Patents

Literature

396results about "Combustion control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

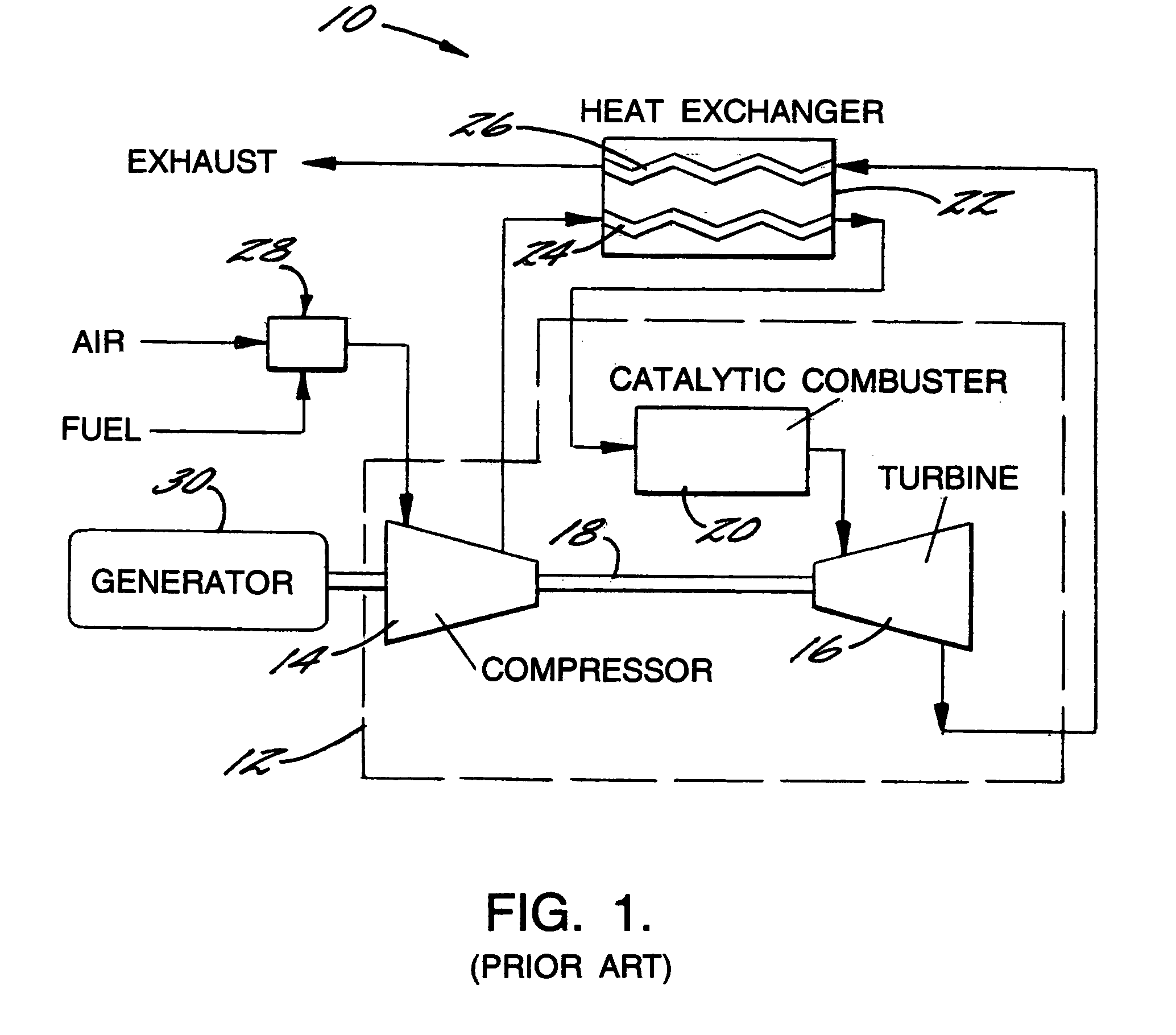

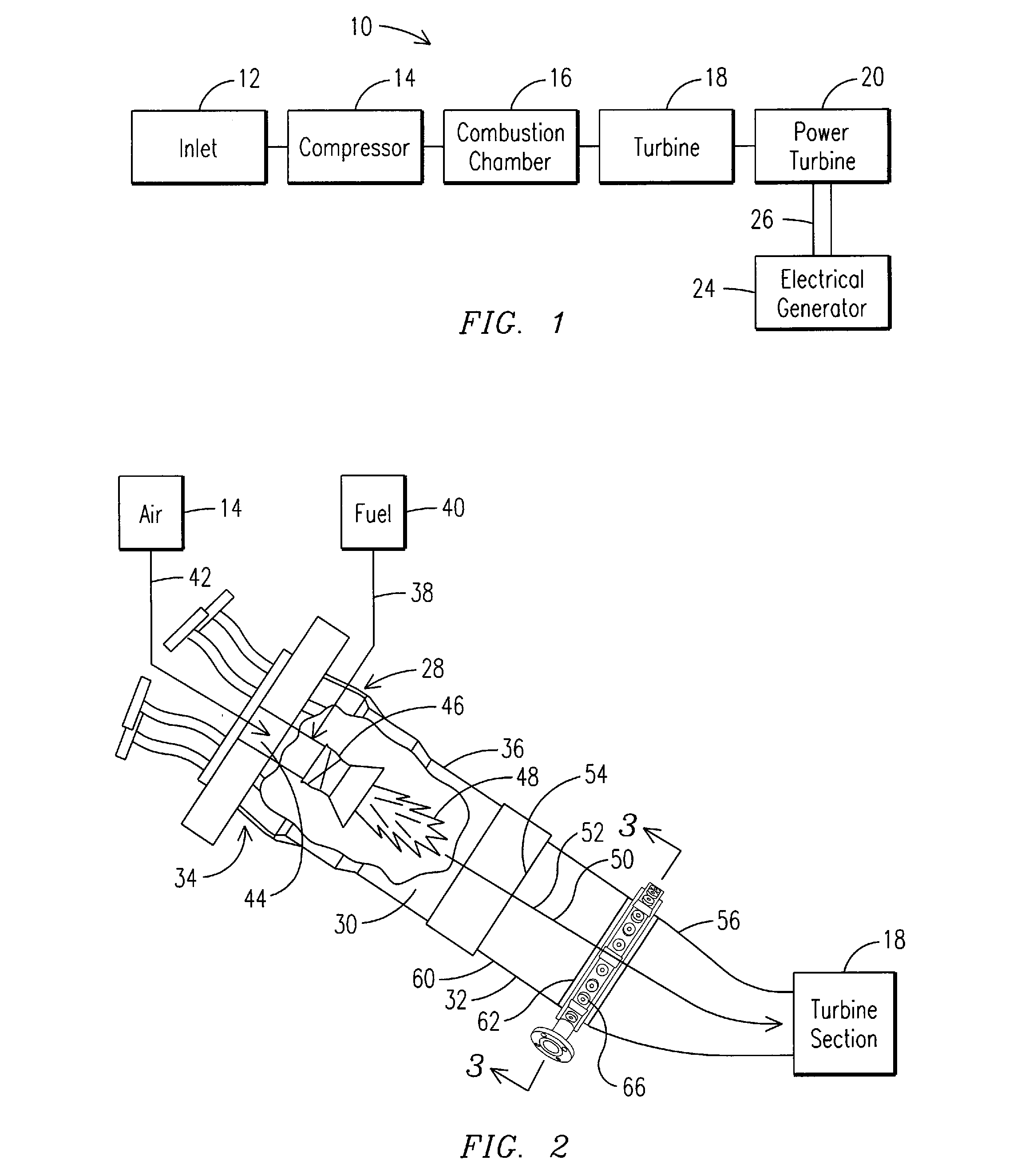

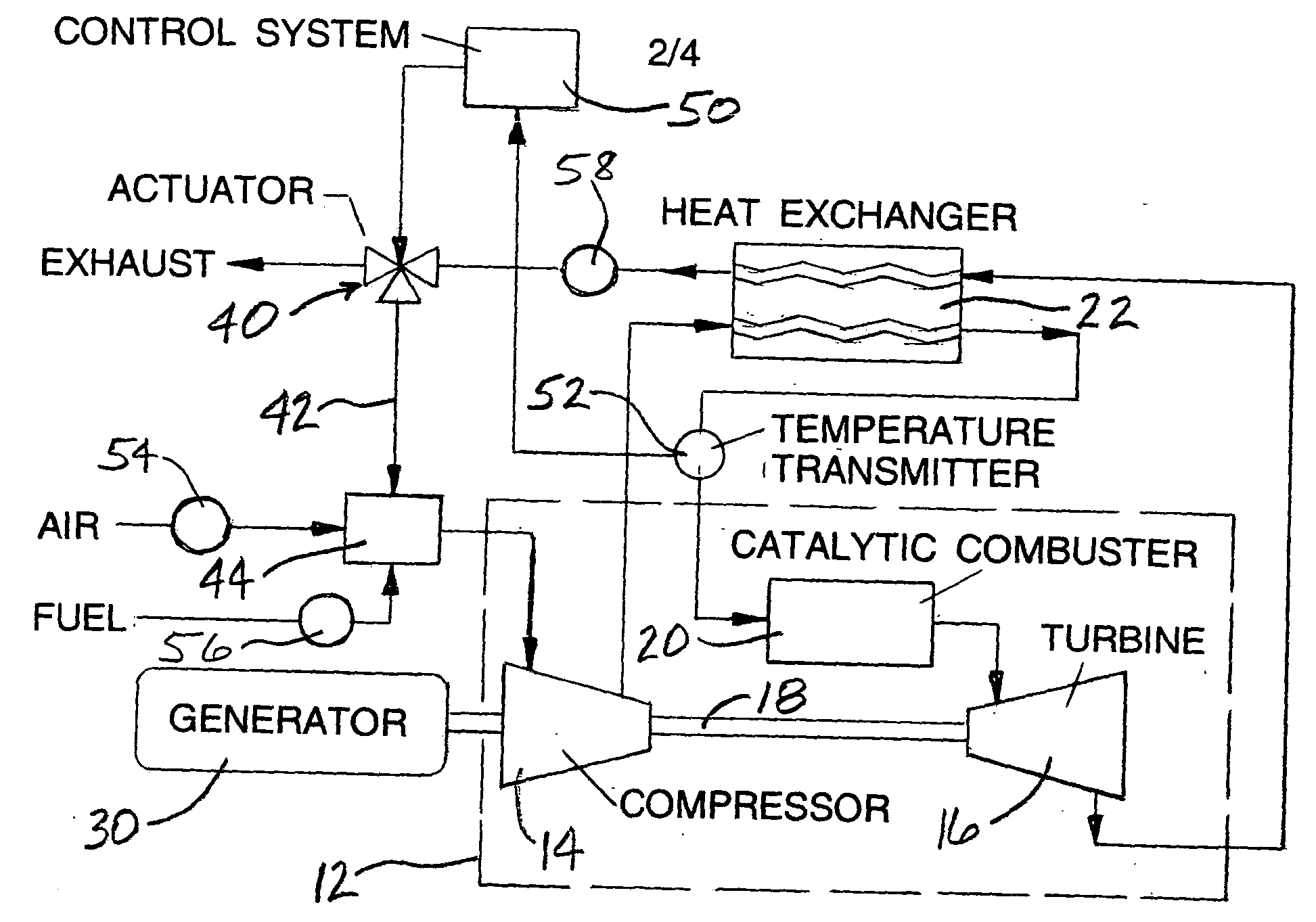

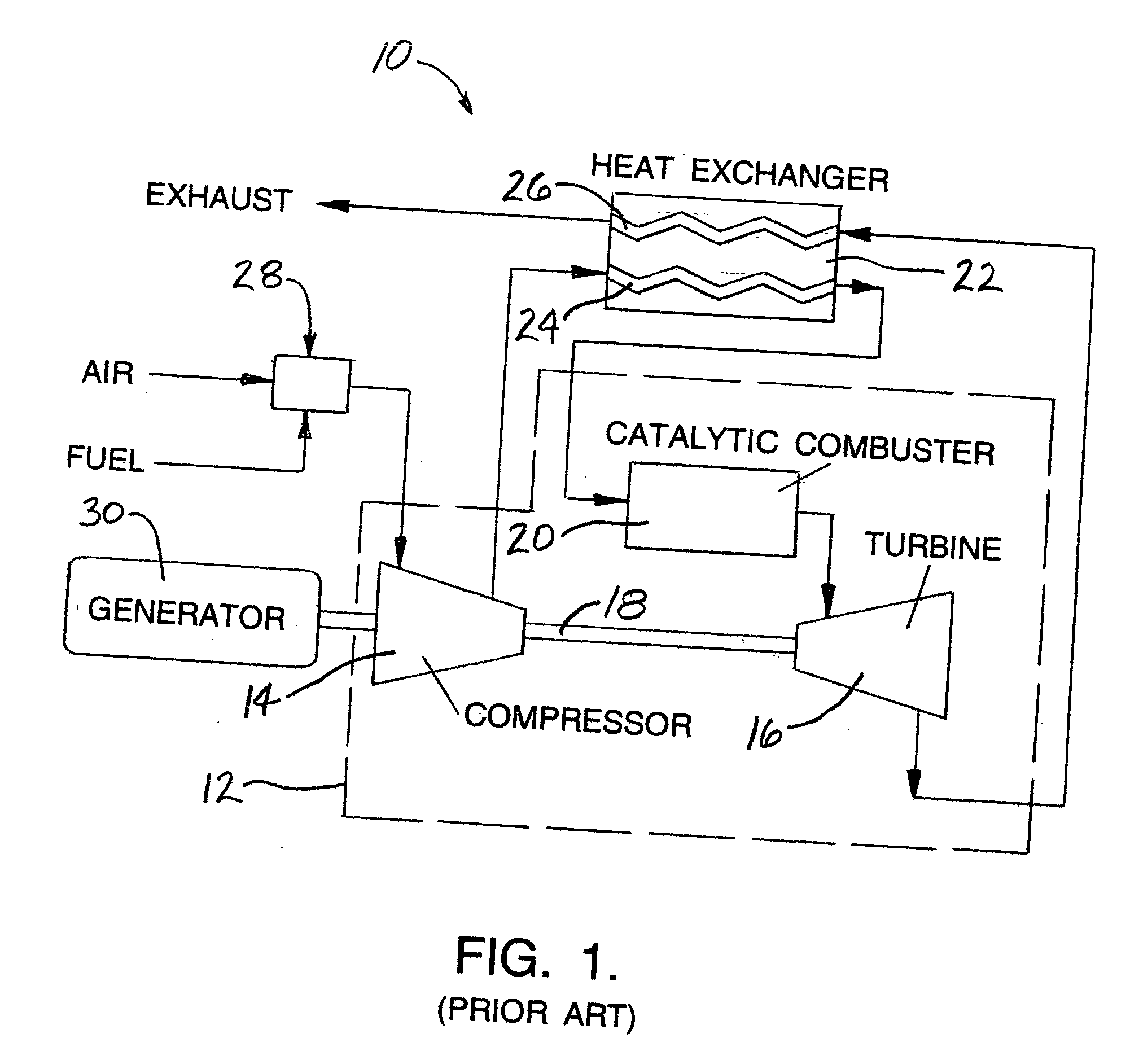

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

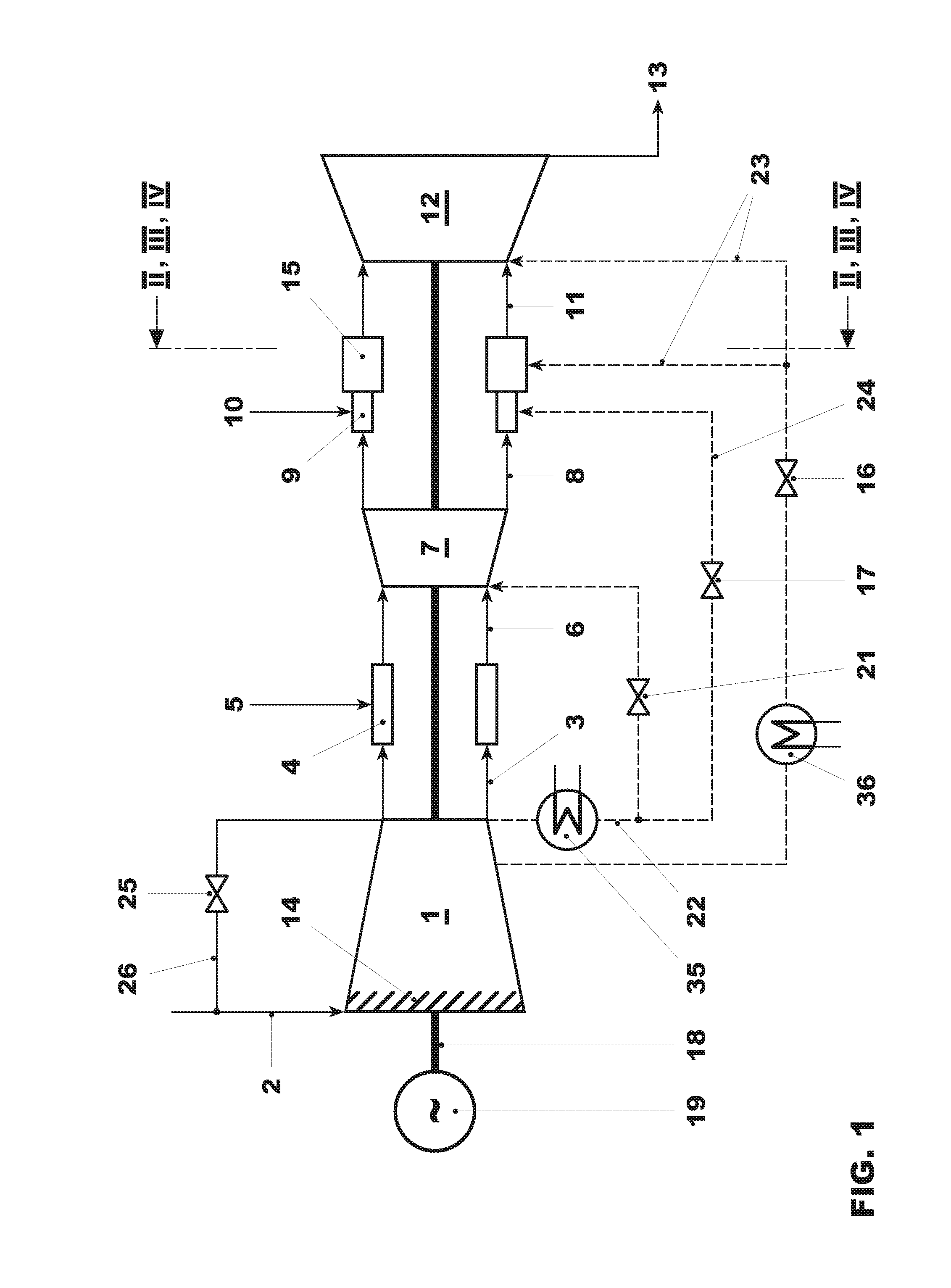

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

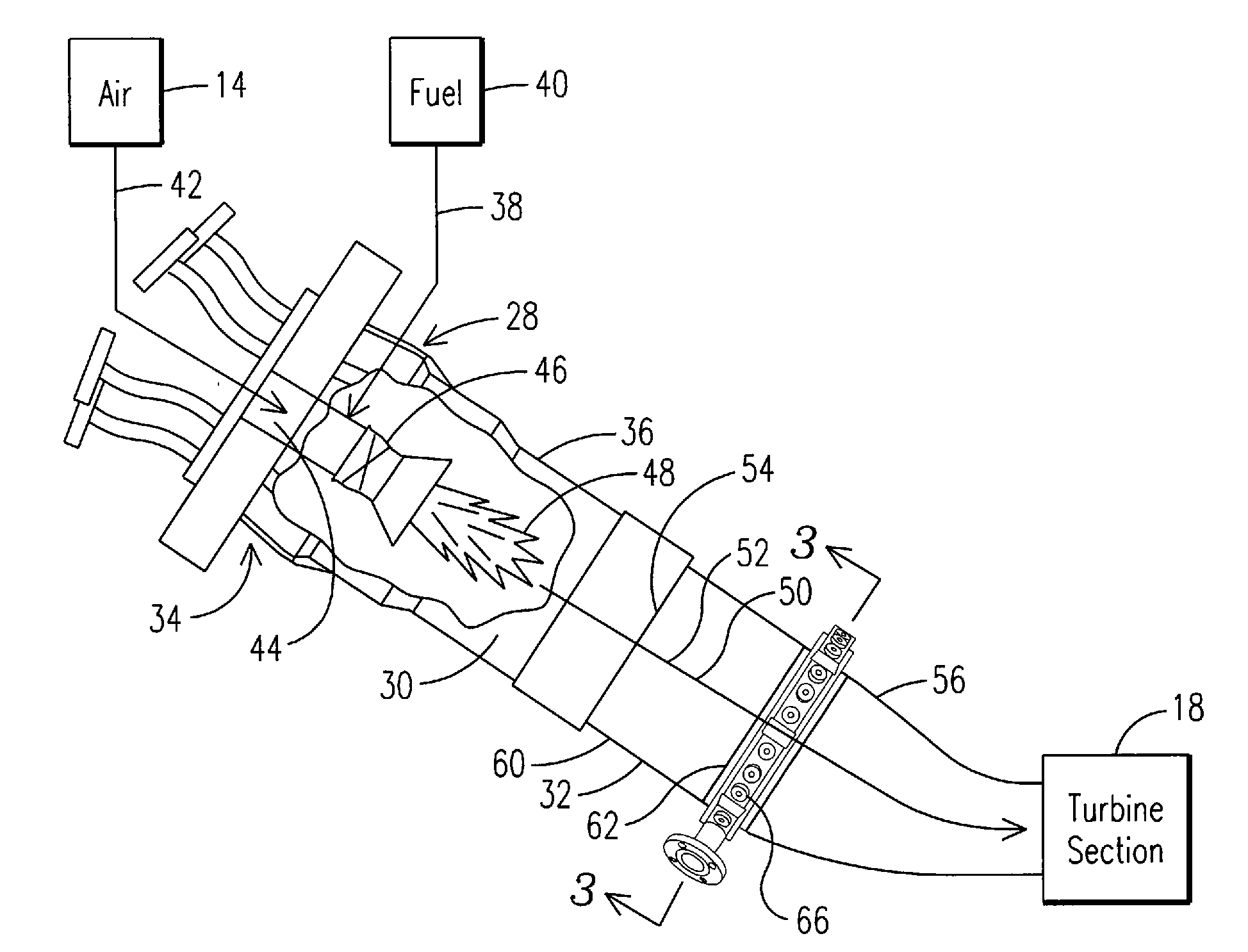

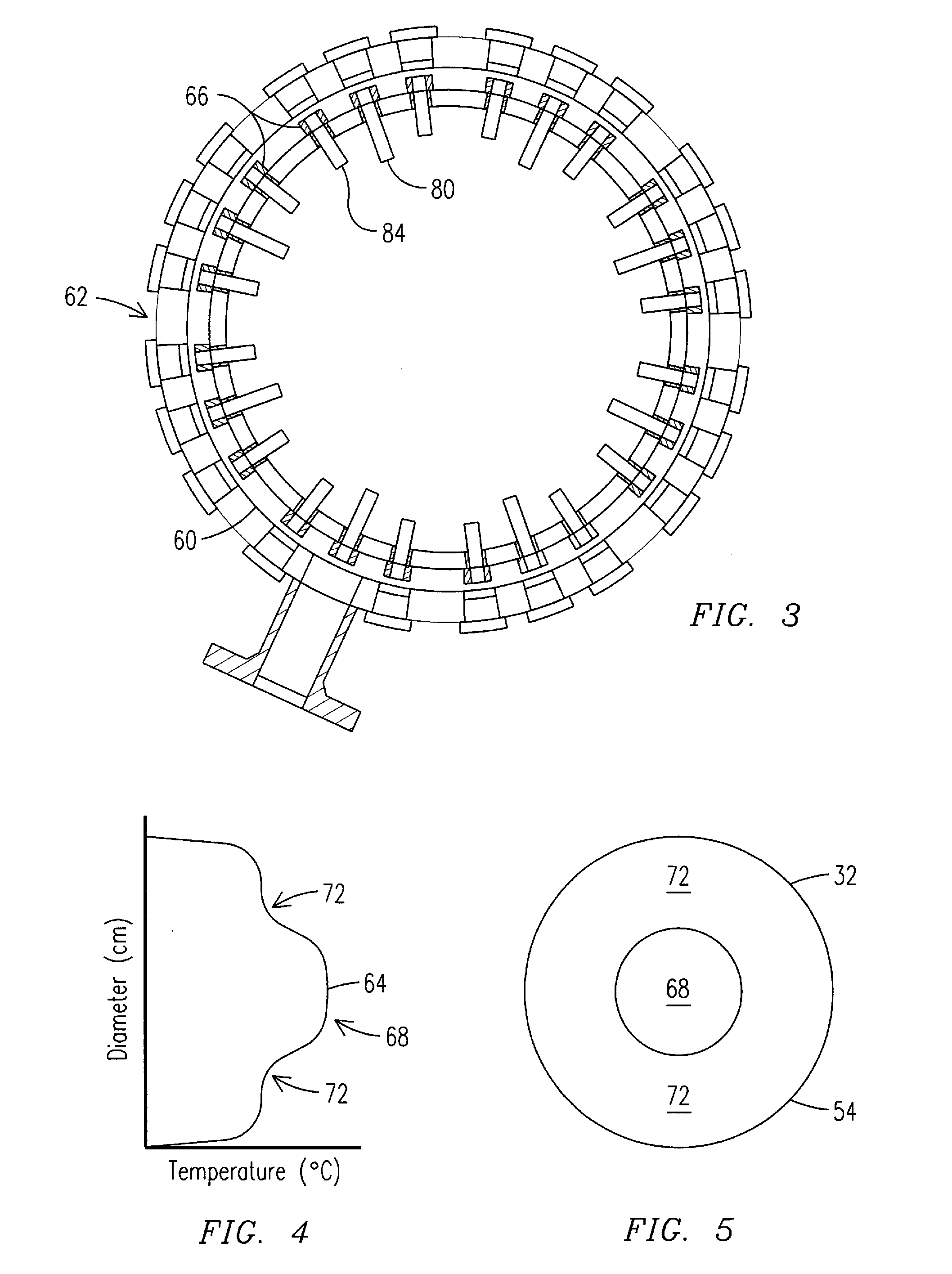

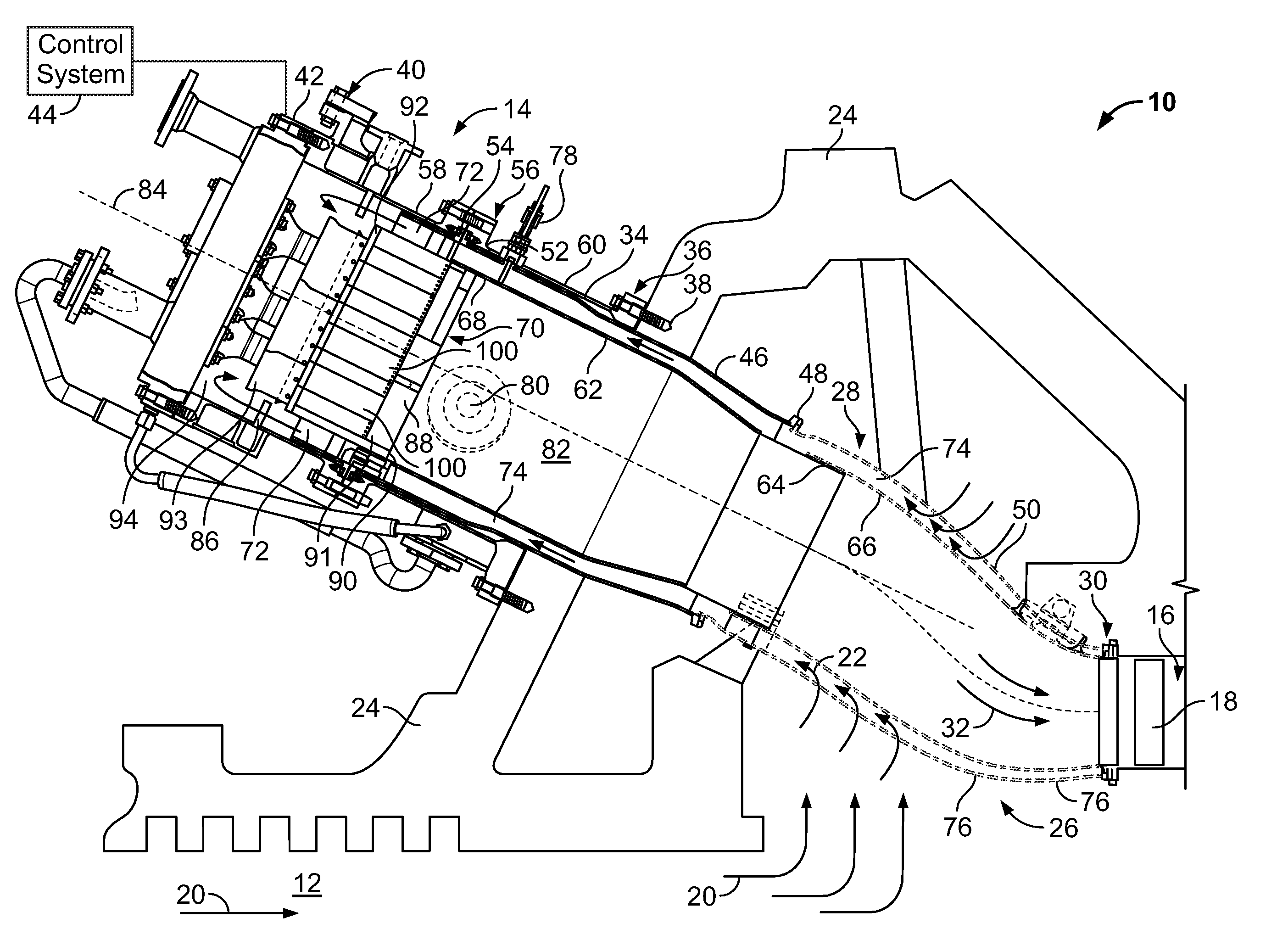

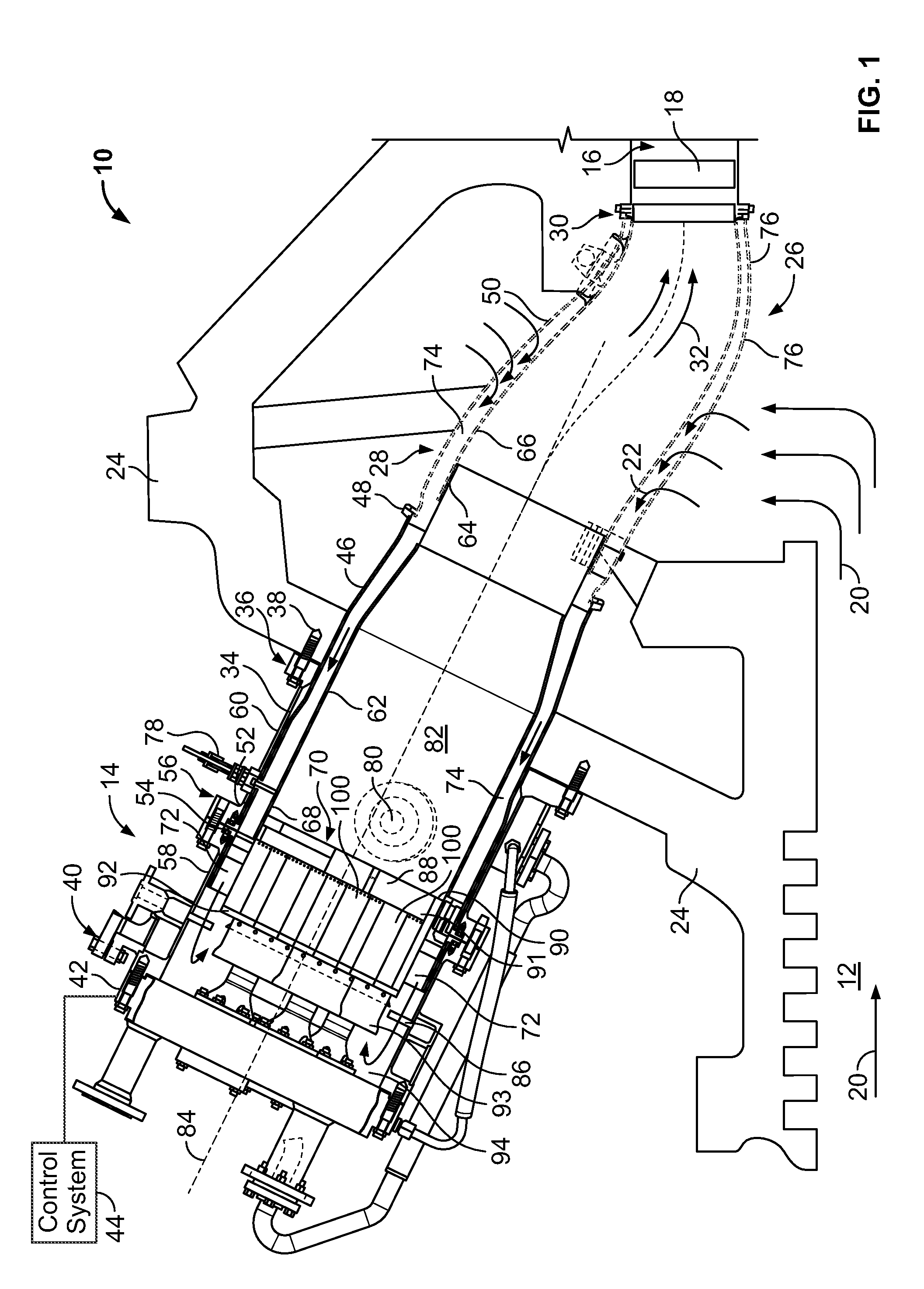

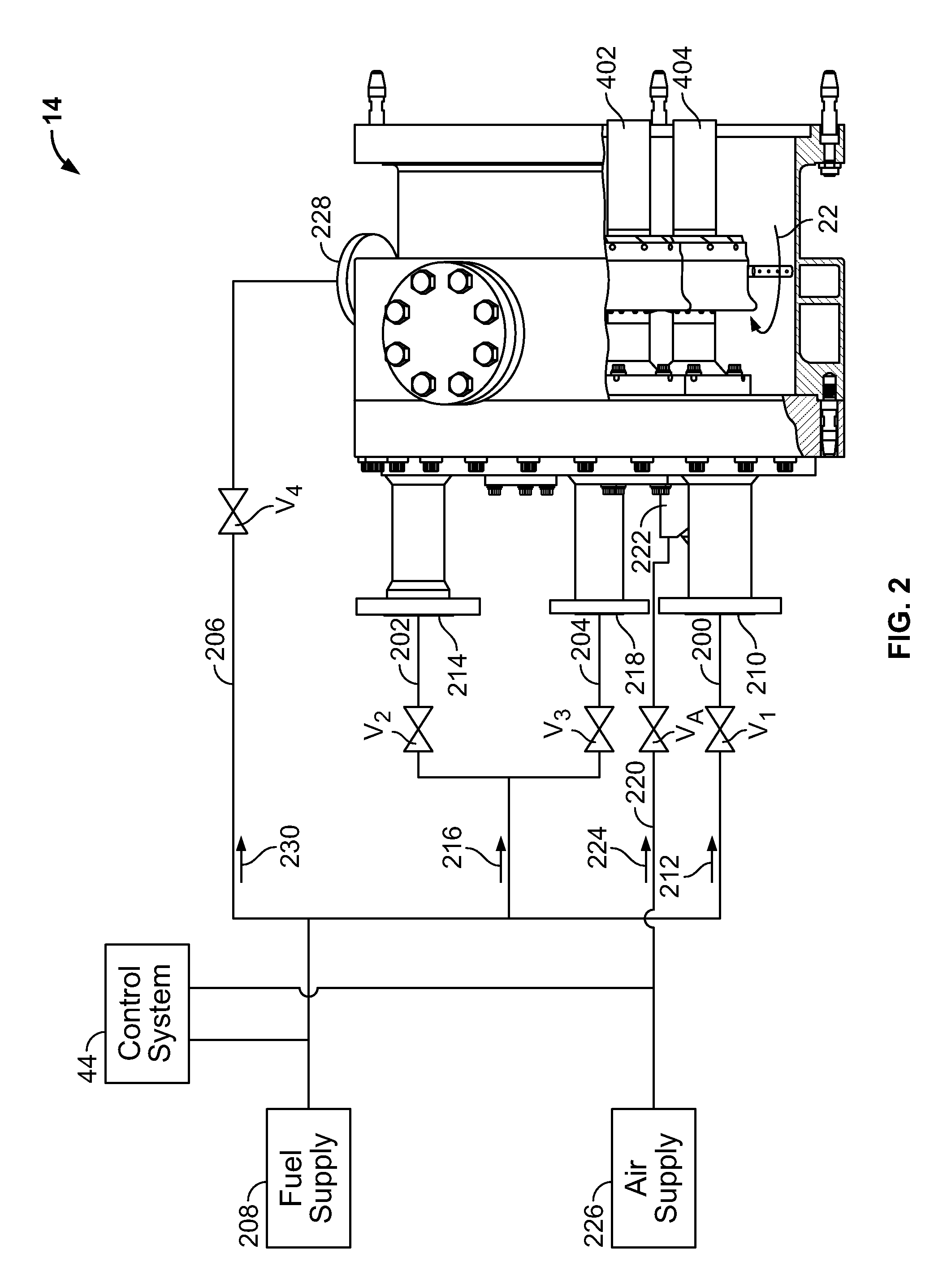

Apparatus and Method for Controlling the Secondary Injection of Fuel

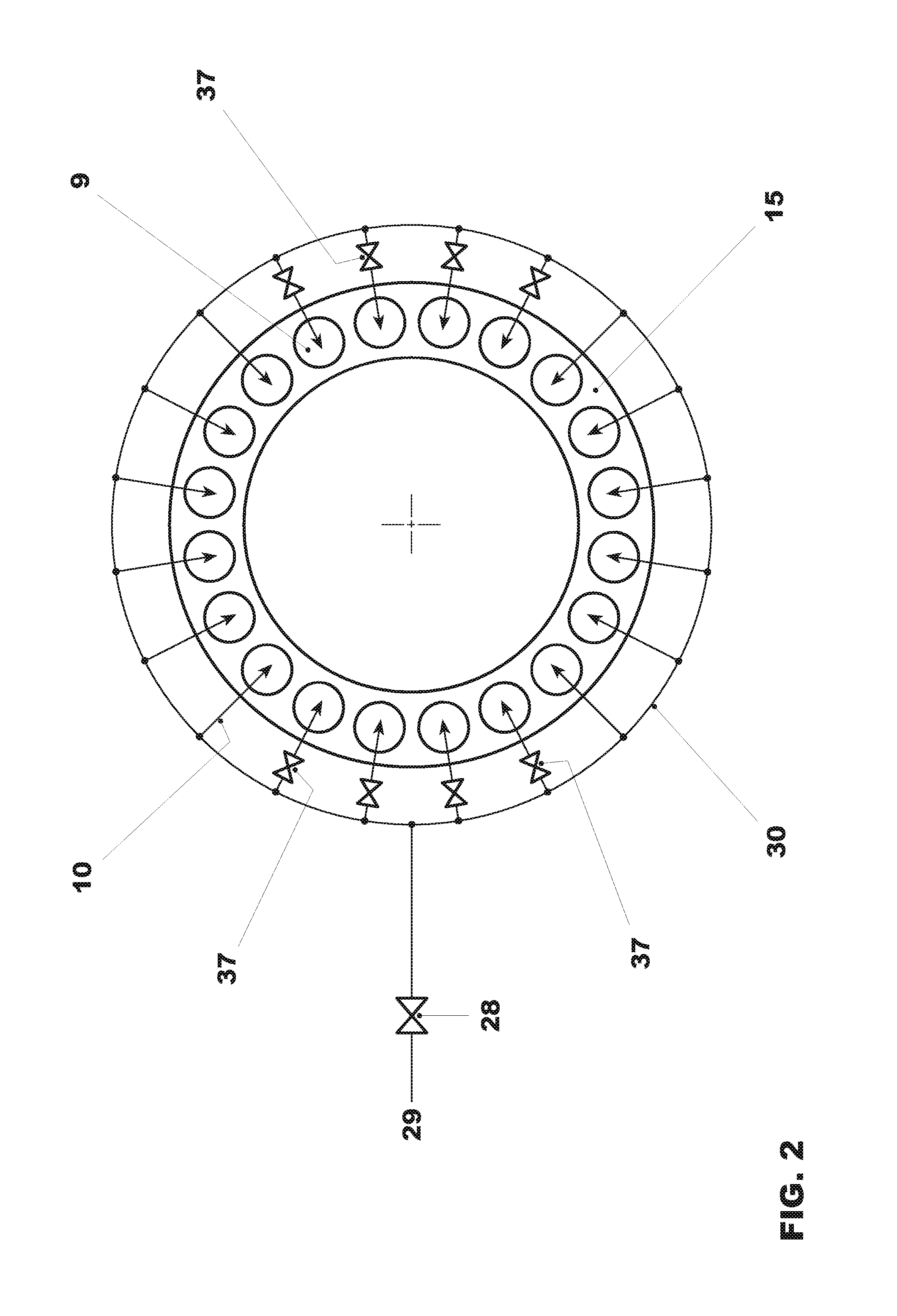

In one embodiment, a combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

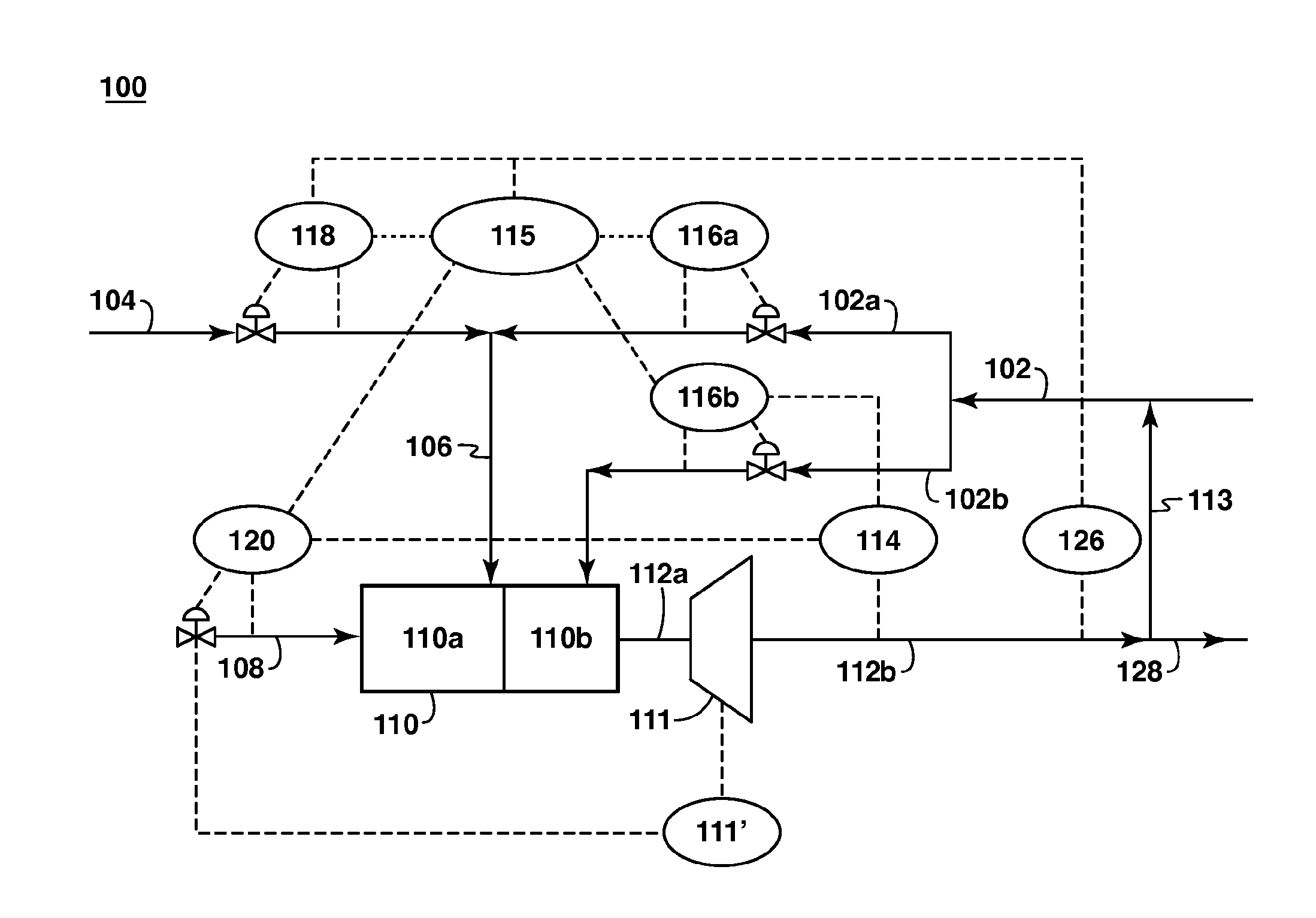

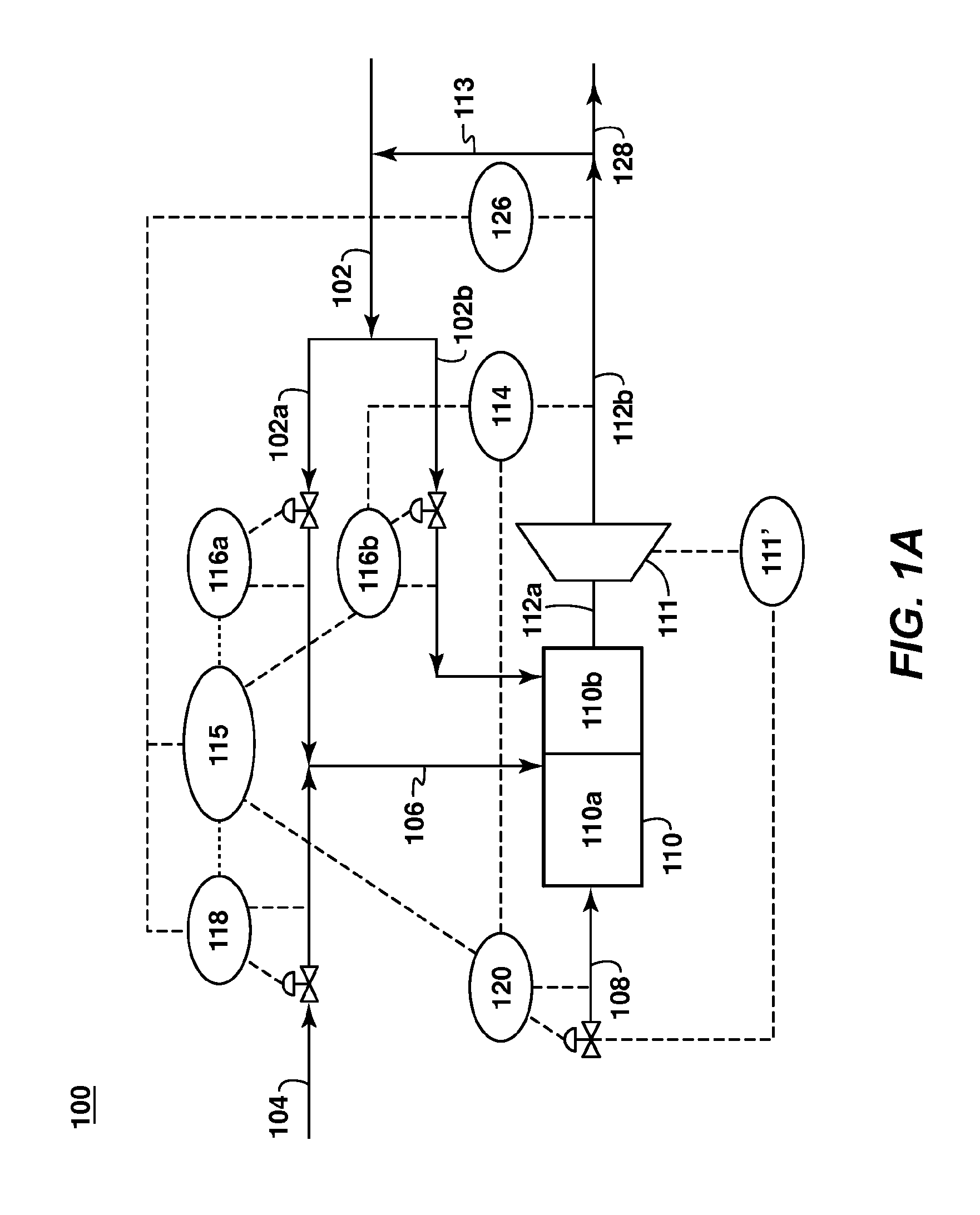

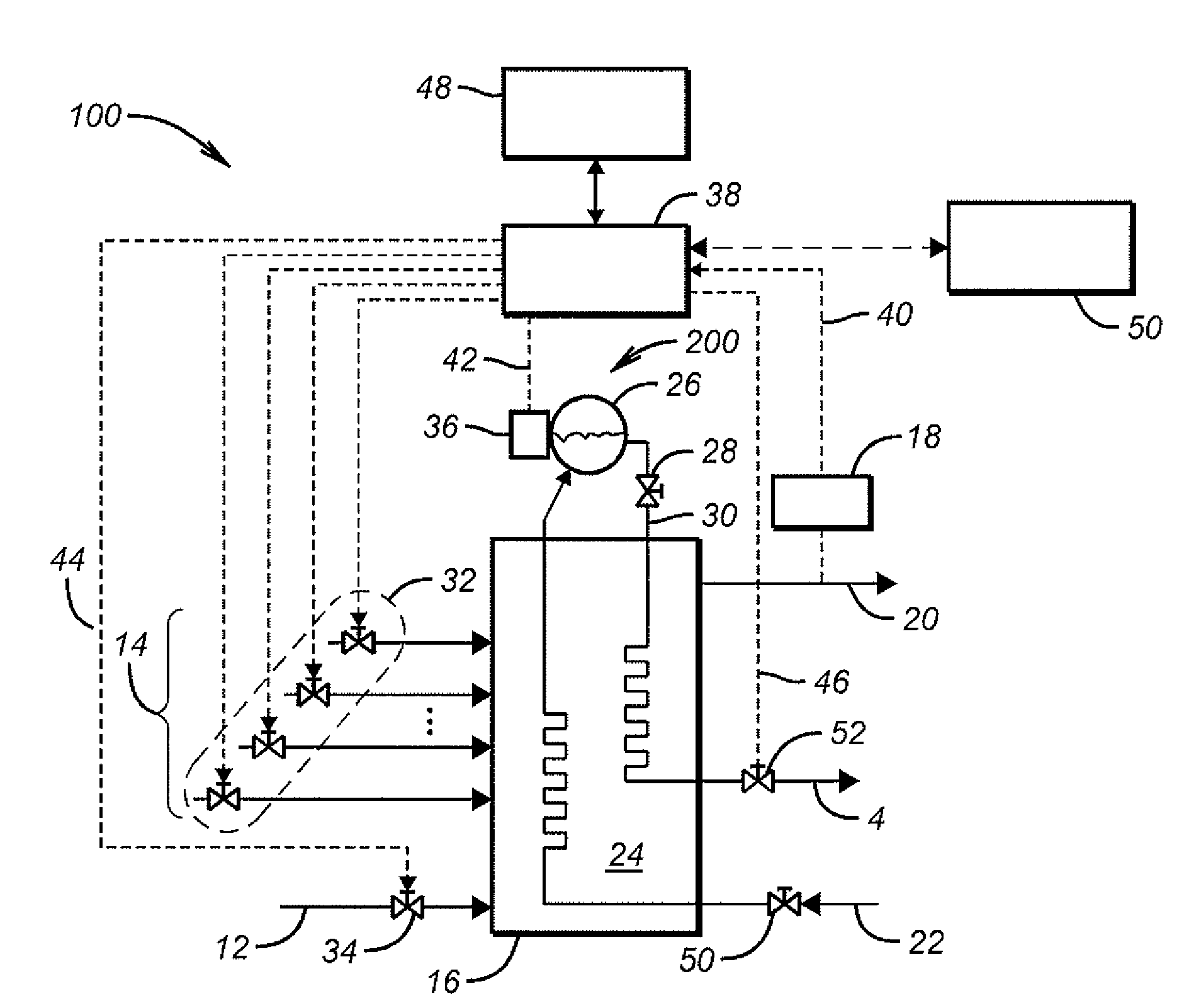

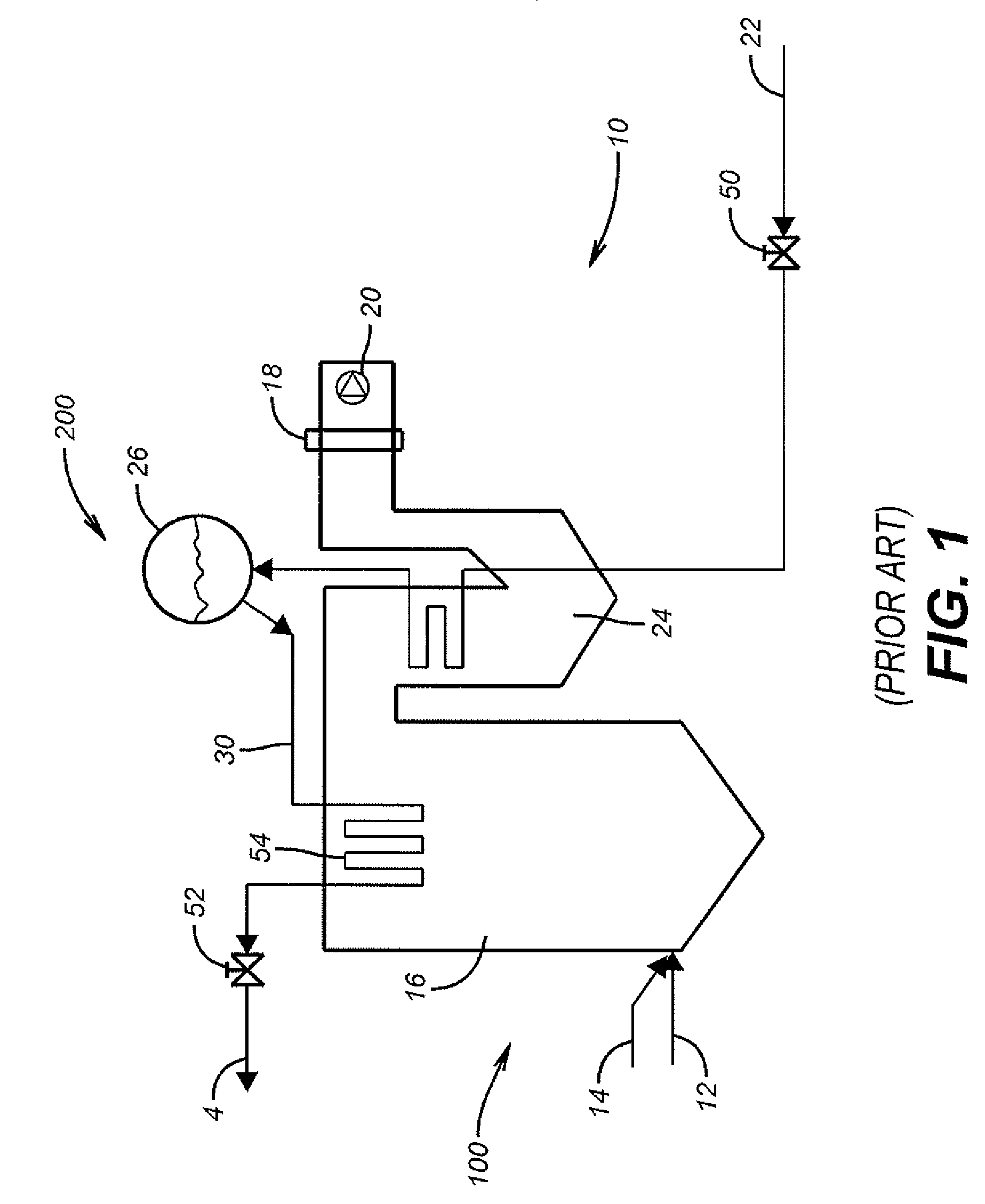

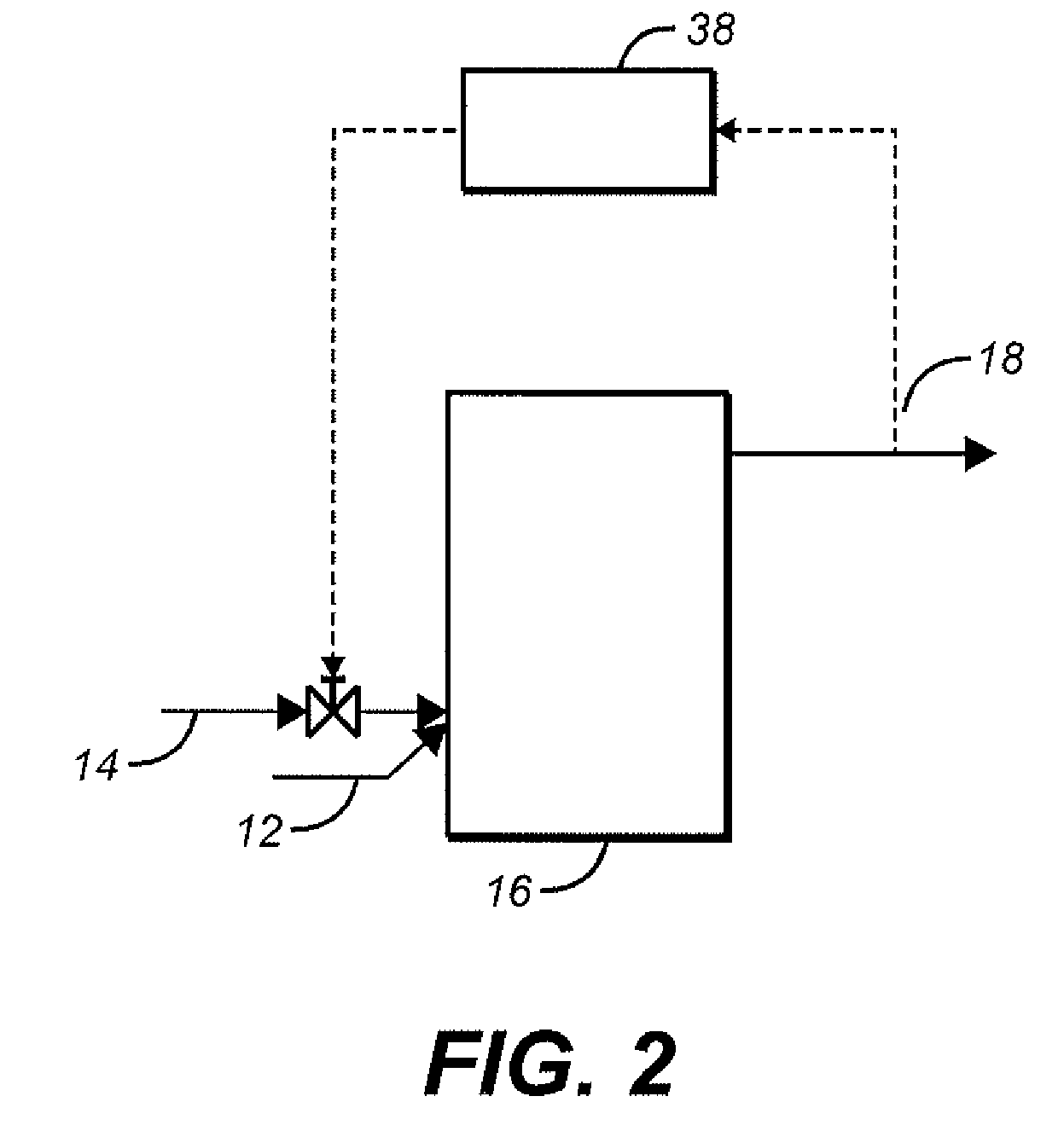

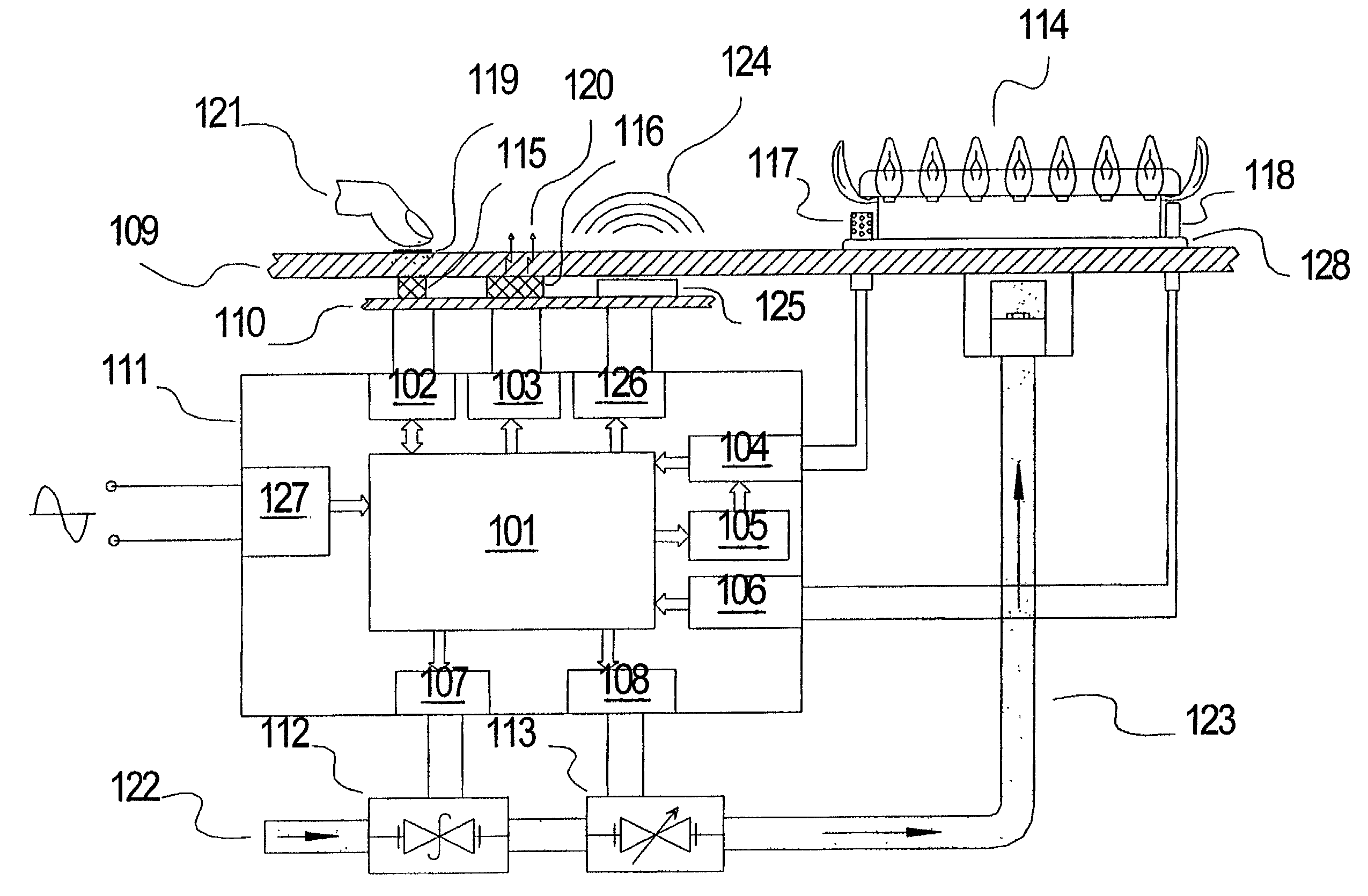

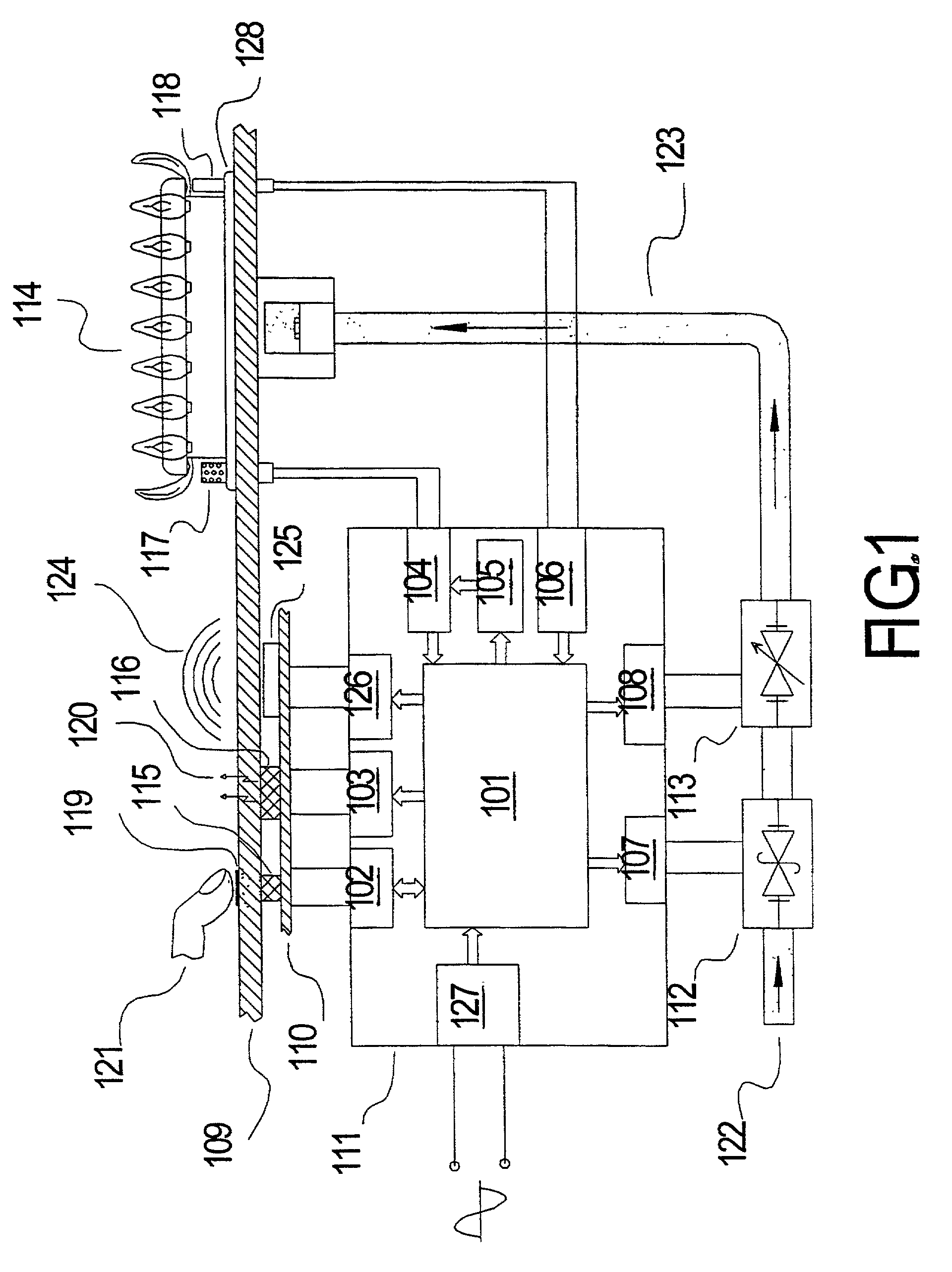

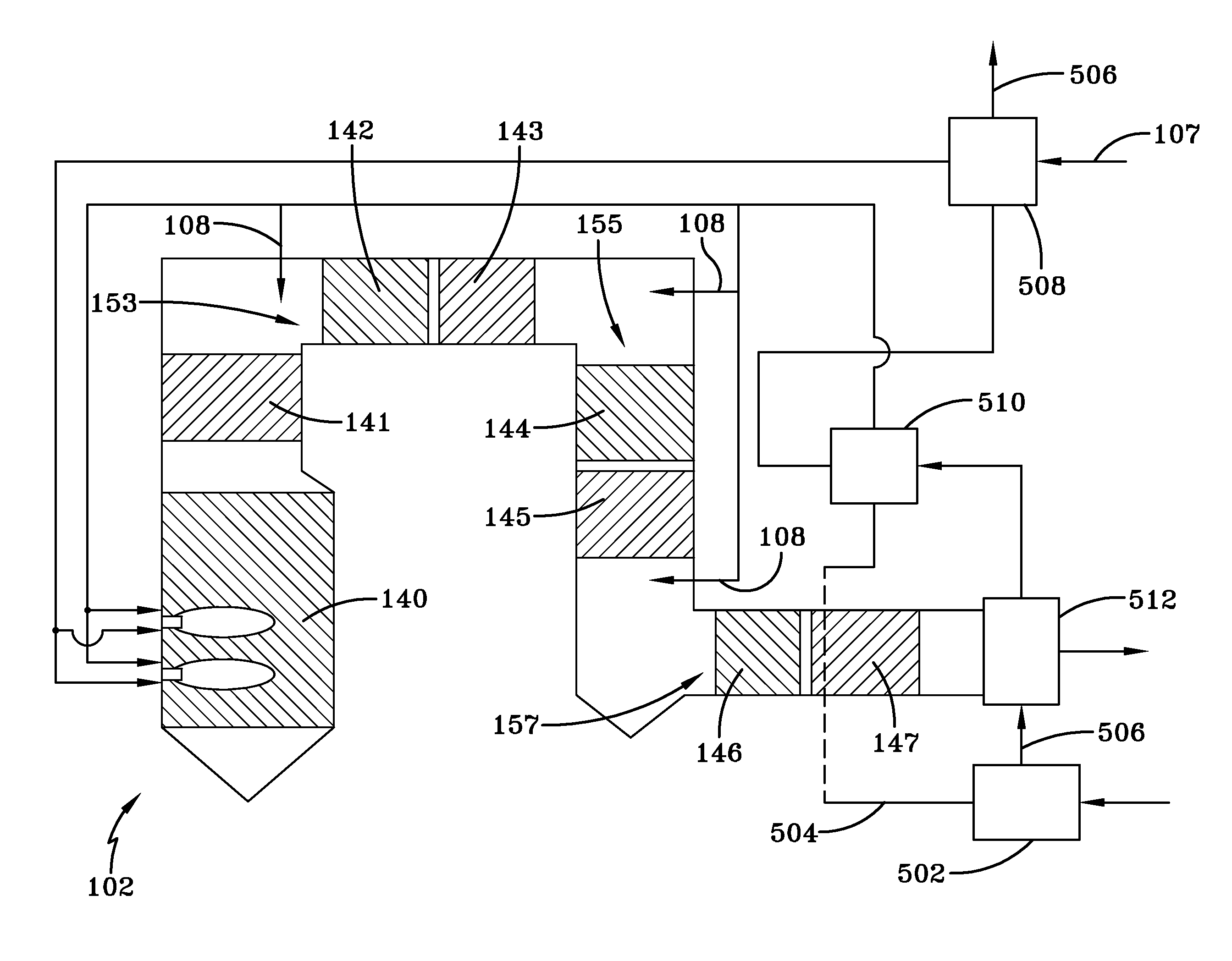

Methods and Systems For Controlling The Products of Combustion

ActiveUS20110300493A1Avoid flame burnoutTemperature regulationGas turbine plantsFluegas recirculationCombustorControl system

The present invention relates to methods and systems for controlling a combustion reaction and the products thereof. One embodiment includes a combustion control system having an oxygenation stream substantially comprising oxygen and CO2 and having an oxygen to CO2 ratio, then mixing the oxygenation stream with a combustion fuel stream and combusting in a combustor to generate a combustion products stream having a temperature and a composition detected by a temperature sensor and an oxygen analyzer, respectively, the data from which are used to control the flow and composition of the oxygenation and combustion fuel streams. The system may also include a gas turbine with an expander and having a load and a load controller in a feedback arrangement.

Owner:EXXONMOBIL UPSTREAM RES CO

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

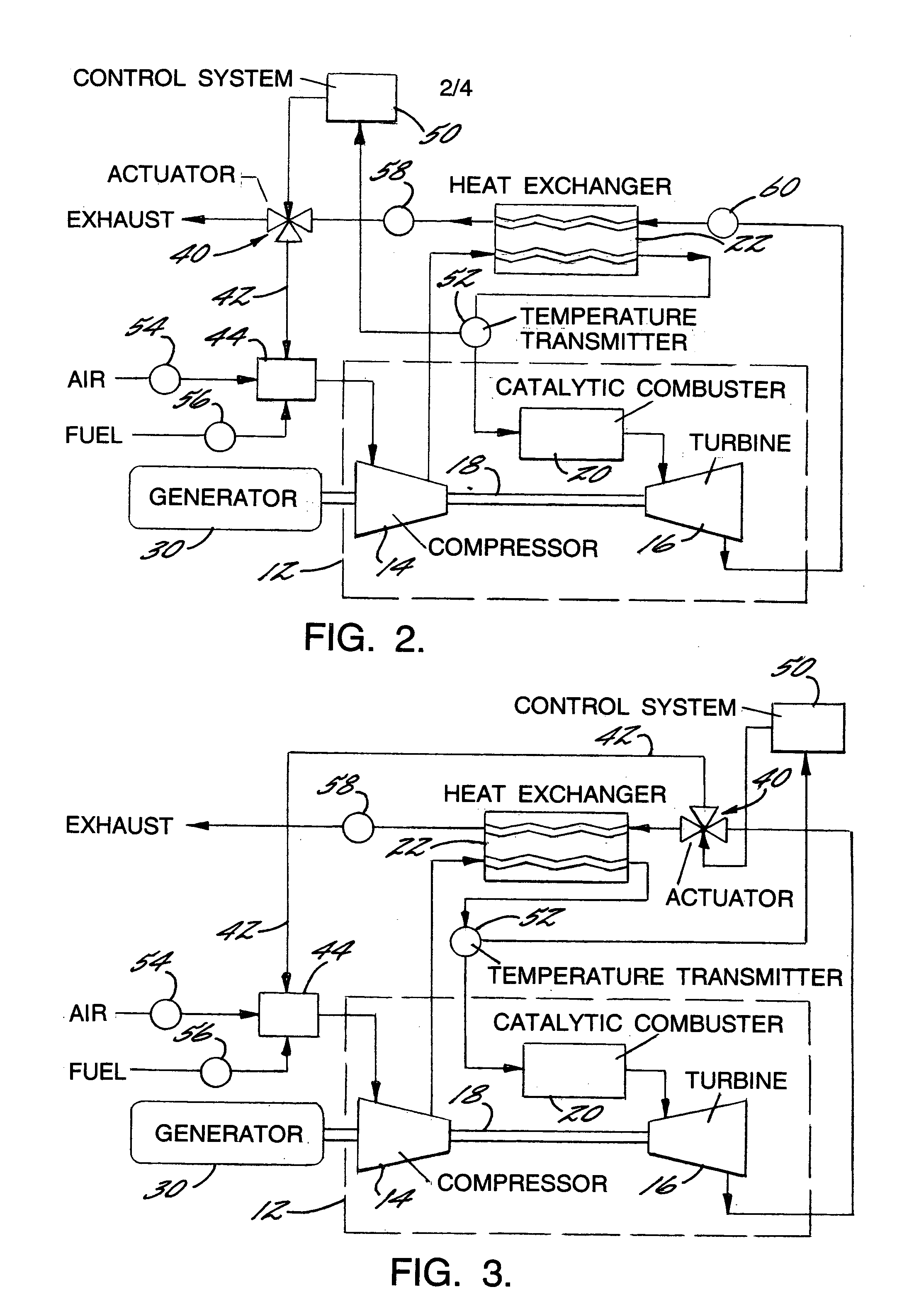

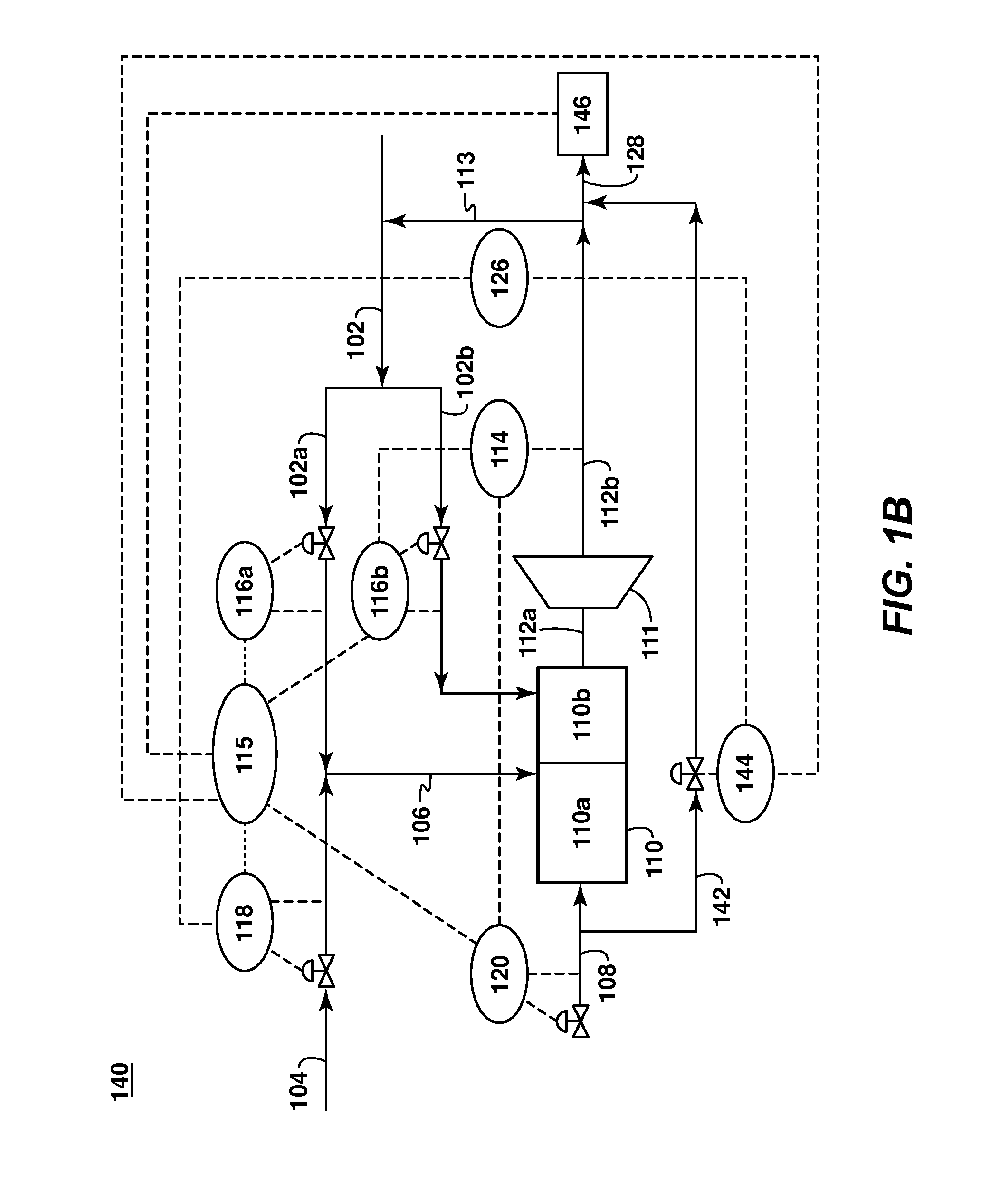

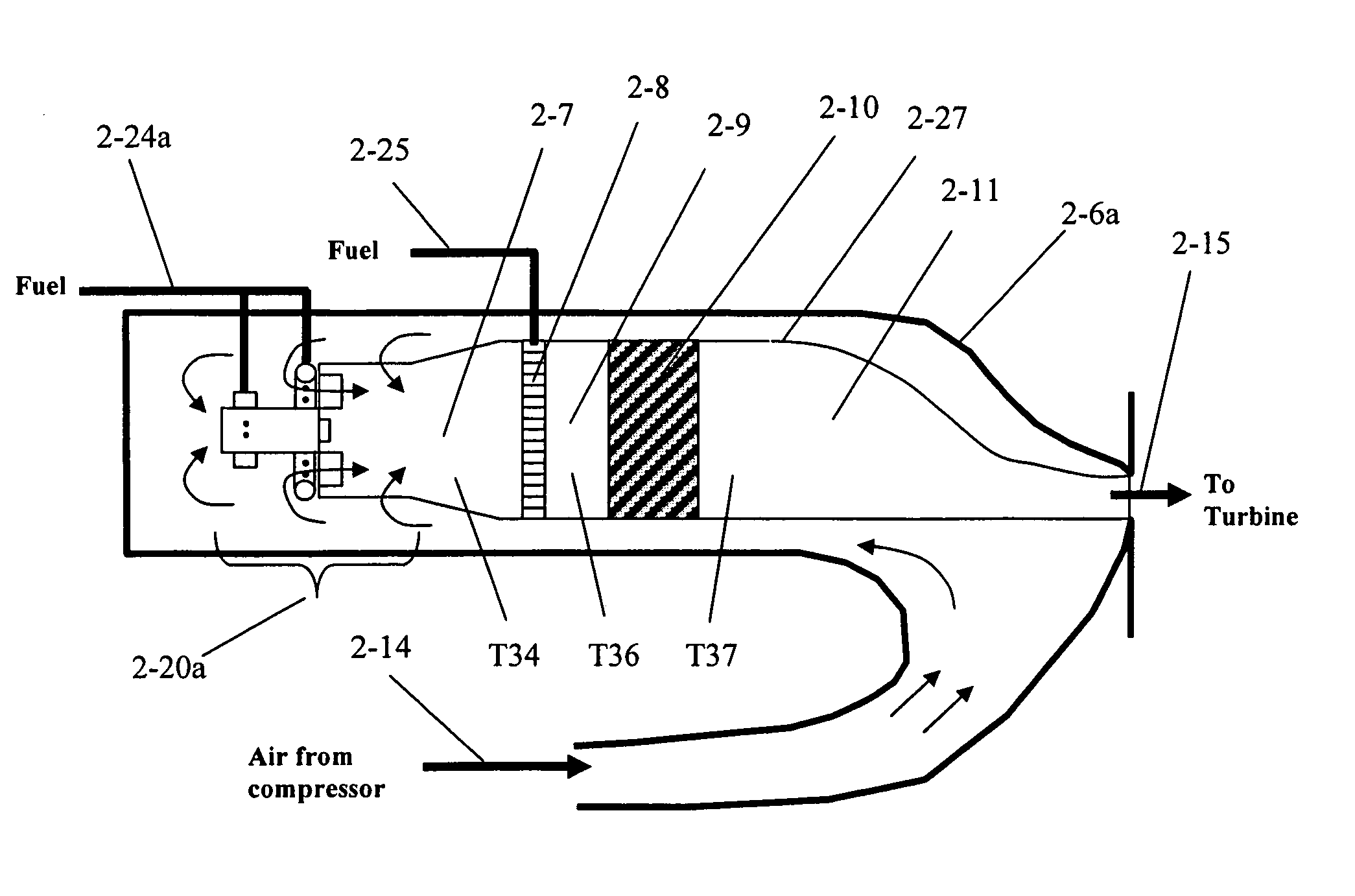

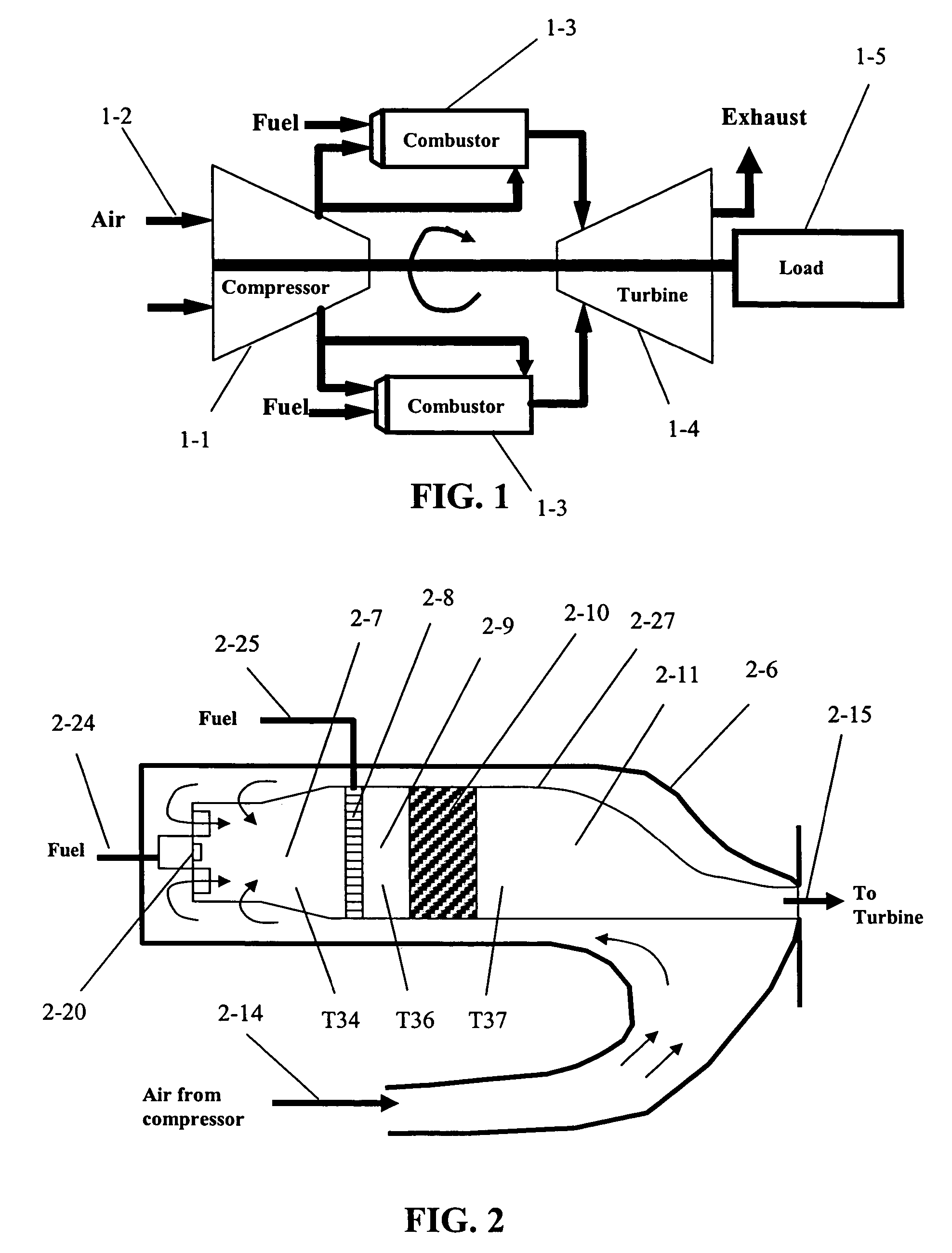

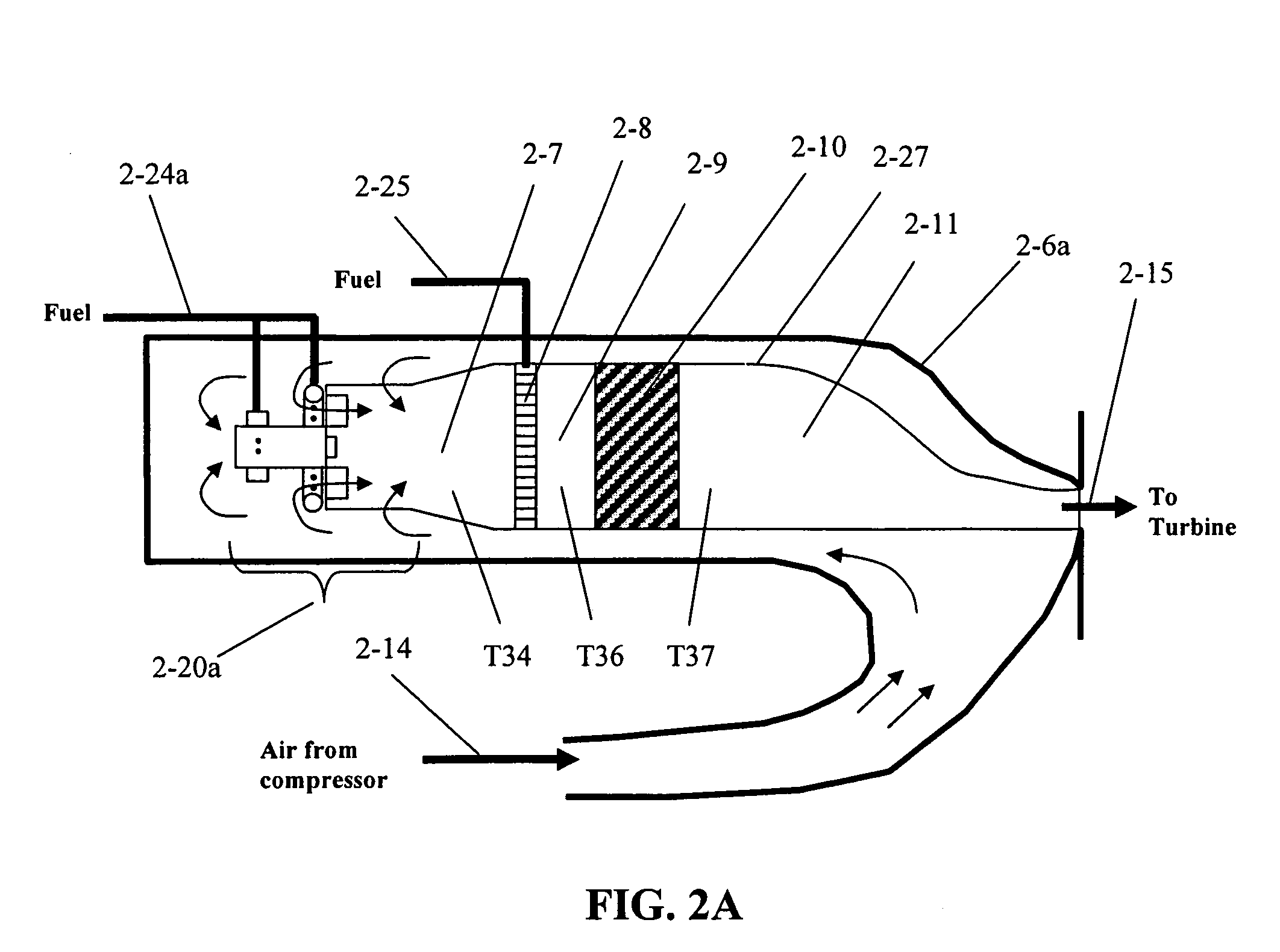

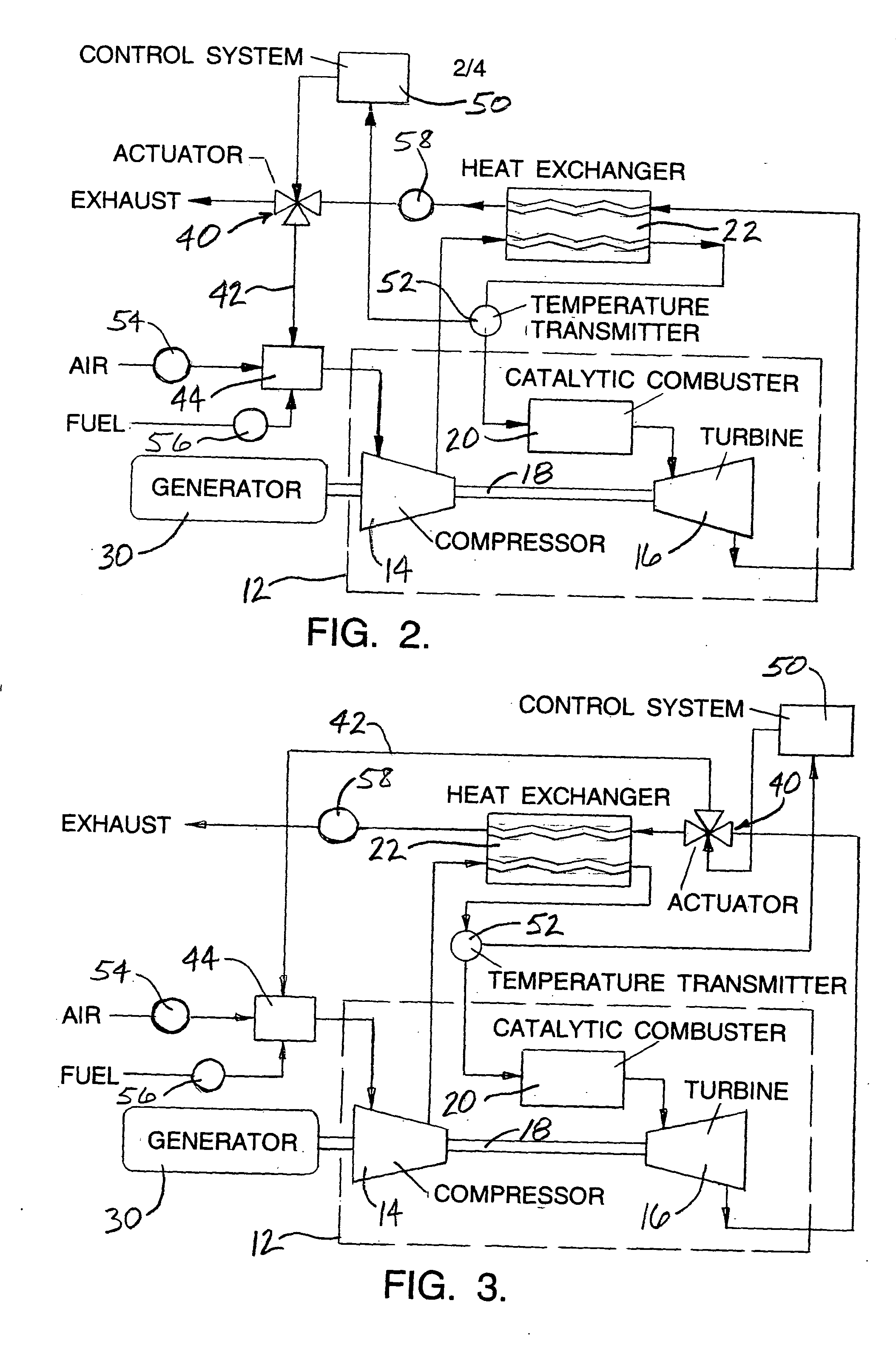

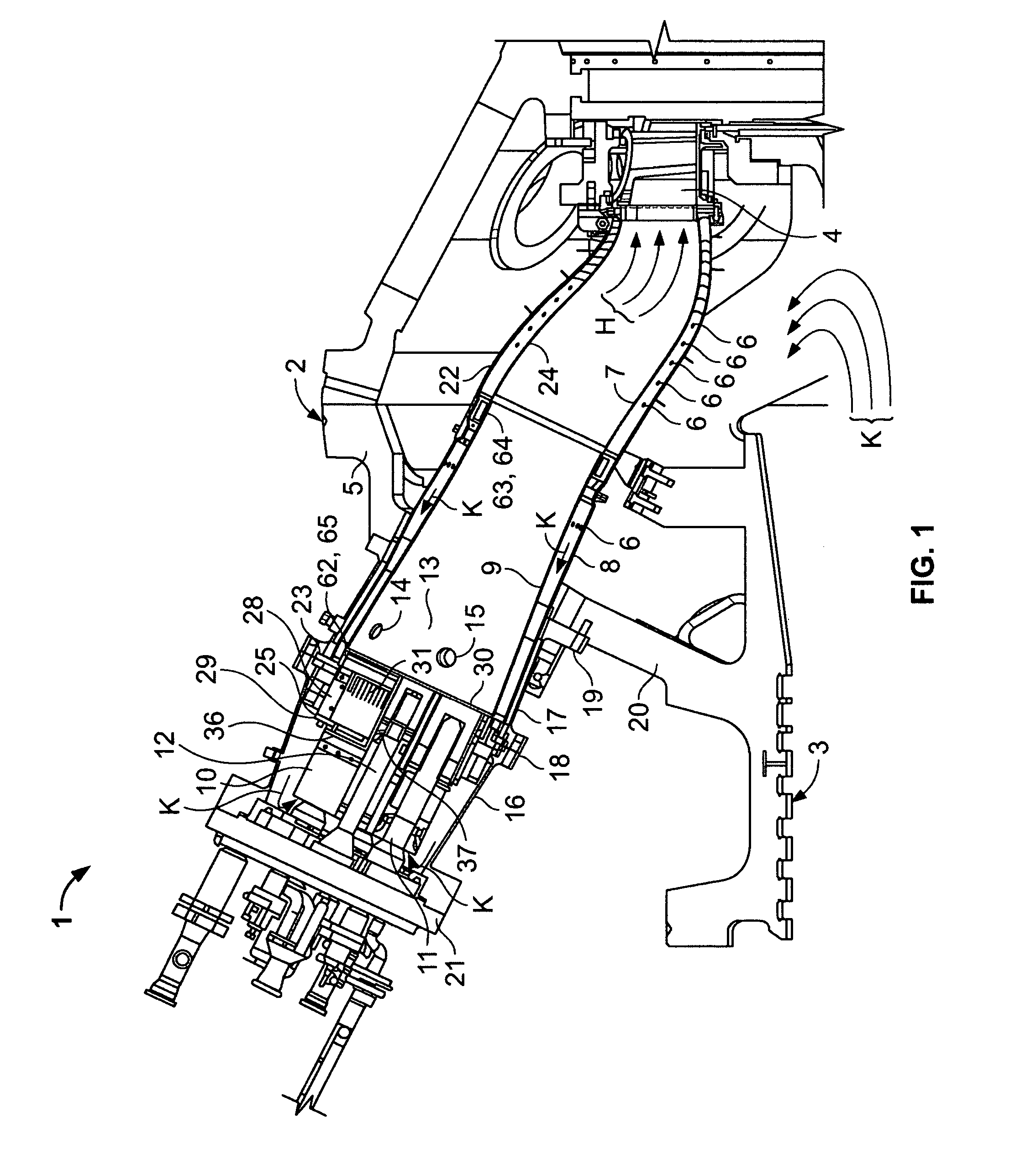

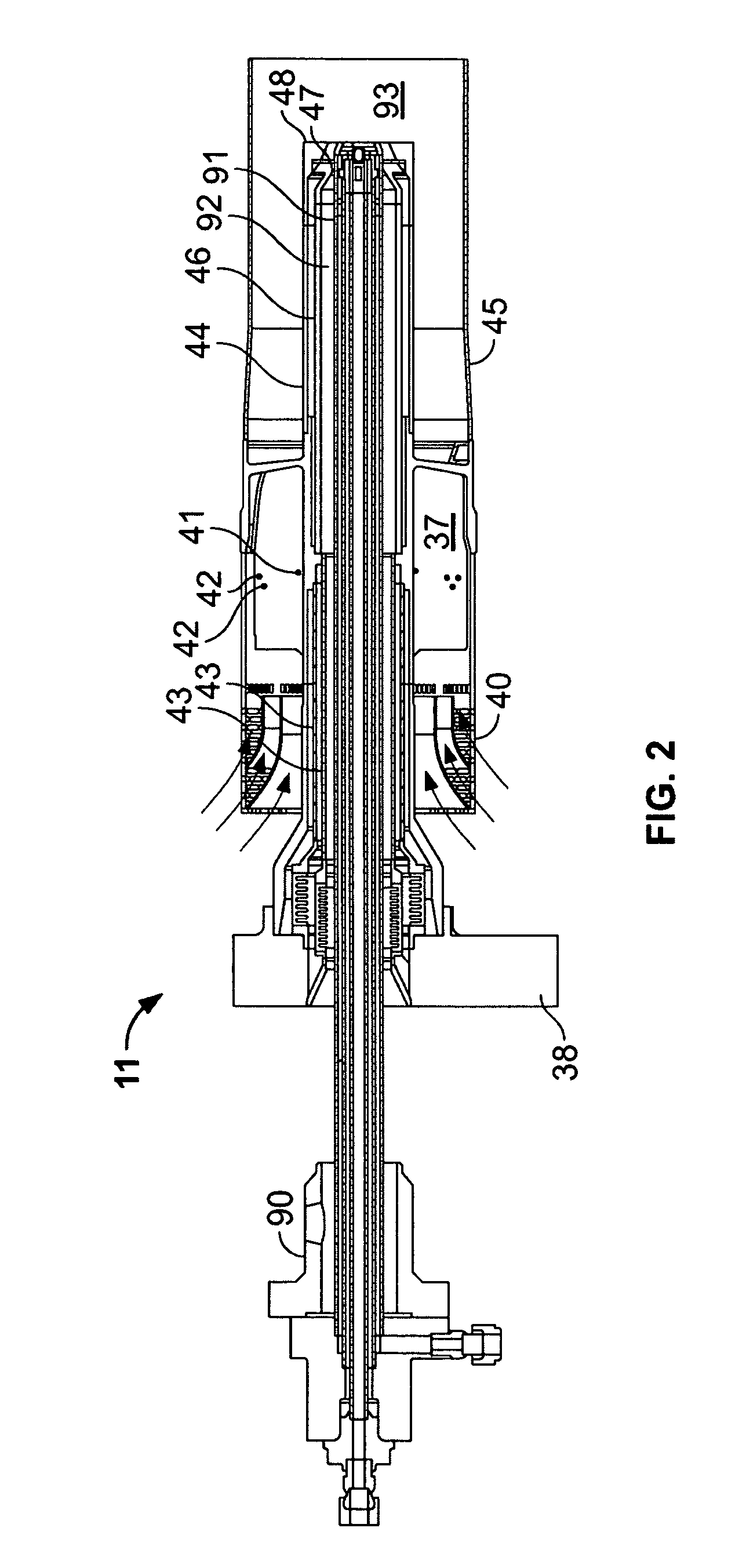

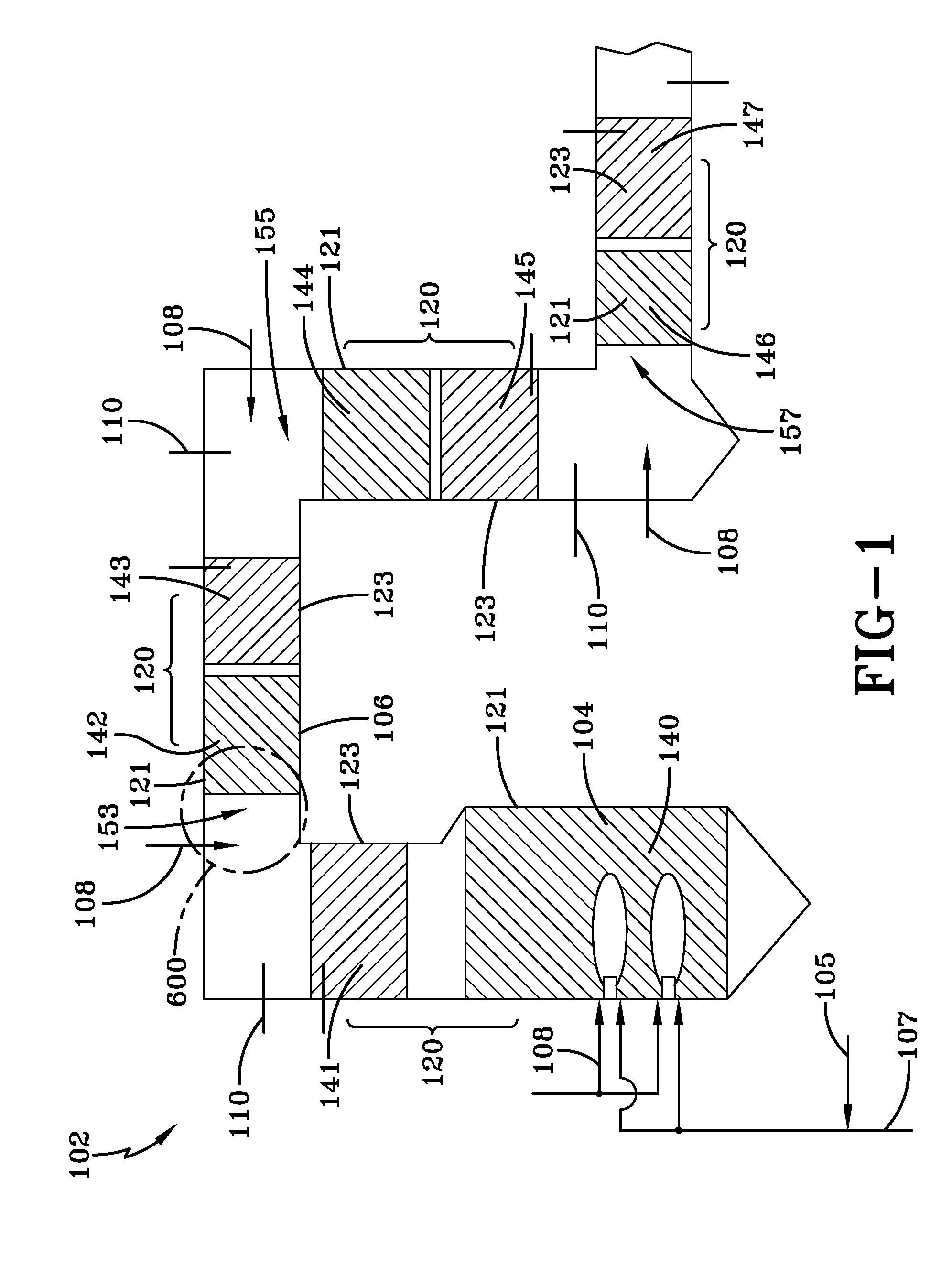

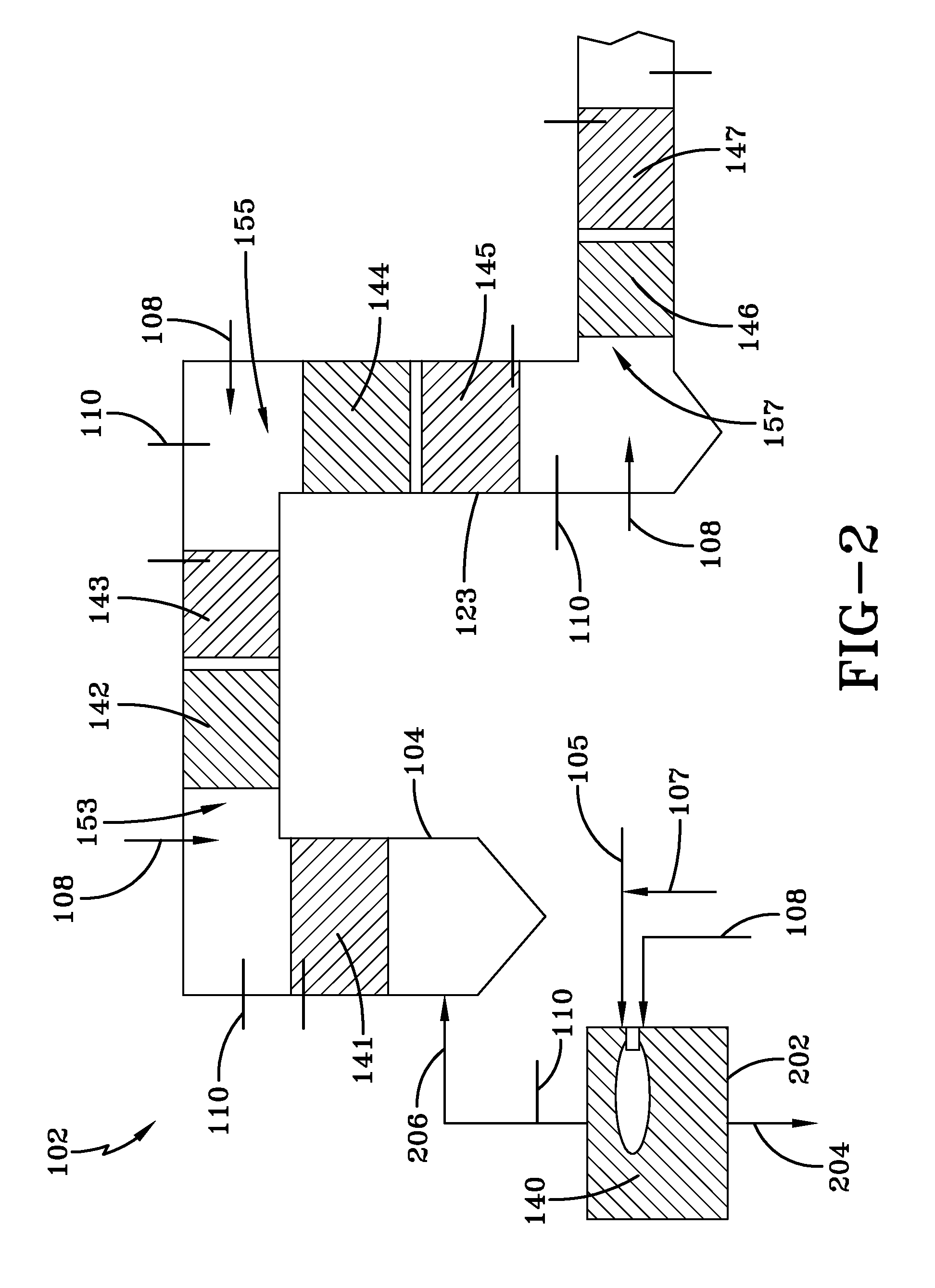

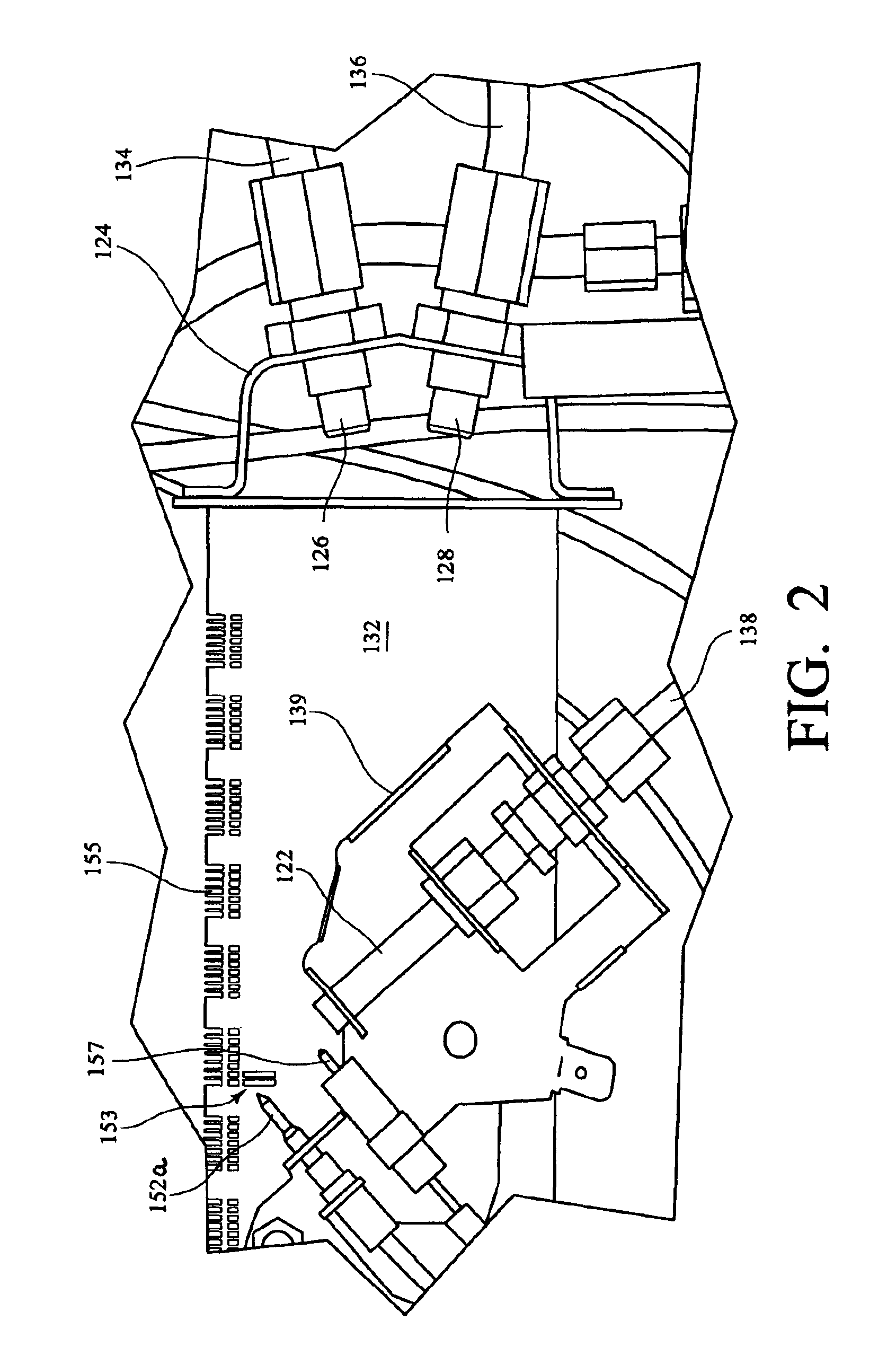

Dynamic control system and method for multi-combustor catalytic gas turbine engine

InactiveUS7152409B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemControl system

According to one aspect, a method of controlling a multi-combustor catalytic combustion system is provided for determining a characteristic of a fuel-air mixture downstream of a preburner associated with a catalytic combustor and adjusting the fuel flow to the preburner based on the characteristic. The characteristic may include, for example, a measurement of the preburner or catalyst outlet temperature or a determination of the position of the homogeneous combustion wave in the burnout zone of the combustor.

Owner:KAWASAKI HEAVY IND LTD

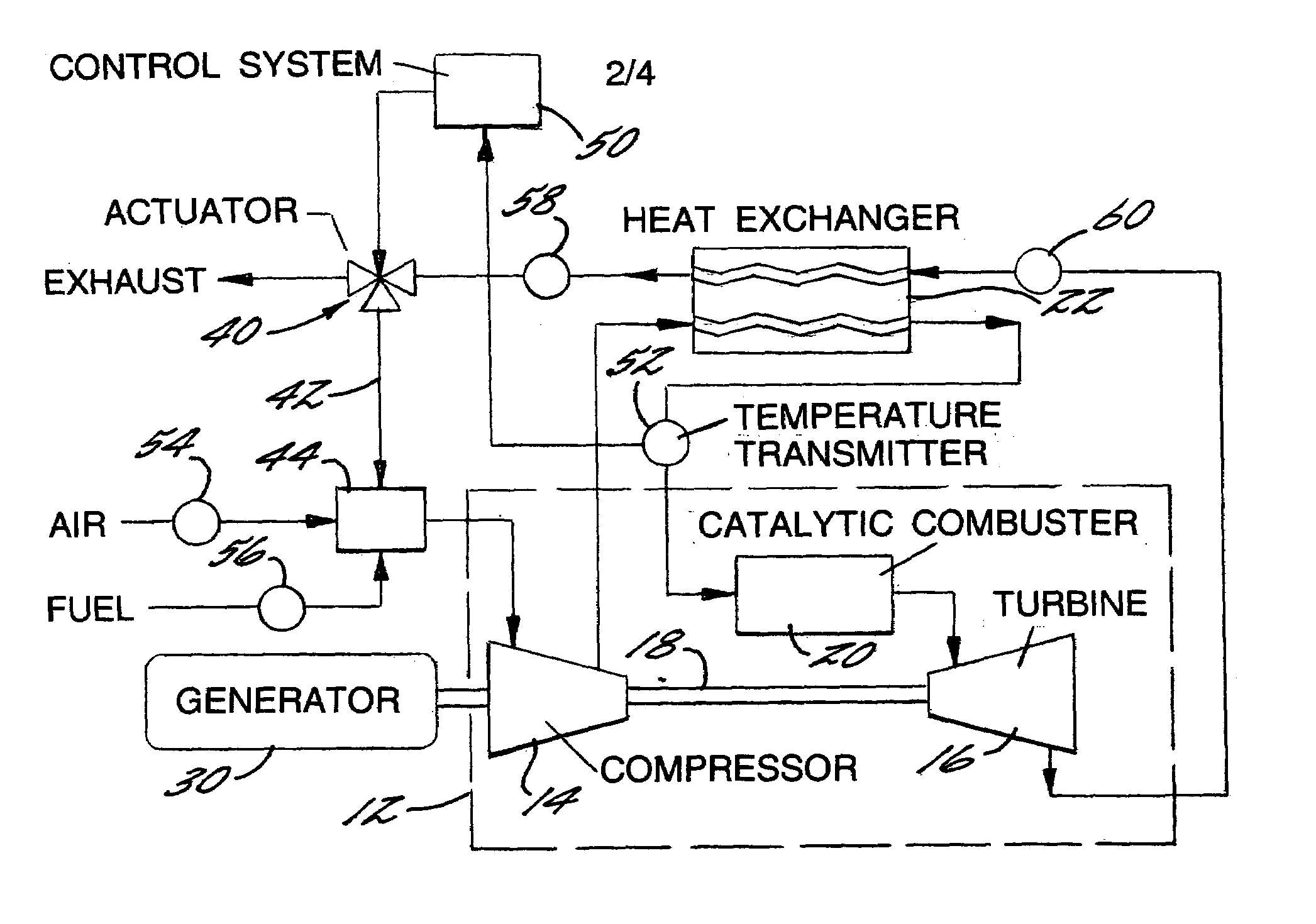

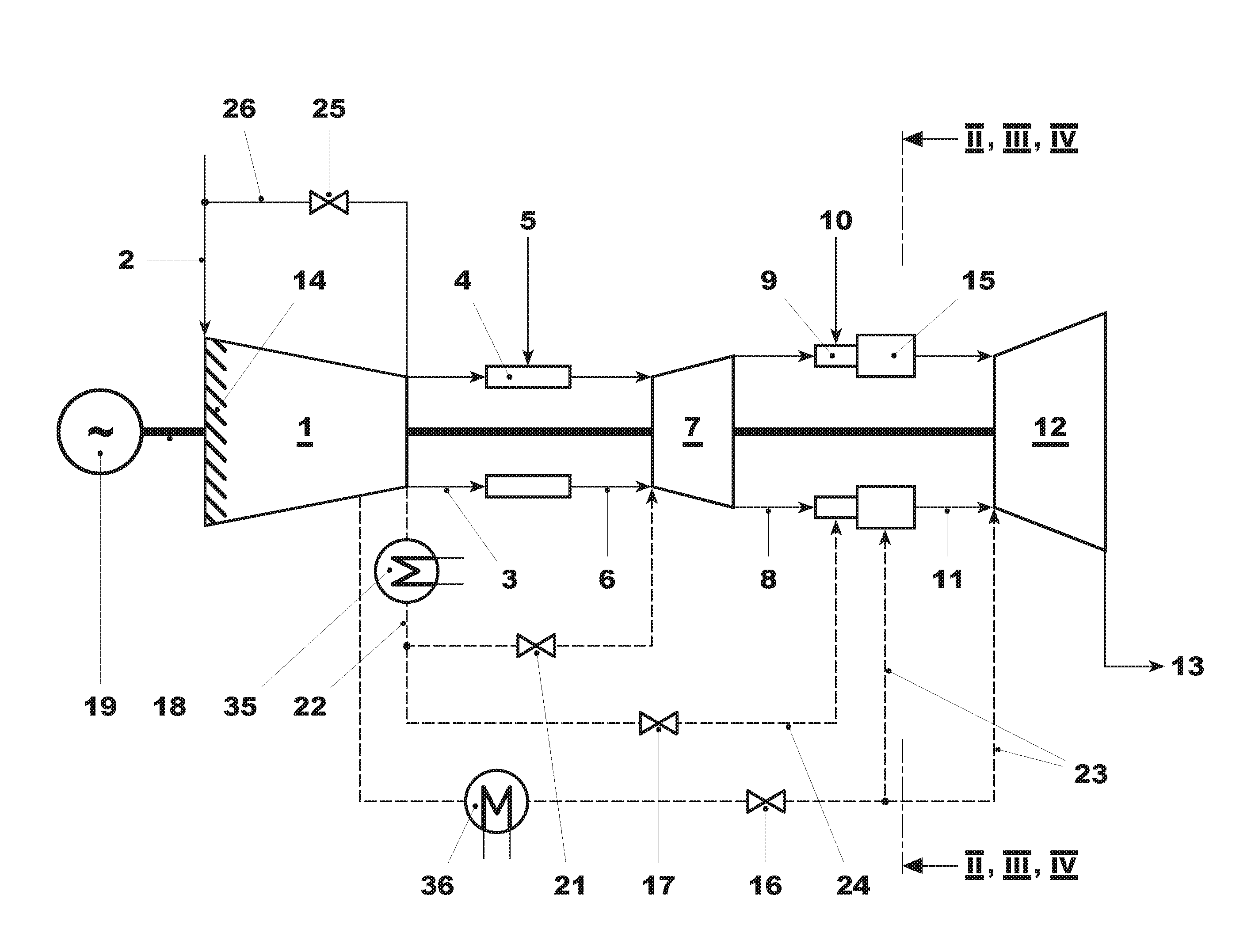

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

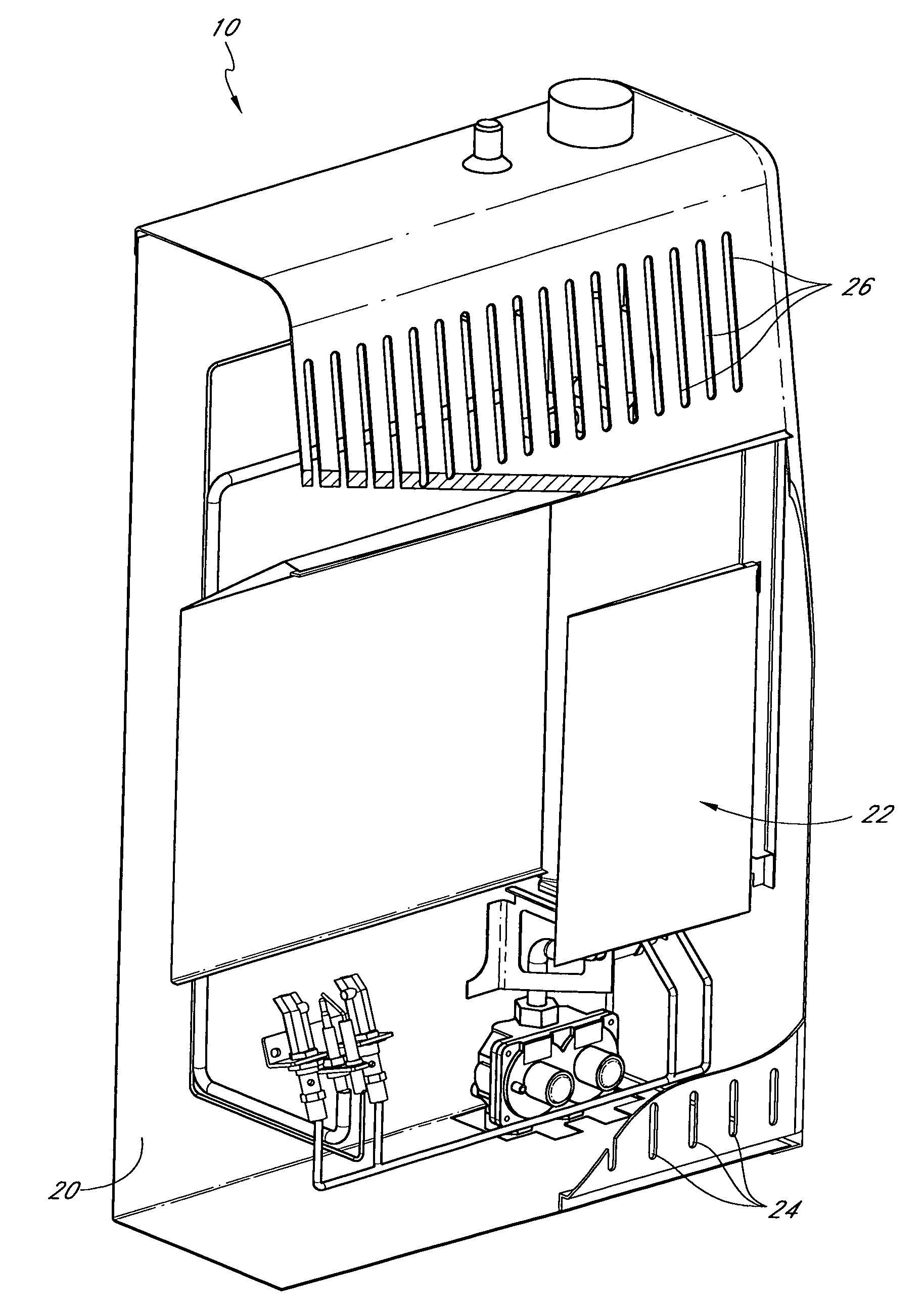

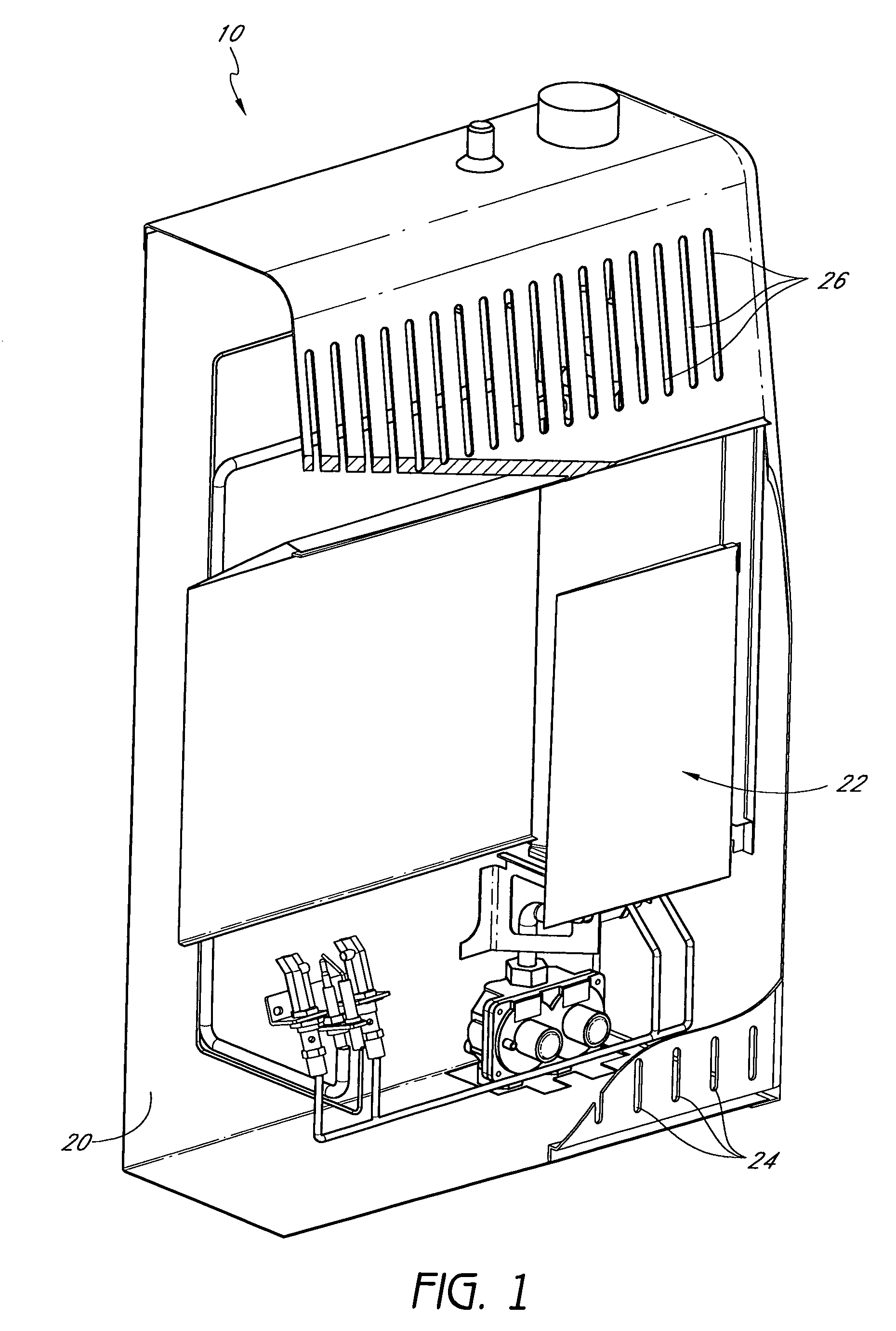

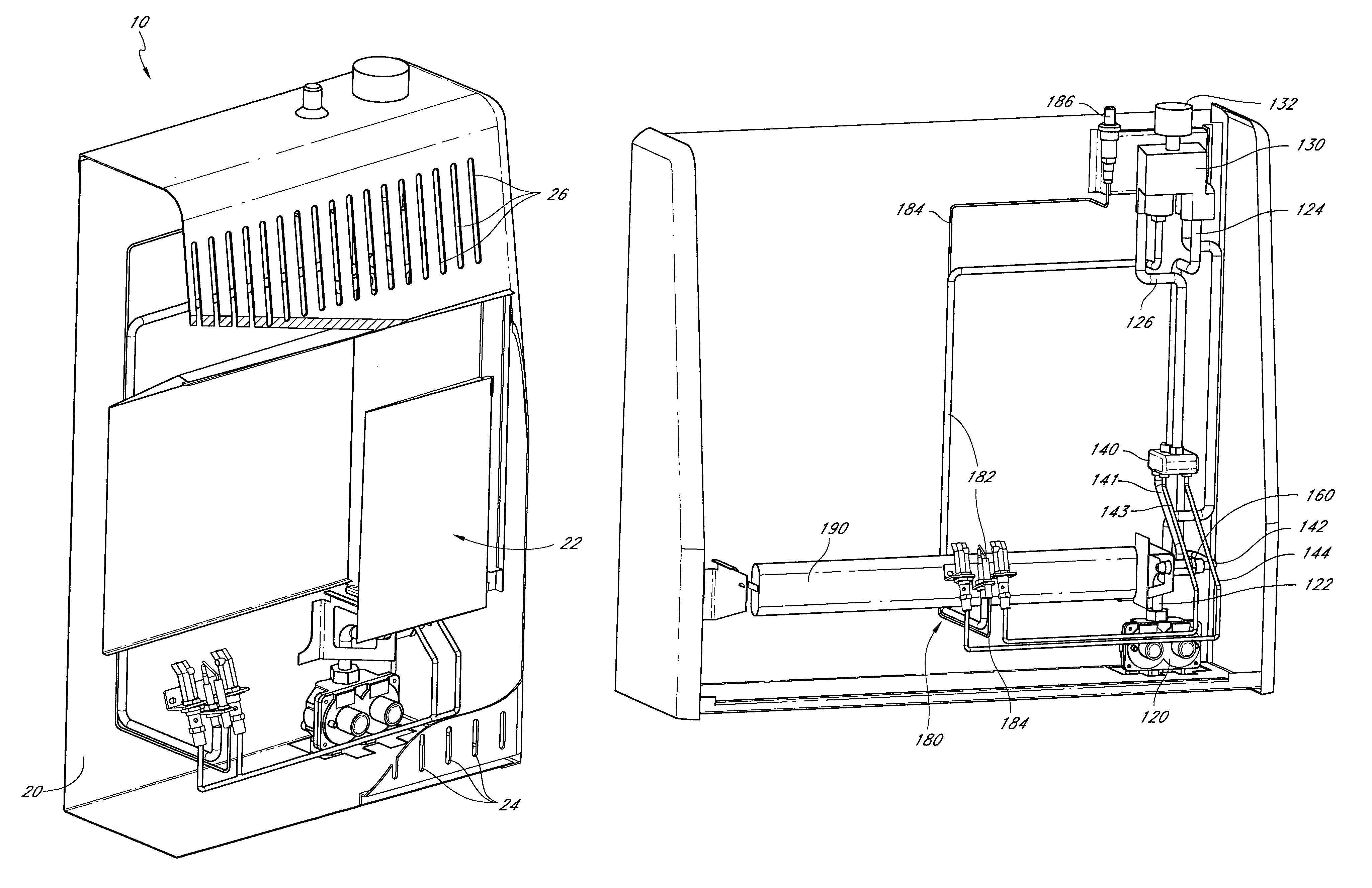

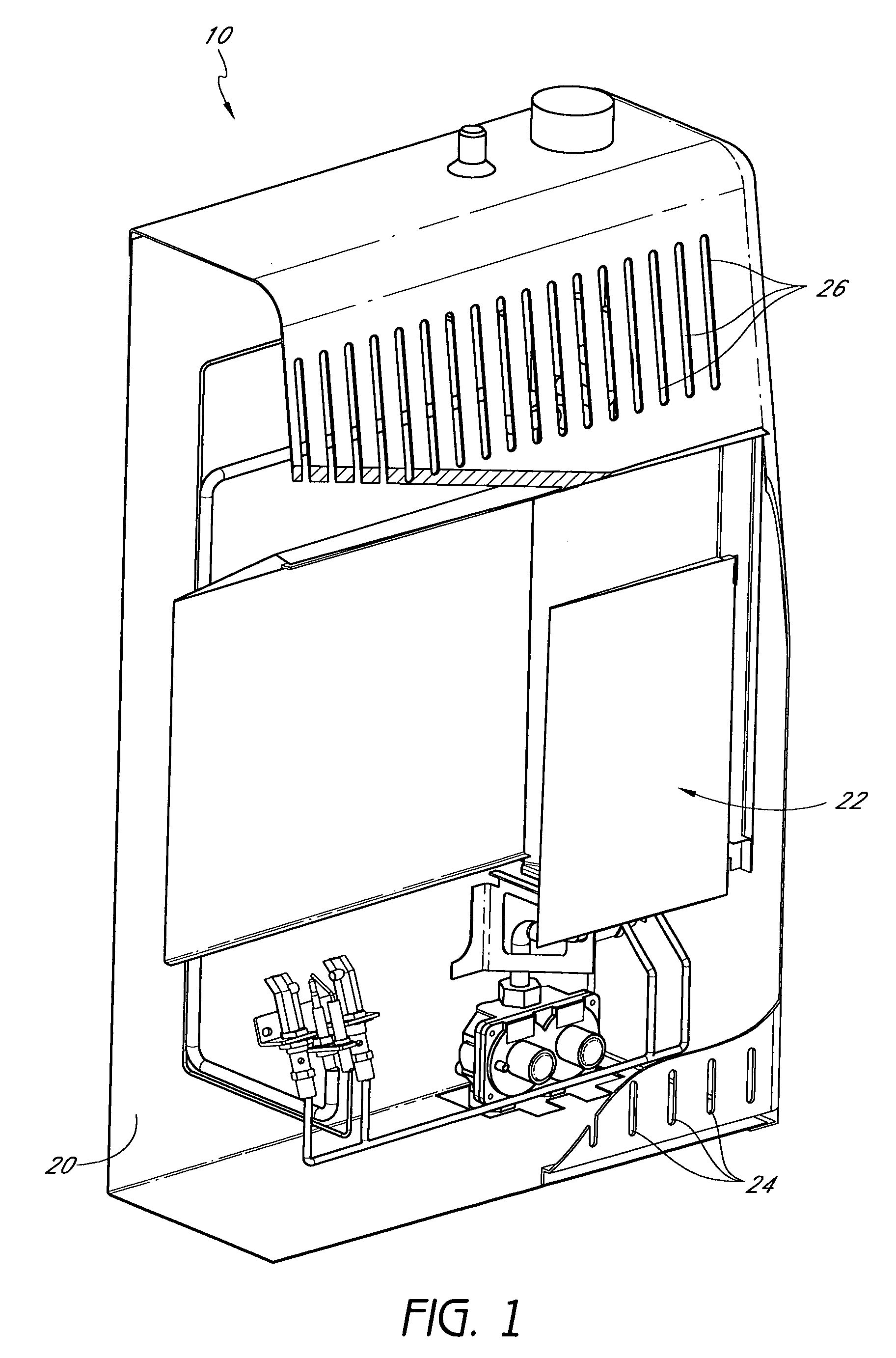

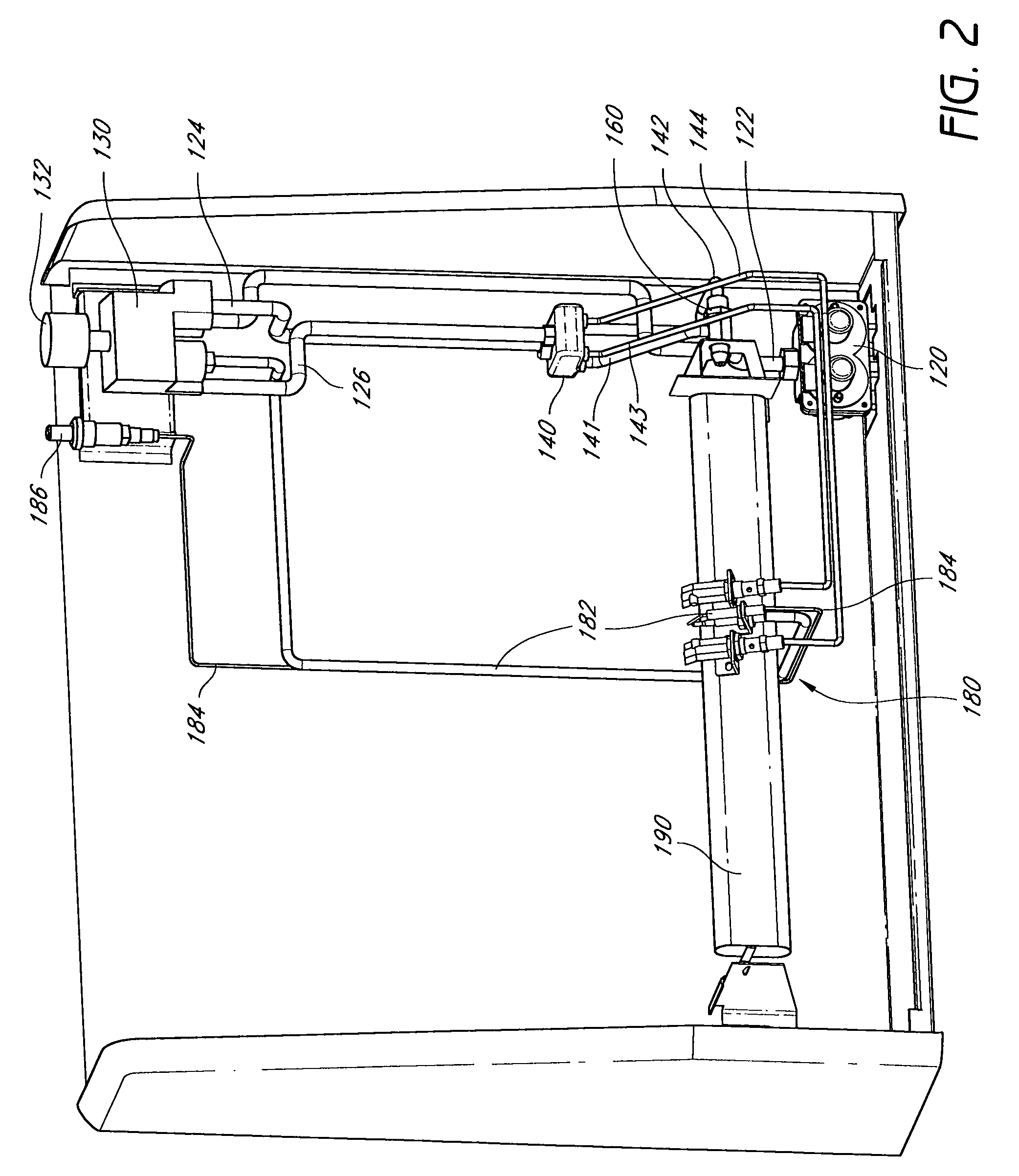

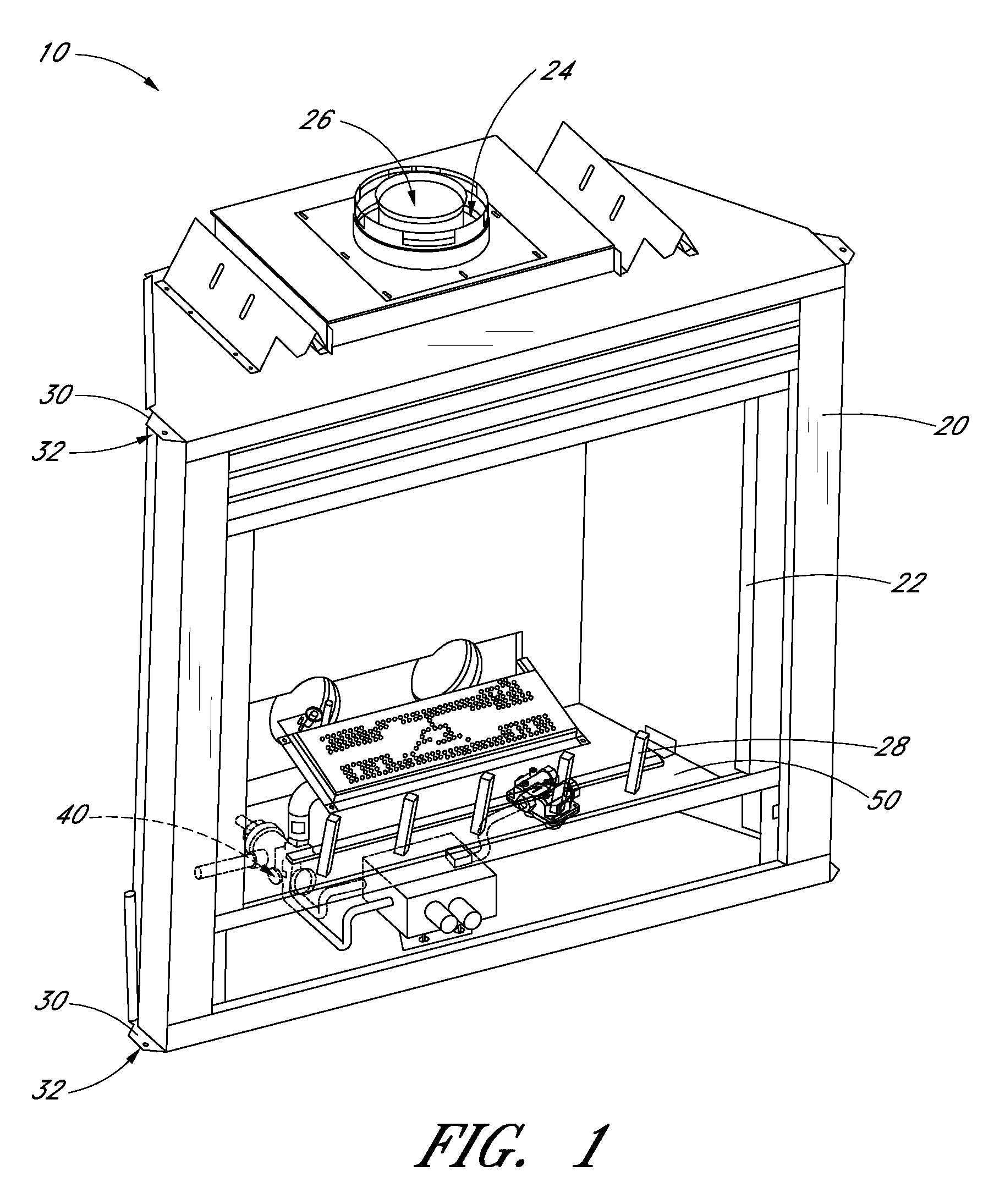

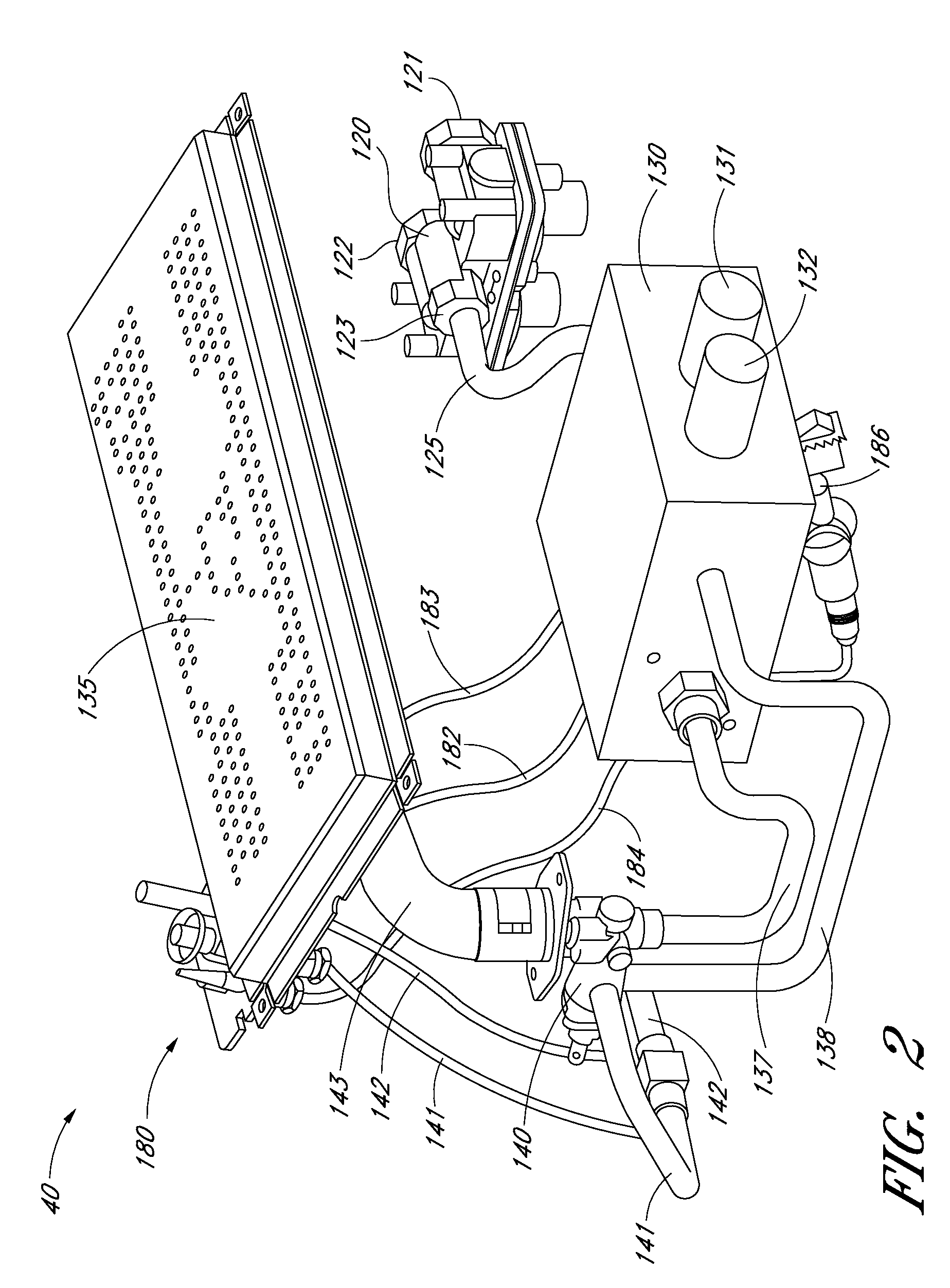

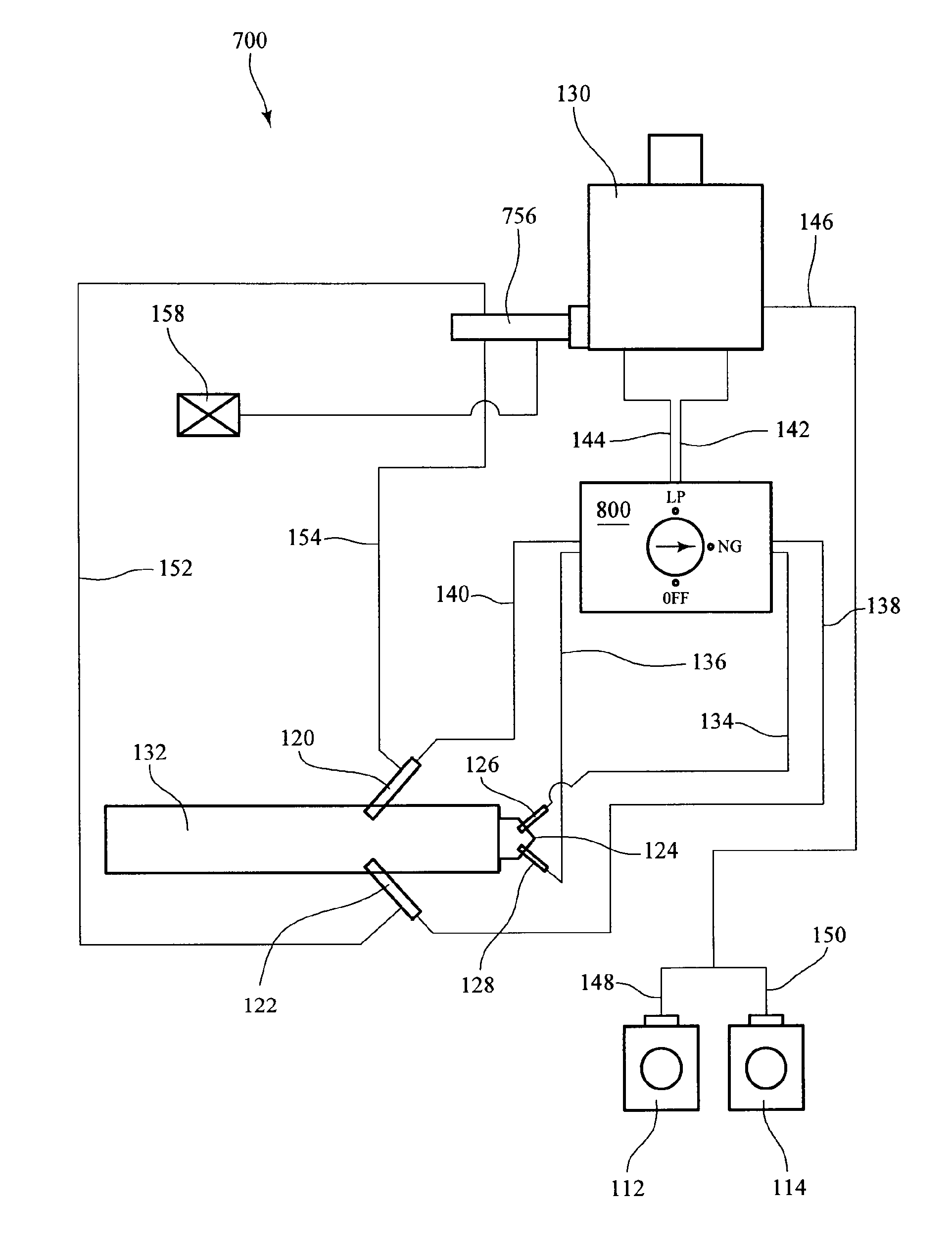

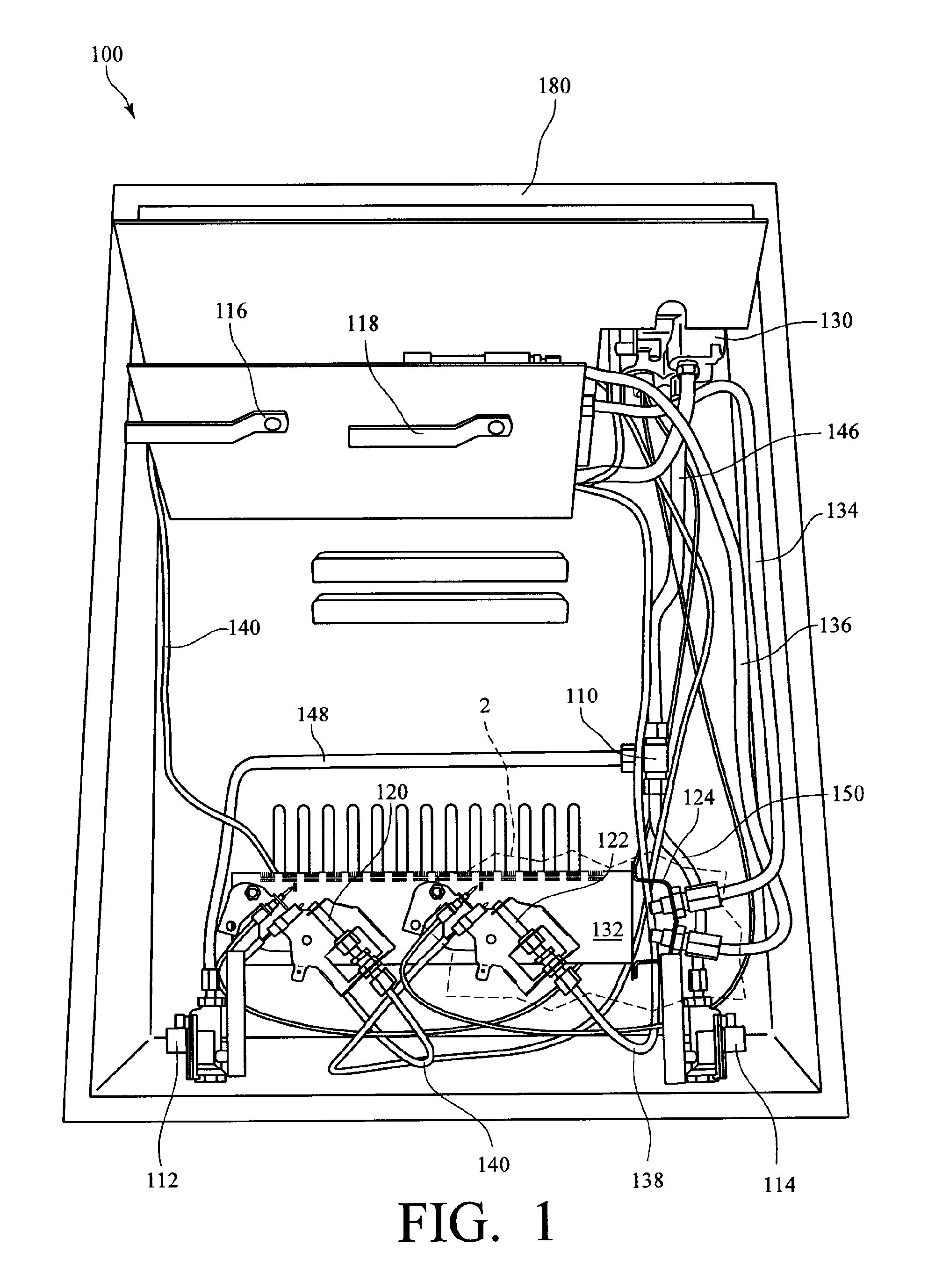

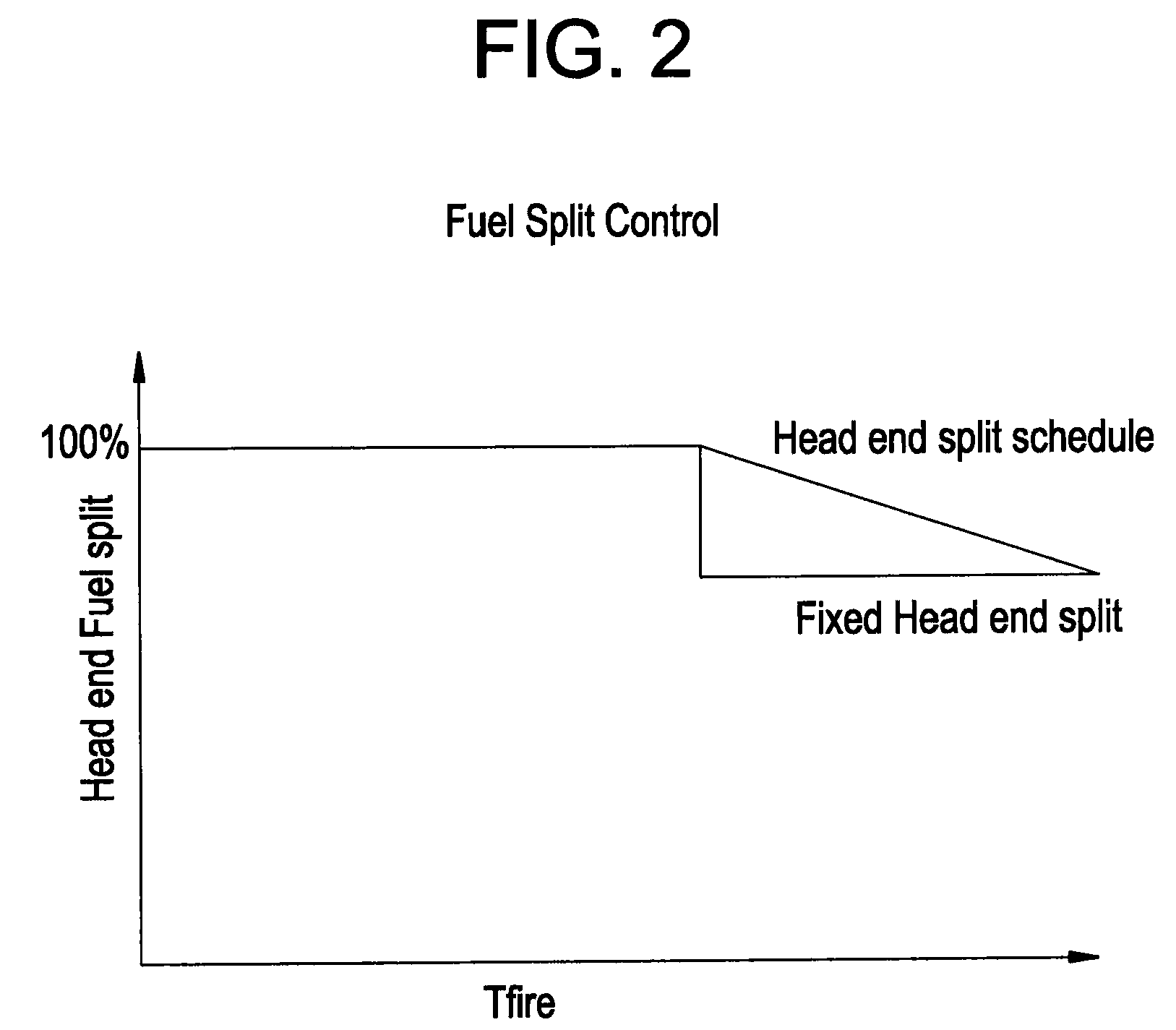

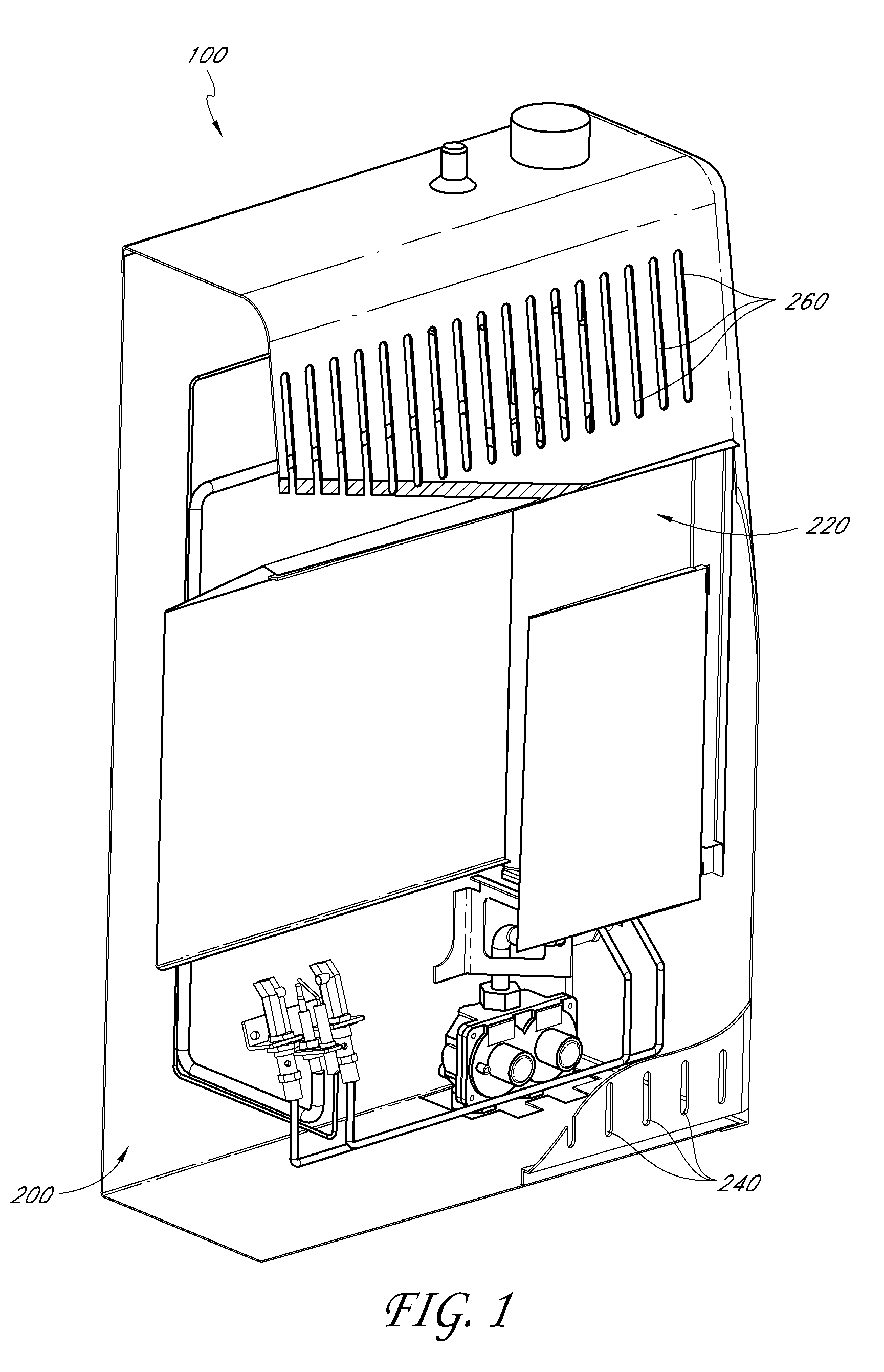

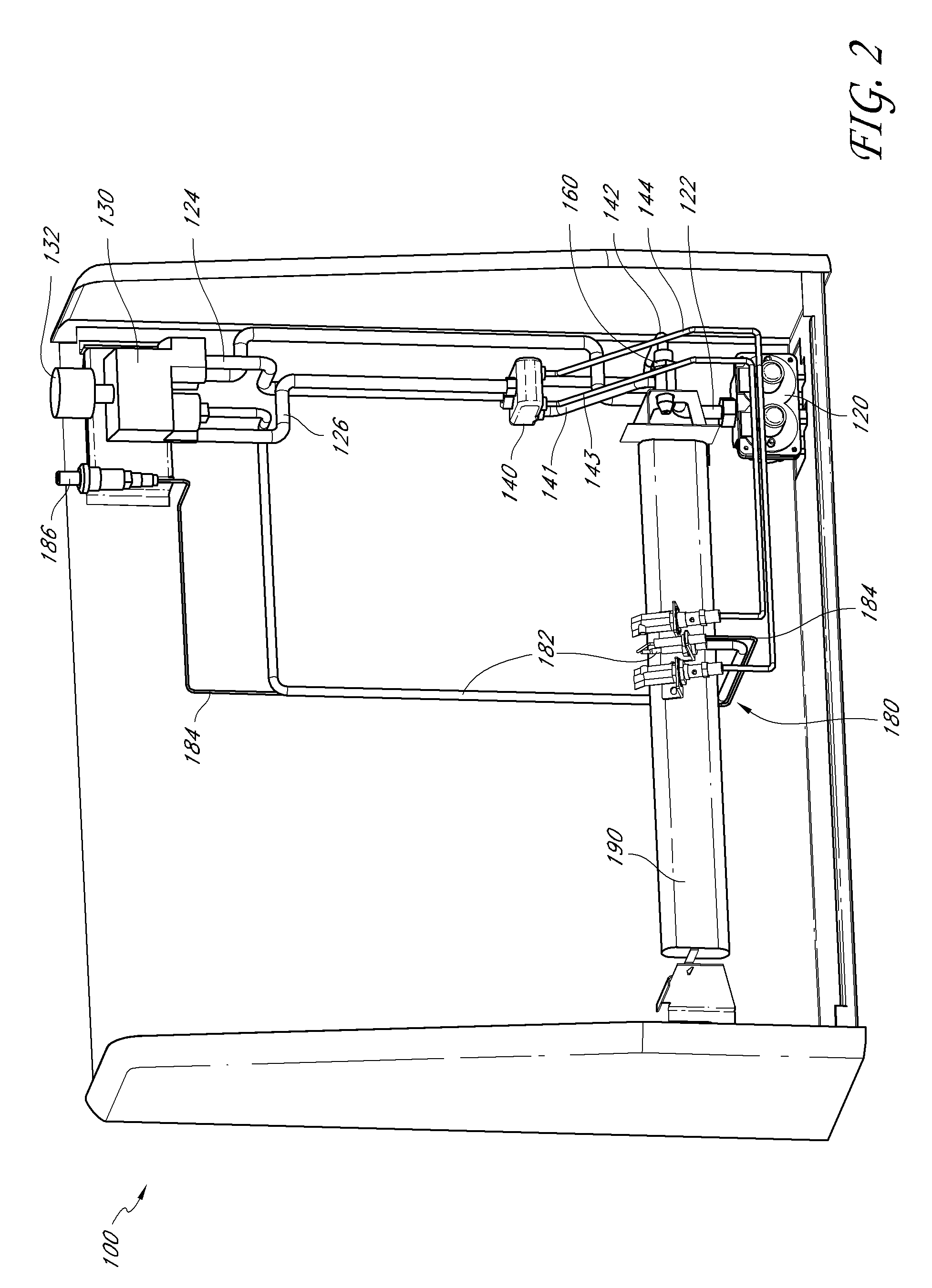

Dual fuel heater

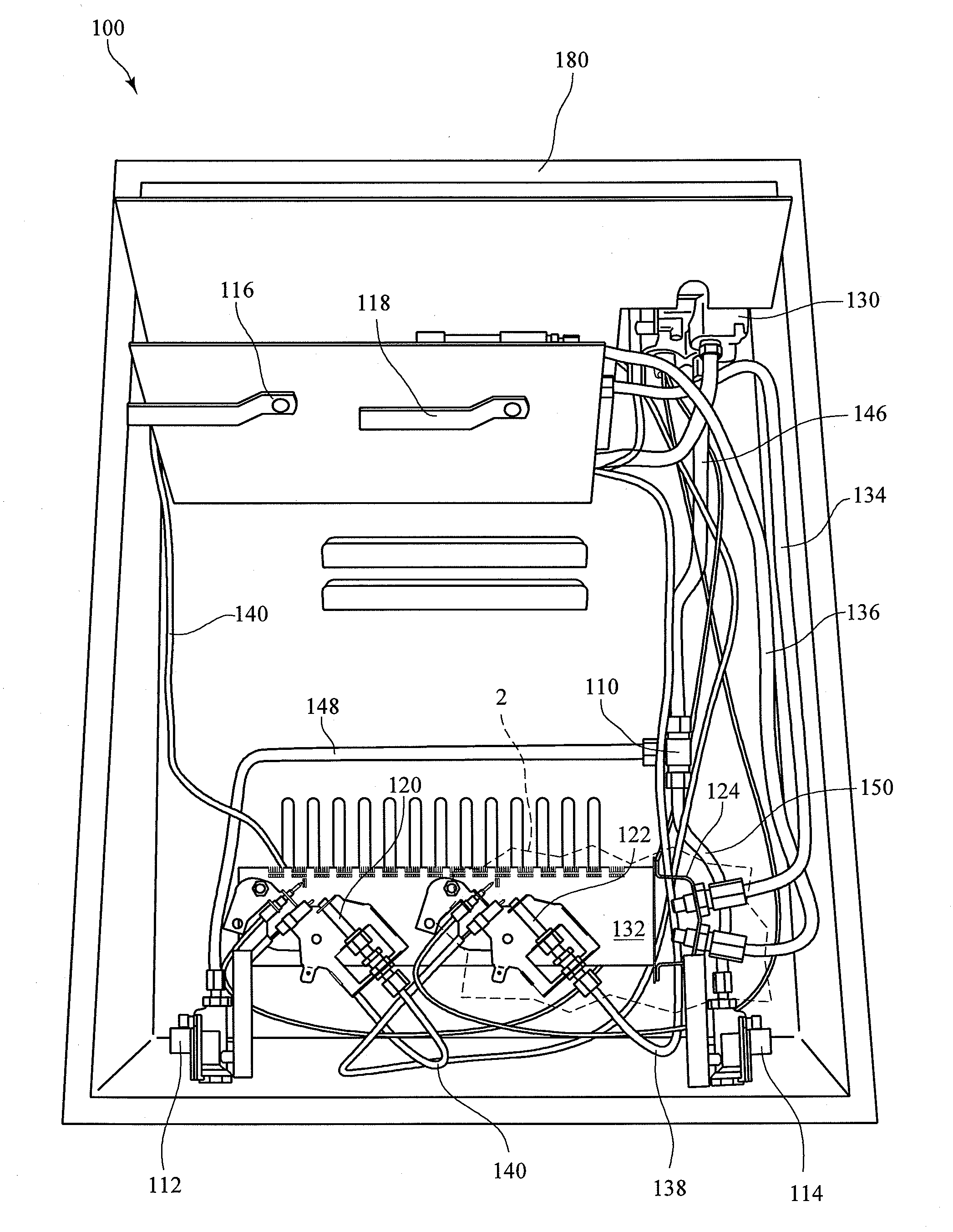

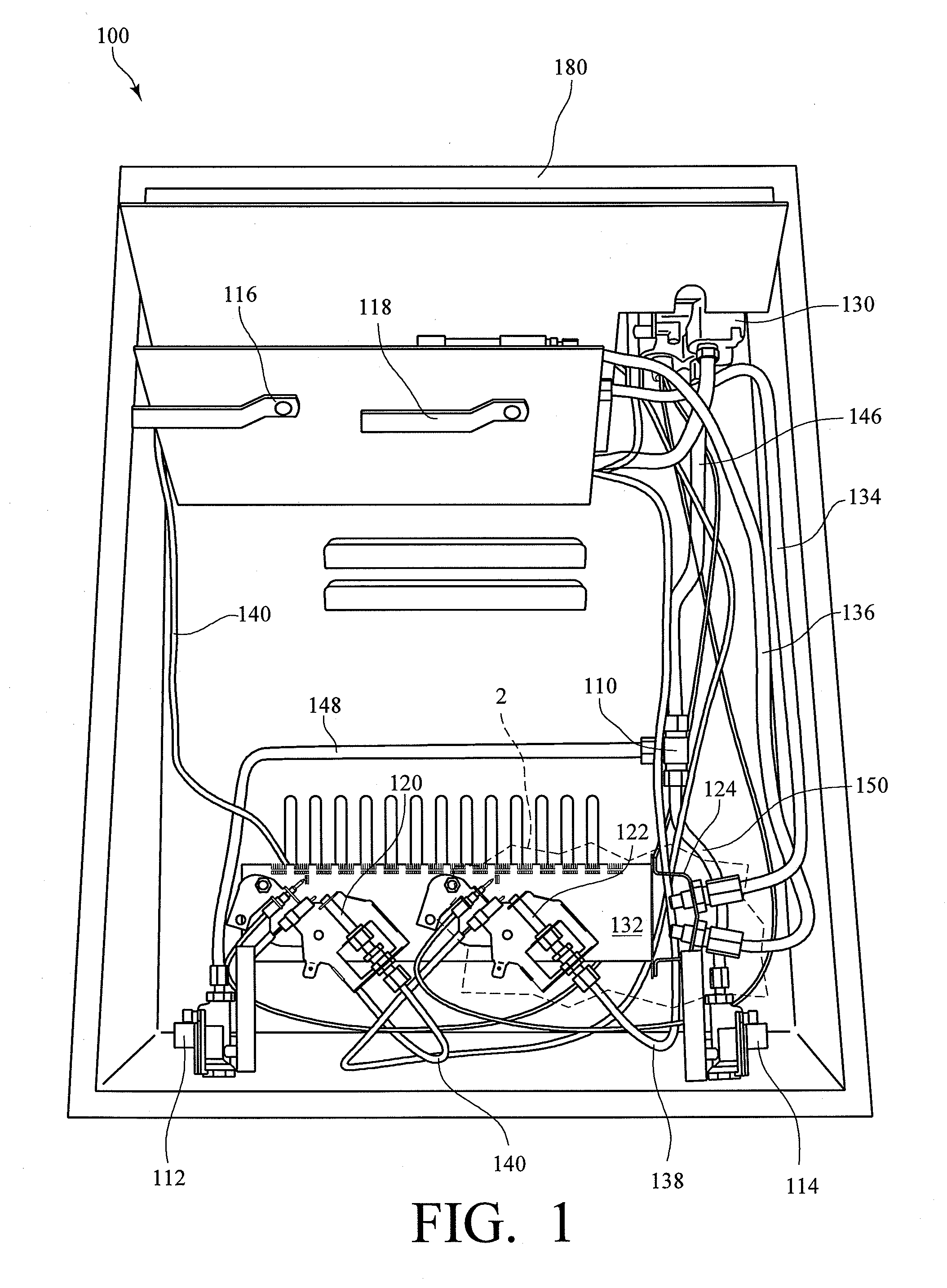

ActiveUS7607426B2Fuel supply regulationDomestic stoves or rangesCombustion chamberNuclear engineering

In certain embodiments, a dual fuel heater has a pressure regulating device for selectively coupling with a first source or a second source operating at different pressures. The dual fuel heater can also include first and second fuel lines, a fluid flow controller, a combustion chamber and first and second oxygen depletion sensor nozzles. The fluid flow controller is configured to selectively permit flow of fuel to either the first fuel line or to the second fuel line. In some embodiments, the first fuel line is connected to the first oxygen depletion sensor nozzle and the second fuel line is connected to the second oxygen depletion nozzle.

Owner:PROCOM HEATING

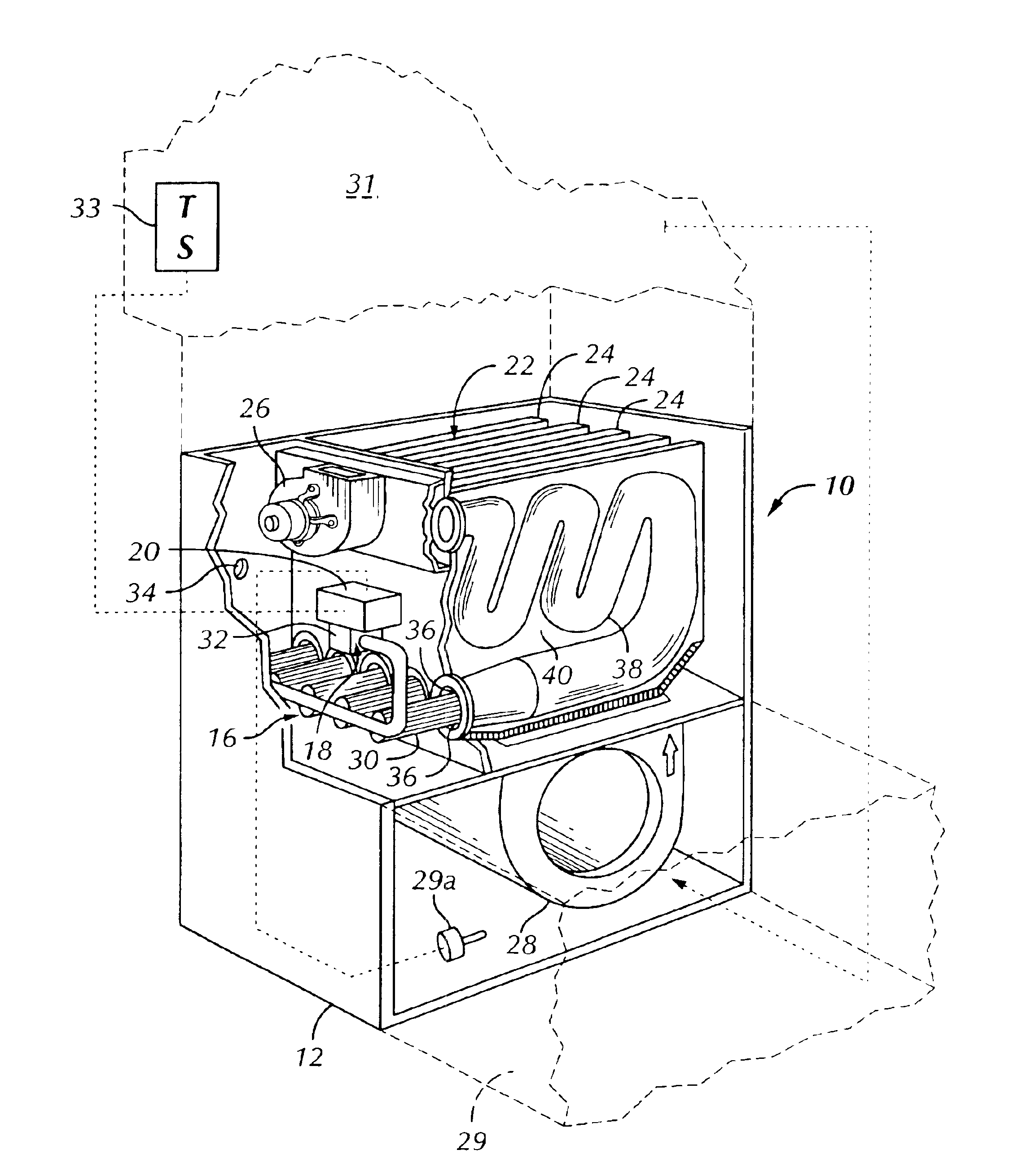

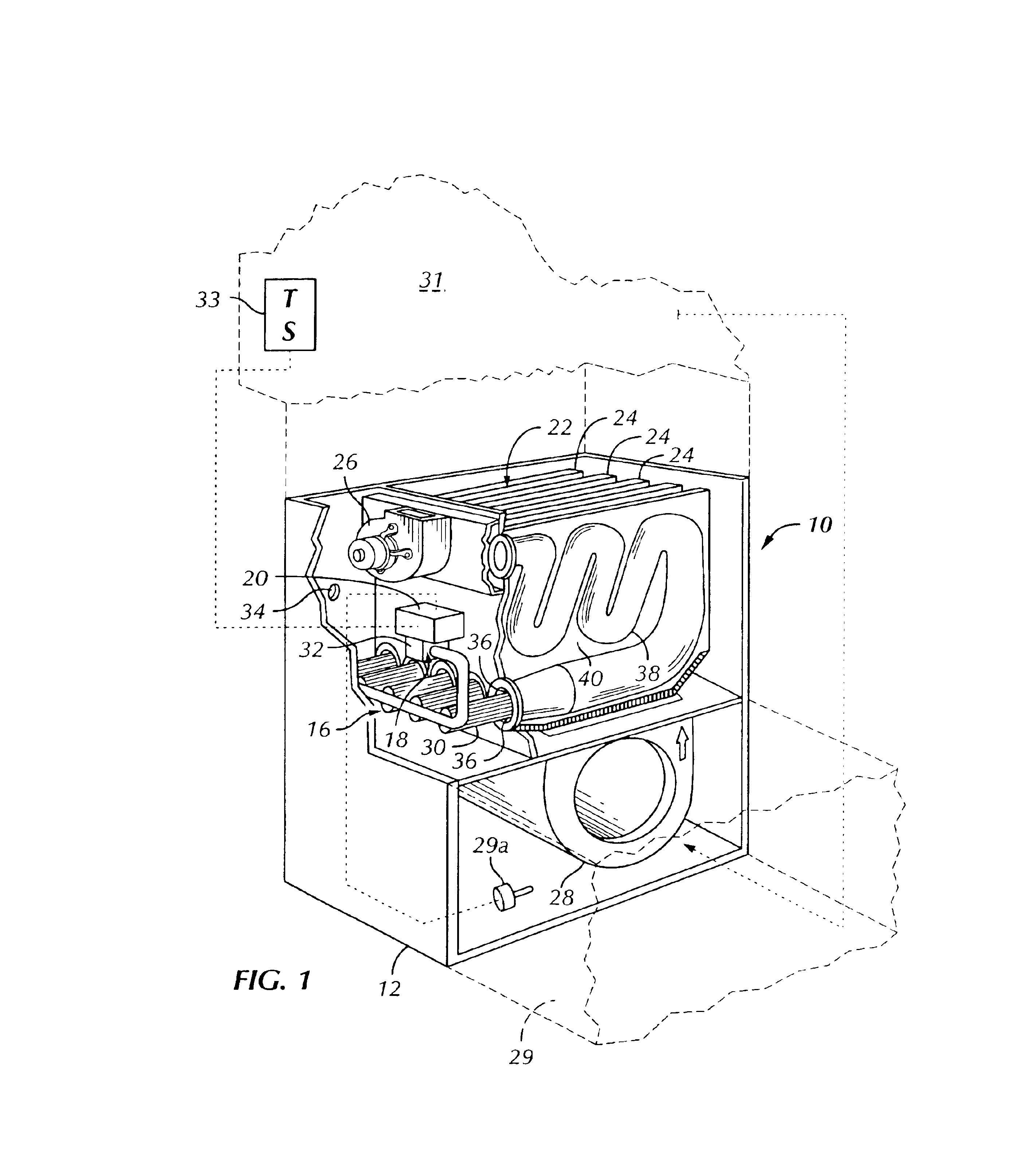

Variable output heating and cooling control

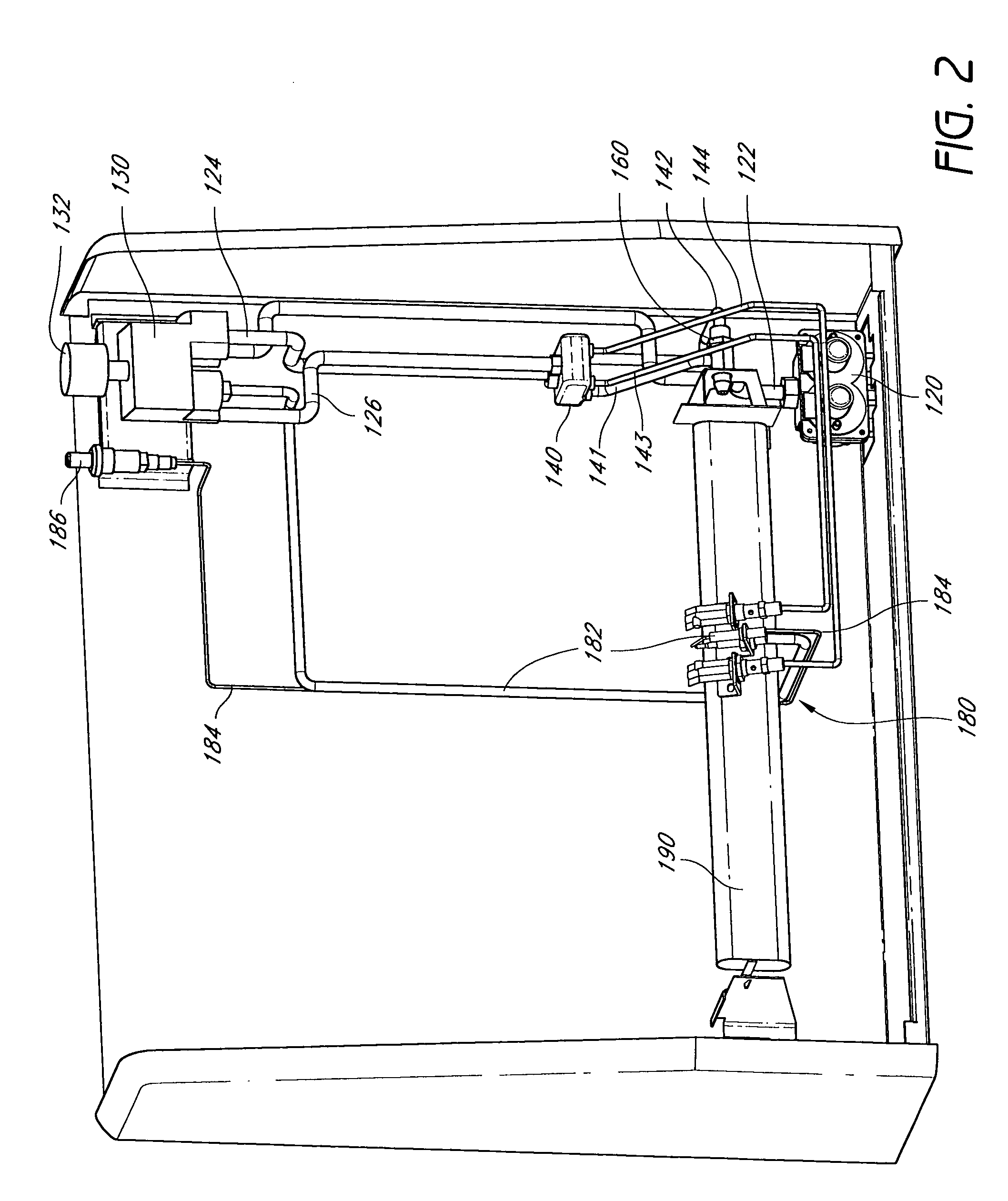

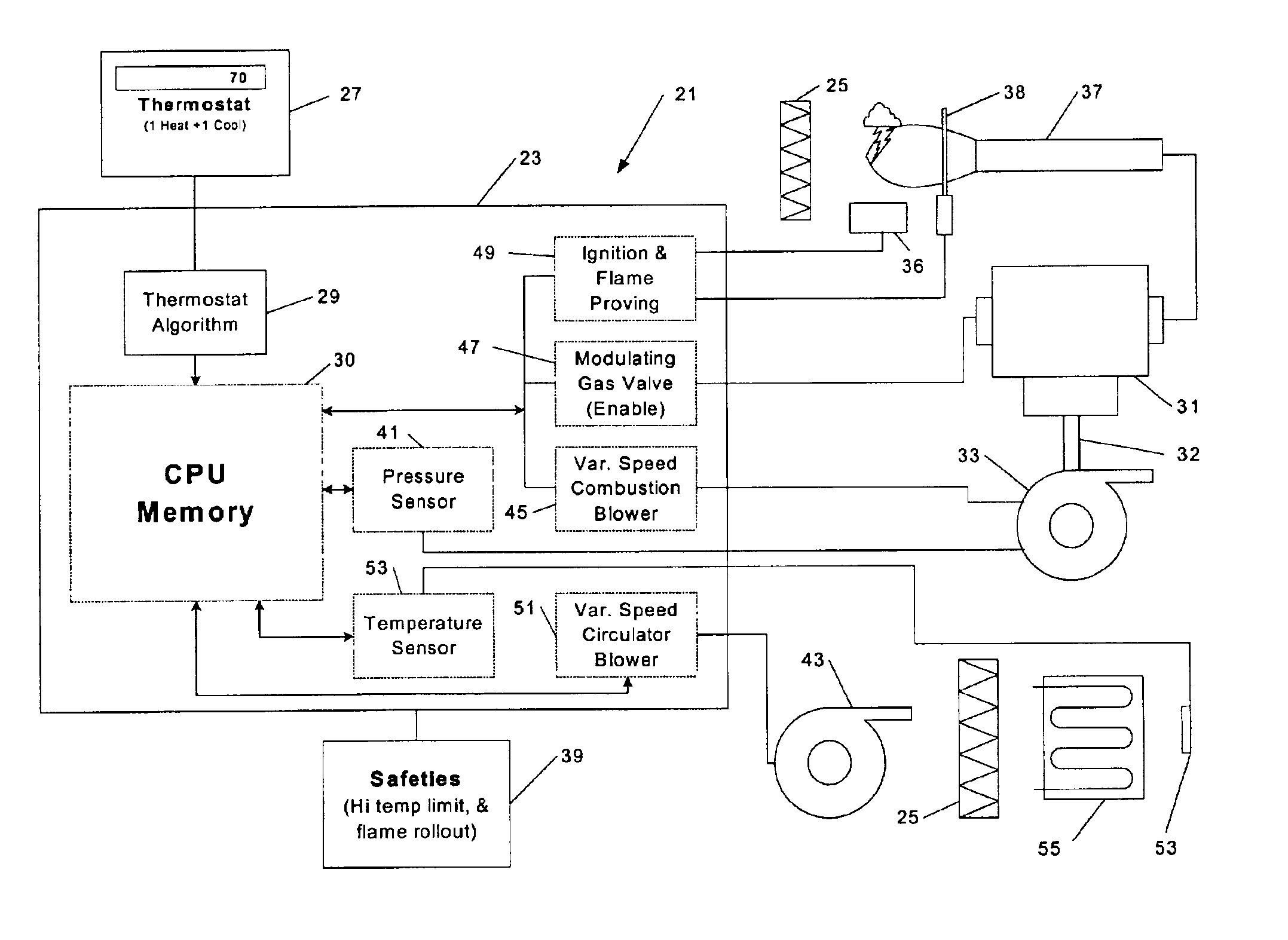

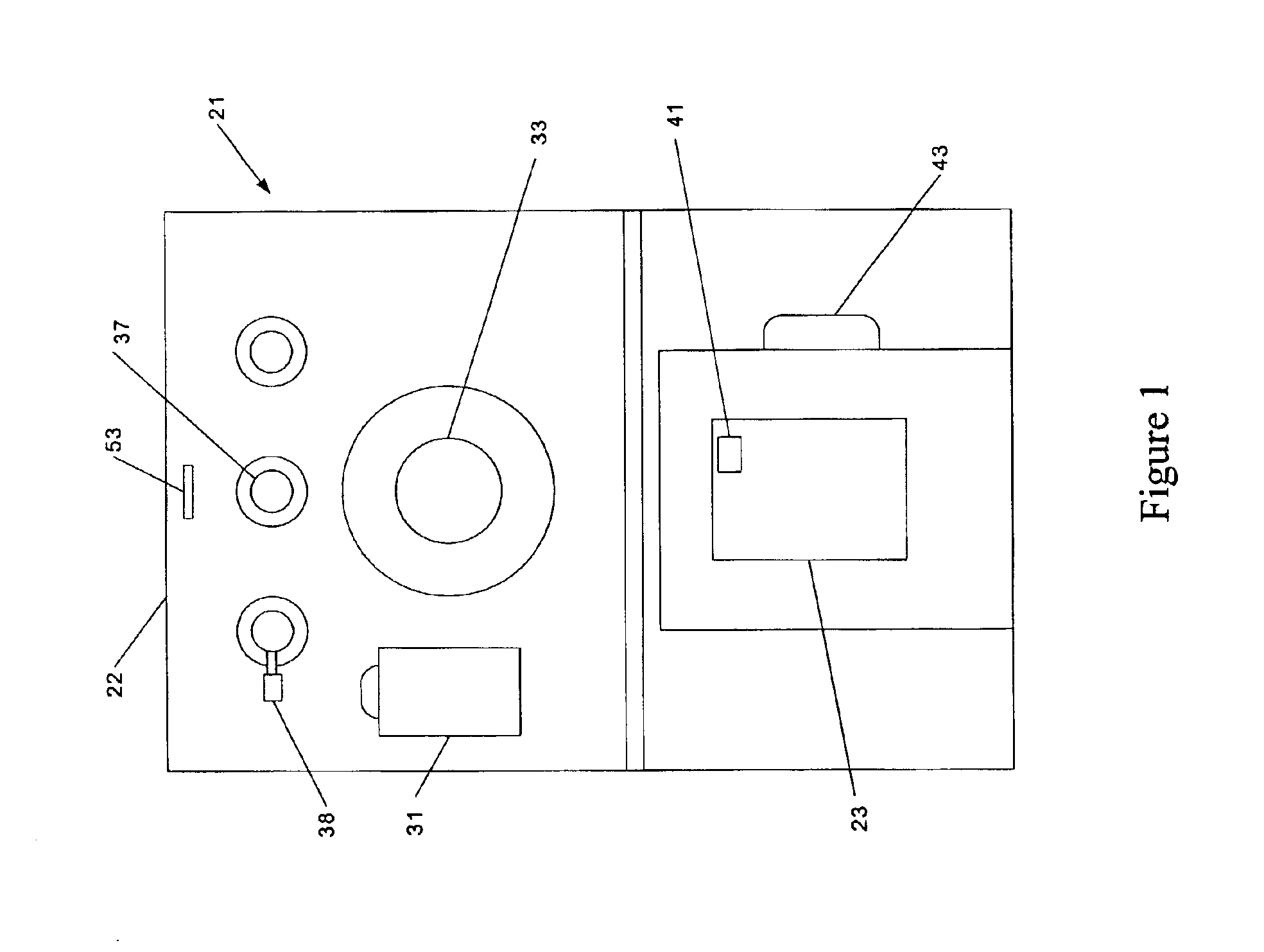

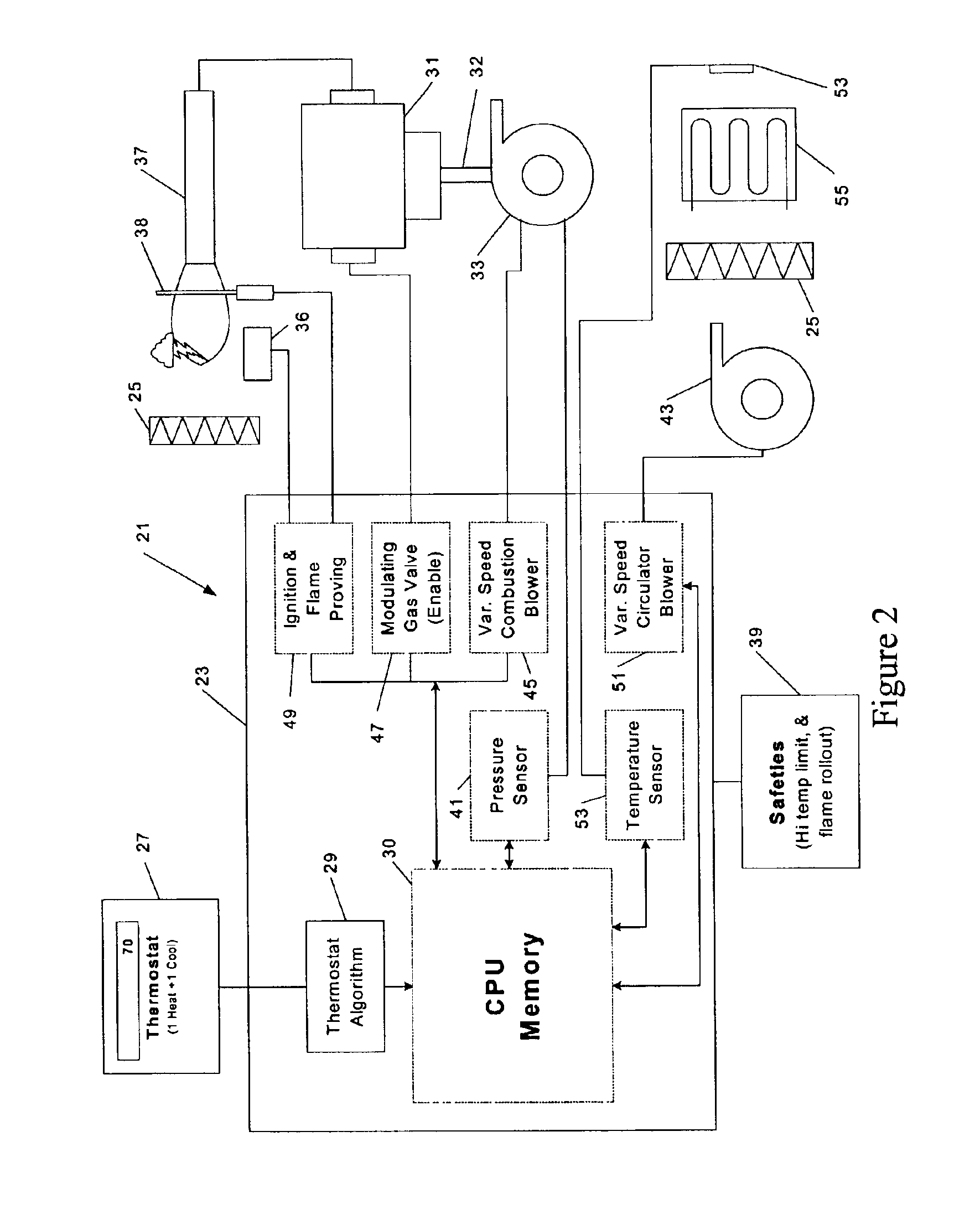

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

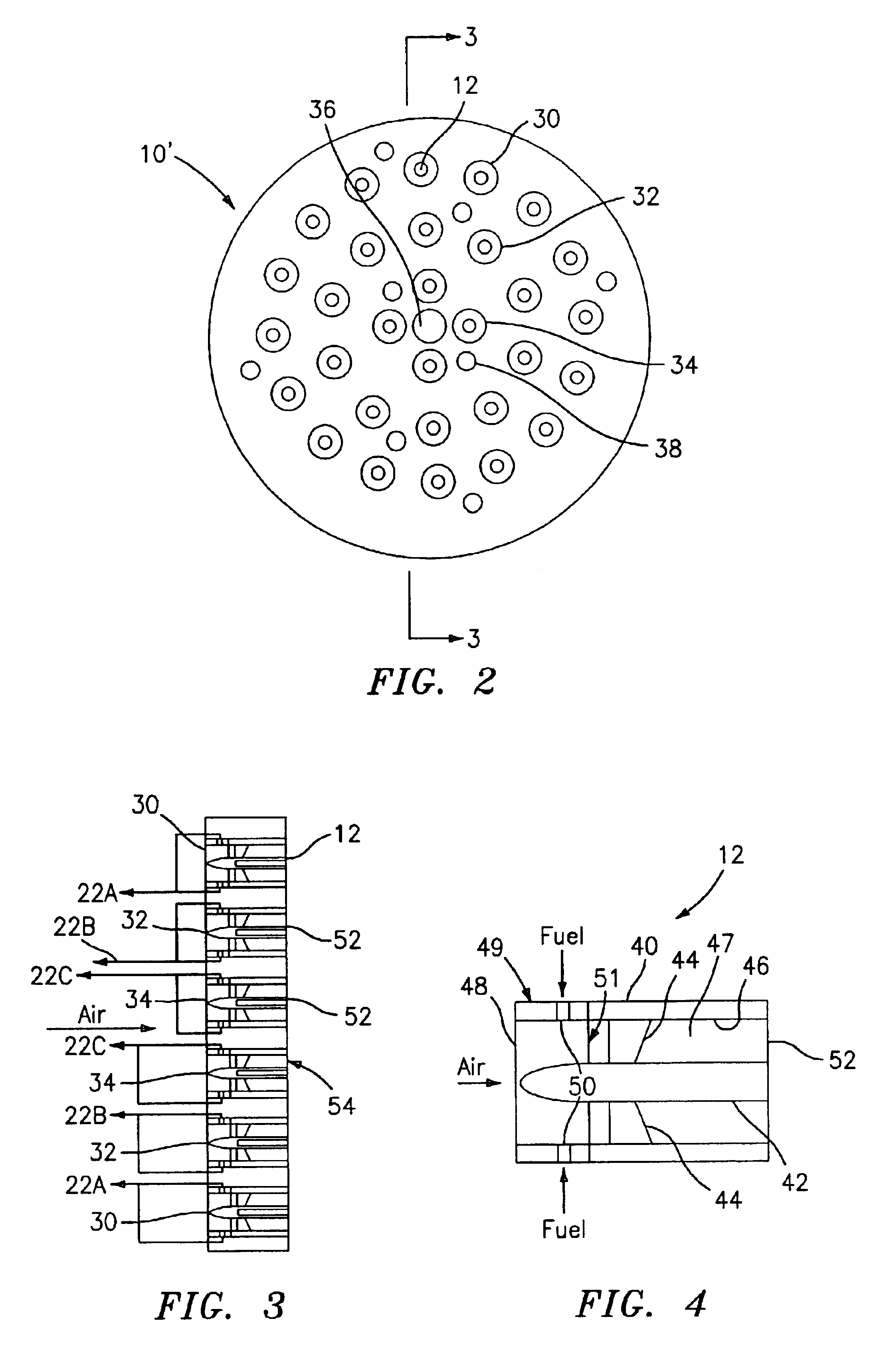

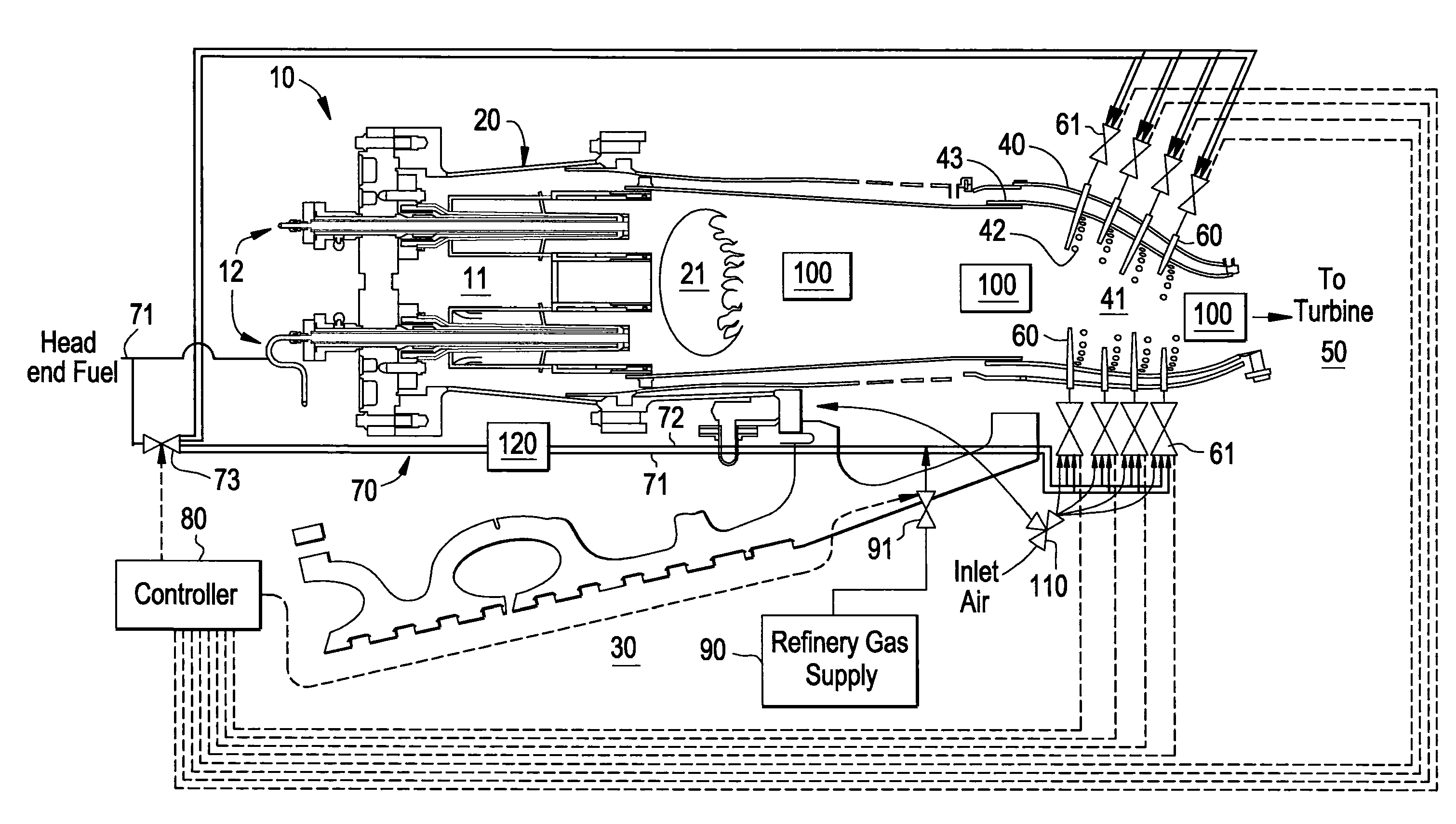

Methods and apparatus for low emission gas turbine energy generation

ActiveUS20050268617A1Reduce nitrogen oxide emissionsFuel supply regulationContinuous combustion chamberEngineeringLow emission

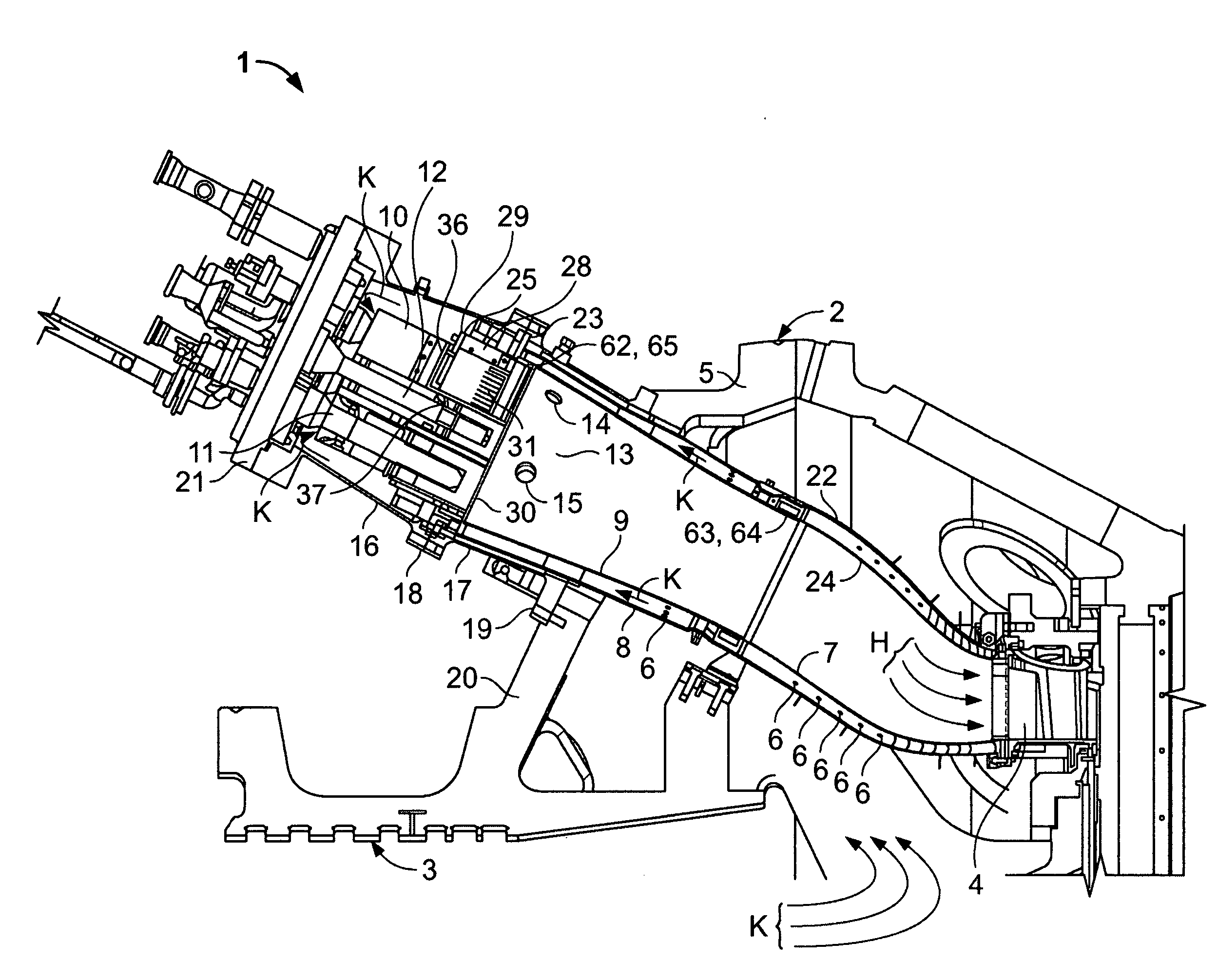

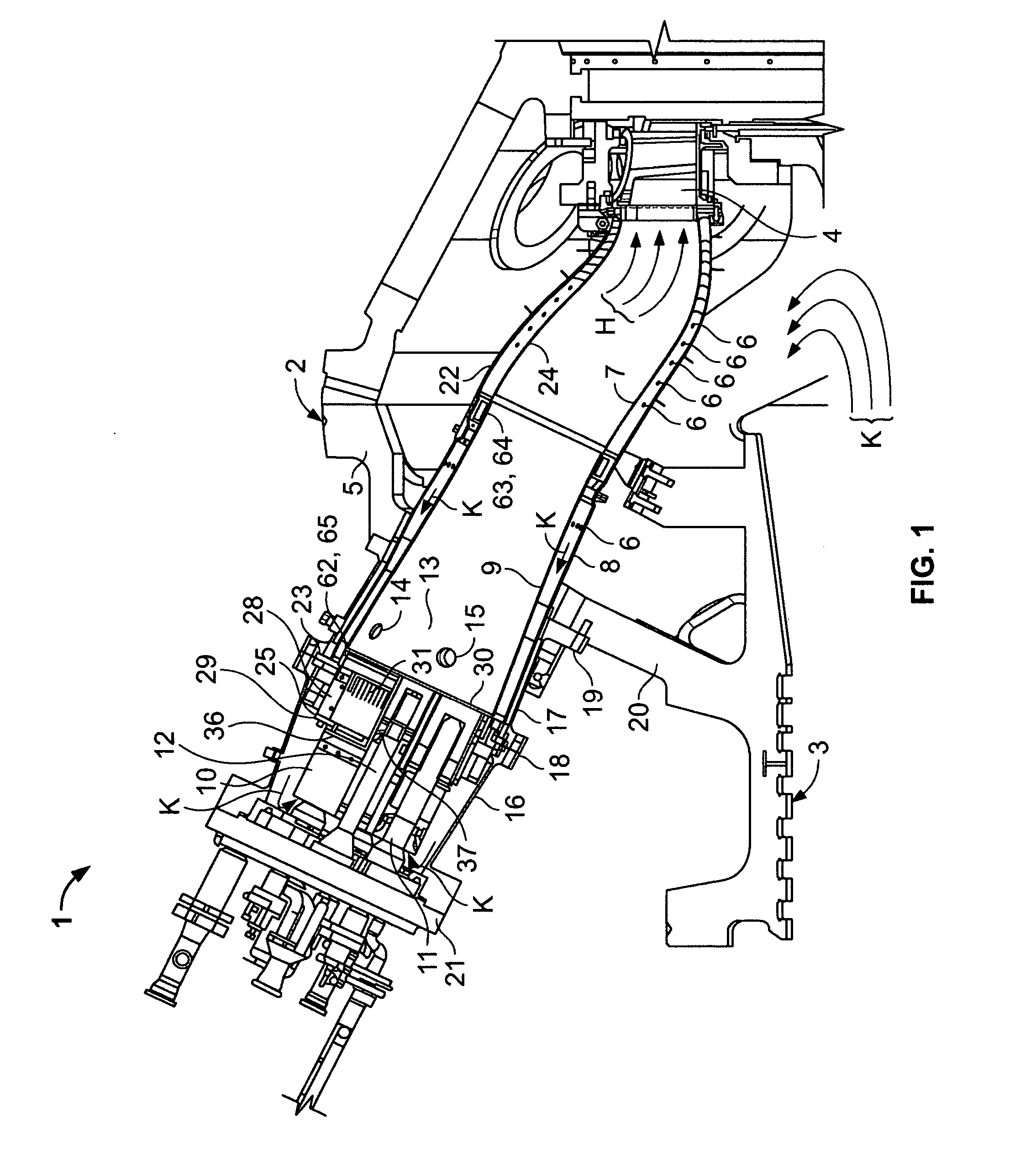

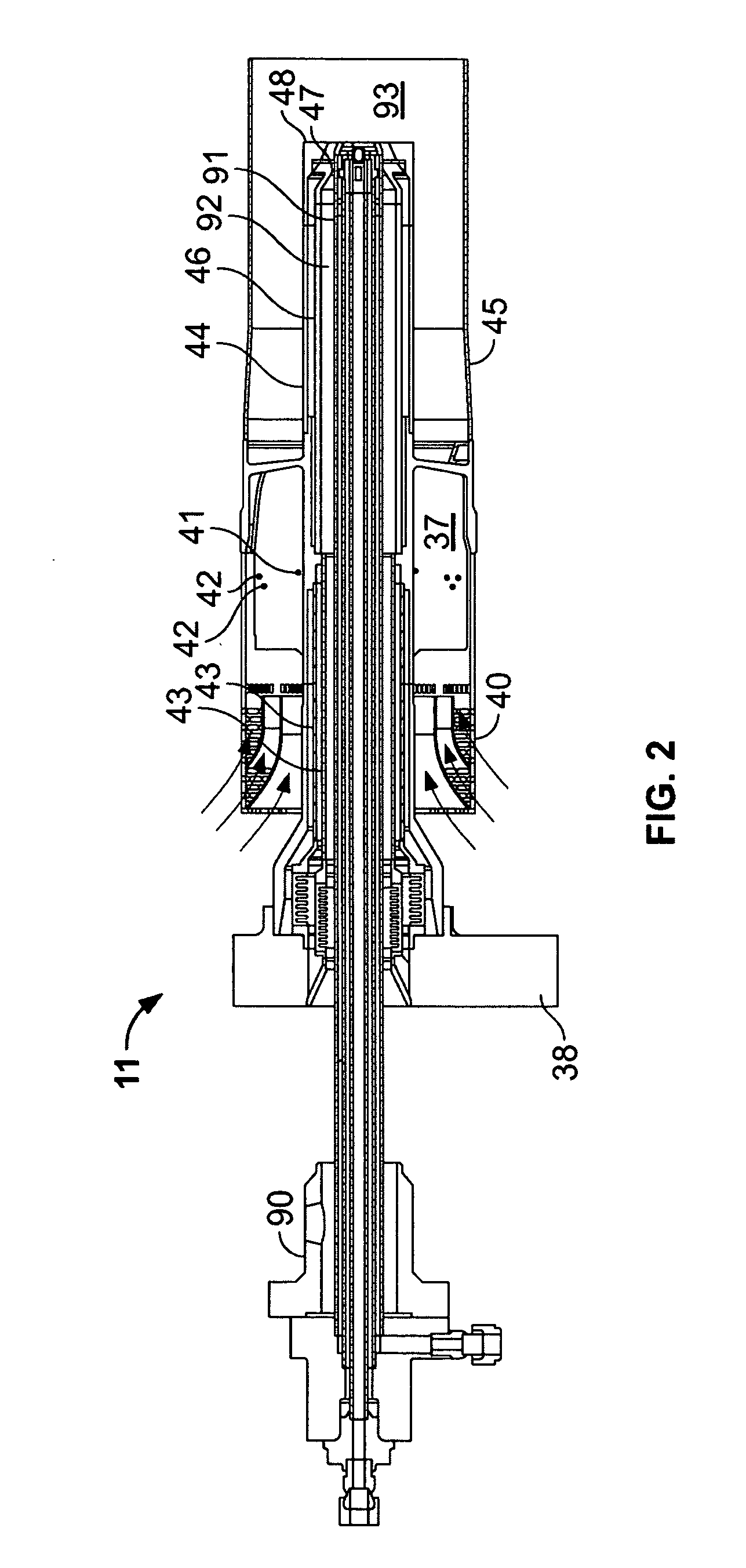

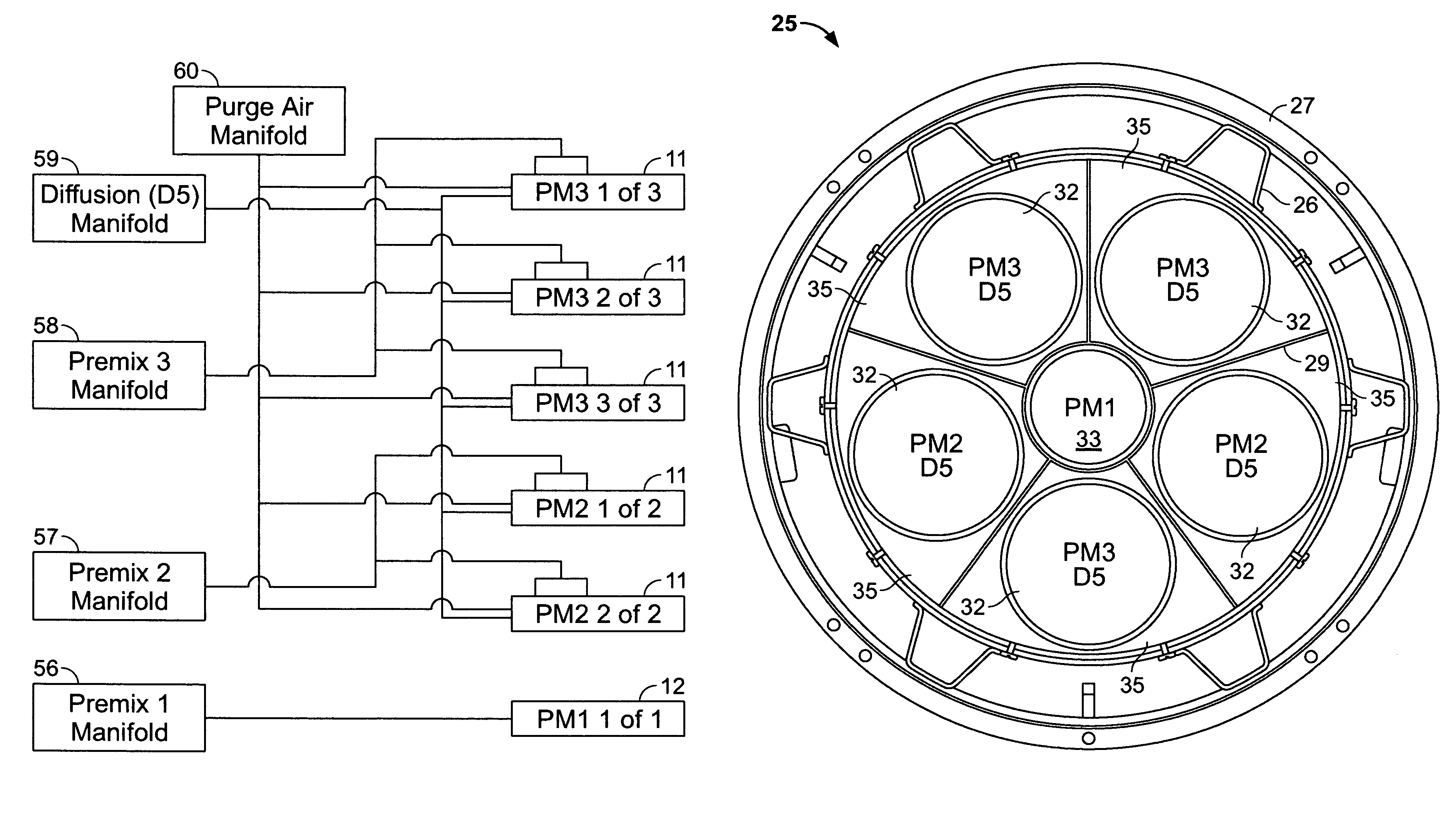

A low-emission method for producing power using a gas turbine includes premixing a plurality of fuel and air mixtures, injecting the fuel and air mixtures into a combustion chamber using a plurality of fuel nozzles, and adjusting a ratio of fuel and air injected by at least one of the nozzles to control a fuel / air concentration distribution within the combustion chamber.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for low emission gas turbine energy generation

ActiveUS7284378B2Reduce nitrogen oxide emissionsFuel supply regulationContinuous combustion chamberCombustion chamberLow emission

A low-emission method for producing power using a gas turbine includes premixing a plurality of fuel and air mixtures, injecting the fuel and air mixtures into a combustion chamber using a plurality of fuel nozzles, and adjusting a ratio of fuel and air injected by at least one of the nozzles to control a fuel / air concentration distribution within the combustion chamber.

Owner:GENERAL ELECTRIC CO

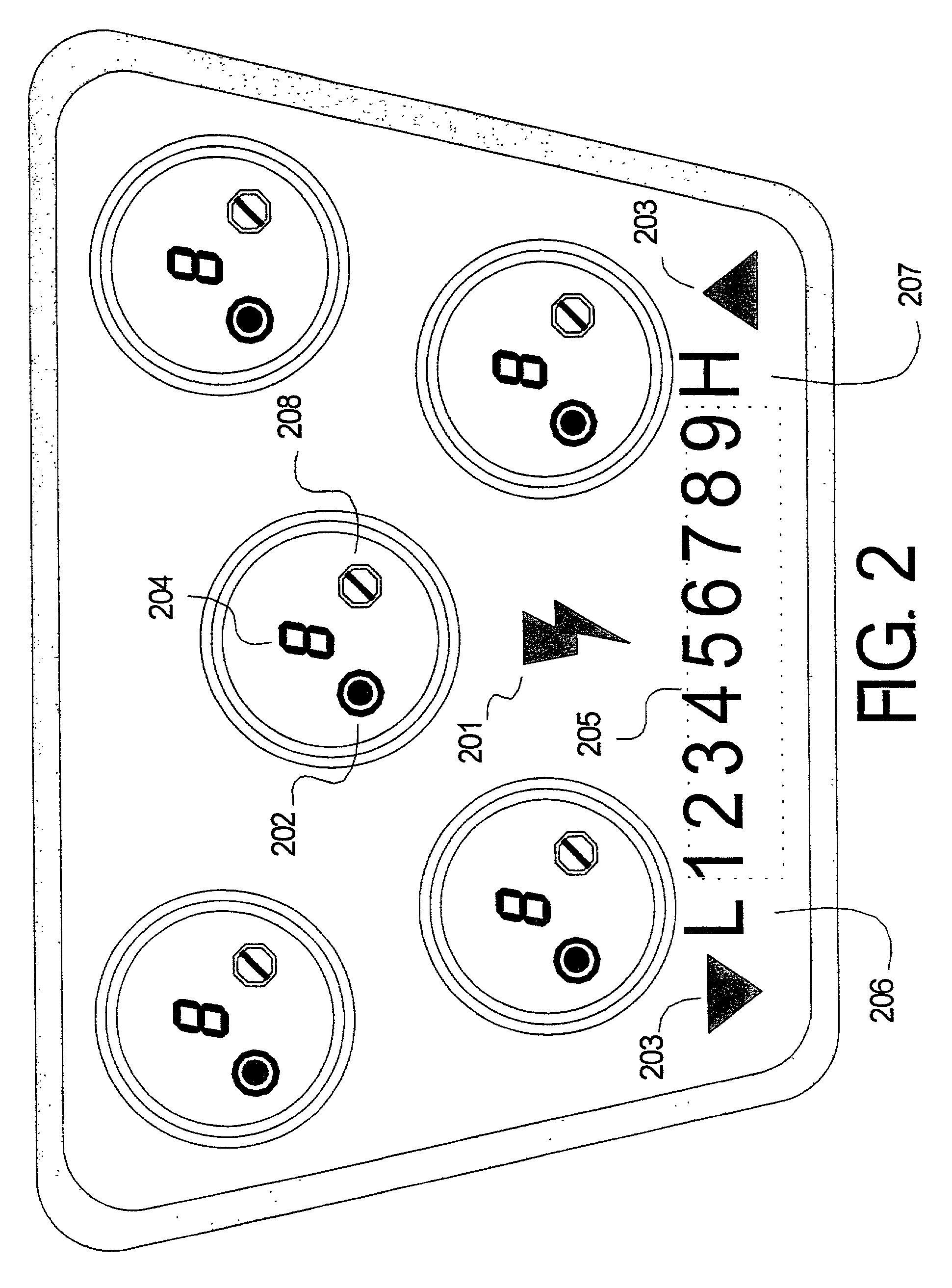

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

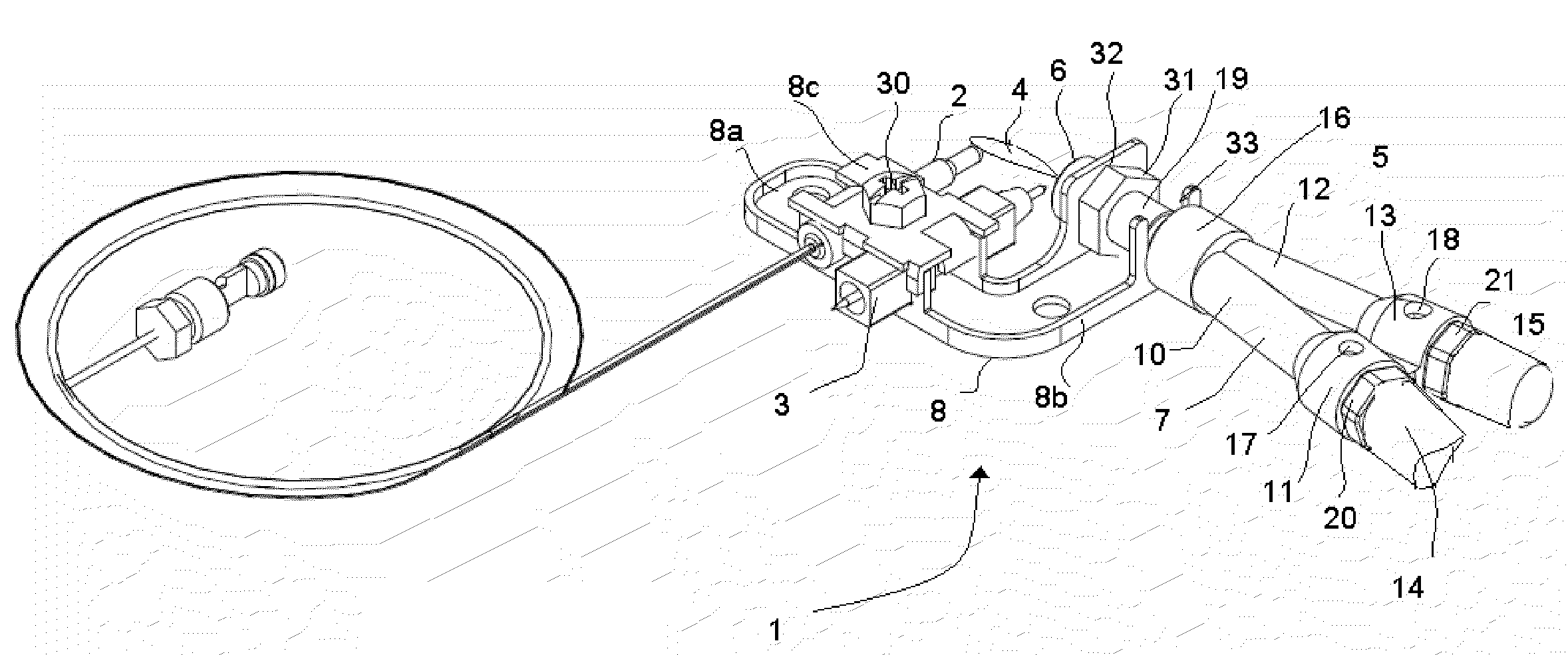

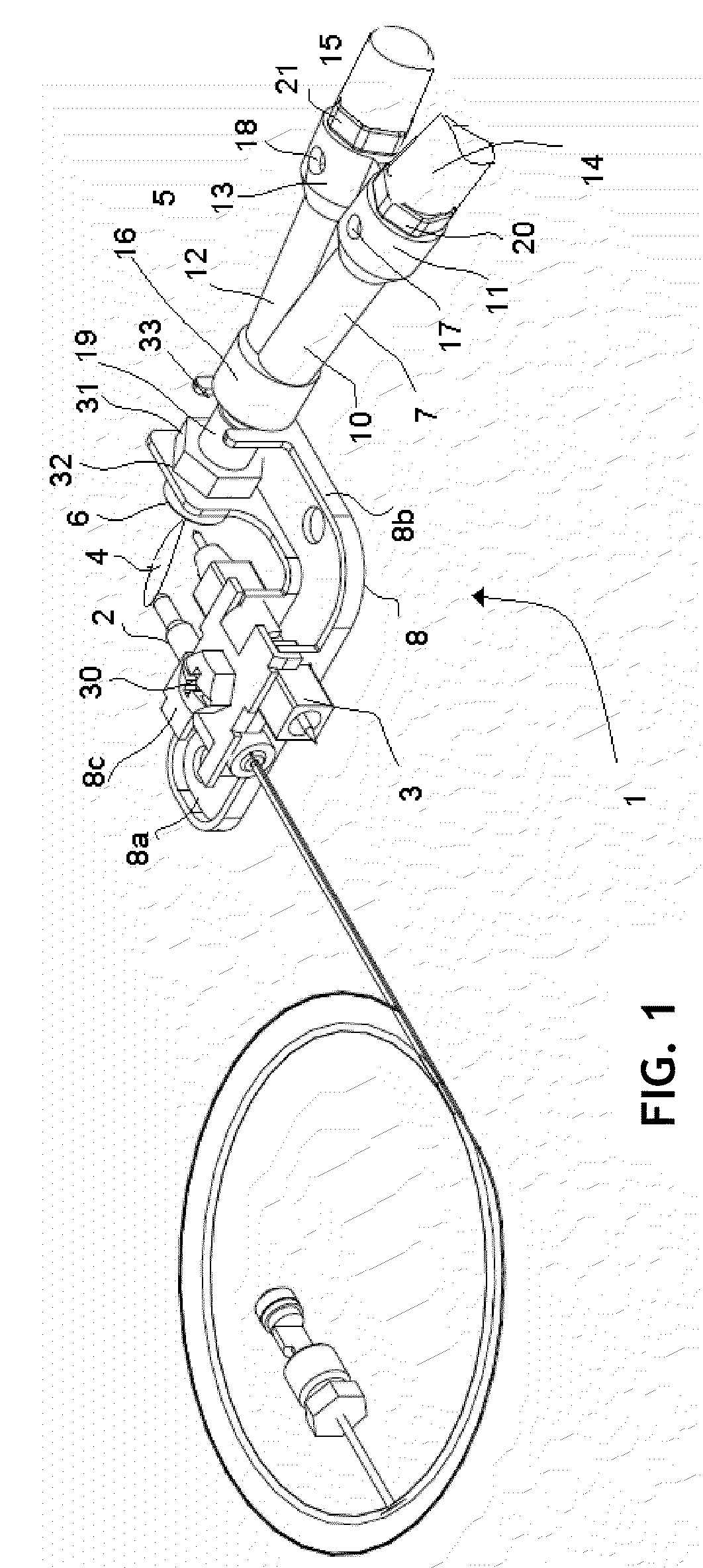

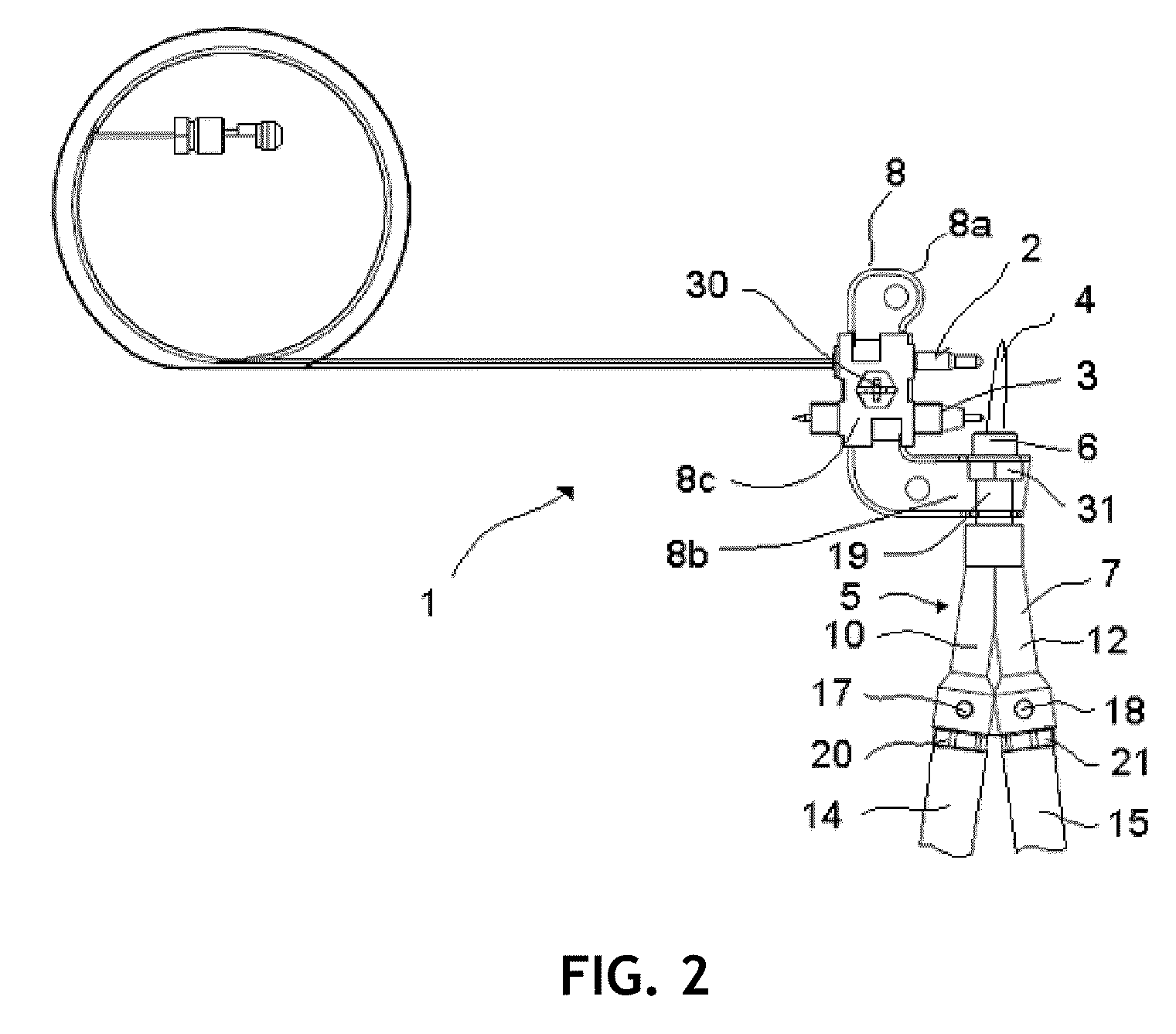

Fuel control mechanism and associated method of use

ActiveUS6938634B2Gaseous fuel feeder/distributionInternal combustion piston enginesEngineeringControl valves

A control device for regulating delivery of fuel and an associated method of use is disclosed. The control device includes an inlet, an electromagnetic safety valve, having a thermocouple connection, a control valve, wherein the electromagnetic safety valve selectively allows fuel to flow from the inlet to the control valve through the electromagnetic safety valve when the thermocouple connection is heated, an actuator valve, a main valve having a pressure responsive device, having a first side and a second side and including an outlet chamber, a regulator valve having a sensing port and an outlet. There is an adjustment mechanism associated with the control valve that can also direct fuel into a pilot assembly.

Owner:ROBERTSHAW CONTROLS CO

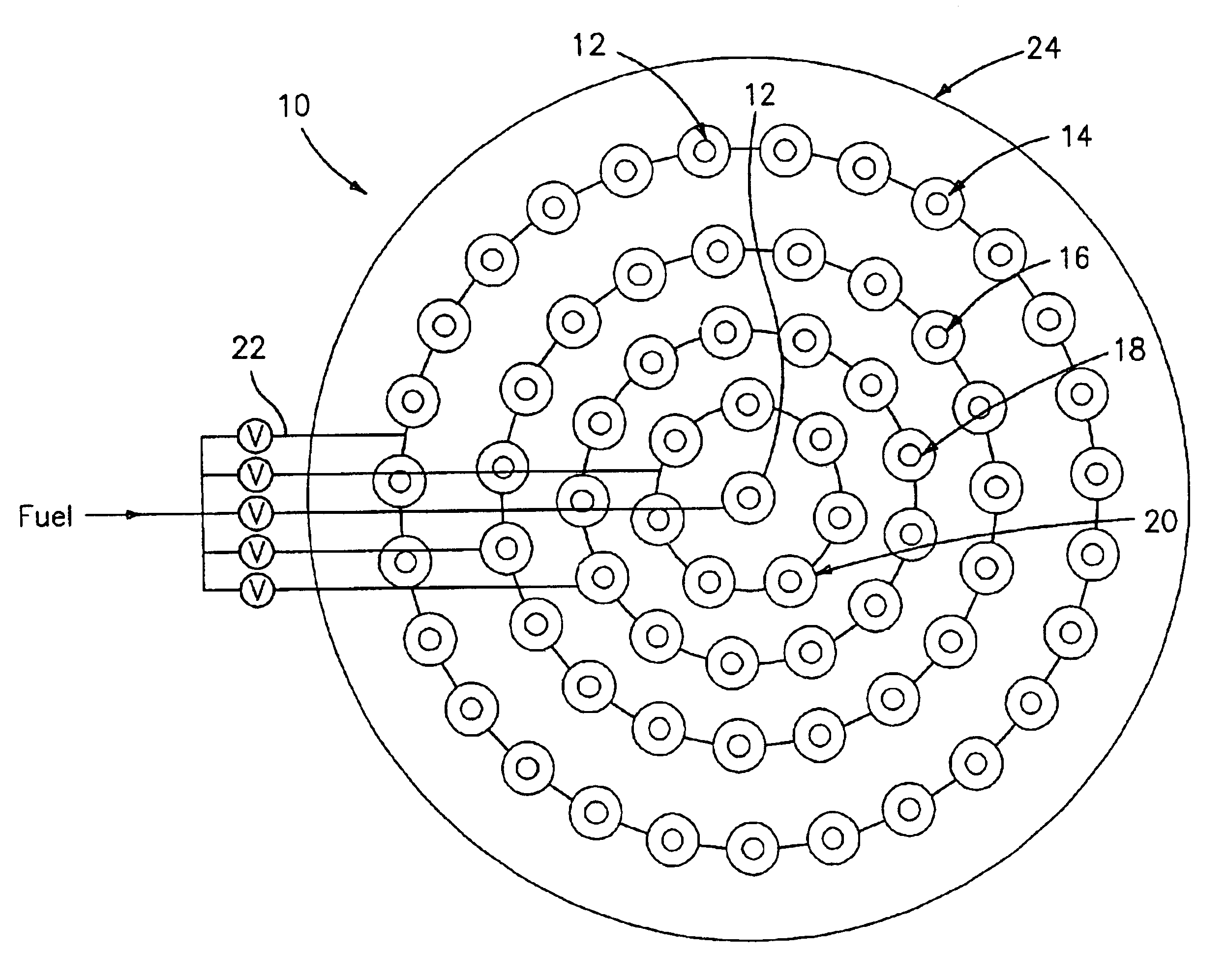

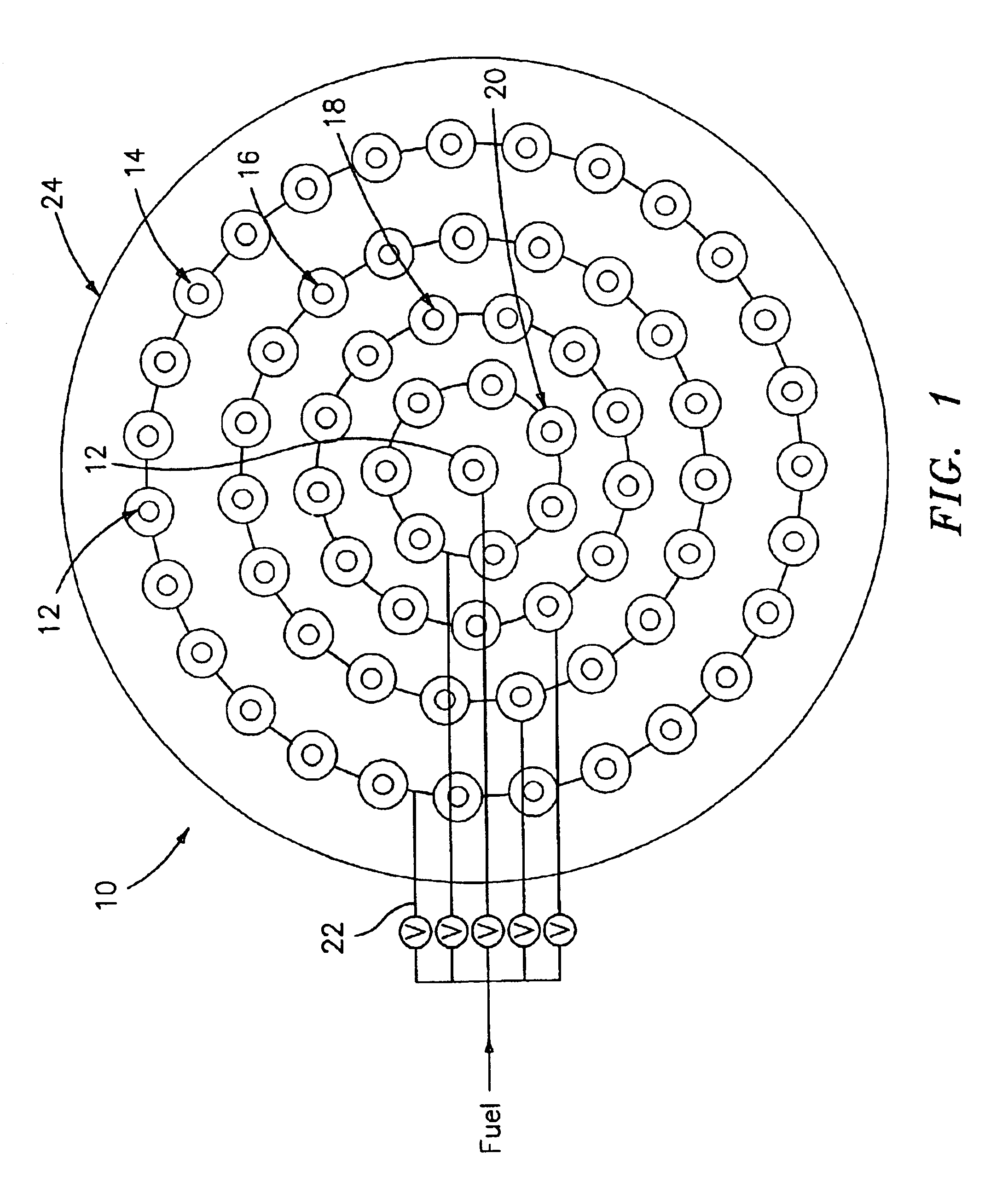

Multi-point staging strategy for low emission and stable combustion

InactiveUS6962055B2Avoids creating excessive CO and UHCBurnersFuel supply regulationCombustorLow emission

The present invention relates to an improved multi-point injector for use in a gas turbine engine or other types of combustors. The multi-point fuel injector has a plurality of nozzles arranged in at least two arrays such as concentric rings. The injector further has different fuel circuits for independently controlling the fuel flow rate for the nozzles in each of the arrays. Each of the nozzles include a fluid channel and one or more swirler vanes in the fluid channel for creating a swirling flow within the fluid channel. A method for injecting a fuel / air mixture into a combustor stage of a gas turbine engine is also described. At least one zone has a flame hot enough to stabilize the entire combustor flame.

Owner:UNITED TECH CORP

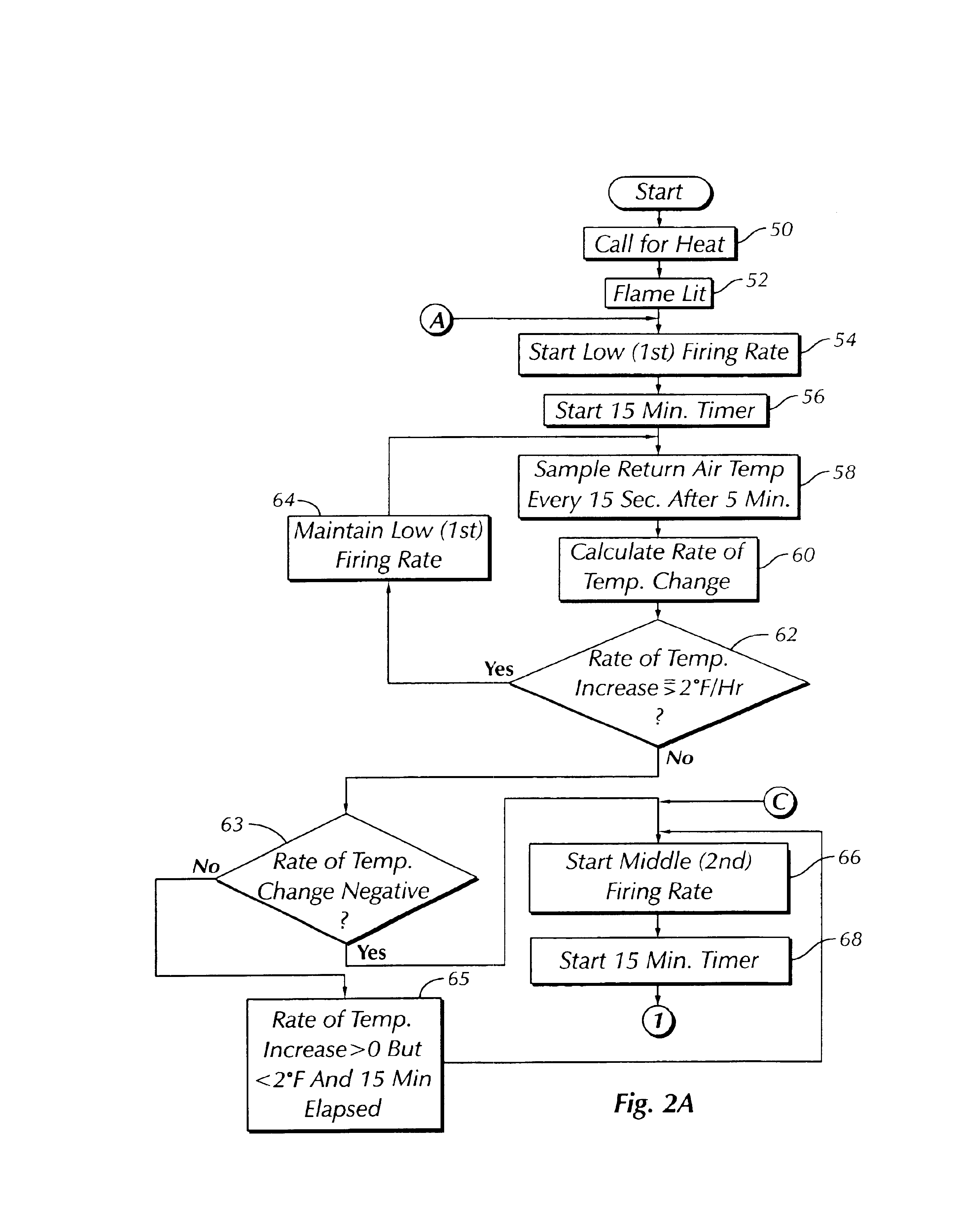

Multistage warm air furnace with single stage thermostat and return air sensor and method of operating same

InactiveUS6925999B2Improve performanceEasy to transformFuel supply regulationMechanical apparatusSingle stageProcess engineering

Owner:AS IP HOLDCO LLC +1

Fuel selectable heating devices

In certain embodiments, an apparatus includes a burner. The apparatus can also include an intake valve that includes an input for receiving fuel from either a first fuel source at a first pressure or a second fuel source at a second pressure. The intake valve can include a first output for directing fuel received from the first fuel source and a second output for directing fuel received from the second fuel source. The intake valve can include an actuator configured to permit fluid communication between the input and the first output or between the input and the second output. The apparatus can include a pressure regulator that can include a first inlet for receiving fuel from the first output of the intake valve and a second inlet for receiving fuel from the second output of the intake valve. The regulator can also include an outlet for directing fuel from the pressure regulator toward the burner.

Owner:PROCOM HEATING

Oxy/fuel combustion system with minimized flue gas recirculation

InactiveUS8316784B2Small sizeLow costFluegas recirculationIndirect carbon-dioxide mitigationCombustion systemCombustion

Owner:AIR PROD & CHEM INC

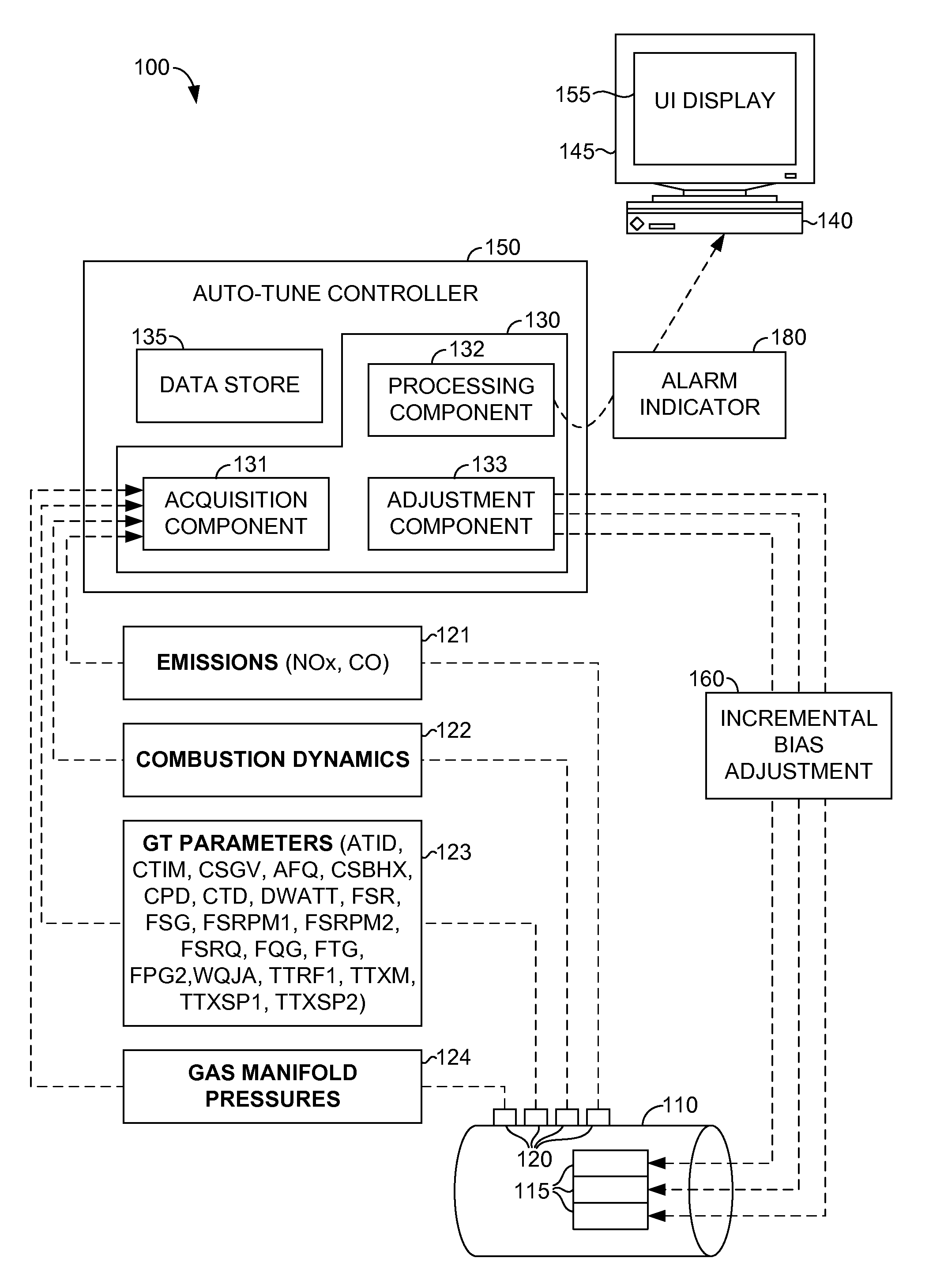

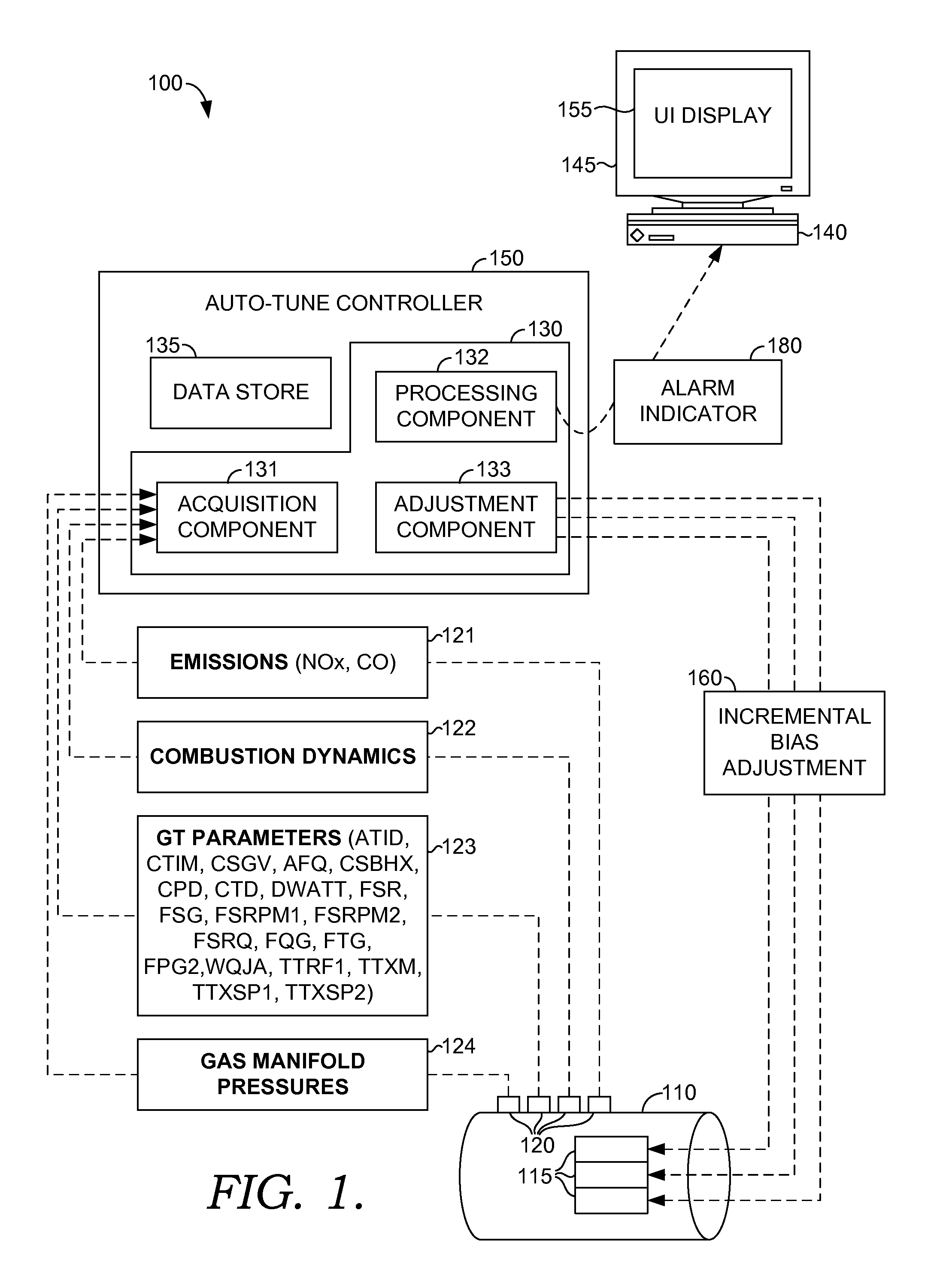

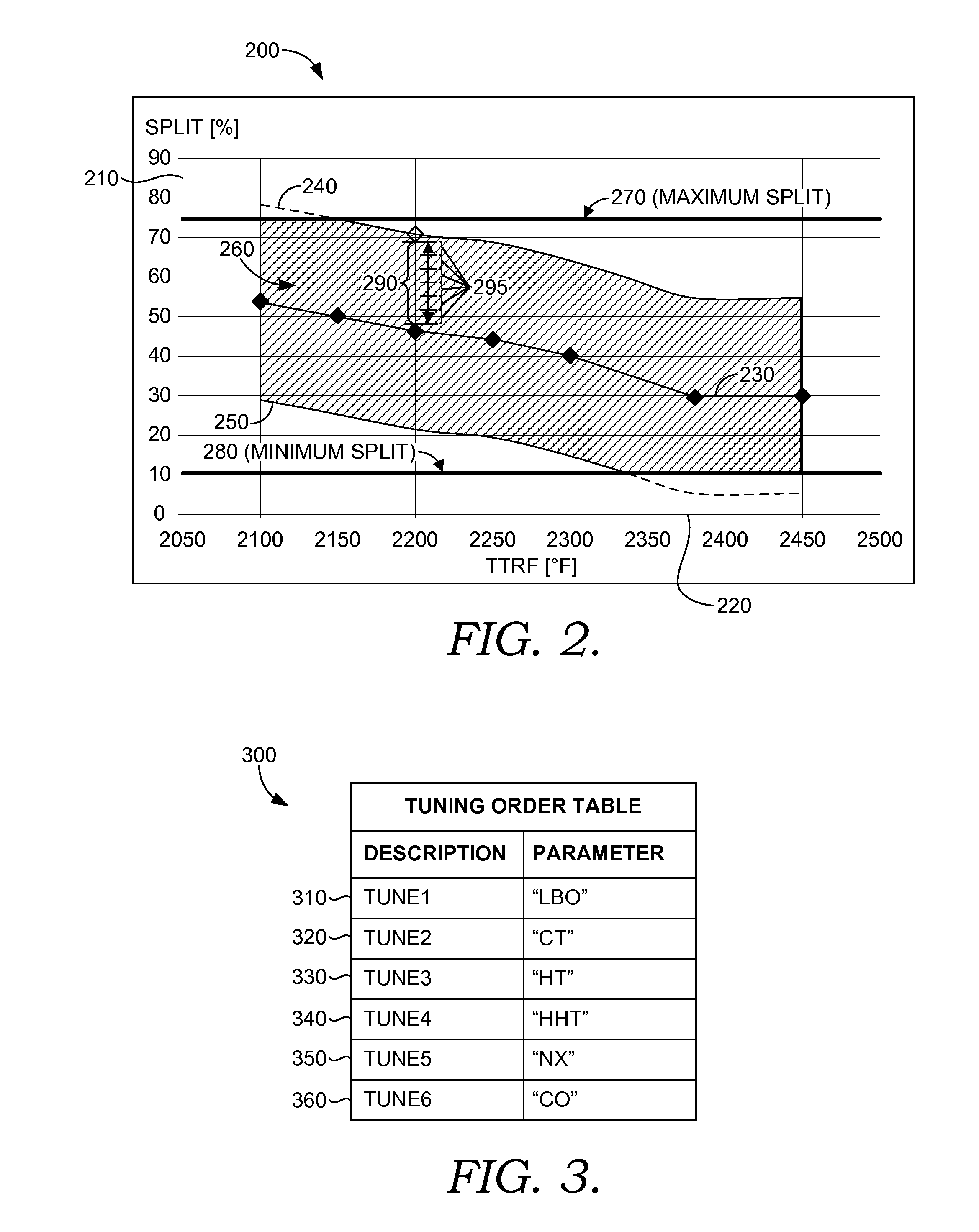

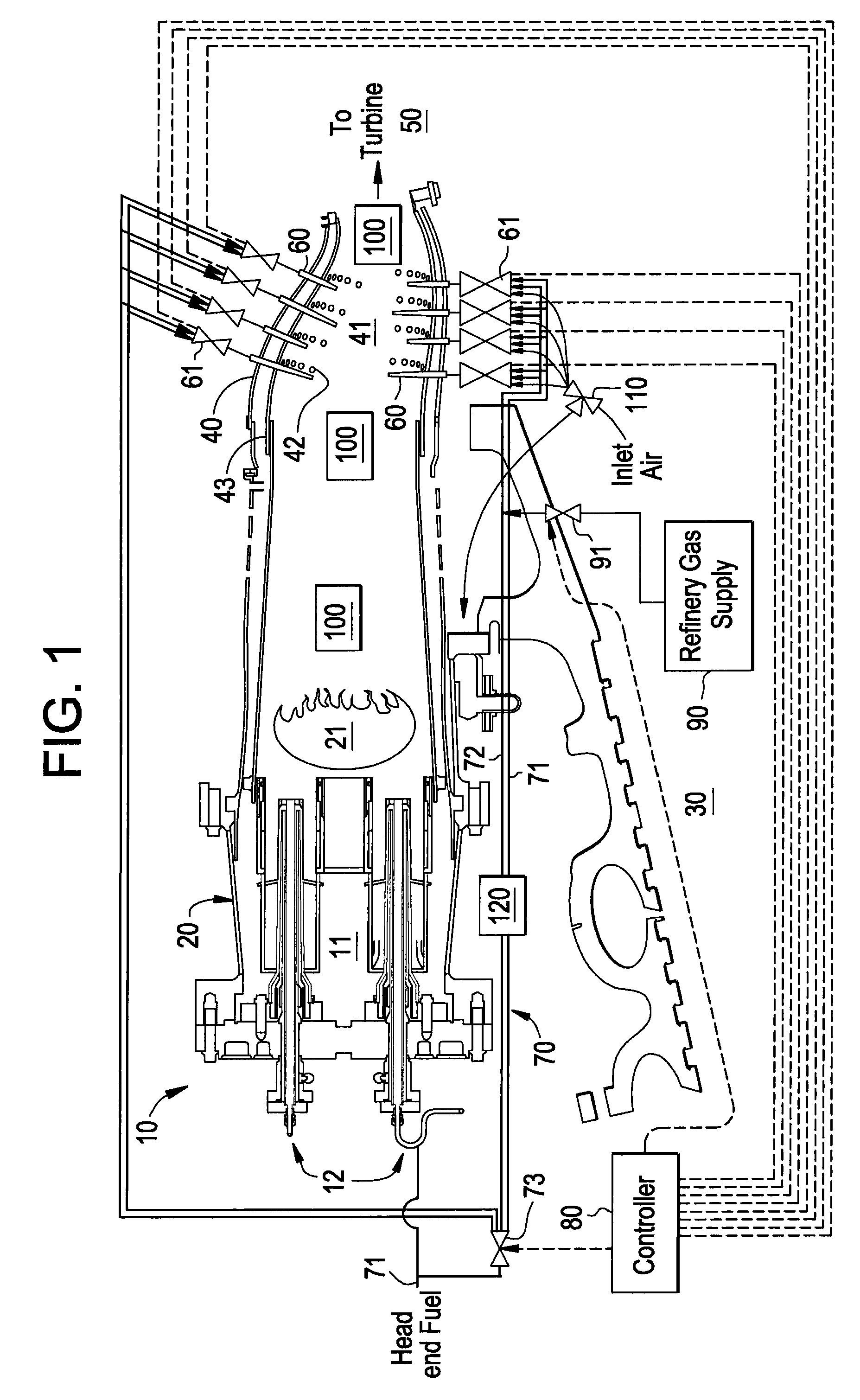

Dynamically Auto-Tuning a Gas Turbine Engine

ActiveUS20110265487A1Save processing timeImprove errorAnalogue computers for vehiclesFuel supply regulationEngineeringCombustion kinetics

Tuning processes implemented by an auto-tune controller are provided for measuring and adjusting the combustion dynamics and the emission composition of a gas turbine (GT) engine via a tuning process. Initially, the tuning process includes monitoring parameters, such as combustion dynamics and emission composition. Upon determining that one or more of the monitored parameters exceed a critical value, these “out-of-tune” parameters are compared to a scanning order table. Upon comparison, the first out-of-tune parameter that is matched within the scanning order table is addressed. The first out-of-tune parameter is then plotted as overlaid slopes on respective graphs, where the graph represents a fuel-flow split. Typically, the slopes are plotted as a particular out-of-tune parameter against a particular fuel-flow split. The slopes for each graph are considered together by taking into account the combined impact on each out-of-tune parameter when a fuel-flow split is selected for adjustment.

Owner:H2 IP UK LTD

Gas turbine with improved part load emissions behavior

InactiveUS20120017601A1Reduce flow rateHigh fuel flow rateFuel supply regulationContinuous combustion chamberCombustorEngineering

In a method for the low-CO emissions part load operation of a gas turbine with sequential combustion, the air ratio (λ) of the operative burners (9) of the second combustor (15) is kept below a maximum air ratio (λmax) at part load In order to reduce the maximum air ratio (λ), a series of modifications in the operating concept of the gas turbine are carried out individually or in combination. One modification is an opening of the row of variable compressor inlet guide vanes (14) before engaging the second combustor (15). For engaging the second combustor, the row of variable compressor inlet guide vanes (14) is quickly closed and fuel is introduced in a synchronized manner into the burner (9) of the second combustor (15). A further modification is the deactivating of individual burners (9) at part load.

Owner:ANSALDO ENERGIA IP UK LTD

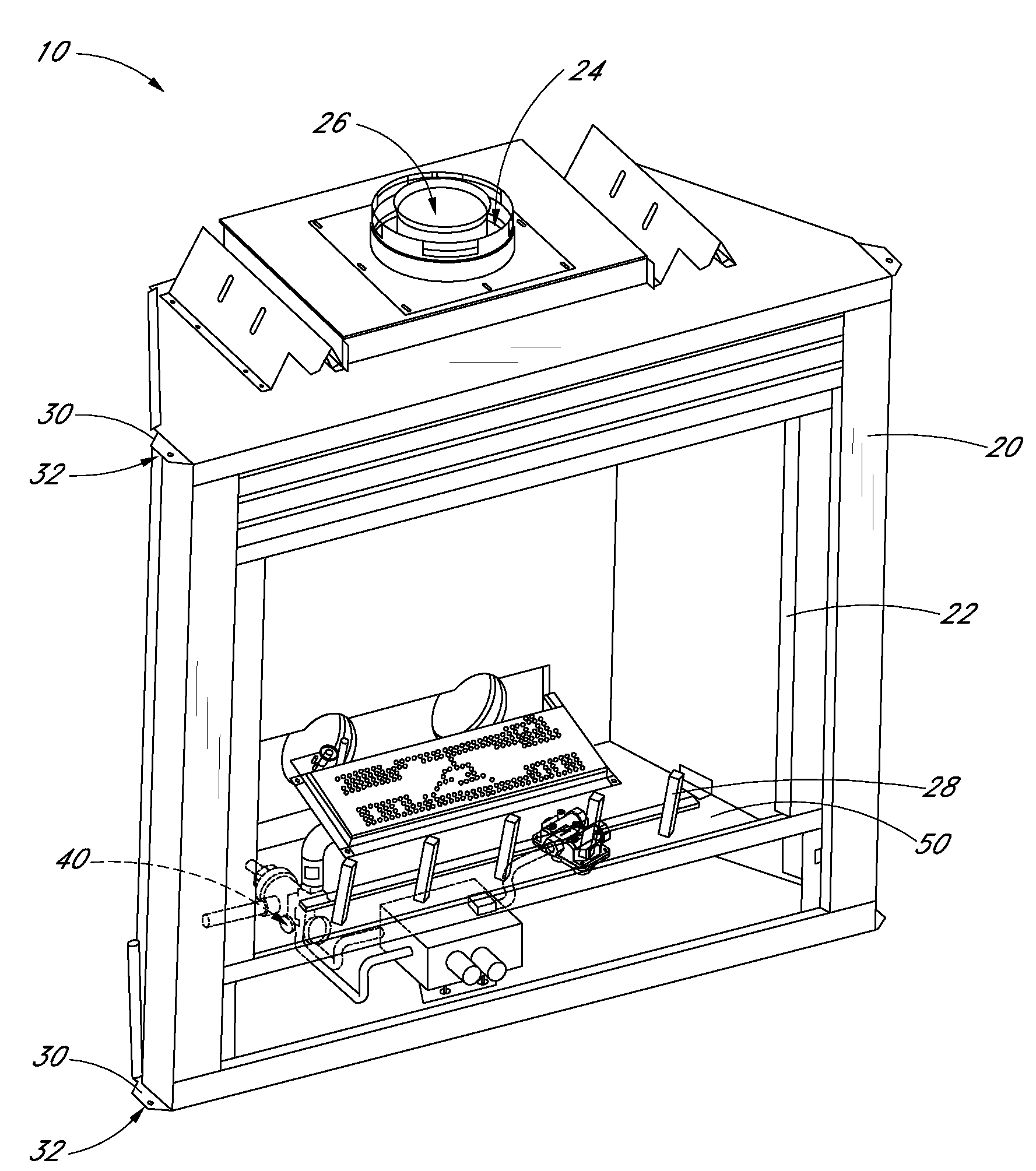

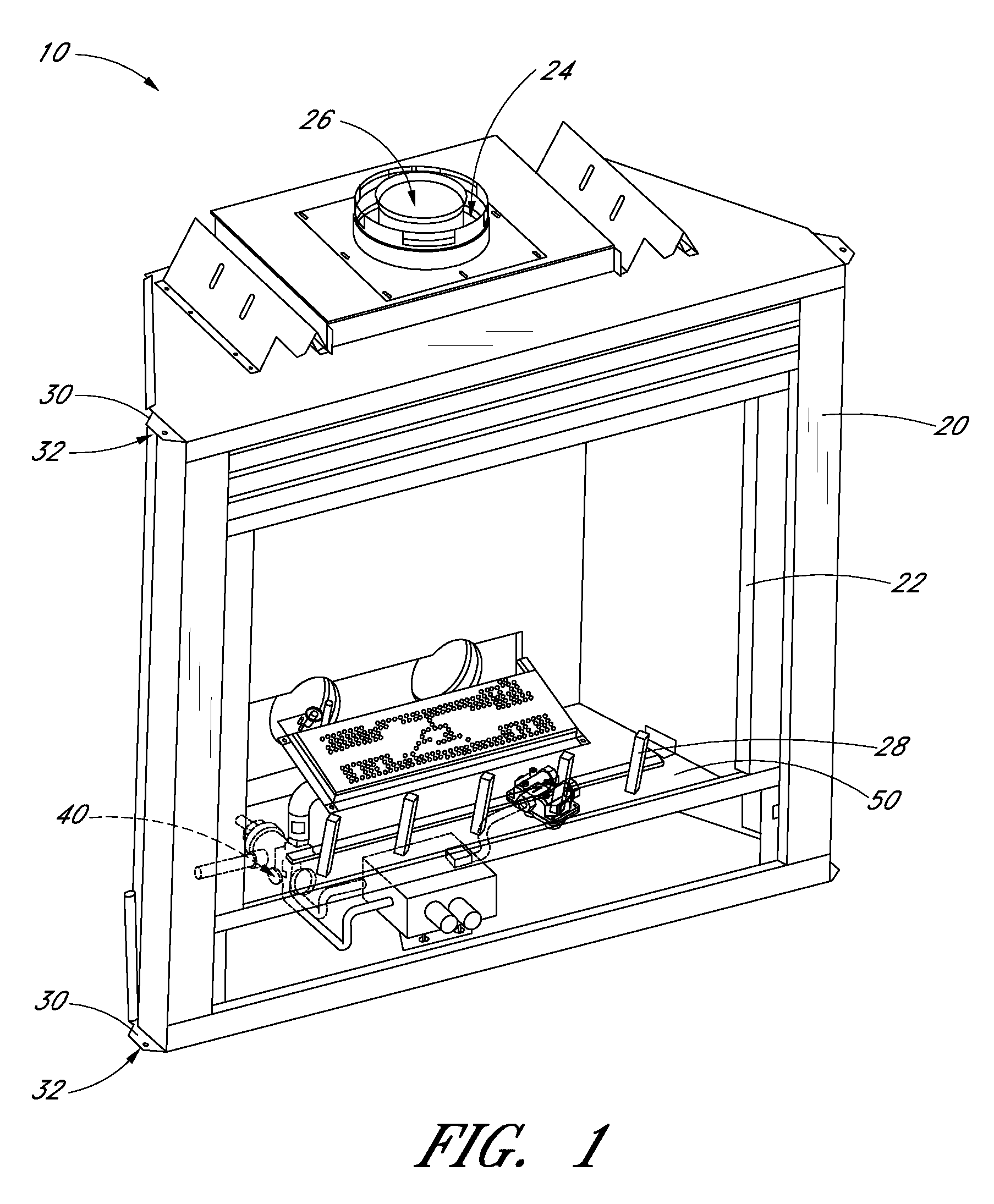

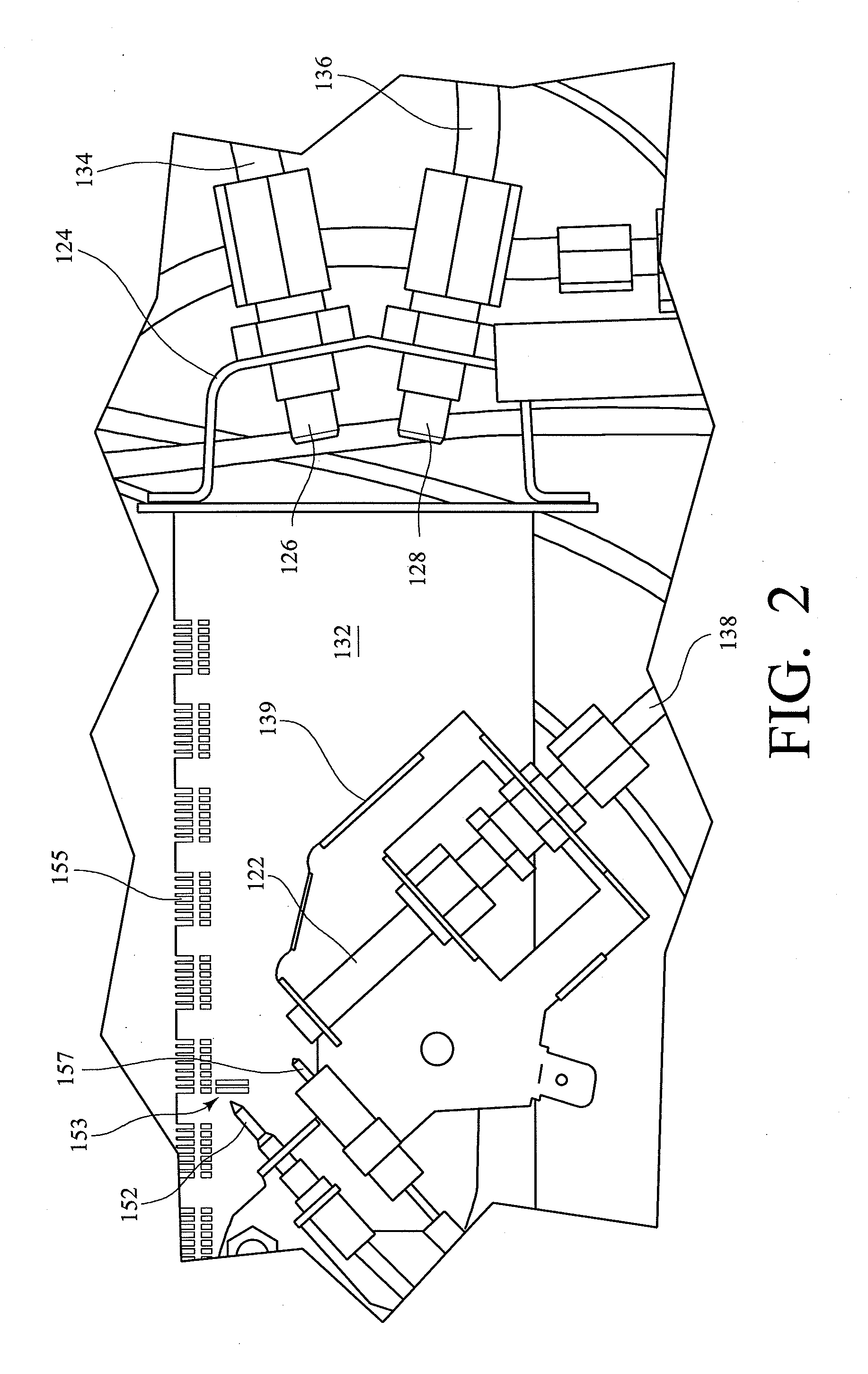

Dual fuel vent free gas heater

ActiveUS20100095945A1Enhanced natural convectionFuel supply regulationAir-treatment apparatus arrangementsControl systemNuclear engineering

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

Heater configured to operate with a first or second fuel

Certain embodiments of a nozzle are configured to dispense a first gas, liquid, or combination thereof at a first pressure in a first mode of operation and dispense a second gas, liquid, or combination thereof at a second pressure in a second mode of operation. In some embodiments, the nozzle is integrated in a heat-producing device, such as, for example, a heater, a fireplace, or a stove. In some embodiments, the heat-producing device including the nozzle can operate with a first combustible fuel at a first pressure, or alternatively, can operate with a second combustible fuel at a second pressure. In some embodiments, the nozzle is used in applications other than heat-producing devices.

Owner:PROCOM HEATING

Method and apparatus for combusting fuel within a gas turbine engine

A method for operating a gas turbine engine including a combustor assembly is provided. The method includes channeling a first fluid through a first nozzle into the combustor assembly, igniting the first fluid within the combustor assembly downstream from the first nozzle, channeling a second fluid through a second nozzle into the combustion assembly when the gas turbine engine attains a speed of greater than 85% of rated speed, igniting the second fluid within the combustor assembly downstream from the second nozzle, terminating a flow of the first fluid through the first nozzle, and channeling the second fluid to the first nozzle.

Owner:GENERAL ELECTRIC CO

Fuel selectable heating devices

In certain embodiments, an apparatus includes a burner. The apparatus can also include an intake valve that includes an input for receiving fuel from either a first fuel source at a first pressure or a second fuel source at a second pressure. The intake valve can include a first output for directing fuel received from the first fuel source and a second output for directing fuel received from the second fuel source. The intake valve can include an actuator configured to permit fluid communication between the input and the first output or between the input and the second output. The apparatus can include a pressure regulator that can include a first inlet for receiving fuel from the first output of the intake valve and a second inlet for receiving fuel from the second output of the intake valve. The regulator can also include an outlet for directing fuel from the pressure regulator toward the burner.

Owner:PROCOM HEATING

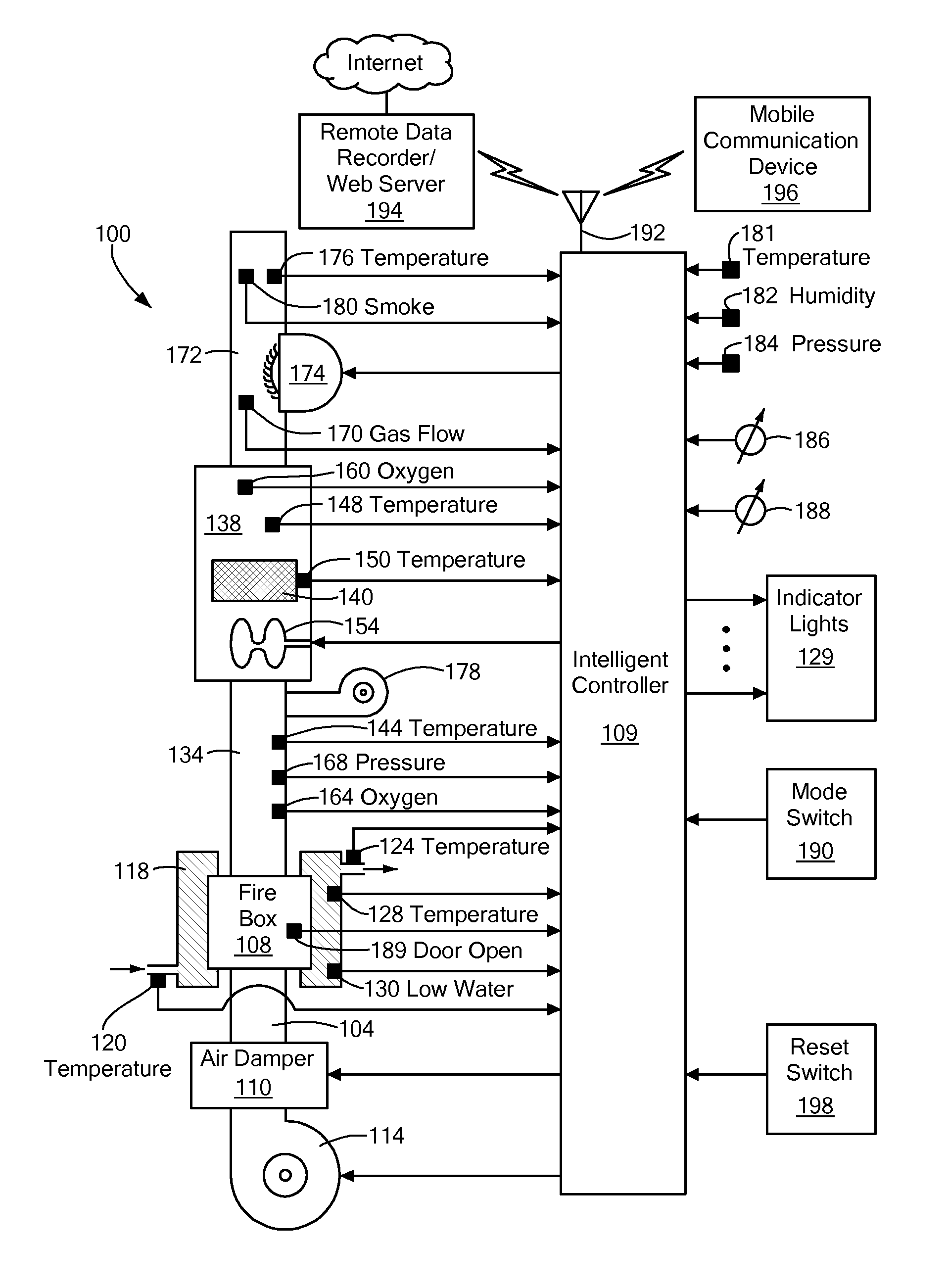

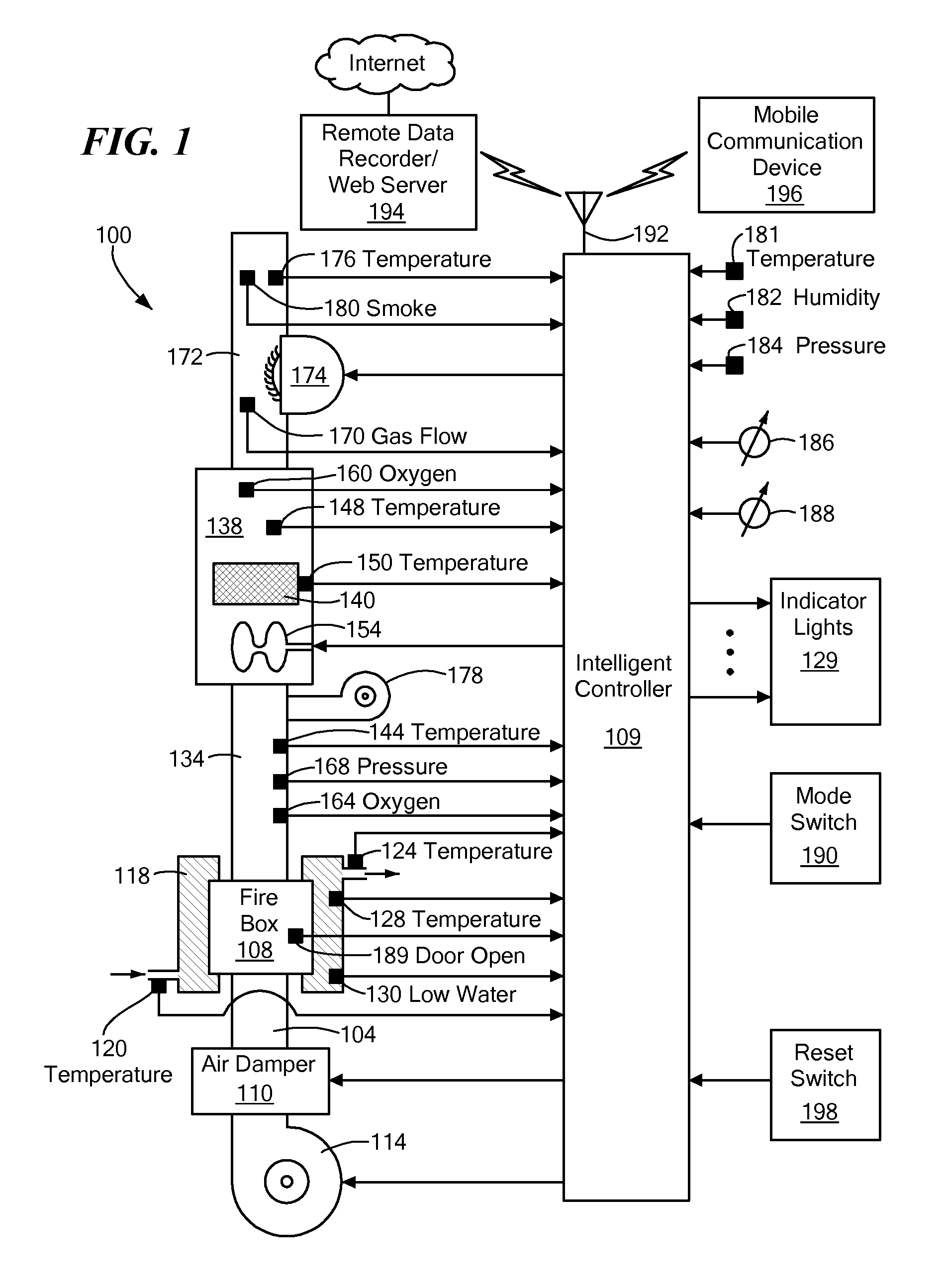

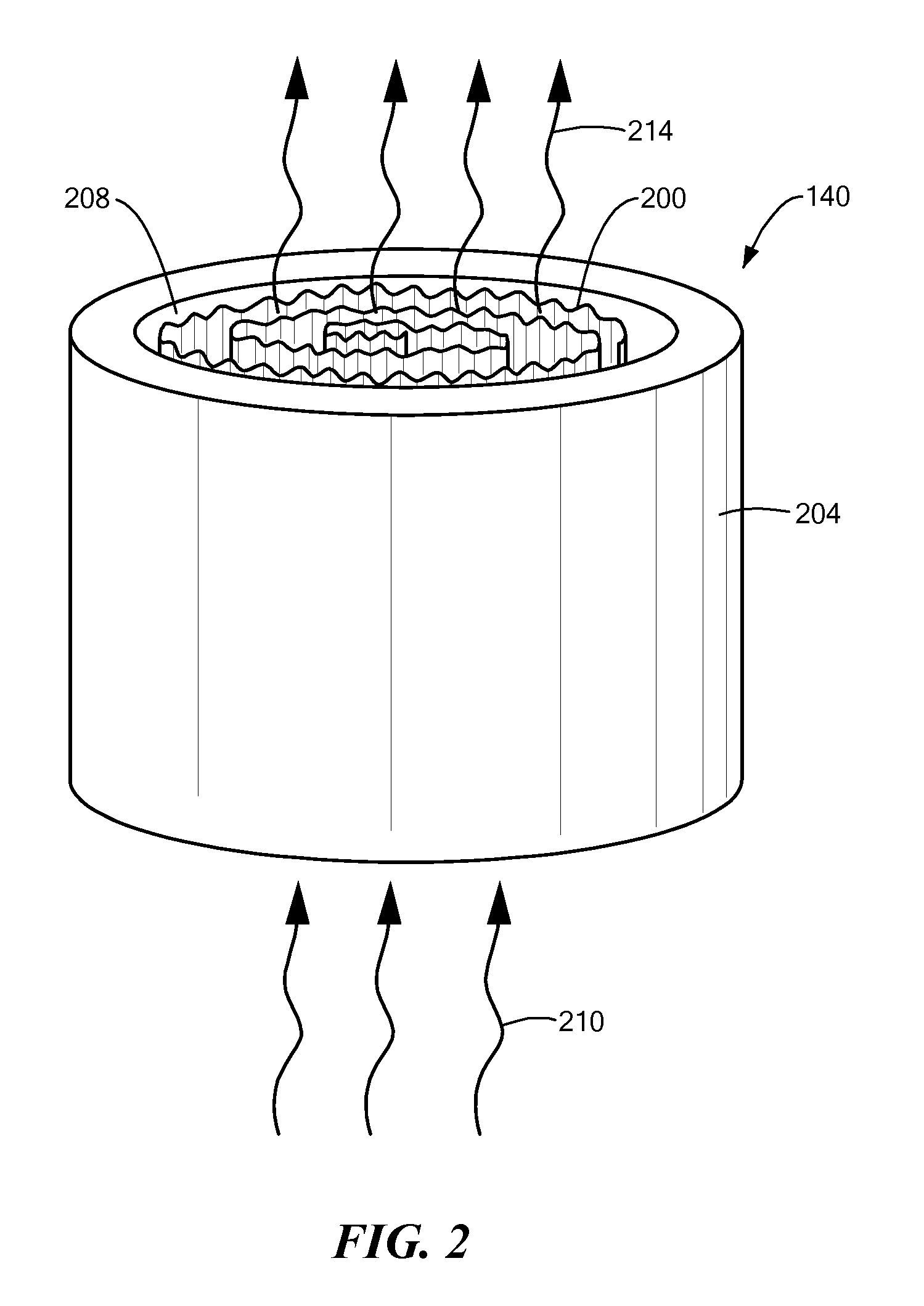

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

Multiple gas pilot burner

ActiveUS20090280448A1Small sizeLow costIncandescent ignitionPipeline expansion-compensationPower flowThermocouple

A multiple gas pilot burner assembly for a household heating appliance. The pilot burner includes an injector having a first conduit for receiving a flow of a first combustible fluid, a second conduit for receiving a flow of a second combustible fluid and a third conduit connected to and in fluid communication with the first and second conduits which is configured to receive the flow of the first combustible fluid from the first conduit or the flow of the second combustible fluid from the second conduit. A single nozzle at the outlet of the third conduit is provided for supplying a pilot flame. The assembly also includes a single flame igniter positioned to cause an ignition of the pilot flame at the nozzle and also a single thermocouple positioned to be heated by the pilot flame and to generate an electrical current when heated.

Owner:COPRECITEC

Temperature control device and method

ActiveUS20090183729A1Control flowFuel supply regulationBoiling over preventionElectronic controllerThermal state

A temperature control system for safely controlling the rate of flow of a flammable fluid at generally constant pressure is disclosed. The system may include a flow control apparatus that is free of a regulator mechanism, for affecting the flow of the fluid. The flow control apparatus may be operable between at least a first flow rate and a second flow rate, and may have at least one upstream opening and at least one downstream opening. The system may also include a first burner in fluid communication with the downstream opening of the flow control apparatus and a conduit in fluid communication at one end thereof with the upstream opening of the flow control apparatus, and configured at the other end thereof for connection to a fuel supply. A thermocouple may be located in the vicinity of the burner or an appliance used in conjunction with the burner. The thermocouple converts a sensed thermal state into an electrical signal. An electronic controller, in communication with the flow control apparatus, for activating the flow control apparatus to one of said first and second flow rates, and being in communication with the thermocouple for receiving the electrical signal from the thermocouple is also provided. An interface connected to the controller for manually inputting a desired temperature may be included, wherein the controller is operable to automatically cycle the flow control apparatus between the first and second flow rates until the temperature sensed by the thermocouple is similar to the desired temperature.

Owner:WOLFEDALE ENG

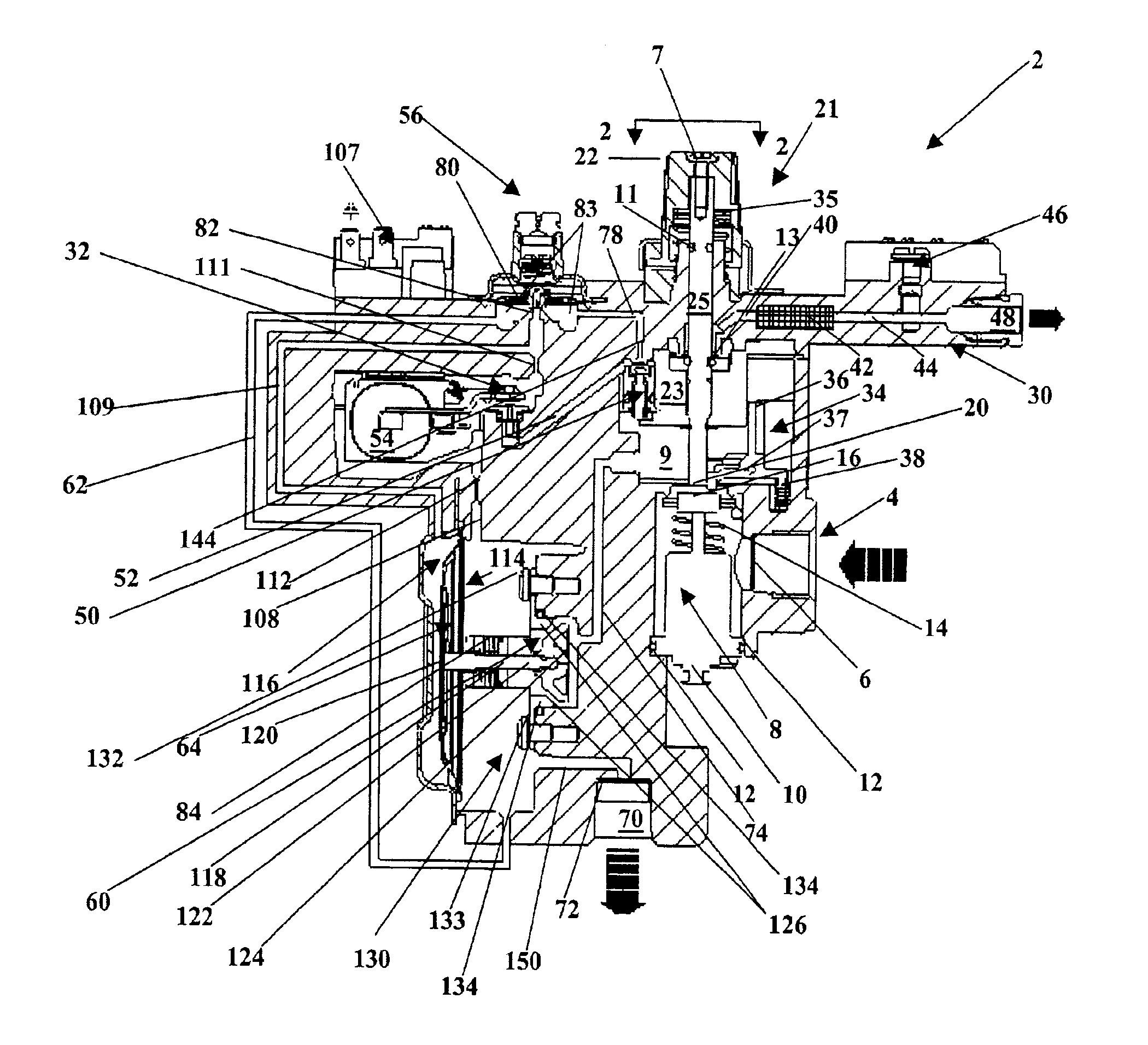

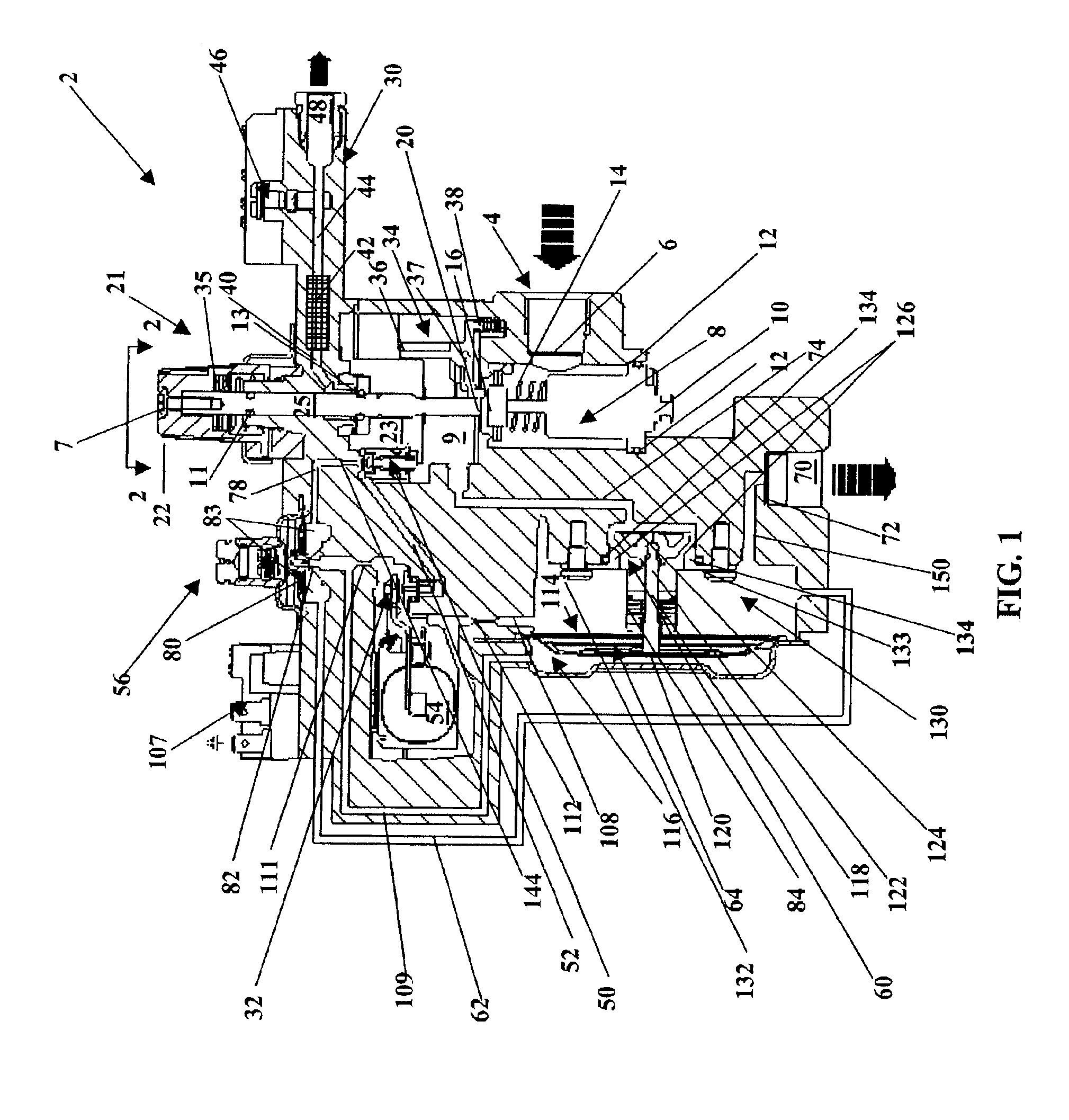

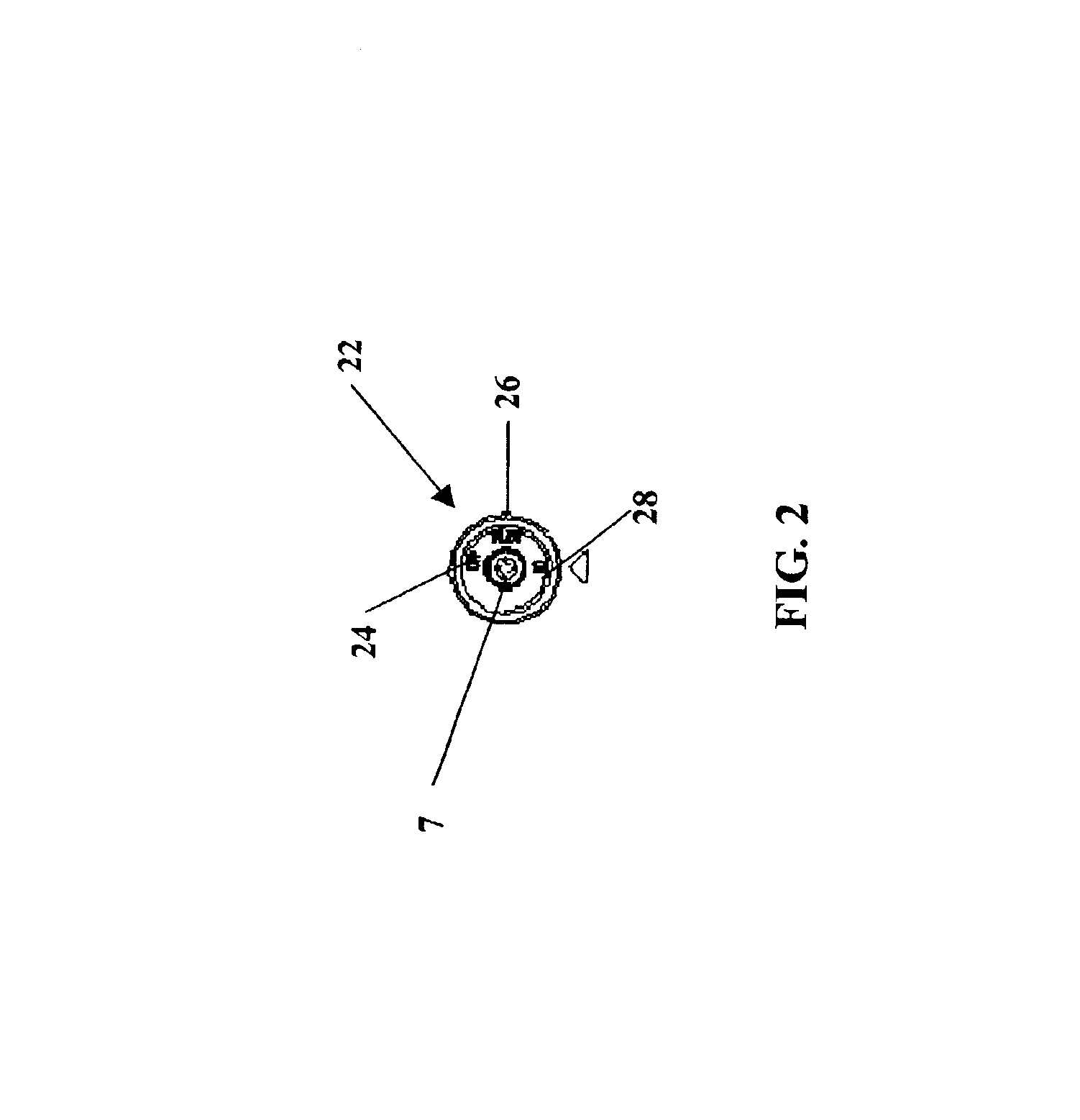

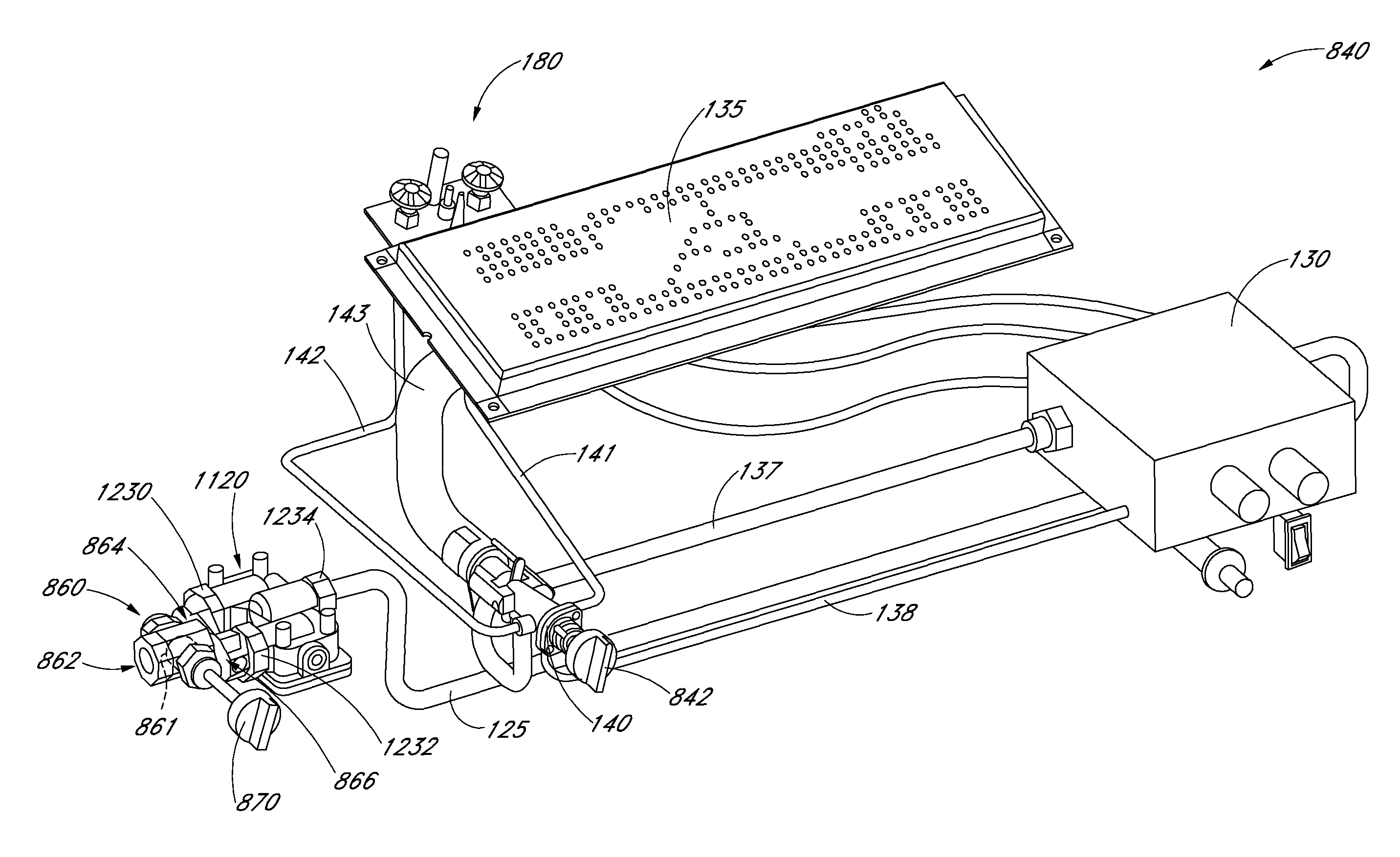

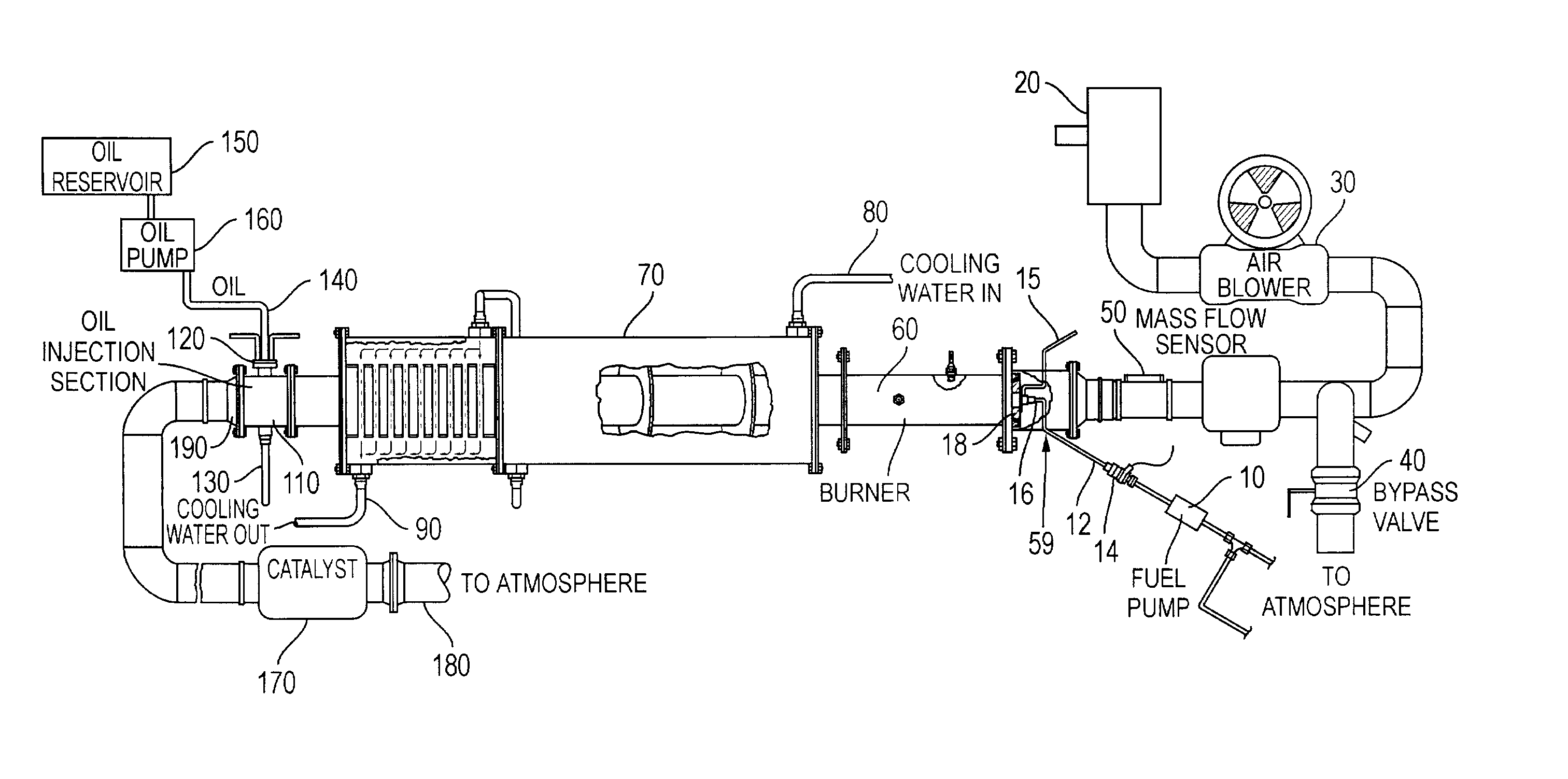

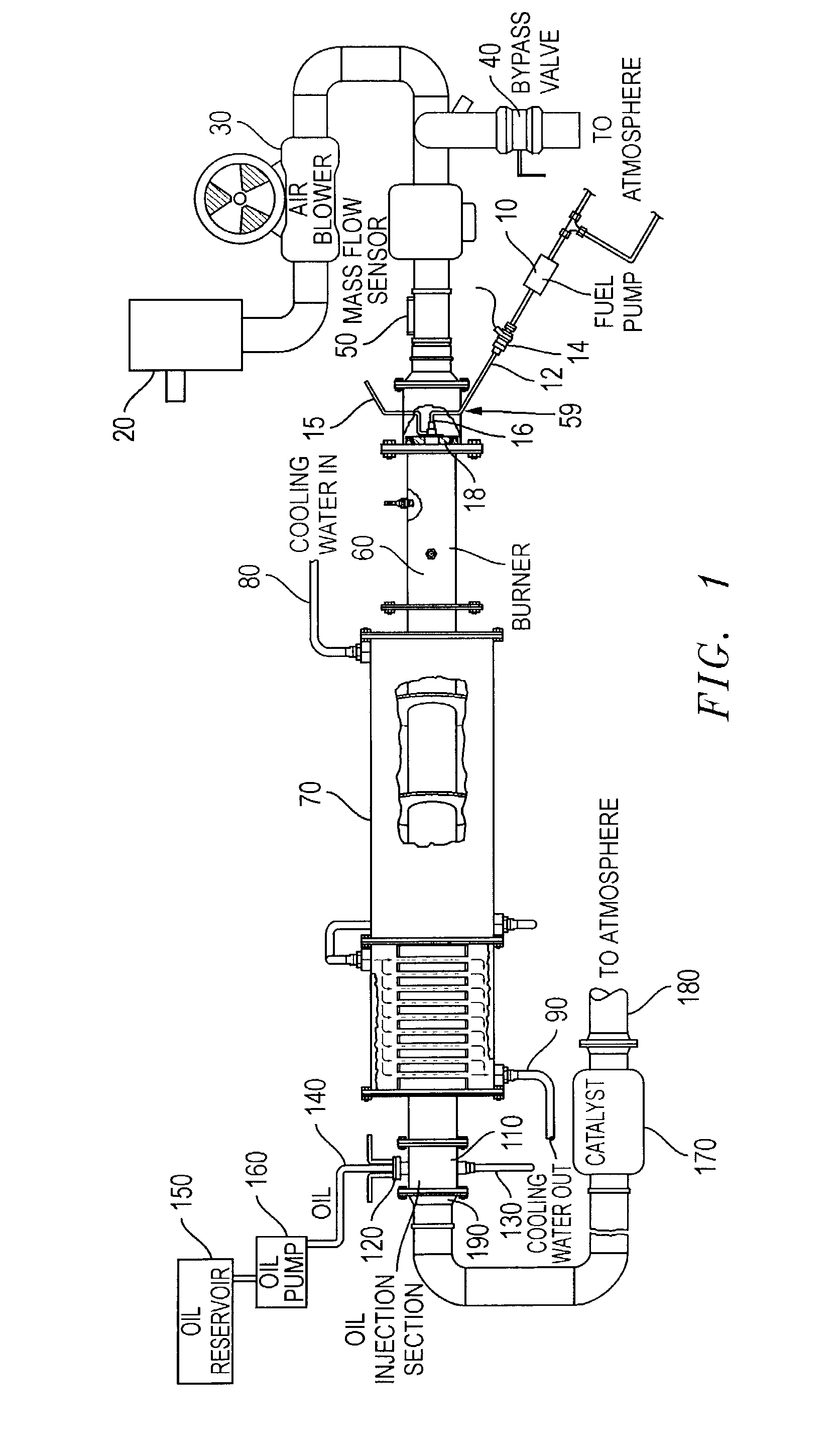

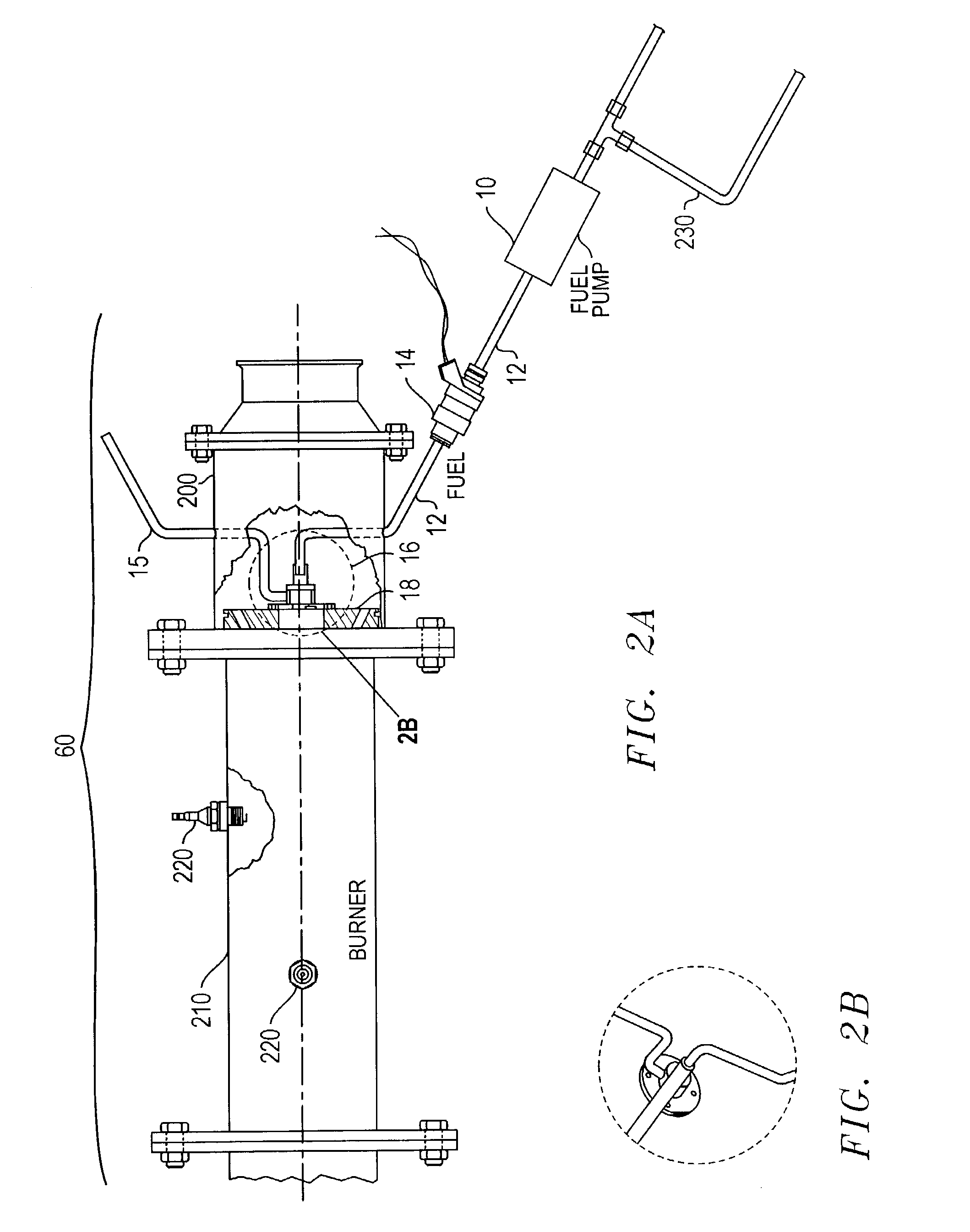

Method and apparatus for testing catalytic converter durability

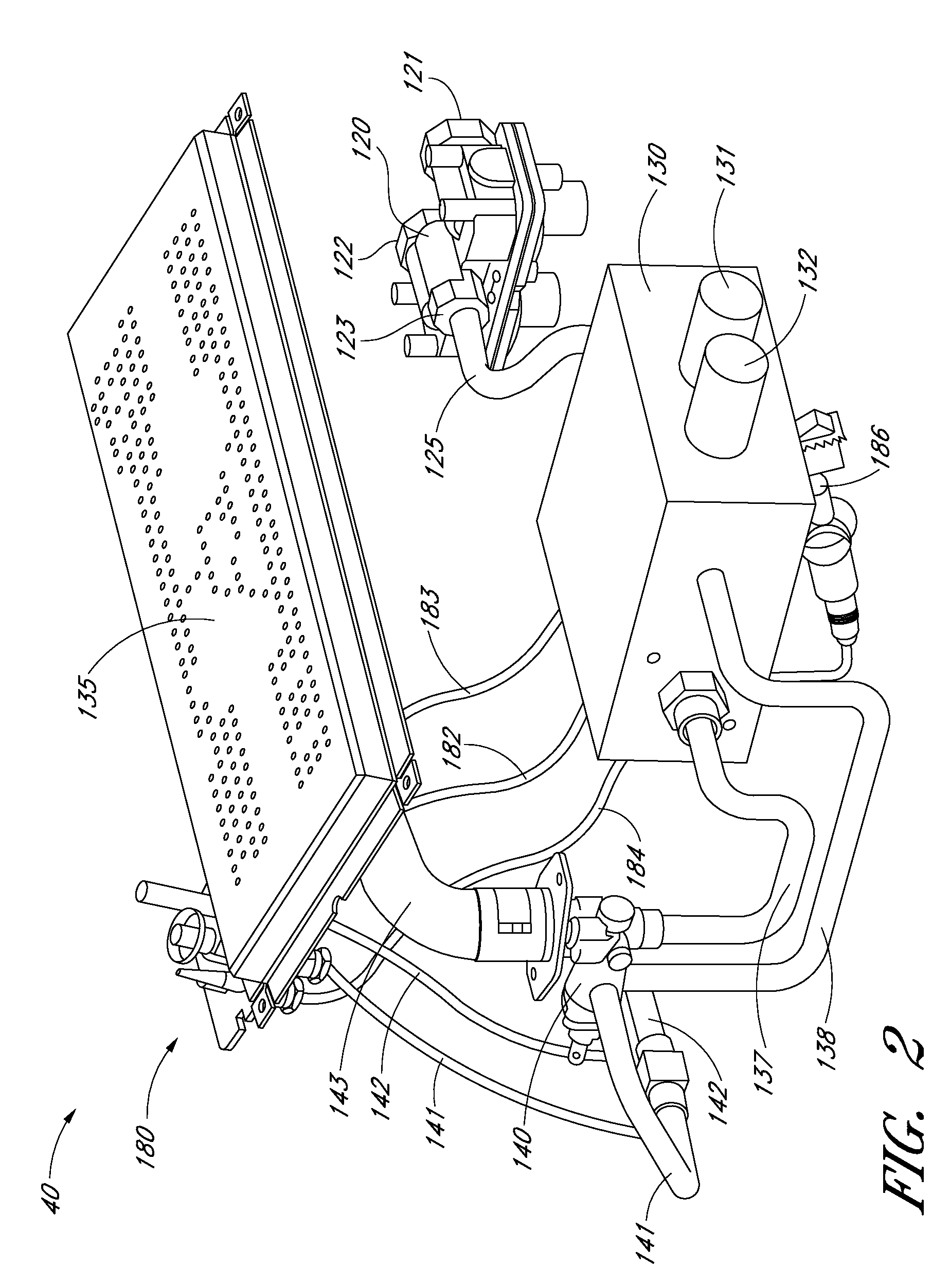

InactiveUS20030079520A1Internal combustion piston enginesExhaust apparatusCombustorChemical measurement

The present application relates in general to an apparatus and to methods for testing the performance of an automotive catalytic converter under conditions simulating those which occur in motor vehicles over extended driving conditions. The application provides a novel swirl plate and a novel fuel injector which enable the burner to run stoichiometric for extended periods of time.

Owner:SOUTHWEST RES INST

Dual fuel vent free gas heater

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

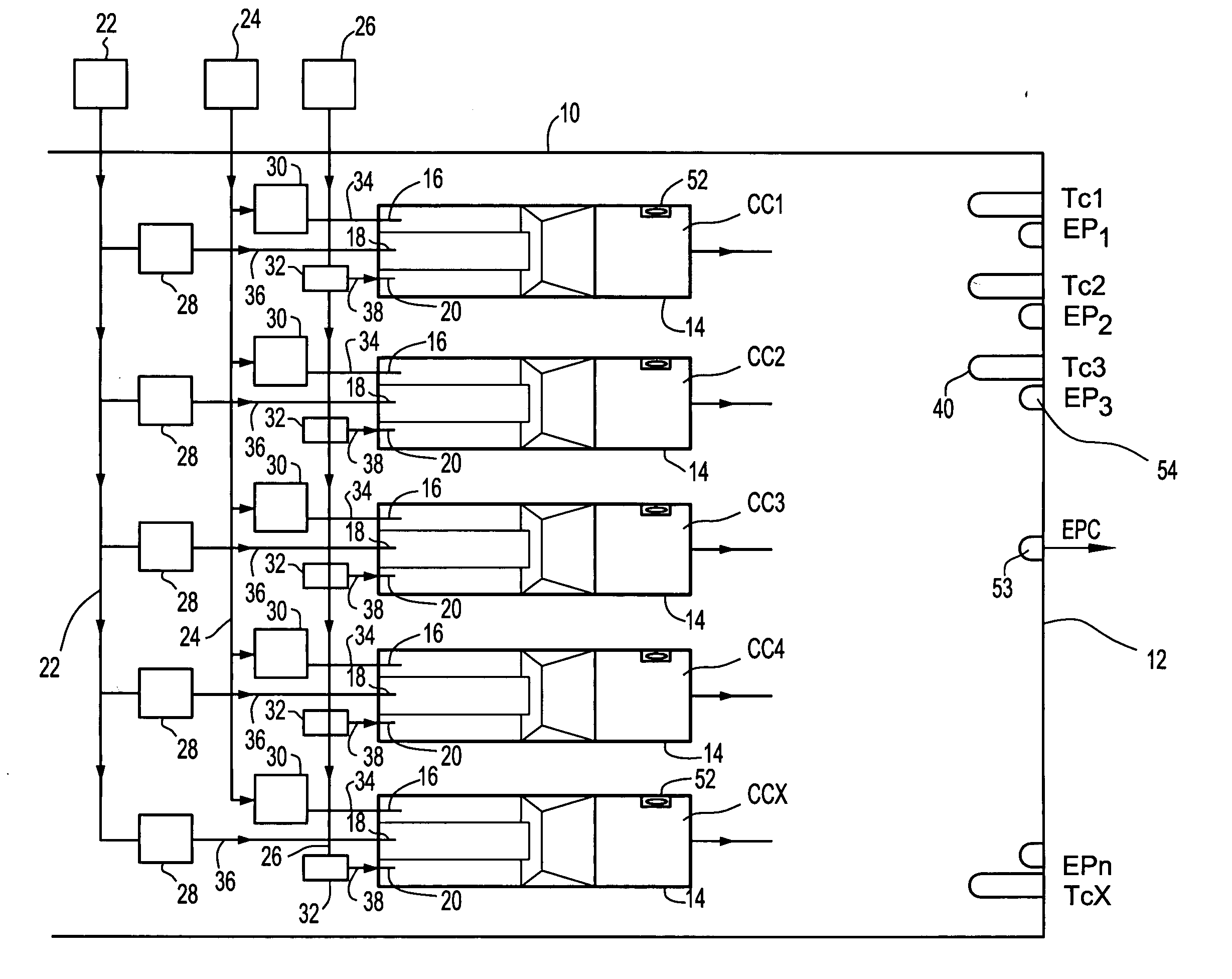

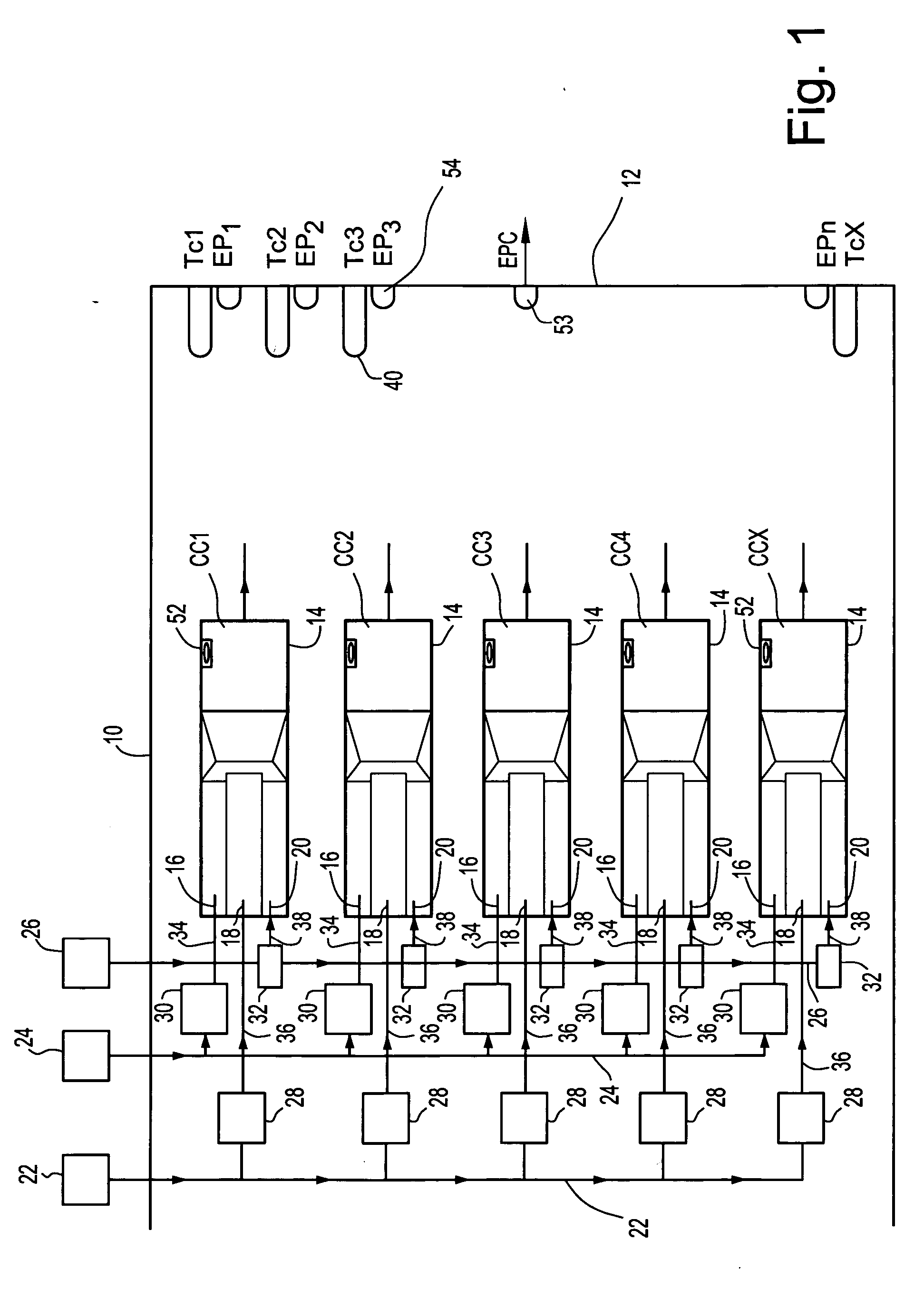

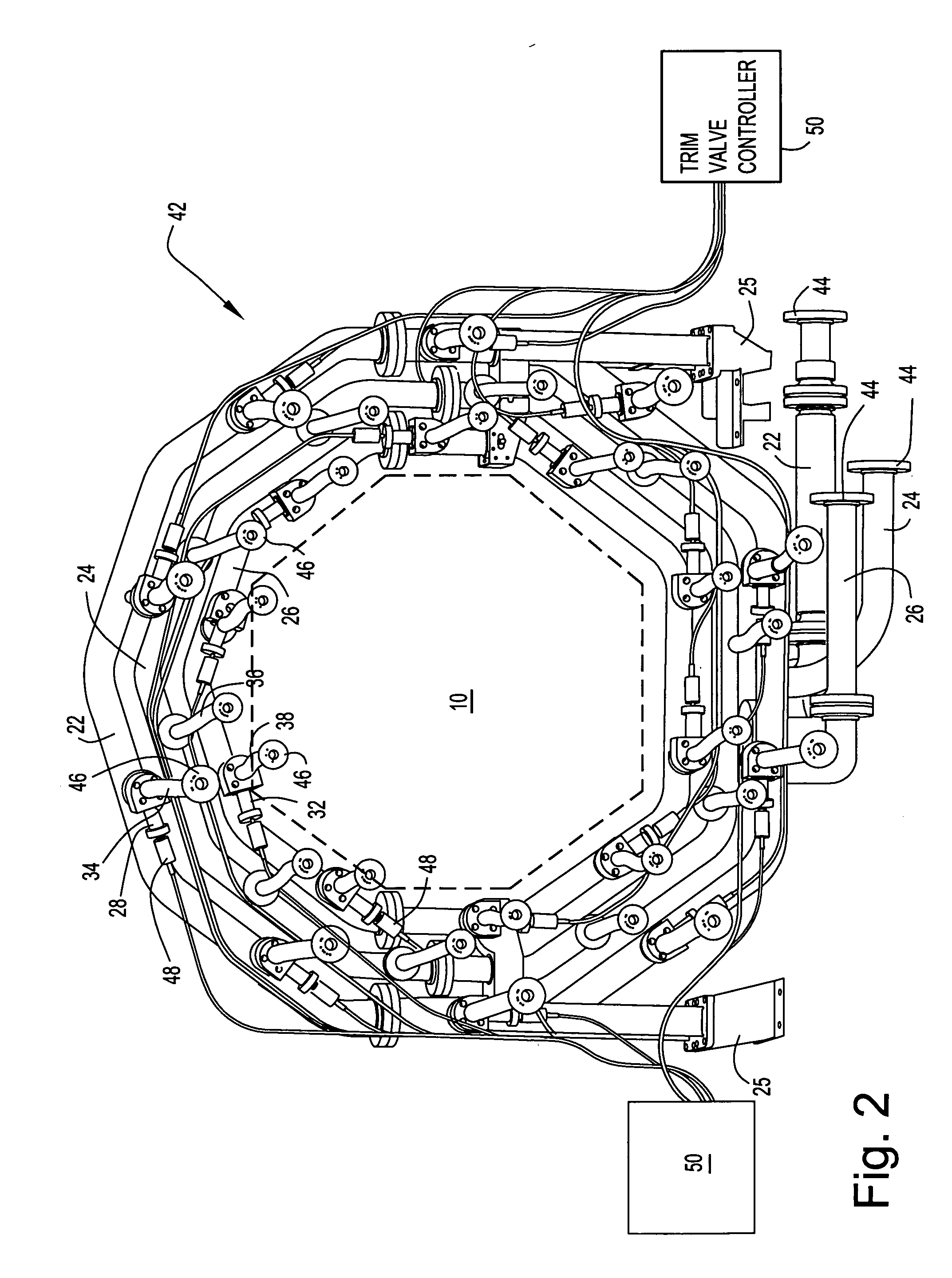

Method and apparatus for automatically actuating fuel trim valves in a gas

InactiveUS20060107666A1Minimized pressure dropClosely arrangedContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustion systemCombustion chamber

A gas turbine combustion system having: a plurality of combustion chambers; a plurality of fuel nozzles for each of combustion chamber; a plurality of manifolds for supplying fuel to at least one fuel nozzle in each of the combustion chambers; each of the manifolds having fuel trim control valves for the fuel nozzles, wherein the fuel trim control valves are mounted on the multiple manifolds for metering the fuel to the fuel nozzles in the combustion chambers, and a trim valve controller automatically actuates one or more of the fuel trim valves to adjust fuel to the fuel nozzles based on gas turbine operating conditions.

Owner:GENERAL ELECTRIC CO

Late lean injection with expanded fuel flexibility

ActiveUS20100170251A1Fuel supply regulationTurbine/propulsion fuel supply systemsCombustorEngineering

A gas turbine engine is provided and includes a fuel circuit, including multiple fuel circuit branches, a combustor having a first interior in which a first fuel supplied thereto by any one of the multiple fuel circuit branches is combustible, a turbine, a transition zone, including a second interior in which a second fuel supplied thereto by any one of the multiple fuel circuit branches, the second fuel including gas receivable by the fuel circuit from an external source, and the products of the combustion of the first fuel are combustible, the transition zone being disposed to fluidly couple the combustor and the turbine to one another, and a plurality of fuel injectors which supply the second fuel to the second interior in any one of a single axial stage, multiple axial stages, a single axial circumferential stage and multiple axial circumferential stages.

Owner:GENERAL ELECTRIC CO

Dual fuel heating source

ActiveUS20100330513A1Avoid flowLiquid fuel feeder/distributionFuel supply regulationEngineeringMechanical engineering

A dual fuel heating source can have a fuel selector valve for selecting between a first fuel and a second fuel different from the first. The dual fuel heating source may selectively have a regulator unit, and an outlet valve. The regulator unit can be configured to regulate the pressure of two different fuels. The outlet valve can be connected to the fuel selector valve such that selecting a fuel can determine the path fuel will flow through the outlet valve and also out of the heating source.

Owner:DENG DAVID

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com