Patents

Literature

30results about How to "Full and efficient combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

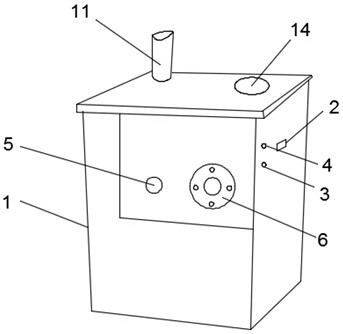

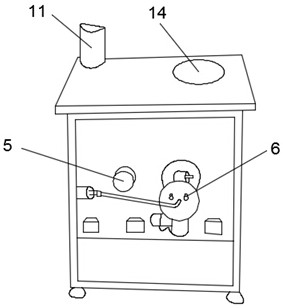

Automatic biofuel-combustion multipurpose furnace

InactiveCN102721169AFull and efficient combustionLow costStove/ranges for heating waterWater heatersAutomatic controlCombustion

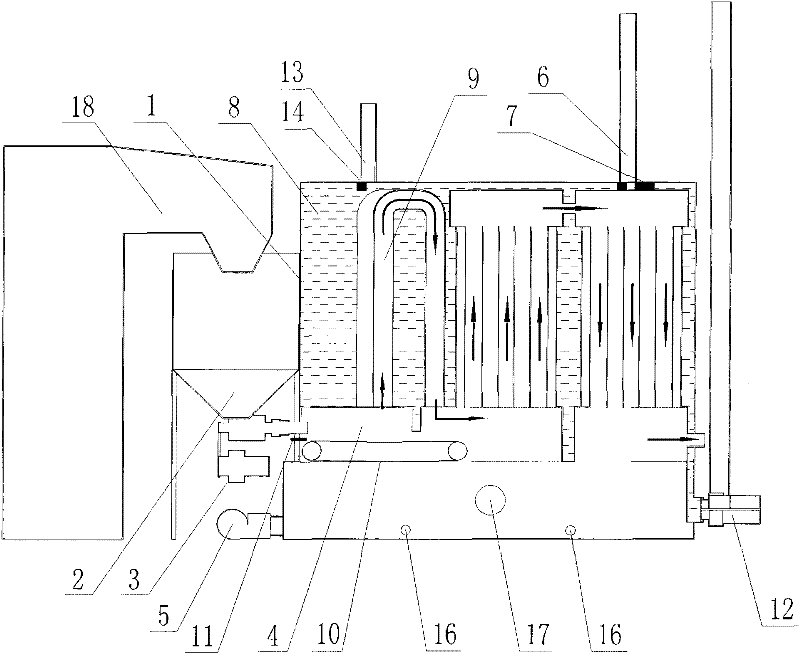

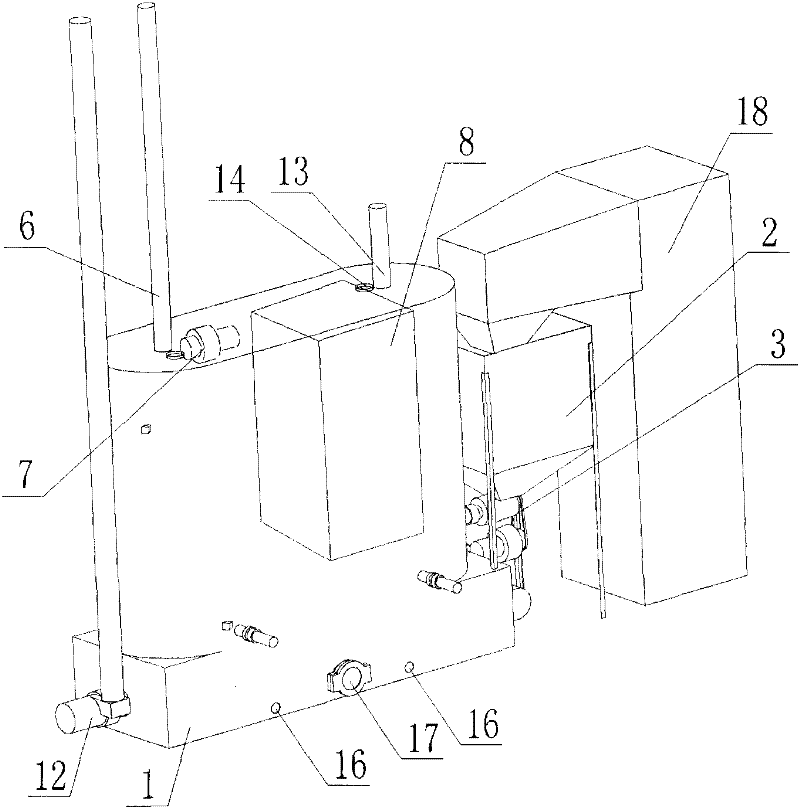

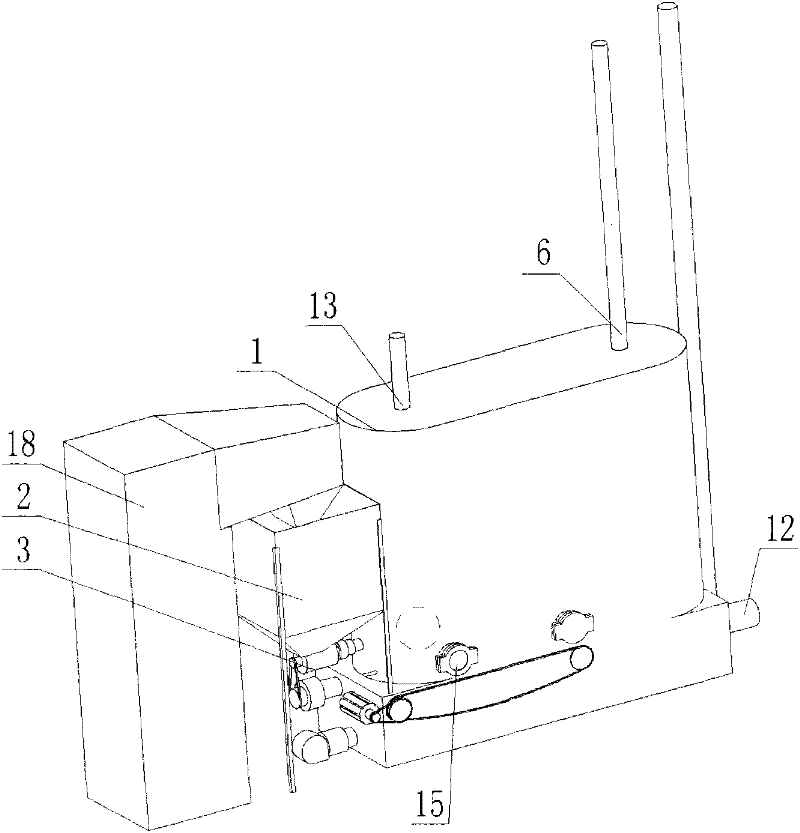

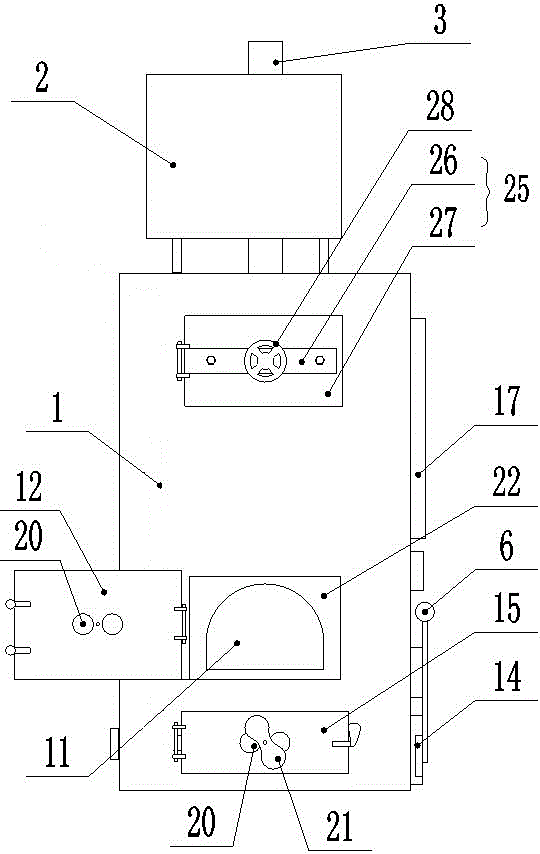

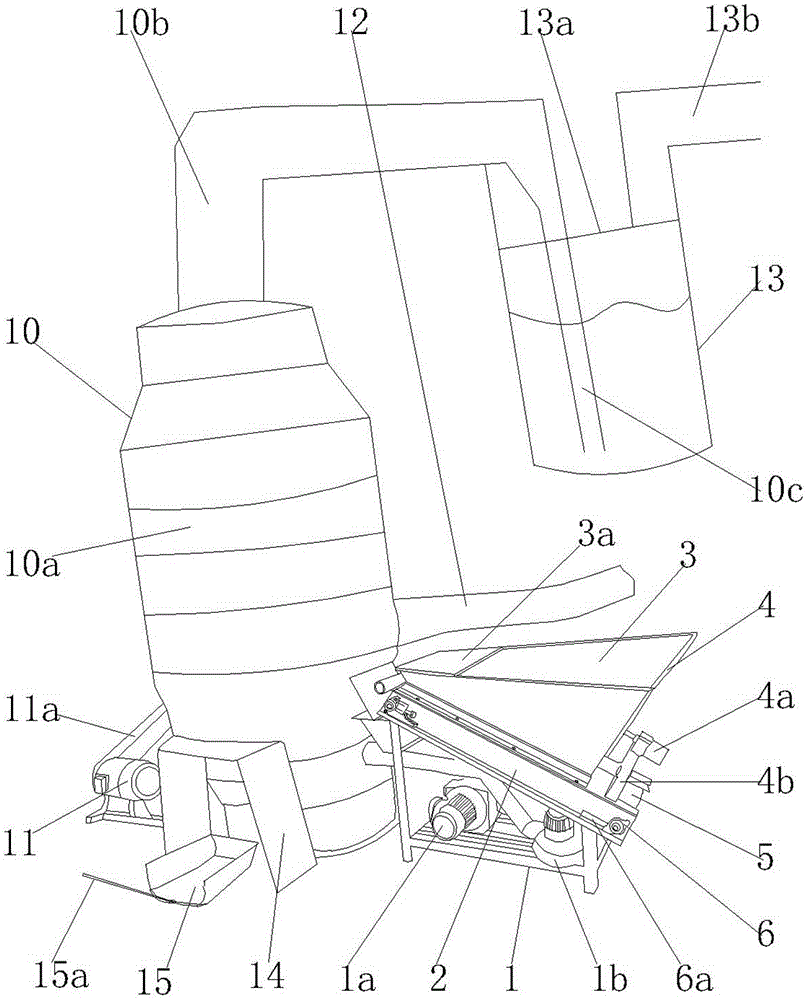

An automatic biofuel-combustion multipurpose furnace comprises a furnace body, wherein the furnace body consists of a combustion furnace, a fuel bucket, a feeding device and an automatic control device, the fuel bucket is positioned above the combustion furnace which is obliquely provided with a feeding pipe and internally provided with a combustion pool, the lower port of the feeding pipe is positioned above the combustion pool, the feeding device is arranged between the upper port of the feeding pipe and the combustion bucket, the furnace body is provided with an automatic igniter, the front end of the automatic igniter is contacted with the combustion bucket, a water drum wall is arranged on the side wall of the combustion furnace, a water inlet and a water outlet corresponding to the water drum wall are arranged on the combustion furnace, a water boiling port is arranged at the upper end of the combustion furnace and provided with a water boiling tray, a slag collection box is arranged under the combustion furnace, the combustion furnace is provided with an air inlet under the automatic igniter, an air outlet is arranged at the lower part of the furnace body and provided with an exhaust fan. The automatic biofuel-combustion multipurpose furnace can save non-renewable resources by combusting biofuel, and has the advantages of environment friendliness and safety.

Owner:烟台市宜和环保设备有限公司

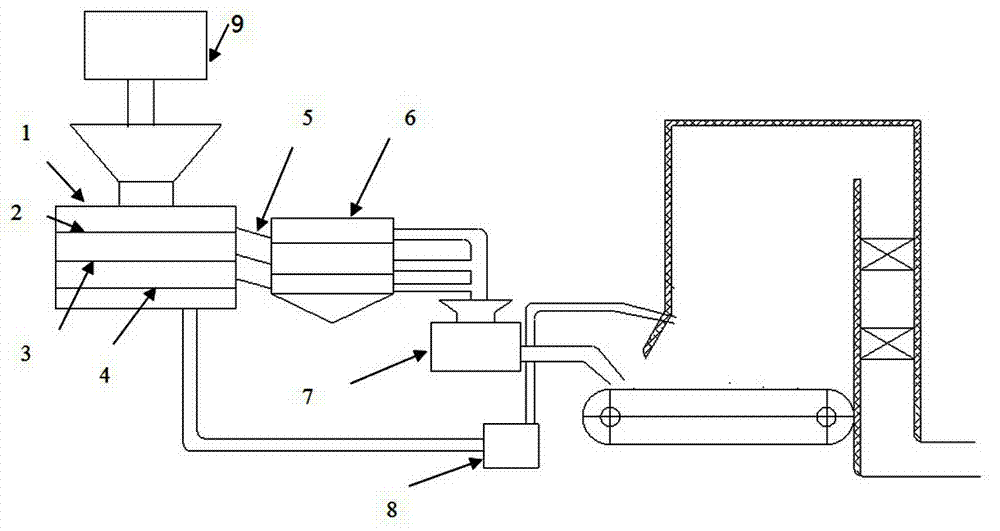

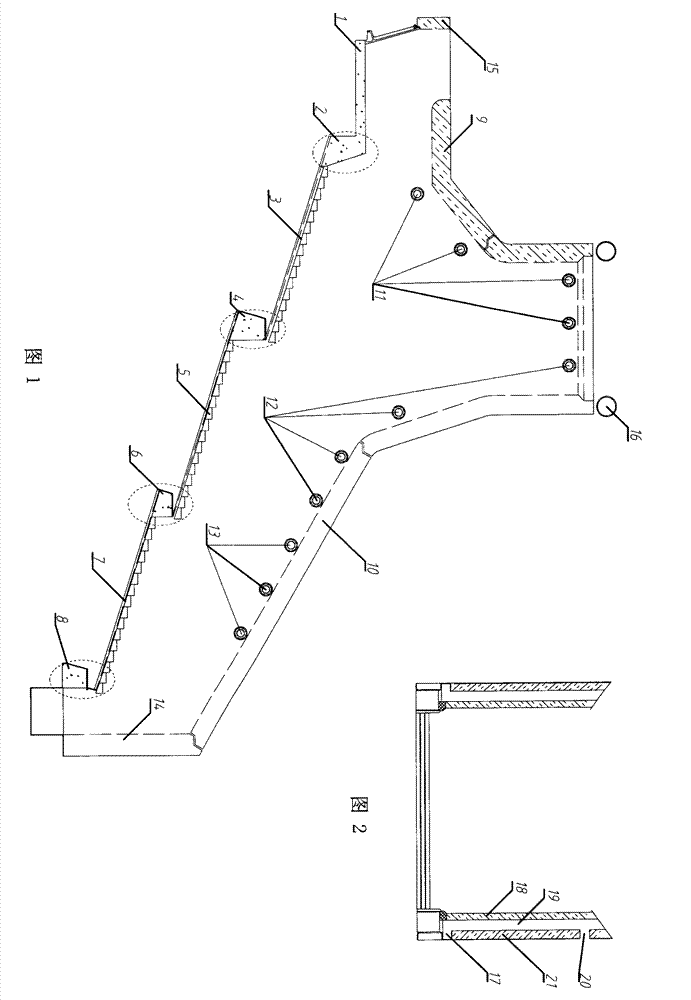

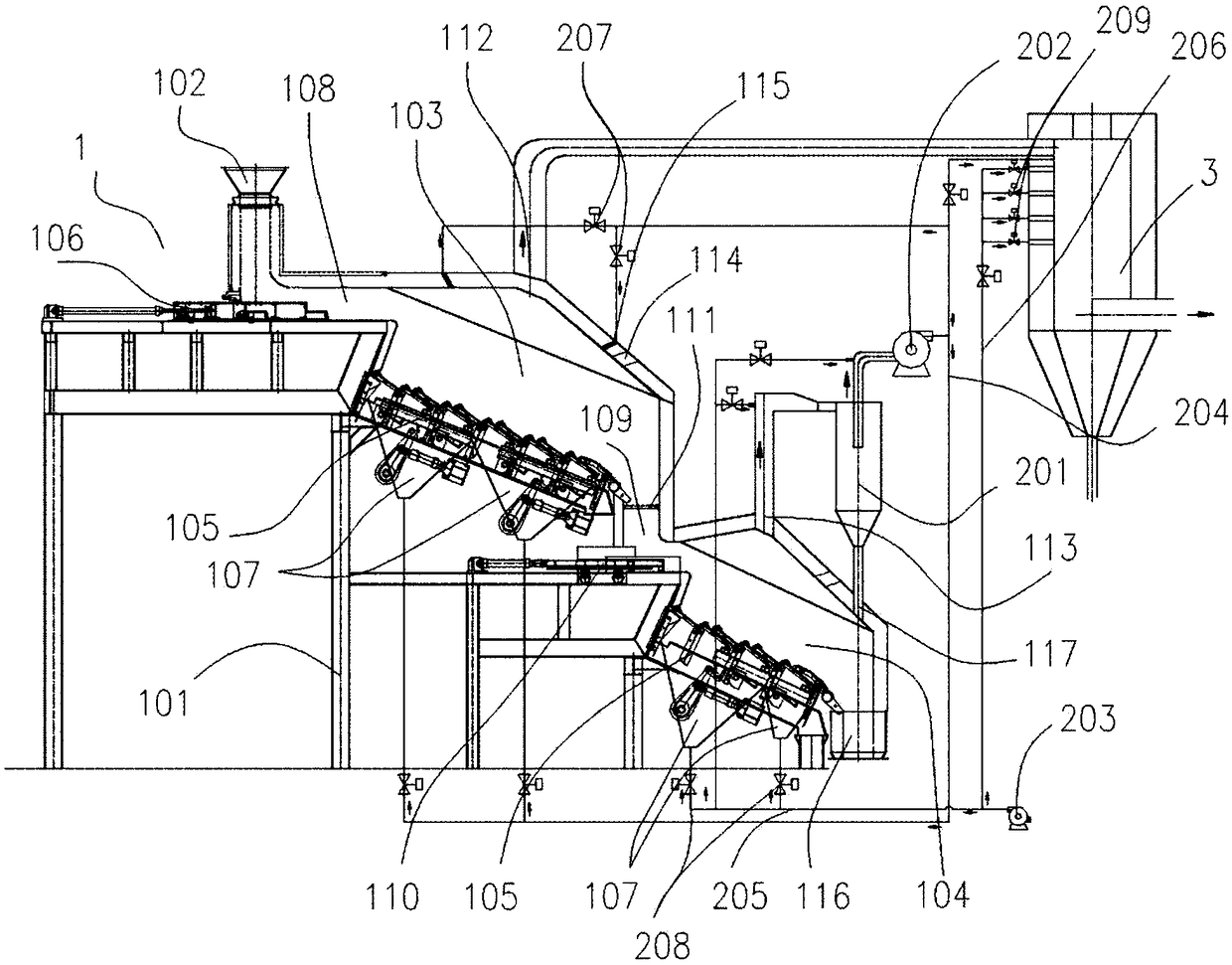

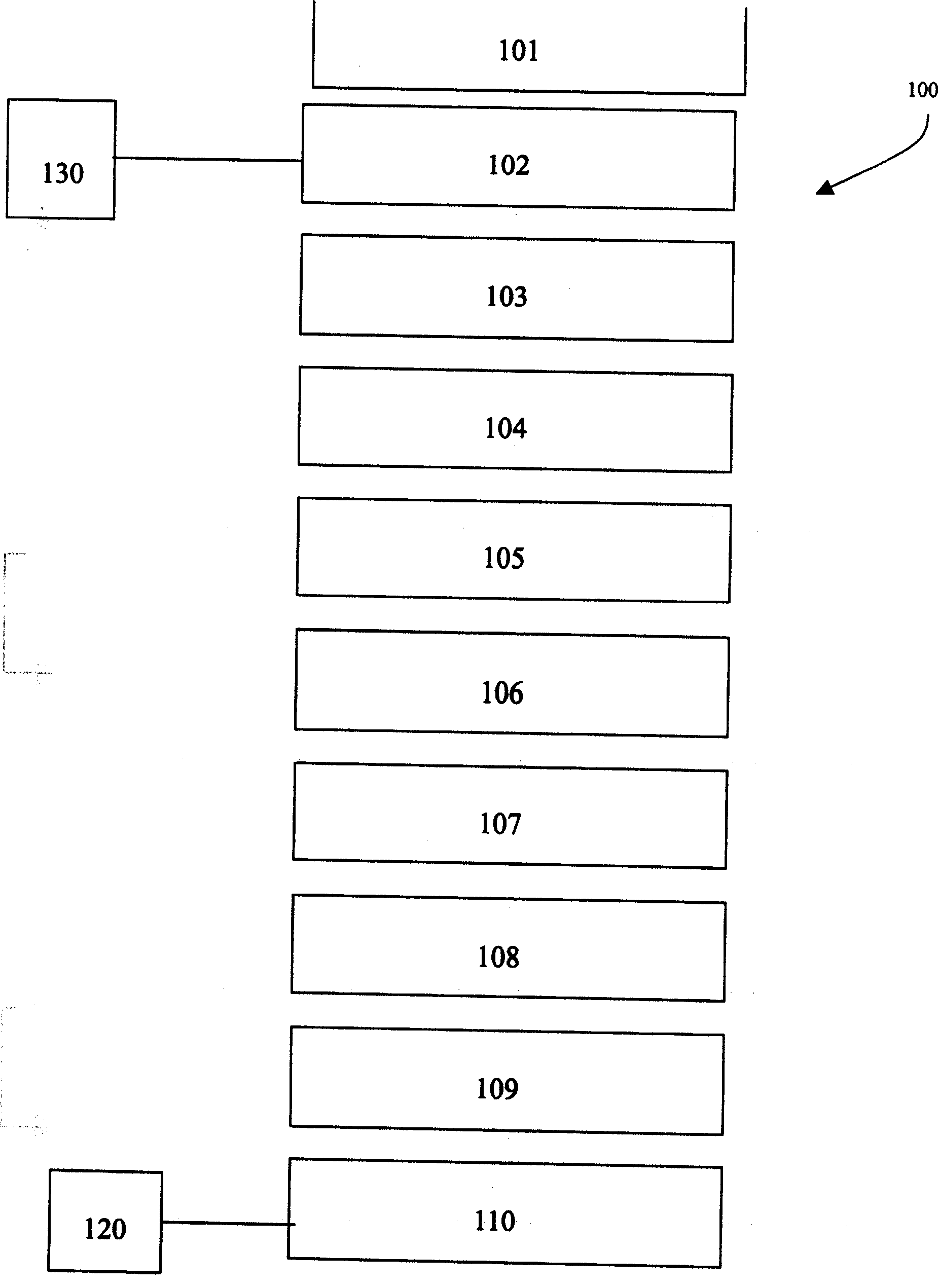

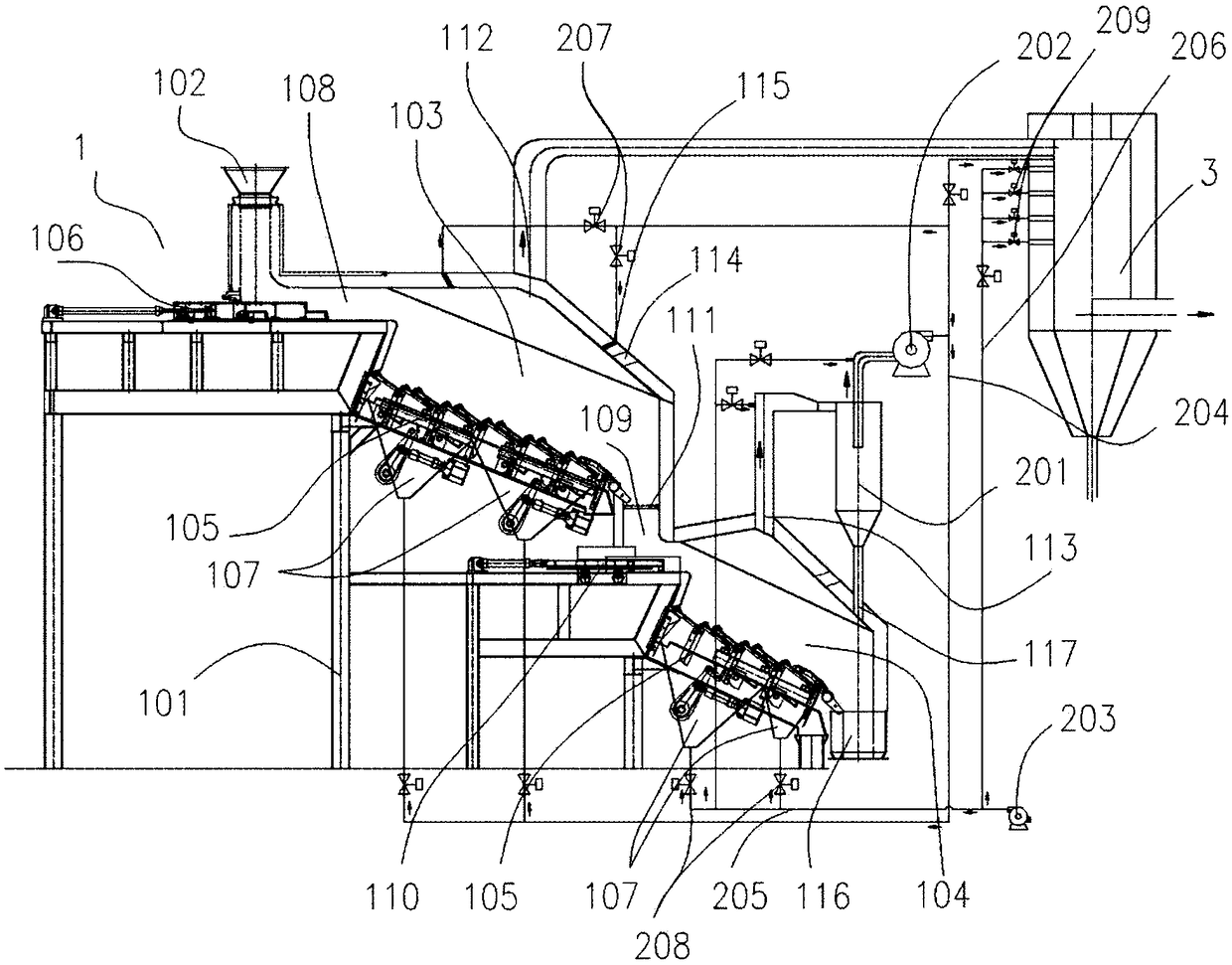

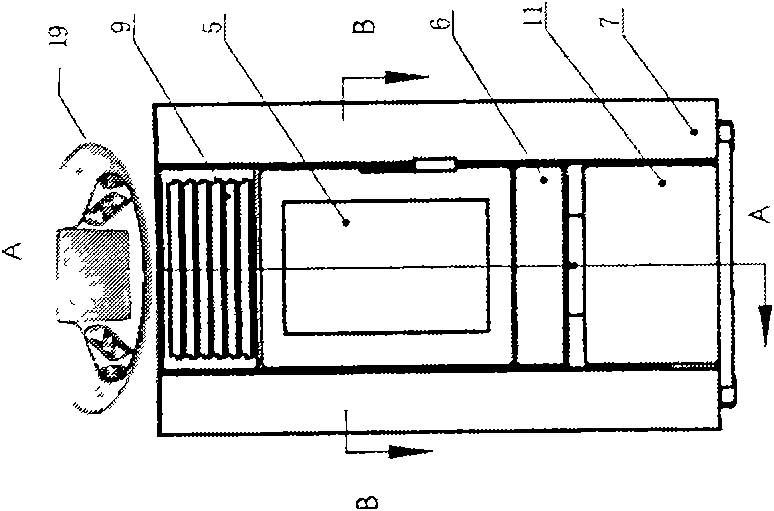

Online automatic classification device and classification method for fuel coal in composite combustion

InactiveCN104515140ARealization of online automatic gradingReasonable online screeningLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationCombustionNitrogen oxides

The invention discloses an online automatic classification device and a classification method for fuel coal in composite combustion, and belongs to the technical field of coal-fired industrial boiler fuel conveying. The online automatic classification device solves the problems of insufficient use of the fuel coal, low heat efficiency and high dust and nitrogen oxide emission in the prior art. The online automatic classification device for the fuel coal in the composite combustion comprises a crusher, a multistage separating screen, classification warehouses, a coal feeder and a coal grinding powder sprayer, the crusher is connected with the multistage separating screen, three screen meshes are fixed on the multistage separating screen, the bottom of the multistage separating screen is connected with the coal grinding powder sprayer through a pipeline, one end of each screen mesh is connected with an inlet of the corresponding classification warehouse through an inclined chute, and layers of the classification warehouses are respectively connected with the coal feeder through pipelines with discharge valves. Wire screening of the fuel coal is realized, coal combustion rate is increased, dust and nitrogen oxide emission is reduced, and the service life of a coal grinder is prolonged.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

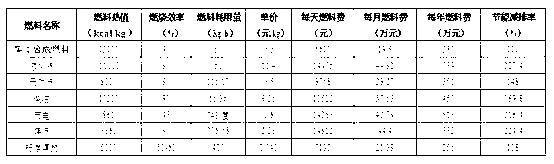

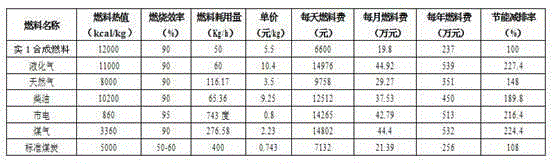

High-energy low-carbon synthetic fuel for kiln

InactiveCN103305289AFull and efficient combustionAchieve the best effect of energy saving and emission reductionLiquid carbonaceous fuelsCoal chemical industryCarbon dioxide

The invention provides a high-energy low-carbon synthetic fuel for a kiln. The high-energy low-carbon synthetic fuel is composed of 40-75% of methanol or ethanol, 5-30% of acetone, 5-25% of water, 0.5-3% of catalyst, 5-10% of combustion improver and 5-20% of emulsifier, 100% in total. The caloric value of the high-energy low-carbon synthetic fuel is 10000 kilocalorie / kg; and if the high-energy low-carbon synthetic fuel is applied to an industrial kiln, carbon dioxide residue can be eliminated; as a result, the fuel is combusted sufficiently so that emission of sulfur dioxide is low and the cost is low; the problem that methanol, ethanol and the like which are the by-products of petroleum and coal chemical industry cannot be taken as the fuel of the industrial kiln directly is solved; and a reliable and effective way is provided for saving energy and reducing emission of the industrial kiln, reducing the production cost and improving the economic benefit. The raw materials of the high-energy low-carbon synthetic fuel for the kiln are easily available and the application value of the high-energy low-carbon synthetic fuel for the kiln is high; and therefore, the high-energy low-carbon synthetic fuel for the kiln is one of the best substitutes for fuel such as liquefied petroleum gas.

Owner:陈惠良 +6

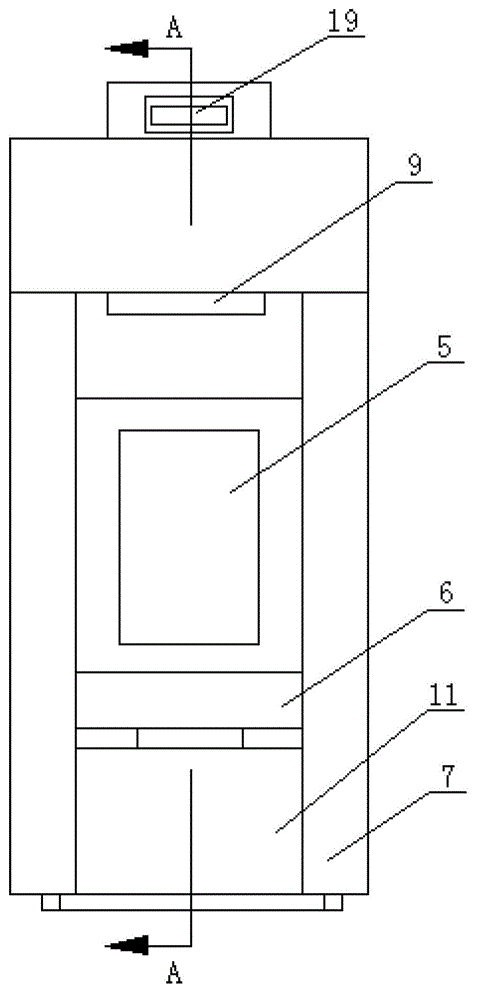

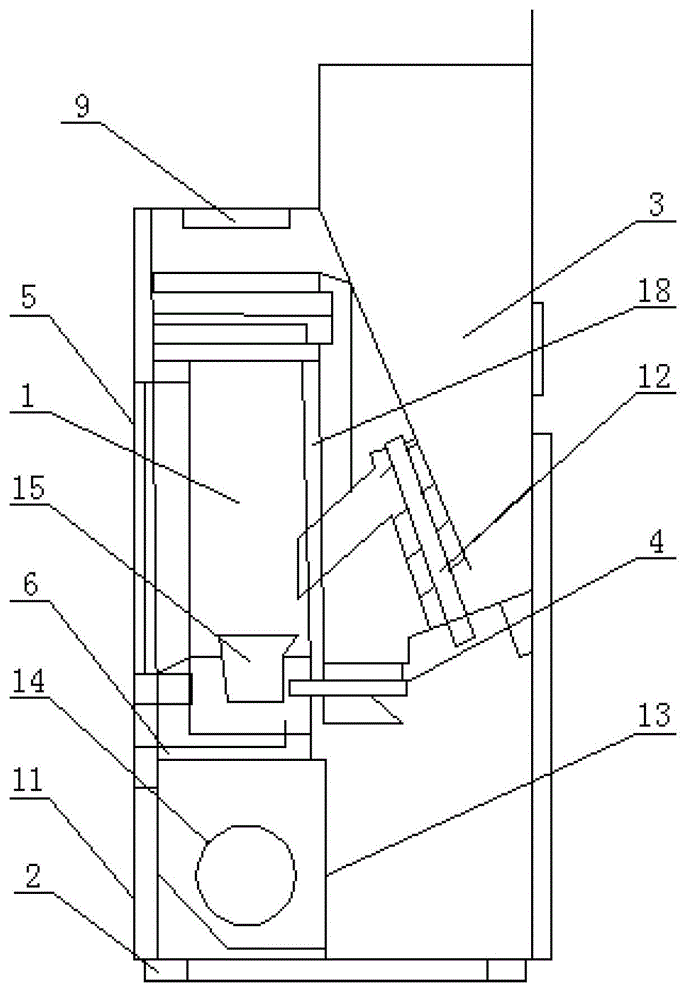

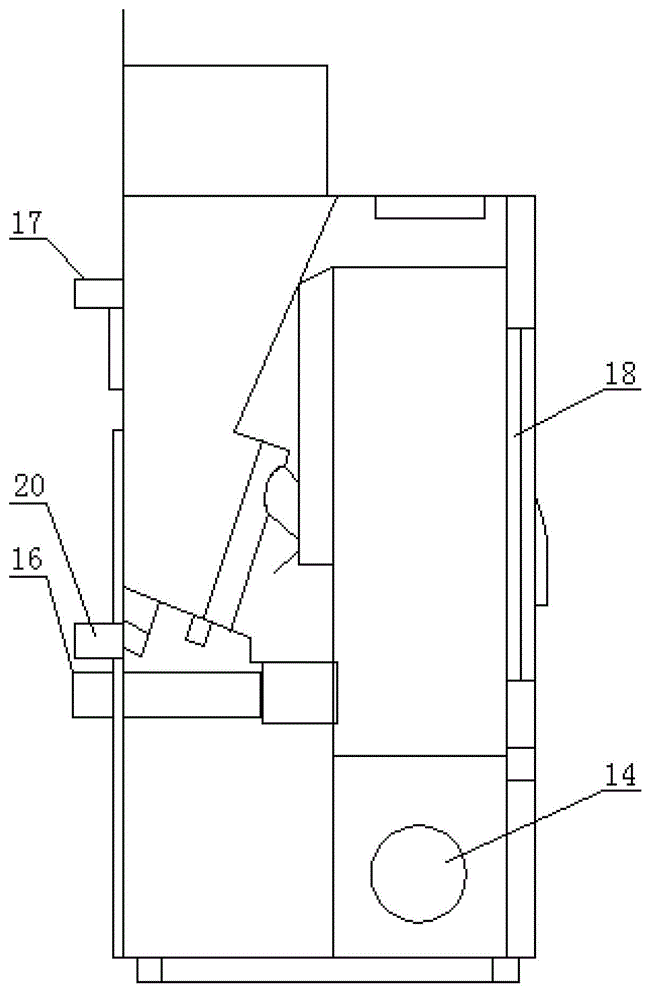

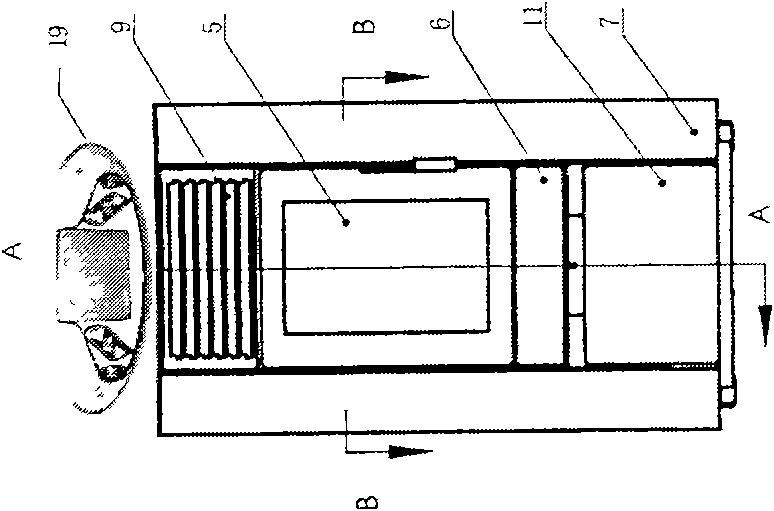

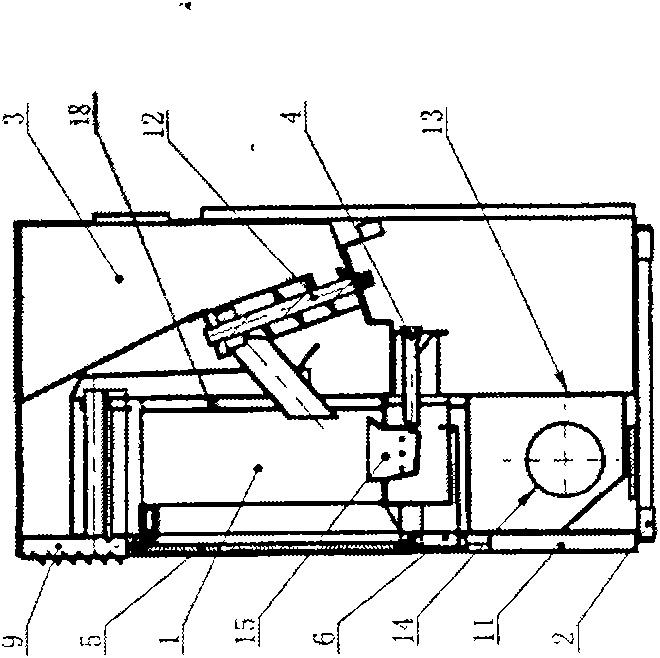

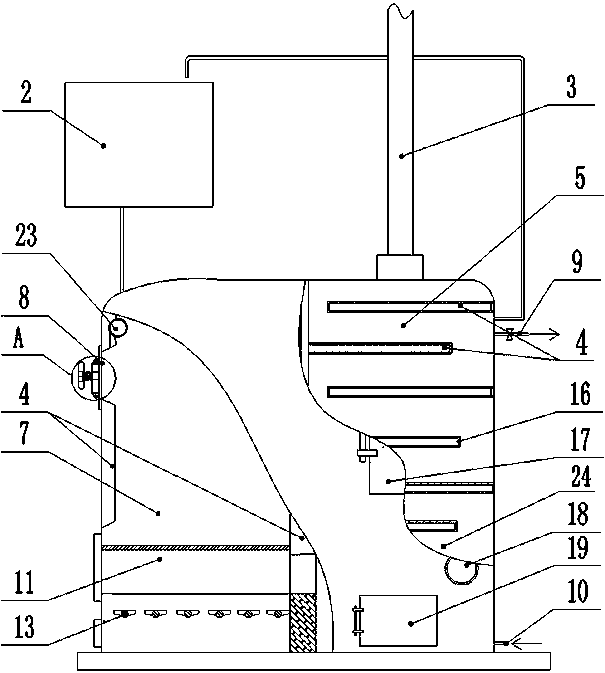

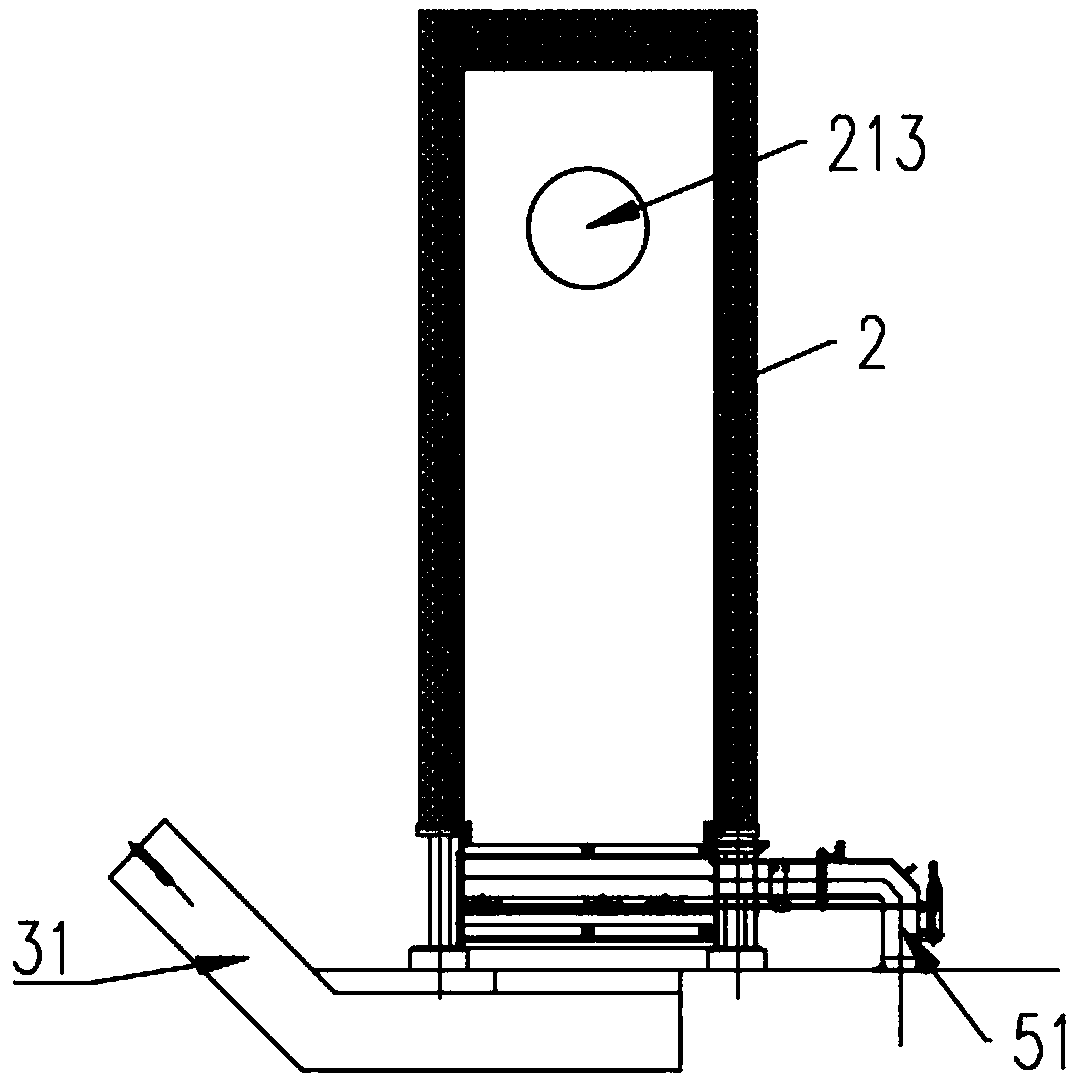

Automatic biological material combusting multipurpose furnace

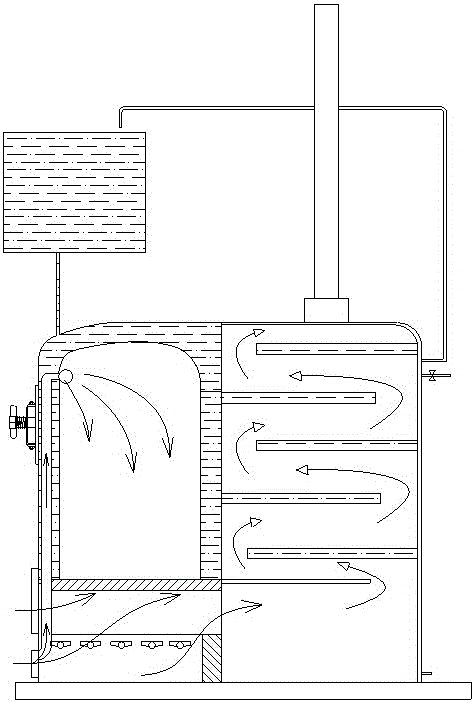

InactiveCN101576271AFull and efficient combustionImprove flammabilityStoves/ranges with convection heatingLighting and heating apparatusRural areaCombustion chamber

The invention discloses an automatic biological material combusting multipurpose furnace, which adopts an automatic ignition, automatic spiral feeding and suspending combustion mode, an enclosed negative pressure type and secondary return air to ensure no leakage of waste gas, simultaneous greatly reduces the discharge capacity of carbon monoxide, is safe, sanitary and environment-friendly, controls temperature outside a combustion chamber in a specific range, adopts a full enclosed combustion mode, can be used separately to achieve the heating effect, and also can be added with water and connected with radiators by pipelines to achieve water circulation heating; in addition, a waste gas discharge pipe can be connected with a hot gas fan of a furnace body through a pipeline to achieve windcirculation; in order to be suitable for rural areas, the furnace can be used for cooking; therefore, the furnace have multiple purposes, combusts waste residue, has high efficiency, low consumption,environment-friendly discharge, energy conservation and emission reduction, and brings safe living environment to life of people; and meanwhile, the furnace utilizes biological granules as fuel, achieves the aims of utilizing the waste and changing the waste into the treasure, makes the environment better, and solves the difficult problem of handling straws, old and useless woodware and peels offruits of urban residents of governments at all levels.

Owner:王义红

Automatic industrial furnace by burning biofuels

InactiveCN102353137ALow costAbundant raw materialsFluid heatersLump/pulverulent fuel feeder/distributionCombustion chamberSlag

The invention provides an automatic industrial furnace by burning biofuels. The furnace comprises a furnace body, a fuel hopper and an automatic feeding mechanism, wherein a combustion chamber, an air inlet, an air outlet, a water tank and a flue gas channel are arranged in the furnace body, the combustion chamber is provided with a conveyor belt device, the conveying tail end of the automatic feeding mechanism extends into the combustion chamber and is positioned above the conveying initial end of the conveyor belt device, the side of the conveying initial end of the conveyer belt device is provided with an automatic igniter, a slag collection box is arranged below the conveyor belt device, the air inlet is provided with an air inlet fan, the air outlet is provided with an air outlet fan, the shell of the air exhaust fan is provided with a flue temperature sensor and a flue pressure sensor, the water tank is provided with an water inlet and a water outlet, the water inlet and the water outlet are arranged on the furnace body and are respectively provided with a water circulation controller and a water temperature sensor, and the outside of the furnace body is provided with a circuit control system. According to the invention, the automatic industrial furnace by burning the biofuels has the advantages of environmental friendliness and safety.

Owner:烟台市宜和环保设备有限公司

Normal-pressure smoke-free environment-friendly combustion furnace

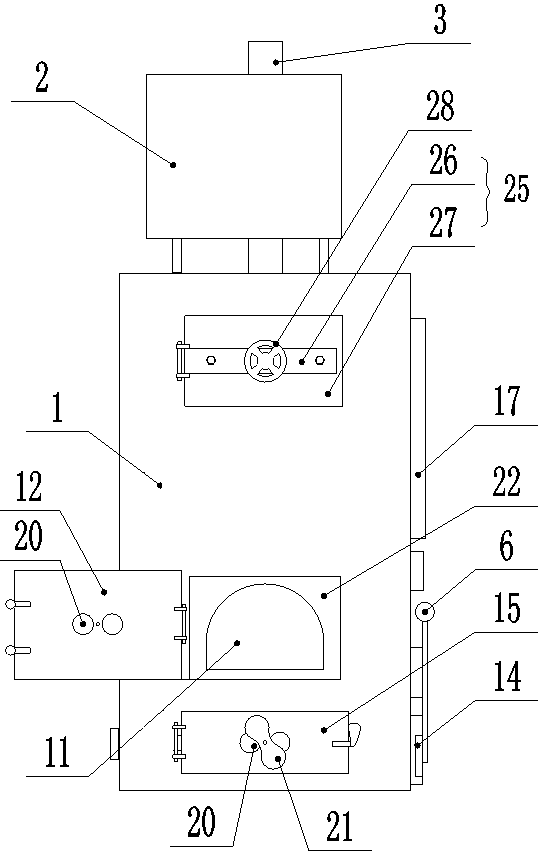

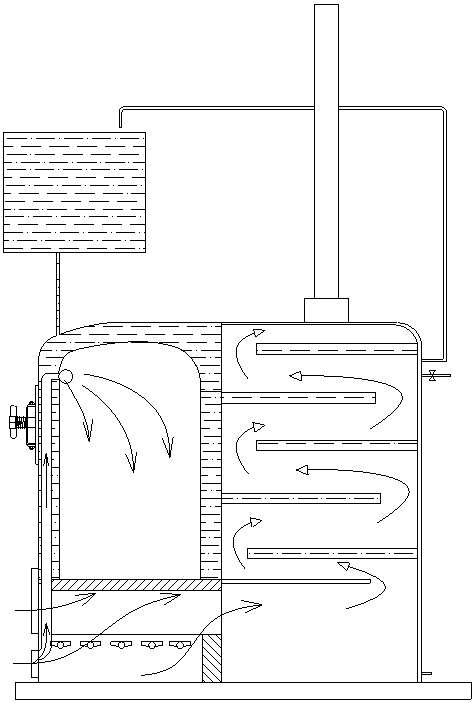

ActiveCN106322439ABurn fullyControl the feeding speedLighting and heating apparatusStove/ranges for heating waterCombustion chamberEngineering

The invention discloses a normal-pressure smoke-free environment-friendly combustion furnace and relates to the technical field of combustion furnaces. The combustion furnace comprises a furnace body and a water jacket, wherein the water jacket is arranged inside the furnace body and is communicated with a water tank; a rotary smoke flue connected with a chimney is arranged at the upper part of the back of the furnace body; a feeding opening communicated with a dry distillation chamber is formed in the upper part of the side wall of the furnace body; a water discharging opening and a water returning opening are formed in the back of the furnace body; a combustion kiln is arranged at the lower part of the dry distillation chamber; the combustion kiln is horizontal; the longitudinal section of the combustion kiln is arched; one end of the combustion kiln is fixed at the front of the furnace body; a kiln door is formed in an open end; the other end of the combustion kiln is fixed in the middle of the furnace body; gaps are formed between two sides of the combustion kiln and the inner wall of the dry distillation chamber; the back of the combustion kiln is communicated with a secondary combustion chamber; a furnace grate is arranged under the combustion kiln; a furnace dust cleaning mechanism connected with the furnace grate is arranged on the outer side of the furnace body; a main dust cleaning door with an air inlet is arranged under the furnace grate. According to the normal-pressure smoke-free environment-friendly combustion furnace, the fuel can be dispersed in the dry distillation chamber and the furnace grate by virtue of the combustion kiln; through the adoption of the combustion kiln and the secondary combustion chamber, the fuel can be fully combusted; through the adoption of the S-shaped rotary smoke flue, the dust emission is reduced; the purposes of saving energy, avoiding smoke and protecting environment can be achieved.

Owner:SHIJIAZHUANG CHUNYAN HEATING EQUIP

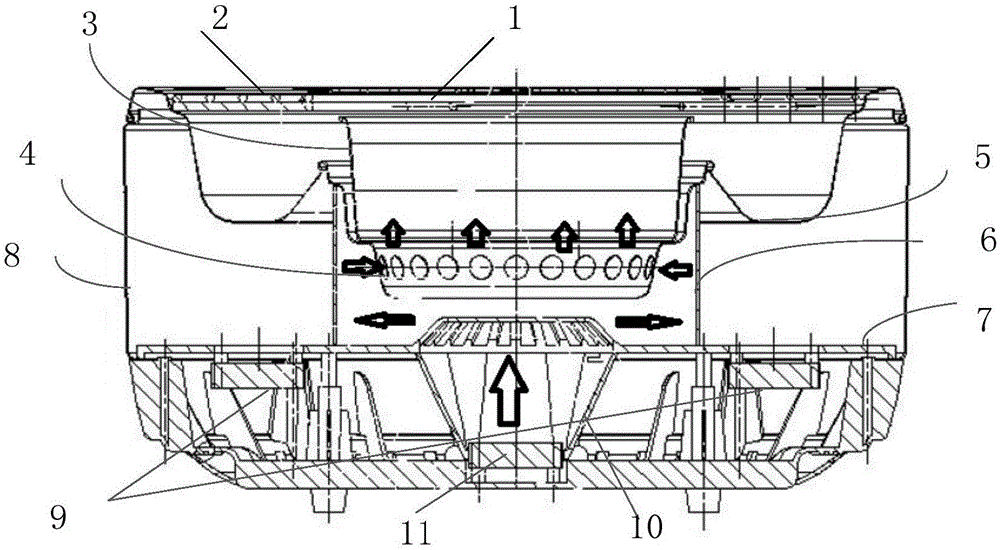

Barbecue stove

The embodiment of the invention relates to a barbecue stove, which comprises a base, a built-in base plate, an air blower, an oil receiving tray, an ignition box, an air baffle plate, a charcoal box and a shell, wherein air delivered by the air blower at the bottom, after being reflected by the air baffle plate, enters the ignition box. According to the embodiment disclosed by the invention, since the air delivered by the air blower at the bottom is reflected by the baffle plate, wind force is softer and more durable, so as to prevent charcoal ash from rising.

Owner:周明敏 +1

Environment-friendly efficient garbage continuous incineration furnace and working method

InactiveCN106958825AImprove combustion efficiencyReduce emissions of harmful substancesIncinerator apparatusEnvironmentally friendlyTuyere

The invention provides an environment-friendly and high-efficiency garbage continuous incinerator, which includes a continuous transport device, a combustion furnace, a material inlet, a linkage wheel, an oxygen supply air pump, a transmission component, a partition, an oxygen supply air pump, an oxygen inlet pipe, a connecting rod, Material blocking block, bracket, rolling wheel, high temperature resistant conveying belt, high temperature resistant plastic block, air guide groove, air supply pipe, air supply pump, drying air outlet; the invention has simple structure, can be continuously dried to improve waste paper pulp combustion High efficiency and continuous feeding to improve combustion efficiency, reduce environmental pollution, energy saving and environmental protection.

Owner:ZHEJIANG HUACHUAN IND GRP

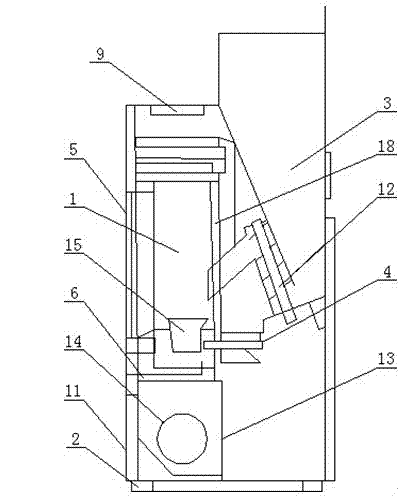

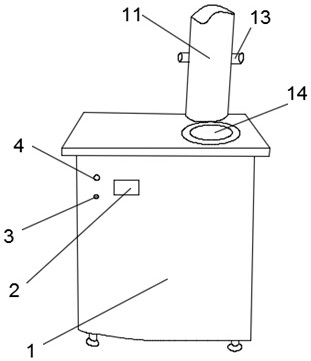

Automated bio-fuel burning multi-purpose furnace

InactiveCN102410623AFull and efficient combustionLow costStove/ranges for heating waterWater heatersThermodynamicsSlag

The invention relates to an automated bio-fuel burning multi-purpose furnace, comprising a furnace body; the furnace body comprises a burning furnace, a fuel bucket, a material loading device and an automatic control device; the fuel bucket is located at one side above the burning furnace; the burning furnace is obliquely provided with a material inlet tube; a burning pool is disposed in the burning furnace; the lower opening of the material inlet tube is located above the burning pool; the material loading device is disposed between the upper opening of the material inlet tube and the fuel bucket; the furnace body is provided with an automatic igniter; the front end part of the automatic igniter is contacted with the fuel bucket; the side wall of the burning furnace is provided with a water heating chamber; the burning furnace is provided with a water inlet and a water outlet corresponding to the water heating chamber; the upper end part of the burning furnace is provided with a water boiling opening; the water boiling opening is provided with a water boiling tray; a furnace slag collecting box is disposed under the burning furnace; the burning furnace is provided with an air inlet under the automatic igniter; the lower part of the furnace body is provided with an air outlet; the air outlet is provided with an exhaust fan. The invention uses bio-fuel, which can save non-renewable resource and has advantages of environment protection and safety.

Owner:烟台市宜和环保设备有限公司

Garbage incinerator combustion chamber

InactiveCN104266198AFull and efficient combustionIncrease temperatureIncinerator apparatusCold airCombustion chamber

The invention discloses a garbage incinerator combustion chamber and relates to the technical field of environmental friendly electric generation. A combustion chamber front arch and a combustion chamber rear arch are formed by hanging refractory bricks; a combustion chamber rear wall and a combustion chamber front wall are formed by casting materials; a pusher level difference wall, a drying section grate level difference wall, a combustion section grate level difference wall and an ash section grate level difference wall between a pusher, a drying section grate, a combustion section grate and an ash section grate are formed by casting materials; bilateral side walls of the drying section grate, the combustion section grate and the ash section grate are formed by air cooling walls; refractory bricks are symmetrically arranged on bilateral sides of the grates; exteriors of the refractory bricks are provided with insulating bricks; an air cooling wall channel is formed between the refractory bricks and the insulating bricks; the upper end and the lower end of the air cooling wall channel are respectively provided with a hot air outlet and a cold air inlet. The garbage incinerator combustion chamber has the advantages of allowing long-time stable combustion and operation, being simple in operation, not only guaranteeing normal combustion of low heating value garbage and but also guaranteeing high heating value garbage not coking the furnace wall.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

High-low type smokeless energy-saving hot water stove

InactiveCN1924448AReasonable structural designIncrease the heat exchange areaStoves/ranges with convection heatingWater heatersHigh energyConnection design

This invention relates to high energy hot water furnace without smoke, wherein, its main part comprises extraction furnace chamber, furnace inside connection water part, center upper and down channels, level fire channel, ash storage bare, furnace stand inner chamber and smoke exit channel; the part is fixed and connected with water for automatically water recycling; the furnace using special center upper and down channel devices with different extra function heat exchange tubes and high level stand inner chamber and exit smoke channel connection design to realize whole furnace heat exchange for large area.

Owner:马彦林

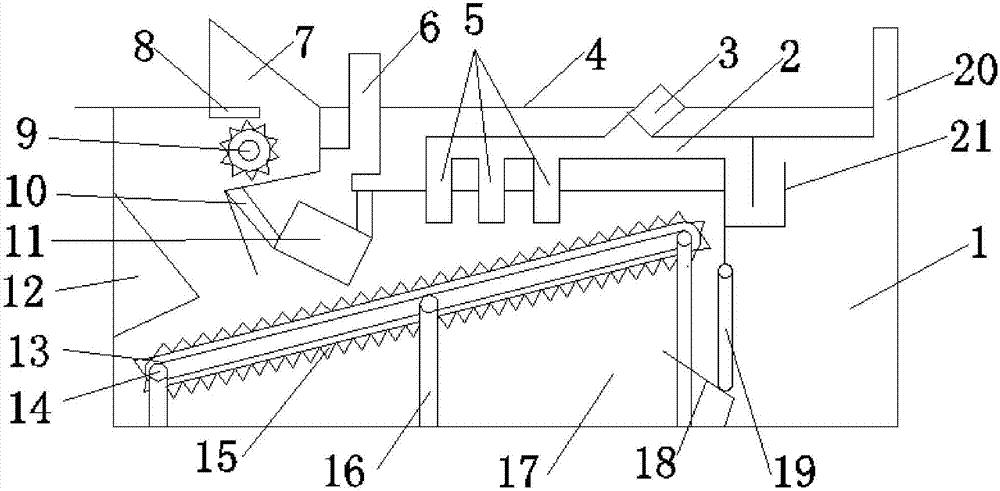

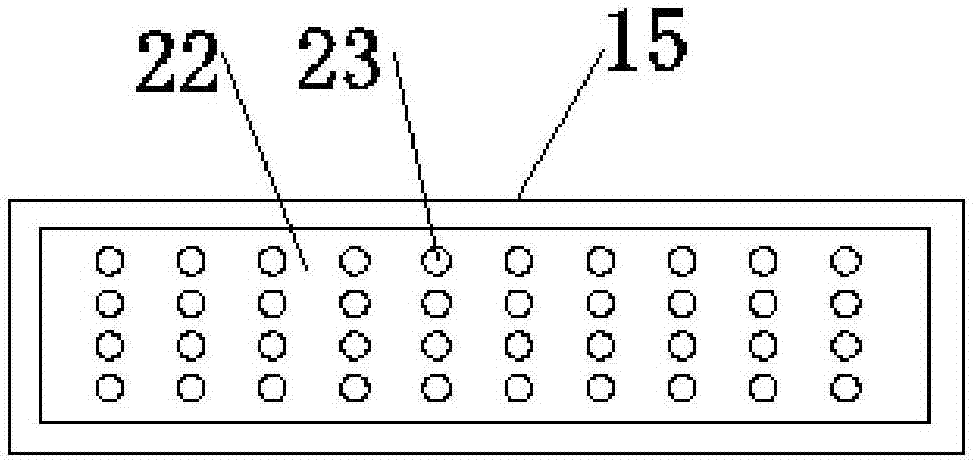

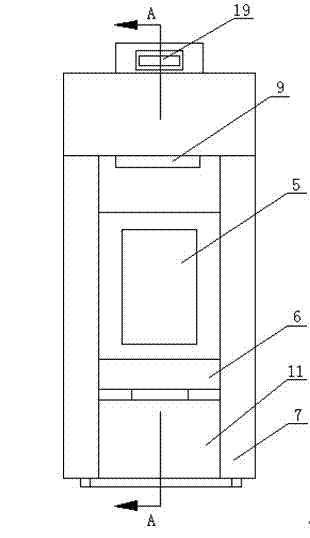

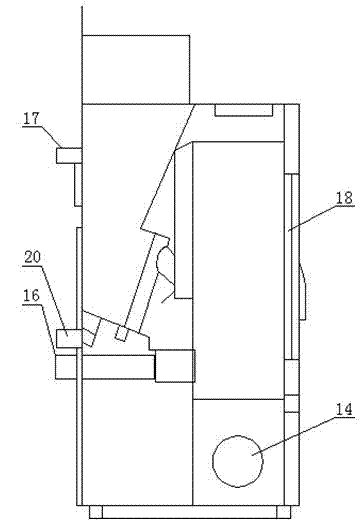

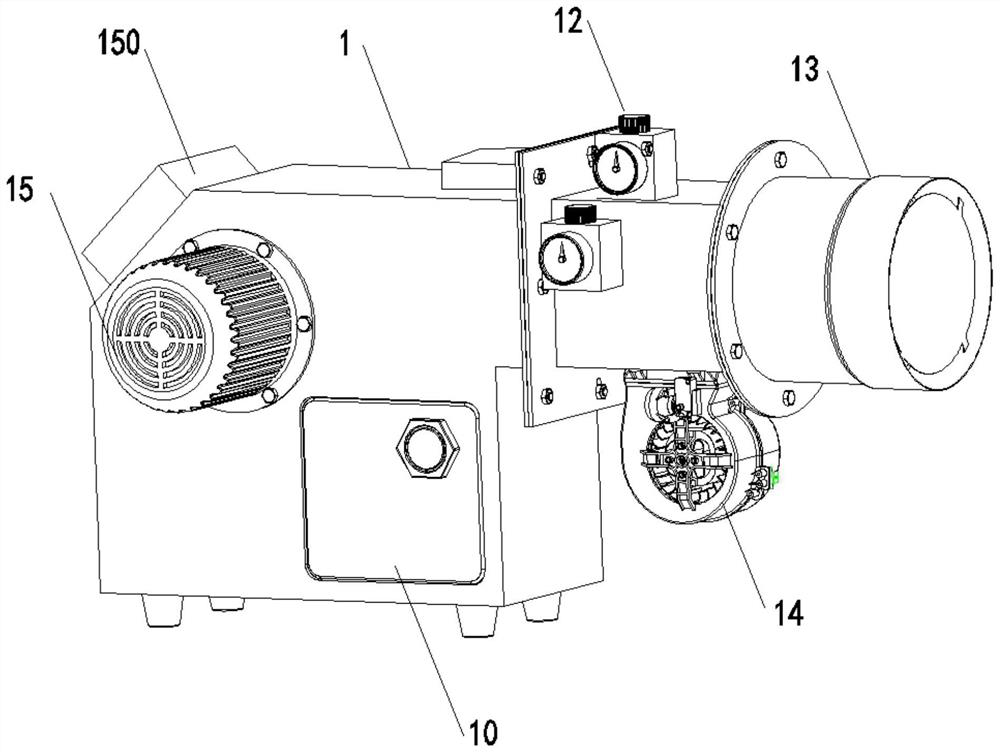

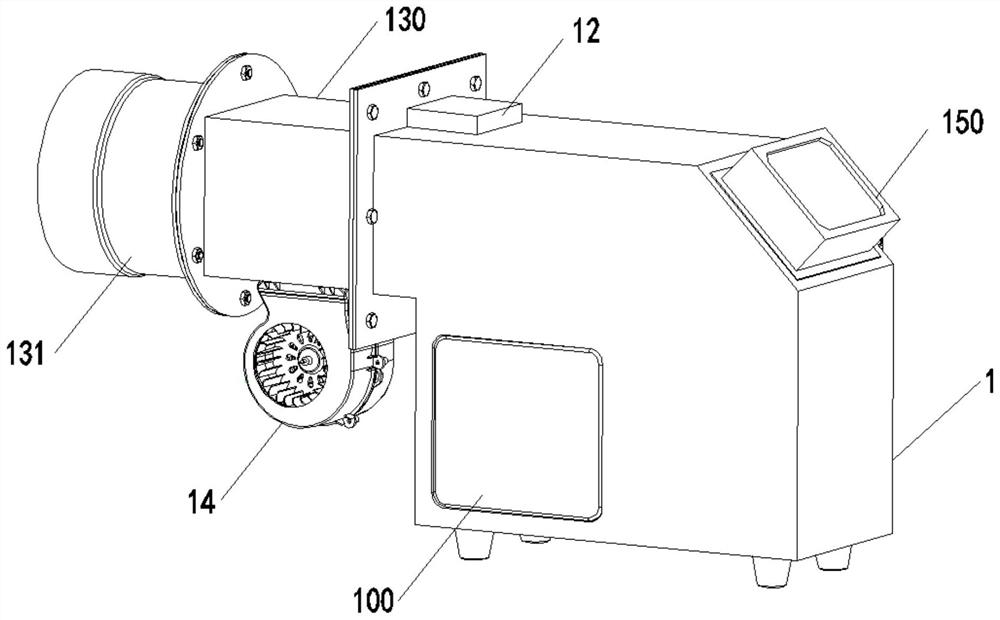

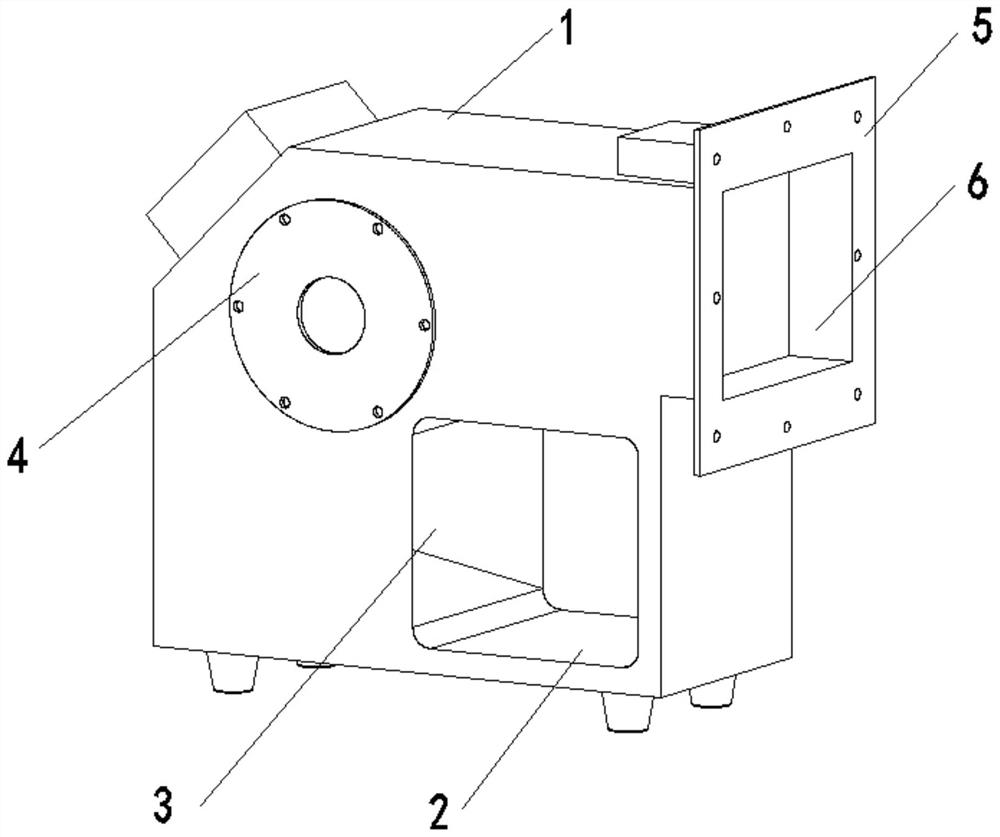

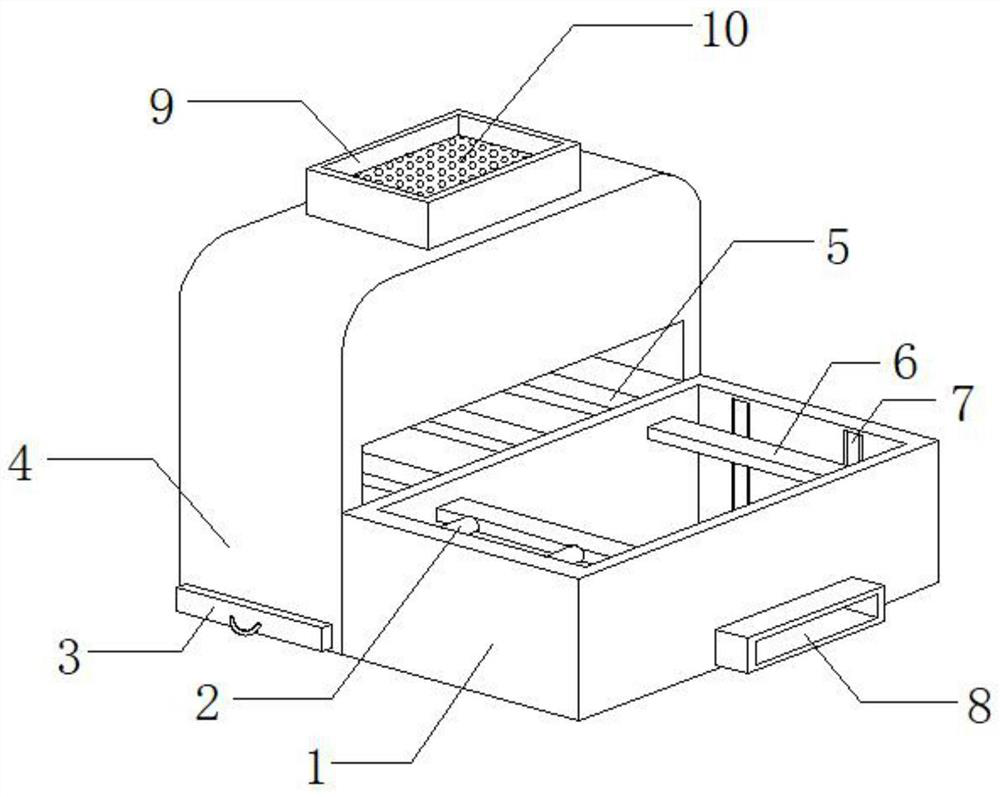

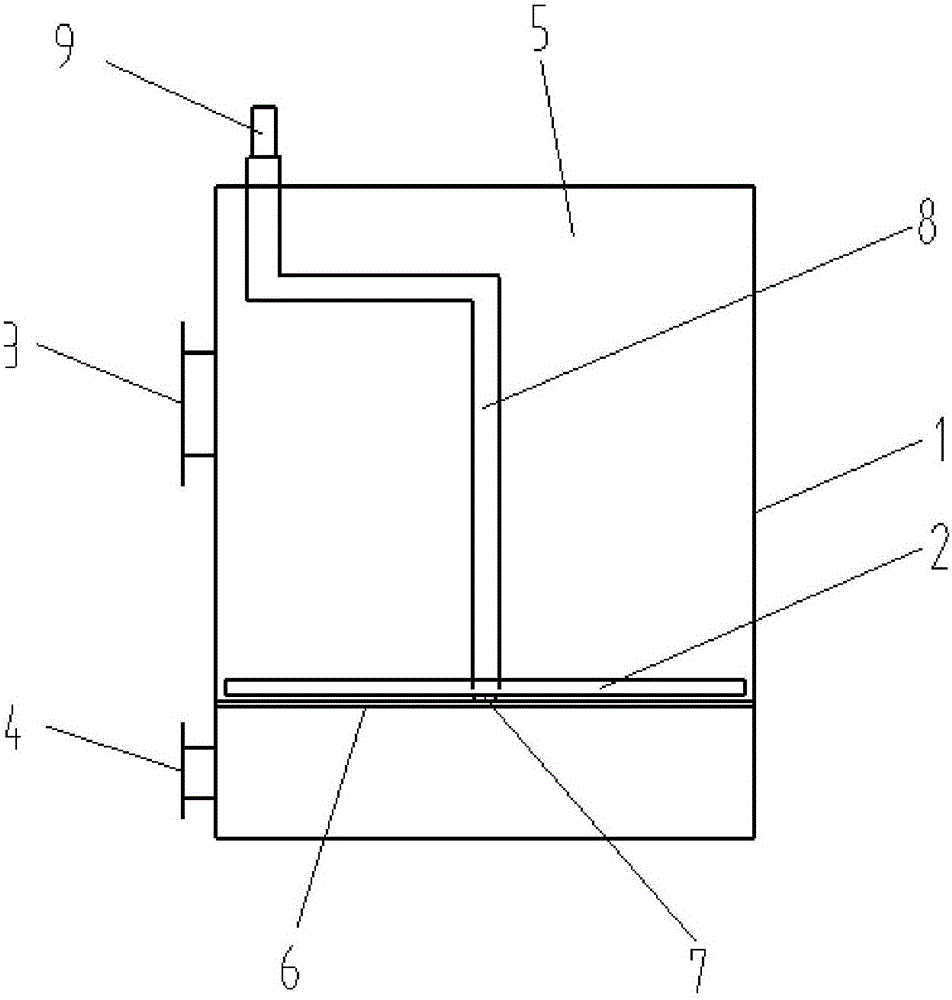

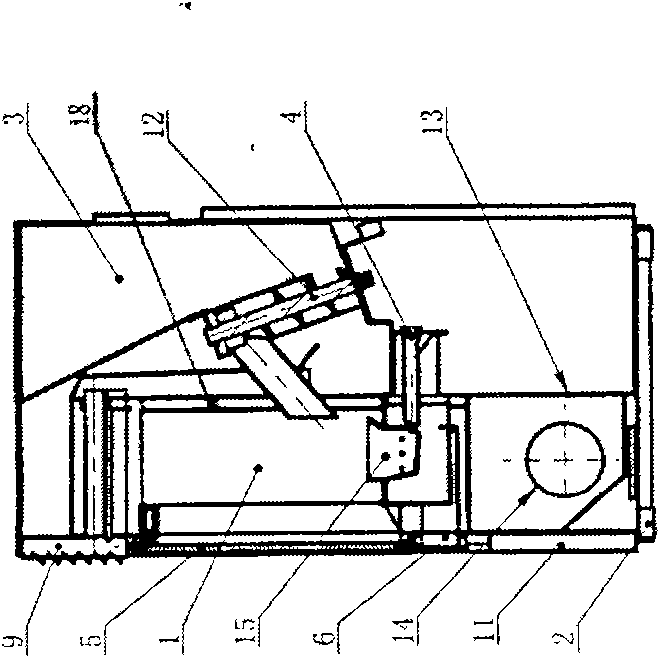

Hot air boiler with automatic charging function

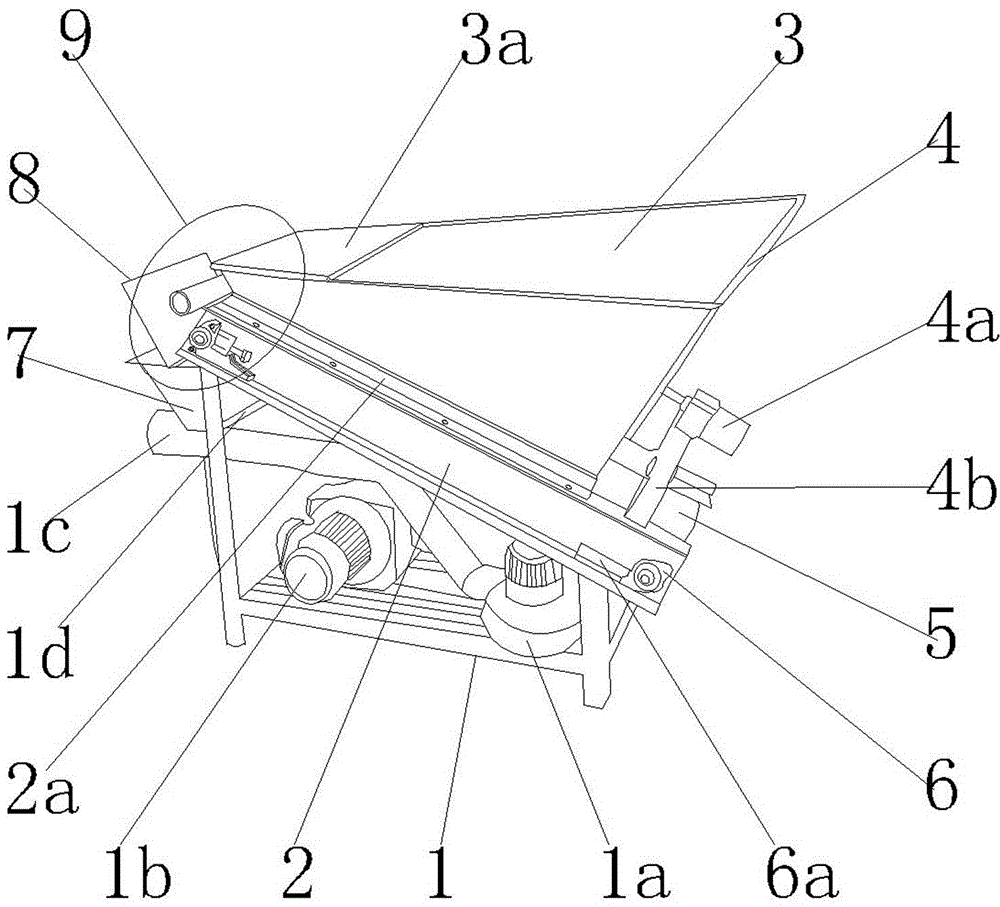

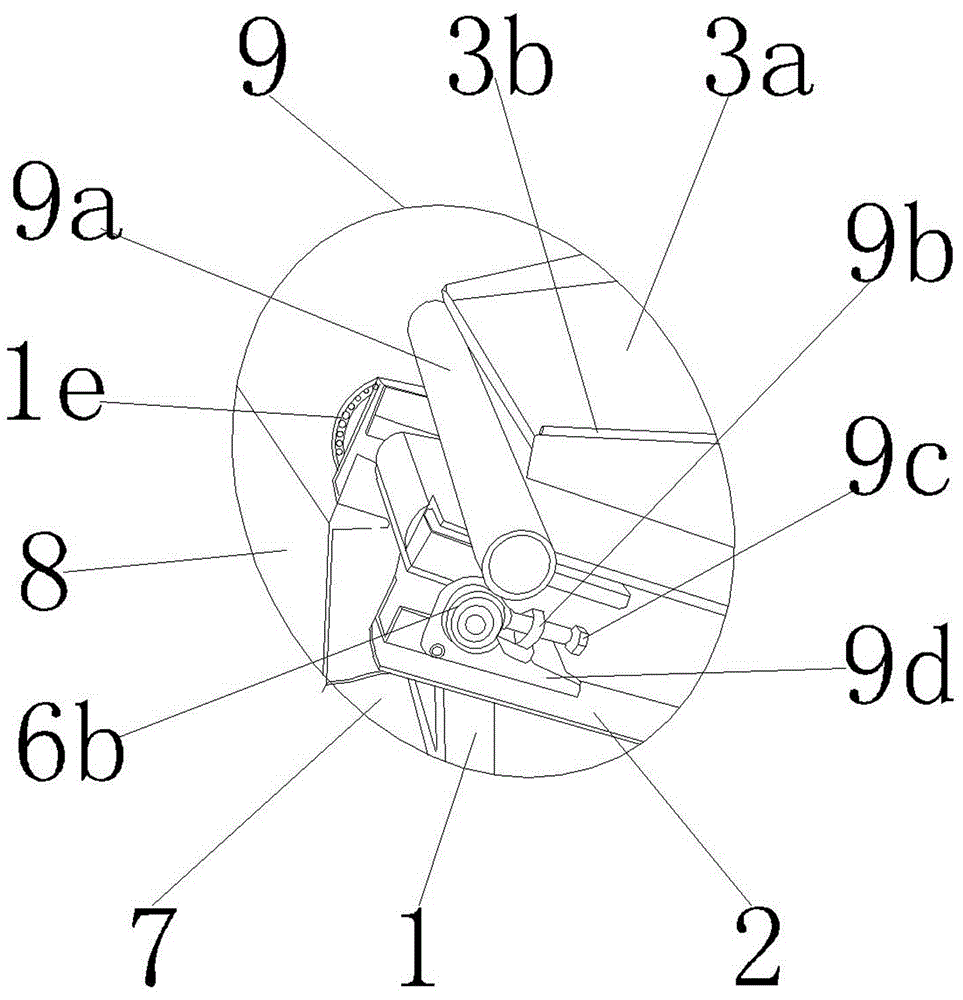

InactiveCN103983016AFull and efficient combustionStable heat deliveryFluid heatersLump/pulverulent fuel feeder/distributionThermal insulationProcess engineering

The invention provides a hot air boiler with an automatic charging function. The boiler comprises a chassis of which the bottom is parallel with the ground; the upper part of the chassis is inclined; the chassis is provided with a conveying plate; the conveying plate and the upper part inclined shape of the chassis are correspondingly fixedly arranged; the conveying plate is provided with a feeding slot of which the backside wall end is provided with a vibration plate; the position, corresponding to the conveying plate, of the lower part of the feeding slot is provided with a conveyor belt; a rotary roll is arranged at the mounting position of the conveyor belt and the conveying plate; a receiving hopper is arranged at the conveyor belt and the front end, for conveying materials, at the left part of the feeding slot; the receiving hopper is provided with a charging plate; a transmission regulation feeding mechanism is arranged at the conveyor belt and the upper part of the left end of the feeding slot; a boiler is arranged at the left side part of the chassis; a thermal insulation layer surrounds around the outer wall of the boiler; a smoke discharging pipeline is arranged at the upper part of the boiler and can be used for automatic charging; waste chips, namely, wood and bamboo chips, generated in the production are fully used, are charged and are supplied to a burning furnace to perform efficient and full burning, thus realizing the advantages of environment friendliness, dedusting, stable heat supply and the like.

Owner:浙江鸿星文具有限公司

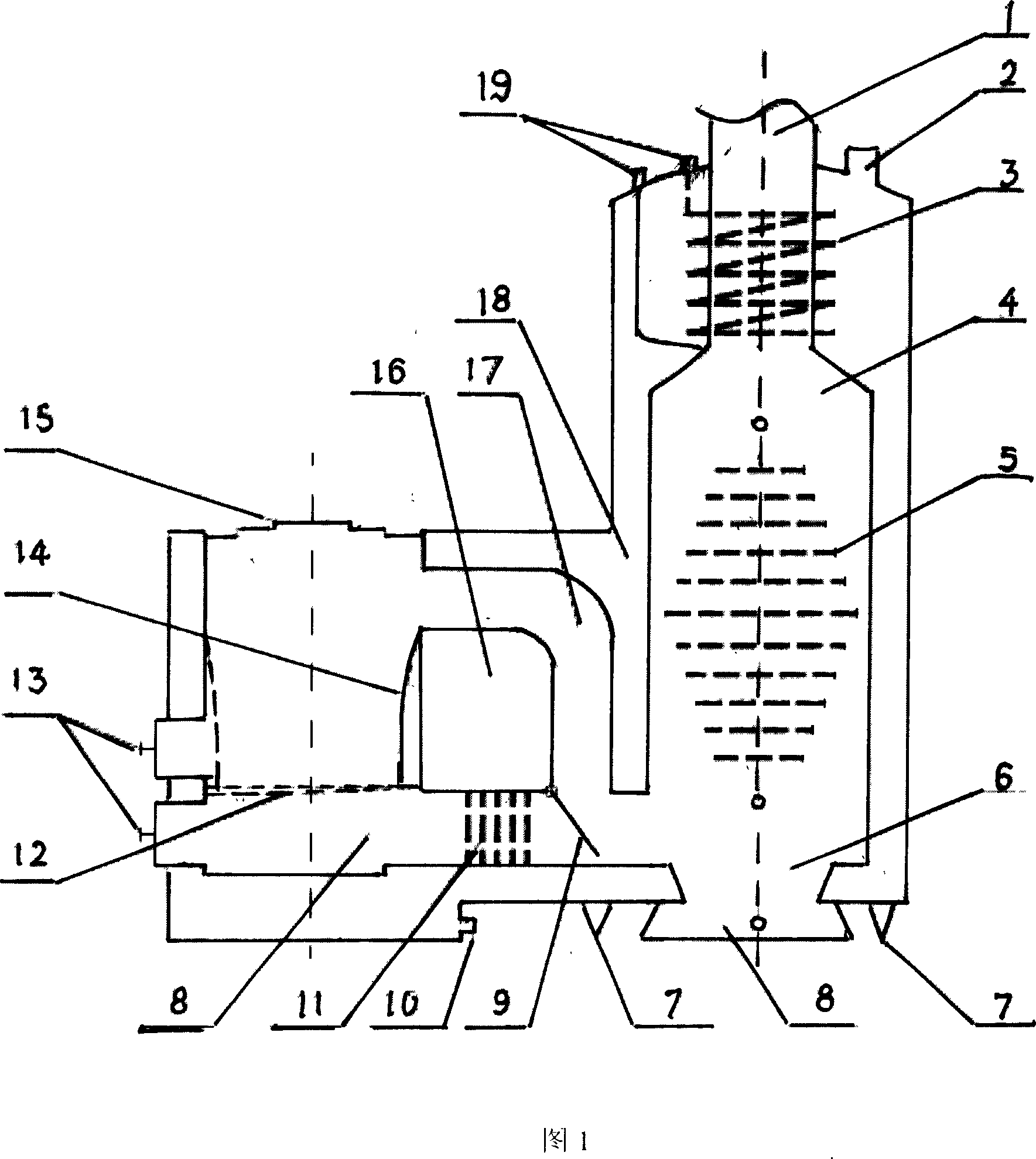

Efficient in-situ fuel gas thermal desorption heating device and method

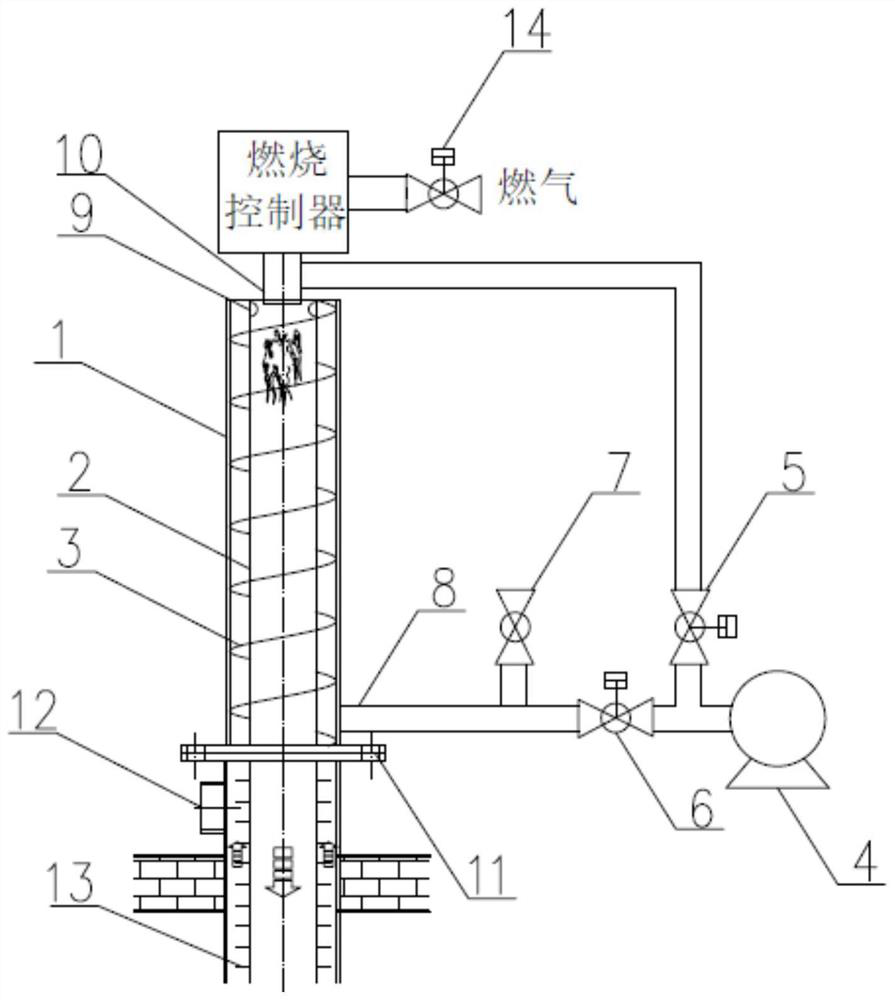

PendingCN114659109AFull and efficient combustionReduce consumptionContaminated soil reclamationAir heatersThermodynamicsFlue gas

The invention discloses an efficient in-situ fuel gas thermal desorption heating device which comprises a combustion controller, a combustion well, an air blower and a heating well. The combustion well is a concentric barrel composed of an inner pipe and an outer pipe, a spiral flow guide groove is formed between the inner pipe and the outer pipe, a plurality of air inlet distribution holes are formed in the inner pipe wall on the upper portion of the top spiral flow guide groove, and the outer pipe of the combustion well is connected with a secondary air spiral air inlet of an air blower. The air blower supplies primary air and secondary air to the combustion well in a grading mode and is interlocked with gas supply, and meanwhile a waste gas connector valve is arranged on a secondary air inlet pipeline. Fins are arranged on the outer wall of the heating well inner pipe in a partitioned mode according to the stratum pollution condition. Secondary air / condensed waste gas is tangentially fed and spirally exchanges heat with combustion high-temperature flue gas, so that the gas inlet temperature is increased, combustion components are fully mixed, efficient combustion of fuel gas is realized, and the comprehensive consumption of the fuel gas is reduced; meanwhile, fins are arranged on the outer wall of the heating well inner pipe in a partitioned mode, the pertinence of heating the underground polluted stratum through heat energy is improved, and comprehensive and efficient utilization of the heat energy is achieved.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

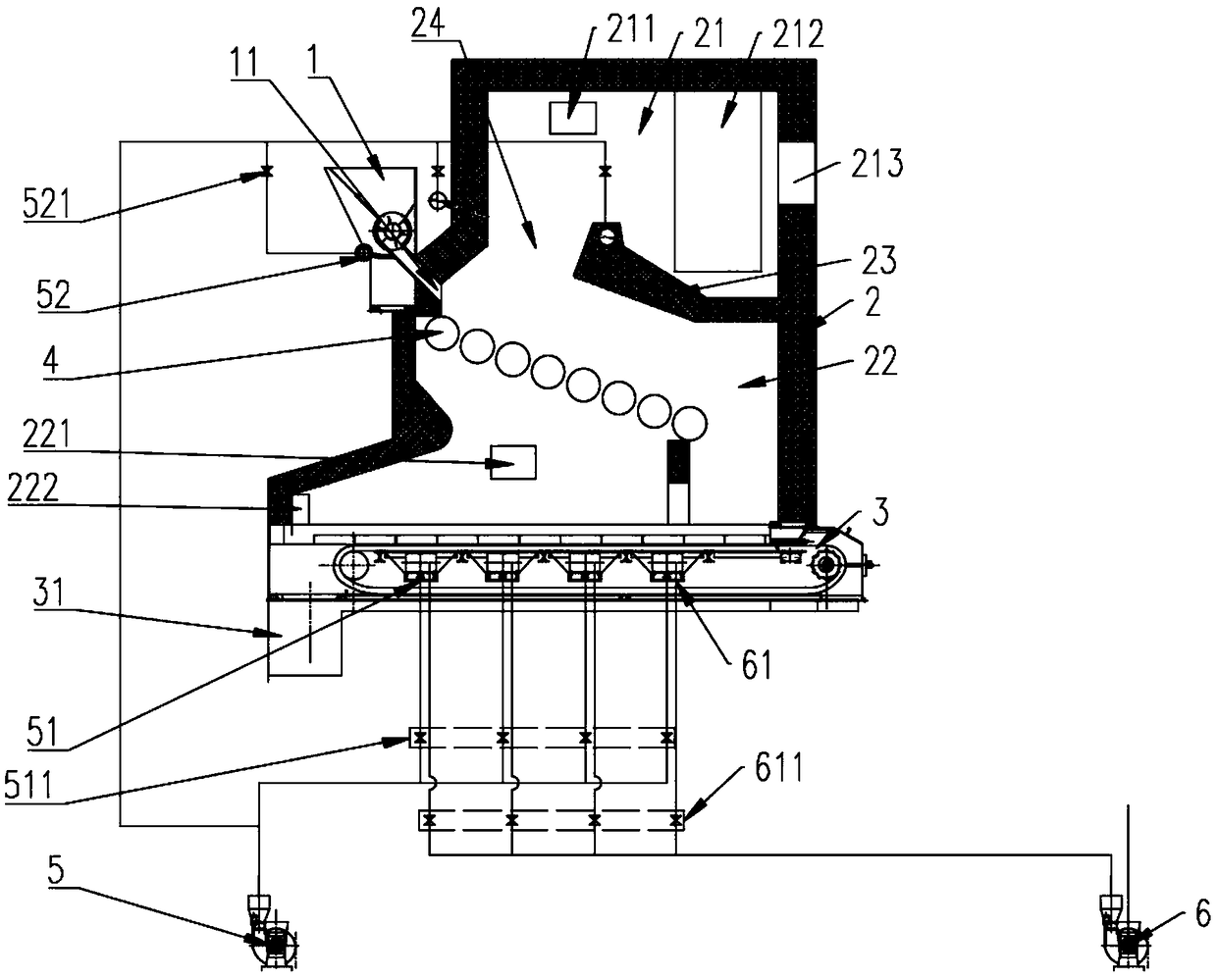

Biomass hot blast stove

InactiveCN109612091ANo pollution in the processReduce pollutionAir heatersCombustion systemCombustion chamber

The invention relates to a biomass hot blast stove. The biomass hot blast stove comprises a hot blast stove body, a combustion chamber, an ash deposition chamber, an air inlet chamber, an air outlet chamber and a blower, wherein the combustion chamber comprises a first combustion chamber and a second combustion chamber; the first combustion chamber is connected with a first feed opening; the second combustion chamber is connected with a second feed opening; the ash deposition chamber is arranged below the second combustion chamber; an ash discharge opening is formed in the bottom of the ash deposition chamber; the air inlet chamber is connected with the blower outside the hot blast stove body; the air outlet chamber is arranged above the air inlet chamber; a hot air outlet is formed in thetop of the air outlet chamber; a first grate is arranged between the first combustion chamber and the second combustion chamber; and a second grate is arranged between the second combustion chamber and the ash deposition chamber. The biomass hot blast stove has the beneficial effects that a secondary combustion manner is adopted, combustion is sufficient and efficient, tar does not exist, the combustion efficiency is high, the heat conversion rate is high, an internal combustion system and an external hot air system are completely independent, the biomass hot blast stove is free from pollution after being used for a long term, and the environmental pollution is reduced; smoke and dust pass through a dust removal device arranged at a hot-blast outlet, so that the smoke and dust are free from black smoke, auxiliary facility is not needed for treatment, and discharge can achieve an environmental-friendly standard; and the biomass hot blast stove is reasonable in design, simple in structure, low in making cost, large in heating area, high in heat efficiency, simple and quick to use and low in maintenance ratio.

Owner:安徽雷普顿热能设备有限公司

Grate-movable gasification and incineration integrated furnace

The invention relates to the field of solid waste incineration treatment, in particular to a grate-movable gasification and incineration integrated furnace. The grate-movable gasification and incineration integrated furnace comprises a first feeding device, a hearth and a lower movable grate arranged below the hearth; the integrated furnace further comprises a partition plate used for partitioningthe hearth into a lower gasification combustion cavity and an upper combustion cavity; the position, close to a discharging port of the first feeding device, of the partition plate is provided with asmoke circulation hole, and the discharging port of the first feeding device is located in the middle of the hearth; in the process that materials move from the discharging port to the lower movablegrate, the materials absorb the heat of smoke flowing to the smoke circulation hole; and the lower gasification combustion cavity and the smoke circulation hole are each provided with a first air inlet and a second air inlet. In the process that the materials move from the discharging port to the lower movable grate, materials located on an upper movable grate absorb the heat of smoke flowing to the smoke circulation hole, water in the materials is evaporated, so that the following combustion is more sufficient and efficient.

Owner:浙江君华智慧物联科技有限公司

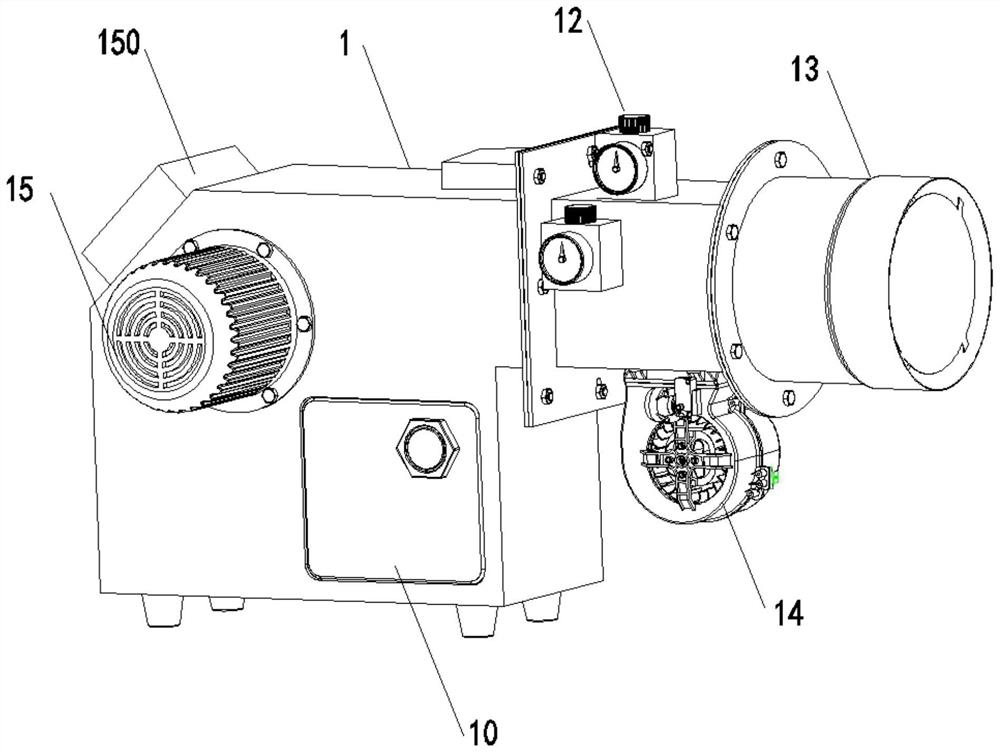

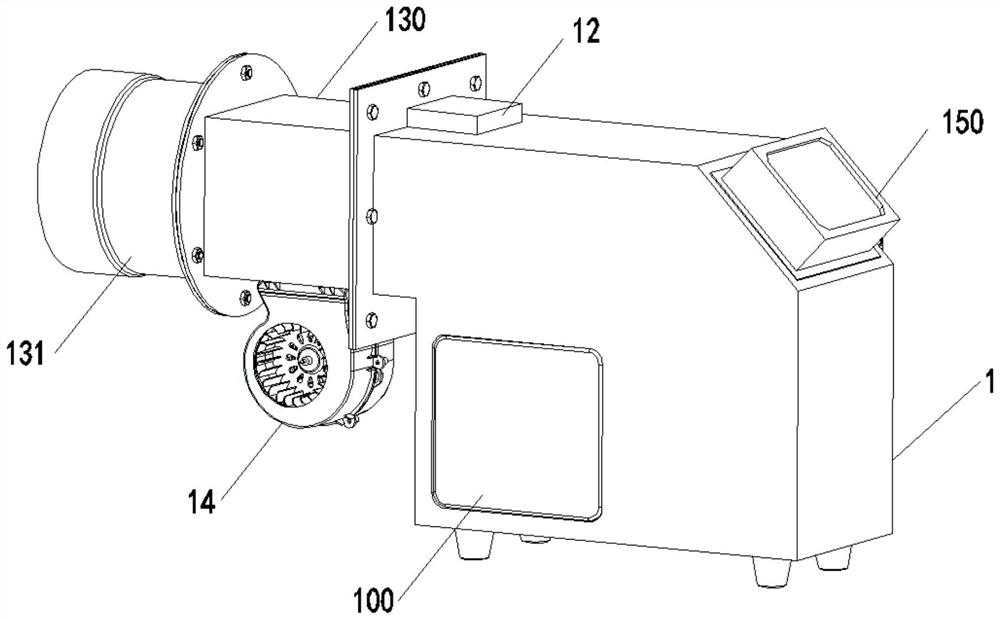

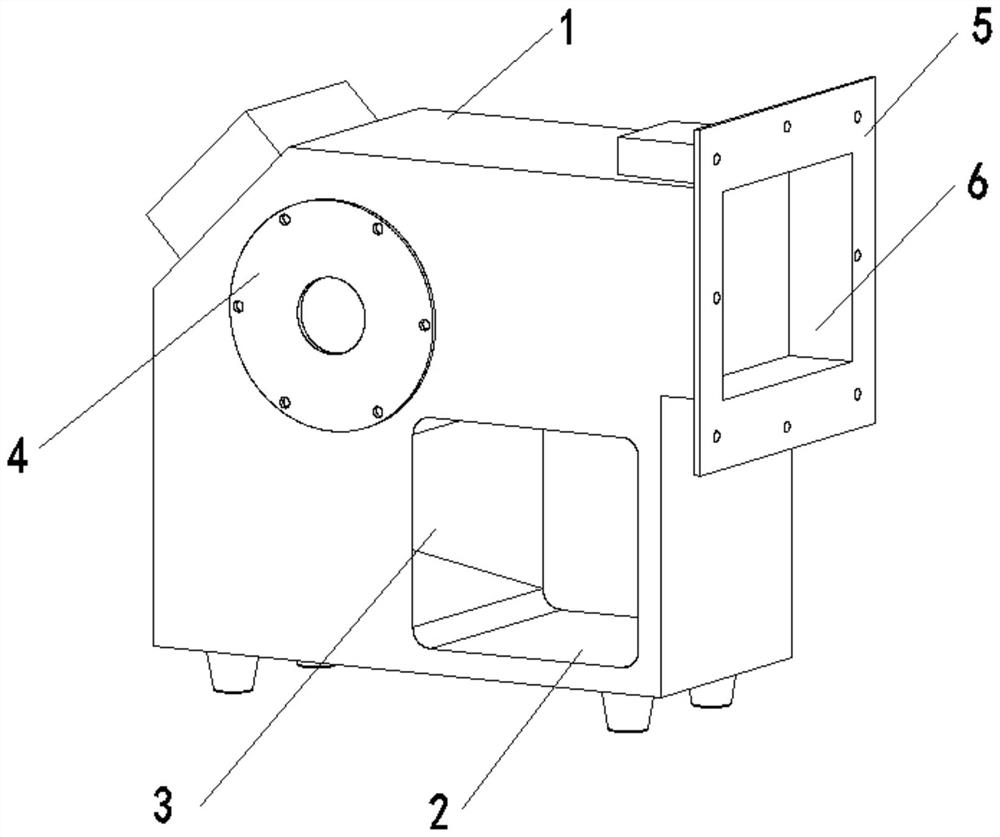

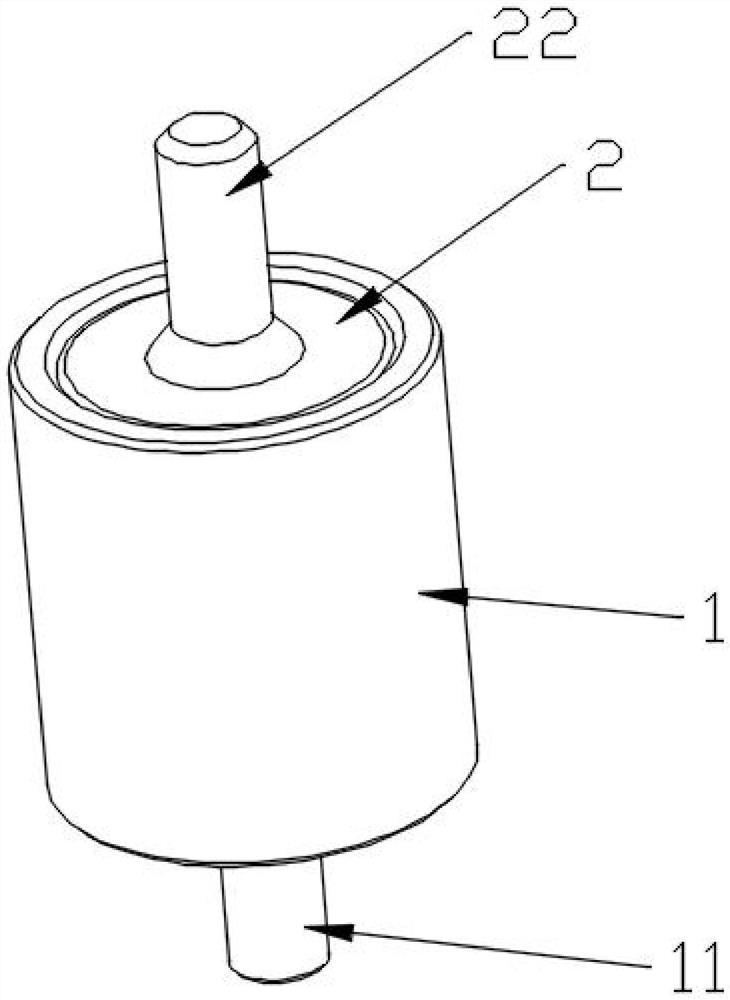

A boiler device for high-efficiency biomass power generation

ActiveCN112378077BReduce churnFull and efficient combustionDispersed particle filtrationIndirect carbon-dioxide mitigationCombustion chamberElectric machine

The invention discloses a boiler device for high-efficiency biomass energy power generation, which includes a feed port. A rectangular feed bin is installed at the bottom of the lower end of the feed port. Cutter, the lower end of the feeding tube is equipped with a cylindrical oxygen-increasing layer, and the lower end of the oxygen-increasing layer is equipped with a cylindrical combustion chamber, which is arranged at the center of the inner side of the boiler body, so that the interior of the combustion chamber can The heat generated during the combustion of biomass fuel is directly transferred to the water body inside the boiler body, thereby avoiding the loss of heat, thereby improving the efficiency of the boiler device. Driven by the third motor, the rotating rod rotates at a high speed, thereby driving The high-speed rotation of the outer ring stirring blade, the stirring blade can not only be used to turn and stir the biomass fuel, but also can generate a certain wind force when the stirring blade rotates at high speed, so that the combustion of the biomass fuel is more efficient and sufficient.

Owner:山西农谷丹峰新能源有限公司

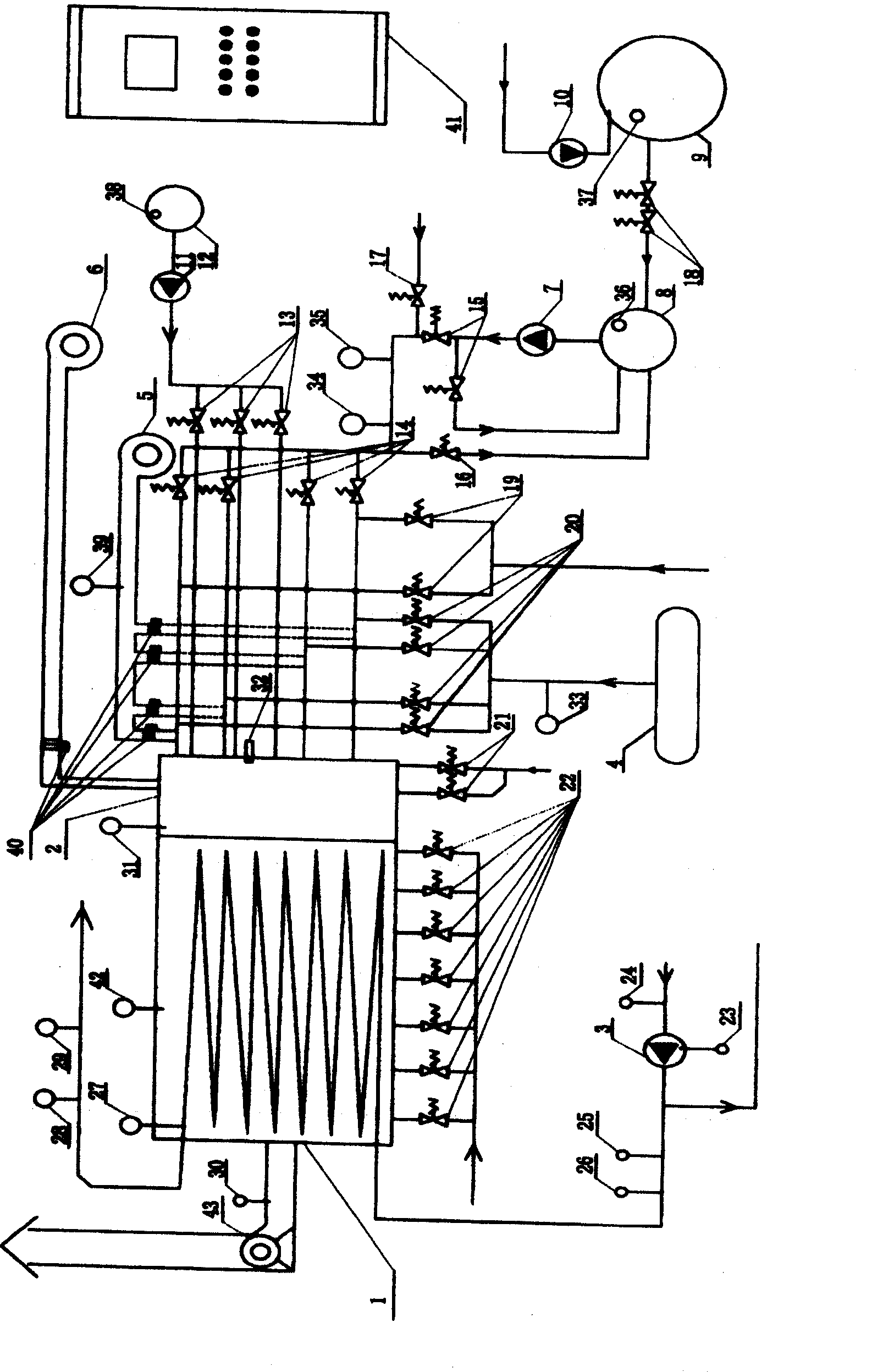

Petroleum coking-slurry burning control system

ActiveCN100467954CStable negative pressureEnhanced atomization strengthCombustion regulationSensing dataAir volume

Owner:CHANGZHOU BOILER +1

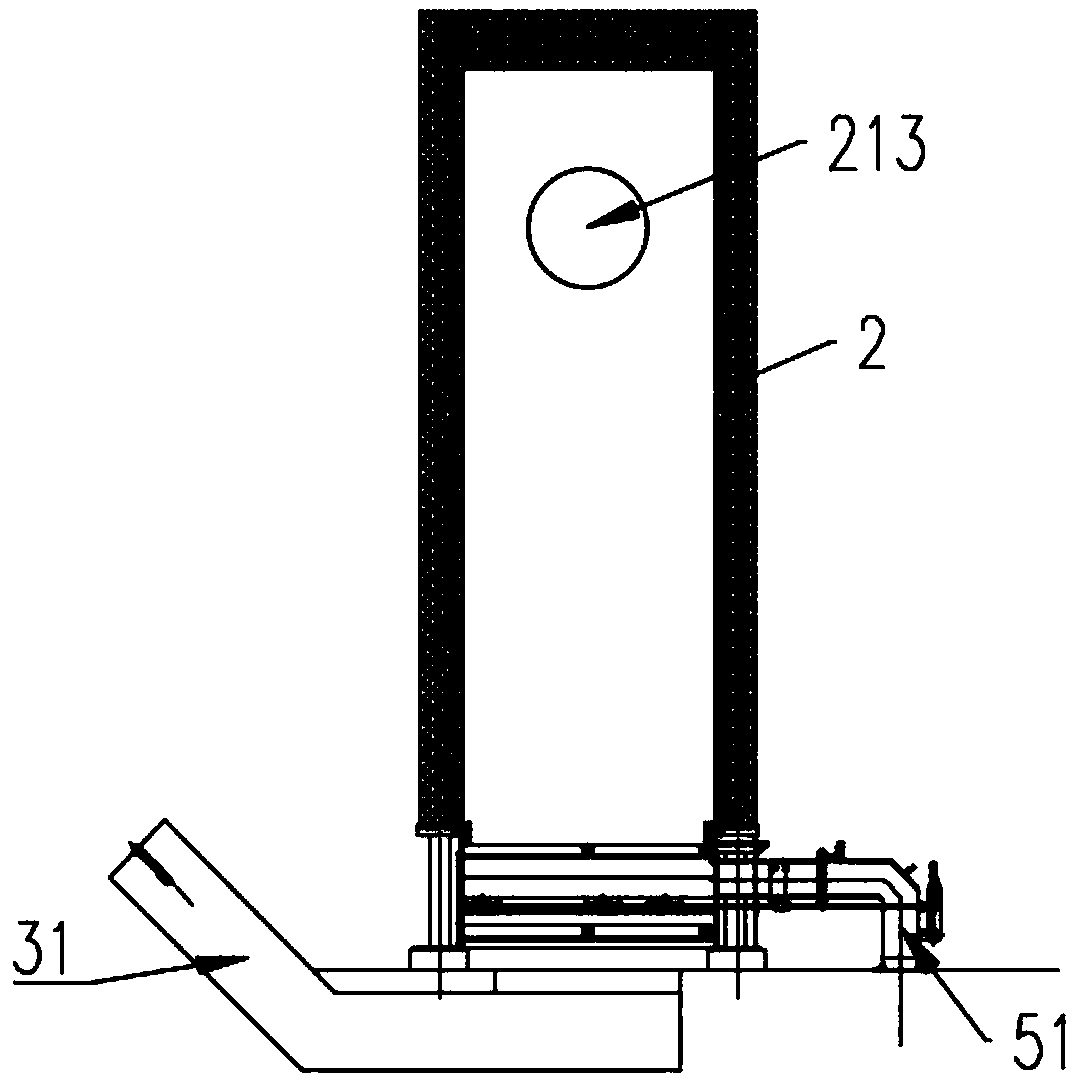

An atmospheric pressure smokeless environment-friendly combustion stove

ActiveCN106322439BBurn fullyControl the feeding speedLighting and heating apparatusStove/ranges for heating waterCombustion chamberWater discharge

The invention discloses a normal-pressure smoke-free environment-friendly combustion furnace and relates to the technical field of combustion furnaces. The combustion furnace comprises a furnace body and a water jacket, wherein the water jacket is arranged inside the furnace body and is communicated with a water tank; a rotary smoke flue connected with a chimney is arranged at the upper part of the back of the furnace body; a feeding opening communicated with a dry distillation chamber is formed in the upper part of the side wall of the furnace body; a water discharging opening and a water returning opening are formed in the back of the furnace body; a combustion kiln is arranged at the lower part of the dry distillation chamber; the combustion kiln is horizontal; the longitudinal section of the combustion kiln is arched; one end of the combustion kiln is fixed at the front of the furnace body; a kiln door is formed in an open end; the other end of the combustion kiln is fixed in the middle of the furnace body; gaps are formed between two sides of the combustion kiln and the inner wall of the dry distillation chamber; the back of the combustion kiln is communicated with a secondary combustion chamber; a furnace grate is arranged under the combustion kiln; a furnace dust cleaning mechanism connected with the furnace grate is arranged on the outer side of the furnace body; a main dust cleaning door with an air inlet is arranged under the furnace grate. According to the normal-pressure smoke-free environment-friendly combustion furnace, the fuel can be dispersed in the dry distillation chamber and the furnace grate by virtue of the combustion kiln; through the adoption of the combustion kiln and the secondary combustion chamber, the fuel can be fully combusted; through the adoption of the S-shaped rotary smoke flue, the dust emission is reduced; the purposes of saving energy, avoiding smoke and protecting environment can be achieved.

Owner:SHIJIAZHUANG CHUNYAN HEATING EQUIP

Coal combustion cleaning catalyst

InactiveCN110387280AIncrease motivationEffective penetrationSolid fuelsFuel additivesCombustorSolvent

The invention relates to the technical field of coal combustion, in particular to a coal combustion cleaning catalyst. The coal combustion cleaning catalyst is prepared from the following components:a solvent, an oxygen-containing free radical component, a permeating component, a catalytic cracking component, a function surface component and a metal organic chelate. The coal combustion cleaning catalyst can promote oxygen-enriched combustion of coal, and can further reduce emission of dust, carbon monoxide and carbon dioxide; and the coal combustion cleaning catalyst can further reduce generation of coke scale in coal-consumed boiler and decoke and descale, improve a working condition of a combustor, improve the production safety, and reduce the operation and maintenance costs of the coalcombustion cleaning catalyst.

Owner:南宁方力电气有限公司

Heating device with high adaptability

ActiveCN113503579AReasonable structural designImprove combustion power and efficiencyGaseous fuel feeder/distributionHydrogen productionExhaust fumesProcess engineering

The invention discloses a heating device with high adaptability. The heating device comprises a heater body, and the heater body comprises a hydrogen and oxygen generating unit which is used for generating hydrogen and oxygen, a drying and storing unit which is used for storing and drying the hydrogen and the oxygen, a gas quantity adjusting unit which is used for adjusting the gas inlet quantity and the combustion-supporting oxygen quantity during hydrogen combustion and a combustion unit which is used for igniting hydrogen gas so that the hydrogen gas is combusted in a combustion chamber. The heating device is reasonable in structural design and can adapt to different atmospheric pressure environments, high-purity hydrogen gas and oxygen gas are generated by setting a hydrogen-oxygen generator, the hydrogen gas is combusted in the combustion chamber after being ignited by the ignition system, the oxygen gas is temporarily stored in the storage tank, and when the ambient atmospheric pressure is thin, oxygen-replenishing air amount is provided for hydrogen combustion, so that sufficient and efficient combustion is achieved, combustion power and efficiency are improved, and meanwhile energy waste and exhaust gas emission amount can be effectively reduced.

Owner:NINGBO BAOGONG ELECTRICAL APPLIANCE

An adaptable heating device

ActiveCN113503579BReduce wasteEmission reductionGaseous fuel feeder/distributionHydrogen productionCombustion chamberAir volume

The invention discloses a heating device with strong adaptability, which comprises a heater body, and the heater body includes a hydrogen-oxygen generating unit for generating hydrogen and oxygen; a dry storage unit for storing and drying hydrogen and oxygen ; A gas volume adjustment unit, used to adjust the amount of intake air and combustion-supporting oxygen when hydrogen is burned; a combustion unit, used to ignite hydrogen and burn in the combustion chamber. The structure of the invention is reasonable and can adapt to different atmospheric pressure environments. Set the hydrogen-oxygen generator to produce high-purity hydrogen and oxygen. The hydrogen is ignited by the ignition system and then burned in the combustion chamber. The oxygen is temporarily stored in the storage tank. To achieve sufficient and efficient combustion, improve combustion power and efficiency, and at the same time effectively reduce energy waste and exhaust emissions.

Owner:NINGBO BAOGONG ELECTRICAL APPLIANCE CO LTD

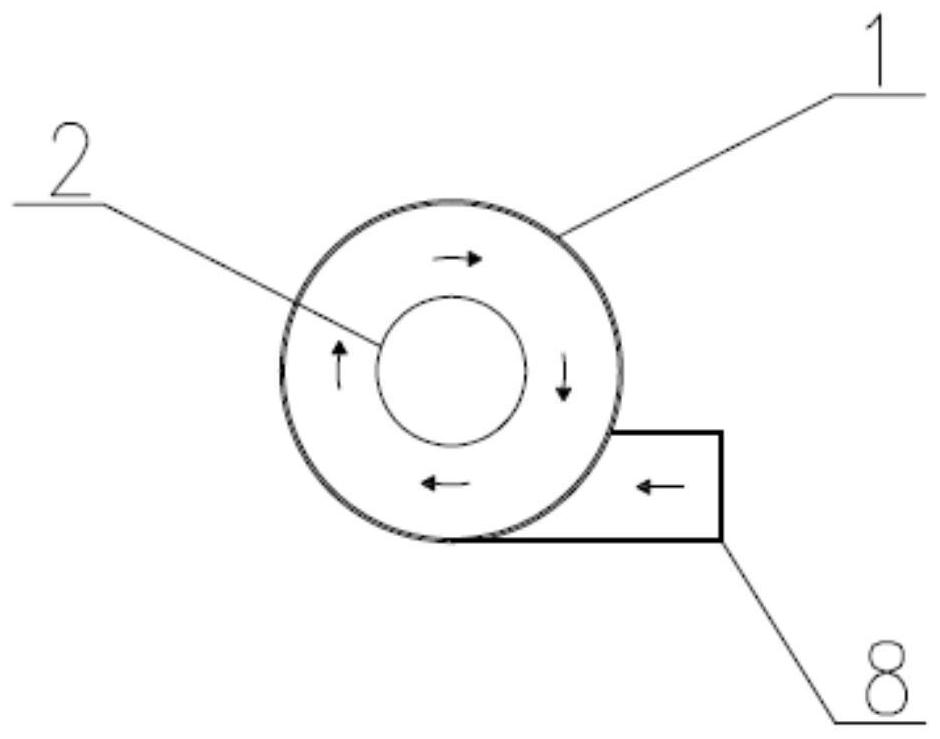

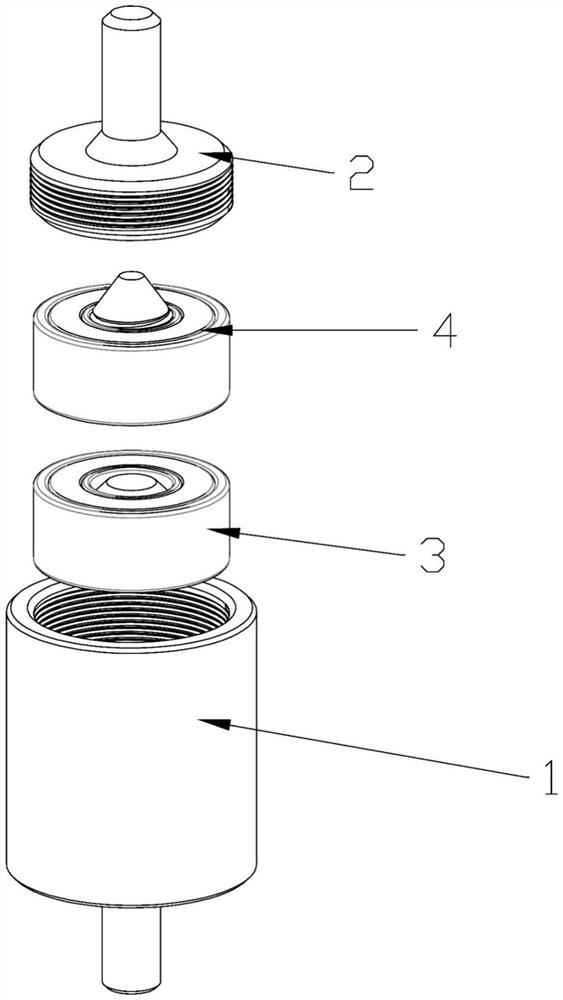

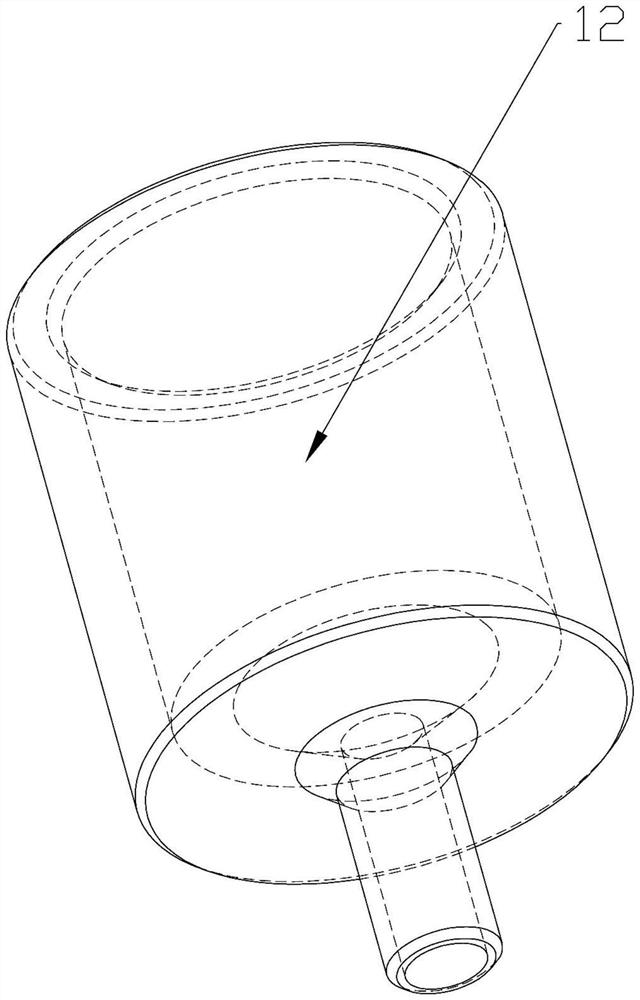

Spiral supercharged fuel oil centrifuge for vehicle

PendingCN114087100AReduce resistanceHigh densityPump componentsLiquid fuel feedersSuction forceFuel oil

The invention discloses a spiral supercharged fuel oil centrifuge for a vehicle. The centrifuge is provided with a shaft sleeve, a sleeve head is arranged at the upper end of the shaft sleeve, an oil inlet pipe is arranged at the lower end of the shaft sleeve, an oil outlet pipe is arranged at the upper end of the sleeve head, a round hole groove, an oil inlet bearing assembly and an oil outlet bearing assembly are arranged in the shaft sleeve, the oil inlet bearing assembly is provided with a bearing I and a threaded core I, and the oil outlet bearing assembly is provided with a bearing II and a threaded core II. According to the invention, two groups of specific sealed bearing assemblies, the shaft sleeve and the sleeve head are assembled, the shaft sleeve is provided with an oil inlet pipe and the oil outlet pipe, and the threaded cores with the spiral spiral grooves are arranged in the middles of the bearing assemblies, so that the threaded cores rotate at a high speed by virtue of suction of vacuum degree of an engine during use, and fuel enters from the oil inlet pipe and is extruded by the spiral spiral groove; and in combination with high-speed rotation of the threaded cores, great oil pressure is generated, then oil is sprayed out from the oil outlet pipe, fuel oil density is improved by squeezing the fuel oil, fuel oil combustion is efficient and sufficient, combustion efficiency is improved, and the effects of saving oil and reducing waste gas emission are achieved.

Owner:王小春

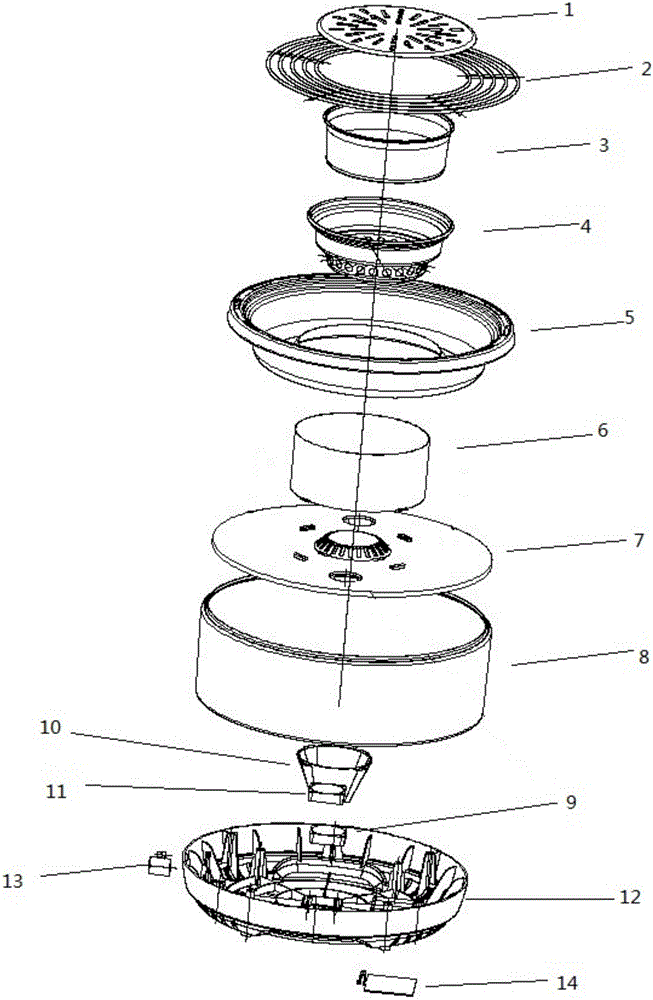

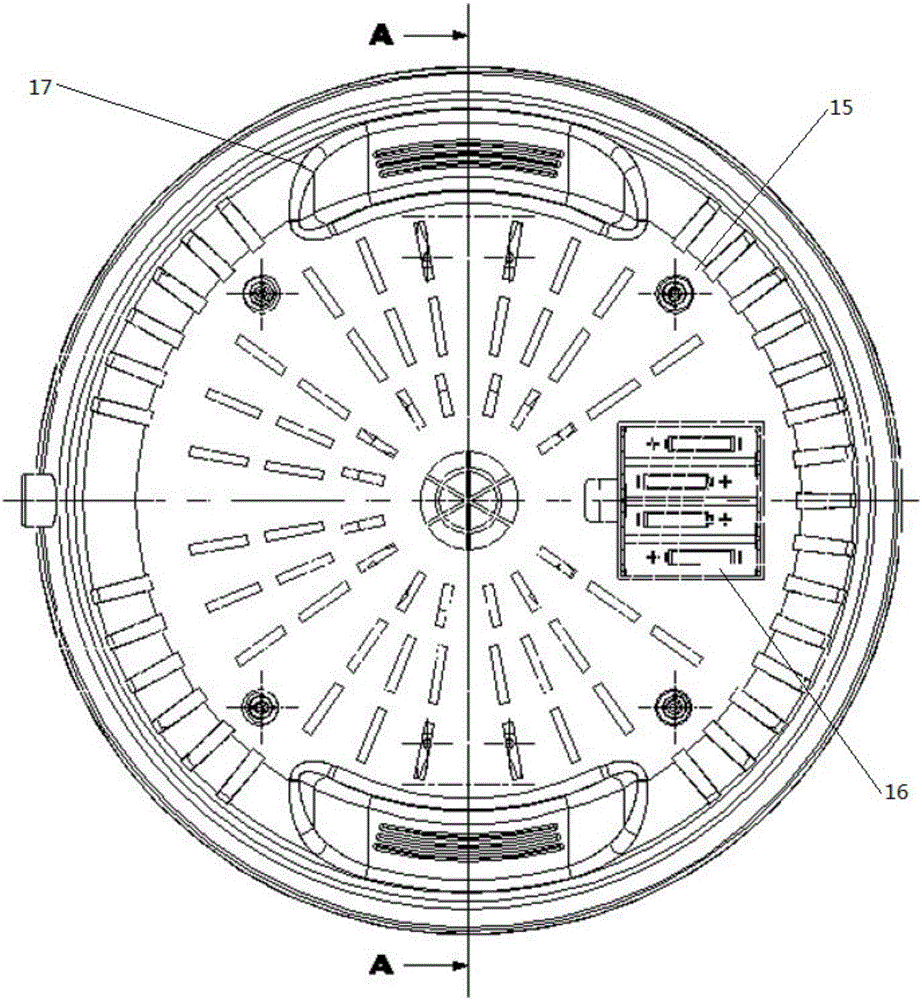

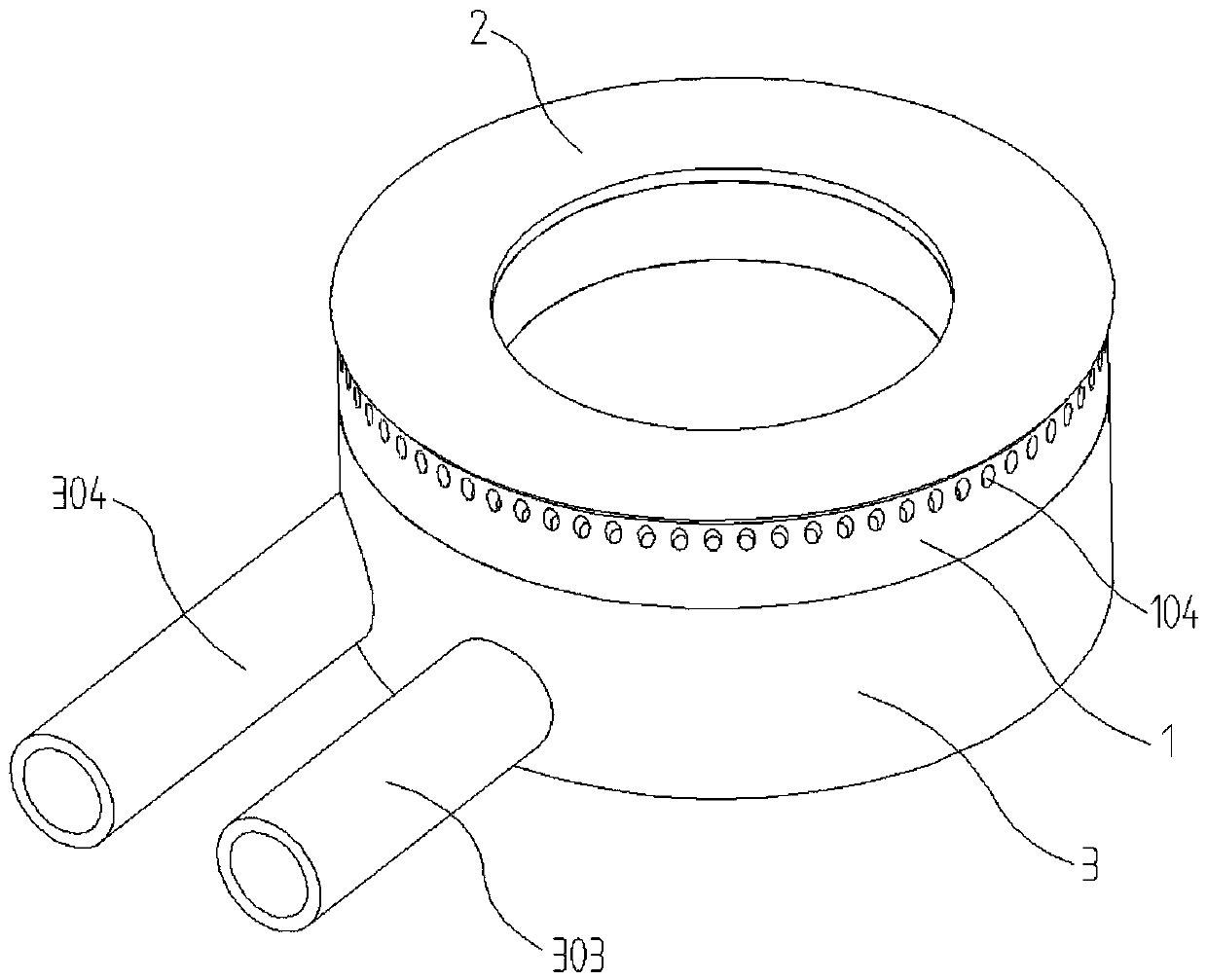

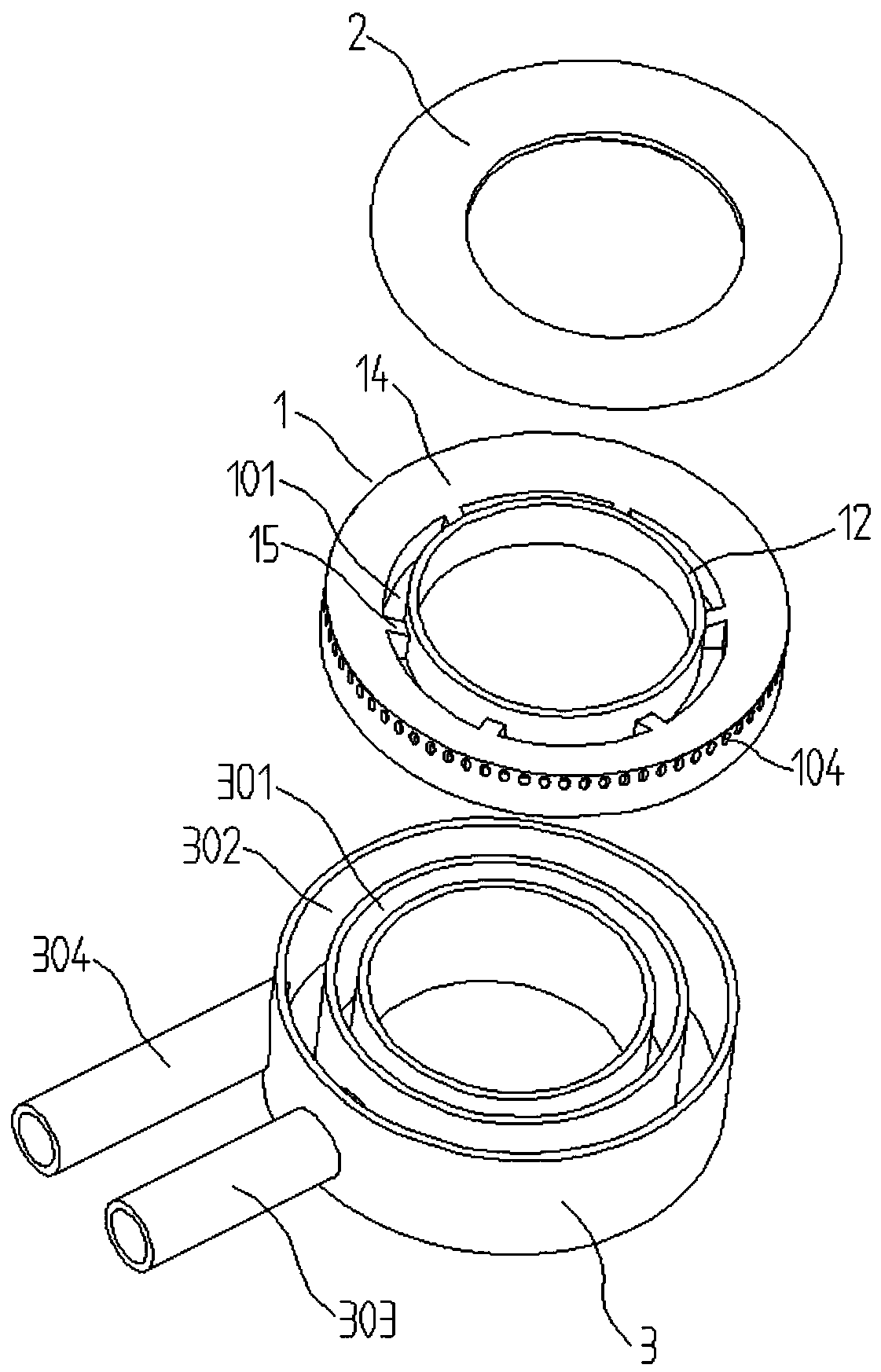

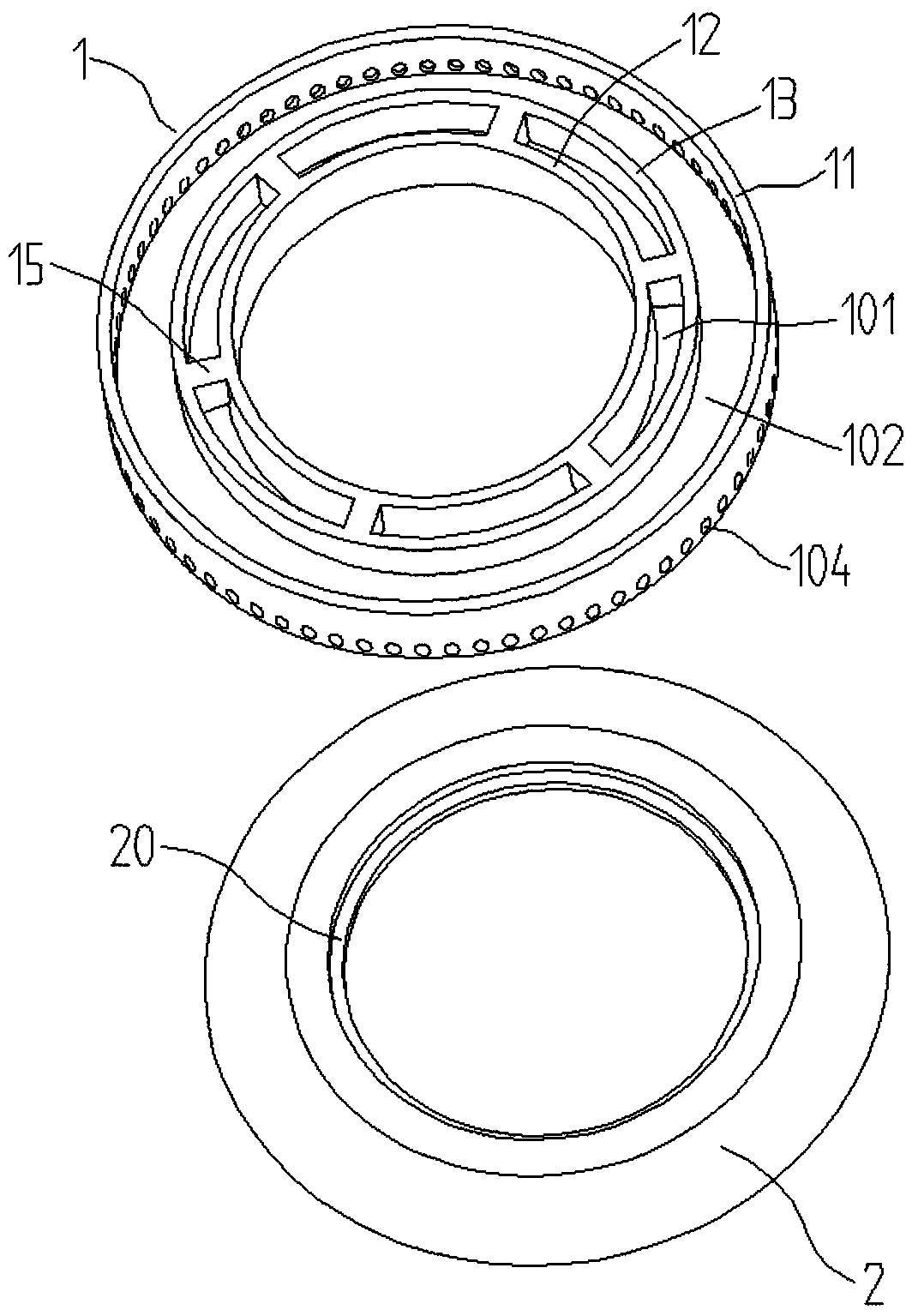

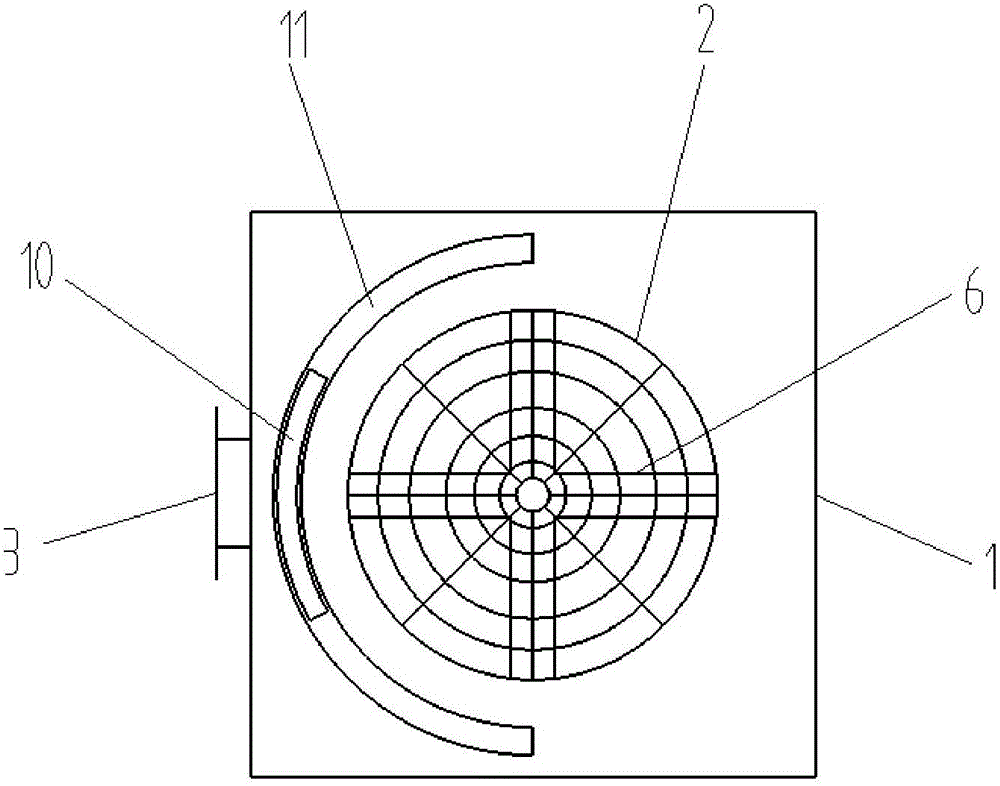

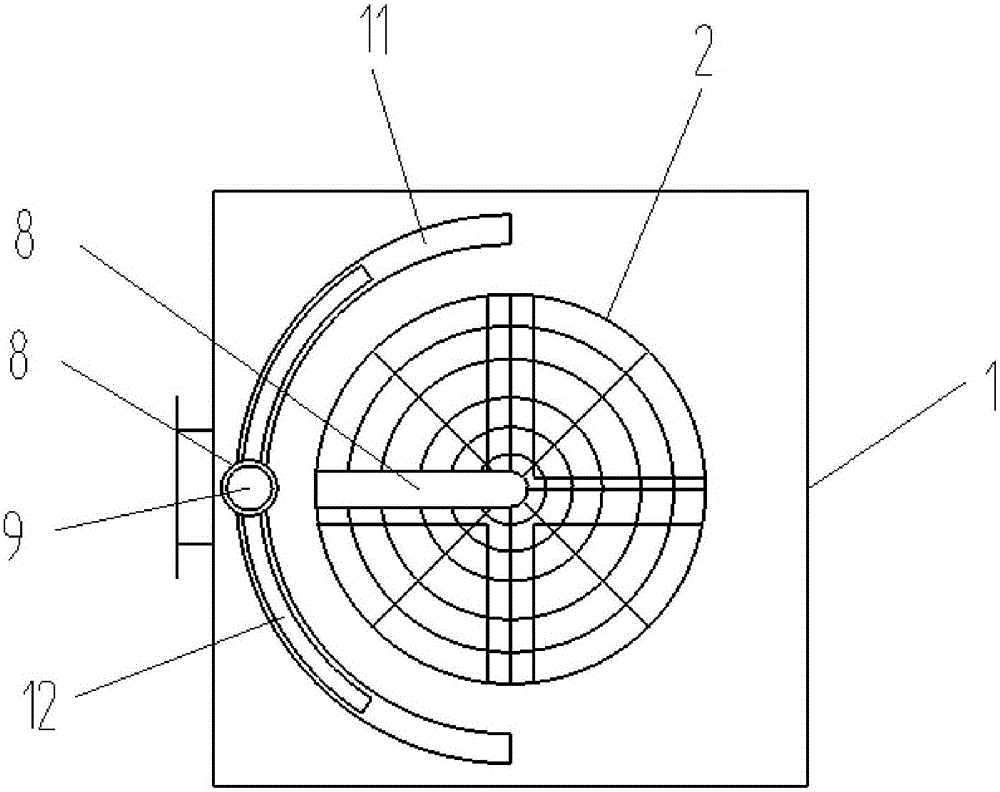

Combustor and gas stove with same

PendingCN109539325AEmission reductionFull and efficient combustionDomestic stoves or rangesGaseous fuel burnerCombustorEngineering

The invention discloses a combustor and a gas stove with the same. The combustor comprises a fire cover, wherein the fire cover comprises a fire cover main body and a cover plate, an independent innerring fuel gas channel and an outer ring fuel gas channel are formed in the fire cover, the cover plate is installed on the fire cover main body, a fire hole channel is formed between the cover plateand the fire cover main body, the inner ring fuel gas channel communicates with the outside by the fire hole channel, a plurality of outer ring fire outlet holes which are distributed at intervals areformed on the outer ring surface of the fire cover main body, and the outer ring fuel gas channel communicates with the outer ring fire outlet holes. The concentration of fuel gas supplied to the inner ring fuel gas channel and the outer ring fuel gas channel is different, the structure is simple, and the emission of nitric oxide can be effectively reduced.

Owner:VATTI CORP LTD

A heat treatment device for the production of copper plate sliders with graphite pores

ActiveCN111607693BImprove sufficiencyReduce contact areaFurnace typesHeat treatment furnacesCombustorEngineering

The invention discloses a heat treatment device for producing a copper plate slider with graphite pores, which comprises a combustion box body, a water reservoir is fixedly installed on the bottom outer wall of one side of the combustion box body, and the inner walls on both sides of the two ends of the water reservoir are First grooves are opened, the inner walls of the four first grooves are fixedly installed with vertically arranged first electric guide rails, and the outer walls of the adjacent ends of the four first electric guide rails are all slidably connected with first electric sliders. The invention proposes a heat treatment device for producing copper plate sliders with graphite pores. By arranging a first burner and a second burner in the combustion box, the copper plate sliders that need to be heat treated can be removed from one of the combustion boxes. The top and bottom of the copper plate slider containing graphite powder are fully and effectively burned by the first burner and the second burner, and the sufficiency of heat treatment is improved to form a copper plate containing graphite powder holes. At the same time, the slider is provided with bumps on the first support plate, which can effectively reduce the contact area between the copper plate slider and the first support plate, and further improves the sufficiency of heat treatment.

Owner:ZHEJIANG WANZHONG MACHINERY MFG

Multifunctional environment-friendly heating stove and manufacturing method

InactiveCN112361447AVersatileGood performanceWater heatersCentral heating systemFlueProcess engineering

The invention relates to the field of heating stove equipment, in particular to a multifunctional environment-friendly heating stove which comprises a stove body, and an electric heater and a burner are installed in the stove body and used for heating water in an inner water channel arranged in the stove body; an electric heater is independently arranged in the stove body and is used for independently heating water in the inner water channel; the interior of the stove body is coiled and is communicated with an inner gas flue of a burning chamber, and the inner water channel is sleeved with theinner gas flue; the burner is used for burning various kinds of fuel in the burning chamber, multiple functions are achieved, the performance is good, methanol fuel can be fully burned, smoke burnedin the burning chamber flows along the coiled inner gas flue, water in the inner water channel is circularly heated, the water in the inner water channel can be fully and efficiently heated, the heatexchange efficiency is high, the coiled inner gas flue can promote sufficient burning of fuel, and therefore, the purposes of saving energy and protecting environment are achieved; and according to amanufacturing method of the multifunctional environment-friendly heating stove, the manufacturing cost is low, the process is simple, and the occupied space of the manufactured finished product is small.

Owner:绛县皓康环保科技有限公司

High-energy and low-carbon synthetic fuel for kilns

InactiveCN103305289BFull and efficient combustionAchieve the best effect of energy saving and emission reductionLiquid carbonaceous fuelsHigh energyPetroleum

The invention provides a high-energy low-carbon synthetic fuel for a kiln. The high-energy low-carbon synthetic fuel is composed of 40-75% of methanol or ethanol, 5-30% of acetone, 5-25% of water, 0.5-3% of catalyst, 5-10% of combustion improver and 5-20% of emulsifier, 100% in total. The caloric value of the high-energy low-carbon synthetic fuel is 10000 kilocalorie / kg; and if the high-energy low-carbon synthetic fuel is applied to an industrial kiln, carbon dioxide residue can be eliminated; as a result, the fuel is combusted sufficiently so that emission of sulfur dioxide is low and the cost is low; the problem that methanol, ethanol and the like which are the by-products of petroleum and coal chemical industry cannot be taken as the fuel of the industrial kiln directly is solved; and a reliable and effective way is provided for saving energy and reducing emission of the industrial kiln, reducing the production cost and improving the economic benefit. The raw materials of the high-energy low-carbon synthetic fuel for the kiln are easily available and the application value of the high-energy low-carbon synthetic fuel for the kiln is high; and therefore, the high-energy low-carbon synthetic fuel for the kiln is one of the best substitutes for fuel such as liquefied petroleum gas.

Owner:陈惠良 +6

Efficient environment-friendly stove

InactiveCN105928014AFull and efficient combustionReduce dosageDomestic stoves or rangesLighting and heating apparatusCombustion chamberEngineering

The invention discloses an efficient environment-friendly stove. A fire grate is rotatably sleeved on a bracket rotary shaft; a rotary arm is fixedly connected above a fire grate; the portion, close to the side edge, at the top end of a stove body is provided with an arc-shaped rotary hole communicating with a combustion chamber; the rotary arm passes through the combustion chamber, and extends out from a rotary hole; the top end of the stove body is provided with an arc-shaped guide slot; the rotary hole is positioned in the guide slot; a baffle plate, which can slide in the guide slot and can completely cover the rotary hole while sliding to any position, is arranged inside the guide slot in a matched manner; and the baffle plate is sleeved on the rotary arm in a penetration manner. According to the efficient environment-friendly stove, the fire gate rotates around the rotary shaft, and unburned fire coal does not leak between the fire grate and a stove hearth, so that the problem that energy is consumed and wasted due to the fact that the unburned coal burns in a stove ash chamber is avoided, and the problem that environmental pollution is caused by a great deal of black smoke generated by extinguishing unburned fire coal in the stove ash chamber is also avoided, and therefore, the fire coal is sufficiently and efficiently combusted, the energy utilization rate is increased, the dosage of fire coal is saved, waste and pollution caused by insufficient burning are avoided.

Owner:TIANJIN JINFENG PIPE IND

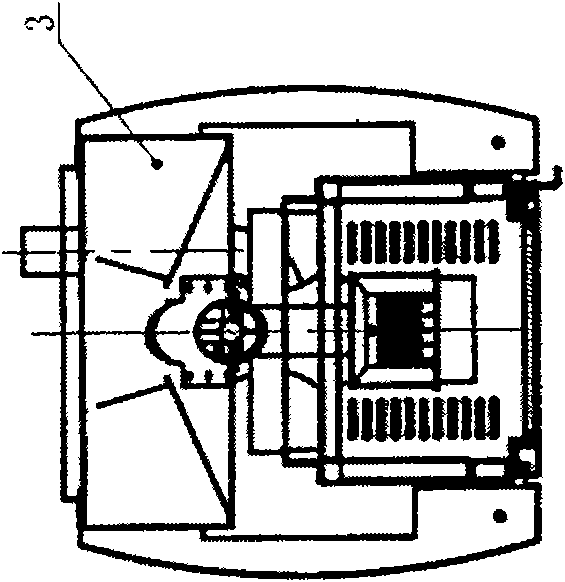

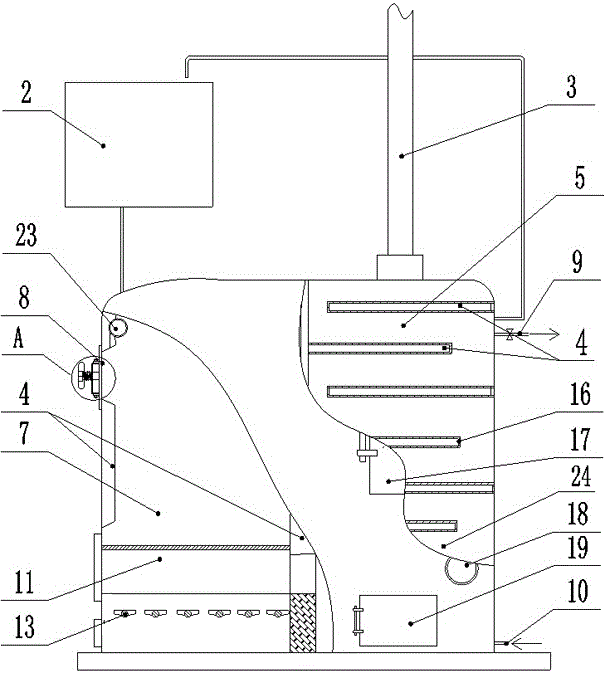

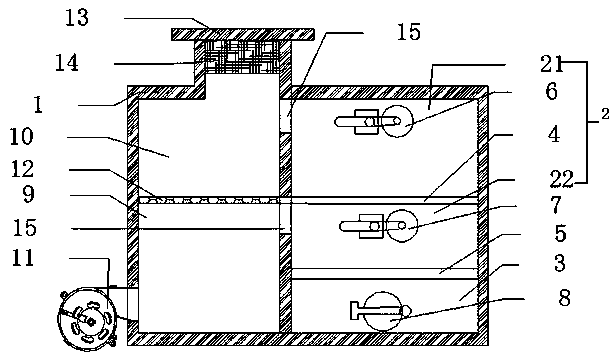

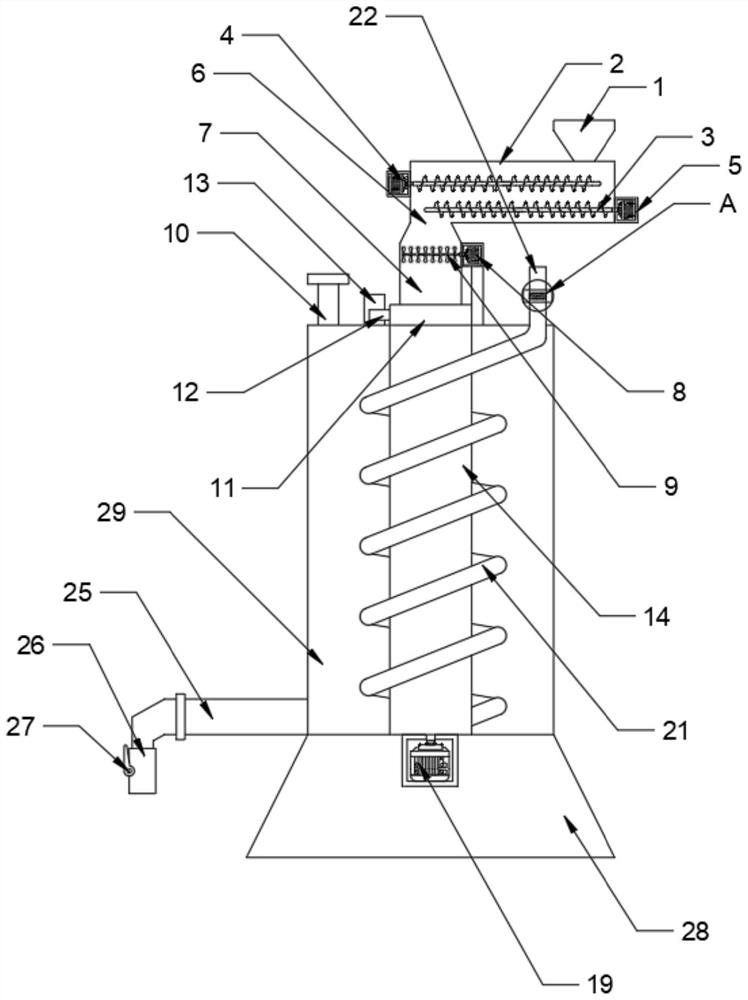

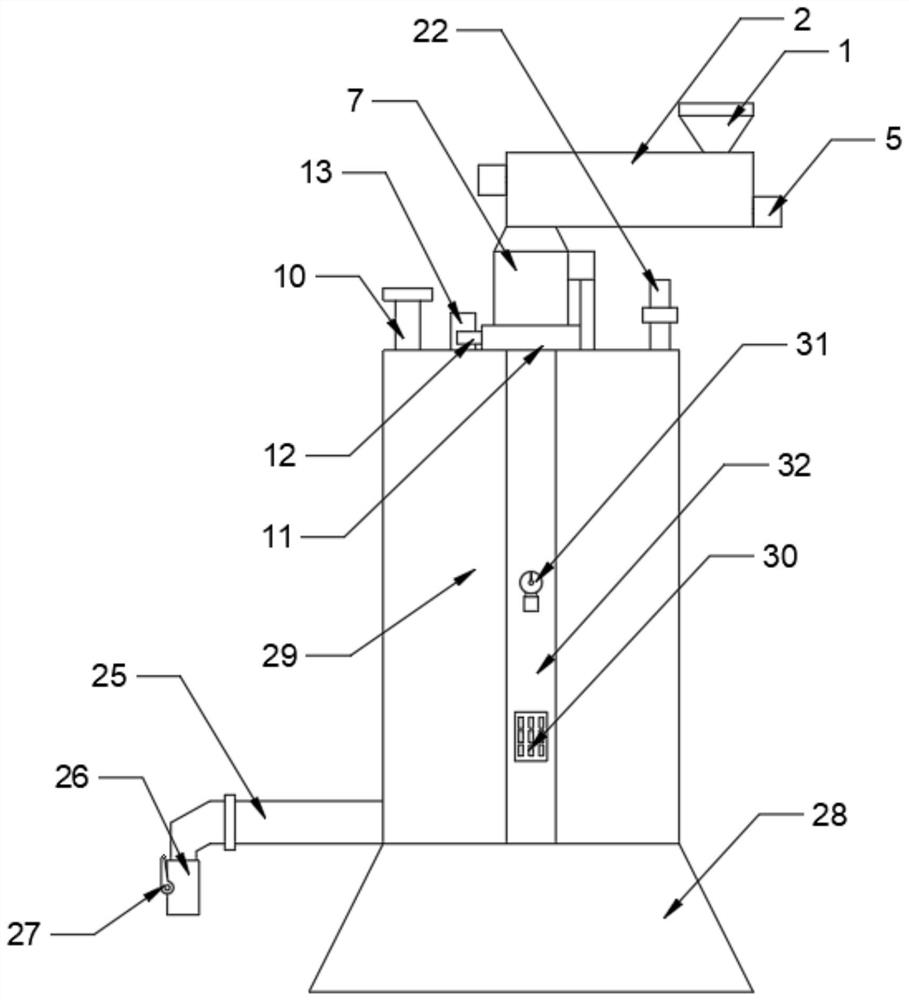

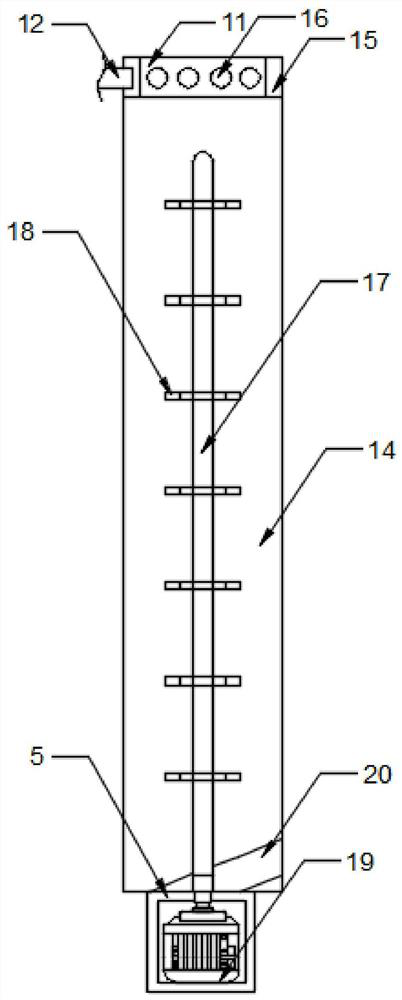

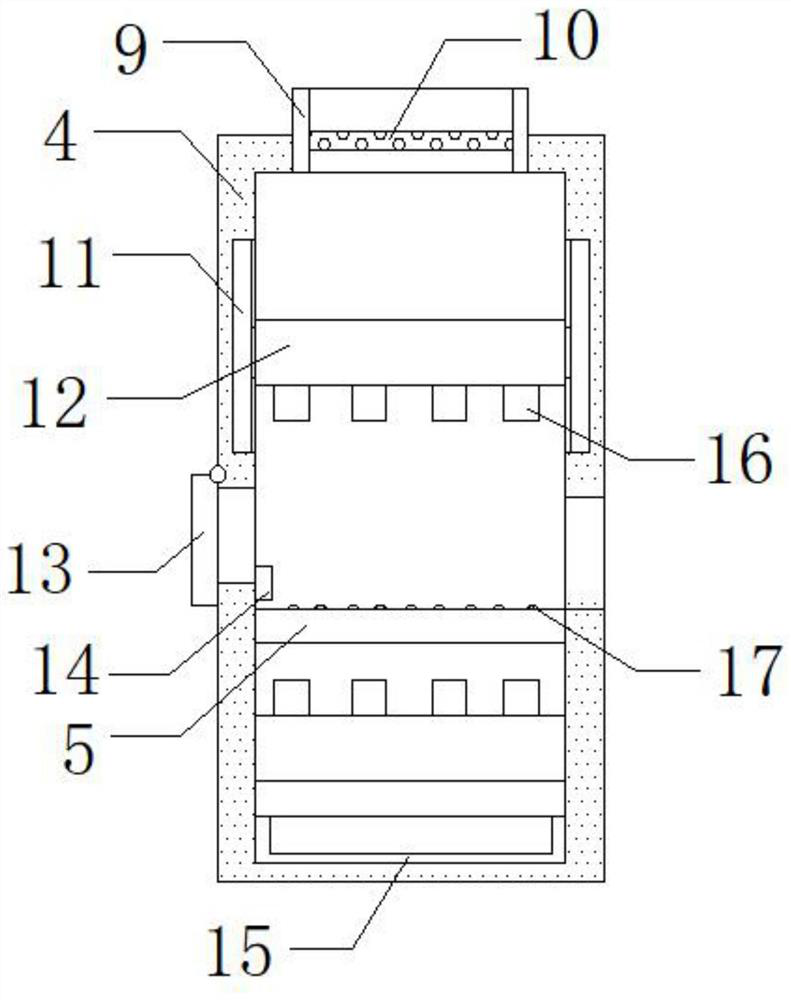

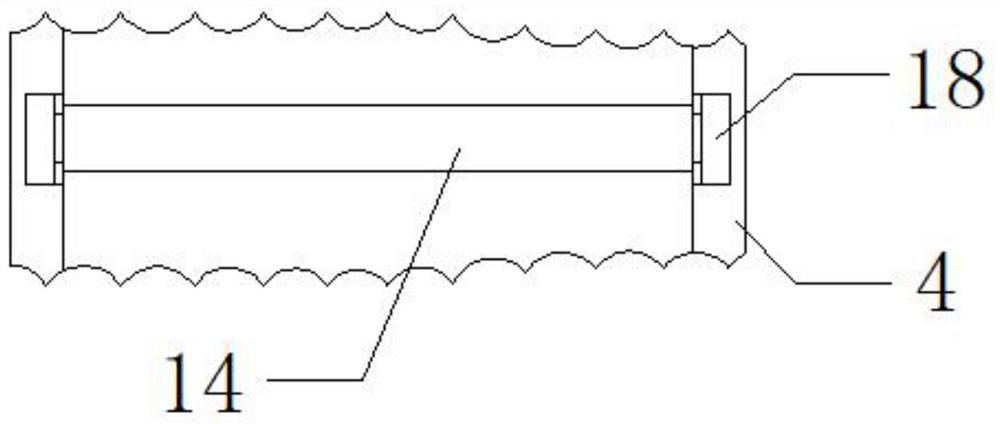

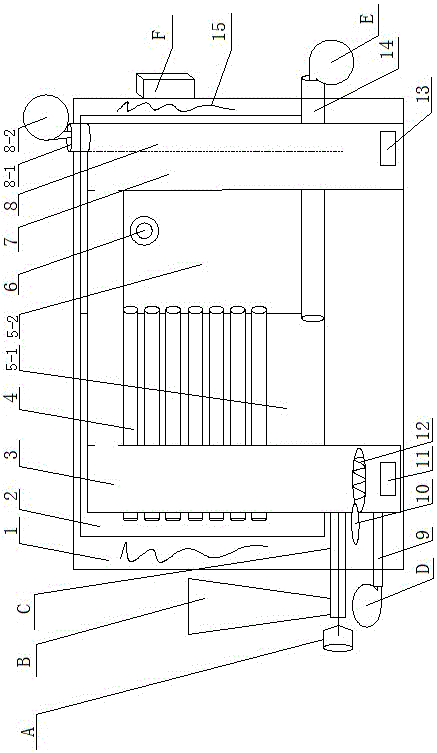

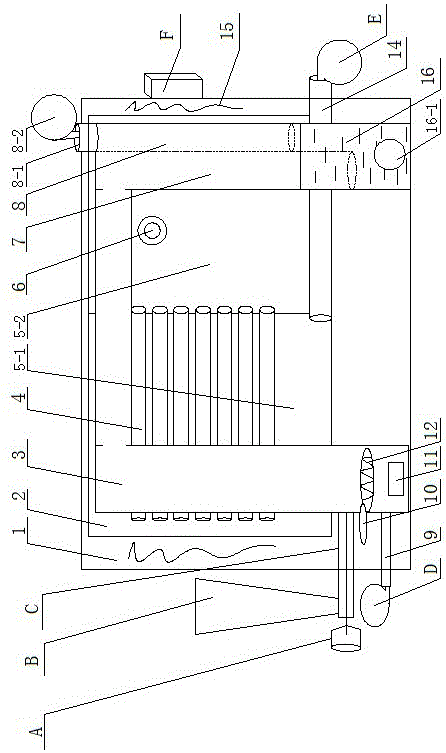

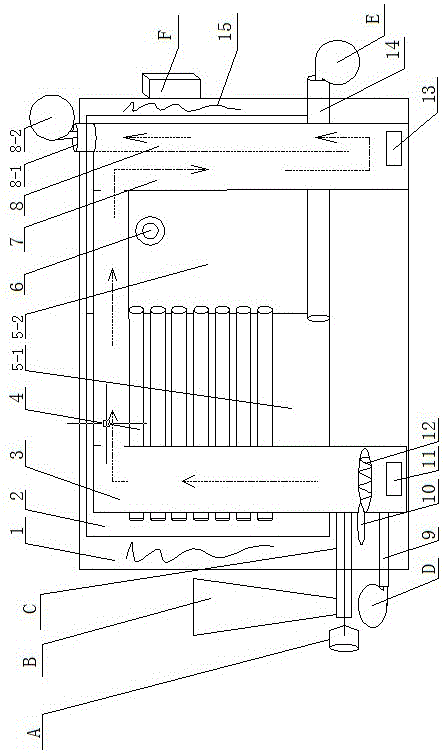

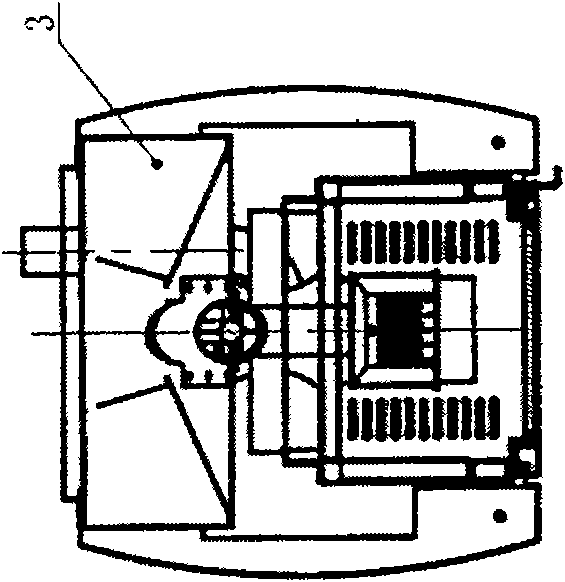

A biomass hot blast stove

InactiveCN103940081BNo pollution in the processReduce pollutionAir heatersAutomatic controlThermal insulation

The invention discloses a biomass hot blast stove and belongs to the technical field of hot blast stoves. The biomass hot blast stove comprises a feeding motor (A), a material barrel (B), a screw feeder (C), a hearth fan (D), a hot air cavity air blower (E), a computer control system (F), a stove body (1), a hot air cavity (2), a hearth (3), a hot air cavity air outlet pipe (4), a heating chamber (5-1), a hot air box (5-2), a hot air outlet (6), a settling pond (7), a chimney (8), a chimney check hole (8-1), a hearth air inlet pipe (9), an ignition bar (10), an ash removing stove door (11), a stove grill (12), a stove door (13), a hot air cavity air inlet pipe (14) and a thermal insulation material (15). A secondary air feeding same-chamber three-dimensional burning mode is adopted, burning is thorough and efficient, tar is avoided, the burning efficiency is high, the heat conversion rate is high, an internal combustion system and an external hot air system are completely independent, automatic control is achieved, and the biomass hot blast stove is free of pollution when used for a long time.

Owner:XUZHOU JIAGU ENVIRONMENTAL PROTECTION TECH

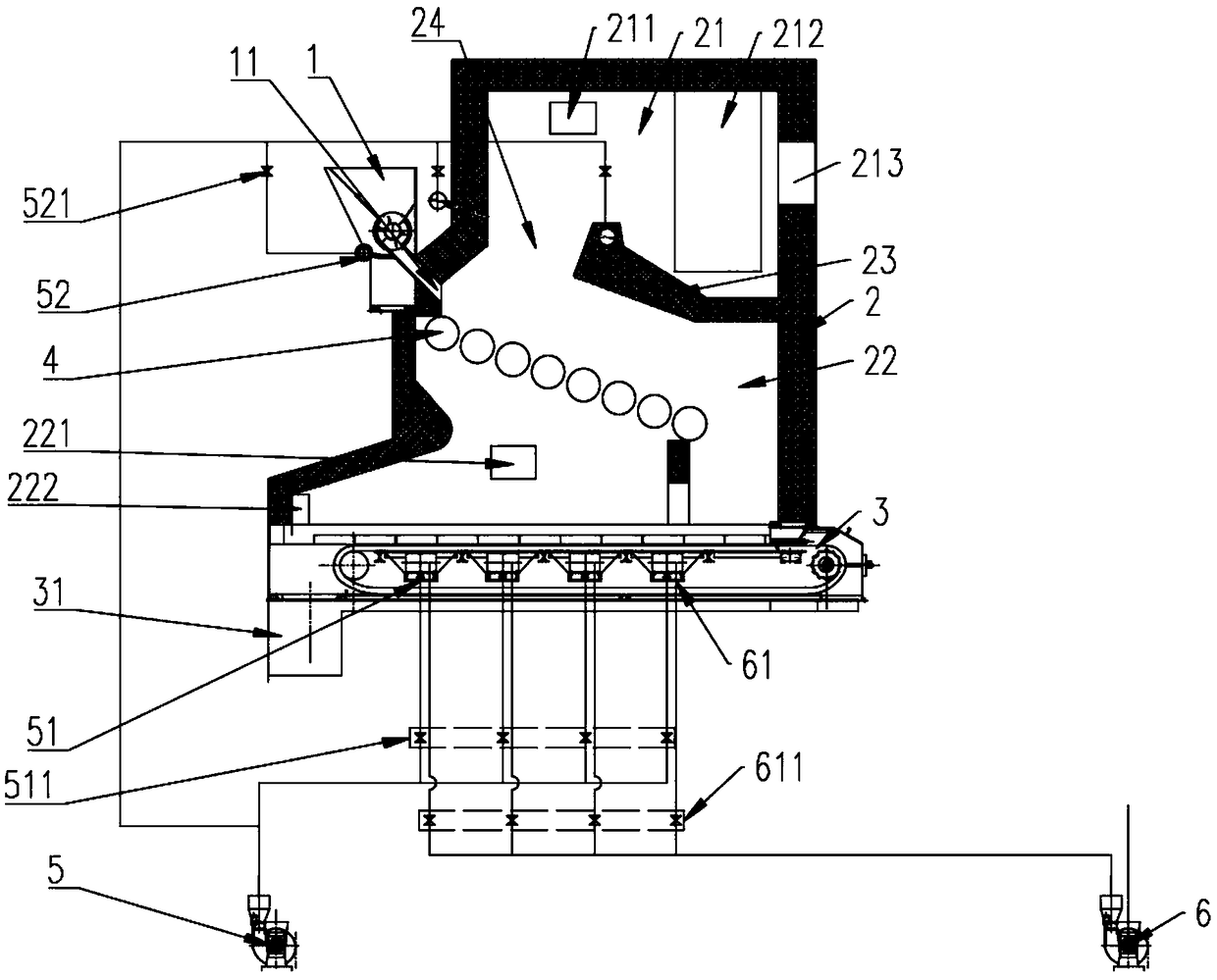

Gasification and incineration method of moving grate gasification and incineration integrated furnace

InactiveCN109506241AFull and efficient combustionIncinerator apparatusCombined combustion mitigationCombustionFlue gas

The invention provides a gasification and incineration method of a moving grate gasification and incineration integrated furnace. A first feeding device, a hearth, a lower moving grate arranged belowthe hearth and a partition plate used for separating the hearth into a lower portion gasification and combustion cavity and an upper portion combustion cavity are included. A flue gas flow through hole is formed in the position, close to a discharging port of the first feeding device, of the partition plate, and the discharging port of the first feeding device is located at the middle portion of the hearth. The lower portion gasification and combustion cavity and the flue gas flow through hole are provided with first air inlets and second air inlets correspondingly. The method includes the steps that the first feeding device is controlled to convey materials towards the interior of the hearth; the materials move towards an upper moving grate and absorb heat of flue gas flowing to the fluegas flow through hole, and drying and gasification are conducted; combustion supporting air is injected into the lower portion gasification and combustion cavity through the first air inlets so that the materials moving to the upper moving grate can be combusted; and combustion supporting air is injected into the glue gas flow through hole through the second air inlets so that the temperature of the flue gas in the flue gas flow through hole can be increased, and pyrolysis of tar in the flue gas can be achieved. The method has the beneficial effects that combustion is more sufficient, and efficiency is high.

Owner:浙江君华智慧物联科技有限公司

Automatic biological material combusting multipurpose furnace

InactiveCN101576271BFull and efficient combustionImprove flammabilityStoves/ranges with convection heatingLighting and heating apparatusRural areaCombustion chamber

The invention discloses an automatic biological material combusting multipurpose furnace, which adopts an automatic ignition, automatic spiral feeding and suspending combustion mode, an enclosed negative pressure type and secondary return air to ensure no leakage of waste gas, simultaneous greatly reduces the discharge capacity of carbon monoxide, is safe, sanitary and environment-friendly, controls temperature outside a combustion chamber in a specific range, adopts a full enclosed combustion mode, can be used separately to achieve the heating effect, and also can be added with water and connected with radiators by pipelines to achieve water circulation heating; in addition, a waste gas discharge pipe can be connected with a hot gas fan of a furnace body through a pipeline to achieve windcirculation; in order to be suitable for rural areas, the furnace can be used for cooking; therefore, the furnace have multiple purposes, combusts waste residue, has high efficiency, low consumption,environment-friendly discharge, energy conservation and emission reduction, and brings safe living environment to life of people; and meanwhile, the furnace utilizes biological granules as fuel, achieves the aims of utilizing the waste and changing the waste into the treasure, makes the environment better, and solves the difficult problem of handling straws, old and useless woodware and peels offruits of urban residents of governments at all levels.

Owner:王义红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com