Patents

Literature

189results about How to "Realize separation and recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

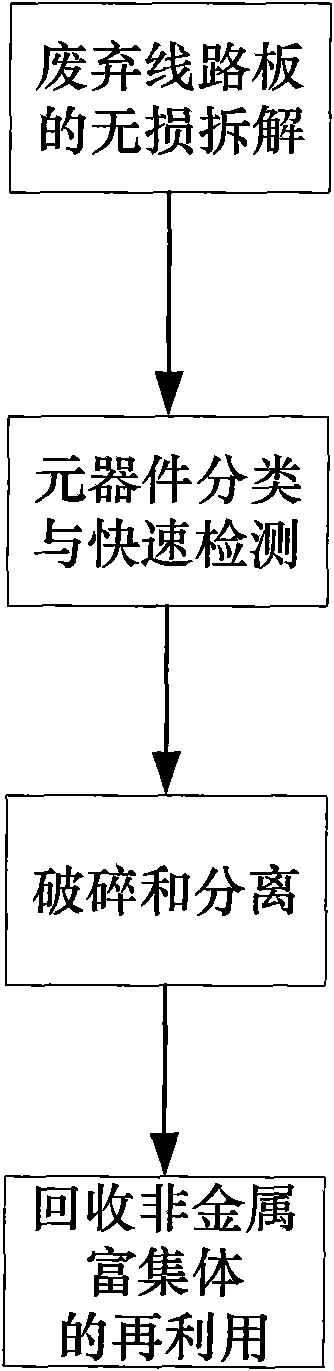

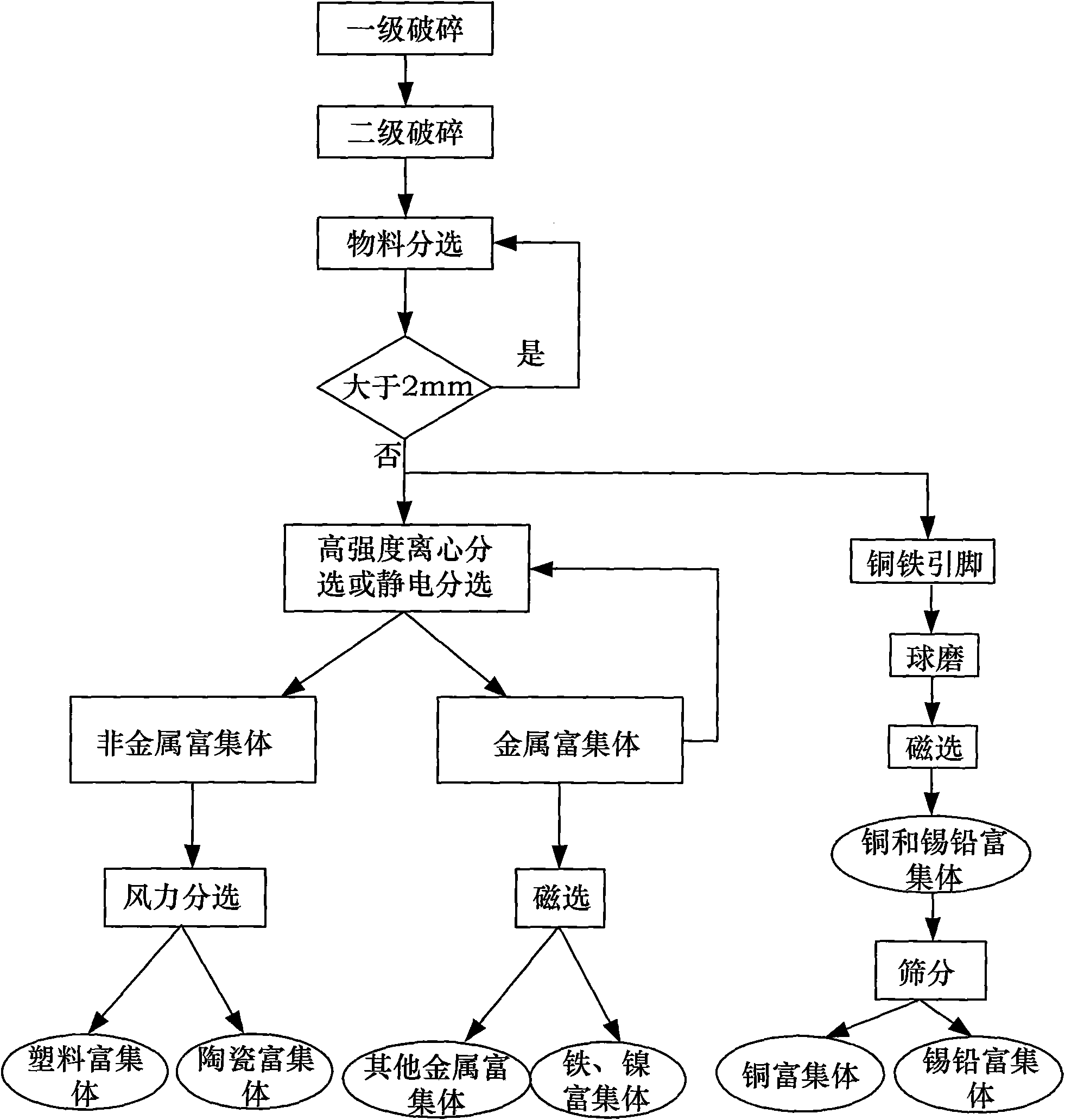

Recycling method of discarded circuit board

InactiveCN101642765ARealize separation and recoverySimplified brokenSolid waste disposalSoldering apparatusEngineeringMetal powder

The invention discloses a recycling method of discarded circuit boards, comprising the following steps: disassembling a discarded circuit board into three parts: a base plate, components and solder, then carrying out sorting and rapid detection on disassembled components; respectively crushing and separating the base plates and various loss-of-function components, and recycling the crushed and separated various powders, wherein the metal powder can be directly reused, and the recycled non-metal powder is used for being prepared into compound material. The method provided by the invention can realize sorting recycling of all resources of the discarded circuit boards; the recycled material can be reused, and therefore, the secondary pollution can not be generated.

Owner:BEIHANG UNIV

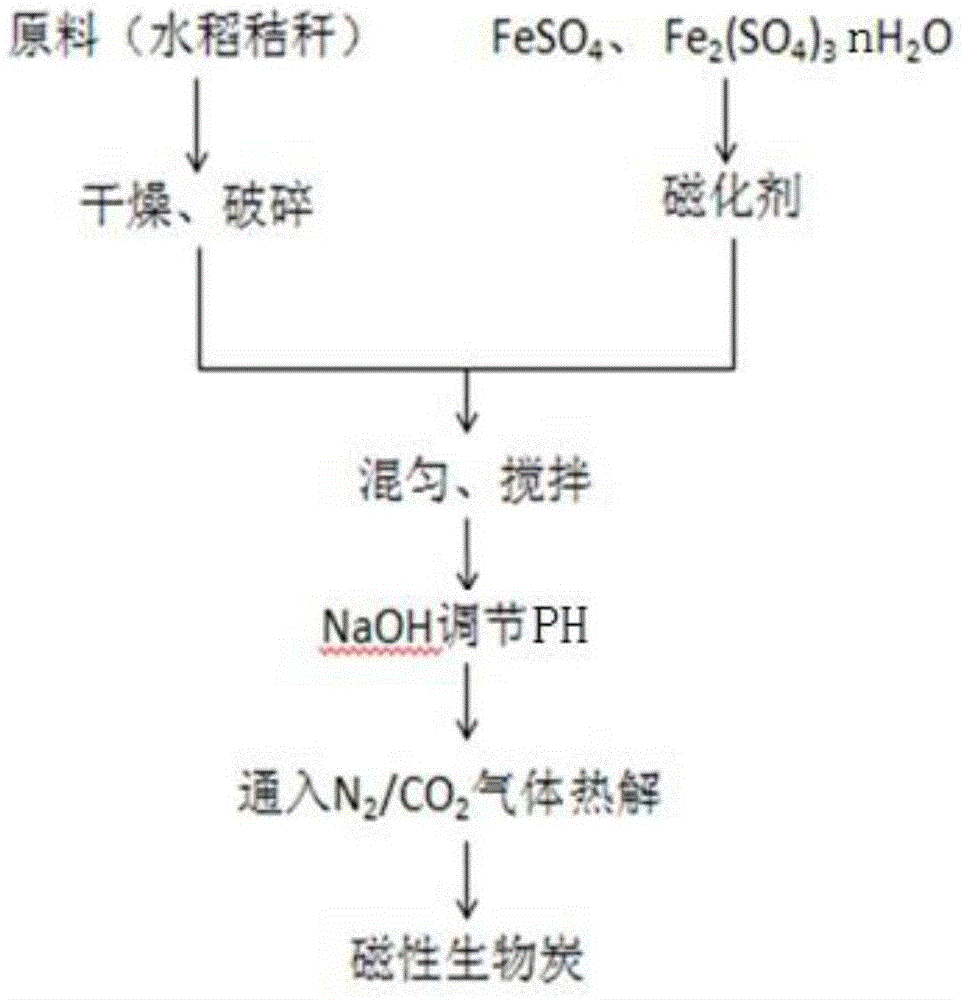

Preparation method for magnetic biological carbon by one-step synthesis

InactiveCN105536703ASimple preparation processGood effectOther chemical processesAlkali metal oxides/hydroxidesBiomassNitrogen gas

The invention discloses a preparation method for magnetic biological carbon by one-step synthesis. The preparation method comprises the following steps: air-drying a biomass raw material under a natural condition and then storing for later use, and adding a dried and crushed biomass raw material into a ferric salt solution; slowly stirring a mixed solution, then, regulating a pH (potential of hydrogen) value with an NaOH solution, then, continuously stirring, then, standing until the biomass raw material absorbs the ferric salt solution to reach a saturation state, performing suction filtration to remove free water in the biomass raw material, pyrolyzing a suction filtration-treated biomass raw material in a pyrolyzing furnace to make carbon, and introducing an inert shielding gas into the pyrolyzing furnace to obtain the magnetic biological carbon. According to the preparation method disclosed by the invention, carbonization and magnetization are combined together to synthetize the magnetic biological carbon by one-step pyrolysis; meanwhile, different magnetic biological carbon materials can be obtained by changing the shielding gas (nitrogen or carbon dioxide); an effect of removing typical heavy metal pollutants in a water body is obvious, and moreover, the typical heavy metal pollutants can be separated and recovered from the water body as well so as to protect the environment from secondary pollution.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Method for recycling carbon and electrolytes from waste cathode carbon block of aluminum electrolytic cell

InactiveCN105821445AReduce dosageReduced dosage of chemicals (reduced amount of collectorElectrolysis componentsCalcium/strontium/barium fluoridesKeroseneFuel oil

The invention discloses a method for recycling carbon and electrolytes from a waste cathode carbon block of an aluminum electrolytic cell. The method comprises the following steps that 1, the cathode carbon block is crushed and grinded; 2, cathode carbon powder obtained from the cathode carbon block subjected to crushing and grinding in the step 1 is stirred and leached in alkali liquor and then filtered, so that a filter cake A1 and filtrate B1 are obtained; and a precipitating agent is added into the filtrate B1, so that a filter cake A2 and filtrate B2 are obtained after filtering is conducted; and 3, the filter cake A1, the filter cake A2, a flotation medium and flotation reagents are subjected to mixing and pulp conditioning, and thus the carbon and electrolytes are obtained through flotation and separation; the flotation reagents comprises the collecting agents, the foaming agents and the conditioning agents; the collecting agents are composed of the collecting agent C1 and the collecting agent C2 at the mass ratio of 0.65-0.75:0.25-0.35; the collecting agent C1 is selected from at least one of coal tar, heavy oil, kerosene and diesel oil; and the collecting agent C2 is selected from at least one of dodecylamine, sodium dodecyl benzene sulfonate, sodium oleate and sodium dodecyl sulfate. According to the method for recycling the carbon and the electrolytes from the waste cathode carbon block of the aluminum electrolytic cell, the carbon powder and the electrolytes are effectively separated and recycled from the waste cathode carbon block.

Owner:CENT SOUTH UNIV

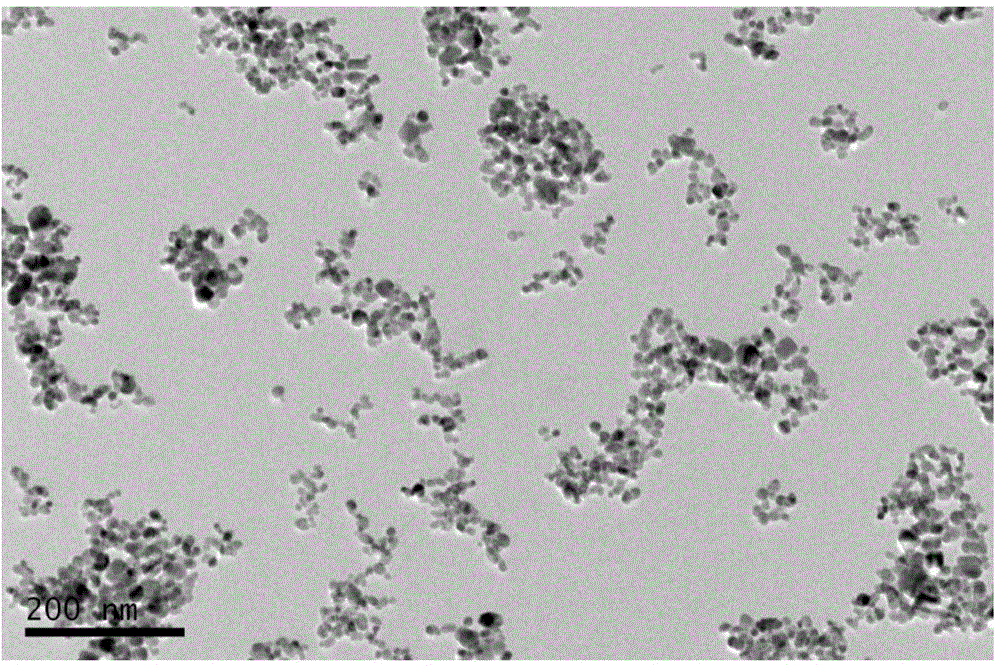

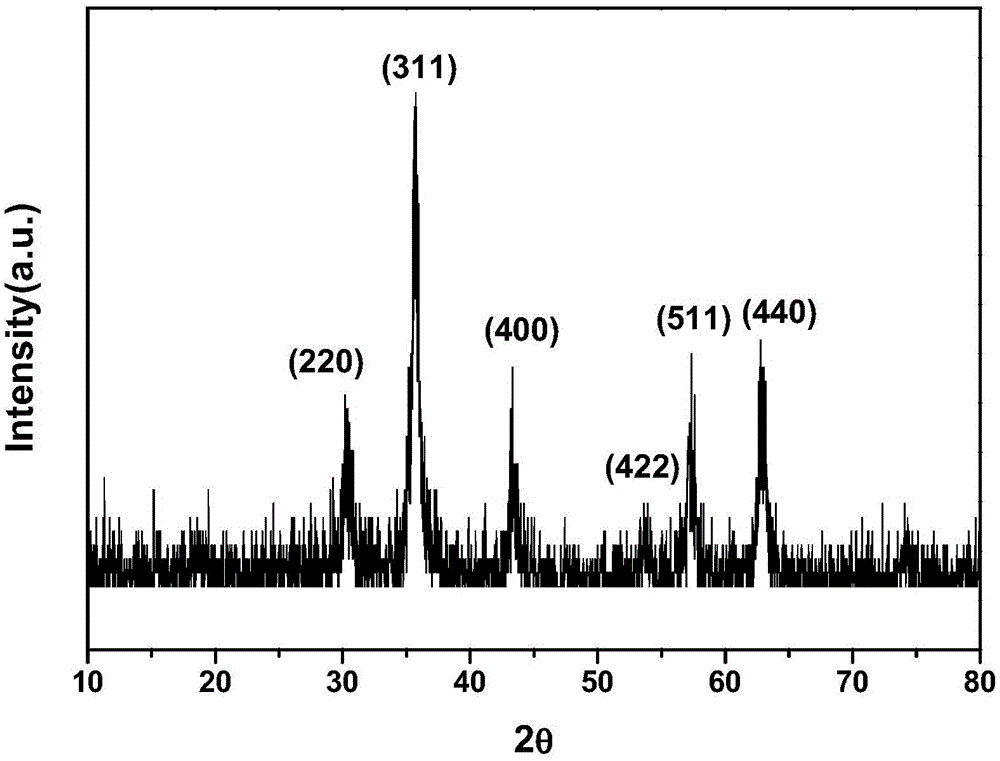

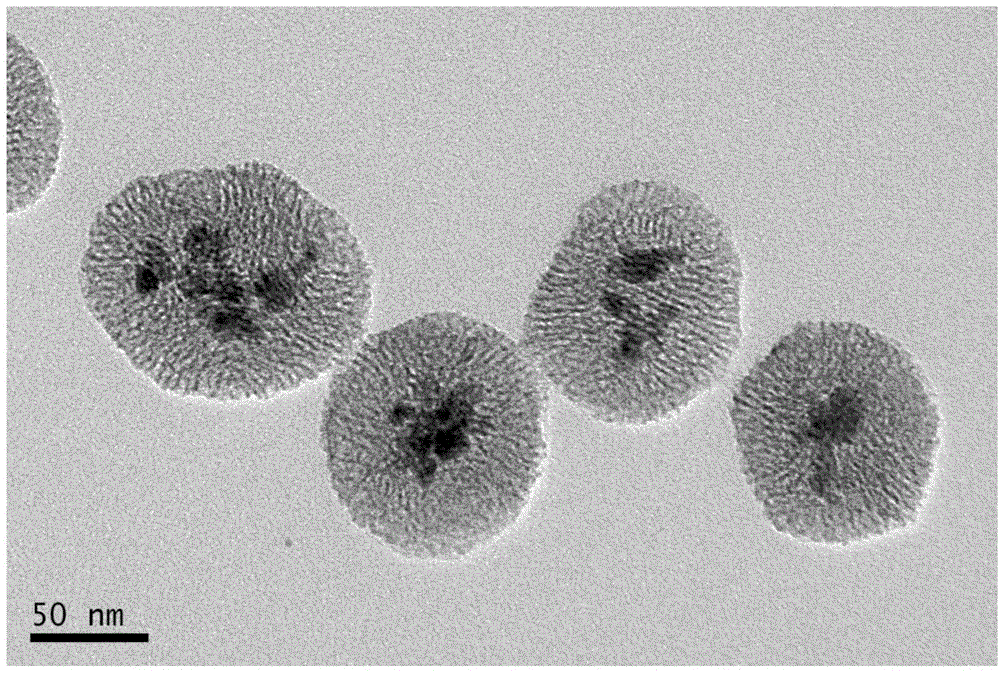

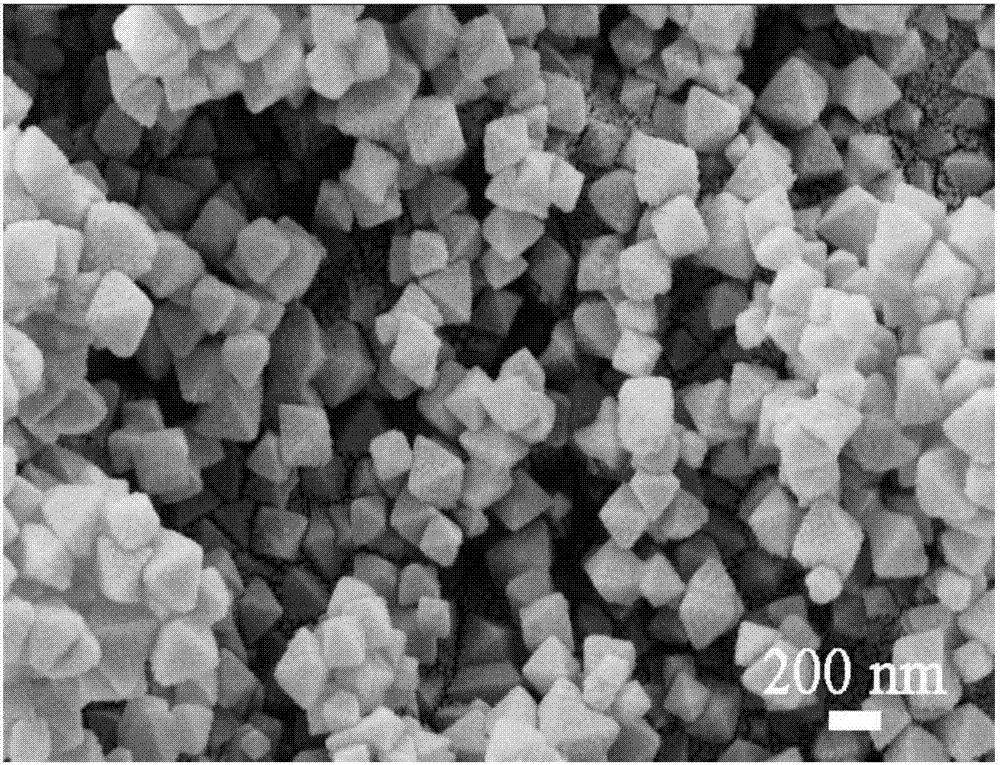

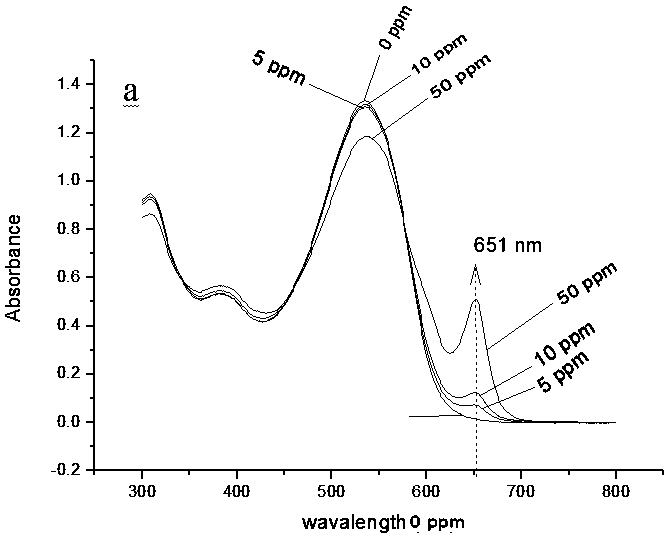

Chitosan-coated magnetic mesoporous silica core-shell structure nano-particle and preparation method and application thereof

InactiveCN104785214AImprove adsorption capacityRealize separation and recoveryOther chemical processesAlkali metal oxides/hydroxidesIon exchangeMesoporous silica

The invention discloses a chitosan-coated magnetic mesoporous silica core-shell structure nano-particle and a preparation method and application thereof. The preparation method is characterized by comprising the following steps: preparing a ferroferric oxide nano-particle by using a co-precipitation method; preparing a magnetic silica nano-particle by using a sol-gel method, and removing a pore-foaming agent by using an ion exchange method to obtain a magnetic mesoporous silica nano-particle; performing surface treatment on magnetic mesoporous silica by using a silane coupling agent, and then grafting chitosan to obtain a target product. The ferroferric oxide nano-particle is introduced into the obtained product, so that after adsorption is completed, the product can be quickly separated and recycled through an external magnetic field; the product has an excellent adsorption effect on methylene blue.

Owner:ANHUI UNIVERSITY

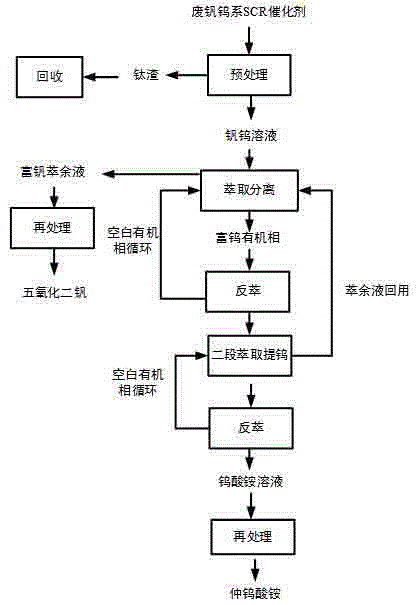

Vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts

ActiveCN104862485ARealize separation and recoveryRealize recycling of resourcesProcess efficiency improvementPtru catalystAmmonium paratungstate

The invention discloses a vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts. The method comprises the following steps: a spent catalyst is pretreated to obtain titanium slag and a vanadium and tungsten solution; the vanadium and tungsten solution is extracted for separation, and an obtained vanadium-rich raffinate is treated again to obtain vanadium pentoxide; a tungsten-rich organic phase obtained through separation is subjected to two-stage extraction for tungsten extraction after back extraction, a product is subjected to back extraction again to obtain an ammonium tungstate solution, and the ammonium tungstate solution is treated to prepare ammonium paratungstate. The blank of lack of a vanadium and tungsten separating, purifying and recovering technology for the spent vanadium and tungsten SCR catalysts in the denitration industry is filled up completely, the recovery rates of vanadium and tungsten both exceed 95%, the obtained vanadium pentoxide and ammonium paratungstate products all meet the high-purity standard, and the purity is higher than 99%.

Owner:BOTREE CYCLING SCI &TECH CO LTD

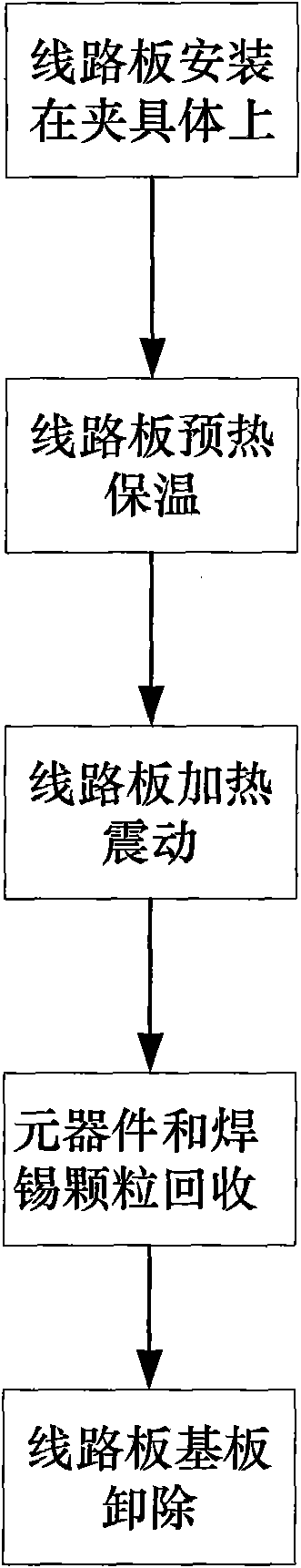

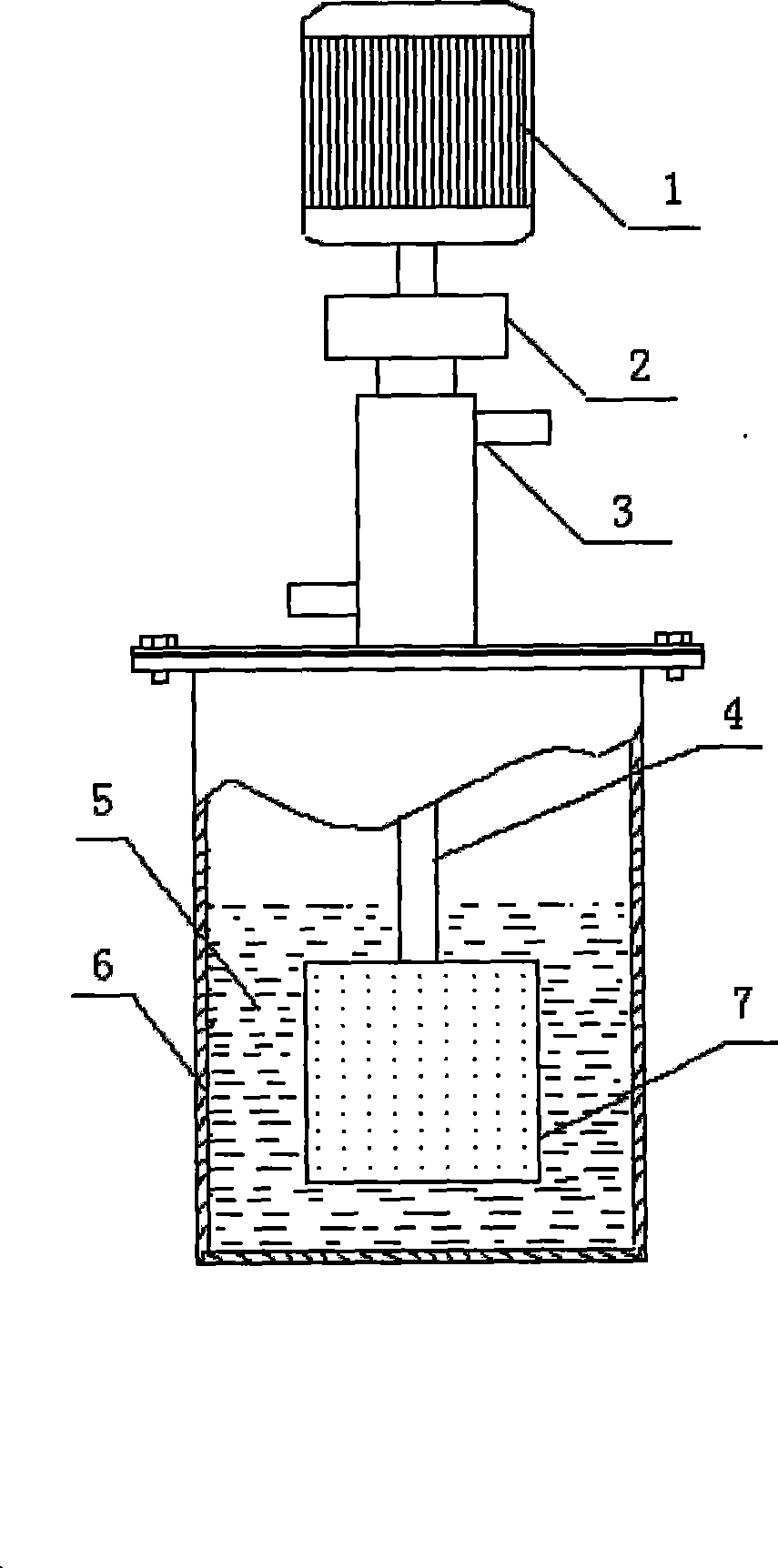

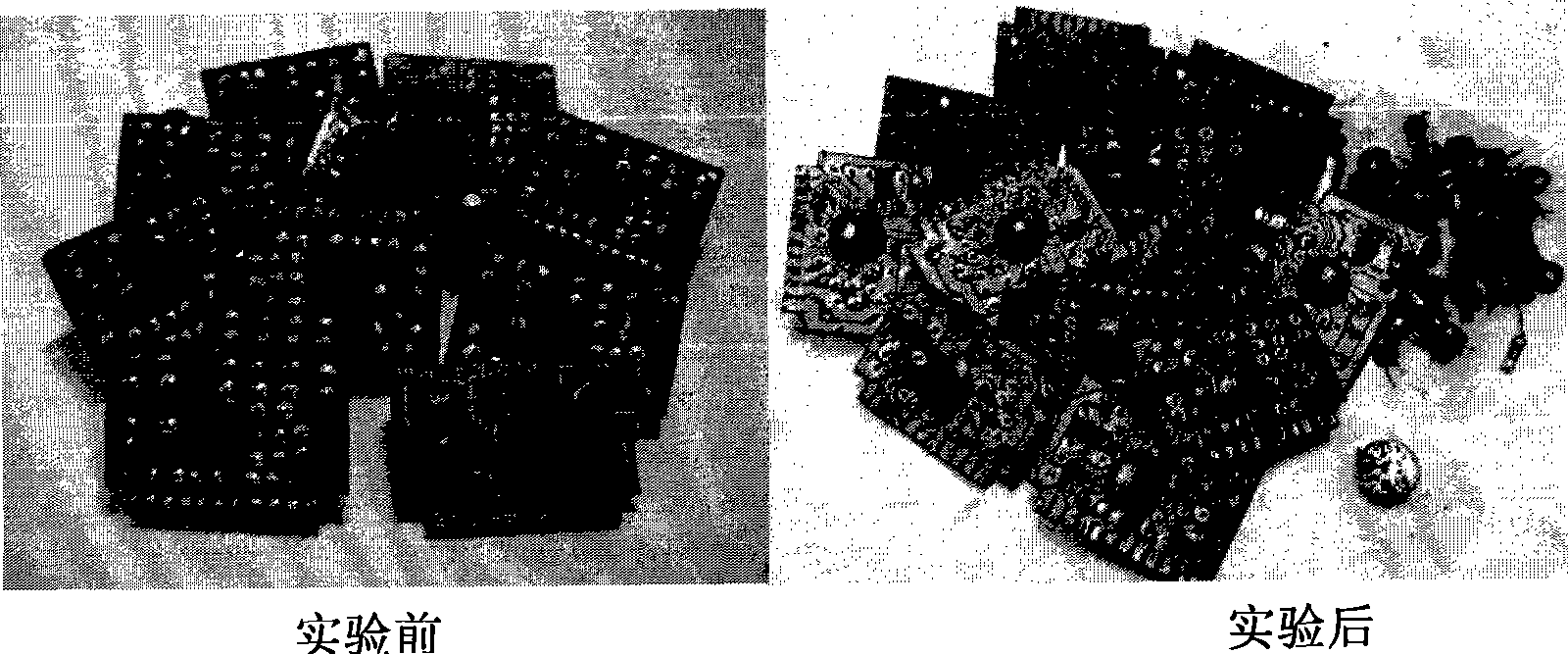

Technique and device for effectively recovering waste printed circuit boards solder

InactiveCN101362143ARealize separation and recoveryNo secondary pollutionSolid waste disposalSoldering apparatusHeat conductingIngot

The invention relates to a technology for high-efficiently recycling soldering tin of discarded printed circuit boards, and a device. In a sealed system, in which liquid heat conducting medium exists, discarded printed circuit boards to be processed and welded with electronic parts are put in a swivel which is provided with a plurality of filtering holes and immersed in the heat conducting medium, the temperature is risen until the soldering tin is melted, after the temperature is constant, the swivel is rotated to centrifugally separate solid and liquid, the soldering tin leaks from the filtering holes, deposits at the bottom and is cooled into ingot, and the electronic parts are separated from the discarded printed circuit boards correspondingly. The method for recycling the soldering tin of discarded printed circuit boards has no environmental pollution, low energy consumption and high efficiency, and can create good condition for high-efficiently recycling other metals.

Owner:CENT SOUTH UNIV

pH (potential of hydrogen) responsive metal organic framework nanometer crystal, preparation method and application

InactiveCN106928465AChange hydrophilicityHigh interface activityCarboxylic acid nitrile preparationOrganic compound preparationHydrogenMetal-organic framework

The invention discloses a pH (potential of hydrogen) responsive metal organic framework nanometer crystal, a preparation method and application. The pH responsive metal organic framework nanometer crystal comprises a metal organic framework and a pH responsive segment, wherein the pH responsive segment is graftedadhered to an organic ligand of the metal organic framework, and can be a pH responsive polymer, a chain segment containing a carboxylic group, or a chain segment containing a pyridine group. The pH responsive metal organic framework nanometer crystal has the advantages that the pH responsive segment is grafted onto the organic ligand of the metal organic framework, so that the contact angle of the metal organic framework is changed, namely that the hydrophilicity and hydrophobicity properties of the metal organic framework are changed, thereby increasing the interface activity of the pH responsive metal organic framework; the pH responsive segment has response property to the change of the pH value of the surrounding environment, the pH responsive metal organic framework has different hydrophilicity and hydrophobicity properties under different pH values, and then the pH responsive metal organic framework can be separated and recycled by adjusting the pH value.

Owner:SHANDONG NORMAL UNIV

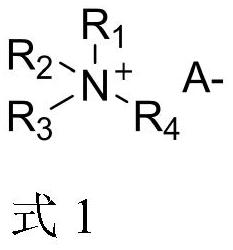

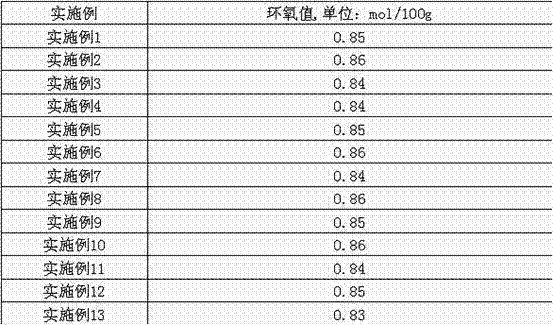

Catalytic preparation method of dicyclopentadiene dioxide by quaternary ammonium heteropoly phosphato tungstate

The invention discloses a catalytic preparation method of dicyclopentadiene dioxide by quaternary ammonium heteropoly phosphato tungstate, which is characterized by comprising the following steps: epoxidation reaction: adding the raw materials of dicyclopentadiene, solvent I and quaternary ammonium heteropoly phosphato tungstate in a reactor, heating the temperature to 30-80 DEG C, stirring and dropwise adding aqueous hydrogen peroxide solution, and reacting for 3-36h under the temperature of 30-80 DEG C after dropwise adding; post-treatment: cooling the reacted materials to room temperature, evaporating solvent I by reduced pressure distillation and separating and removing water to obtain the mixture of the product and the quaternary ammonium heteropoly phosphato tungstate catalyst, dissolving and filtering the mixture by ethyl acetate to obtain filter cake, namely the recovered quaternary ammonium heteropoly phosphato tungstate catalyst, recovering ethyl acetate by performing reduced pressure distillation on filtrate to obtain the crude product, performing recrystallization on the crude product by solvent II, and drying to obtain the product. The invention has the advantages of convenient operation, high safety, small pollution, simple post treatment, and high product yield and purity.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Method for floatation-recovering valuable metals in superfine cyanided tailings by using high-cyanogen backwater

ActiveCN104073645AReduce pollutionSave waterFlotationProcess efficiency improvementSulfurHydrometallurgy

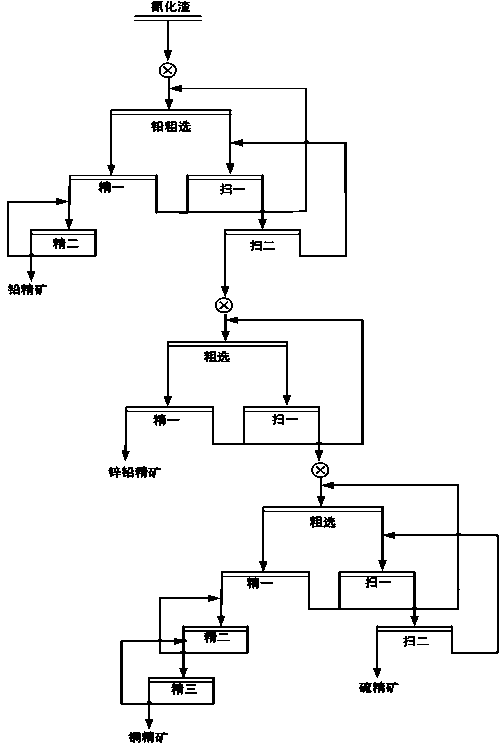

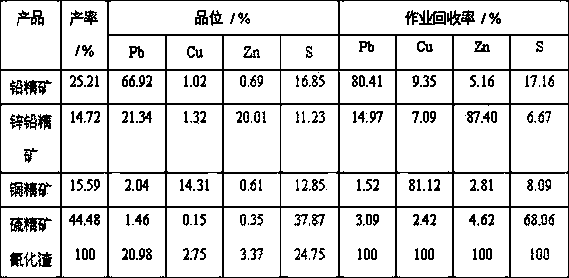

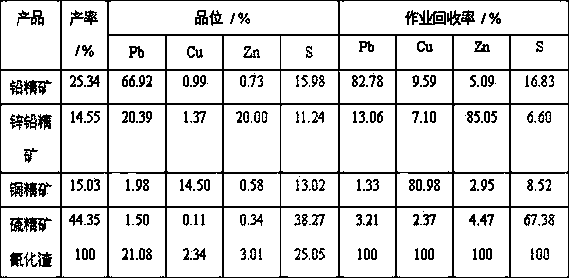

The invention belongs to the field of wet metallurgy, and particularly relates to a method for carrying out floatation recovering of valuable metals in superfine cyanided tailings by using high-cyanogen backwater. The method comprises the following steps: firstly, carrying out pulp mixing by utilizing a method for carrying out floatation recovering of valuable metals in superfine cyanided tailings by using high-cyanogen backwater during cyaniding operation, delivering the ore pulp to a flotation unit, regulating the pH of the ore pulp to be 10-12 with lime, recovering lead by adopting 'one-roughing, two-cleaning and two-scavenging' flow, concentrating the lead scavenged tailings and then adding into high-cyanogen backwater for mixing pulp, recovering zinc-lead concentrate by adopting 'one roughing, one cleaning and one scavenging' flow, concentrating the zinc-lead scavenged tailings and then adding into high-cyanogen backwater for mixing pulp, recovering copper concentrate by adopting 'one roughing, three cleaning and two scavenging' flow, carrying out twice scavenging on the copper scavenged tailings again, finally concentrating, and enabling bottom flow to flow through a filtering machine to obtain a concentrate product. Floatation is carried out by utilizing high-cyanogen high-base backwater and adopting combined floatation and inhibition chemicals, the separation and recovery of lead, zinc, copper and sulfur can be realized, and various valuable metals in the cyanided tailings can be effectively utilized.

Owner:NORTHEASTERN UNIV

Oily sludge recycling and treatment method

InactiveCN107253813AImprove extraction efficiencyAvoid separation and recycling inefficientWaste water treatment from quariesSludge treatmentChemistryUltrasonic oscillation

The invention discloses an oily sludge recycling and treatment method. The oily sludge recycling and treatment method comprises the following steps: mixing oily sludge, water and an extracting agent in a mass ratio of 1:2:(0.3-0.7), wherein the extracting agent is a mixture containing a low-boiling-point organic solvent, a dispersing agent and an anionic surfactant; carrying out ultrasonic oscillation on the mixture in the step S1, and forming an oily sludge extracting agent mixed solution; carrying out solid-liquid centrifugal separation on the oily sludge extracting agent mixed solution, so that deoiled sludge and oil-water extracting agent mixed solution are obtained; and carrying out water separation and oil purification and recycling on the oil-water extracting agent mixed solution. The oily sludge recycling and treatment method provided by the invention is low in separation cost and high in efficiency and can realize extraction and recycling of petroleum in oily sludge, so that resources are utilized again.

Owner:湖南云平环保科技有限公司

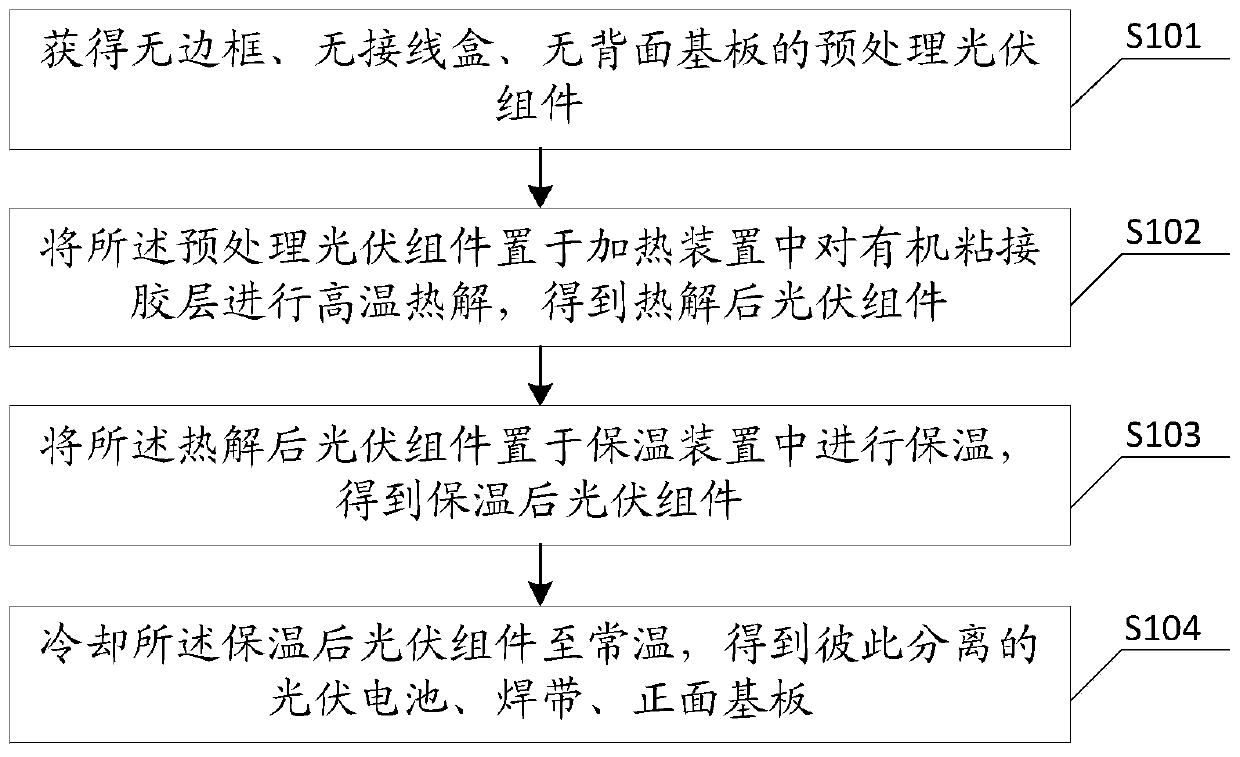

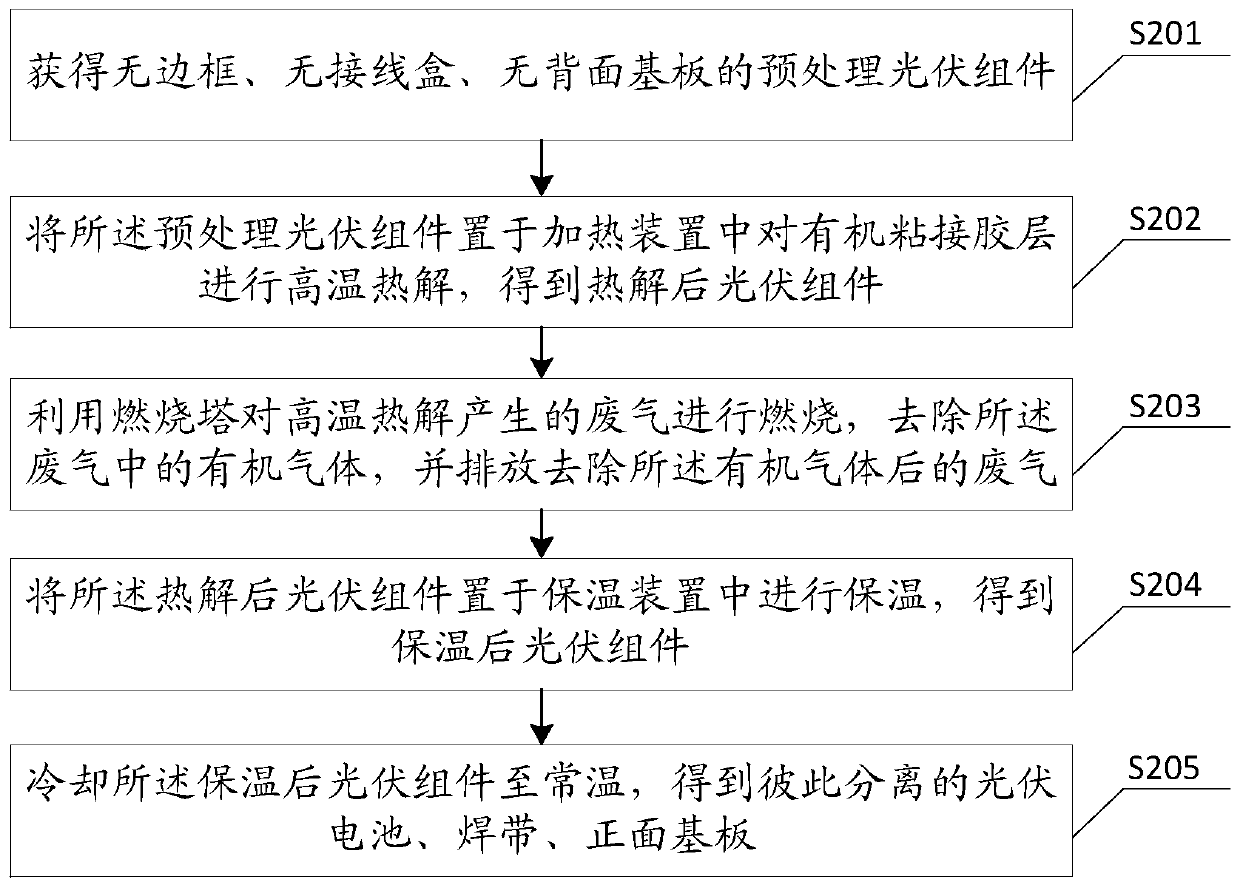

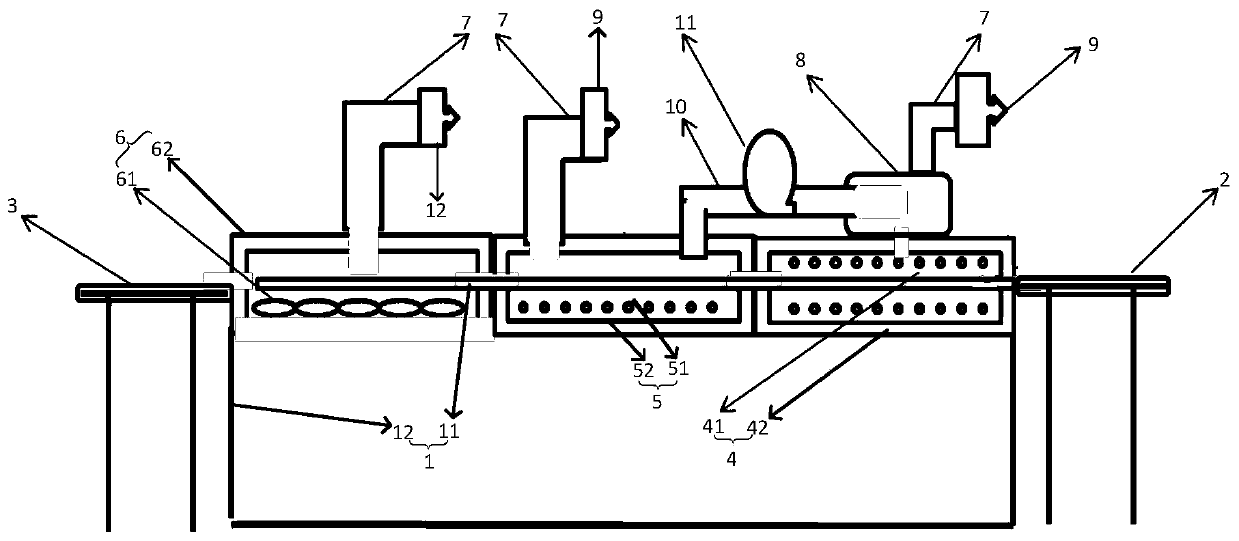

Photovoltaic module recovery method and equipment

ActiveCN110961432ARealize separation and recoveryImprove integrityWaste processingTransportation and packagingAdhesiveHeat conservation

The invention discloses a photovoltaic module recovery method. The method comprises the following steps: obtaining a pre-processed photovoltaic module without a frame, a junction box or a back substrate; placing the pre-processed photovoltaic module in a heating device to perform high-temperature pyrolysis on an organic adhesive layer to obtain a pyrolyzed photovoltaic module; placing the pyrolyzed photovoltaic module in a heat preservation device for heat preservation to obtain a heat-preserved photovoltaic module; and cooling the photovoltaic module to normal temperature after heat preservation to obtain a photovoltaic cell, a solder strip and a front substrate which are separated from one another. According to the recovery method disclosed by the invention, the pre-processed photovoltaic module is subjected to high-temperature pyrolysis to obtain the pyrolyzed photovoltaic module,; the pyrolyzed assembly is subjected to heat preservation and cooling treatment in sequence, the photovoltaic cell, the welding strip and the front substrate which are separated from one another are obtained, separation and recovery of the photovoltaic assembly are achieved, completeness of a cell piece and the front substrate can be achieved, loss is small, the recovery rate is high, an acid solution does not need to be used for dissolution, and the recovery speed is increased. The invention further provides recovery equipment with the advantages.

Owner:JINKO SOLAR CO LTD +1

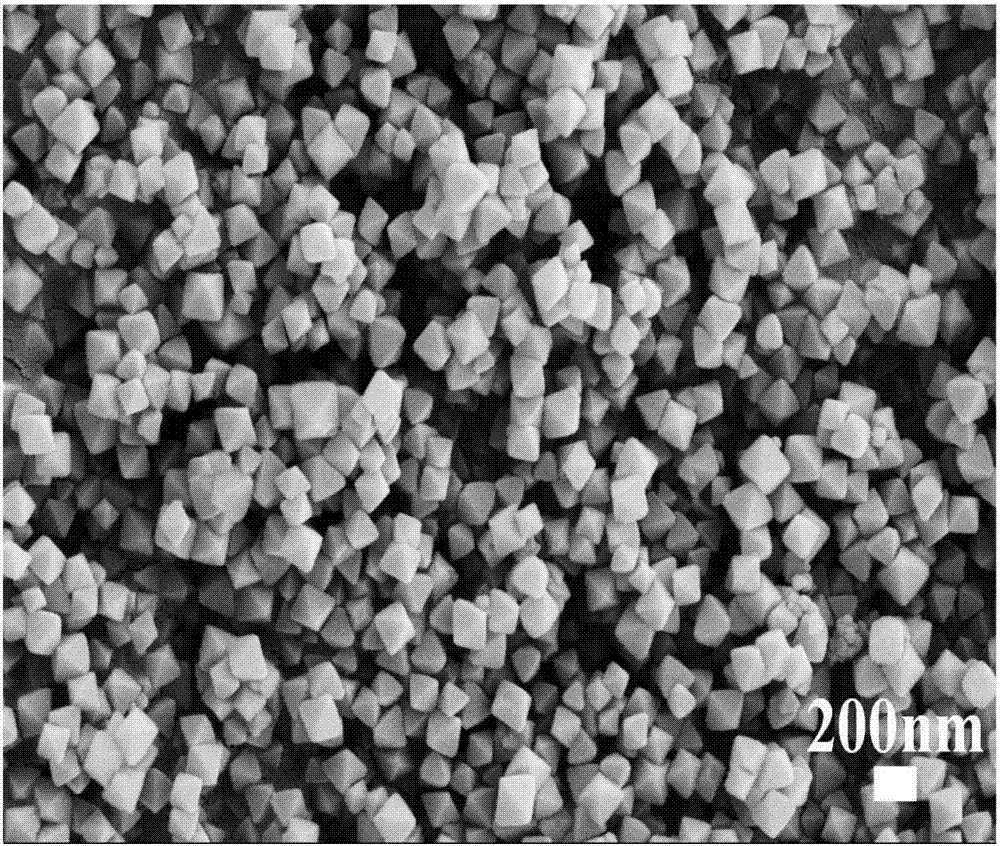

Charcoal and magnetic Fe3S4 composite nano-adsorbent, and preparation method and application thereof

InactiveCN106861615ASettling fastImprove processing efficiencyOther chemical processesWaste water treatment from metallurgical processSorbentIon exchange

The invention relates to a charcoal and magnetic Fe3S4 composite nano-adsorbent, and a preparation method and an application thereof. The adsorbent is obtained through loading Fe3S4 nano-crystals on a carrier charcoal in an in-situ manner, wherein the mass proportion of the Fe3S4 nano-crystals is 20-80%. The adsorbent is prepared from an iron salt-containing solution, a sulfur source and charcoal through a low-temperature loading technology, and is used for removing copper, chromium and nickel ions from electroplating wastewater. Compared with adsorbents in the prior art, the adsorbent prepared in the invention has the advantages of very good electroplating wastewater treatment effect through using rapid ion exchange, effective removal of heavy metals from the wastewater, convenience in use, no increase of a device or a technology, implementation of magnetic separation recovery through using magnet after adsorption completion, and effective reduction of the electroplating wastewater treatment cost.

Owner:SHANGHAI JIAO TONG UNIV

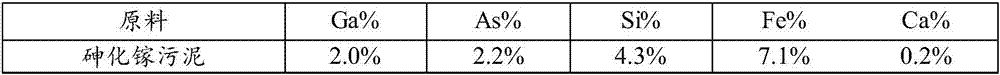

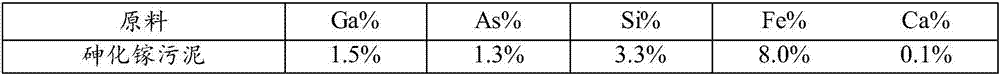

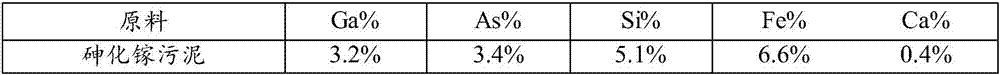

Method for separating and recovering gallium in gallium arsenide sludge

The invention provides a method for separating and recovering gallium in gallium arsenide sludge. The method comprises the following steps that (a) the gallium arsenide sludge and water are mixed according to the solid-to-liquid ratio being 1:(5-6) to form slurry, strong base is added for alkaline leaching, and lixivium is obtained after filtering is carried out; (b) the lixivium obtained throughthe step (a) is neutralized and filtered to obtain neutralizing slag; (c) the neutralizing slag obtained through the step (b), water and concentrated sulfuric acid are mixed to be subject to acid leaching silica removal, and gallium containing filter liquor is obtained after filtering; and (d) the gallium containing filter liquor and sodium hydroxide ate mixed to be subject to gallium deposition,and gallium hydroxide is obtained after filtering is carried out. Compared with the prior art, the method adopts specific processes of slurry alkaline leaching, neutralizing, acid leaching silica removal and gallium deposition, and separation and recovery of the gallium from the gallium arsenide sludge are achieved; the method for separating and recovering the gallium in the gallium arsenide sludge is high in recovery rate; and in addition, high temperature furnace burning is not needed, the energy consumption is low, and meanwhile, poisonous and harmful gas cannot be generated, and pollutionis avoided.

Owner:清远先导材料有限公司

Method for preparing phosphorus-removing adsorbent by utilizing sludge of sewage treatment plant

InactiveCN105688814ARealize resource utilizationWide variety of sourcesOther chemical processesWater/sewage treatment by sorptionSludgeSorbent

The invention discloses a method for preparing a phosphorus removal adsorbent by using sewage treatment plant sludge, which is characterized in that it comprises the following steps: (1) drying the sewage treatment plant sludge in a constant temperature drying box at 80-105°C to constant weight; then crush and grind the dried sludge into particles with a particle size of 0.5 to 5 mm; (2), put the sludge particles treated in step (1) into a muffle furnace for pyrolytic carbonization, and pyrolytic carbonization The parameters are: the operating temperature is 500-800°C, the time is 15-90min, the heating rate is 10-25°C / min, and then the pyrolysis carbonized product is crushed and ground into particles with a particle size of 0.5-5mm to obtain the product. The phosphorus removal adsorbent of the present invention does not isolate oxygen in the muffle furnace during the preparation process, which greatly simplifies the preparation process and makes the operation more convenient. At the same time, it is prepared by using the surplus sludge of the sewage treatment plant as the raw material, which has wider applicability and is conducive to the recycling and utilization of sludge resources.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

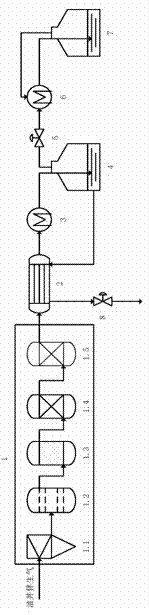

Oilfield associated gas complete liquefaction recovery system and method thereof

InactiveCN104845692ARealize separation and recoveryAchieve liquefactionGaseous fuelsResource savingEngineering

The invention discloses an oilfield associated gas complete liquefaction recovery system and a method thereof. The system comprises, sequentially connected, an associated gas pretreatment apparatus, a heat regenerator, a first condenser, a gas-liquid separation device, a throttle valve, a second condenser, an LNG storage tank and a regulating valve, the associated gas pretreatment apparatus comprises, sequentially connected, an oil removal device, a dedusting purification device, an acidic gas removal device, a hydration device and a nitrogen adsorption and separation device, the light hydrocarbon outlet of the heat regenerator is connected with the regulating valve, and the lower portion of the gas-liquid separation device is connected with the light hydrocarbon inlet of the heat regenerator. Separating recovery of light hydrocarbons in the oilfield associated gas and liquefaction of natural gas are simultaneously realized by using cold energy provided with above two stage condensing heat exchange devices. The system and the method have the advantages of solving of the recovery problem of remote region oil and gas wellhead associated gas, convenient operation, low cost, high resource recovery rate, no pollution, realization of zero discharge in the oilfield oil extraction process, and obvious resource saving and environment protection effects.

Owner:ZHEJIANG UNIV +1

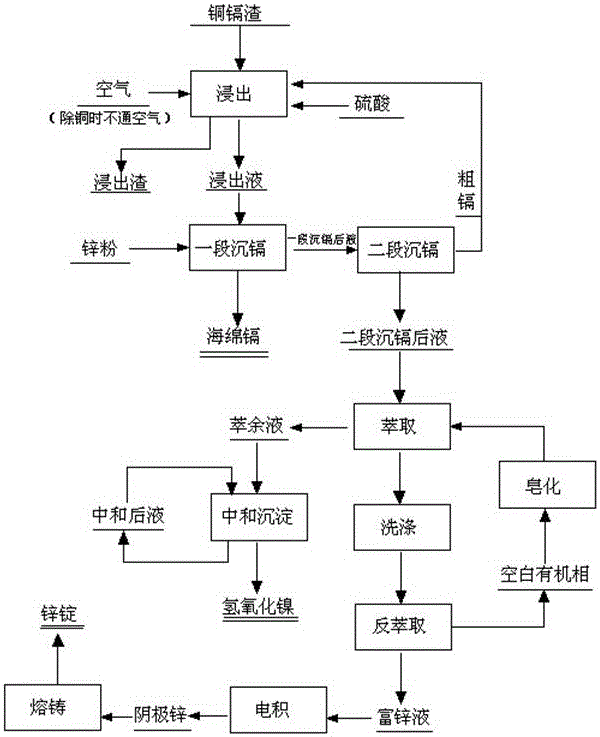

Method for comprehensively recovering zinc nickel cadmium from copper cadmium residues

InactiveCN106435213AAvoid leachingAchieve removalProcess efficiency improvementPregnant leach solutionNickel cadmium

The invention relates to a method for comprehensively recovering zinc nickel cadmium from copper cadmium residues. The method is characterized by including the steps: A leaching and purifying: simultaneously leaching and purifying the copper cadmium residues and filtering the copper cadmium residues to obtain leach liquor; B primary cadmium settling: adding zinc powder into the leach liquor in the step A to obtain primarily cadmium settled liquor and a sponge cadmium product; C secondary cadmium settling: adding substitute zinc powder into the primarily cadmium settled liquor in the step B to obtain secondarily cadmium settled liquor and crude cadmium; D zinc ingot production: performing 'extraction-washing-back extraction-electrodeposition-casting' procedures for the secondarily cadmium settled liquor obtained by the step C to produce a zinc ingot product; E nickel hydroxide neutralization and precipitation: precipitating and neutralizing nickel in zinc extraction raffinate obtained in the step D to obtain a nickel hydroxide product. The method is simple in process, low in cost and high in metal recovery rate, has the advantages of short process cycle, high efficiency and easiness in realizing automation and continuity, and is a clean pollution-free production process.

Owner:江西自立环保科技有限公司

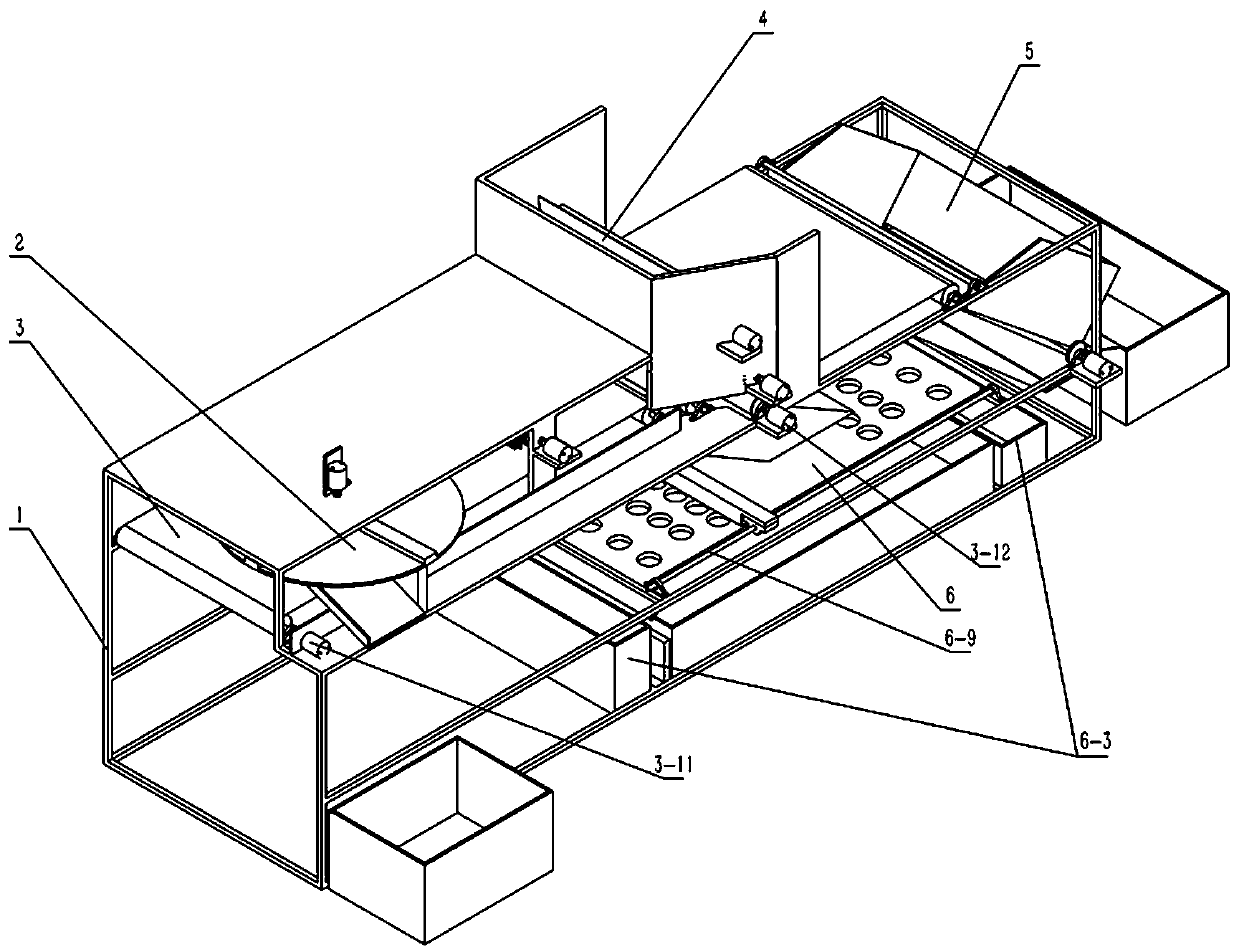

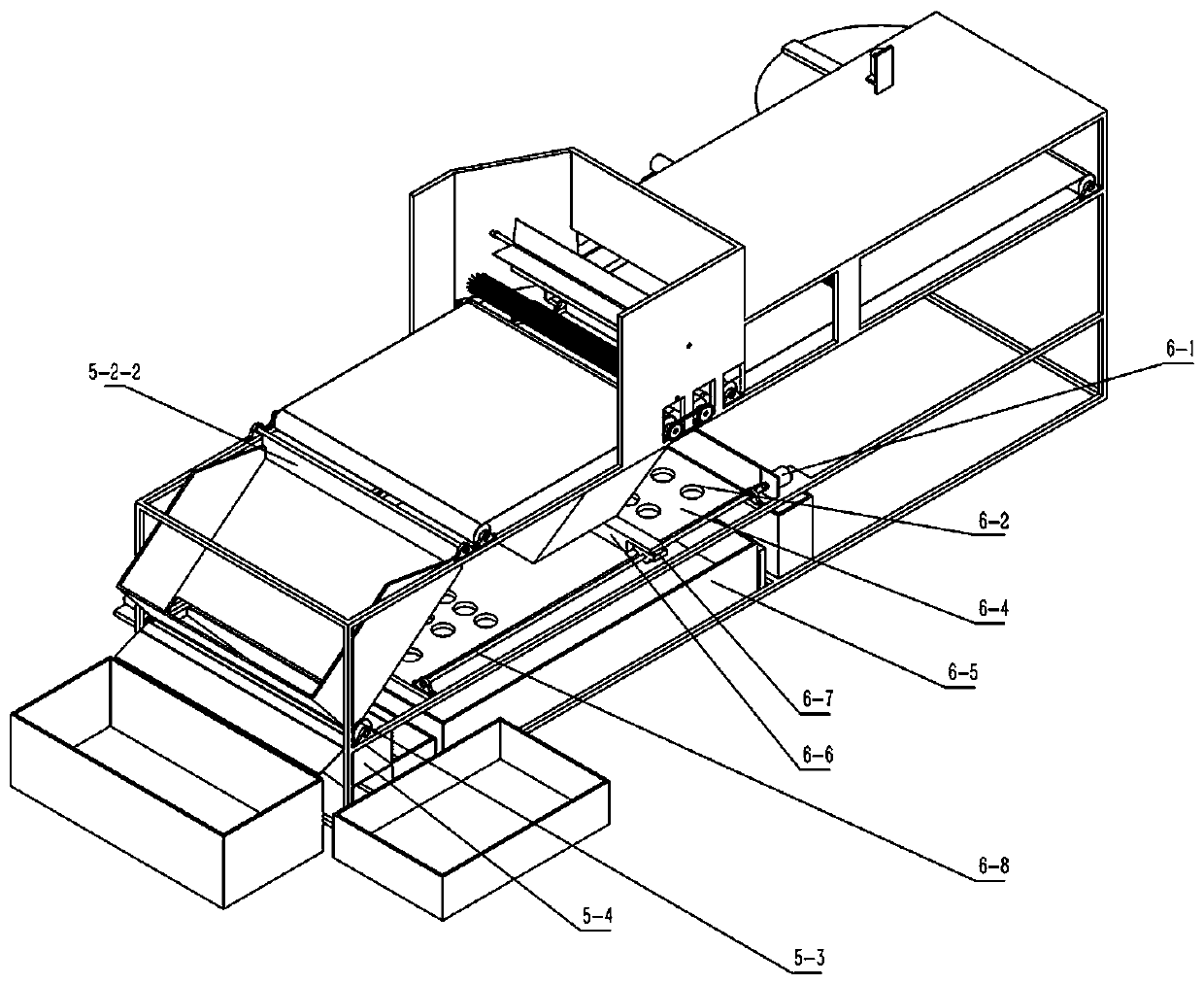

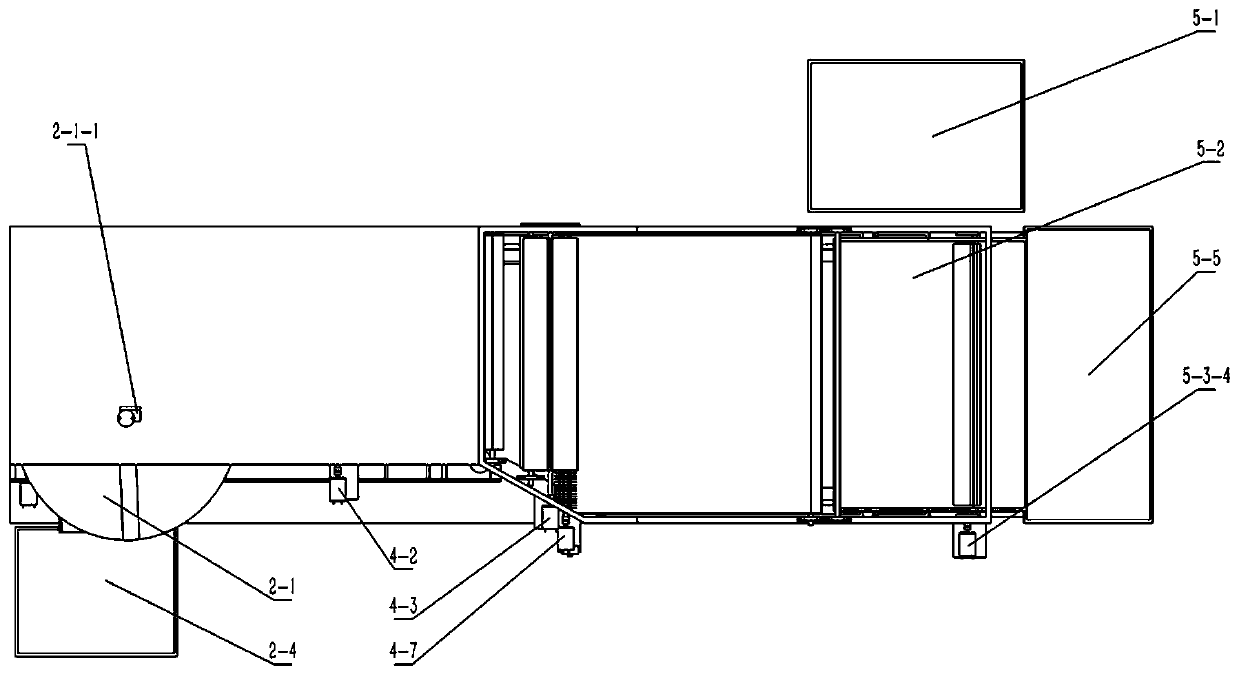

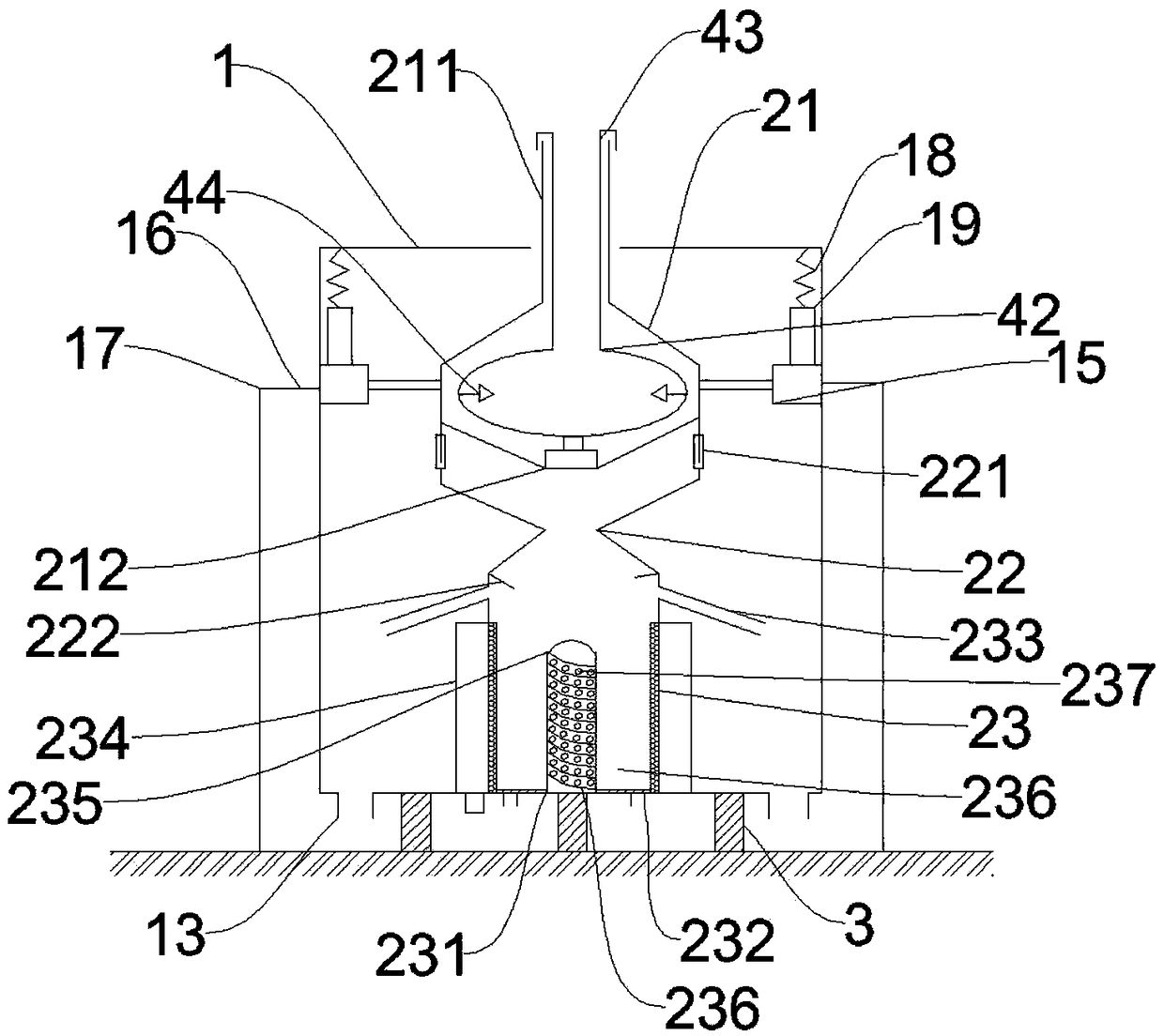

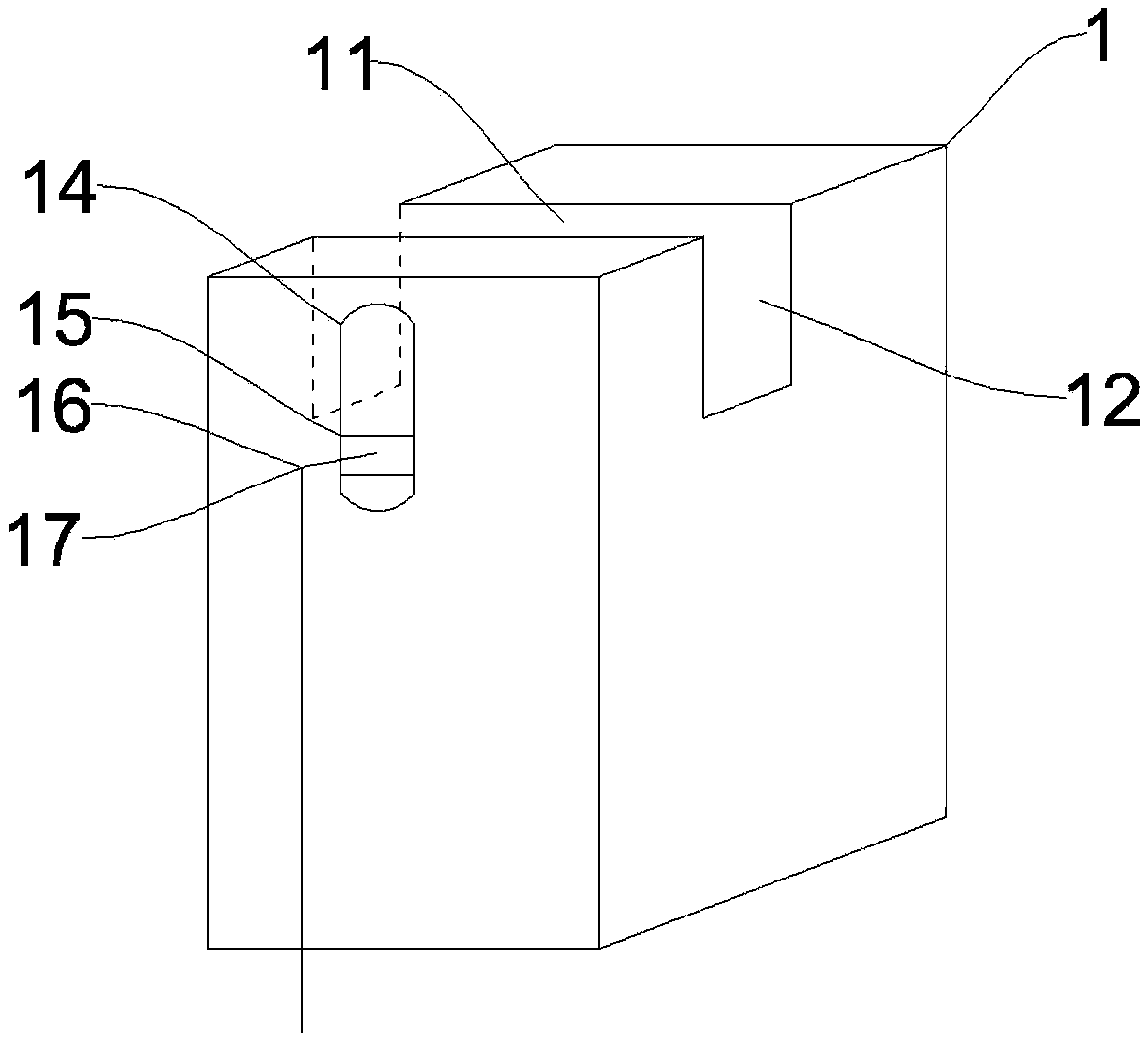

Fully-automatic tableware classifying and recovering integrated machine

PendingCN109567714AFully automatedTimely recyclingTableware washing/rinsing machine detailsSortingEngineeringFully automatic

The invention relates to the field of catering, in particular to a fully-automatic tableware classifying and recovering integrated machine. The fully-automatic tableware classifying and recovering integrated machine comprises a spoon separation mechanism, a transmission mechanism, a rice and chopstick screening mechanism, a rice and chopstick separation mechanism and a bowl and disk separation mechanism; the transmission mechanism is used for sequentially transmitting tableware to the spoon separation mechanism, the rice and chopstick screening mechanism and the bowl and disk separation mechanism; the spoon separation mechanism comprises a spoon suction mechanism, a spoon blocking plate and a spoon sliding way, and is used for separating spoons and putting the spoons into a spoon collecting box; the rice and chopstick screening mechanism is used for separating blow, chopsticks and residues from service plates, and comprises a bowl washing mechanism, a disk washing mechanism and a bowlpush mechanism; the rice and chopstick separation mechanism comprises a horizontal reciprocating mechanism and a rice leaking grid plate, and is used for separating the chopsticks and the residues andputting the chopsticks and the residues into a chopstick collecting box and a residue collecting box correspondingly; the bowl and disk separation mechanism is used for separating and recovering thebowls and the service plates, and comprises a screening hopper and an up-and-down reciprocating vibrating mechanism; and a bowl outlet and a service plate outlet are formed in the screening hopper.

Owner:BINZHOU UNIV

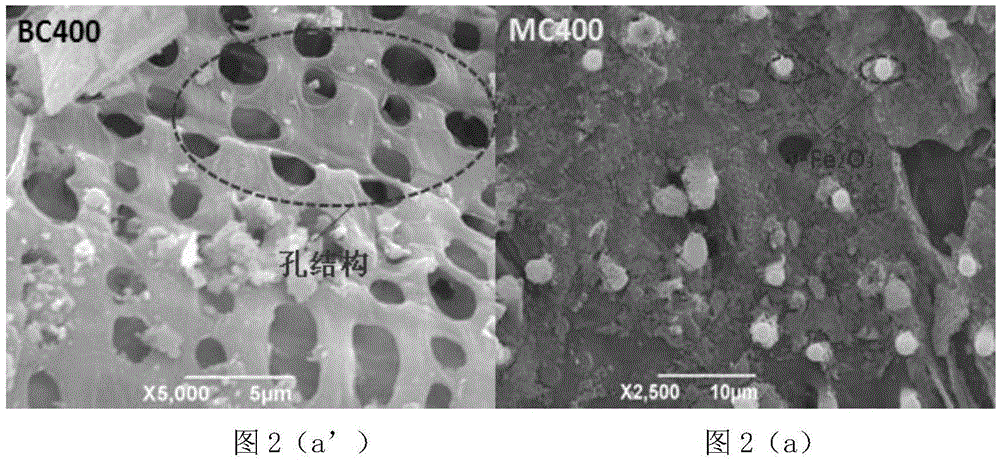

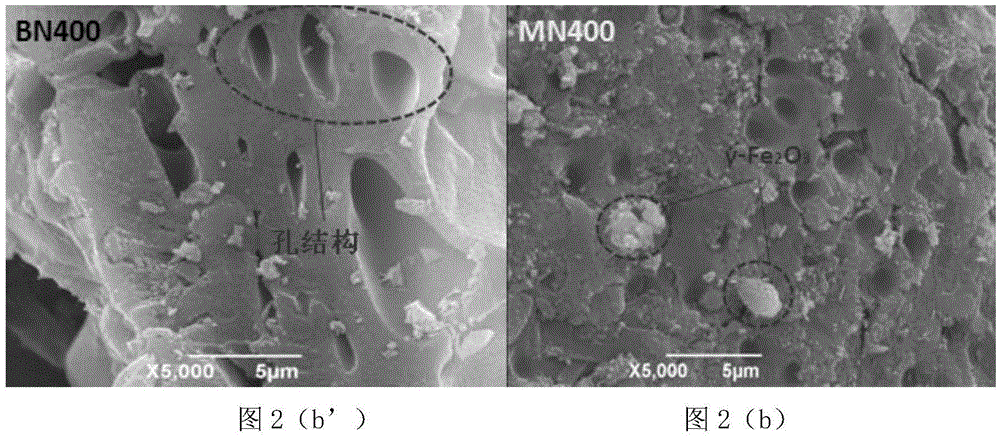

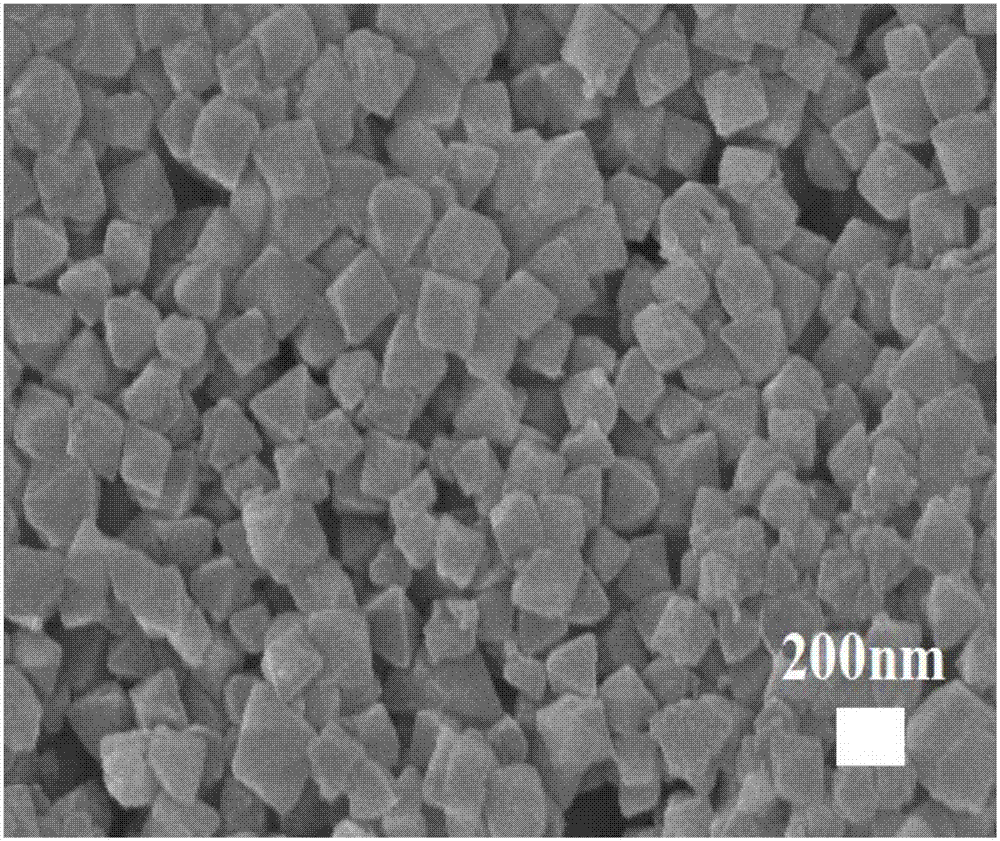

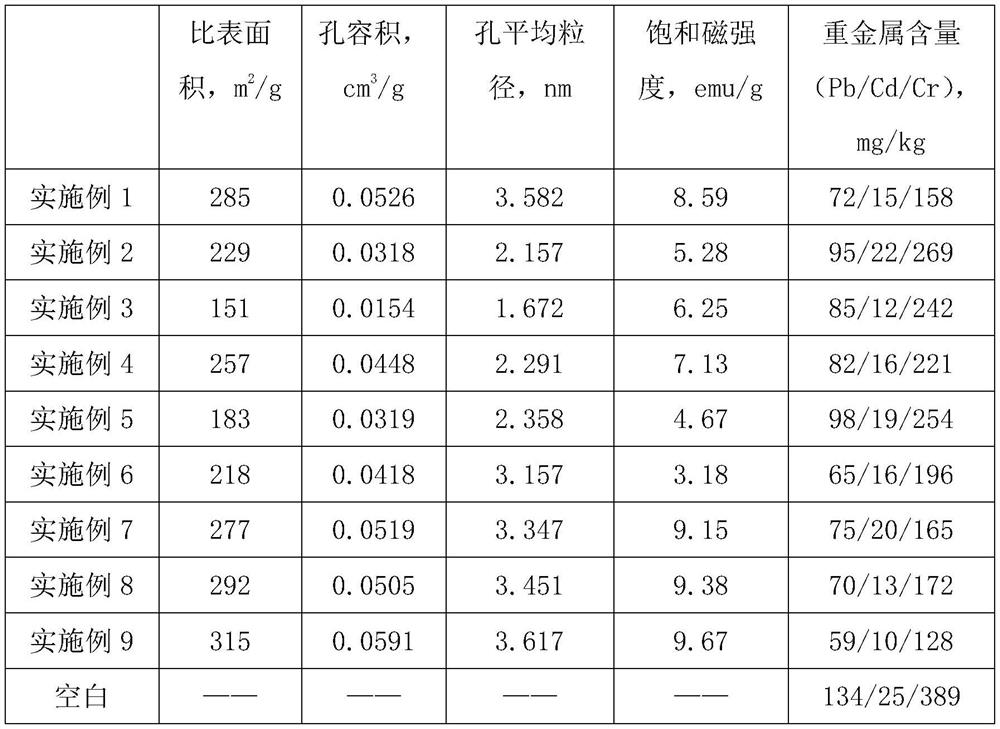

Preparation method of magnetic biochar material

PendingCN113181877AGuaranteed adsorption effectAvoid technical problems of specific surface area reductionOther chemical processesAlkali metal oxides/hydroxidesSoil scienceFreeze-drying

The invention provides a preparation method of a magnetic biochar material, and relates to the technical field of biochar preparation, and the magnetic biochar material is obtained by pretreating crop straw as a raw material and then sequentially carrying out ferric salt impregnation, freeze drying, high-temperature pyrolysis and post-treatment. The magnetic biochar material is prepared by performing freeze-drying treatment on crops impregnated with ferric salt and then performing high-temperature pyrolysis, and due to the fact that ferric salt solution is adsorbed in the crop raw materials, in the freeze-drying process, a large number of pore structures are generated in the crops in the sublimation process of moisture components in the crop raw materials; therefore, the pore structure of the raw material is further increased while the adsorption capacity of the ferric salt is ensured, the prepared biochar material has larger specific surface area and adsorption capacity, and the technical problem that the specific surface area of biochar is reduced due to loading of the ferric salt is avoided. Therefore, the biochar material can be separated and recycled after adsorbing pollutants such as heavy metals, and the problem of secondary pollution is avoided.

Owner:SHENYANG AGRI UNIV

Method for separating and extracting vanadium and chromium from vanadium slag sodium-modified roasting water leachate

ActiveCN112442595AEfficient separationAchieve recyclingProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention discloses a method for separating and extracting vanadium and chromium from vanadium slag sodium-modified roasting water leachate. The method comprises the following steps: adding ammonium salt into the vanadium slag sodium modified roasting water leachate, controlling the pH value of the solution system at pH7.5-9.5, stirring to react, and carrying out solid-liquid separation to obtain ammonium metavanadate crystals and filtrate A; extracting an organic phase B and the filtrate A to obtain raffinate A1 and a loaded organic phase B1; subjecting the loaded organic phase B1 to backextraction by adopting a sodium hydroxide solution to obtain strip liquor A2; recycling the raffinate A1; adding a vanadium precipitation agent into the strip liquor A2, carrying out ball milling atroom temperature, and filtering to obtain vanadium-containing filter residues C1 and chromium-containing filtrate A3; adding the raffinate A1 into the vanadium-containing filter residue C1, carrying out ball milling, and filtering to obtain filter residues C2 and vanadium-containing filtrate A4; and calcining the filter residues C2, continuously using the calcined filter residues C2 as a vanadiumprecipitation agent, separating and recovering vanadium in the vanadium-containing filtrate A4 by adopting an ammonium salt vanadium precipitation method, removing impurities from the chromium-containing filtrate A3, and carrying out evaporative crystallization to obtain a sodium chromate product. The method has the advantages that vanadium and chromium can be separated and recycled, and the sodium element and the vanadium and chromium extracted liquid can be recycled.

Owner:CENT SOUTH UNIV

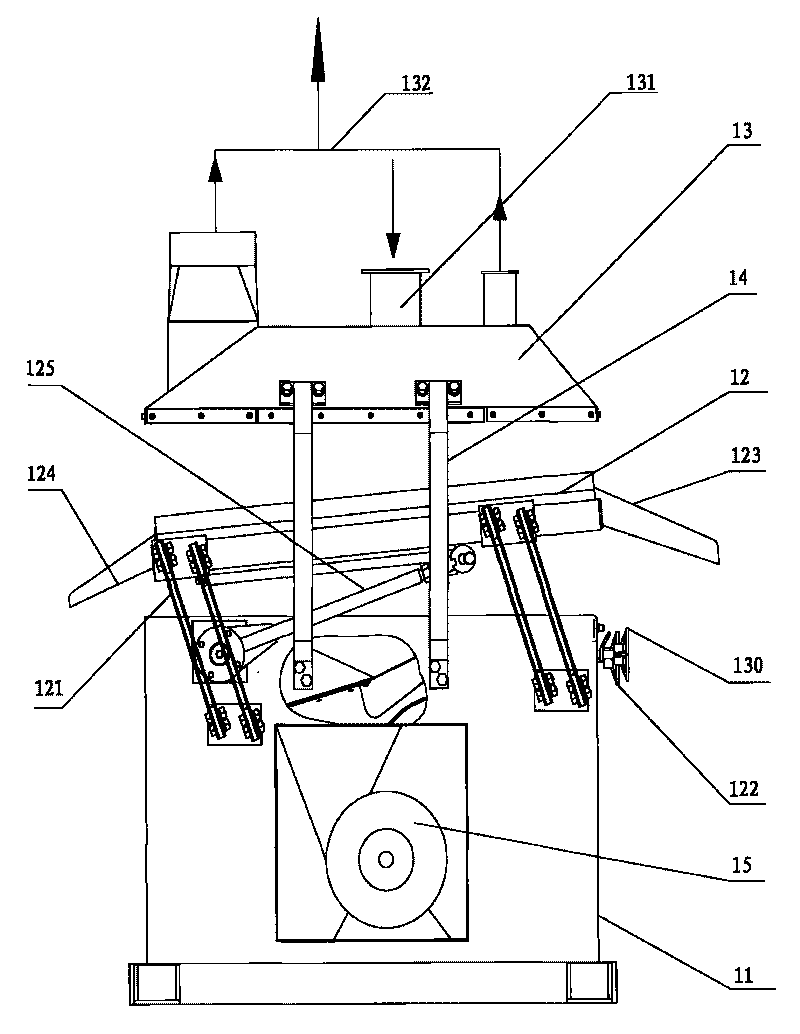

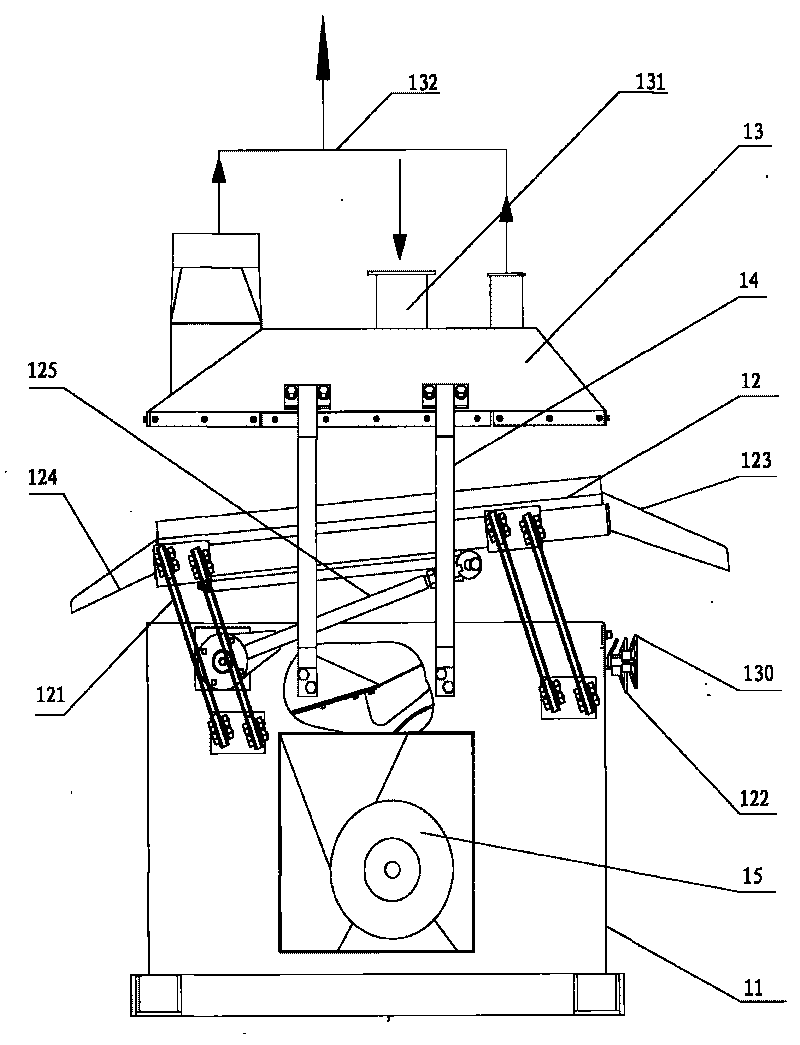

Airflow oscillating separator

InactiveCN101758025ARealize separation and recoveryEasy to recycleSievingGas current separationEngineeringMetal powder

The invention relates to an airflow oscillating separator, which comprises a frame, an oscillating screen, and a hood. The frame is fixedly arranged on a working table; the oscillating screen is arranged on the frame through an oscillating elastic sheet; and the hood is arranged above the oscillating screen and fixedly arranged on the frame through a support bar. A crank connecting rod mechanism is also arranged between the oscillating screen and the frame. A feed inlet and a negative pressure discharge outlet are formed on the hood, and a fan is arranged in the frame under the oscillating screen. The airflow oscillating separator is used for performing separation and classification and sorting treatment on crushed waste printed circuit boards and other powder efficiently, and can separate metal and non-metal powder, separate fine powder and coarse powder in the non-metal powder for recycling respectively.

Owner:HUNAN VARY TECH

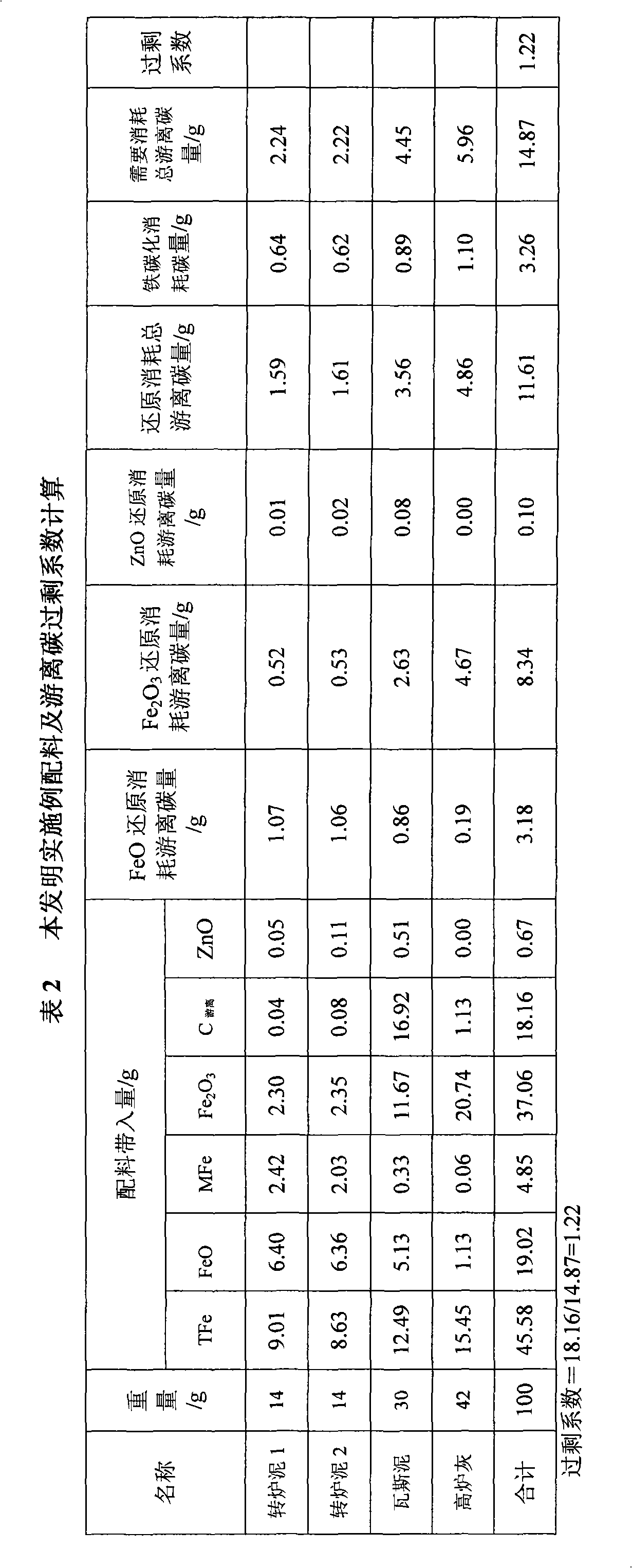

Method for treating zinc-iron-containing dust and sludge

ActiveCN101818264ARealize separation and recoveryLow costBlast furnace detailsManufacturing convertersZincSmoke

The invention provides a method for treating zinc-iron-containing dust and sludge. The method comprises the following steps of: (1) material preparation, namely performing calculation according to components of different dusts and sludge to ensure that the excess coefficient of free carbon in the materials reaches 1.0 to 1.4; (2) material mixing, namely uniformly mixing the materials and drying natural particle materials or cold bound pellets to be sent to a storage bin for later use; (3) material feeding, namely adding dust and sludge into an empty molten iron tank after molten iron is just poured from the molten iron tank and preheating the dust and sludge materials by using waste heat of the empty molten iron tank; (4) zinc and iron separation, namely recovering zinc-containing smoke by using dust-collection equipment; and (5) material melting, namely further reducing the dust and sludge materials by using high-temperature molten iron in a blast furnace casting process and melting the reduced materials, and mixing the melted materials and blast furnace molten iron to form molten iron for a converter. The zinc-iron-containing dust and sludge can be recovered by using conventional equipment without adding a reducing agent or a catalyst, or needing any special equipment, and has the advantages of convenience and operability, short process, low cost and good effect; and the recovery rate of iron reaches over 90 percent, and the recovery rate of zinc is more than 95 percent.

Owner:ANGANG STEEL CO LTD

Synthesis method of diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate

InactiveCN102391211AHigh activityGood catalytic effectOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventChemistry

The invention discloses a synthesis method of diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate. The method is characterized by comprising the steps of: epoxidation: adding a raw material tetrahydrophthalic acid diglycidyl ester, a solvent, a quaternary ammonium phosphotungstate catalyst and alkaline phosphate into a reactor; heating to 30-80 DEG C; stirring and adding the aqueous solution of hydrogen peroxide, and reacting for 3-12 hours at 30-80 DEG C; and postprocessing: cooling the material after the reaction, standing still for layering; removing the aqueous phase; filtering the organic phase solution to obtain a filter cake, namely that recycled quaternary ammonium phosphotungstate catalyst; distilling the organic phase filtrate and recycling the solvent; and drying the remaining product to obtain a liquid product. The method disclosed by the invention is easy to operate and has the advantages of high safety, low pollution, simple postprocessing and high yield.

Owner:四川东材绝缘技术有限公司

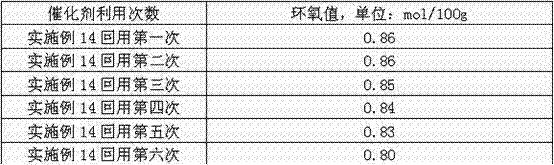

Low-temperature condensing vapour recovery unit

InactiveCN101244344AEmission complianceEffective synergyDispersed particle separationVapor condensationFlame arresterAir pump

The invention relates to a cooled oil gas recovery apparatus under low temperature, which is characterized in that a valve is connected with an inlet pipe of an oil-gas separator; the upper outlet of the oil-gas separator is connected with an inlet of a condenser; the lower outlet is connected with a main recovery tank; the outlet of the condenser is connected with the main recovery tank; the outlet of the condenser is connected with the inlet of a low-temperature tower through a bend pipeline; the upper outlet of the low-temperature tower is connected with the inlet of an active carbon absorber; the outlet of the active carbon absorber is connected with a discharge pipeline through a blower; the lower outlet of the low-temperature tower is connected with the main recovery tank through a valve; an oil-gas mixing pump is connected with a pipeline parallel connected with the inlet pipeline of the oil-gas separator; an oil absorbing pump is connected with the pipeline parallel connected with the pipeline connecting the outlet of the condenser and the main recovery tank; a flame arrester and a nitrogen pipeline are respectively connected with a discharge pipeline; the nitrogen pipeline is connected with the inlet of the active carbon absorber. The cooled oil gas recovery apparatus has the advantages of low cost, stable operation, convenient repair, exhaust gas emission within the prescribed standard, and environmental protective effect.

Owner:胡永海

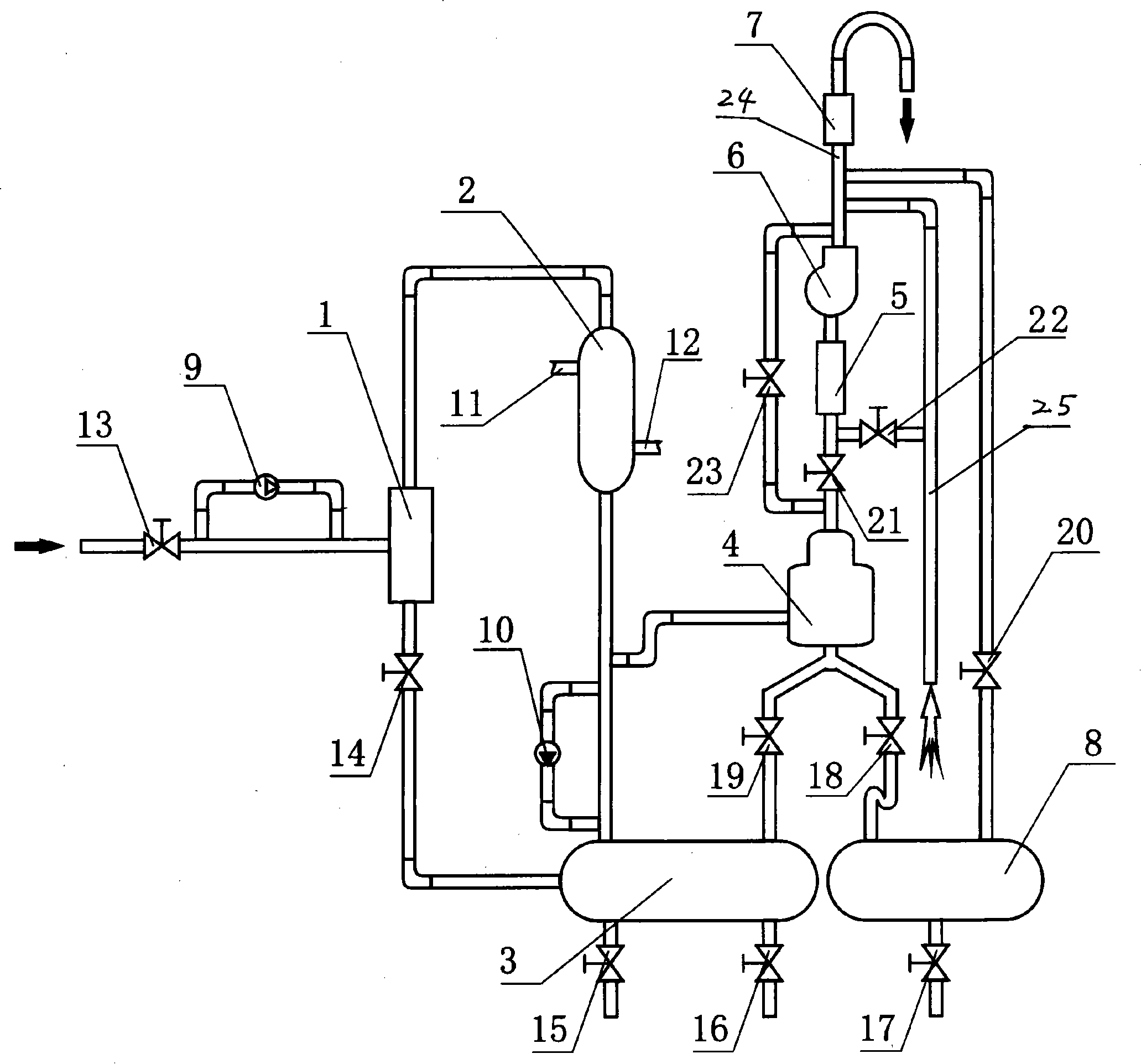

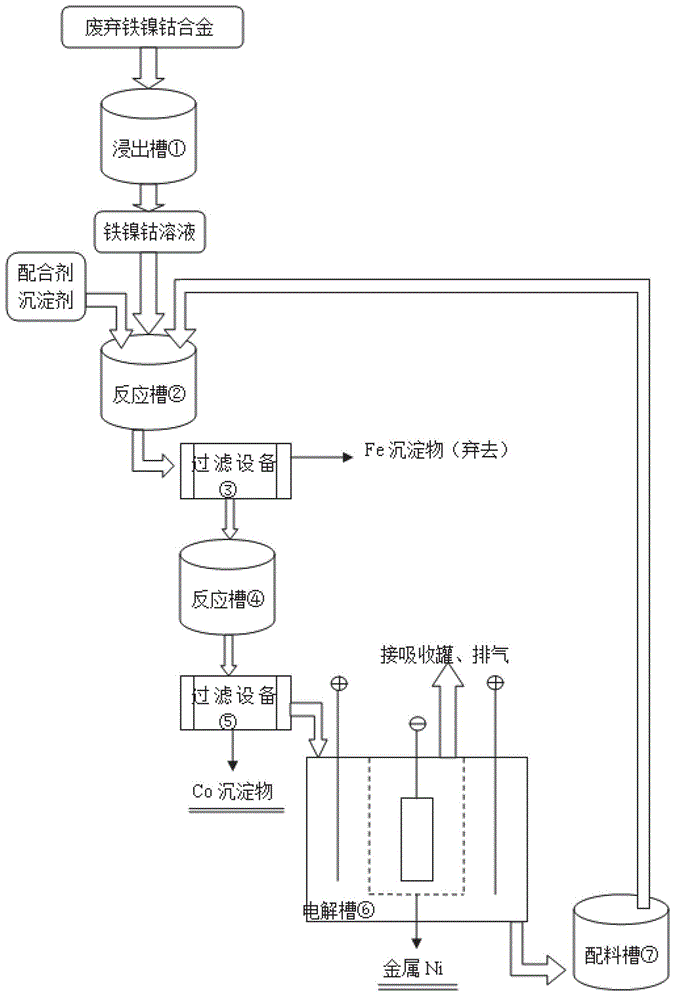

Method for recovering cobalt and nickel from waste iron nickel cobalt alloy

ActiveCN102912137ARealize separation and recoveryCooperate effectivelyPhotography auxillary processesProcess efficiency improvementFractional PrecipitationPregnant leach solution

The invention discloses a method for separating and recovering cobalt and nickel from waste iron nickel cobalt alloy, and belongs to the technical field of nonferrous metallurgy. The method comprises the steps as follows: 1) leaching the waste iron nickel cobalt alloy with 54% of Fe, 18% of Co and 28% of Ni through acidity of sulfuric acid to obtain a leaching solution with main metal of iron, nickel and cobalt; 2) forming a 'compounding agent-precipitating agent' system by utilizing one or more of the compounding agents of OH<->, NH3 and C2N2H8 and the precipitating agent of CO32, acting on the nickel-cobalt-iron leaching solution, and separating the iron and the cobalt through fractional precipitation to obtain a cobalt compound; and 3) compounding the nickel in the solution, and further electrolyzing to obtain the nickel. The method has the benefits as follows: the cobalt and the nickel in the solution of the waste iron nickel cobalt alloy are recovered through integration of the 'compounding agent-precipitating agent' system and the process steps, the cobalt in the leaching solution is separated from the compound nickel in the form of a precipitate, the nickel compound solution is electrolyzed to recover the nickel, and the 'compounding agent-precipitating agent' barren solution can be recycled. The method makes full use of secondary resources, and is simple in process and easy for continuous and automatic production.

Owner:BEIJING UNIV OF TECH

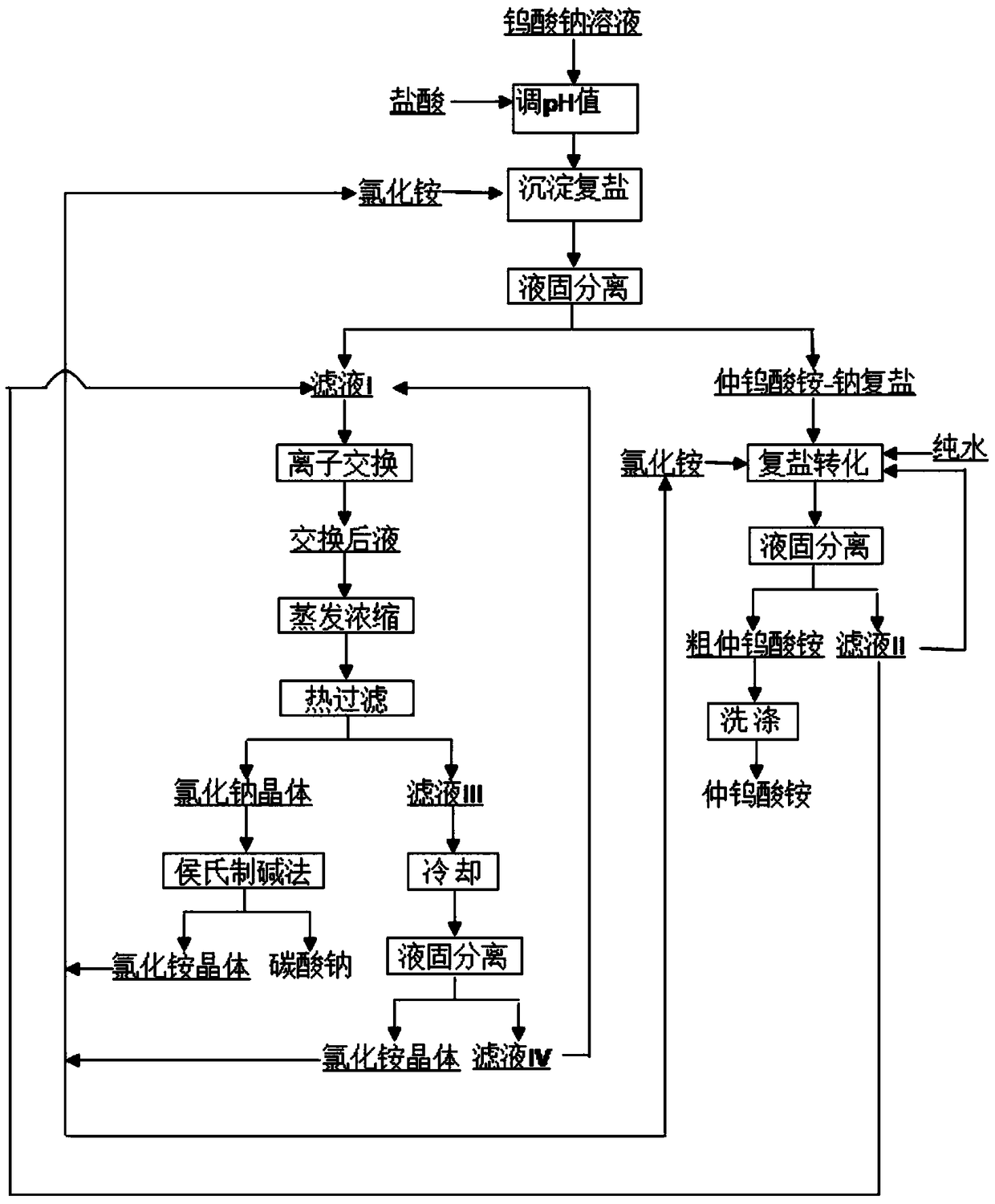

Preparation method of ammonium paratungstate

ActiveCN108557890AControl the sodium ion impurity contentReduce volumeAlkali metal halide purificationAmmonium chlorideHigh concentrationLiquid waste

The invention discloses a preparation method of ammonium paratungstate and belongs to the technical field of tungsten metallurgy. The ammonium paratungstate is prepared by taking high-concentration sodium tungstate solutions as raw material, WO3 concentration in the sodium tungstate solutions can reach 100-500g / L, a great deal of dilute water is reduced as compared with that in a traditional ion exchange method, and salt bearing liquid waste obtained in preparation of the ammonium paratungstate is small in size, high in concentration and convenient in treatment. By setting up a plurality of processes of 'internal microcirculation' to treat wastewater effluent, ammonium chloride and sodium chloride are separated and recycled through 'evaporative crystallization-hot filtration', sodium chloride is converted into ammonium chloride cyclically used in the production process and sodium carbonate used for high pressure leaching of sodium carbonate from tungsten minerals by introducing a 'Hou's process for soda production', preparation of the ammonium paratungstate directly by high-concentration sodium tungstate solutions is realized, the salt bearing liquid waste generated during the process is effectively reclaimed, pollution of the wastewater and waste salt on environment is removed, waste is turned into wealth, and cleaning production is realized.

Owner:CENT SOUTH UNIV

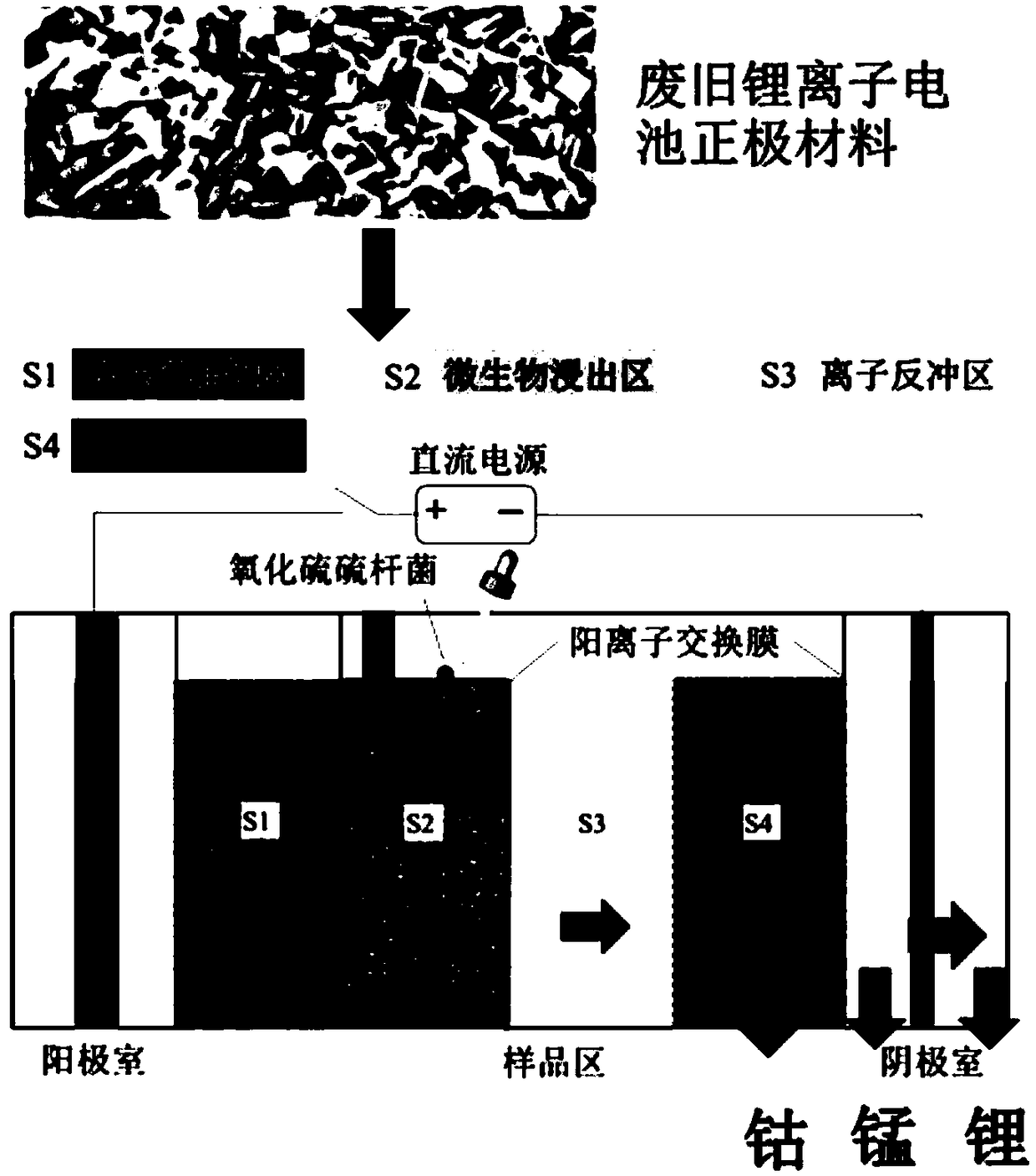

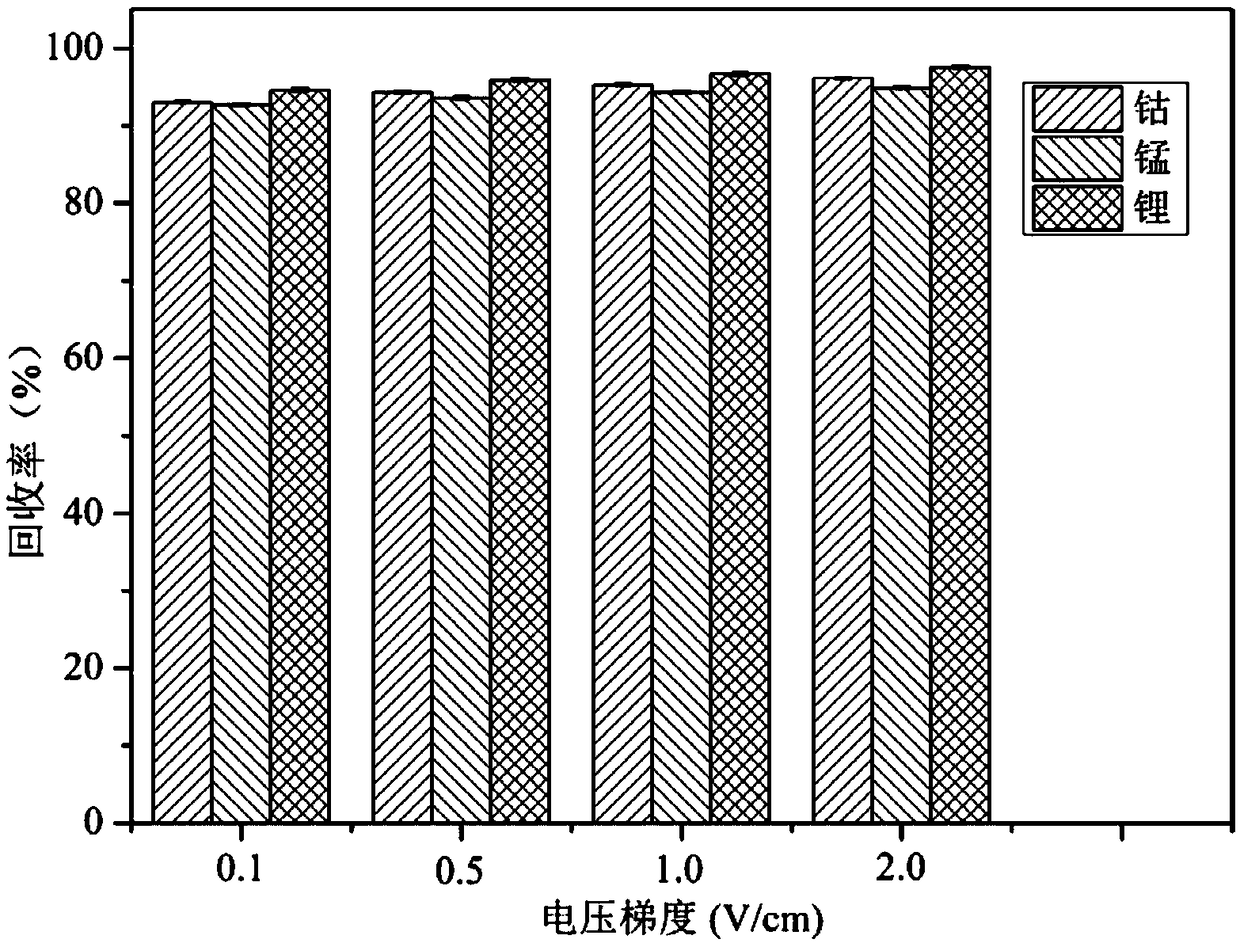

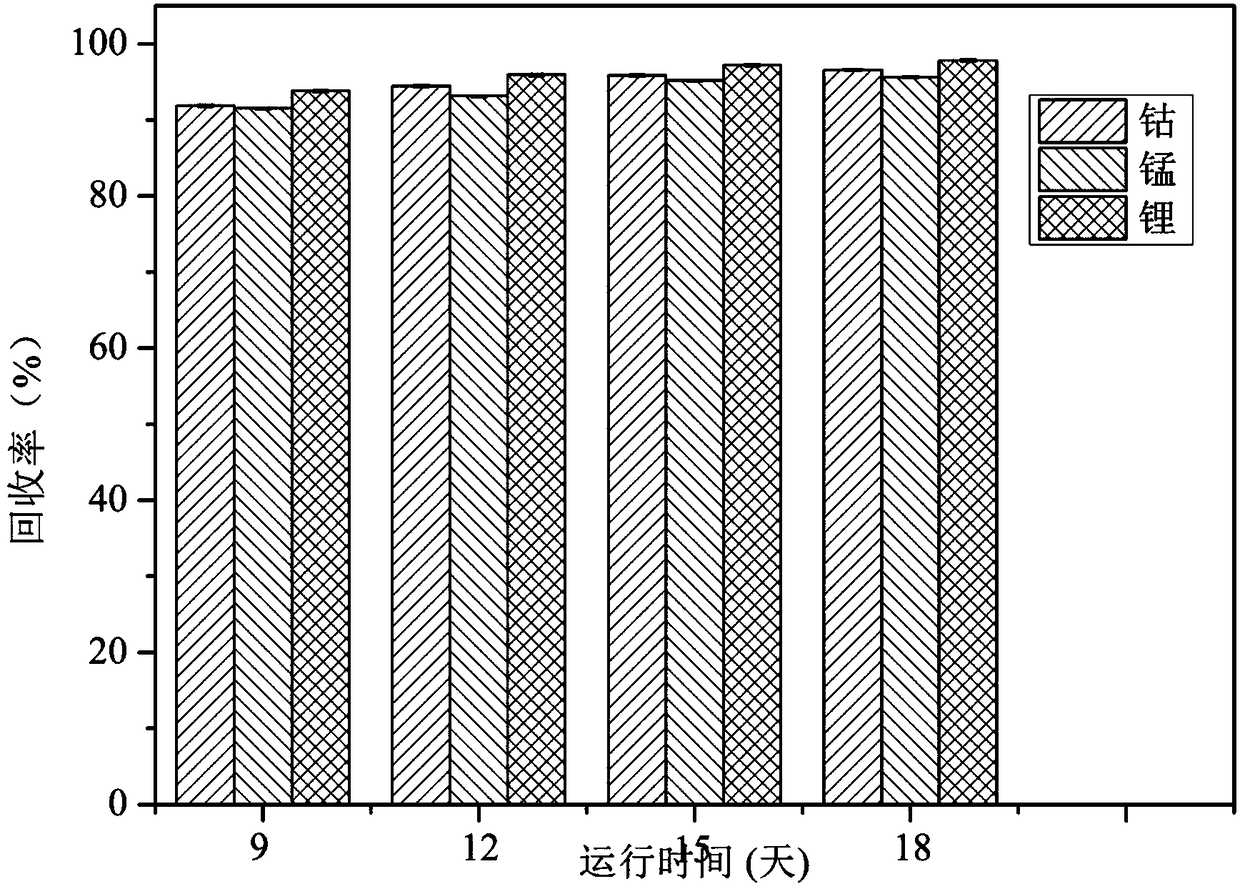

Method for synchronously separating and recycling cobalt, lithium and manganese from cathode material of waste lithium ion battery

ActiveCN108808151AEfficient separation and recoverySimple recycling processWaste accumulators reclaimingProcess efficiency improvementThiobacillus ferrooxidansManganese

The invention discloses a method for synchronously separating and recycling cobalt, lithium and manganese from a cathode material of a waste lithium ion battery. The method comprises the following steps of firstly, uniformly dividing a sample area of an electrolytic cell into four subareas by a polyethylene grid, respectively filling the same amount of solid powder, and slowly injecting deionizedwater into the third subarea; inoculating a sulfur oxide thiobacillus solution into the second subarea, placing the electrolyte cell after inoculating for 2 to 4 days at the room temperature, connecting the electrolyte cell and a direct-current power source through a cathode and an anode, and maintaining the electrolyte cell to run for 9 to 18 days; collecting the activated carbon, cathode precipitate and cathode liquid, so as to separate and recycle the cobalt, lithium and manganese from the cathode material of the waste lithium ion battery. The method has the advantages that the recycling process is greatly simplified, the operation is simple and convenient, the feasibility is strong, the production amount of secondary pollution waste liquid and the treatment cost in the process are reduced, and the resource and energy source are certainly saved.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

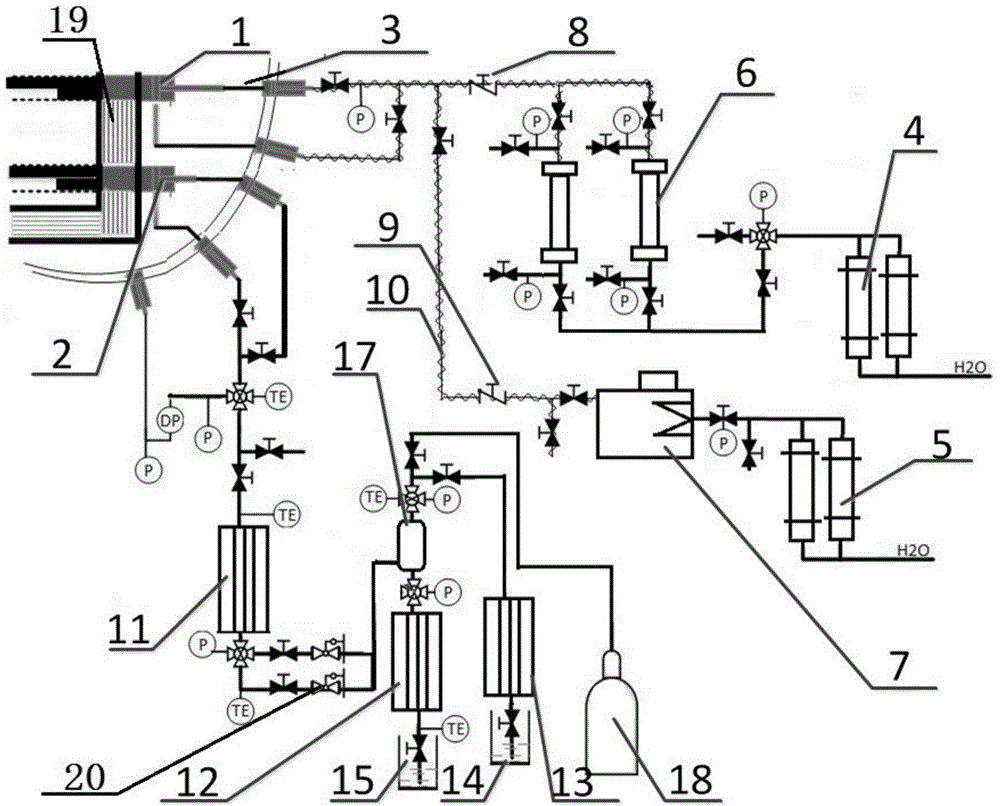

Solvent-assisted SAGD three-dimensional physical simulation experiment method and device

ActiveCN104948153ASteady injectionStable pressureFluid removalVapor–liquid separatorProcess engineering

The invention provides a solvent-assisted SAGD three-dimensional physical simulation experiment method and device. The device comprises an injection device, a simulated oil reservoir model and a recycling device, a first pump unit in the injection device is communicated with a piston container unit, a second pump unit is communicated with a steam generator, the piston container unit and the steam generator are communicated with a gas injection well of the simulated oil reservoir model respectively, one end of a first condenser of the recycling device is communicated with a production well of the simulated oil reservoir model while the other end of the same is communicated with a feeding port of a gas-liquid separator, a second condenser is communicated with a liquid outlet of the gas-liquid separator, a third condenser is communicated with a gas outlet of the gas-liquid separator, a raw oil and water collection container is connected with the second condenser, and a solvent recycling container is connected with the third condenser. By the method and the device, mining conditions of solvent-assisted SAGD technology can be simulated, and mechanism of solvent in the process of SAGD can be studied so as to optimize and improve existing solvent-assisted SAGD technology according to oil reservoir conditions.

Owner:PETROCHINA CO LTD

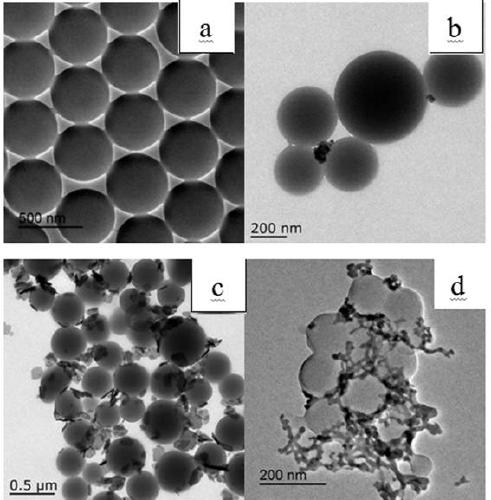

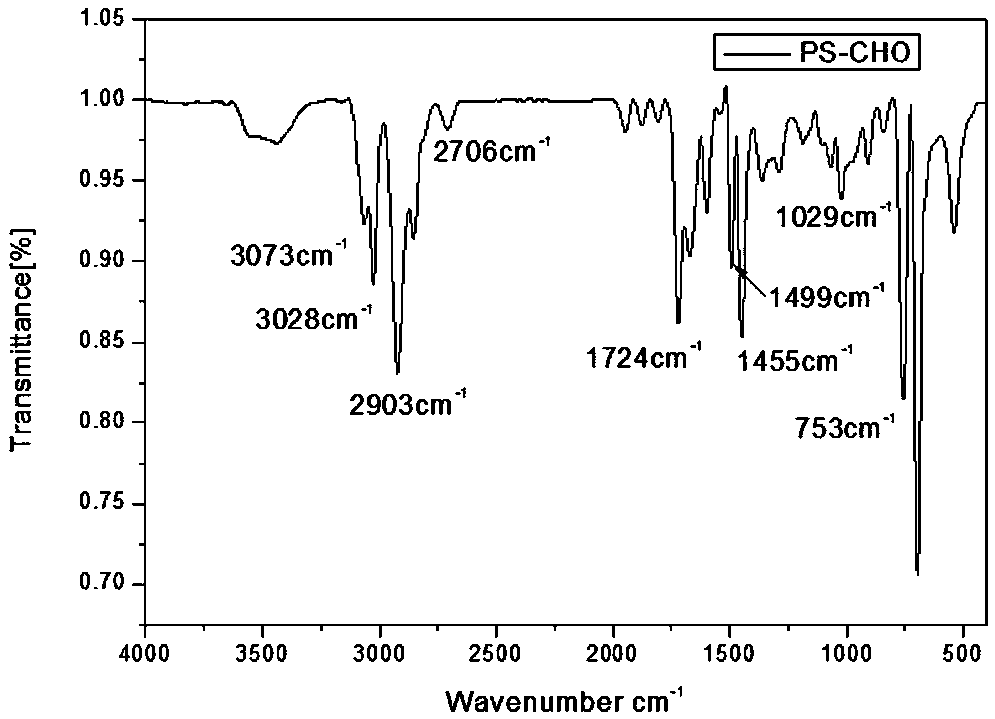

Method for recovering uranium oxide from uranium containing wastewater

ActiveCN110127762ASimple processEasy to recycleOther chemical processesAlkali metal oxides/hydroxidesUranium borideOxide

The invention relates to a method for recovering uranium oxide from uranium containing wastewater. Polystyrene functional microspheres, whose surface is rich in aldehyde groups, are synthesized through a copolymerization mode. Then the microspheres are used to process uranium containing wastewater. Aldehyde groups on the surface of the microspheres provide binding sites to adsorb free uranyl ions(UO22+); oxygen in the system can oxidize free uranyl ions; and finally polystyrene aldehyde-group microspheres with enriched uranium oxide are obtained. The prepared composite microspheres are burned or purified by an organic solvent to obtain yellow uranium oxide, and then solid powder is recovered. The solid powder is characterized by infrared spectroscopy (FT-IR), transmission electron microscope (TEM), ultraviolet-visible spectrophotometer (UV-VIS), and X-ray photoelectron spectroscopy (XPS). The provided method has the advantages that the processing process is simple, the conditions aremild, and the repeatability is good.

Owner:YANGZHOU UNIV

Catering sewage floatation treatment device

InactiveCN108892260AIn line with the concept of green environmental protectionEasy to collectWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSewageEngineering

The invention discloses a catering sewage floatation treatment device. The catering sewage floatation treatment device comprises a shell, an upper cavity, a centrifugal mechanism, a middle cavity anda lower cavity; the shell is of a cubic structure with the bottom provided with a pair of oil-leak ports, the top horizontally provided with a first strip hole and two opposite walls vertically provided with second strip holes; the upper cavity is arranged in the shell, a feed sleeving is vertically arranged in the top of the upper cavity, and the bottom of the upper cavity is open; the centrifugal mechanism is arranged in the upper cavity and comprises a first motor arranged on the filter screen, a centrifugal barrel fixedly connected with the output shaft of the first motor and a feed pipe communicated with the centrifugal barrel; the middle cavity is located below the upper cavity and is of a funnel-shaped structure; the lower cavity is located under the middle cavity, the top of the lower cavity is open, and the middle cavity is hermetically connected with the lower edge of the middle cavity. By the arrangement, residues, oil and water in catering sewage are screened and separated,secondary use of the residues is facilitated, oil and water are separated completely, good separation effect is achieved, and oil content of the separated sewage is greatly reduced.

Owner:王小平

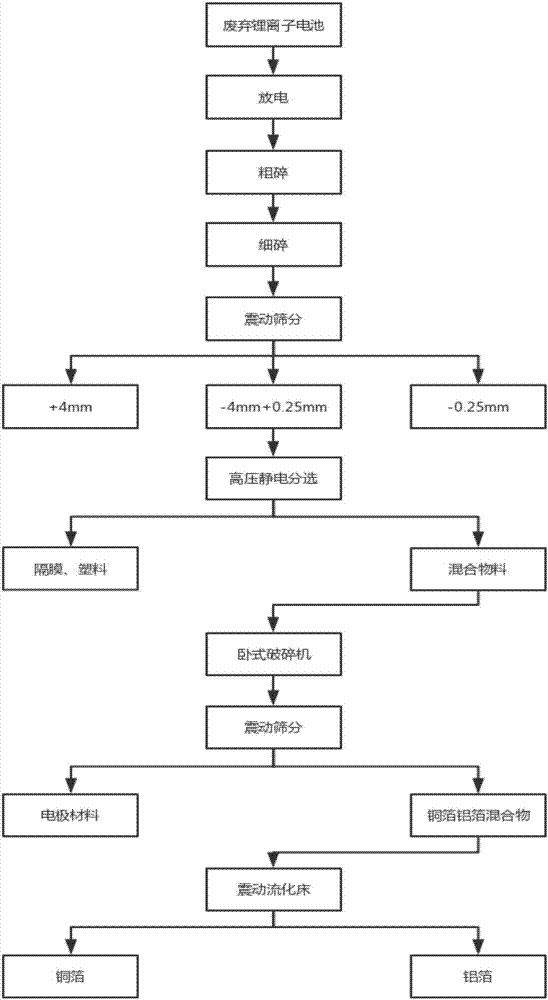

Method for recycling copper foils and aluminum foils in waste lithium ion batteries

InactiveCN107293818AMature technologyExperienceWaste accumulators reclaimingBattery recyclingCopper foilLithium electrode

The invention discloses a method for recycling copper foils and aluminum foils in waste lithium ion batteries. The method comprises the following steps: (1) putting the discharged waste lithium ion batteries into a roller crushing machine and a vertical impact crushing machine, putting products after two stages of crushing into a vibrating screen for screening classification, dividing the products into three size fractions, and taking the products with an intermediate size fraction; (2) carrying out high-voltage electrostatic separation on a mixture with the intermediate size fraction, removing diaphragms and plastic, and putting the products into a horizontal crushing machine, so that the copper foil and aluminum foil mixture is crushed into the target size fraction; and (3) separating the products in the horizontal crushing machine through a vibration fluidized bed, discharging light products through the upper part to obtain the aluminum foils, and discharging heavy products through a scraping plate to obtain the copper foils. According to the method disclosed by the invention, separation and recycling of the copper foils and the aluminum foils in the waste lithium ion batteries are realized, and the method has the advantages of high operability, environmental protection, low cost and the like.

Owner:深圳市恒创睿能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com