Vibration inhibition control method and system for electric vehicle driving motor

A drive motor and vibration suppression technology, which is applied in the field of vibration suppression control of electric vehicle drive motors, can solve the problems of reducing vehicle operation response, poor effect, and inability to achieve instantaneous vehicle acceleration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

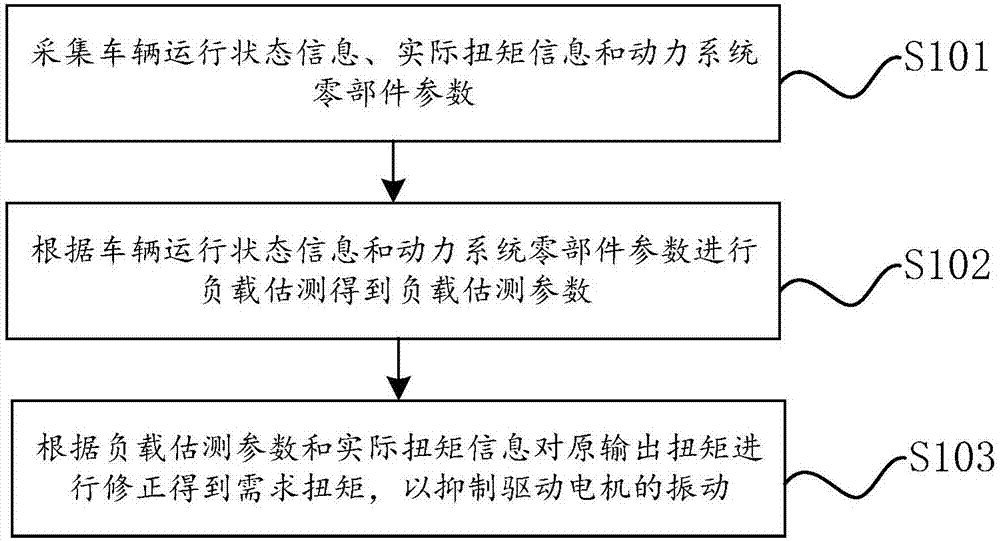

[0060] figure 1 It is a flowchart of a vibration suppression control method for an electric vehicle drive motor provided by an embodiment of the present invention.

[0061] refer to figure 1 , the electric vehicle drive motor vibration suppression control method includes:

[0062] Step S101, collecting vehicle running status information, actual torque information and power system component parameters;

[0063] Specifically, the actual torque information is the actual torque output value fed back by the drive motor, and the power system component parameters include drive motor, reducer, and drive shaft system parameters.

[0064] Step S102, performing load estimation according to the vehicle operating state information and the power system component parameters to obtain load estimation parameters;

[0065] Step S103, correcting the original output torque according to the estimated load parameter and the actual torque information to obtain the required torque, so as to suppre...

Embodiment 2

[0102] Due to the instantaneous torque force transmission will produce a non-linear relationship between the transmission system and the traction force of the vehicle, resulting in more or less vibrations when the motor is driven. Therefore, the embodiment of the present invention mainly utilizes a nonlinear torque observer and a load estimator (inertia follower) to observe the torque at the moment of driving the electric vehicle motor, and perform torque compensation, so as to suppress and correct the occurrence of the momentary power transition. The vibration phenomenon improves the driving comfort of the vehicle.

[0103] Such as Image 6 As shown in this electric vehicle transmission system architecture diagram, when the motor produces torque instantly, the direct coupling between the motor and the reducer, as well as the coupling between the transmission shaft and the differential will all cause abnormal transmission due to the rigid transmission connection. Linear torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com