Patents

Literature

31results about How to "Movement is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

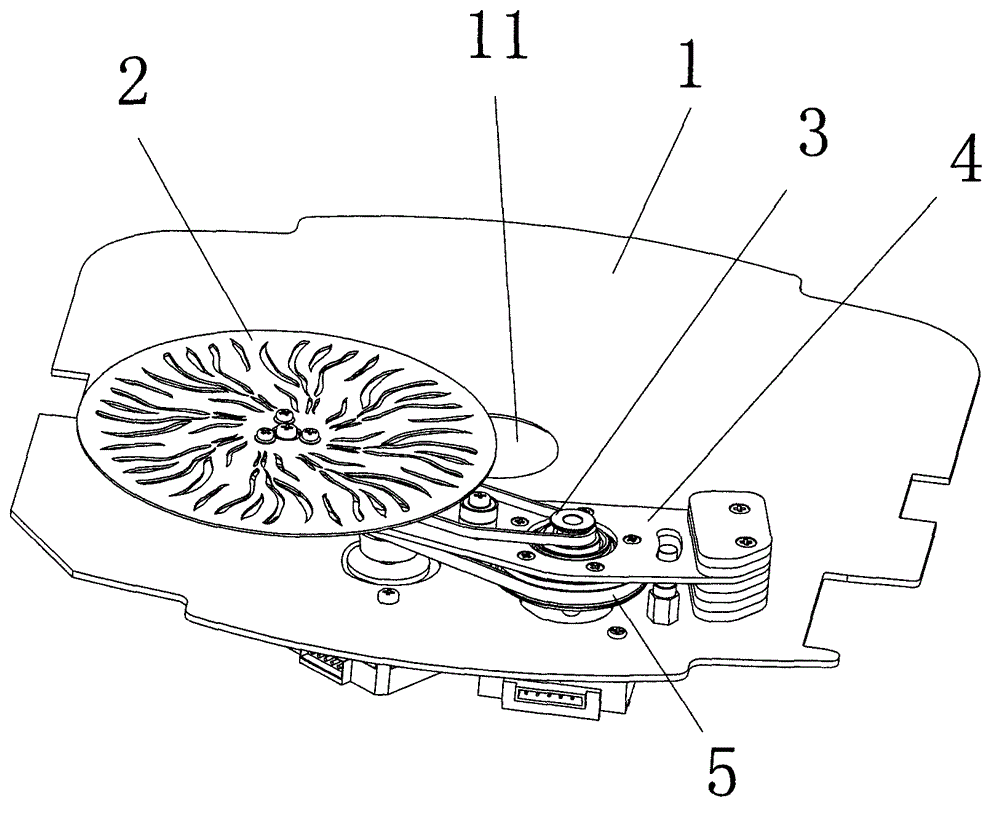

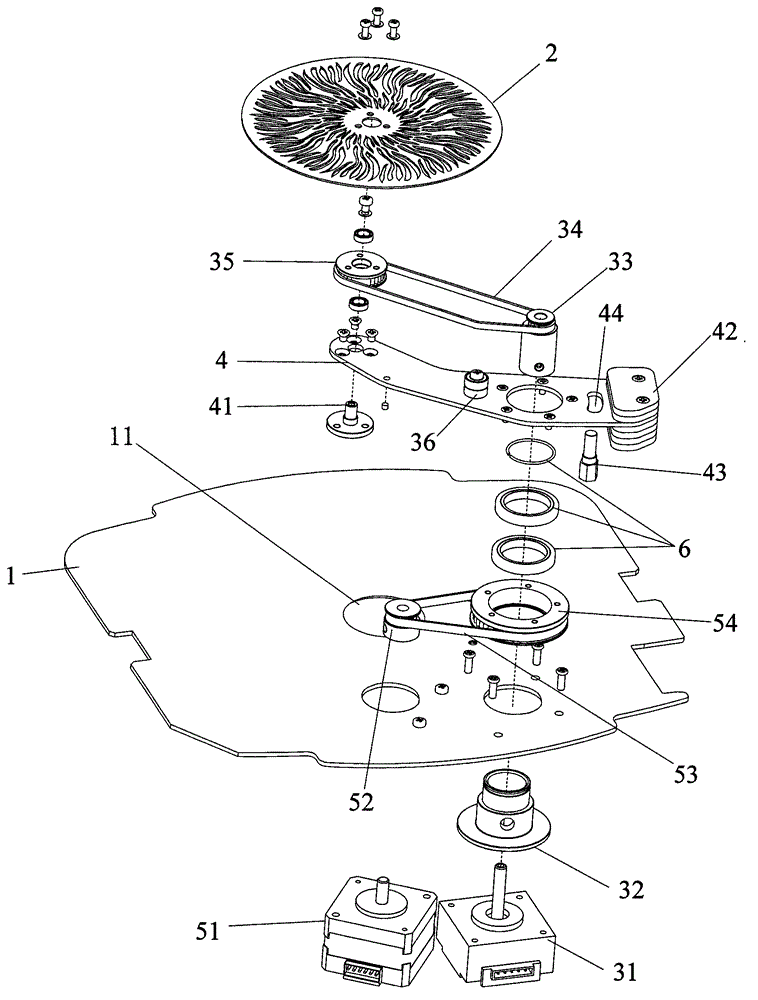

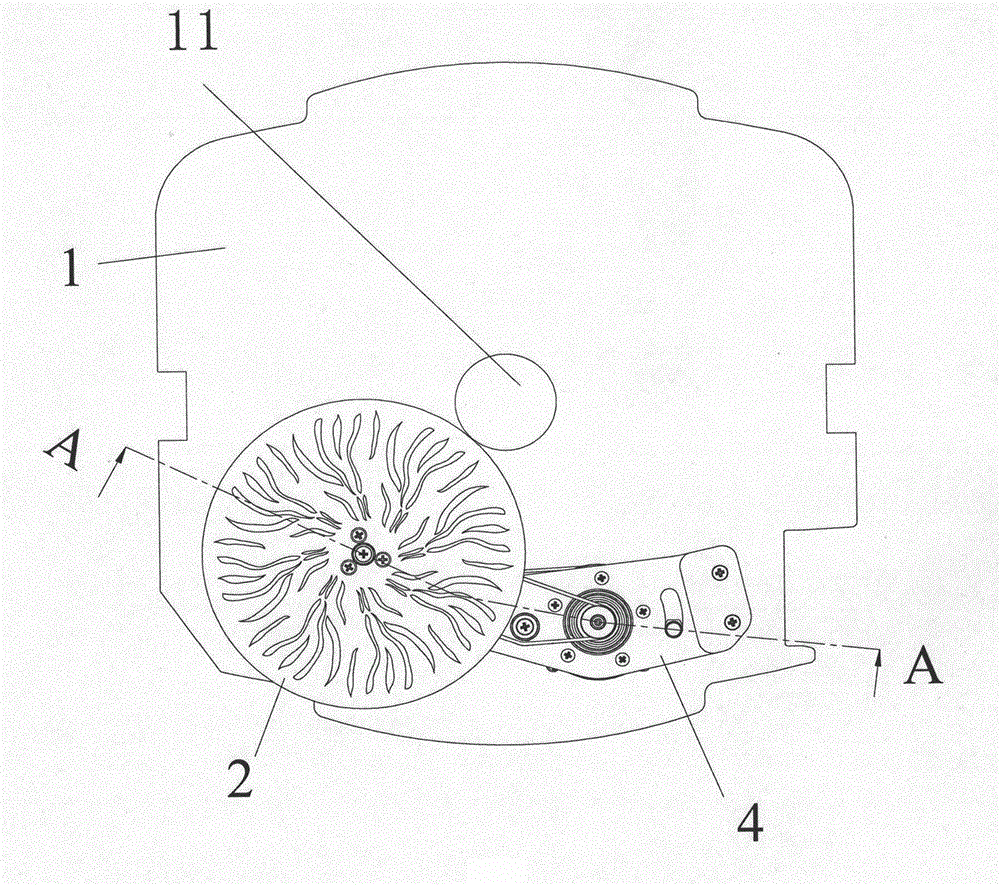

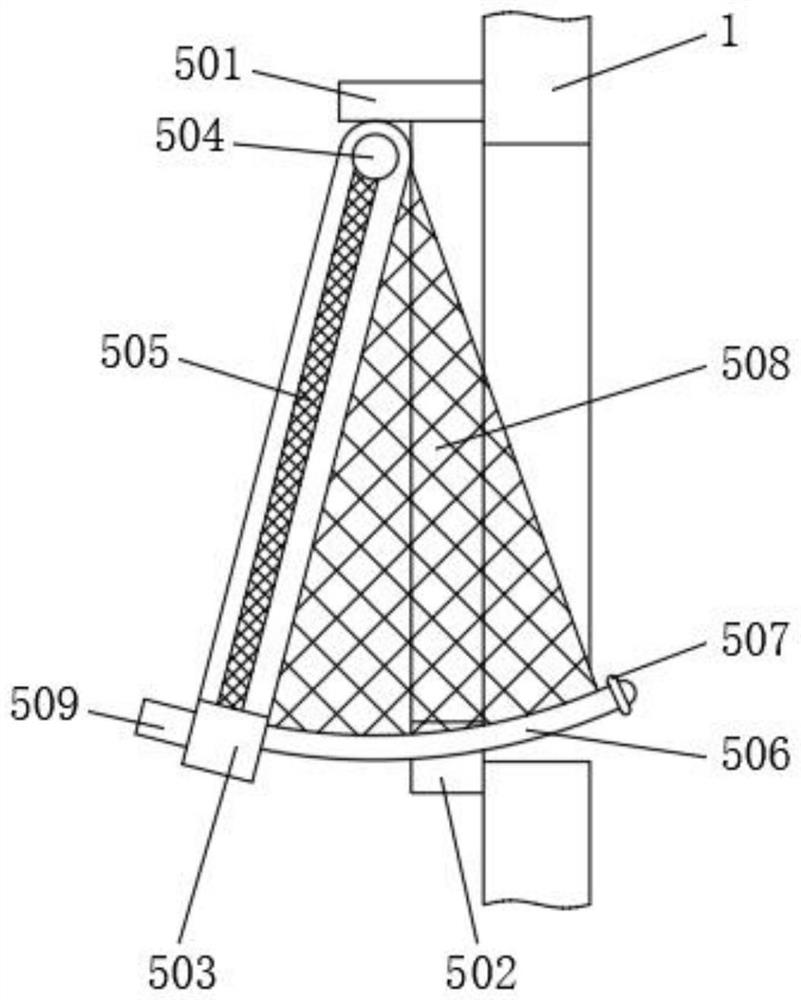

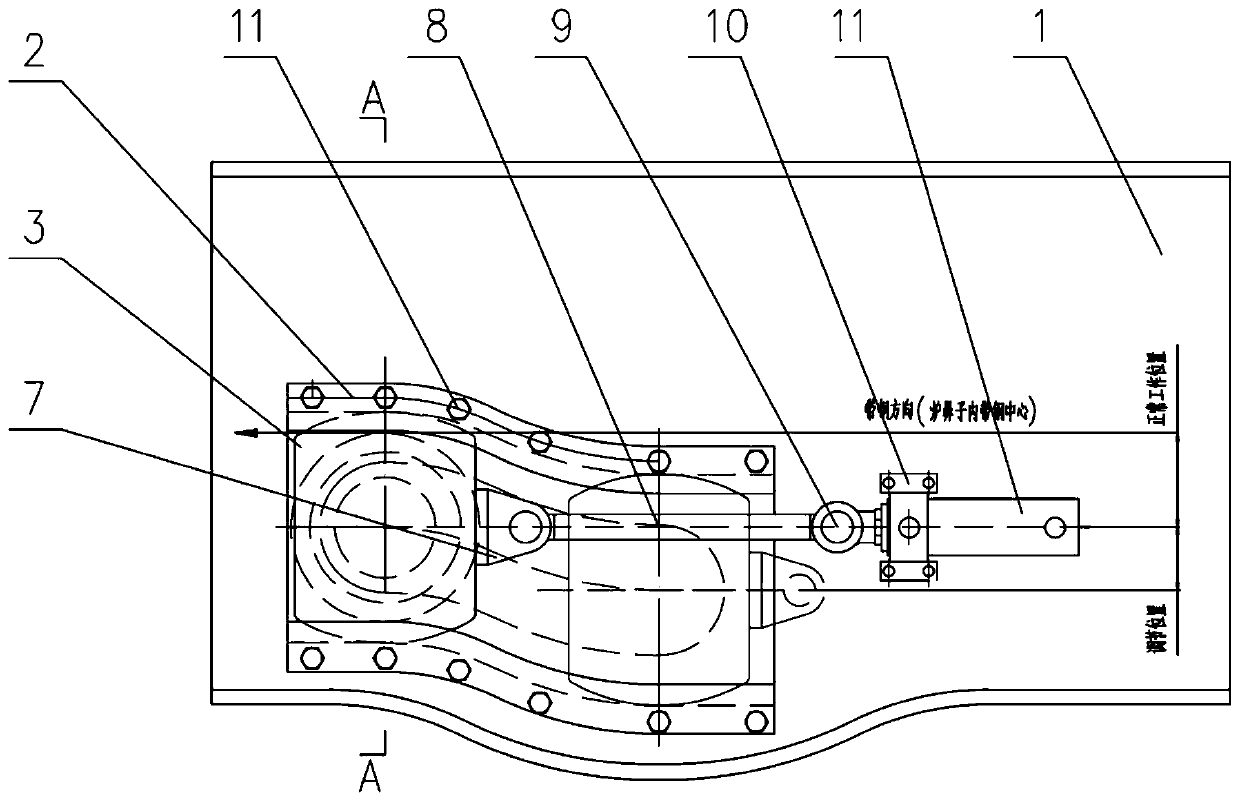

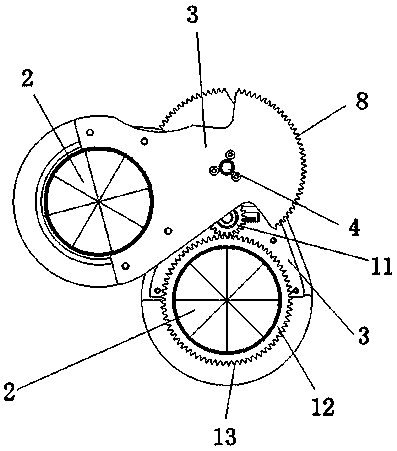

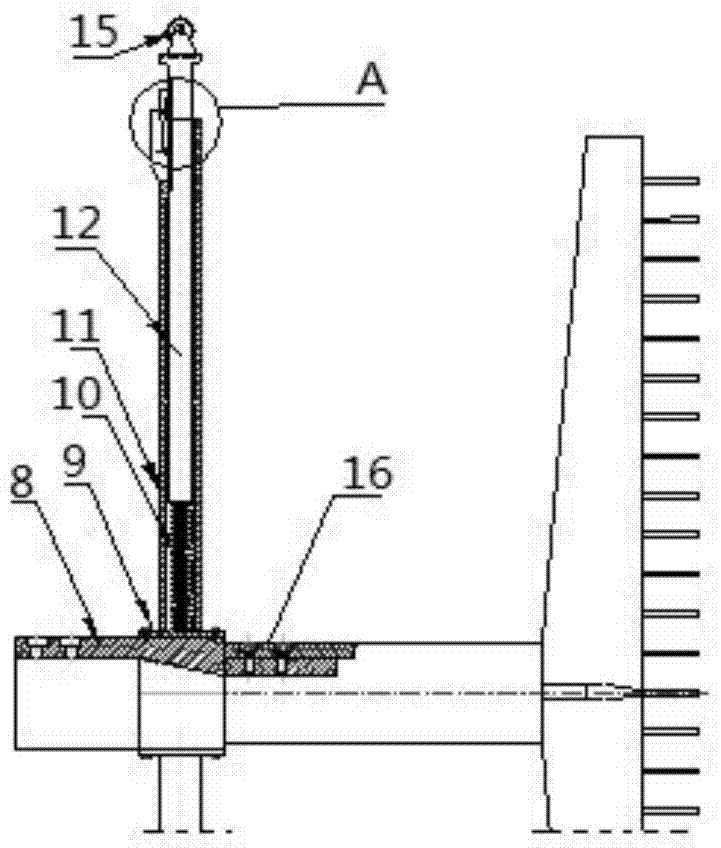

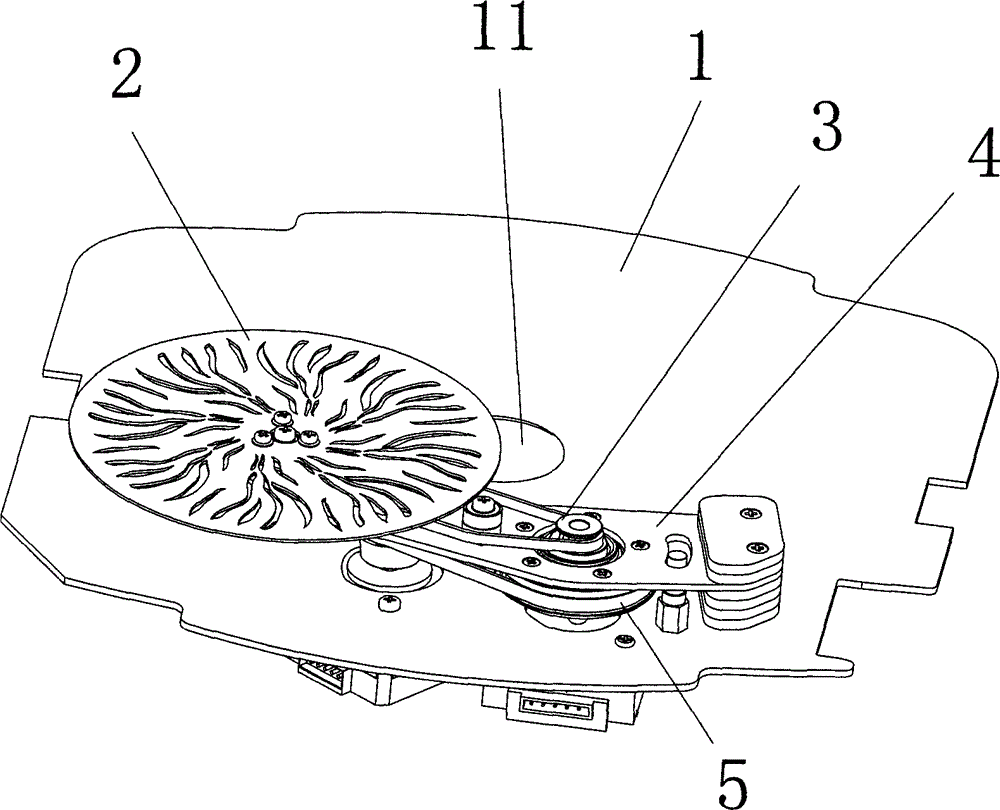

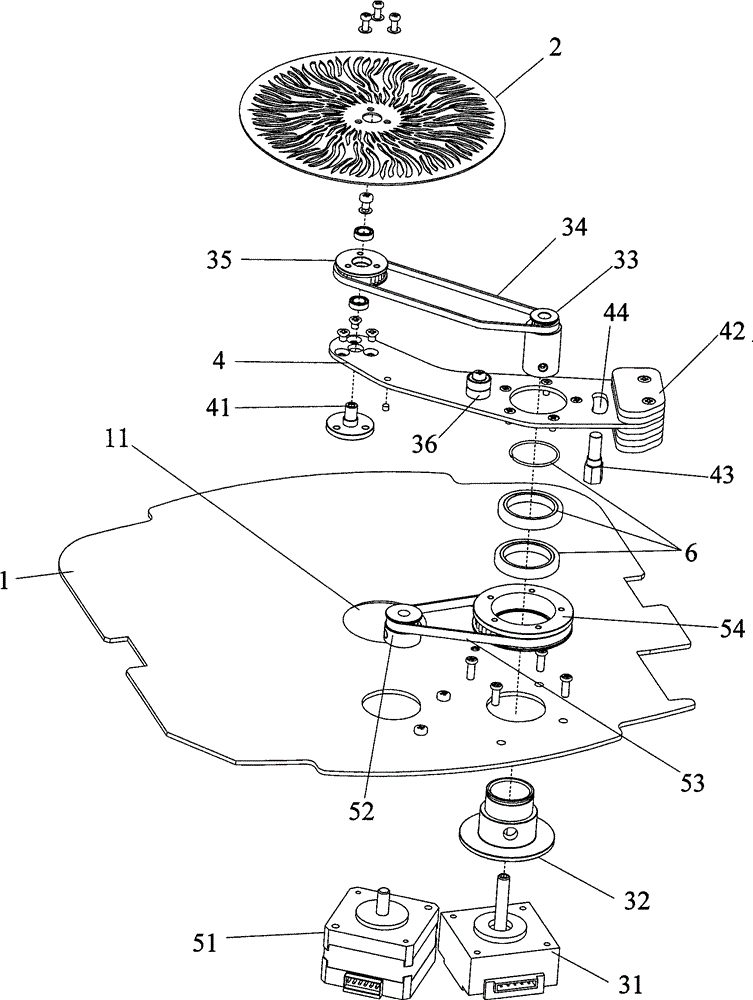

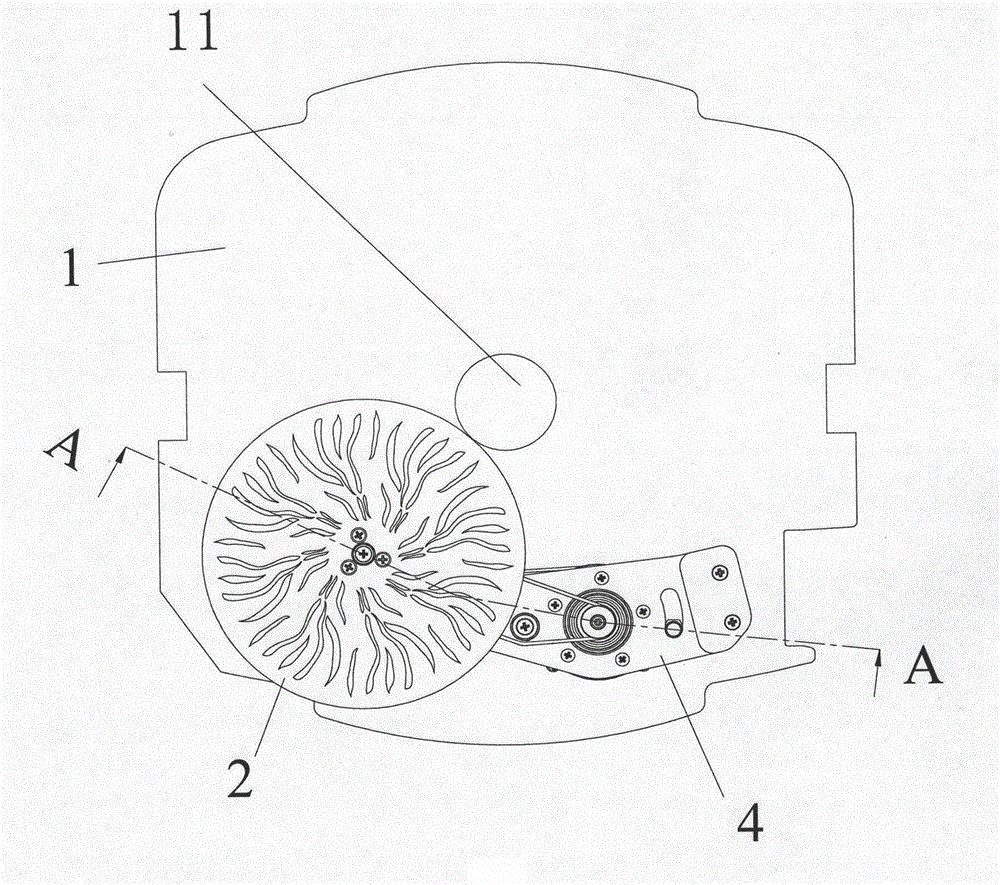

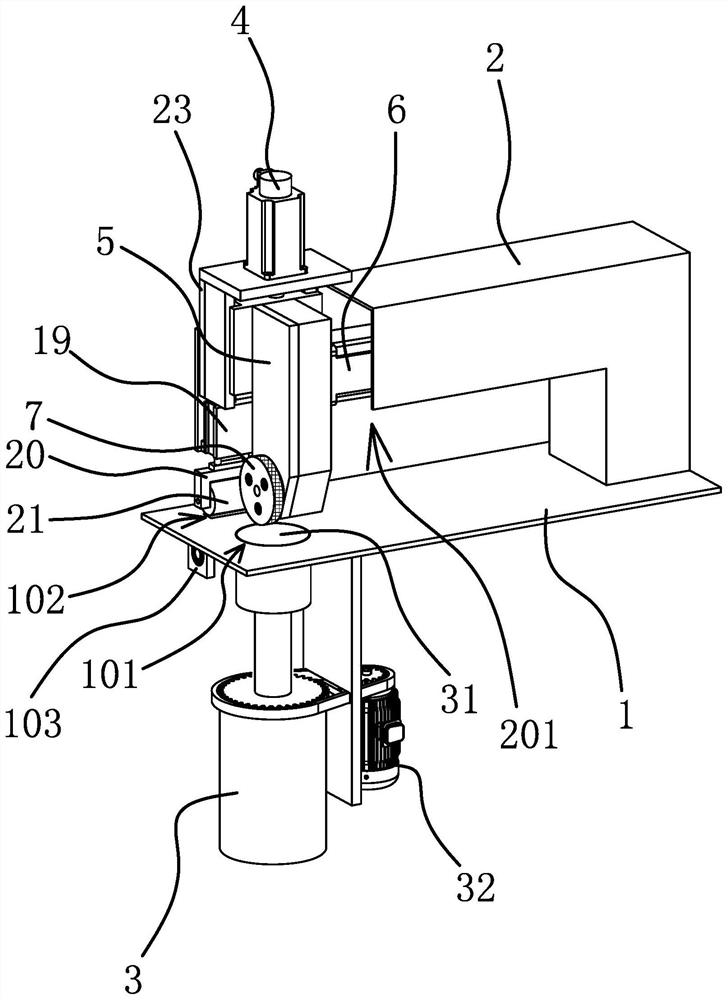

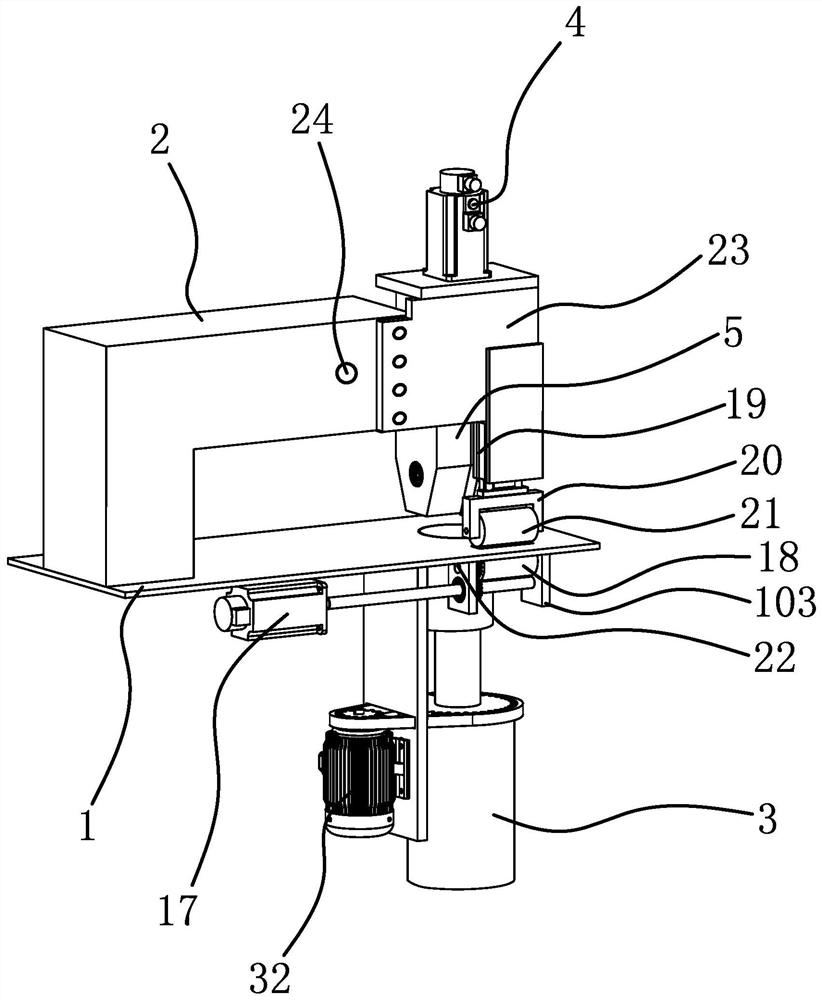

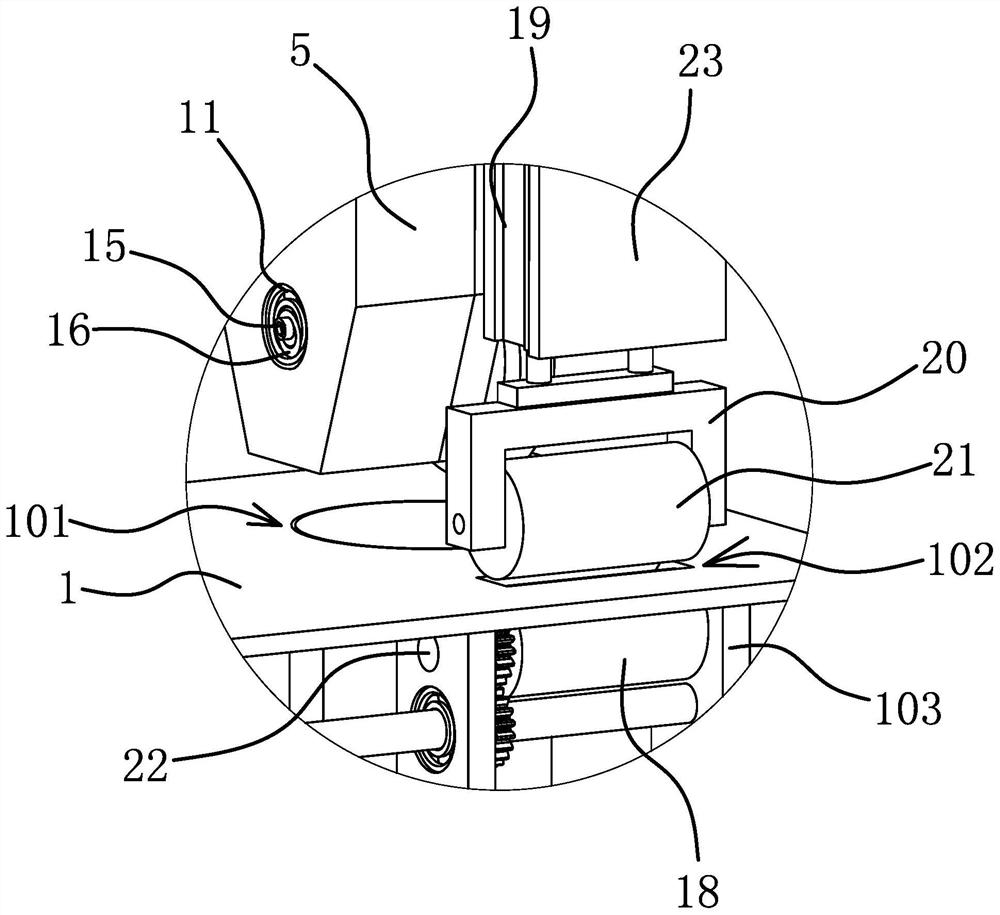

Effect device for forming stage-lighting effects

ActiveCN102943996AMove fastFlexible movementLighting applicationsTheatre/circusStage lightingEngineering

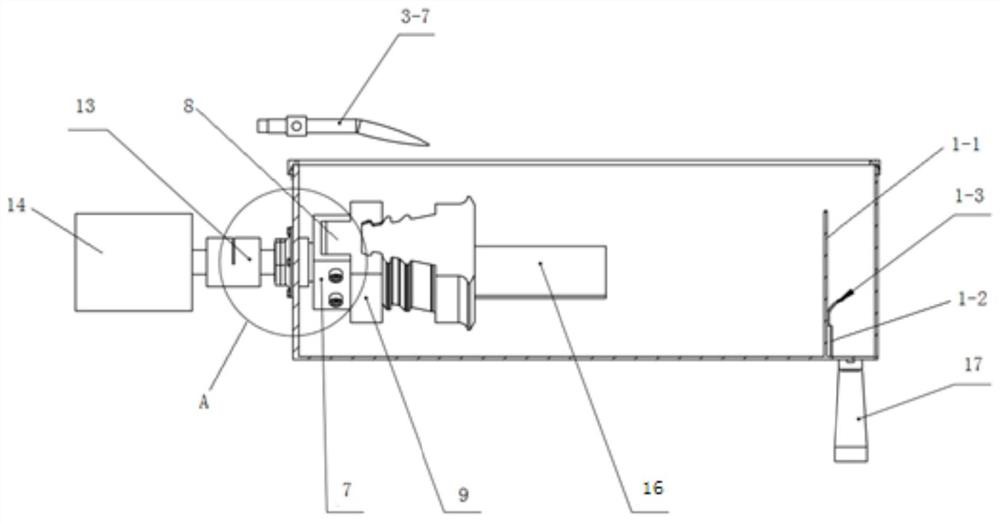

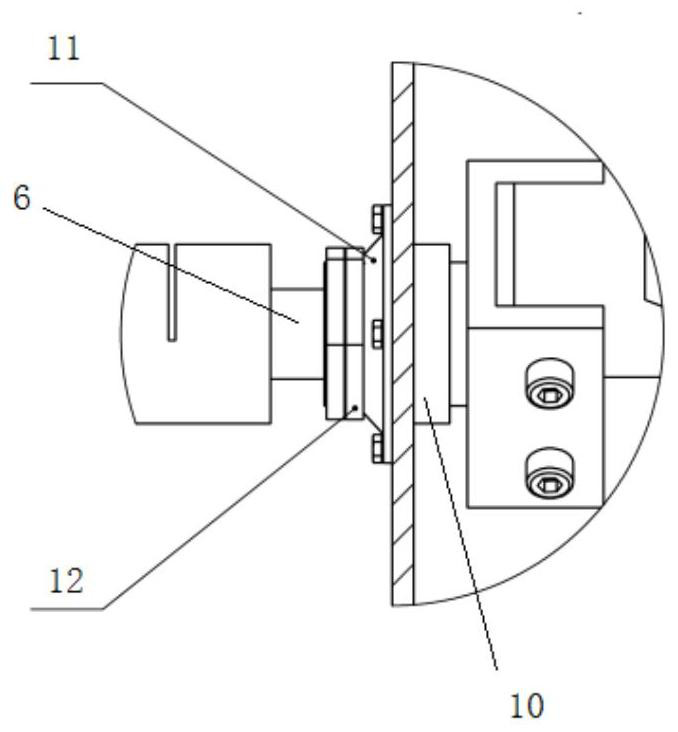

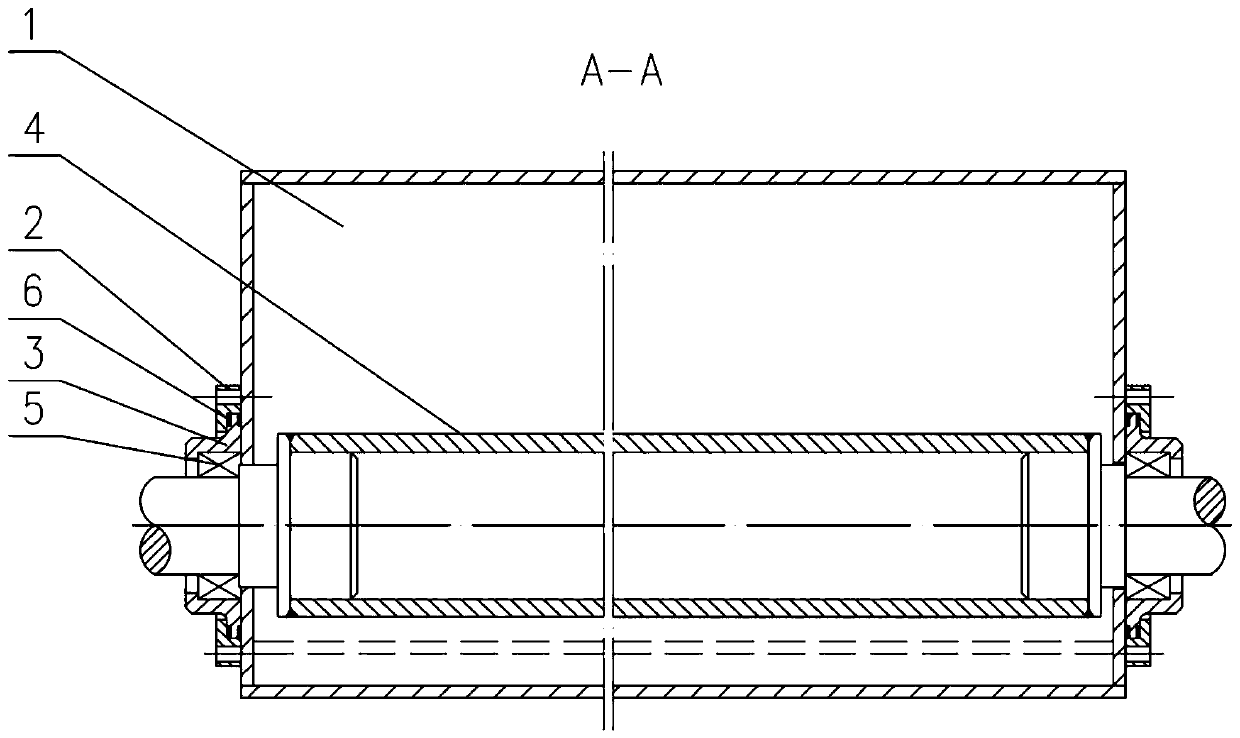

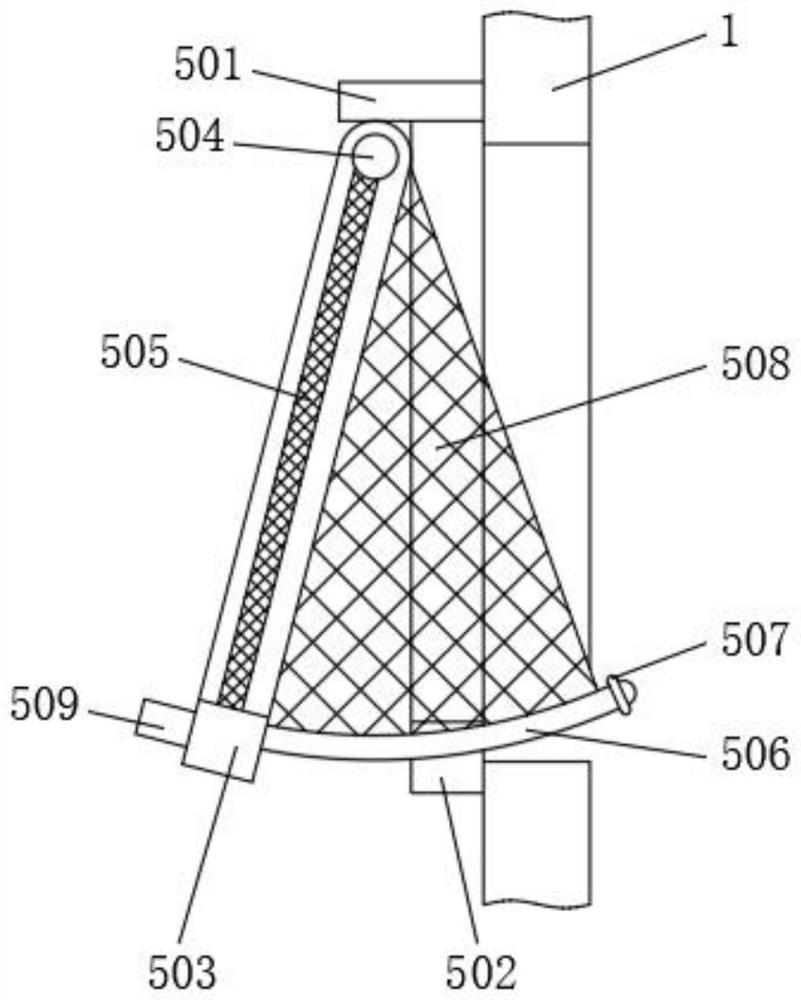

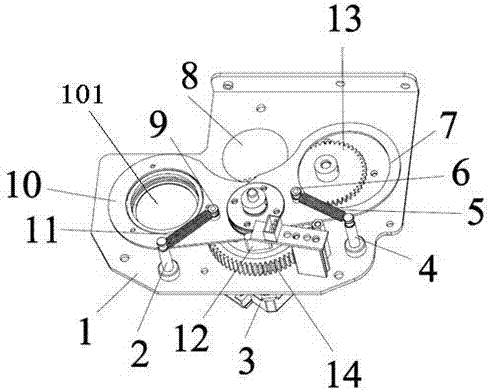

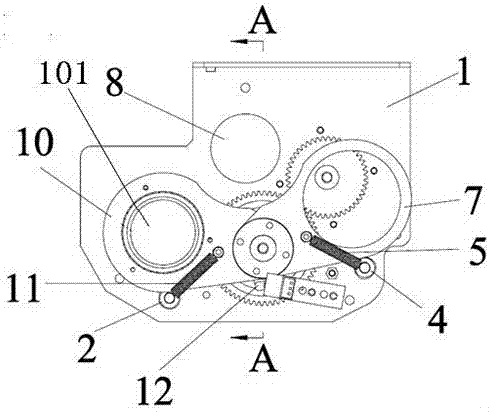

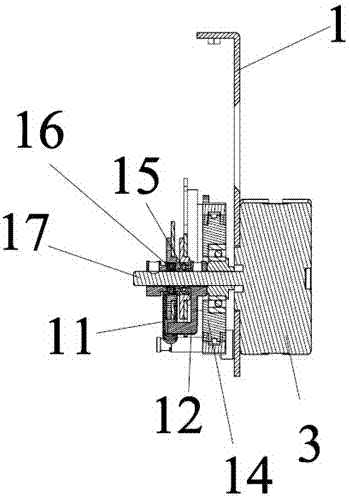

The invention discloses an effect device for forming stage-lighting effects. The effect device comprises a main support, an effect wheel, a rotating mechanism and a moving mechanism, a light hole is arranged on the main support, the rotating mechanism is connected with the effect wheel and drives the effect wheel to rotate, the moving mechanism is used for enabling the effect wheel to move relative to the light hole, is mounted on the main support and comprises a rocker arm and a moving driving mechanism, the moving driving mechanism is connected with the rocker arm and drives the rocker arm to rotate, and the effect wheel is connected with the rocker arm. Relative movement of the effect wheel and the light hole is controlled by the rocker arm, the effect wheel can synchronously move with a moving motor, the change of pattern effects is greatly accelerated, the lighting effects are better, and the size of a lamp can be reduced.

Owner:GUANGZHOU FINEART LIGHTING

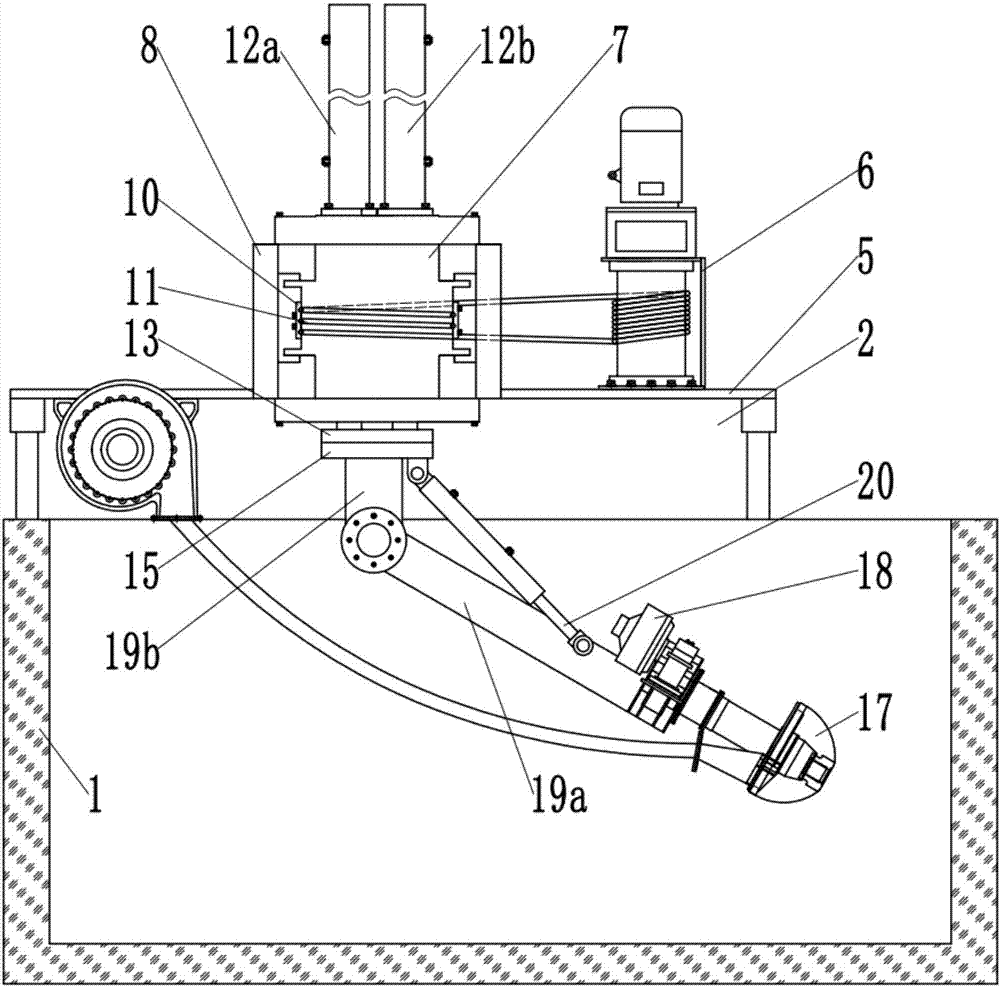

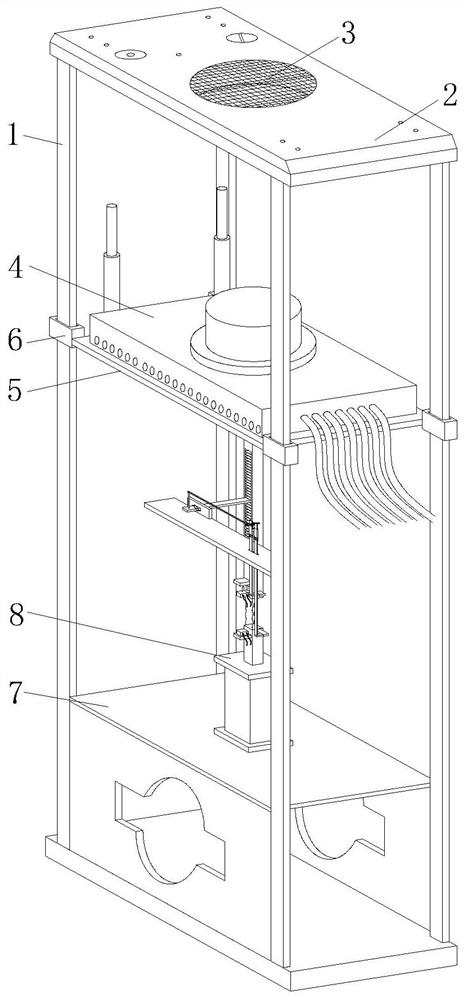

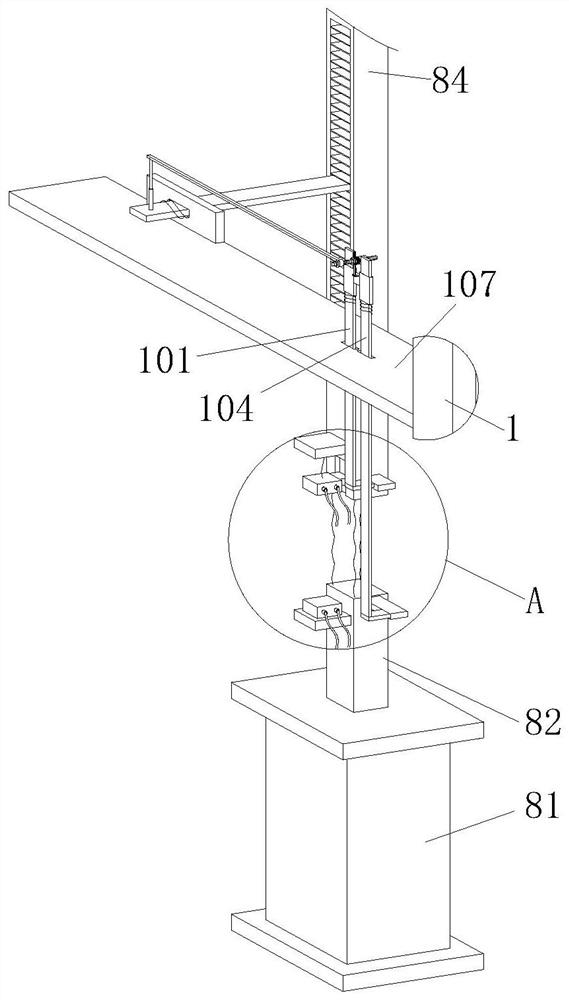

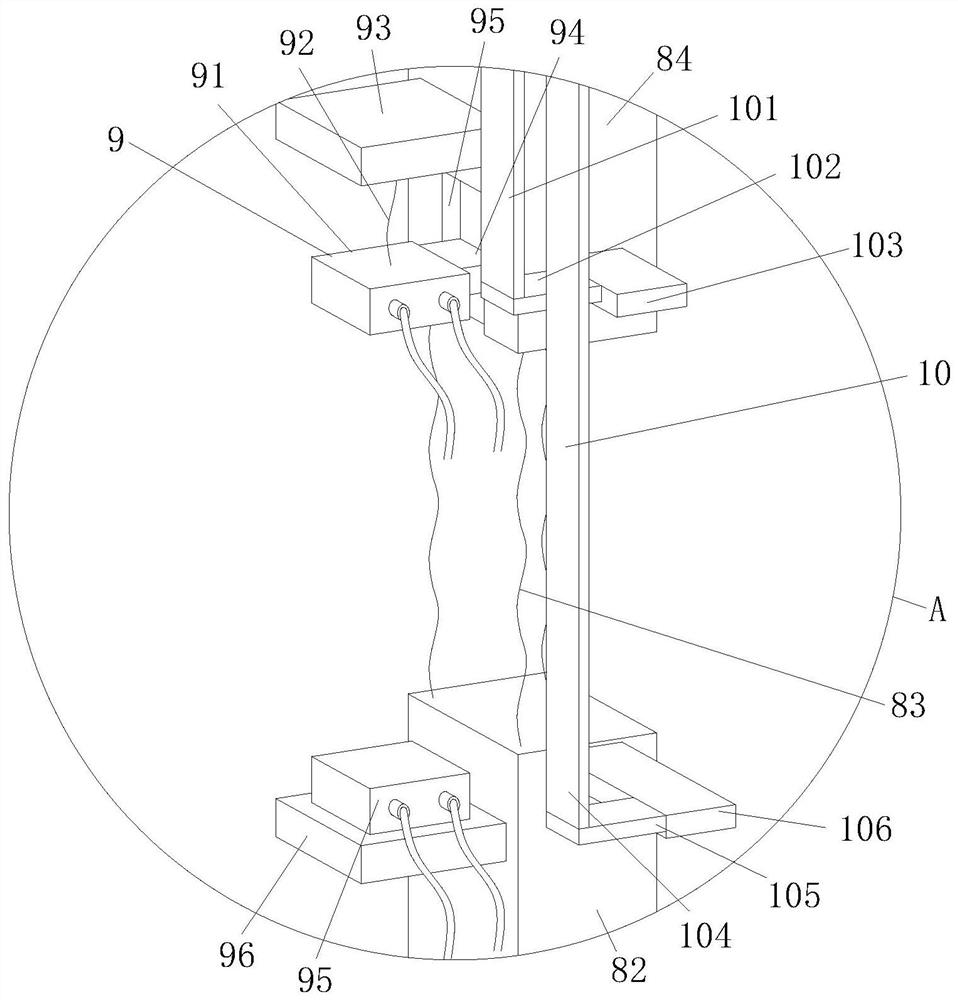

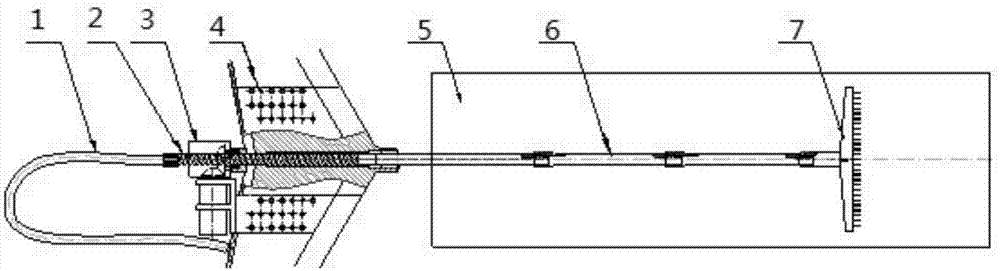

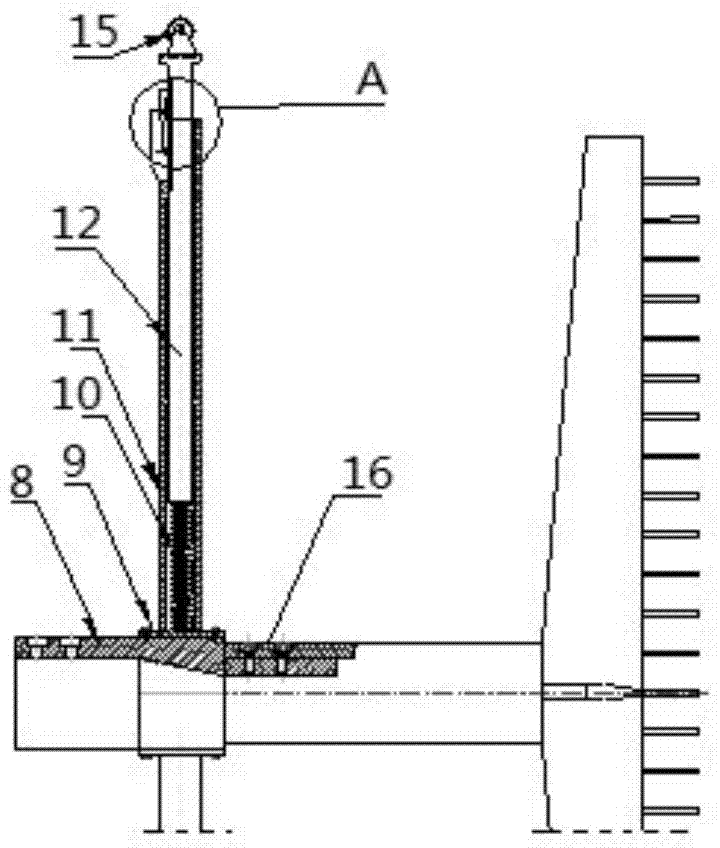

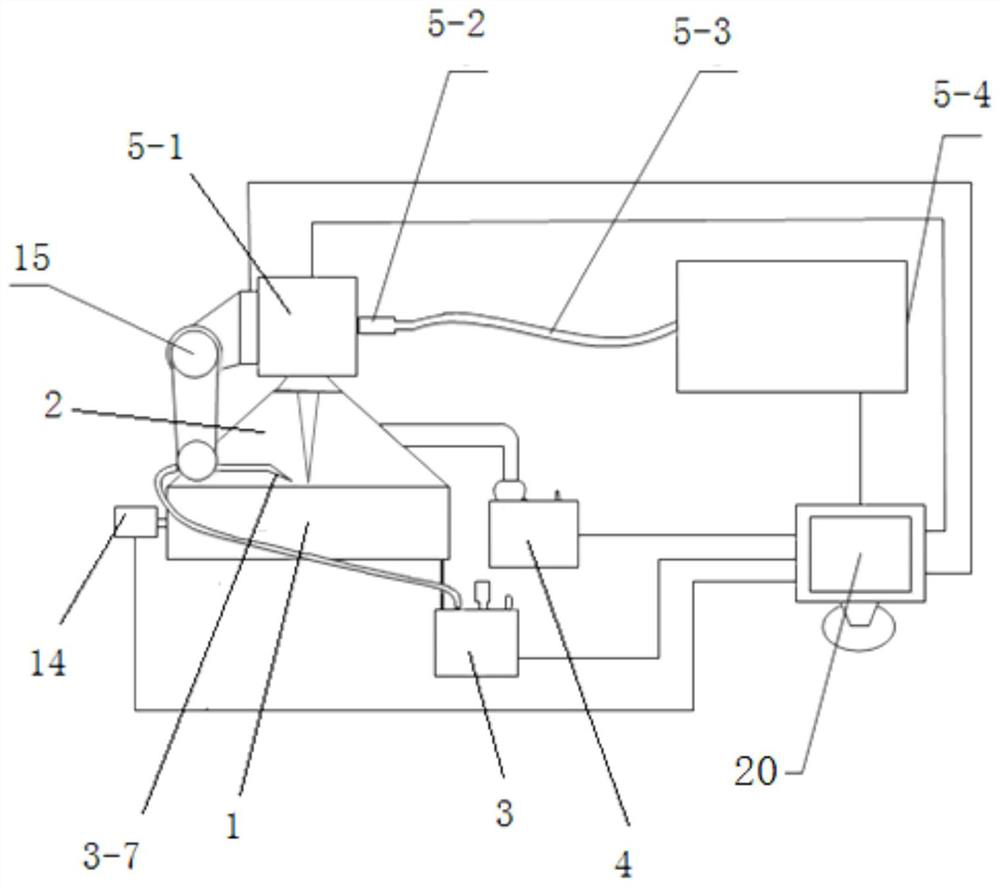

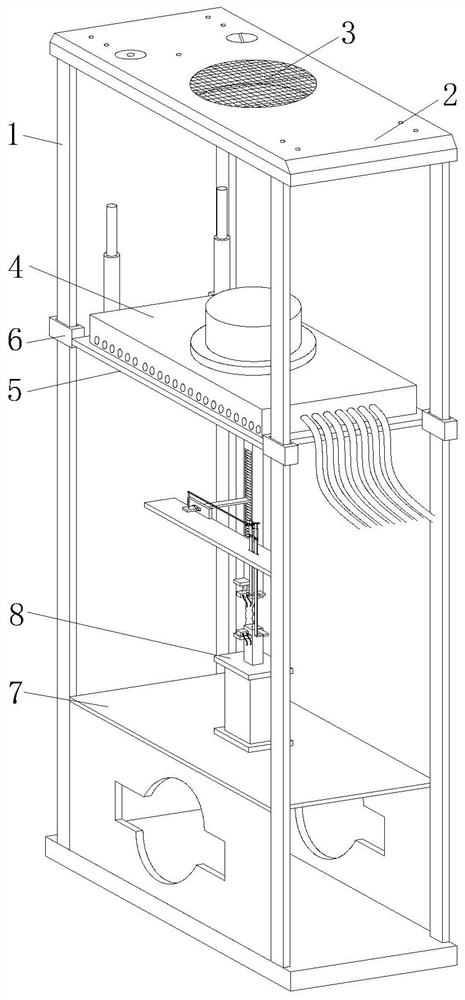

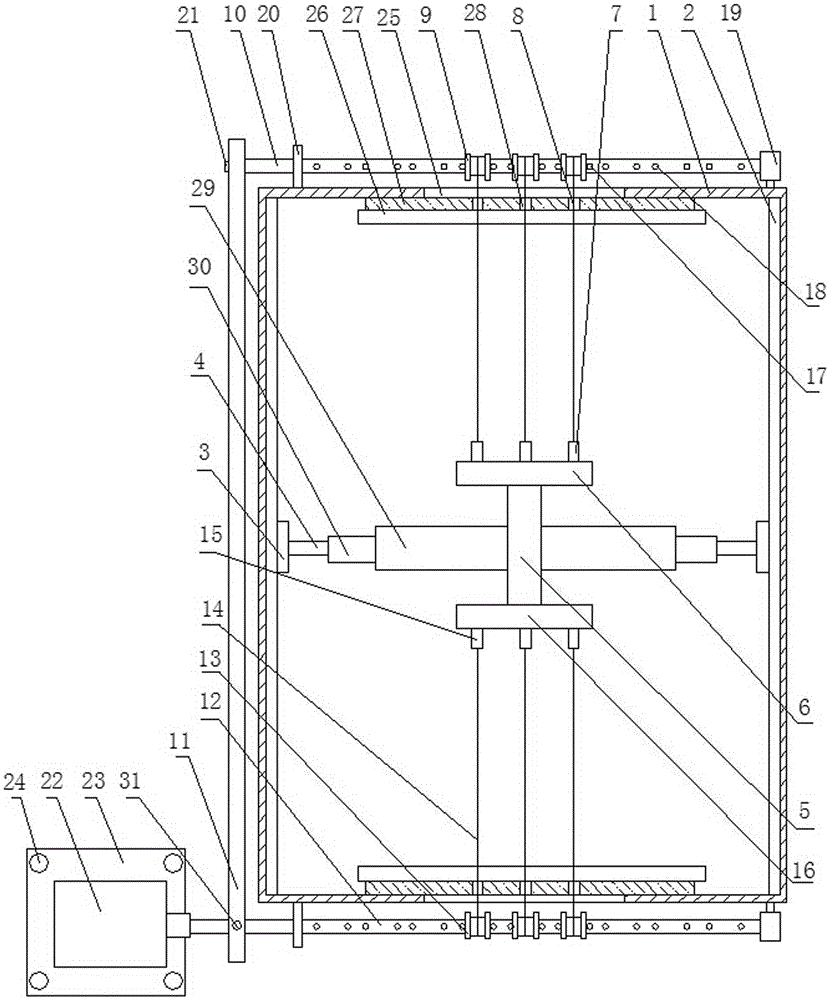

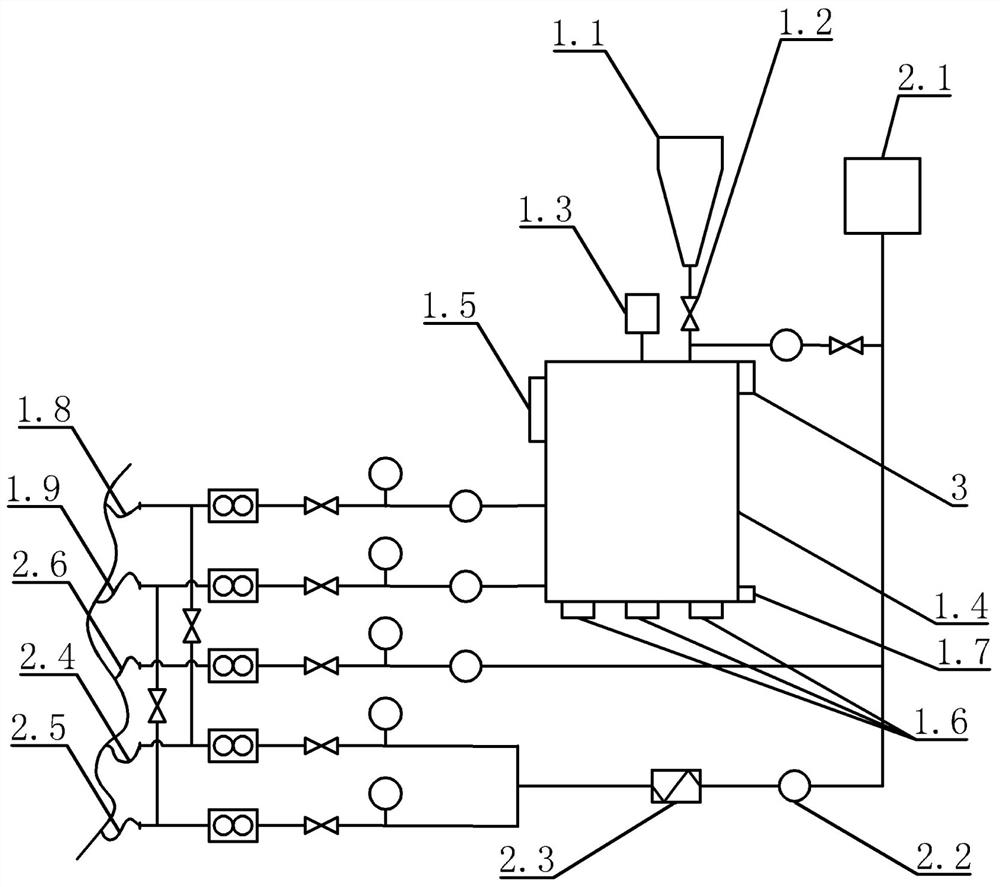

Cutter-suction dredger operation simulator

InactiveCN106875818AFlexible adjustment of feed amountReduce design difficultyEducational modelsOptical axisEngineering

The invention discloses a cutter-suction dredger operation simulator. The bottom of a vertical planetary hoist is installed on a bench stepping mechanism through a flange. A groove is arranged in the circumference of a cylindrical drum. The steel rope of the vertical planetary hoist is wound inside the groove. In a bridge height adjustment mechanism, a front flange hydraulic lever I and a front flange hydraulic lever II are installed in the cylindrical drum through front flanges. A connecting block I is provided with two shaft holes which match the optical shaft of the front flange hydraulic lever I and the optical shaft of the front flange hydraulic lever II respectively and are axially positioned through shaft shoulders and round nuts. In a reamer power output mechanism, one end of a reamer bridge II is welded to a connecting block II, a rotating shaft is arranged between the other end of the reamer bridge II and one end of a reamer bridge I, and the rotating shaft is arranged on the reamer bridge I through a rolling bearing. The device can be adjusted based on different soil quality, and improve the output of dredgers. The device has a longer service life.

Owner:WUHAN UNIV OF TECH

Improved intelligent air conditioner power environment monitoring equipment and using method thereof

ActiveCN112747209AReduce addSave resourcesEfficient regulation technologiesStands/trestlesControl engineeringDust control

Owner:安徽康赛威电子科技有限公司

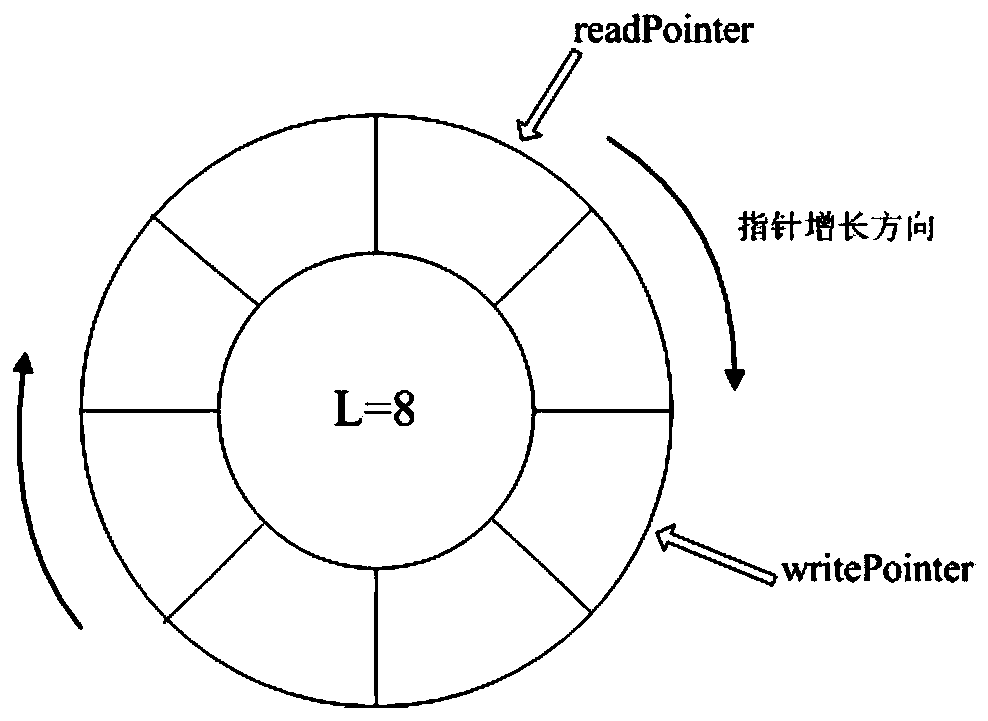

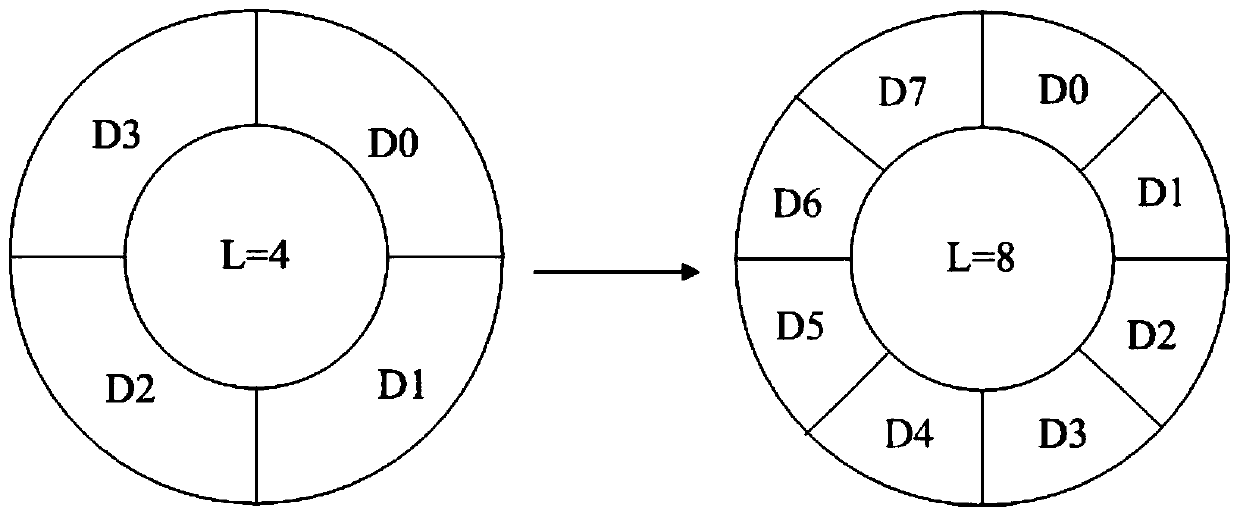

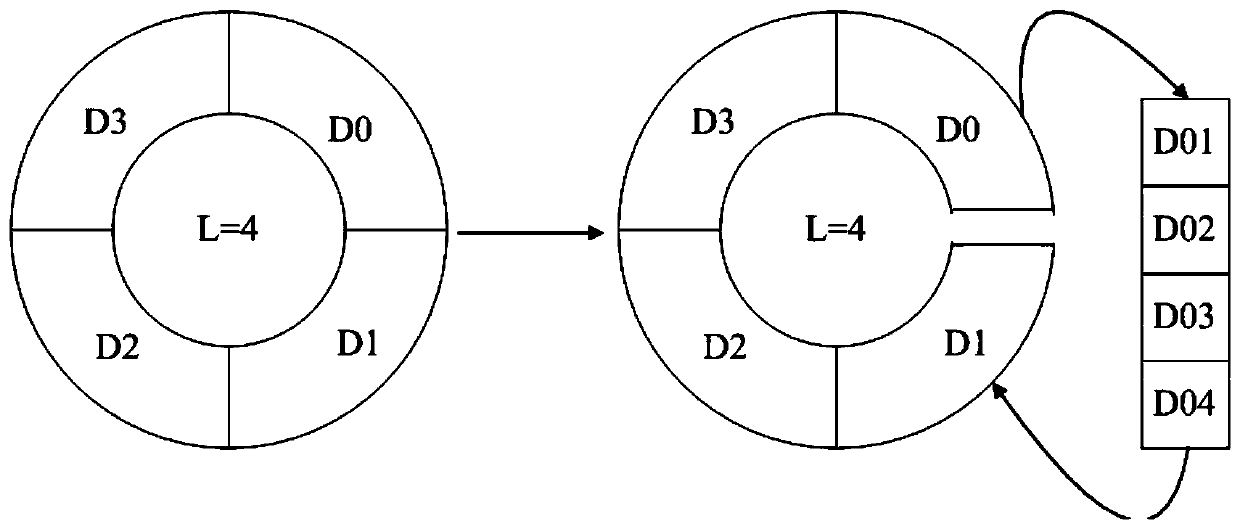

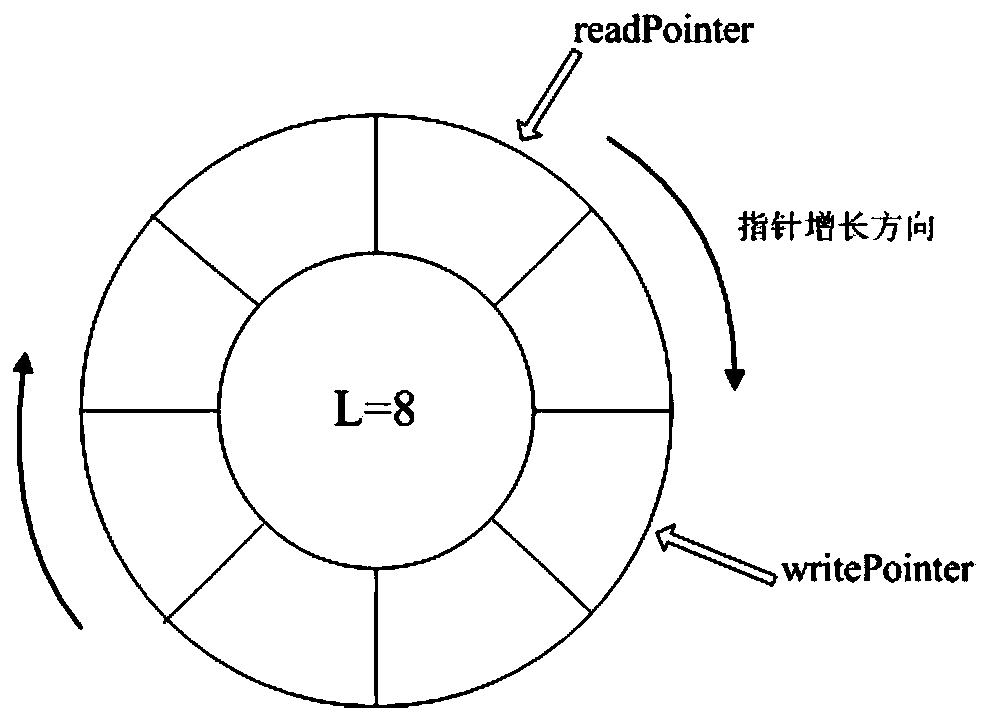

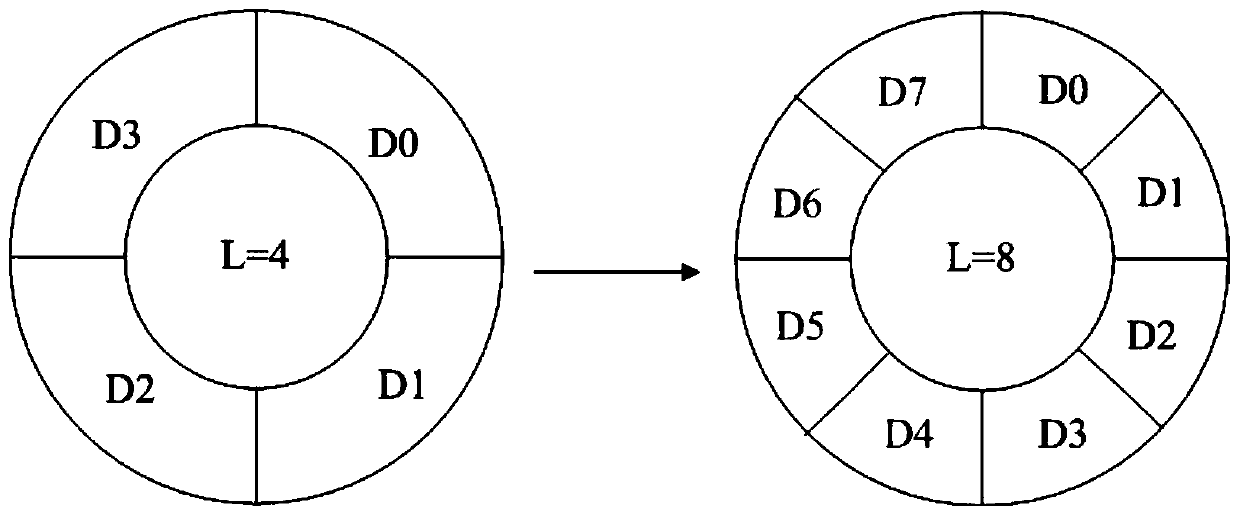

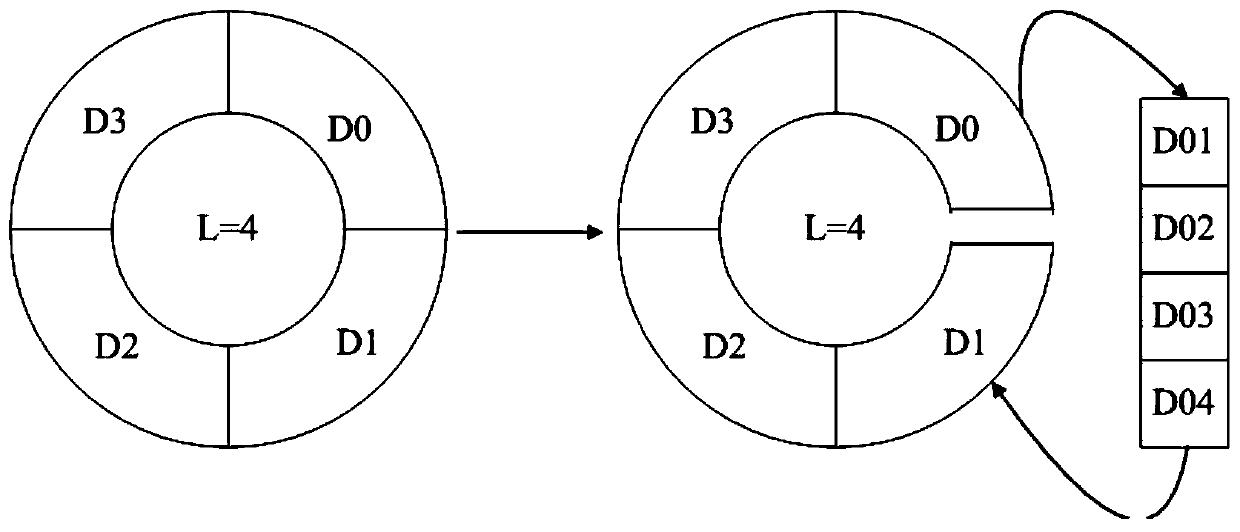

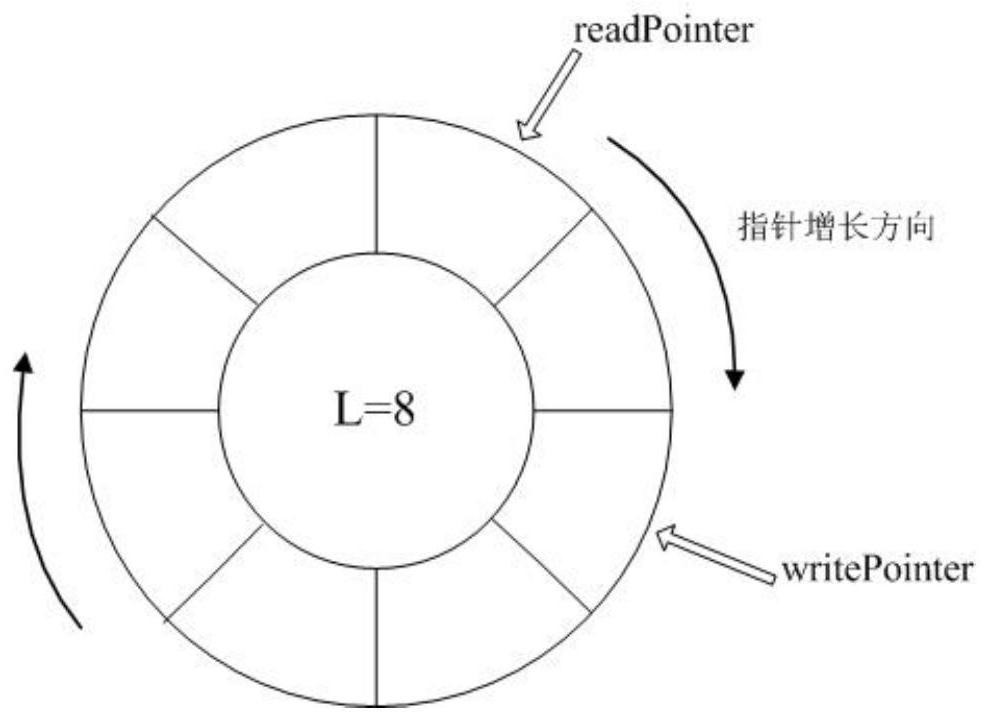

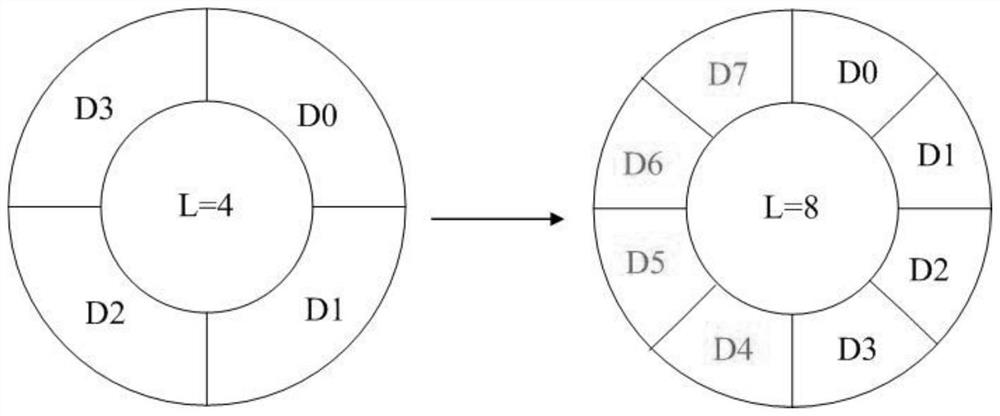

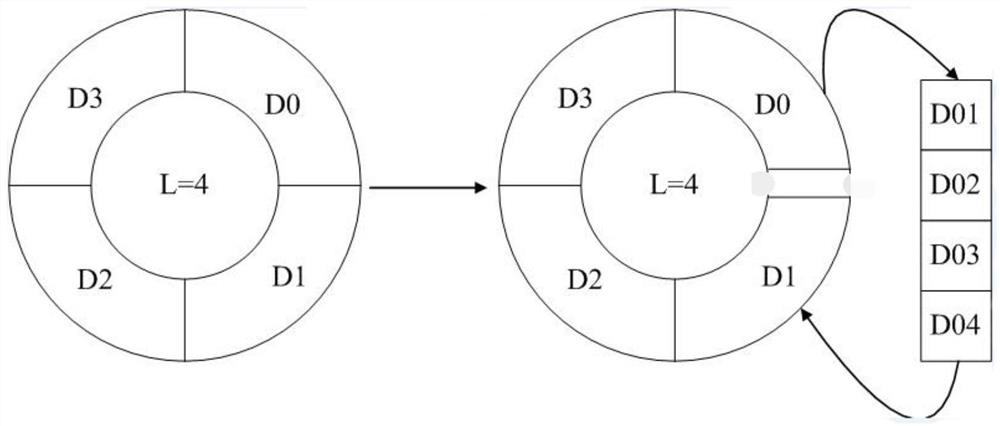

Data processing method and device of annular buffer based on dynamic adjustment

ActiveCN111290708ADoes not occupy memory resourcesMovement is not affectedInput/output to record carriersComputer hardwareParallel computing

The invention provides a data processing method of an annular buffer area based on dynamic adjustment. The data processing method comprises the following steps of normally reading and writing data bythe annular buffer area; obtaining residual writable units of the annular buffer area; when no residual writable unit exists in the annular buffer area, dynamically opening up a data buffer area according to the number of to-be-written data; and if a plurality of to-be-written data exist, sequentially opening up a plurality of data buffer areas, connecting each data buffer area through a linked list, and writing the to-be-written data into the data buffer areas at the same time. By adopting the technical scheme, the data buffer area is dynamically developed, the application is flexible and feasible, the dynamically established buffer area is released by the system after being used, and the memory of the system is not occupied invalidly.

Owner:CHENGDU ZHONGQIAN AUTOMATION ENG

Lightweight partition wall fixing device and using method thereof

InactiveCN110295758AMovement is not affectedRealize clampingBuilding material handlingStructural engineering

Owner:CITIC GUOAN CONSTR GRP CO LTD

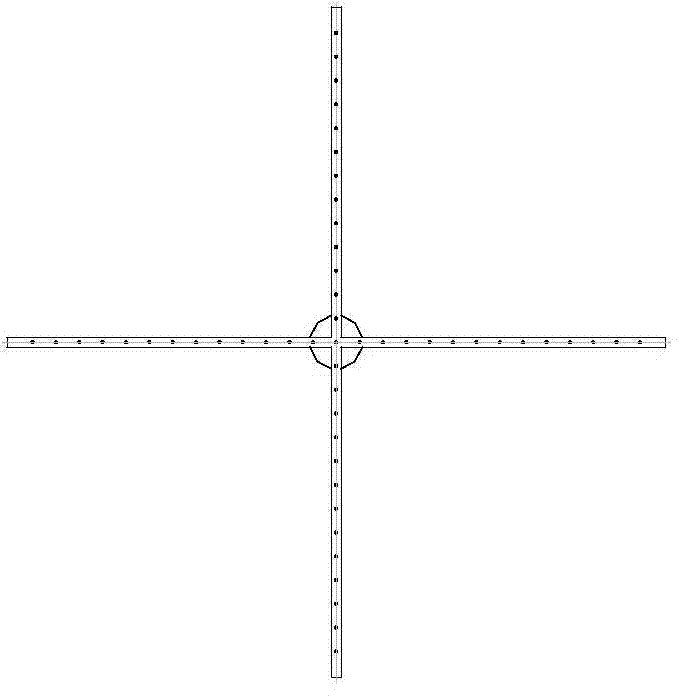

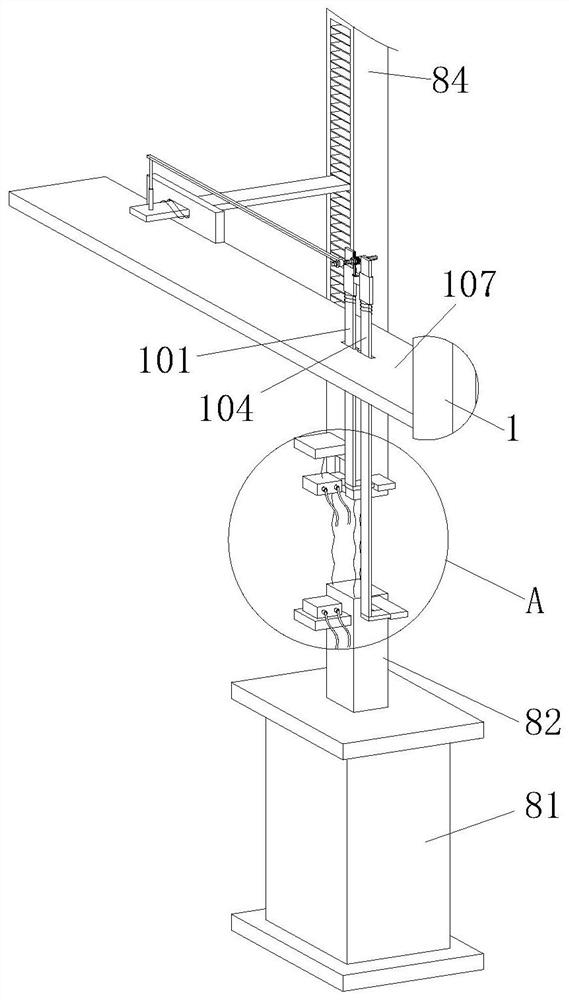

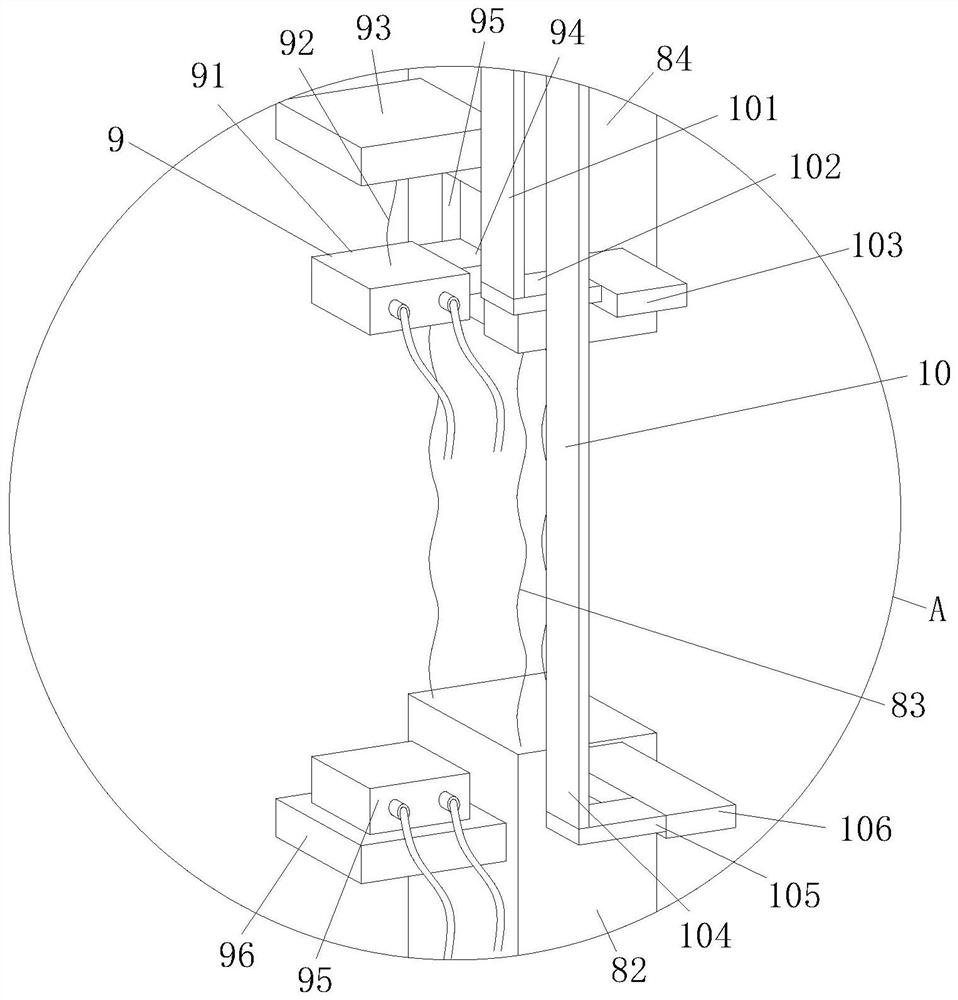

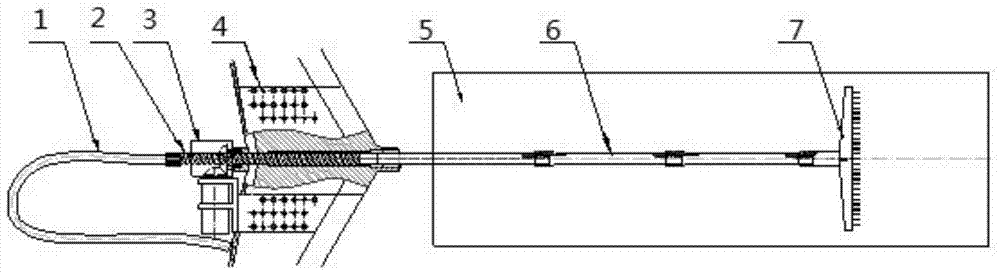

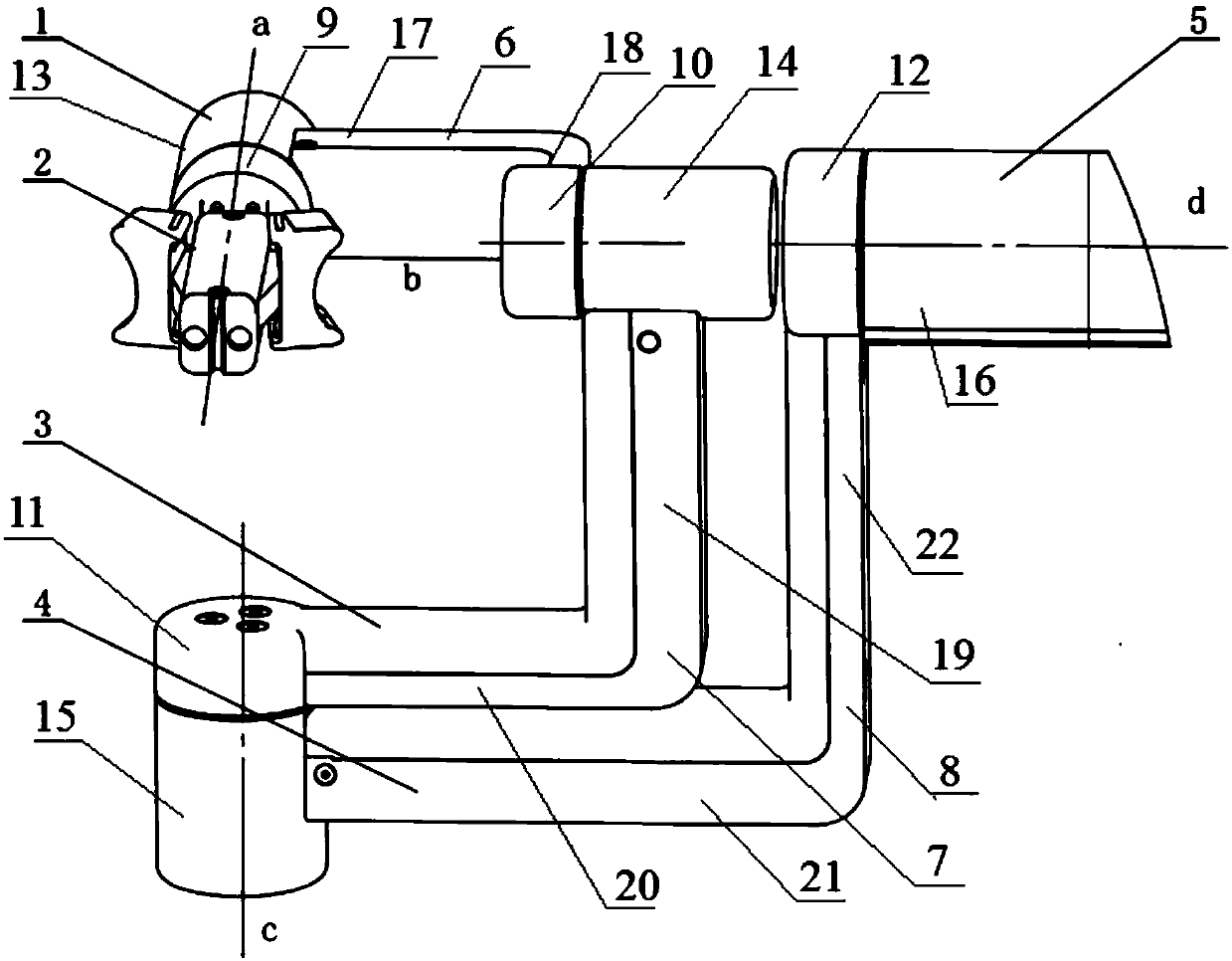

Supersonic wind tunnel velocity field calibration and measurement total pressure tube vibration suppression device

The invention discloses a supersonic wind tunnel velocity field calibration and measurement total pressure tube vibration suppression device comprising a connecting seat and four supporting mechanisms. The connecting seat is provided with a first axis and comprises two connecting ends distributed on the axis; the supporting mechanisms comprise supporting sleeves, supporting rods and first elastic components; one ends of the supporting sleeves are connected to the connecting seat, the other ends are provided with openings, the supporting rods are sleeved with the supporting sleeves, the free ends of the supporting rods extend out of the openings, and the first elastic components are arranged in the supporting sleeves and provide the applied force which is parallel to the length of the supporting sleeves and which orient to the outer sides of the supporting sleeves; the supporting mechanisms are arranged on the connecting seat and are distributed in a radiating manner corresponding to the axis. The vibration of the total pressure tube can be suppressed effectively, the rigidity of a total pressure tube test system is improved, and the testing accuracy is improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

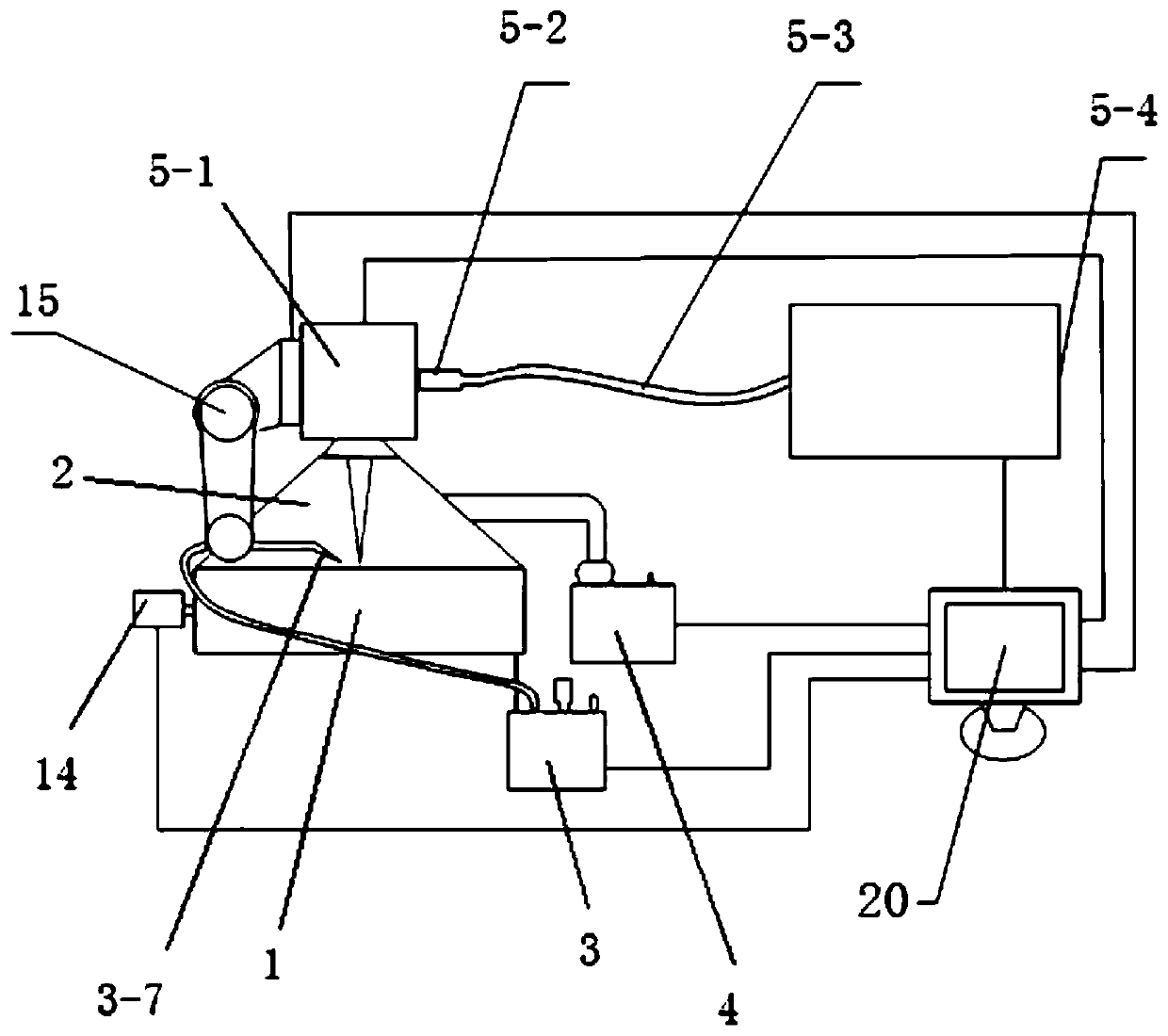

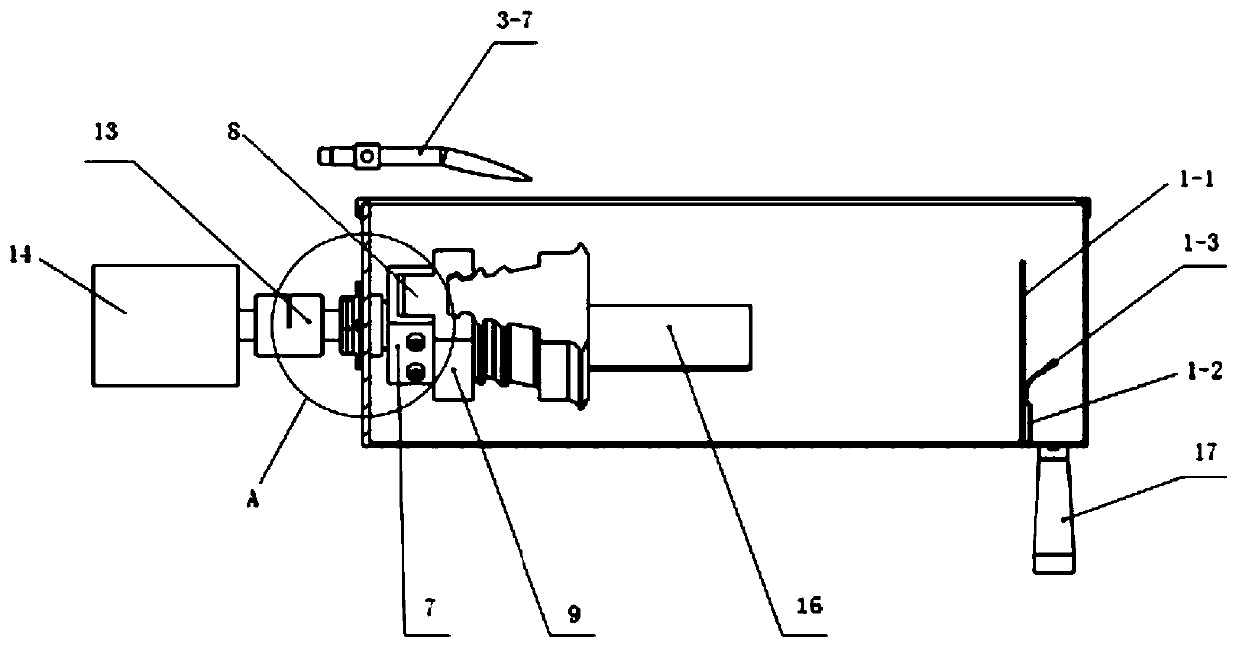

Aviation engine blade film hole processing device and working method

ActiveCN110202277AImprove processing qualityAchieve reuseTurbinesWelding/cutting auxillary devicesAviationLaser processing

The invention relates to an aviation engine blade film hole processing device and a working method. The aviation engine blade film hole processing device comprises a working box, wherein a clamping mechanism is arranged in the working box and is used for clamping a workpiece; a cover body with an inner space communicating with an inner space of the working box is connected to the upper part of a workpiece box; a laser processing mechanism is connected to the top end of the cover body and can produce a laser ray so as to carry out laser processing on the workpiece in the working box; the coverbody is connected with a liquid feeding mechanism and an acid gas filtering mechanism; the liquid feeding mechanism can inject an acid solution to the workpiece in the workpiece box; the working box can collect the acid solution; and the acid gas filtering mechanism can filter acid steam produced in the filtering processing process. According to the processing device provided by the invention, a recasting layer can be effectively removed, and the film hole processing quality is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

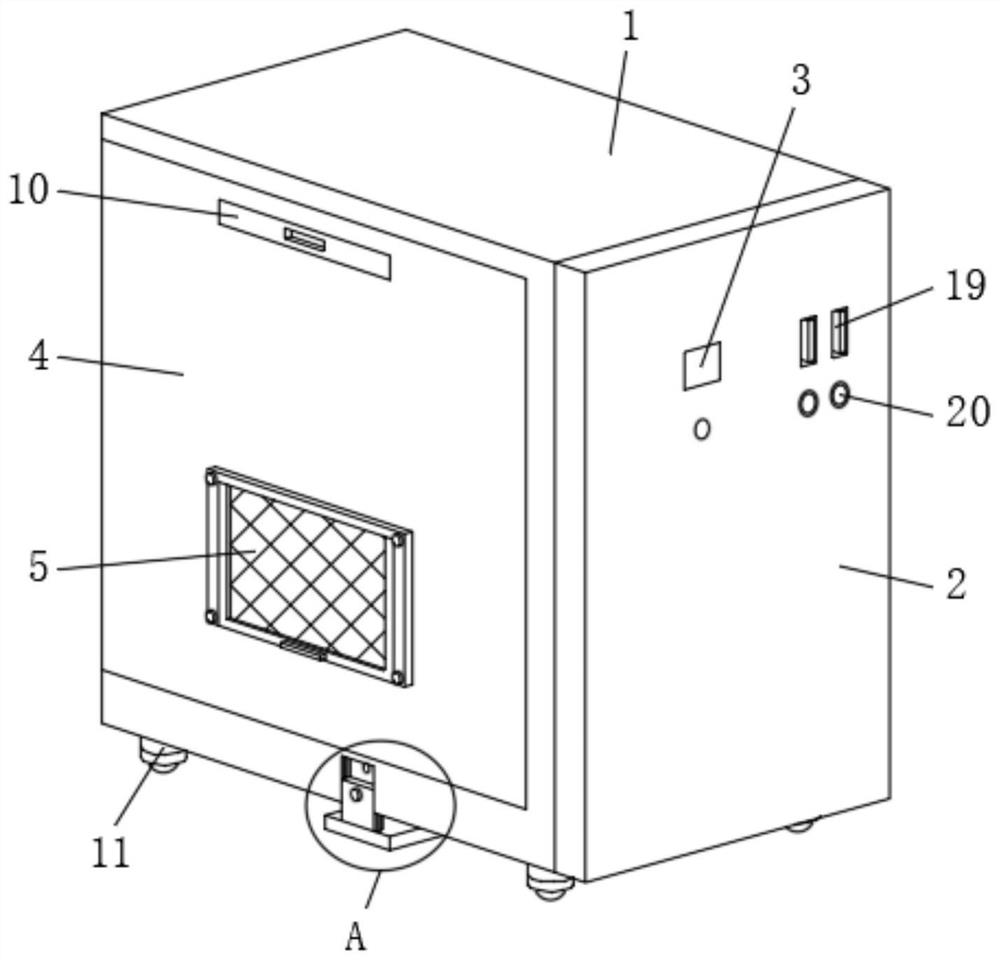

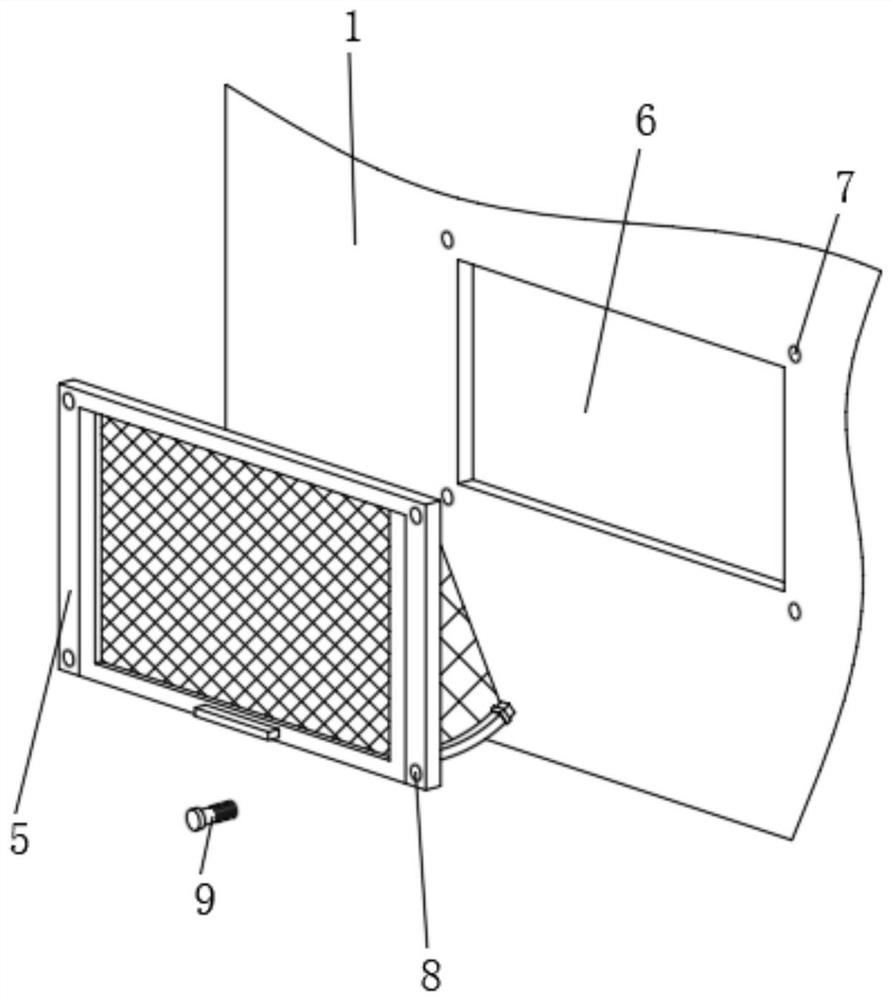

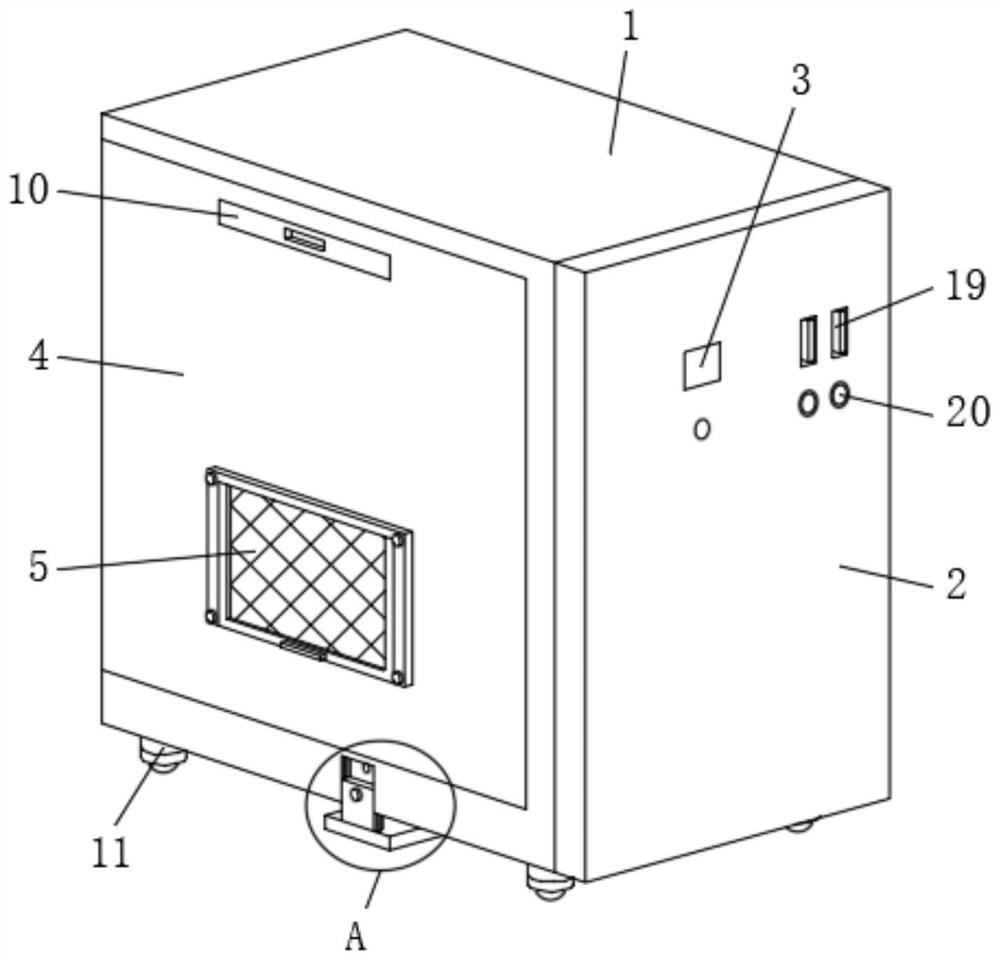

Dustproof computer mainframe box

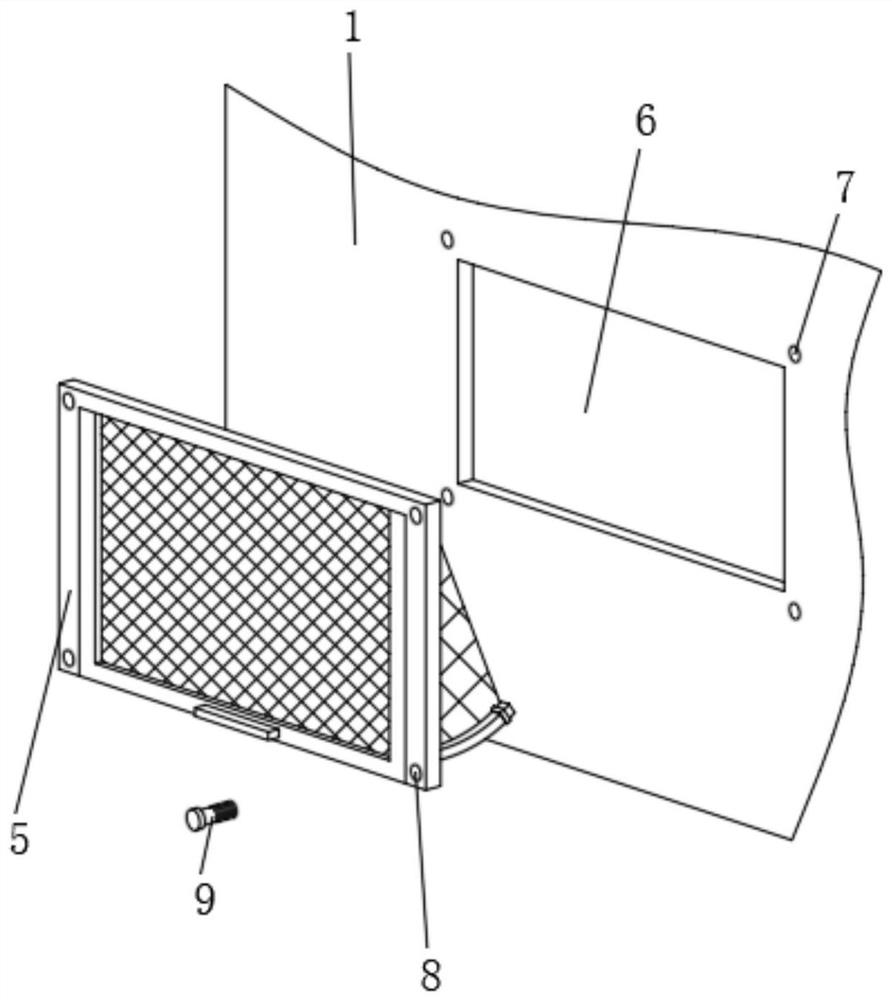

ActiveCN111766926AEffective dustproofEasy to adjustDispersed particle filtrationDigital processing power distributionMobile workElectrical and Electronics engineering

The invention discloses a dustproof computer mainframe box, which comprises a box body, wherein a front cover plate is fixedly installed at the front end of the box body, a switch is arranged on the front cover plate, and side plates are arranged on the two sides of the box body. According to the invention, a dustproof heat dissipation structure can effectively perform dustproof operation, and canbe adjusted as required so as to enhance heat dissipation effect; a portable structure can carry the whole mainframe box to move so as to facilitate long-distance mobile work, and can store when notin use so as to save space; a moving structure facilitates short-distance movement of the mainframe box; rolling balls in the structure can rotate at any angle so as to improve flexibility during moving, and can be replaced so as to ensure the using effect; and the stability degree of the mainframe box during using can be guaranteed through a fixing structure, it can be guaranteed that the mainframe box is not affected during moving through adjustment, a detachable fixing plate can be detached, and a user can conveniently detach the detachable fixing plate to replace the detachable fixing plate.

Owner:广州市中晟科技有限公司

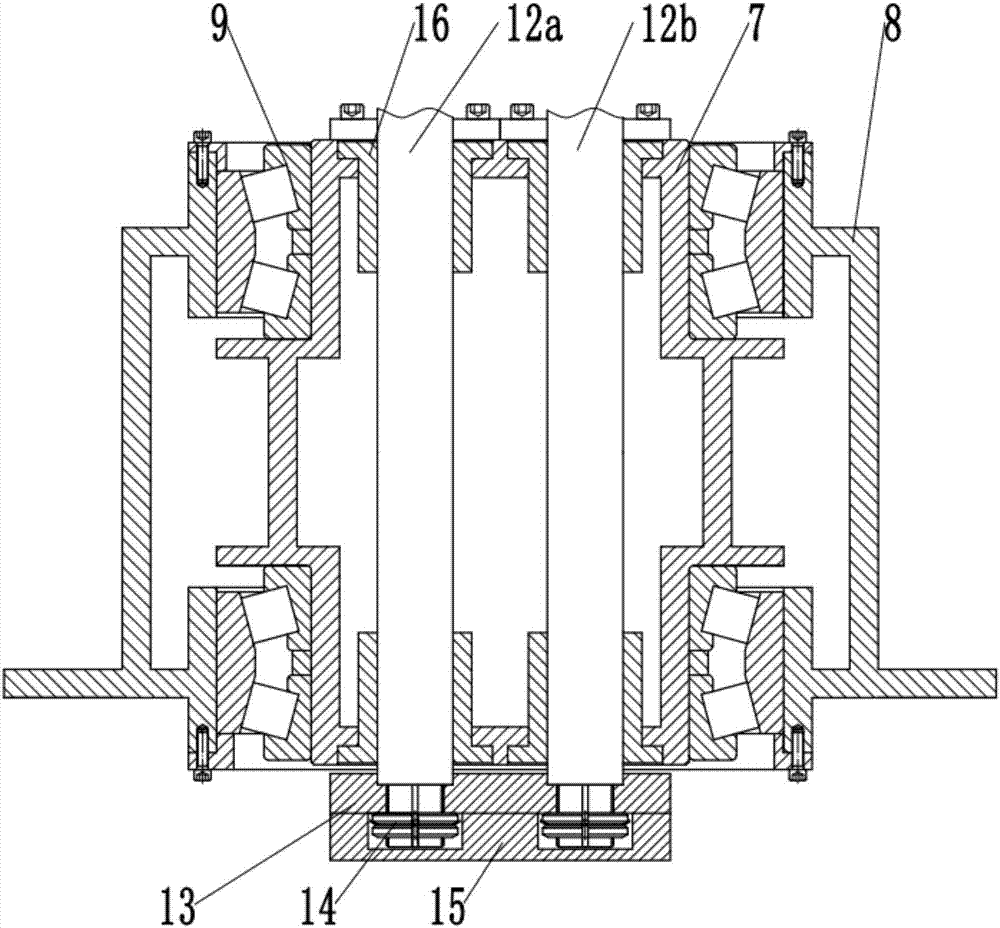

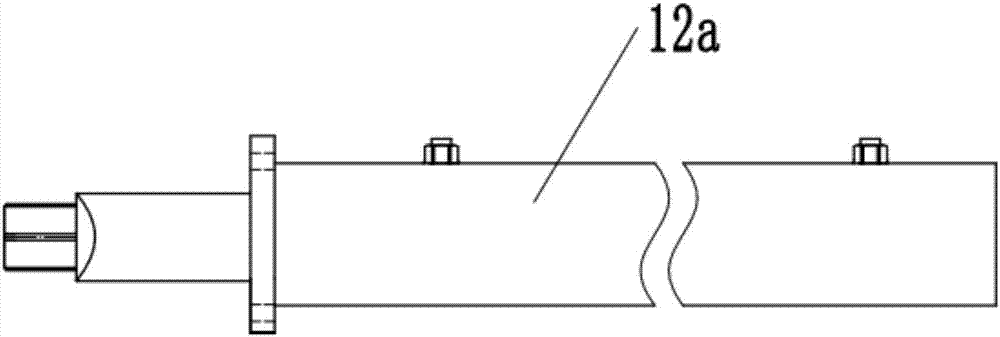

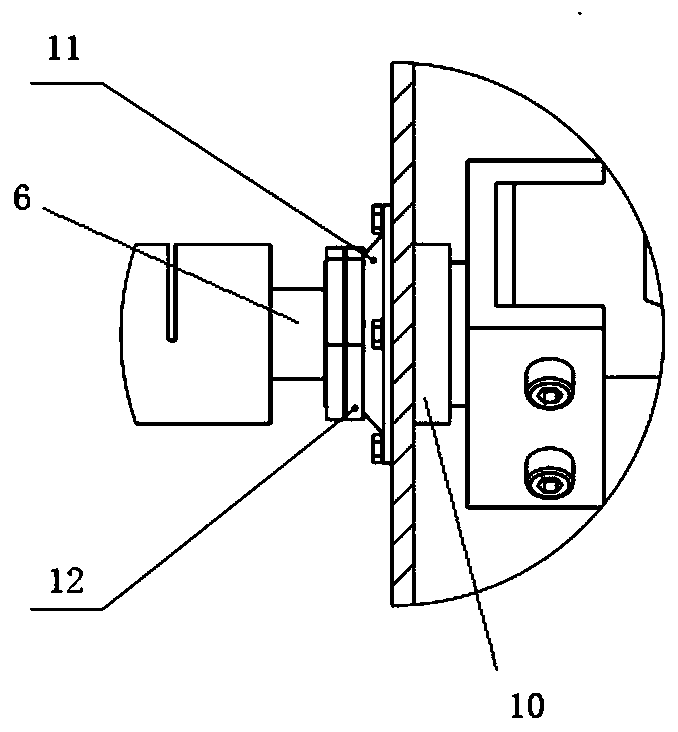

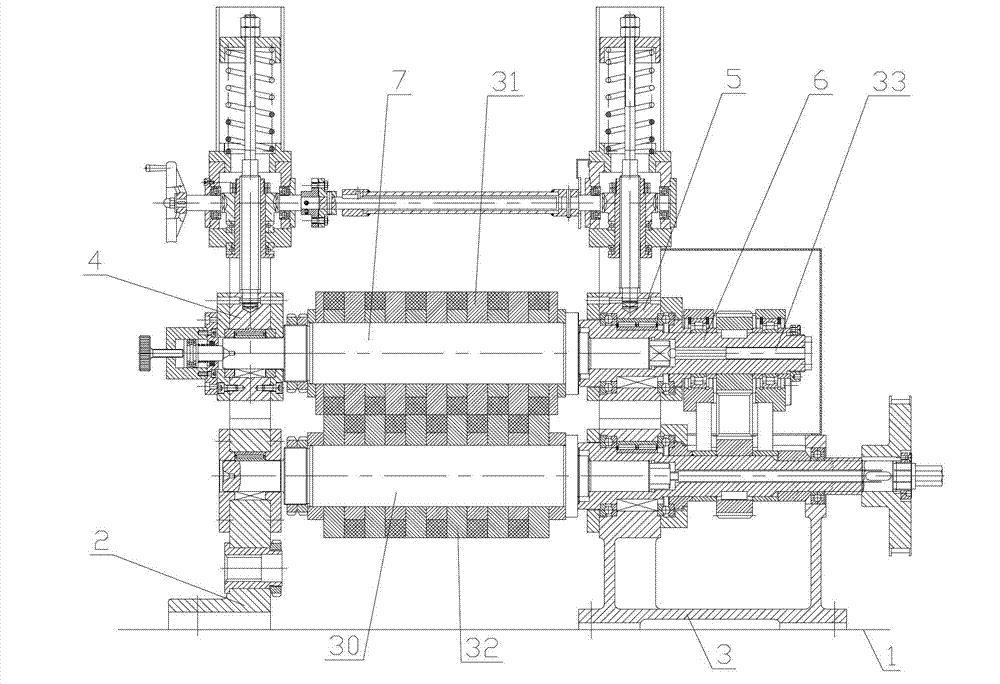

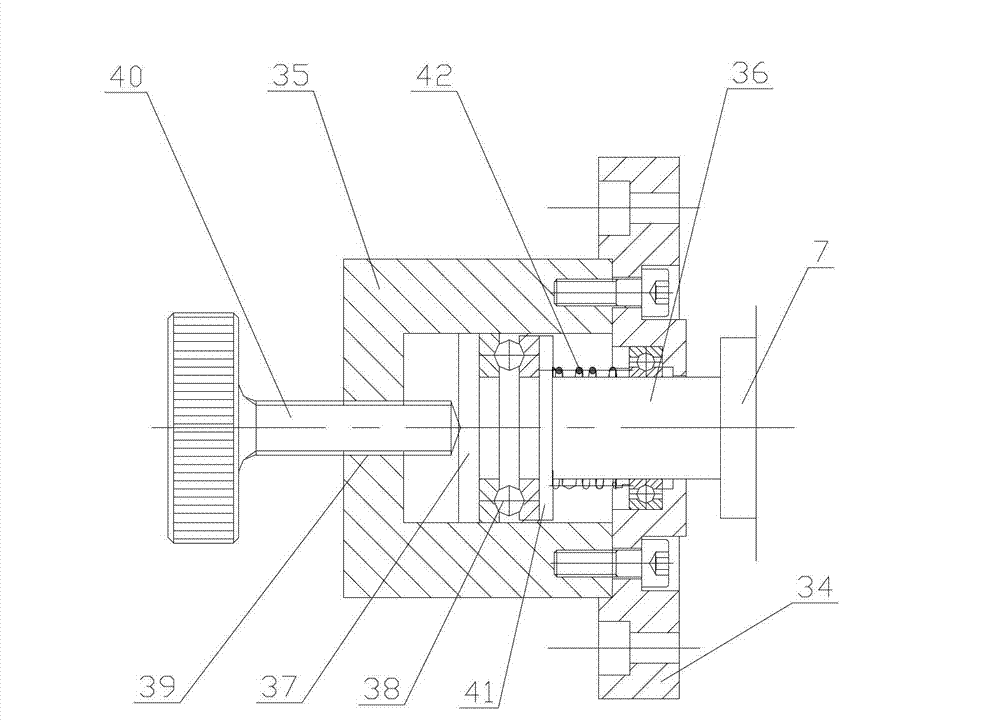

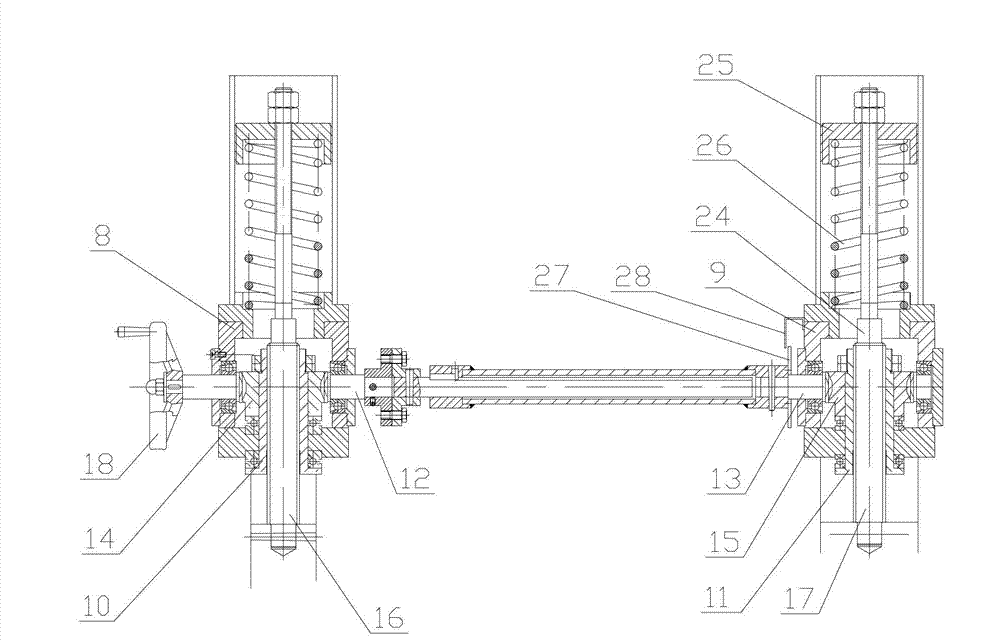

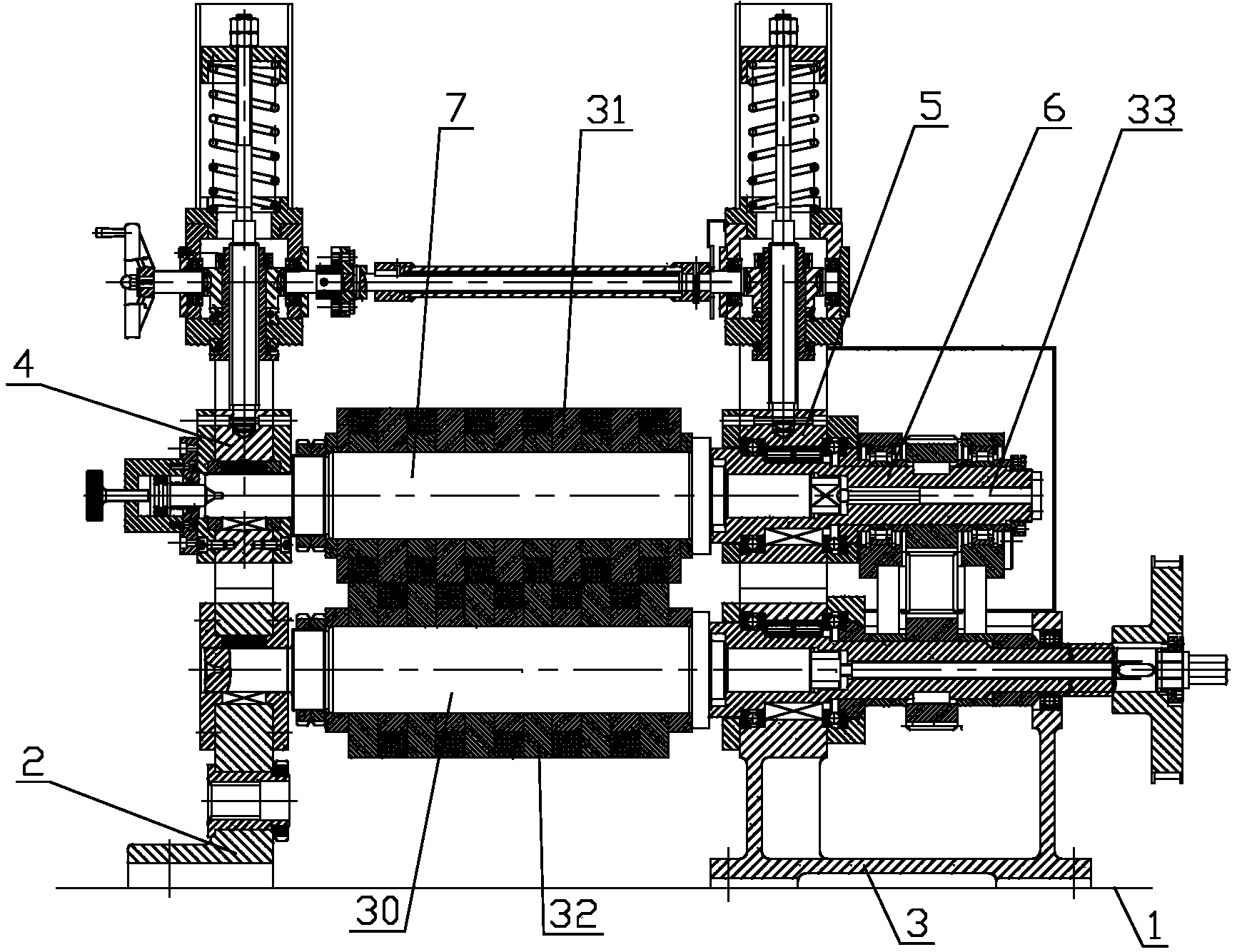

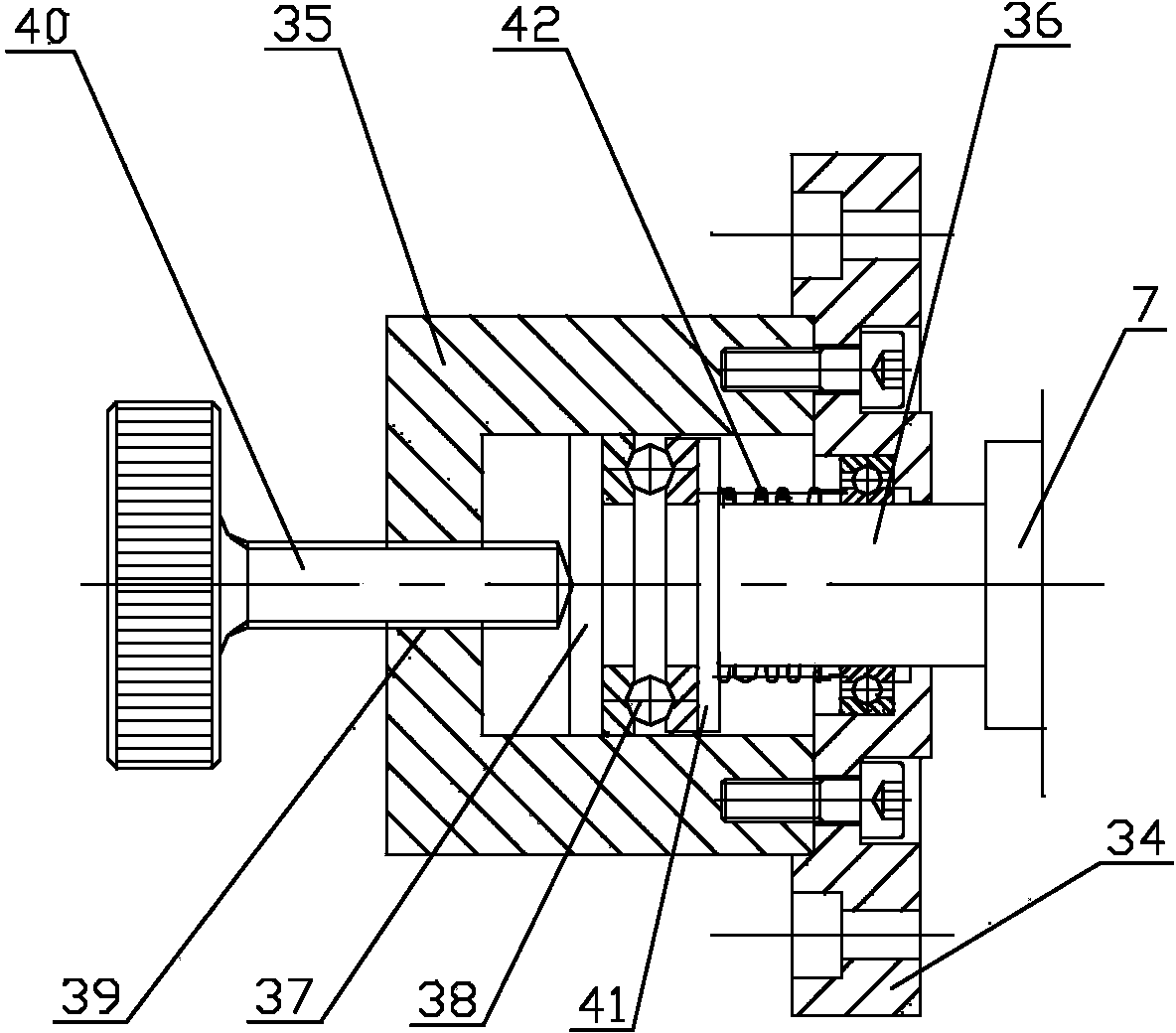

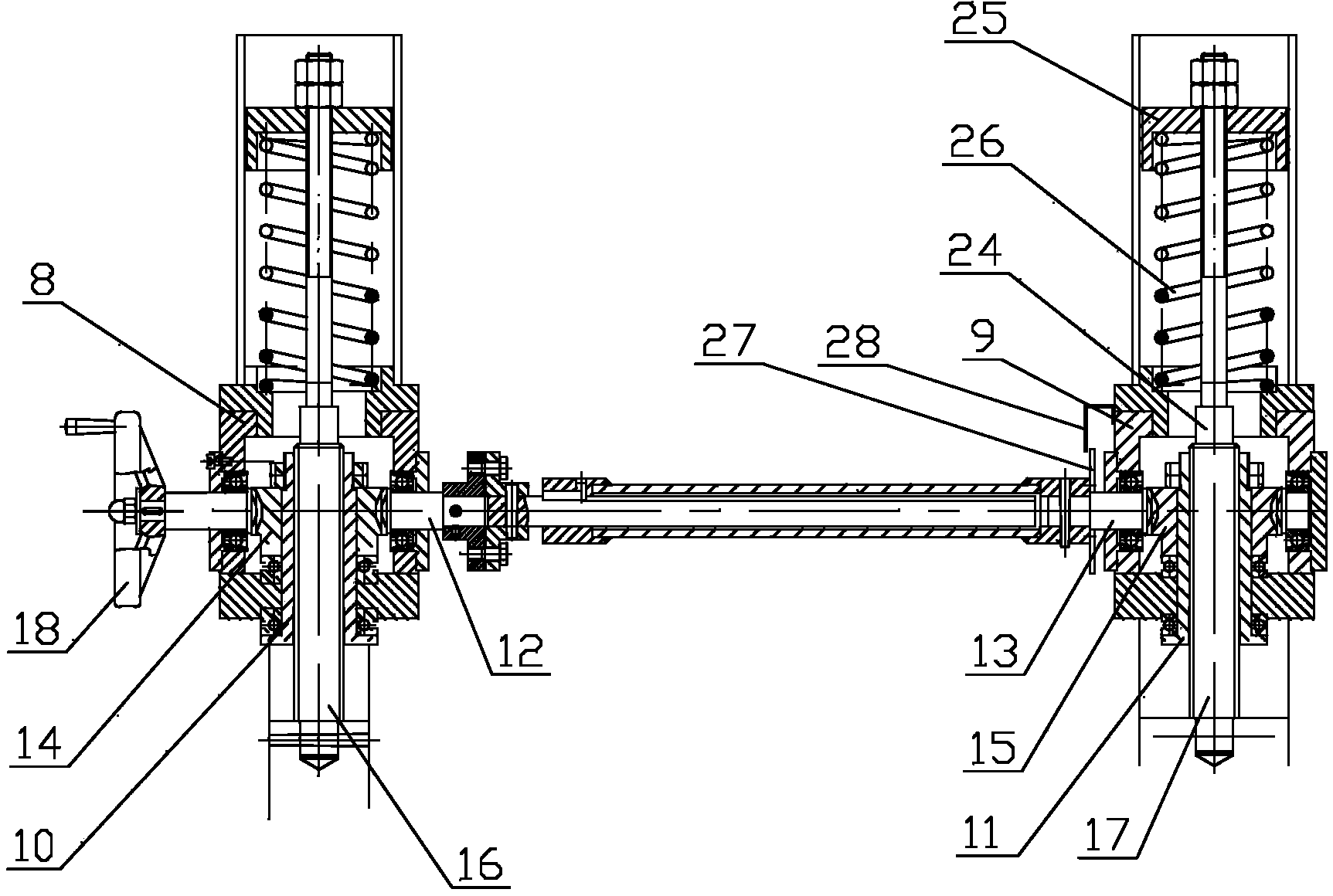

Upper cutter shaft regulation device of amorphous strip precision shearing machine

ActiveCN102950507AEasy to adjustAvoid damageAutomatic control devicesShearing machinesCouplingEngineering

The invention provides an upper cutter shaft regulation device of an amorphous strip precision shearing machine. Firstly, a pair of a worm and a gear are utilized to synchronously drive and lift a lead screw, so that an upper cutter shaft generates displacement along the radial direction, a gap between an upper cutting disc and a lower cutting disc is regulated through radially and finely regulating the upper cutter shaft, a telescopic shaft coupling device is used to connect a pair of worms, a pair of gears can be enabled to synchronously rotate, and the movement of a left wall board cannot be influenced when the upper cutter shaft and a lower cutter shaft are dismounted; and secondarily, a side gap between the upper cutting disc and the lower cutting disc is regulated through the axial floating of the upper cutter shaft. The radial synchronous fine regulating and axial flexible fine regulating of the upper cutter shaft can be effectively ensured, accordingly, the gap and the side gap between the upper cutting disc and the lower cutting disc can be quickly and accurately adjusted, the working efficiency is increased, the damage to the cutting discs due to inappropriate cutter regulating is reduced, and accordingly, the shearing efficiency and shearing quality can be ensured.

Owner:宝鸡市精机设备有限责任公司

Air film hole processing device and working method of aero-engine blade

ActiveCN110202277BImprove processing qualityAchieve reuseTurbinesWelding/cutting auxillary devicesInterior spaceLaser processing

The invention relates to an air film hole processing device and working method of an aero-engine blade, comprising a working box, a clamping mechanism is arranged inside the working box, the clamping mechanism is used to clamp workpieces, and the upper part of the workpiece box is connected with an inner space and a working The cover body connected to the inner space of the box, the top of the cover body is connected with a laser processing mechanism, the laser processing mechanism can generate laser rays, and perform laser processing on the workpiece in the working box, the cover body is connected with the liquid supply mechanism and the acid gas The filter mechanism is connected, the liquid supply mechanism can spray acid solution to the workpiece in the workpiece box, the work box can collect the acid solution, and the acid gas filter mechanism can filter the acid steam produced in the process, and the processing device of the present invention can The recasting layer is effectively removed, and the processing quality of the gas film hole is improved.

Owner:QINGDAO UNIV OF TECH

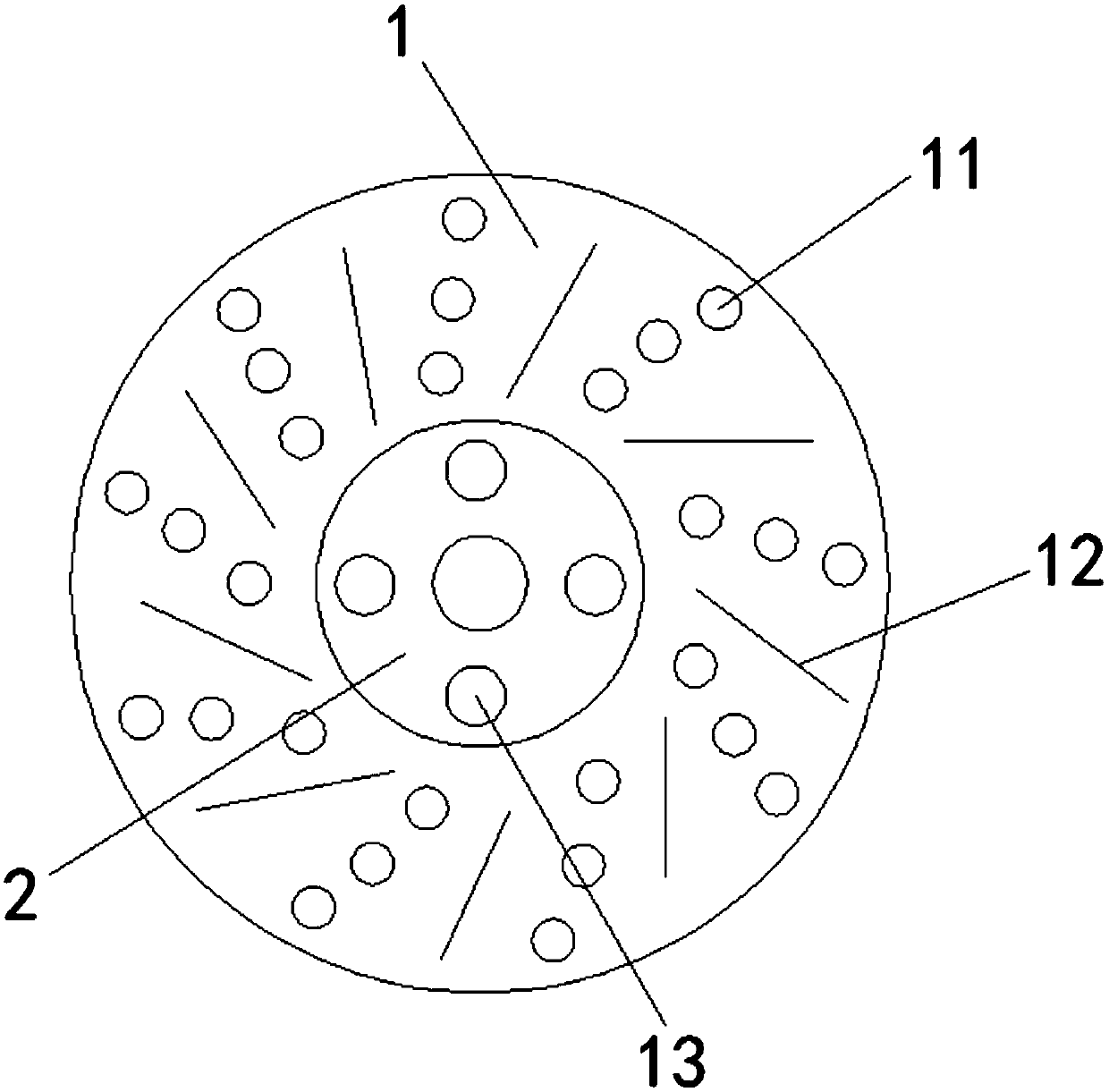

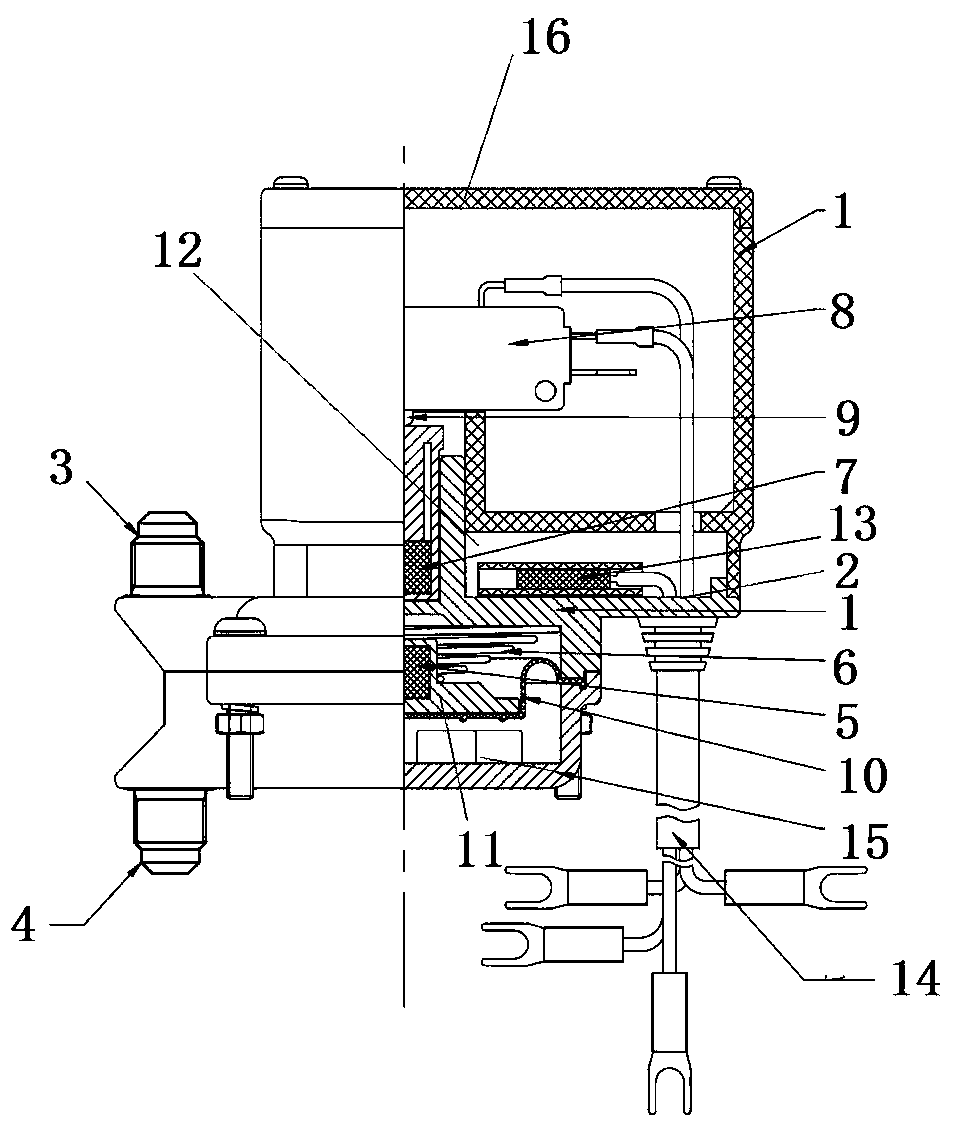

Disc brake with floating caliper

InactiveCN108050174AStable performanceImprove braking effectAxially engaging brakesBrake actuating mechanismsDisc brakePiston

The invention relates to a disc brake with a floating caliper. The disc brake with the floating caliper includes a brake disc, a hub, a brake caliper, a piston and an oil tube, the hub is arranged atthe right center position of the left side of the brake disc, and the hub is fixedly connected with the brake disc and is provided with a plurality of bolt holes; and first bolts are arranged in the bolt holes, and two side surfaces of the brake disc are provided with a plurality of aslant arranged scratches. According to the disc brake with the floating caliper, positioning screws and guide ringsare arranged to fix the position of the brake caliper, the movement of the brake caliper is not affected while the position of the brake caliper is fixed, the performance is steady, and the brake caliper is not slant during moving; the brake effect is improved, the full contact of friction plates and the brake disc can be ensured, the loss is slowed, a connecting rod is arranged above the brake caliper and a sleeve is arranged above the connecting rod, and the connecting rod and the sleeve are slidably connected; and when the friction plates or the piston in the brake caliper is broke, the brake disc and the other devices do not need to be overall dismounted, and check and maintenance can be performed only need to take down the brake caliper.

Owner:方秀萍

Dynamically adjustable annular buffer area

ActiveCN111290709ADoes not occupy memory resourcesMovement is not affectedInput/output to record carriersComputer hardwareParallel computing

The invention provides a dynamically adjustable annular buffer area. The area comprises an annular buffer area body with a fixed length and a plurality of data buffer units which are dynamically established according to the number of data to be written when the annular buffer area body is full, the data buffer units are linked in a linked list mode, and a linked list header points to the data buffer unit which is established firstly. By adopting the technical scheme, the data buffer area is dynamically developed, the application is flexible and feasible, the dynamically established data bufferarea is released by the system after being used, and the memory of the system is not occupied invalidly.

Owner:CHENGDU ZHONGQIAN AUTOMATION ENG

Heating-type differential water pressure switch

The invention discloses a heating-type differential water pressure switch, which comprises a shell. The shell comprises an upper shell and a lower shell arranged up and down. One side of the shell isalso provided with a heating cavity, which is close to the inner chamber of the shell. A heating body is arranged in the heating cavity. The heating body is connected to an external power supply through a wire. The heating-type differential water pressure switch of the invention uses the heating body to heat the body to ensure that water inside the body will not be frozen, so that the movement ofa magnet is not affected and the function is continuous and effective. Compared with an existing differential water pressure switch, the heating-type differential water pressure switch has the following advantages: with the additional arrangement of the electric heating function, the heating-type differential water pressure switch meets the requirement of usage in a low-temperature environment of0 to 30 DEG C, and the product performance is improved.

Owner:JIEAIXI ELECTROMECHANICAL KUNSHAN CO LTD

An improved intelligent air conditioner dynamic environment monitoring device and its use method

ActiveCN112747209BReduce addSave resourcesEfficient regulation technologiesStands/trestlesControl engineeringDust control

Owner:安徽康赛威电子科技有限公司

A data processing method and device based on dynamically adjusted ring buffer

ActiveCN111290708BDoes not occupy memory resourcesMovement is not affectedInput/output to record carriersComputer hardwareComputer architecture

The invention provides a data processing method based on a dynamically adjusted ring buffer, which includes the following steps: the ring buffer performs normal reading and writing of data; obtains the remaining writable units of the ring buffer; when there is no remaining writable unit in the ring buffer When entering the unit, the data buffer is dynamically opened according to the number of data to be written; if there is multiple data to be written, multiple data buffers are opened in sequence, and each data buffer is connected through a linked list, and at the same time, the data buffer to be written is opened Data is written to the data buffer. The technical solution of the present invention is used to dynamically open a data buffer, which is flexible and feasible in application. The dynamically established buffer will be released by the system after use, and will not occupy system memory in an invalid manner.

Owner:CHENGDU ZHONGQIAN AUTOMATION ENG

In-furnace stabilizing roller regulating device

ActiveCN109750246ASuppress jitterDrive unaffectedHot-dipping/immersion processesEngineeringTension band

The invention discloses an in-furnace stabilizing roller regulating device. The in-furnace stabilizing roller regulating device comprises a furnace nose, arc-shaped groove rails, stabilizing rollers and a push rod mechanism, wherein the arc-shaped groove rails are symmetrically arranged at the two sides of the furnace nose; the stabilizing rollers are correspondingly installed inside the arc-shaped grooved rails arranged at the two sides by virtue of bearing seats; the push rod mechanism can be used for driving each stabilizing roller to move along the corresponding arc-shaped grooved rail byvirtue of the corresponding bearing seat; the top surface and the bottom surface, making contact with the inner wall of a groove of the corresponding arc-shaped grooved rail, of each bearing seat areeach a circular arc surface; the distance between the most remote ends of the two circular arc surfaces is adaptive to the distance between the arc-shaped grooved rails; when each bearing seat moves to a high-position point of the corresponding arc-shaped groove rail, the corresponding stabilizing roller can be tangential to tension band steel; and when each bearing seat moves to a low-position point of the corresponding arc-shaped groove rail, the corresponding stabilizing roller is positioned over a sunken region. The in-furnace stabilizing roller regulating device disclosed by the inventioncan be used for regulating the position of each stabilizing roller, realizes quick and smooth switching of the working state and the overhauling state of the stabilizing rollers and enlarges the installation space for the furnace nose.

Owner:武汉钢铁有限公司

Composite calender fermentation device with cleaning function

Owner:BEIDAHUANG FENGYUAN GRP +1

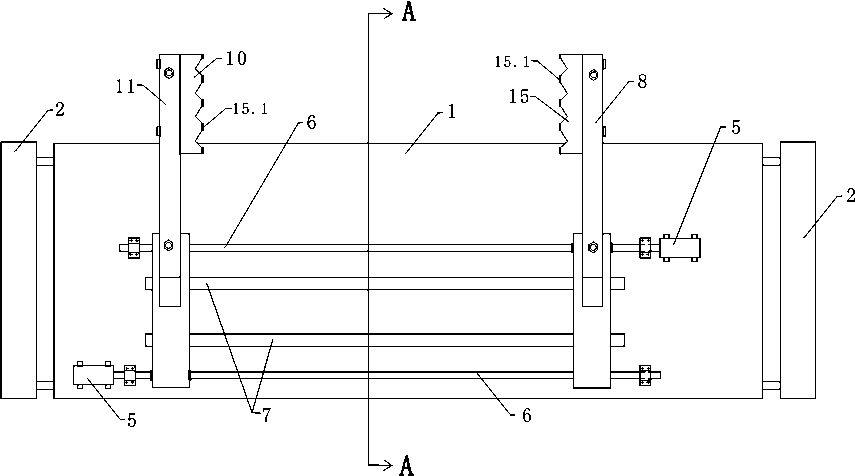

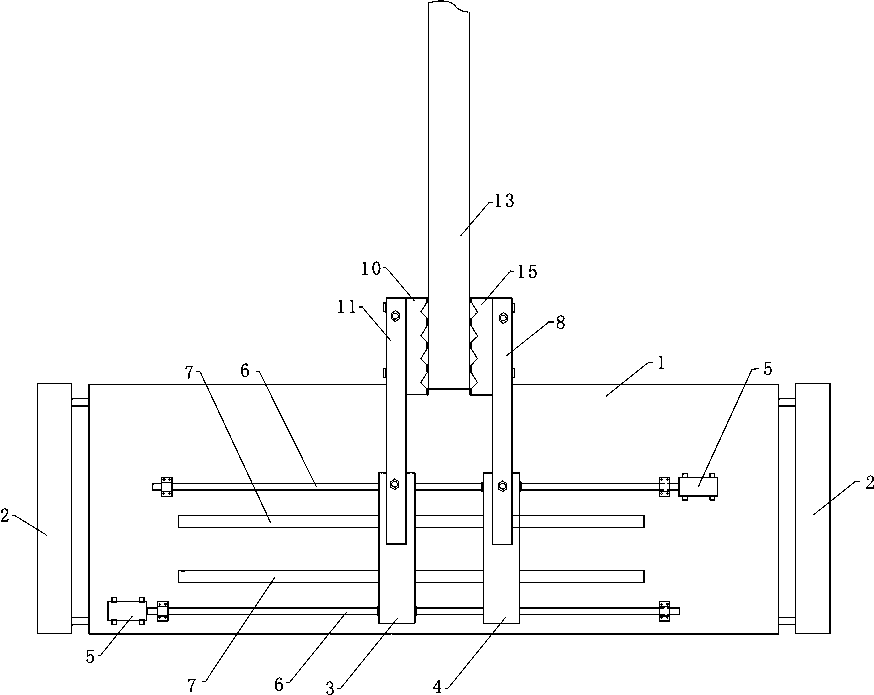

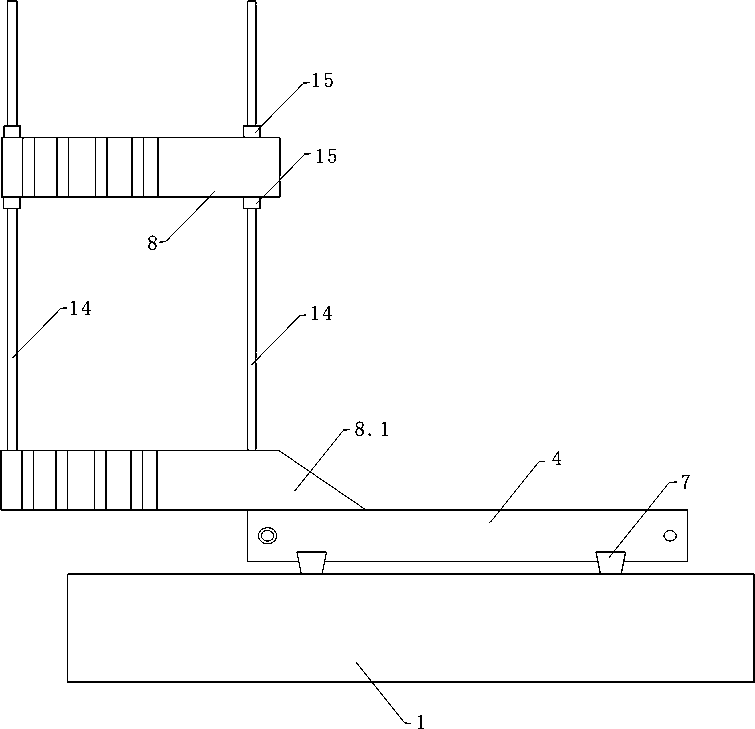

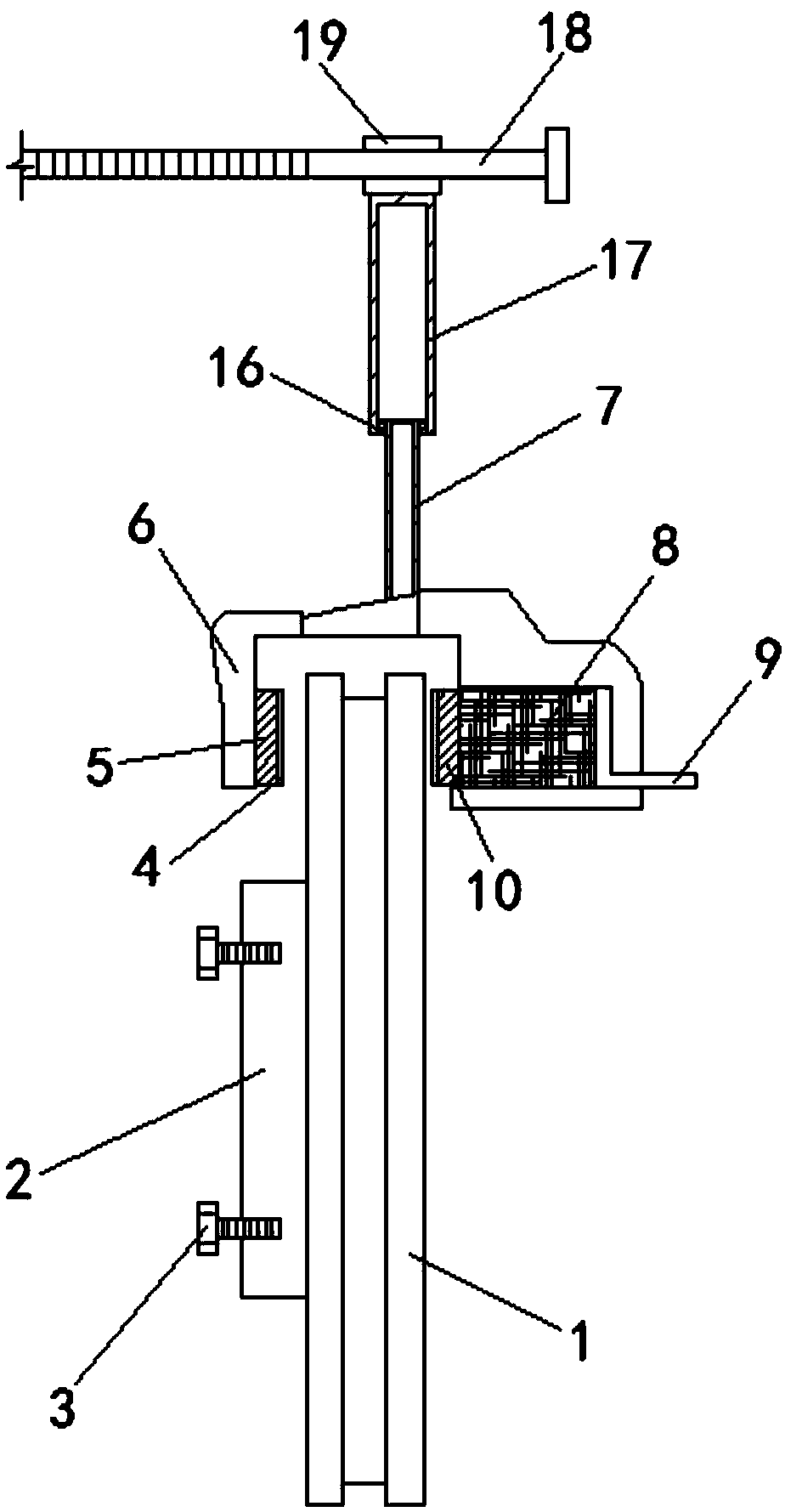

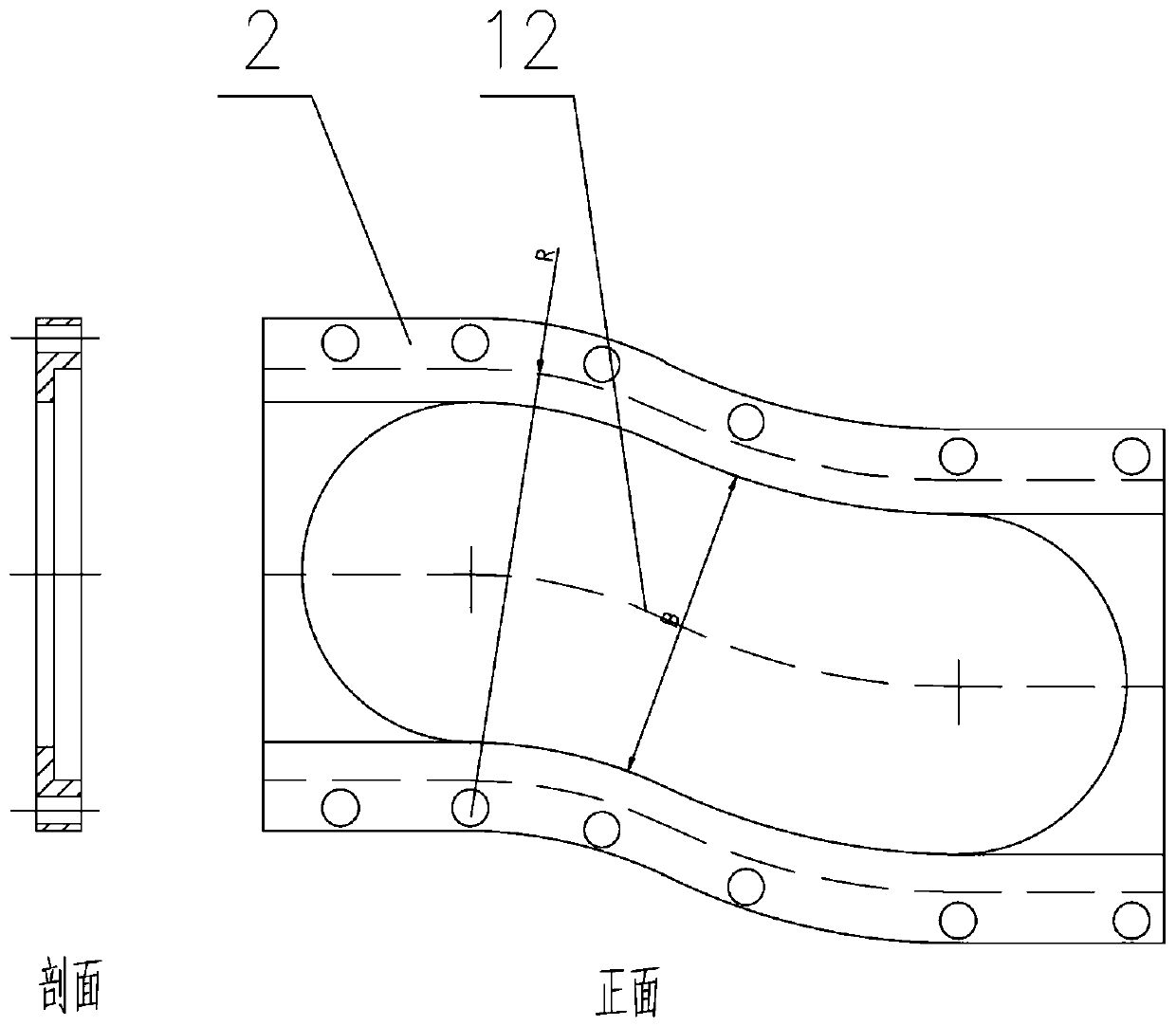

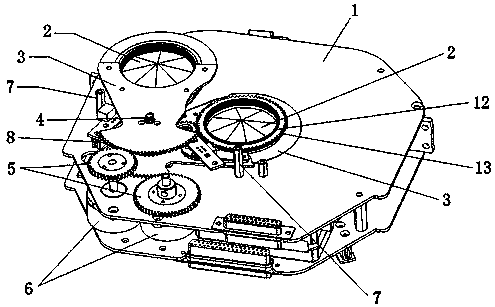

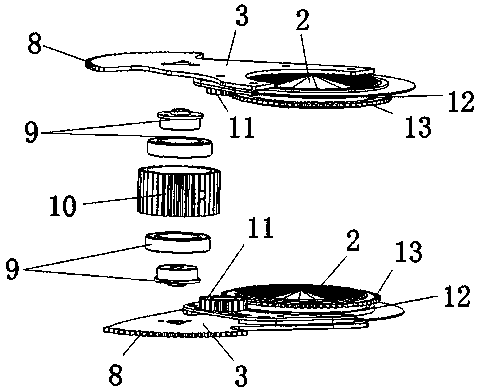

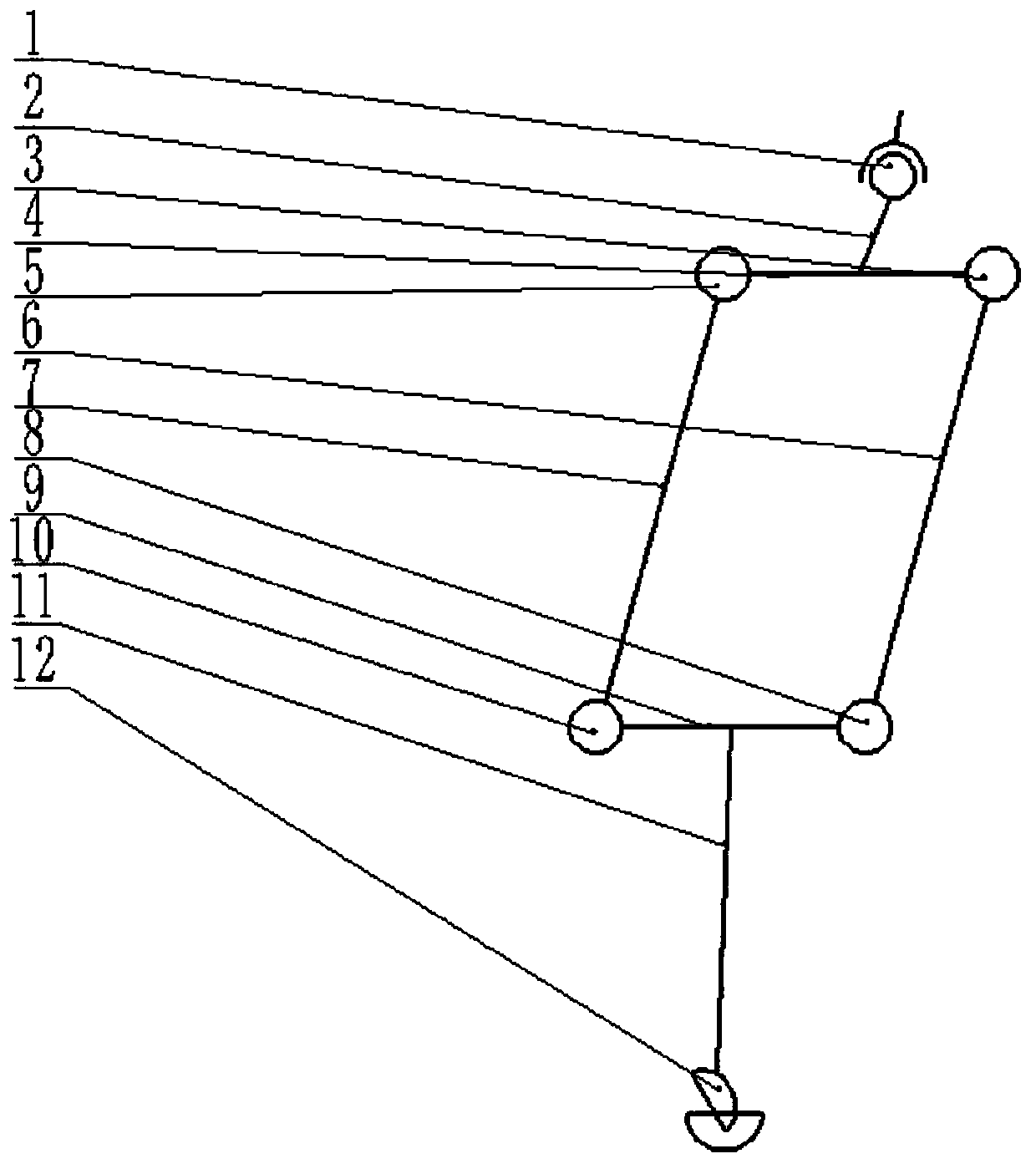

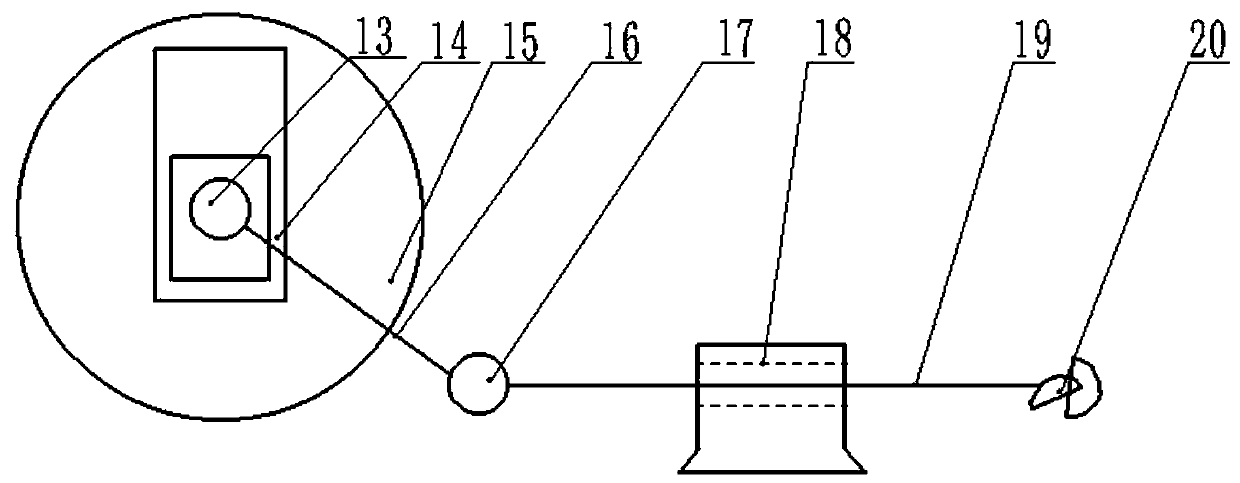

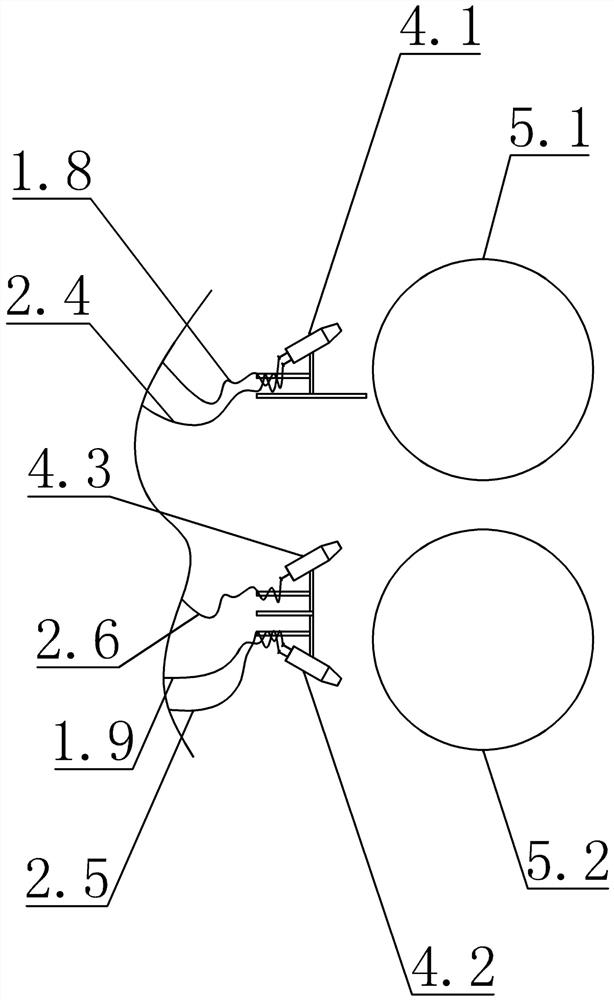

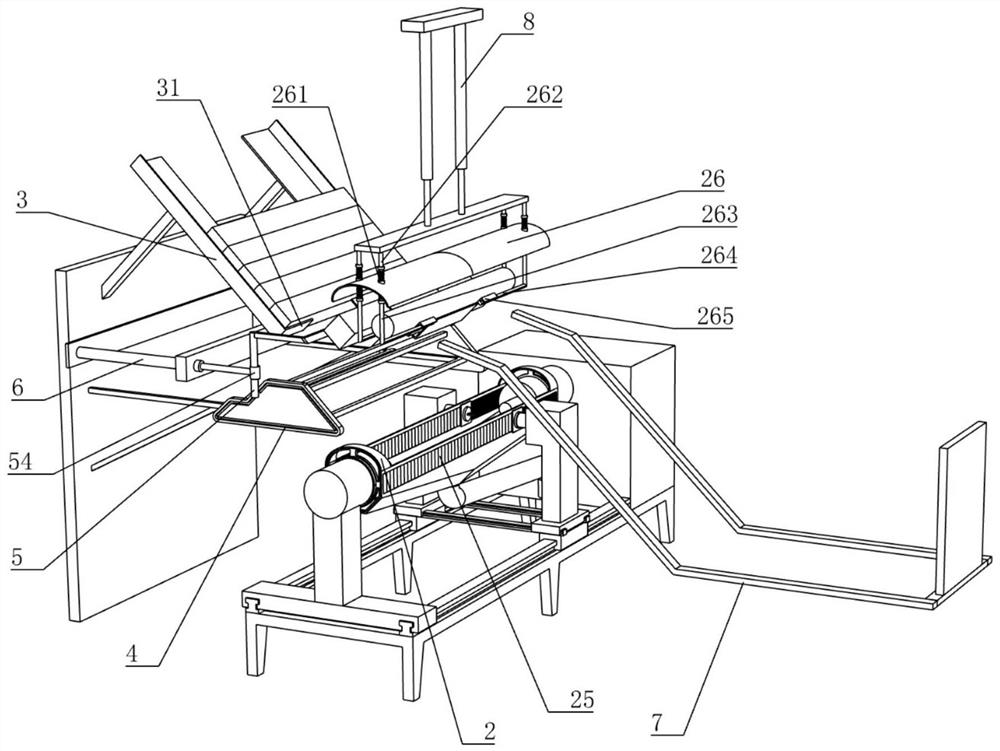

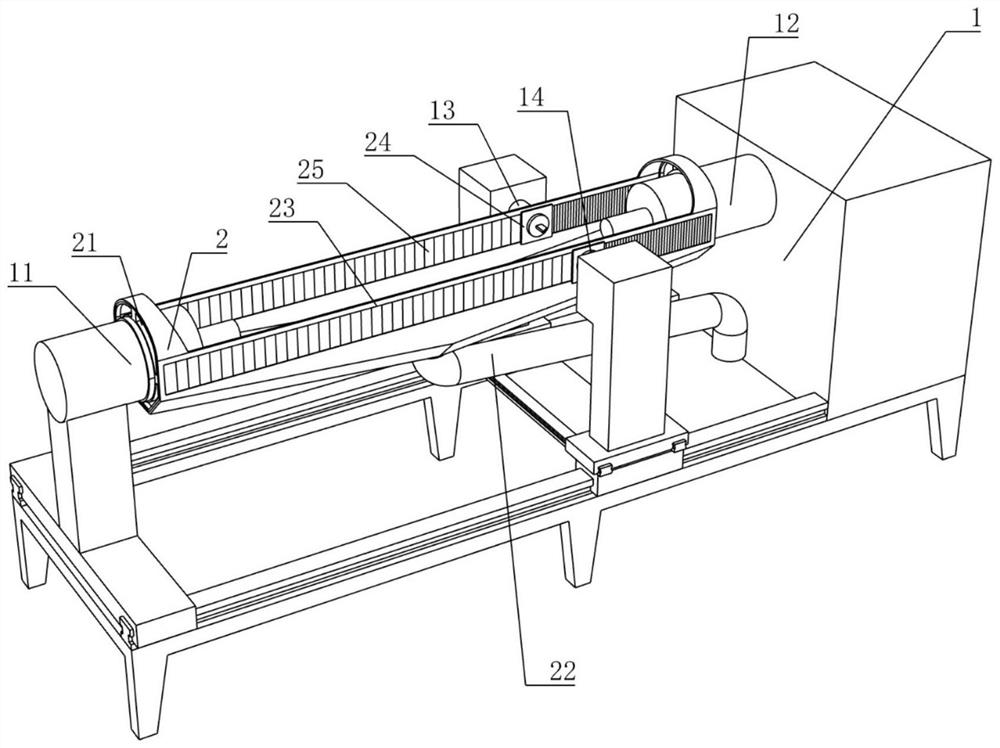

A driving system for stage lighting optical components

ActiveCN105114902BReduce usageEasy to solveLighting applicationsLighting support devicesStage lightingLight beam

A stage lighting optical component drive system comprises a support board (1), two or more optical component supports (3), and two or more optical components. Each of the optical components is correspondingly mounted on one of the optical component supports, and each of the optical component supports is correspondingly connected to a set of drive mechanism arranged on a support plate. A light passing hole is provided on the support plate and configured to pass a light beam. The drive system further comprises a rotating main shaft (4) on which the optical component supports are rotatably mounted and stacked in layers. A toothed structure (8) engaging with a corresponding drive mechanism is provided at an edge of an end portion of each of the optical component supports. The drive system is simple in structure and has a reasonable layout, reducing a space occupied in stage lighting equipment.

Owner:GUANGZHOU HAOYANG ELECTRONICS CO LTD

Vibration suppression device for supersonic wind tunnel velocity field calibration and measurement of total pressure exhaust pipe

The invention discloses a shake suppression device for calibrating the velocity field of a supersonic wind tunnel to measure the total pressure discharge pipe, comprising: a connecting seat, which has an axis, and the connecting seat has two connecting ends distributed on the axis; The support mechanism includes a support sleeve, a support rod and a first elastic member, wherein one end of the support sleeve is connected to the connecting seat, and the other end has an opening, and the support rod is sleeved on the support sleeve and the free end of the support rod protrudes from the opening, the first elastic member is arranged inside the support sleeve to provide the support rod parallel to the length direction of the support sleeve and The force directed to the outside of the support sleeve; wherein at least four support mechanisms are arranged on the connection seat and are radially distributed relative to the axis. The invention can effectively suppress the vibration of the total pressure discharge pipe, enhance the rigidity of the total pressure discharge pipe test system, and improve the test accuracy.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

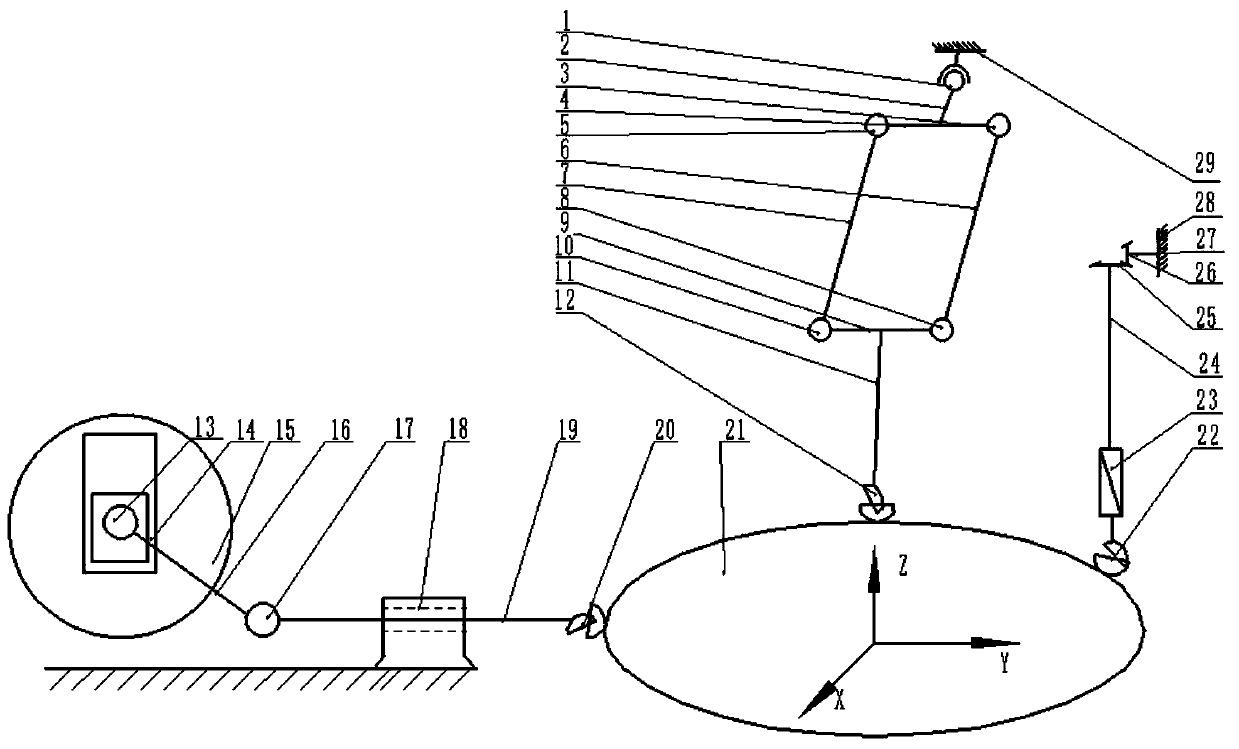

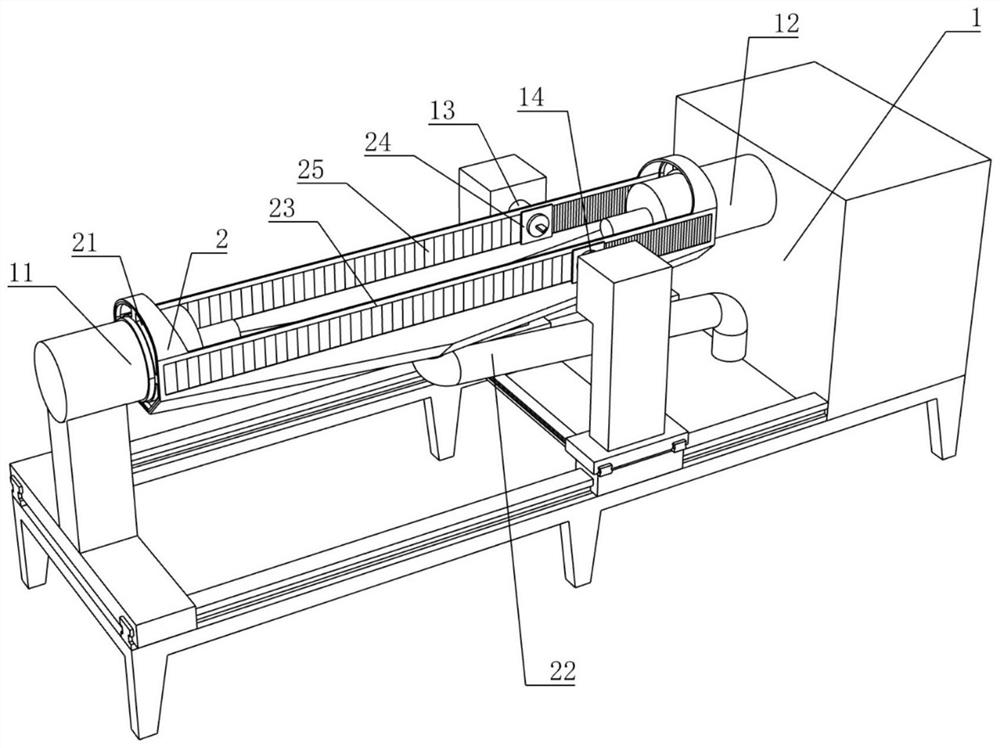

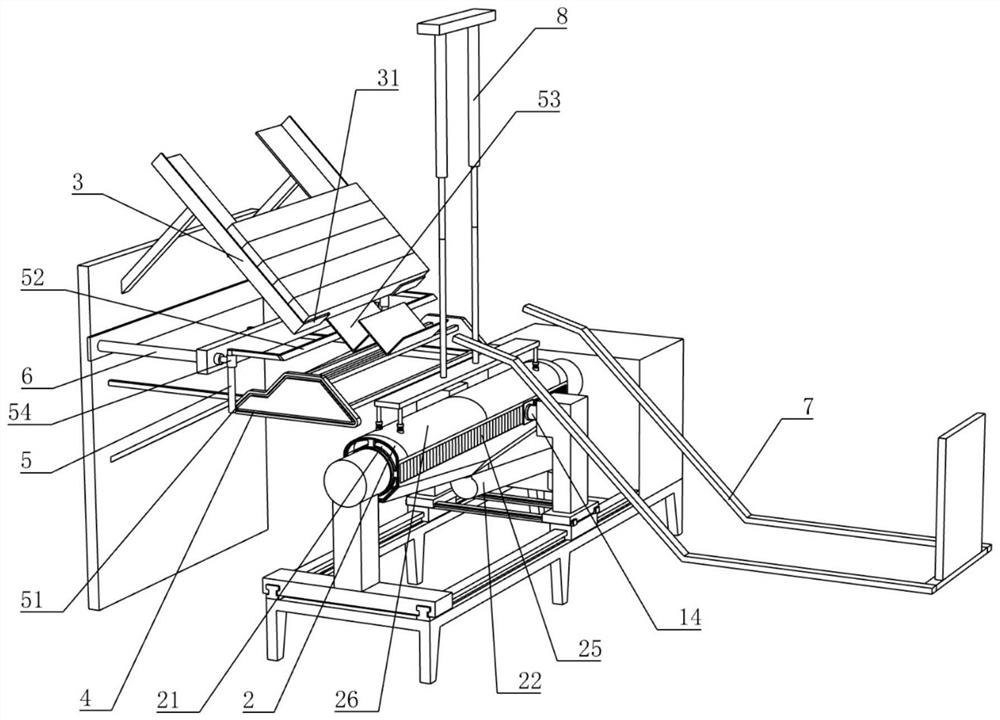

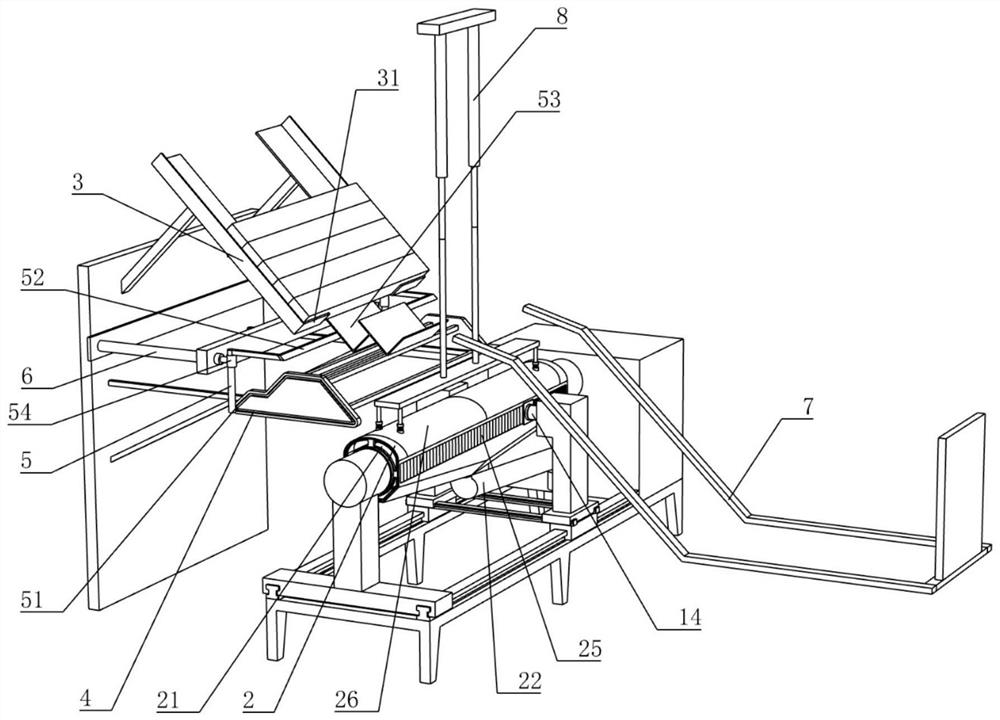

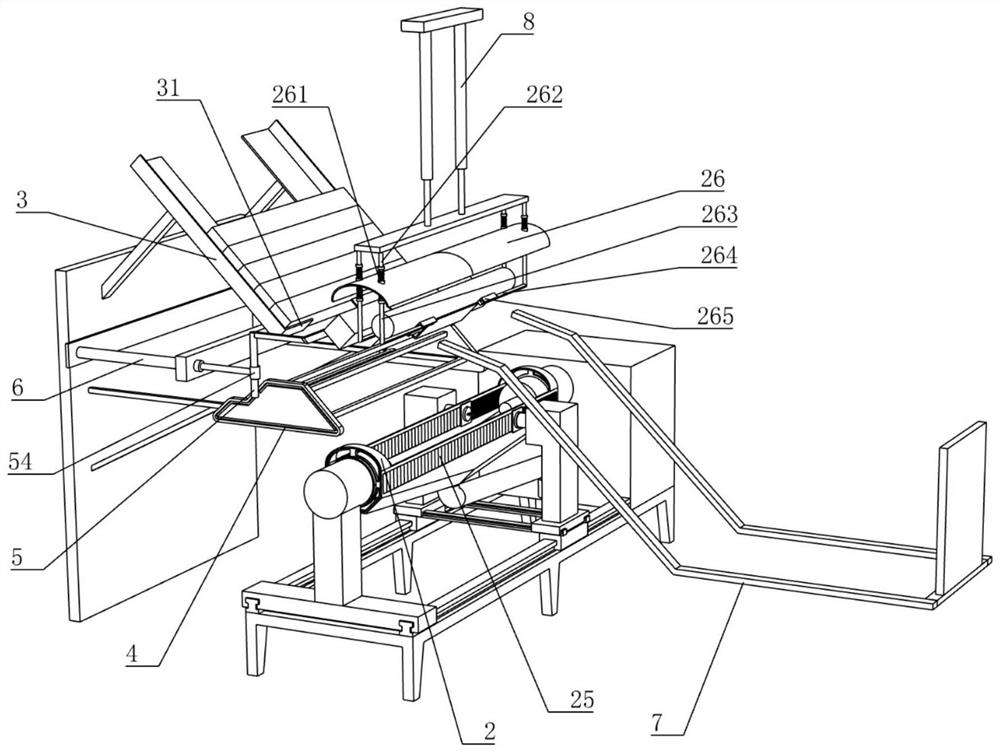

A parallel vibrating screen for maggot material separation

The invention discloses a parallel vibrating screen used for maggot separation and particularly relates to the field of industry utilizing solid poultry excrement to breed fly maggots. The parallel vibrating screen comprises a static platform, a first branch chain, a second branch chain, a third branch chain and a screen framework, wherein movement pair hooke joints at the bottom ends of the first branch chain, the second branch chain and the third branch chain are all connected with the screen framework, and at the same time, a power source of each branch chain is started; and by driving the three branch chains, the rotating of the screen framework around a Y axle, the rotating vibration of the screen framework around an X axle, the translation vibration of the screen framework around the Y axle and the translation vibration of the screen framework around a Z axle can be realized. By designing the fly maggot separation vibrating screen based on a parallel mechanism, the defects of the existing fly maggot separation treatment technology can be compensated, the rapid controllable separation of the fly maggots from solid poultry excrement particles is realized, the sieving efficiency is greatly increased, and the whole equipment is small in spatial size, large in rigidity and stable and reliable in sieving performance and has practical significance in factory application.

Owner:JIANGSU UNIV

Aluminum cast rolling efficient cooling device and cooling process

PendingCN113649417AEvenly distributedNot easy to gatherDomestic cooling apparatusLighting and heating apparatusAutomatic controlGraphite

The invention discloses an aluminum cast rolling efficient cooling device and cooling process. The aluminum cast rolling efficient cooling device comprises a graphite and liquid nitrogen mixing device, a spraying device and a control device with a manual control mode and an automatic control mode. The spraying device comprises an upper nozzle, an upper nozzle base, a lower nozzle and a lower nozzle base; the graphite and liquid nitrogen mixing device comprises a nano graphite discharging device, a mixing box and a liquid nitrogen source; and finally, the upper nozzle gathers one path of nitrogen and one path of liquid nitrogen graphite emulsion, the lower nozzle also gathers one path of nitrogen and one path of liquid nitrogen graphite emulsion, and in addition, a water baffle is further arranged and used for receiving condensate water on the outer wall of a liquid nitrogen related pipeline. The aluminum cast rolling efficient cooling device can be matched with the new process, and metal circulation is accelerated on the premise that the surface quality of a cast-rolled plate is guaranteed.

Owner:洛阳万基铝钛合金新材料有限公司

Effect device for forming stage-lighting effects

ActiveCN102943996BMove fastFlexible movementLighting applicationsTheatre/circusStage lightingEffect light

The invention discloses an effect device for forming stage-lighting effects. The effect device comprises a main support, an effect wheel, a rotating mechanism and a moving mechanism, a light hole is arranged on the main support, the rotating mechanism is connected with the effect wheel and drives the effect wheel to rotate, the moving mechanism is used for enabling the effect wheel to move relative to the light hole, is mounted on the main support and comprises a rocker arm and a moving driving mechanism, the moving driving mechanism is connected with the rocker arm and drives the rocker arm to rotate, and the effect wheel is connected with the rocker arm. Relative movement of the effect wheel and the light hole is controlled by the rocker arm, the effect wheel can synchronously move with a moving motor, the change of pattern effects is greatly accelerated, the lighting effects are better, and the size of a lamp can be reduced.

Owner:GUANGZHOU FINEART LIGHTING

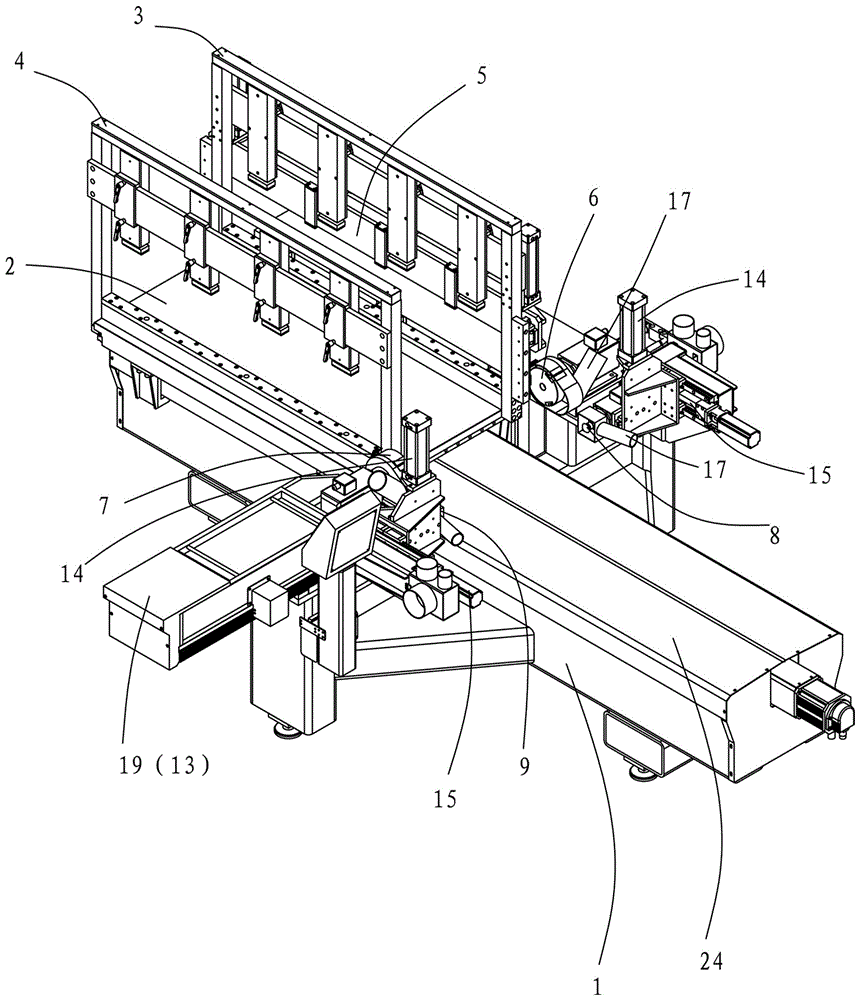

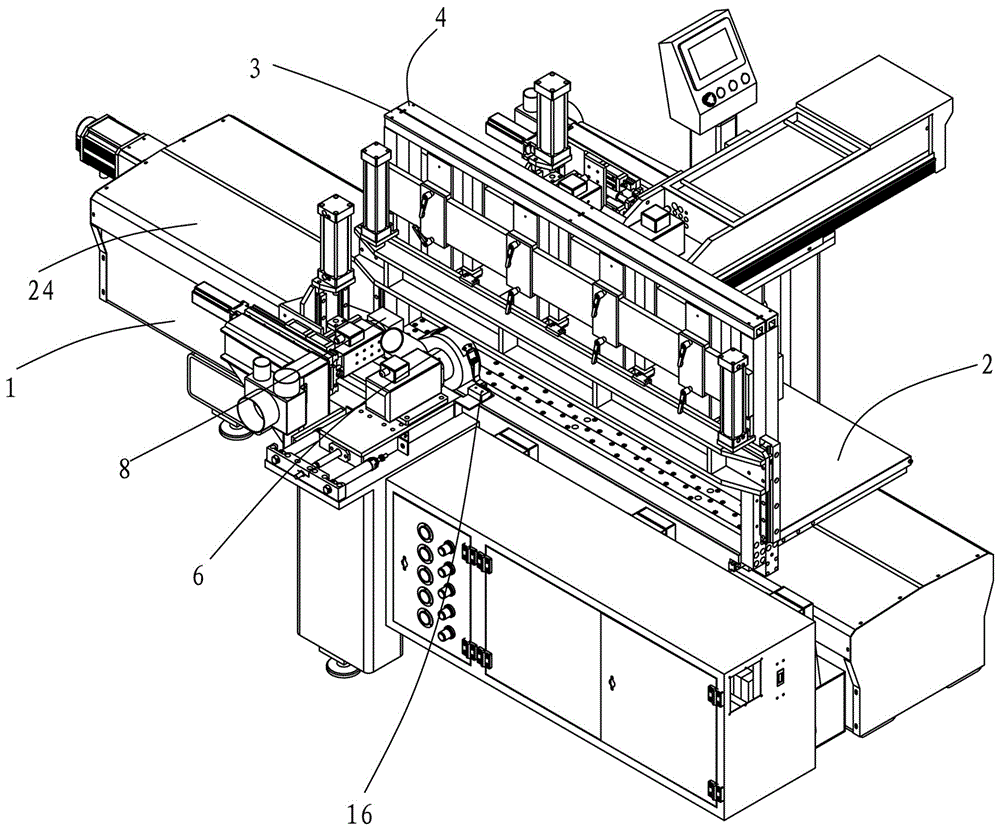

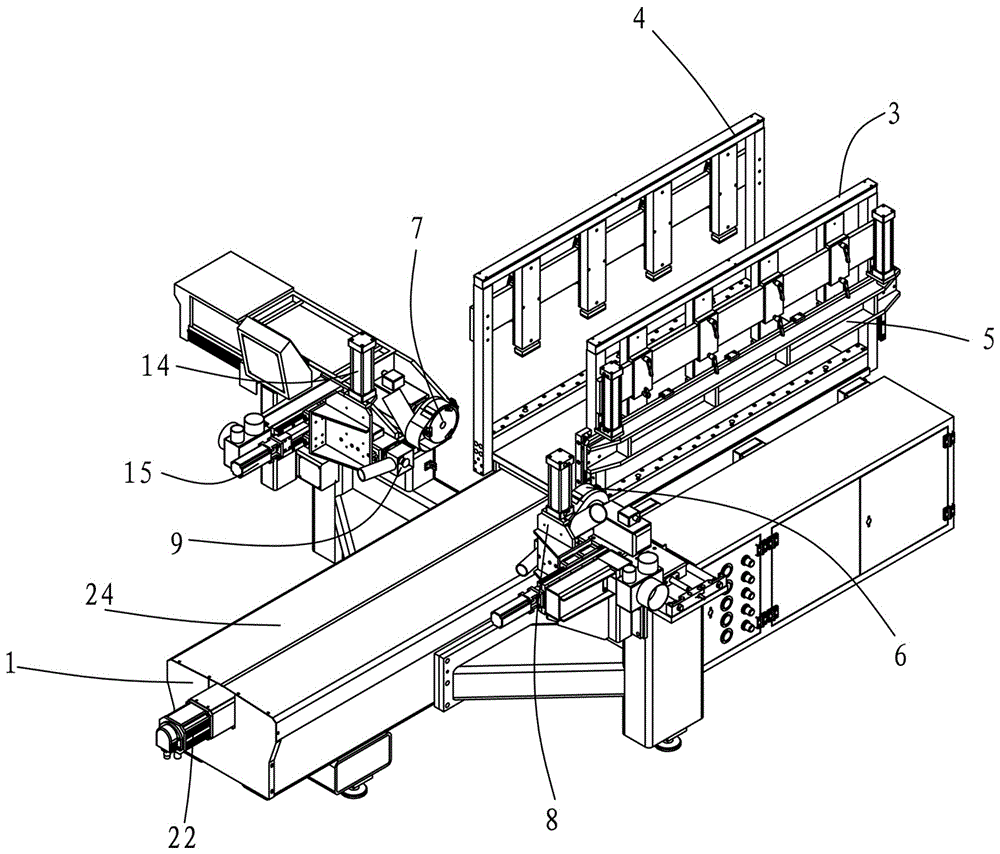

A dust-collecting woodworking machine tool with automatic refueling

ActiveCN114311173BAchieve full coverageMovement is not affectedStationary drilling machinesMulti-purpose machinesWoodworking machineMachine tool

The invention discloses a dust-collecting woodworking machine tool with automatic material change, comprising: a machine tool body, the machine tool body includes a tool end for processing, a fixed end and a pressing end for fixing wood; a dust collecting cylinder, one end of the dust collecting cylinder is sleeved It is connected to the fixed end, and the other end is slidably sleeved on the abutting end. The side wall of the dust collecting cylinder is provided with a processing hole, the dust collecting cylinder is provided with a cover that can be opened and closed, and the dust collecting cylinder is provided with a A material carrier that can be lifted and lowered; a material changer assembly, the material changer assembly includes a loading bracket and an unloading bracket. In the present invention, by arranging parts such as a dust collecting cylinder, a processing hole, a cylinder cover, a telescopic piece, etc., under the premise of not affecting the movement of the abutting end and the cutter end, the wood material being processed can be covered, and the wood chips during processing can be prevented from being scattered everywhere; At the same time, the present invention is provided with an automatic material changing mechanism that cooperates with the dust collecting cylinder, and the material changing assembly can remove the processed wood and put new wood on it, which solves the problem of the urgent shortage of dust-collecting woodworking machines with automatic loading and unloading on the market at present. .

Owner:XUZHOU FENG ZHAN MACHINERY

Plastic plate periphery polishing machine

InactiveCN106625113AReduce processLow costEdge grinding machinesPolishing machinesEngineeringMotor drive

The invention relates to a polishing machine for polishing the periphery of a plastic plate. The polishing machine for polishing the periphery of the plastic plate comprises a machine tool, a sliding table, a material pressing device and polishing devices; the sliding table is located above the machine tool and can move along the machine tool; the material pressing device is arranged on the sliding table; the polishing devices are arranged on the two sides of the machine tool; the two sides of the machine tool are further each provided with a material cutting device; each material cutting device comprises a tool and a motor; the motors drive the tools to rotate; each material cutting device is provided with a position adjusting mechanism; and a position detector is further arranged on the side face of the machine tool and is in signal connection with each material cutting device. Polishing and chamfering can be performed at the same time, or polishing and grooving are performed at the same time as long as a chamfering device or a grooving device is added behind the polishing devices, the work procedures are greatly reduced, cost is greatly reduced, the automation degree is remarkably improved, chamfering of the chamfering device is fast, grooving of the grooving device is fast, and position adjustment of the material cutting devices is convenient and accurate.

Owner:佛山市顺德区新大陆机械制造有限公司

A dust-proof main computer case

ActiveCN111766926BEffective dustproofEasy to adjustDispersed particle filtrationDigital processing power distributionEngineeringShort distance

The invention discloses a dust-proof main computer box, which comprises a box body, a front cover plate is fixedly installed on the front end of the box body, and a switch is arranged on the front cover plate, side panels are arranged on both sides of the box body. plate. The dust-proof main computer box of the present invention has a dust-proof and heat-dissipating structure, which can effectively prevent dust, and can be adjusted when necessary to enhance the heat dissipation effect. The portable structure can carry the entire main box for movement, which is convenient for long-term use. It can be moved for a long distance, and it can be stored when not in use, saving space. The mobile structure is convenient for short-distance movement of the main box. The balls in the structure can be rotated at any angle, which improves the flexibility when moving. At the same time, the balls can be replaced. The use effect is guaranteed, and the fixed structure can ensure the stability of the main box when it is used. It can also be adjusted to ensure that the main box will not be affected when it moves. The detachable fixing plate can be disassembled, which is convenient for users to disassemble and replace.

Owner:广州市中晟科技有限公司

Upper knife shaft adjustment device of amorphous strip precision shearing machine

ActiveCN102950507BEasy to adjustAvoid damageAutomatic control devicesShearing machinesCircular discCoupling

The invention provides an upper cutter shaft regulation device of an amorphous strip precision shearing machine. Firstly, a pair of a worm and a gear are utilized to synchronously drive and lift a lead screw, so that an upper cutter shaft generates displacement along the radial direction, a gap between an upper cutting disc and a lower cutting disc is regulated through radially and finely regulating the upper cutter shaft, a telescopic shaft coupling device is used to connect a pair of worms, a pair of gears can be enabled to synchronously rotate, and the movement of a left wall board cannot be influenced when the upper cutter shaft and a lower cutter shaft are dismounted; and secondarily, a side gap between the upper cutting disc and the lower cutting disc is regulated through the axial floating of the upper cutter shaft. The radial synchronous fine regulating and axial flexible fine regulating of the upper cutter shaft can be effectively ensured, accordingly, the gap and the side gap between the upper cutting disc and the lower cutting disc can be quickly and accurately adjusted, the working efficiency is increased, the damage to the cutting discs due to inappropriate cutter regulating is reduced, and accordingly, the shearing efficiency and shearing quality can be ensured.

Owner:宝鸡市精机设备有限责任公司

Ultrasonic lace machine

PendingCN111607931AAvoid messAvoid the problem of easy snagging of wire tubesPattern makingEngineeringWorkbench

The invention provides an ultrasonic lace machine, belonging to the technical field of lace machines and solving a problem that the existing lace machine is inconvenient to arrange. The ultrasonic lace machine provided by the invention comprises a workbench, a machine head, an ultrasonic transduction component, a first driving piece and a sliding frame fixedly connected on an output end of the first driving piece, the workbench comprises a penetrating first through hole, a stitching end at a top part of the ultrasonic transduction component is embedded in the first through hole, the first driving piece can drive the sliding frame to move up and down, the top part of the sliding frame is fixedly connected with a second driving piece, and the second driving piece is located in the machine head; a transmission mechanism is arranged in the sliding frame, a bottom part of the sliding frame is provided with a lace wheel, and by the transmission mechanism, the second driving piece can drive the lace wheel to rotate; and the stitching end and the lace wheel interact with each other to realize stitching. The ultrasonic lace machine has the advantages that a driving component driving the lace wheel to rotate occupies small installation space, and the ultrasonic lace machine is convenient to arrange.

Owner:台州通宇服装机械科技有限公司

Stage lighting driving system and stage lighting using the system

ActiveCN104456429BLarge interior spaceEasy to useLighting applicationsMechanical apparatusMotor driveStage lighting

The invention relates to the technical field of stage lighting, and particularly relates to a driving system for stage lamps. The driving system comprises a base, a driving motor and at least two optical element brackets and optical elements, wherein the optical elements are mounted on the optical element brackets; the driving motor is arranged on the base; the base is provided with light holes; the optical element brackets sleeve a rotating shaft of the driving motor in a rotatable manner; a pushing component is fixedly connected onto the rotating shaft of the driving motor, and is used for pushing the optical element brackets to move; a reset component is arranged on each optical element bracket. The driving system simply needs one set of motor driving structure to drive a plurality of optical element brackets, can greatly reduce the manufacturing cost, is simple and reasonable to mount, and can greatly reduce occupied internal space meanwhile, so that internal structural space of the stage lamps is enlarged, and the using effect of the lamps is improved.

Owner:GUANGZHOU HAOYANG ELECTRONICS CO LTD

Dust collection woodworking machine tool capable of automatically changing materials

ActiveCN114311173AAchieve full coverageMovement is not affectedStationary drilling machinesMulti-purpose machinesWoodworking machineMachine tool

The invention discloses an automatic material changing dust collection woodworking machine tool which comprises a machine tool body, and the machine tool body comprises a machining cutter end, a fixing end and an abutting end, one end of the dust collection cylinder is connected to the fixed end in a sleeving mode, the other end of the dust collection cylinder is connected to the abutting end in a sliding and sleeving mode, a machining hole is formed in the side wall of the dust collection cylinder, a cylinder cover capable of being opened and closed is arranged on the dust collection cylinder, and a material carrying bracket capable of ascending and descending is arranged in the dust collection cylinder; and the material changing assembly comprises a feeding bracket and a discharging bracket. By arranging the dust collecting cylinder, the machining hole, the cylinder cover, the telescopic piece and other parts, wood in machining is covered on the premise that movement of the abutting end and the cutter end is not affected, and wood chips are prevented from scattering everywhere during machining; and meanwhile, the automatic material changing mechanism matched with the dust collecting barrel is arranged, the material changing assembly can take down the machined wood and place new wood on the wood, and the problem that the dust collecting woodworking machine tool with the automatic feeding and discharging function is abruptly lacked in the current market is solved.

Owner:XUZHOU FENG ZHAN MACHINERY

Pitching freedom degree redundant posture structure of connecting rod structure manipulator

PendingCN107901043AImprove flexibility and operating spaceReduce difficultyProgramme-controlled manipulatorDexterity problemsHorizontal diameter

The invention discloses a pitching freedom degree redundant posture structure of a connecting rod structure manipulator, relates to a redundant posture structure, and belongs to the field of manipulators. The problems that in the prior art, the master-slave mode teleoperation structure is adopted, pitching, deflecting and rotating actions of manipulators serve as postures, consequently, singularity configuration are caused easily, and the flexibility of a main manipulator is influenced are solved. The pitching freedom degree redundant posture structure comprises a posture pitching mechanism, aposture swing mechanism, a posture deflecting mechanism, a posture pitching redundant mechanism, a horizontal rod mechanism, a first L-shaped rod, a second L-shaped rod and a third L-shaped rod. Theposture pitching mechanism comprises a first posture swing motor and a first rotation body. The posture deflecting mechanism comprises a second posture swing motor and a second rotation body. The posture pitching redundant mechanism comprises a third posture swing motor and a third rotation body. The horizontal rod mechanism comprises a fourth posture swing motor, a fourth rotation body and a horizontal rod.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com