Power train for a motor vehicle

a technology for motor vehicles and power trains, applied in the direction of electric generator control, engine starters, gearing, etc., can solve the problems of increasing weight and cost, and achieve the effects of cost saving, long operating life of interactive connections, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

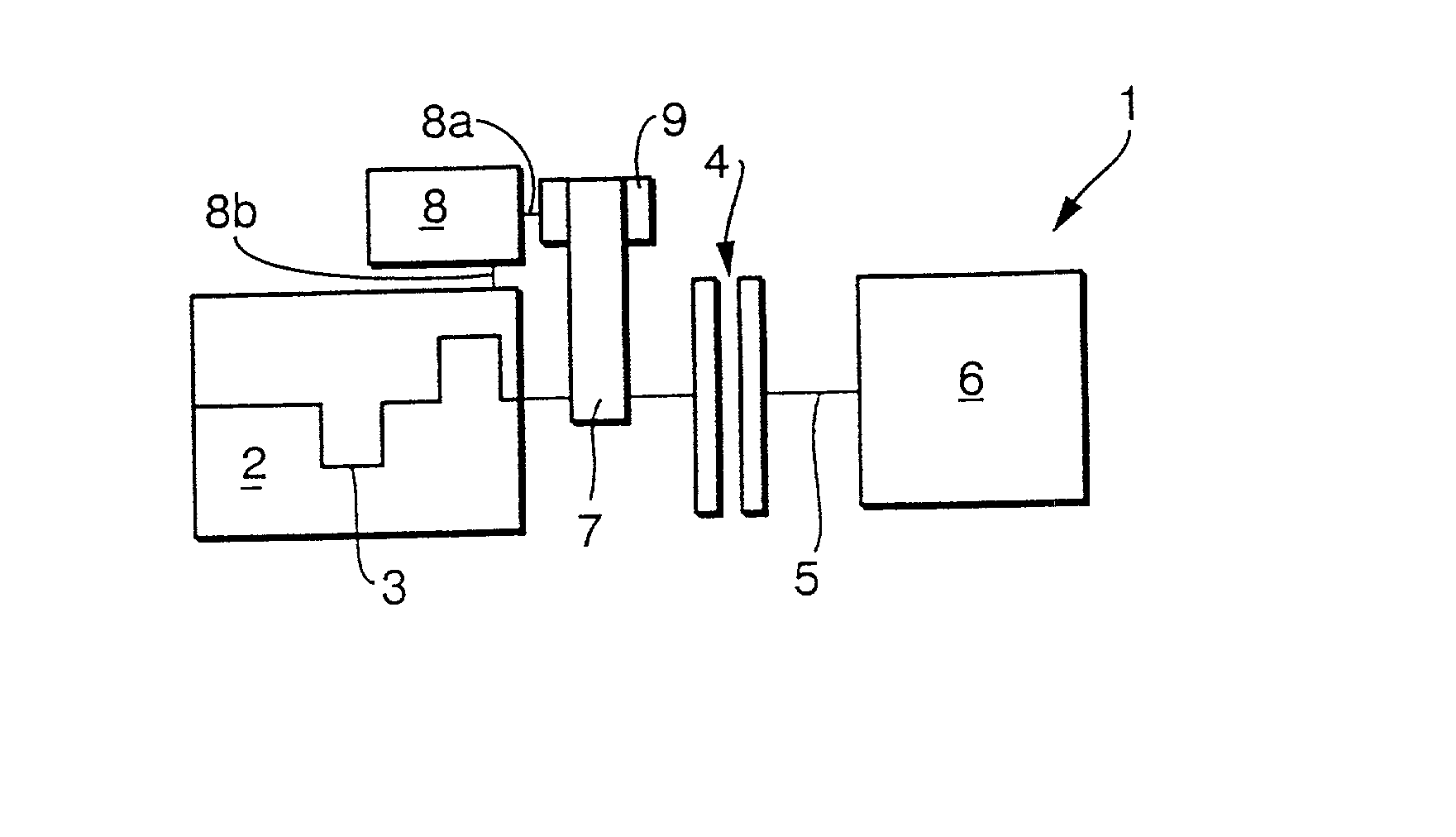

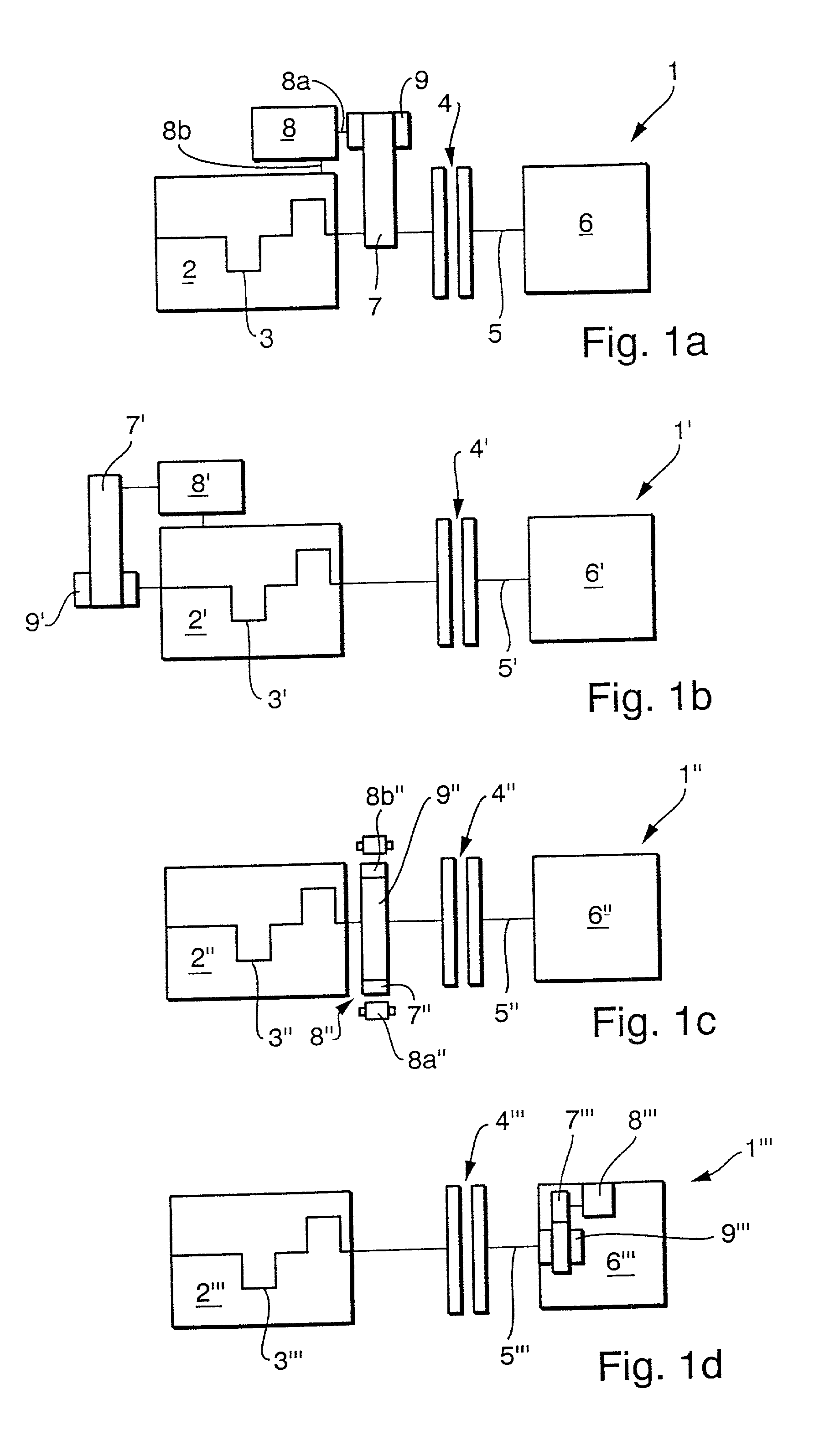

[0073] FIGS. 1a-d illustrate different possible arrangements of a power train 1, 1', 1", 1'" according to the invention with a drive source 2, 2', 2", 2'", e.g., a combustion engine, with a driving shaft or output shaft 3, 3', 3", 3'" that can be coupled by means of a clutch 4, 4', 4", 4'" to the input shaft 5, 5', 5", 5'" of a driven unit 6, 6', 6", 6'", e.g., a transmission such as a speed-changing transmission, an automatic transmission with multiple steps, or a continuously variable transmission (CVT). An electro-mechanical energy converter 8, 8', 8", 8'" is connected to the output shaft 3, 3', 3" in FIG. 1a-c, and to the input shaft 5'" in FIG. 1d through an interactive transfer connection 7, 7', 7", 7'" that transfers torque and shifts the torque-transfer ratio automatically dependent on the torque-flow direction by means of a rotary transfer device 9, 9', 9", 9'".

[0074] In the embodiment of FIG. 1a, the interactive connection 7 between the clutch 4 and the combustion engine 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com