Longitudinally arranged type back-burning energy-saving single-drum horizontal type boiler

A horizontal boiler and single-drum technology, which is applied in steam boilers, water tube steam boilers, fluid heaters, etc., can solve the problems of large amount of refractory materials, high transportation costs, and low thermal efficiency, so as to reduce the cost of materials and Transportation cost, effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

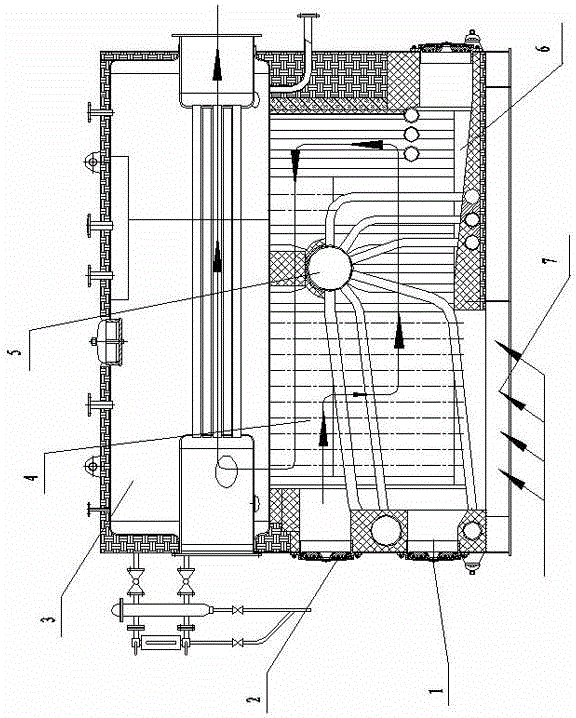

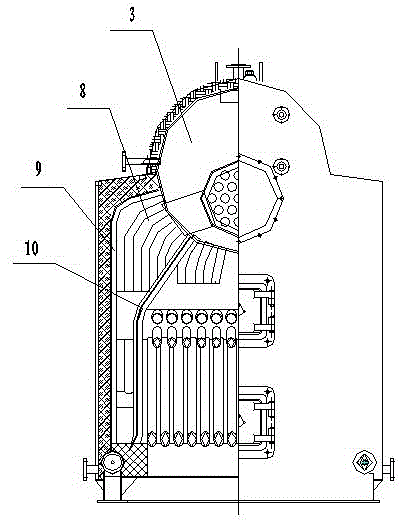

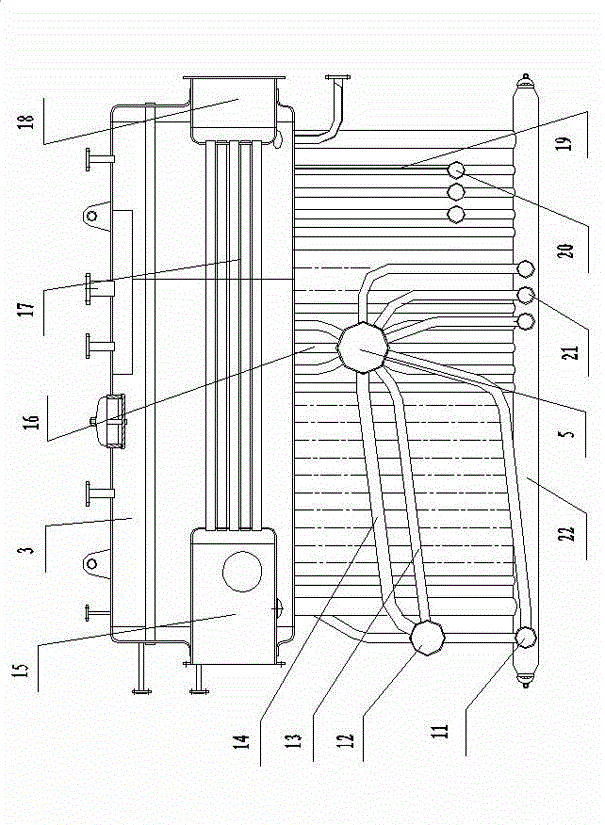

[0016] A vertical reverse combustion energy-saving single-drum horizontal boiler is provided with a furnace body, the furnace body includes an upper drum 3 and a furnace 4, the upper drum 3 is arranged on the top of the furnace body, and the left and right sides of the bottom of the furnace body are arranged There are two longitudinal headers 22, the upper drum 3 and the two longitudinal headers are connected through the outer pipe wall 9, and the front lower horizontal header 11 is arranged between the two longitudinal headers 22 at the front end of the furnace body. The front middle horizontal header 12 is arranged above the front lower horizontal header 11, and the front lower horizontal header 11 and the front middle horizontal header 12 are connected through the front pipe wall 23, and the front pipe wall 23 is provided with The lower furnace door 1 is provided with an upper furnace door 2 on the furnace body between the front middle horizontal header 12 and the upper drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com