Motorcycle frame assembly checking tool

A technology for motorcycles and frames, applied in the field of detection tooling for motorcycle parts, can solve problems such as low detection efficiency and difficult detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

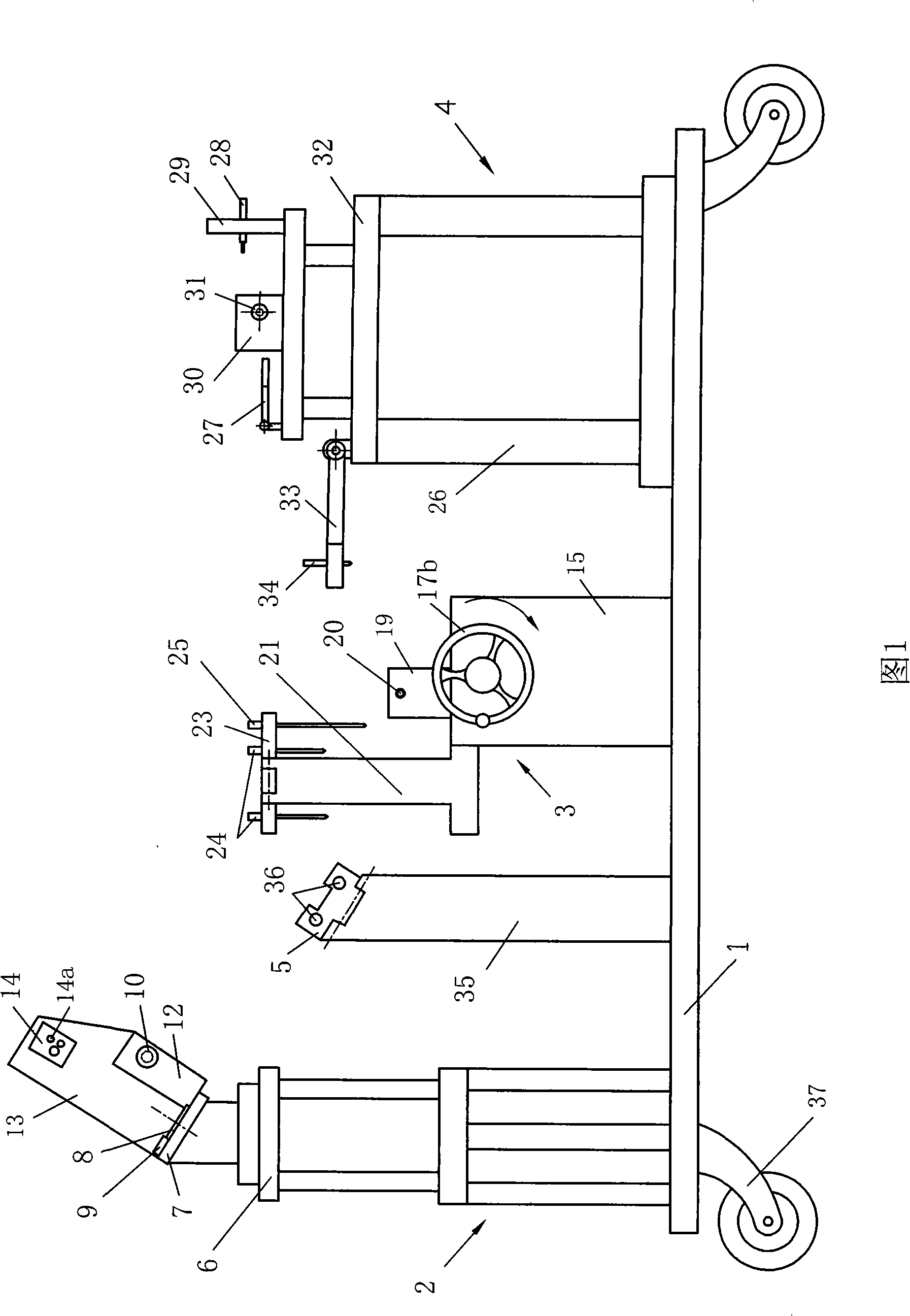

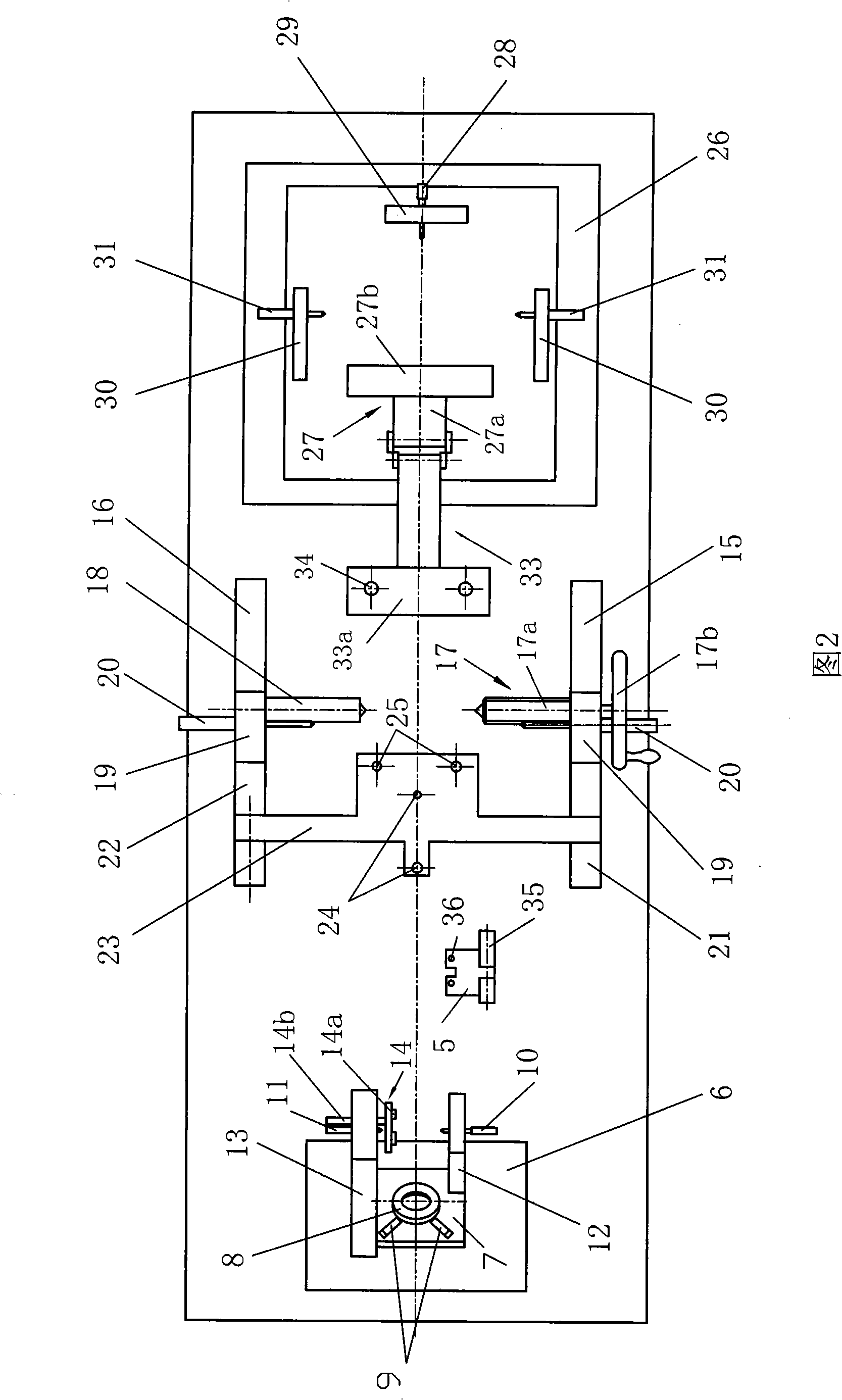

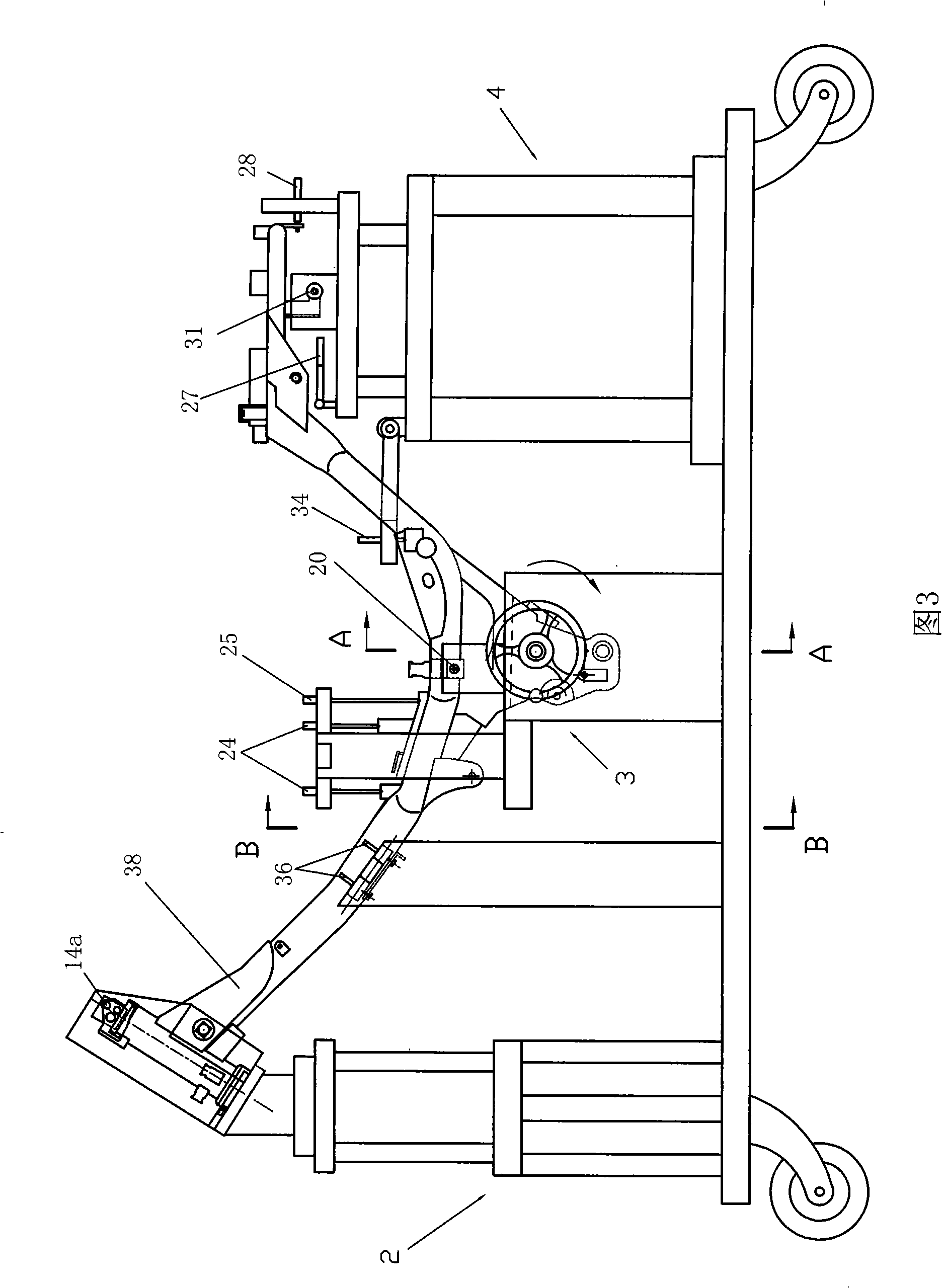

[0024] Below in conjunction with accompanying drawing and embodiment the utility model is further described:

[0025] As shown in Fig. 1 and Fig. 2, the utility model is made up of base plate 1, head detection mechanism 2, middle part detection mechanism 3, tail detection mechanism 4, control valve detection block 5 and roller 37. Wherein the head detection mechanism 2, the middle detection mechanism 3 and the tail detection mechanism 4 are successively arranged on the front, middle and rear of the upper surface of the bottom plate 1 along the longitudinal centerline of the bottom plate 1, and the control valve detection block 5 passes through the control valve detection branch. The plate 34 is arranged between the head detection mechanism 2 and the middle detection mechanism 1, and is located on the front left side of the middle detection mechanism 3. Rollers 37 are installed on the lower surface of the bottom plate 1, so that the utility model can move flexibly and convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com