Petroleum coking-slurry burning control system

A control system and petroleum coke technology, which is applied in the direction of controlling combustion, lighting and heating equipment, etc., can solve the problems of unable to burn petroleum coke slurry stably and effectively, and achieve the effects of lowering temperature, avoiding coking, and increasing atomization intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

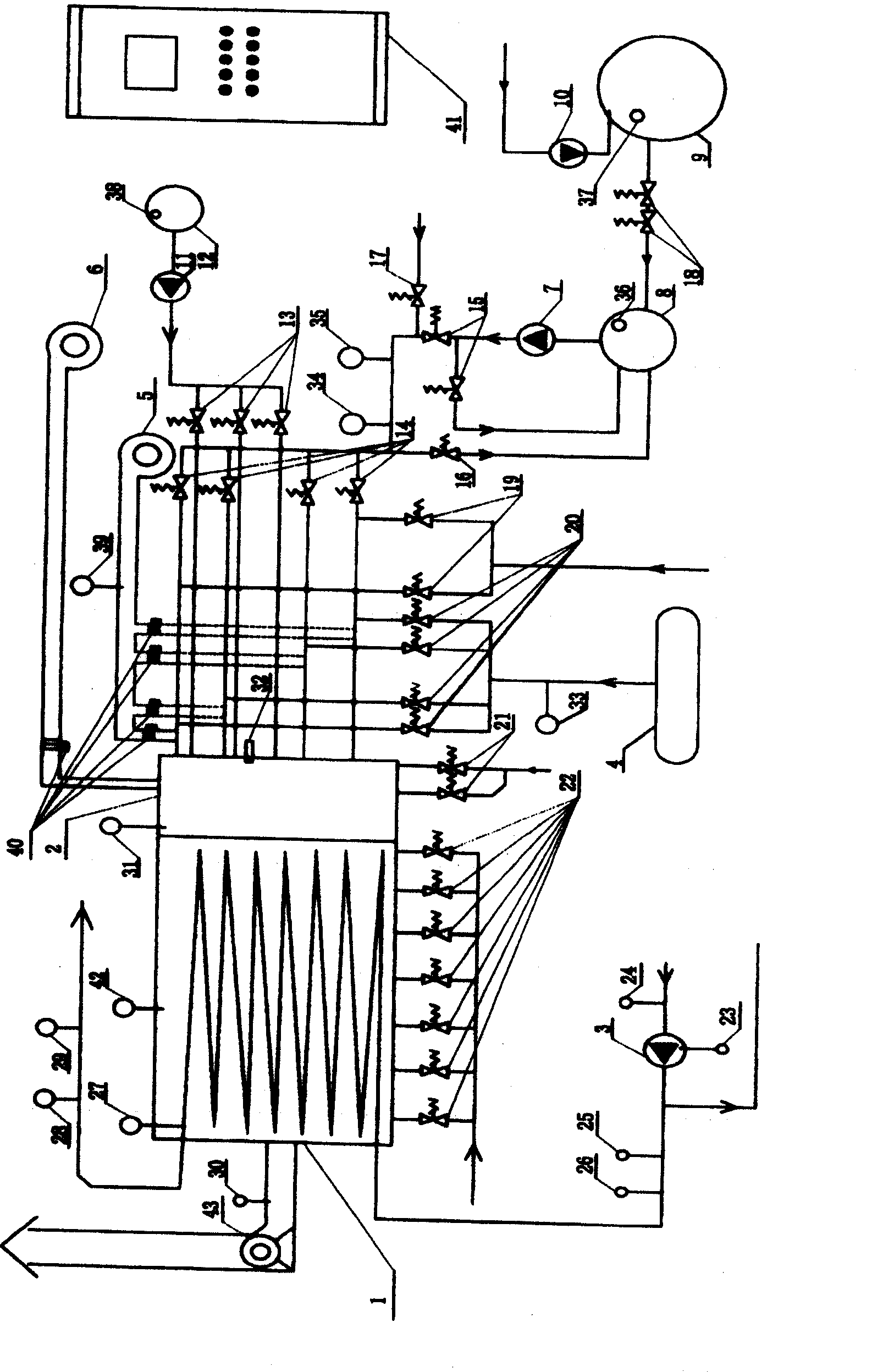

[0022] Please refer to figure 1 and figure 2 , the petroleum coke slurry combustion control system of the present invention is used to control a combustion device so that the petroleum coke slurry in it can be burned stably and fully, wherein the petroleum coke slurry can be water coke slurry or oil coke slurry.

[0023] In this embodiment, the petroleum coke slurry combustion control system is used in an oil field steam injection boiler, which includes a furnace 1, a stable combustion chamber 2, a furnace tube, a water supply pump 3, an air compressor 4, a DC blower 5, Side cyclone fan 6, four petroleum coke slurry burners, slurry supply pump 7, slurry tank 8, slurry storage tank 9, slurry delivery pump 10, three oil burners, oil supply pump 11, oil tank 12, oil supply valve 13. Slurry supply valve 14, slurry inlet / return valve 15, return valve 16, main slurry inlet valve 18, high pressure air valve 20, two gas burners, air supply valve 21, high pressure soot blowing valve ...

Embodiment 2

[0037] As another embodiment of the present invention, the petroleum coke slurry combustion control system of the present invention can be used in other various types of combustion devices, such as steam boilers, water bath furnaces, or kiln equipment.

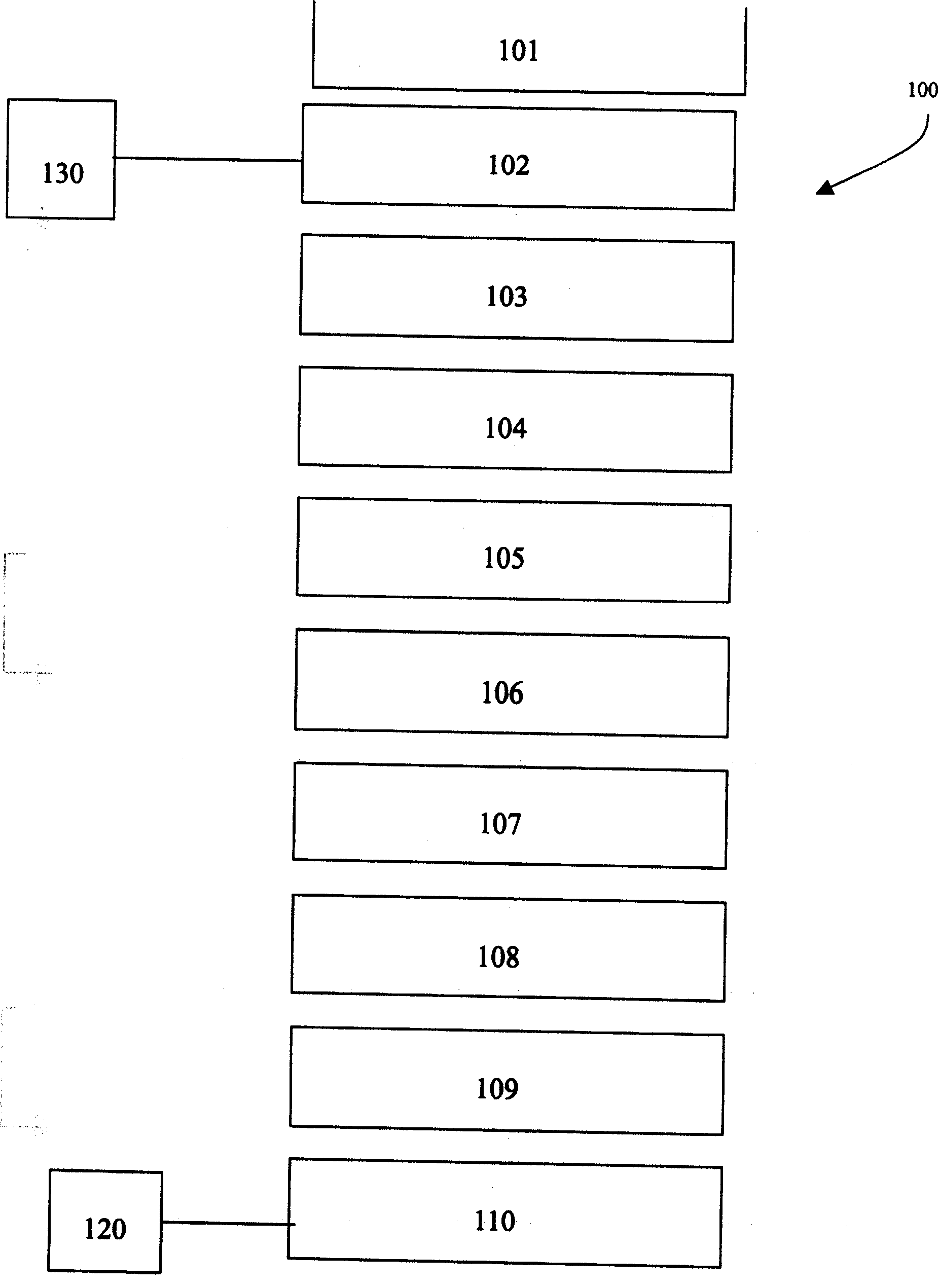

[0038] Petroleum coke slurry combustion control system of the present invention can only comprise combustion chamber temperature sensor 31, combustion chamber pressure sensor 42 and program controller 100, or mainly comprise combustion chamber temperature sensor 31, combustion chamber pressure sensor 42 and program controller 100, In addition, one or more of the following elements are included: oil pressure sensor 23, water flow meter 25, water pressure sensor 26, pipe wall temperature sensor 27, steam pressure sensor 28, steam temperature sensor 29, flue gas temperature sensor 30, flame Detector 32, slurry pressure transmitter 34, slurry flow meter 35, slurry supply level sensor 36, slurry storage level sensor 37, oil level se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com