Air inlet damper apparatus

a technology of damper and air inlet, which is applied in the direction of lighting and heating equipment, gaseous heating fuel, stoves or ranges, etc., can solve the problems of negative pressure in the house, increased cycle frequency accelerated aging of the tube heater, so as to prevent the uncontrolled intrusion of outside air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

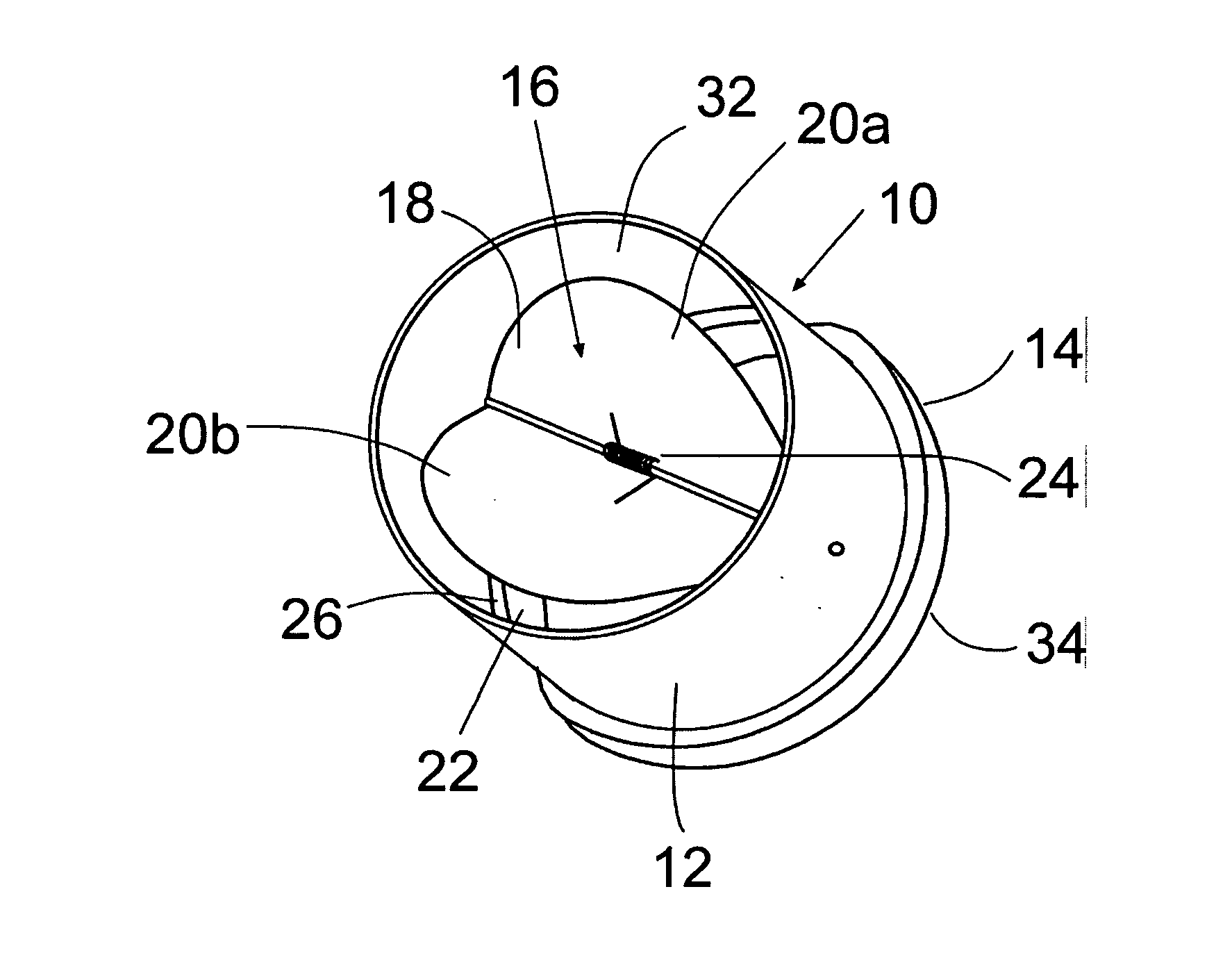

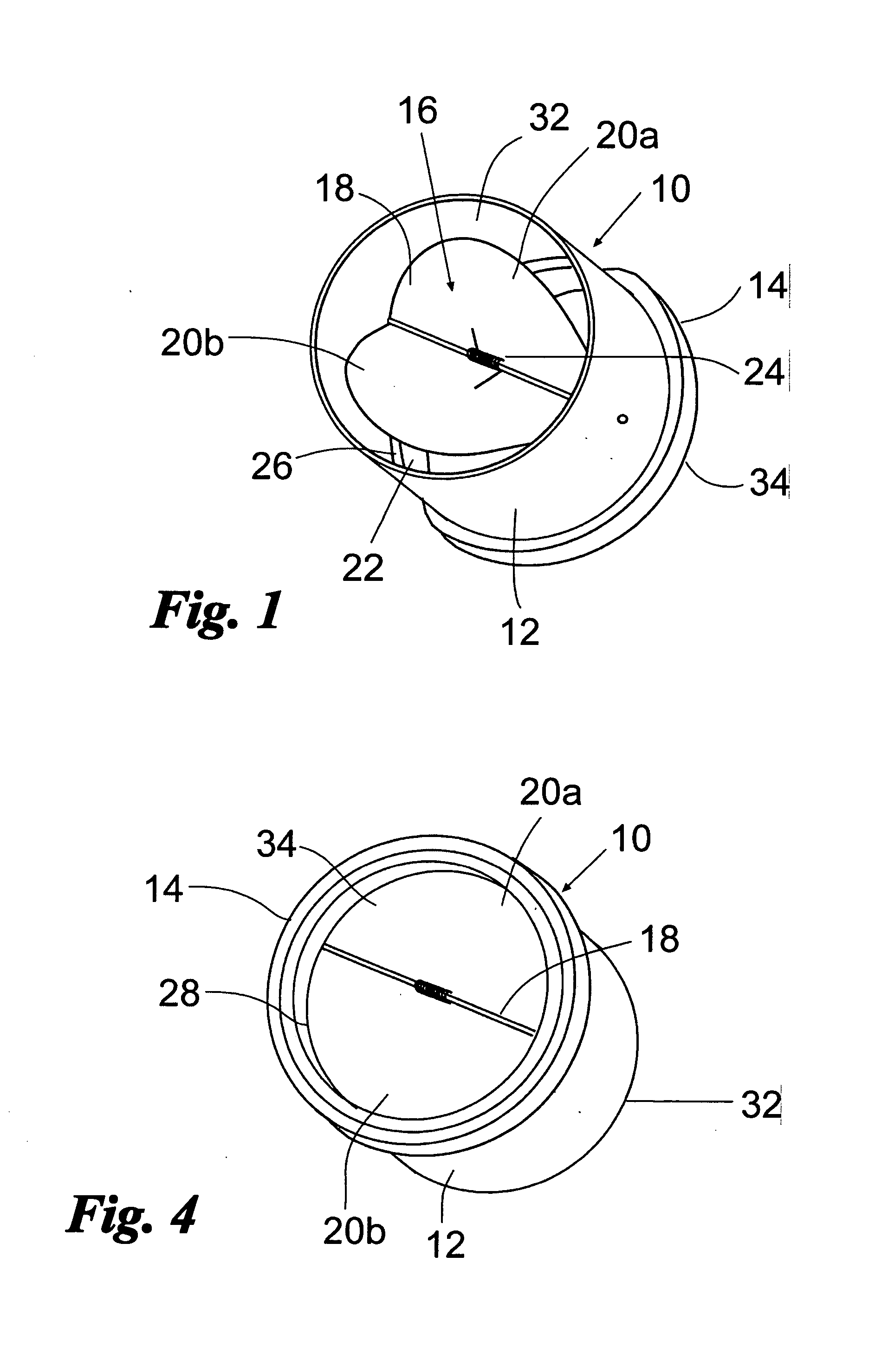

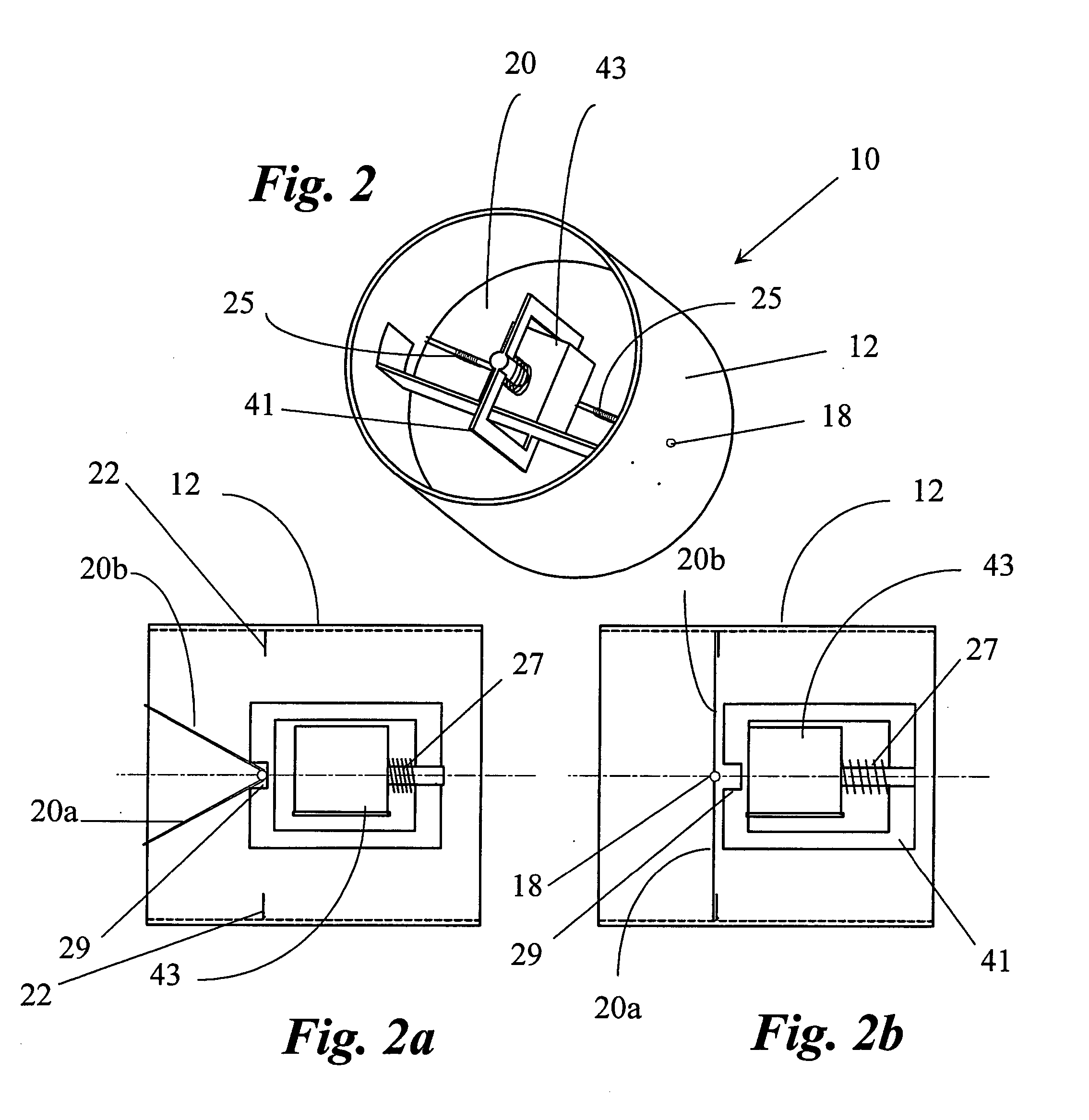

[0028] The invention is an air inlet damper apparatus 10 for minimizing the entrance of air into a poultry house or similar building having a negative pressure. The negative pressure is typically produced by exhaust fans to ventilate the building. The apparatus is comprised of: a housing having a passage; a pin that spans the passage and divides the apparatus into a low pressure side and an outside high pressure side; a damper blade connected to the pin; an inner housing stop against which the dampening blade can form a seal; and a means for controlling the damper blade, wherein said controlling means is responsive to pressure. The damper blade pivotally opens away from the stop upon reaching a static pressure differential between the low-pressure side and the high-pressure side. The static pressure differential is based on a predetermined pressure differential, which is usually higher than the negative pressure effected by the exhaust fans, but less than the static pressure differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com