Nozzle capable of achieving atomization under synergy of bubbles

A technology of nozzles and bubbles, which is applied in the field of nozzles capable of synergistic atomization with bubbles, can solve problems such as insufficient power of bubble two-phase flow, poor atomization effect of bubbles, and insufficient spray intensity, so as to improve atomization efficiency and effect, prolong Length, effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

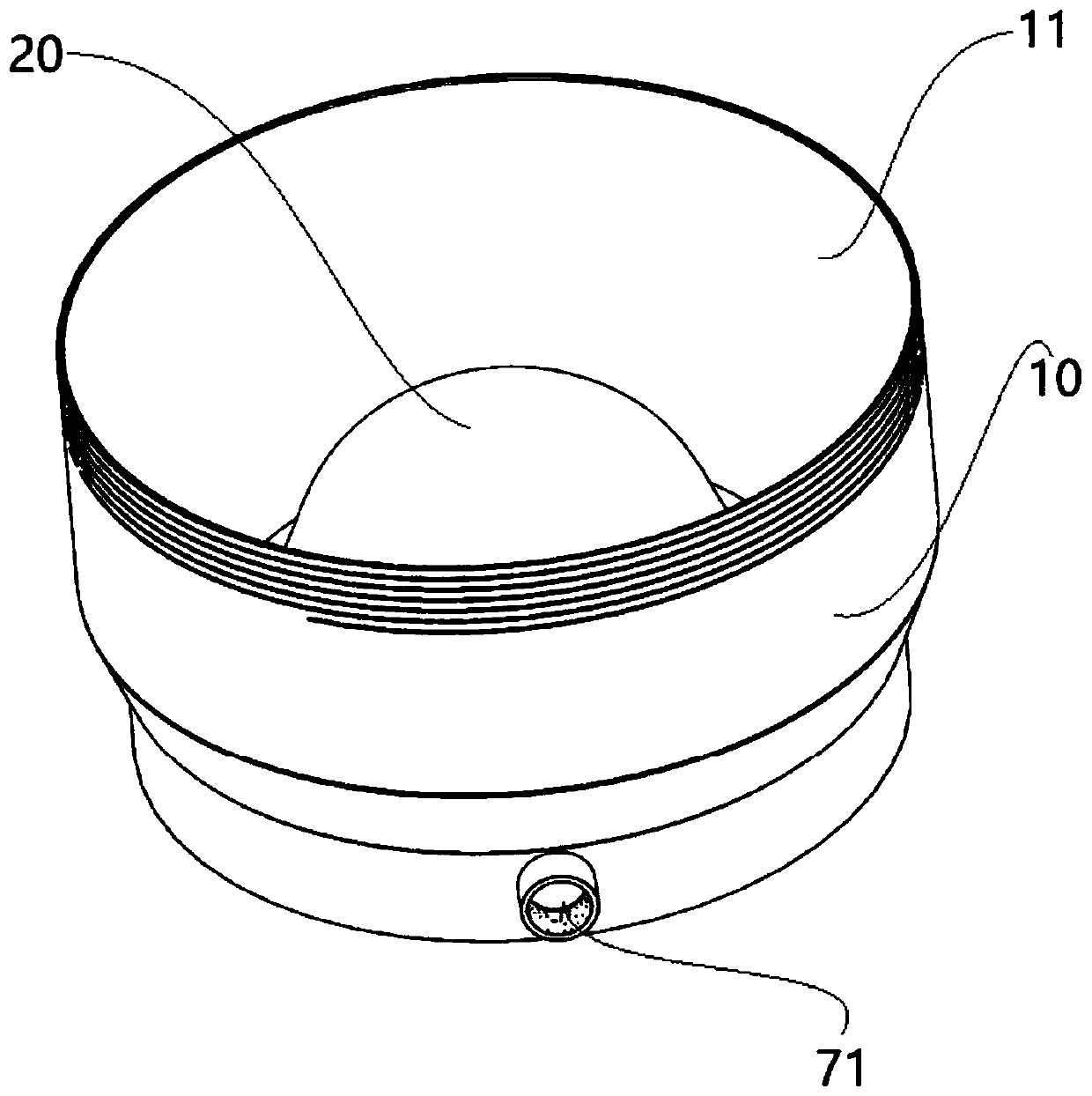

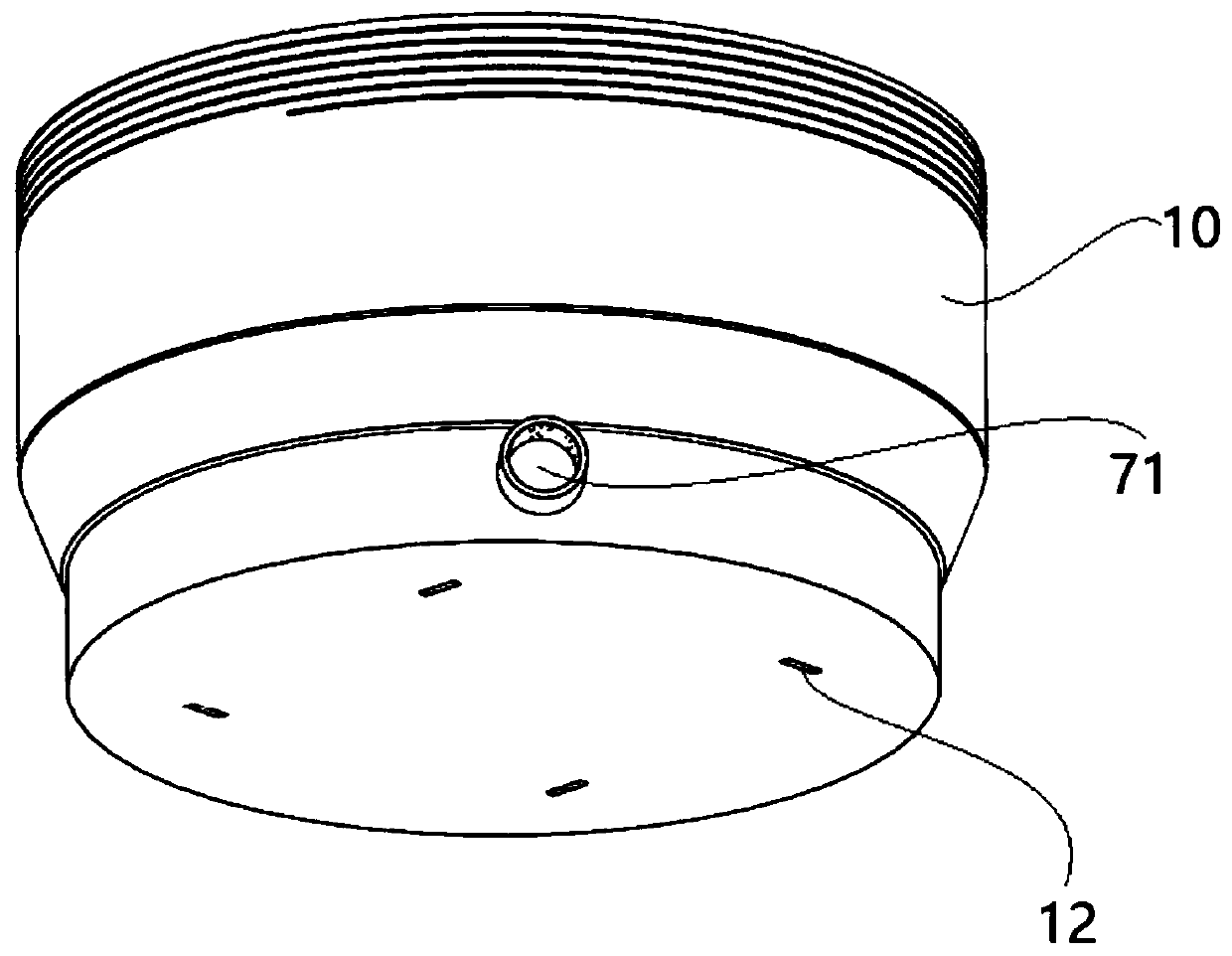

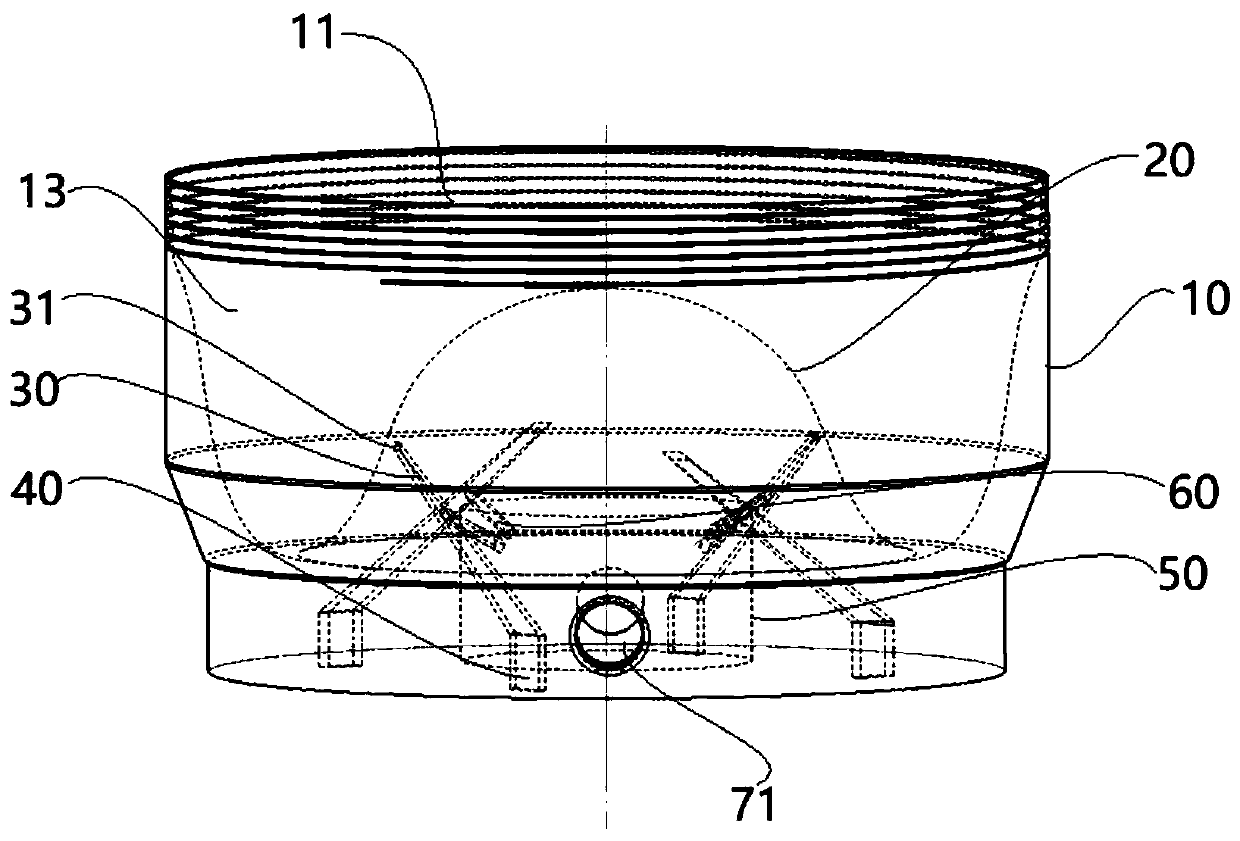

[0049] A nozzle that can be atomized with air bubbles in this embodiment, such as Figure 1 to Figure 5As shown, it includes a housing 10, at least one swirl flow channel 30 and at least one gas injection channel 60, the housing 10 has at least one liquid inlet 11 and at least one injection port 12 communicated with the liquid inlet 11; the swirl flow The channel 30 communicates between the liquid inlet 11 and the injection port 12; one end of the gas injection channel 60 communicates with the flow channel body of the swirl flow channel 30 located in the middle of the liquid inlet 11 and the injection port 12, and the other end is suitable for connecting with the gas source (not shown) connected.

[0050] For ease of description, the inlet end of the swirl flow channel 30 is named as the first inlet port 31, the outlet end (not shown) of the swirl flow channel 30 is named the first outlet end, and the gas injection channel 60 is named as the first outlet end. The inlet port (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com