Patents

Literature

595 results about "Flame arrester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A flame arrester (also spelled arrestor), deflagration arrester, or flame trap is a device that stops fuel combustion by extinguishing the flame.

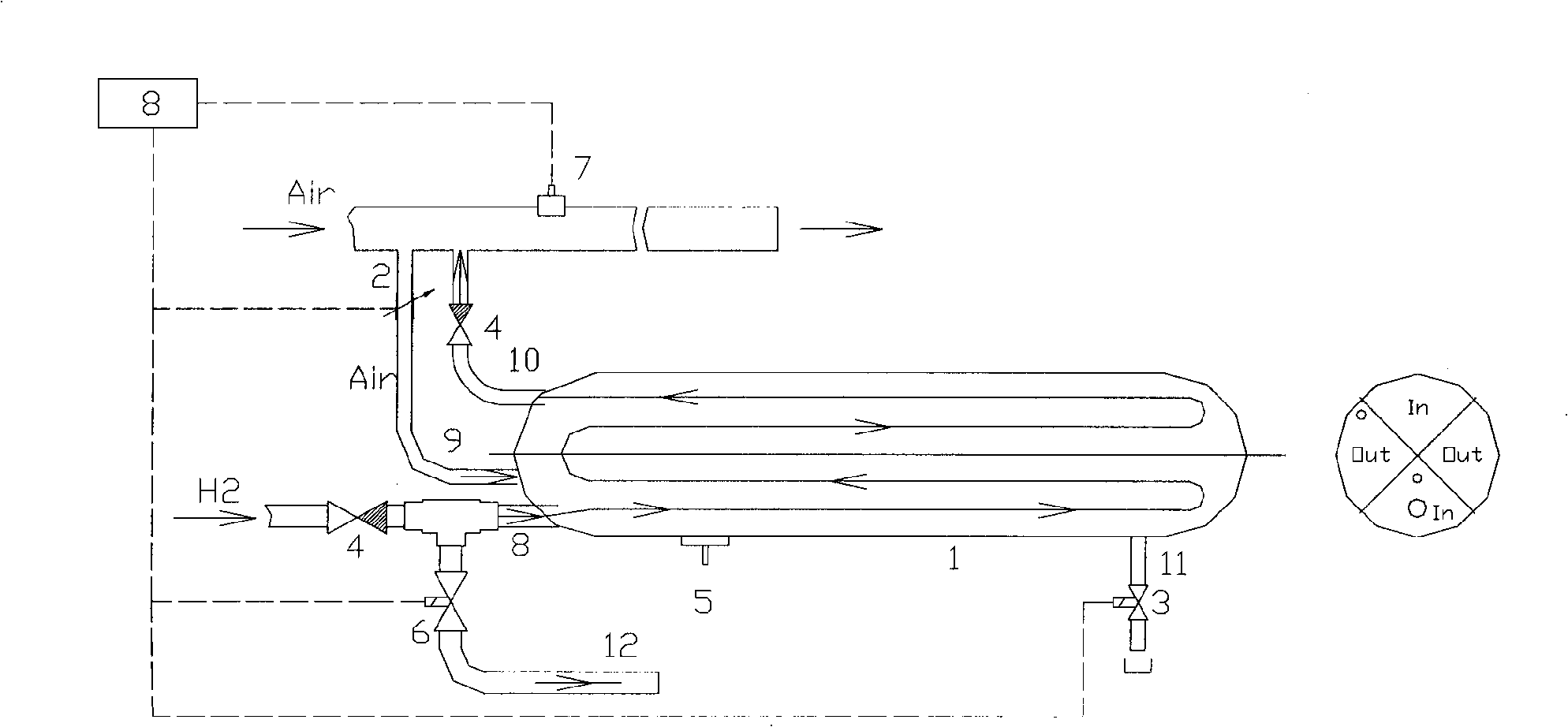

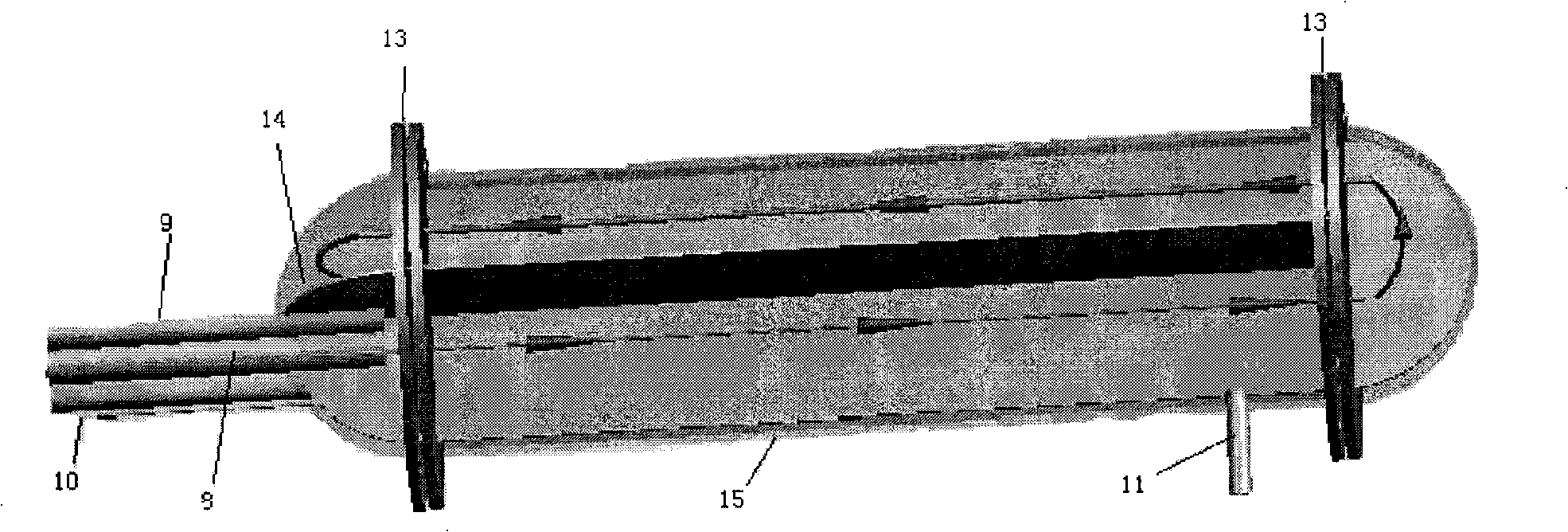

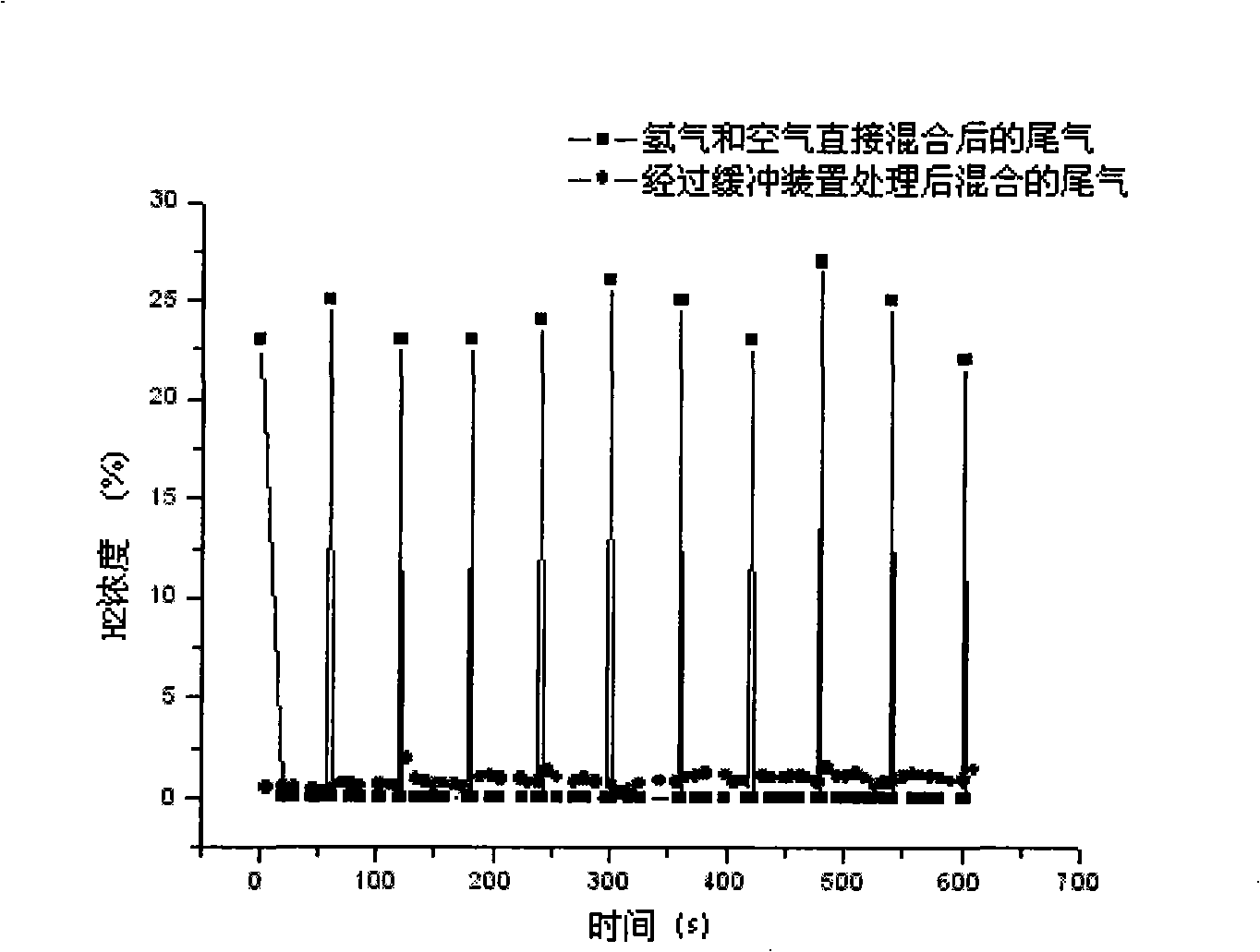

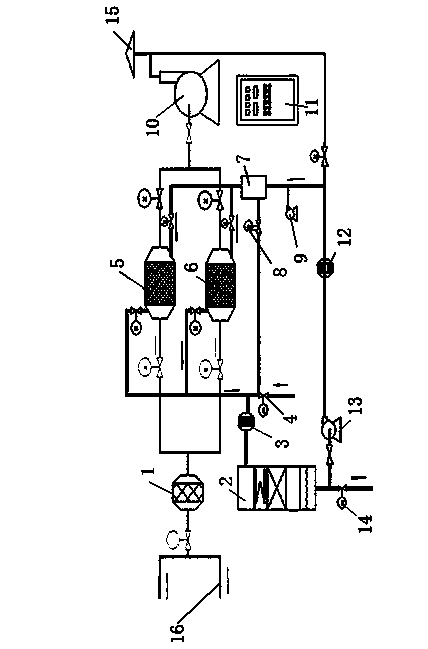

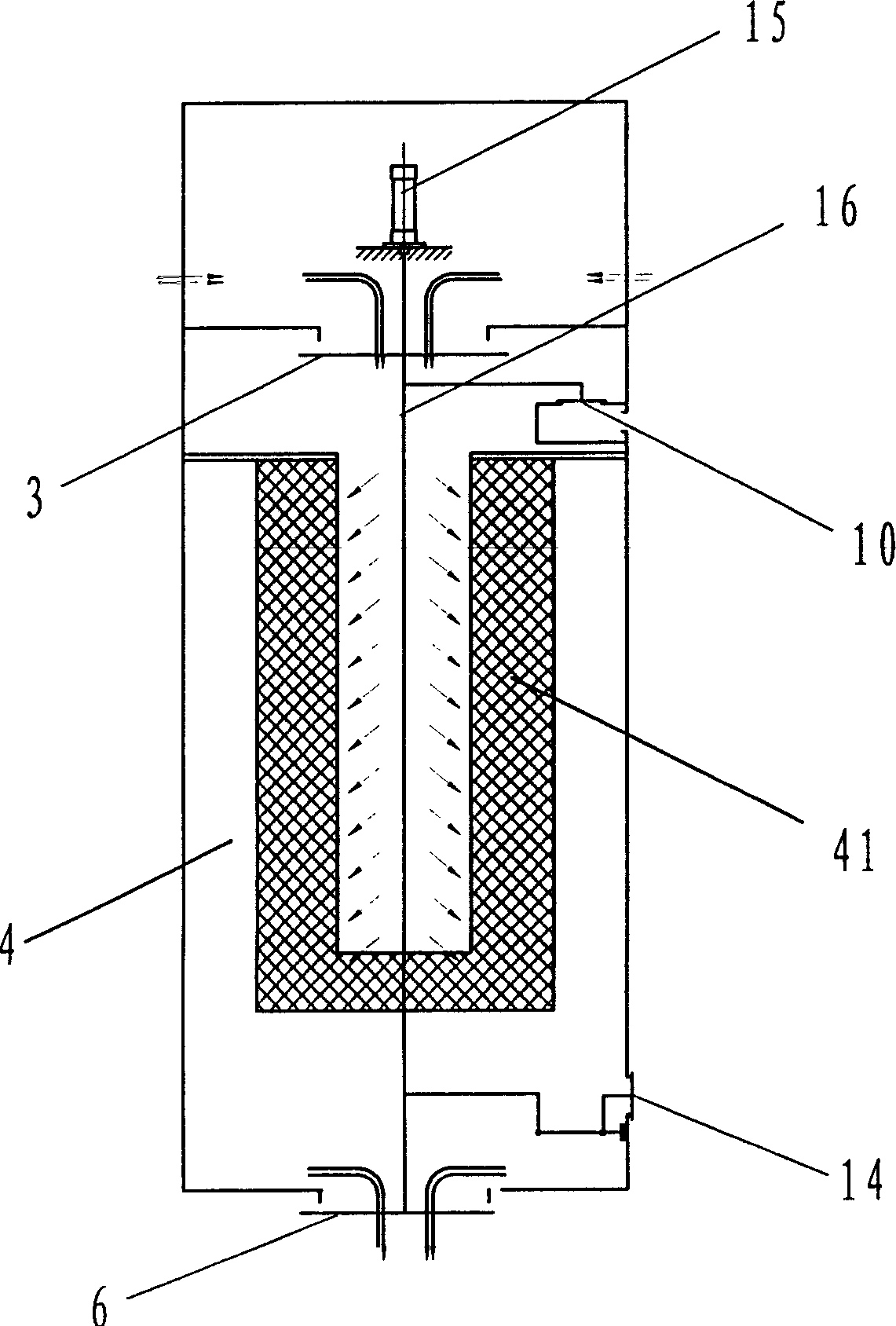

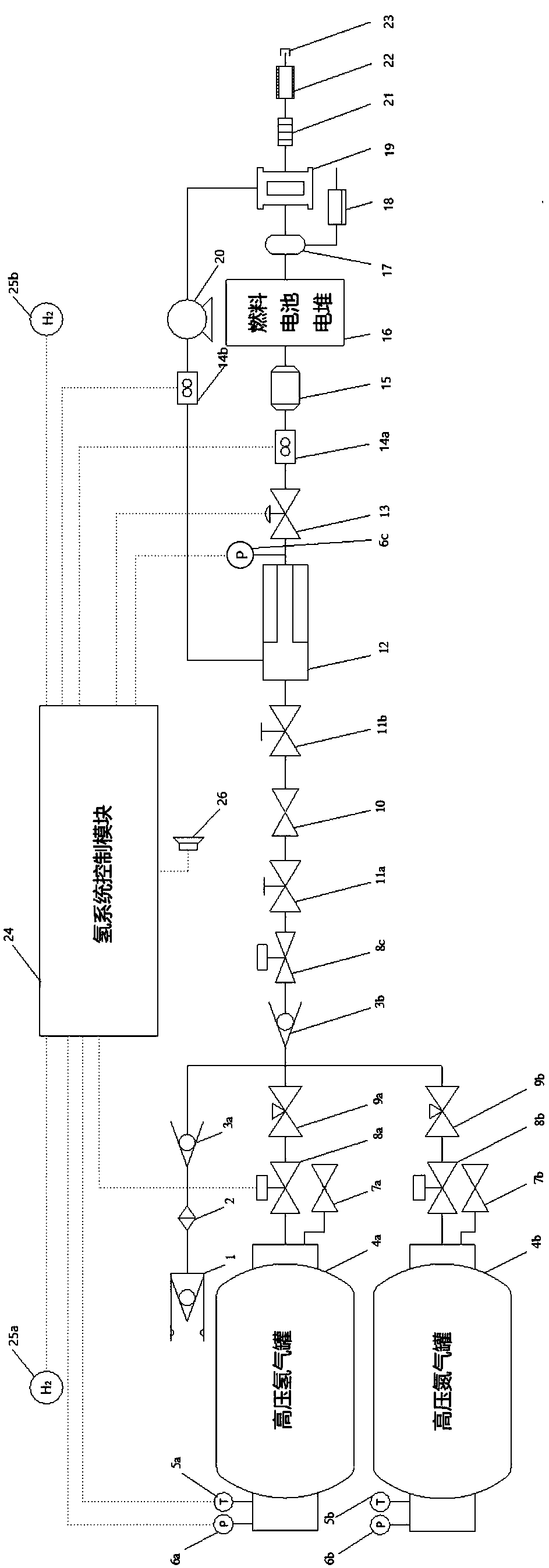

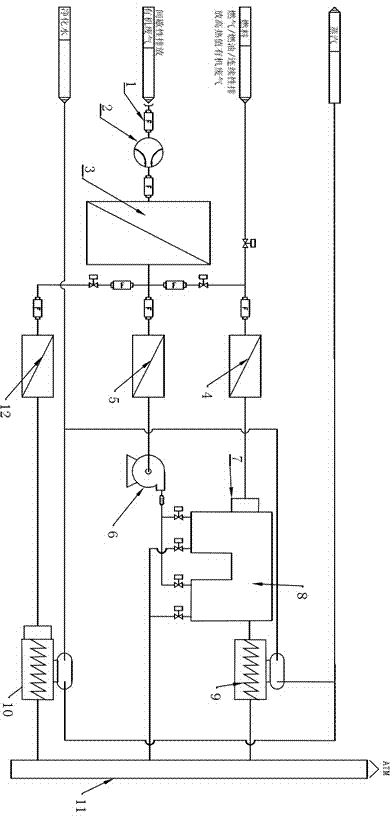

Exhaust processing method and apparatus for safety dumping of fuel cell automobile hydrogen gas

ActiveCN101409353AReduce hydrogen concentrationGood buffer dilution treatment effectFuel cellsPropulsion unit gas exhaustFlame arresterExhaust valve

The invention discloses a tail gas buffer dilution treatment method for safe emission of hydrogen from a fuel cell vehicle and a device thereof. The device comprises a hydrogen buffer, a flow control valve, a draining valve, a flame arrester, an earth terminal, an emergency hydrogen exhaust valve, a hydrogen sensor and a control module. The pulse hydrogen emitted from an anode side of the fuel cell is firstly buffered by the buffer, and a small stream of air introduced from an air path emitted from the cathode side dilutes and sweeps the hydrogen in the buffer; then the diluted hydrogen emitted from the buffer and the gas from a main air pipeline are mixed, thus the volume concentration of the tail hydrogen emitted from the fuel cell vehicle is controlled below the explosion limit concentration 4%, and the purified water discharged from a condenser can be recycled. The tail gas buffer dilution treatment device utilizes the techniques of self-diffusion, multi-tube pass buffer, air mixing and exchange, expansion, condensation and the like to buffer and dilute the hydrogen-containing tail gas emitted from the fuel cell vehicle and separate the water and gas in the hydrogen-containing tail gas, thus eliminating the possible fire hazard and ensuring the safe running of the fuel cell vehicle.

Owner:TONGJI UNIV

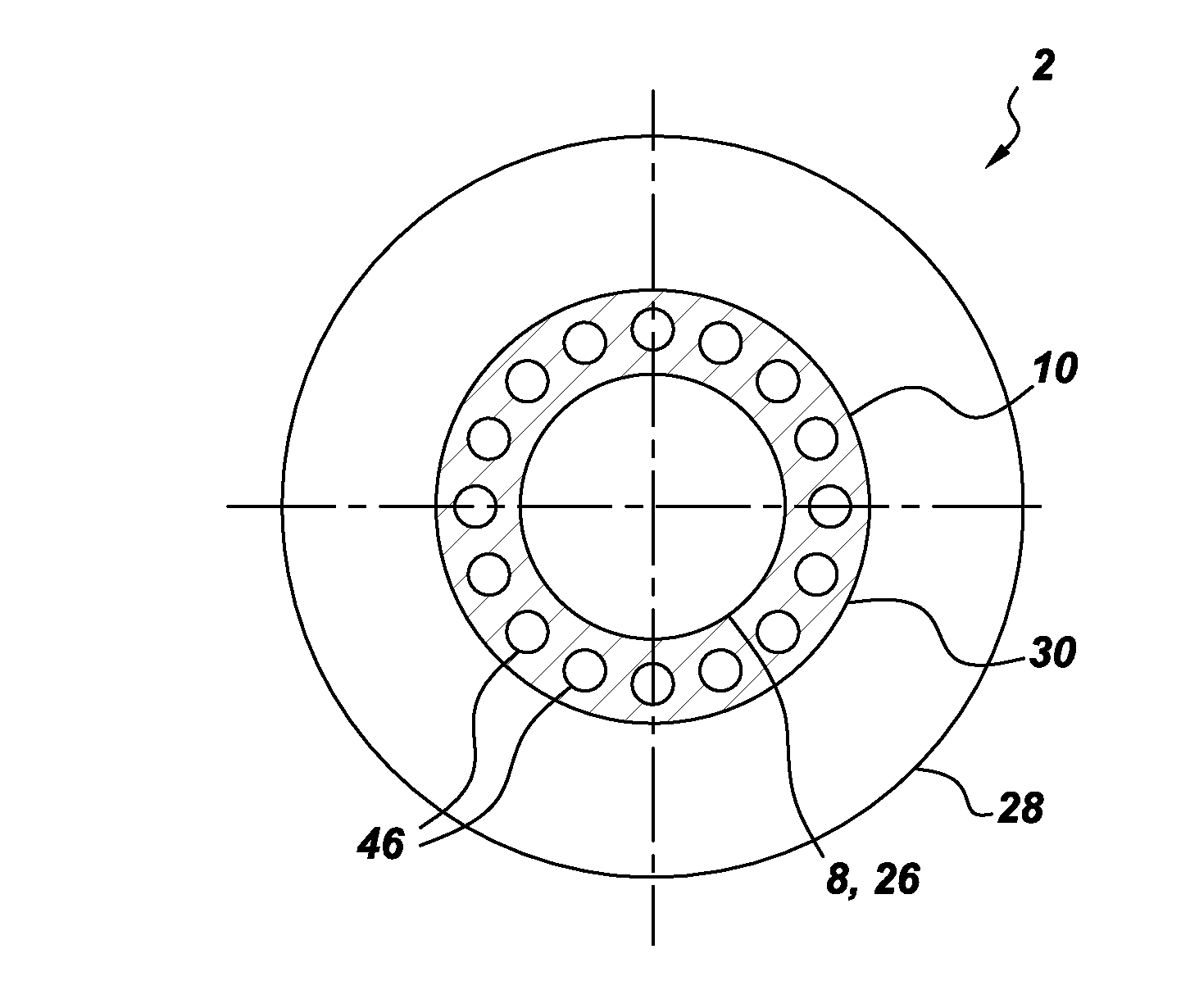

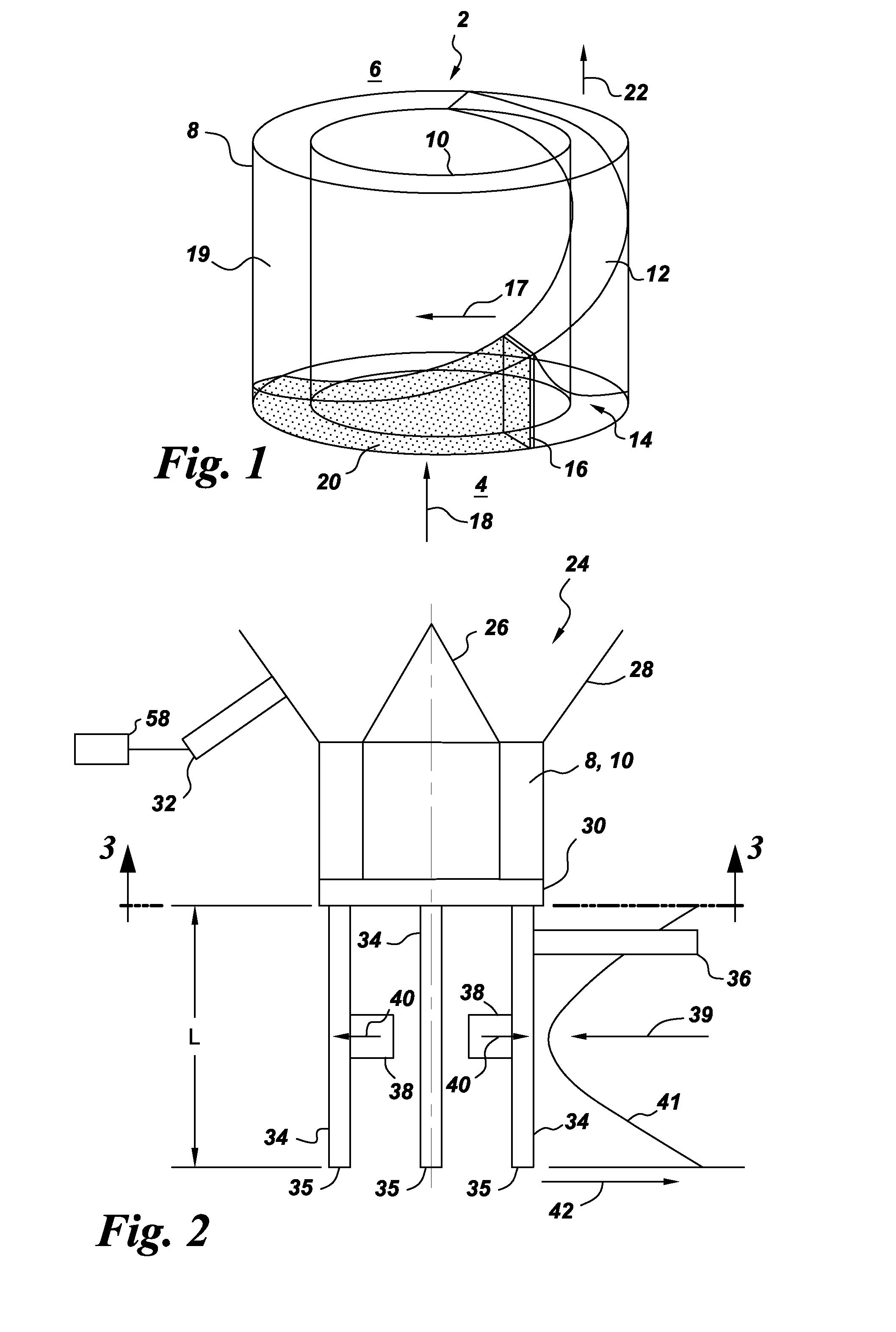

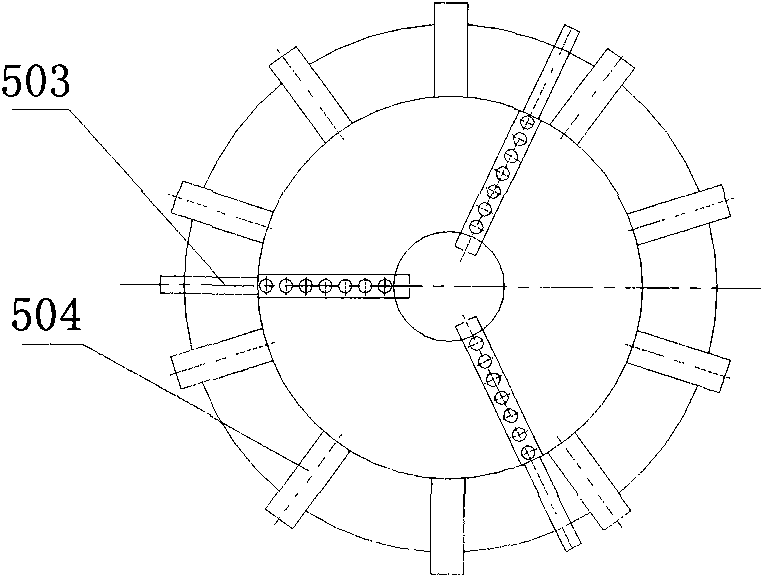

Tuned cavity rotating detonation combustion system

ActiveUS20150167544A1Continuous combustion chamberInternal combustion piston enginesFlame arresterCombustion system

A tuned cavity rotating detonation combustion system includes a an annular chamber having an inlet and an outlet; a valve plate at the inlet of the annular chamber and comprising a plurality of openings spaced circumferentially around the inlet; a plurality of tubes each having an open end in communication with a corresponding opening of the valve plate and a closed end forming a tuned cavity, and a first opening between the open end and the closed end for injection of air; and a plurality of fuel injectors corresponding to the plurality of tubes, each fuel injector being configured to inject fuel into the tube between the first opening and the open end. Each of the tuned cavities has a length sized to resonate at a same frequency as a continuous detonation frequency of at least one detonation wave in the annular chamber. Alternately, or additionally, a plurality of flame arresters corresponding to the plurality of tubes are configured to arrest the at least one detonation wave generated in the detonation chamber from travelling into the tube.

Owner:GENERAL ELECTRIC CO

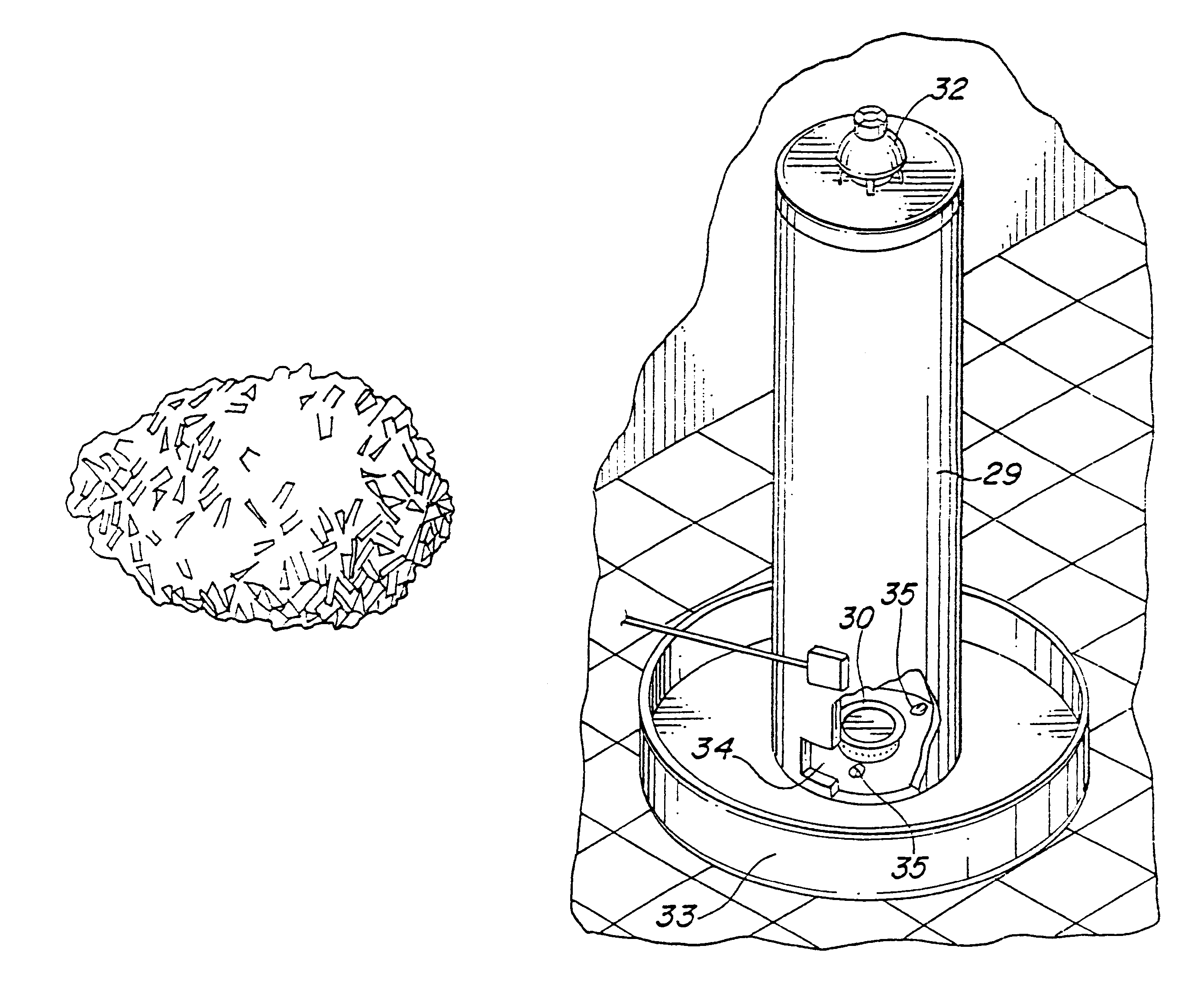

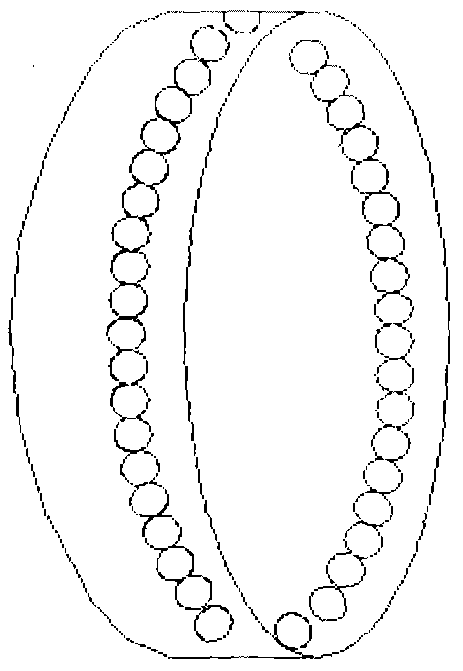

Flame arrester

InactiveUS6216791B1Improve abilitiesEasy to assemblePaper/cardboard articlesMachines/enginesCombustion systemFlame arrester

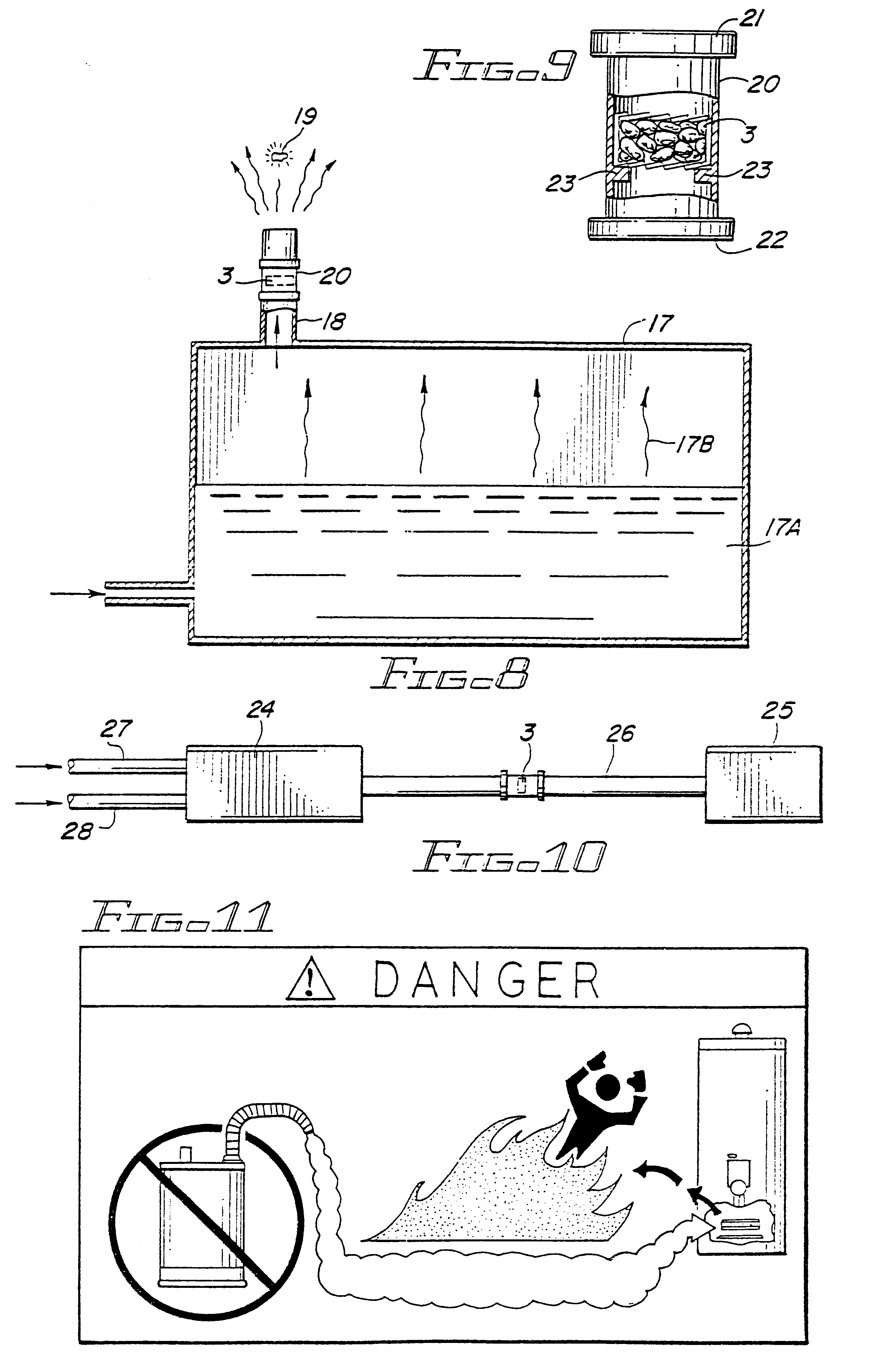

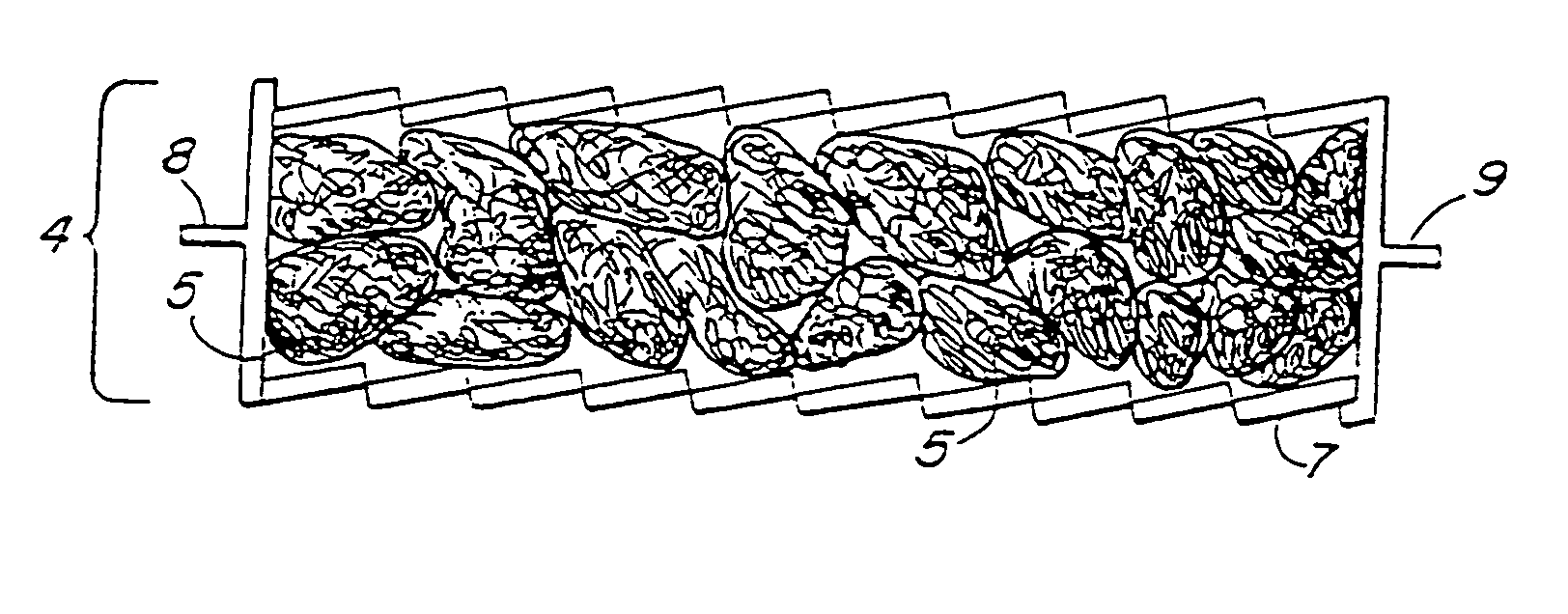

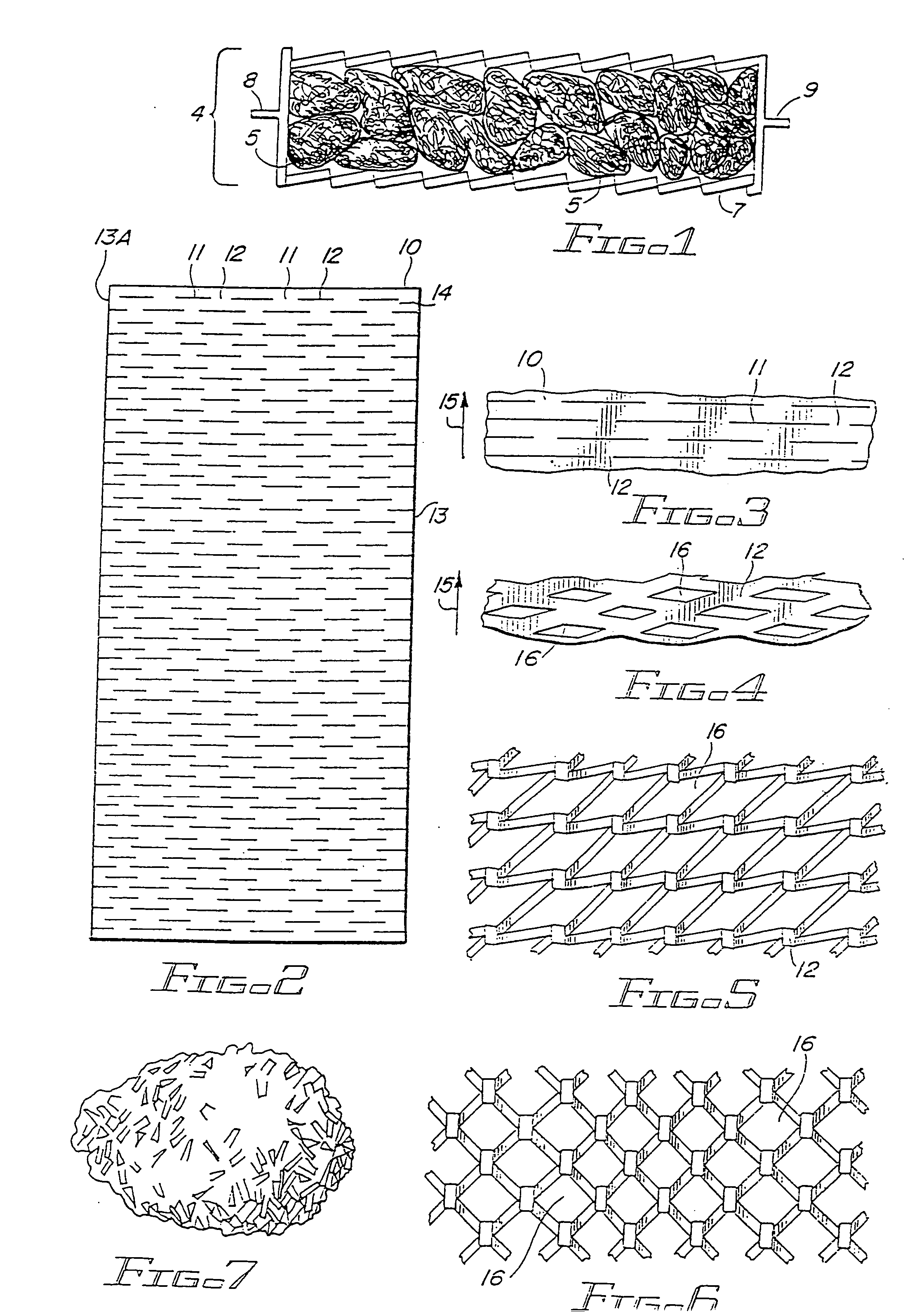

A highly efficient flame arrester adapted for use in preventing an external flame from backflashing upstream in a pipe, or a conduit, or a stream carrying a flammable substance. The flame arrester comprises a contained layer of nested ellipsoids formed from expanded metal sheets made from magnesium alloy foil. The arrester is useful in fuel tanks, combustion systems, sea-going tankers, hot water, or space heaters, and the like.

Owner:ALHAMAD SHAIKH GHALEB MOHAMMAD YASSIN

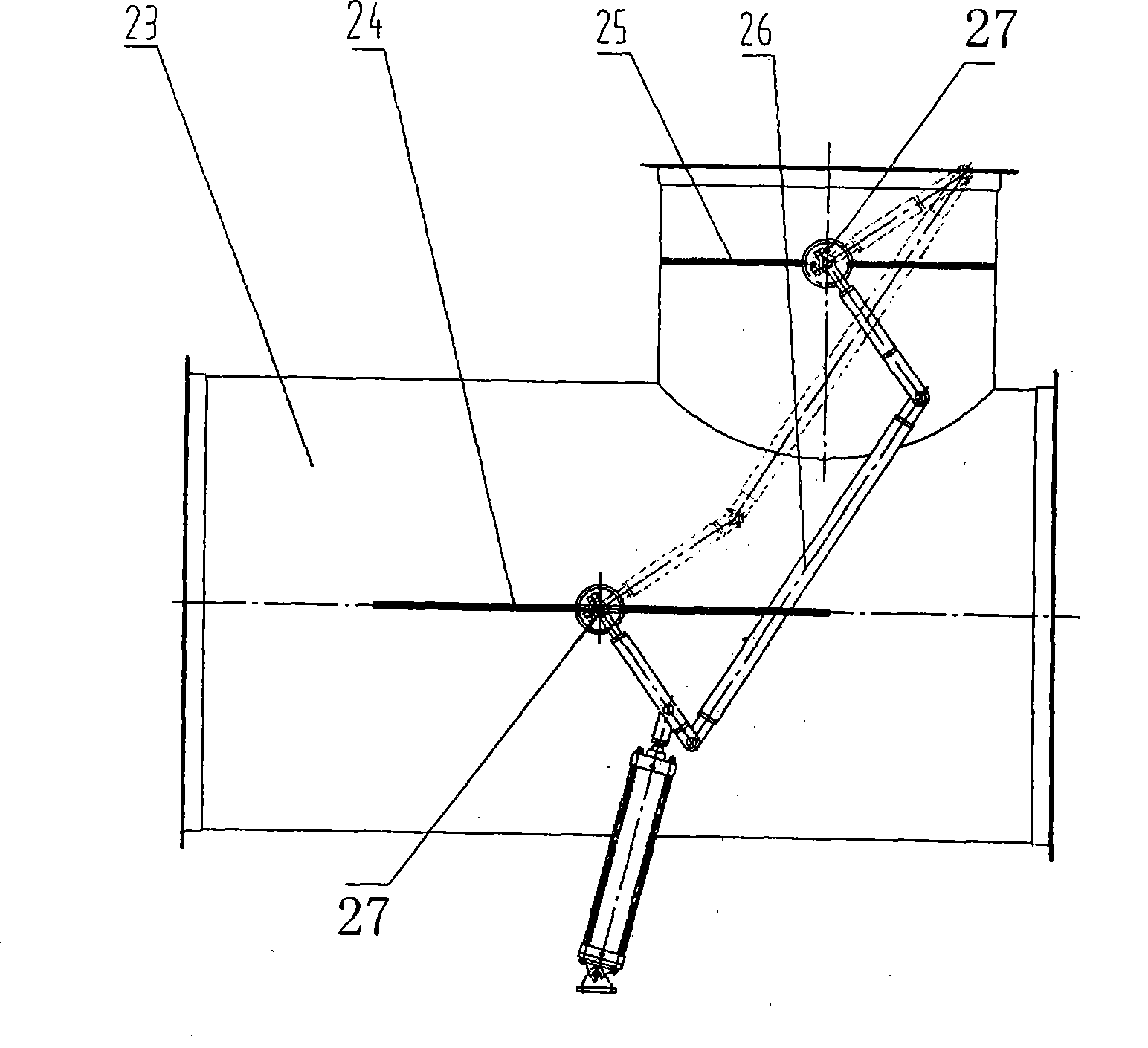

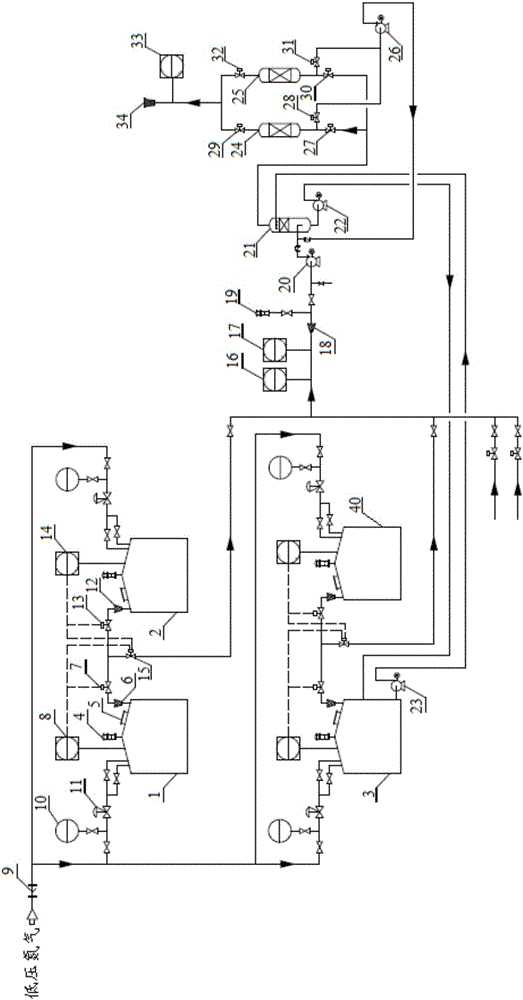

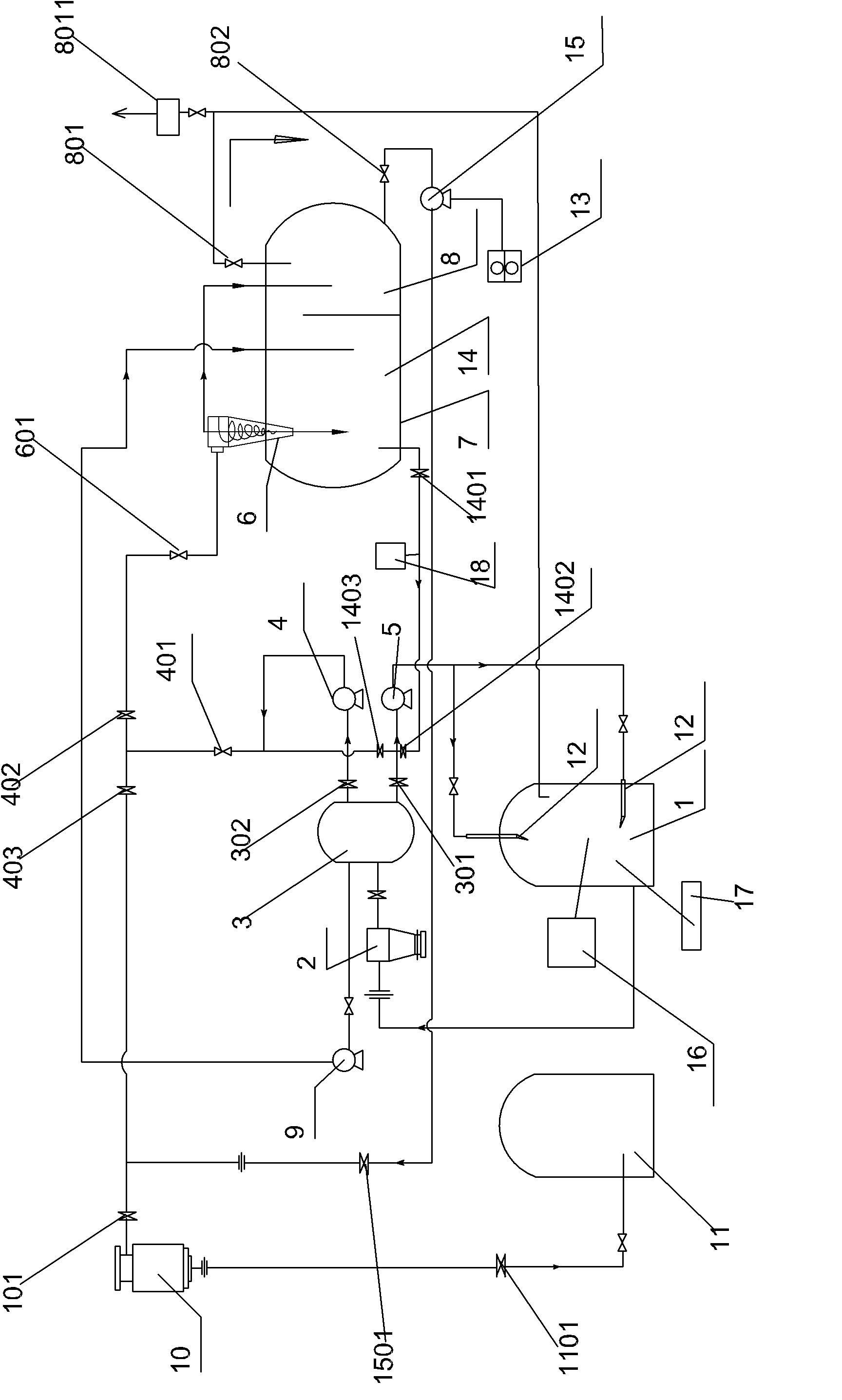

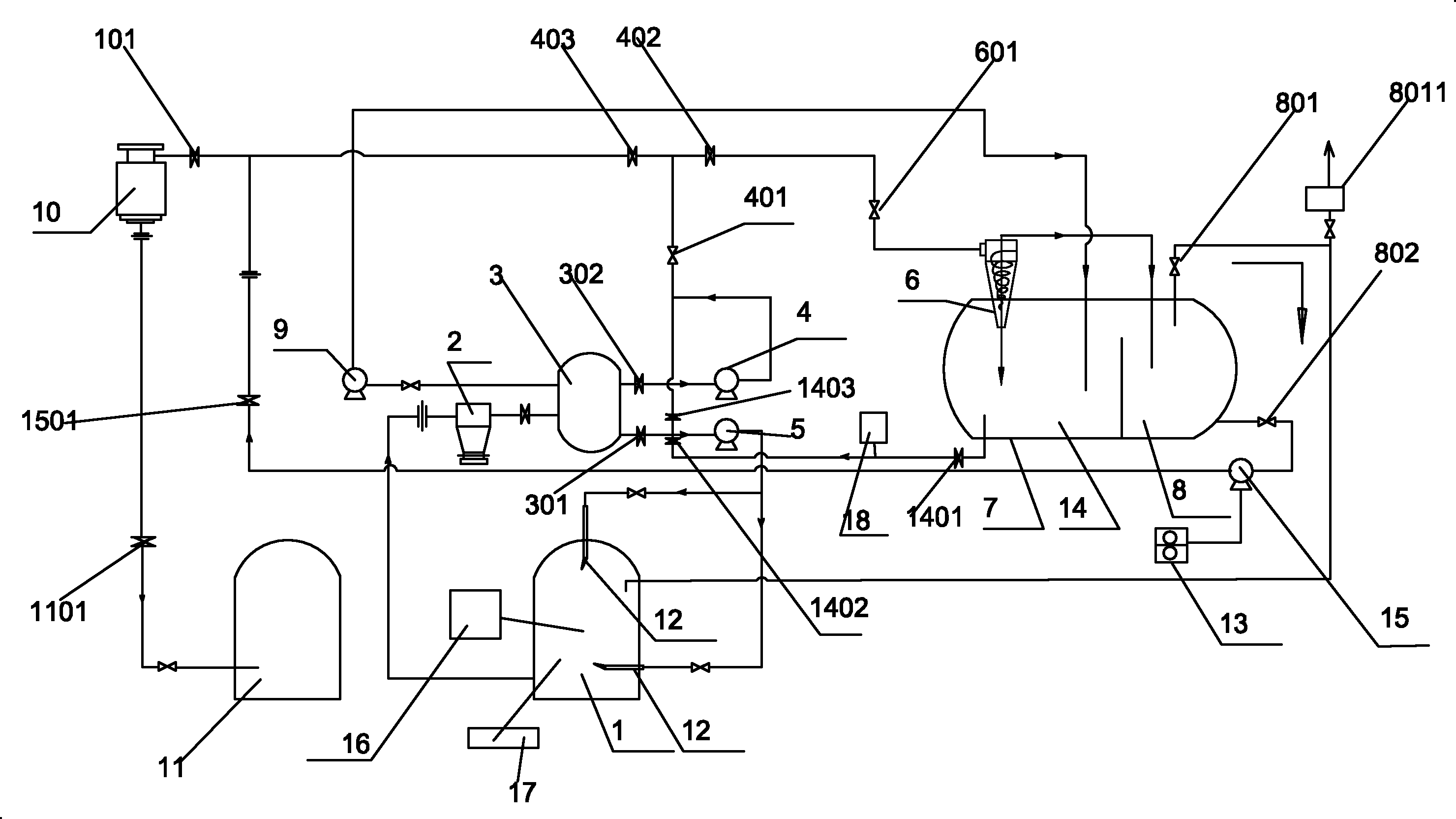

Coal mine ventilation air methane oxidation device, mash gas adding system and security protection mechanism

InactiveCN101418702ANo need to add pressureAnti-overheatingDust removalFire preventionFlame arresterElectricity

A gas adding system and a safe protection mechanism for mine lack air methane oxidation device are disclosed. The gas extraction and lack air mixing gas intake system of the oxidation device comprises a gas extracting pipeline and a manual valve mounted thereon, a gas intake main pipeline for mixed extracted gas and lack air and fans mounted thereon, a safety valve and a connection pipe connected with a mechanical cutting valve; the safety protection mechanism comprises a wet type flame arrester, a dry type flame arrester, a quick disconnect valve, a gas adding amount control and regulate valve, and a mechanical cutting valve which are connected from up to down along the flow direction of extracted gas; an electric control system comprises a controller and a power source electrically connected with the same, the controller is also electrically connected with a methane concentration sensor and a level sensor in parallel, and the power source is also electrically connected a discharge valve, the gas adding amount control and regulate vale, the safety valve, the quick disconnect valve and the fans in parallel. The invention has the characteristics of convenient operation, energy conservation, safety, and protection, and can be widely applied to gas adding system for mine methane extraction oxidation devices.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

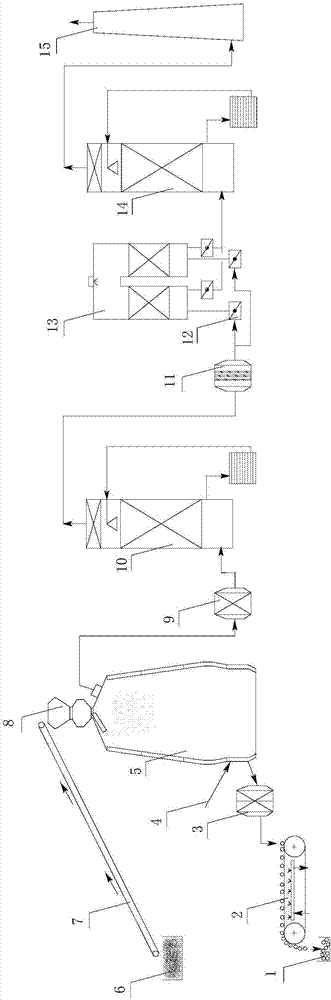

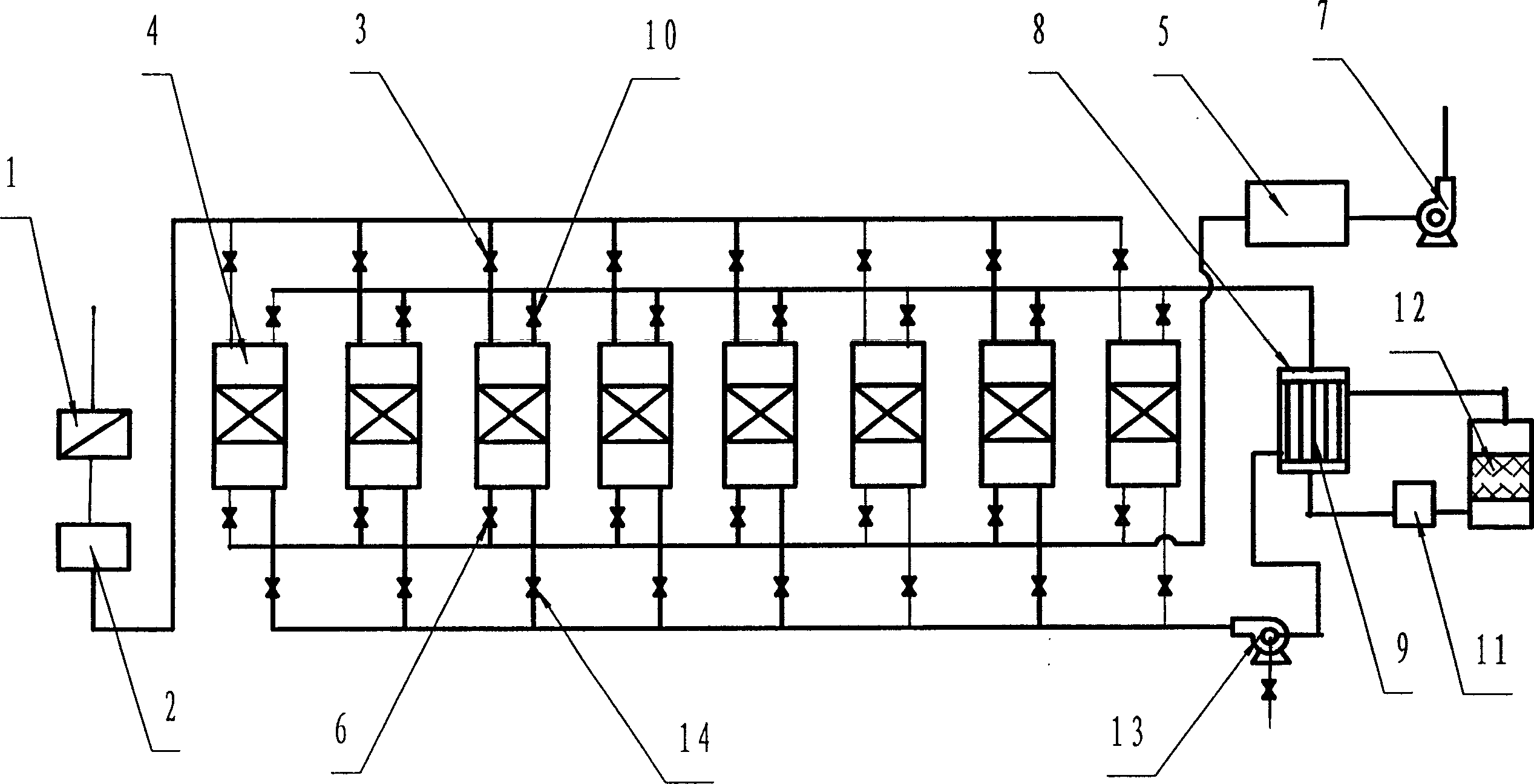

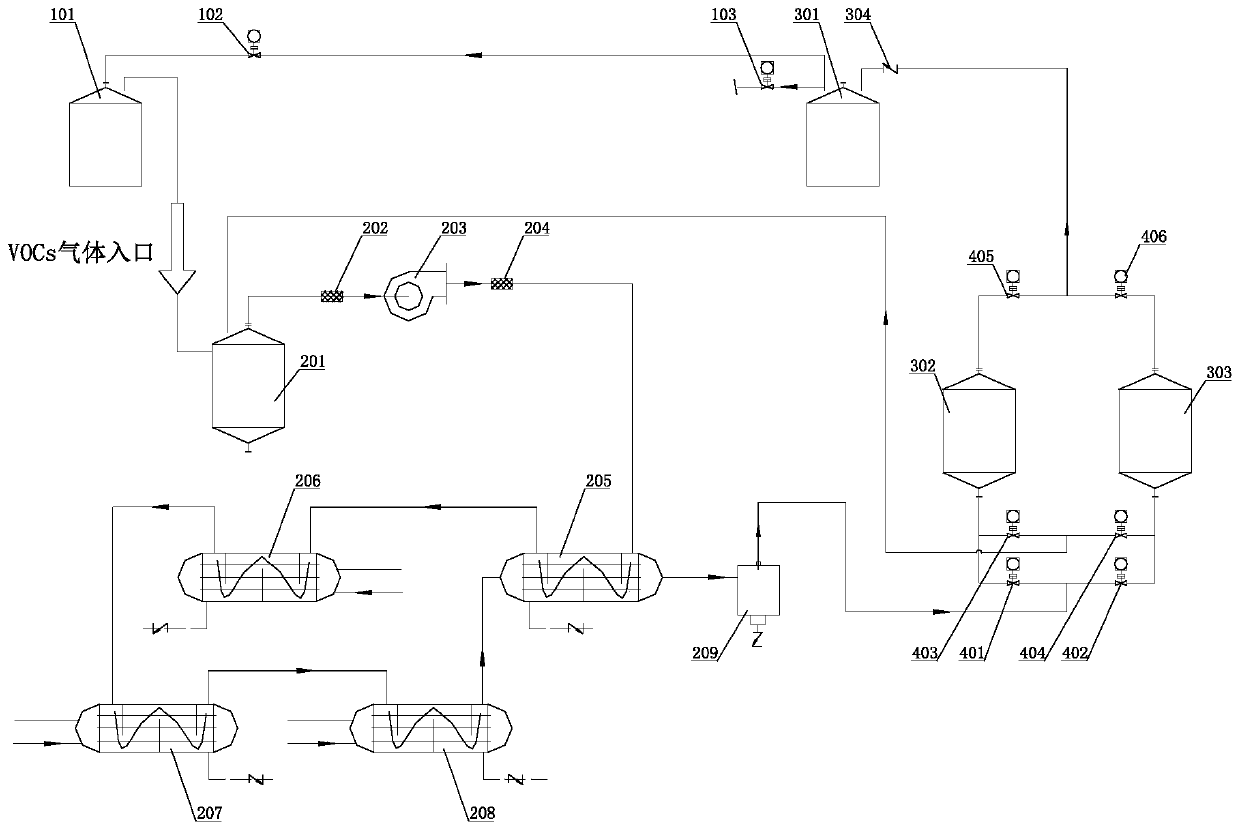

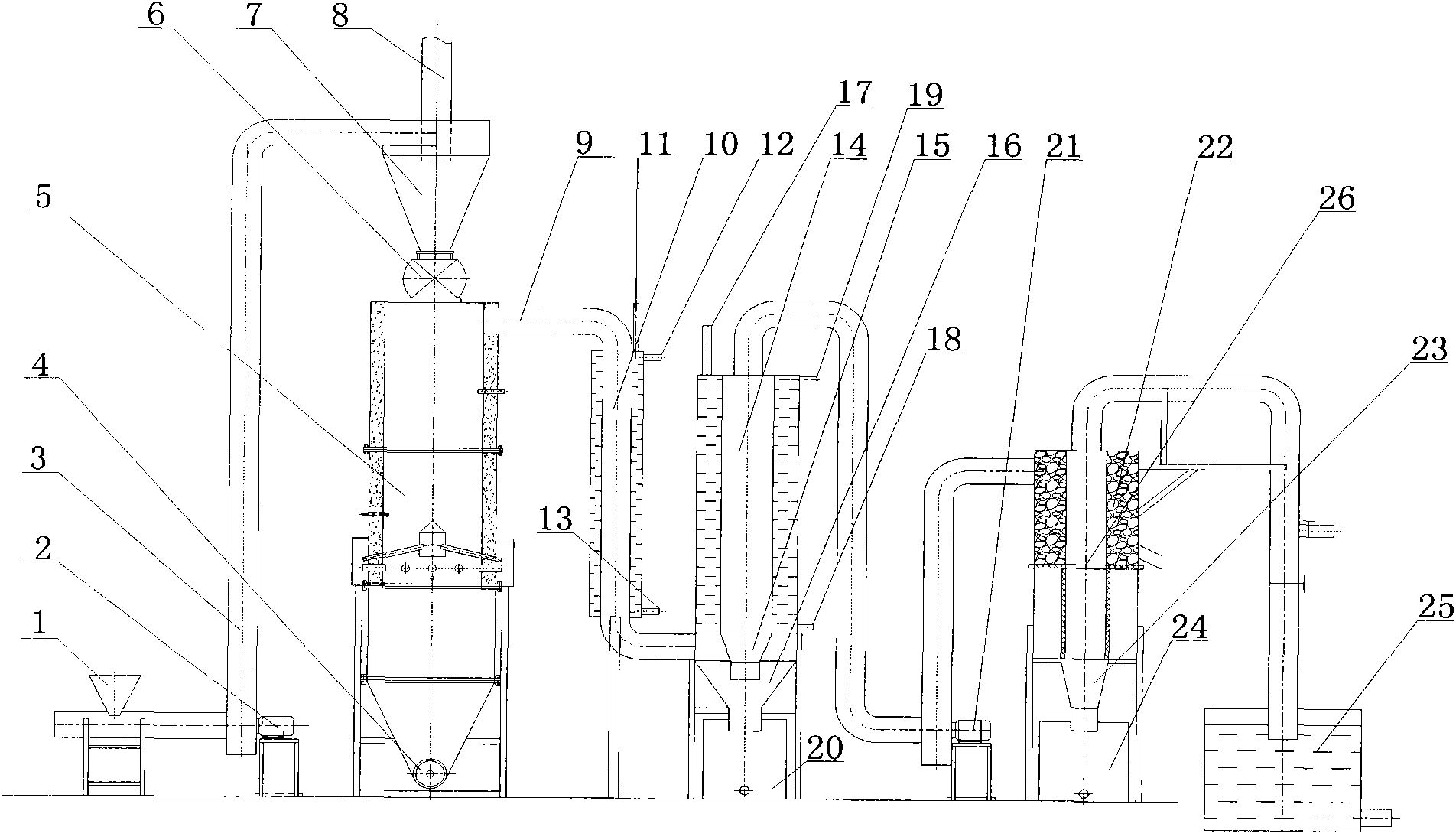

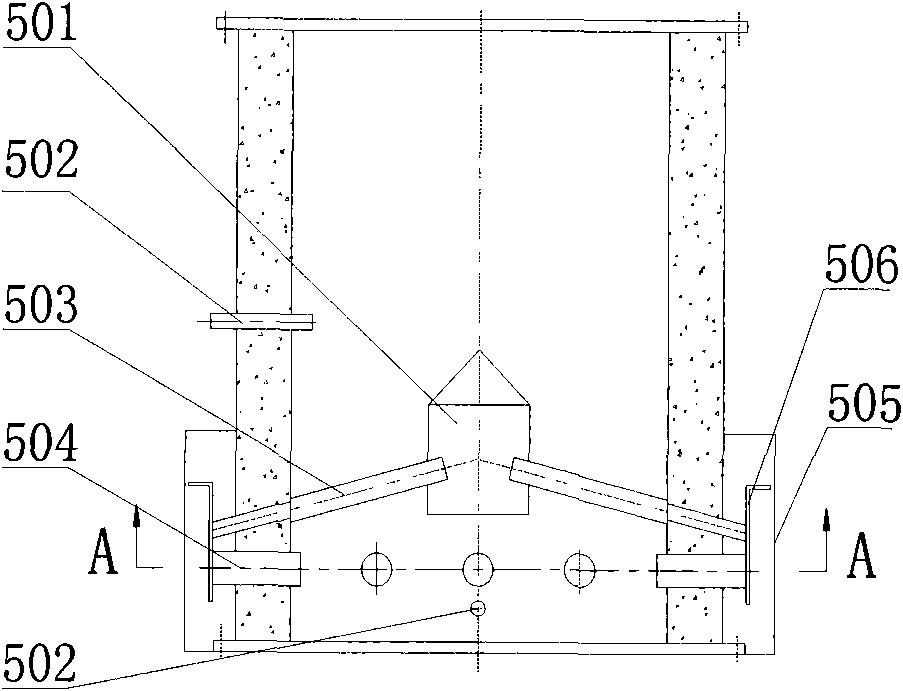

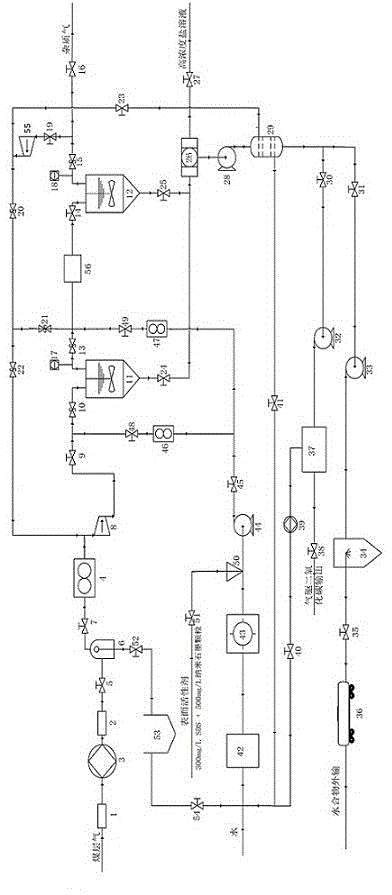

Organic waste gas adsorption and desorption concentration catalytic combustion equipment system

ActiveCN103438467AExtended replacement timeReduce replacement timeCombination devicesIncinerator apparatusActivated carbonFlame arrester

The invention discloses an organic waste gas adsorption and desorption concentration catalytic combustion equipment system which comprises a dry-type filtering device. The organic waste gas adsorption and desorption concentration catalytic combustion equipment system is characterized in that a catalytic combustion bed is connected to the lower end of the dry-type filtering device, a flame arrester a is connected to the right end of the catalytic combustion bed, a cold air supplement valve is connected to the lower right end of the flame arrester a, and a temperature adjusting valve is further connected to the lower end of the catalytic combustion bed. According to the organic waste gas adsorption and desorption concentration catalytic combustion equipment system, the replacement interval of activated carbon is greatly prolonged, the replacement time of the activated carbon is shortened, the activated carbon can be effectively used for desorption, regeneration and recycling, organic waste gas after desorption is thoroughly decomposed into CO2 and H2O after catalytic combustion is carried out, no secondary pollution exists, a PLC and a human-computer interface are adopted in the system to control an operation system, the operation is easy to achieve, and the possibility of misoperation is reduced.

Owner:KUNSHAN GONGTONG ENVIRONMENTAL PROTECTION MACHINECO

Storage tank volatile organic compound recovery system

ActiveCN106241099ALower energy costsLow running costDispersed particle separationLarge containersFlame arresterPressure transmission

The invention provides a storage tank volatile organic compound recovery system. The storage tank volatile organic compound recovery system includes a first storage tank, a nitrogen sealed system, a second storage tank, a volatile organic compound collection system, and a volatile organic compound recovery system; the nitrogen sealed system includes a Y-shaped filter, a pressure gage and a self-actuated regulation valve; the volatile organic compound collection system includes pipeline flame arresters, automatic stop valves, and pressure transmission devices which are arranged on the tops of the first storage tank and the second storage tank, and an automatic stop valve positioned on a volatile organic compound collection pipe; and the volatile organic compound recovery system includes a third storage tank, an induced draft fan, a suction tower, pumps, adsorption towers, a vacuum pump and an anti-explosion flame-arrest ventilation cap. The storage tank volatile organic compound recovery system can recover crude oil and volatile organic compounds which are discharged by a product tank field in a non-organization manner.

Owner:中石油吉林化工工程有限公司

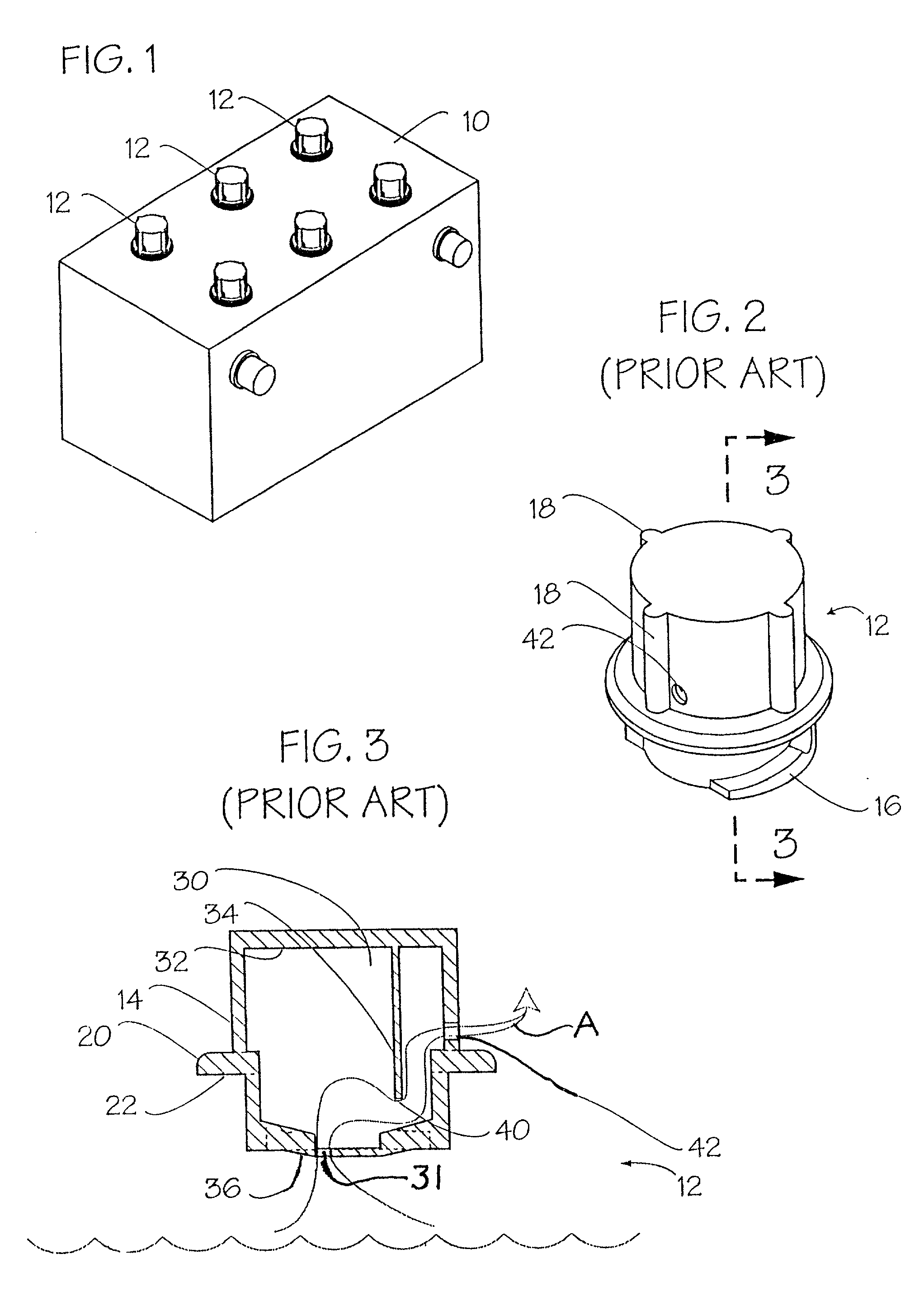

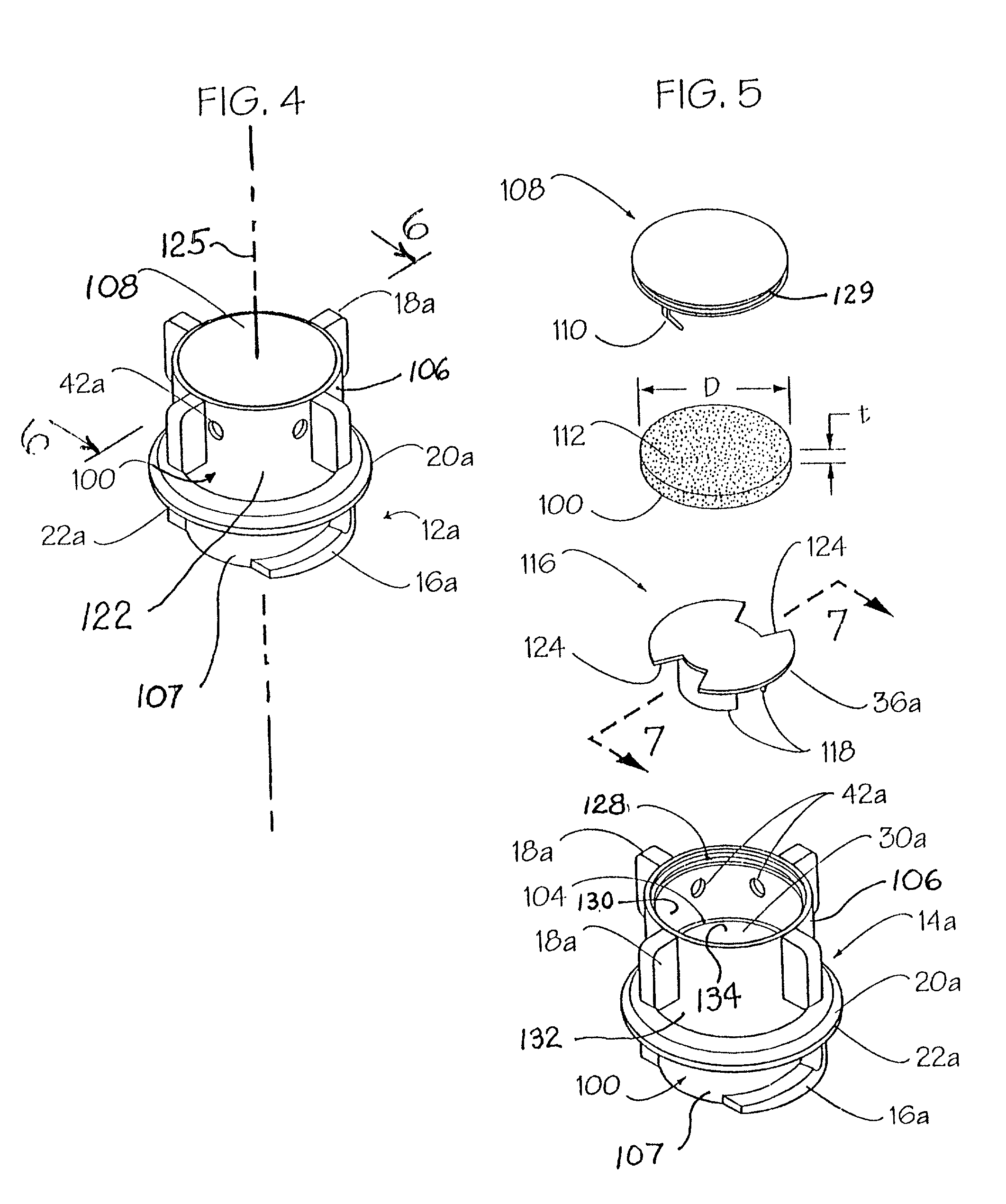

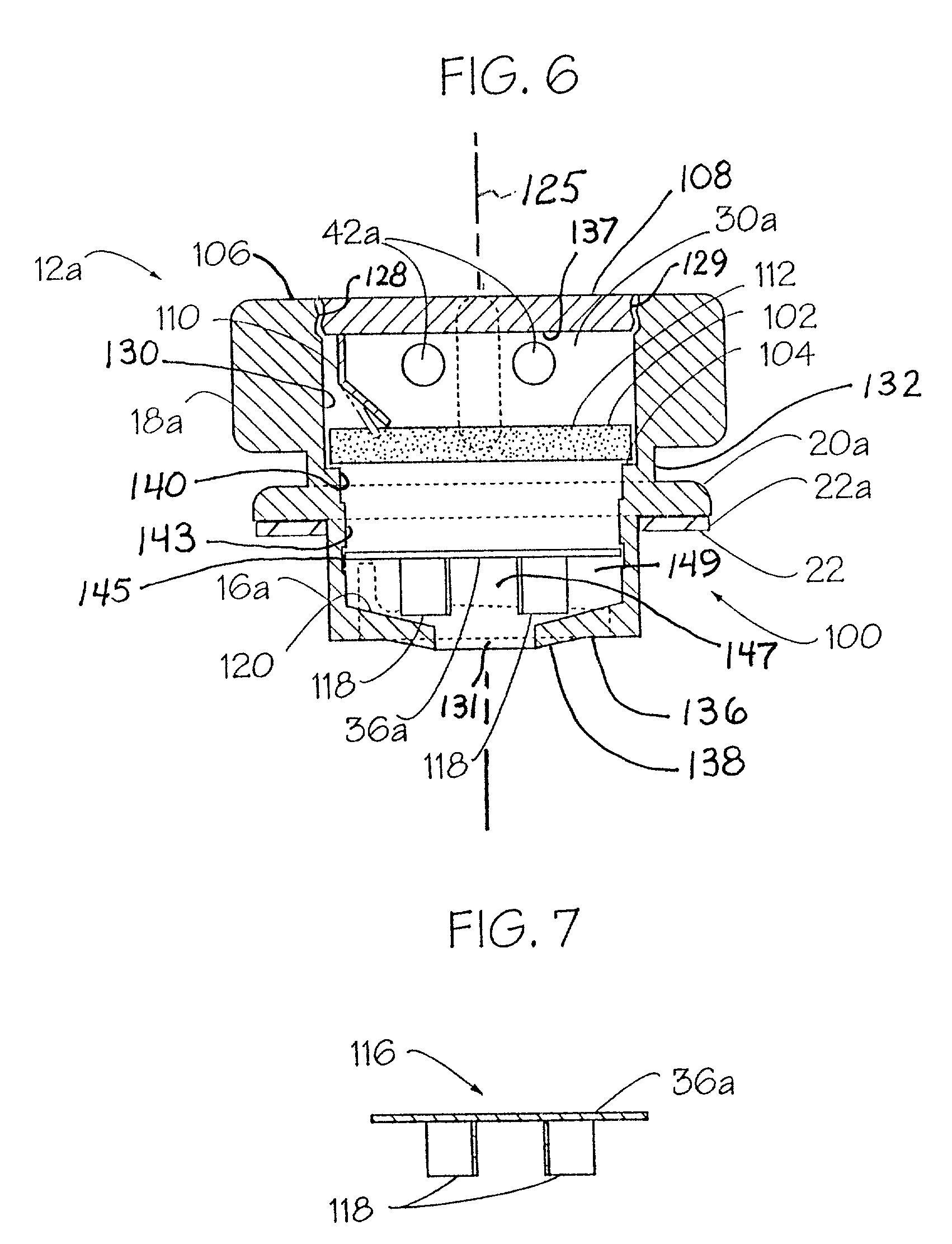

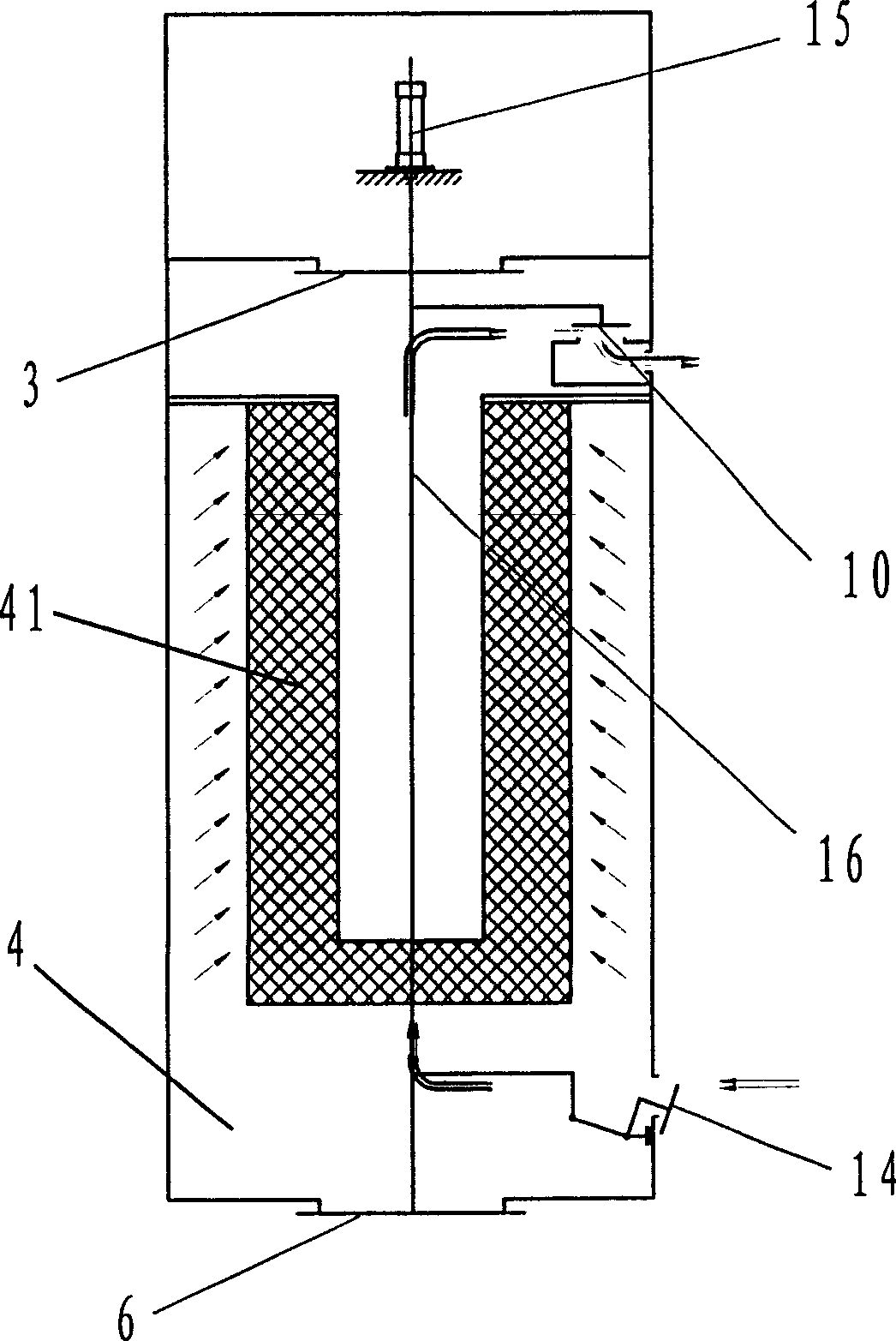

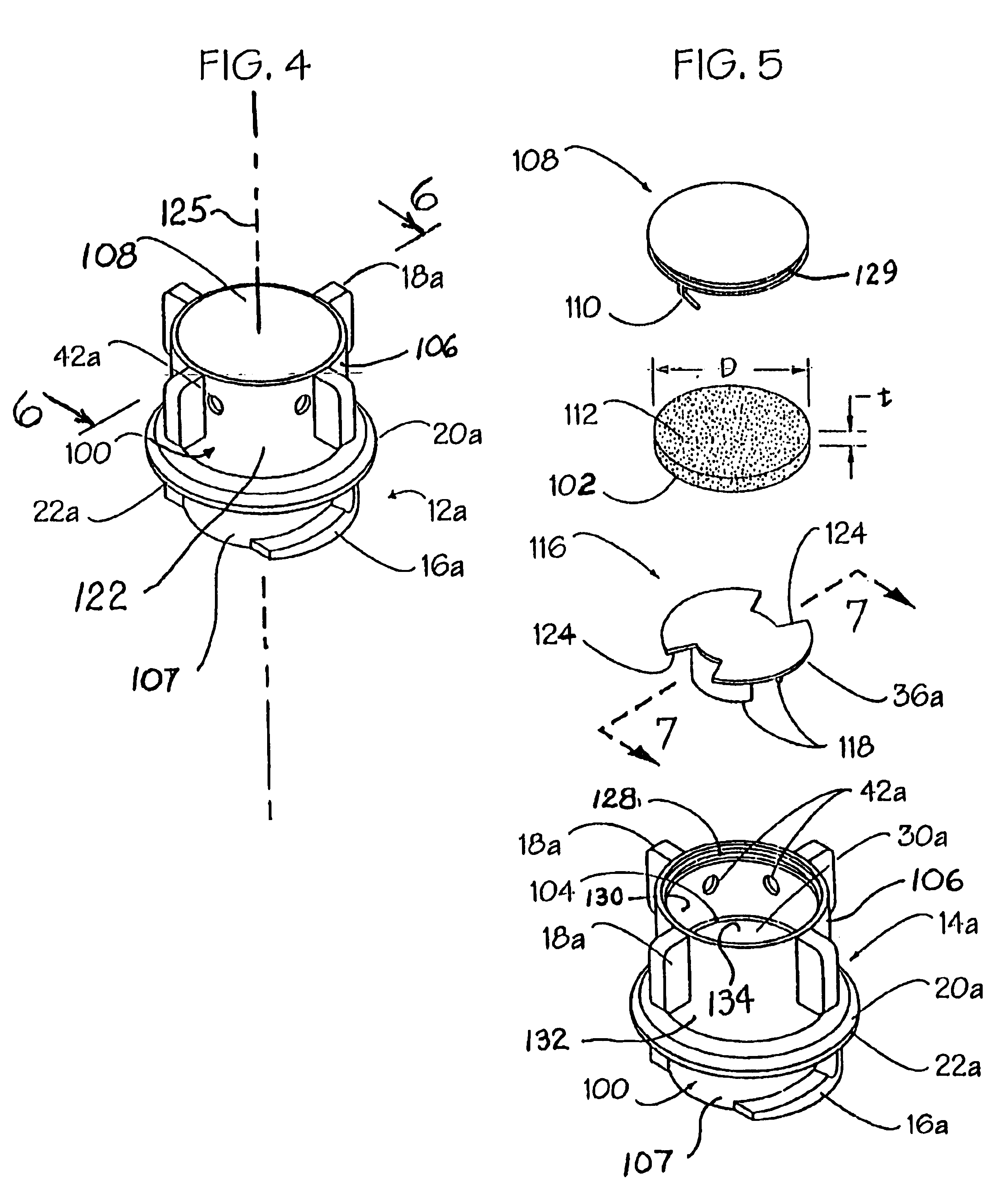

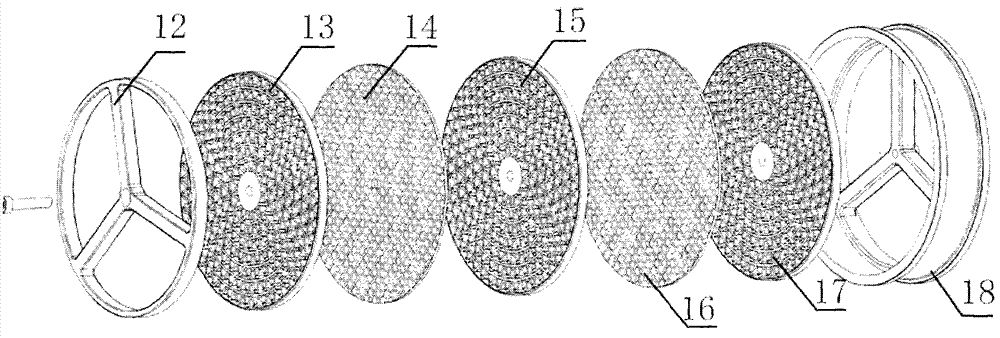

Lead-acid safety battery cap

A battery cap is provided for engagement in a fill port of a cell of a deep cycle, lead-acid electrical storage battery. The battery cap is formed of a hollow, tubular body having an upper end with an expansive mouth opening, and a lower end at which a transverse floor extends radially inwardly. The floor includes a central, annular convex downwardly projecting portion that defines a central fluid passage opening. The interior of the tubular wall defines a radially inwardly projecting flame arrester seat spaced from both the upper and lower ends of the body. A pair of gas escape ports are defined in the tubular wall between the flame arrester seat and the mouth opening. A diverter is located in the lower portion of the tubular body beneath a disc shaped micropore filter that serves as the flame arrester and which is seated on the flame arrester seat. The diverter is formed with a generally disc shaped, horizontal plate having diametrically opposed notches at its peripheral edge and a pair of legs of that have an arcuate cross-section and which rest upon the floor to partially surround the central opening in the floor. A battery cap having this internal structure causes drops of electrolyte to intermittently lodge in the central floor opening, thereby forming a temporary fluid seal that is repeatedly broken to allow venting of gas and reestablished to aid in protecting the micropore filter from contaminants.

Owner:SCHWARZ WILLIAM R

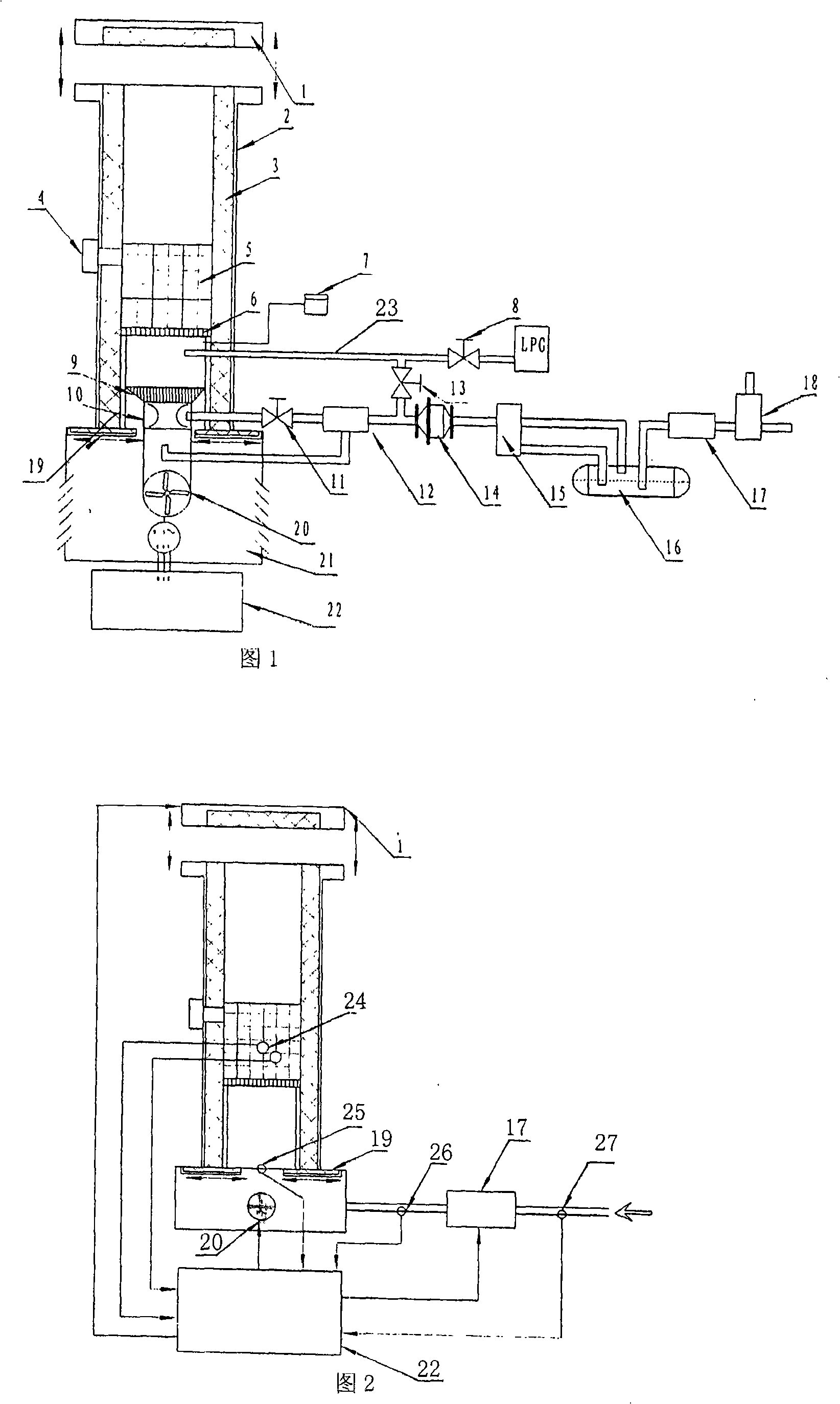

Coal mine mash gas incineration torch

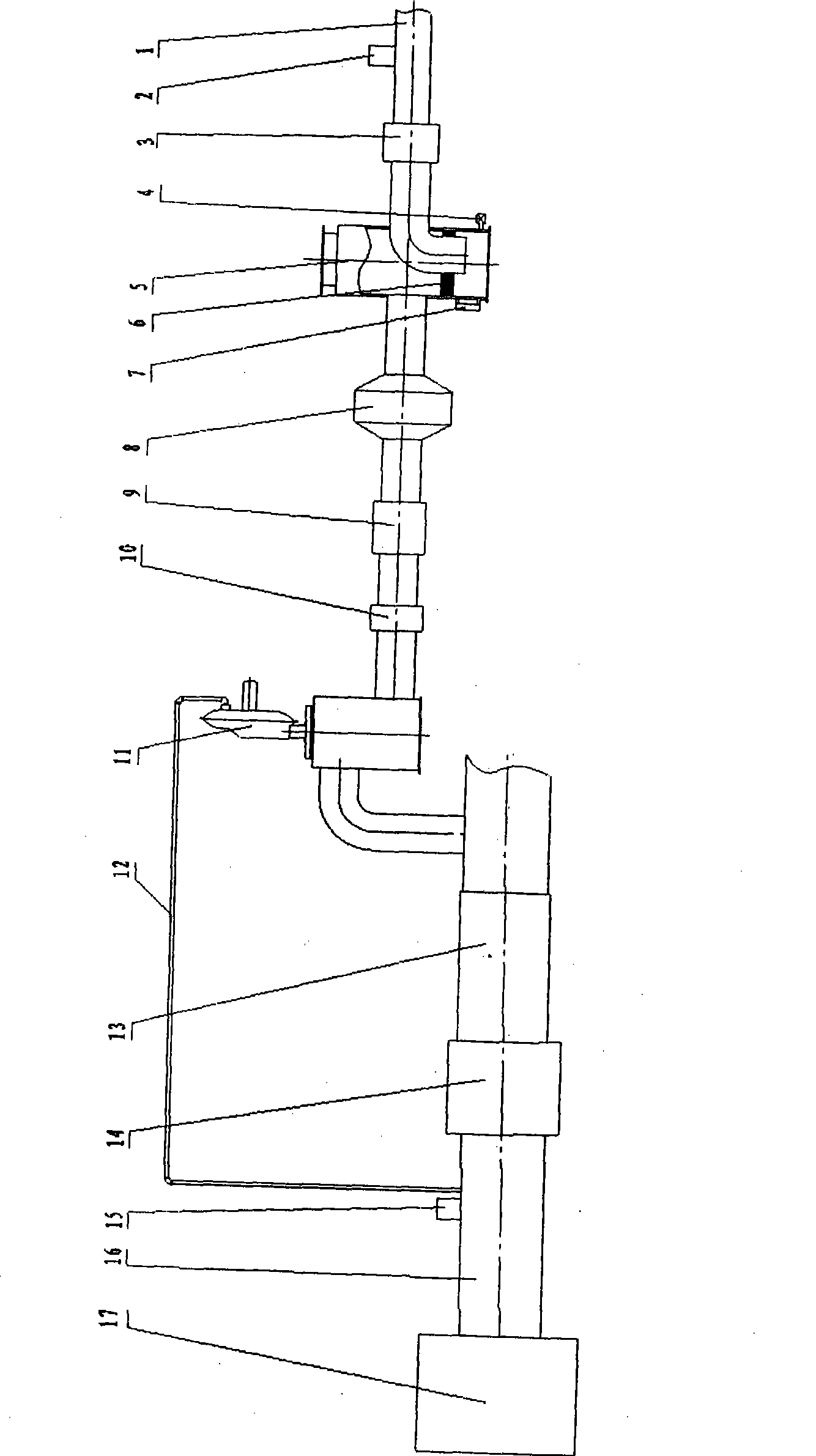

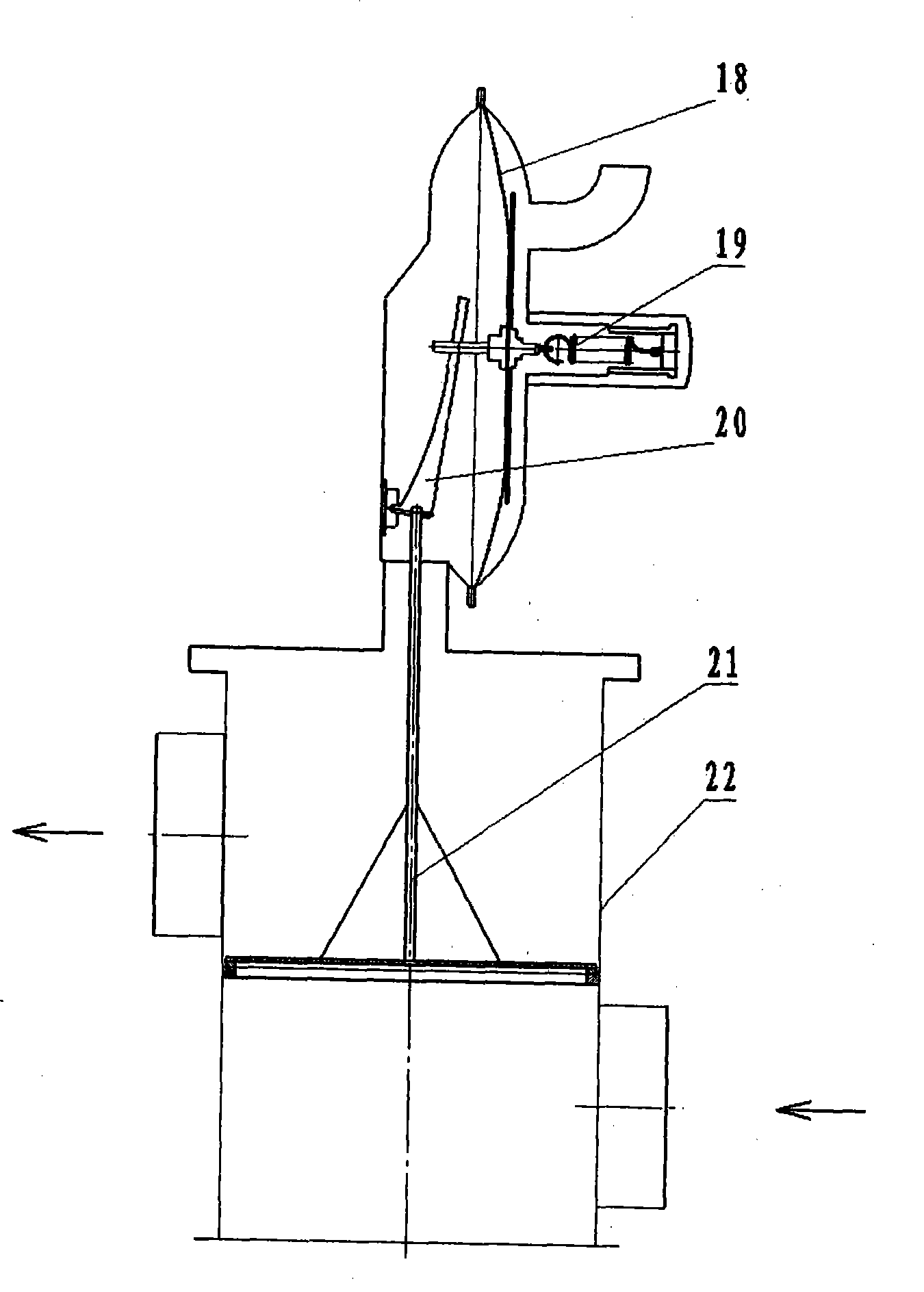

InactiveCN101329067AStable lean burnBurn fullyIncinerator apparatusGaseous fuel burnerFlame arresterInsulation layer

The invention discloses a coal-mine gas-burning torch which comprises a burner and etc. systems including an insulation layer arranged inside a casing; a regenerative honeycomb ceramics and a bracket thereof which are arranged in the middle of the insulation layer, a proportioning mixer and a multi-head mixed-gas nozzle which are arranged on a lower part of the bracket; an upper sealing cover arranged at the upper end of the casing and a lower sealing cover and a base which are arranged at the lower end of the casing; a pipeline and a main gas supply valve which are connected with the proportioning mixer; a pressure-regulating valve, a flame arrester, a filtering dehydrator, a hydroseal flame arrester, an electronic-control valve and a gas diffusion valve which are sequentially connected; a fan which is arranged inside the base under the casing and connected with the lower part of the proportioning mixer; an electronic ignition system comprising an LPG fuel supply valve, a gas supply valve connected with a gas transferring pipeline and an electronic igniter communicated with the lower part of the burner; a temperature sensor arranged in the regenerative honeycomb ceramics; an air pressure sensor arranged at the back of the fan; a gas concentration sensor, a gas pressure sensor and an electronic-control valve which are arranged in the gas transferring pipeline system and a controller arranged on the lower part of the casing.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

Waste salt recycling process and special device thereof

InactiveCN107321755AFully mineralizedHigh net salt puritySolid waste disposalTransportation and packagingFlame arresterPollutant emissions

The invention discloses a waste salt recycling process and a special device thereof. According to the process, a waste salt supply system, a waste salt melting system, a tail gas treatment system and a molten salt cooling and pelleting system are included. The special device comprises a waste salt feeder, a waste salt distributor, a drying, preheating and melting integrated salt-melting furnace, a belt cooling and pelleting machine, an RTO furnace, a filter, a fire arrester, an alkaline washing tower and the like. By means of the waste salt recycling process and the special device thereof, organic matter in waste salt is completely burnt out, the recycling standard is met, organic matter generated in the purifying process of waste salt is further treated in a thermal destruction mode, and emission of secondary pollutants like waste water and waste gas in the utilization process of the waste salt is avoided. Meanwhile, the vertical salt-melting furnace is adopted, the waste salt drying, preheating and melting processes are achieved in the furnace, high investment and waste gas pollution caused by equipment units for drying, grinding and the like are reduced, and the problem that it is difficult for the device to operate continuously and stably due to salt adhesion is solved.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

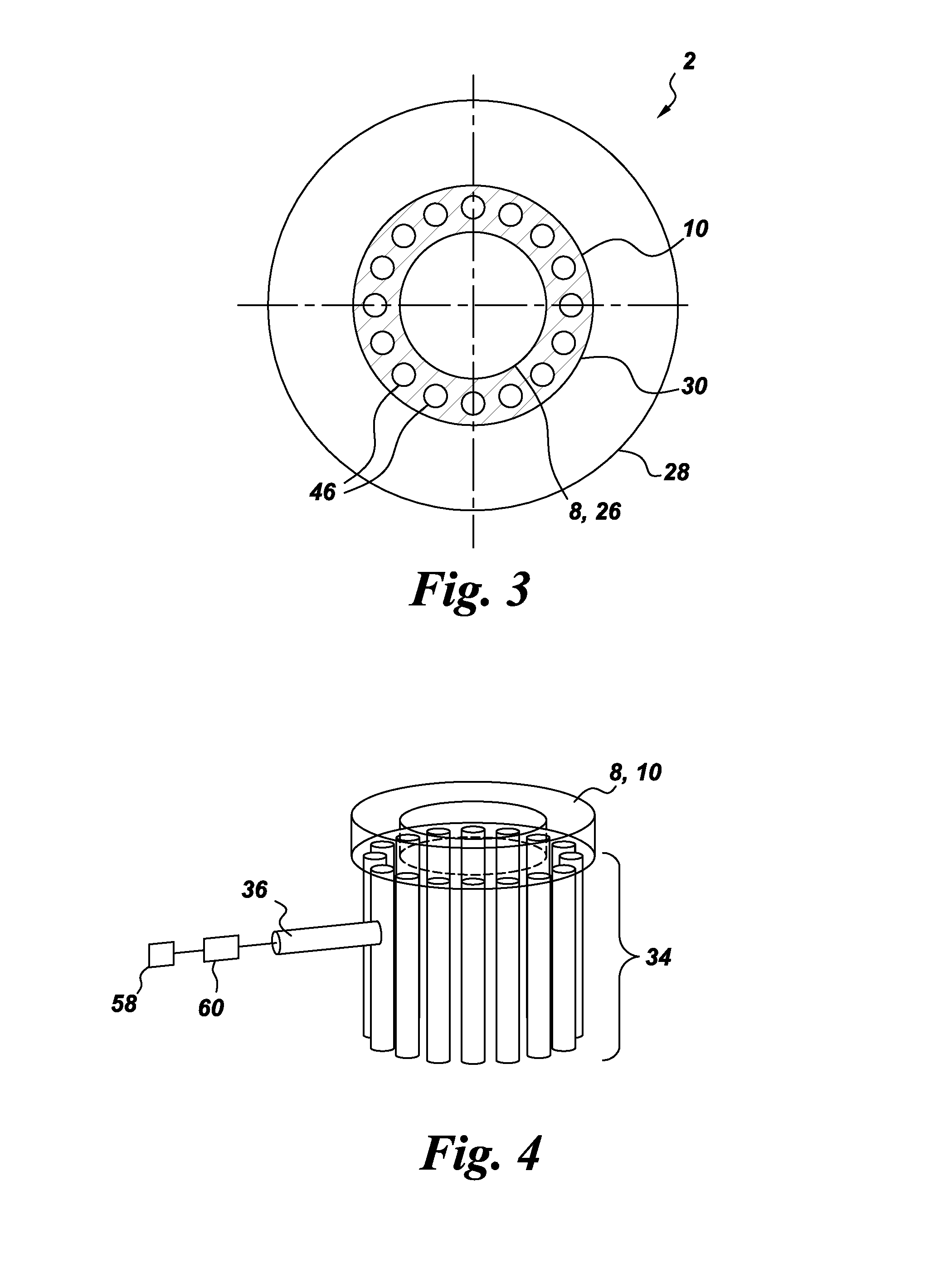

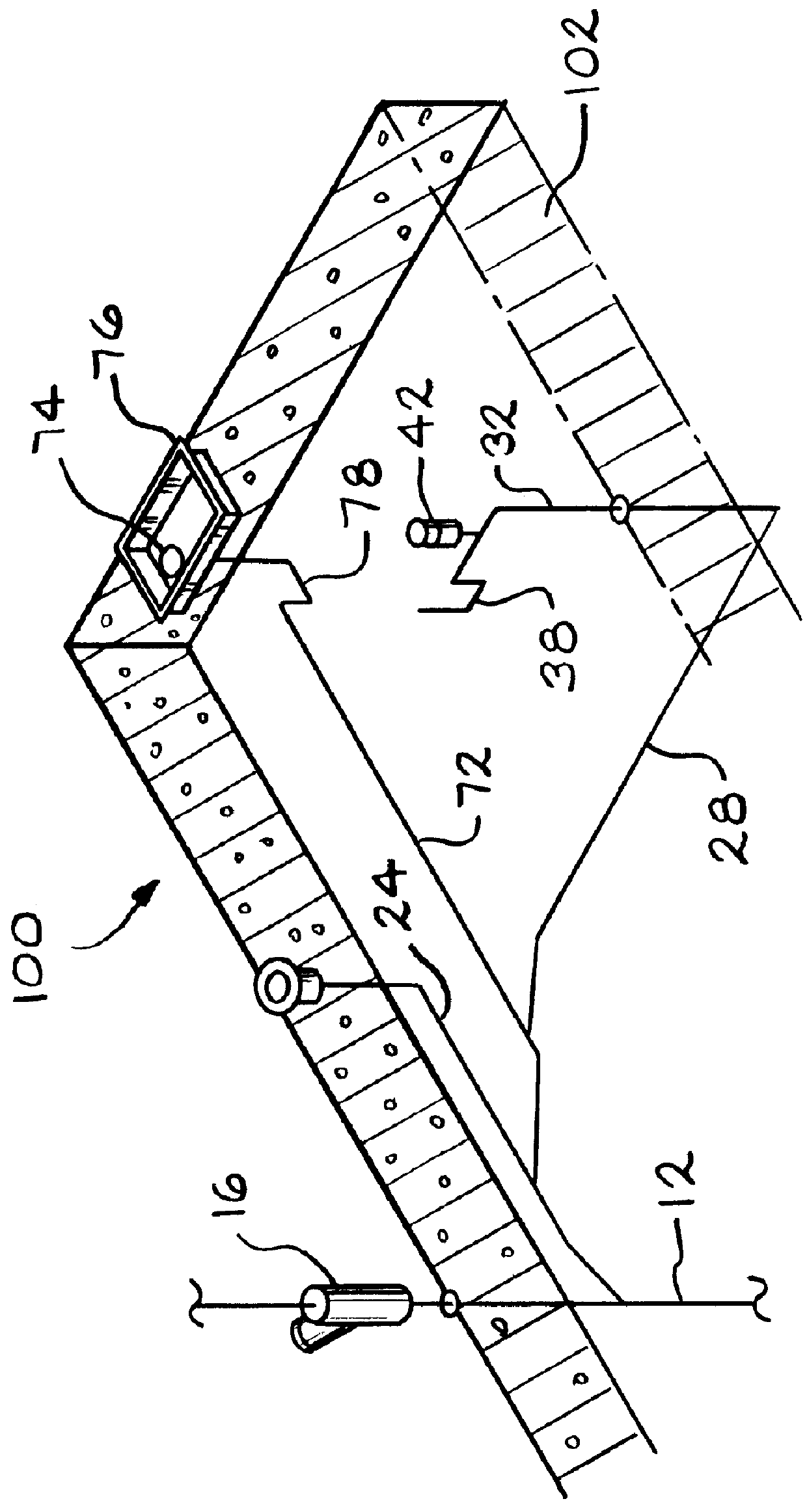

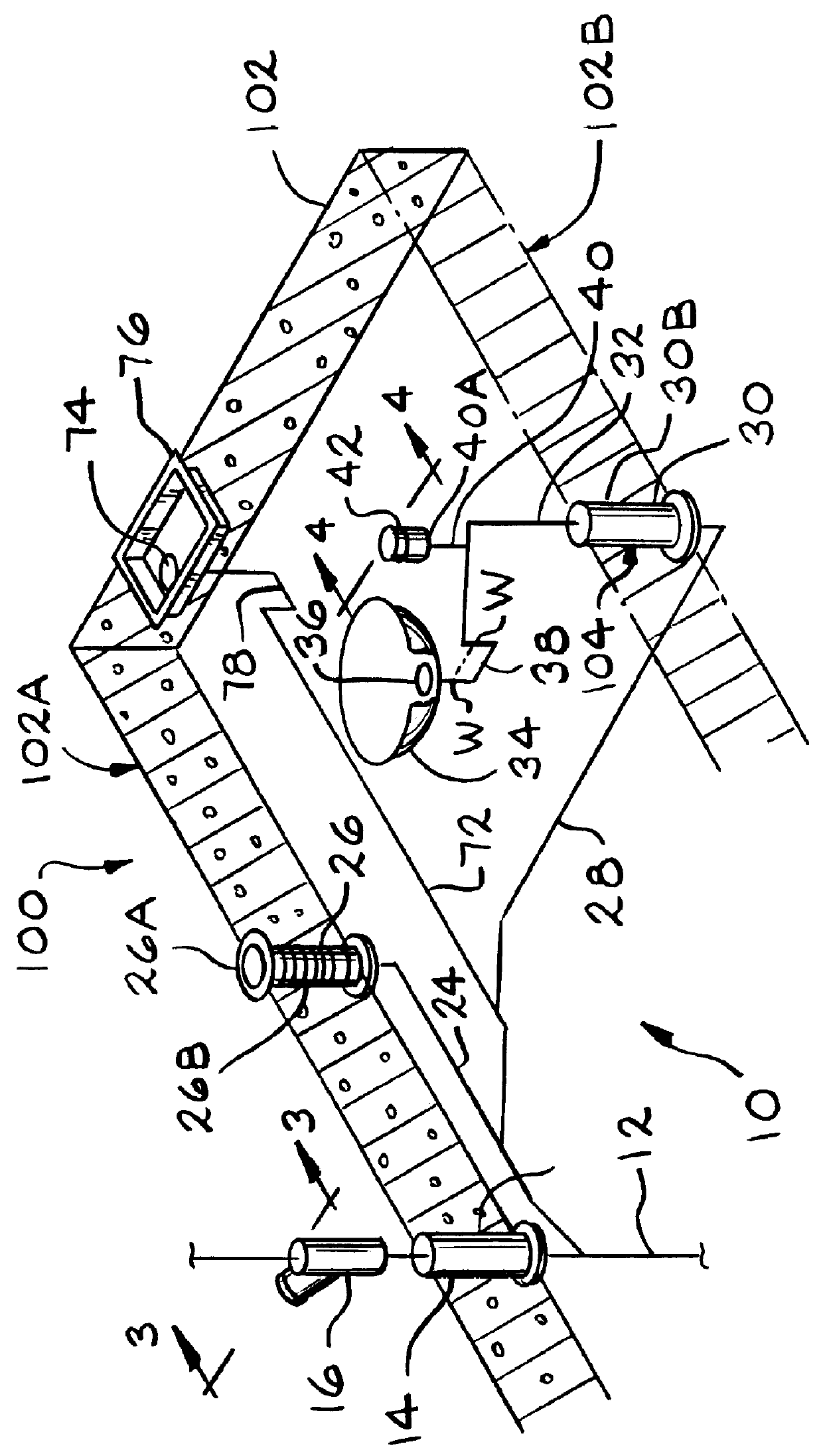

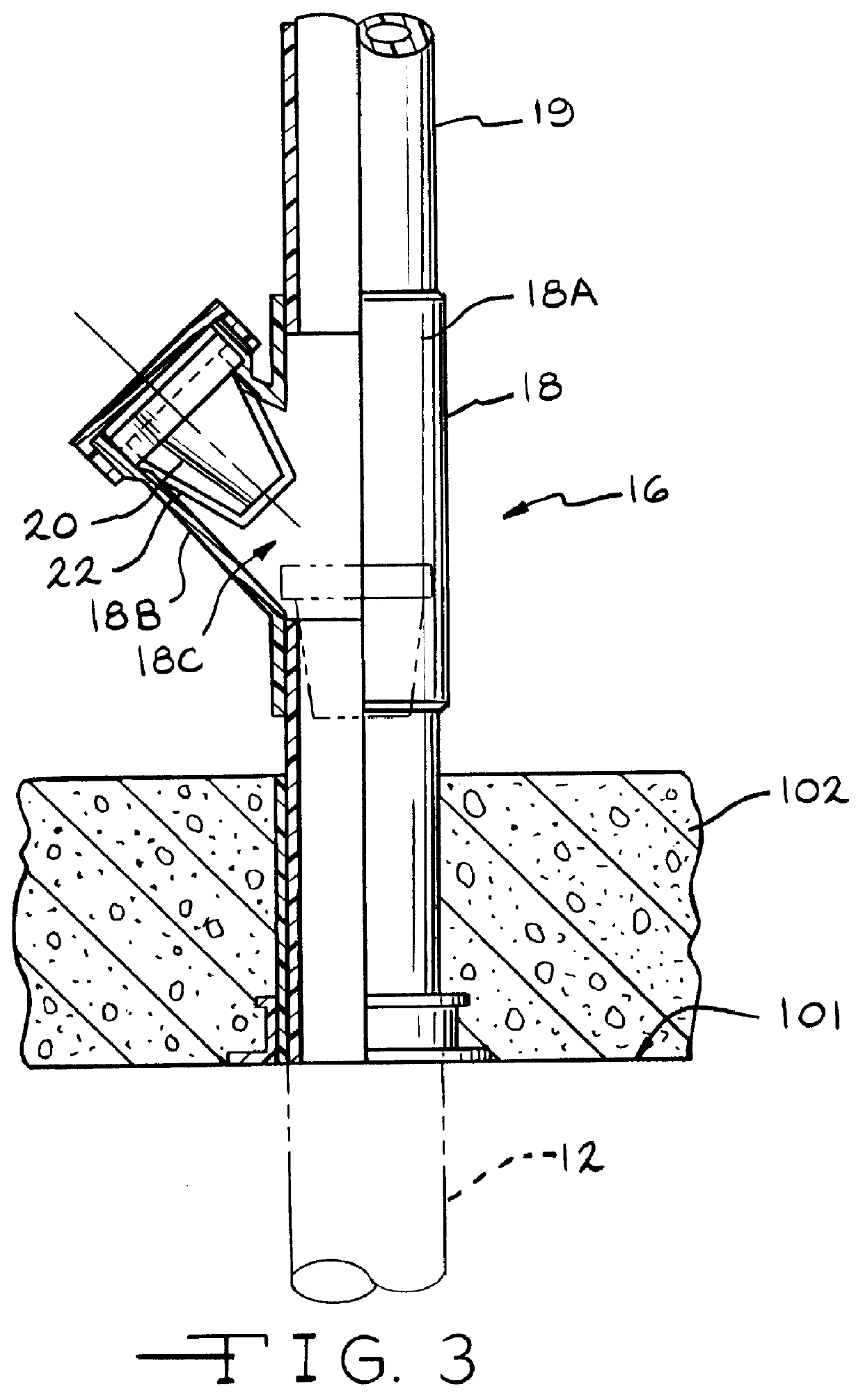

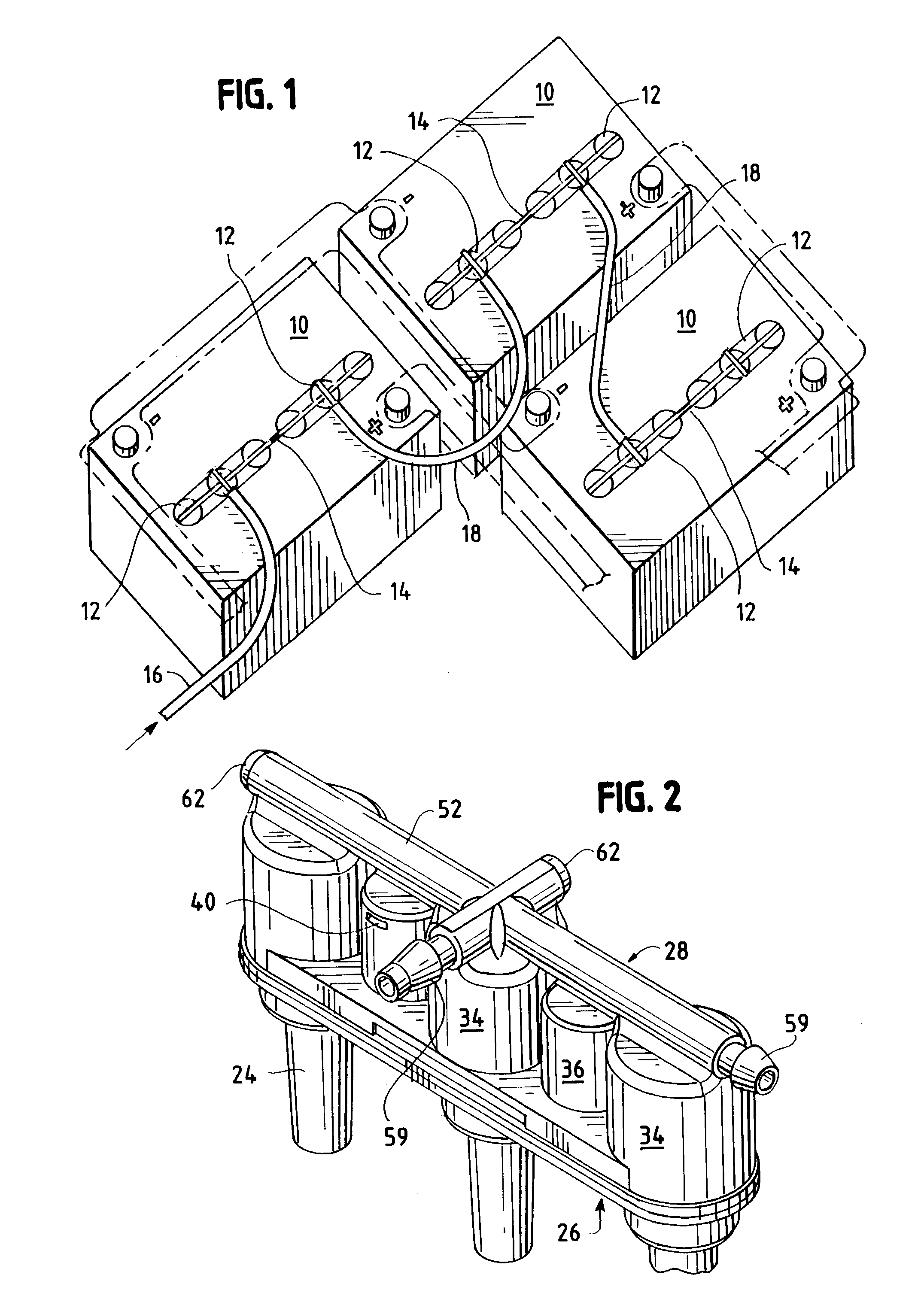

Fire transmission prevention system

A fire transmission prevention system (10) for use in a drainage system (100) to prevent the transmission of smoke and fire through the drainage system. The system is intended to be used in drainage systems in multi-story structures. The system includes a firestop (16), couplings (14, 26 and 30) and an air vent (42). The firestop prevents fire and smoke from moving through the inner passageways (44D) of the pipes (12, 24, 28 and 72) of a drainage system by blocking the inner passageway of the pipes with a fire resistant plug (20). The couplings are mounted in the floor (102) of the structure and are constructed and secured in the floor such as to prevent fire and smoke from passing around the couplings between the couplings and the floor. The air vent is provided in a vent pipe (40) of the system above a trap (38 or 78) of the system. The vent acts to prevent ambient air and thus, oxygen from entering the inner passageway of the pipes of a system when positive pressure, such as that caused by high temperature and fire, is present in the inner passageway of the pipes.

Owner:CORNWALL KENNETH R

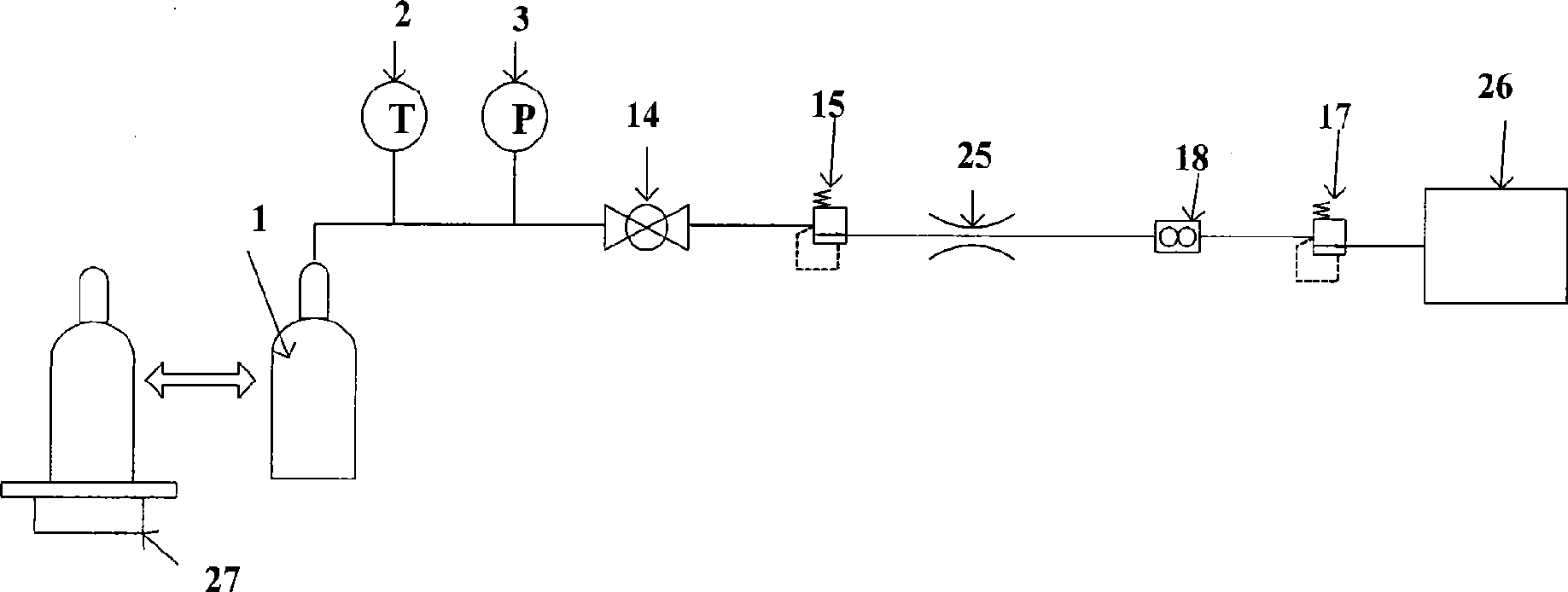

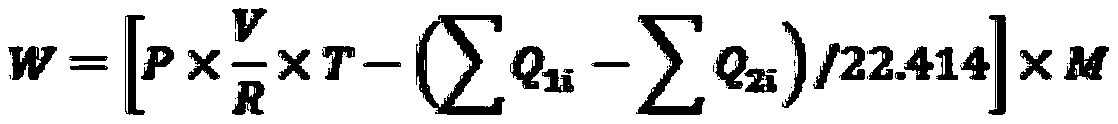

Detection system and method for mesomeric state hydrogen gas consumption

InactiveCN101470020AEasy to pour directlyEasy to pour directly intoFuel cell auxillariesWeighing apparatus for materials with special property/formFlame arresterGas cylinder

The invention relates to a steady hydrogen gas consumption detection system and a detection method thereof, belonging to the gas detection technical field. In the system, the main pipeline connected with the bottle valve of a high pressure bottle is mounted with a bottle mouth electromagnetic valve, a ferrule type joint, a detachable pipeline swirling valve, a primary road electromagnetic valve, a primary road manual valve, a first stage decompression valve, a safety valve, a second decompression valve, a flux controller and a flame arrester in turn. The method measures the weights before and after discharging the gas of the gas bottle, the temperatures and the pressures at the tail block of the gas bottle and the bottle valve, to obtain three hydrogen gas consumption value groups. The invention arranges a hydrogen bottle, a hydrogen gas bottle purging pipeline and a temperature pressure sensor in the bottle to improve measurement accuracy, comprises a filling pipeline to simply and directly fill gas into the high pressure gas bottle, and utilizes weighting method and counter weight calibration as reference, thus being convenient for the research on steady hydrogen gas consumption detection.

Owner:TSINGHUA UNIV

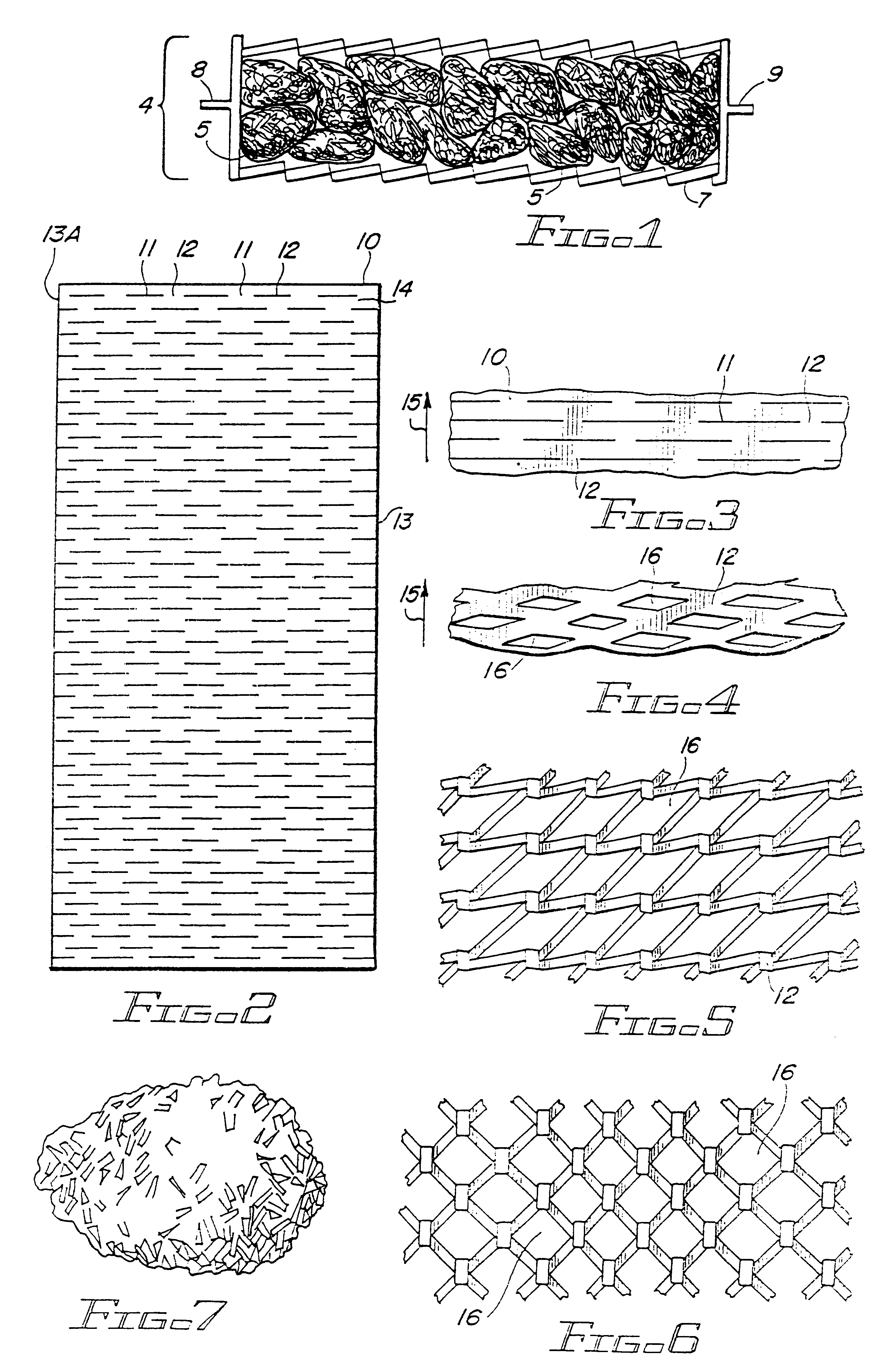

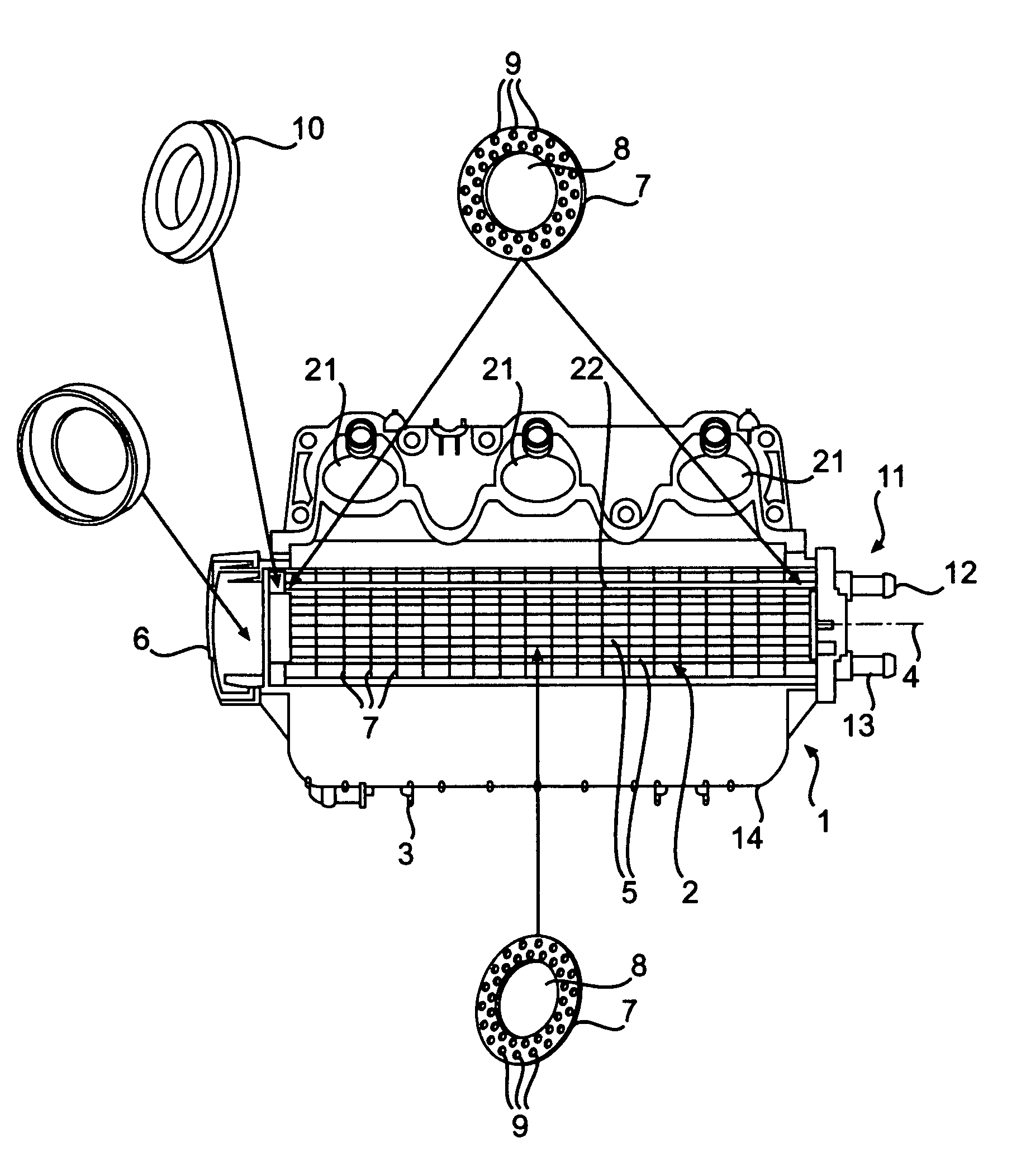

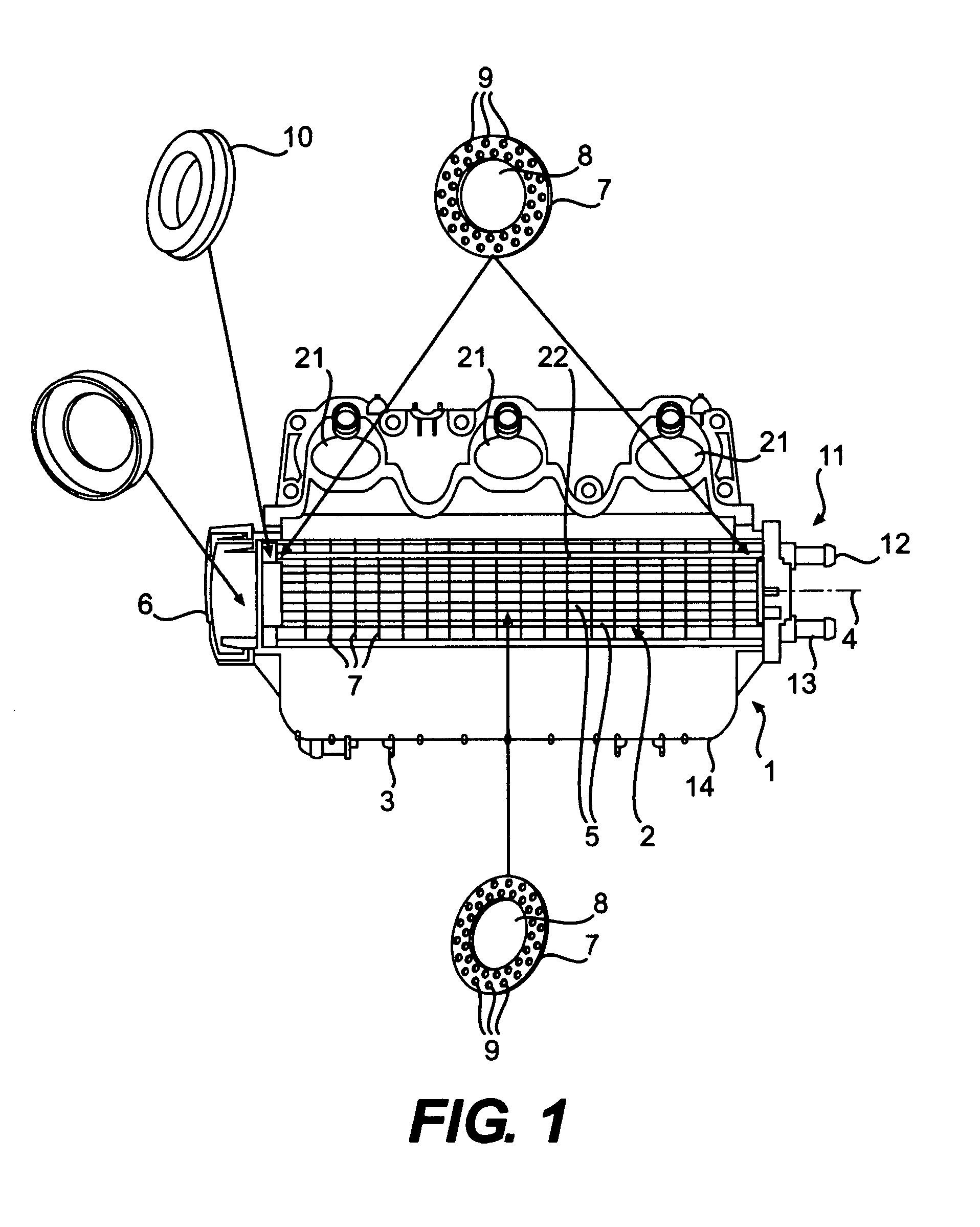

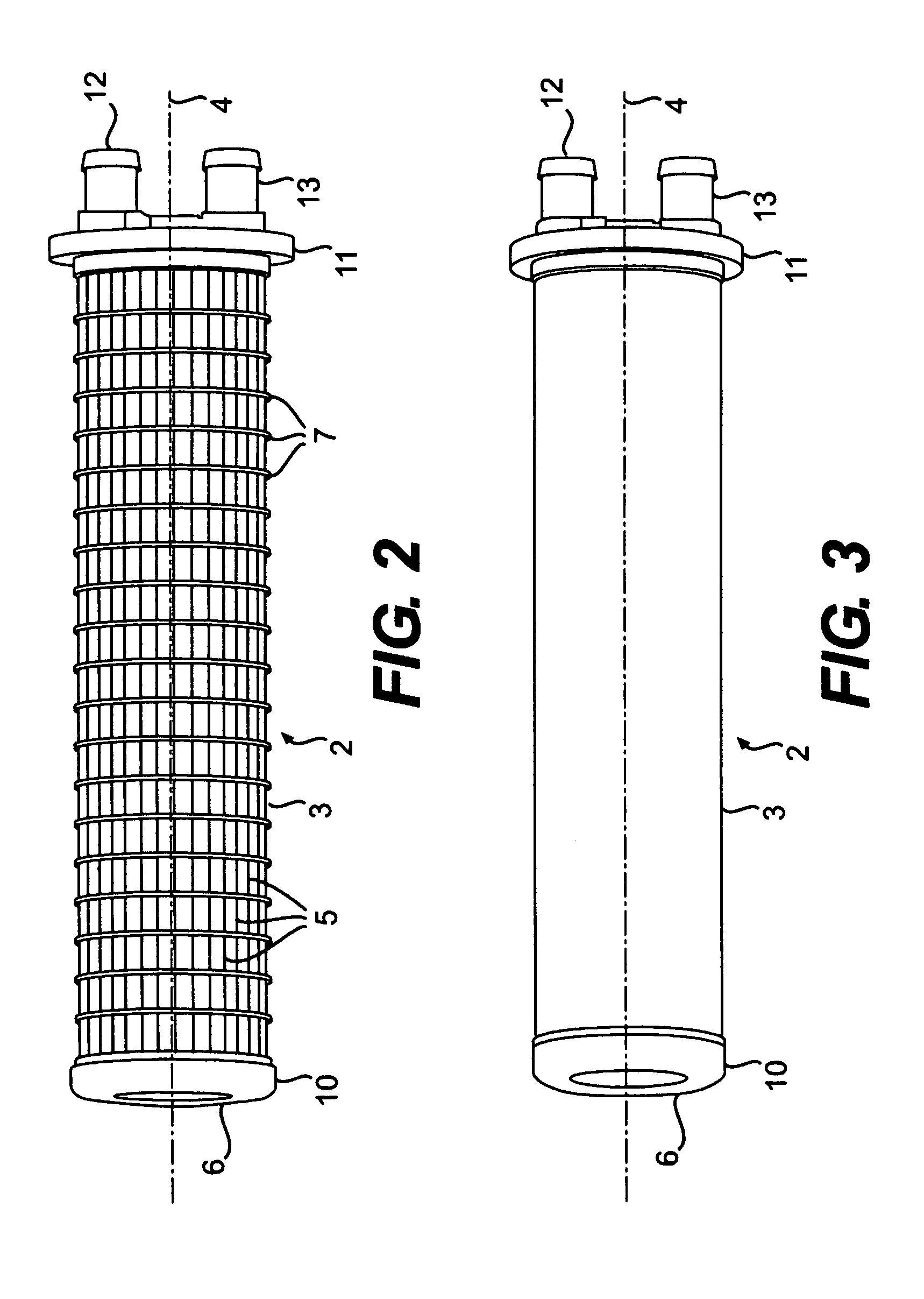

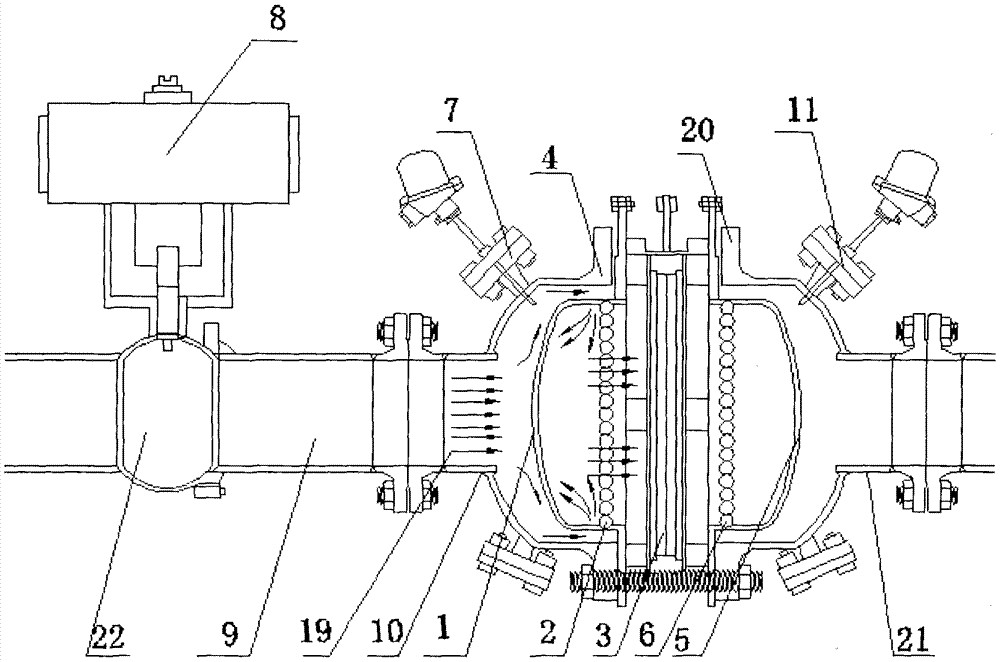

Combined intercooler and flame arrester

ActiveUS7077113B2Minimized volumeRestricts passageDomestic stoves or rangesInternal combustion piston enginesFlame arresterIntercooler

A combined flame arrester and intercooler for cooling intake gas for an internal combustion engine is disclosed. The intercooler comprises an elongated body having a longitudinal axis. The elongated body has a central passageway that extends substantially parallel to the longitudinal axis. An inlet opening is located on one end of the elongated body such that the intake gas enters the central passageway though the inlet opening. The intercooler further includes a plurality of cooling tubes forming at least a portion of the elongated body. The plurality of tubes substantially surround the central passageway. Each of the cooling tubes is spaced from an adjacent cooling tube such that an air flow path is formed there between. The intake gas is cooled by flowing past the cooling tubes. Preferably, the intake gas flows along the central passageway in the elongated body and radially outward therefrom through the air flow path between the cooling tubes. The intercooler includes at least one plate extending substantially orthogonal to the longitudinal axis. Each plate includes a central opening therein, which corresponds to the central passageway in the elongated body such that the intake gas is capable of flowing through the central opening. Each plate has a plurality of openings formed thereon about a periphery of the plate. One cooling tube is fed through each opening.

Owner:BRP ROTAX

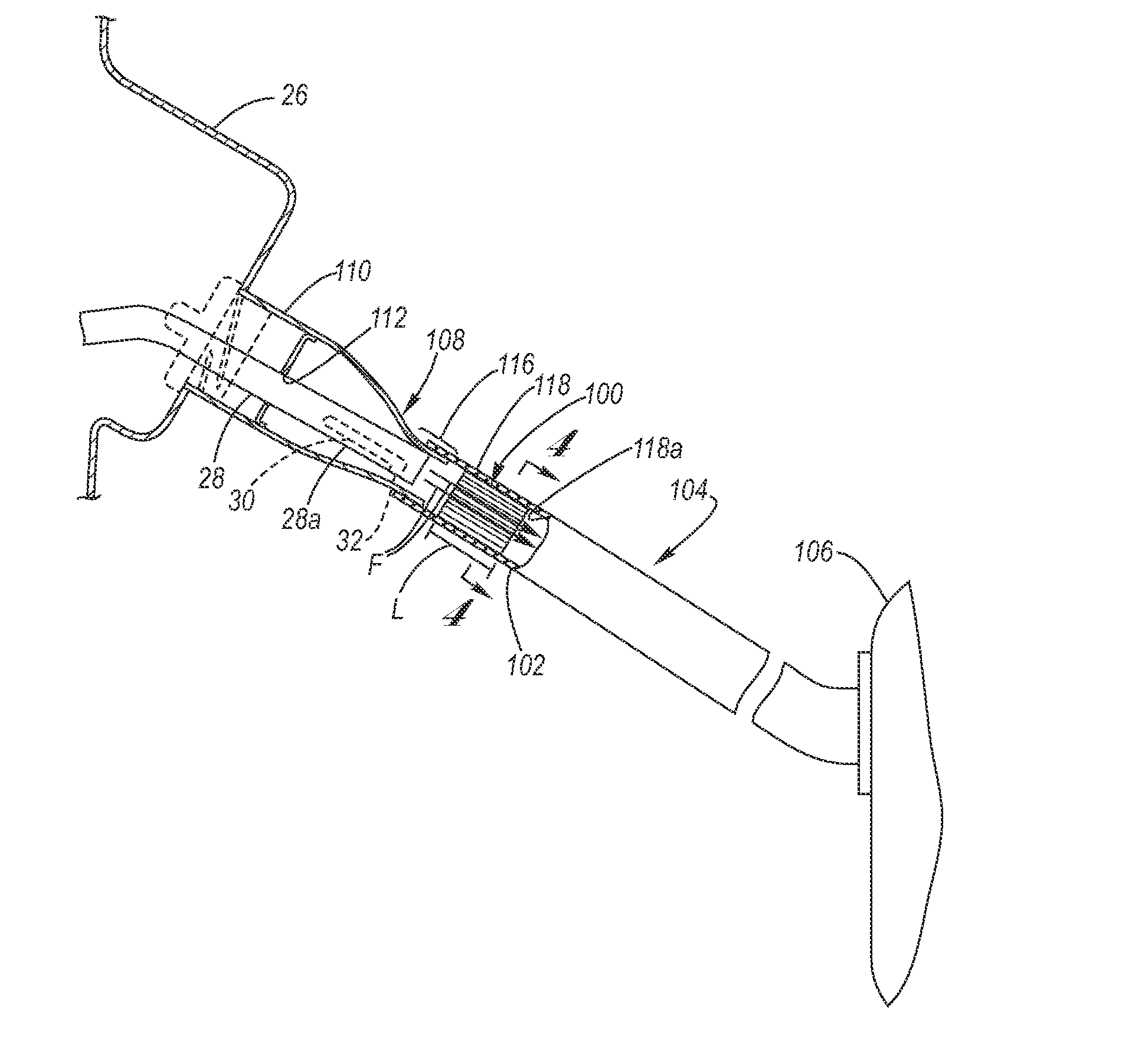

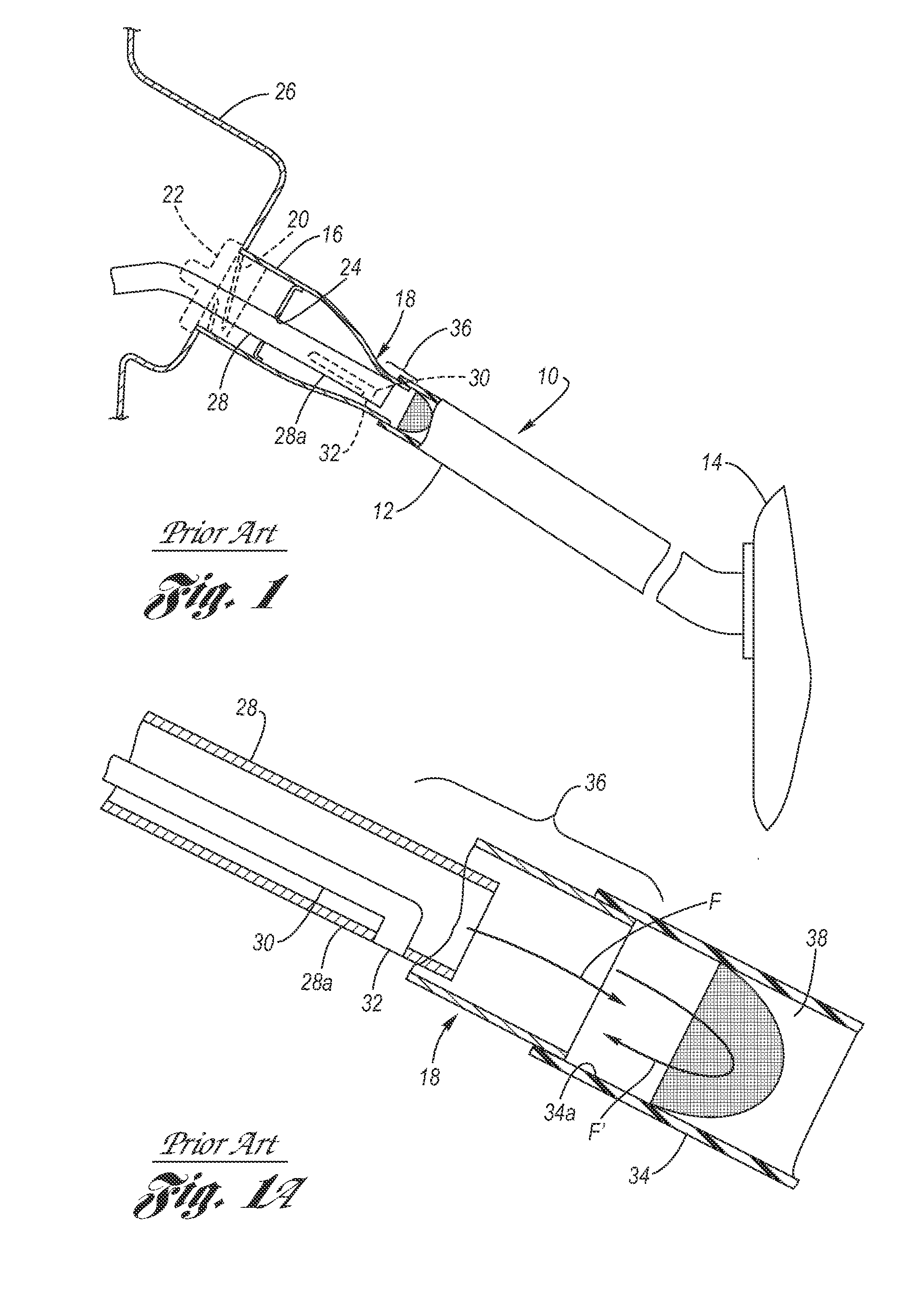

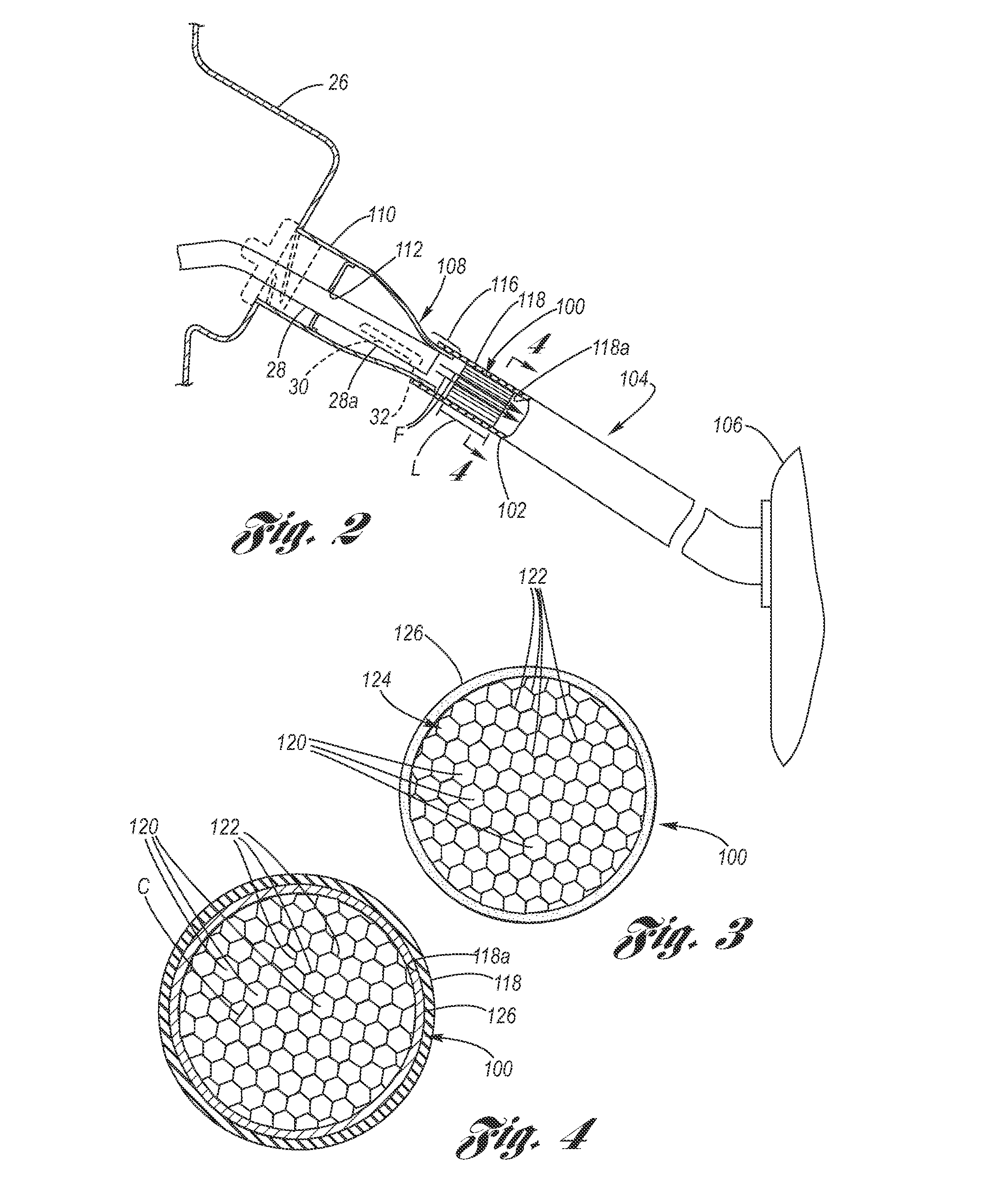

Honeycomb Flame Arrester and Flow Straightener for a Fuel System Fuel Fill Pipe

InactiveUS20080271814A1Ensure efficient flowSpeed up the flowFire rescueLiquid transferring devicesFlame arresterEngineering

A motor vehicle filler pipe flame arrester and fuel flow straightener configured to effectively quench a moving flame front, while providing laminar fuel flow therethrough. A multi-channel (or multi-cell) configuration, most preferably a honeycomb configuration, provides effective flame arresting due to its heat sink capacity and large effective surface area for flame arrestment, while attendantly limiting availability of fuel and oxygen to the flame, thereby providing quenching of a flame wave as it propagates through the channels. Service station pump nozzle shut-off sensor disruption is avoided because the channels encourage laminar flow of the fuel through the multi-channel filler pipe flame arrester and fuel flow straightener.

Owner:GM GLOBAL TECH OPERATIONS LLC

Organic waste gas purifying device

InactiveCN1883761AIncrease profitSimple structureDispersed particle separationFlame arresterPlate heat exchanger

The invention relates to an organic exhaust gas purifier, characterized in that: a filtering flame arrester connects to a airflow distributor, and a group of air inlets of absorption purification chamber communicates with airflow distributor in parallel via pipe and valve respectively; a gas collector inlet communicates with purifier outlet of absorption purification chambers in parallel via pipe and valve; a fan connects to gas collector outlet via pipe; a heat exchanger communicates with desorption exhaust gas outlet of absorption purification chambers in parallel via pipe and valve; a preheating chamber connects with other end of heat exchanger pipe in heat exchanger via pipe; an inlet and a outlet of catalytic chamber communicate with above preheating chamber and heat exchanger respectively; and the double end of air heater respectively communicates with outlet of heat exchanger and heat steam inlet of absorption purification chambers in parallel via pipe and valve. In the purifier, absorption process and desorption can be carried out simultaneously.

Owner:北京绿创环保设备股份有限公司

Lead-acid safety battery cap

A battery cap is provided for engagement in a fill port of a cell of a deep cycle, lead-acid electrical storage battery. The battery cap is formed of a hollow, tubular body having an upper end with an expansive mouth opening, and a lower end at which a transverse floor extends radially inwardly. The floor includes a central, annular convex downwardly projecting portion that defines a central fluid passage opening. The interior of the tubular wall defines a radially inwardly projecting flame arrester seat spaced from both the upper and lower ends of the body. A pair of gas escape ports are defined in the tubular wall between the flame arrester seat and the mouth opening. A diverter is located in the lower portion of the tubular body beneath a disc shaped micropore filter that serves as the flame arrester and which is seated on the flame arrester seat. The diverter is formed with a generally disc shaped, horizontal plate having diametrically opposed notches at its peripheral edge and a pair of legs of that have an arcuate cross-section and which rest upon the floor to partially surround the central opening in the floor. A battery cap having this internal structure causes drops of electrolyte to intermittently lodge in the central floor opening, thereby forming a temporary fluid seal that is repeatedly broken to allow venting of gas and re-established to aid in protecting the micropore filter from contaminants.

Owner:SCHWARZ WILLIAM R

Flame arrester

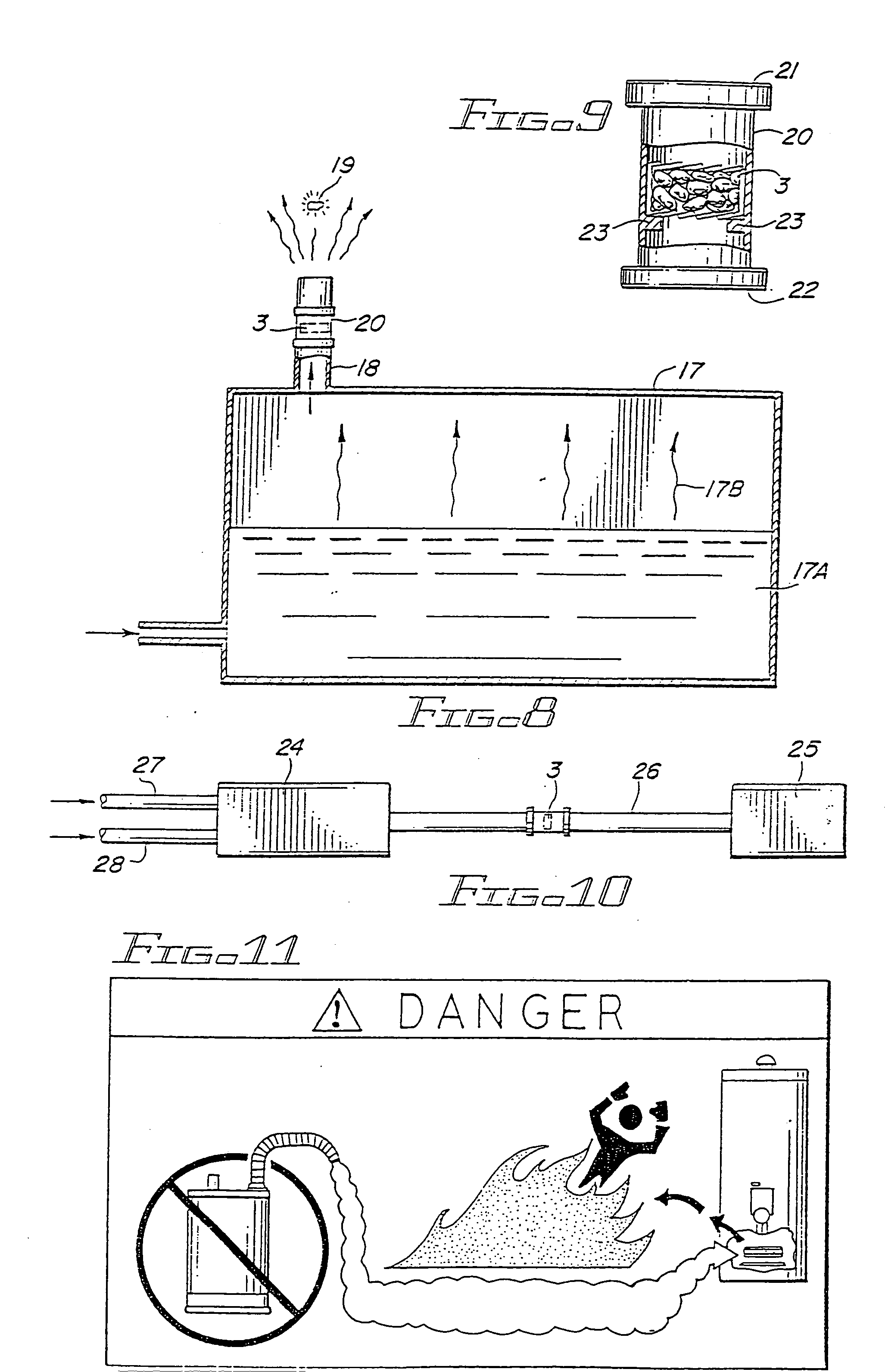

InactiveUS20050053886A1Avoid flashHeating can be extremeMachines/enginesWater heatersFlame arresterCombustion system

A highly efficient flame arrester adapted for use in preventing an external flame from backflashing upstream in a pipe, or a conduit, or a stream carrying a flammable substance. The flame arrester comprises a contained layer of nested ellipsoids formed from expanded metal sheets made from magnesium alloy foil. The arrester is useful in fuel tanks, combustion systems, sea-going tankers, hot water or space heaters, and the like.

Owner:ALHAMAD SHAIKH GHALEB MOHAMMAD YASSIN

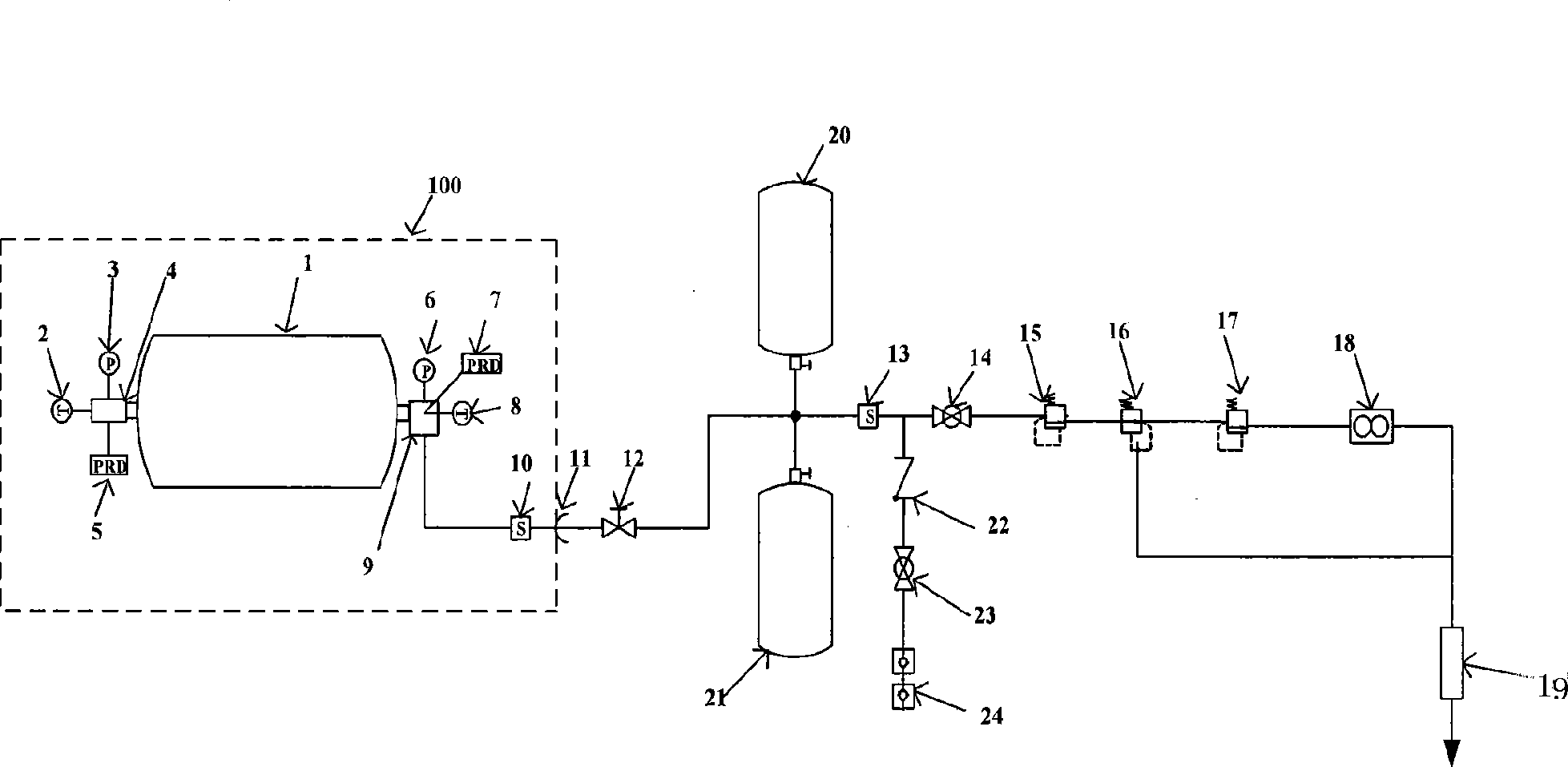

Hydrogen supply and regulation system

ActiveCN108916653ARealize real-time monitoringIncrease profitPipeline systemsIncinerator apparatusFlame arresterDetonation

The invention discloses a hydrogen supply and regulation system, comprising a high-pressure hydrogen bottle hydrogen supply pipeline, an electric pile hydrogen supply pipeline, a hydrogen circulationpipeline, an exhaust treatment pipeline and a communication line, wherein the high-pressure hydrogen cylinder hydrogen supply pipeline comprises a hydrogen feeding inlet, a filter, a cylinder hydrogensupply pipeline check valve, a high pressure hydrogen cylinder manual shut-off valve, a high pressure hydrogen cylinder solenoid valve, a high pressure hydrogen cylinder, a high pressure hydrogen cylinder safety valve, a high pressure hydrogen cylinder temperature sensor and a high pressure hydrogen cylinder pressure sensor. According to the hydrogen supply and regulation system, a hydrogen leakage monitoring system is arranged to monitor hydrogen leakage in real time; the hydrogen circulation pipeline is arranged to improve the hydrogen utilization rate and avoid hydrogen leakage; the exhaust treatment pipeline is arranged to perform catalytic treatment on untreated hydrogen; and a pipeline explosion-proof and detonation-resistant type flame arrester can ensure the safety of the system in case of accident.

Owner:BEIJING JIAOTONG UNIV

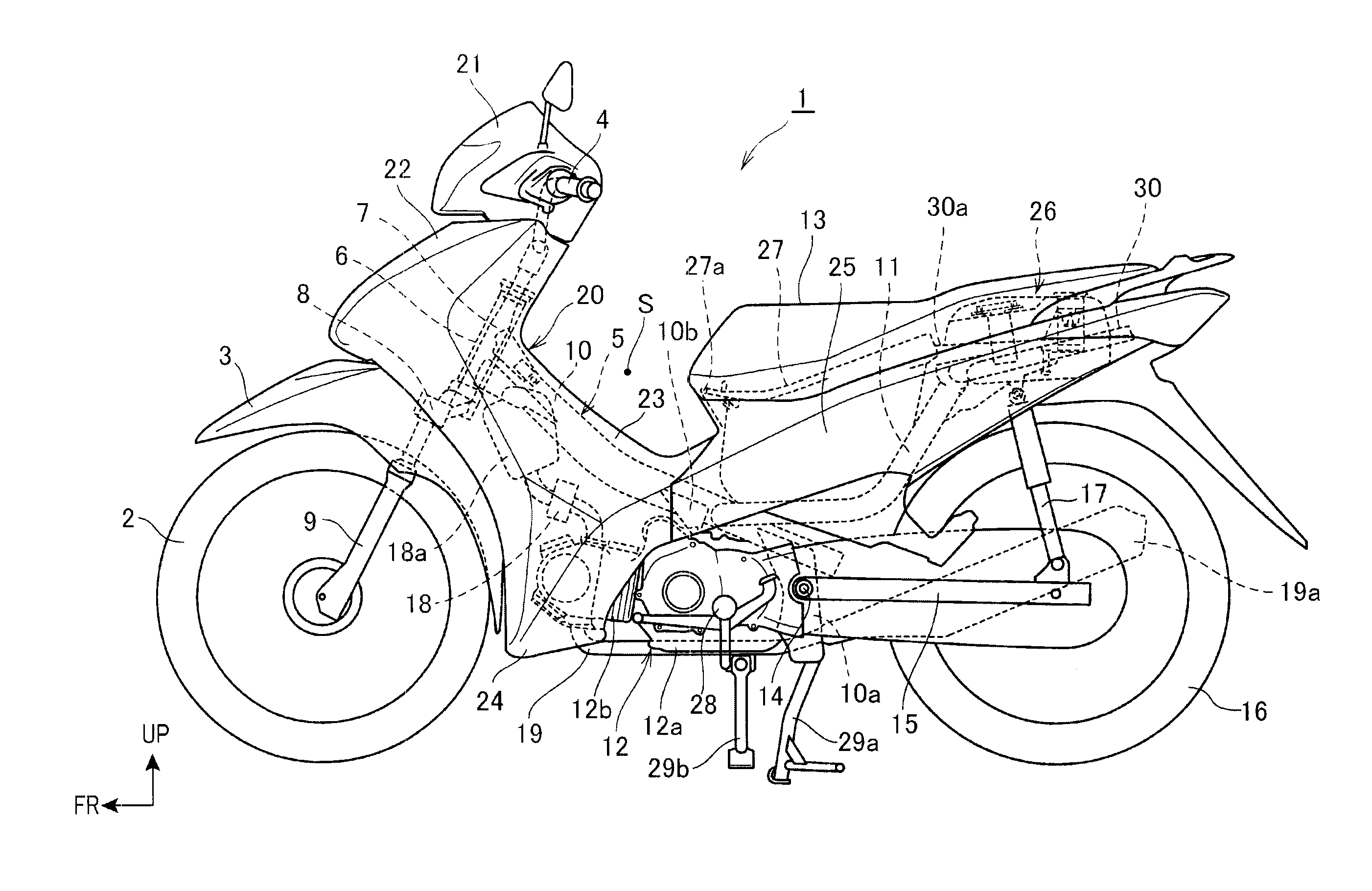

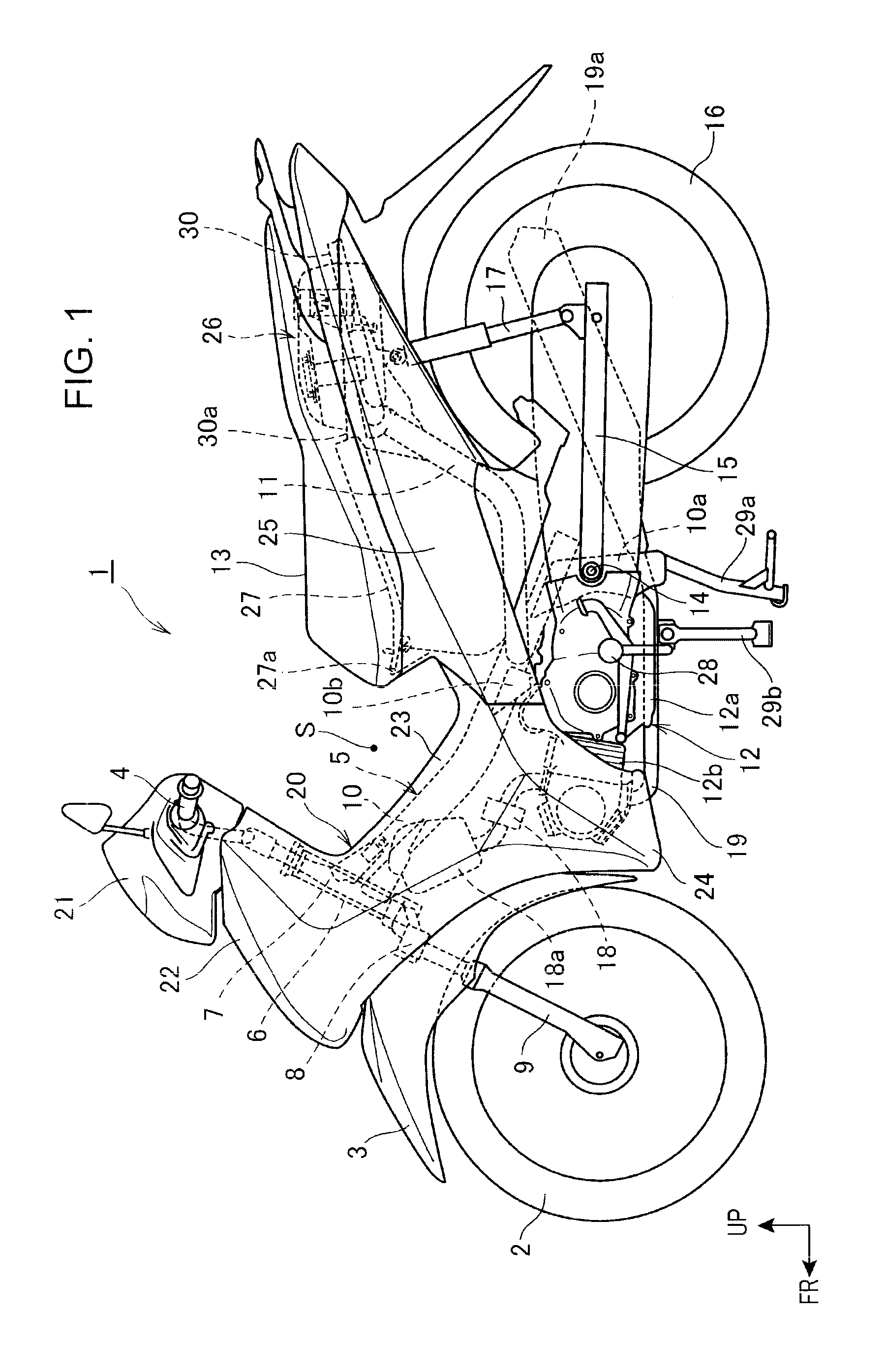

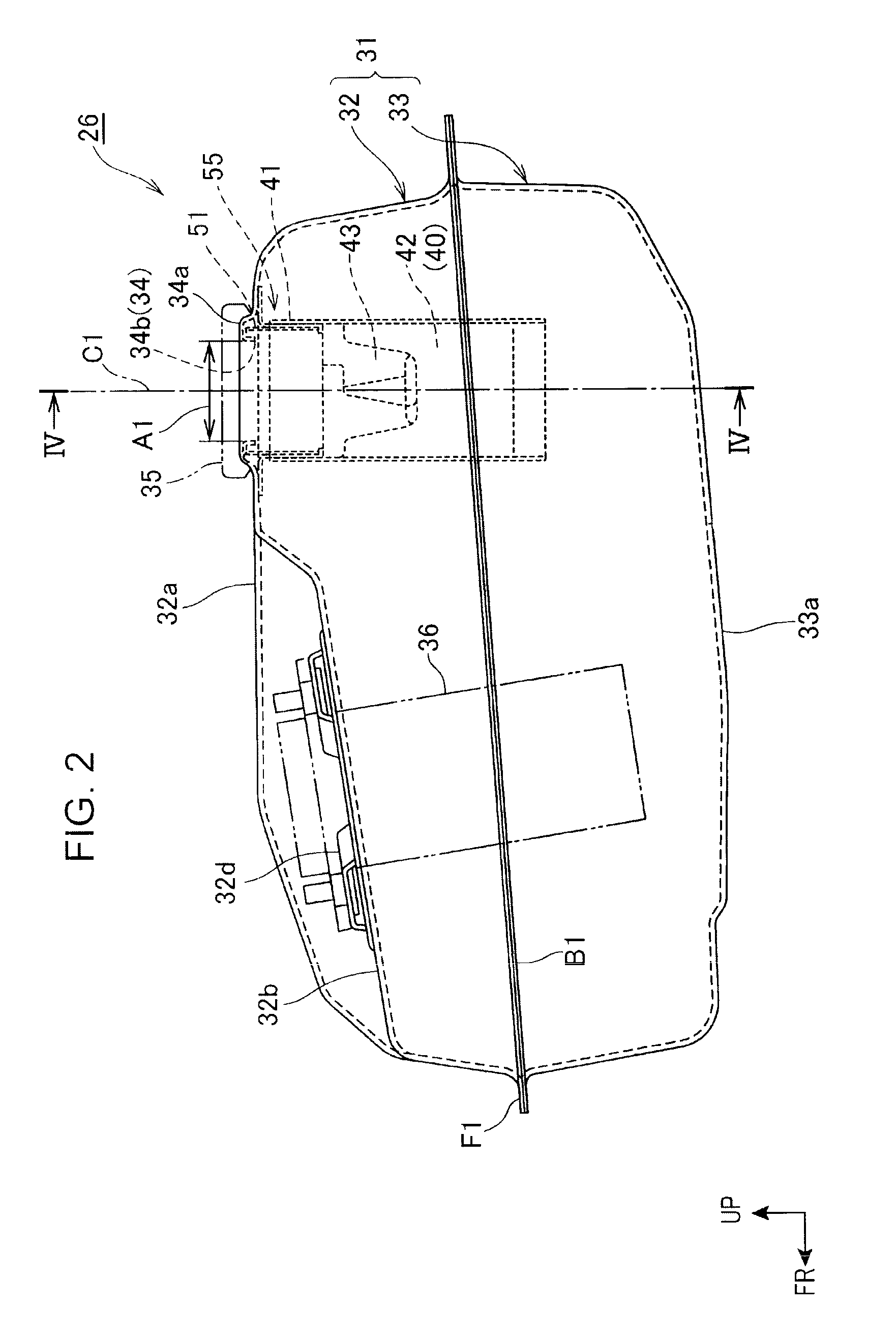

Fuel tank structure

InactiveUS20120074139A1Convenience to workSimple structureCapsMotorised scootersFlame arresterDevice form

A fuel tank structure including a fuel tank, a fuel filler port device formed in a cylindrical shape and arranged in the fuel tank, and a flame arrester arranged in the fuel filler port device and disposed inside the fuel tank. A fuel bleeding opening is formed in a peripheral wall part of the fuel filler port device and an arrester peripheral wall part. A cylindrical ring disposed so as to urge itself against the peripheral wall part and block the fuel bleeding opening.

Owner:HONDA MOTOR CO LTD

Mechanical cleaning device for product oil tank

ActiveCN102125919ATaking into account fixed useEasy to useHollow article cleaningFlame arresterOil water

The invention provides a mechanical cleaning device for a product oil tank. The mechanical cleaning device comprises a to-be-cleaned oil tank, a water chamber, and a washing pump. The mechanical cleaning device for the product oil tank is characterized in that the to-be-cleaned oil tank is orderly communicated with a filter and a vacuum suction tank, and the vacuum suction tank is divided into three routes, wherein the first route is orderly communicated with the washing pump, at least one ejector, and the to-be-cleaned oil tank; the second route is communicated with a recovery pump and divided into two routes, wherein one route is orderly communicated with an ultrafilter and a recovered oil tank, and the other route is communicated with an oil-water separation tank by a cyclone separator; and the third route is orderly communicated with a vacuum pump and the oil-water separation tank; an upper pipe of the oil-water separation tank is divided into two routes, wherein one route is connected with an evacuation pipe through a flame arrester, and the other route is connected with the to-be-cleaned oil tank; a lower pipe of the oil-water separation tank is divided into two routes through a valve and a membrane pump, wherein one route is communicated with the recovered oil tank through the ultrafilter, and the other route is communicated with an air compressor; and a water pipe of the oil-water separation tank is divided into two routes through a valve, wherein one route is communicated with the cleaning pump, and the other route is communicated with the oil-water separation tank by the cyclone separator. The mechanical cleaning device can efficiently, safely and conveniently clean the to-be-cleaned oil tank.

Owner:CHINA OIL HBP SCI & TECH CO LTD +1

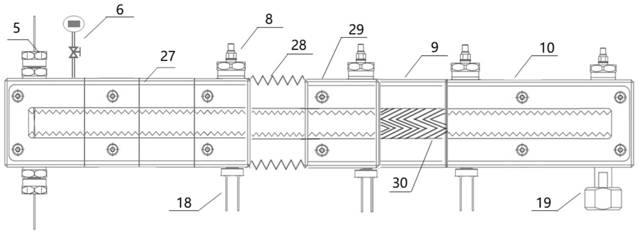

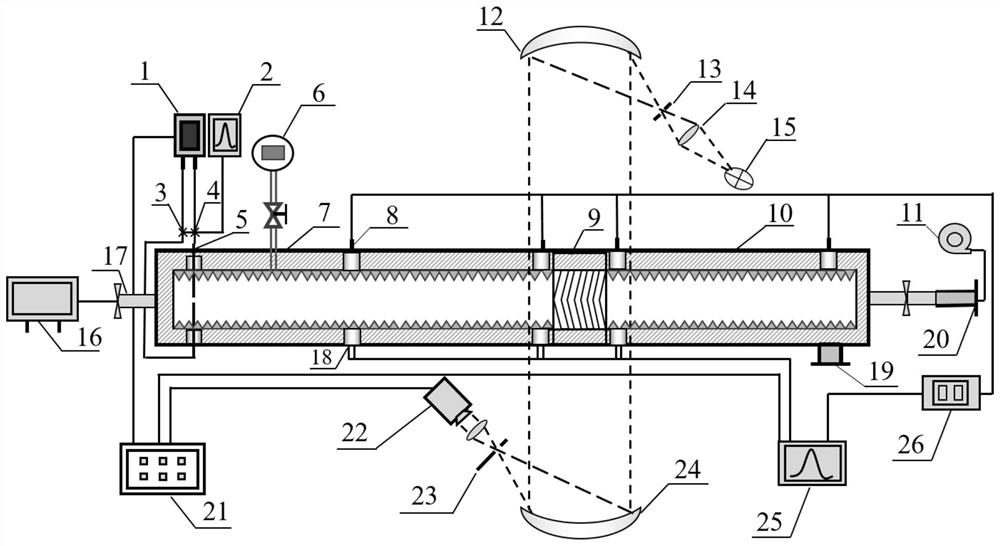

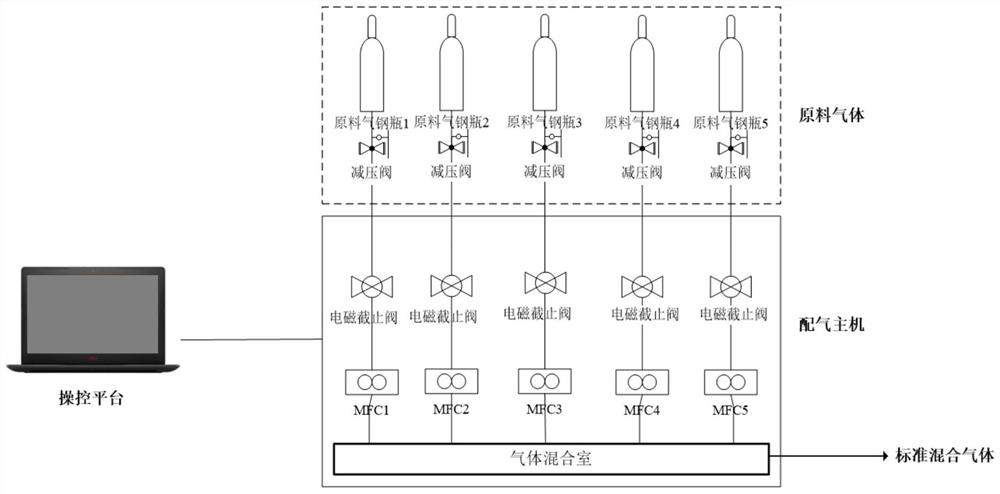

Visual test device for accurately testing effect of flammable gas unsteady detonation flame arrester

PendingCN112082798AOvercoming the Difficulties in Fire-stopping Effect of Unsteady DetonationOvercome difficultiesTelevision system detailsStructural/machines measurementFlame arresterVisual test

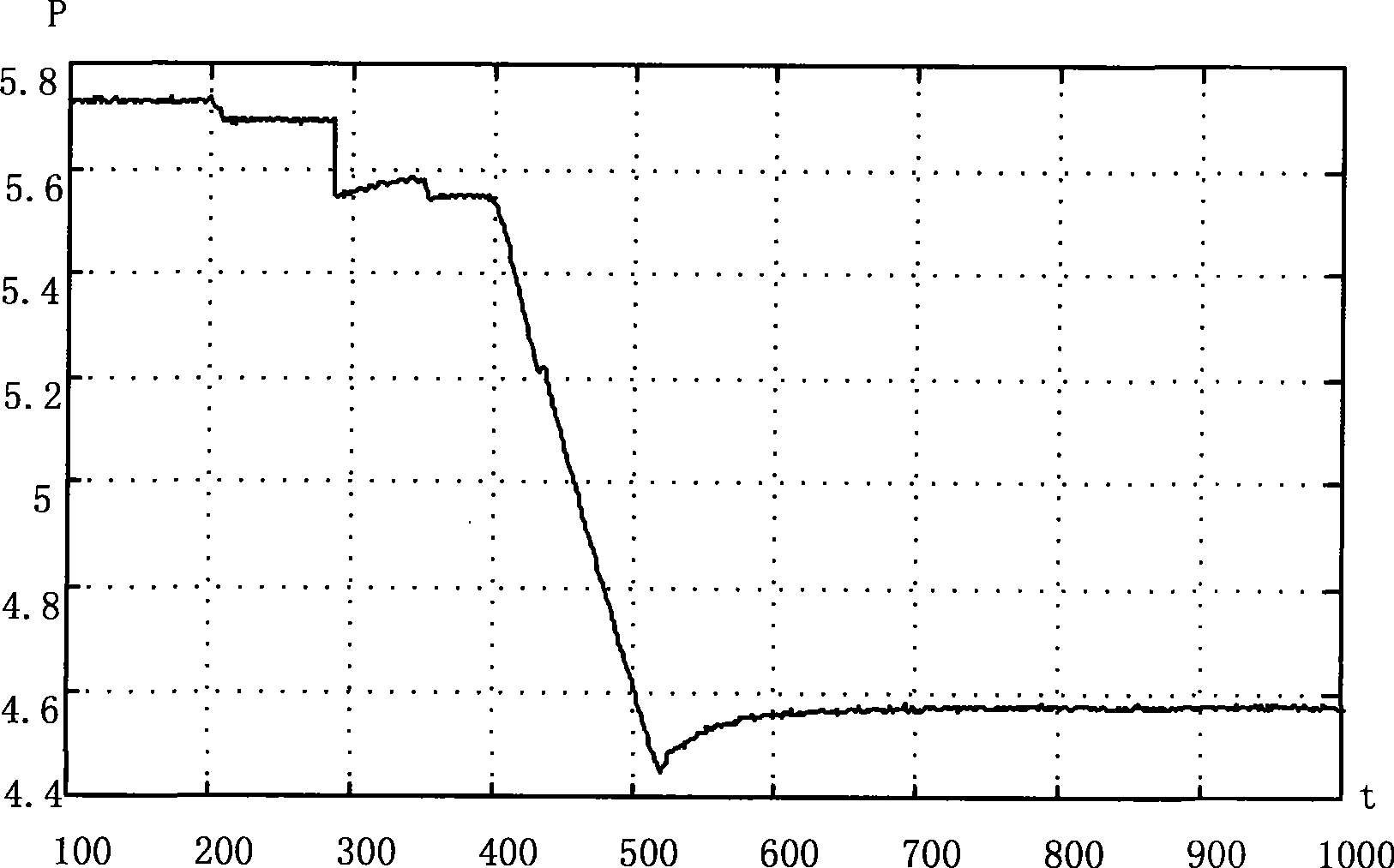

The invention discloses a visual test device and method for accurately testing the effect of a flammable gas unsteady detonation flame arrester. The visual test device comprises a vacuum system, an automatic gas distribution system, a schlieren camera system, an unsteady detonation blocking test combustion pipeline, a test and data acquisition system and a high-pressure ignition and synchronous control system. According to the invention, a method combining a high-speed camera shooting technology and a schlieren optical technology is adopted to shoot and record a deflagration-to-detonation conversion process and a flame arrester flame arresting process in a pipeline, so that visualization of the whole process of unsteady detonation generation and blocking is realized, and a dynamic change rule of shapes and positions of flames and detonation waves along with time is accurately and visually presented. A pressure sensor is used for measuring the dynamic rising characteristic of the pressure in the pipeline, and the mutual relation between the pressure in the pipeline and the flame and detonation wave characteristics can be analyzed in combination with high-speed schlieren images. Light intensity changes in the pipeline are detected through a photodiode, so that position changes of initial flames and later detonation waves are obtained, and the propagation speeds of the flames andthe detonation waves at all moments can be obtained through analysis and calculation in combination with the high-speed schlieren images.

Owner:UNIV OF SCI & TECH OF CHINA

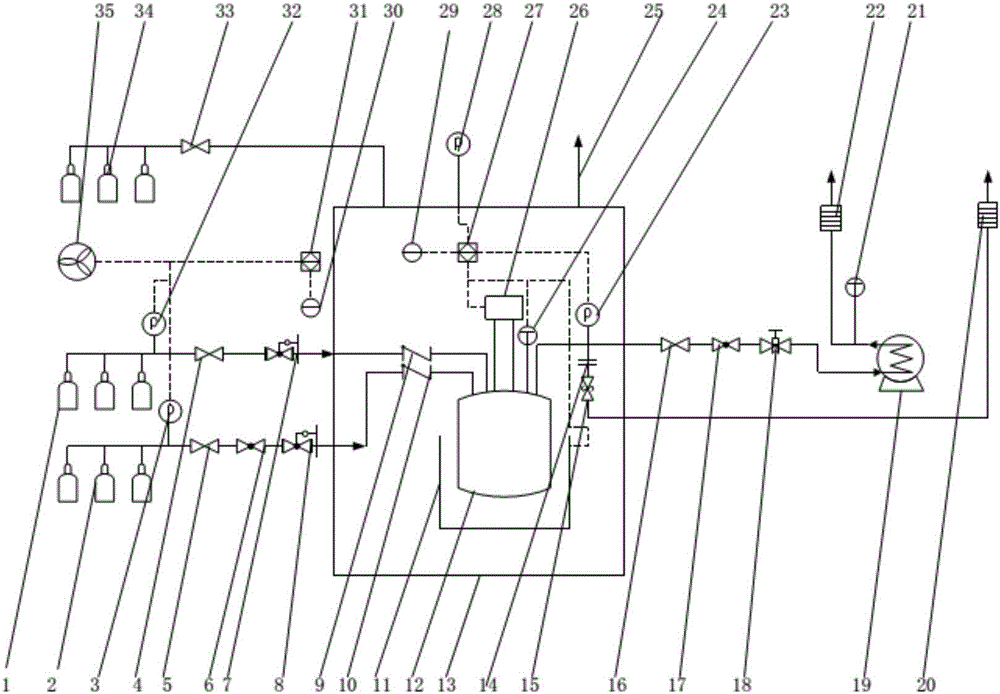

Stretching stress testing machine used in high-temperature and high-pressure hydrogen environment

InactiveCN106018119ATensile test synchronizationGuaranteed isolationMaterial strength using tensile/compressive forcesFlame arresterGas cylinder

The invention discloses a stretching stress testing machine used in a high-temperature and high-pressure hydrogen environment. The stretching stress testing machine used in the high-temperature and high-pressure hydrogen environment comprises a safety room, a stretcher, a high-temperature autoclave system and a gas supply and exhaust system, wherein the safety room comprises an airtight safety isolation room; a gas inlet and a gas exhaust port are formed in the safety isolation room; a carbon dioxide gas cylinder group is connected with the gas inlet of the safety isolation room; the high-temperature autoclave system is arranged in the safety isolation room and comprises a high-temperature autoclave placed in a heating furnace; a stretching rod inlet, a nitrogen inlet, a hydrogen inlet and a gas exhaust port are formed in the high-temperature autoclave; the gas supply and exhaust system comprises a nitrogen inlet pipeline, a hydrogen inlet pipeline, a gas exhaust pipeline and a safety pipeline. Through the safety isolation room and a flame arrester and by a high-temperature thermal starting and stopping experiment process, the circumstance that high-temperature hydrogen leaks and is in contact with air is prevented, and the possible circumstance of serious hydrogen embrittlement of an autoclave body material in a normal and low temperature region at the temperature of 220 DEG C or below is avoided, so that the purposes of accurate testing, safe testing, operation convenience and long service life of equipment are achieved.

Owner:XI AN JIAOTONG UNIV

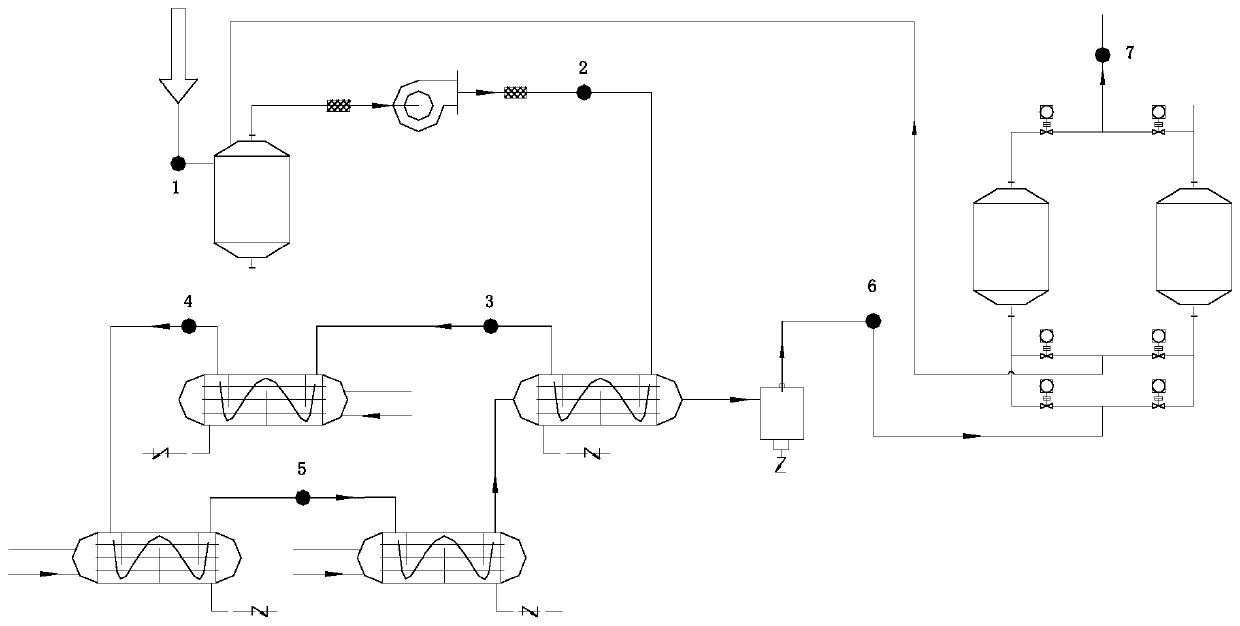

Intermittently discharged organic waste gas gathering and processing method

InactiveCN104501187AIncrease motivationAchieve energy saving effectIncinerator apparatusAir quality improvementFlame arresterDirect combustion

The invention discloses an intermittently discharged organic waste gas gathering and processing method. After the intermittently discharged organic waste gas passes through a flame arrester, a booster pump and a waste gas gathering cabinet, if the organic waste gas is very high in concentration, the organic waste gas can be burnt directly or directly burnt in a combustion device / a boiler after passing through a purification / decontamination device B, and the heat generated by burning directly generates steam. If the organic waste gas is low in purity, the organic waste gas is thinned to the concentration lower than an explosion limit through a thinning device, the thinned organic waste gas is conveyed to heat storage oxidization / heat storage catalysis / catalytic oxidation devices to oxidize and decontaminate, one part of the gas is switched between the heat storage oxidization / heat storage catalysis / catalytic oxidation devices, one part of the heat generated by oxidization heats the waste gas to arrive at a combustible temperature, and most of the heat generates steam through a waste heat boiler. The intermittently discharged organic waste gas gathering and processing method is capable of realizing energy conservation and environment protection, a pollutant discharge enterprise even can gain profit when treating pollutant, and accordingly the pollutant treatment enthusiasm of the enterprise is greatly increased.

Owner:德州奥深节能环保技术有限公司

Combustion heated hair dryer

A portable hair dryer that utilizes portable stove and portable grill sized propane tanks to supply fuel to a heat exchanger including a gas burner. The discharge vent of the heat exchanger includes a flame arrester screen at least three inches form the outer edge thereof.

Owner:PORTER KATHERINE

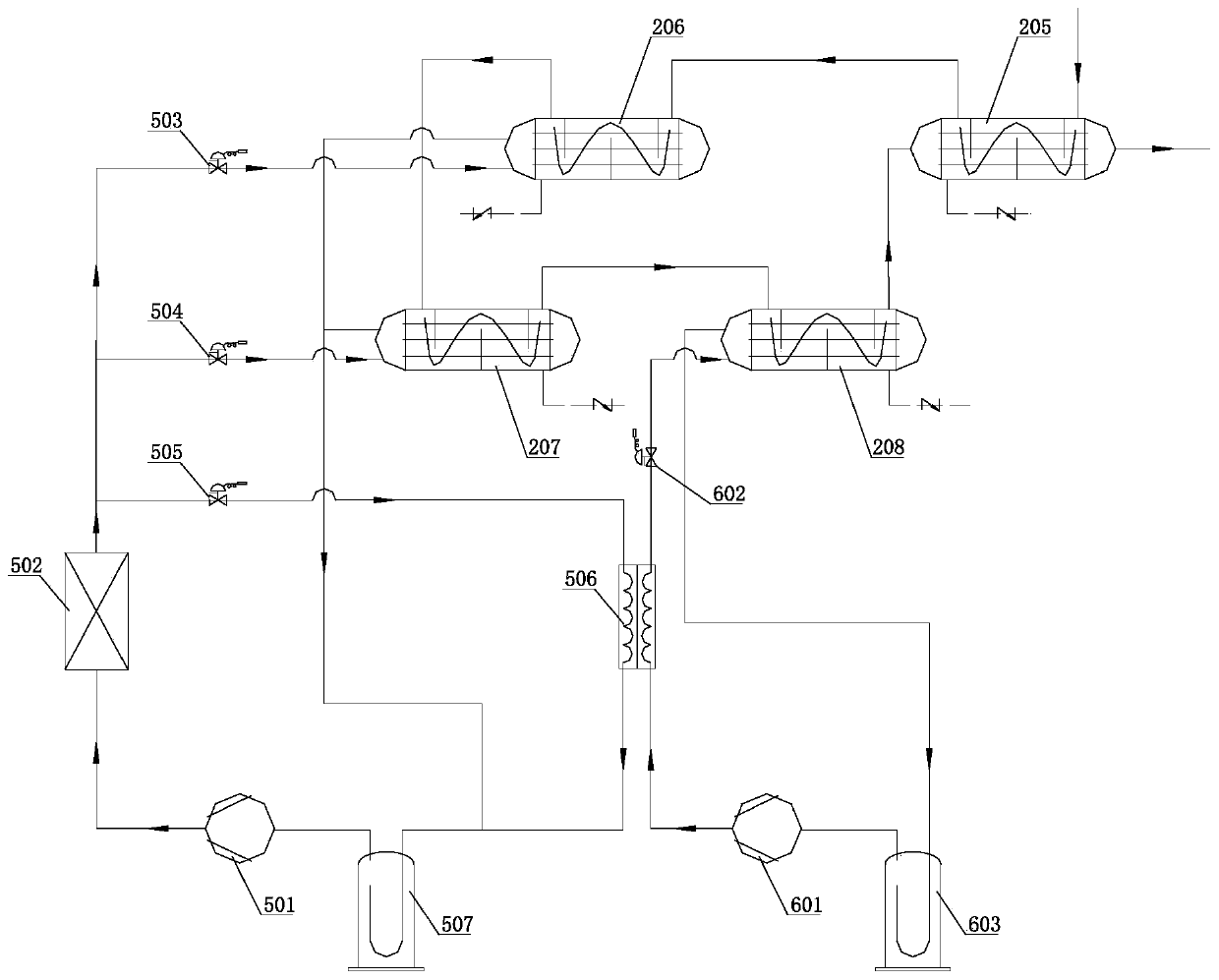

System and method for recovering VOCs at top of tank and reusing nitrogen gas

ActiveCN110420536AReduce the saturated adsorption capacityEfficient removalNitrogen purification/separationDispersed particle separationFlame arresterRefrigeration compressor

The invention discloses a system and a method for recovering VOCs at the top of a tank and reusing nitrogen gas. The system comprises a pressurization subsystem, a condensation subsystem, a pressure swing adsorption subsystem and a nitrogen recovery subsystem, wherein the pressurization subsystem comprises a pressurization air pump and a flame arrester; the condensation subsystem comprises a regenerative heat exchanger, a precooling heat exchanger, a shallow cooling heat exchanger, a cryogenic heat exchanger, an explosion-proof refrigeration compressor, a condensation heat exchanger, an evaporation condensation heat exchanger, a throttling element and the like; the pressure swing adsorption subsystem comprises more than two groups of pressure swing adsorption devices which are arranged inparallel; and the nitrogen recovery subsystem comprises a nitrogen buffer tank and a one-way valve. According to the invention, the pressure regenerative heat exchanger, the precooling heat exchanger,the shallow cooling heat exchanger and the cryogenic heat exchanger are used for gradual cooling condensation, pressure swing adsorption recovery and purification of the VOCs gas at the top of the tank, and finally the VOCs are recycled; the nitrogen at the top of the tank is reused after purification; and the unit does not have any secondary pollution during operation.

Owner:NANJING DOULE REFRIGERATION EQUIP

Apparatus for the preparation of biomass chars returned into field and the recovery and utilization of gas waste heat

The invention discloses an apparatus for the preparation of biomass chars returned into field and the recovery and utilization of gas waste heat. The apparatus comprises a pneumatic feeding device, a coking chamber, a heat exchanger, a purifier, a carbon filter and a water-seal flame arrester, which are connected in sequence via a gas transmission pipeline. Clean and dry combustible gas is finally obtained after high temperature combustible gas mingled with dust, water vapor and tar gas, which is generated during the burning of biomass in the above apparatus, are subjected to primary cooling in the heat exchanger, secondary cooling and separation in the purifier and tertiary adsorption and separation in the carbon filter. Then the clean and dry combustible gas is fed into the water-seal flame arrester to be prevented from temper and back burning. The apparatus provided by the invention is applicable to further preparation of biochar fertilizer to be returned into field. Clean and dry combustible gas is obtained after the cooling, purification and filtering of high temperature combustible gas by means of the above primary, secondary and tertiary cooling and purification devices. Hot water obtained by heat exchange can be used for the special aquaculture of greenhouse soft-shelled turtles. Tail gas discharged out of the apparatus meets the requirement of environment protection.

Owner:ZHEJIANG UNIV

Detonating type flame arrester

InactiveCN104274929AUnique designReduce manufacturing costFire rescueFlame arresterBiochemical engineering

The invention discloses a detonating type flame arrester, and belongs to the technical field of pipeline safety equipment. The detonating type flame arrester comprises shells, a flame arrester and a pipe joint, wherein the shells are connected through bolts; the detonating type flame arrester is characterized in that the flame arrester is arranged between the shells; a buffer device is arranged between the pipe joint and a flame arresting plate respectively; and a circle of through holes are formed in the edge of the buffer device. Because of the action of the buffer device, a requirement on the flame arresting plate is greatly reduced, so that production cost is reduced; and the flame arrester disclosed by the invention is beneficial for comprehensive utilization and application.

Owner:FINEKAY TIANJIN VALVE MFG CO LTD

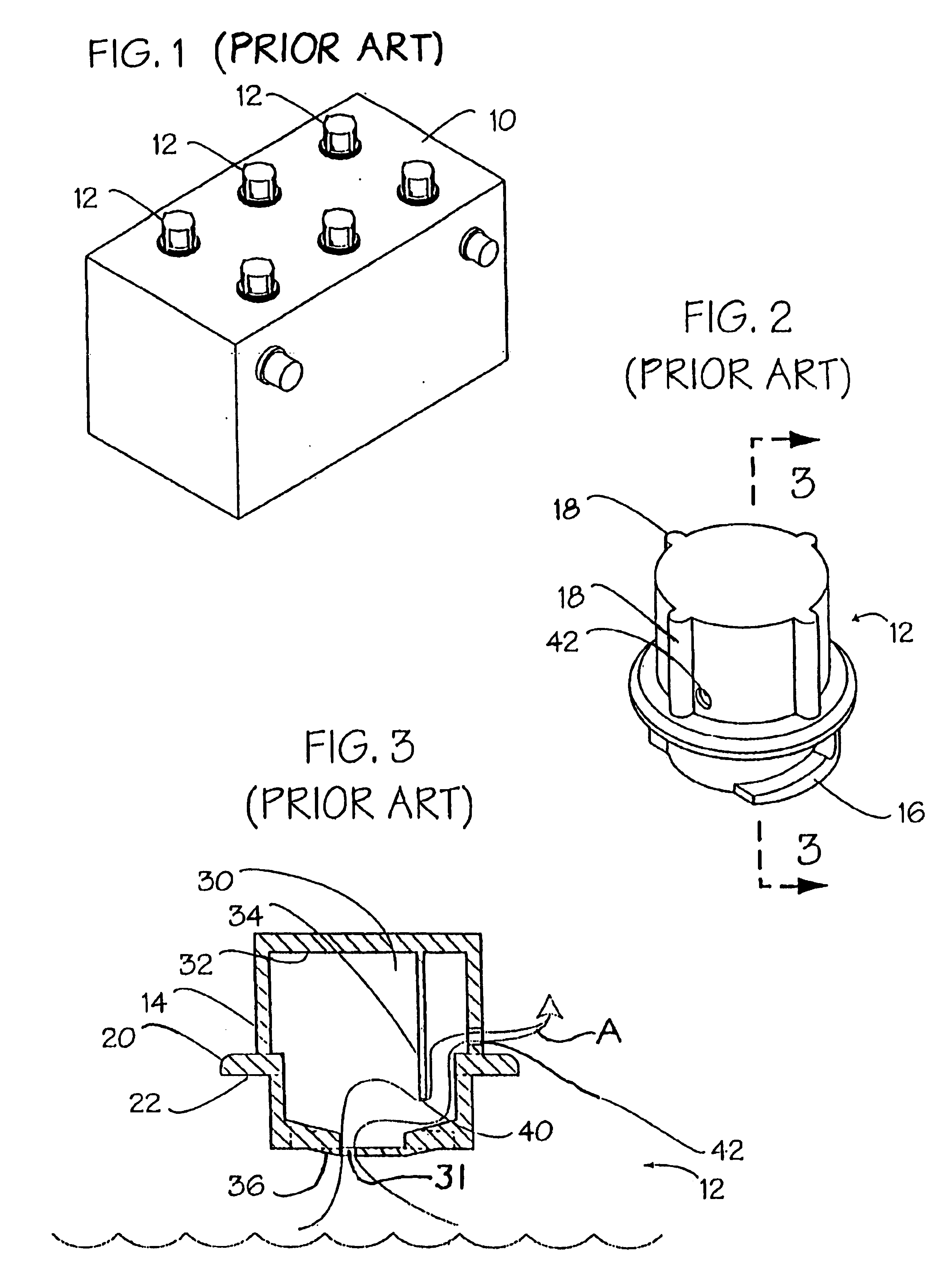

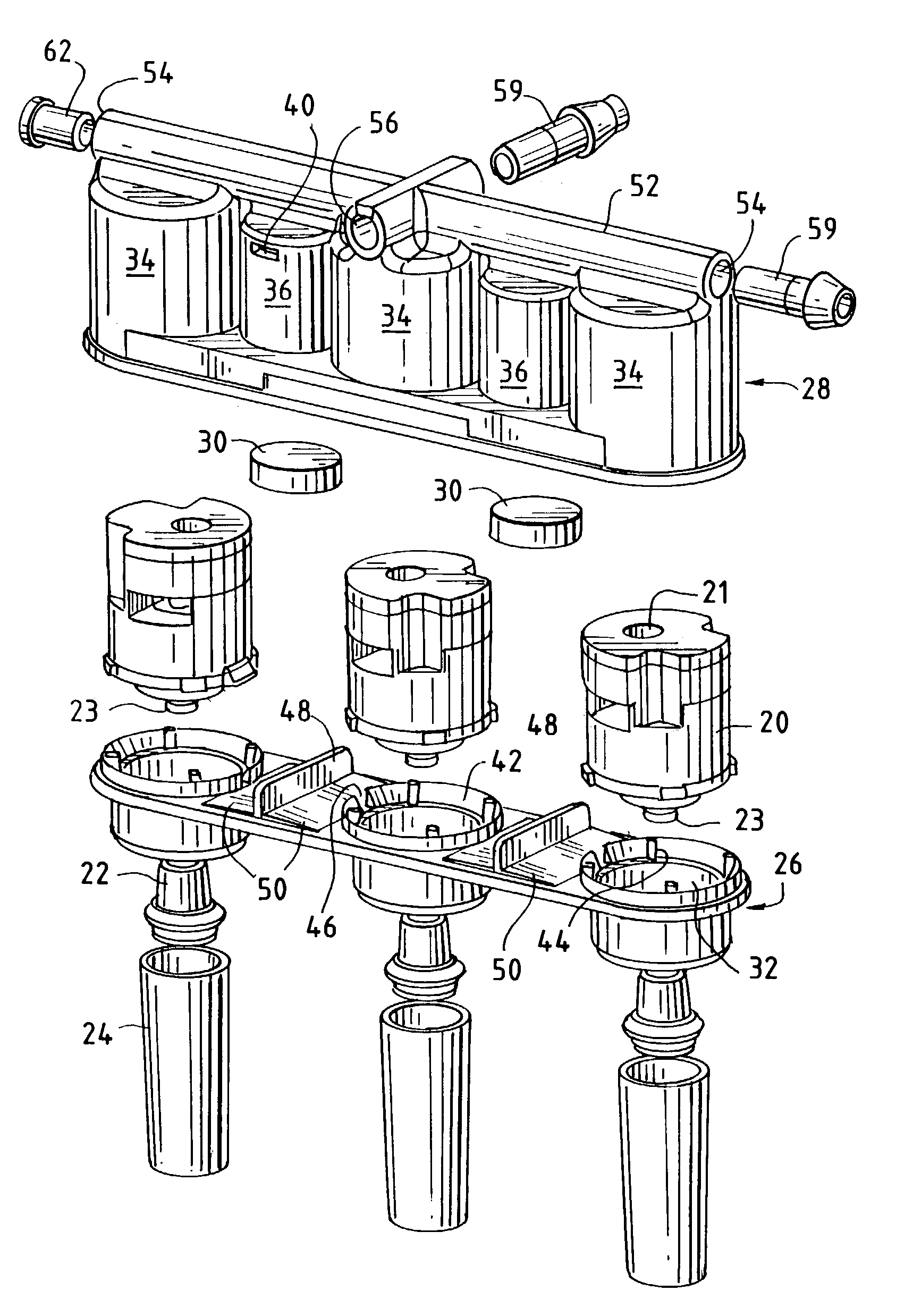

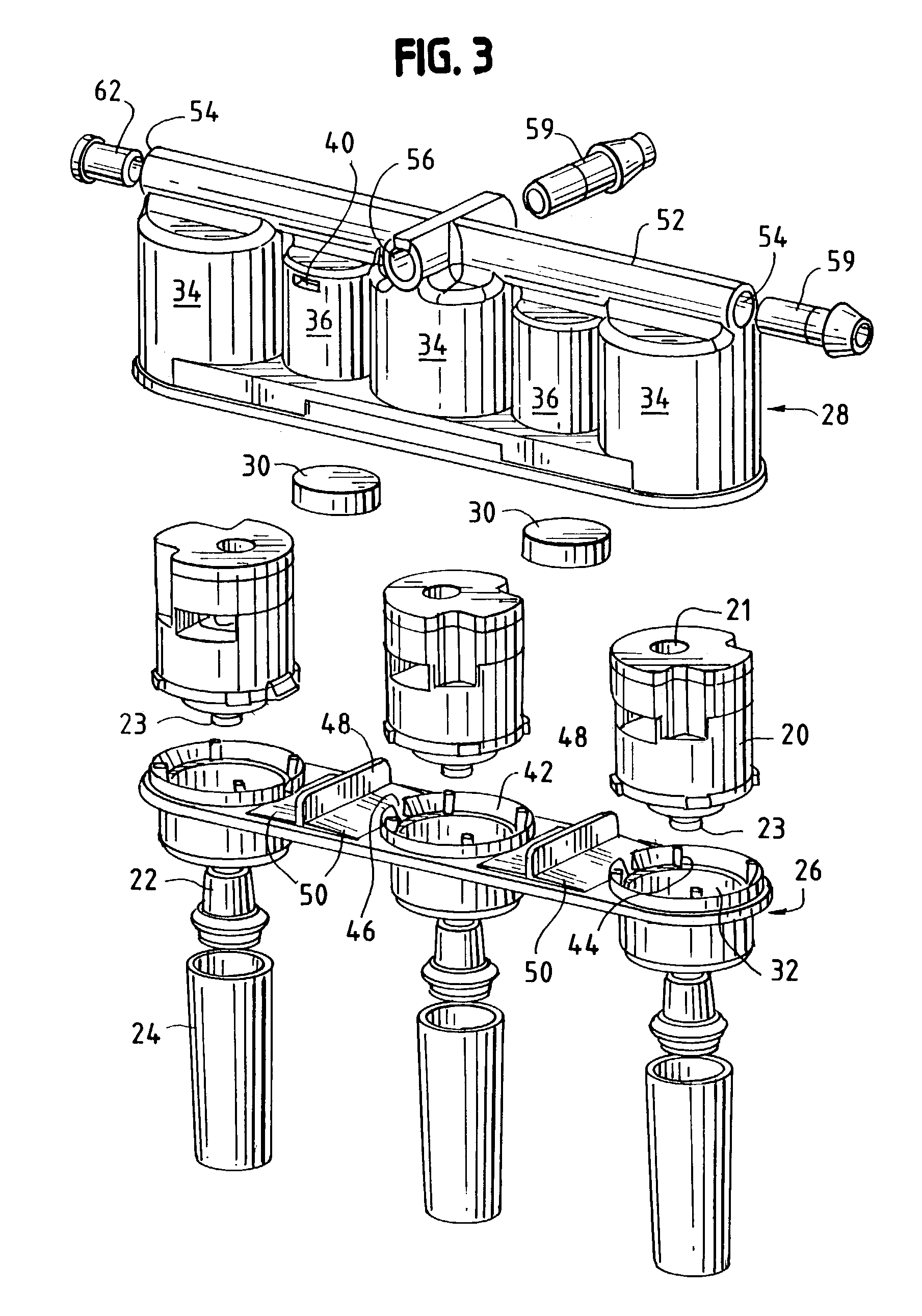

Single point watering apparatus for lead-acid battery

ActiveUS7029786B2Primary cell to battery groupingLead-acid accumulatorsGastric tube feedingSingle point

The present invention is directed to a single point watering system for use with a lead-acid battery having a plurality of battery cell access ports. The system comprises a plurality of refill valves and a plurality of refill valves and a manifold having (i) a water feed tube with at least one external port and a plurality of outlets each communicating with one of the plurality of refill valves, and (ii) at least one passageway housing a flame arrestor to permit the discharge of gases from the battery cells to the surrounding environment only through the flame arrestor. The manifold is removably and sealably mountable to the battery so that each refill valve is in fluid communication with one of the battery cell access ports.

Owner:FLOW RITE CONTROLS

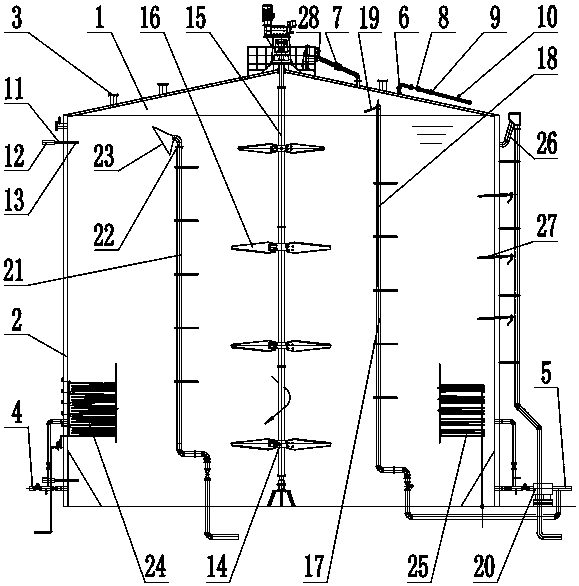

Large livestock manure and straw mixed raw material anaerobic fermentation tank and method thereof

PendingCN107760600AStir fully and evenlySolve the problem that the effect of plugging and mixing will be reducedBioreactor/fermenter combinationsBiological substance pretreatmentsFlame arresterLivestock manure

The invention discloses a large livestock manure and straw mixed raw material anaerobic fermentation tank and a method thereof. The tank body is formed by a thick steel plate. The diameter of the tankbody is 18-22m, the height-diameter ratio of the tank body is (0.9-1.2): 1, and the volume of the tank body is 5000-6000m<3>; a biogas outlet, a positive and negative pressure protector, a pressure transmitter and an observation light hole are formed at the top of the tank body, and the pressure in the tank body is maintained at a normal positive and negative pressure state; a flame arrester, a biogas mass flowmeter and a biogas analyzer are separately mounted at the biogas outlet and an overflow tube is arranged at the liquid level in the upper portion of the tank body, so that the safety ofthe large fermentation tank and the biogas quality are effectively guaranteed; a material mixing degree measuring device effectively controls a material fermenting process in the tank body immediately; a plurality of temperature transmitters which are mounted on the tank body are matched with a heating coil device, and an insulating layer coats the outer side of the tank body, so that the temperature of slurry in the tank body is controlled effectively; a central stirring device, a circular spraying and cracking device and a dross cutting and cracking device are also mounted in the tank body,so that the stirring efficiency and the cracking efficiency are improved effectively, the gas yield is high, and the large livestock manure and straw mixed raw material anaerobic fermentation tank isenergy-saving and emission-reducing.

Owner:湖北中涢环保能源科技有限公司

Device and method for purifying and concentrating coal bed gas and treating produced water

ActiveCN104479780AIncrease concentrationEasy to transportGaseous fuelsMultistage water/sewage treatmentHigh concentrationFlame arrester

The invention relates to the technical field of exploitation and utilization of coal bed gases, and in particular relates to a device and a method for purifying and concentrating a coal bed gas and treating produced water. The device comprises a wet flame arrester, a water ring vacuum pump, a gas flow meter, a one-way gas valve, a separator, a fireproof and explosion-proof compressor, a safety valve, a hydrate generating unit, a gas-liquid two-phase valve, a gas concentration monitor, a stop valve, a filter, a one-way liquid valve, a slurry pump, a three-phase separator, a granulating machine, a stop valve, an outer transportation vehicle, a hydrate decomposing unit, a water pump, an ice making device, a grinding device, a liquid flow meter, a Laval spray valve and a clarifier. Two hydrate reactors are adopted to fix CO2 and methane in the coal bed gas respectively, and the CO2 released after regeneration is used as a gas-driving raw gas for improving the recovery ratio of the coal bed gas, so that the release of CO2 of a gas field is reduced, and high-concentration methane hydrate is granulated and transported outwards for application; and a salt draining effect during formation of the hydrate is used to ensure that a lot of salt-containing produced water during exploitation of the coal bed gas can be treated to meet requirements for reinjection to a stratum layer, so that resources are saved, and the environment is protected.

Owner:江苏智芯今创科技有限公司

Fire-proof material, fire retardant module and fire-proof plate prepared from the same

InactiveCN101168478AGood expansion performanceImprove expansion propertiesFireproof paintsFlame arresterThermal expansion

The invention discloses a fireproof material and a fireproof module and a fireproof board made of the material. It includes raw vermiculite and mainly includes the following components, and the parts by weight of each component are: 1 to 40 parts of raw vermiculite; 50-90 parts of cooked vermiculite; 15-25 parts of binder; 2 parts or less of graphite; the preferred amount of each component is: 10-20 parts of raw vermiculite; 60-80 parts of cooked vermiculite; 20 parts of binder parts; graphite is less than or equal to 1 part. The fire-blocking module and the fire-proof board are made of the above-mentioned fire-proof materials mixed and pressed. Utilizing the characteristics of thermal expansion of raw vermiculite, raw vermiculite is used instead of expanded graphite, which is a safe and effective fireproof material. It can be applied to various fireproof materials, and is especially suitable for fireproof modules, fireproof modules, firewalls, fireproof boards and the like made of fireproof materials.

Owner:陈振铎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com