Pellet stove

a technology of pellet stoves and stoves, applied in the field of system and method of heating buildings, can solve the problems of high noise, limited user interface, and limited work options of users in cleaning and maintenance operations, and achieve the effect of less choice for users and high nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

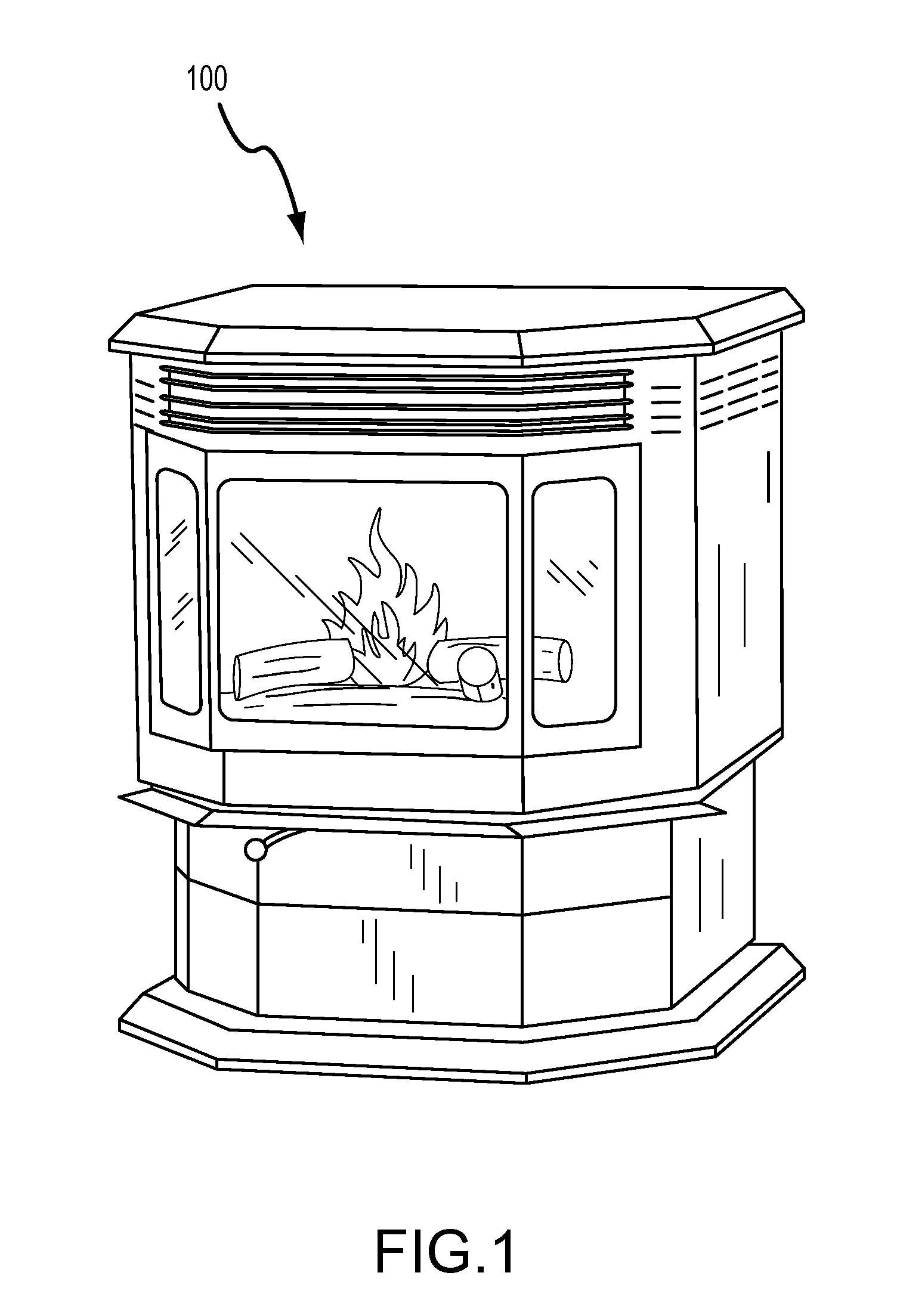

[0057] An exemplary pellet stove 100 is illustrated in FIG. 1. Embodiments of pellet stoves in accordance with the present invention provide greater power efficiency than conventional pellet stoves, enable a user to set a wider range of parameters than in the past, and provide automated features for stove cleaning, ignition, temperature control, and blower control, based on parameters such as, for example, fuel type. Embodiments of pellet stoves described herein are able to burn a wider variety of types of biomass solid fuels, including without limitation: corn, wood pellets, cherry pits, nut shells, sunflower seeds, and pea pellets. Advantageously, pellet stoves according to embodiments of the present invention can automatically adapt various functions based on the type of fuel, and other user preset parameters. In addition, assembly of pellet stoves and / or components of pellet stoves is made easier by unique component attributes, such as a single piece fuel hopper, a rail-based cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com