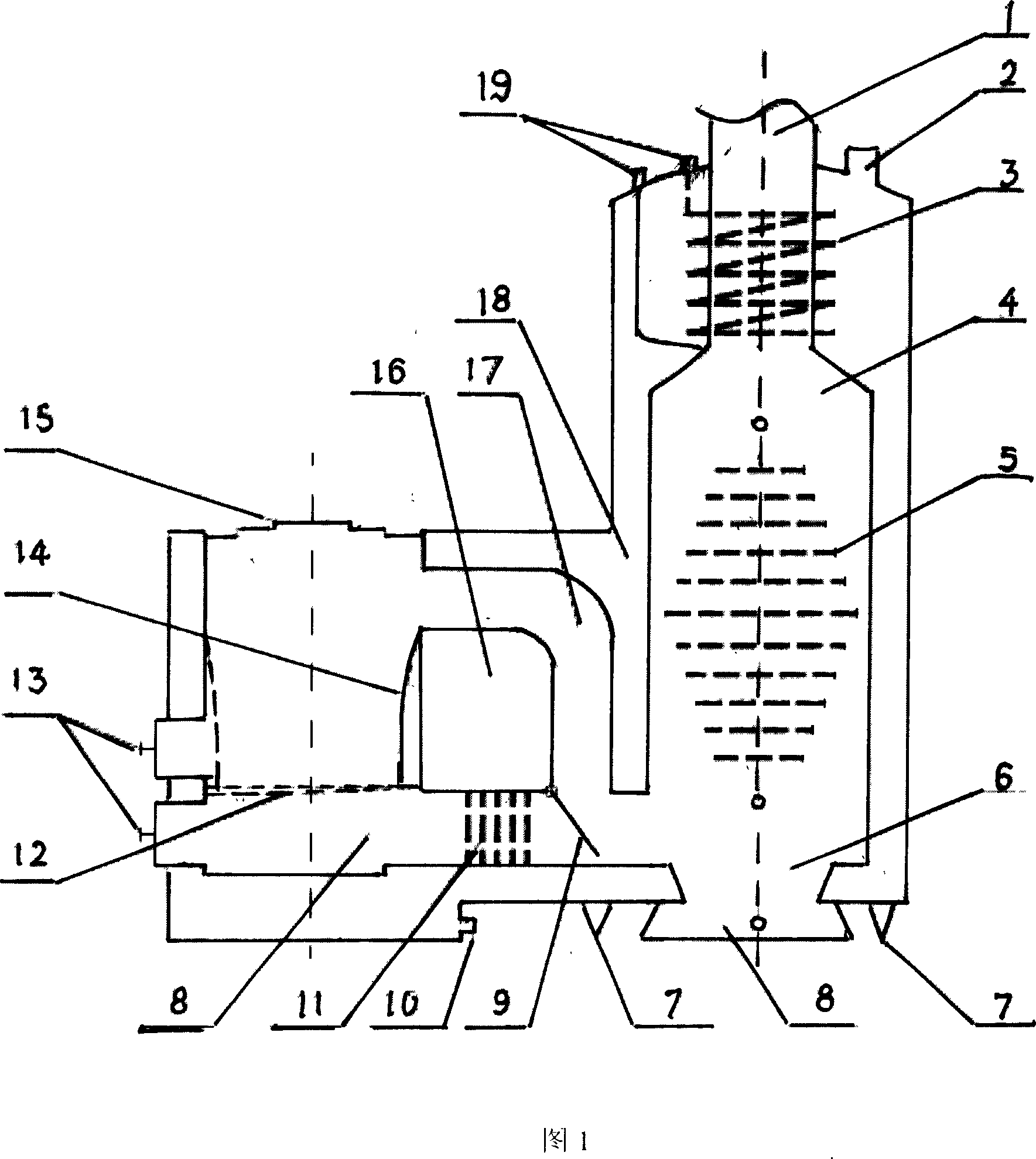

High-low type smokeless energy-saving hot water stove

A technology for water heaters and boilers, which is applied in the field of high-low smokeless energy-saving water heaters, and can solve the problem of small heating area of the water-cooled wall of the exhaust channel at the tail of the boiler, small detour space for fuel and combustible flue gas, and ineffective utilization of high-temperature flue gas To achieve the effect of avoiding the emission of black smoke and combustible and harmful gases, fully and efficiently utilizing, and rationally designing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Fill coal at the top of the furnace (14), and the coal is preheated, dried and burned in the combustion chamber of the furnace above the fire grate. If the fire-sealing switch (9) is placed below, the cooking pot can be placed on the top of the furnace (14) for heating, and the upper and lower fire passages (17) in the center have a uniquely designed shell structure, and are connected with the smoke passage ( 1) Connected, when the hot air flow passes, it can not only greatly increase the heat exchange area of the water-cooled wall, but also ensure that the soot flowing through the fire channel can slide down in time to avoid blockage, but smoke will be generated at this time; if the fire-sealing switch (9) Place it above, and close the upper and lower furnace doors (13), and the air volume is controlled by the movable furnace cover. The central horizontal fire channel (17) is connected with the smoke outlet channel (1). Since the hot flame is below the fuel, the fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com