System and control method of oil burner's suitable burning ratio using air pressure sensor

A technology of air pressure and air-fuel ratio, applied in the combustion method, control combustion, burner and other directions, can solve the problems of changing the blower, changing the resistance of the blower, and unstable combustion of the oil furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Reference will now be made in detail to preferred embodiments of the present invention.

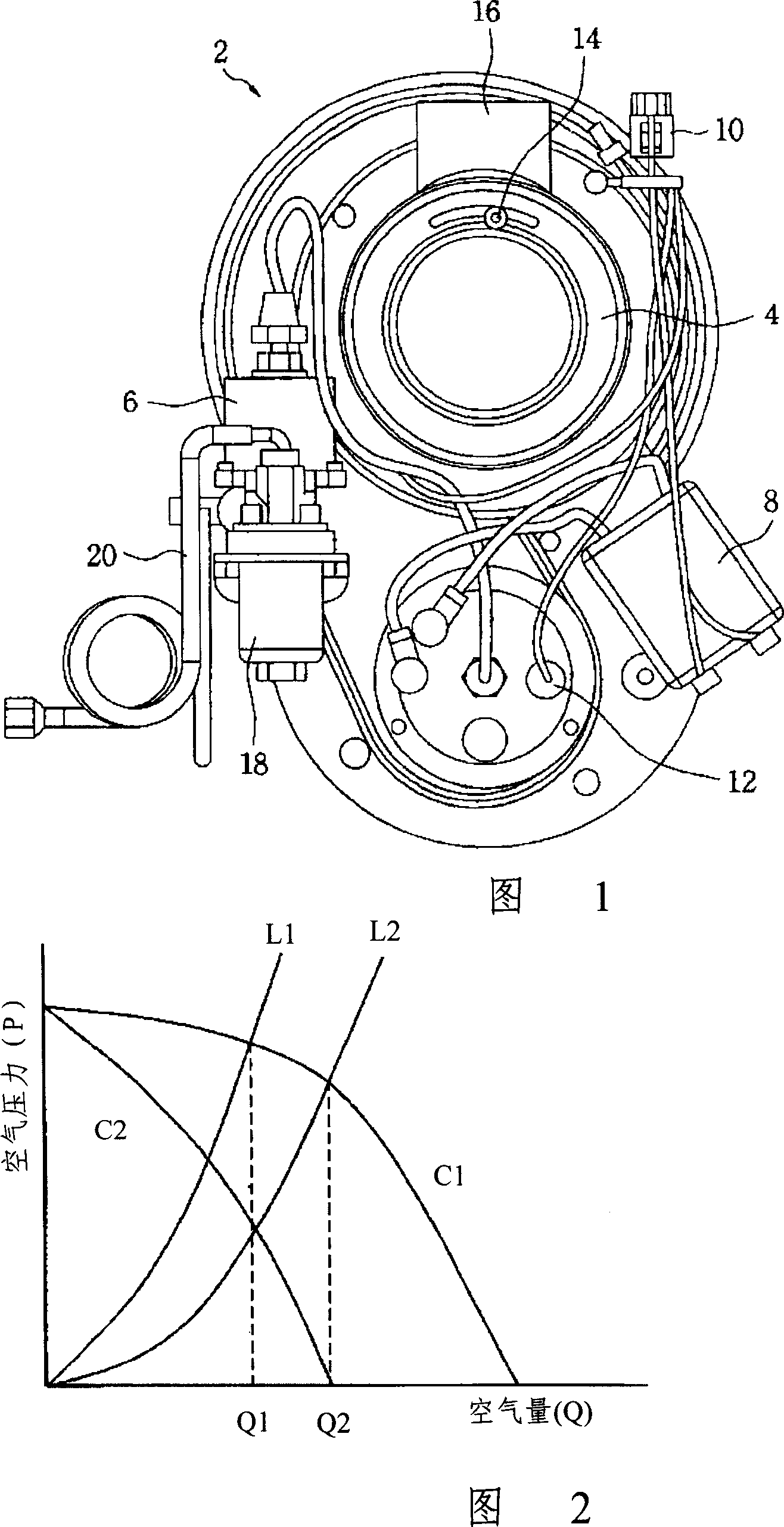

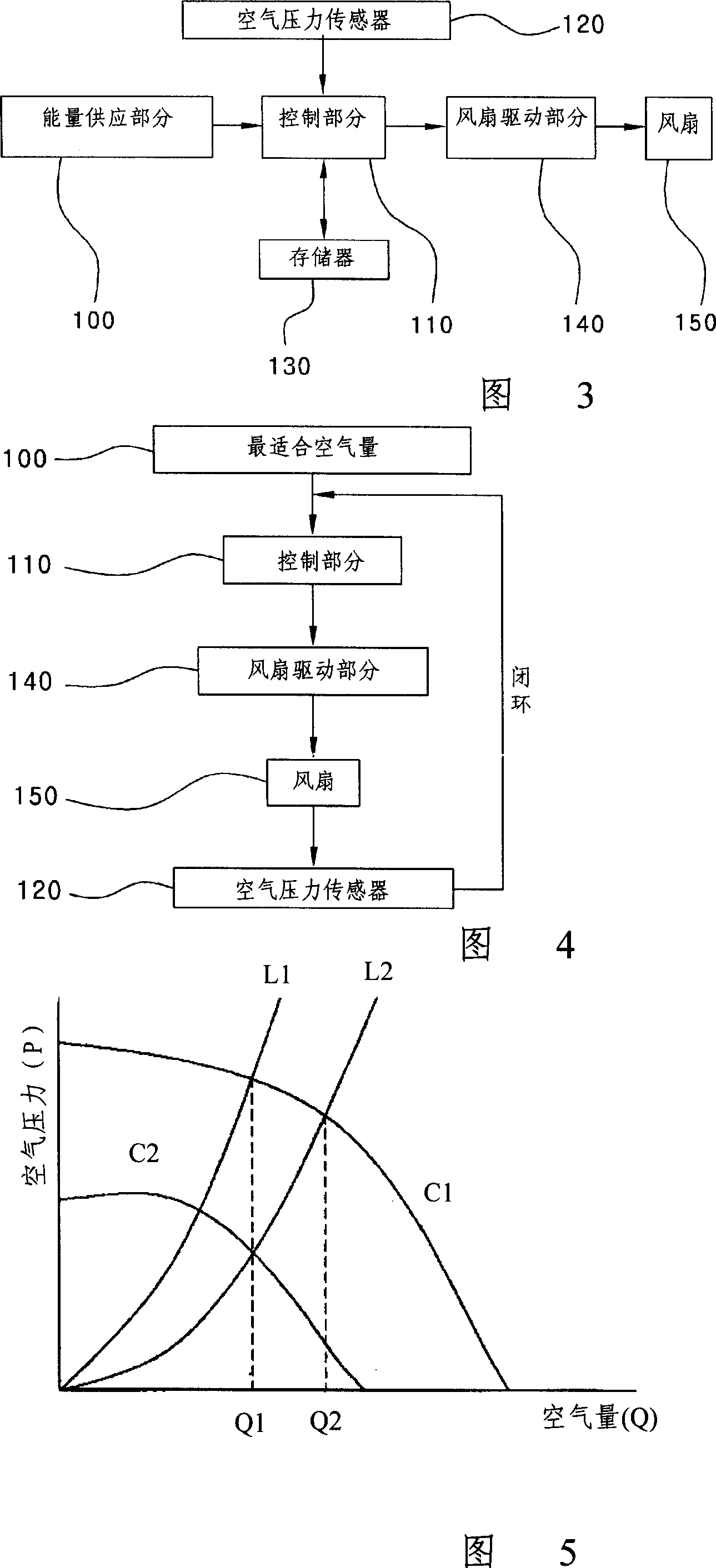

[0027] 3 is a block diagram illustrating a system structure for controlling the air-fuel ratio by an air pressure sensor in the present invention, FIG. 4 is a diagram illustrating a program for controlling the air-fuel ratio of an oil burner in the present invention, and FIG. Diagram for the method of adjusting the air volume by changing the RPM of the fan installed inside the oil furnace.

[0028] Referring to Fig. 3, the system among the present invention comprises energy supply part 100, and this energy supply part 100 is used for receiving electrical energy, converts electrical energy into predetermined driving voltage, and driving voltage is provided to the system; Fan 150, is used for from The energy supply part 100 receives the basic driving energy, then supplies the required air for the combustion of the oil burner; the fan drive part 140 is used to drive the fan 150 as a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com