Patents

Literature

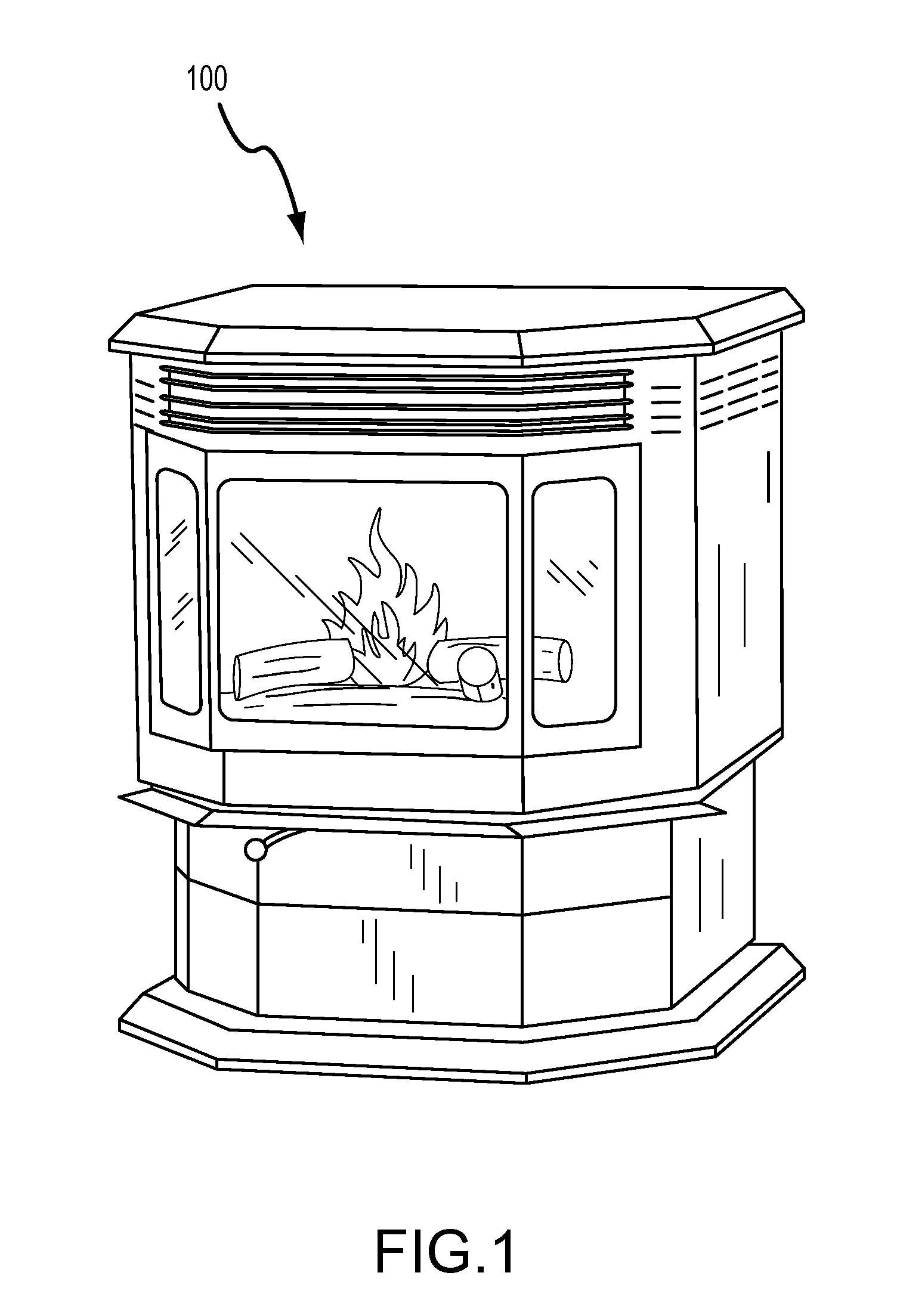

177results about "Stoves/ranges with convection heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

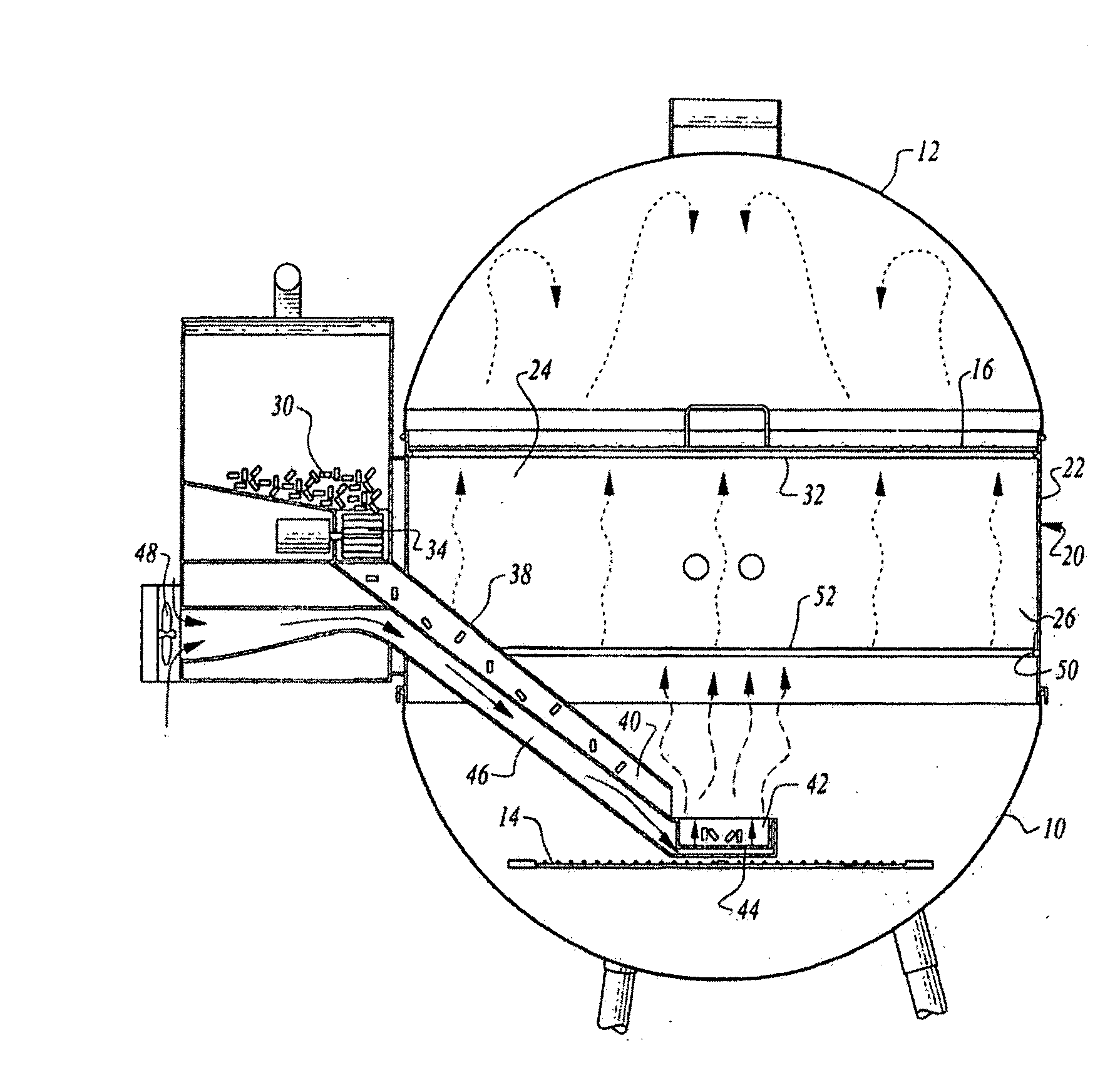

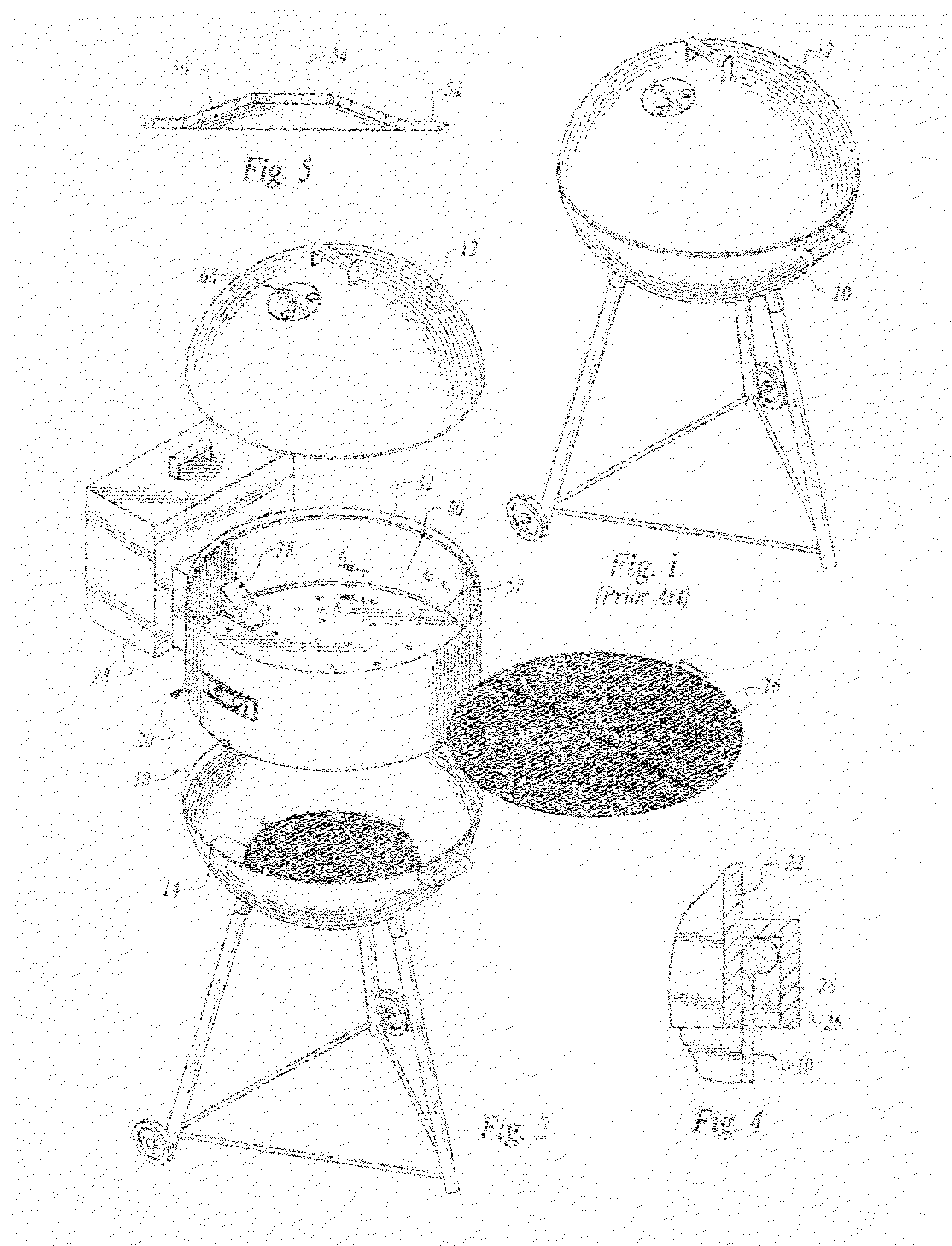

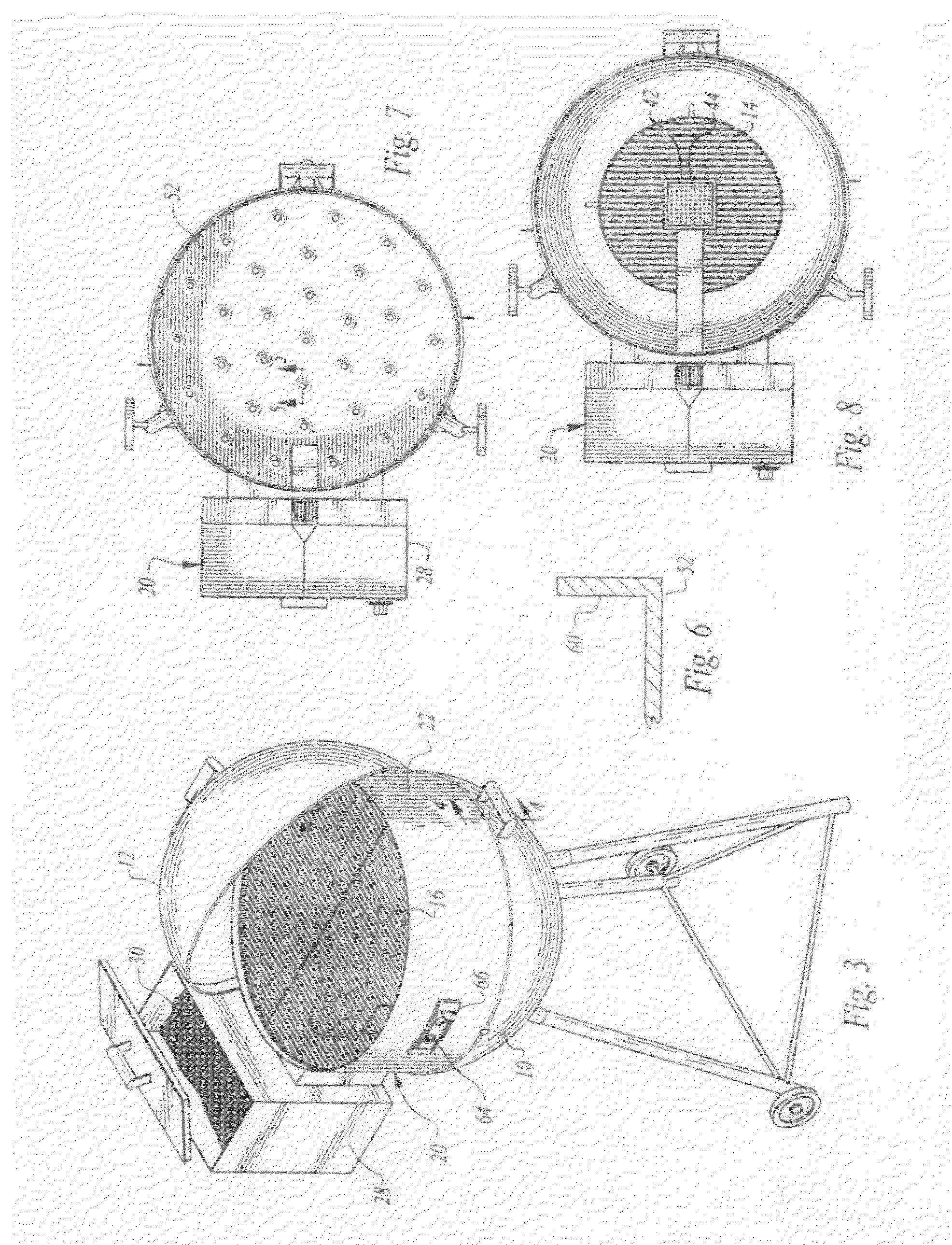

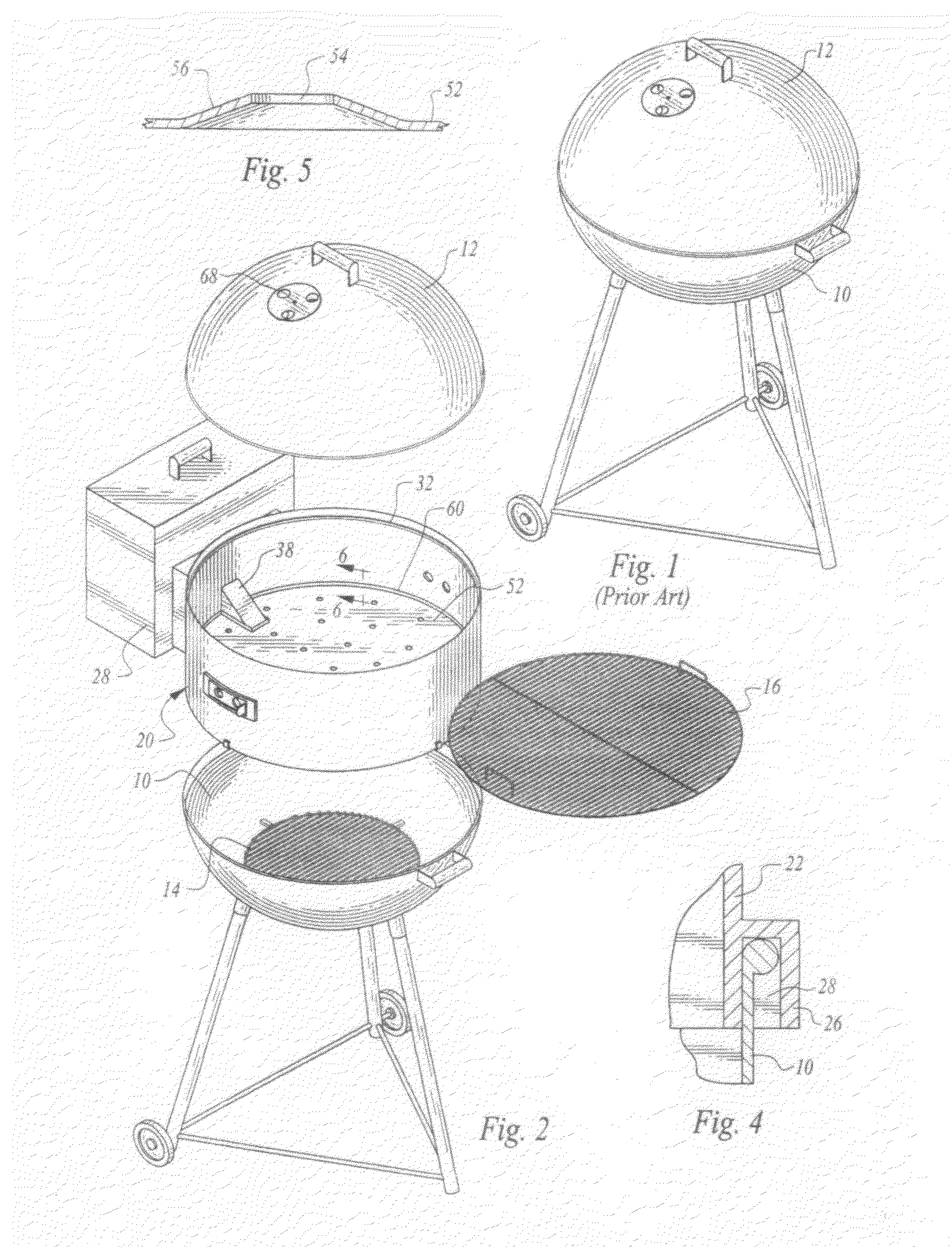

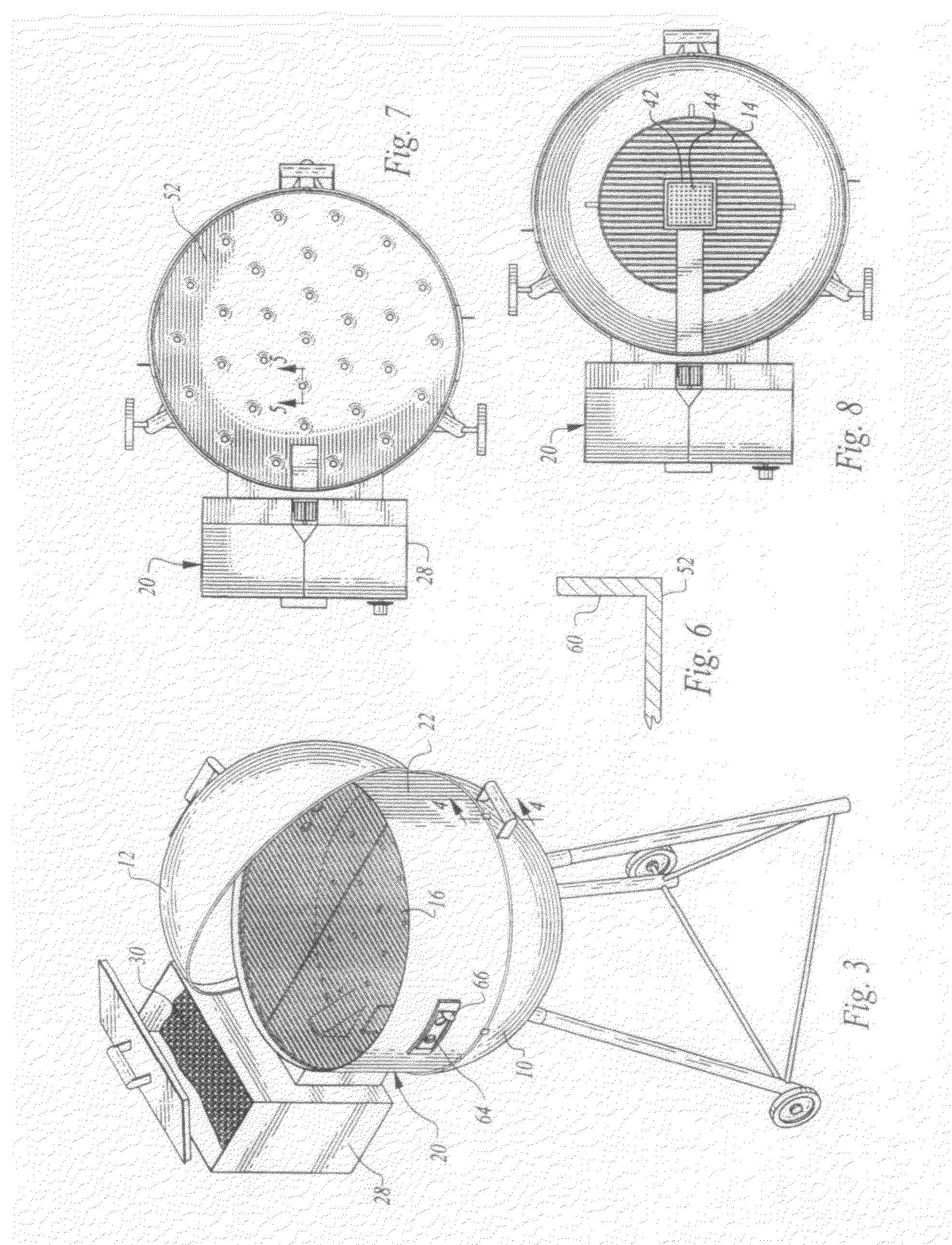

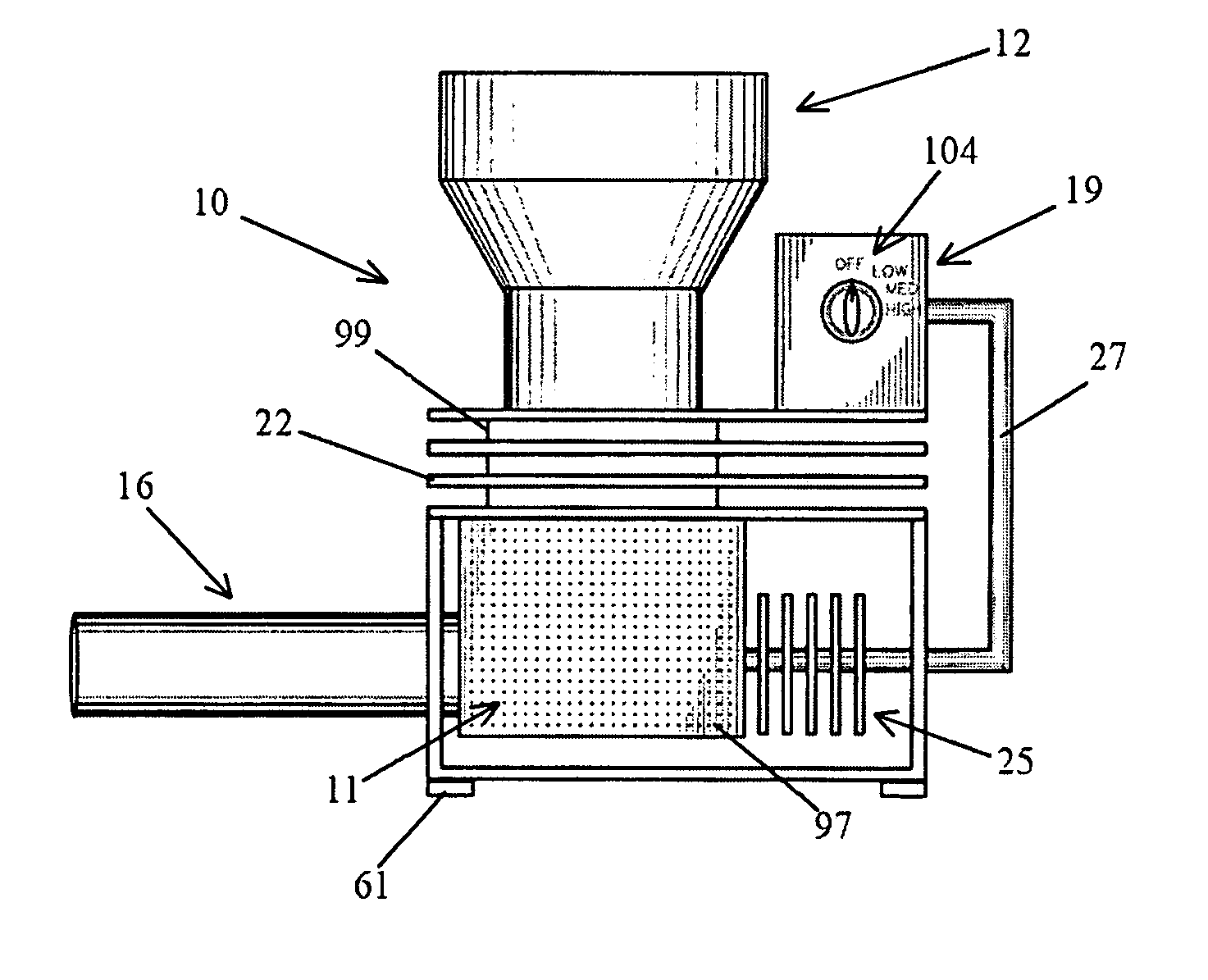

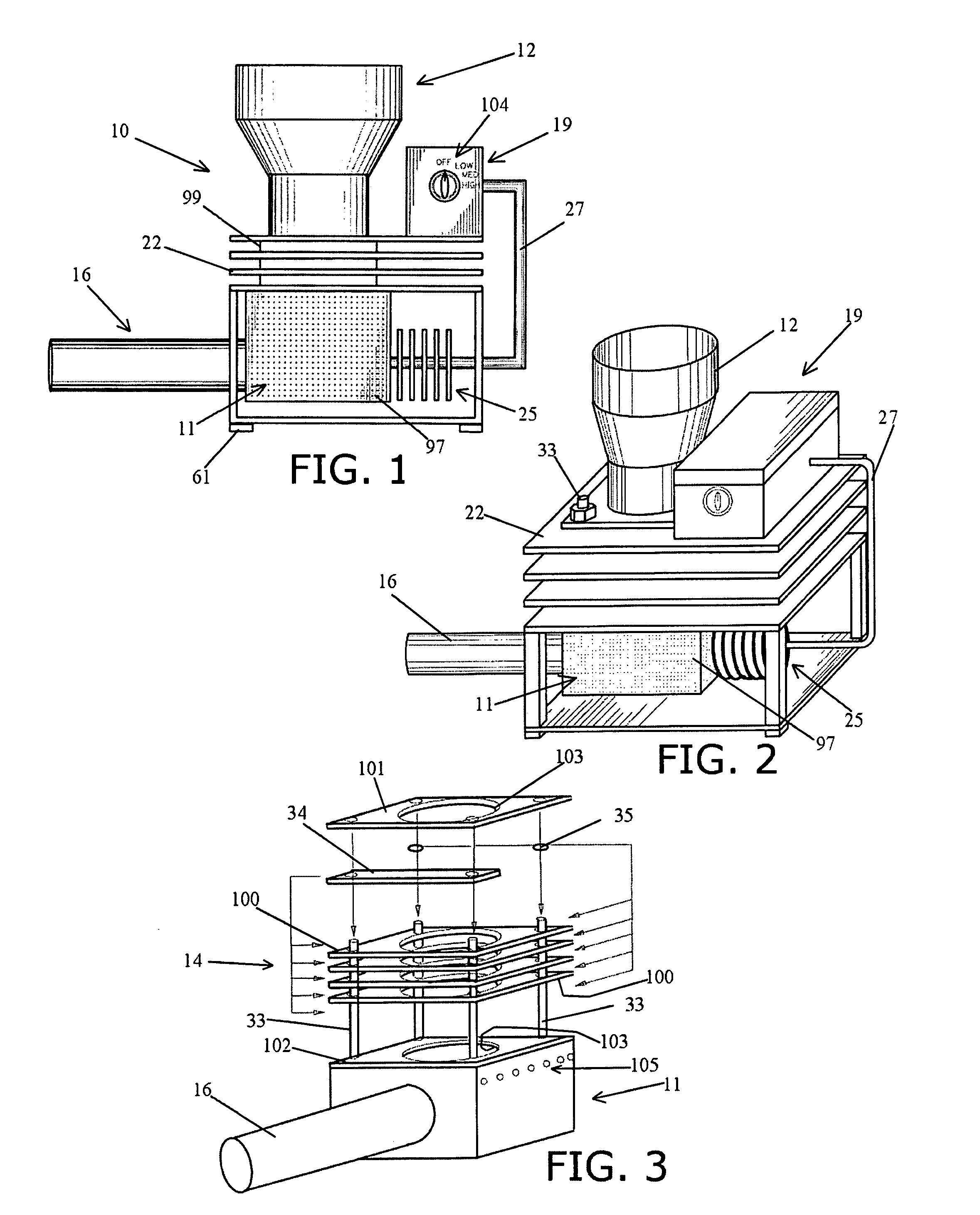

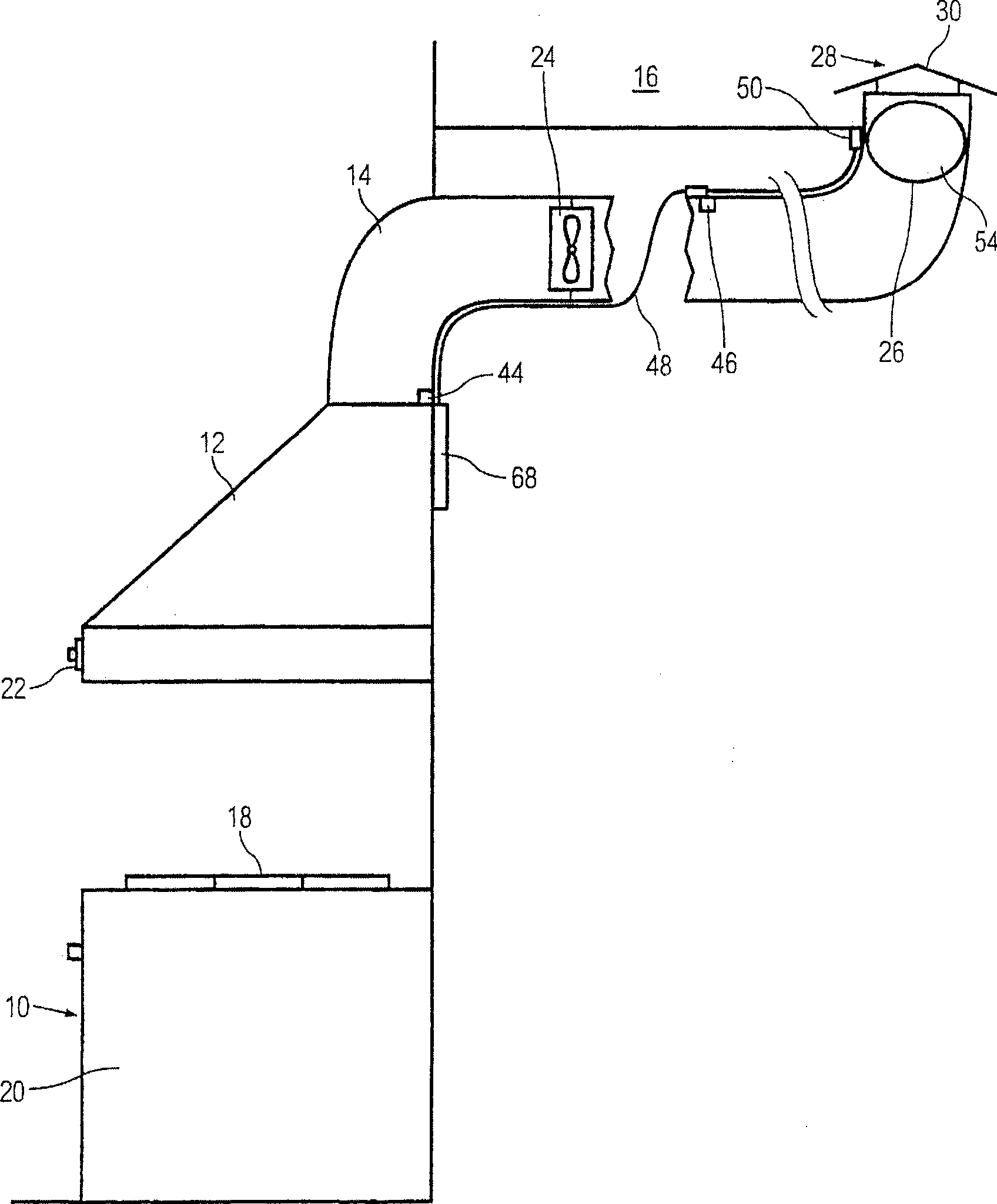

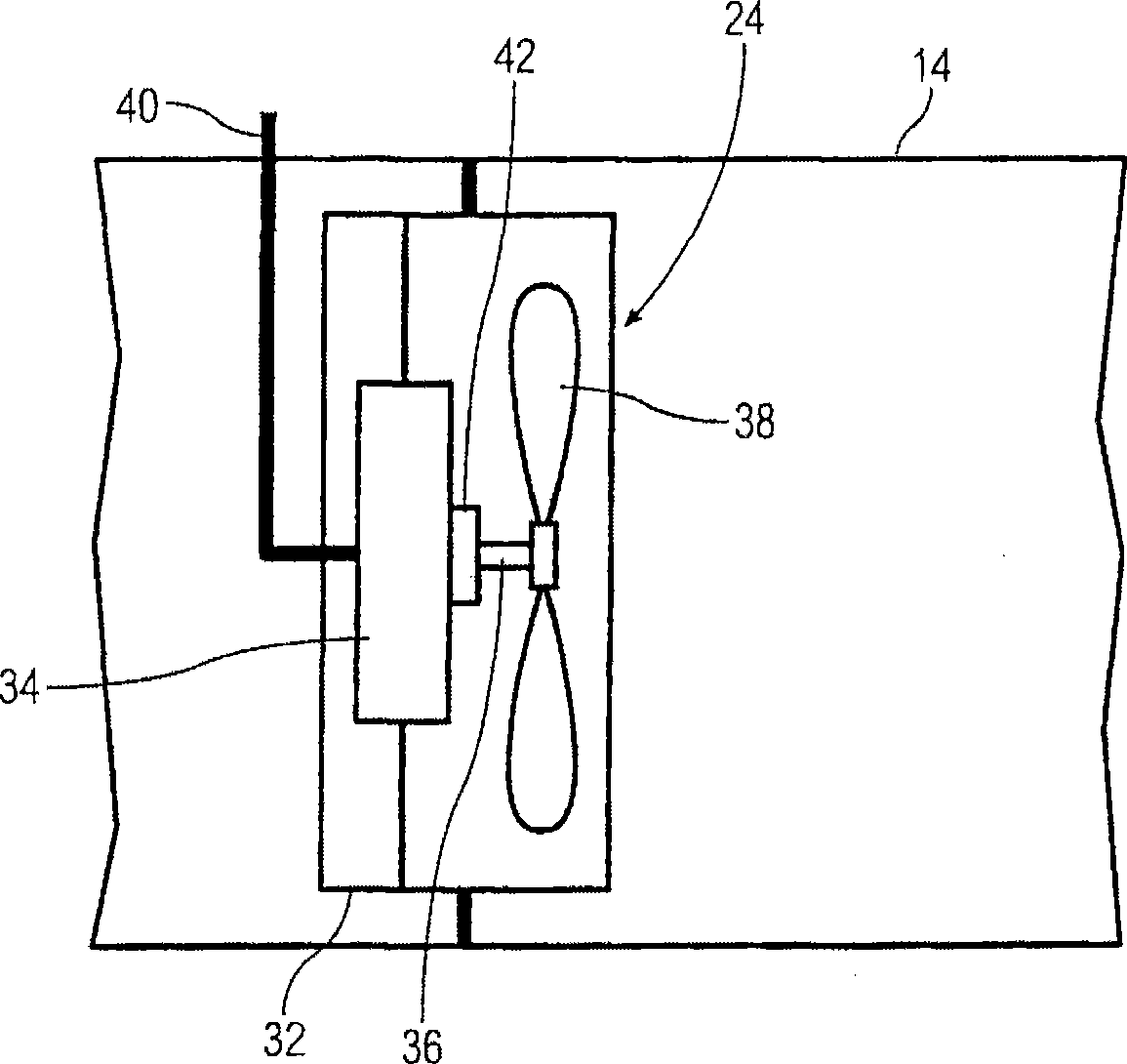

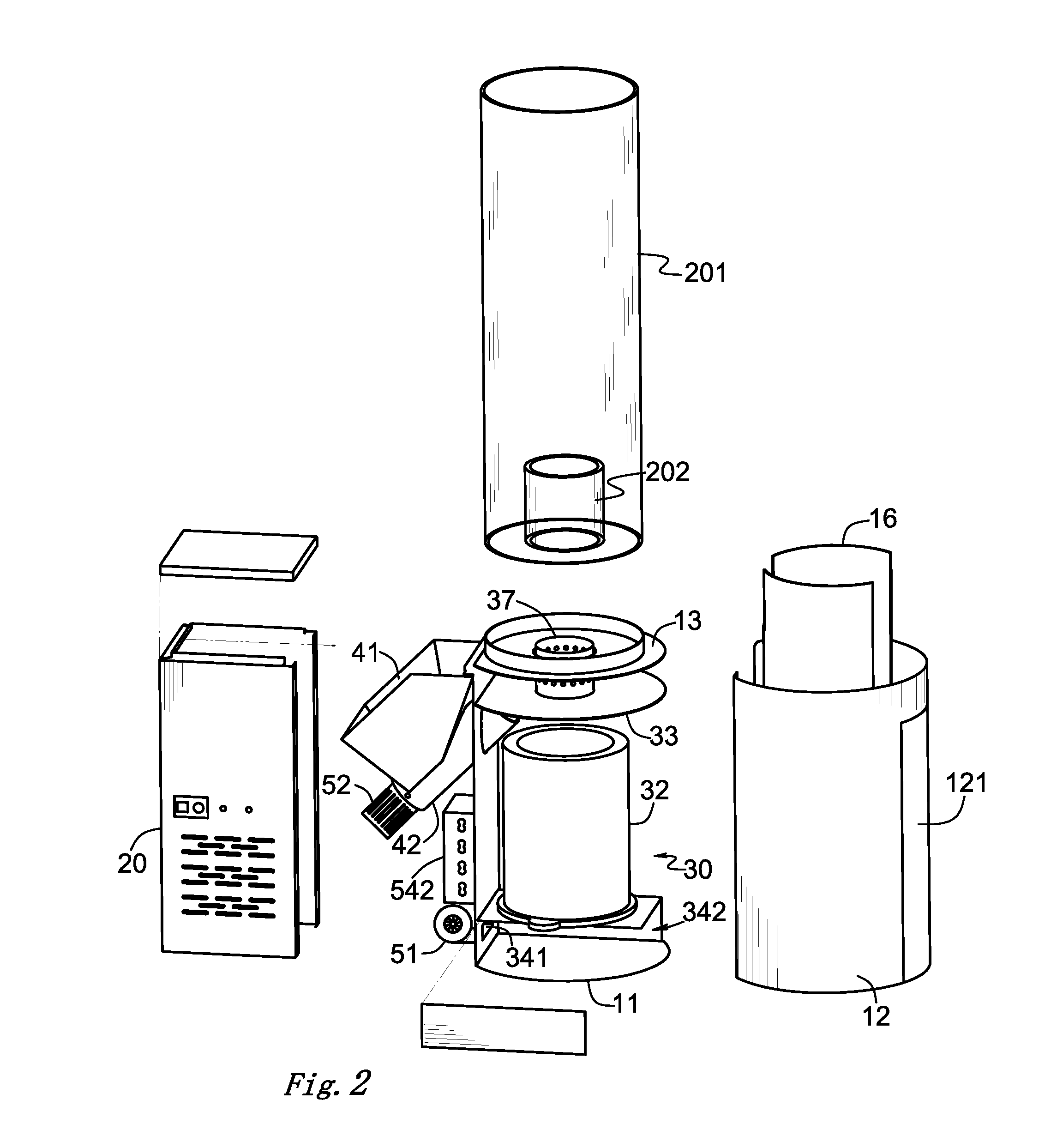

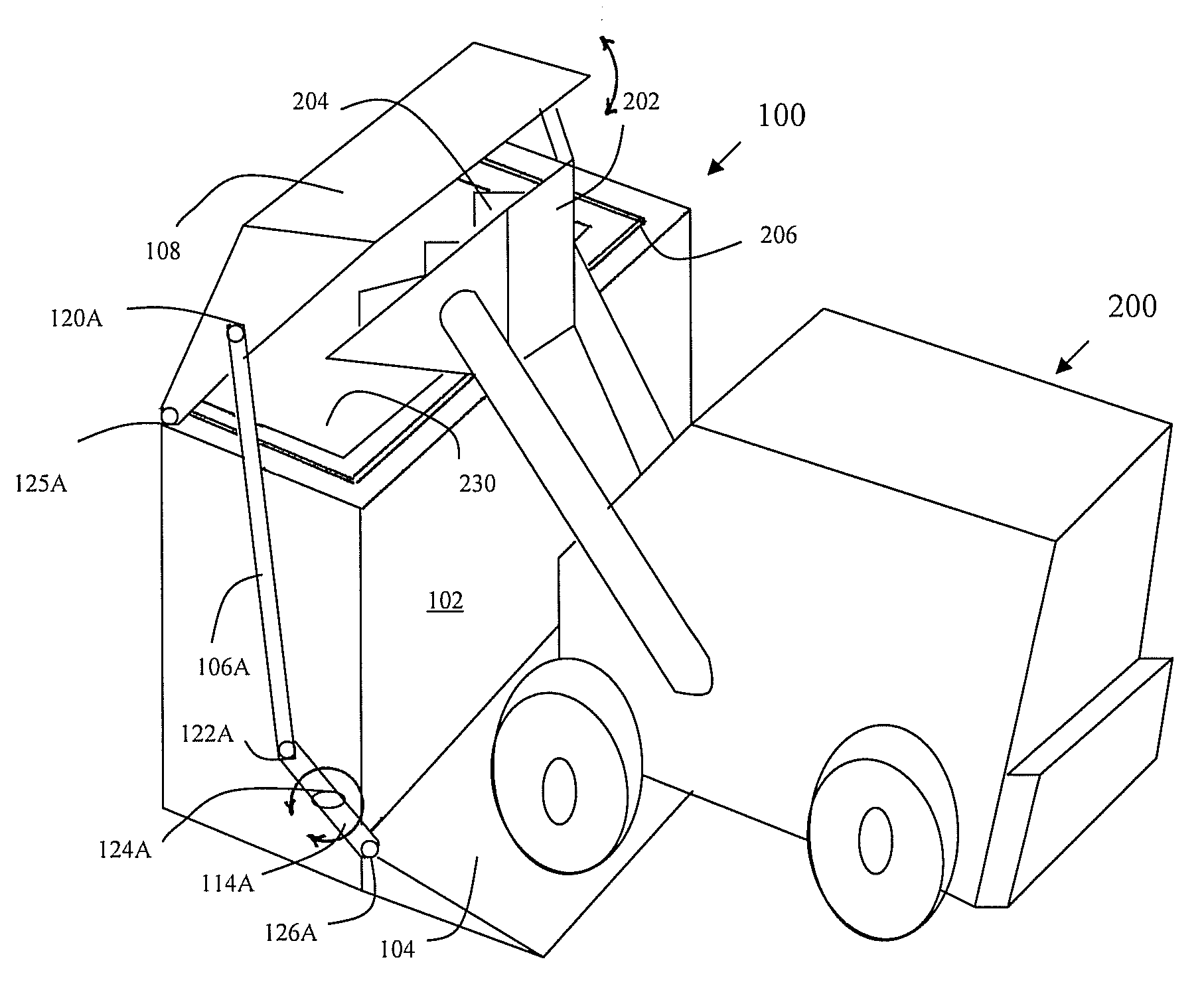

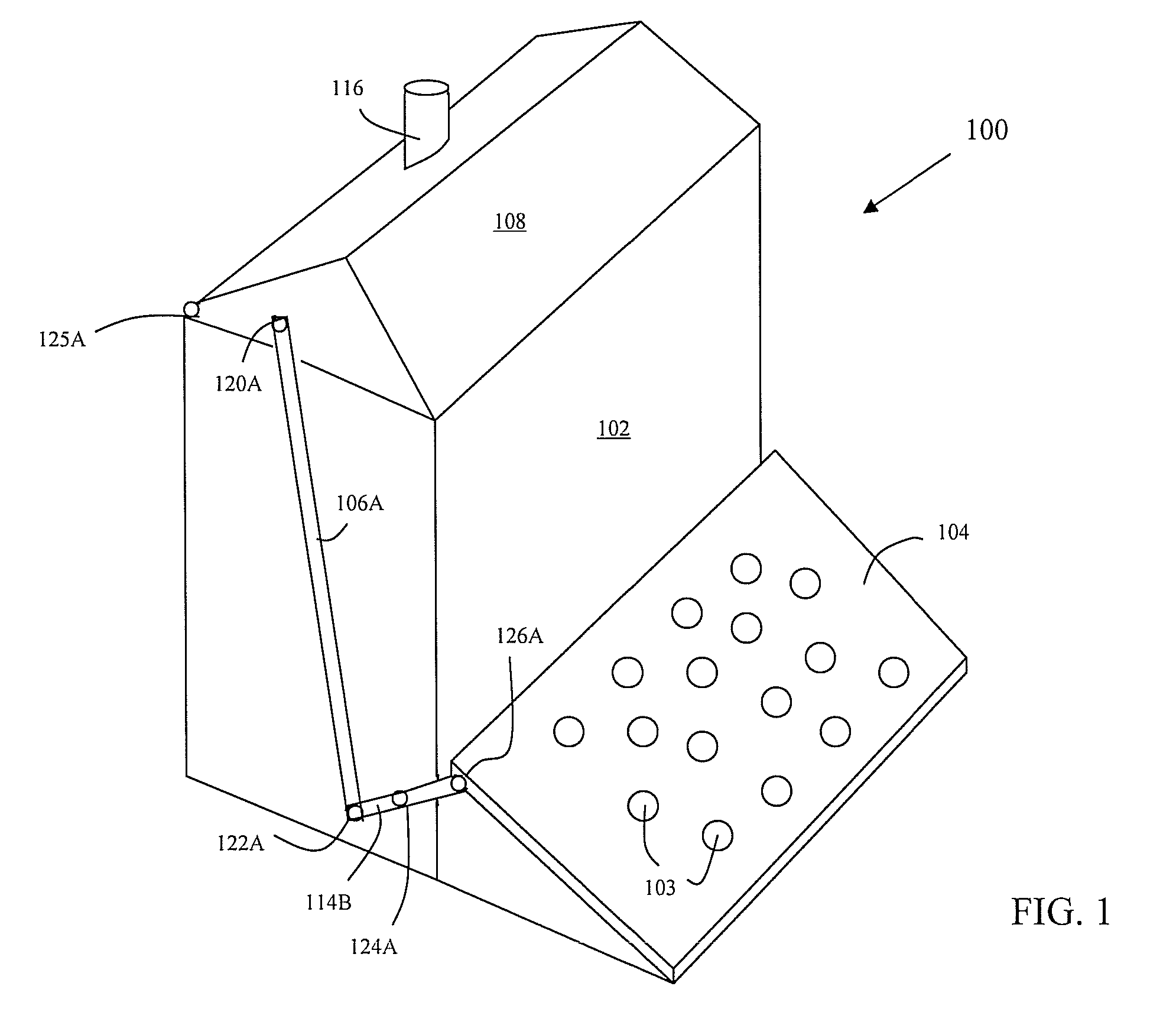

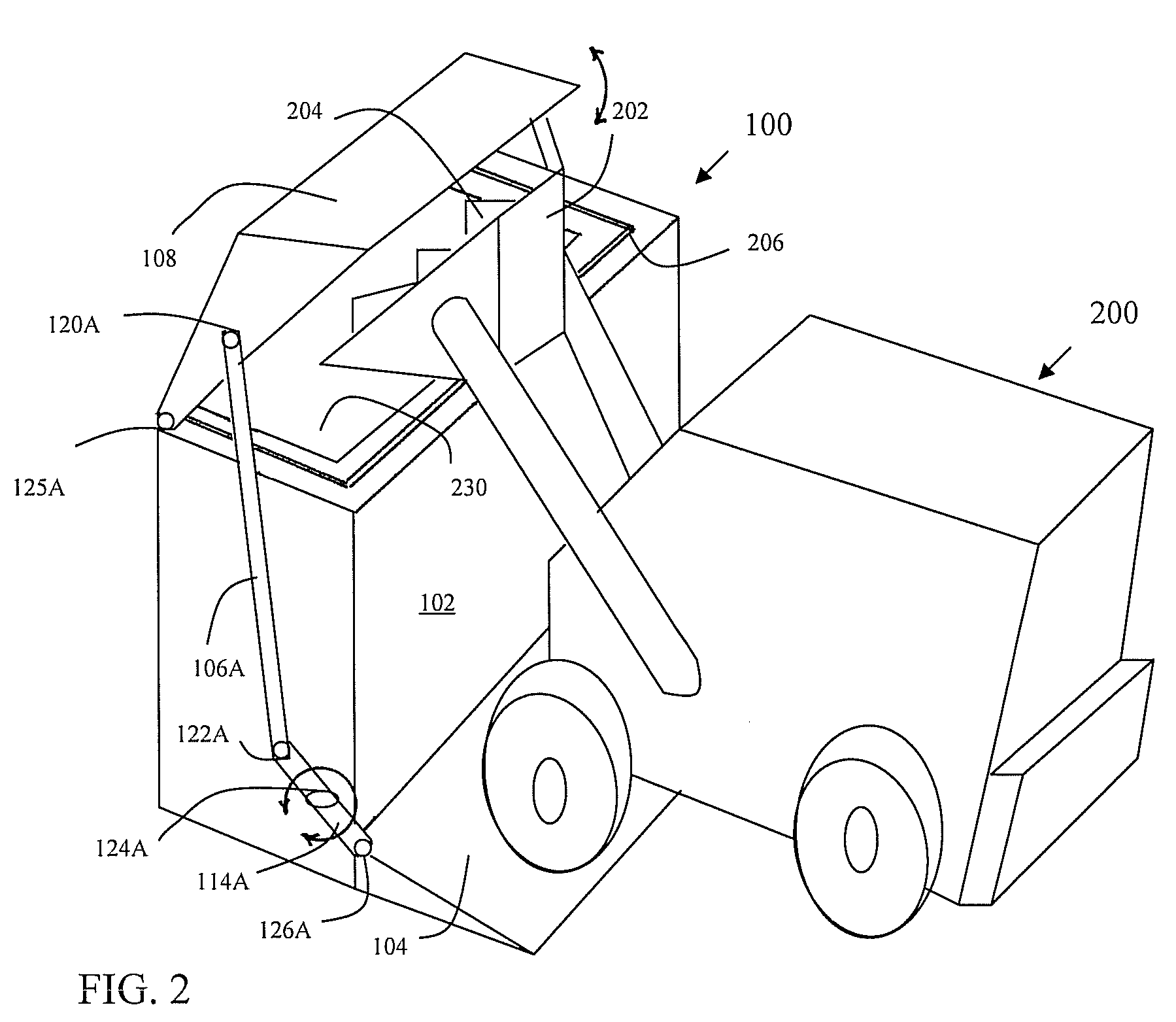

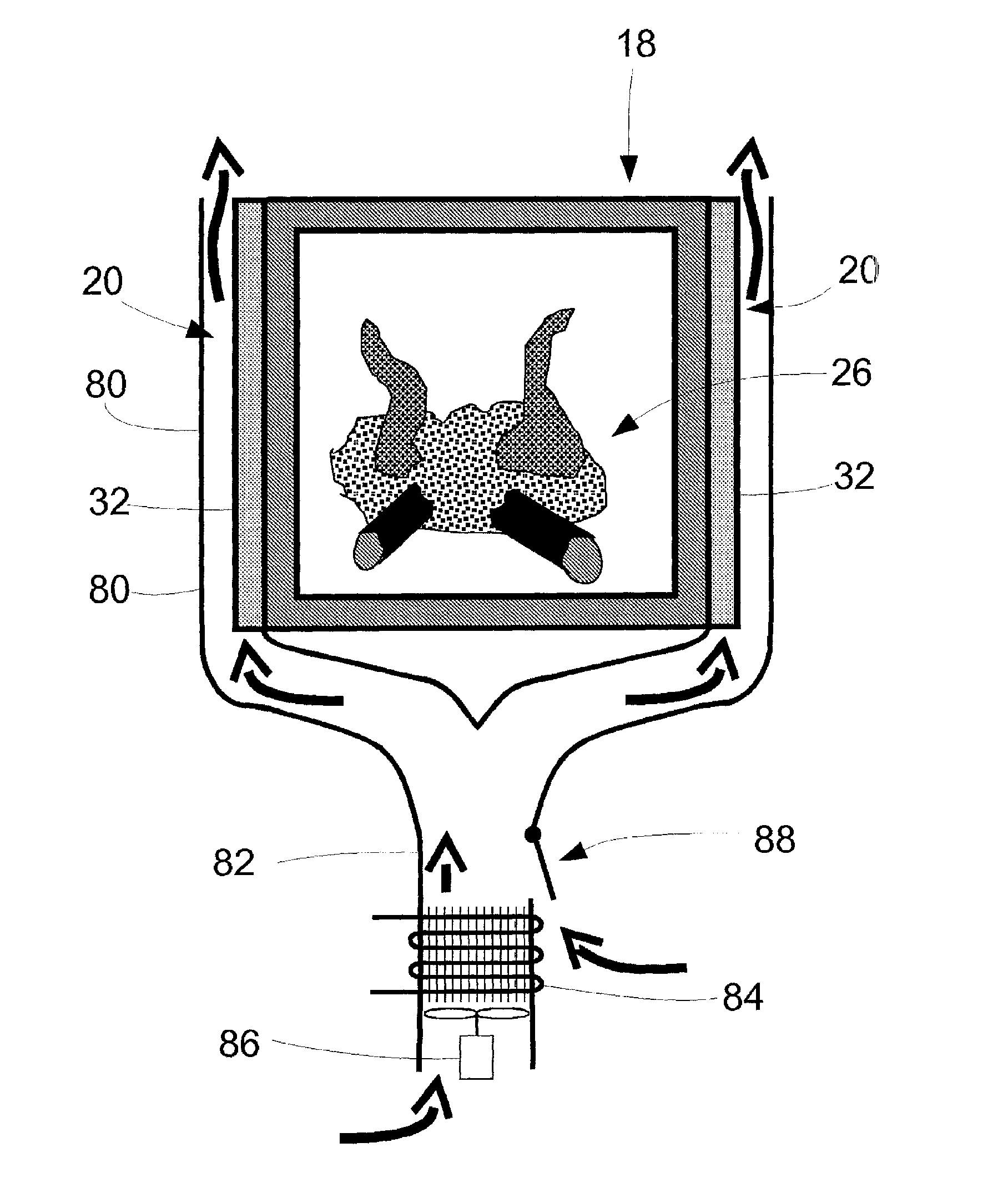

System for converting a kettle-type barbecue to employ fuel pellets

ActiveUS20100218754A1Easy to installQuickly and easily retrofitStoves/ranges with convection heatingLighting and heating apparatusMechanical engineeringEngineering

An apparatus and method used with a conventional barbecue, such as a kettle-type barbecue, which enables the barbecue to be fueled by fuel pellets burned in a fire box. The apparatus includes a support, a hopper and feeder structure for the fire box combined into a unitary construction selectively positionable as a unit on the barbecue body of the barbecue or removed therefrom. In embodiments illustrated, the fire box is positioned so as to direct heat to a desired location within the apparatus.

Owner:KUNTZ JOHN

System for converting a kettle-type barbecue to employ fuel pellets

ActiveUS8267078B2Easy to installQuickly and easily retrofitStoves/ranges with convection heatingLighting and heating apparatusEngineeringMechanical engineering

Owner:KUNTZ JOHN

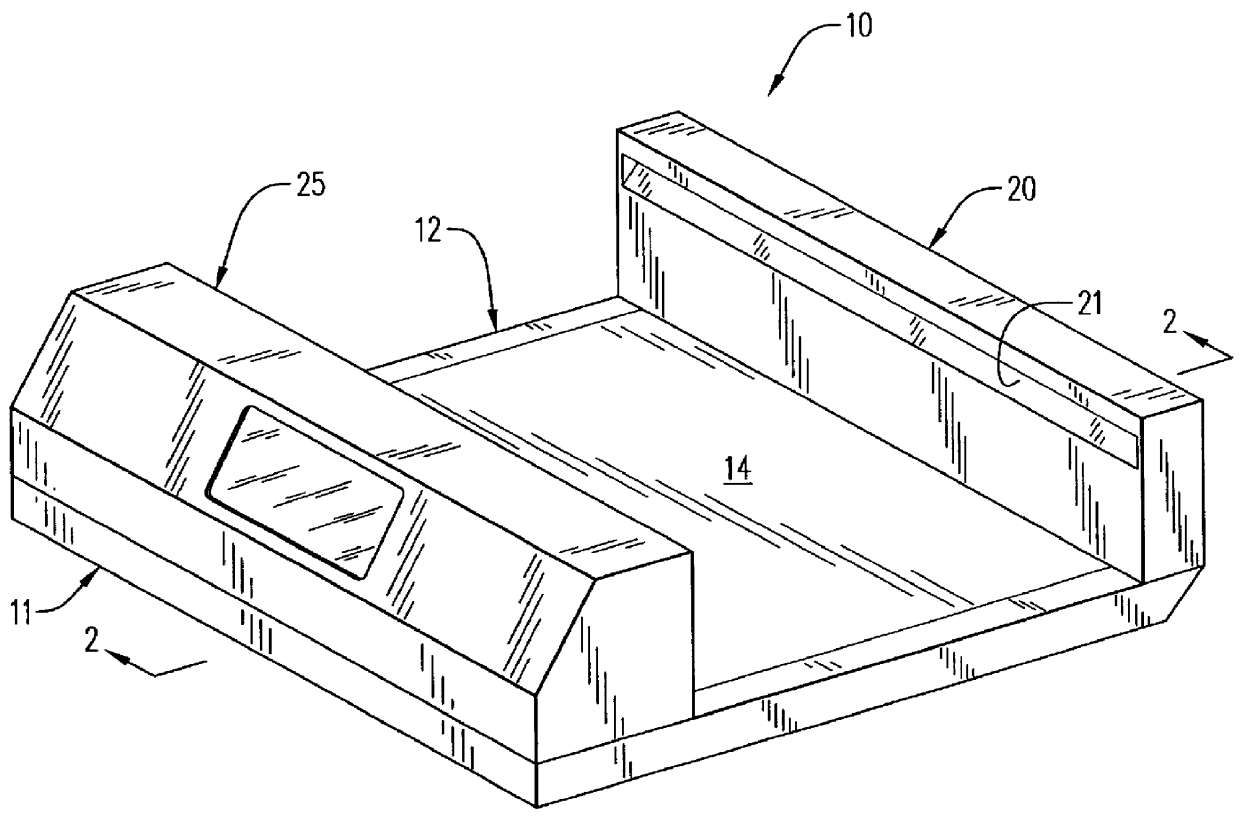

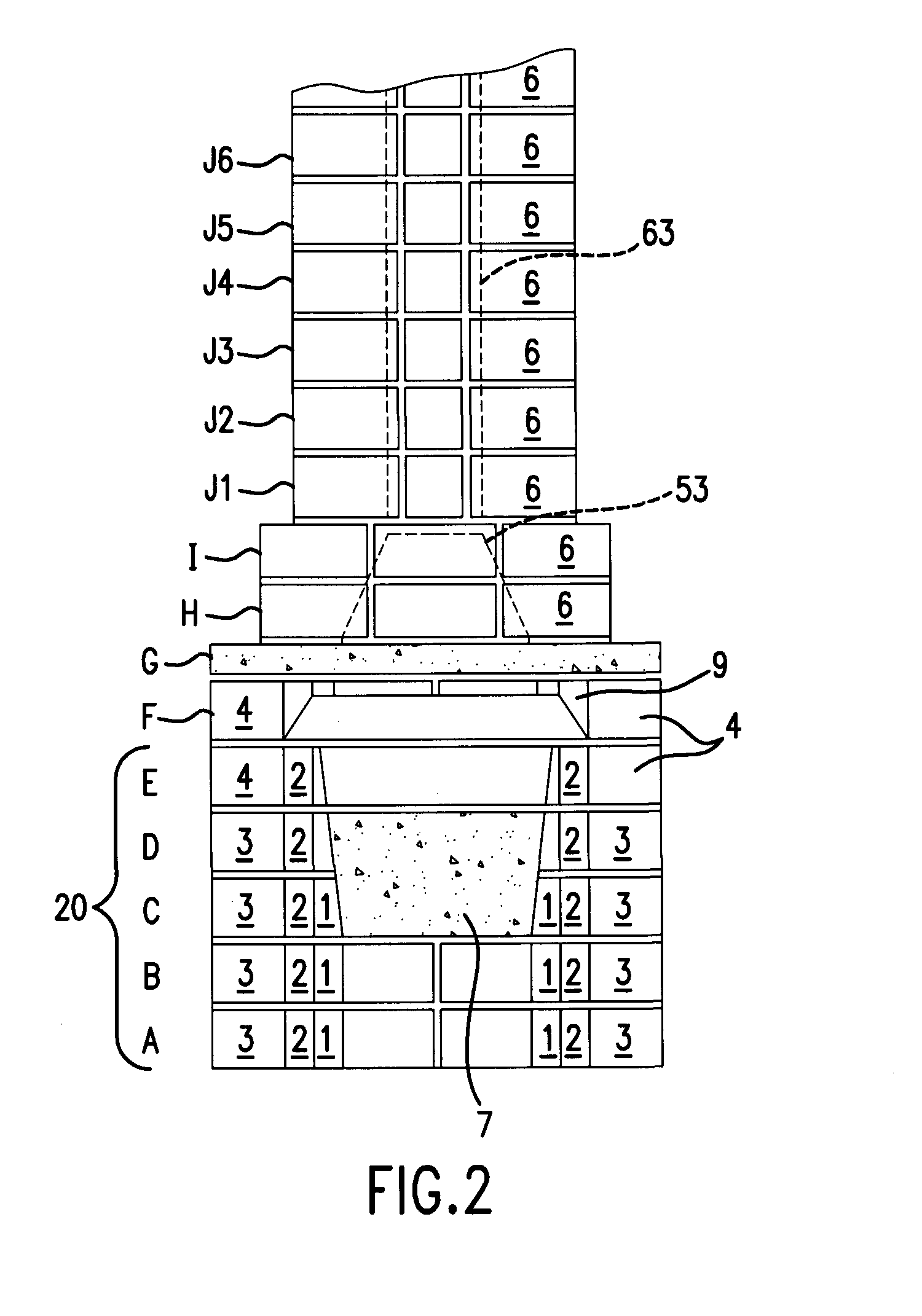

Device and method for keeping food warm

A food warming device having a bin for holding food products. The bin has an air delivery port and an air intake port located at first and second end walls that are disposed at first and second opposite edges of the bottom portion. The regions above the bottom portion and along the third and fourth opposite edges between the first and second walls are substantially open whereby the food products are clearly visible to customers. The bottom portion has a heated surface for receiving food products to be warmed. An air circulating means forms a stream of circulating heated air that moves from the air delivery port over the heated surface to the air intake port. The food products are warmed by heat emanating from the heated surface and by warm air from the stream of circulating heated air. A balancing system maintains the circulating air in balance by diverting a portion of the return air to ambient atmosphere through a bleed exhaust port.

Owner:THE FRYMASTER CORP LLC

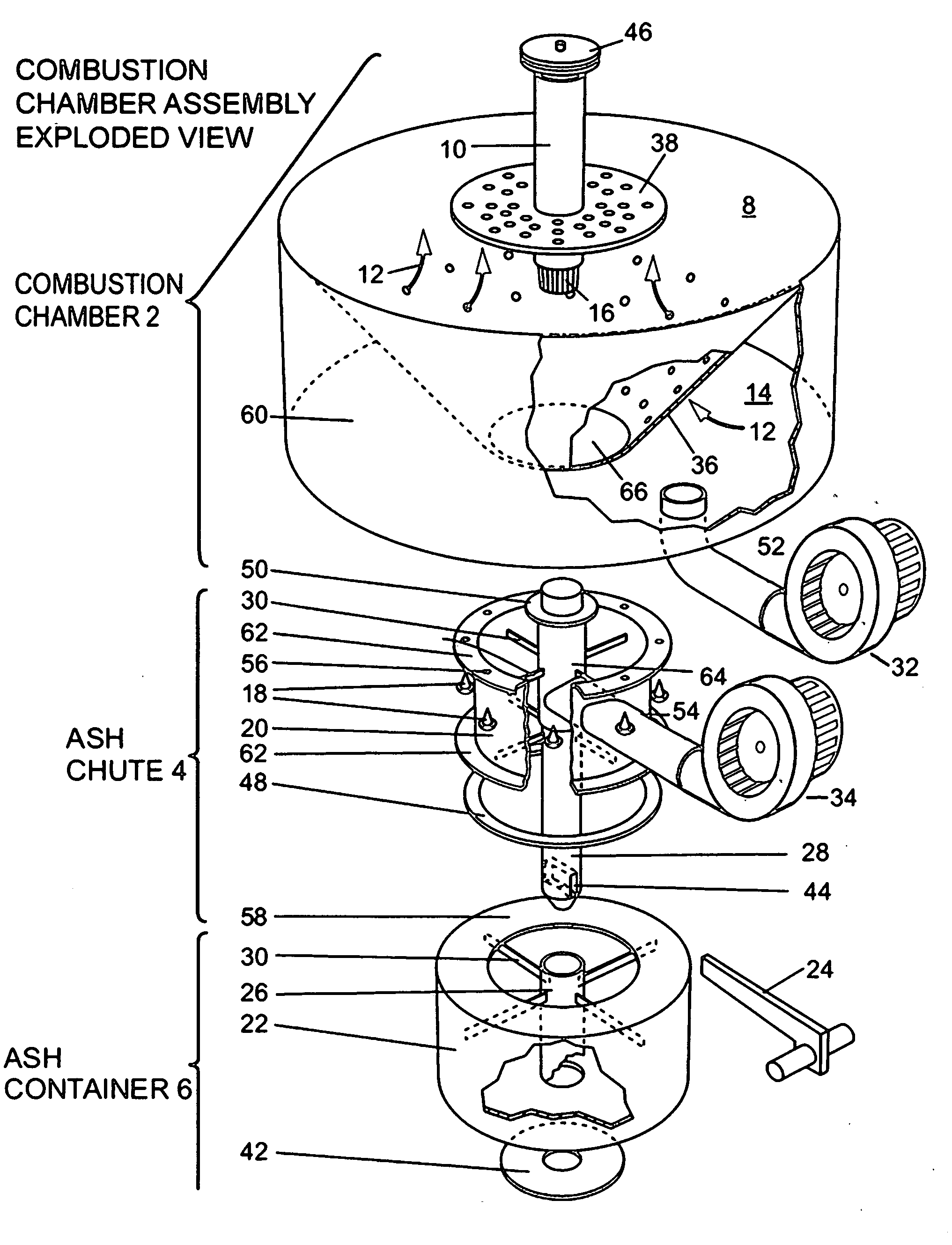

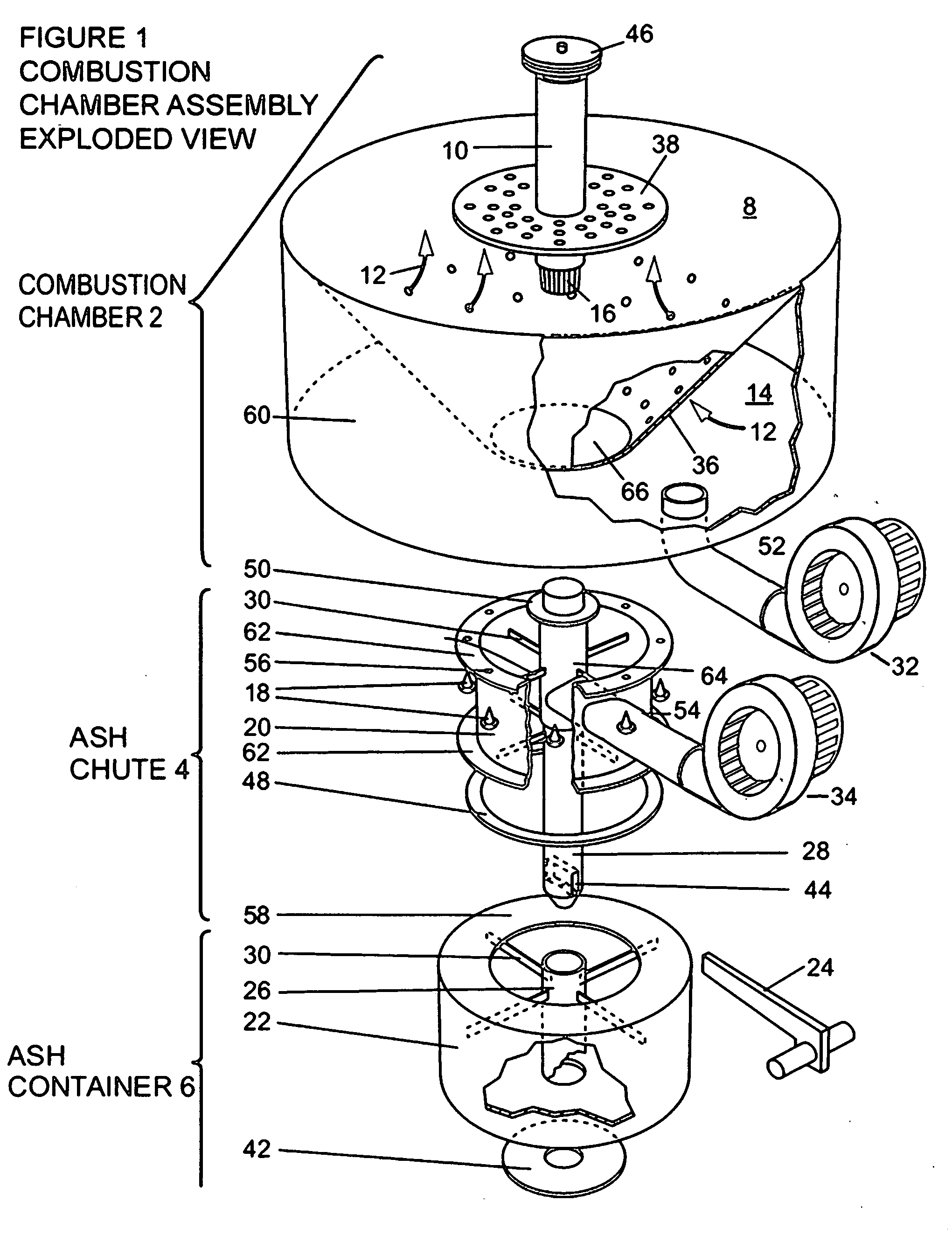

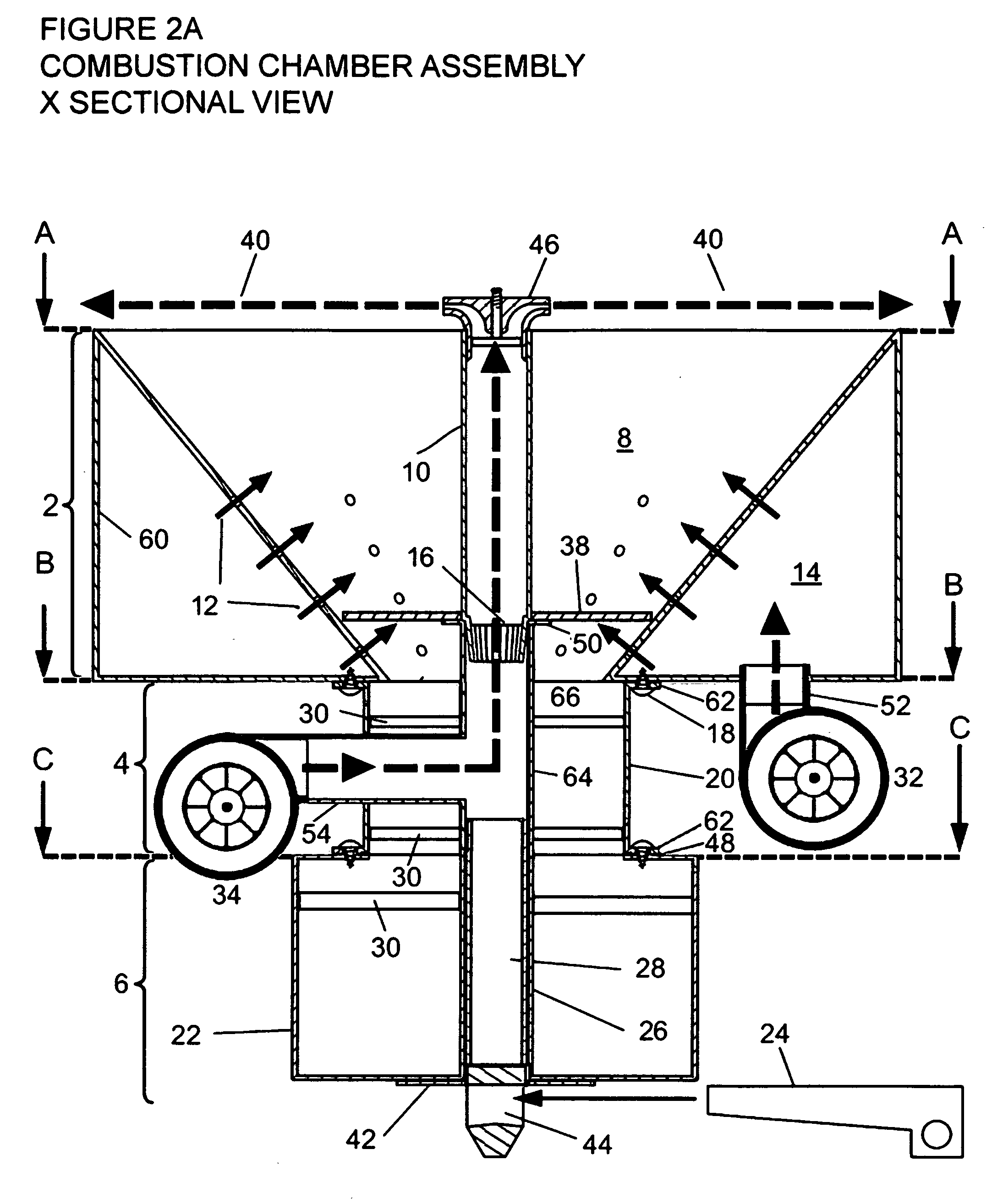

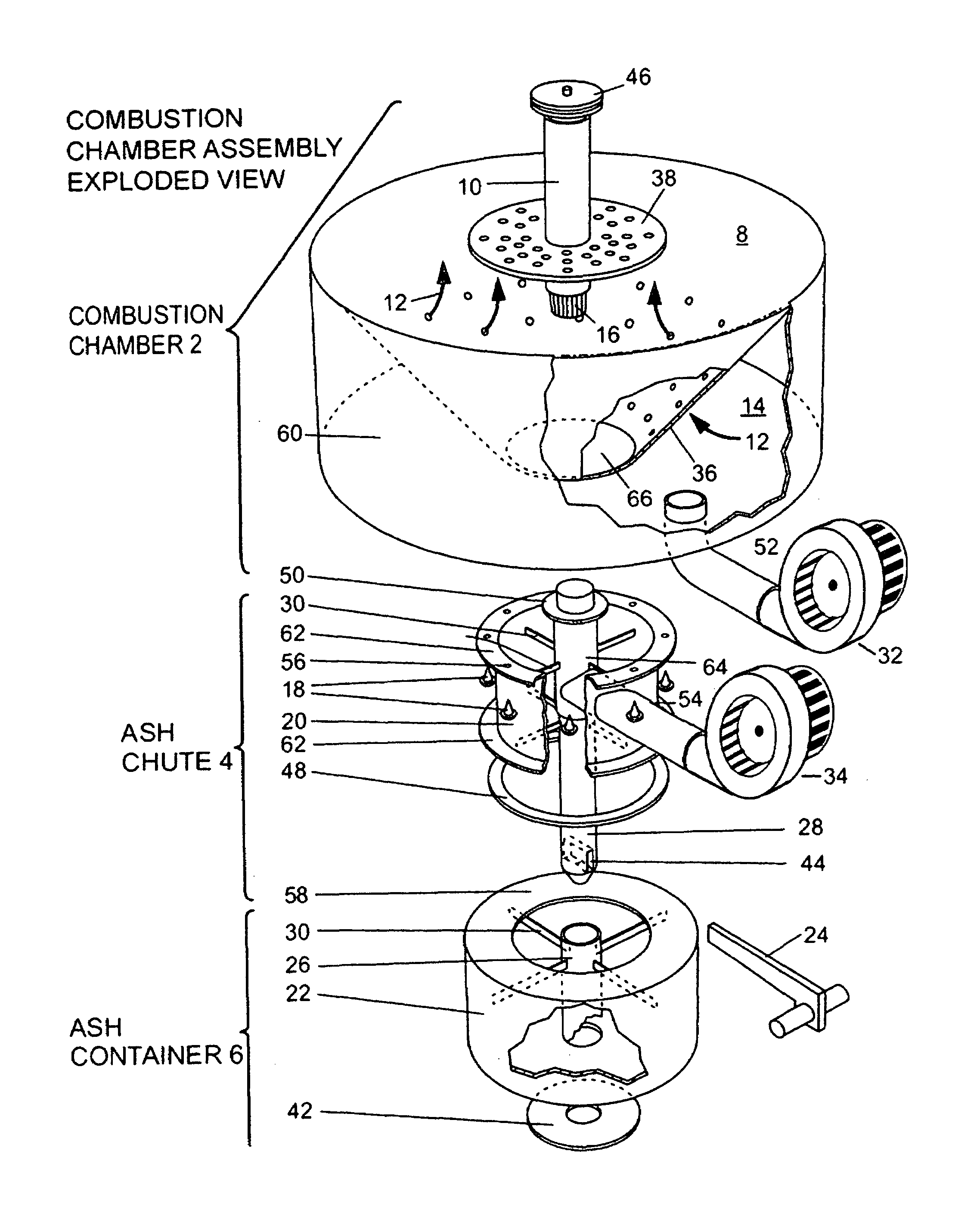

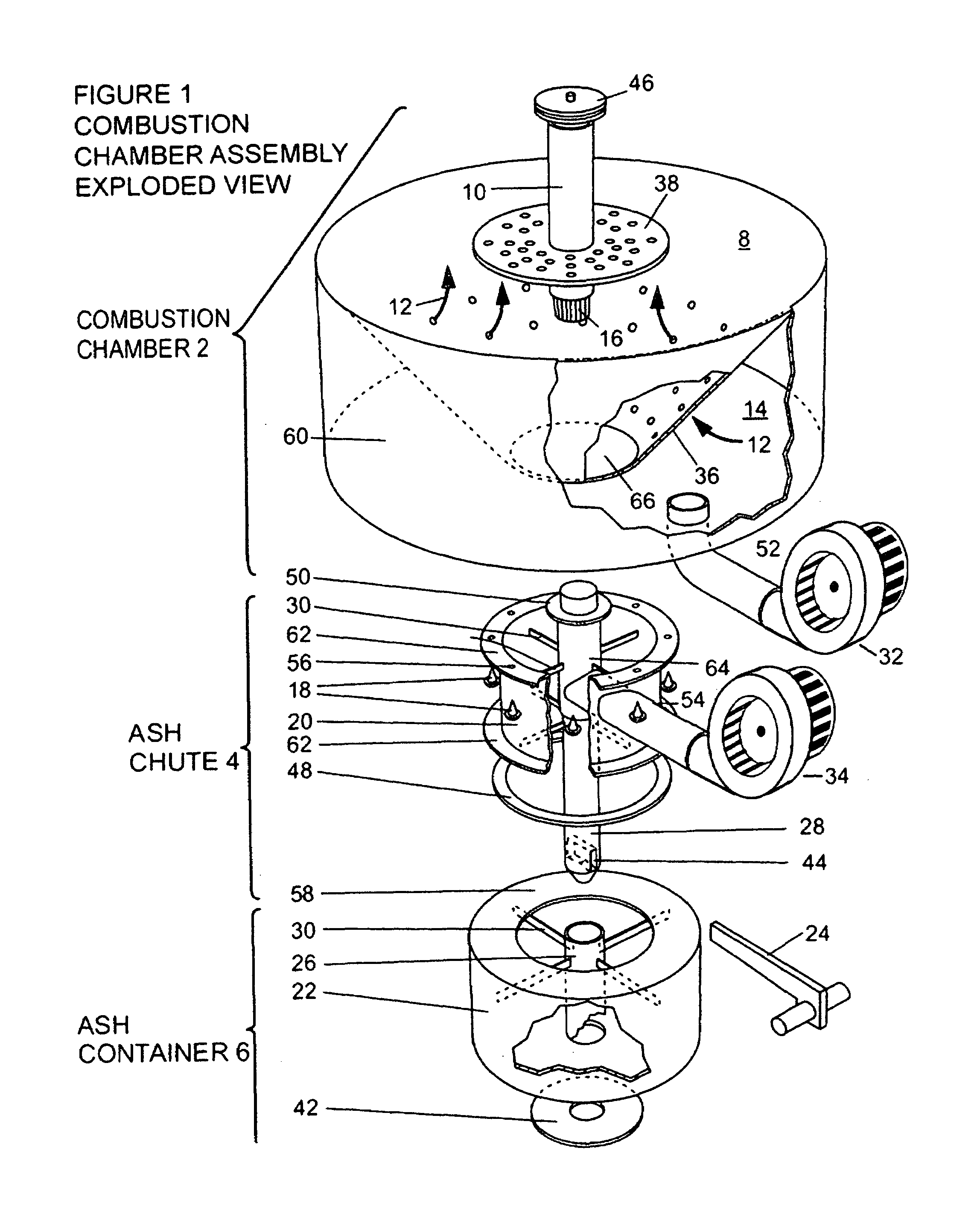

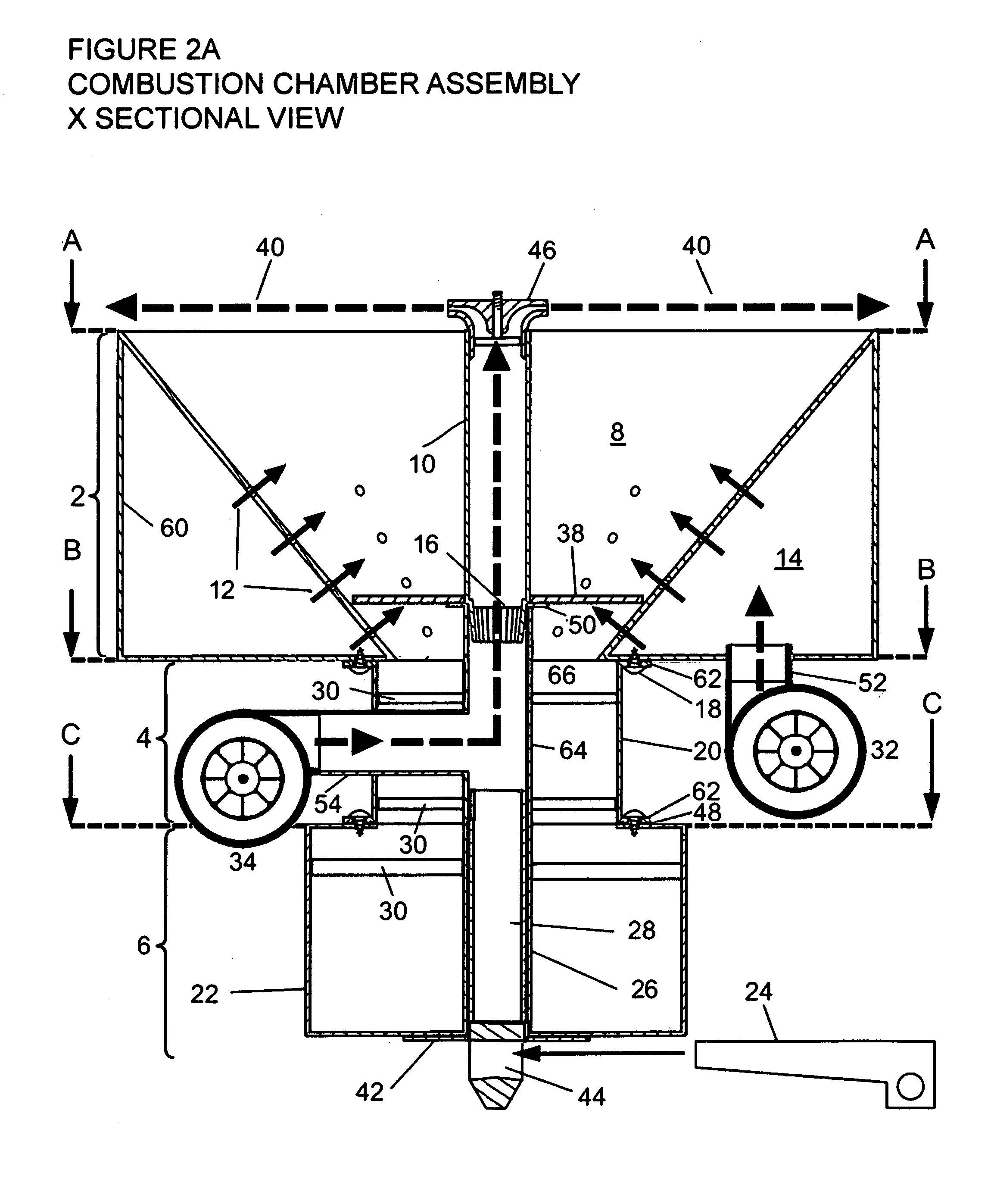

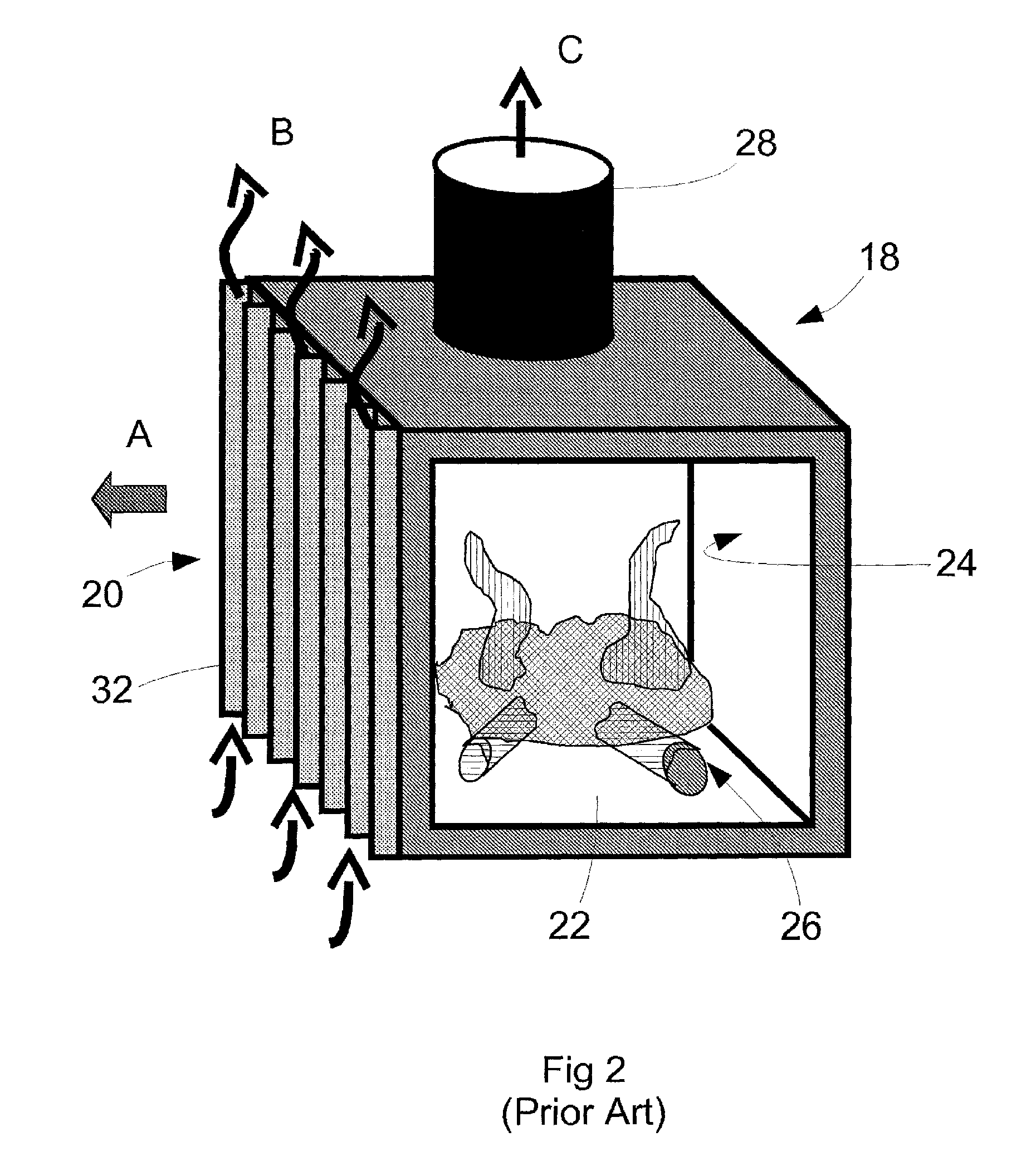

Charcoal / Air BBQ Combustion Chamber Assembly

InactiveUS20090056695A1Master quicklyPrevents excessive and contaminationStoves/ranges with convection heatingCapillary burnersBottom ashCombustor

An open “funnel shaped” Inner Burner inside an open top Outer Casing. The casings closed base has a central hole accommodating the burners small open bottom Ash Exit. The space between the Inner Burner wall and Outer Casing wall forms an Annular Air Plenum that's supplied by an electric variable speed blower. Air enters the Burner Combustion space through perforations in the Burner / Plenum wall. This ensures rapid ignition and controls combustion rate (Temp). This also precipitates ash from burner Ash Exit, through the Ash Chute and into Storage Container fitted to outer casings base. A Radial diffuser centered on the heating surface provides a variable speed Lateral Air Sheet between heating and grill surfaces, instantly blowing “Smoke and Flare-Ups” to the outer burner perimeter. Unit is designed as a “Drop-In” unit to fit a manufacturer BBQ cart suitably equipped to specify basic installation requirements.

Owner:BARRY COSGROVE

Portable radiant heater with two reflectors

InactiveUS6188836B1Beautiful appearanceStoves/ranges with convection heatingElectrical heating fuelElectricityRadiant heater

A portable radiant heater comprises an electrically energized heating element extending along a vertical axis. A first, multi-faceted, concave reflective surface is positioned to the rear of the heating element. A second reflector is positioned forward of and in close proximity to the heating element. The first reflector directs radiant energy received directly from the heating element and indirectly from the second reflector forward with minimal radial dispersion.

Owner:APPLIANCE DEVMENT

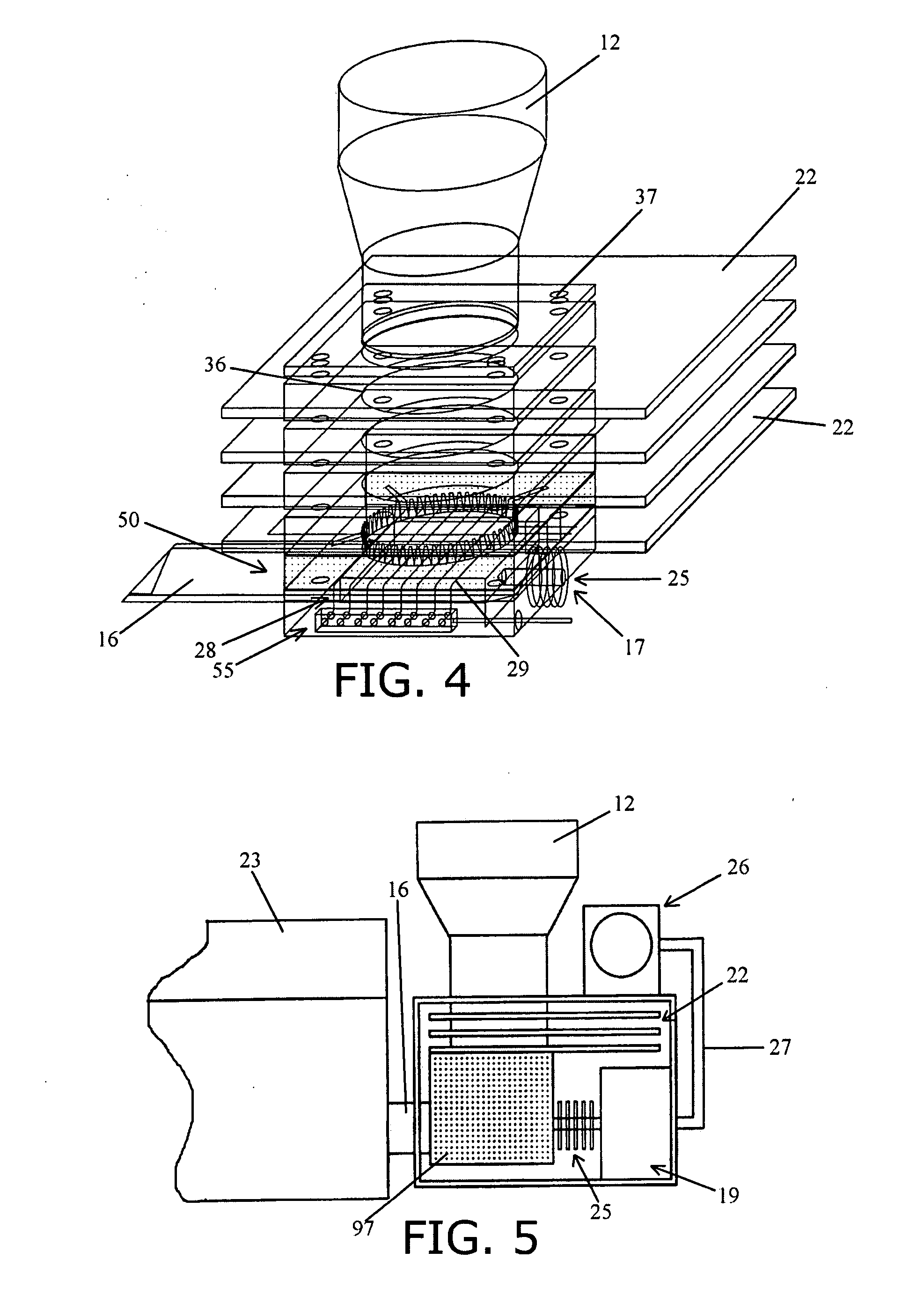

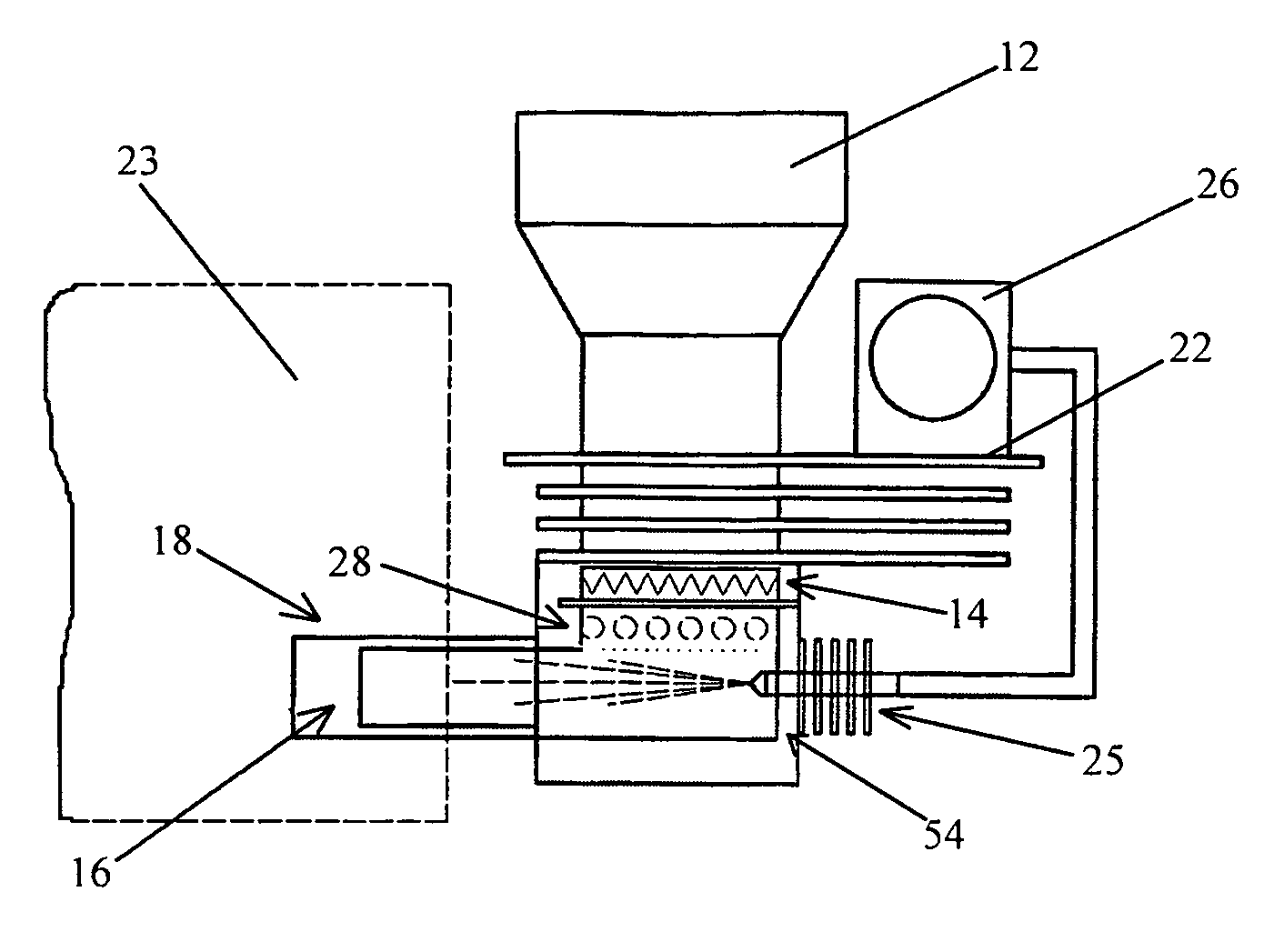

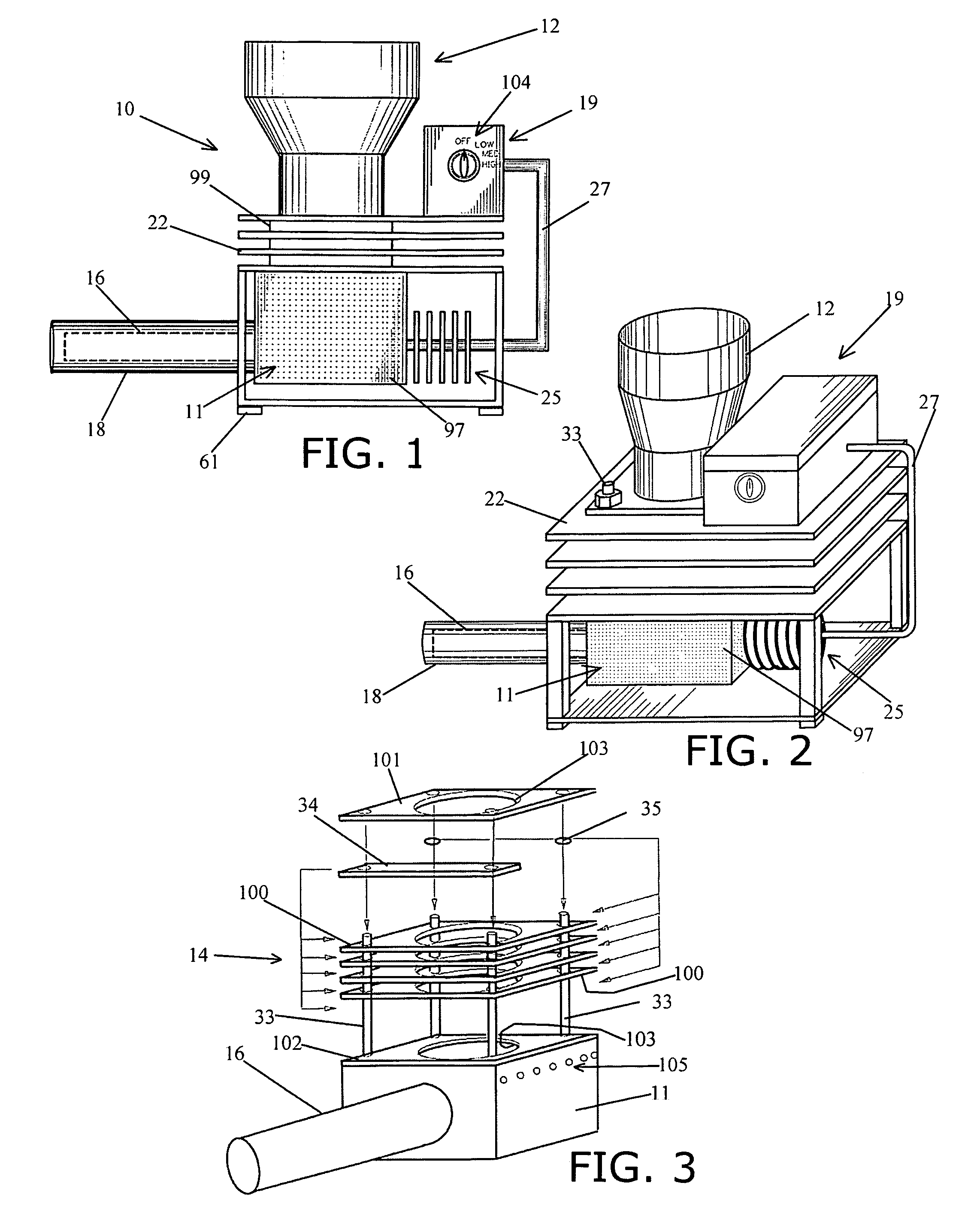

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

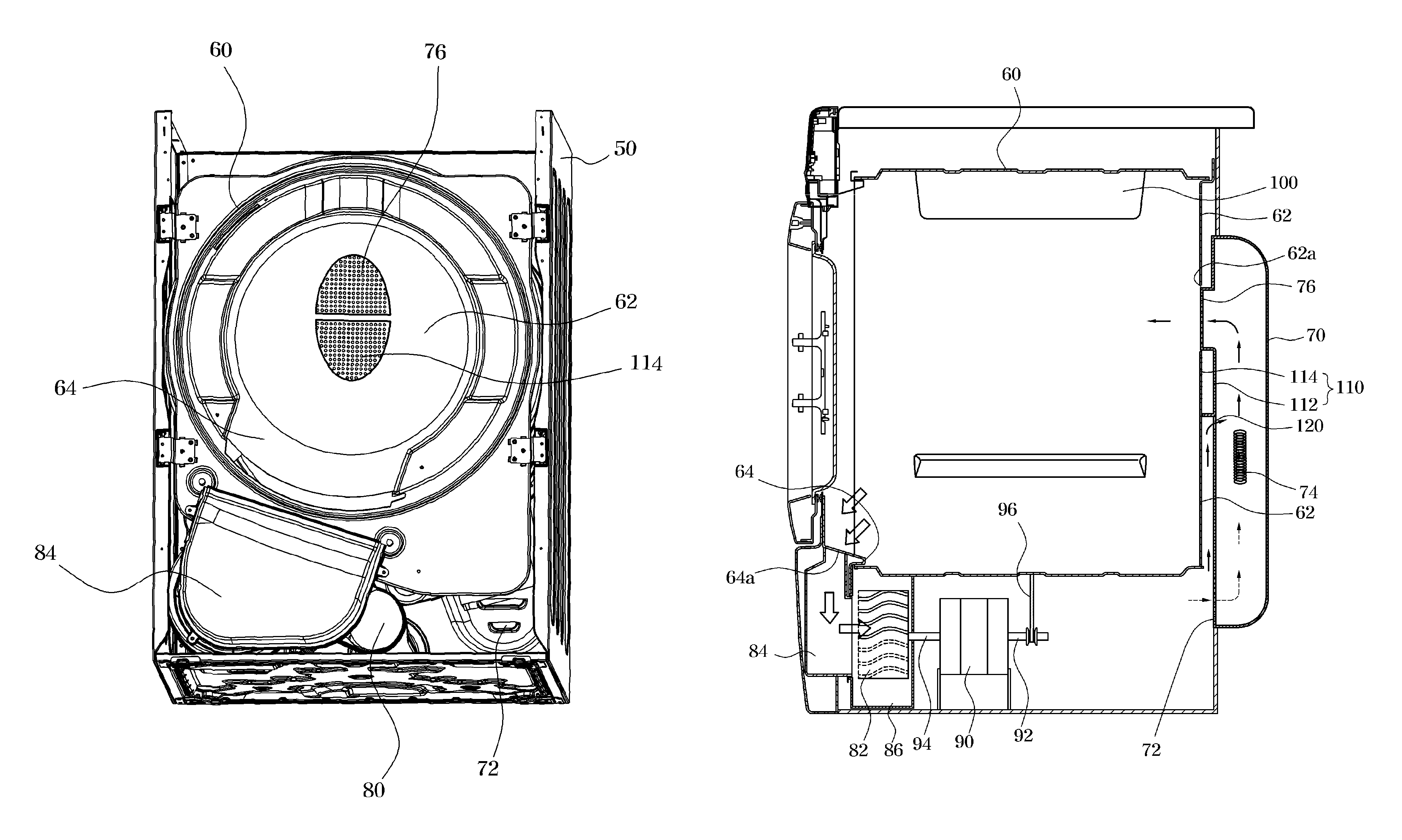

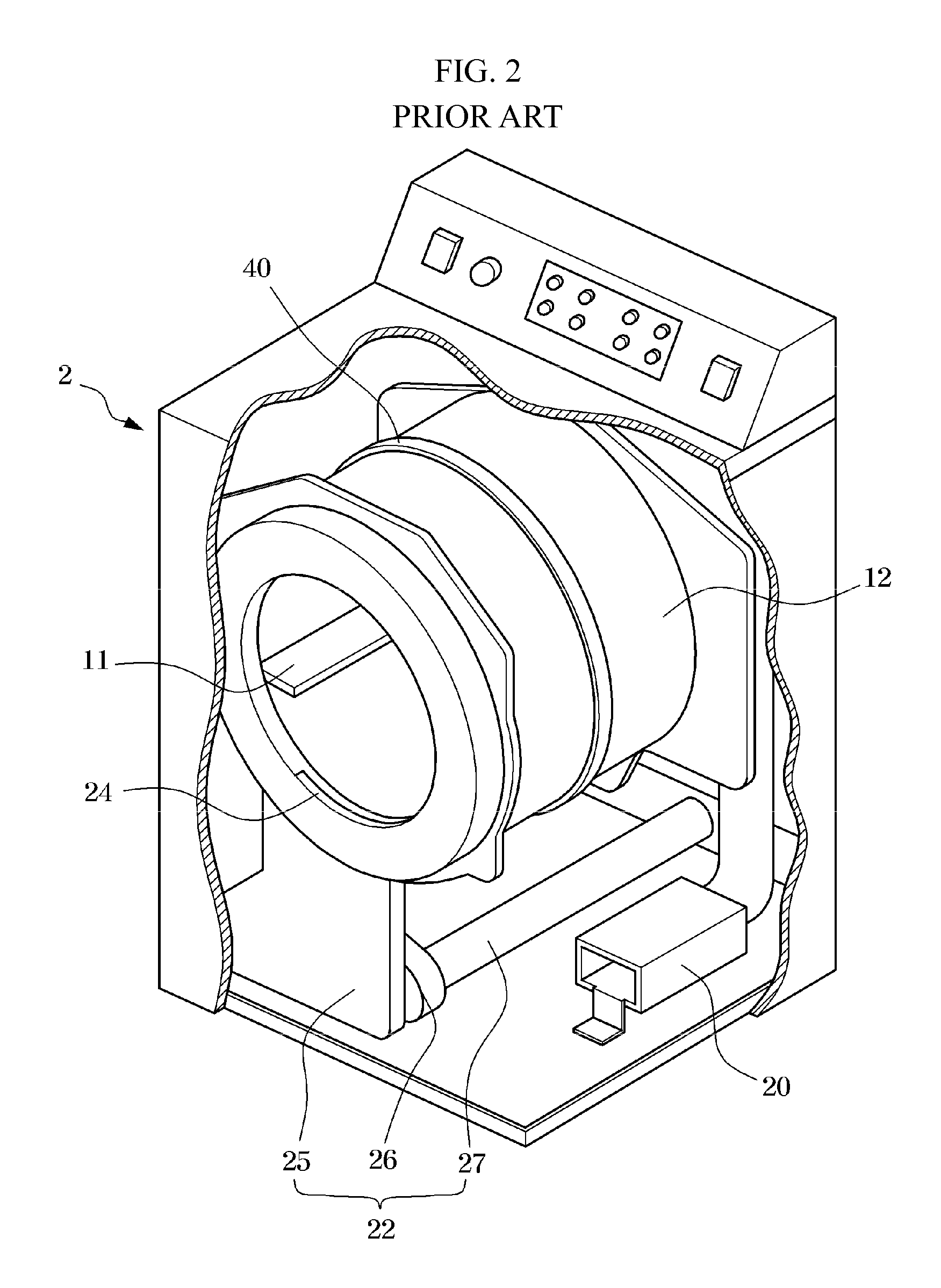

Dryer having intake duct with heater integrated therein

InactiveUS7992322B2Avoid overall overheatingReduce heat lossStoves/ranges with convection heatingDispersed particle filtrationEngineering

Owner:DAEWOO ELECTRONICS CO LTD

Pellet burning heating assembly

Owner:GRILLSON

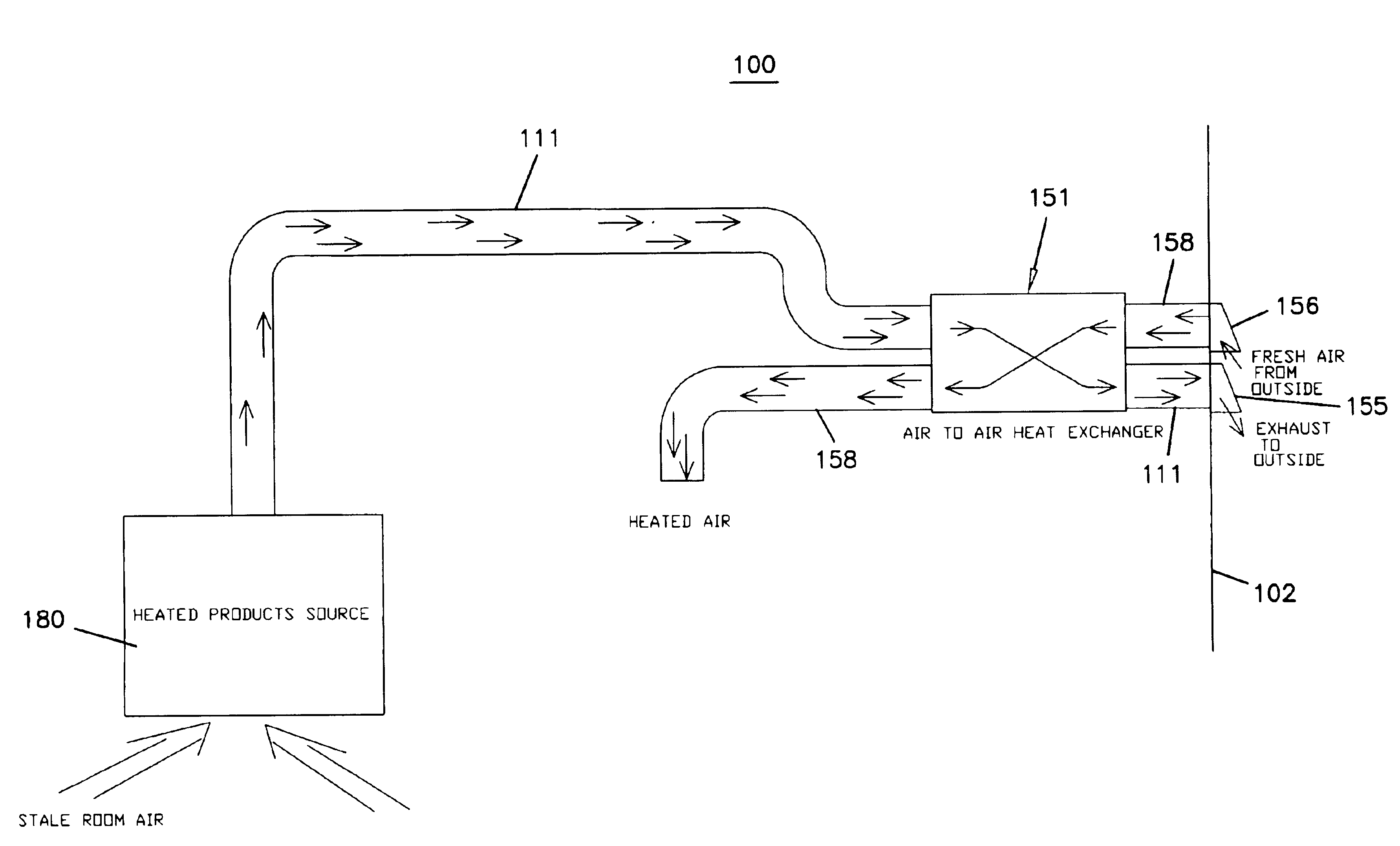

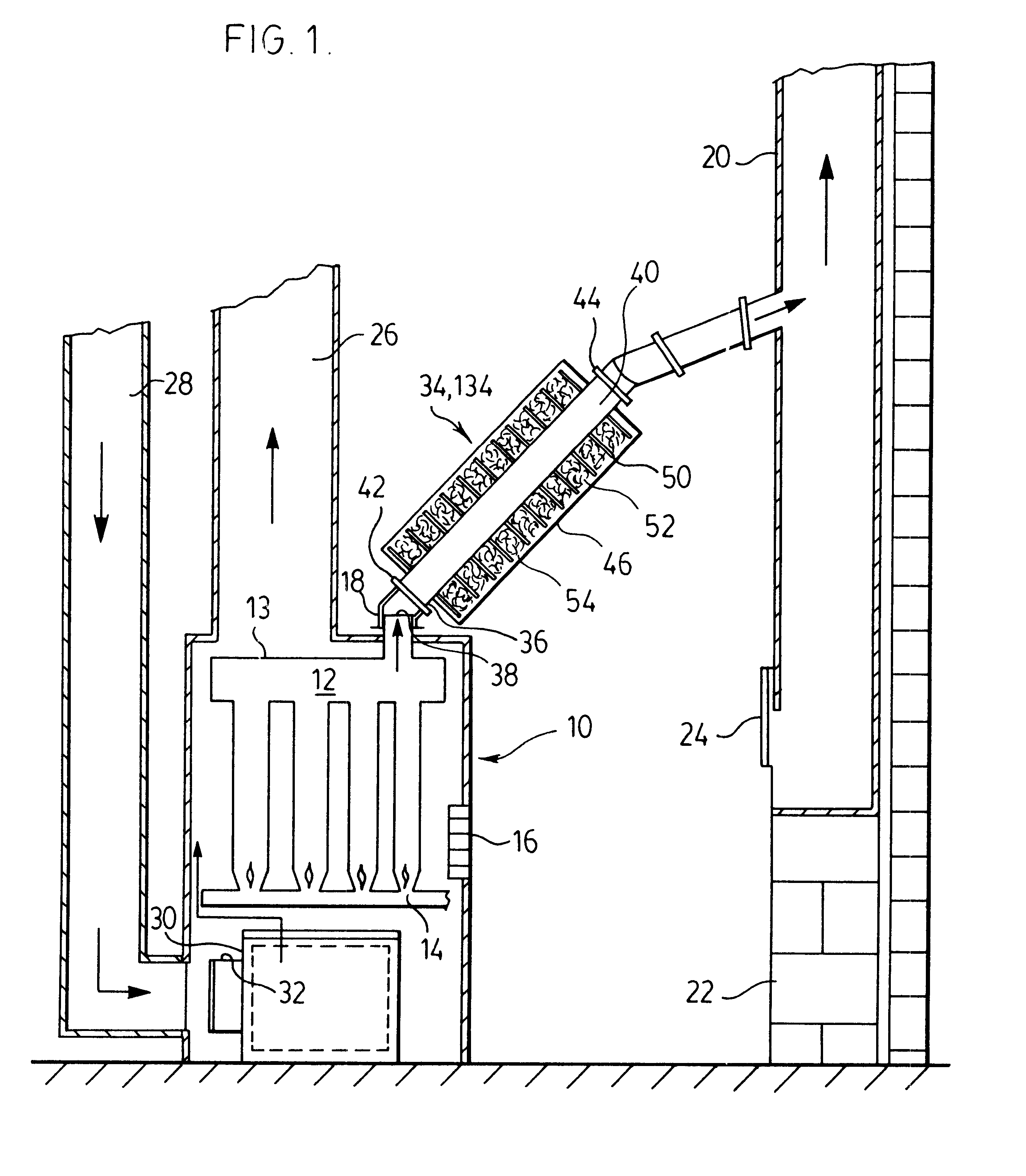

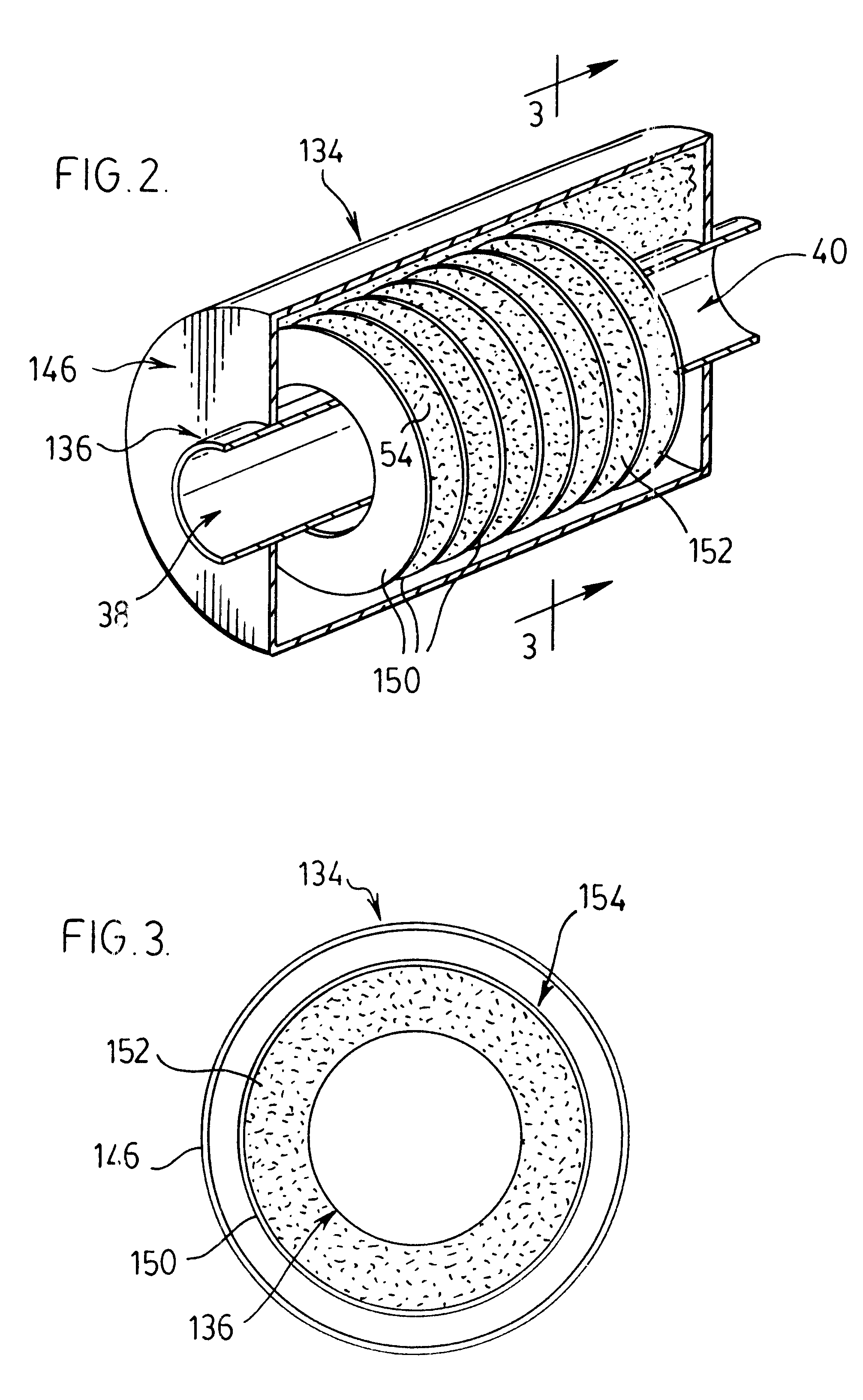

Heat exchange system

A heat exchange system and method for heating outside air provided to a structure are disclosed. The system uses and recovers heat from waste products that are being exhausted from the structure. A heated products source generates heated waste products as a result of combustion. An exhaust duct passes the heated waste products through a heat exchanger before exhaustion from the structure. An intake duct that supplies fresh outside air to the structure also passes through the heat exchanger. The heat exchanger couples the exhaust duct and the intake duct and transfers otherwise unused heat from the waste products to the outside air to increase the overall efficiency of the heated product source.

Owner:HNI TECH INC

Heat regulating unit

InactiveUS6572370B1Eliminate riskMuffle furnacesStoves/ranges with convection heatingFlueHeating system

A forced air heating system has a heat regulating unit assembled therewith, the heating system comprising a furnace having fuel burner and a flue pipe for outlet gases. The heat regulating unit has a metal flue conduit with a flue gas inlet and a flue gas outlet connected to the flue pipe in proximity to the furnace to form a portion of the flue pipe. An elongated casing surrounds the flue conduit and defines with the flue an annulus in which a series of equispaced metal fins extend radially from the flue conduit to the casing to define chambers containing a heat-absorbing material such as metal wool. The heat regulating unit functions as a heat-sink to absorb heat from the hot fuel and a heat source gases for return to the furnace by conduction and convection.

Owner:HAMPDEN CHRIS

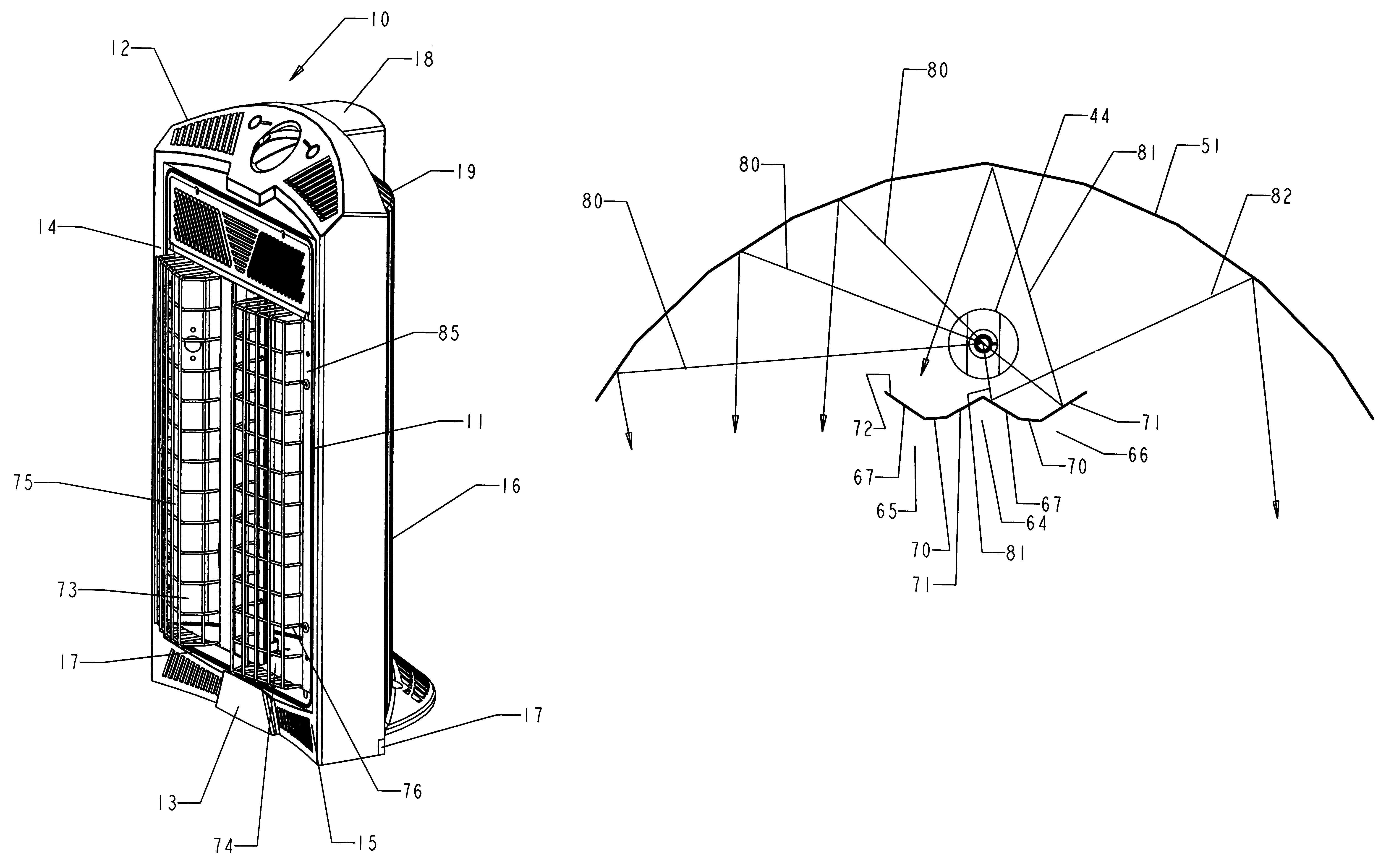

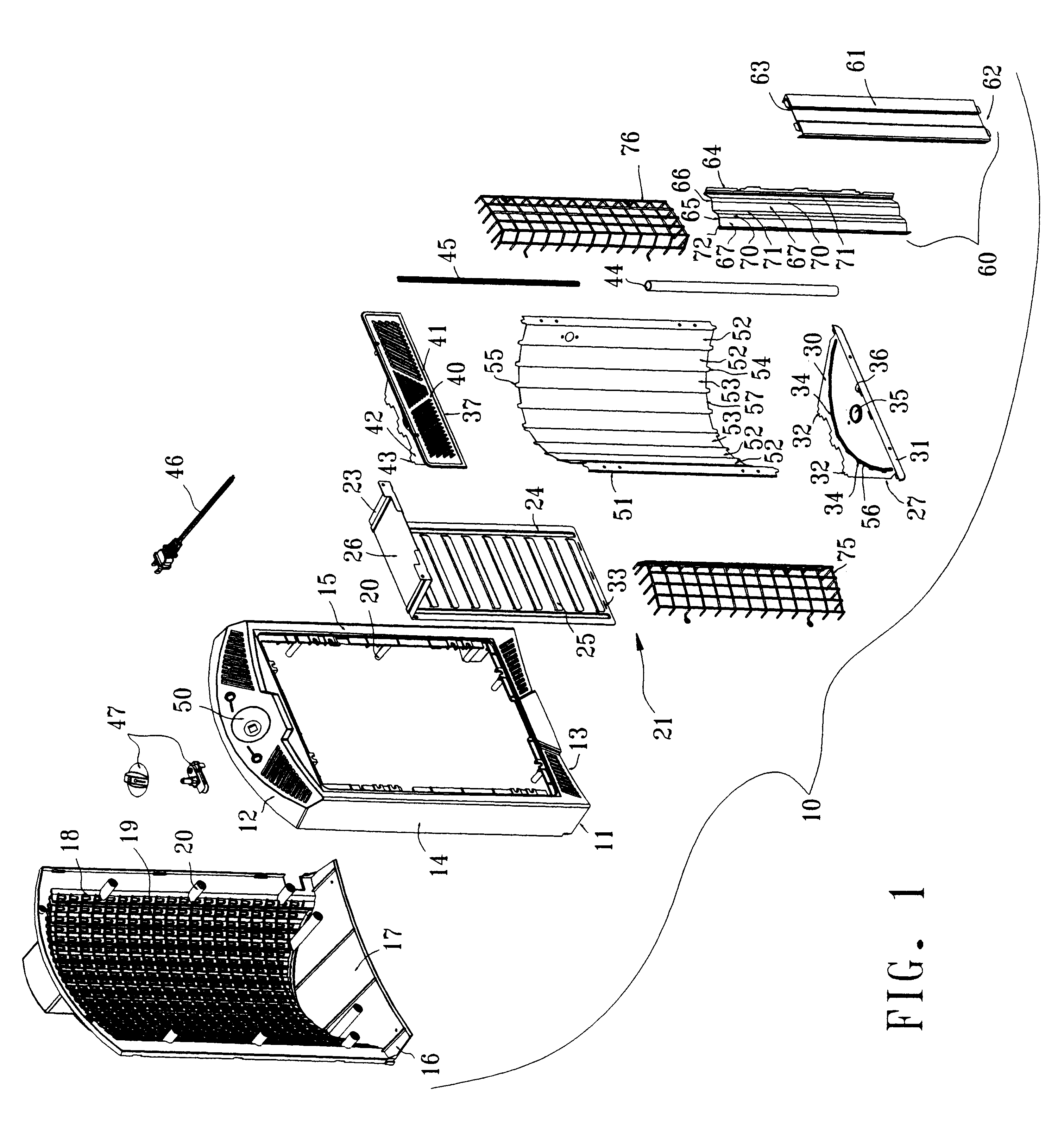

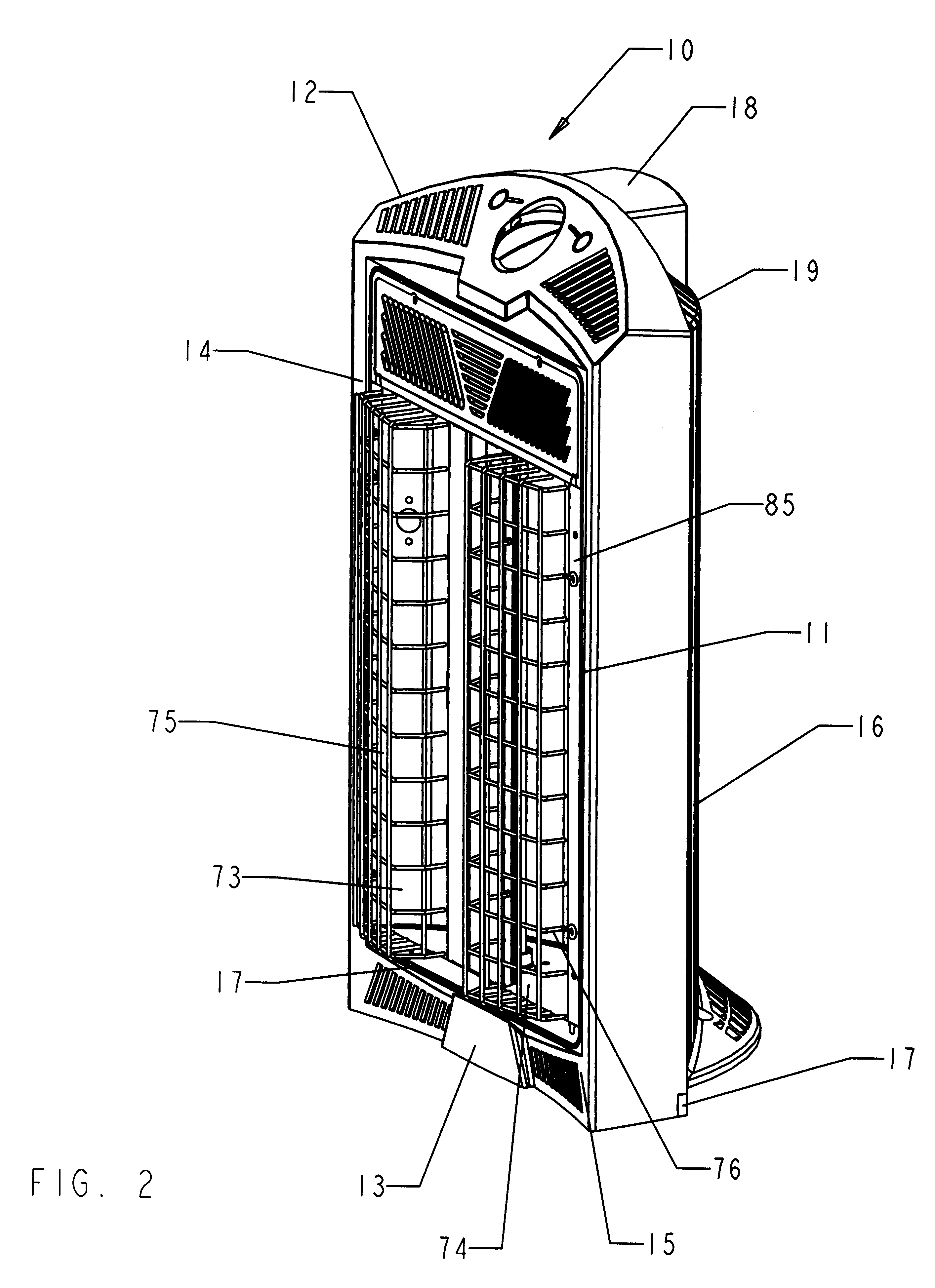

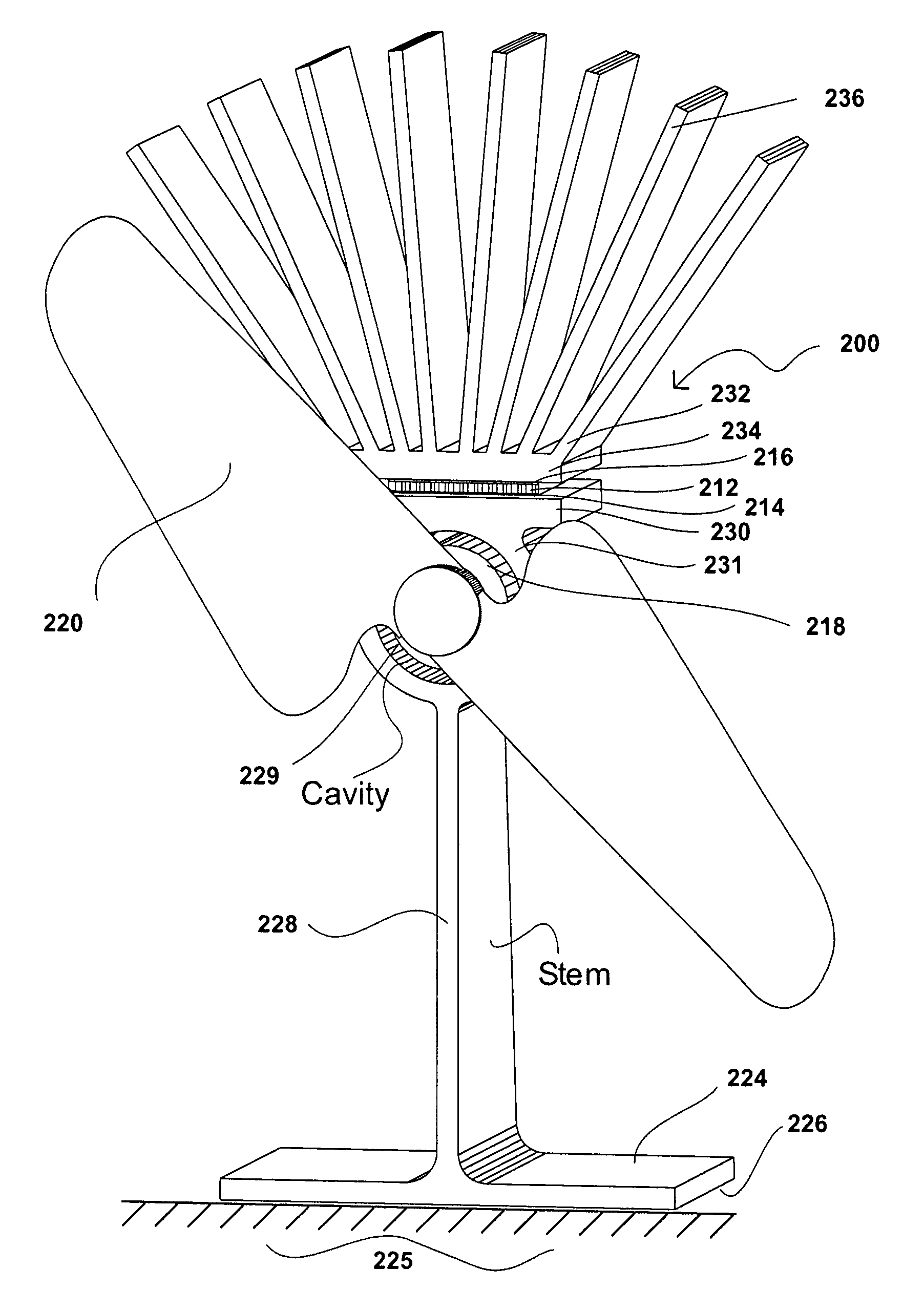

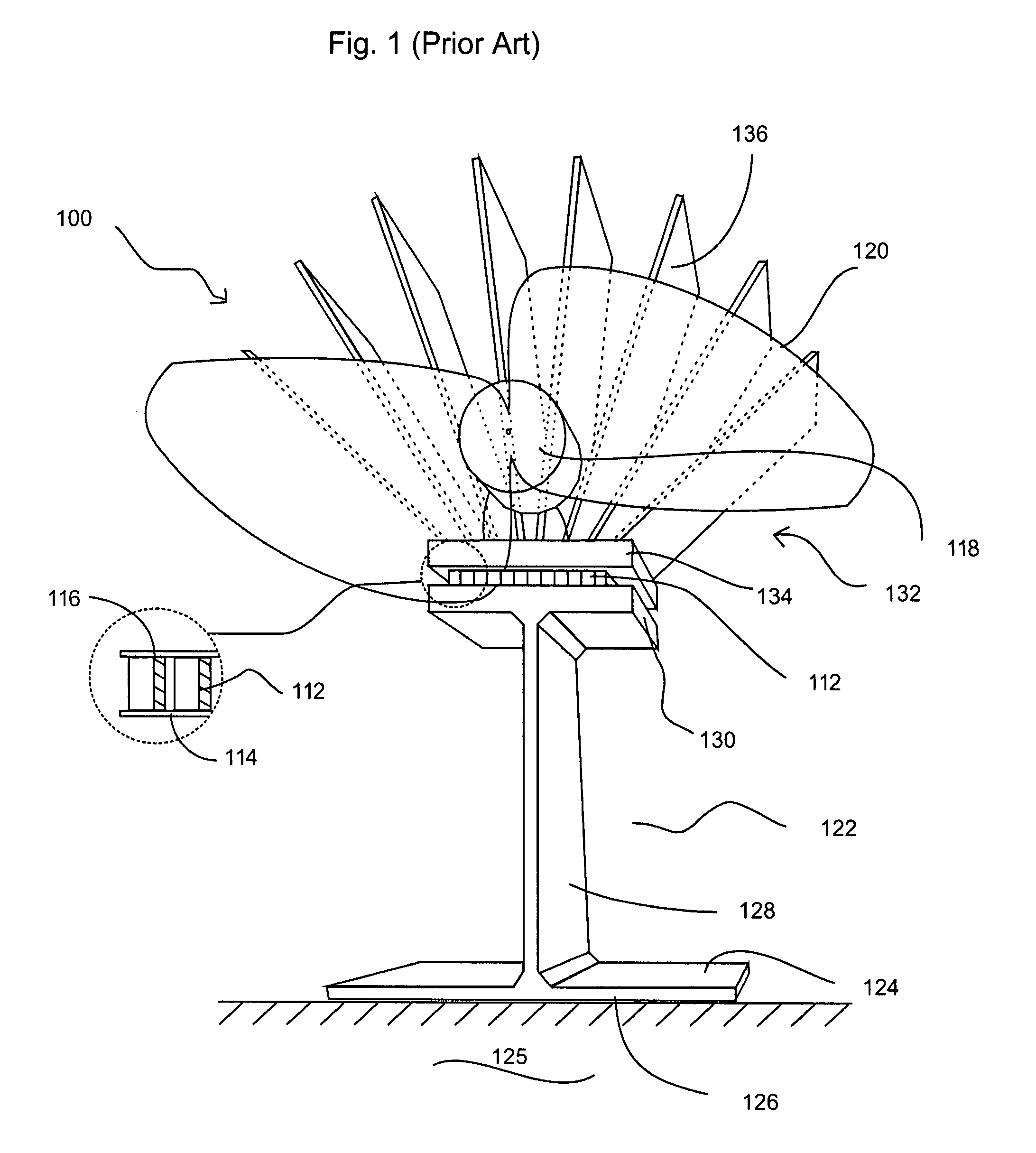

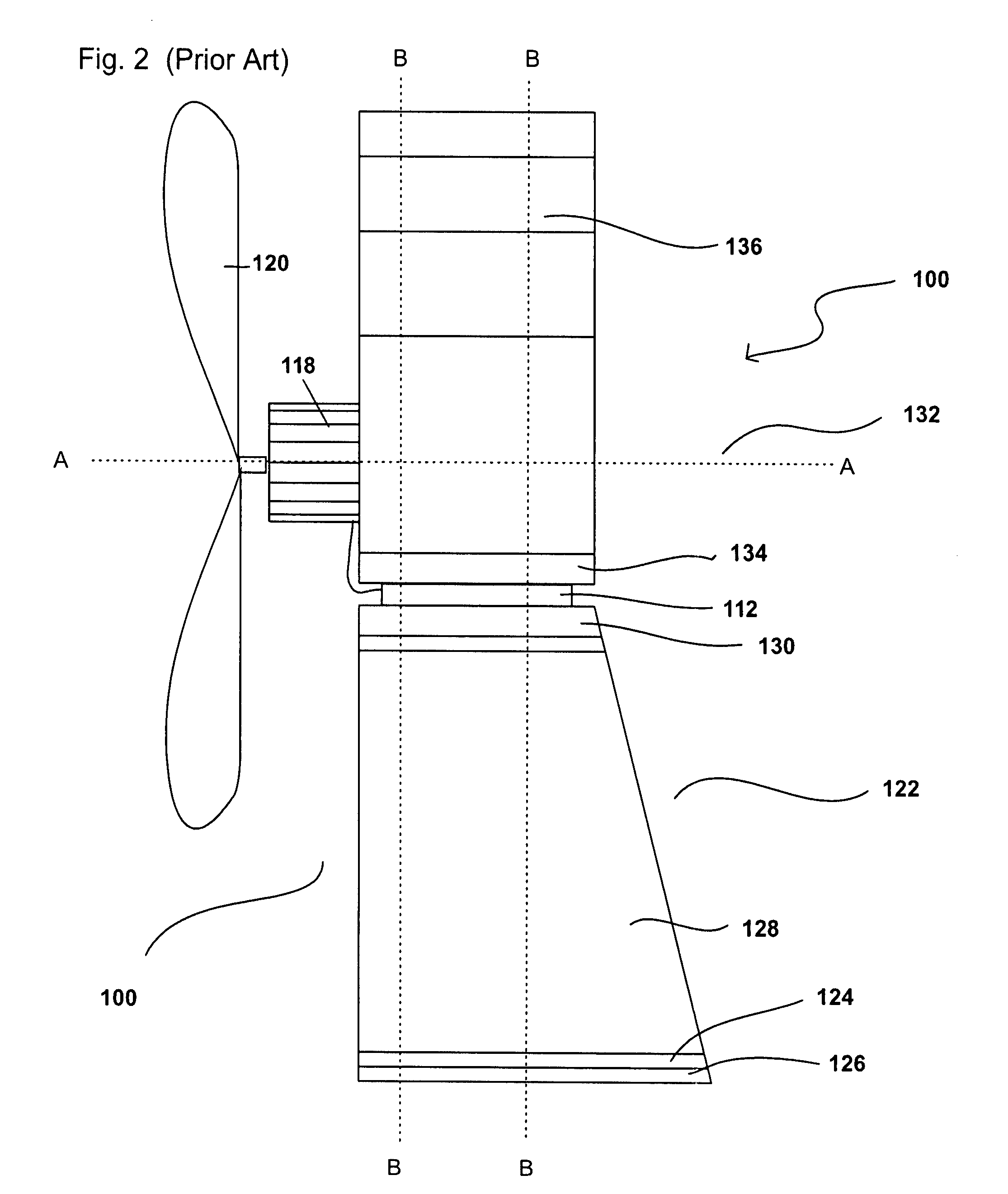

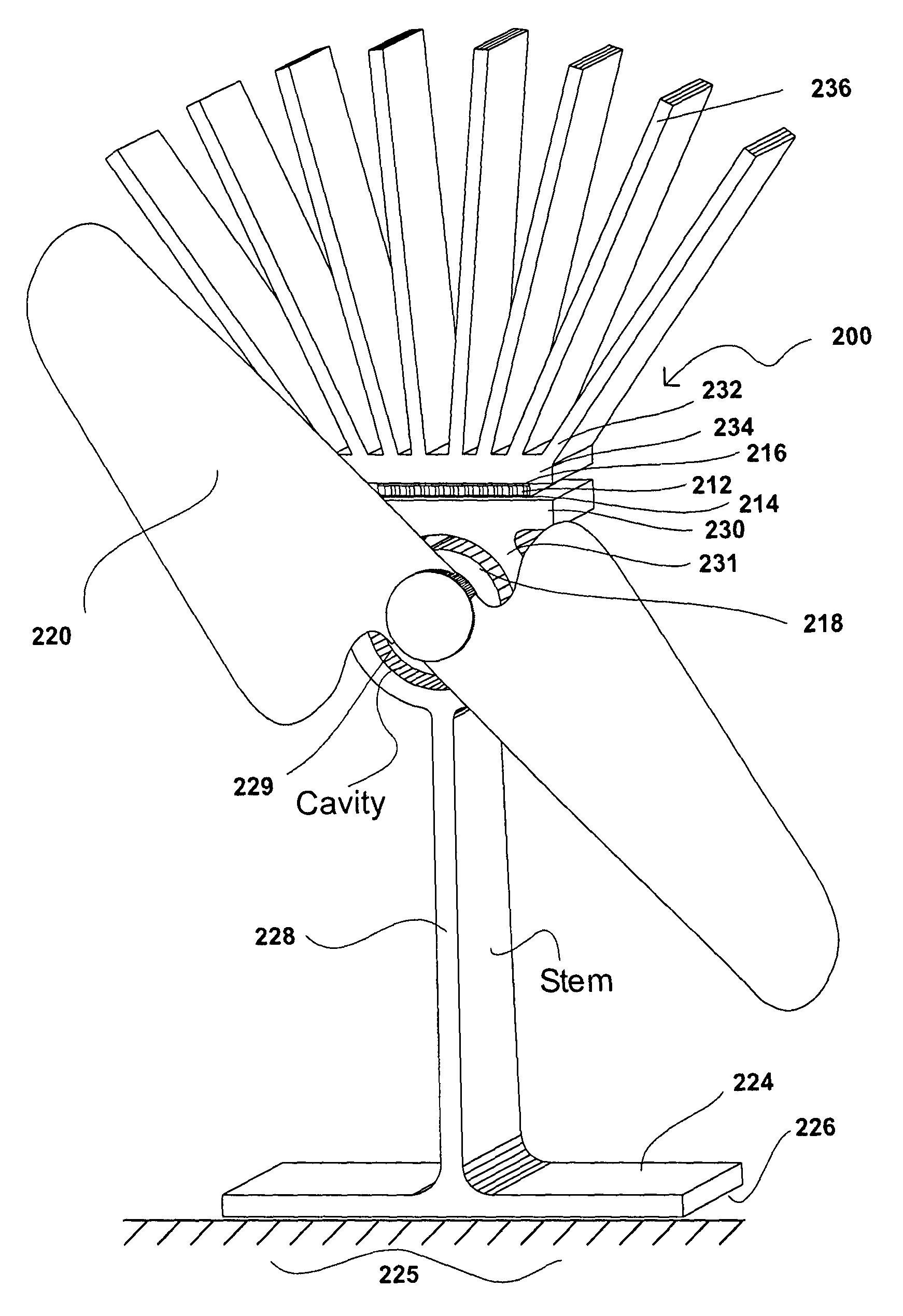

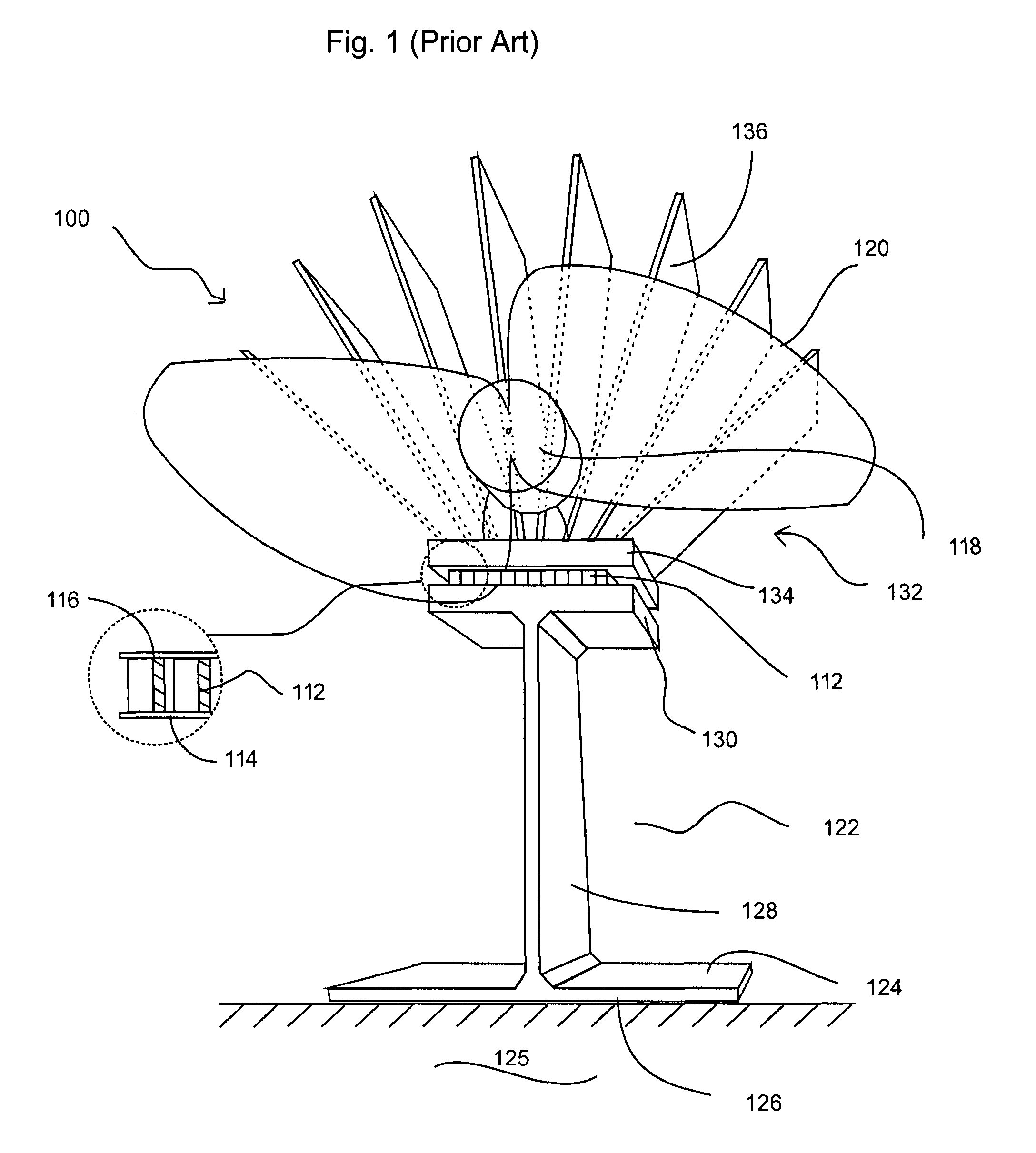

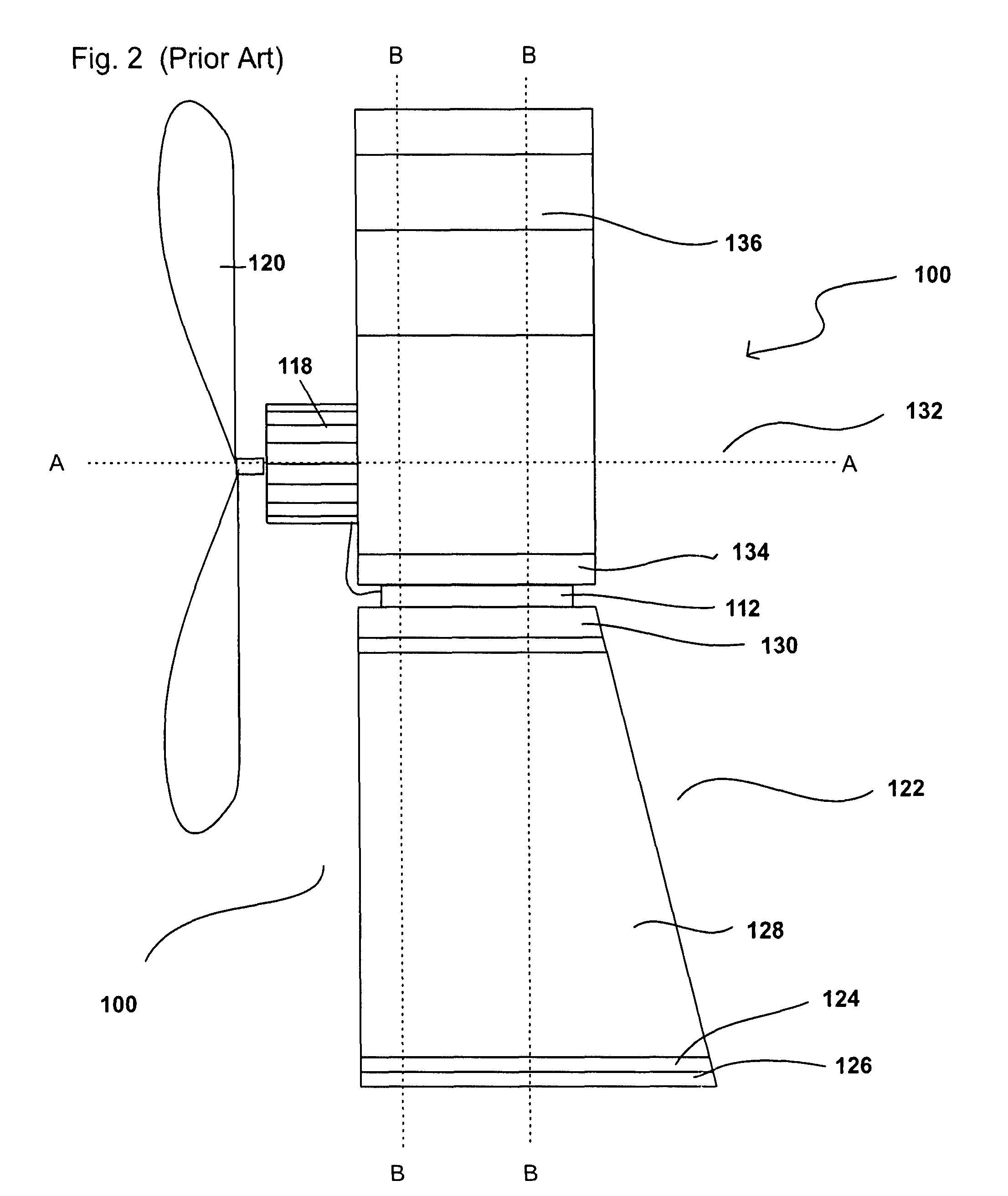

Self powered heat transfer fan

ActiveUS20080134690A1Satisfactory air circulationNot be reduced to practiceStoves/ranges with convection heatingThermoelectric device with peltier/seeback effectEngineeringFan blade

A self-powered fan for circulating air for use in cooperation with a heat source, such as a wood stove, and having a first heat transfer member thermally and physically connected with the heat source. The fan blades operably create a first or warm air flow and a second or cooler air flow. The fan has a second heat transfer member with a thermocouple module structure located between the two heat transfer members. The first heat transfer member is of suitable material, size, mass and shape as to provide a suitable temperature gradient between the thermocouple structure and the heat source to operably allow of such sufficient heat transfer from the first heat transfer member to the thermocouple to generate sufficient power to effect rotation of the blades, but not to cause thermal damage to the thermocouple structure. The fan blades are constructed and arranged to cause a portion of the second air flow to be drawn past the first heat transfer member to effect a cooling heat transfer effect upon the first heat transfer member. The improvement is wherein the motor located on the first transfer member adjacent a side of the thermocouple structure remote from the second transfer member does not hinder the second air flow, and is suitably located as to not be operably thermally damaged by the first heat transfer member or the heat source.

Owner:REID RANDALL H

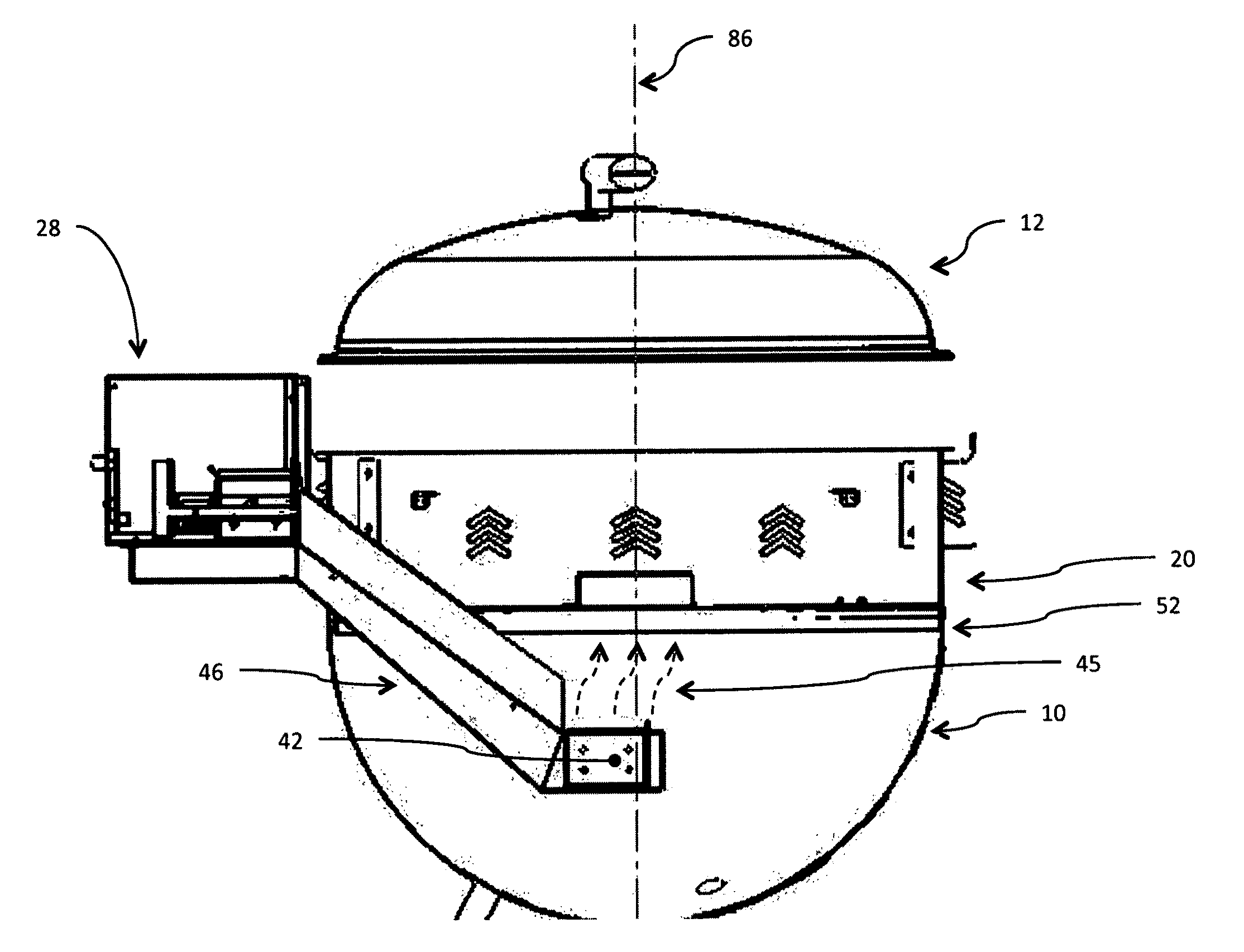

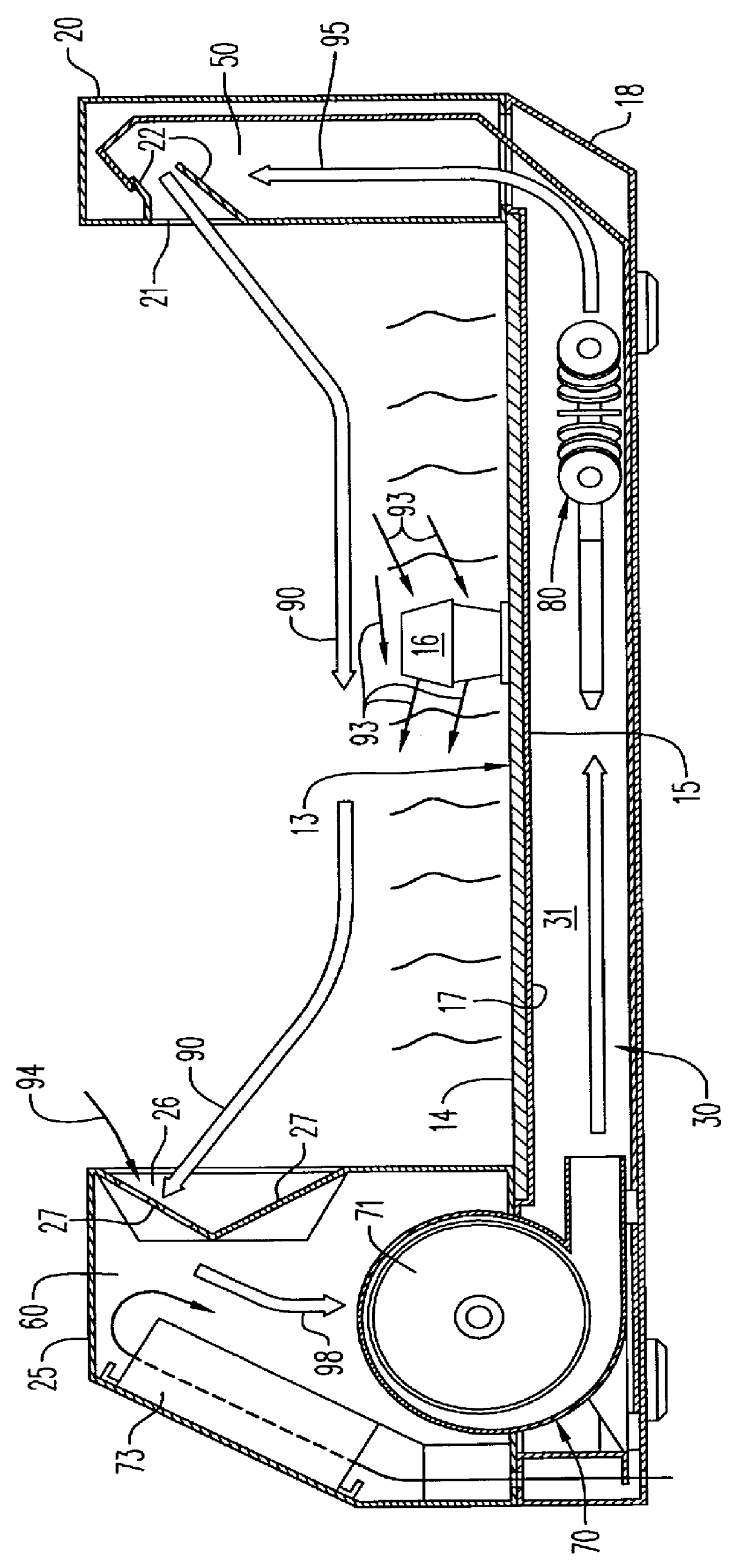

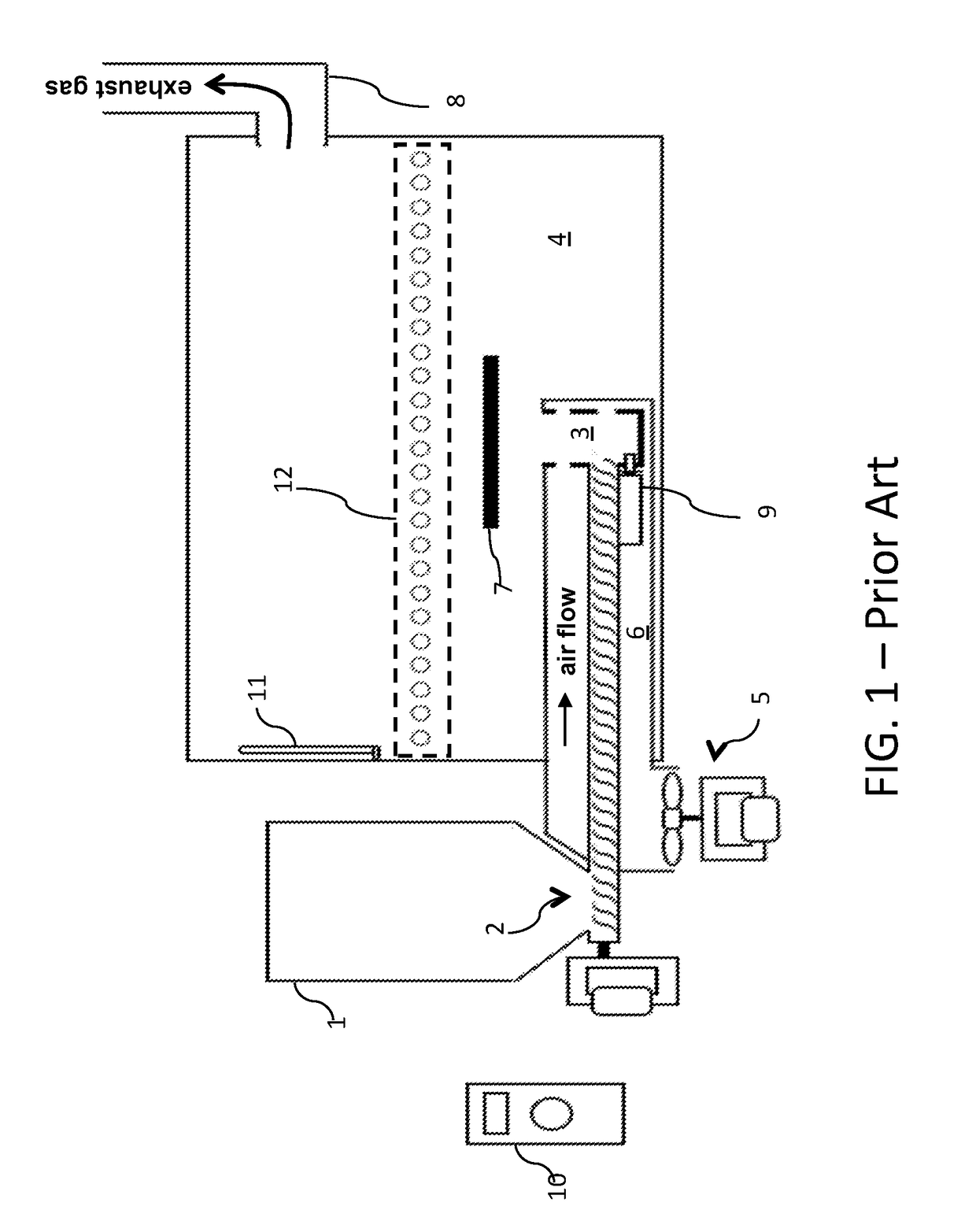

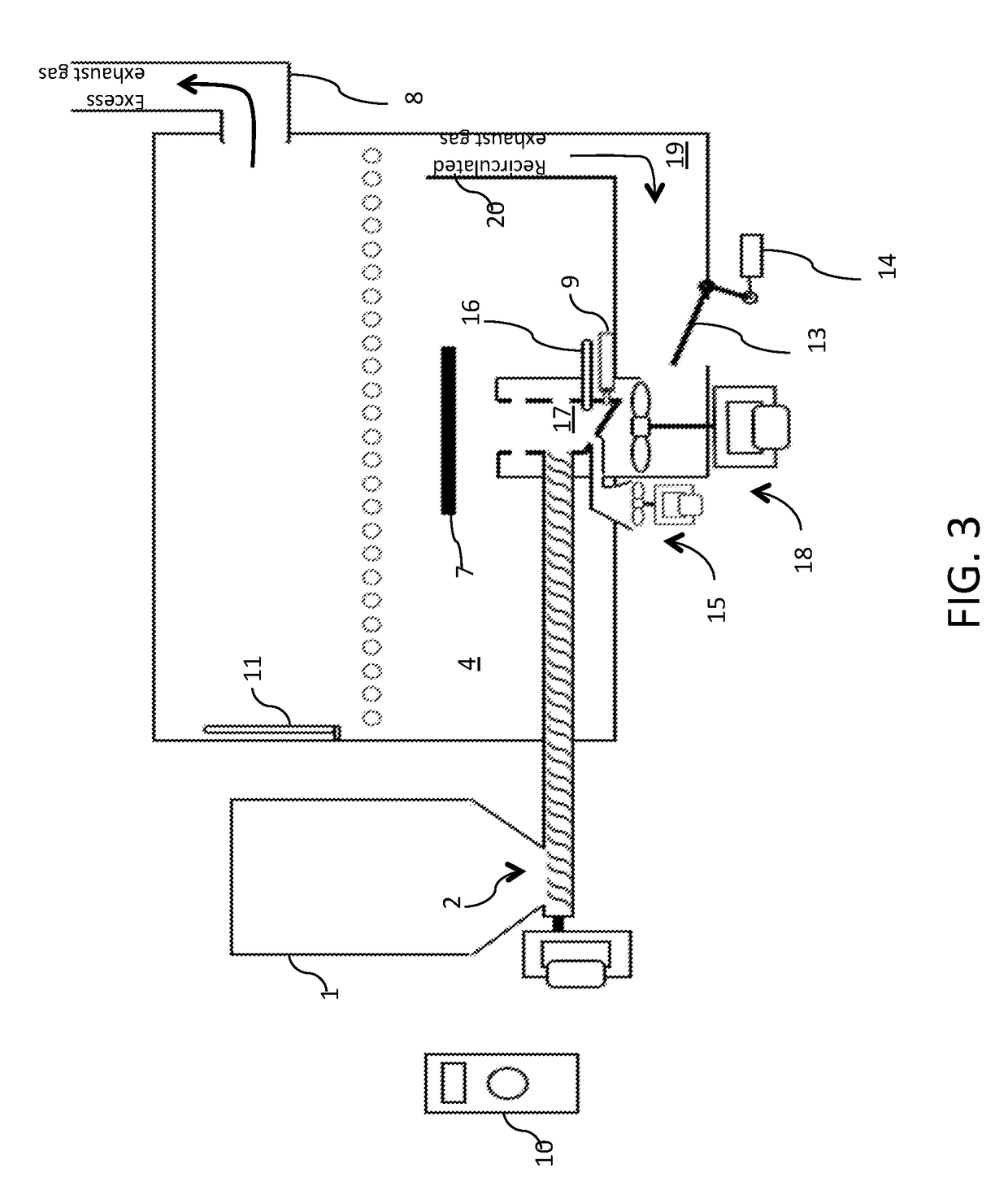

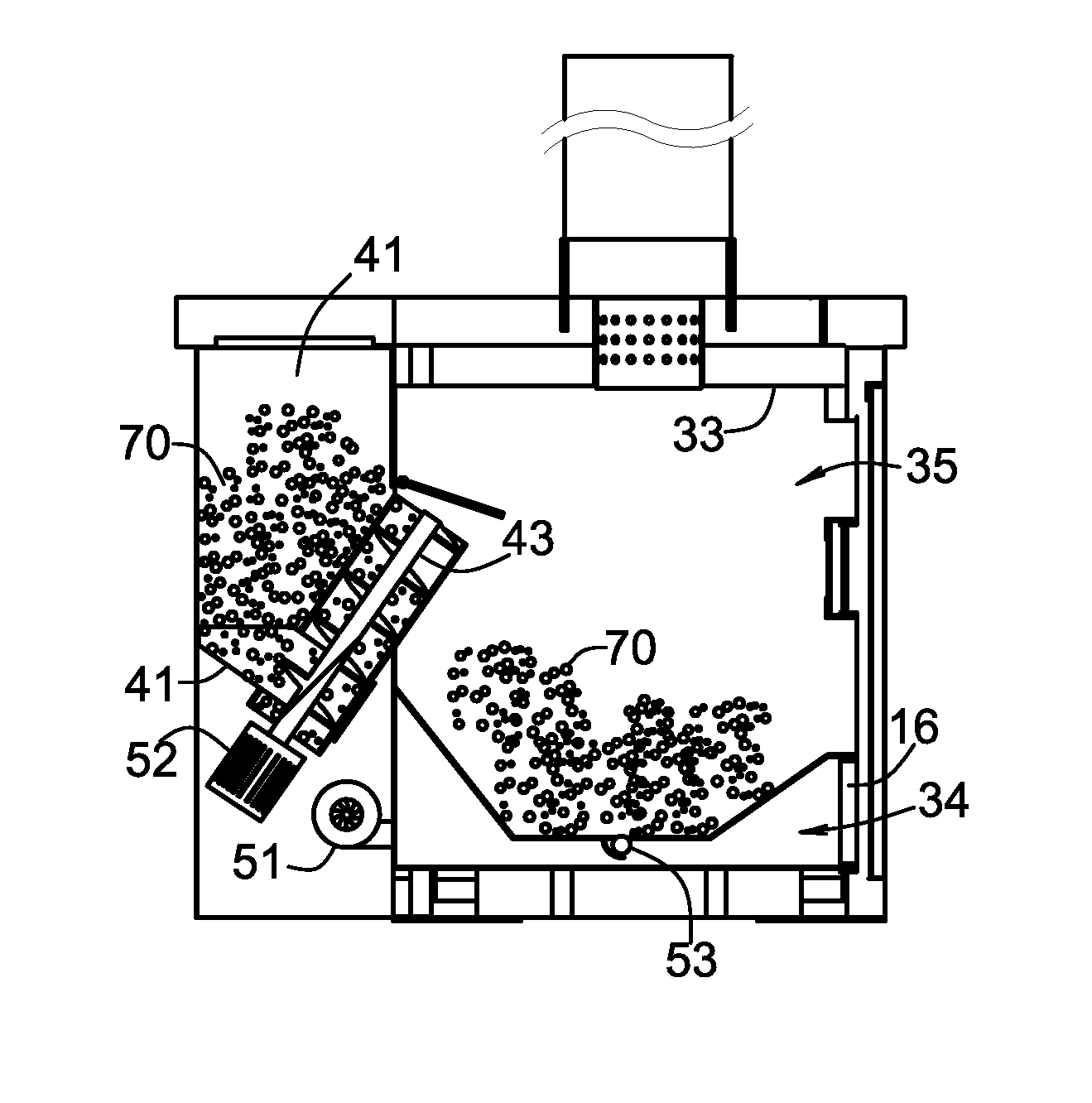

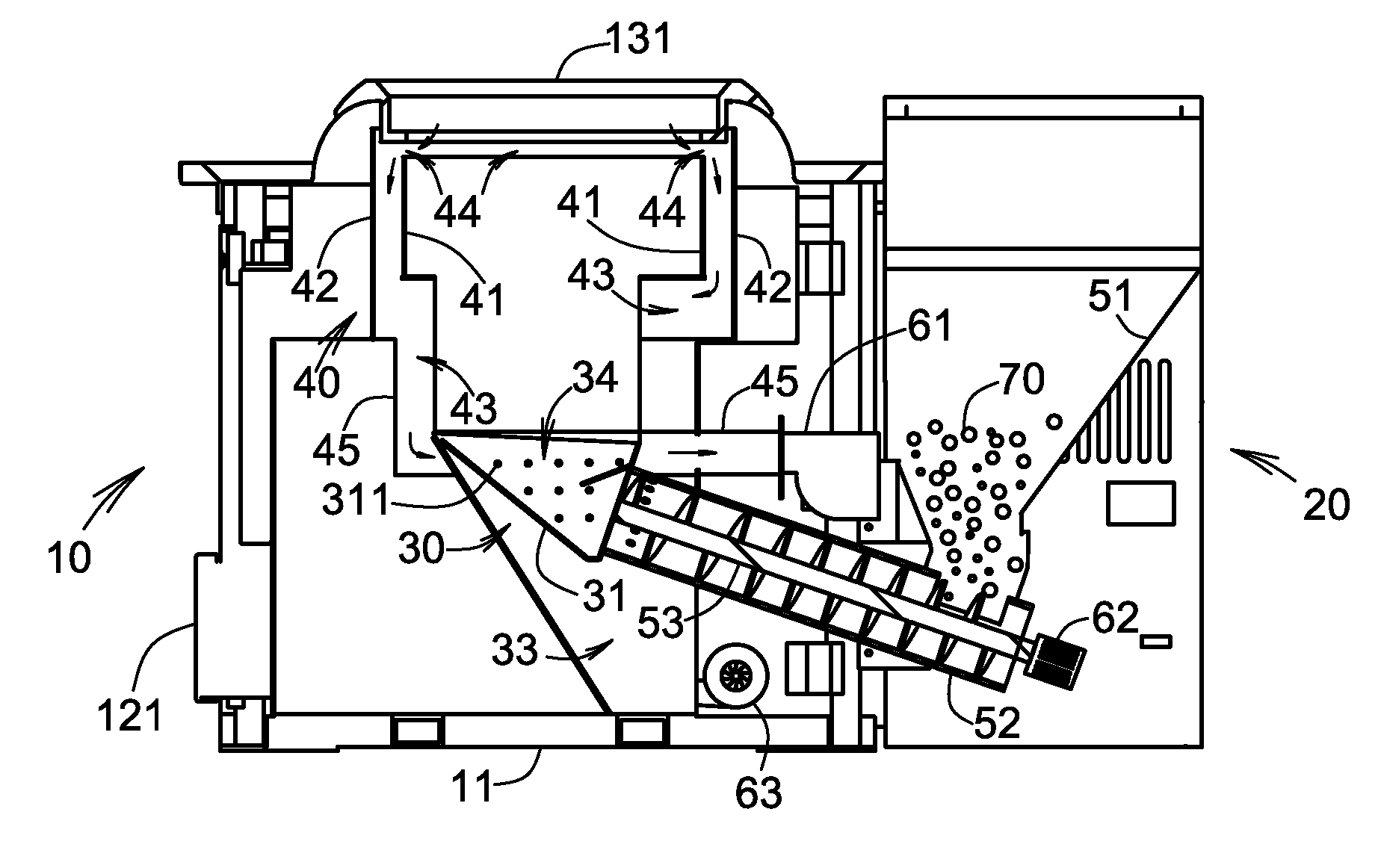

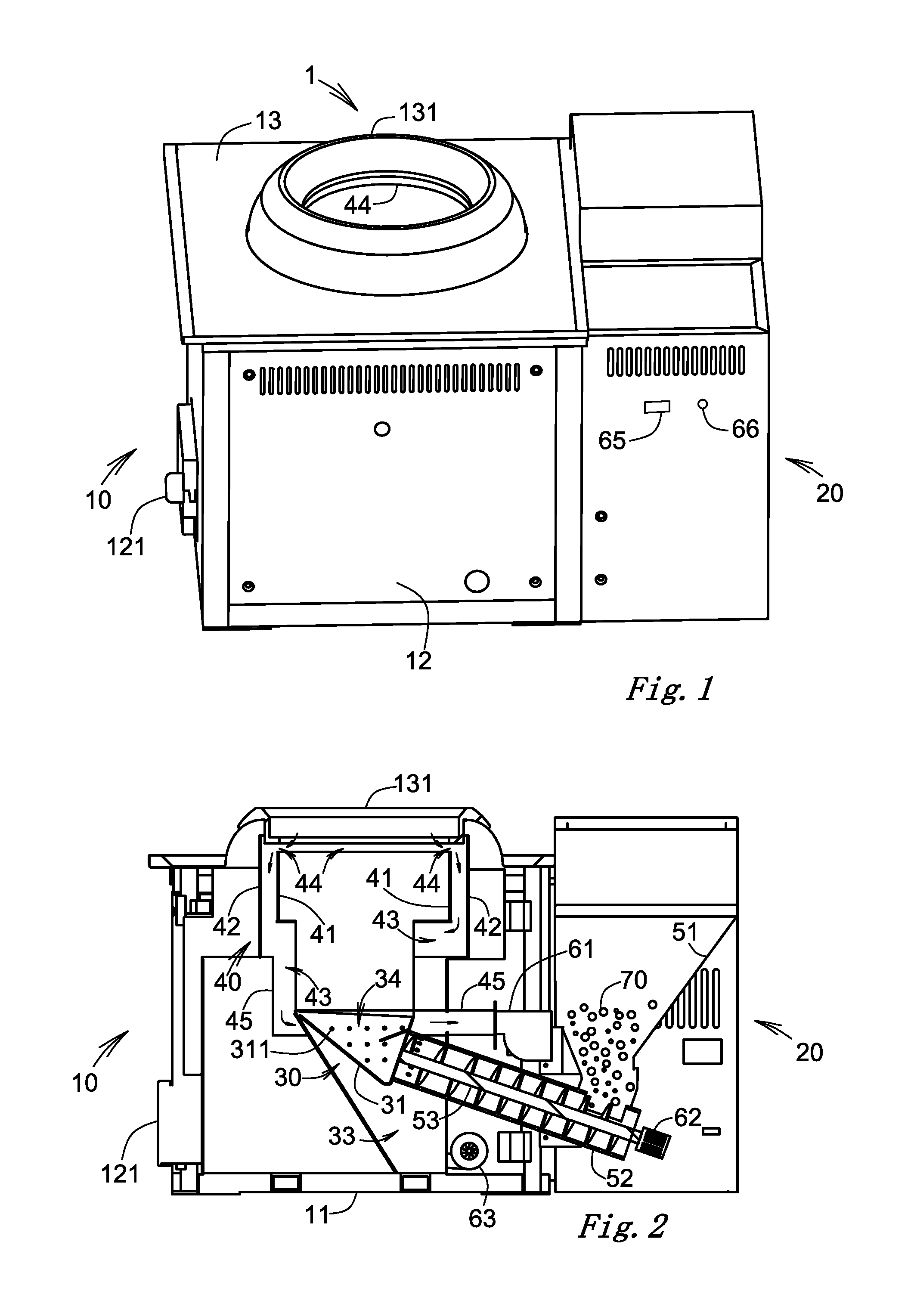

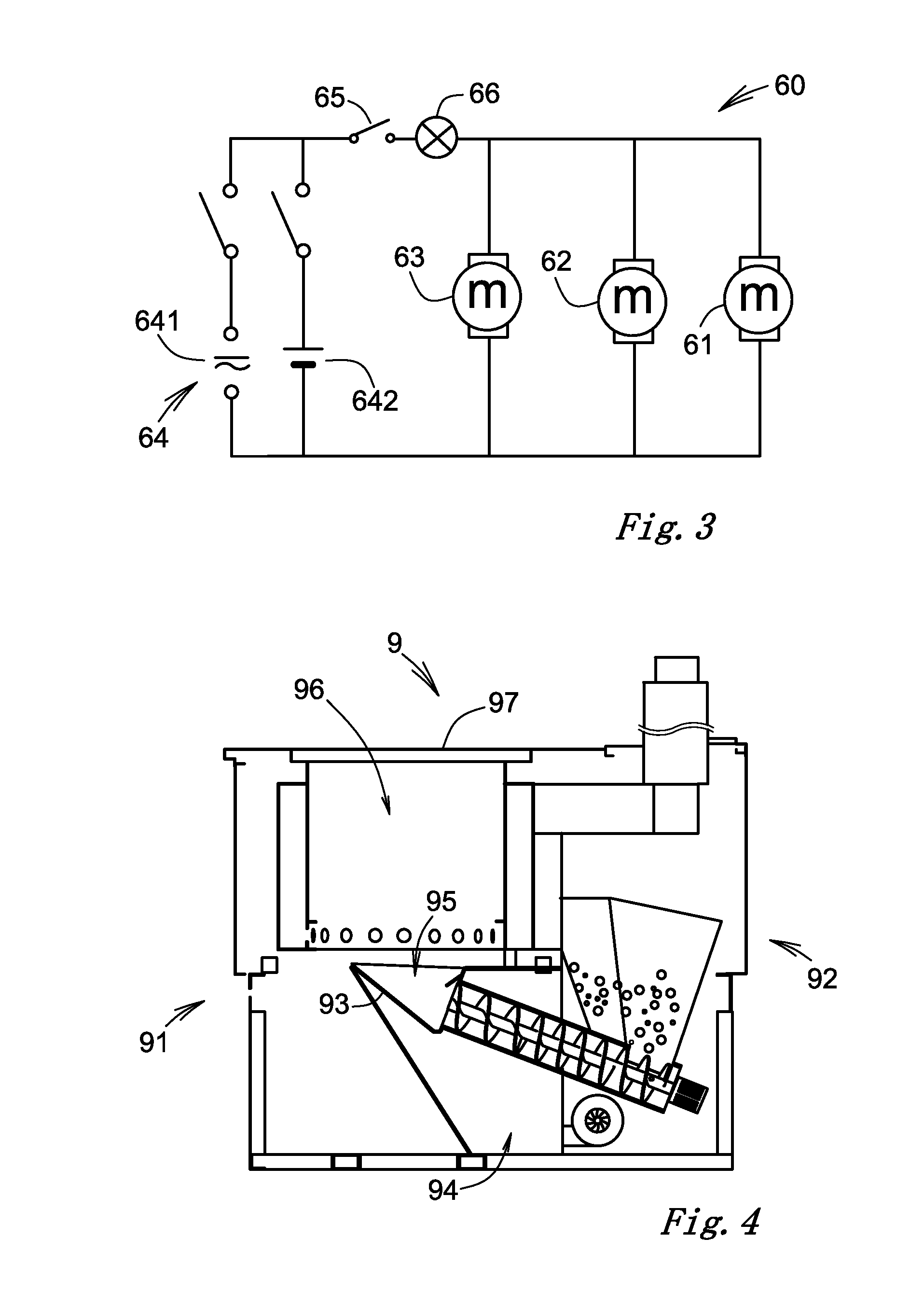

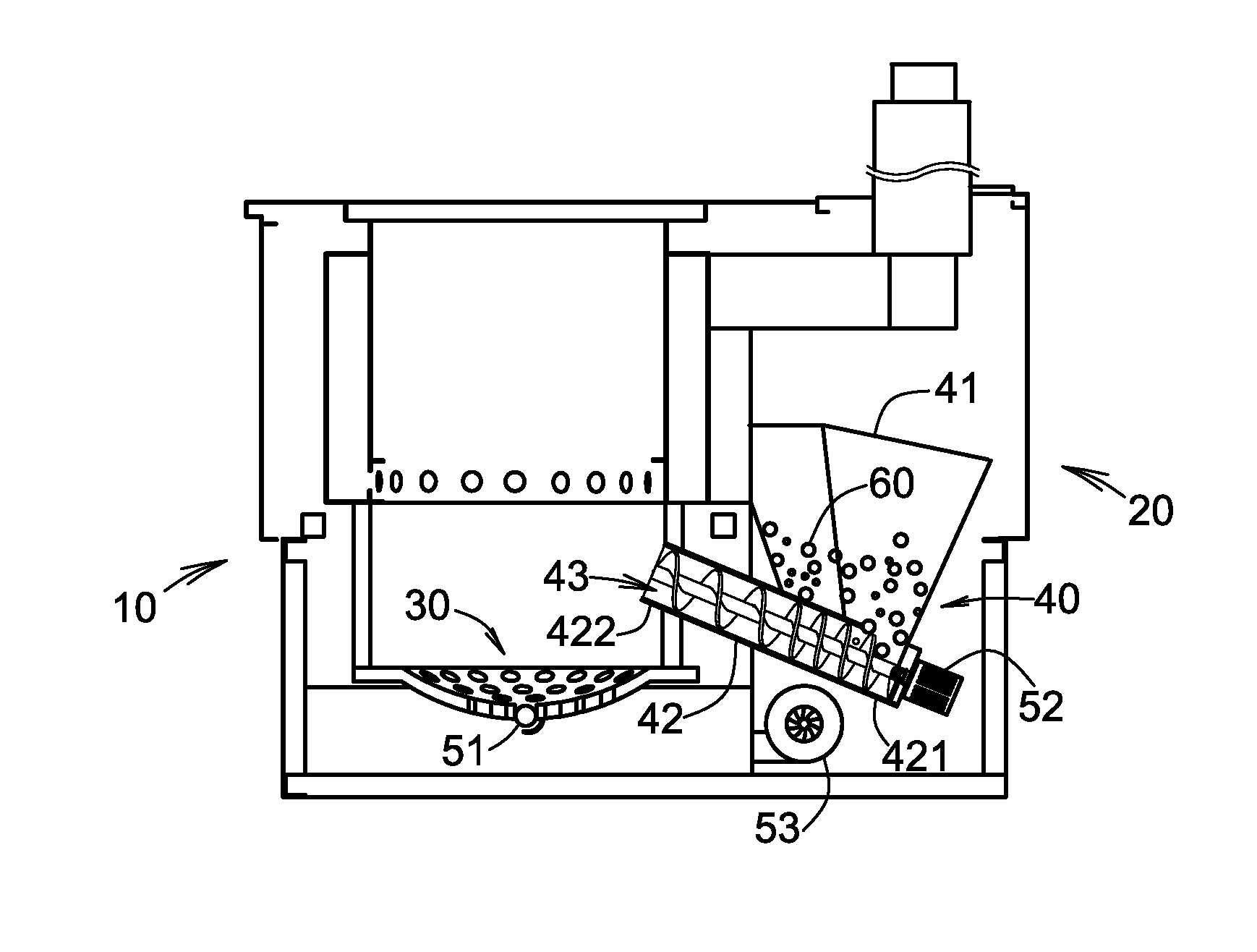

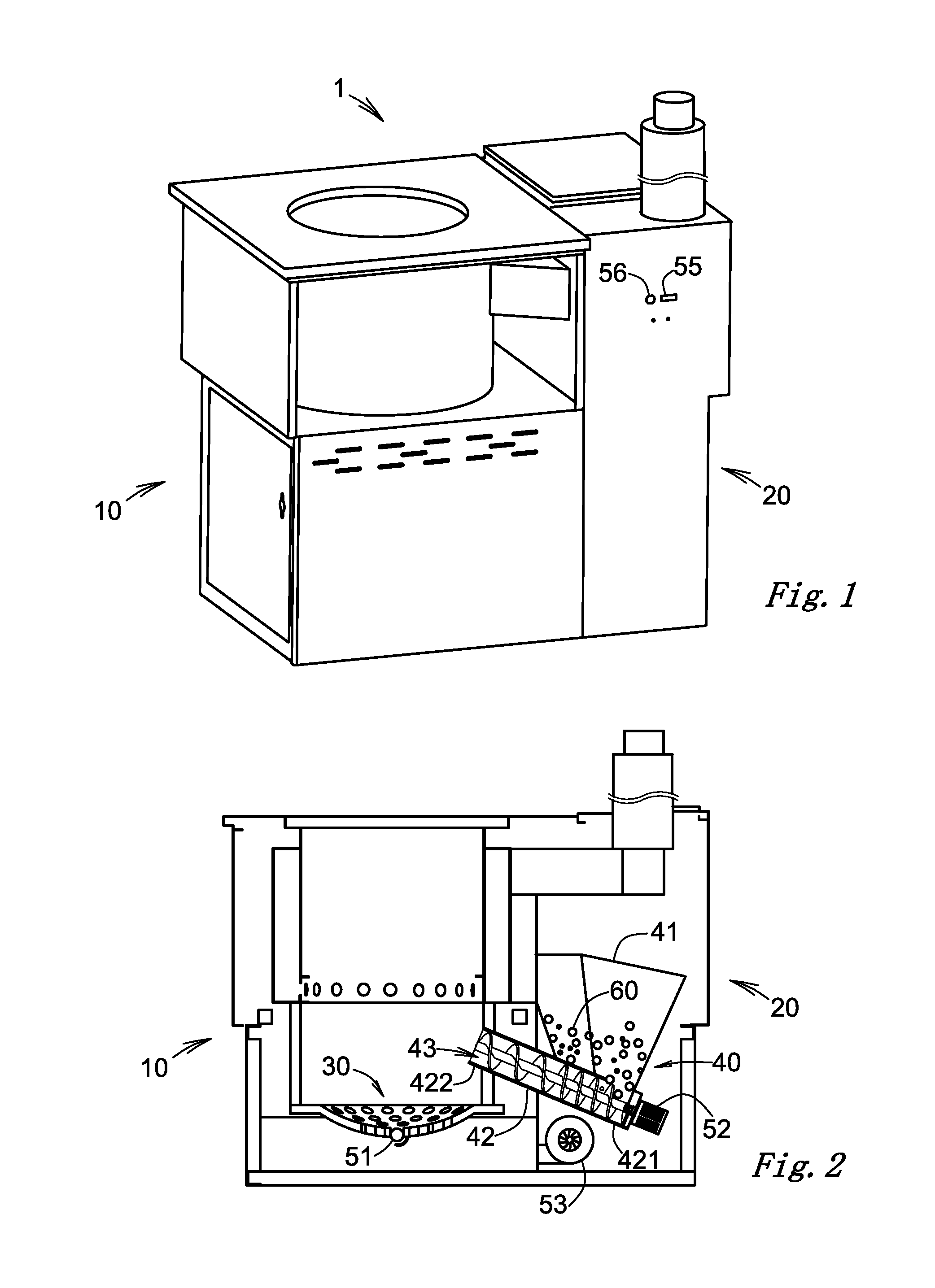

Pellet Barbecue with Exhaust Gas Recirculation

ActiveUS20190008321A1Reduce burnMore of smoke tasteStoves/ranges with convection heatingLighting and heating apparatusProcess engineeringExhaust gas recirculation

A pellet barbecue configured to recirculate exhaust gas, allowing for the reduction of oxygen in the cooking chamber. The pellet barbecue is configured with an exhaust gas recirculation system, and an angled bottom fire pot. The electric gas recirculation fan pulls gases from a gas recirculation channel, and blows it onto the angled bottom fire pot. The gas recirculation channel is equipped with a movable mixer flap to control how much of the gas pulled by the gas recirculation fan is exhaust gas or outside air. The pellet barbecue controller monitors the conditions in the cooking chamber, and controls the gas recirculation fan speed and positioning of the mixer flap to maintain a desired temperature, while optimizing the concentration of wood taste compounds from the pellets in the cooking chamber.

Owner:ALLMENDINGER KLAUS KARL

Charcoal/air BBQ combustion chamber assembly

InactiveUS7637258B2Prevents excessive and contaminationStoves/ranges with convection heatingCapillary burnersBottom ashCombustion chamber

Owner:BARRY COSGROVE

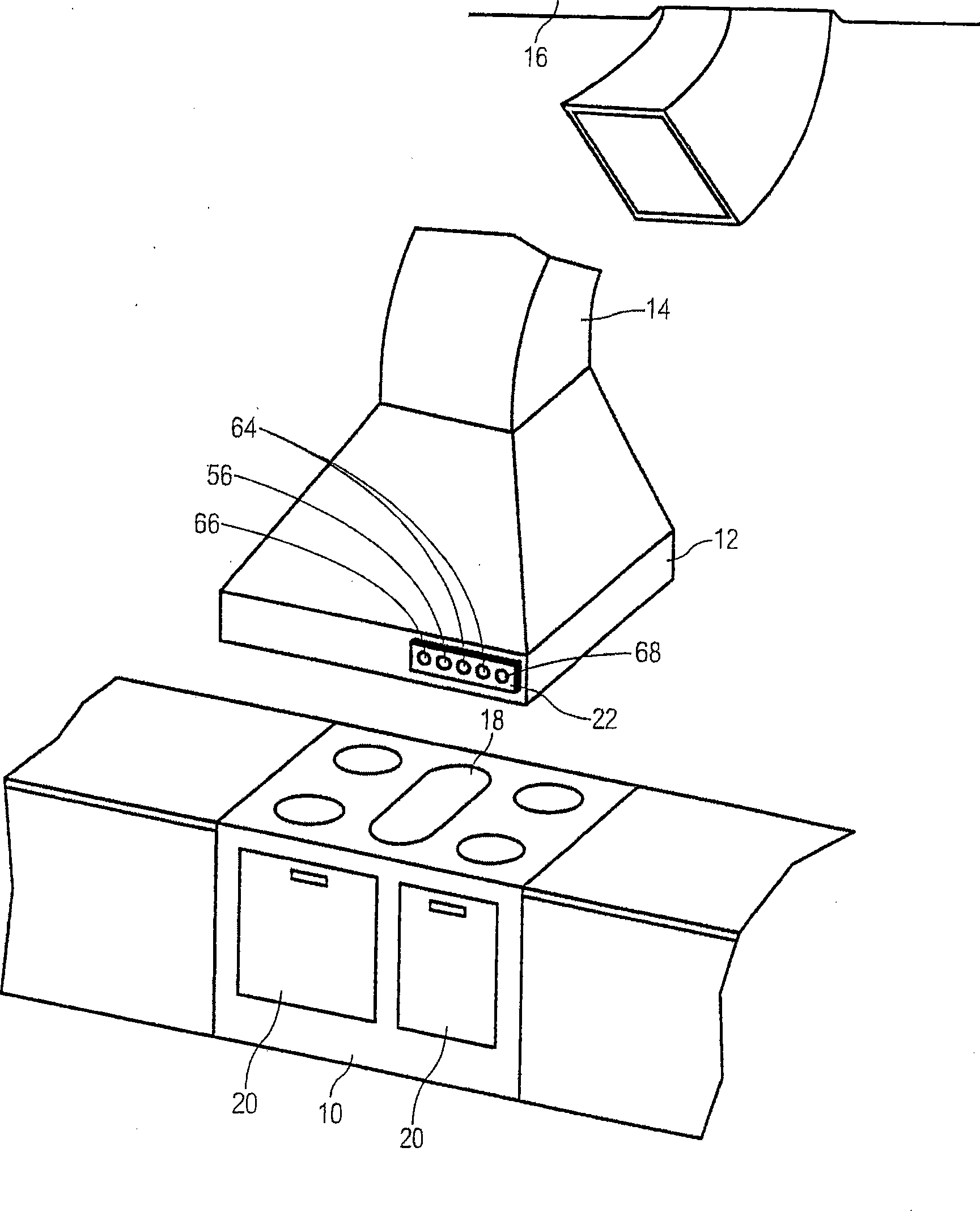

Controls for ventilation and exhaust ducts and fans

InactiveCN101443595AStoves/ranges with convection heatingLighting and heating apparatusEngineeringMechanical engineering

Owner:苏剑蕾

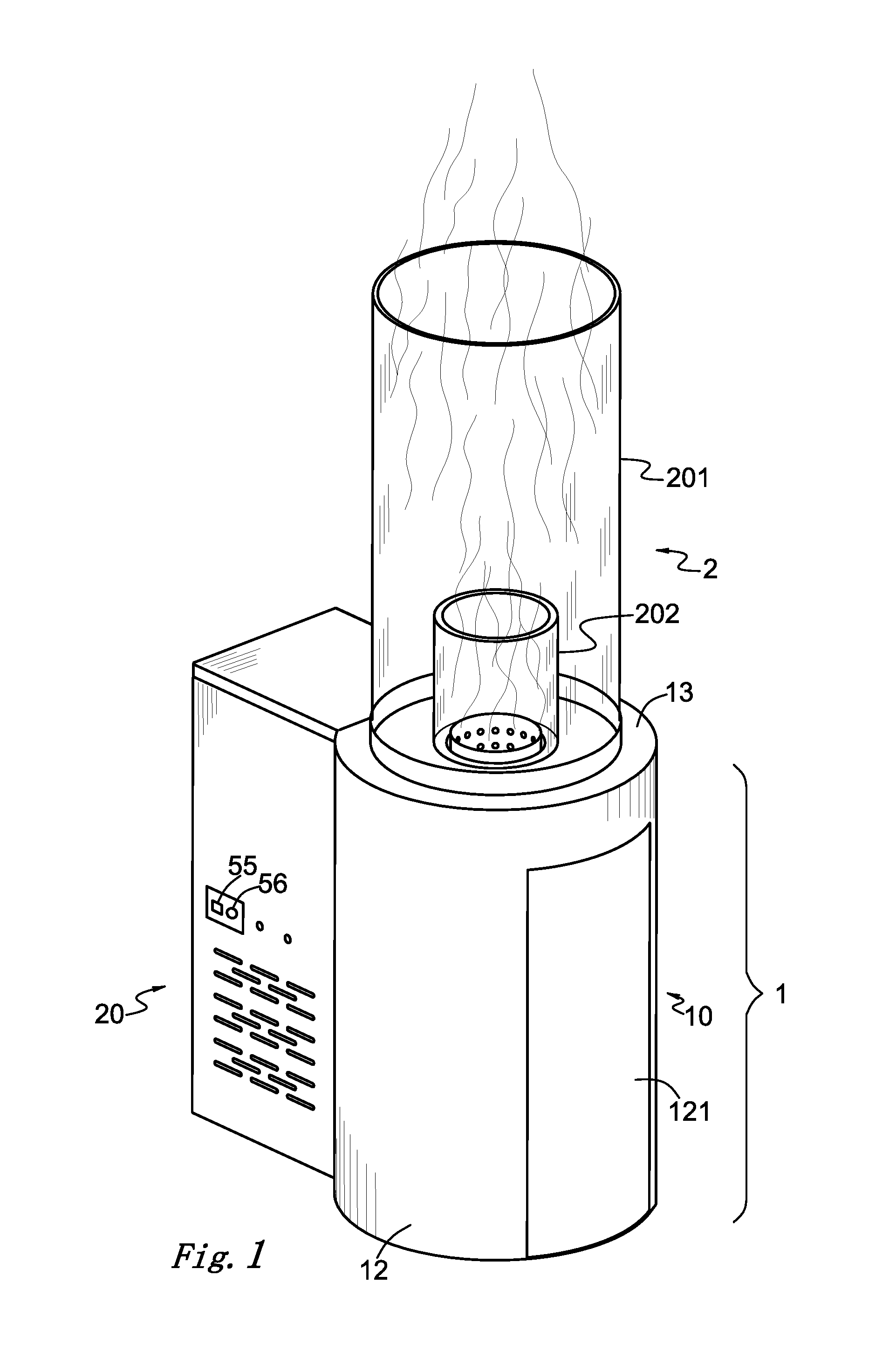

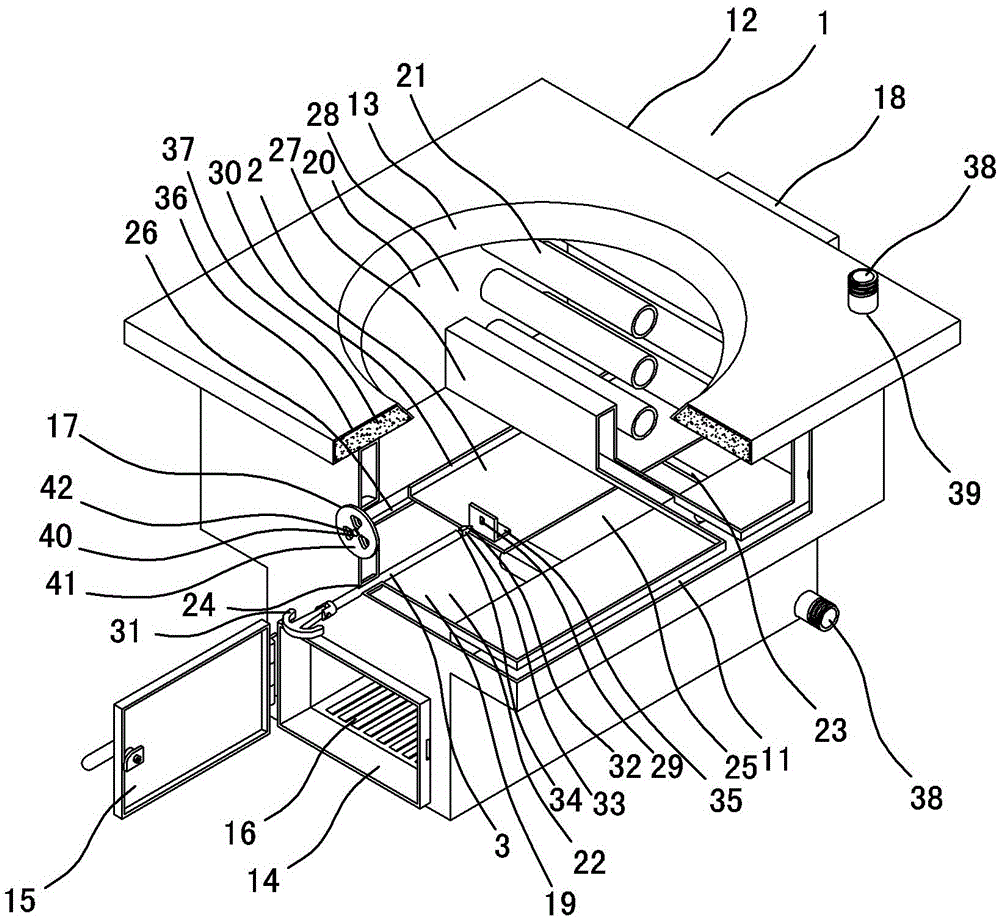

Bonfire oven

InactiveUS20140238282A1Easy to transportShort timeStoves/ranges with convection heatingCapillary burnersCombustorCombustion chamber

A bonfire oven has a body placeable on the ground. The body has a combustion cabinet and an auxiliary equipment cabinet. A burner contained in the combustion cabinet has a fire grate, a side plate extending upward from the fire grate, a top plate opposite to the fire grate, a blowing space beneath the fire grate, and a hearth defined by the fire grate and the side plate. A fuel supply mechanism, an electrical equipment and an air blower is contained in the auxiliary equipment cabinet. The bonfire oven further has a flame portion on the top which is a flame roaring space formed by at least one piece of high temperature resistant glass.

Owner:ZHU HONGFENG

Oven without dust rise

InactiveUS20140373827A1Not always easyReduce pollutionStoves/ranges foundationsStoves/ranges with convection heatingCombustion chamberCombustor

Owner:ZHU HONGFENG

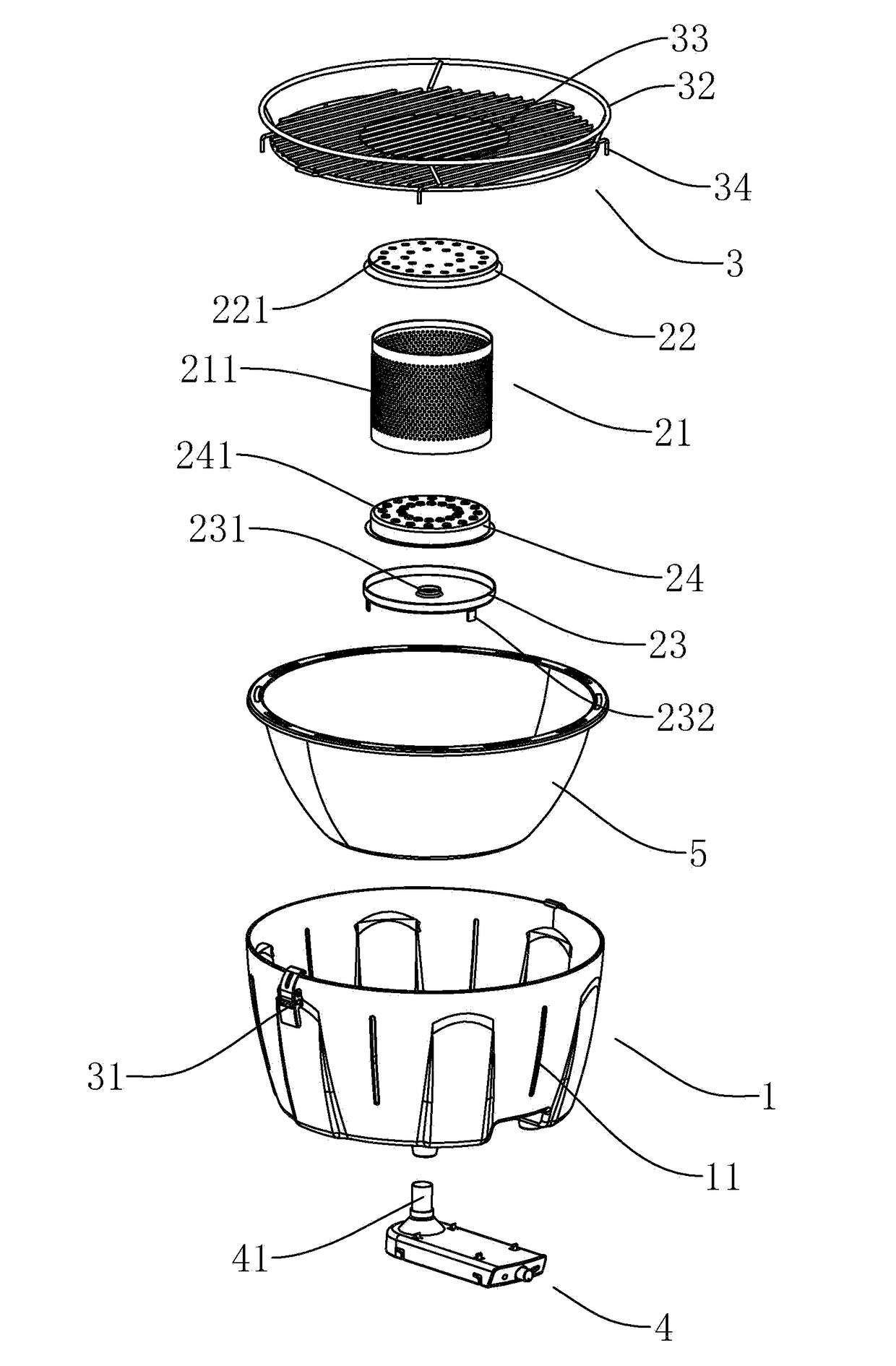

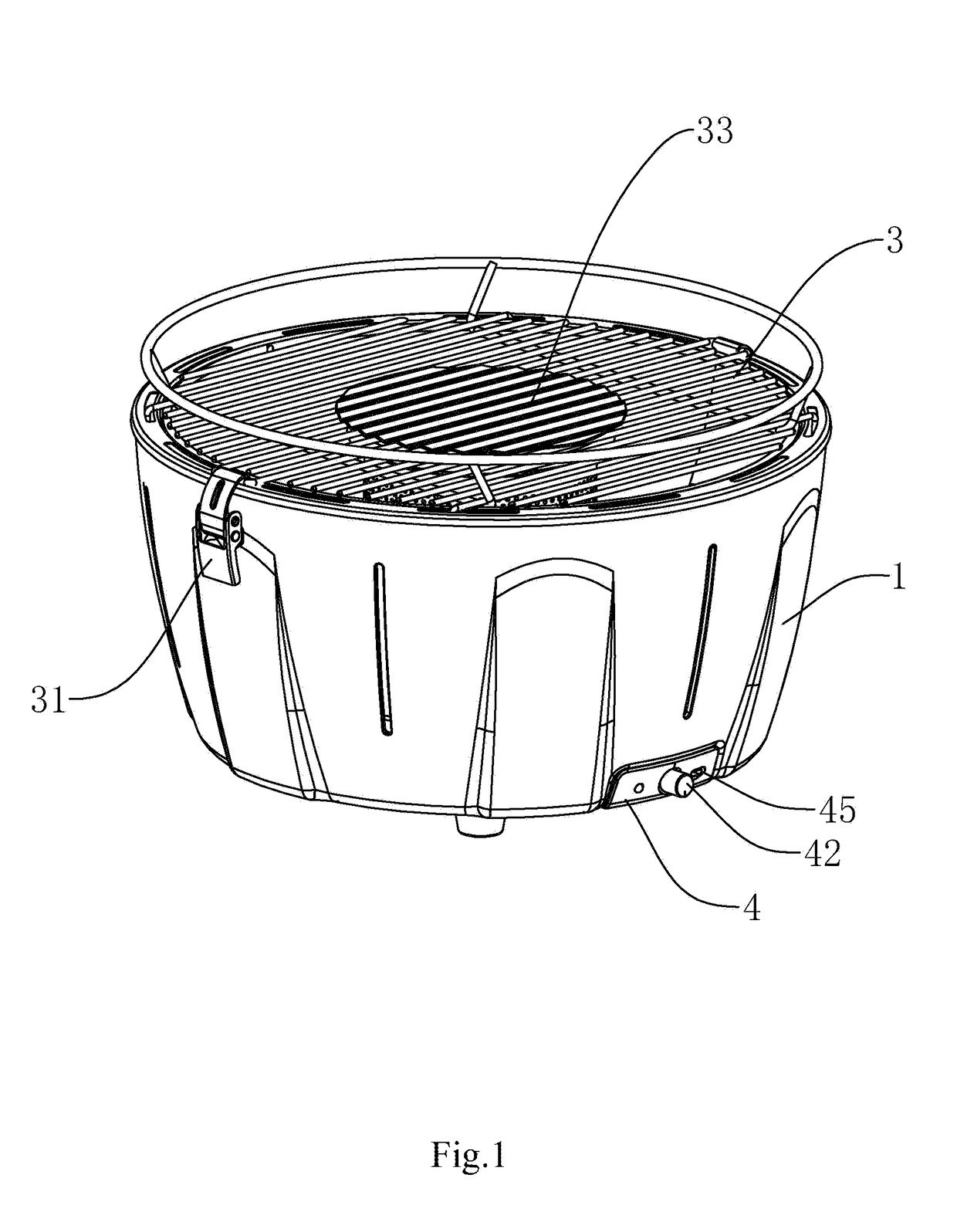

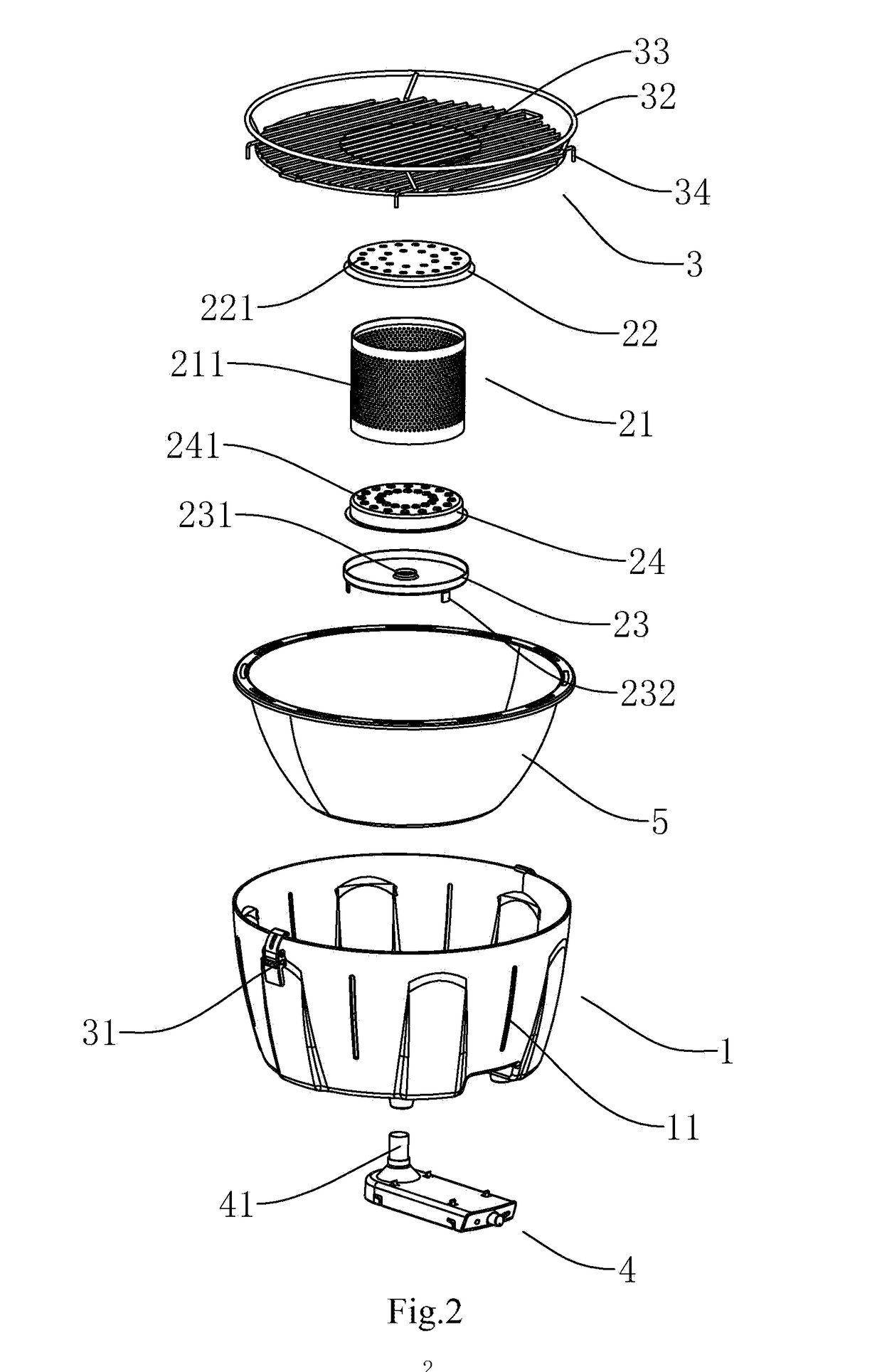

BBQ Grill Equipped with a Removable Fan

InactiveUS20170150847A1PowerfulGuaranteed uptimeStoves/ranges with convection heatingLighting and heating apparatusCombustion chamberEngineering

A barbeque grill equipped with a removable fan, includes a grill body, the barbeque grill body including a housing, a combustion chamber, a grid, and a fan assembly. A heat collection liner is provided inside the housing, the combustion chamber is provided inside the heat collection liner, the grid is provided above the housing, and the fan assembly is provided on the housing via a removable structure, and connected with the combustion chamber via an air channel The fan assembly controls the speed of air flow in the combustion chamber, such that the grill can operate normally under the condition of calm or lack of air flow, and the fan assembly can be removed to be used as a handheld fan, to meet different requirements of blowing and heat dissipation.

Owner:FENG PEIYING

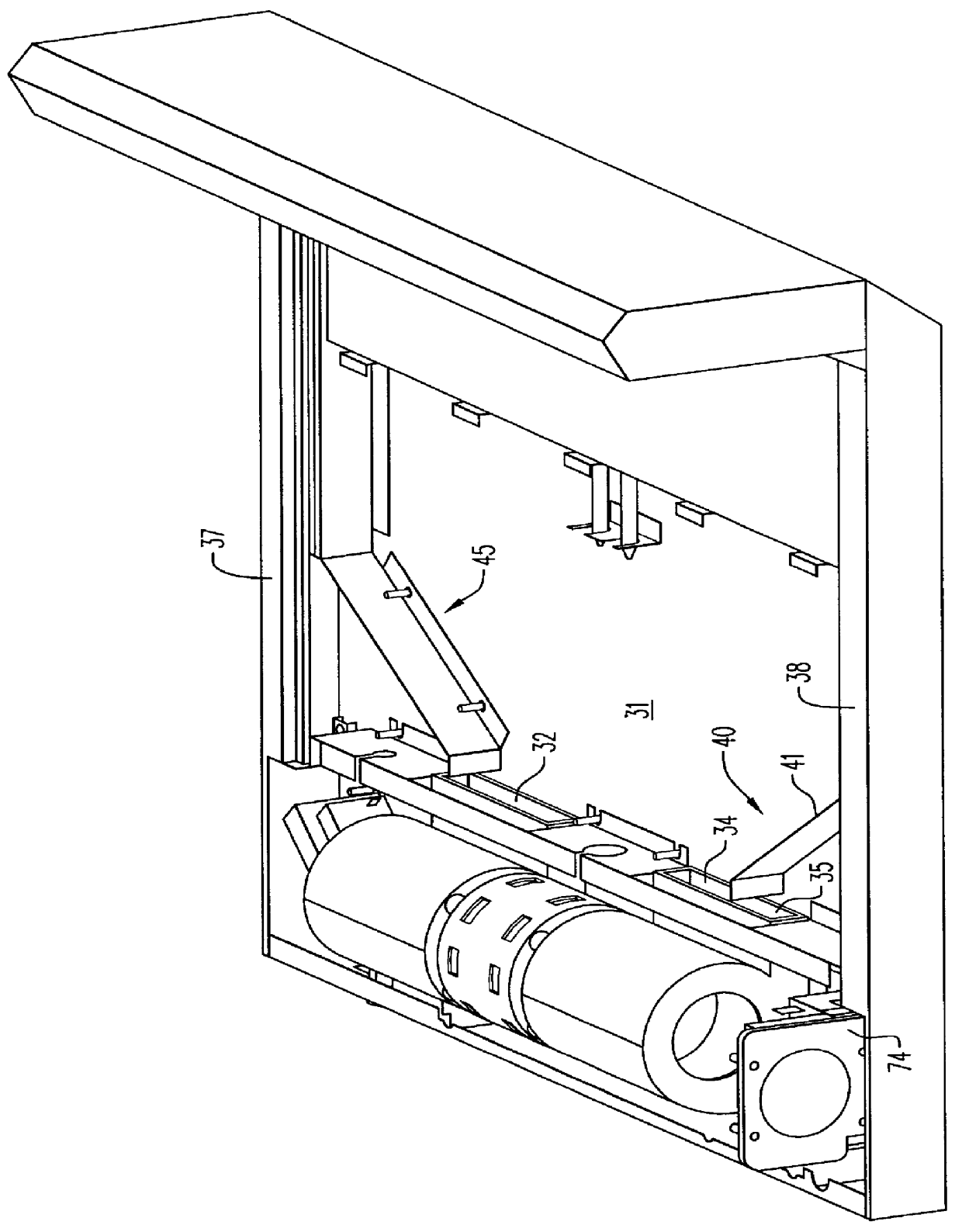

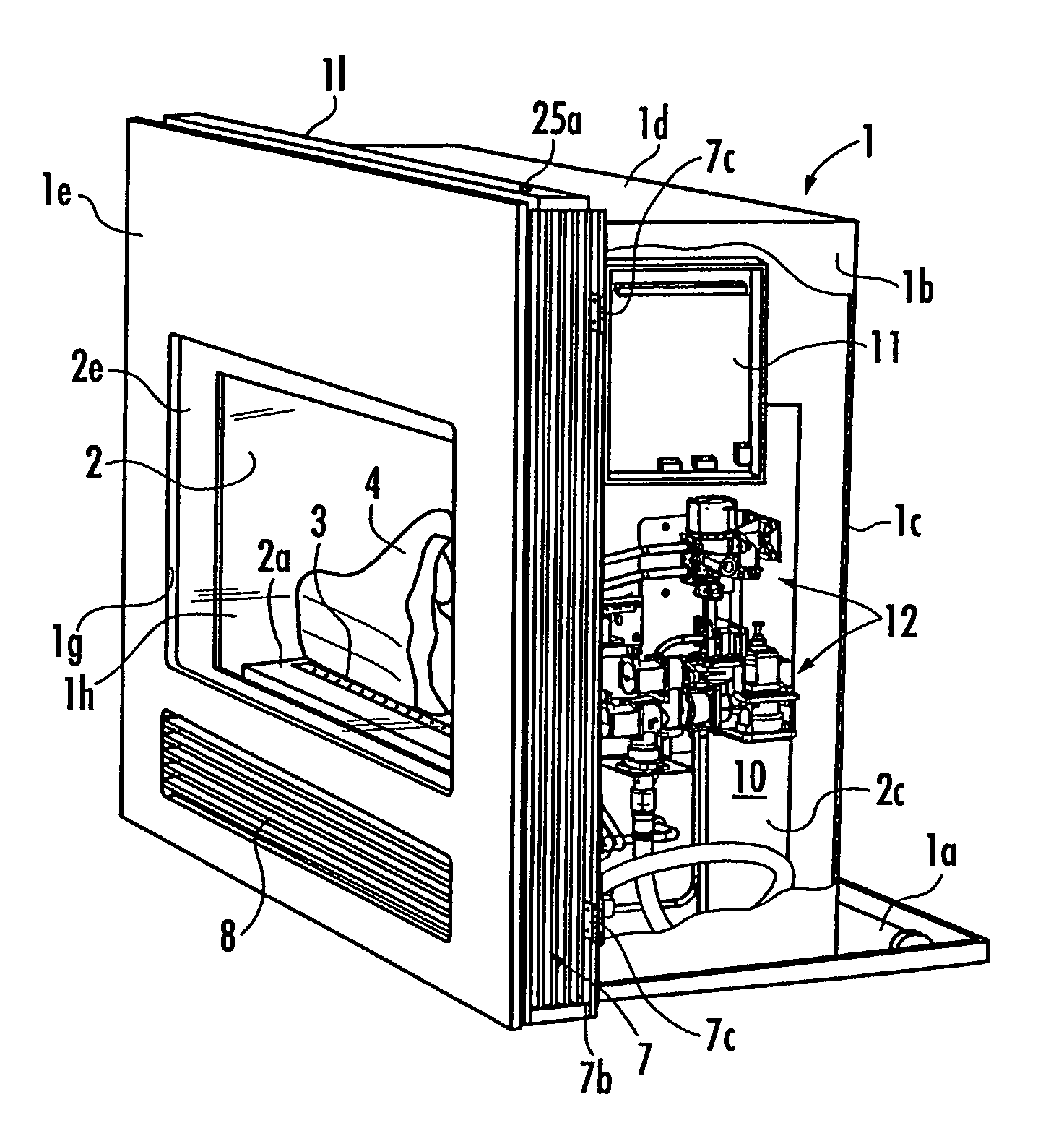

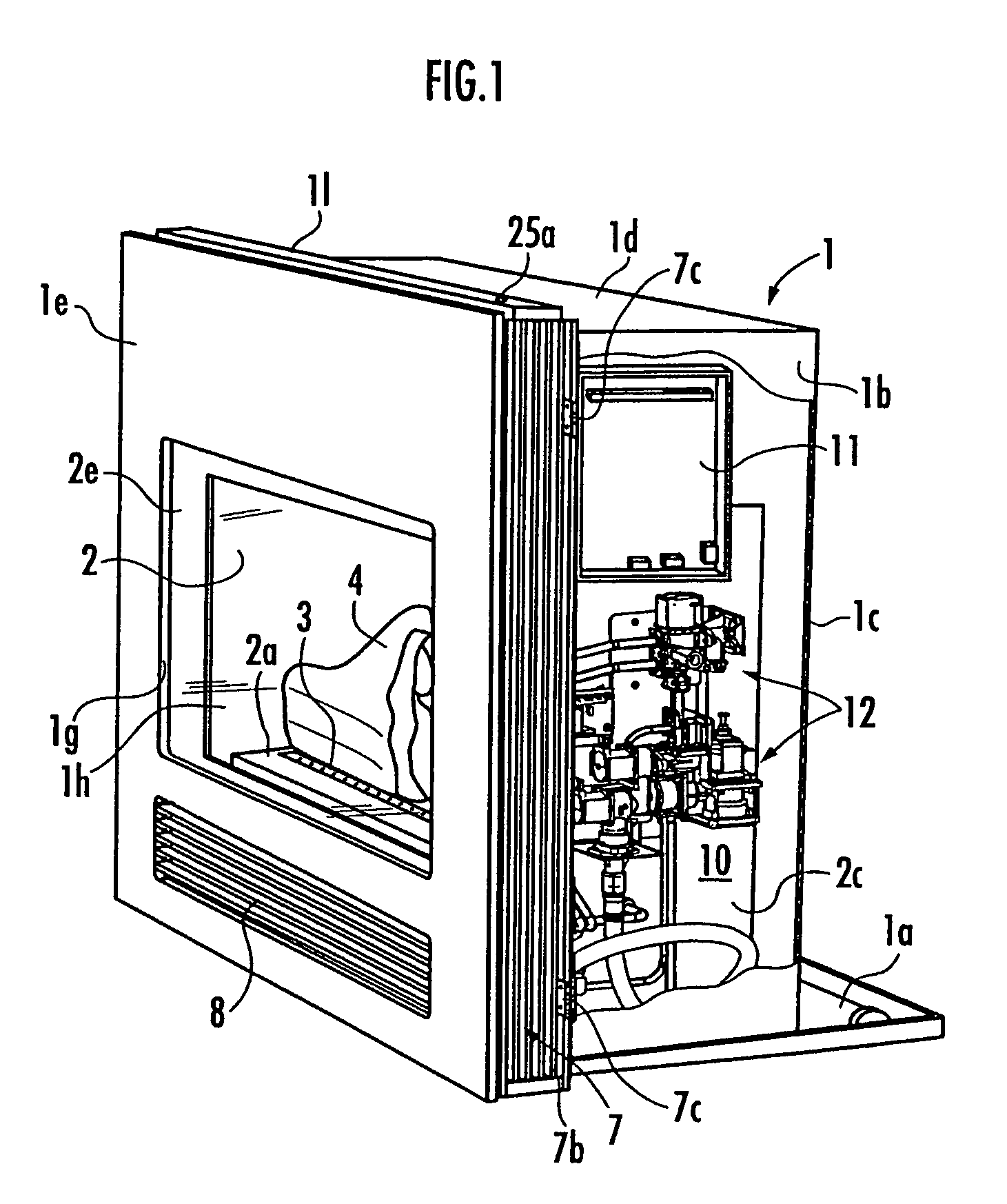

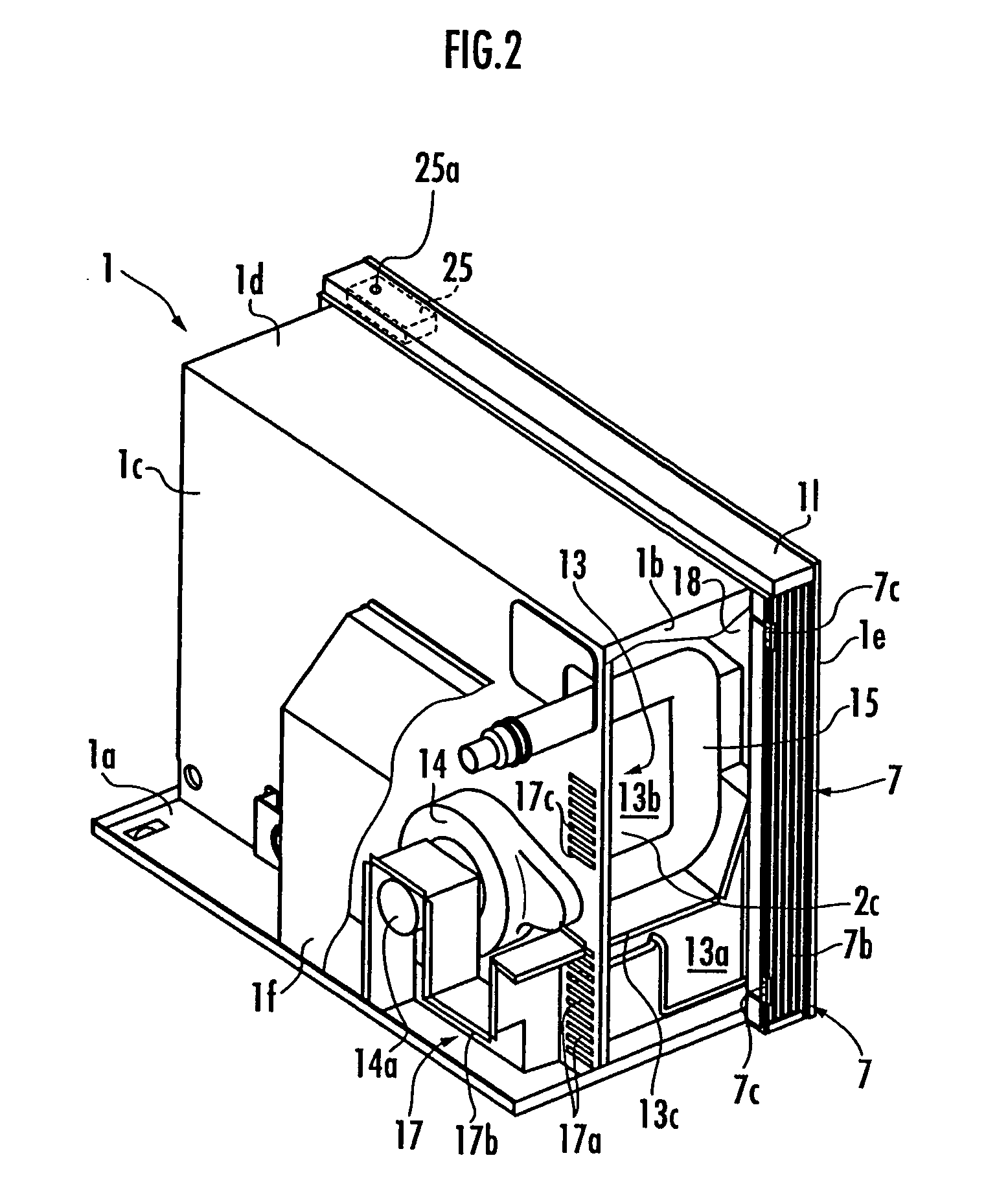

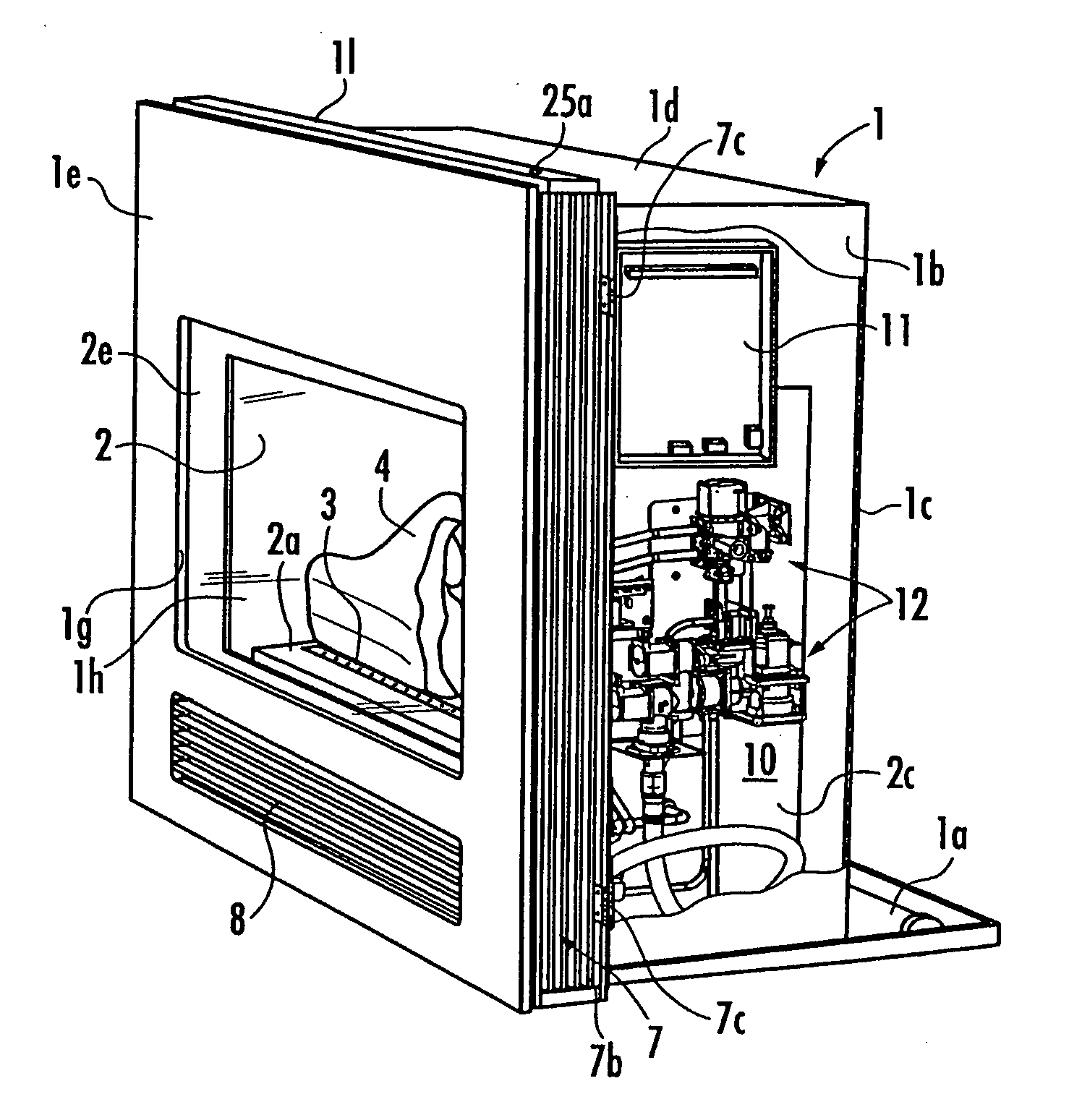

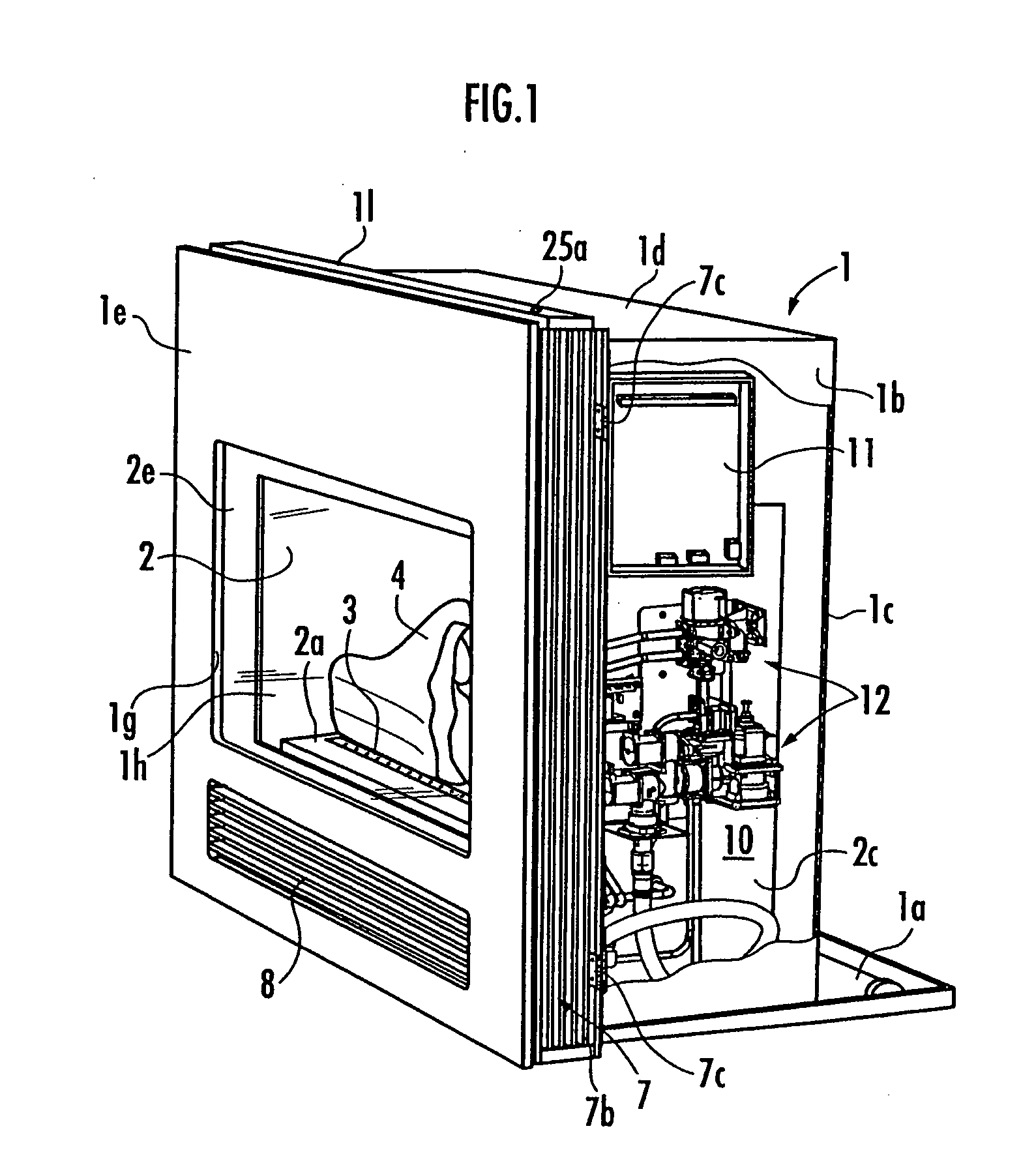

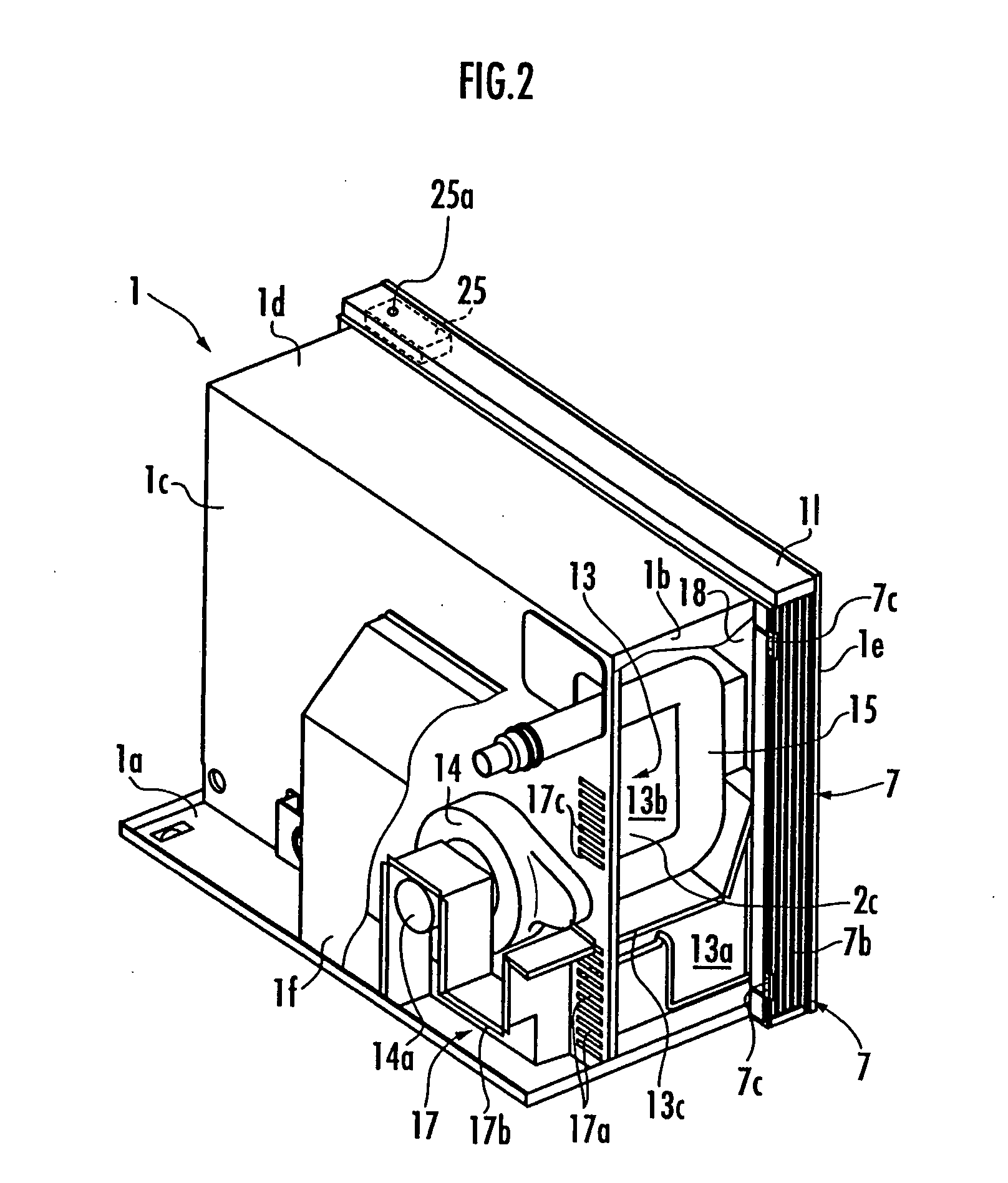

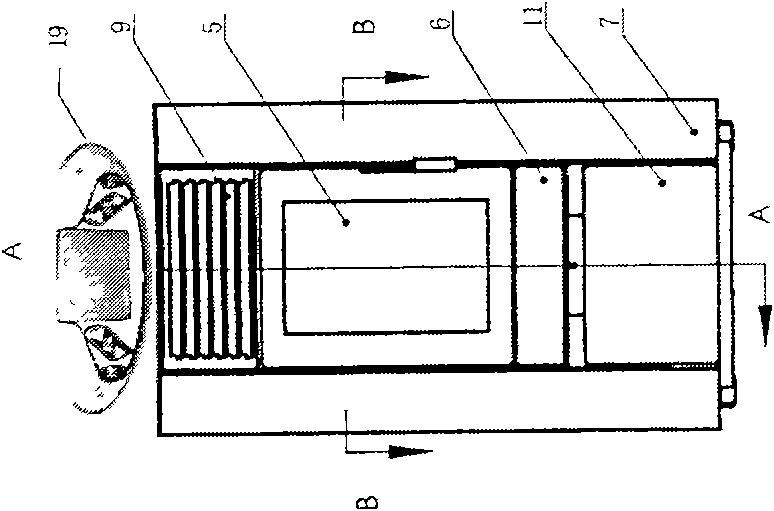

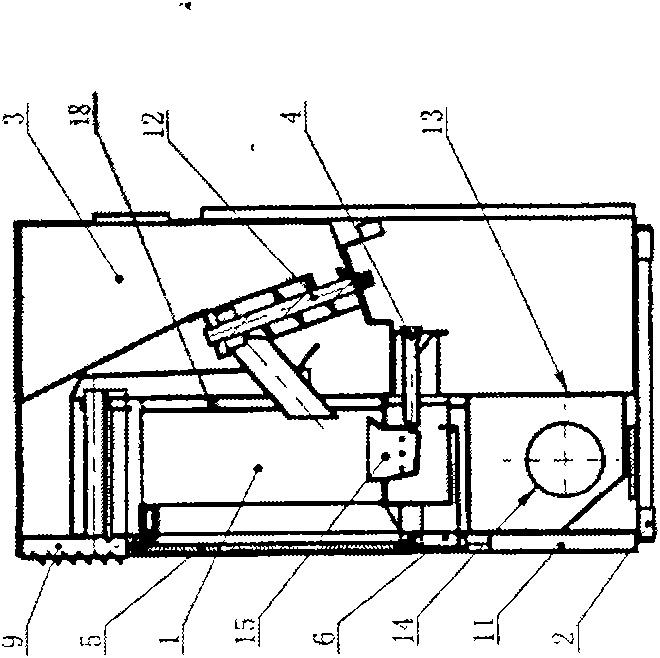

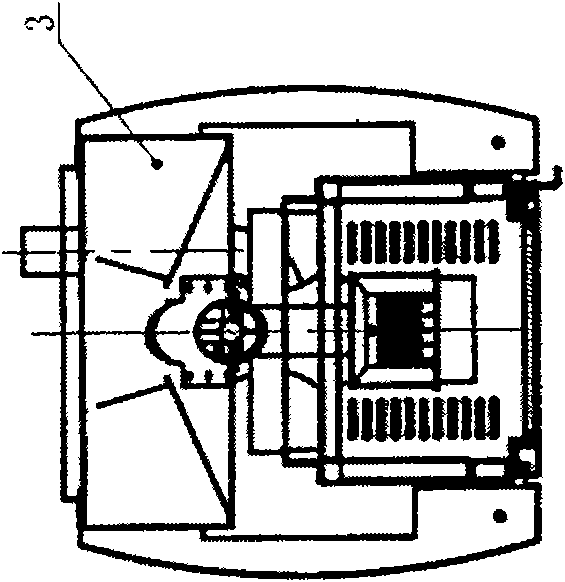

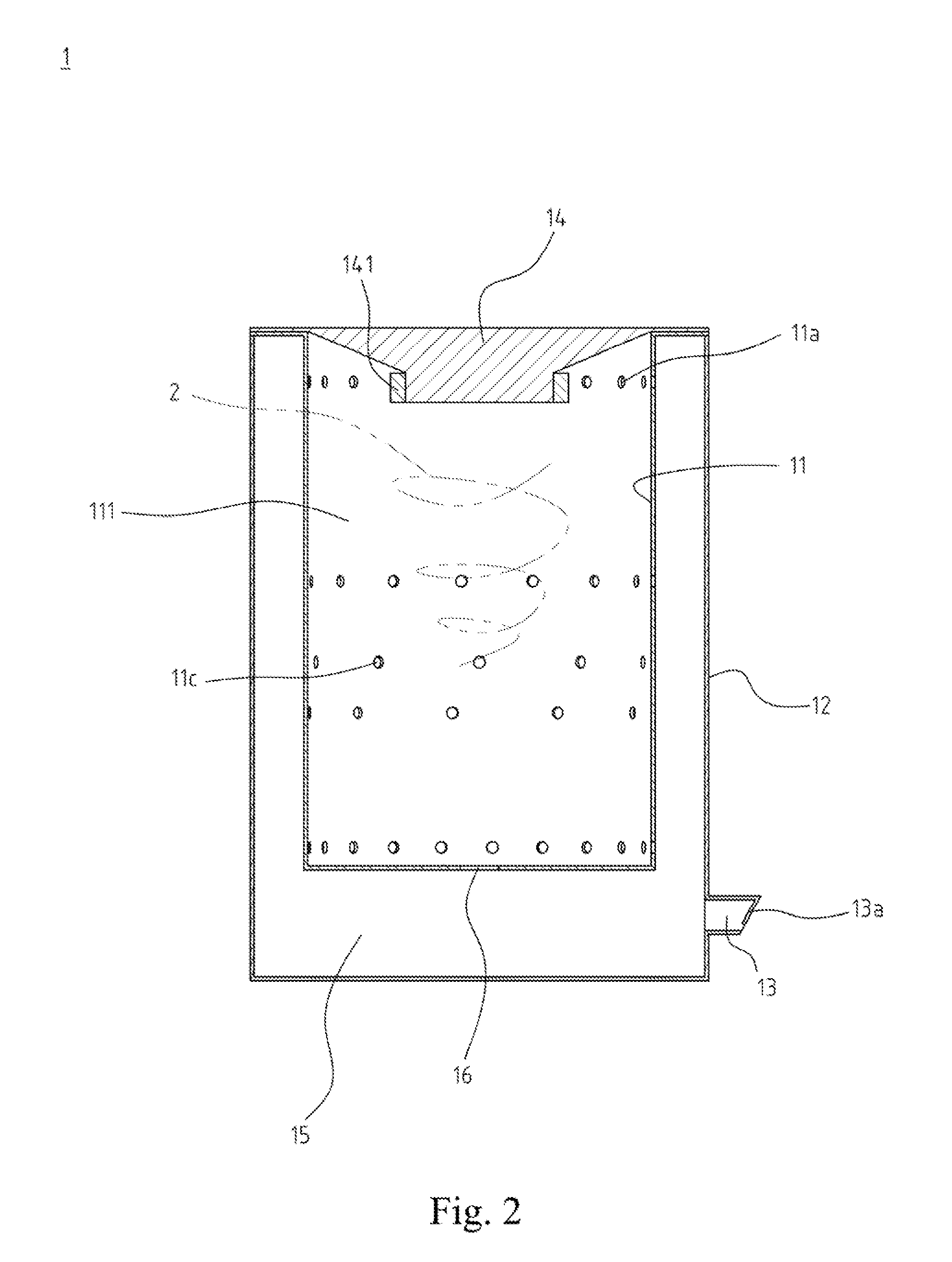

In-wall heater

InactiveUS7806345B2Good adhesionEasy detachmentHot-air central heatingStoves/ranges with convection heatingCombustionEngineering

In an in-wall heater, in which control equipment 11, 12 is disposed in a side space 10 on one lateral side of a combustion housing 2 within an outer case 1 and an exhaust duct 15 is disposed in a side space 13 on the other lateral side of the combustion housing 2, the cooling performance of each of the side spaces is increased and noise due to a sucked-in sound of room air can be reduced. In a side plate portion of the outer case 1 on both lateral sides, an air intake opening 7, which is vertically long, is provided in a position in a front side portion exposed to a front of a room wall. Each side space 10, 13 within the outer case 1 is formed in a ventilation flue on the suction side where the room air from each of the air intake openings 7 is conducted into the warm air fan 9.

Owner:RINNAI CORP +1

In-wall heater

InactiveUS20060137678A1Good adhesionEasy detachmentHot-air central heatingStoves/ranges with convection heatingEngineeringMechanical engineering

In an in-wall heater, in which control equipment 11, 12 is disposed in a side space 10 on one lateral side of a combustion housing 2 within an outer case 1 and an exhaust duct 15 is disposed in a side space 13 on the other lateral side of the combustion housing 2, the cooling performance of each of the side spaces is increased and noise due to a sucked-in sound of room air can be reduced. In a side plate portion of the outer case 1 on both lateral sides, an air intake opening 7, which is vertically long, is provided in a position in a front side portion exposed to a front of a room wall. Each side space 10, 13 within the outer case 1 is formed in a ventilation flue on the suction side where the room air from each of the air intake openings 7 is conducted into the warm air fan 9.

Owner:RINNAI CORP +1

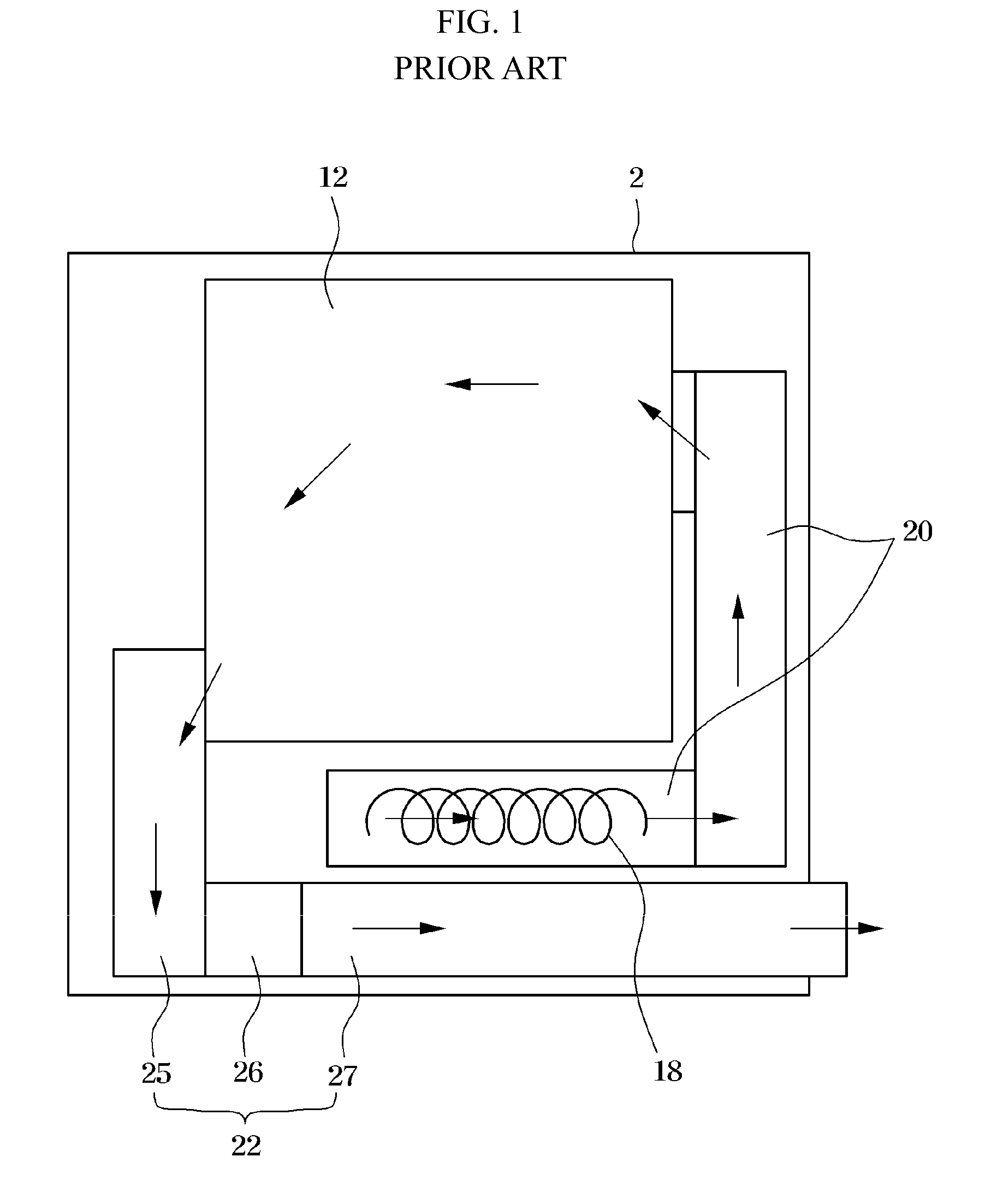

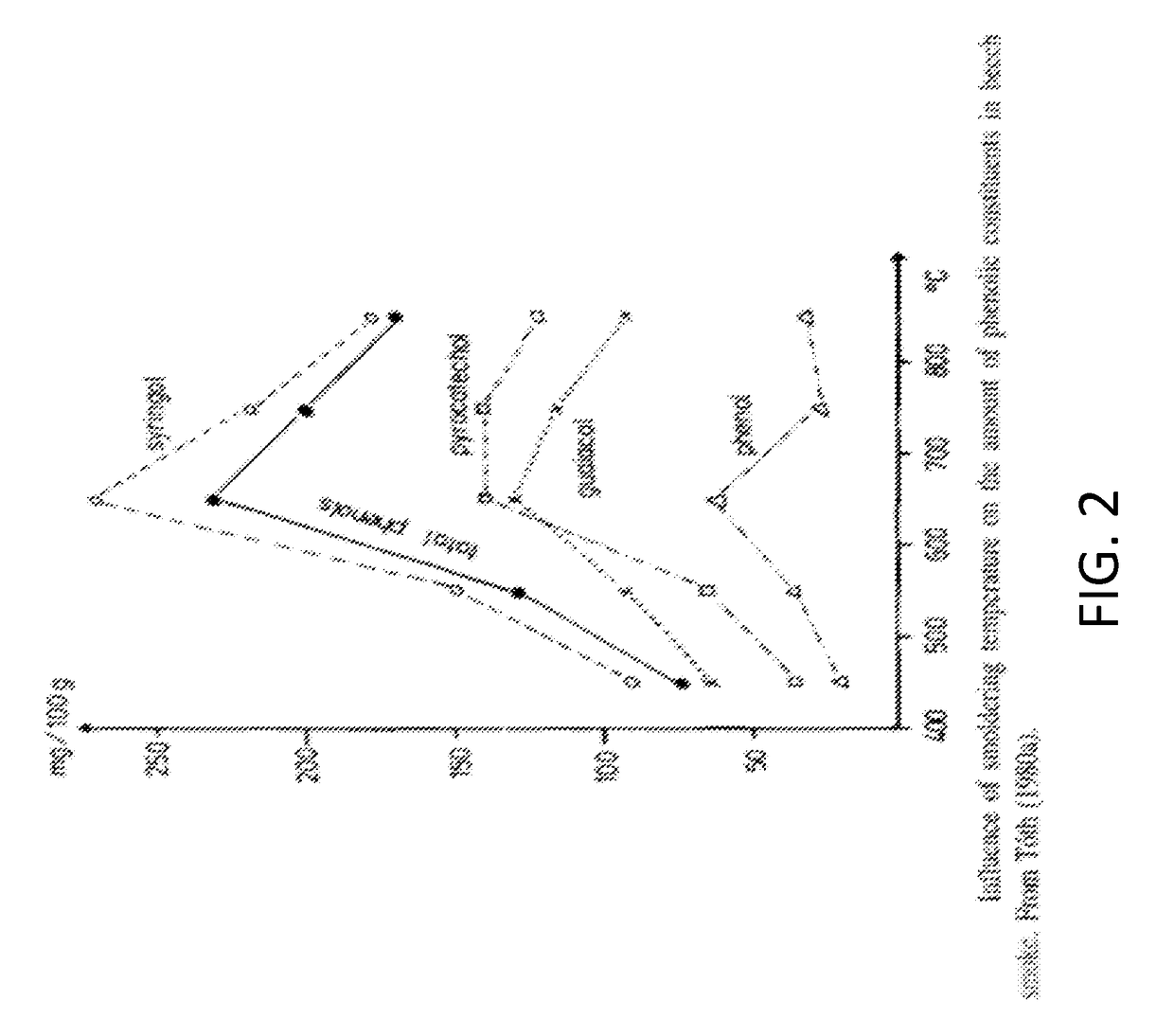

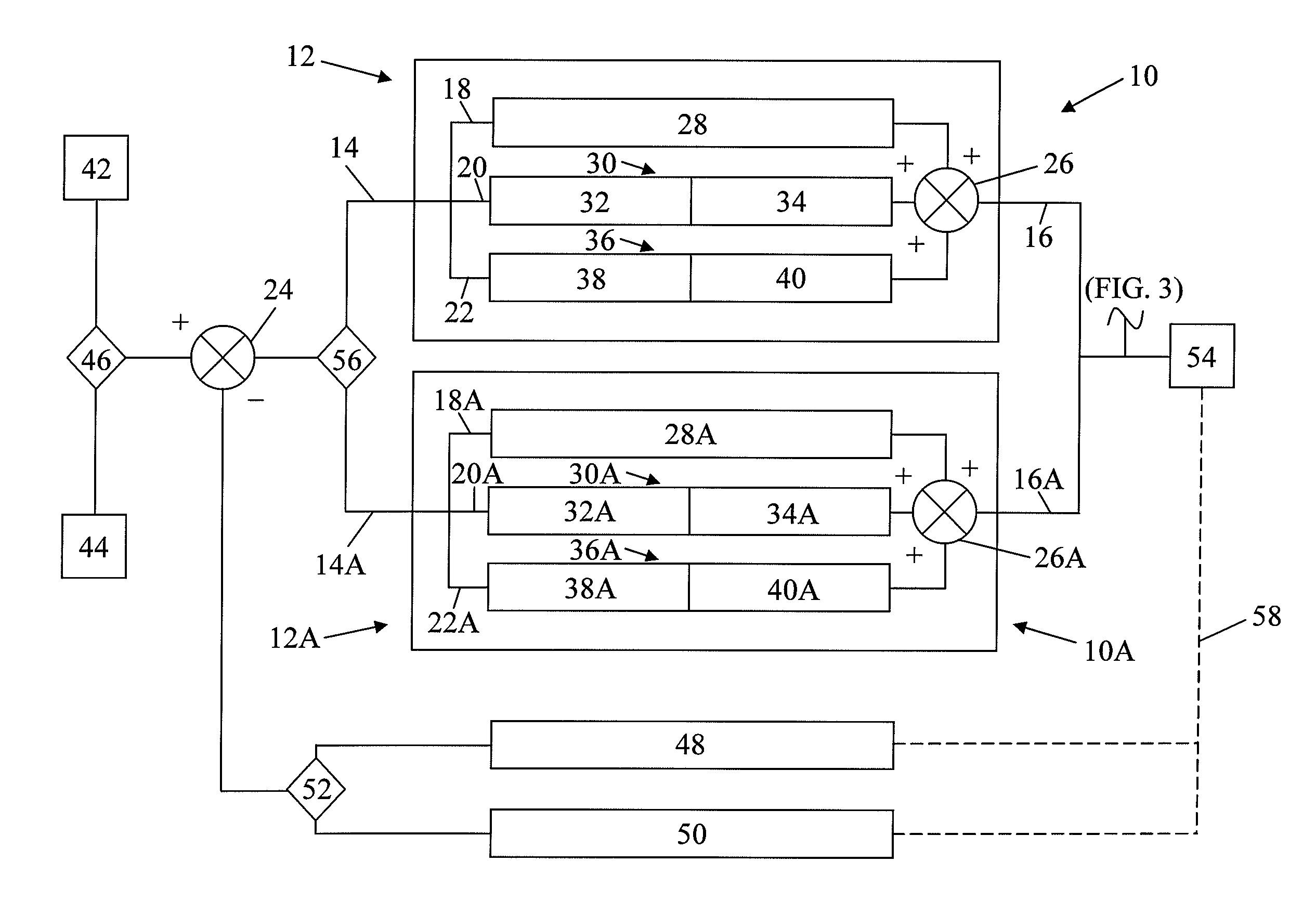

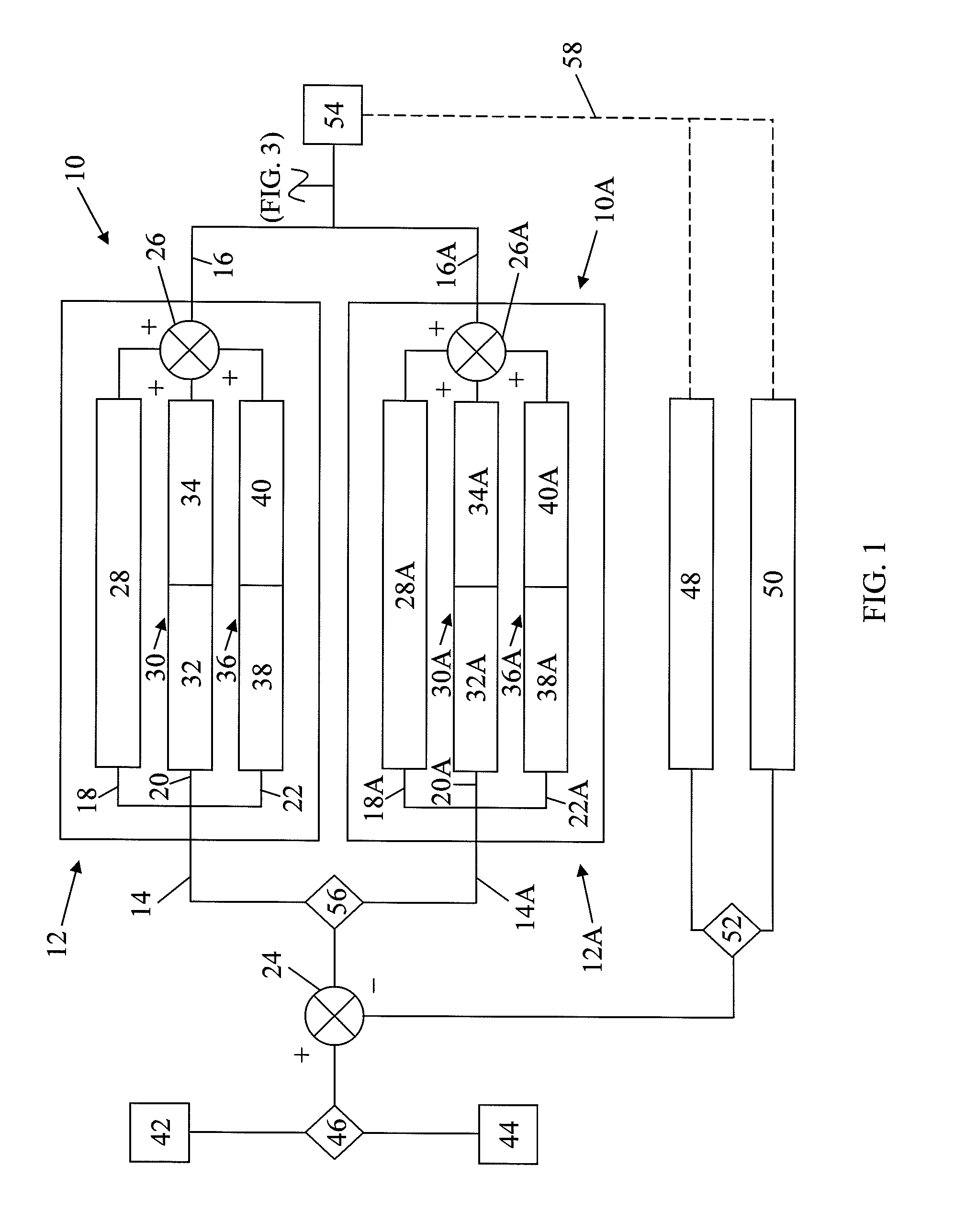

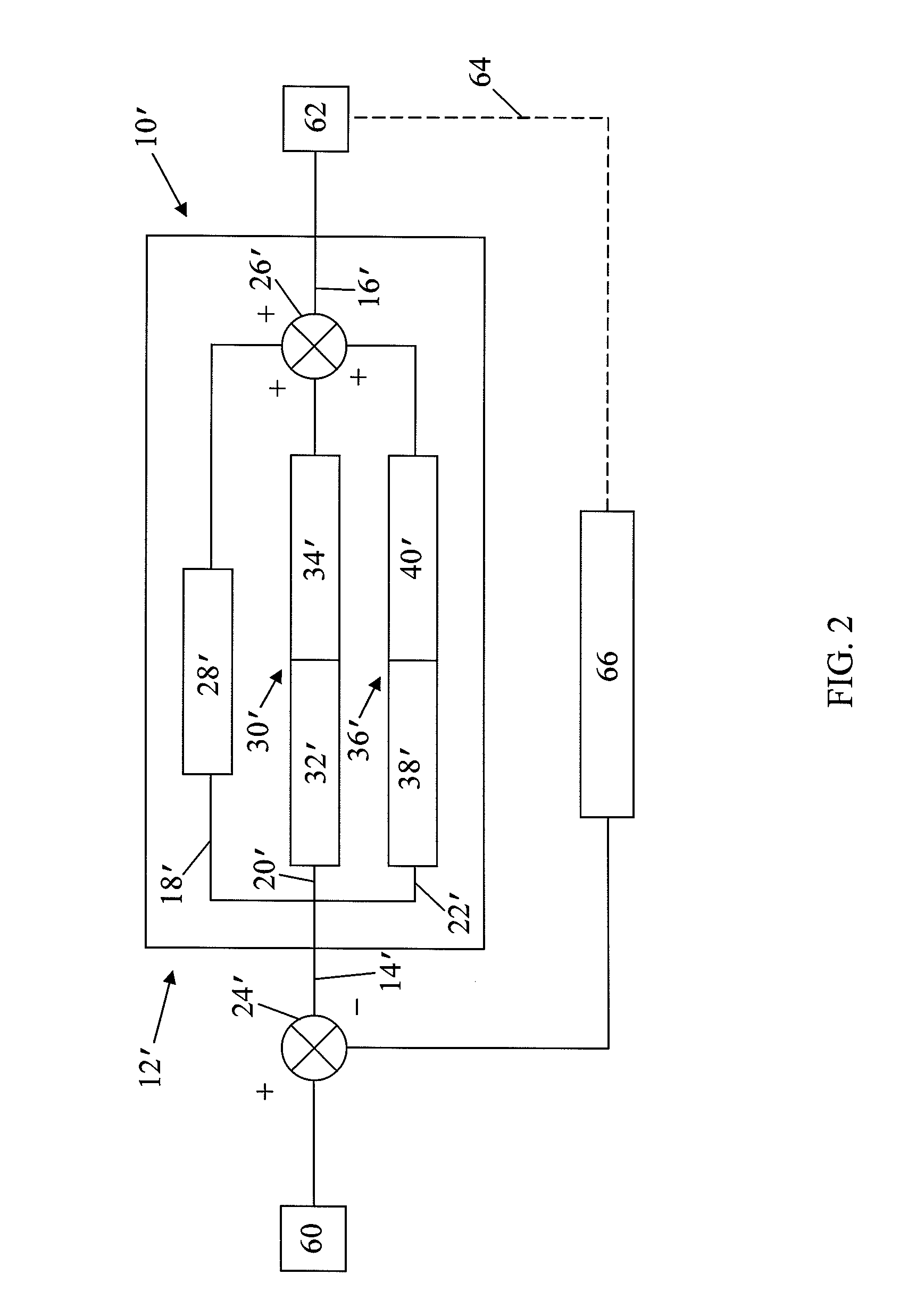

Process control methodologies for biofuel appliance

InactiveUS7457689B2Stoves/ranges with convection heatingTemperatue controlOperating pointLoop control

Apparatus for controlling the operation of a biomass stove utilizes three proportional integral derivative (PID) controllers as part of a closed loop to control the fuel feed rate, the convection fan speed and the combustion fan speed. The first loop controls room temperature, the second loop controls the convection fan speed and the third loop controls the combustion fan. Appropriate temperature readings are utilized for the first and second loop. The third loop, which utilized feedback of the ratio between the heat exchanger temperature to the exhaust temperature, in addition to measuring these temperatures also references a library of look-up tables of such ratios over the entire heat range of the stove that have been correlated to combustion efficiency, as an input. This enables the operator to optimize the heat output for any operating point.

Owner:HESTIA HEATING PRODS

Automatic biological material combusting multipurpose furnace

InactiveCN101576271AFull and efficient combustionImprove flammabilityStoves/ranges with convection heatingLighting and heating apparatusRural areaCombustion chamber

The invention discloses an automatic biological material combusting multipurpose furnace, which adopts an automatic ignition, automatic spiral feeding and suspending combustion mode, an enclosed negative pressure type and secondary return air to ensure no leakage of waste gas, simultaneous greatly reduces the discharge capacity of carbon monoxide, is safe, sanitary and environment-friendly, controls temperature outside a combustion chamber in a specific range, adopts a full enclosed combustion mode, can be used separately to achieve the heating effect, and also can be added with water and connected with radiators by pipelines to achieve water circulation heating; in addition, a waste gas discharge pipe can be connected with a hot gas fan of a furnace body through a pipeline to achieve windcirculation; in order to be suitable for rural areas, the furnace can be used for cooking; therefore, the furnace have multiple purposes, combusts waste residue, has high efficiency, low consumption,environment-friendly discharge, energy conservation and emission reduction, and brings safe living environment to life of people; and meanwhile, the furnace utilizes biological granules as fuel, achieves the aims of utilizing the waste and changing the waste into the treasure, makes the environment better, and solves the difficult problem of handling straws, old and useless woodware and peels offruits of urban residents of governments at all levels.

Owner:王义红

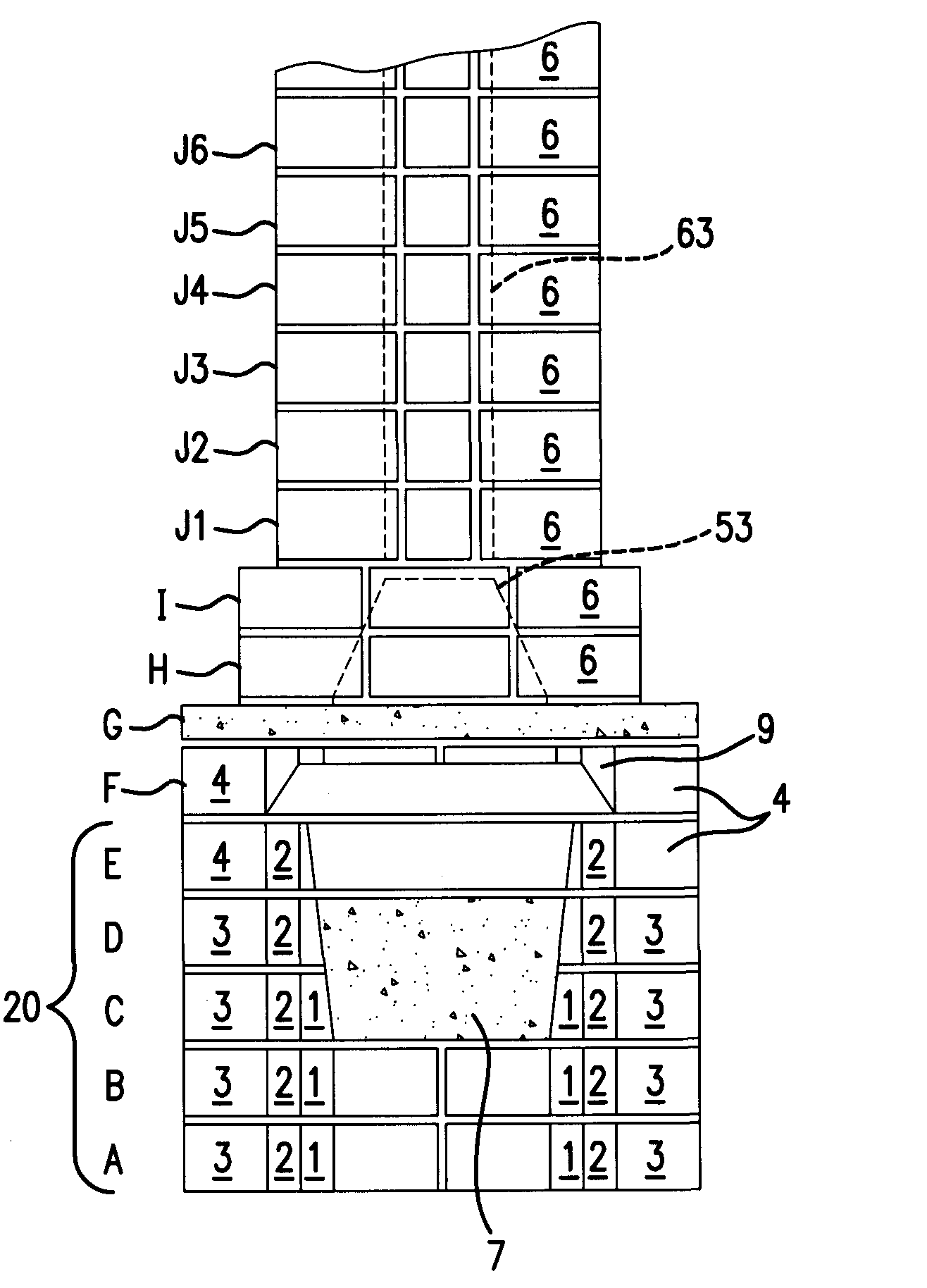

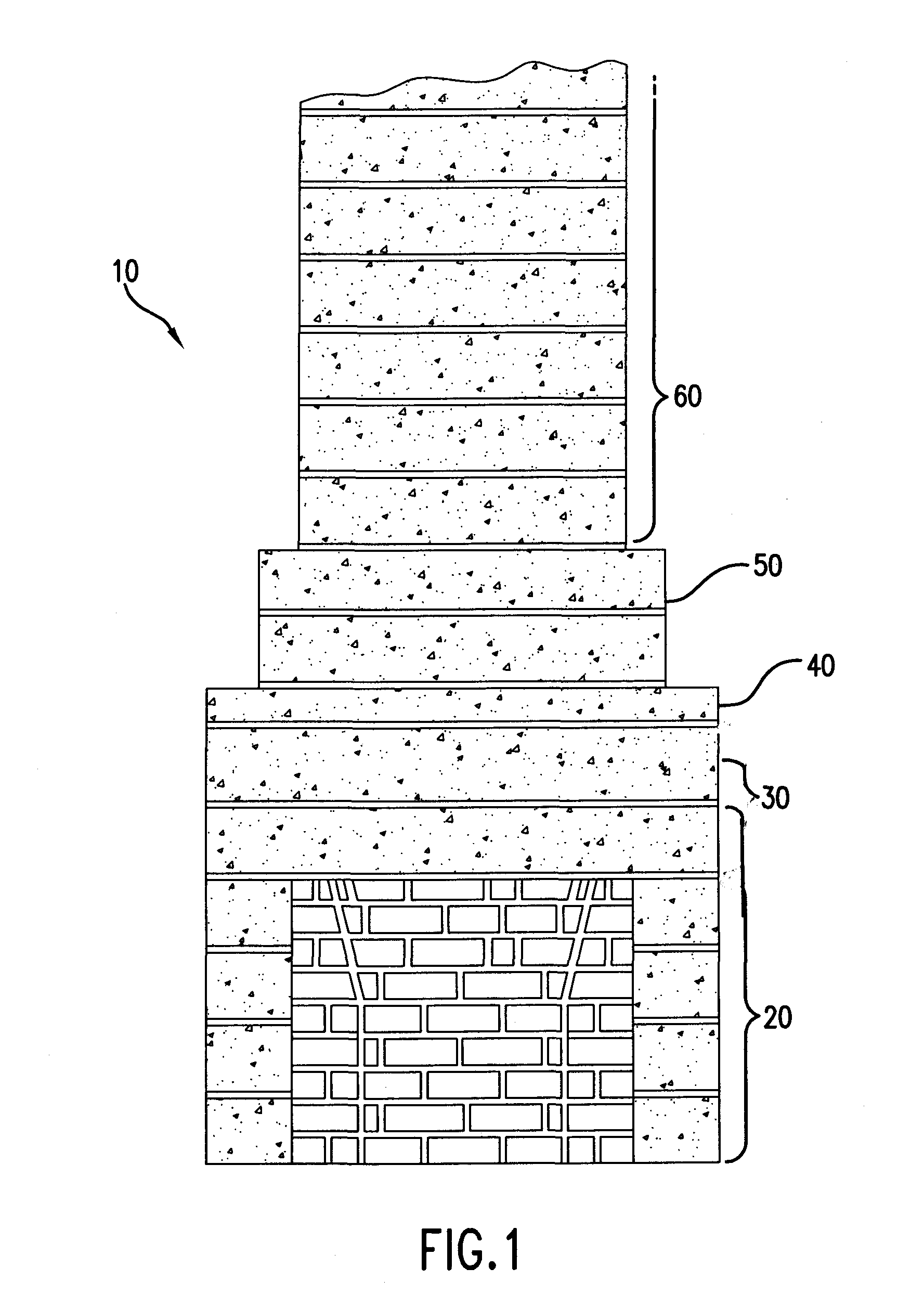

Modular fireplace and chimney

InactiveUS20080184988A1Simplifies masonry constructionSimple processStoves/ranges with convection heatingTowersEngineeringFireplace

The fireplace and chimney is provided made of specially formed stacked modular concrete units laid with several modular concrete masonry units in horizontal masonry courses, and specifically designed so a traditional clay flue liner may be inserted into the modular chimney as it is being erected. The sections making up the fireplace and chimney are the firebox, the damper level, the structural shelf level, the tapered smoke chamber level, and the chimney to form a naturally drafted masonry fireplace assembly.

Owner:MULLIN RICK

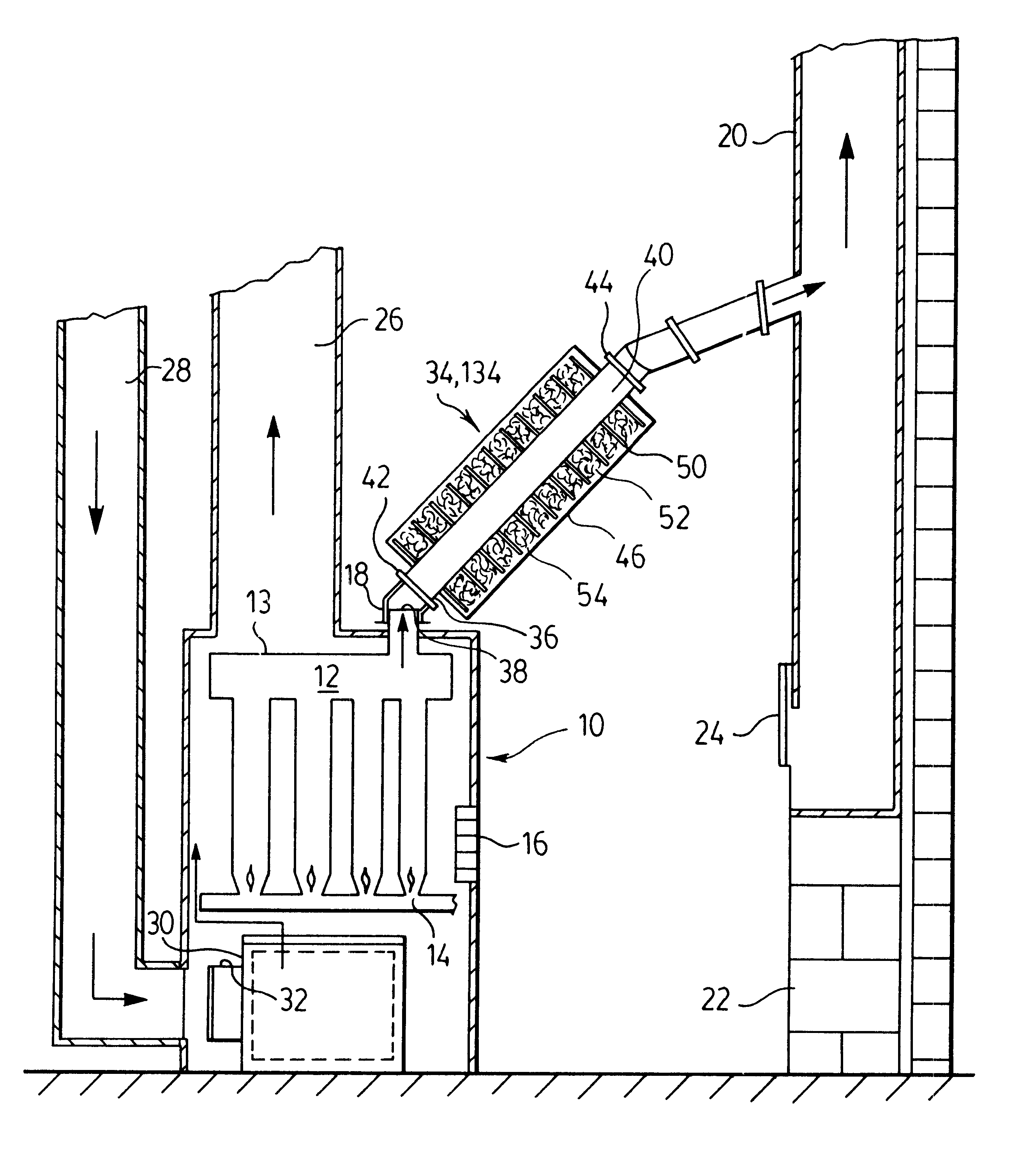

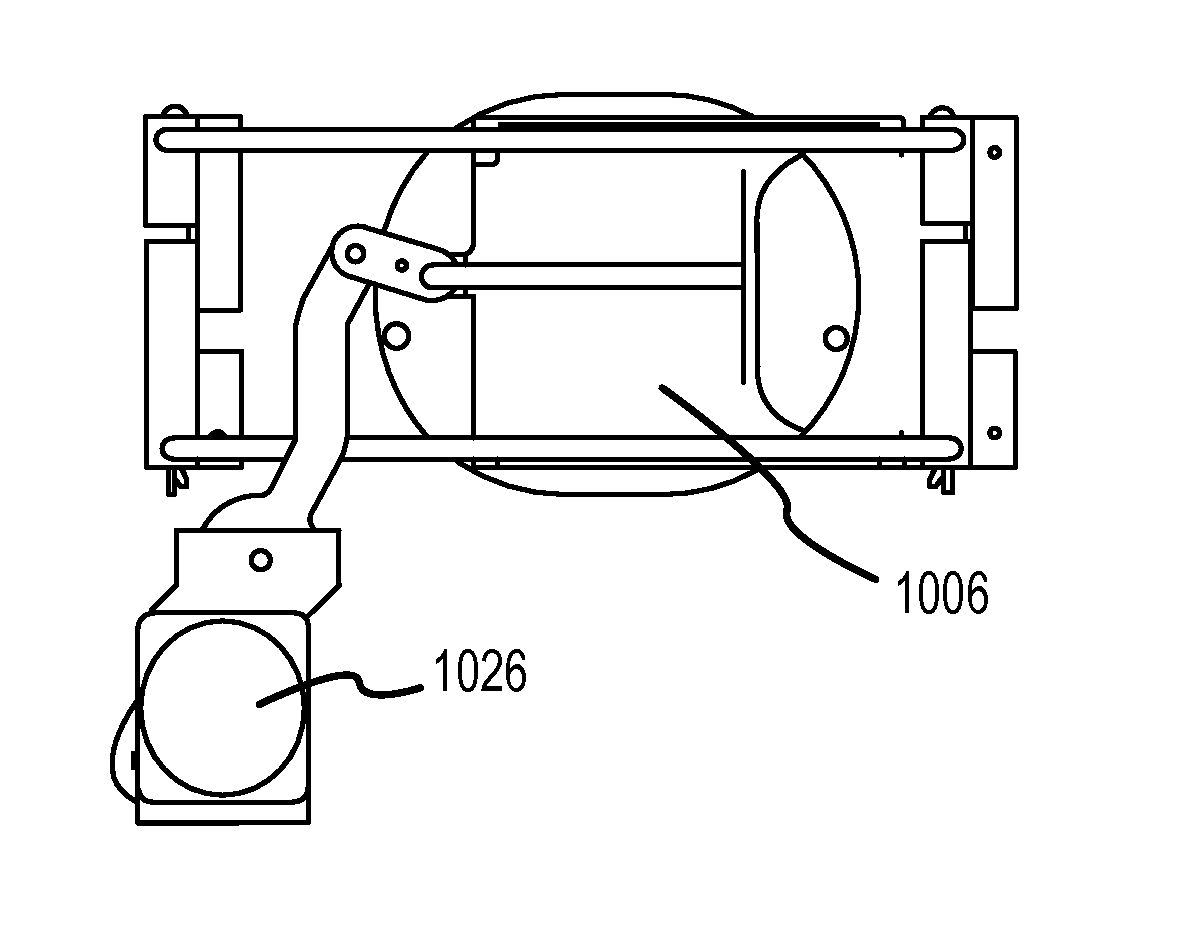

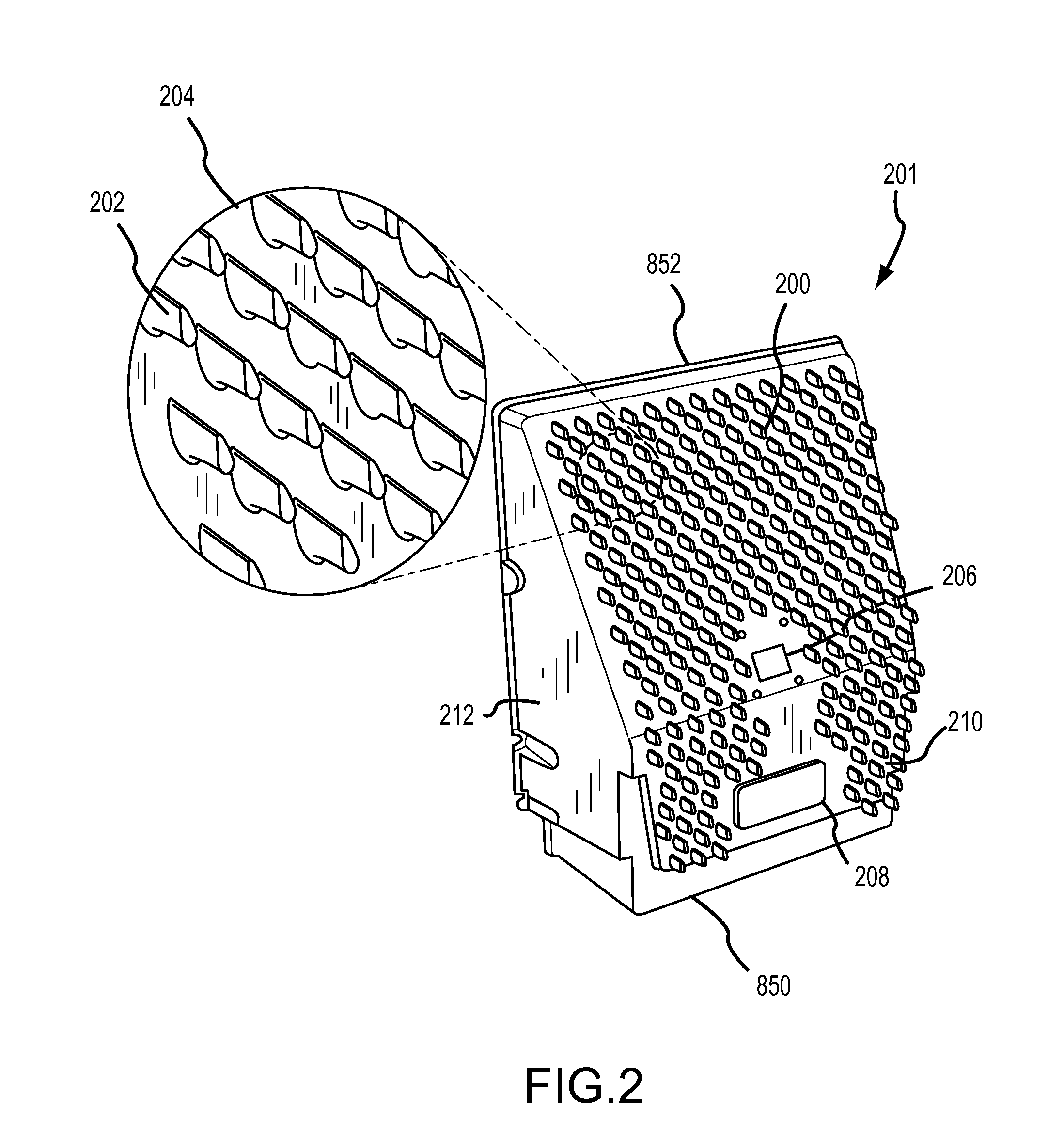

Pellet stove

According to embodiments of the present invention, a pellet stove includes a firepot assembly with a bottom plate slideable along rails to move between a closed position during combustion in the firepot and an open position during ash removal. According to other embodiments, a firebox or combustion enclosure includes a plurality of airfoils formed on the inner and outer surfaces of the enclosure to facilitate heat exchange between exhaust gases flowing across the inner surface of the enclosure and air blown across the outer surface of the enclosure. According to some embodiments, the airfoils and enclosure are of integral unibody construction. According to yet other embodiments, a user sets parameters via a wall control unit, and a stove control unit receives the parameters and automatically controls fuel feed rate, ignition, convection blower, combustion blower, and / or firepot cleaning based on the one or more parameters.

Owner:HNI TECH INC

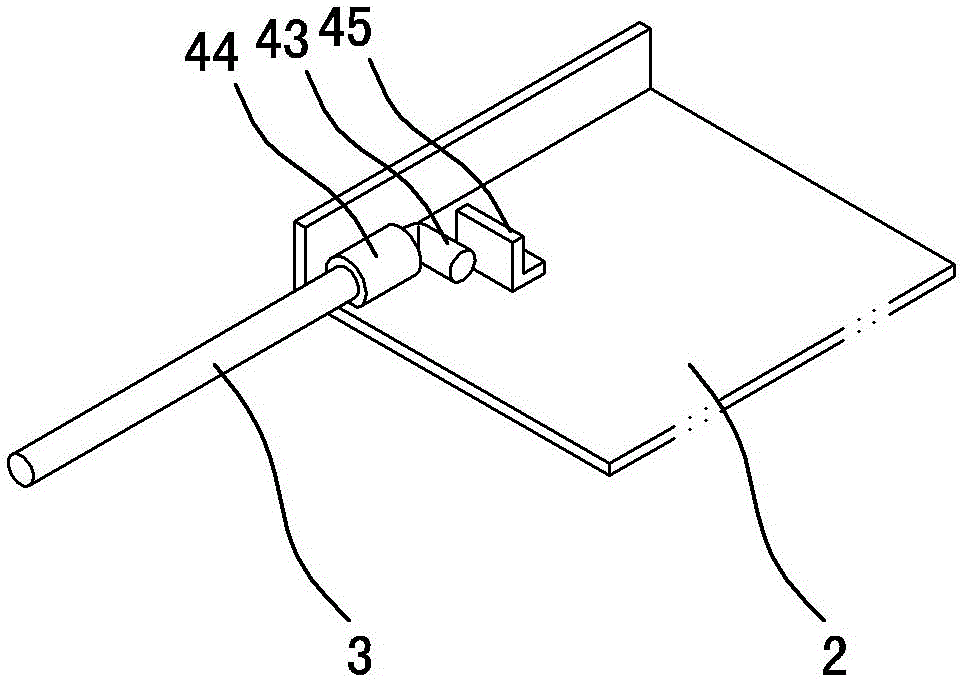

Single sliding door forward-pull and backward-push controlled pot table type heating boiler

ActiveCN105091034ANo diffuseAffect the service lifeHot-air central heatingStoves/ranges with convection heatingPush pullEngineering

The invention relates to a single sliding door forward-pull and backward-push controlled pot table type heating boiler which comprises a pot table type boiler body (1), wherein a sliding door (2) is slidingly mounted in a position between a lower boiler chamber (19) and an upper boiler chamber (20) in a front-back direction; a push-pull rod hole (24) is formed in the front wall of the boiler body (1) along the front-back sliding direction of the sliding door (2); a push-pull rod (3) with a handle (31) positioned outside the boiler body (1) is slidingly mounted in the push-pull rod hole (24); and the front end of the push-pull rod (3) can be matched with the sliding door (2) to pull and push the sliding door (2) to slide forwards and backwards. The heating boiler has the advantages of convenience in operation, simple structure, low difficulty in processing and manufacture, and low labor and material costs. One sliding door capable of being pulled forwards and pushed backwards can replace two doors, so that the heating boiler is more convenient to use. The heating boiler can be converted between a cooking pot and a heating tool, realizes the effects of cooking, heating and waste heat utilization, facilitates the life of people, and saves energy.

Owner:穆棱福善采暖设备制造有限公司

Stove with door opening mechanism

InactiveUS7594506B2Stoves/ranges with convection heatingLighting and heating apparatusBiological activationElectrical and Electronics engineering

Owner:LUNDBERG WILLIAM RICHARD

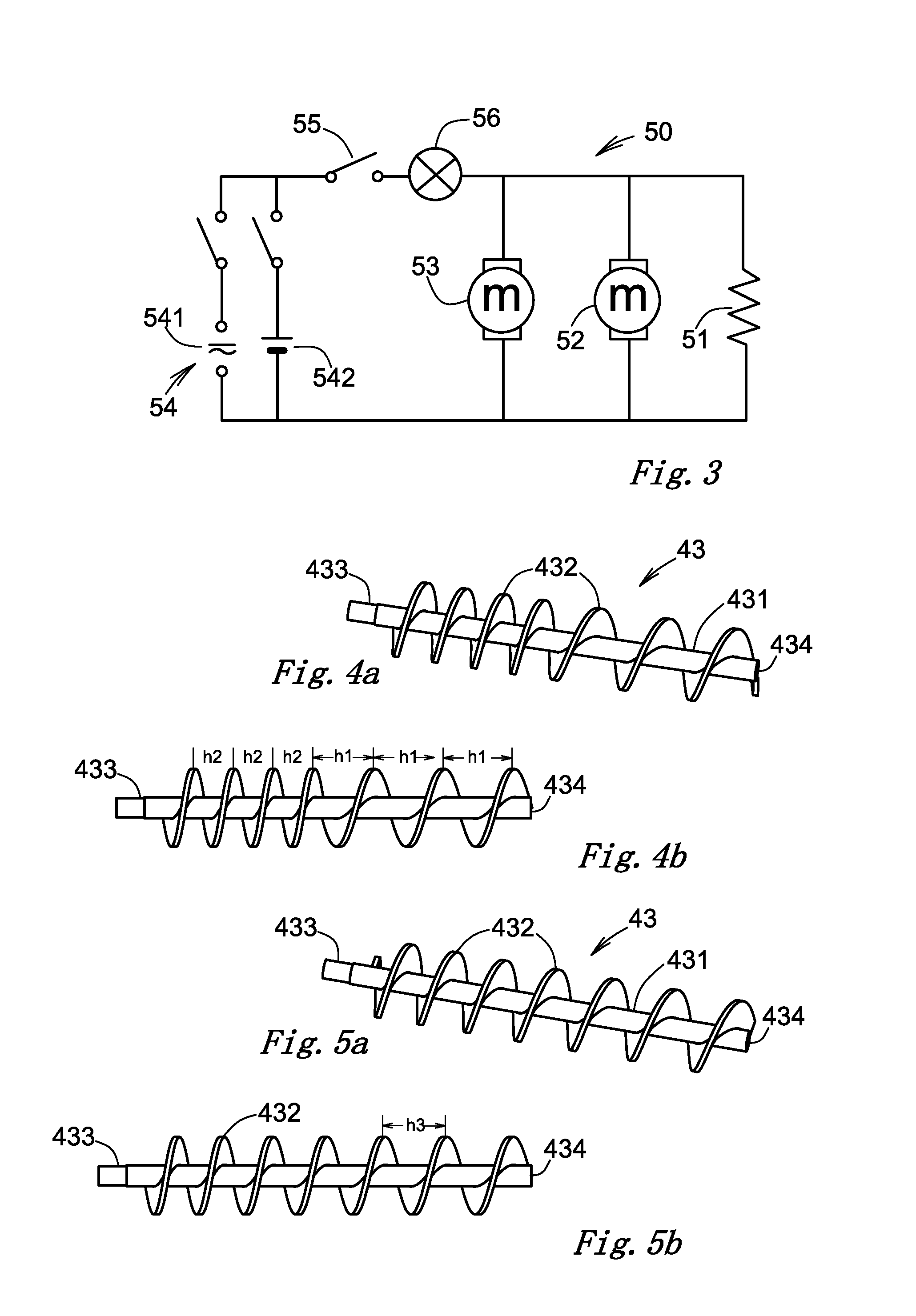

Variable pitch fuel supplier and an oven for use with the same

InactiveUS20150020790A1Reduce cloggingImprove performanceStoves/ranges with convection heatingSolid fuel combustionCombustion chamberMotor drive

An oven for use with a variable pitch fuel supplier and for use with biomass fuel. The oven has a body which is able to be placed on the ground. The body has a combustion cabinet and an auxiliary equipment cabinet. The combustion cabinet has a burner received therein and the auxiliary equipment cabinet has a fuel supplier and an electrical equipment received therein. The fuel supplier has a hopper, a fuel tube, and a rotary vane feeder rotatably received in the fuel tube. The electrical equipment has a power supply and a feeding motor driving the rotary vane feeder. Pitches vary larger from a tail end to a free end of the rotary vane feeder.

Owner:ZHU HONGFENG

Self powered heat transfer fan

ActiveUS7812245B2Not be reduced to practicePump componentsStoves/ranges with convection heatingEngineeringFan blade

A self-powered fan for circulating air for use in cooperation with a heat source, such as a wood stove, and having a first heat transfer member thermally and physically connected with the heat source. The fan blades operably create a first or warm air flow and a second or cooler air flow. The fan has a second heat transfer member with a thermocouple module structure located between the two heat transfer members. The first heat transfer member is of suitable material, size, mass and shape as to provide a suitable temperature gradient between the thermocouple structure and the heat source to operably allow of such sufficient heat transfer from the first heat transfer member to the thermocouple to generate sufficient power to effect rotation of the blades, but not to cause thermal damage to the thermocouple structure. The fan blades are constructed and arranged to cause a portion of the second air flow to be drawn past the first heat transfer member to effect a cooling heat transfer effect upon the first heat transfer member. The improvement is wherein the motor located on the first transfer member adjacent a side of the thermocouple structure remote from the second transfer member does not hinder the second air flow, and is suitably located as to not be operably thermally damaged by the first heat transfer member or the heat source.

Owner:REID RANDALL H

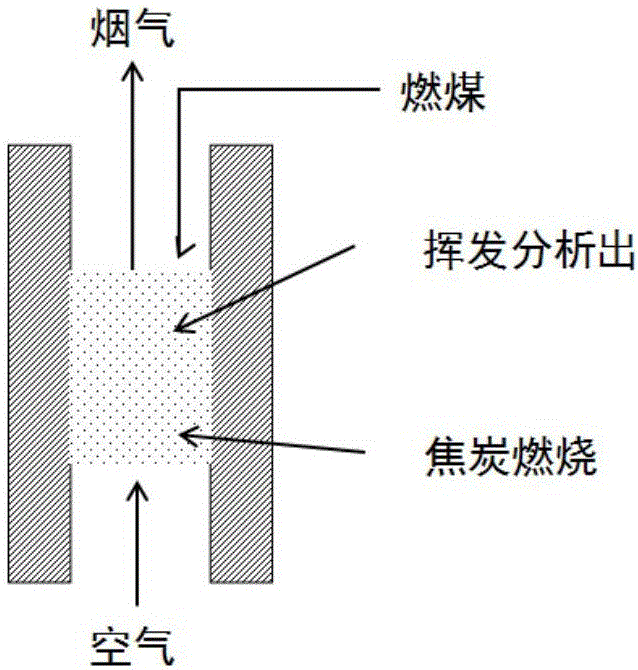

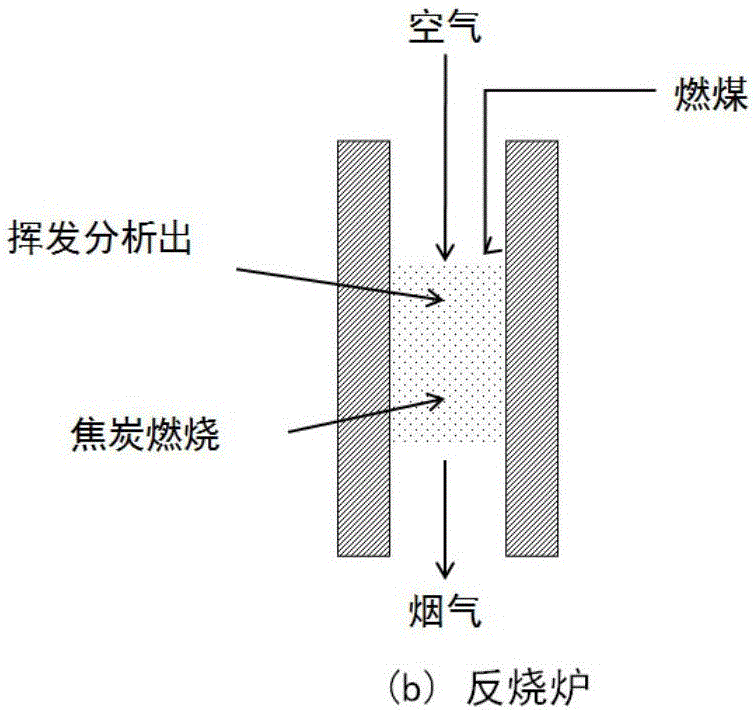

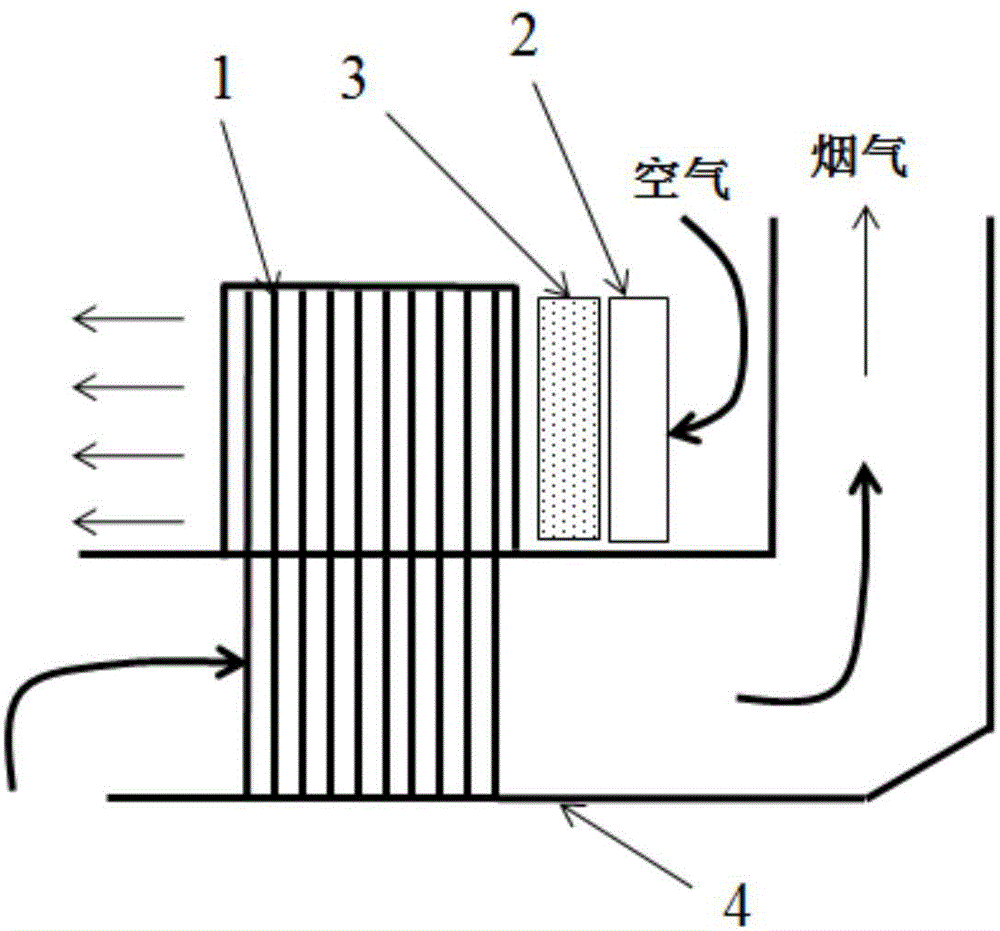

Air circulated heating and purifying device for coal-fired furnace and coal-fired furnace using air circulated heating and purifying device and processing method for coal-fired furnace

PendingCN107435948AEfficient recyclingImprove utilization efficiencyMechanical apparatusStoves/ranges with convection heatingAir filterEngineering

The invention provides an air circulated heating and purifying device for a coal-fired furnace and the coal-fired furnace using the air circulated heating and purifying device and a processing method for the coal-fired furnace. The air circulated heating and purifying device comprises a heat pipe exchanger, an induced draft fan and an air filtering device. A heat exchange pipe is installed in the heat pipe exchanger, and the heat exchange pipe is filled with a heat transfer substance. A horizontally placed smoke discharging pipe is extended from a smoke discharging port of the coal-fired furnace. The lower part of the heat pipe exchanger is installed in the smoke discharging pipe. One side of the upper part of the heat pipe exchanger is provided with an air inlet. One side, opposite to the air inlet, is provided with an air outlet. The induced draft fan is installed at the air inlet or the air outlet. The air filtering device is installed at the air inlet or the air outlet. The air circulated heating and purifying device is installed at the smoke outlet pipeline of the coal-fired furnace, so the heat quantity in the smoke can be effectively recycled and the indoor air can be purified simultaneously. The air circulated heating and purifying device is capable of greatly improving the utilization efficiency of the smoke heat quantity of the coal-fired furnace, so the air can be heated by only smaller heat quantity.

Owner:YANKUANG GRP CO LTD +1

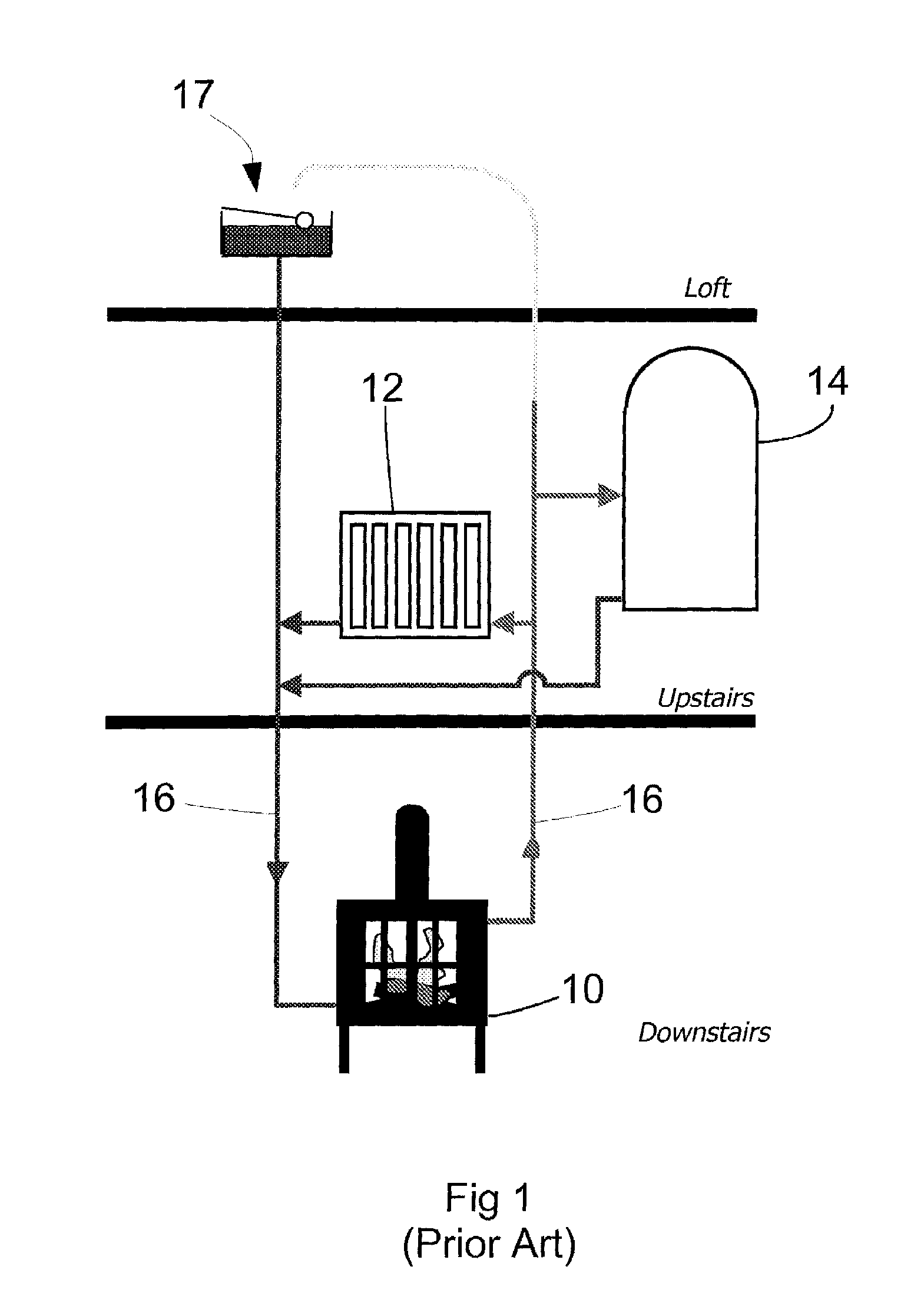

Apparatus for capturing heat from a stove

InactiveUS20110271948A1Minimize flowSpeed up the flowFluid heatersCentral heating with accumulated heatWater flowEngineering

Apparatus for capturing heat from a stove to enable it to be transferred to a central heating system is disclosed. The apparatus comprises an air-water heat exchanger, the heat exchanger having an air side and a water side and being operative to transfer heat between air on the air side and water flowing in channels in the water side. The apparatus includes an air duct through which air heated by a stove can pass by convection to contact the air side of the heat exchanger and control means operable to control the amount of air flowing to the heat exchanger. The control means may include a fan that can be operated to direct the flow of air to the heat exchanger.

Owner:KINXERG LTD

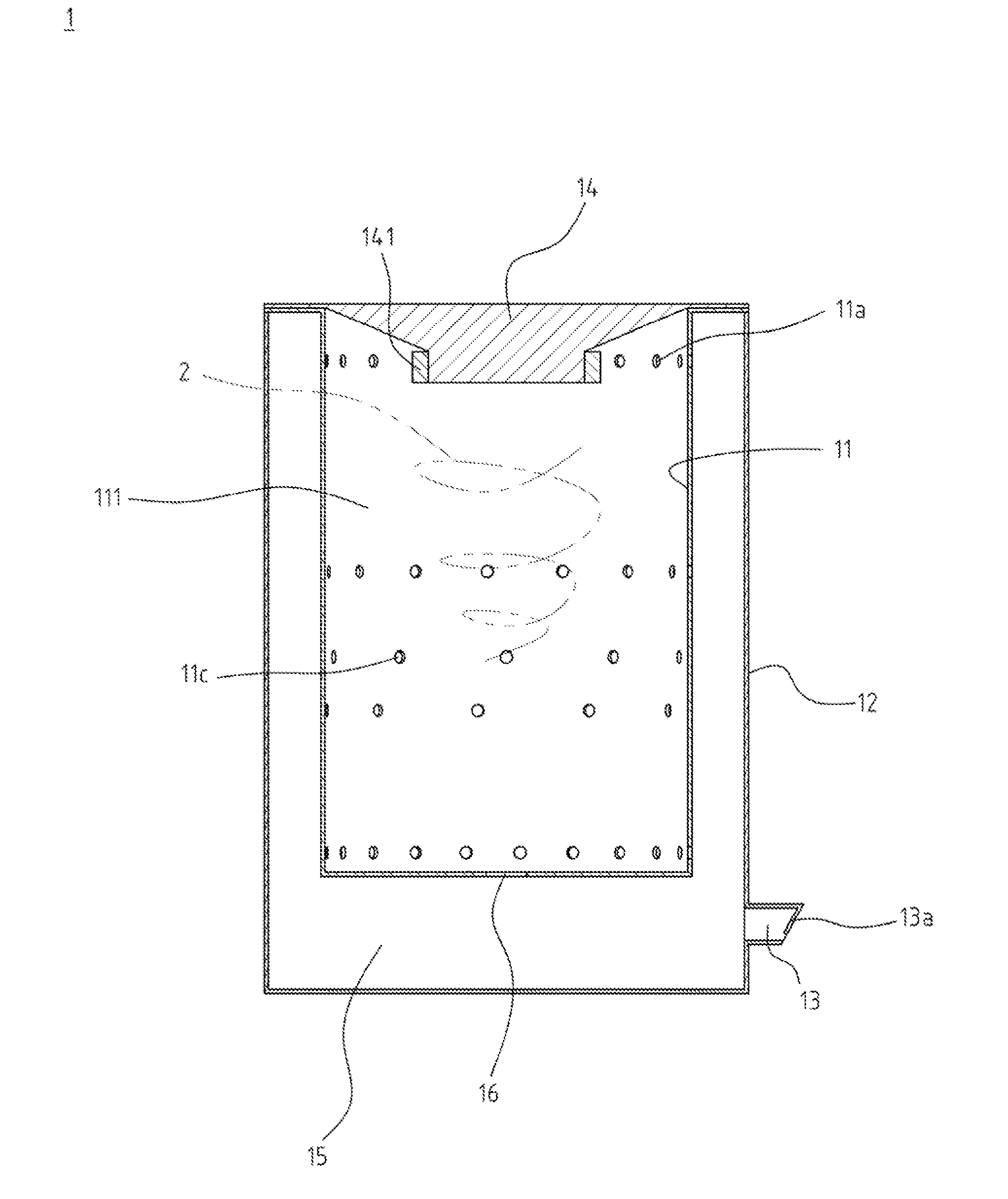

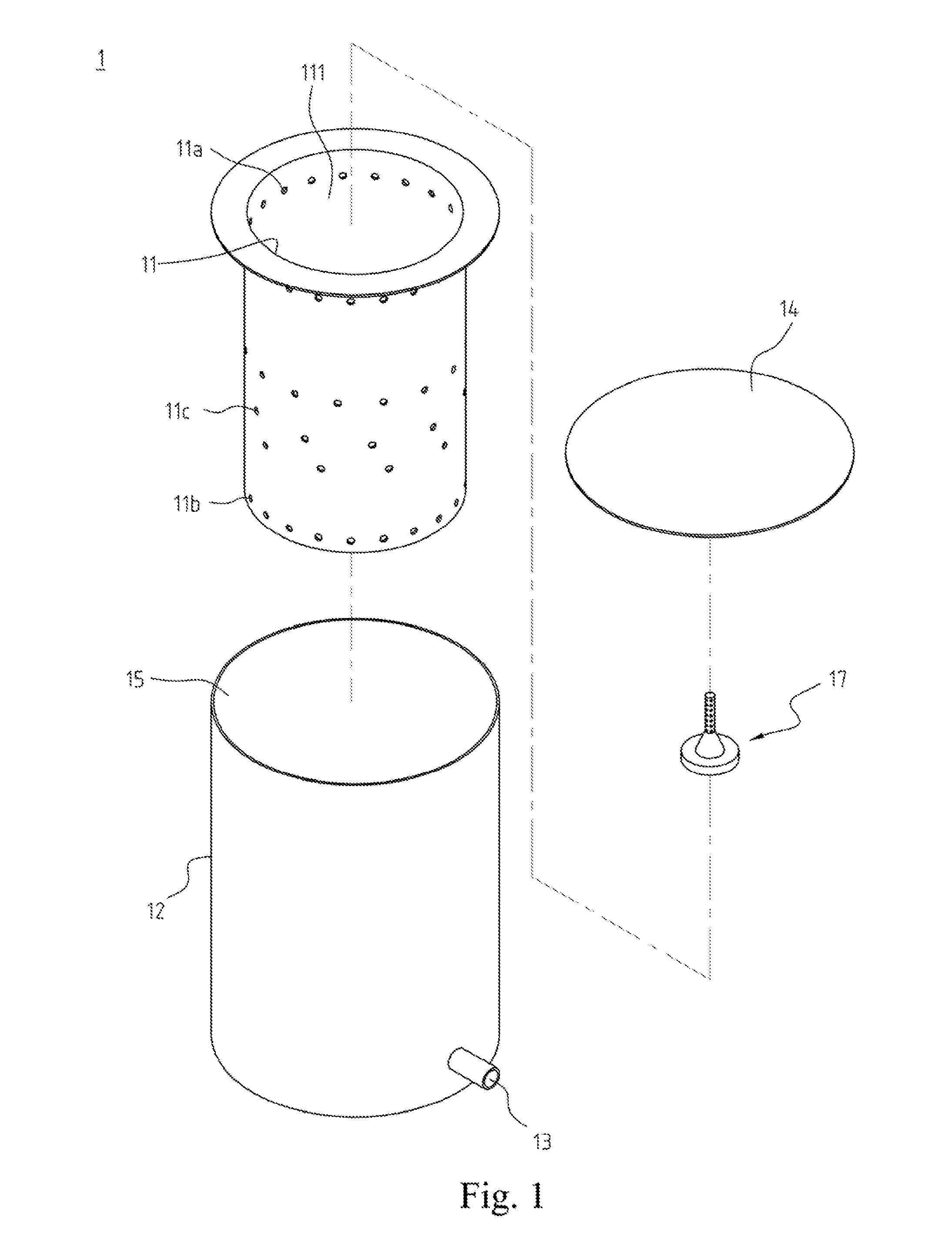

Combustion furnace

ActiveUS20160209043A1Improve combustion effectEasy accessStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesStomaCombustion

A combustion furnace includes an inner shell, an outer shell, a gas inlet piping and a flame inhibiting cover. The inner shell defines a receiving cavity therein. The inner shell defines a plurality of first gas holes around the periphery of a top portion thereof. The inner shell defines a gas inlet hole at a bottom thereof. The outer shell encloses the inner shell such that a gas flowing space is defined between the inner shell and the outer shell. The gas inlet piping has an opening formed at one end thereof, and the gas inlet piping communicates with the gas flowing space. The flame inhibiting cover is atop the outer shell and the inner shell, and a lower flange of the flame inhibiting cover is below the first gas holes.

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com