Fuel injector with perturbation spray nozzle

A technology of fuel injectors and nozzles, which is applied in the direction of engine components, fuel injection devices, machines/engines, etc., to achieve the effects of uniform oil and gas mixing, huge market space, and high atomization intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

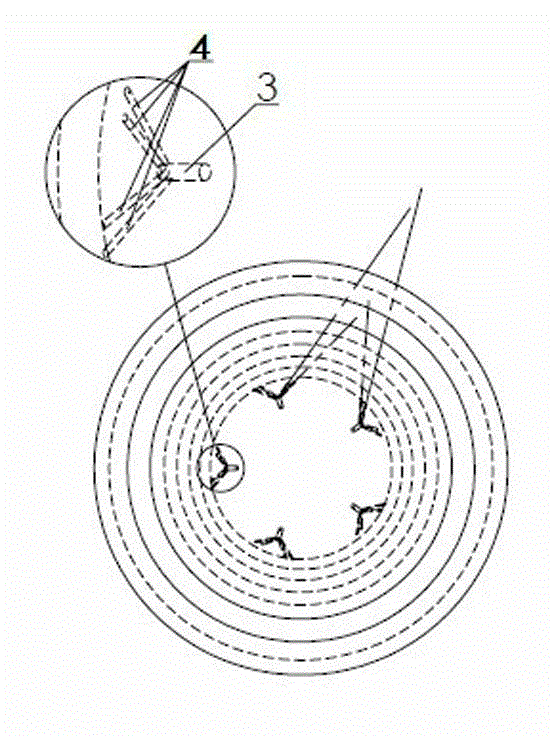

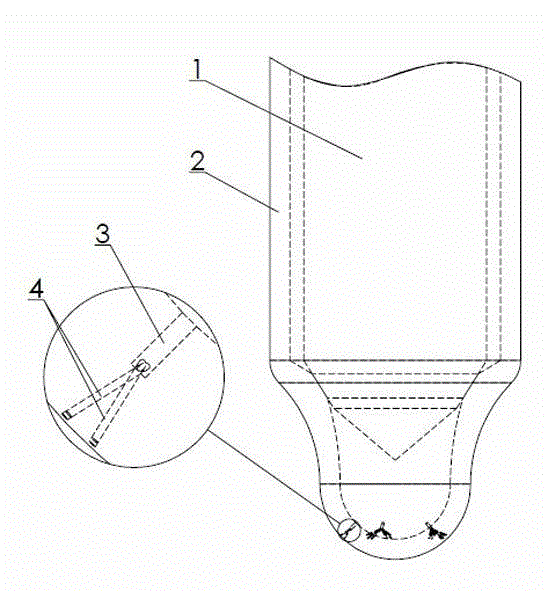

[0012] Examples of the present invention figure 1 , figure 2 As shown, the disturbing nozzle injector includes a needle valve 1 and a needle valve body 2, which is characterized in that there are at least five main injection holes 3 in a uniform array along its center line in the needle valve body 2, corresponding to each main injection hole 3 There are four sub-nozzles 4 on the needle valve body 2, the sub-nozzles 4 communicate with the main nozzle 3, and branch at the same position in the main nozzle 3, each sub-nozzle 4 on the main nozzle 3 The two groups are equally divided into a left half group and a right half group, and the left half group and the right half group are distributed around the center line of the main nozzle hole 3, and the sub nozzle holes 4 in the left half group and the right half group The bifurcated positions in the nozzle holes 3 are arranged in a divergent shape at the center, the cross-sectional area of the main nozzle holes 3 is smaller than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com