Center back-burning vertical type three-pass gas-fired boiler

A gas-fired boiler, three-pass technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of short flue gas flow, large heat energy loss, high boiler exhaust temperature, etc., to increase radiation heat transfer The effect of increasing the heat transfer time and prolonging the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

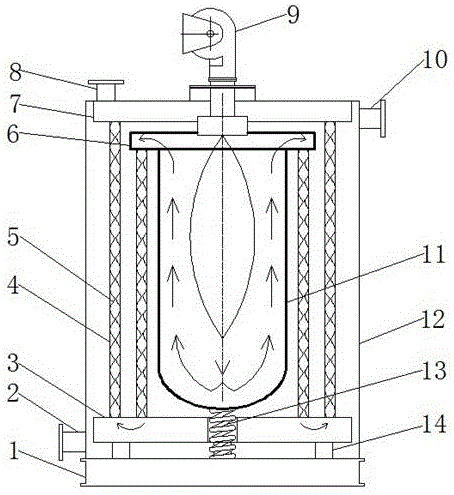

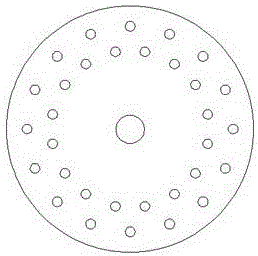

[0014] A central backfiring vertical three-pass gas boiler, including a cylinder, a furnace, a burner, a smoke pipe, a spiral steel sheet, a smoke collection box, an up-turning smoke chamber, a down-turning smoke chamber, an inlet pipe, an outlet pipe, and an exhaust pipe. Smoke pipe, spring and base. The burner is located at the top of the vertical boiler cylinder, fixed at the center of the smoke collecting box and the upward turning smoke chamber, and the nozzle faces downward toward the furnace; the furnace is welded by a cylinder and an oval The annular tube plate of the smoke transfer chamber is fixed by welding; the lower end surface of the upper transfer smoke chamber communicates with the lower transfer smoke chamber through the second return smoke pipe, and the lower end surface of the smoke collection box communicates with the lower transfer smoke chamber th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com