In-furnace stabilizing roller regulating device

A technology of adjusting device and stabilizing roller, which is applied in the direction of coating, metal material coating process, hot-dip plating process, etc., and can solve problems such as jamming, product quality accidents, and easy scratching of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

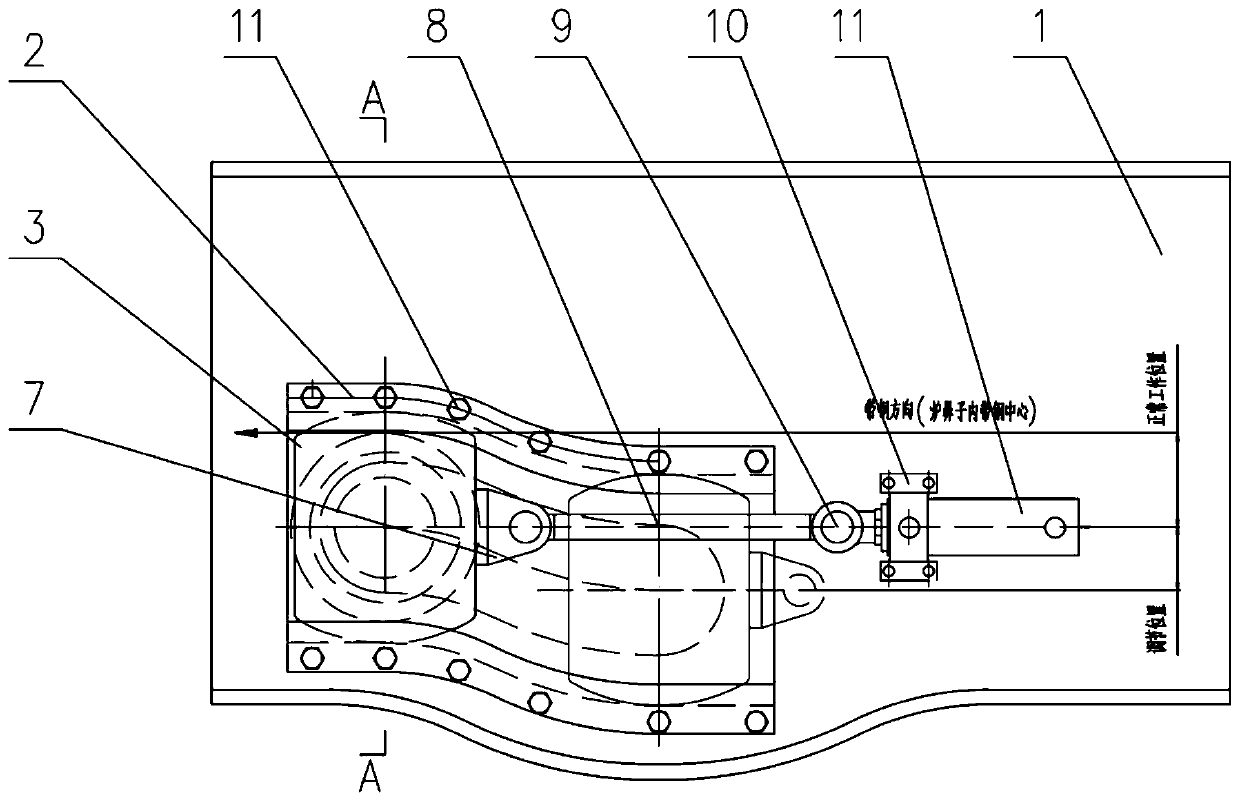

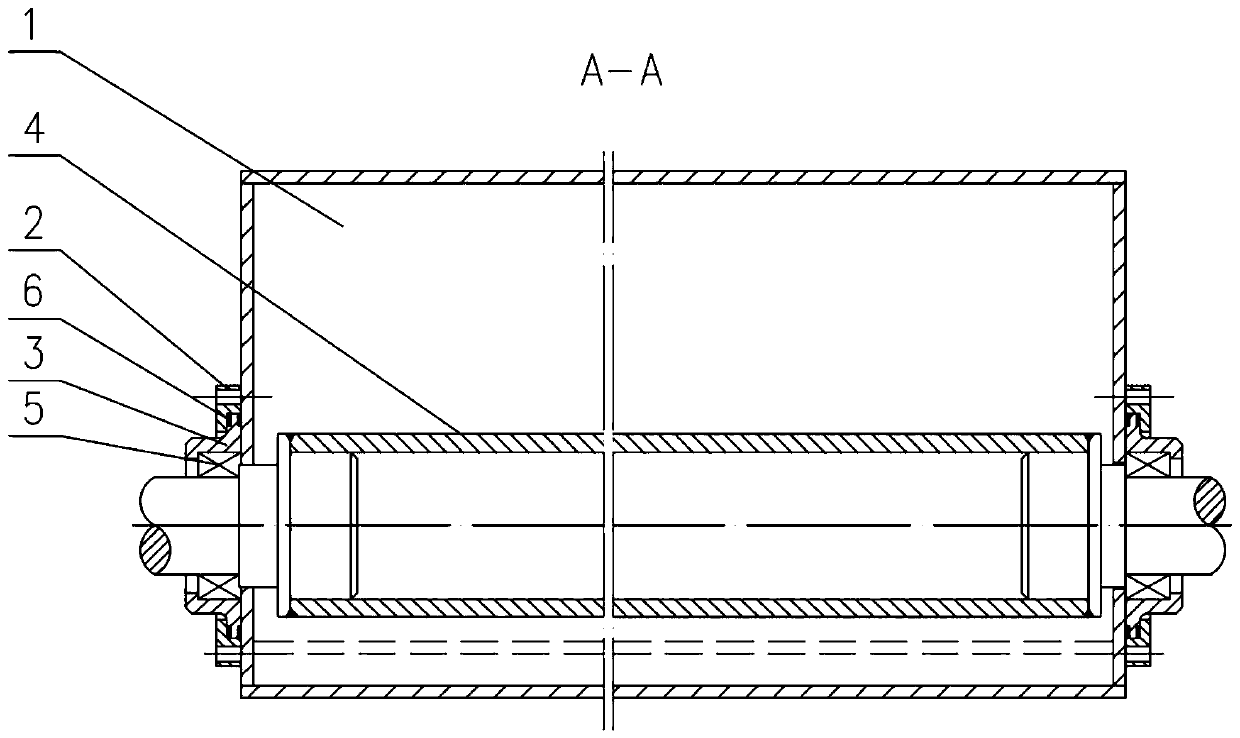

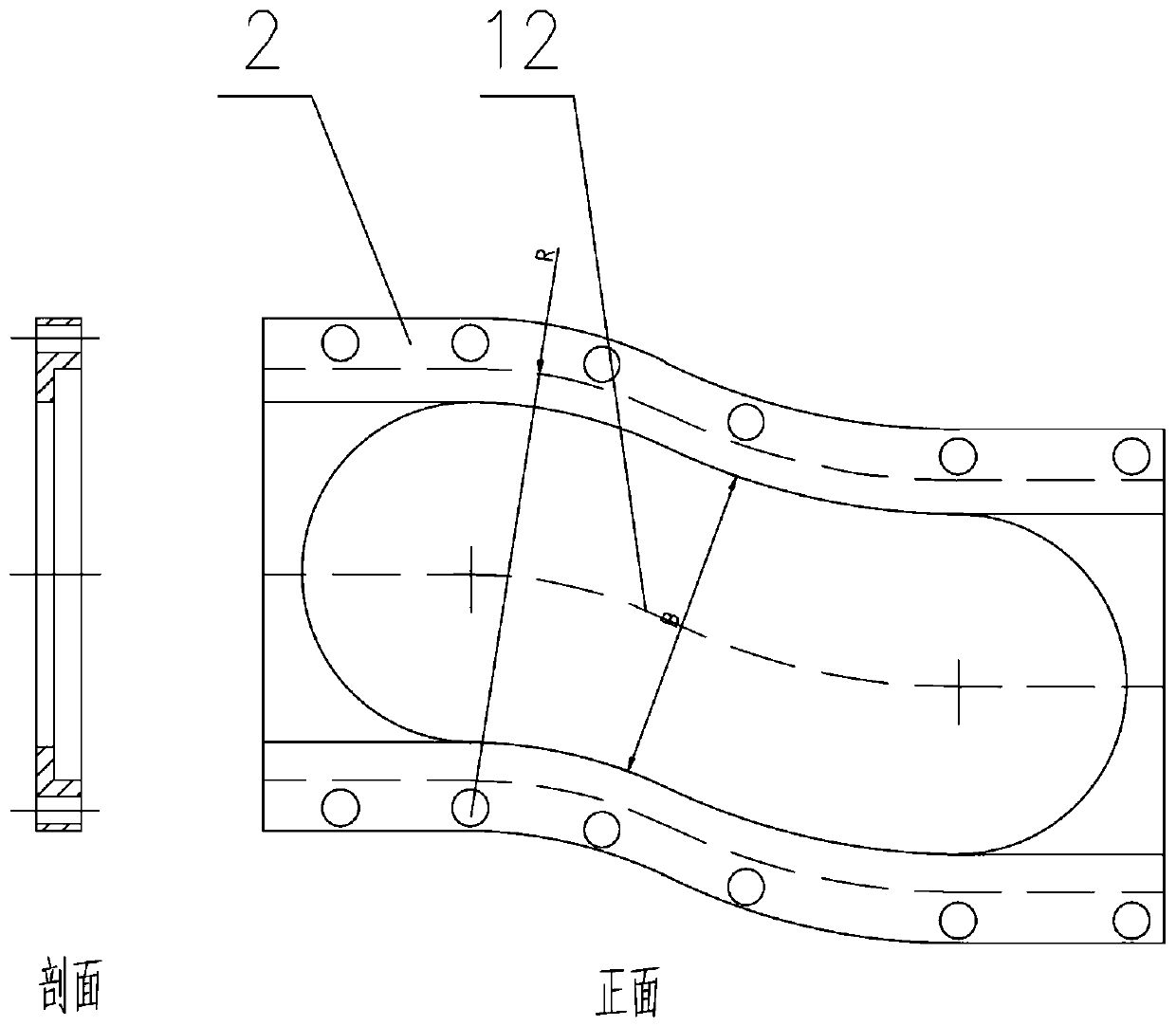

[0022] Such as Figure 1 to Figure 4 As shown, a stabilizing roller adjustment device in a furnace includes a furnace nose 1 with a streamlined concave area at the bottom, arc-shaped groove rails 2 symmetrically arranged on both sides of the furnace nose 1, and installed on the furnace through bearing seats 3 on both ends. The stabilizing roller 4 in the arc-shaped groove rail 2 on both sides, the push rod mechanism that can drive the stabilizing roller 4 to move along the arc-shaped groove rail 2 through the bearing seat 3, the top surface of the bearing seat 3 in contact with the groove inner wall of the arc-shaped groove rail 2 and the bottom surface are both arc surfaces 13 and the farthest distance between the two arc surfaces 13 is compatible with the gauge of the arc groove rail 2. When the bearing seat 3 moves to the high point of the arc groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com