Device and method for positioning, clamping and installing any curved sheet piece in plane

A flat curve, positioning and clamping technology, used in metal processing, metal processing equipment, manufacturing tools, etc., to avoid deformation, precise positioning and clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

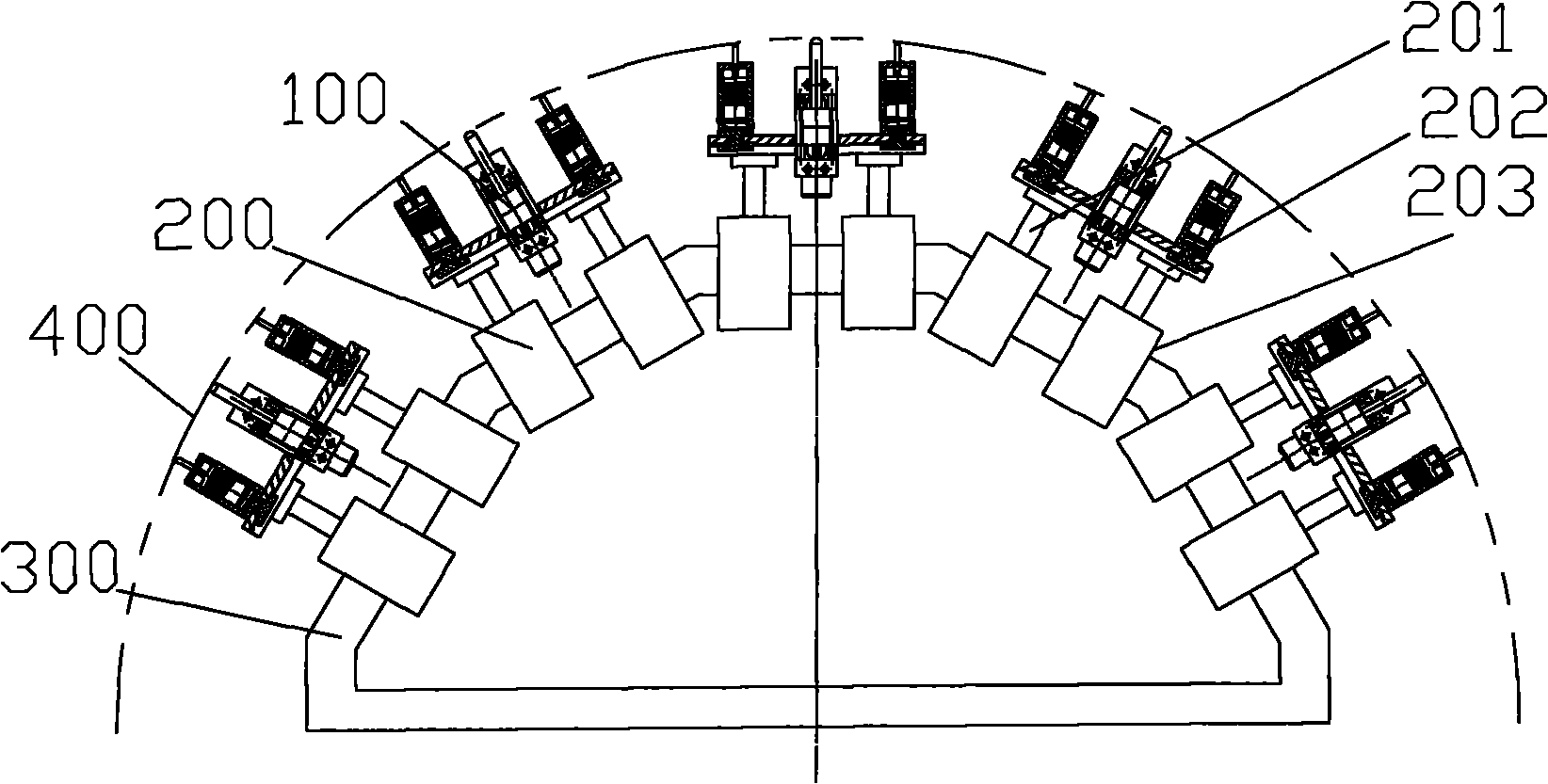

[0026] Such as figure 1 As shown, the positioning, clamping and installation device for thin plate parts with arbitrary plane curves of the present invention is composed of a flexible positioner 100 , a diameter reducing device 200 and a base plate 300 . The flexible positioner 100 is connected to the diameter reducing device 200 through pins and screws, the diameter reducing device 200 is connected to the base plate 300 through pins and screws, and the arc thin plate part 400 is installed on the flexible positioner 100 .

[0027] Wherein, the reducing device 200 is composed of a driving device 203 , a push rod 201 , and a transition plate 202 . The flexible positioner 100 is mounted on the transition plate 202 of the diameter reducing device 200 , the transition plate 202 is mounted on the push rod 201 , and the push rod 201 is mounted on the driving device 203 .

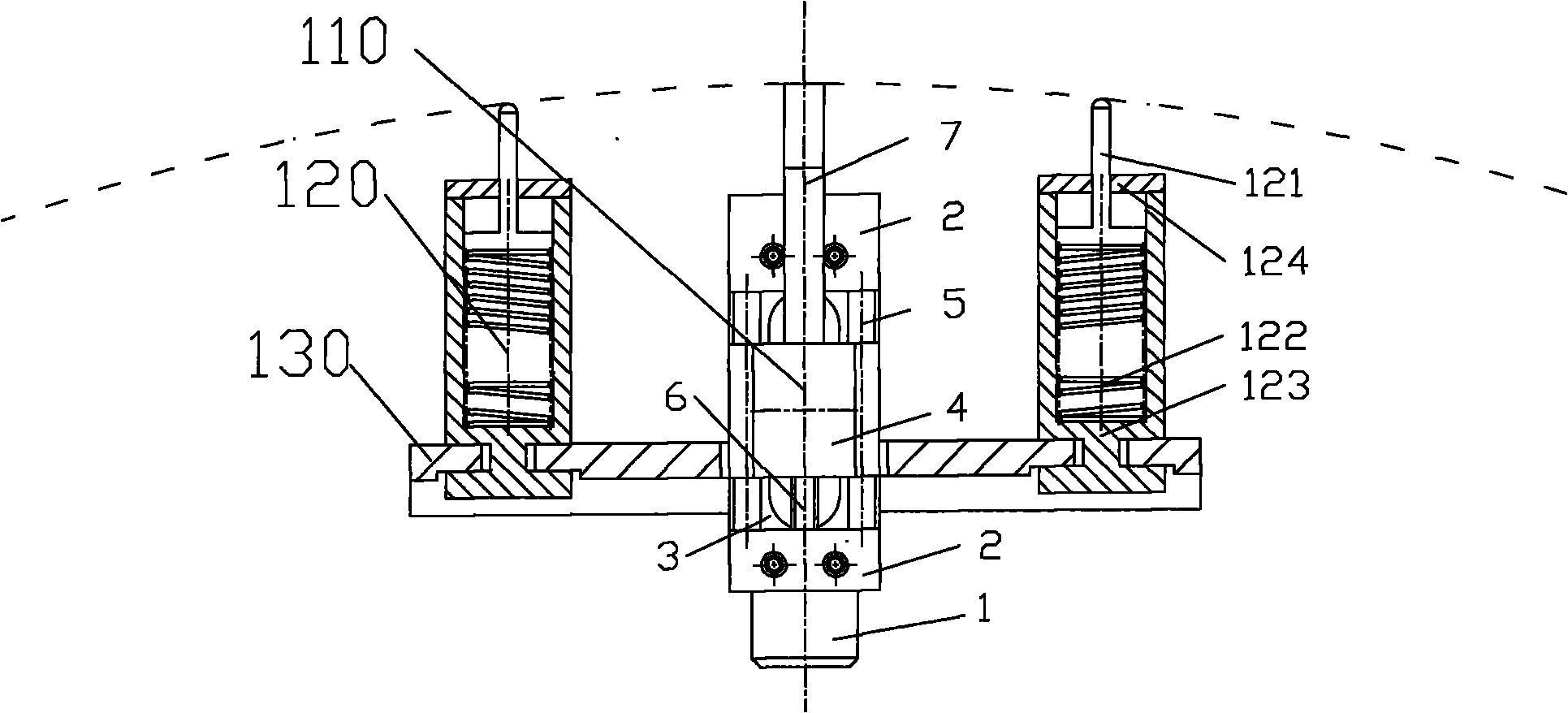

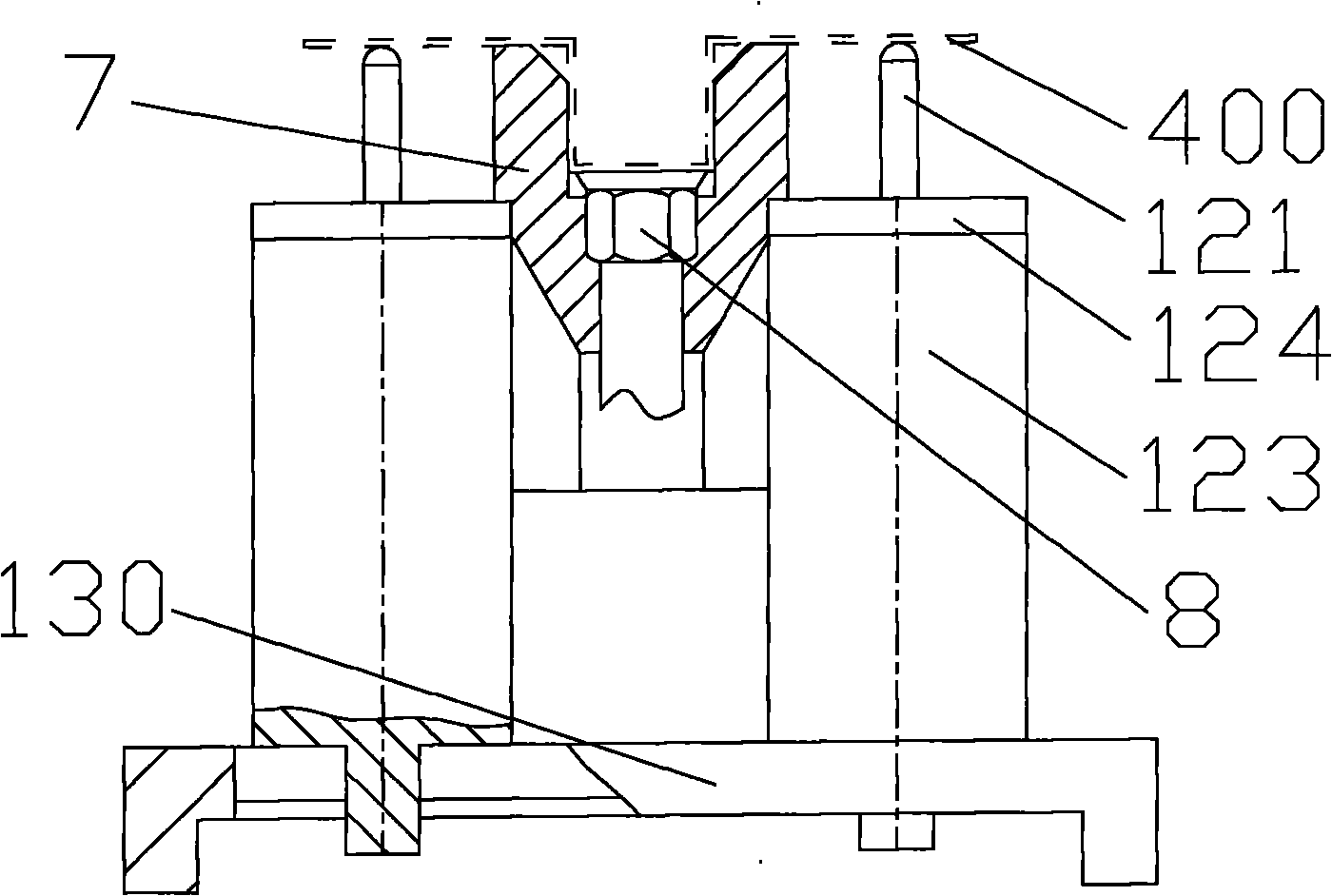

[0028] Such as figure 2 , image 3 As shown, the flexible positioner 100 of the present invention includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com