Patents

Literature

59 results about "Back burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Back burning is utilized in controlled burning and during wildfire events. While controlled burns utilize back burning during planned fire events to create a "black line", back burning or backfiring is also done to stop a wildfire that is already in progress.

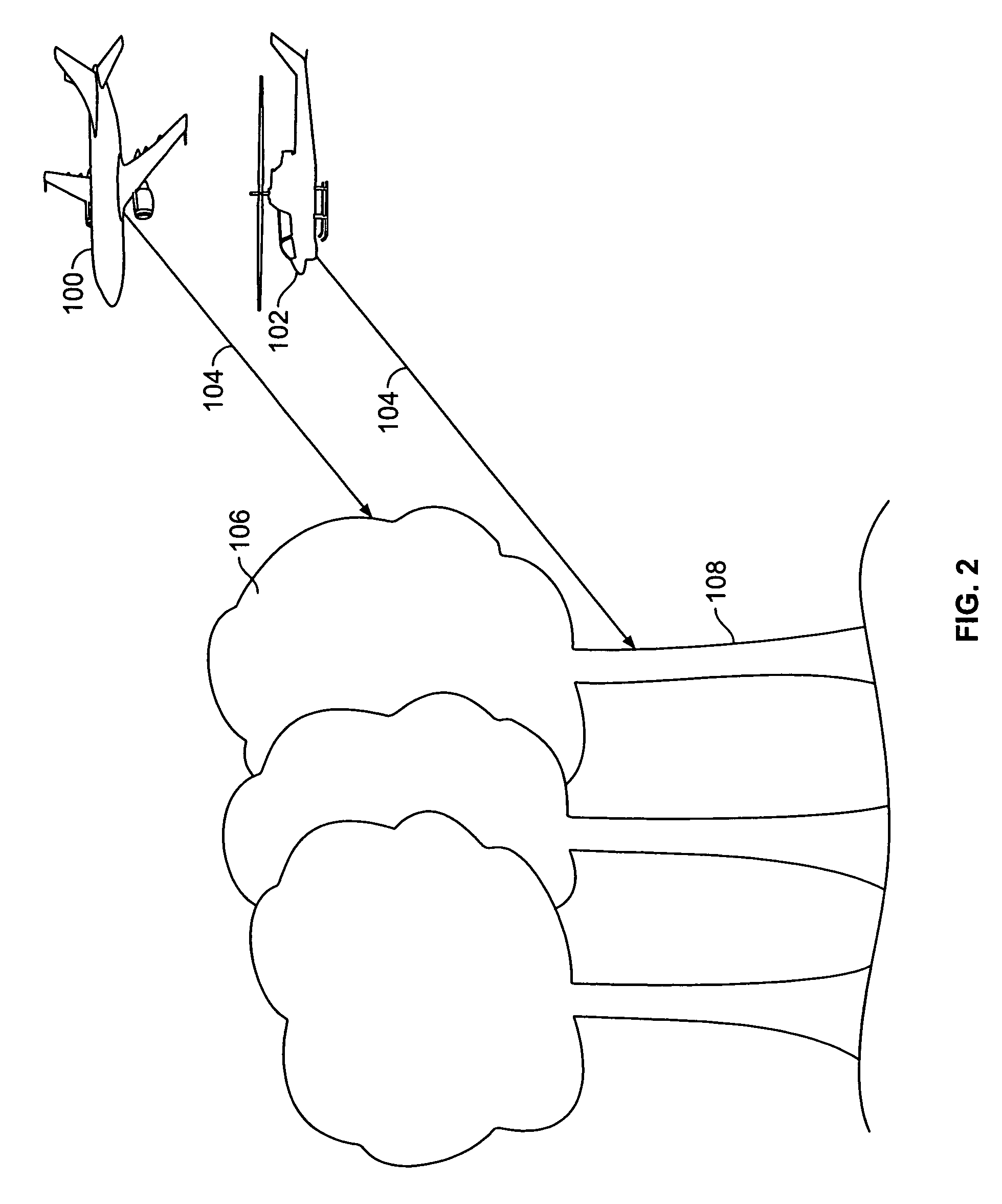

Method of controlling fires

A forest fire is brought under control and extinguished through the use of ordnance to create a fire break. The fire break location is chosen along a front in the direction of travel of the fire. Ordnance is used to quickly knock down trees and other potential fuel for the fire. The fuel is then removed from the fire break. A back burn is optionally used to further create a fire break. The back burn is ignited using ordnance. Mop-up operations make use of ordnance to expose and disperse smoldering fuels by exploding hot spots.

Owner:MCNEIL STEVEN D

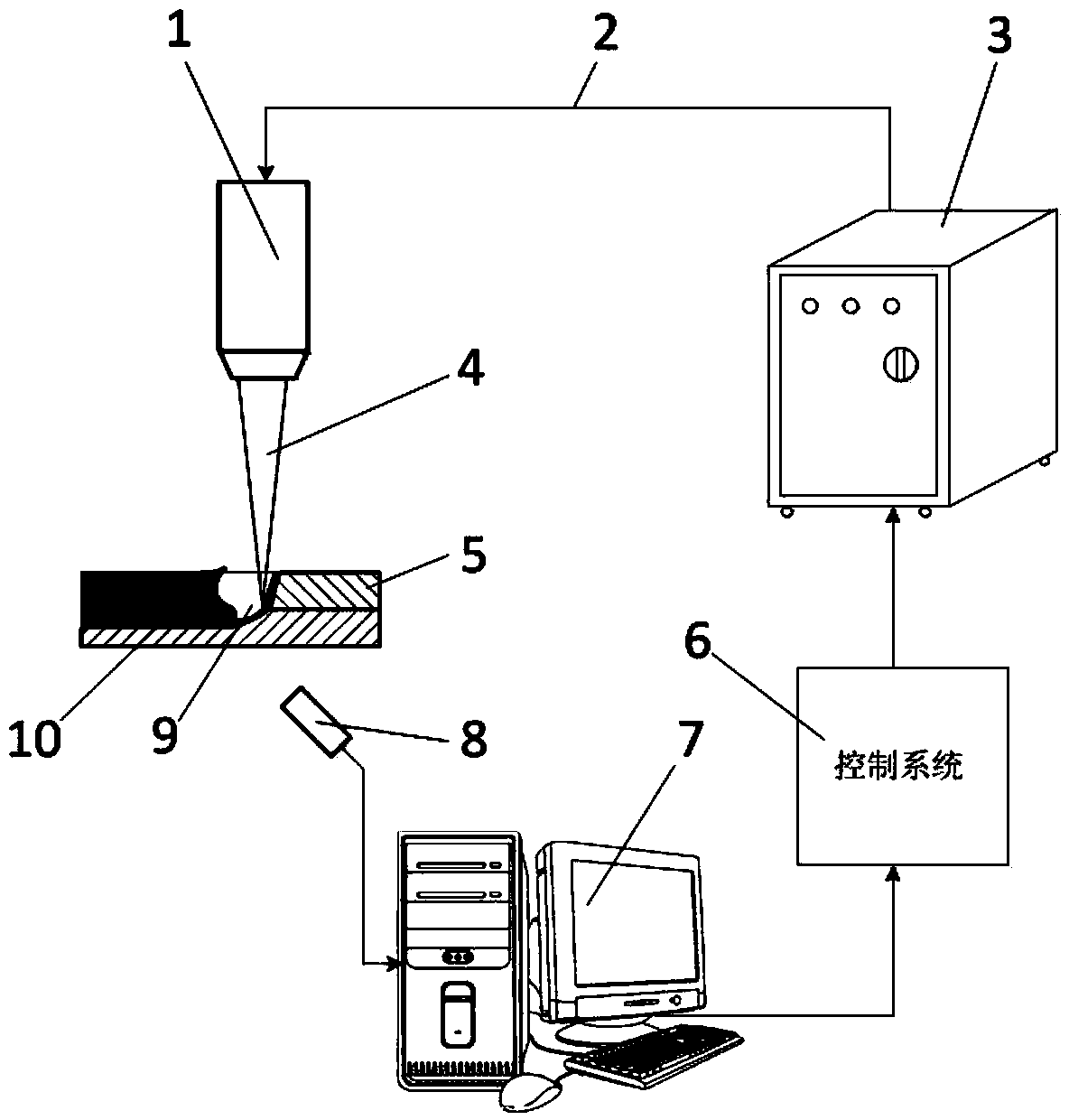

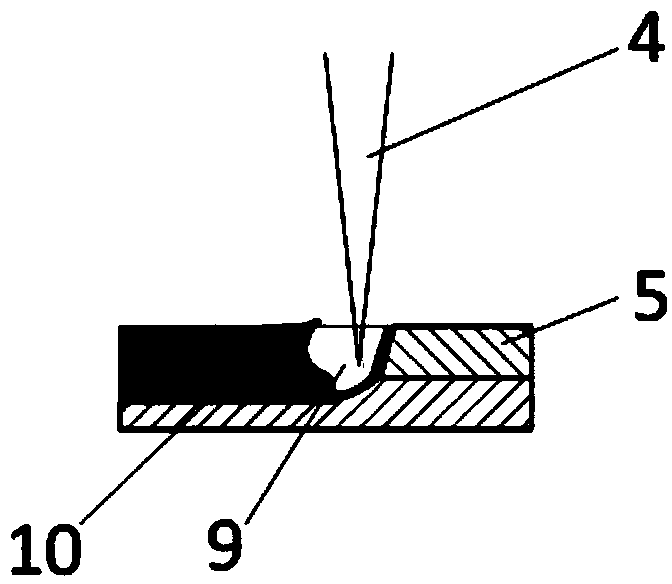

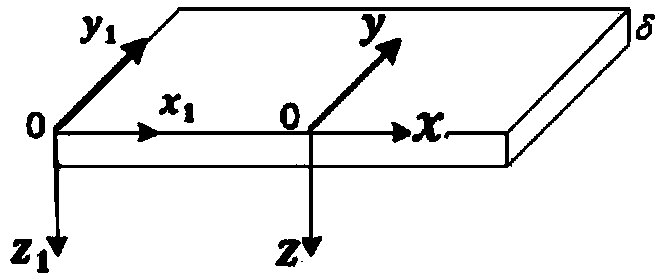

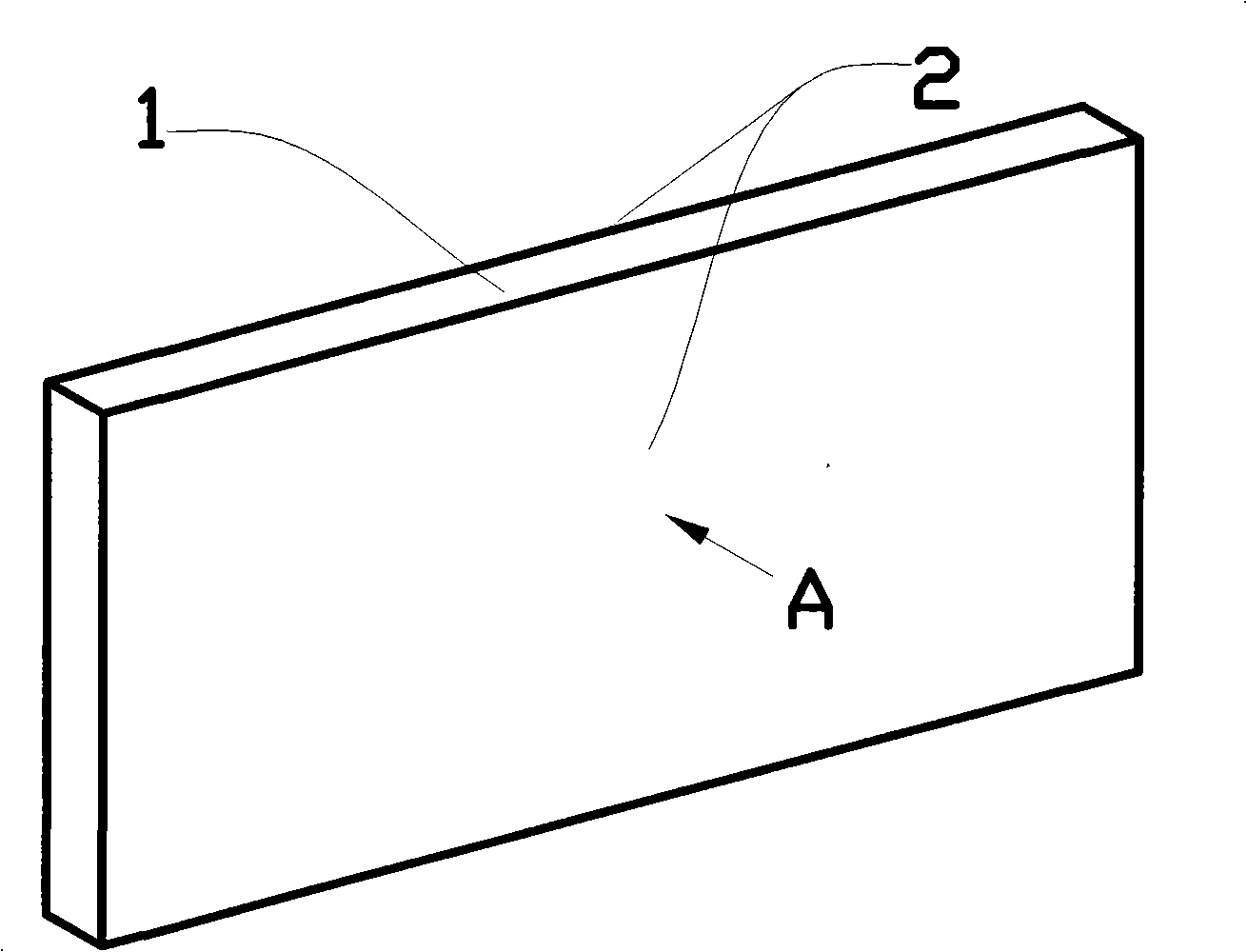

Non-penetration laser welding apparatus and non-penetration laser welding method

InactiveCN104002044AAdaptableImprove anti-interference abilityLaser beam welding apparatusControl systemLaser light

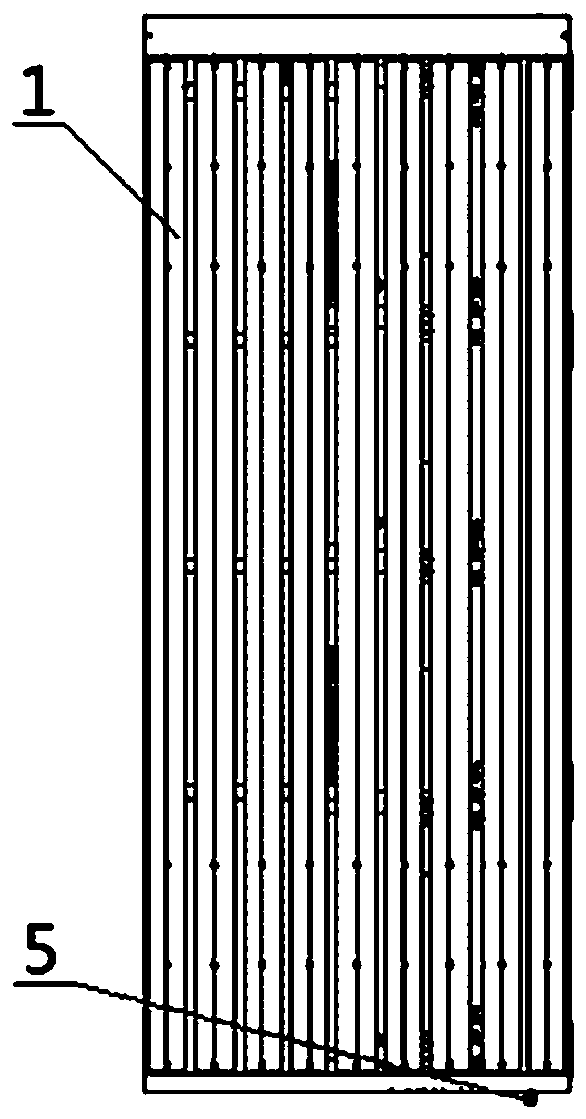

The invention relates to a non-penetration laser welding apparatus. The non-penetration laser welding apparatus comprises a laser welding head (1), a transmitting optical fiber (2), a laser (3), a feedback control system (6), a computer (7) and an infrared temperature acquisition system (8); the non-penetration laser welding apparatus is characterized in that the laser light output by the laser (3) is transmitted to the laser welding head (1) by virtue of the optical fiber (2), a laser beam (4) focused by a focusing lens in the welding head acts on the surface of a welding material (5) to weld the material, the infrared temperature acquisition system (8) is used for capturing the temperature of the back surface of a weld joint in the welding process online, obtaining the present welding penetration condition of the material and transferring control information to the feedback control system (6), and the feedback control system (6) is used for controlling the laser (3) to adjust the power of the laser light in real time. The non-penetration laser welding apparatus is capable of performing accurate control on non-penetration welding adopted in industries so that the welded joint can be protected against non-fusion and back burn; the non-penetration laser welding apparatus is high in practicability.

Owner:HUNAN UNIV

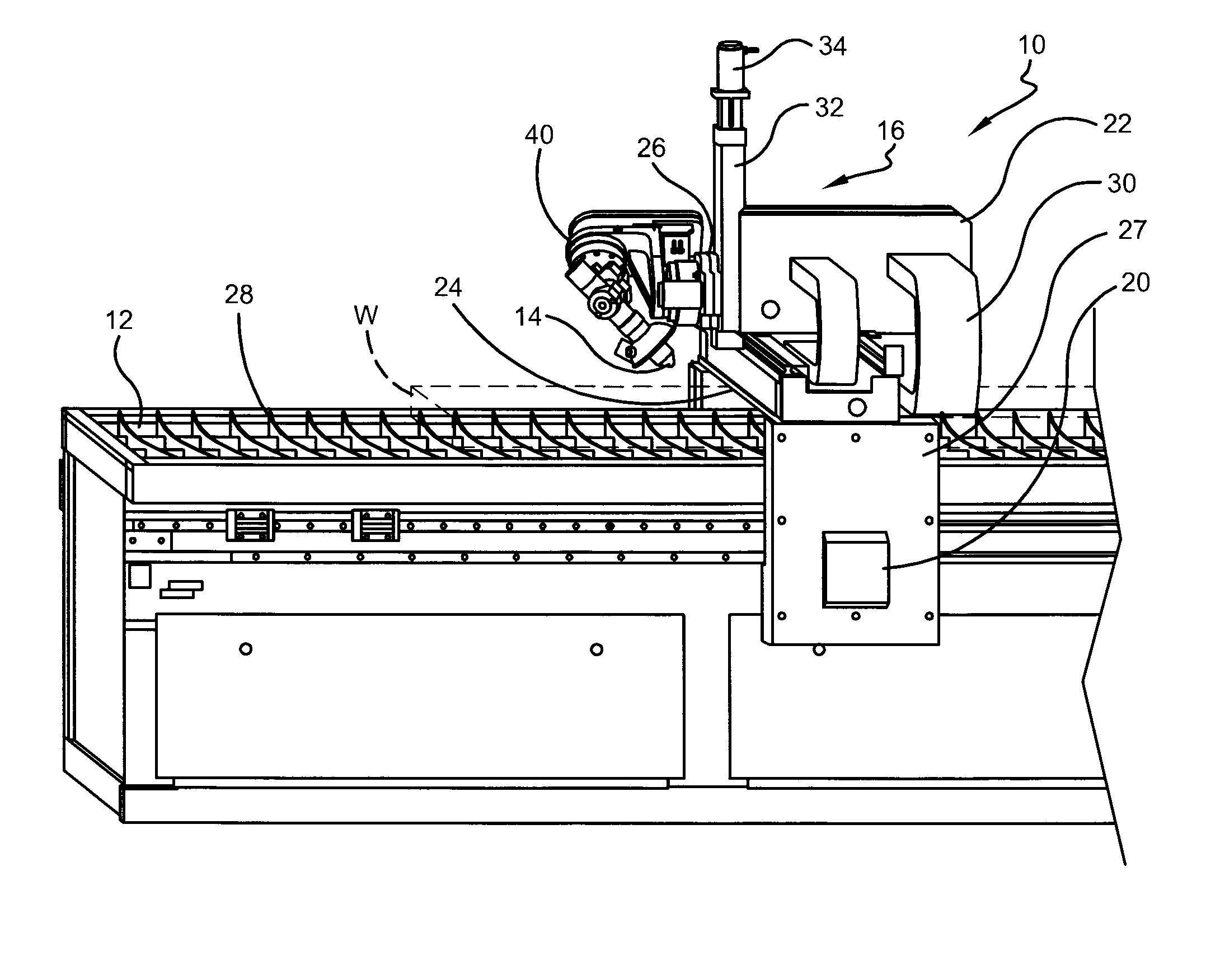

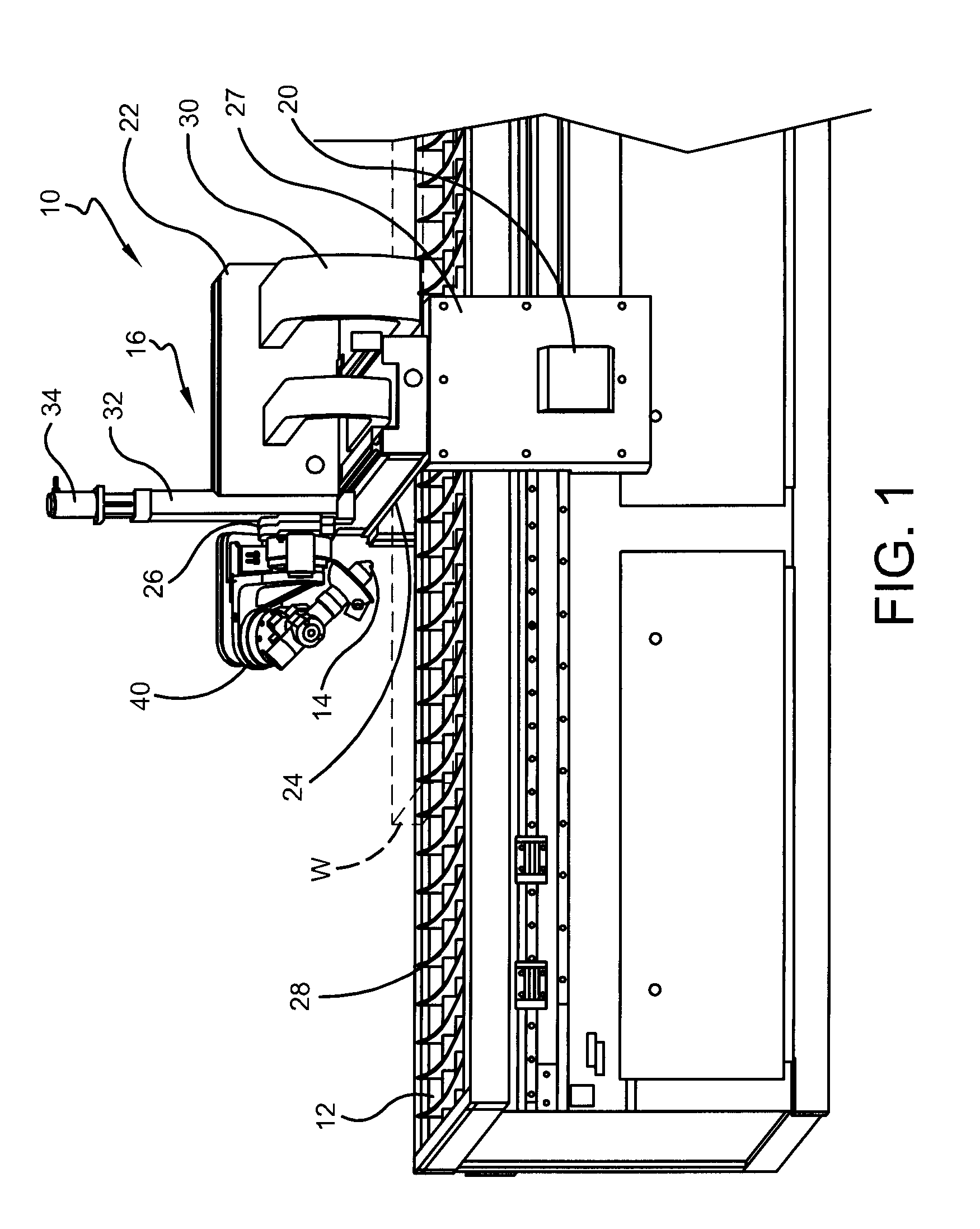

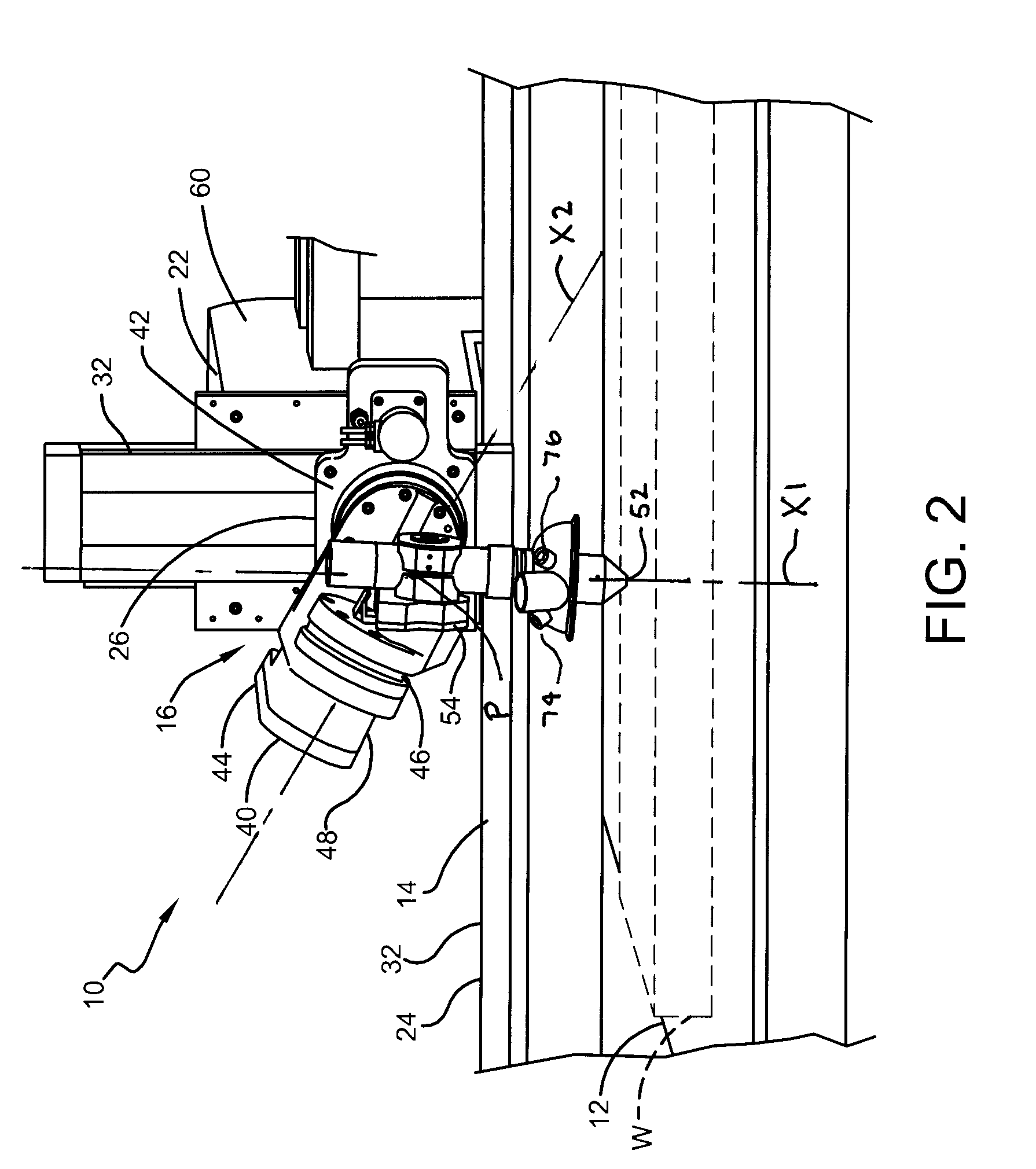

Plasma torch cutting device and process

ActiveUS8395075B2Welding/cutting auxillary devicesArc welding apparatusDegrees of freedomEngineering

A method of operating a plasma arc torch system includes placing a work piece to be cut on a table of the plasma arc torch system, wherein at least a portion of the work piece has a planer surface facing away from the table. A plasma arc torch is positioned adjacent the planer surface of the work piece using a positioning apparatus, wherein the positioning apparatus has at least five degrees of freedom about which it can move the plasma arc torch relative the work piece for cutting the work piece on the table. The method further includes angling the torch relative the planer surface of the work piece such that the torch is held at an angle of between about 1 and about 4 degrees from perpendicular with the planer surface to back burn a produced kerf such that a kerf edge is perpendicular relative the planer surface of the work piece. Additionally, the planer surface of the work piece is calculated by contacting the work piece with the torch at least three times.

Owner:KIFFER INDS

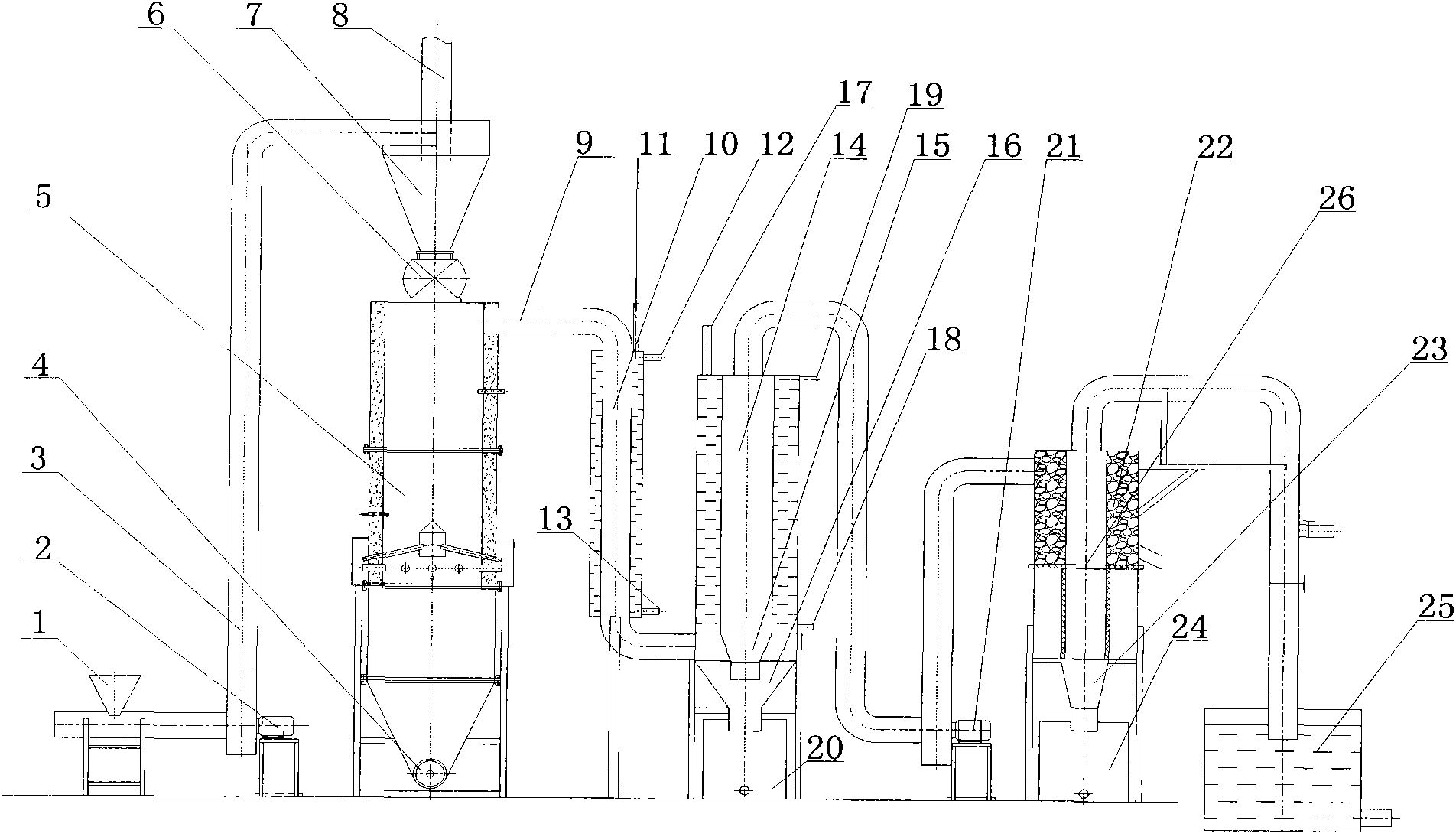

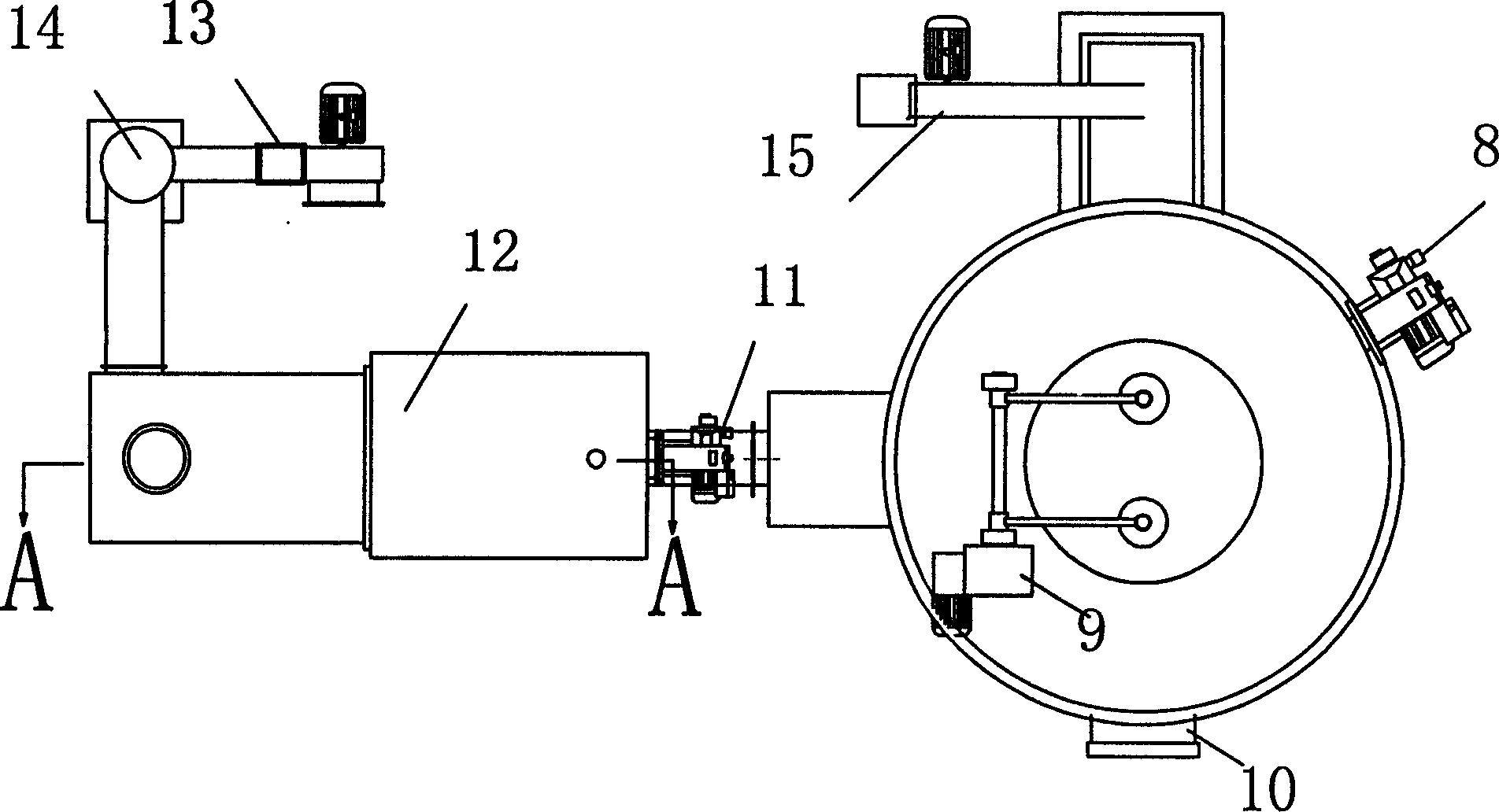

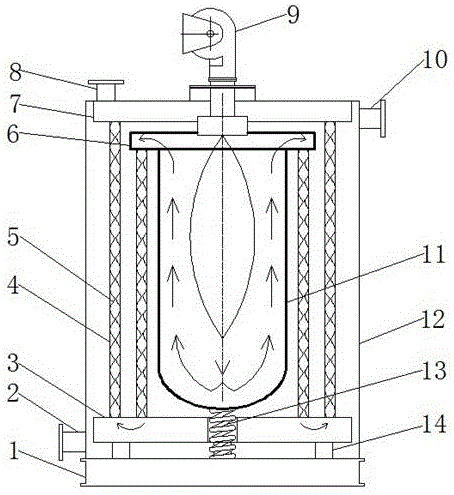

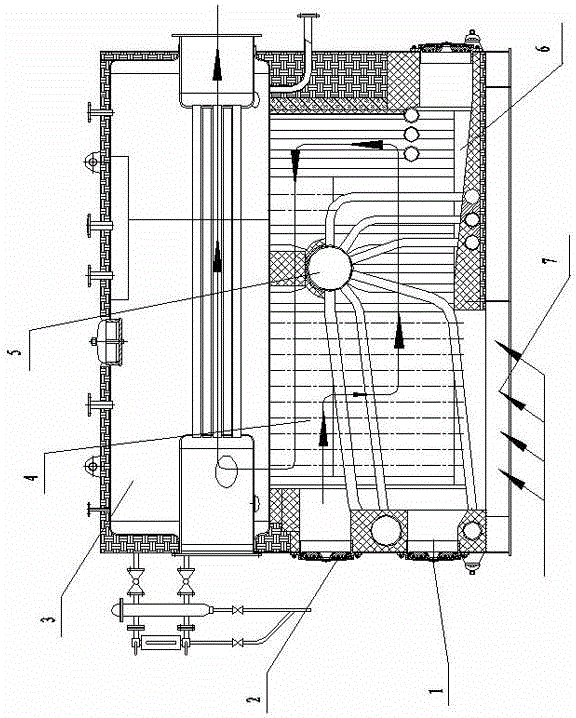

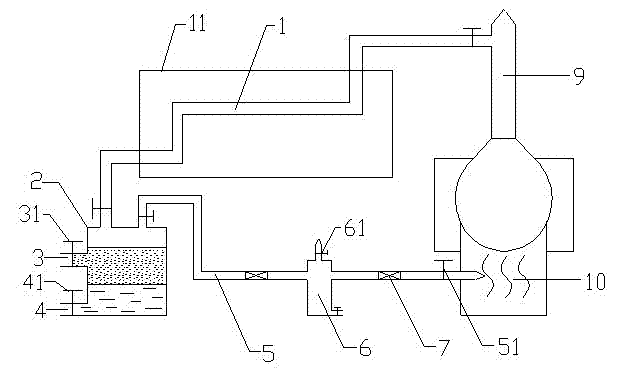

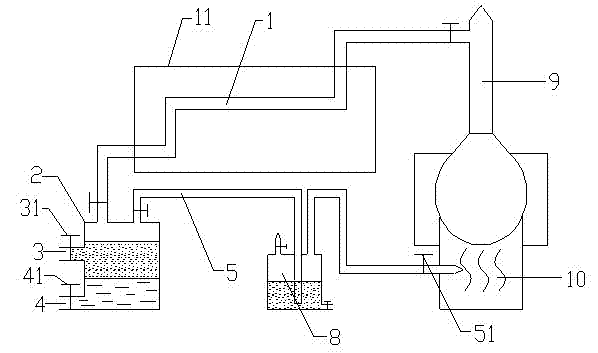

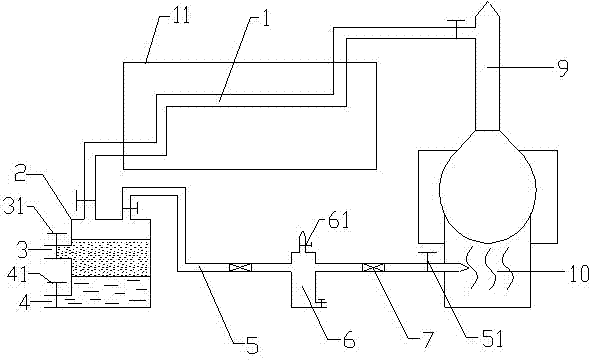

Apparatus for the preparation of biomass chars returned into field and the recovery and utilization of gas waste heat

The invention discloses an apparatus for the preparation of biomass chars returned into field and the recovery and utilization of gas waste heat. The apparatus comprises a pneumatic feeding device, a coking chamber, a heat exchanger, a purifier, a carbon filter and a water-seal flame arrester, which are connected in sequence via a gas transmission pipeline. Clean and dry combustible gas is finally obtained after high temperature combustible gas mingled with dust, water vapor and tar gas, which is generated during the burning of biomass in the above apparatus, are subjected to primary cooling in the heat exchanger, secondary cooling and separation in the purifier and tertiary adsorption and separation in the carbon filter. Then the clean and dry combustible gas is fed into the water-seal flame arrester to be prevented from temper and back burning. The apparatus provided by the invention is applicable to further preparation of biochar fertilizer to be returned into field. Clean and dry combustible gas is obtained after the cooling, purification and filtering of high temperature combustible gas by means of the above primary, secondary and tertiary cooling and purification devices. Hot water obtained by heat exchange can be used for the special aquaculture of greenhouse soft-shelled turtles. Tail gas discharged out of the apparatus meets the requirement of environment protection.

Owner:ZHEJIANG UNIV

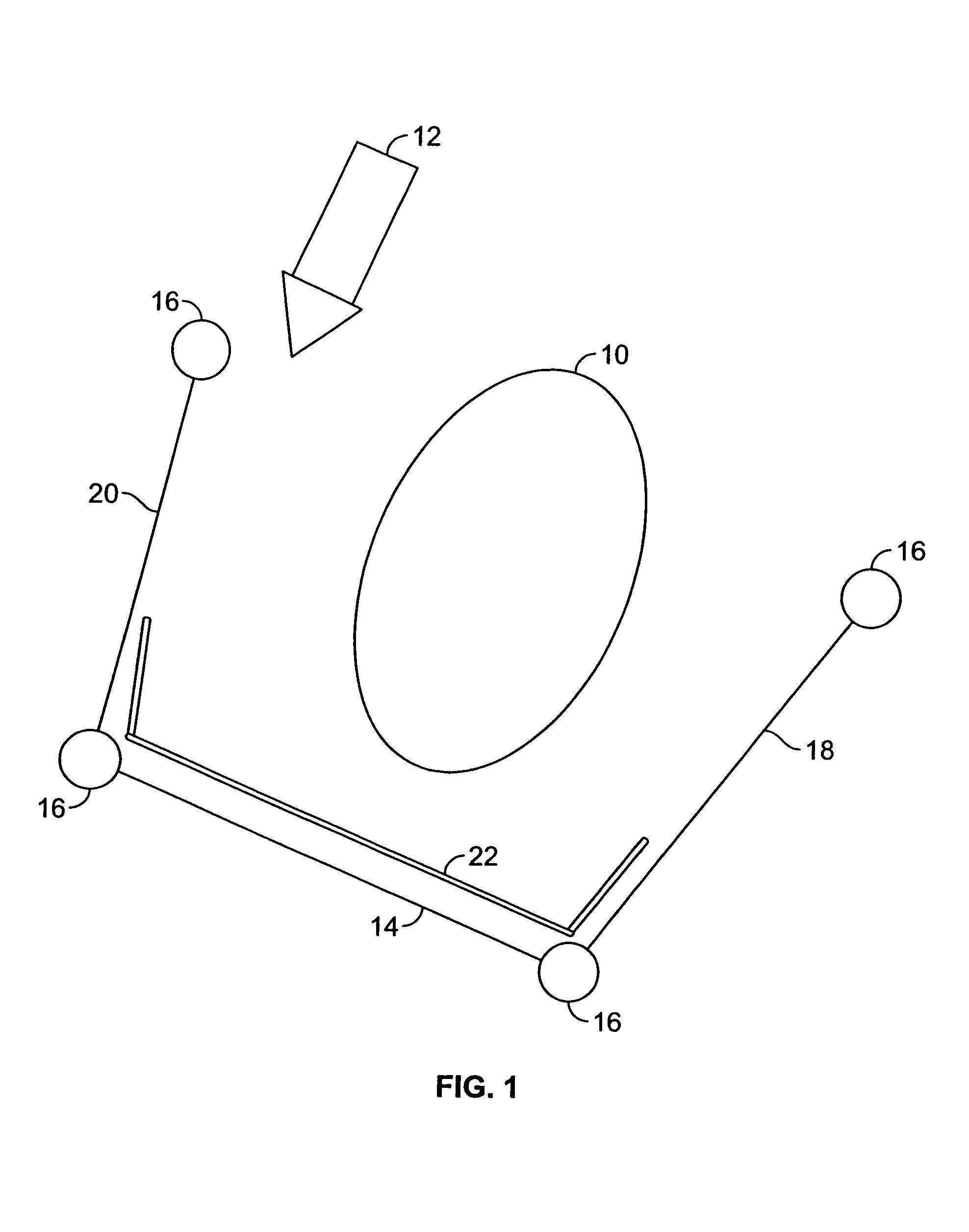

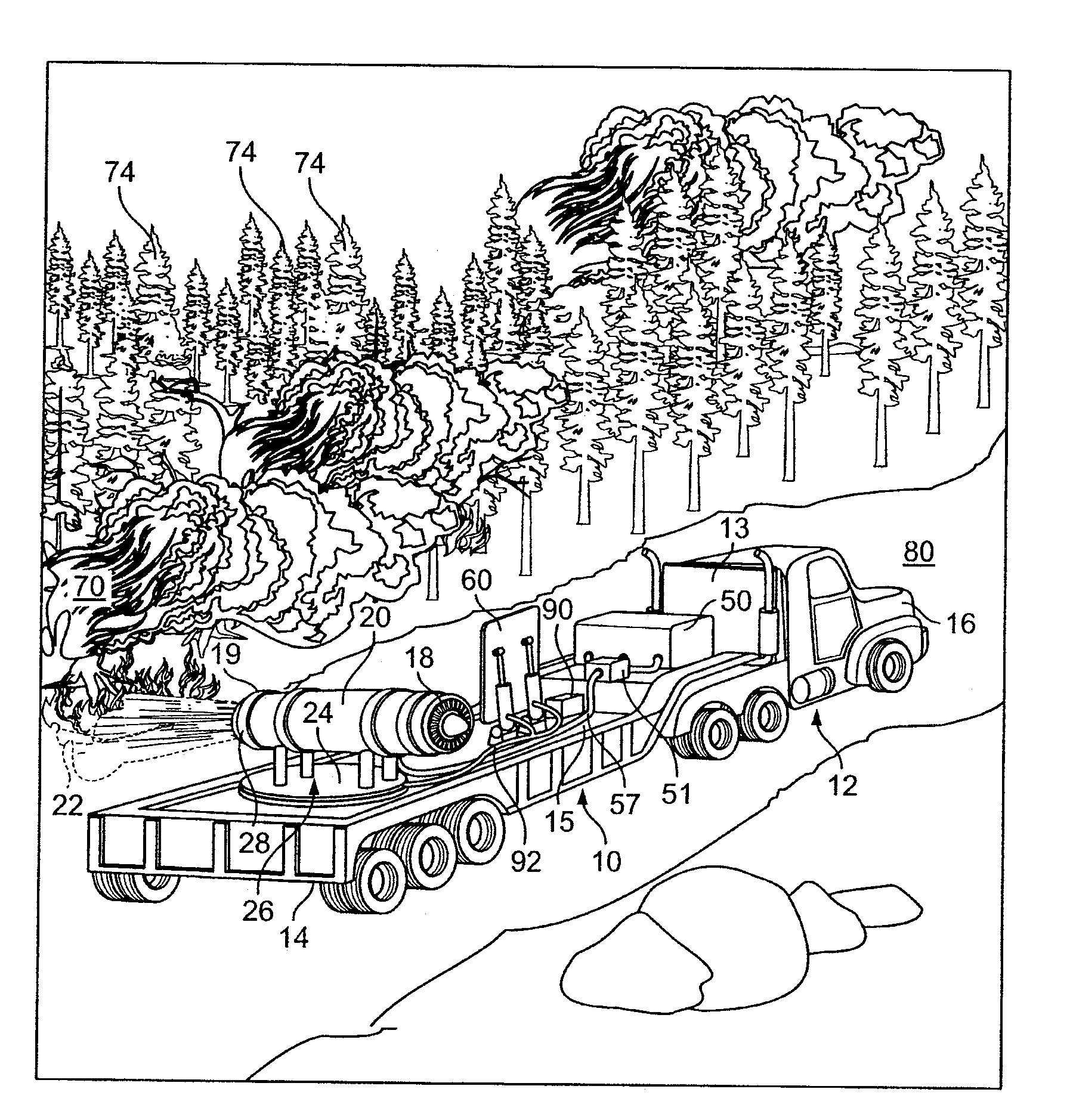

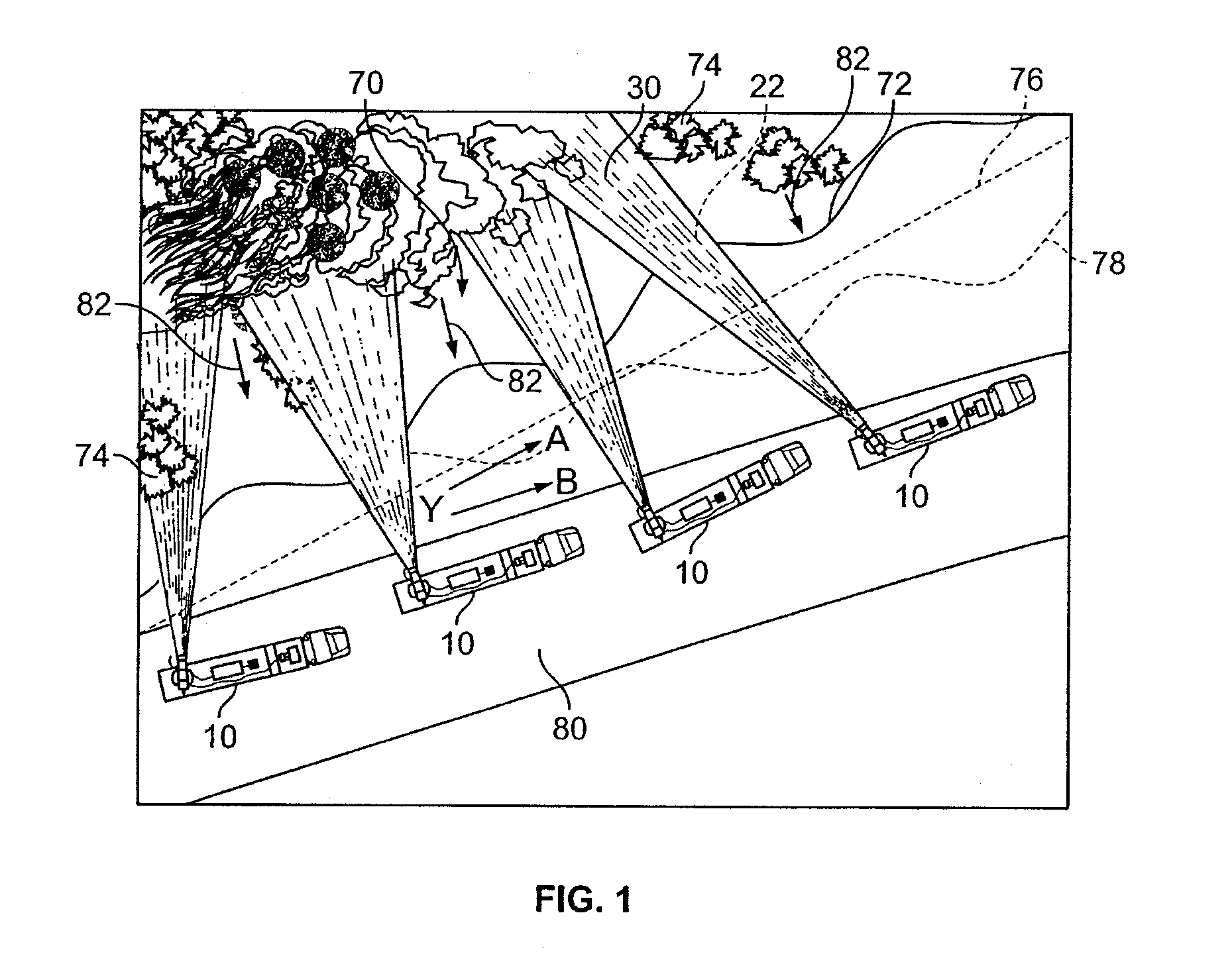

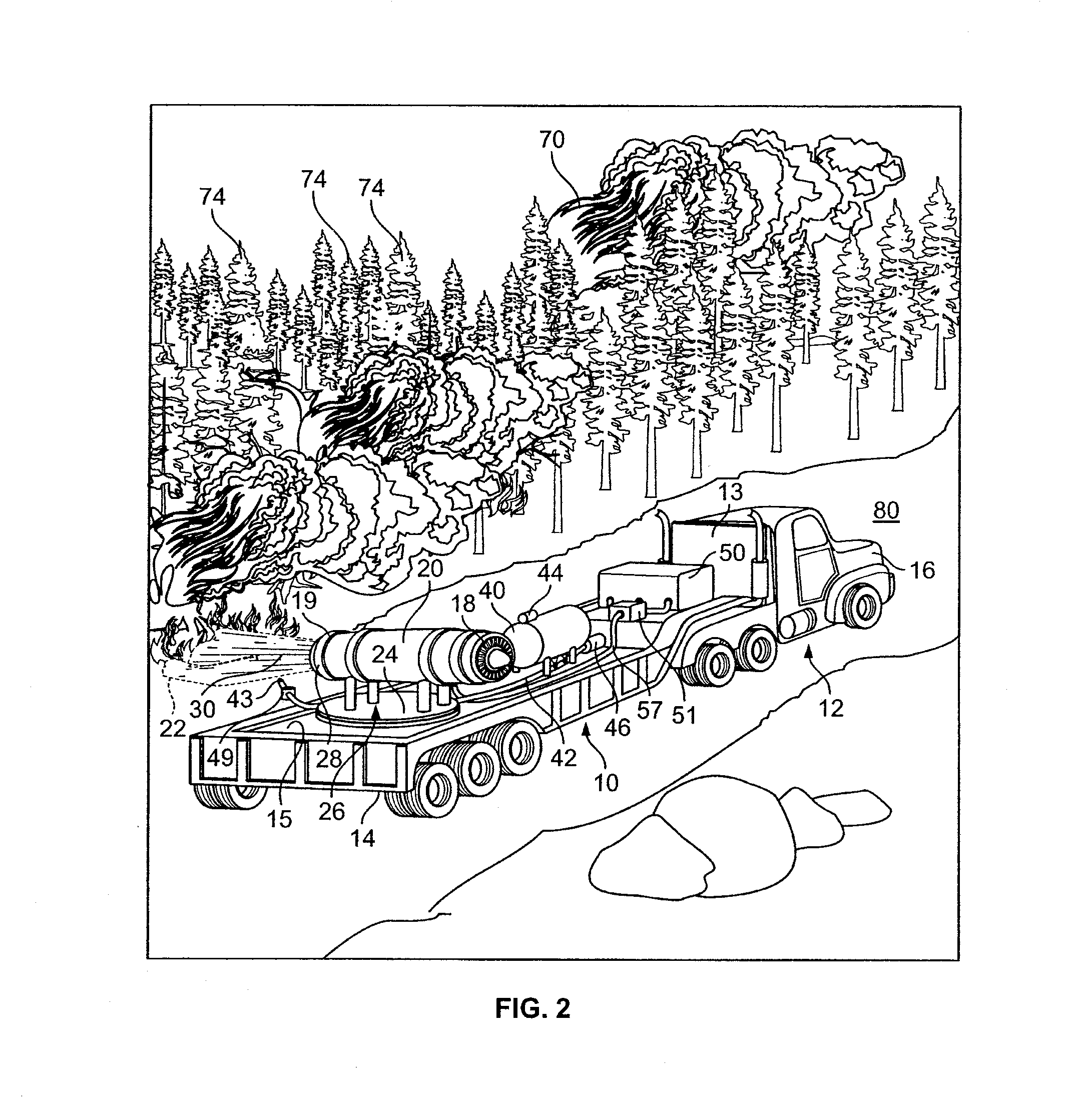

Method of Extinguishing Fires

A method for subduing a fire is described. A fire is intentionally set in front of a larger advancing fire to create a back burn. A vehicle supporting a jet turbine is moved to a front of the back burn. The jet turbine is operated to draw surrounding, ambient air therein and therethrough to form an exhaust. The burning of the back burn is accelerated by directing the exhaust either directly at or to the front of the of the back burn. The back burn leaves a swatch of burned land in the path of the advancing larger fire providing a reduced supply of fuel for the advancing larger fire to burn once the larger advancing fire reaches the swatch.

Owner:GULF COAST HOT MIX EQUIP LEASING

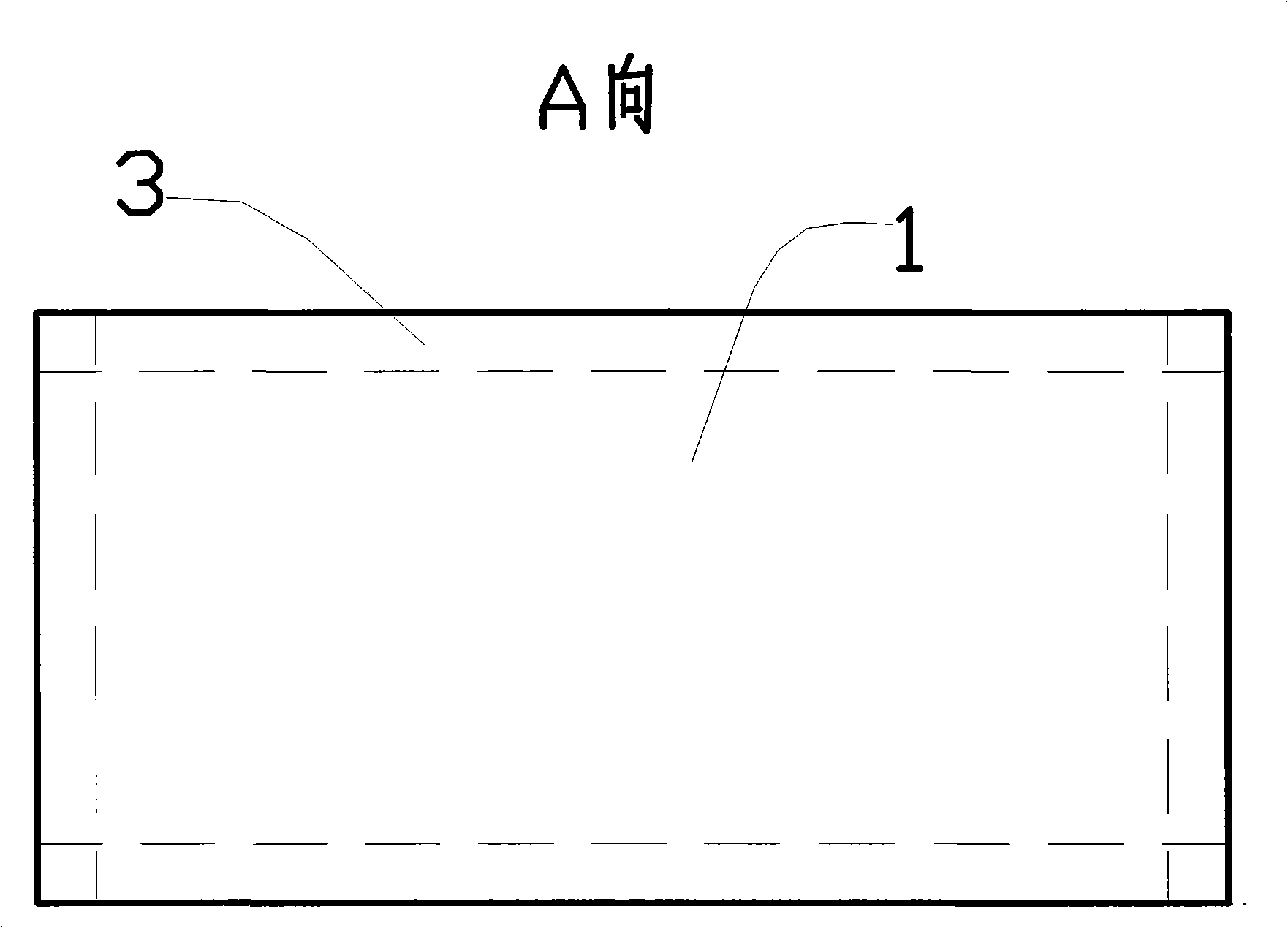

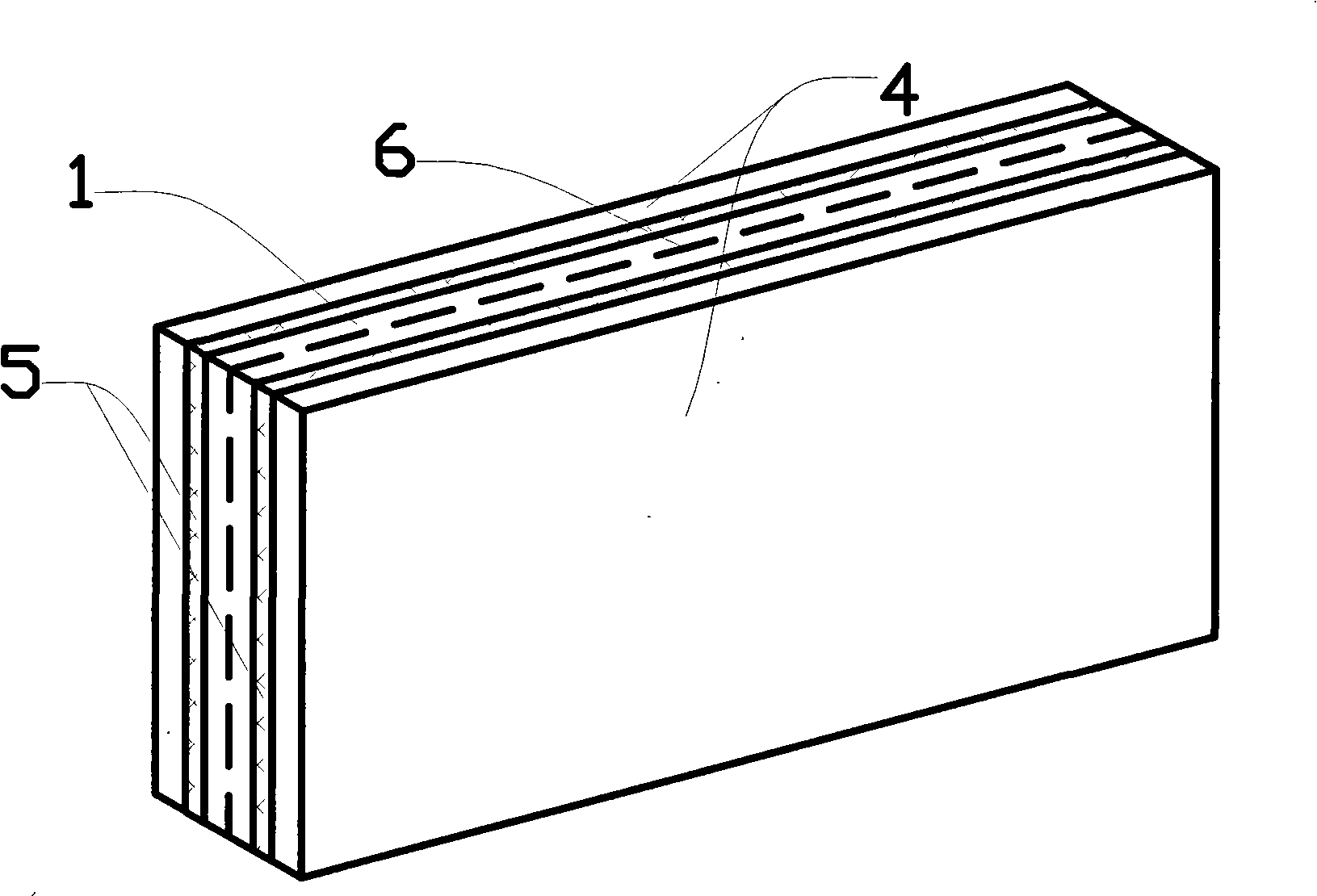

Process for manufacturing ultra-thin stone honeycombed sheet for fire surface

InactiveCN101318396AEasy to prepareLow costLamination ancillary operationsLaminationBurn treatmentSTONE CUTTER

The invention relates to a manufacturing method of a burning surface ultrathin stone honeycomb plate. The manufacture steps include that: 1) a natural stone slab is fetched, burning treatment is carried out on the front and the back surfaces of the natural stone slab to form burning surfaces; 2) a stone glue is coated on the surrounding of the front and the back burning surfaces; two stone transition backing boards are respectively stuck on the front and the back burning surfaces; the three stones form a whole after being spliced; 3) a stone cutter is adopted to cut the combined body of the three stones into two halves along the central position of the thickness of the natural stone slab to form two natural stone composition boards provided with the backing boards; 4) the cutting surface of the composition boards is processed to lead the natural stone slab to reach the designed thickness for forming a ultrathin natural stone slab; 5) a stone compound glue is coated on the back of the burning surface, a honeycomb plate or a foaming plate is stuck, the natural stone slab is taken out after being pressurized and solidified under normal temperature to lead the ultrathin natural stone slab to become the ultrathin natural stone slab that one surface of which is spliced with the transition backing board and the other surface with the honeycomb plate or the foaming plate by the glue; 6) a cutting device is adopted to cut off the surroundings of the ultrathin natural stone slab the two surfaces of which are respectively provided with the transition backing board and the honeycomb plate or the foaming plate, thus leading the transition backing board to separate from the natural stone slab. The finished product has the good properties of high intensity, impact resistance, heat preservation, heat insulation, water resistance, anti-shaking and high application value.

Owner:福州盛山超薄石材有限公司

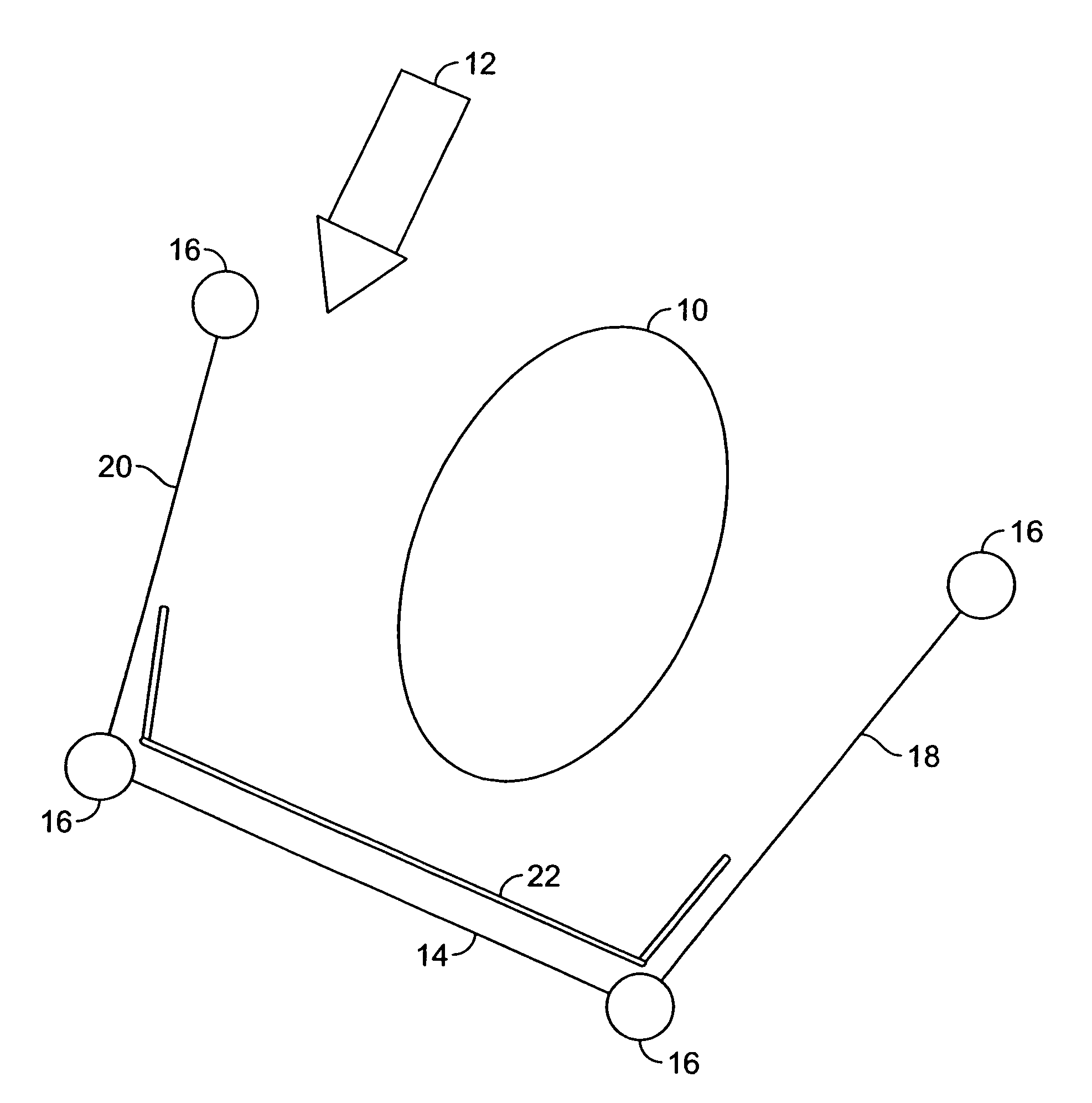

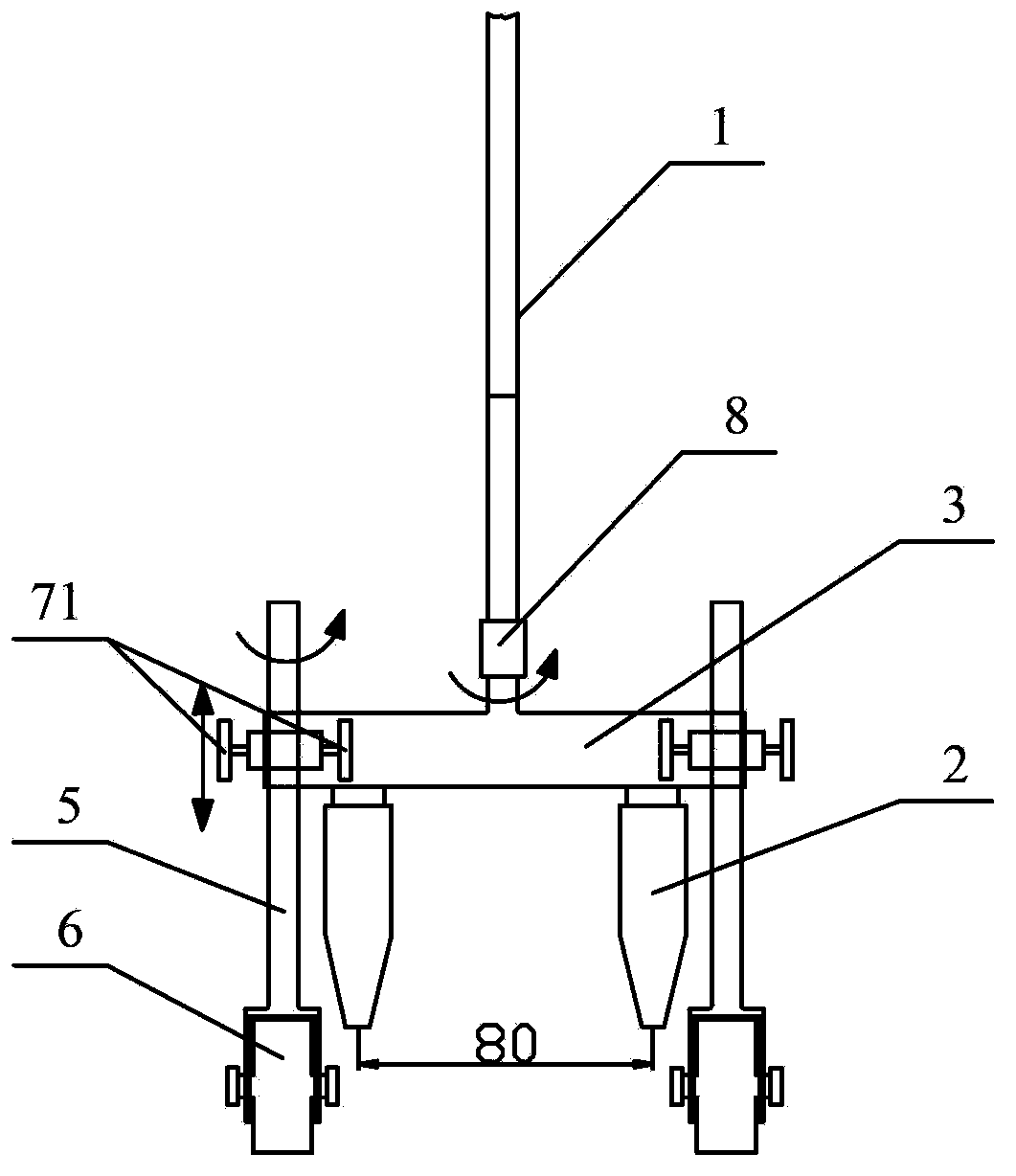

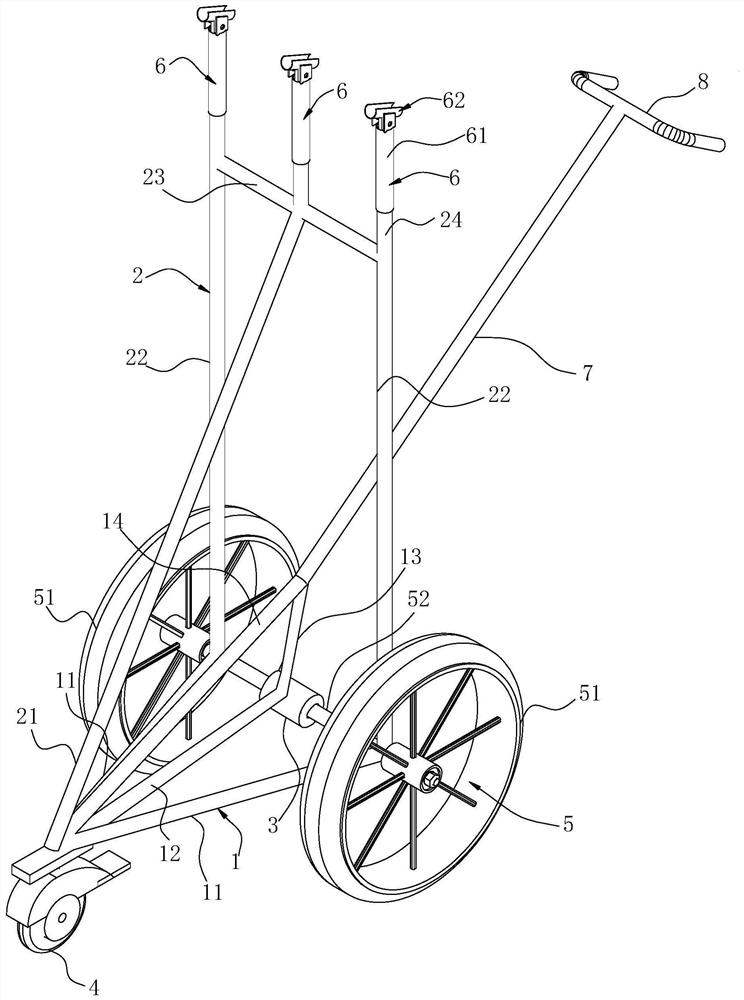

Hot-working back burning distortion corrector

ActiveCN103773930AReduce labor costsReduce manpower requirementsFurnace typesHeat treatment furnacesHot workingBack burning

The invention provides a hot-working back burning distortion corrector. The hot-working back burning distortion corrector comprises a dolly, air inlet tubes and acetylene inlet tubes, the dolly is fixedly provided with a control box and a support, two ends of the support are respectively provided with a mixed gas tube, the mixed gas tubes are connected with the air inlet tubes and the acetylene inlet tubes respectively, and the bottom of each of two ends of each of the mixed gas tubes is provided with a flame nozzle. The hot-working back burning distortion corrector allows the dolly to automatically push two flame nozzles at two ends of the support in order to carry out the heating distortion correction of a steel plate structure, so the hot-working back burning distortion work can be completed only through one-time running of the dolly, thereby the hot-working back burning work efficiency is greatly improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

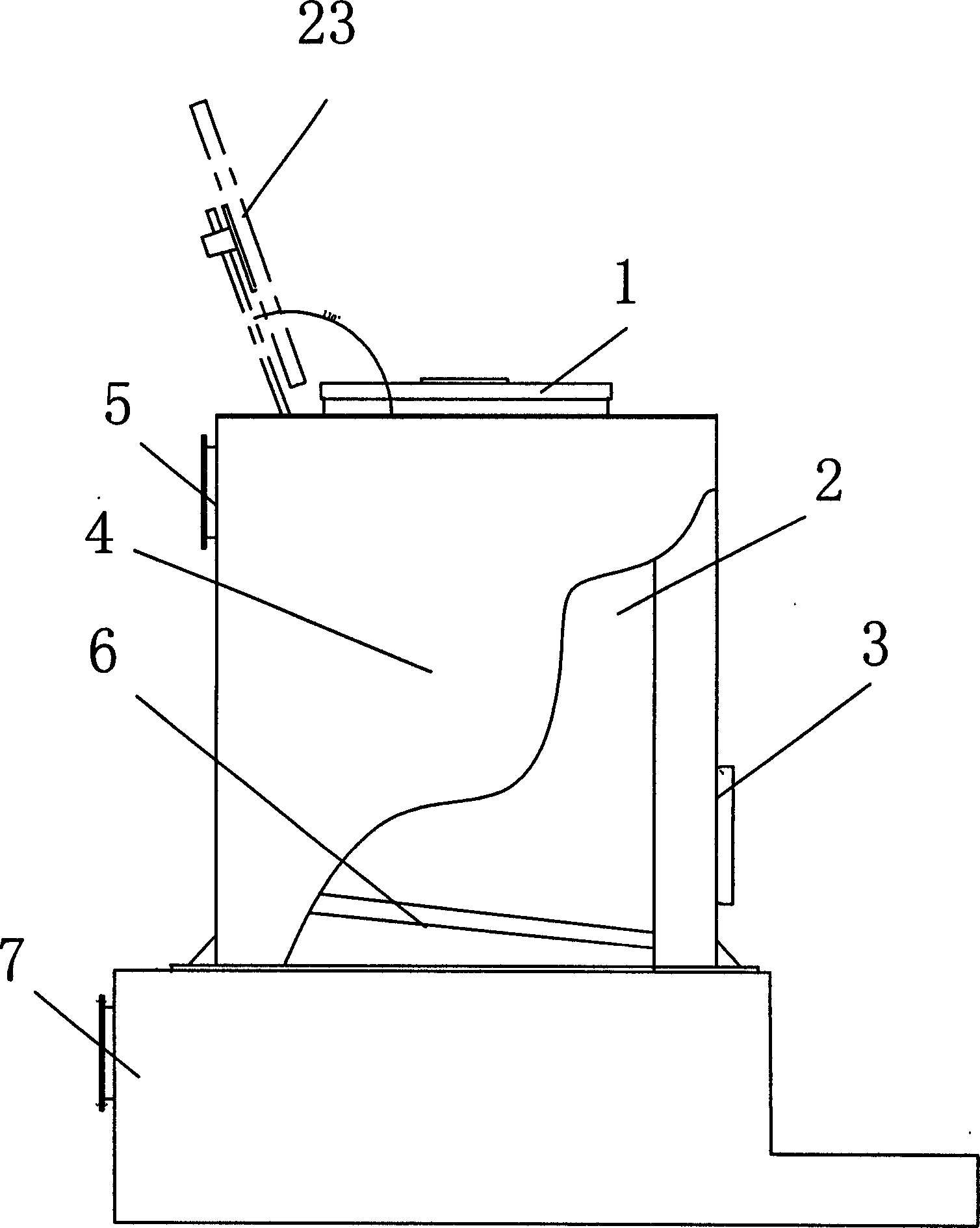

Garbage incinerator device using backfire method

InactiveCN1793731ARealize harmless treatmentRemove harmful ingredientsIncinerator apparatusCombustorCombustion chamber

The invention relates to a back-burning rubbish incinerator, comprising a furnace body provided with feed inlet and fume outlet, where the feed inlet is made in the upper part of the furnace body, the fume outlet is made in the bottom of the furnace and connected with a secondary combustion chamber through secondary fume inlet, the second combustion chamber is connected with a secondary combustor, and the fume outlet of the second combustion chamber is connected with a chimney; and the secondary combustion chamber mainly comprises secondary combustion hearth, secondary air feed pipe, combustion supporter interface and mixed fume flow stabilizing chamber, where the secondary combustor is connected with the secondary combustion hearth through the combustion supporter and the secondary combustion hearth is connected with the fume outlet of the secondary combustion chamber through the mixed fume flow stabilizing chamber. Its beneficial effects: 1. low operating expenses, needing no long time combustion supporting, and as long as starting ignition, automatic combusting; 2. applied to high-water content rubbishes and realizing fast drying; 3. converting rubbishes into gas for secondary combustion, saving secondary combustion expenses and able to eliminate harmful components from the fume, and realizing harmless processing of rubbishes.

Owner:徐顺宽

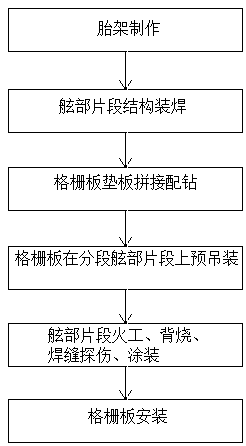

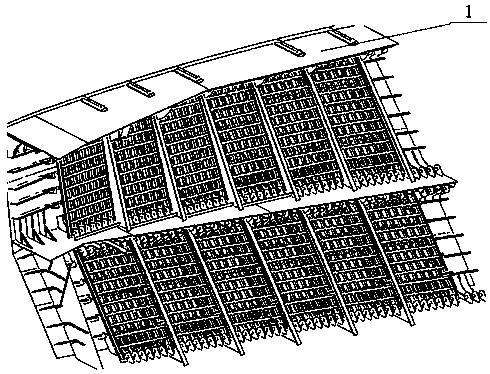

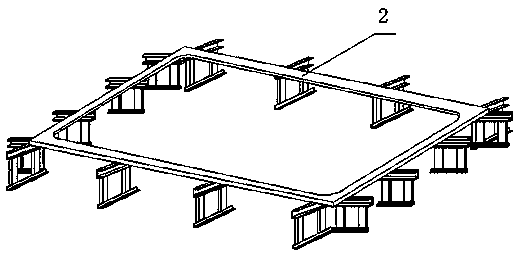

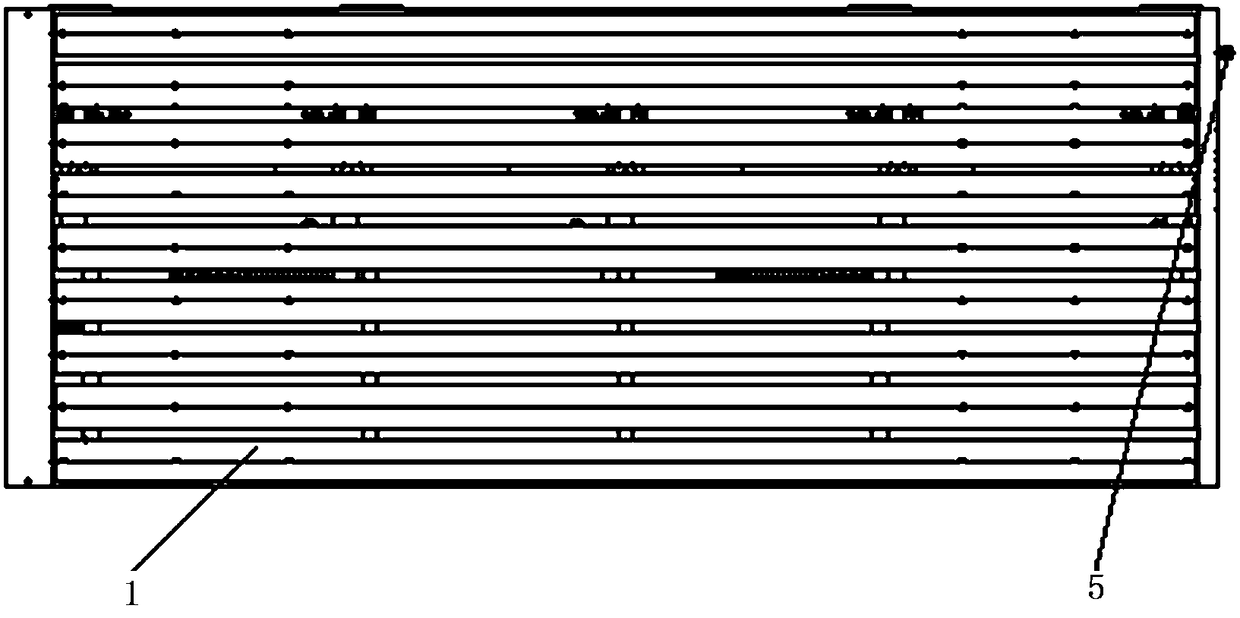

Pre-assembling process of grating plate on subsection

The invention relates to a pre-assembling process of a grating plate on a subsection. The pre-assembling process comprises the following steps: S1, manufacturing a jig frame; S2, assembling and welding a board segment structure; S3, splicing and drilling the grating plates; S4, pre-hoisting the grating plate on the segmented broadside segments; S5, conducting side segment fire work back burning, weld joint flaw detection and coating; and S6, installing the grating plate. Through the construction process, the grating plate and the grating base plate are connected through fasteners such as bolts, and the technical problems that the grating plate is hoisted into the shipboard segment, the installation space is small, the hoisting difficulty is large, the included angle of a shipboard segmentframework is small, welding is difficult in a narrow space, the shipboard framework is dense, and coating cannot be conducted after segment construction in a local area is completed are solved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

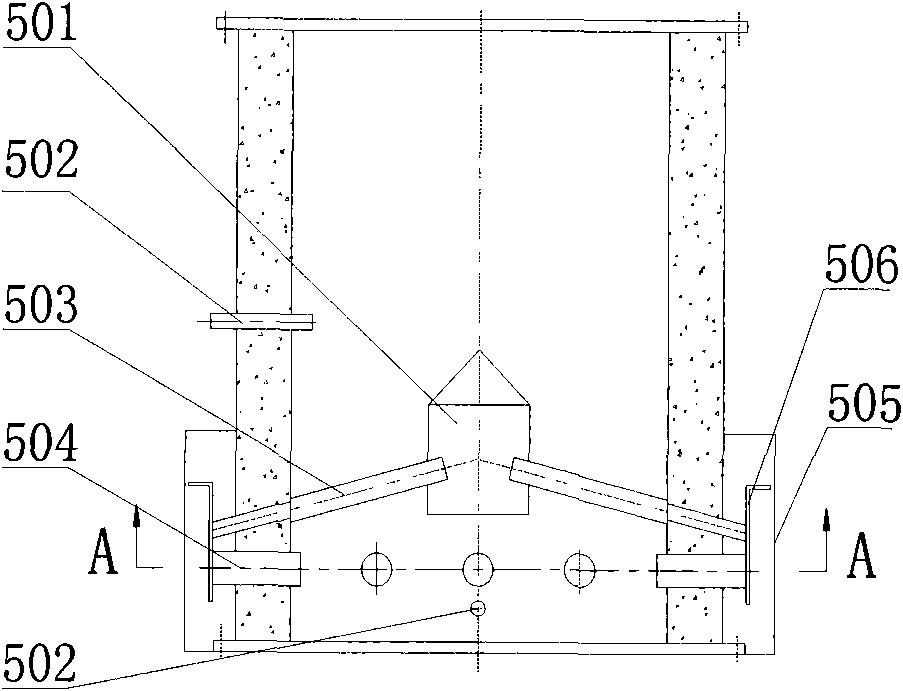

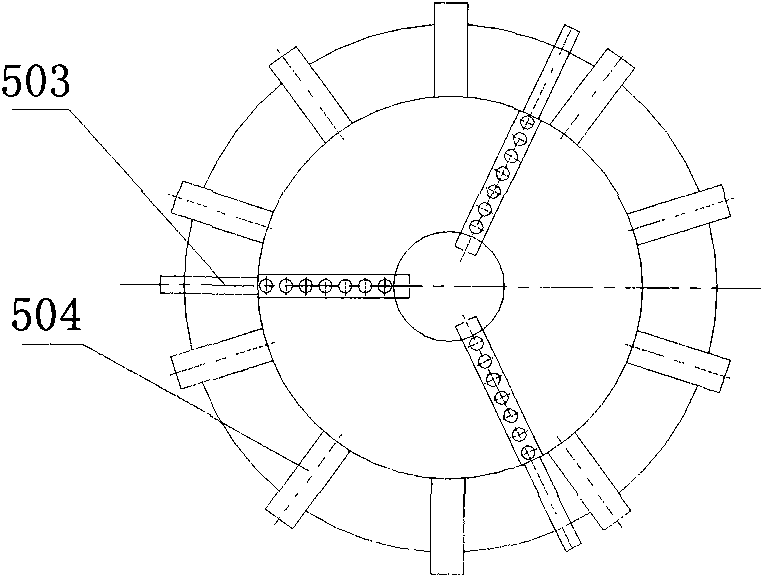

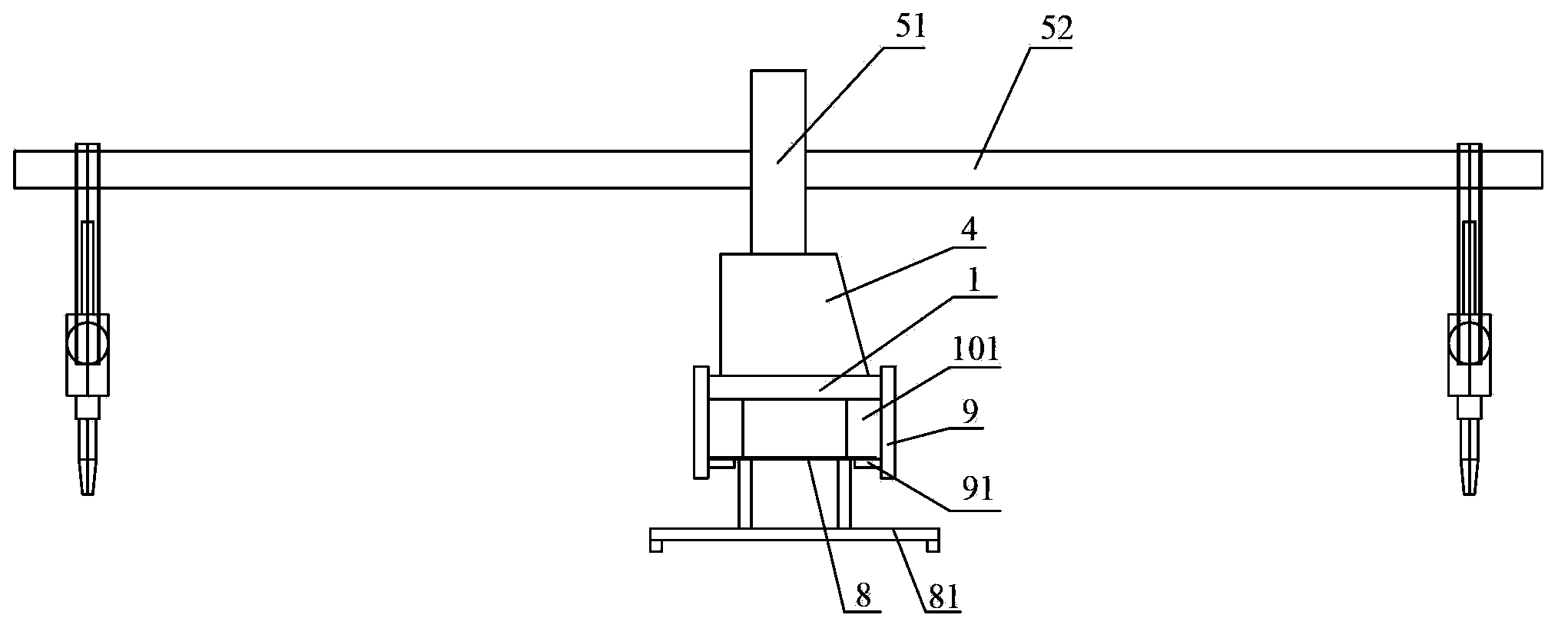

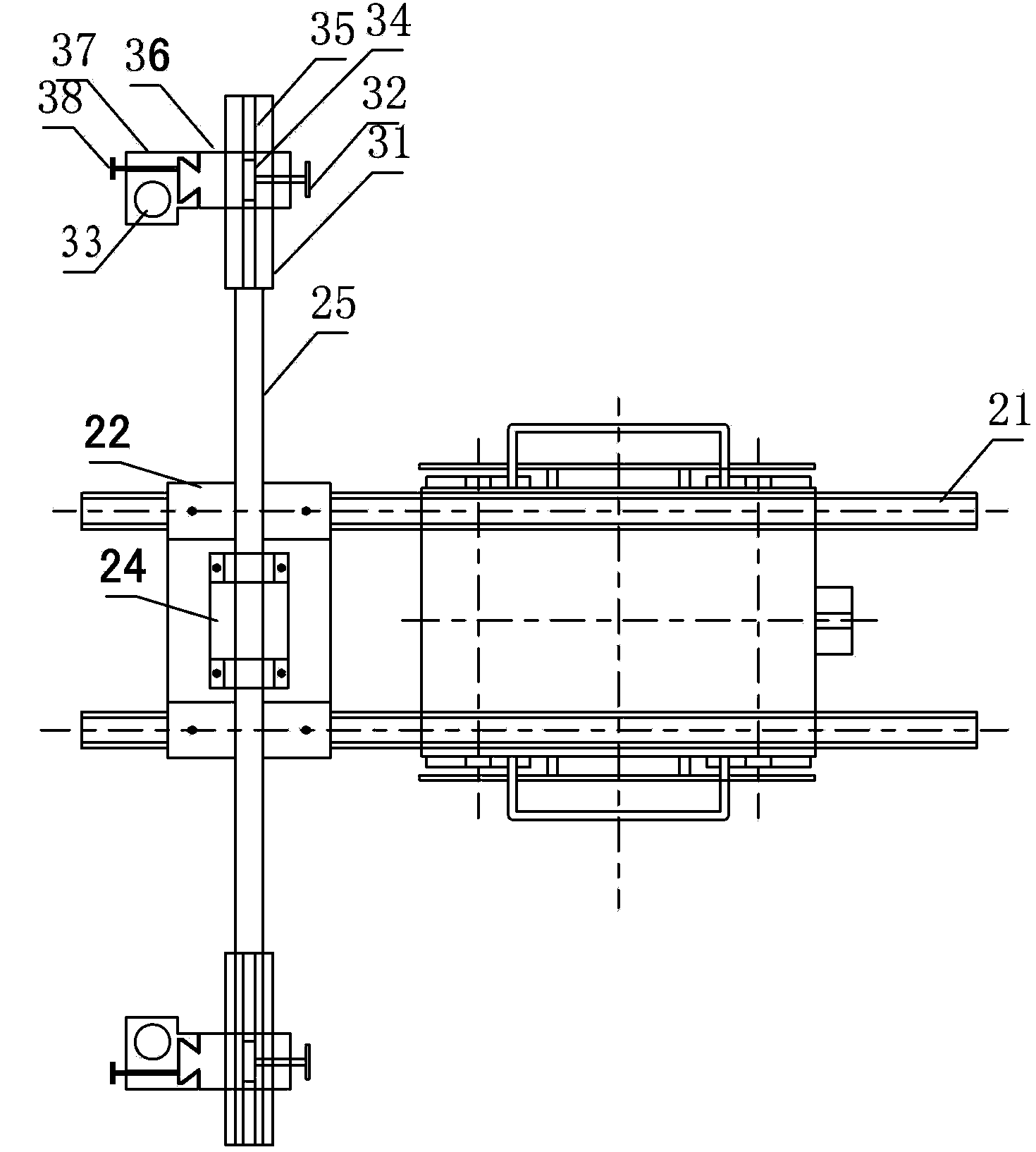

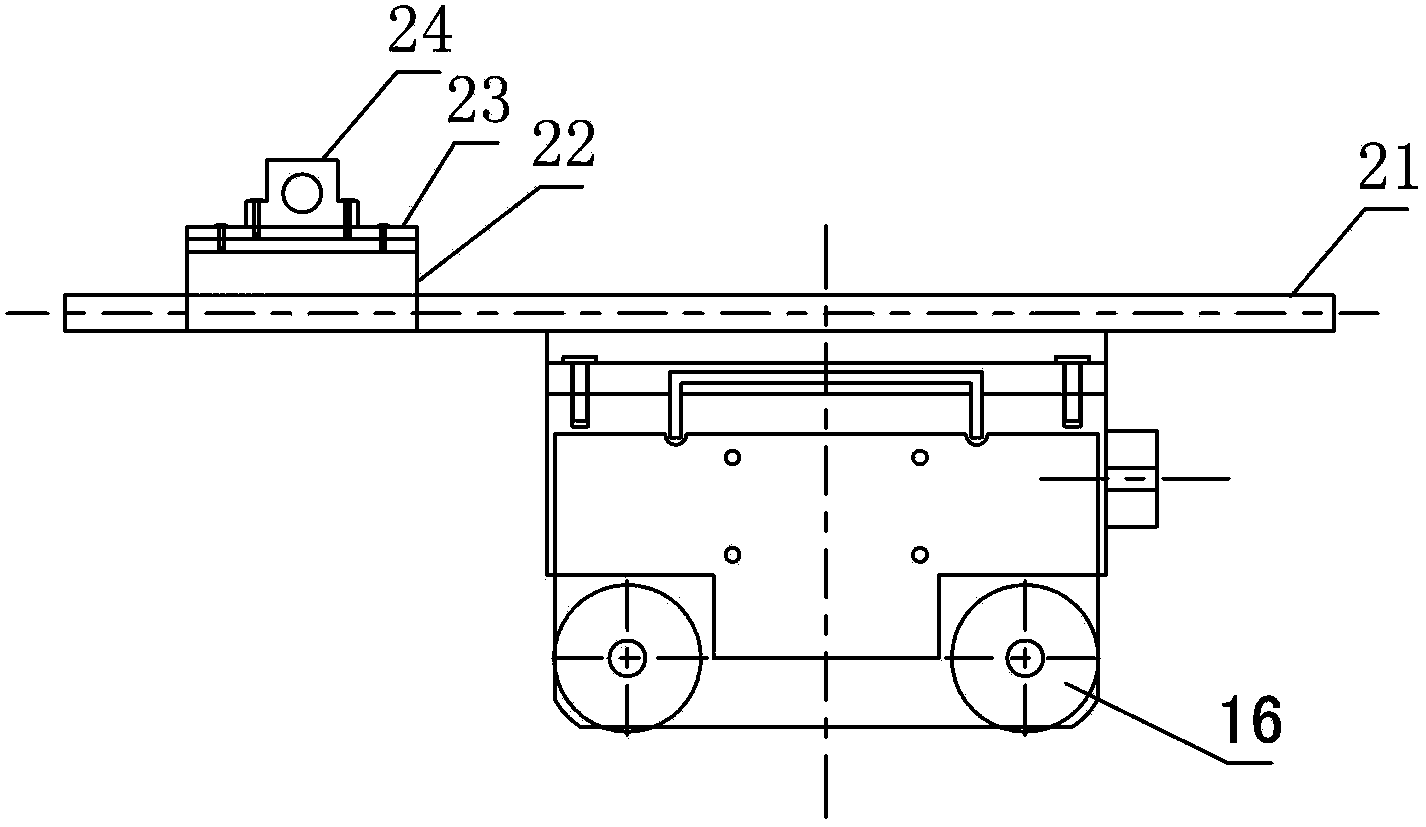

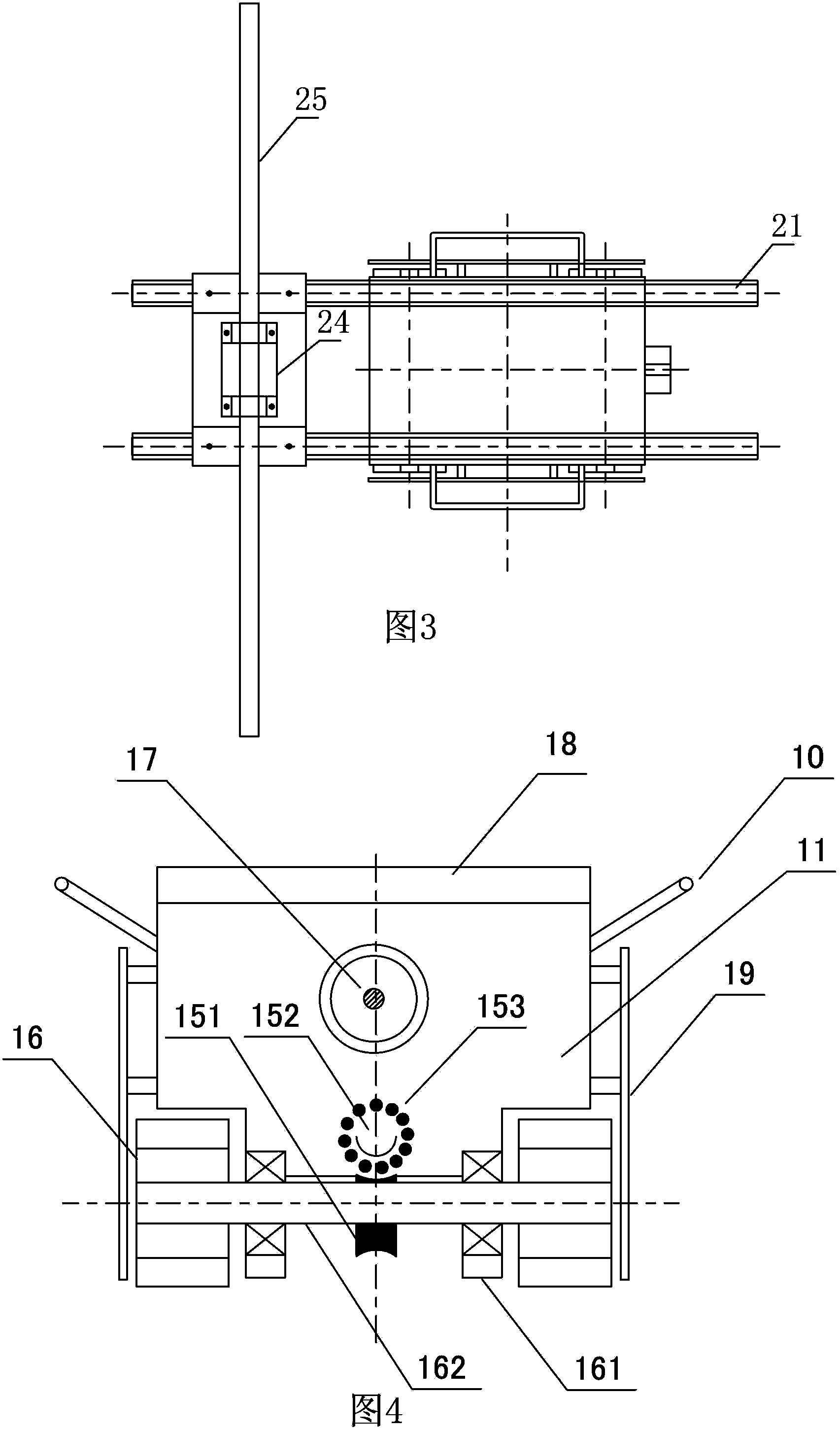

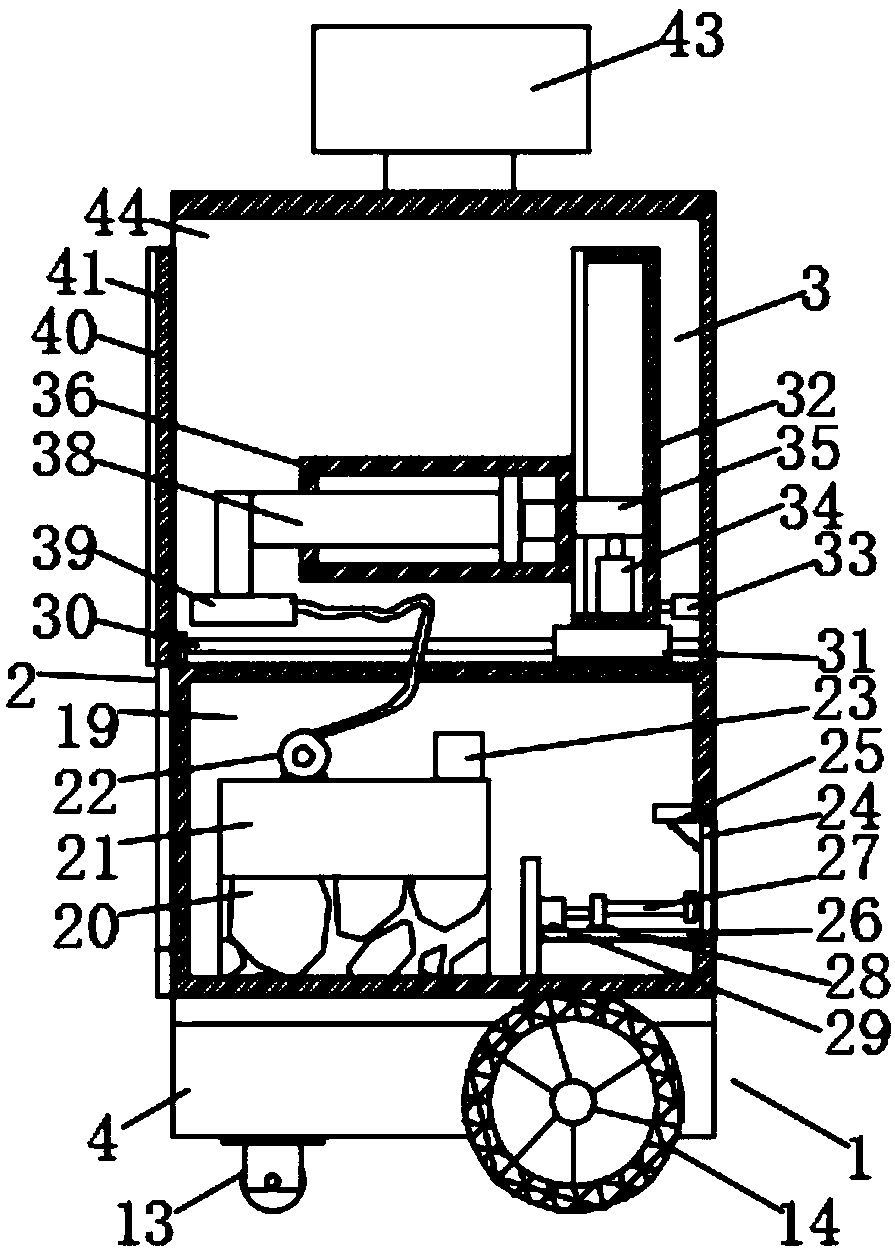

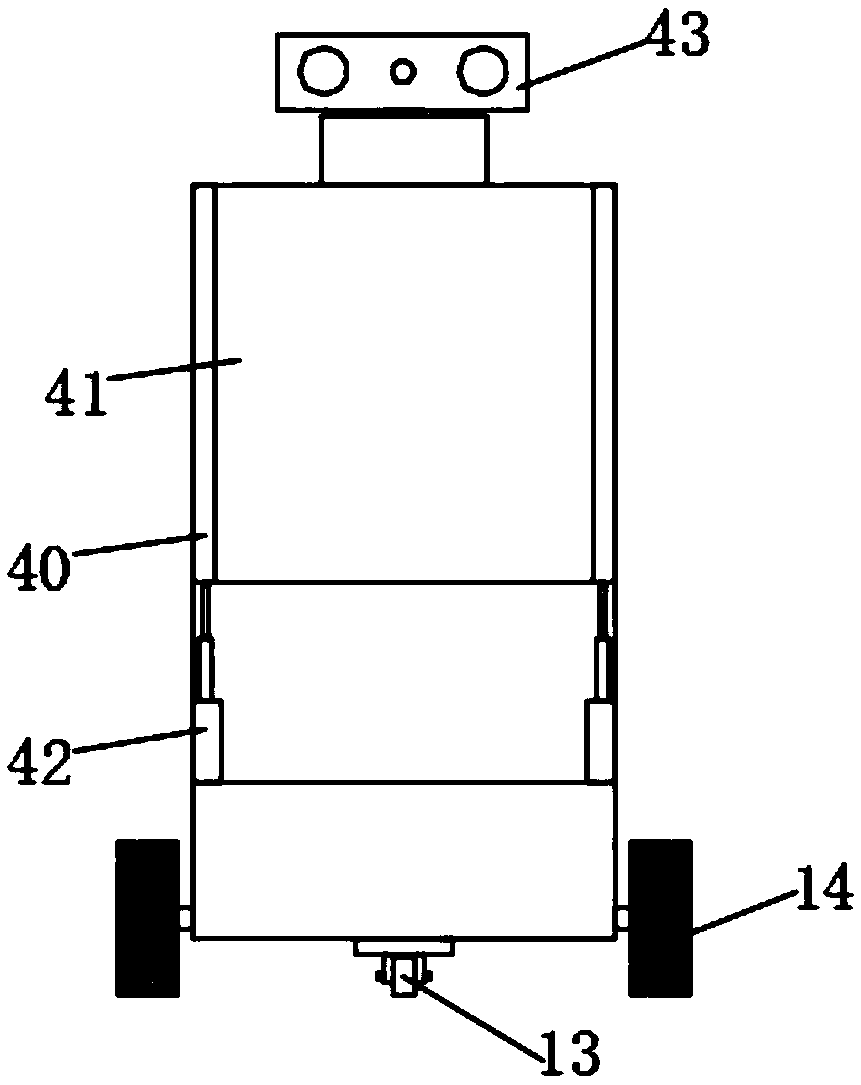

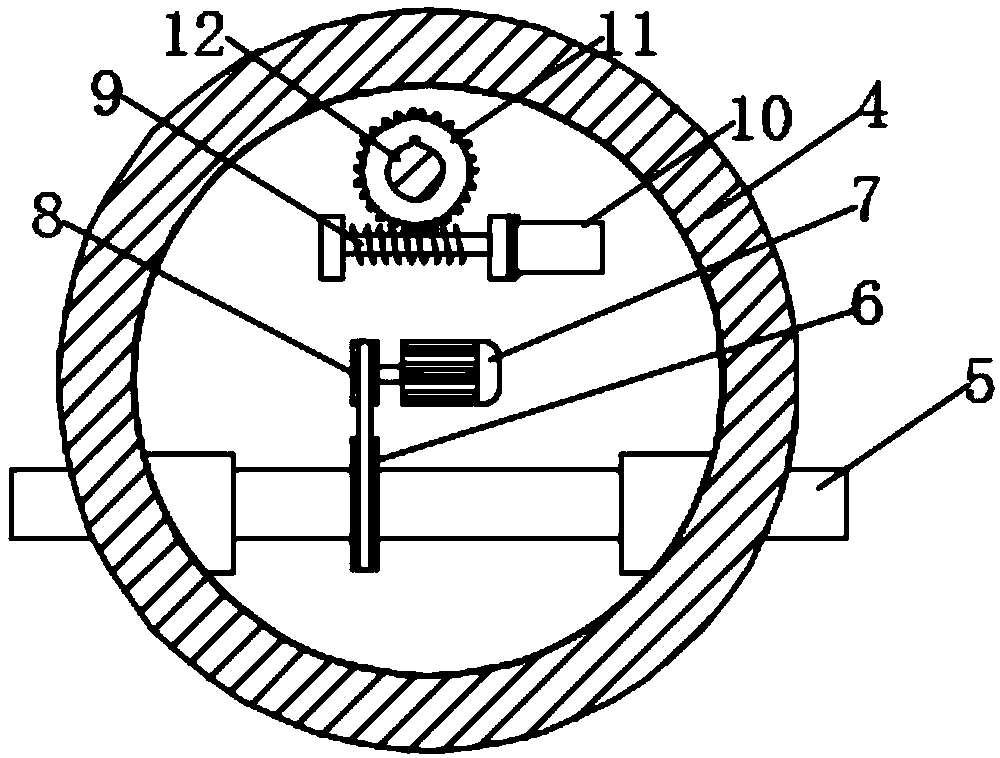

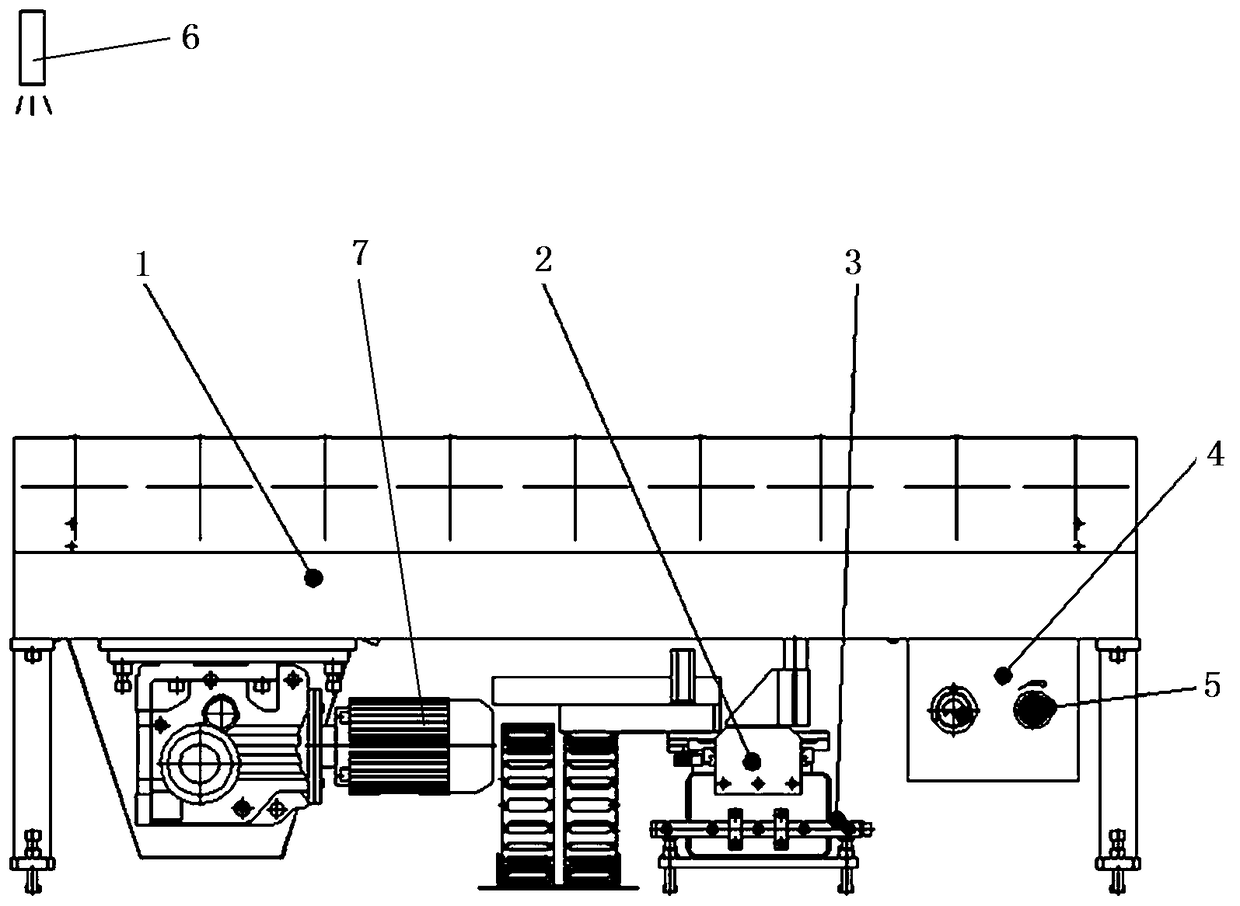

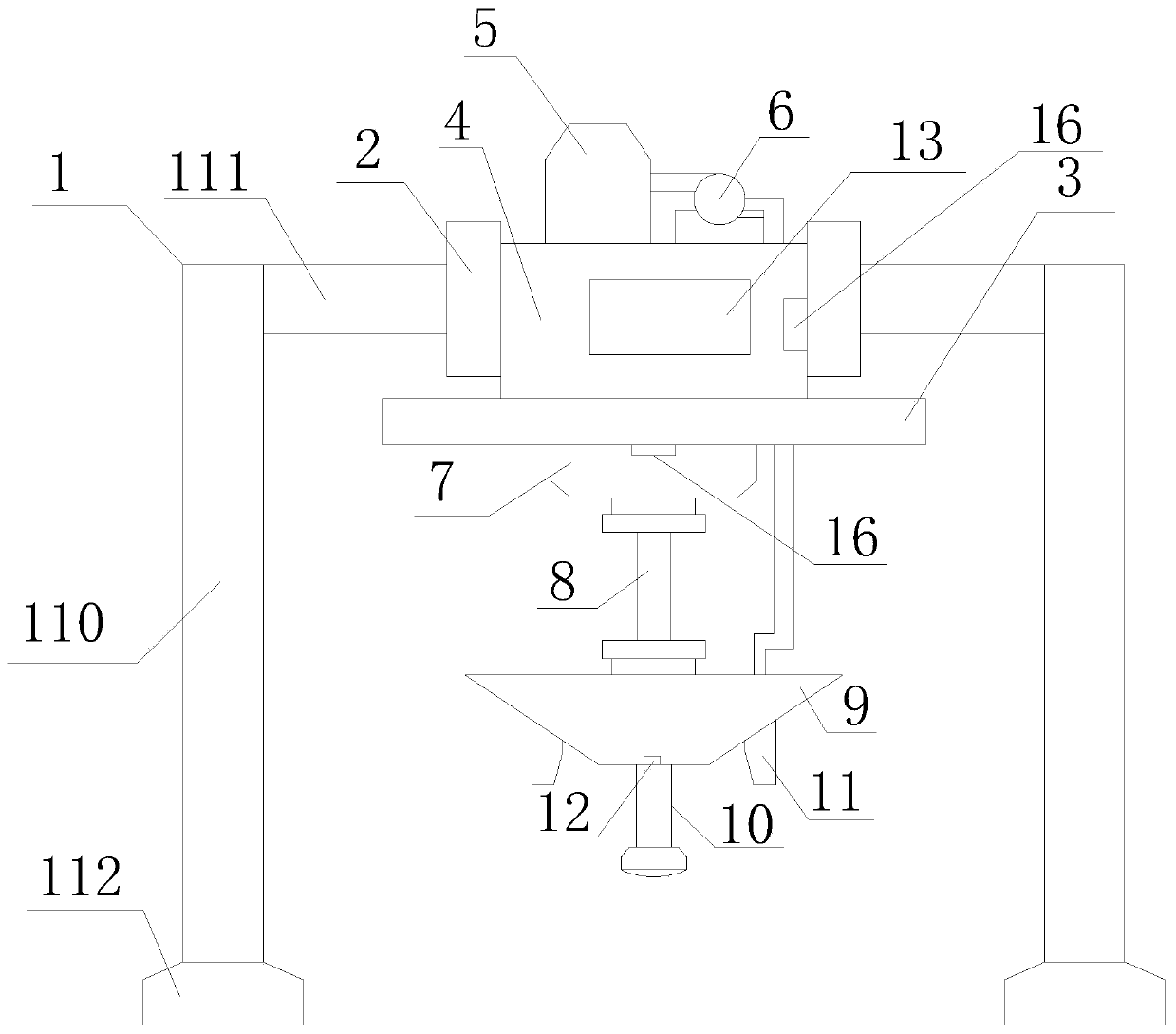

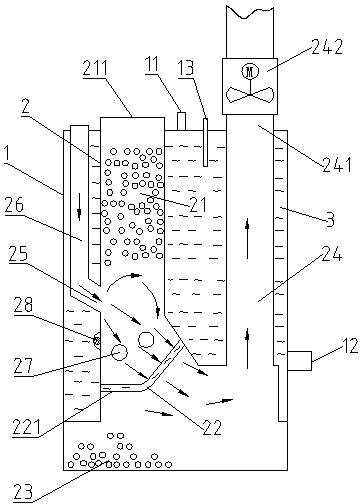

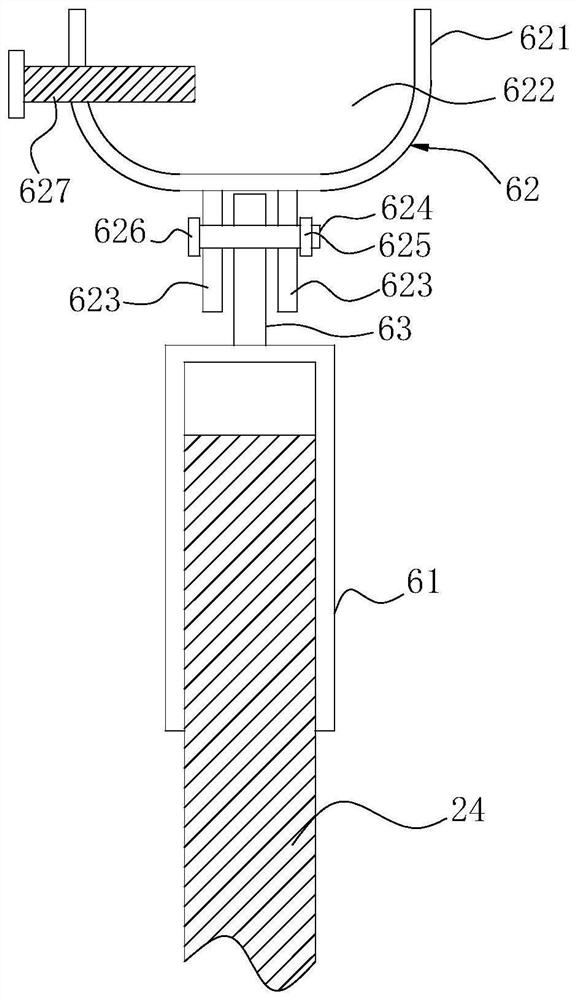

Shipbuilding track-free back burning machine

InactiveCN103509918AImprove work efficiencyReduce work intensityFurnace typesHeat treatment furnacesDrive wheelEngineering

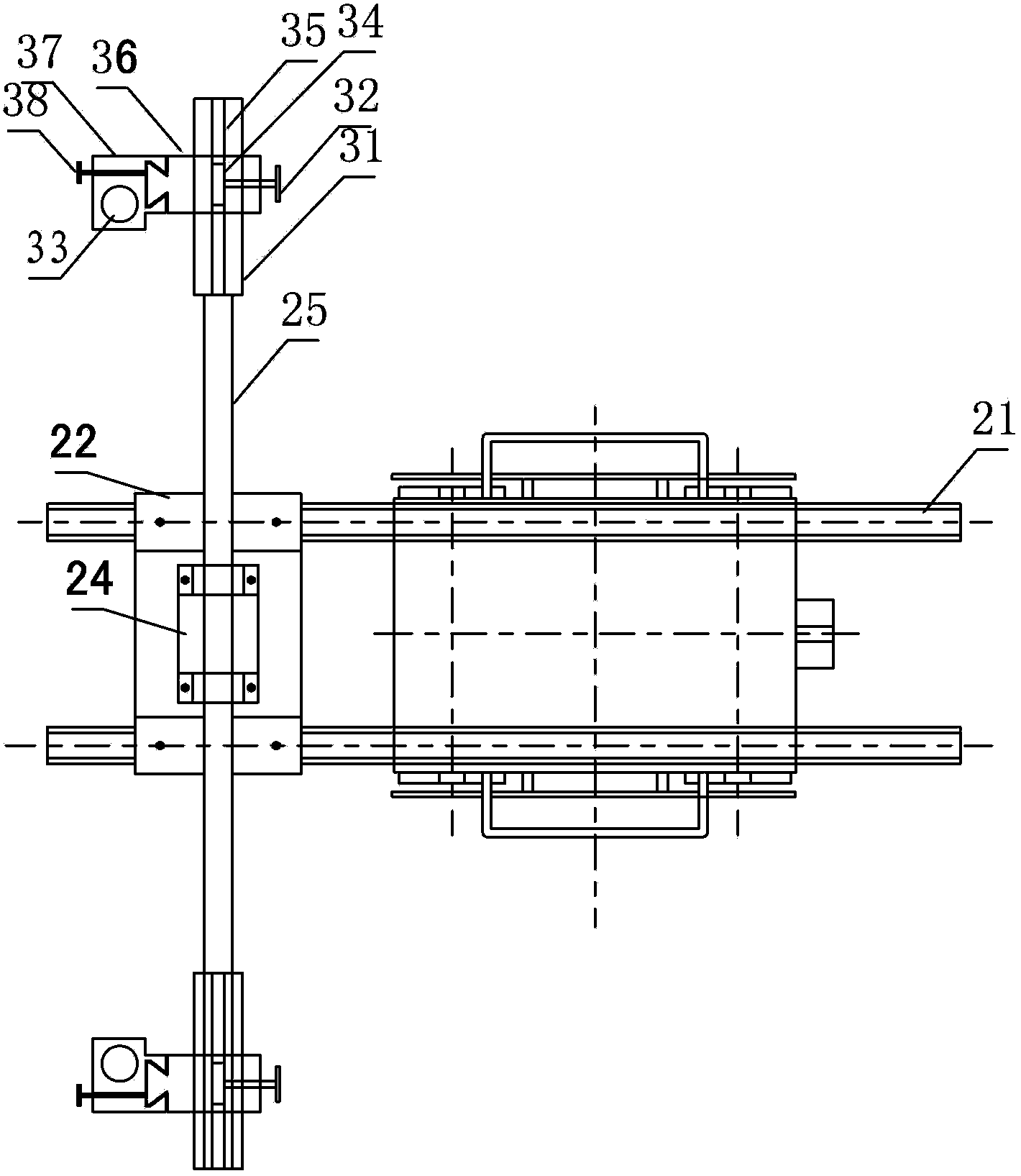

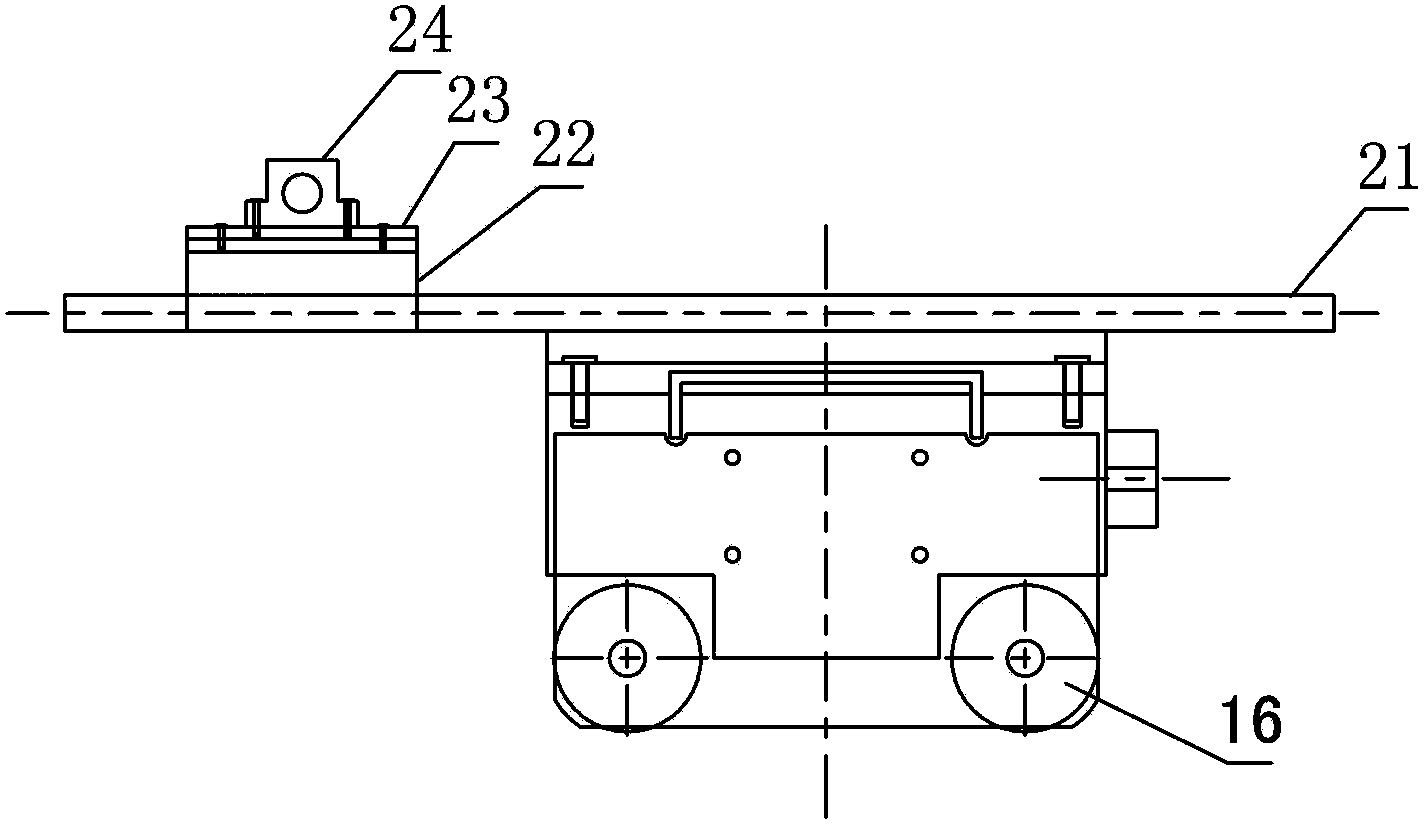

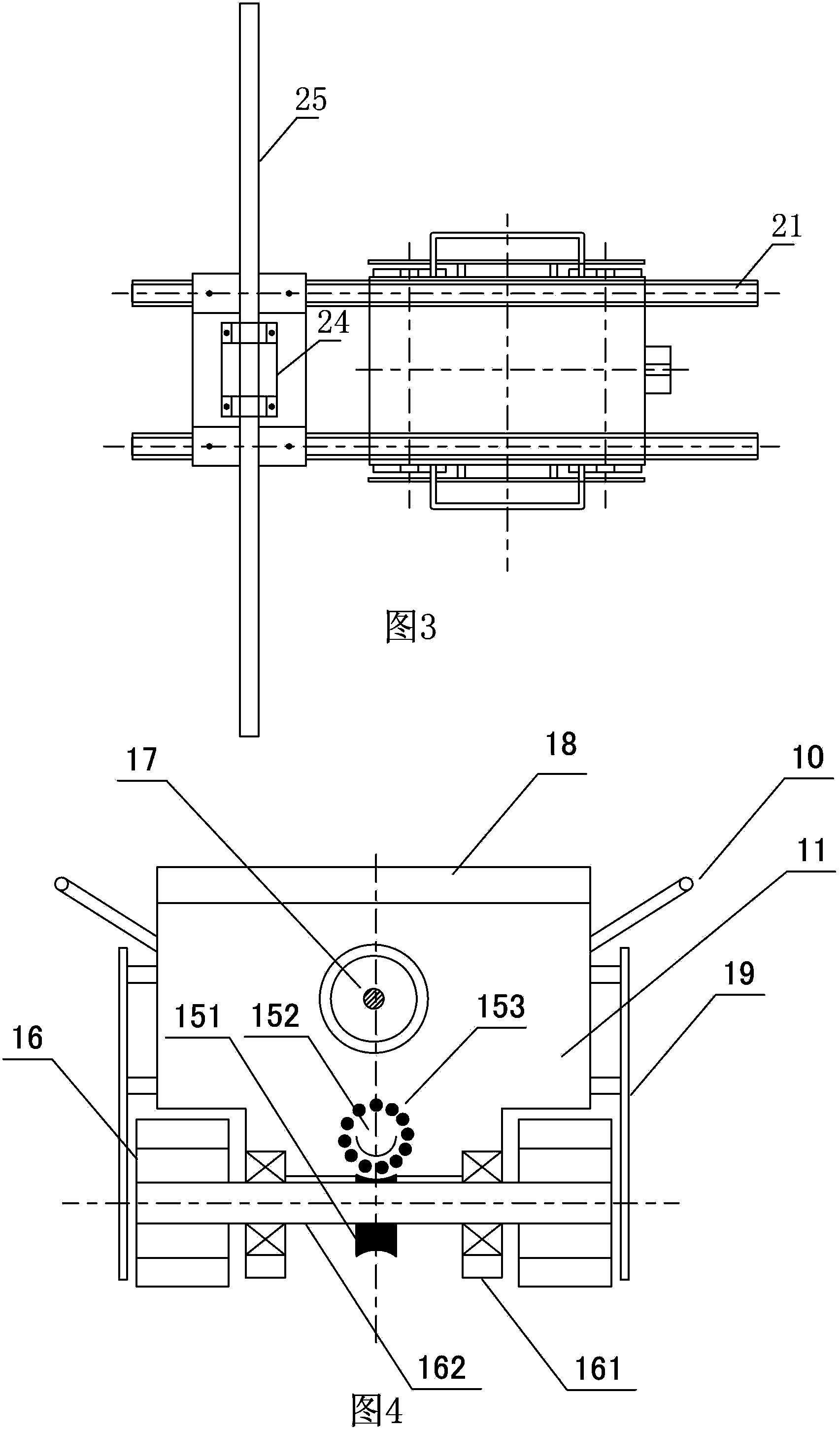

The invention discloses a shipbuilding track-free back burning machine, which includes a machine body (11) equipped with permanent magnetic driving wheels (16) at the bottom, a motor and a transmission mechanism driving the driving wheels in the machine body, and roasting torches that are fixed on the machine body and utilize a pipeline to connect a fuel gas source. The shipbuilding track-free back burning machine provided in the invention can efficiently and automatically realize back burning in a ship steel structure construction process, meets the needs of ship production, improves the back burning quality and efficiency, and is more conducive to improving the building accuracy of the ship steel structure. Specifically, by setting a roasting torch longitudinal and transverse adjustment unit, the use range of the equipment provided by the invention is broadened. At the same time, two roast torches are arranged in the same equipment, and realize simultaneous work, thus improving the work efficiency. The machine provided by the invention mainly aims to meet flame distortion rectification of shipbuilding, especially in areas needing workers to look up flame distortion rectification. The machine eliminates the welding internal stress, alleviates the labor intensity of workers, improves the working efficiency of workers, and enhances the shipbuilding accuracy and appearance.

Owner:大连理研船舶装备有限公司

Center back-burning vertical type three-pass gas-fired boiler

Owner:ZHENGZHOU UNIV

Intelligent robot that can return to charge

ActiveCN108972588AEasy to moveEasy to self-applyMedical atomisersManipulatorSteering wheelBack burns

Owner:付小芹

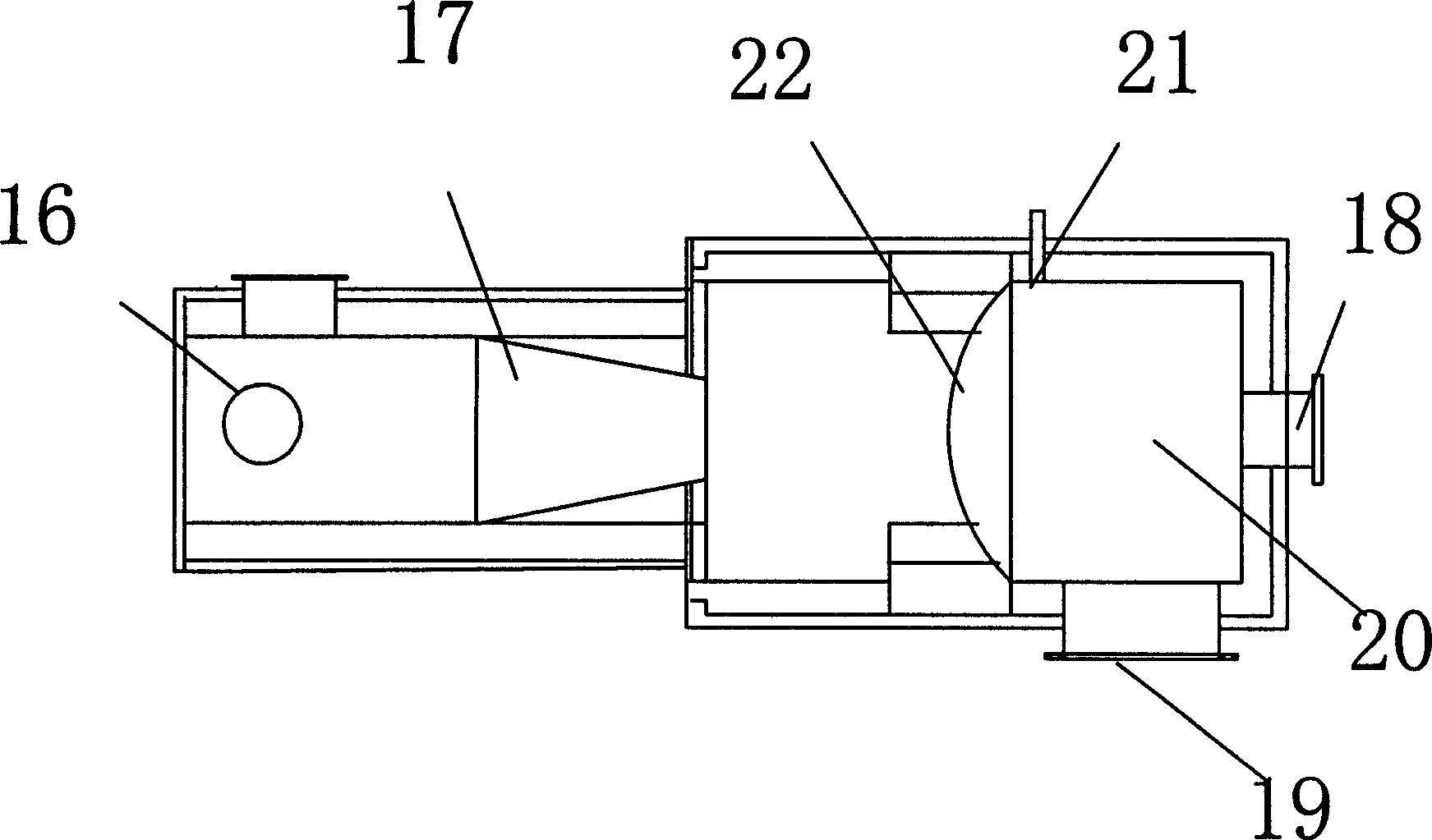

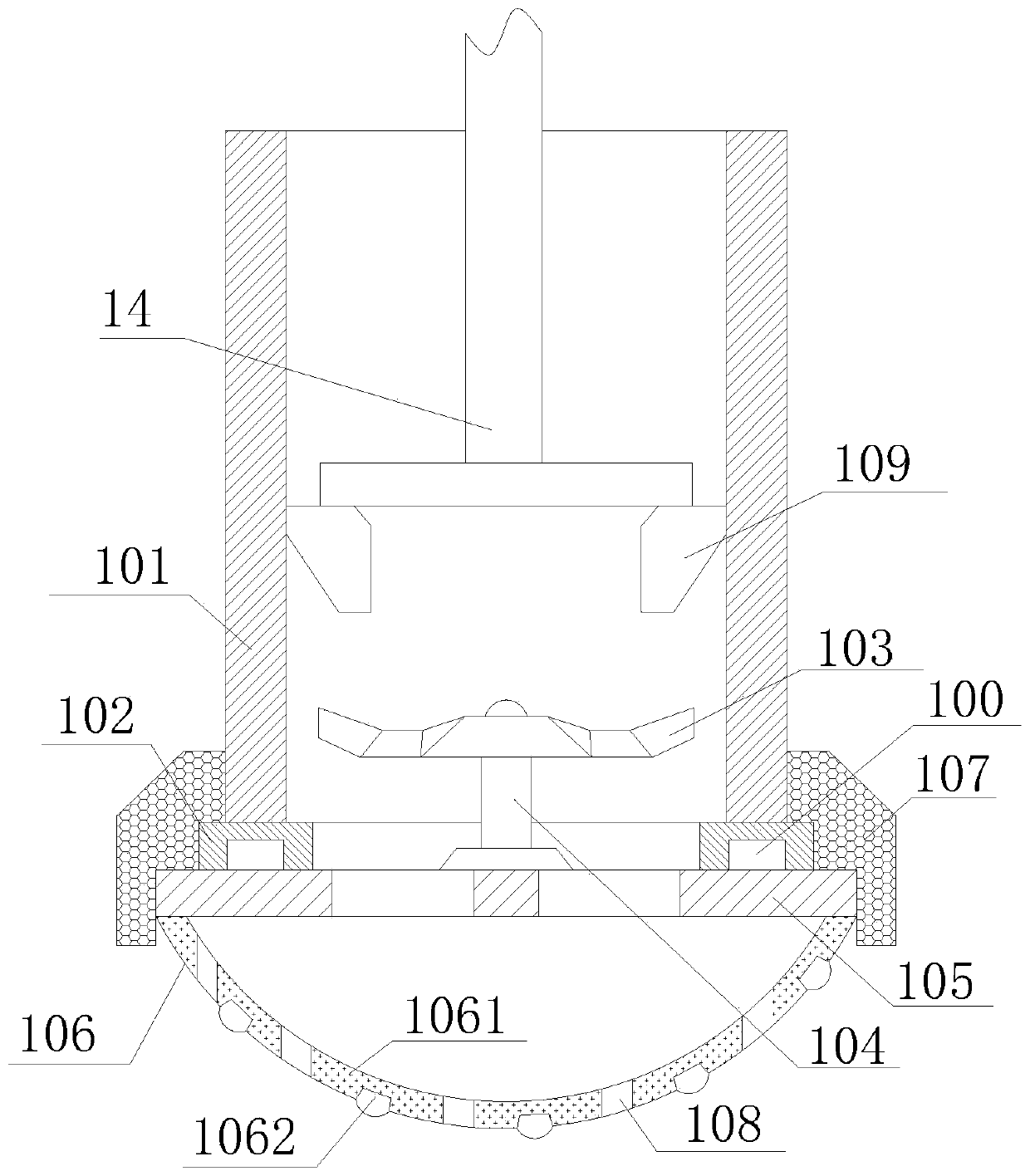

Backfire preventing device for hydrogen oxygen generator

InactiveCN104279566AEffective barrierEffective connectivityBurner safety arrangementsGaseous fuel burnerHydrogenProduct gas

The invention relates to the field of energy, in particular to a backfire preventing device for a hydrogen oxygen generator. The backfire preventing device for the hydrogen oxygen generator comprises a tank body; an isolation pipe is arranged in a cavity of the tank body, so the cavity of the tank body is partitioned into an isolation cavity positioned in the isolation pipe and an outer cavity; a suspension pipe of which the lower section is suspended in the isolation cavity is arranged at the upper part of the tank body; the upper section of the suspension pipe is provided with an air outlet exposed out of the outer part of the tank body; an air inlet communicated to the outer cavity is formed in the bottom end of the tank body. When a backfire occurs to a use end, the backfire preventing device can ensure the effective isolation of back burning flame from gas generated by the hydrogen oxygen generator, and the backfire preventing effect is improved.

Owner:北京首位能源科技有限公司

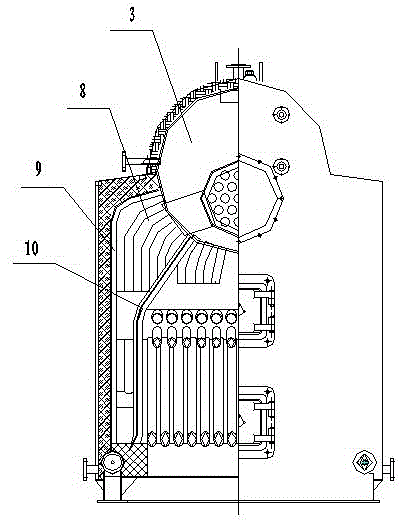

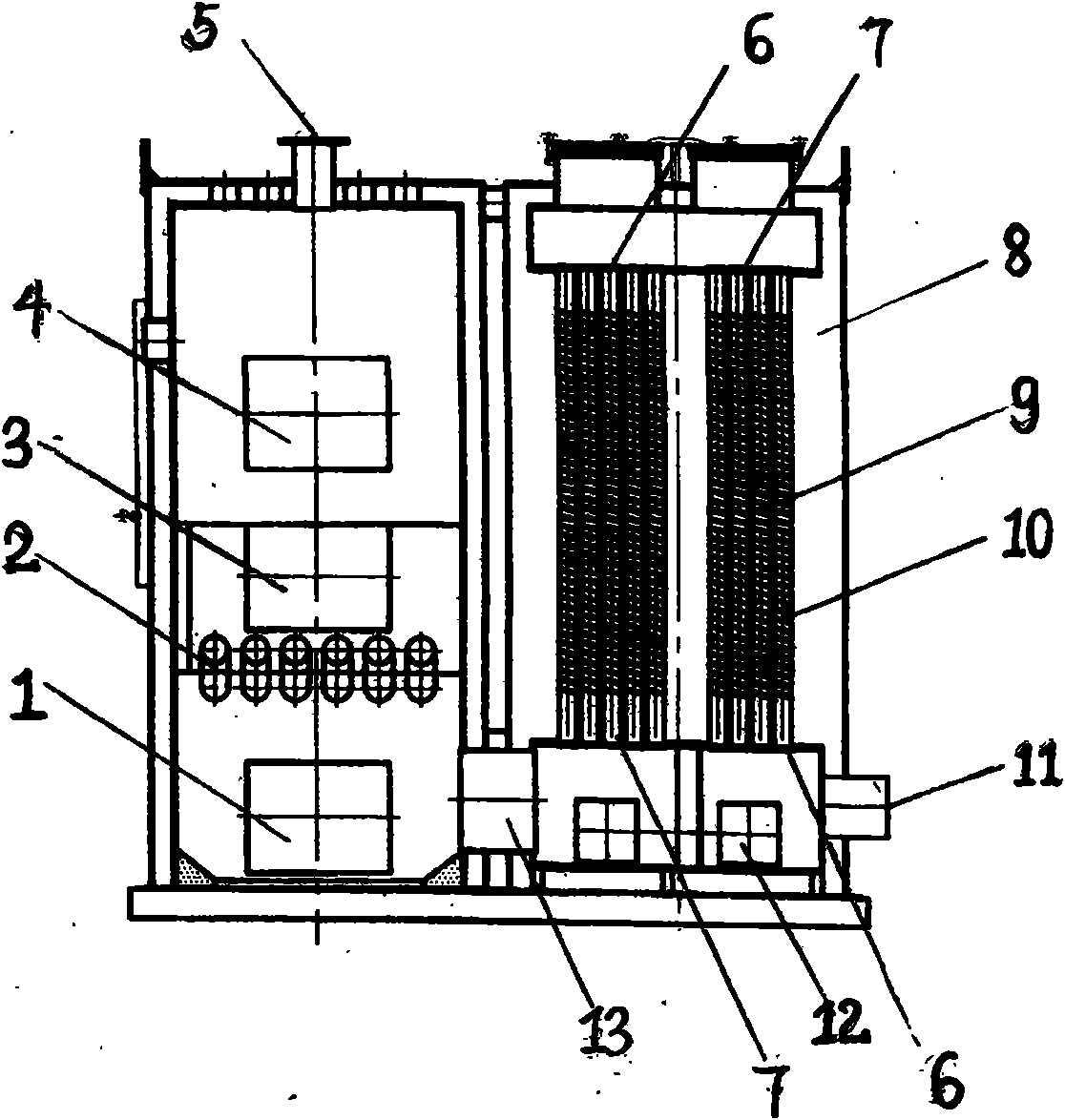

Double layer back burning radiation jet flow hot pipe air heating furnace

The present invention relates to a double-layer back-combustion radiation jet heat-pipe hot-air furnace. It is a high-effective high-temp, novel hot-air indirectly-heating hot-air furnace which is made up by using heat-pipe heat-exchanger with high efficiency and small flow resistance and high-temp, radiation jet impact heat-exchanger with double-layer back-combustion furnace cavity by means of back flame path series-connection. Said invention also provides its concrete structure, its hot-air temperature can be up to 200-500deg.C and its heat efficiency can be up to about 85%.

Owner:吴江市普天热管技术推广应用研究所

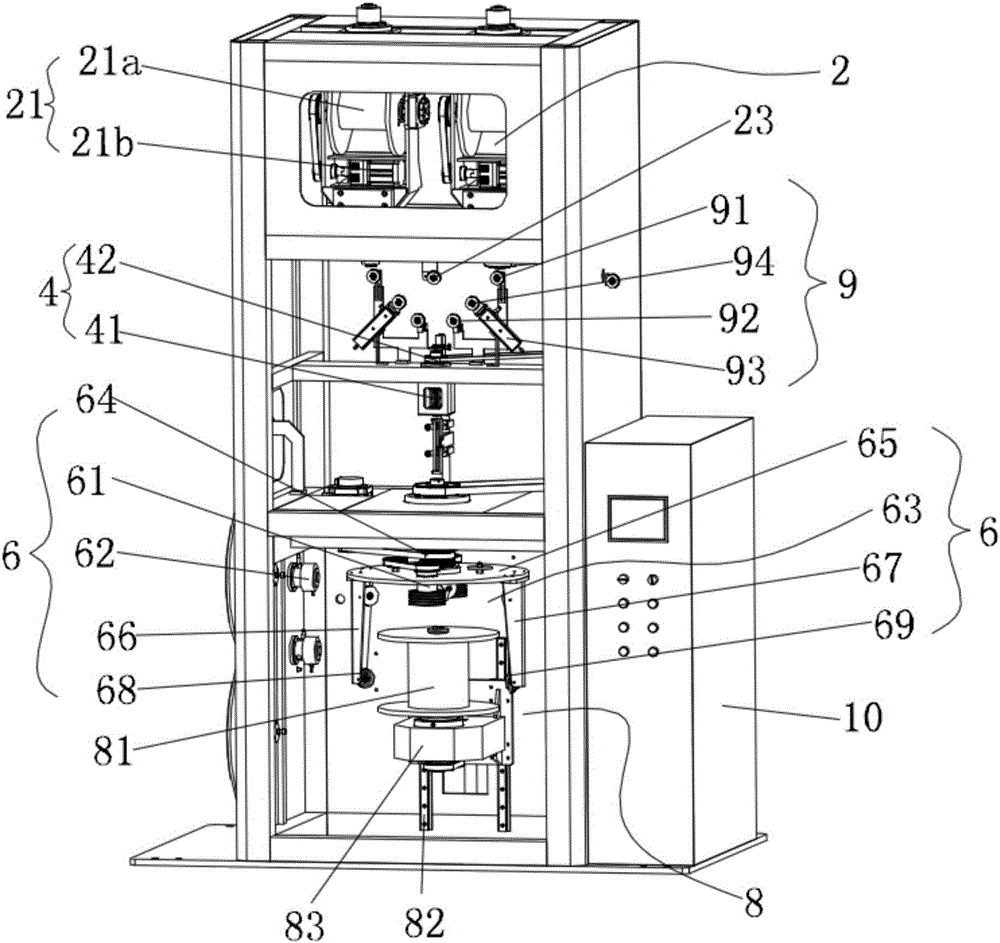

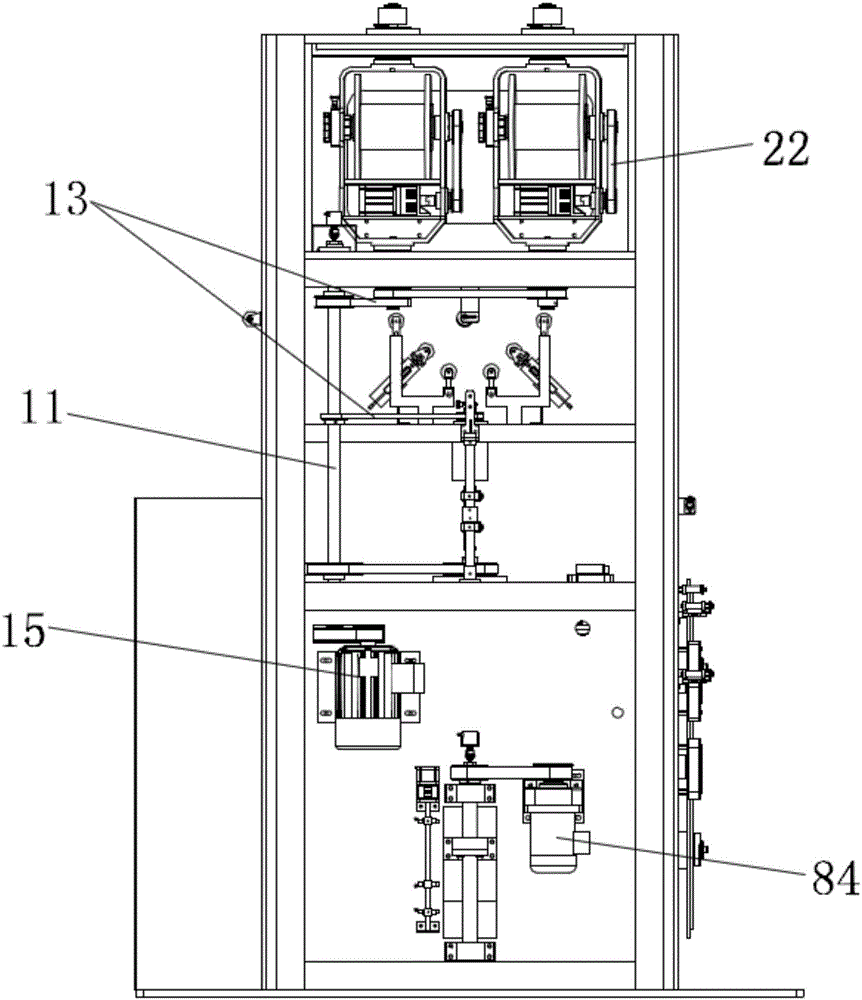

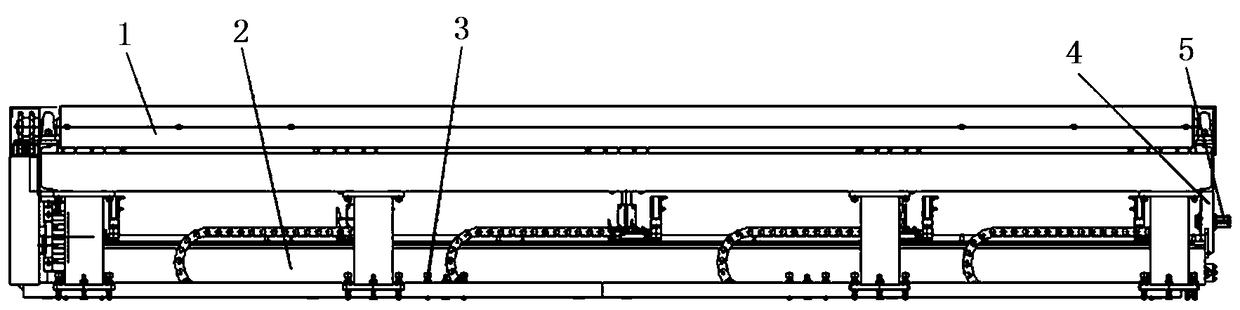

Vertical back burning single twist machine

ActiveCN106057372ACompact structureSmall footprintCable/conductor manufactureElectrical conductorCrystal structure

The invention provides a vertical back burning single twist machine which is a vertical standing machine and comprises a back burning back twist device, a pre-twist device, a lead leading device and a wire retreating device which are arranged in the vertical standing machine from the top to the bottom in turn. The back burning back twist device, comprises a back scroll and a first rotator. The pre-twist device comprises a wire twist module group and a second rotator. The lead leading device comprises a first shaft, a second shaft, a cantilever component and a third rotator. The first rotator, the second rotator and the third rotator synchronously rotate through a spindle and a transmission system. According to the vertical back burning single twist machine, arrangement of the vertical standing machine is adopted, configuration of all parts is optimized and then the structure is compact so that space occupation of the whole machine can be greatly reduced in comparison with the convenient horizontally arranged single twist machine, and relocation and installation are facilitated; meanwhile, the three rotators synchronously rotate so that signal core wires are enabled to be constantly in the tensioning state in the process of wire feeding and twisting without damaging the crystal structure of the conductor surface, and thus transmission loss and delay difference of the cabled wires can be reduced.

Owner:SUZHOU CHAOLONG MACHINERY

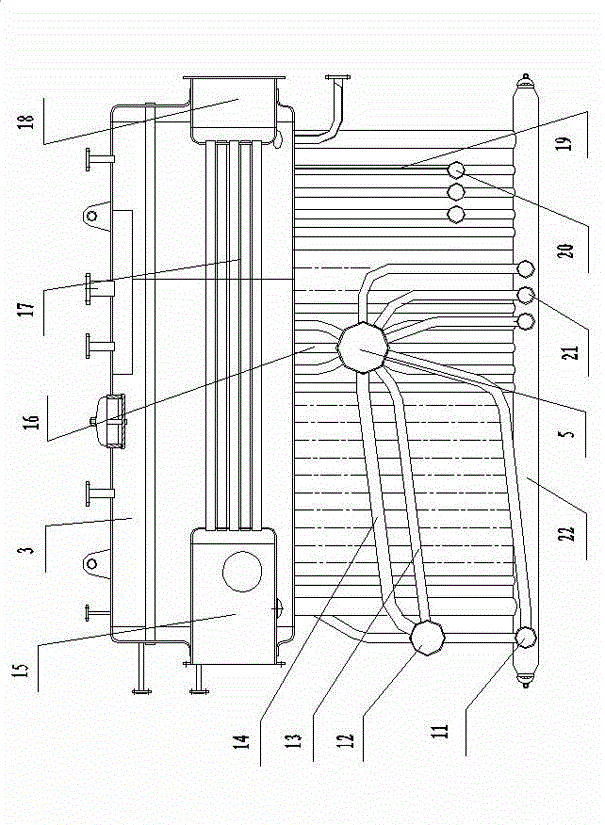

Longitudinally arranged type back-burning energy-saving single-drum horizontal type boiler

ActiveCN102944058AAccelerate evaporationFully absorbedWater-tube boilersWater heatersHearthEngineering

The invention discloses a longitudinally arranged type back-burning energy-saving single-drum horizontal type boiler. The boiler is provided with a boiler body, wherein the boiler body comprises an upper drum and a hearth; the upper drum is arranged on the top of the boiler body; two longitudinal collection boxes are arranged on the left side and the right side of the bottom of the boiler body; the upper drum is connected with the two longitudinal collection boxes through an outer pipe wall; a middle transverse collection box is arranged below the middle of the upper drum; the hearth is arranged between the middle transverse collection box and the front end of the boiler body; the hearth comprises an inner pipe wall, an upper fire grate and a lower fire grate which are arranged between the upper drum and the two longitudinal collection box; smoke passes through the upper hearth and the upper fire grate and reaches the lower hearth to form a smoke first returning channel; a smoke second returning channel is formed between the inner pipe wall and the outer pipe wall; and a plurality of heat exchange pipes are arranged between a front smoke chamber and a rear smoke chamber in the upper drum to form a smoke third returning channel. A back-burning mode of a multi-layer fire grate pipe structure is adopted; a fireproof material wall is not arranged in the hearth, so that the radiation heated surface arranged in the hearth space is used to the maximum extent; the weight of the boiler body is reduced; and the production efficiency is improved.

Owner:仲伟军

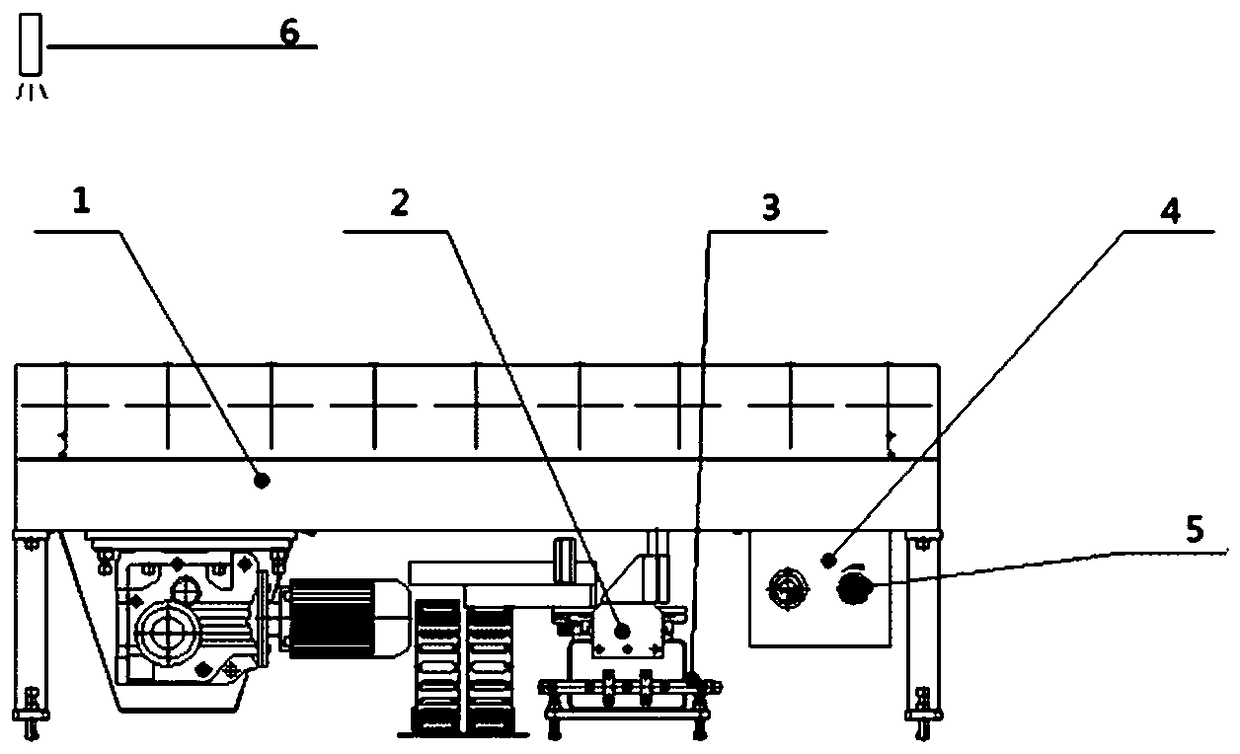

Group standing robot online automatic back-burning device and back-burning operation method

ActiveCN109333550AMobile location is accurateShorten the timeFurnace typesManipulatorSlide plateTorch

The invention relates to a group standing robot online automatic back-burning device, which comprises a conveying roller table mechanism, a plurality of back-burning flame mechanisms, an air source box, a flow separating line, a positioning sensor and an upper computer; the conveying roller table mechanism comprises a conveying roller table and a reduction motor, the conveying roller table is horizontally arranged, and the back-burning flame mechanisms are arranged below the conveying roller table mechanism; each back-burning flame mechanism comprises a base, a linear track and a power assembly are installed on the base, the linear tracks are in the horizontal direction and perpendicular to the conveying direction of the conveying roller table, linear track sliding blocks are installed onthe linear tracks, the power assemblies drive the linear track sliding blocks to move on the linear tracks, sliding plates are installed on the linear track sliding blocks, supporting fixing assemblies are installed on the sliding plates, and baking torches and ignition devices are installed on the supporting fixing assemblies. The invention further provides a back-burning operation method. The upper computer is used for controlling the back-burning flame mechanisms and the conveying roller table to work, thus a workpiece is moved accurately and the back-burning baking torches is moved accurately, the time of back burning operation is shortened and the efficiency of back burning operation is improved.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所)

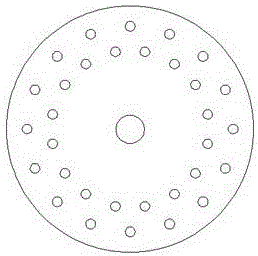

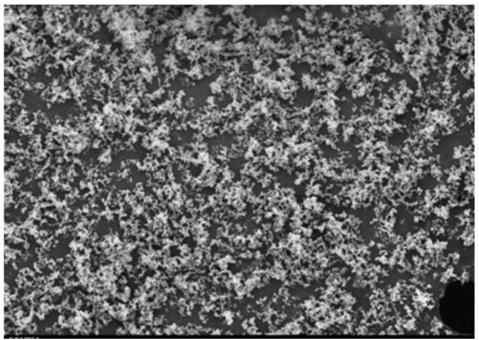

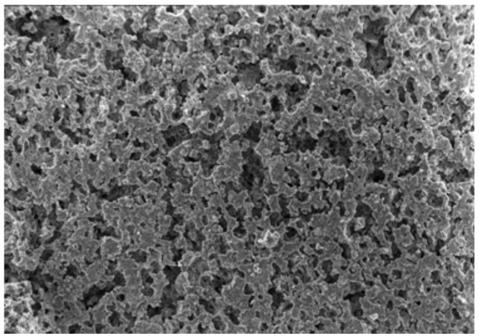

Method for preparing gasoline vehicle particle catcher by using fumed silica

The invention relates to the technical field of exhaust pollutant post-treatment of gasoline vehicles, and particularly relates to a method for preparing a low-pressure drop and low-expansion coefficient cordierite gasoline vehicle exhaust particle catcher by using fumed silica. The method comprises the following steps: (1) mixing inorganic raw materials by a dry method, and adding a binder; (2) kneading; (3) practicing; (4) extruding, microwaving and drying; (5) cutting and sintering; (6) punching holes, blocking the holes and then putting the holes into a kiln for back burning. The fumed silica material is adopted as the raw material catcher, the pore-forming effect is remarkable, and the micro-pore connectivity is good, so that the pressure drop and the thermal expansion coefficient ofthe catcher can be reduced; meanwhile, the fumed silica can replace common silica, thereby not only achieving the function of serving as an inorganic component, but also achieving the pore-forming effect and reducing the adding amount of the organic pore-forming agent; the use of the fumed silica not only can meet the use requirements, but also reduces the production cost and improves the production efficiency.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

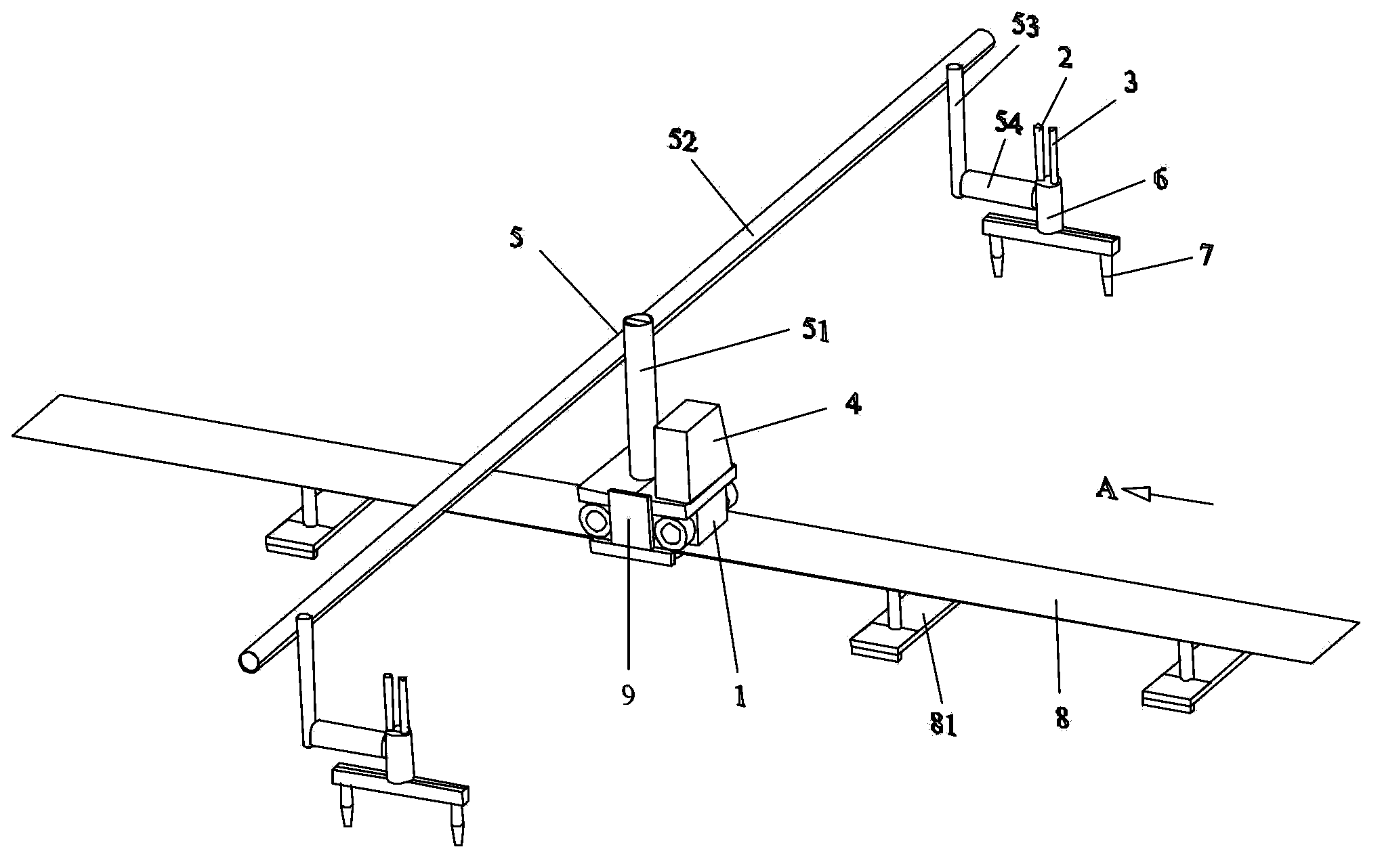

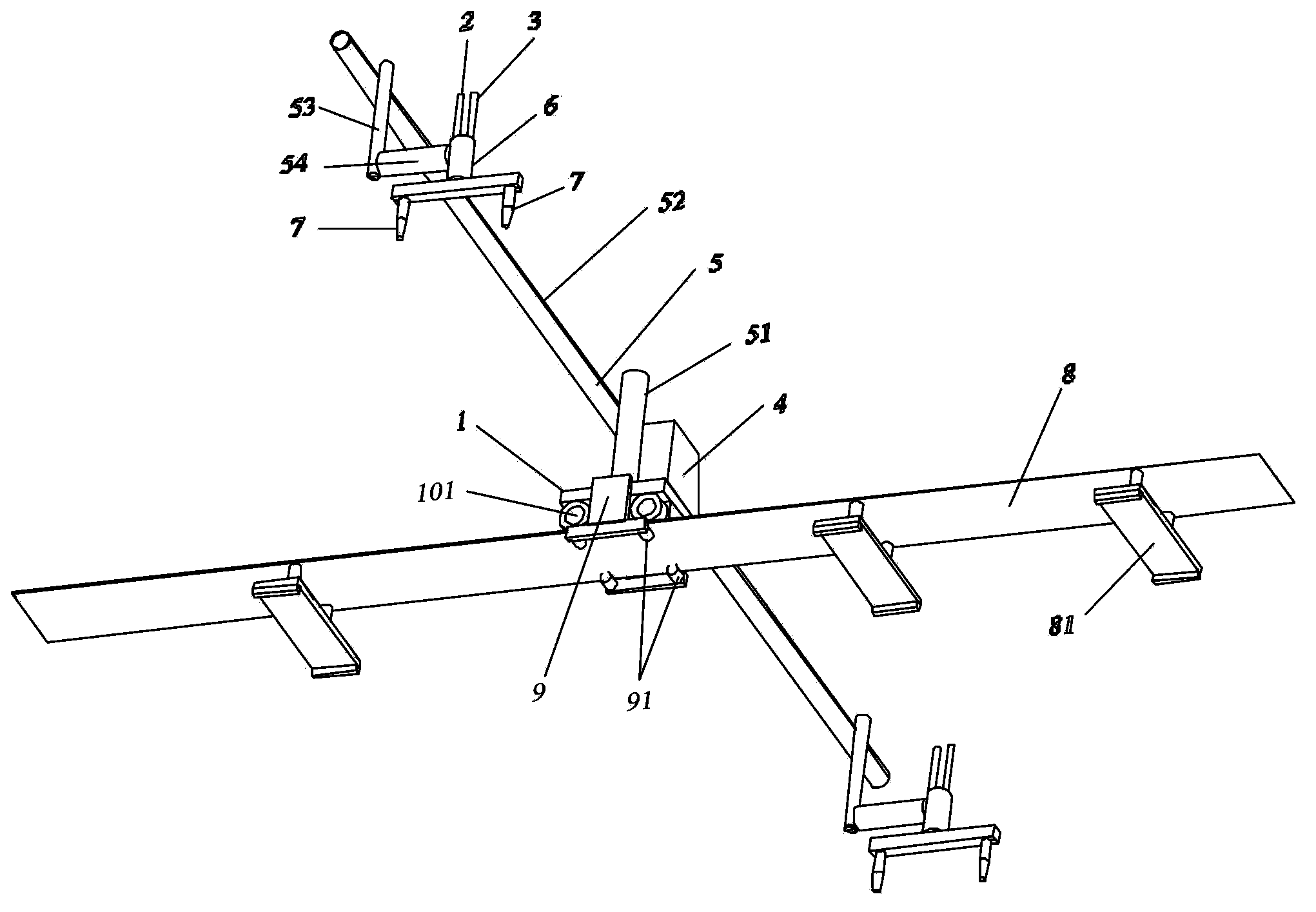

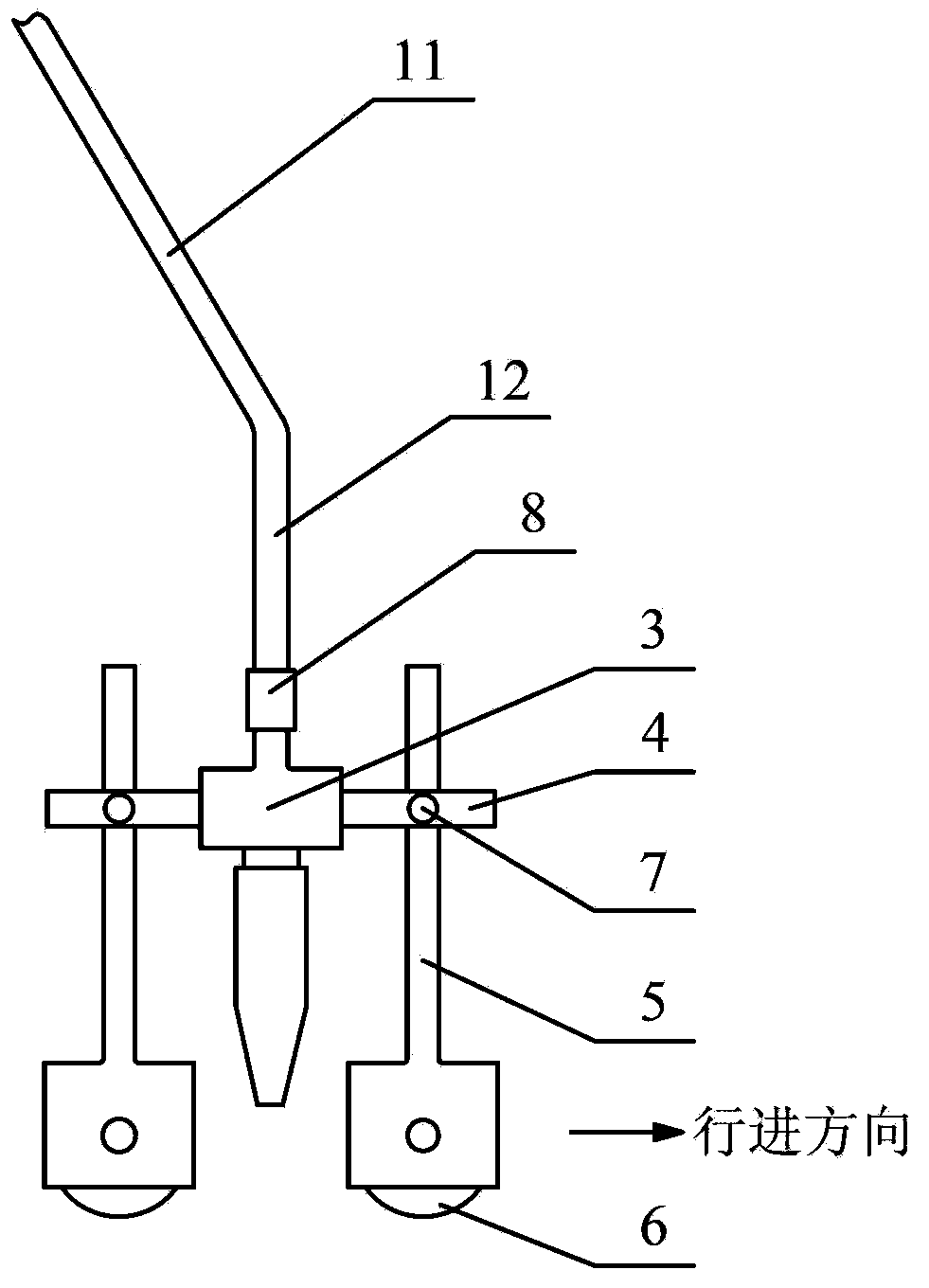

Manual double-spark plug fire work tap

ActiveCN103968380AReduce labor intensityEasy to adjustGaseous fuel burnerMixed flowArchitectural engineering

The invention provides a manual double-spark plug fire work tap, which comprises a handheld air intake pipe, a mixed flow pipe and two spark plugs, wherein the lower end of the handheld air intake pipe is communicated with the mixed flow pipe via a nut; the two spark plugs are fixedly connected under the mixed flow pipe; two connecting rods downwards extending are arranged at the two ends of the mixed flow pipe; one travelling wheel is fixedly installed at the lower end of each connecting rod; the connecting rods are rotationally connected with the mixed flow pipe and are fixed on the mixed flow pipe via locking devices. During actual operation, an operator regulates a distance between the two spark plugs in the direction of the axles of the travelling wheels via rotating the mixed flow pipe and the connecting rods according to different flame path widths, and further achieves fire work back burning. According to the manual double-spark plug fire work tap, the distance between the two spark plugs can be very conveniently regulated, and the whole structure is simple, as a result, filed construction environment is ameliorated, constructors' labor intensity is lowered, construction efficiency and the quality of back burning are effectively boosted, and further effects of energy economization, cost reduction and benefit increment are realized.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Medical surgery back burning scab polishing instrument

ActiveCN110432952ARelieve painSimple structureMedical applicatorsAbrasive surgical cuttersKeelEngineering

The invention provides a medical surgery back burning scab polishing instrument. The medical surgery back burning scab polishing instrument comprises a bearing keel, a main driving guide rail, an auxiliary driving guide rail, an operation platform, a medicament jar, a pressurizing pump, a sliding block, a lifting adjusting rod, a bearing foundation support, a cleaning head, a pressure sensor, a stroke sensor and a control circuit, wherein the main driving guide rail is embedded to the upper end surface of the bearing keel; the side surface of the operation platform is in sliding connection with the main driving guide rail; the medicament jar and the pressurizing pump are connected with the upper end surface of the operation platform; the auxiliary driving guide rail is arranged on the lower end surface of the operation platform, and is connected with the sliding block; the front end surface of the sliding block is hinged to the lifting adjusting rod; the lifting adjusting rod is hingedto the rear end surface of the bearing foundation support; and the cleaning head is connected with the lower end surface of the bearing foundation support. Through the adoption of the medical surgeryback burning scab polishing instrument disclosed by the invention, the requirements for performing the operation of polishing and cleaning scabs on a burn wound of patients of different burning illness states and different physical structure characteristics can be effectively met; besides, the efficiency and the control accuracy of wound cleaning operation are high; and besides, the power outputof the cleaning operation is flexible in regulation and mild.

Owner:昆明医科大学第二附属医院

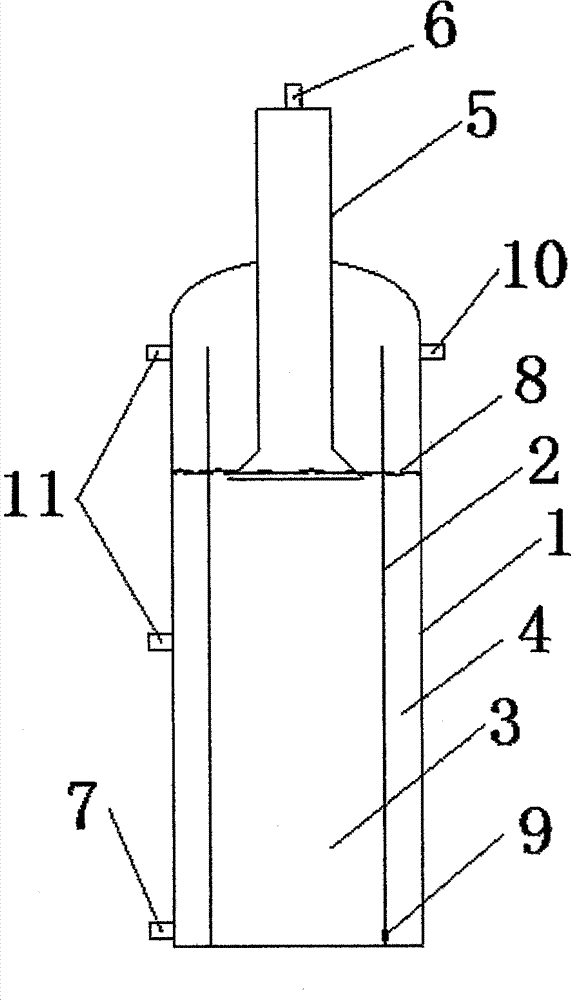

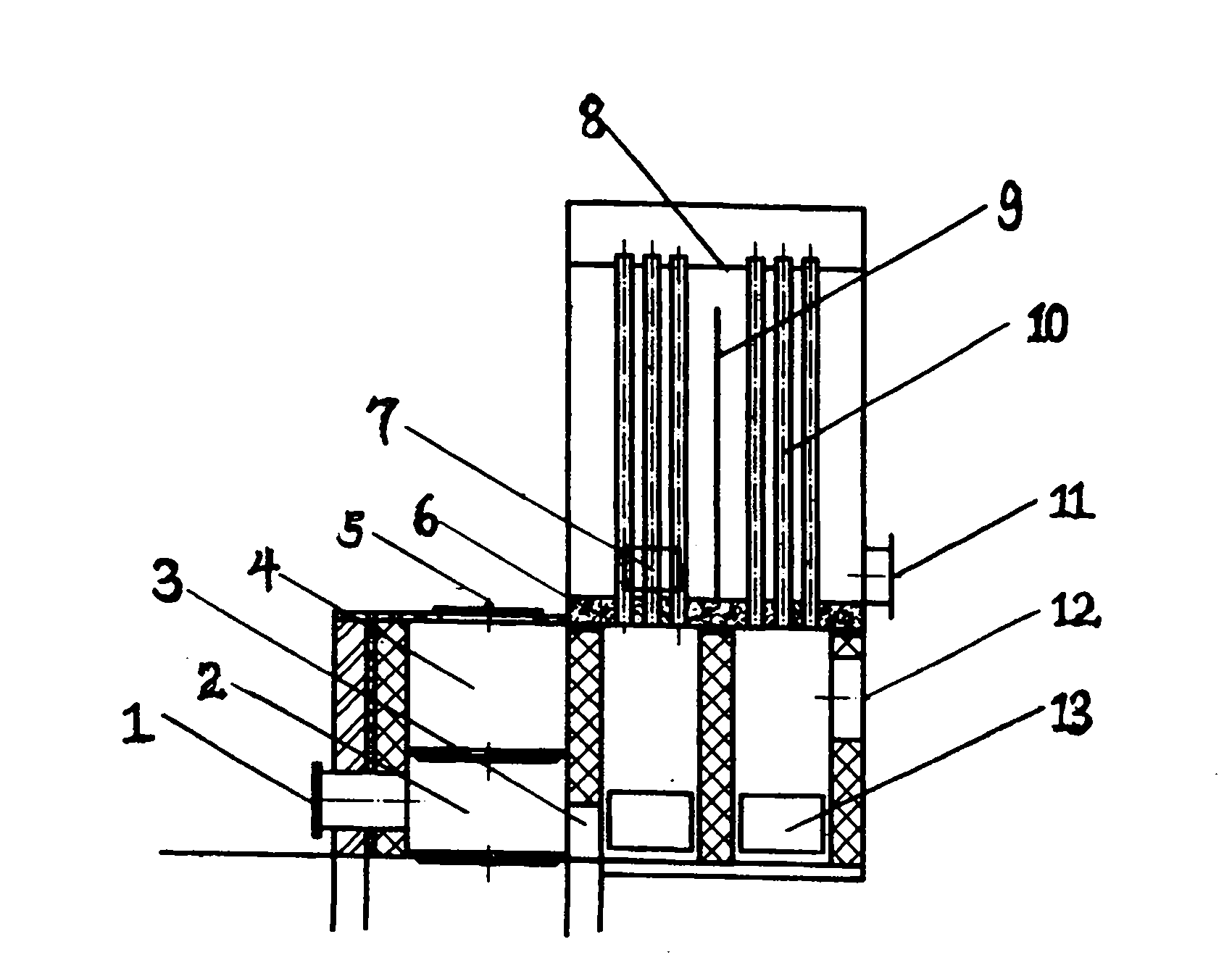

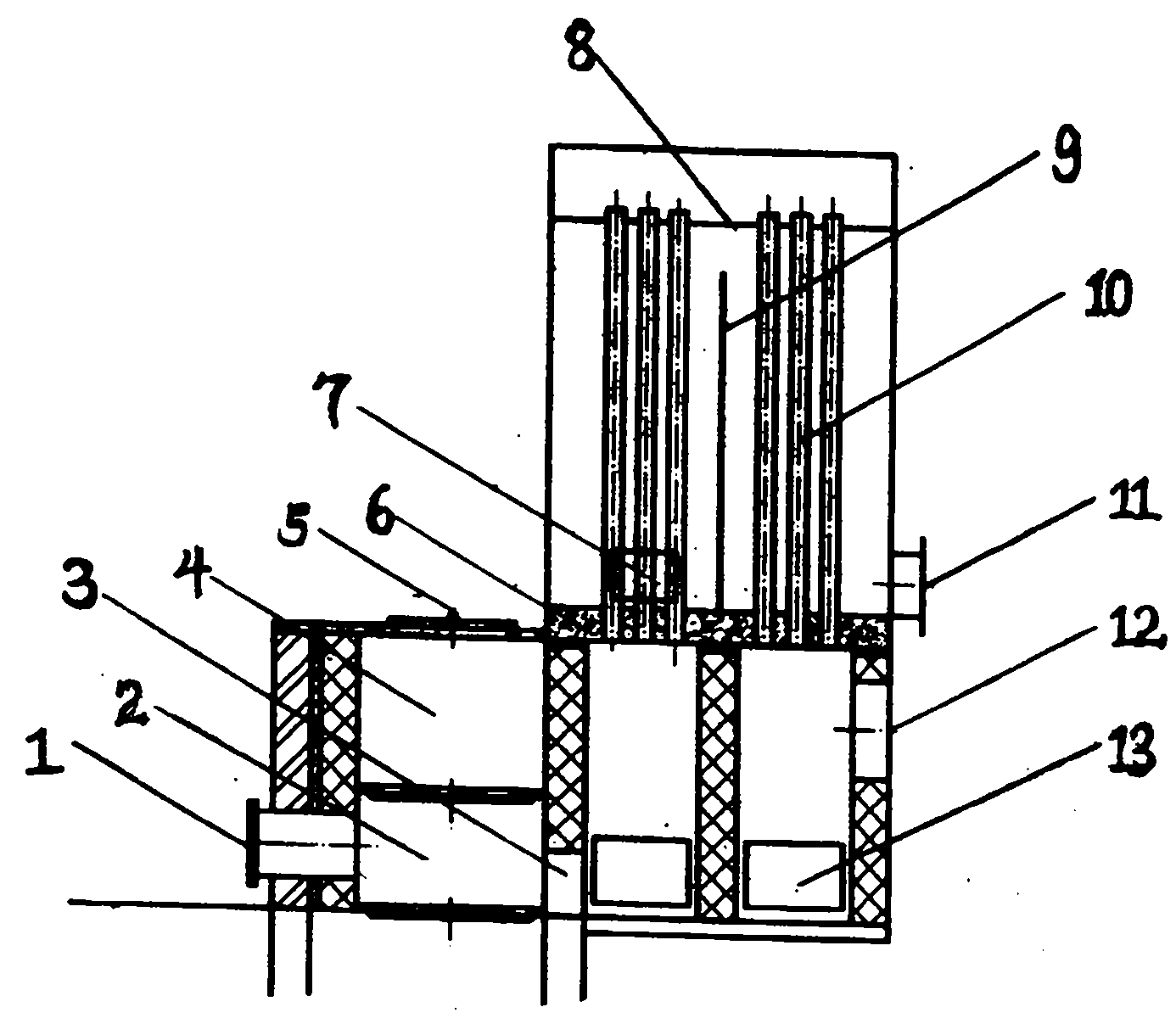

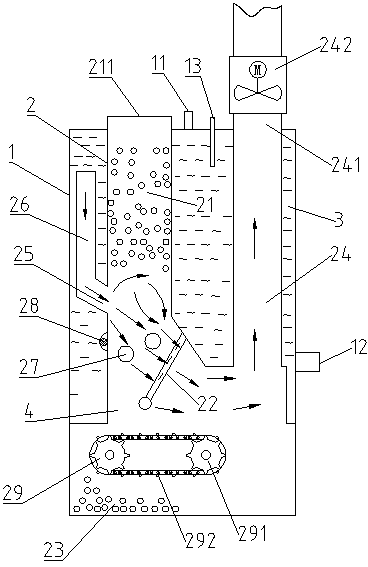

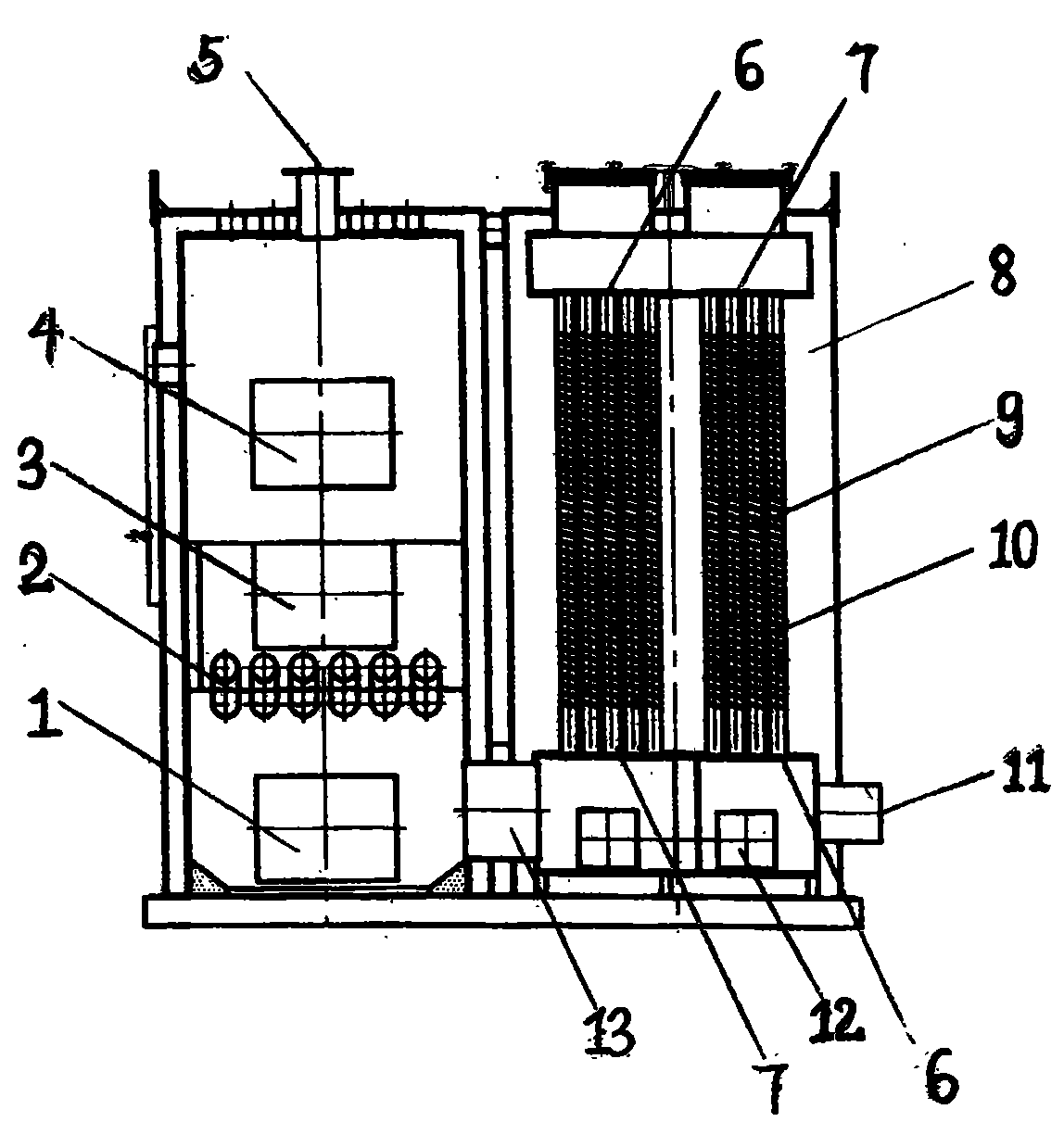

Biomass back-burning multi-return low-carbon energy-saving blast stove

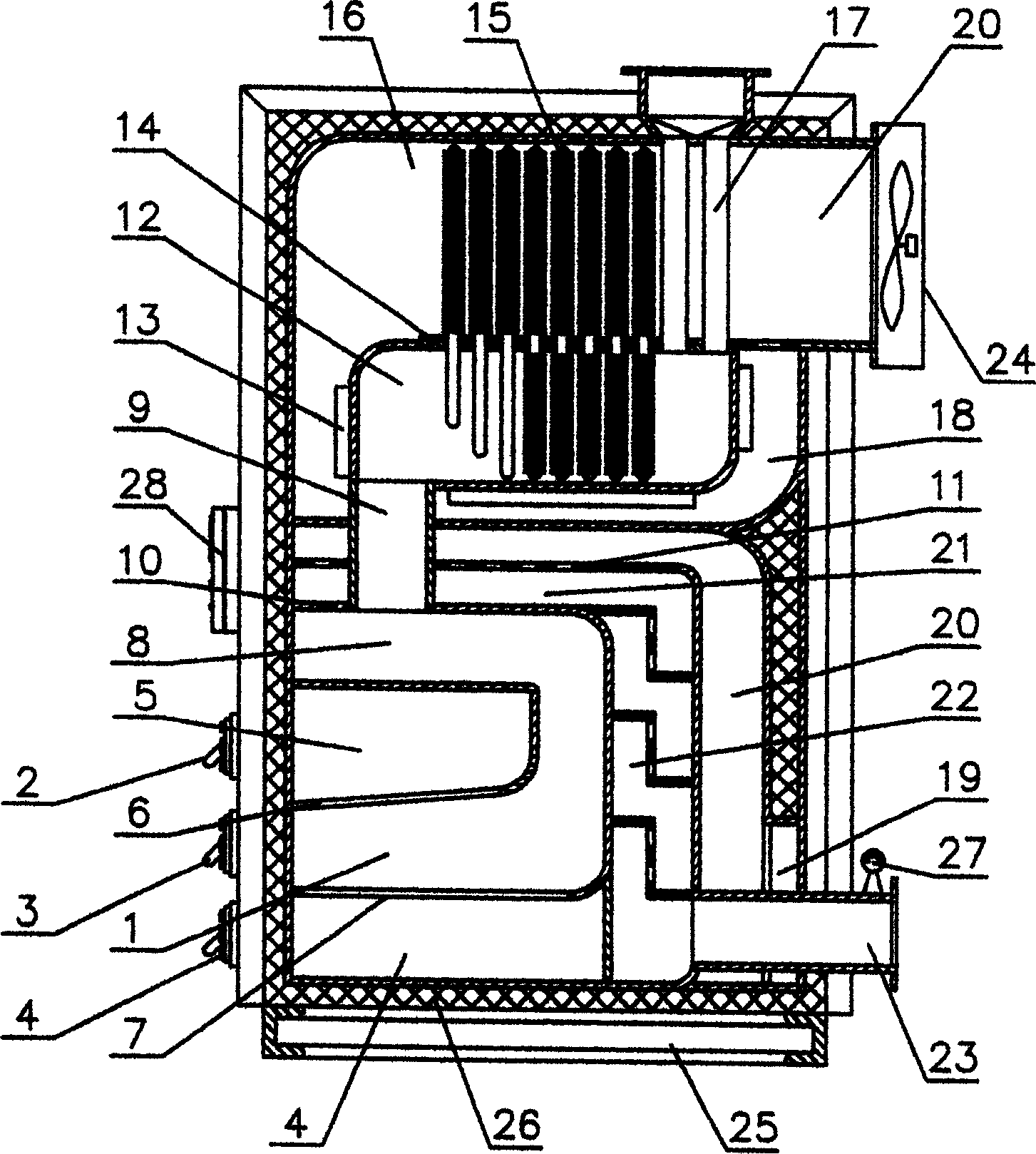

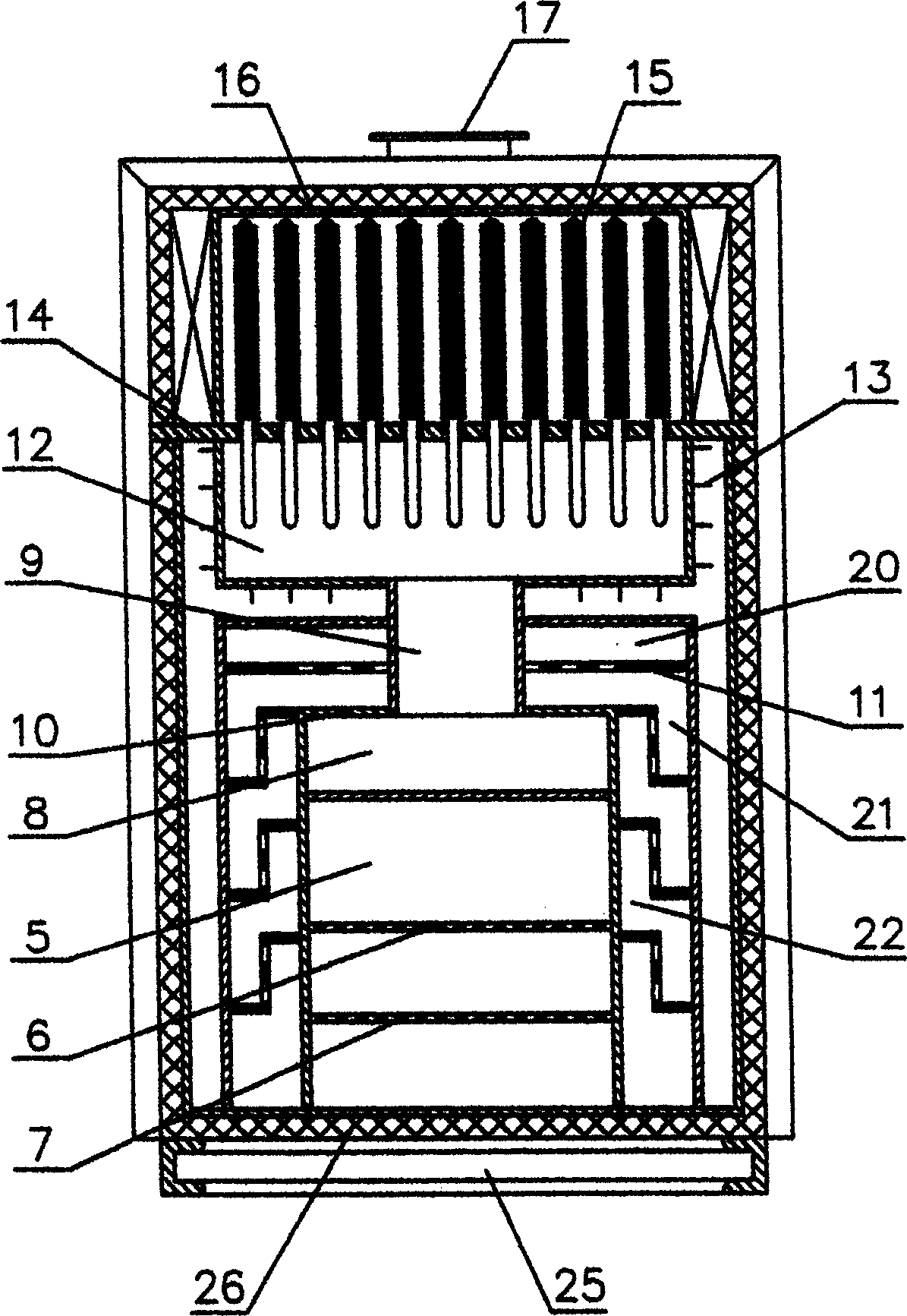

The invention discloses a biomass back-burning multi-return low-carbon energy-saving blast stove, which consists of a stove door (1), a biomass back-burning hearth (2), a biomass back-burning fire hole (3), a biomass hearth (4), a biomass charging hole (5), a refractory material (6), a cold air inlet (7), a sealing plate (8), an air partition board (9), a biomass multi-return fire tube (10), a hot air outlet (11), a smoke receiving pipe hole (12) and an access door (13). The fire tube of the blast stove is vertically welded. A layer of refractory material is filled and compacted below the fire tube. Flame flows bottom up in the vertical tube and then returns top down in another channel to form a plurality of back-burning returns. The blast stove is made from iron plates, iron pipes and the refractory material. The biomass back-burning multi-return low-carbon energy-saving blast stove realizes full burning, has long service life, and is energy-saving and environment-friendly.

Owner:SHANXI RONGSHENDA SCI & TECH

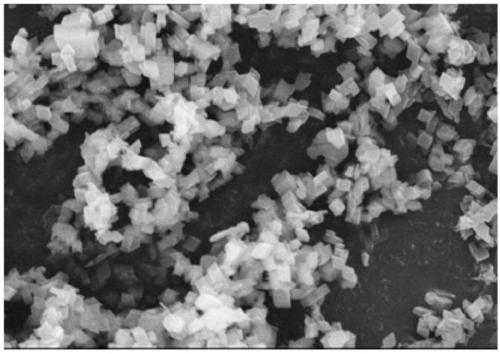

Preparation method of substrate film of high-frequency circuit board

InactiveCN108219329ALow dielectric lossStable dielectric constantGlass fiberTemperature control mode

The invention relates to a preparation method of a substrate film of a high-frequency circuit board and belongs to the technical field of fluoro-plastic processing. The preparation method includes steps of: 1) raw material blending: mixing polytetrafluoroethylene suspension resin and glass fibers in a material mixer; 2) pre-pressing to manufacture a green body: feeding the mixture into a cavity ofa green body producer and applying pressure by means of an upper pressing block, wherein air exhaustion is carried out for more than 3 times during pressure application; 3) sintering of green body: sintering the green body in a sintering furnace in a gradient temperature control mode; 4) back-burning of the green body: back-burning the green body before processing the substrate film; 5) lathe turning of the basic film: fixing the back-burned green body on a fixture of a turning lathe to processing the substrate film, thickness being 20-30 [mu]m and width being not less than 1500 mm; and 6) finishing of the substrate film: cutting and splitting the substrate film. The method has simple process and convenient operation. The product is ultra-long and ultrathin, has large breadth, has uniformand compact appearance and stable dielectric constant, and is extensive in available temperature range.

Owner:TIANJIN TIANSU SCI & TECH GROUP

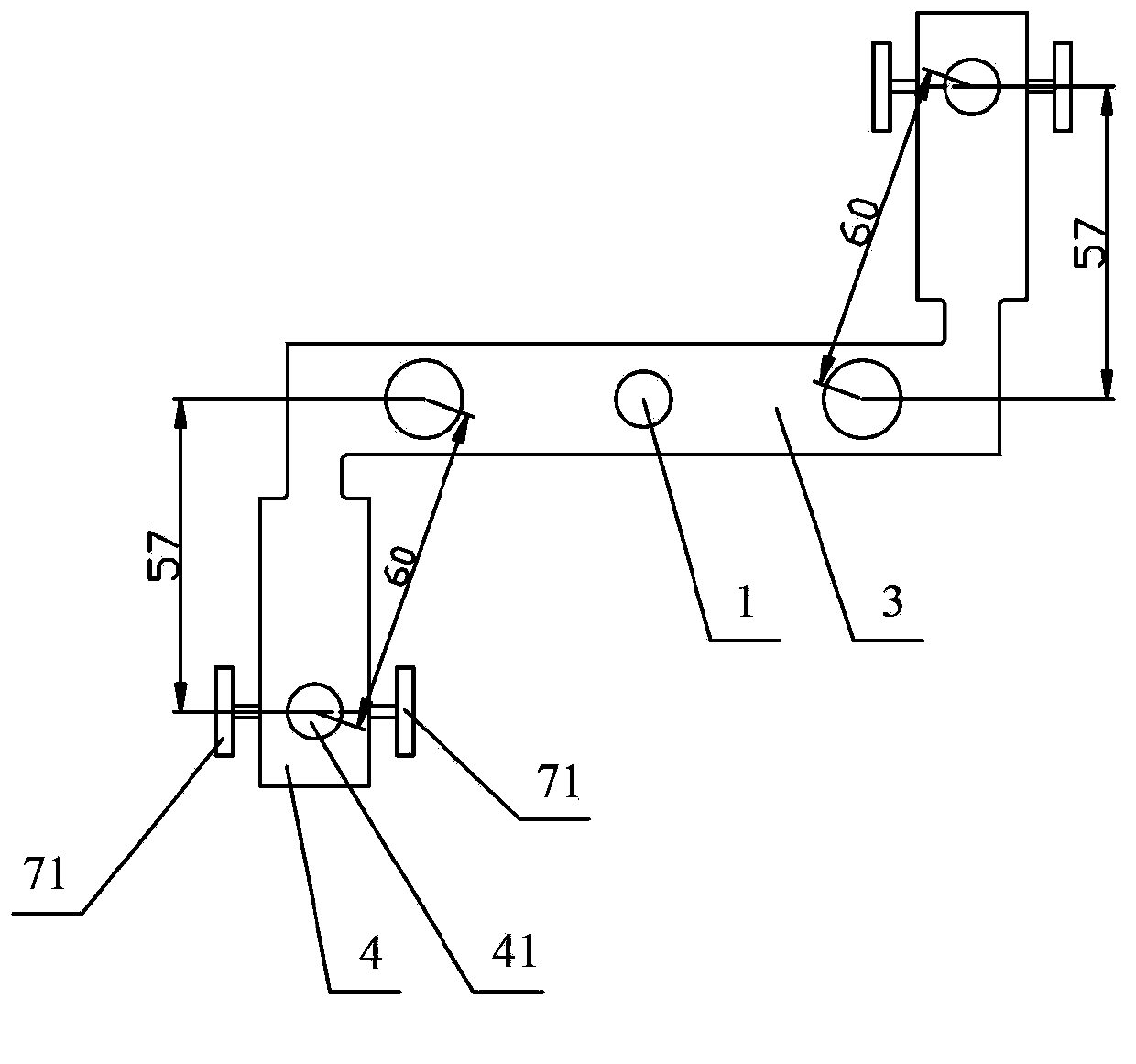

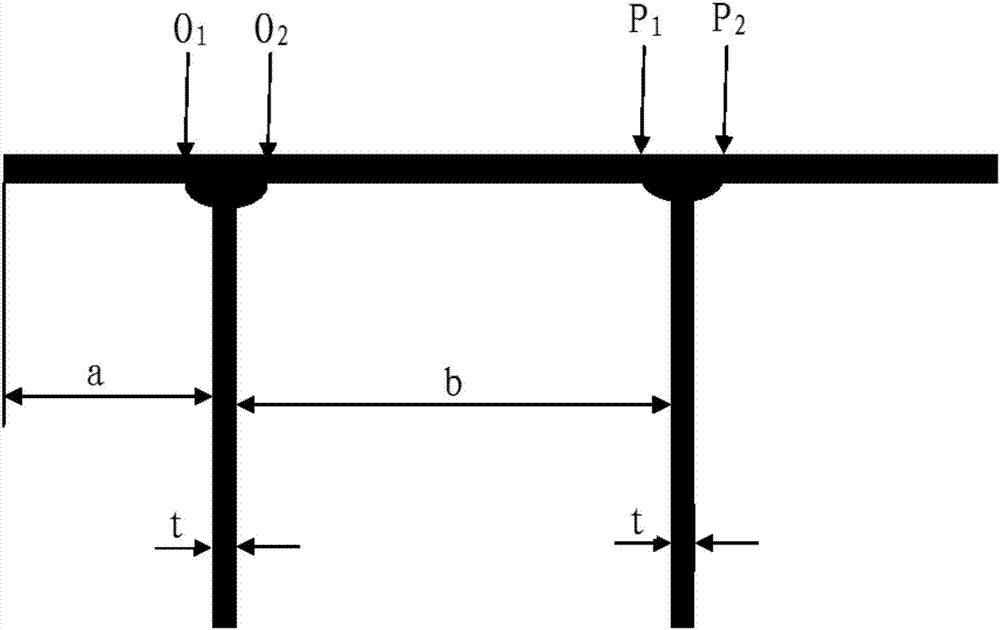

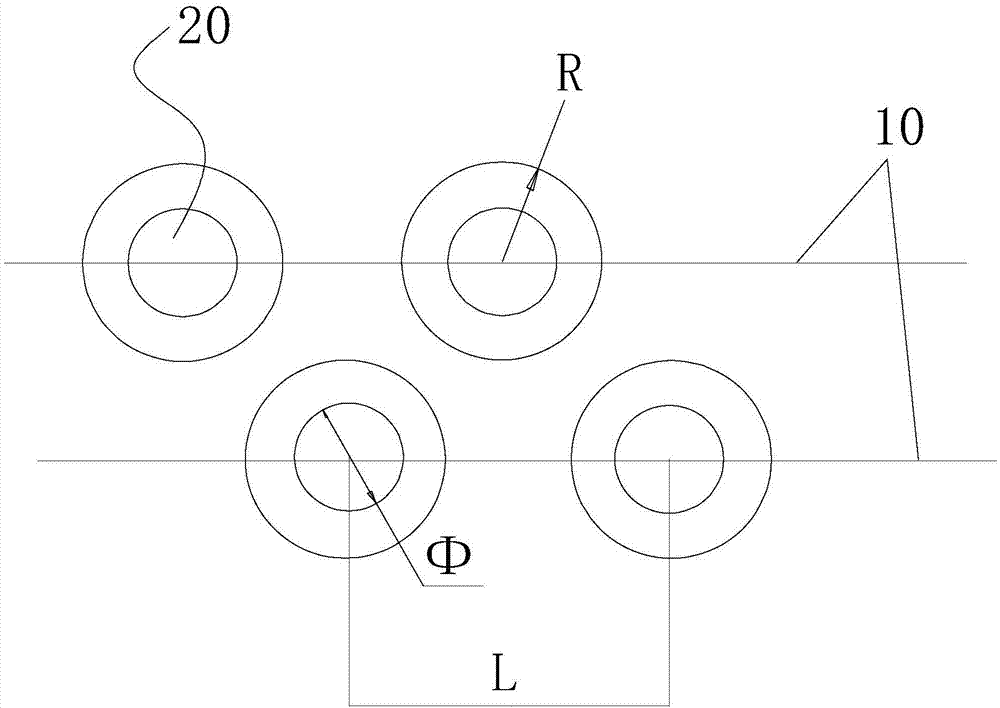

Back burning method for vessel body group vertical-position welding component

The invention discloses a back burning method for a vessel body group vertical-position welding component. The back burning method comprises the steps of marking a heating position, selecting the flame characteristics, determining the size of a heating spot, selecting the heating temperature, and selecting the heating depth and the heating rate. In the step of marking the heating position, heating reference line marking and heating spot marking are carried out sequentially; when the heating reference line marking is carried out, two parallel heating reference lines are marked in the surface of a plate by adopting a barge spot line snapping method; when the heating spot marking is carried out, heating spots are marked in the two heating reference lines in a staggered manner, and the center distance between the adjacent heating spots of each heating reference line is 60-100mm; and in the step of selecting the flame characteristics, the selection of the flame characteristics, the selection of the flame widths and the selection of the flame distance are carried out. According to the back burning method, the operation intensity of operators is reduced substantially, and the production efficiency of fire work back burning of the group vertical-position welding component is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

High-temp.-resistant boule back-burning fire grate

InactiveCN1438449AHigh thermal efficiencyLower requirementSolid bar grateCombustion chamberEngineering

The invention relates to a kind of high-temperature resistant corundum reverse burning grate. It is made up of transverse and lengthways bars, the monomer is corundum solid body. The coal burns on the grate. The temperature of the grate can reach 1000-1800 deg.C, it can boost up the burning assistant and enhances the temperature of the burning house, burns the smoke and dust in the high temperature sufficiently.

Owner:朱晓明

Waste oil smelting exhaust gas back-burning device

The invention discloses a waste oil smelting exhaust gas back-burning device. The device comprises a separation cabinet communicated with a condensation oil outlet pipe, wherein an oil outlet and a water outlet are arranged on the separation cabinet; and an oil outlet valve and a water outlet valve are arranged on the oil outlet and water outlet respectively. The device also comprises an exhaust gas back-burning pipe, wherein one end of the exhaust gas back-burning pipe is communicated with the top of the separation cabinet, and the other end is communicated with a hearth of an oil smelting furnace; and an exhaust gas control valve is arranged at the end close to the oil smelting furnace, of the exhaust gas back-burning pipe. As an exhaust gas back-burning device is additionally arranged in the oil smelting system, a small amount of non-condensable gas can be separated and introduced to be burnt in the hearth of the oil smelting furnace and recycled, thereby saving energy, avoiding atmospheric pollution caused by direct discharge, and protecting environment.

Owner:KAI COUNTY SHUANGXING RENEWABLE ENERGY

Energy-saving environment-friendly type back burning boiler

The invention discloses an energy-saving environment-friendly type back burning boiler which is formed by a pot body and a boiler body. The pot body is arranged outside the boiler body, a cavity formed between the pot body and the boiler body is used for containing water, a fuel bin is formed in the upper portion of the boiler body, a boiler grate is arranged at the bottom of the fuel bin, a boiler ash bin is formed below the boiler grate, a smoke outlet pipe is arranged at the bottom of the fuel bin in a communicated mode, a feeding opening is formed in the top end of the fuel bin, a smoke outlet of the smoke outlet pipe is formed in the top of the boiler body, and an air inlet is formed in the position, above the boiler grate, of the side wall of the boiler body, and communicated with the outside through an air inlet pipe. According to the energy-saving environment-friendly type back burning boiler, sufficient burning of fuel can be guaranteed, and the energy-saving aim is achieved; meanwhile, the heating efficiency of the energy-saving environment-friendly type back burning boiler is high, and the burning condition of the fuel inside the energy-saving environment-friendly type back burning boiler and the water temperature can be automatically detected in real time; in addition, an automatic slag removal device is arranged at the position corresponding to the boiler grate, and therefore block-shaped waste slag can be automatically discharged into the boiler ash bin.

Owner:赵永万

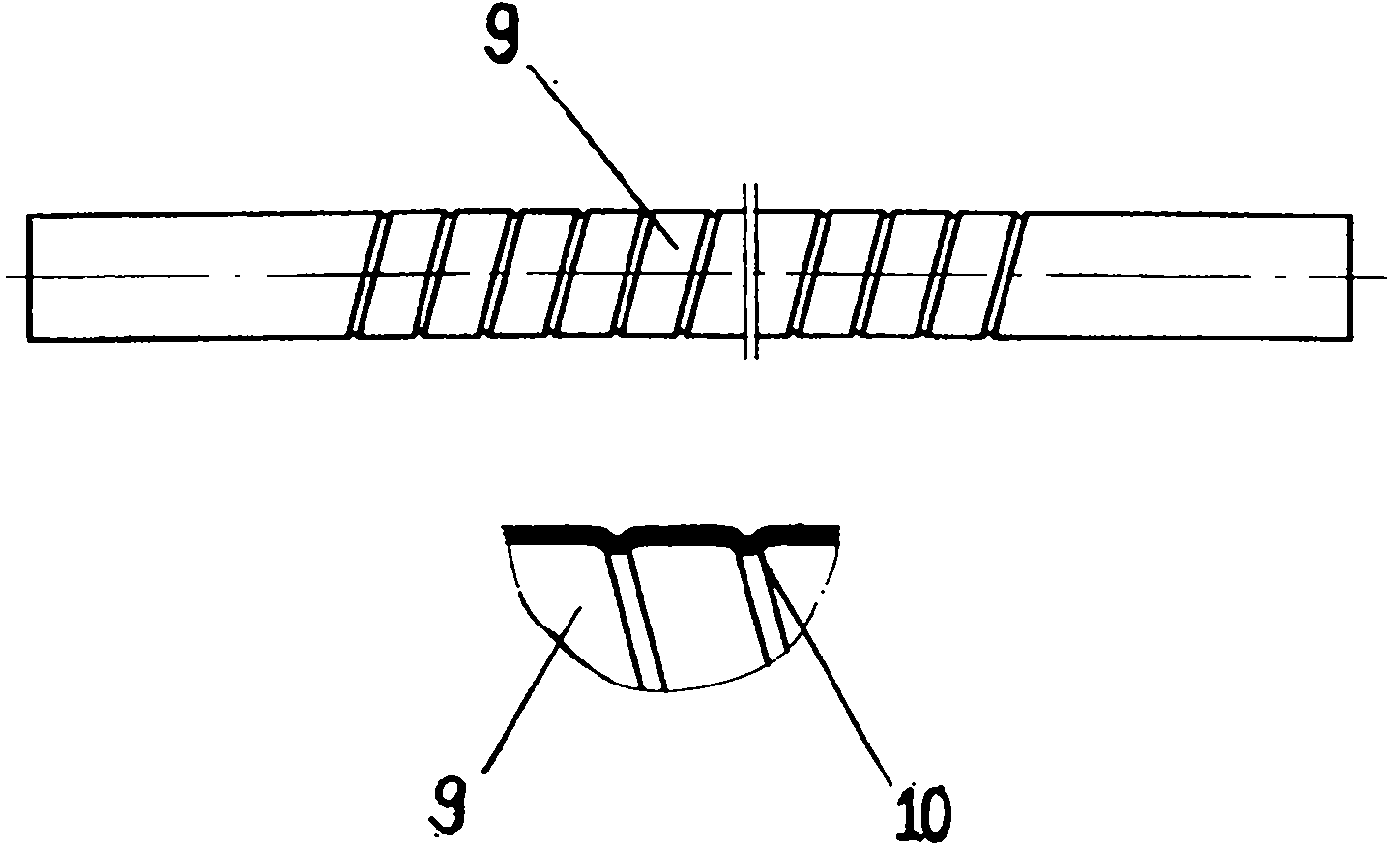

Biomass low-carbon energy-saving boiler with spiral grain fire tube

The invention discloses a biomass low-carbon energy-saving boiler with a spiral grain fire tube, mainly comprising a secondary burning chamber (1), a boiler bridge (2), a semi-gasification burning chamber (3), a feeding door (4), a banking smoke outlet (5), a fire outlet (6), a fire inlet (7), a water jacket (8), a spiral grain fire tube (9), a spiral grain fire tube convex edge (10), a smoke drum joint (11), an ash cleaning door (12) and a back burning port (13), wherein the spiral grain fire tube is vertically welded or welded in a boiler body in a balanced manner, the upper part and the lower part of the spiral grain fire tube are sealed, the fire inlet and the fire outlet are provided, and in burning, the flame enters the fire tube and is directed to move by the convex edge in the spiral grain tube without rising or being discharged directly. The biomass low-carbon energy-saving boiler has the advantages of full burning, high heat utilization ratio, energy conservation, emission reduction, easiness for promotion and implementation and better economic benefit.

Owner:SHANXI RONGSHENDA SCI & TECH

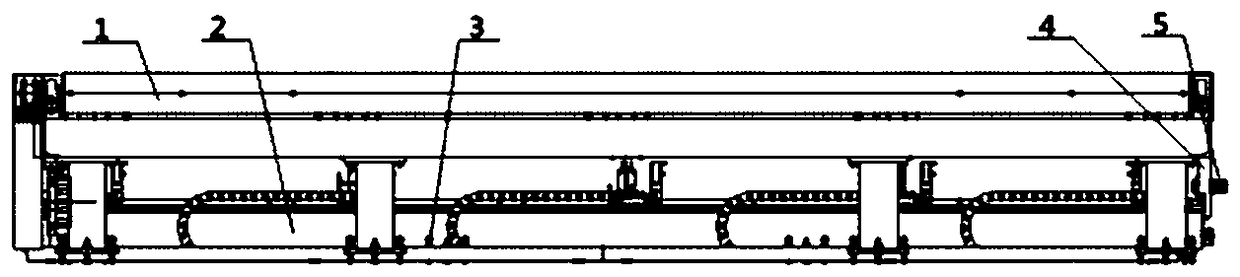

Device for releasing reinforcing plate welding internal stress and using method of device

The invention relates to a device for releasing the reinforcing plate welding internal stress. The device comprises a conveying roller path which is arranged on a bracket and back burning flame mechanisms which are matched with the conveying roller path; a shunting row which is connected with each back burning flame mechanism is arranged below the conveying roller path; one end of the conveying roller path is provided with a gas source tank and a pressure regulating valve; a positioning sensor is arranged above the conveying roller path; and each back burning flame mechanism comprises a plurality groups of roasting flares, a transmission mechanism used for moving the roasting flares and dragging chains which are matched with the roasting flares respectively. By adopting the device, a coordinate of a reinforcing plate needing back burning is determined through the positioning sensor, and then operation of each back burning flame mechanism is regulated, so that the purpose of simultaneously, rapidly and effectively finishing back burning is achieved by controlling operation of the back burning flame mechanisms, the trouble and the labor are saved, and the working efficiency is improved.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

Baking torch equipment and using method thereof and back burning machine for shipbuilding

InactiveCN103512031AMeet production needsHigh precisionVessel partsGaseous fuel burnerTorchEngineering

The invention discloses a using method of baking torch equipment. When fire is extinguished and the equipment is switched off, the valve of an oxygen supply pipeline is closed lagging behind the timing closing of the valve of a flammable gas supply pipeline, supplying of oxygen and flammable gas is cut off, and therefore using safety of the baking torch is guaranteed. The invention further provides equipment for achieving the method, and operation is made to be easier and more reliable through relay switches. In addition, the invention further provides a back burning machine for shipbuilding and facilitating control, the back burning machine for the shipbuilding is equipment specifically using the method. The back burning machine for the shipbuilding can achieve back burning of ship steel structures effectively and automatically in a building process, meets production requirements of ships, improves back burning quality and efficiency, is beneficial to improving the building precision of the ship steel structures, and has the advantages of being low in cost, high in working efficiency, long in service life and the like.

Owner:大连理研船舶装备有限公司

Electric back burning vehicle

InactiveCN112265615AReduce difficultyReduce labor intensityWaterborne vesselsFurnace typesVehicle frameControl theory

A disclosed electric back burning vehicle comprises a vehicle body, an electric motor and a firer gun clamping mechanism, the vehicle body comprises a vehicle frame, a front wheel set and a rear wheelset, the front wheel set and the rear wheel set are both arranged at the bottom of the vehicle frame, the firer gun clamping mechanism is arranged at the top of the vehicle frame, and the firer gun clamping mechanism is used for clamping a firer gun; and the front wheel set and the rear wheel set are distributed in a spaced mode, the rear wheel set comprises two rear wheels, the two rear wheels are located on the two opposite sides of the vehicle frame respectively and connected through a rotating shaft, the rotating shaft is connected with an electric motor, and the electric motor drives therotating shaft to rotate so as to drive the vehicle body to move. Through the driving of the electric motor, the difficulty of back burning operation is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com