Patents

Literature

606results about How to "Large installation space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

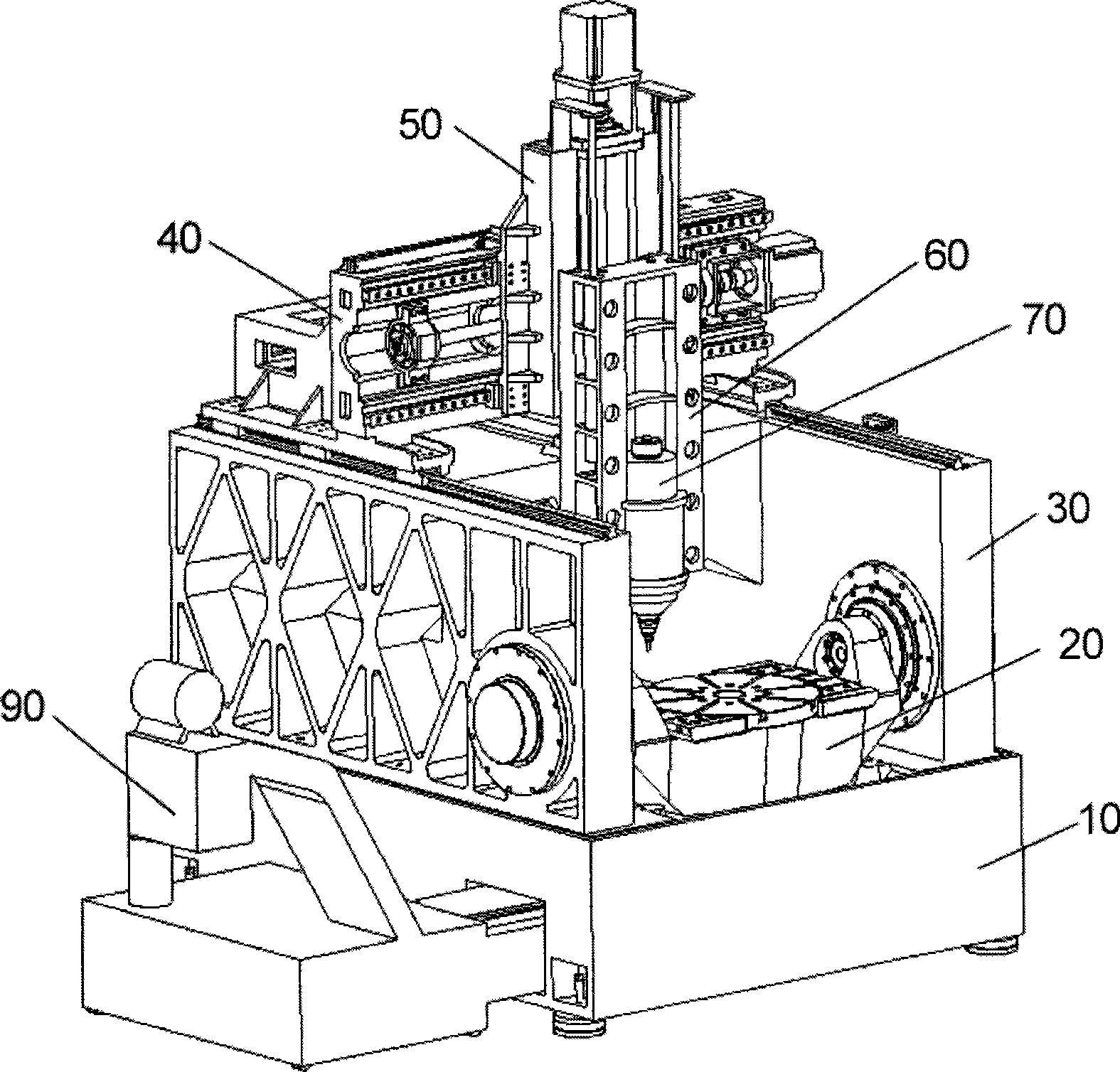

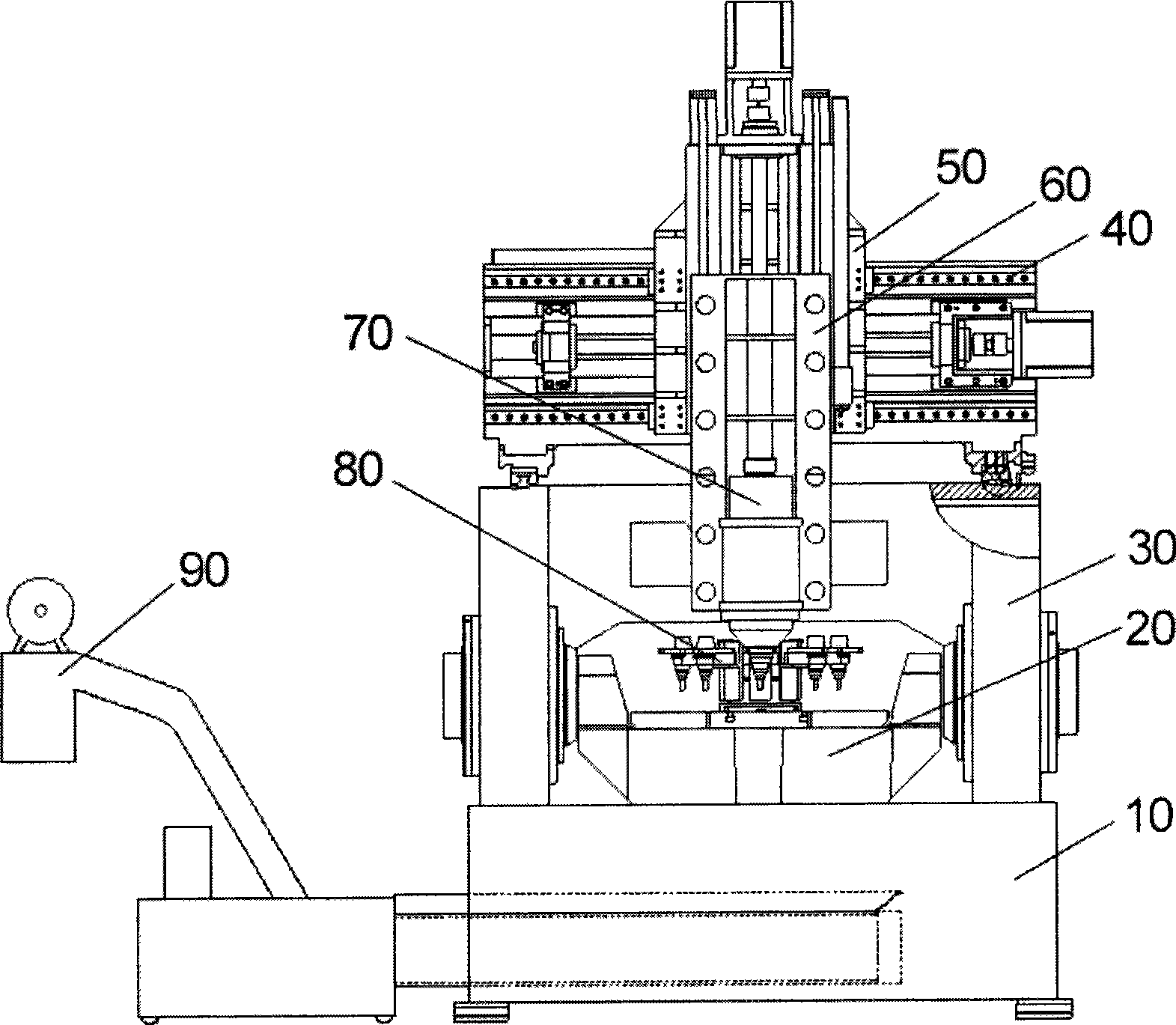

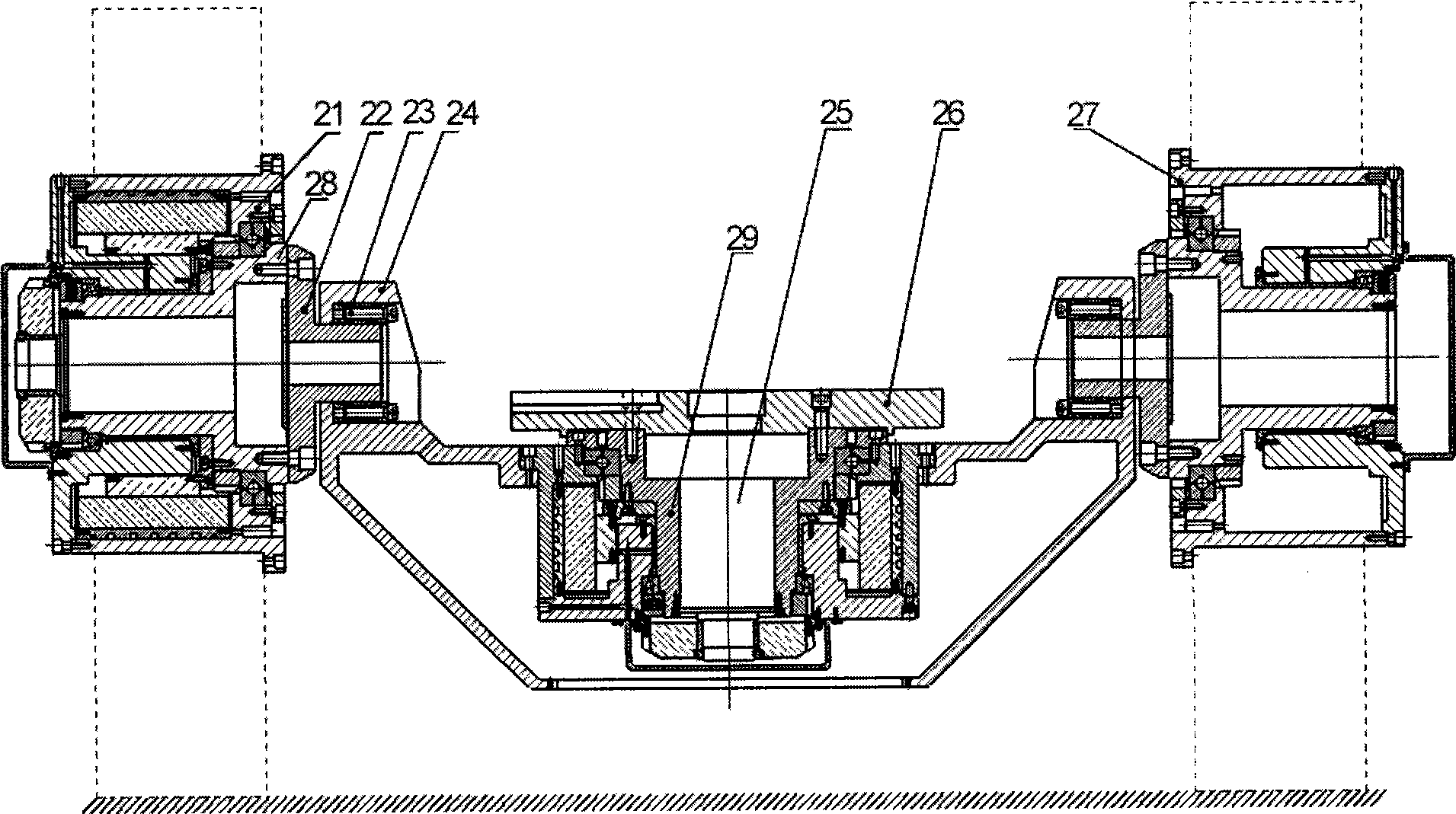

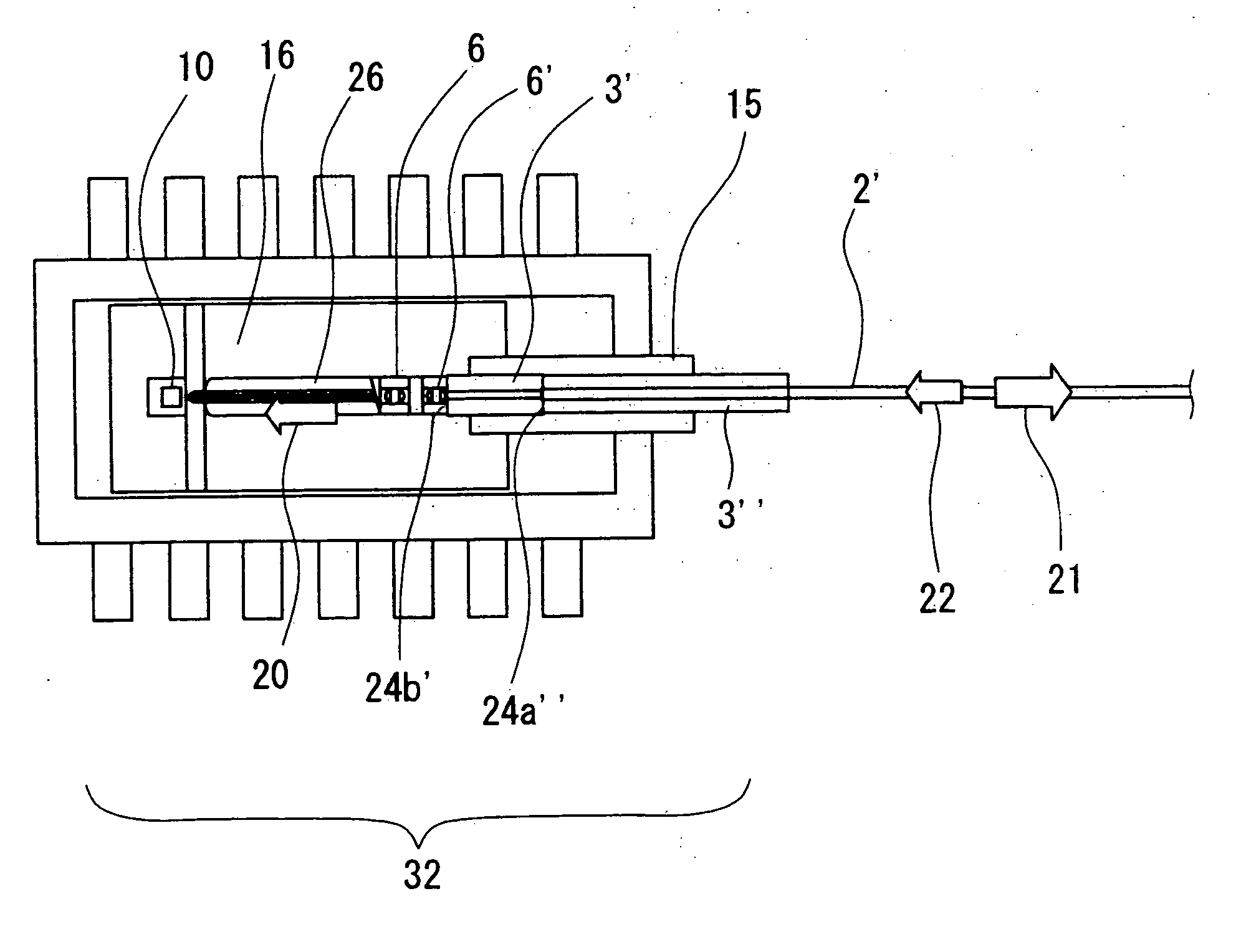

Five-shaft linkage numerical control machining center

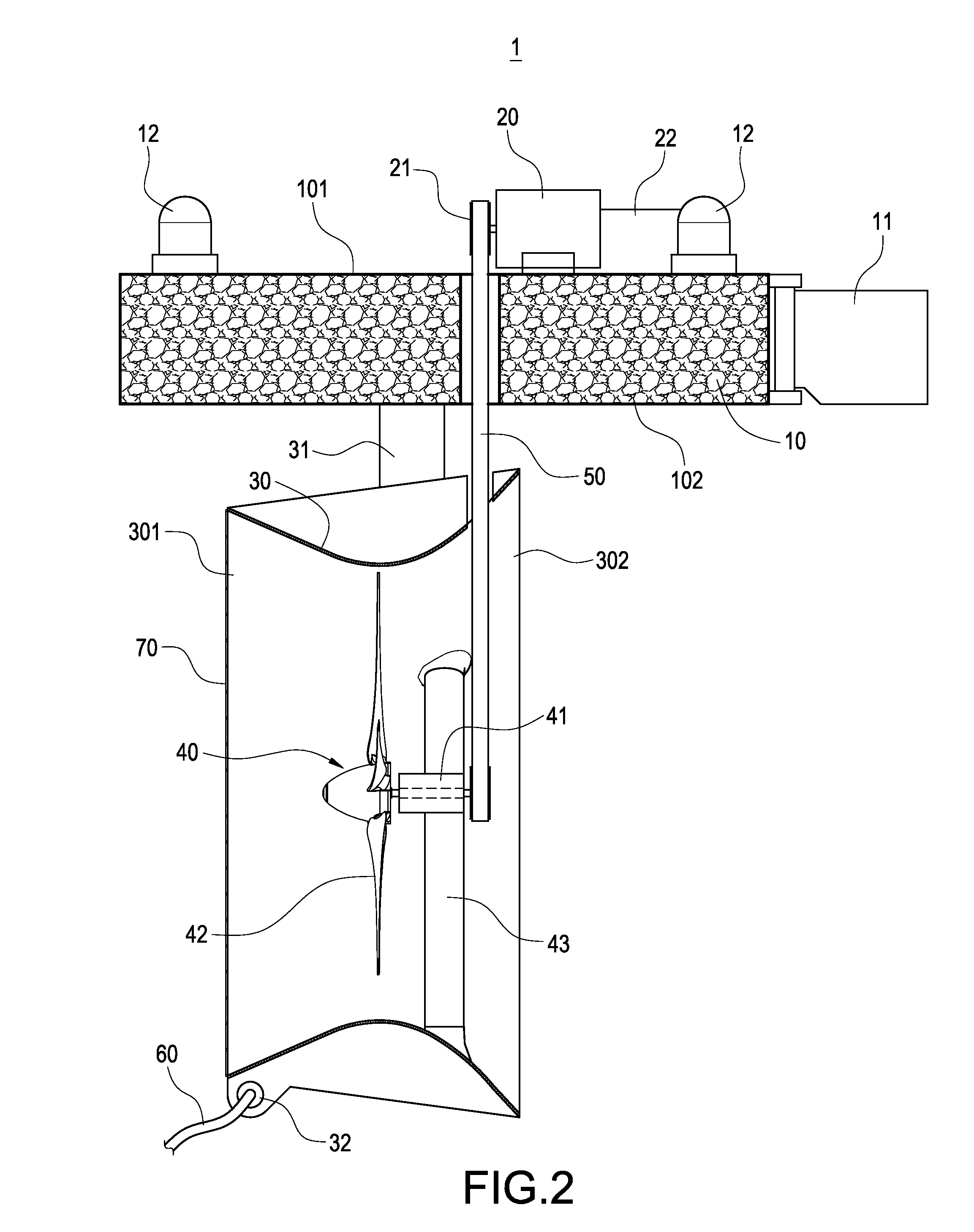

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

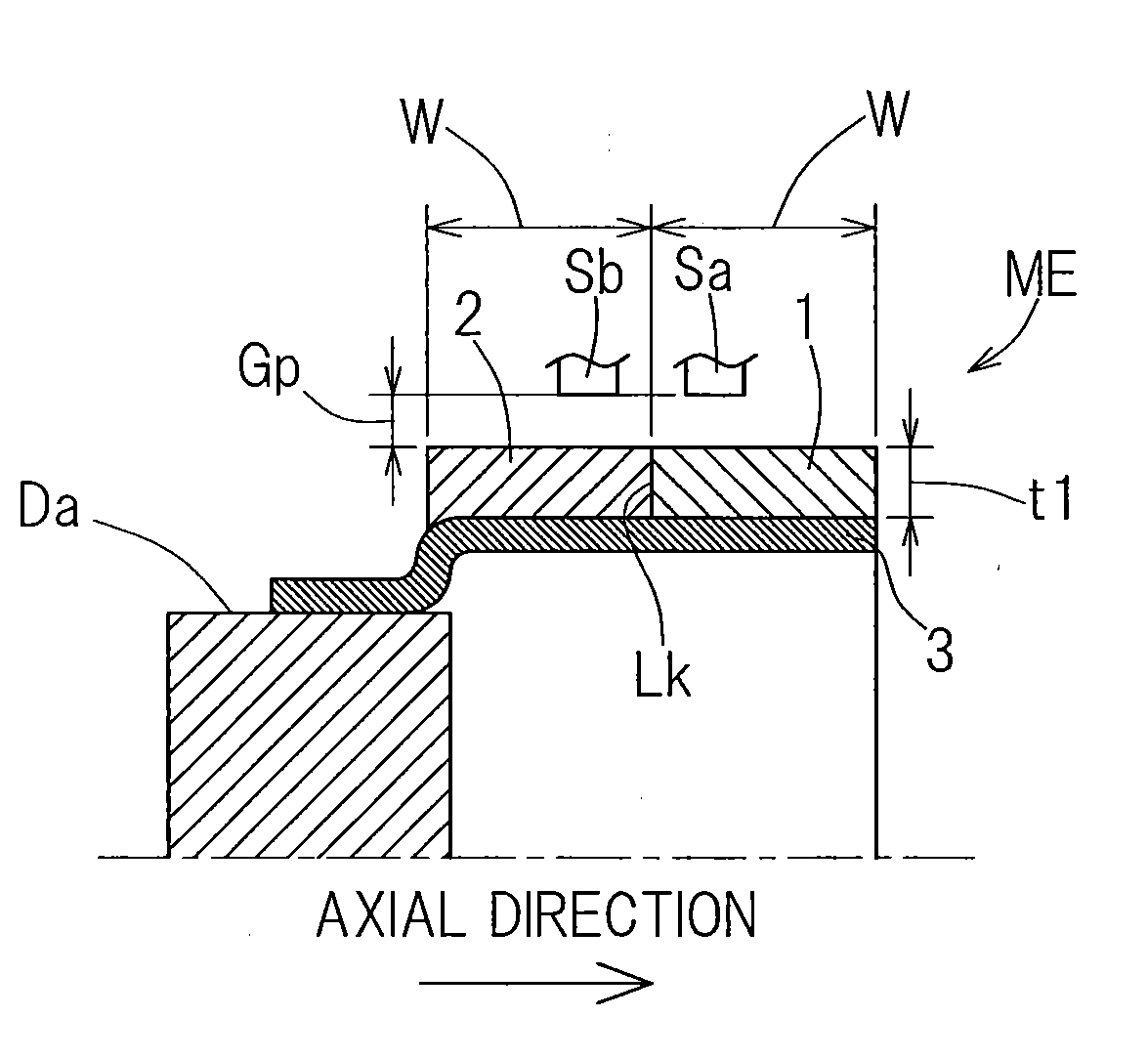

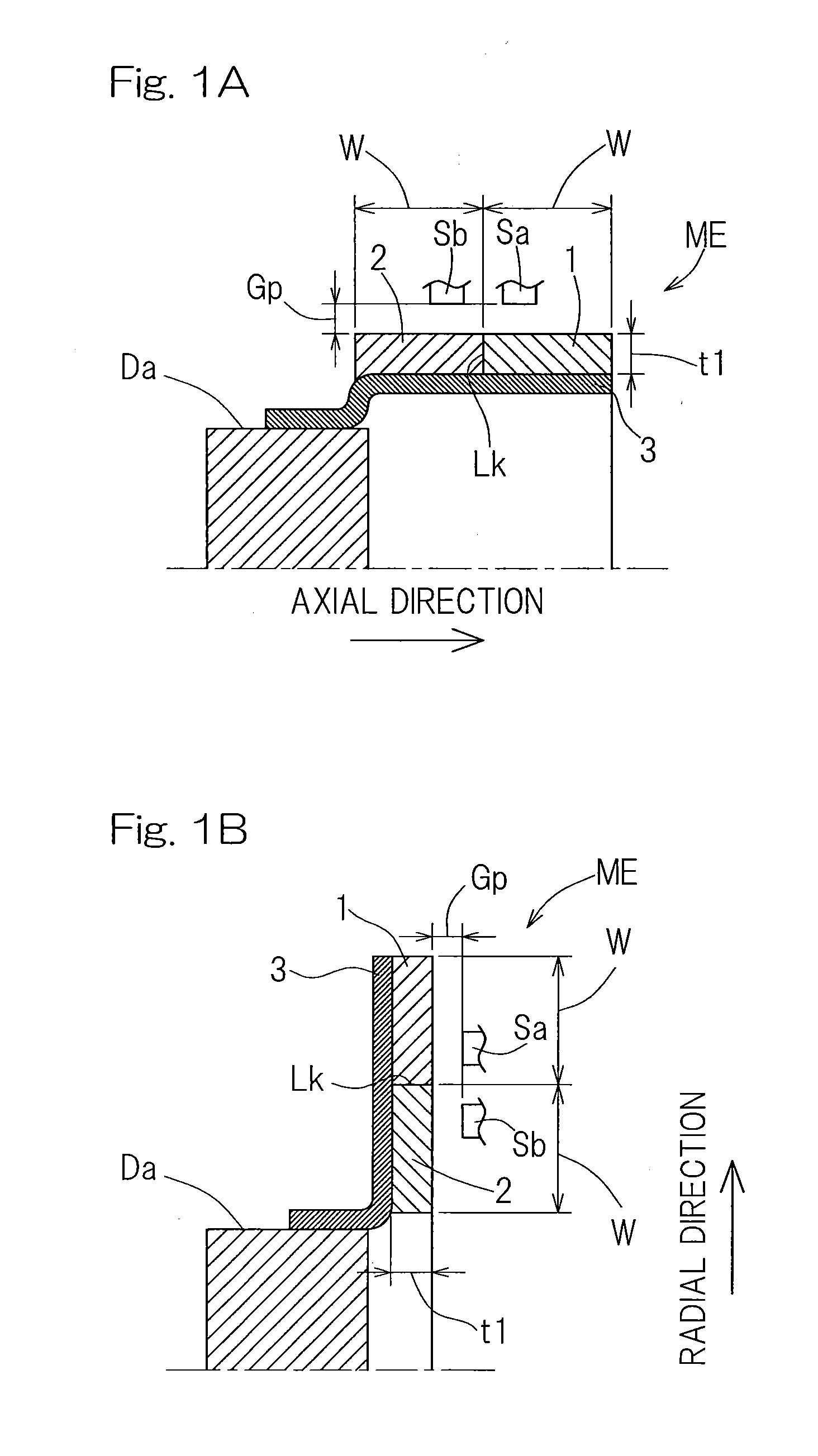

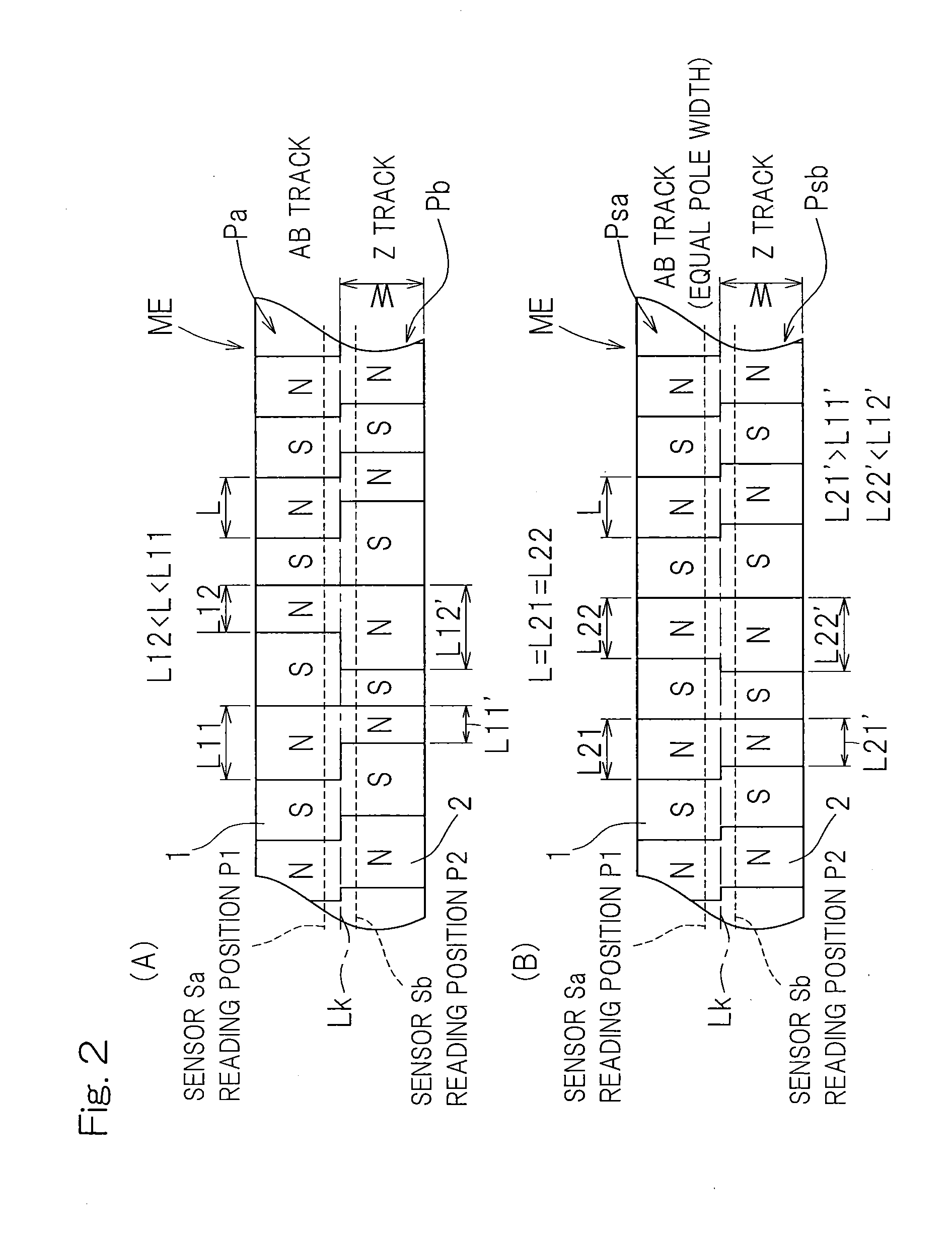

Magnetic encoder

ActiveUS20130063138A1Improve interferenceLow detection sensitivityUsing electrical meansConverting sensor outputEncoderMagnetic signal

Provided is a magnetic encoder which includes plural rows of magnetic encoder tracks. One magnetic encoder track of the magnetic encoder tracks includes magnetic pattern magnetized thereto to generate signals of equal pitch for detection of rotation. The magnetized magnetic pattern includes N poles and S poles arranged in alternate fashion. The magnetic encoder is configured to be employed spaced through an air gap from sensors that read magnetic signals of the respective magnetic encoder tracks. The magnetic encoder track is configured such that the magnetic pattern thereof acting on position of the corresponding sensor is, under the interference of magnetism of the plural rows of magnetic encoder tracks, detected by the corresponding sensor as an equal pitch magnetic pattern.

Owner:NTN CORP

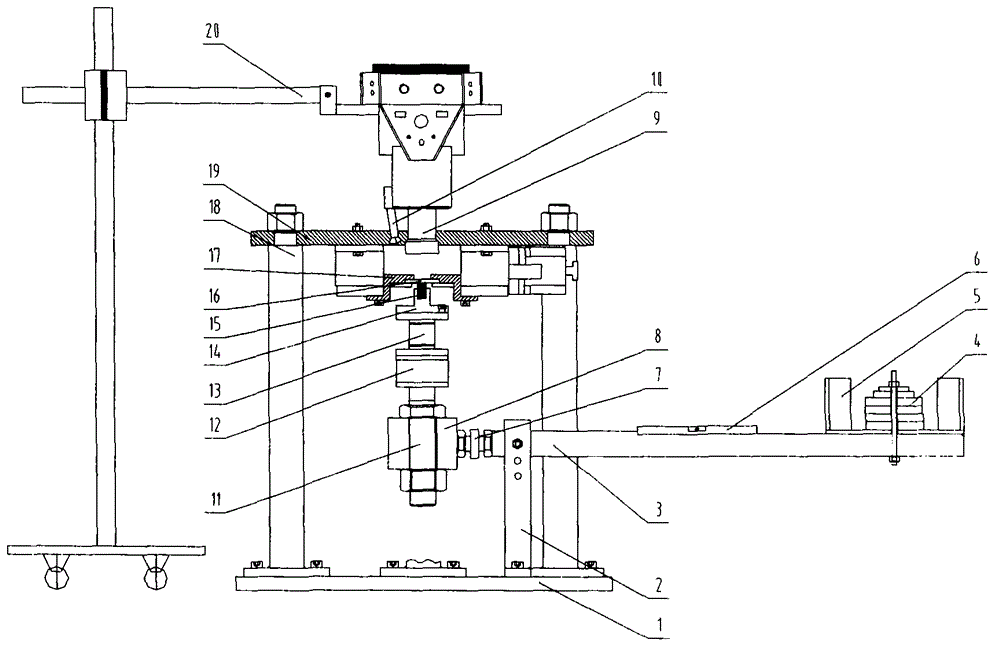

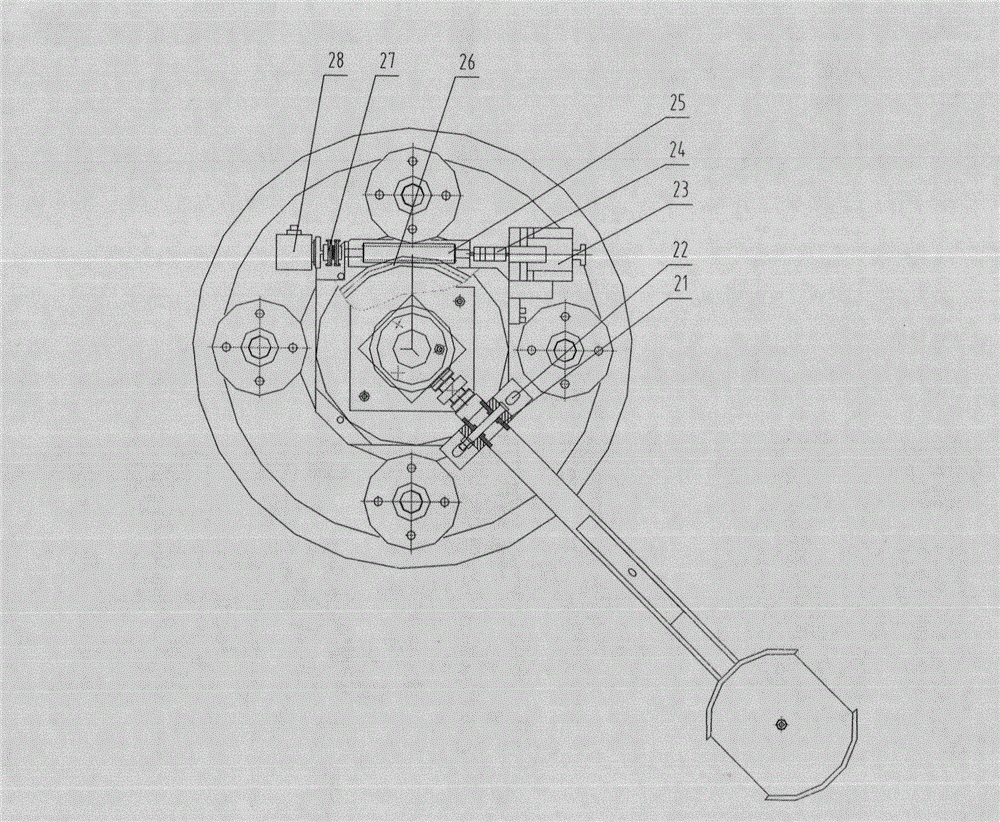

Test machine and test method for real-time and dynamic observation of end surface torsion friction and abrasion of friction interface

ActiveCN102944512AHigh rotation accuracyRun smoothlyUsing mechanical meansMaterial analysisElectric machineryGear transmission

The invention discloses a test machine and a test method for real-time and dynamic observation of end surface torsion friction and abrasion of a friction interface. The test machine comprises a pressure applying device, a rotary platform, a friction interface observing device and an adjusting device, wherein the pressure applying device comprises a lever, a lever bracket and weights, the rotary platform comprises a motor, a shaft encoder and a worm and gear transmission mechanism, the friction interface observing device comprises a high-speed camera, a torque sensor and a pressure sensor, and the adjusting device comprises a level and a vertical adjustable rod element. The axial loading is applied to a lower specimen by the lever and the weights, the rotary platform drives an upper specimen to do reciprocating torsion, the high-speed microscopic camera is used for observing the friction interface, the torsion friction and abrasion tests under different external loads are simulated by the adding and reducing of the weights, the change of the torsion frequency and the like, then the friction coefficient, the abrasion shape and the abrasion chip real-time movement in the friction process are obtained, and the friction and abrasion performances of transparent material in the whole process are evaluated. The test machine has the advantages that the structure is simple, the operation is convenient, and the repetitiveness is high.

Owner:CHINA UNIV OF MINING & TECH

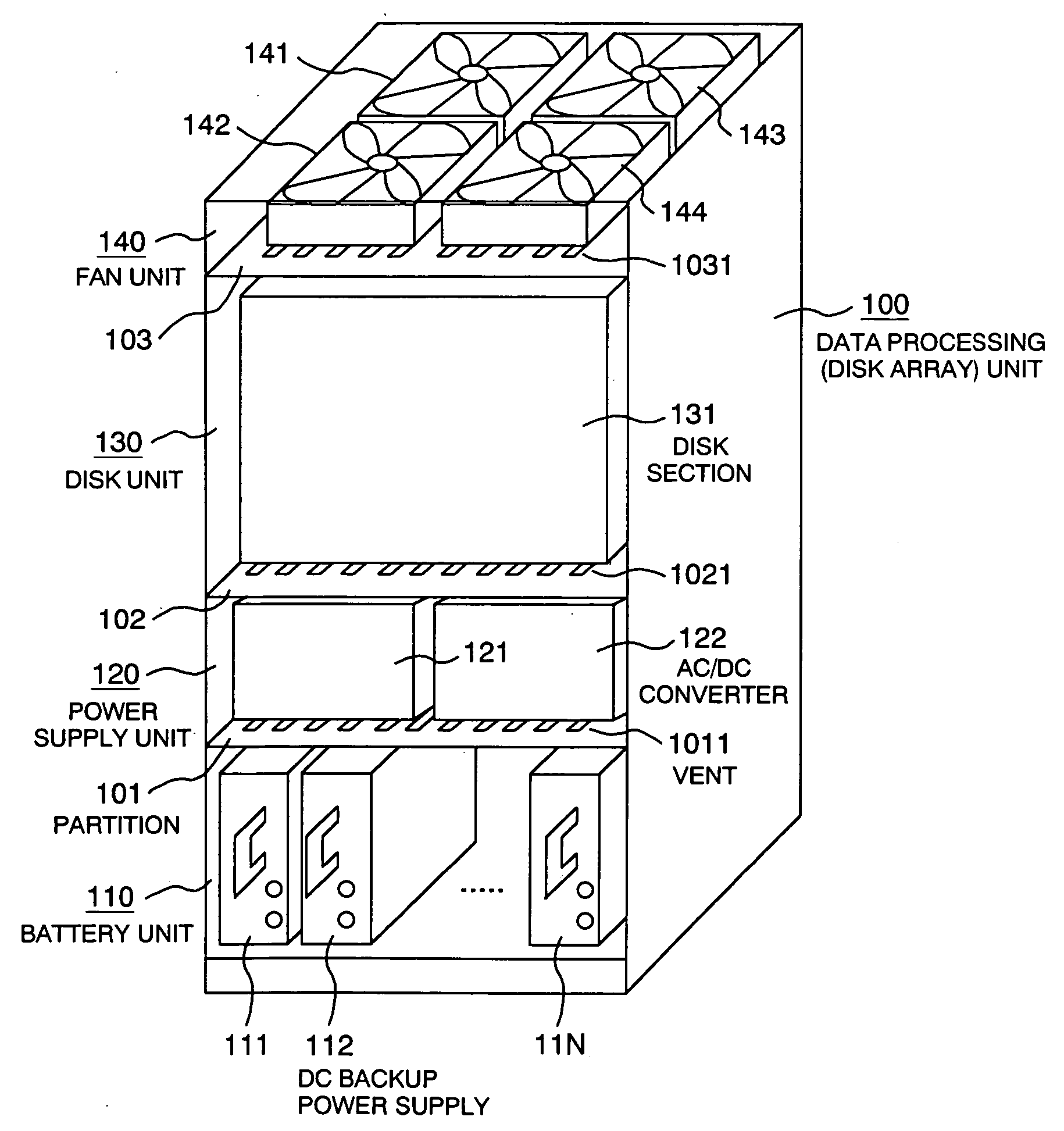

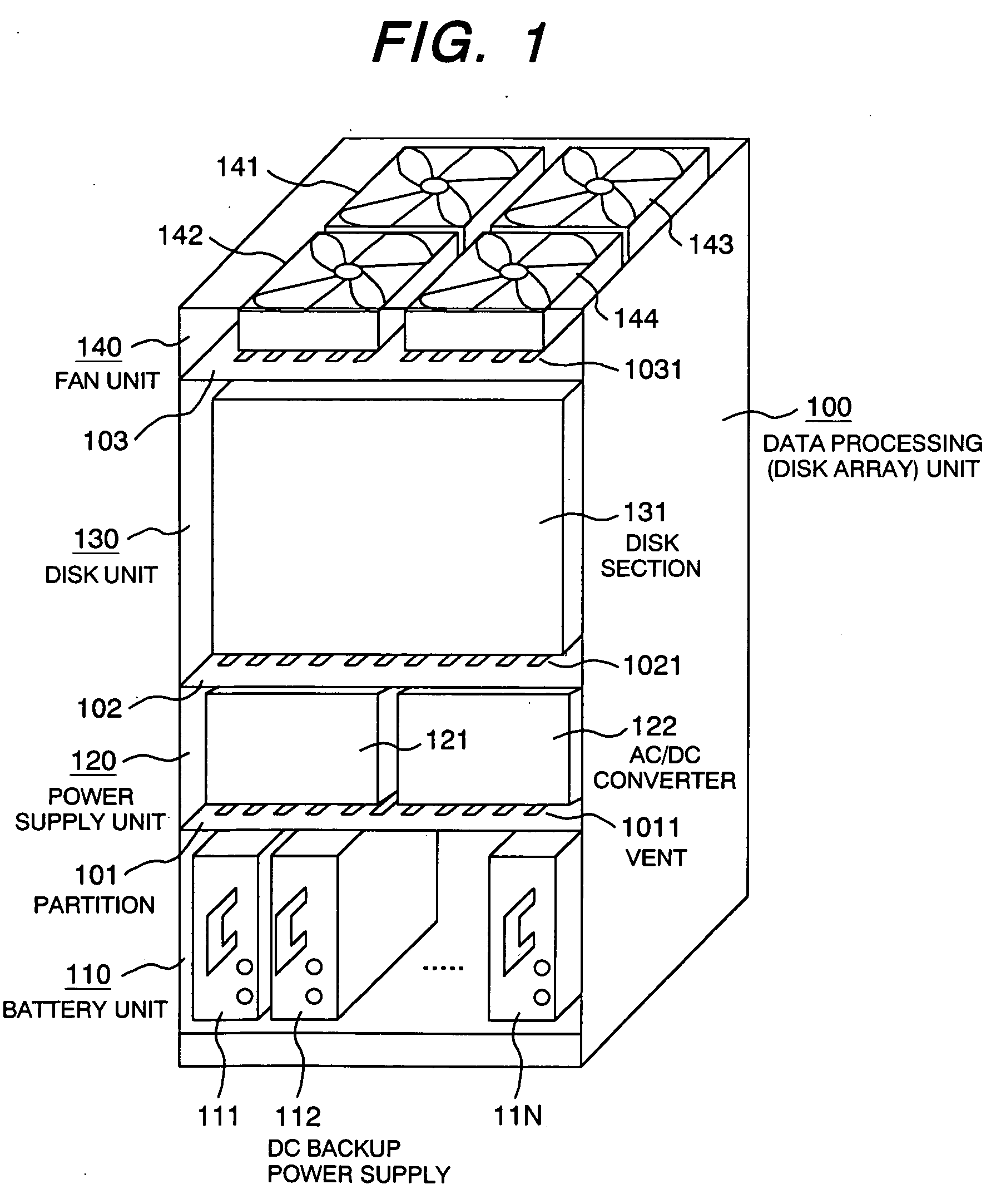

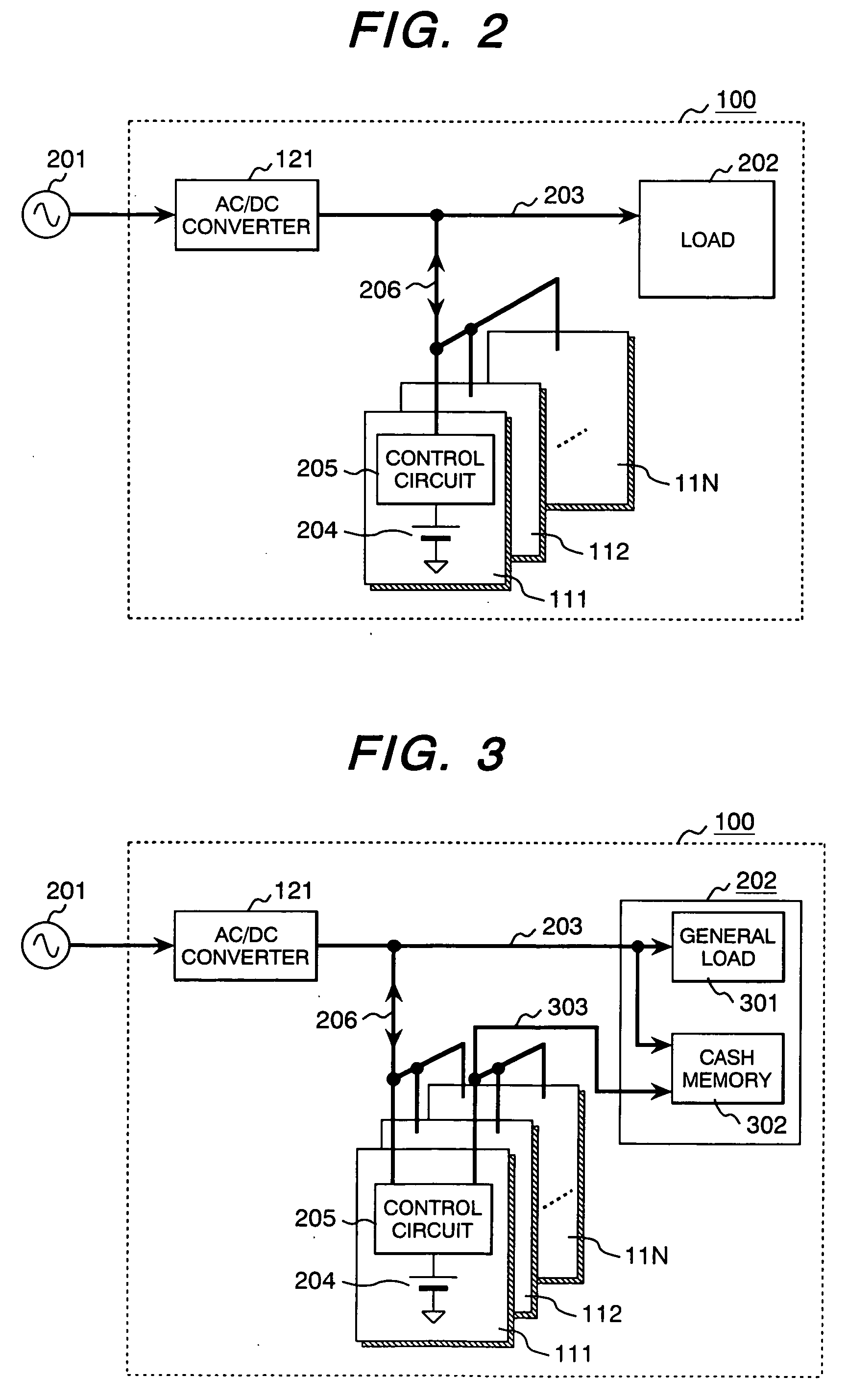

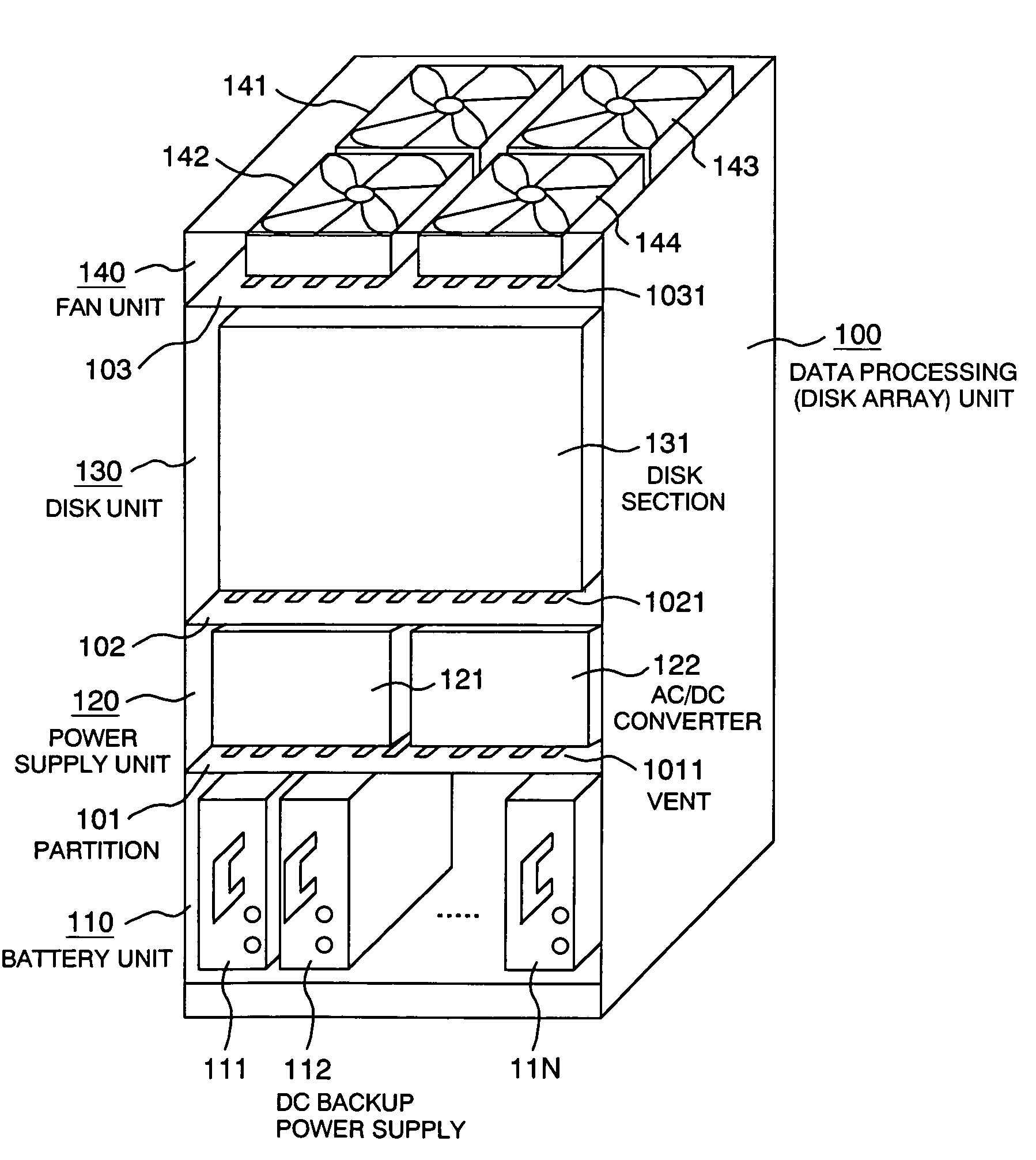

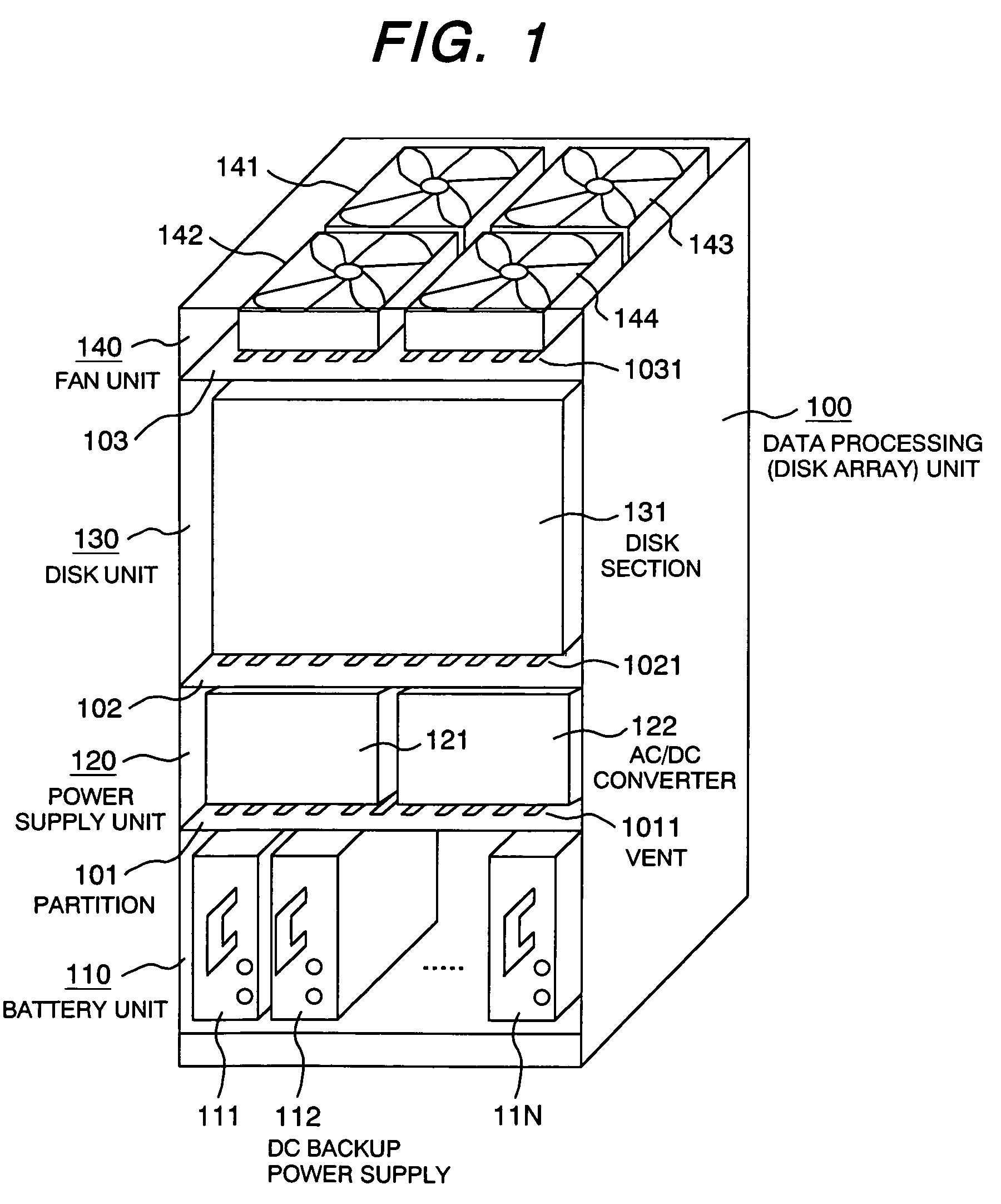

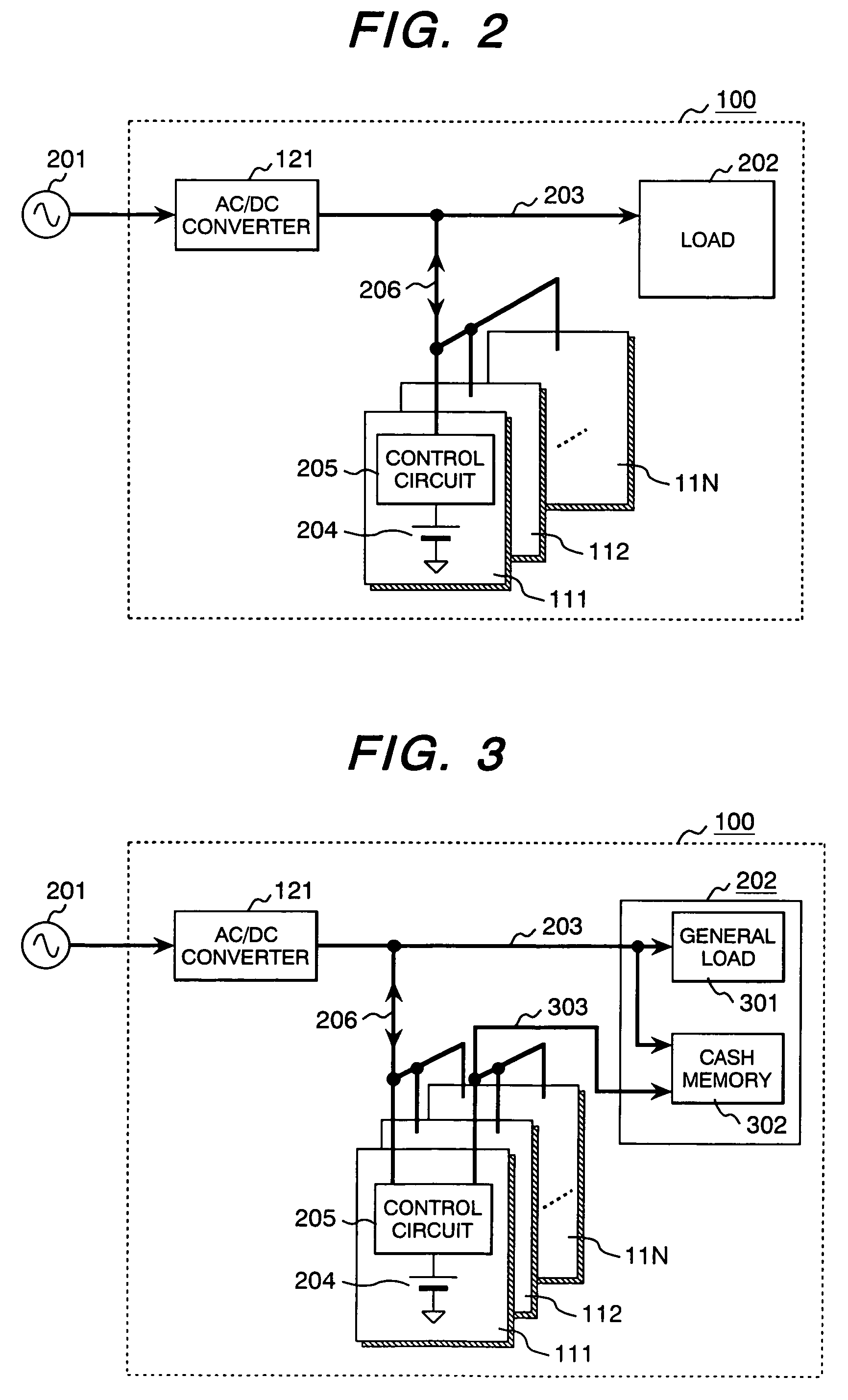

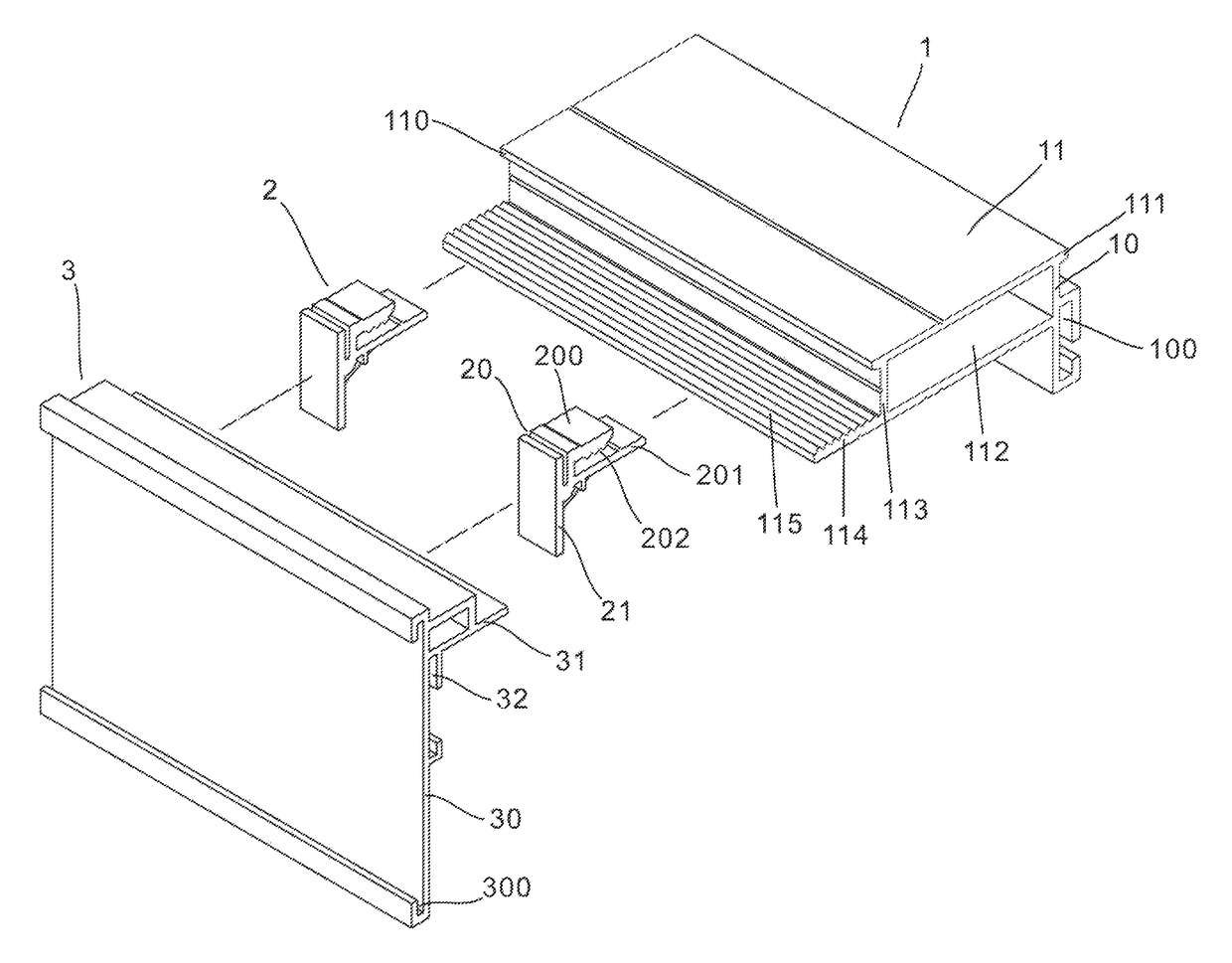

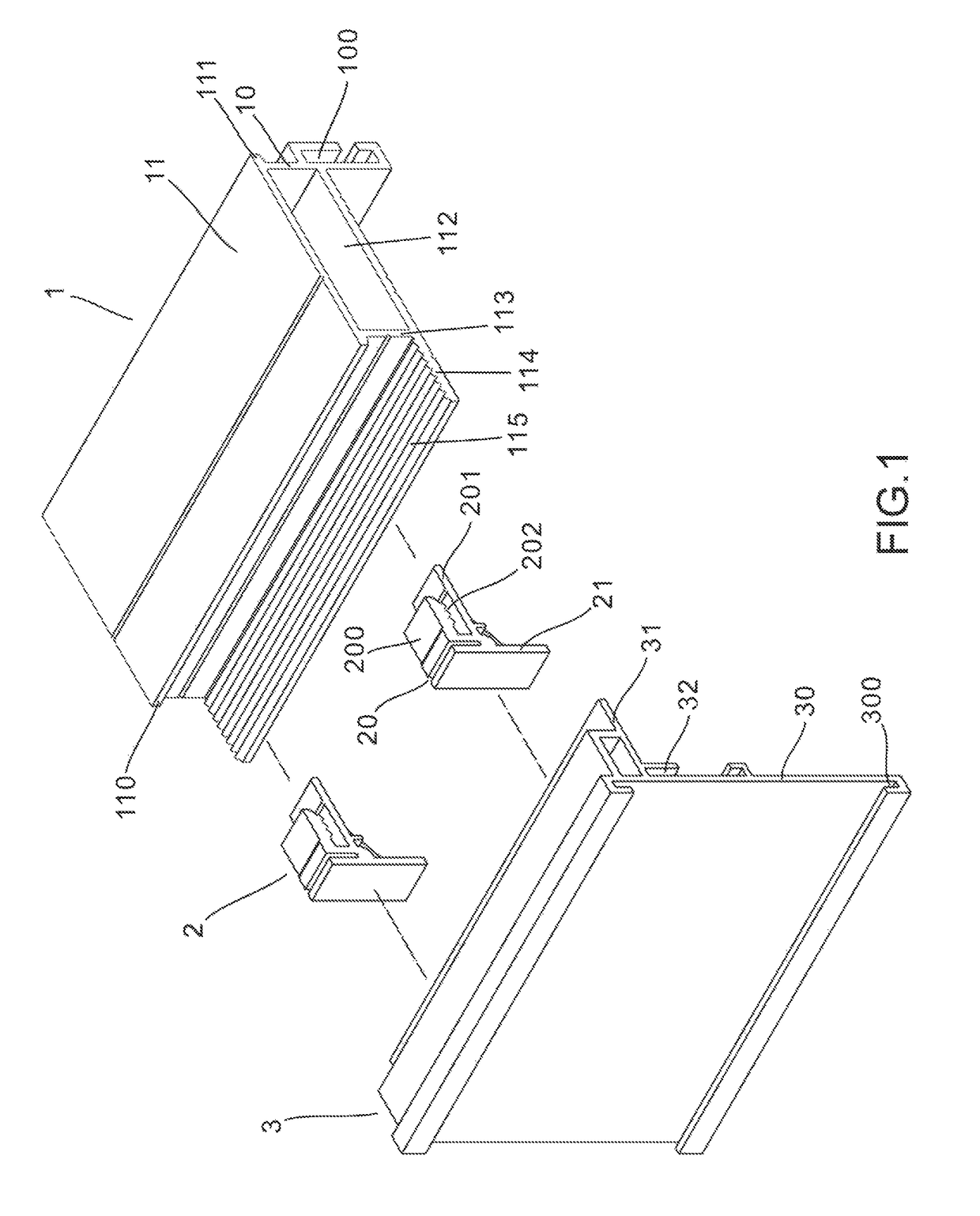

Data processing unit and DC backup power supply

InactiveUS20060056142A1Compact and economicImprove discharge capacityDigital data processing detailsVolume/mass flow measurementElectrical batteryStandby power

A backup power supply is so constructed that it is provided with multiple DC backup power supplies 111 to 11N, each containing nickel-metal hydride battery, stored upright on the bottom of the disk array unit 100; cooled by cooling air through the vents 1011 for ventilation from the bottom to the top; and connected with the output of the AC / DC converters 121, 122 with the backboard 151. Very compact disk array unit with an uninterruptible power supplying function can be realized.

Owner:HITACHI INFORMATION & TELECOMM ENG LTD

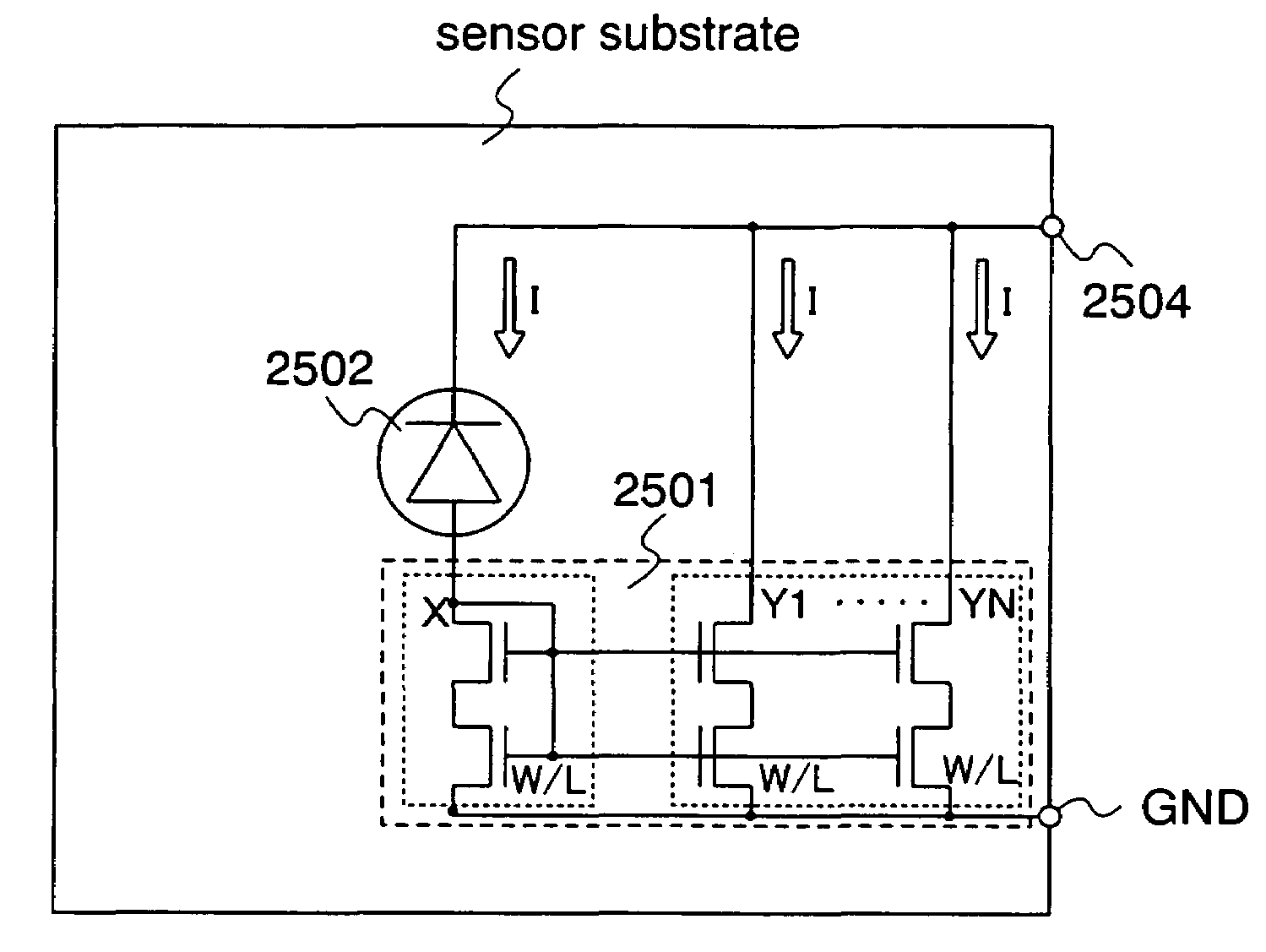

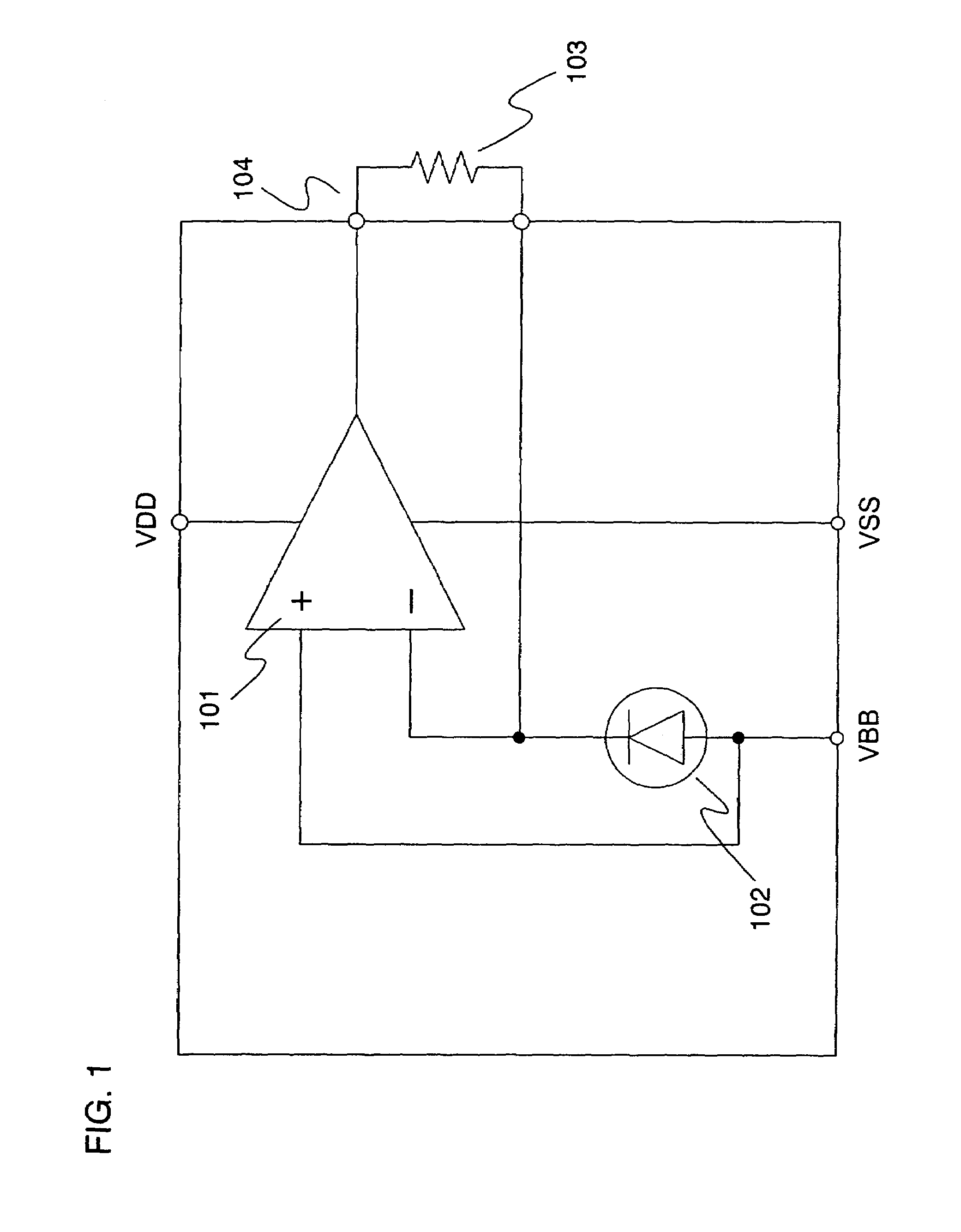

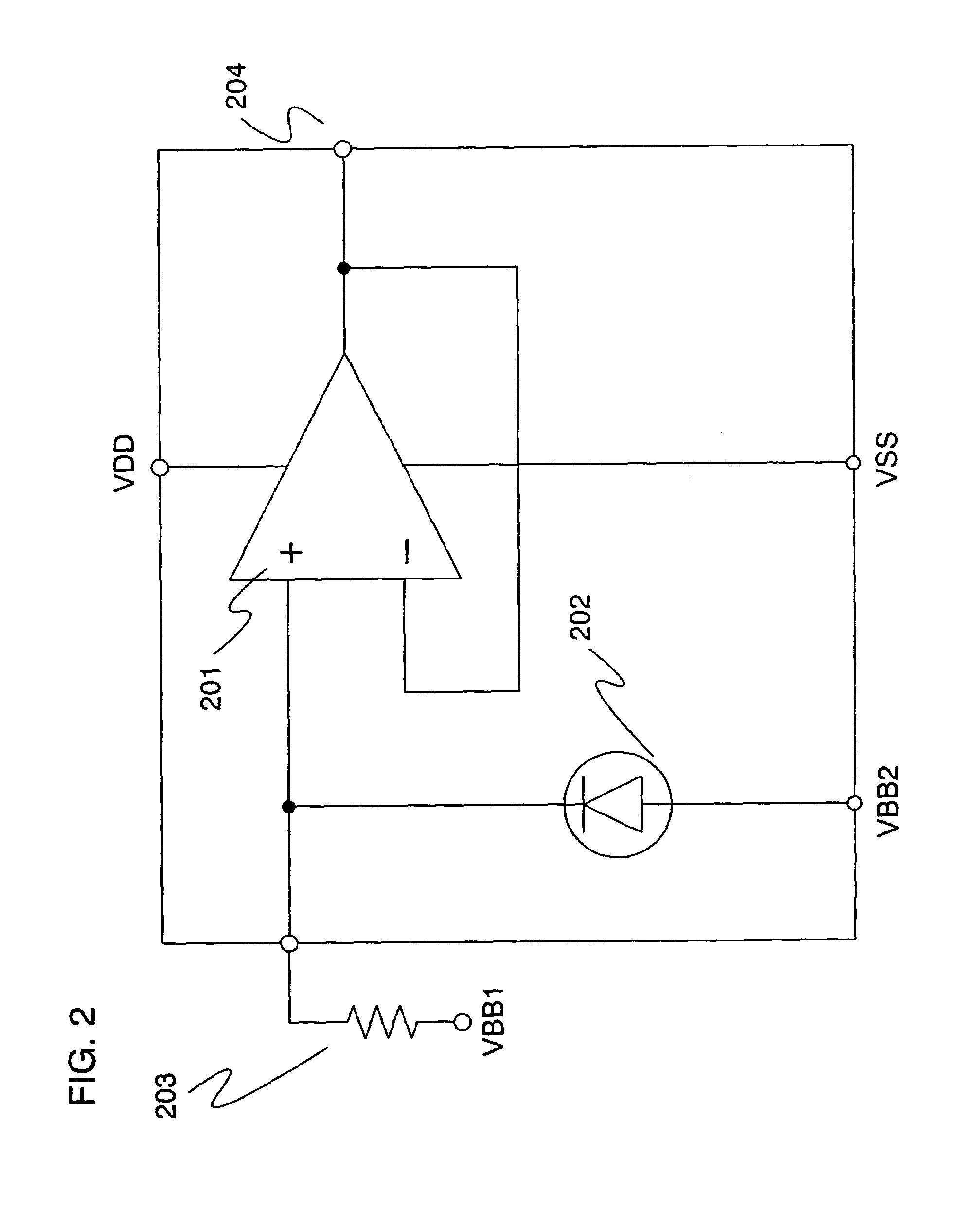

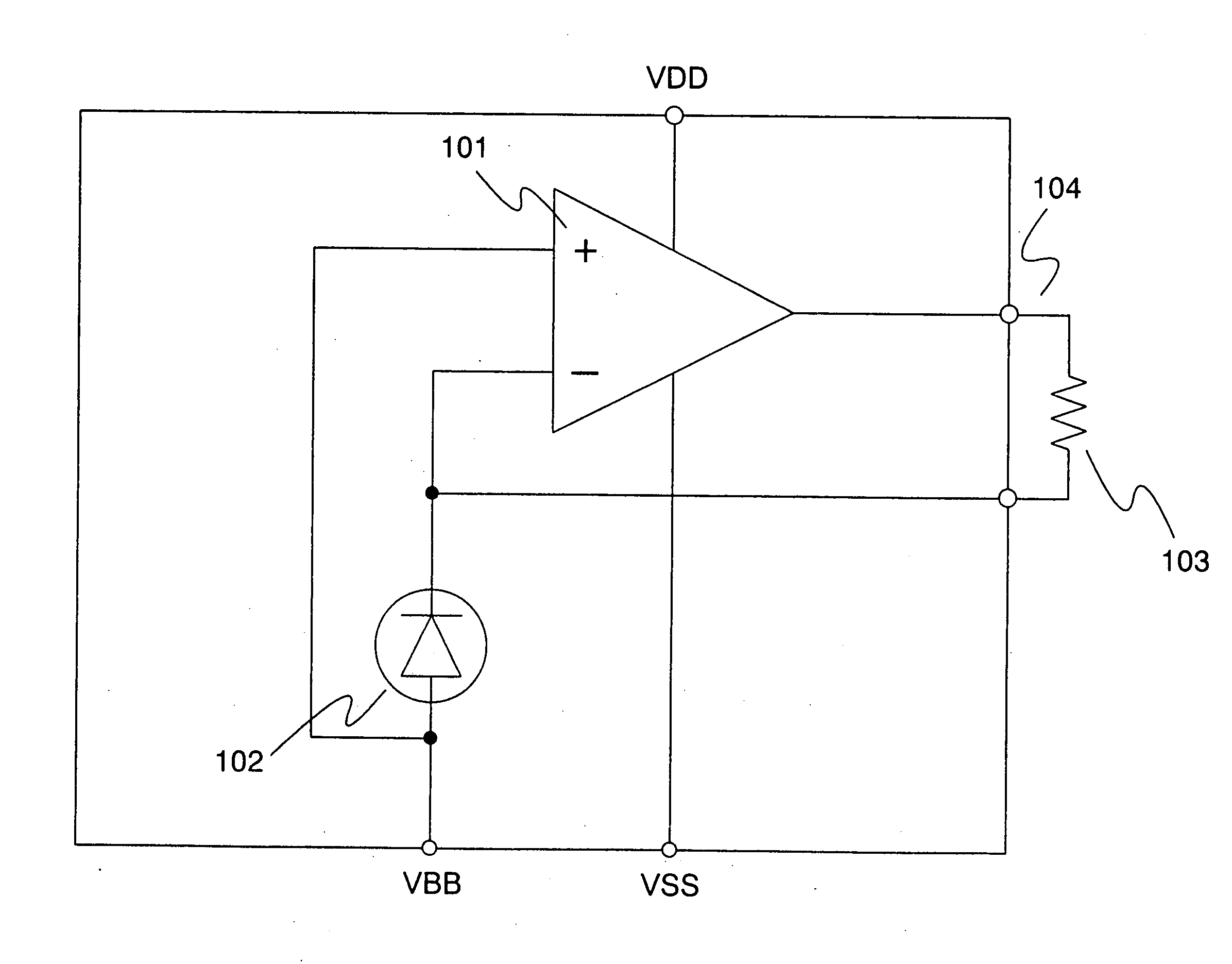

Optical sensor device and electronic apparatus

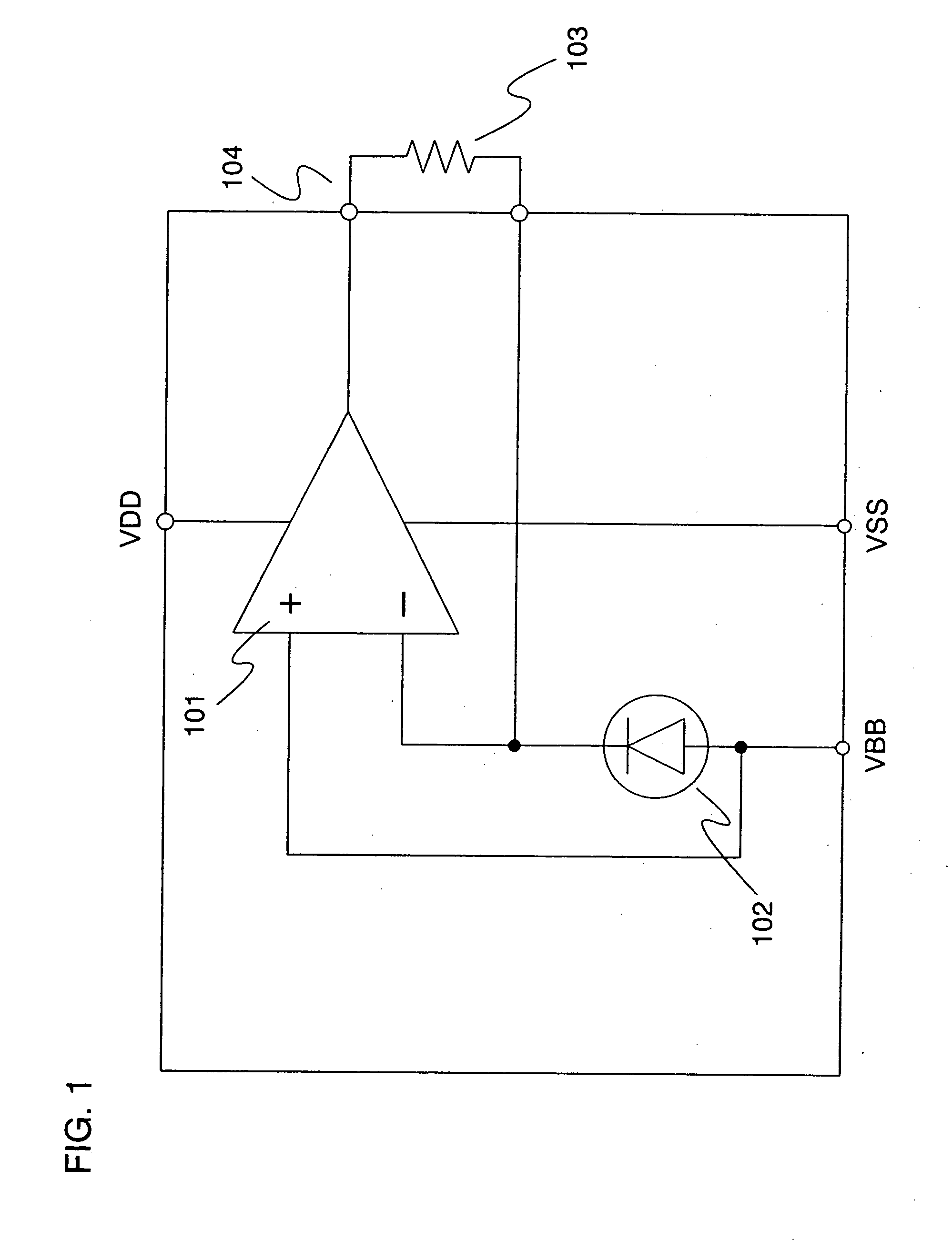

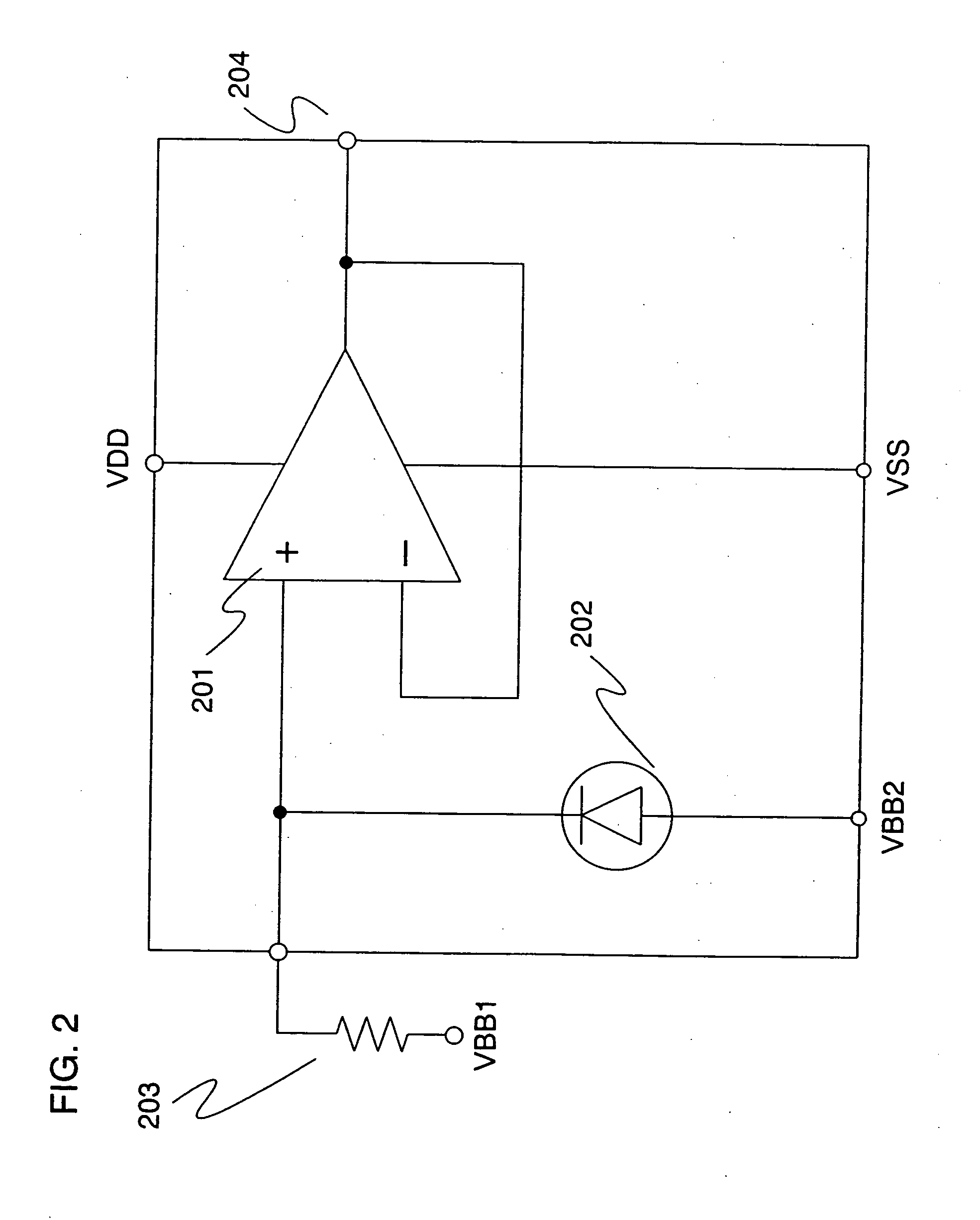

InactiveUS7253391B2Low costLarge installation spaceSolid-state devicesMaterial analysis by optical meansAudio power amplifierAmorphous silicon

In an optical sensor device employing an amorphous silicon photodiode, an external amplifier IC and the like are required due to low current capacity of the sensor element in order to improve the load driving capacity. It leads to increase in cost and mounting space of the optical sensor device. In addition, noise may easily superimpose since the photodiode and the amplifier IC are connected to each other over a printed circuit board. According to the invention, an amorphous silicon photodiode and an amplifier configured by a thin film transistor are formed integrally over a substrate so that the load driving capacity is improved while reducing cost and mounting space. Superimposing noise can be also reduced.

Owner:SEMICON ENERGY LAB CO LTD

Optical sensor device and electronic apparatus

InactiveUS20050082463A1Low costReduction in mounting spaceSolid-state devicesMaterial analysis by optical meansAudio power amplifierAmorphous silicon

In an optical sensor device employing an amorphous silicon photodiode, an external amplifier IC and the like are required due to low current capacity of the sensor element in order to improve the load driving capacity. It leads to increase in cost and mounting space of the optical sensor device. In addition, noise may easily superimpose since the photodiode and the amplifier IC are connected to each other over a printed circuit board. According to the invention, an amorphous silicon photodiode and an amplifier configured by a thin film transistor are formed integrally over a substrate so that the load driving capacity is improved while reducing cost and mounting space. Superimposing noise can be also reduced.

Owner:SEMICON ENERGY LAB CO LTD

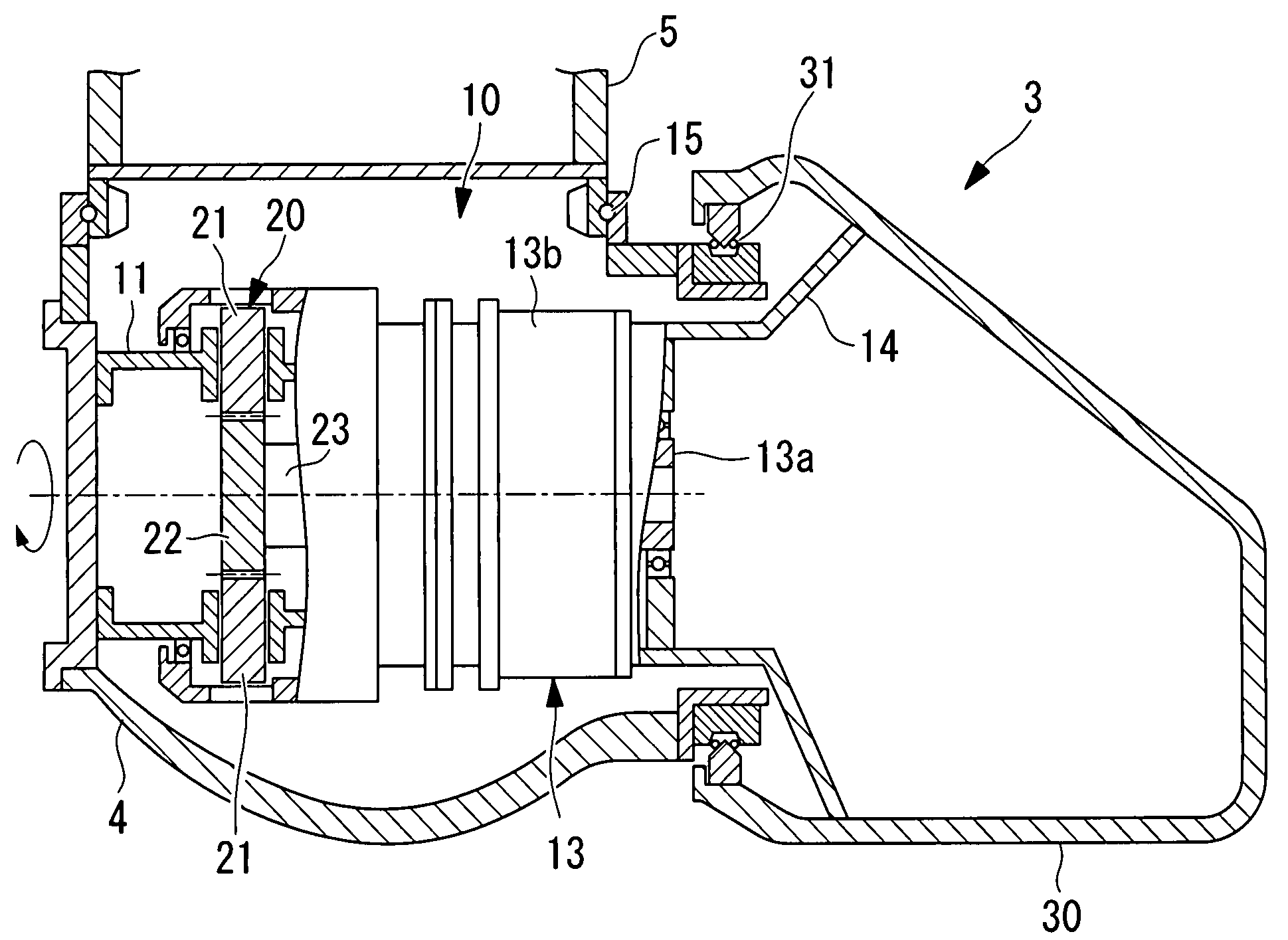

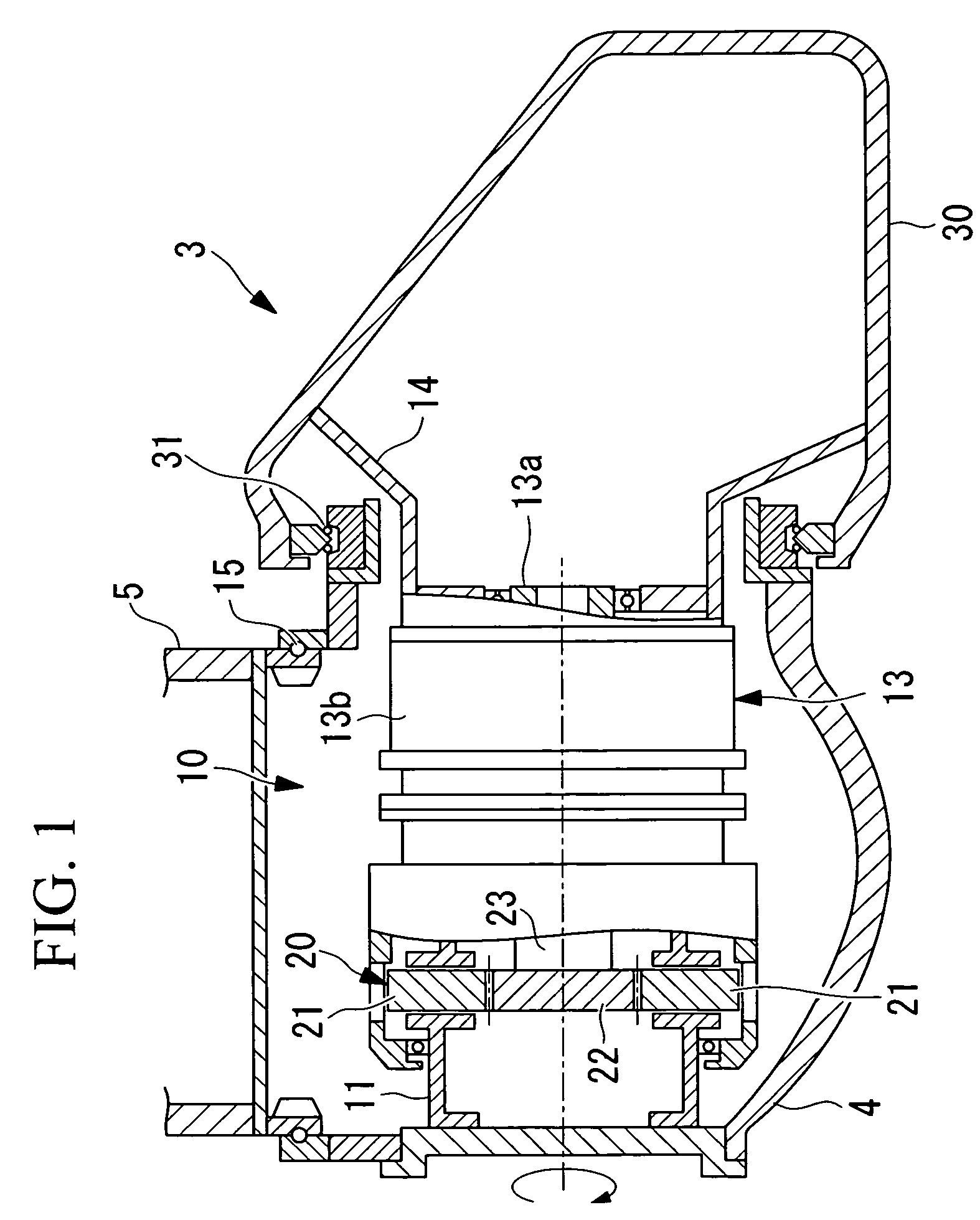

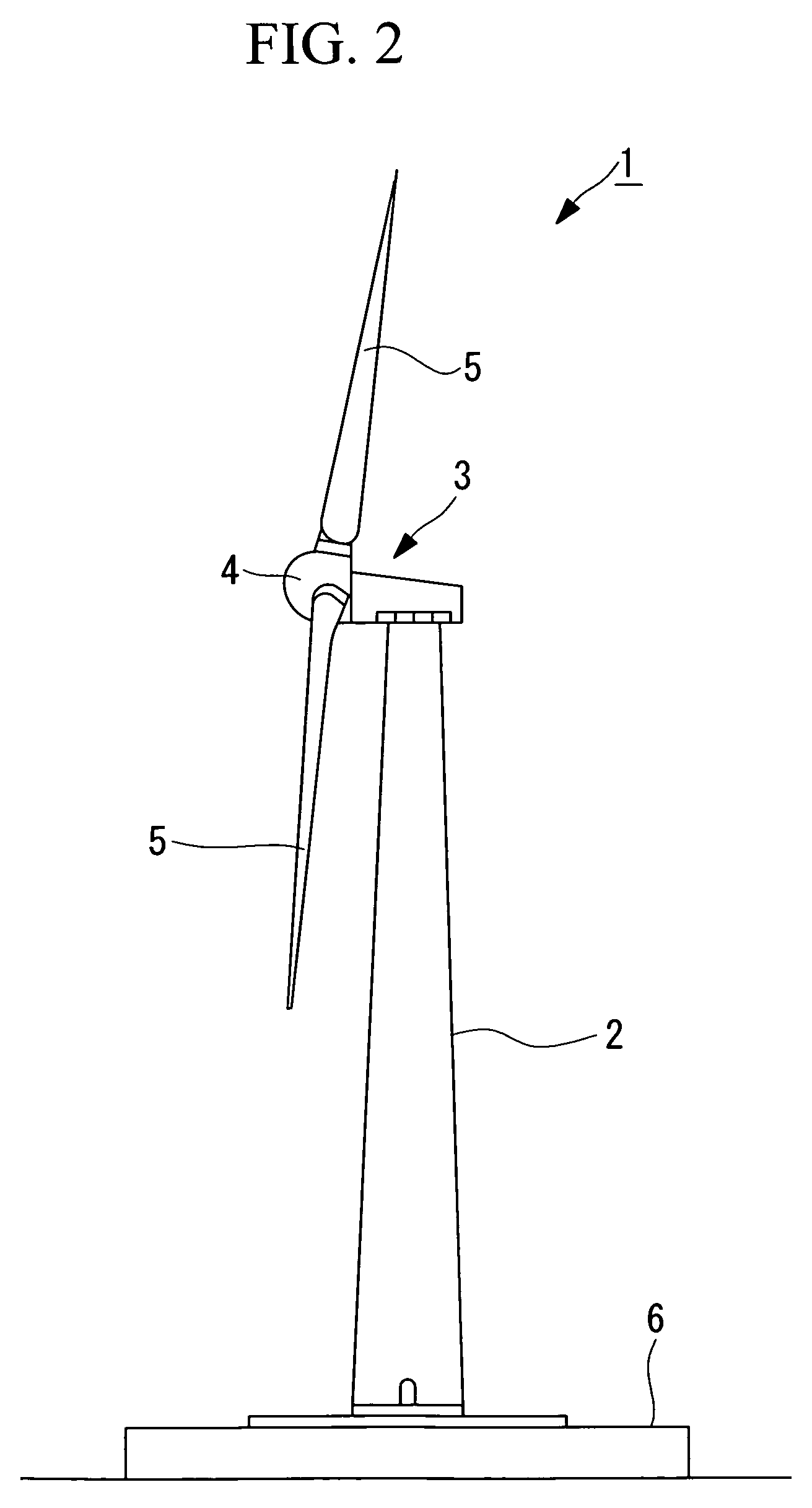

Wind turbine generator

InactiveUS7259472B2Reduce weight and sizeReduced dimensionWind motor controlEngine fuctionsNacelleDrivetrain

A wind turbine generator including a nacelle having reduced size and weight is provided. The wind turbine generator includes a nacelle disposed on a tower. The nacelle includes a main shaft that is connected to a rotor head equipped with blades and that integrally rotates with the rotor head, a gearbox that increases the rotational speed of the main shaft and that outputs the resulting rotational speed, and a generator driven by the output from the gearbox. In the wind turbine generator, a drivetrain extending from the main shaft to the generator via the gearbox is disposed in the rotor head.

Owner:MITSUBISHI HEAVY IND LTD

Data processing unit and DC backup power supply

InactiveUS7589436B2Improve discharge capacityIncrease energy densityDigital data processing detailsVolume/mass flow measurementElectrical batteryStandby power

A backup power supply is so constructed that it is provided with multiple DC backup power supplies 111 to 11N, each containing nickel-metal hydride battery, stored upright on the bottom of the disk array unit 100; cooled by cooling air through the vents 1011 for ventilation from the bottom to the top; and connected with the output of the AC / DC converters 121, 122 with the backboard 151. Very compact disk array unit with an uninterruptible power supplying function can be realized.

Owner:HITACHI INFORMATION & TELECOMM ENG LTD

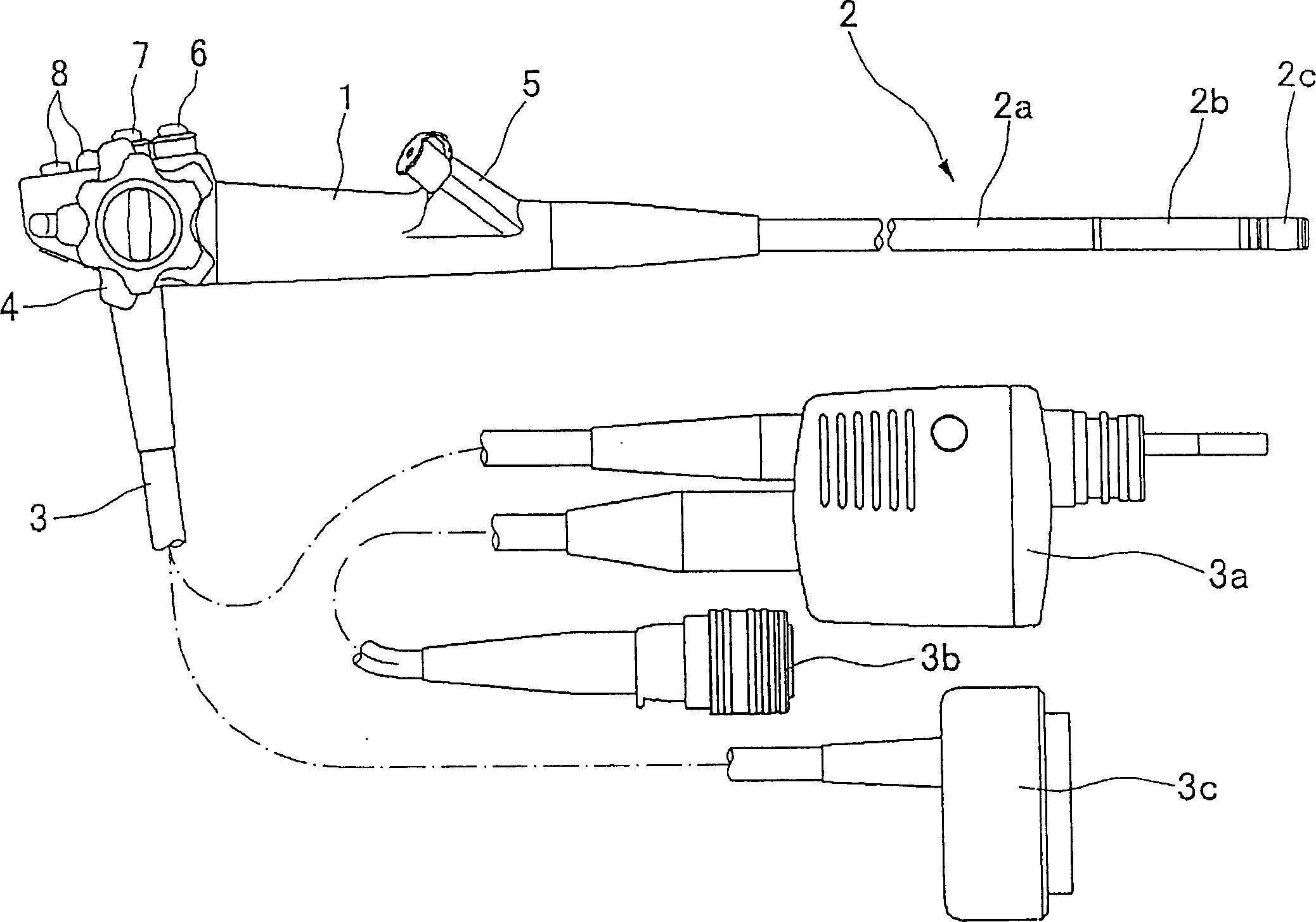

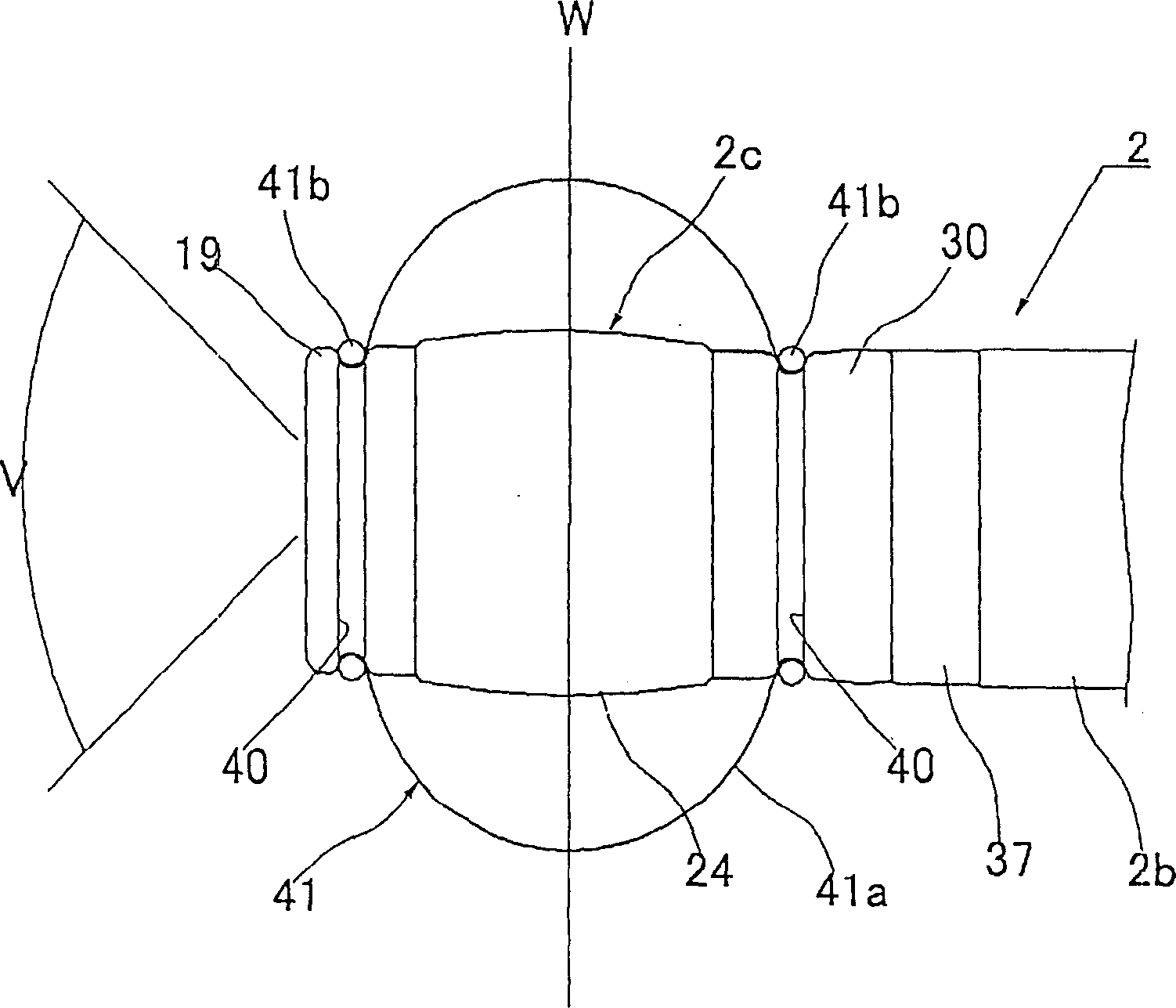

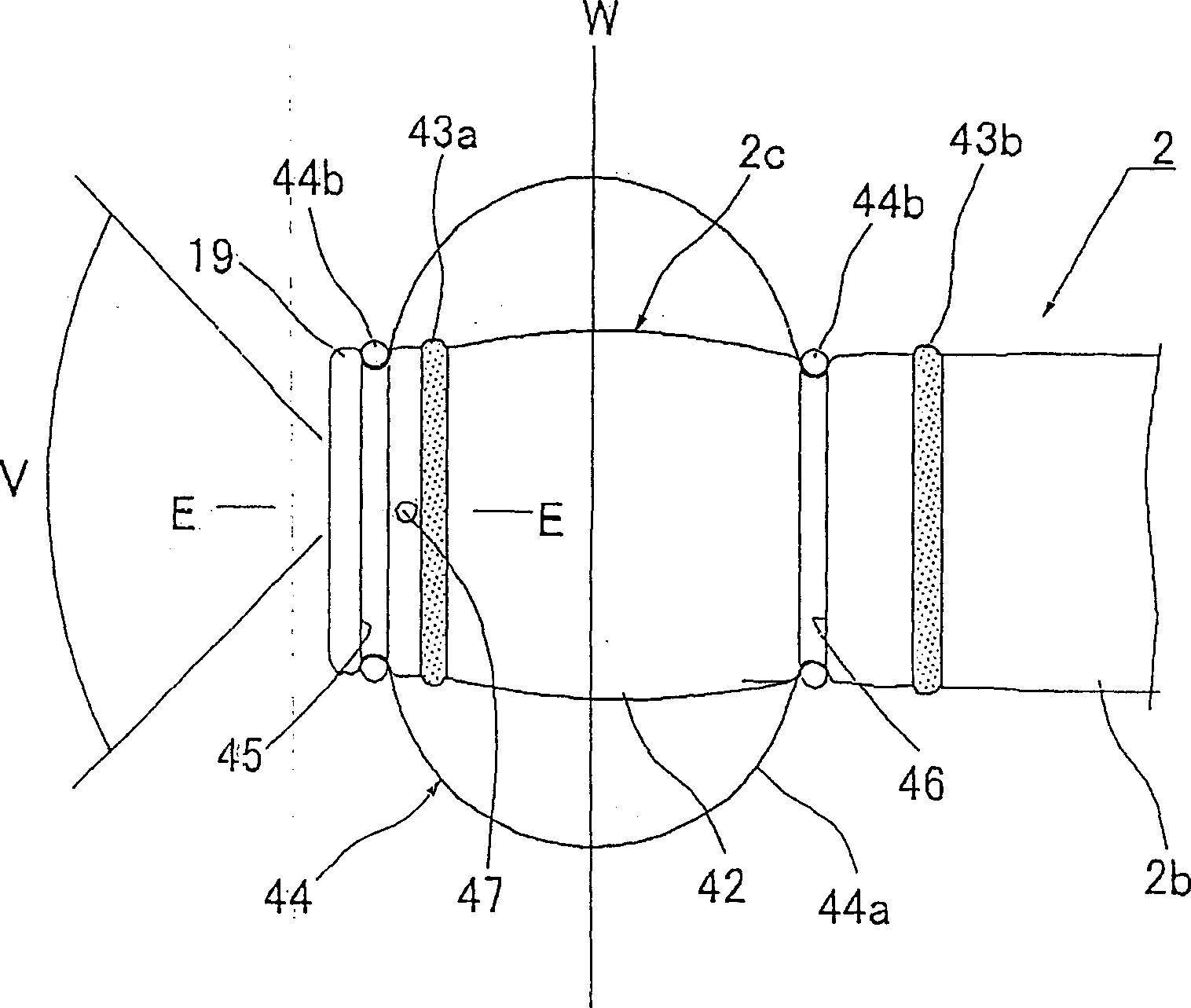

Ultrasonic endoscope

InactiveCN1718165AImprove airtightnessThe overall thickness is thinSurgeryCatheterWave transmissionObservation unit

An ultrasonic endoscope comprises an insertion portion comprising a distal hard portion which has: an endoscopic observation unit; and an ultrasonic observation unit having ultrasonic transducers arranged circumferentially on an outer circumferential section of the distal hard portion, wherein the ultrasonic observation unit comprises an ultrasonic-wave transmission / reception unit having an tunnel-shaped path which has an inner circumferential surface formed as a backing layer; a distal block is arranged on a distal side in an axial direction of the distal hard portion with respect to a location where the ultrasonic-wave transmission / reception unit is arranged, and distal ends of respective members constituting the endoscopic observation unit are fixed to the distal block; and part of the members which constitute the endoscopic observation unit are fitted so as to be partially protruded from an inside diameter of the tunnel-shaped path toward an outer circumferential side thereof.

Owner:FUJI PHOTO OPTICAL CO LTD

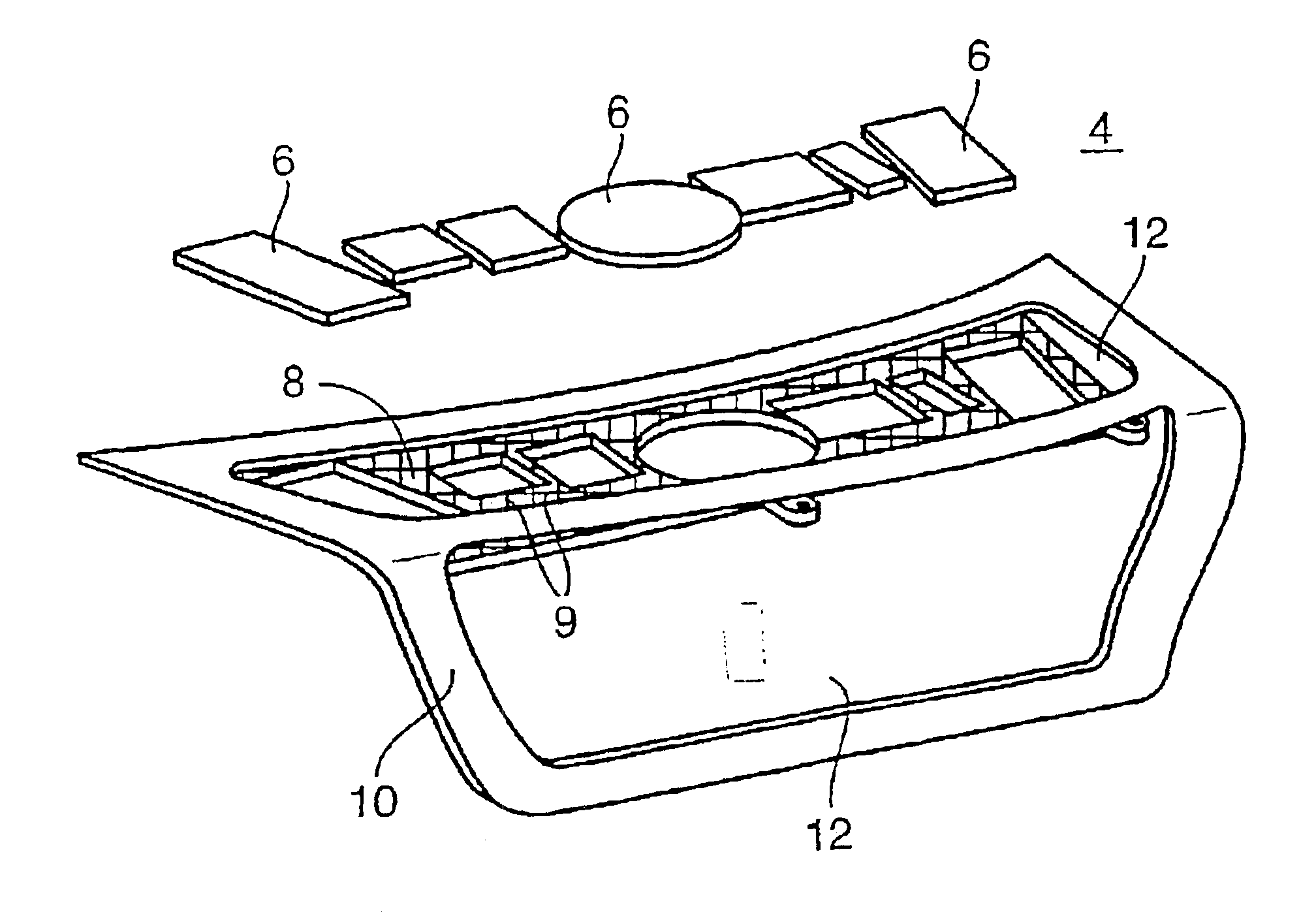

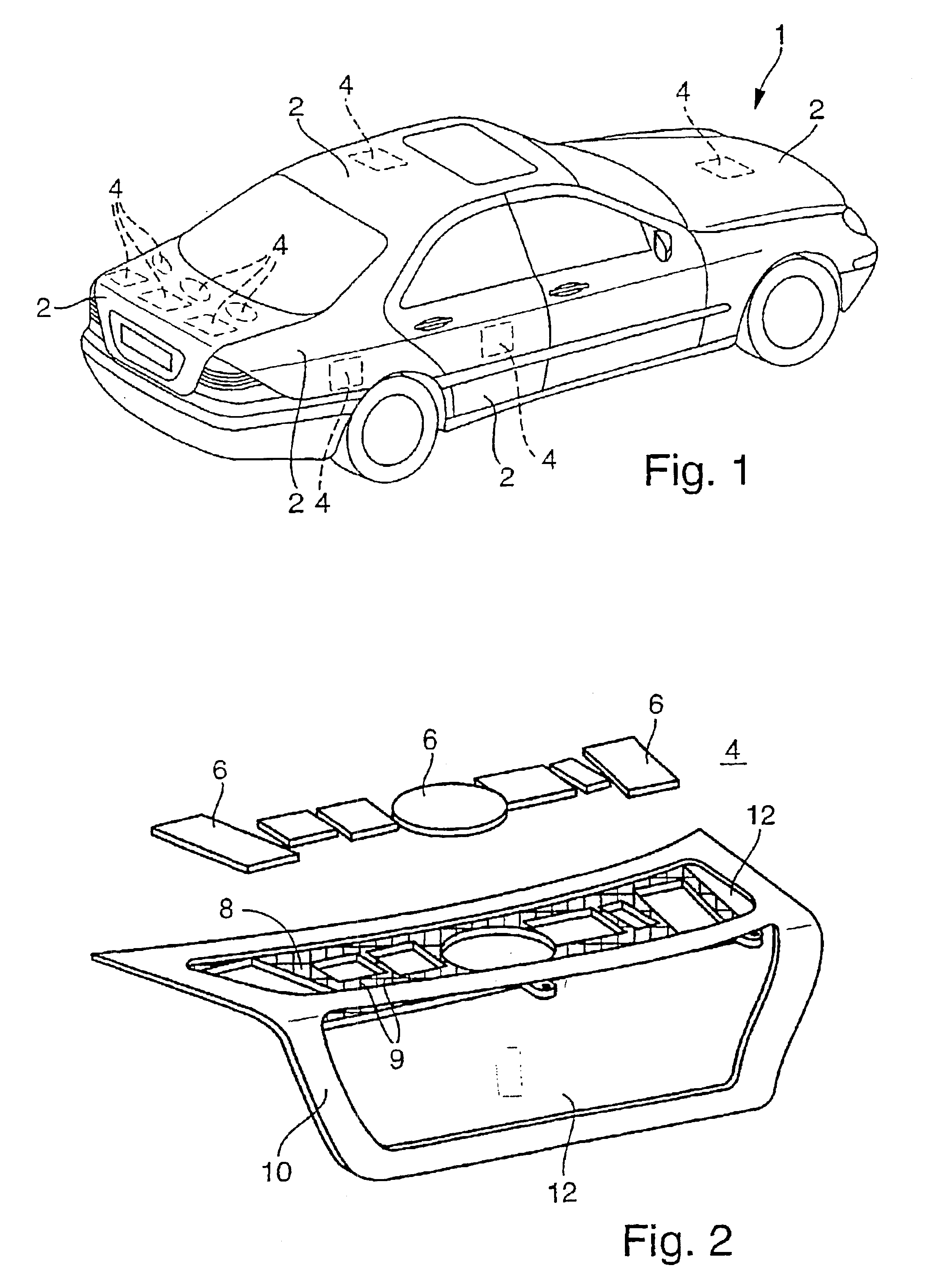

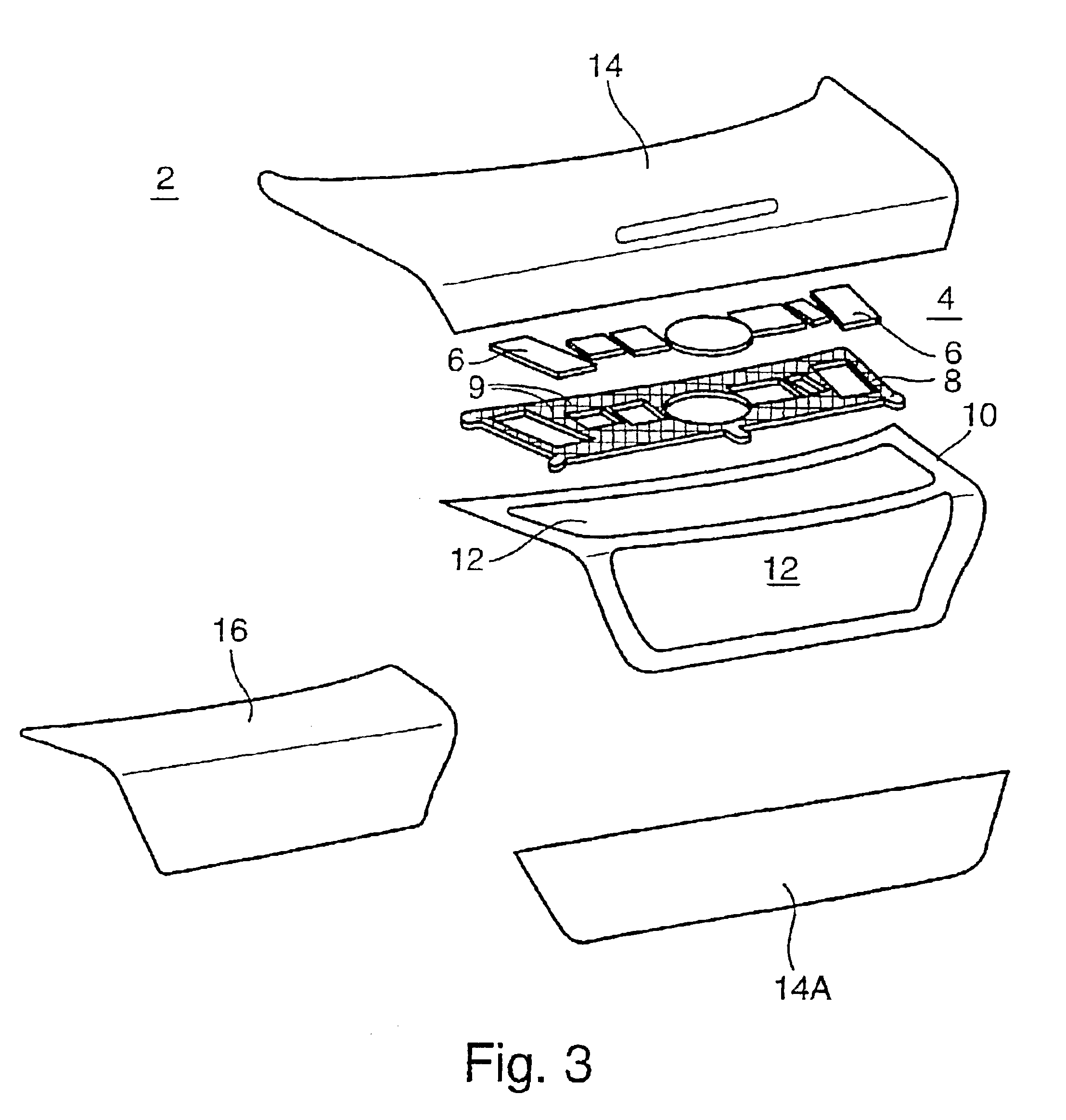

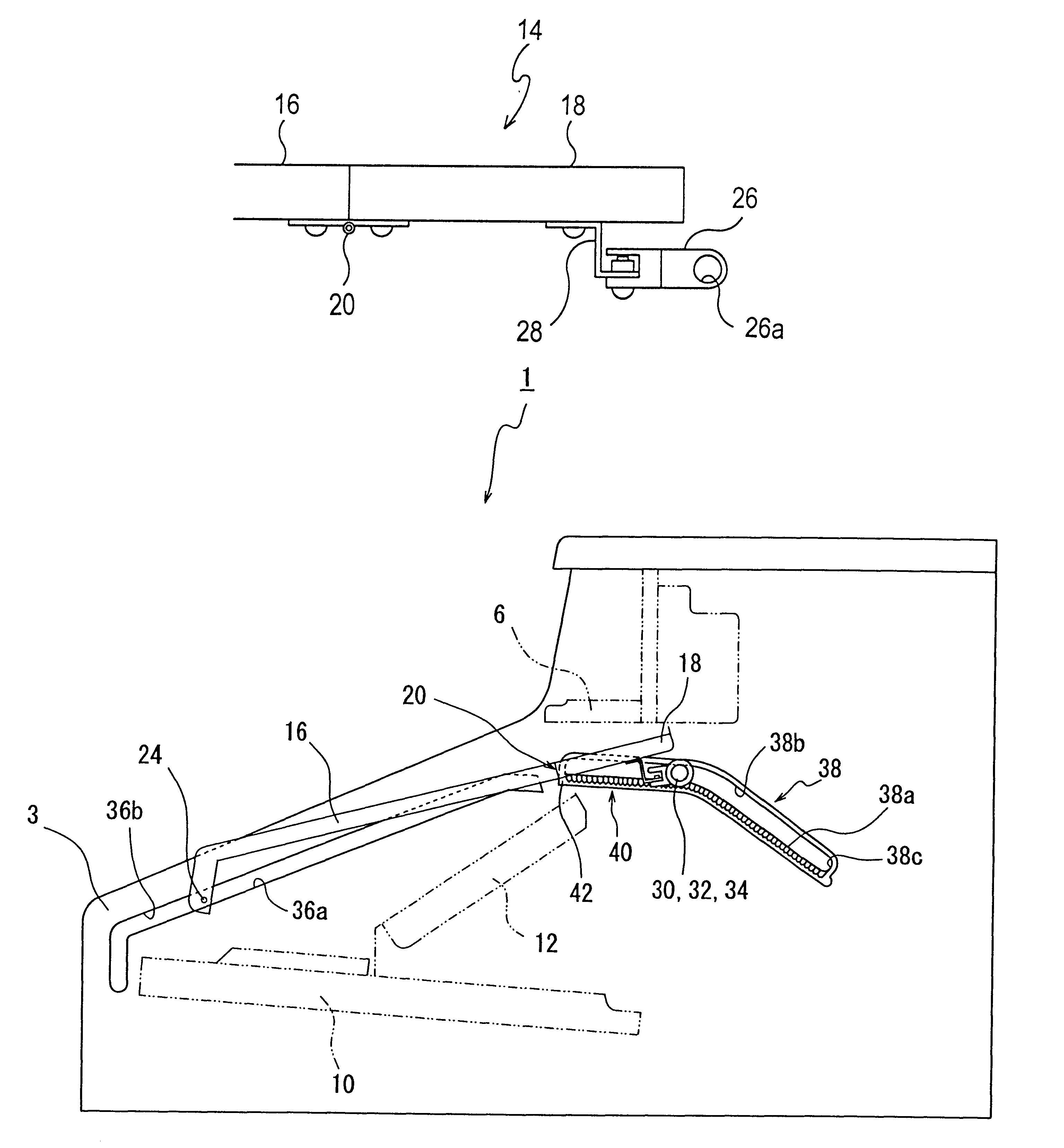

Bodywork part with integrated antenna

InactiveUS6900769B2Large installation spaceWithout expenditureAntenna adaptation in movable bodiesProtective material radiating elementsEngineeringIntegrated antenna

A bodywork part (2) is provided with an integrated antenna arrangement (4) and with a carrier unit (8) on which the antenna arrangement (4) is detachably arranged. This construction permits an antenna to be integrated and replaced easily.

Owner:MONTAPLAST +2

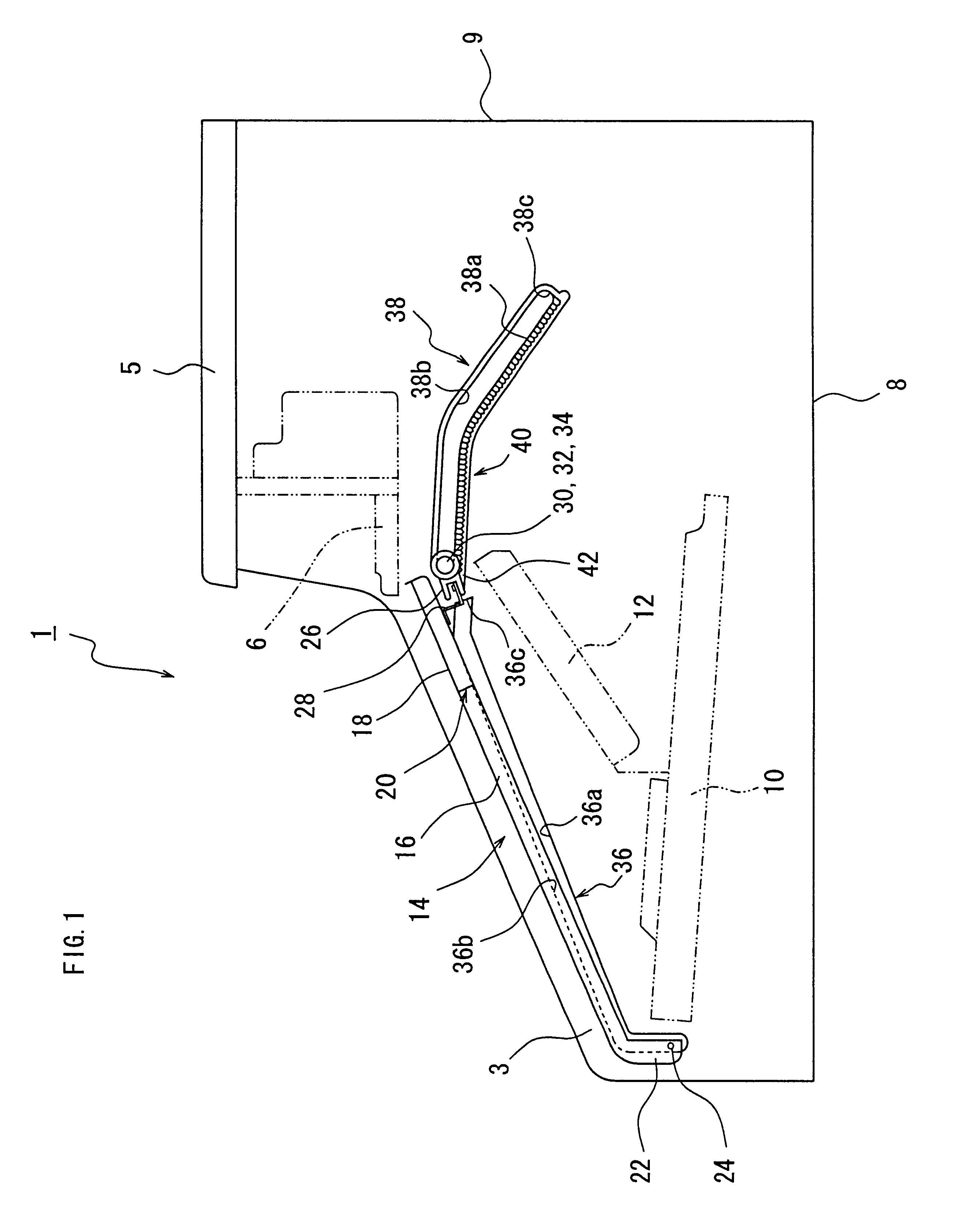

Keyboard lid opening and closing mechanism for keyboard musical instrument and keyboard musical instrument

InactiveUS6673991B2Large installation spaceSimple structureElectrophonic musical instrumentsStringed musical instrumentsEngineeringMoving parts

A keyboard lid opening and closing mechanism for a keyboard musical instrument having a simple structure and not requiring a large space for installation thereof. To house a keyboard lid in the folded state inside the keyboard musical instrument, the mechanism is provided with a reverse V-shape forming portion disposed at the place where the undersurface of the keyboard lid passes while moving, a rotation support portion including first connecting groove walls, and a keyboard lid stop portion including second connecting groove walls. Therefore, the structure of the mechanism for opening and closing the keyboard lid is simplified, and a large space for installation of the mechanism is not necessary since these portions include no movable parts.

Owner:KAWAI MUSICAL INSTR MFG CO

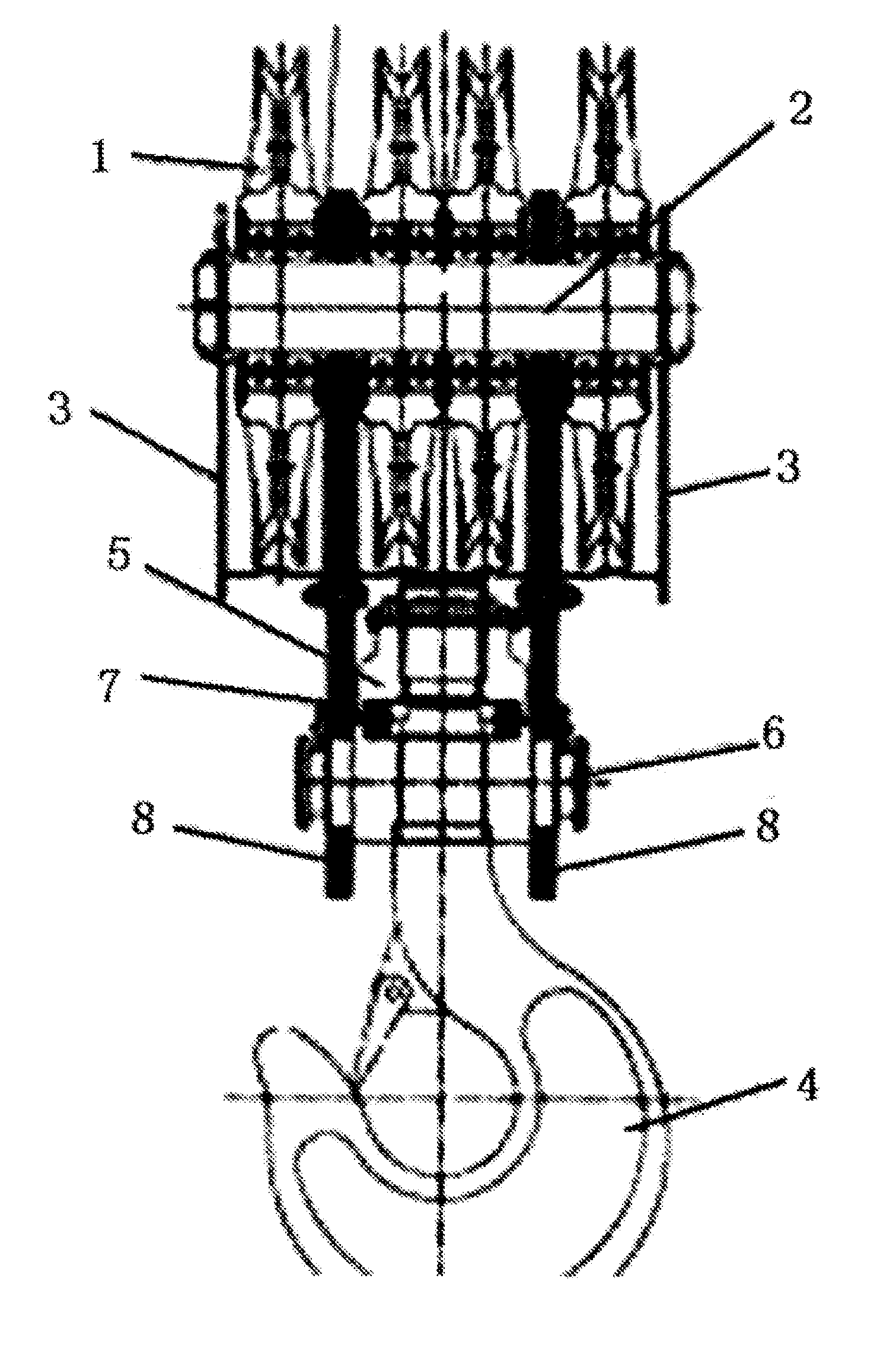

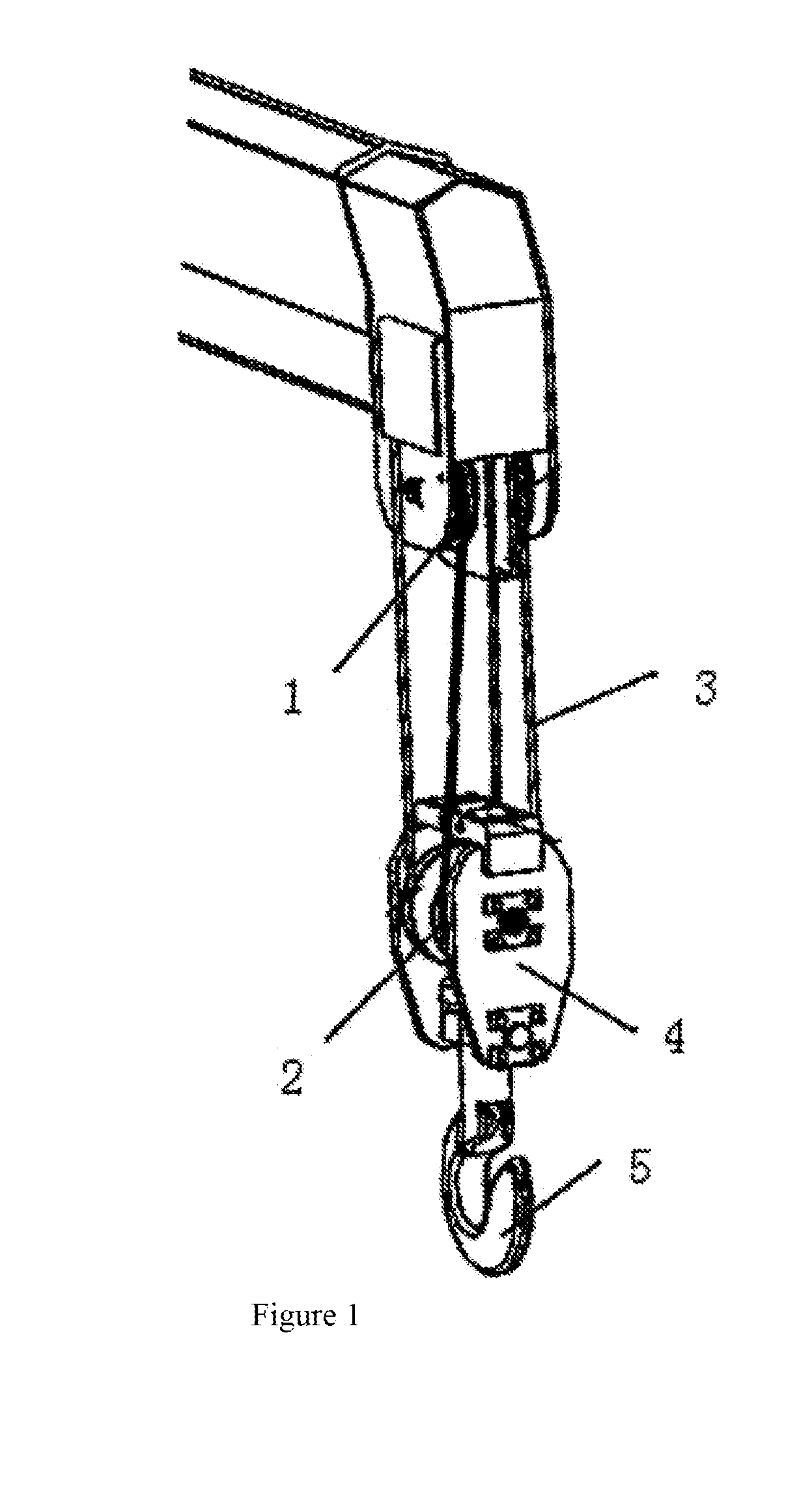

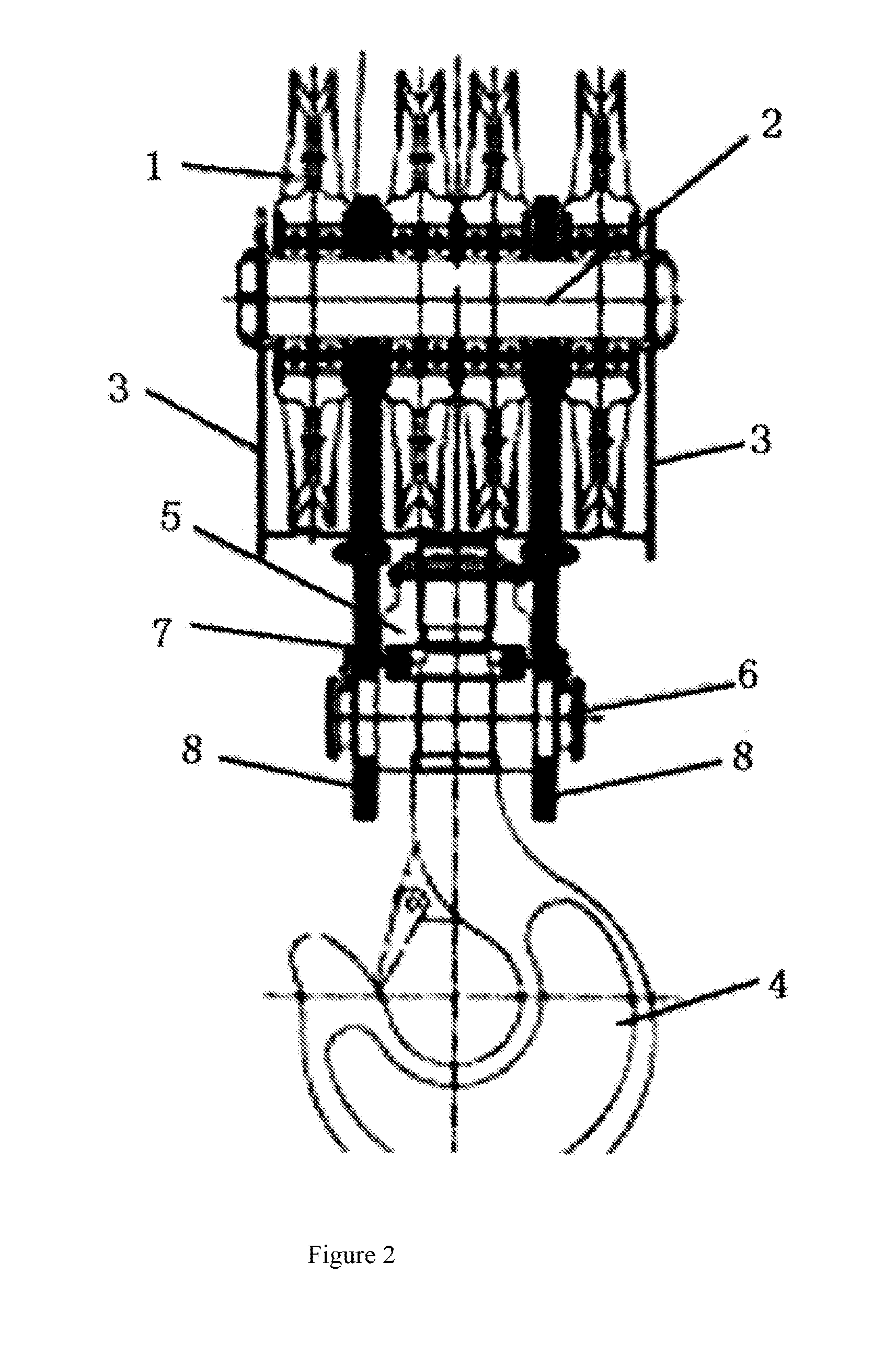

Detection, monitoring device of the hook angle and its crane

InactiveUS20150353329A1Easy to determineIncrease the lengthDrilling/boring measurement devicesMeasurement/indication equipmentsMeasuring instrumentEngineering

The present invention provides with a detection and monitoring device of the hook angle and its crane relating to the crane field, wherein between the movable pulley of the lifting pulley assembly of the crane and the hook or between the fixed pulley and the fixed point of the lifting pulley assembly of cranes is cascaded a part, it meets that the plane of the platform fixed on the part is a horizontal plane when the hook angle being 0 degree, so that the action line of the lifting force of the lifting pulley assembly via the hook is perpendicular to the plane of the platform under the different angles of the hook; fixedly install a platform on the part; and provided with the angle measuring instrument on the platform plane. The device provided by the present invention can be used for all types of cranes.

Owner:LIN HANDING

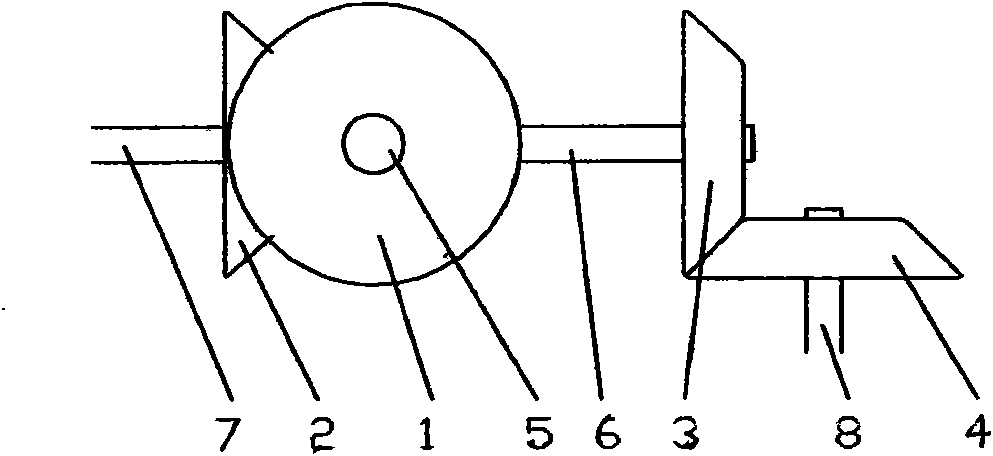

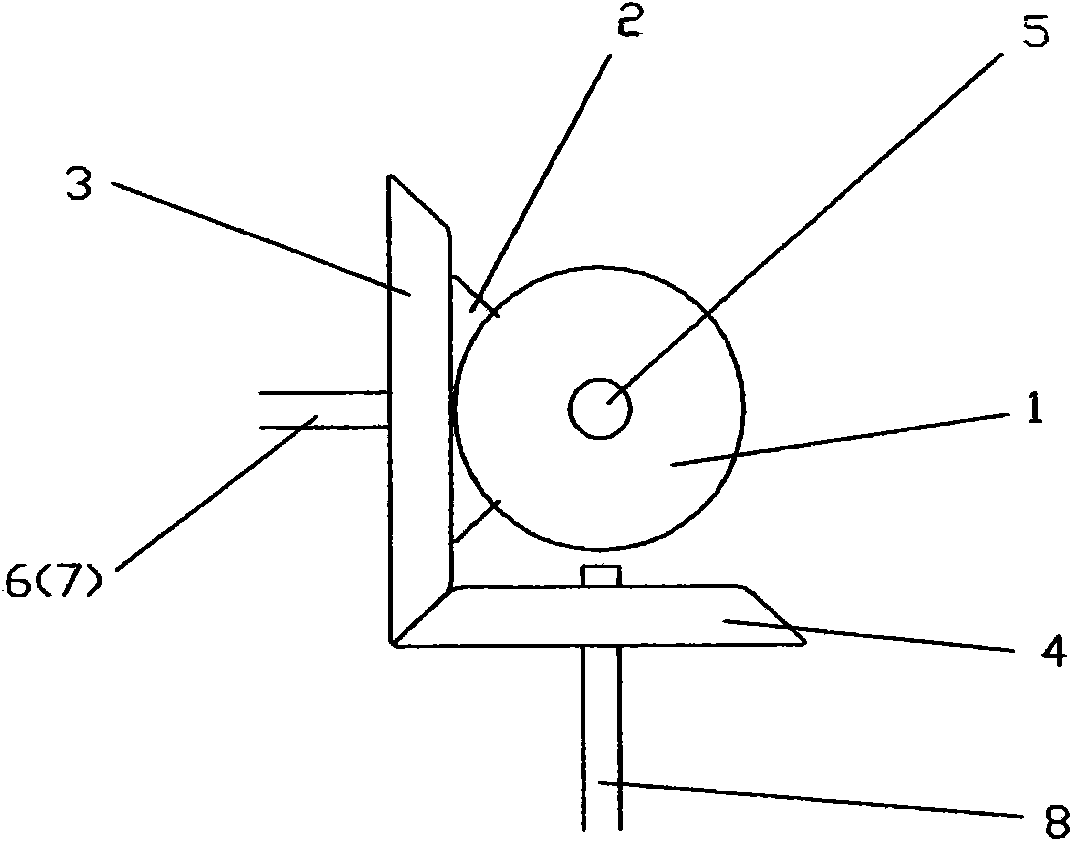

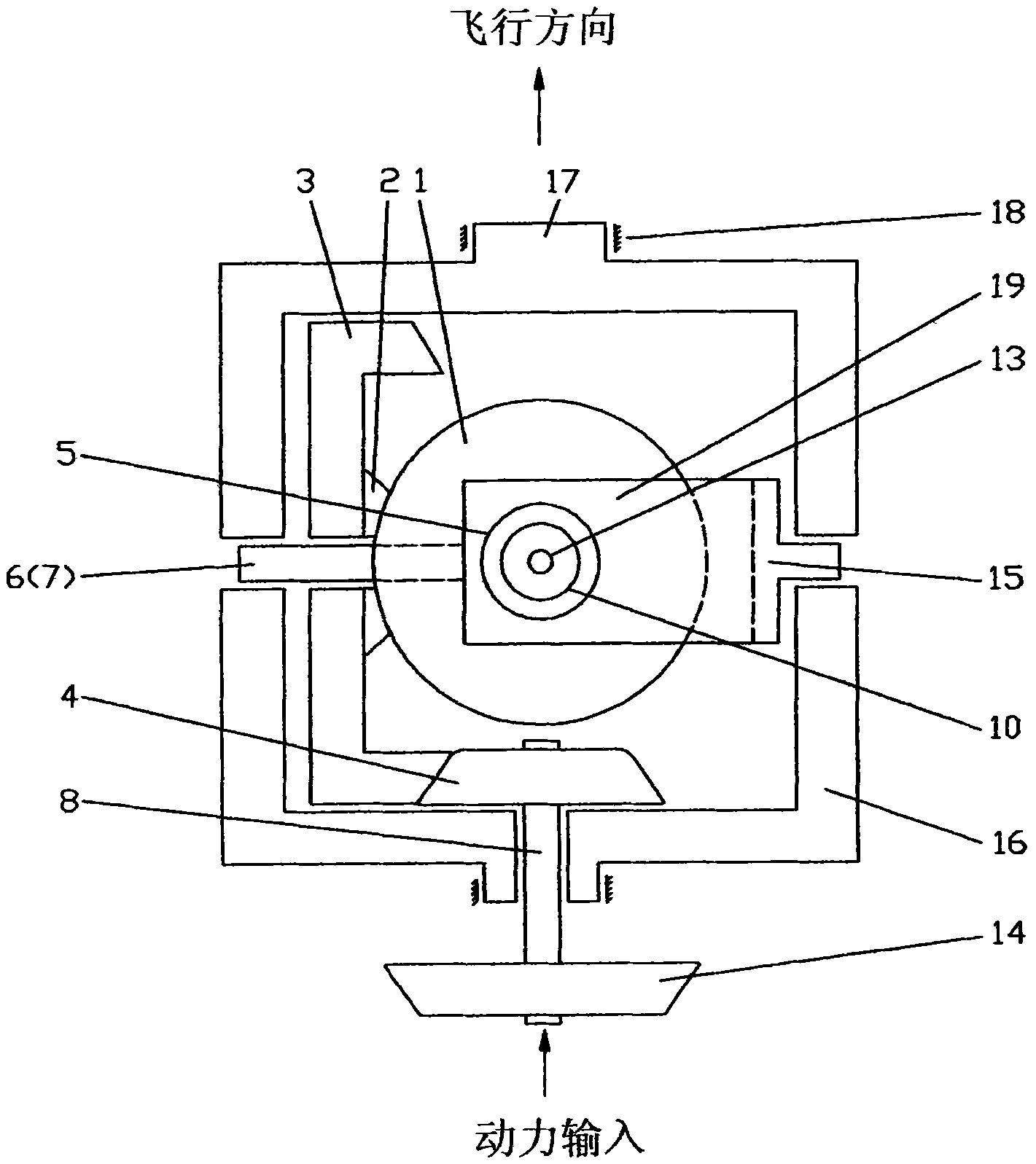

Direct inclination control rotor helicopter

InactiveCN102030105BLarge installation spaceIncrease the number of teethRotocraftPropellerHorizontal axis

Owner:林定荣

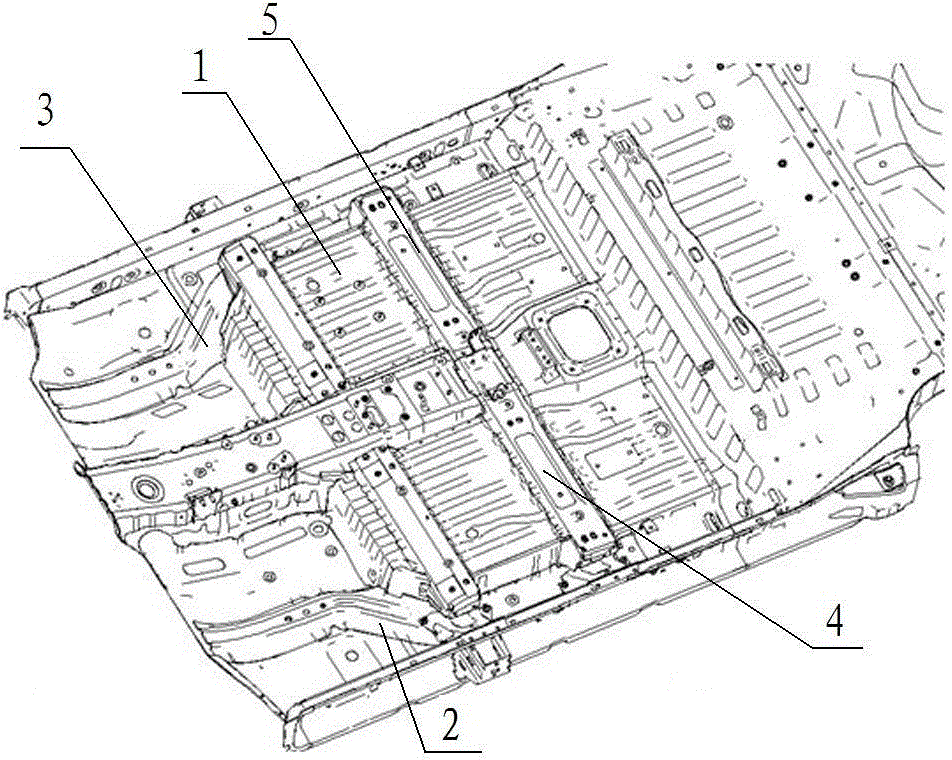

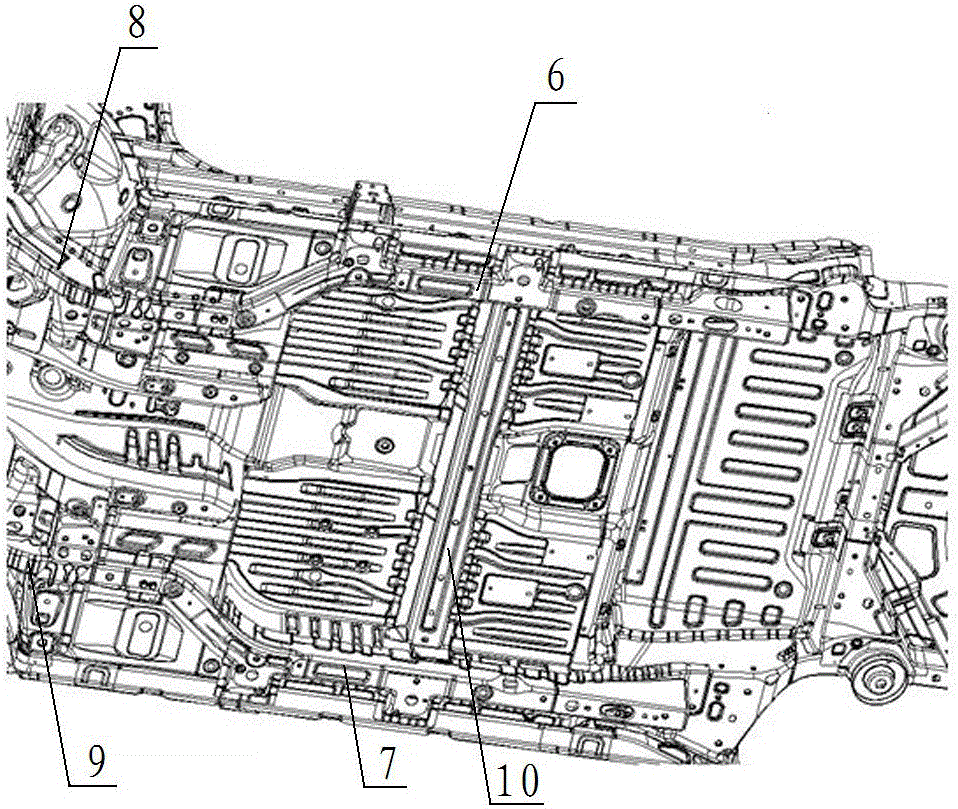

Vehicle body of electric vehicle

ActiveCN106005044ALarge installation spaceRegular installation spaceElectric propulsion mountingSuperstructure subunitsAutomotive batteryEngineering

The invention discloses a vehicle body of an electric vehicle, and relates to the technical field of automobile manufacturing. The vehicle body of the electric vehicle comprises a left front longitudinal beam, a right front longitudinal beam and a floor. A floor upper portion left reinforcing longitudinal beam and a floor upper portion right reinforcing longitudinal beam are arranged on the floor. The positions of front seats on the floor protrude upwards to reserve battery pack mounting space. The floor upper portion left reinforcing longitudinal beam and the floor upper portion right reinforcing longitudinal beam turn in the protruding positions and extend to a front seat left rear cross beam and a front seat right rear cross beam. A floor lower portion left reinforcing longitudinal beam and a floor lower portion right reinforcing longitudinal beam are arranged in the positions, corresponding to the floor upper portion left reinforcing longitudinal beam and the floor upper portion right reinforcing longitudinal beam, of the bottom face of the floor correspondingly and are connected with the left front longitudinal beam and the right front longitudinal beam correspondingly. A transverse reinforcing beam is arranged between the floor lower portion left reinforcing longitudinal beam and the floor lower portion right reinforcing longitudinal beam. According to the vehicle body of the electric vehicle, the wide and regular mounting space is provided for a battery pack of the electric vehicle, vehicle body deformation in collision of the electric vehicle is effectively reduced, and the safety of passengers and the battery pack is protected.

Owner:DONGFENG LIUZHOU MOTOR

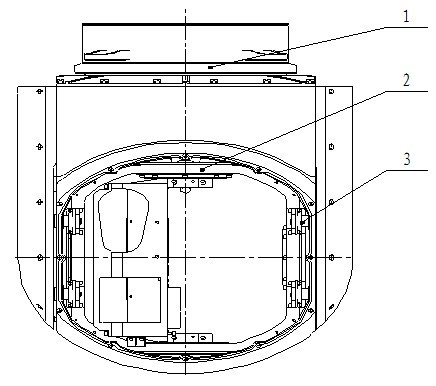

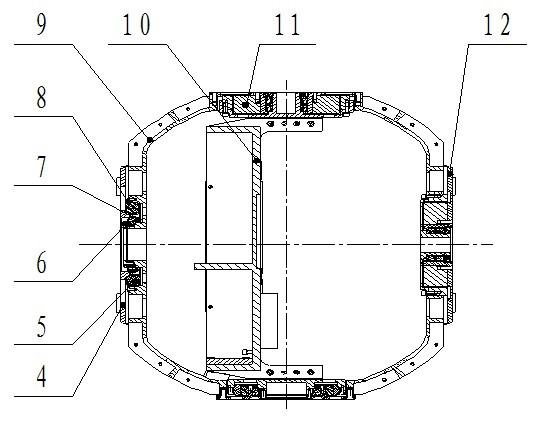

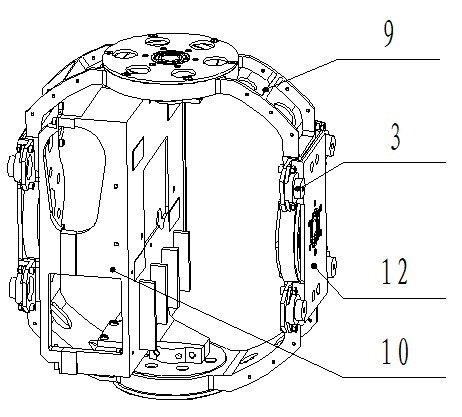

Photoelectric stable platform

InactiveCN102155517AOutstanding FeaturesHighlight significant effectNon-rotating vibration suppressionIsolation effectImaging quality

The invention relates to a photoelectric stable platform, which has a vibration-isolating inner ring and a plurality of frames. The photoelectric stable platform comprises an outer ring frame, an inner ring frame and an even number of vibration isolators of the same specifications, wherein various sensors are placed on the inner ring frame; and the vibration isolators are symmetrically installed relative to the centre of mass of the integration of the inner ring frame in which the various sensors which are installed. The invention has the advantages that: an isolation effect of the photoelectric stable platform on external interference is good; imaging quality and stabilization precision are high; the photoelectric stable platform is small in size, light in weight, large in bearing capacity, and convenient for assembly and disassembly; the weight of the platform can be reduced effectively; the assembly of the photoelectric stable platform can be adjusted quickly and conveniently according to requirements; and the photoelectric stable platform is characterized by simple structure, wide application range and the like.

Owner:武汉华中天经通视科技有限公司

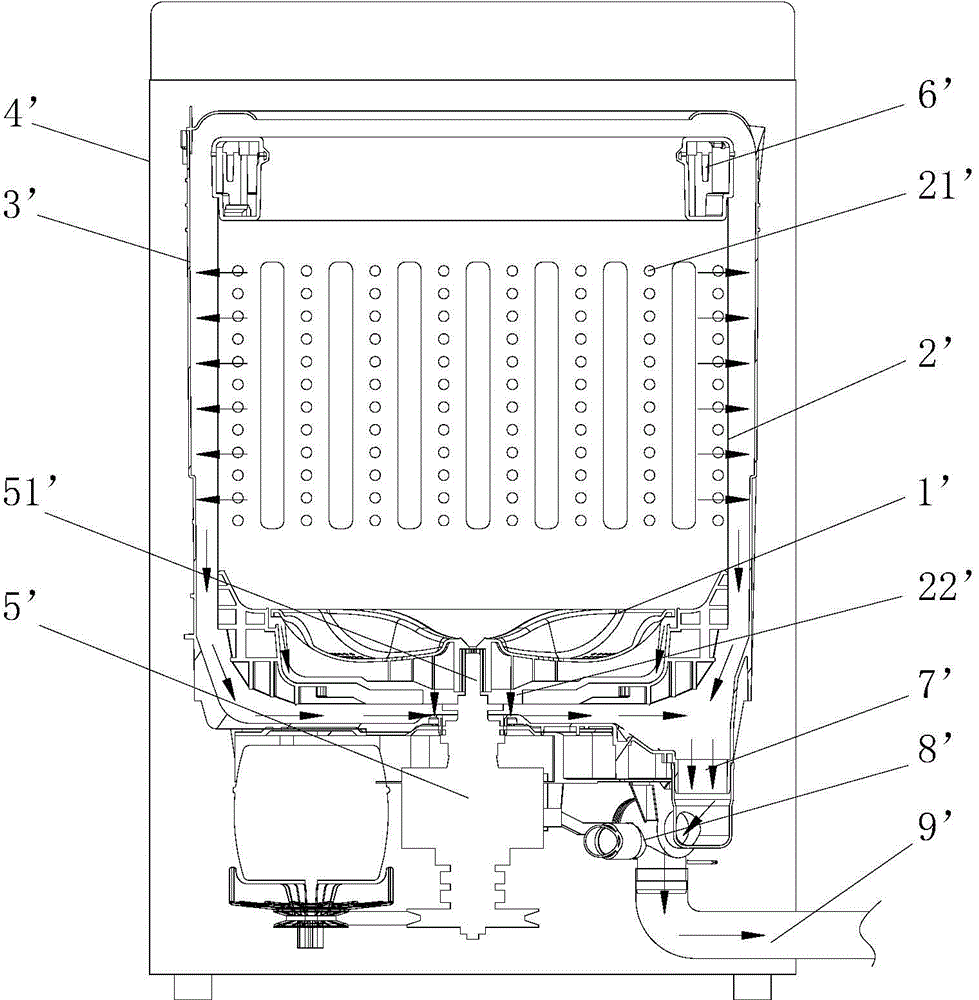

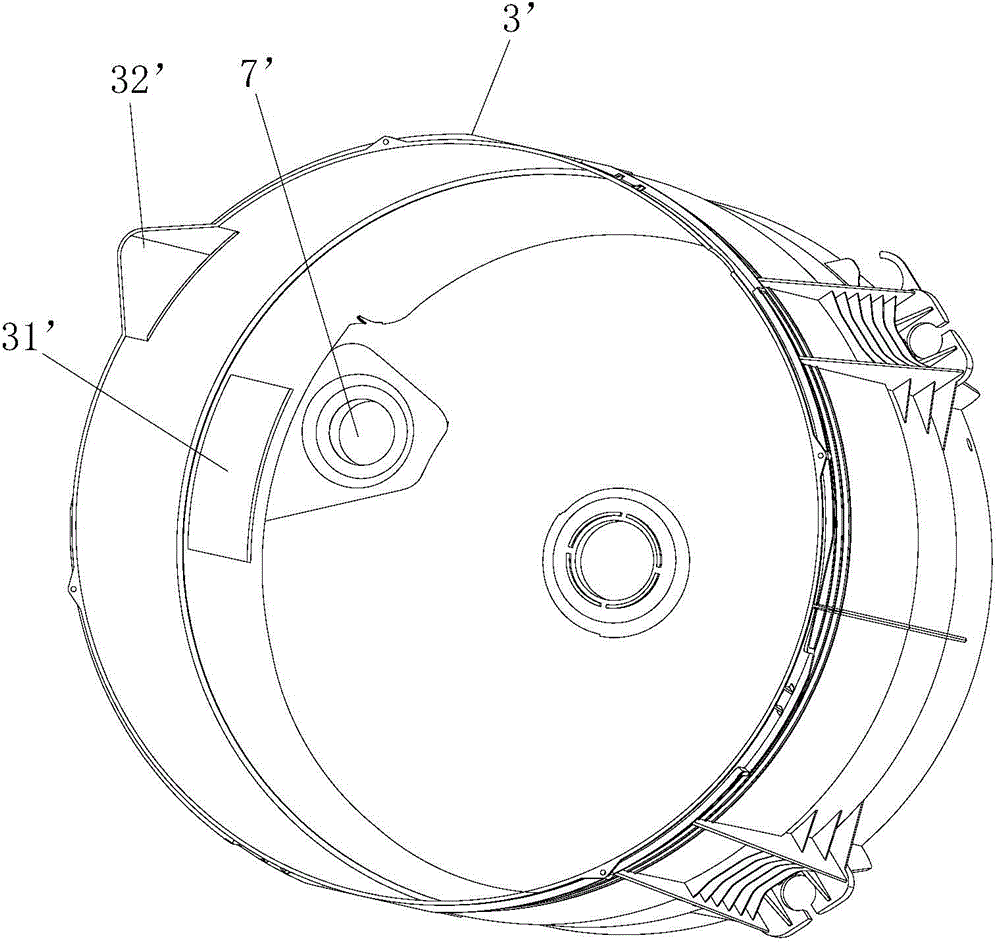

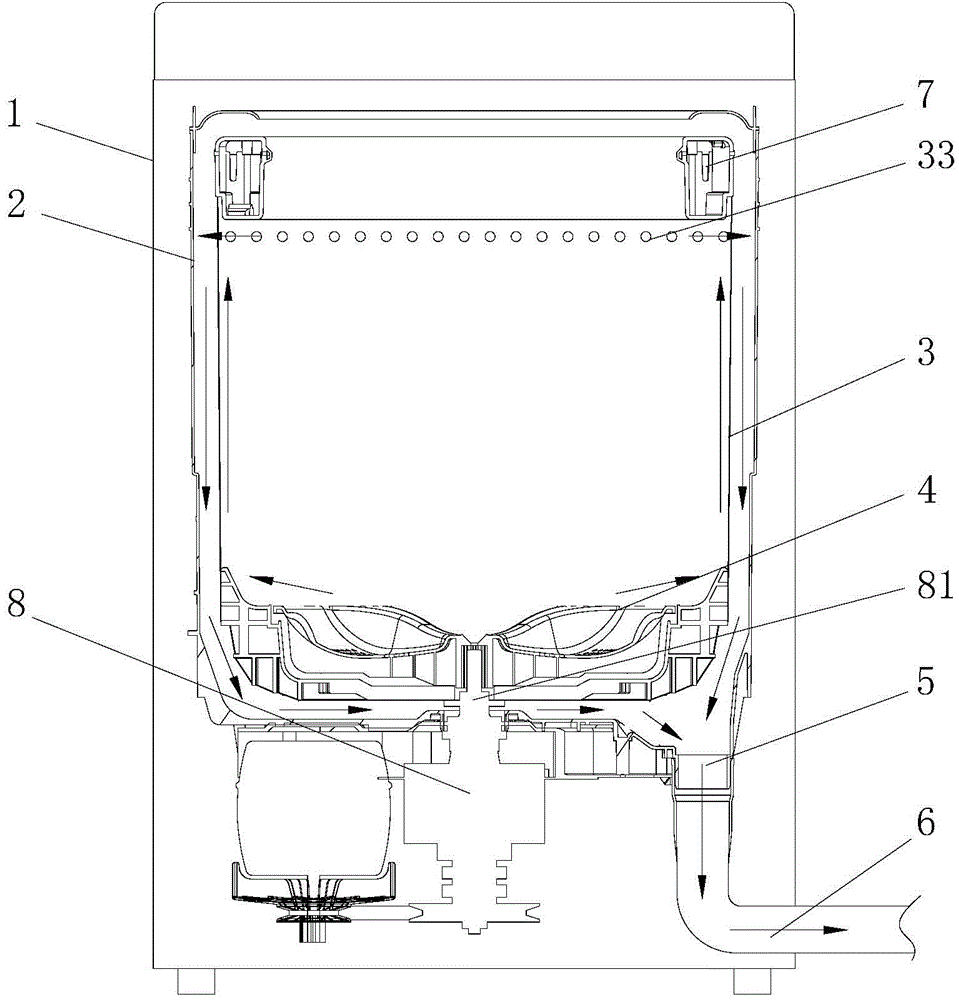

Impeller full-automatic washing machine

PendingCN105463790AReduce deliveryAvoid cross infectionOther washing machinesTextiles and paperImpellerWater discharge

The invention discloses an impeller full-automatic washing machine comprising an external barrel, an internal barrel disposed in the external barrel and an impeller disposed in the internal barrel. A drainage port is arranged on the bottom of the external barrel; the washing machine does not have a draining valve; the drainage port of the external barrel is directly communicated with a drain pipe; during washing and rinsing, washing water is only accommodated in the internal barrel and the external barrel contains no washing water; during dehydration, the washing water passes through the external barrel, the external barrel drainage port and the drain pipe from the upper part of the internal barrel and then is directly discharged; during water inlet, water is only charged into the internal barrel; after washing is finished, the internal barrel is driven to rotate at high speed to produce centrifugal force; water in the internal barrel and water in the clothes spirally rise and are discharged out of the external barrel via water discharging holes of the internal barrel; and the water can be directly discharged via the drain pipe. Without the draining valve, assembling technology of the external barrel components can be reduced, installation space of a barrel bottom driving device can be increased and cost can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

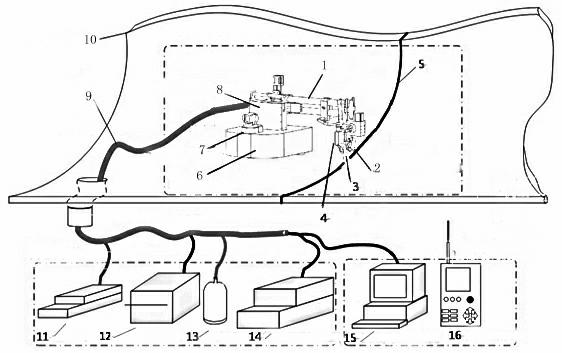

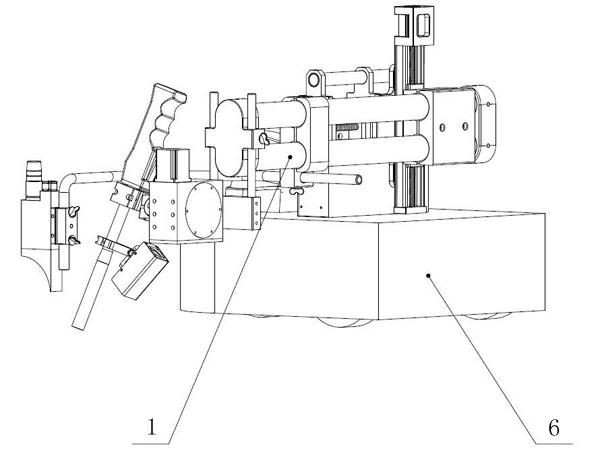

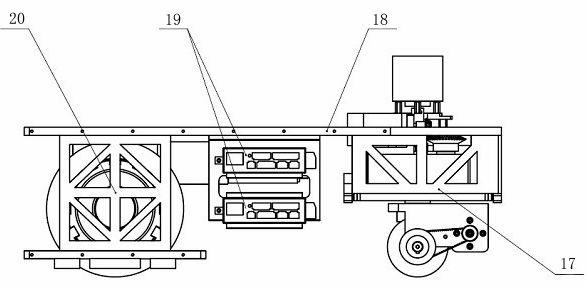

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

Run-of-river hydroelectric power generation apparatus

InactiveUS20100295313A1Low costEasy to installEngine fuctionsMachines/enginesImpellerTransmission belt

A hydroelectric power generation apparatus includes a buoy having a buoyancy for floating on a water surface, an electric generator including a rotating shaft installed at a top surface of the buoy, a hollow case tapered from both ends towards the center of the case, and a side of the case being coupled to the bottom of the buoy and a vane wheel installed at the bottom of the buoy and including a wheel shaft and a plurality of vanes installed in the case, and a transmission belt installed around both wheel shaft and rotating shaft for providing a transmission between the wheel shaft and the rotating shaft, such that when the water current flows through the vanes to drive the wheel shaft to rotate, the transmission of the transmission belt drives the rotating shaft of the electric generator to rotate, so as to generate electric energy.

Owner:SMART ENERGY

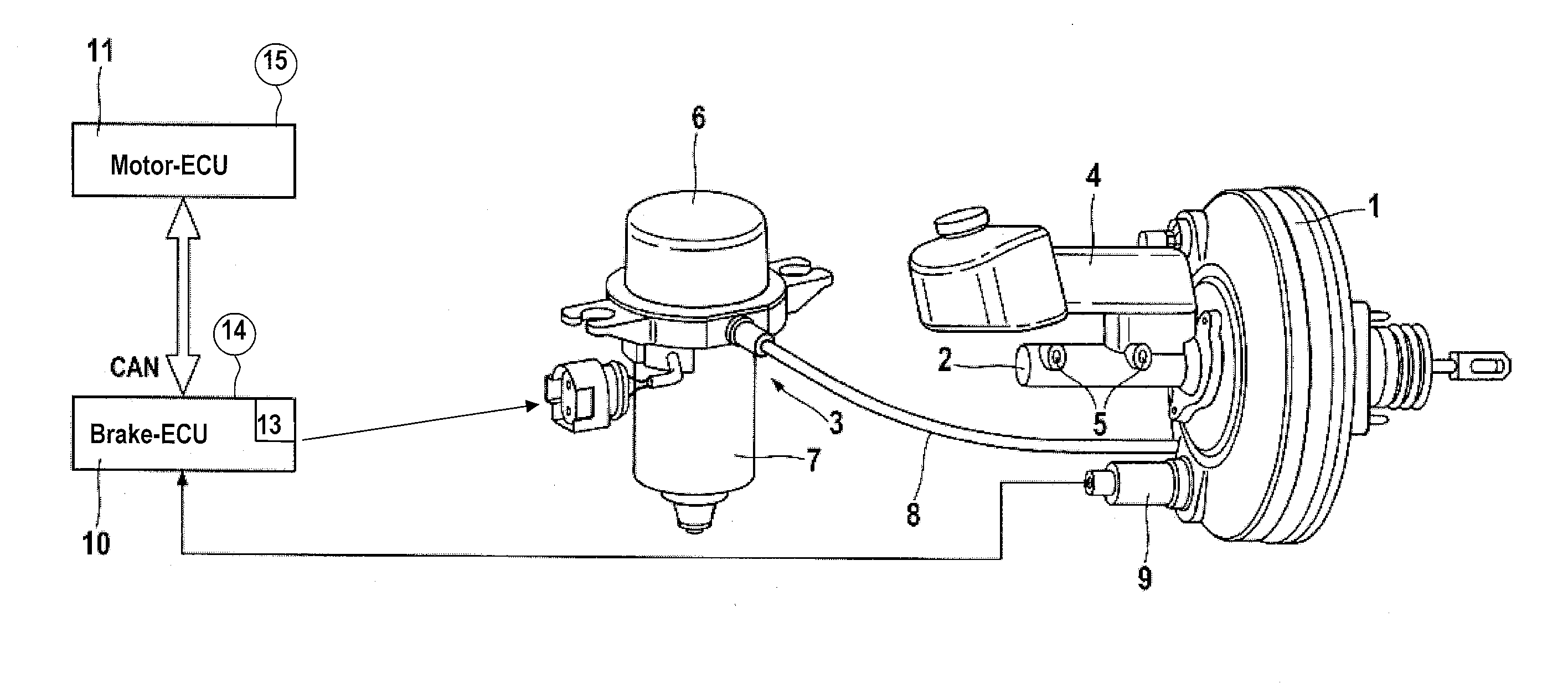

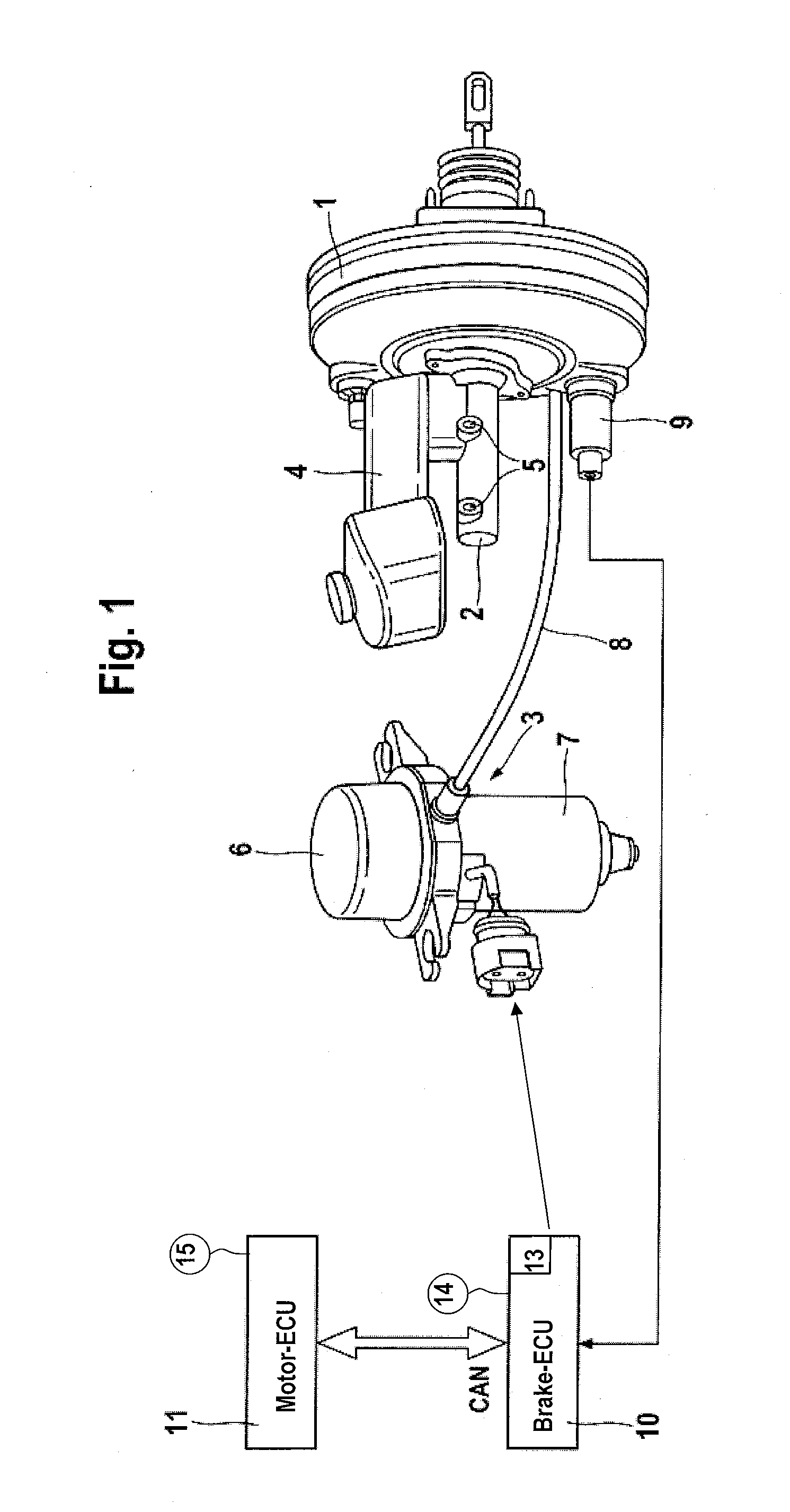

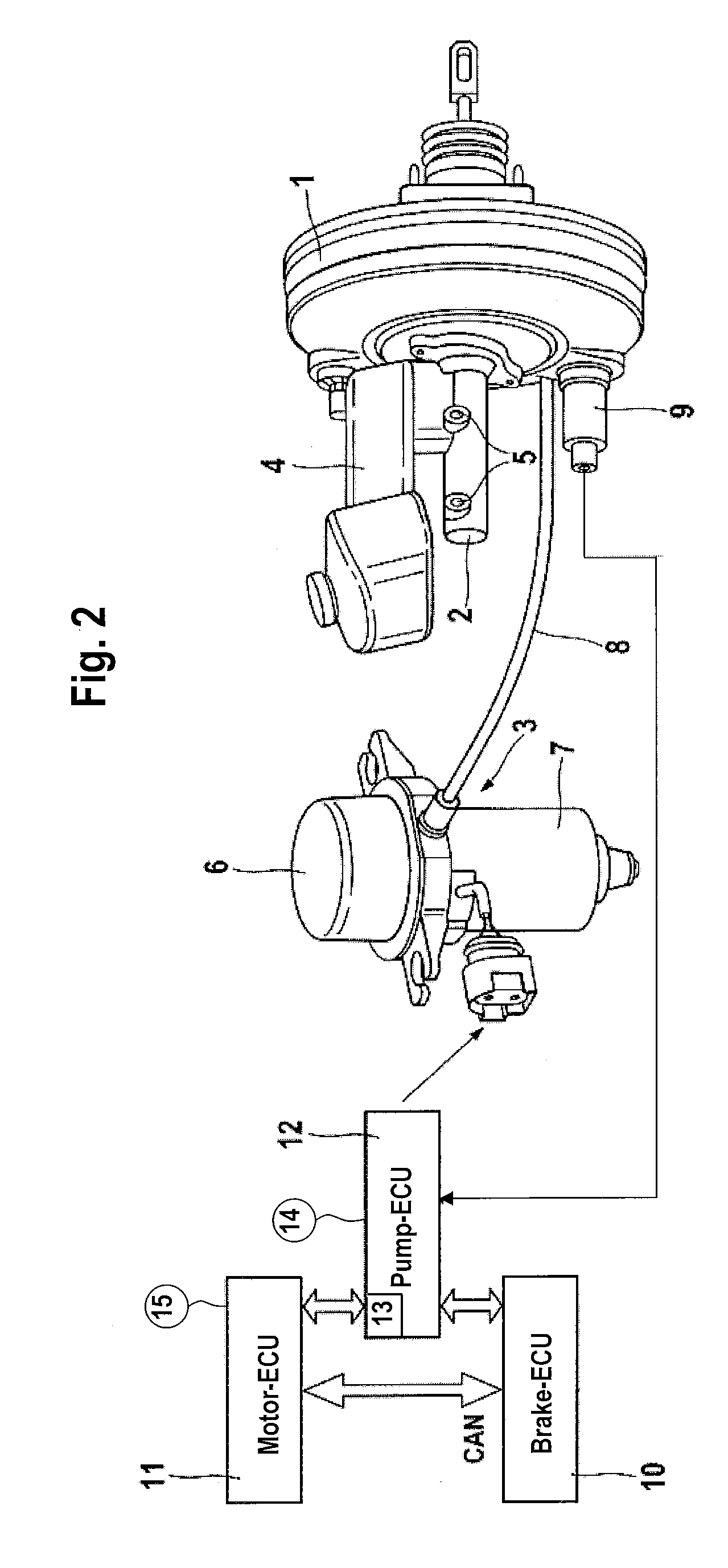

Device for supplying pressure to an actuation unit of a motor vehicle brake system and method for controlling said device

ActiveUS20100269500A1Low costLarge installation spaceHybrid vehiclesBraking action transmissionMotor vehicle partEngineering

A device for supplying pressure to an actuation unit of a vehicle brake system, in particular to a vehicle brake system of the ‘brake-by-wire’ type, comprising a pneumatic motor-and-pump assembly with a pump and a motor driving the pump, wherein the motor-and-pump assembly is controlled by an electronic control unit depending on a pressure level or pressure difference in a pneumatic brake booster of the actuation unit, with the pressure level in a chamber or a difference in pressure between two chambers of the brake booster being detected by means of a sensor. In order to maintain the availability of the service brake function as high as possible and to obtain a maximum possible redundancy, the control unit, used to control the motor-and-pump assembly comprises a logic module and a power module, which are arranged separately of each other.

Owner:CONTINENTAL TEVES AG & CO OHG

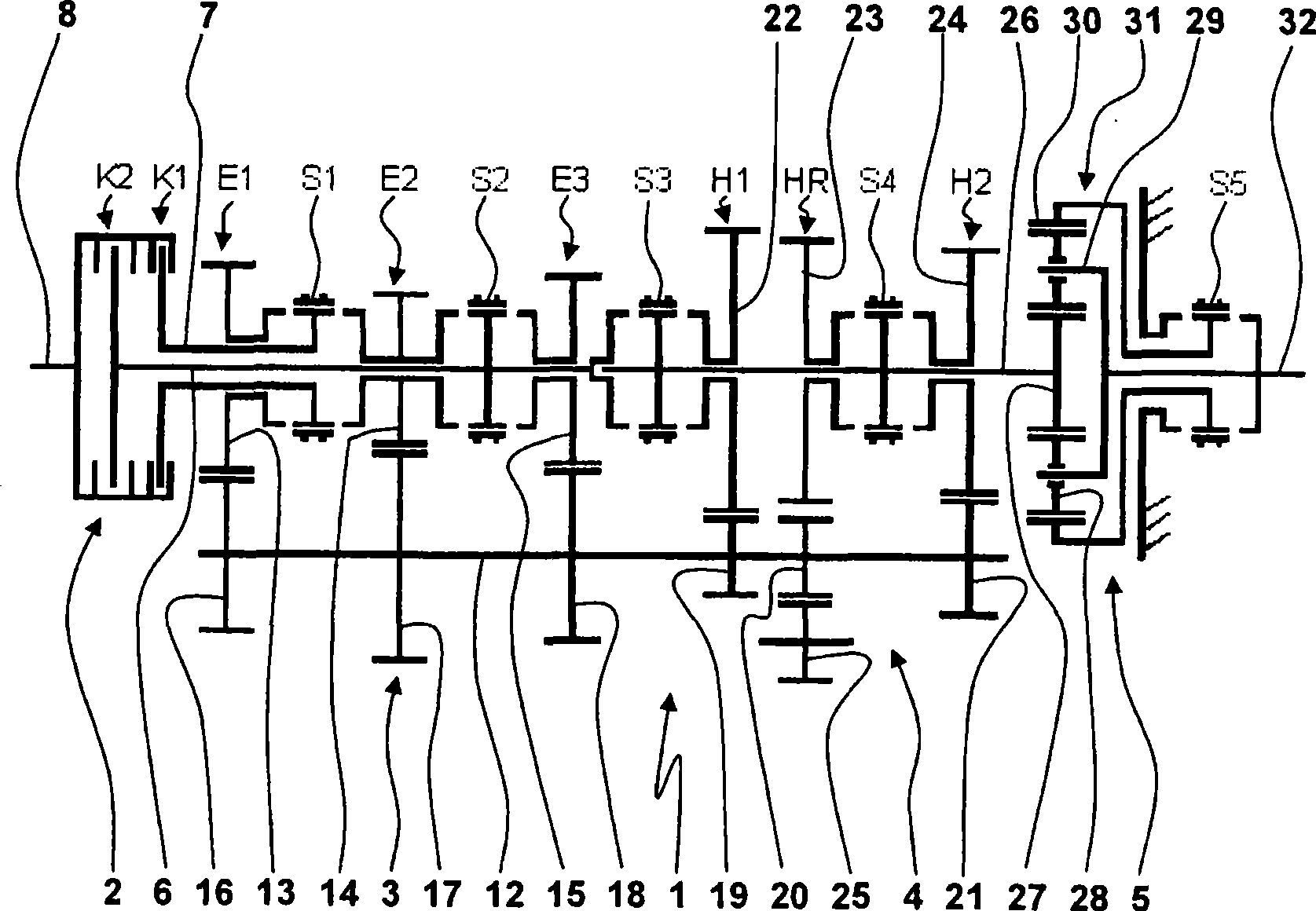

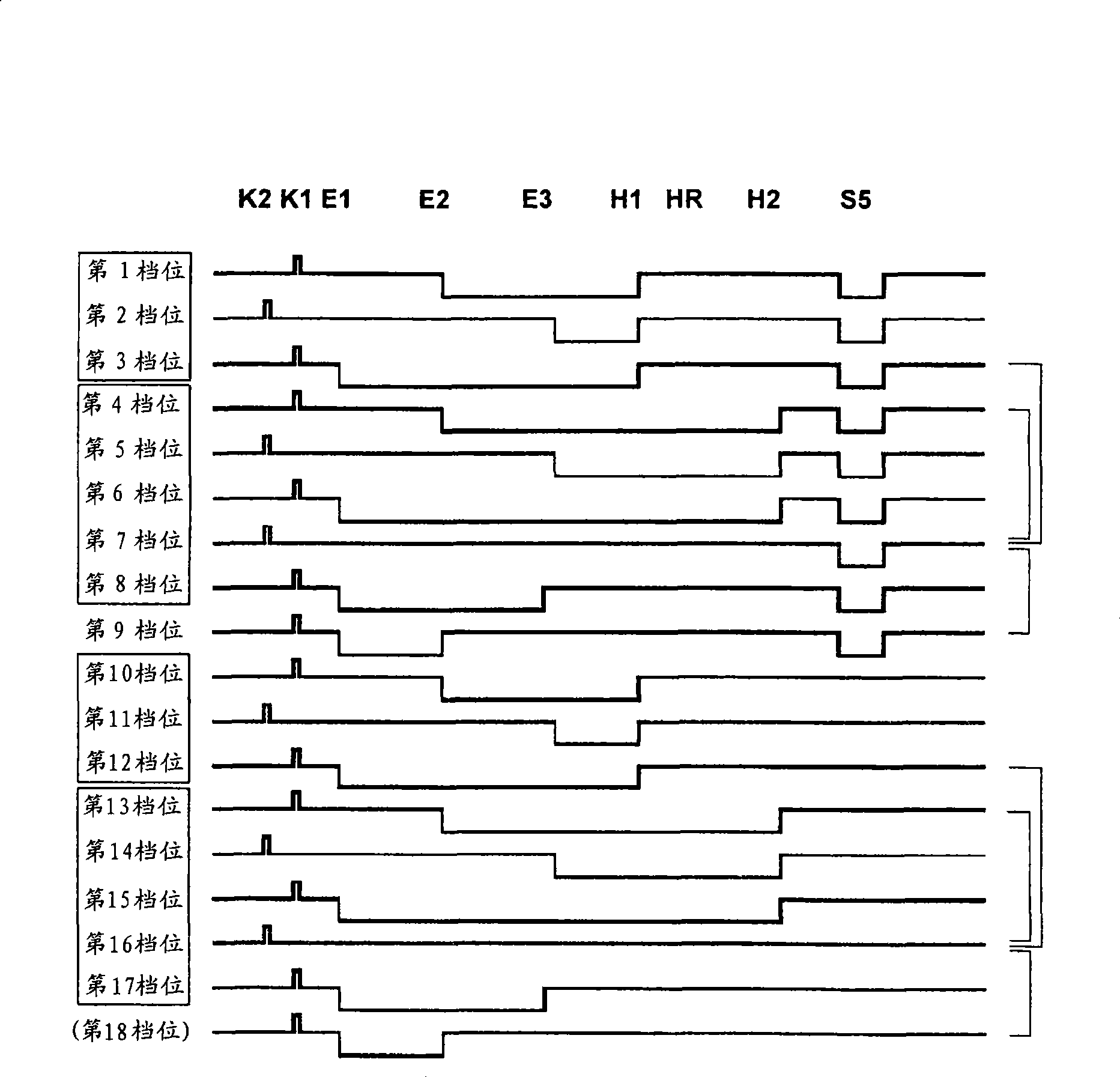

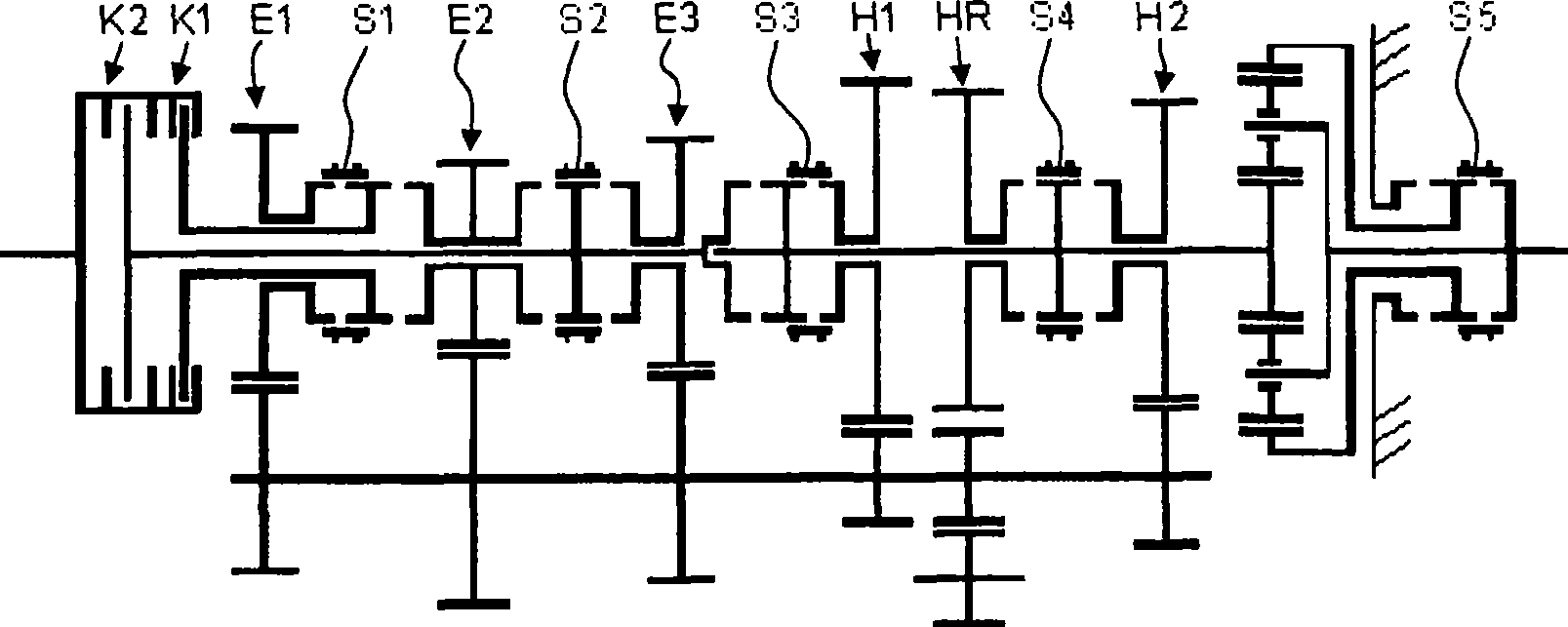

Power-shift transmission for a commercial vehicle

InactiveCN101415967ALarge installation spaceSave installation spaceToothed gearingsTransmission elementsPower flowEngineering

The invention relates to a power-shift transmission for a commercial vehicle having a split group (3), a main group (4) and a range group (5). According to the invention, it is possible to connect a loose wheel (14) of an input constant (E2) fixedly in terms of rotation, optionally via the shifting elements (S1) and (S2), to two input shafts (6, 7) which can be coupled in each case via clutches (K1, K2) to a transmission input shaft (8). An idler shaft (12) can be driven via three input constants (E1, E2, E3), wherein a power flow takes place via the idler shaft (12) in all forward gears with the exception of a direct gear. With a simple construction, the design according to the invention results in the possibility of sequential gearshifts without interruptions in traction forces and multiple-gear upshifts and multiple-gear downshifts.

Owner:DAIMLER AG

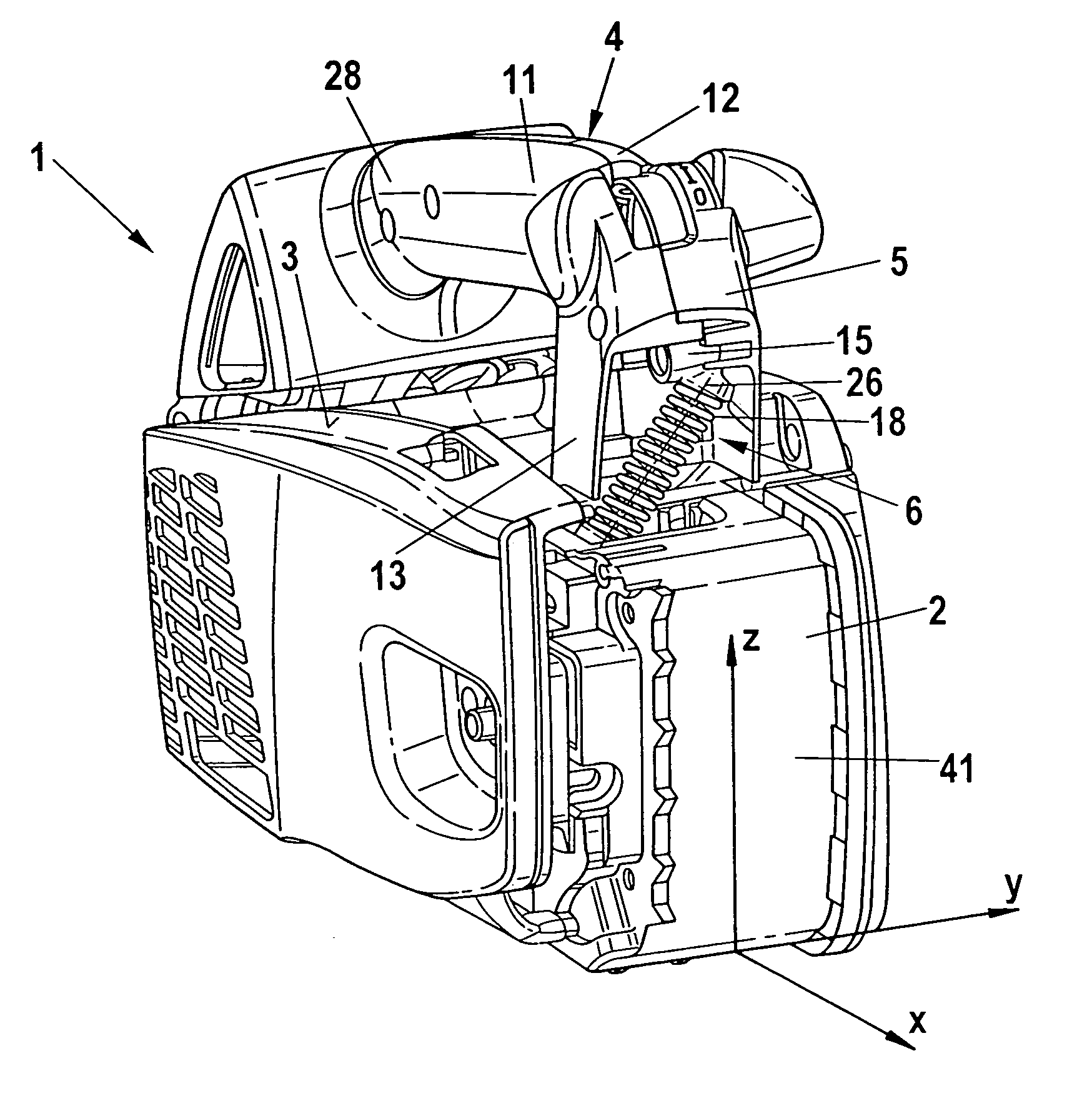

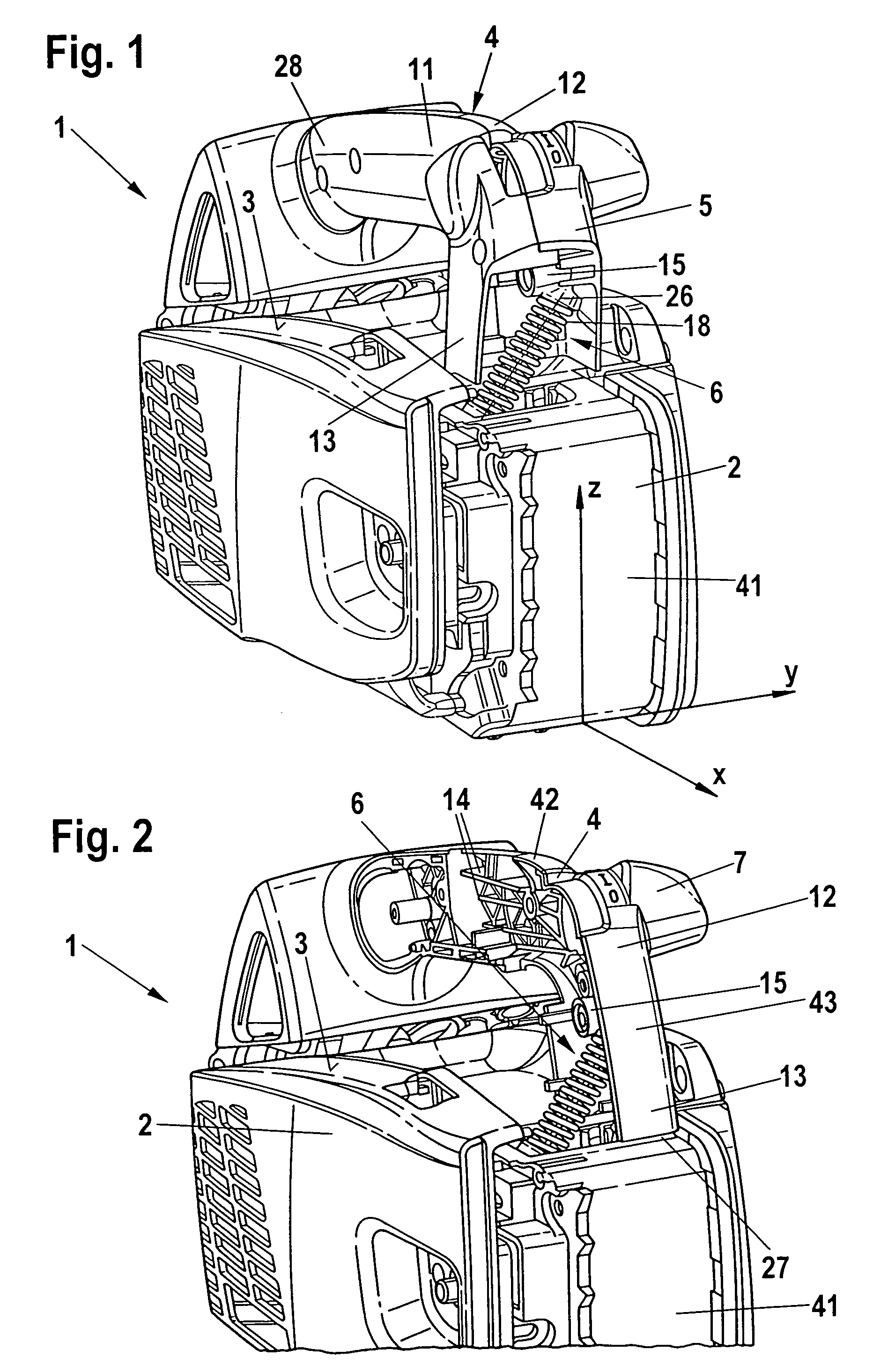

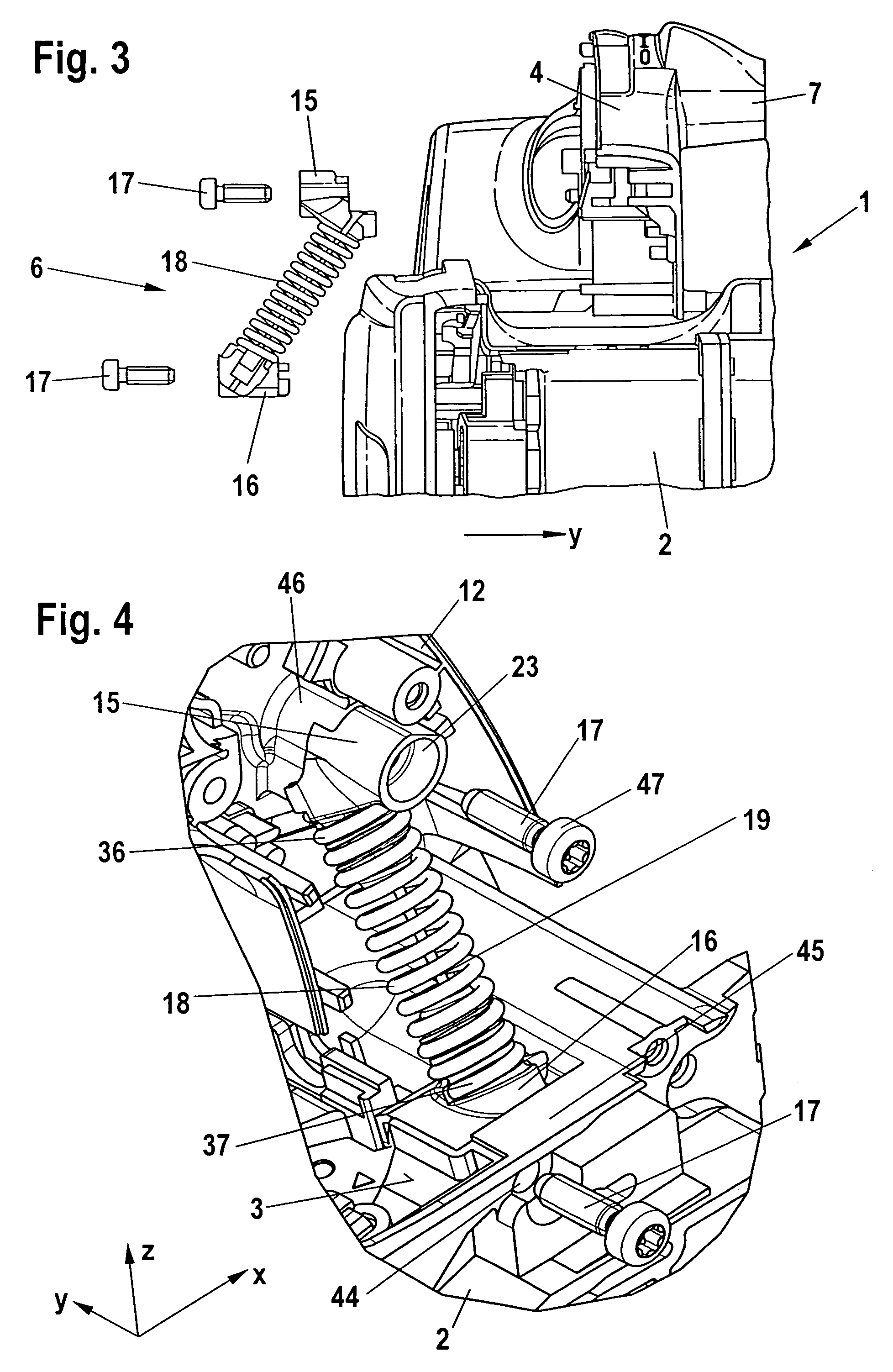

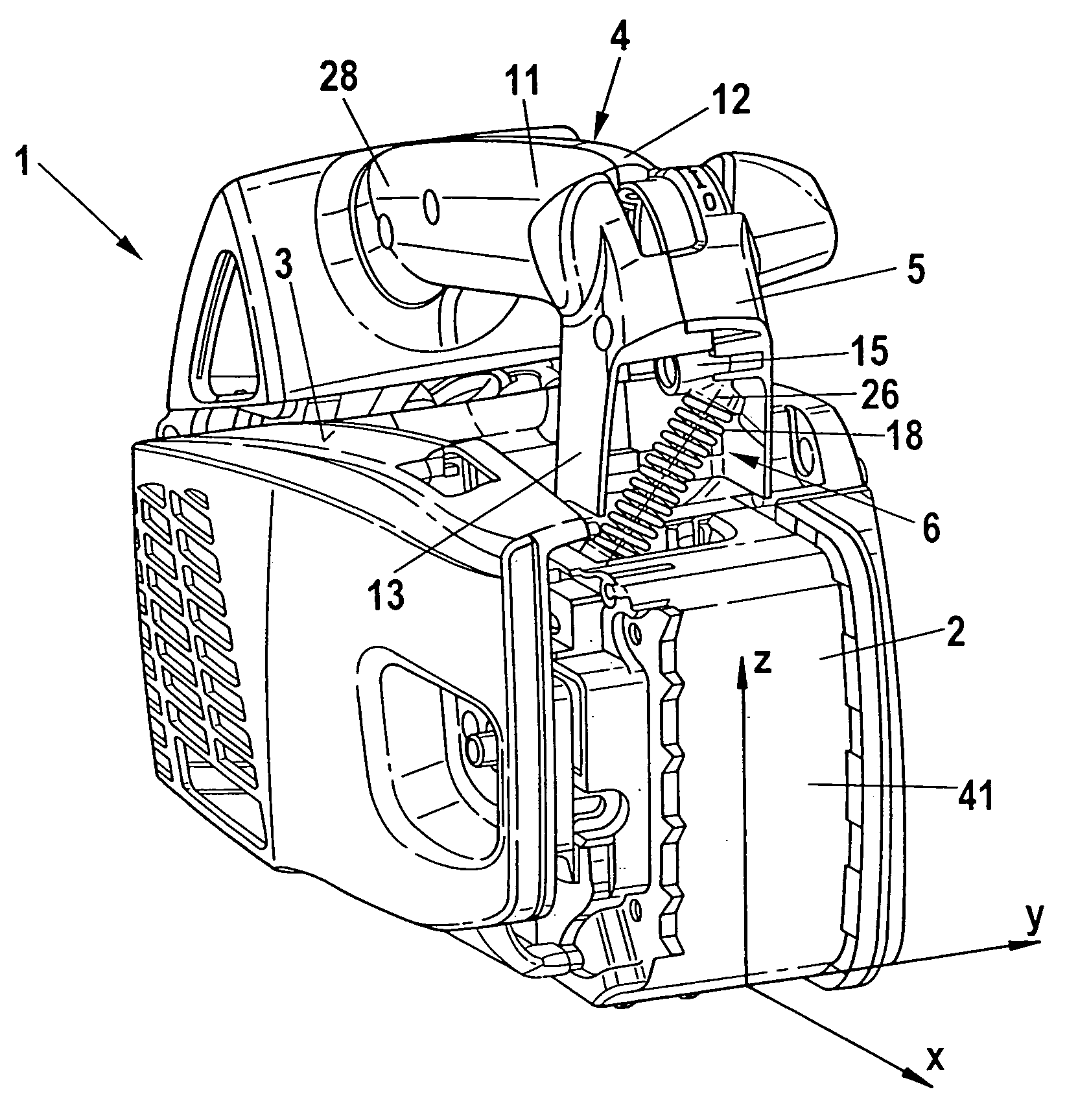

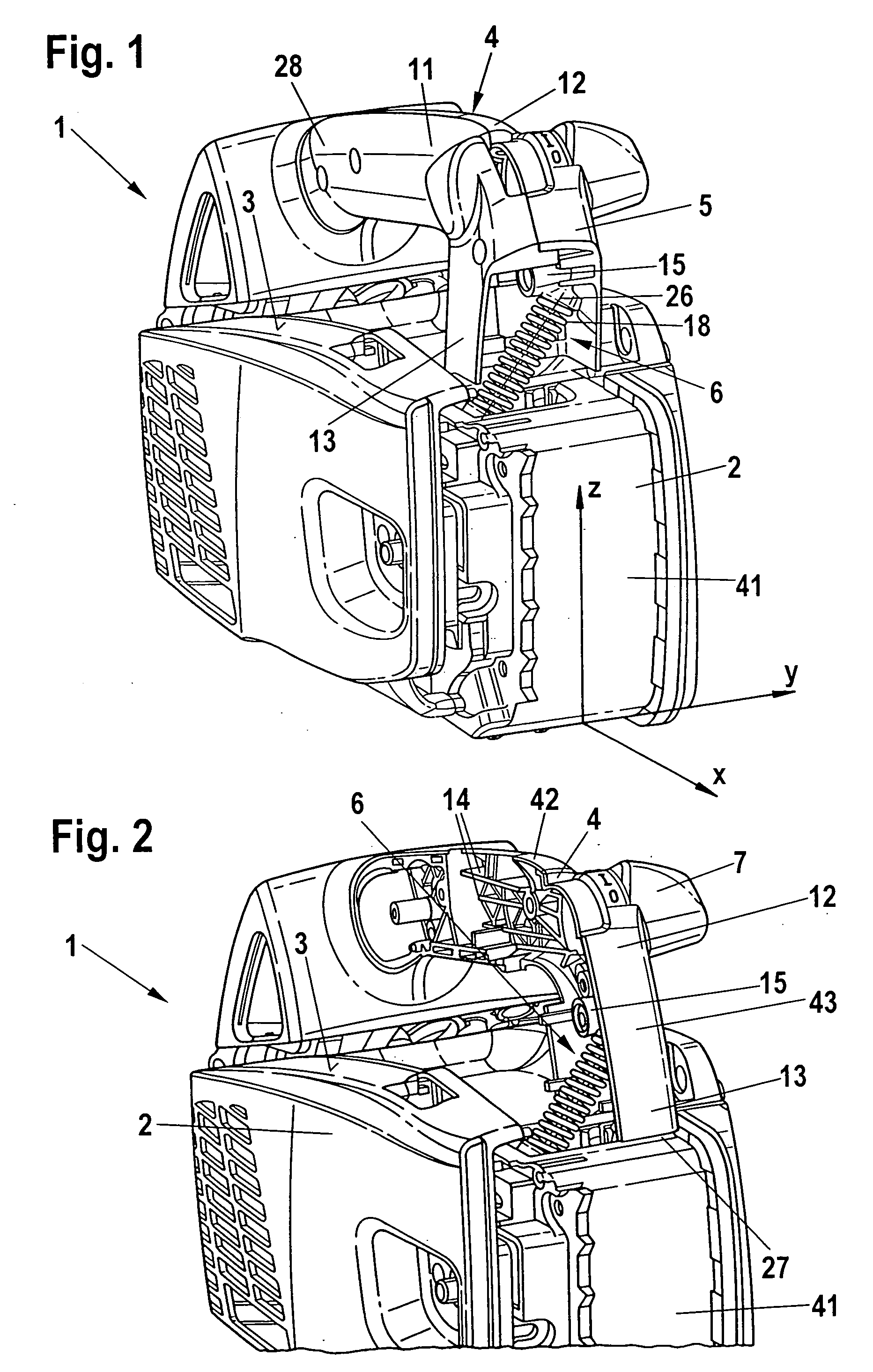

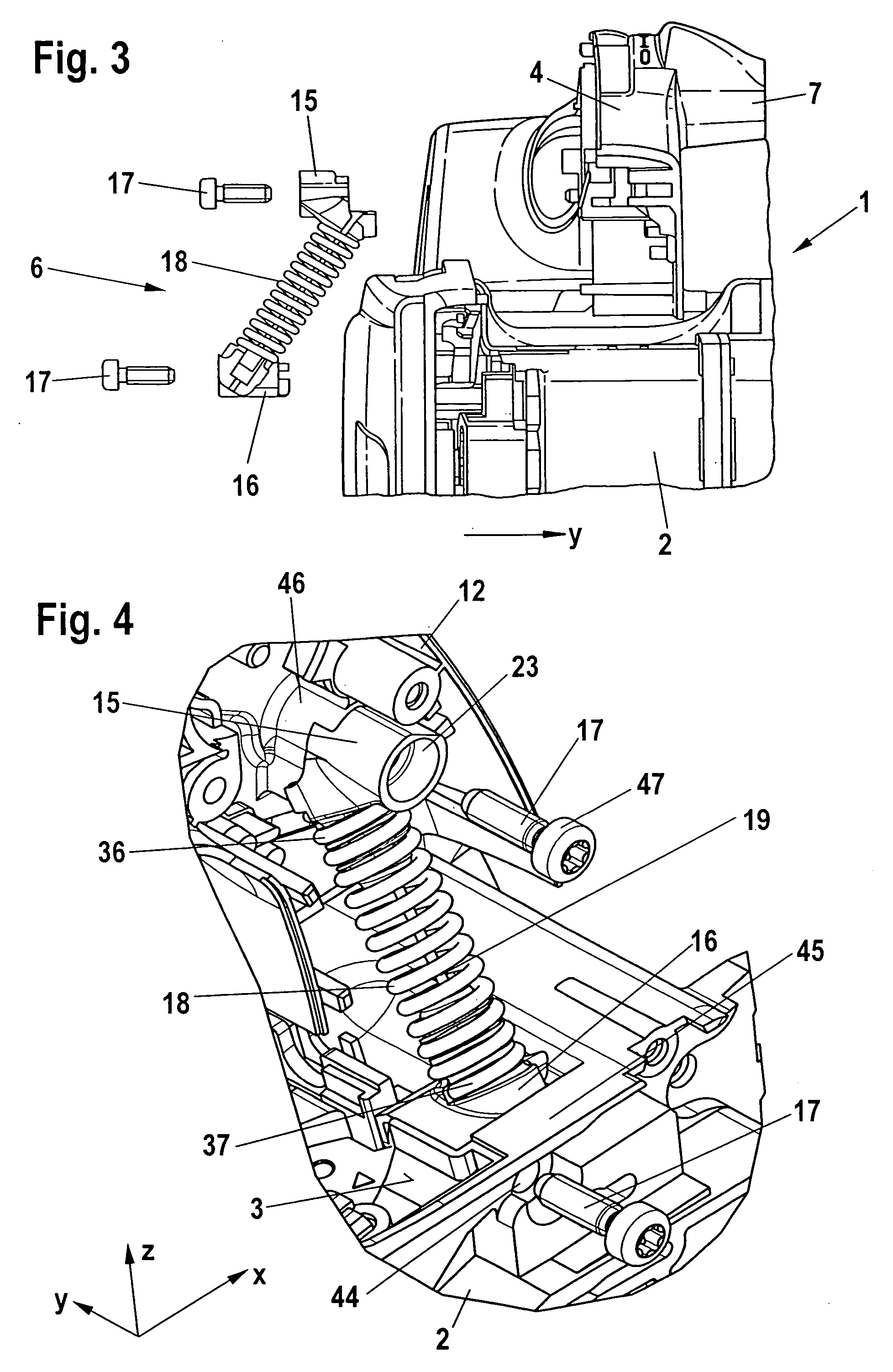

Manually guided implement

ActiveUS7412959B2Convenient lengthDampening properties of the antivibration element can be better adaptedMetal sawing devicesNon-fuel substance addition to fuelEngineeringInternal combustion engine

A manually guided implement having a housing that accommodates an internal combustion engine for driving a tool. At least an upper handle extends in a longitudinal direction of the implement on an upper side thereof. A first antivibration element connects the handle to the housing, wherein a longitudinal central axis of the antivibration element is inclined relative to a longitudinal central plane of the implement.

Owner:ANDREAS STIHL AG & CO KG

Manually guided implement

ActiveUS20060000438A1Easy constructionConvenient lengthMetal sawing devicesNon-fuel substance addition to fuelEngineeringInternal combustion engine

A manually guided implement having a housing that accommodates an internal combustion engine for driving a tool. At least an upper handle extends in a longitudinal direction of the implement on an upper side thereof. A first antivibration element connects the handle to the housing, wherein a longitudinal central axis of the antivibration element is inclined relative to a longitudinal central plane of the implement.

Owner:ANDREAS STIHL AG & CO KG

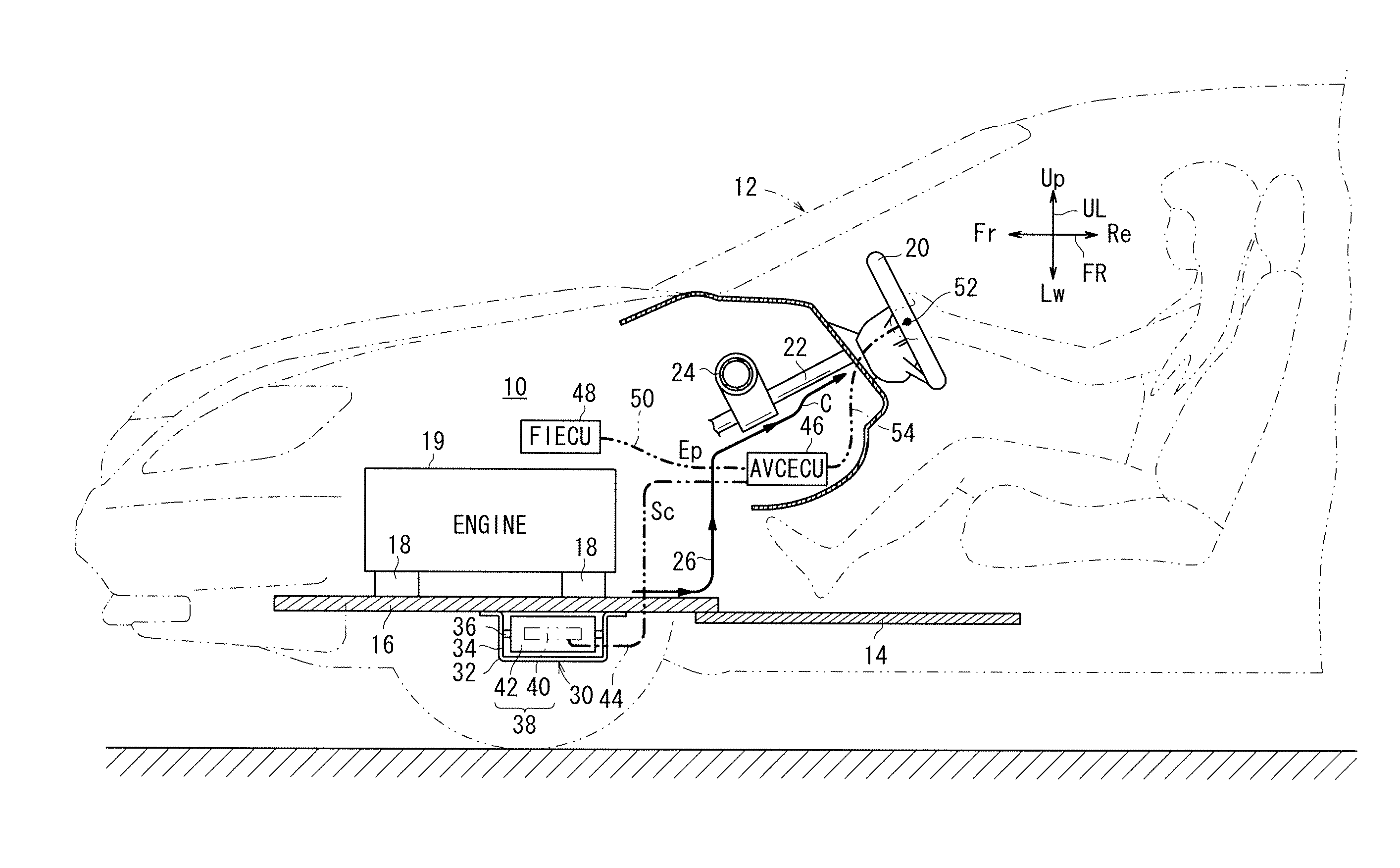

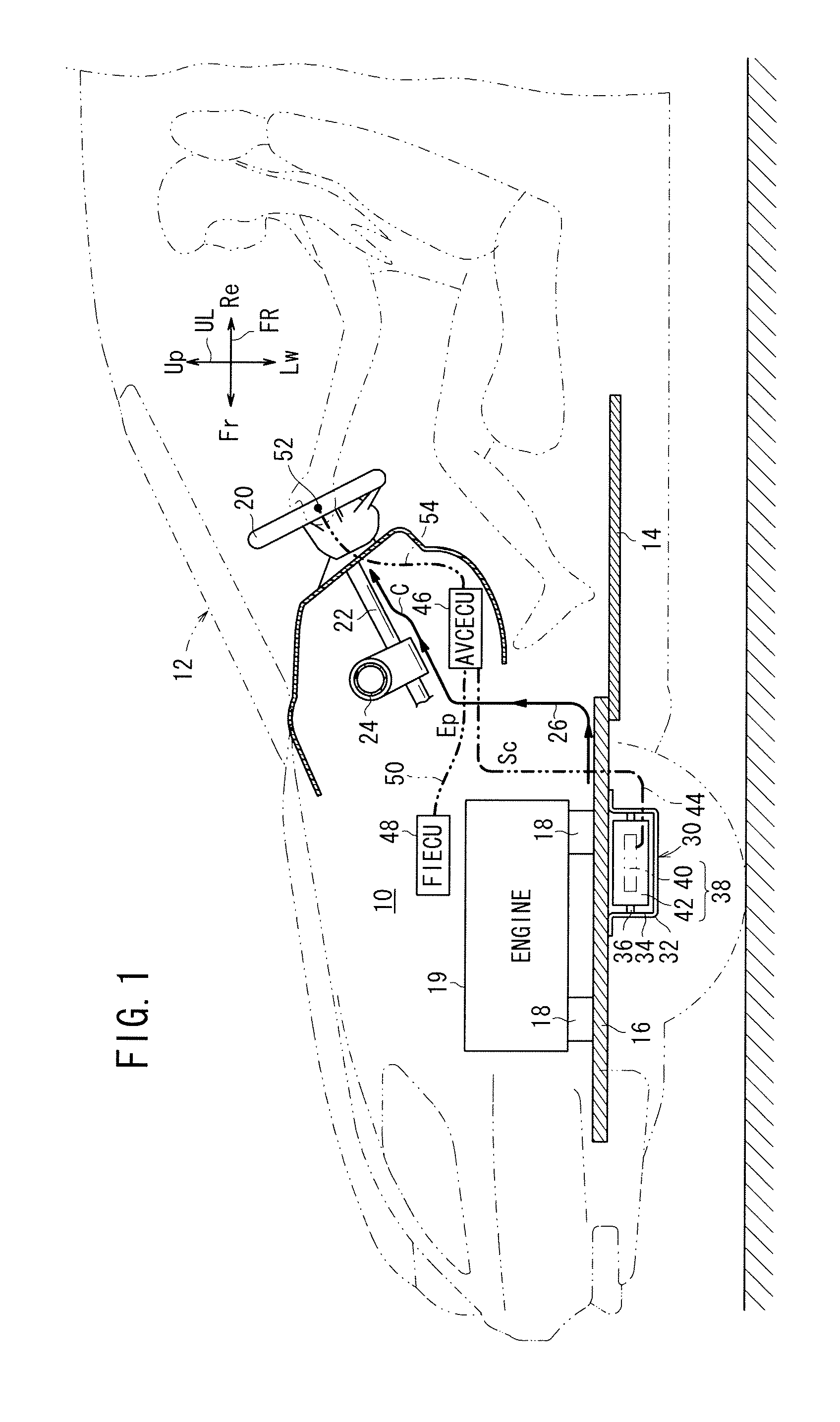

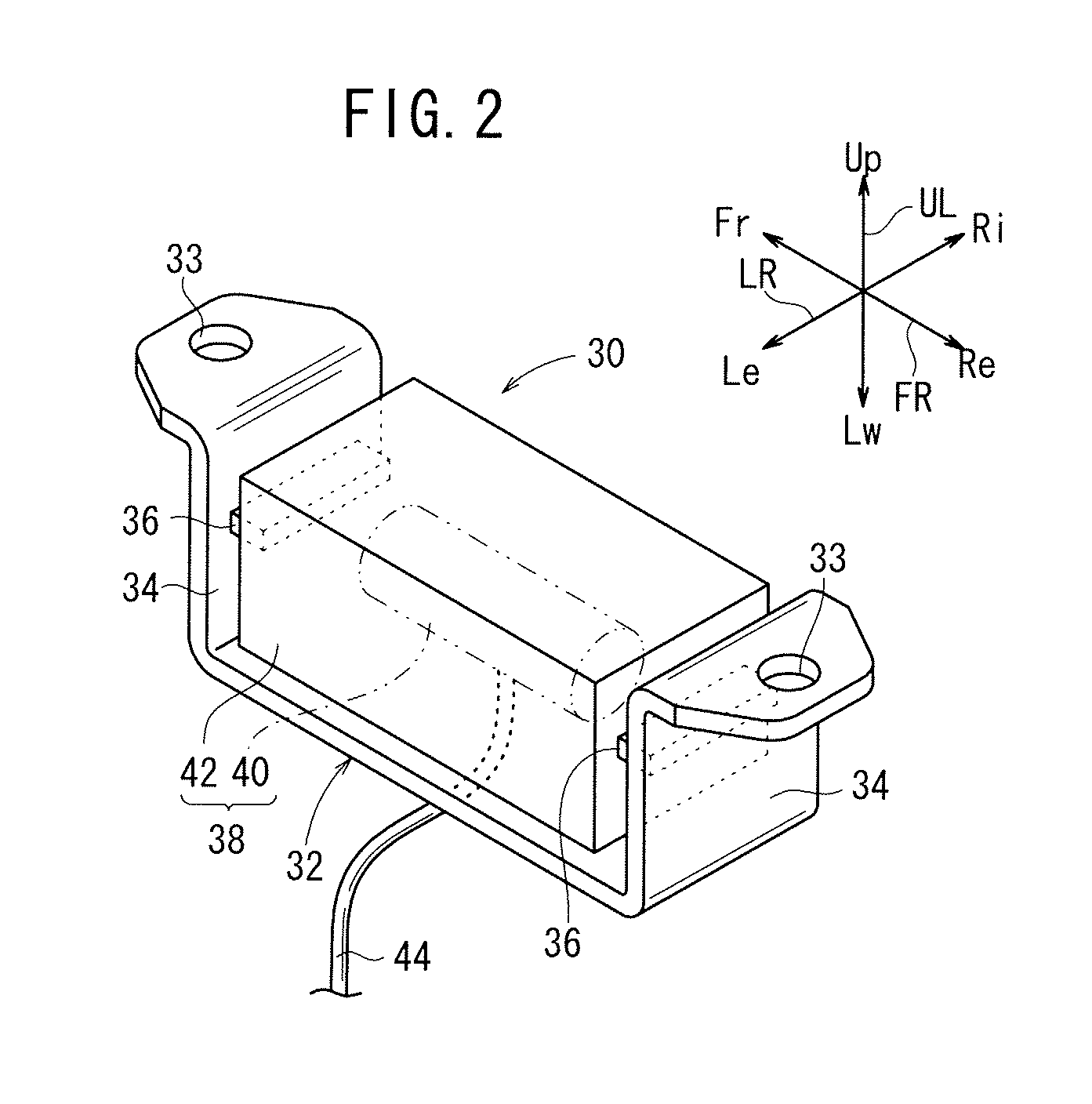

Vehicle-mounted active vibration reducing device

InactiveUS20110272229A1Improve fuel economyReduce vibrationNon-rotating vibration suppressionShock absorbersIn vehicleActuator

Provided is a vehicle-mounted active vibration reducing device wherein vibrations in a plurality of directions are reduced by a single dynamic damper. Since an actuator is attached so as to be supported by an elastic member attached to a bracket, the actuator can be used as a mass of a dynamic damper. The moving directions of the actuator are the forward and rearward directions, and are different from the moving directions of the dynamic damper using the actuator as a mass, i.e., the upward and downward directions. Accordingly, vibrations can be controlled in the forward and rearward directions which correspond to the moving directions of the actuator as well as the upward and downward directions which correspond to the moving directions of the dynamic damper.

Owner:HONDA MOTOR CO LTD

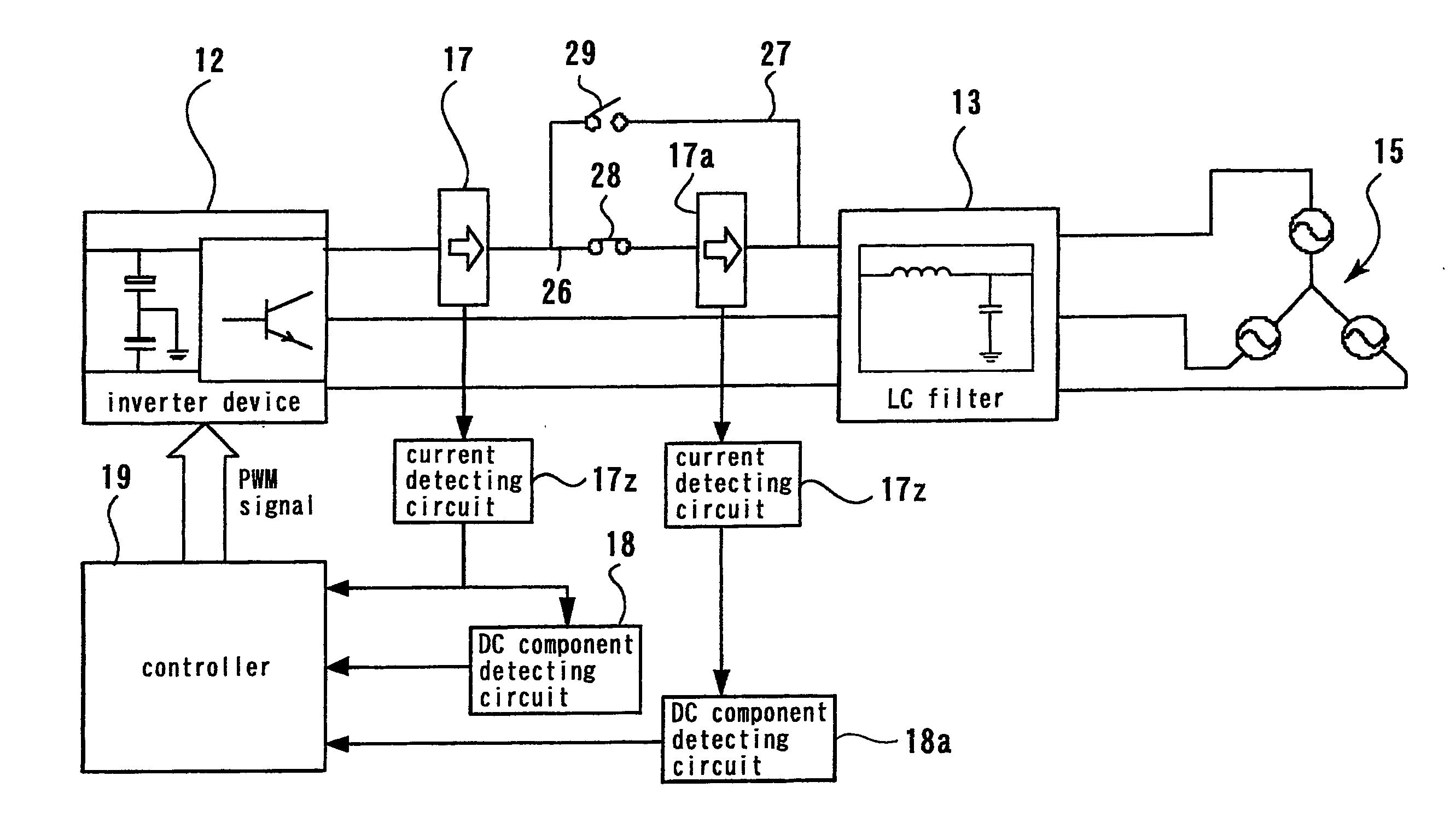

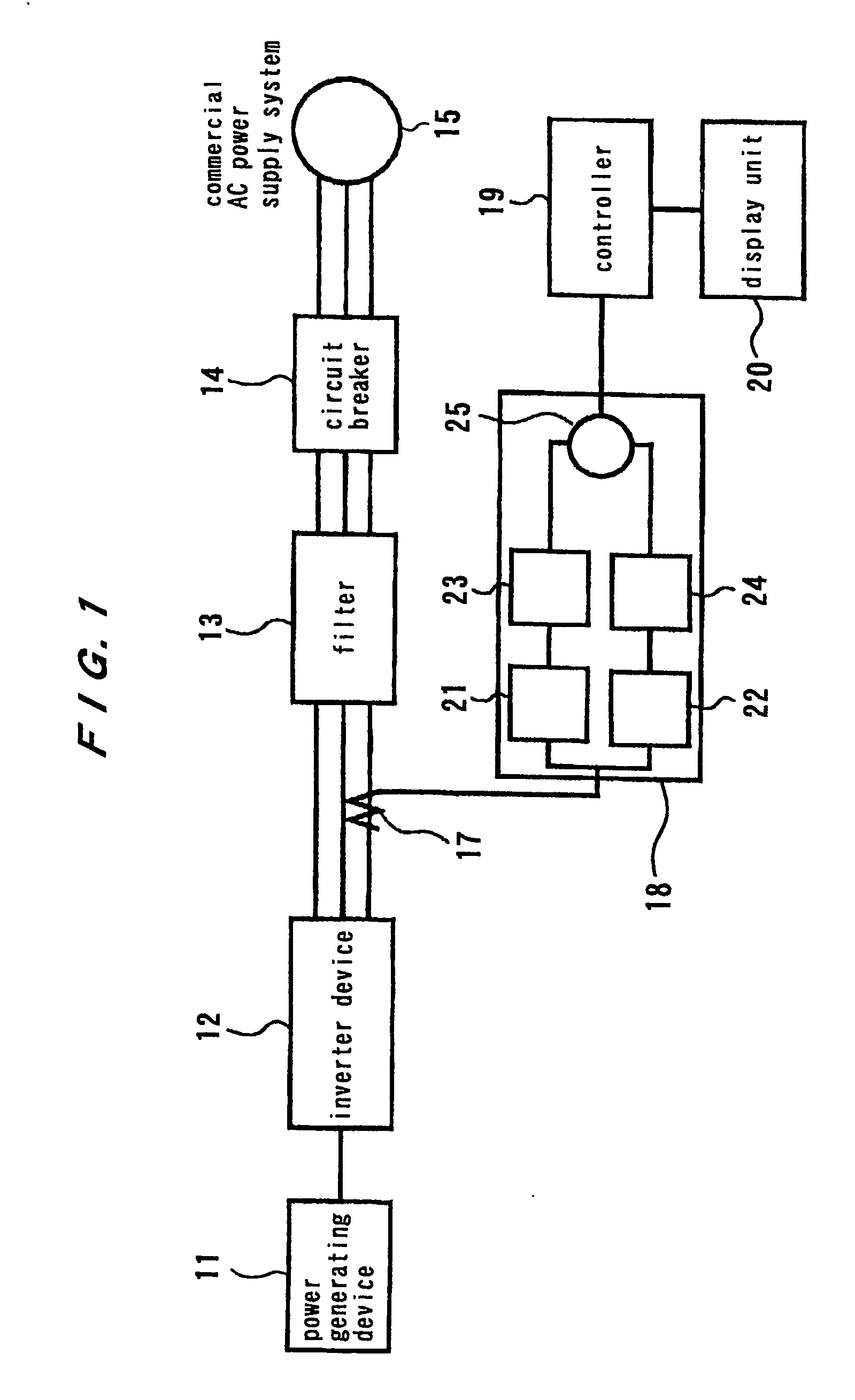

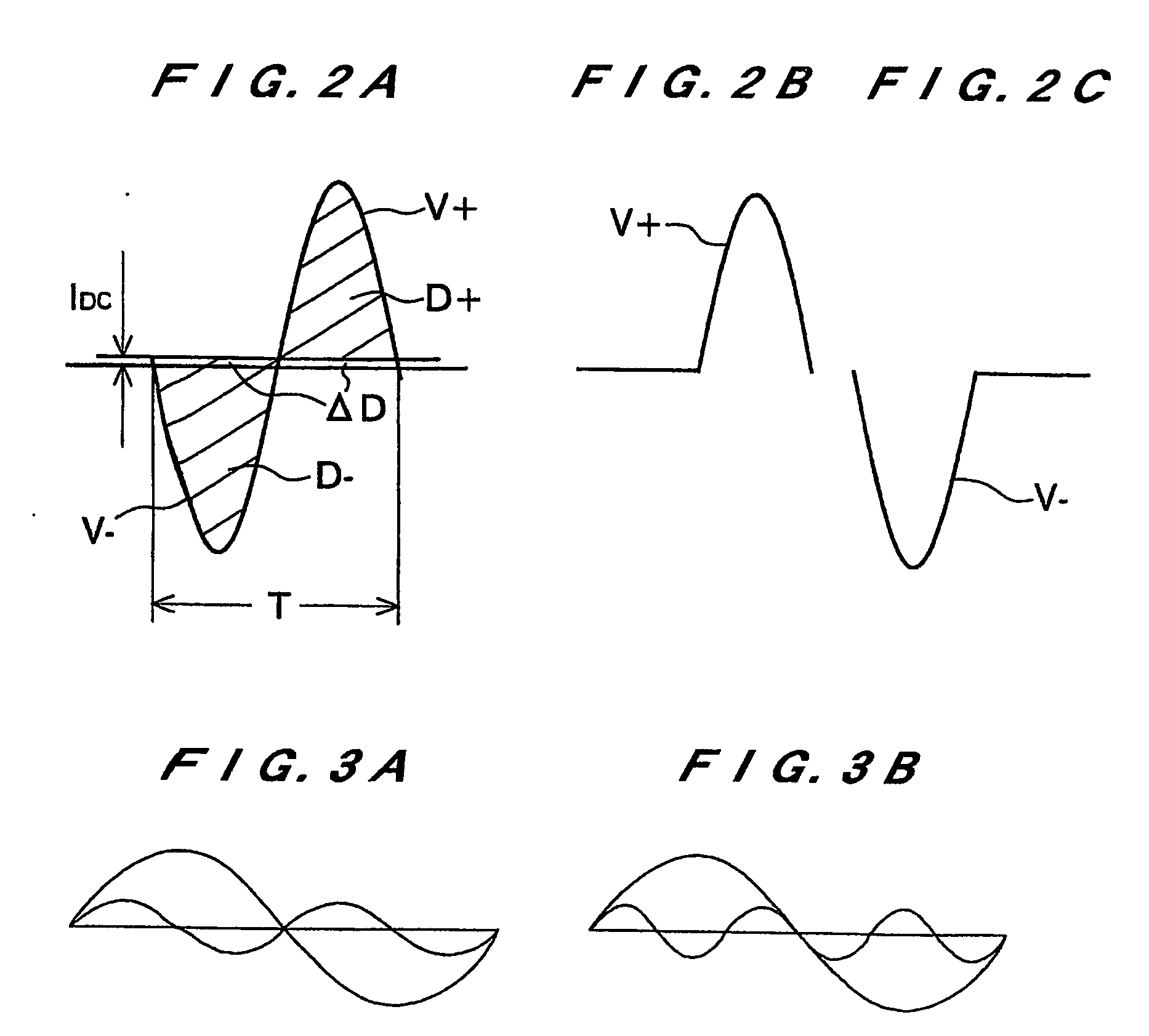

Circuit and system for detecting dc component in inverter device for grid-connection

InactiveUS20070007969A1Small componentImprove accuracyFrequency selective voltage/current level measurementDc-ac conversion without reversalIntegratorPower grid

A DC component detecting circuit (18) detects a small DC component contained in the AC output power of a grid-connection inverter device (12), accurately within a short period of time, and has a simple, small-size, and lightweight configuration. The DC component detecting circuit (18) comprises separators (21, 22) for separating a voltage which is proportional to the output current of the inverter device into voltages in positive and negative half periods, integrators (23, 24) for integrating the separated voltages in the positive and negative half periods, and an adder (25) for adding integral signals in the positive and negative half periods from the integrators (23, 24).

Owner:EBARA DENSAN KK

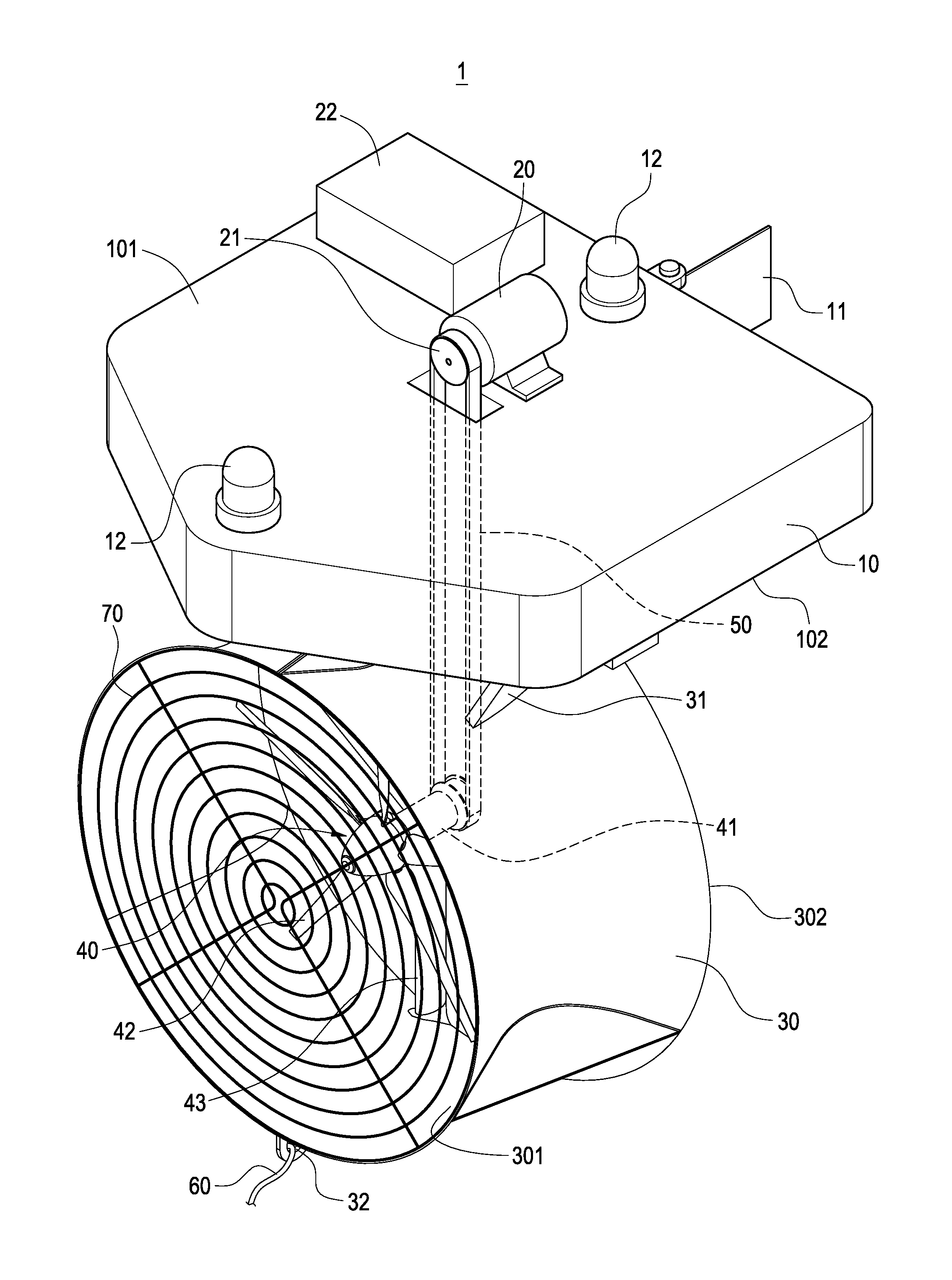

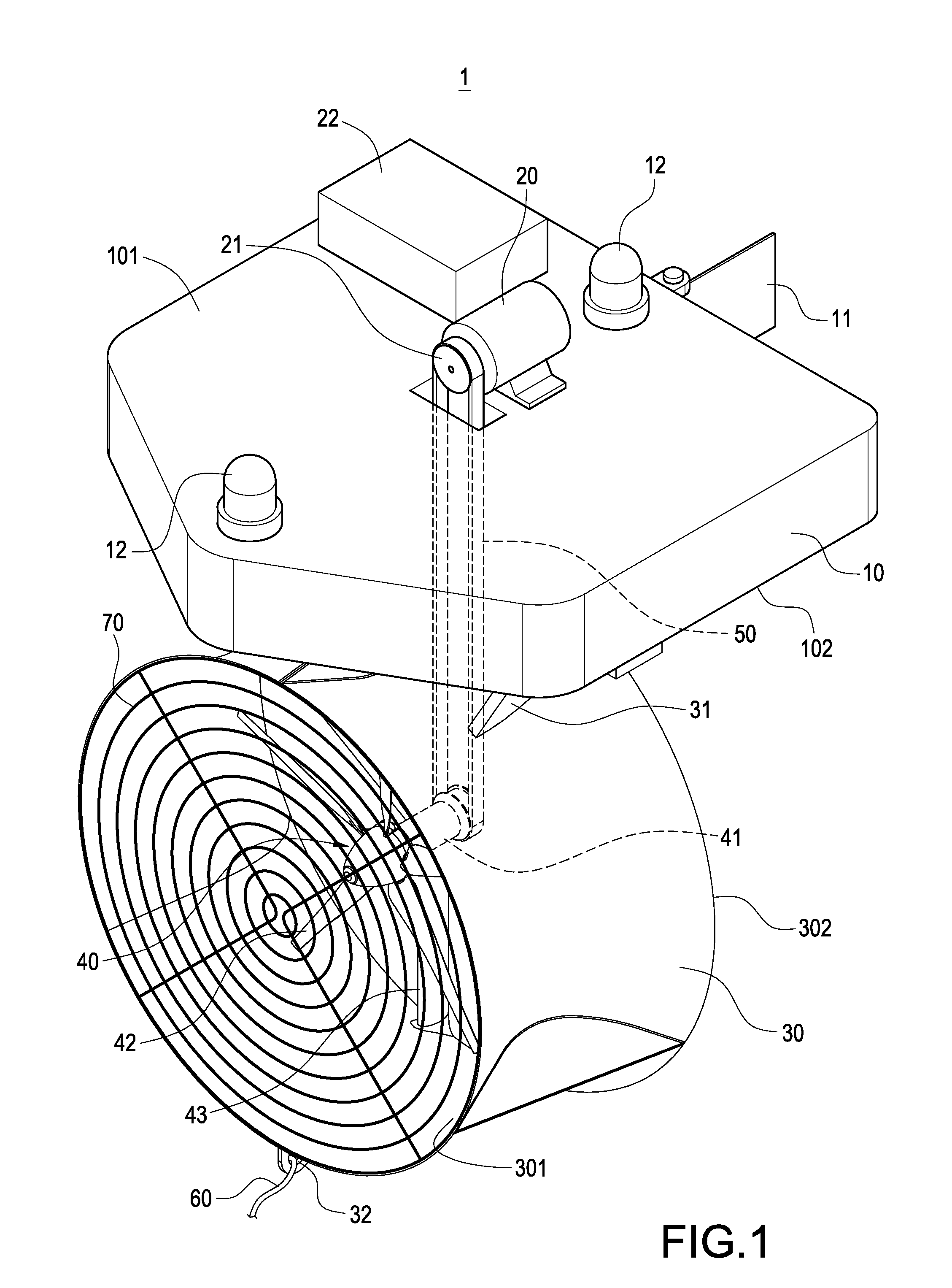

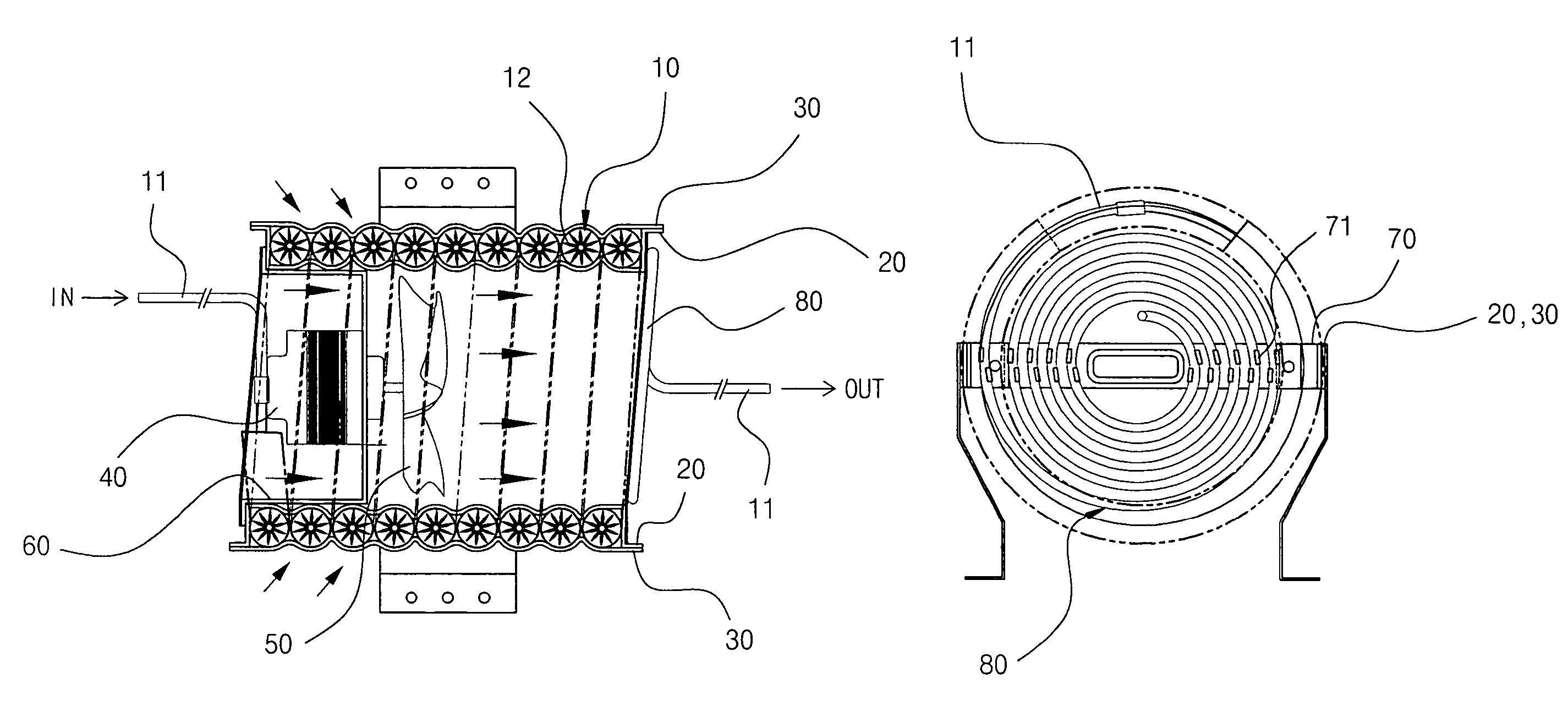

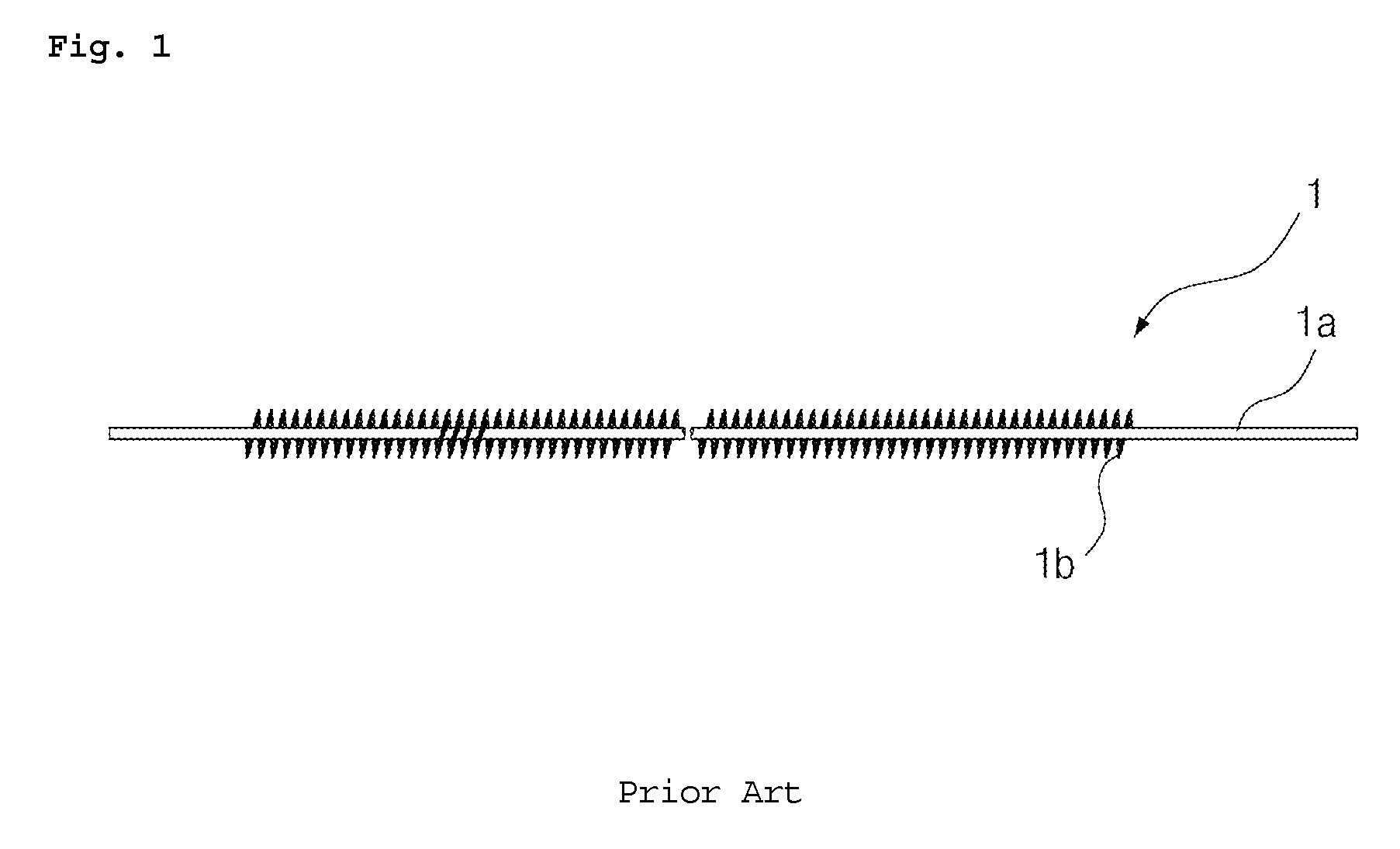

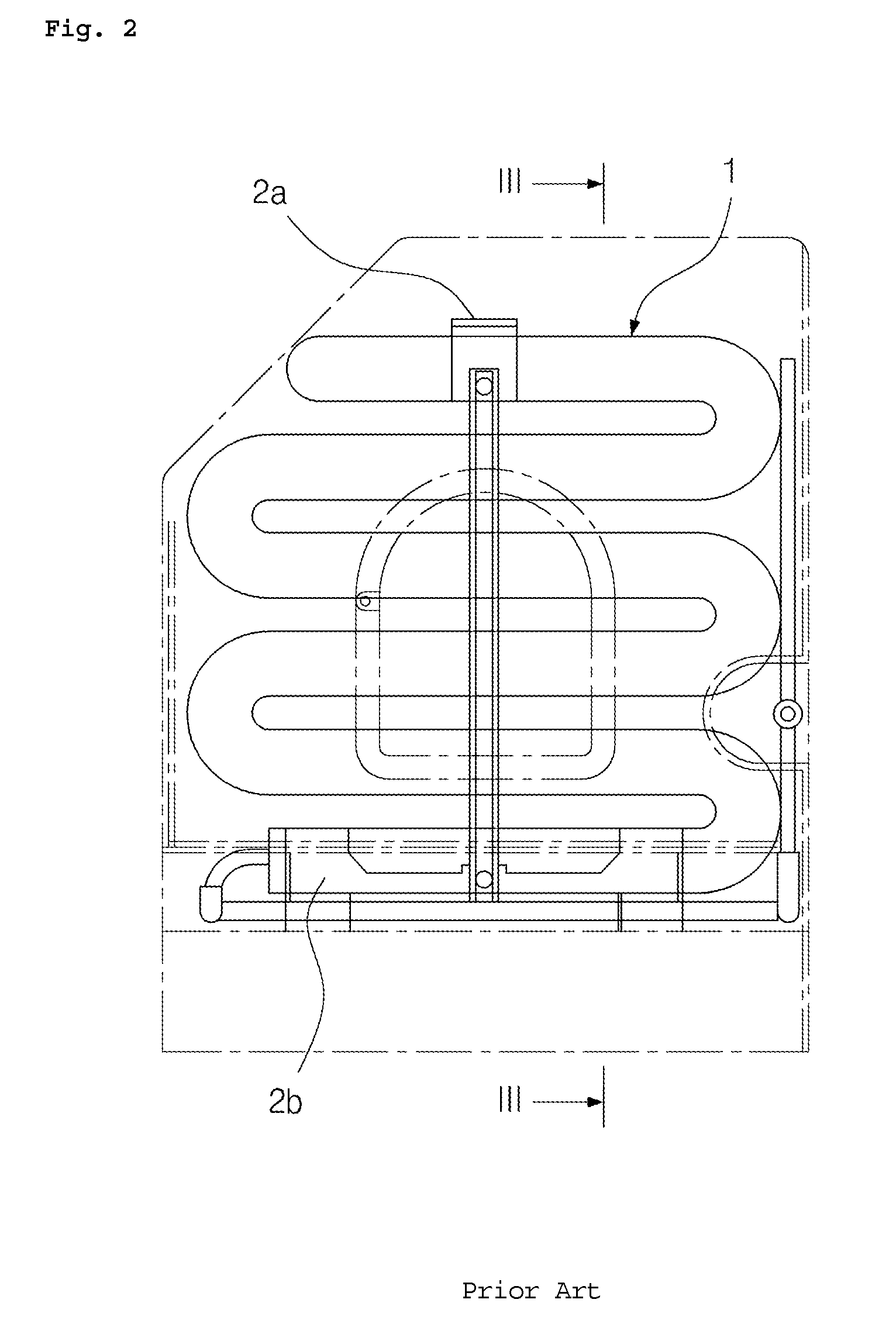

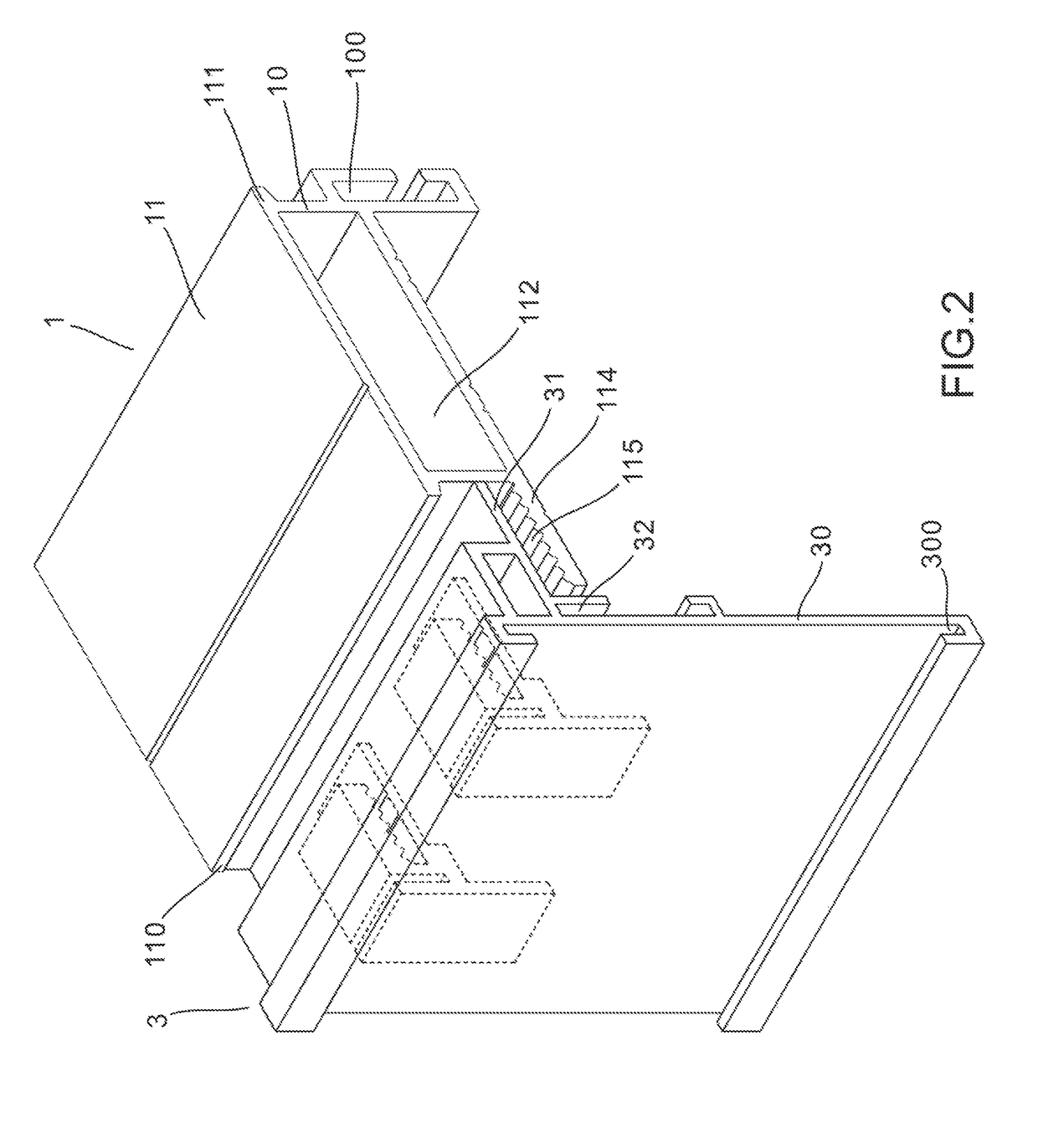

Coil type turn-fin condenser

InactiveUS7367380B2Large mount spaceHeat exchange efficiency be improveDomestic stoves or rangesDomestic refrigeratorsInterior spaceEngineering

Disclosed herein is a turn-fin condenser. The turn-fin condenser employs a turn-fin tube adhesively wound in a spiral shape around an outer surface of the tube in which refrigerant flows. The condenser comprises a coil type turn-fin tube 10 wound in a coil shape and fixed by inner and outer brackets 20 and 30 surrounding an outer peripheral surface of the coil type turn-fin tube, a motor 40 positioned in an inner space formed by the coil type turn-fin tube 10, a blowing fan 50 for taking ambient air in the coil type turn-fin tube 10 after being driven by the motor 40, and a tube wall 80 spirally wound with tube 11 extending out of the inner and outer brackets 20 and 30 at the rear side of the coil type turn-fin tube 10. The turn-fin condenser is easily manufactured and allows a greater quantity of air contact with turn-fins, thereby enhancing heat exchange efficiency.

Owner:KOREA BUNDY

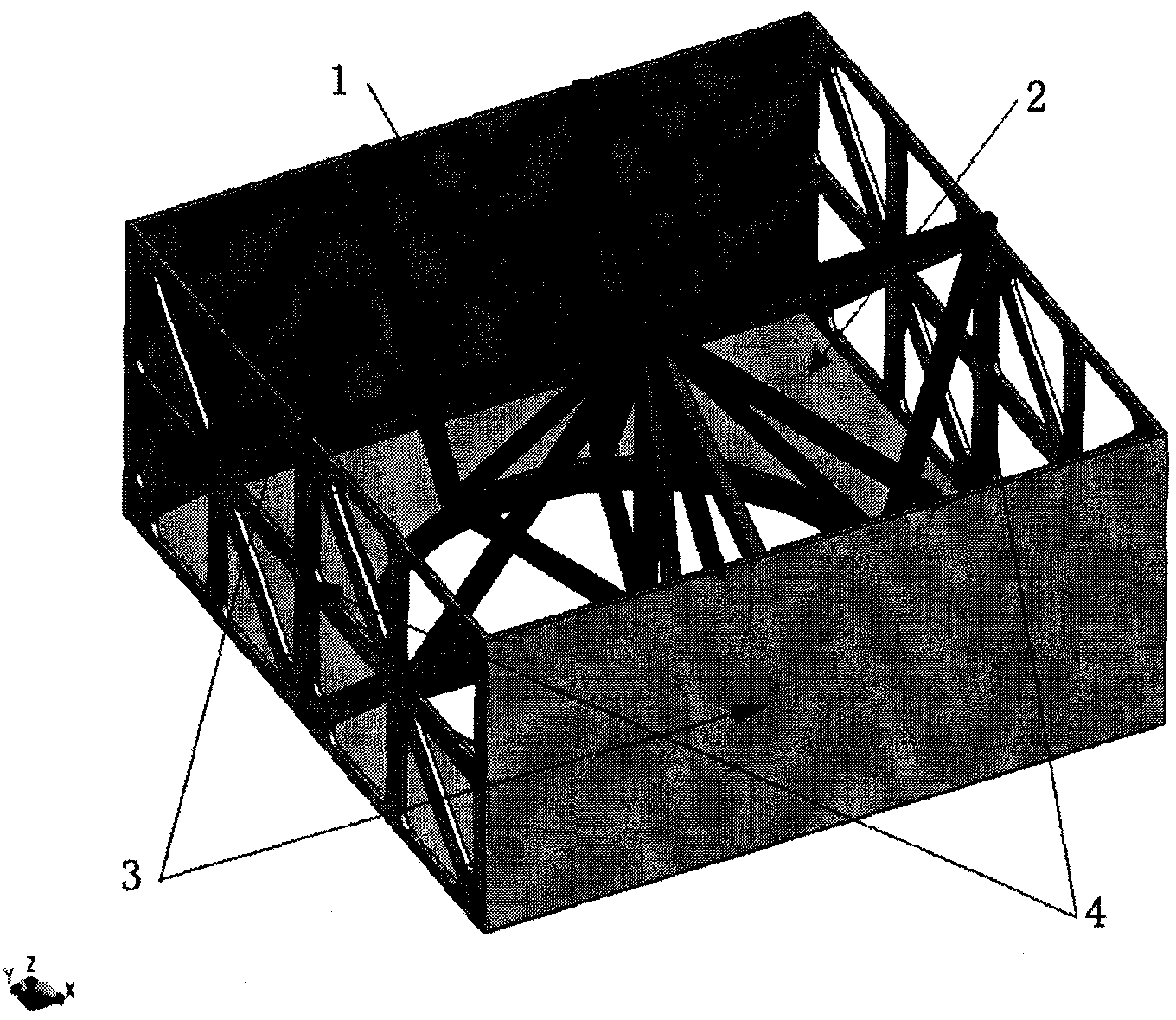

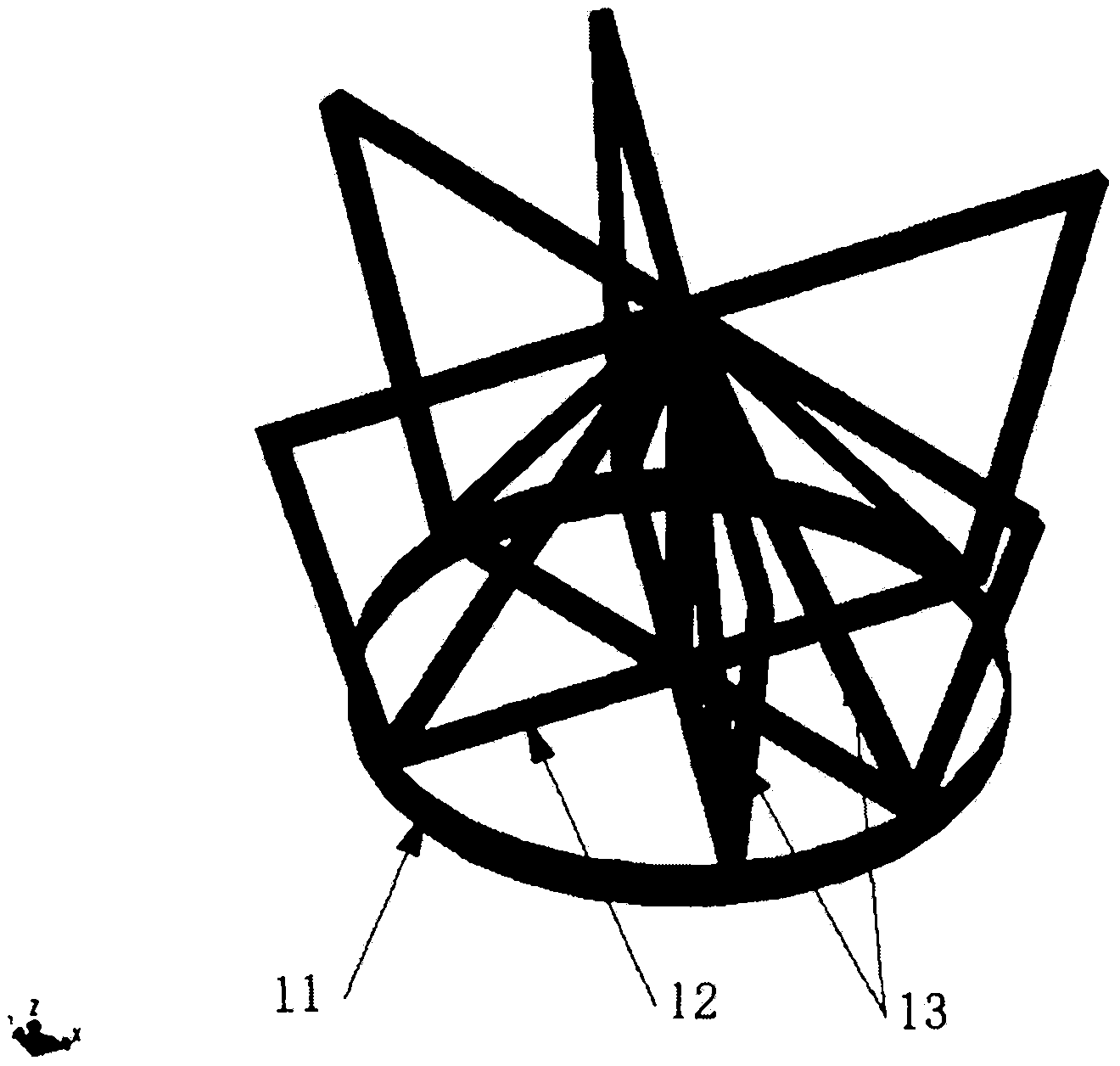

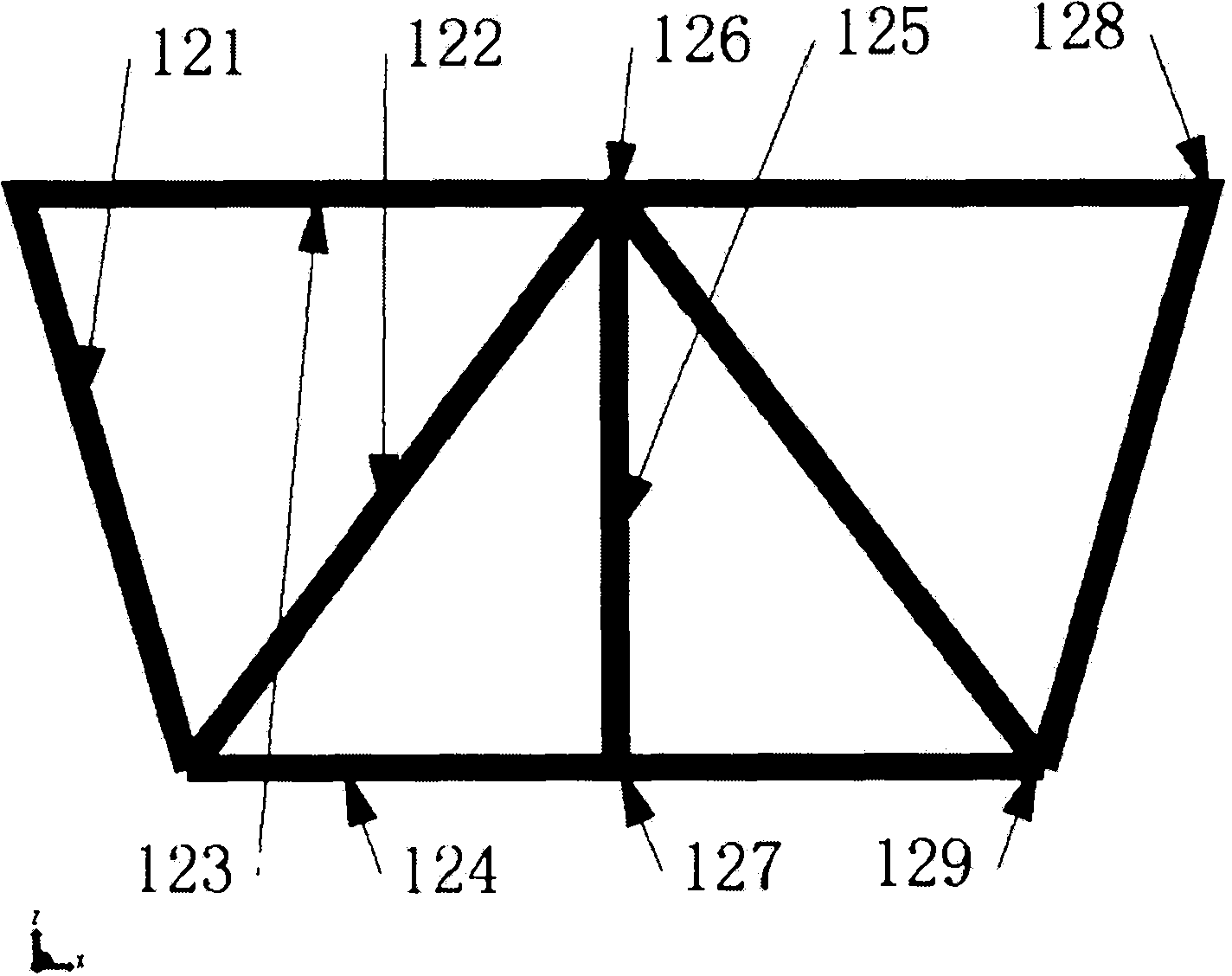

Truss type satellite main structure public platform

ActiveCN105659738BReduce the overall heightCompact structureCosmonautic vehiclesCosmonautic partsBe starComputer module

The invention discloses a new truss-type satellite main structure public platform, which consists of a star-shaped central load-bearing frame (1), a bottom plate (2), a pair of ±Y-directed side plates (3) parallel to each other, and a pair of ±X-directed The side plate (4) is composed of; the star-shaped central bearing frame (1) includes the star-arrow docking ring (11), one X-direction W-shaped plane truss (12) and two symmetrically distributed Y-direction W-shaped plane trusses (13 ); 3 W-shaped plane trusses are star-shaped, i.e. distributed in a * shape, connected as a whole and connected to the side plates respectively; 3 W-shaped plane trusses are connected to the star arrow docking ring (11) through the bottom outer joint (129); The bottom plate (2) is connected with the star arrow docking ring (11) at the position of the opening in the middle. The platform of the present invention meets the satellite layout requirements while ensuring a reasonable force transmission path, can carry various types of payload compartments (or modules), and is suitable for use when the weight of the entire satellite exceeds 6 tons and the diameter of the storage tank is greater than 1 meter.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

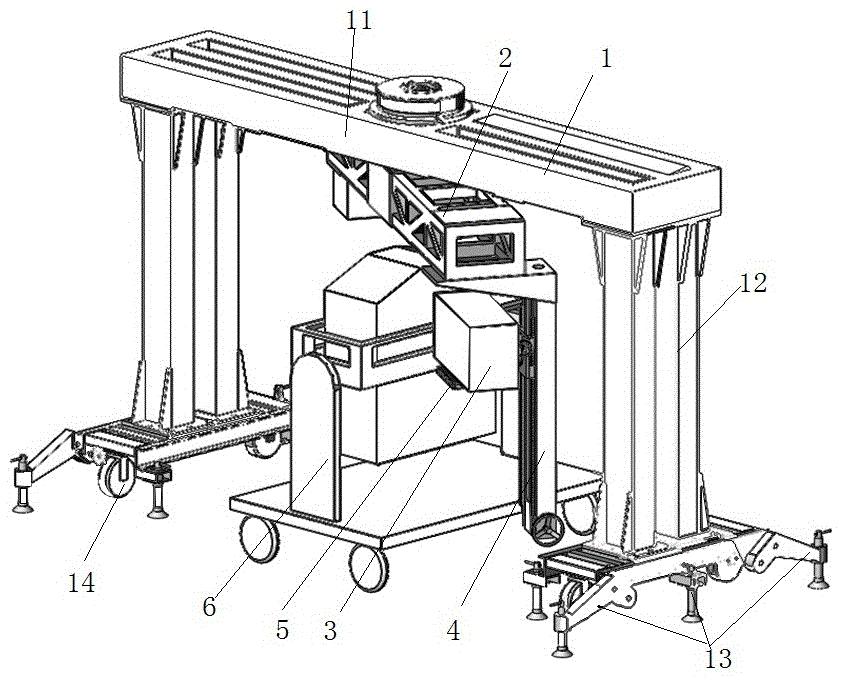

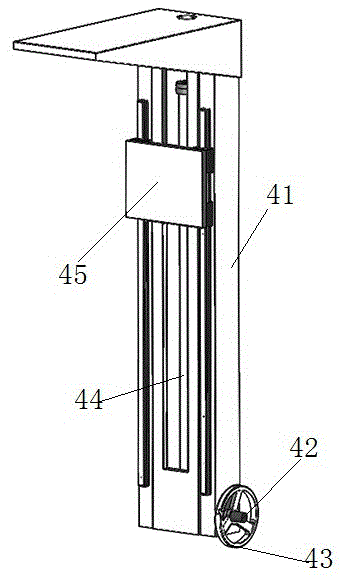

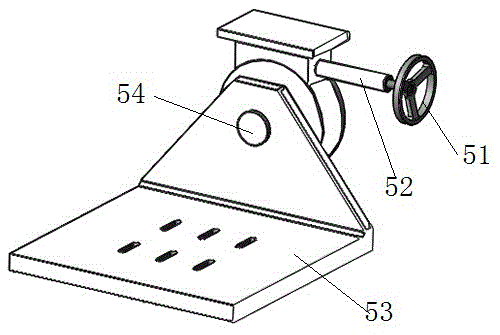

Dynamic target tracking accuracy test device for photoelectric detection equipment

ActiveCN105589062ASmall volume limitImprove versatilityWave based measurement systemsCantilevered beamEngineering

The invention relates to a dynamic target tracking accuracy test device for photoelectric detection equipment. The device comprises a target source arranged to orient towards to-be-tested photoelectric detection equipment, a door-shaped framework with an upper crossbeam. The part of the upper crossbeam, corresponding to the to-be-tested photoelectric detection equipment, is provided with a central rotation shaft capable of extending along the up-and-down direction. A cantilever beam is rotatably assembled at the coaxial position of the rotation shaft. The target source is arranged at the far-end part of the cantilever beam that is far away from the central rotation shaft. The cantilever beam is capable of driving the target source to conduct the circumferential revolution within the range of the door-shaped framework. During usage, the to-be-tested photoelectric detection equipment is placed below the lower crossbeam of the door-shaped framework, so that a large installation space is easily provided. The device has little limitation on the size of the to-be-tested photoelectric detection equipment, and good in generality. Meanwhile, the target source is driven by the cantilever beam to conduct the circumferential revolution. Therefore, a largest target tracking range is provided for the to-be-tested photoelectric detection equipment.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

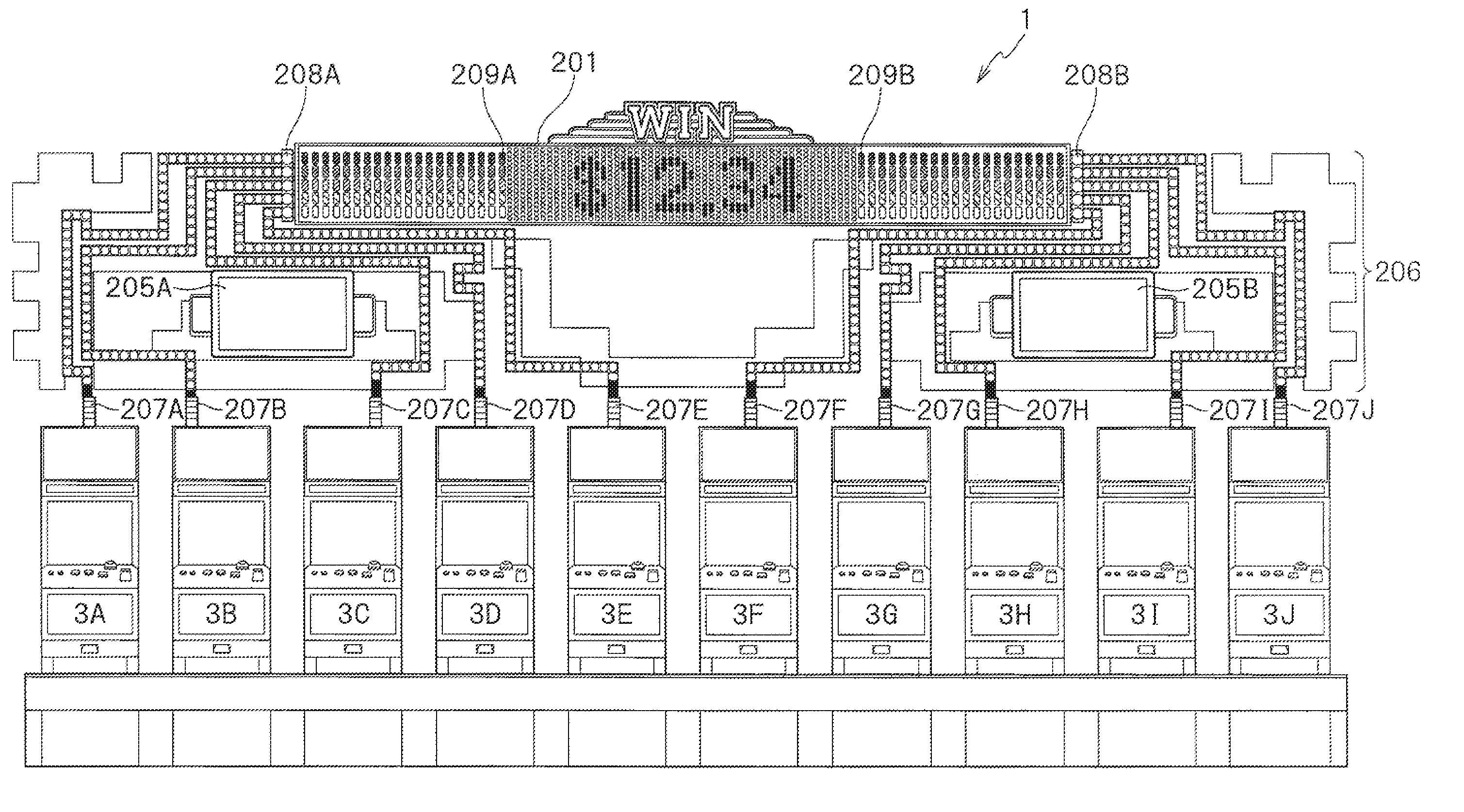

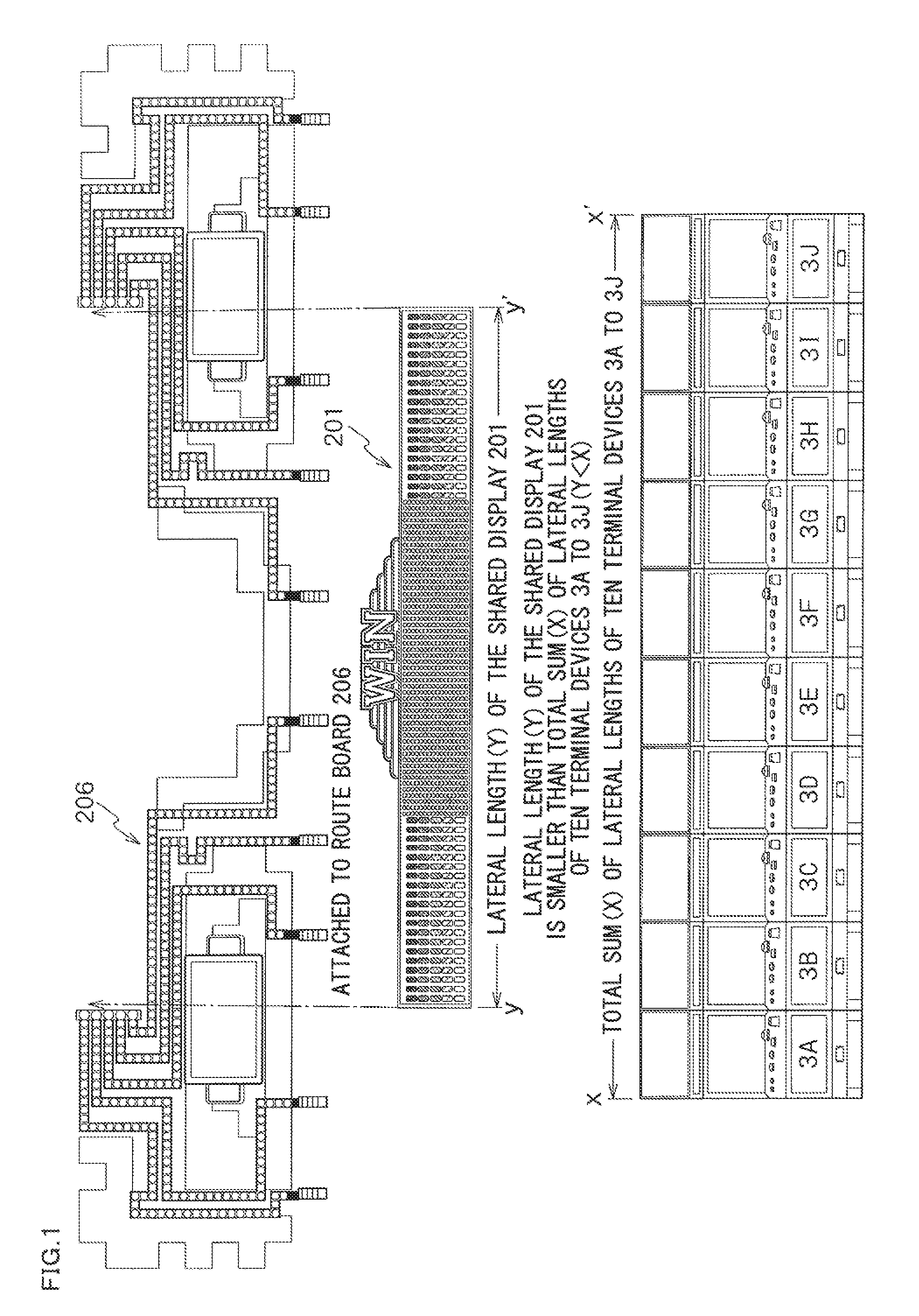

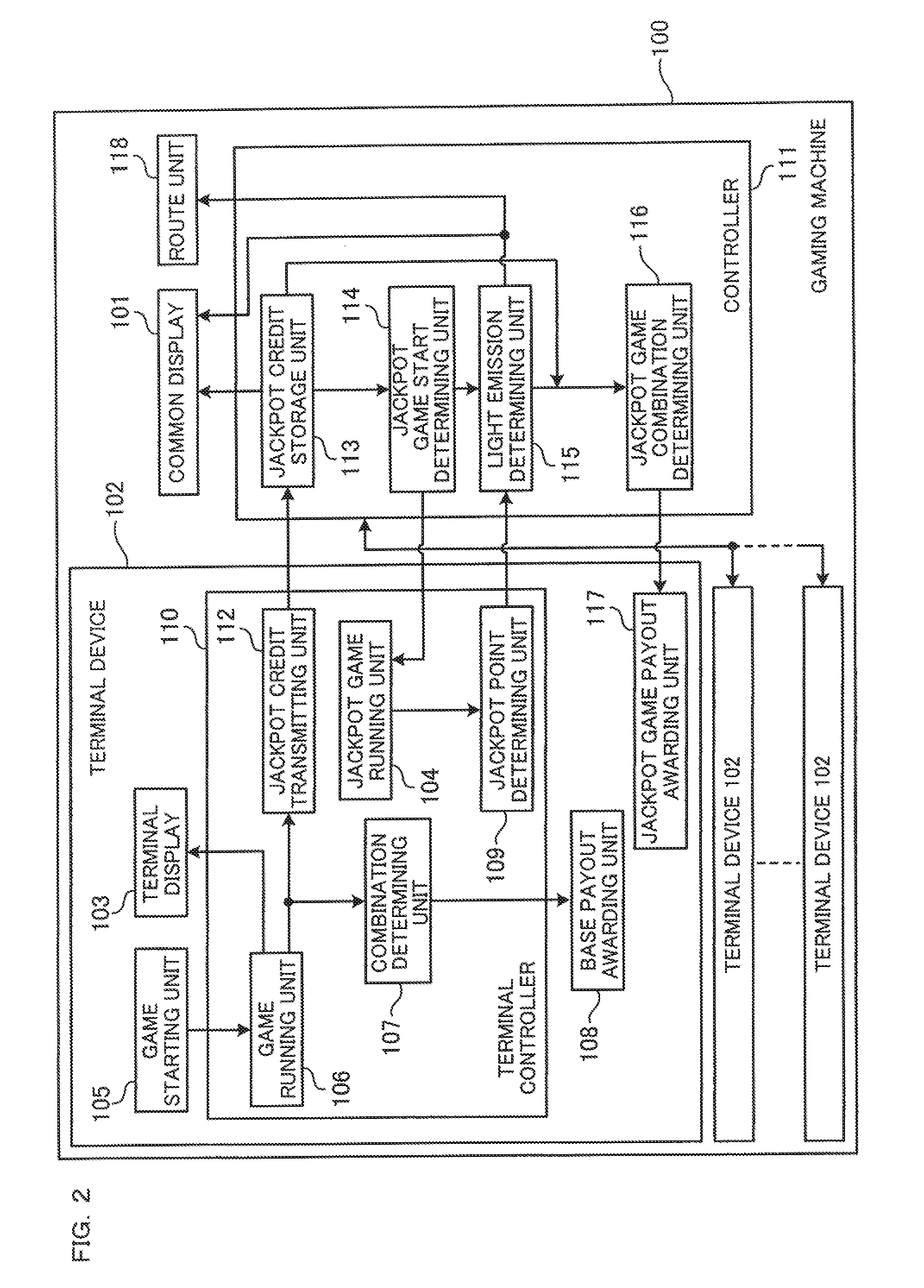

Gaming machine having a plurality of terminals and playing method thereof

InactiveUS20090312091A1Improve efficiencyLarge installation spaceApparatus for meter-controlled dispensingVideo gamesDisplay deviceTerminal equipment

A gaming machine of the present invention is configured to include: terminal devices each of which executes a base game with a game value being bet and awards a prize according to a predetermined winning; routes each formed by continuously disposing route light emitters from a corresponding terminal device out of the terminal devices to a common display; the common display having common display light emitters arranged in a matrix and route light emitters arranged so as to form several straight lines each acting as an extension route, the common display being attachably / detachably unitized with the routes; and a controller.

Owner:UNIVERSAL ENTERTAINMENT CORP

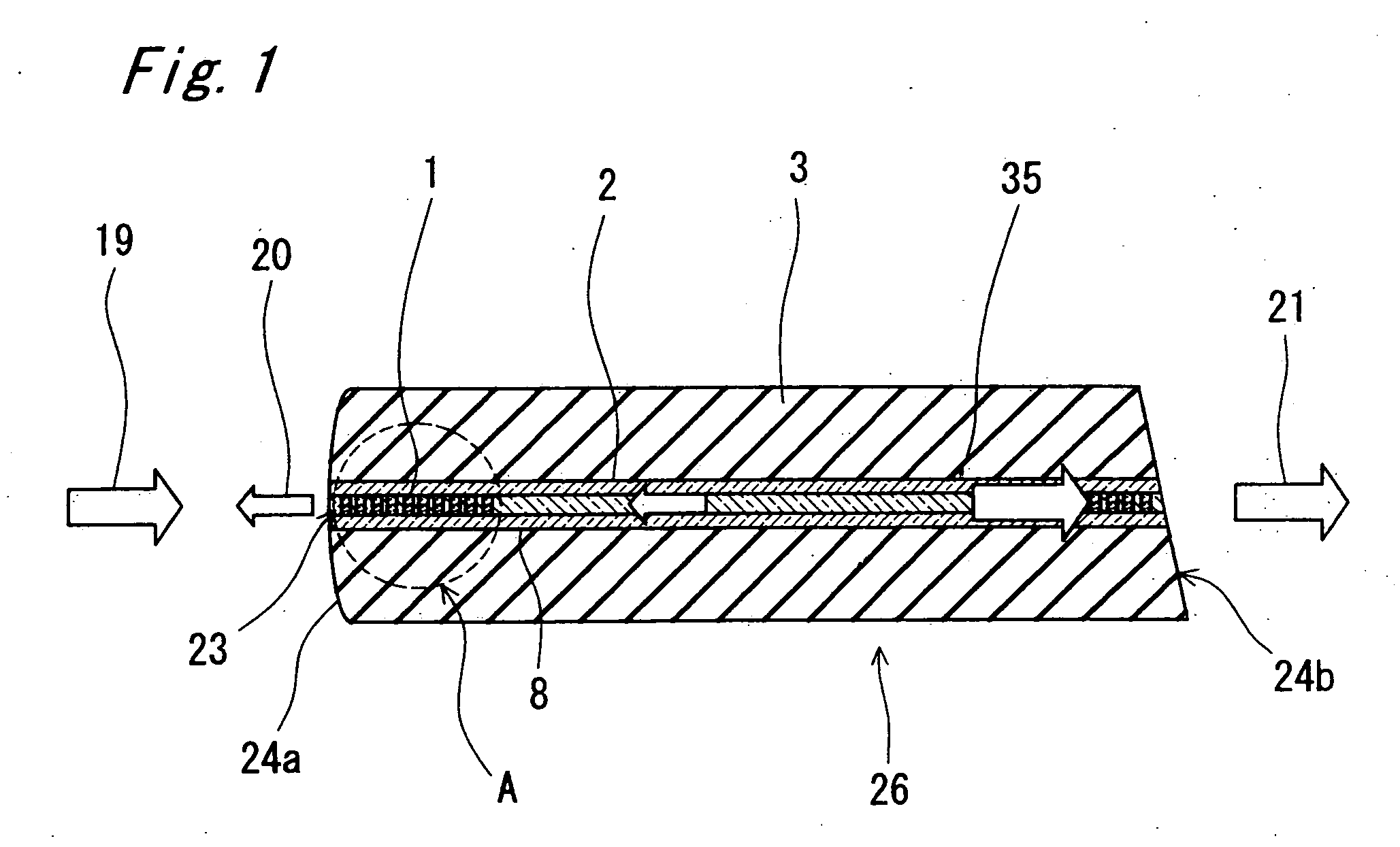

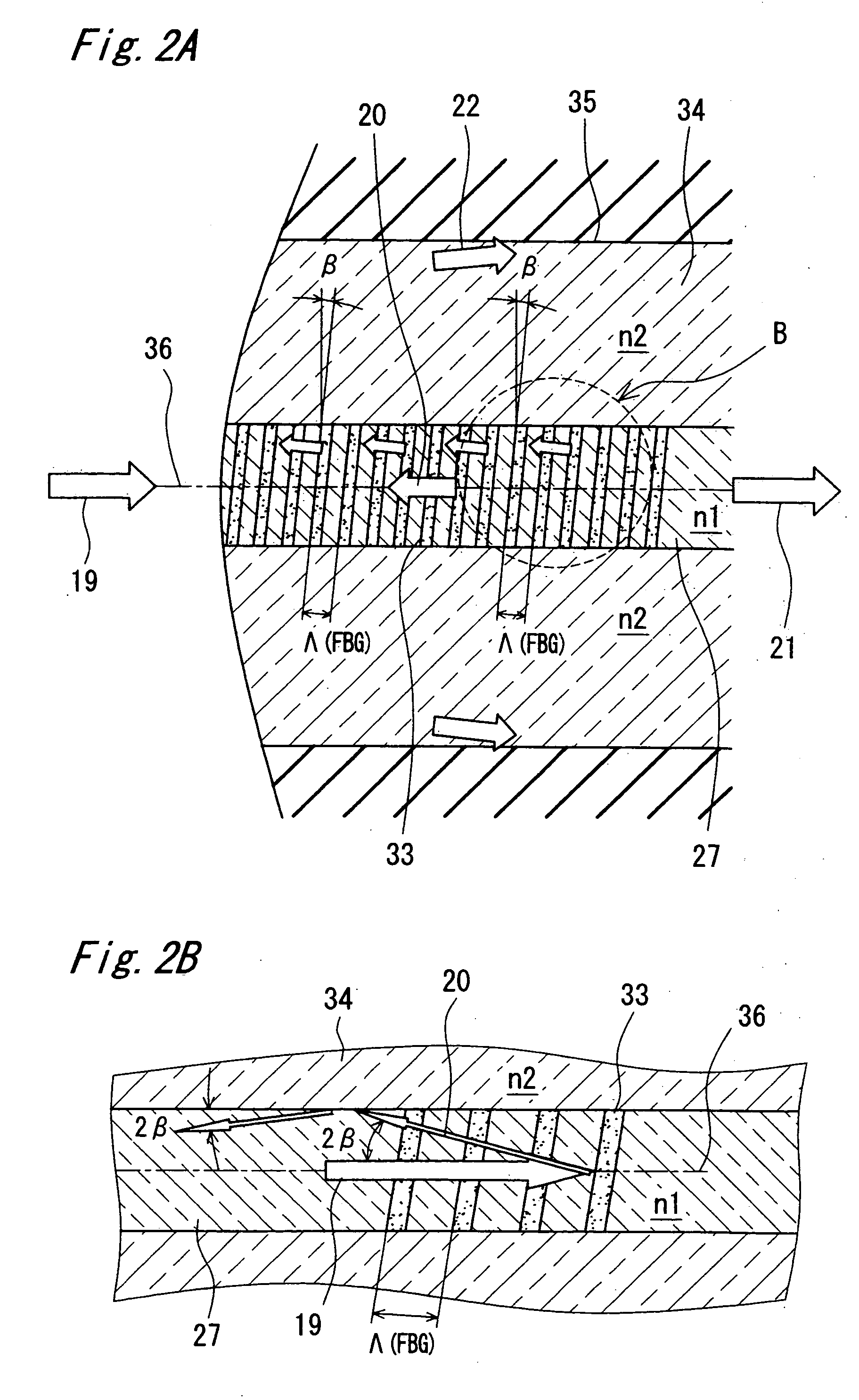

External resonator and semiconductor laser module using the same

InactiveUS20050220163A1Fabry-Perot resonation can be suppressedLarge installation spaceLaser optical resonator constructionCladded optical fibreFiberPhase grating

An external resonator is provided with a fiber having a fiber Bragg grating for reflecting light of a specific wavelength and a ferrule which holds the above described fiber inside thereof. At least some phase gratings from among the respective phase gratings that form fiber Bragg grating are inclined relative to the optical axis of the fiber.

Owner:KYOCERA CORP

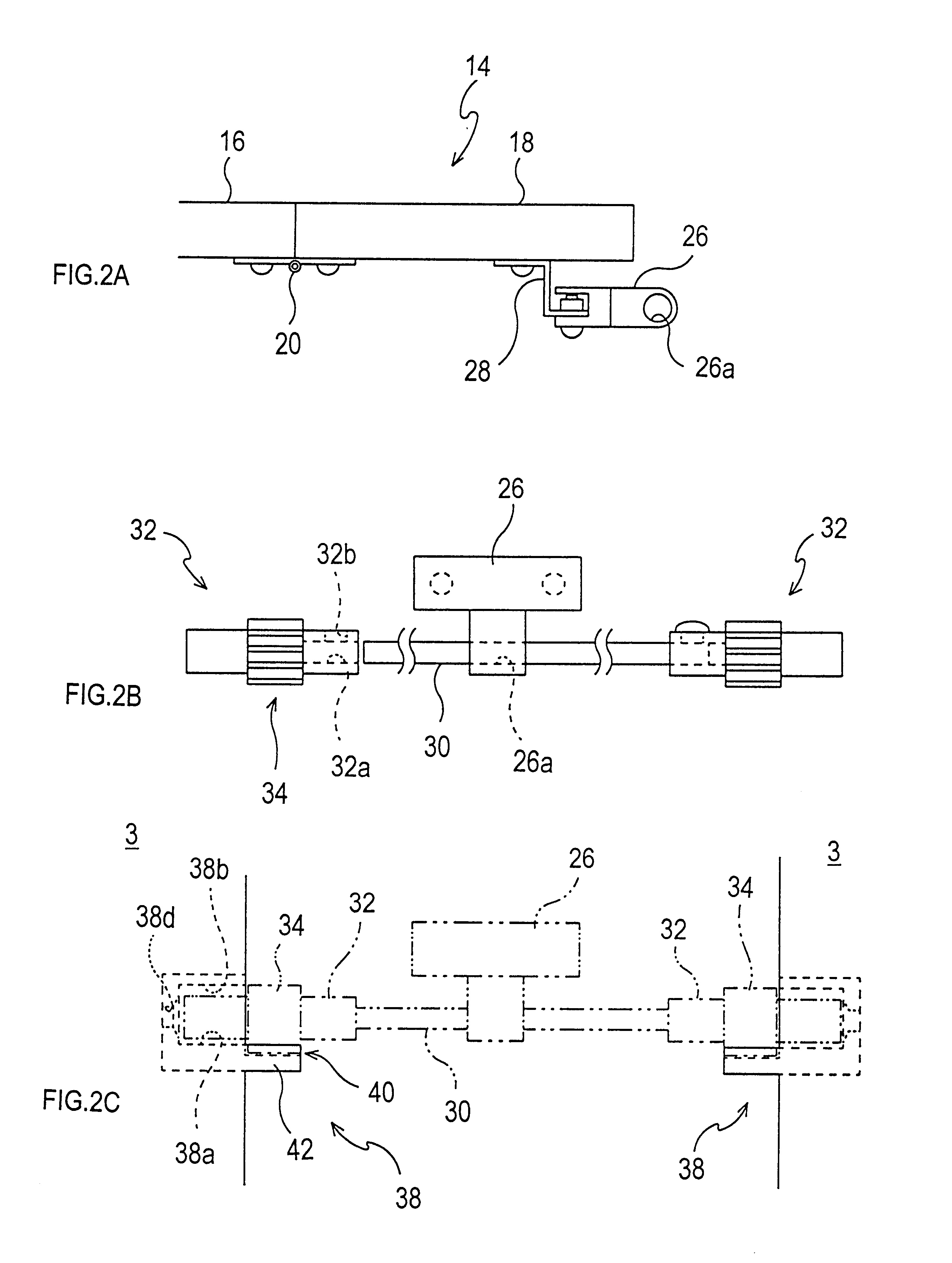

Extensible curtain rail

ActiveUS9617785B2Easy to installLarge installation spaceLight protection screensShow shelvesEngineeringMechanical engineering

An extensible curtain rail includes a rail main body, more than one connection seat and a decorative panel. The decorative panel and the rail main body are assembled and connected with each other by means of the connection seat. The connection seat can be inward contracted or outward extended to adjust the gap between the decorative panel and the rail main body in accordance with different sizes of curtain assemblies to facilitate installation thereof. The decorative panel is detachable from the rail main body to provide larger installation space and more quickly install the curtain assembly.

Owner:CHOU TSER WEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com