Impeller full-automatic washing machine

A fully automatic washing machine, pulsator-type technology, applied in the field of washing machines, can solve the problems of affecting the washing effect of clothes, laundry cross-infection, etc., to achieve the effects of avoiding cross-infection, reducing assembly process, and saving washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

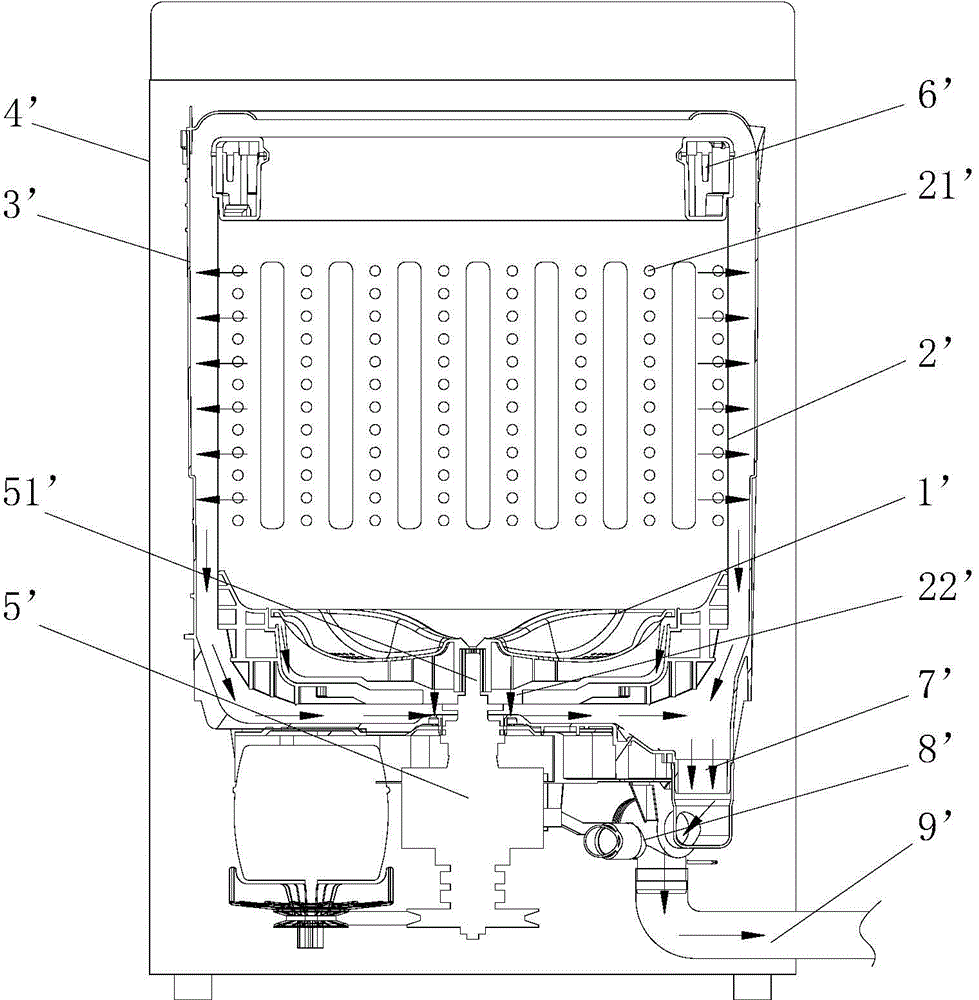

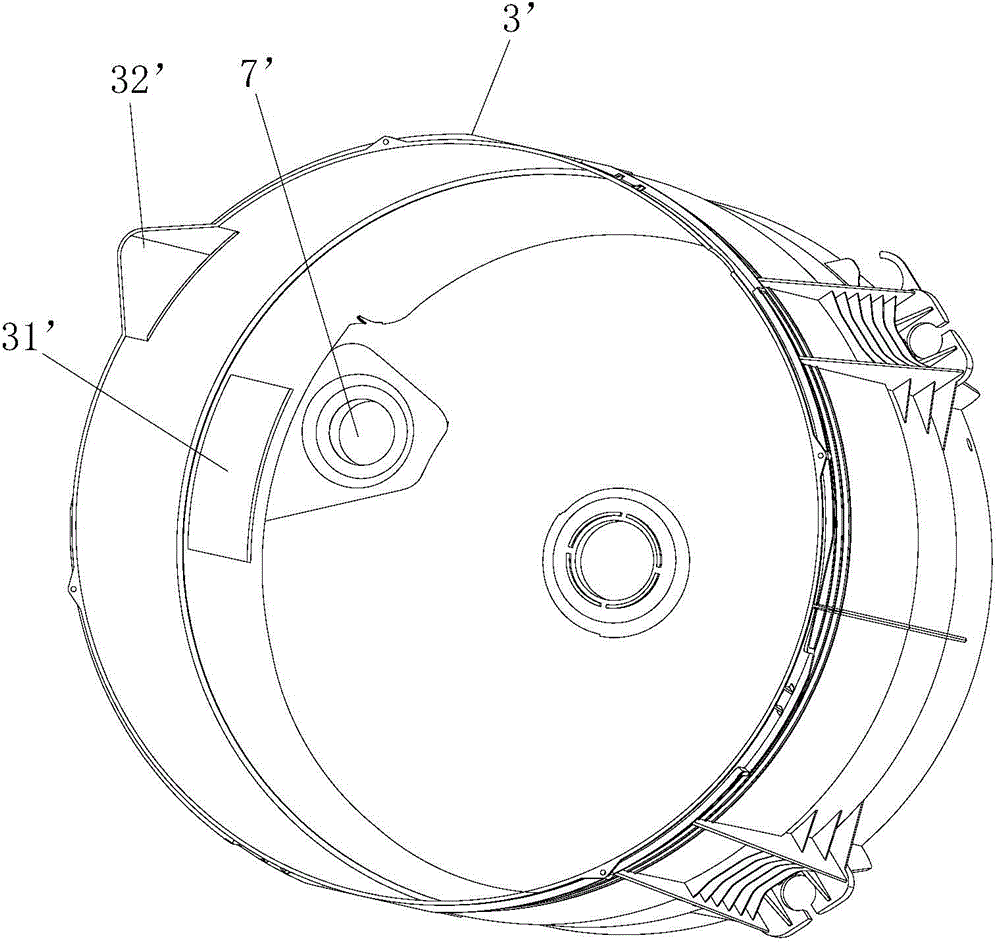

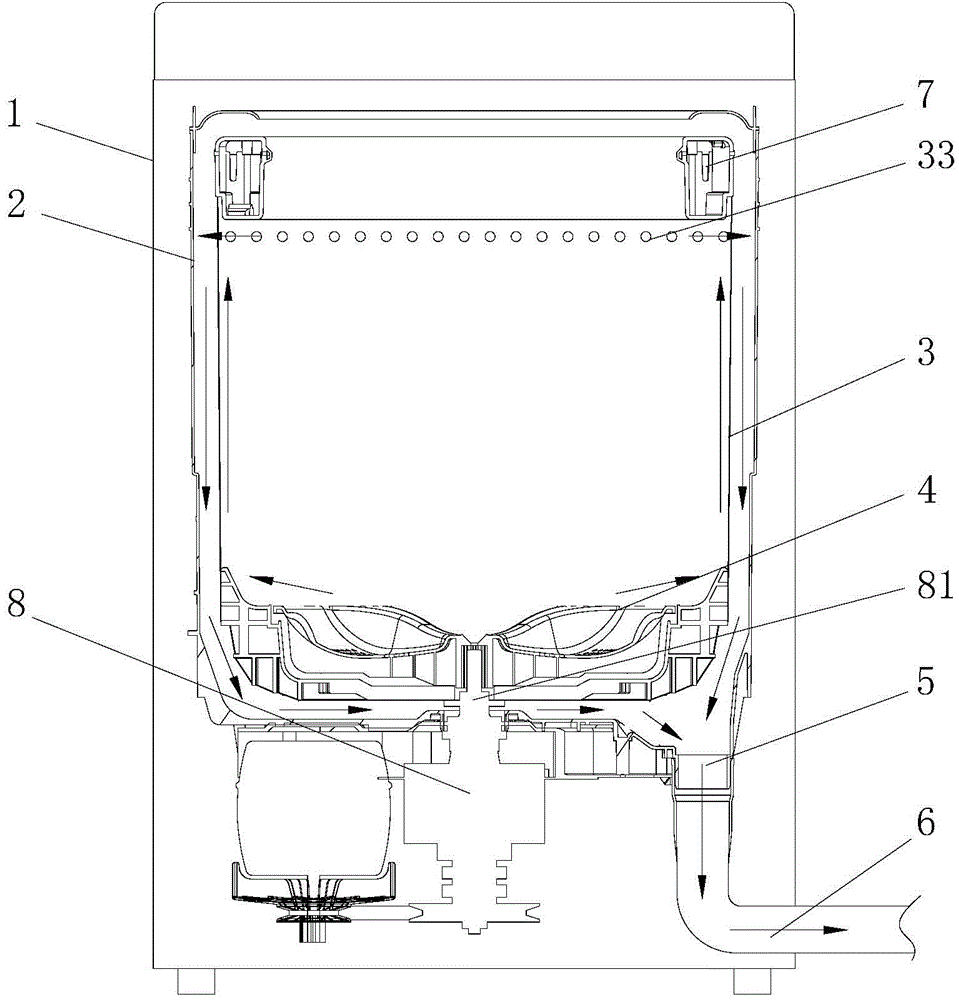

[0044] Such as Figure 4 As shown, there is no water outlet hole in the area between the position corresponding to the maximum water intake and the bucket bottom 32 on the bucket body 31 described in this embodiment, and a water outlet hole 33 is provided in the area between the bottom of the balance ring 7 and the position corresponding to the maximum water intake. The outer barrel 2 below is provided with a driving device 8, and the driving device 8 is connected with the inner barrel 3 and the pulsator 4 through its drive shaft 81.

[0045] The bucket body 31 and the bucket bottom 32 described in this embodiment are separate structures, and the two are sealed.

Embodiment 2

[0047] The difference between the present embodiment and the first embodiment is that the bucket body 31 and the bucket bottom 32 are integrally structured.

Embodiment 3

[0049] Such as Figure 5 As shown, the inner barrel 3 described in this embodiment has a circular frustum structure with a large opening at the top and a small opening at the bottom.

[0050] Alternatively, the angle α between the peripheral wall of the inner tub 3 and the vertical direction is 0-4°, preferably α is 1°-2°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com