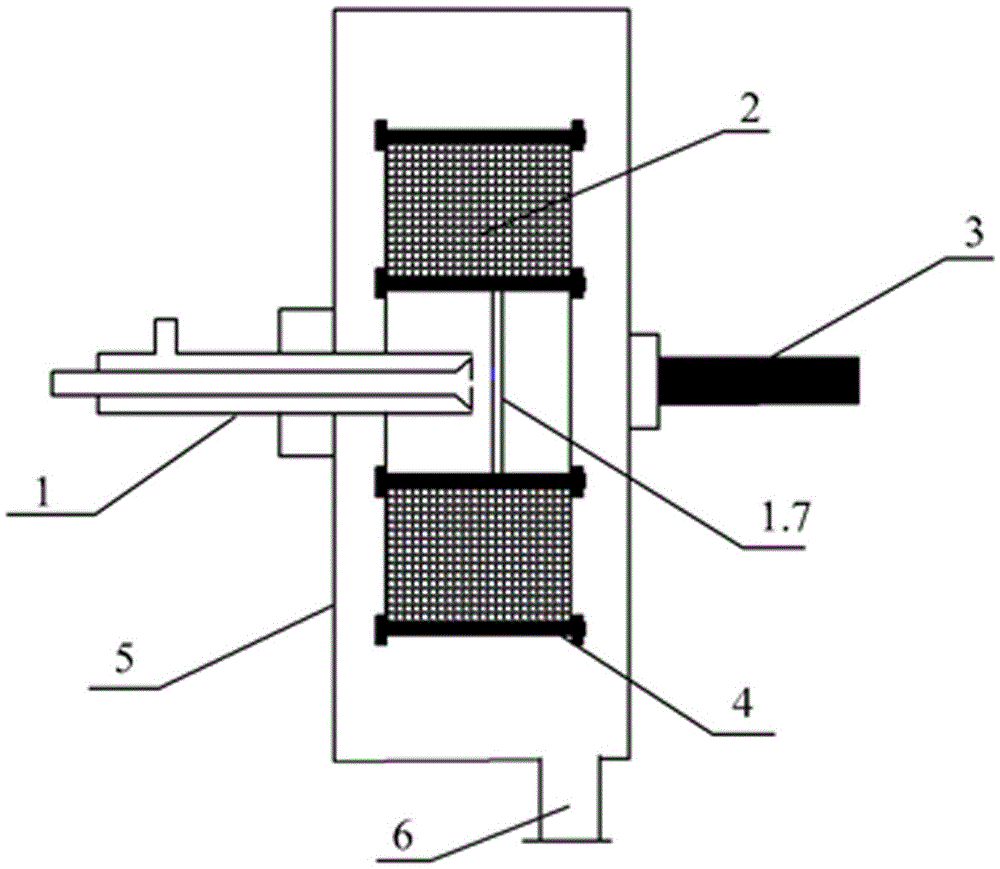

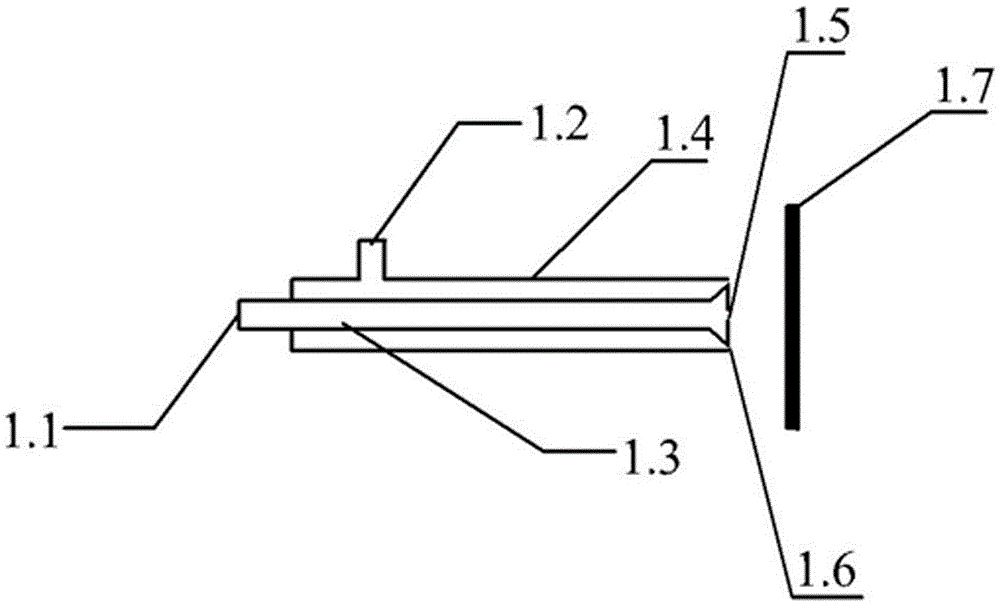

Single reflection-ring nozzle impinging flow structure and rotating packed bed device

A technology of rotating packed bed and impinging flow, applied in feeding devices, chemical/physical/physical-chemical nozzle reactors, chemical methods of reacting liquids with liquids, etc. Micro mixing effect, reduced momentum loss, enhanced energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

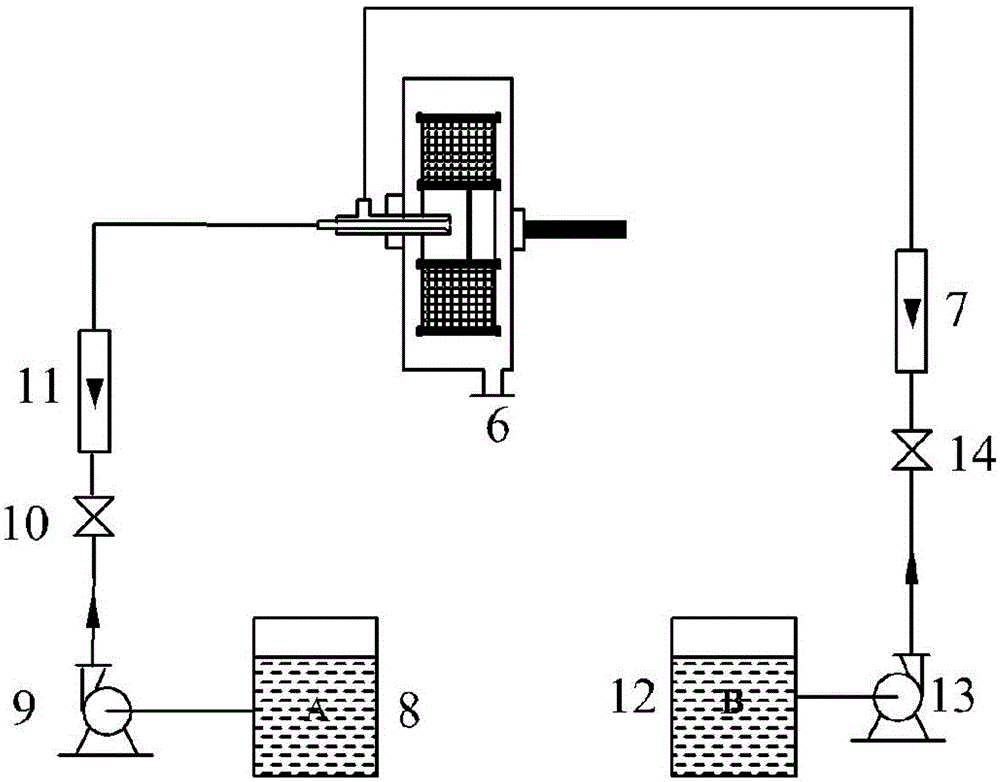

[0032] Such as image 3 As shown, using a single reflection-ring nozzle impingement flow-rotating packed bed device, d 1 / d 2 =1.5, L 1 / d 1 =50,d 3 / D 2 =3,d 2 / D 2 =1, d 1 / D 1 =1,d 4 / d 1 =1, the volume flow ratio of A and B solutions is 5, the viscosity of A solution is 300mPa·s, and the viscosity of B solution is 200mPa·s, a circular baffle with a downward depression and a rough surface is used for the research of paraffin emulsification. The solution A paraffin is placed in the liquid storage tank I8, and 6% of the emulsifier obtained by compounding Span80, K12 and co-emulsifier A is placed in the liquid storage tank II12, which is solution B. Corrosion pump II13, liquid flowmeter I11, and liquid flowmeter II15 are first impacted in the cavity of the rotor through the single reflection-ring nozzle impact flow reactor, and the formed mixed fluid enters the packing layer 2, and the rotor 4 is on the shaft 3 When the rotation speed is 1200r / min, the strong centr...

Embodiment 2

[0034] Such as image 3 As shown, a single reflection-ring nozzle impingement flow-rotating packed bed device is used d 1 / d 2 =5,L 1 / d 1 =10,d 3 / D 2 =15,d 2 / D 2 =30, d 1 / D 1 =20,d 4 / d 1 =5, the volume flow ratio of A and B solutions is 15, the viscosity of A and B solutions is 2mPa·s, and the circular baffle plate with downward depression and rough surface is used for the research on the preparation of ultrafine magnesium hydroxide. Solution A with a NaOH concentration of 1.5mol / L is placed in the liquid storage tank I8, and solution B with a magnesium chloride concentration of 1.5mol / L is placed in the liquid storage tank II12, respectively through the corrosion-resistant pump I9, the corrosion-resistant pump II13 and the liquid flow rate The meter I11 and the liquid flow meter II15 are first impacted in the cavity of the rotor through the single reflection-ring nozzle impact flow reactor, and the formed mixed fluid enters the packing layer 2, and the rotor 4...

Embodiment 3

[0036] Such as image 3 As shown, a single reflection-ring nozzle impingement flow-rotating packed bed device is used d 1 / d 2 =10,L 1 / d 1 =20,d 3 / D 2 =50, d 2 / D 2 =50, d 1 / D 1 =100, d 4 / d 1 = 2, the volume flow ratio of A and B solutions is 1, the viscosity of A solution is 20mPa·s, and the viscosity of B solution is 100mPa·s. A circular baffle with a downward depression and a rough surface is used for the research on diesel emulsification. 0.8600g / mL diesel oil is stored in the liquid storage tank I8, which is solution A, and 3% emulsifier obtained by compounding Tween80 and Span is placed in the liquid storage tank II12, which is solution B, which is respectively passed through the corrosion-resistant pump I9 , corrosion-resistant pump II13, liquid flowmeter I11, and liquid flowmeter II15, through the single-reflection-ring nozzle impingement flow reactor for the first impact in the cavity of the rotor, the formed mixed fluid enters the packing layer 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com