Cross jet hole fuel spray nozzle

A fuel injection nozzle and injection hole technology is applied in the field of in-cylinder direct injection internal combustion engine fuel injection devices to achieve the effects of sufficient combustion, simple structure, and obvious economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

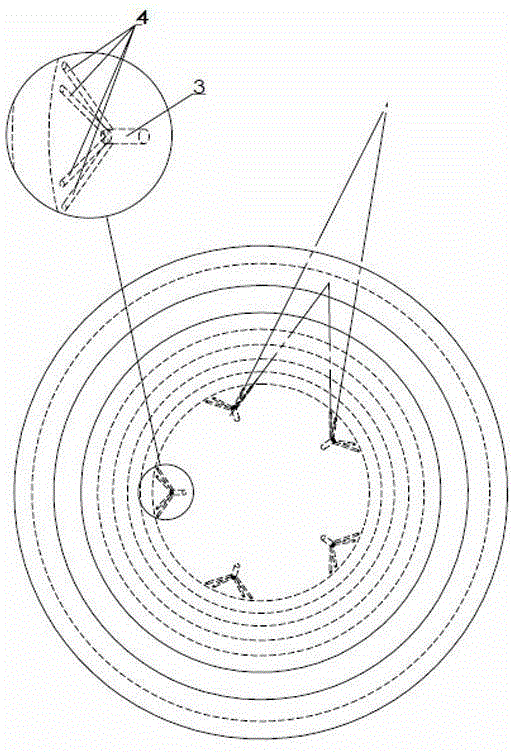

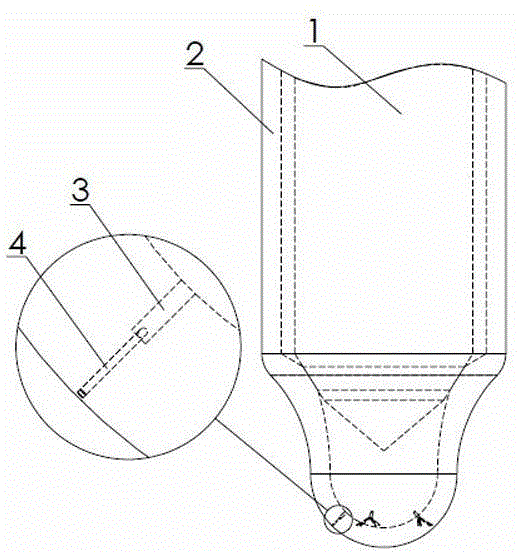

[0013] Examples of the present invention figure 1 , figure 2 As shown, the cross-spray nozzle includes a needle valve 1 and a needle valve body 2, which is characterized in that there are at least five main nozzle holes 3 in a uniform array along its center line in the needle valve body 2, corresponding to each main nozzle The hole 3 is provided with four sub-nozzles 4 on the needle valve body 2. The sub-nozzles 4 communicate with the main nozzle 3 and branch at the same position in the main nozzle 3. The sub-nozzles on each main nozzle 3 4 Two groups are equally divided into a left half group and a right half group, and the left half group and the right half group are symmetrically distributed with the center line of the main nozzle hole 3 as the axis of symmetry, and the sub nozzle holes 4 in the left half group and the right half group are The bifurcation position in the main nozzle hole 3 is arranged as the center in a divergent shape, and the centerline extensions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com