Patents

Literature

386results about How to "Easy to clamp and position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

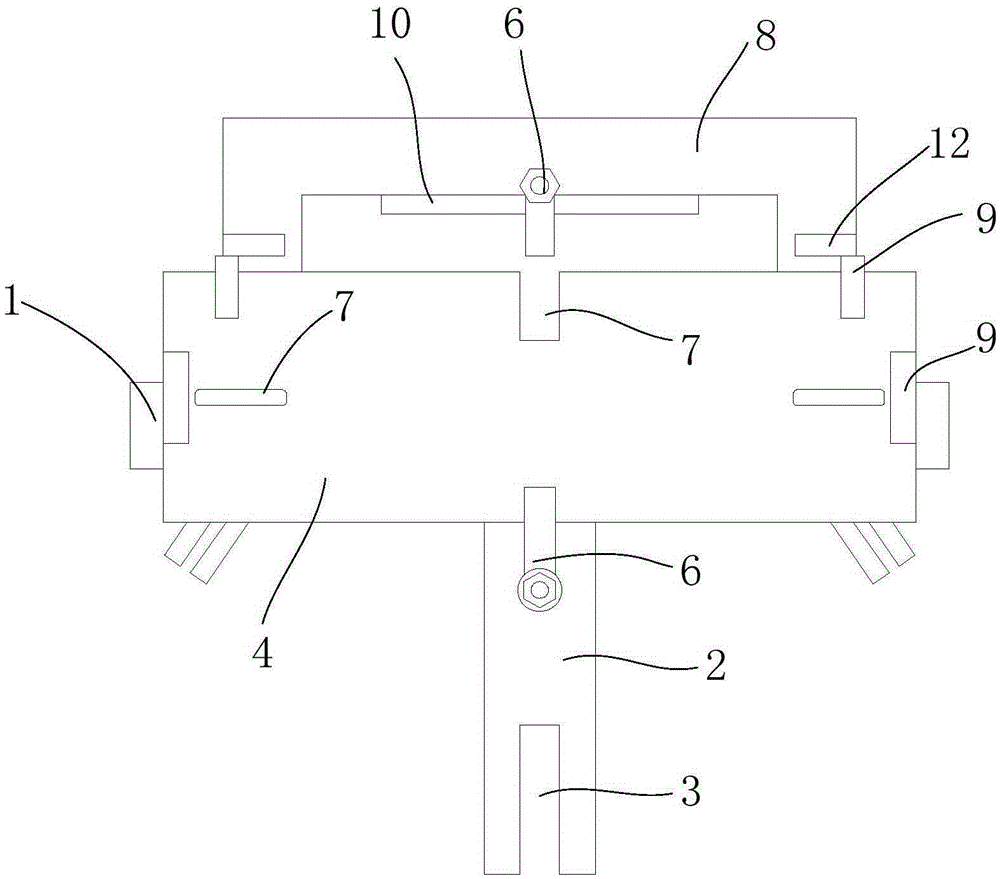

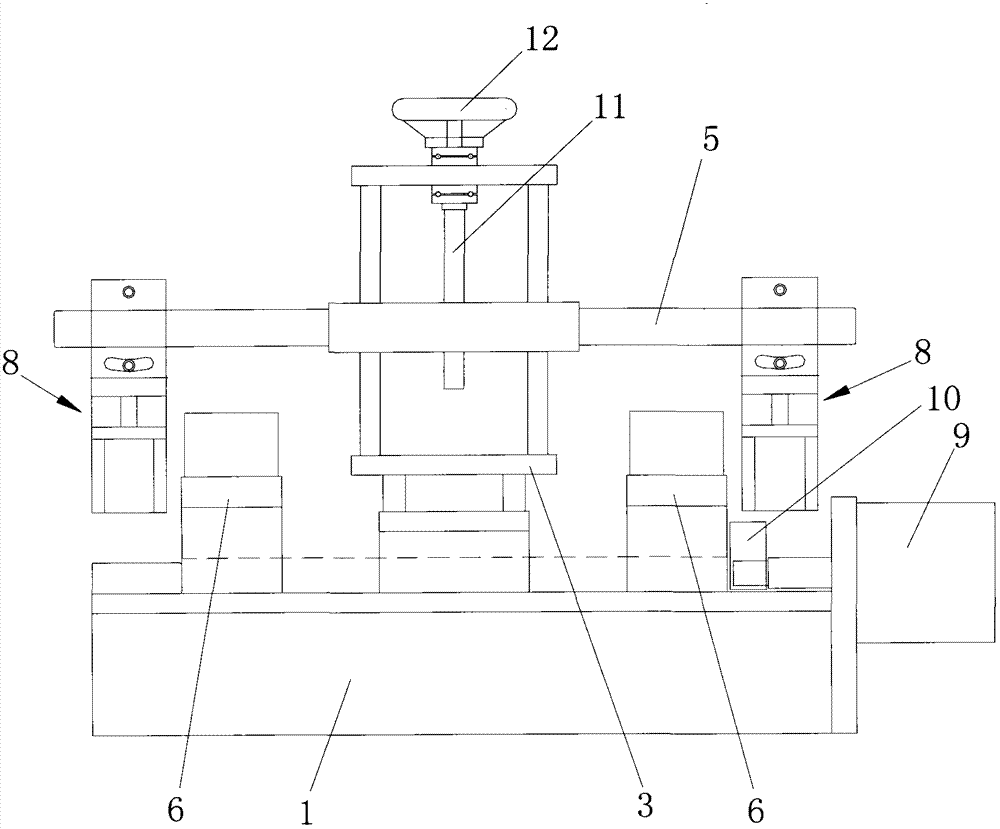

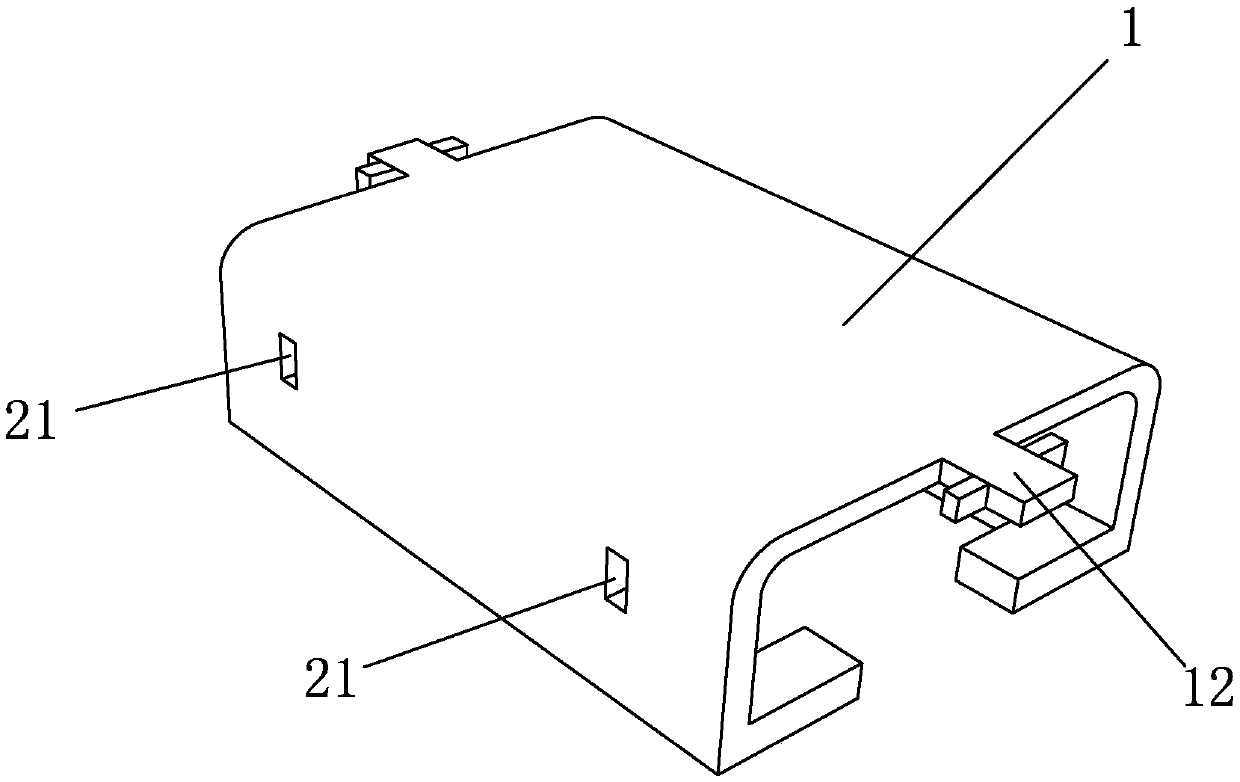

Clamping deformation resistant jig for machining large-diameter elbow

InactiveCN102139457AGuaranteed machining accuracyAbundant resourcesPositioning apparatusMetal-working holdersThin walledEngineering

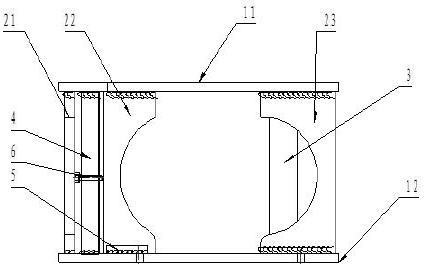

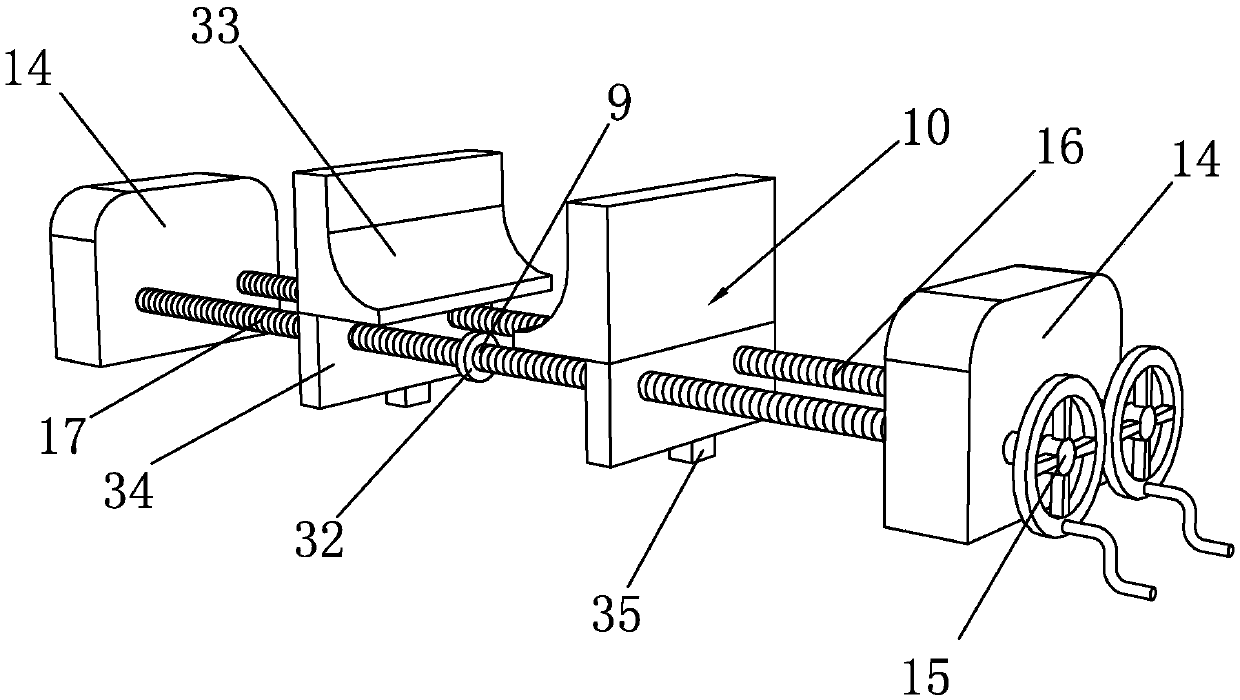

The invention discloses a clamping deformation resistant jig for machining a large-diameter elbow. Three combined clamping blocks are arranged on a clamping base plate, each combined clamping block consists of an upper clamping block, a lower clamping block, a base plate and connecting bolts, inner sides of the upper clamping blocks and the lower clamping blocks are provided with circular arc-shaped gaps and form a circle consistent with the outer circumference of an elbow to be machined after closed, the upper clamping blocks and the lower clamping blocks are connected and fastened by the connecting bolts, and the base plates are arranged at the bottoms of the lower clamping blocks and are provided with chutes. Lock bolts pass through the chutes on the base plates of the combined clamping blocks and fix the combined clamping blocks on the clamping base plate after being fastened. In the invention, the large-diameter elbow is clamped by adopting a way of directly clamping a pipe blank in a surface-contact manner, thus the elbow does not generate a radial compaction force in the clamping process and is not easy to generate the radial forced deformation and the torsional moment; in addition, the clamping deformation resistant jig disclosed by the invention is applied to machining of a large-diameter thin-wall elbow machine, thereby ensuring the machining precision of the elbow.

Owner:扬州华宇管件有限公司

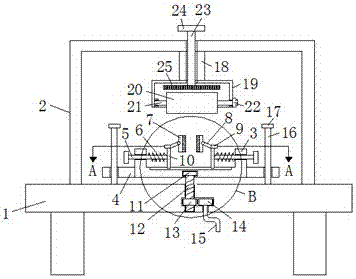

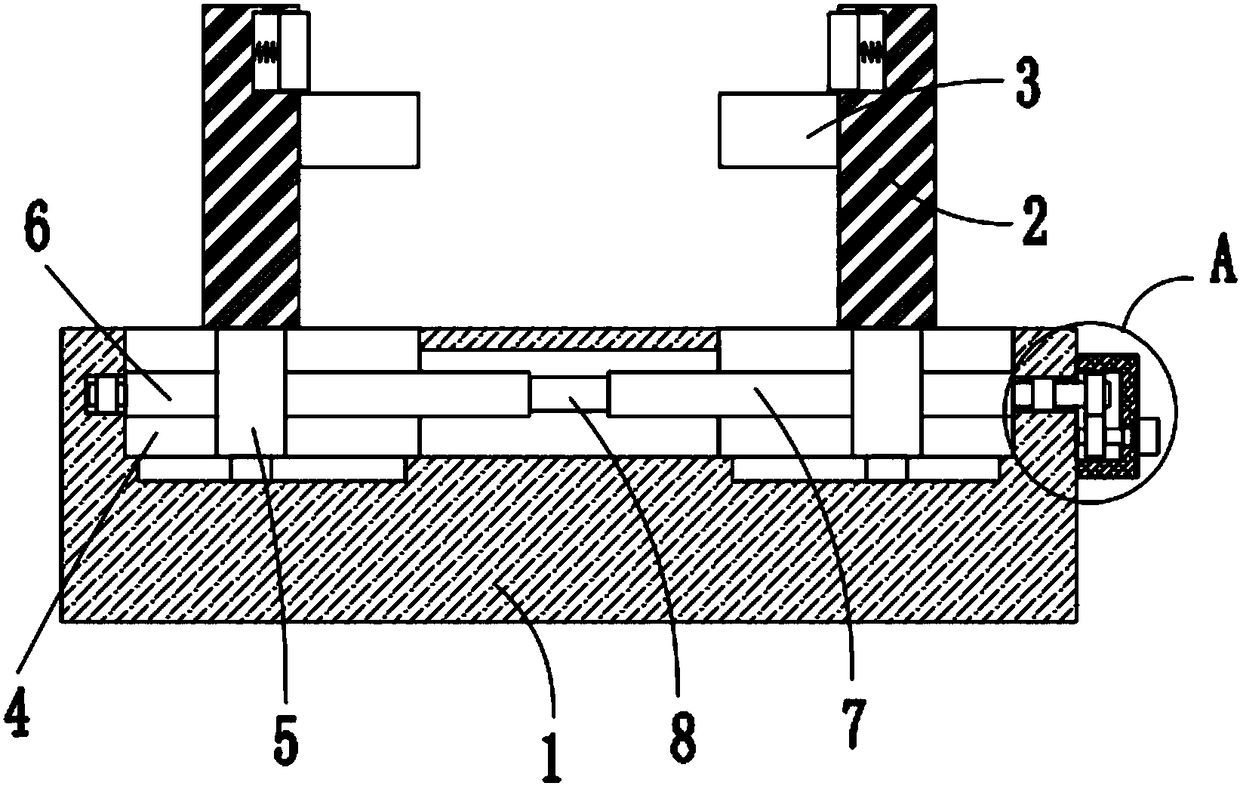

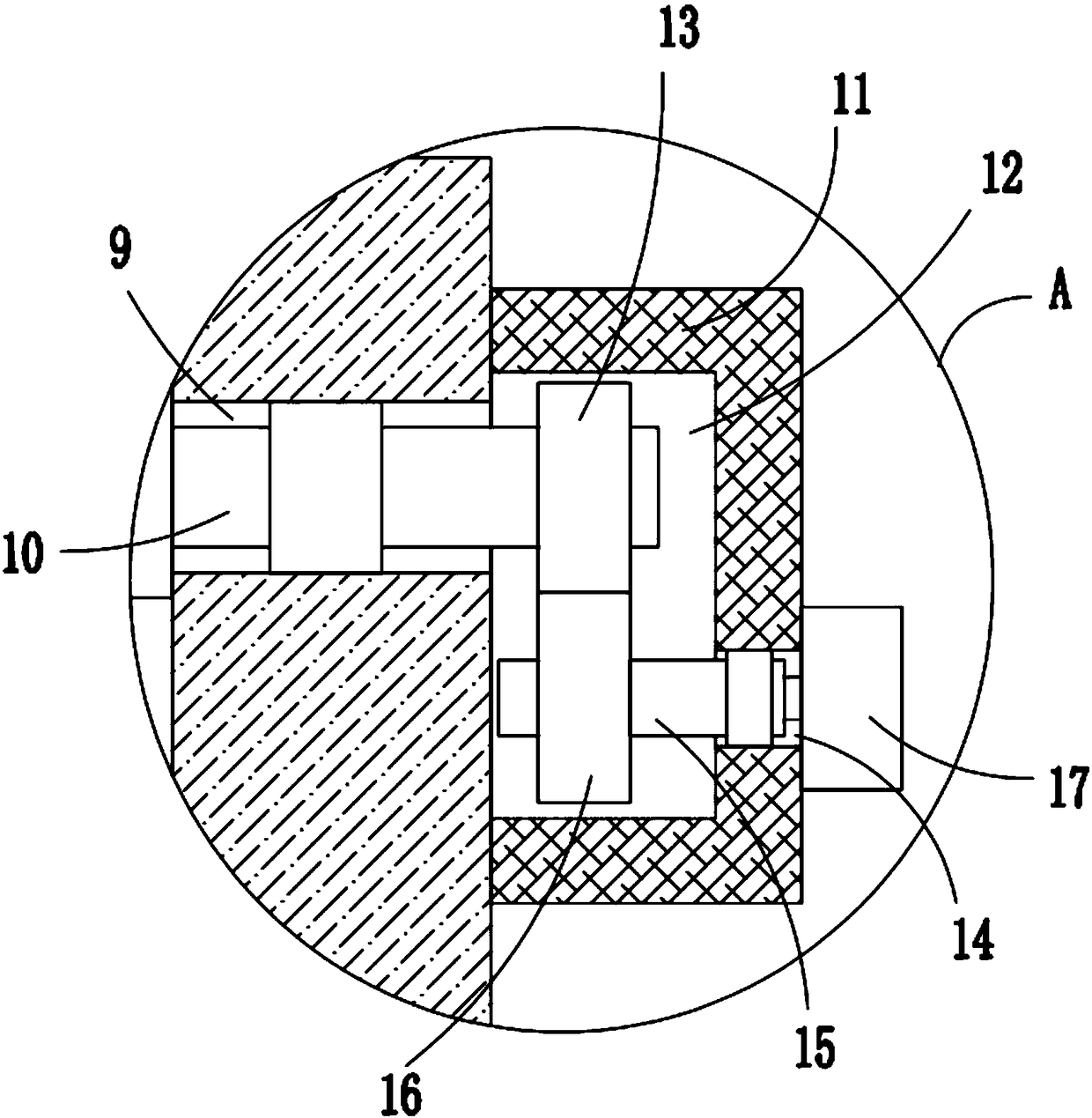

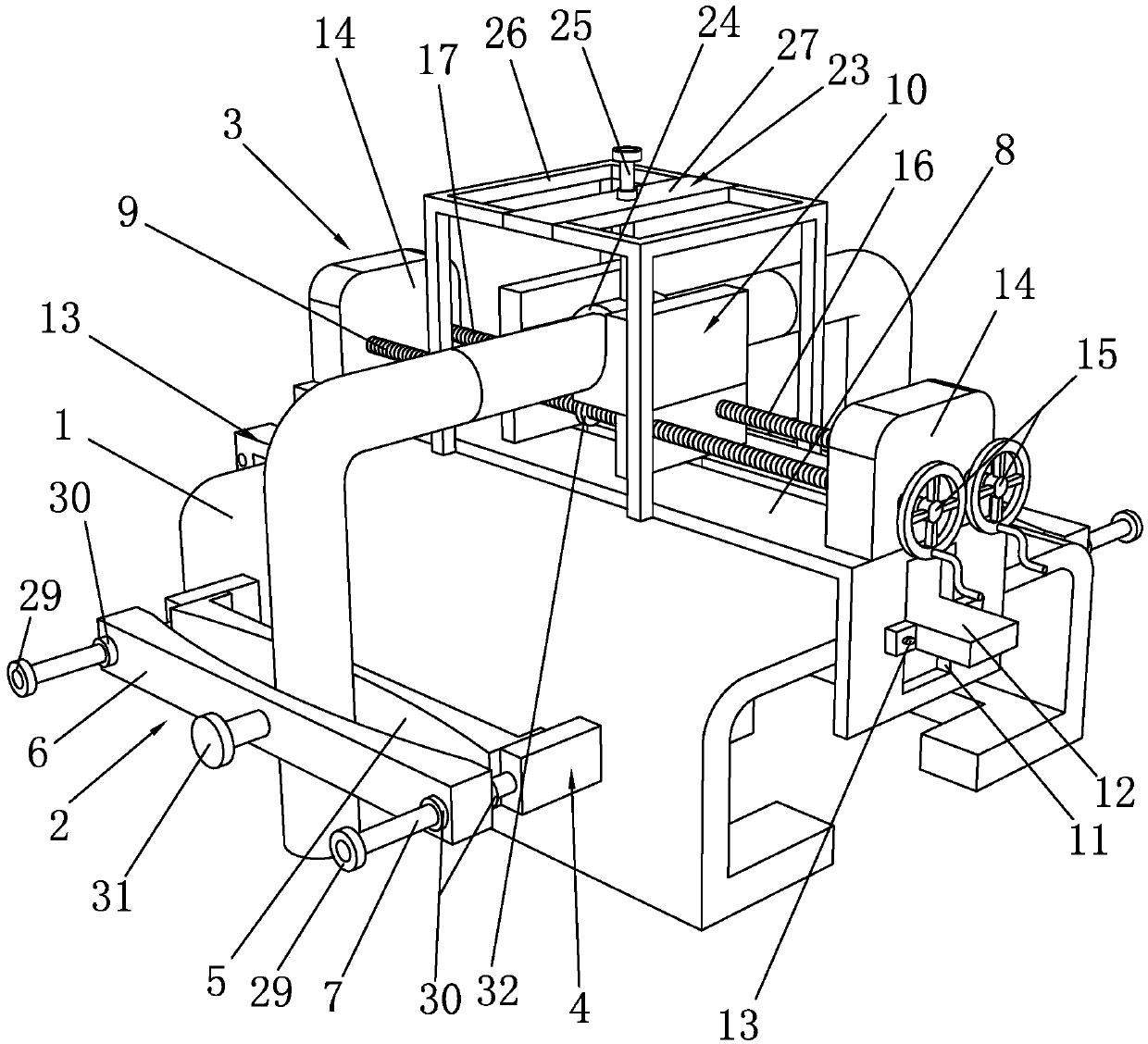

Drilling machine for machining hardware fittings

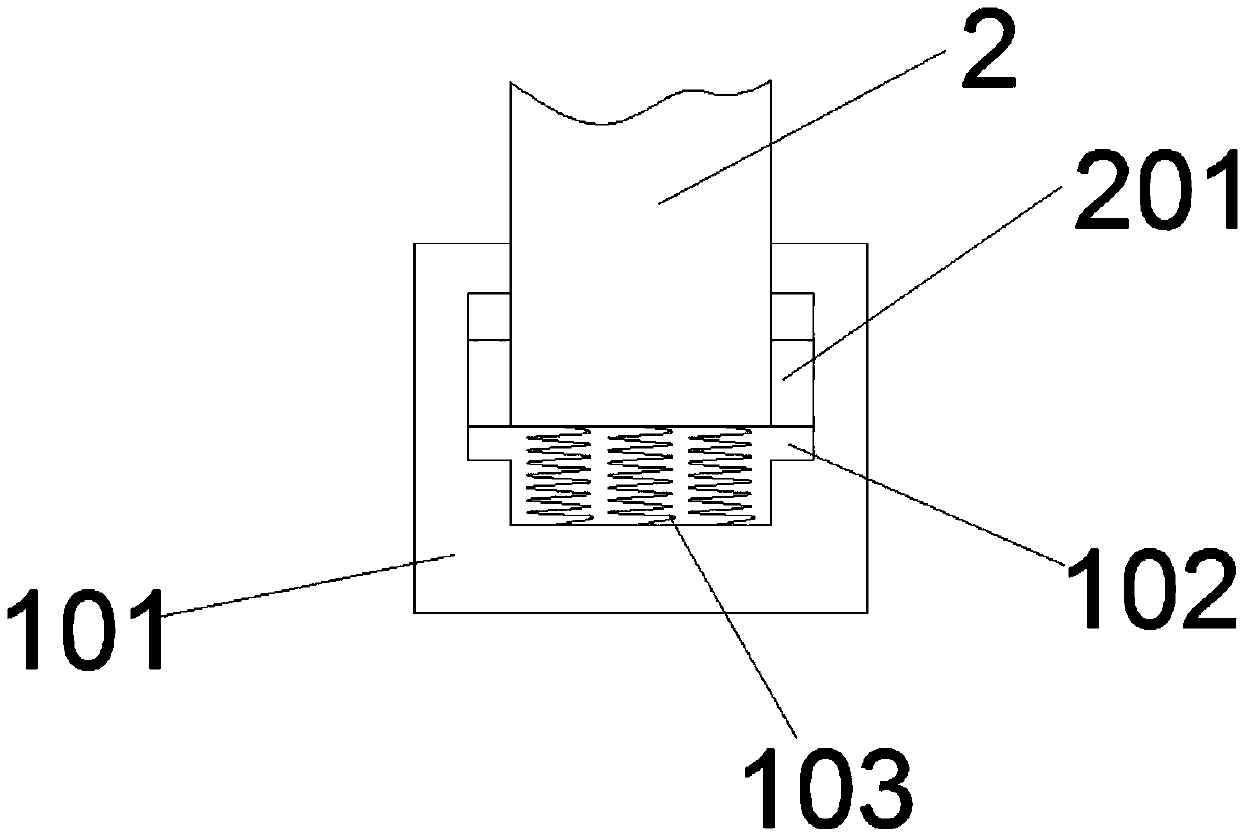

InactiveCN107824835AEasy to adjust the widthEasy to collectNon-rotating vibration suppressionDirt cleaningShock mountEngineering

The invention discloses a drilling machine for machining hardware fittings. The drilling machine comprises damping seats, wherein the damping seats comprise shells; sliding grooves are formed in the left sides and the right sides of the interiors of the shells; springs are arranged at the bottom ends of the interiors of the shells; supporting columns are arranged at the upper ends of the springs;and first sliding blocks are arranged at the left sides of the bottoms of the supporting columns and the right sides of the bottoms of the supporting columns. According to the drilling machine, the structure is simple, and the operation is easy; a movable clamping plate is moved by shaking a handle so as to clamp a machined workpiece, so that the operation is more convenient and labor-saving, andthe widths of the clamping plates can be conveniently adjusted for machining machined workpieces with different sizes; meanwhile, anti-slip mats are arranged on one sides of the outer walls of the clamping plates respectively, so that the surface friction force between the contact surfaces of the clamping plates and the machined workpiece is increased; after a fan works, the influence of debris particles on normal operation is avoided, the working efficiency is improved, and potential safety hazards caused by the debris particles to physical health of workers are eliminated; and the damping seats are arranged at the bottom of the drilling machine, so that the effects of damping and noise reduction are achieved when the drilling machine works.

Owner:WUXI WEI KELAI TECH CO LTD

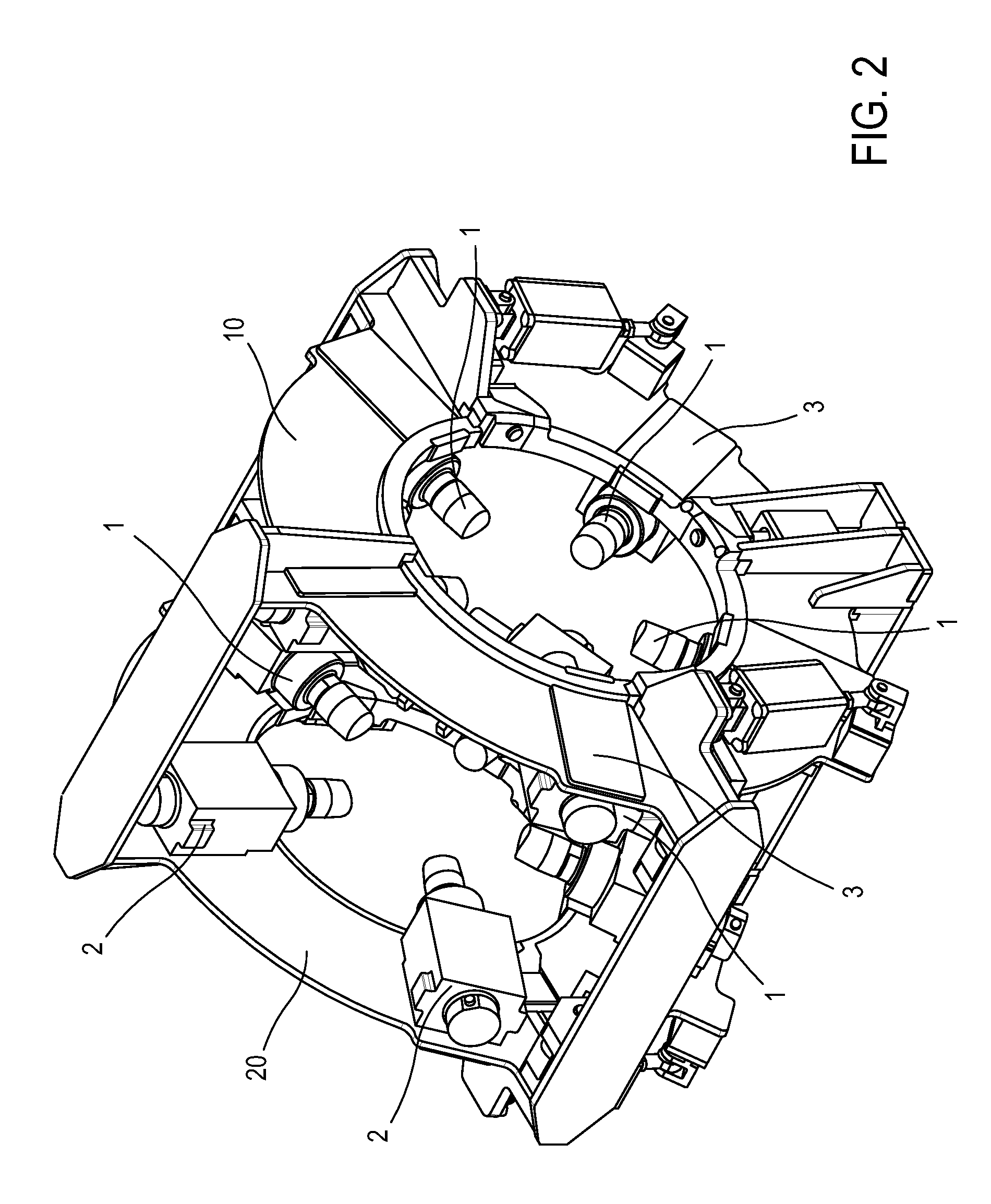

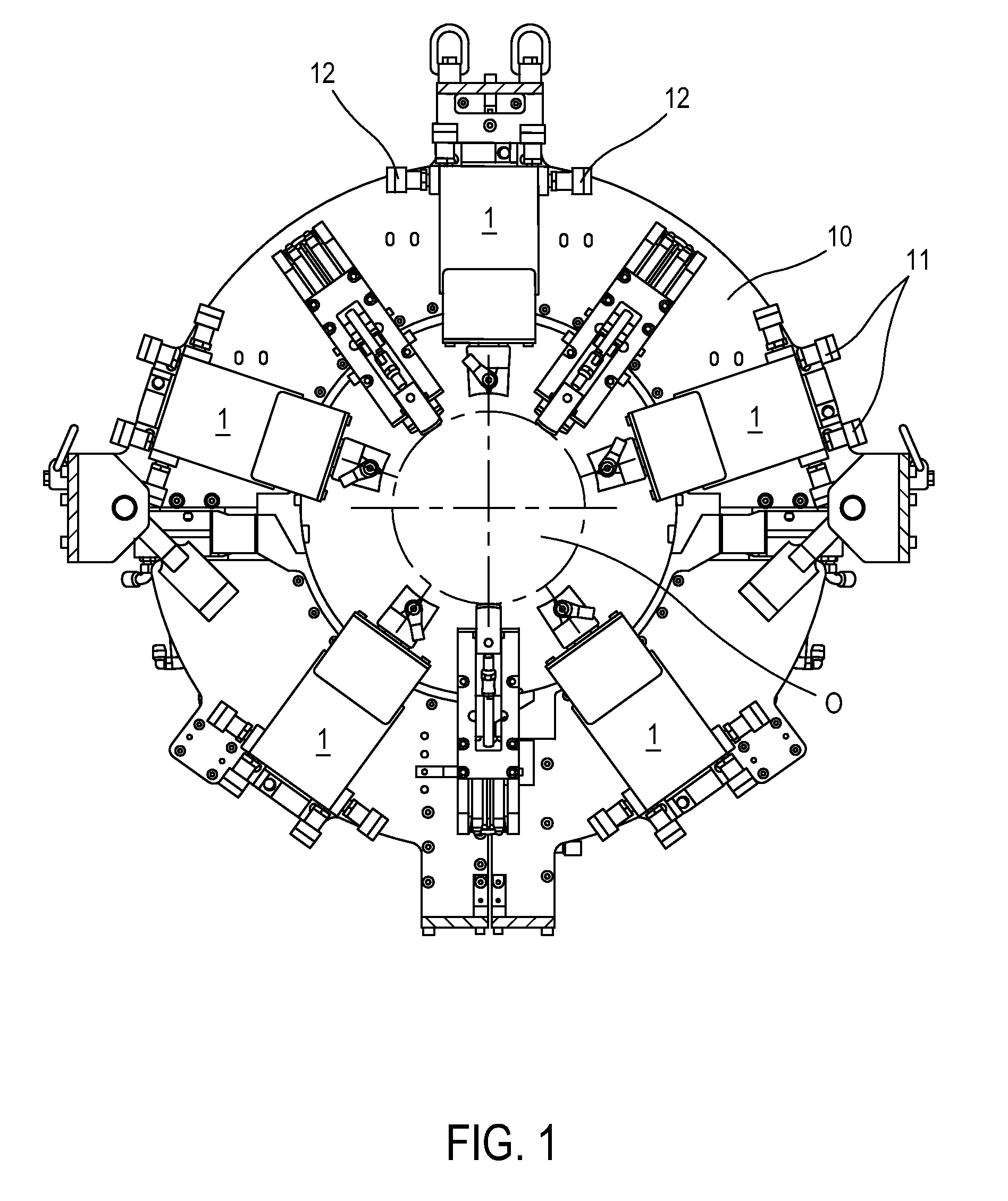

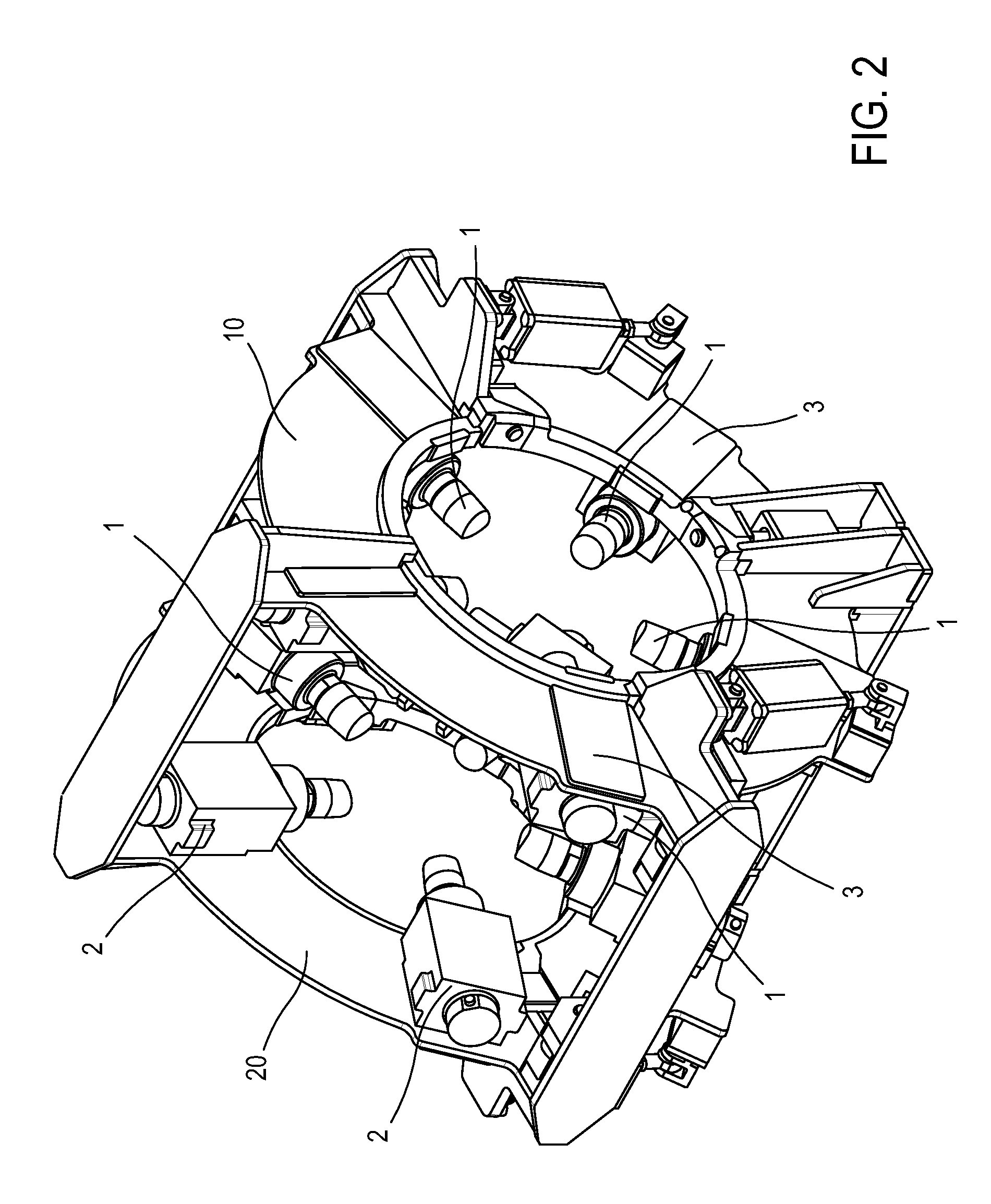

Method and device for positioning a first pipe with respect to a second pipe

ActiveUS20120074205A1Easy to clamp and positionOvercome disadvantagesWelding/cutting auxillary devicesFeeding apparatusEngineeringControl unit

This invention relates to a method for axial positioning of a first pipe with respect to a second pipe for the welding of said pipes at their ends thereof of which the faces have been previously machined and define a joint plane, according to which a plurality of jacks are distributed around the first and second pipes, and said jacks are connected to a central processing and control unit.According to the invention, the movement of each of the jacks is controlled with respect to said external surface of the first and / or second pipe so as to align and center the internal end surfaces of the first and second pipes. The invention also relates to an associated device.

Owner:SERIMAX

Artware polishing grinding device bringing convenience to positioning

InactiveCN107350951AIncrease frictionGood positioning and clamping effectPolishing machinesGrinding drivesEngineering

The invention discloses a handicraft polishing and polishing device which is convenient for positioning, which comprises a fixed frame and a workbench. A grinding cover is fixedly connected to the lower end of the grinding cover, and a grinding roller is arranged inside the grinding cover. The limit rod is fixed on the upper end of the fixed frame. A pull rod is connected, the outer wall of the pull rod is sleeved with a spring, and the end of the pull rod is fixedly connected with a movable rod, the upper end of the movable rod is fixedly connected with a fixed block, and the outer wall of the fixed block is symmetrically provided with connecting rods, The end of the connecting rod away from the fixed block is rotatably connected with a clamping block. The invention is simple in structure, easy to operate, can effectively locate handicrafts, has good clamping effect, and avoids damage during polishing.

Owner:浙江千鹤工艺品有限公司

Low-melting point alloy for machining connecting conduct, its production and use

ActiveCN1940105ARipple EliminationEliminate wrinklesMilling equipment detailsTurning machinesEllipseAlloy

This invention belongs to the machinery processing technology, it relates to the improvement of the bending and machining method of the tubing especially to the thin-wall tubing or the similar thin-wall part. The low-melting alloy in this invention, whose proportion by weight of the component contents is as following: Lead 25- 32%, tin 12- 15%, cadmium 9- 13%, zinc 0- 4%, stibium 0- 5%, bismuth margin. The low-melting alloy can ensure the request of ellipse degree of the pipe after processing, and it can eliminate cockles, corrugation.

Owner:AECC AVIATION POWER CO LTD

Method and device for positioning a first pipe with respect to a second pipe

ActiveUS8313016B2Easy to clamp and positionOvercome disadvantagesWelding/cutting auxillary devicesFeeding apparatusEngineeringControl unit

This invention relates to a method for axial positioning of a first pipe with respect to a second pipe for the welding of said pipes at their ends thereof of which the faces have been previously machined and define a joint plane, according to which a plurality of jacks are distributed around the first and second pipes, and said jacks are connected to a central processing and control unit.According to the invention, the movement of each of the jacks is controlled with respect to said external surface of the first and / or second pipe so as to align and center the internal end surfaces of the first and second pipes. The invention also relates to an associated device.

Owner:SERIMAX

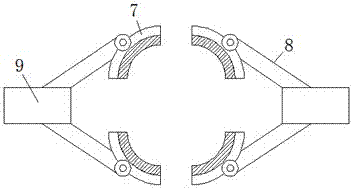

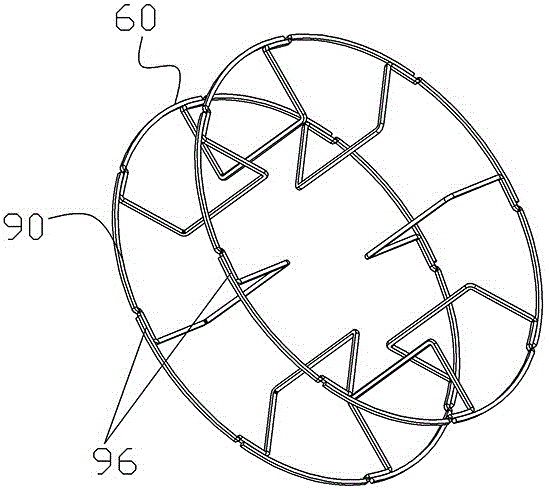

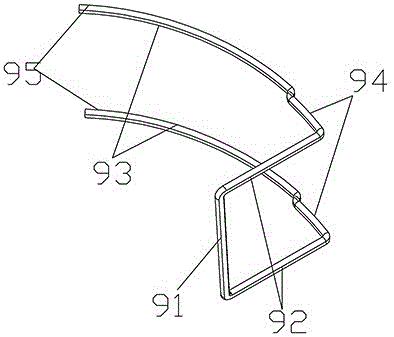

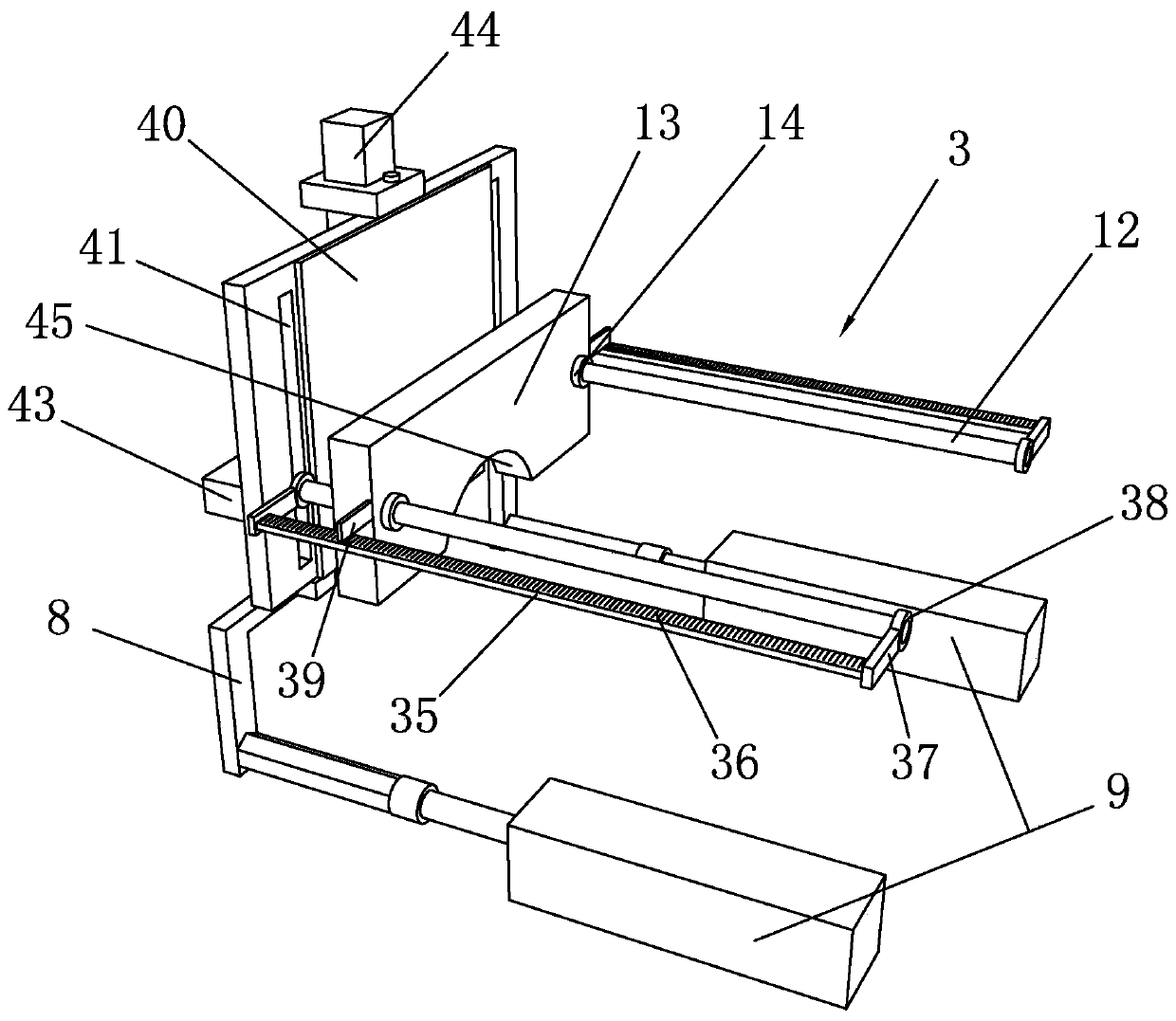

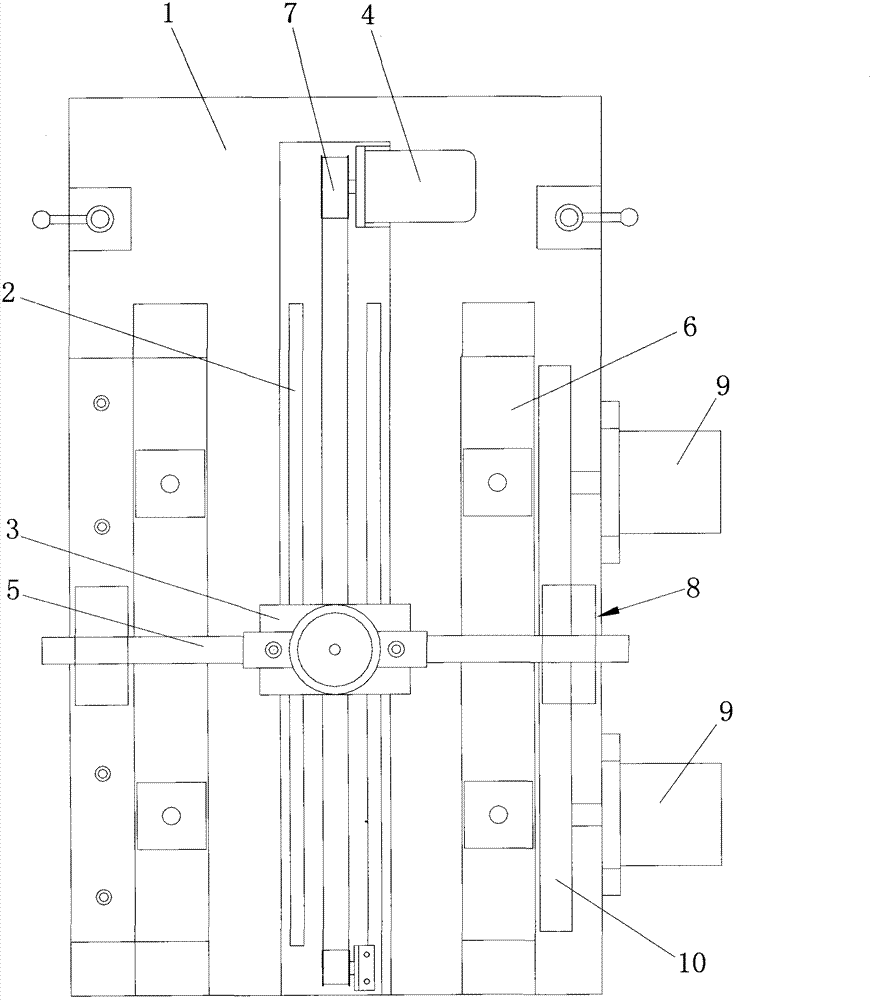

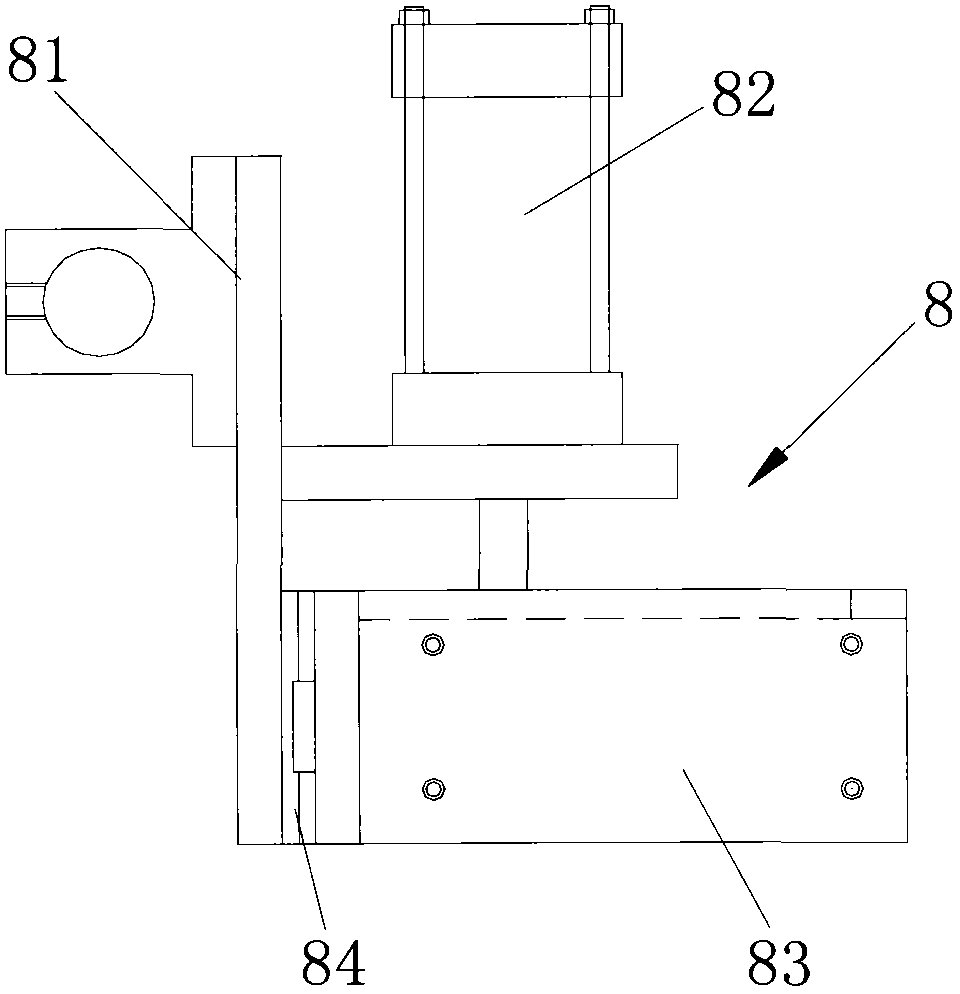

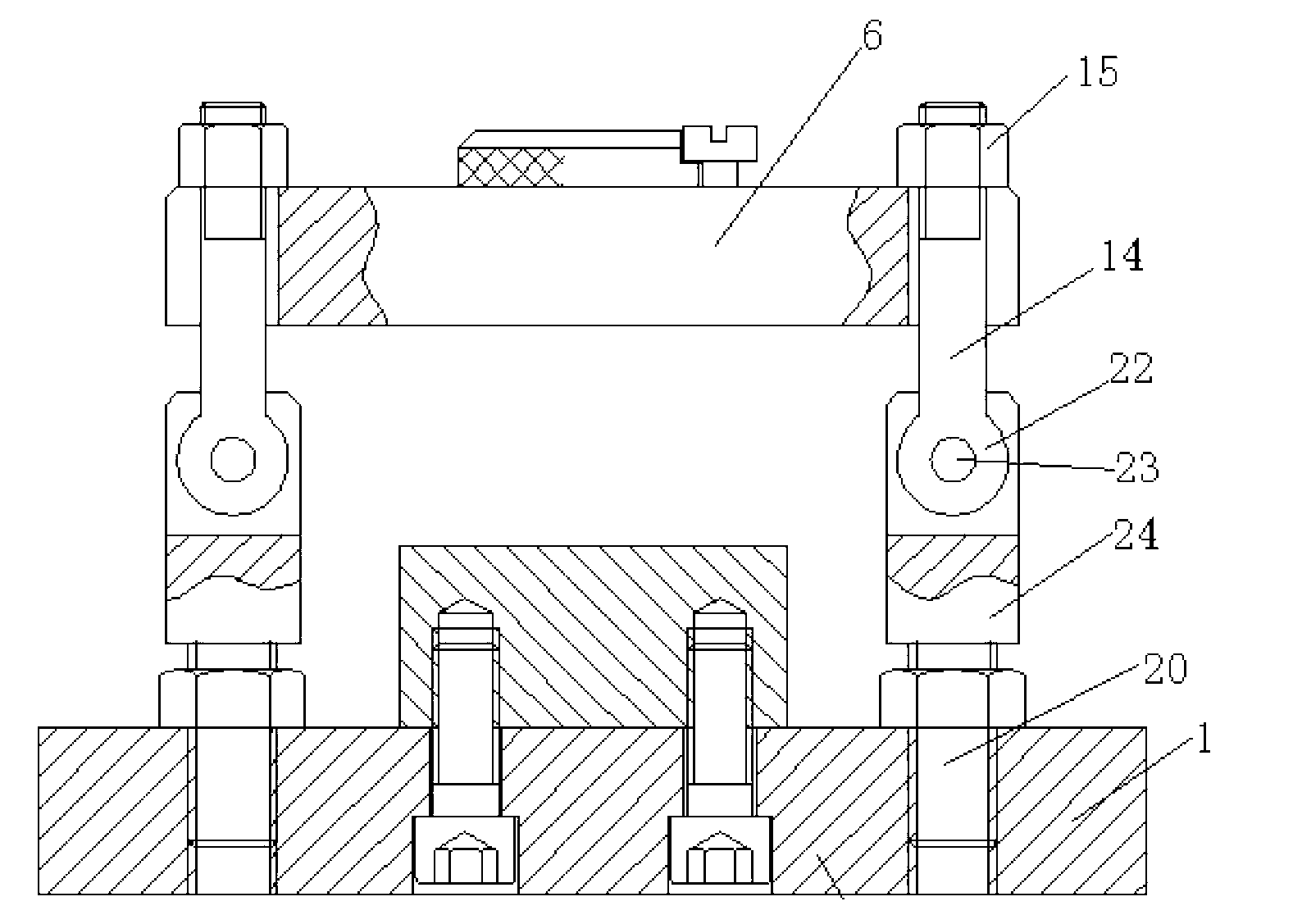

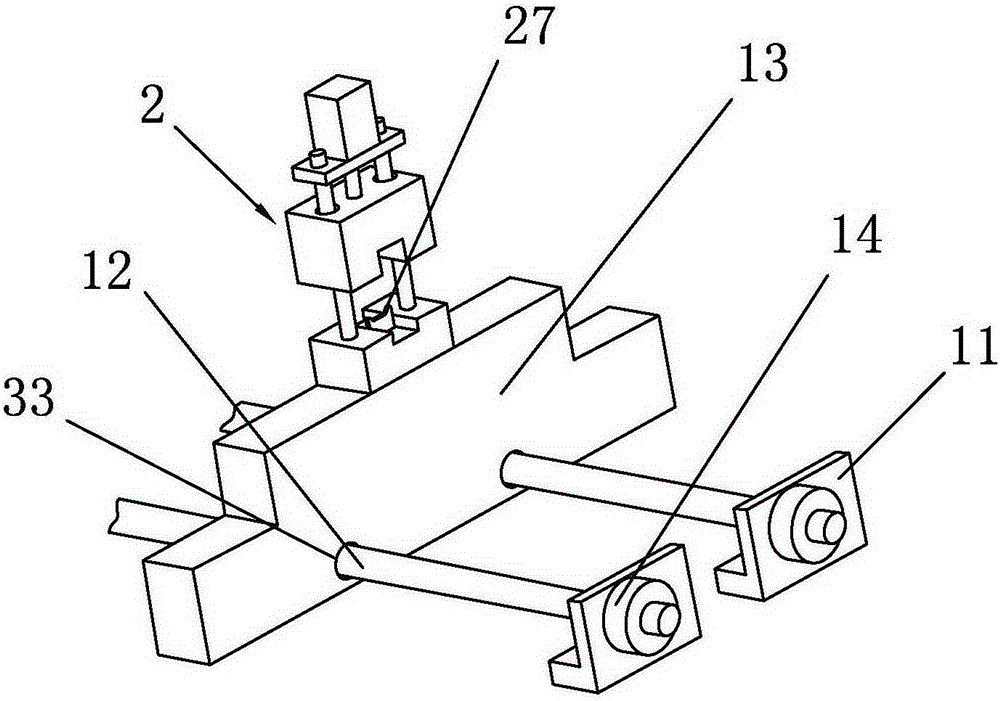

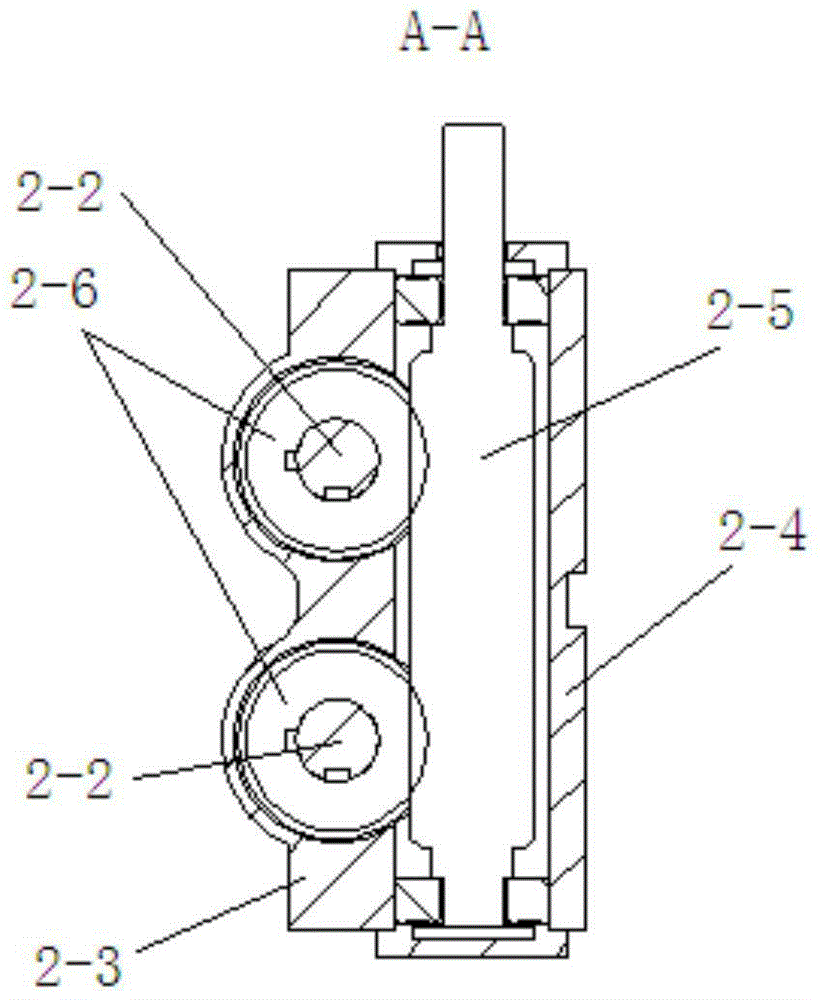

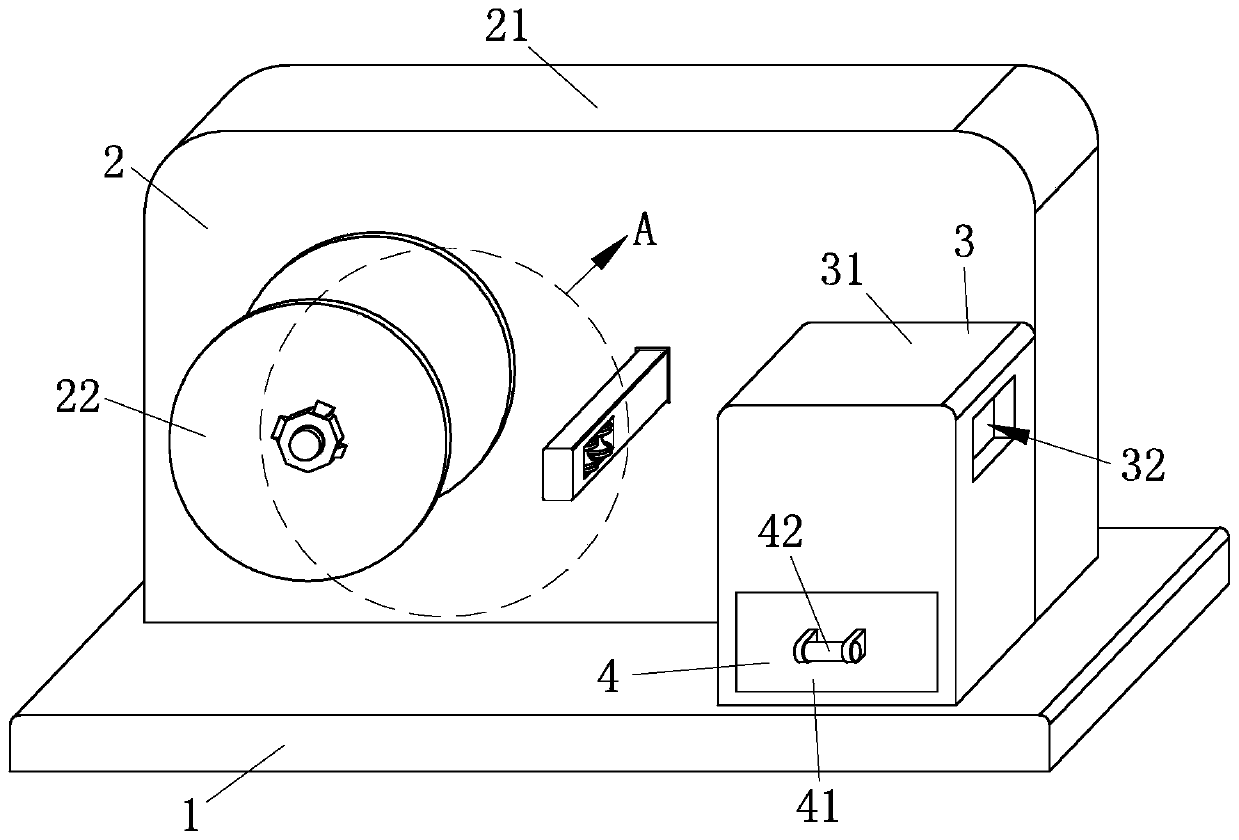

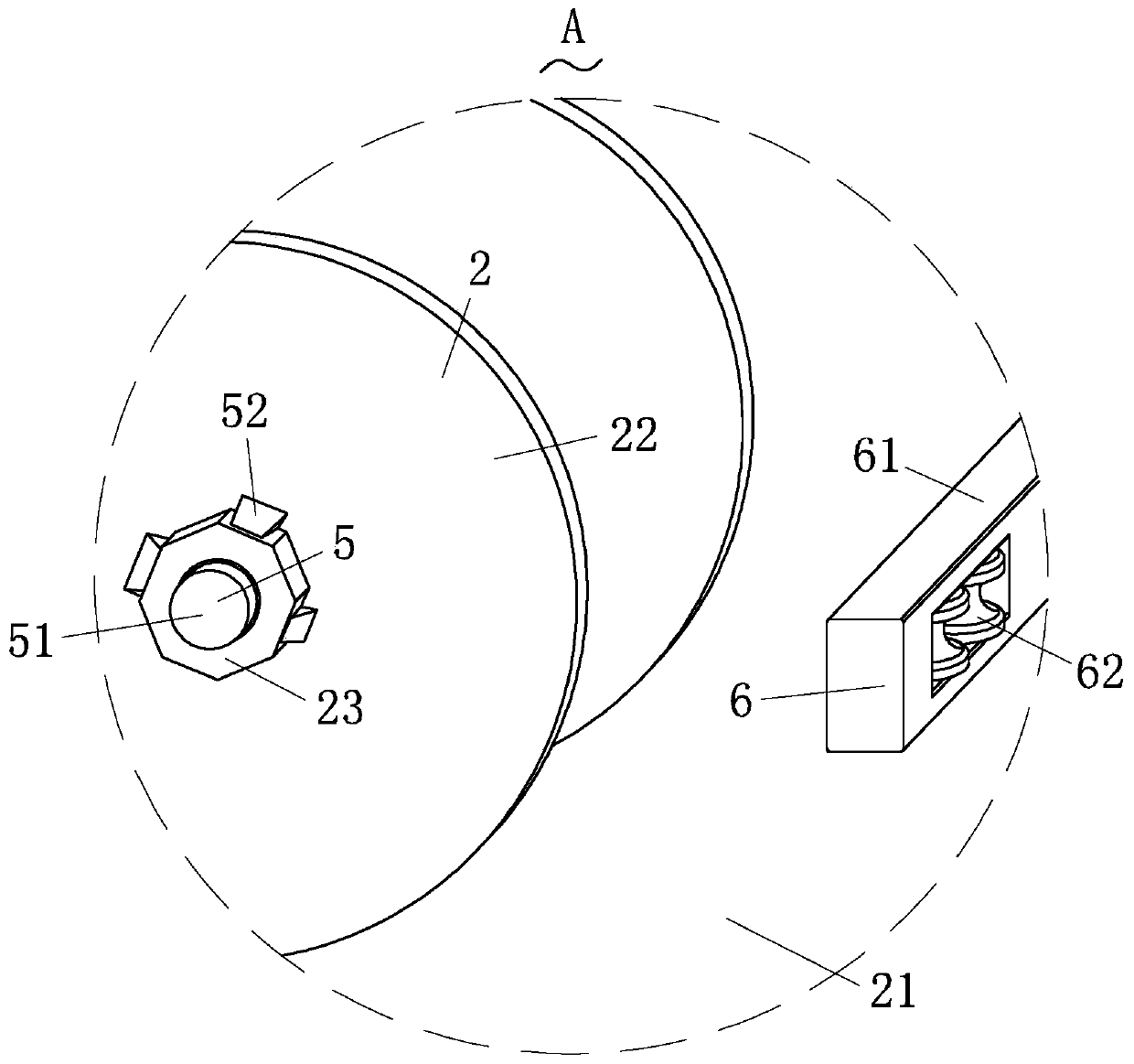

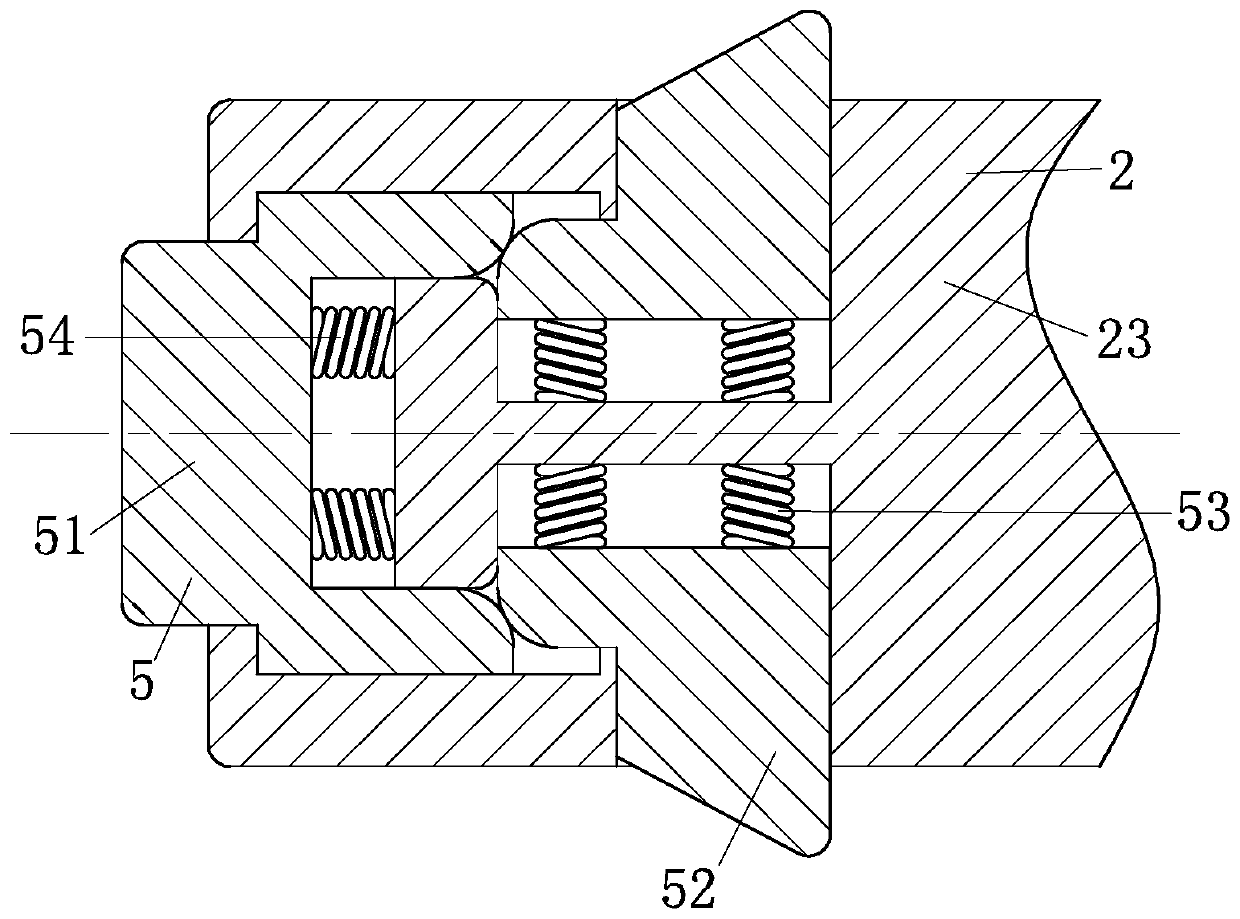

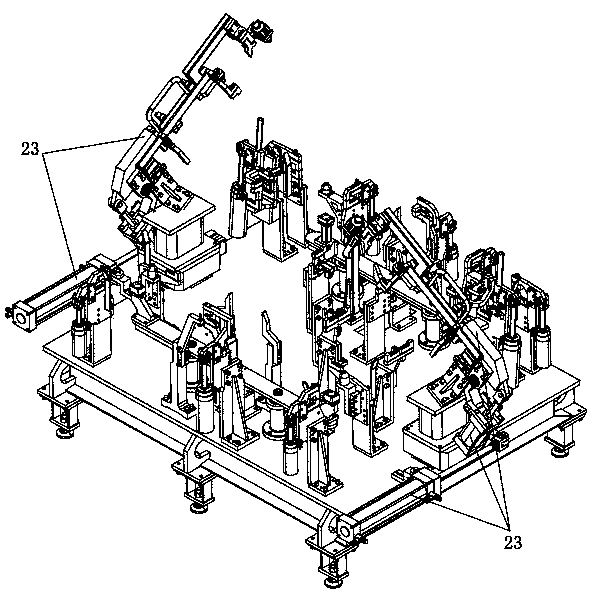

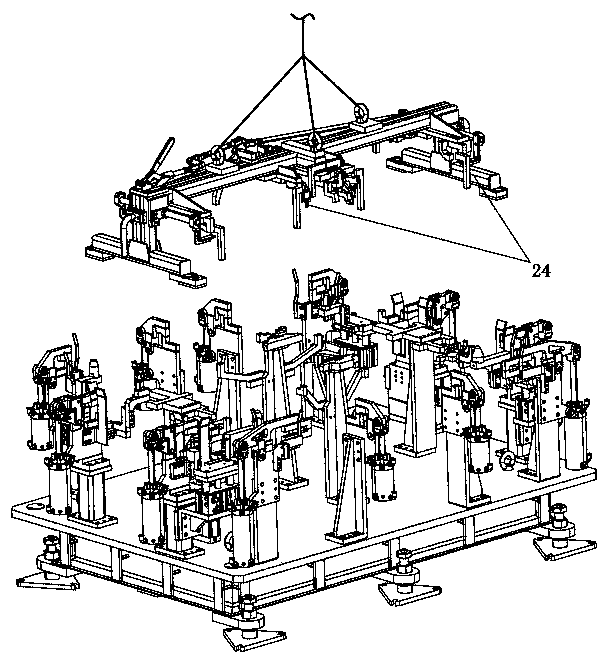

Workpiece clamping clamp and wire spool welder using same

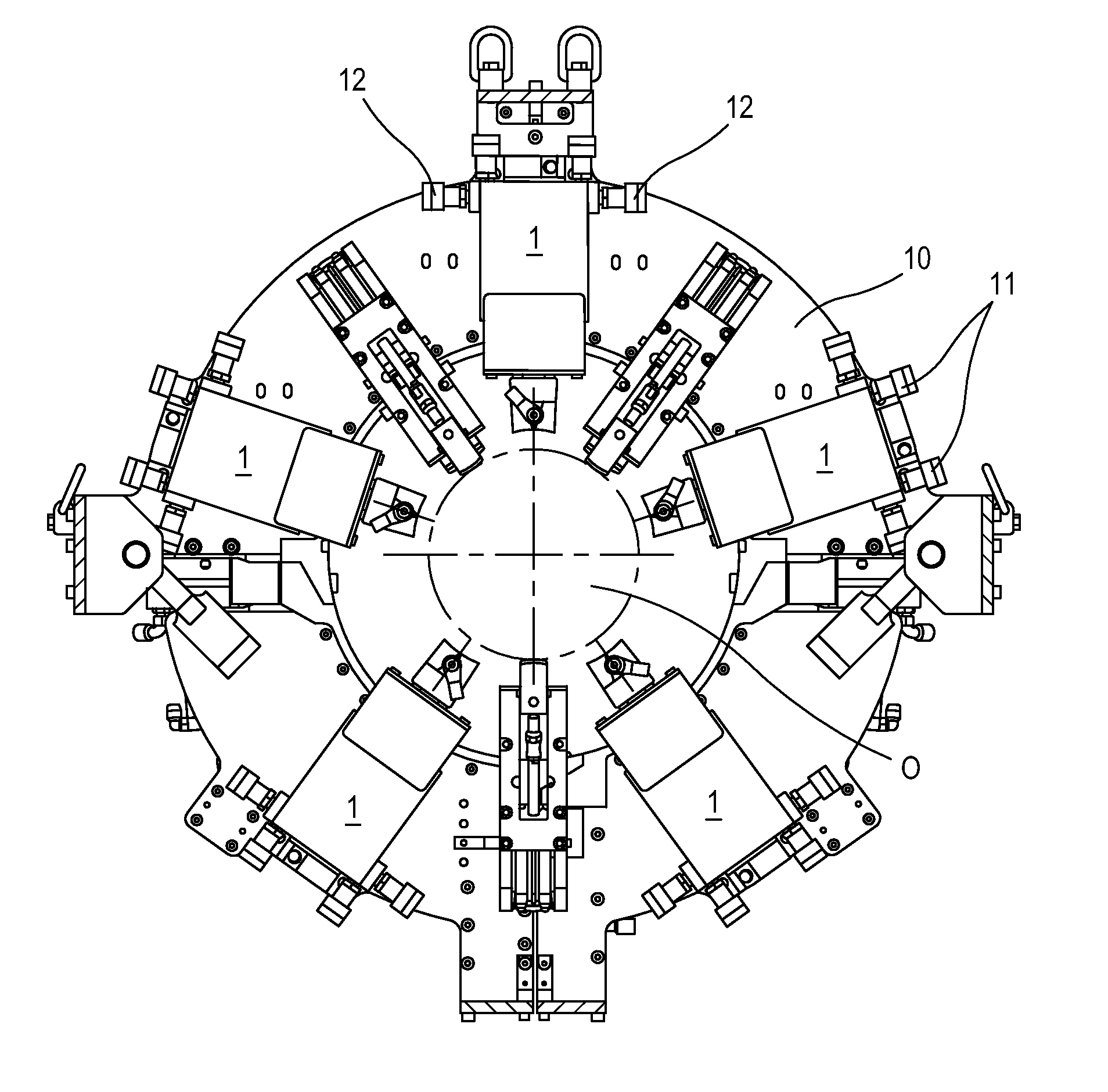

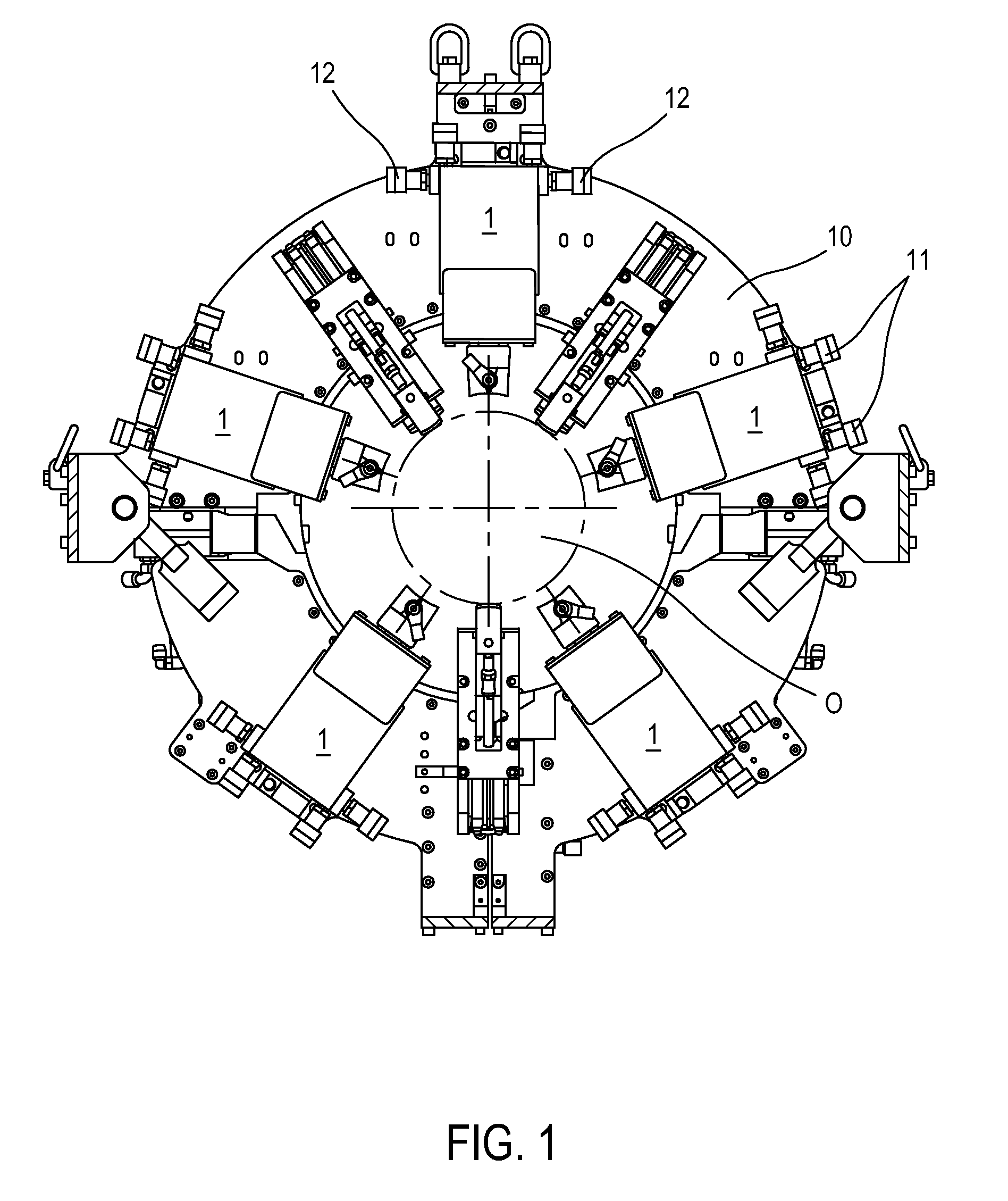

ActiveCN104985369ARealize automatic and accurate positioningEnsure automatic and accurate positioningWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

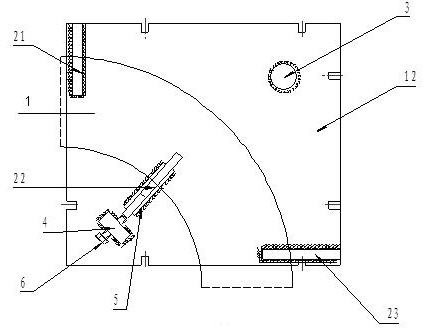

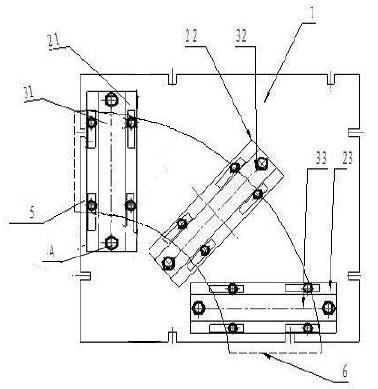

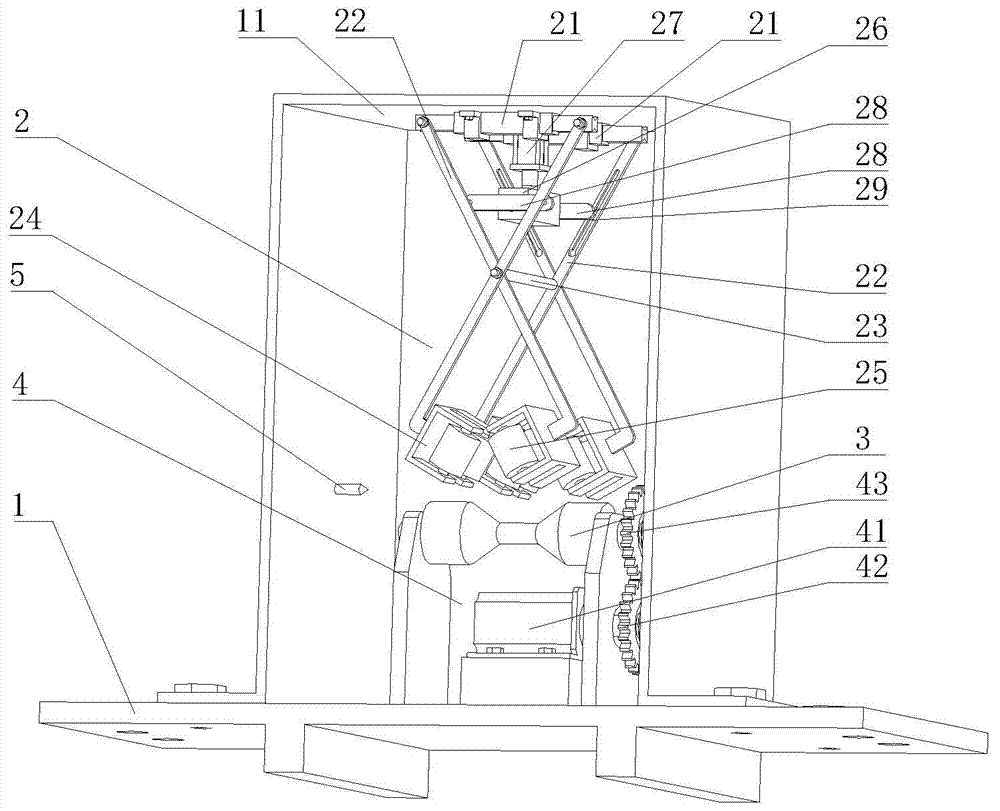

The invention provides a workpiece clamping clamp and a wire spool welder using same. The welder comprises a clamping clamp, wherein a circumferential datum plane is arranged on a positioning base of the clamping clamp; a plurality of clamping assemblies are arranged on the clamping clamp; each clamping assembly can reciprocate in a guiding mode along the circumference; a clamping block of each clamping assembly is driven by a clamping drive mechanism to close to clamp the constitutional units when each clamping assembly moves towards the corresponding circumferential datum plane, and to open when each clamping assembly moves away from the corresponding circumferential datum plane; and each clamping assembly is provided with a fixed station on reciprocating motion stroke, so that an arc-shaped part of each constitutional unit is resisted against the corresponding circumferential datum plane when each clamping assembly moves to the fixed station. When the constitutional units are clamped and fixed by the clamping assemblies, the arc-shaped parts of the constitutional units are further directly resisted against and fixed on the circumferential datum plane by the clamping assembly which moves towards the circumferential datum plane, so that automatic and accurate positioning of each constitutional unit is finally guaranteed.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

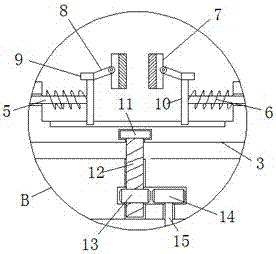

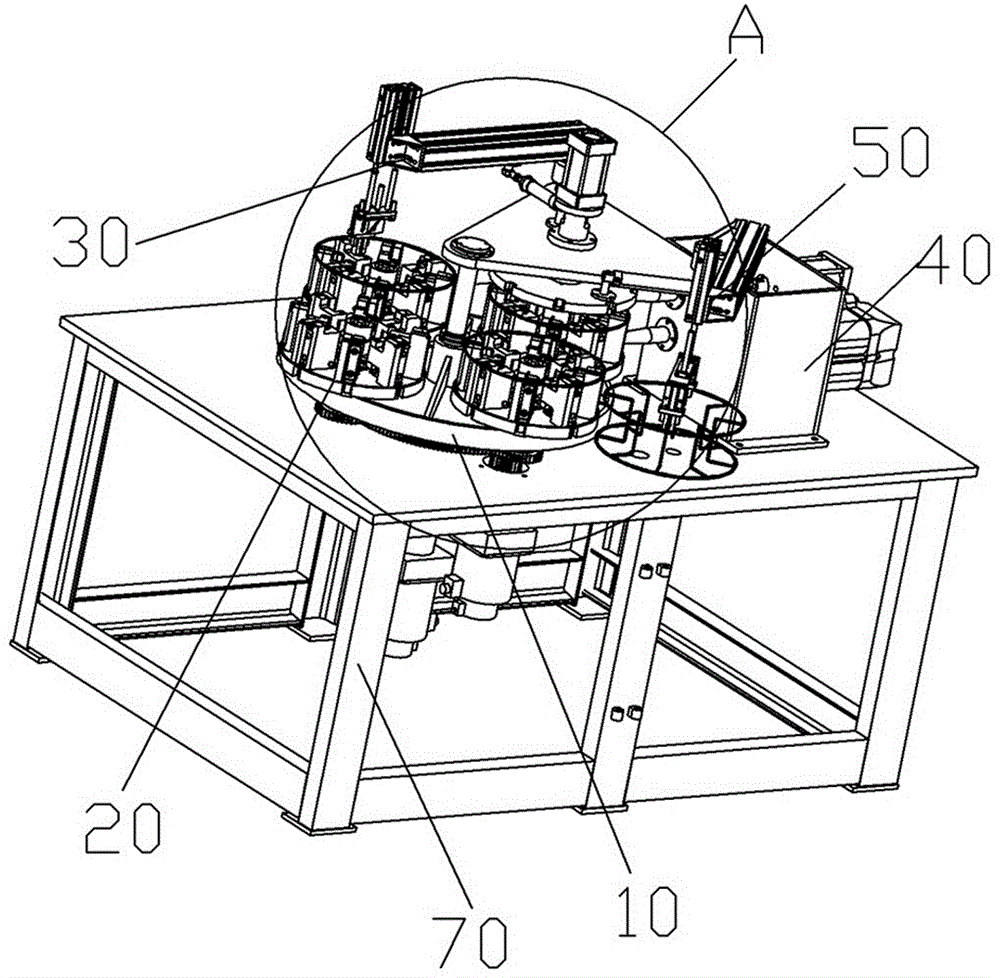

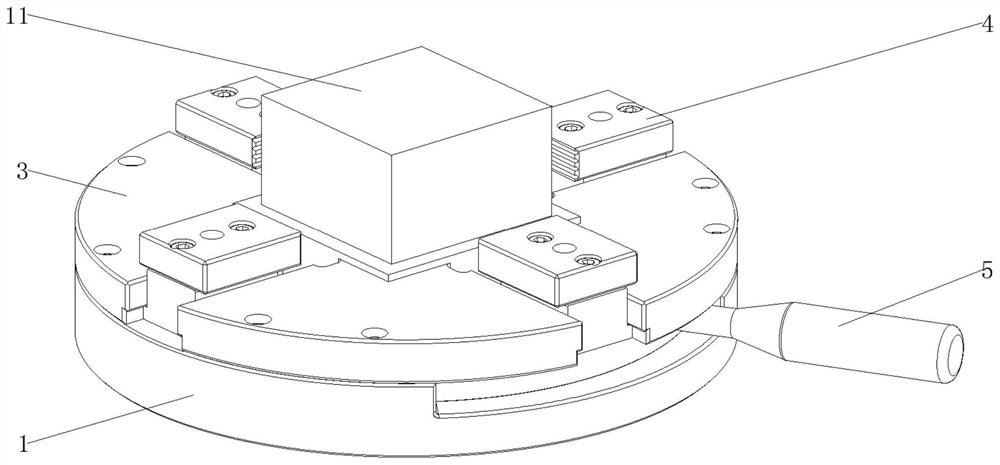

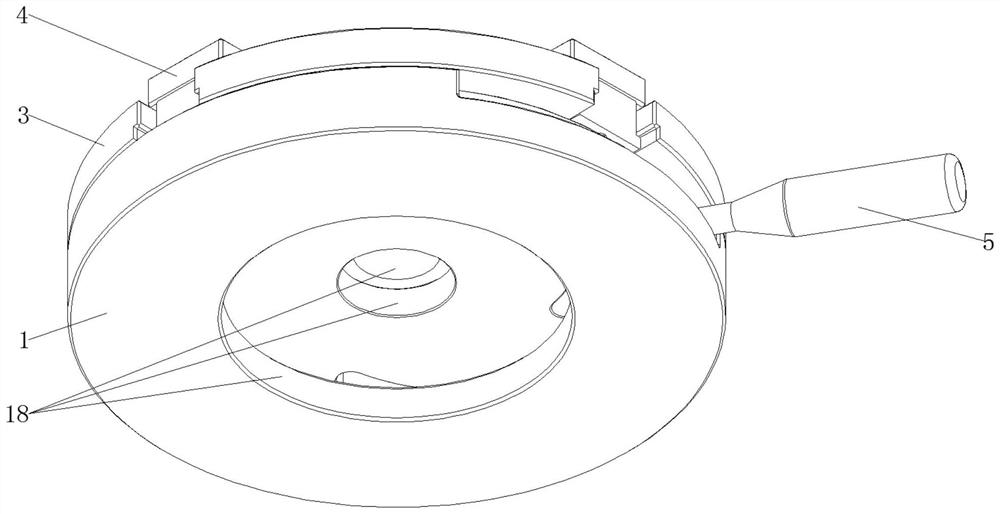

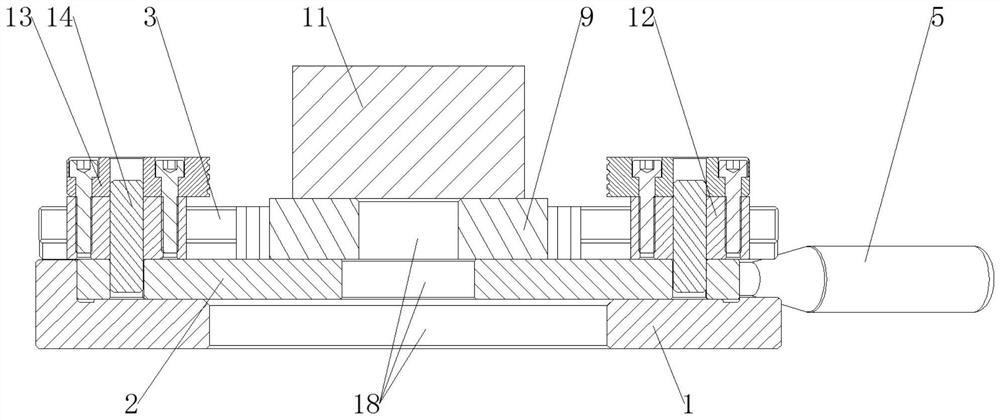

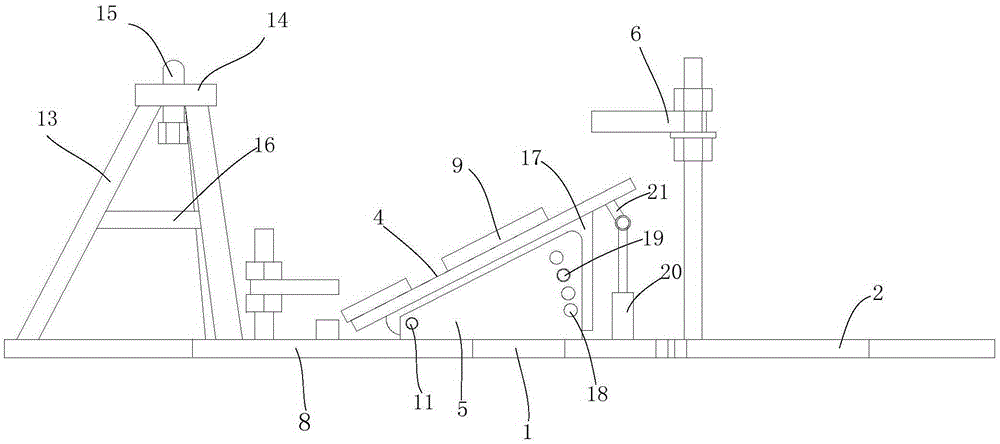

Centering and clamping tooling

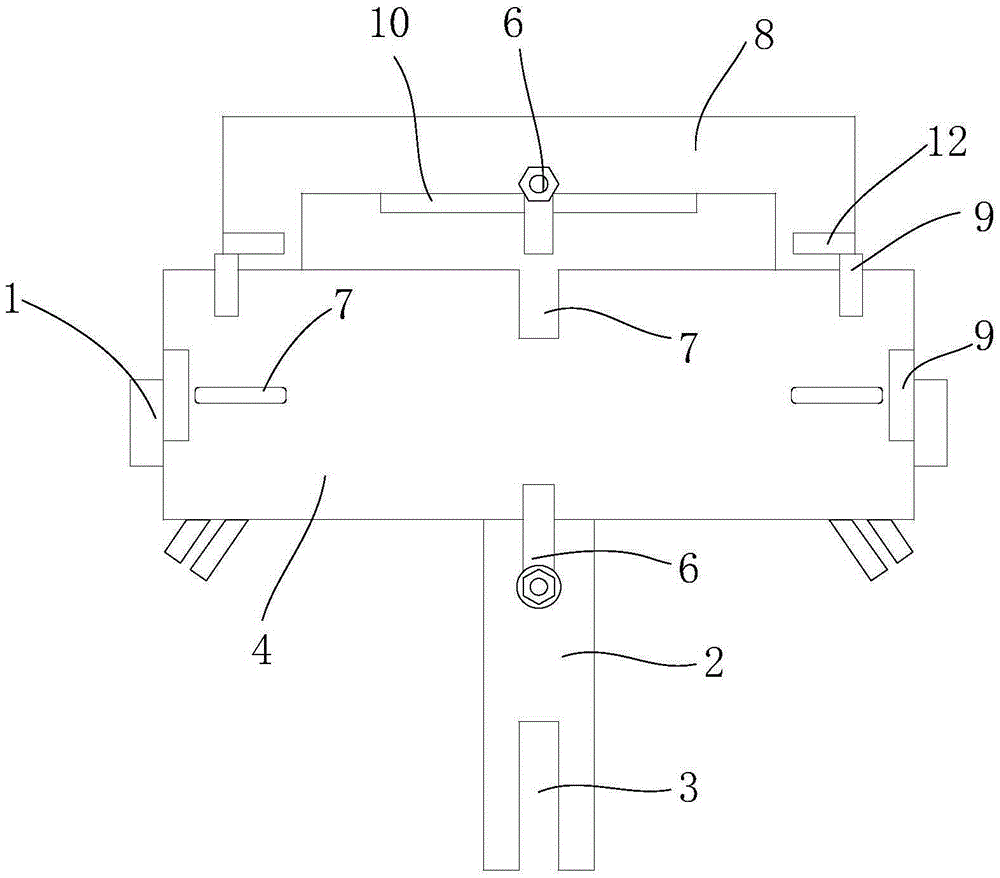

PendingCN111804942ASimplify upfront workEasy to clamp and positionChucksPositioning apparatusEngineeringMachine tool

The invention provides centering and clamping tooling and relates to the technical field of clamping devices. The tooling solves the technical problem that according to the prior art, a universal clamping tool fails to realize rapid positioning and clamping of a workpiece and the overall height of the clamping tool is high so the machining space of a machine tool is affected. The centering and clamping tooling comprises a base which is provided with a containing groove, a rotating plate which is rotatably arranged in the containing groove, a top plate which is fixedly connected with the base,a clamping assembly which is used for connection with the workpiece in an abutting mode, and a handle which is fixedly connected with the rotating plate; a plurality of guiding grooves are formed in the rotating plate; the first ends of the first guiding grooves are arranged near the edges of the rotating plate; the second ends extend in a curving direction along the circumference of the rotatingplate and gradually near the central axis of the rotating plate; the top plate comprises a platform and a plurality of second guiding grooves which are formed along the axial direction of the top plate; and a plurality of clamping assemblies are respectively arranged in the second guiding grooves and the lower parts of the clamping assemblies can be clamped into corresponding first guiding groovesin a sliding mode. The tooling can be used for rapidly conducting self-alignment centering and clamping of the workpiece.

Owner:英诺莱比(北京)科技有限公司

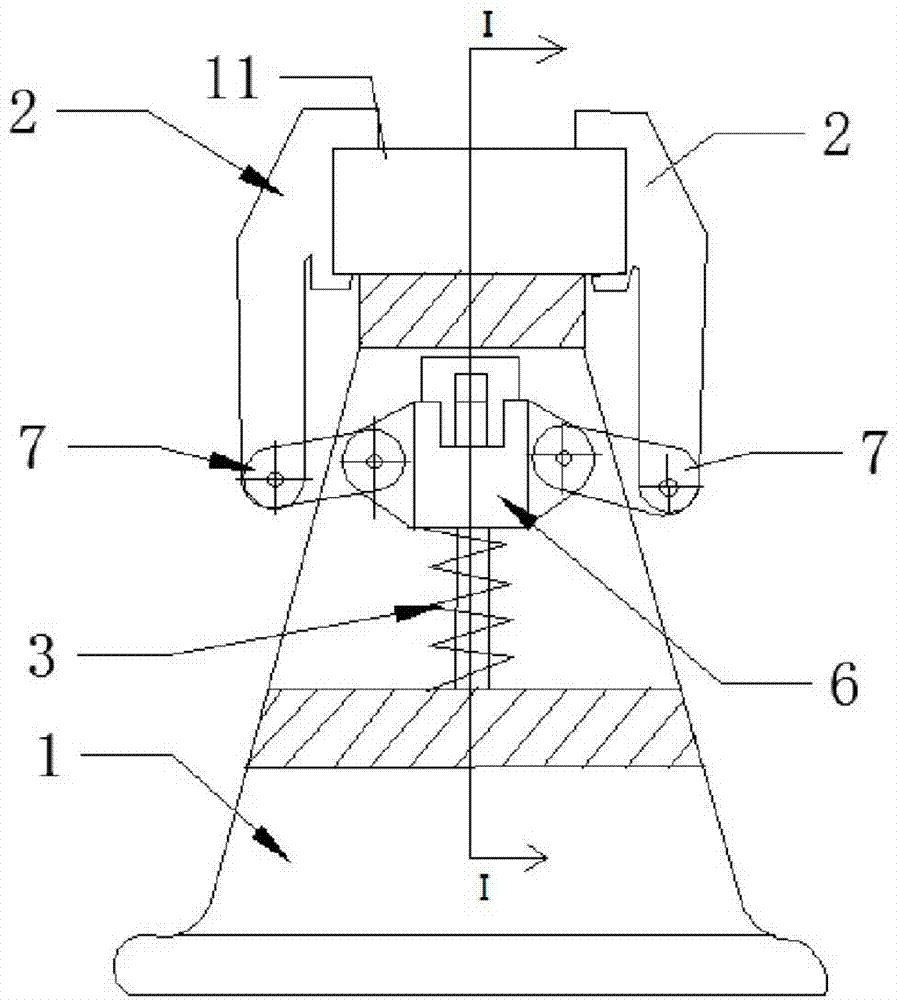

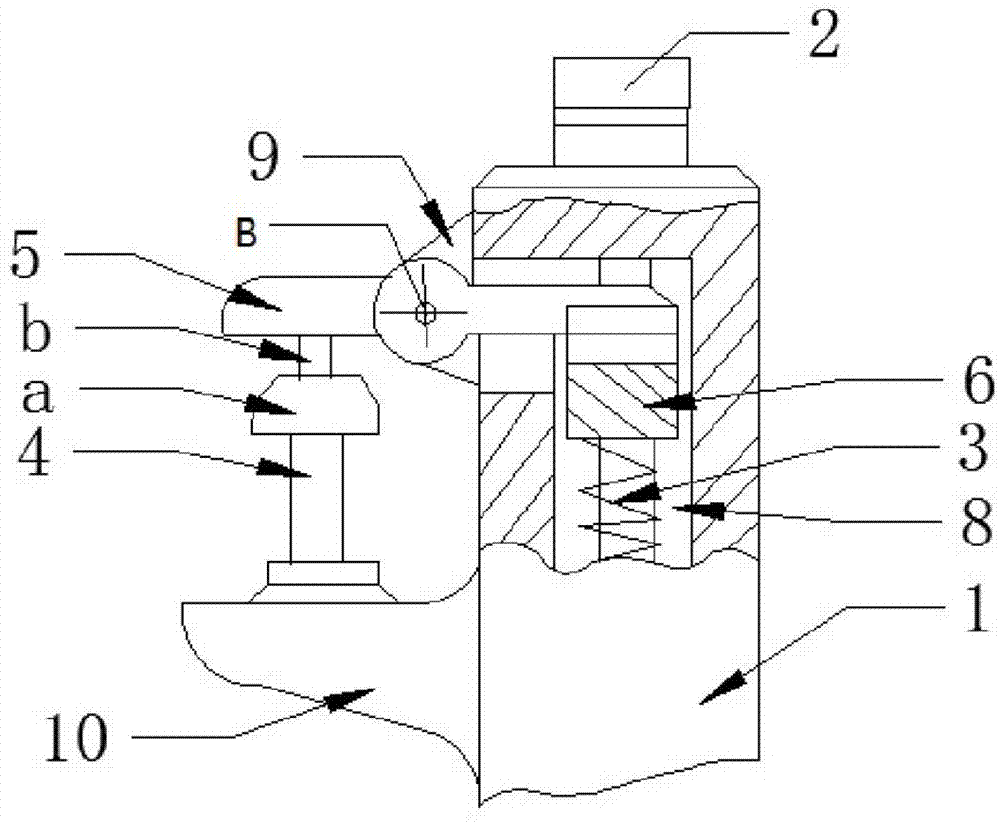

Screw lever type clamping mechanism

PendingCN104511768AEasy to lock and holdEasy to clamp and positionPositioning apparatusClampsIsosceles trapezoidEngineering

The invention discloses a screw lever type clamping mechanism which comprises a supporting table, a locking part and a driving part. The supporting table is of an isosceles trapezoid structure, a connecting plate and a supporting plate are arranged on one side face of the supporting table, and a slide rail is arranged in the supporting table. The driving part comprises a screw, a nut, a cap-shaped object, a first lever, a first pin, a first connecting member, a spring and second connecting members, wherein the screw is connected to the supporting plate through threads, the nut and the cap-shaped object are connected to the screw, the cap-shaped object is arranged above the nut, the first lever is connected to the connecting plate through the first pin, one end of the first lever abuts against the cap-shaped object, the other end of the first lever abuts against the first connecting member, the first connecting member is in sliding connection with the slide rail, the left end and the right end of the first connecting member are respectively connected two second connecting members through pins, and the spring is connected between the first connecting member and the slide rail. The locking part comprises a clamping claw provided with a limiting groove, wherein the clamping claw is connected with the second connecting members through pins. The screw lever type clamping mechanism is firm in structure and adjustable in locking pressure.

Owner:CHONGQING XIHUA BELT PULLEY MACHINERY MFG CO LTD

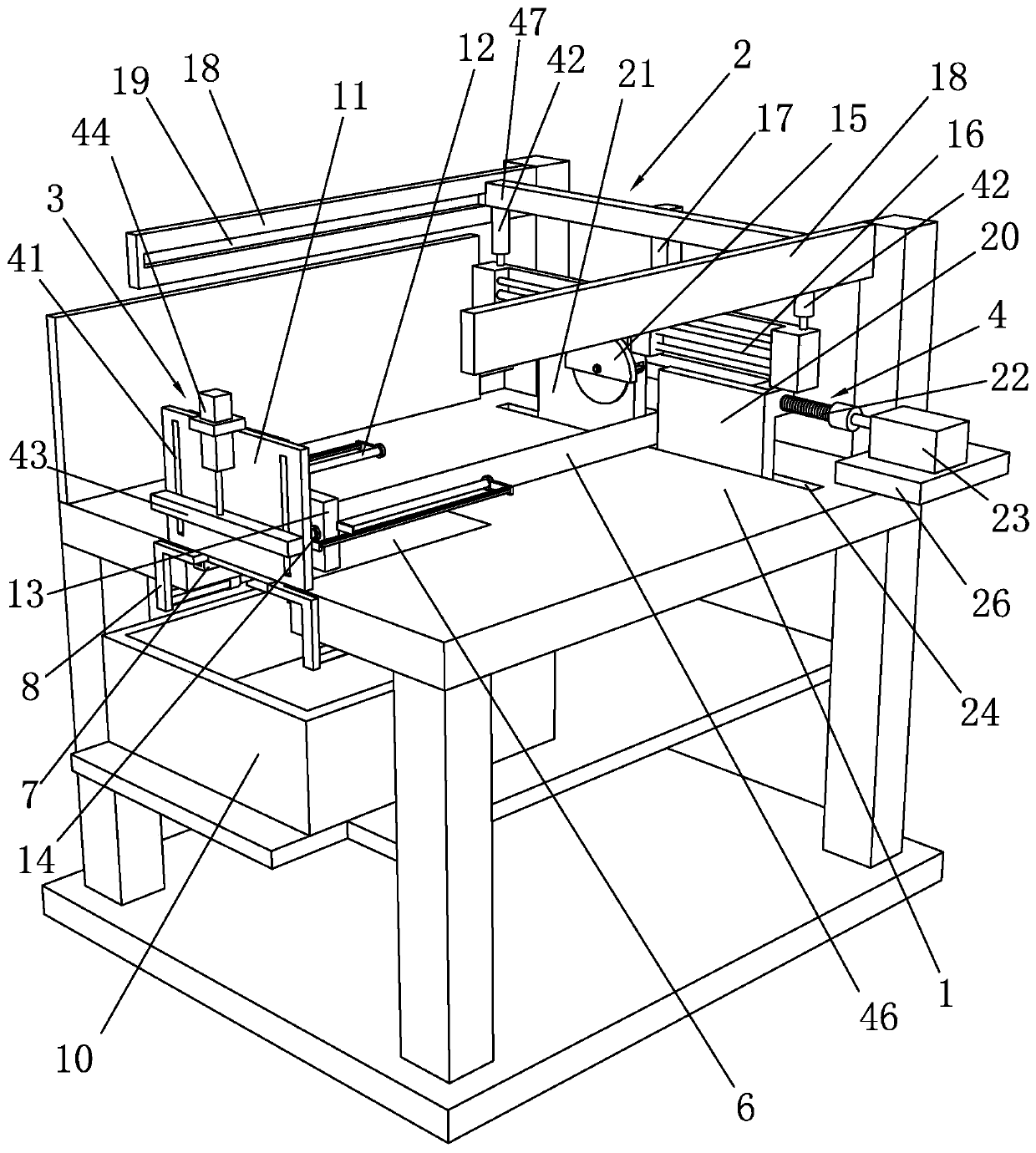

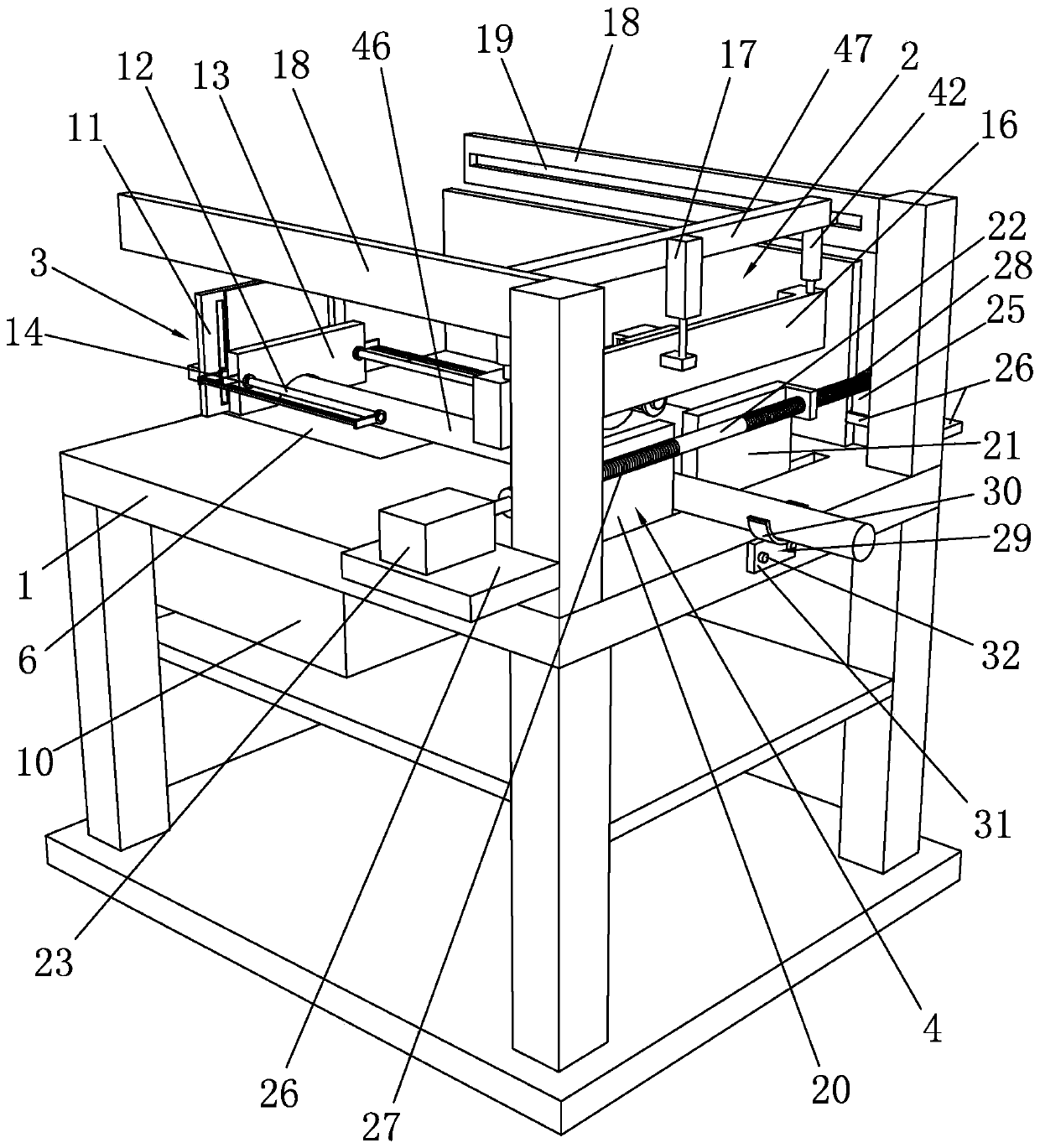

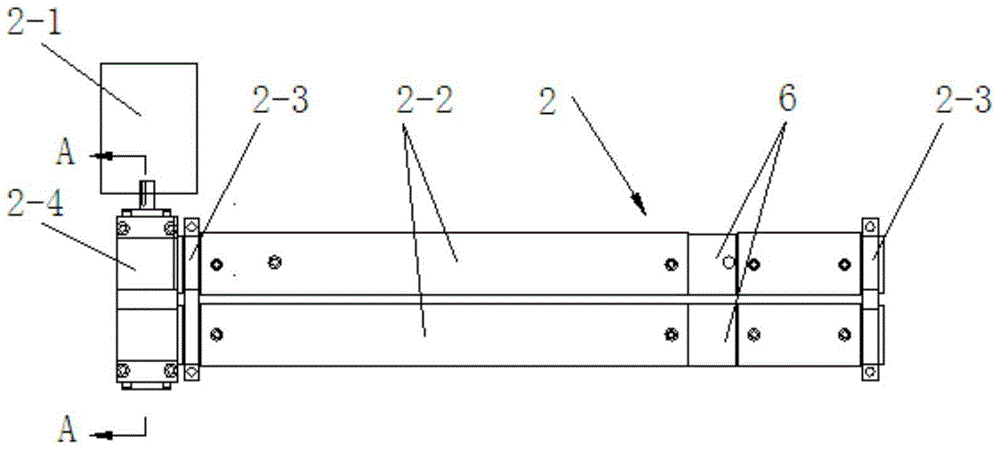

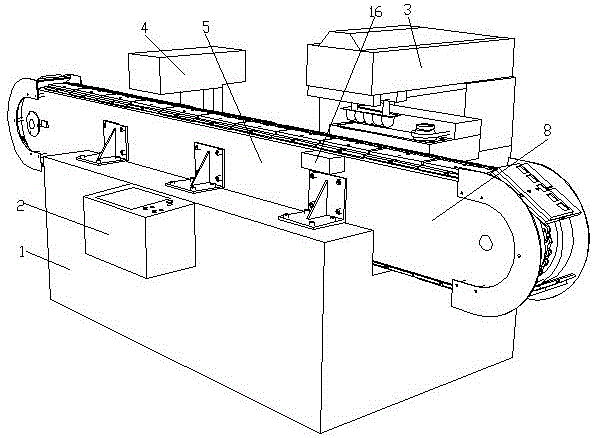

Fixed-length cutting device for stainless steel tube

ActiveCN109719570ACompact and reasonable structure designEasy to useMeasurement/indication equipmentsFeeding apparatusEngineeringLength measurement

The invention discloses a fixed-length cutting device for a stainless steel tube. The fixed-length cutting device for a stainless steel tube comprises a cutting platform and a cutting head group, andfurther comprises a length determining assembly and a clamping assembly; the left side end of the cutting platform is provided with an opening groove, a cutting panel is arranged in the opening groove, and a material collecting box is arranged under the cutting panel; and the length determining assembly comprises a fixed side plate, positioning screws and a positioning pressing plate, the fixed side plate is located over the left end of the opening groove and fixedly connected with the top face of the cutting platform, the positioning screws are symmetrically arranged on the front side and theback side of the fixed side plate, and the two ends of the positioning pressing plates are arranged on the two positioning screws in a sleeving mode separately. According to the fixed-length cuttingdevice for the stainless steel tube, the structure is simple, the practicability is high, operation is easy, use is convenient, not only can the cutting rate and the cutting precision of the stainlesssteel tube be improved, but also the cutting length standard can be guaranteed every time only through one time of cutting length measurement, the manual labor intensity is effectively reduced, the error rate brought by each time of manual measurement is decreased, and resources and the cost are saved.

Owner:ANHUI KINGWE PIPE IND

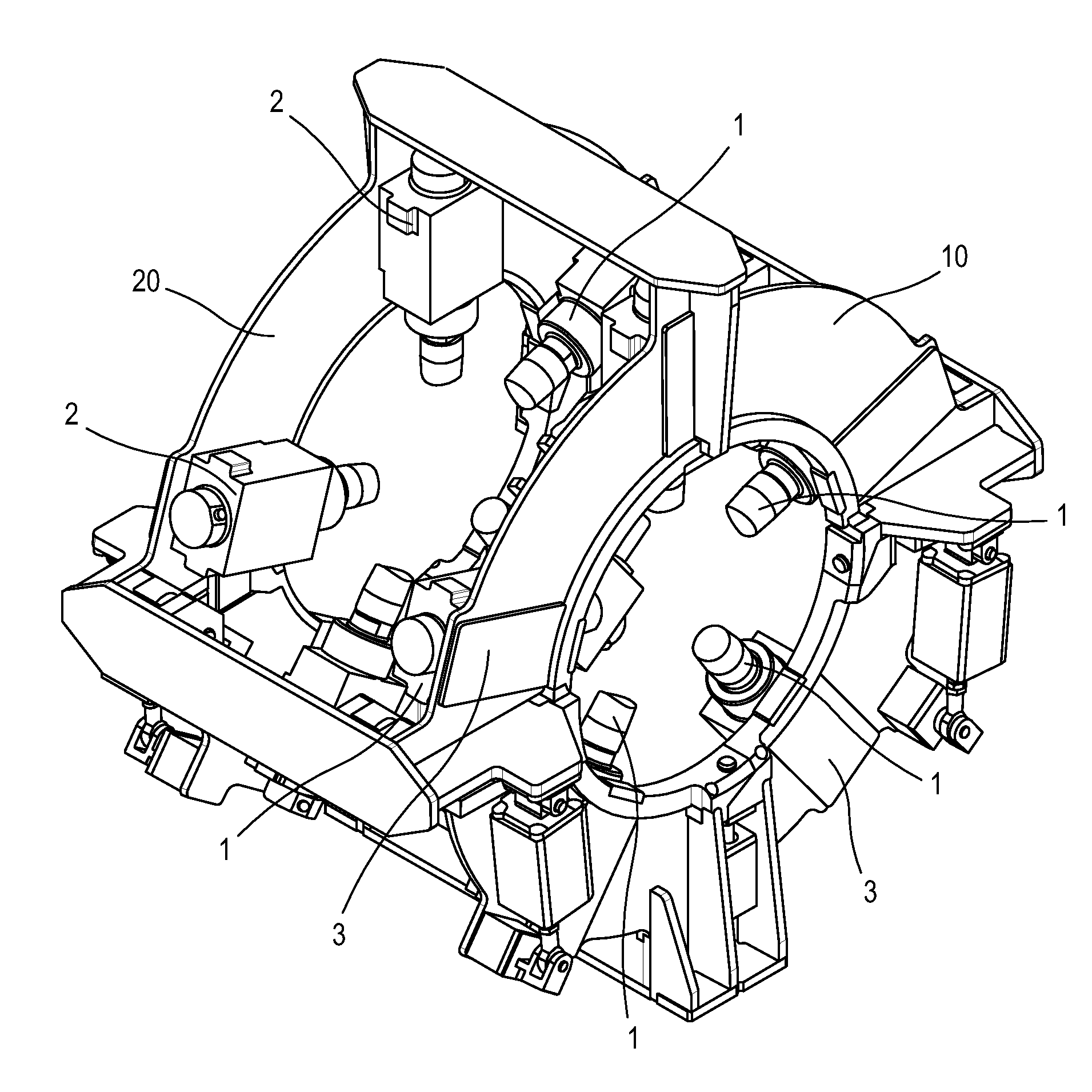

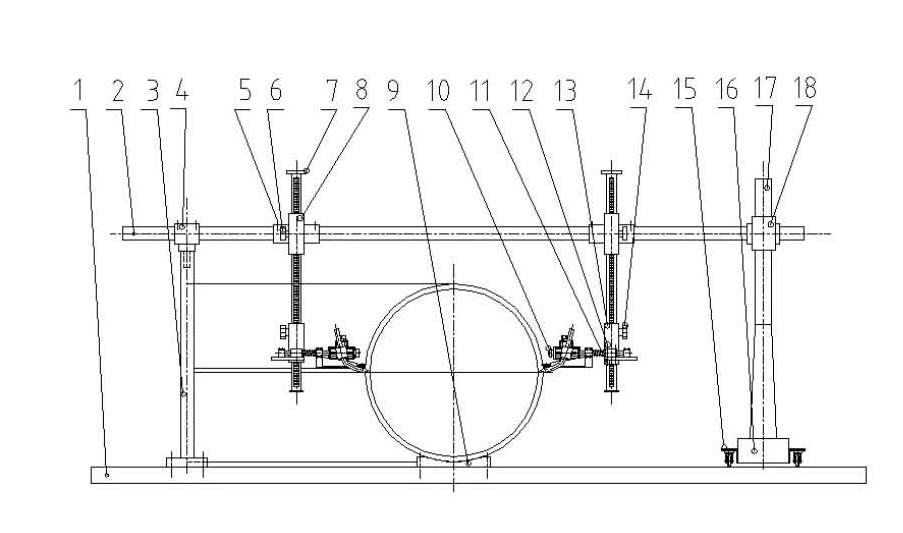

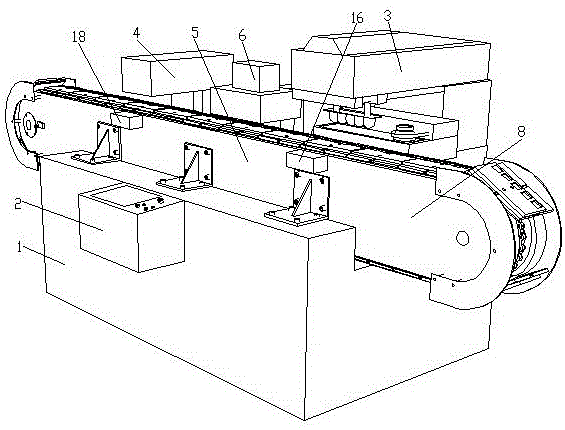

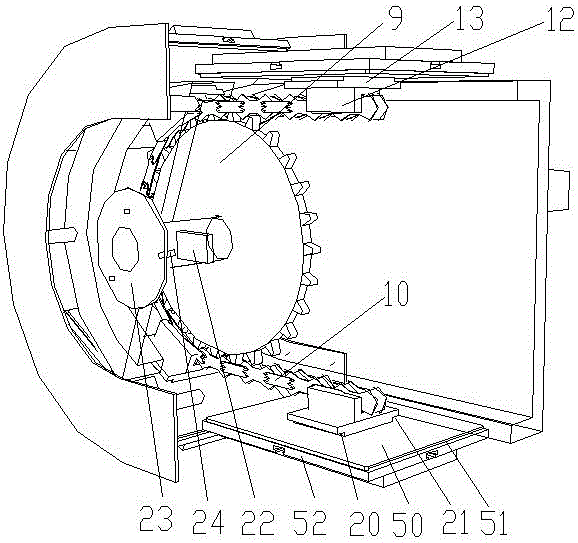

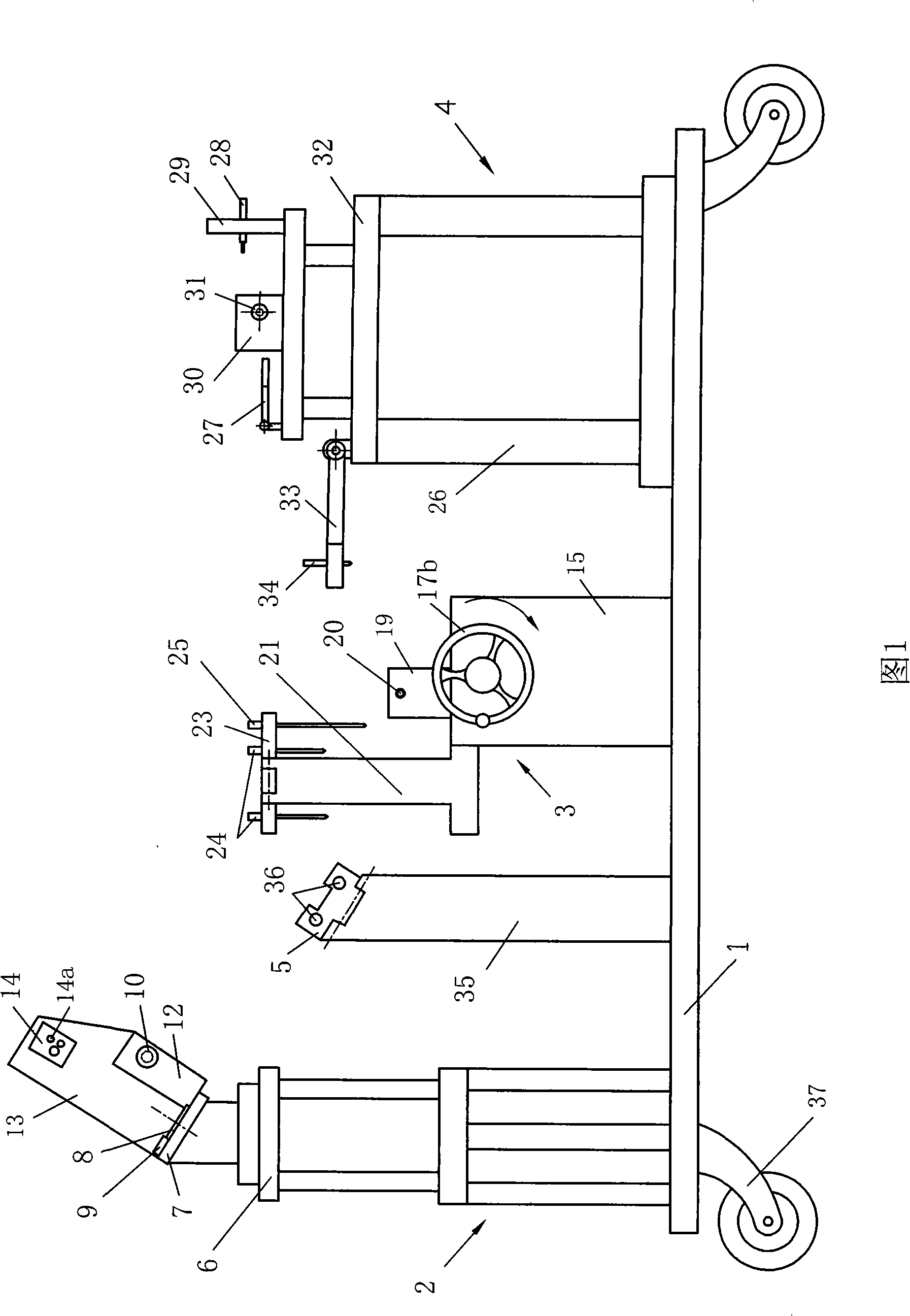

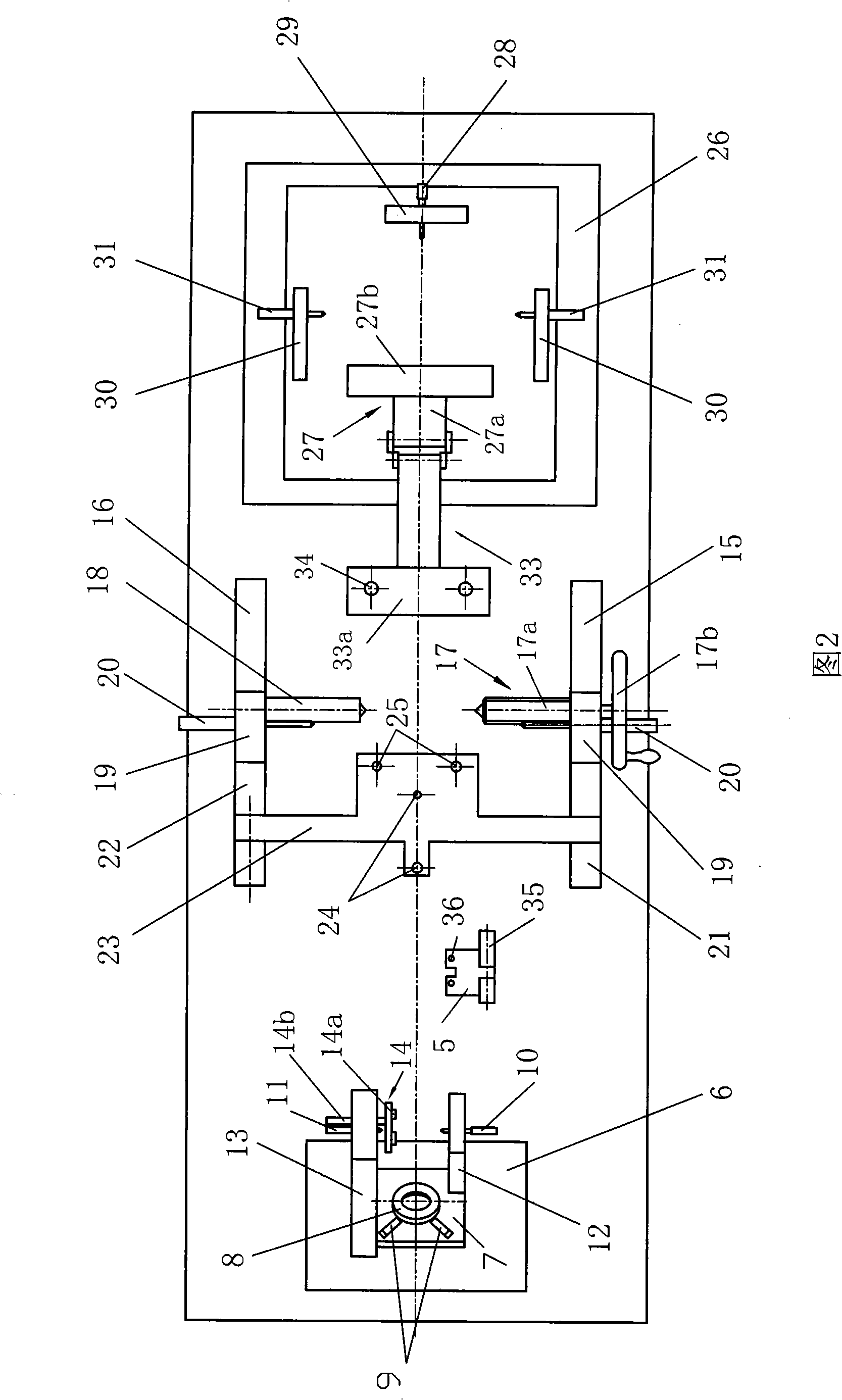

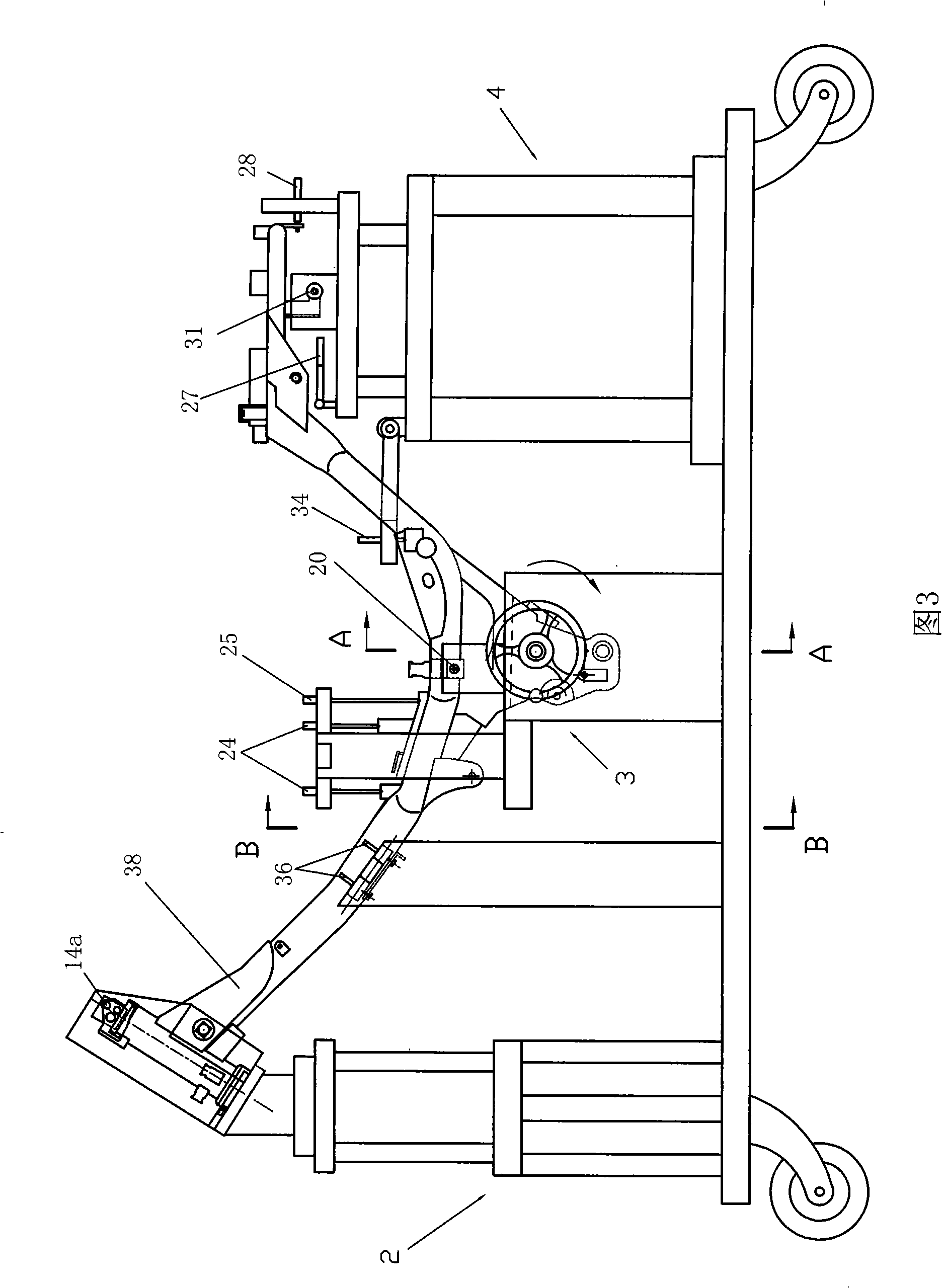

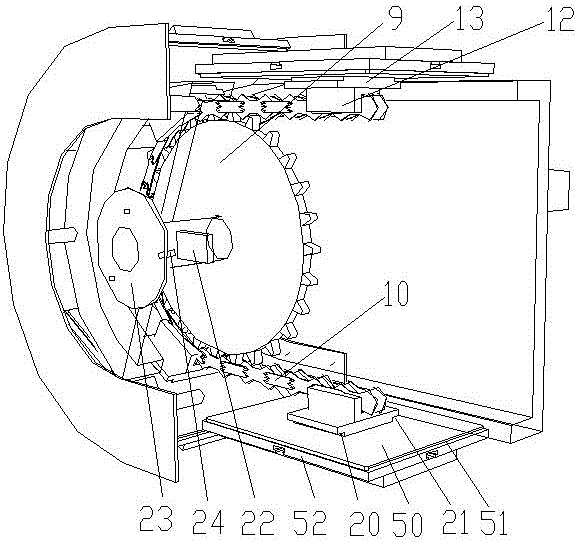

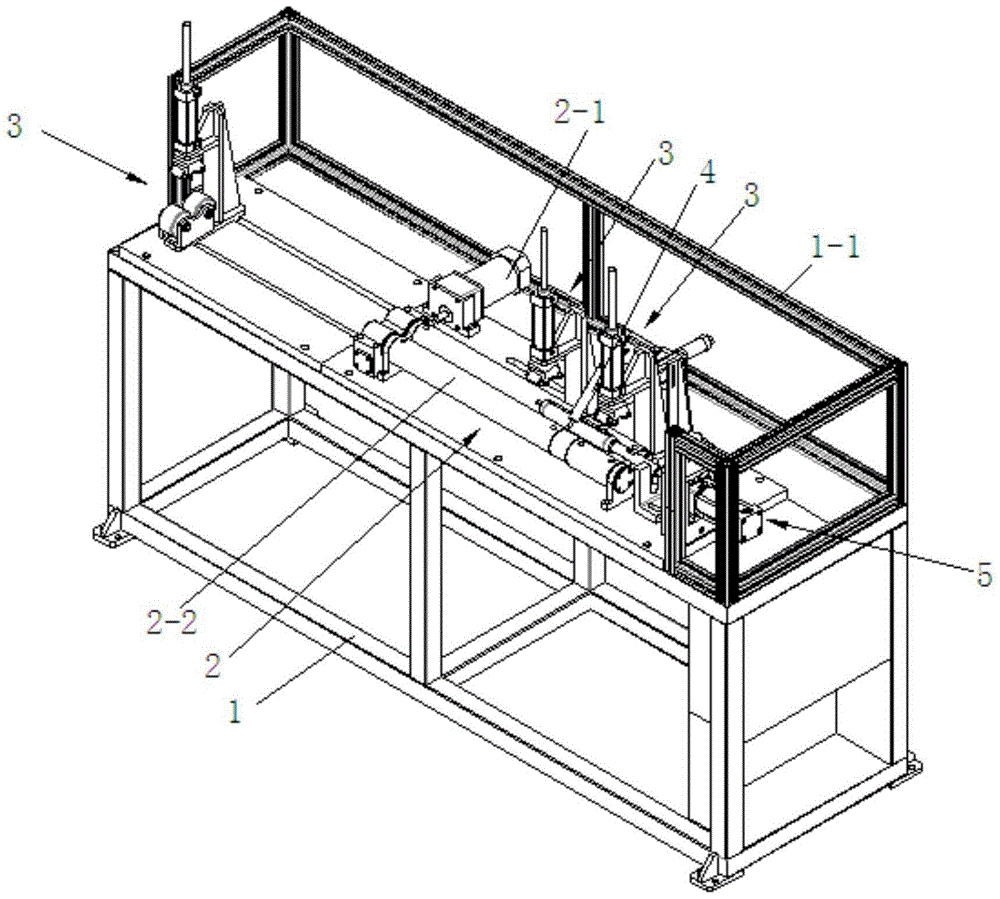

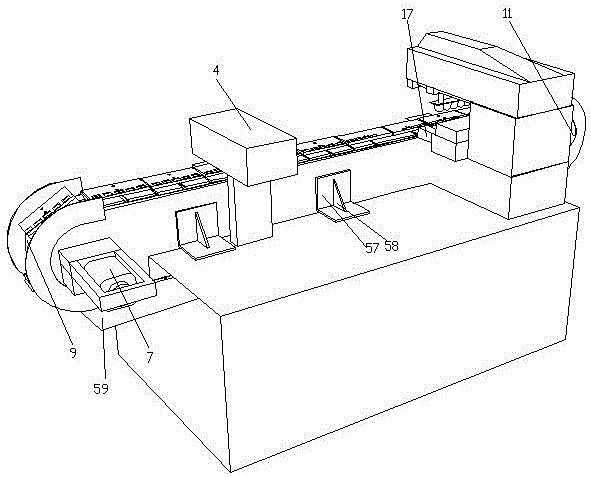

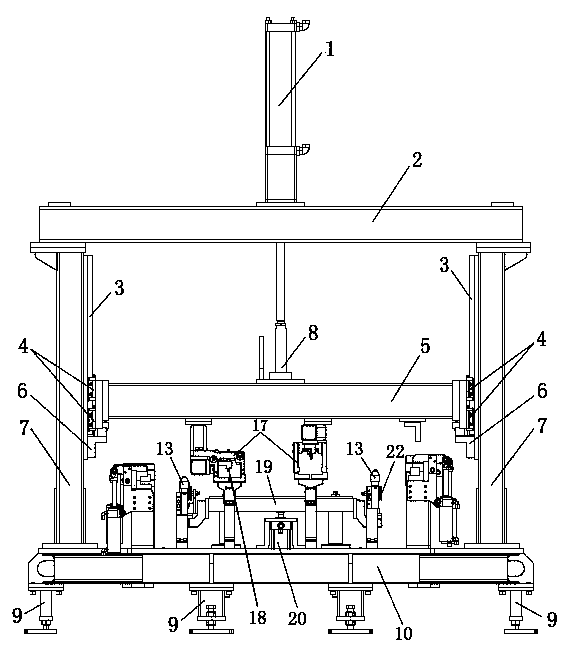

Automatic horizontal position welding device for circular arc groove welds of elbow made of steel plate

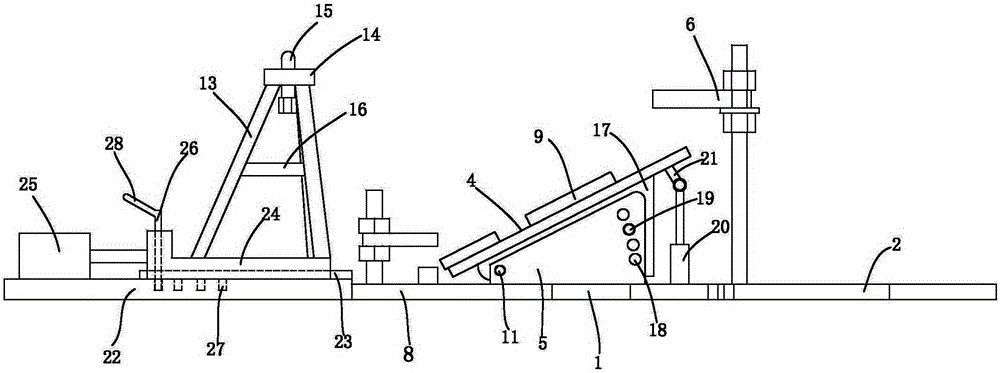

InactiveCN102059467AEasy clamping and positioningEnsure the correct position and welding qualityWelding apparatusSteel platesSizing

The invention discloses an automatic horizontal position welding device for circular arc groove welds of an elbow made of a steel plate, comprising a working platform, a trolley positioning, rotating and traveling mechanism and a welding gun positioning mechanism; wherein the working platform is provided with a trapezoidal groove and a V-shaped sizing block; the trolley positioning, rotating and traveling mechanism comprises a central shaft, a connecting rod rotating shaft, a connecting rod, a connecting rod upright column connecting piece, a trolley upright column and a traveling trolley; the welding gun positioning mechanism comprises a rack upright tube, a cross connected pipe fitting, a rack connecting piece, a guide plate, a check block, a guiding axle, a box-type slide block, a spring, a supporting frame, a cross sliding plate, a horizontal slide block and a welding gun chuck, wherein a welding gun is fixed to the welding gun chuck. The device has the advantages of simple structure, easiness for manufacture, convenience for operation, adjustable welding speed, stable running, good welding quality and capability of realization of multi-layered and multiple automatic horizontal position welding for the circular arc groove welds inside and outside the elbow and realization of welding tasks of groove welds of various specifications of elbows with different diameters from small diameter of about 400mm to large diameter of about1420mm.

Owner:CNPC BOHAI EQUIP MFG +1

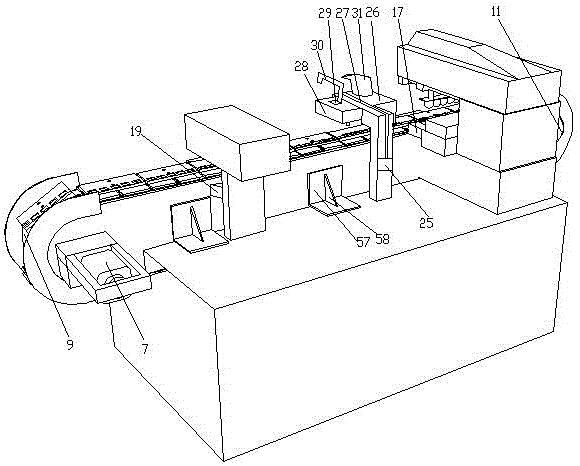

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

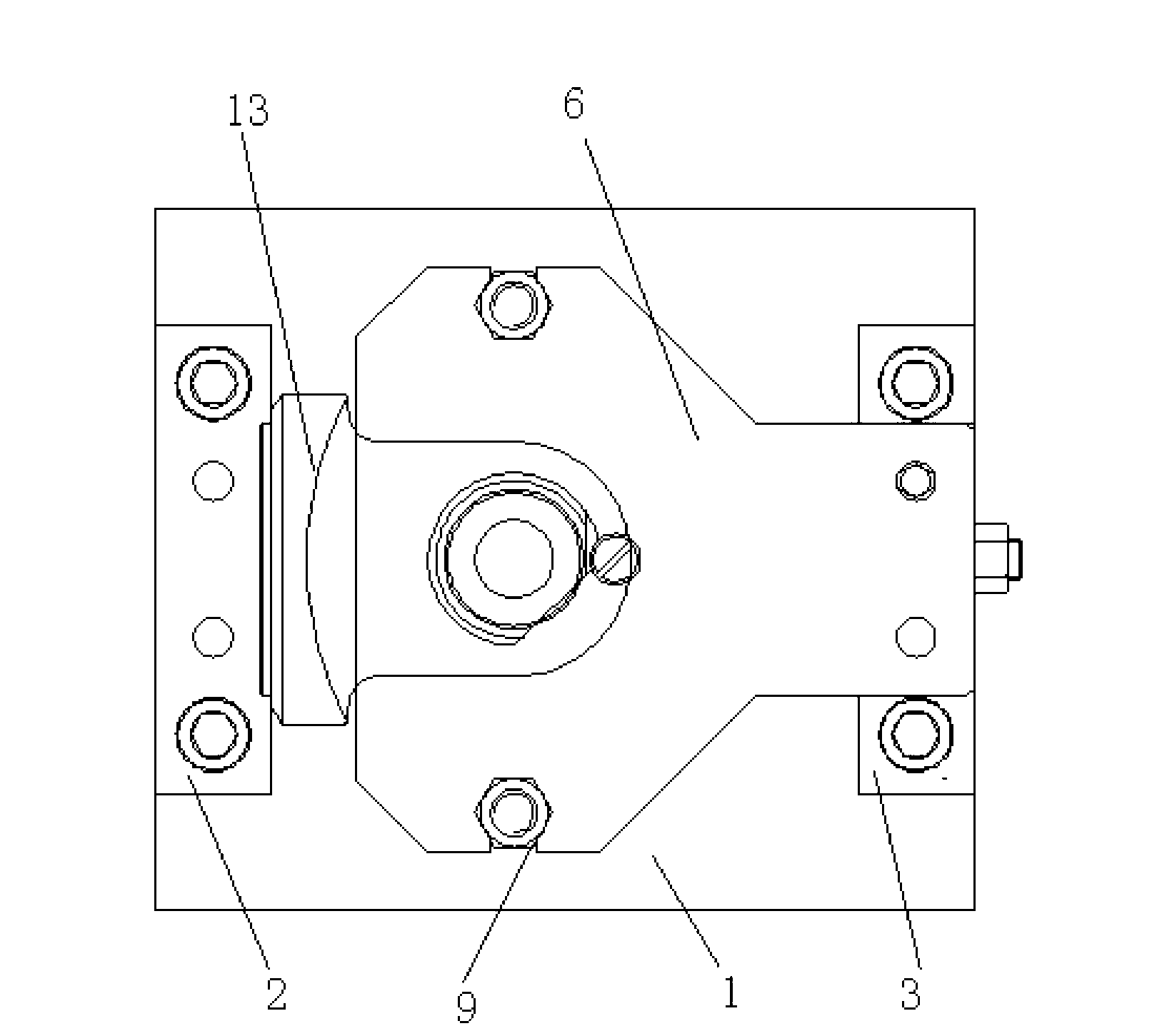

Angle-adjustable inclined valve body clamping mechanism

ActiveCN105328602ARealize clampingAchieve positioningWork holdersPositioning apparatusEngineeringFlange

The invention provides an angle-adjustable inclined valve body clamping mechanism which comprises a base, a supporting plate and a compression mechanism. The base is provided with two inclined supporting blocks. The supporting plate is installed on the supporting blocks in an inclined mode with the lower front portion and the higher rear portion. The bottom of the supporting plate is provided with two adjusting plates corresponding to the supporting blocks. The front portions of the adjusting plates are rotationally connected with the front portions of the supporting blocks through rotating shafts. The rear portions of the adjusting plates are provided with locking holes. The rear portions of the supporting blocks are provided with a plurality of height adjusting holes. The adjusting plates and the supporting blocks are fixed through positioning pin shafts penetrating in the height adjusting holes and the locking holes. A supporting mechanism used for supporting the upper end of a valve body is arranged in front of the base. When the angle-adjustable inclined valve body clamping mechanism is in use, an inclined flange face of the inclined valve is supported on the supporting plate, primary positioning is achieved through a bolt and a positioning hole, and then compression is carried out through a compressing mechanism. The angle of the supporting plate can be adjusted when the adjusting plates rotate around the rotating shafts, and therefore valve bodies of different inclined angles can be clamped.

Owner:CHONGQINGZHICHENG MACHINERY CO LTD

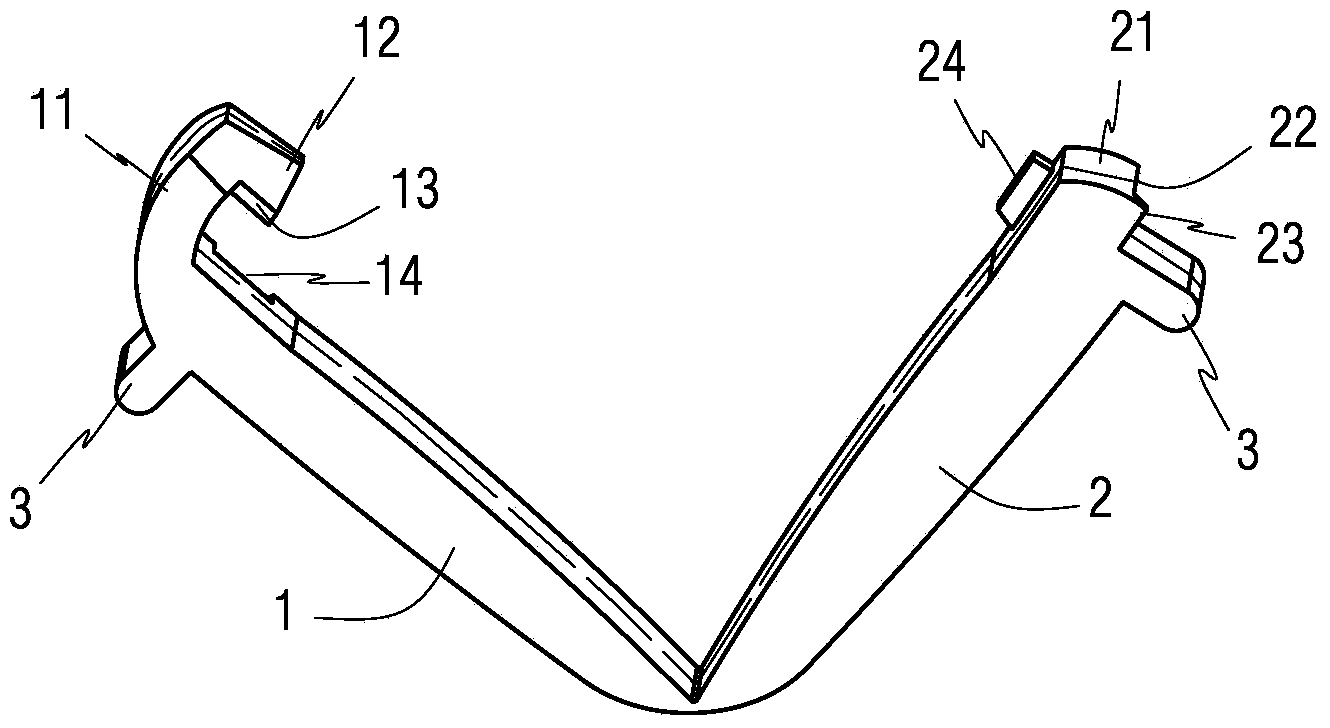

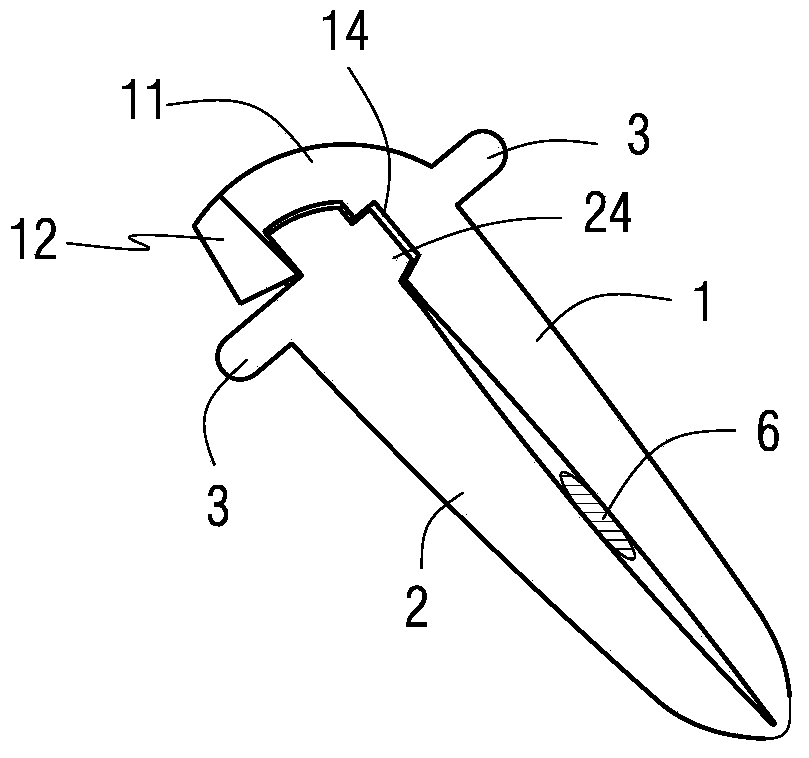

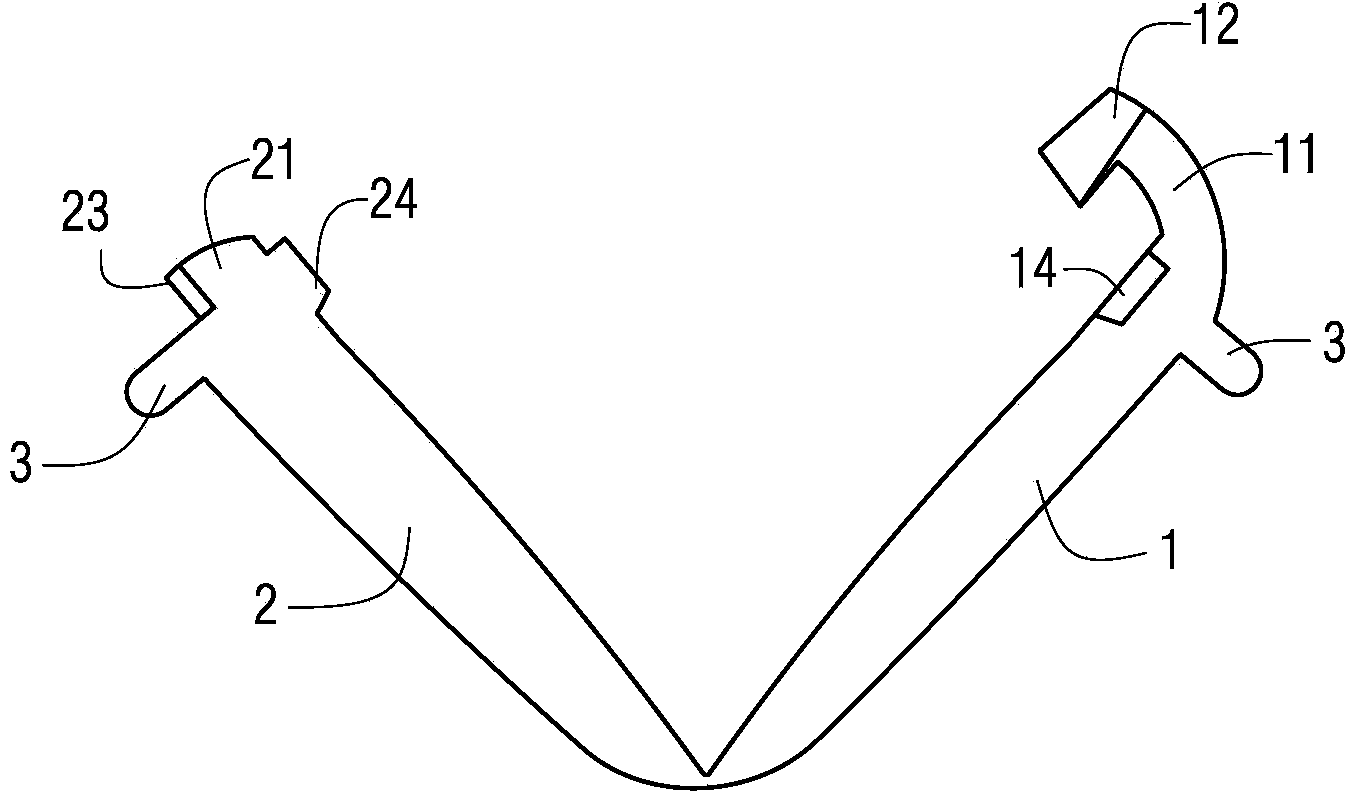

Absorbable ligature clamp and manufacturing method thereof

ActiveCN103549985ALow technical requirementsPromote absorptionWound clampsOrthodontic ligatureHumans tissues

The invention discloses a ligature clamp which comprises a first clamp arm and a second clamp arm. Clamping projections are symmetrically arranged on the outer sides of the first clamp arm and the second clamp arm respectively, the reverse outer sides of the first clamp arm and the second clamp arm are of straight structures, the first clamp arm and the second clamp arm are of V-shaped structures in symmetrical shapes from the clamping projections on the respective sides to a connecting portion of the two clamp arms, a first cylindrical hollow portion is arranged in the first clamp arm, a second cylindrical hollow portion is arranged in the second clamp arm, and annular grooves are uniformly formed in the first hollow portion and the second hollow portion. The invention further provides a method for manufacturing the absorbable ligature clamp. By the aid of the clamp arms with the straight structures, the two clamp arms are of the basically symmetrical V-shaped structures, and an opening cannot shift in the closing process and is easily clamped and positioned. In addition, the absorbable ligature clamp can generate uniform fragments in the degrading process and is conveniently absorbed by human tissues.

Owner:HANGZHOU MEDZONE BIO-TECH CO LTD

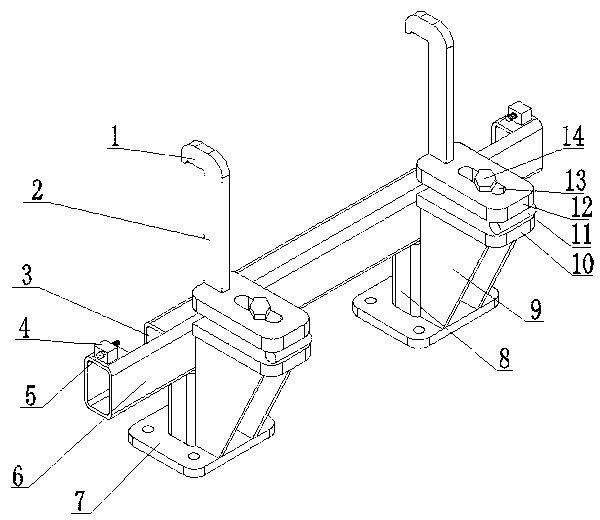

Motorcycle frame assembly checking tool

InactiveCN101270970AEasy to clamp and positionMeet the design requirementsMechanical measuring arrangementsVehicle frame

A testing fixture for a motorcycle frame assembly uses a rear fork mounting hole and a stand pipe lower end of the vehicle frame to be located, and detects the position of installing pole or spacial dimension of each part to be measured on the vehicle frame. In the invention, a head testing institution, a control value testing block, a middle testing institution and a tail testing institution are mounted in turn in longitudinal direction of the bottom plate through simulating each installation position of the vehicle frame assembly. The active testing bolts mounted on each testing institution and control value testing block are respectively located at the axis line of each mounting hole to be measured. The invention has simple structure and convenient operation, which can accurately and rapidly detect the spatial position of deviation block and each mounting hole to be measured on the vehicle frame and the opening size of the liner, and use the result as standard to correct the unqualified part of the vehicle frame, and decrease detection and correction efficiency of the vehicle frame.

Owner:力帆科技(集团)股份有限公司

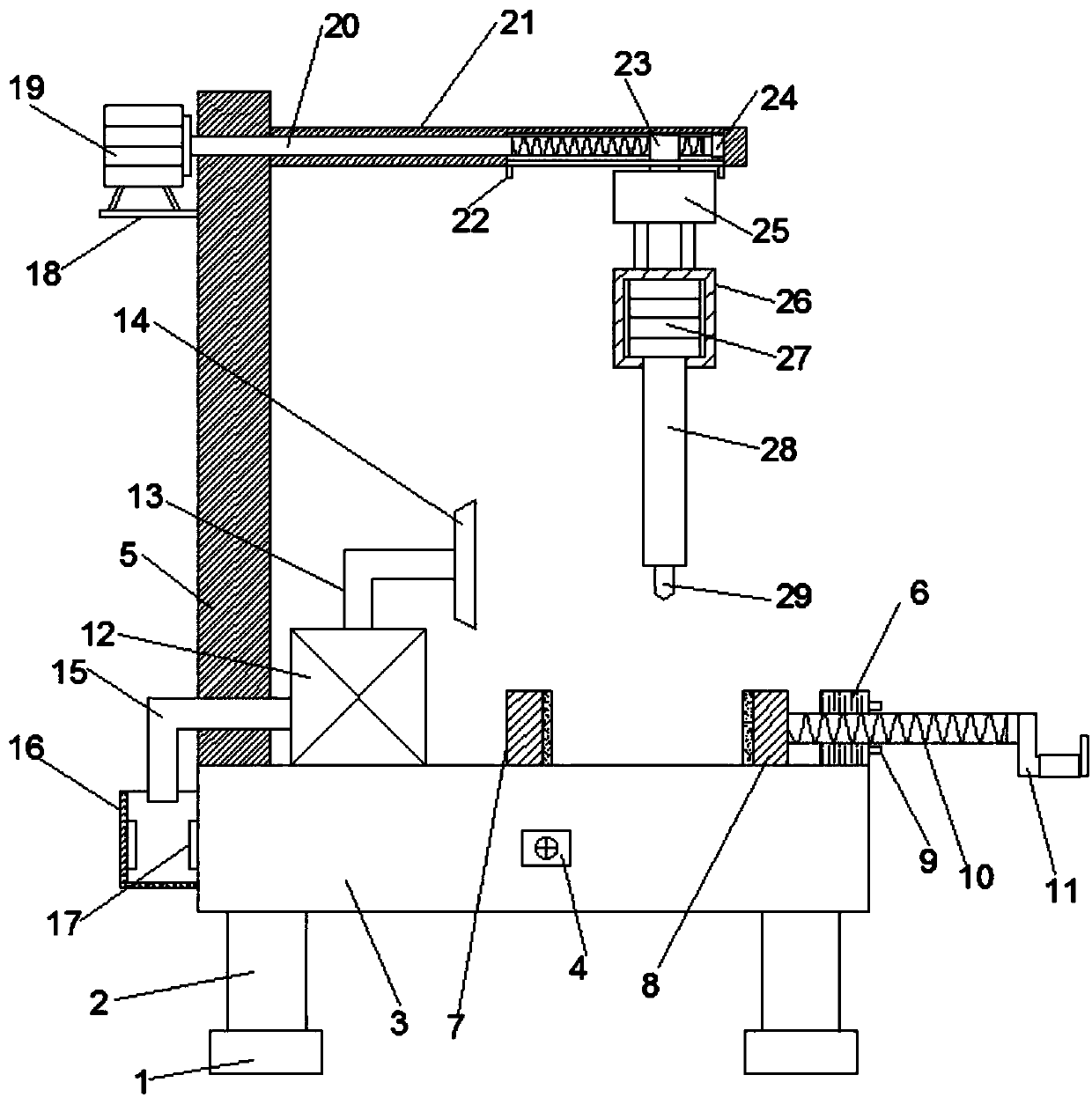

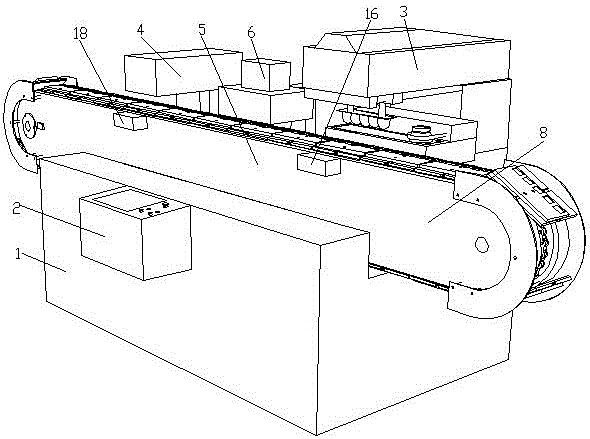

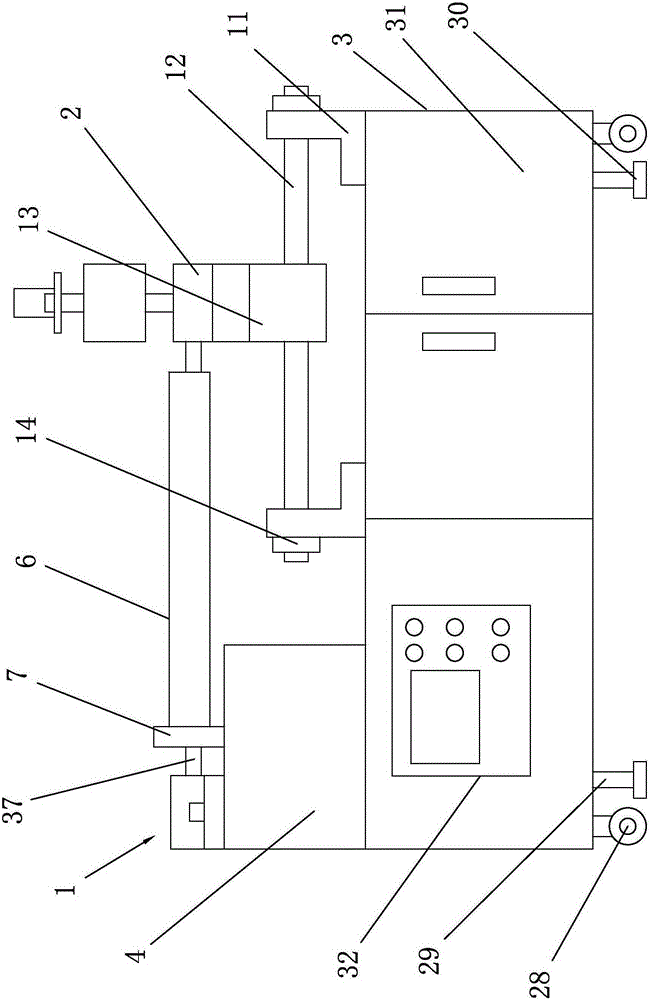

Double-end automatic straight seam welding machine

InactiveCN102785000AEasy clamping and positioningImprove welding efficiencyWelding/cutting auxillary devicesArc welding apparatusSeam weldingWeld seam

The invention relates to the technical field of welding equipment, particularly to a double-end automatic straight seam welding machine. The straight seam welding machine comprises a machine seat provided with a linear guide sliding table, a variable frequency motor,a cross frame and a positioning seat; the variable frequency motor is driven to be connected with the sliding table through a transmission mechanism, and the two ends of the cross frame extend to two sides of the machine seat and provided with welding devices respectively; and a material pressing cylinder and a material pressing plate are arranged on the outer side of the positioning seat, and an output end of the material pressing cylinder is connected with the material pressing plate. According to the straight seam welding machine, the material pressing cylinder is adopted to perform pneumatic positioning and material pressing clamping, clamping positioning is rapid, convenient and accurate, the left and right welding devices are equipped with a set of welding guns respectively, servo driving is performed through the variable frequency motor, the sliding table, the cross frame and the welding devices are controlled to move longitudinally for welding, the programmable logic controller (PLC) is used for controlling dimensions of welding seams and arc starting and suppression actions, double-end straight seam welding can be performed automatically, the welding efficiency is high, the quality of the welding seams is high, and the straight seam welding machine can be applied to mass produced products with straight welding seams.

Owner:DONGGUAN JIALONG LEATHER MACHIERY

Continuous transfer-printing coding method

ActiveCN106379042AClear outlineSqueegee steps increaseRotary pressesPrinting press partsContinuous operationLaser

The invention discloses a continuous transfer-printing coding method. The continuous transfer-printing coding method comprises the following steps: step (a) inking an etching plate by using a sealed oil cup of a transfer-printing coding device; step (b) forwards pushing a rubber head of a transfer printing machine to the upper portion of the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and downwards pressing the rubber head to make the rubber head be stained with ink with patterns; step (c) backwards pushing the rubber head to a transfer printing work position, and then driving the rubber head to be pressed downwards so that the rubber head is capable of printing the ink with patterns on a to-be-printed object inside a mold groove; step (d) moving the transfer-printed object to a drying work position for drying by using a conveying component; step (e) moving the transfer-printed and dried object to a coding work position and coding the transfer-printed and dried object by using a laser coding machine. The continuous transfer-printing coding method disclosed by the invention is capable of realizing continuous operation on large-batch to-be-printed objects and improving the production efficiency; the patterns are clearer after the printed objects are dried at the drying work position; a coded product is high in exquisite degree and is fadeless after being used for a long time.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Locating-position-adjustable clamping locating device

InactiveCN103252609AEasy clampingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesElectrical and Electronics engineeringEngineering

The invention discloses a locating-position-adjustable clamping locating device which comprises an installation plate and a connection plate. The installation plate and the connection plate are connected through a supporting plate, limiting blocks are arranged at end portions of two sides of an upper end face of the connection plate, limiting bolts are arranged on the limiting blocks, fixed plates are arranged at two ends of a vertical lateral face of the connection plate, the fixed plates are provided with threaded holes, locating plates are arranged at upper end faces of the fixed plates, sliding grooves are formed in the locating plates, bolts penetrates through the sliding grooves to be matched with the threaded holes, the locating plates are fixed at upper end faces of the fixed plate through the bolts, adjusting cylinders are further arranged between the locating plates and the fixed plates, the upper end face, arranged at one end of each connection plate, of each locating plate is connected with a clamping plate, and the upper portions of the clamping plates are bent to form hook-shaped clamping structures. The locating-position-adjustable clamping locating device can accurately clamp and locate a rear car frame in a reasonable error range, can adjust the axial locating position of the rear car frame, facilitates clamping and welding and is strong in safety and practicability.

Owner:CHENGDU HAILINGDA MACHINERY

Strength-strengthening method for use in super-thin complicated part processing

InactiveCN101069949AMeet lightweight requirementsReduce processing deformationPositioning apparatusMetal-working holdersAlloyUltimate tensile strength

The invention belongs to mechanical cool-working technology, which relates to an intensity enhancing method to process ultra-thin complex parts. The invention casts low melting point alloy outside the parts to process ultra-thin (<= 0.5mm) complex cavity parts. It can process ultra-thin products with different shapes to meet the lightweight requirements. It has small processing distortion and the roundness errors of the processed holes are controlled within 0.007mm. It has high processing precision and can realize multi-surface process with one clamping, which can guarantee the correlating size precision. The shapes of the workpieces can be designed as cuboids to facilitate the clamping and positioning.

Owner:中国航空工业第一集团公司第六一三研究所

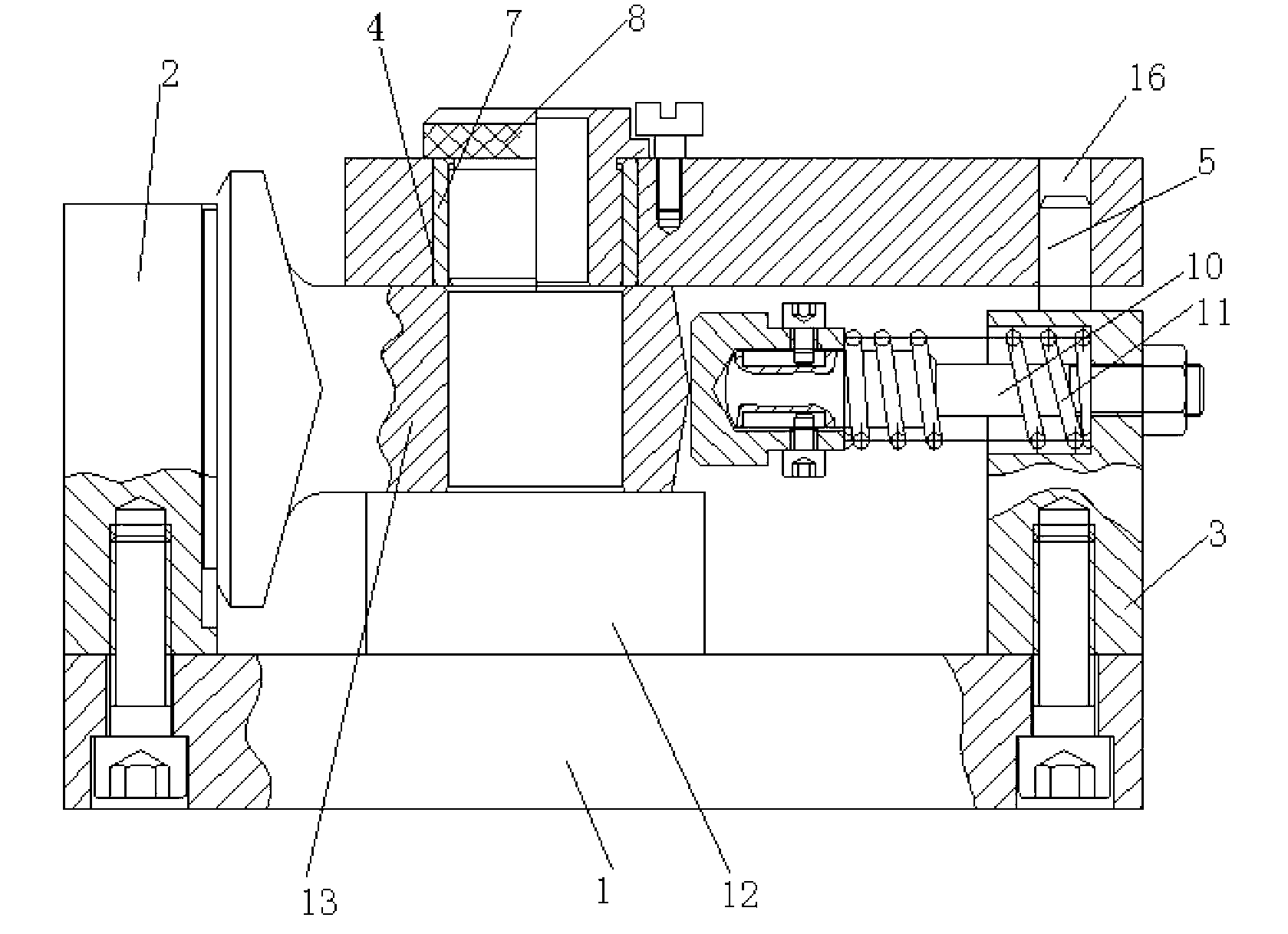

Jig tool for inclined oil cylinder bottom bush hole

InactiveCN103286349AQuick clampingEasy to installPositioning apparatusMetal-working holdersEngineeringDrill

The invention discloses a jig tool for an inclined oil cylinder bottom bush hole, which comprises a jig bottom plate, wherein a left baffle and a right baffle are arranged on the two sides of the jig bottom plate; a jig plate is mounted on the right baffle in a matching manner by inserting a locating pin in a locating hole; a guide hole is formed in the jig plate; a fixed drill sleeve is mounted in the guide hole in a matching manner; a quick-change drill sleeve is mounted in the fixed drill sleeve in a matching manner; U-shaped grooves are formed on the two sides of the other end of the jig plate; a pushing rod is screwed in the middle of the right baffle; a spring is mounted on the pushing rod in a sleeving manner; a pushing block is mounted at the end part of the pushing rod; a cushion block is arranged in the middle of the jig bottom plate; hinge screw seats are mounted on the jig bottom plate on the two sides of the cushion block respectively; articulated screws are mounted on the hinge screw seats; and the upper end parts of the articulated screws are matched with the U-shaped grooves of the jig plate, and locked and fixed by nuts. The special jig tool for the inclined oil cylinder bottom bush hole is convenient and quick in clamping, time-saving and labor-saving, improves the working efficiency, and meets a requirement of batch processing production.

Owner:ANHUI ZHENYE MACHINERY

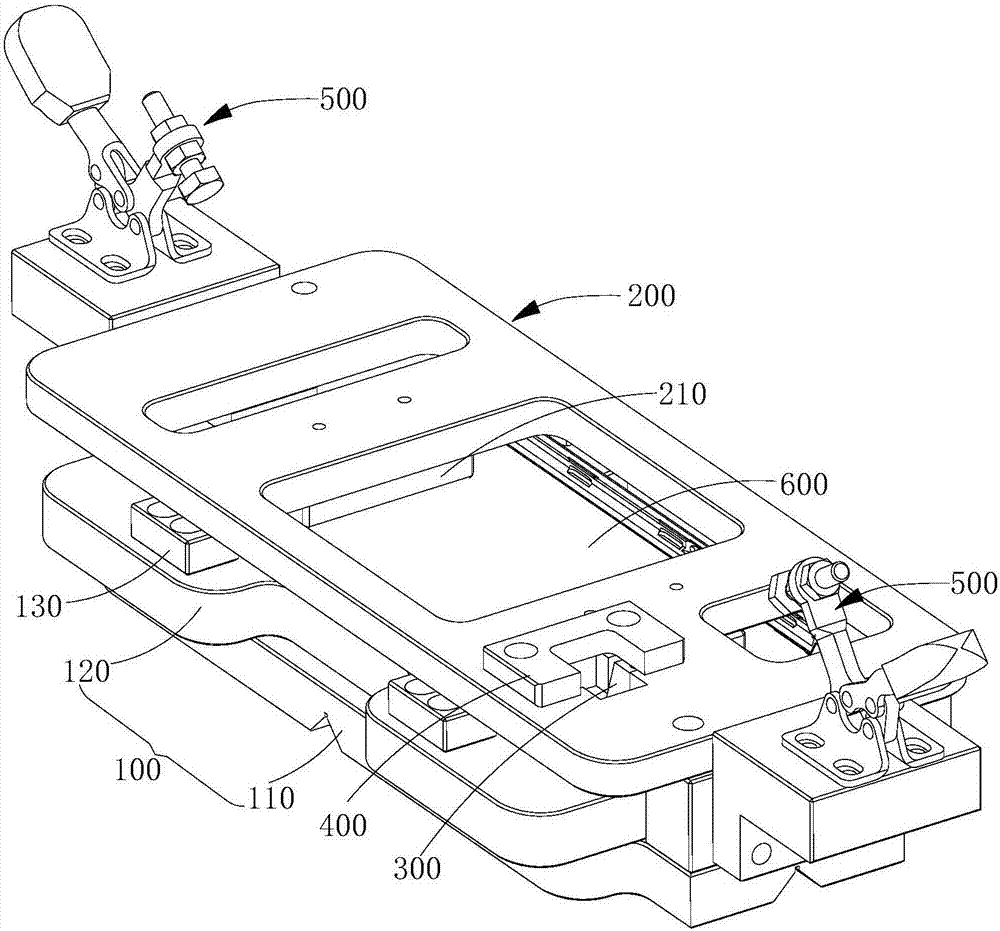

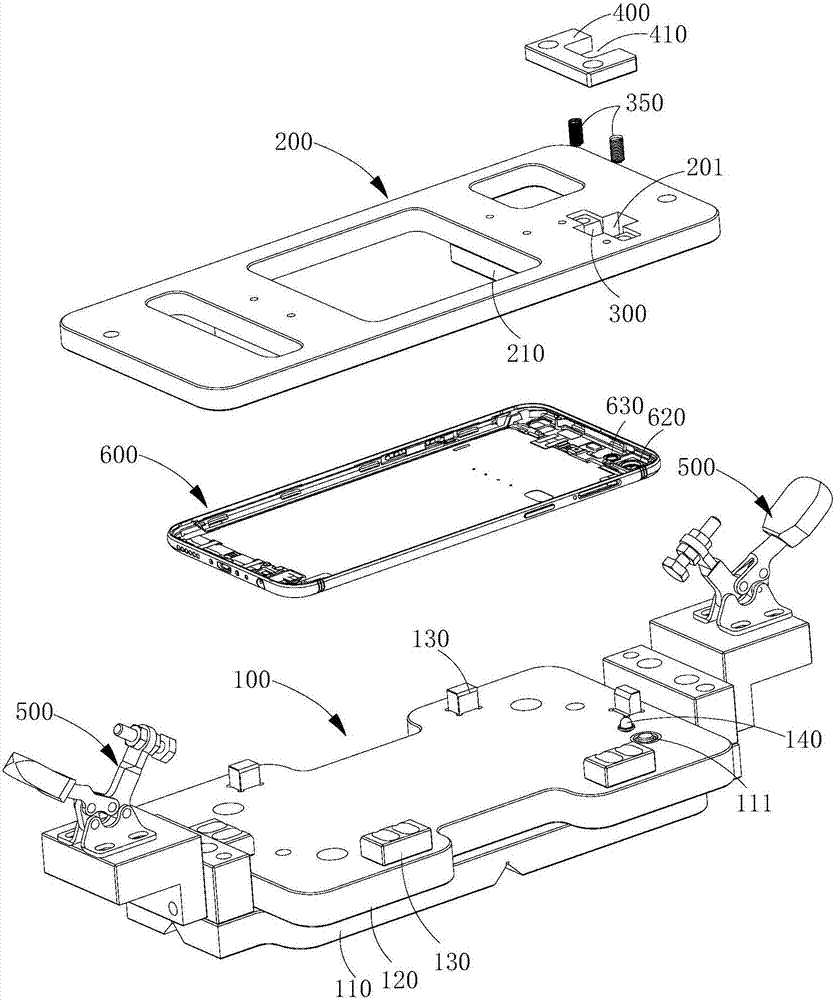

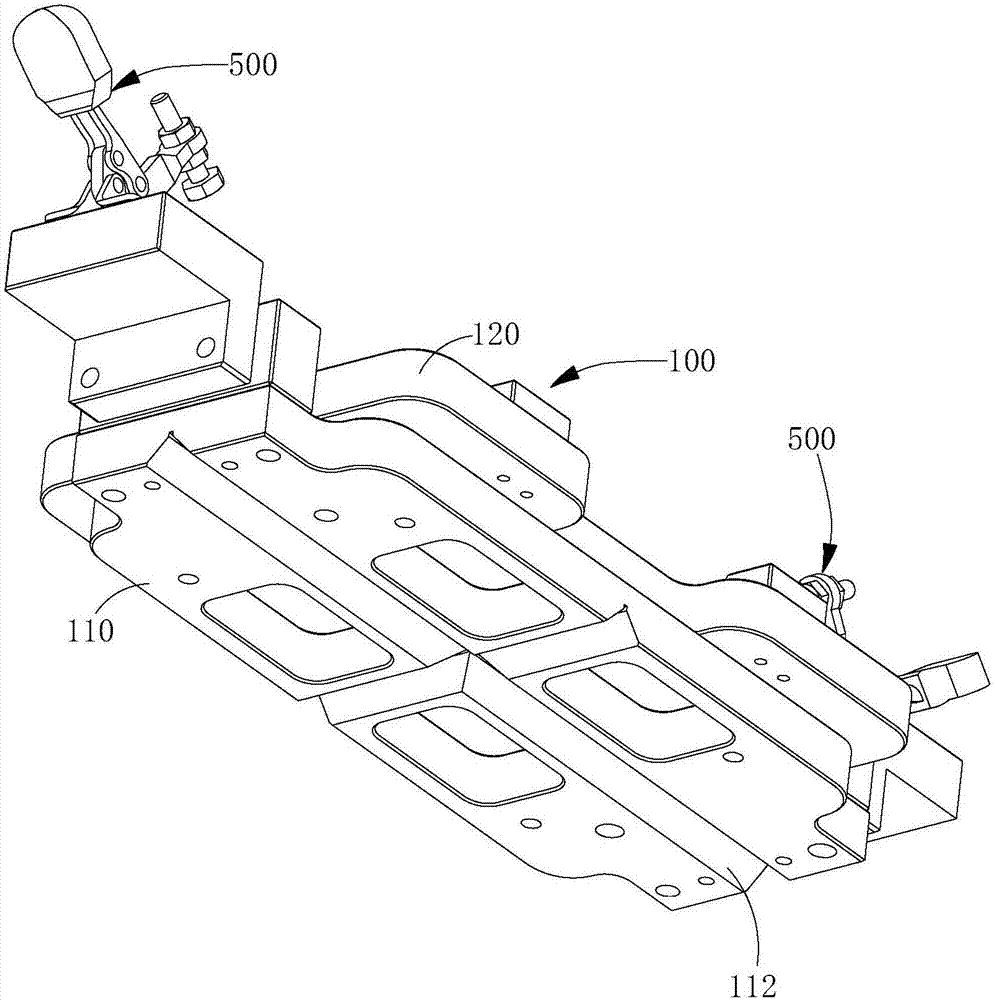

Soldering jig

ActiveCN106975876AEasy to operateEasy to clamp and positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The present invention relates to a soldering jig. The soldering jig comprises a pedestal provided with a working station for positioning a workpiece; a cover plate covering a top face of the pedestal and being provided with a through hole at a position corresponding to a camera to-be-soldered part of the workpiece; a pressure head assembly arranged between the cover plate and the workpiece, the bottom part of the pressure head assembly covering a perimeter zone of a camera soldering face of the workpiece; and a clamping member arranged on the pedestal to press the cover plate and to enable the pressure head assembly to press the workpiece. According to the soldering jig provided by the invention, the pressure head assembly is arranged between the cover plate and the pedestal, and the bottom part of the pressure head assembly can cover the perimeter zone of the camera soldering face of the workpiece, so during soldering, the perimeter zone of the soldering face cannot be blackened by soldering soot, the appearance is not impacted, the soldering effect is excellent, clamping and positioning operation of the workpiece is simple, and the soldering jig is convenient to operate.

Owner:GUANGDONG EVERWIN PRECISION TECH

Punching mold convenient to position

InactiveCN108435925AEasy to clamp and positionAvoid damageShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a punching mold convenient to position. The punching mold comprises a worktable; two clamping plates are slidingly mounted at the top of the worktable; placing plates are fixedly mounted on the approaching sides of the two clamping plates; the two placing plates are both positioned above the worktable; two movable grooves are formed in the top of the worktable; movable blocks are slidingly mounted in the two movable grooves; the tops of the two movable blocks are fixedly connected with the bottoms of the two clamping plates; a first lead screw and a second lead screw are rotationally mounted on the inner sides of the leaving sides of the two movable grooves; external threads are arranged on the outer sides of the first lead screw and the second lead screw; the two external threads are opposite in rotating direction; and the two movable blocks are in threaded connection with the first lead screw and the second lead screw. The punching mold is convenient to clampand position workpieces, achieves a buffer effect during clamping to prevent damage of the workpieces, and is simple in structure and convenient to use.

Owner:柳州市钜诚科技有限公司

Cutting device applied to production and processing of tubular glass

InactiveCN105271686AEasy to installEasy to fixGlass severing apparatusMechanical engineeringEngineering

The invention discloses a cutting device applied to production and processing of tubular glass. The cutting device comprises a workbench, a clamping device, a sliding component and a cutting component, wherein the workbench comprises a first workbench and a second workbench; the clamping device comprises clamping blocks and clamping air cylinders; the sliding component comprises a support frame, a sliding bar and a sliding block; and the cutting component comprises a fixing block, a bracket, a moving block, a cutting knife and a telescopic air cylinder. The cutting device is simple in structure and strong in practicability; with the design of the clamping device, the tubular glass is more convenient and simpler to fix and clamp; the cutting stability of the tubular glass is improved; a cut surface after cutting is smoother; then, with the design of the sliding block component and the cutting component, the tubular glass is cut more automatically; furthermore, the position of the cutting knife can be adjusted by the sliding block component and the cutting component, so that the cutting device is applicable to cutting the tubular glass with different diameters; the application scope of the cutting device is enlarged; and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

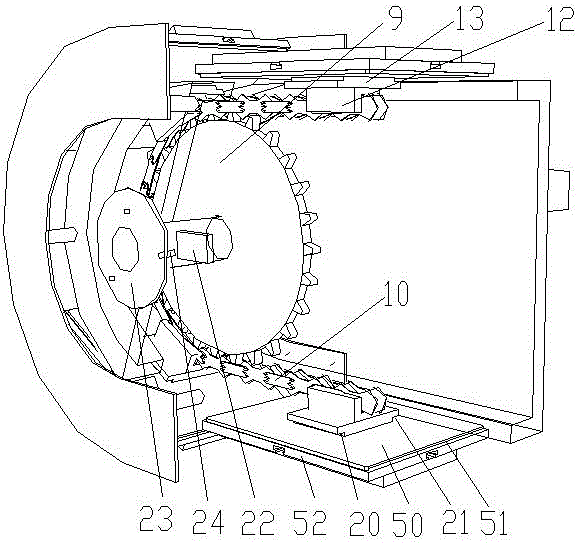

Automatic welding machine for stainless steel circumferential weld

InactiveCN106607639AEasy to clamp and positionImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses an automatic welding machine for a stainless steel circumferential weld. The automatic welding machine comprises a rack, a pipe rotating device, pressing devices and a welding gun, wherein the welding gun is fixedly connected with the rack; the pipe rotating device comprises a motor, two rotating shafts, shaft seats, a worm seat, a worm and worm wheels; the shaft seats are fixedly connected with the rack; two ends of the two rotating shafts are connected with the corresponding shaft seats in a rotatable manner; each worm wheel is arranged at one end of each rotating shaft; the worm seat is fixedly connected with the rack; the worm is matched with the worm seat in a rotatable manner and connected with the motor in a transmission manner; the worm is meshed with the two worm wheels; the pressing devices comprise mounting frames, pressing cylinders, pressing blocks and pressing block rolling shafts; the mounting frames are fixedly connected with the rack; the pressing cylinders are connected with the mounting frames in an assembling manner; the pressing blocks are fixedly connected with the lower ends of output rods of the pressing cylinders; and the pressing block rolling shafts are matched with the pressing blocks in a rotatable manner. The automatic welding machine is convenient for clamping and locating, further improves the welding efficiency and realizes automatic production.

Owner:镇江中焱数控设备有限公司

Transfer printing and coding equipment

ActiveCN106364151AEasy to clamp and positionGood pauseRotary pressesPrinting press partsElectricityFinesse

The invention discloses transfer printing and coding equipment which comprises a workbench, a PLC and a transfer printer, and further comprises a laser coding machine and a conveying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. Multiple fixing bases are fixed to the chain and connected with positioning blocks. A bracket is connected to the positioning blocks and provided with die grooves. The side wall of the transmission case is provided with a transfer printing positioning part. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disc. Three sensing columns are distributed on the wheel disc. The infrared sensor, the transfer printer and the laser coding machine are electrically connected with the PLC. By means of organic combination of transfer printing and coding, continuous transfer printing and coding operation of large batches of printed products is achieved, the production efficiency is greatly improved, transfer printing and coding are clearer, and the finesses degree is higher.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

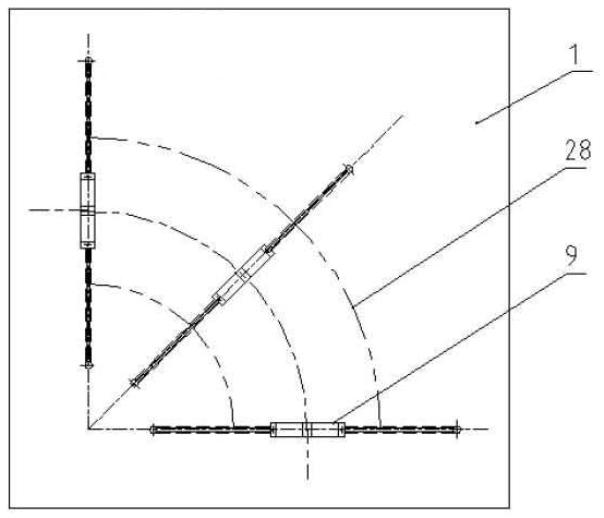

PE pipe bending device facilitating packaging

InactiveCN111470128AEasy to fix and workGuarantee normal workHollow article cleaningFilament handlingStructural engineeringMechanical engineering

The invention relates to the field of PE pipes, and particularly relates to a PE pipe bending device facilitating packaging. The PE pipe bending device comprises a base, a bending mechanism, a cleaning mechanism, a storage mechanism, a limiting mechanism, a positioning mechanism and a swing mechanism. A fixing plate is installed through the base, and therefore the bending mechanism can be conveniently fixed and work, and PE pipes can be conveniently rolled and stored; meanwhile, the bending mechanism is locked in an abutting manner under the action of the limiting mechanism, and normal work ofthe bending mechanism is guaranteed; under work of the positioning mechanism, the PE pipes in the bent and rolled process can be conveniently positioned and guided, and the PE pipes can be conveniently stored and bent; meanwhile, the swing mechanism is driven by the bending mechanism to work, the positioning mechanism slides, and the PE pipes can be conveniently stored in order and in layers; andafter the cleaning mechanism cleans the PE pipes in the sliding process, dust and sundries attached to the side walls of the PE pipes are cleaned away, the cleaned dust and sundries fall into the storage mechanism to be stored, and meanwhile subsequent cleaning is facilitated.

Owner:SHANDONG ZHONGLU PIPE IND

Fixture used for welding of automobile front floor and front row seat installation crossbeam

ActiveCN104308437ASmall working radiusStable structureWelding/cutting auxillary devicesAuxillary welding devicesSelf lockingEngineering

The invention relates to a fixture used for welding of an automobile front floor and a front row seat installation crossbeam. The fixture comprises a front floor positioning clamping device and a front row seat installation crossbeam positioning clamping device, wherein the front floor positioning clamping device and the front row seat installation crossbeam positioning clamping device are arranged on a fixture base. The front row seat installation crossbeam positioning clamping device comprises four upright columns divided into two groups, fixing beams connecting the top ends of the two groups of upright columns and a gantry framework structure formed by the upright columns and the fixing beams. A sliding beam is arranged under the fixing beams, the two ends of the sliding beam are connected with the upright columns in a sliding mode, and the middles of the fixing beams are provided with a self-locking cylinder, and the head of a piston rod of the self-locking cylinder is downward and is fixedly connected with the middle of the sliding beam. The upright columns are provided with limiting blocks, the sliding beam is provided with a cantilever moving in the front-back direction, clamping components are arranged on the cantilever, and positioning pins are disposed on the clamping components. The fixture can precisely position the front row seat installation crossbeam longitudinally and horizontally, the front row seat installation crossbeam does not shake during positioning, stability is good, and safety hidden hazards caused by shaking are avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

External pipeline paving device of large-scale air purifying equipment

The invention discloses an external pipeline paving device of large-scale air purifying equipment. The device comprises a fixing cover, horizontal positioning frames and a vertical positioning frame;the vertical positioning frame comprises a U-shaped bottom plate, transverse sliding rods and supporting brackets, the front end and the rear end of the transverse sliding rods are provided with firstthreaded sections and second threaded sections, and the thread directions of the first thread sections and the second thread sections are opposite, and the first threaded sections and the second threaded sections are provided with supporting brackets. According to the device, the external pipeline is integrally supported and fixed through the paving device, so that the overall stability of the pipeline is ensured, then the paving device and the equipment are connected and fixed, the operation difficulty of directly paving the pipeline on the surface of the equipment is reduced, and the pipeline and the inner pipeline in the equipment can be conveniently connected and fixed, and the tight performance after the pipeline is in butt joint is improved, and the multiple parts of the pipeline can be simultaneously supported and positioned through the paving device, the structure stability of the external pipeline is effectively ensured, and the effects of damping and noise reducing are achieved.

Owner:嘉兴市良友制衣有限公司

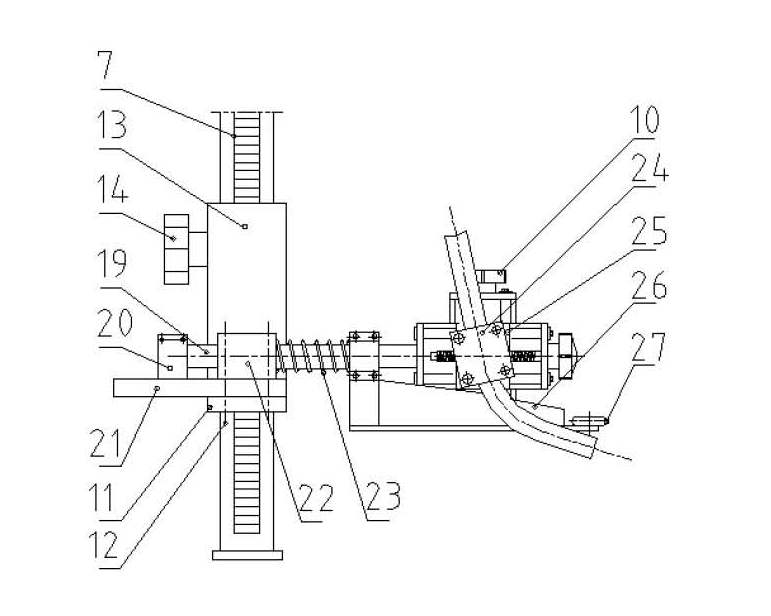

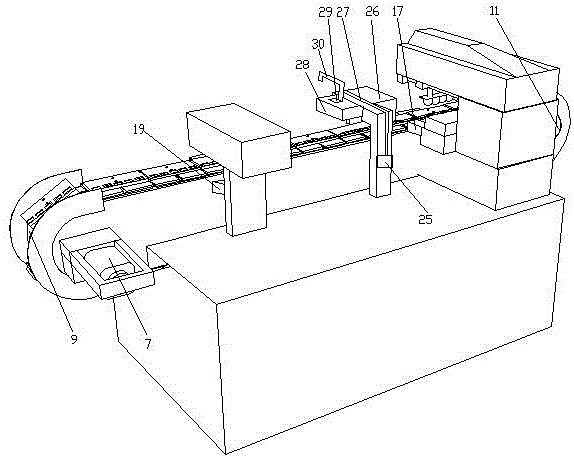

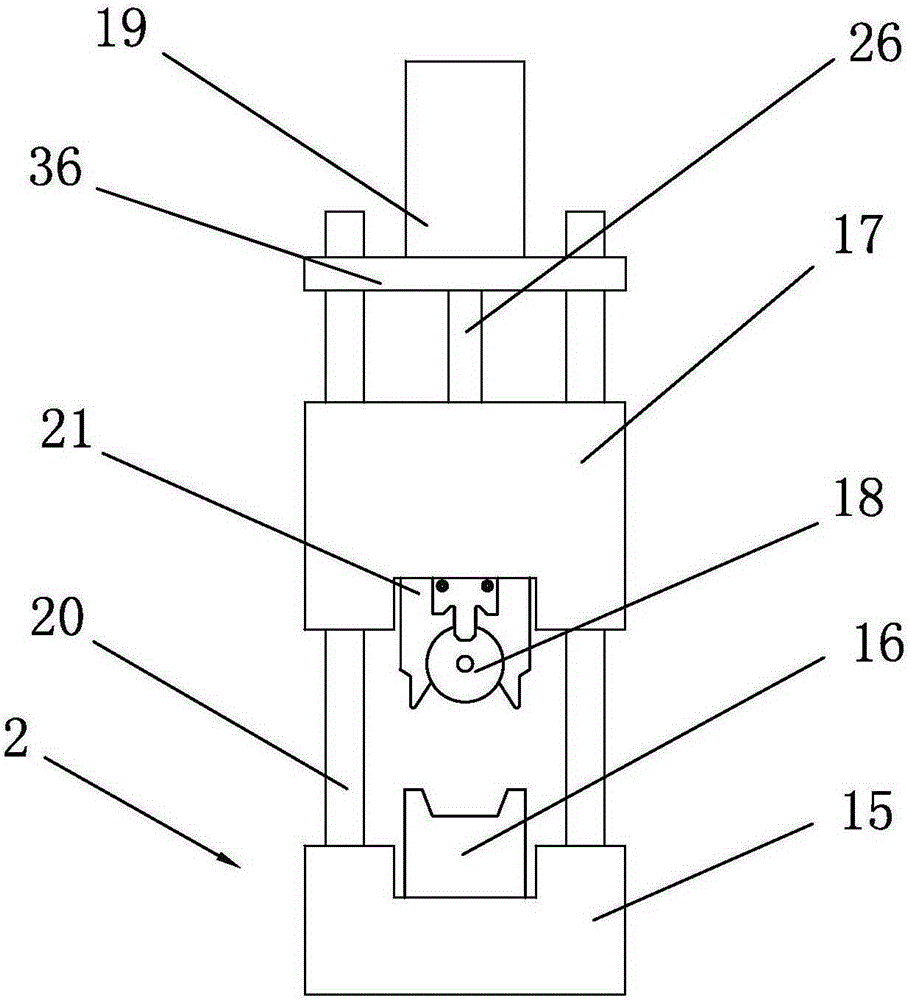

Clamping and pushing device of pipes

ActiveCN103934581APrecise positioningEasy to clamp and positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringIdler-wheel

The invention discloses a clamping and pushing device capable of accomplishing feeding of pipes automatically and conducting centering and clamping on the pipes. The clamping and pushing device comprises a mounting base which is provided with a top board, and a clamping and centering mechanism is arranged on the lower surface of the top board. A feeding idler wheel and a power mechanism driving the feeding idler wheel are movably arranged at the position, below the centering and clamping mechanism, of the mounting base. A photoelectric sensor detecting the pipes is arranged at the position, in front of the feeding idler wheel, of the mounting base.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

Inclined valve processing clamp convenient to regulate

ActiveCN105364592ARealize clampingAchieve positioningWork clamping meansPositioning apparatusEngineeringVALVE PORT

The invention provides an inclined valve processing clamp convenient to regulate. The inclined valve processing clamp comprises a base, a supporting plate and a pressing mechanism, wherein two inclined supporting blocks are arranged on the base; the supporting plate, with a front that is lower than the rear, is mounted on the supporting blocks in an inclined mode; the bottom of the supporting plate is provided with two regulating plates which correspond to the supporting blocks; the front parts of the regulating plates are rotatably connected with the front parts of the supporting blocks through a rotary shaft; the rear part of each regulating plate is provided with a locking hole; the rear part of each supporting block is provided with a plurality of height regulating holes; the regulating plates and the supporting blocks are fixed by virtue of positioning pin rolls which are arranged in the height regulating holes and the locking holes in a penetration mode; and a supporting mechanism which is used for supporting the upper end of a valve is arranged in front of the base. In use, an inclined flange surface of the inclined valve is supported on the supporting plate, and is pressed by virtue of the pressing mechanism after being initially positioned through a bolt and a positioning hole; and the supporting plate can be regulated in angle by rotating the regulating plates around the rotary shaft, so that clamping for valves with different angles of inclinations is adapted.

Owner:CHONGQINGZHICHENG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com