Patents

Literature

349results about "Combustion measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

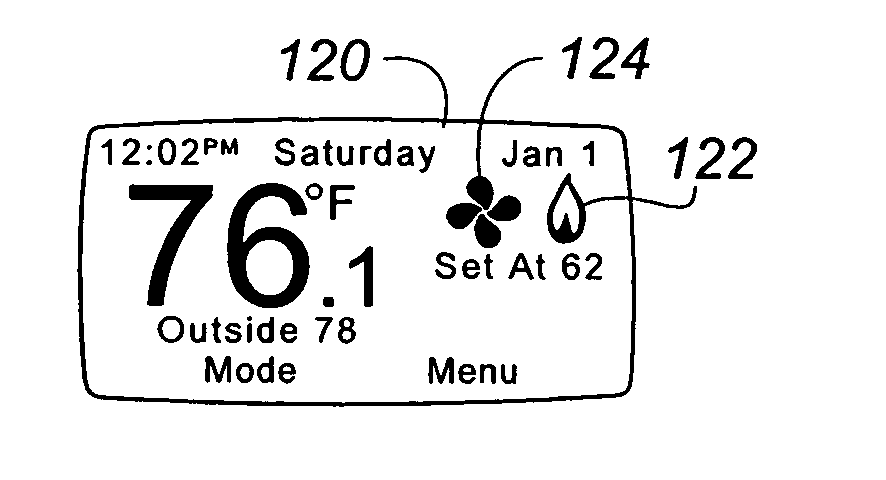

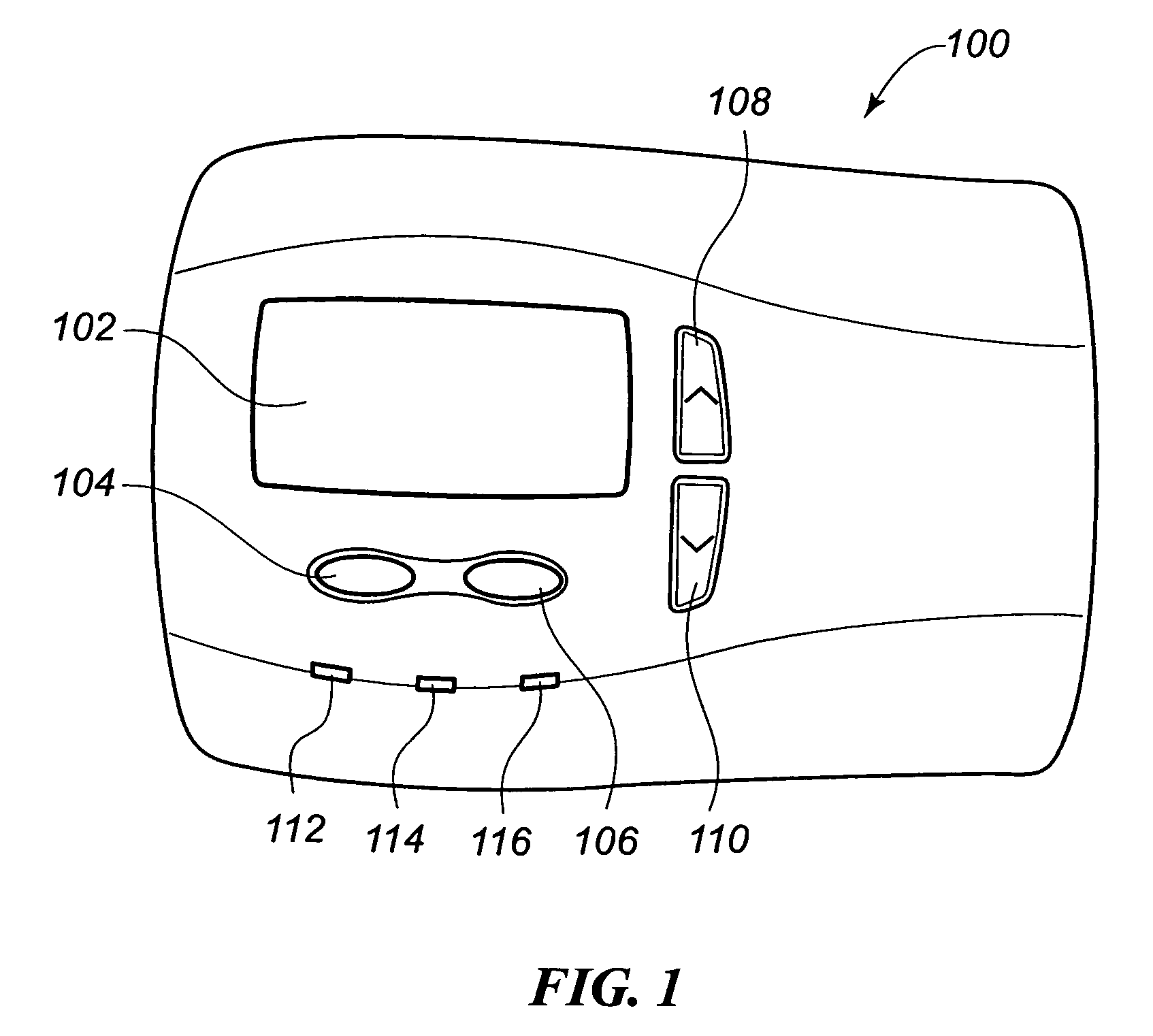

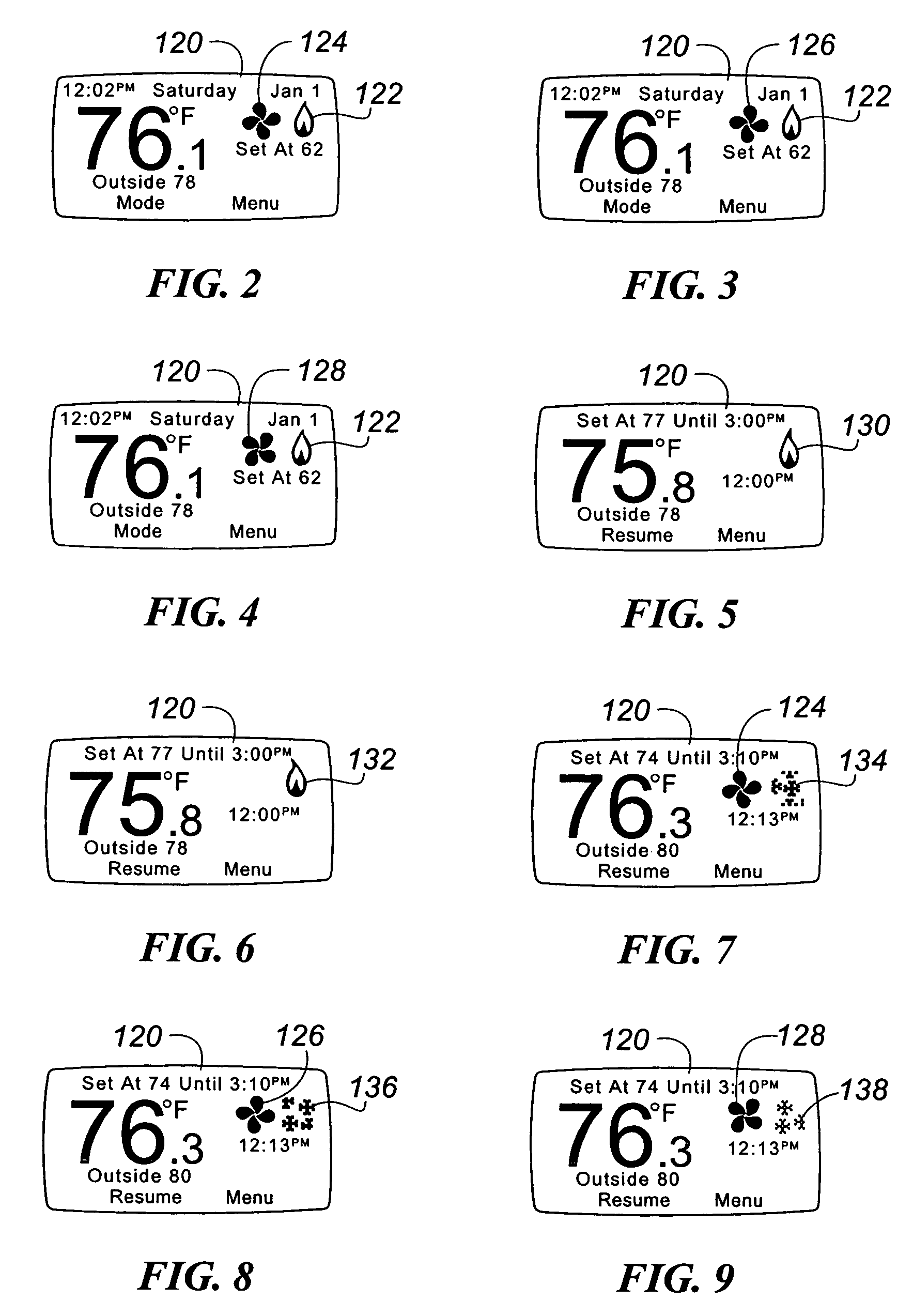

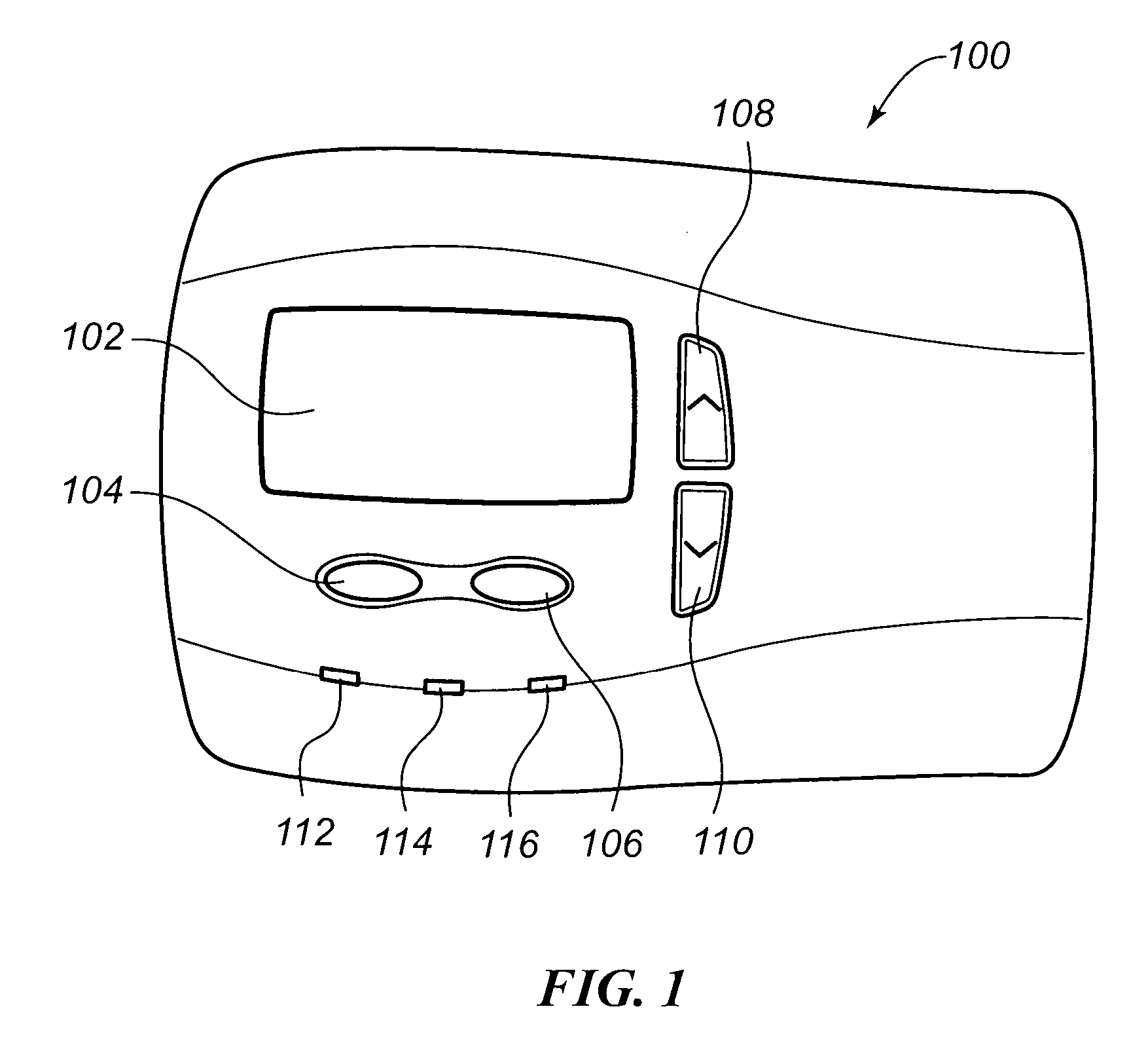

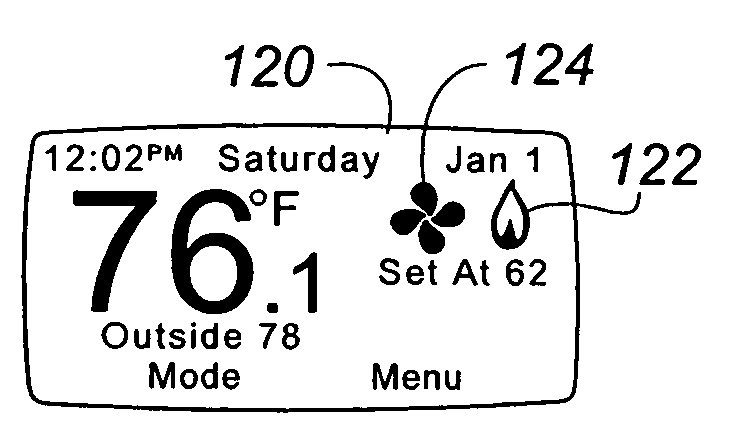

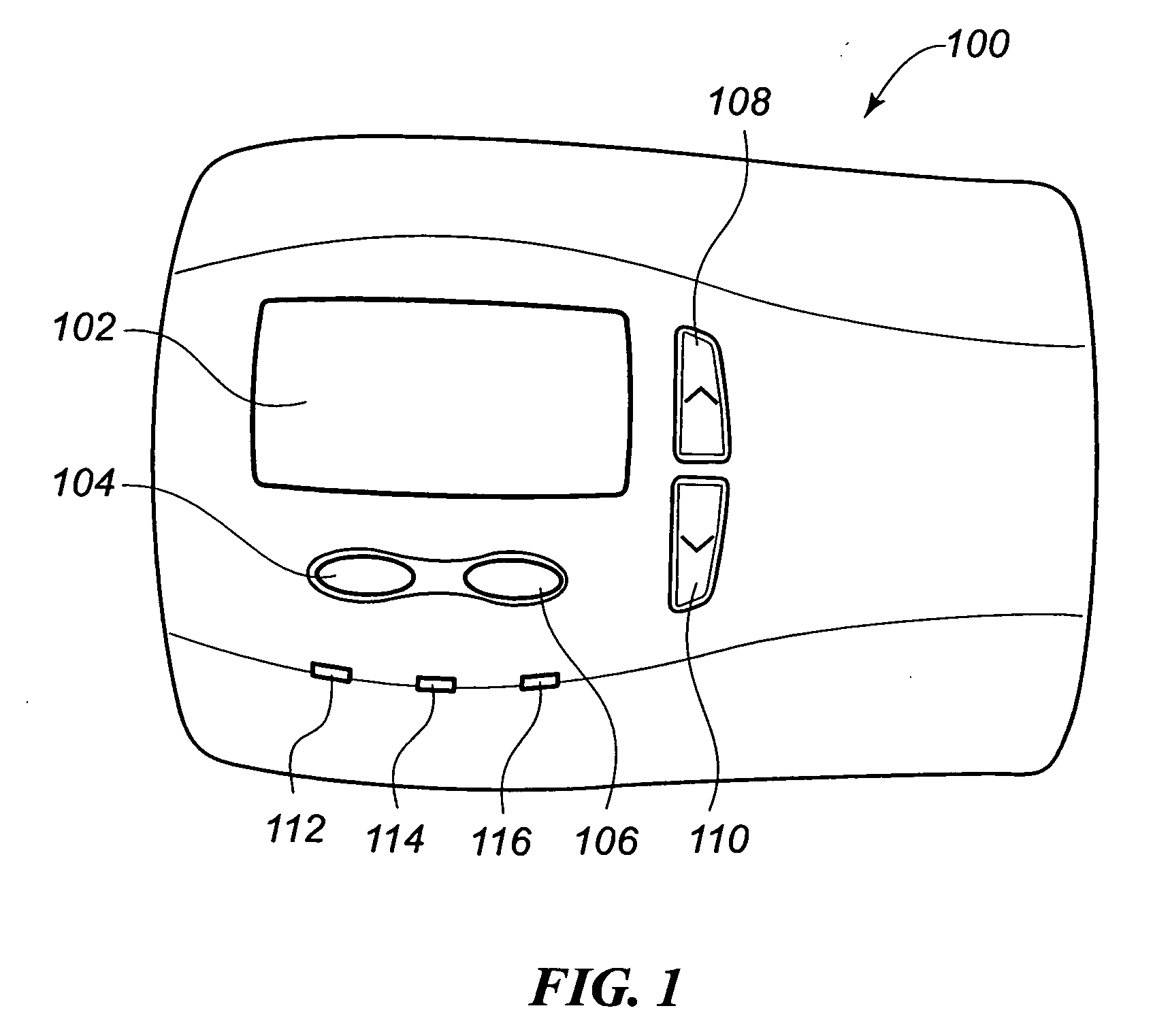

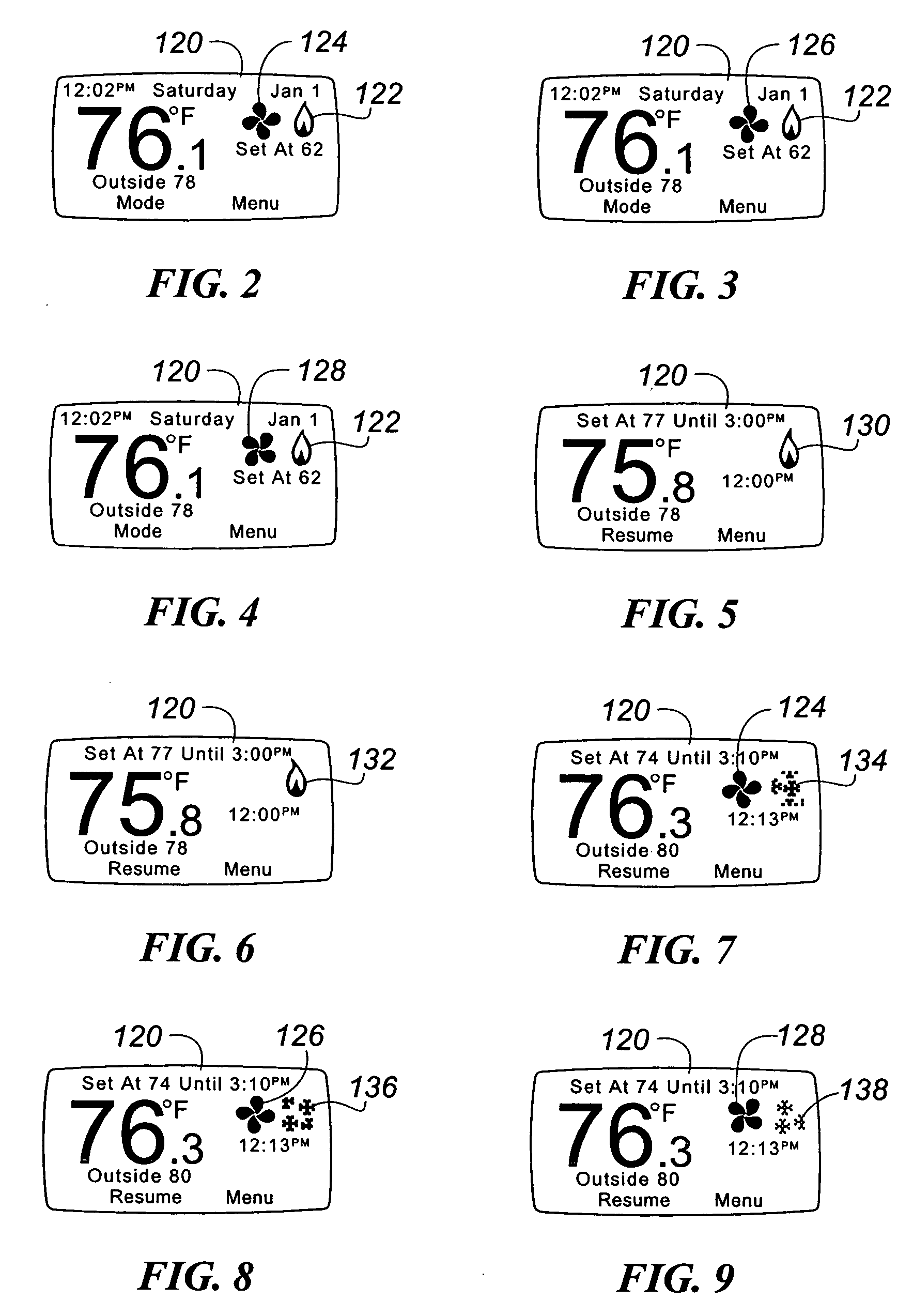

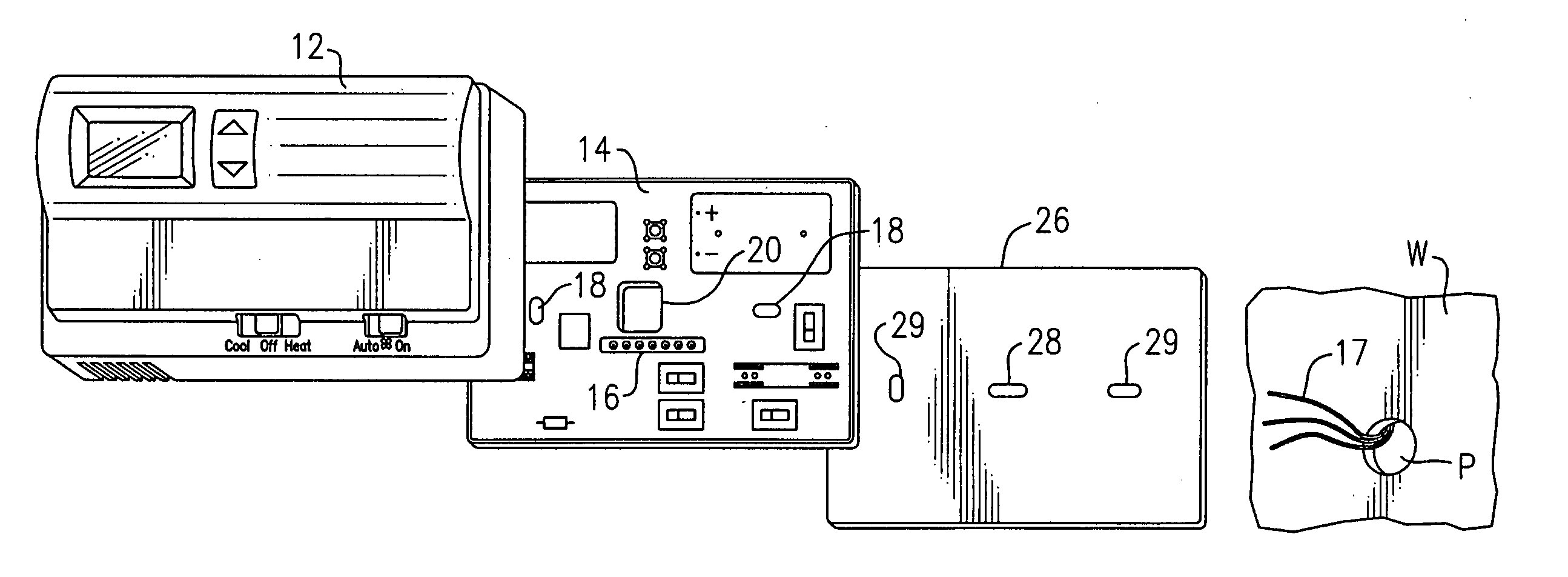

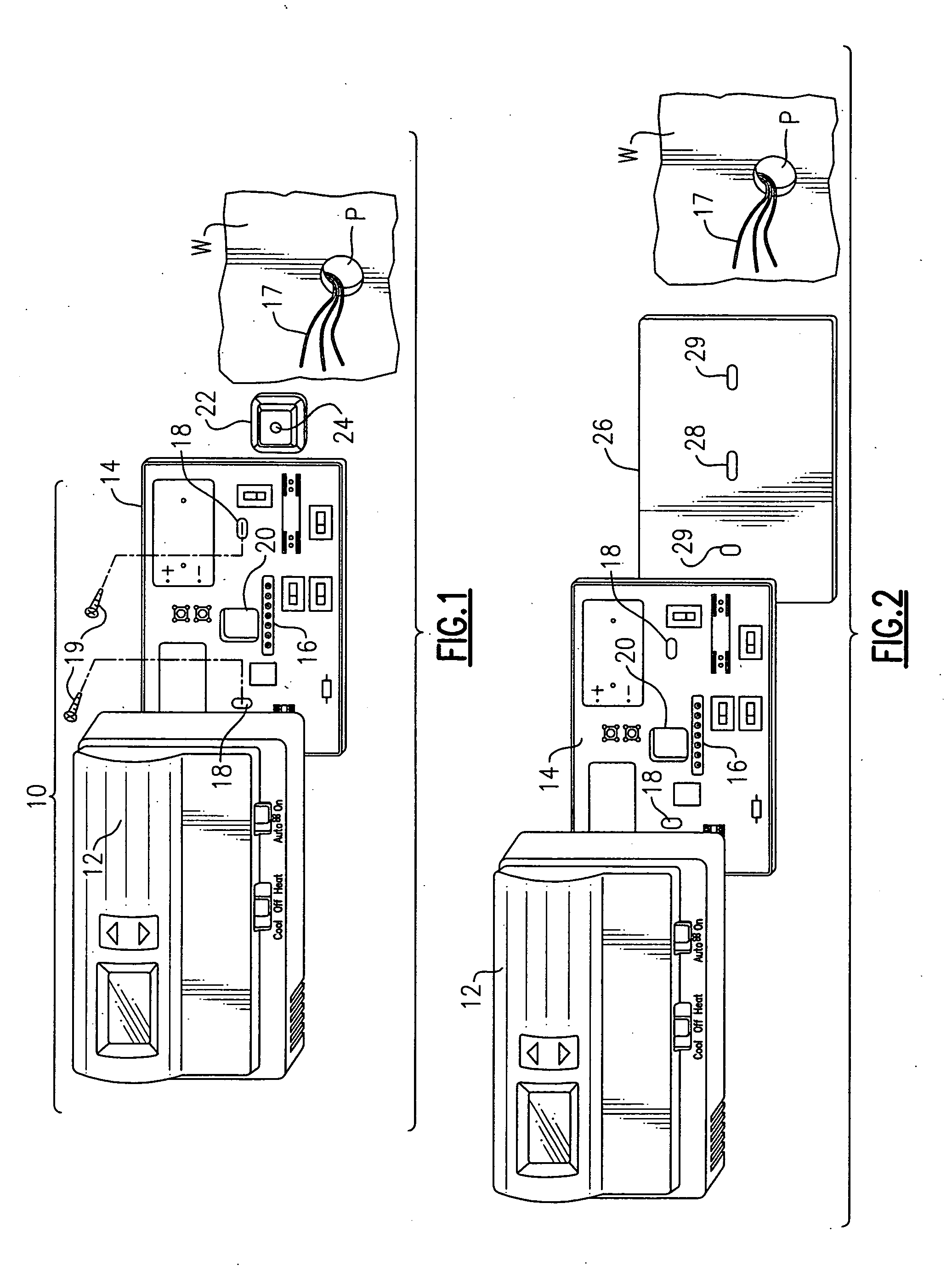

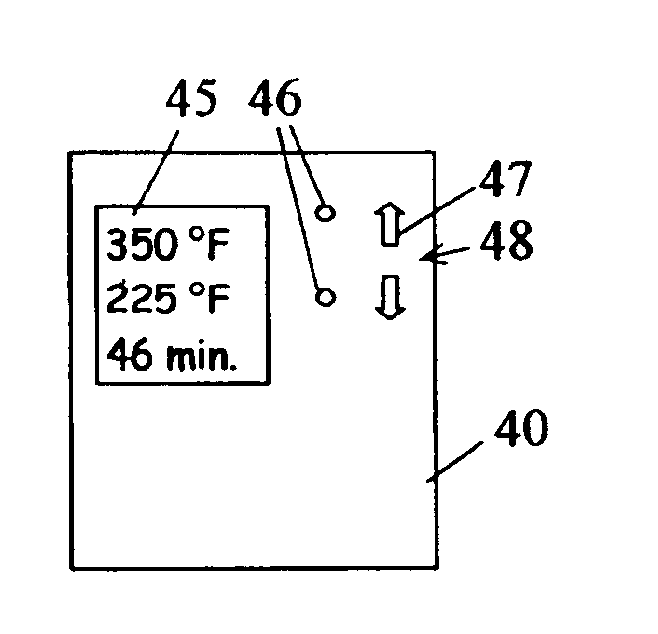

Thermostat display system providing animated icons

InactiveUS7455240B2Energy efficiencyExtend battery lifeMechanical apparatusTemperature control with auxillary non-electric powerAnimationThermostat

A visual display system and method for a digital thermostat having a user display screen to provide operational status information of the heating and / or cooling equipment controlled by the thermostat is provided. This visual display system utilizes animated icons to show operational status of the heating and / or cooling equipment. Static icons may also be used in one embodiment to indicate the current mode of the thermostat. Animated icons for the heating system, the cooling system, and fan operation are provided. The illusion of animation is provided by overwriting or replacing a displayed image with another image at a predetermined frequency. This predetermined frequency may be changed programmatically, and varied to provide different visual effects.

Owner:RANCO OF DELAWARE

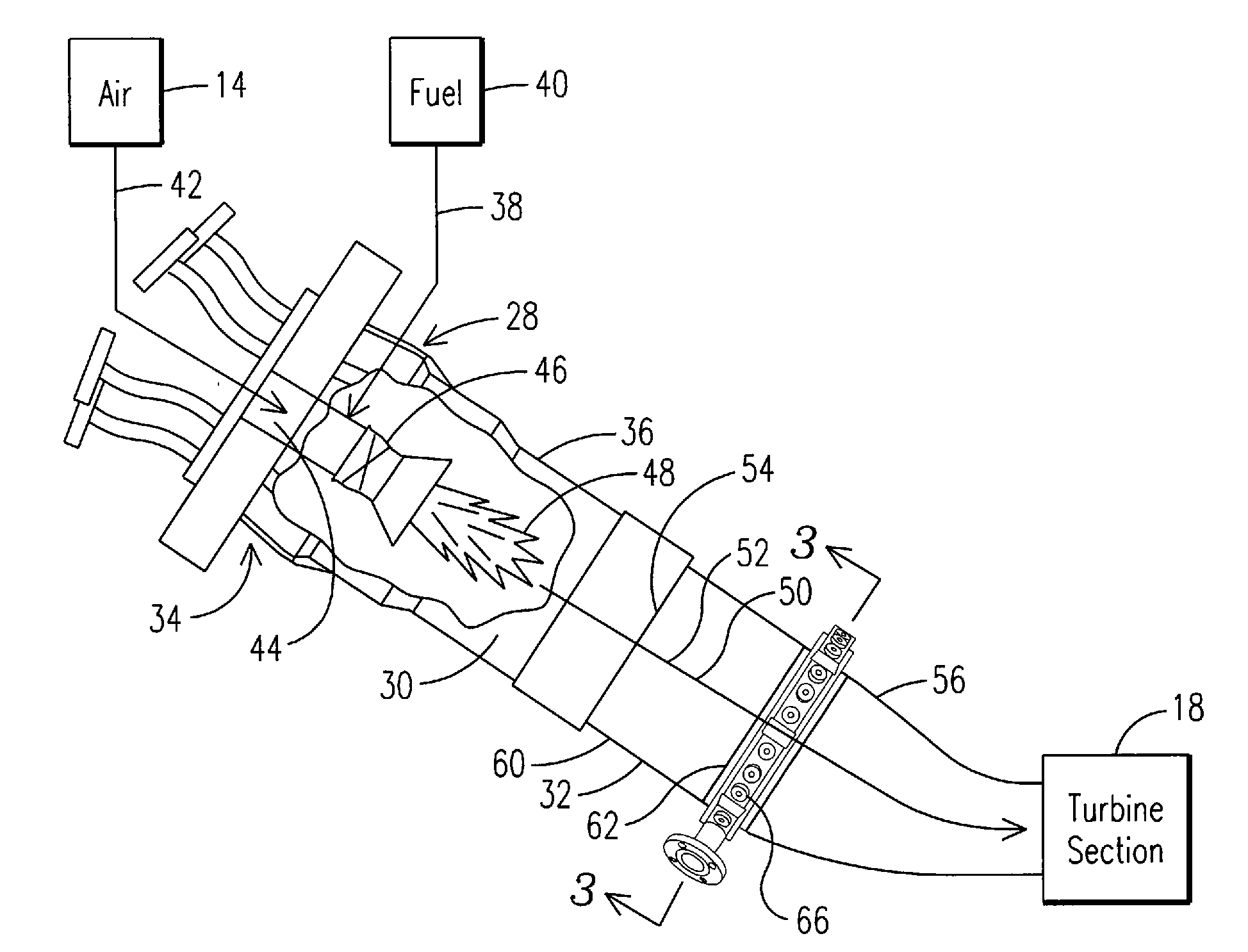

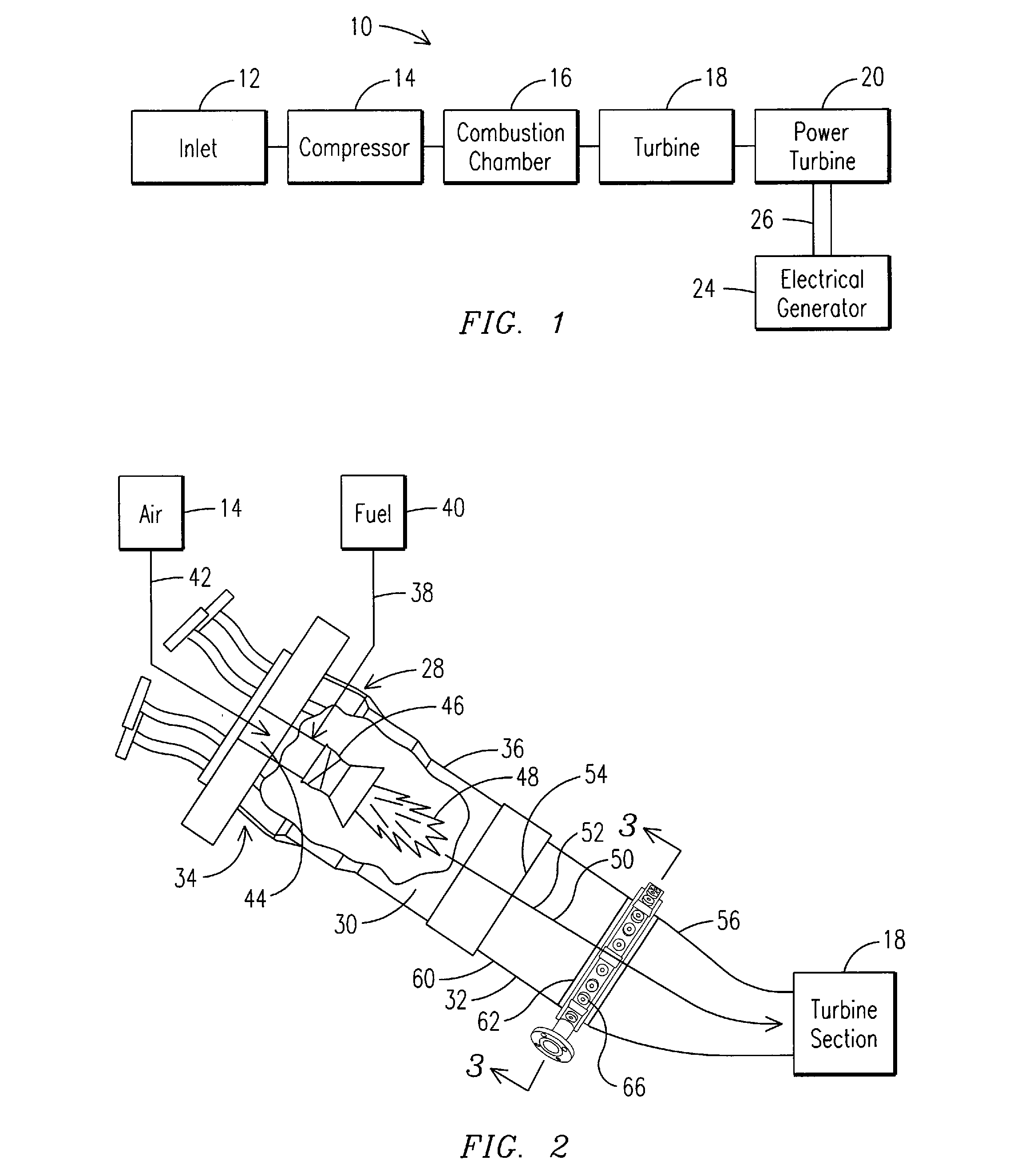

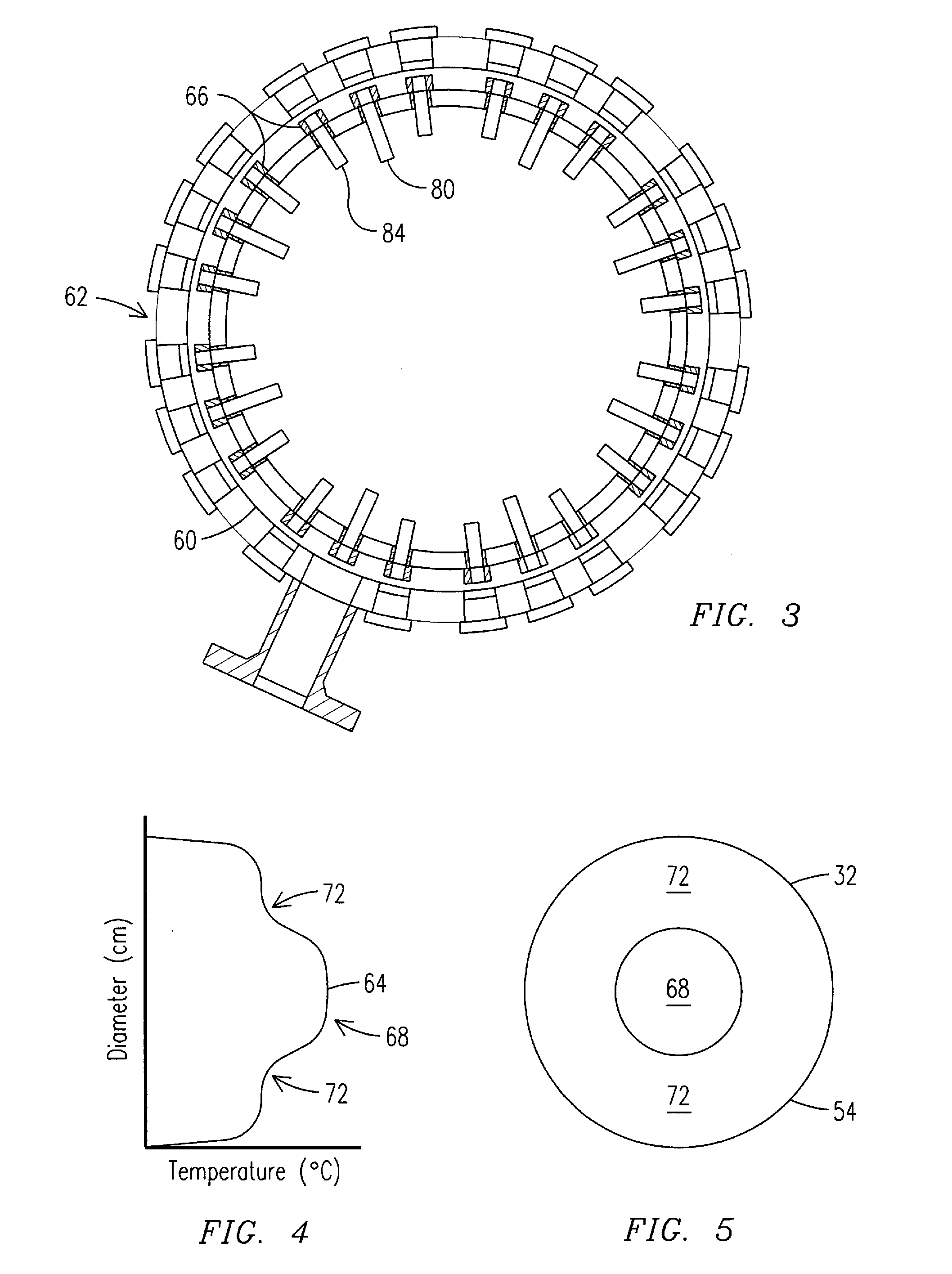

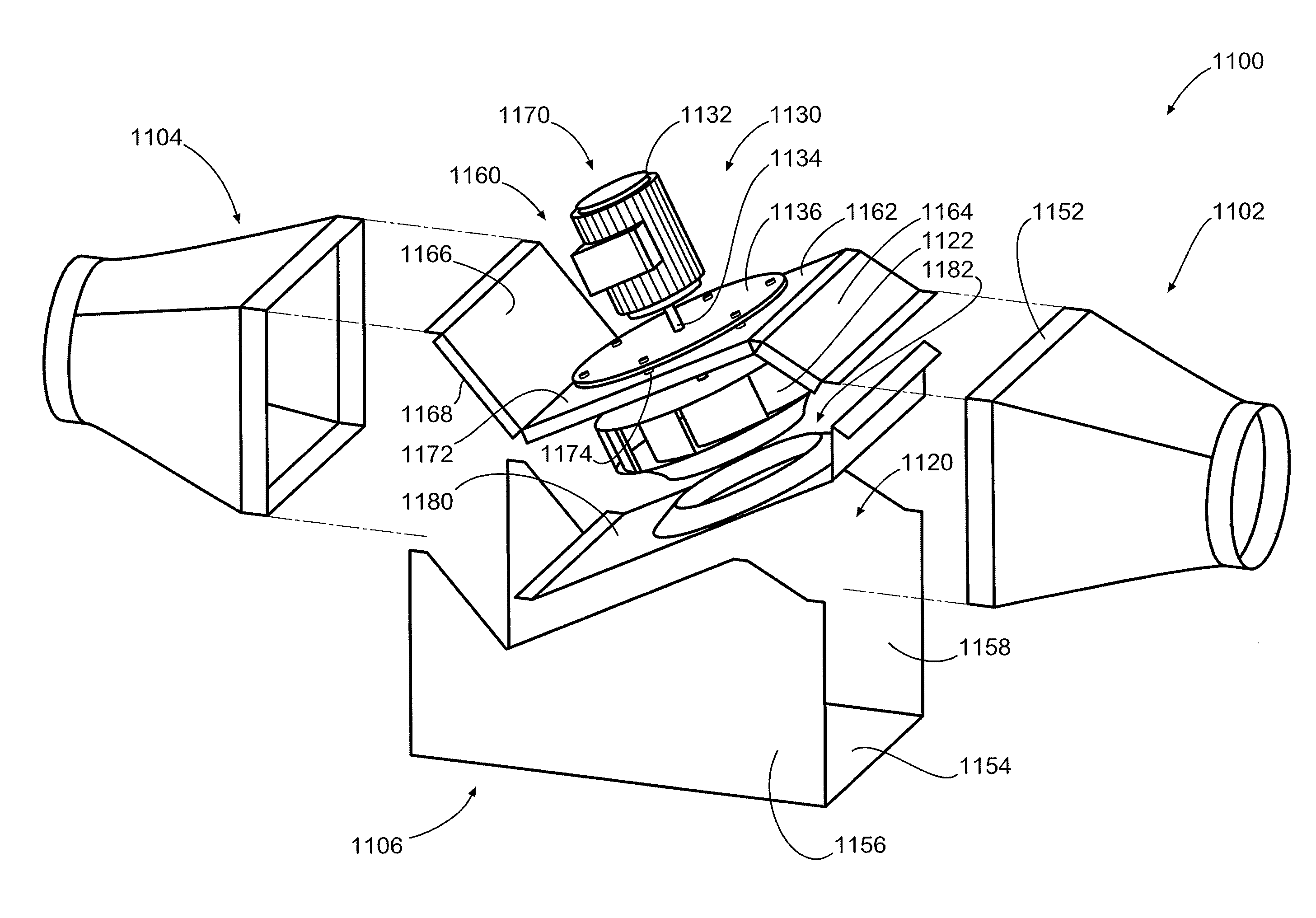

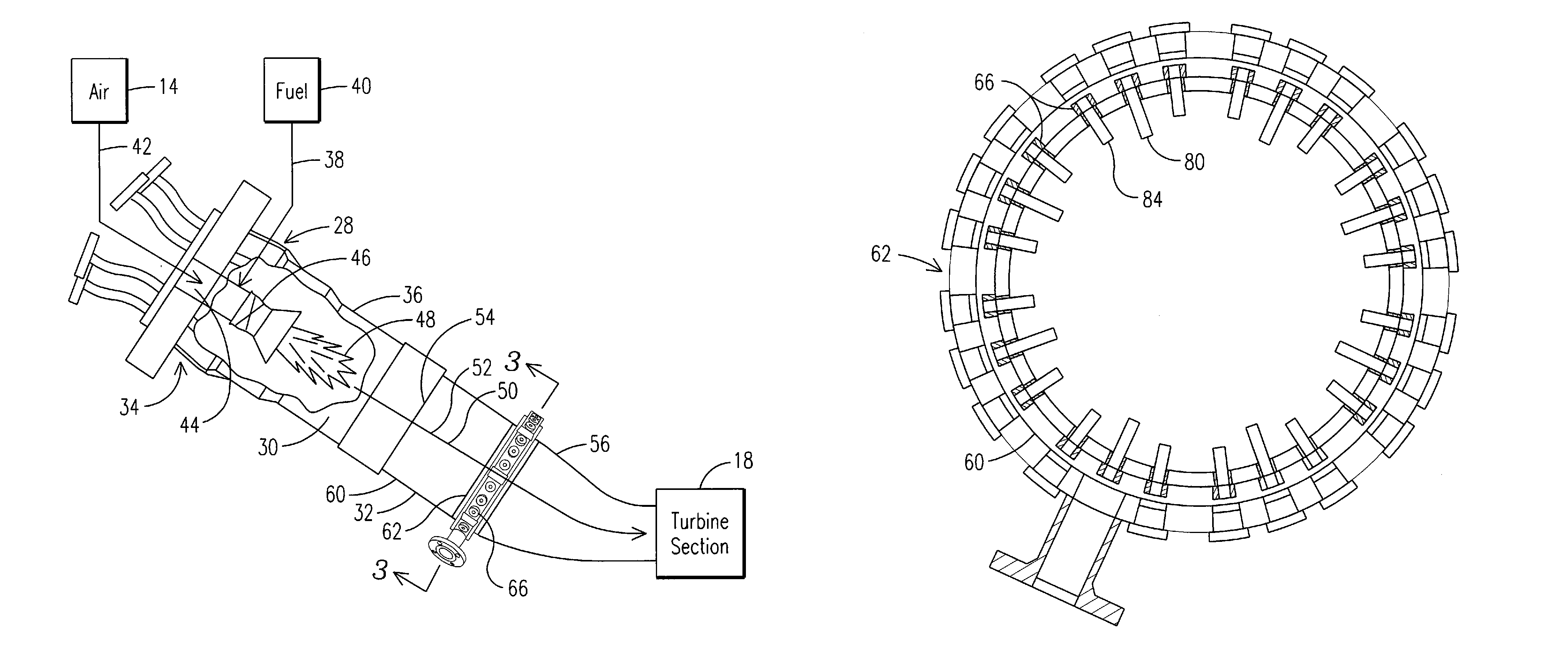

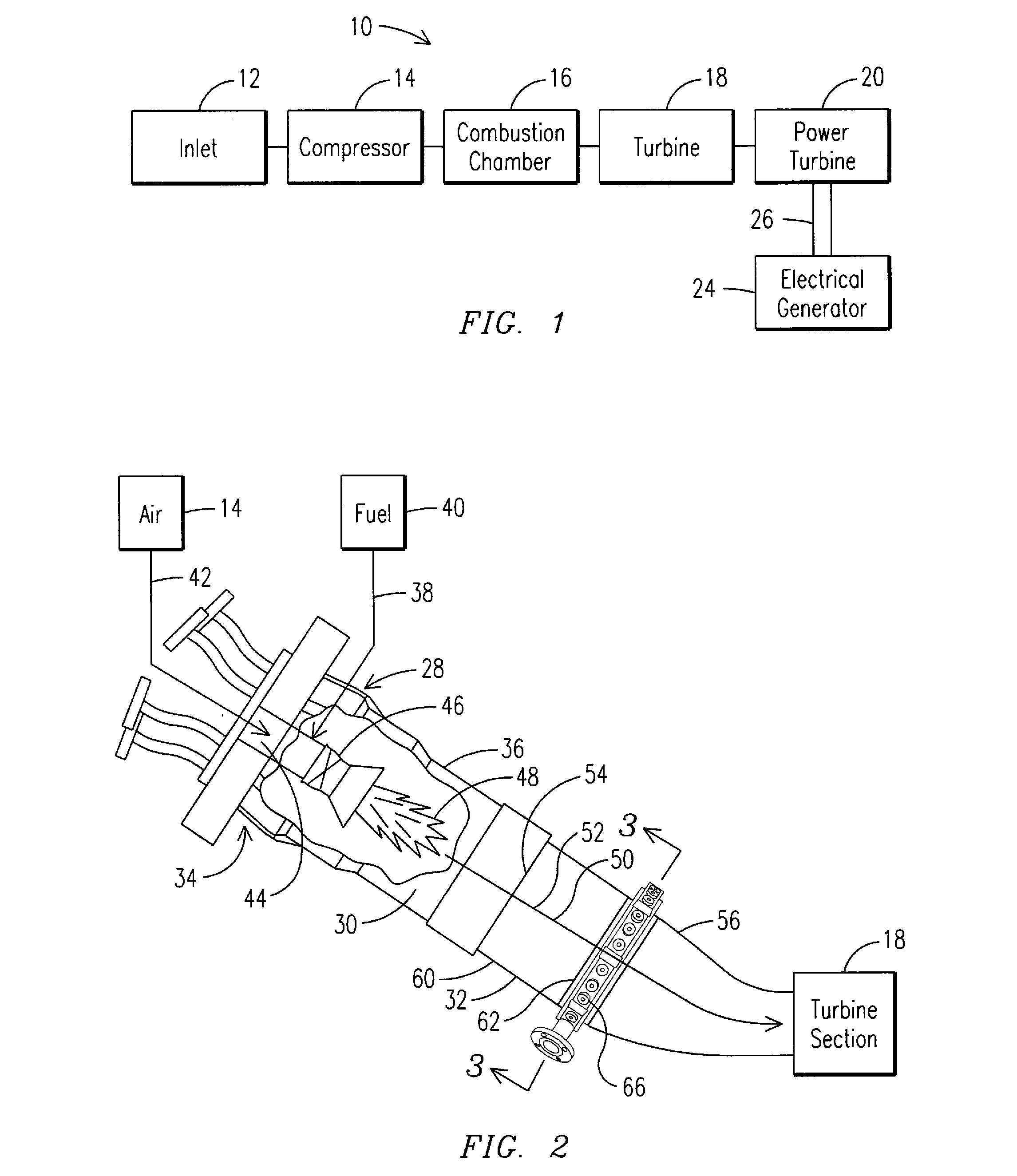

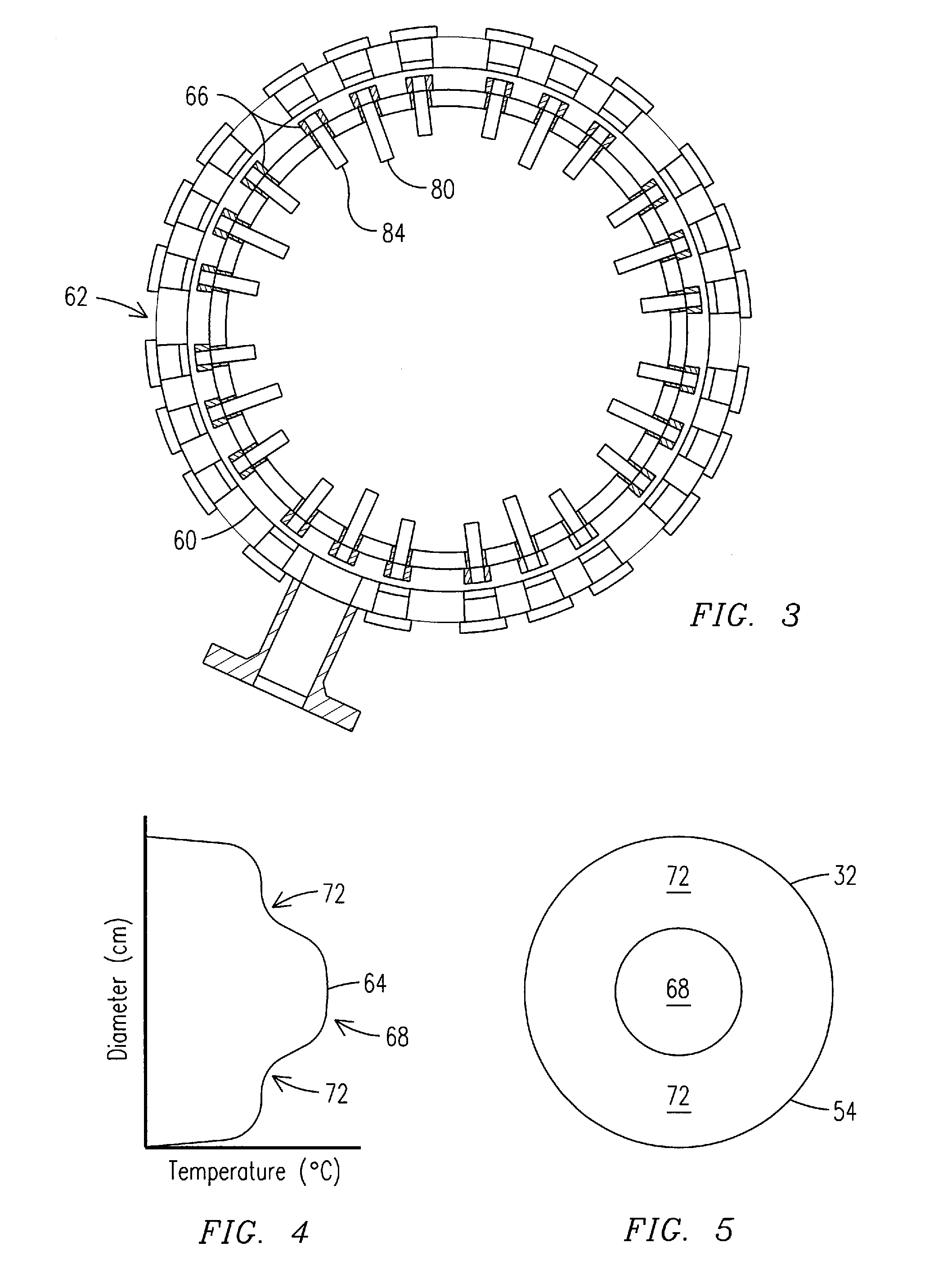

Apparatus and Method for Controlling the Secondary Injection of Fuel

In one embodiment, a combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

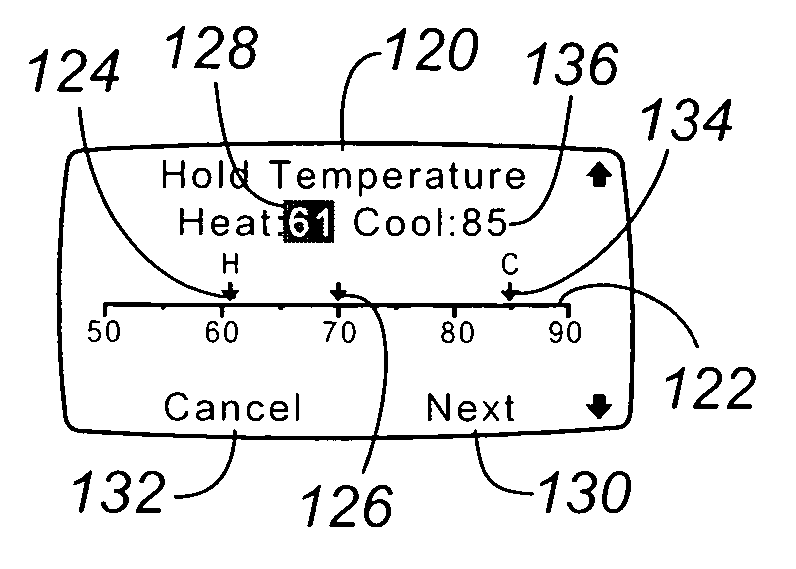

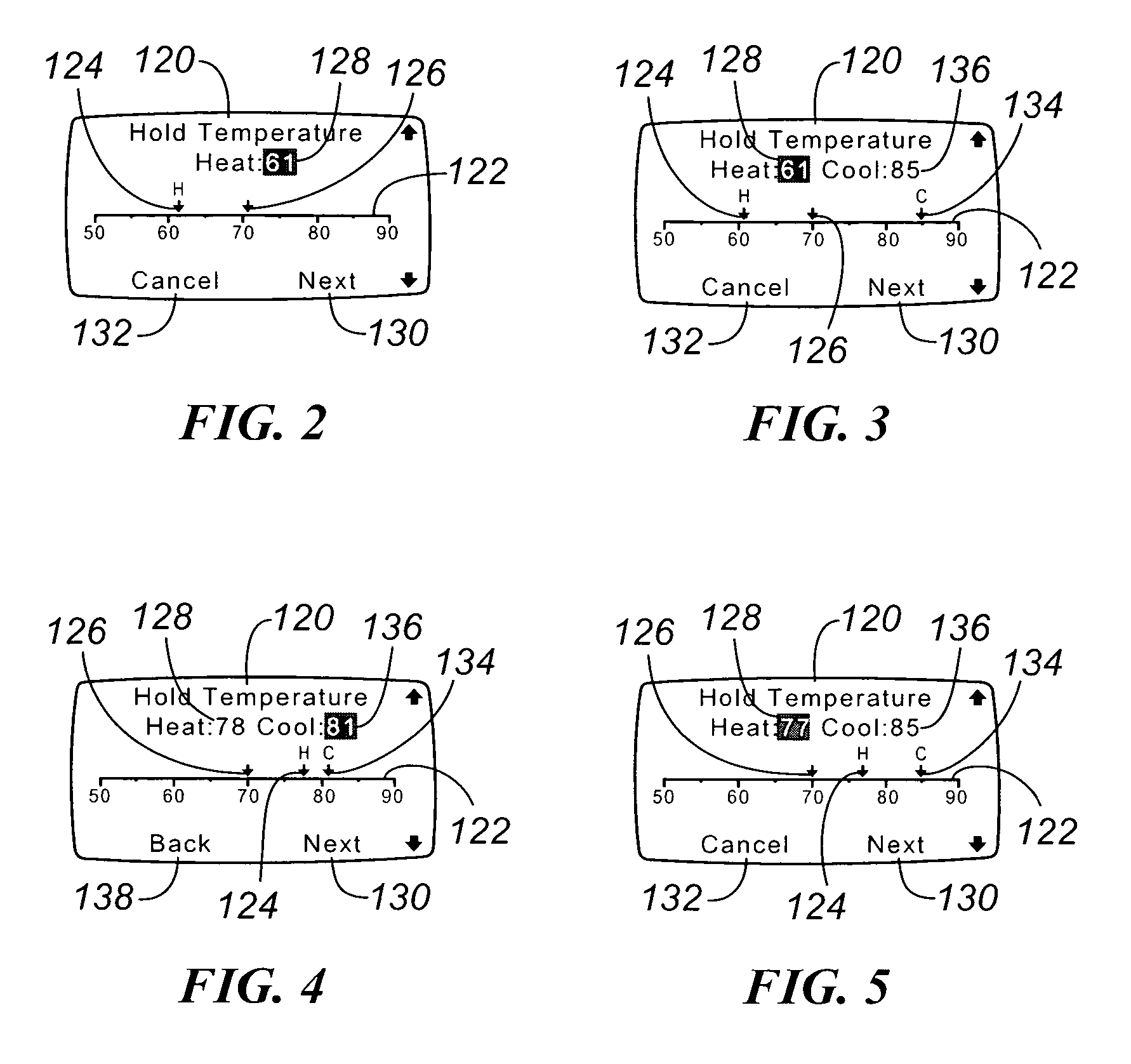

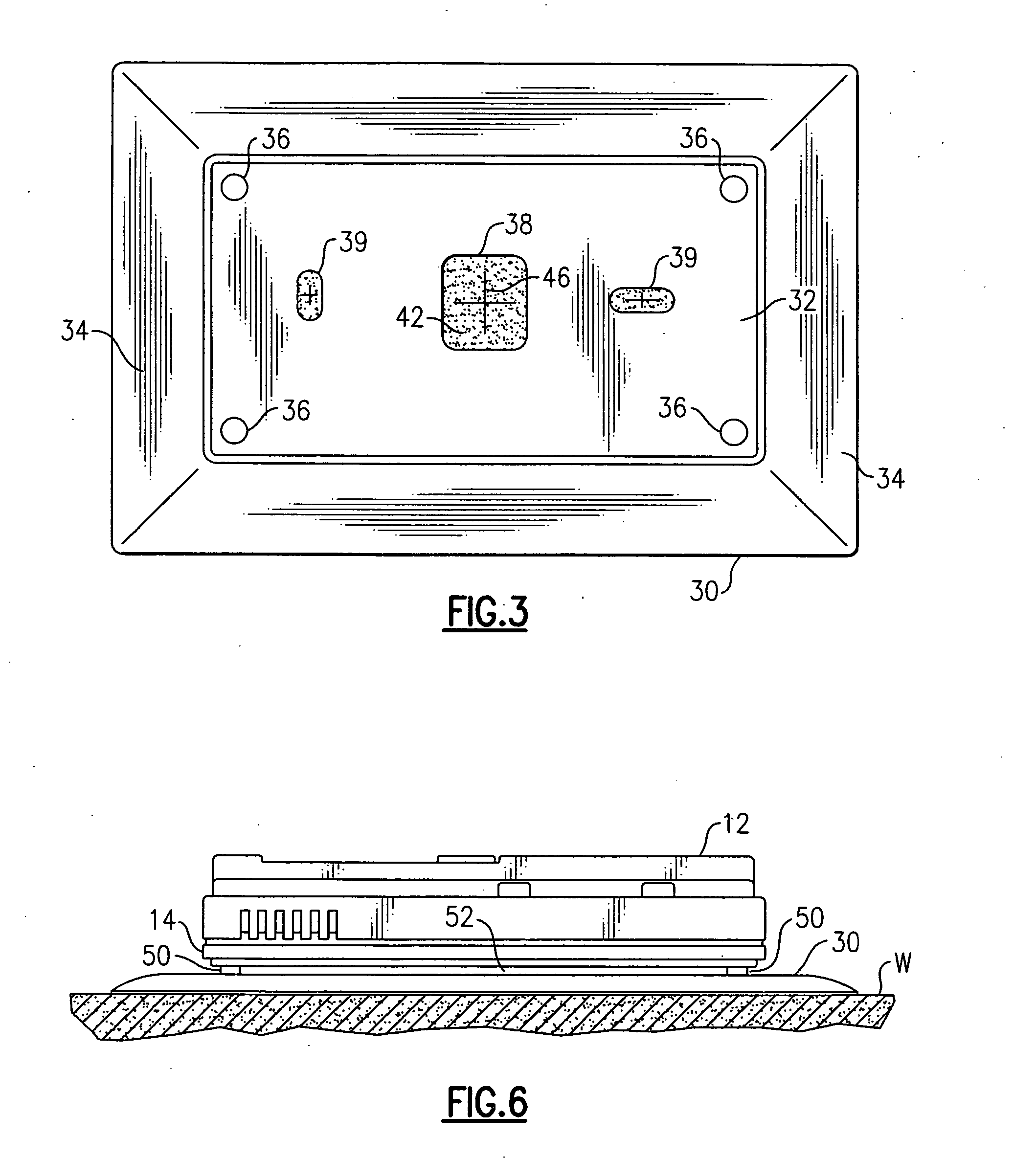

Thermostat including set point number line

A thermostat temperature programming display system for a digital thermostat that provides a graphical illustration of the relationship between the heating, cooling, and ambient temperatures is provided. This display system illustrates this relationship as digital markers along a linear temperature set point line on the display. As a set point is varied, the digital marker moves along the set point line. The heating and cooling set point markers are bounded by one another in a variable relationship based on a user defined dead band temperature during an automatic change over mode of operation. Only an appropriate marker is illustrated on the set point line based on the operating mode of the thermostat.

Owner:RANCO OF DELAWARE

Thermostat display system providing animated icons

InactiveUS20070045433A1Energy efficiencyExtend battery lifeMechanical apparatusComputer controlIllusionAnimation

A visual display system and method for a digital thermostat having a user display screen to provide operational status information of the heating and / or cooling equipment controlled by the thermostat is provided. This visual display system utilizes animated icons to show operational status of the heating and / or cooling equipment. Static icons may also be used in one embodiment to indicate the current mode of the thermostat. Animated icons for the heating system, the cooling system, and fan operation are provided. The illusion of animation is provided by overwriting or replacing a displayed image with another image at a predetermined frequency. This predetermined frequency may be changed programmatically, and varied to provide different visual effects.

Owner:RANCO OF DELAWARE

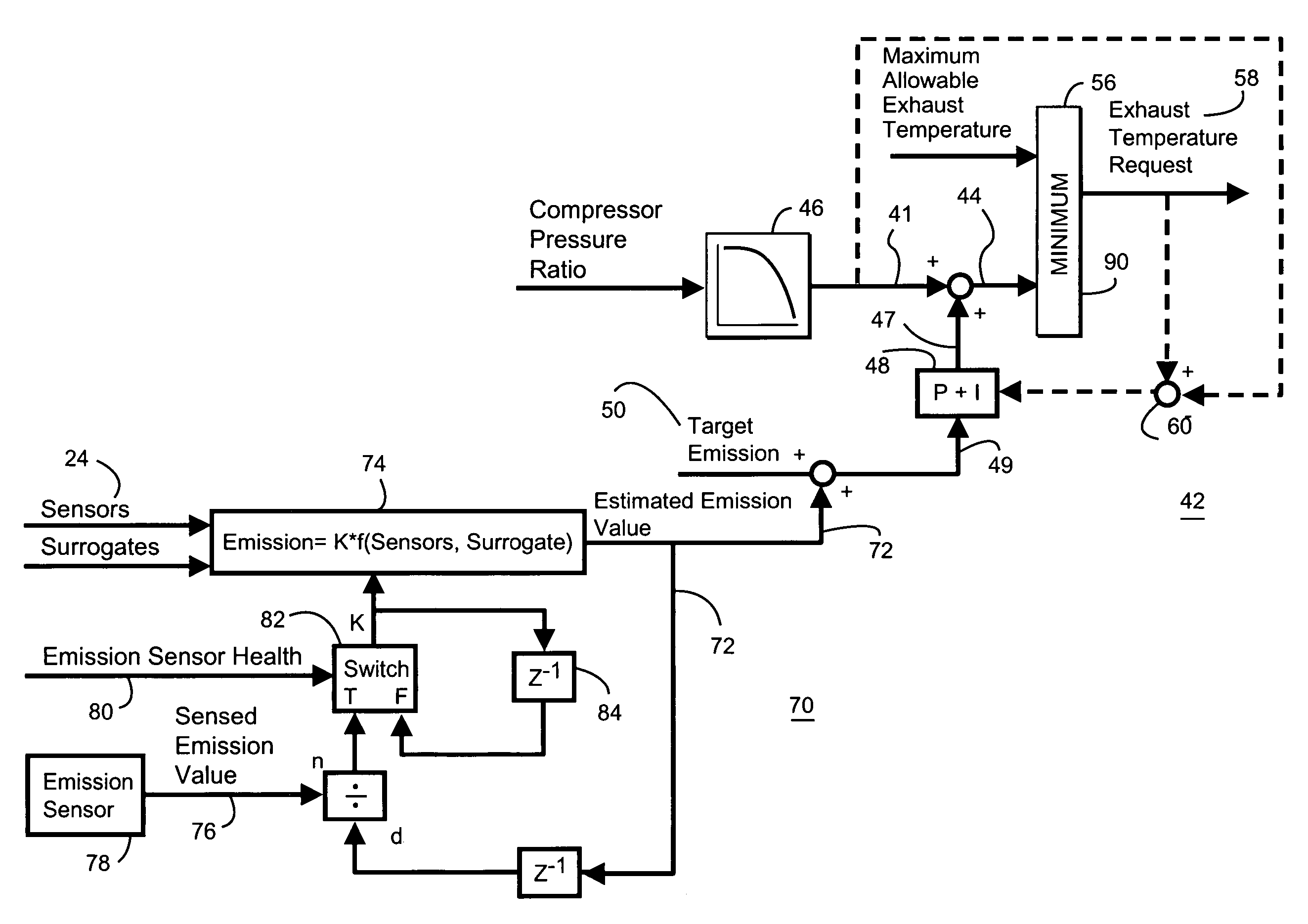

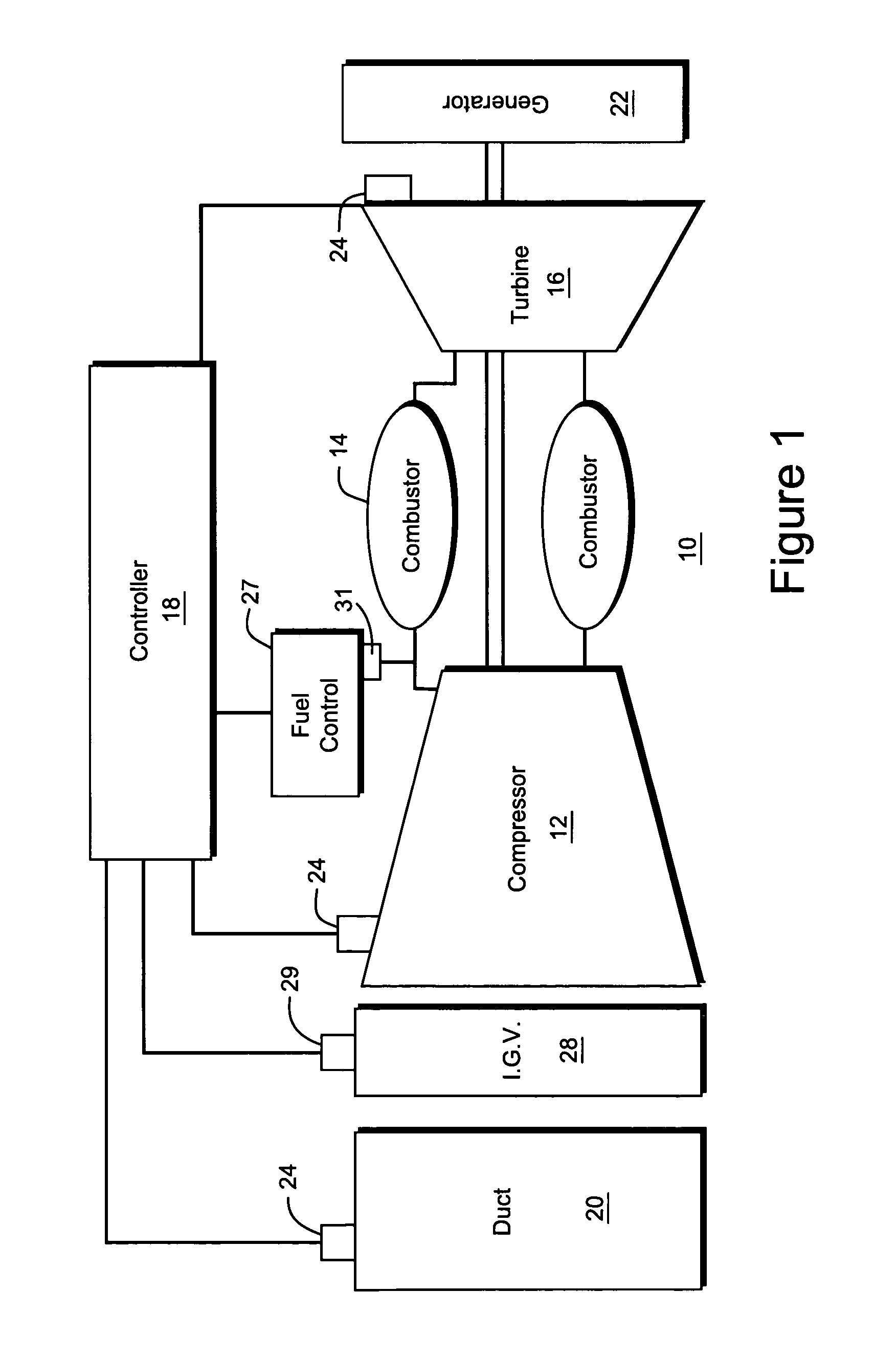

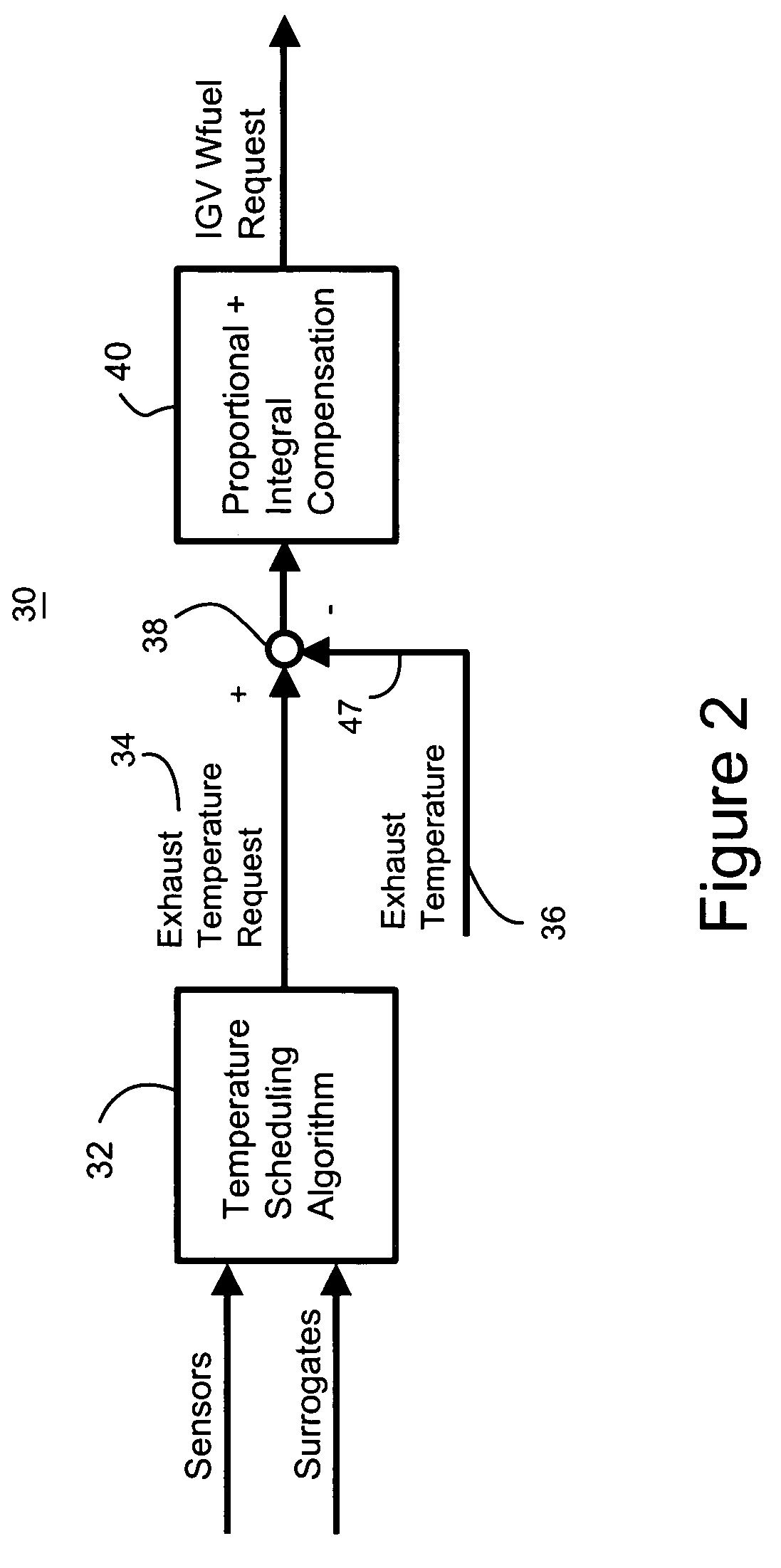

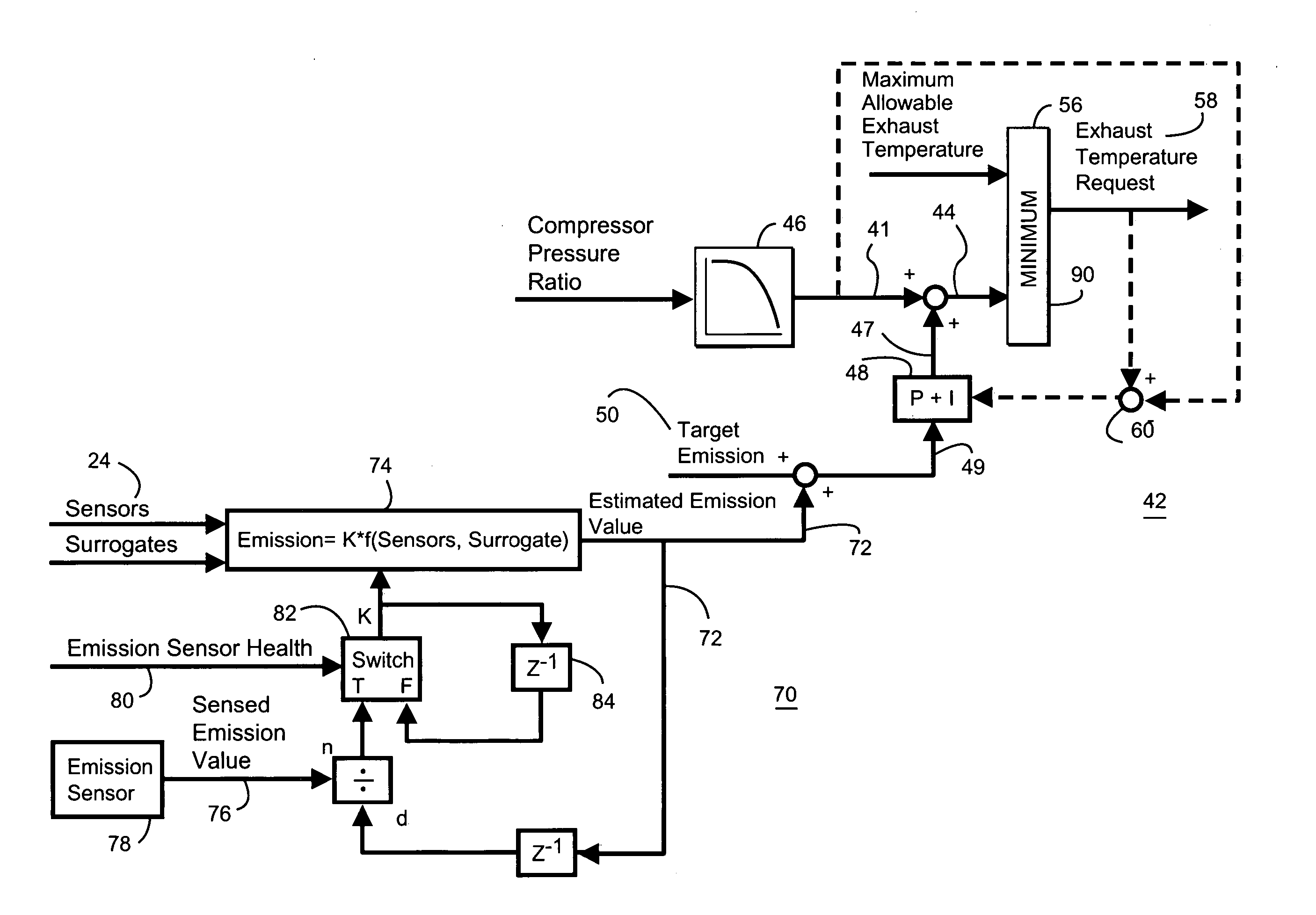

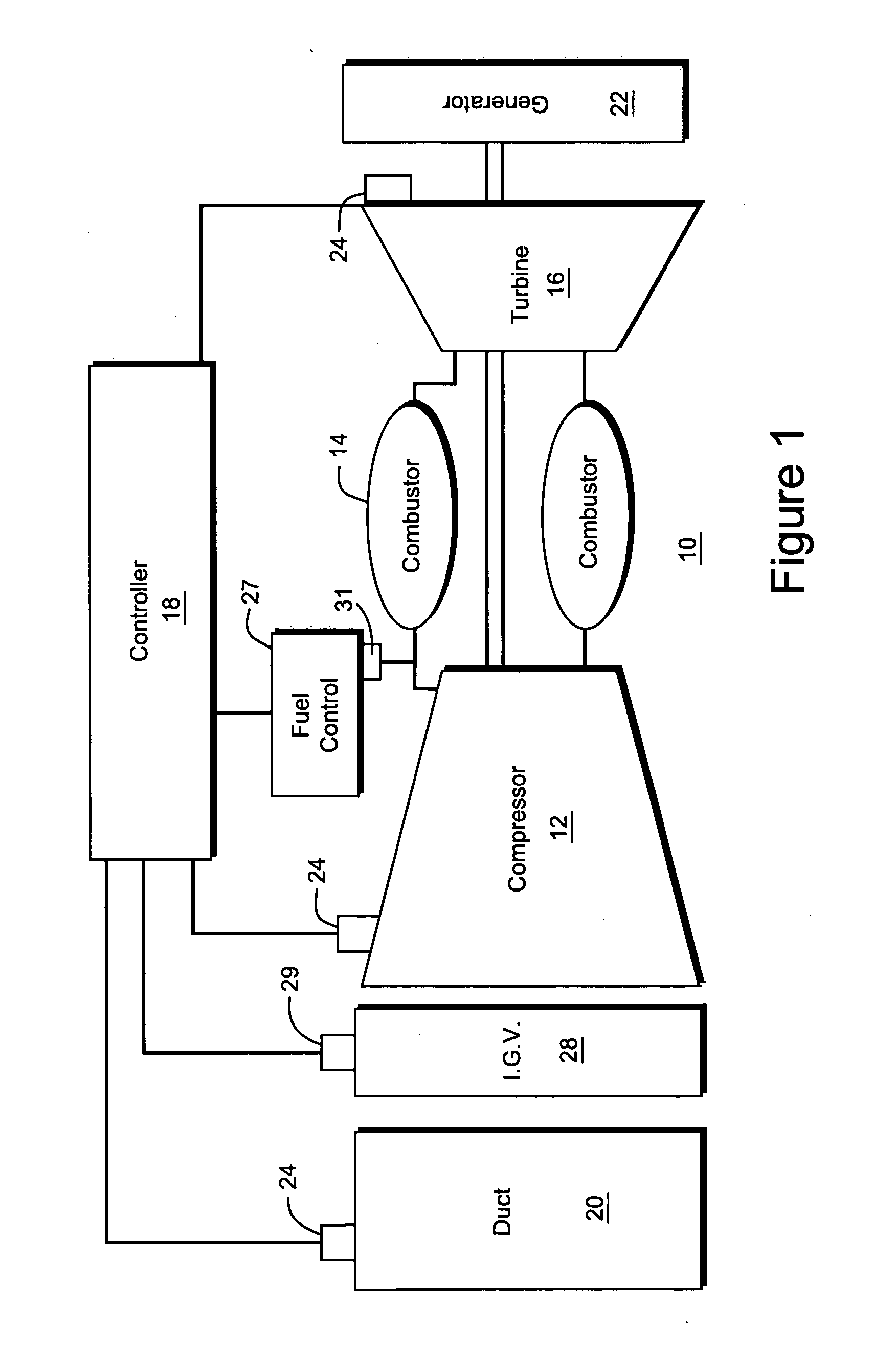

Method and system for incorporating an emission sensor into a gas turbine controller

A method for determining an estimated operating parameter for a gas turbine including the steps of: determining an estimated operating parameter using an algorithm have an input from a sensor, wherein the algorithm includes a trim factor; determining a first trim factor based on a comparison of the first estimated operating parameter and the output of the sensor when a condition of the sensor is in a first mode, and during a subsequent determination of the estimated operating parameter, applying the first trim factor to subsequently determine the estimated operating condition if the condition of second sensor is in a second mode.

Owner:GENERAL ELECTRIC CO

Intrusion barrier and thermal insulator for thermostat

InactiveUS20060006244A1Easy to installTemperature control without auxillary powerTemperature control with auxillary non-electric powerEngineeringThermostat

A wall plate for a wall thermostat blocks intrusion air from the thermostat. The wall plate has a wire passage aligned with the wall penetration through which the thermostat wires emerge. The wall plate member directs any intrusion air that flows out the penetration away from the cavity of said thermostat. An insulating layer, e.g., a closed-cell foam sheet, in the wall plate insulates the thermostat from direct thermal contact with the wall. The closed-cell material closes around the thermostat wires. Bosses or feet on the thermostat back plate create a standoff between the wall plate and the thermostat.

Owner:INT CONTROLS & MEASUREMENT

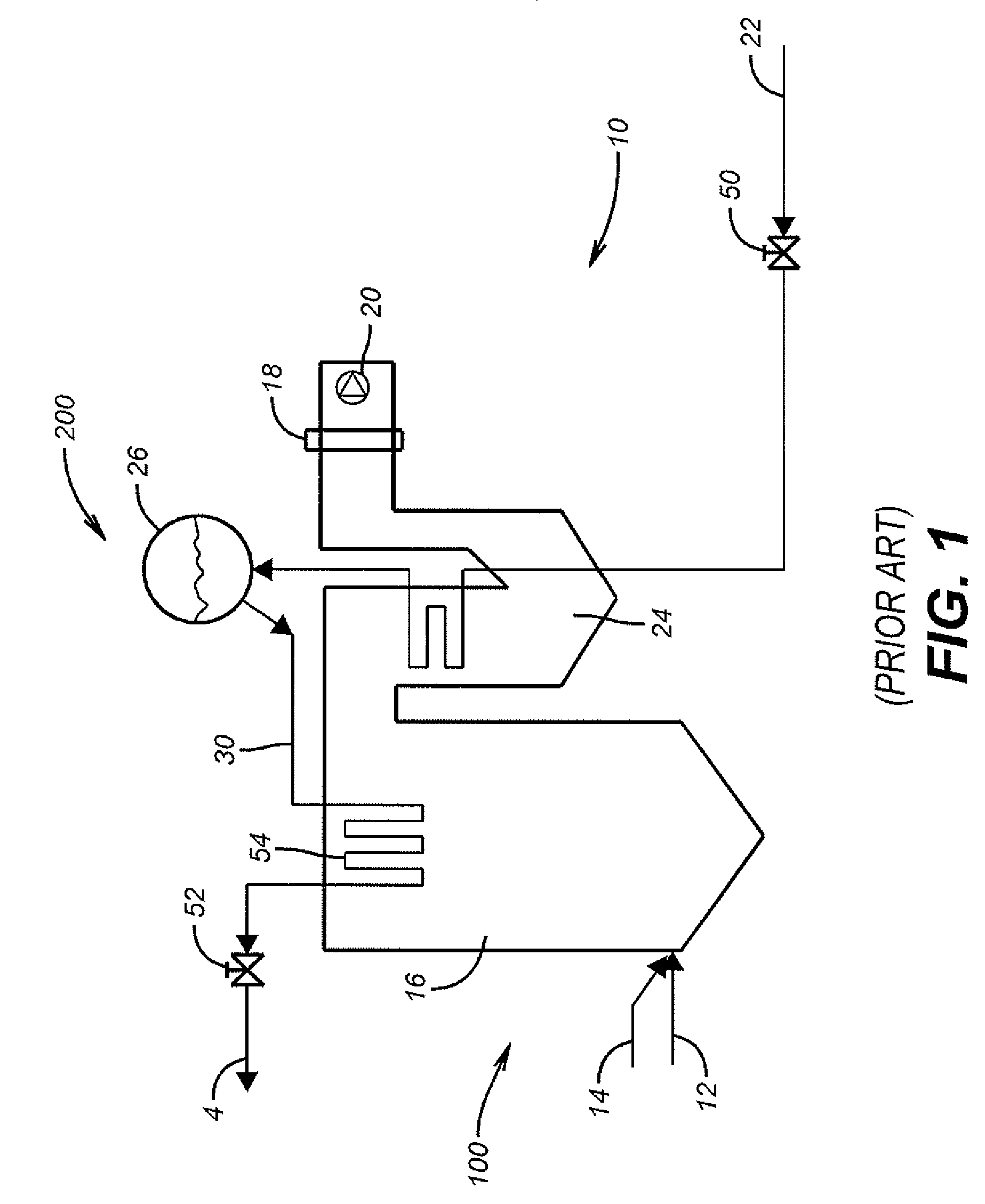

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

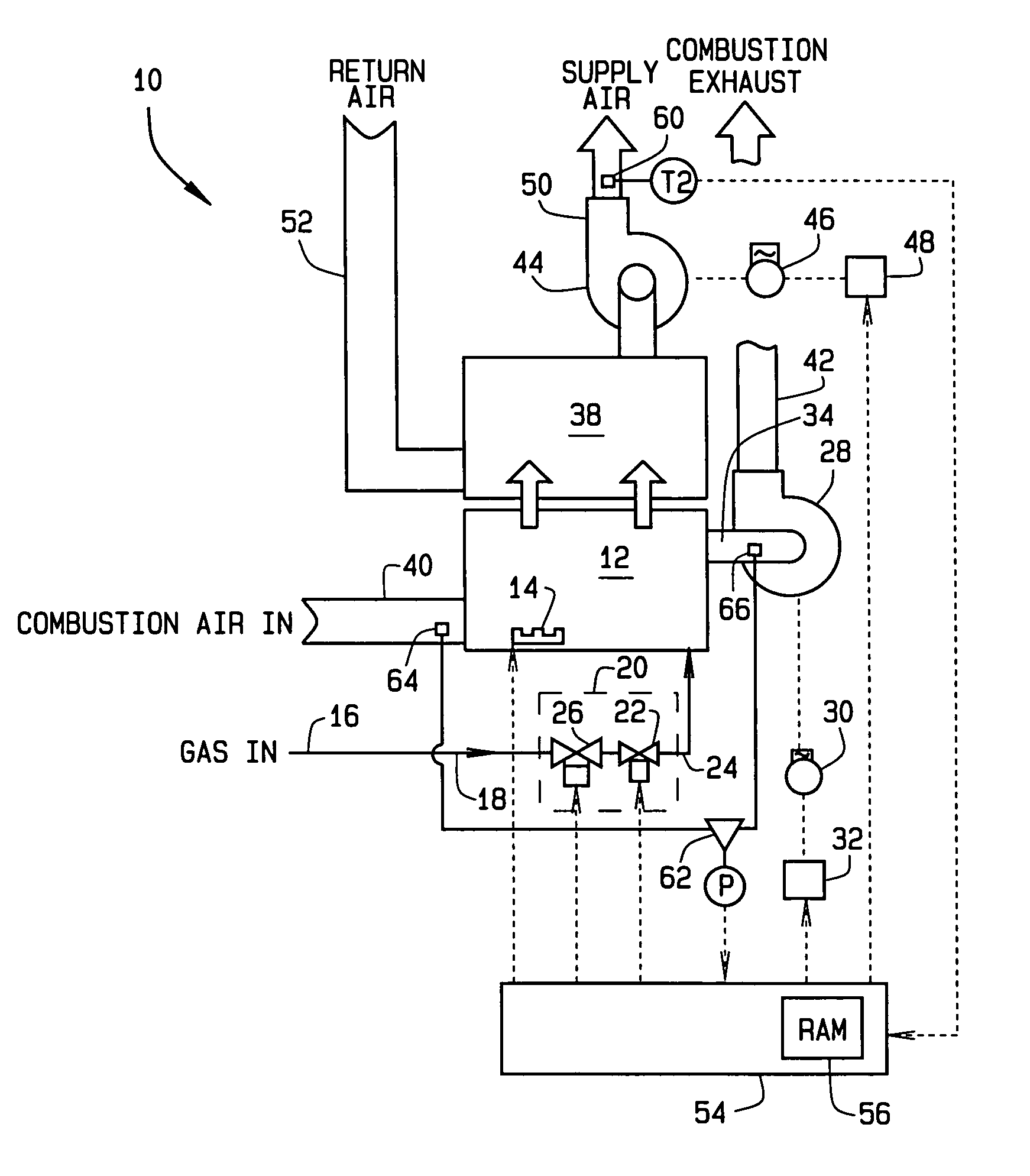

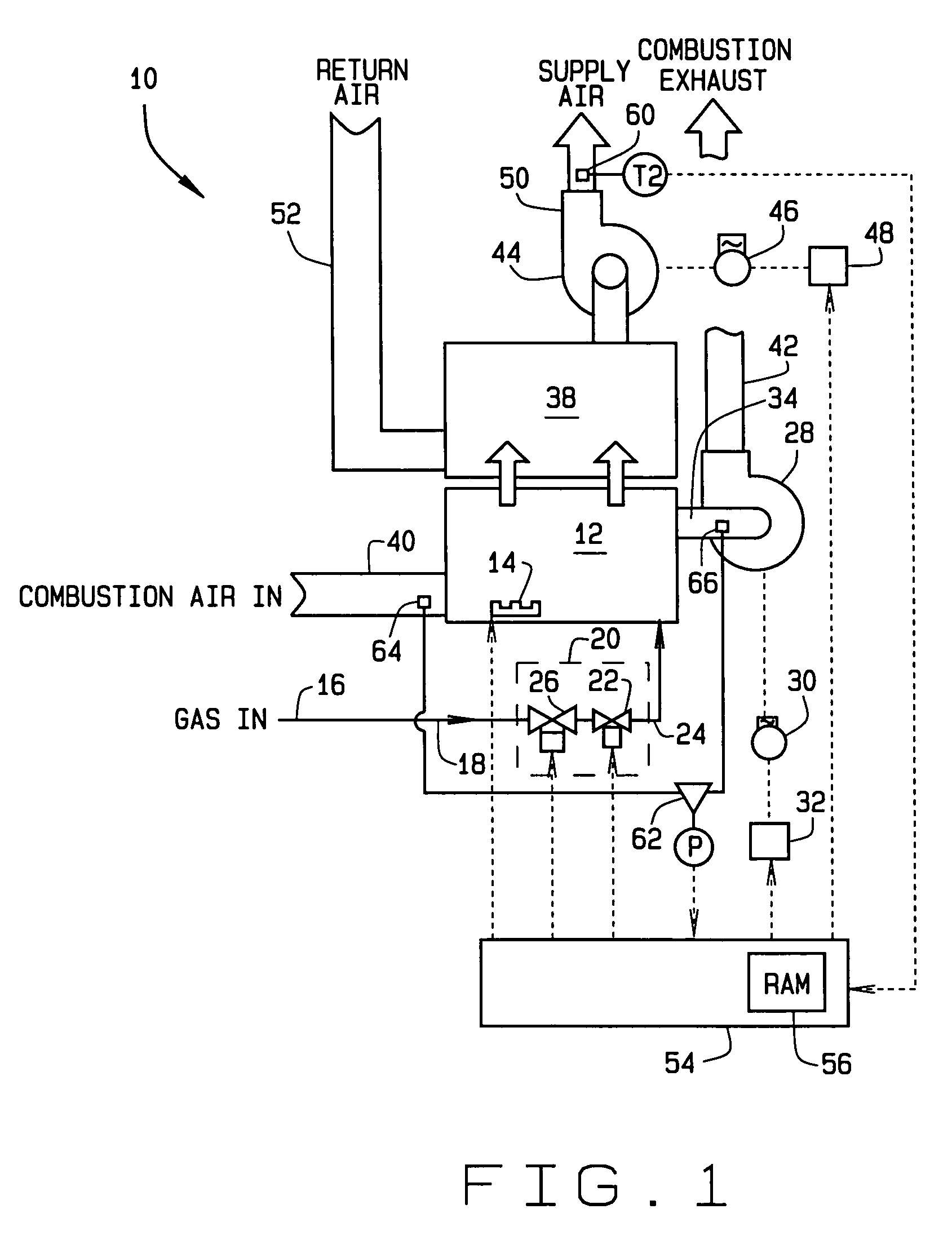

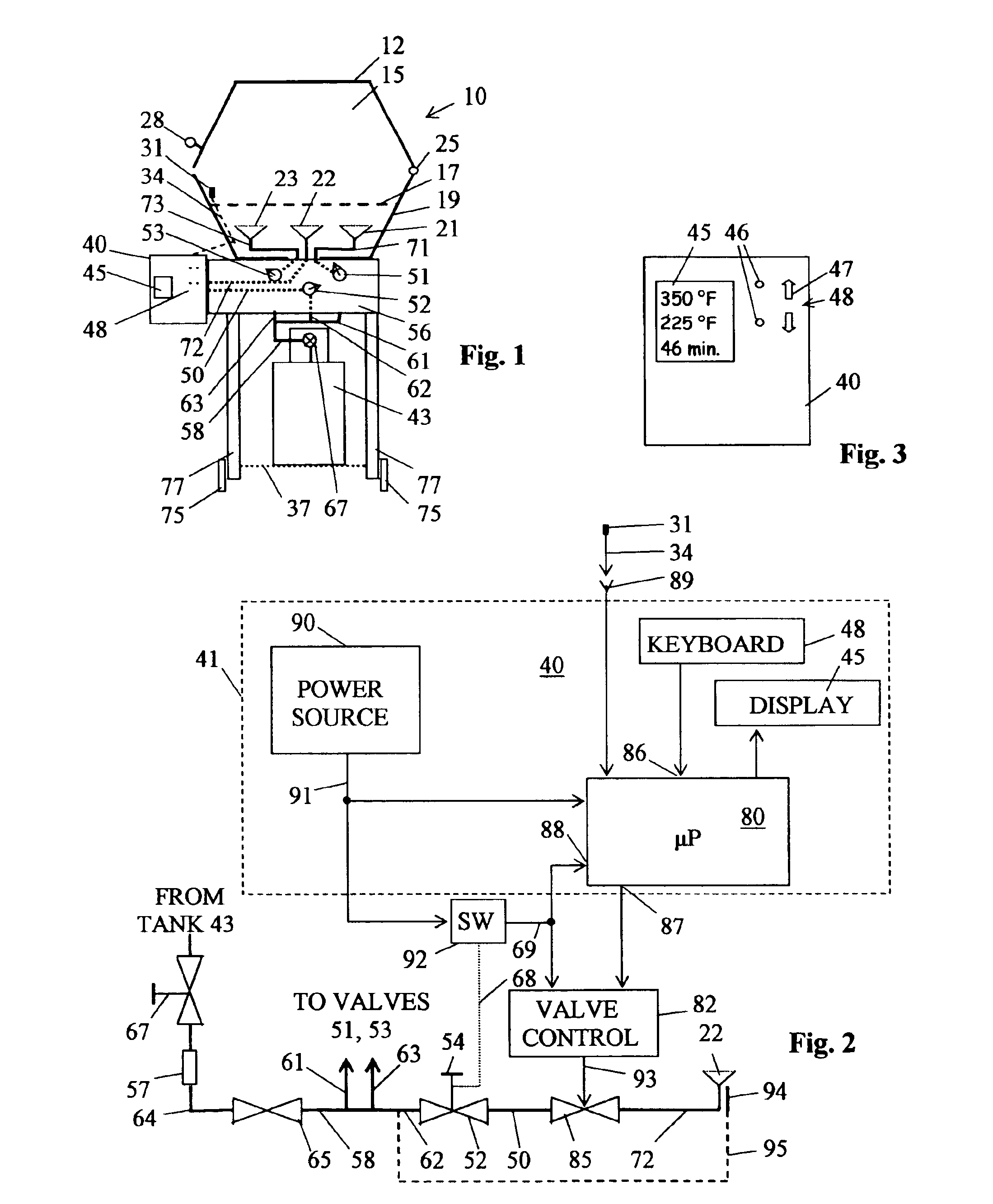

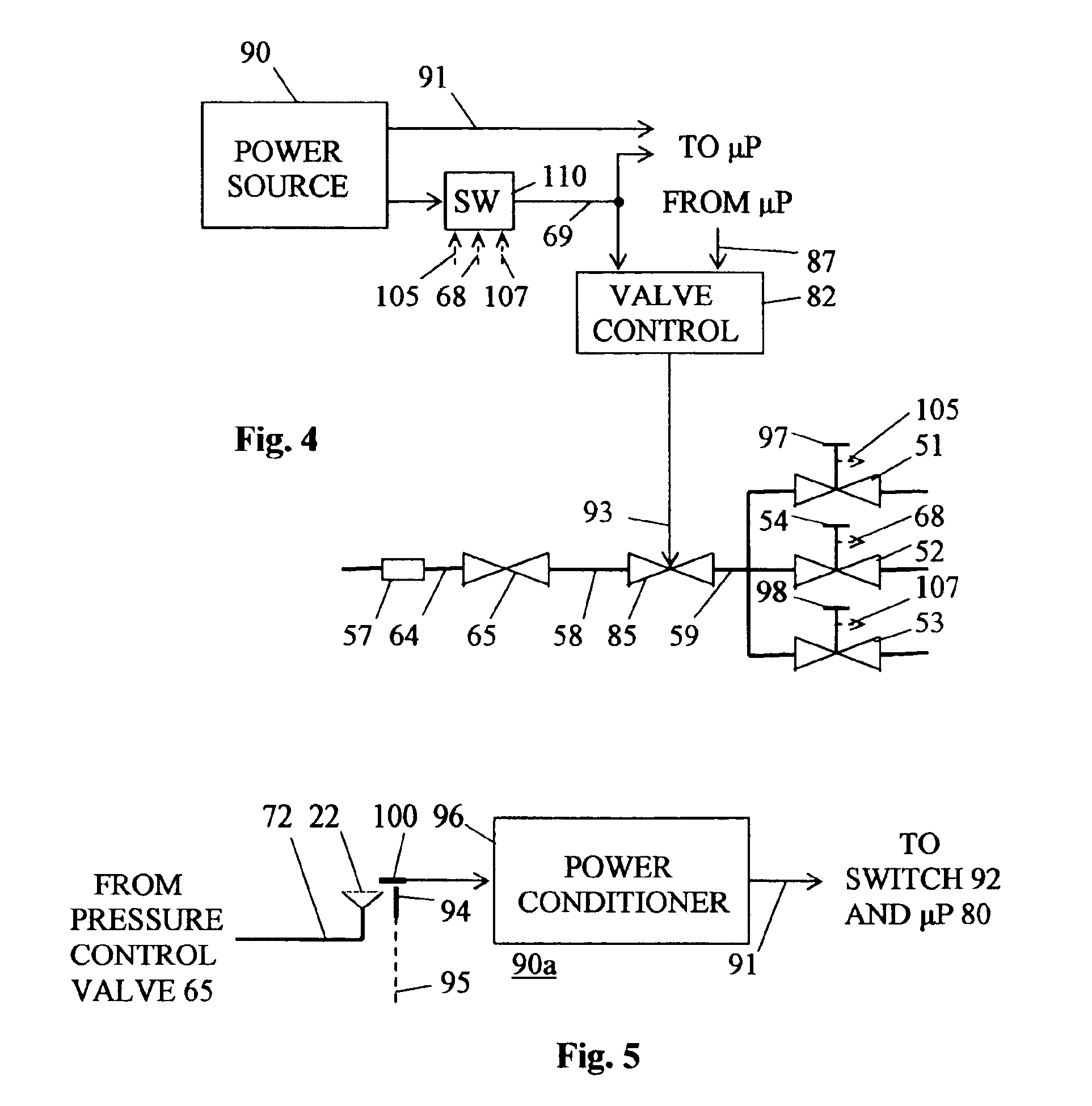

Apparatus and methods for variable furnace control

InactiveUS7101172B2Speed of can varyGreat pressure dropFuel supply regulationAir supply regulationMotor speedCombustion chamber

A furnace control system for controlling a gas-fired induced-draft furnace having a variable speed inducer blower. A control apparatus, responsive to a signal corresponding to the magnitude of a pressure difference between an inlet and outlet of the combustion chamber, controls blower motor speed to maintain the pressure difference at a predetermined magnitude corresponding to a selected gas flow rate. Inducer blower motor speed is varied directly and precisely to maintain an optimal pressure drop across the combustion chamber. The control system can be used in multi-stage and modulating furnace systems and in furnace systems utilizing pressure-assist modulating gas valves.

Owner:COPELAND COMFORT CONTROL LP

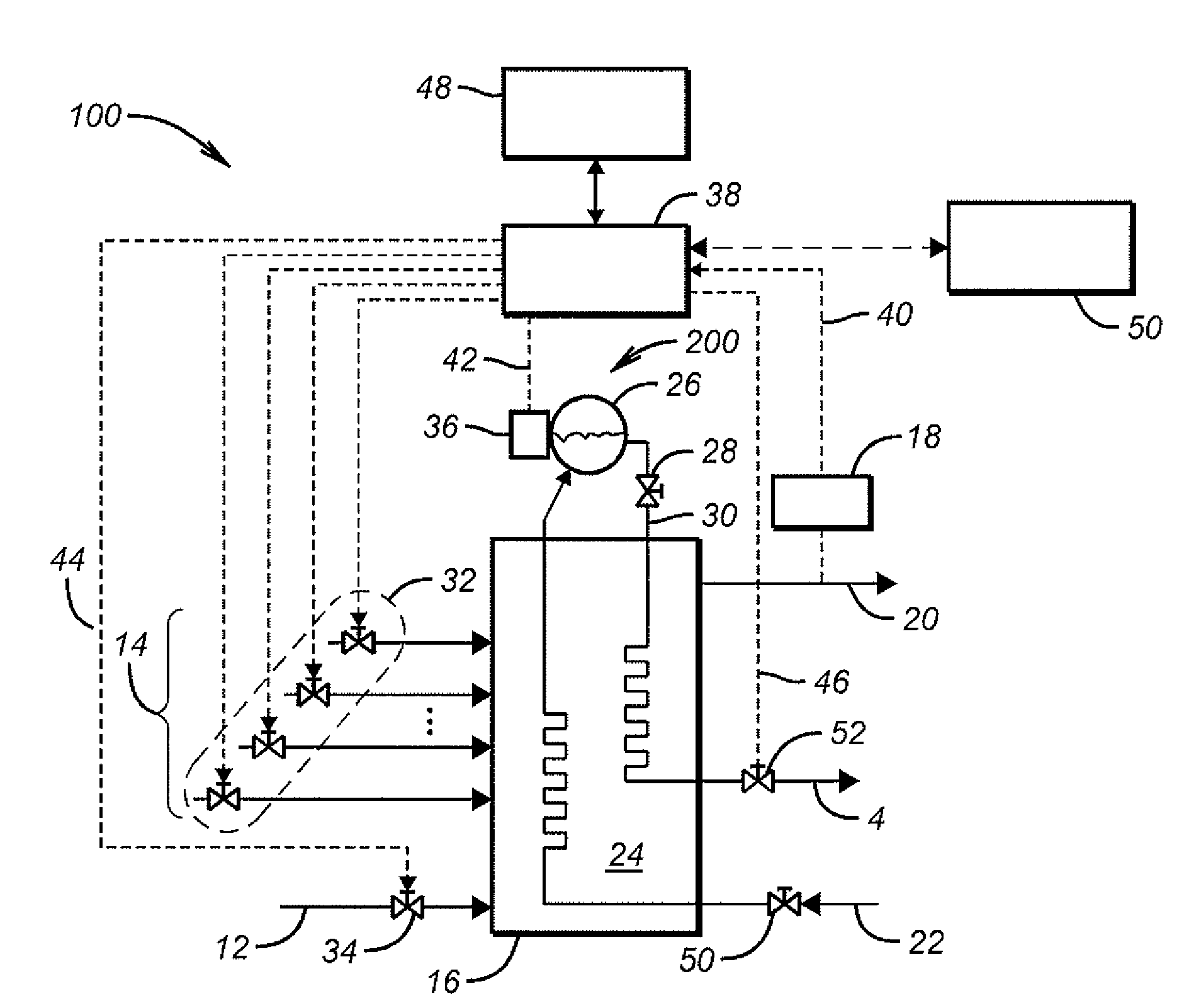

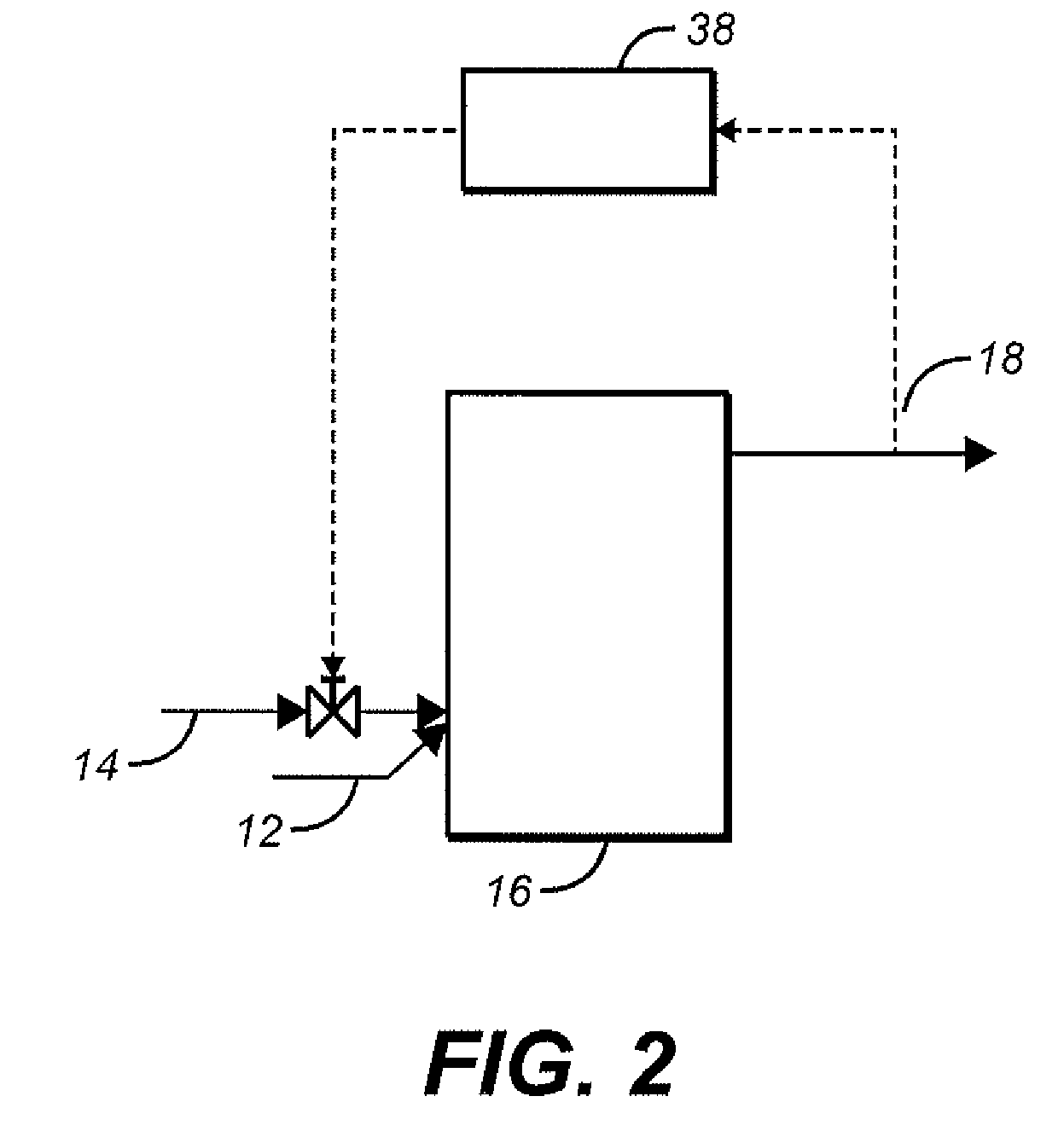

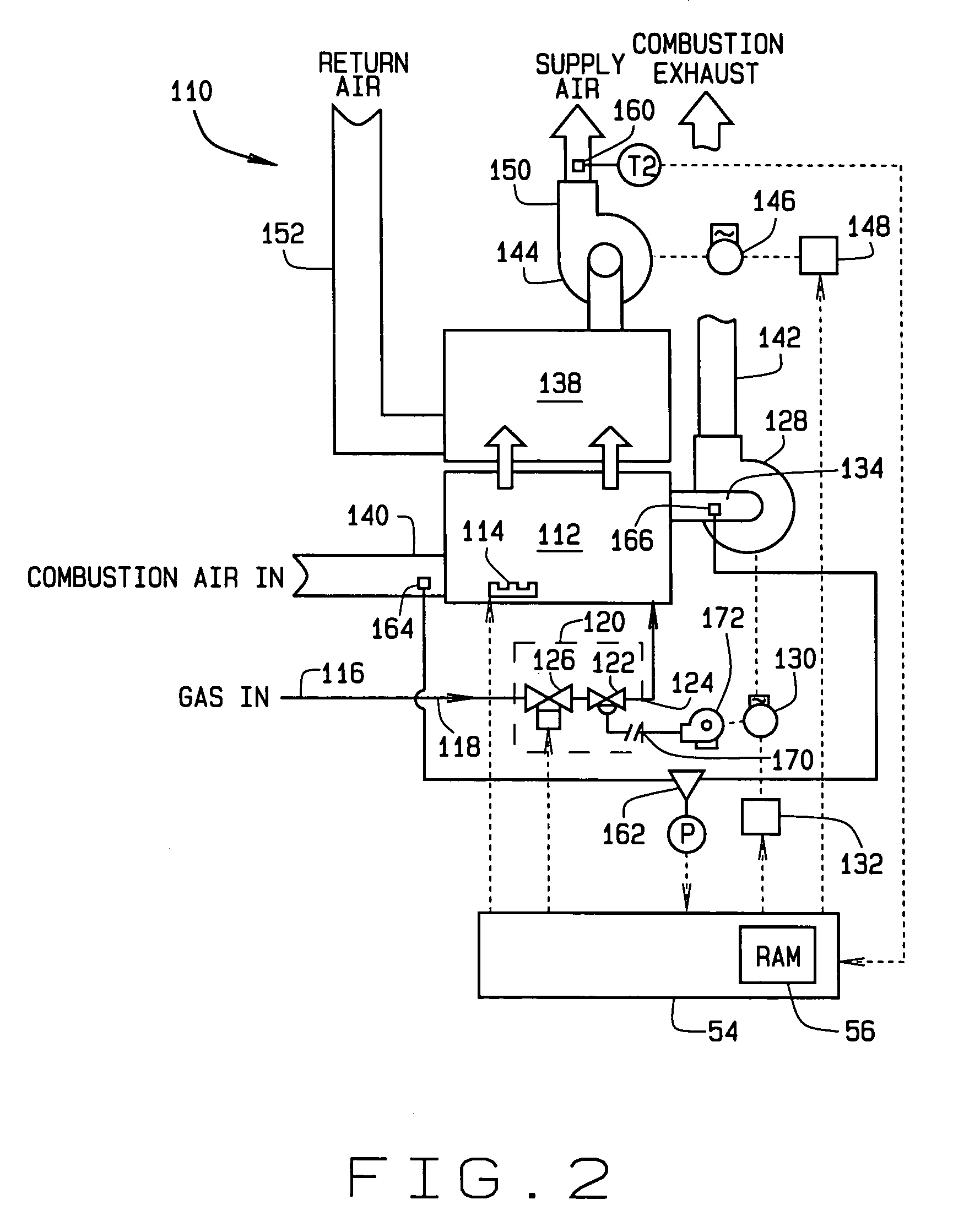

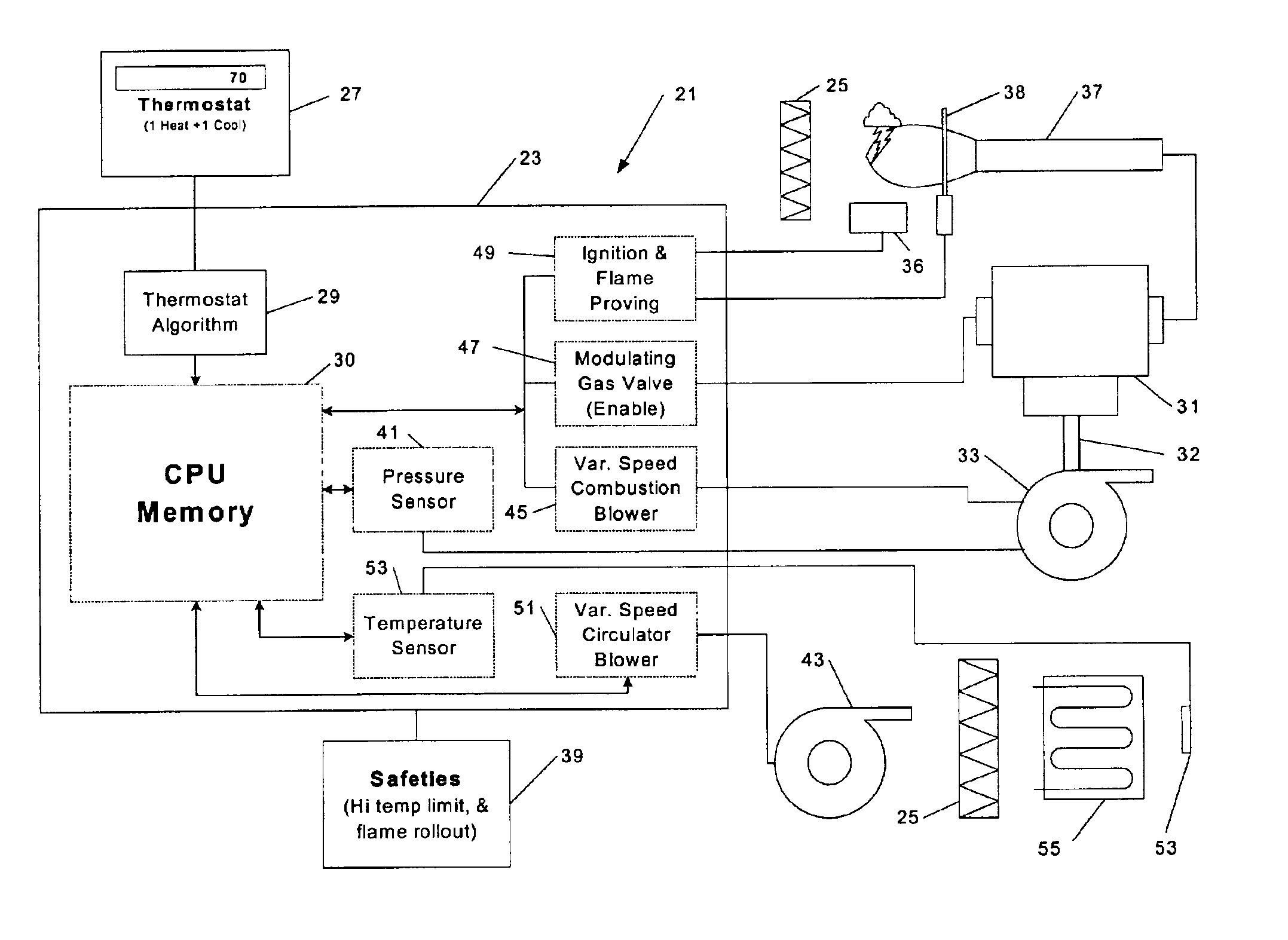

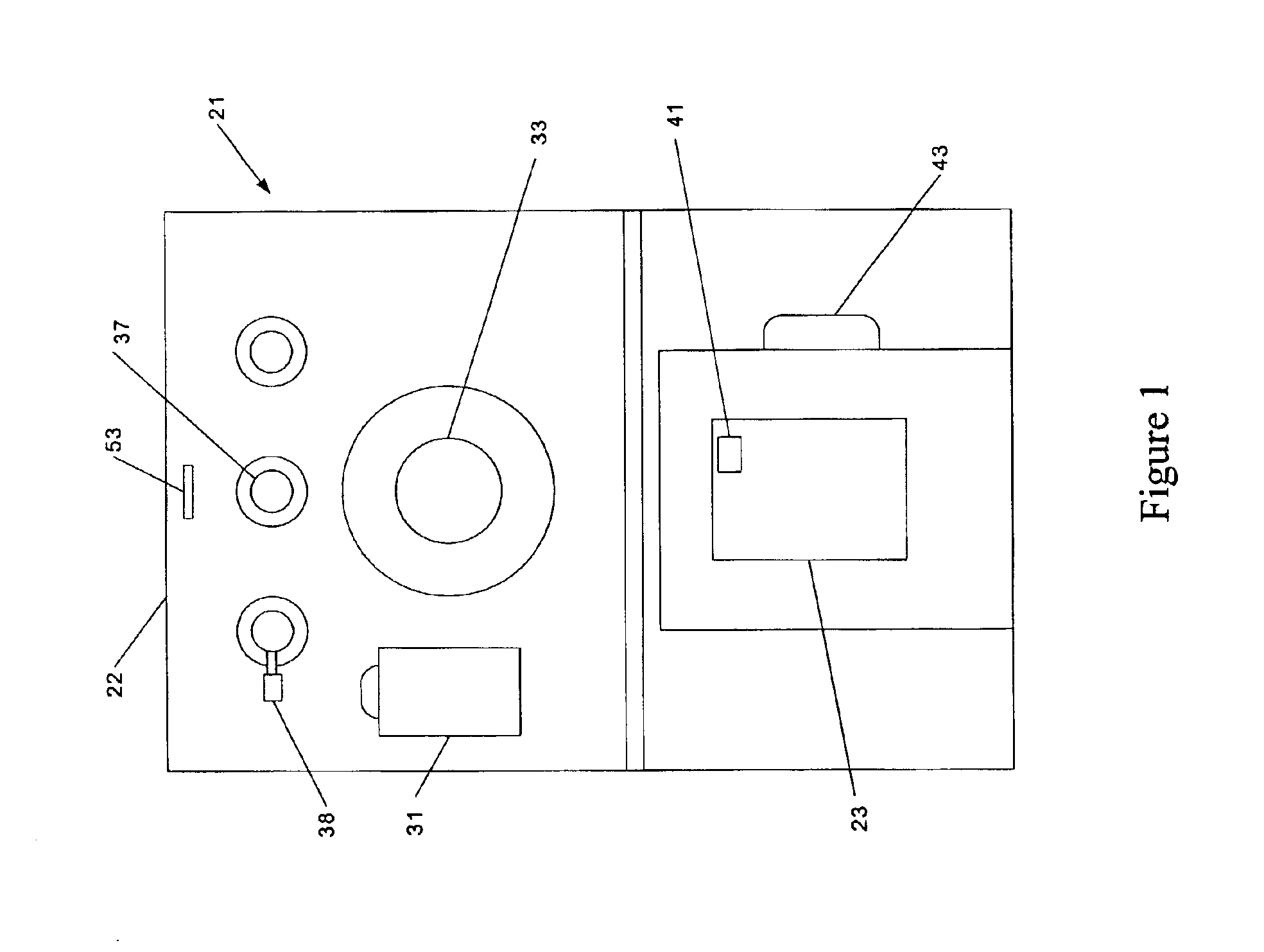

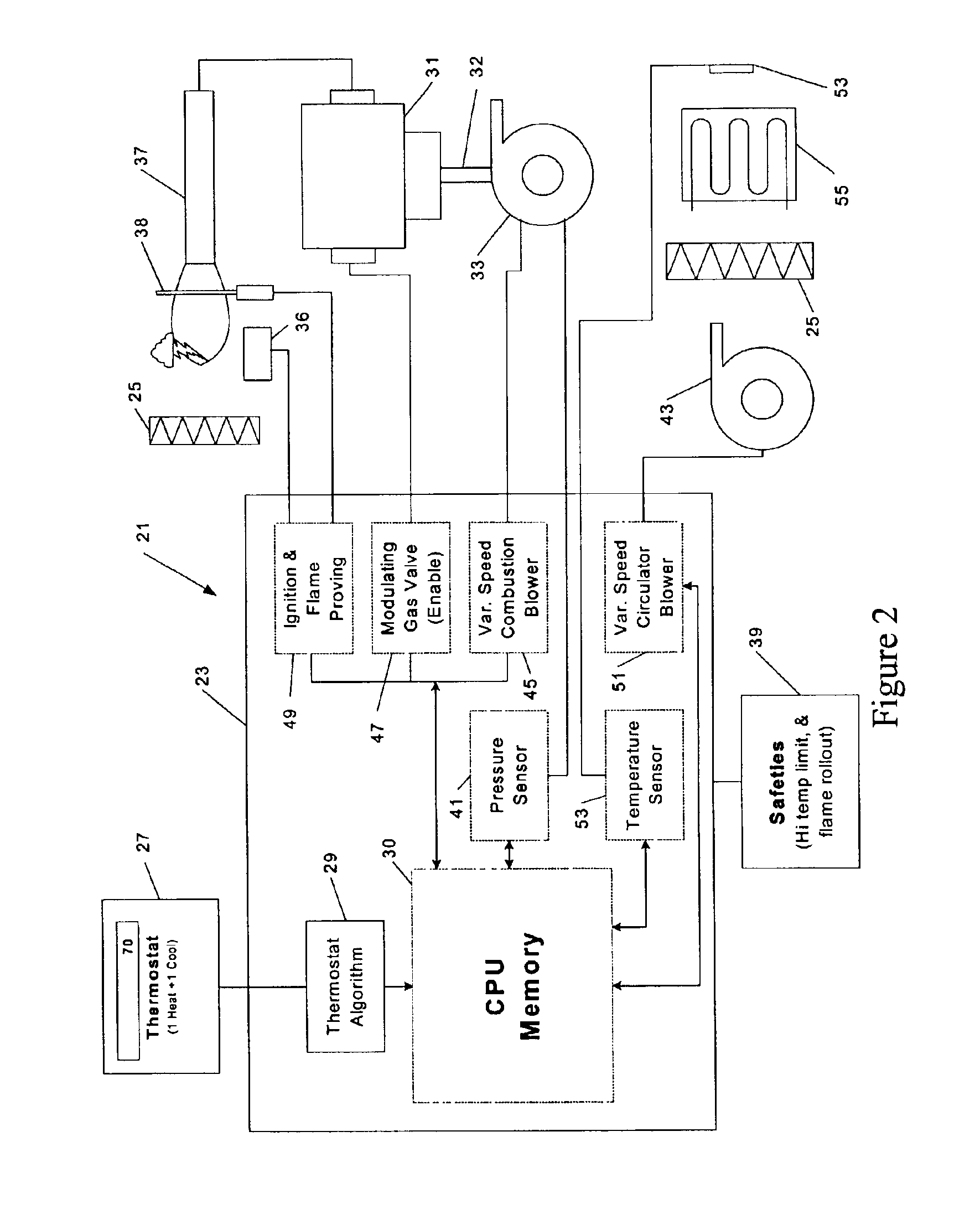

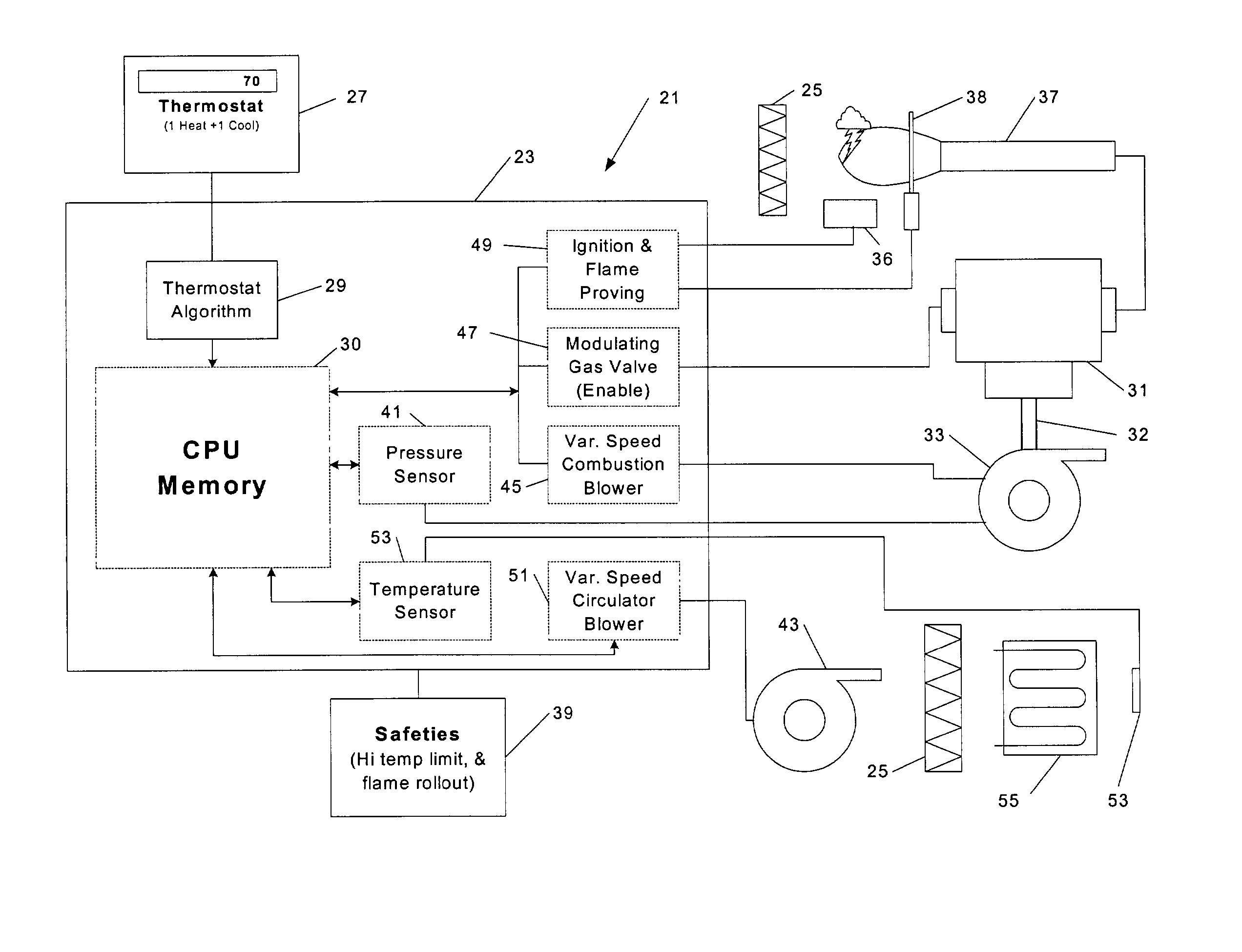

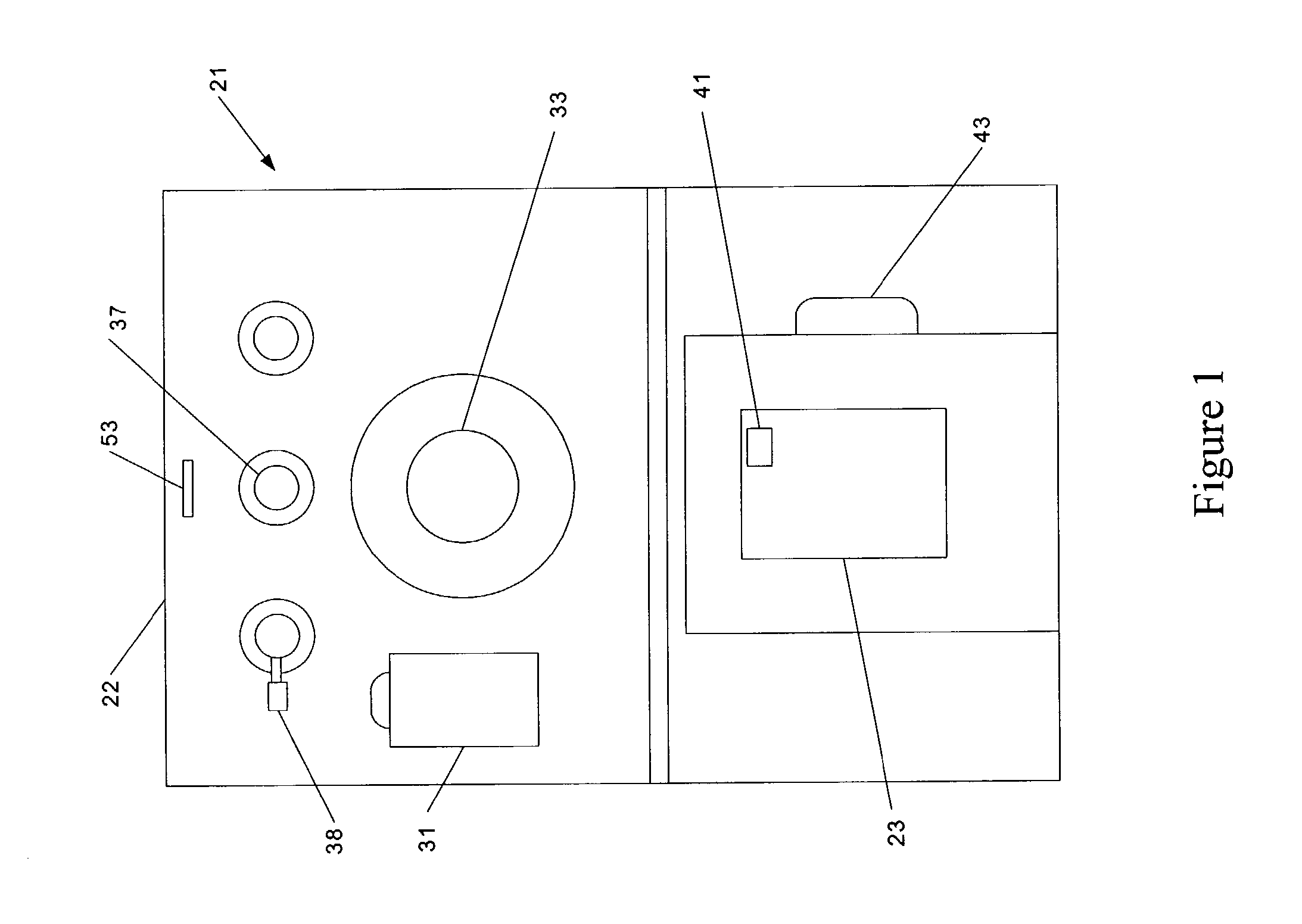

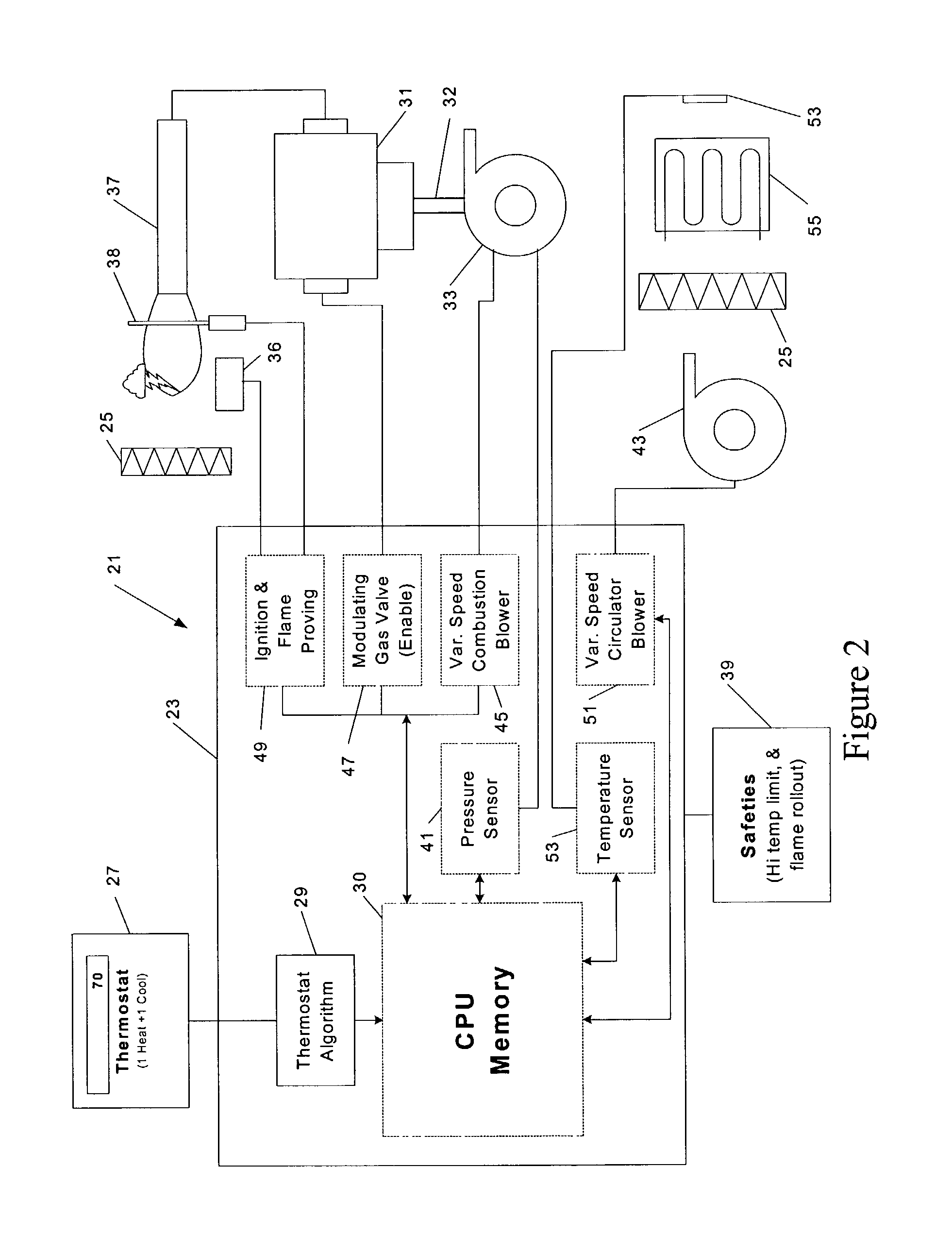

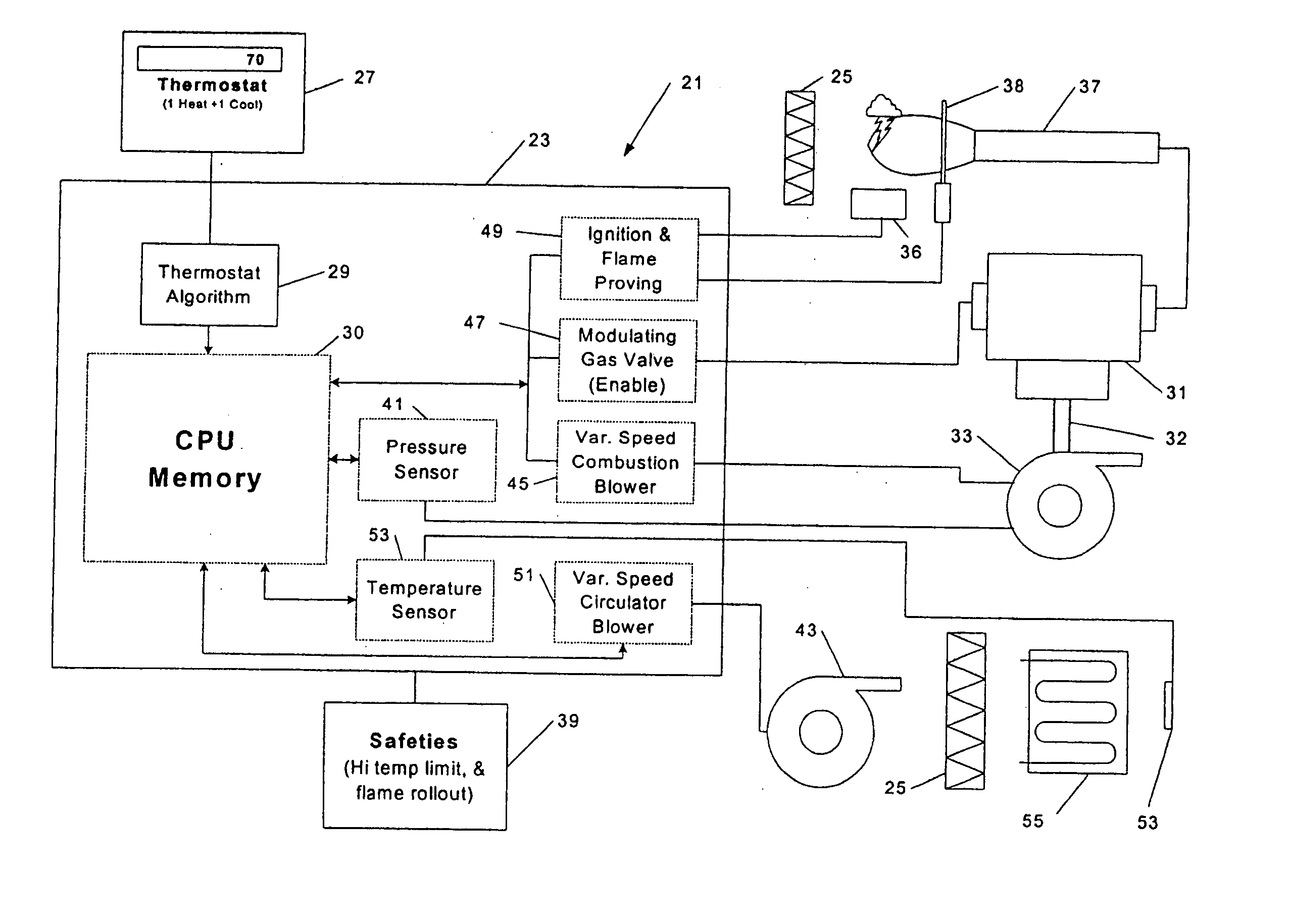

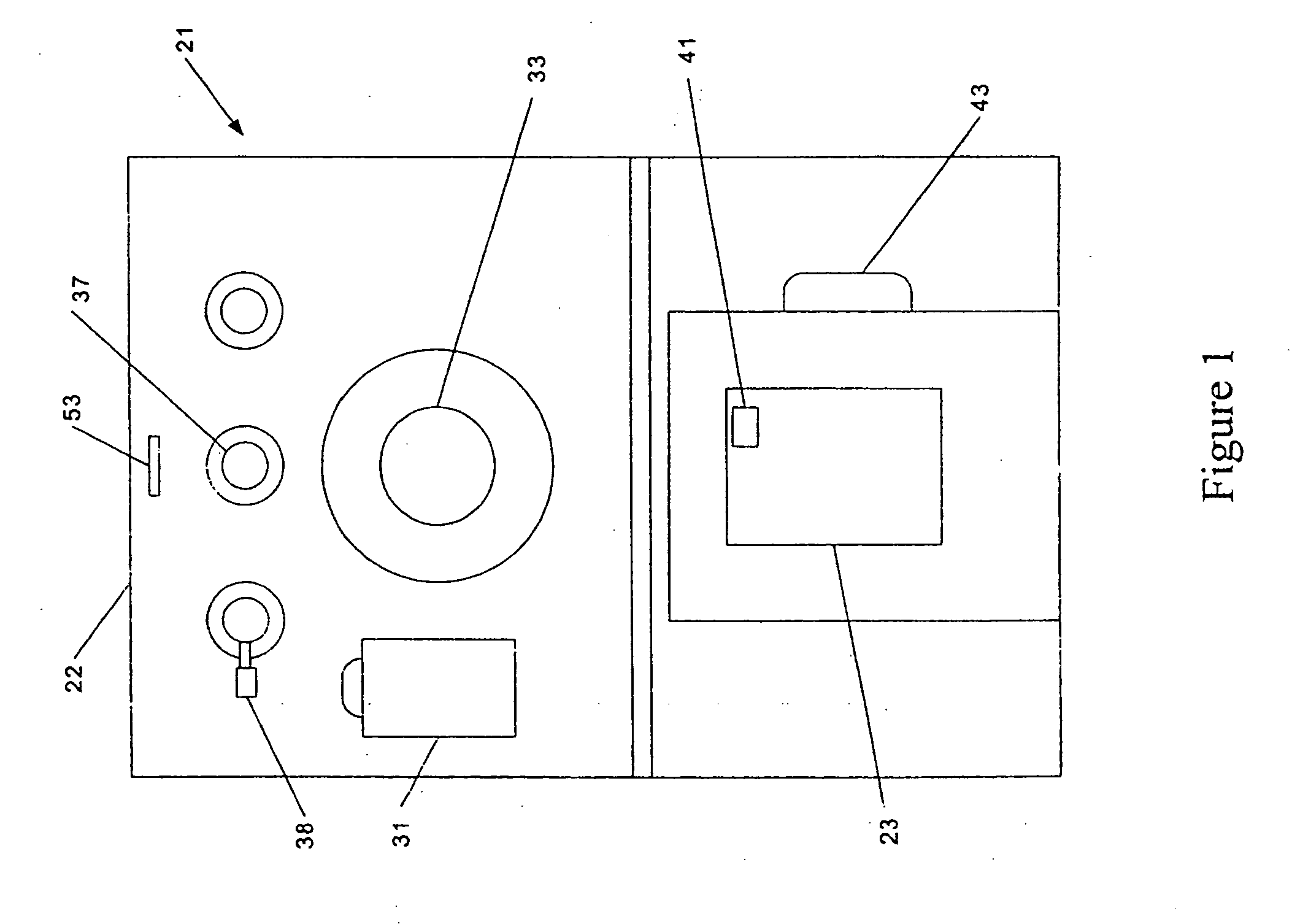

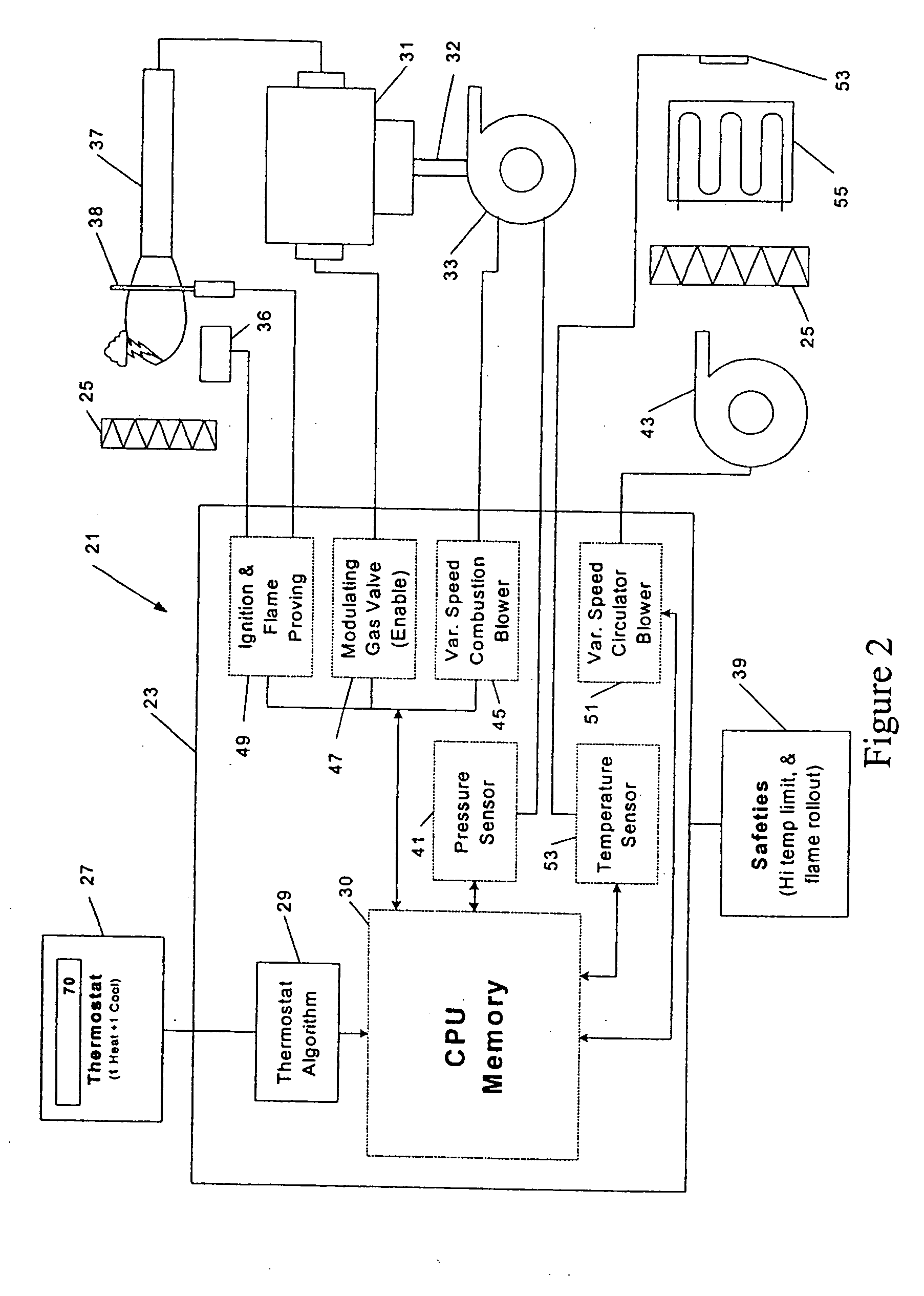

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

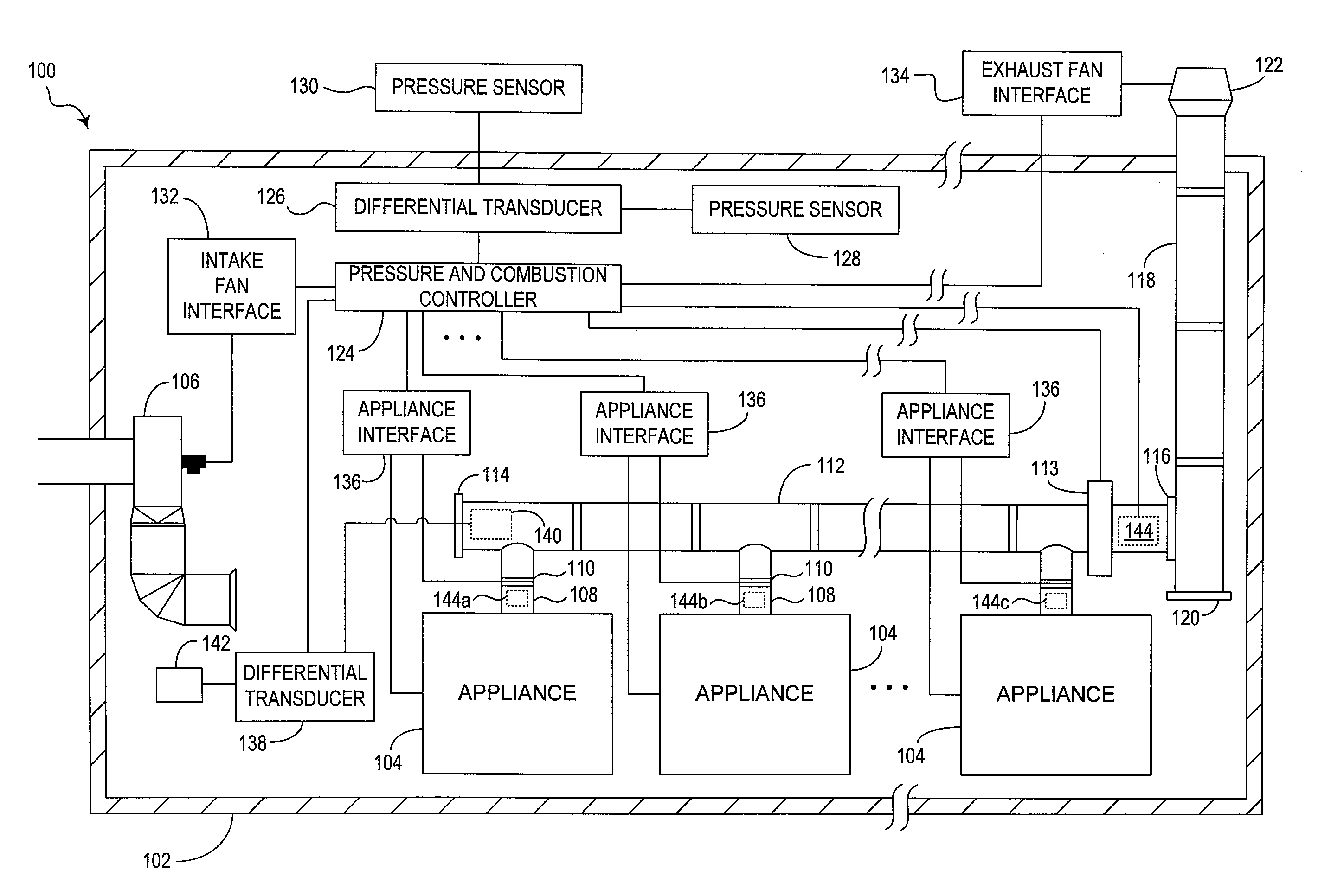

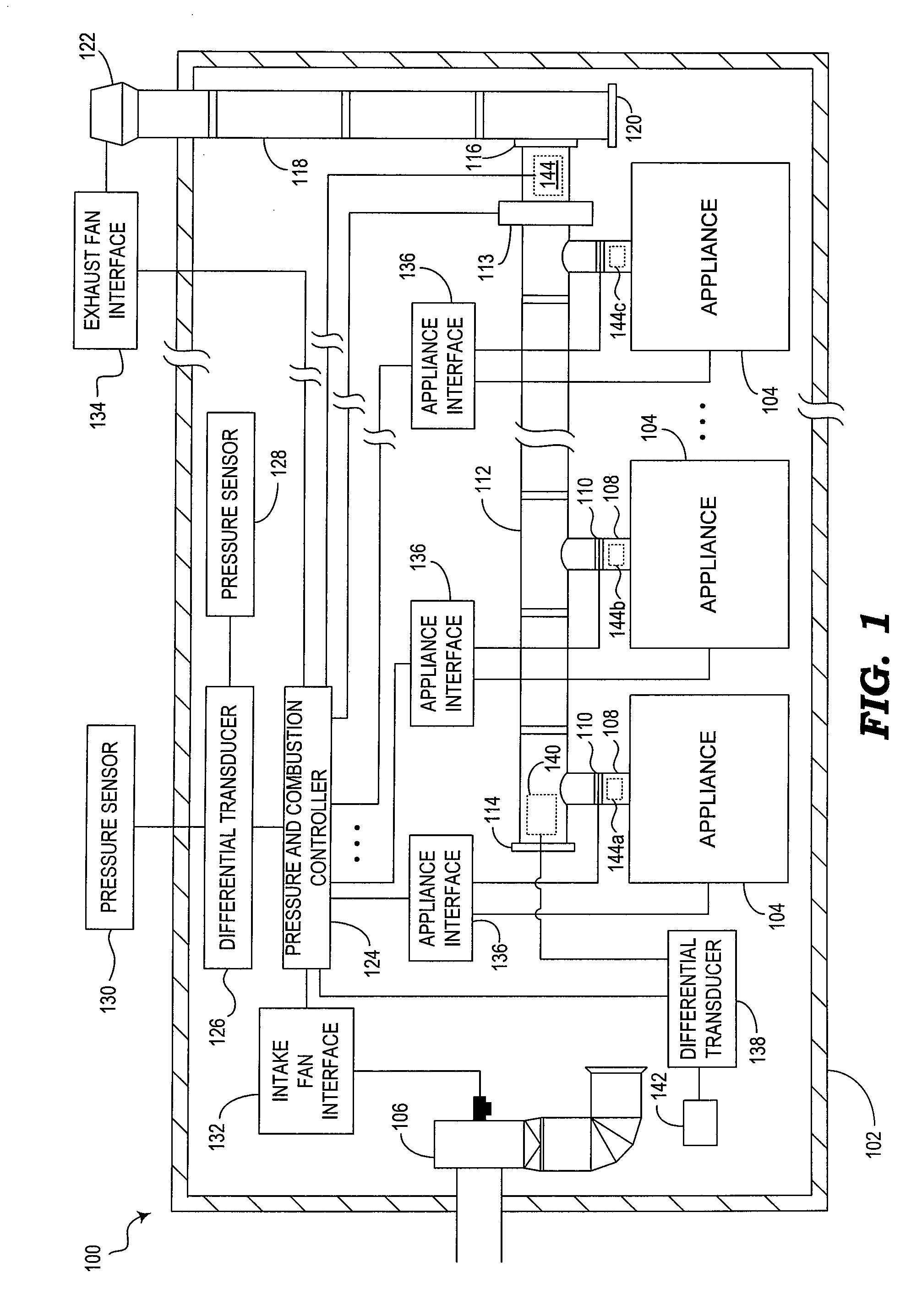

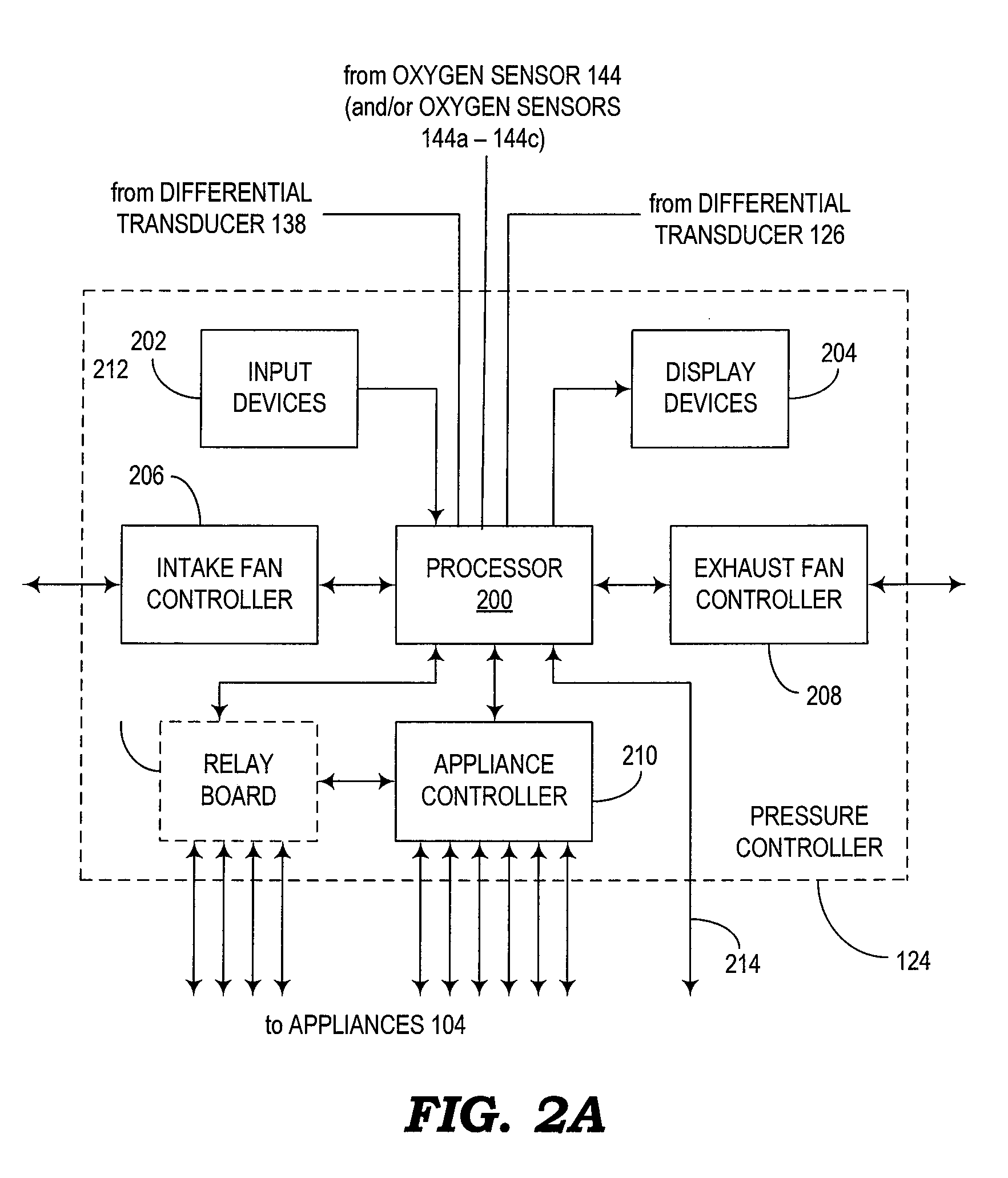

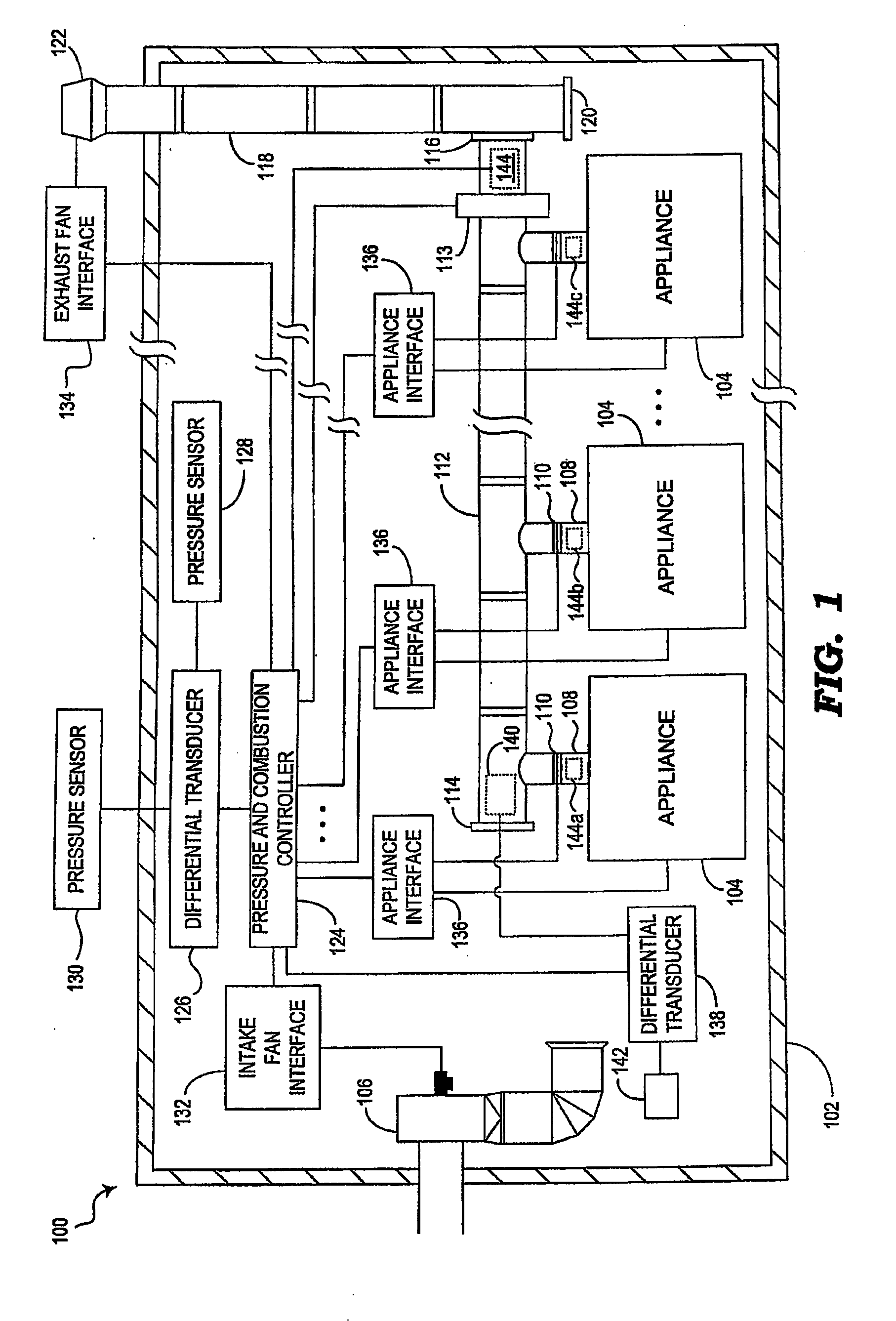

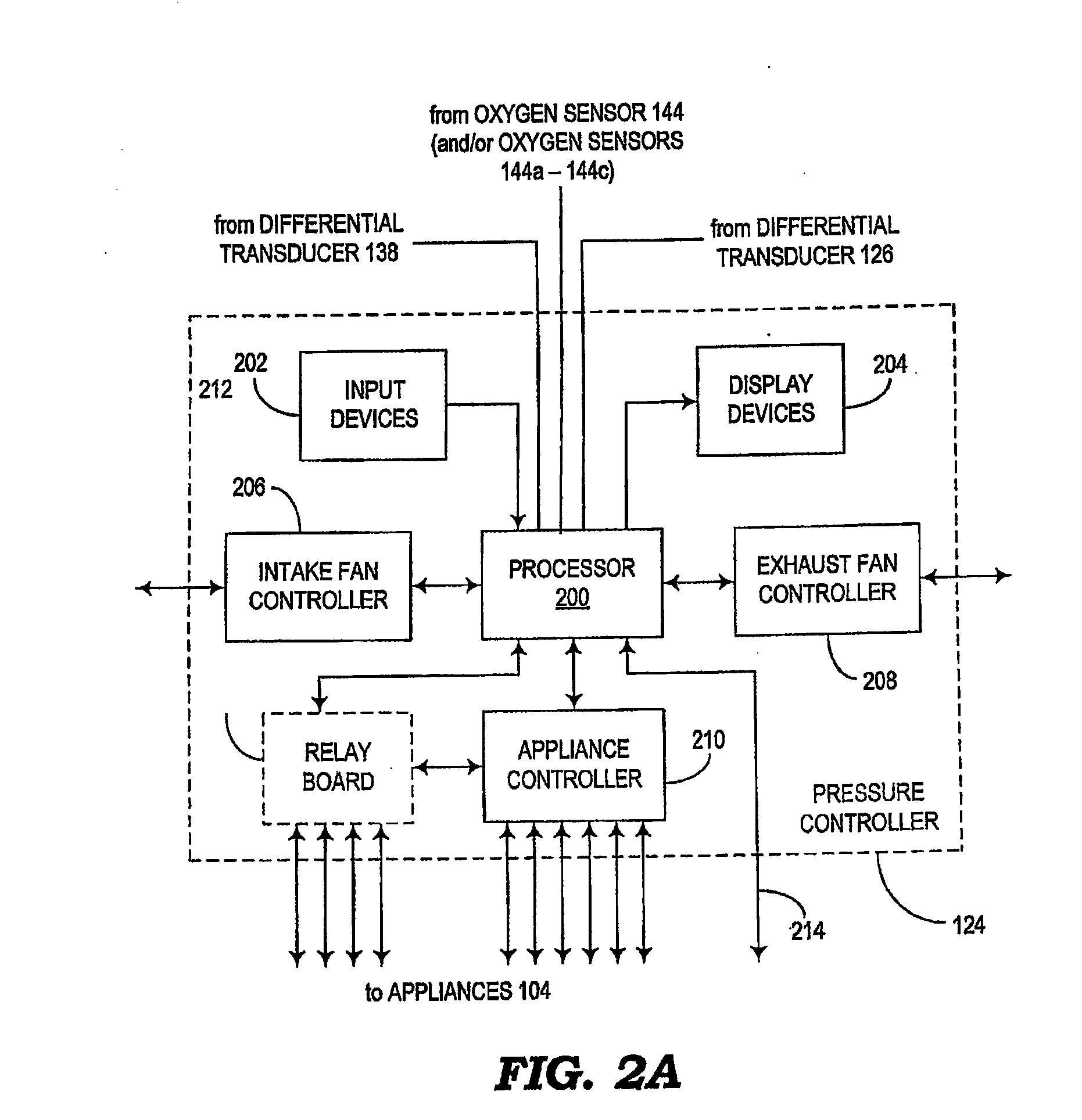

Pressure Controller for a Mechanical Draft System

InactiveUS20070209653A1Mechanical apparatusAir supply regulationDifferential pressureAtmospheric pressure

Systems and method for controlling the flow of air through a mechanical draft system are disclosed herein. A pressure controller for controlling air pressure comprises an appliance controller configured to control the operation of a plurality of appliances, an intake fan controller configured to control the speed of an intake fan, and an exhaust fan controller configured to control the speed of an exhaust fan. The pressure controller also includes a processor configured to receive a differential pressure signal and to control the operation of the appliances, the speed of the intake fan, and the speed of the exhaust fan in response to the differential pressure signal.

Owner:ENERVEX

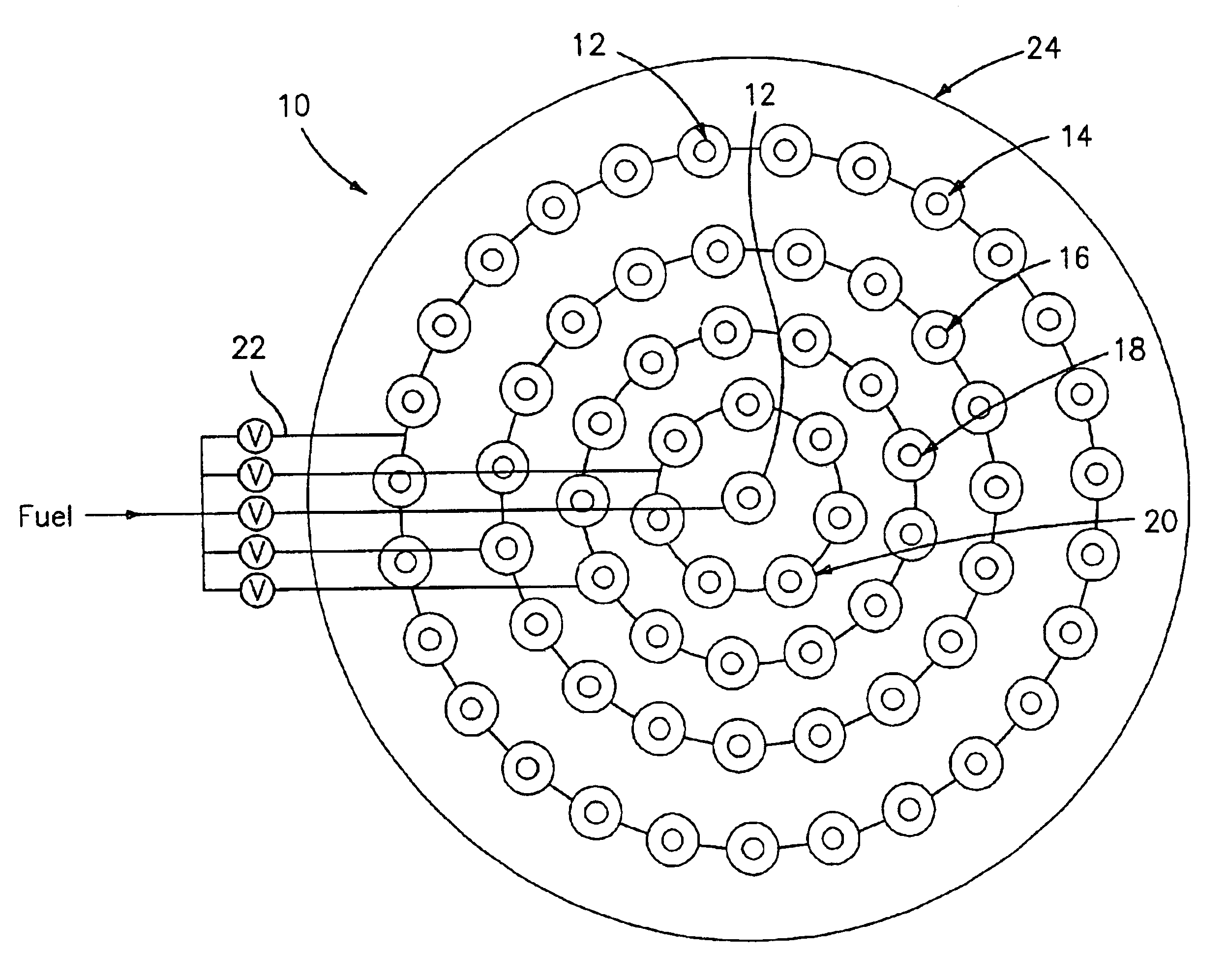

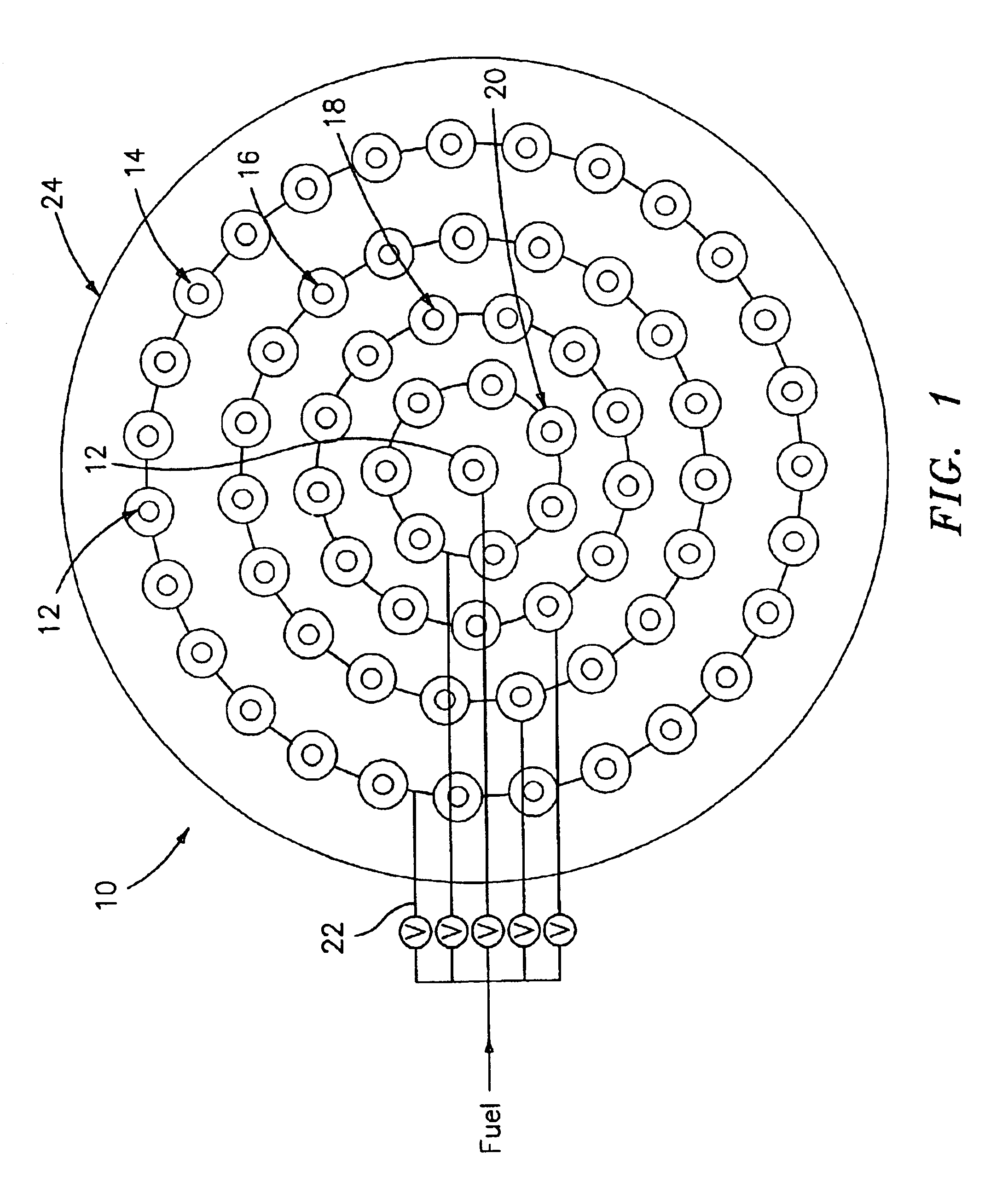

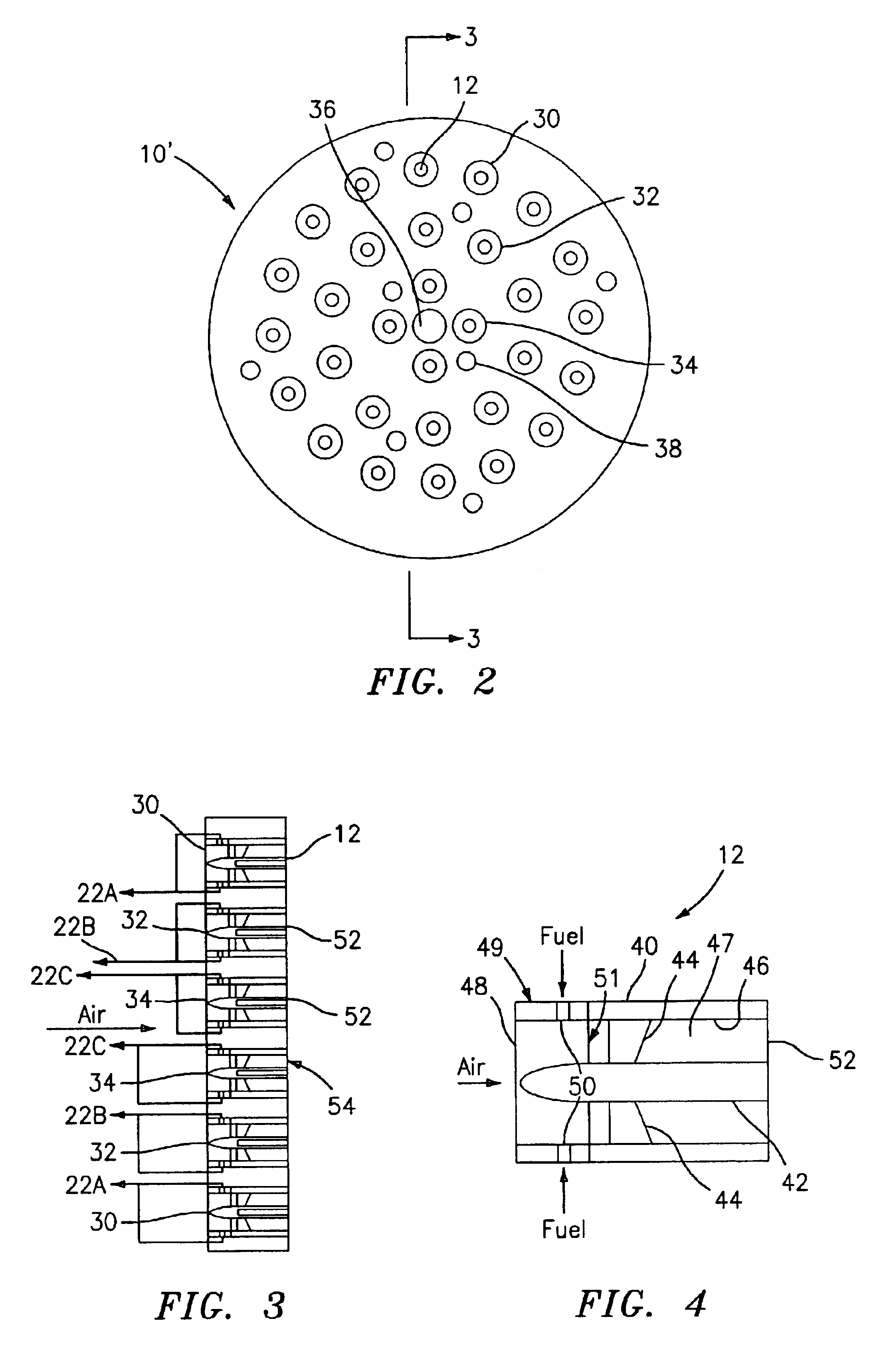

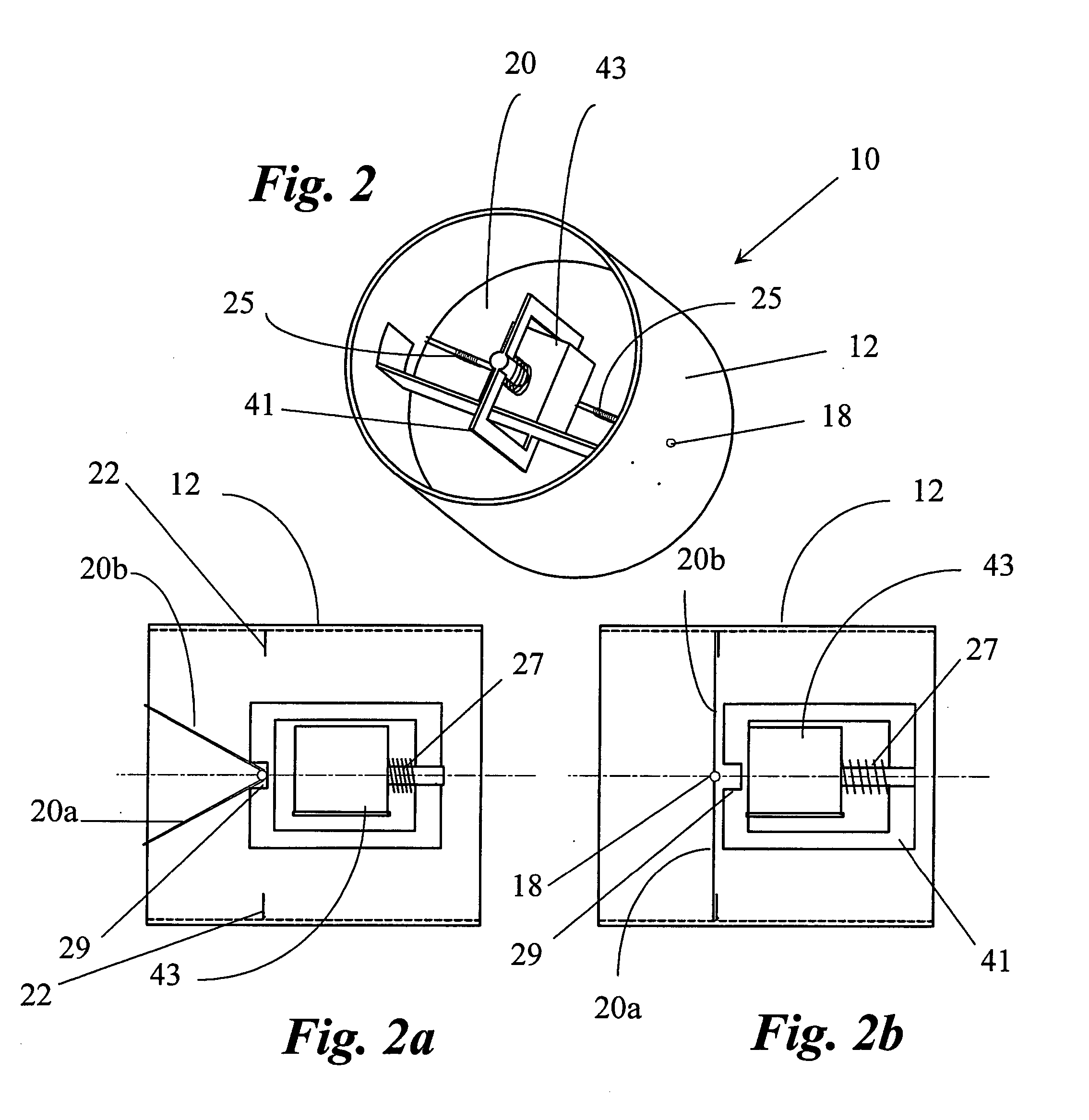

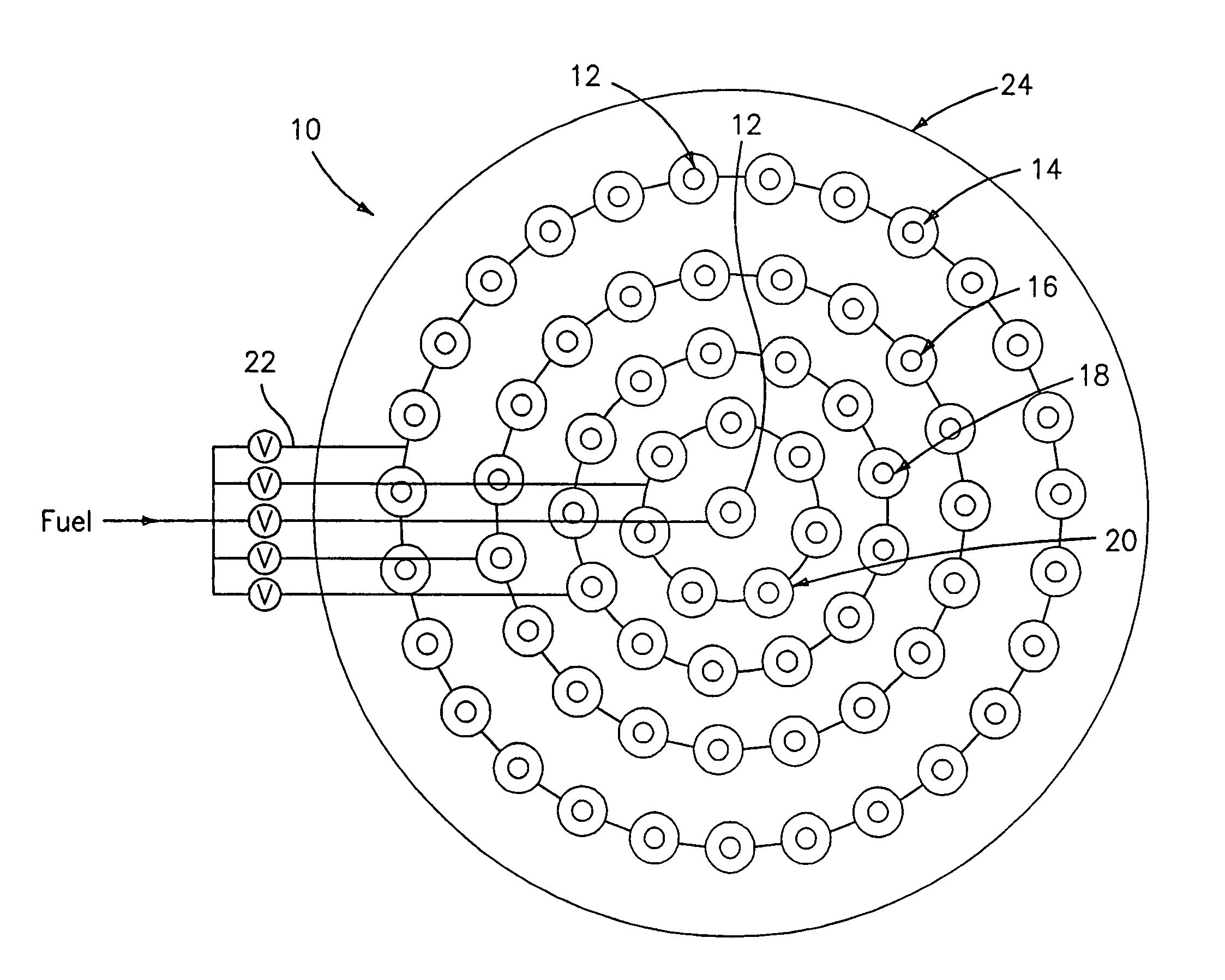

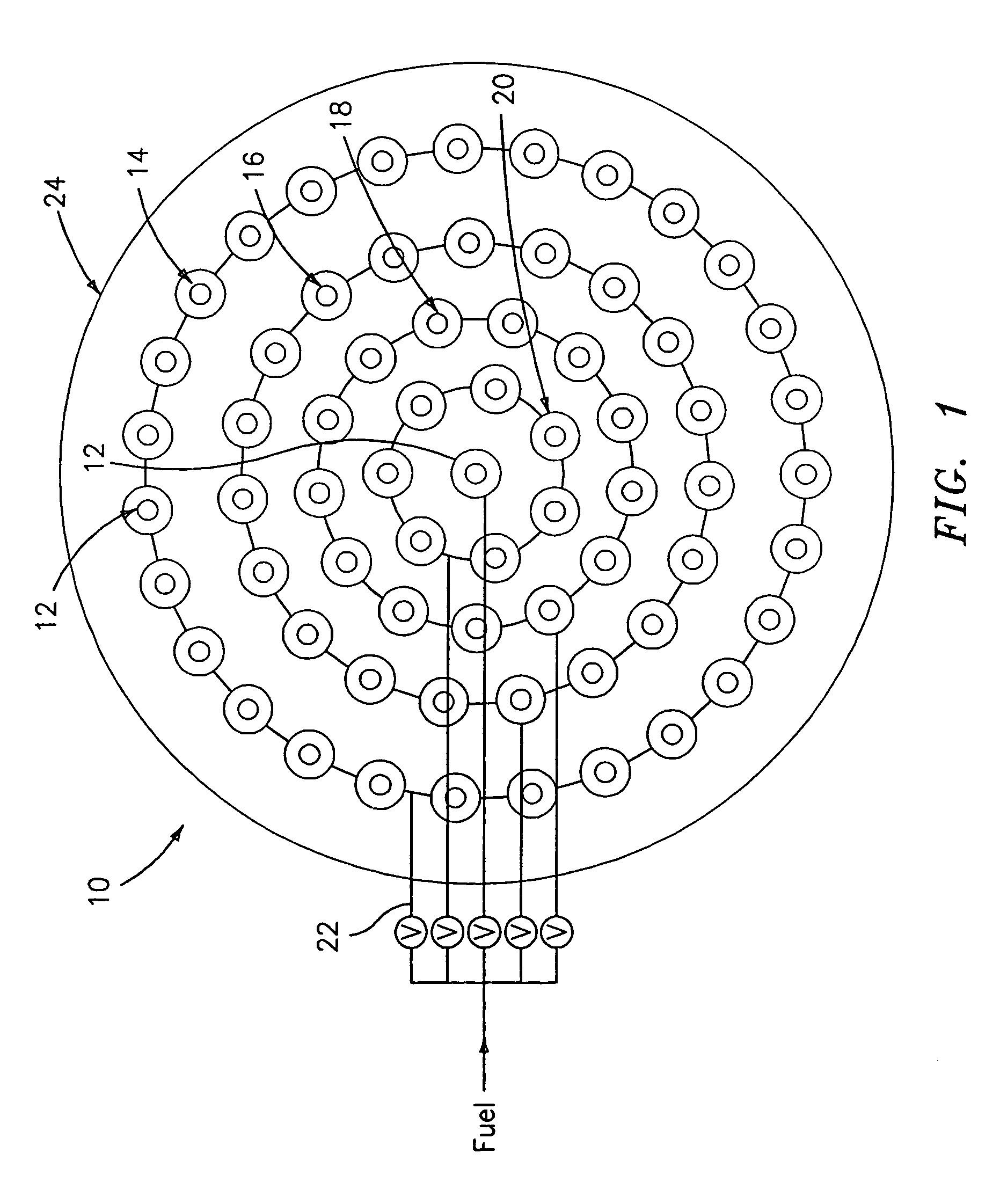

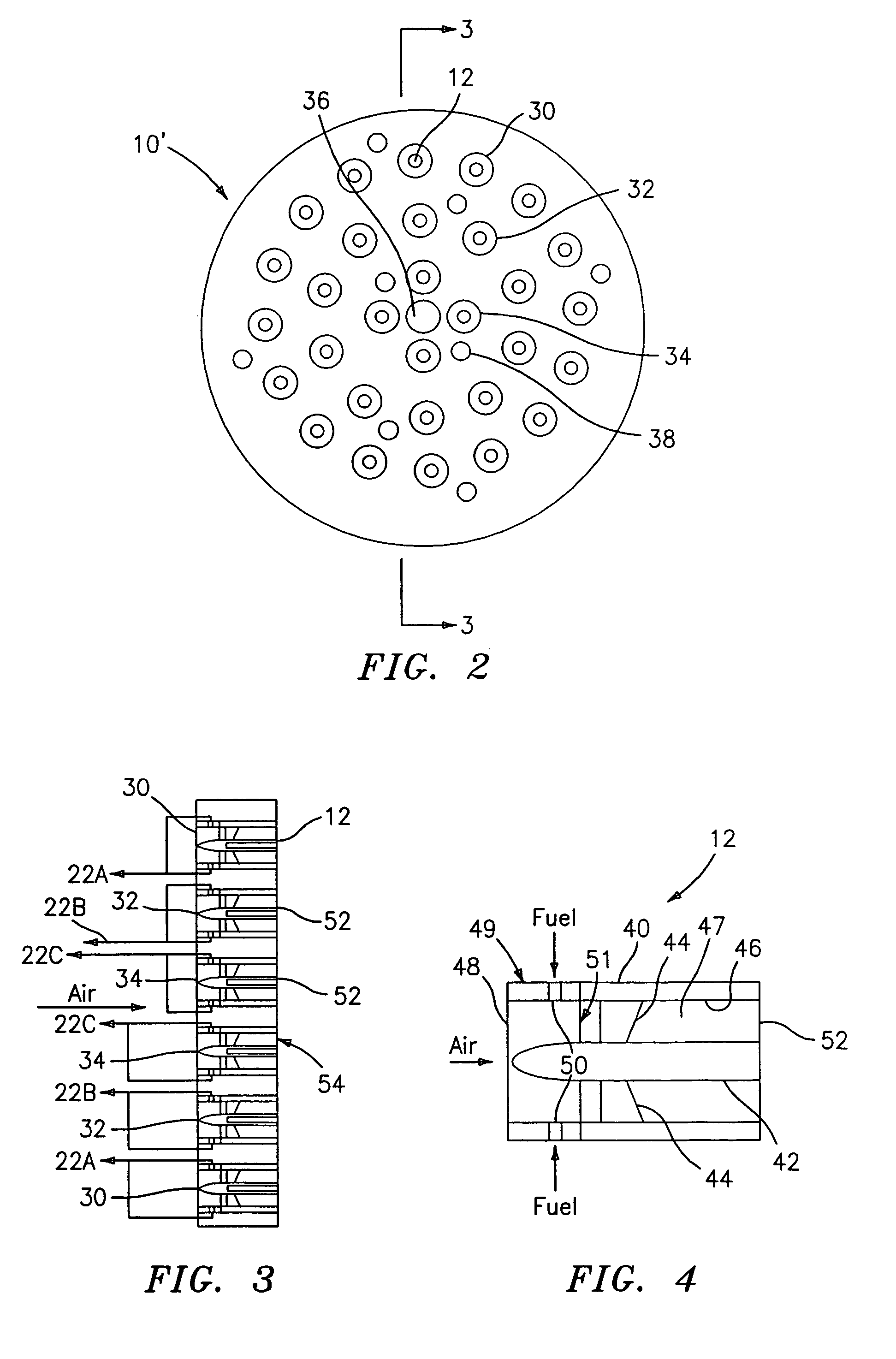

Multi-point staging strategy for low emission and stable combustion

InactiveUS6962055B2Avoids creating excessive CO and UHCBurnersFuel supply regulationCombustorLow emission

The present invention relates to an improved multi-point injector for use in a gas turbine engine or other types of combustors. The multi-point fuel injector has a plurality of nozzles arranged in at least two arrays such as concentric rings. The injector further has different fuel circuits for independently controlling the fuel flow rate for the nozzles in each of the arrays. Each of the nozzles include a fluid channel and one or more swirler vanes in the fluid channel for creating a swirling flow within the fluid channel. A method for injecting a fuel / air mixture into a combustor stage of a gas turbine engine is also described. At least one zone has a flame hot enough to stabilize the entire combustor flame.

Owner:UNITED TECH CORP

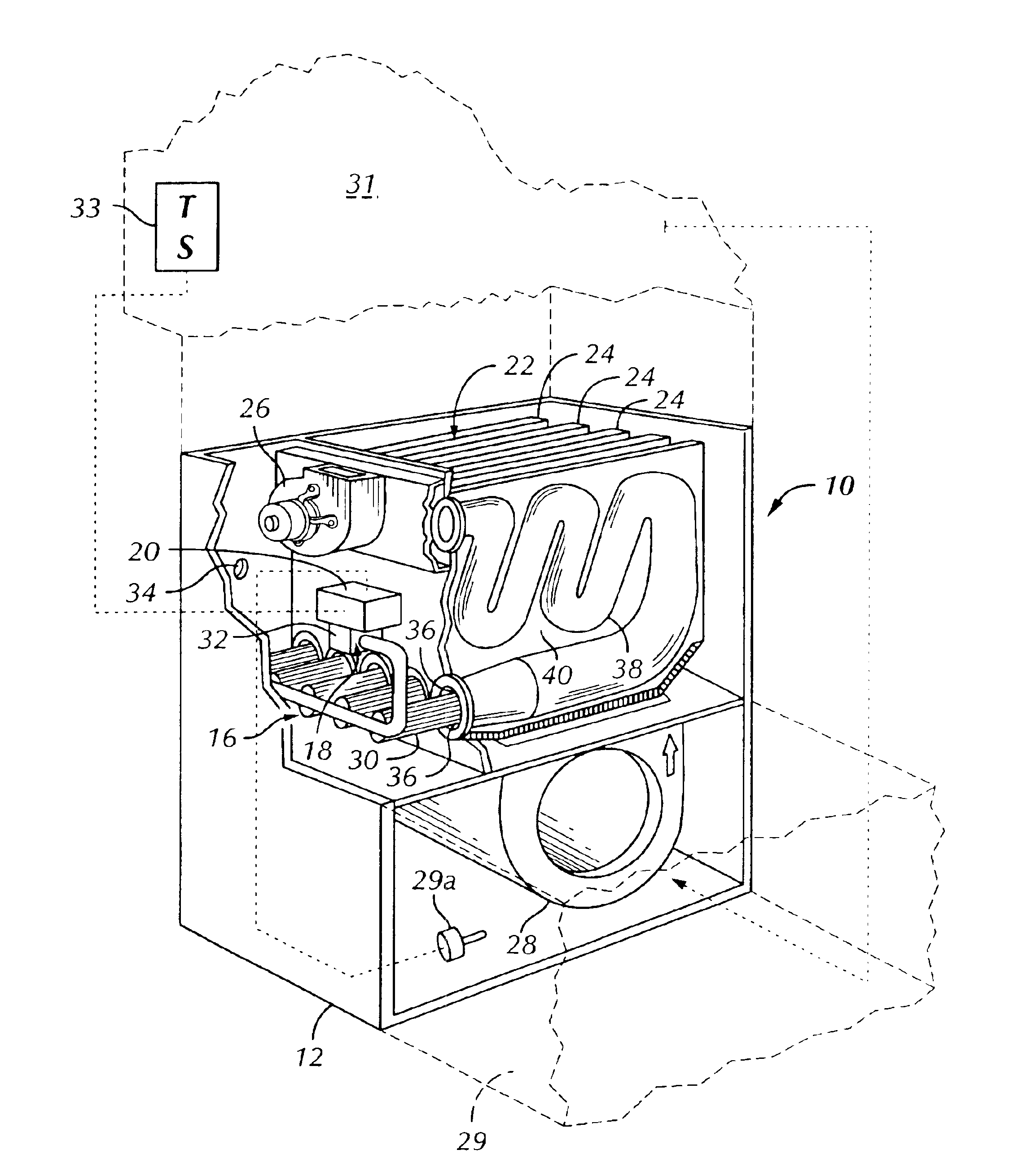

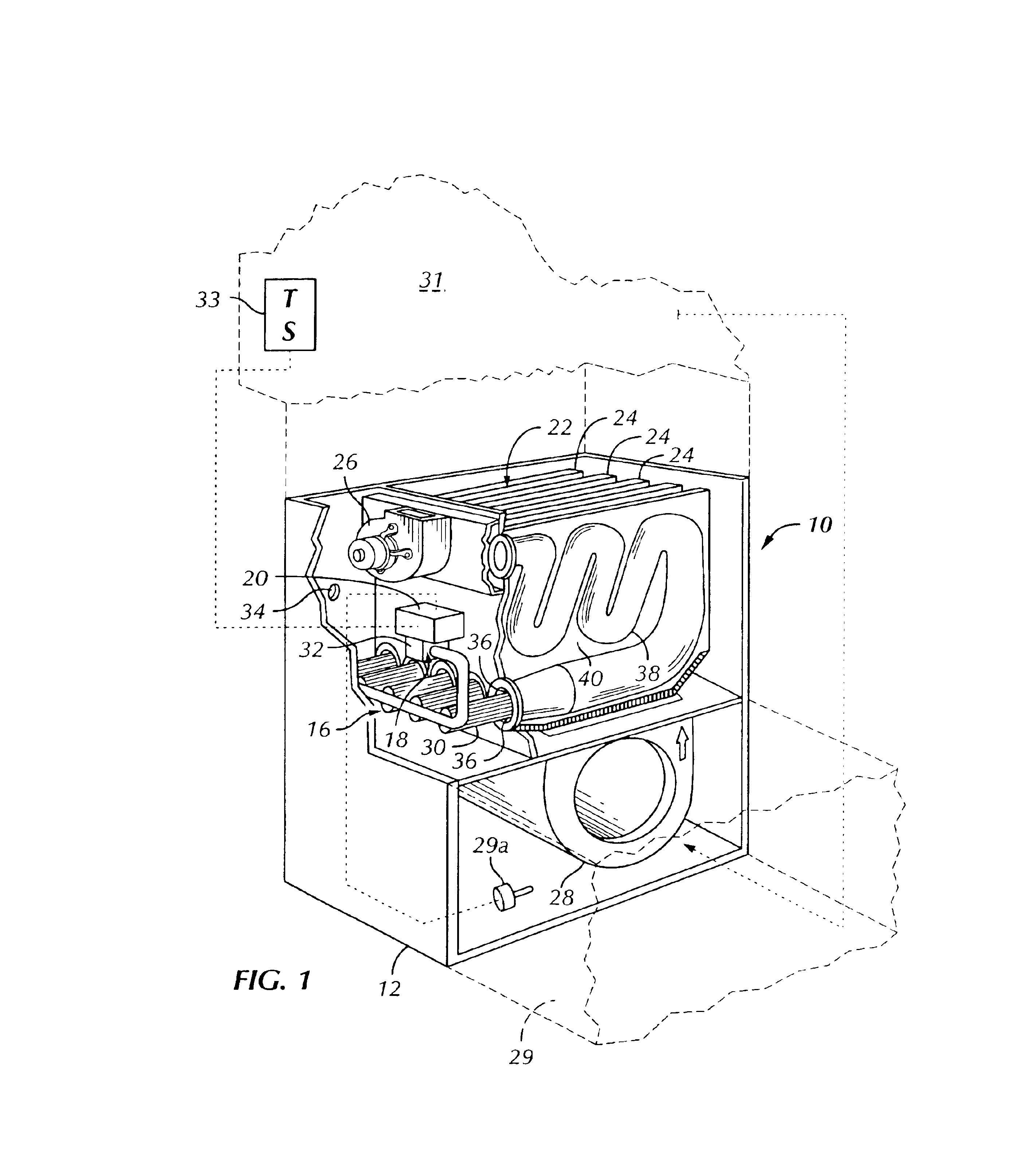

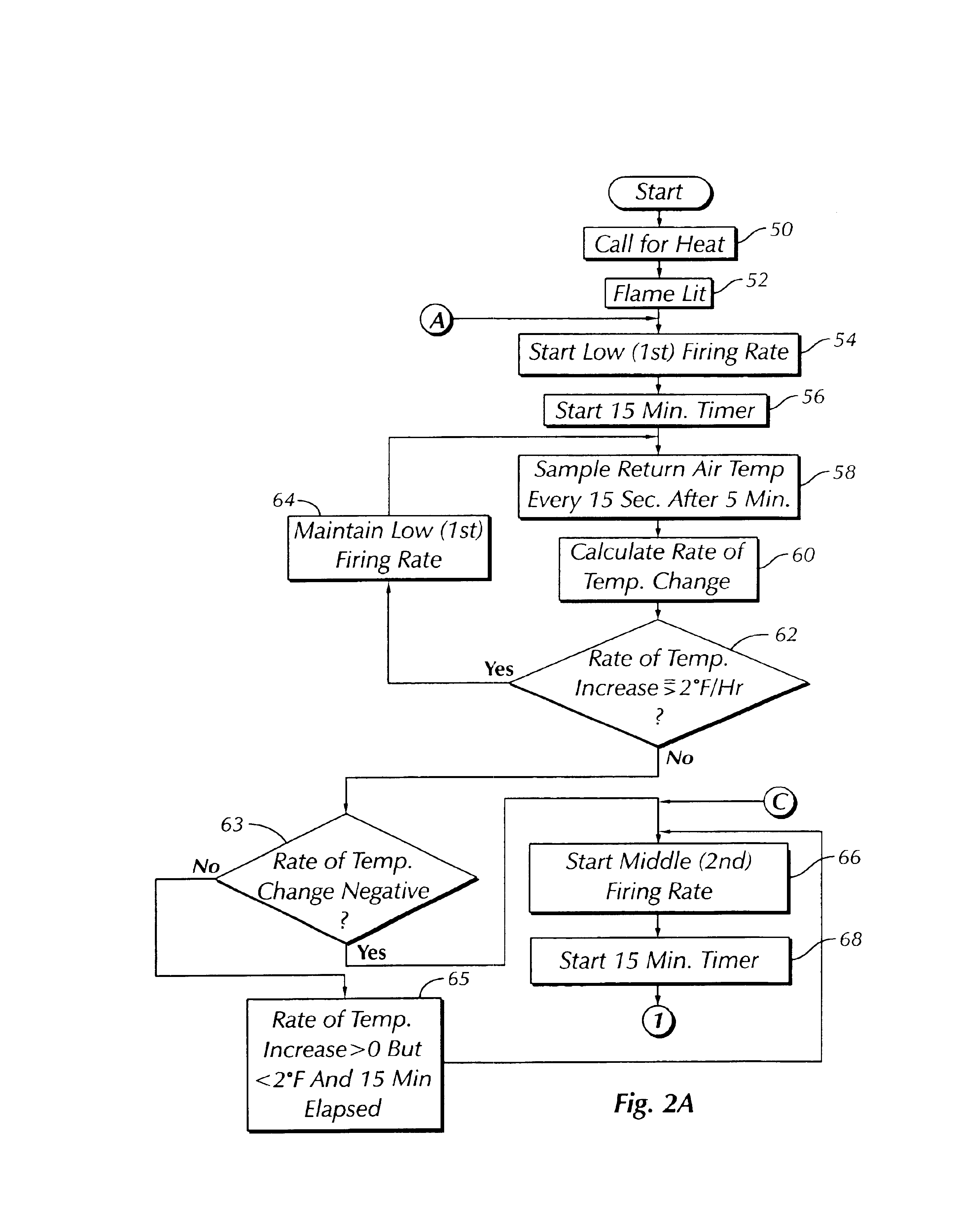

Multistage warm air furnace with single stage thermostat and return air sensor and method of operating same

InactiveUS6925999B2Improve performanceEasy to transformFuel supply regulationMechanical apparatusSingle stageProcess engineering

Owner:AS IP HOLDCO LLC +1

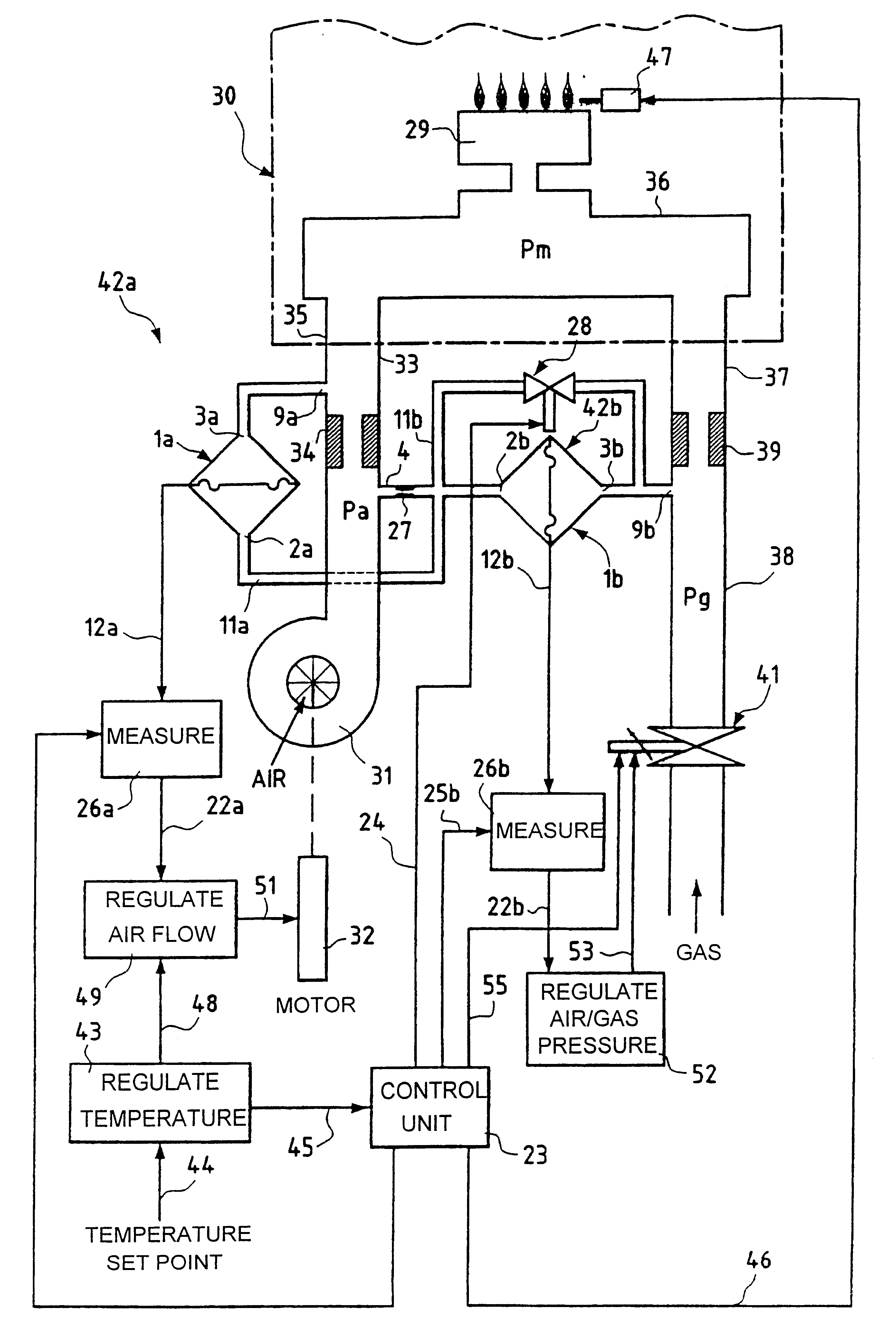

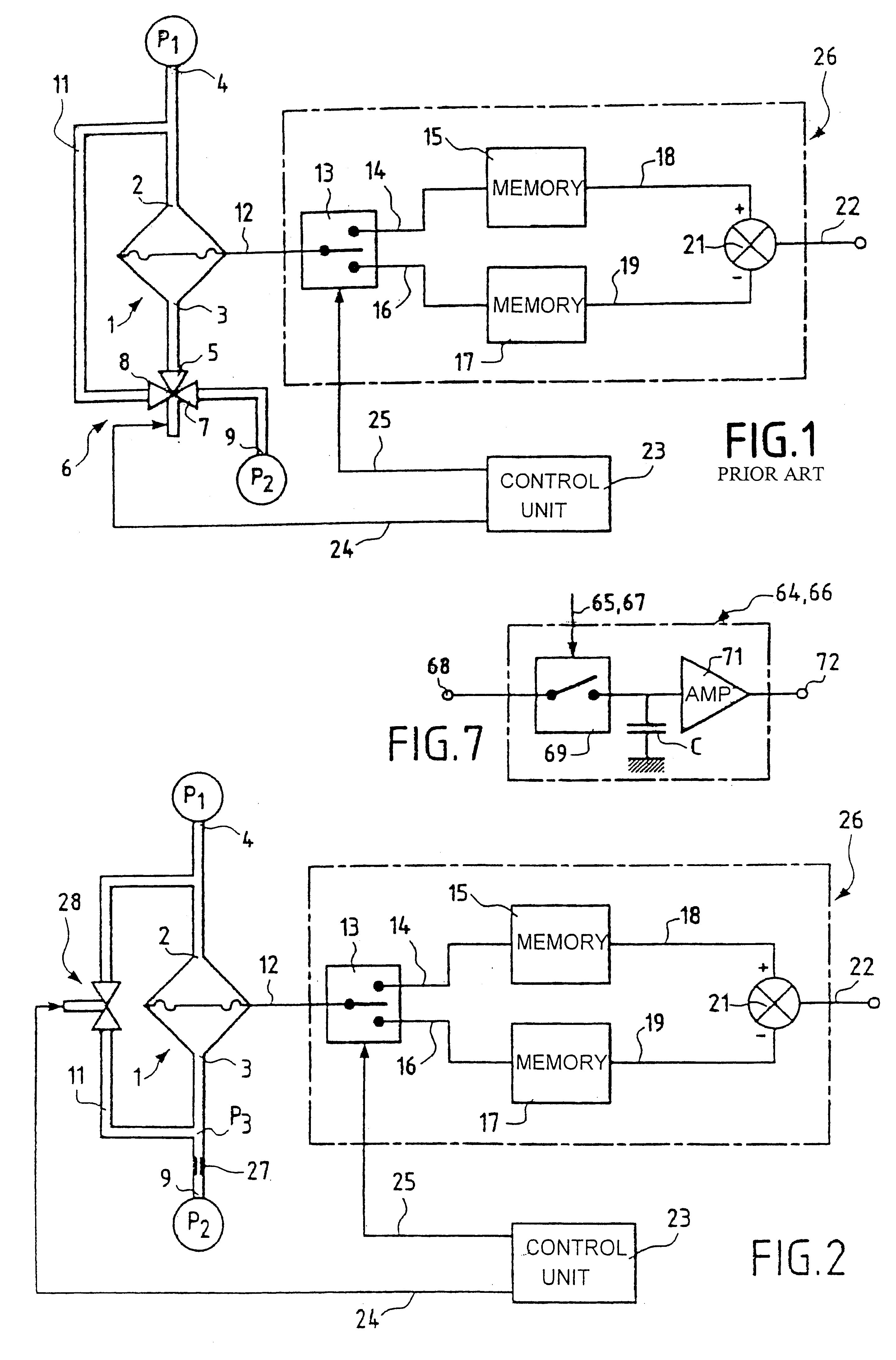

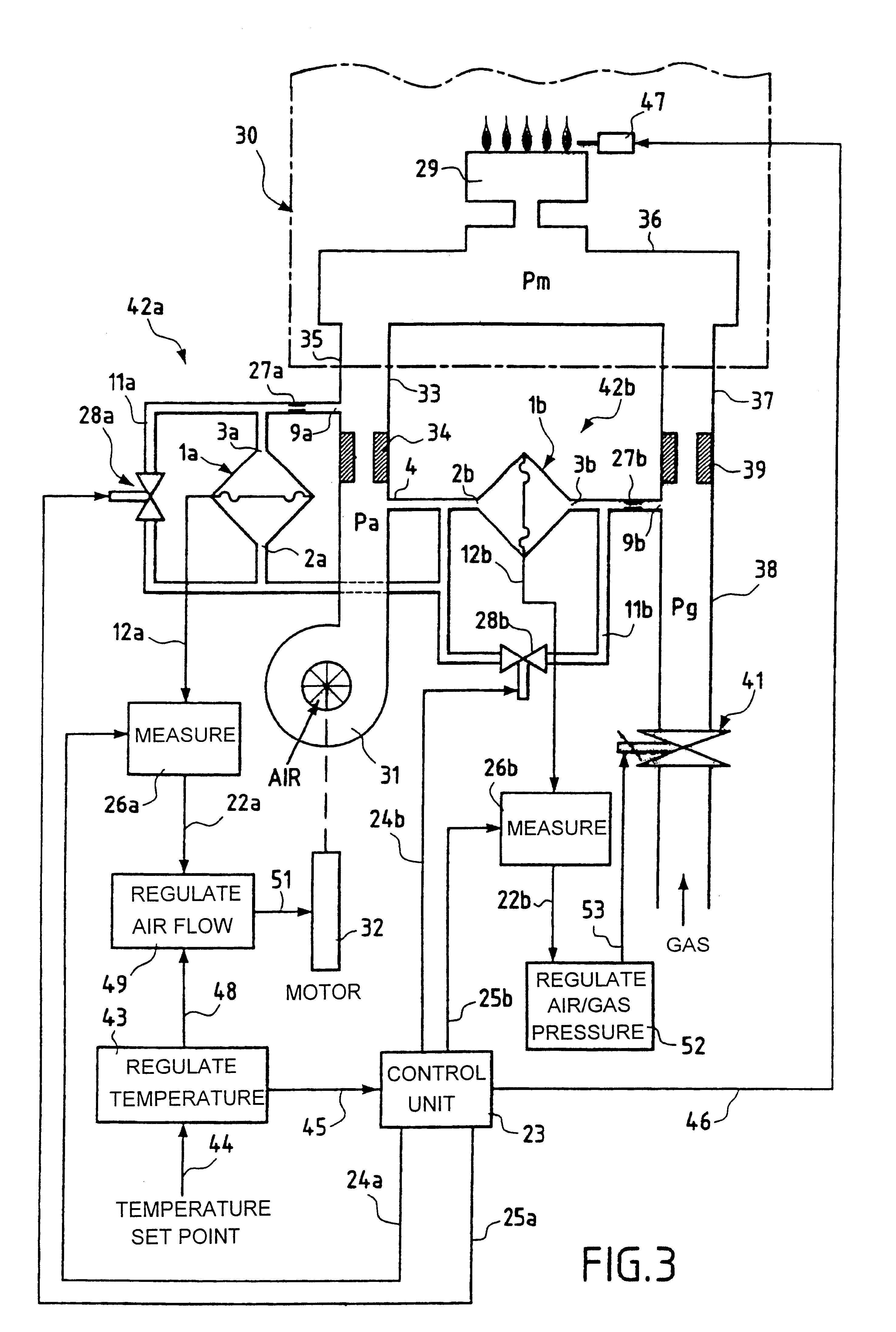

System for active regulation of the air/gas ratio of a burner including a differential pressure measuring system

InactiveUS6533574B1Simpler and less-costlyLess costlyFuel supply regulationCombustion ventilatorsCombustorDifferential pressure

The system for active regulation of the air / gas ratio of a burner comprises one or two differential pressure measuring systems each of which has a differential pressure sensor with two inlet orifices. The orifices are respectively connected to pressure ports in one of which there is a calibrated throttling orifice. The regulator system comprises a 2-channel valve which, when closed, isolates the two inlet orifices from each other, and, when open, connects them to each other. A measurement circuit is provided and has memory means for storing at least two values of the output signal of the sensors, a control unit for switching the valve and controlling the storage of a first value of an output signal of the sensor in the memory means when the valve is closed and the storage of a second value of the output signal of the sensor when the valve is open, and subtractor means for calculating the difference between the two stored values of the output signal of the sensor and thereby eliminating any drift. In a preferred variant, the regulator system includes only one differential pressure measuring system.

Owner:A THEOBALD

Fan Assemblies, Mechanical Draft Systems and Methods

InactiveUS20090215375A1Facilitate independentFacilitate locally controlled ignitionDomestic stoves or rangesLiquid heating fuelDirect combustionControl theory

Fan assemblies, mechanical draft systems and methods are provided. In this regard, a representative mechanical draft system for use with multiple appliances includes: a chimney operative to direct combustion products from multiple appliances; a chimney fan operative to draw combustion products from the chimney; and a controller operative to adjust an operating speed of the chimney fan such that, responsive to a change in pressure in the chimney, the controller adjusts the operating speed of the chimney fan to maintain a desired pressure in the chimney.

Owner:GREENVEX

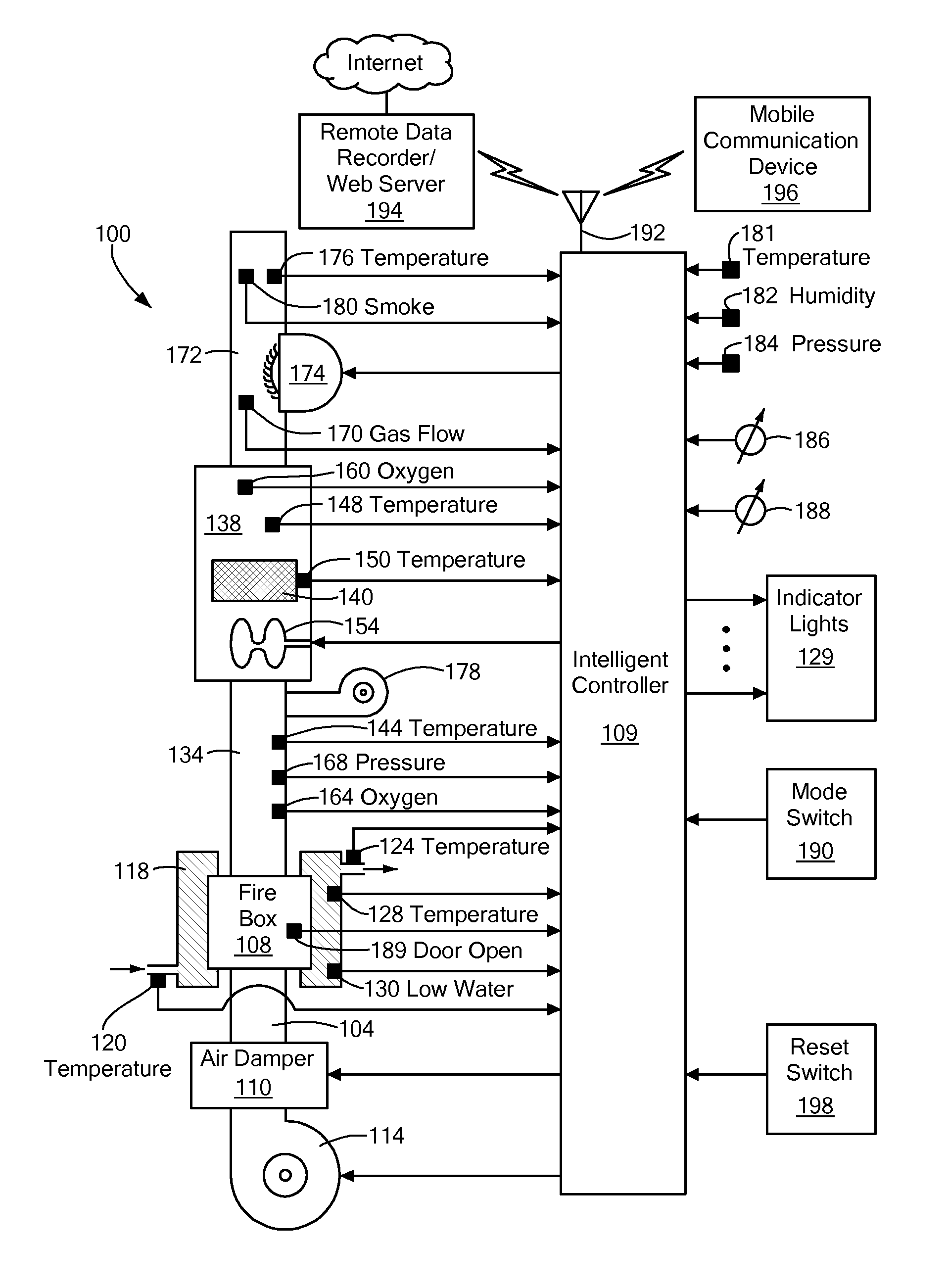

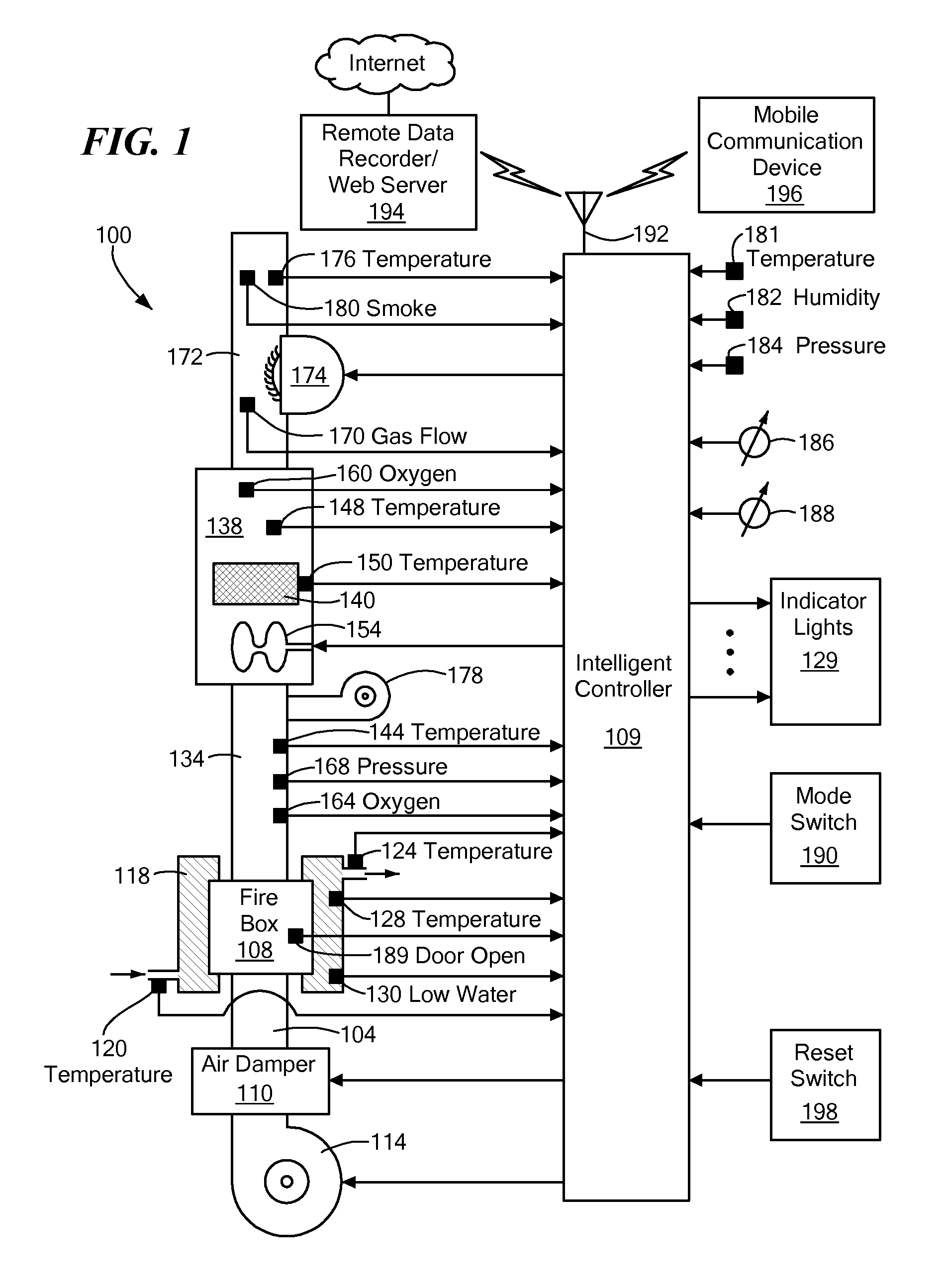

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

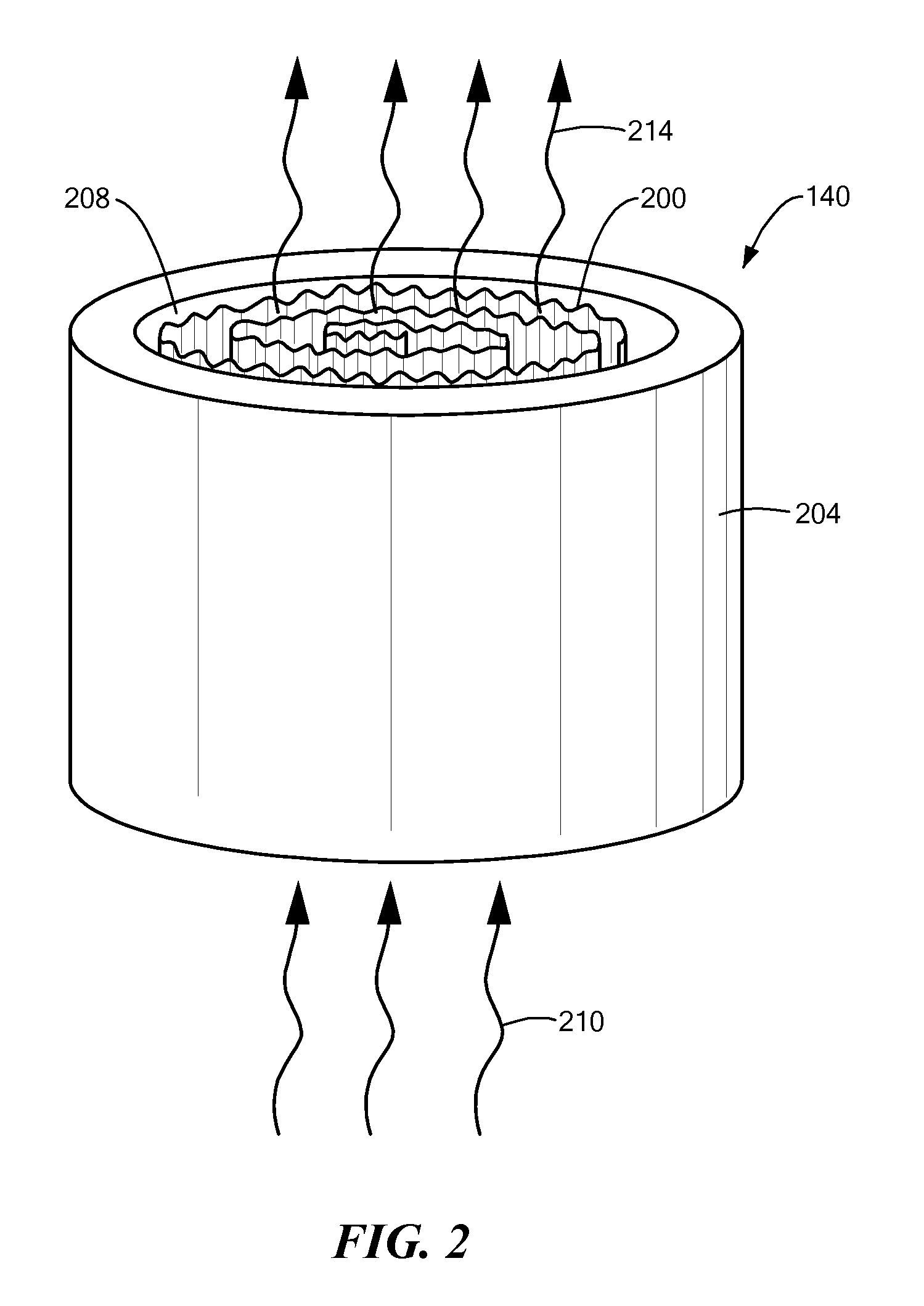

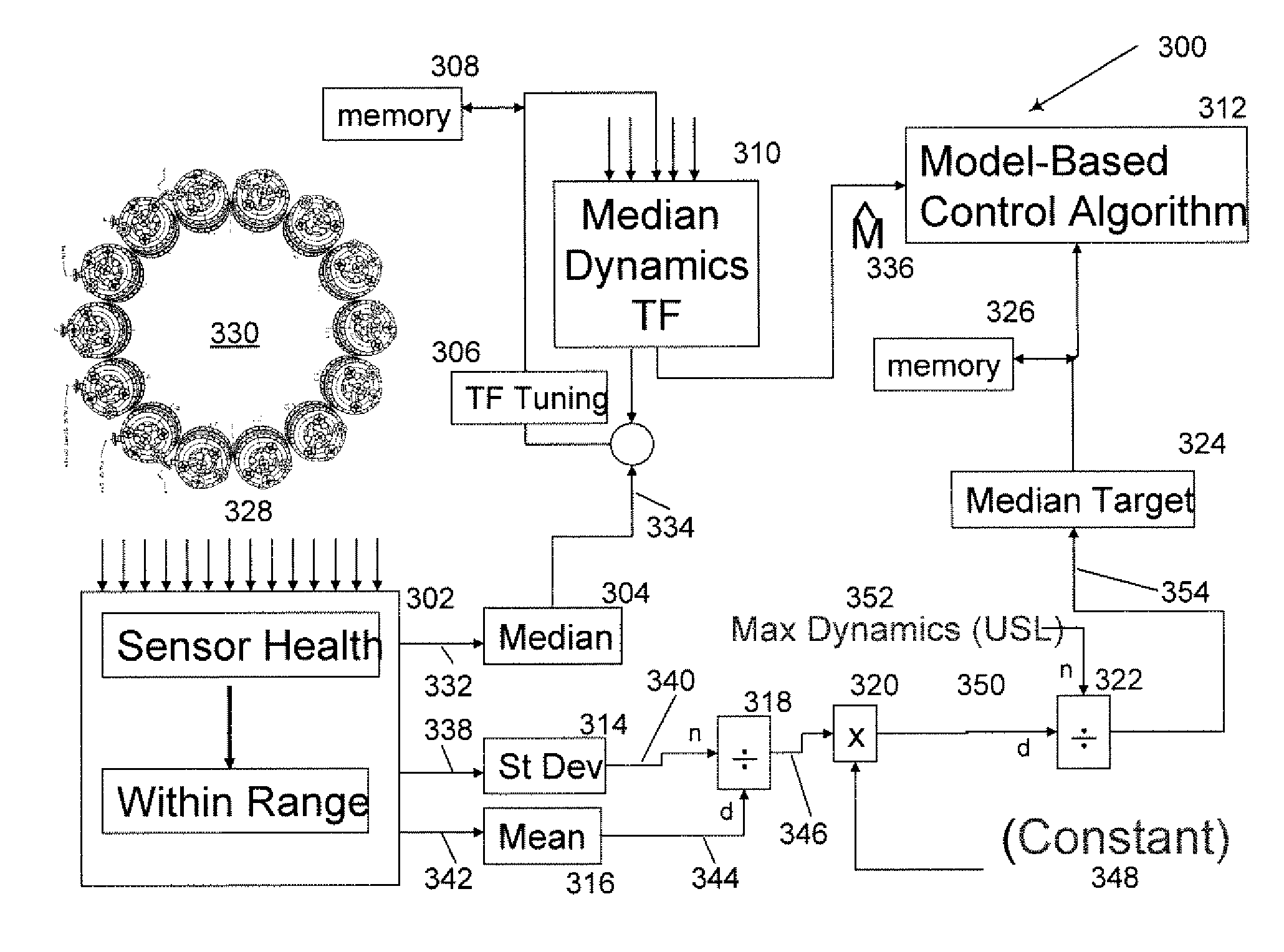

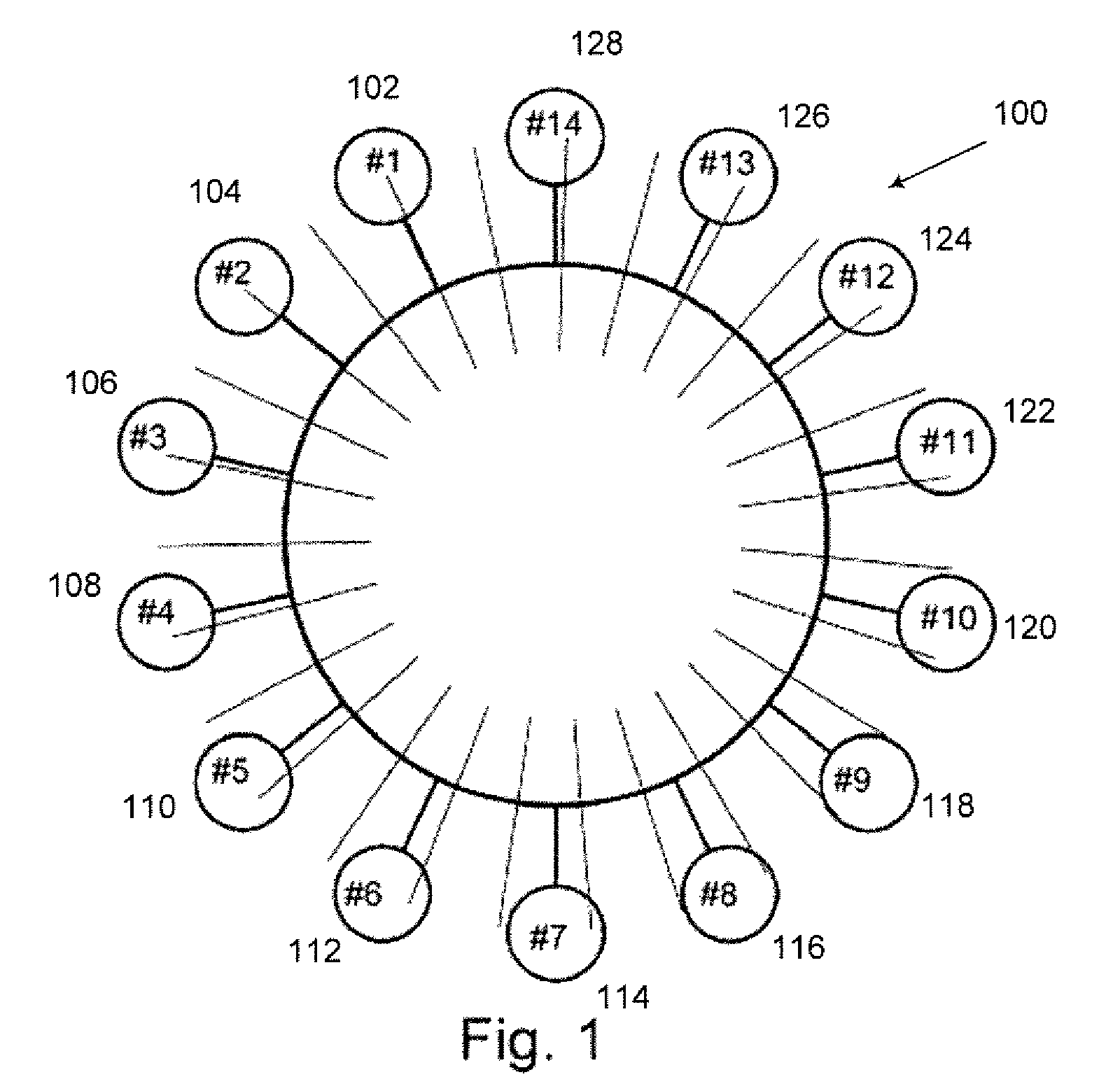

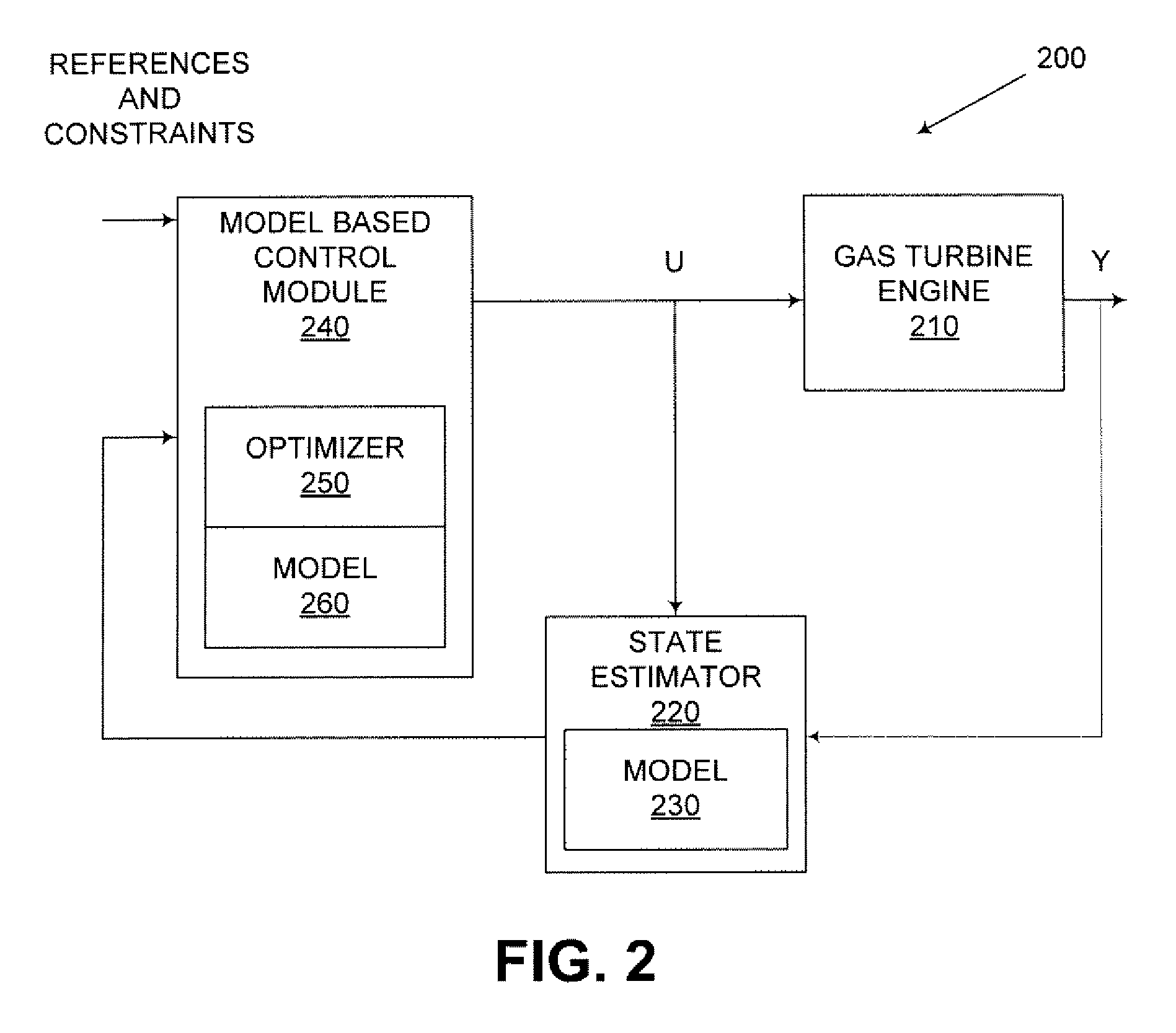

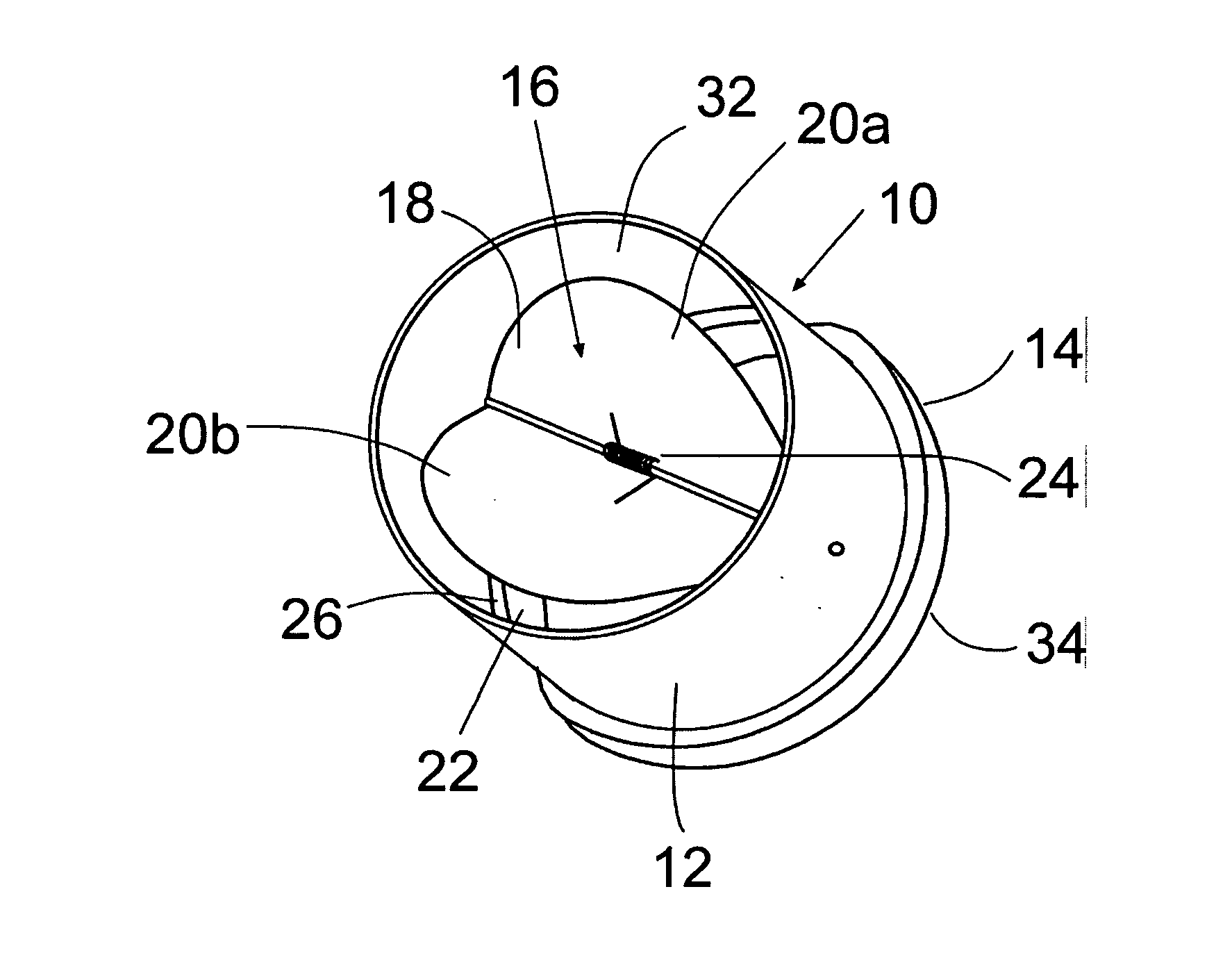

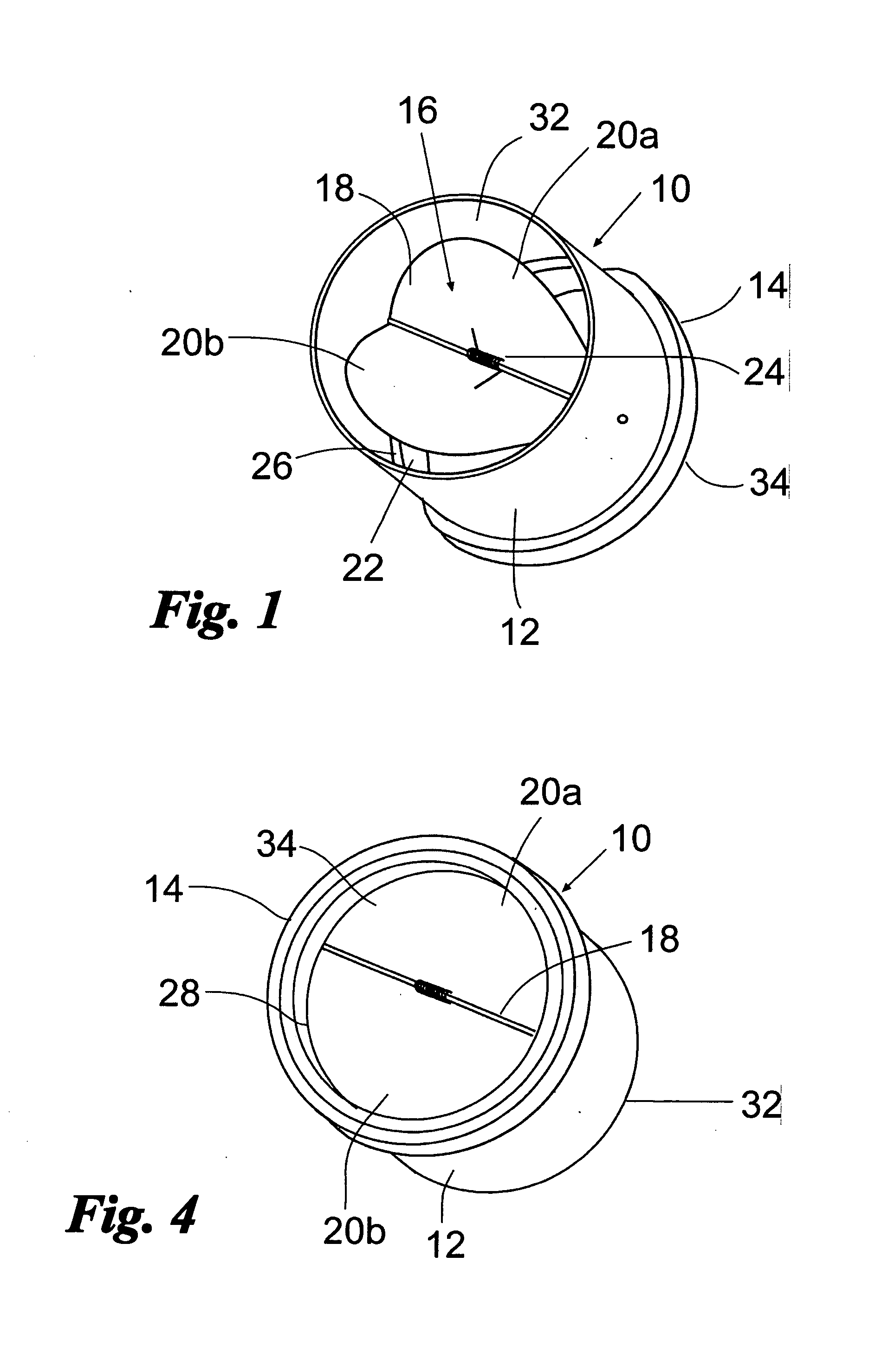

Systems and methods for using a combustion dynamics tuning algorithm with a multi-can combustor

Embodiments of the invention can provide systems and methods for using a combustion dynamics tuning algorithm with a multi-can combustor. According to one embodiment of the invention, a method for controlling a gas turbine engine with an engine model can be implemented for an engine comprising multiple cans. The method can include obtaining operating frequency information associated with multiple cans of the engine. In addition, the method can include determining variation between operating frequency information of at least two cans. Furthermore, the method can include determining a median value based at least in part on the variation. Moreover, the method can include inputting the median value to an engine model, wherein based at least in part on the median value, the engine model determines an engine control action. In addition, the method can include outputting a control command to implement the engine control action.

Owner:GENERAL ELECTRIC CO

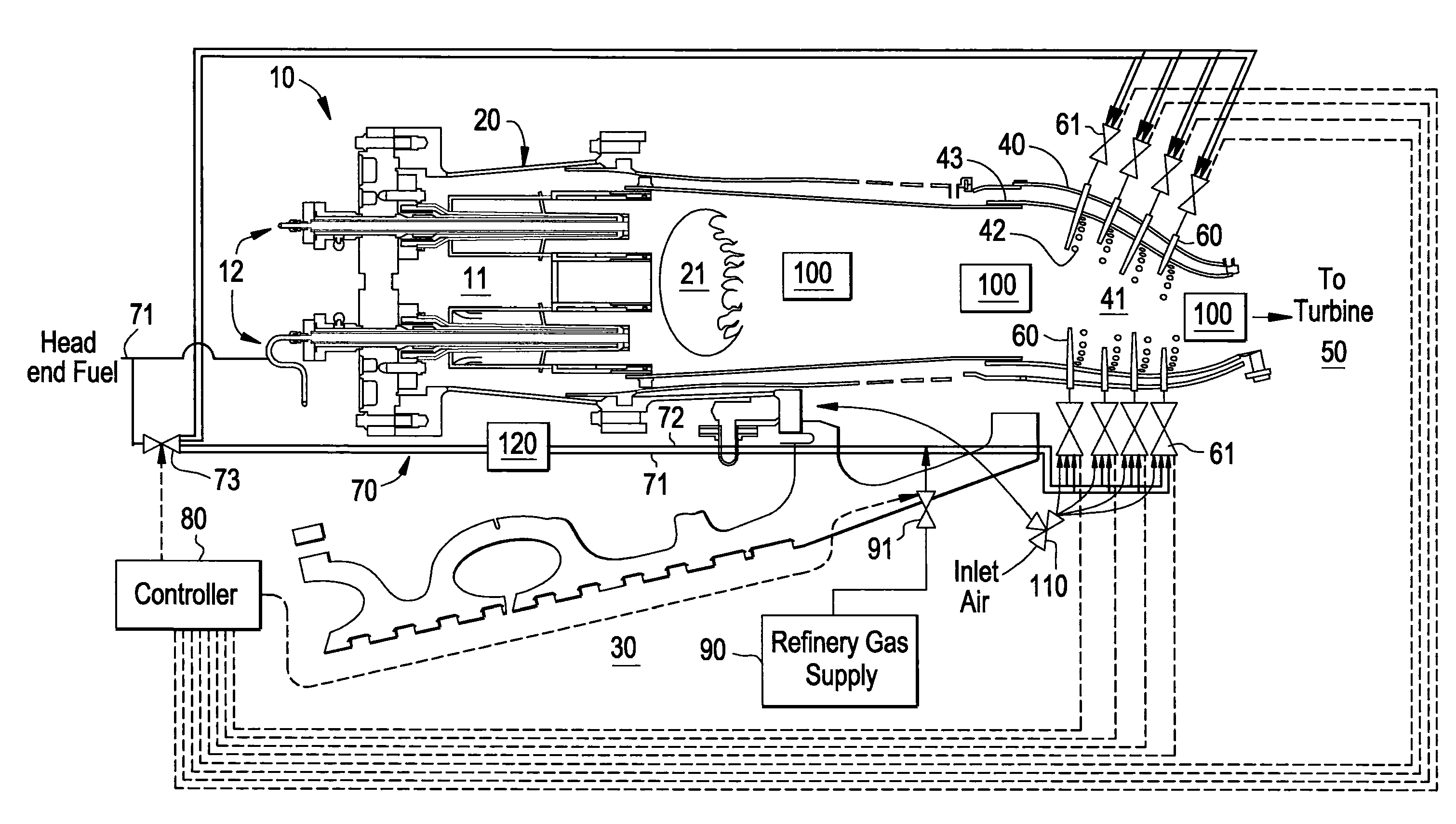

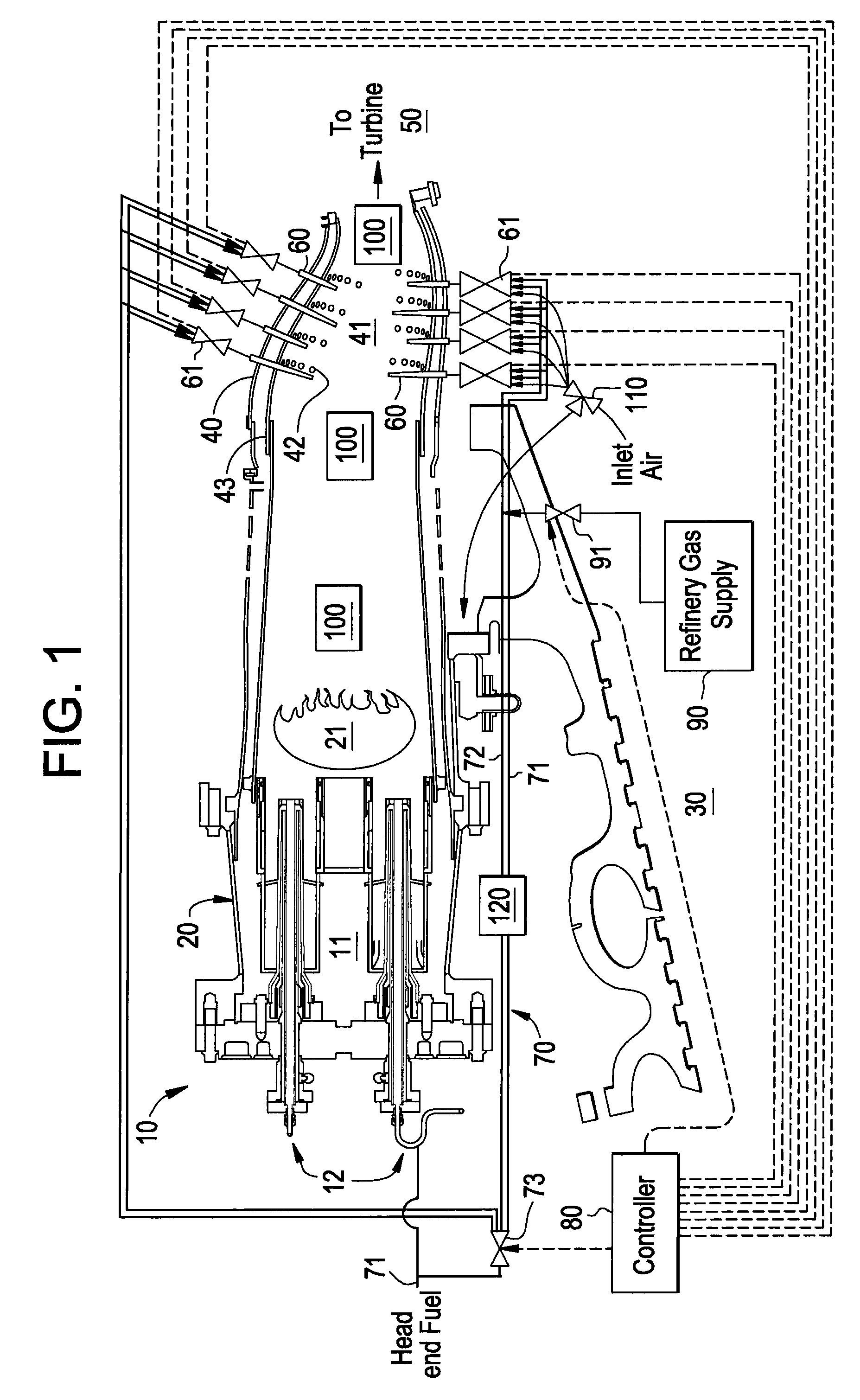

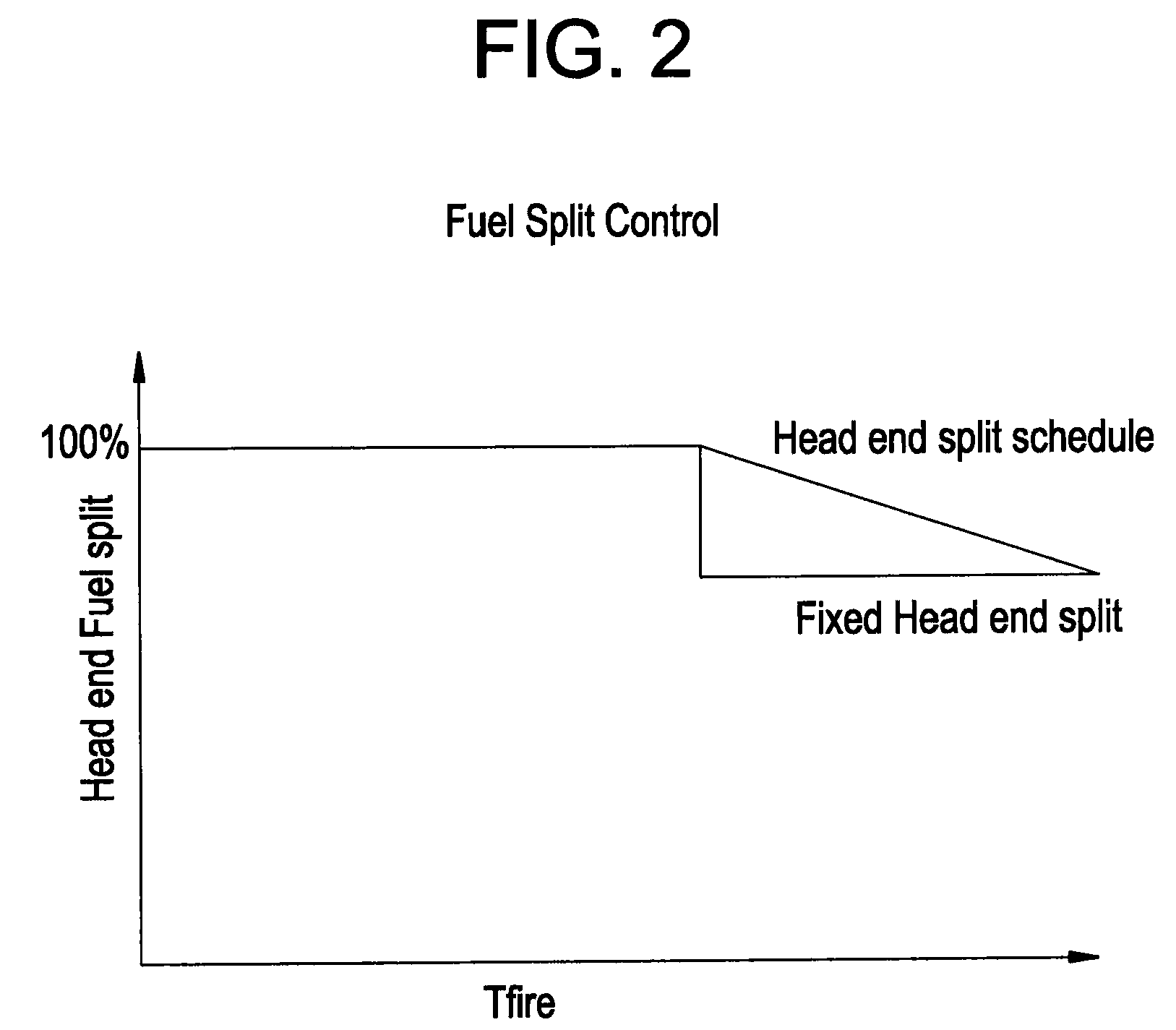

Late lean injection with expanded fuel flexibility

ActiveUS20100170251A1Fuel supply regulationTurbine/propulsion fuel supply systemsCombustorEngineering

A gas turbine engine is provided and includes a fuel circuit, including multiple fuel circuit branches, a combustor having a first interior in which a first fuel supplied thereto by any one of the multiple fuel circuit branches is combustible, a turbine, a transition zone, including a second interior in which a second fuel supplied thereto by any one of the multiple fuel circuit branches, the second fuel including gas receivable by the fuel circuit from an external source, and the products of the combustion of the first fuel are combustible, the transition zone being disposed to fluidly couple the combustor and the turbine to one another, and a plurality of fuel injectors which supply the second fuel to the second interior in any one of a single axial stage, multiple axial stages, a single axial circumferential stage and multiple axial circumferential stages.

Owner:GENERAL ELECTRIC CO

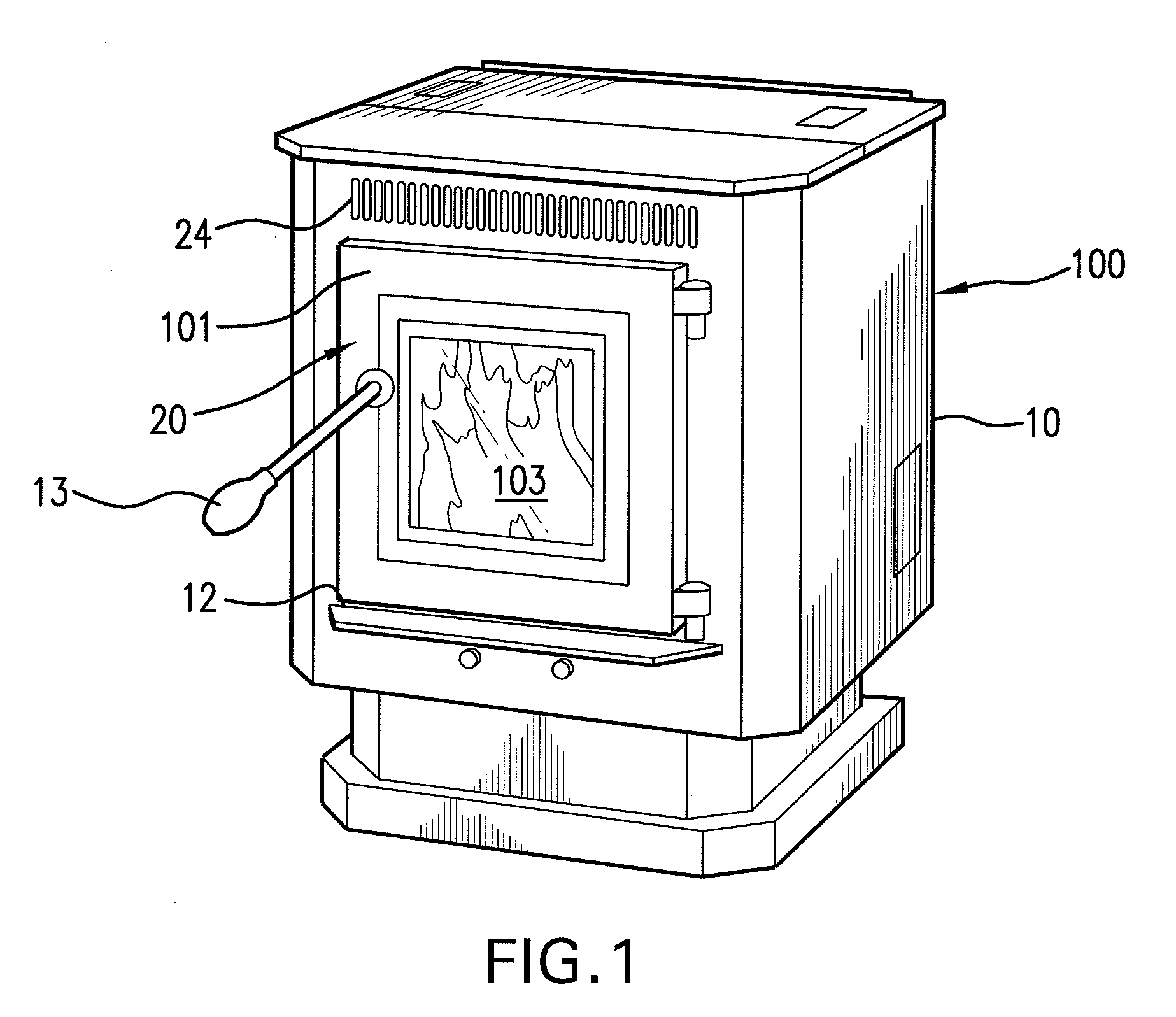

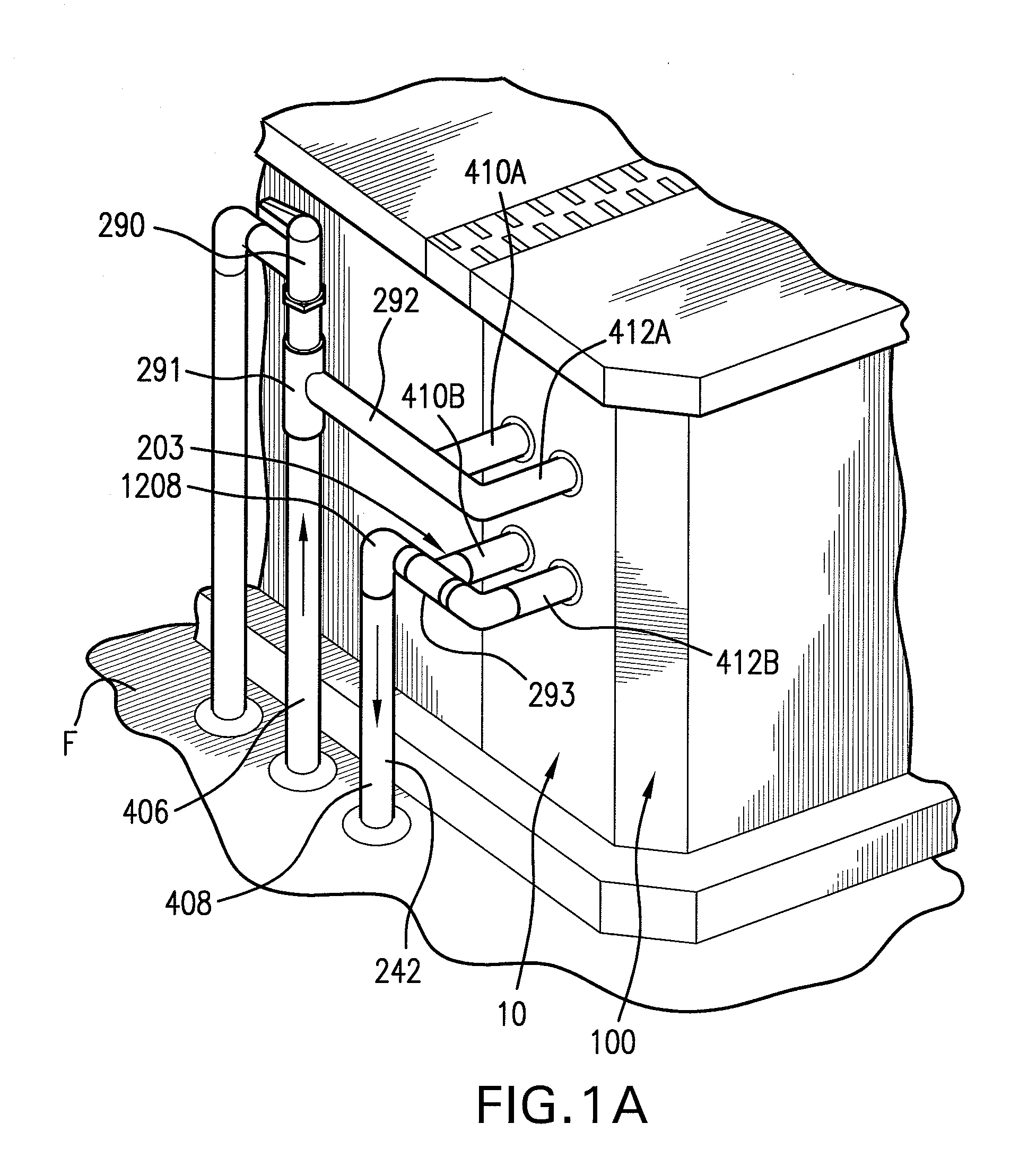

Fluid heating system

ActiveUS20100251973A1Facilitate control of fluid flowAvoid the needMechanical apparatusDomestic stoves or rangesEngineeringBiological activation

A fluid heat exchange system with a fluid flow circuit having a heat exchange fluid flow loop, a heat absorption component (as in a domestic hot water tank inclusive of small commercial use tanks as in tanks of 20 to 120 gallons), a heat exchanger and preferably also a pump. A controlled and automated fuel supply source based heater (as in a pellet stove) is in heat passage communication with the said heat exchanger. A control unit triggers activation of the pump upon fluid in the heat absorption component reaching or dropping below a preset temperature, and the fluid flow circuit is arranged such that, during times of non-activation of the pump, fluid is free to flow in a unidirectional flow within the fluid circuit based on thermodynamic temperature differentials alone. A retrofitting of a domestic hot water tank is also featured preferably making use of preexisting drain and safety vent porting for in-feed and out-feed porting in the exchange loop side. Also, the flow circuit preferably is free of check valves and steam accommodation equipment.

Owner:DONGO KENNETH A +1

Method and system for incorporating an emission sensor into a gas turbine controller

A method for determining an estimated operating parameter for a gas turbine including the steps of: determining an estimated operating parameter using an algorithm have an input from a sensor, wherein the algorithm includes a trim factor; determining a first trim factor based on a comparison of the first estimated operating parameter and the output of the sensor when a condition of the sensor is in a first mode, and during a subsequent determination of the estimated operating parameter, applying the first trim factor to subsequently determine the estimated operating condition if the condition of second sensor is in a second mode.

Owner:GENERAL ELECTRIC CO

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

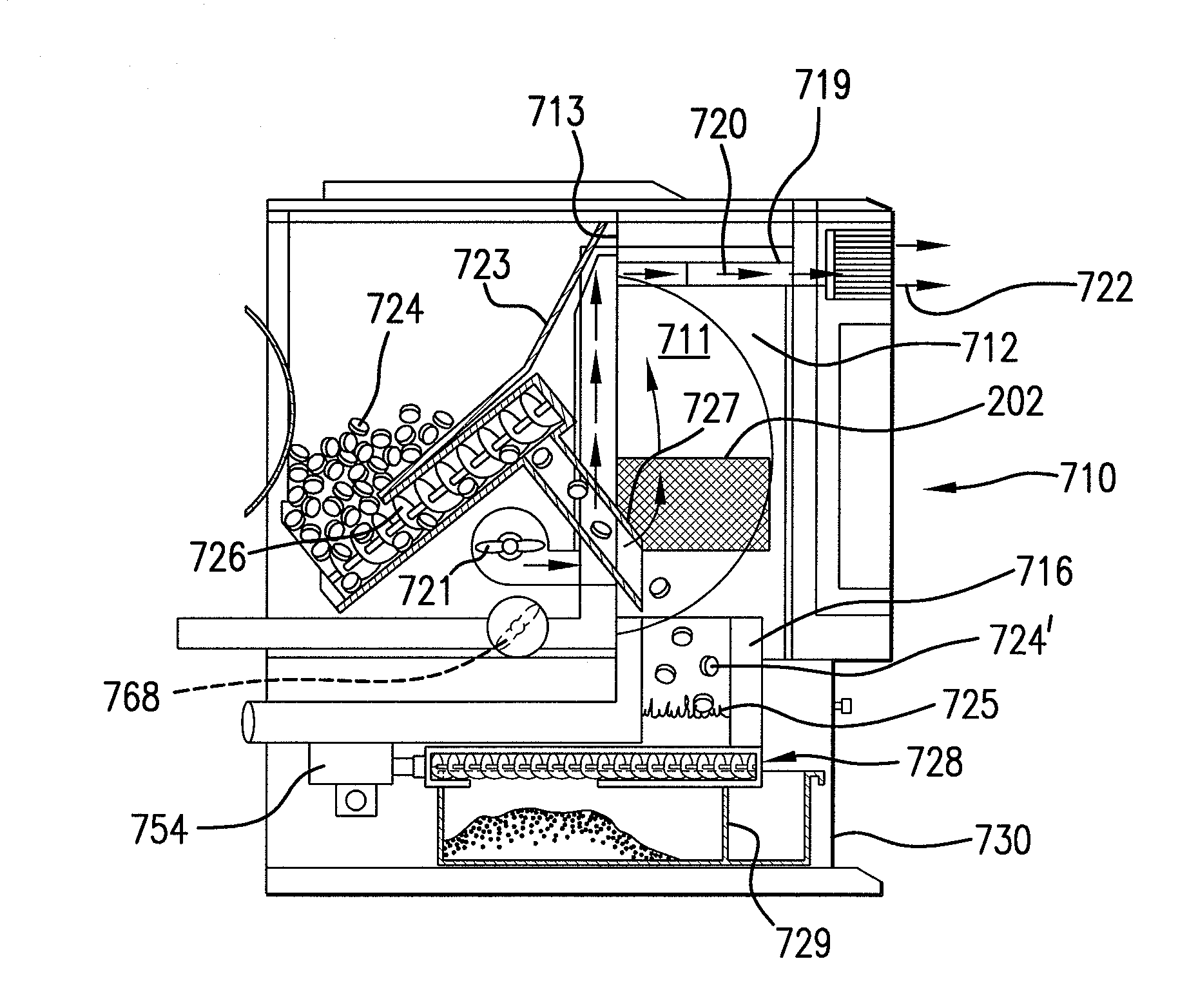

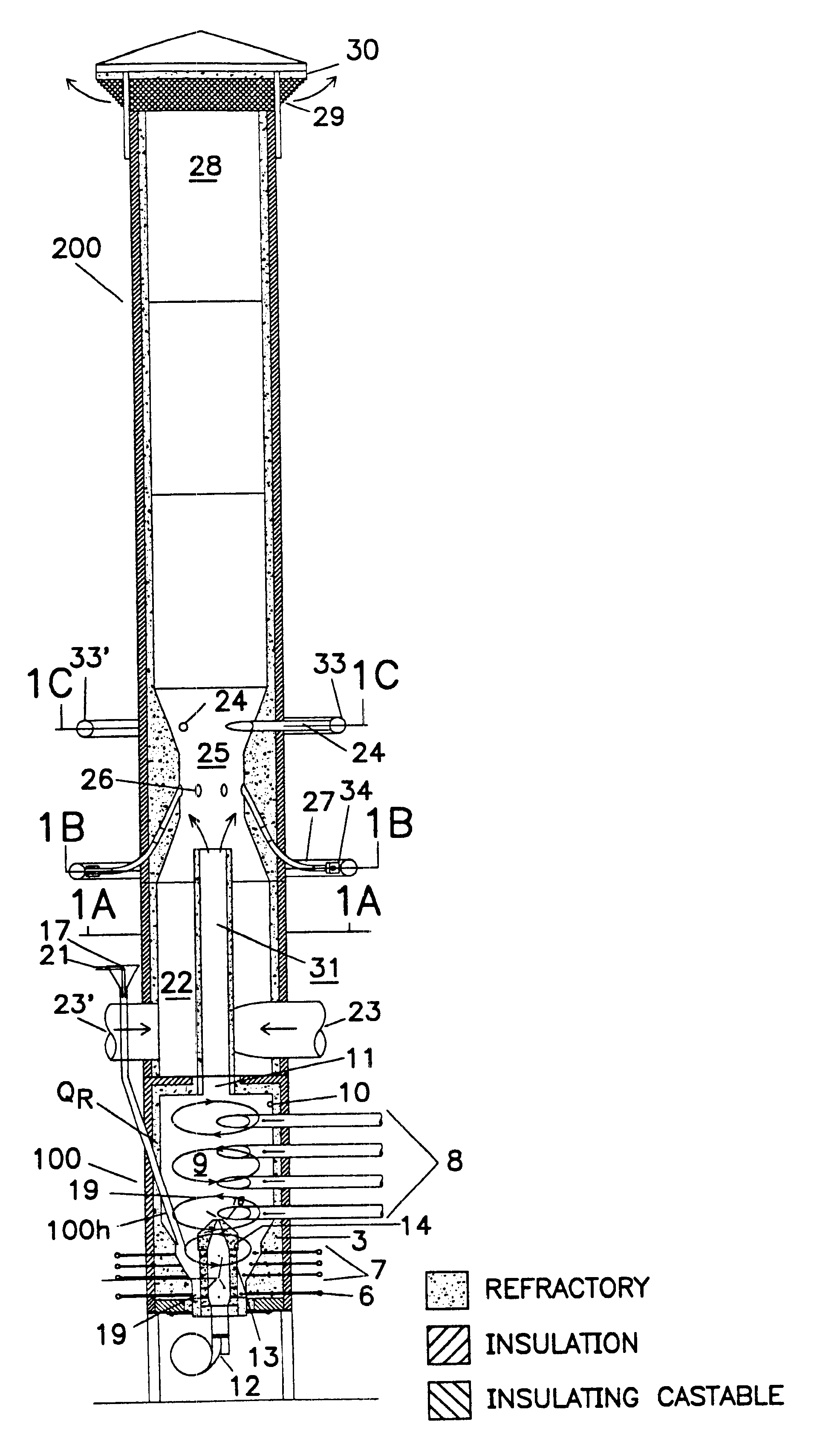

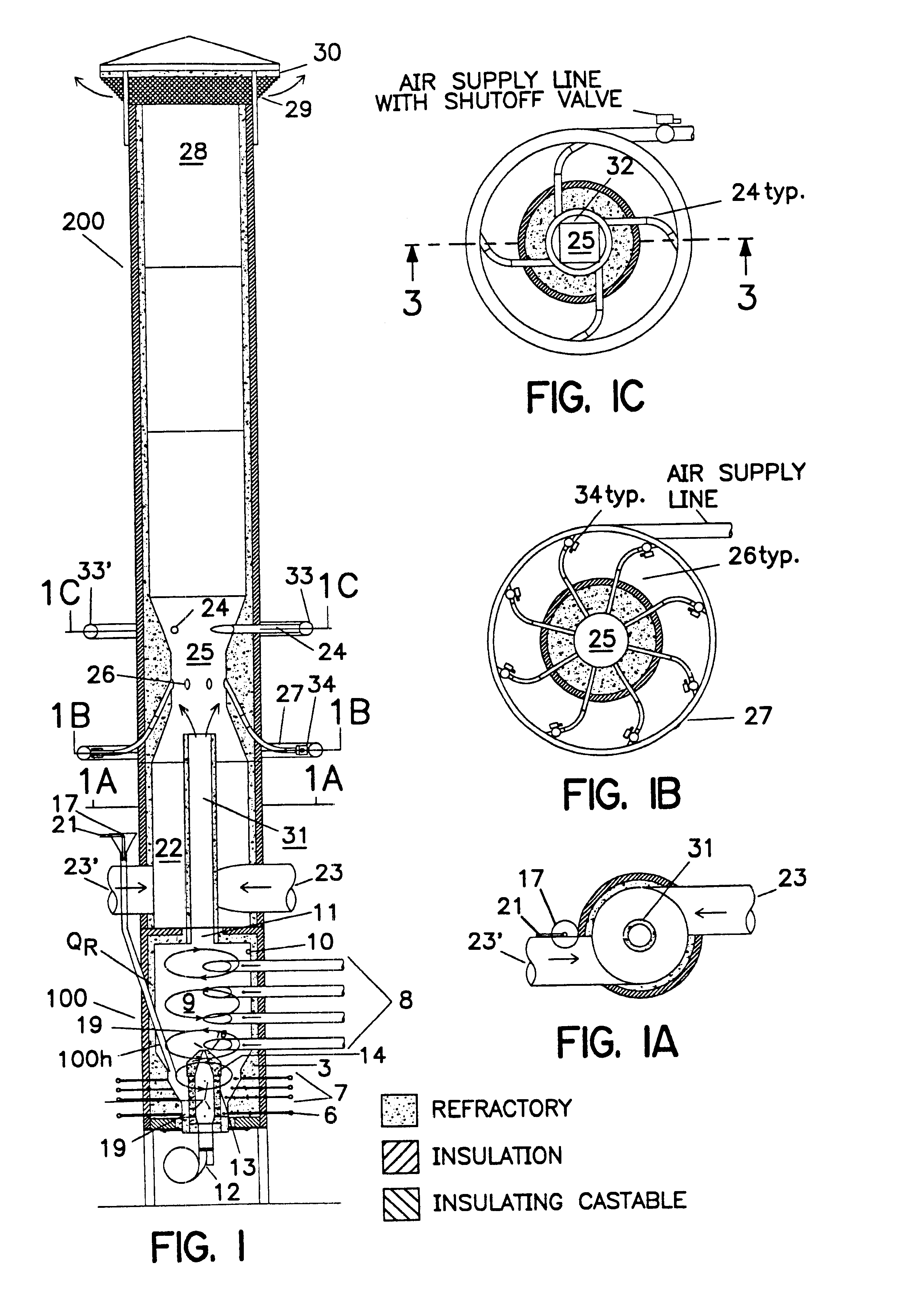

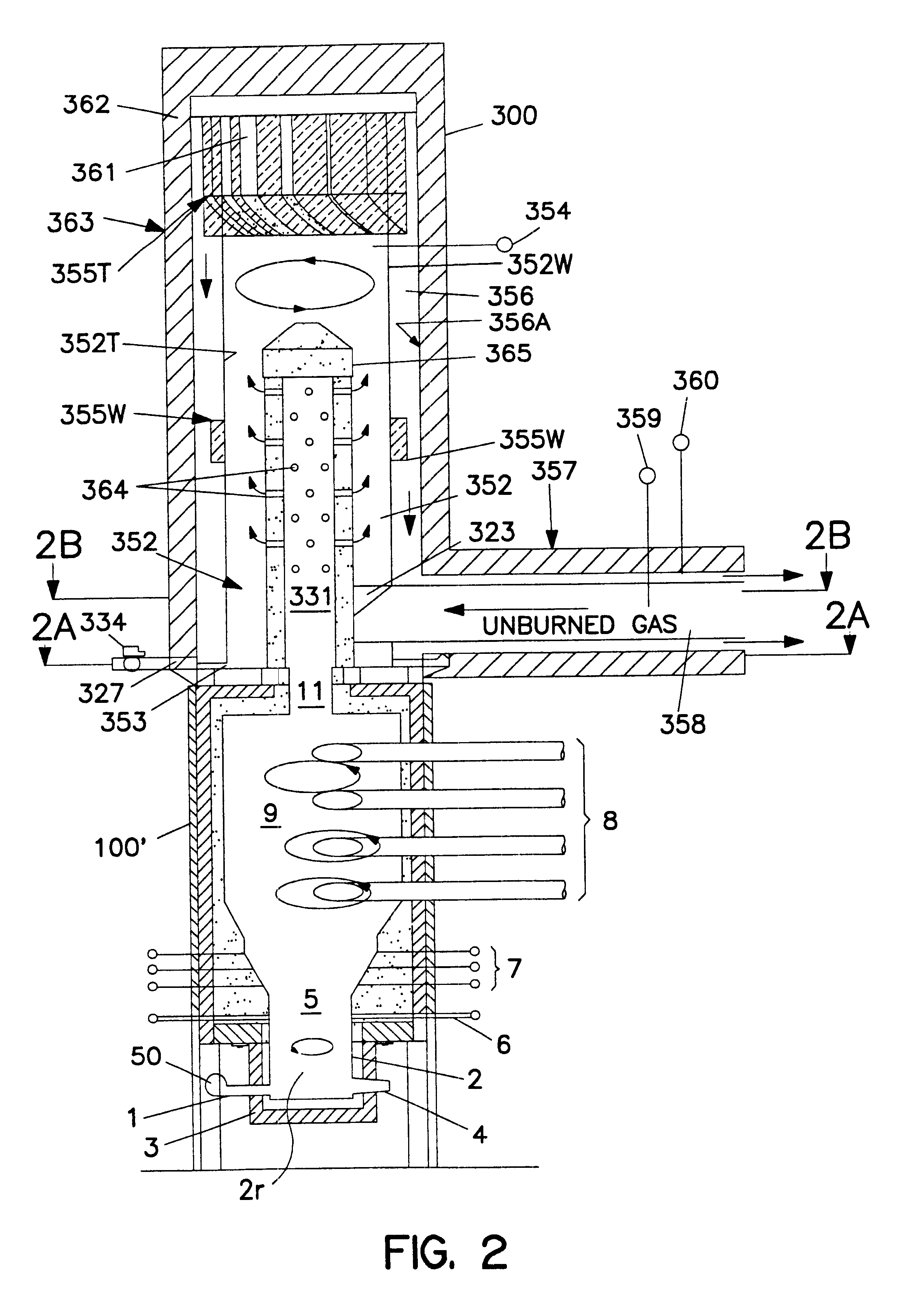

Combustors and burners with high turndown ratio

InactiveUS6363868B1Improve efficiencyIncrease flexibilityFuel supply regulationSolid waste disposalParticulatesCombustion chamber

Various smoke and combustible gas combustors (200, 300) are disclosed, and also disclosed are systems (100, 200) combining gas combustor with inventive burner. Such a burner (100 or 100') provides combustion of a particulate fuel such as sawdust, and many types of varying moisture content biomass fuels such as poultry litter. The combustors and burners exhibit a high turndown ratio ["TDR"].The smoke or combustible gas combustors (200, 300) are combined synergistically with such a burner (100, 100'), or combined with another suitable burner, so as to provide high temperature burner output gases to the combustor, which has coaxial inner and outer combustion chambers (352, 356) inlet tuyere(s) connected to the inner combustion chamber for introducing combustible smoke or other gases to be burned into the inner combustion chamber at one end thereof with cyclonic flow, and in which combustion air is mixed with combustible smoke or other gases to form a gas stream moving through the inner combustion chamber with cyclonic movement. A preheat tube (331) within the combustible gas heating chamber receives heated exhaust gases from the burner, and communicates with the inner combustion chamber exit through a plurality of apertures (364) for controlled flow of said heated exhaust gases into the gas stream and so heating same by mixing the exhaust gases with the stream of air and combustible gases.

Owner:INDEPENDENT STAVE

Temperature controlled burner apparatus

InactiveUS6881055B2Easy to controlMore powerTemperature control without auxillary powerSelf-cleaning stoves/rangesTemperature controlCombustor

A system for controlling temperature in an enclosure operates in a low heat or a high heat mode with flame always present. The presently intended use is for providing a cooking grill with a controlled temperature cooking space. An electrically controlled valve having high flow rate and low flow rate settings is interposed in the fuel line for at least one of the burners in the grill. A temperature sensor signals cooking space temperature to a controller that may be a microprocessor. The system includes a keyboard allowing the user to communicate a selected set point to the microprocessor and the microprocessor communicates status to a display. The microprocessor selects the setting of the electrically controlled valve. In a preferred embodiment, the electrically controlled valve is placed in series fuel flow with one of the manually adjustable valves commonly found on cooking grills.

Owner:ADEMCO INC

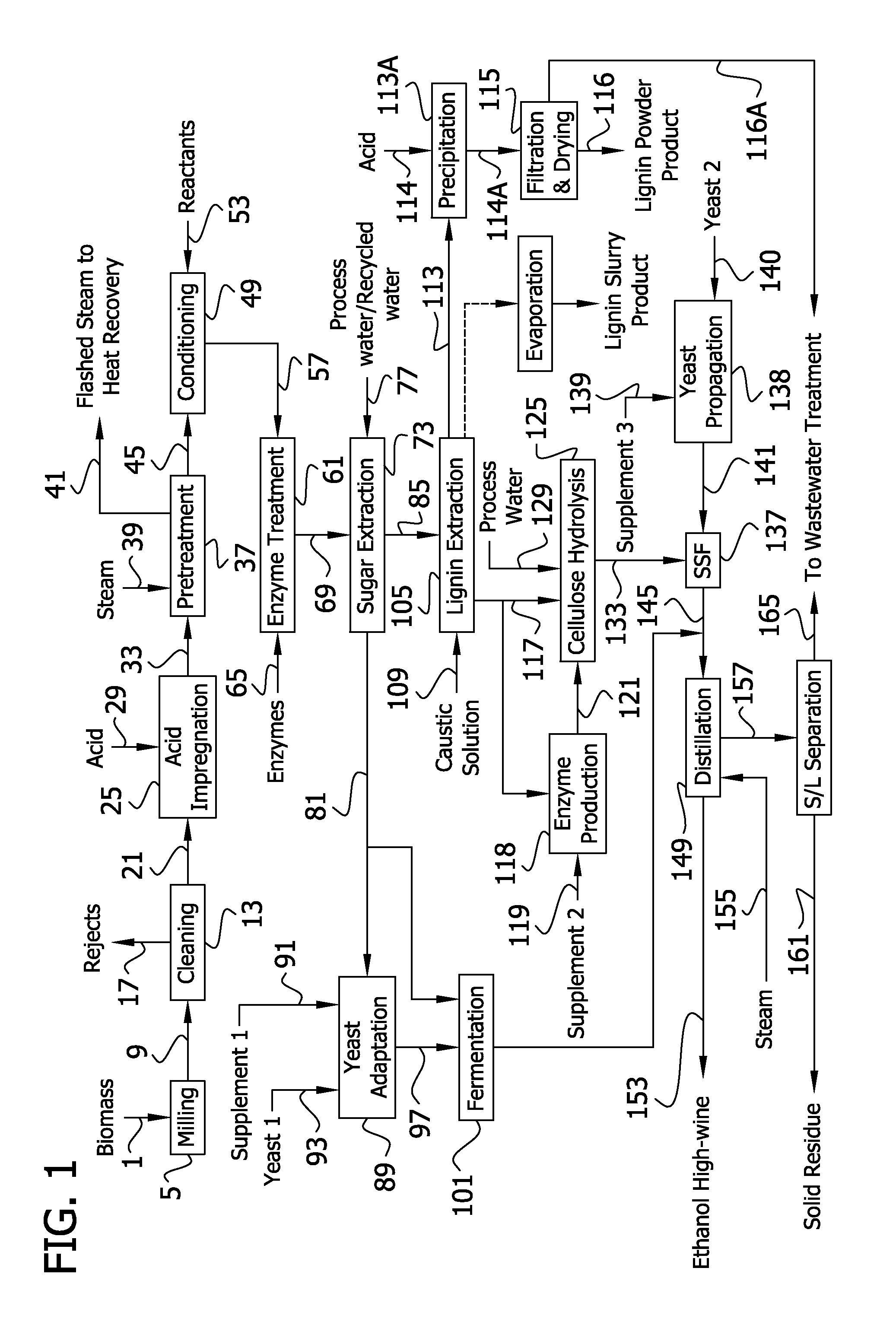

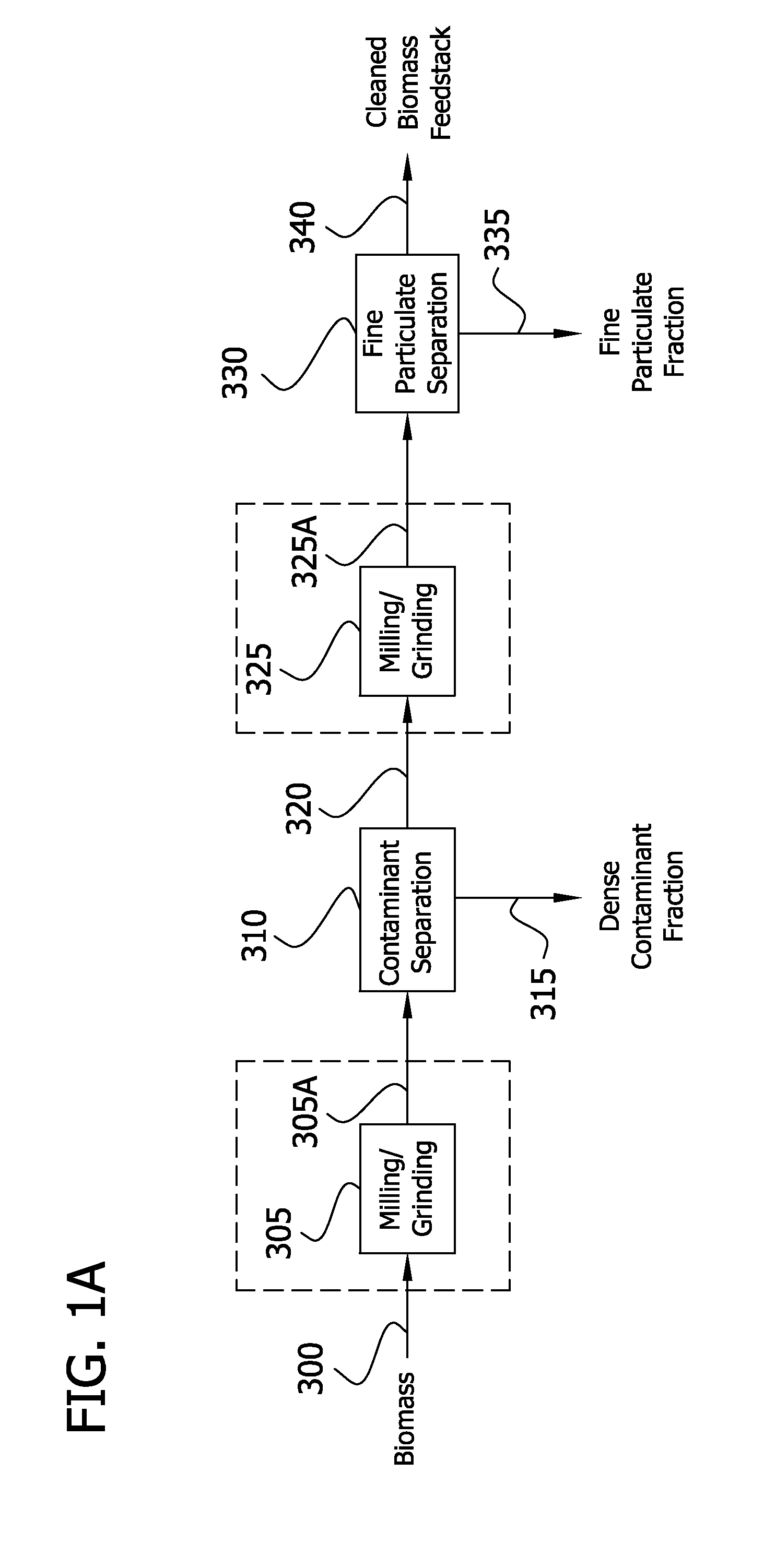

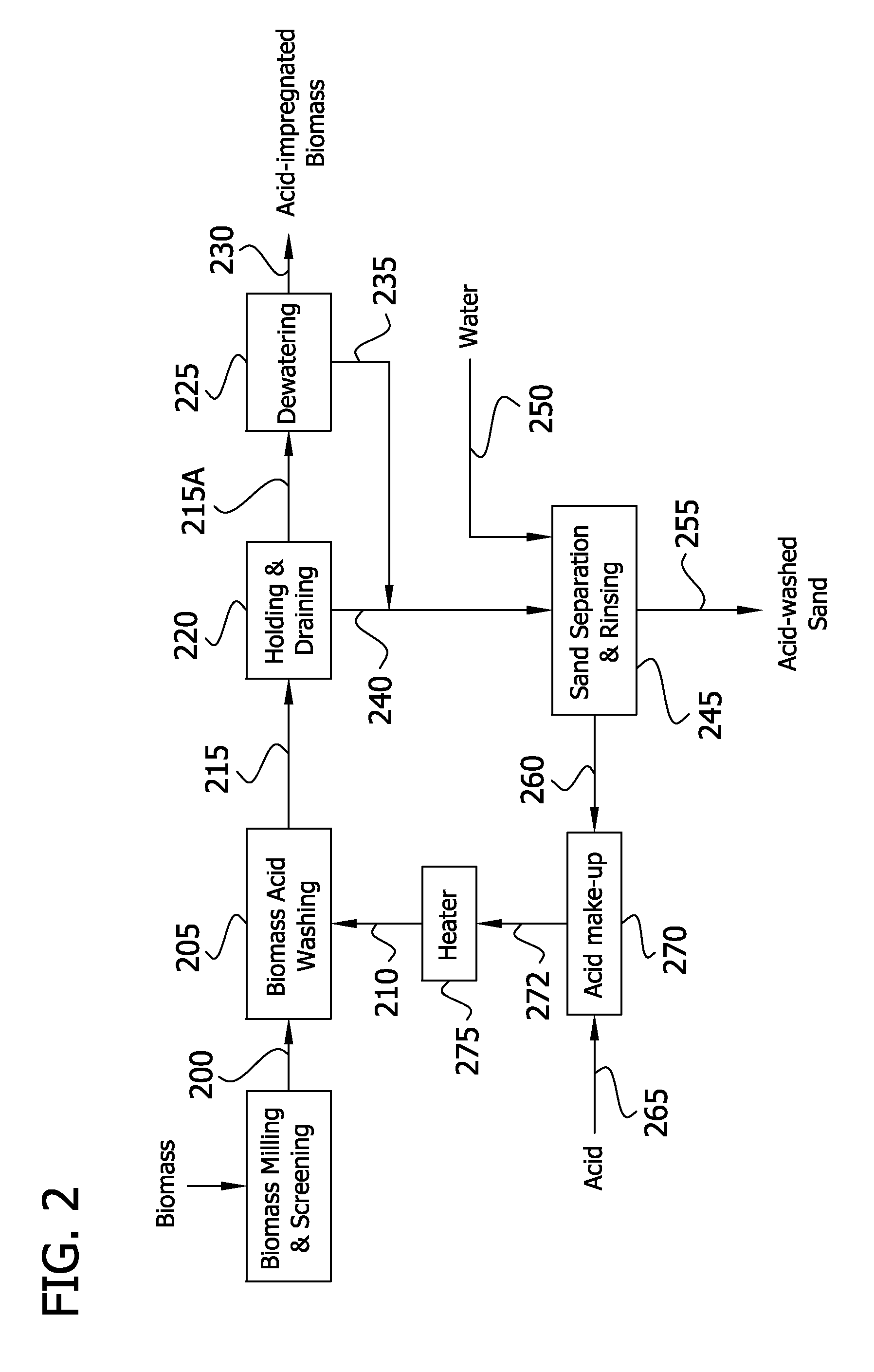

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20110262984A1Increased ethanol productionImproved co-productsPretreatment with acid reacting compoundsBiofuelsCelluloseCo product

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

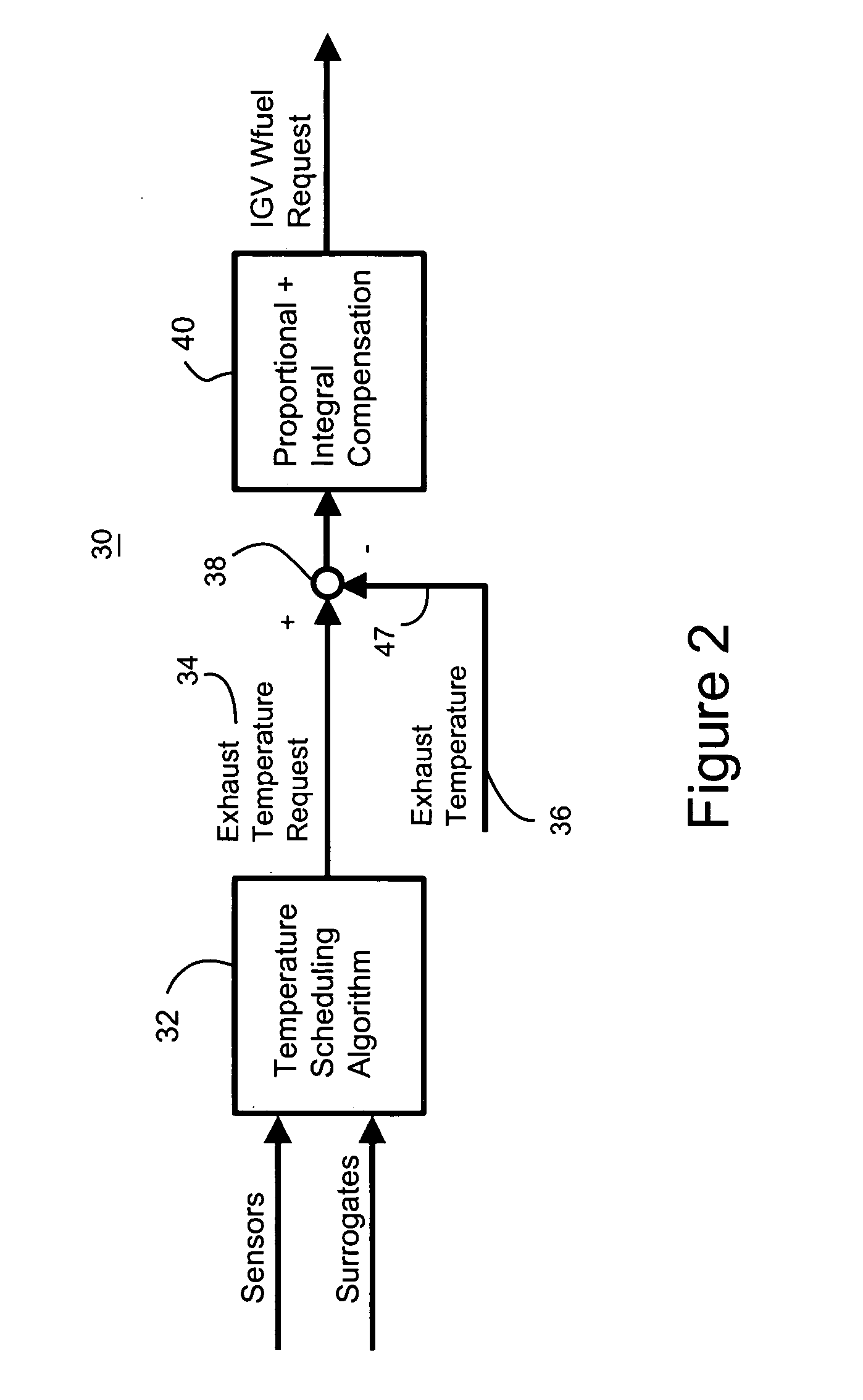

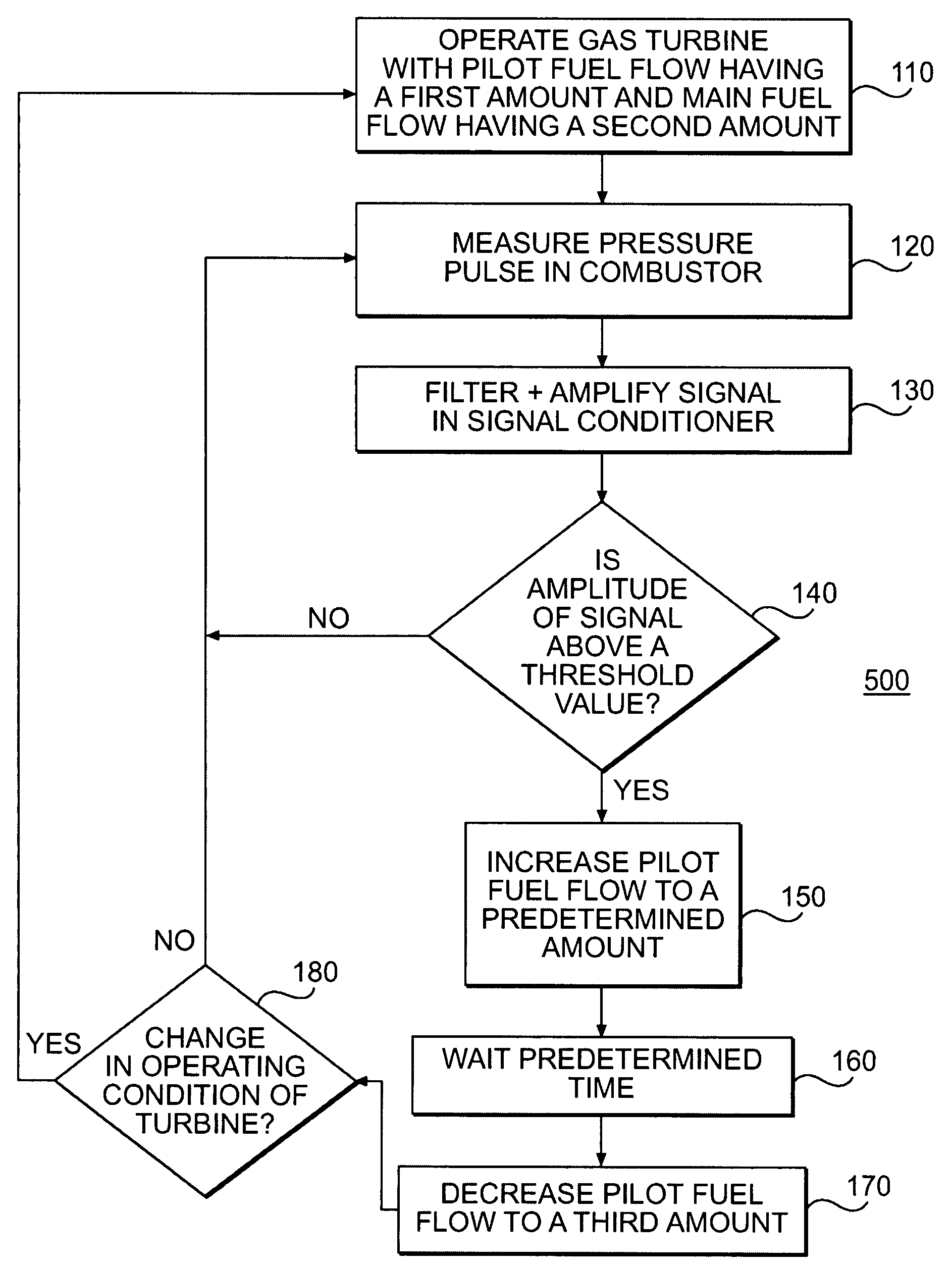

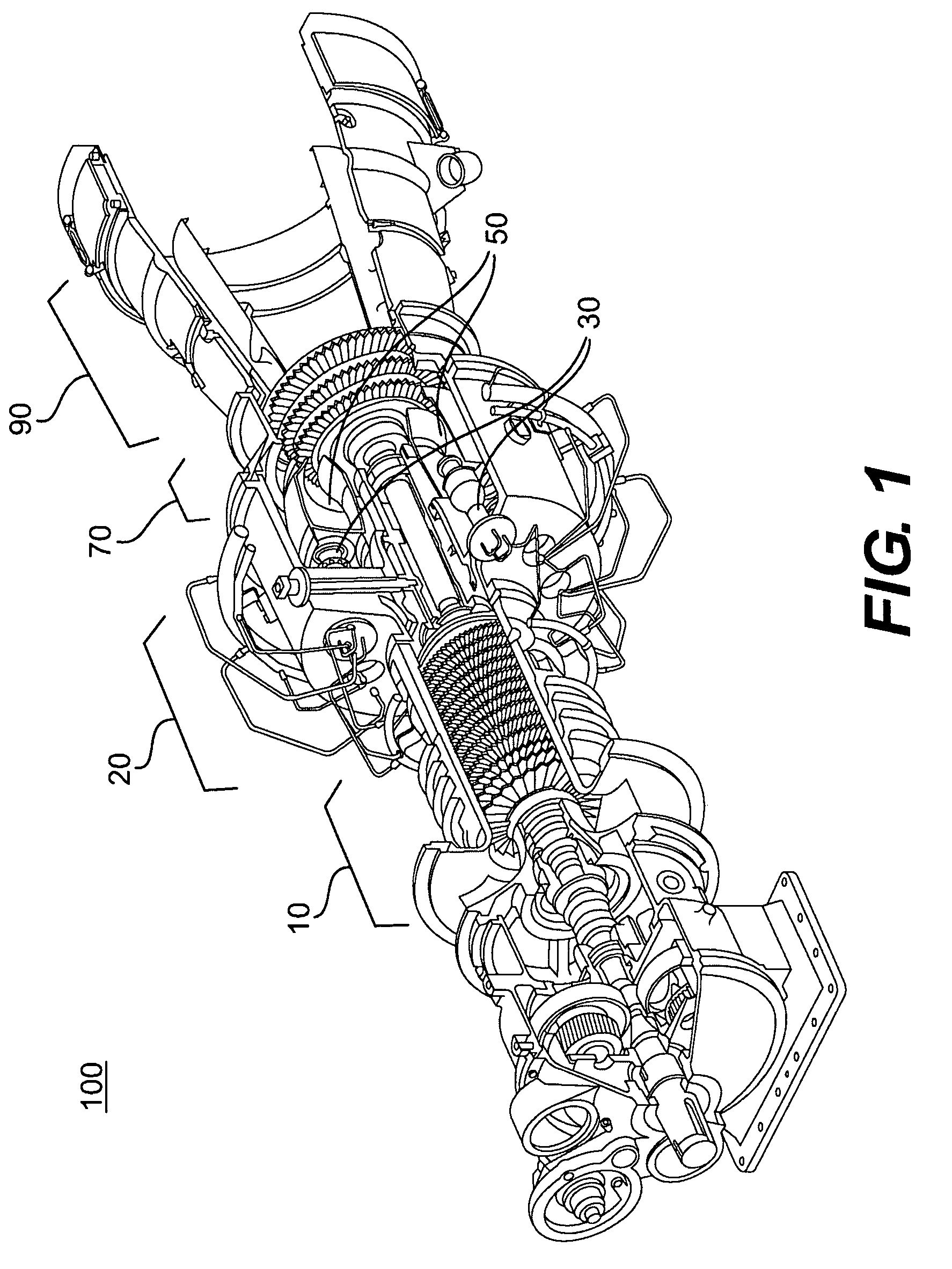

Active combustion control for a turbine engine

ActiveUS20090133379A1Reduce amountIncrease volumeAnalogue computers for vehiclesContinuous combustion chamberElectricityCombustor

A combustion control system for a turbine engine is disclosed. The combustion control system includes a fuel injector having a main fuel supply and pilot fuel supply coupled to a combustor of the turbine engine. The combustion control system also includes a sensor coupled to a transfer tube. The transfer tube is fluidly coupled to the combustor, and the sensor is configured to detect a pressure pulse in the combustor. A semi-infinite coil is also coupled to the transfer tube. The combustion control system also includes a controller electrically connected to the sensor. The controller is configured to compare an amplitude of the pressure pulse within a frequency range to a threshold amplitude, and adjust the pilot fuel supply in response to the comparison.

Owner:SOLAR TURBINES

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

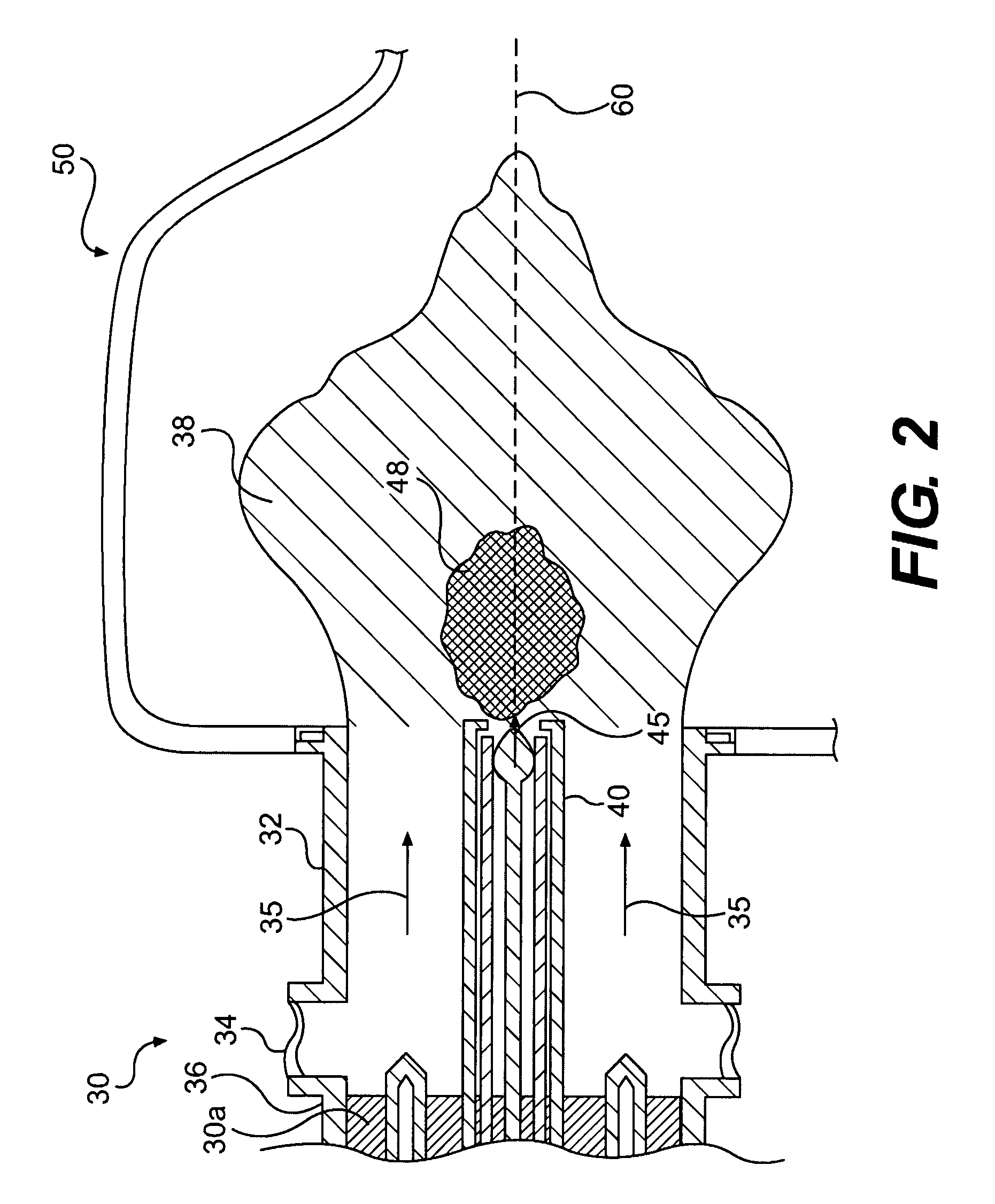

Apparatus and method for controlling the secondary injection of fuel

A combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

Air inlet damper apparatus

InactiveUS20070044787A1Prevents uncontrolled intrusionAvoid problemsDomestic stoves or rangesCombustion valves/nozzle/pumpsCombustionCoupling

An air inlet damper apparatus for minimizing the entrance of outside air into a poultry house when the ventilation exhaust fans are running and the radiant tube heater is not operating. The apparatus has a housing with a passage and a coupling flange; a pin that spans the passage and divides the apparatus into a low pressure side and an outside high pressure side, where the low pressure side is in fluid communication with a blower supplying combustion air to the tube heater; a damper blade connected to the pin; a stop; and a means for controlling the damper blade. The controlling means is responsive to pressure. The damper blade pivotally opens away from the stop when there is a static pressure differential that is higher than the negative pressure created by the ventilation exhaust fans, or when the controlling means electromechanically actuates the damper blade.

Owner:GAS FIRED PRODS

Multi-point staging strategy for low emission and stable combustion

InactiveUS7107772B2Avoids creating excessive CO and UHCBurnersFuel supply regulationCombustorLow emission

Owner:UNITED TECH CORP

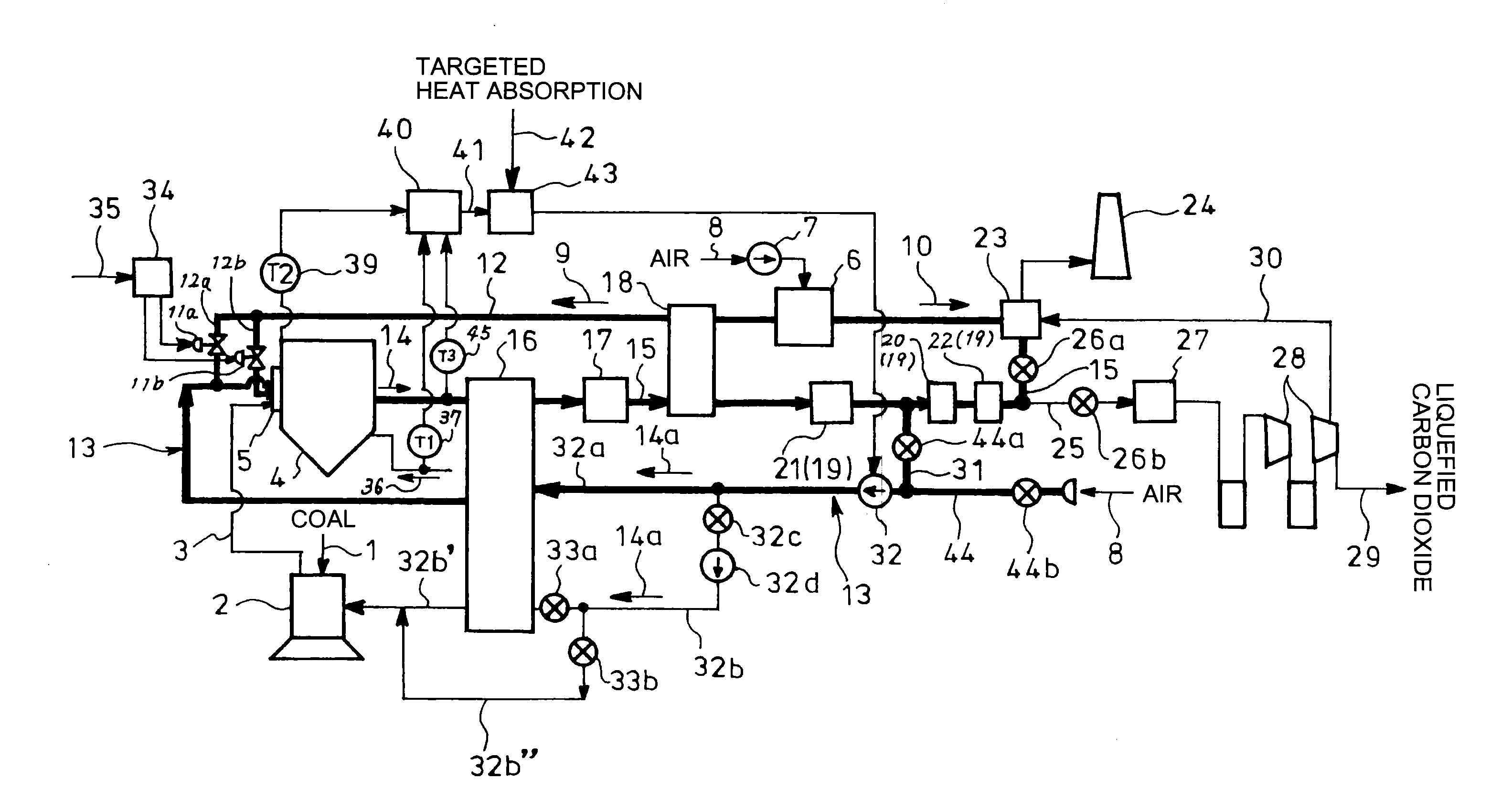

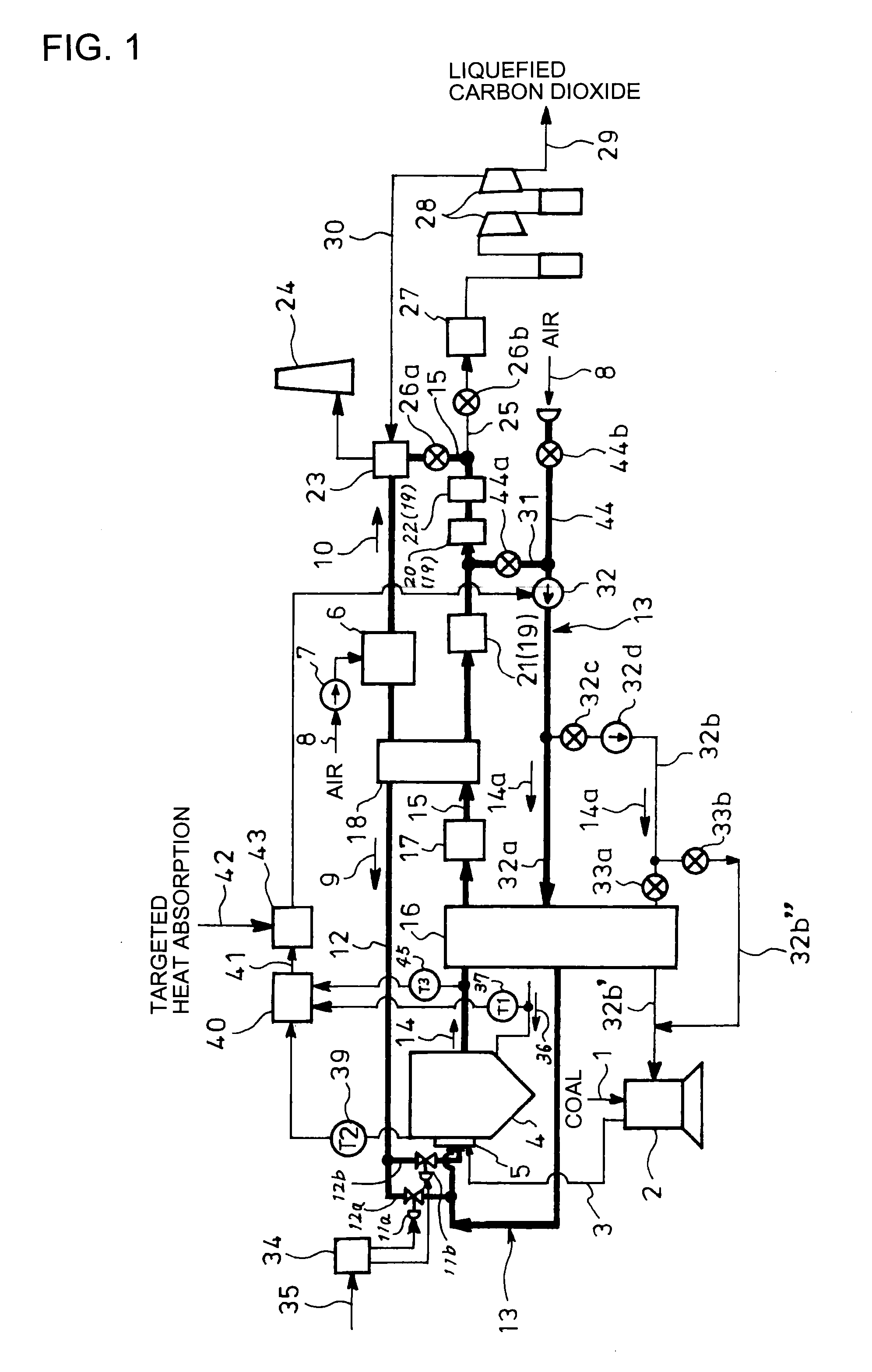

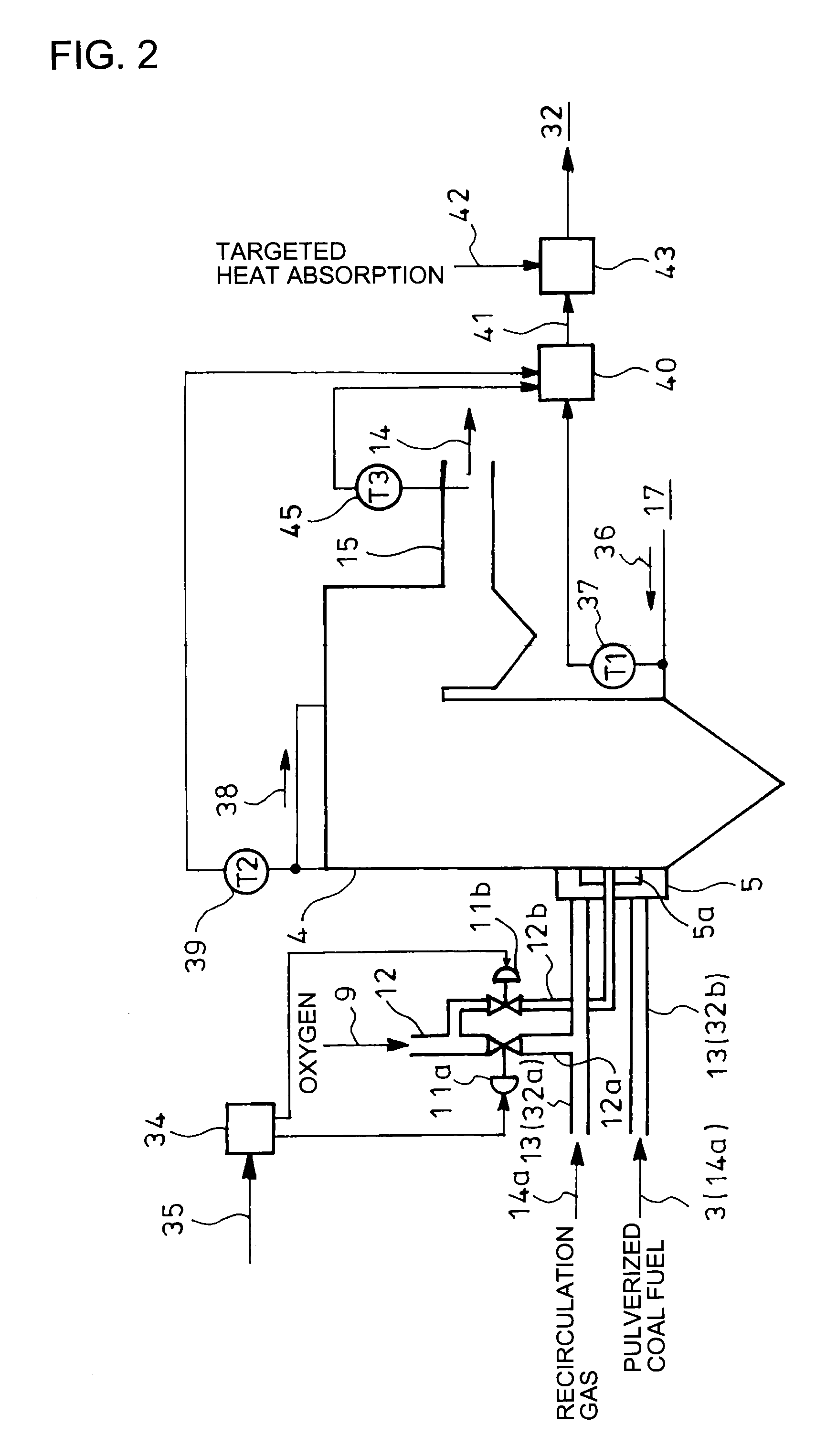

Method and apparatus for controlling combustion in oxygen fired boiler

ActiveUS20090272300A1Great advantageGood effectMechanical apparatusFluegas recirculationCombustionEngineering

Provided are a method and an apparatus for controlling combustion in an oxygen fired boiler which are easily applicable to an existing air fired boiler for easy and stable control of the combustion.Oxygen with a setting amount in accordance with a boiler load demand 35 is supplied to a boiler body 4. Heat absorption amount of the boiler is measured from inlet temperature of feedwater supplied to the boiler body 4 and outlet temperature of steam. Recirculation flow rate of combustion exhaust gas 14a is controlled such that heat absorption amount 41 of the boiler body 4 becomes equal to a targeted heat absorption amount 42 to thereby control oxygen concentration in all gas guided to the boiler body 4.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY +1

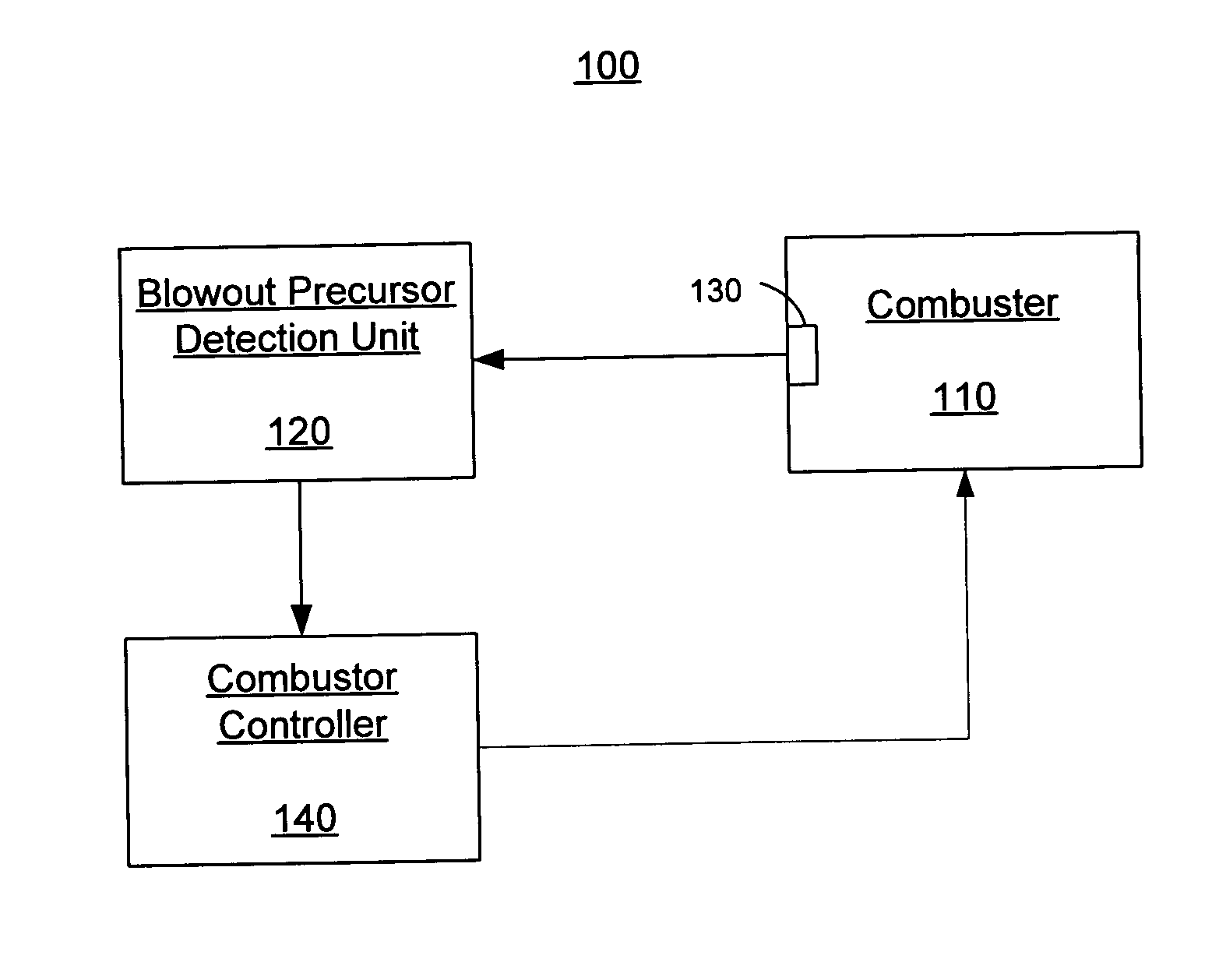

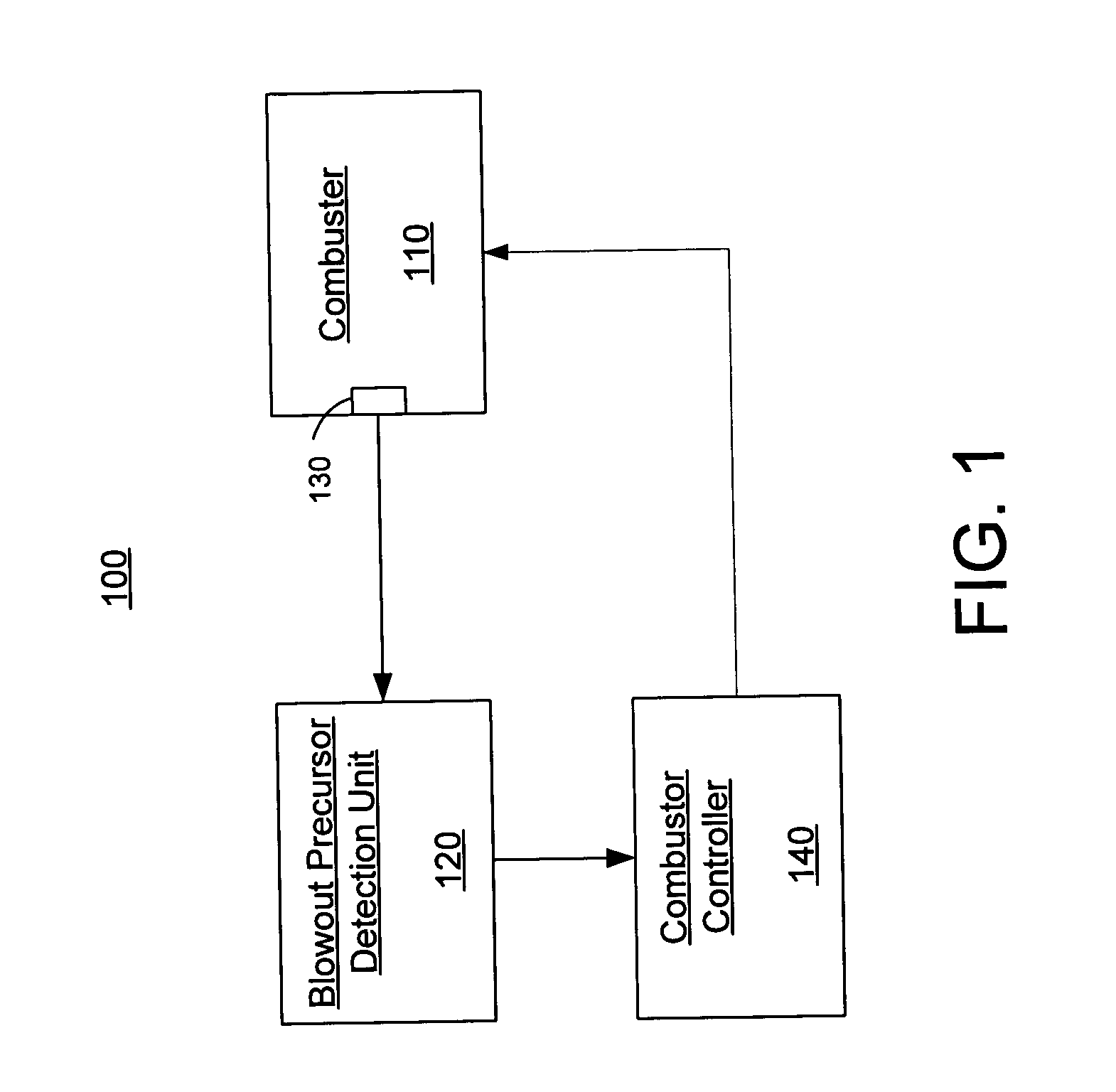

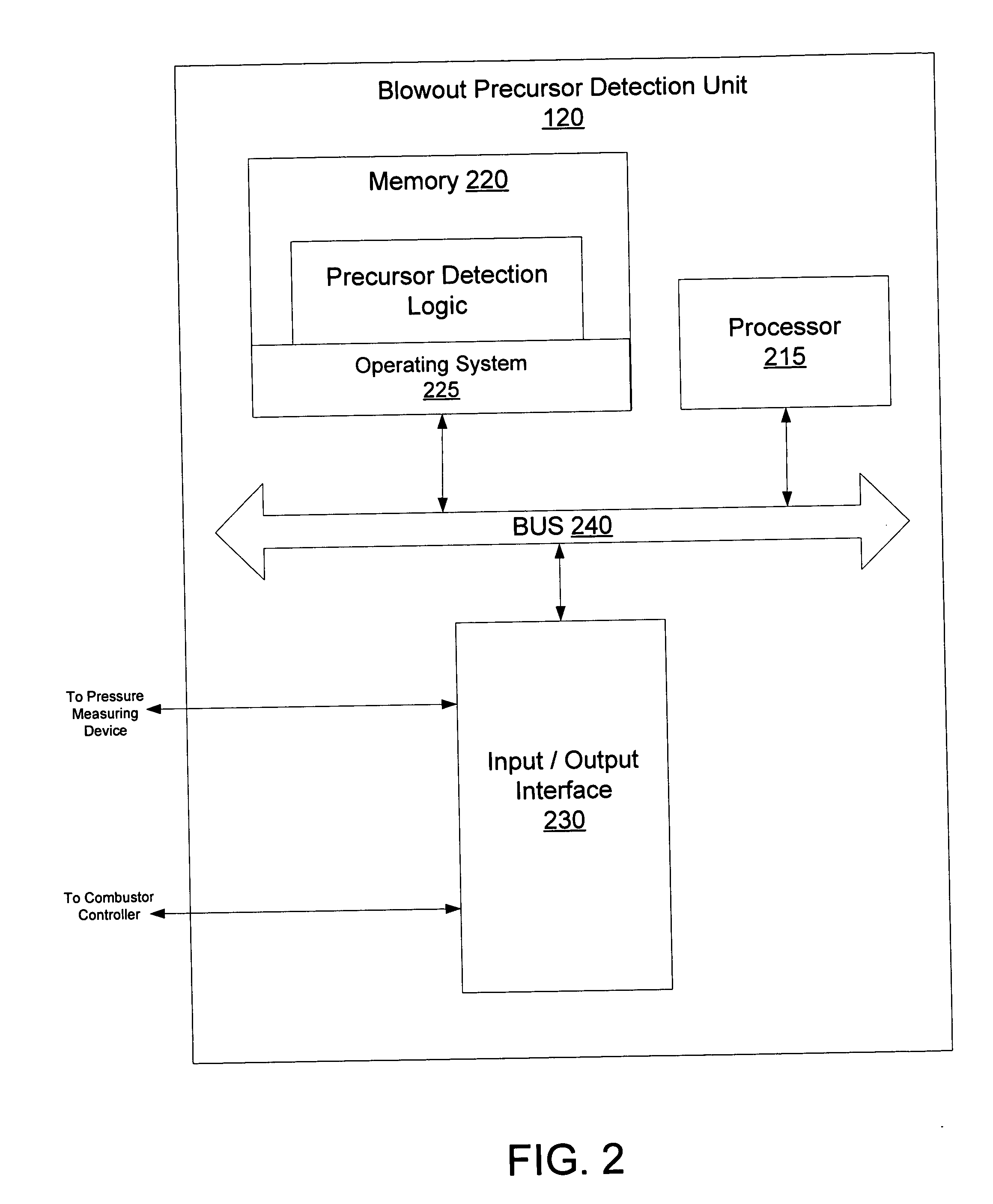

Systems and methods for detection of blowout precursors in combustors

The present invention comprises systems and methods for detecting flame blowout precursors in combustors. The blowout precursor detection system comprises a combustor, a pressure measuring device, and blowout precursor detection unit. A combustion controller may also be used to control combustor parameters. The methods of the present invention comprise receiving pressure data measured by an acoustic pressure measuring device, performing one or a combination of spectral analysis, statistical analysis, and wavelet analysis on received pressure data, and determining the existence of a blowout precursor based on such analyses. The spectral analysis, statistical analysis, and wavelet analysis further comprise their respective sub-methods to determine the existence of blowout precursors.

Owner:GEORGIA TECH RES CORP

Popular searches

Air-treatment apparatus arrangements Space heating and ventilation details Programme control in sequence/logic controllers Central heating system Turbine/propulsion fuel flow conduits Stators Turbine/propulsion fuel control Jet propulsion plants Combustion control Hot gas positive displacement engine plants

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com