Water-based LED (light emitting diode) chip cleaning agent

A technology of LED chip and cleaning agent, which is applied in the field of cleaning agent, can solve the problems of detection failure, corrosion and corrosion, short circuit and open circuit, etc., and achieve the effect of fast volatilization rate, strong decontamination ability and reduced surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with specific examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

[0020] Unless otherwise specified, the technical means used in the examples are conventional means well known to those skilled in the art, and the raw materials used are all commercially available. Various procedures and methods not described in detail are conventional methods well known in the art.

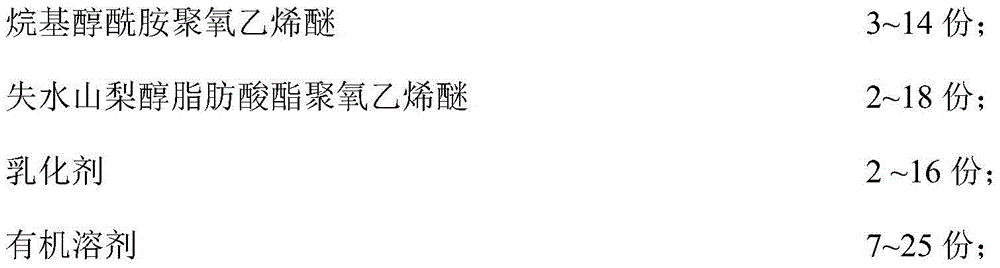

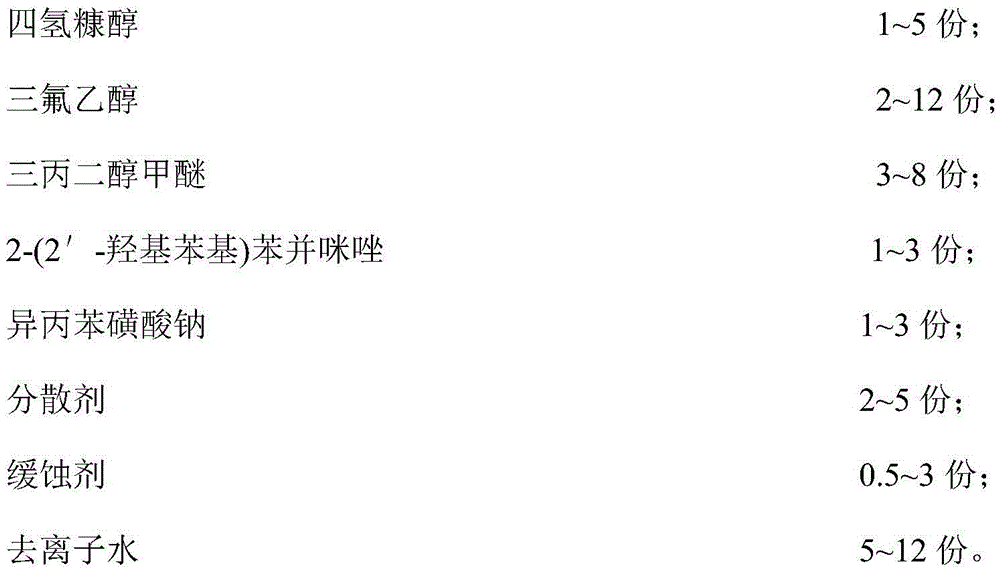

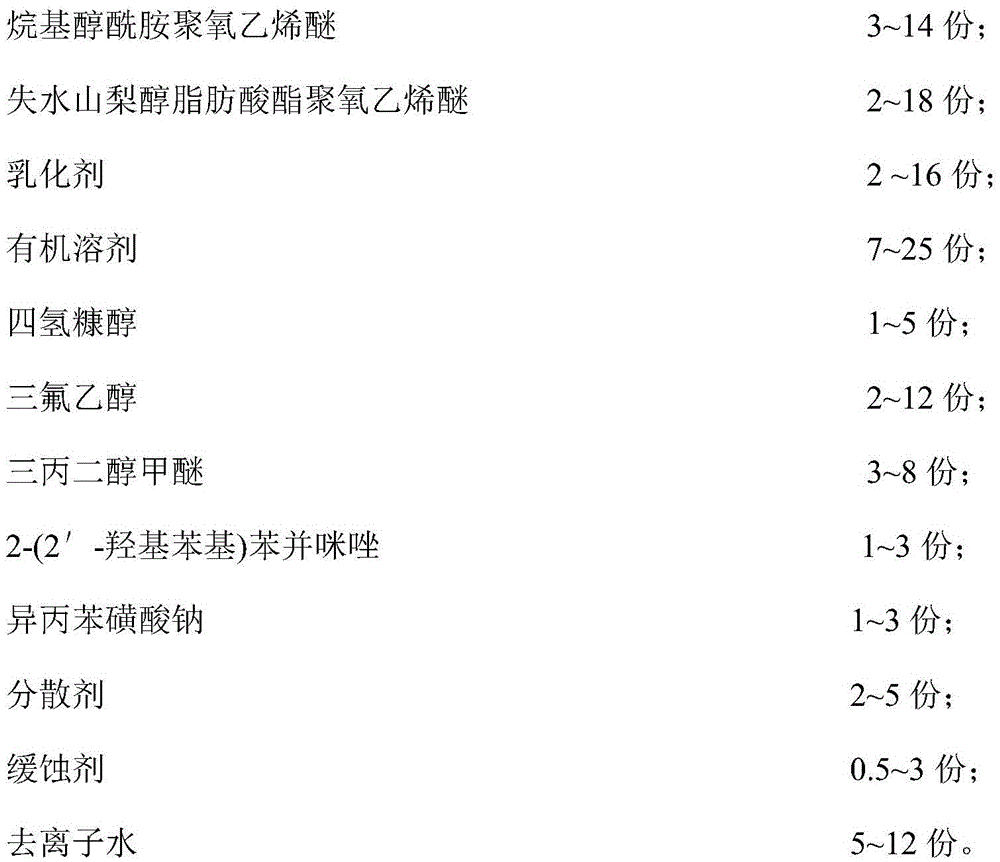

[0021] A water-based LED chip cleaning agent, comprising the following components by weight:

[0022]

[0023] As a further improvement of the present invention, the corrosion inhibitor is one or two of benzotriazole, sodium benzoate and ammonium benzoate.

[0024] As a further improvement of the present invention, the alkyl alcohol amide polyoxyethylene ether is a product obtained by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com