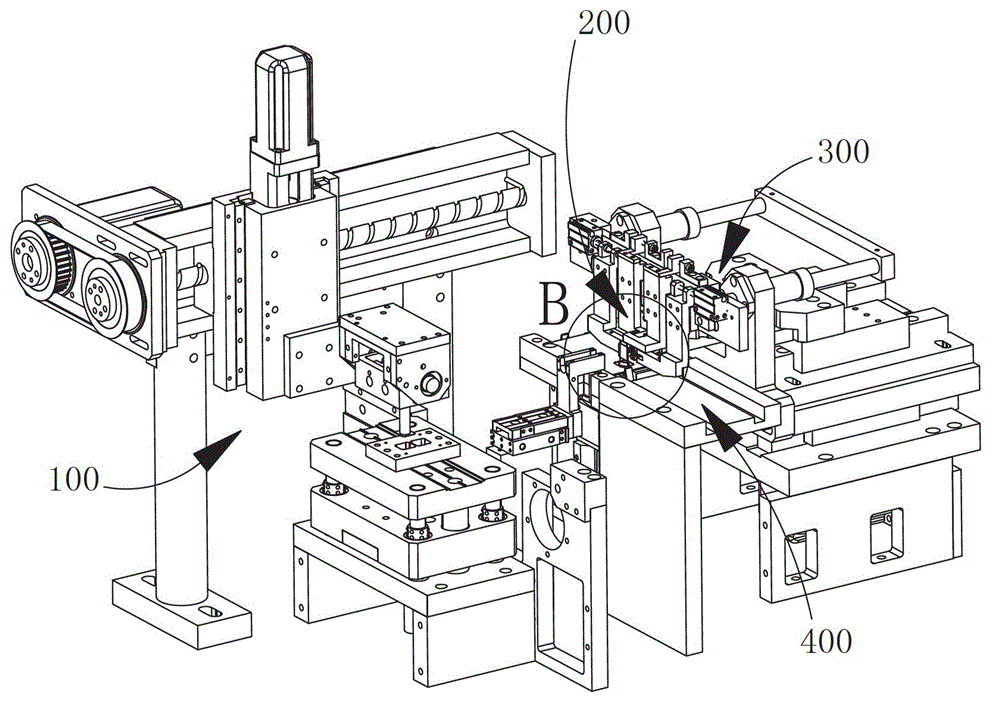

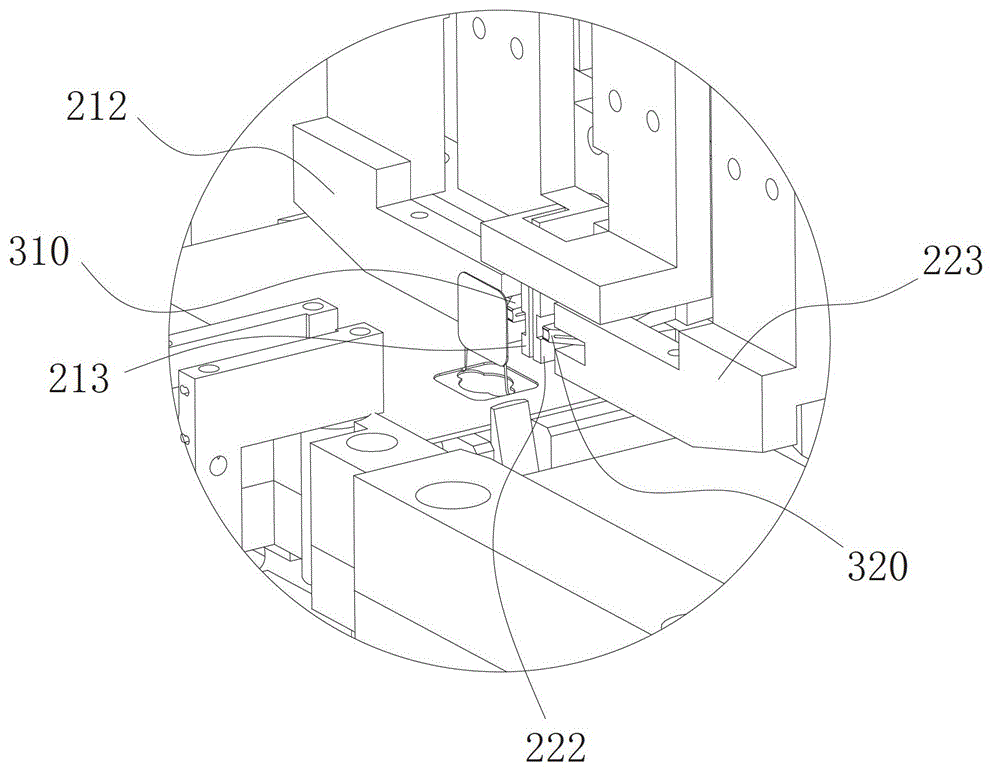

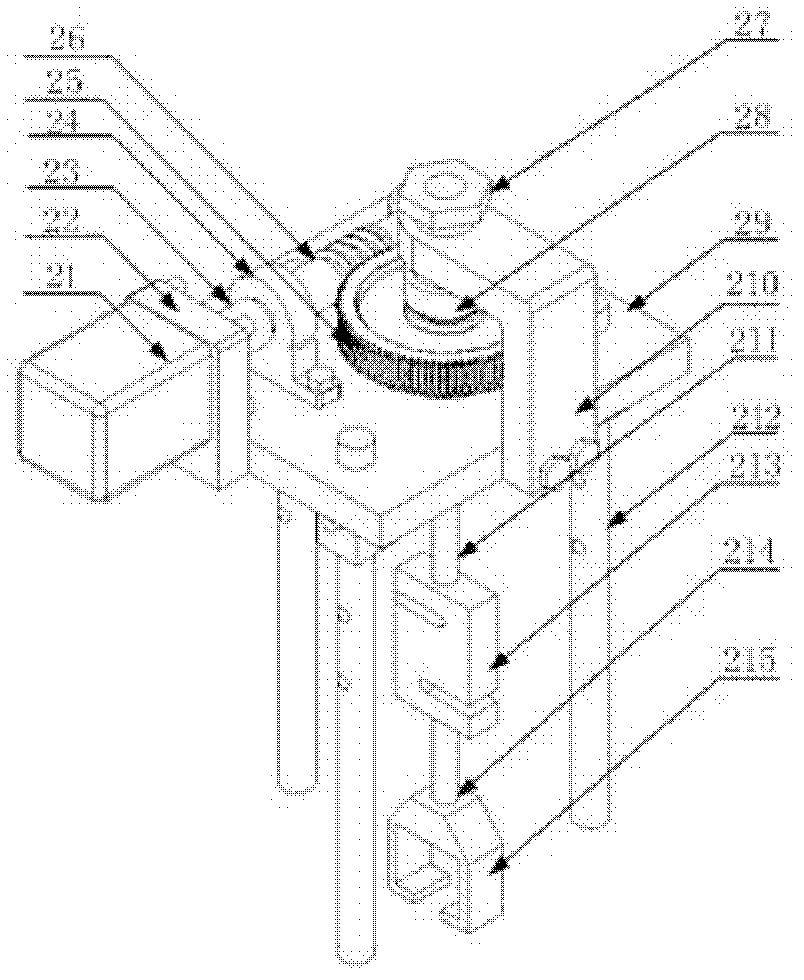

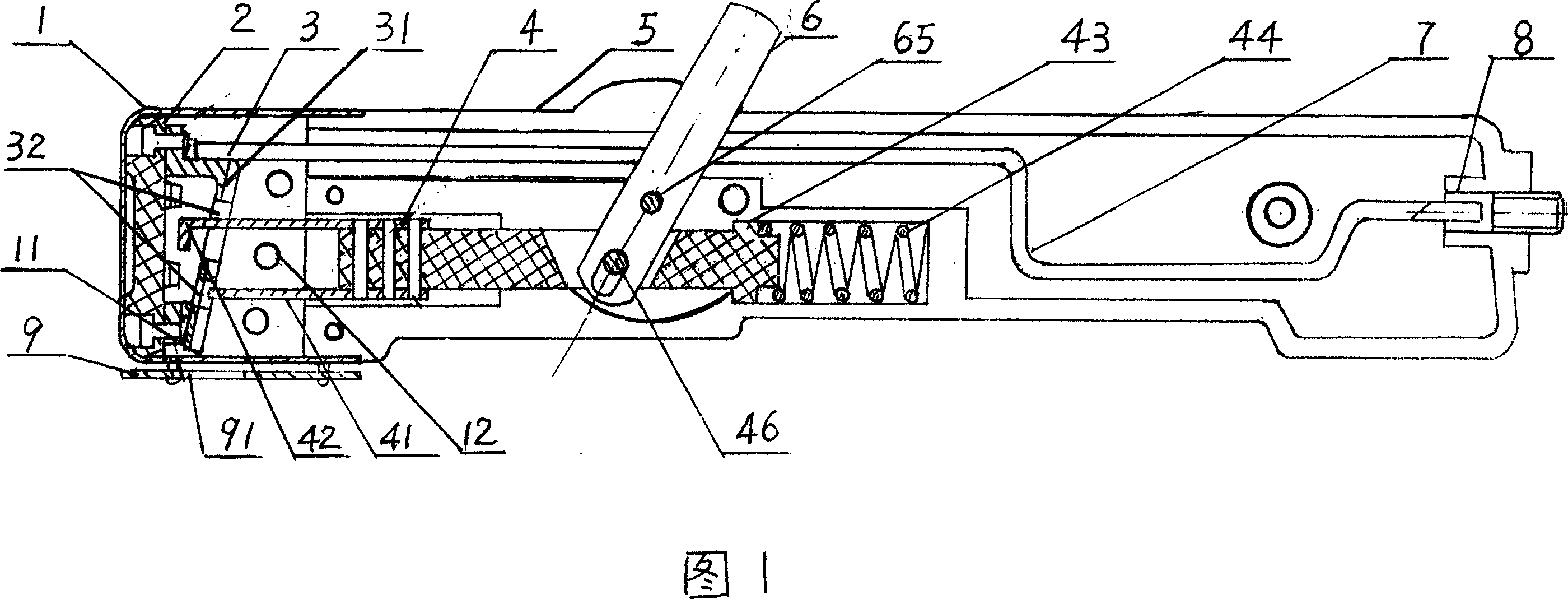

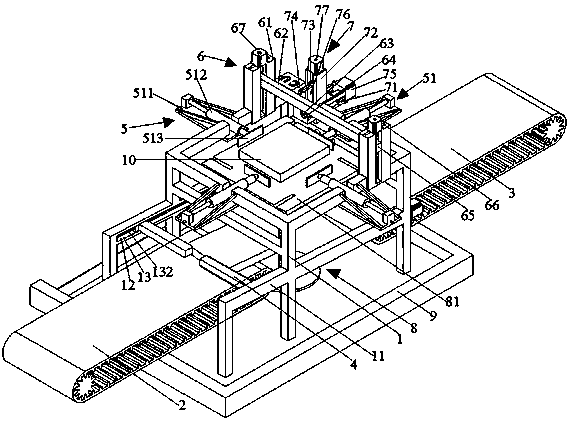

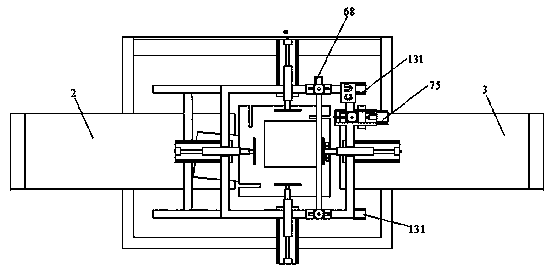

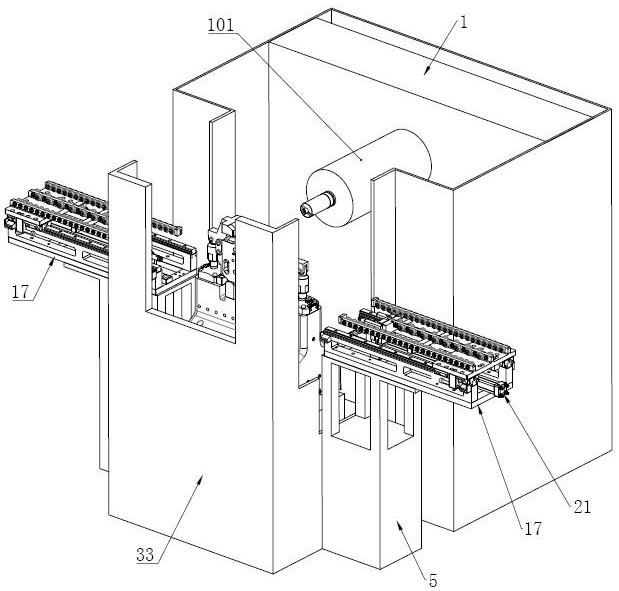

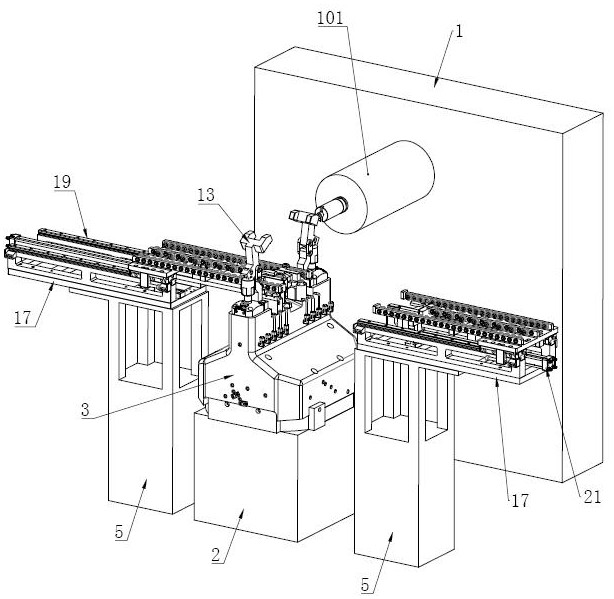

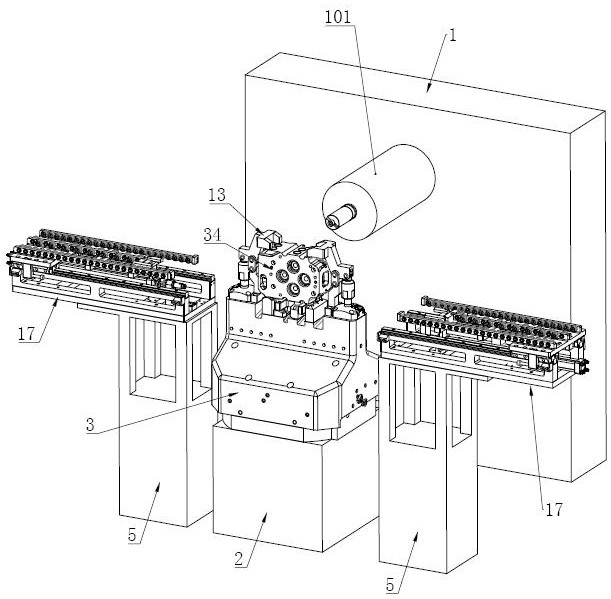

Chip welding method of dual-interface card and equipment thereof

InactiveCN103182577AImprove work efficiencyReduce labor intensitySoldering apparatusEngineeringElectrical and Electronics engineering

The invention discloses a chip welding method of a dual-interface card. The chip welding method of the dual-interface card comprises the following steps: 1, a card body is conveyed by a card body conveying device to a position on which the chip is to be welded, wherein the two ends of an antenna of the card body are at an erect state; and a chip pickup device picks up a chip and reaches the position on which the chip is to be welded to be welded; 2, an antenna clamping device clamps the two ends of the antenna at the same time and positions the antenna at the welded position of the chip; 3, a dual-touch welding head welds the two ends of the positioned antenna on the chip; and 4, after welding, all components return and the card body conveying device takes away the welded card body. The invention further discloses chip welding equipment of the dual-interface card for implementing the chip welding method of the dual-interface card. The chip welding equipment of the dual-interface card comprises the chip pickup device, the antenna clamping device, the card body conveying device and the dual-touch welding head, wherein the chip pickup device is arranged on one side of the antenna clamping device; and the dual-touch welding head is arranged on the other side of the antenna clamping device. By the chip welding method and the chip welding equipment, the two ends of the antenna can be welded on the chip by one step.

Owner:GUANGZHOU MINGSEN TECH CO LTD

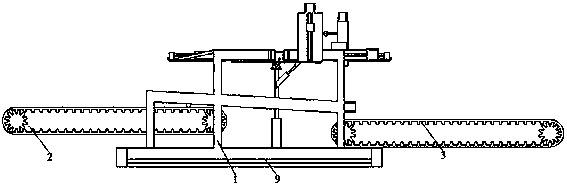

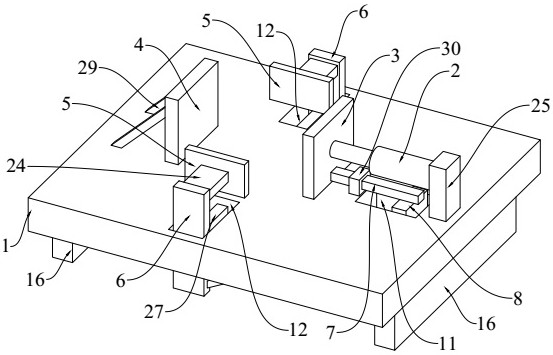

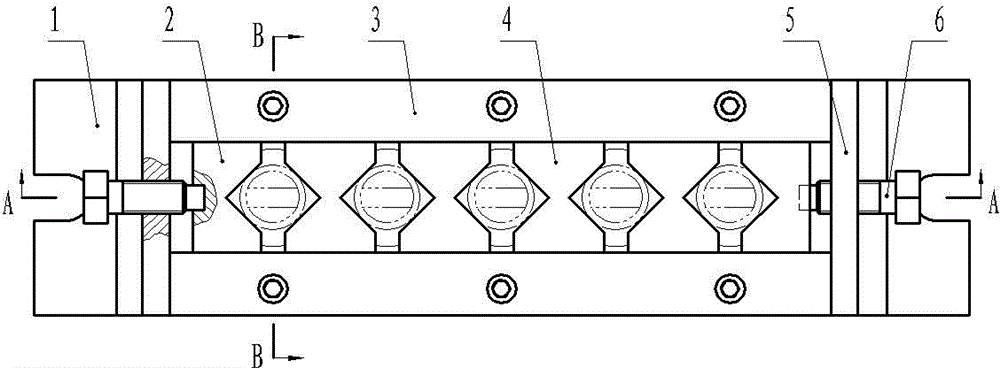

Double-end automatic straight seam welding machine

InactiveCN102785000AEasy clamping and positioningImprove welding efficiencyWelding/cutting auxillary devicesArc welding apparatusSeam weldingWeld seam

The invention relates to the technical field of welding equipment, particularly to a double-end automatic straight seam welding machine. The straight seam welding machine comprises a machine seat provided with a linear guide sliding table, a variable frequency motor,a cross frame and a positioning seat; the variable frequency motor is driven to be connected with the sliding table through a transmission mechanism, and the two ends of the cross frame extend to two sides of the machine seat and provided with welding devices respectively; and a material pressing cylinder and a material pressing plate are arranged on the outer side of the positioning seat, and an output end of the material pressing cylinder is connected with the material pressing plate. According to the straight seam welding machine, the material pressing cylinder is adopted to perform pneumatic positioning and material pressing clamping, clamping positioning is rapid, convenient and accurate, the left and right welding devices are equipped with a set of welding guns respectively, servo driving is performed through the variable frequency motor, the sliding table, the cross frame and the welding devices are controlled to move longitudinally for welding, the programmable logic controller (PLC) is used for controlling dimensions of welding seams and arc starting and suppression actions, double-end straight seam welding can be performed automatically, the welding efficiency is high, the quality of the welding seams is high, and the straight seam welding machine can be applied to mass produced products with straight welding seams.

Owner:DONGGUAN JIALONG LEATHER MACHIERY

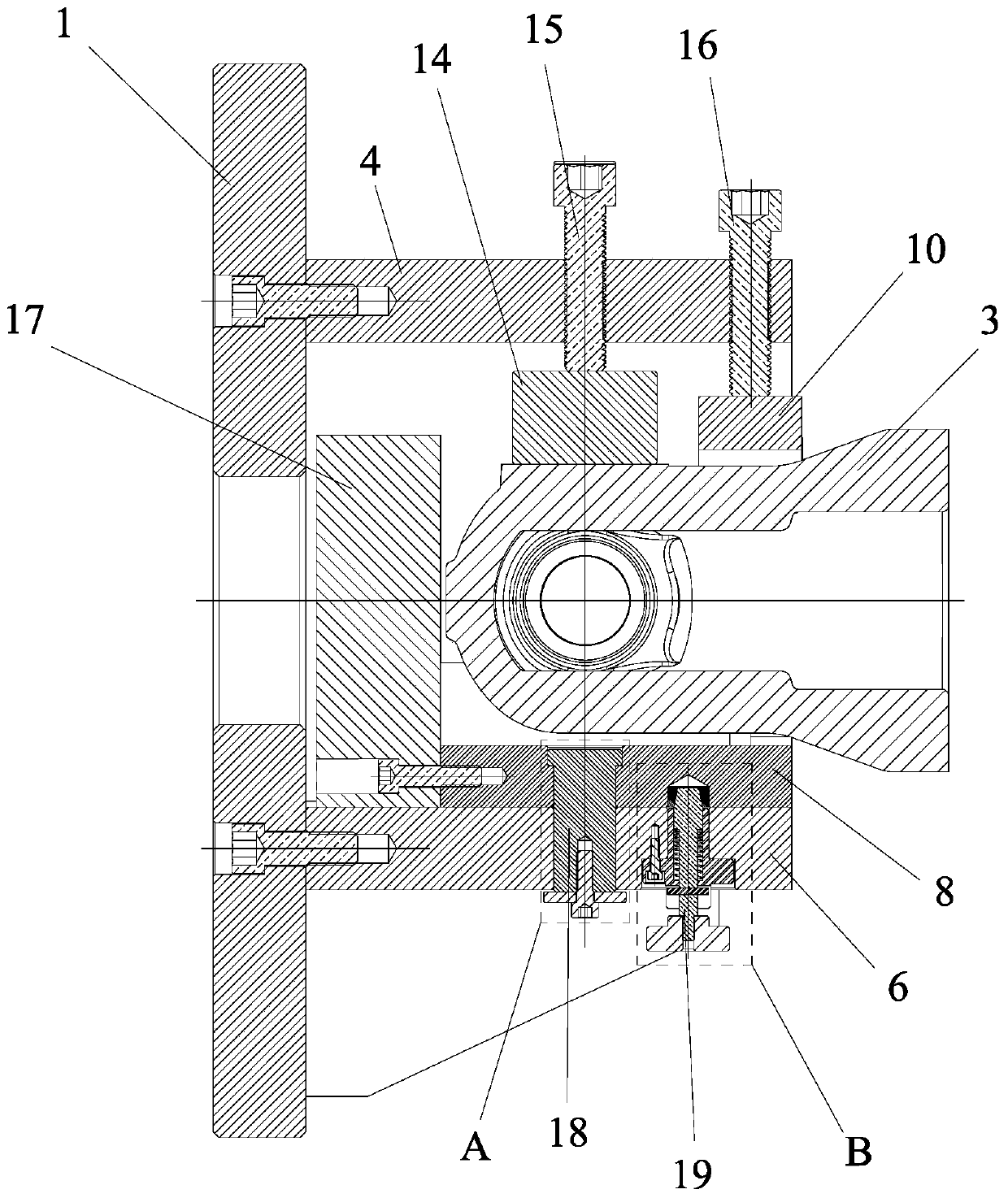

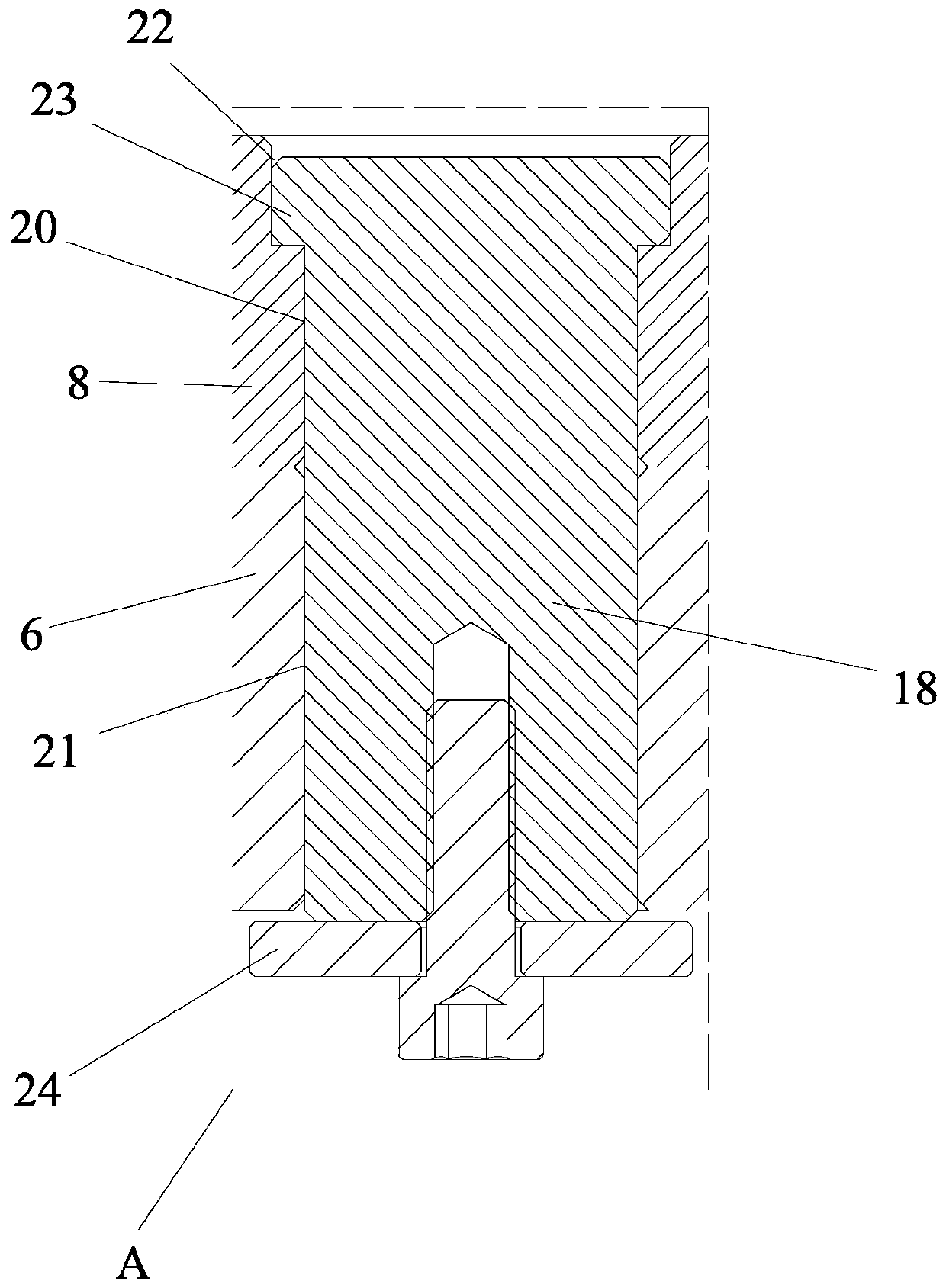

Valve body machining tool clamp for butt welding connection of high-pressure valve

ActiveCN110936196AAccurate clamping and positioningGuaranteed machining accuracyPrecision positioning equipmentPositioning apparatusButt weldingEngineering

The invention discloses a valve body machining tool clamp for butt welding connection of a high-pressure valve. The clamp comprises a clamping rotary disc, a positioning frame is arranged on the clamping rotary disc in a linked mode, the positioning frame comprises an upper positioning plate, a right positioning plate, a lower positioning plate and a left positioning plate which are sequentially connected to form a closed loop, a base used for containing a valve body is arranged on the lower positioning plate in a rotating mode, and a clamping mechanism used for clamping the valve body is arranged on the base; a plurality of positioning holes are formed in the base in the rotating direction of the base, and a positioning mechanism arranged in one positioning hole in a penetrating mode andpositioning the base is arranged on the lower positioning plate. The clamp is firm in clamping, safe, reliable, high in machining efficiency and accurate in clamping and positioning, and the machiningprecision of the valve body is guaranteed.

Owner:CHAODA VALVE GRP

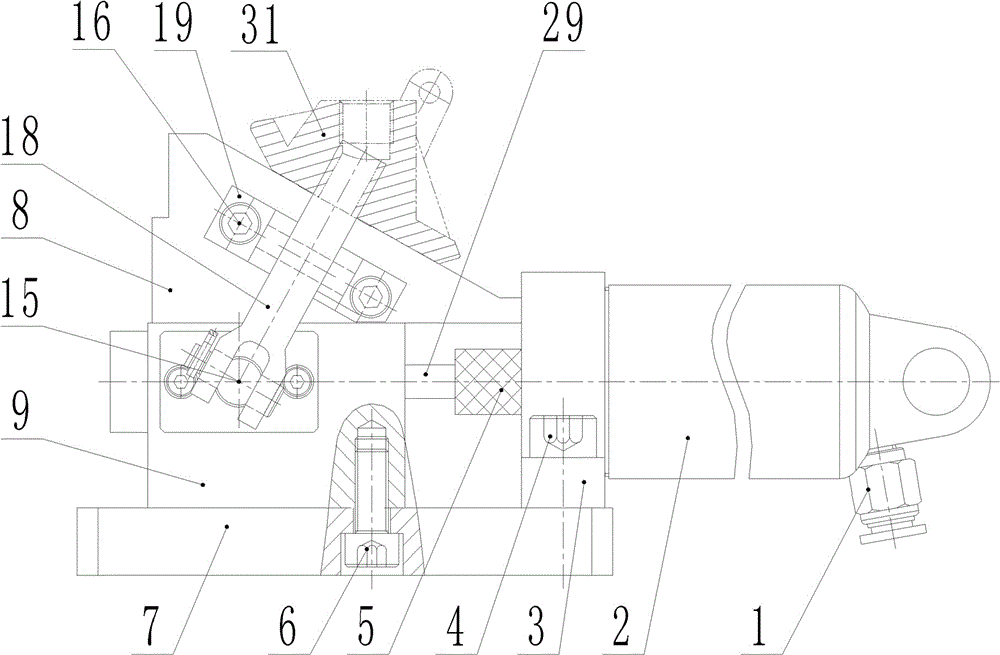

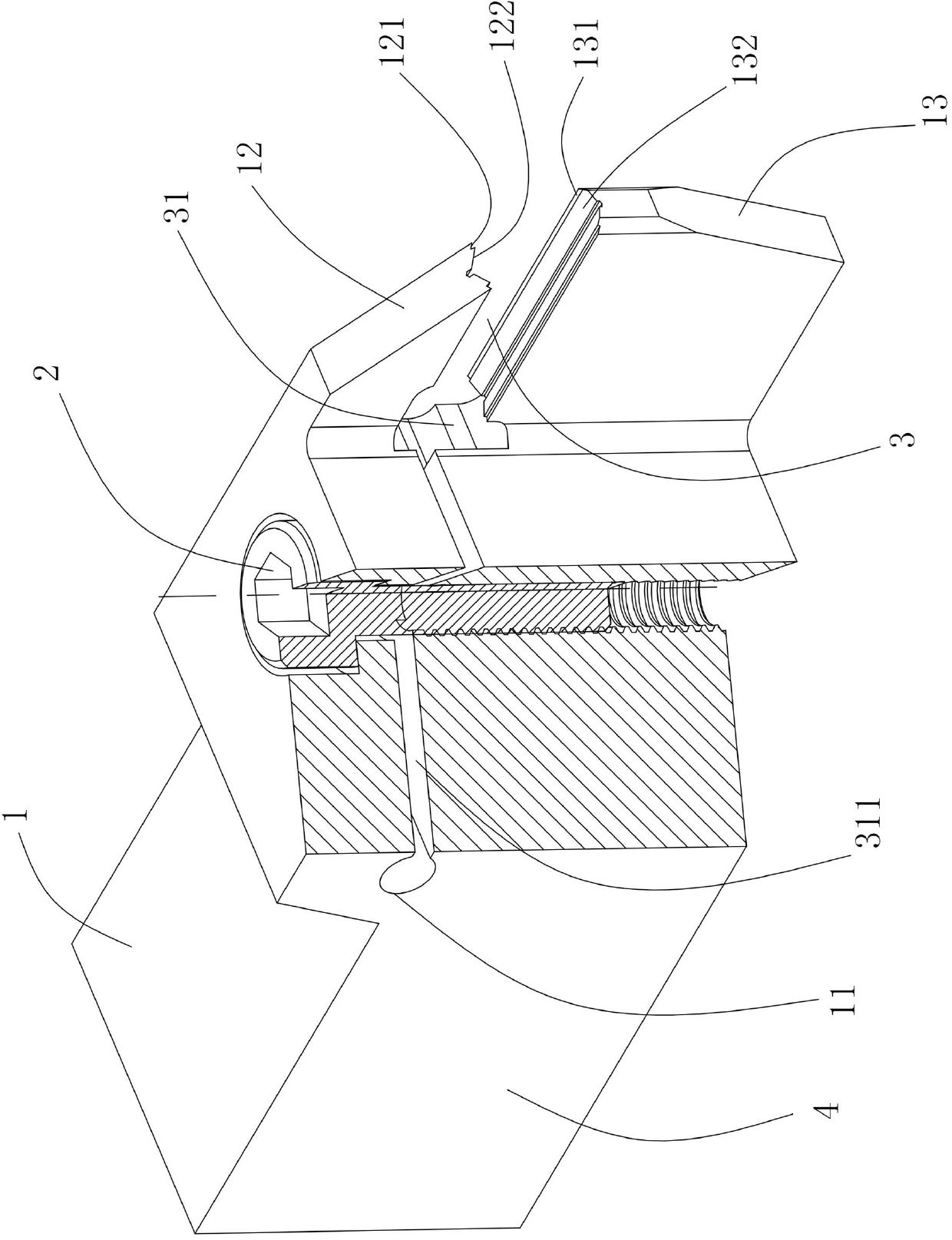

Portable multi-purpose quick self-locking fixture

ActiveCN105855960AFast self-lockingMove quicklyPositioning apparatusMetal-working holdersMachine partsEngineering

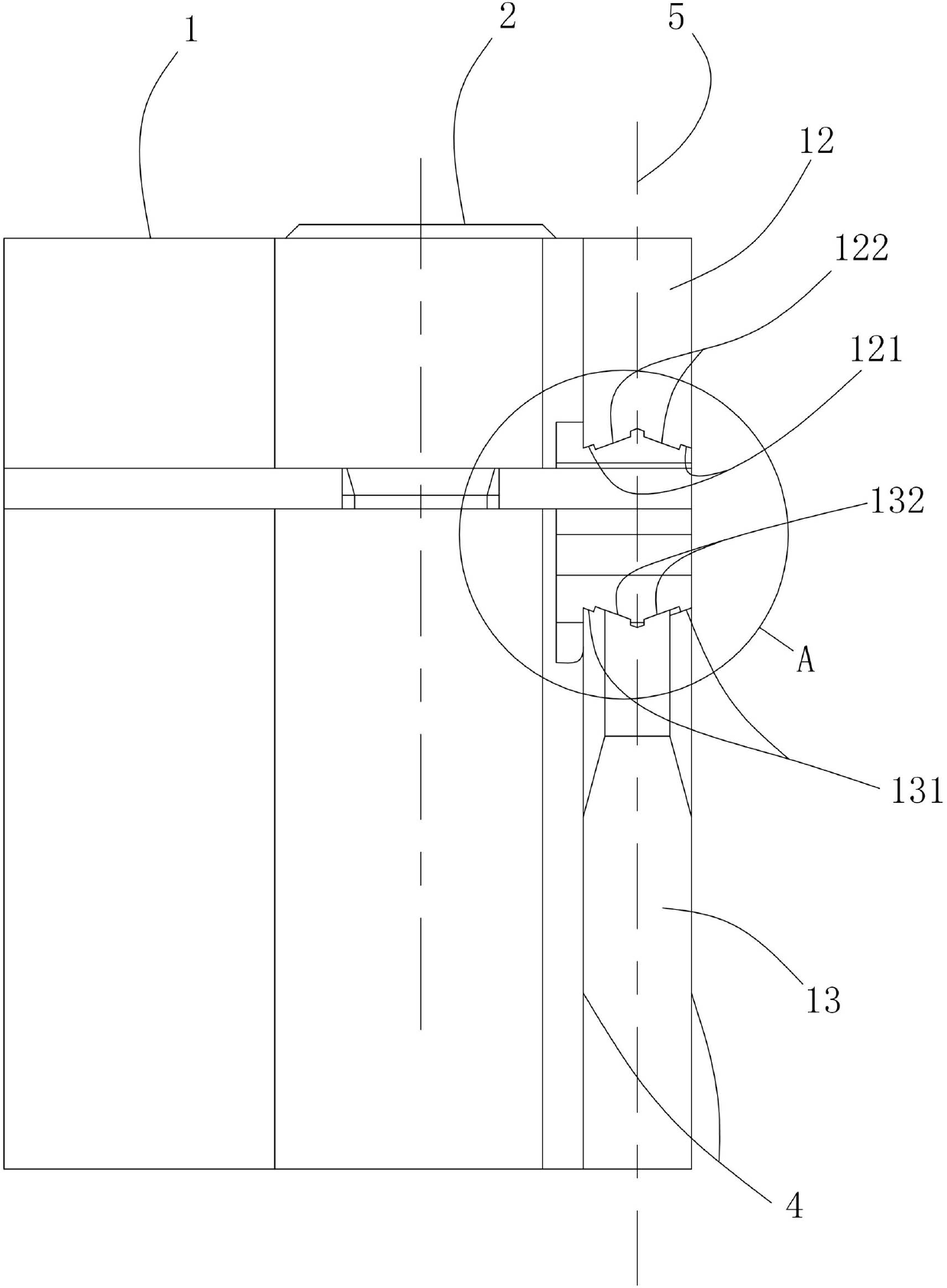

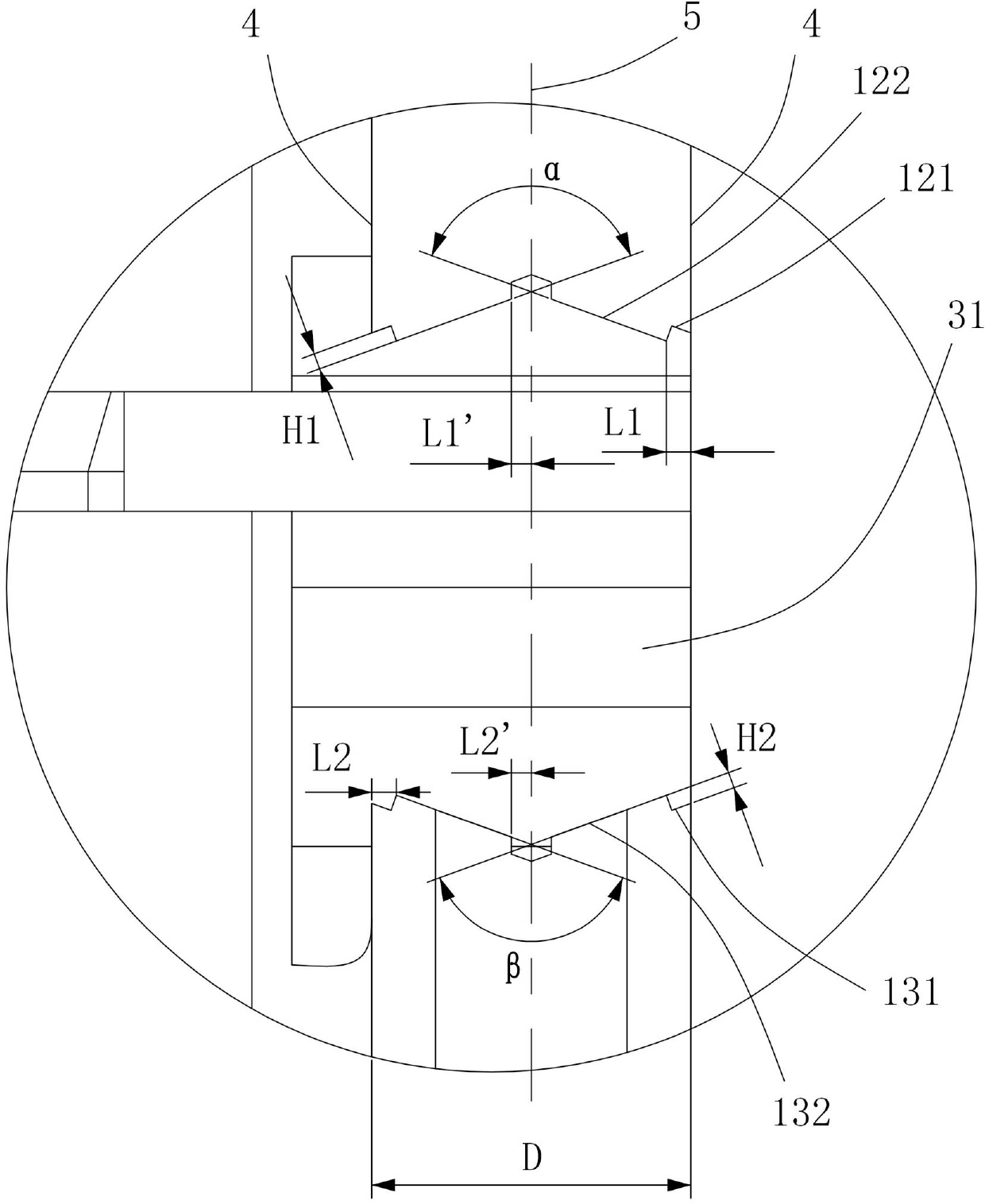

The invention relates to a portable multi-purpose quick self-locking fixture. The fixture comprises a clamping device, wherein the clamping device adopts a wedge clamping mechanism, the wedge clamping mechanism comprises a wedge column (11) and rollers (12), a piston rod mounting screw hole is formed in the back end surface of the wedge column (11), and the rollers (12) are arranged on two sides of the wedge column (11). Compared with the prior art, the fixture has the beneficial effects as follows: clamping self-locking is controlled by the aid of a single air source, and the fixture can clamp a to-be-machined part firmly and realize quick self-locking in an instant and can also release the to-be-machined part in an instant after machining is completed, so that the mounting and dismounting efficiency is substantially improved; the fixture is high in universality and applicable to machining equipment such as machining centers, gang drills, drilling machines, milling machines, special machines and the like; the fixture is small in shape and portable, an air cylinder can be used as a handle when the self-locking fixture is required to be moved on a workbench, thus quick movement is realized, and then machining of multiple to-be-machined planes or machining in multiple steps such as surface reaming, tapping, hole drilling, hole reaming and the like is realized.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

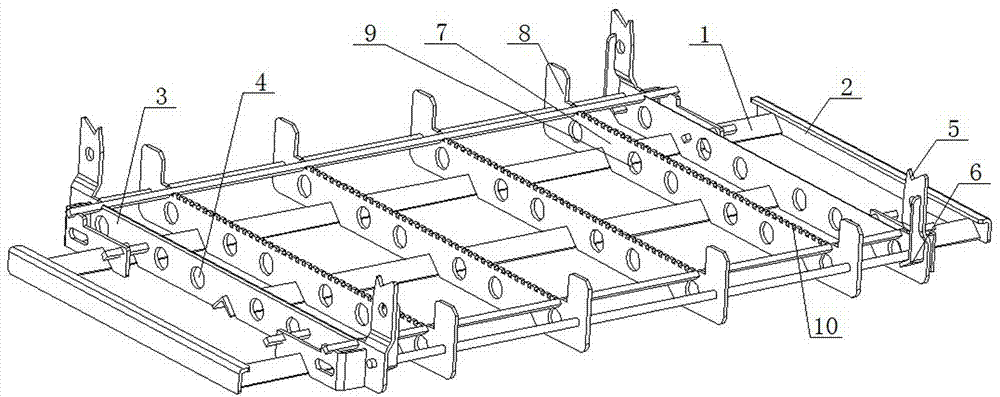

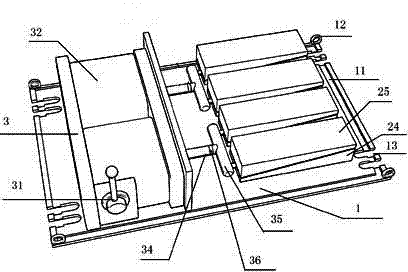

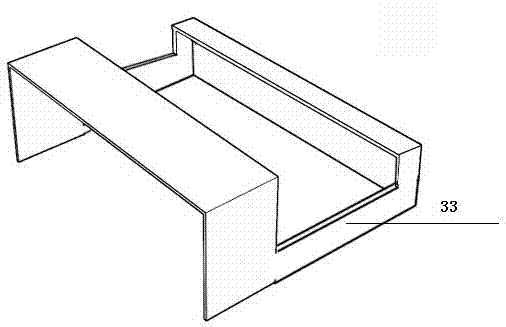

Aluminum soldering radiator clamp

InactiveCN103659126AEasy to operateAccurate clamping and positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention discloses an aluminum soldering radiator clamp which is good in clamping effect and comprises a clamping frame. Handles are arranged on the two sides of the clamping frame respectively, a plurality of transverse supporting plates are arranged on the two sides of the clamping frame respectively, a plurality of holes are formed in the transverse supporting plates, supporting grooves are formed in the upper ends of the transverse supporting plates, supporting plates matched with the supporting grooves are arranged at the lower ends of the transverse supporting plates, a plurality of transverse supporting ribs are arranged at the position, located between the two transverse supporting plates, of the clamping frame, supporting legs are arranged on the two sides of each transverse supporting rib respectively, through holes are formed in the transverse supporting ribs, and a plurality of teeth are arranged at the upper ends of the transverse supporting ribs. The aluminum soldering radiator clamp has the advantages of being capable of repeatedly used, easy to operate, accurate in clamping and positioning, lower in use cost, and free of damaging the surface of a water tank core body in the use process, and ensuring the product quality.

Owner:JIANGSU KANGJIE MACHINERY

End effector and application thereof

InactiveCN103358312AReduce labor intensitySimple structureBreathing protectionGripping headsEmergency rescueEngineering

Owner:SOUTH CHINA AGRI UNIV

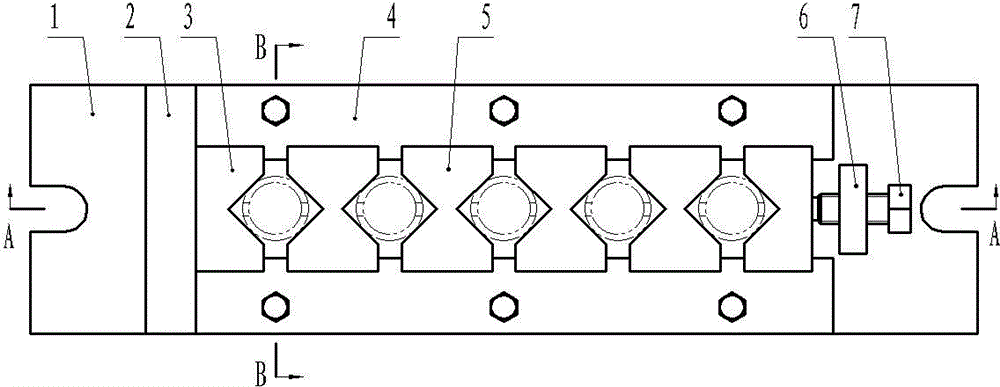

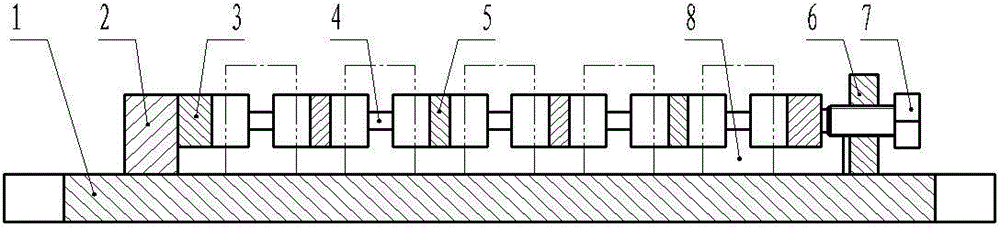

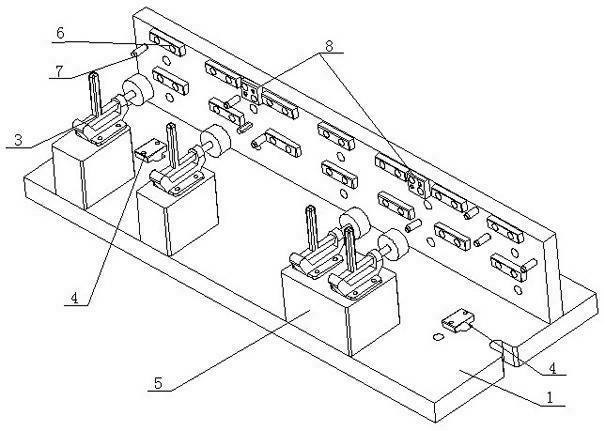

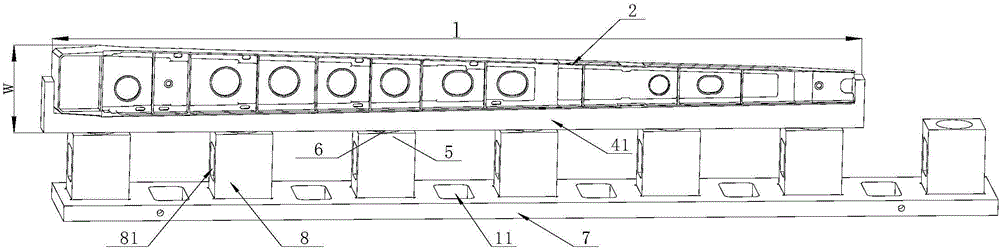

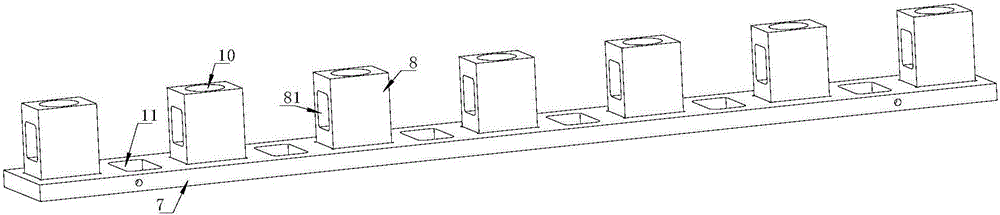

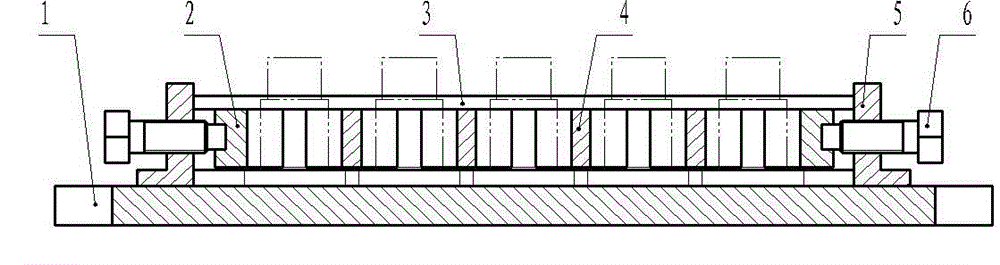

Multi-station milling clamp of bushing

InactiveCN104589107AIncrease productivityReduce processing costsWork clamping meansPositioning apparatusMachiningEngineering

The invention discloses a multi-station milling clamp of a bushing and relates to the technical field of machining. The multi-station milling clamp comprises a clamp body, wherein the clamp body is provided with a bottom plate and baffle plates connected to the two sides of the bottom plate; guide plates extending out of the inner sides of the baffle plates are arranged above the two baffle plates; two first clamping plates are arranged between the two guide plates; a plurality of second clamping plates are arranged between the two first clamping plates; the first clamping plates and the second clamping plates are both provided with guide grooves matched with the two guide plates; the place between each first clamping plate and each second clamping plate, as well as between two adjacent second clamping plate is a station; a limit plate is arranged at the outer end of one first clamping plate; a jacking screw fixed to the bottom plate through a supporting plate is arranged at the outer end of the other first clamping plate. Compared with the prior art, the multi-station milling clamp has the advantages that due to the fact that a plurality of workpieces can be clamped to be subjected to groove milling, the production efficiency is greatly improved, and the machining cost is reduced.

Owner:LIUZHOU JULONG TECH

Intake manifold milling plane clamp device

InactiveCN102554658AAccurate clamping and positioningReliable positioning and clampingPositioning apparatusMetal-working holdersUltimate tensile strengthMachine tool

The invention discloses an intake manifold milling plane clamp device, which can solve the problems of low workpiece positioning accuracy, instable machining quality and high labor intensity of workers brought by only clamping the workpiece by using a pressing plate in the conventional intake manifold milling plane machining. The intake manifold milling plane clamp device comprises a bottom plate, a workpiece positioning plate, a high-power clamp hand and a machine tool positioning block, wherein the workpiece positioning plate is vertically arranged on the bottom plate; the high-power clamp hand is fixed to the bottom plate through a cushion block and is just opposite to a positioning surface of the workpiece positioning plate; and the machine tool positioning block penetrates through the bottom plate and is fixed to the bottom plate through a bolt.

Owner:WUXI DAWN DIE & STAMPING

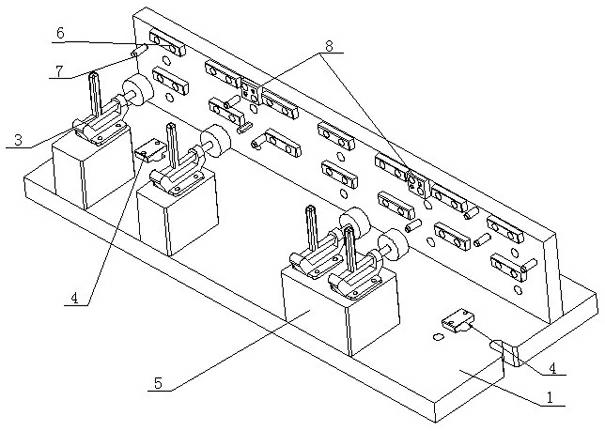

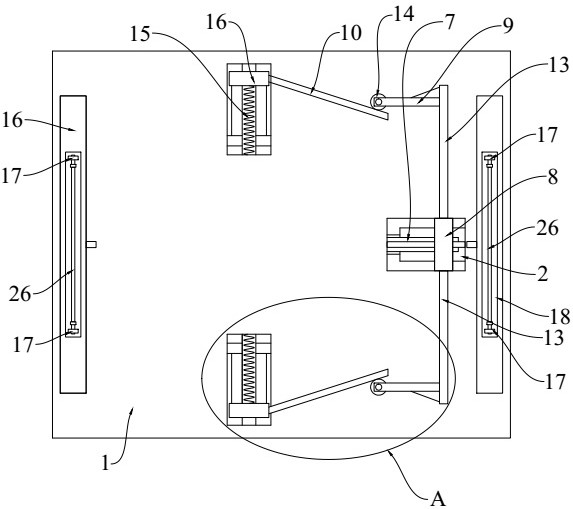

Motorcycle frame rear body assembly welding jig

InactiveCN104690472AMeets targeting requirementsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameLeft half

The invention discloses a motorcycle frame rear body assembly welding jig. The motorcycle frame rear body assembly welding jig is characterized in that a lower bottom plate is provided with a left half body assembly positioning mechanism, a right half body assembly positioning mechanism, a fuel tank rear mounting bracket component positioning mechanism, a left and right connecting plate positioning mechanism, and a seat lock mounting bracket component positioning mechanism; the left half body assembly positioning mechanism and the right half body assembly positioning mechanism are symmetrically arranged; an upper front bottom plate and an upper rear bottom plate are respectively arranged on the two sides of the lower bottom plate through support structures; a certain space is reserved between the upper front bottom plate and the upper rear bottom plate, so that a left half body assembly support pipe and a right half body assembly support pipe can pass in a downwardly inclined manner. The motorcycle frame rear body assembly welding jig provided by the invention has the advantages that clamp positioning of all parts of a motorcycle frame rear body assembly is integrated, so that the jig structure is simplified, fewer clamp positioning points and rapid clamping are achieved, accordingly, the product loading / unloading time for the jig is shortened, and the welding efficiency is improved; meanwhile, the positioning of all the parts is more accurate and precise, and the assembly positioning requirements are better met, so that the forming quality of the welded frame rear body assembly is higher.

Owner:力帆科技(集团)股份有限公司

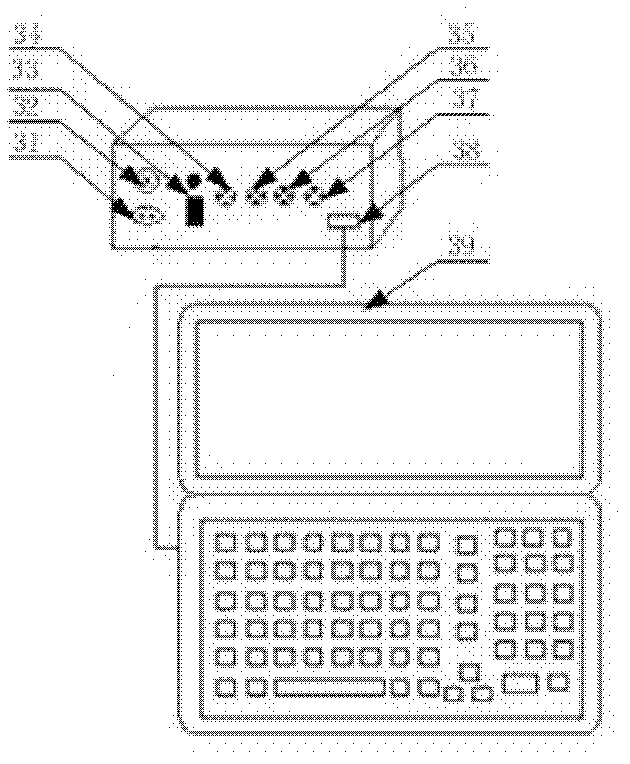

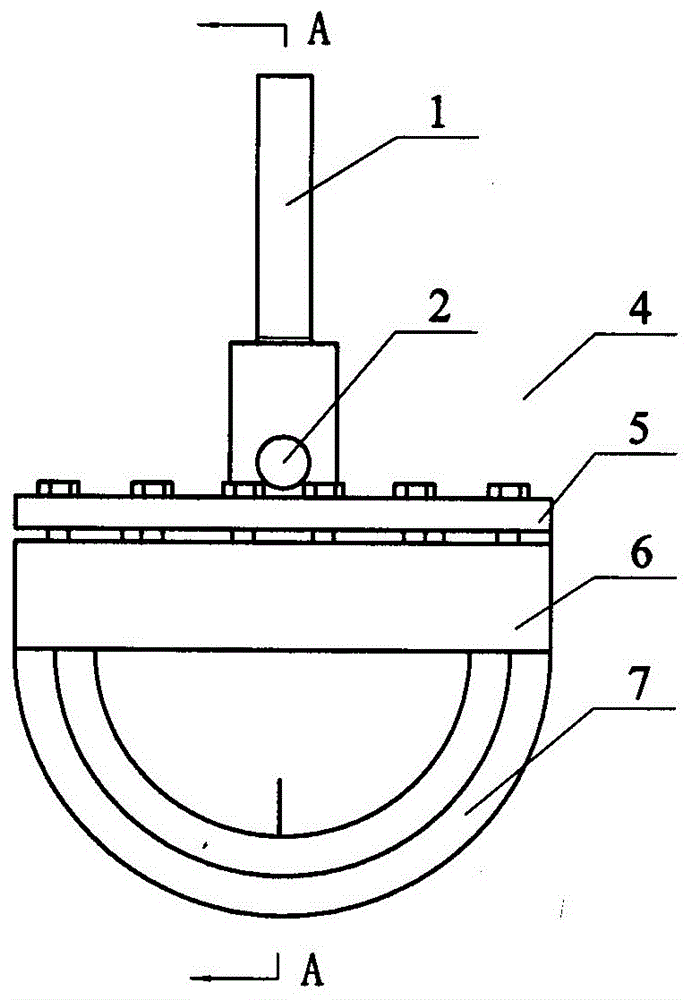

Safety valve on-line detector driven by stepping motor

InactiveCN102435425AEasy to carryAccurate clamping and positioningMachine part testingMeasurement of fluid loss/gain rateSafety valveElectrical and Electronics engineering

The invention provides a safety valve on-line detector driven by a stepping motor. The safety valve on-line detector comprises a mechanical fixture system used for fixing a detecting device on a safety valve, a stepping motor system used for providing the tension needed for lifting the safety valve, and an electric detecting system used for transmitting feedback data of the stepping motor system and controlling the stepping motor system. The safety valve on-line detector has the advantages that the accuracy and the repeatability of the safety valve on-line detector are higher, the carrying and the mounting are facilitated, the detachment is convenient, the verification is rapid, and the judgment is objective and accurate.

Owner:ZHEJIANG UNIV OF TECH +1

Load-bearing connector test specimen clamp for fatigue test machine

ActiveCN106840866AAccurate clamping and positioningEasy loading and unloadingNuclear energy generationStrength propertiesCrankClassical mechanics

The invention provides a load-bearing connector test specimen clamp for a fatigue test machine, and solves the problems that the existing clamp cannot meet the requirements of correct clamping, accurate detection, multi-position stretching and fatigue test and the like. The load-bearing connector test specimen clamp for the fatigue test machine comprises a clamping mechanism, an angle regulating mechanism and a base, wherein the clamping mechanism is assembled between upper and lower connecting rods of the fatigue test machine and is used for clamping and installing a load-bearing connector test specimen. The load-bearing connector test specimen clamp is mainly characterized in that the clamping mechanism consists of upper and lower clamping plates and a fastening element screw bolt; screw bolt holes are formed in the peripheries of the upper and lower clamping plates; the load-bearing connector test specimen is hinged to the upper connecting rod through a pin shaft; the base is assembled with a fatigue test machine platform through the lower connecting rod; the angle regulating mechanism consists of a box body provided with a crank transmission mechanism and a semicircular worm wheel block assembled in a box body rotating groove. The load-bearing connector test specimen clamp has the advantages that the structural design is reasonable; the clamping and positioning accuracy of the load-bearing connector test specimen is ensured; the mounting and the dismounting are convenient; the clamping is stable; the connection of components and the effective transmission and distribution of the load can be really simulated; the multi-position stretching and fatigue test result accuracy can be obviously improved.

Owner:SHENYANG SHENGYUAN INSPECTION TECH

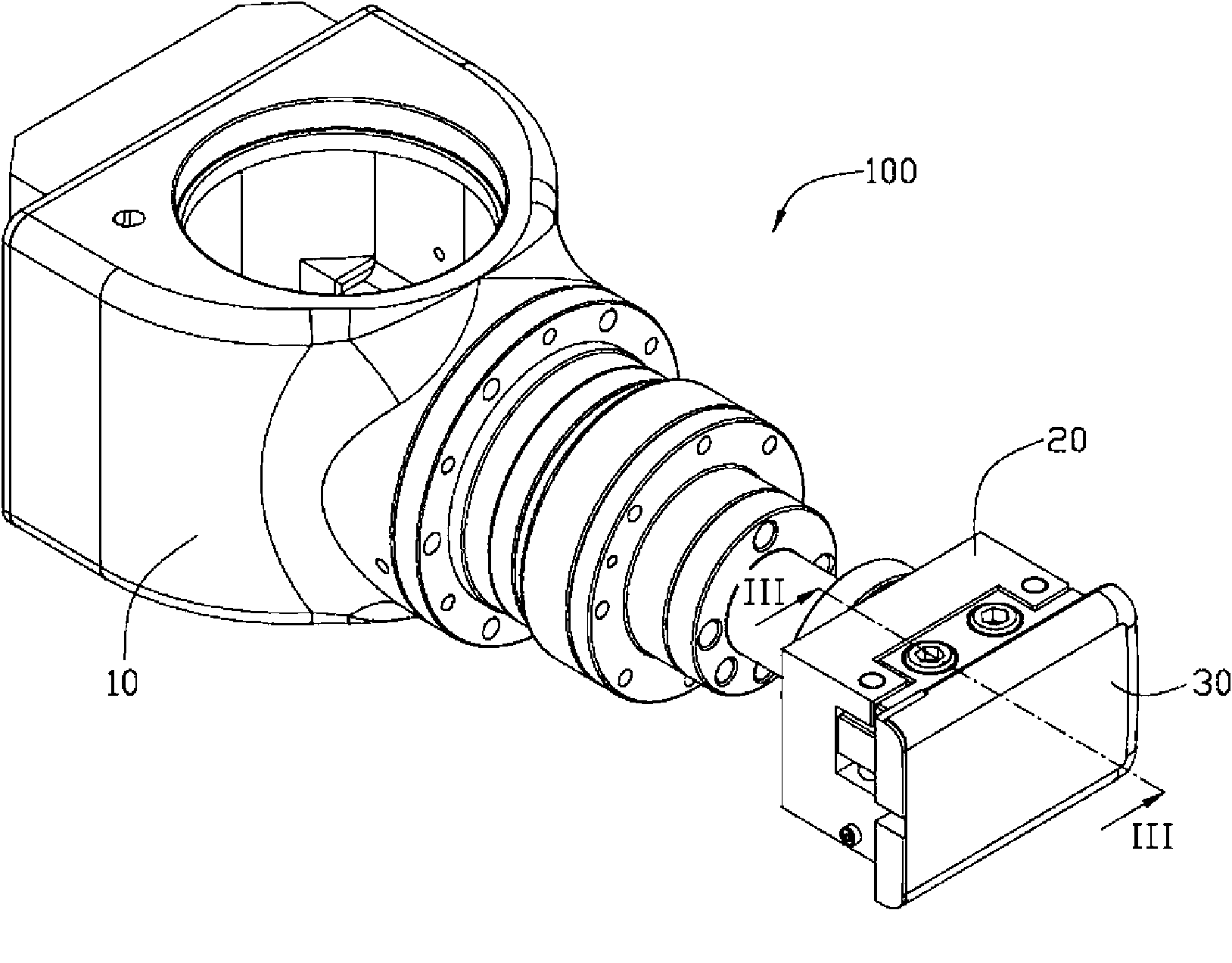

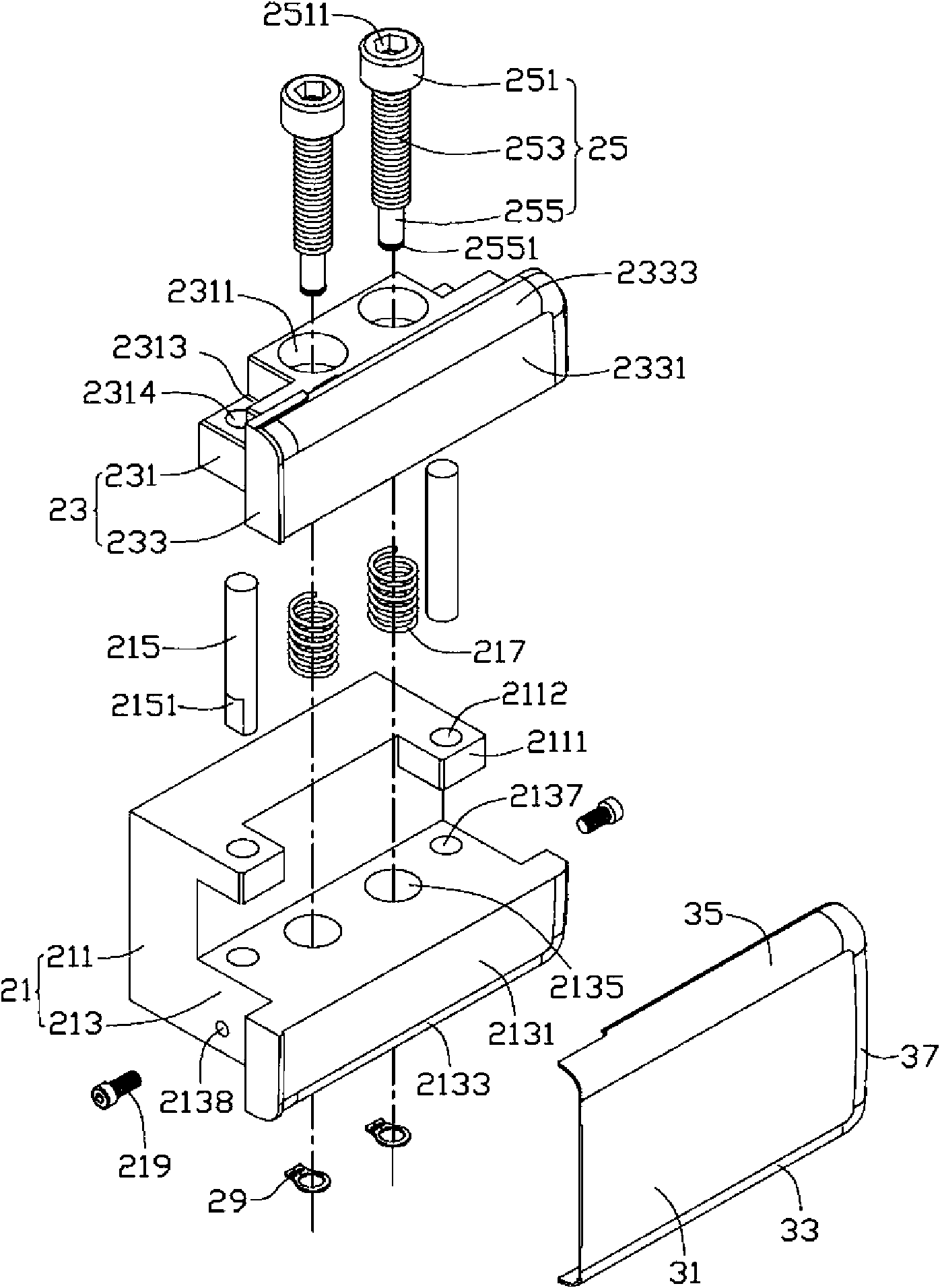

Clamping mechanism and manipulator using same

InactiveCN101987451AAccurate clamping and positioningEasy to process in one timeProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a clamping mechanism, comprising a fixed clamping member, a movable clamping member and a driving member. The fixed clamping member is provided with a first clamping portion and the movable clamping member is provided with a second clamping portion. The movable clamping member is movably connected with the fixed clamping member via the driving member. The driving member leads the movable clamping member to translation in relation to the fixed clamping member so that the second clamping portion is away from the first clamping portion. The clamping mechanism has the advantages of high clamping precision and fast processing speed. The invention further provides a manipulator using the clamping mechanism.

Owner:SHENZHEN SHENGTIANDA AUTOMATION TECH CO LTD

Device and method for positioning, clamping and installing any curved sheet piece in plane

InactiveCN101797688ASolve the positioning clamping problemMeet toolingMetal working apparatusIn planeWaste management

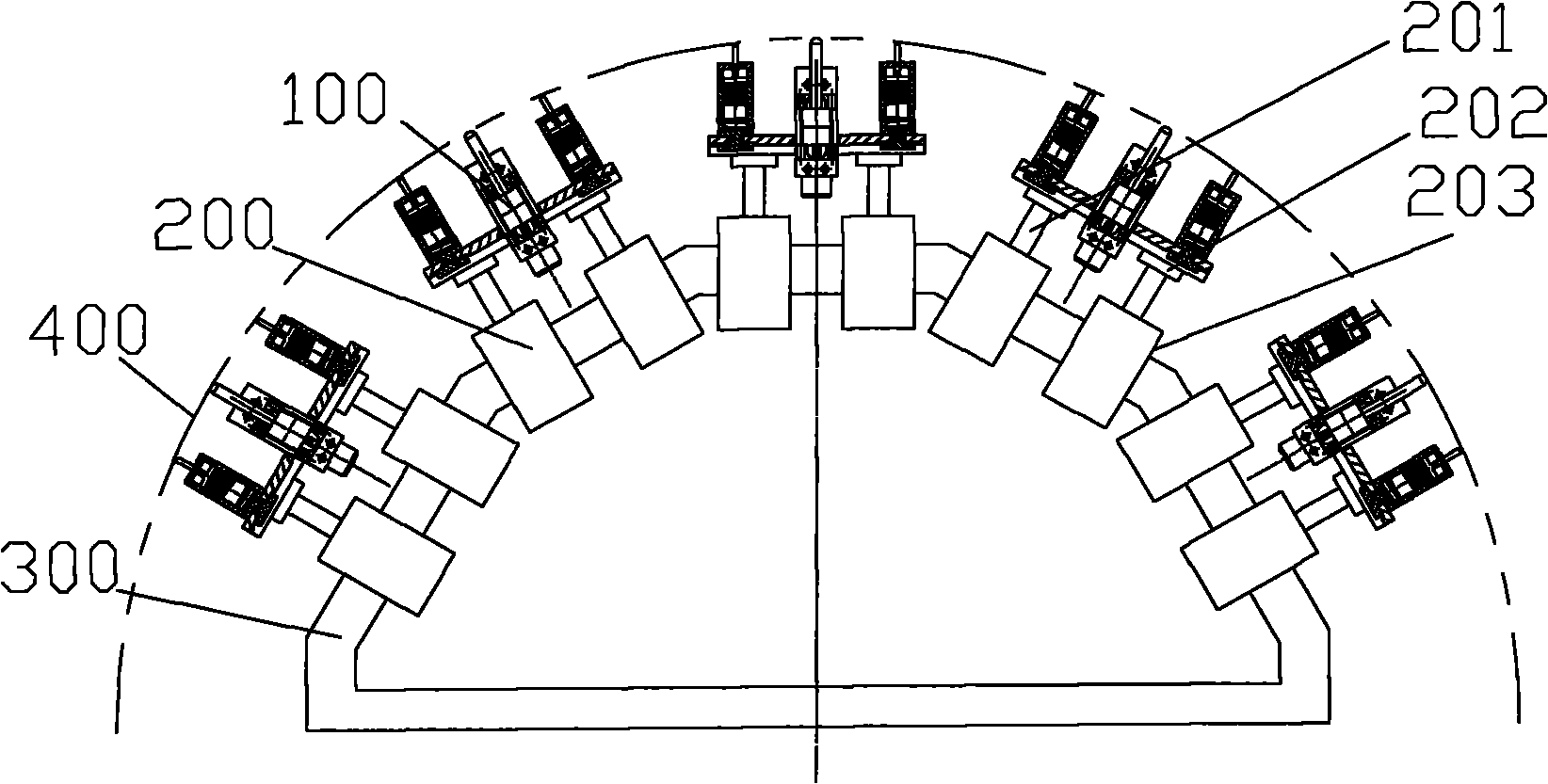

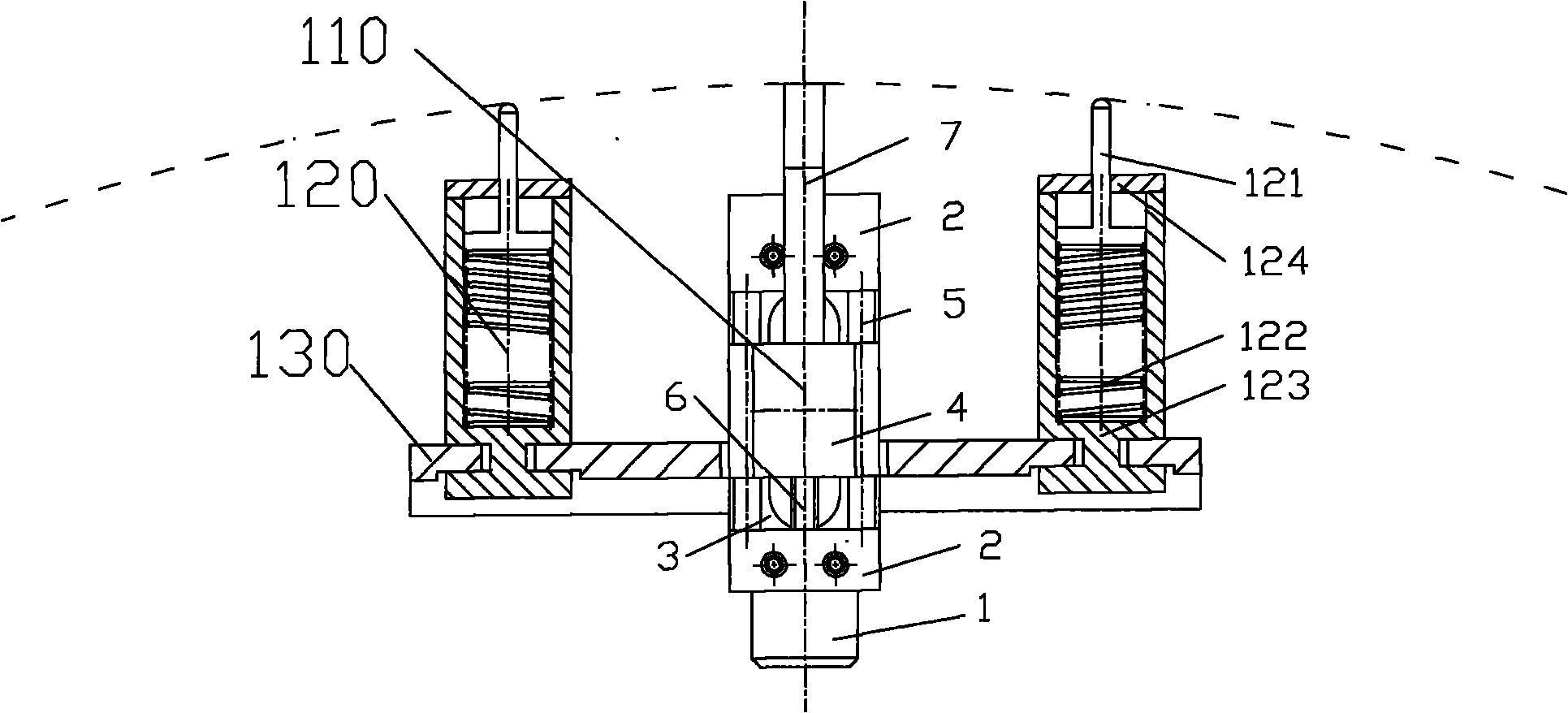

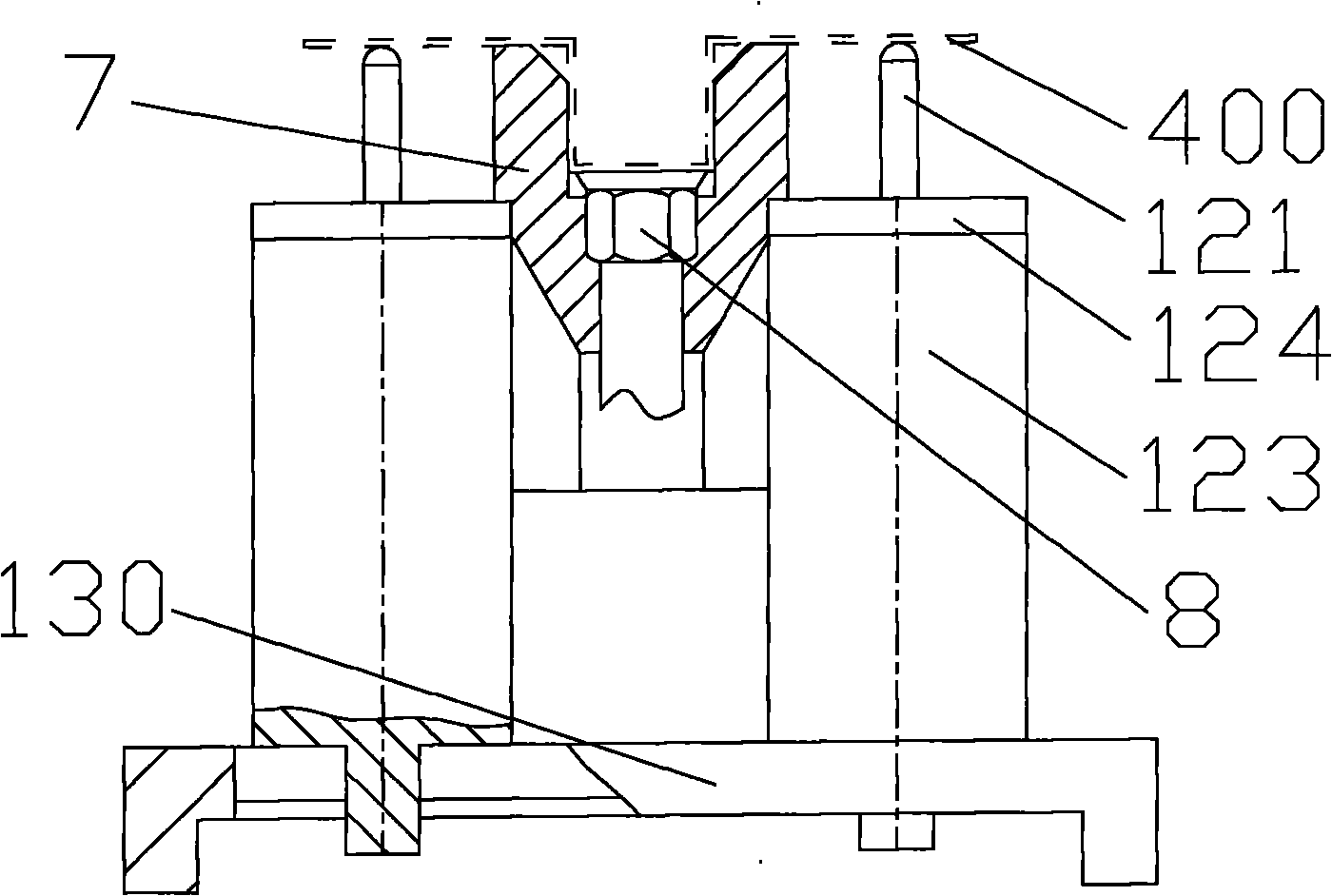

The invention relates to a device and a method for positioning, clamping and installing any curved sheet piece in a plane. The device consists of flexible positioners, diameter varying devices and a base plate. The diameter varying devices are distributed in form of a circular arc on the outer rim of the base plate and are connected through pegs and bolts; the flexible positioners are arranged on the diameter varying devices; and one flexible positioner is arranged on the handspikes of two diameter varying devices and is connected through pegs and bolts. The device is capable of positioning, clamping and installing any curved sheet piece in the plane according to the production requirement to satisfy the requirement for positioning, clamping and installing any curved sheet piece in the plane. The device has great flexibility, convenient installation and simple structure and can be conveniently adjusted and quickly restructured when the device is used to install any curved sheet piece in any plane.

Owner:DONGHUA UNIV

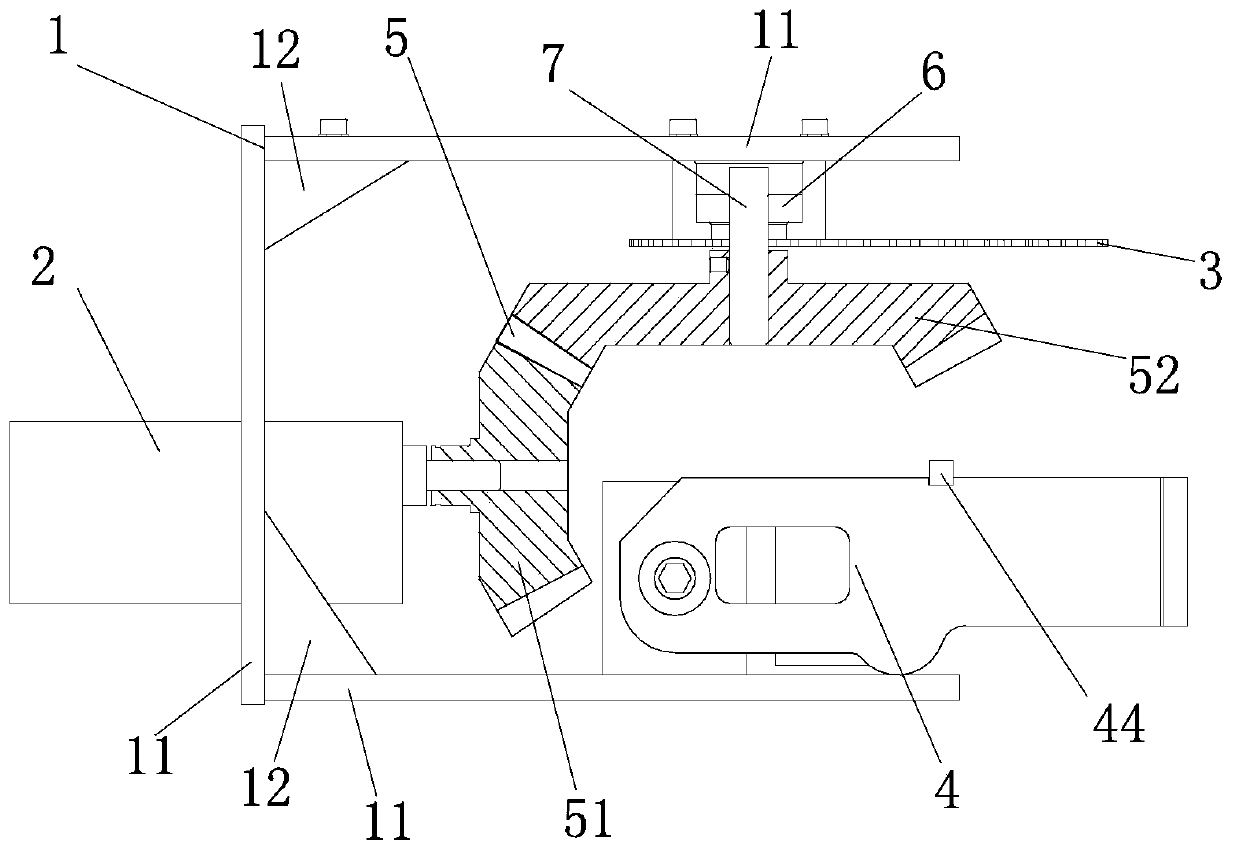

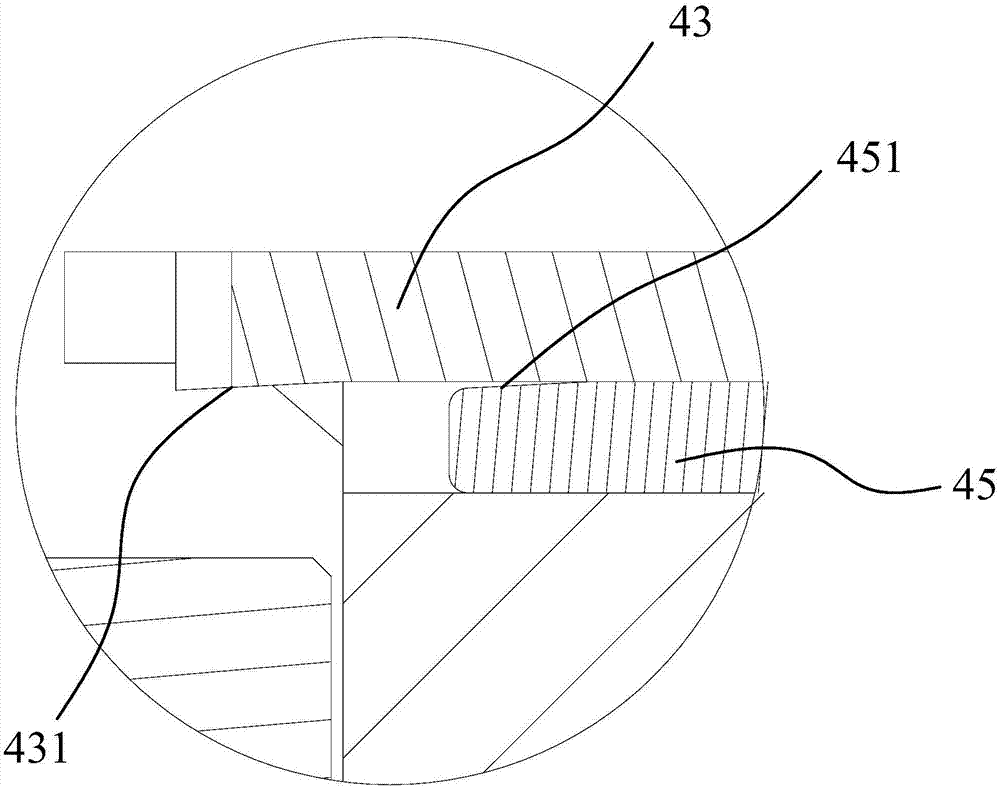

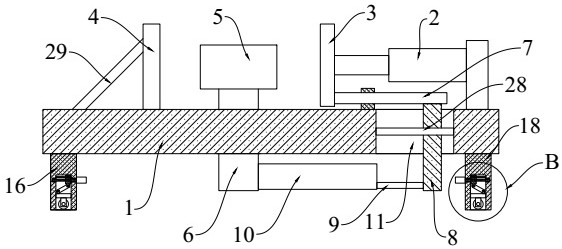

Clamping tool for lower shell of engine thermostat

ActiveCN107971791AStable clamping positioningPrecise positioningPositioning apparatusMetal-working holdersThermostatEngineering

The invention discloses a clamping tool for a lower shell of an engine thermostat. The clamping tool comprises a machine frame (1); a base plate (2) is arranged on the machine frame (1); positioning column (3), a horizontal clamping mechanism and a plurality of vertical pressing mechanisms are arranged on the base plate (2); the positioning columns (3) are used for supporting a product to be machined; a first clamping device (4) and a second clamping device (5) which are oppositely arranged are further fixedly arranged on the base plate (2) and are used for carrying out relative clamping and limiting on the two sides of the lower shell; the vertical pressing mechanisms are fixedly arranged on the base plate (2) in the circumferential direction of the product; and when the product is placedon the positioning columns (3), the horizontal pressing mechanism clamps and limits the product in the horizontal direction, and the vertical pressing mechanisms press and limit the product the vertical direction. The clamping tool for the lower shell of the engine thermostat has the advantages that, the positioning of the product in the horizontal direction is stable, the adjustment is convenient, and in addition, the occupied space is small.

Owner:宁波裕隆汽车制泵有限公司

Electrode holder

InactiveCN1923440AAccurate clamping and positioningStable and powerful clamping and positioningResistance electrode holdersWelding/cutting auxillary devicesElectrical conductorElectric cables

The invention relates to a welding clamper used to mount and replace welding bar. Wherein, it is formed by clamping support and clamper made from conductors; the support has V-shape groove; the clamper is formed by clamping plate whose end surface has V-shape cut relative to the V-shape groove, connected pushing rod, and spring; the middle of pushing rod has pushing button; the wire is through the chamber of frame, while its front end is connected to the upper end of support and tail is connected to cable via screw; the frame of support has cover connected to the front of frame. The invention will not hurt head in welding.

Owner:张凤林

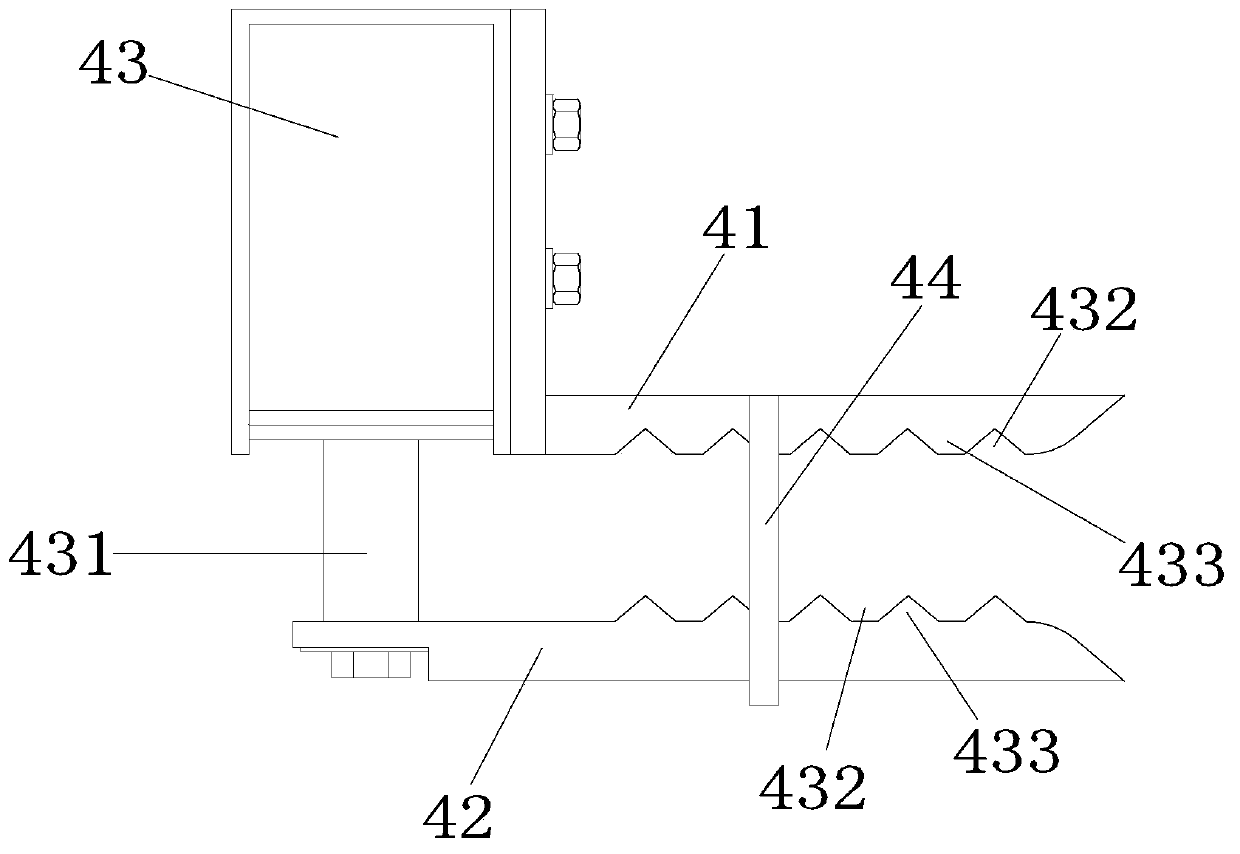

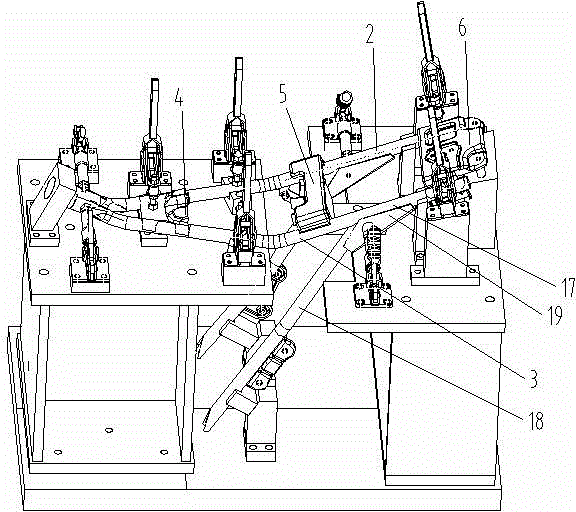

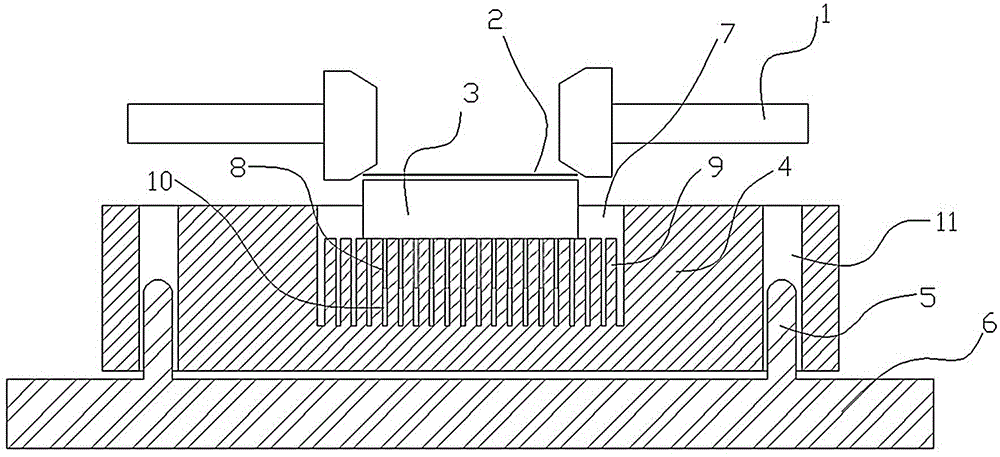

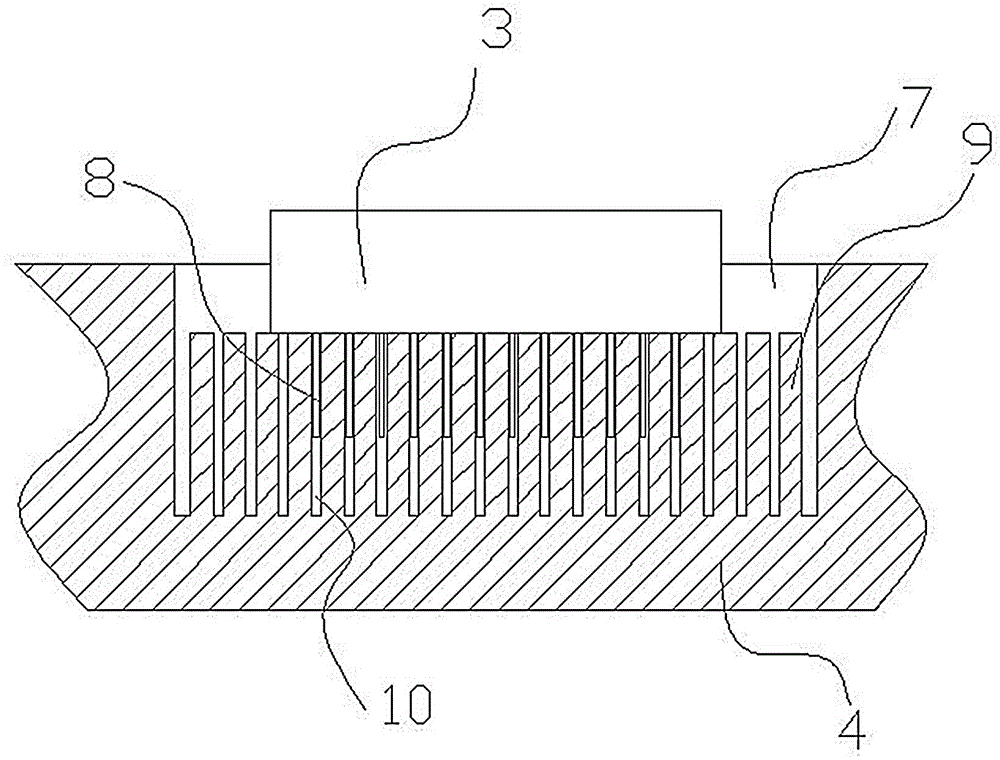

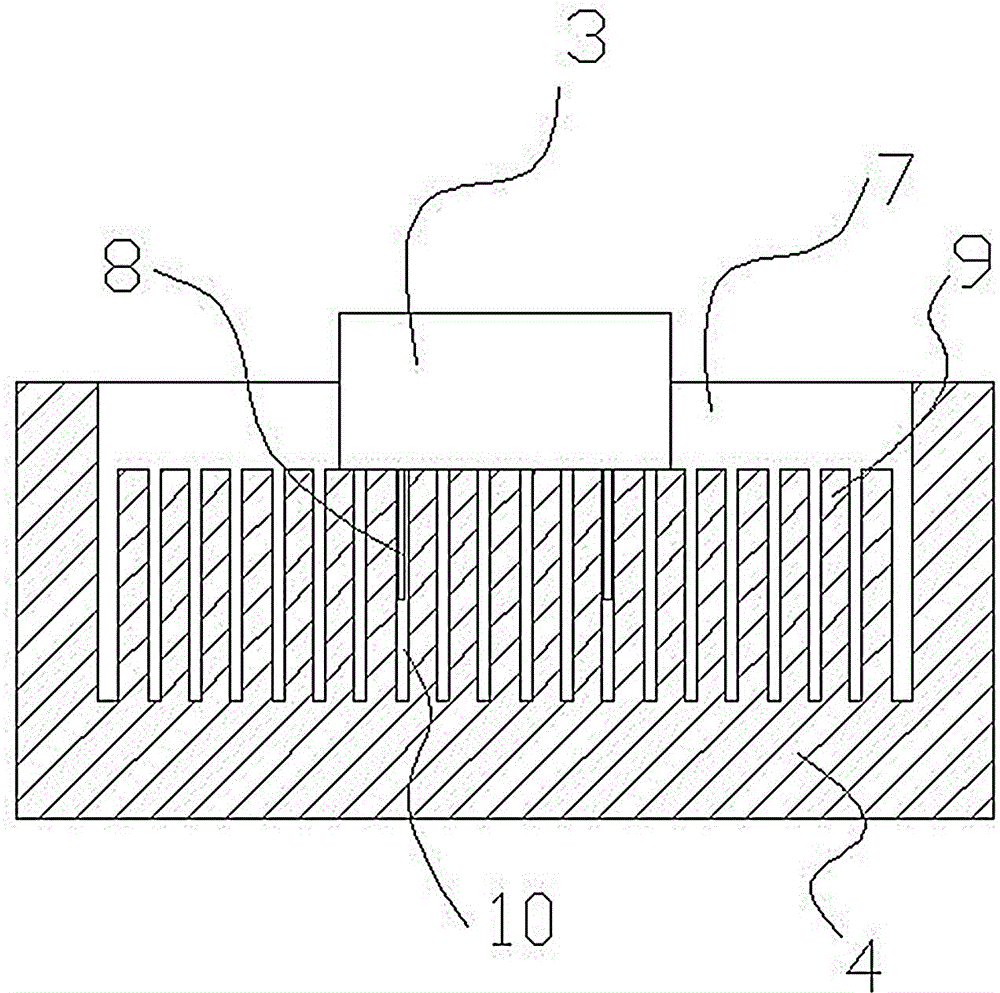

Parallel seam welding packaging device

InactiveCN104148795AAccurate clamping and positioningLow costWelding/cutting auxillary devicesRectilinear seam weldingSeam weldingEngineering

The invention discloses a parallel seam welding packaging device. The device comprises a base (4) which is arranged on a parallel seam welding piece bearing table, and a square groove (7) is formed in the top surface of the base (4). The depth of the square groove is smaller than the height of a dual-in-line outer metal shell (3) needing clamping, and rectangular pillars (9) are evenly distributed vertically in the square groove (7) in an arrayed mode. The number of the rectangular pillars (9) is an odd number in the transverse direction and an even number in the longitudinal direction. Grooves (10) are formed between the adjacent rectangular pillars and are uniform in width. The grooves (10) are in clearance fit with pins (8) of the outer metal shell (3) to form pair insertion. Because the distance of the pins of the dual-in-line outer metal shell is integer multiples of 2.54 mm, various types of dual-in-line outer metal shells can be accurately clamped and positioned, cost is reduced, frequent device replacing is not needed, and production efficiency is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Square power battery shell disassembling device

PendingCN110943264AAccurate clamping and positioningCutting job goes wellWaste accumulators reclaimingBattery recyclingEngineeringPower battery

The invention discloses a disassembling device for a square power battery shell. A leading-in conveying belt and a leading-out conveying belt are arranged on the two sides of the machine frame respectively. A shifting fork, a clamping mechanism, a horizontal cutting assembly and a vertical cutting assembly are sequentially arranged on the machine frame in the moving direction of the conveying belt, an auxiliary conveying mechanism is arranged at the bottom of the machine frame, the machine frame and the auxiliary conveying mechanism are fixed to the bottom workbench, and power elements in thedevice are all controlled by a control unit EU. The disassembling device can be suitable for disassembling square batteries of different sizes, in the disassembling process, the clamping mechanism canaccurately clamp and position the batteries, cutting work can be smoothly conducted, the whole cutting process is integrally completed through the device, manpower is remarkably saved, and the working efficiency can be greatly improved.

Owner:JIANGSU UNIV OF TECH

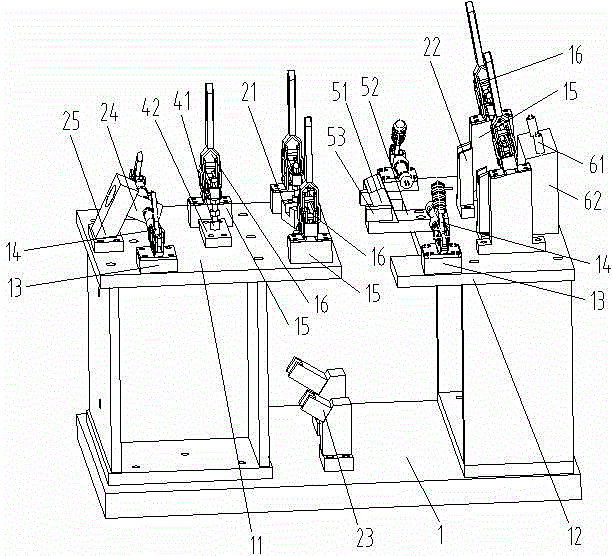

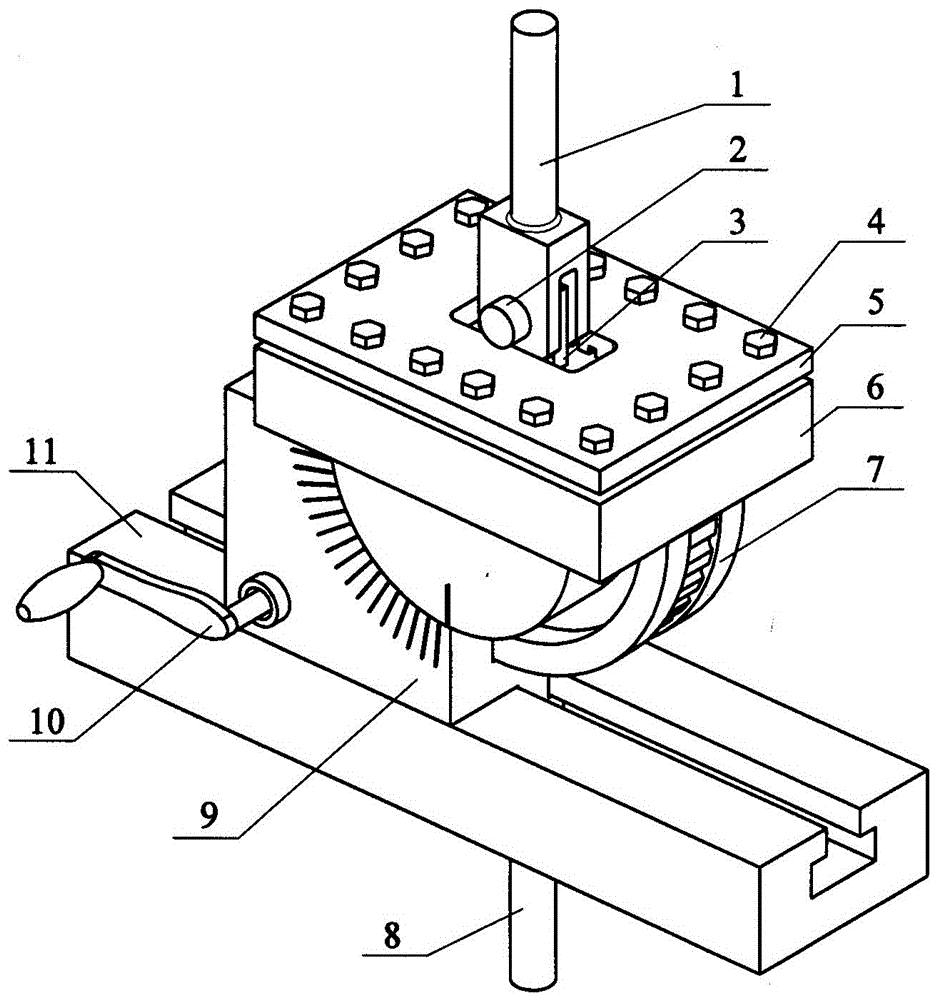

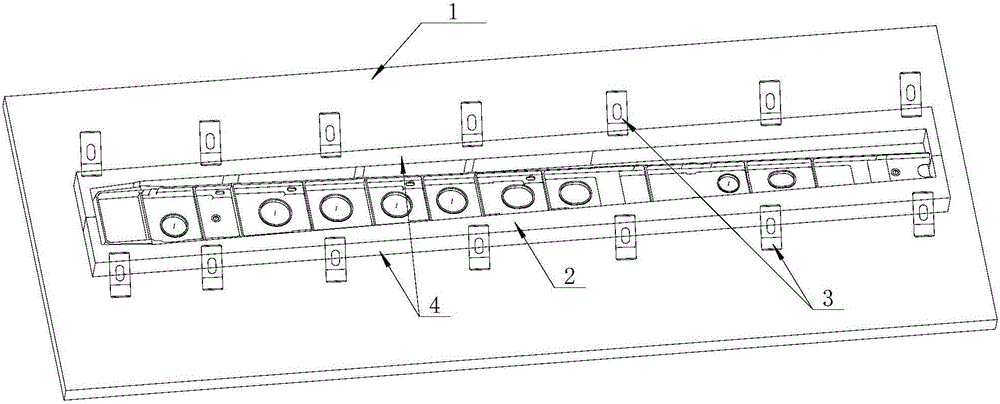

Method for rapidly improving machining efficiency of aviation beam type products and device of method

InactiveCN106141581AReduce process flowImprove processing efficiencyPositioning apparatusMetal-working holdersAviationEngineering

The invention discloses a method for rapidly improving the machining efficiency of aviation beam type products and a device of the method, and belongs to the field of aviation product machining. A zero point positioning device is used for conducting vertical clamping on a to-be-machined aviation beam type component, and machine tool machining is conducted in a vertical clamping state; in vertical clamping, a clamping tool is used for clamping and fixing the to-be-machined aviation beam type component in the states of the horizontal length direction and the vertical width direction of the to-be-machined aviation beam type component, wherein the clamping tool comprises the zero point positioning device and a positioning fixing device, and the positioning fixing device comprises a bottom plate and a plurality of supporting blocks fixed to the bottom plate; and a plurality of positioning connectors are arranged on the bottom edge, in the length direction, of the to-be-machined aviation beam type component, the position below each positioning connector corresponds to one supporting block, and zero point locators are arranged on the top faces of the supporting blocks. According to the method, the process procedures are reduced, and the machining efficiency is improved; the machining period is shortened, and cost is reduced; clamping and positioning are accurate, and product loading and unloading are rapid; and repeated clamping work is reduced.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Rapid clamping device for sensor testing

PendingCN113714946ARealize clamping and fixingAccurate clamping and positioningWork holdersControl engineeringMechanical engineering

The invention discloses a rapid clamping device for sensor testing, and belongs to the technical field of testing equipment. The following scheme is provided for solving the problems that an existing sensor fixing mode is tedious in operation, low in efficiency and large in manpower consumption, and a testing device is inconvenient to move. The device mainly comprises a test bed, a fixing plate located at the top of the test bed, a clamping plate and two pressing plates. The rapid clamping device is reasonable in structural design, an air cylinder drives the clamping plate to move and drives the two pressing plates to move towards the sides close to each other, a sensor is clamped and fixed in the front-back direction and / or the left-right direction in cooperation with the fixing plate, therefore the clamping and fixing efficiency and stability of the sensor are improved, and the problems that an existing sensor fixing device is tedious in operation, low in efficiency and large in manpower consumption can be effectively solved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Driving pin shaft processing method

InactiveCN104551149ASimple processing methodEasy to operateMilling equipment detailsPositioning apparatusProcessing costMachining

The invention discloses a driving pin shaft processing method and relates to the technical field of machining; a multi-station milling fixture is adopted to process, wherein the multi-station milling fixture comprises a base plate, wherein a long groove and two side baffle plates which are oppositely arranged are arranged on the base plate; convex strips which extend towards inner sides are arranged at the upper ends of the two side baffle plates; two first clamping plates and a plurality of second clamping plates are slidingly connected between the two side baffle plates; V-shaped clamping surfaces are formed at the inner ends of the first clamping plates, and screw limiting holes are formed at the outer ends; V-shaped clamping surfaces are formed at both ends of the second clamping plates; and pre-tightening screws which are fixed on the base plate by virtue of supporting plates are arranged at the outer ends of the first clamping plates. The processing method comprises the following processing steps: A. mounting the fixture; B. mounting workpieces; C. milling a groove; and D. detaching all workpieces. Compared with the prior art, the processing method disclosed by the invention can be used for clamping a plurality of machined parts at one time for milling and processing, so that production efficiency is greatly improved and processing cost is reduced.

Owner:LIUZHOU JULONG TECH

Tool holder for grooving cutting blade

ActiveCN102601403AAvoid deformationReduced positioning contact areaTurning toolsTool holdersEngineeringSupport surface

The invention discloses a tool holder for grooving a cutting blade. The tool holder comprises a tool holder body and a fastener, a clamping portion of the tool holder body consists of an upper clamping portion and a lower supporting portion, an upper positioning surface of the upper clamping portion and a lower positioning surface of the lower supporting portion enclose a blade clamping groove, a rear supporting surface and an elastic extending section are arranged at the rear end of the blade clamping groove, the elastic extending section extends backwards to the neck of the tool holder body, the fastener penetrates through the upper portion and the lower portion of the elastic extending section, M discontinuous upper positioning tables are arranged on the upper positioning surface, and N discontinuous lower positioning tables are arranged on the lower positioning surface, wherein 2<=M<=6, and 2<=N<=6. The tool holder for grooving the cutting blade has the advantages that positioning positions and angles can be automatically adjusted, plastic deformation of the tool body can be effectively suppressed, and the tool holder is stable in structure and long in service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Bending pipe and clamping tool thereof

ActiveCN106363556AEasy to clamp and positionAccurate clamping and positioningWork holdersSiphonsMechanical engineeringStructural engineering

The invention relates to a bending pipe body and a clamping tool of the bending pipe body. A first process boss, a second process boss, a third process boss and a fourth process boss are arranged on the bending pipe body, and therefore clamping and positioning of the bending pipe body are facilitated; a first end fixing device of a first end port compresses and fixes the first end port, and a first supporting column supported on the lower supporting positioning face of the second process boss and a first pressing device compressed on the upper surface of the first process boss ensure that the bending pipe body is accurately clamped and positioned, and therefore the machining precision is greatly improved, and the product quality is ensured.

Owner:山东盛祥智能制造有限公司

Shell leakage testing clamp

ActiveCN104236825AQuick positioning clampingAccurate clamping and positioningMeasurement of fluid loss/gain rateBiomedical engineeringAutomation

The invention relates to a shell leakage testing clamp. The shell leakage testing clamp comprises stand columns and a clamp body arranged at the upper ends of the stand columns. Pneumatic pressing devices are arranged on the front portion, the rear portion and the left portion of the clamp body respectively. A supporting and positioning device is arranged in the middle of the clamp body. A nozzle sealing device is arranged on the right portion of the clamp body. The shell leakage testing clamp has the advantages of being reasonable in structural design, high in automation degree, convenient to operate and regulate and the like, can rapidly clamp and position an automobile water pump shell, and is high in operation efficiency and accurate in positioning and clamping accuracy; the sealing performance of the sealing position is ensured, and therefore detection quality can be improved, and the possibility of wrong detection can be lowered.

Owner:HENAN FEILONG WUHU AUTOMOBILE PARTS

Wedge type auxiliary fixture for milling machine

ActiveCN103612145AAccurate clamping and positioningQuick positioning clampingPositioning apparatusMaintainance and safety accessoriesMechanical engineeringPiston rod

The invention discloses a wedge type auxiliary fixture for a milling machine, and relates to the technical field of milling machine fixtures. The fixture comprises a base and a piston-type telescopic mechanism, and the piston-type telescopic mechanism is connected with a fixture body. The fixture body at least comprises a set of clamping mechanism, each set of the clamping mechanism comprises a fixed type upper pressing board, and an upper sliding wedge board and a lower sliding wedge board are arranged below the fixed type upper pressing board. An upper sliding track and a lower sliding track of the upper sliding wedge board are also arranged on the fixed type upper pressing board. The lower sliding wedge board is connected with a piston rod of the piston-type telescopic mechanism. The wedge type auxiliary fixture for the milling machine has the advantages of being capable of clamping and positioning a workpiece accurately and rapidly, simple in structure, and capable of improving working efficiency greatly.

Owner:CRRC SHIJIAZHUANG CO LTD

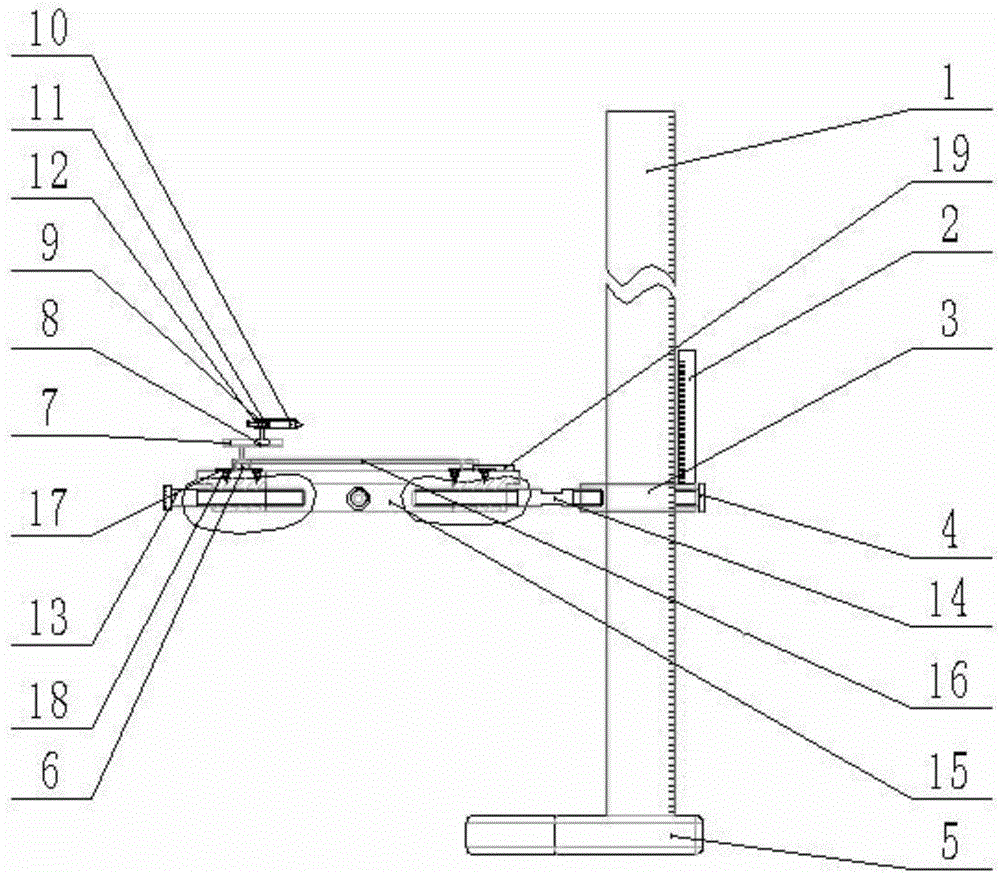

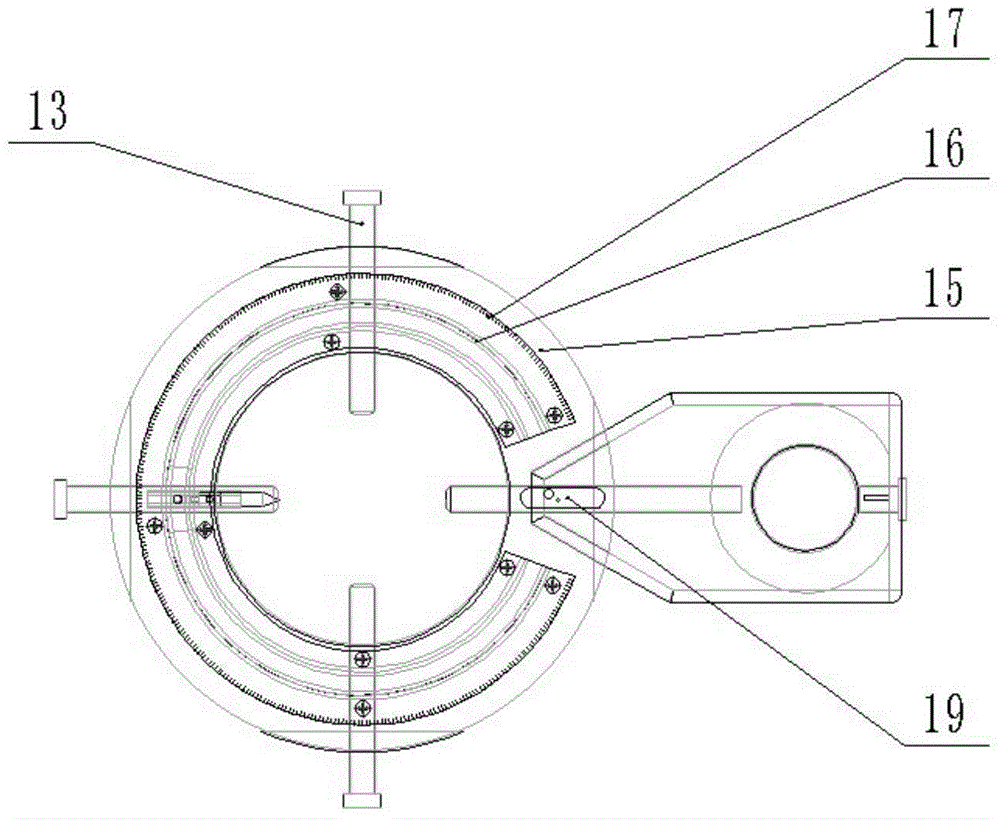

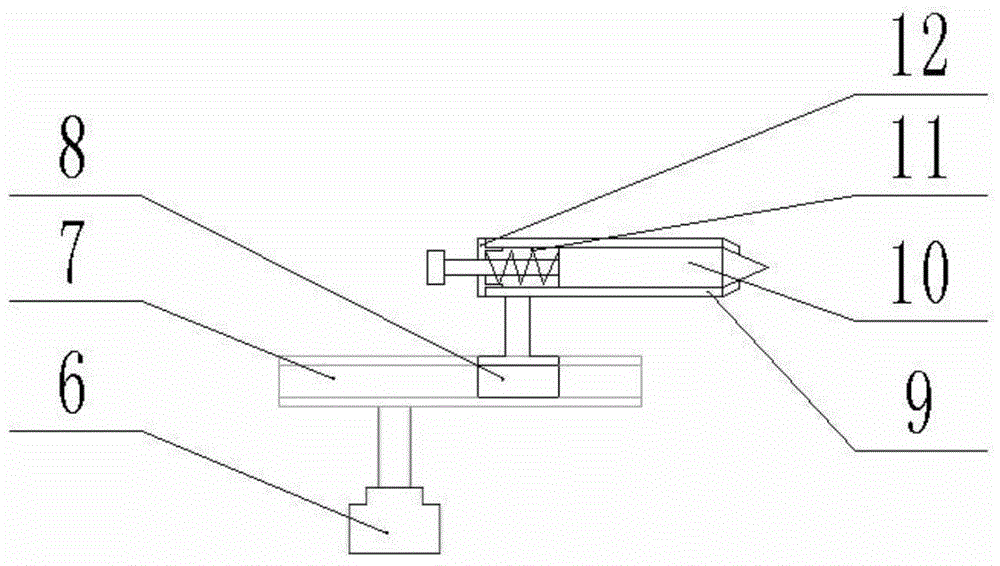

Welding positioning dotter of pipe fittings

ActiveCN104400264AEasy to operateHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesCircular discPipe fitting

The invention discloses a welding positioning dotter of pipe fittings. A height gauge of the dotter is welded on a base; a vernier gauge is welded on a fixed ring; a fastening screw is in threaded connection into the fixed ring; a fixed disc is connected with the fixed ring through a stud, and can vertically move along with the fixed ring; an adjustable screw is in threaded connection to the fixed disc; a first slide block is inlaid in a circular chute, and can slide in the circular chute; the circular chute is in spot welding with an angle measuring disc, and is connected to the fixed disc through a self-tapping screw; a second slide block is inlaid in a linear chute; a dotting pen is inlaid in a dotting pen shell; a spring is placed between the dotting pen and a dotting pen end cover; and a level is glued on the fixed disc. The dotter can precisely position welded points of the pipe fittings without a welded bracket.

Owner:GUANGXI UNIV

OP20 horizontal machining hydraulic clamp for automobile parts

InactiveCN107398763AAccurate clamping and positioningSmooth chip removalCleaning using gasesCleaning using liquidsMotor vehicle partHydraulic pump

The invention relates to an OP20 horizontal machining hydraulic clamp for automobile parts. The OP20 horizontal machining hydraulic clamp for the automobile parts sequentially comprises a horizontal machining workbench, a pedestal plate, an inclined base plate, a cushion block, an oil way adapter block and an oil way distributor from bottom to top, wherein clamp mounting inclined planes are arranged on the inclined base plate; a positioning mechanism, a main pressing mechanism, a supporting nail with a gas tightness detecting function, and an auxiliary pressing mechanism are arranged on each clamp mounting inclined plane; the positioning mechanism comprises a positioning and guiding post, a first positioning rhombic pin, a second positioning cylindrical pin and guiding rods; the main pressing mechanism comprises a main pressing plate; the auxiliary pressing mechanism comprises a first auxiliary pressing plate, a second auxiliary pressing plate and a third auxiliary pressing plate; cleaning nozzles are formed near the auxiliary pressing mechanism. The OP20 horizontal machining hydraulic clamp for the automobile parts has an obvious scrap-discharging effect by virtue of the outer shape; the OP20 horizontal machining hydraulic clamp for the automobile parts is accurate to clamp and position, so that the repeated positioning accuracy is improved, the operation rate of equipment is improved, and the machining accuracy of a product is ensured.

Owner:KUNSHAN YONG XIANG PRECISION MACHINERY

Full-automatic finish machining device for air cylinder cover

ActiveCN112091705AReduce the impact of inertial impactEnsure accuracy in placeMeasurement/indication equipmentsMetal working apparatusEngineeringMachine tool

The invention belongs to the technical field of air cylinder cover machining equipment, and provides a full-automatic finish machining device for an air cylinder cover. The full-automatic finish machining device comprises a machine tool, a mounting base is arranged on the side, provided with a main shaft, of the machine tool, a tool base driven by a first driving device is rotationally mounted onthe mounting base, a workpiece supporting plate driven by a second driving device is arranged on the tool base, a lifting positioning pin used for achieving pre-positioning of the air cylinder cover is arranged on the bearing face of the workpiece supporting plate, and a clamping positioning pin used for achieving clamping of the air cylinder cover, a supporting table and a clamping mechanism arefurther arranged on the tool base; and feeding bases are arranged on the two sides of the mounting base respectively, conveying devices used for achieving feeding and discharging of the air cylinder cover are arranged on the feeding bases respectively, and the two conveying devices are arranged correspondingly. Compared with traditional air cylinder cover machining equipment, full-automatic finishmachining of the air cylinder cover is achieved, conveying, positioning and clamping of the air cylinder cover are accurate and reliable, and the machining efficiency and the finish machining qualityof the air cylinder cover are greatly improved.

Owner:潍坊思博精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com