Low-temperature condensing vapour recovery unit

A recovery device, low temperature condensation technology, applied in the direction of vapor condensation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of short service life of activated carbon, oil and gas loss, unreasonable structure of the condensation device, etc., to achieve environmental protection and ensure operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

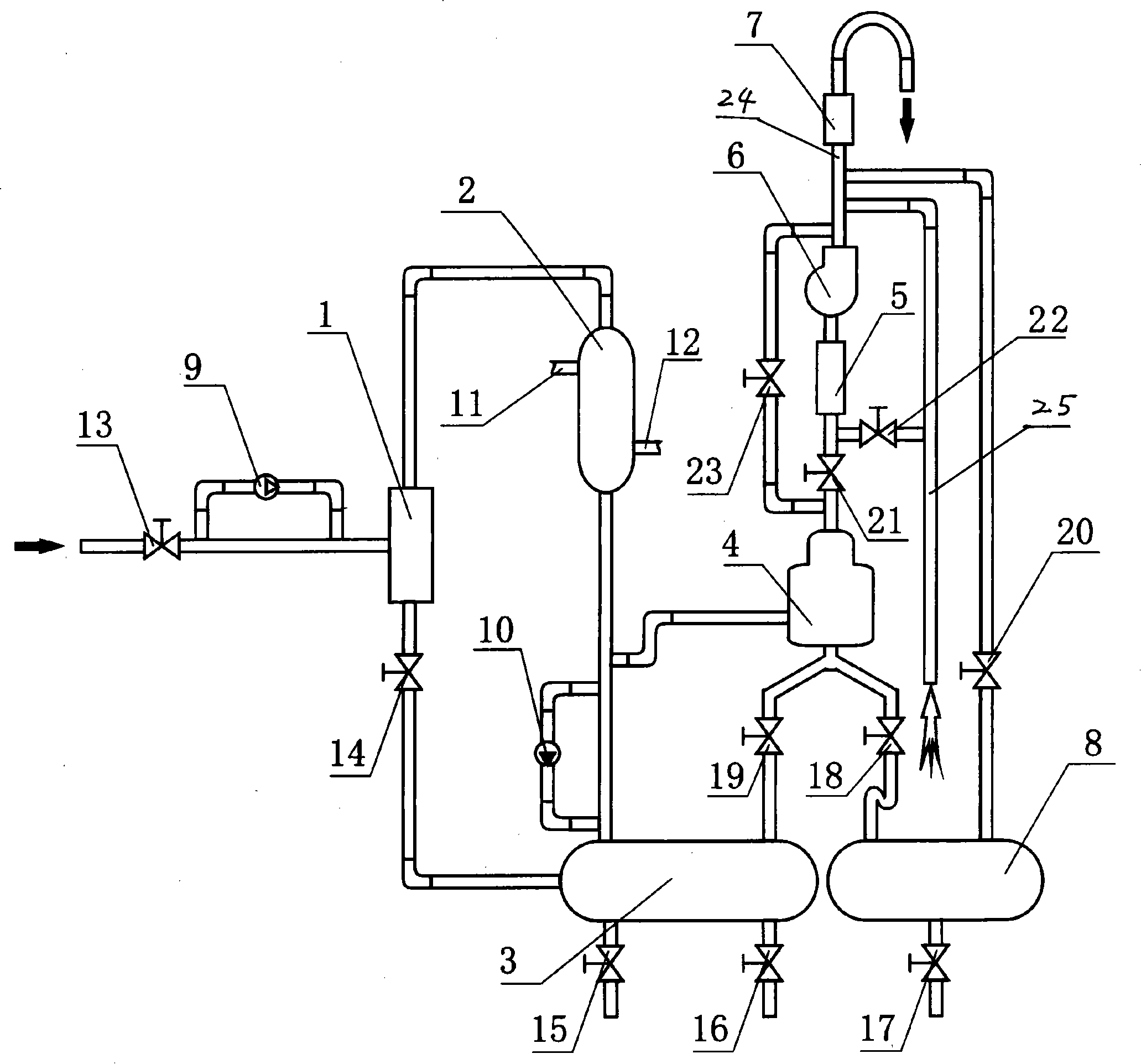

[0022] Embodiment: naphtha, English name Naphtha, another name light gasoline. The oil-gas mixture volatilized by naphtha is separated and recovered by using the low-temperature condensed oil-gas recovery device of the present invention. The oil-gas mixture volatilized by naphtha was analyzed and detected on site, among which: C3 accounted for 16.88%, C4 accounted for 43.2%, C5 accounted for 31.4%, C6 accounted for 7.22%, C7 accounted for 1.2%, and C8 accounted for 0.08%. Connect the exhaust pipe of the naphtha unloading platform vacuum pump of the chemical ethylene enterprise to the inlet pipeline of the oil-gas separator 1 of the low-temperature condensed oil vapor recovery device of the present invention, and the oil-gas mixture volatilized by the on-site naphtha passes through the naphtha unloading platform vacuum pump The exhaust pipe is sent to the inlet pipeline of the oil-gas separator 1, the outlet temperature of the condenser 2 is 7°C, the temperature range in the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com