Clamping mechanism and manipulator using same

一种夹紧机构、夹紧件的技术,应用在机械手、程序控制机械手、夹头等方向,能够解决难以保证装夹精度、多人力、影响壳体加工速度等问题,达到装夹定位精确、提升加工速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The clamping mechanism and the manipulator of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

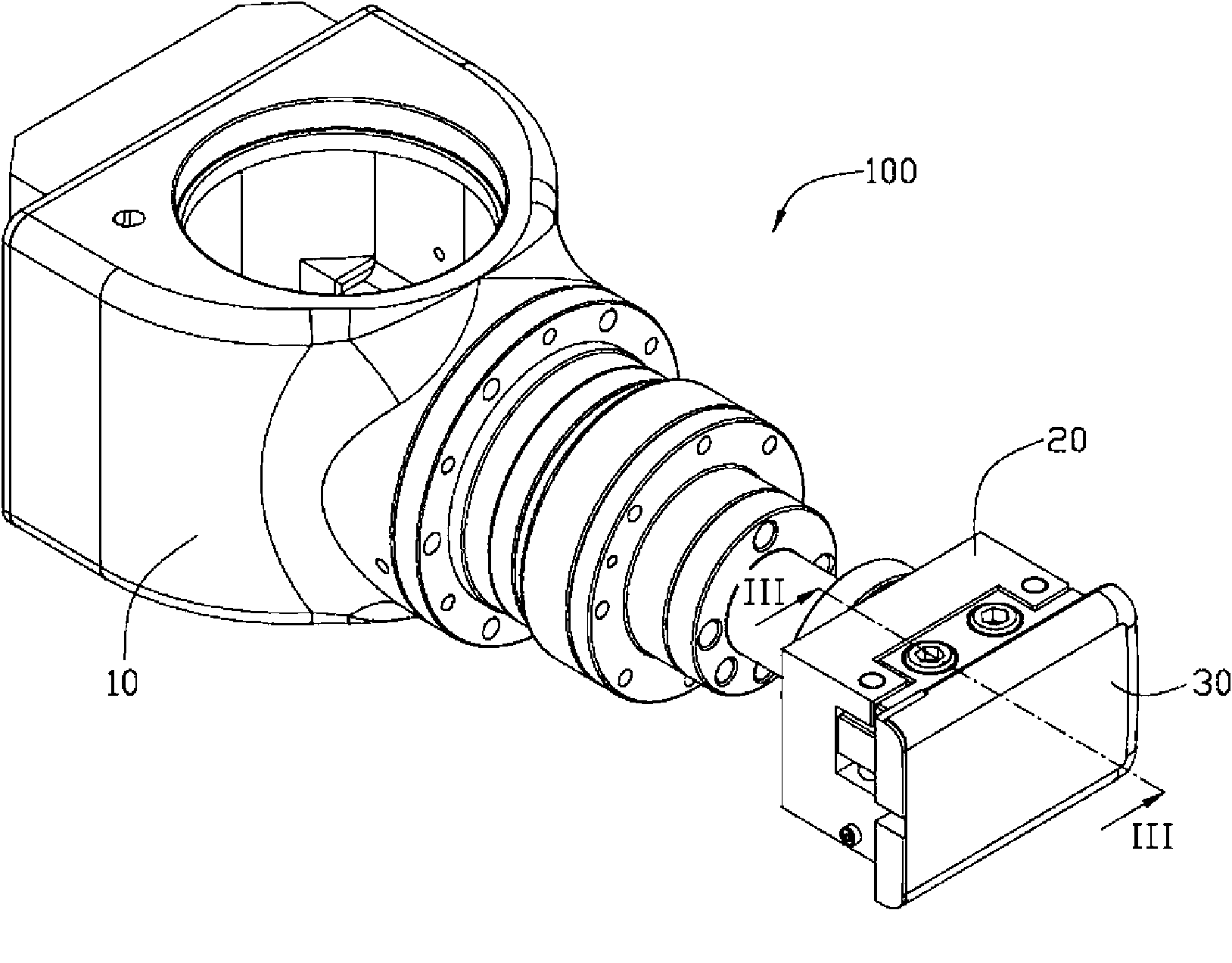

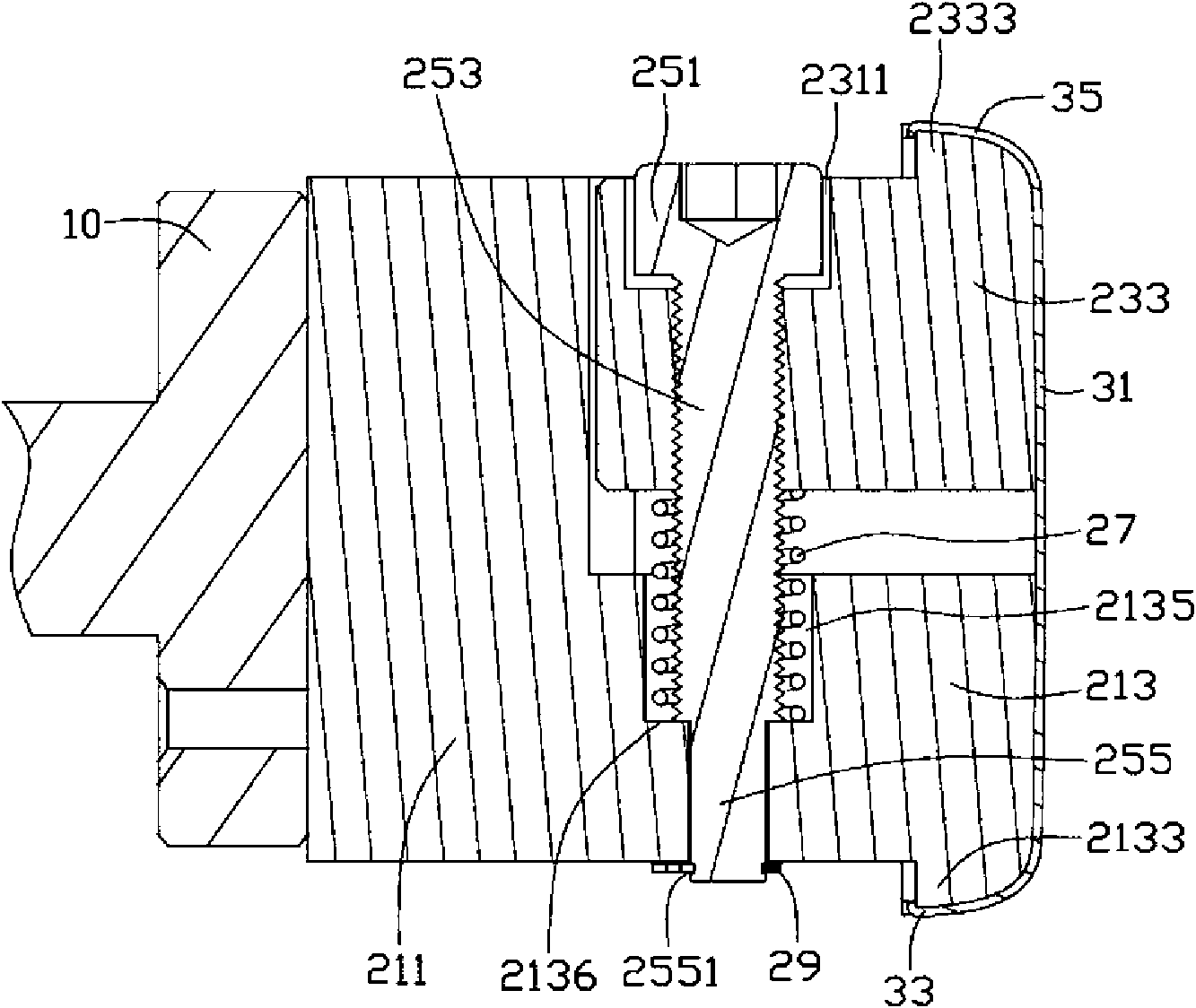

[0012] see figure 1 , the manipulator 100 of the embodiment of the present invention includes a manipulator 10 and a clamping mechanism 20 fixed at the end of the manipulator 10 . The clamping mechanism 20 is used to fix a workpiece 30 . The mechanical arm 10 can drive the clamping mechanism 20 and the workpiece 30 fixed on it to make various complex movements such as translation and rotation. In this embodiment, the manipulator 100 cooperates with a grinder (not shown in the figure) to grind multiple surfaces of the workpiece 30 .

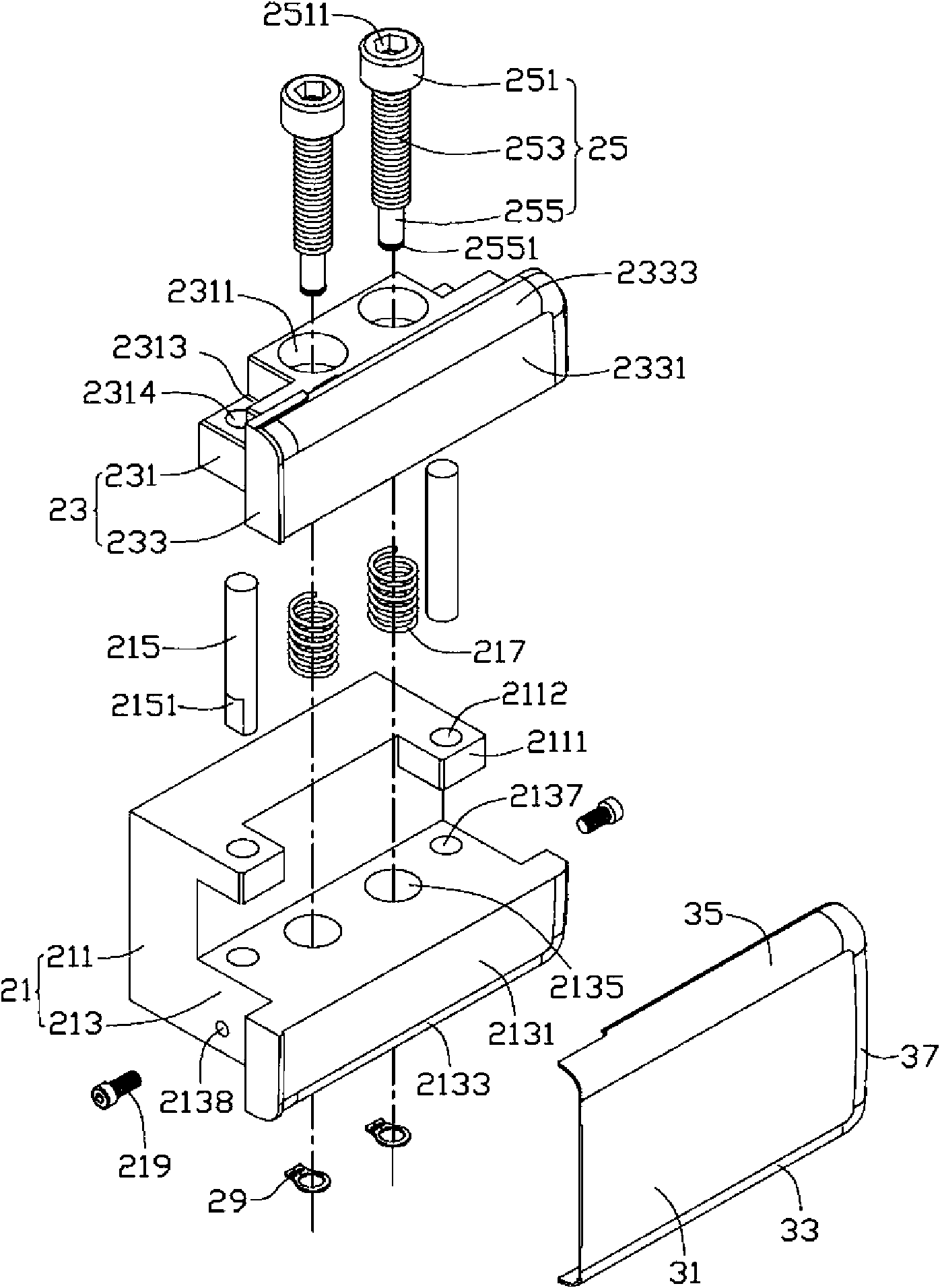

[0013] see figure 2 The workpiece 30 to be processed includes a bottom wall 31 and a first side wall 33 , a second side wall 35 and a third side wall 37 extending along the edge of the bottom wall 31 to the same side. The first sidewall 33 and the second sidewall 35 are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com