Fuel injection nozzle with multi-angle spray orifices

A fuel injector, multi-angle technology, applied in the direction of fuel injection device, charging system, machine/engine, etc., to achieve the effect of evenly mixing oil and gas, increasing space, and huge market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

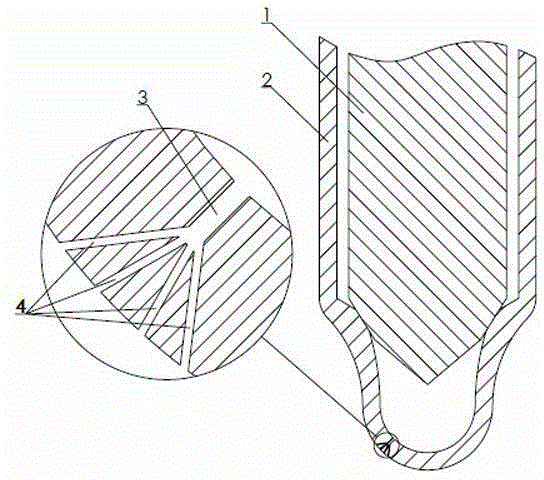

[0010] Examples of the present invention figure 1 As shown, the multi-angle injection nozzle includes a needle valve 1 and a needle valve body 2. The needle valve 1 and the needle valve body 2 form a pair of precision couplings. There are three uniform arrays in the needle valve body 2 along its axis. The main spray hole 3, corresponding to each main spray hole 3, is provided with four sub-spray holes 4 on the needle valve body. The axes of the holes 4 are distributed on the same vertical plane, and they are arranged in a divergent shape with the bifurcation position in the main nozzle hole 3 as the center. The cross-sectional area of the main nozzle hole 3 is smaller than the sum of the cross-sectional areas of the sub-nozzles 4. The internal flow velocity of 3 is higher than the internal flow velocity of sub-nozzle 4; when working, the high-pressure fuel reaches the bifurcation position of sub-nozzle 4 through the main nozzle 3 at high speed and is ejected from sub-nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com