Patents

Literature

121results about How to "Reduce washing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

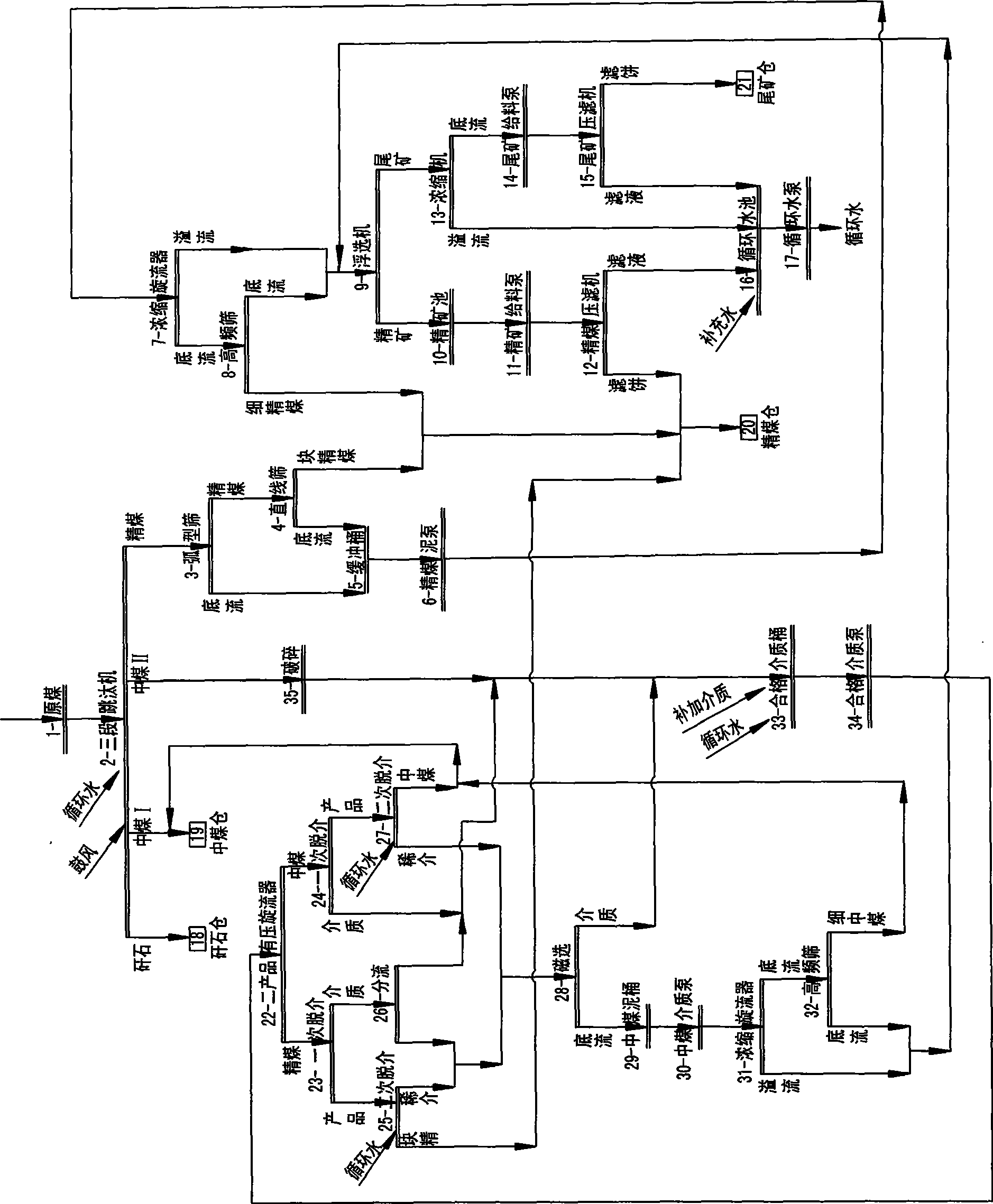

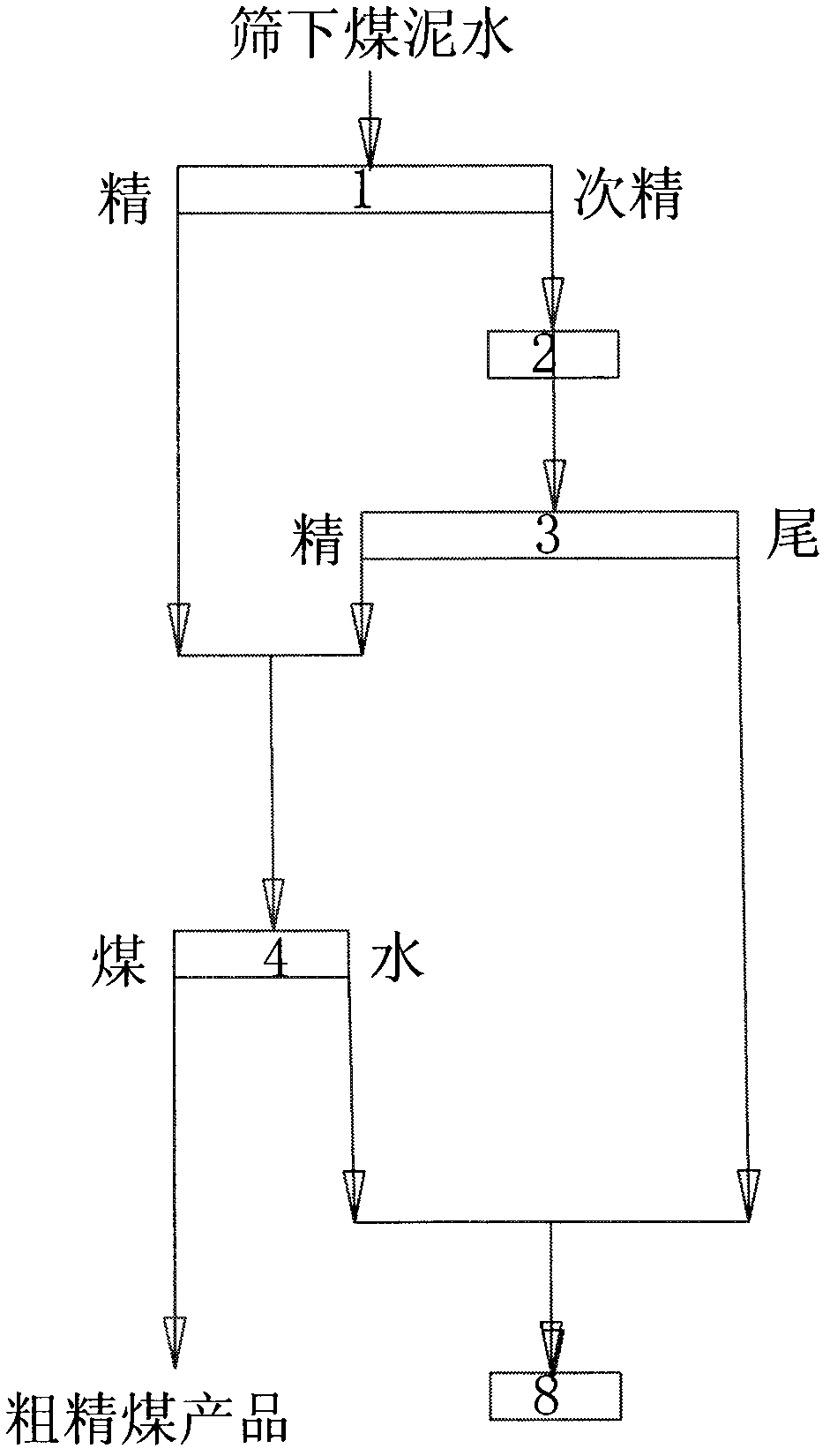

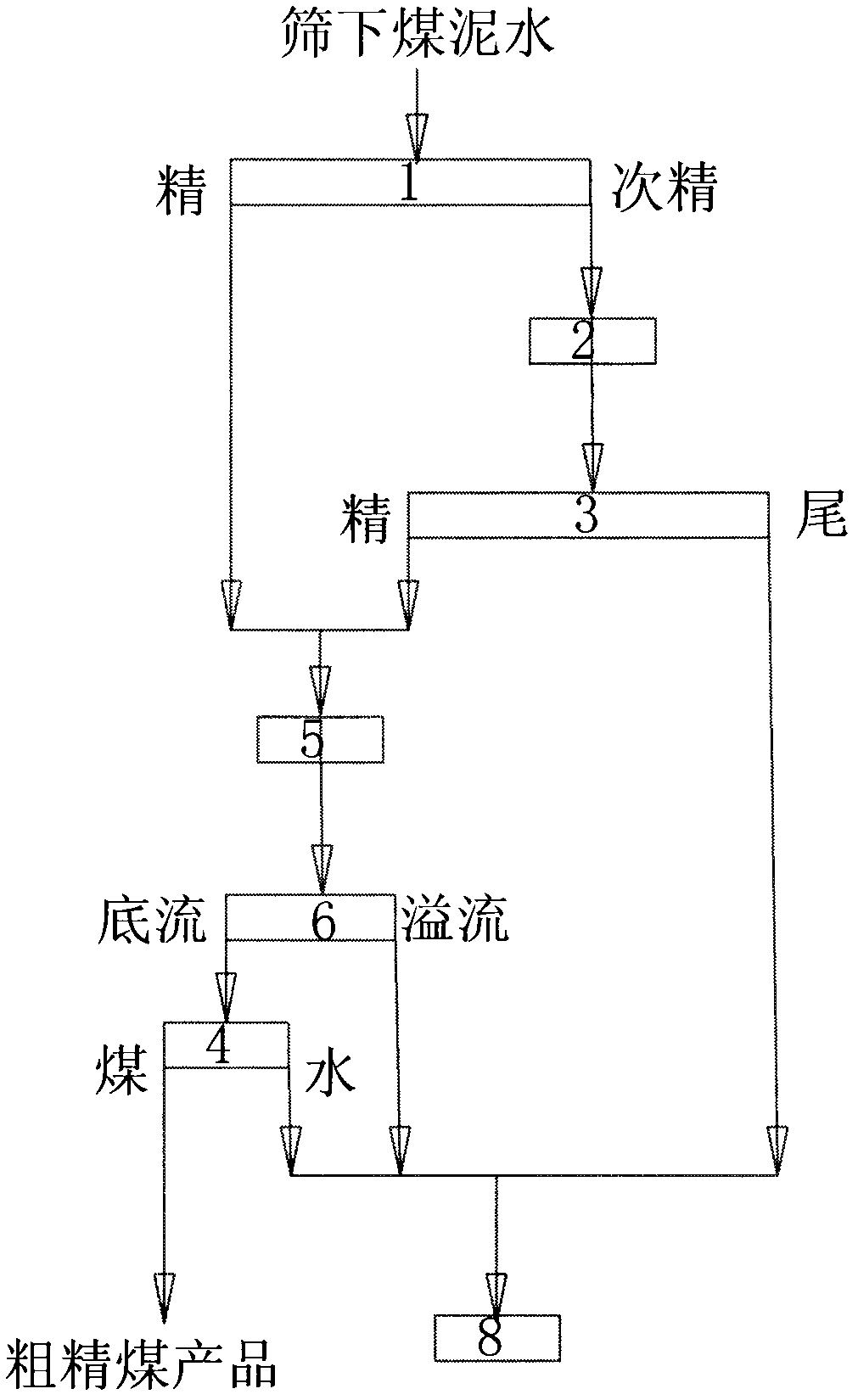

A coal dressing method and system of four-product jigging primary cleaning, secondary head coal small simplified heavy medium reelecting

ActiveCN101530824AReduce investmentLow operating costSievingScreeningTotal investmentSeparation technology

The invention discloses a coal dressing method and system of four-product jigging primary cleaning and secondary head coal small simplified heavy medium reelecting. The invention is a coal dressing method and system that selects the secondary head coal product through the four-product jigging technique and then reelects the secondary head coal with small simplify heavy medium separation technology. The adoption of the invention to select coal is characterized by less total investment, simpler system and lower operational expense, which can improve the stability of the system, reduce the powerconsumption, simplify the managing and maintaining work. The method can be easily realized with present technical merits, which is beneficial to be popularized in the middle and small coal washeries where the management level is low and if the method is used in oversize coal washeries, the cost for washing is lower.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

Efficient low-foam special cleaning agent for stainless steel plate

The invention discloses an efficient low-foam special cleaning agent for a stainless steel plate. The efficient low-foam special cleaning agent comprises the following components by weight percent: 5-10% of surface active agent, 0.2-2% of complexing agent, 1-4% of cleaning assistant, 1-4% of cosolvent, 1-4% of re-precipitating resisting agent, 0.2-2% of antifoaming agent, 2-5% of alkali metallic hydroxide, and the balance of deionized water. The cleaning agent provided by the invention is safe, reliable, environment-friendly, low in cost, convenient to transport and store and excellent in cleaning effect, and generates few foams during a cleaning process.

Owner:HAIMEN SENDA DECORATION MATERIAL CO LTD

Fabric detergent with colour-preserving function and preparation method thereof

InactiveCN101798552AReduced or diminished appearanceReduce or reduce lossesOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsBetaineN-Butanol

The invention provides a fabric detergent with colour-preserving function and preparation method thereof. The detergent contains sodium fatty alcohol ether sulphate, laurylamide propyl betaine, alkyl glucoside, fatty alcohol polyoxyethylene (9) ether, sodium alpha-olefin sulphonate, 3-methooxyl-3-methyl-1-butyl alcohol, 1-vinyl pyrrolidone, 1-vinyl copolymer, sodium chloride, 1, 2-benzisothiazolin-3-one, essence, citric acid monohydrate and deionized water. The invention obtain favourable detergency in clothing washing process while realizing colour-preserving effect; the detergent is environmentally friendly, cleaning and colour-preserving are completed in one step, the detergent is non-toxic and non-irritant, and resource is saved.

Owner:北京绿伞科技股份有限公司

Integrated machine of washing vegetables, washing bowl, and disinfecting

InactiveCN101427891ASave electricityShorten washing timeKitchen equipmentTableware washing/rinsing machinesWater flowKitchen utensils

An integrative machine with functions of vegetable washing, dish washing and disinfection solves the problems of repeated expenditure and large occupied area of the prior separated vegetable washing machine and dish washing machine. The integrative machine is characterized in that two buckles are arranged on the left side of the upper end of a moving basket bracket; two pins are respectively arranged on the front and the rear sides of the left end of the moving basket bracket; an exhaust fan is fixed on the upper part of a housing and is communicated with a sealed chamber; the air inlet of a one-way air discharge door is fixed on the air outlet of the exhaust fan; and the air outlet of the one-way air discharge door is connected with an exhaust pipe. The fruits and vegetables can be washed by swaying and rotating the basket for the first time and then by swaying and sprinkling the basket for the second time. Water droplets on the washed dishes can be blown off by the fan, and the dished can be dried by a FIR drying device. No dead corners are present for the UV rays and the ejected water flow due to the swaying of the dish washing basket.

Owner:宋大伟

Impeller full-automatic washing machine

PendingCN105463790AReduce deliveryAvoid cross infectionOther washing machinesTextiles and paperImpellerWater discharge

The invention discloses an impeller full-automatic washing machine comprising an external barrel, an internal barrel disposed in the external barrel and an impeller disposed in the internal barrel. A drainage port is arranged on the bottom of the external barrel; the washing machine does not have a draining valve; the drainage port of the external barrel is directly communicated with a drain pipe; during washing and rinsing, washing water is only accommodated in the internal barrel and the external barrel contains no washing water; during dehydration, the washing water passes through the external barrel, the external barrel drainage port and the drain pipe from the upper part of the internal barrel and then is directly discharged; during water inlet, water is only charged into the internal barrel; after washing is finished, the internal barrel is driven to rotate at high speed to produce centrifugal force; water in the internal barrel and water in the clothes spirally rise and are discharged out of the external barrel via water discharging holes of the internal barrel; and the water can be directly discharged via the drain pipe. Without the draining valve, assembling technology of the external barrel components can be reduced, installation space of a barrel bottom driving device can be increased and cost can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Fabric softener with bactericidal function and preparation method thereof

ActiveCN101514305ASolution synergiesFix stability issuesCationic surface-active compoundsFibre treatmentSolubilityFatty alcohol

The invention relates to a fabric softener with bactericidal function and a preparation method thereof. The fabric softener comprises the following components in portion by weight: 4.5 to 10 portions of quaternary amine ester (C18), 1 to 3 portions of dialkyl quaternary ammonium salt (C8-10), 1 to 2 portions of fatty alcohol polyoxyethylene ether (5), 0.5 to 1.5 portions of fatty alcohol polyoxyethylene ether (7), 0.1 to 0.5 portion of essence, 0.05 to 0.3 portion of citric acid, and 82.7 to 92.8 portions of deionized water. The fabric softener has good solubility and good softness, protects the fabric, has strong sterilizing power, and can reduce washing cost.

Owner:北京绿伞科技股份有限公司

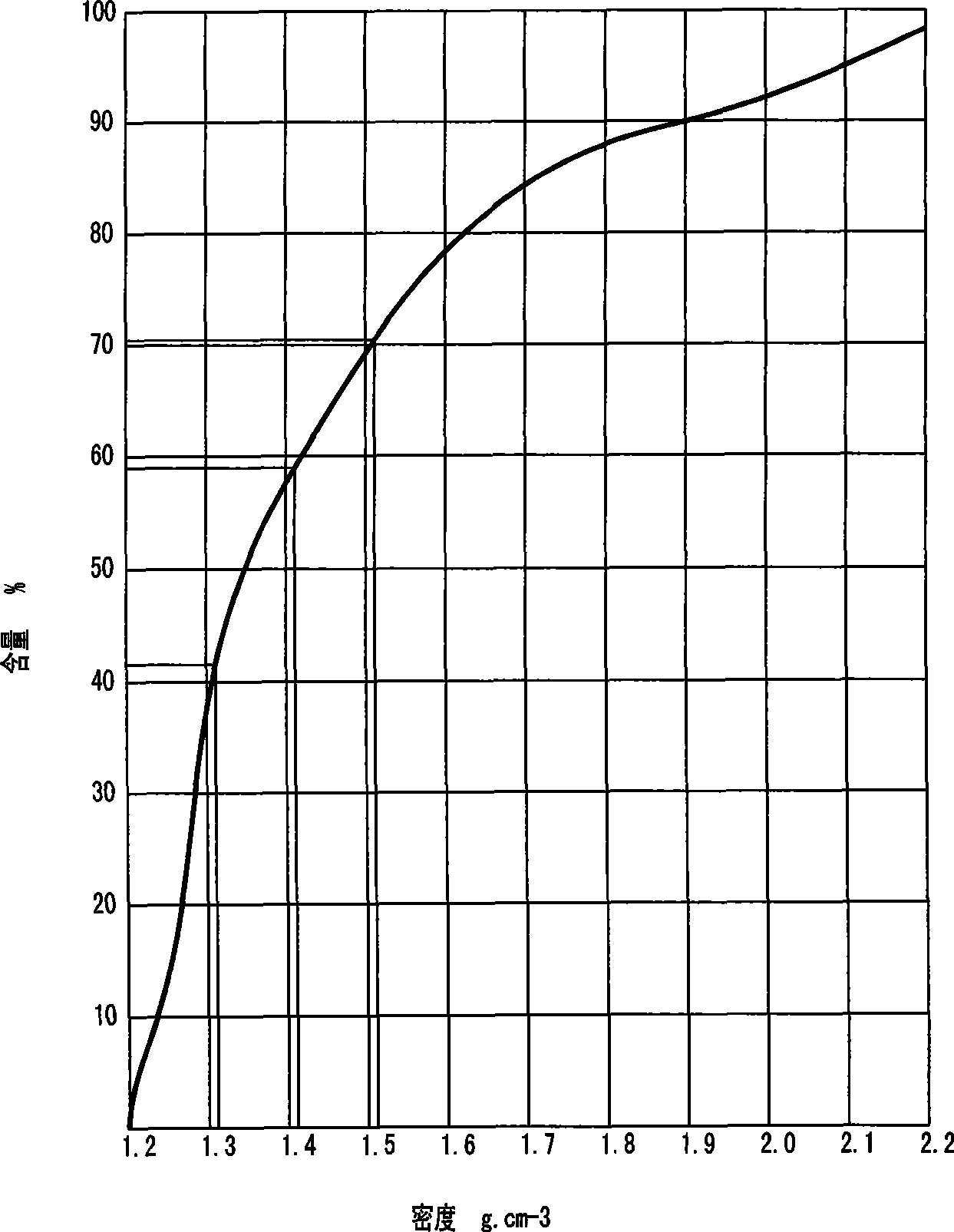

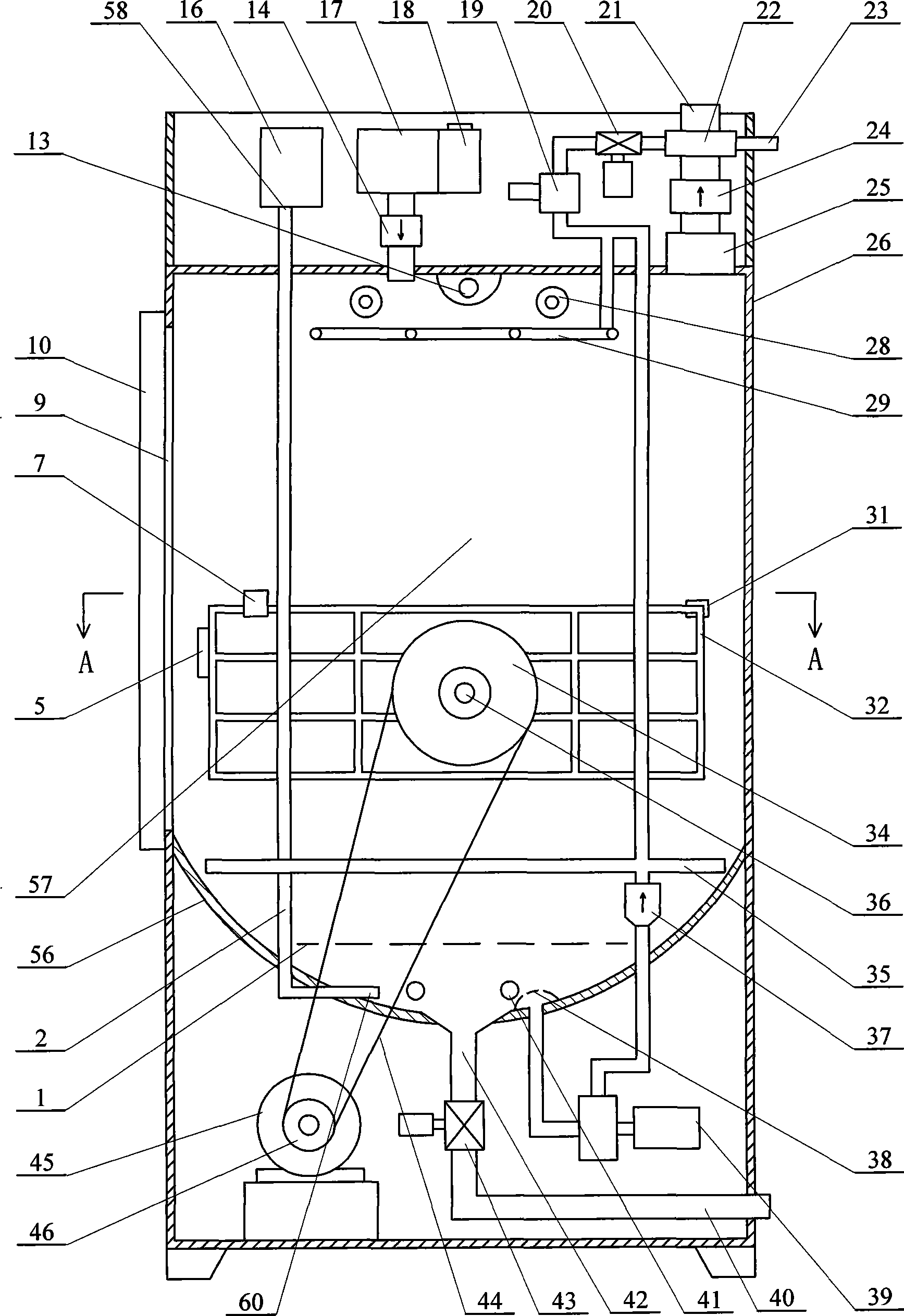

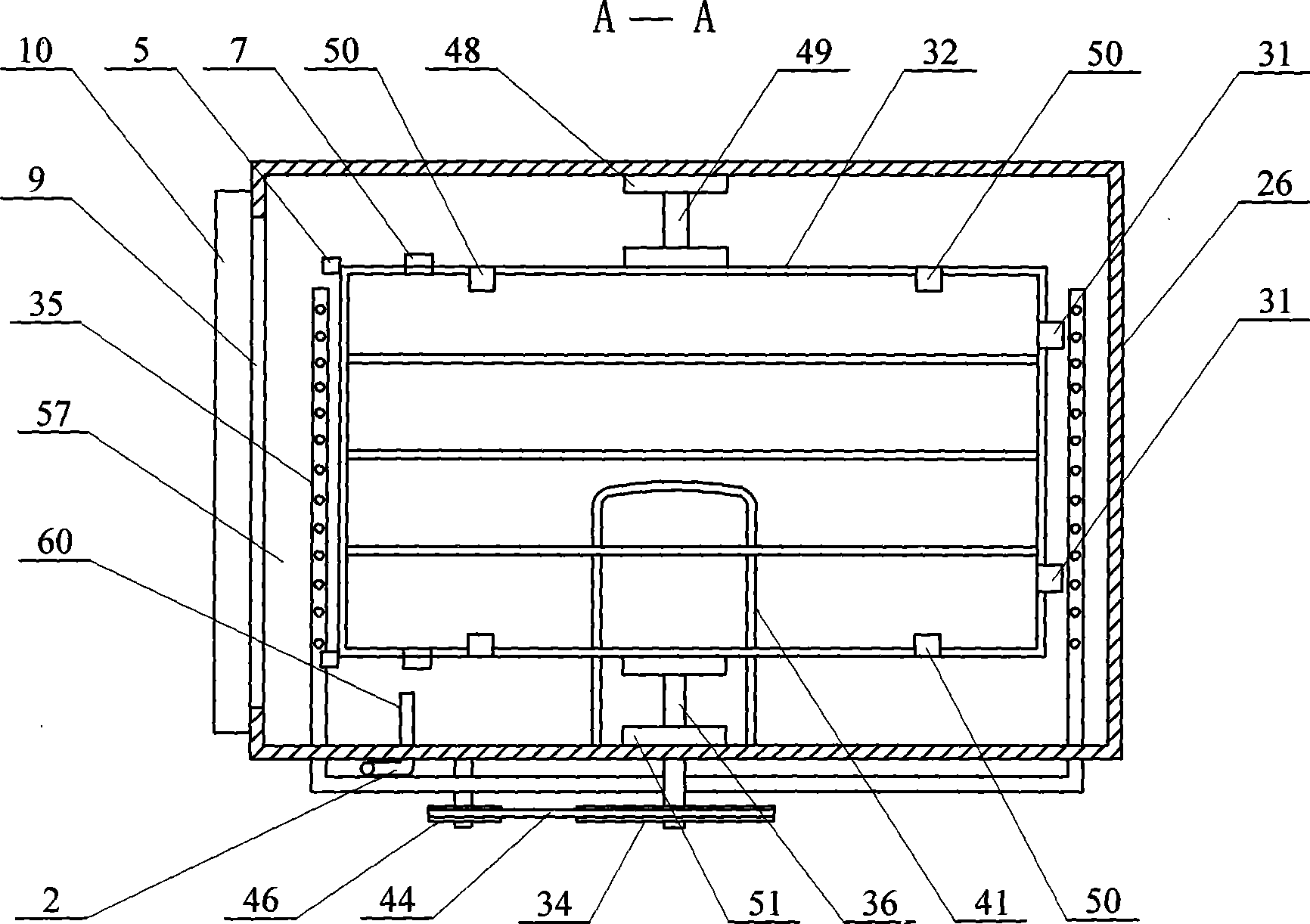

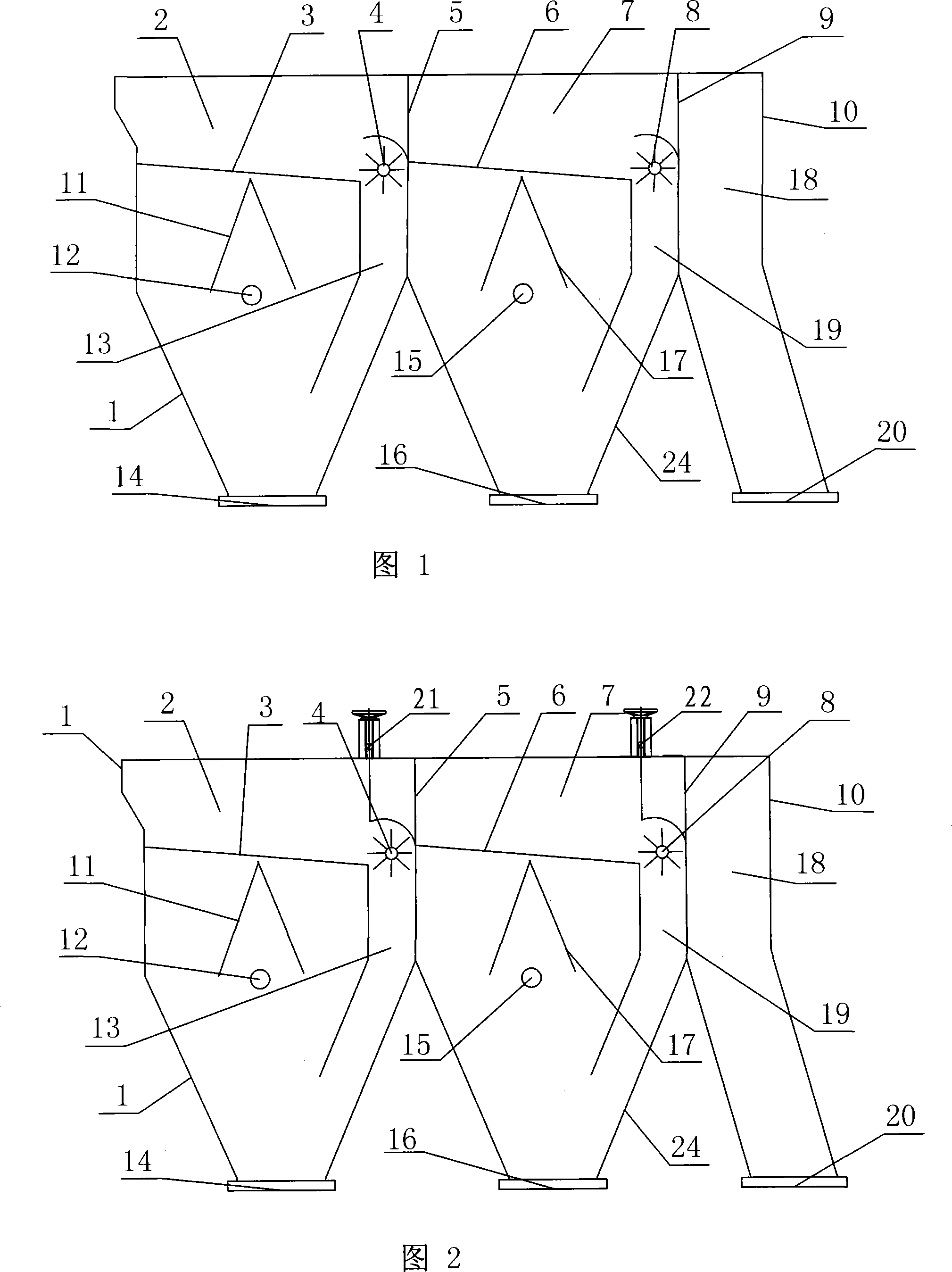

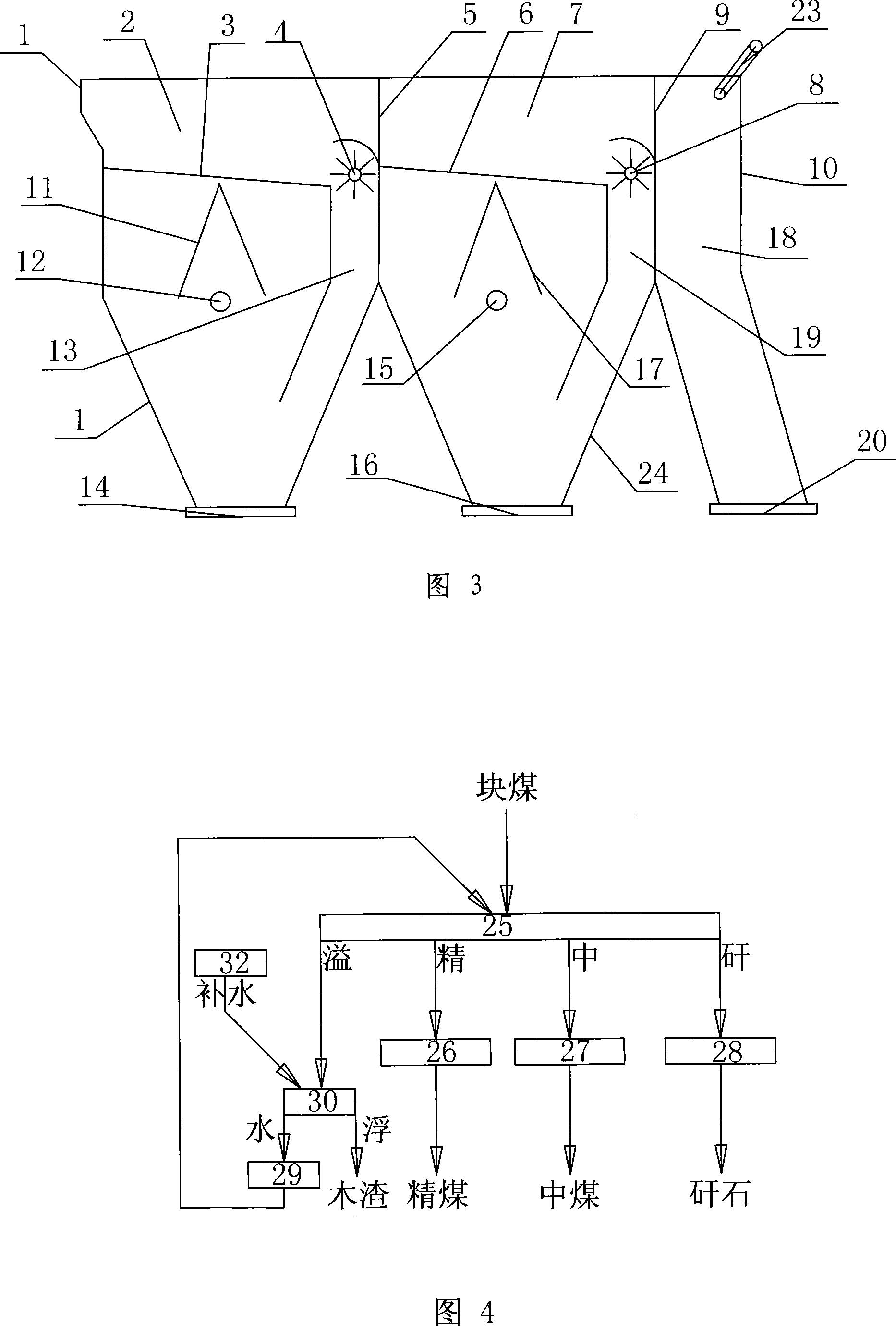

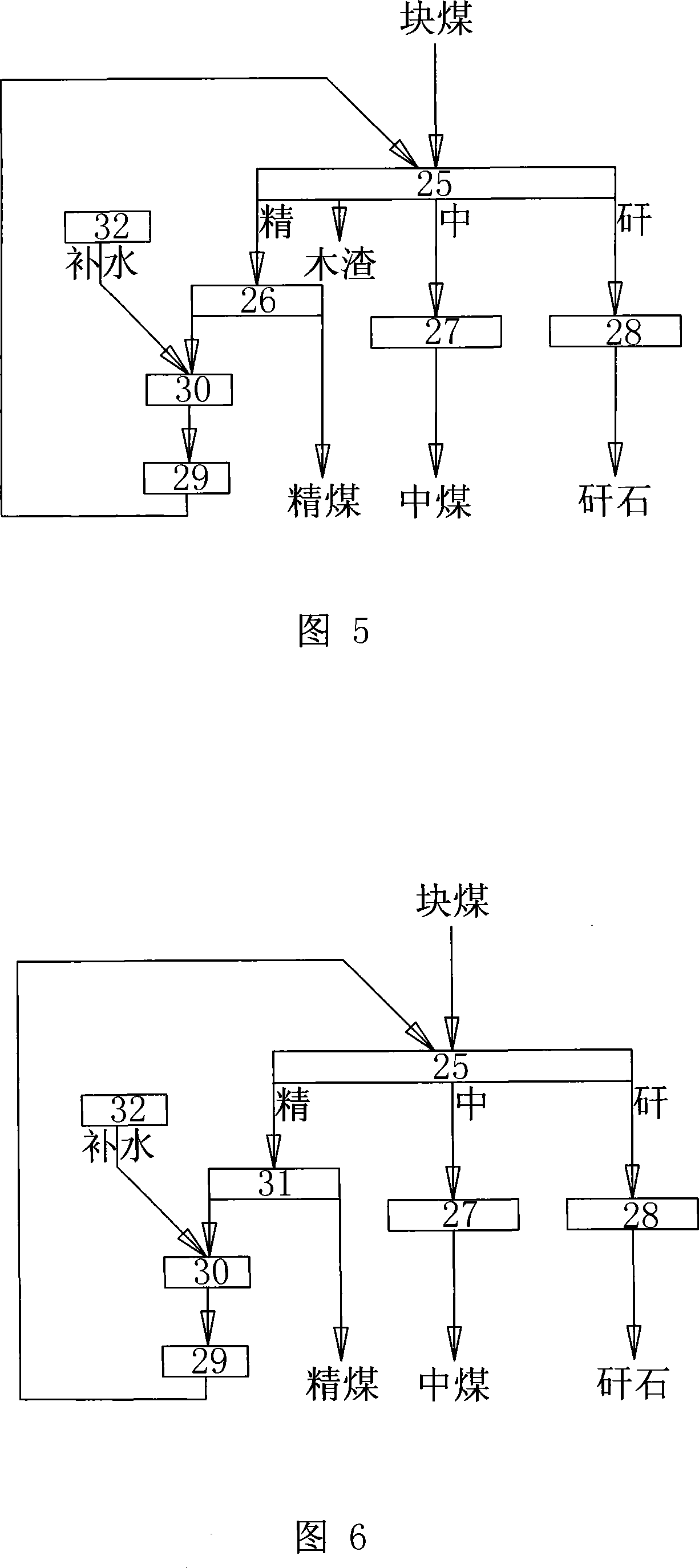

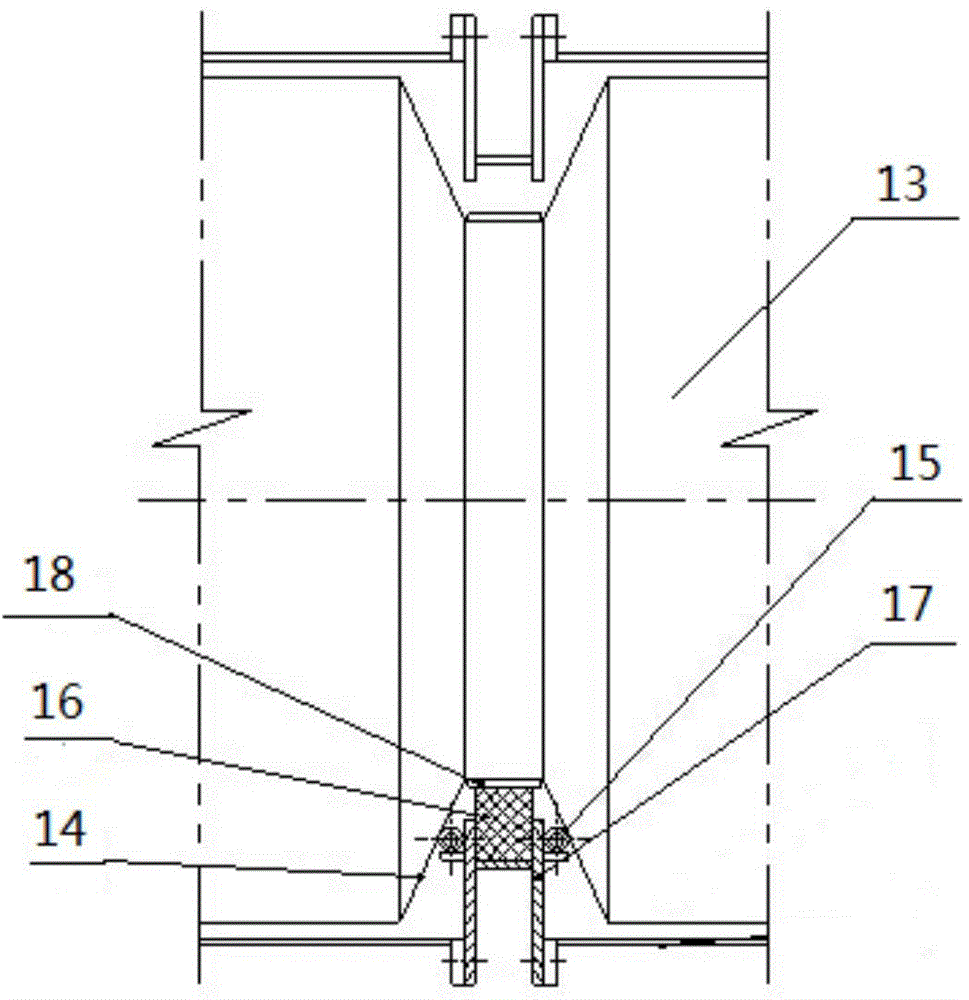

Torbanite washbox, coal separation system and coal separation method thereof

InactiveCN101185912AUse less waterReduce or eliminate top waterWet separationWater savingProcess engineering

The invention discloses a coal block jigger, a coal selection system and a coal selection method, which belongs to coal jigging selection field and is more particularly suitable for select coal blocks. The coal block jigger of the invention is formed by multiplying the inclined angle of a filter board of the existing multi-section jigger and changing a overflow spillway into a clean coal outlet passage; the coal selection system of the coal block jigger comprises the coal block jig, a rock refuse bucket elevator, a middling bucket elevator, a clean coal bucket elevator, a recycling water bucket, a recycling water pump, a water supply device and so on; and the coal selection of the coal block jigger can one-time select rock refuse, middlings, clean coal and a plurality of other products, and the water supply amount in selection is small. By adopting the invention to select coal blocks, processing amount can be increased, a great deal of water can be saved, washing and cleaning cost can be lowered, system steps can be simplified and system overall investment is reduced, thus achieving the effect that can not be achieved by the existing multi-section jigger. The invention is a brand new coal blocks selection jigger, a coal selection system and a coal selection method, which can be used for selecting steam coal and can also substitute dense medium vertical wheelers and inclined wheelers for coal block selection.

Owner:唐山易通科技开发有限公司

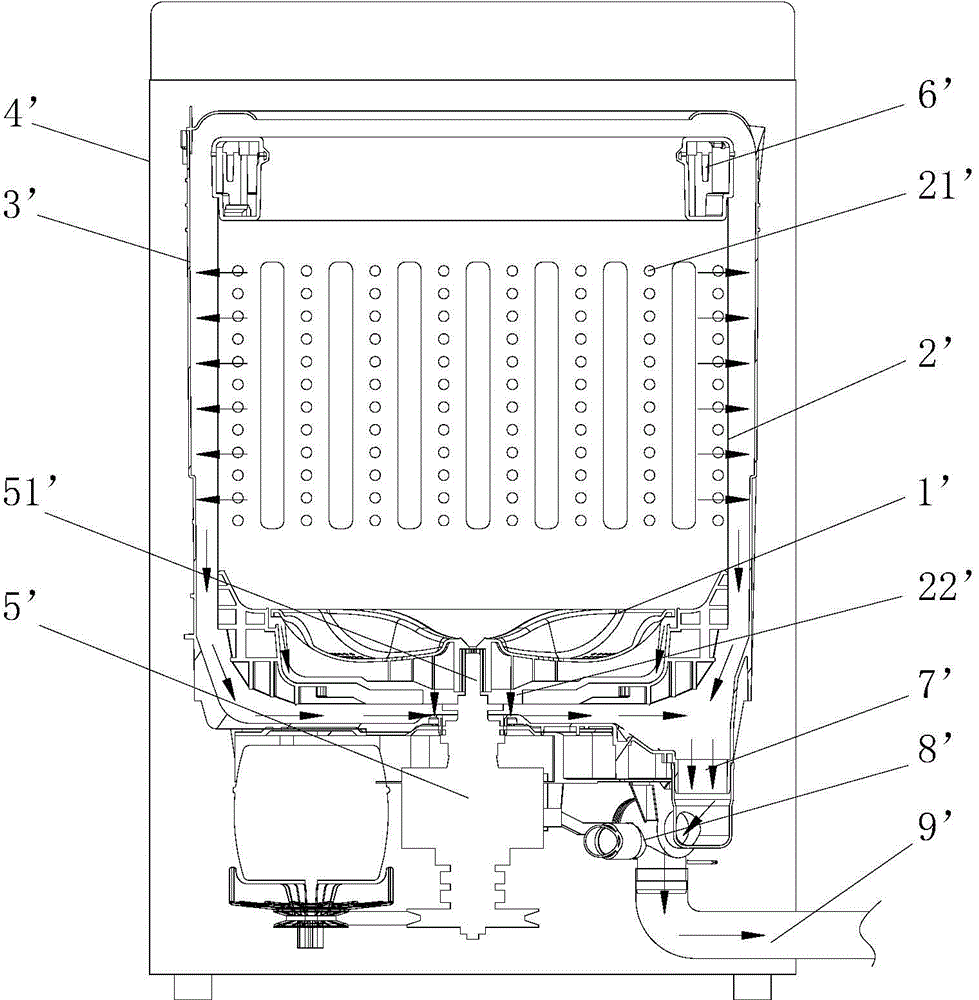

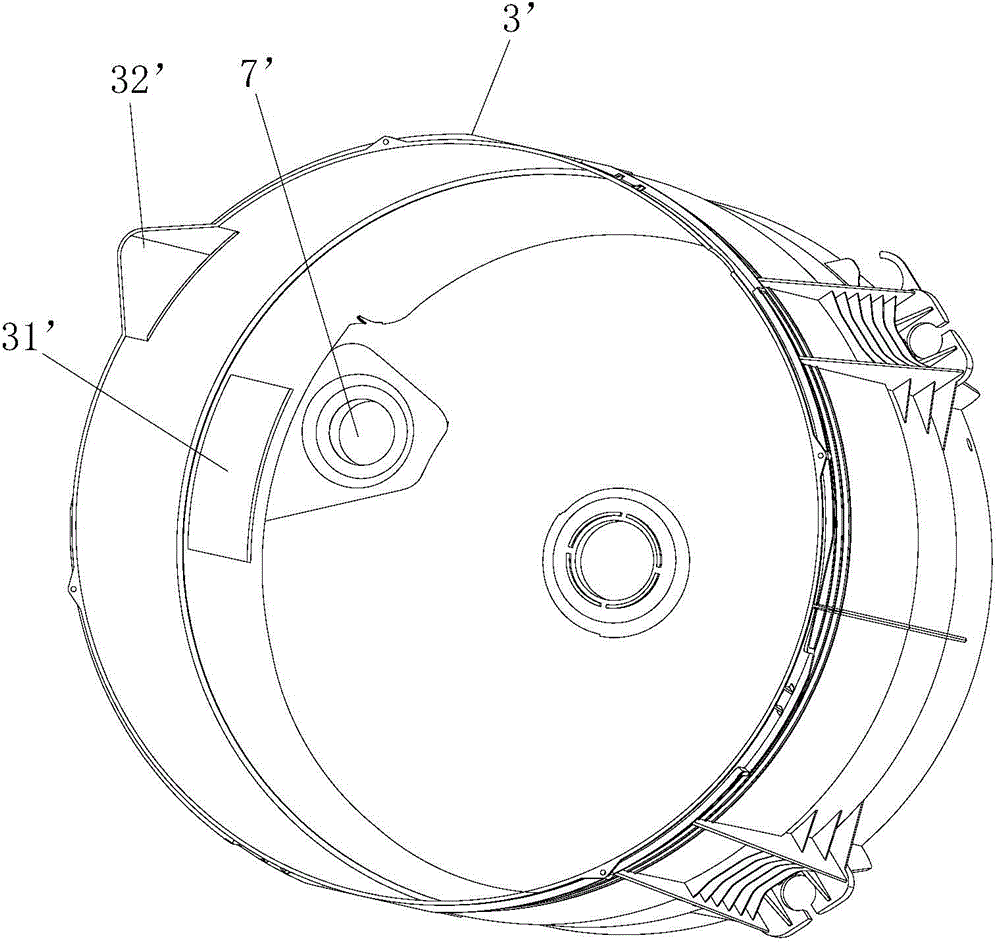

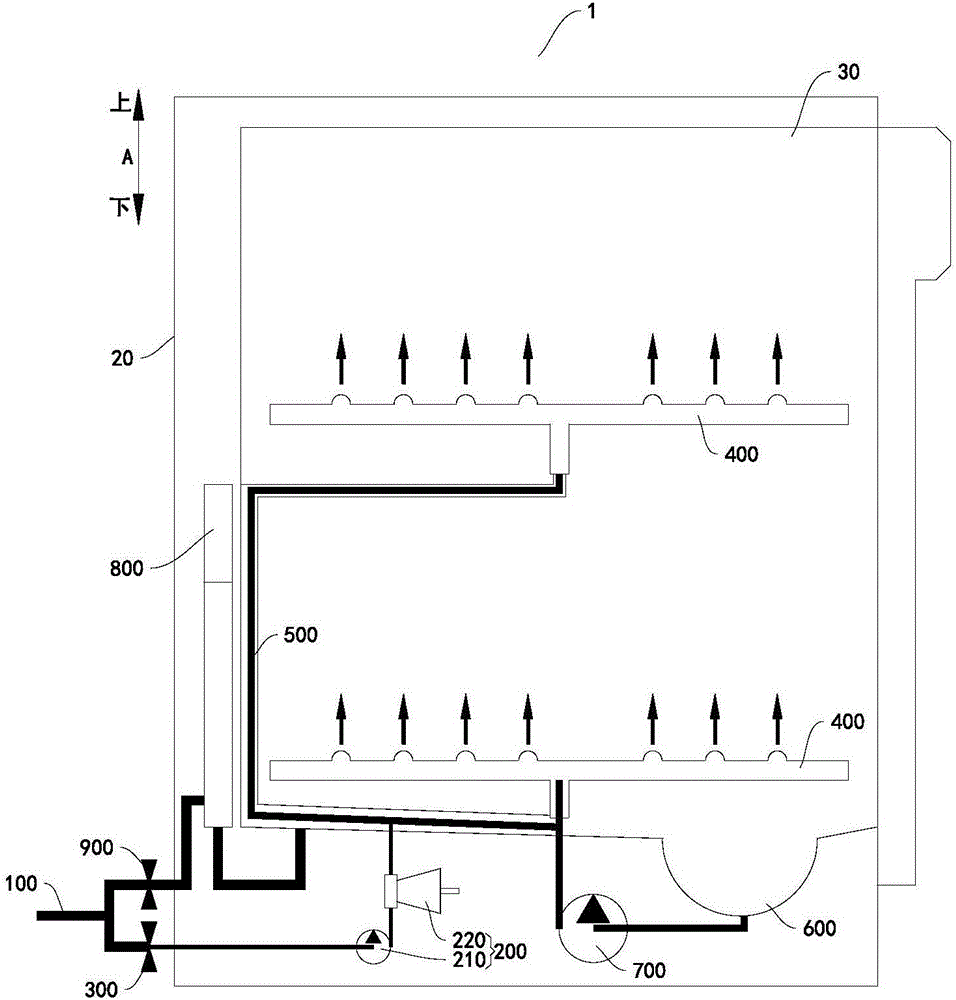

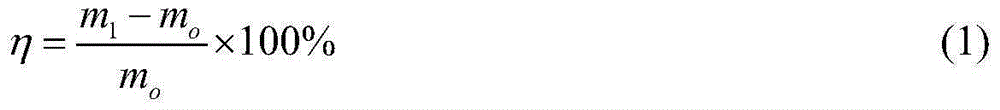

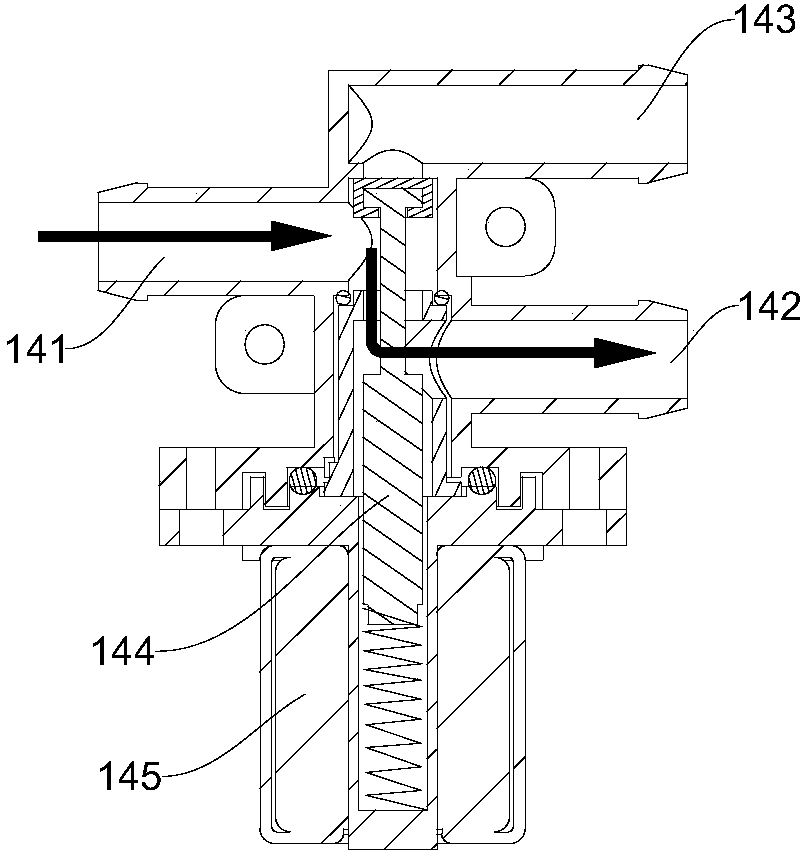

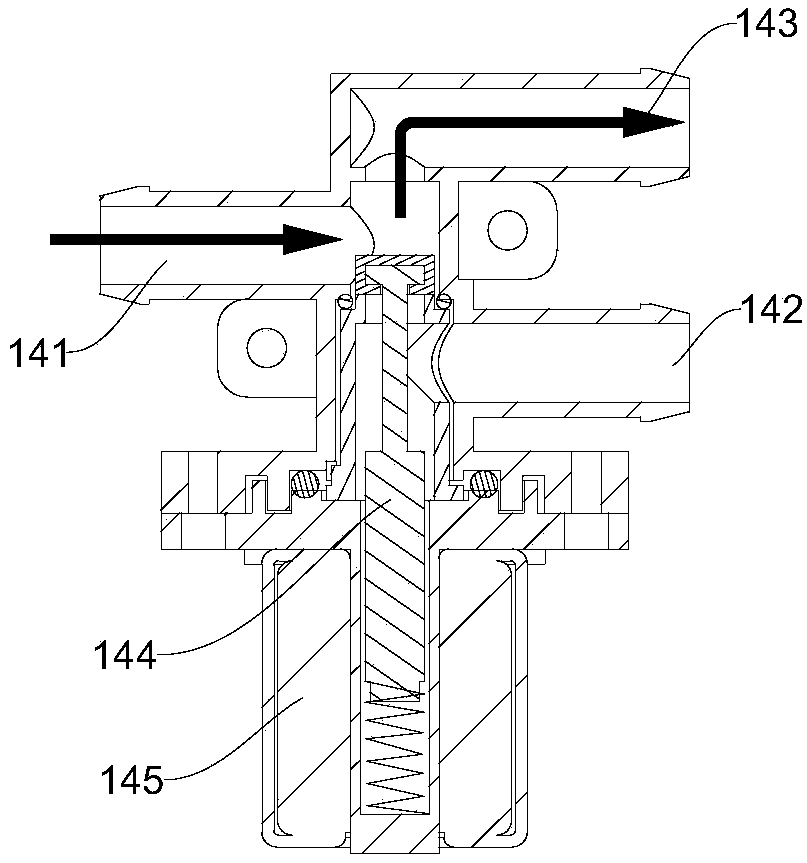

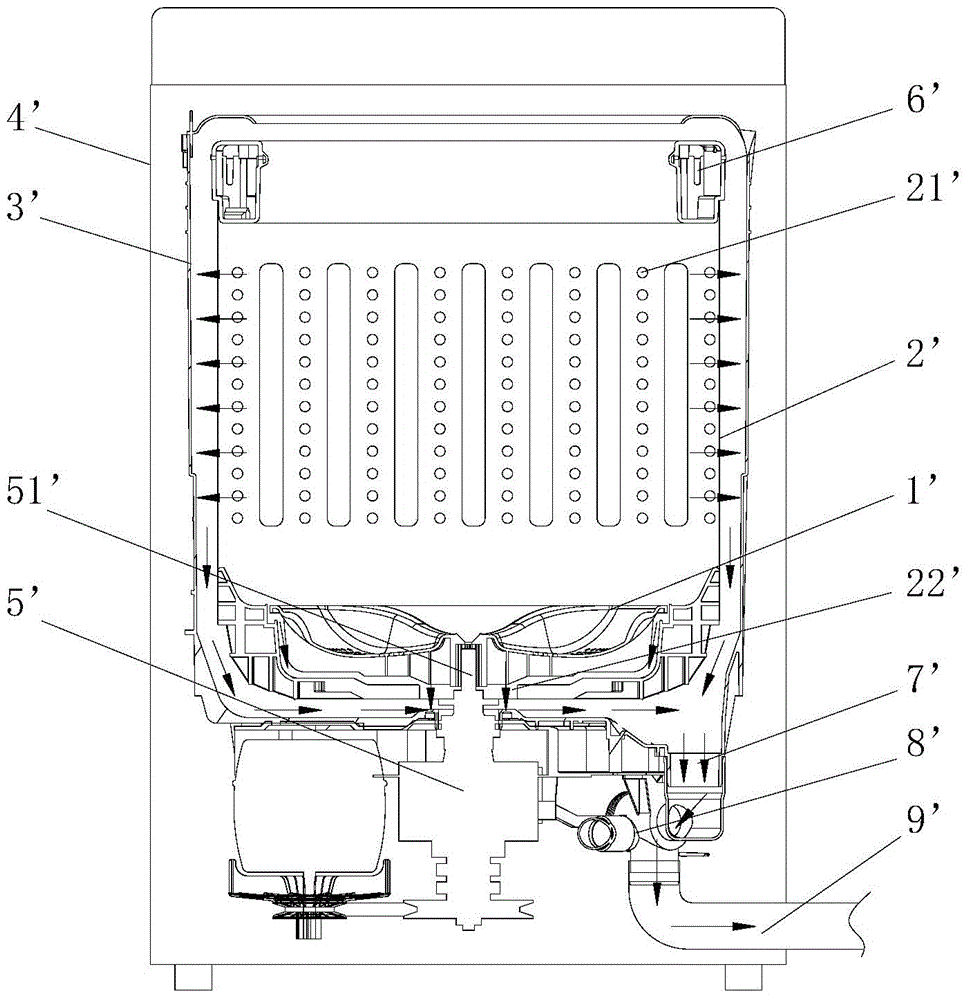

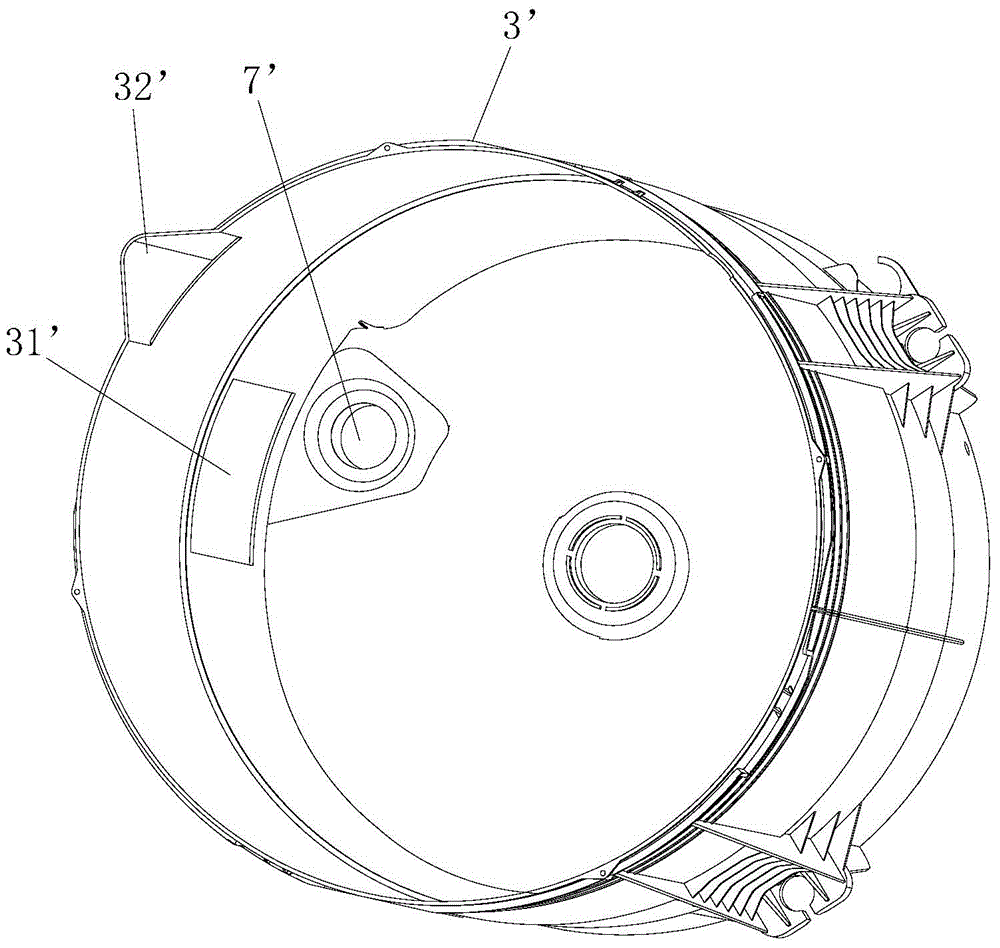

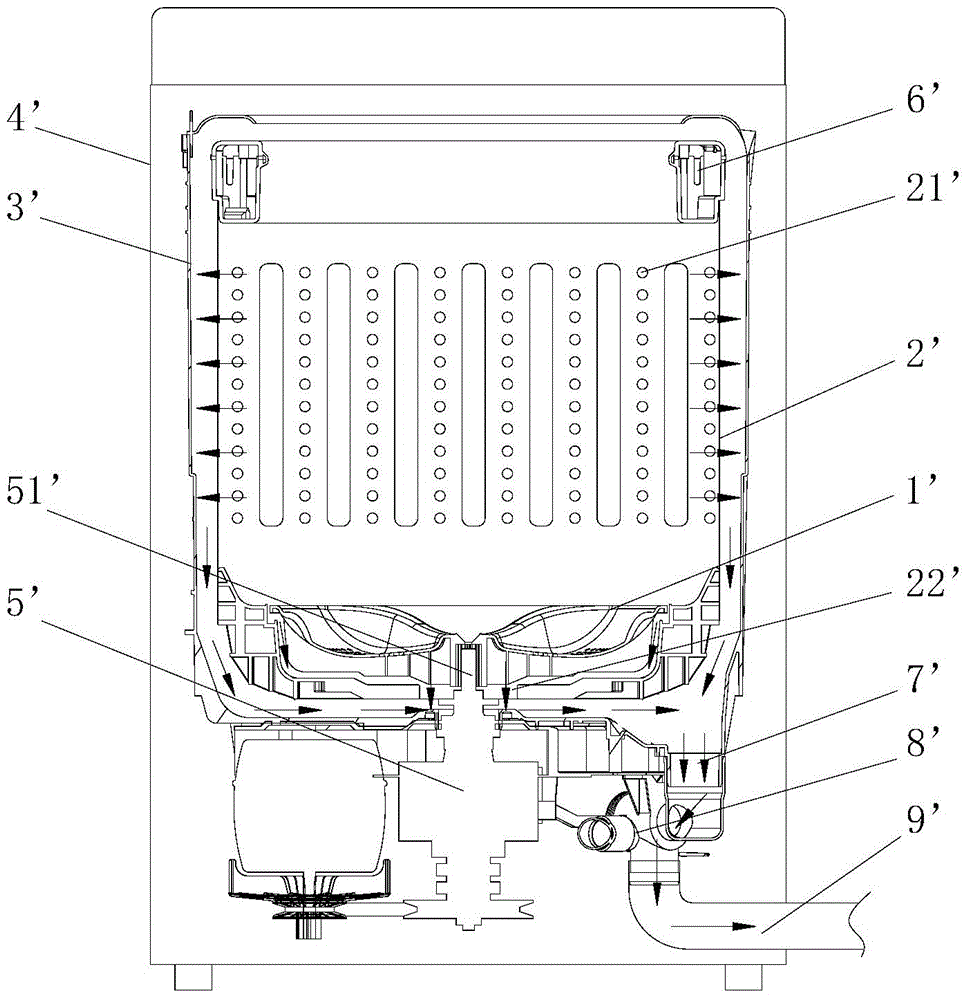

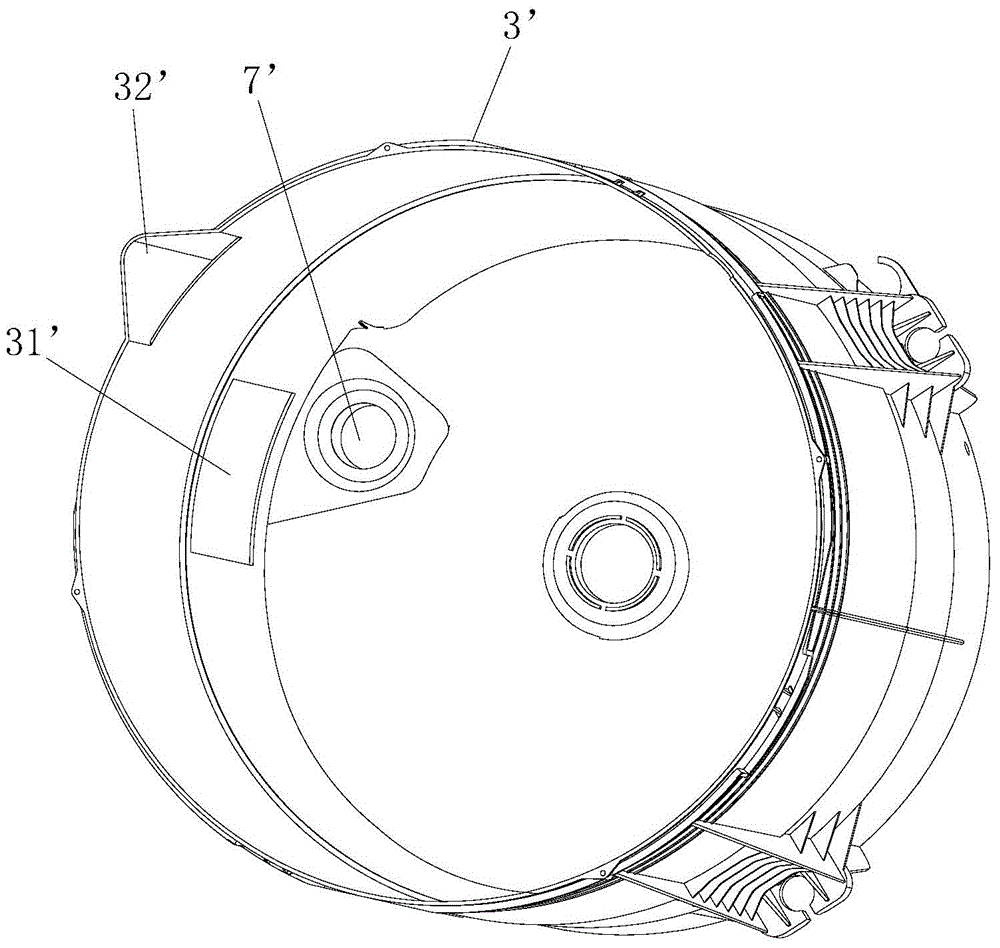

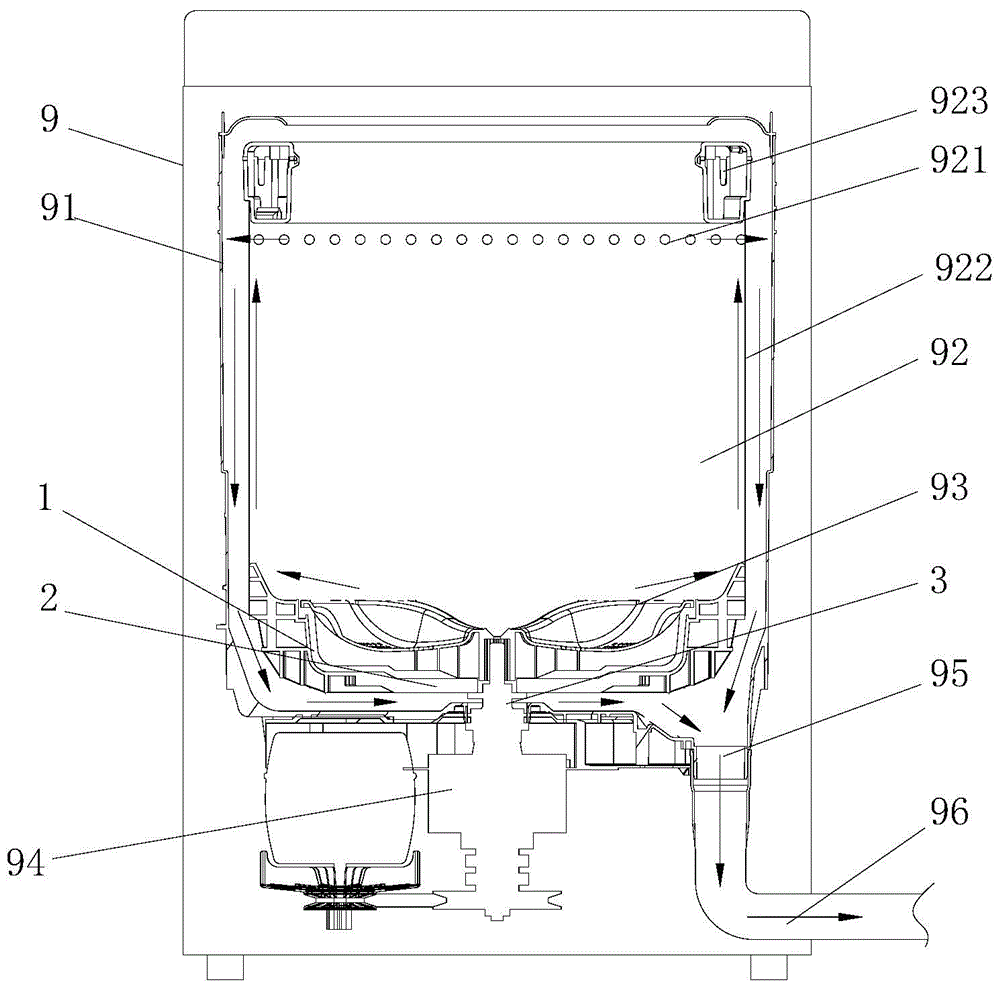

Dishwasher washing system and dishwasher system with same

InactiveCN106821261AImprove washing effectReduce washing costsTableware washing/rinsing machine detailsMicro nanoControl valves

The invention discloses a washing system of a dishwasher and a dishwasher system having the same. The washing system of the dishwasher comprises: a water inlet unit; The washing liquid supplied by the water inlet unit generates micro-nano bubbles in the washing liquid; a first control valve, the first control valve is arranged between the water inlet unit and the micro-nano bubble generating system On the pipeline, wherein the micro-nano bubble generation system is in fluid communication with the inner container of the dishwasher, so as to supply the washing liquid containing micro-nano bubbles generated by the micro-nano bubble generation system to the dishwasher Inside. The washing system of the dishwasher according to the embodiment of the present invention has the advantages of good washing effect, low washing cost, clean and environment-friendly, and the like.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

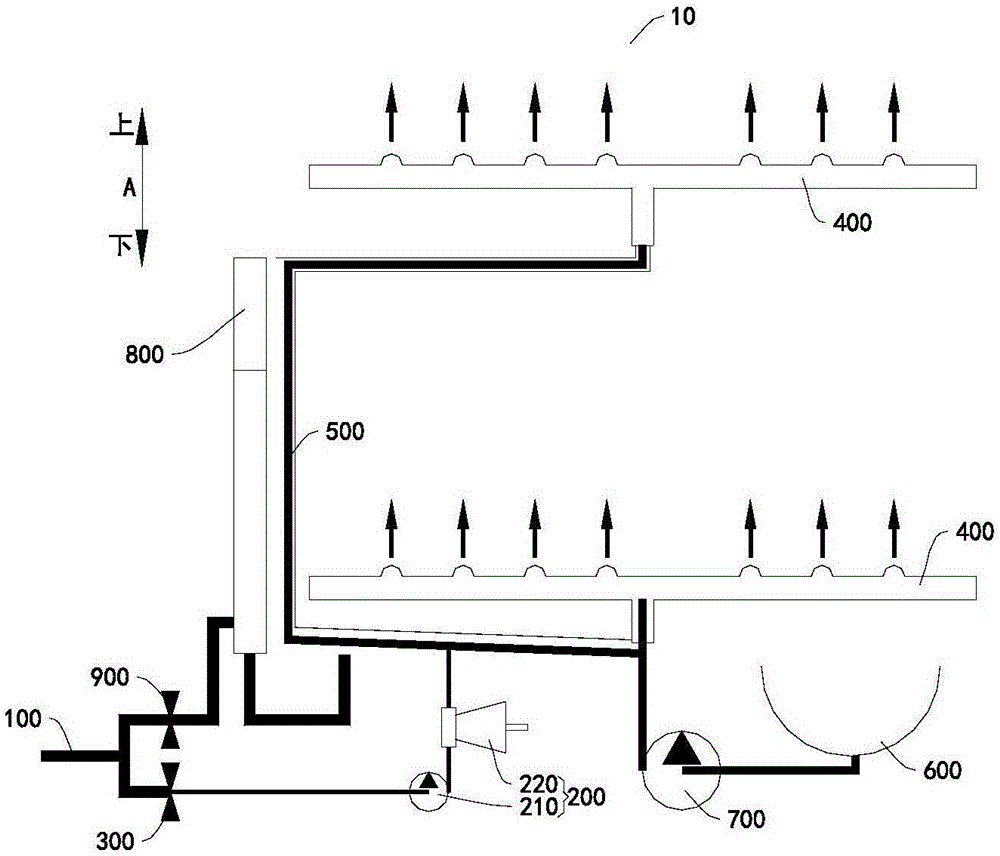

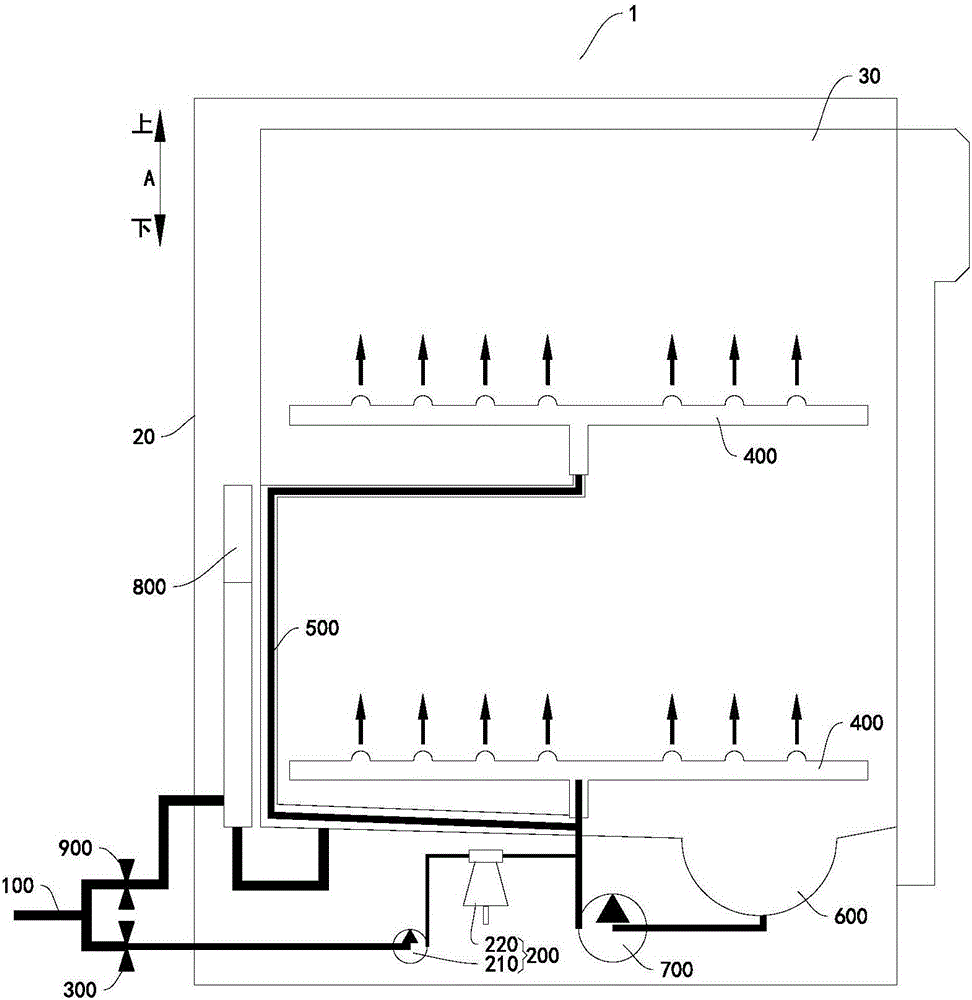

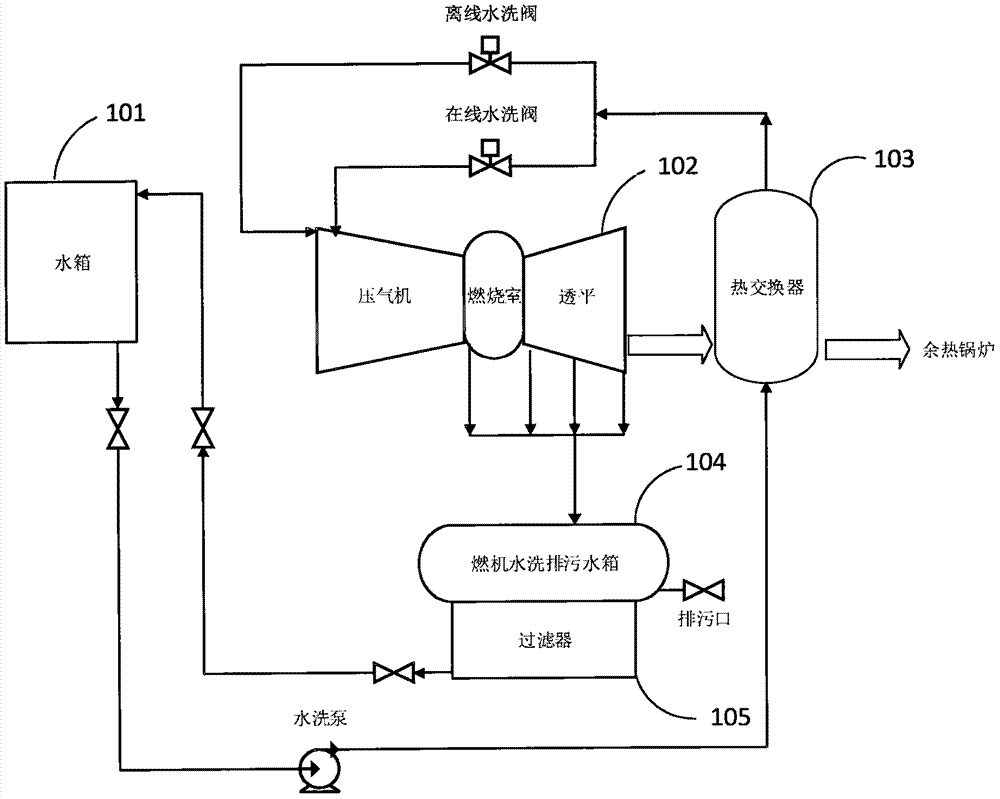

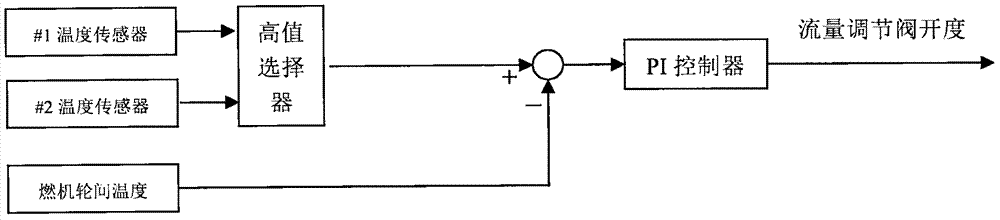

Gas turbine compressor washing device and method

InactiveCN107304712AImprove descaling efficiencyShorten washing timePump componentsGas turbine plantsWater filterWastewater

The invention provides a gas turbine compressor washing device and method. The device comprises a heat exchanger located behind the exhaust section of a gas turbine and a waste water filtering and recycling device of a gas turbine washing pollution discharge water tank. A compressor washing pipeline passes through the heat exchanger before entering a compressor. The heat exchanger heats gas turbine washing water through waste heat of tail gas of the gas turbine, the washing water temperature is increased, and the difference value between the washing water temperature and the wheel-wheel temperature is controlled to be within a set range. By means of the waste water filtering and recycling device of the gas turbine washing pollution discharge water tank, waste water in the water tank is filtered and recycled and flows back to a gas turbine washing tank to be recycled, and washing water is greatly saved. The washing cost is reduced, meanwhile, the compressor washing efficiency is improved, descaling is effectively achieved, the compressor performance can be basically recovered to the optimum condition, and it is ensured that a unit is safely and efficiently operated.

Owner:BEIJING OILKING GASOLINEEUM TECH & DEV

Steam washing machine and washing method

ActiveCN106906608ASimple structureLow costOther washing machinesControl devices for washing apparatusInlet valveEngineering

The invention discloses a steam washing machine. The steam washing machine comprises an outer cylinder, an inner cylinder contained in the outer cylinder, a water inlet valve, a heater and a control circuit. The heater is located at the bottom of the outer cylinder and between the inner cylinder and the outer cylinder, and a temperature detector is arranged at the bottom of the outer cylinder; a water level sensor is arranged on the inner wall of the outer cylinder; the heater is used for heating water to generate steam; the control circuit is used for controlling the heater to work to control the steam amount. Water inflows from the water inlet, the water inlet valve is turned off when the water level threshold is reached, and the heater starts to heat the water to generate the steam; when the water temperature is increased to a first water temperature threshold, the heater stops heating; the inner cylinder starts to rotate to conduct steam washing on clothes; when the water temperature is reduced to a second water temperature threshold, the inner cylinder stops rotating, and the steam washing procedure is completed; a lot of water inflows from the water inlet valve for later washing. The washing machine is simple in structure and easy to use, and the cost of the steam washing machine is reduced on the premise that the washing effect is not affected.

Owner:NANJING LG PANDA APPLIANCES

Environment-friendly water-based automobile shellac cleaning agent and preparation method thereof

InactiveCN102559401ANon-volatileReduce washing costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedShellac

The invention discloses an environment-friendly water-based automobile shellac cleaning agent. The environment-friendly water-based automobile shellac cleaning agent consists of the following components: fatty alcohol-polyoxyethylene ether phosphate, limonene, fatty acid diethanol amide, sodium carbonate and deionized water. The cleaning agent is prepared by compounding various non-toxic surfactants with excellent biodegradability and aids, has obvious synergistic effect among the components, can effectively remove shellac dirt form the surface of the automobile and has a good anti-rust effect on metal. The production method is simple to operate and low in production cost, and has good environmental and economic value.

Owner:任航

Oil dirt cleaning agent and preparation method thereof

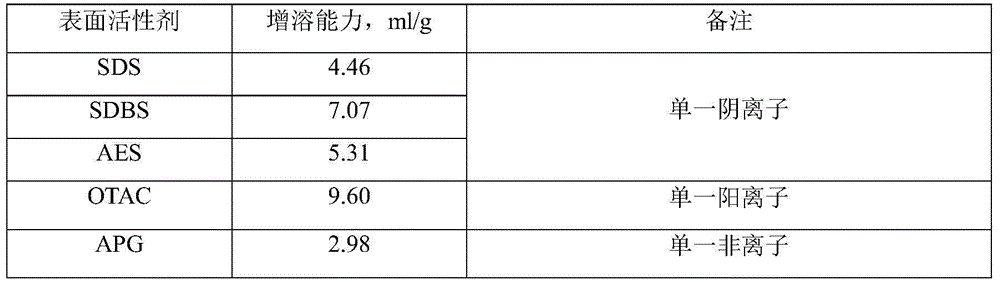

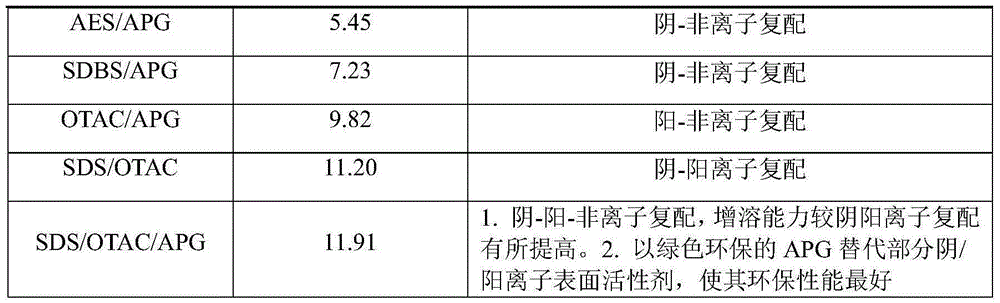

ActiveCN105154269AHigh economic valueEnhance solubilizationSurface-active non-soap compounds and soap mixture detergentsChemistryEnvironmental resistance

The invention provides an oil dirt powerful cleaning agent and a preparation method thereof. The oil dirt cleaning agent comprises the following components in parts by weight: 35-50 parts of oil, 21.5-53.5 parts of water, 1-5 parts of cationic surfactant, 1-5 parts of anionic surfactant, 1-5 parts of nonionic surfactant, 8-12 parts of cosurfactant n-butyl alcohol, 0-0.5 part of sodium chloride and 0.5-1 part of builder sodium tripolyphosphate. The oil dirt cleaning agent has the beneficial effects that the oil dirt cleaning agent uses compound microemulsion of the anionic / cationic surfactant with stronger solubilizing capacity and the nonionic surfactant with degradability as mother liquor and adopts several property assistants, so that the oil dirt cleaning agent achieves the advantages of rust prevention and decontamination, multiple reutilization of the lotion and environment friendliness, does not have limits to the oil content and has great economic value; meanwhile, the oil dirt cleaning agent also achieves diversification of cleaning objects, can be used for the materials, such as metals, glass, plastics, cloths, leather, ceramics and rubber and has a better application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Dish-washing machine pipeline connecting structure and dish-washing machine

InactiveCN108209824AAvoid consumptionReduce usageTableware washing/rinsing machine detailsHome appliance efficiency improvementWater softeningEngineering

The invention relates to the field of cleaning equipment and discloses a dish-washing machine pipeline connecting structure and a dish-washing machine. The dish-washing machine pipeline connecting structure comprises a water inlet pipeline, a first water supply pipeline, a second water supply pipeline, a three-way valve and a water softening device. The three-way valve is respectively connected with the water inlet pipeline and communicated with the first water supply pipeline and the second water supply pipeline; and the water softening device is used for softening water at the downstream ata first water outlet. The dish-washing machine comprises a dish-washing tank and the dish-washing machine pipeline connecting structure, and the first water supply pipeline and the second water supplypipeline are communicated with the dish-washing tank. Therefore, water can be softened and then injected into the dish-washing tank via the first water supply pipeline, or the water is not softened and is directly injected into the dish-washing tank via the first water supply pipeline. According to the pipeline connection manner, the water softening device is still used in a washing mode of not softening the water, and consumables needed by water softening treatment are consumed. Therefore, equipment loss is reduced, usage of the consumable is saved, and the washing cost is reduced.

Owner:佛山市海汇洗涤技术服务有限公司

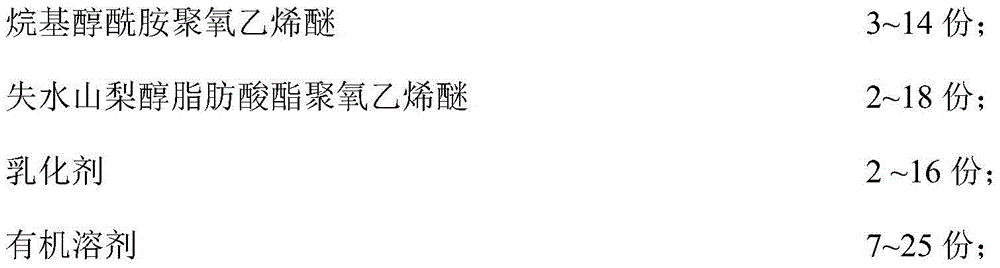

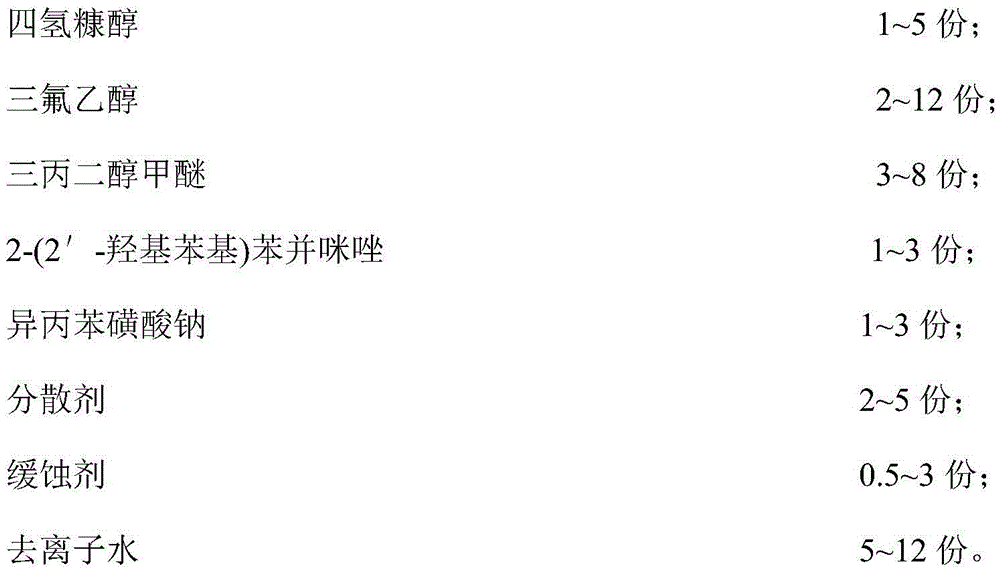

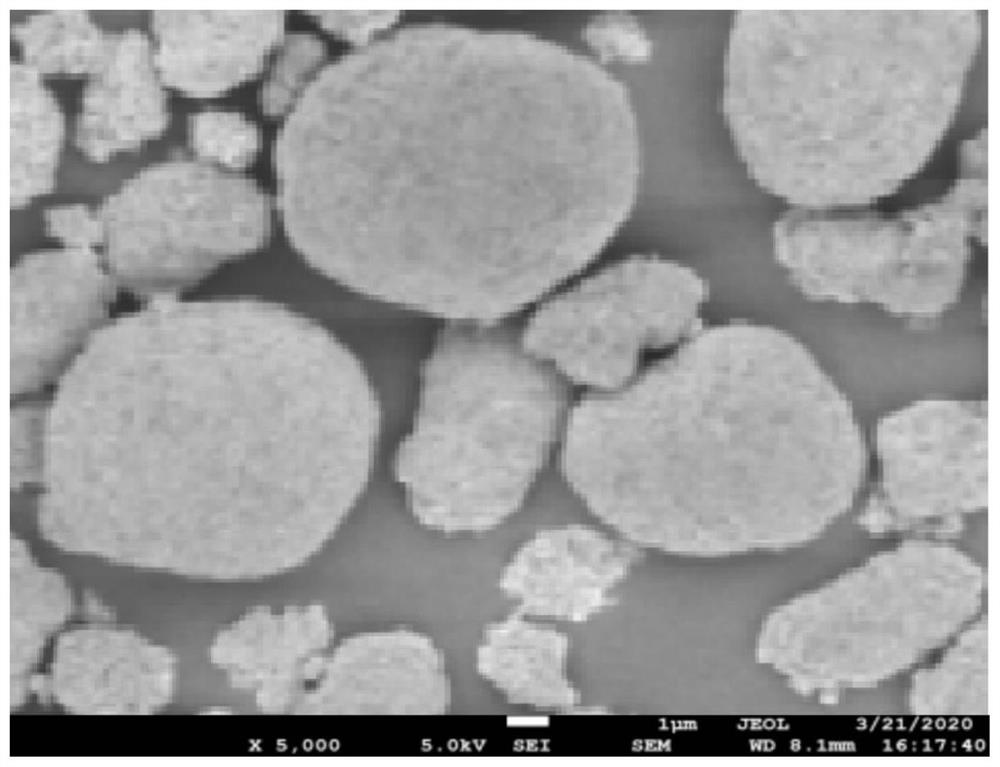

Water-based LED (light emitting diode) chip cleaning agent

InactiveCN105542990ANo generationReduce harmOrganic detergent compounding agentsSurface-active detergent compositionsWater basedCleansing Agents

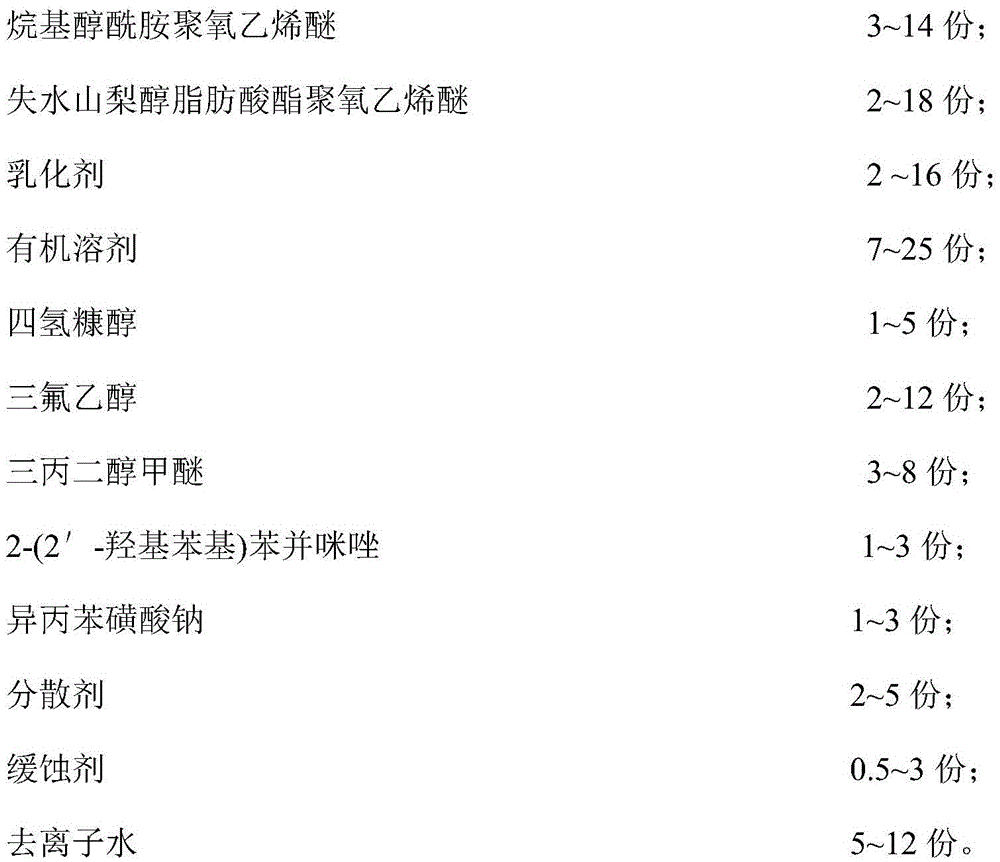

The invention discloses a water-based LED (light emitting diode) chip cleaning agent, prepared from the following components of alkylolamide polyoxyethylene ether, polyoxyethylene sorbitan fatty acid ester, an emulsifier, an organic solvent, tetrahydrofurfuryl alcohol, trifluoroethanol, tripropylene glycol monomethyl ether, 2-(2'-hydroxylphenyl)benzoimidazole, sodium cumenesulfonate, a dispersant, a corrosion inhibitor and deionized water. The cleaning agent provided by the invention has the advantages that the effects of high cleaning efficiency, strong detergency, good safety performance, freeness from environmental pollution, energy saving and low washing cost are achieved; an LED is not damaged in a washing process; a protective film can be formed on the surface of a chip through the cleaning agent, so that air is isolated, and the chip is prevented from being corroded by moisture and other molecules in the air, therefore the effect of oxidation resistance is achieved, and a next production process is conveniently performed.

Owner:SUZHOU JIAYIDA ELECTRICAL APPLIANCES

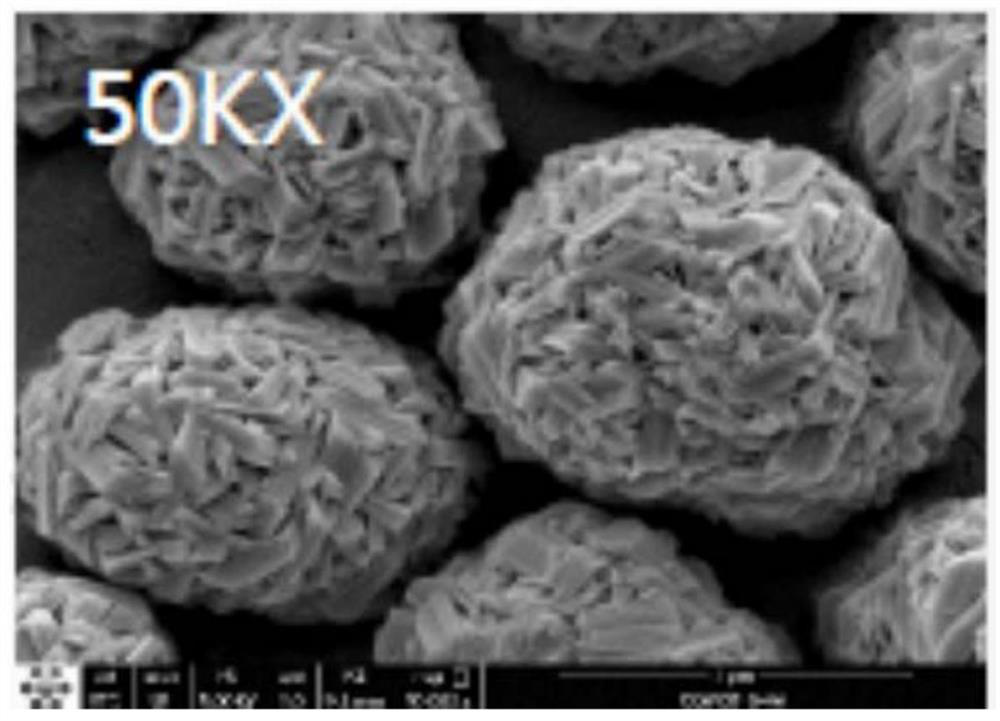

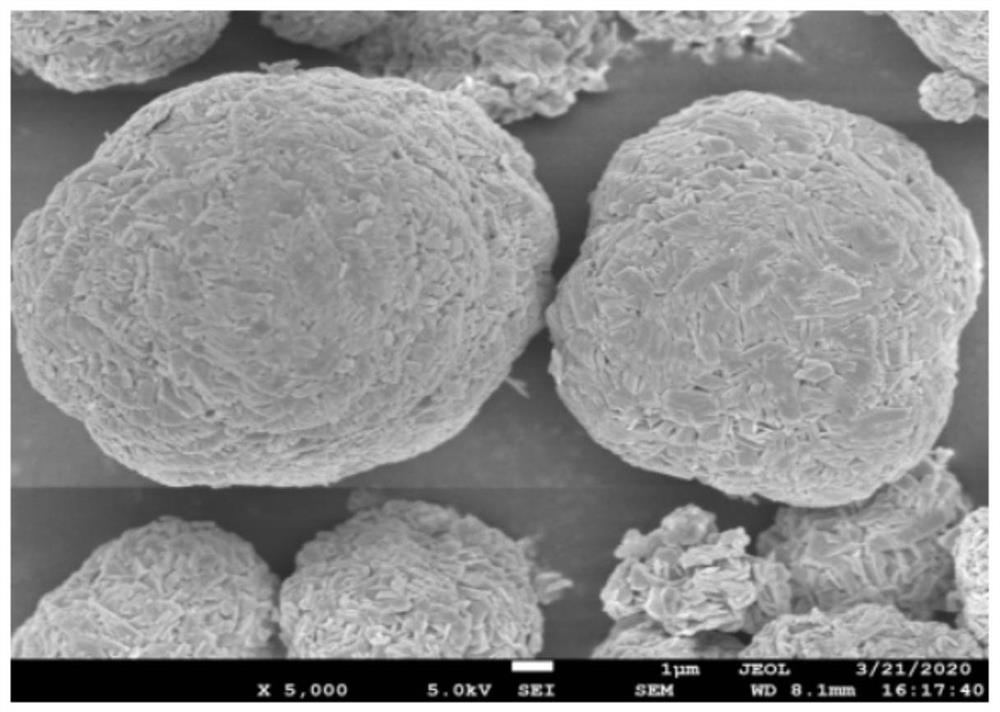

Ternary positive electrode material precursor with specific morphology and preparation method thereof

ActiveCN111725497APerfect shapeUniform sizeCell electrodesSecondary cellsLarge particleMaterials science

The invention relates to the technical field of lithium battery cathode materials and particularly relates to a preparation method of a ternary positive electrode material precursor with a specific morphology. A molecular formula of a precursor is Ni<x>Co<y>Mn<1-x-y>(OH)2, wherein x is larger than or equal to 0.5 and smaller than or equal to 0.9, y is larger than or equal to 0.05 and smaller thanor equal to 0.2, z is larger than or equal to 0 and smaller than or equal to 0.15, tap density is larger than or equal to 1.95 g / cm<3>, the specific surface area is 8-15 m<2> / g, apparent density is 1.4-2.0 g / cm<3>, the Na content is smaller than or equal to 100 ppm. According to the positive electrode material precursor, primary particles are 200-300nm in size, the size is uniform, and the sphericity degree of a small-particle precursor and a large-particle precursor is perfect; compared with the prior art, the lath-shaped ternary positive electrode material precursor provided by the inventionprovides good processability for subsequent washing, sintering and the like.

Owner:福建常青新能源科技有限公司 +1

Full-automatic washing machine

PendingCN105525485AHygienic useEnvironmental protectionOther washing machinesTextiles and paperImpellerWater saving

The invention discloses a full-automatic washing machine. The full-automatic washing machine comprises an outer drum and an inner drum disposed inside the outer drum; a drainage port is arranged at the bottom of the outer drum; the drainage port of the outer drum directly communicates with a drainage pipe; and a driving device used for driving the inner drum and impellers to work is arranged below the outer drum. The inner drum comprises a drum body, an inner drum bottom arranged at the lower portion of the drum body, and a balance ring arranged at the upper opening of the drum body. The upper portion of the inner drum is provided with water outlets. The portion, below the water outlets, of the inner drum is sealed and does not leak. The drum body is provided with a drainage channel through which the water obliquely and upwardly moves to the water outlets from the bottom portion of the inner drum. The washing machine employs the inner drum to hold water for washing, so that water can be saved. Through an upper portion dewatering and dehydrating manner, the washing water is directly discharged sequentially through water outlets in the upper portion of the inner drum, the outer drum, the drainage port of the outer drum and the drainage pipe along the drainage channel, and water flows upwardly through the high-speed rotation of the inner drum and then is discharged from the water outlets, so that lint floating in the water cannot be left on the clothes and can be entirely discharged, and the clothes can be more cleaner.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

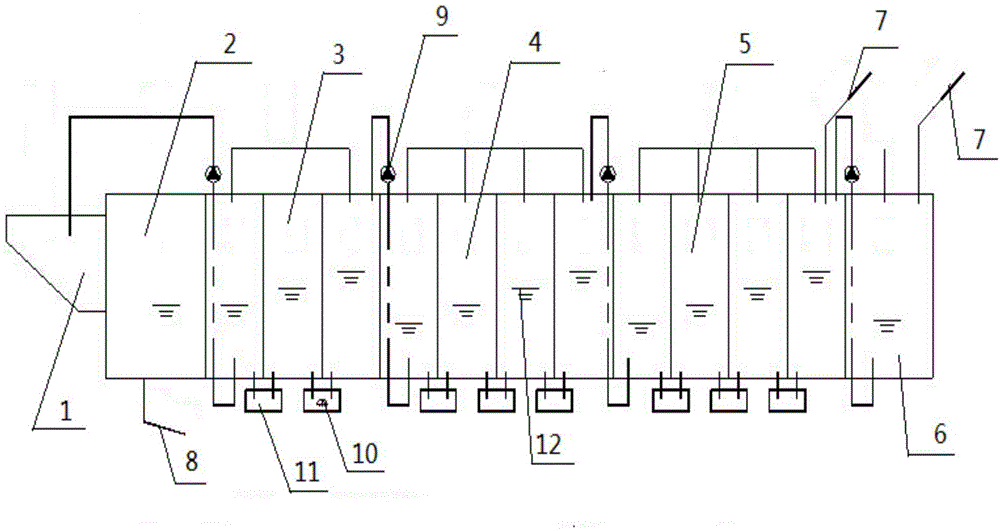

Linen washing process of tunnel-type washing machine

InactiveCN104131441AIncrease profitImprove cleaning rateOther washing machinesTextiles and paperProcess engineeringPre washing

The invention discloses a linen washing process of a tunnel-type washing machine. The linen washing process mainly includes the following steps: (1), adding a certain amount of washing water into each washing bin of the washing dragon; (2), sliding to-be-washing linen into a humidifying bin through a feeding funnel; (3), humidifying the linen; (4), pre-washing the linen; (5), primarily washing the linen; (6), enabling the linen to go through clean water; (7), neutralizing the linen. The linen washing process has the advantages that utilization rate of media like the washing water, steam and chemical materials is greatly improved, more energy is saved, washing cost is reduced, cleaning rate of the linen of the washing machine is increased, and the linen washing process has quite high popularization value.

Owner:上海艾斯维洗涤机械工程技术有限公司

Rust-proof cleaning agent for metal articles

The invention relates to the technical field of surface treatment of metal articles and particularly relates to a rust-proof cleaning agent for metal articles. The rust-proof cleaning agent for metal articles comprises the following components in parts by weight: 4-7 parts of anhydrous trisodium phosphate, 5-9 parts of 4-methyl-4-pentenyl-2-ol, 4-7 parts of calcium stearoyl lactylate, 4-7 parts of N-acylamino acid type surfactant, 4-7 parts of alcohol ether carboxylate, 2-6 parts of a defoaming agent, 5-8 parts of sodium tripolyphosphate and 4-8 parts of burkeite. The rust-proof cleaning agent disclosed by the invention is a concentrated product in formula component, can be applied by diluting at a low concentration and has the advantages of relatively safe application, relatively strong degreasing capability, few foams and economically efficient cleaning effect, the excellent enhanced synergistic effect can be generated by the effective combination of various components, no damage to a metal device occurs in the cleaning process and no corrosion to the metal device is generated after the metal device is cleaned by the cleaning agent and the cleaning agent is applicable in popularization.

Owner:ZHANGJIAGANG FREE TRADE ZONE GUANXIANG TRADE

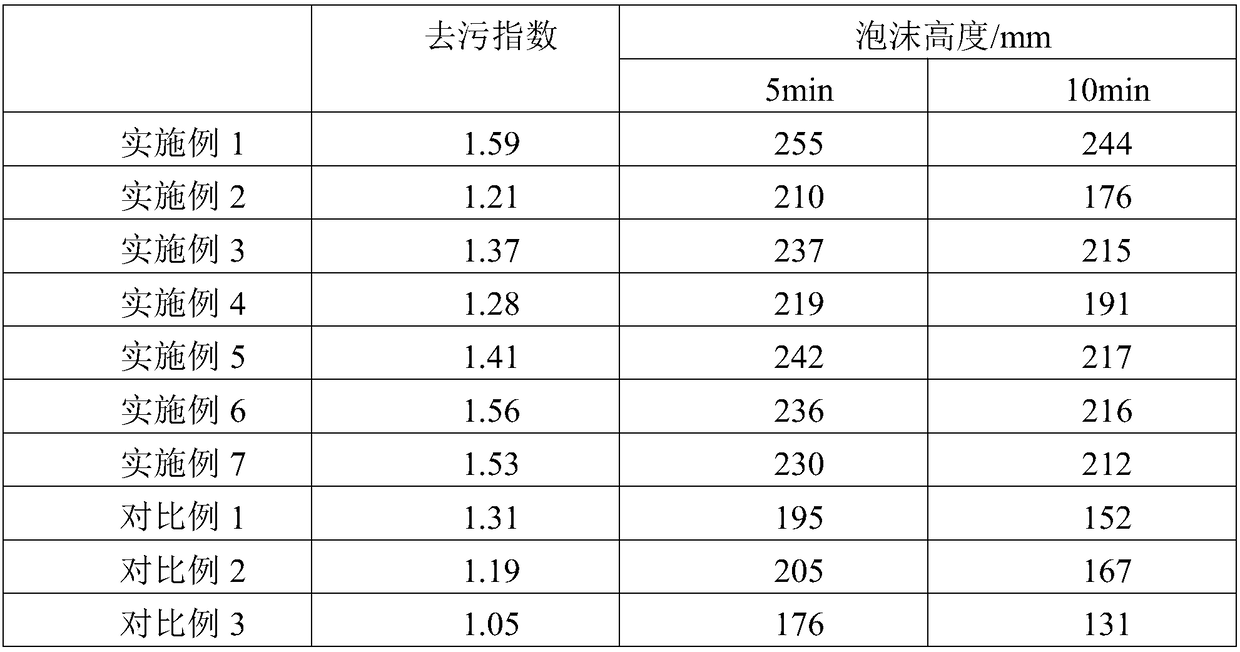

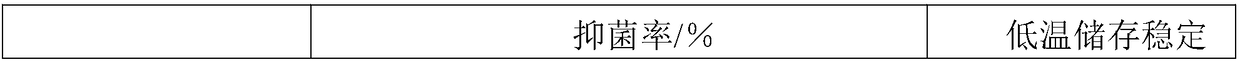

Towel washing process and detergent

ActiveCN108330035AGood decontamination effectStrong decontaminationSucessive textile treatmentsSurface-active non-soap compounds and soap mixture detergentsChemistryLaundry washing machine

The invention discloses a towel washing process and detergent. The towel washing process includes the following steps: (1) main washing: putting 20-50 kg of towels into a drum of a washing machine, adding the detergent with the mass of 0.1%-0.5% that of the towels, injecting water, washing for 15-30 minutes, and draining, wherein the water amount of water injection is 3-8 times the mass of the towels; (2) rinsing: injecting water, washing for 1-5 minutes, draining, injecting water again, washing for 3-5 minutes, and draining again, wherein the amount of each time of water injection is 3-8 times the mass of the towels; and (3) dehydrating: dehydrating for 3-10 minutes. The towel washing process has the advantages of good detergency, high washing efficiency, low washing cost, and low energyconsumption; the towels after washing have the advantages of no deformation, softness, comfort and elasticity. The used detergent is rich and stable in foams and strong in detergency, and has good antibacterial properties and storage stability.

Owner:佛山市芳菲丽特清洁用品有限公司

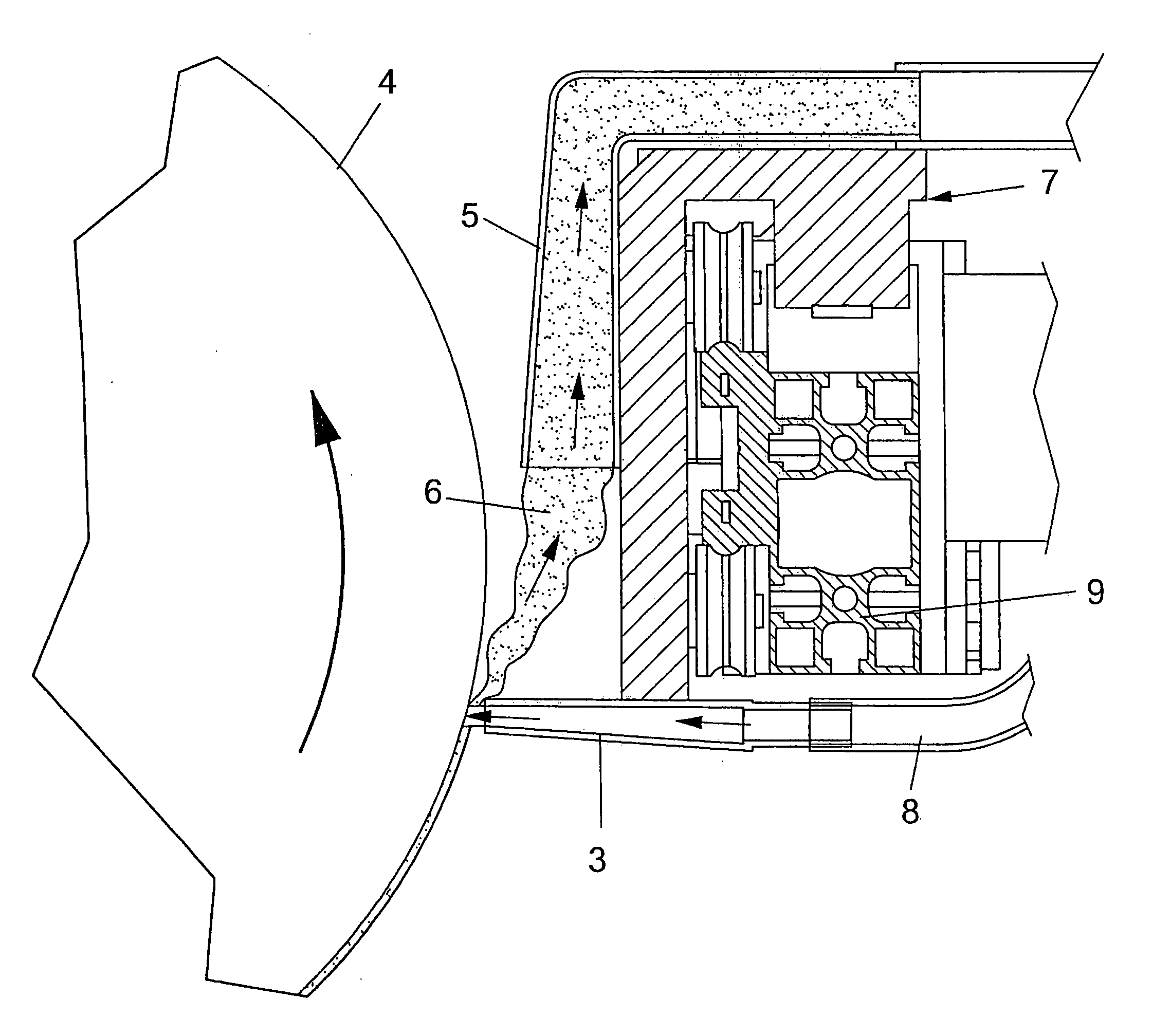

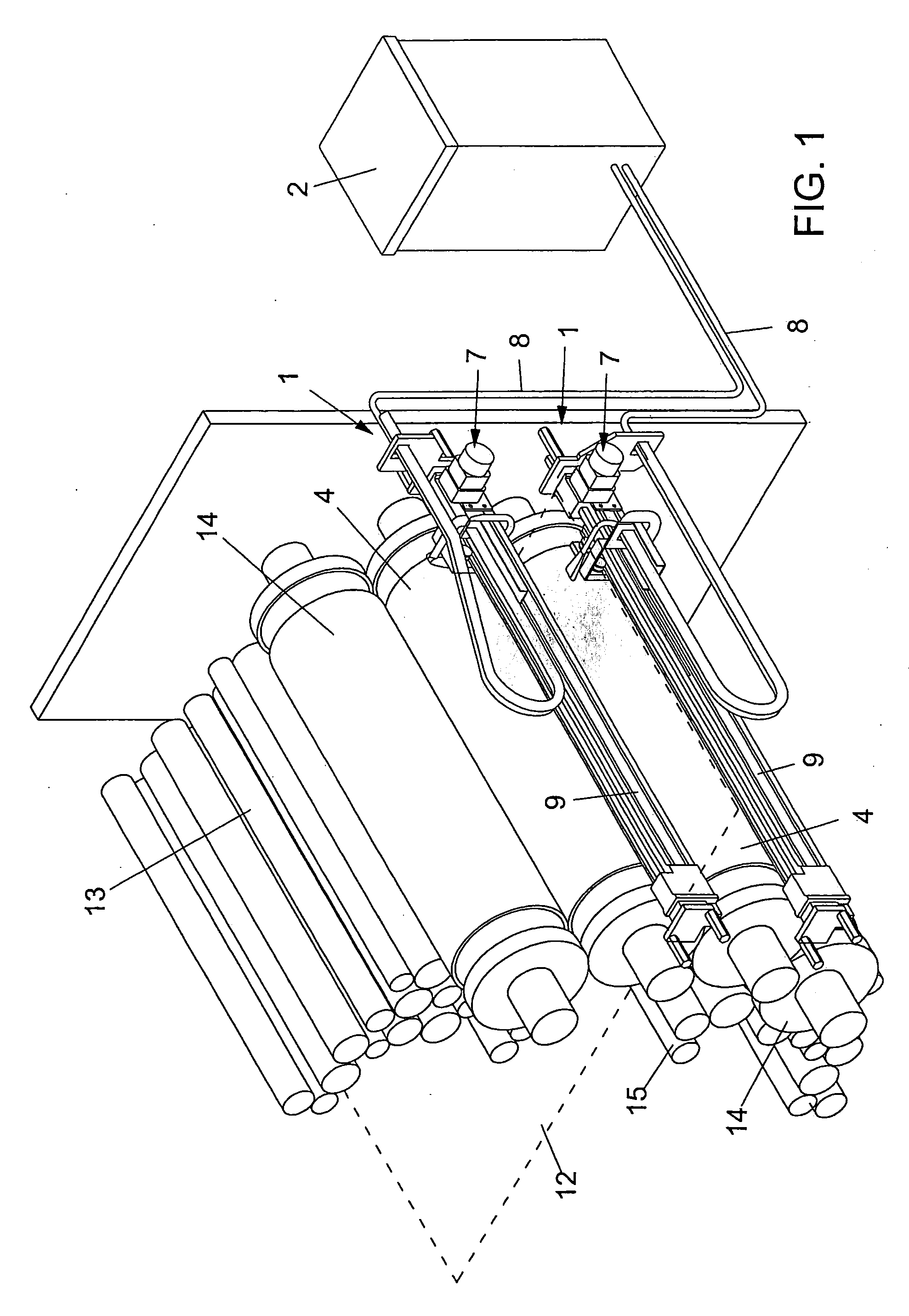

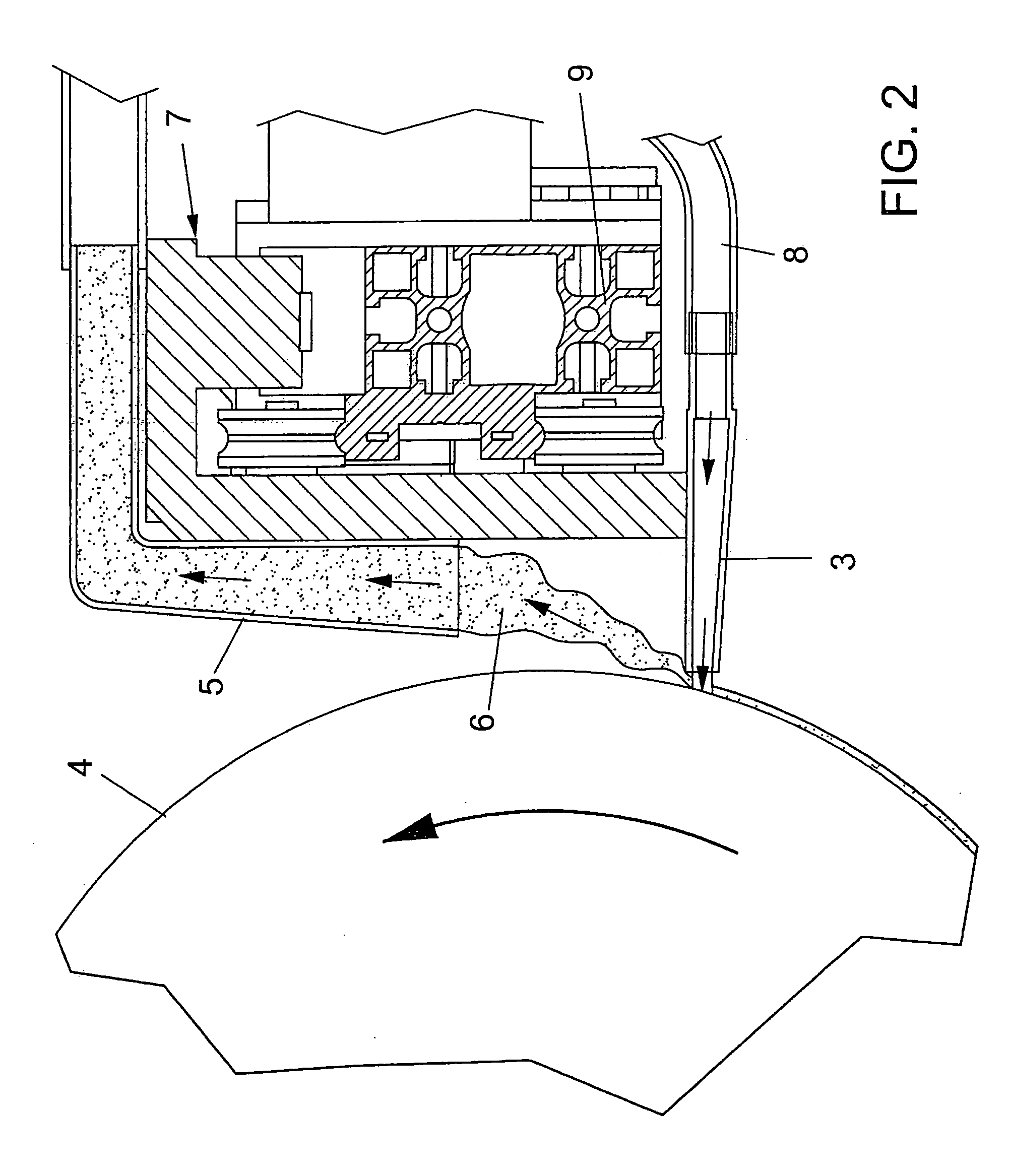

Cleaning apparatus for cleaning priniting machine rotary cylinders

InactiveUS20120318155A1Reduce printing cylinder washing costGuaranteed uptimeOffice printingPrinting press partsPrinting pressNozzle

A cleaning apparatus for cleaning printing machines rotary cylinders, characterized in that said cleaning apparatus comprises a delivery device providing a cleaning material to nozzle means for spraying said cleaning material on a cylinder to be cleaned, said cleaning apparatus further comprising suction means for sucking the used cleaning material and guide means allowing to displace said nozzle and suction means along a cylinder directrix line to perform a cleaning operation through the overall extension of said cylinder.

Owner:FAPPIANO CHRISTIAN +1

Washing machine without operation display panel and utilization method thereof

PendingCN107151895AEasy to operateReduce manufacturing costOther washing machinesControl devices for washing apparatusThe InternetComputer module

The invention discloses a washing machine without an operation display panel, and belongs to the field of home appliances. According to the washing machine, the problem of the high utilization limitation of washing machines of the Internet of things in the prior art is solved. According to the technical scheme, the washing machine mainly comprises a machine body and NFC tags. The machine body is provided with a control center and an NFC module, the NFC module is connected with the control center, an NFC induction area corresponding to the NFC module is arranged on the machine body, and the NFC tags comprise at least one first NFC tag stored with a washing program. The washing machine is mainly used for clothes washing. Moreover, the invention further provides a utilization method of the washing machine without the operation display panel, wherein the method is applicable to common people.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

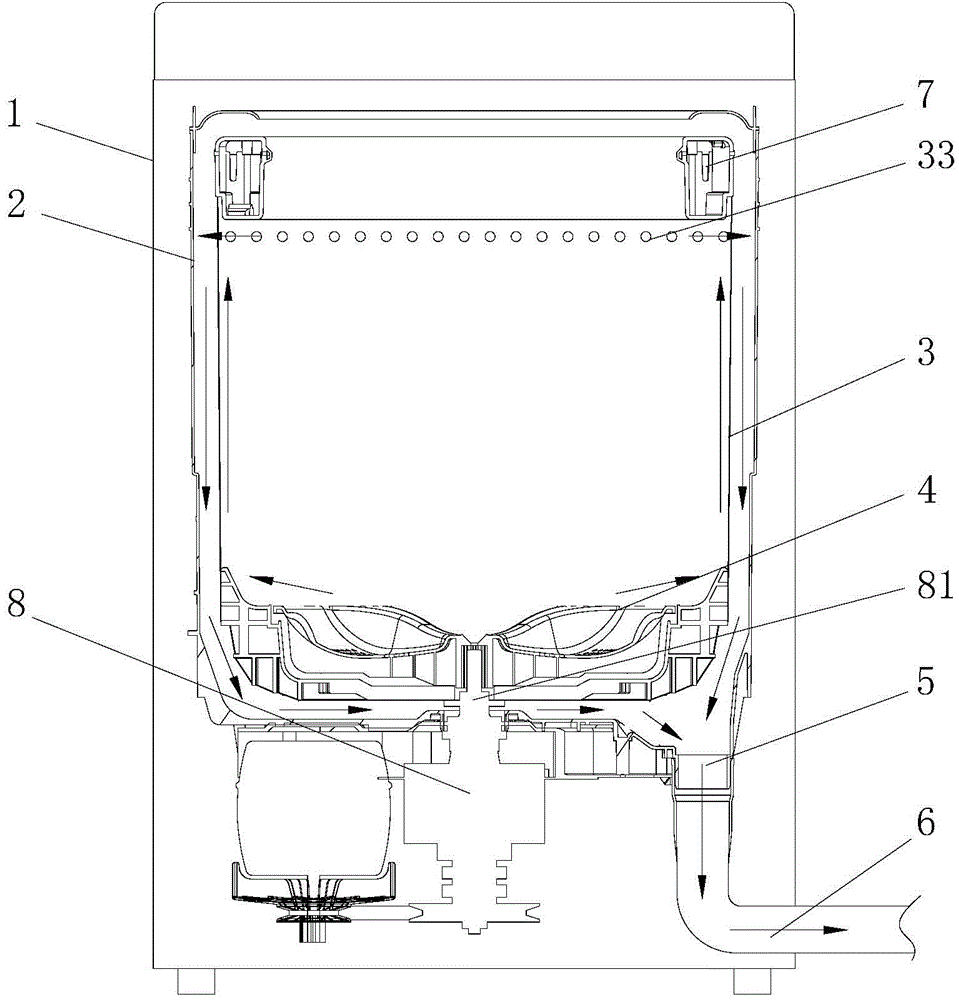

Washing machine inner barrel bottom seal structure

PendingCN105544140ASave washing waterReduce washing costsEngine sealsOther washing machinesEngineeringFlange

The invention discloses a washing machine inner barrel bottom seal structure comprises an inner barrel bottom, an inner barrel flange and a dehydration shaft; the inner barrel bottom is connected with the inner barrel flange in a seal manner; the dehydration shaft is connected with the inner barrel flange in a seal manner; the center of the inner barrel bottom wall is a hollow portion; the inner barrel flange and the dehydration shaft are cooperated to block the hollow portion; a seal structure is arranged between the inner barrel flange and the inner barrel bottom wall; a seal structure is arranged between the dehydration shaft and the inner barrel flange; the dehydration shaft is provided with a gasket supporting the inner barrel flange; the dehydration shaft penetrates the inner barrel flange, and fixed by a nut; a seal pad is arranged on the gasket and / or under the nut so as to seal the dehydration shaft with the inner barrel flange; or, the dehydration shaft is a T-shape hollow sleeve structure, comprises a shaft sleeve and a small flange on the top, and the inner barrel flange and the small flange are sealed by a second seal ring. The washing machine inner barrel bottom seal structure is simple in structure, convenient in mounting, and good in sealing effect.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

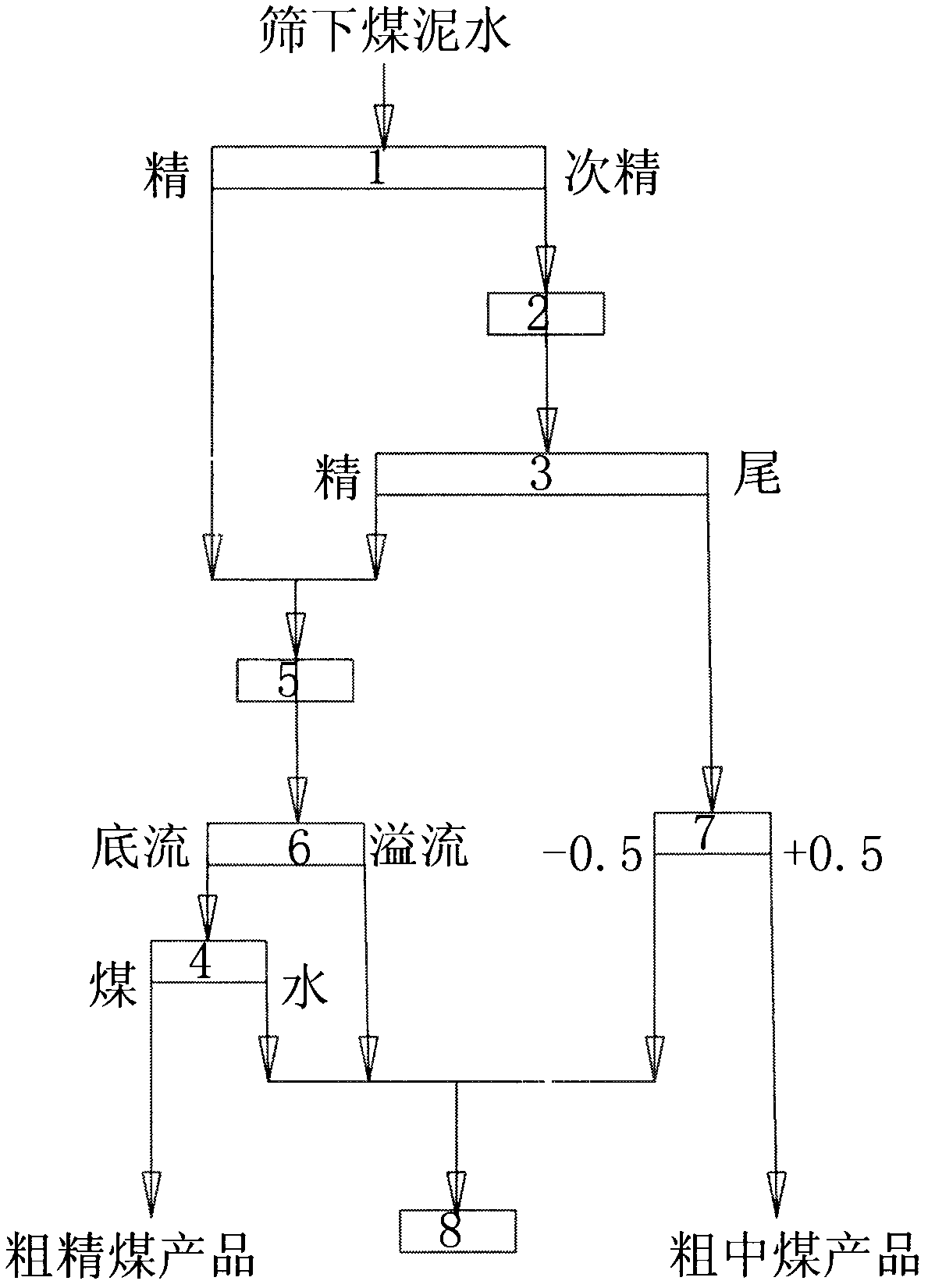

Coarse slime separating system and method

The invention discloses a coarse slime separating system and method, belongs to the field of coal separation, and particularly adaptable to direct separation of whole low-concentration slime water in the process of jigging coal separation. The system comprises a water power separating device, a feeding pump, a hydrocyclone, a dewatering device and a flotation device. Rough separation is performed on low-concentration slime water through the water power separating device, concentrated underflow of the water power separating device is separated through the hydrocyclone. By the aid of the coarse slime separating system and method, the whole low-concentration slime water can be separated directly, cost is reduced, system links are simplified, total system investment is reduced, and simple and practical effect that the existing coarse slime separating method cannot achieved is obtained.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

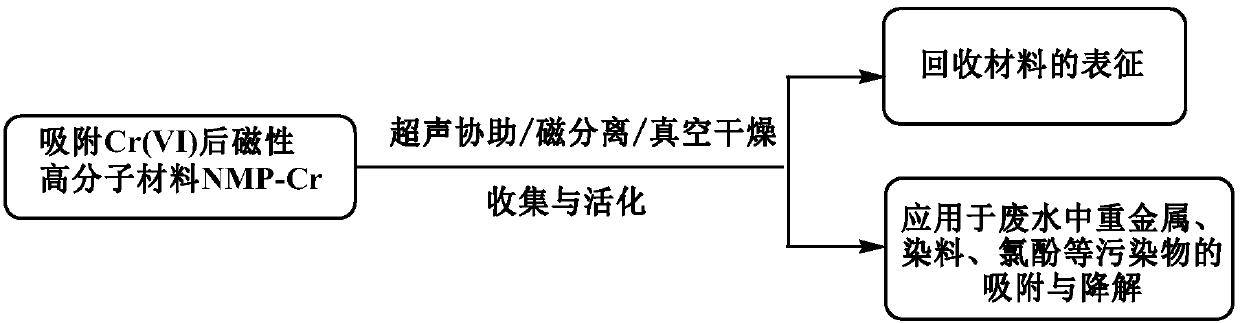

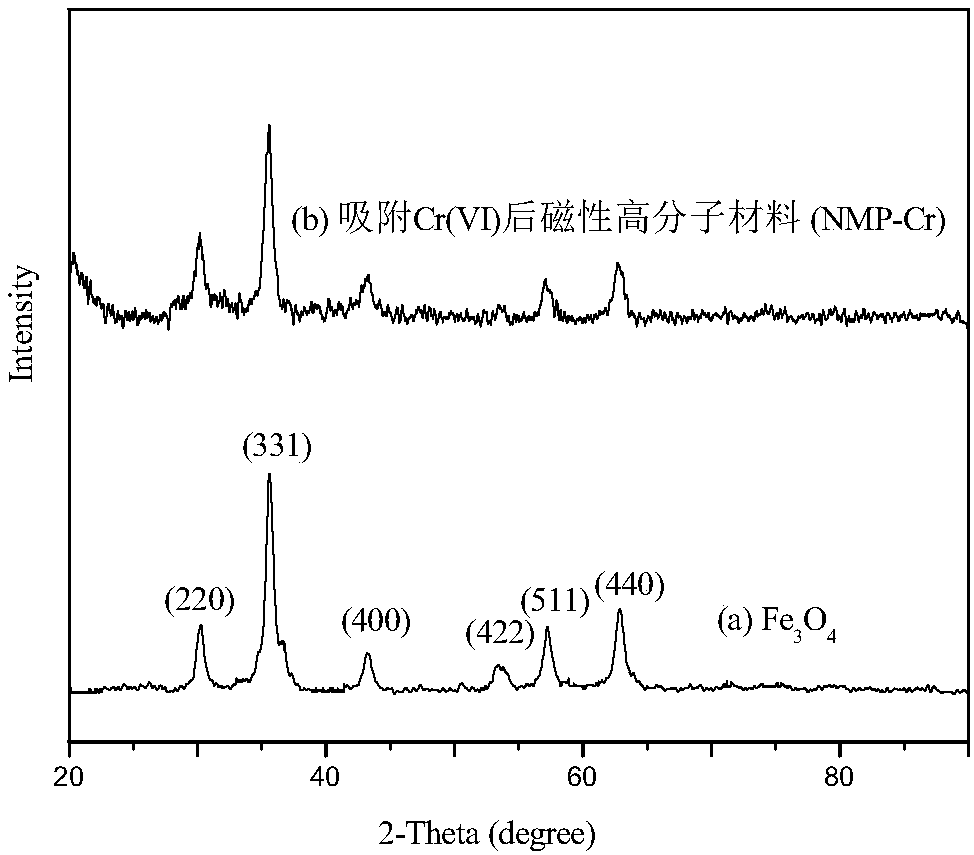

Comprehensive utilization method of Cr(VI) (hexavalent chromium)-adsorbed magnetic macromolecular material

InactiveCN107915270AGood dispersionSimple processOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsChlorophenolHexavalent chromium

The invention discloses a comprehensive utilization method of a Cr(VI) (hexavalent chromium)-adsorbed magnetic macromolecular material. The comprehensive utilization method comprises the following steps of firstly, collecting the Cr(VI)-adsorbed magnetic macromolecular material, uniformly mixing, cleaning in an ultrasonic wave-assisted or microwave-assisted way, magnetically separating, and activating; then, sampling, and representing; finally, applying the Cr(VI)-adsorbed magnetic macromolecular material to absorb and degrade the heavy metal, methylene blue pigment and chlorophenol environment pollutants in wastewater. The comprehensive utilization method has the advantages that the Cr(VI)-adsorbed magnetic macromolecular material NMP-Cr is collected, activated and recycled by an ultrasonic wave-assisted, magnetic separating and vacuum drying cooperating method; the dispersivity is good, the technology is simple, the recycling efficiency is high, and the like; the defects of easinessin agglomeration, poor dispersivity and the like of the magnetic composite material in the recycling process can be overcome; the morphology of the magnetic composite material is favorably stored, theprocedure and cost are reduced, and the pollution to environment due to chromium-containing waste material flowing into the environment system can be avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

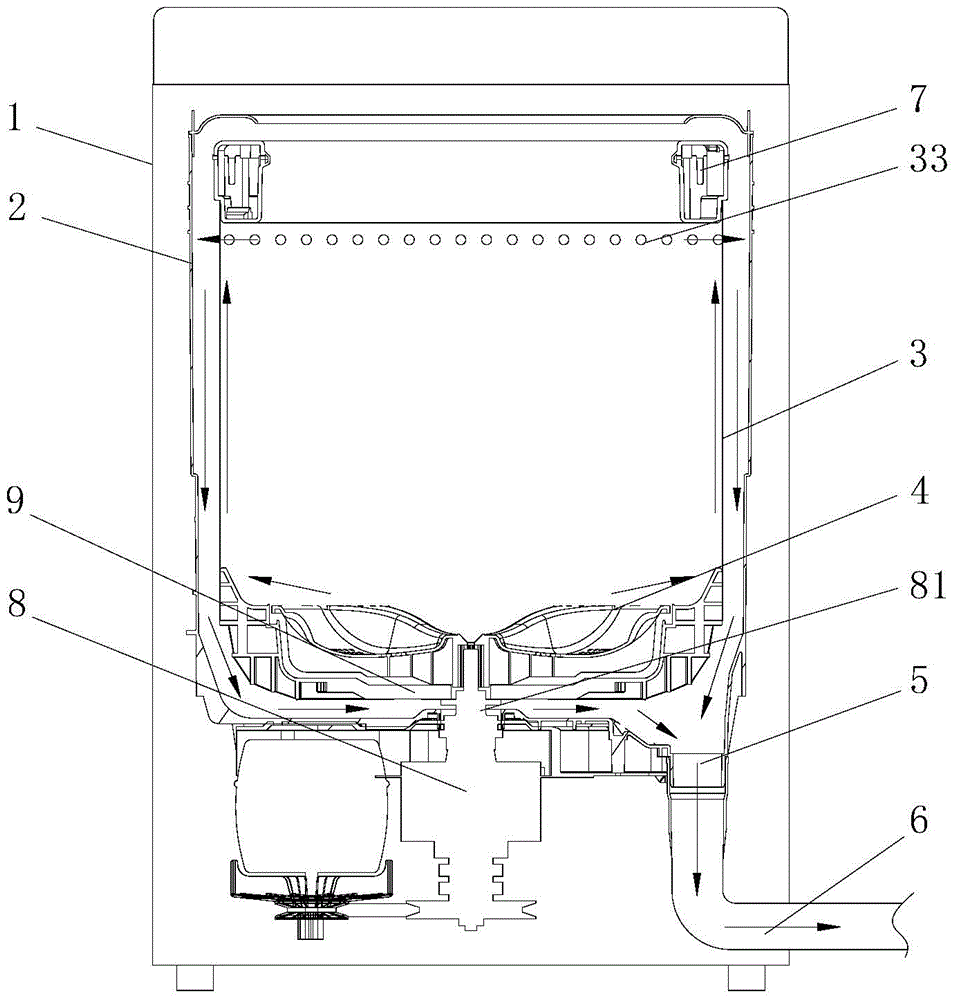

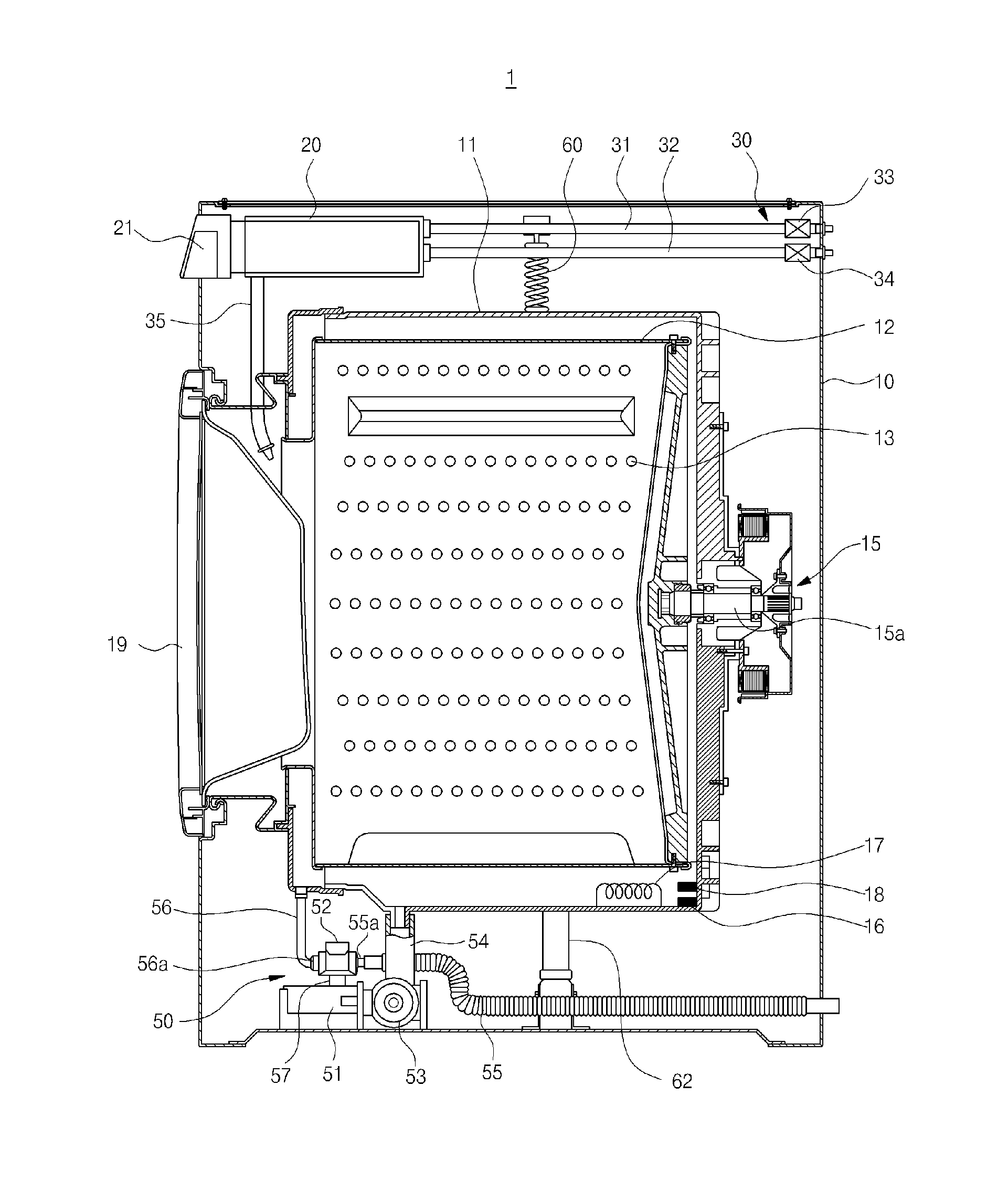

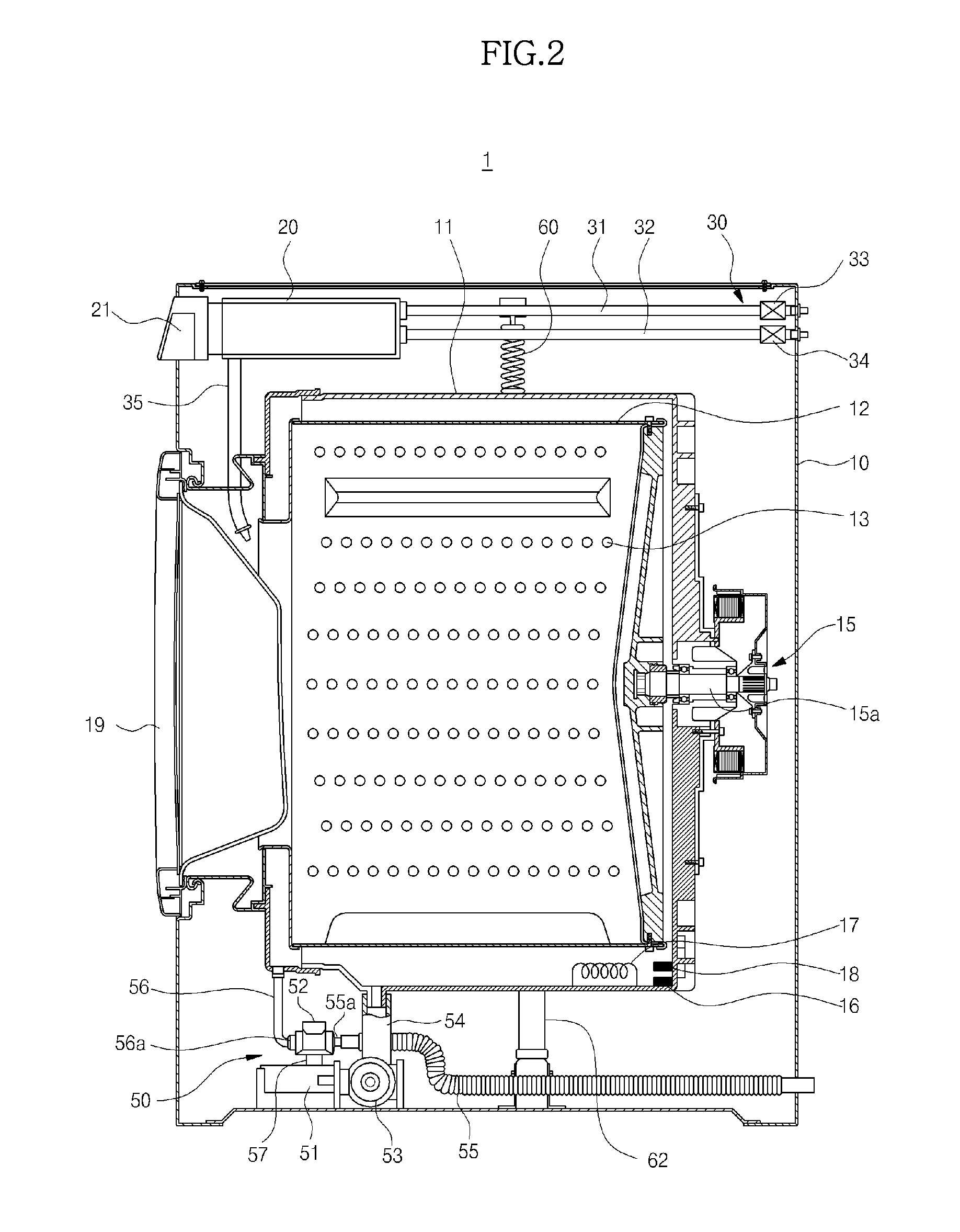

Washing machine and control method thereof

InactiveUS20130291313A1Improve washing effectSimple structureOther washing machinesControl devices for washing apparatusProcess engineeringDissolution

A washing machine provided with a structure thereof capable of draining and circulating by using a single pump and capable of enhancing washing performance by using a circulation of water and a rotation of a drum, and a control method thereof, in which the structure of the washing machine is simplified through the change of the flow path that enables the draining and the circulation of water by using a general pump while decreasing the number of the components of the washing machine. The manufacturing cost of the washing machine is reduced, because the washing machine accelerates the dissolution of detergent by generating large amount of bubbles by using the circulation of water and the rotation of the drum, without additional components, thereby washing performance of the washing machine is enhanced, and by maintaining the bubbles that are generated, the non-tangible quality that a user feels in the course of washing is enhanced.

Owner:SAMSUNG ELECTRONICS CO LTD

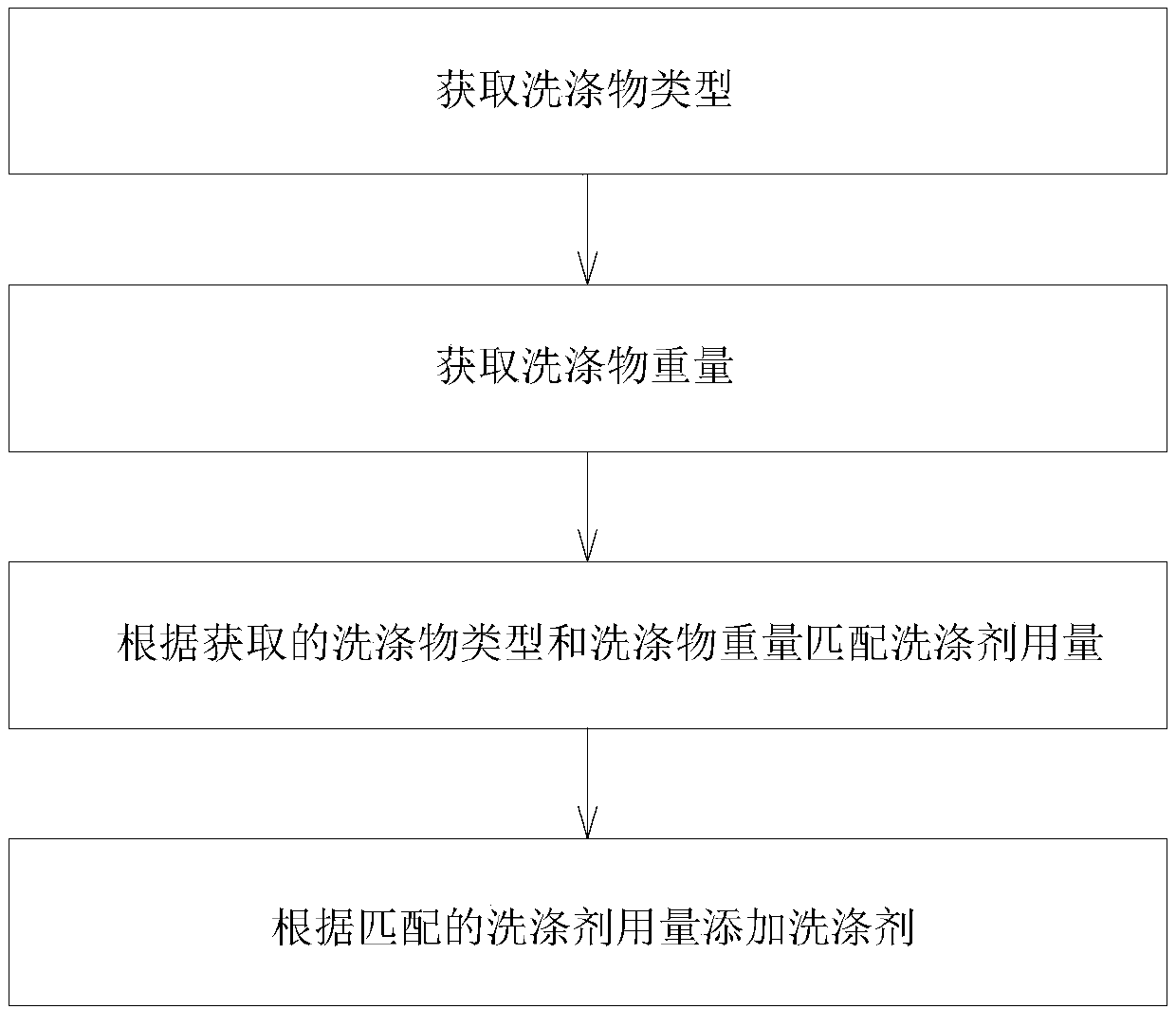

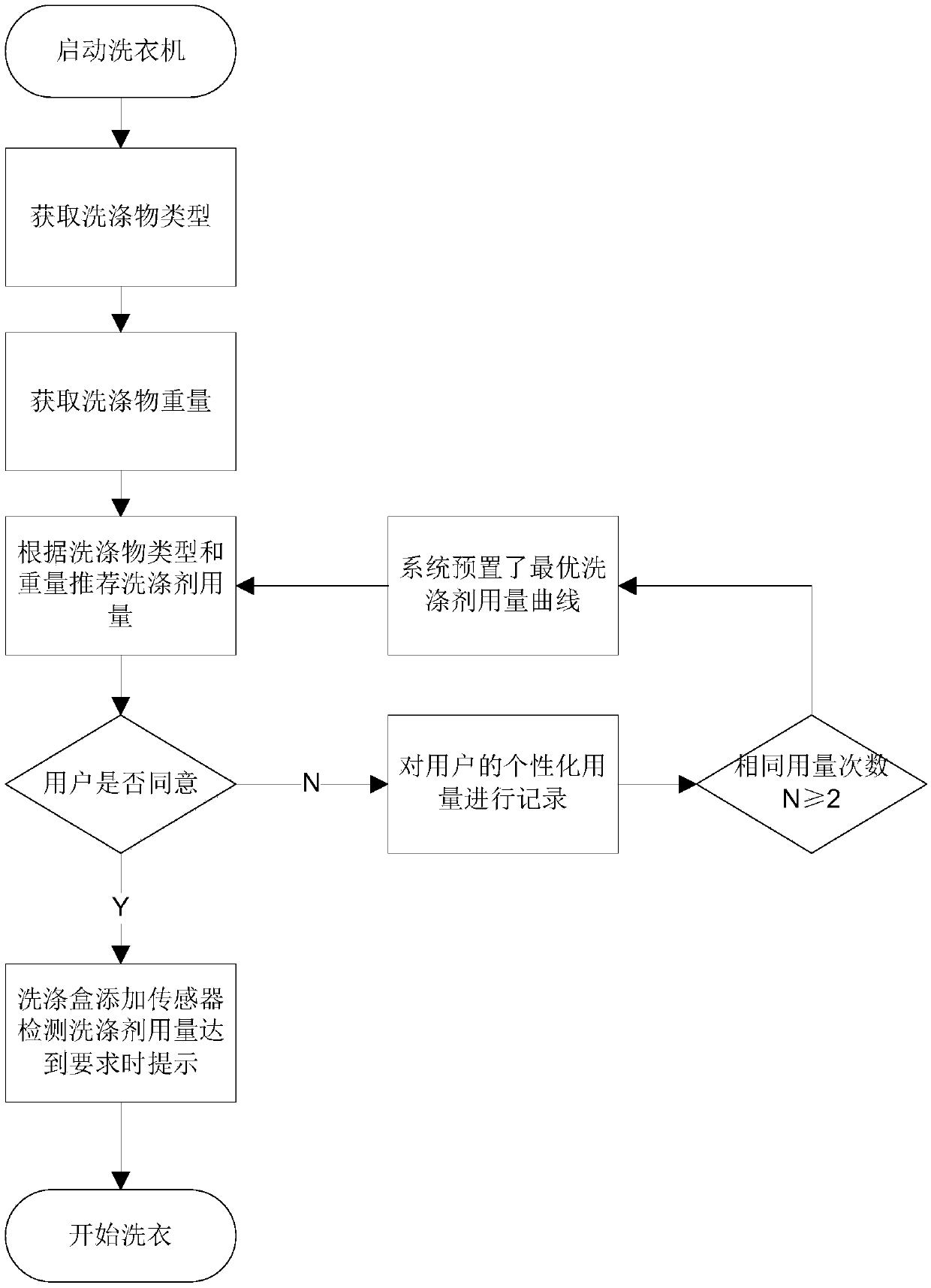

Method and device for controlling usage amount of washing agent of washing machine

InactiveCN109629184AAdequate dosageAvoid wastingOther washing machinesControl devices for washing apparatusProcess engineering

The invention provides a method and device for controlling the usage amount of a washing agent of a washing machine. The method for controlling the usage amount of the washing agent of the washing machine comprises the steps of obtaining the type of washings; obtaining the weight of the washings; according to the type of the washings and the weight of the washings, matching the usage amount of thewashing agent; according to the matched usage amount of the washing agent, adding the washing agent. According to the method for controlling the usage amount of the washing agent of the washing machine, the amount of the washing agent required by clothes washing can be accurately controlled, the washing effect is ensured, and moreover, waste of the washing agent is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

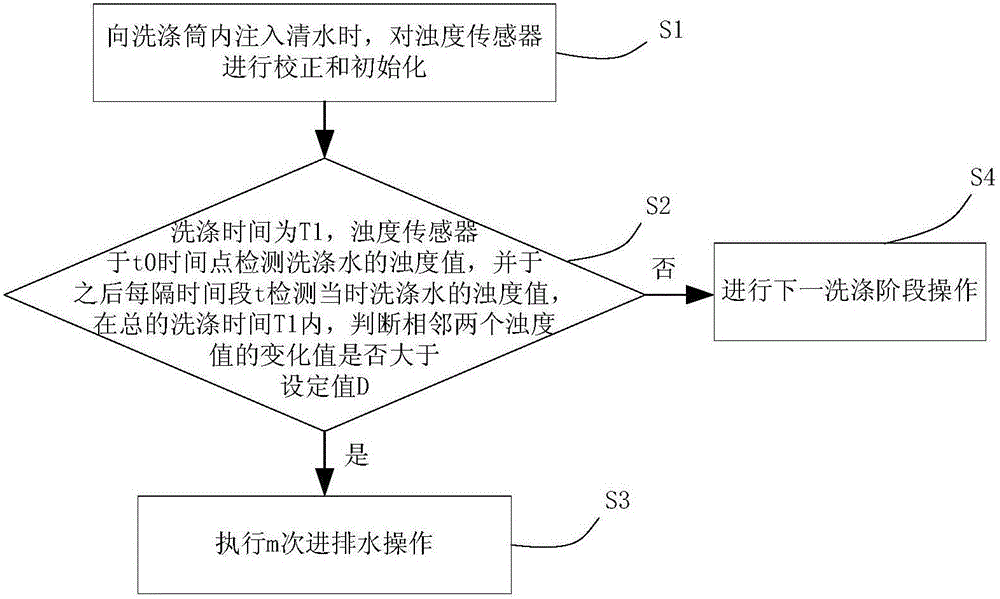

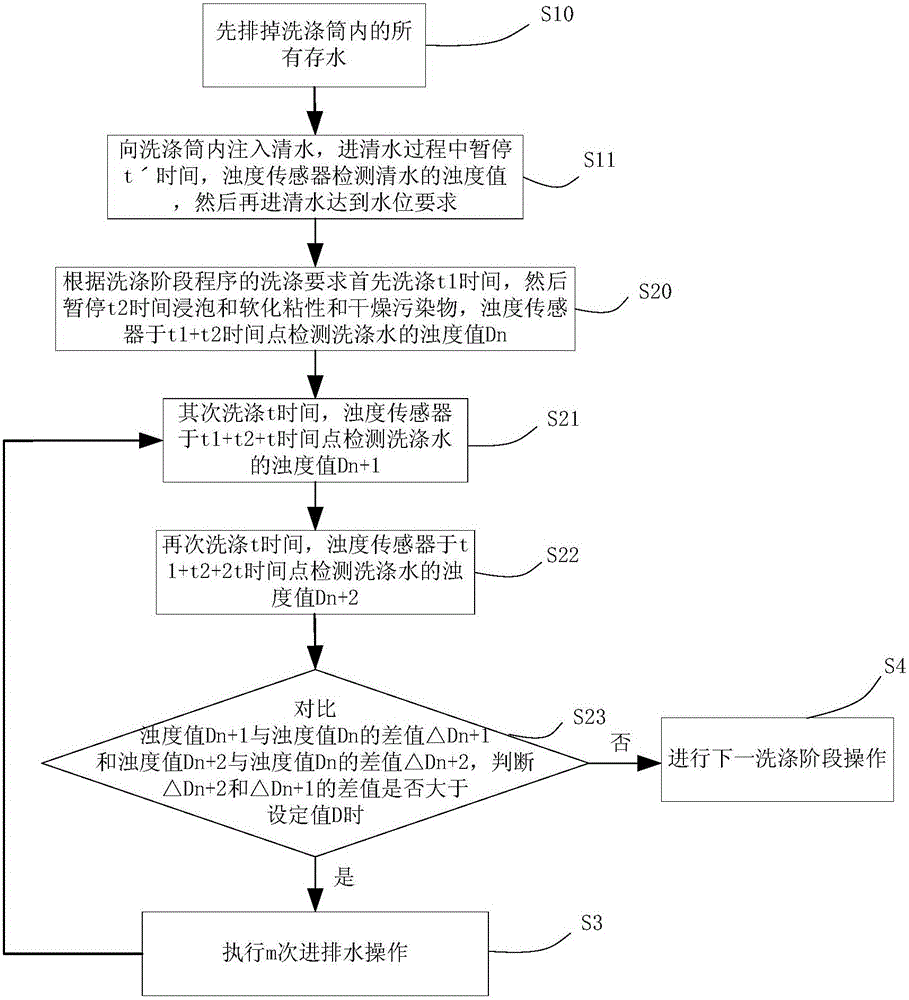

Method for improving cleaning rate and washing equipment

ActiveCN106691343AImprove cleaning rateImprove washing efficiencyTableware washing/rinsing machinesHome appliance efficiency improvementTurbidityEngineering

The invention discloses a method for improving cleaning rate and a washing equipment, which relates to the technical field of the washing equipment. The method for improving cleaning rate is that in the washing process the washing equipment, according to a washing stage and a turbidity of washing water, carries out several times the operation of draining into water and pouring into dirty water. At the same time, the invention also provides the washing device applying the method for improving the cleaning rate. The method not only reduces water consumption, and improves the cleaning rate, but also increases the washing efficiency, and lowers the washing cost.

Owner:QINGDAO HAIER DISHWASHER

Damage-free detergent for metal equipment

The invention discloses a damage-free detergent for metal equipment, which is prepared from the following raw materials in parts by weight: 4.3-6.2 parts of coconut oil monoethanolamide, 5.1-7.3 parts of polymaliec acid anhydride, 3.4-5.3 parts of tetrasodium ethylenediamine tetraacetate, 4.4-7.5 parts of 2-carboxyethylphosphonic acid, 7.3-10.4 parts of alkylphenol polyoxyethylene, 2.3-4.2 parts of surfactant and 3.7-5.4 parts of ethanolamine-triethanolamine mixture. The detergent has the cleaning effects of high economy and high efficiency, belongs to a concentrated product, and can be used after being diluted to a low concentration; all the components are combined effectively to generate an excellent synergic enhancement effect, so the detergent has favorable oil removal and antirust effects, and the average cleaning cost is low; the detergent has high safety performance, and does not pollute the environment; the detergent has the advantages of energy saving and low cleaning cost; and the detergent does not damage the metal equipment in the cleaning process, and does not corrode the metal equipment after cleaning.

Owner:QINGDAO HUIERTONG TRADING

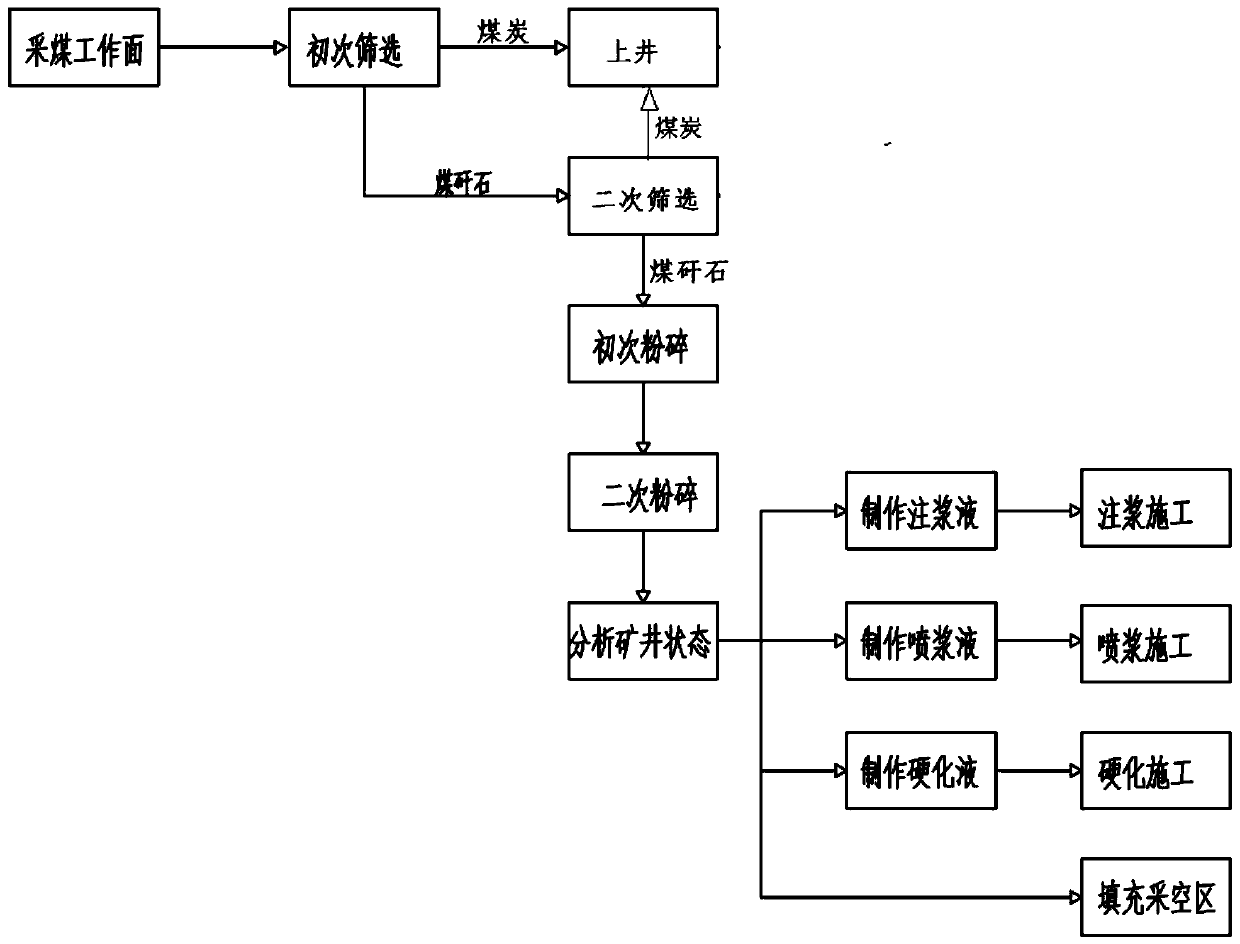

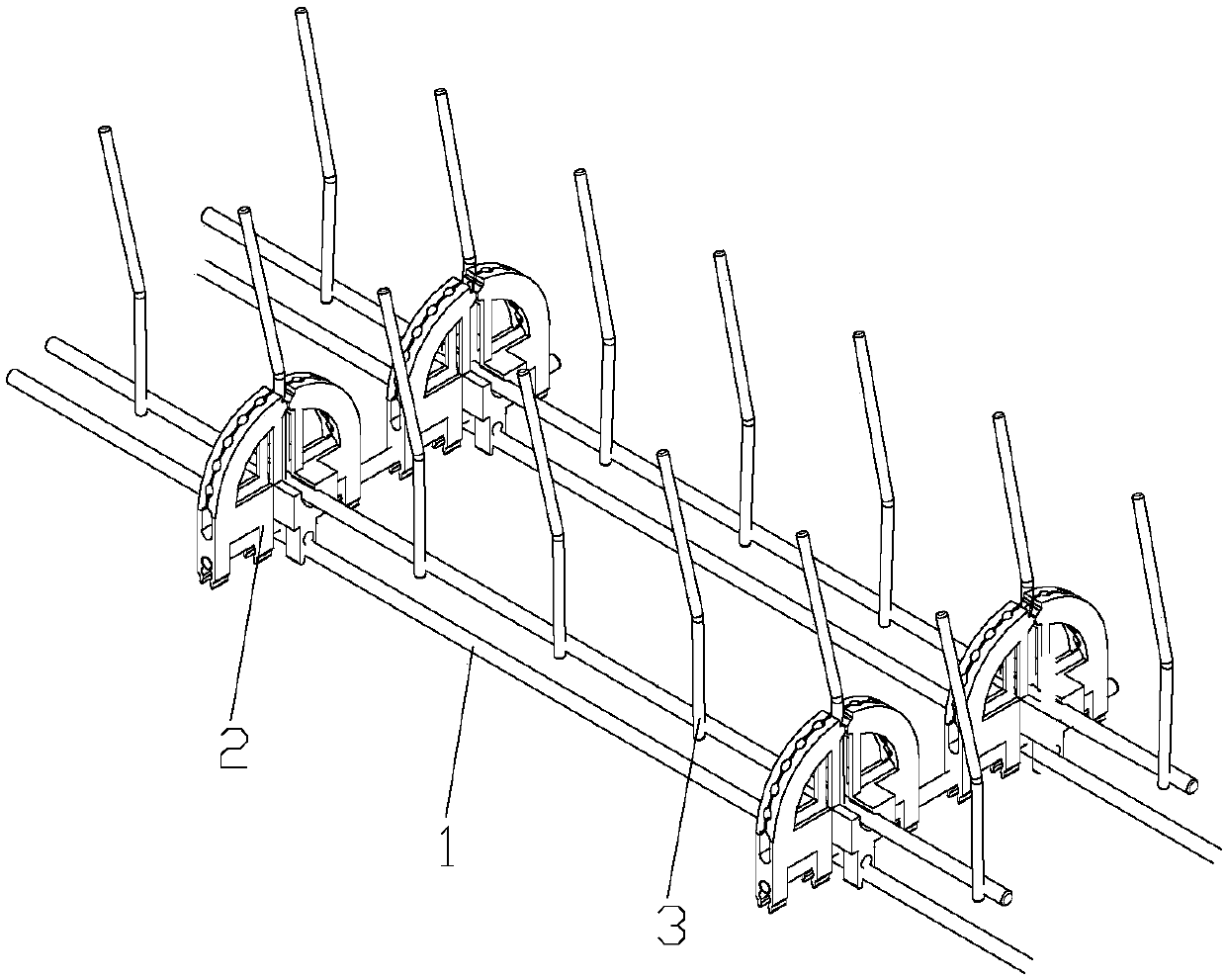

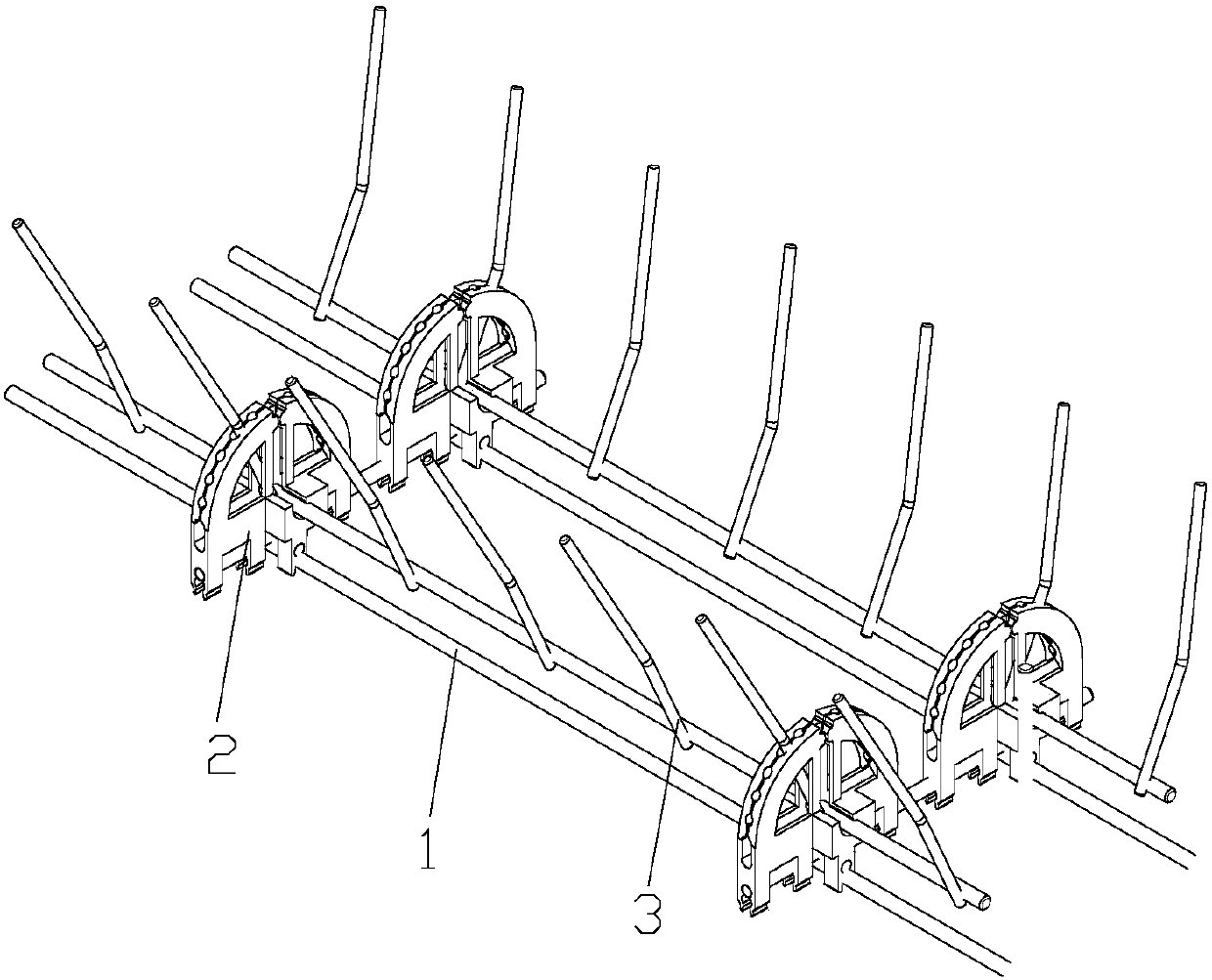

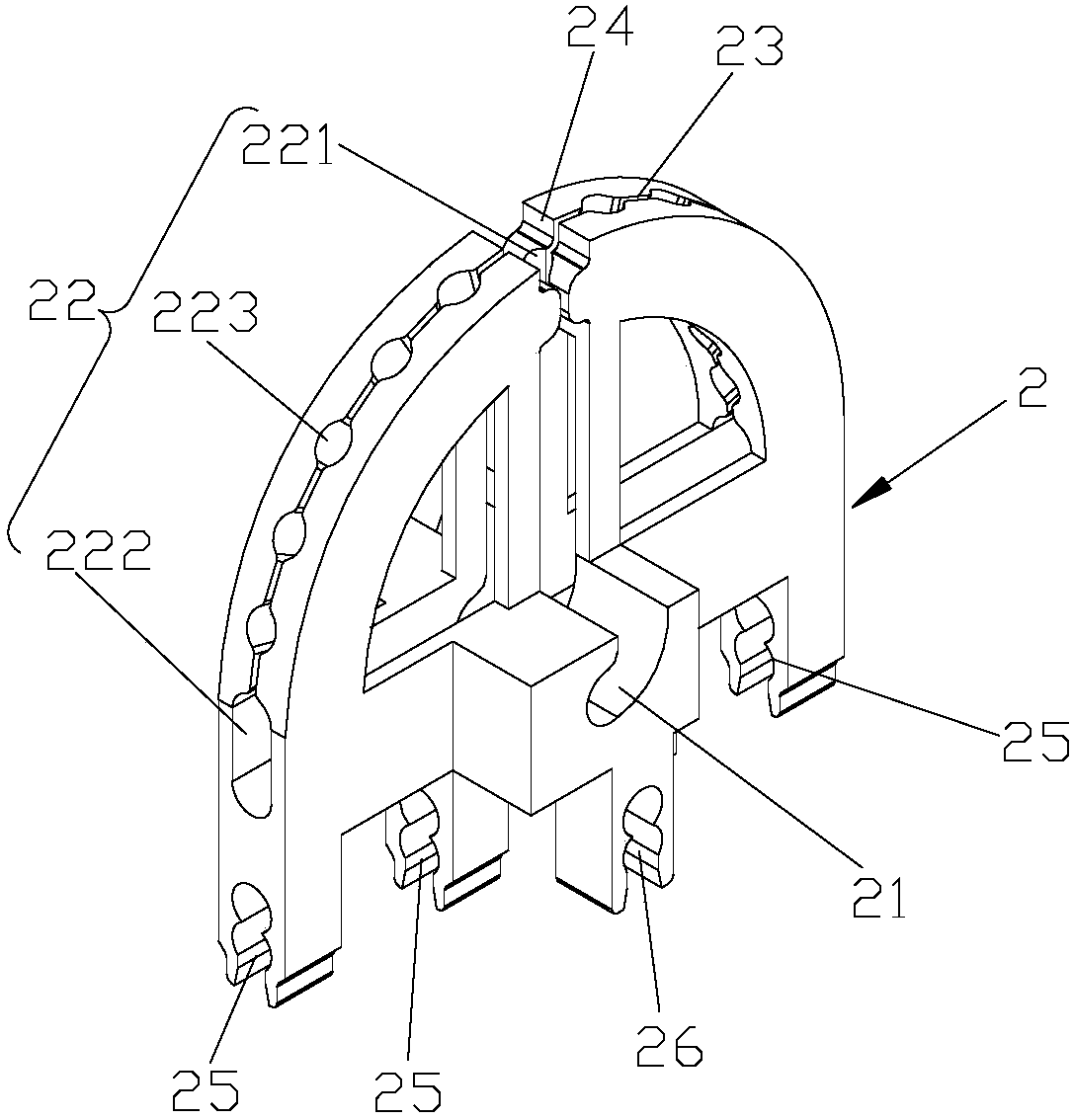

Coal gangue downhole processing method

InactiveCN111266172AQuality improvementReduce washing costsSievingUnderground chambersMining engineeringCoal gangue

The invention provides a coal gangue downhole processing method. The coal gangue downhole processing method comprises the following steps that excavated coal gangue is screened, coal is conveyed out of a mine, and the coal gangue is screened and left under the mine; the coal gangue is conveyed to a gangue warehouse to be stored; the coal gangue is subjected to smashing treatment; a mine state is analyzed, and construction is conducted on the mine with the coal gangue as a raw material according to the mine state. According to the coal gangue downhole processing method, by classifying the coaland the coal gangue under the mine, the coal quality is improved, and the sorting and cleaning cost of the coal after the coal is conveyed out of the mien is reduced. For the produced coal gangue, themine is reinforced specifically according to the situation of the mine with the coal gangue as the raw material, and the safety of the mine is improved. Processing of the coal gangue is completed under the mine, the cost for conveying the coal gangue out of the mine is reduced, pollution to the environment is reduced, and the coal gangue downhole processing method can be widely applied to the field of coal mining.

Owner:山西鸿太旭飞建设有限公司

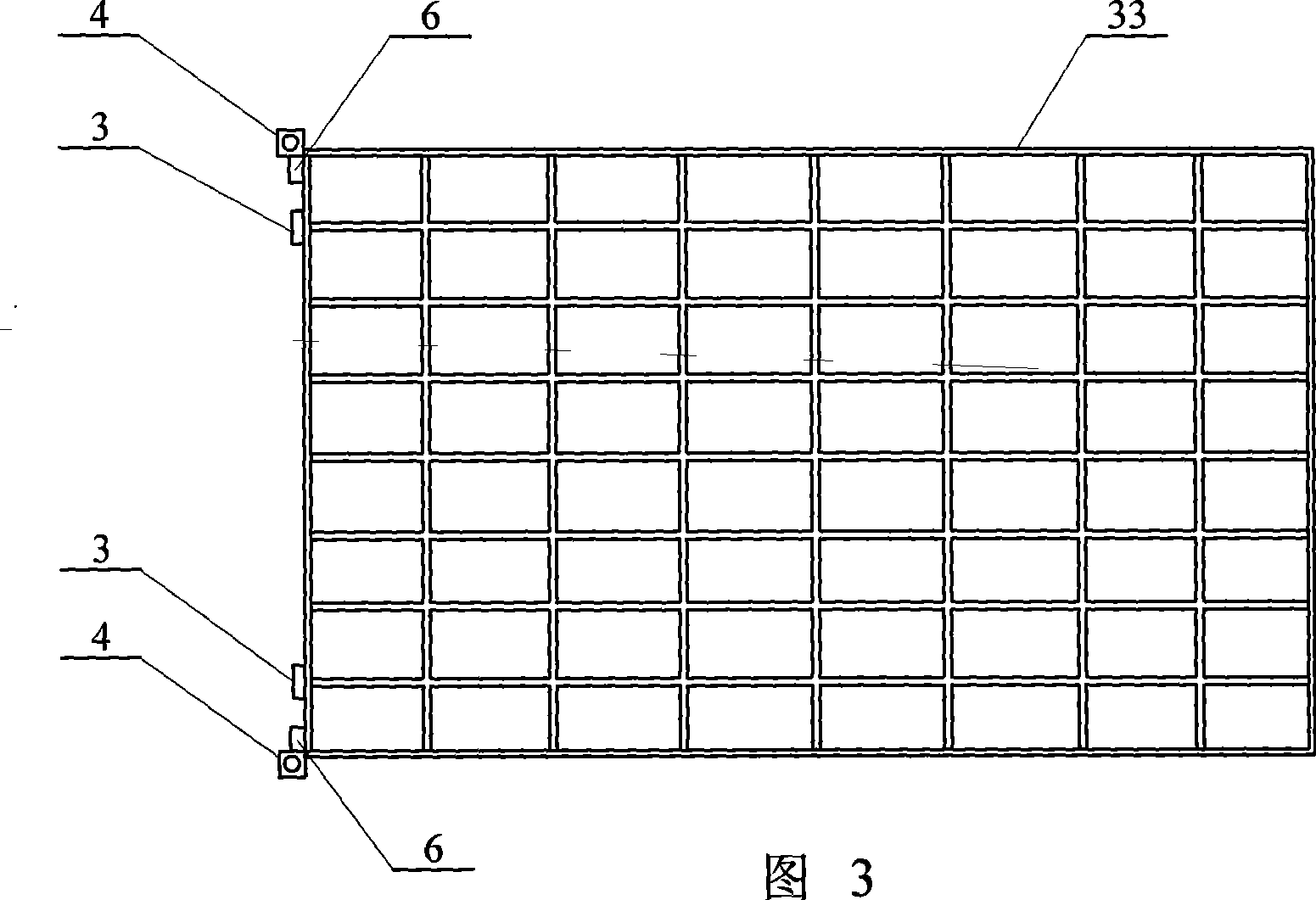

Dish-washing machine dish placing rack and dish-washing machine with same

InactiveCN107713953AWide range of rotation anglesGuaranteed stability and securityTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses a dish-washing machine dish placing rack, and relates to the technical field of dish-washing machines. The dish-washing machine dish placing rack comprises a bottom frame. Thebottom frame is provided with at least two base groups in parallel. Each base group comprises a left base and a right base which are opposite. Each base is internally provided with a holding groove. Two opposite holding grooves are internally rotatably provided with a bowl support. The bowl support is uniformly provided with a plurality of support teeth. To-be-cleaned tableware is placed between two adjacent support teeth. Each base is provided with a plurality of positioning holes at interval in range of 0-180 DEG. Support teeth on two ends of the bowl support can respectively slide into opposite positioning holes, and the support teeth are used to fix the bowl support at a certain angle. The invention also discloses a dish-washing machine. The dish placing rack can adapt to bowls in different depth and diameters, and inclination angles of tableware can be effectively adjusted, so as to realize maximization of the number of tableware washed in the same region, greatly save washing cost of users, and effectively improve washing effect of the dish-washing machine.

Owner:QINGDAO HAIER DISHWASHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com