Closed-type high-pressure water mist fire-extinguishing nozzle

A technology of high-pressure fine water mist and fire extinguishing nozzles, which is applied in fire rescue and other fields, can solve the problems of small droplet diameter, temperature-sensitive glass balls unable to support high-pressure water flow, and large droplet impulse, so as to achieve small droplet diameter and large impulse , the effect of large spray angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

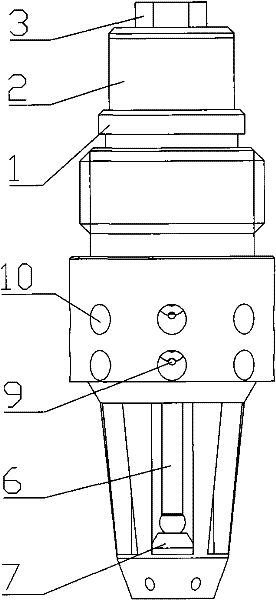

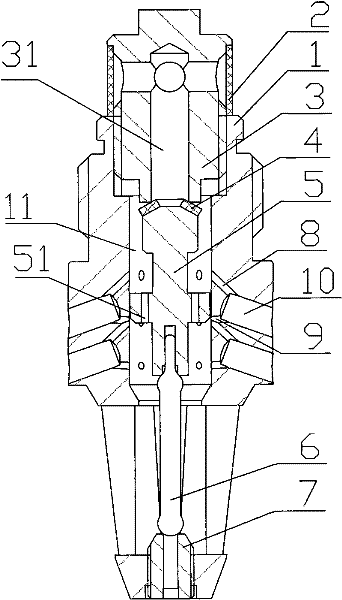

[0024] Figure 1 ~ Figure 3 Combined with a closed high-pressure water mist fire extinguishing nozzle, it includes a nozzle housing 1, a filter screen 2, and a compression structure 3, a sealing gasket 4, a support 5, and a temperature sensing element arranged in sequence from top to bottom 6 and fastening bolt 7.

[0025] The nozzle housing 1 is composed of upper and lower sections, an intermediate cavity 11 is arranged in the upper section of the nozzle housing 1, and the lower section of the nozzle housing 1 is a frame.

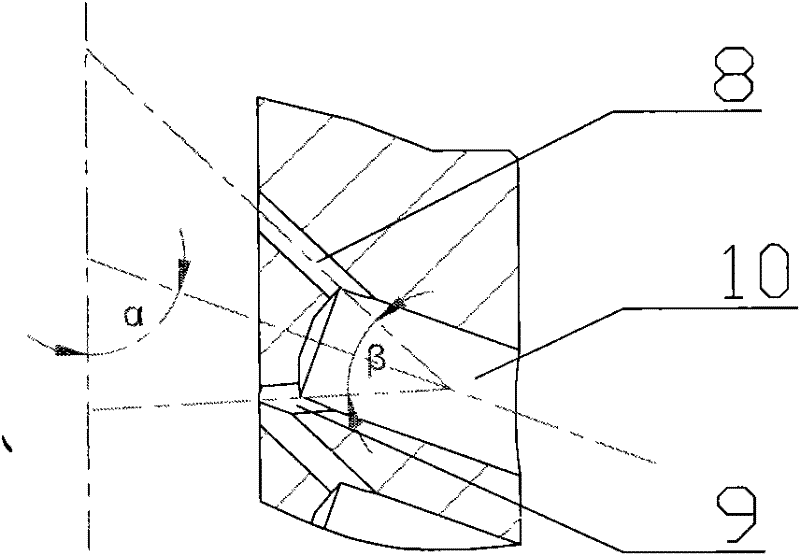

[0026] A support member 5 is provided in the middle cavity 11 of the nozzle housing 1, and the top end of the support member 5 is conical. The pressing structure 3 is located directly above the supporting member 5 and is movably connected with the nozzle housing 1 in the form of screw connection, that is, the pressing structure 3 can move up and down along the nozzle housing 1 . A water flow channel 31 is provided in the compression structure 3 , and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com