Patents

Literature

52results about "Combustion fuels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

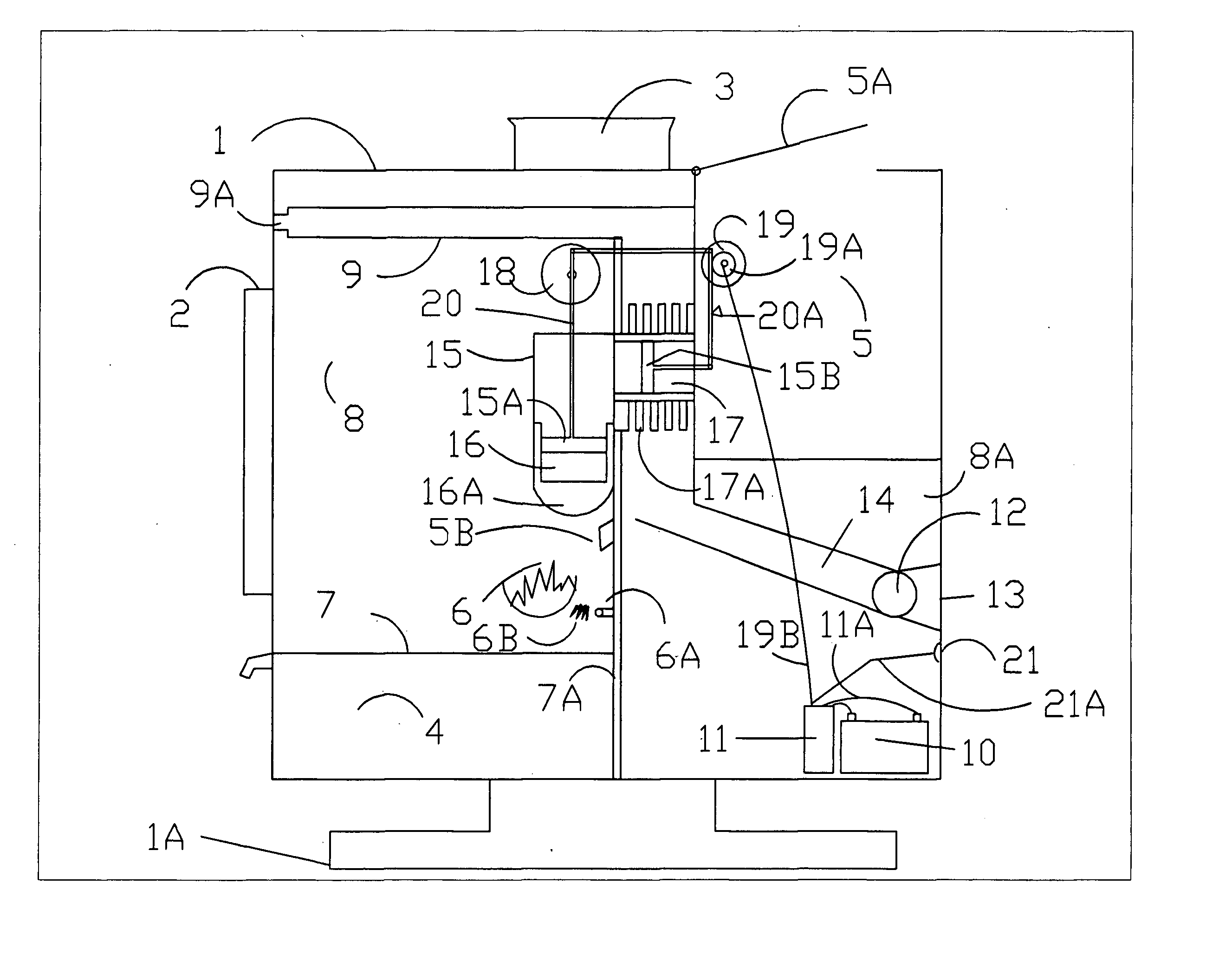

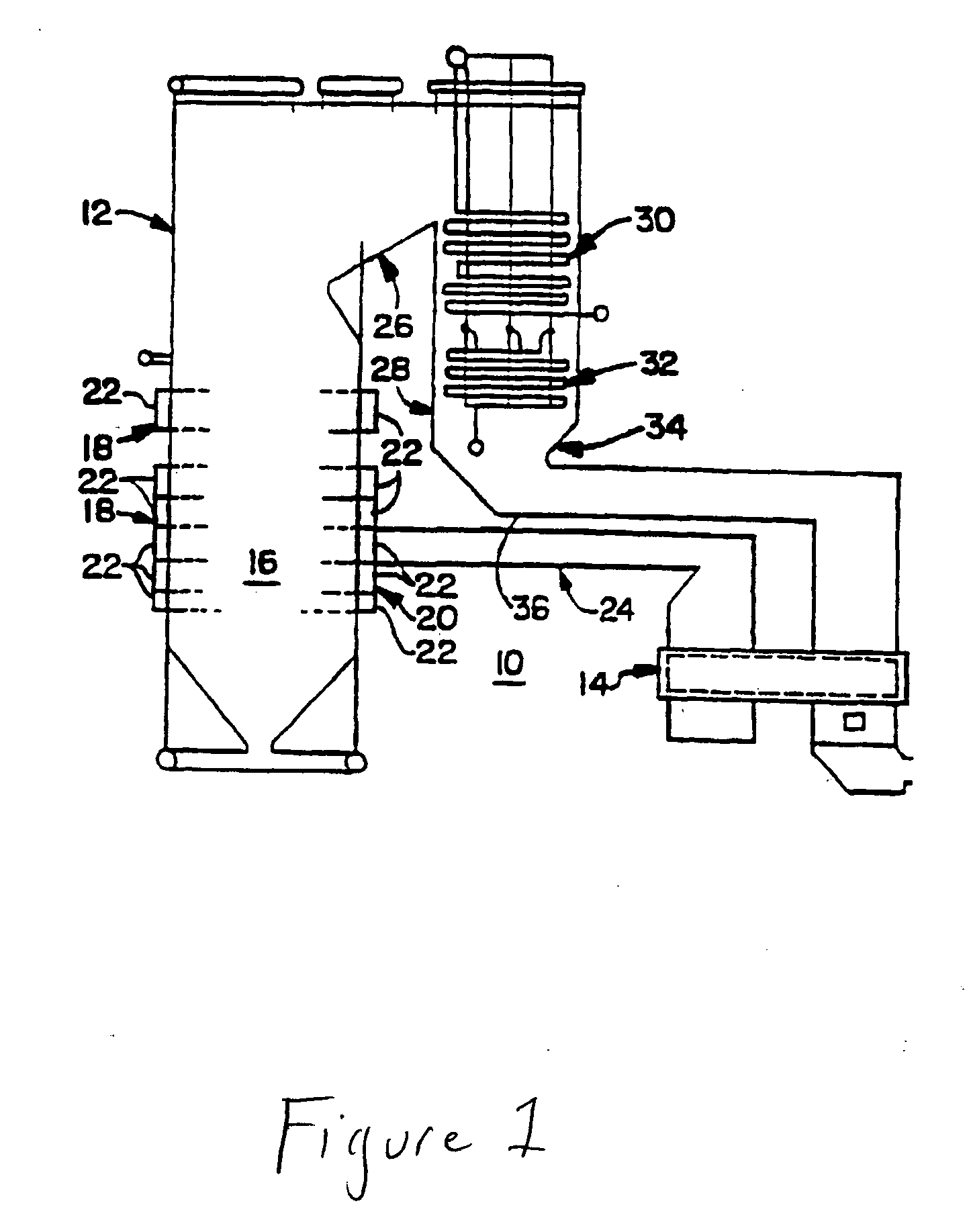

Self powered pelletized fuel heating device

InactiveUS20070221205A1Low costGood engineering designDomestic stoves or rangesSolid fuel combustionLow voltageEngineering

A self powered pelletized fuel heating device comprising a thermal electric generator (TEG) unit therein powering a typical collection of low voltage system components including a storage power unit. Non-typically, the heating device requires no external power supply and relies on thermodynamic principles using the pelletized fuel as a heat source. The TEG is configured and positioned optimally for conventional operation and installation requirements without modification to normal form or function.

Owner:LANDON RICHARD BENSON

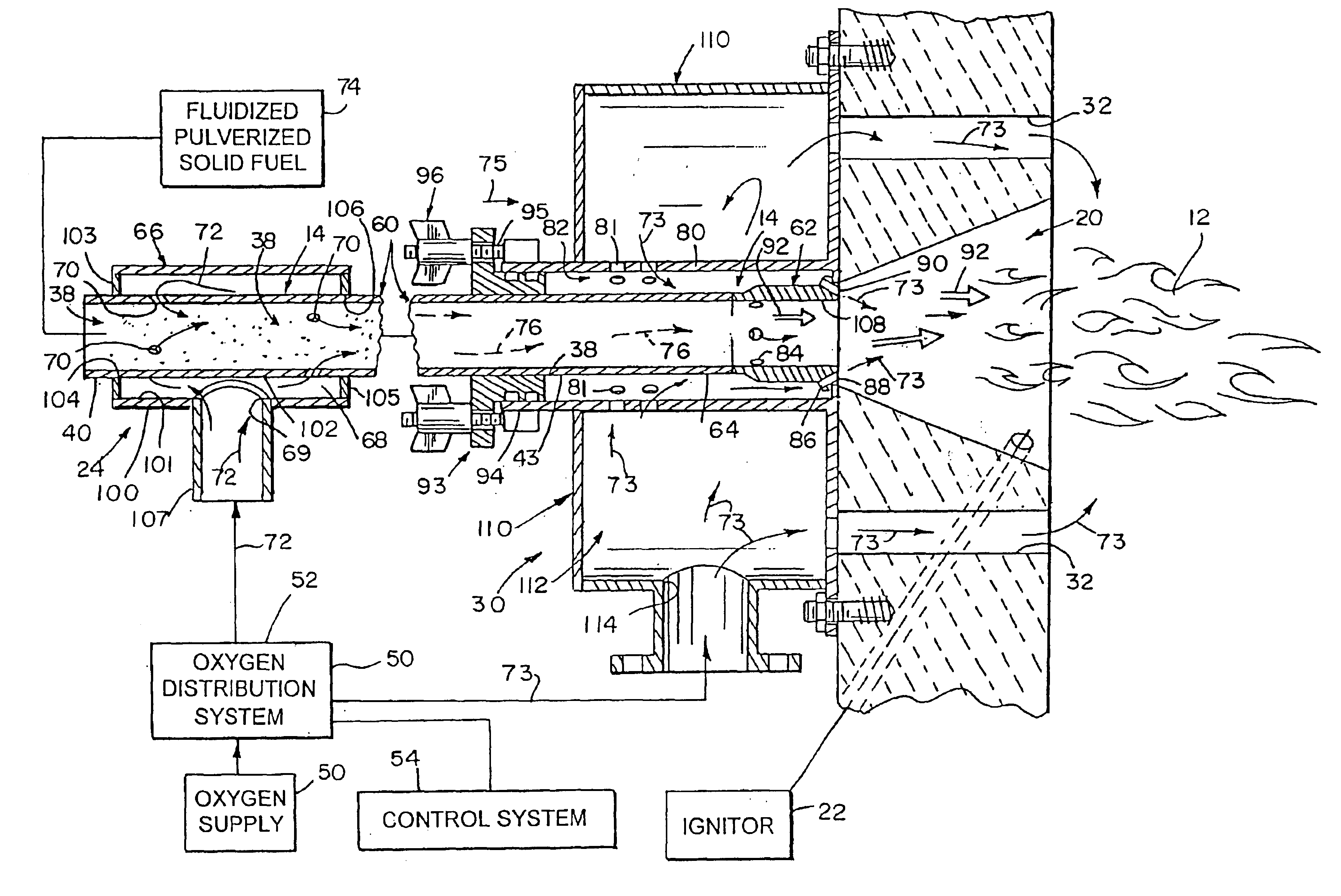

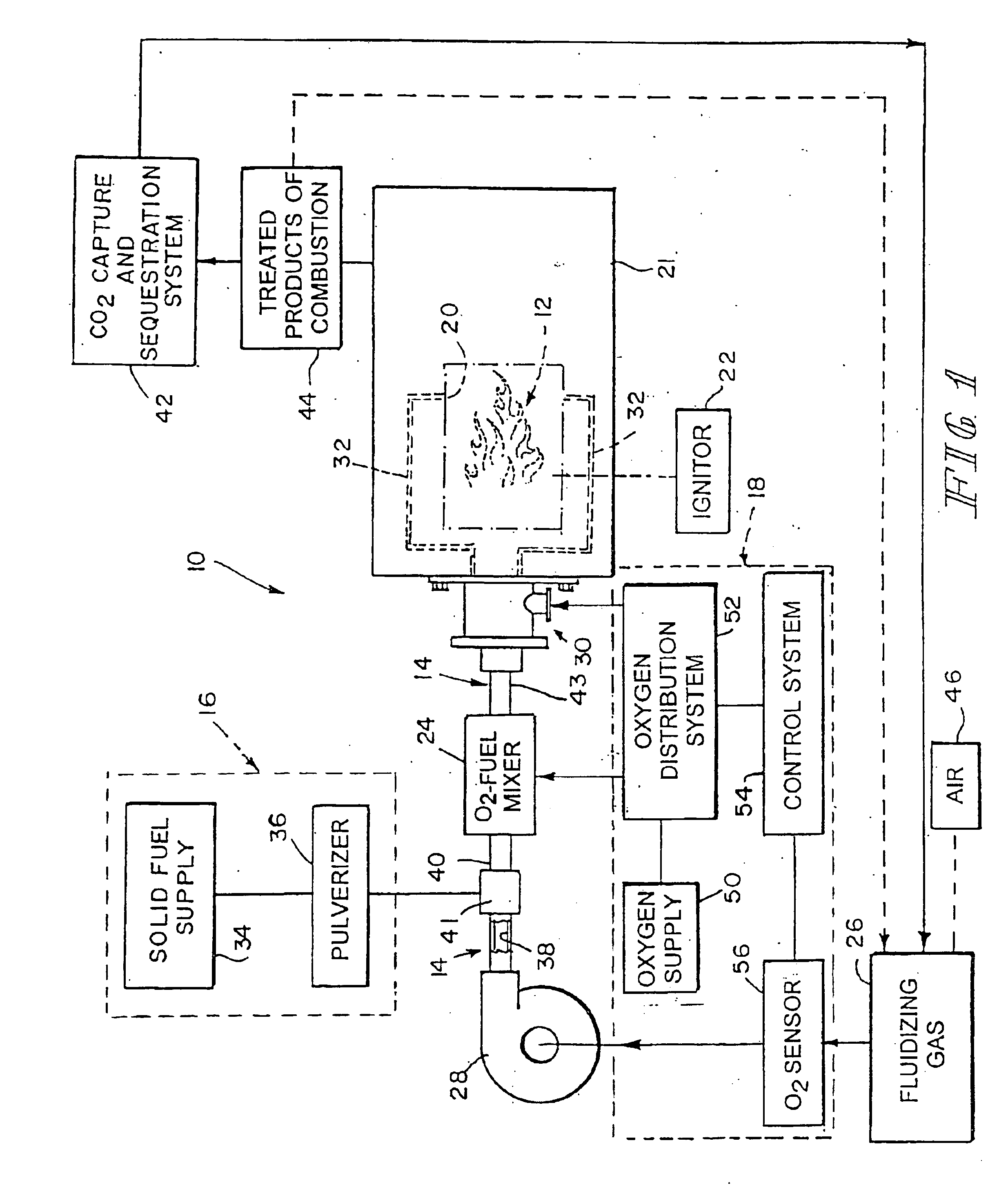

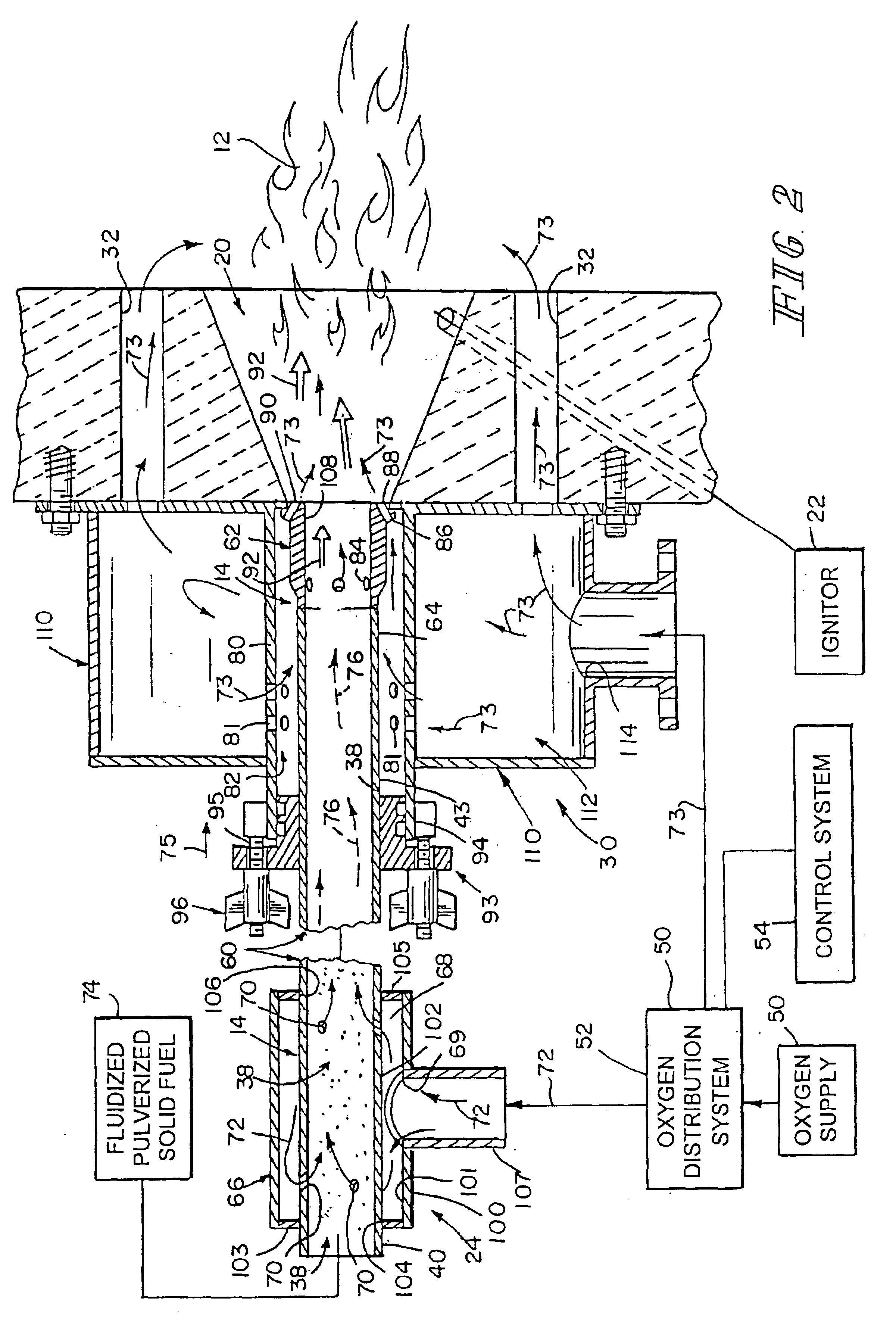

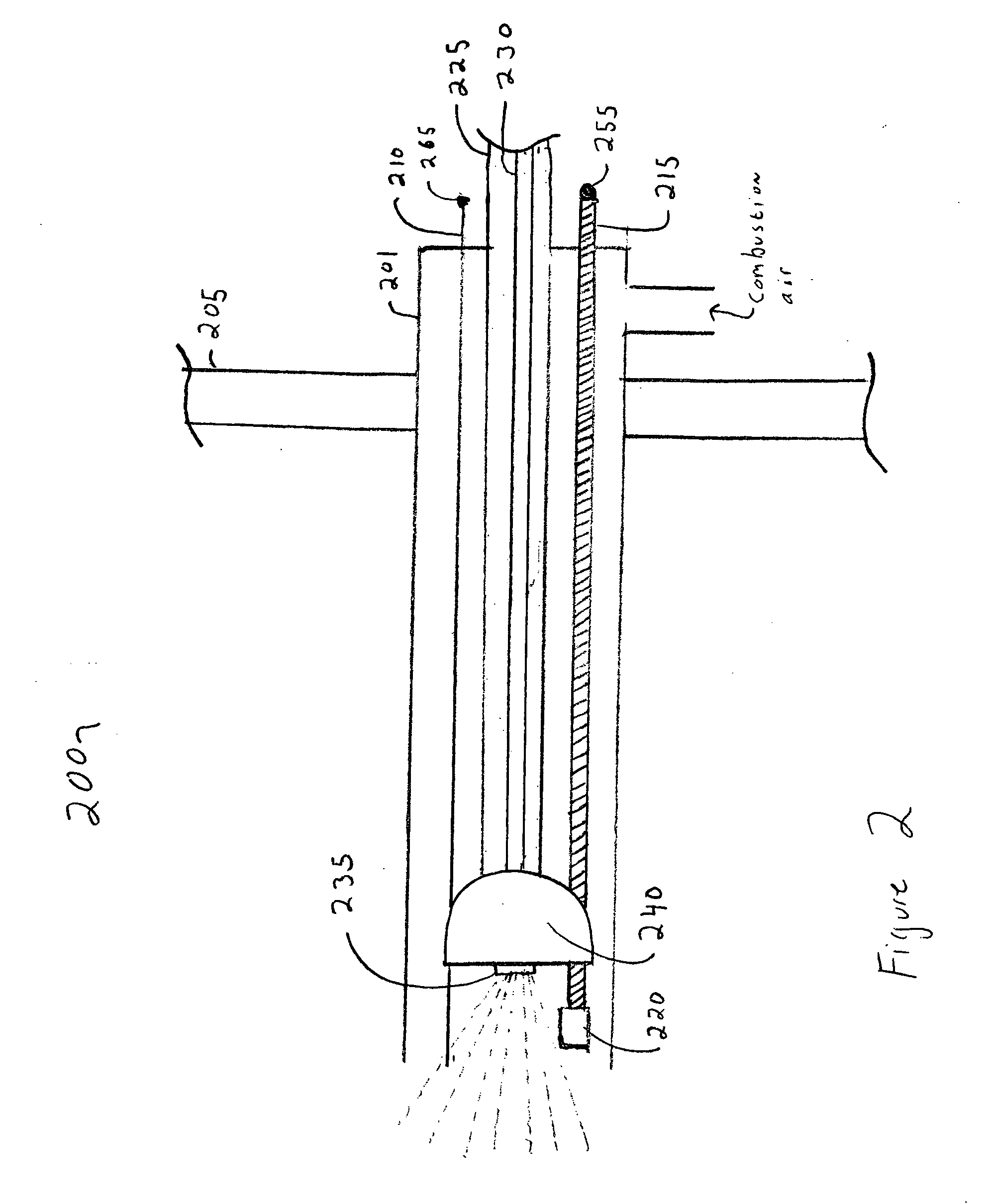

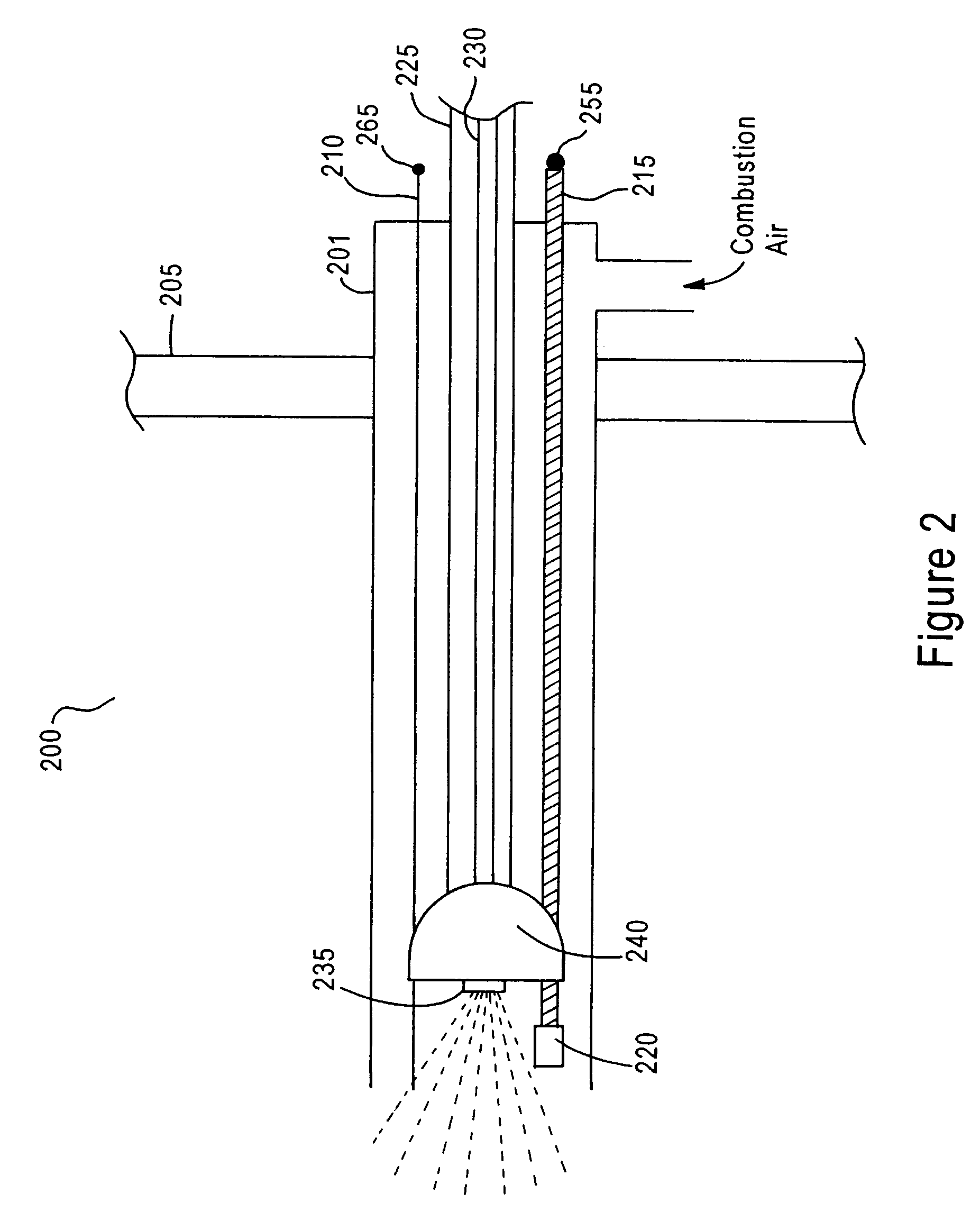

Burner with oxygen and fuel mixing apparatus

InactiveUS6843185B1Reduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemSolid fuel

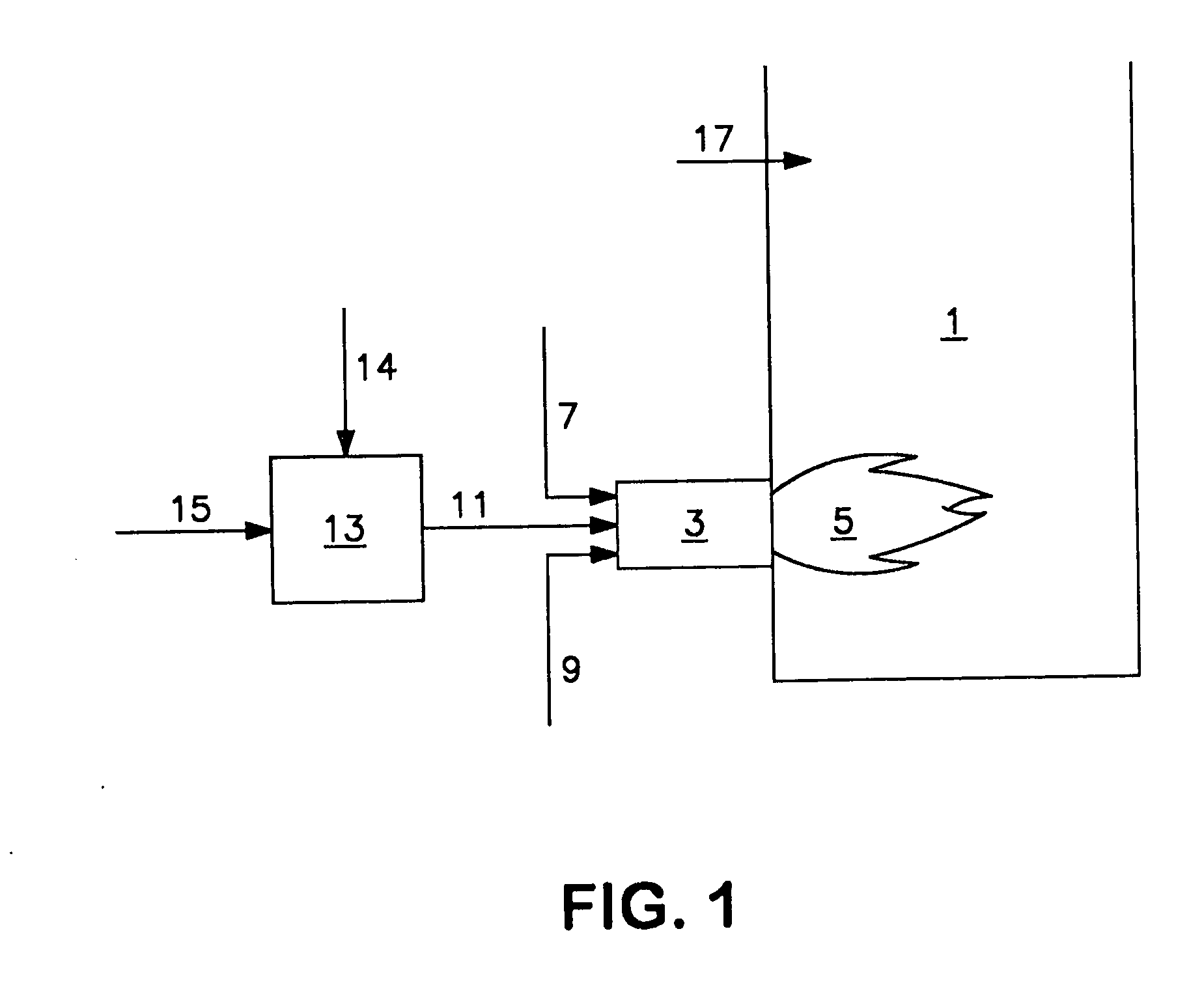

An oxygen-fuel combustion system combines oxygen and fuel to produce a flame. The system distributes oxygen to a stream of fluidized, pulverized, solid fuel at various sites before and after ignition. The system is operable to vary the concentration of oxygen in an oxygen-fuel mixture extant at those sites.

Owner:MAXON

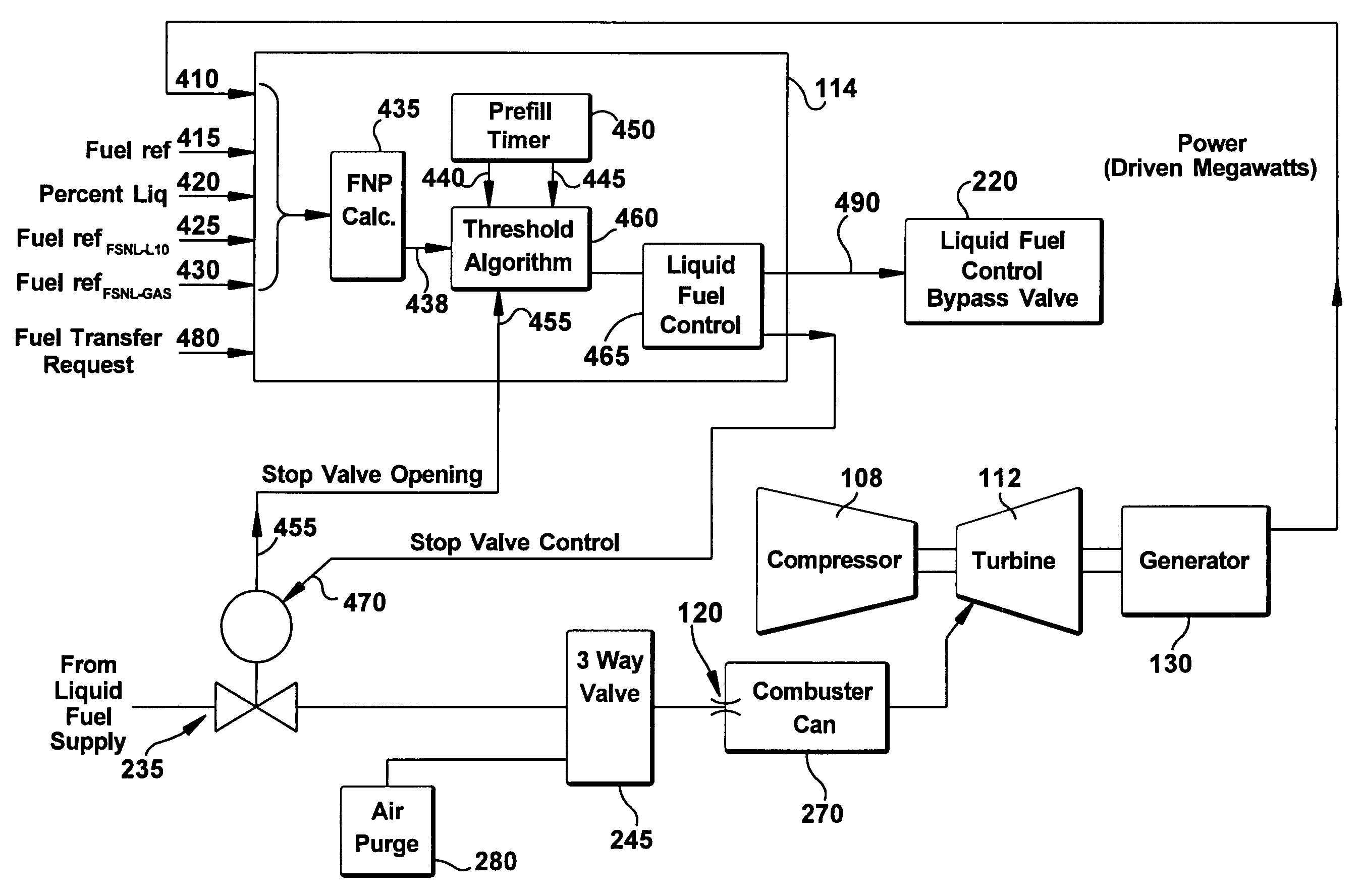

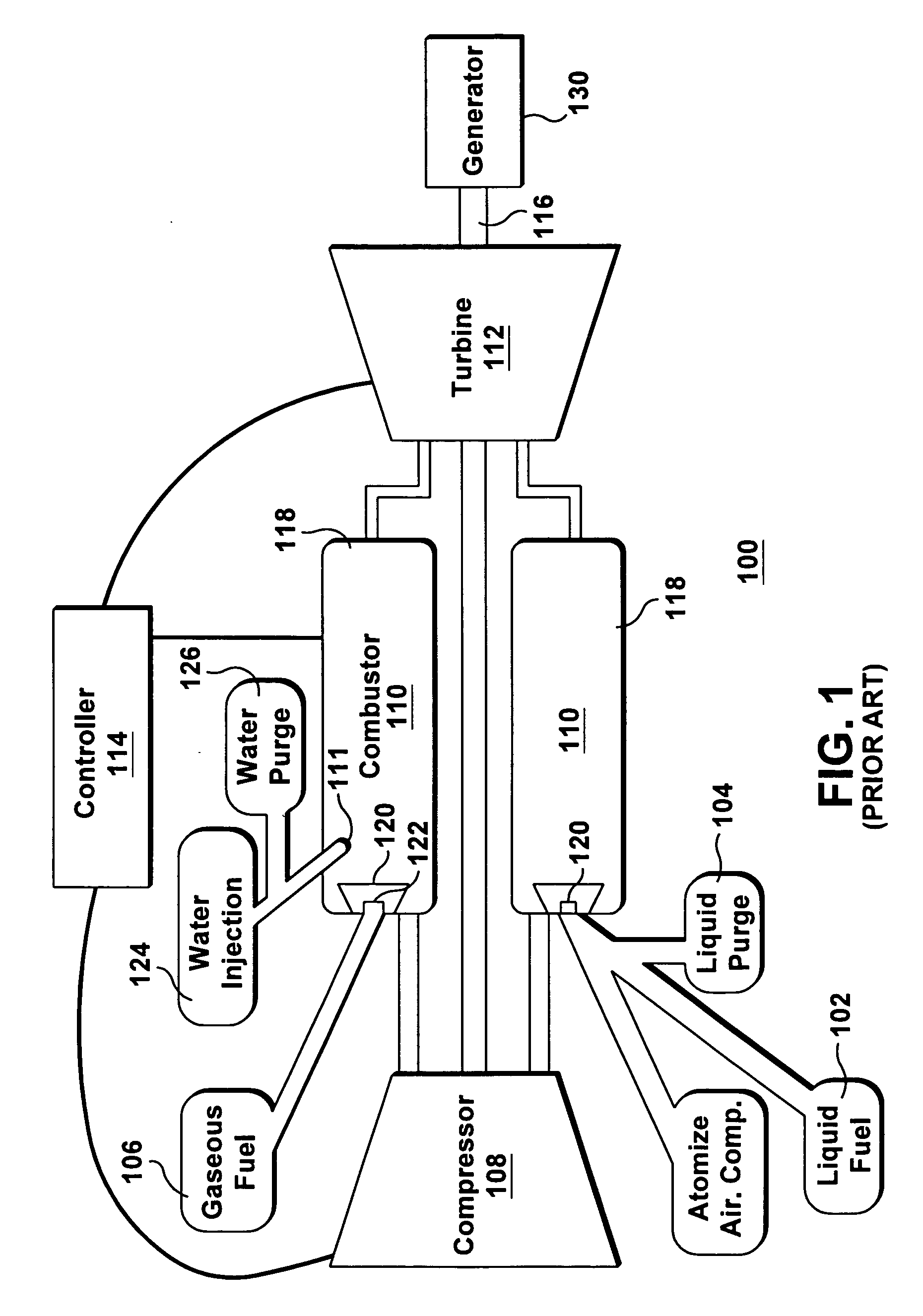

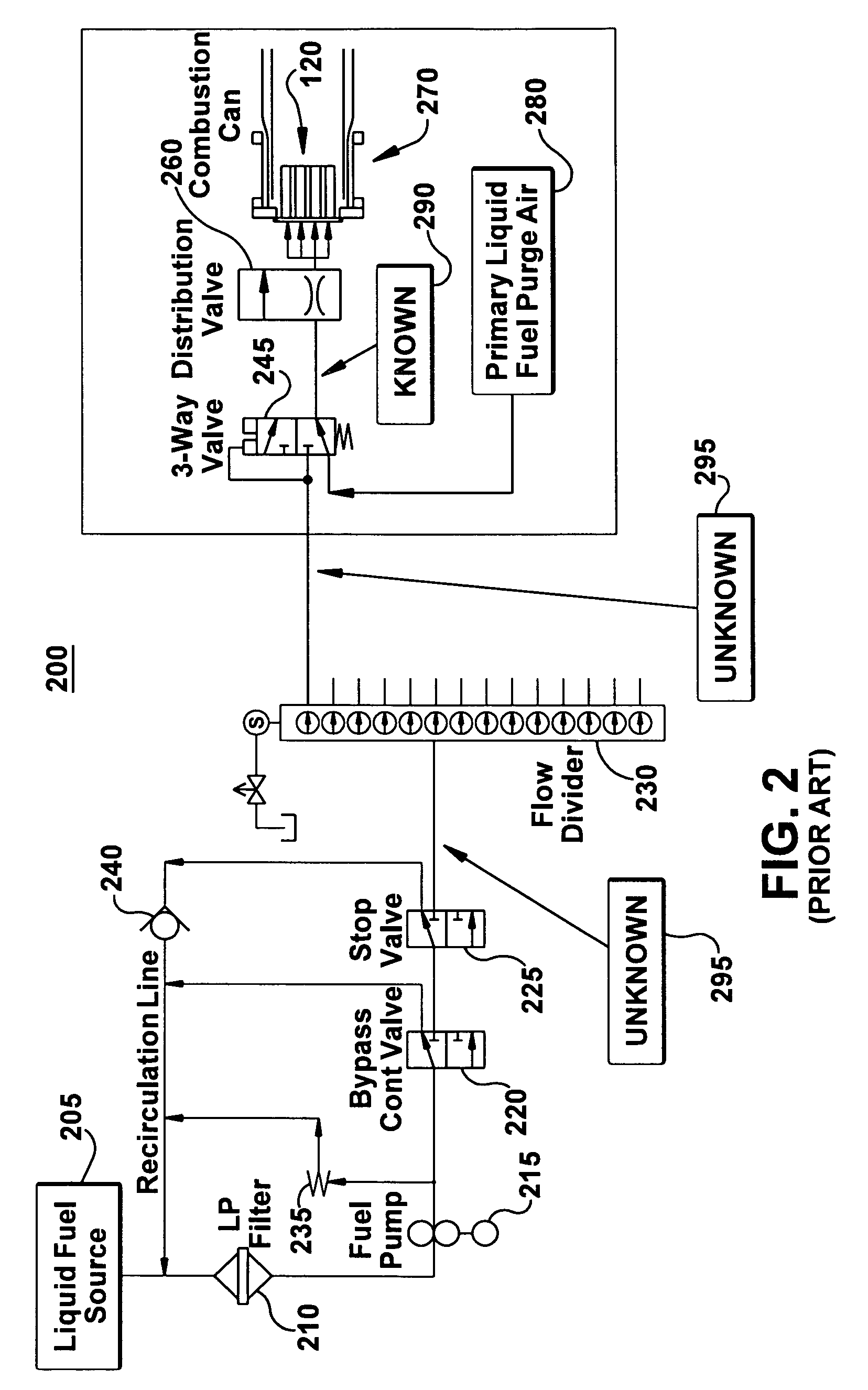

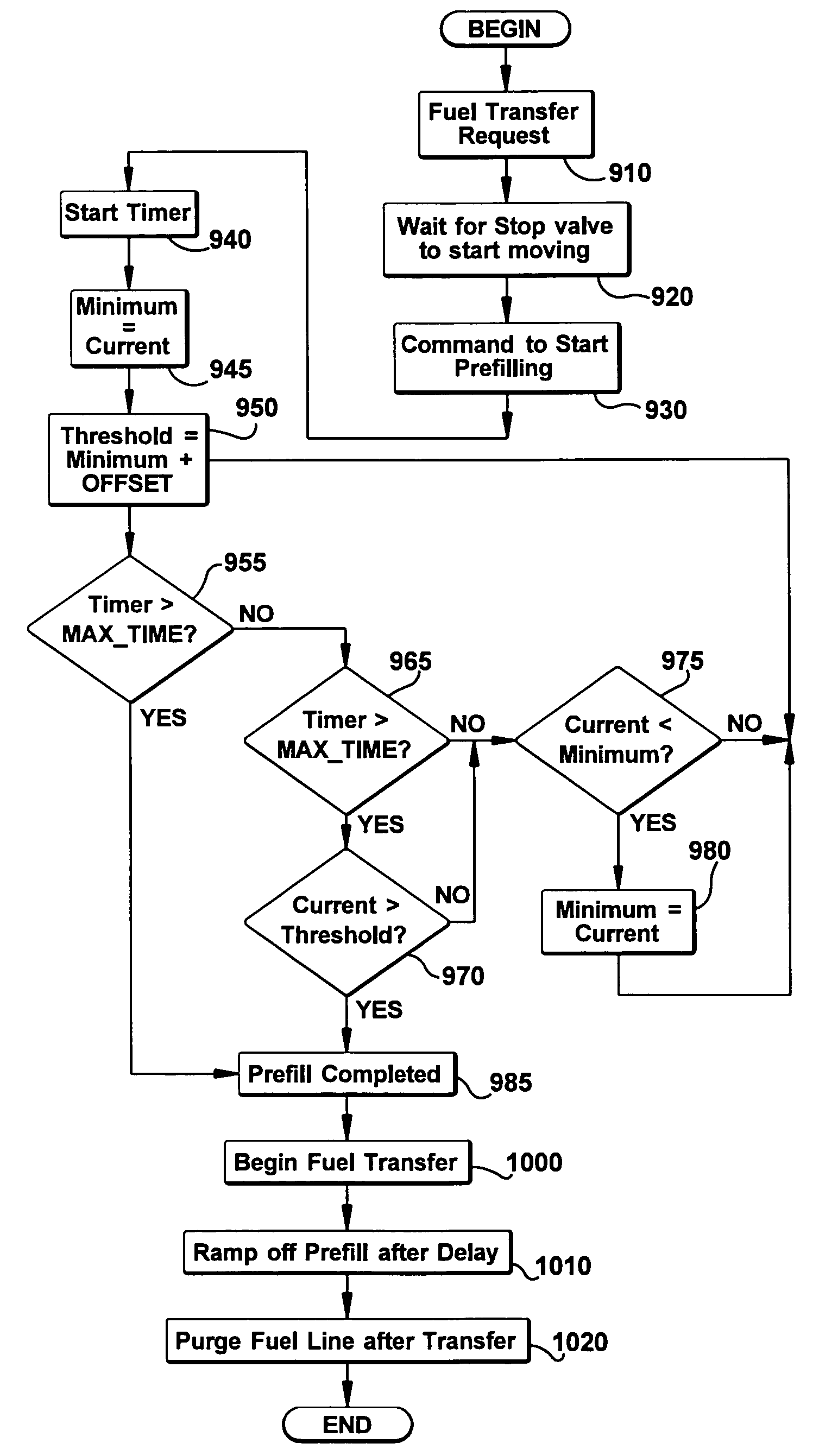

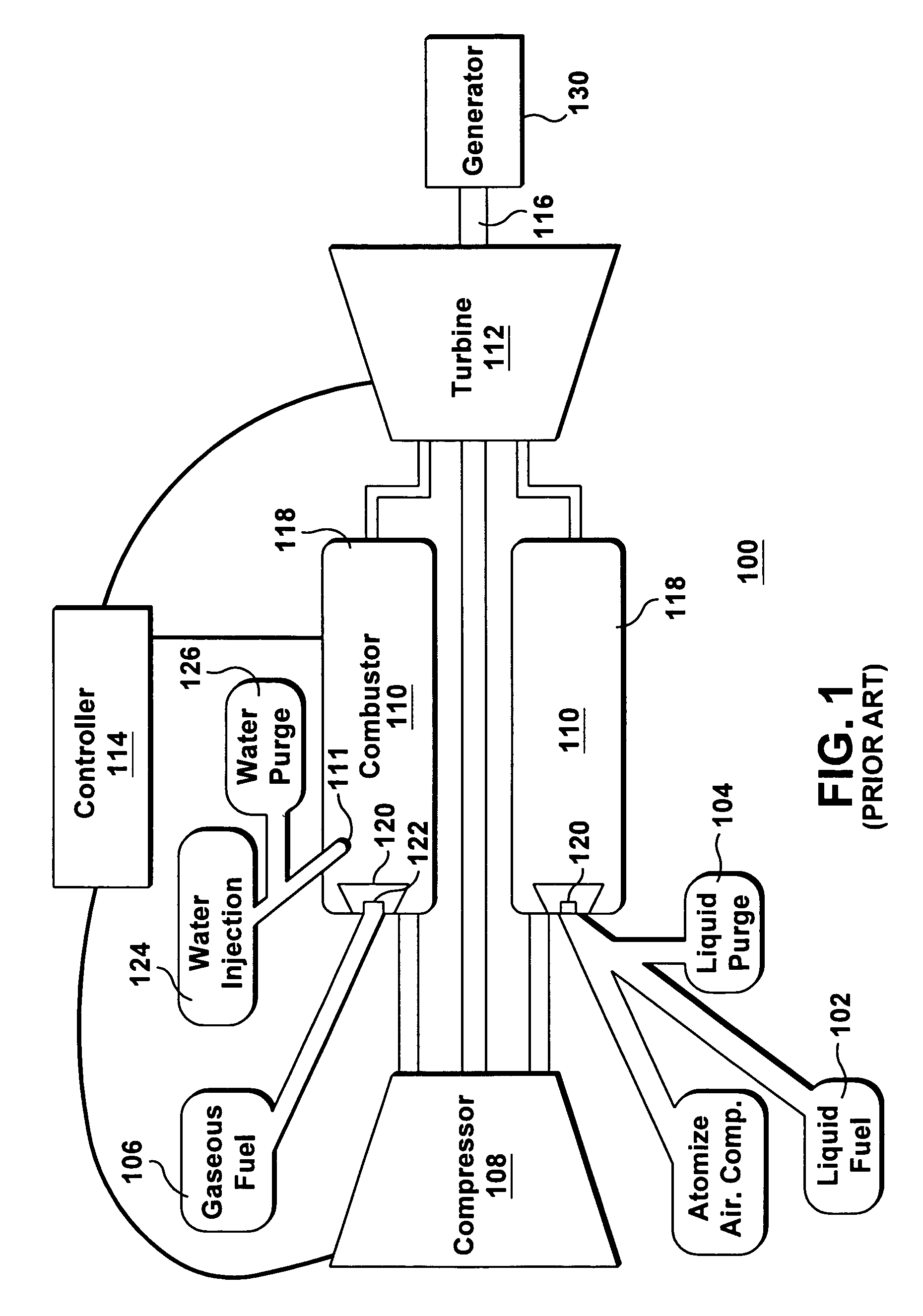

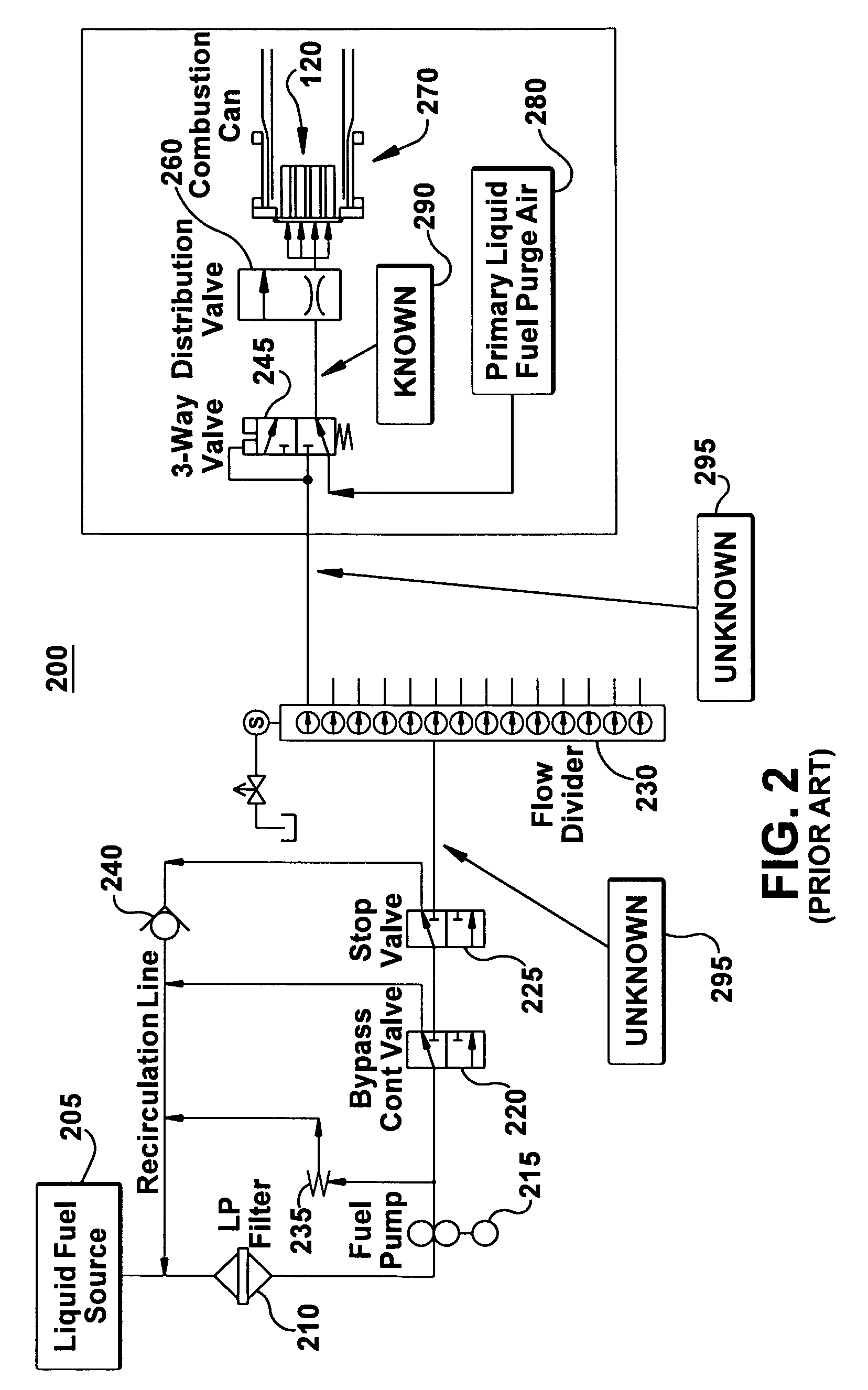

Method for detecting onset of uncontrolled fuel in a gas turbine combustor

ActiveUS20080098746A1Improve reliabilitySmall transientFuel supply regulationContinuous combustion chamberCombustorLiquid fuel

A method is provided for performing a transfer from gas fuel operation to liquid fuel operation in a gas turbine with a dual fuel system. The method includes initiating a predetermined uncontrolled liquid fuel prefill flow rate through the liquid fuel system, sensing an onset of the uncontrolled liquid fuel flow to the combustor nozzles, and initiating transfer from gas fuel operation to liquid fuel operation when the flow of uncontrolled liquid fuel at the combustor nozzles is sensed. The onset of uncontrolled liquid fuel flow to the combustor nozzles is determined by monitoring changes of Fuel Normalized Power (FNP), a parameter sensitive to uncontrolled liquid fuel flow, and determining when FNP exceeds a threshold algorithm value.

Owner:GENERAL ELECTRIC CO

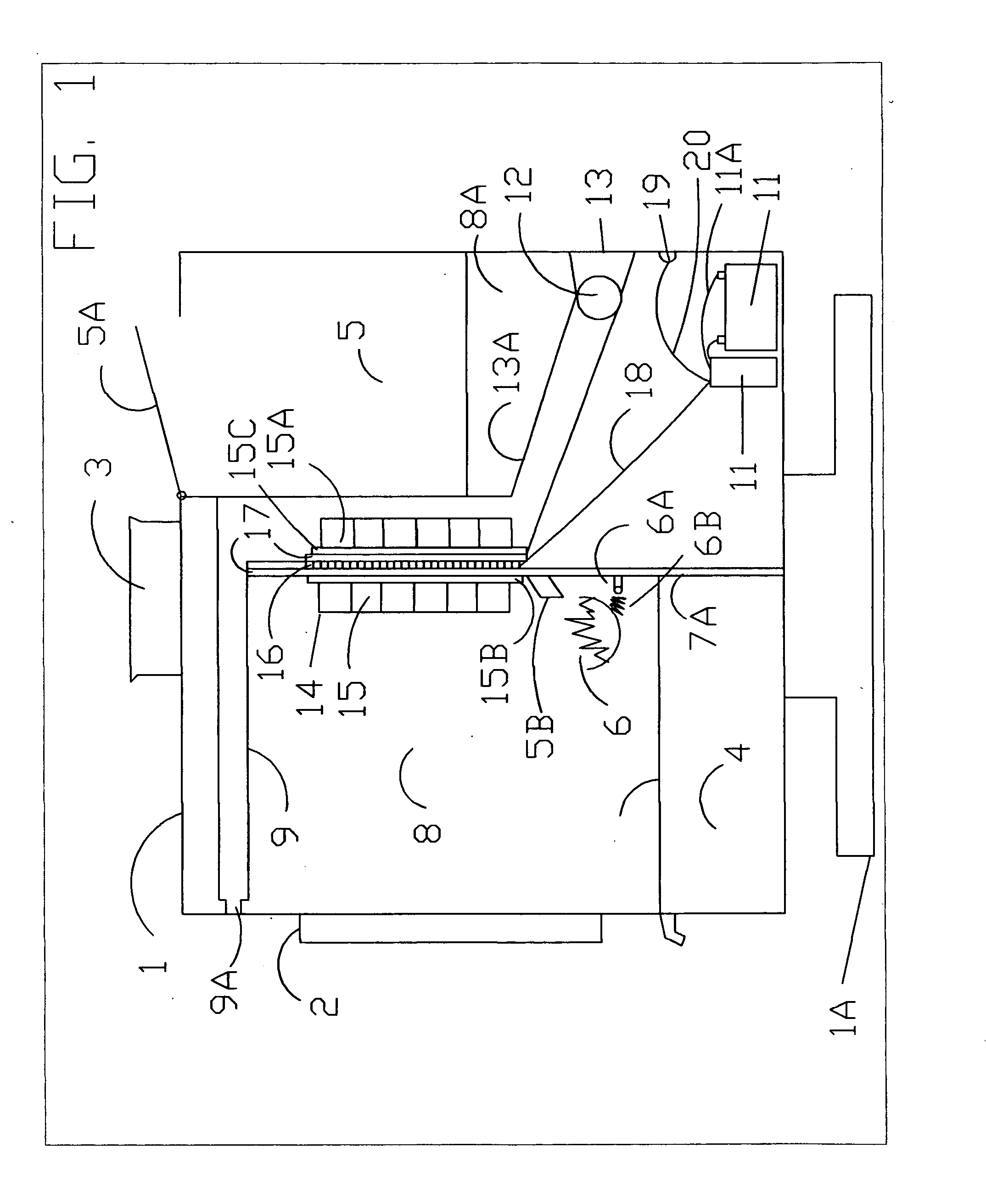

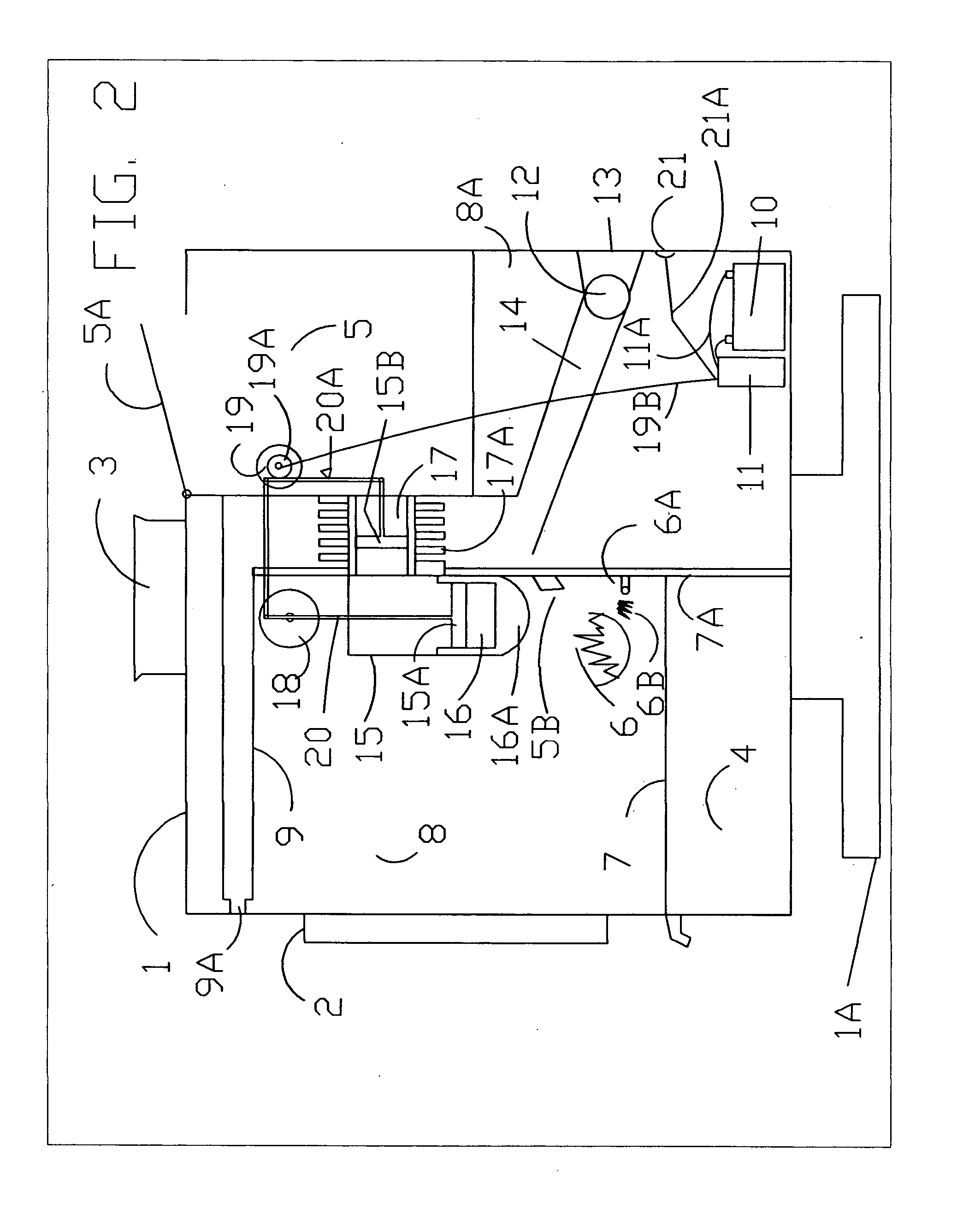

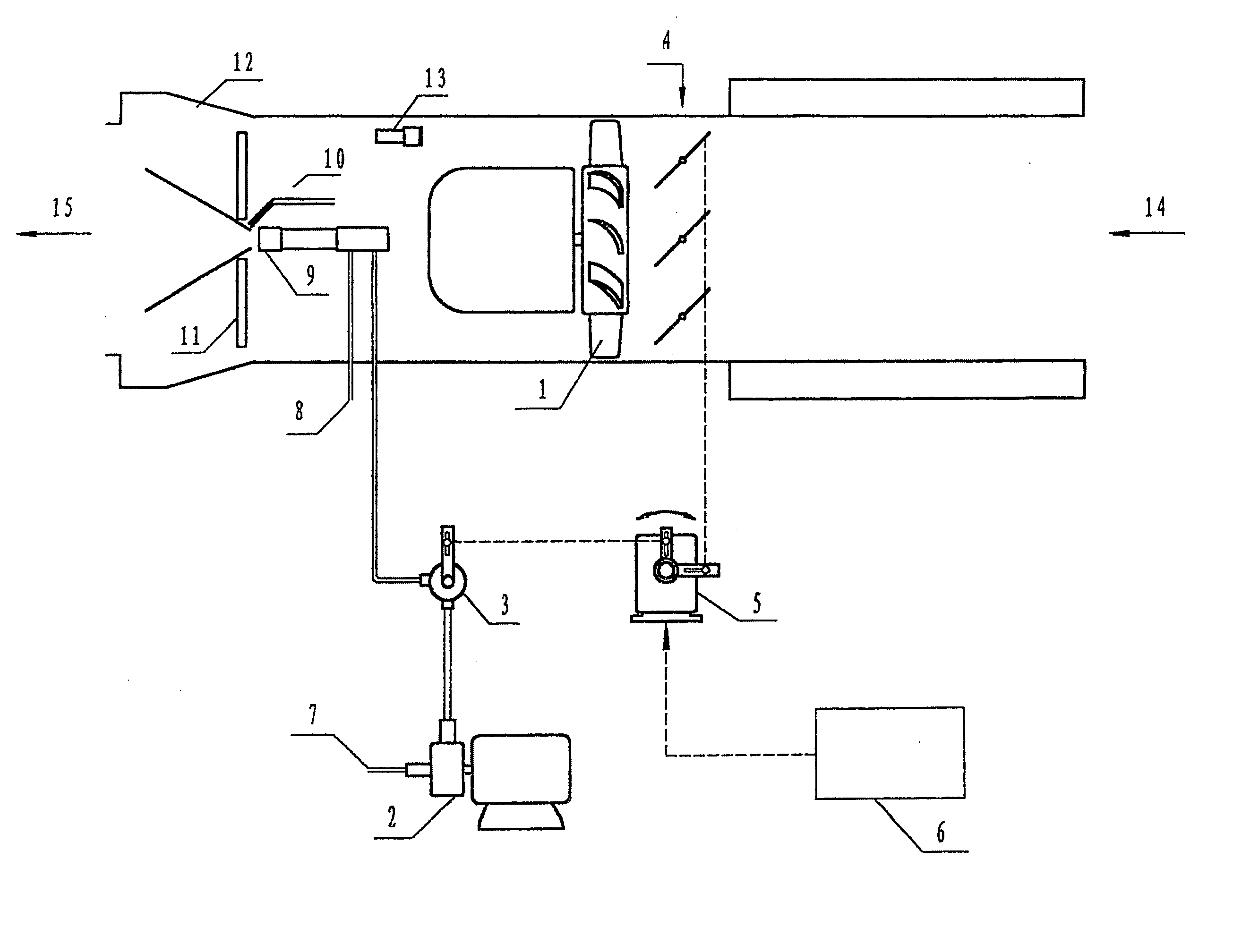

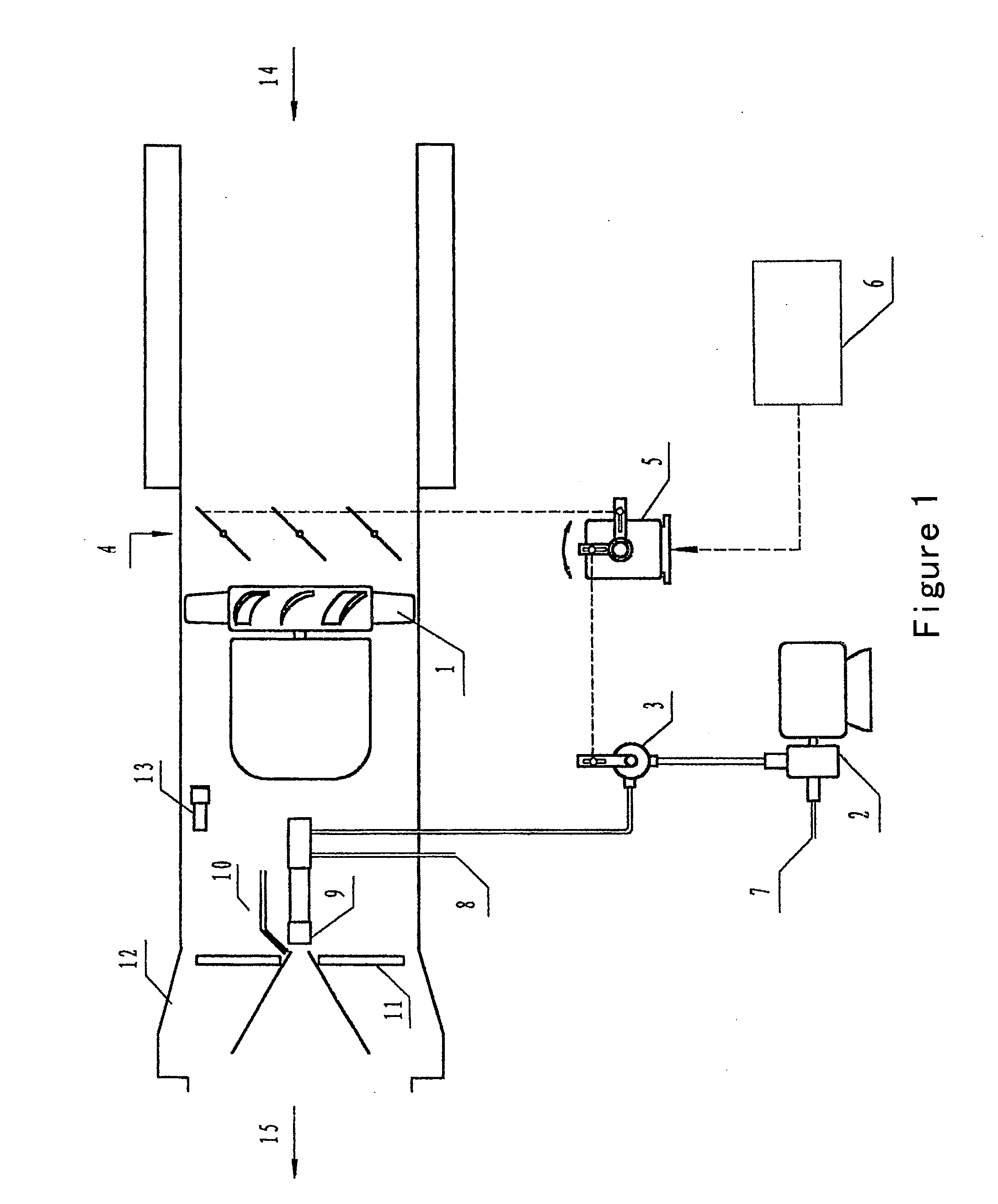

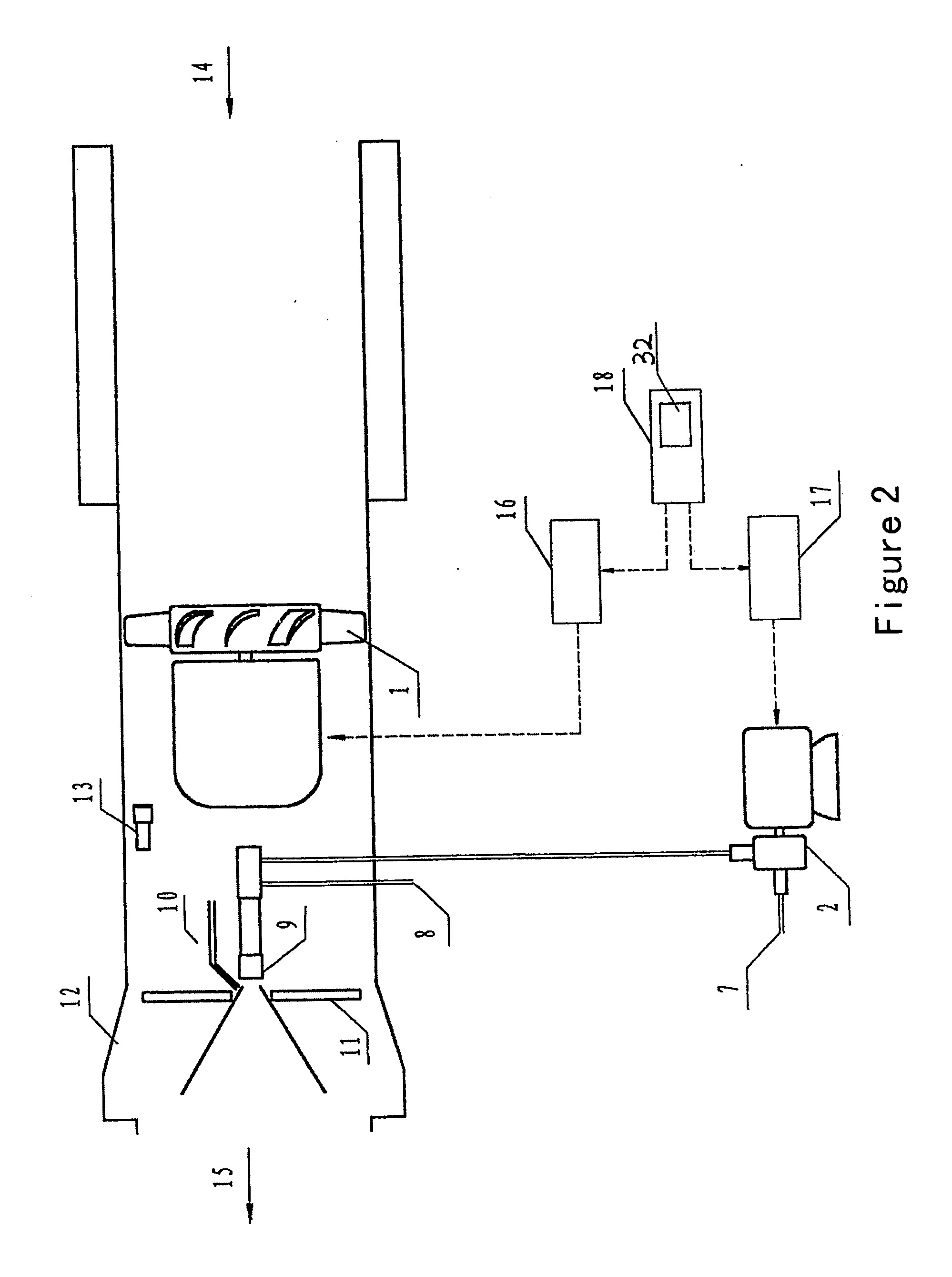

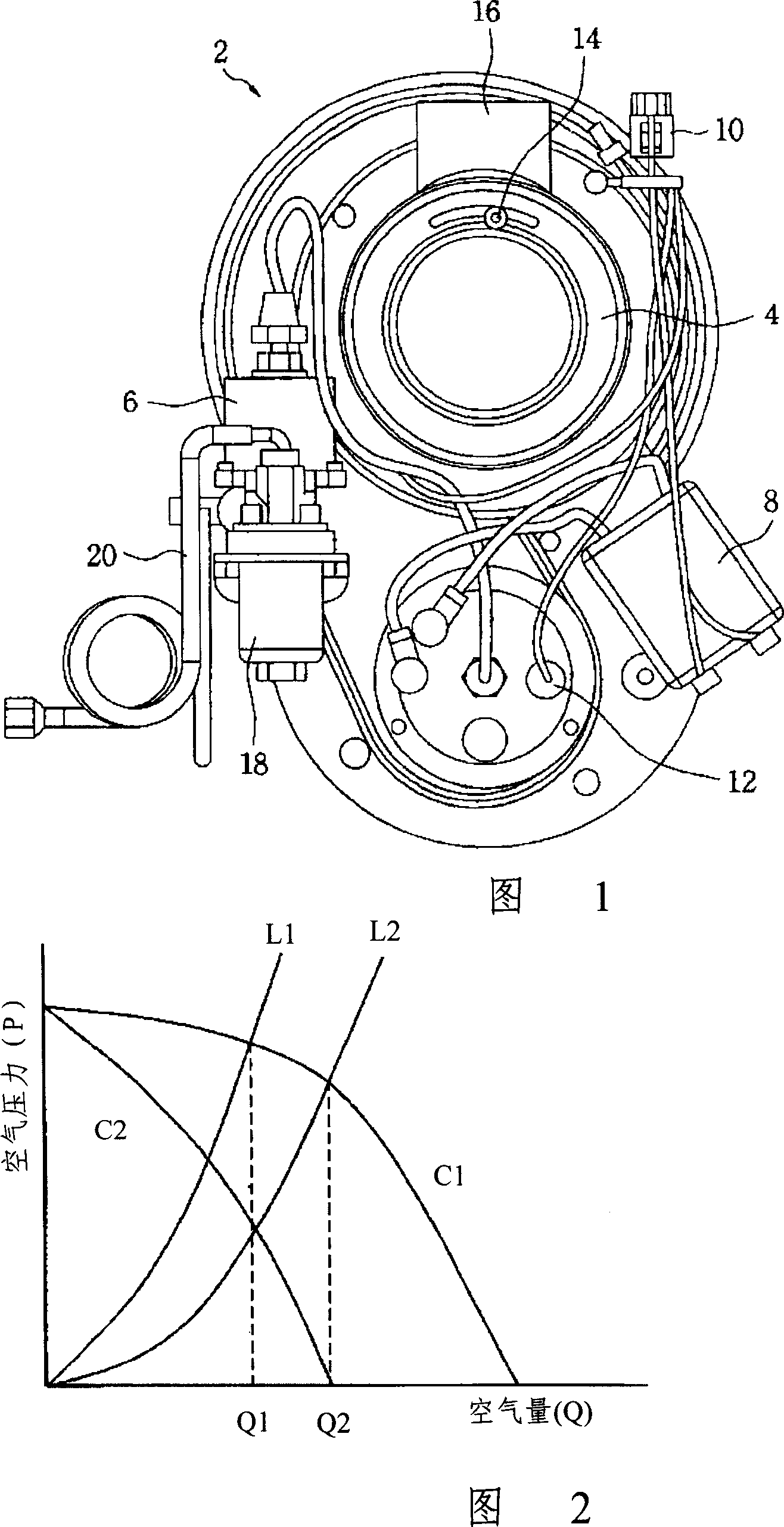

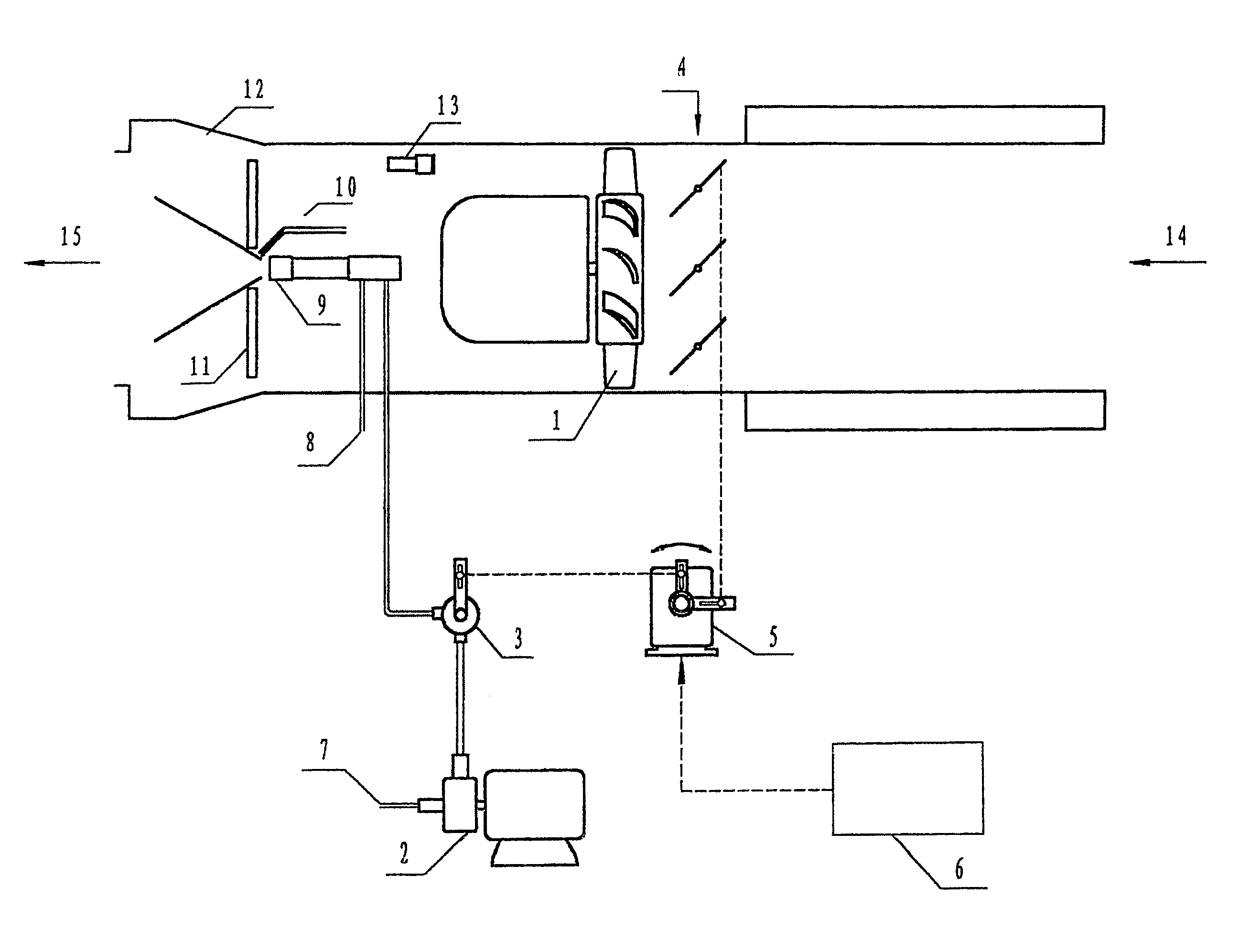

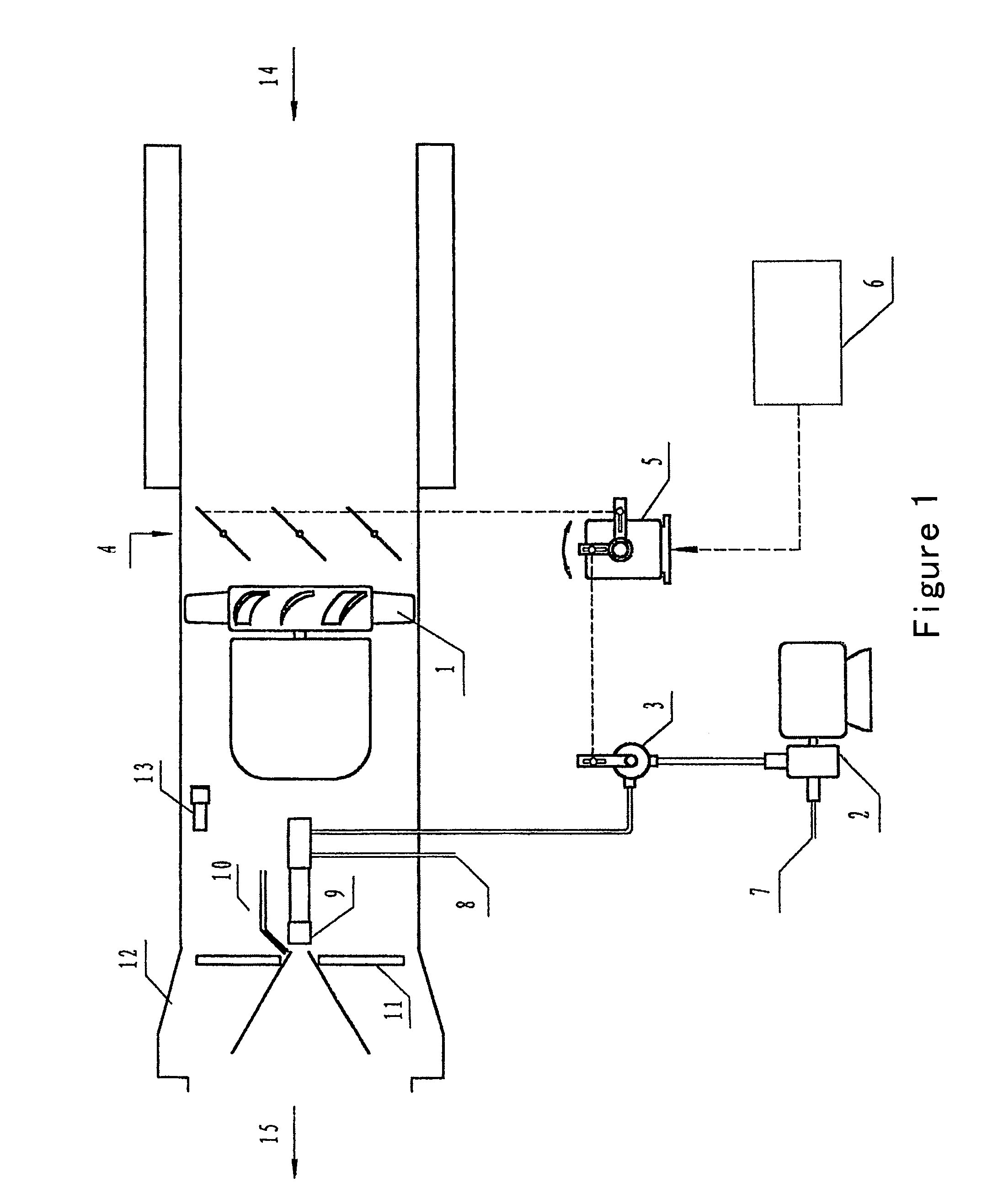

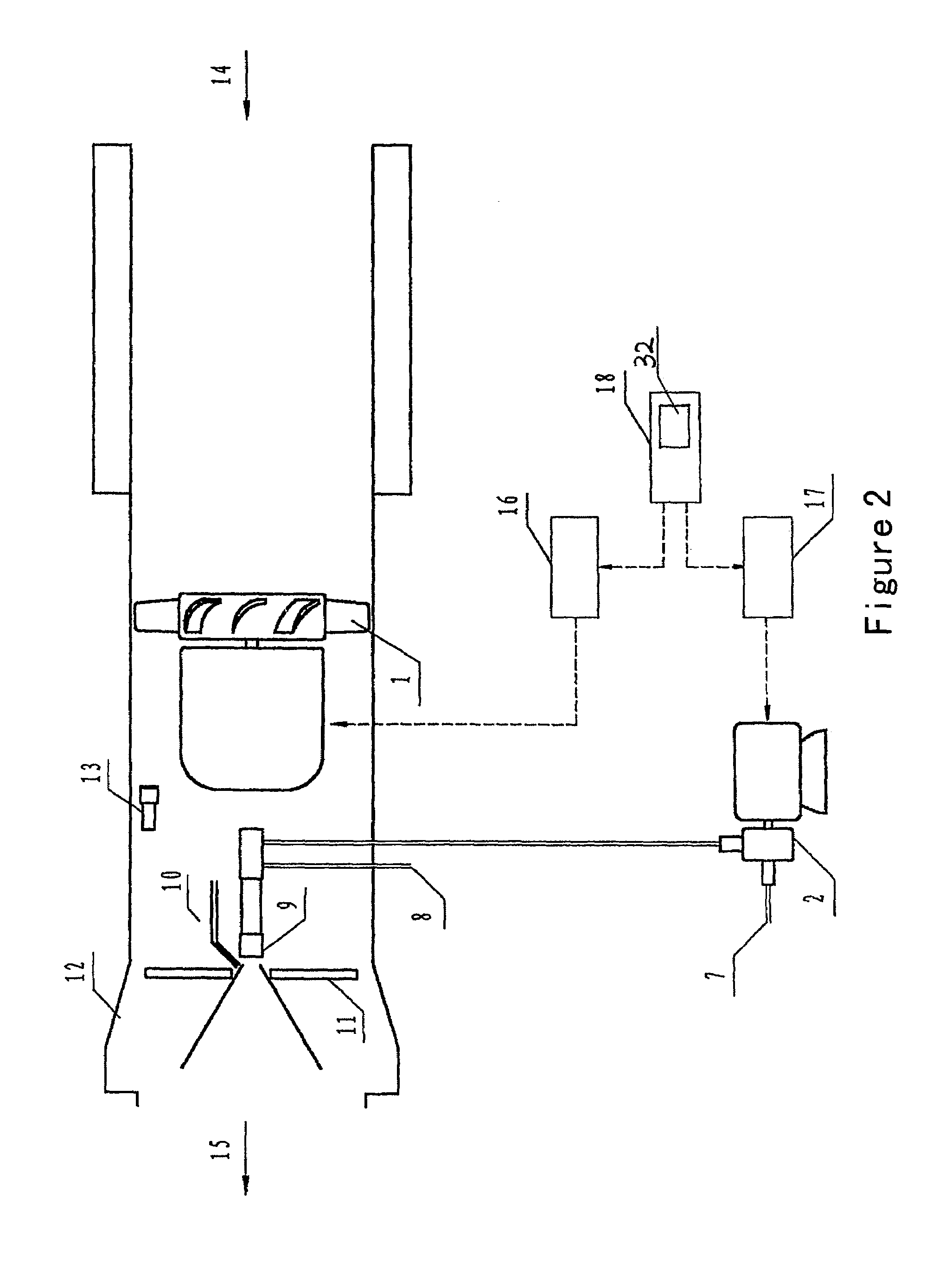

Autocontrol burner and a combustion control method

InactiveUS20060068347A1Improve efficiencyReduce energy consumptionBurnersFuel supply regulationMotor speedCombustor

A combustion control method for a burner comprises: the fuel supplying means outputs a given amount of fuel oil to the fuel oil atomizing means; the fuel atomizing means sprays fuel atomized gas; said gas is ignited by the igniter; the amount of air is sent to facilitate burning by the air blowing means; the outputting flow rate of fuel oil and the flow rate of air are adjusted automatically, simultaneously and proportionally by controlling the rotating speed of the electric motors of the fuel supplying means and the air blowing means. An autocontrol burner comprises a main body, an oil pump (2), a blower fan (1), a spray gun (9) and an ignition gun (10), and further comprises a programmable control unit (18), motor speed controller (16,17) and a signal acquisition assembly. The output port of the signal acquisition assembly is connected with the input port of the programmable control unit (18). The oil pump (2) and the blower fan (1) are connected with the programmable control unit (18) by the motor speed controller (16, 17).

Owner:LI YANXIN

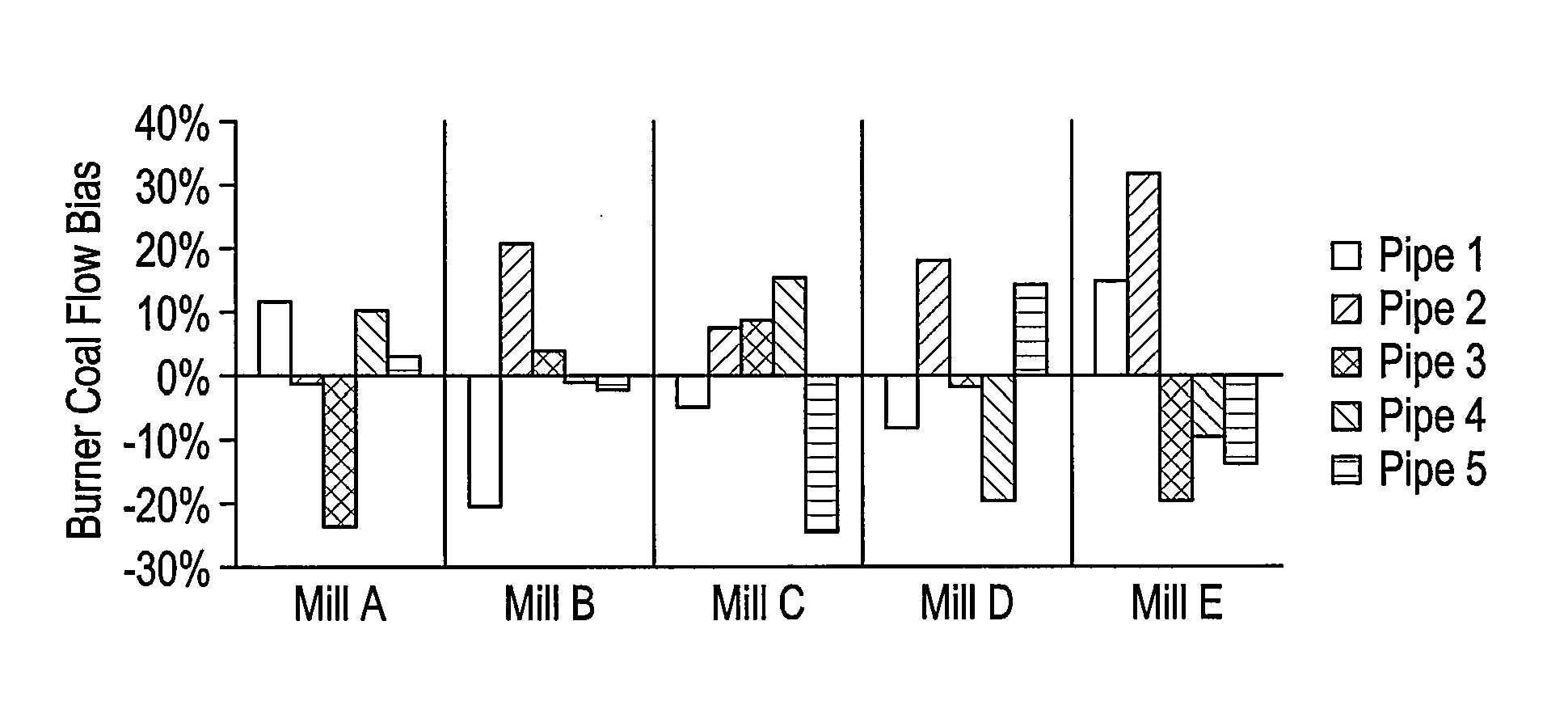

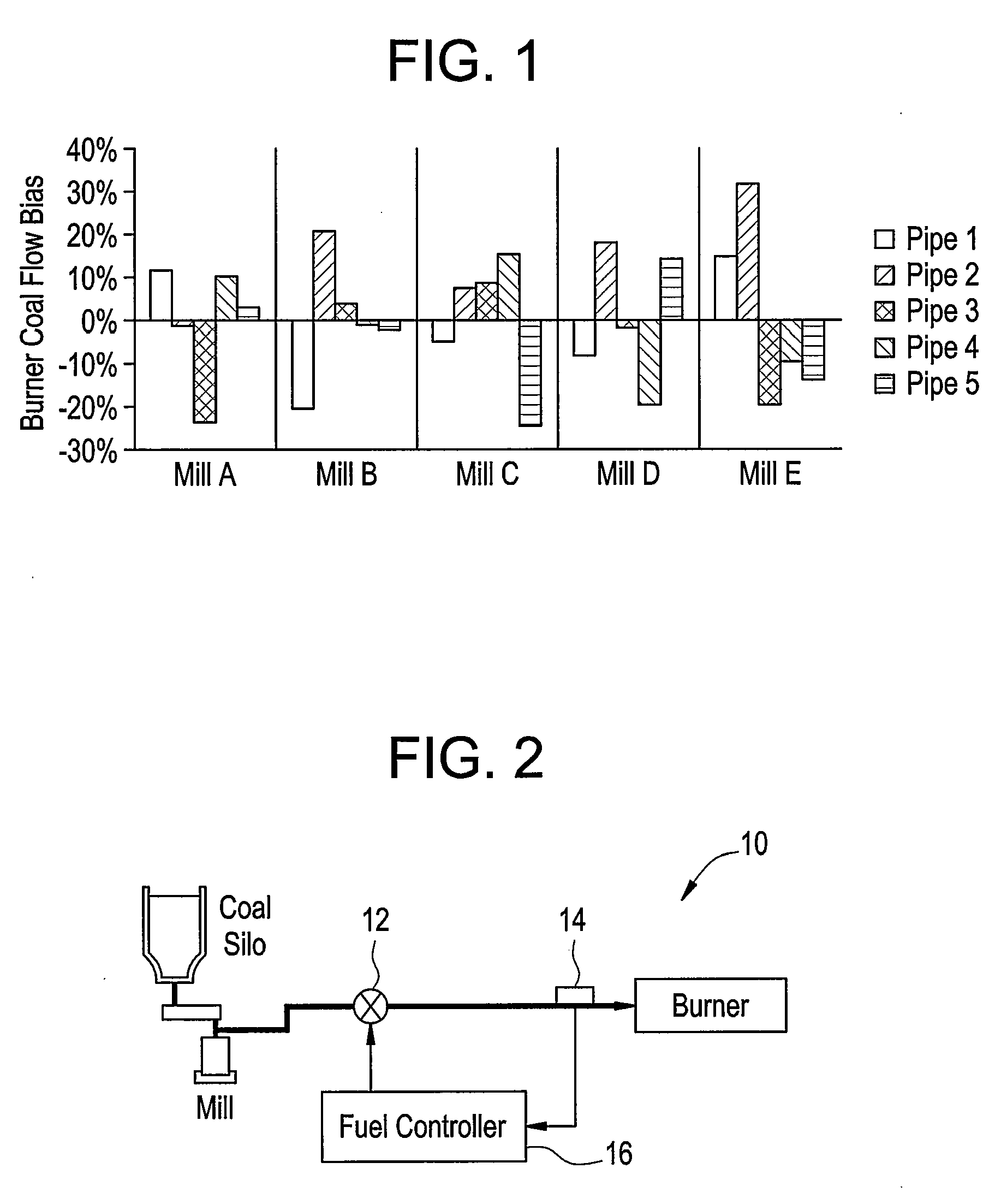

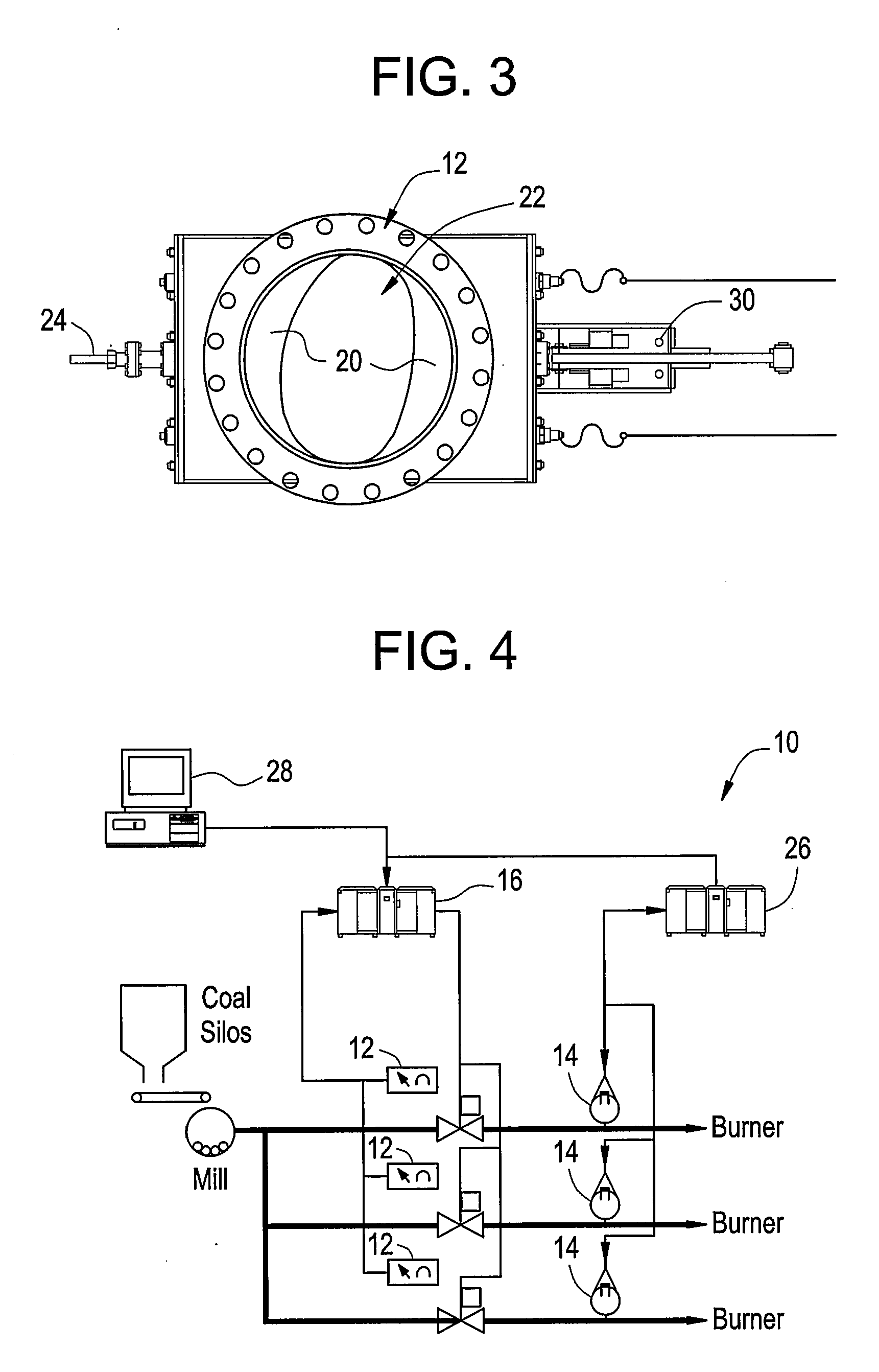

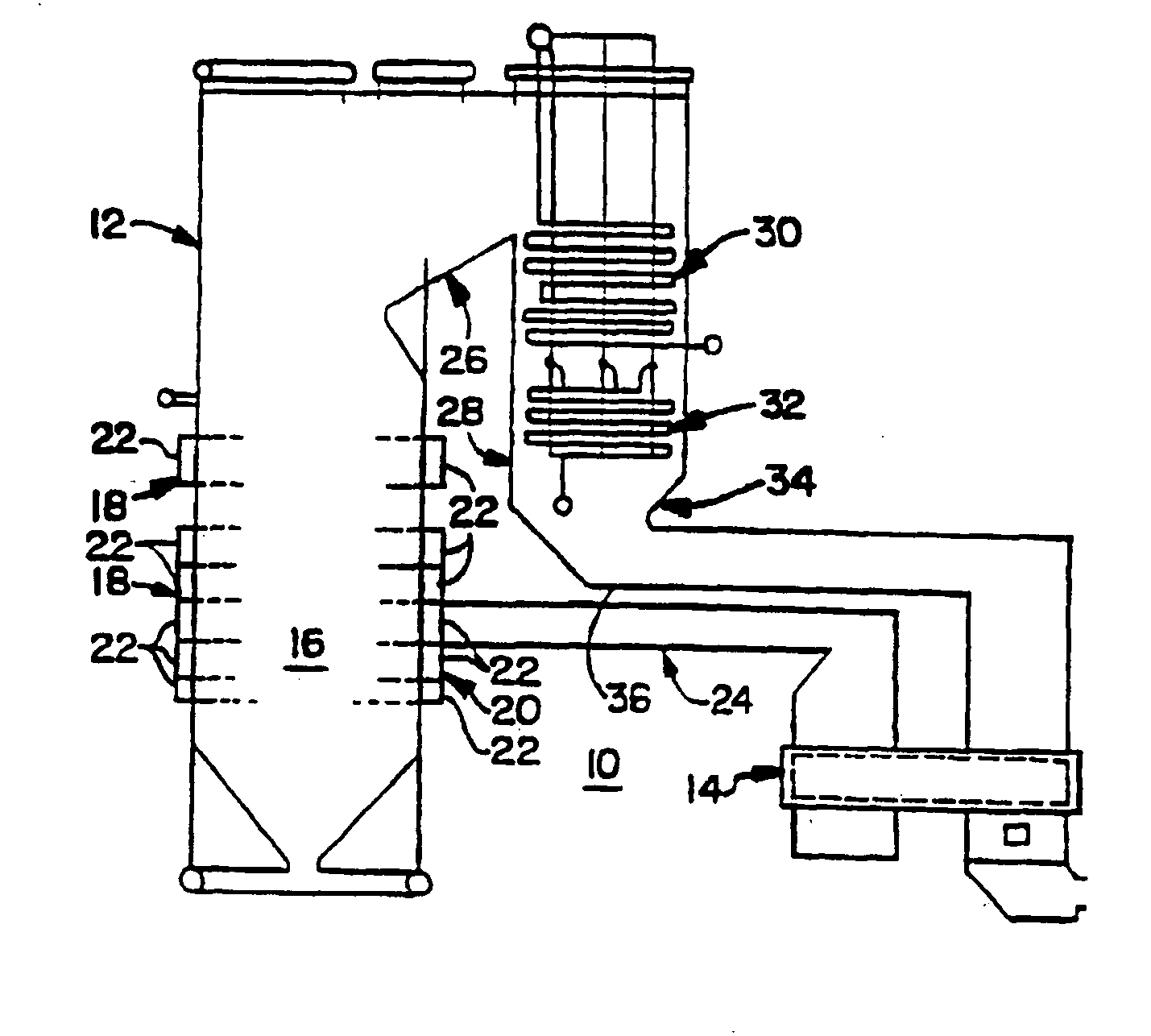

Method and System for controlling coal flow

A system for controlling coal flow in a coal-fired boiler including: a coal flow damper in operable communication with a burner pipe; a coal flow sensor in operable communication with the burner pipe which generates a coal flow signal; and a fuel trim controller in operable communication with the coal flow damper, the fuel trim controller controlling the coal flow damper responsive to the coal flow signal.

Owner:GENERAL ELECTRIC CO

Modifying transport air to control NOX

InactiveUS20100275825A1Reduce the amount of solutionFuel supply regulationEmission preventionCombustion systemTransport medium

Using oxygen-lean gas as the transport medium in which pulverized fuel solids are conveyed to the burner of a combustion system permits combustion at levels of combustion rate and NOx production under circumstances under which those levels would not be attainable if the transport medium were air.

Owner:PRAXAIR TECH INC

Flow rate sensor, flow meter, and discharge rate control apparatus for liquid discharge machines

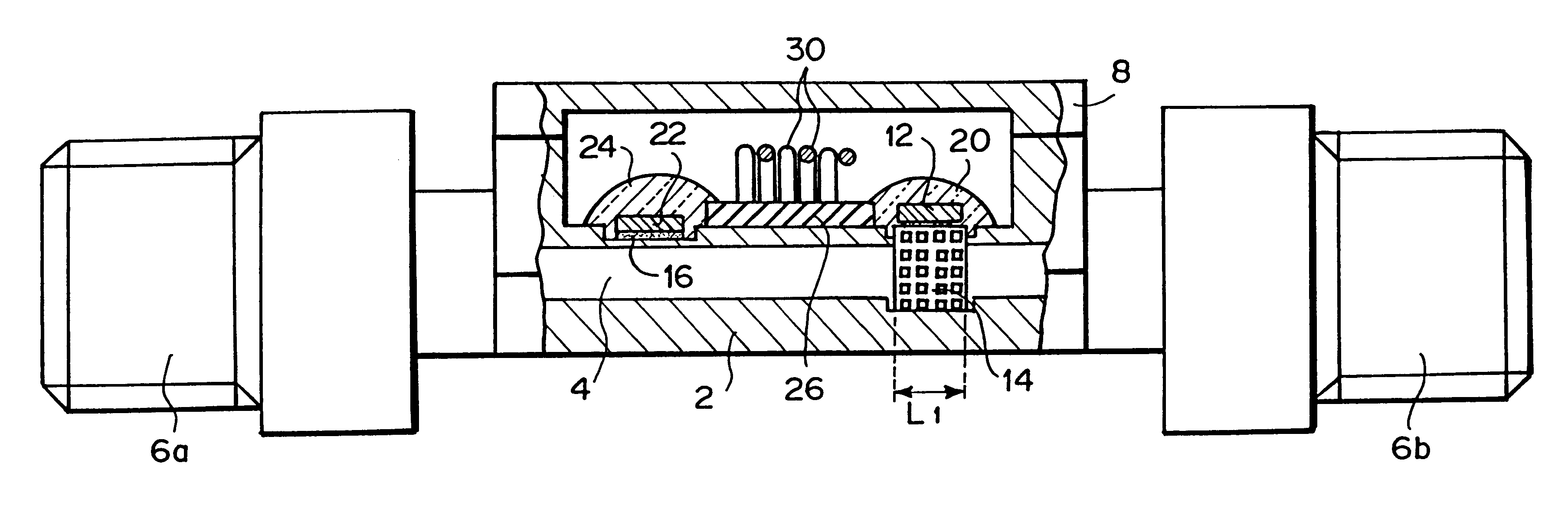

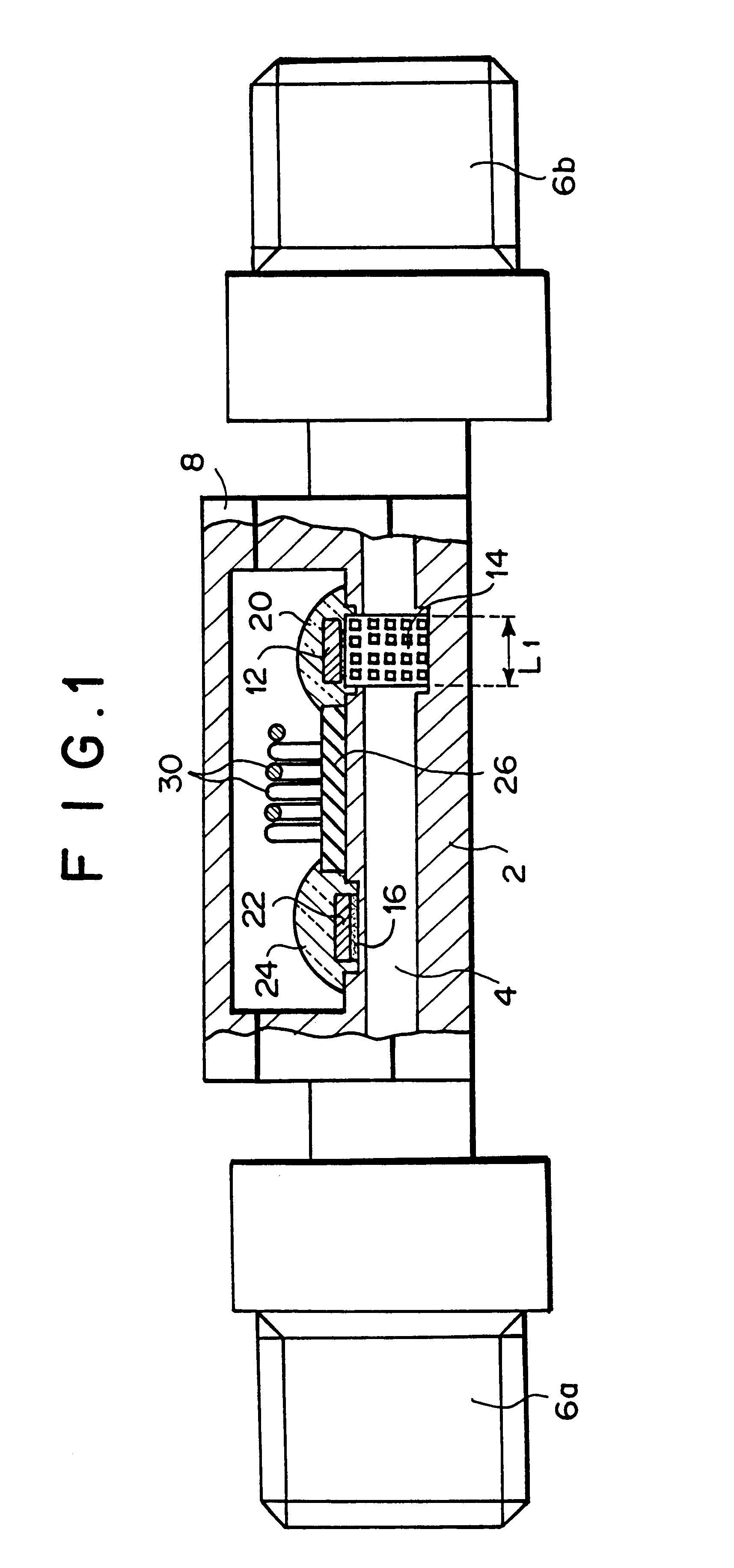

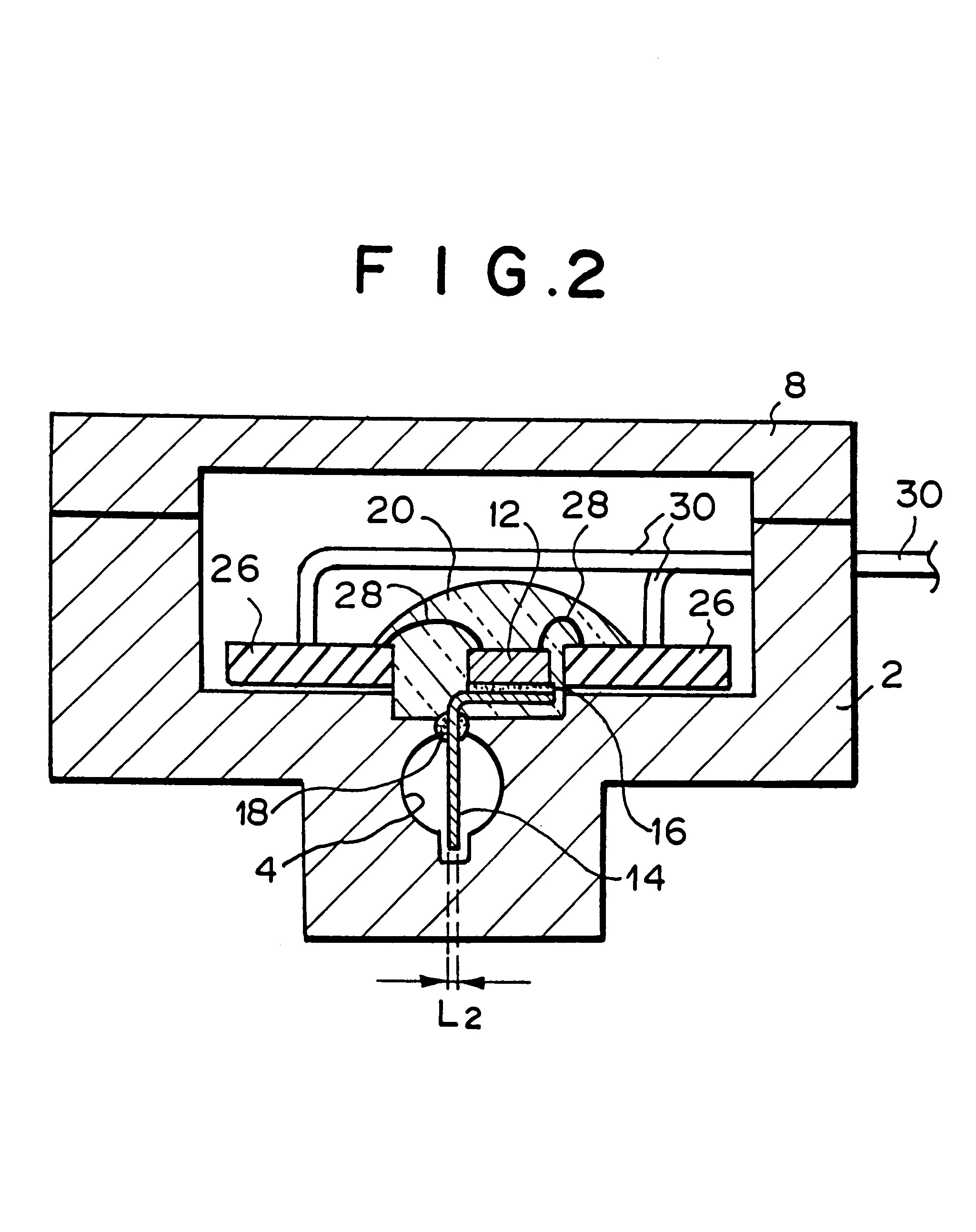

InactiveUS6647777B1Accurately measure flow rate of fluid flowingAccurate flowBurnersLiquid fuel feeder/distributionLine tubingEngineering

A pipe line for fluid to be detected is formed so that heat from a flow rate detector in which a thin-film heating element and a thin-film temperature sensing element are laminated on a first surface of a substrate through an insulating layer is transferred to and absorbed by the fluid. In the flow rate detector, the temperature sensing which is affected by the heat absorption of the fluid due to the heating of the thin-film heating element is executed by the thin-film temperature sensing element, and the flow rate of the fluid in the pipe line is detected on the basis of the temperature sensing result. A fin plate extending into the pipe line is joined to a second surface of the substrate of the flow rate detector by a joint member, and the fin plate extends so as to pass through the central portion on the circular section of the pipe line. The dimension of the fin plate in the direction of the pipe line is larger than the dimension L2 of the thickness. Accordingly, even when the fluid is viscous fluid having relatively high viscosity, and further even when the flow rate is relatively small or under a broad environmental temperature condition, the flow rate of the fluid-flowing in the pipe line can be accurately measured.

Owner:SAN-A

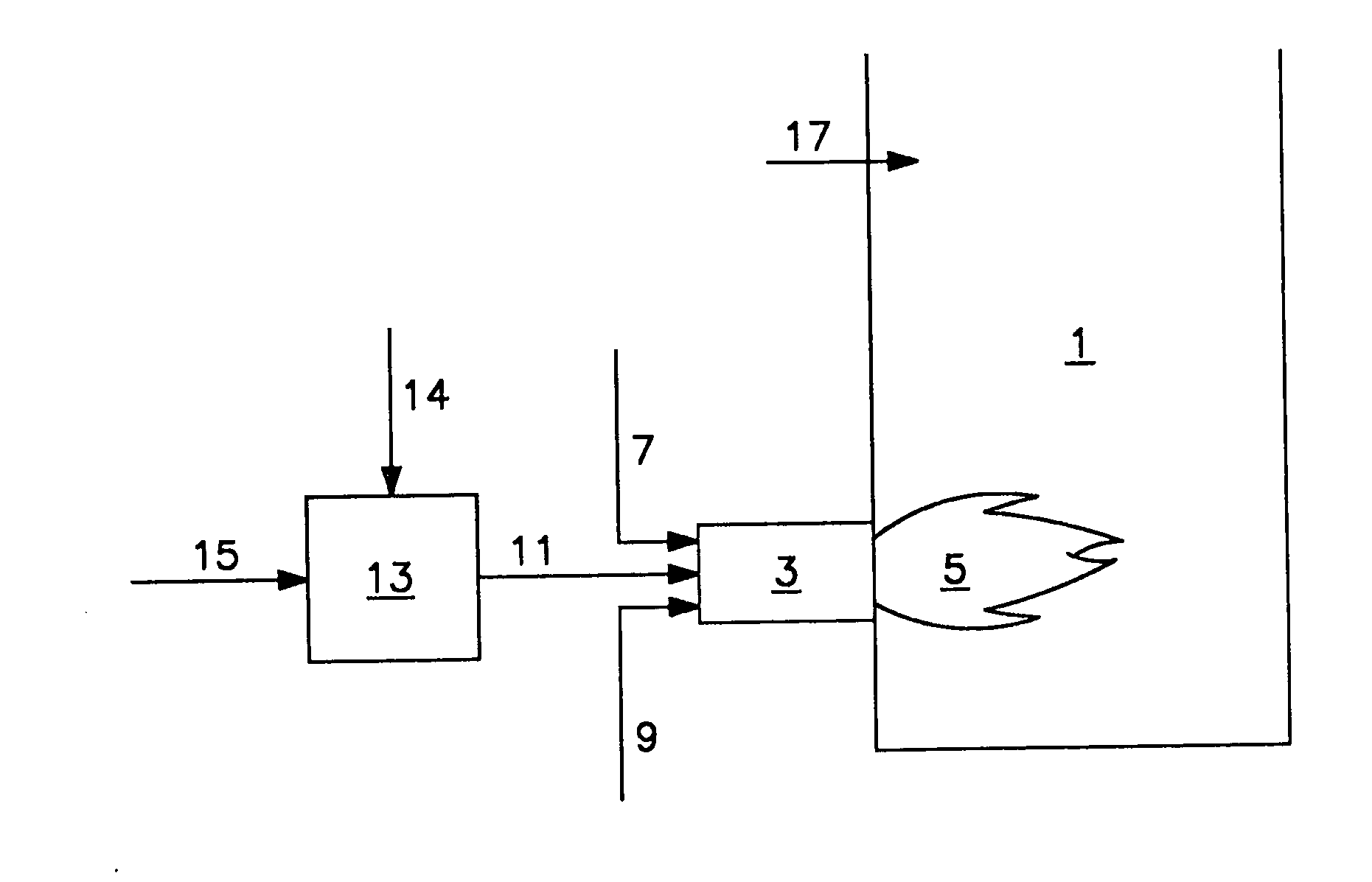

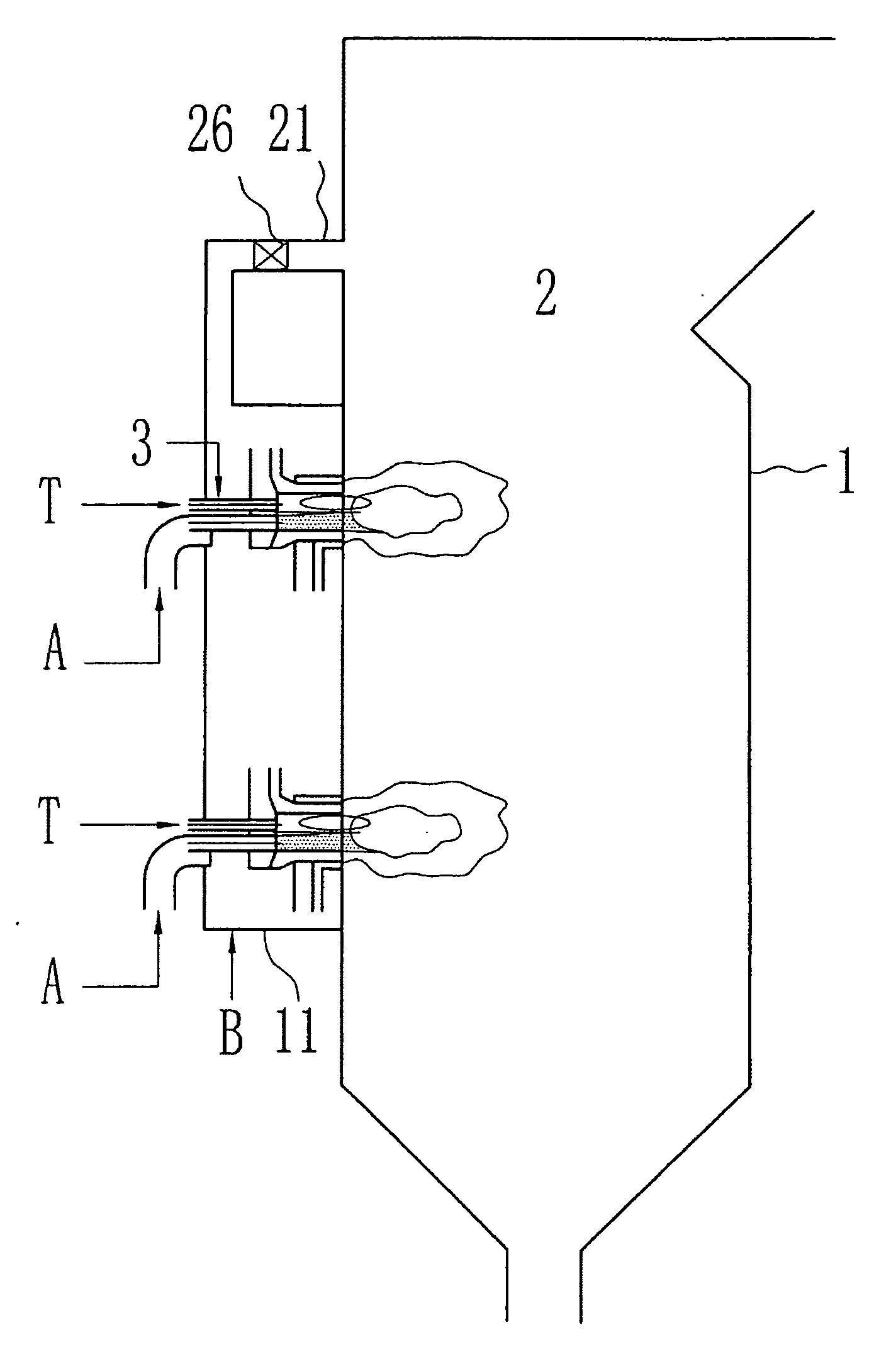

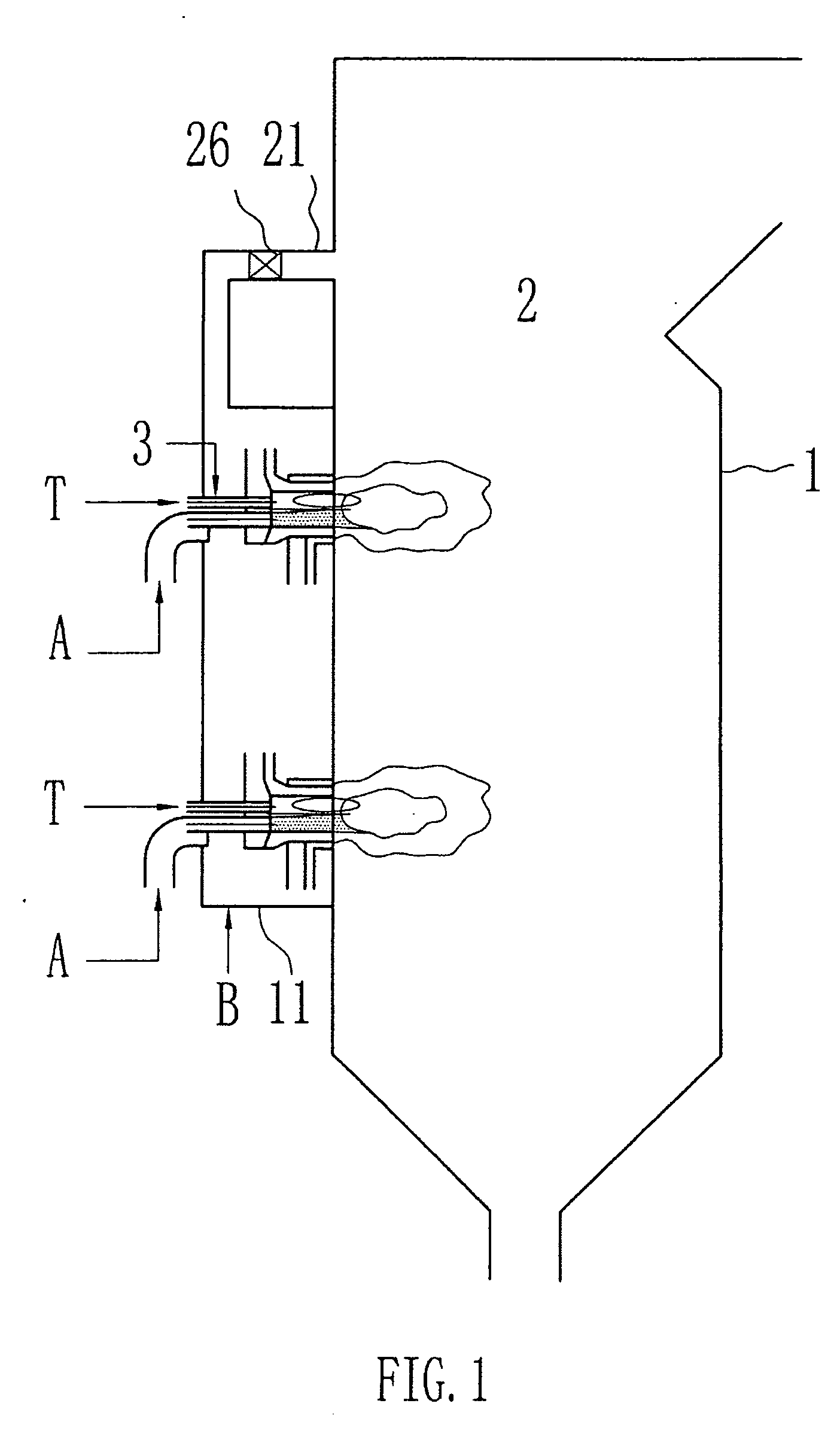

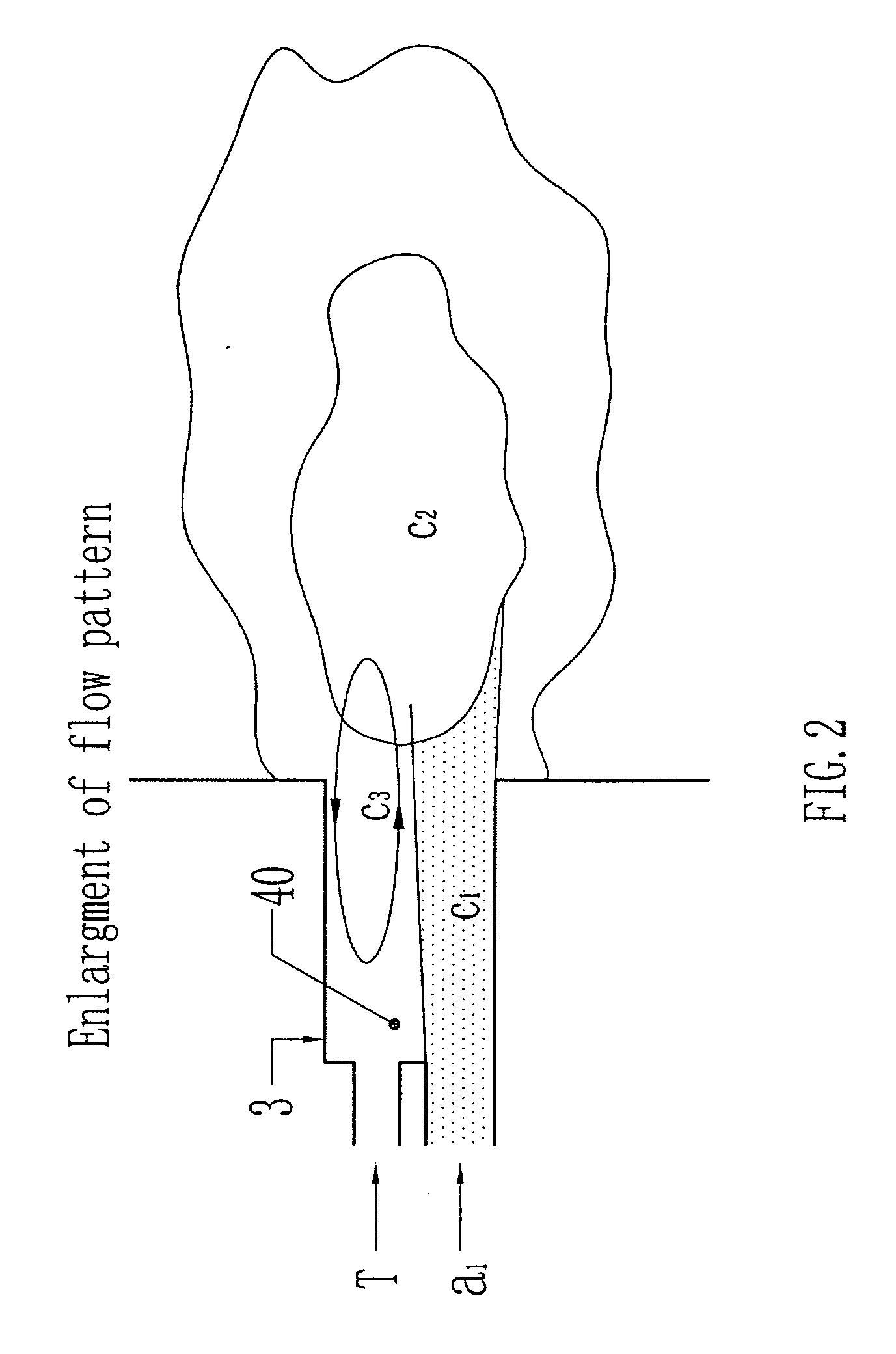

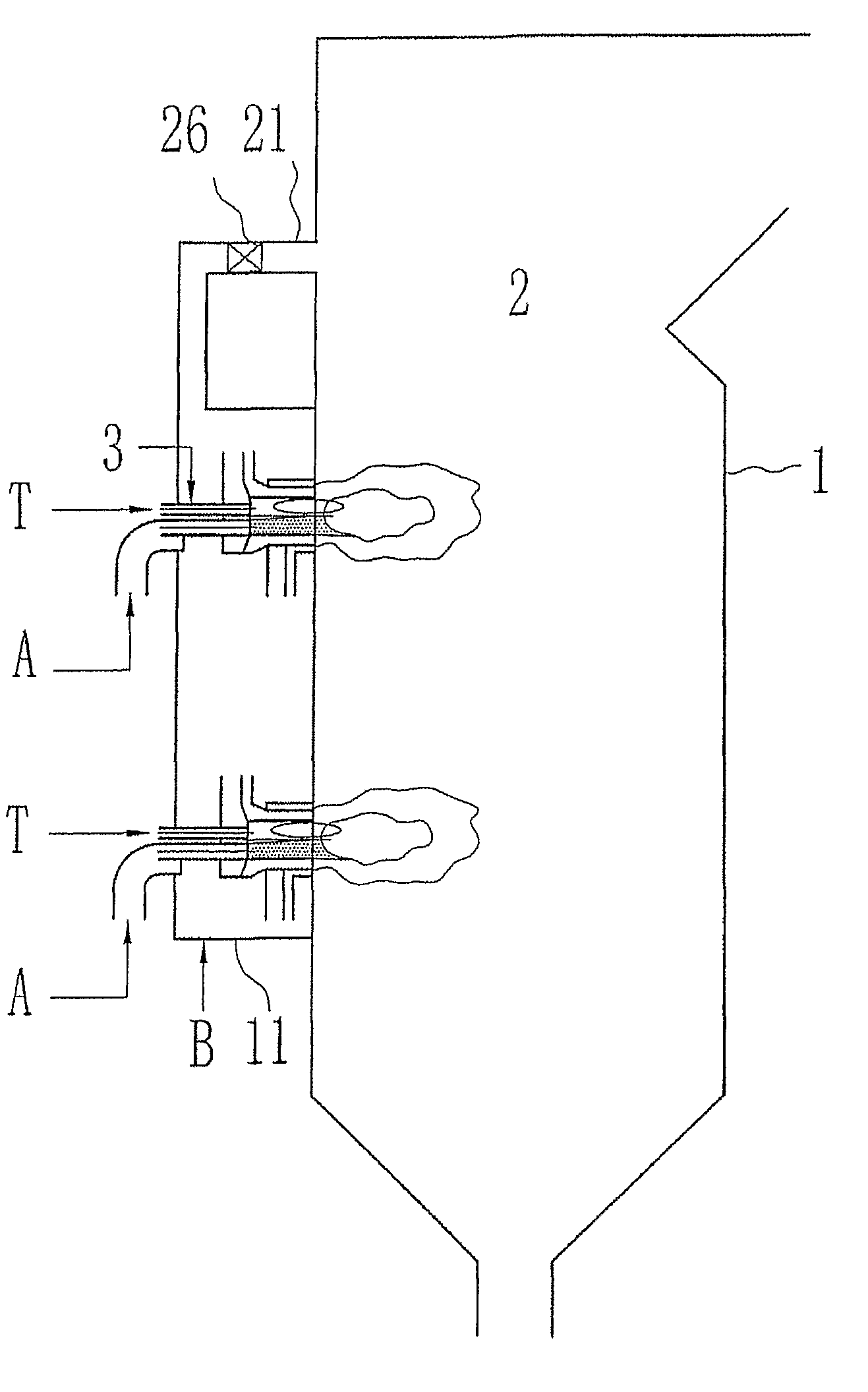

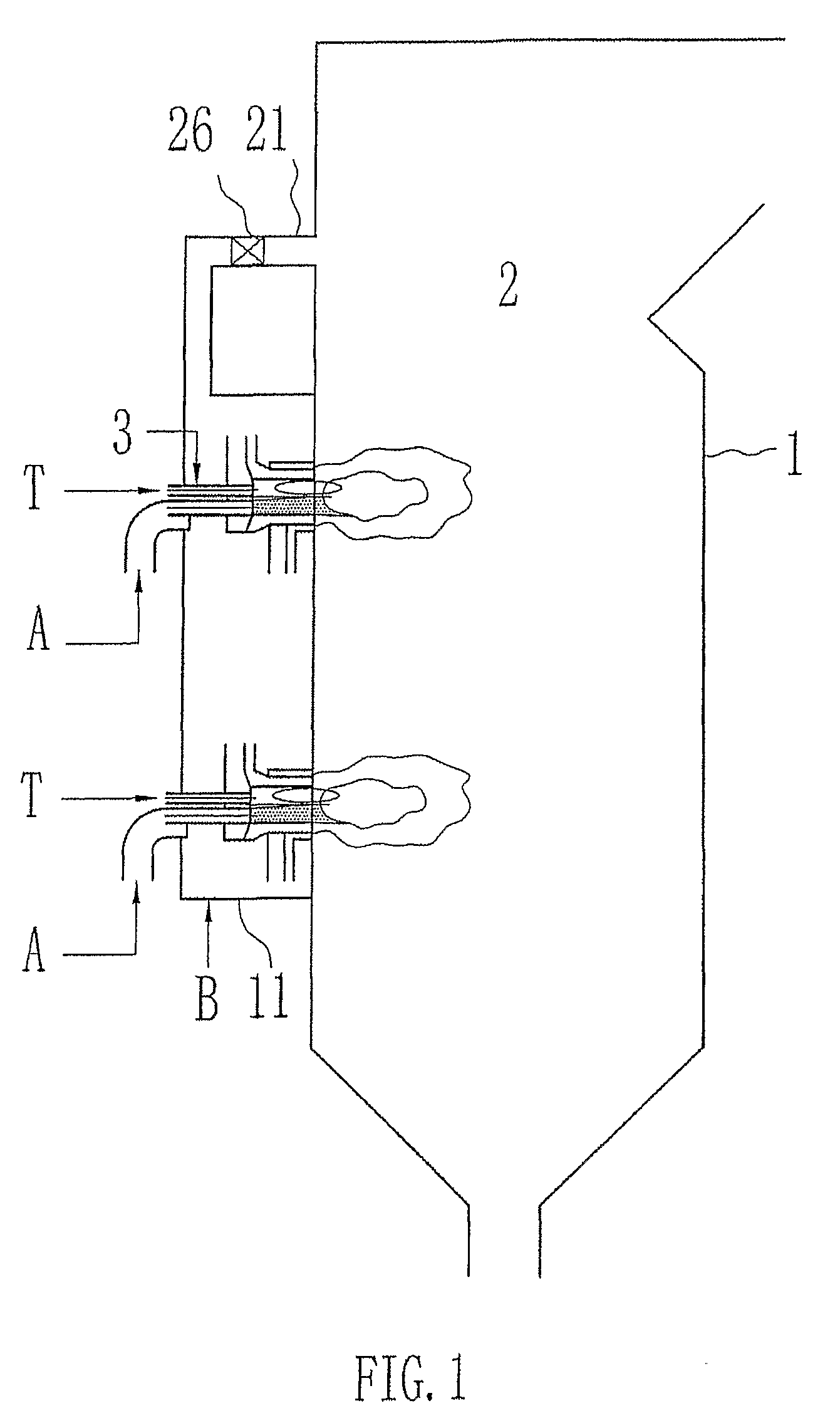

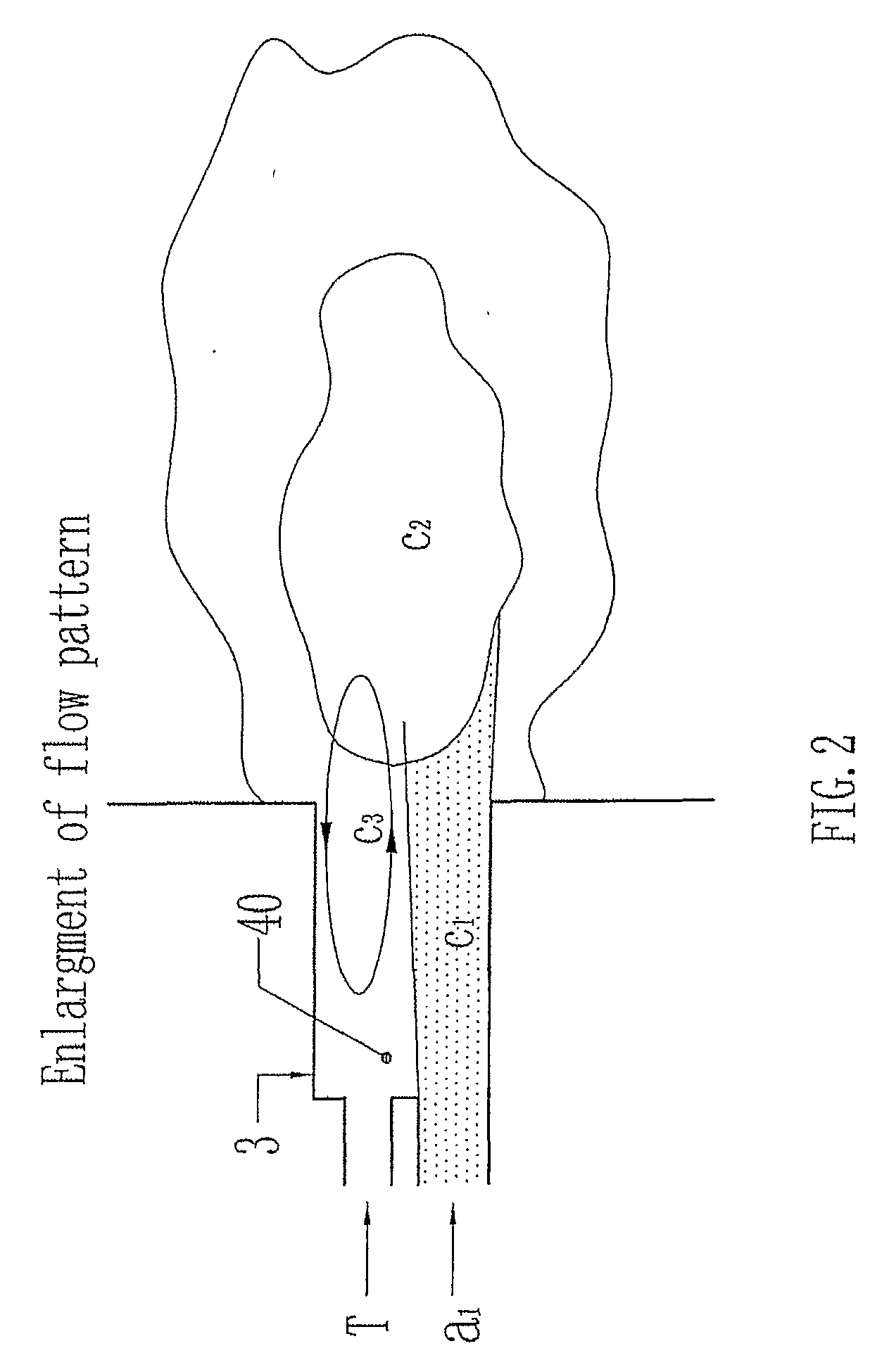

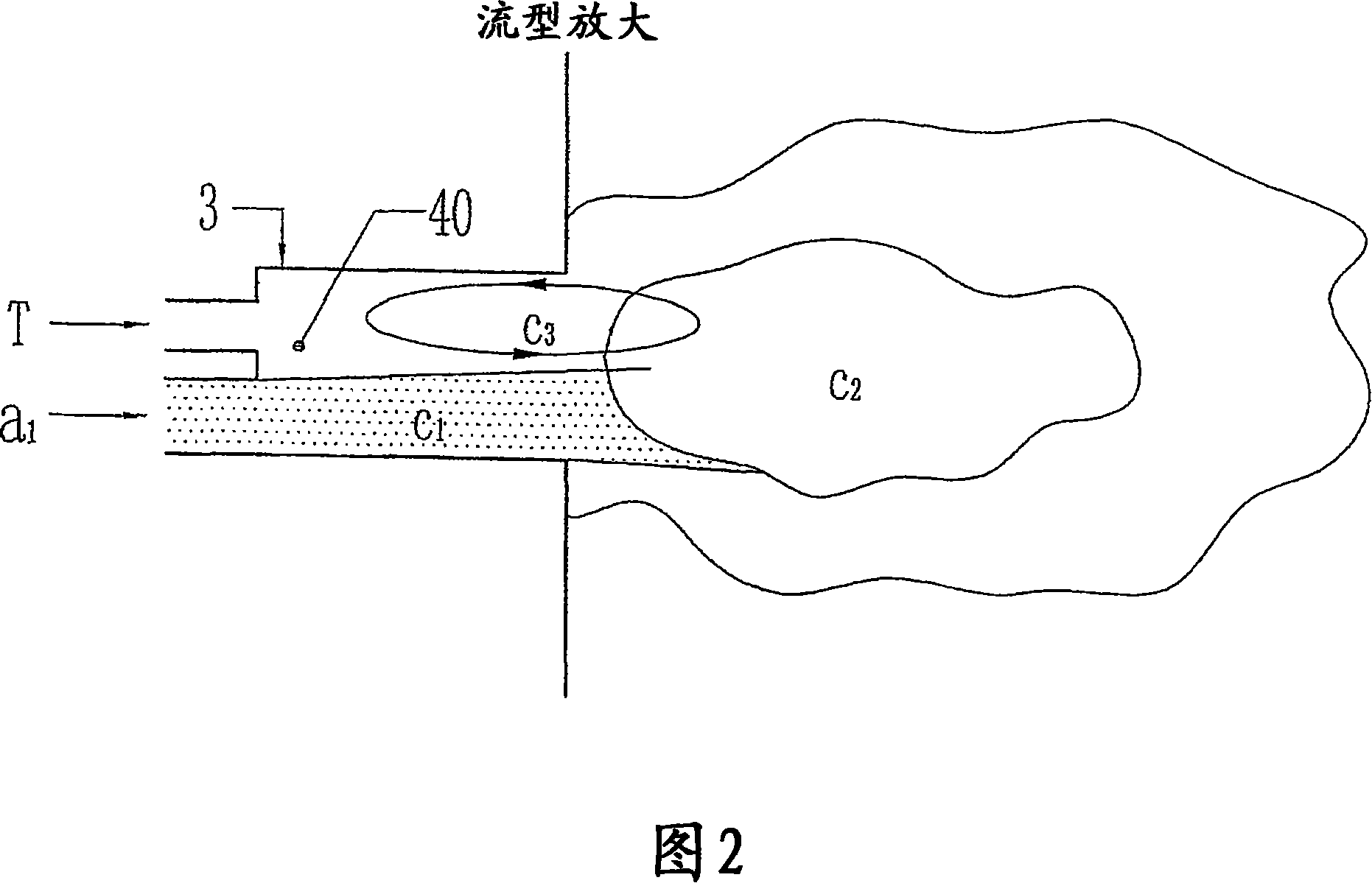

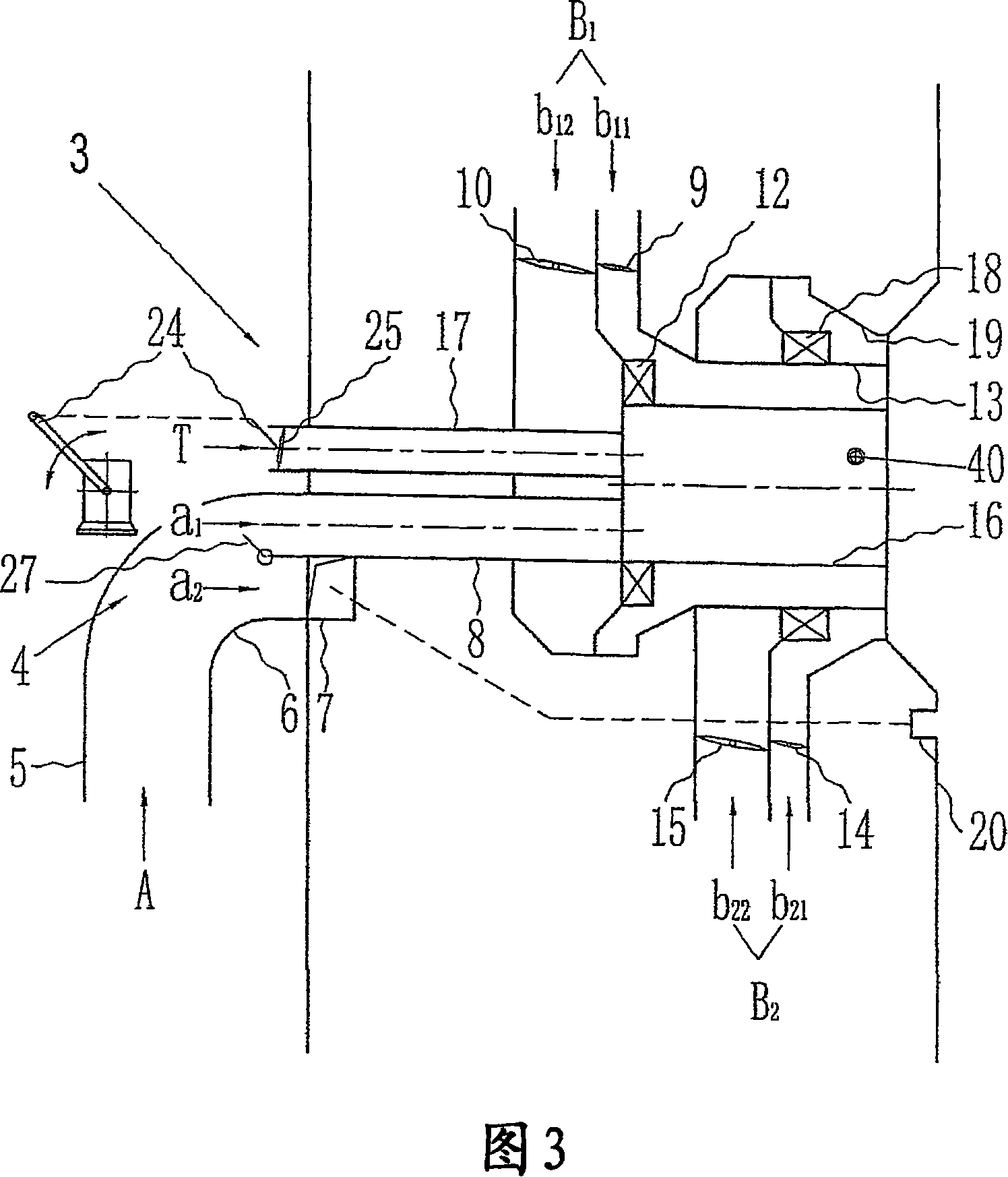

Combustion method and system

ActiveUS20060191451A1Reduce the differenceReduce nitrogen oxide emissionsFuel supply regulationCombustion signal processingCombustorCombustion chamber

A method of combustion for pulverized hydrocarbonaceous fuel includes injecting a concentrated fuel and air stream into a burner, causing a low-pressure zone; directing a flow of a high-temperature combustion gas from a combustion chamber into the low-pressure zone in the burner; mixing the high-temperature combustion gas with the injected concentrated stream to heat the injected concentrated stream; injecting the heated concentrated stream from the burner to the combustion chamber, wherein the concentrated stream is rapidly devolatilized and combusted in a flame that has a fuel-rich flame zone; sensing a combustion parameter; and, based on the sensed combustion parameter, controlling combustion to achieve at least one of a desired NOx reduction and a desired distance from the burner to a flame front.

Owner:CLEAN COMBUSTION TECH

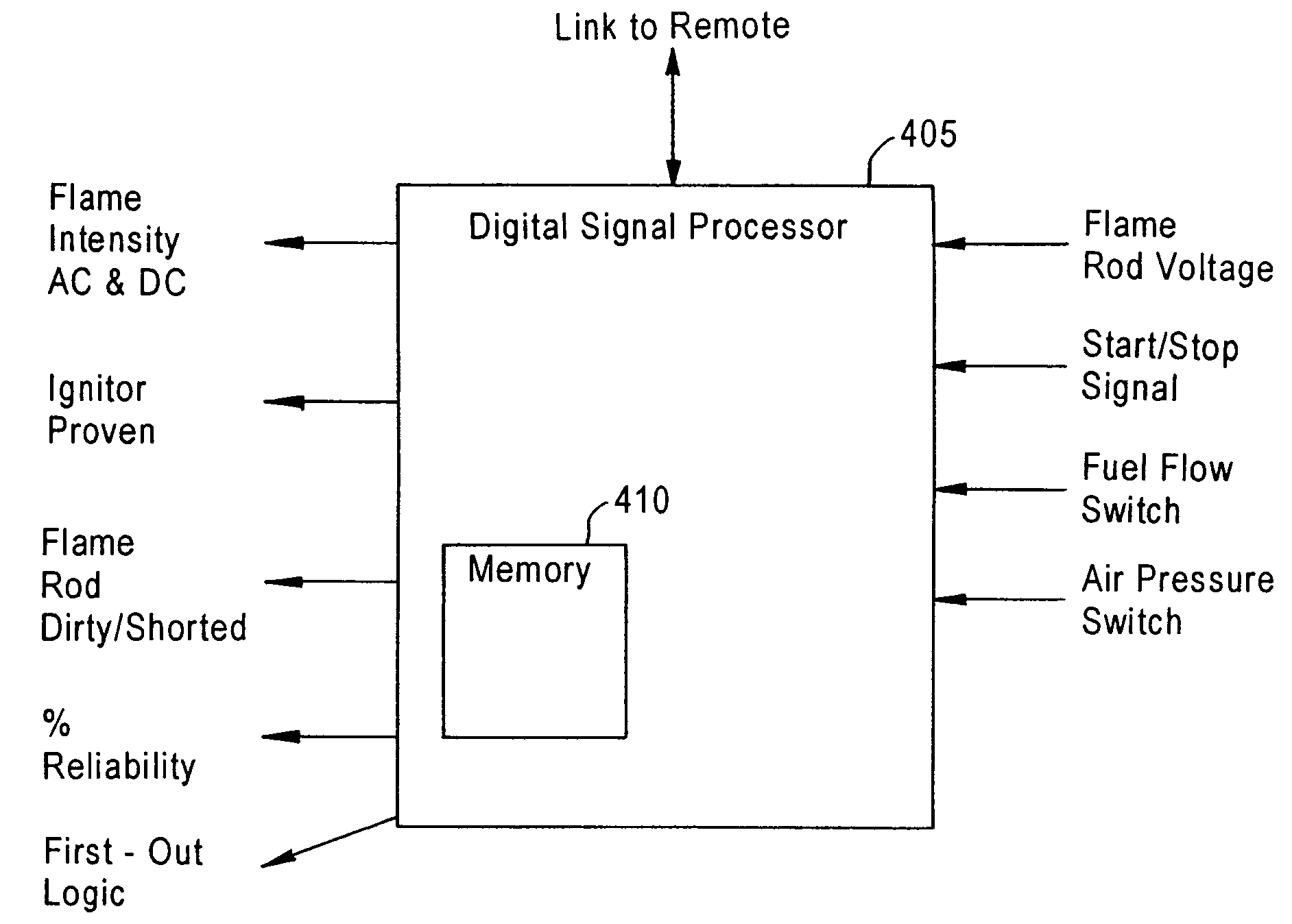

Self diagonostic flame ignitor

InactiveUS20060199122A1Reliable spark actionReliable actionBurnersCombustion signal processingEngineeringBiological activation

Techniques for monitoring operation of a flame ignitor are provided. In one embodiment, multiple inputs are received. The inputs are received from at least one of a first group of inputs and a second group of inputs. The first group includes a flame rod voltage, a stop signal for deactivation of the flame ignitor, a fuel supply interruption signal, and an air supply interruption signal. The second group includes a start signal for activation of the flame ignitor, and a flame proven signal indicating presence of a flame produced by the flame ignitor. If inputs from the first group are received, a cause of a failure of the flame ignitor is determined. If inputs from the second group are received, a reliability of the flame ignitor is determined.

Owner:GENERAL ELECTRIC TECH GMBH

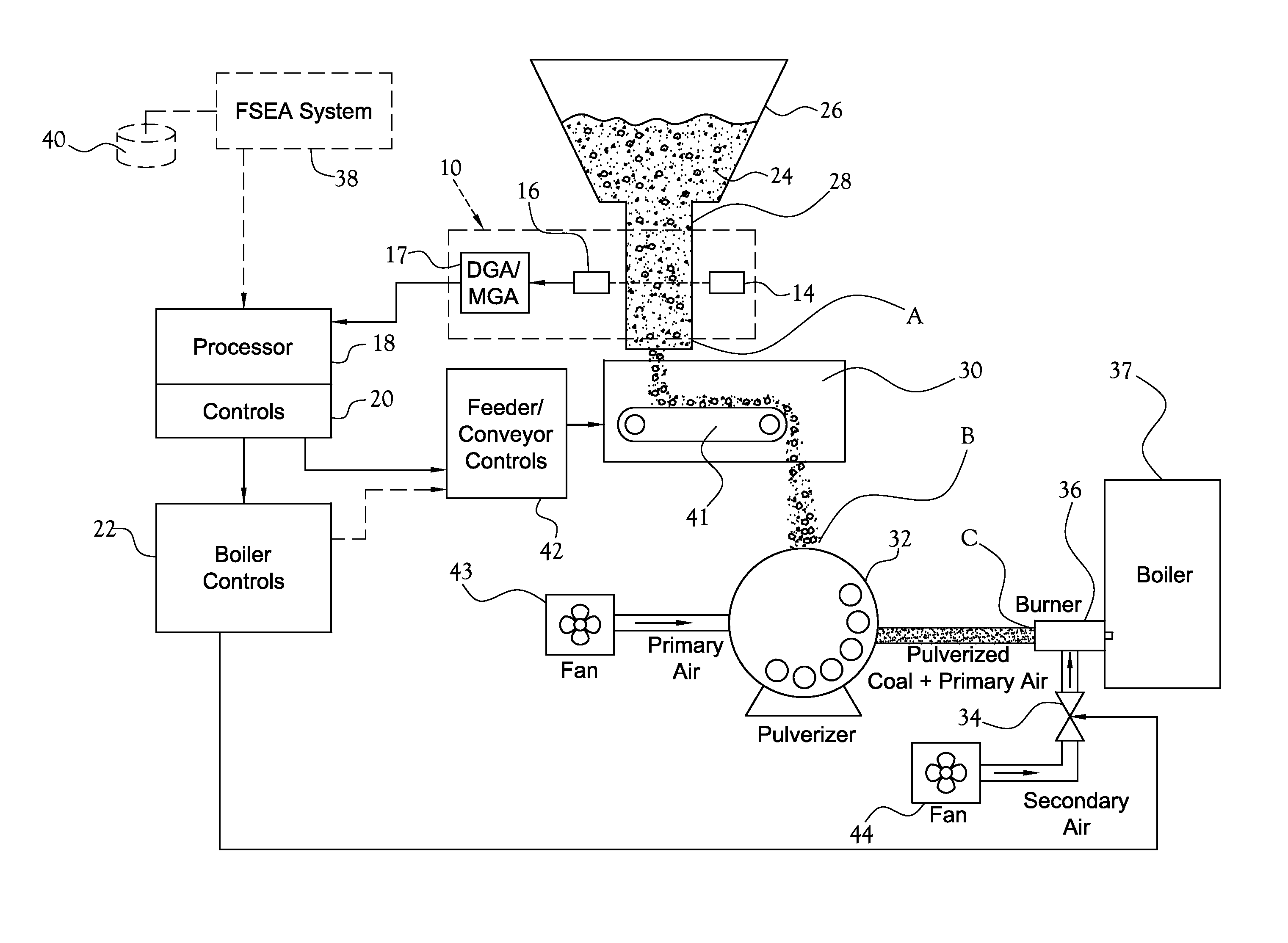

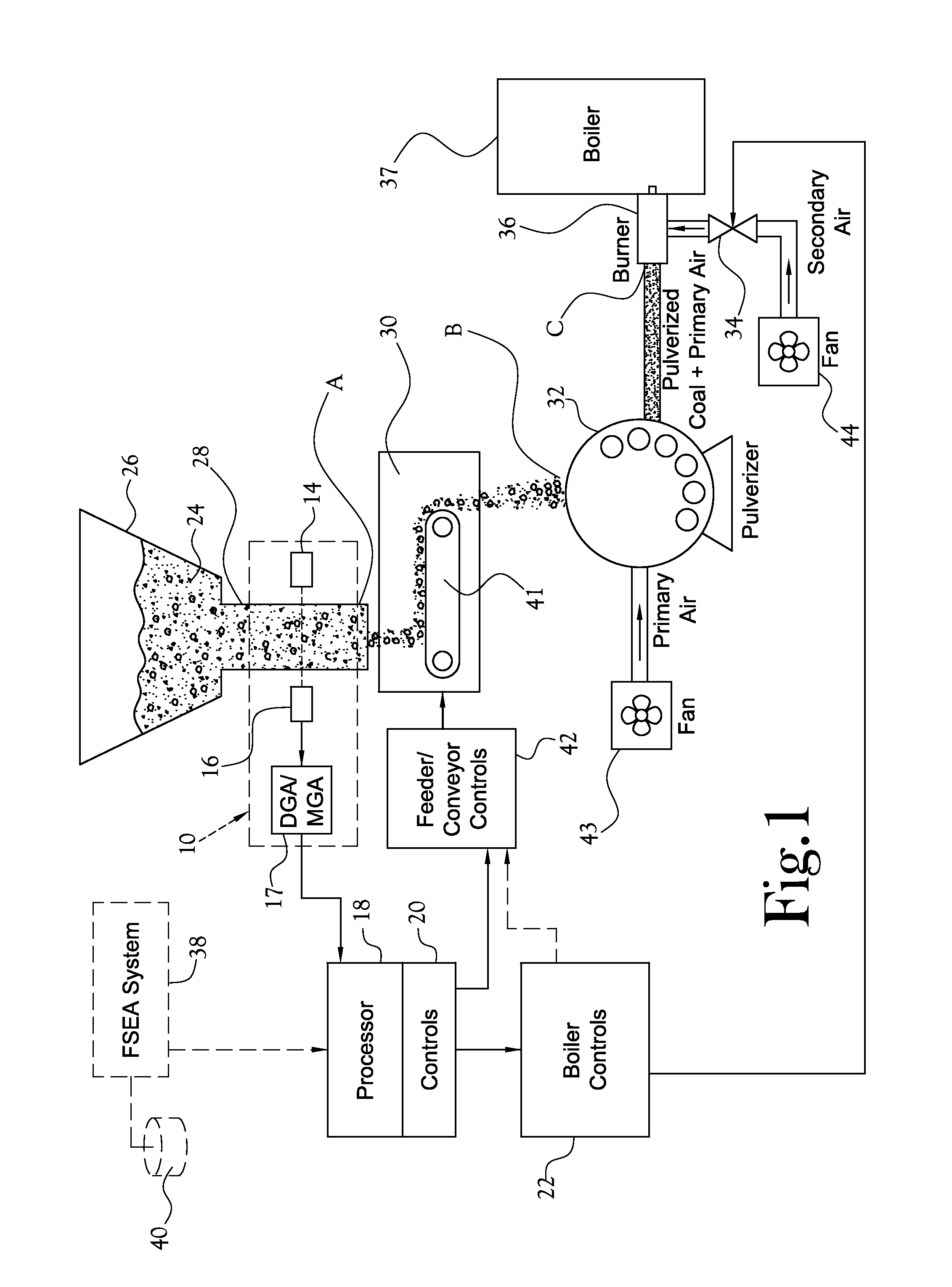

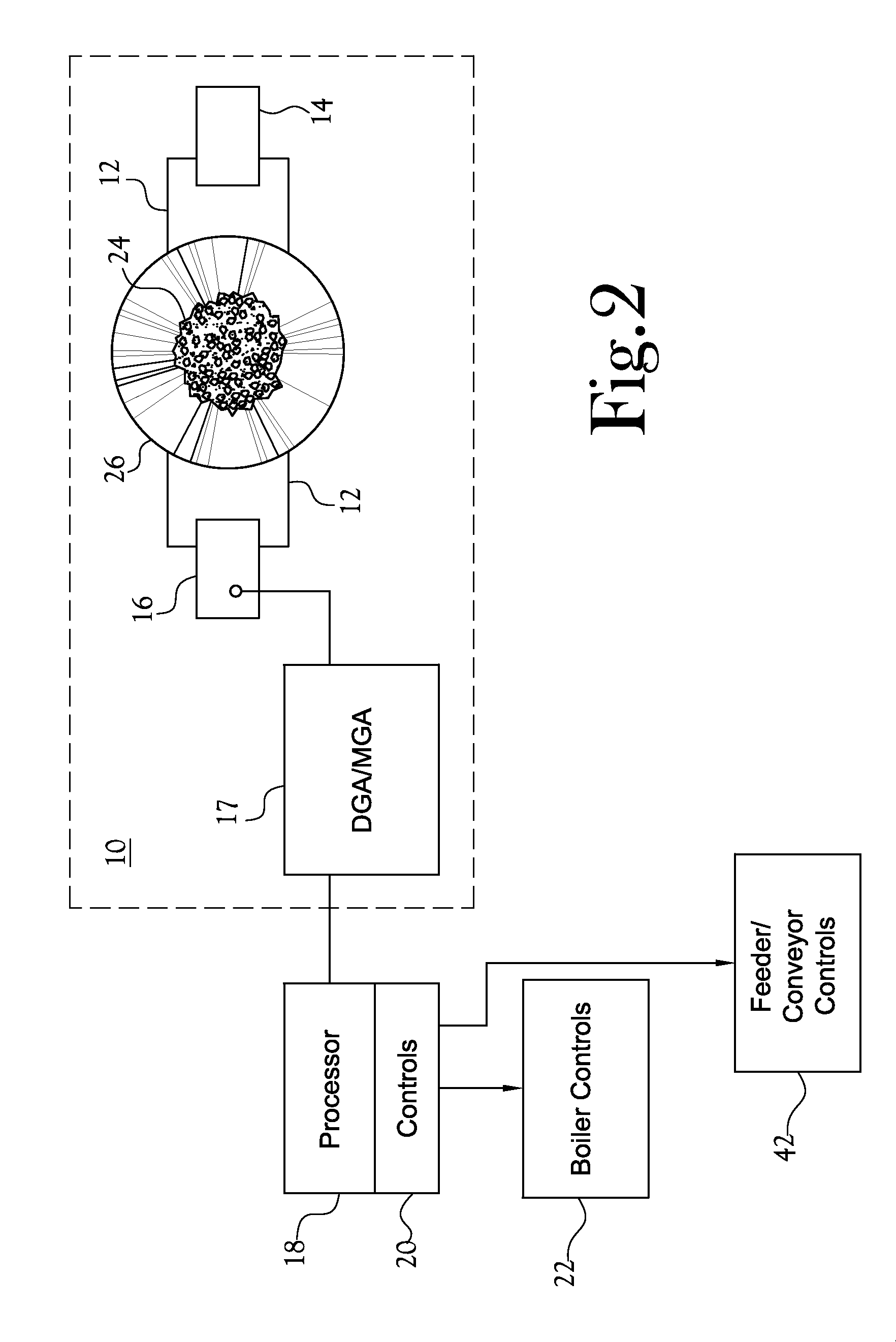

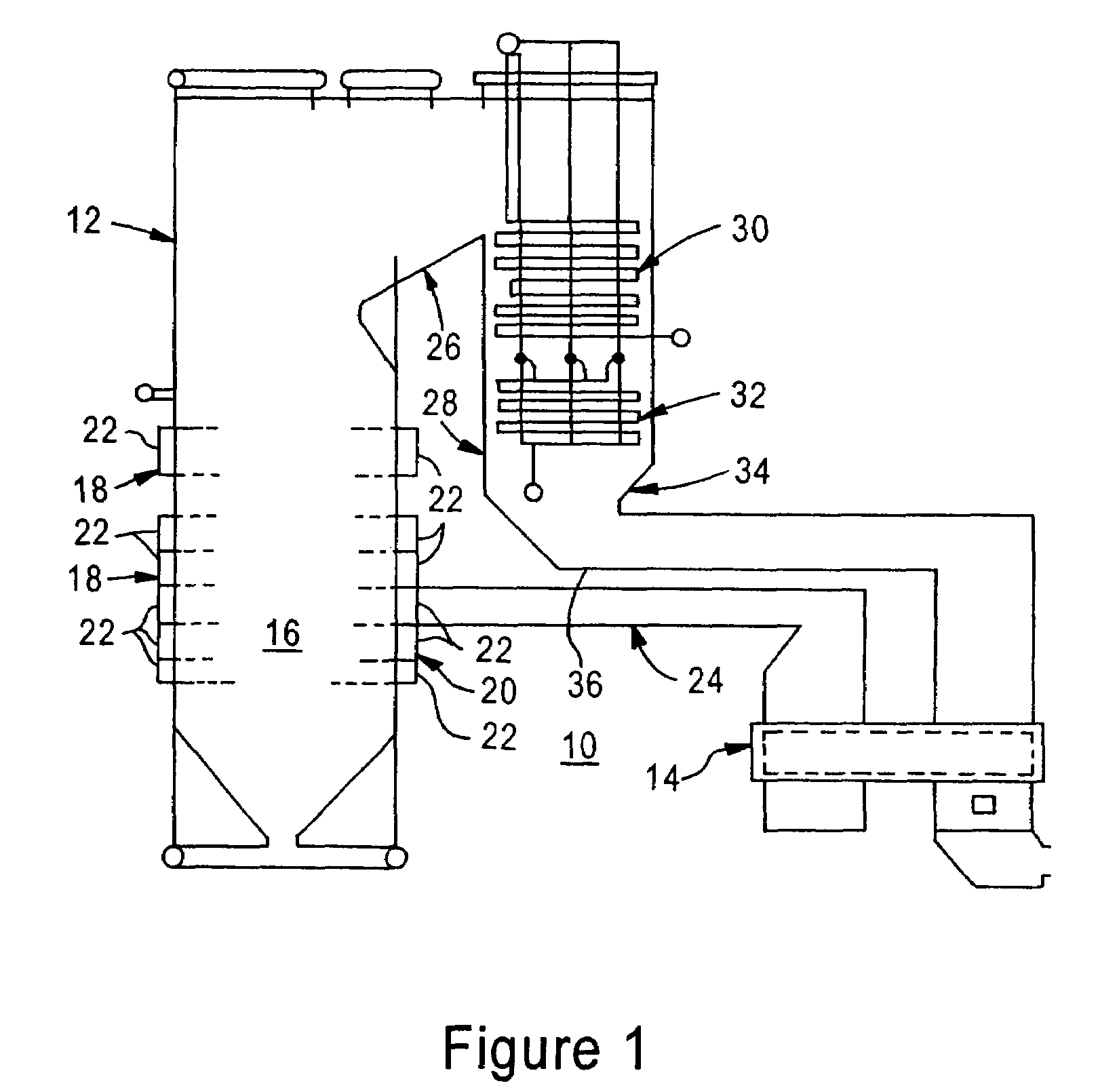

Continuous Real Time Heating Value (BTU)/Coal Flow Balancing Meter

ActiveUS20100330517A1Improve burner stoichiometryImprove system performanceFuel supply regulationFuel feeding arrangementsUltrasound attenuationCombustor

A method and an apparatus for continuous real time heating value / coal flow balancing of coal from a coal feeder to a burner. The apparatus includes a Dual-energy Gamma Attenuation (DGA) / Multi-energy Gamma Attenuation (MGA) device for measuring coal quality at a specific location between the coal silo / bunker and the coal feeder in a coal fired plant in order to control the individual burner stoichiometries according to the measured coal quality. By strategically placing the DGA / MGA device, continuous accurate real-time coal quality information is accomplished for making individual adjustments in order to improve stoichiometry to optimize performance of the system.

Owner:ENERGY TECH

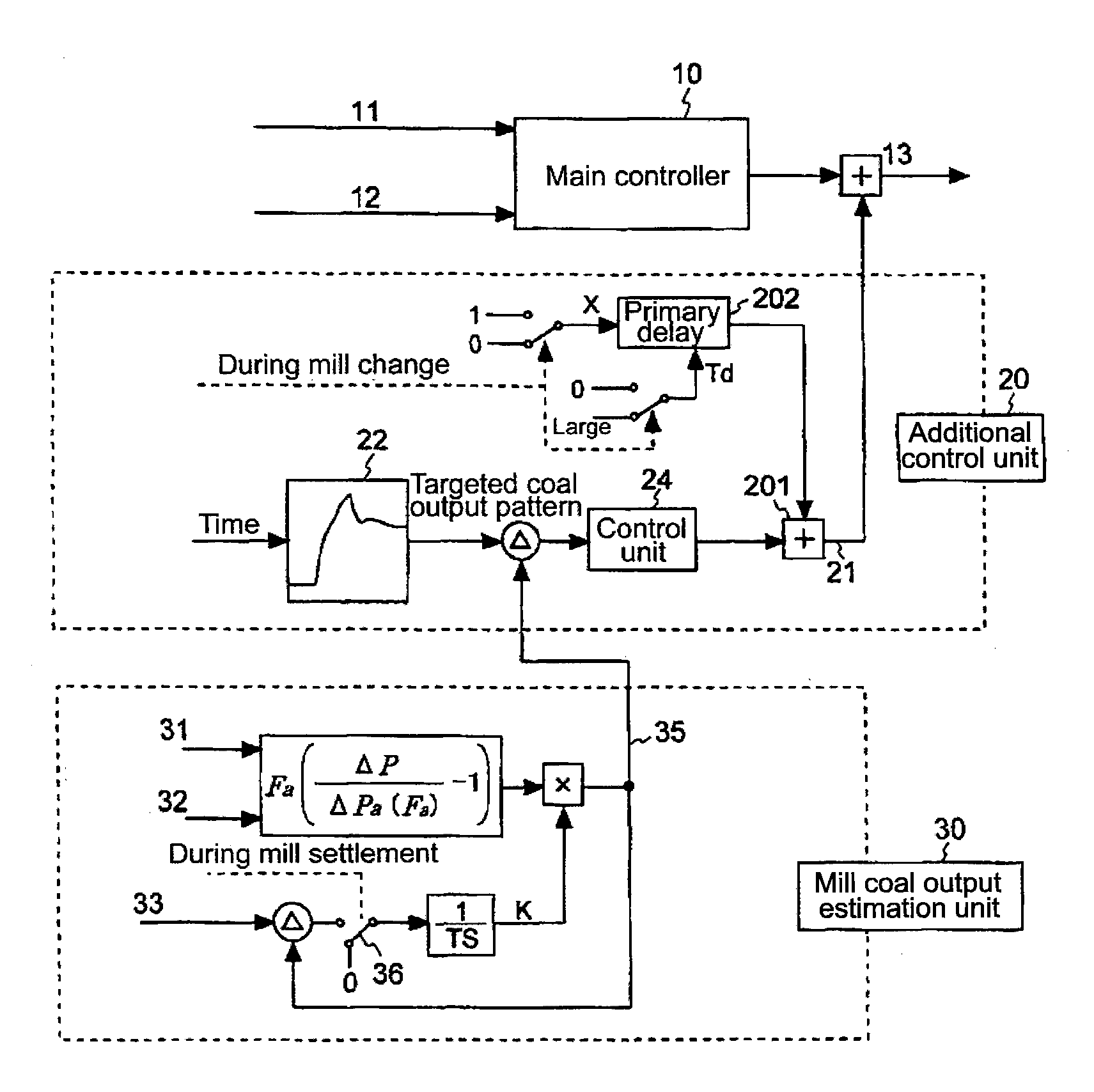

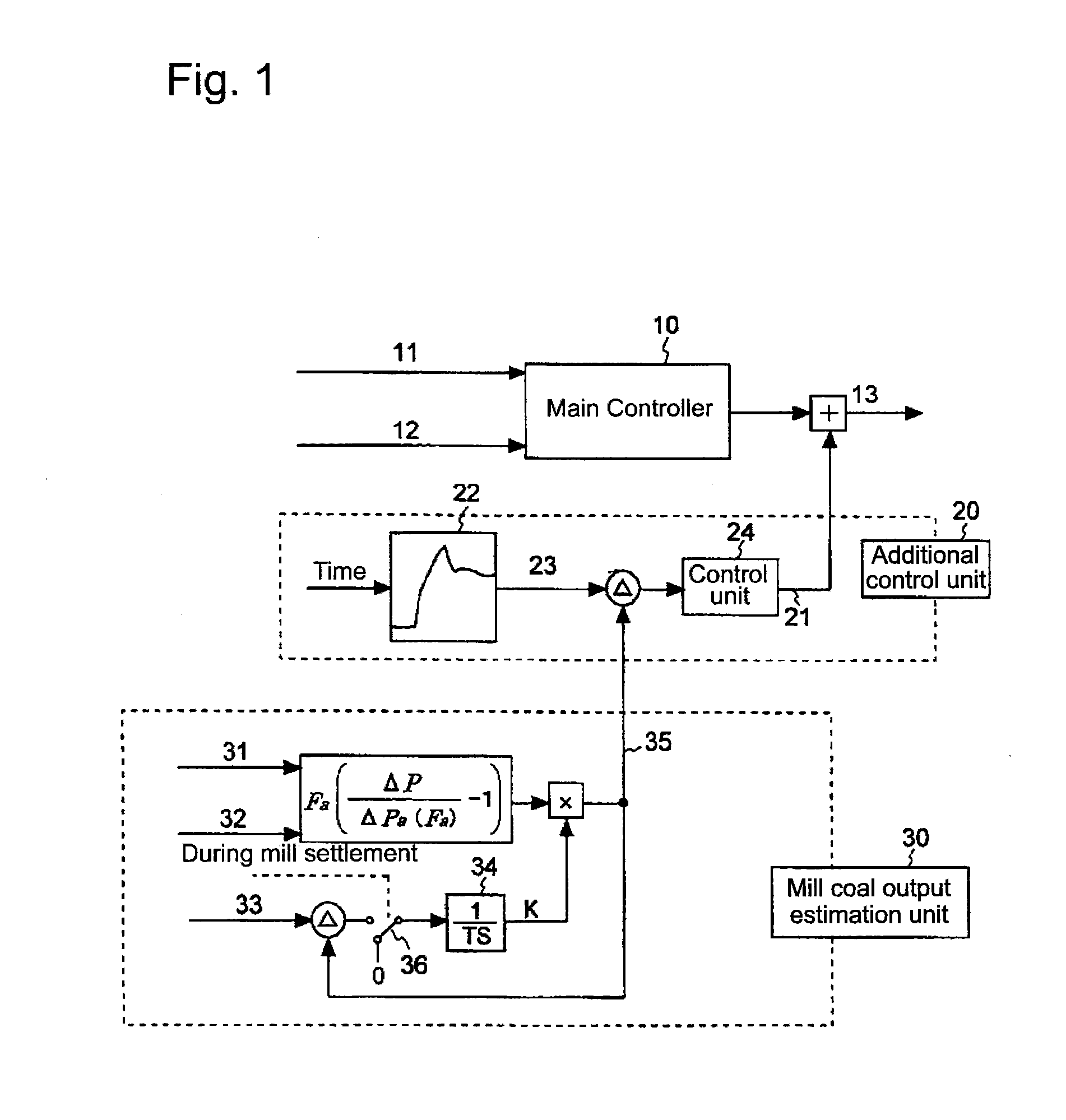

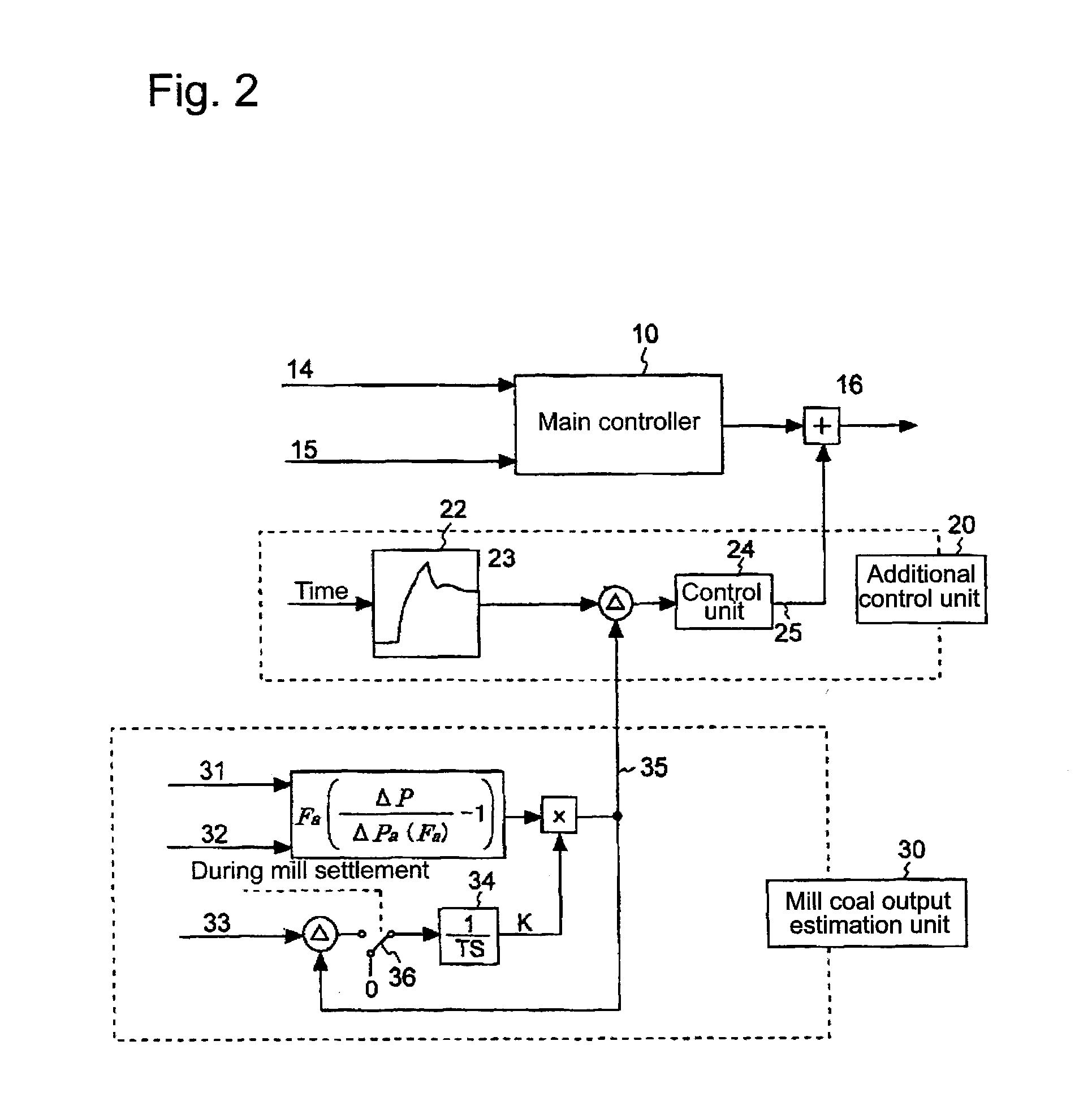

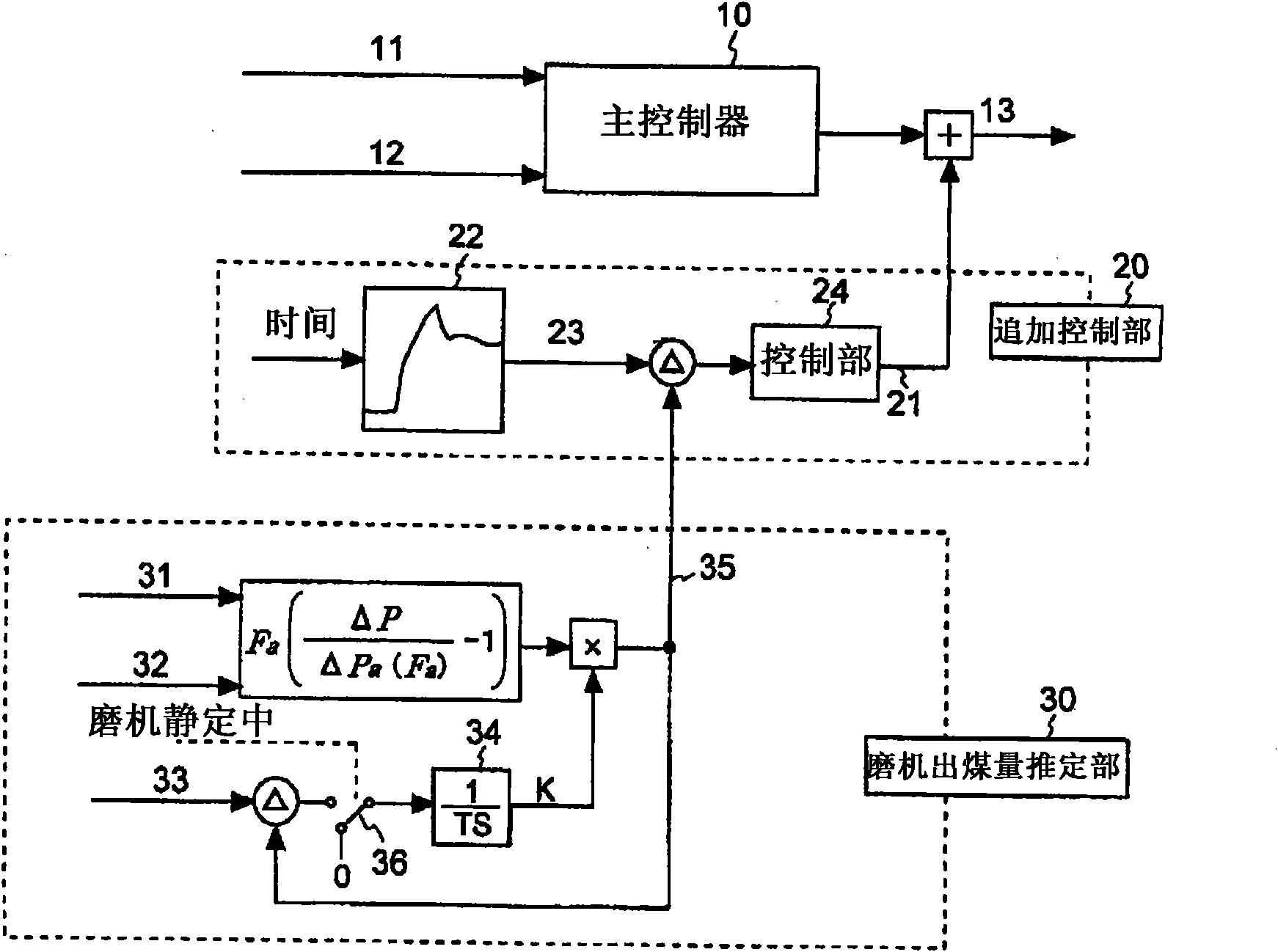

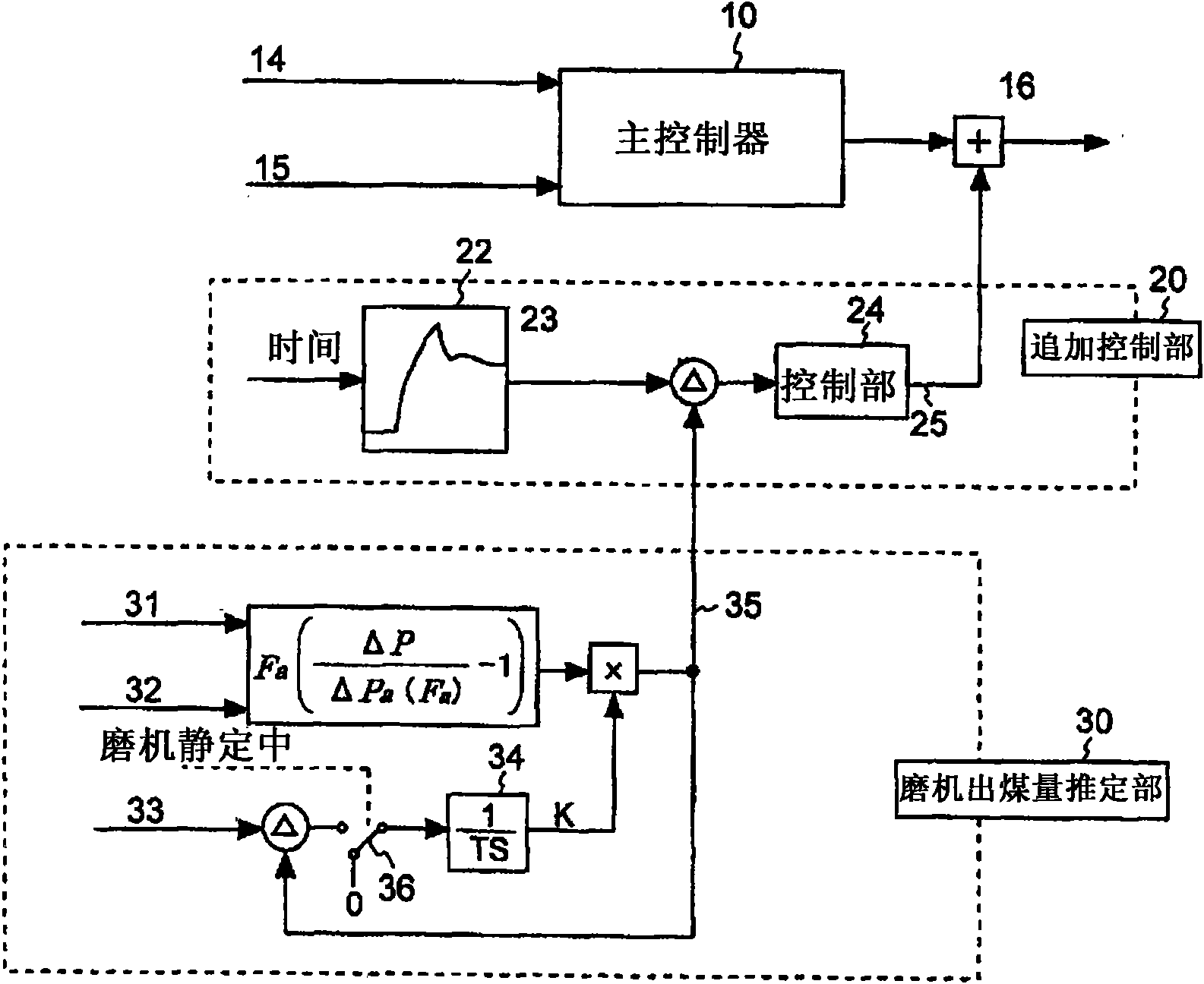

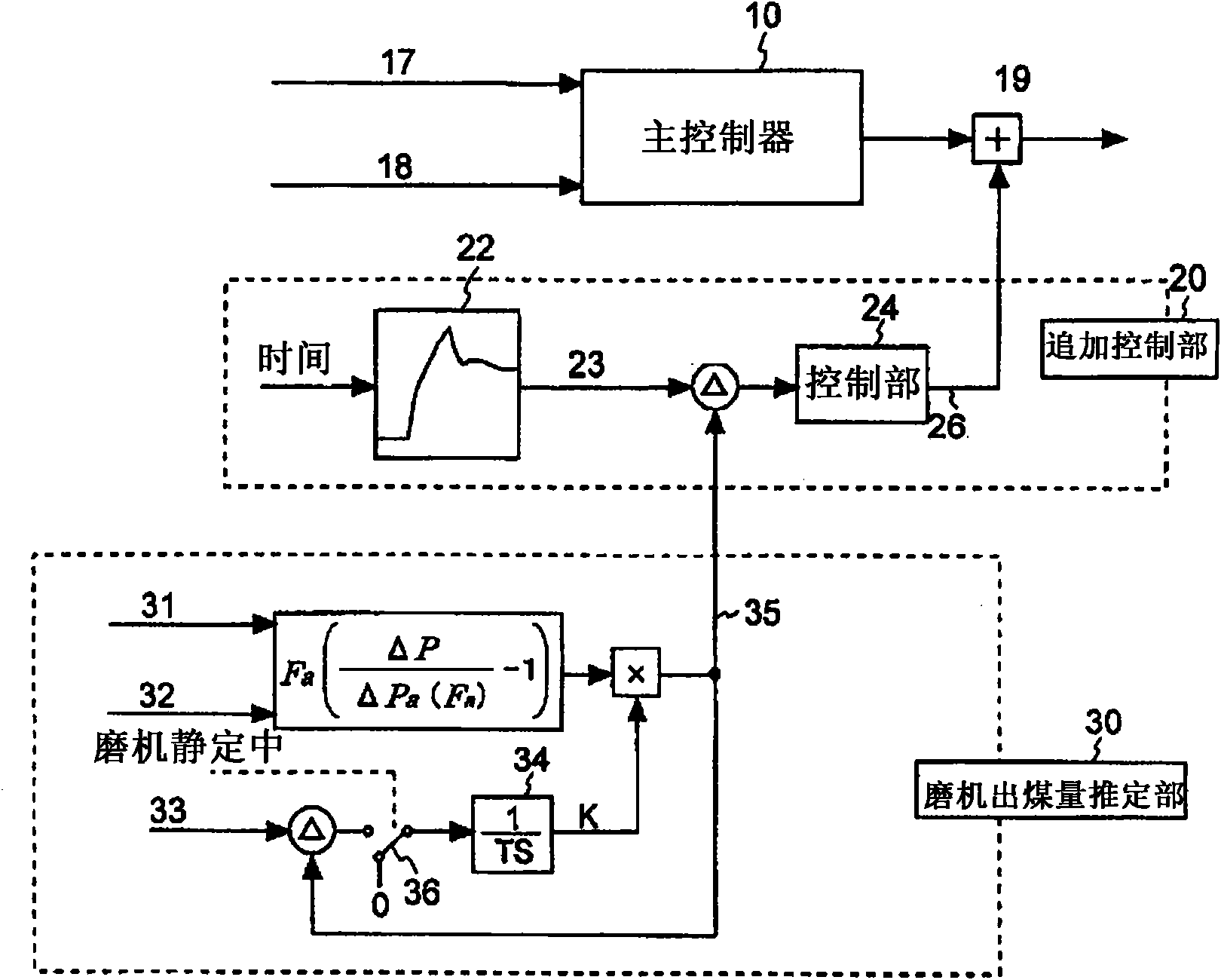

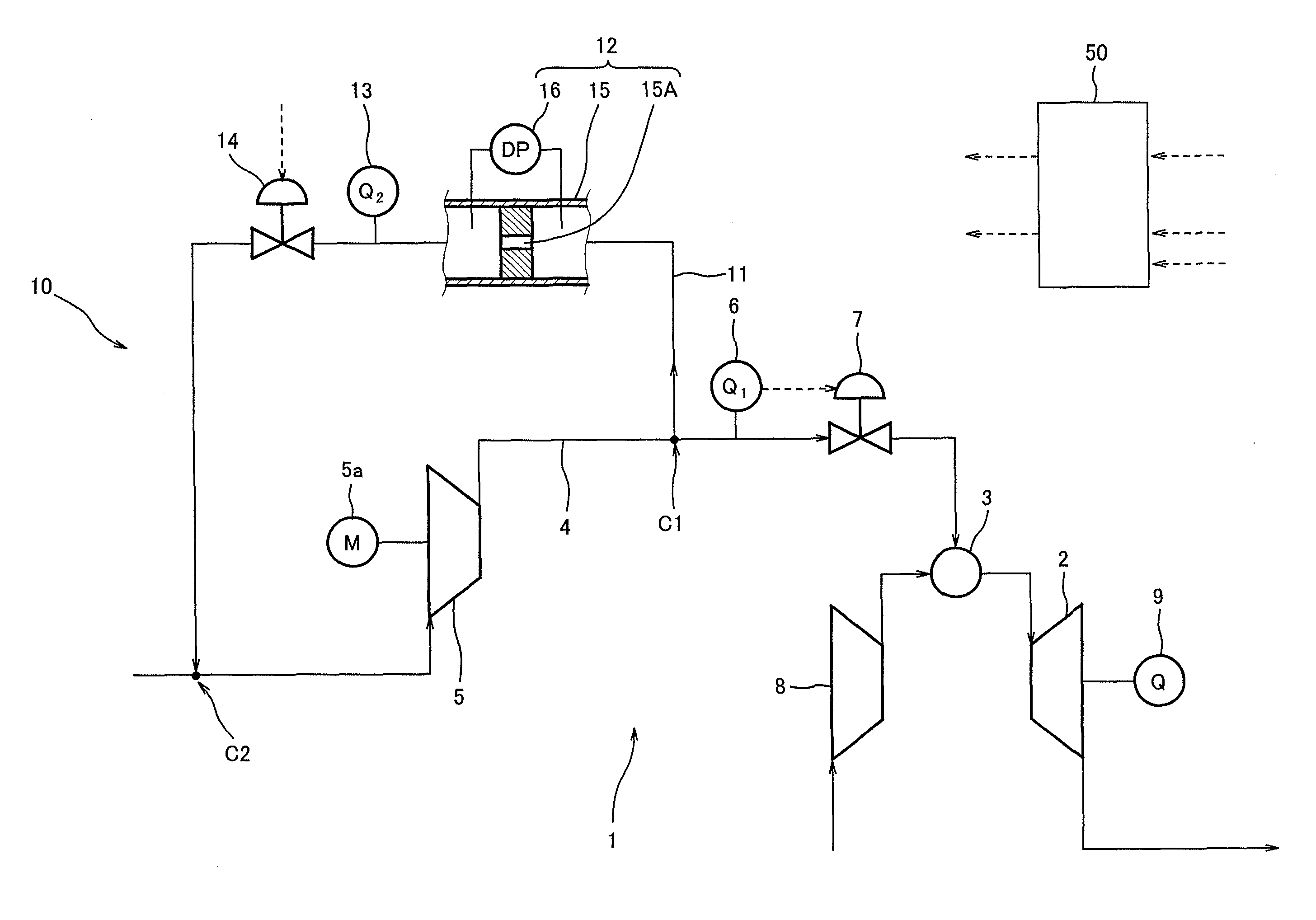

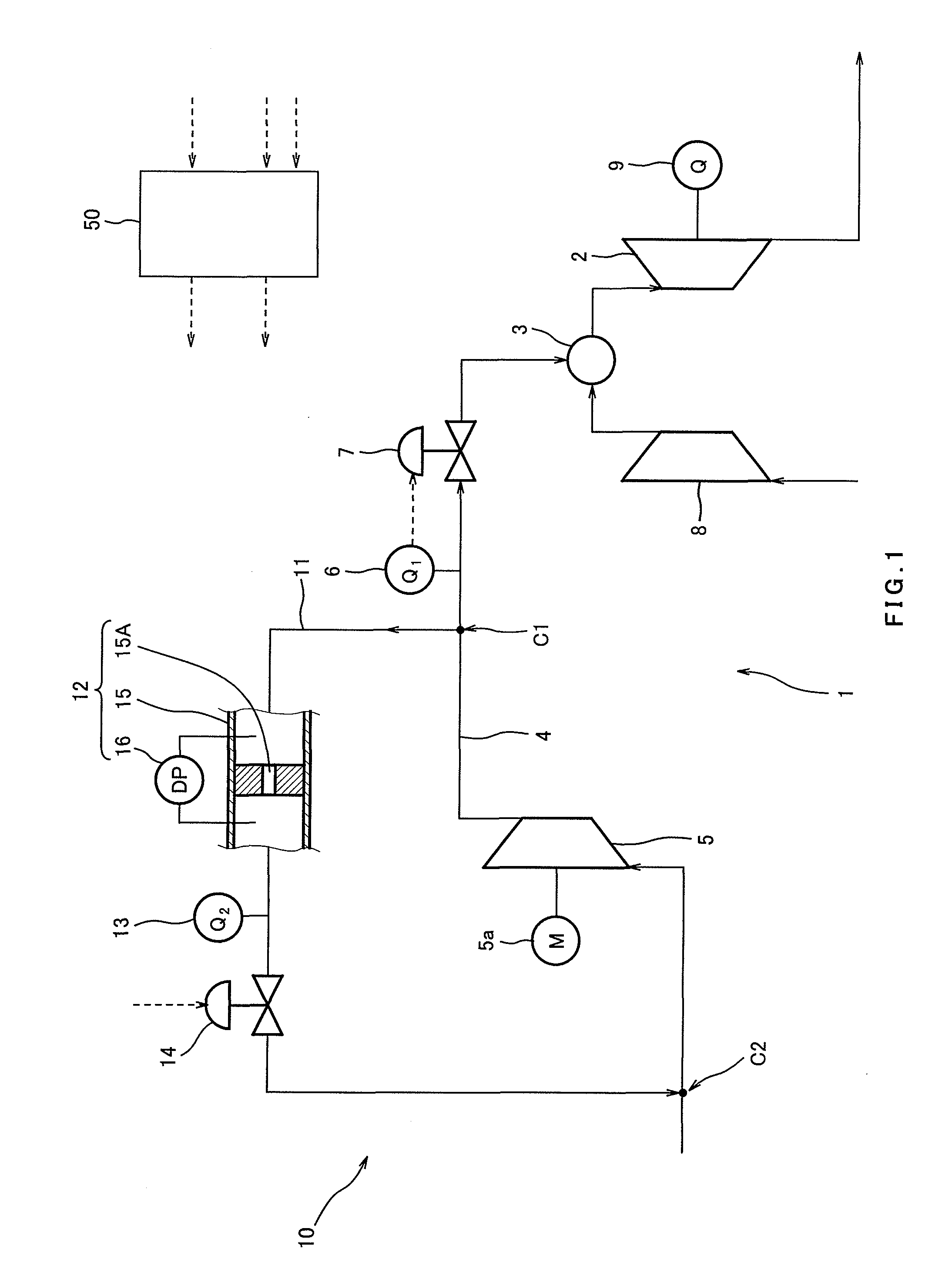

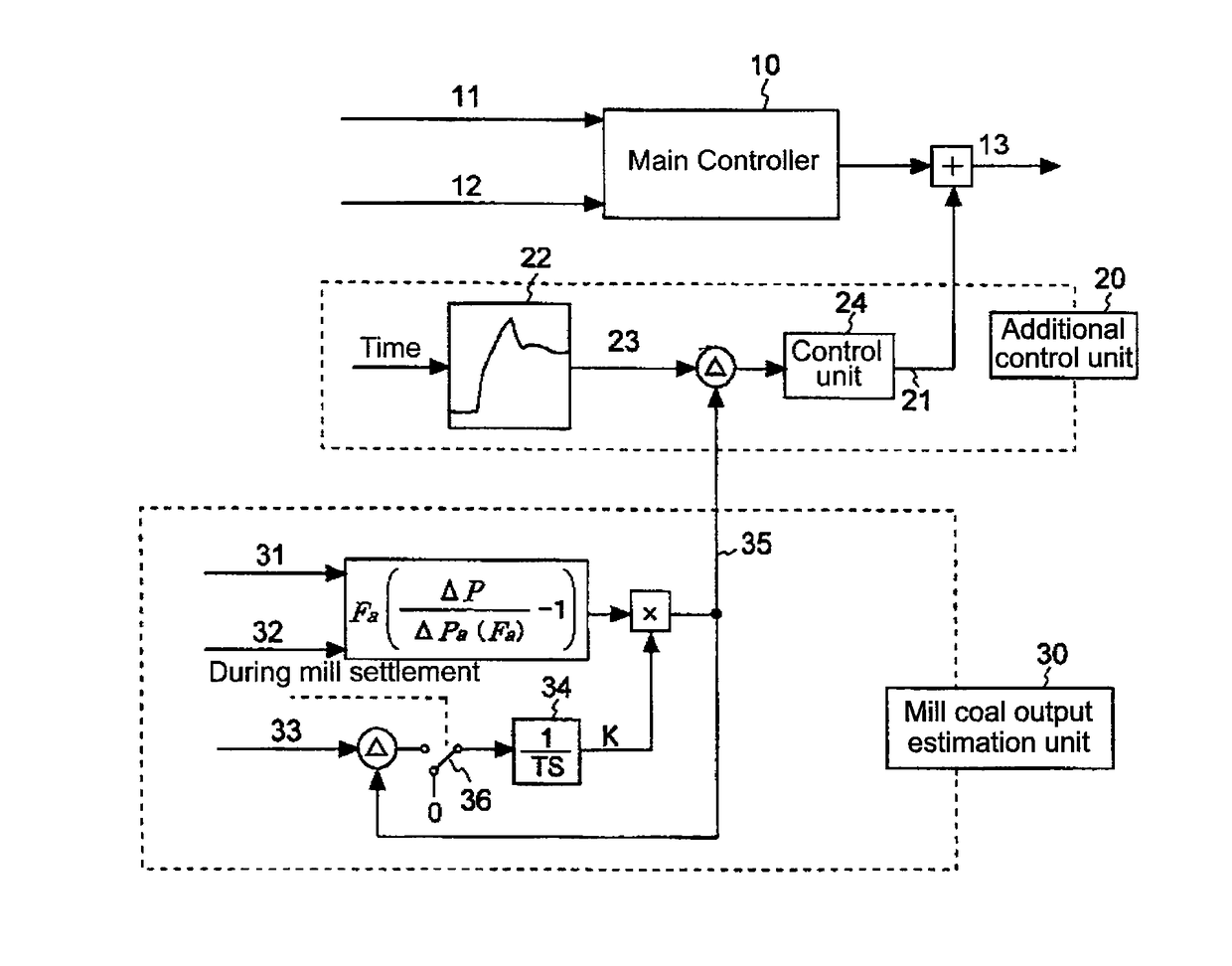

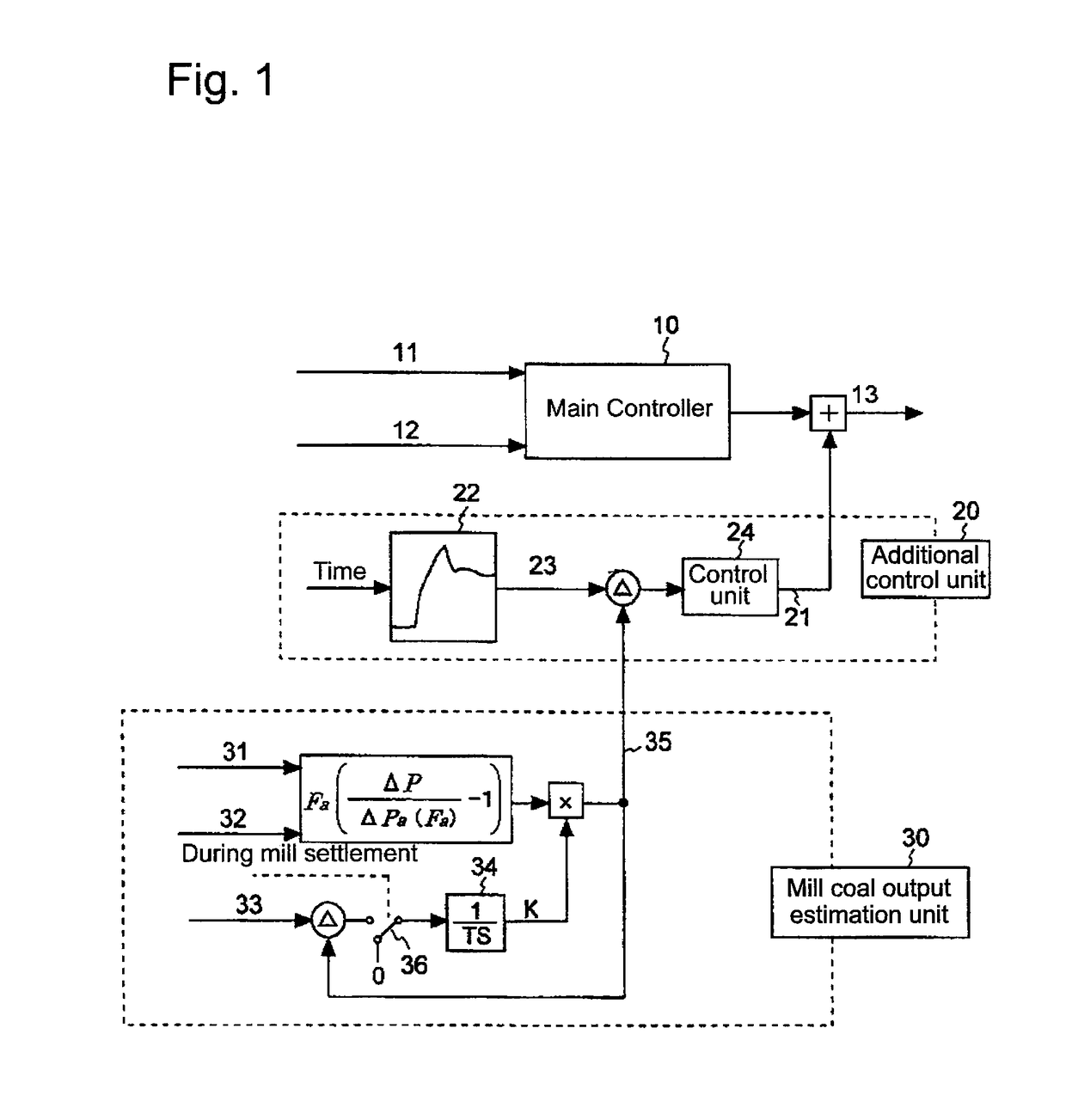

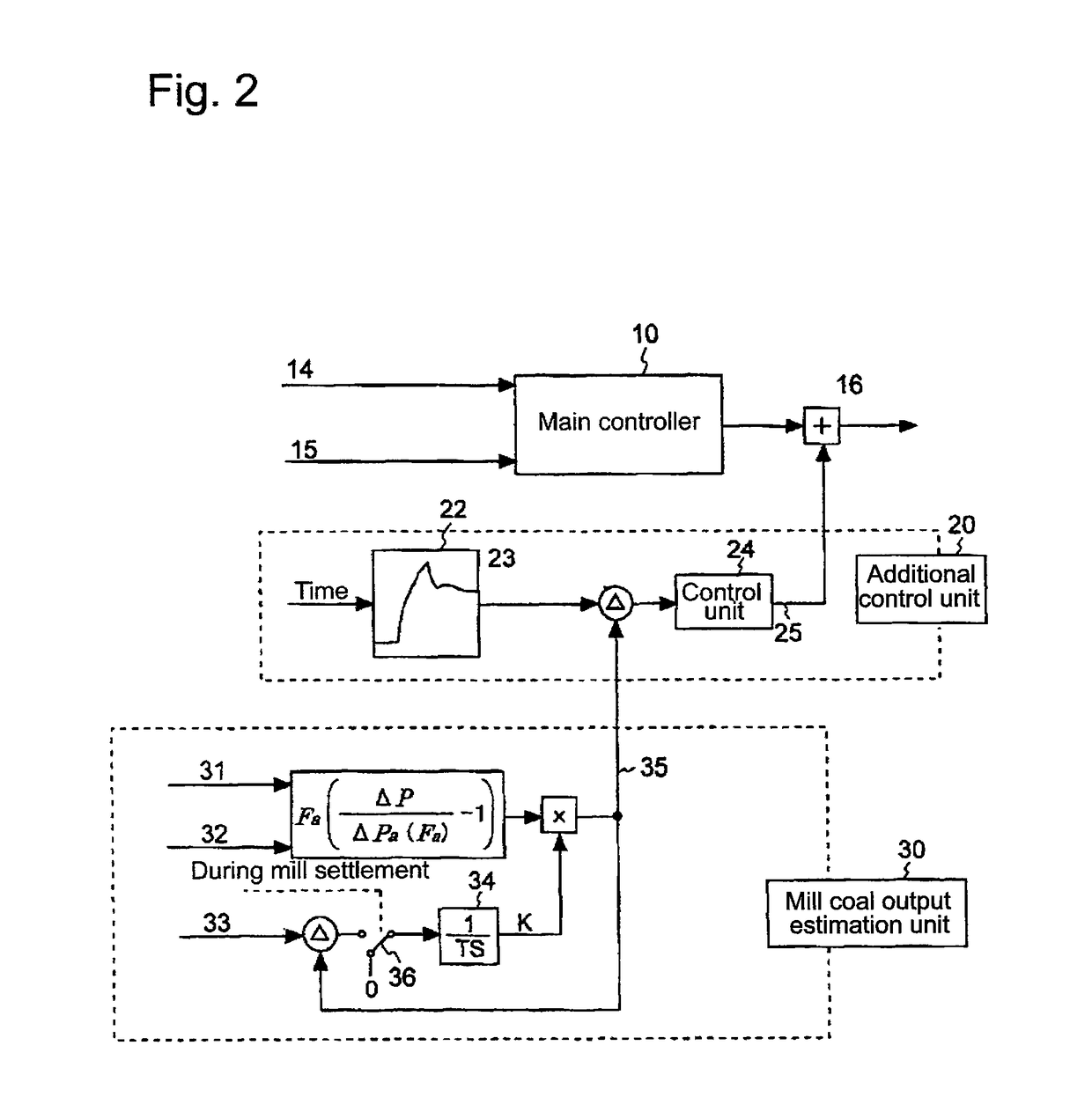

Control device of coal pulverizer

ActiveUS20100326337A1Stable response controlAvoid large deviationFuel supply regulationSolid fuel pretreatmentProcess engineeringCoal

There is provided a control device of a coal pulverizer which enables estimation of a coal output with a precision suited for a purpose. In a control device of a coal pulverizer which pulverizes coal by the coal pulverizer and estimates coal output by which the pulverized coal is output to a boiler, the control device includes a main operation circuit which calculates a command signal associated with a coal feed rate on the basis of detection data from a boiler or a power generator connected to the boiler, and an additional control unit which calculates the deviation between a standard coal output pattern preset in the coal pulverizer, and a current coal output pattern, and adds a calculation result by the additional control unit to the main operation circuit as a correction signal.

Owner:MITSUBISHI POWER LTD

Device for controlling coal mill

ActiveCN101945707AStable controlStability response controlSolid fuel pretreatmentBoiler controlProcess engineeringCoal

Disclosed is a device for controlling a coal mill capable of estimating the amount of coal outputted with a desired accuracy. The device estimates the amount of coal pulverized by the coal mill and outputted to a boiler. The device includes a main computing circuit for computing a command signal relating to the amount of coal supplied from detected data sent from the boiler or a generator connected to the boiler and an additional control unit for computing the difference between a normal amount-of-coal-outputted pattern predetermined for the coal mill and the current amount-of-coal-outputted pattern. The result of the computation by the additional control unit is applied to the main computing circuit as a correction signal.

Owner:MITSUBISHI POWER LTD

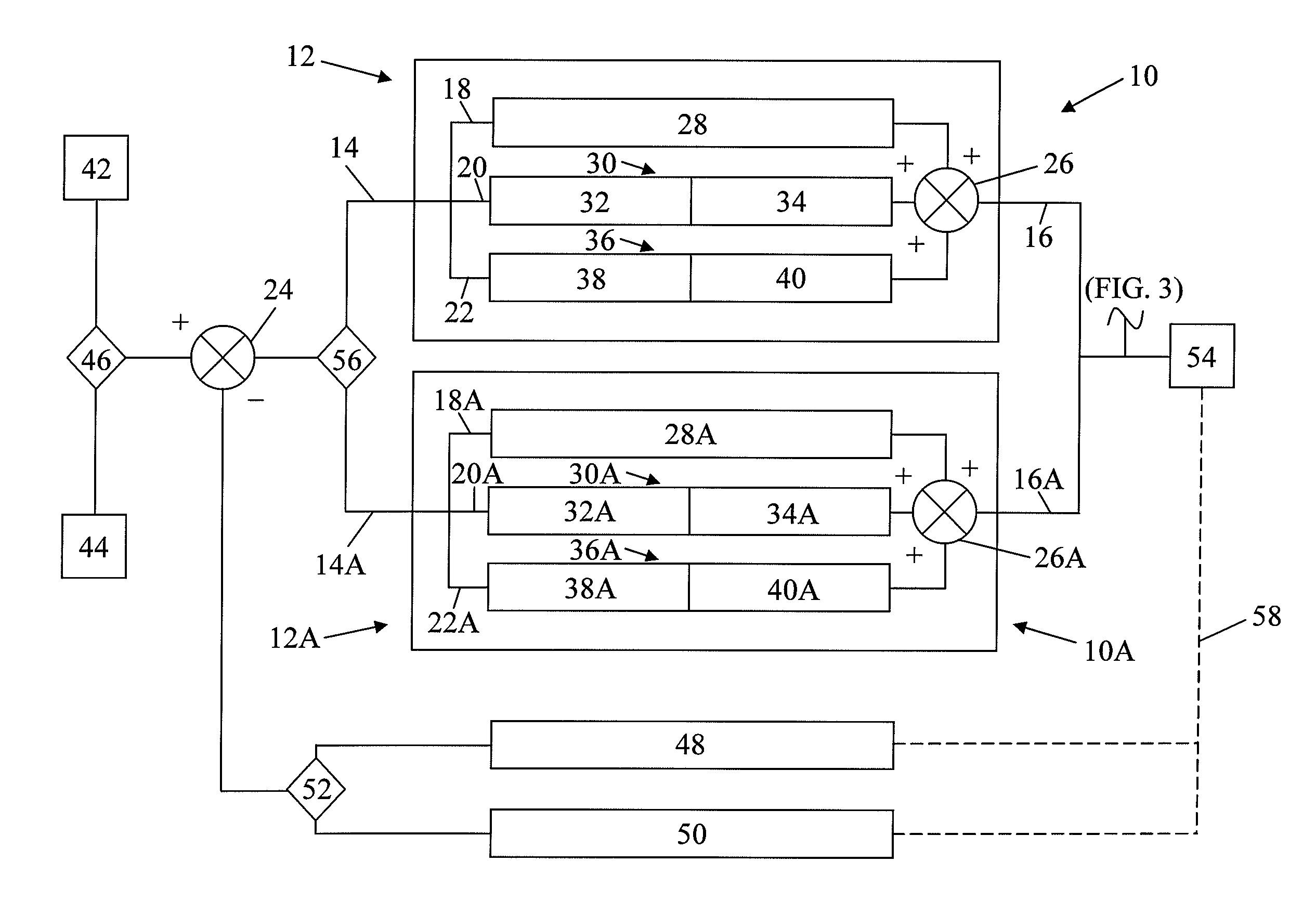

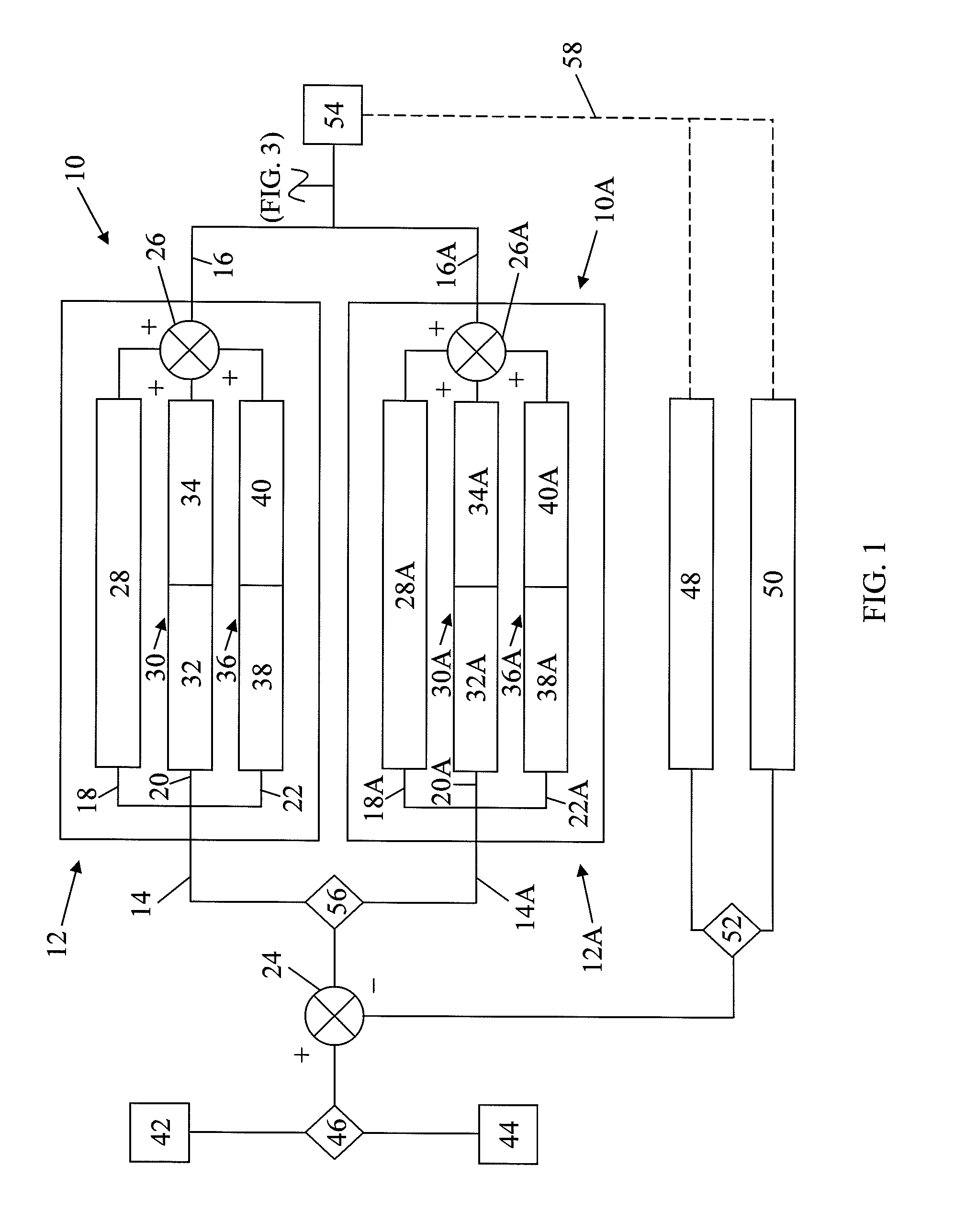

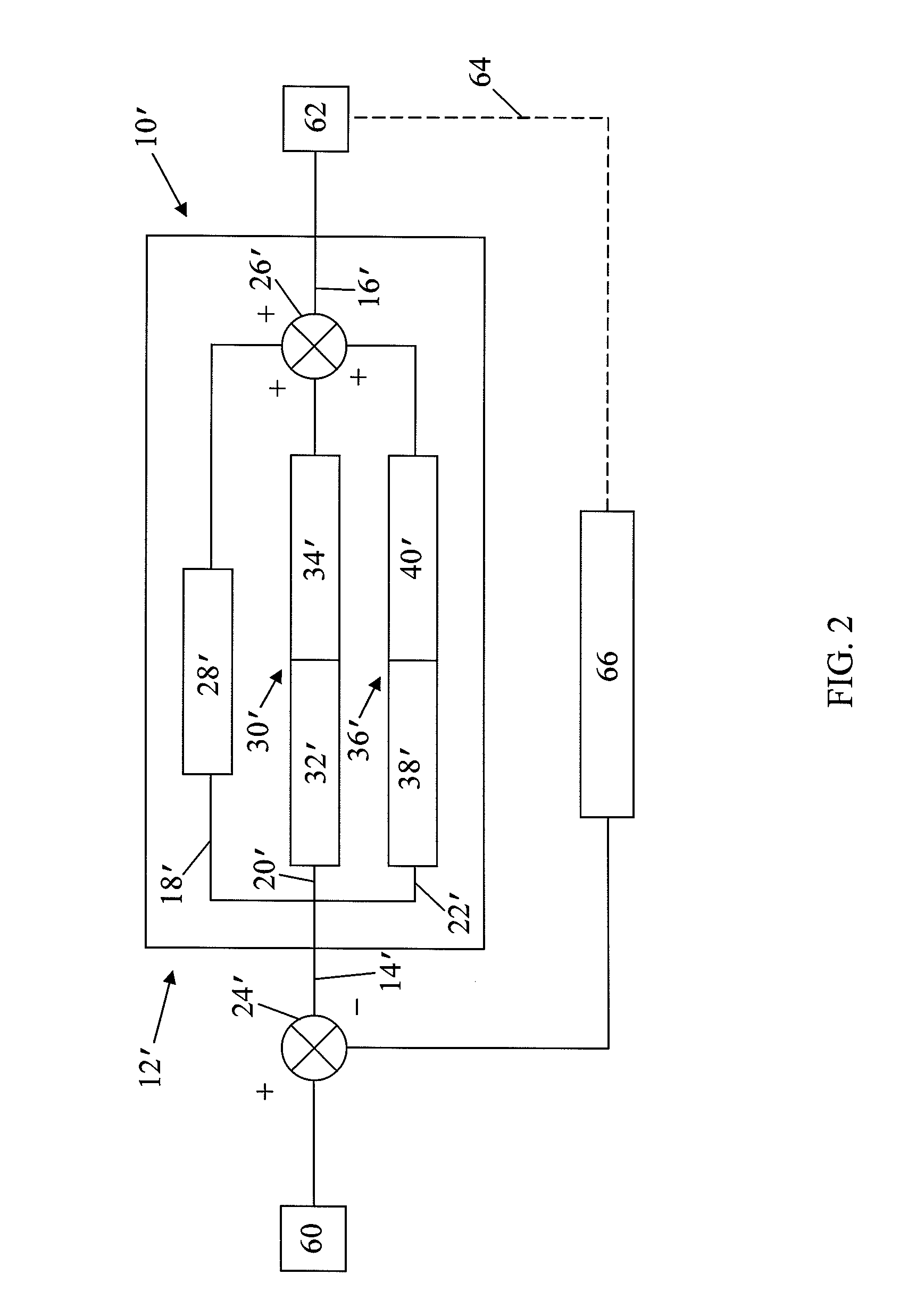

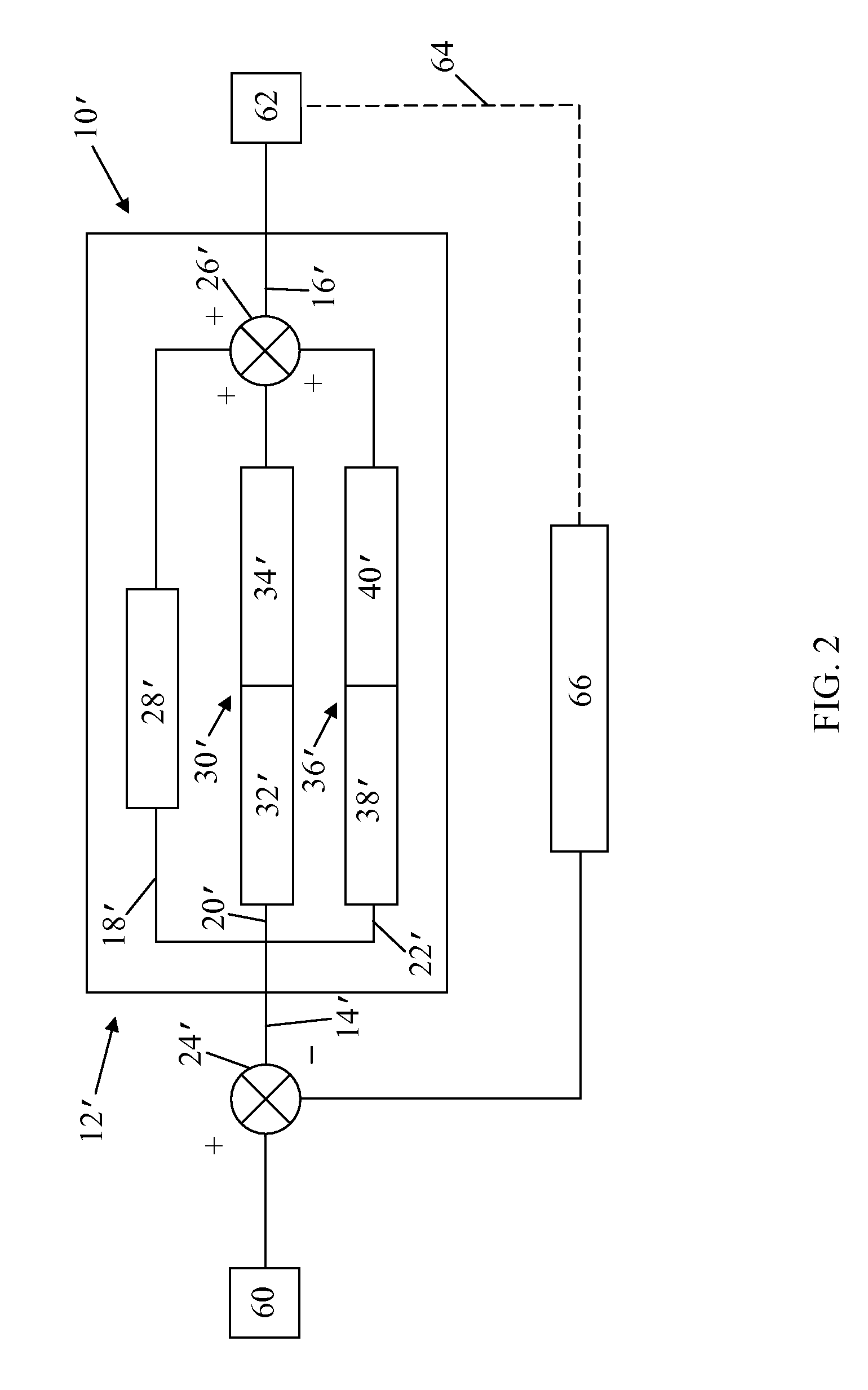

Process control methodologies for biofuel appliance

InactiveUS7457689B2Stoves/ranges with convection heatingTemperatue controlOperating pointLoop control

Apparatus for controlling the operation of a biomass stove utilizes three proportional integral derivative (PID) controllers as part of a closed loop to control the fuel feed rate, the convection fan speed and the combustion fan speed. The first loop controls room temperature, the second loop controls the convection fan speed and the third loop controls the combustion fan. Appropriate temperature readings are utilized for the first and second loop. The third loop, which utilized feedback of the ratio between the heat exchanger temperature to the exhaust temperature, in addition to measuring these temperatures also references a library of look-up tables of such ratios over the entire heat range of the stove that have been correlated to combustion efficiency, as an input. This enables the operator to optimize the heat output for any operating point.

Owner:HESTIA HEATING PRODS

Self diagonostic flame ignitor

InactiveUS7492269B2Reliable actionImprove reliabilityBurnersCombustion signal processingThermodynamicsProcess engineering

Techniques for monitoring operation of a flame ignitor are provided. In one embodiment, multiple inputs are received. The inputs are received from at least one of a first group of inputs and a second group of inputs. The first group includes a flame rod voltage, a stop signal for deactivation of the flame ignitor, a fuel supply interruption signal, and an air supply interruption signal. The second group includes a start signal for activation of the flame ignitor, and a flame proven signal indicating presence of a flame produced by the flame ignitor. If inputs from the first group are received, a cause of a failure of the flame ignitor is determined. If inputs from the second group are received, a reliability of the flame ignitor is determined.

Owner:GENERAL ELECTRIC TECH GMBH

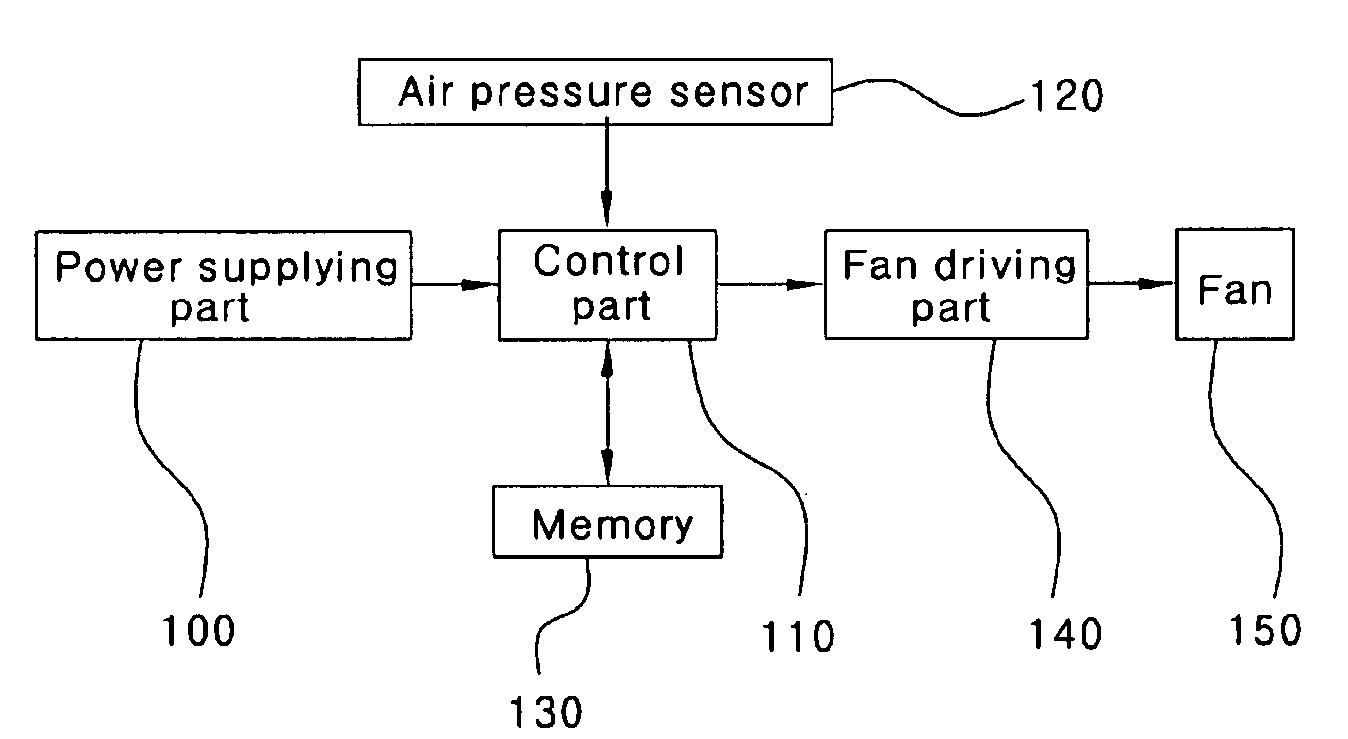

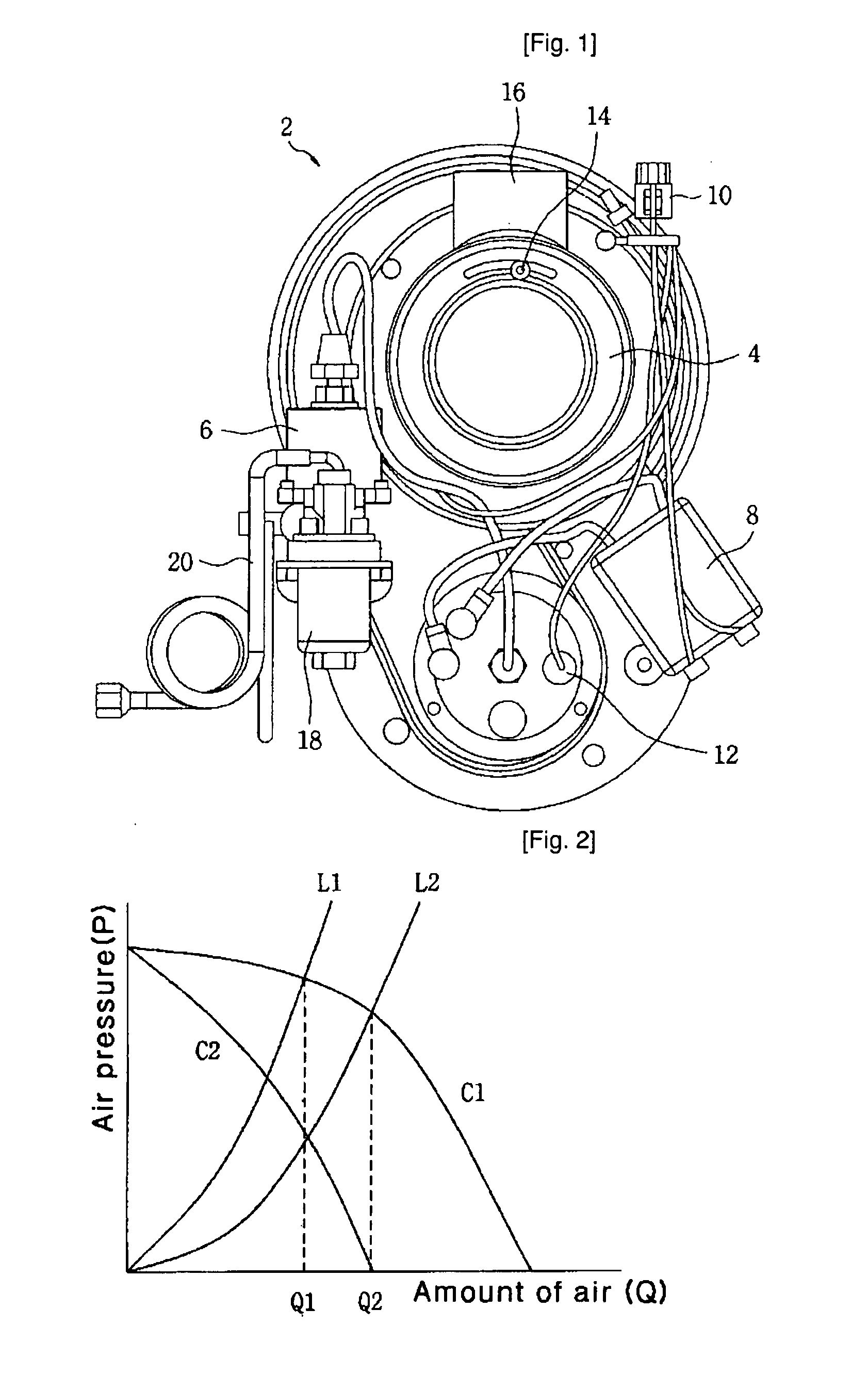

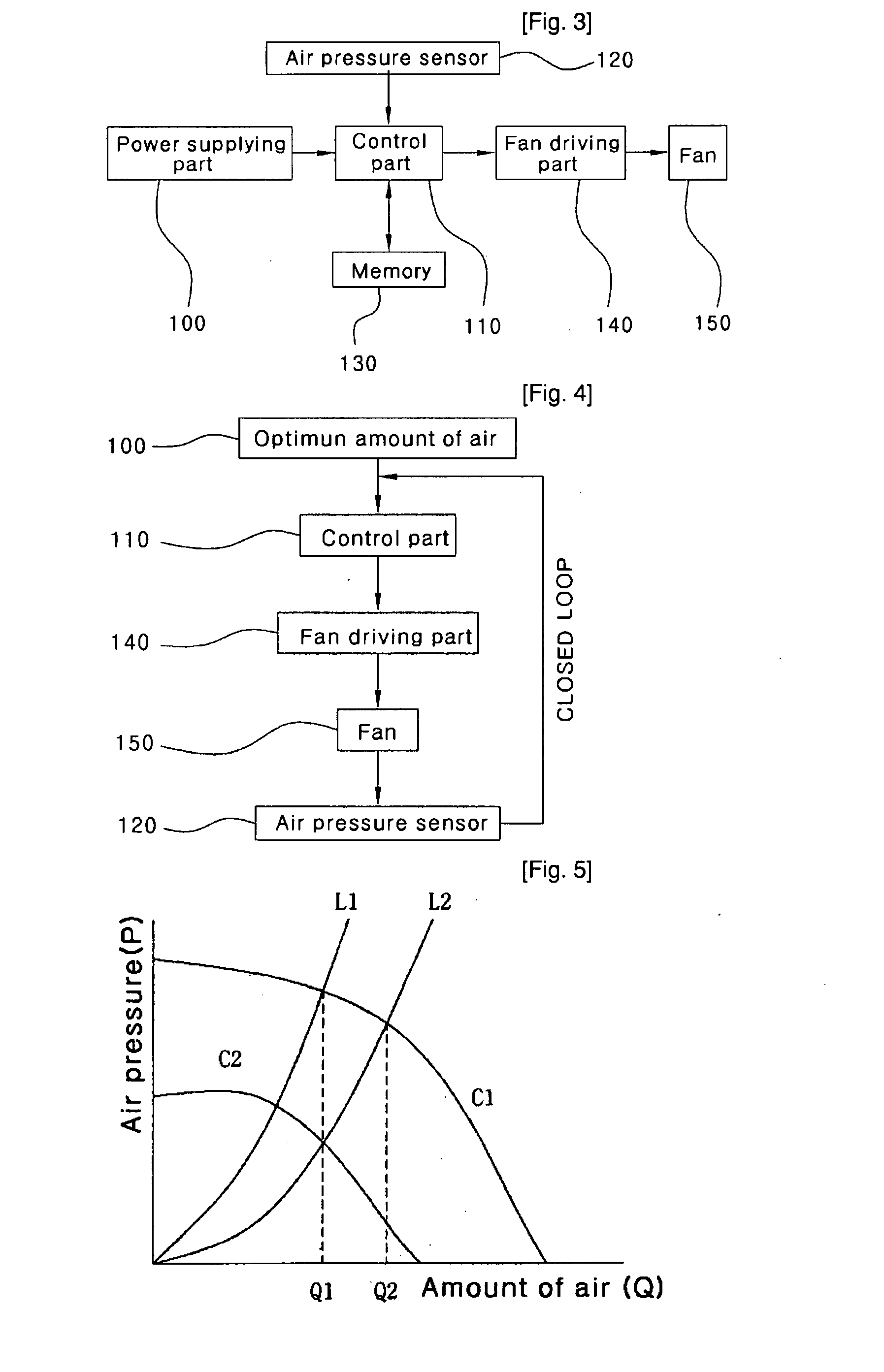

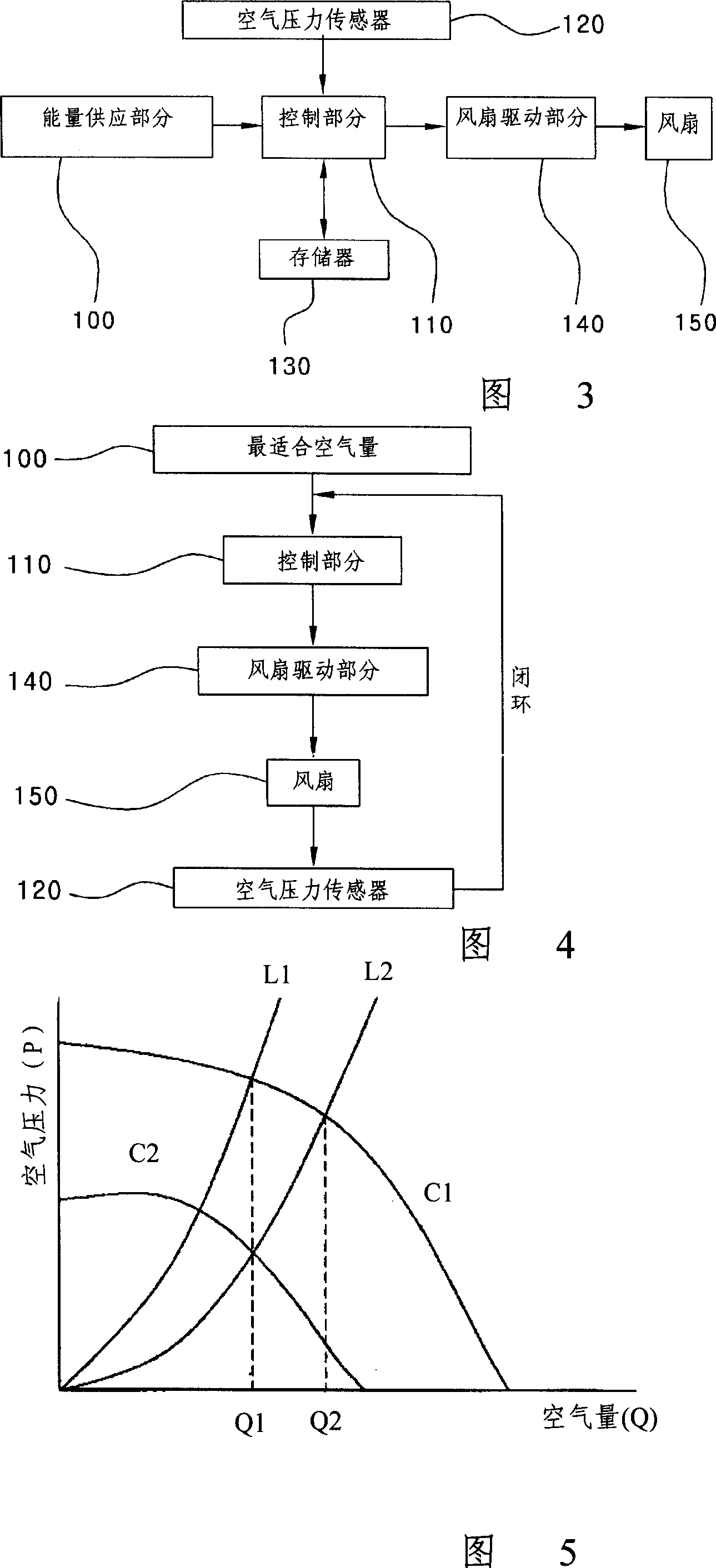

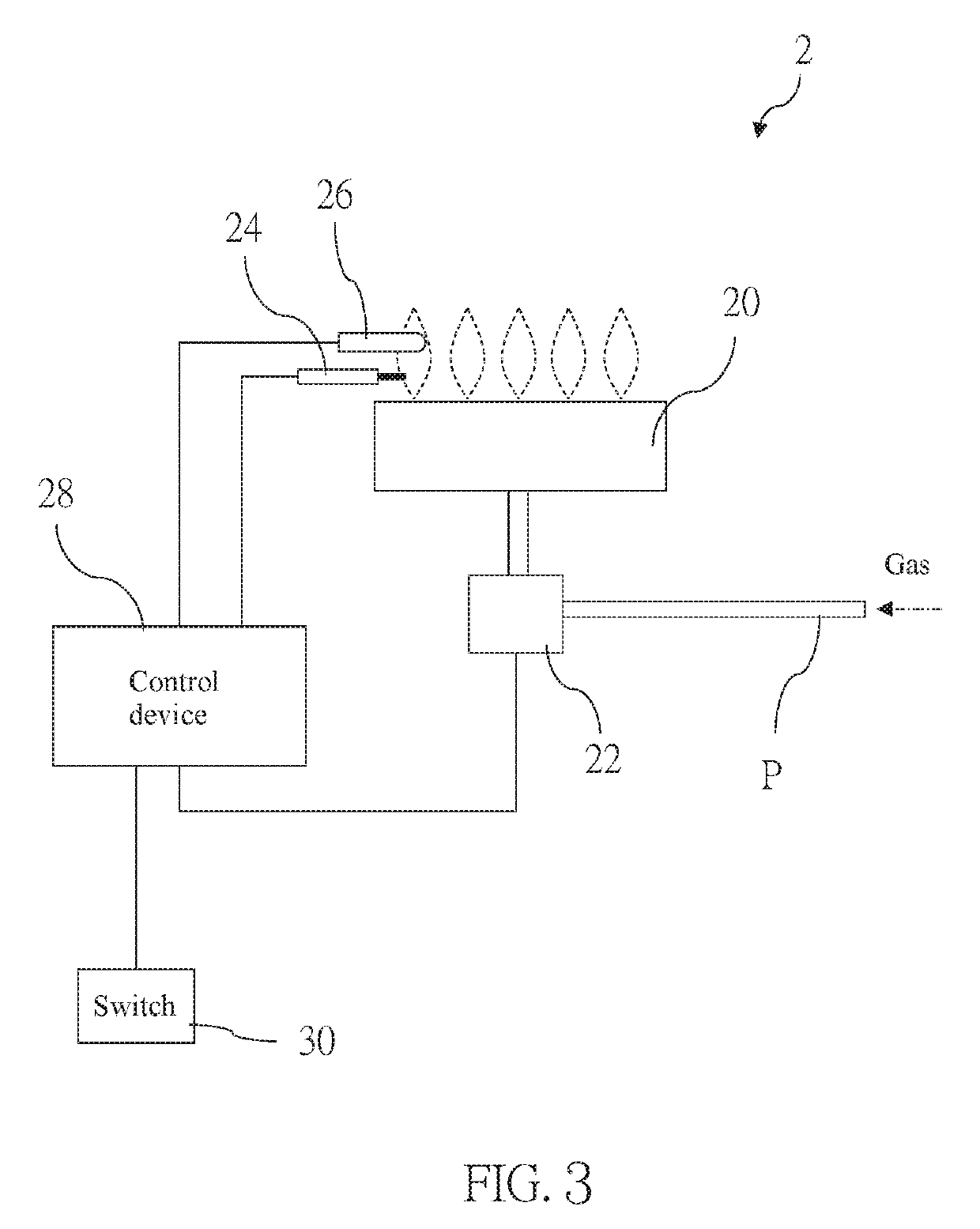

System and Control Method of Oil Burner's Suitable Burning Ratio Using Air Pressure Sensor

InactiveUS20080118877A1Stably control air fuel ratioBurnersFluid heatersControl theoryGas pressure transducer

Disclosed are a system and a method for precisely controlling an air fuel ratio of an oil burner, which is extensively used in a household boiler, an industrial boiler, or a heater, using an air pressure sensor. The system includes a power supplying part, a fan for supplying air required for combustion of the oil burner by receiving driving voltage from the power supplying part, a fan driving part serving as a controller which drives the fan, an air pressure sensor, which is installed at a side of a flow path of air supplied from the fan so as to detect an amount of the supplied air, and a control part for outputting an optimum RPM of the fan to the fan driving part by comparing a signal detected by the air pressure sensor with preset data related to an optimum amount of air. The method includes the steps of detecting an amount of air being supplied through a fan using the air pressure sensor, calculating an optimum RPM of the fan using a controller by comparing a signal about the amount of the air with preset data related to an optimum amount of air, outputting the RPM calculated by means of the controller to a fan driving part, and rotating the fan according to the calculated RPM input into the fan driving part.

Owner:KYUNGDONG NETWORK

Porous Medium Premixing Combustor

ActiveUS20190353346A1Effectively avoid occurrenceAvoid it happening againFlow mixersTransportation and packagingCombustorPorous medium

A porous-medium premixing combustor is provided, which includes: an air-fuel gas mixer, a combustor body, a thermocouple, an ignition electrode, and a detecting electrode. The combustor body includes a casing connected to the air-fuel gas mixer; an outer and an inner burner-block, wherein the outer burner-block and the casing are connected, forming a square chamber, and the inner burner-block is provided inside the square chamber, with a via hole communicating with a pipe; and a mixed gas distributing plate, an ordered porous plate, a small-pore foamed ceramic plate, and a big-pore foamed-ceramic plate sequentially provided along an axis direction of the via hole of the inner burner-block. The thermocouple is provided at the casing and extends into the square chamber. The ignition electrode is provided close to an end of the big-pore foamed-ceramic plate. The detecting electrode is provided close to an exit end of the big-pore foamed-ceramic plate.

Owner:WUHAN UNIV OF SCI & TECH

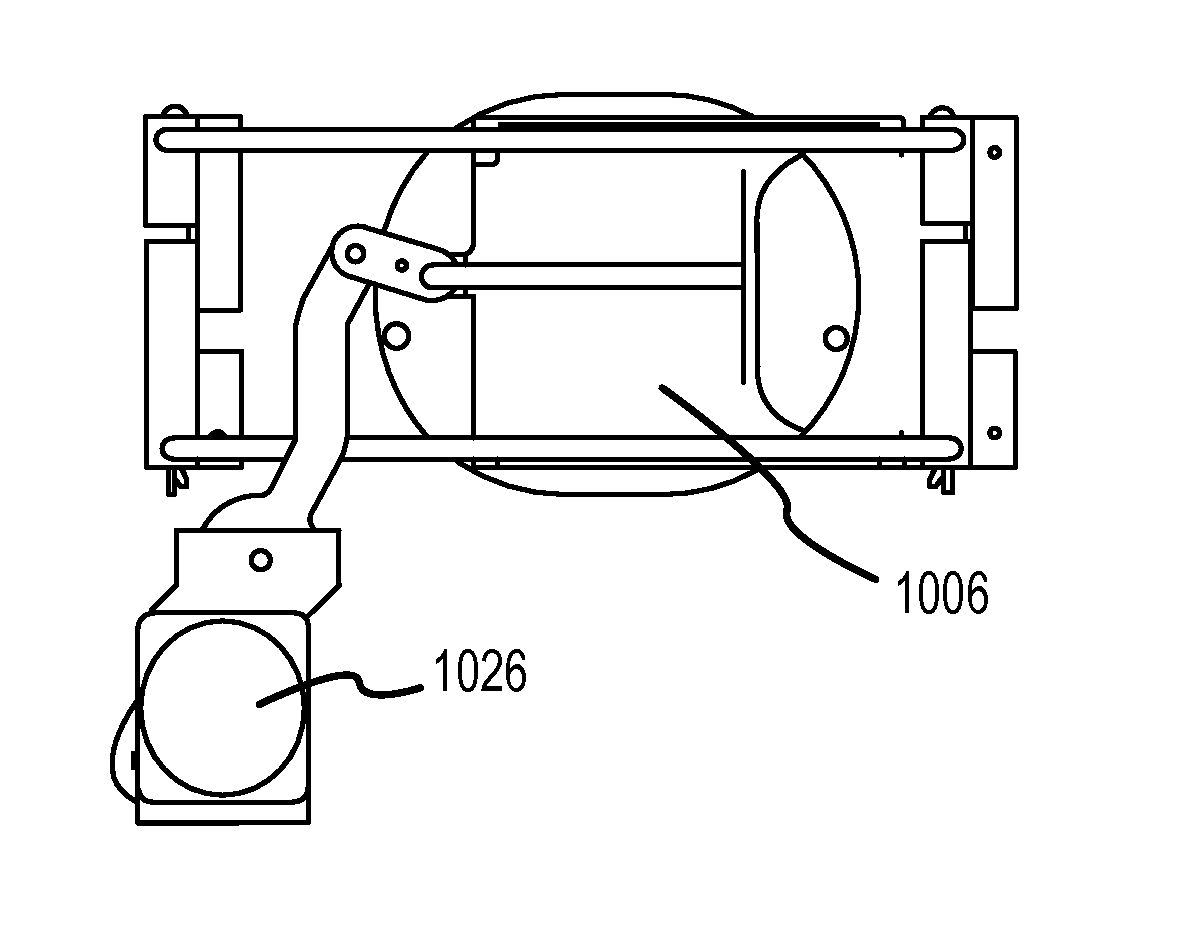

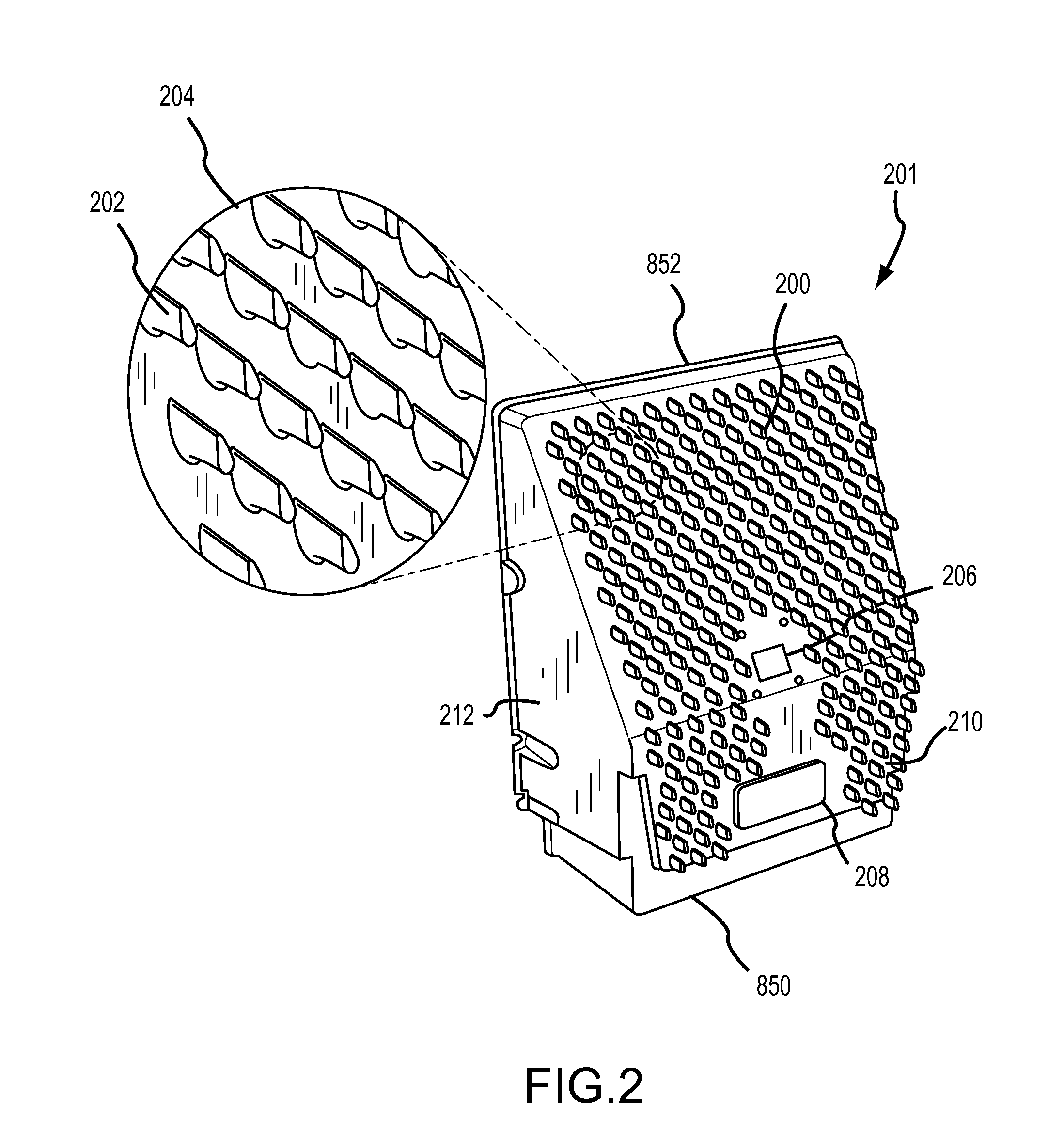

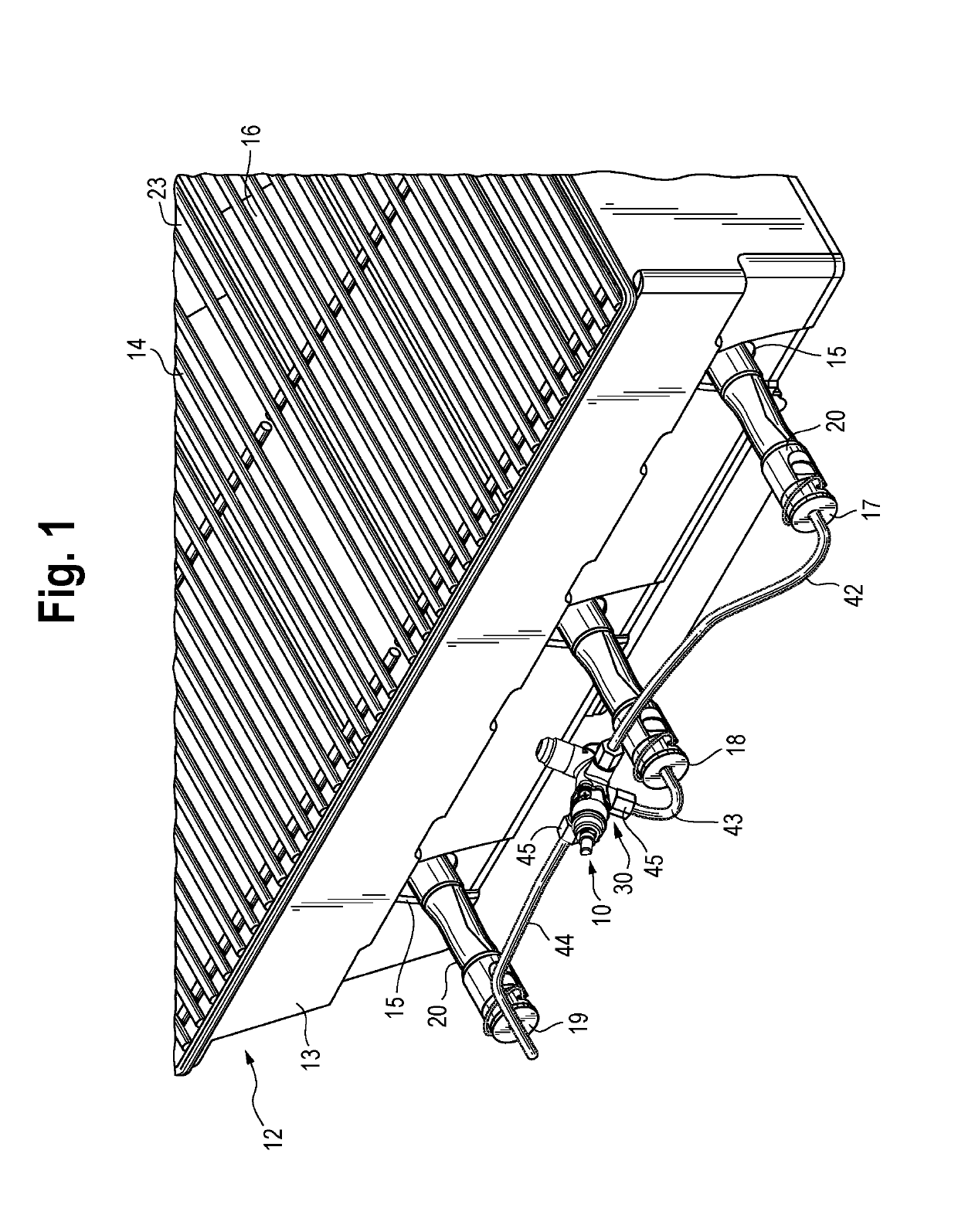

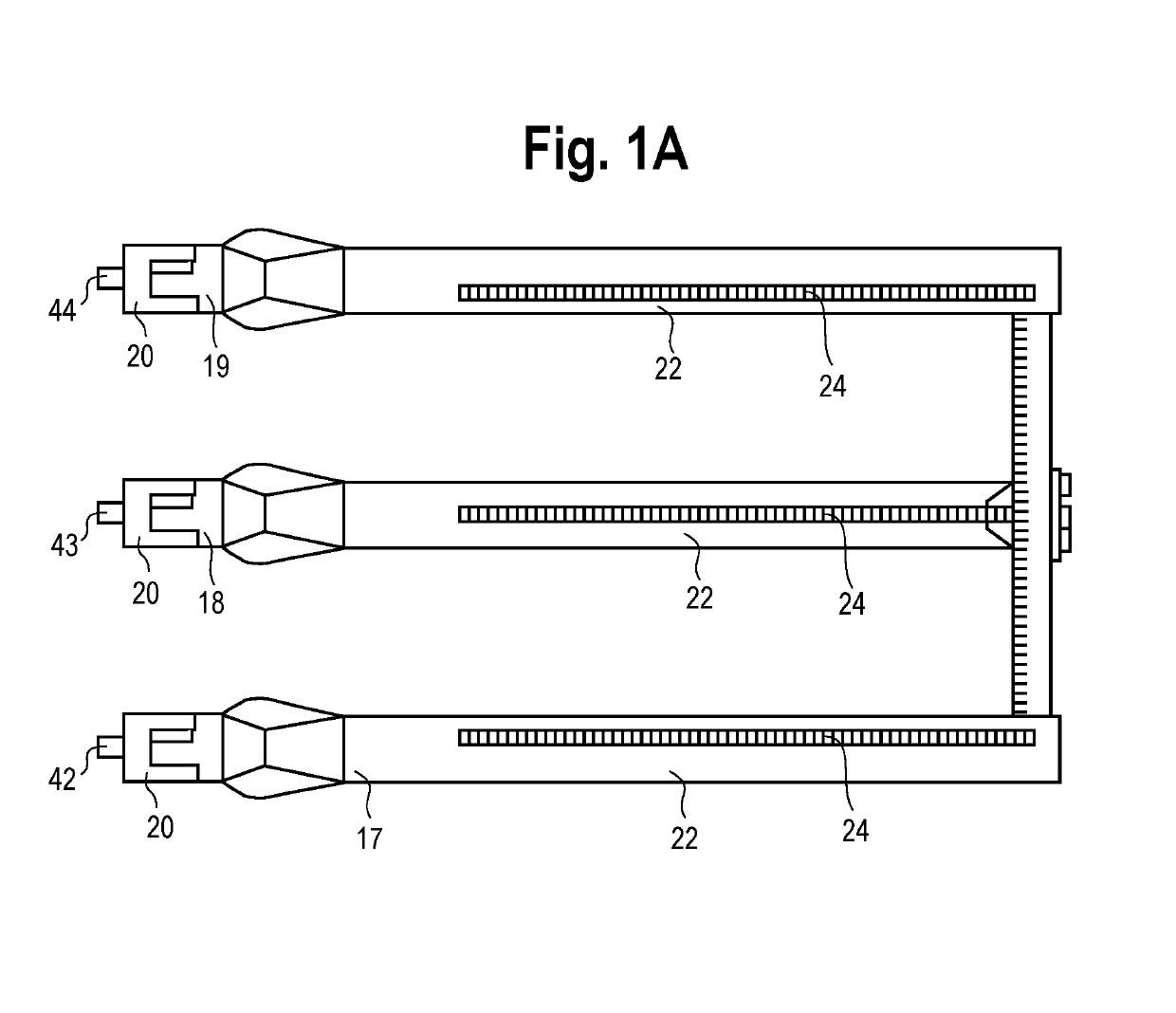

Pellet stove

According to embodiments of the present invention, a pellet stove includes a firepot assembly with a bottom plate slideable along rails to move between a closed position during combustion in the firepot and an open position during ash removal. According to other embodiments, a firebox or combustion enclosure includes a plurality of airfoils formed on the inner and outer surfaces of the enclosure to facilitate heat exchange between exhaust gases flowing across the inner surface of the enclosure and air blown across the outer surface of the enclosure. According to some embodiments, the airfoils and enclosure are of integral unibody construction. According to yet other embodiments, a user sets parameters via a wall control unit, and a stove control unit receives the parameters and automatically controls fuel feed rate, ignition, convection blower, combustion blower, and / or firepot cleaning based on the one or more parameters.

Owner:HNI TECH INC

Method for detecting onset of uncontrolled fuel in a gas turbine combustor

ActiveUS7950238B2Improve reliabilityFuel supply regulationContinuous combustion chamberCombustorLiquid fuel

Owner:GE INFRASTRUCTURE TECH INT LLC

Combustion Method and System

InactiveUS20080250990A1Rapidly combustedRapidly devolatilizedCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorCombustion chamber

Owner:CLEAN COMBUSTION TECH

System and control method of oil burner's suitable burning ratio using air pressure sensor

InactiveCN101115955AStable control of air-fuel ratioControl air fuel ratioFluid heatersBurnersControl theoryAir–fuel ratio

Disclosed are a system and a method for precisely controlling an air fuel ratio of an oil burner, which is extensively used in a household boiler, an industrial boiler, or a heater, using an air pressure sensor. The system includes a power supplying part, a fan for supplying air required for combustion of the oil burner by receiving driving voltage from the power supplying part, a fan driving part serving as a controller which drives the fan, an air pressure sensor, which is installed at a side of a flow path of air supplied from the fan so as to detect an amount of the supplied air, and a contro 1 part for outputting an optimum RPM of the fan to the fan driving part by comparing a signal detected by the air pressure sensor with preset data related to an optimum amount of air. The method includes the steps of detecting an amount of air being supplied through a fan using the air pressure sensor, calculating an optimum RPM of the fan using a controller by comparing a signal about the amount of the air with preset data related to an optimum amount of air, outputting the RPM calculated by means of the controller to a fan driving part, and rotating the fan according to the calculated RPM input into the fan driving part.

Owner:KYUNGDONG NETWORK

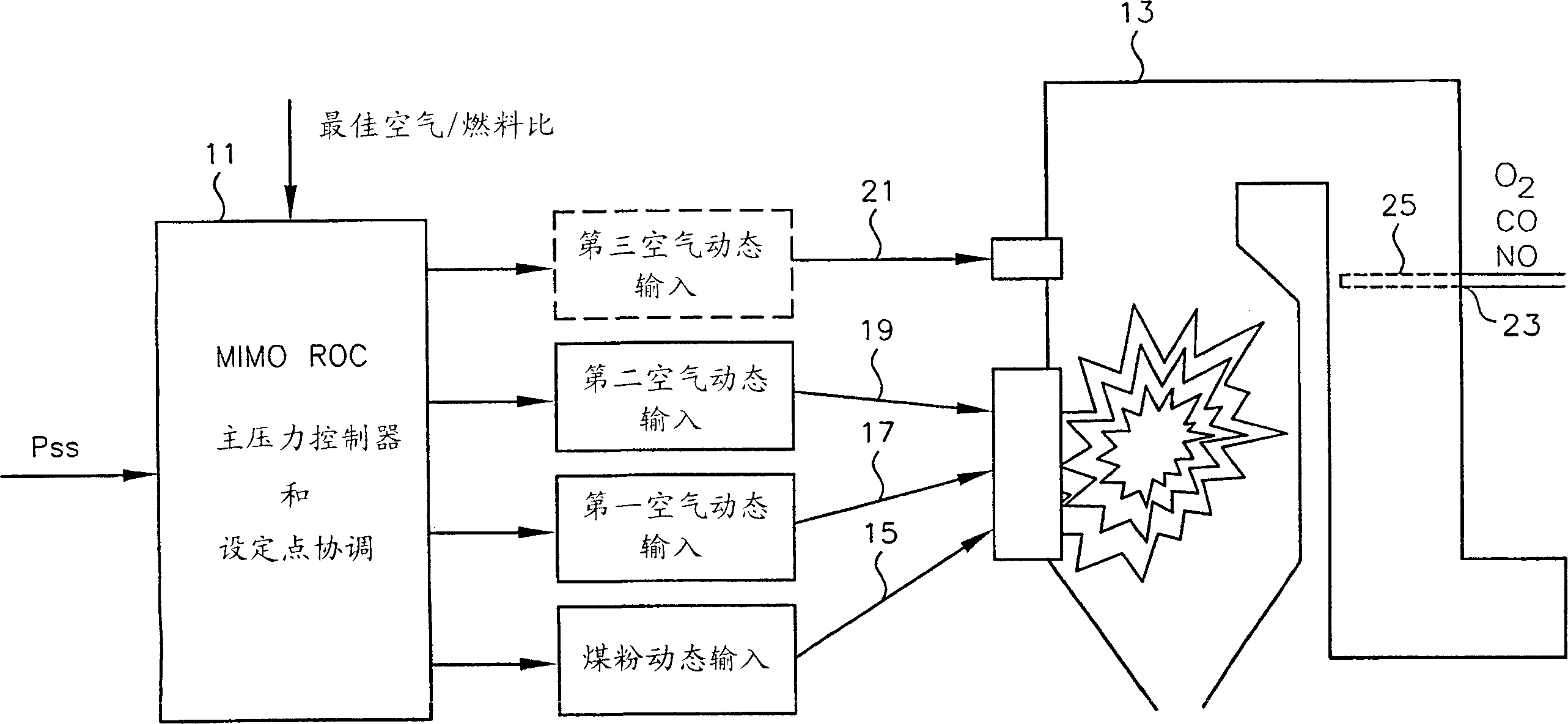

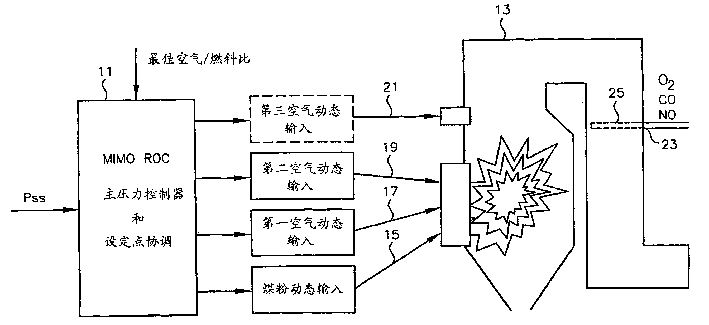

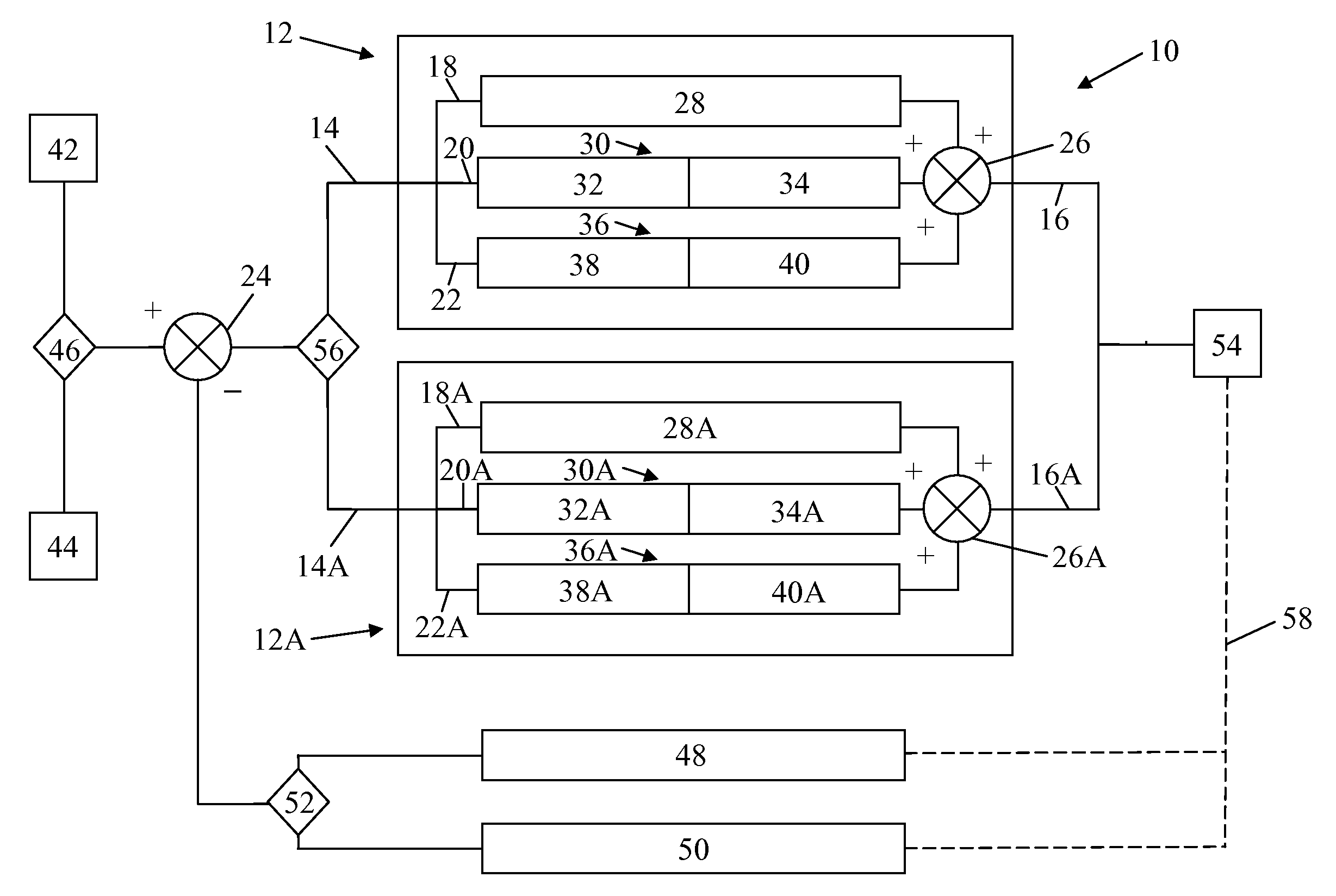

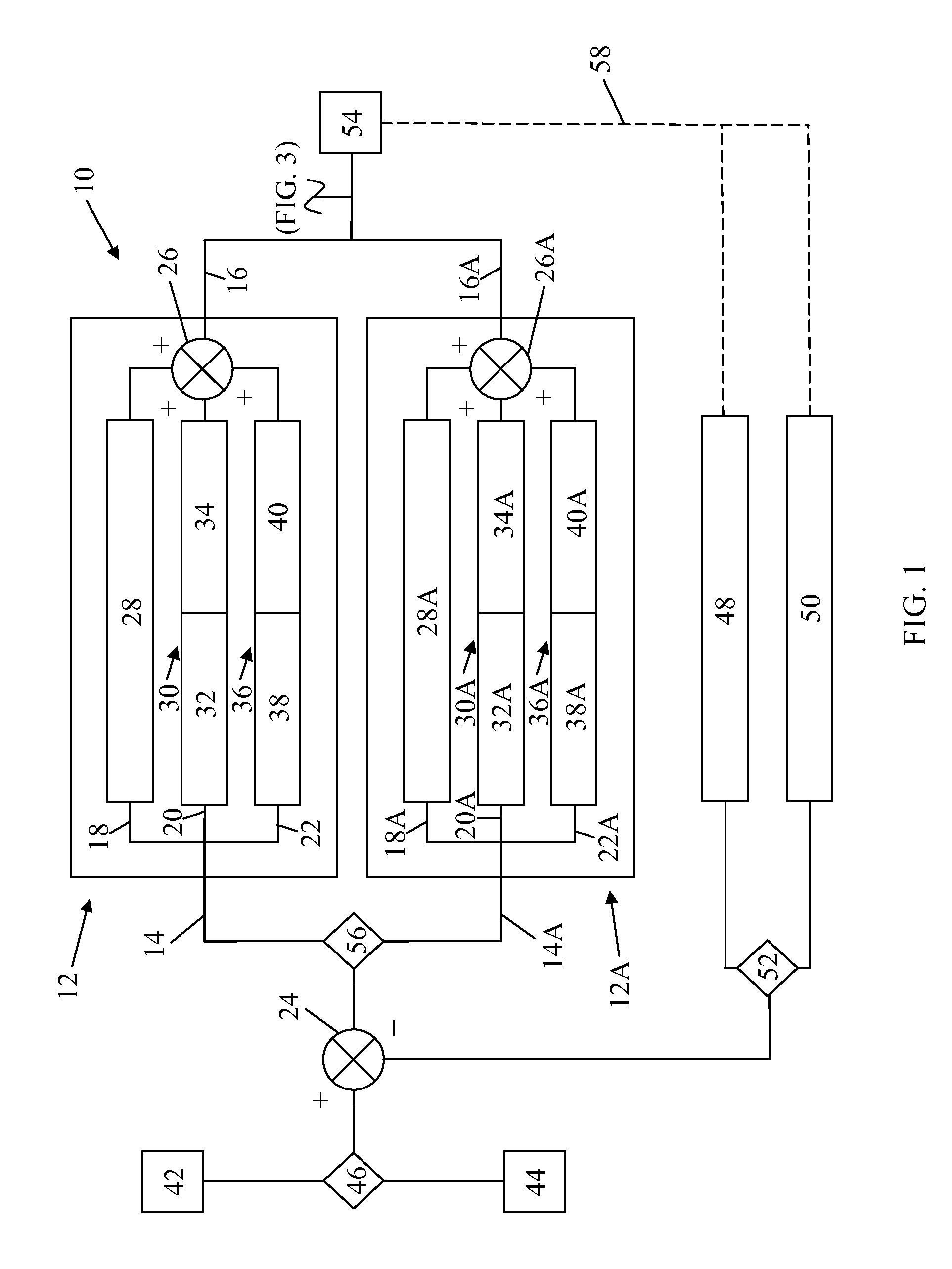

Combustion optimization with inferential sensor

InactiveCN1541315AImprove efficiencyFuel supply regulationCombustion signal processingCombustionFlue gas

A method and system for combustion of fuel in a boiler in which flue gasses are produced. The boiler includes a source of fuel, a source of air, and a controller for controlling the ratio of the source of air and the source of fuel inputted into the boiler. A sensor is used for measuring the concentration of oxygen in the flue gasses. The controller is adapted to calculate the amount of air entering the boiler based on the amount of oxygen in the flue gasses to thereby adjust the air to fuel ratio to include calculated air input and air input from the source of air. A preferred fuel is pulverized. coal. The method and system provide for the air to fuel ratio to be adjusted to optimize efficiency as well as to minimize NOx production.

Owner:HONEYWELL INT INC

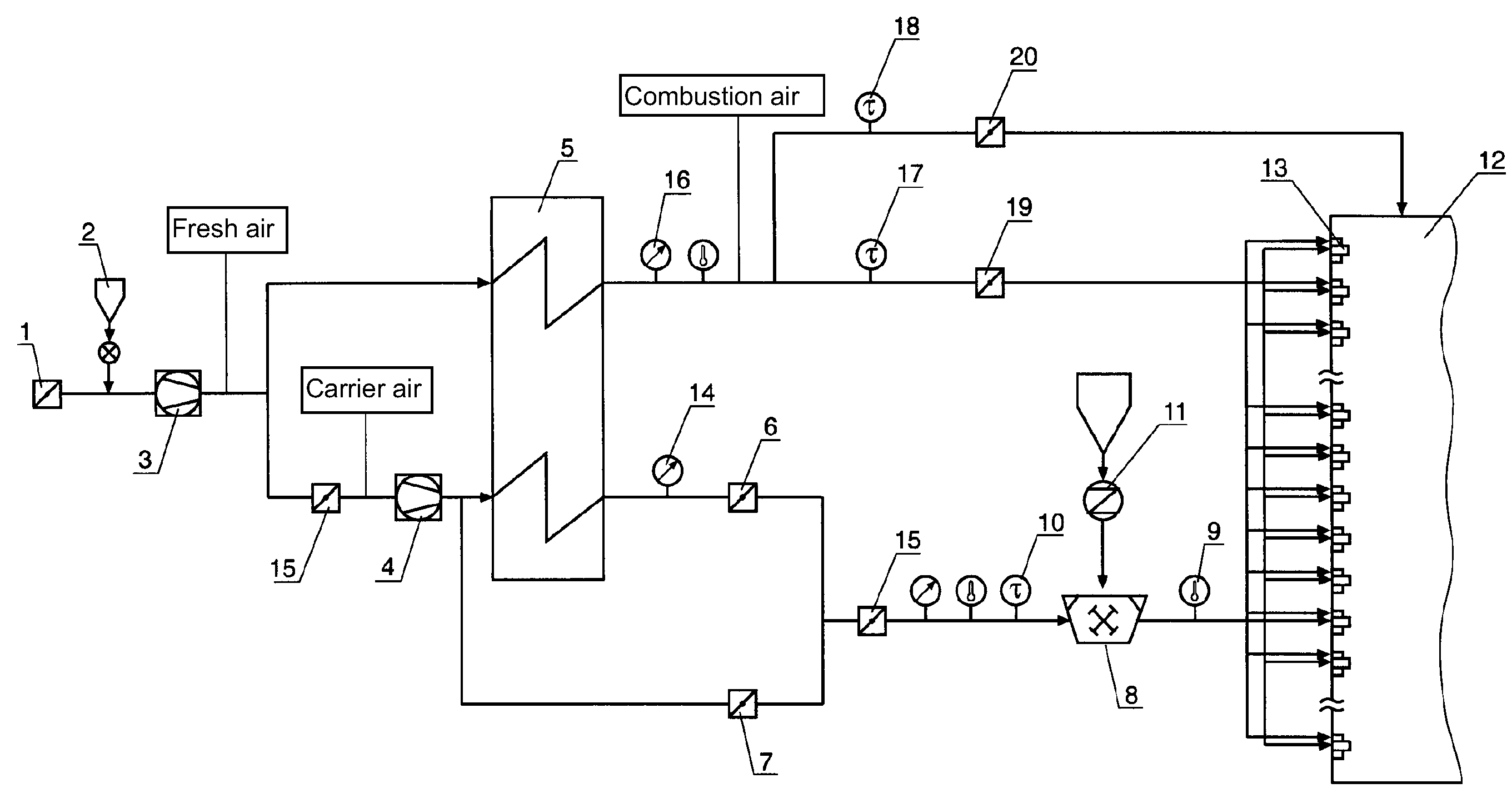

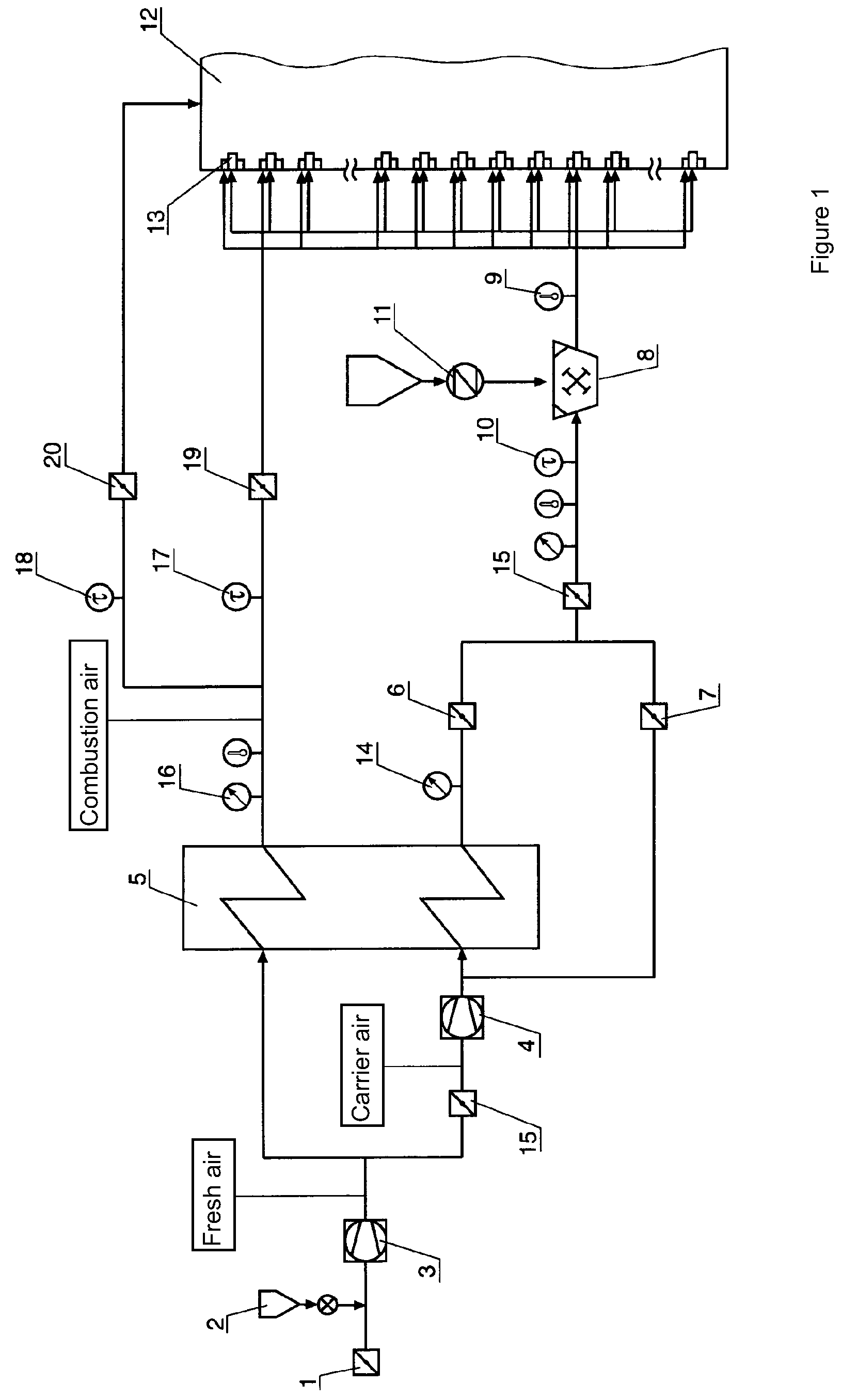

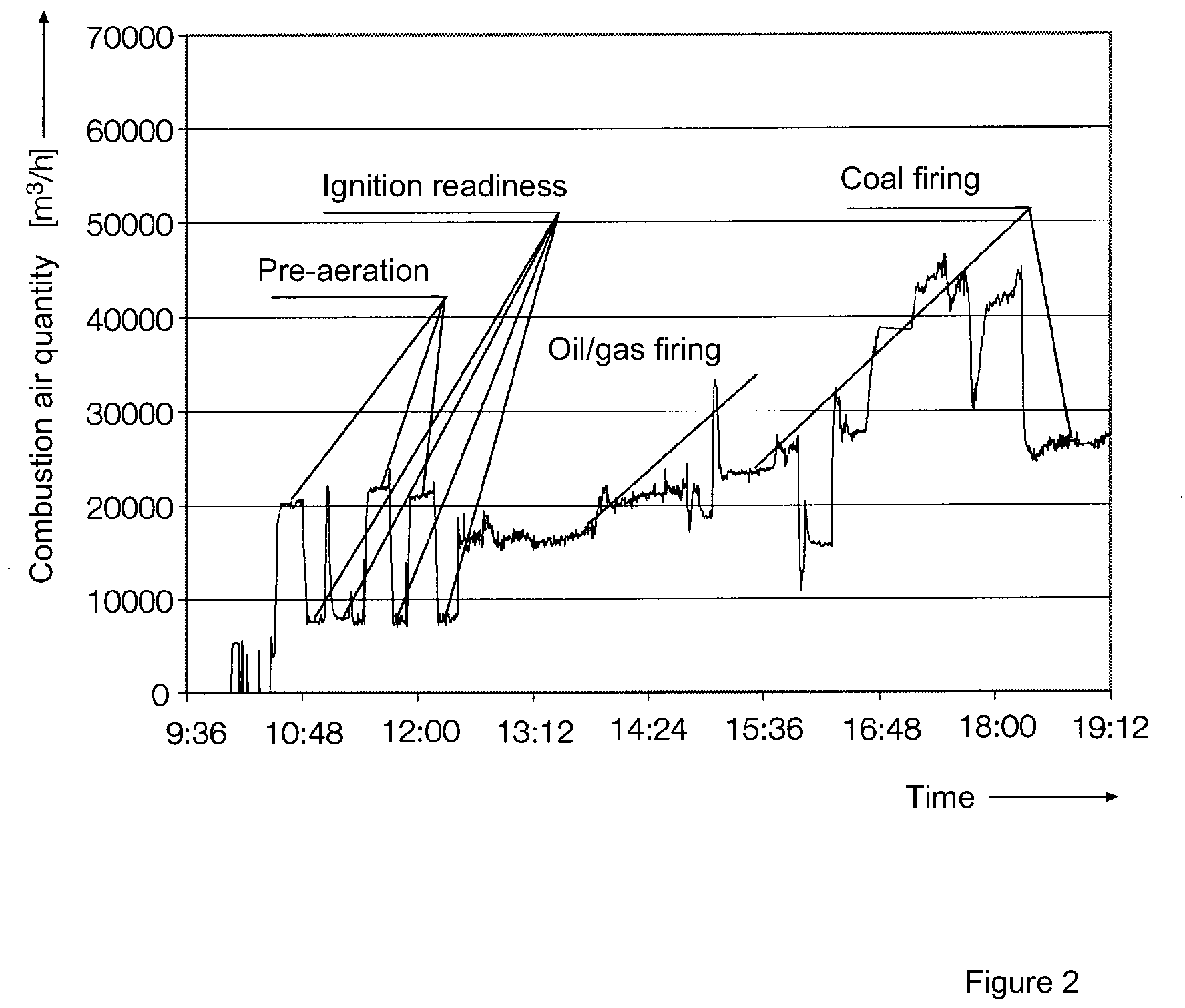

Device and method for controlling the fuel-air ratio during the combustion of ground coal in the firing system of a coal power plant

InactiveUS8601957B2Improve reliabilityReduce maintenance costsFuel feeding arrangementsSolid fuel pretreatmentElectricityMeasurement device

A device and method for controlling fuel-air ratio during combustion of ground in a coal power plant, including pneumatic delivery of ground coal to the burners and feeding combustion air to burners while controlling the combustion air and the amount of carrier air. A high reliability of control combined with low maintenance of the air mass measurement devices is achieved. This is achieved by a measurement device for measuring the amount of combustion air which, according to correlation measurement, evaluates the triboelectric effects on sensors. Between 0.1 mg and 10 mg of fine-grained particles of a diameter between 20 μm and 200 μm are introduced per m3 air into suctioned fresh air, which is carried out during the starting of the firing system. This is done by correlation measurement that evaluates triboelectric effects on sensors, arranged in series in carrier air stream in direction of flow of the carrier air.

Owner:PROMECON PROZESS & MESSTECHN CONRADS

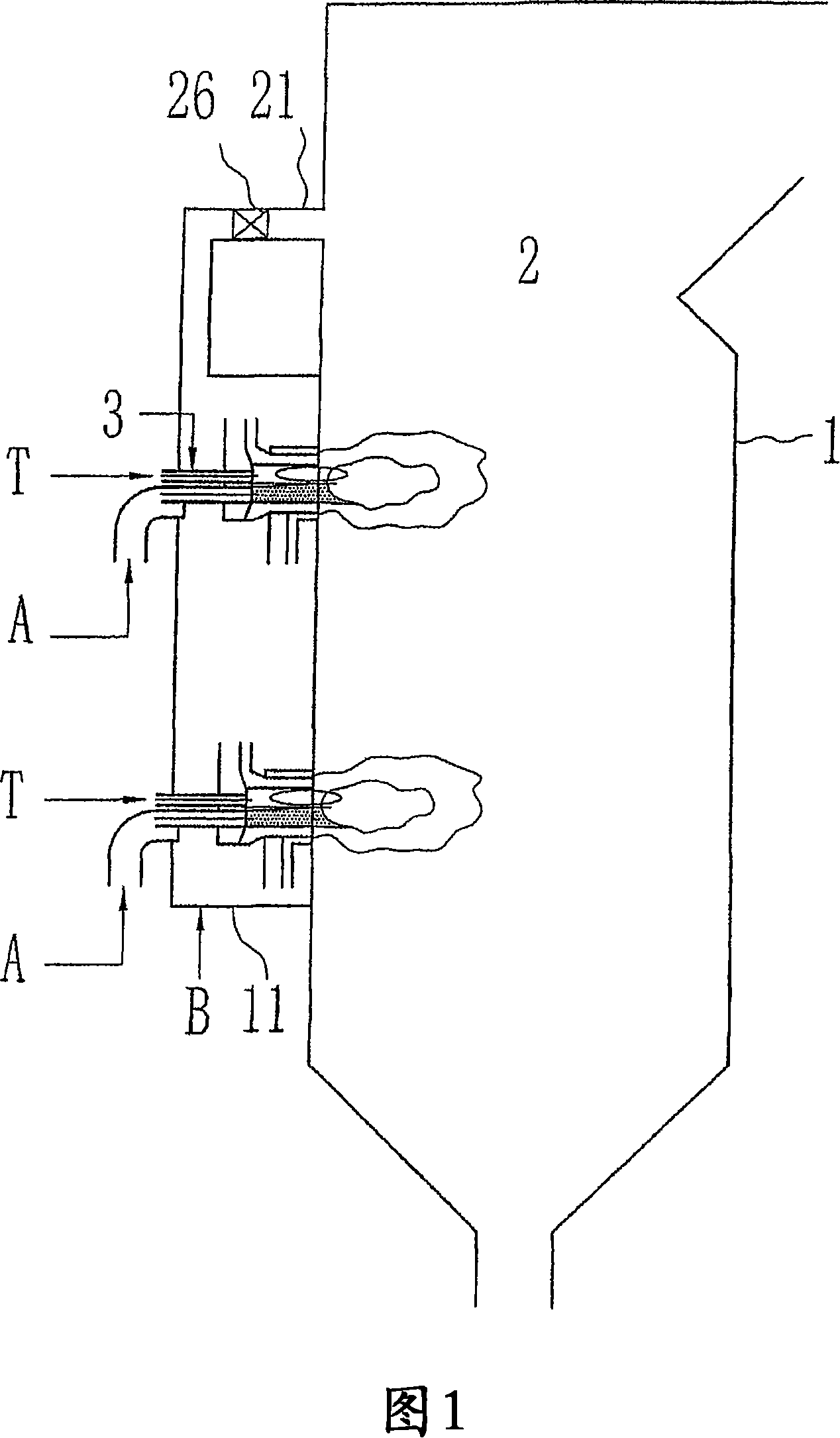

Combustion method and system

ActiveCN101142447AEmission reductionLess unburned carbonFuel supply regulationMechanical apparatusCombustion chamberCombustor

A method for burning the powdered hydrocarbon fuel comprises the following procedures: injecting air / fuel current into the burner to generate the low pressure area; leading the high-temperature burning gas current from the burner to the low pressure area in the burner; mixing the high-temperature burning gas with the injected air / fuel current to heat the injected air / fuel current, and injecting the heated air / fuel current from the burner into the burning chamber, wherein the air / fuel current is rapidly devolatilized and is burned in the high-temperature flame; sensing the combustion parameter; and controlling the burning according to the sensed combustion parameter to get at least one goal of expected NOx reduction and expected distance from the burner to the flame front edge.

Owner:CLEAN COMBUSTION TECH

Process control methodologies for biofuel appliance

InactiveUS20080097649A1Stoves/ranges with convection heatingTemperatue controlLoop controlOperating point

Apparatus for controlling the operation of a biomass stove utilizes three proportional integral derivative (PID) controllers as part of a closed loop to control the fuel feed rate, the convection fan speed and the combustion fan speed. The first loop controls room temperature, the second loop controls the convection fan speed and the third loop controls the combustion fan. Appropriate temperature readings are utilized for the first and second loop. The third loop, which utilized feedback of the ratio between the heat exchanger temperature to the exhaust temperature, in addition to measuring these temperatures also references a library of look-up tables of such ratios over the entire heat range of the stove that have been correlated to combustion efficiency, as an input. This enables the operator to optimize the heat output for any operating point.

Owner:HESTIA HEATING PRODS

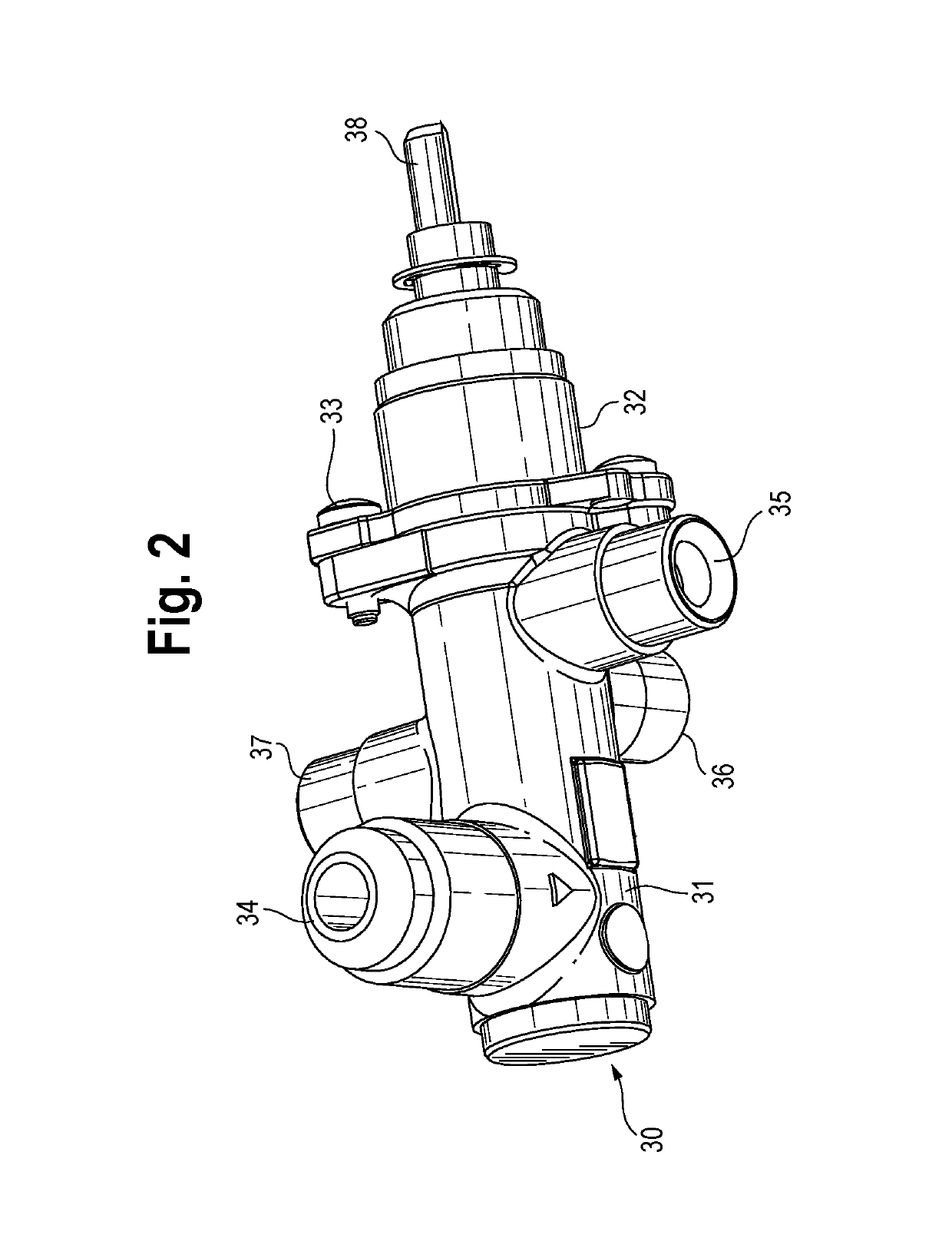

Single valve for gas grill with multiple burners

InactiveUS20190093885A1Fuel supply regulationCombustion valves/nozzle/pumpsCombustorProcess engineering

A gas delivery system for gas grills is provided, the delivery system including one gas valve that controls the gas flow to a plurality of burner tubes.

Owner:WEBER-STEPHEN PRODUCTS

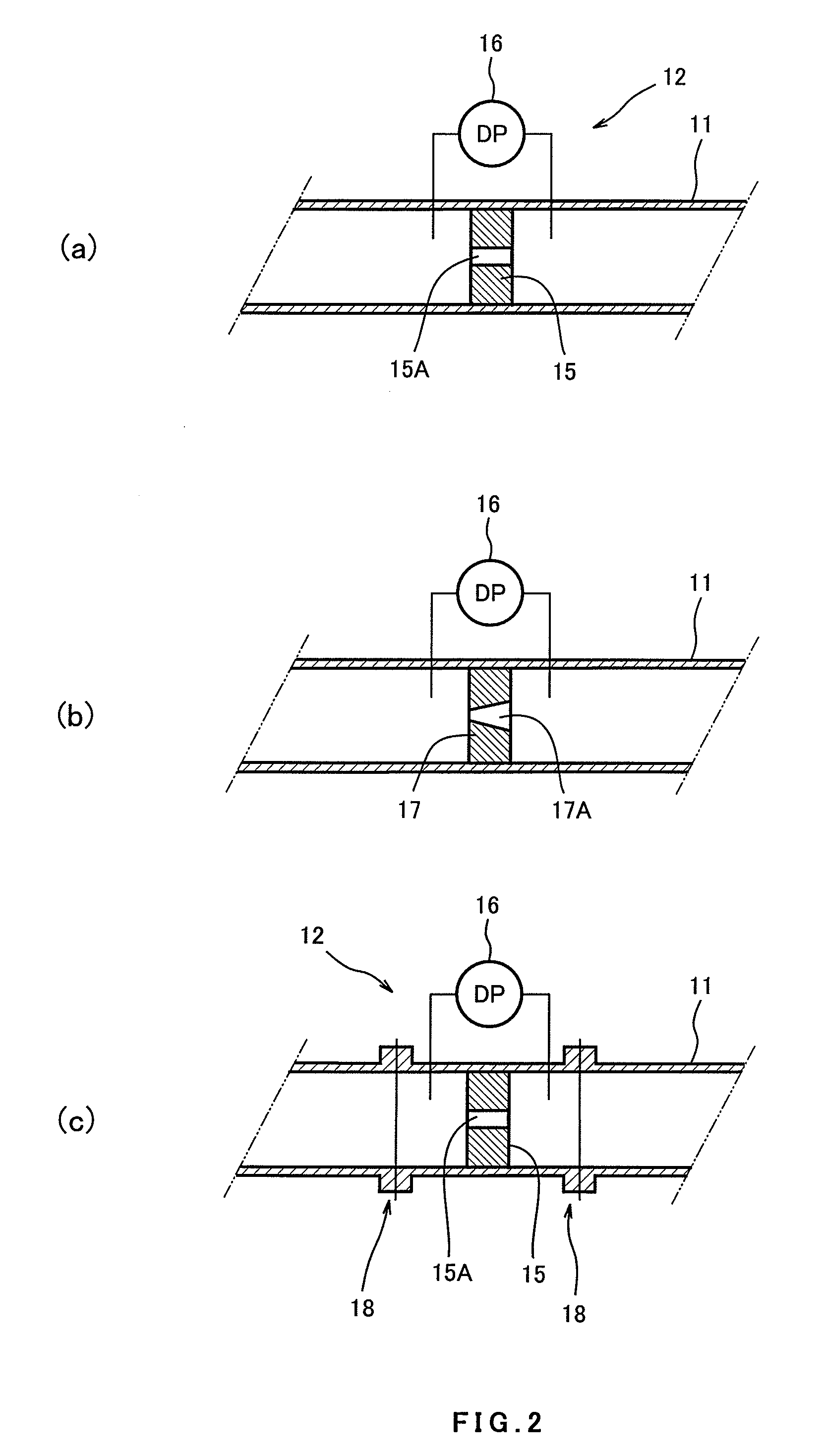

Gum substance monitoring apparatus, gum substance detecting method, and gas turbine system

InactiveUS8499620B2Inexpensively and easily estimate and detect adhesionStop operationFuel supply regulationTurbine/propulsion fuel supply systemsCombustorGas turbines

A gum substance monitoring apparatus for inexpensively and easily estimating and detecting adhesion and deposition of a gum substance produced in a fuel gas onto a combustor and fuel gas supply piping extending to the combustor, includes: detection piping branched from the fuel gas supply piping configured to supply to the combustor with the fuel gas for allowing a part of the fuel gas as a sample gas to pass therethrough; and a gum substance detecting device provided on the detection piping and configured to detect an extent of adhesion of the gum substance produced in the fuel gas, the gum substance detecting device including a simulated passage member having a simulated passage for passage of the sample gas therethrough which is formed by simulating fuel gas piping of the fuel gas supply piping extending in a portion subject to gum substance monitoring which is located downstream of a branch point at which the detection piping is branched from the fuel gas supply piping, the gum substance detecting device being configured to be capable of detecting an extent of adhesion of the gum substance onto the simulated passage member.

Owner:KAWASAKI HEAVY IND LTD

Autocontrol burner and a combustion control method

InactiveUS7306456B2Reduce energy consumptionImprove efficiencyBurnersFuel supply regulationMotor speedCombustor

A combustion control method for a burner comprises: the fuel supplying means outputs a given amount of fuel oil to the fuel oil atomizing means; the fuel atomizing means sprays fuel atomized gas; said gas is ignited by the igniter; the amount of air is sent to facilitate burning by the air blowing means; the outputting flow rate of fuel oil and the flow rate of air are adjusted automatically, simultaneously and proportionally by controlling the rotating speed of the electric motors of the fuel supplying means and the air blowing means. An autocontrol burner comprises a main body, an oil pump (2), a blower fan (1), a spray gun (9) and an ignition gun (10), and further comprises a programmable control unit (18), motor speed controller (16, 17) and a signal acquisition assembly. The output port of the signal acquisition assembly is connected with the input port of the programmable control unit (18). The oil pump (2) and the blower fan (1) are connected with the programmable control unit (18) by the motor speed controller (16, 17).

Owner:LI YANXIN

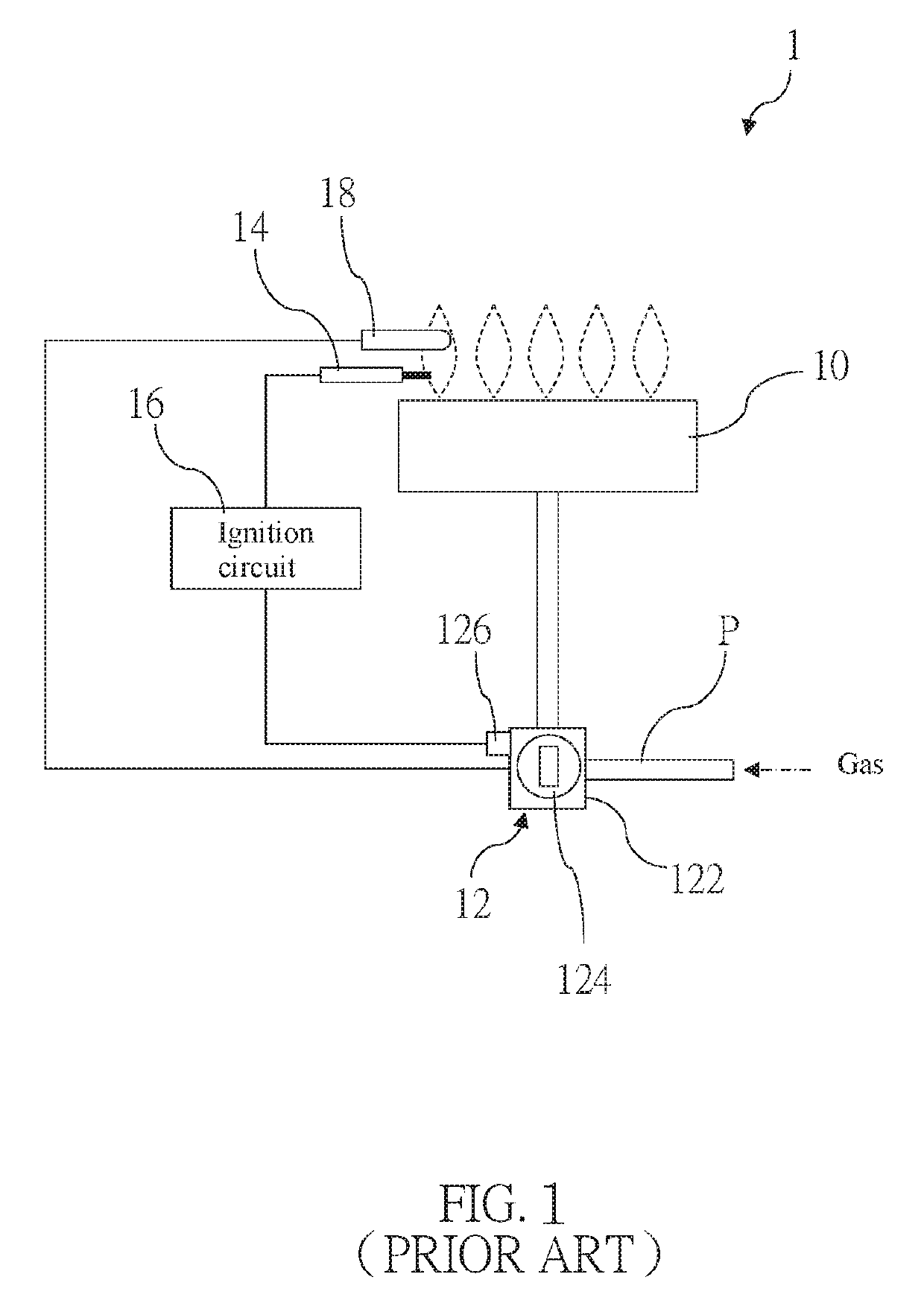

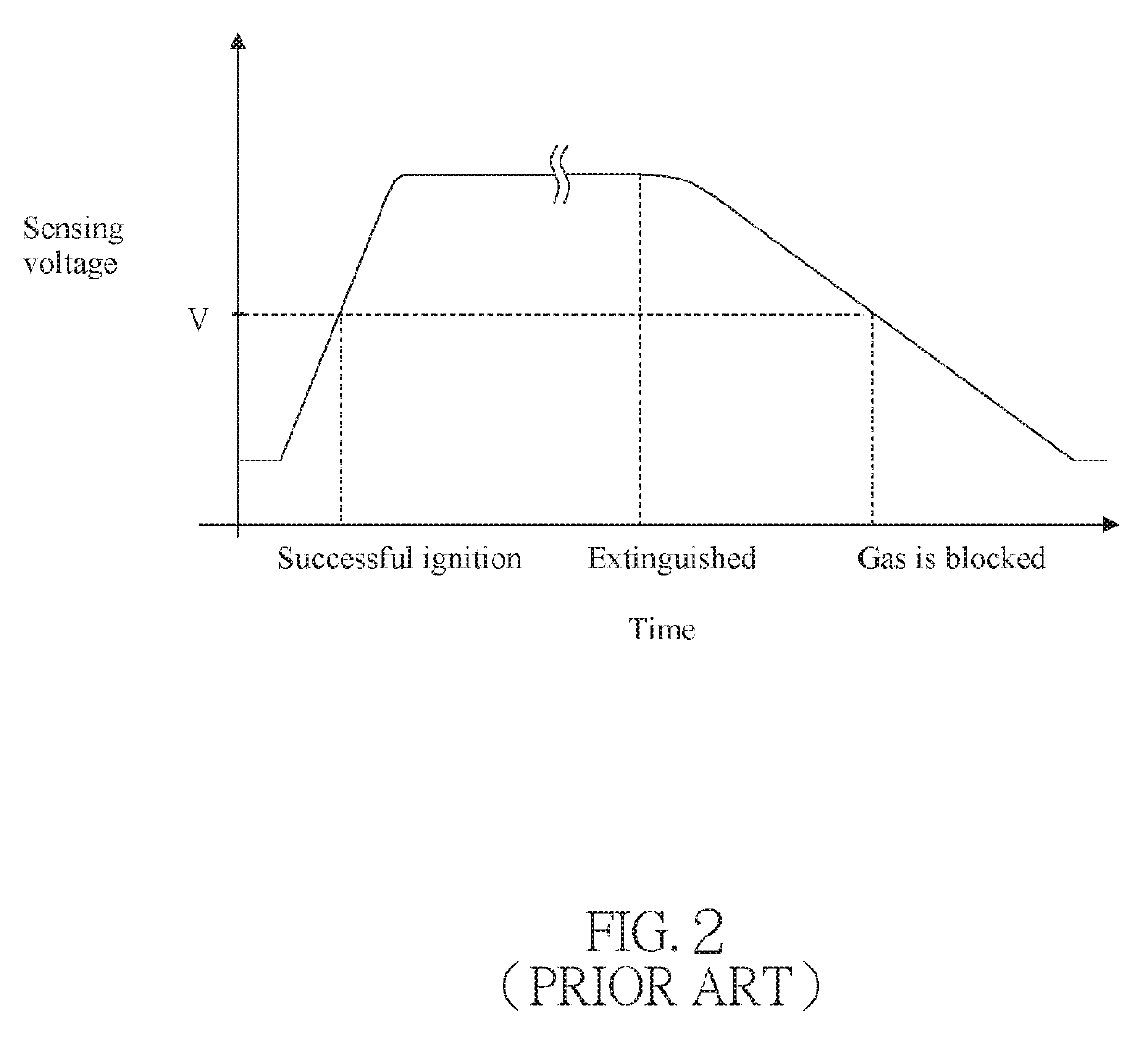

Gas appliance and control method thereof

ActiveUS20190338951A1Improve securitySpeedDomestic stoves or rangesElectric spark ignitersCombustorEngineering

A gas appliance includes a burner, a gas valve, an ignitor, a thermocouple, and a control device, wherein the control device is adapted to execute a control method comprising the following steps: controlling the ignitor to ignite and the gas valve to open; receiving a sensing voltage output from the thermocouple; stop the ignitor from igniting and controlling the gas valve to keep a gas pipe be in an open state when the sensing voltage increases to a first voltage; receiving the sensing voltage output from the thermocouple continuously, and controlling the gas valve to block the gas pipe when the sensing voltage decreases from higher than a second voltage to lower than the second voltage, wherein the second voltage is higher than the first voltage. Whereby, an ignition procedure could be speeded up and the gas could be blocked earlier as the flames are extinguished.

Owner:GRAND MATE

Control device of coal pulverizer

ActiveUS9731298B2Stable controlSolid fuel pretreatmentGrain treatmentsProcess engineeringEngineering

There is provided a control device of a coal pulverizer which enables estimation of a coal output with a precision suited for a purpose. In a control device of a coal pulverizer which pulverizes coal by the coal pulverizer and estimates coal output by which the pulverized coal is output to a boiler, the control device includes a main operation circuit which calculates a command signal associated with a coal feed rate on the basis of detection data from a boiler or a power generator connected to the boiler, and an additional control unit which calculates the deviation between a standard coal output pattern preset in the coal pulverizer, and a current coal output pattern, and adds a calculation result by the additional control unit to the main operation circuit as a correction signal.

Owner:MITSUBISHI POWER LTD

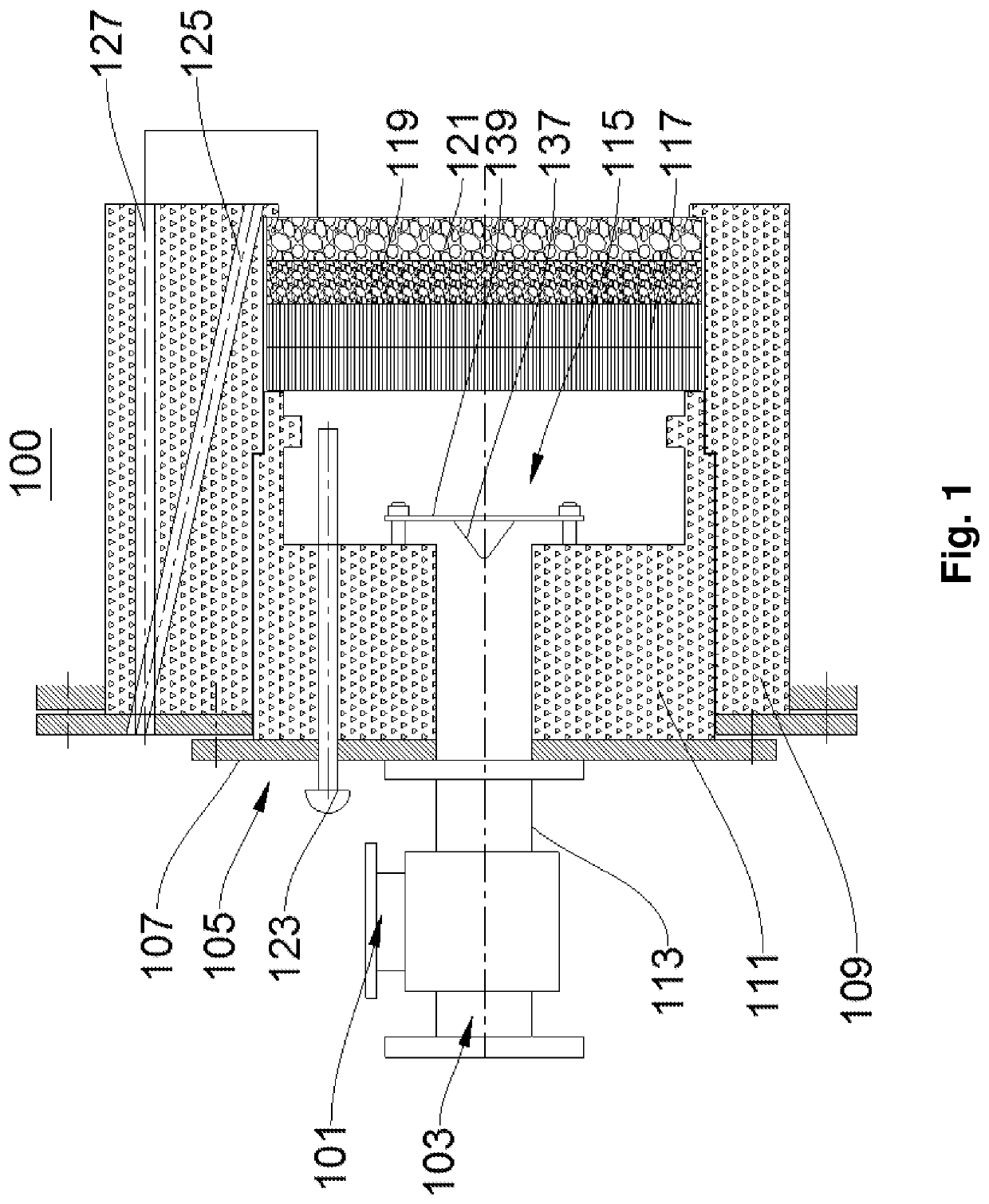

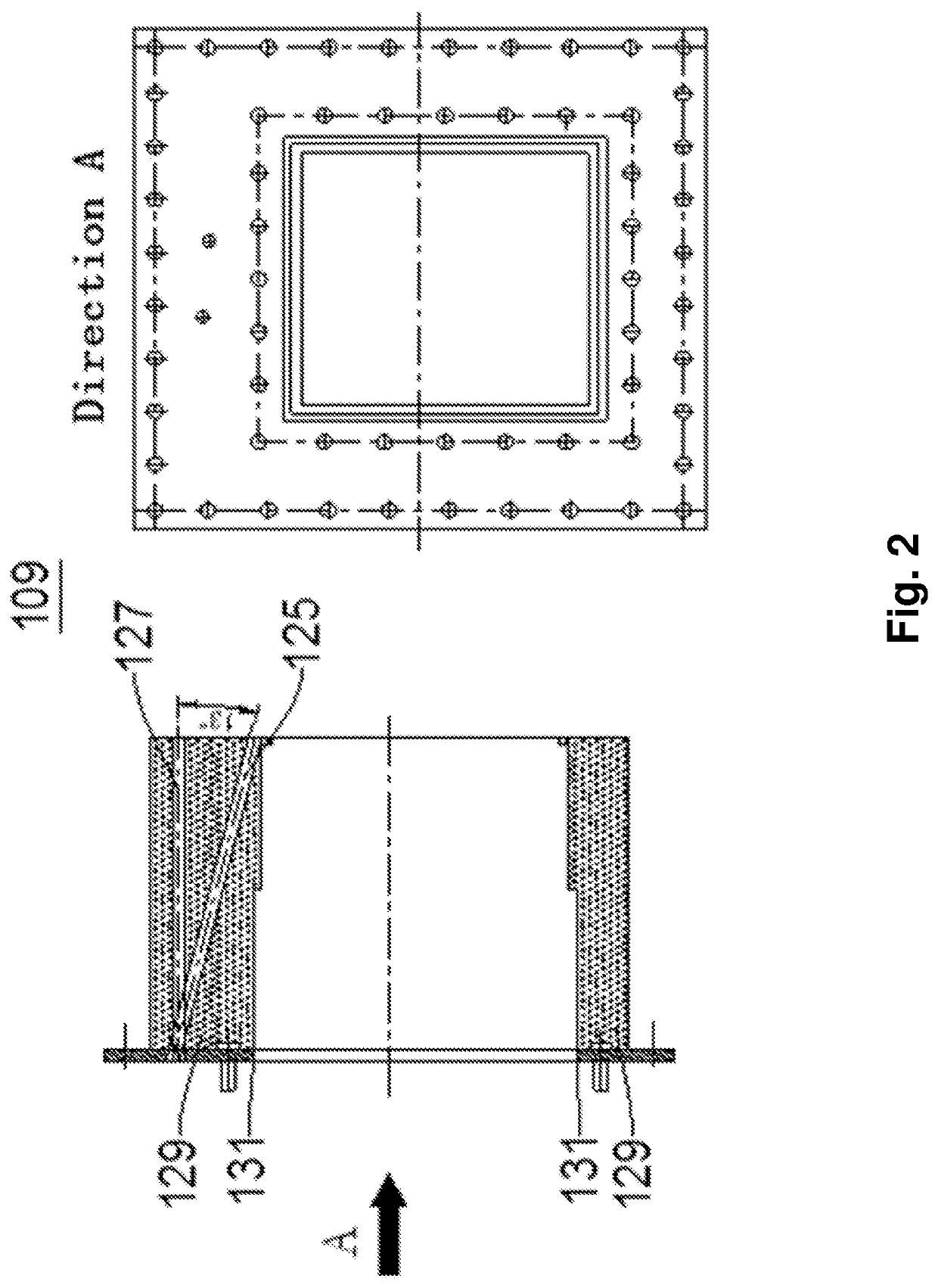

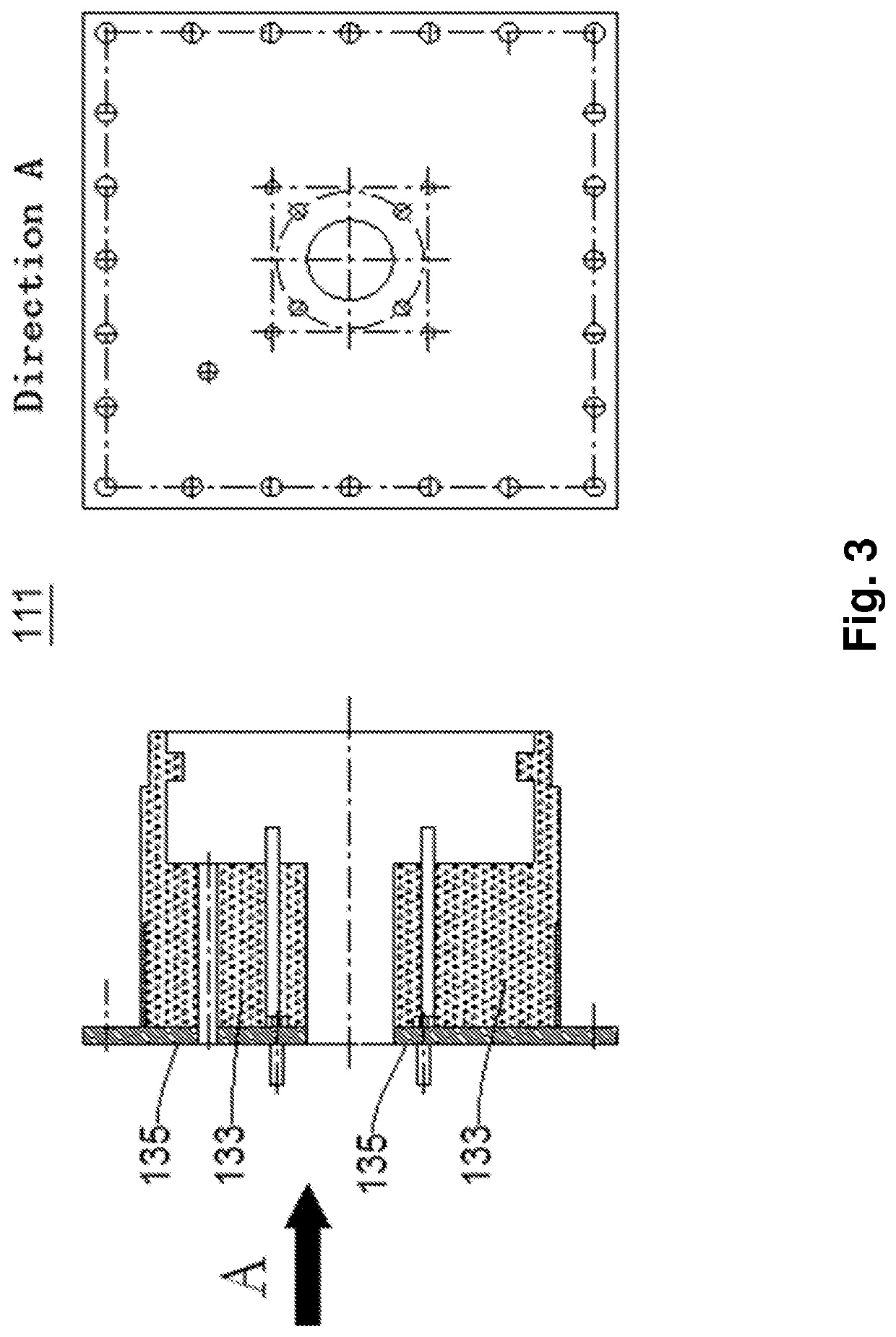

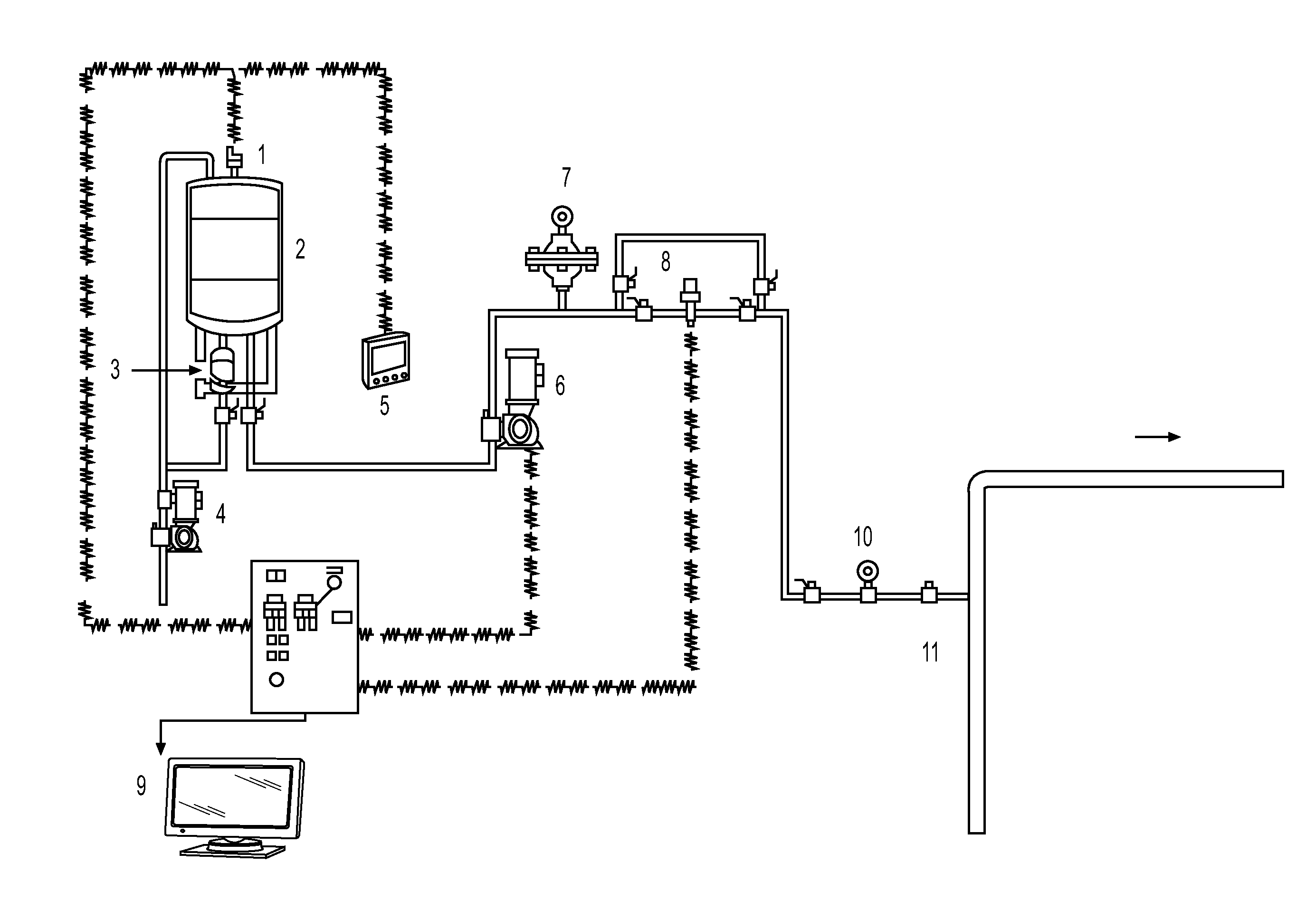

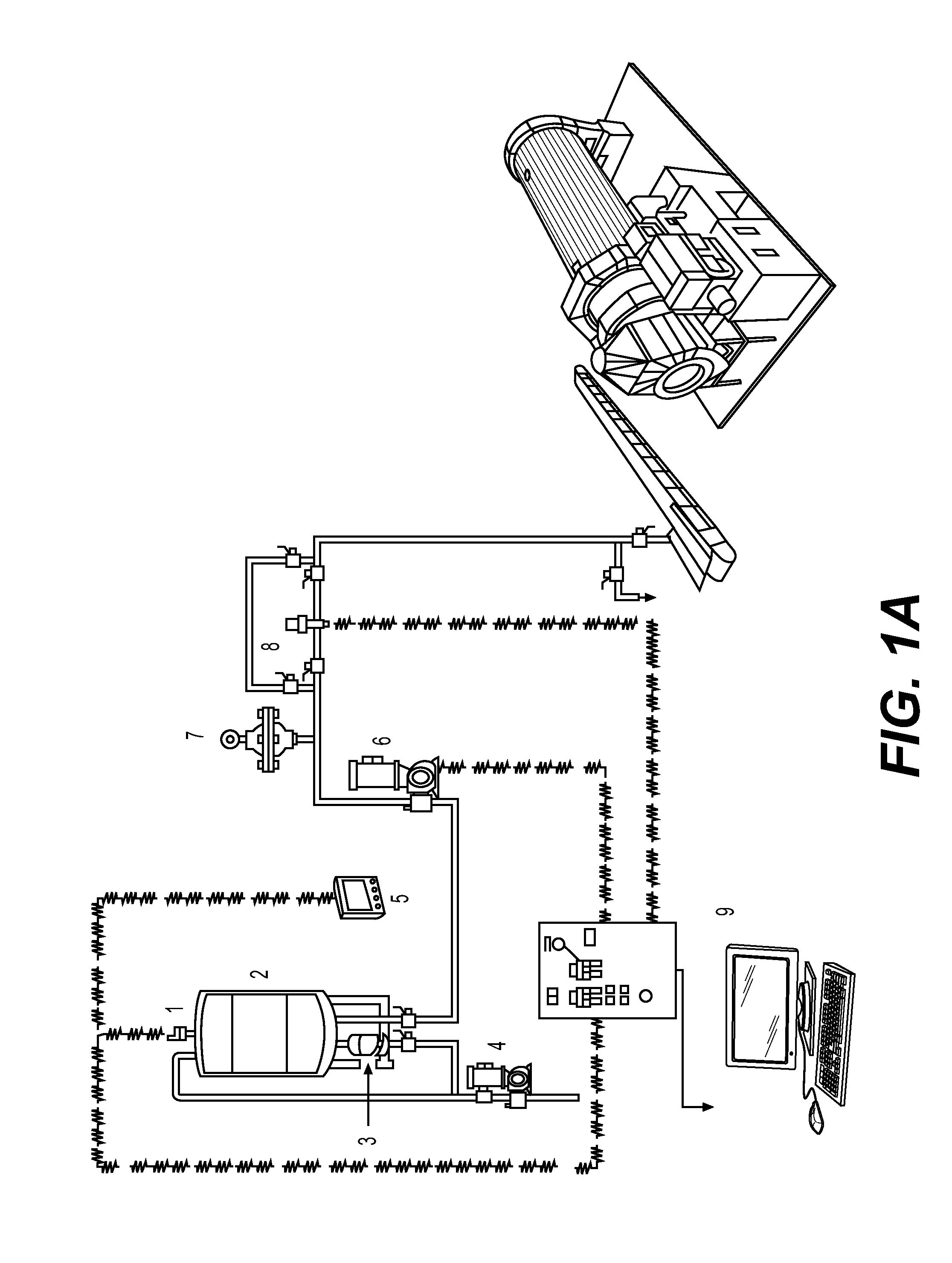

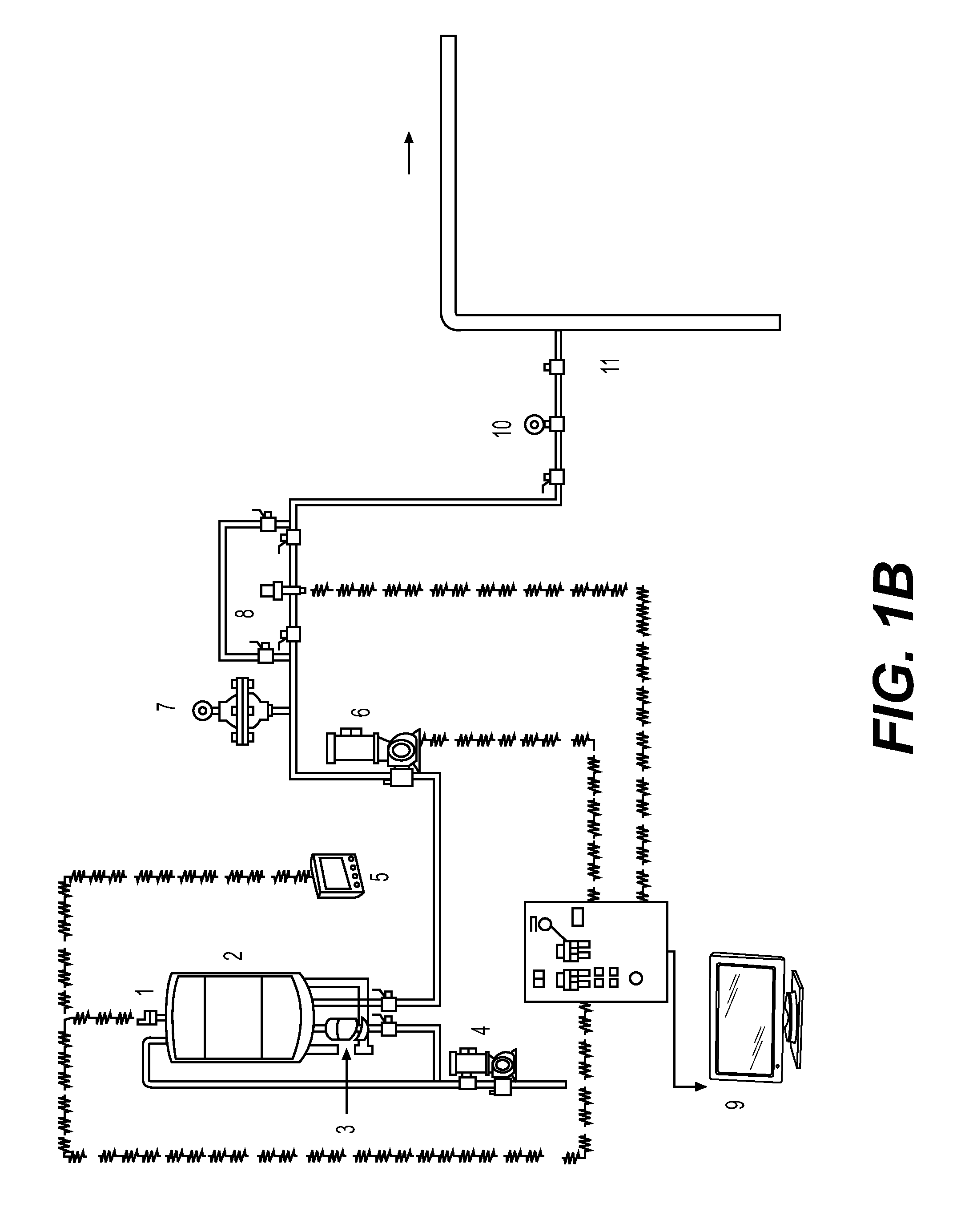

System for the dosing of additives/inhibitors containing magnesium oxide applied to fuels used for the production process of clinker/cement in rotary furnaces and steam generating boilers

InactiveUS20150053284A1Harmful to environmentHuman life loseFuel supply regulationValve arrangementsAlternative fuelsSulfur

This invention refers to a system that is automated and controlled through a software; for the storage and application of additives and / or sulfur inhibitors containing magnesium oxide and their accurate dosing in solid or liquid fossil and alternate fuels, preferably used in rotary furnaces for the production of Clinker / cement and in steam generating boilers. Additionally, this invention is characterized for having the power to increase the use of fossil and alternate fuels without altering the characteristics of cements or concretes as the final product of cement.

Owner:GONZALEZ GARZA JORGE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com