OP20 horizontal machining hydraulic clamp for automobile parts

A technology for hydraulic fixtures and auto parts, applied in the field of auto parts processing, can solve the problems of decreased machining accuracy, easy generation of defective products, accumulated errors, etc., and achieves the effect of improving the operation rate, obvious chip removal effect, and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

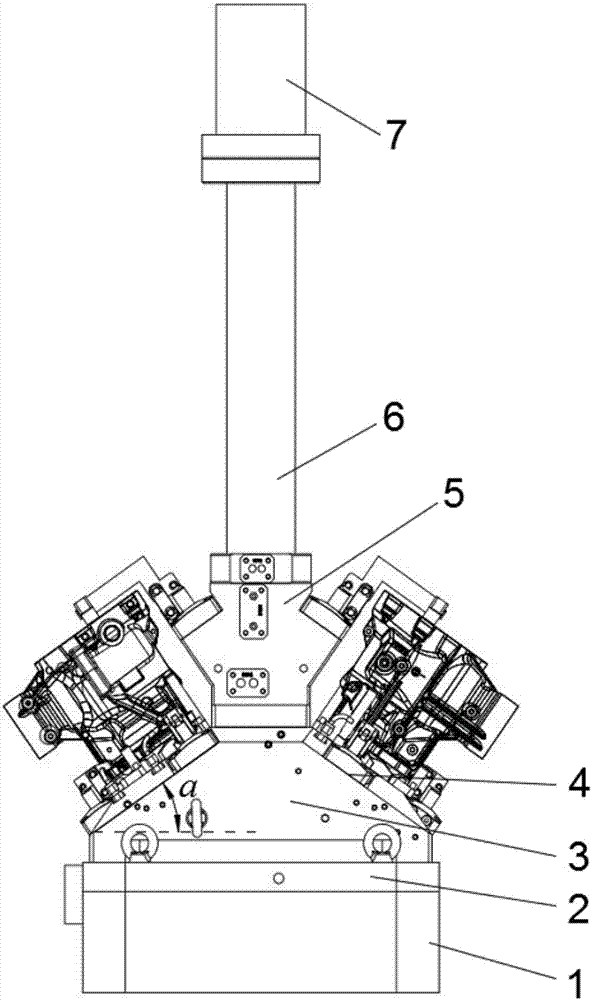

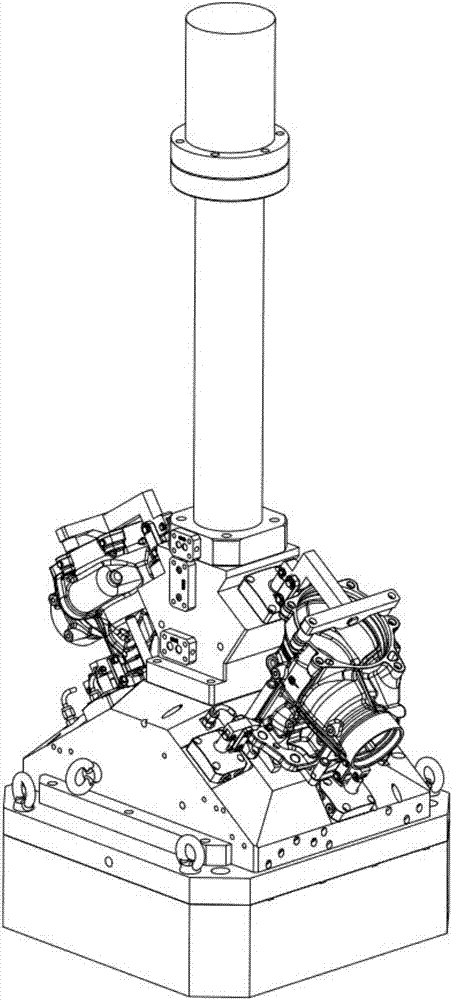

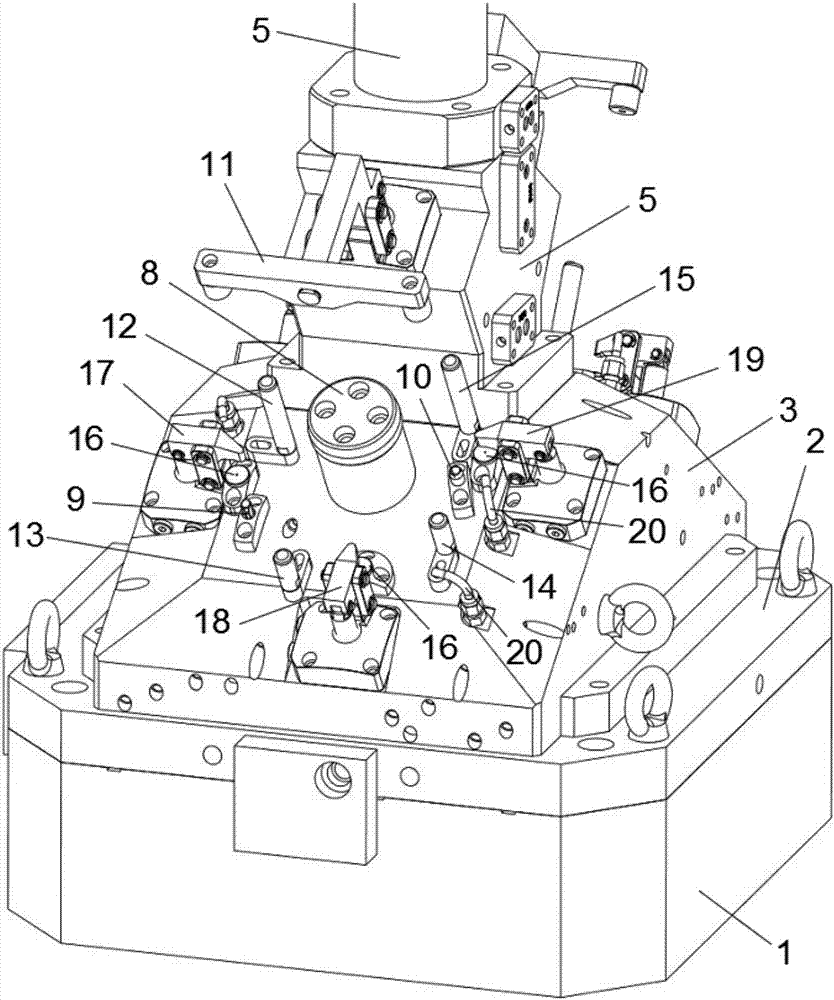

[0018] Such as Figure 1 to Figure 3 As shown, this embodiment provides an OP20 hydraulic clamp for horizontal loading of auto parts, which sequentially includes a horizontal processing table 1, a base plate 2, an inclined seat plate 3, a cushion block 5, and an oil circuit adapter block from bottom to top. 6 and an oil distributor 7; the left and right sides of the inclined seat plate 3 are symmetrically provided with a fixture installation slope 4; the pad 5 is provided with a main pressure mechanism installation surface parallel to the fixture installation slope 4; the fixture The installation slope 4 is provided with a positioning mechanism, a main pressing mechanism, a support nail 16 with airtight detection, and an auxiliary pressing mechanism; 8 The first positioning diamond pin 9 on the left front, the second positioning cylindrical pin 10 positioned on the right rear of the positioning guide post 8, and the first guide rod 12, the second guide rod 13, and the third gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com