Inclined valve processing clamp convenient to regulate

A technology of tilting valve and fixture, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconvenient processing of horizontal flange surface, inability to clamp and position, and the structure is not stable enough, so as to achieve convenient clamping and positioning. , to ensure the effect of processing and guaranteeing the stability of the support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

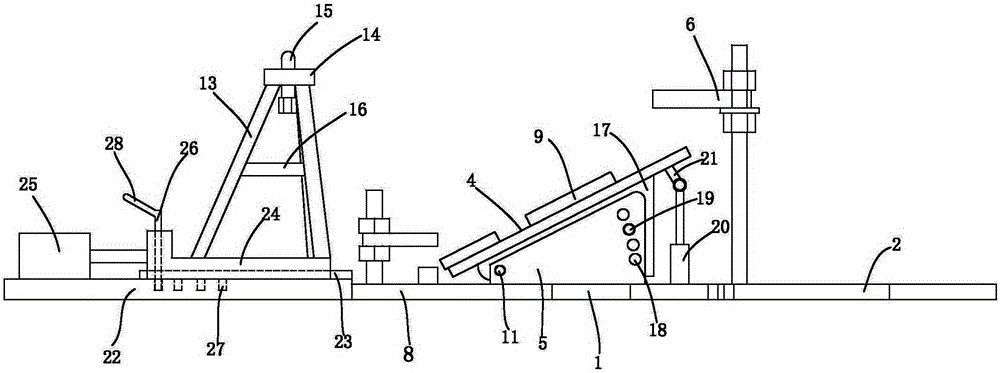

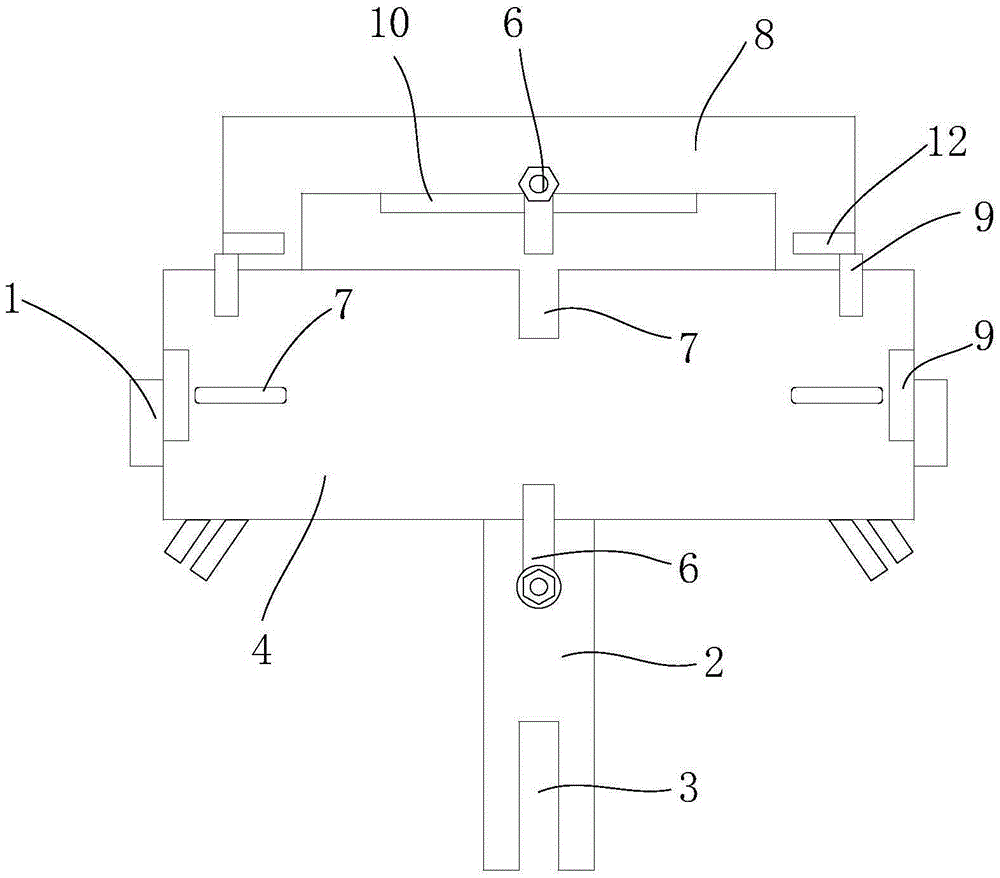

[0050] Such as Figure 1 to Figure 2 As shown, an easy-to-adjust inclined valve body processing fixture includes a base 1, a support plate 4 and a pressing mechanism 6. Two inclined support blocks 5 are arranged on the base. On the block 5, two adjusting plates 17 corresponding to the supporting block 5 are provided at the bottom of the supporting plate, the front portion of the adjusting plate 17 is rotationally connected with the front portion of the supporting block 5 through the rotating shaft 11, and the rear portion of the adjusting plate 17 is provided with a locking hole The back of the support block 5 is provided with a plurality of height adjustment holes 18, and the adjustment plate 17 and the support blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com