Patents

Literature

241results about "Combustion signal processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

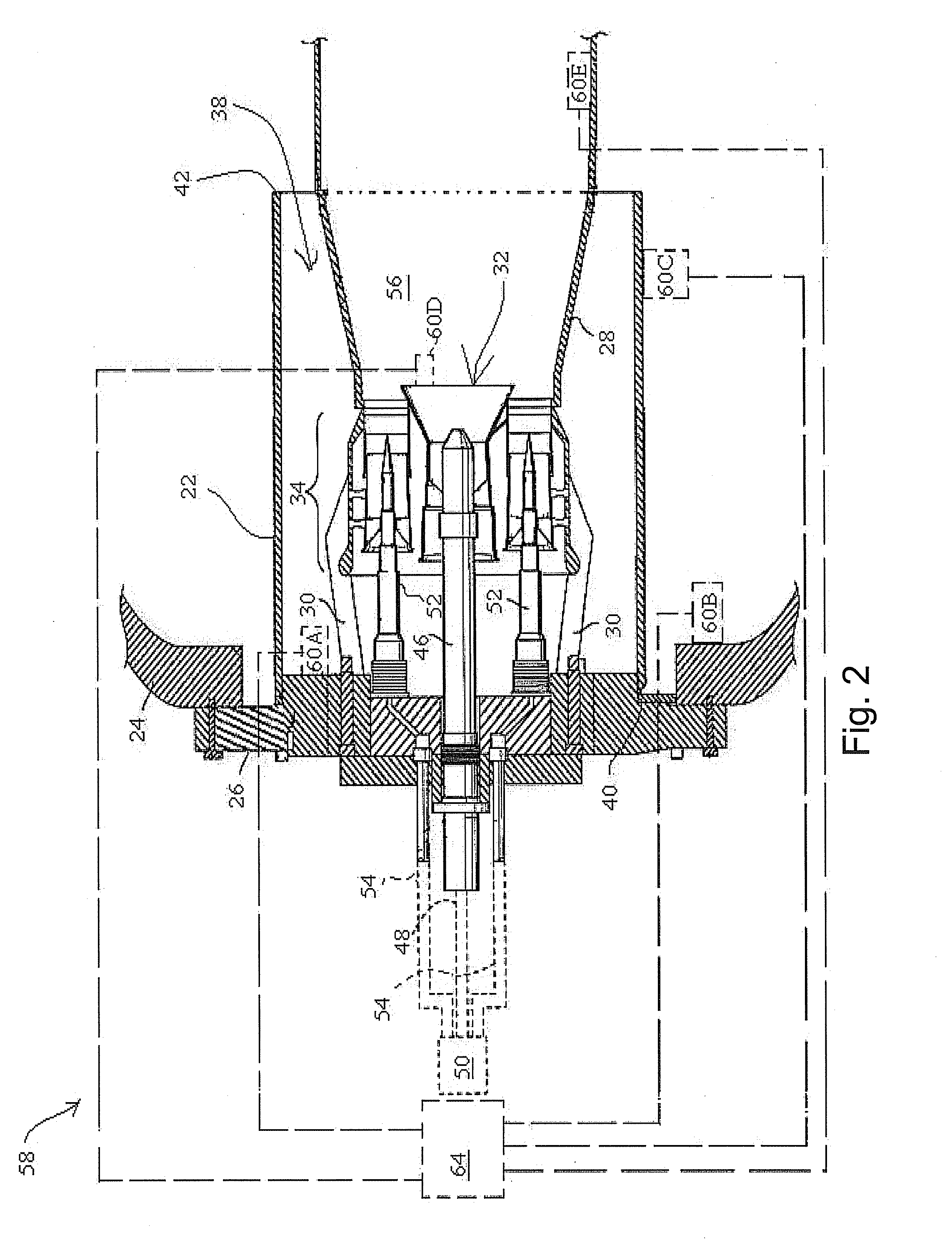

Thermostat control system providing power saving transmissions

ActiveUS7537171B2Reduce power consumptionMaintain reliabilityResonant long antennasTransmission systemsControl systemThermostat

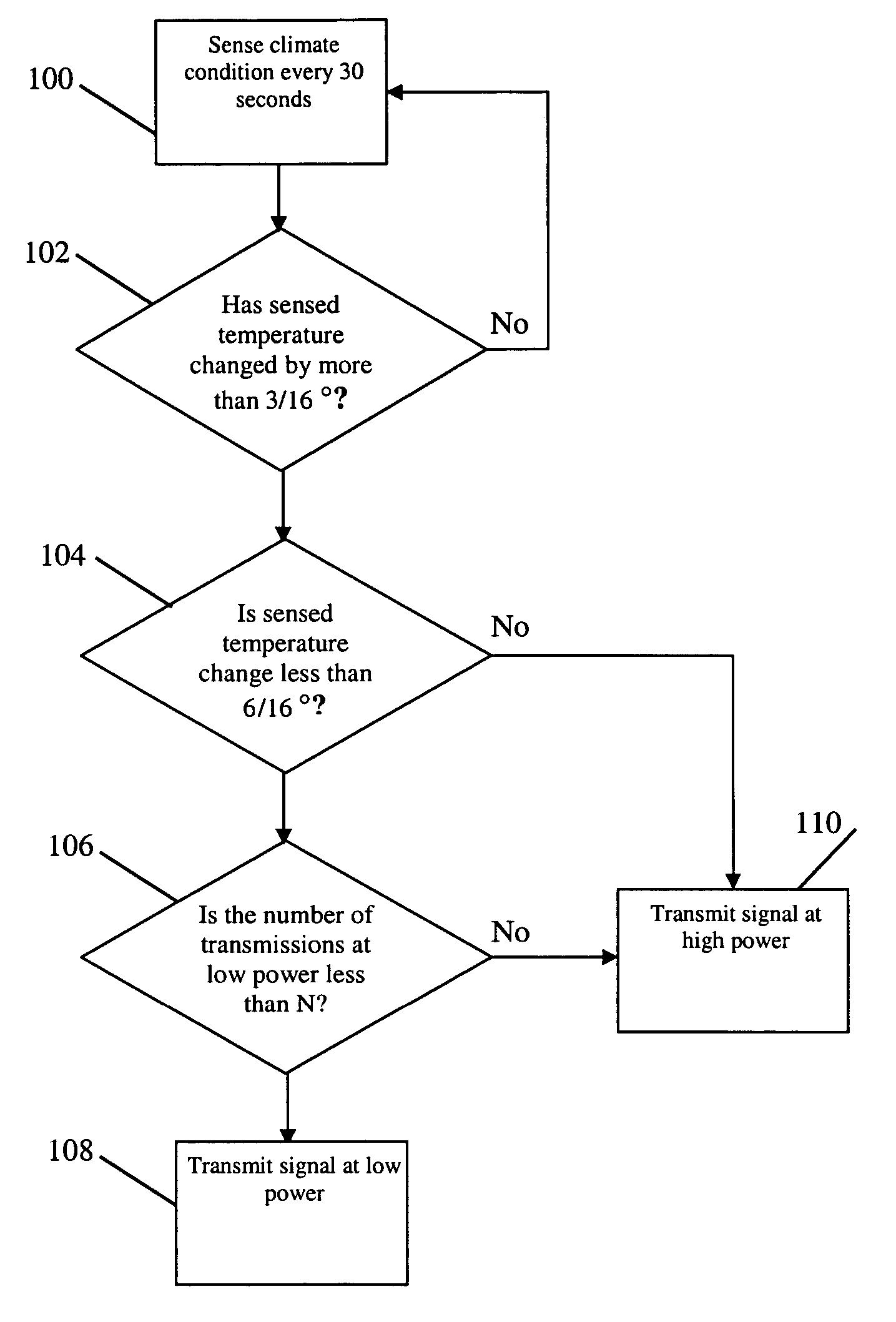

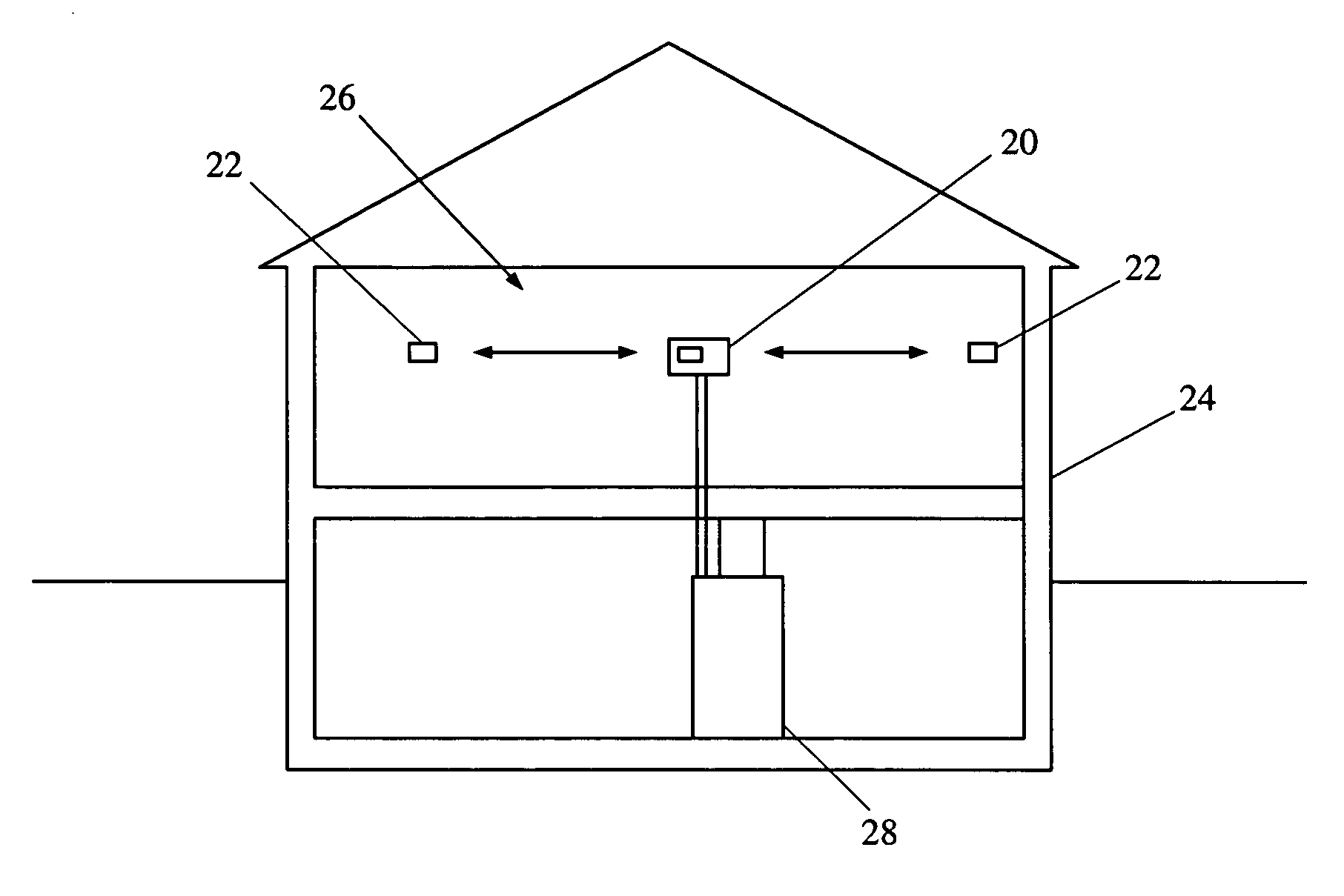

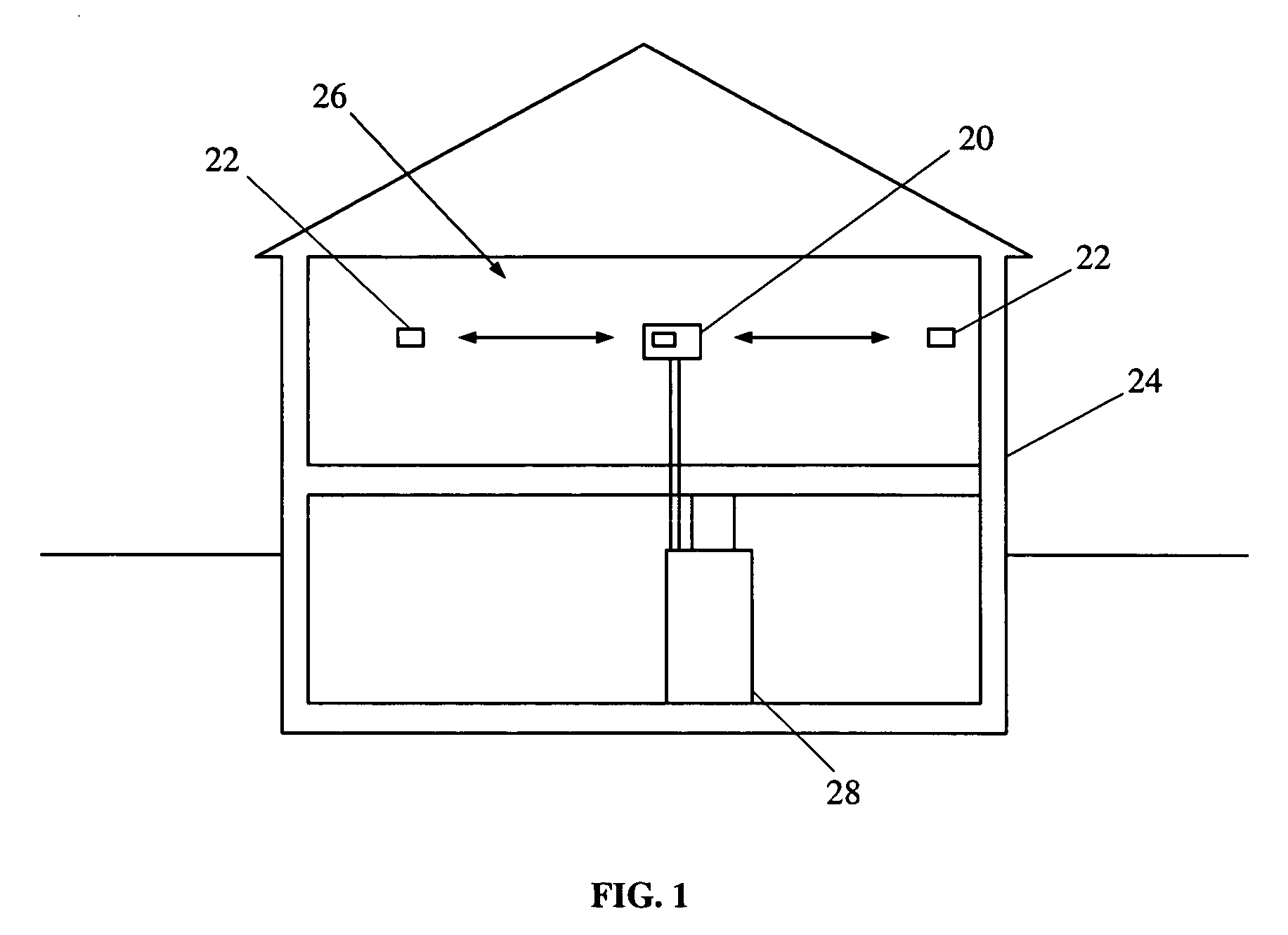

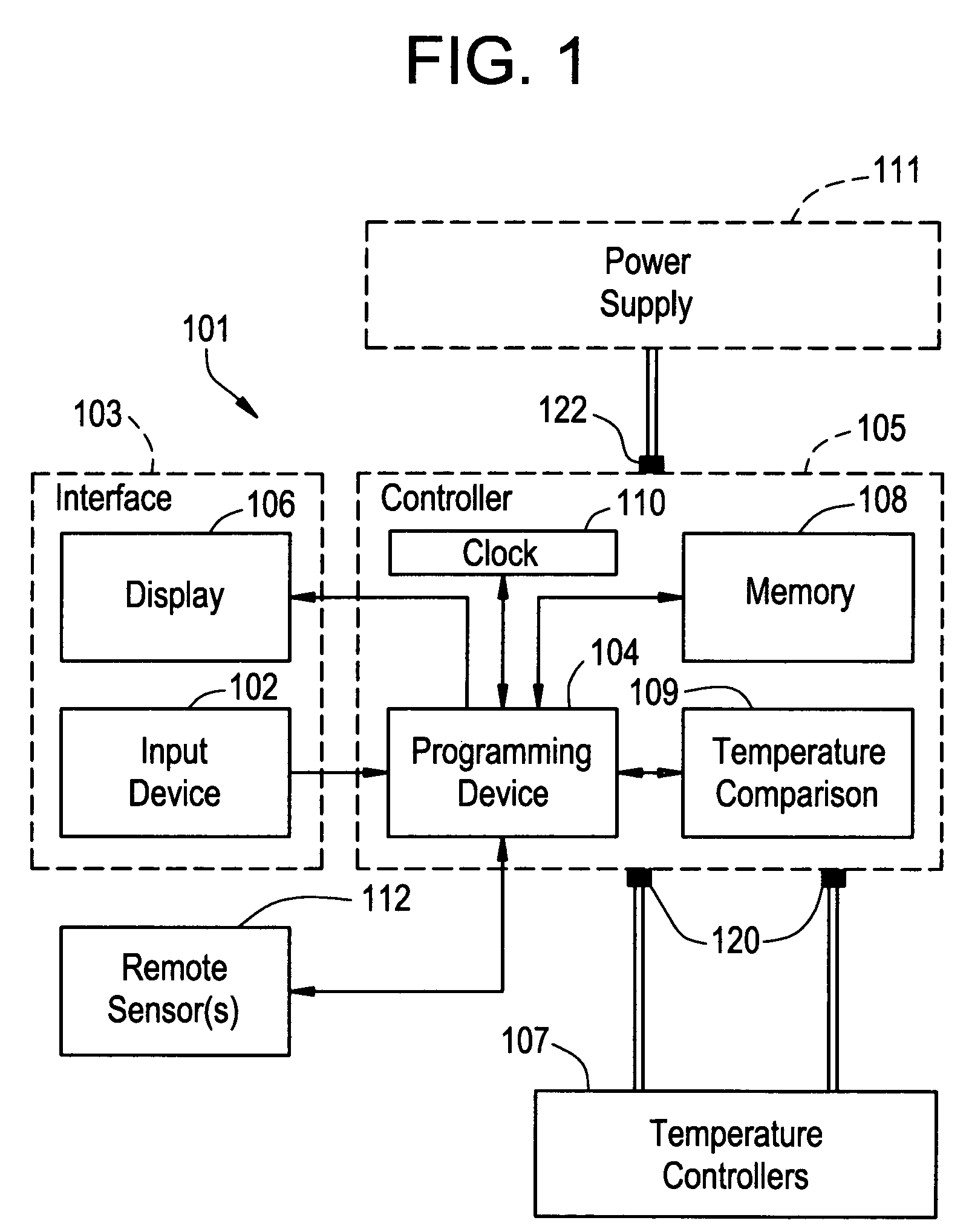

A thermostat control system having remote devices and / or other internally powered devices provides transmissions at different power levels and at different data transfer rates to conserve power life. Thermostat control system components and devices may be powered by replaceable power supplies that are conserved by transmitting at a lower power level more often than at a higher power level. A higher power level transmission is provided at a lower data transfer rate, and a lower power level transmission is provided at a higher data transfer rate. A higher power transmission is provided periodically to ensure reliable communication of temperature information.

Owner:COPELAND COMFORT CONTROL LP

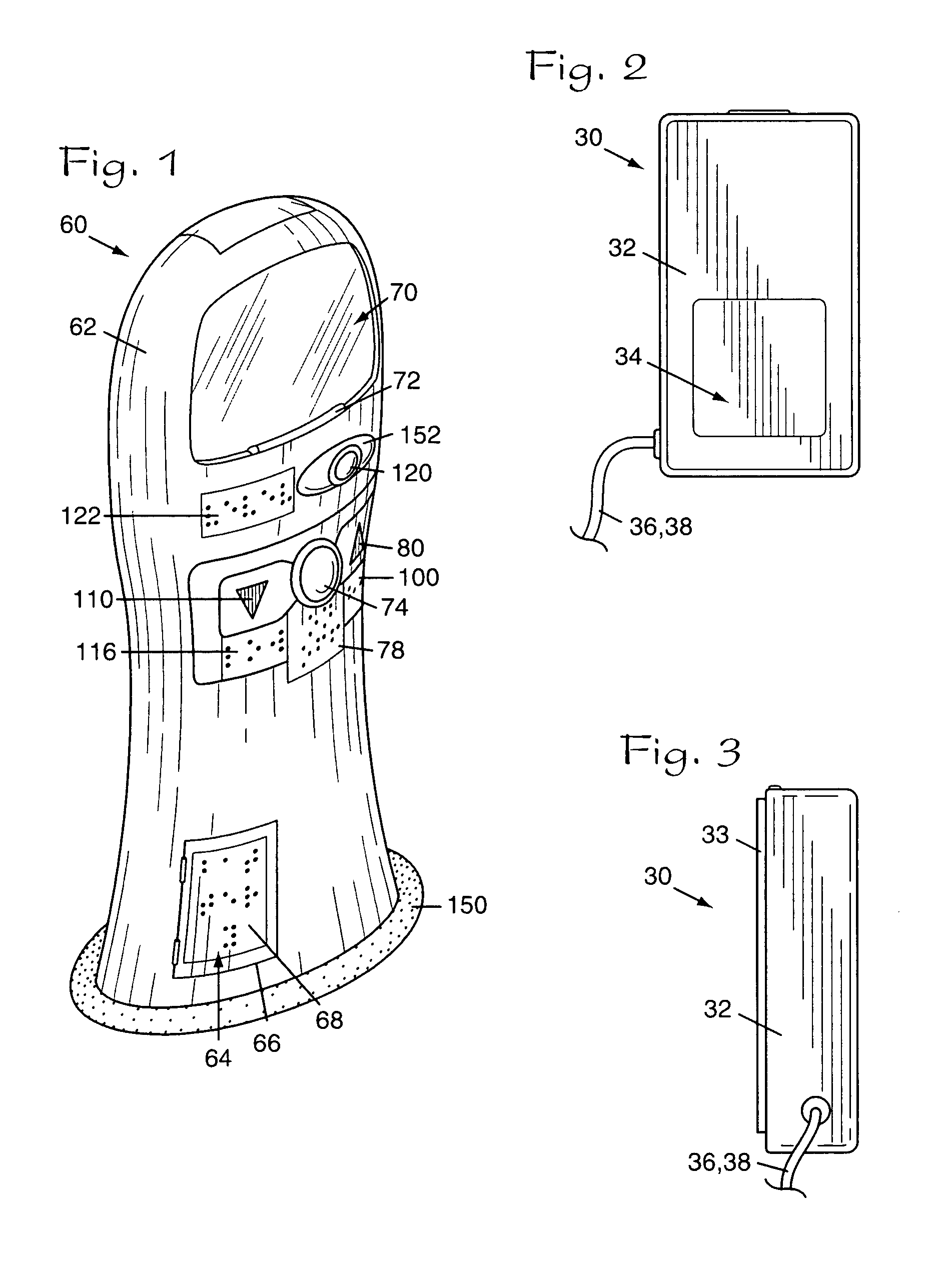

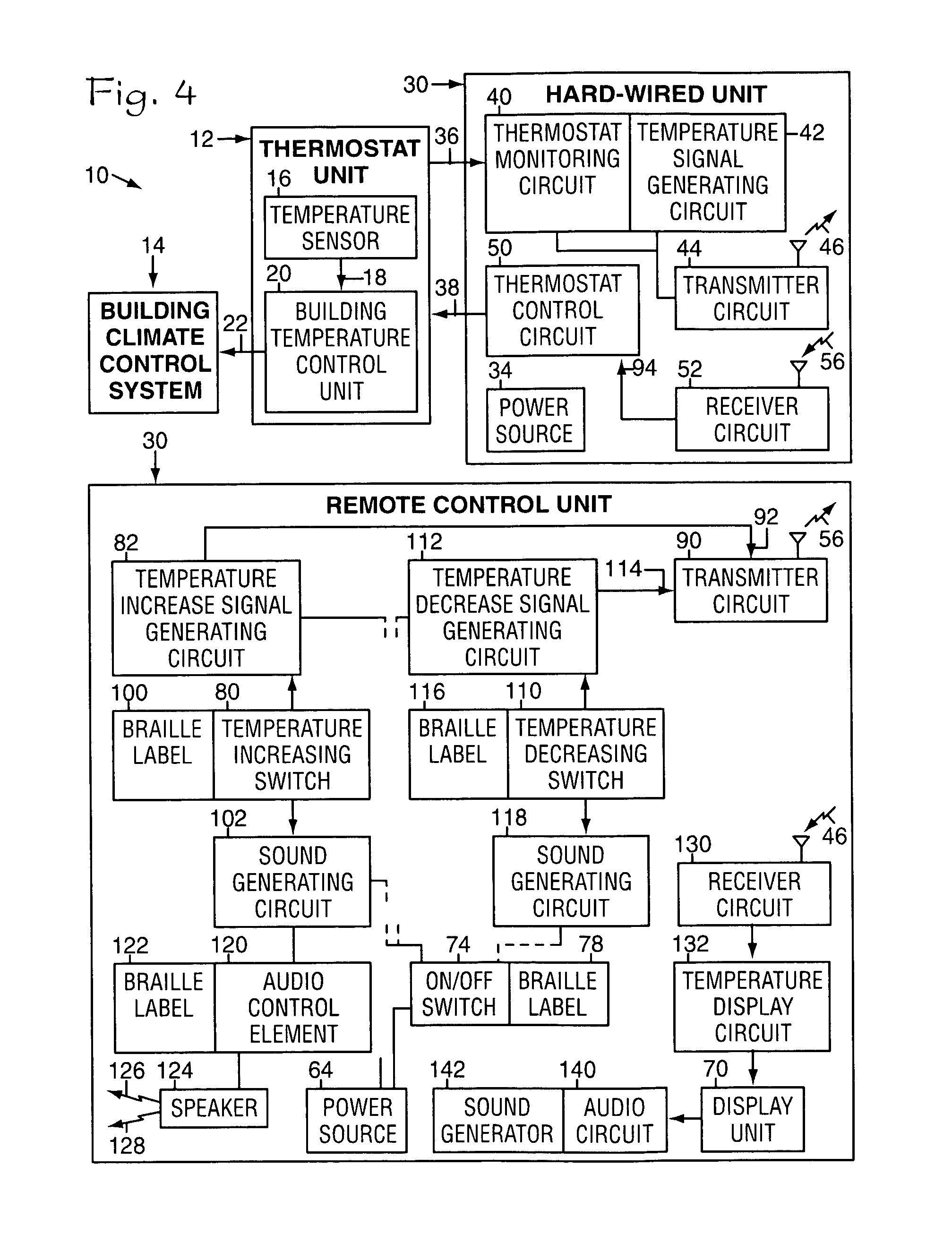

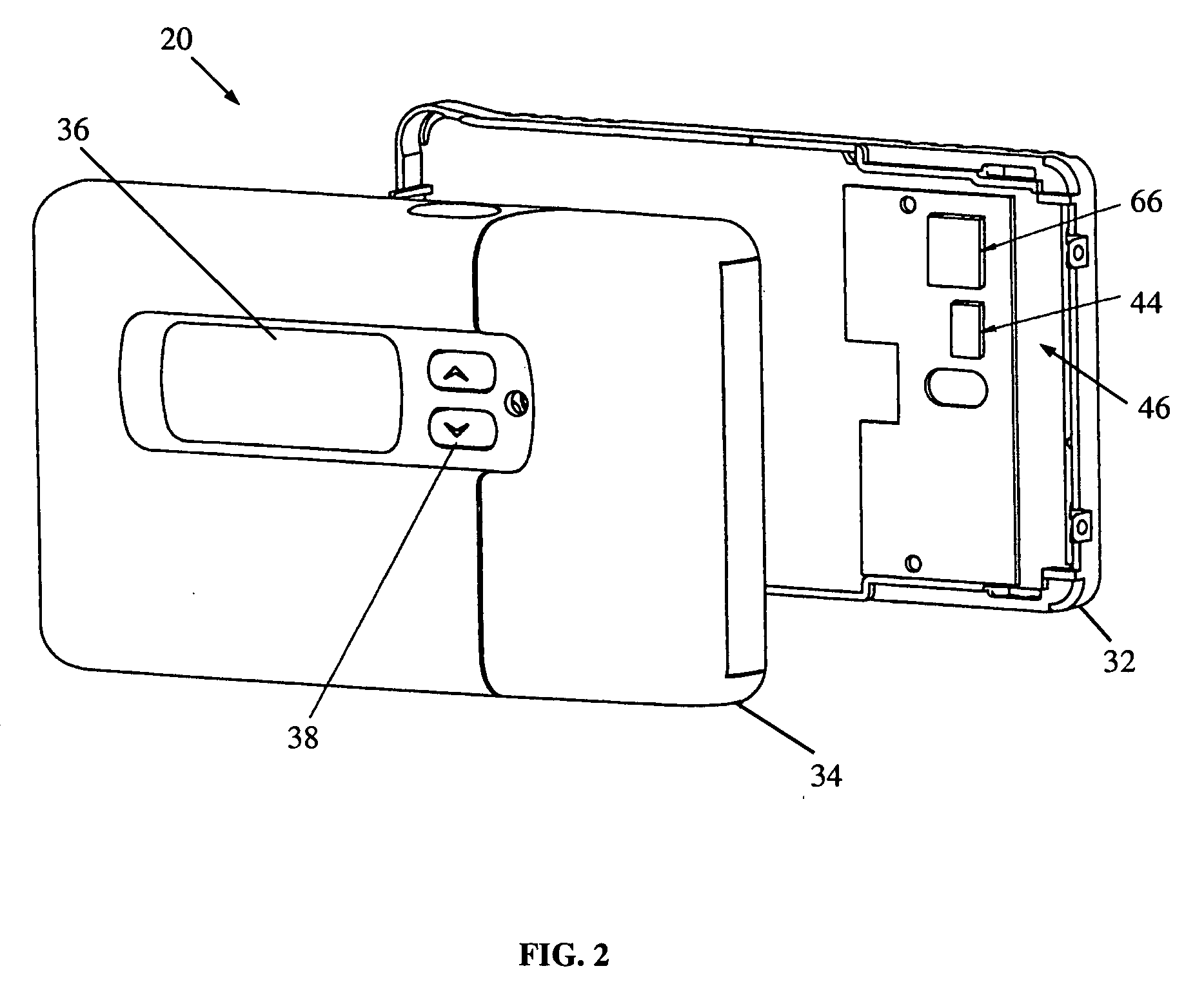

Remote controlled thermostat system for the sight-impaired

InactiveUS7108194B1Easy to findEasily and quickly retro-fitMechanical apparatusSpace heating and ventilation safety systemsRemote controlThermostat

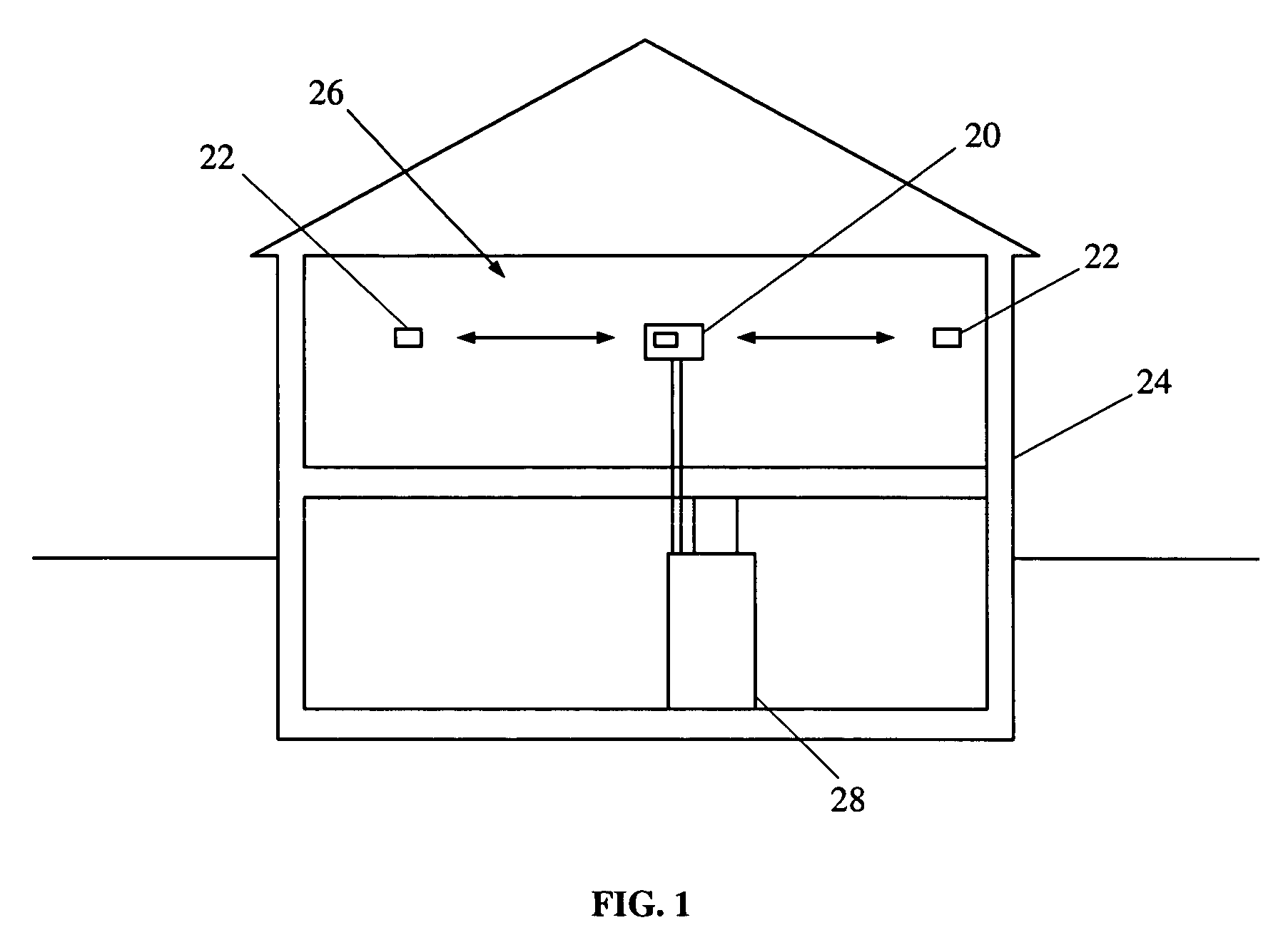

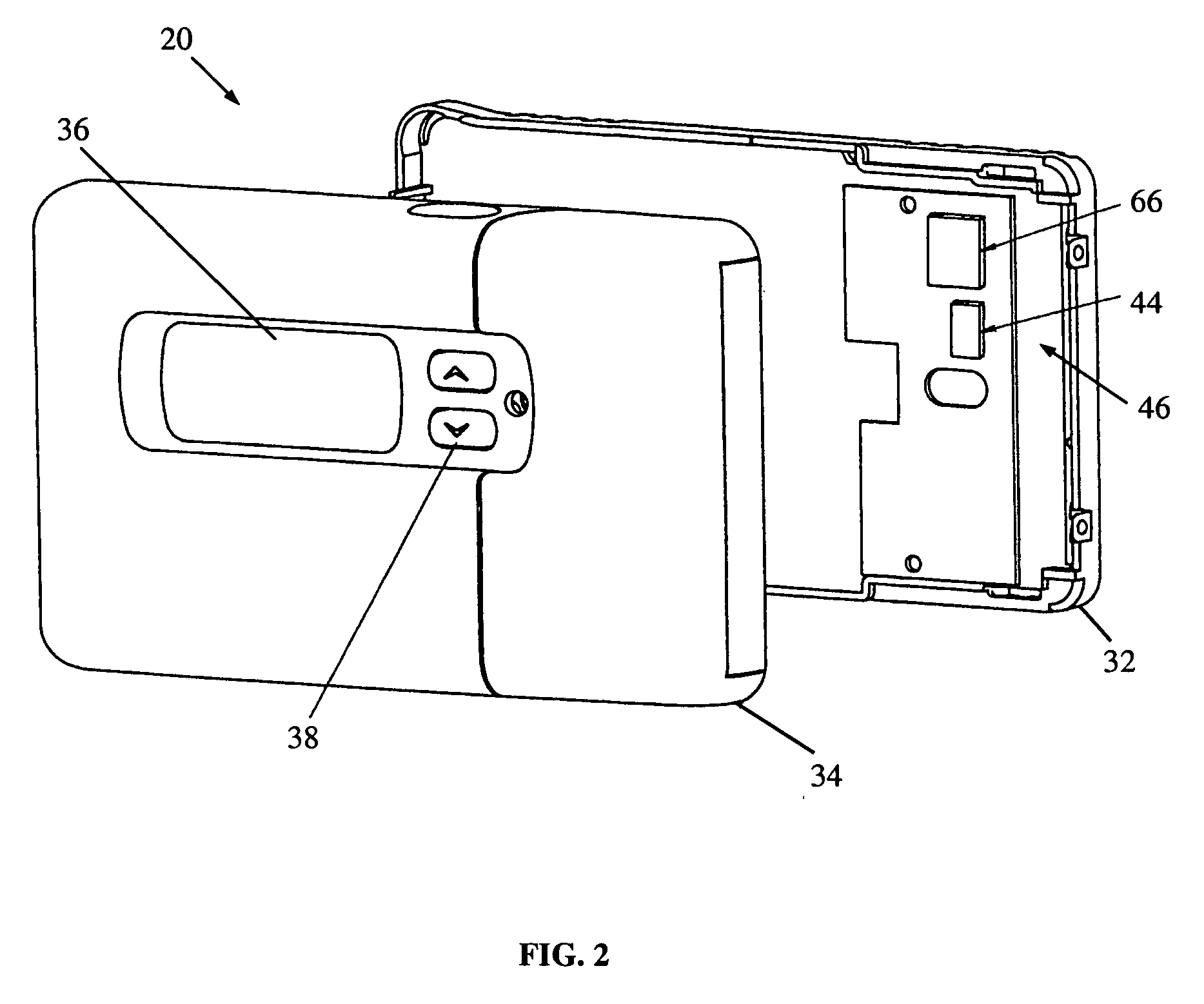

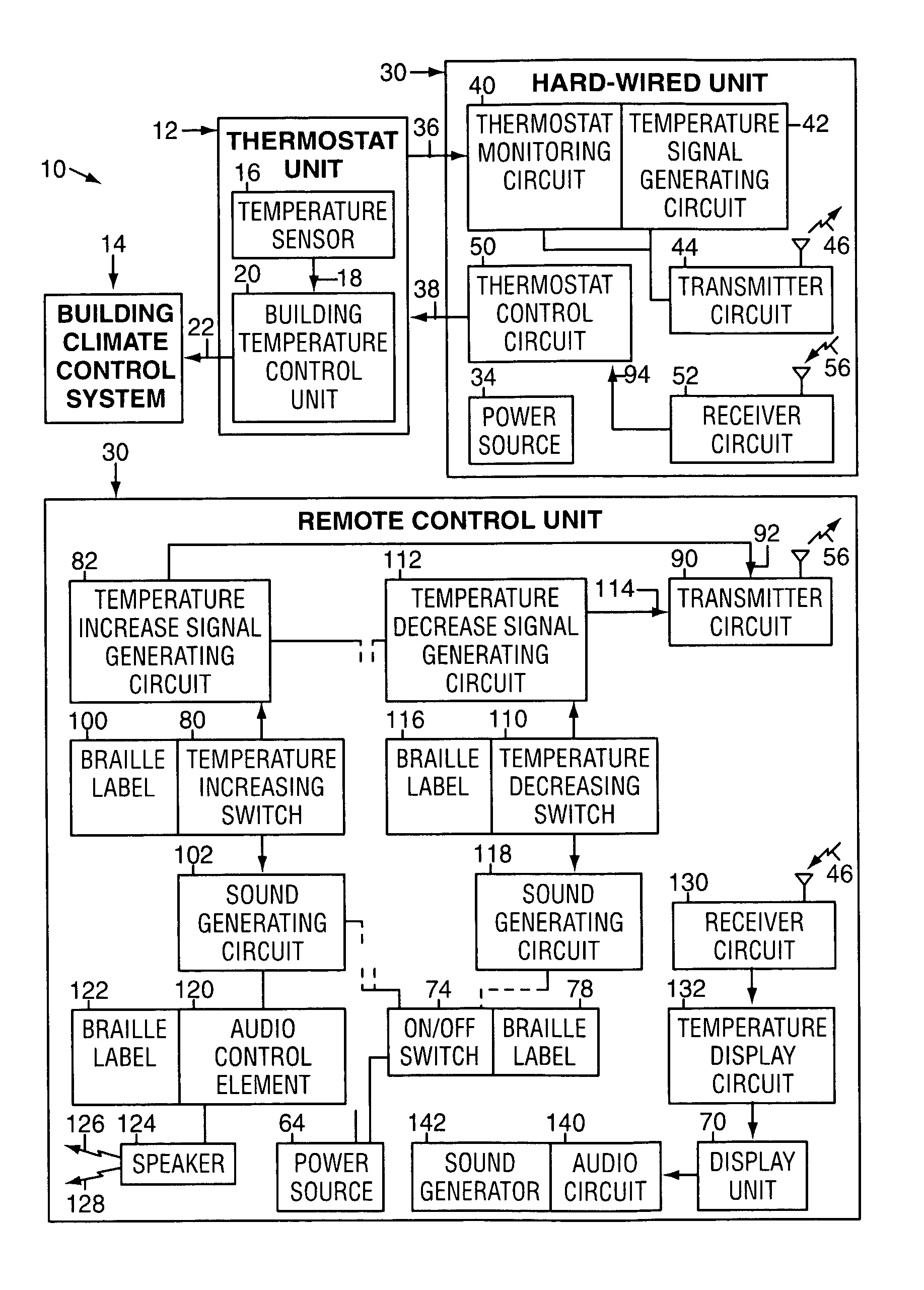

A thermostat remote control system includes a transmitter / receiver unit hard wired to a building climate control thermostat and a remote control unit that communicates with the hard-wired transmitter / receiver unit via wireless signals. The remote control unit includes braille labels associated with the control elements and further includes sound generators that generate audible signals that correspond to the temperature sensed by the thermostat and that also correspond to actions taken using the remote control.

Owner:HANKINS II ROBERT E

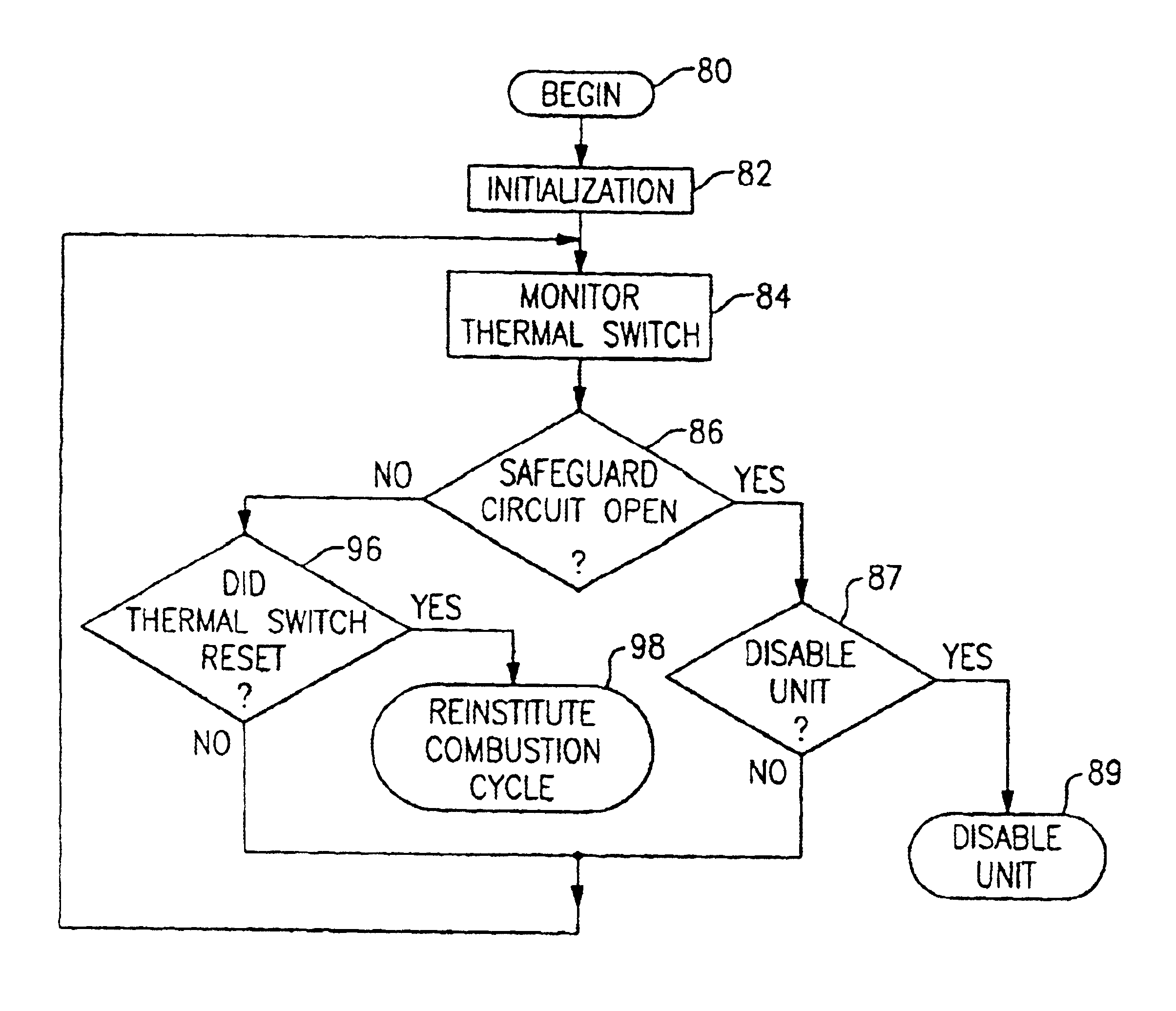

System and method for draft safeguard

A gas furnace responsive to a thermostat includes a thermal switch wired in series between the furnace power supply and the thermostat. A microprocessor connected to the thermal switch detects when the switch opens and closes, carrying out prearranged programs in response thereto. The thermal switch is mounted so that it opens when an over-pressure in the furnace draft system is detected, as evidenced by hot flue gasses passing over the thermal switch probe. The switch is allowed to cycle at least one time before the furnace is disabled. After a certain period of the time, the combustion cycle is reinitiated and the above steps are repeated if the thermal switch again resets.

Owner:CARRIER CORP

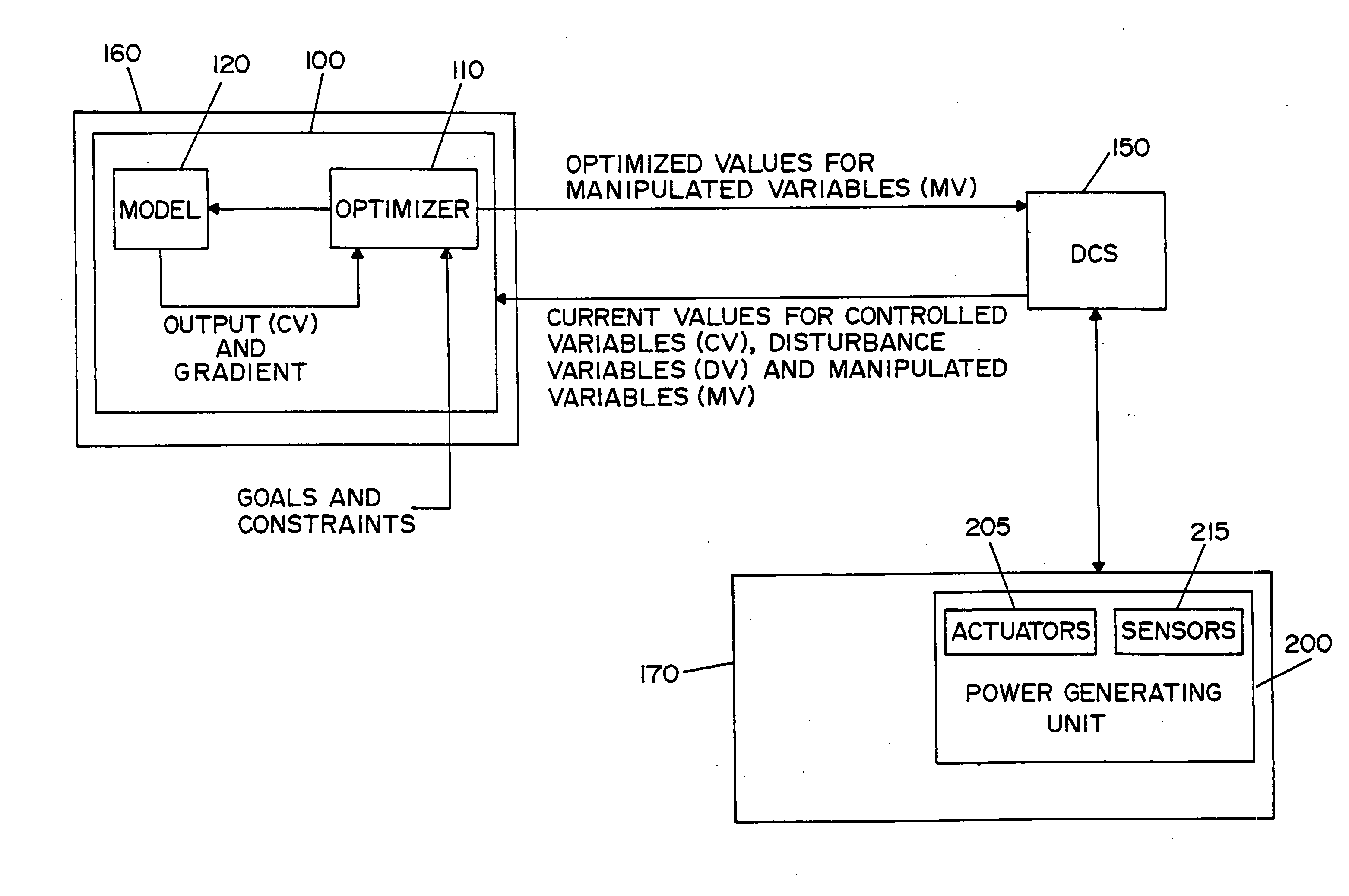

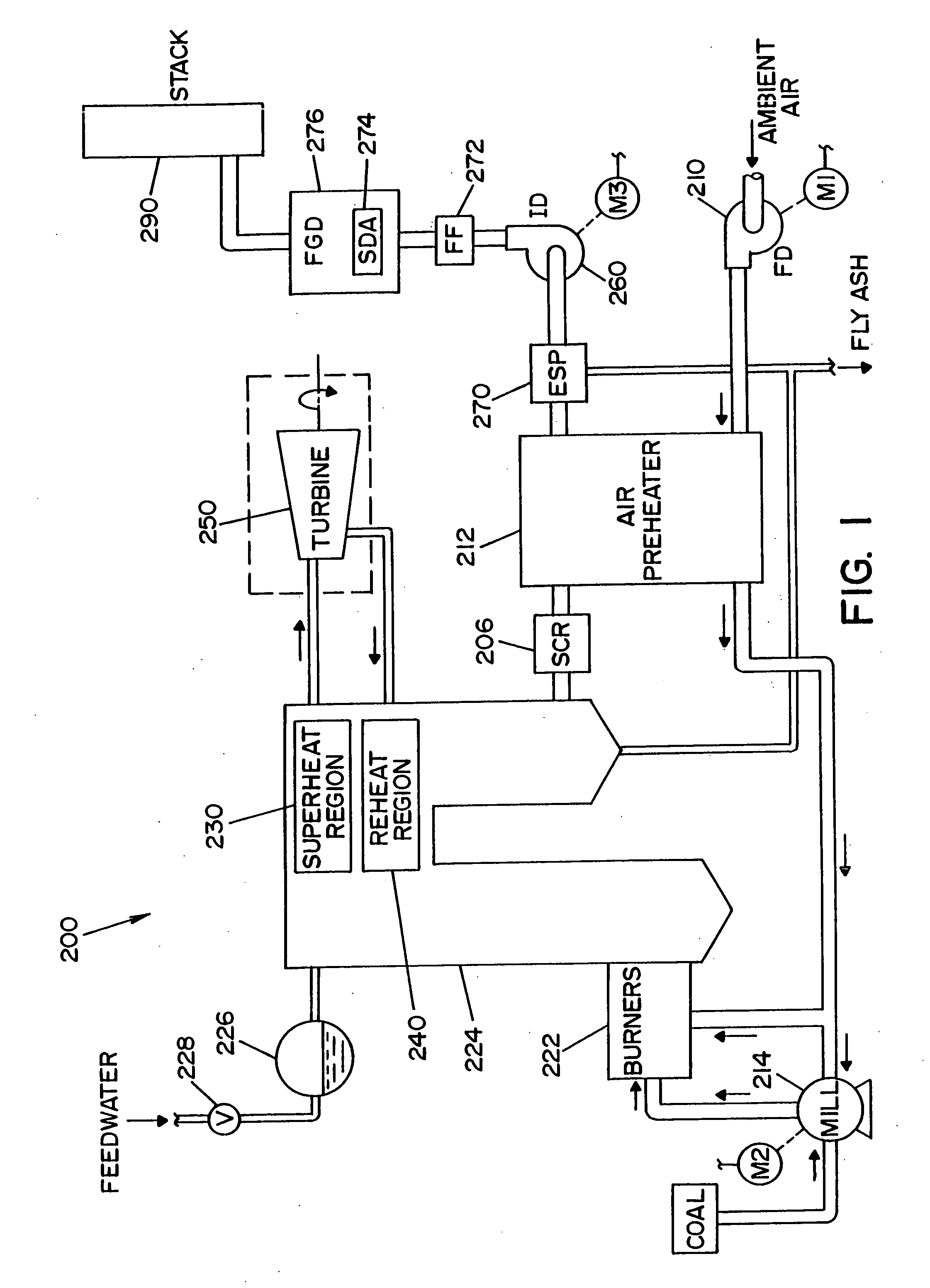

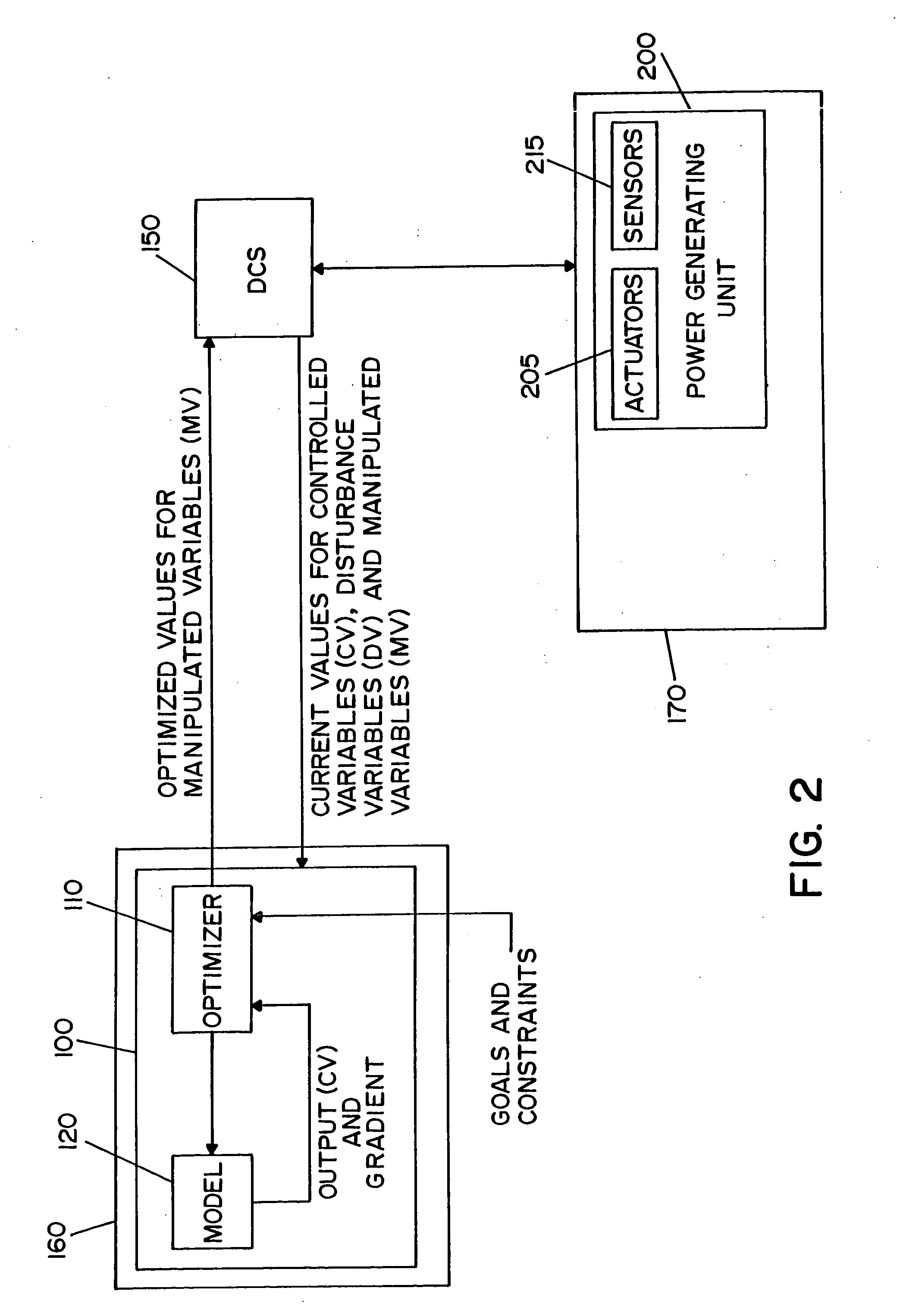

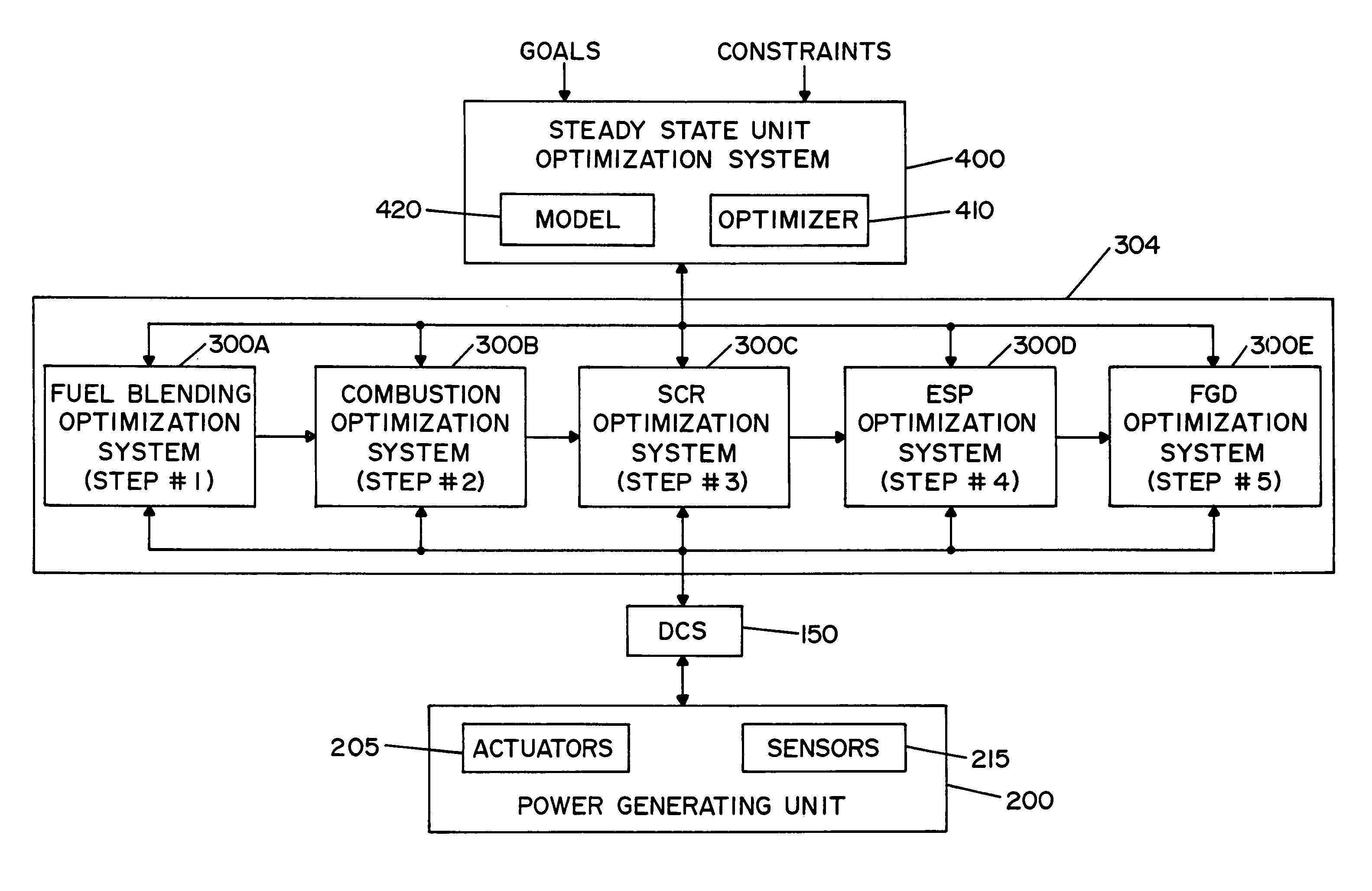

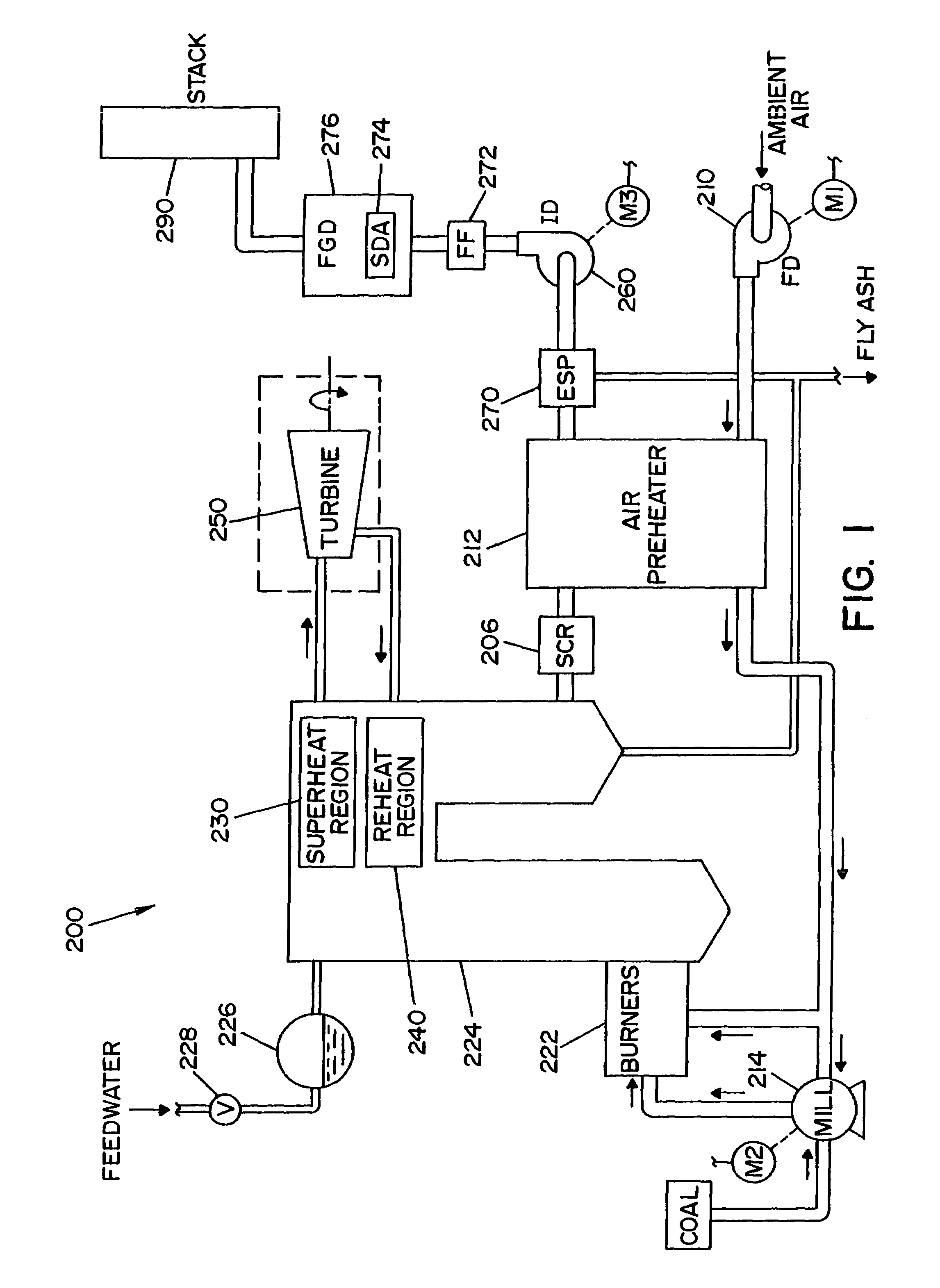

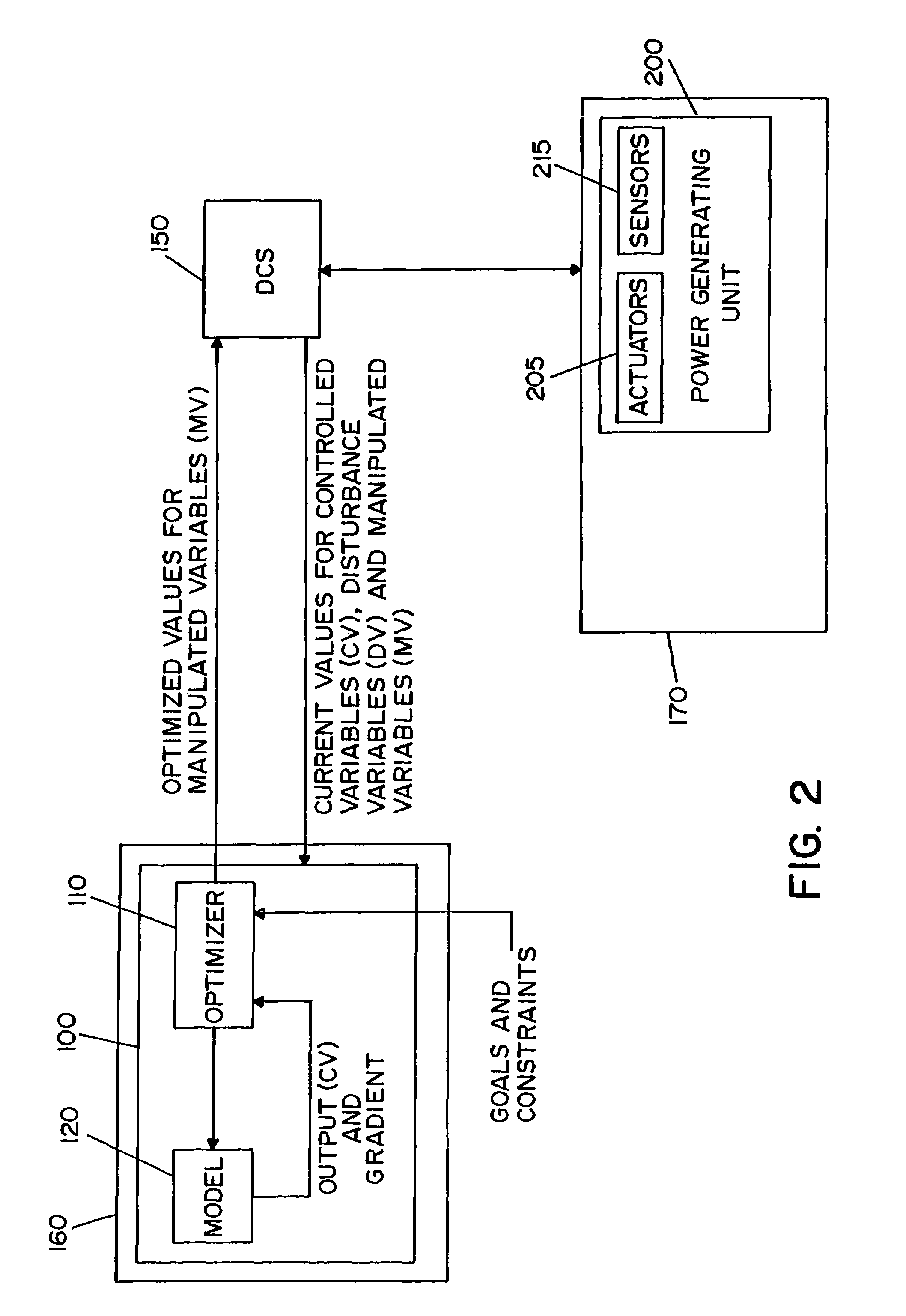

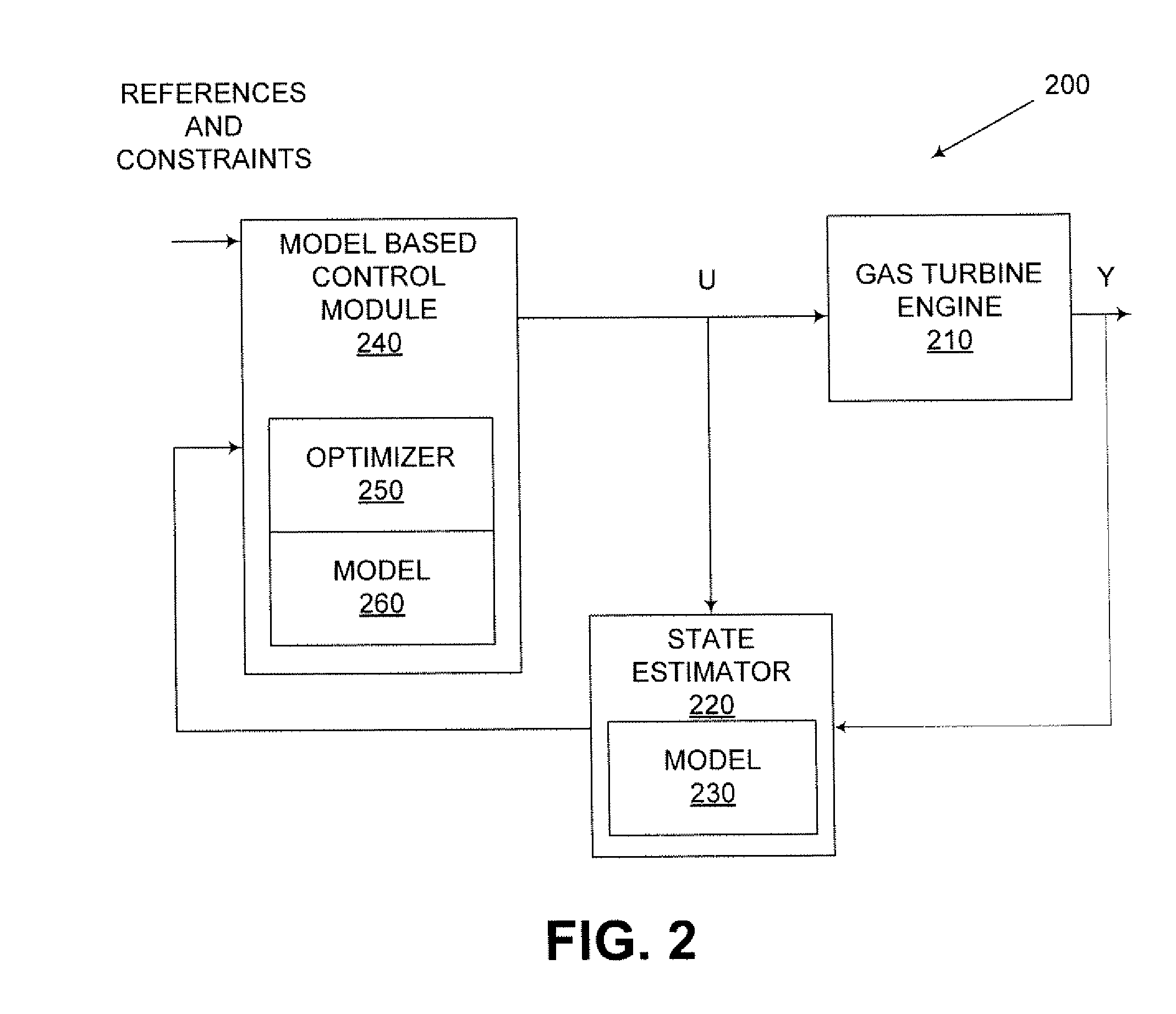

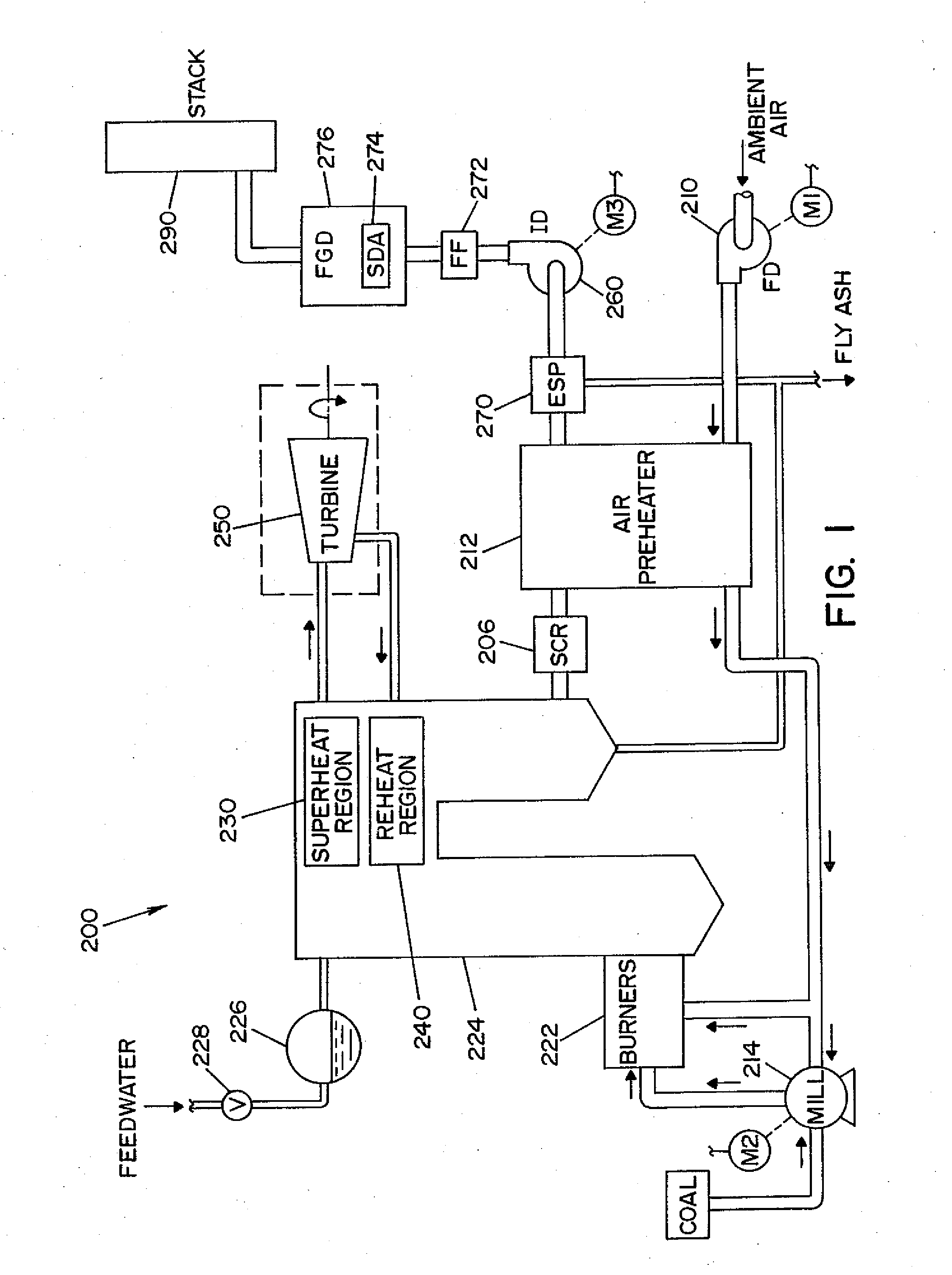

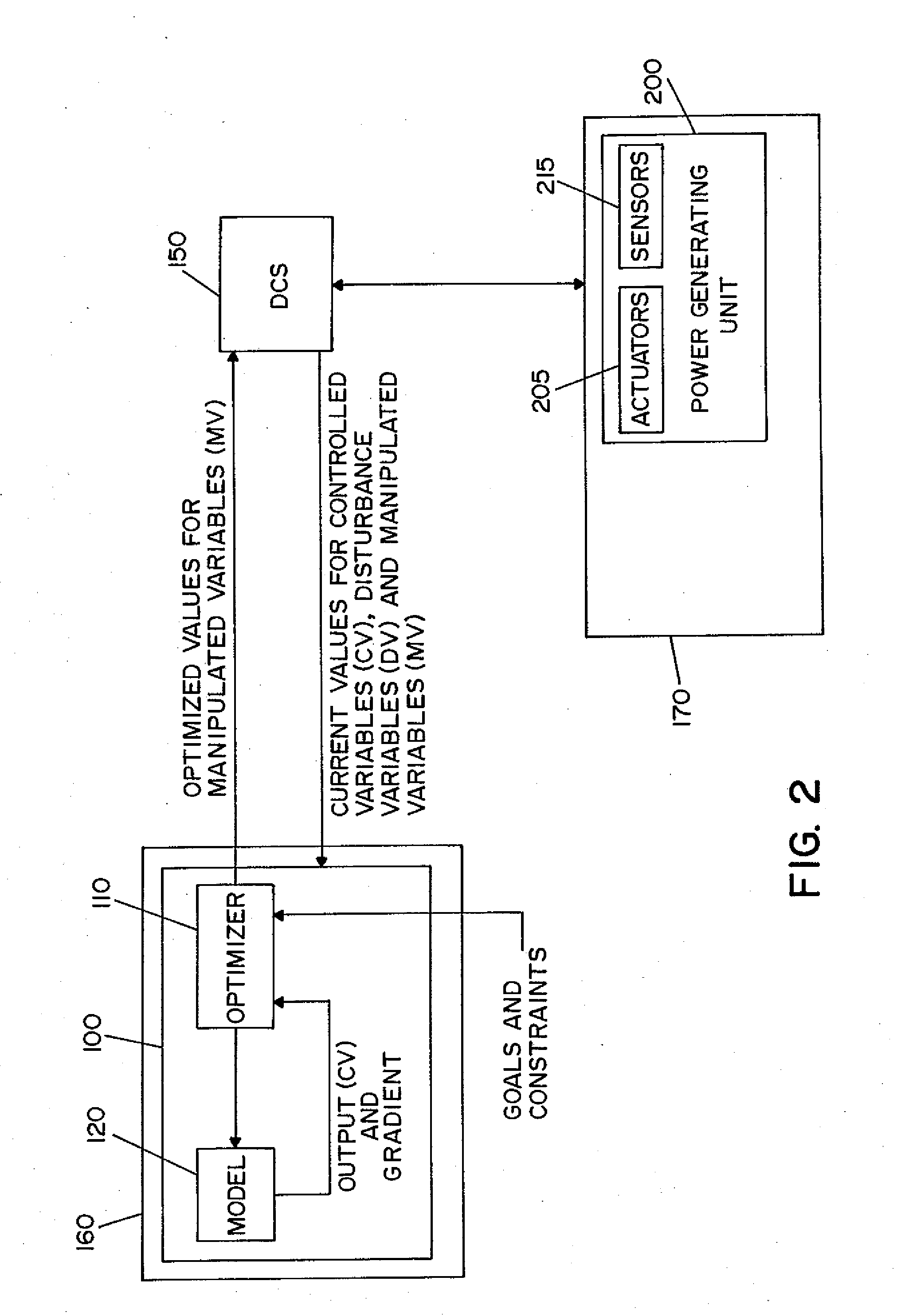

Model based optimization of a single or multiple power generating units

ActiveUS20070142975A1Easy to operateApparent advantageProgramme controlMechanical power/torque controlMulti unitDynamic models

A method and apparatus for optimizing the operation of a single or multiple power generating units using advanced optimization, modeling, and control techniques. In one embodiment, a plurality of component optimization systems for optimizing power generating unit components are sequentially coordinated to allow optimized values determined by a first component optimization system to be fed forward for use as an input value to a subsequent component optimization system. A unit optimization system may be provided to determine goals and constraints for the plurality of component optimization systems in accordance with economic data. In one embodiment of the invention, a multi-unit optimization system is provided to determine goals and constraints for component optimization systems of different power generating units. Both steady state and dynamic models are used for optimization.

Owner:GENERAL ELECTRIC CO

Thermostat control system providing power saving transmissions

ActiveUS20060102731A1Reduce power consumptionMaintain reliabilityTemperature control without auxillary powerResonant long antennasControl systemThermostat

A thermostat control system having remote devices and / or other internally powered devices provides transmissions at different power levels and at different data transfer rates to conserve power life. Thermostat control system components and devices may be powered by replaceable power supplies that are conserved by transmitting at a lower power level more often than at a higher power level. A higher power level transmission is provided at a lower data transfer rate, and a lower power level transmission is provided at a higher data transfer rate. A higher power transmission is provided periodically to ensure reliable communication of temperature information.

Owner:COPELAND COMFORT CONTROL LP

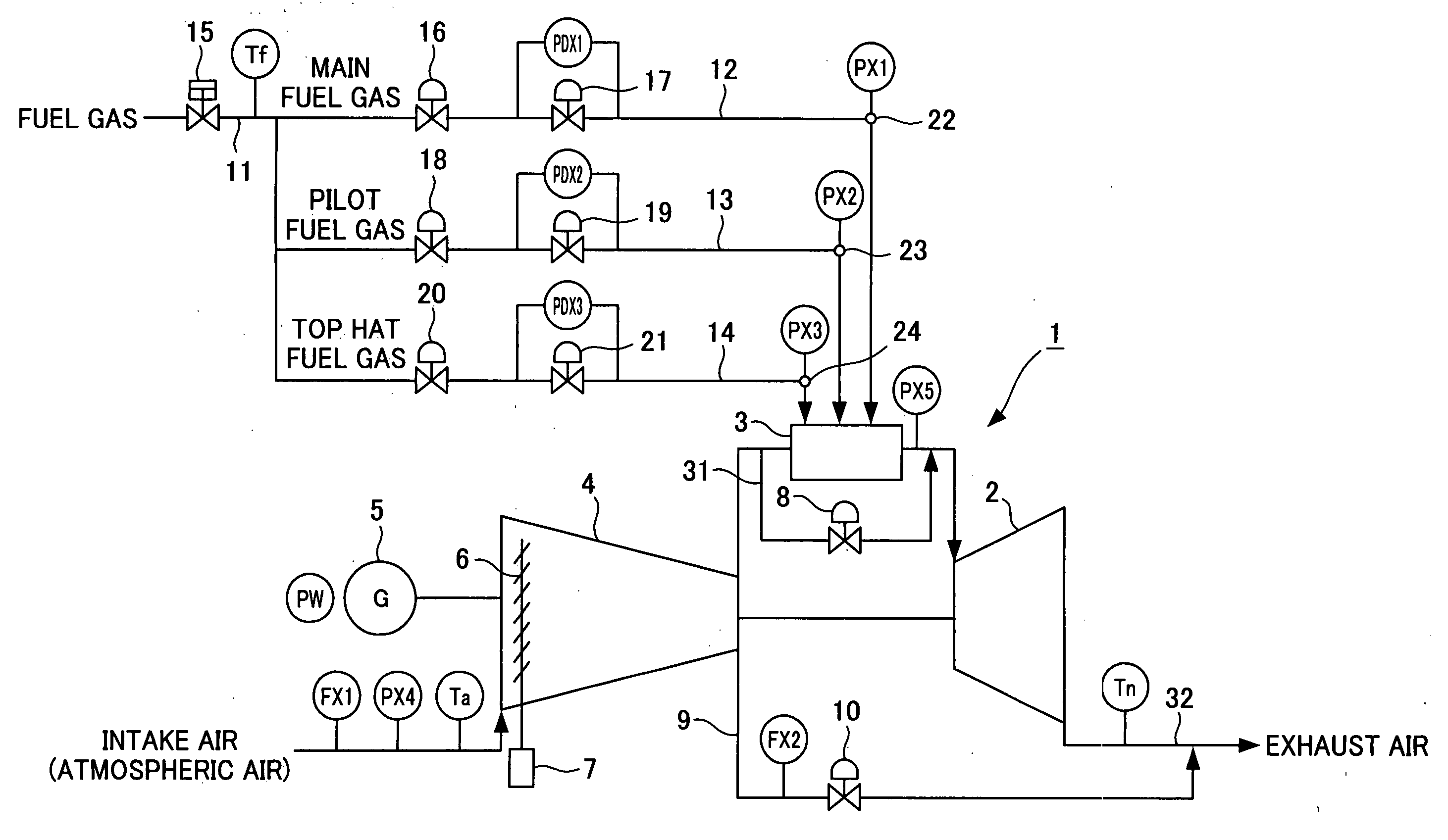

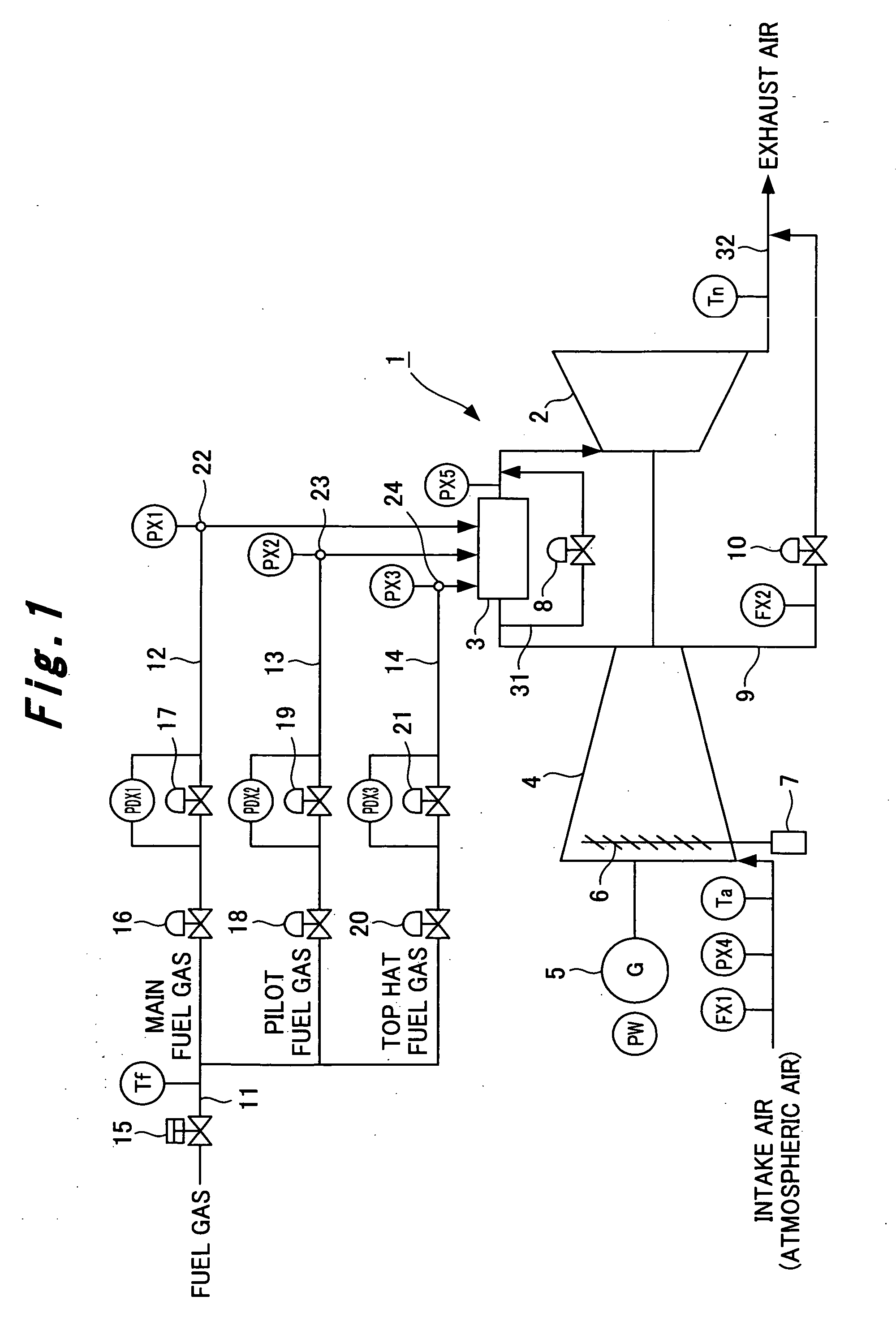

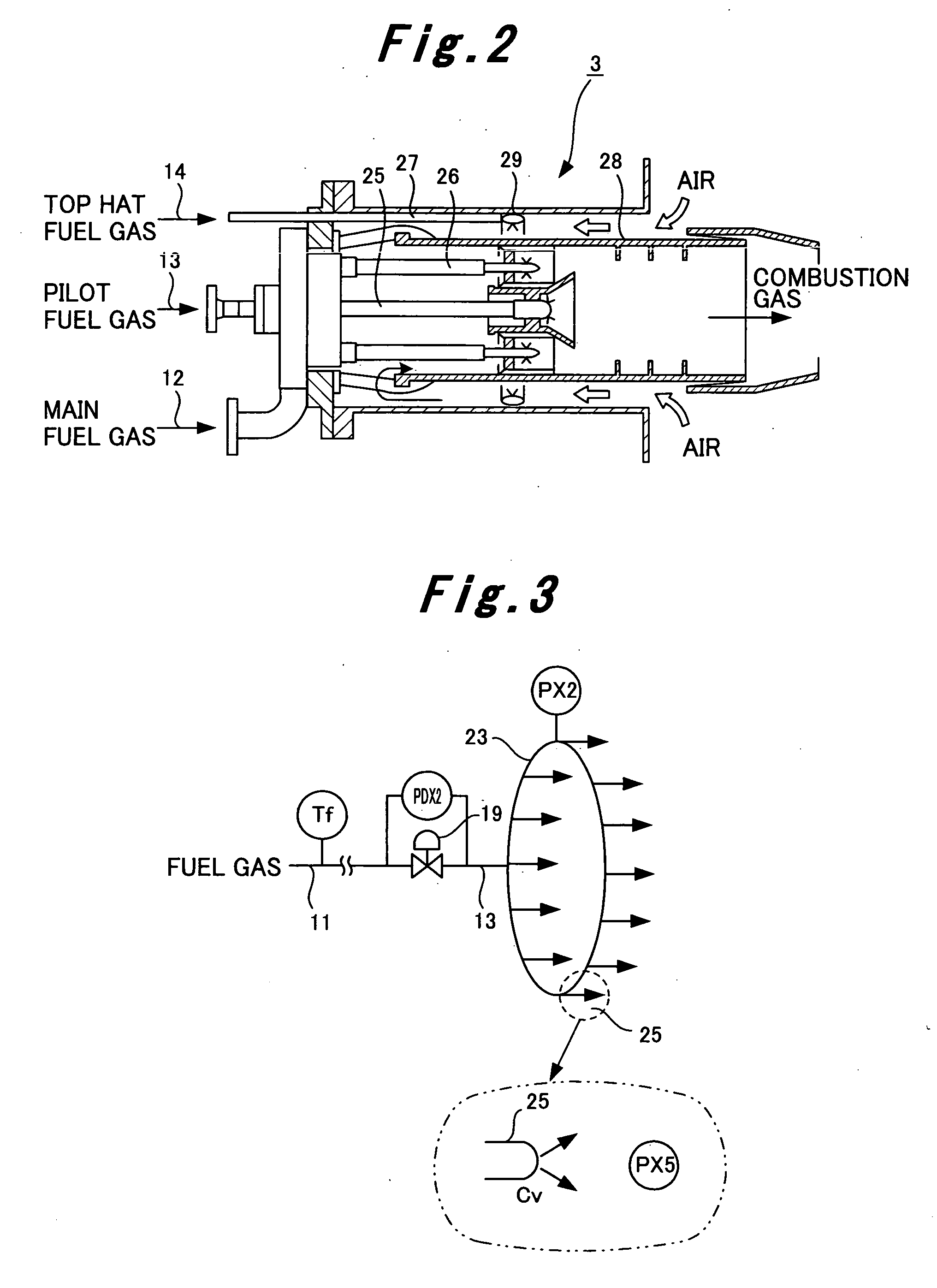

Gas turbine output learning circuit and combustion control device for gas turbine having the same

ActiveUS20070271024A1Shorten study timeEasy to correctAnalogue computers for vehiclesProgramme-controlTemperature controlCombustion

A gas turbine output learning circuit is configured to compute a current combustion gas temperature TIT at an inlet of a gas turbine by linear interpolation by use of two characteristic curves A and B respectively representing relations between a pressure ratio and an exhaust gas temperature in the cases of the combustion gas temperature at the inlet of the gas turbine at 1400° C. and 1500° C., then to compute ideal MW corresponding to this combustion gas temperature TIT at the inlet of the gas turbine by linear interpolation according to 1400° C.MW and 1500° C.MW (temperature controlled MW), and then to correct the 1400° C.MW and the 1500° C.MW so as to match the ideal MW with a measured gas turbine output (a power generator output).

Owner:MITSUBISHI POWER LTD

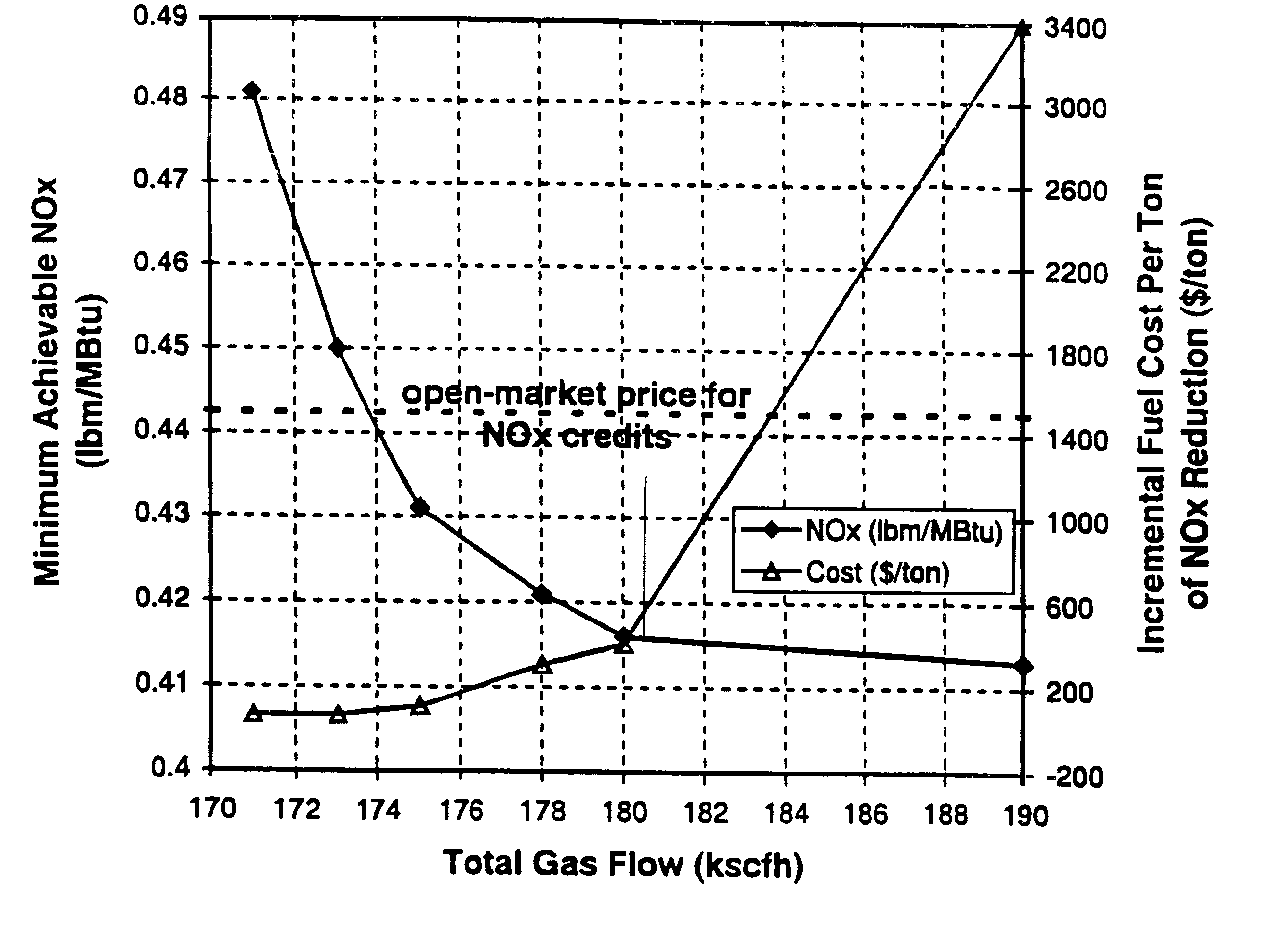

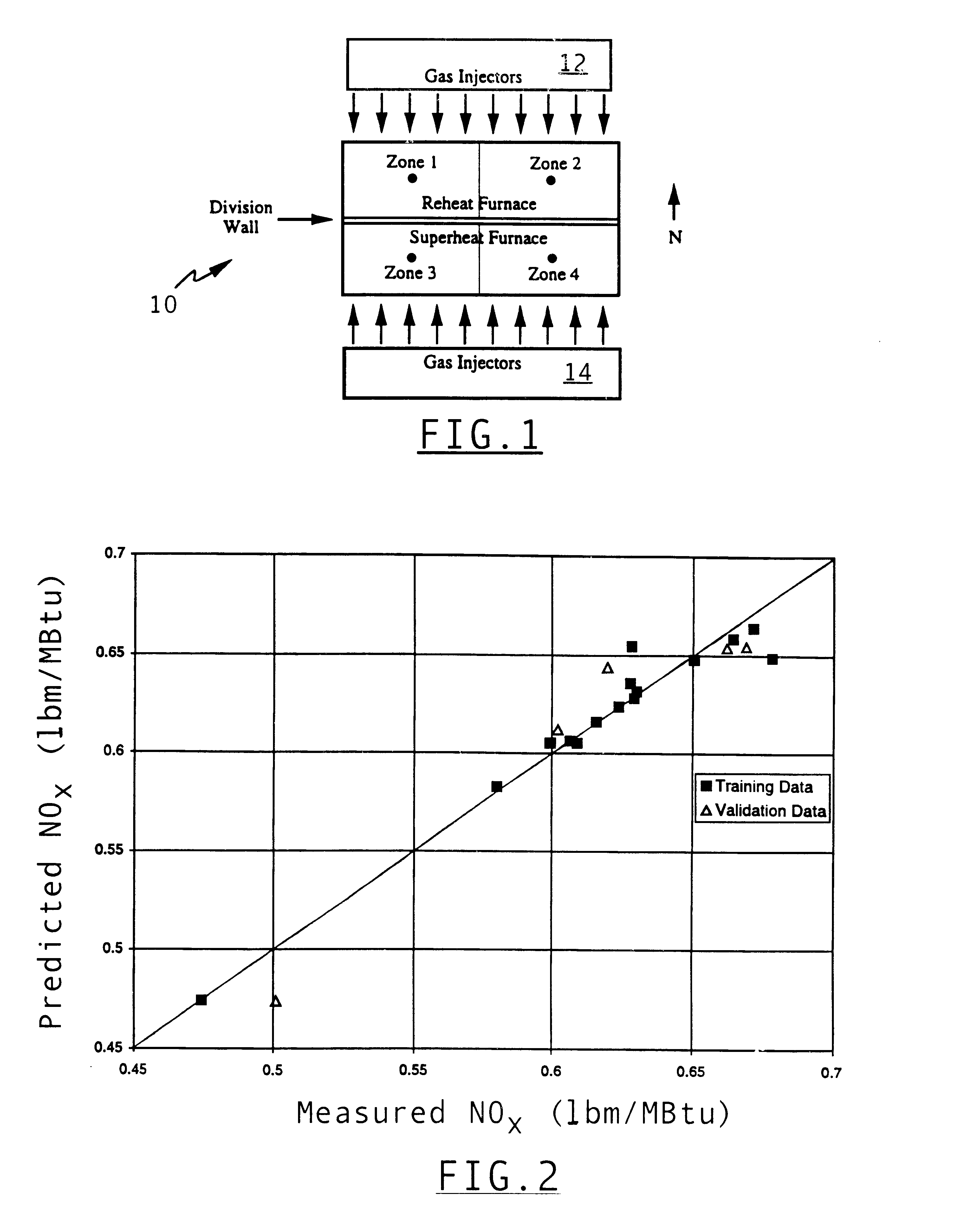

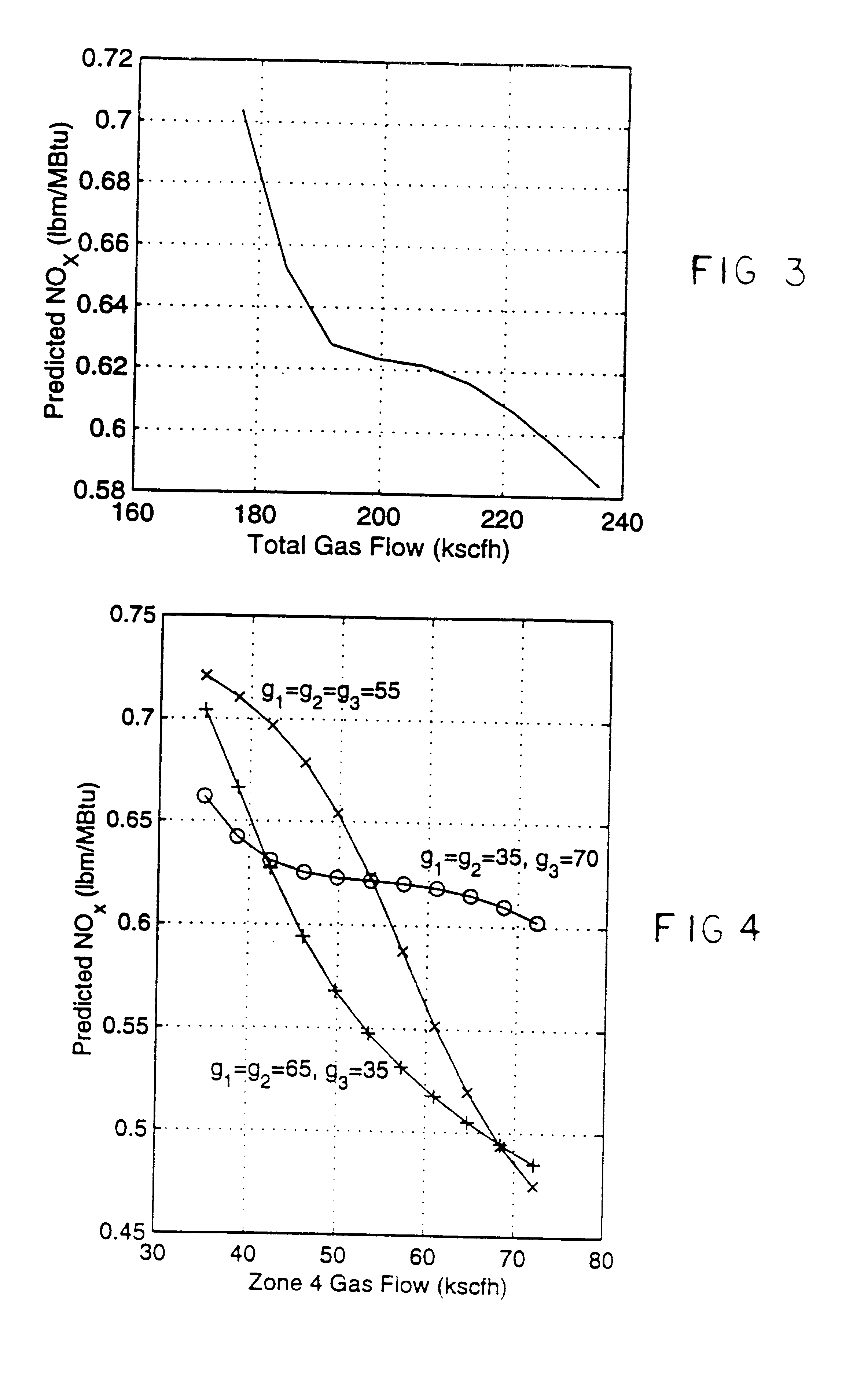

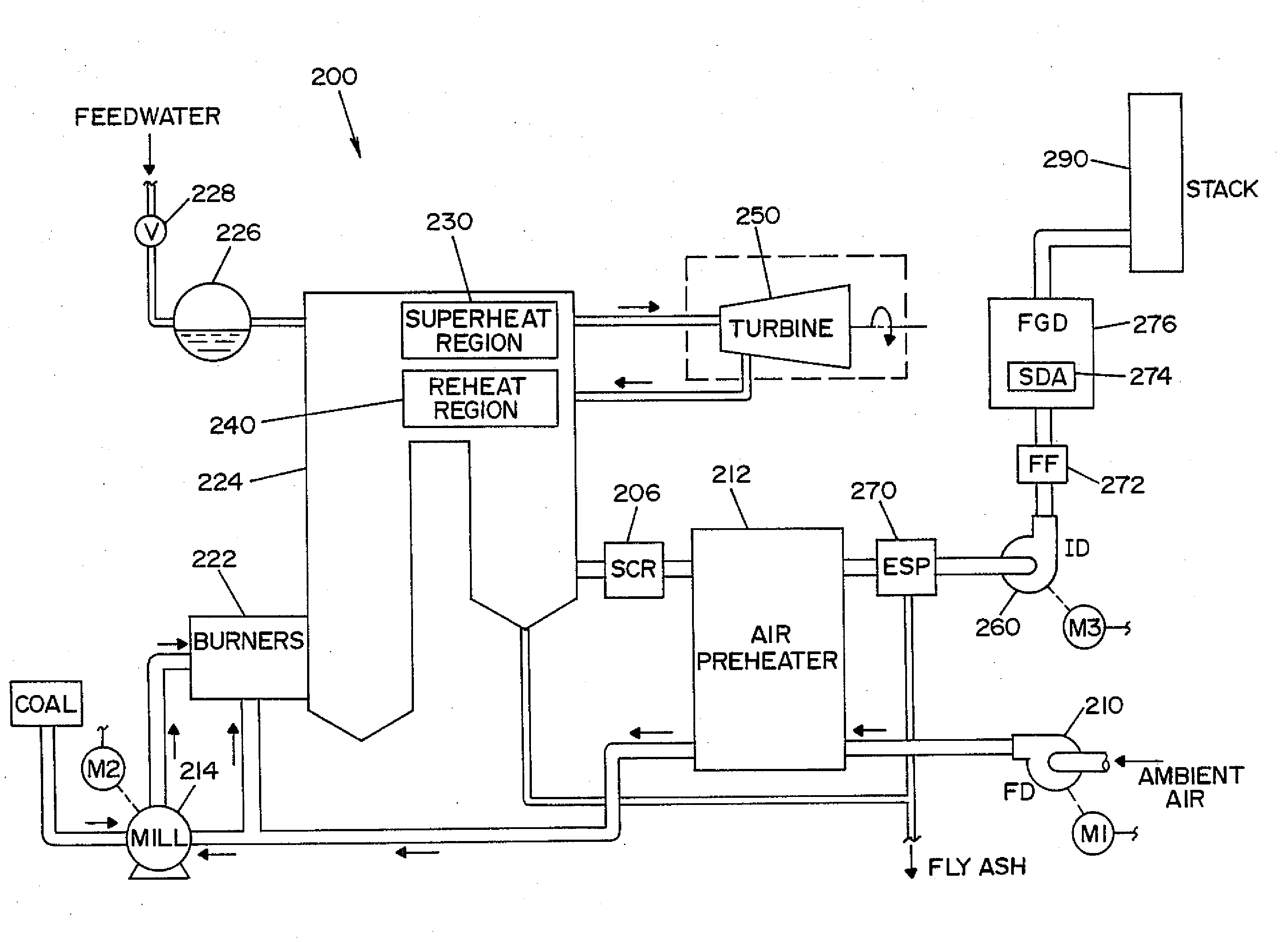

Intelligent emissions controller for substance injection in the post-primary combustion zone of fossil-fired boilers

InactiveUS6507774B1Emission reductionReduce pollutant emissionsSampled-variable control systemsCombustion signal processingWater oil emulsionU s economy

The control of emissions from fossil-fired boilers wherein an injection of substances above the primary combustion zone employs multi-layer feedforward artificial neural networks for modeling static nonlinear relationships between the distribution of injected substances into the upper region of the furnace and the emissions exiting the furnace. Multivariable nonlinear constrained optimization algorithms use the mathematical expressions from the artificial neural networks to provide the optimal substance distribution that minimizes emission levels for a given total substance injection rate. Based upon the optimal operating conditions from the optimization algorithms, the incremental substance cost per unit of emissions reduction, and the open-market price per unit of emissions reduction, the intelligent emissions controller allows for the determination of whether it is more cost-effective to achieve additional increments in emission reduction through the injection of additional substance or through the purchase of emission credits on the open market. This is of particular interest to fossil-fired electrical power plant operators. The intelligent emission controller is particularly adapted for determining the economical control of such pollutants as oxides of nitrogen (NOx) and carbon monoxide (CO) emitted by fossil-fired boilers by the selective introduction of multiple inputs of substances (such as natural gas, ammonia, oil, water-oil emulsion, coal-water slurry and / or urea, and combinations of these substances) above the primary combustion zone of fossil-fired boilers.

Owner:ENERGY SYST ASSOCD +1

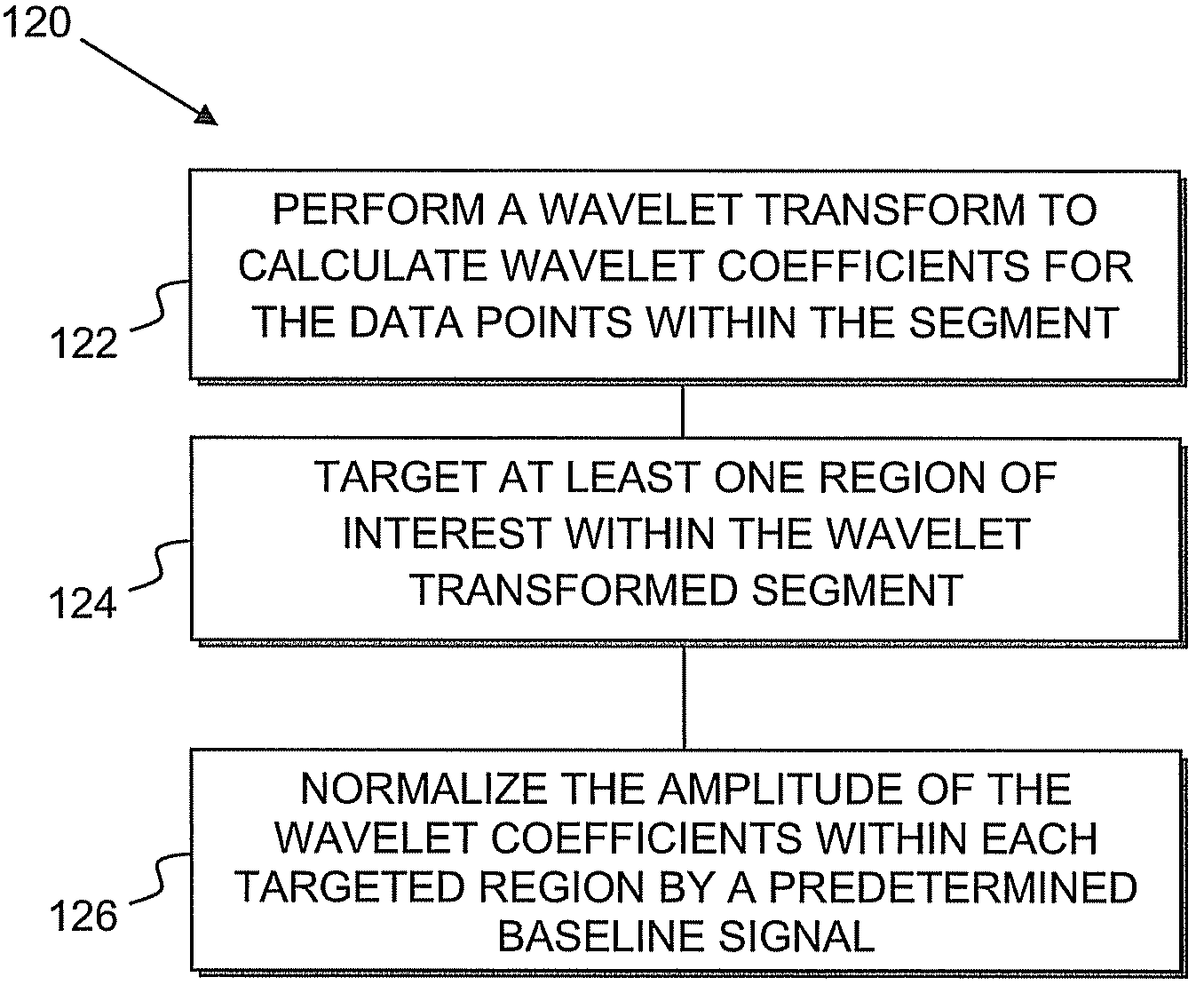

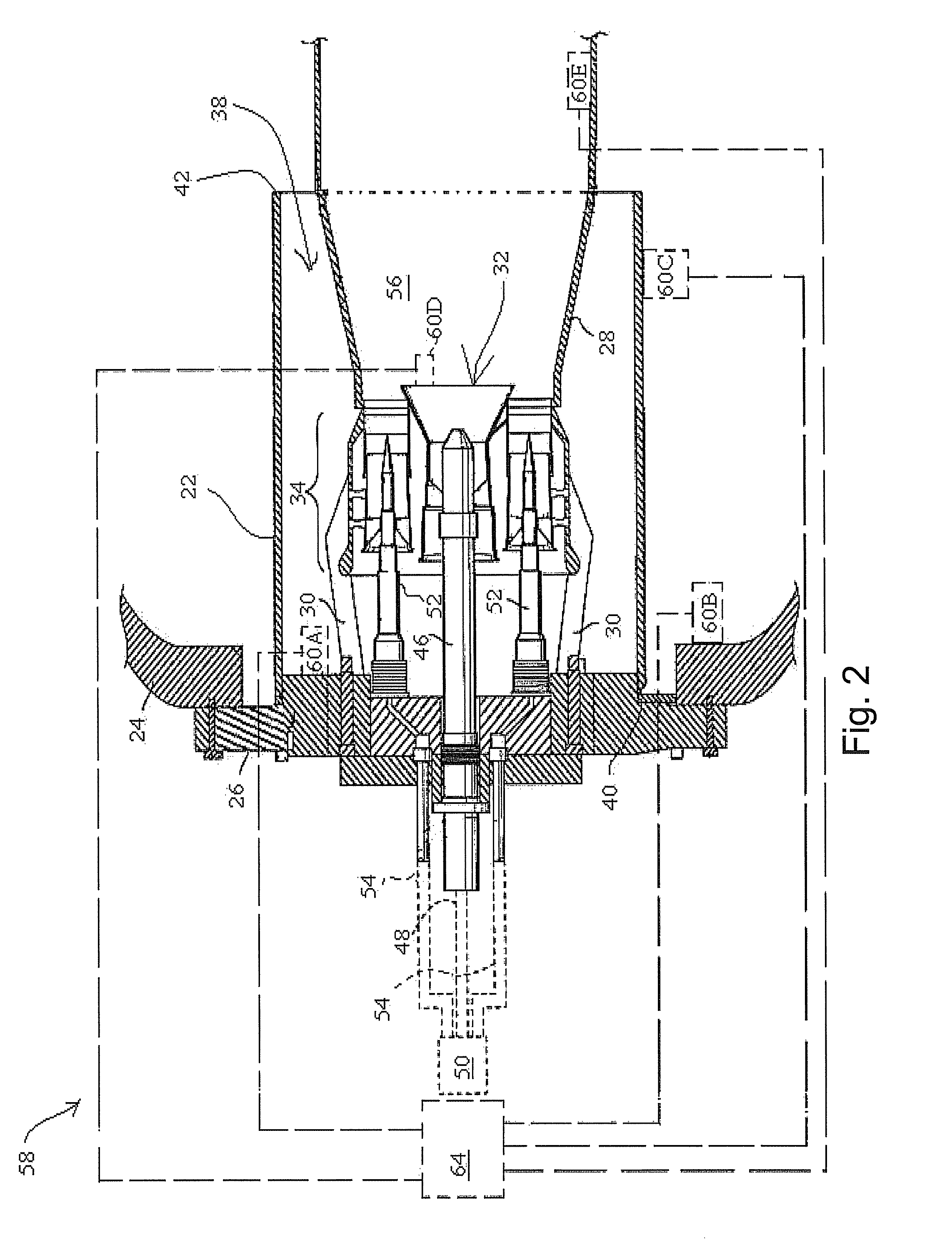

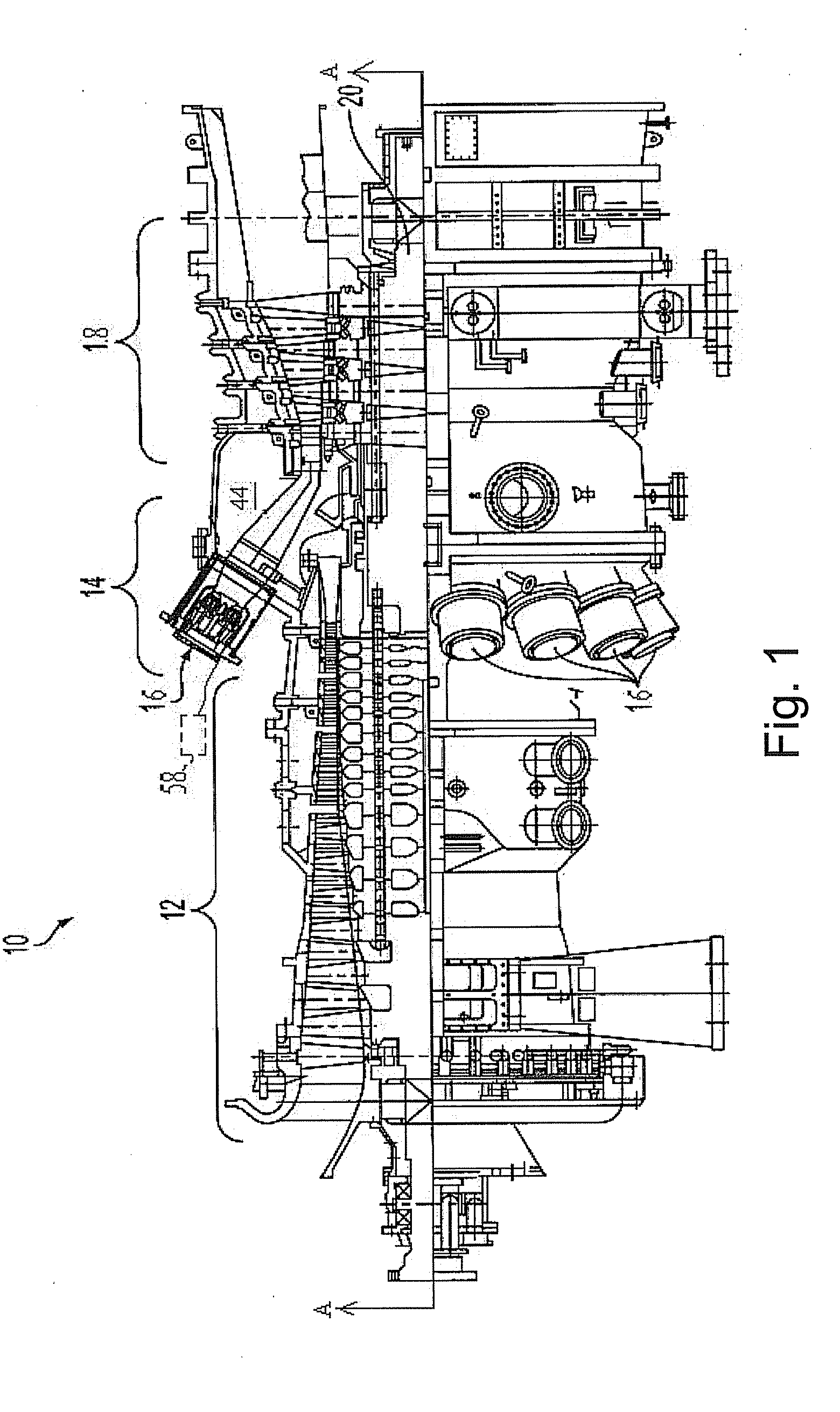

Combustion anomaly detection via wavelet analysis of dynamic sensor signals

The detection of combustion anomalies within a gas turbine engine is provided. A sensor associated with a combustor of the engine measures a signal that is representative of combustion conditions. A sampled dynamic signal is divided into time segments to derive a plurality of data points. The sampled dynamic signal is transformed to a form that enables detection of whether the sensed combustion conditions within the combustor are indicative of any combustion anomalies of interest. A wavelet transform is performed to calculate wavelet coefficients for the data points and at least one region of interest is targeted. The amplitude of each wavelet coefficient within each targeted region is normalized by a baseline signal. The normalized amplitudes of the wavelet coefficients are used to determine whether any combustion anomalies have occurred by comparing the normalized amplitudes of the wavelet coefficients within each target region to a predetermined threshold amplitude.

Owner:SIEMENS ENERGY INC

Combustion anomaly detection via wavelet analysis of dynamic sensor signals

The detection of combustion anomalies within a gas turbine engine is provided. A sensor associated with a combustor of the engine measures a signal that is representative of combustion conditions. A sampled dynamic signal is divided into time segments to derive a plurality of data points. The sampled dynamic signal is transformed to a form that enables detection of whether the sensed combustion conditions within the combustor are indicative of any combustion anomalies of interest. A wavelet transform is performed to calculate wavelet coefficients for the data points and at least one region of interest is targeted. The amplitude of each wavelet coefficient within each targeted region is normalized by a baseline signal. The normalized amplitudes of the wavelet coefficients are used to determine whether any combustion anomalies have occurred by comparing the normalized amplitudes of the wavelet coefficients within each target region to a predetermined threshold amplitude.

Owner:SIEMENS ENERGY INC

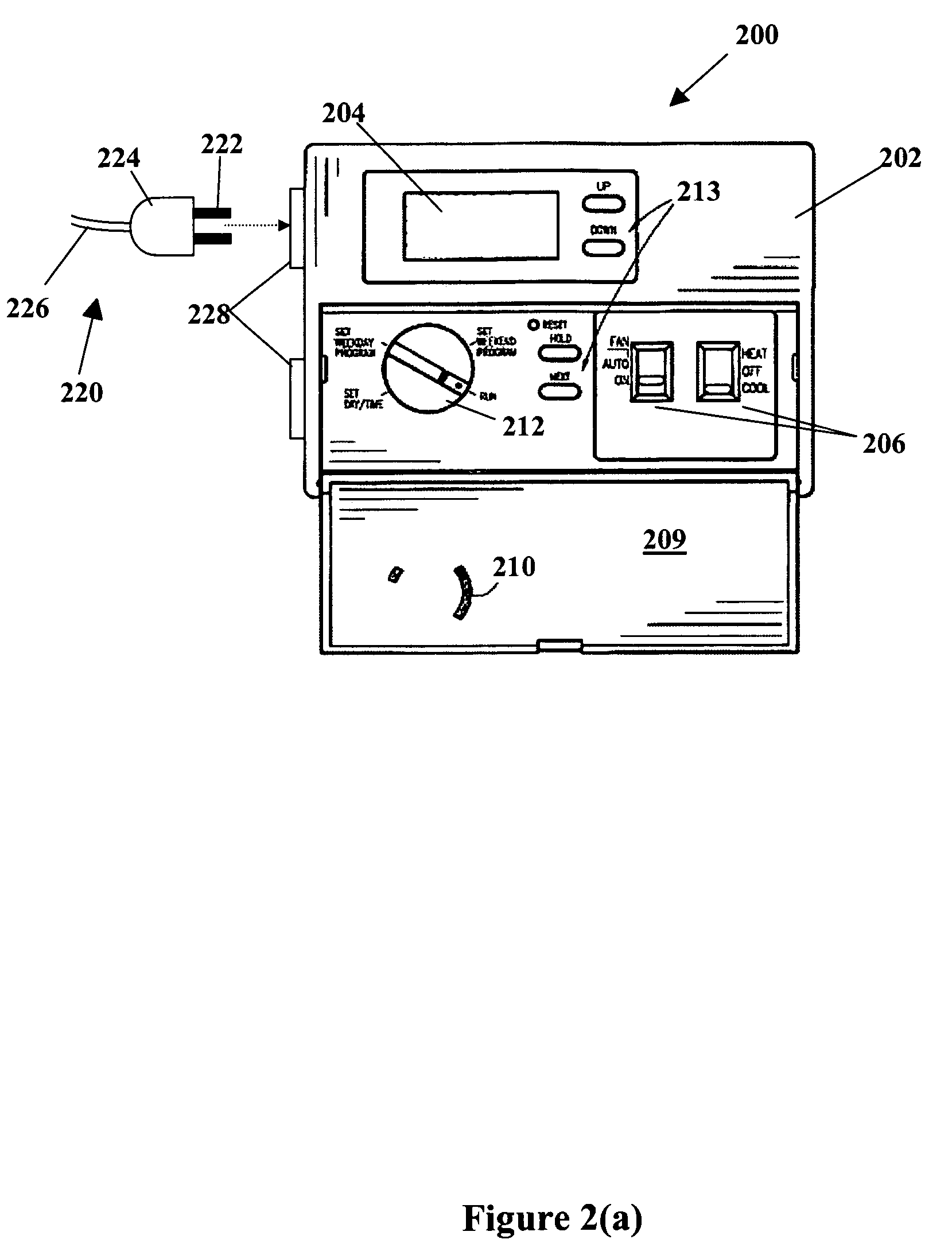

Removable programmable thermostat for air conditioning and heating systems

ActiveUS7175098B2Temperature control without auxillary powerMechanical apparatusTemperature controlPower controller

Owner:JOHNSON CONTROLS INC

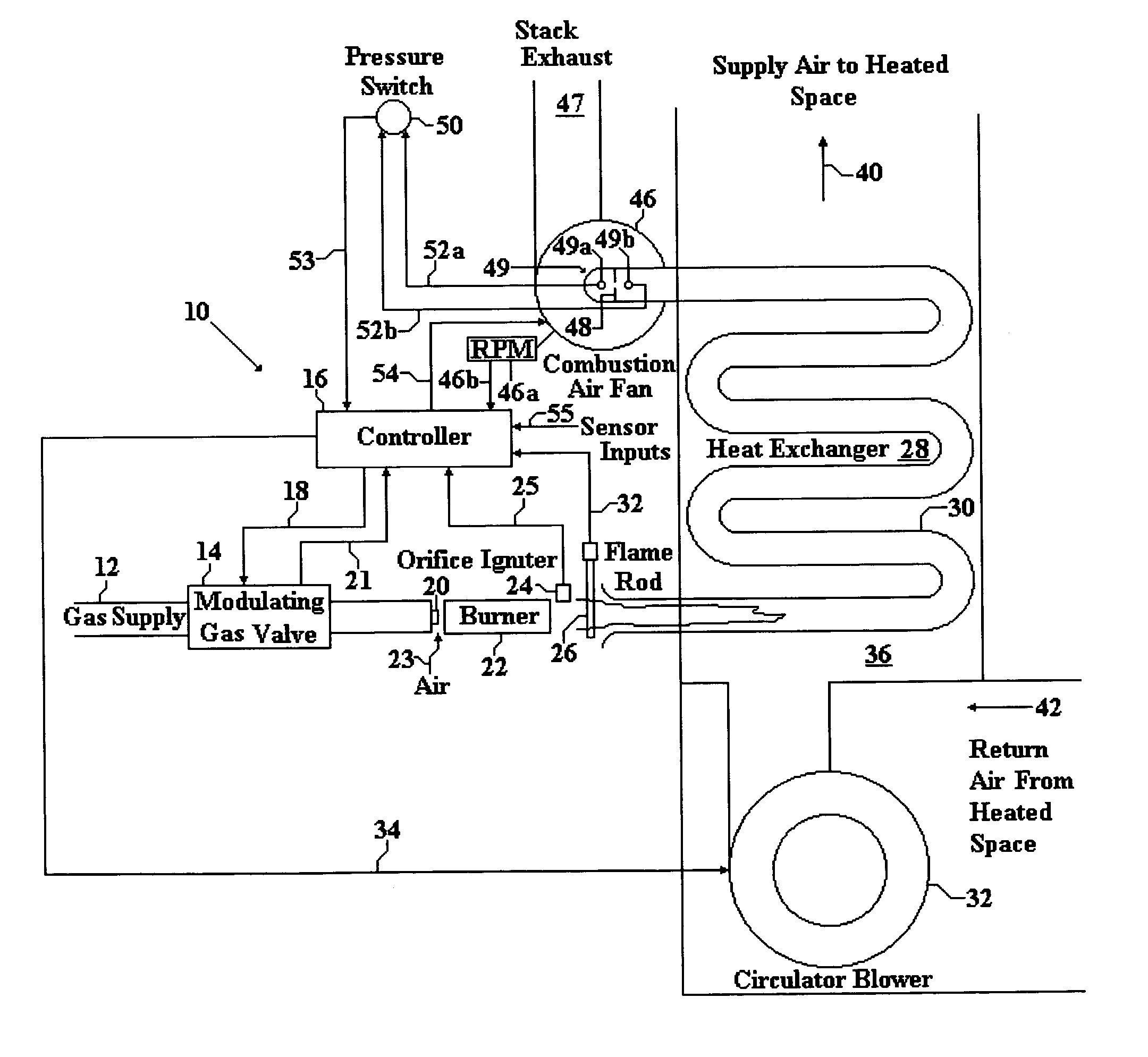

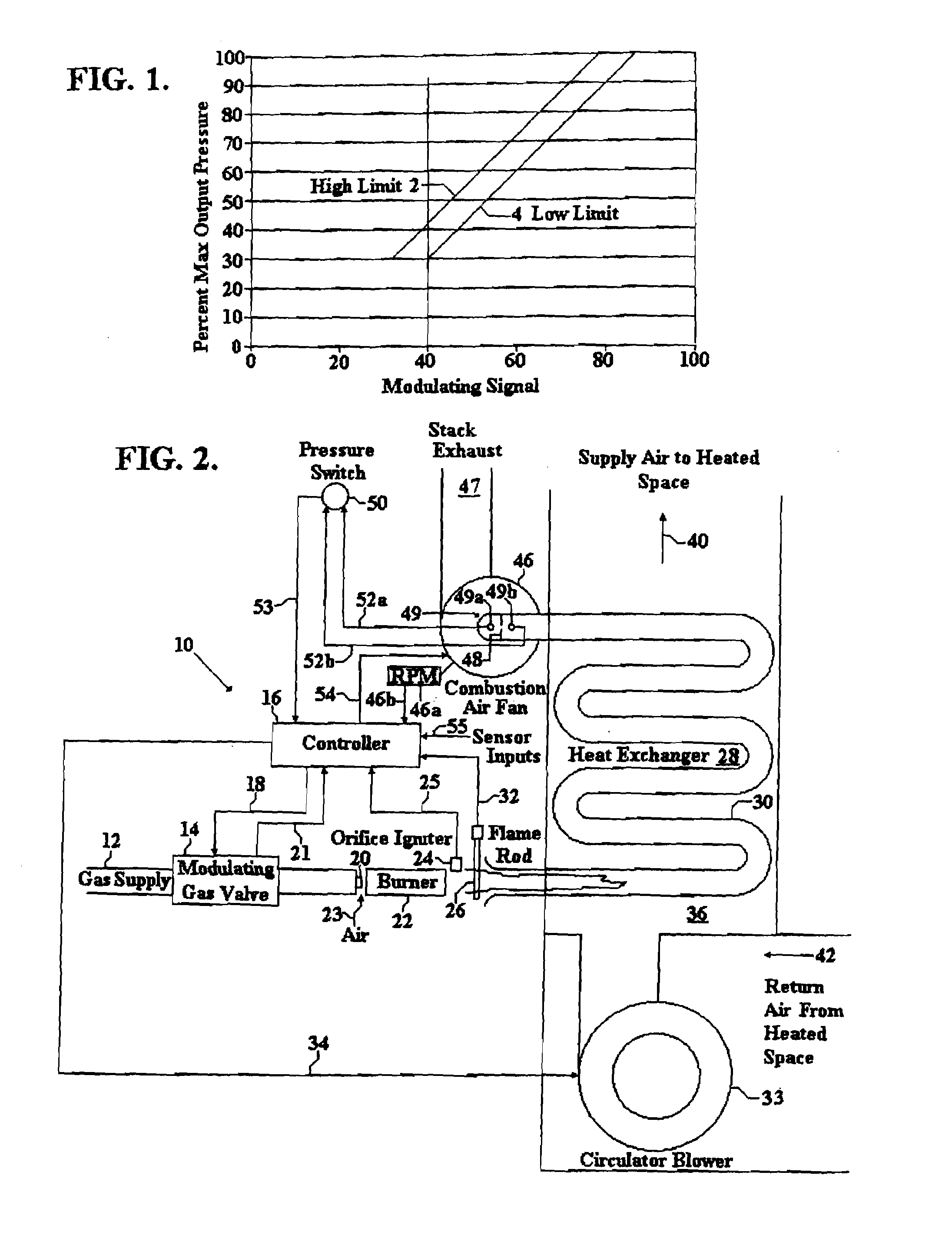

Feedback control for modulating gas burner

Owner:ADEMCO INC +1

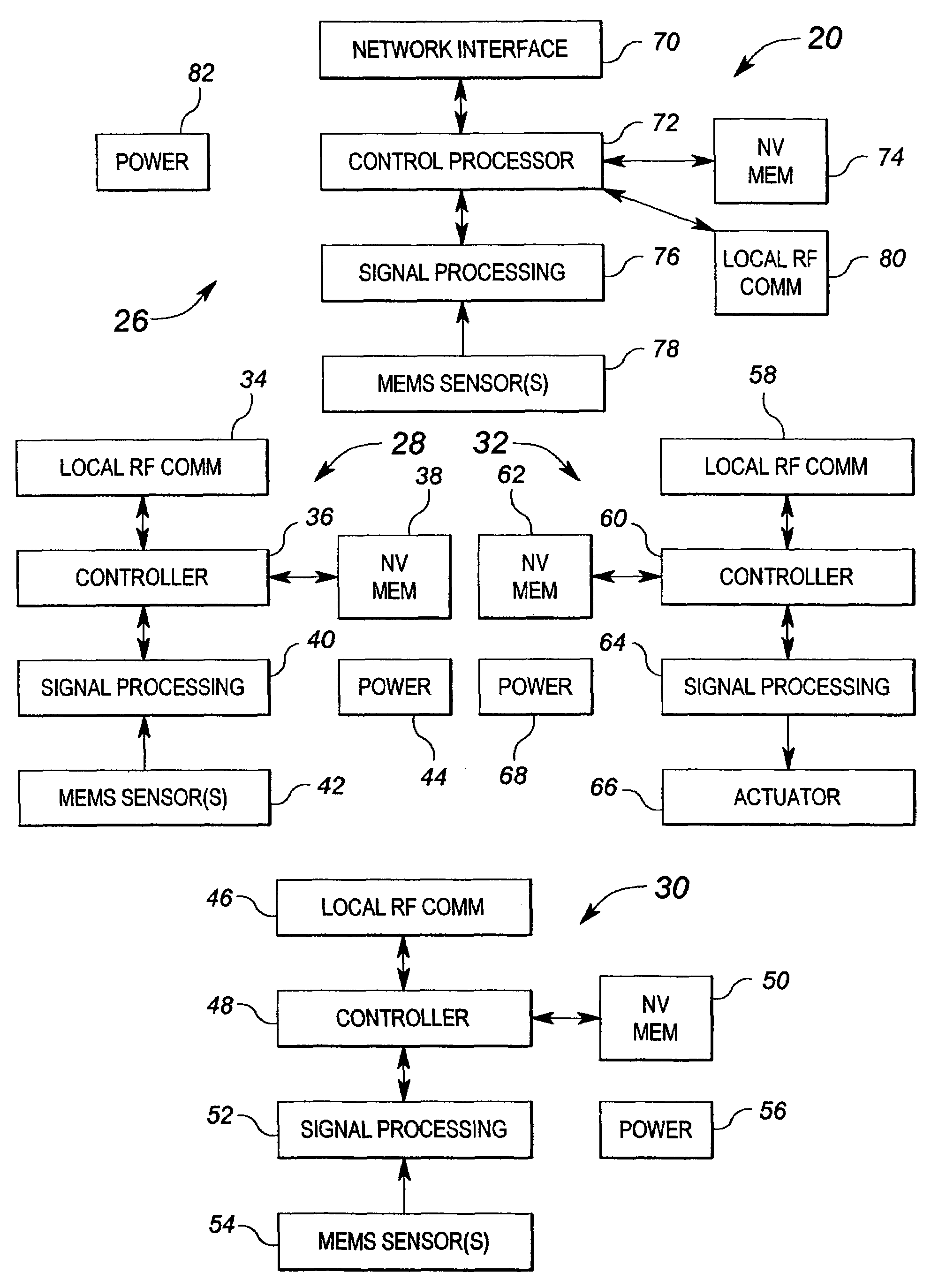

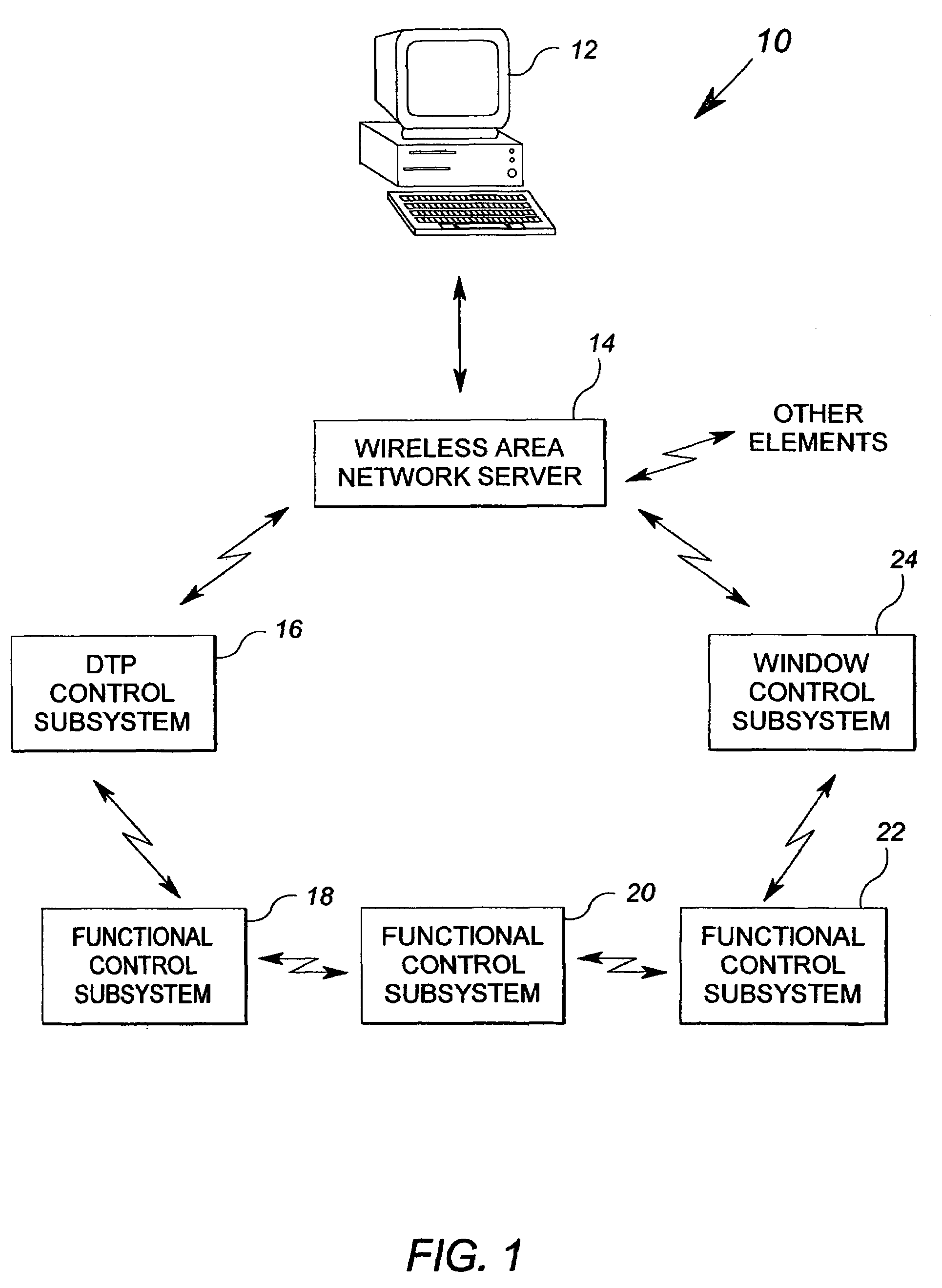

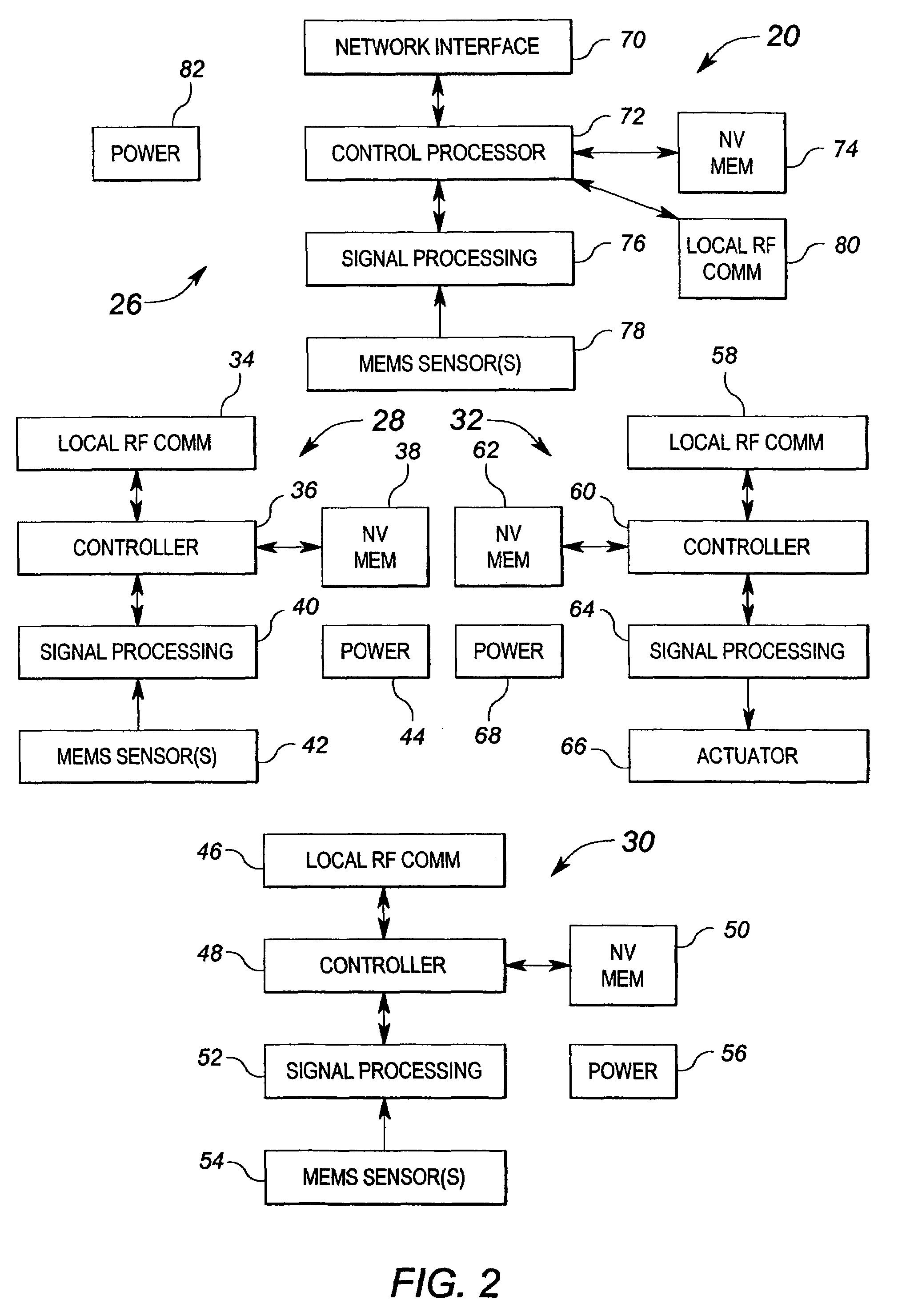

Method and apparatus for an integrated distributed MEMS based control system

ActiveUS7665670B2Space heating and ventilationTemperatue controlDistributed control systemComputer module

An integrated distributed control system incorporates a plurality of micro electromechanical system (MEMS) modules formed into a functional network which is in turn integrated into a management network. The functional network is configured to sense a condition such as an operating characteristic of a machine or the temperature within an area and to provide control functions to effect changes in the condition.

Owner:SIEMENS IND INC

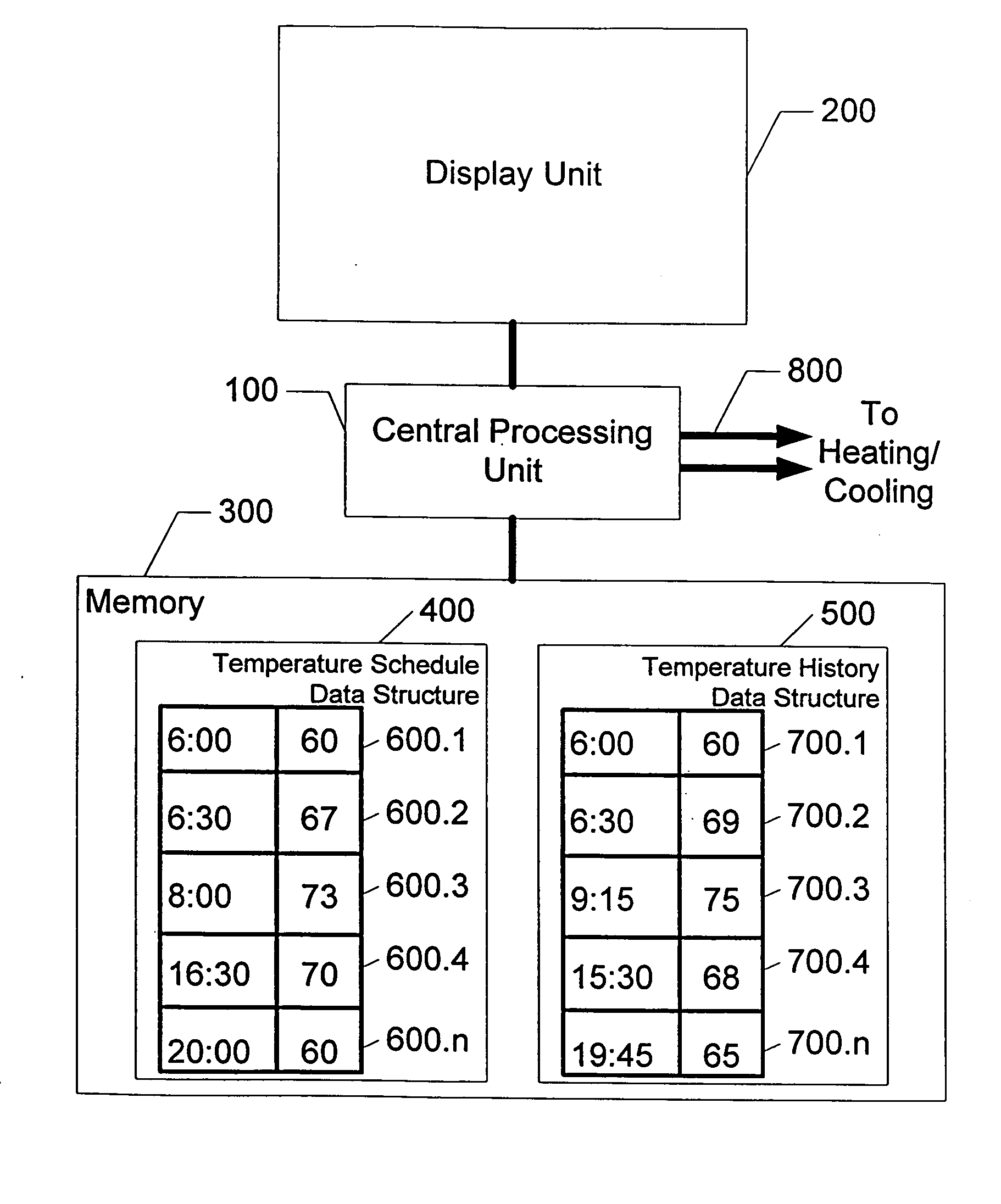

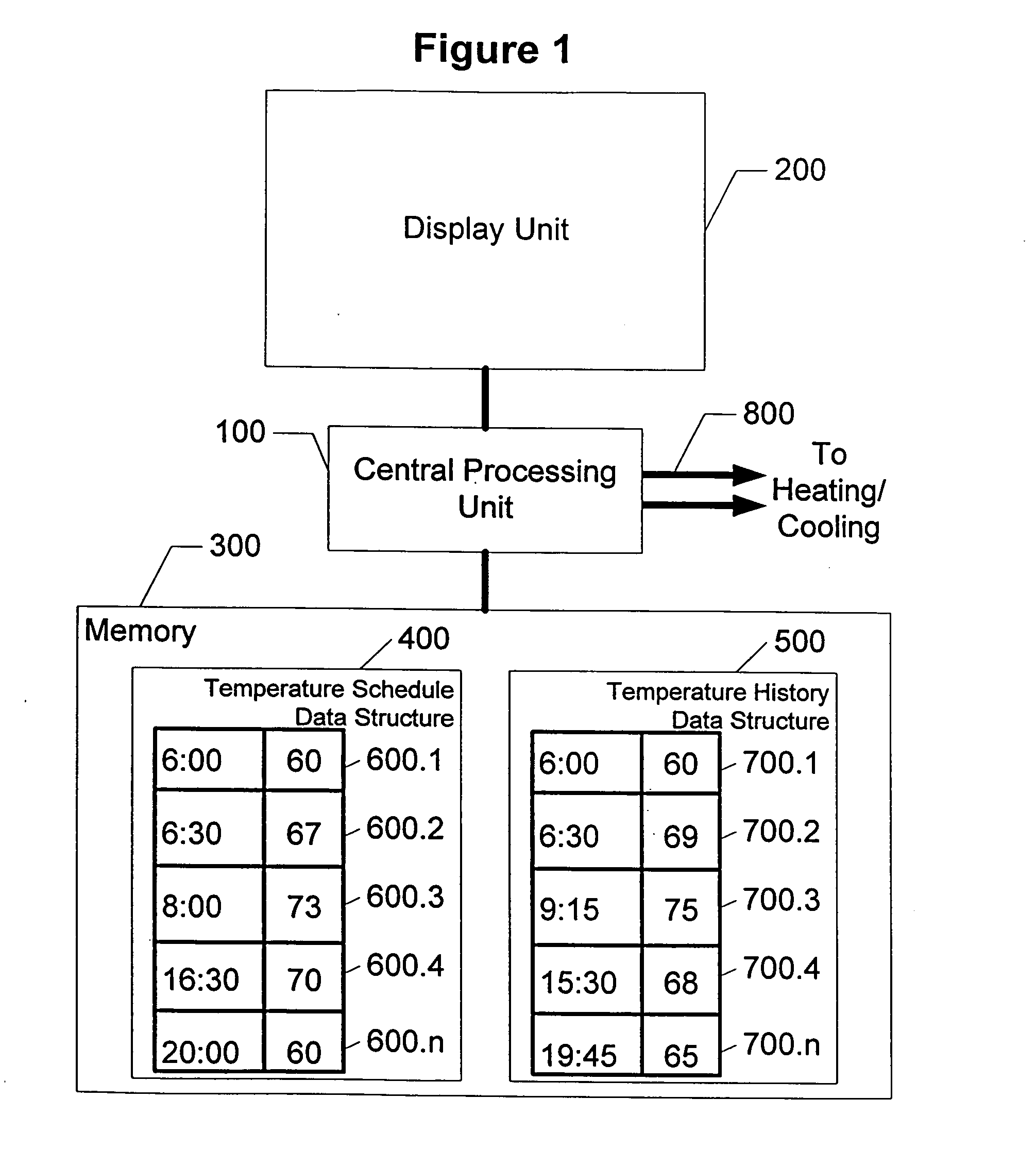

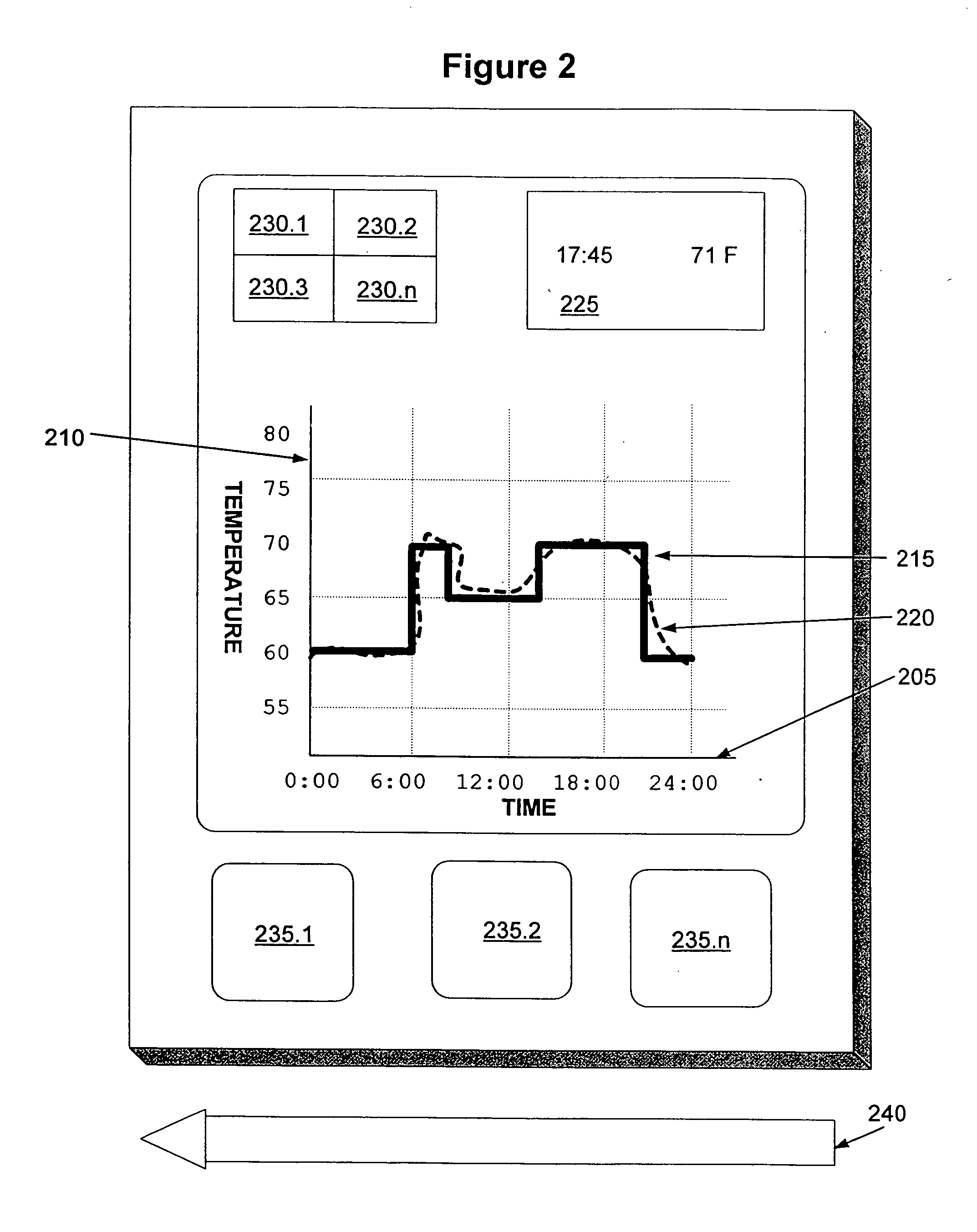

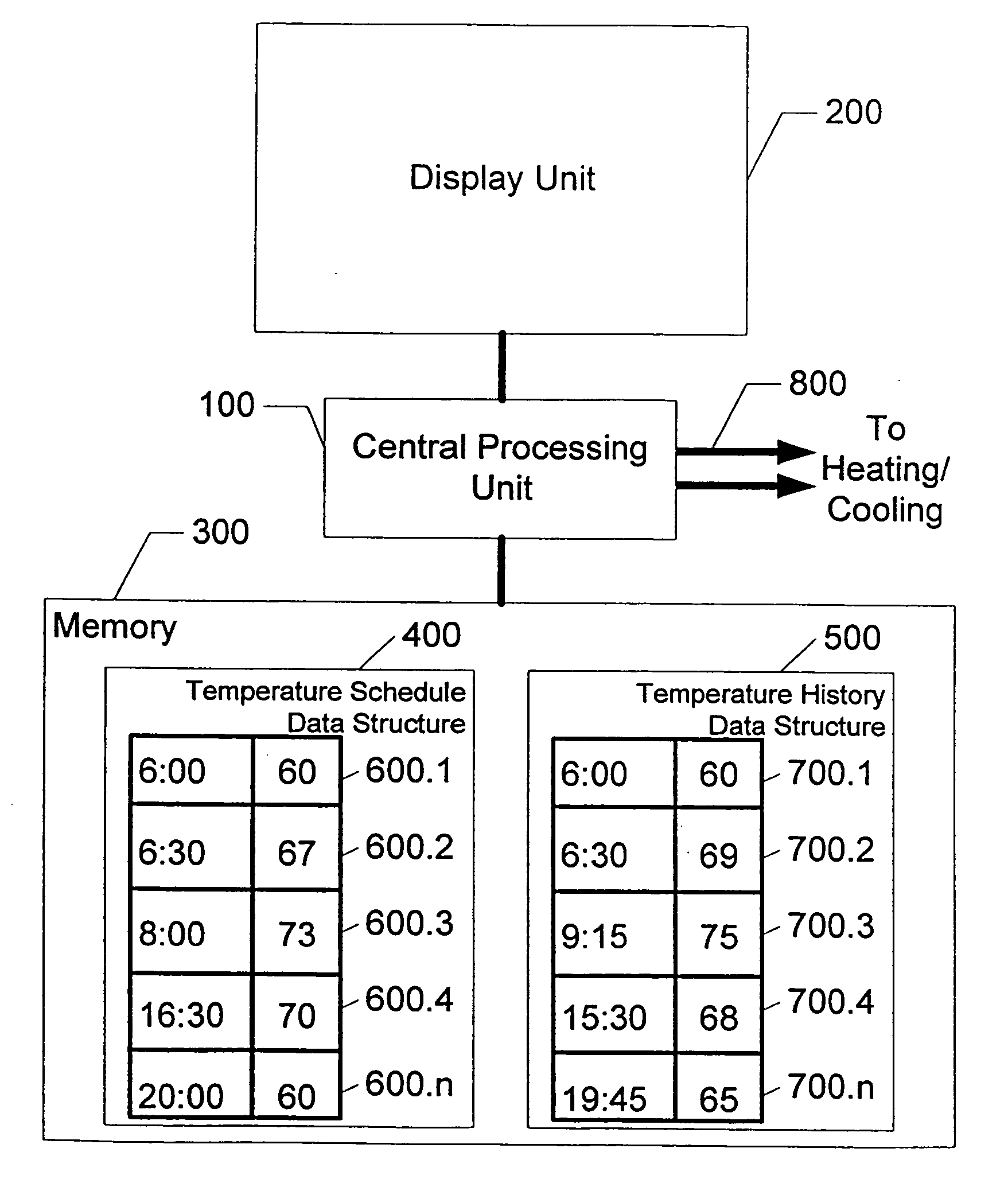

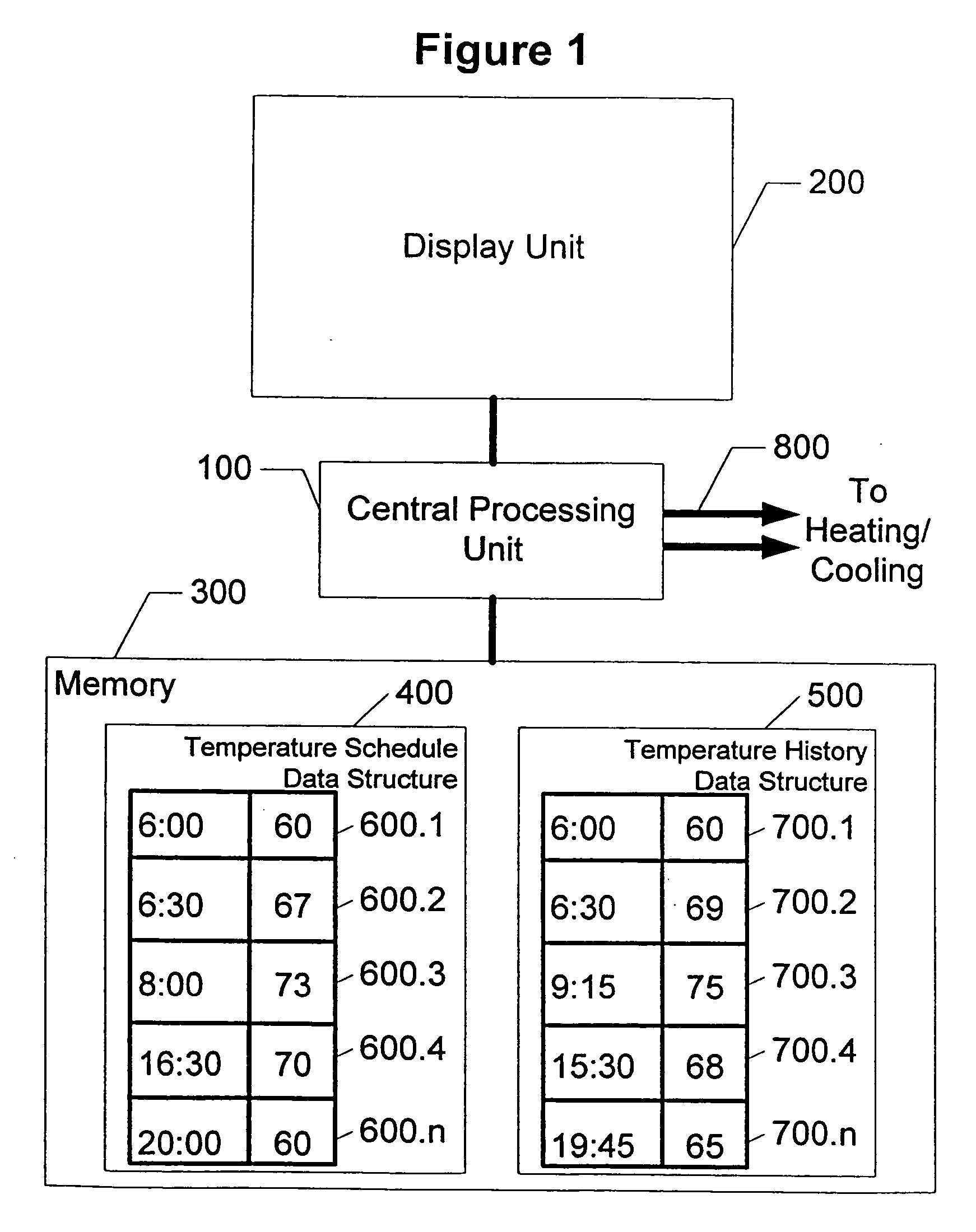

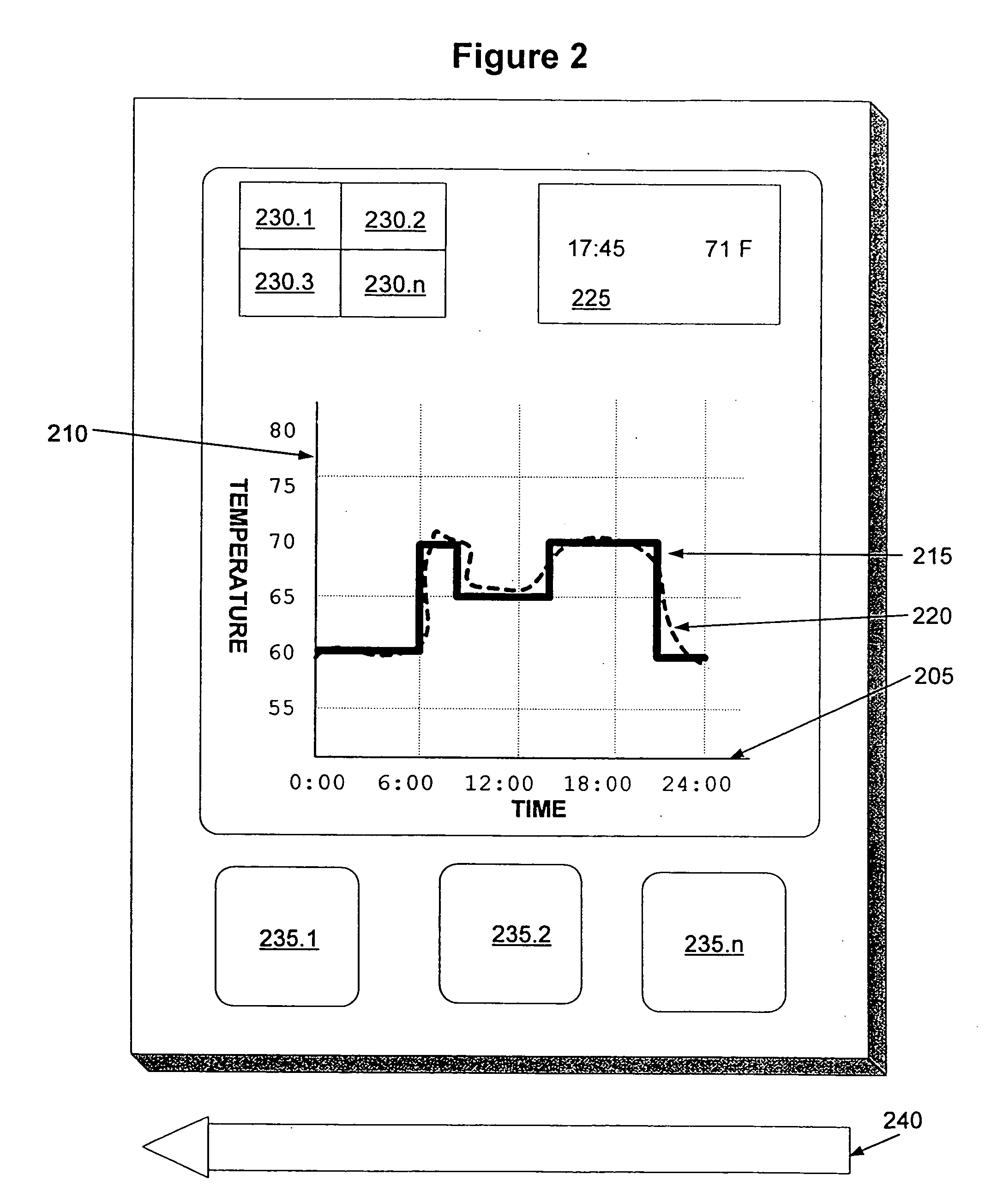

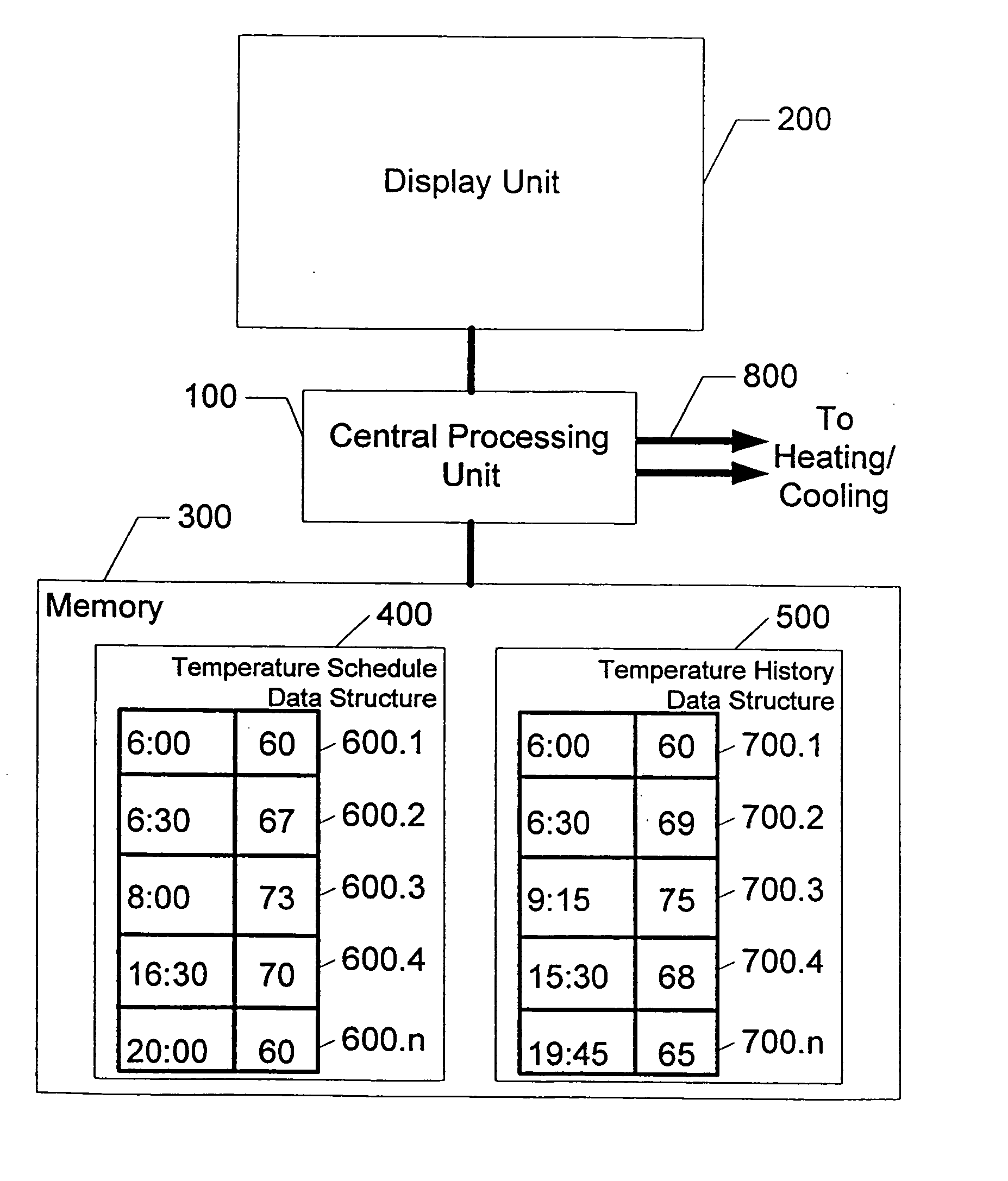

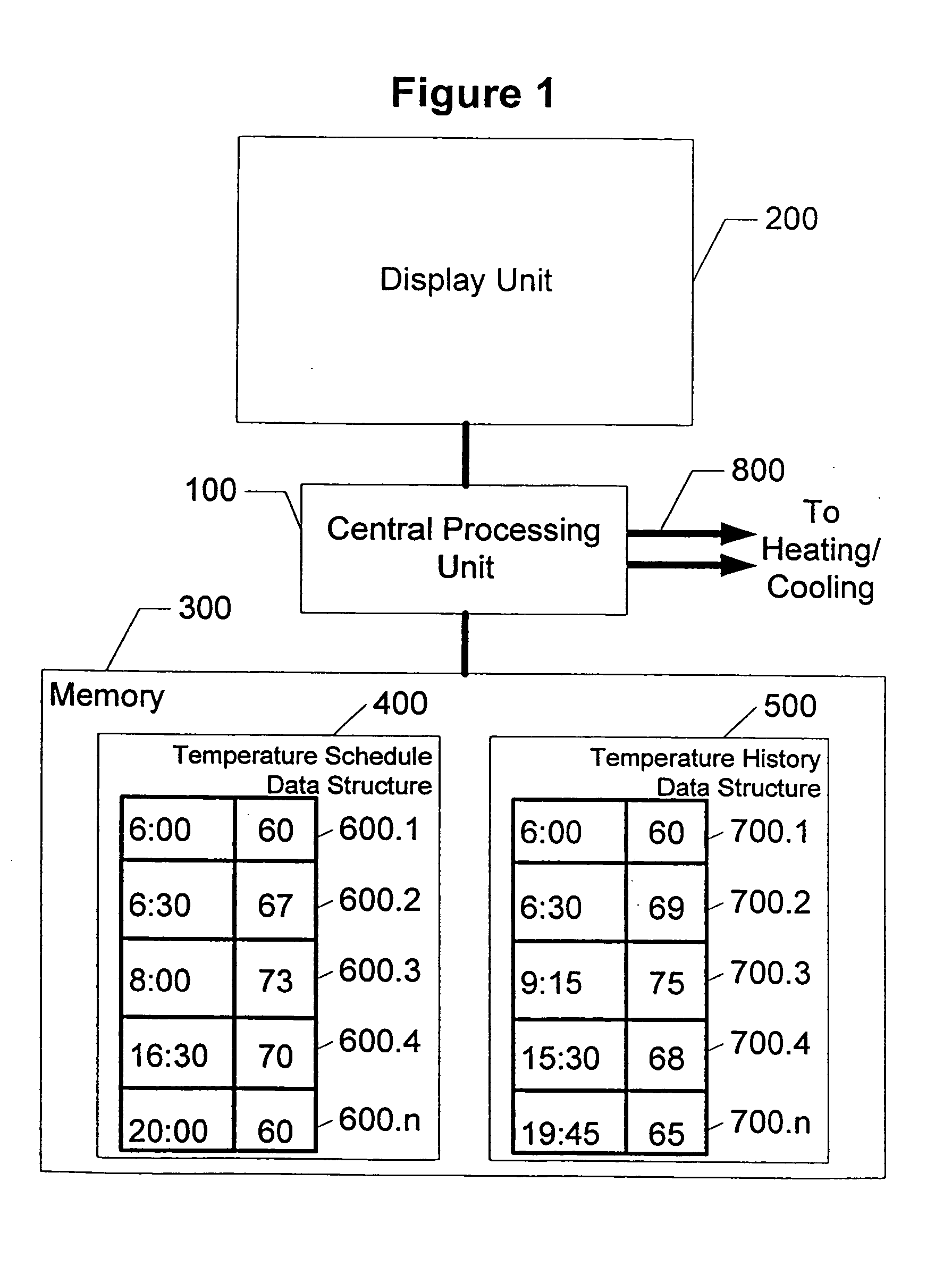

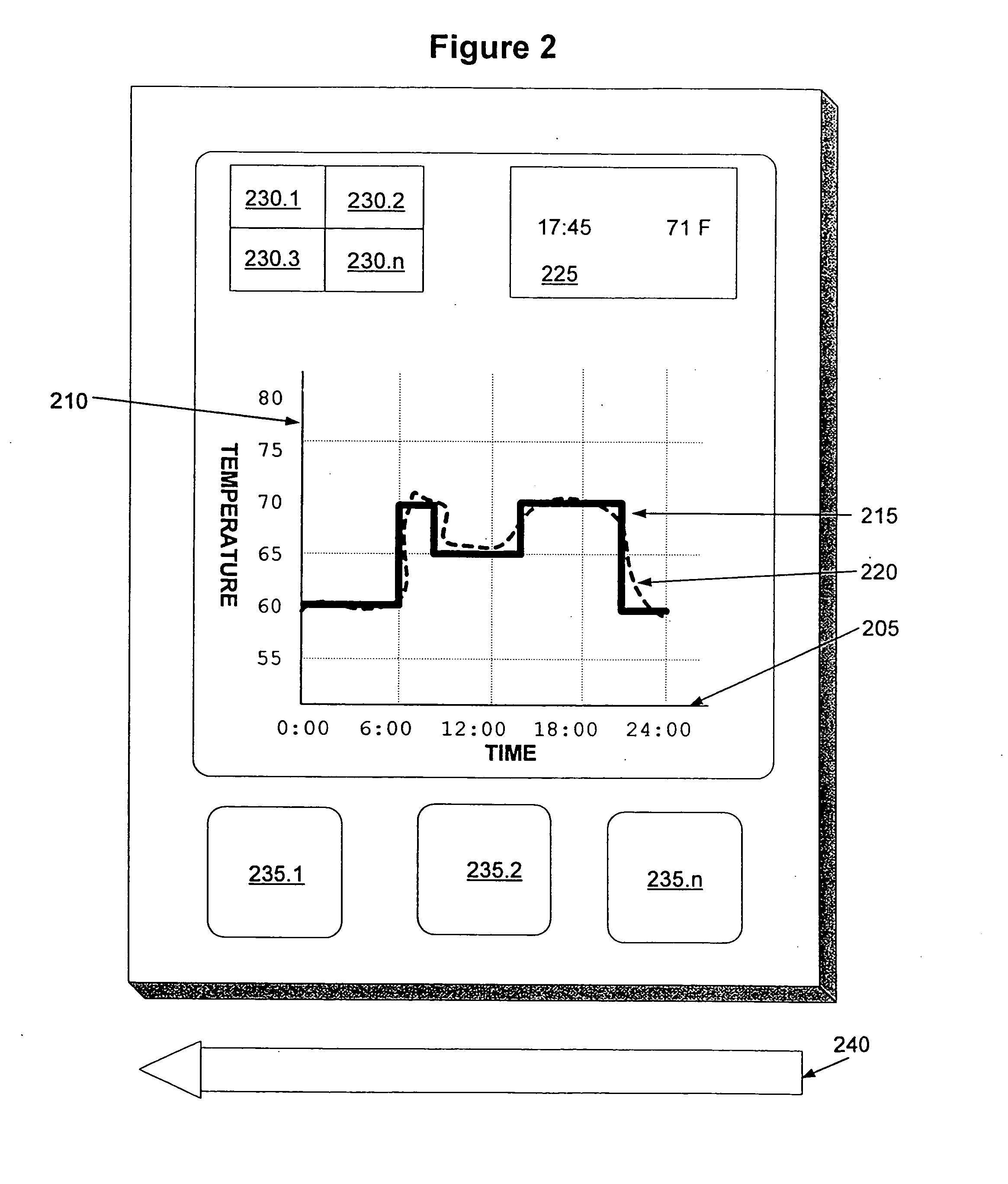

Graphical user interface system for a thermal comfort controller

InactiveUS20070198099A9Easily and intuitively programEasy programmingMechanical apparatusStatic/dynamic balance measurementGraphicsGraphical user interface

A graphical user interface system for a thermal comfort controller. The user interface system has a central processing unit coupled to a memory and a touch sensitive display unit. The memory stores a temperature schedule data structure and perhaps a temperature history data structure. The temperature schedule data structure is made up of at least one set-point. The temperature history data structure is made up of at least one Actual-Temperature-Point. The display presents the set-points and / or the Actual-Temperature-Points. One representation of the display is a graphical step-function. The user uses a finger or stylus to program the set-points by pointing and dragging a portion of the step-function.

Owner:ADEMCO INC

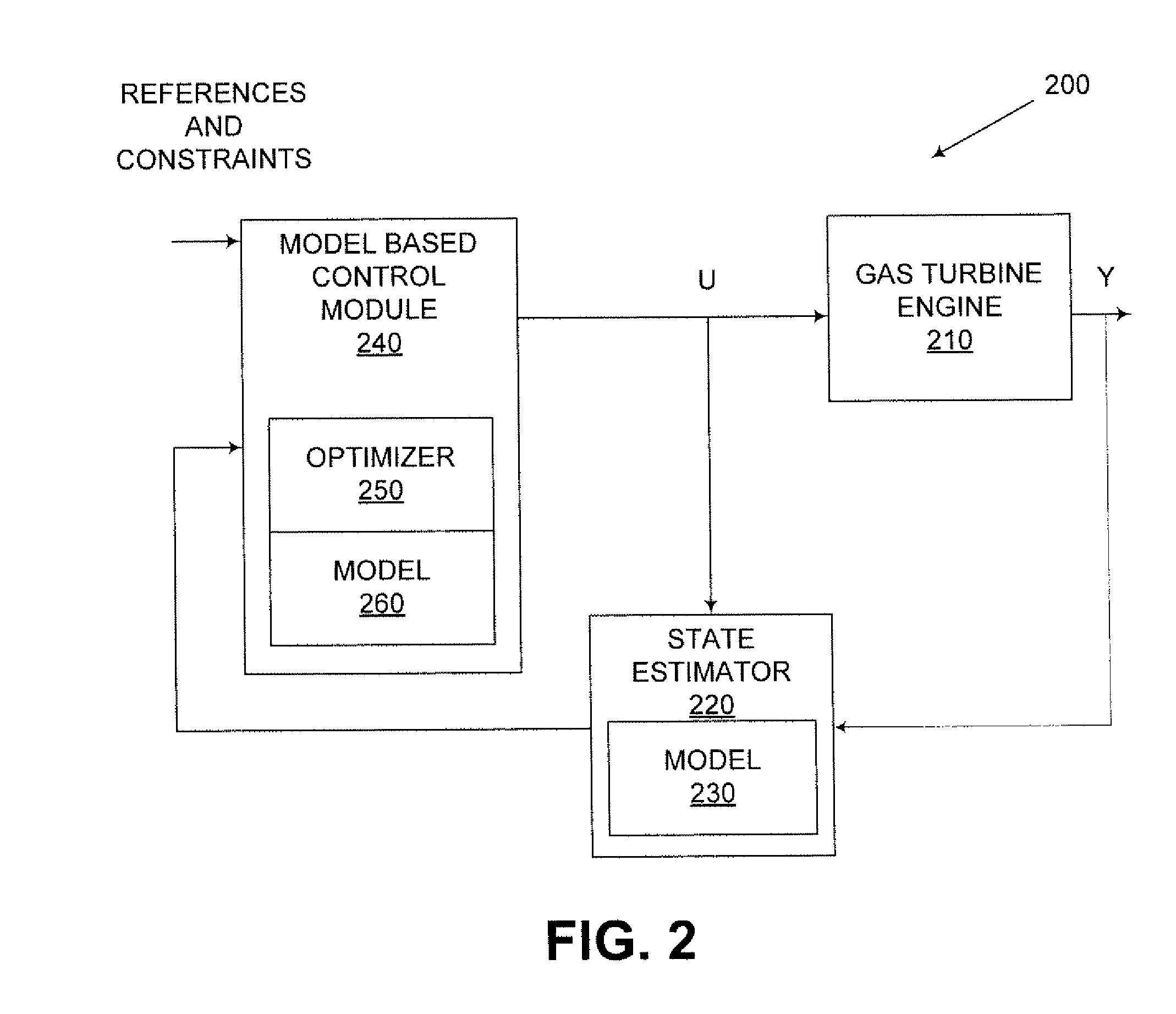

Model based sequential optimization of a single or multiple power generating units

A method and apparatus for optimizing the operation of a single or multiple power generating units using advanced optimization, modeling, and control techniques. In one embodiment, a plurality of component optimization systems for optimizing power generating unit components are sequentially coordinated to allow optimized values determined by a first component optimization system to be fed forward for use as an input value to a subsequent component optimization system. A unit optimization system may be provided to determine goals and constraints for the plurality of component optimization systems in accordance with economic data. In one embodiment of the invention, a multi-unit optimization system is provided to determine goals and constraints for component optimization systems of different power generating units. Both steady state and dynamic models are used for optimization.

Owner:GE DIGITAL HLDG LLC

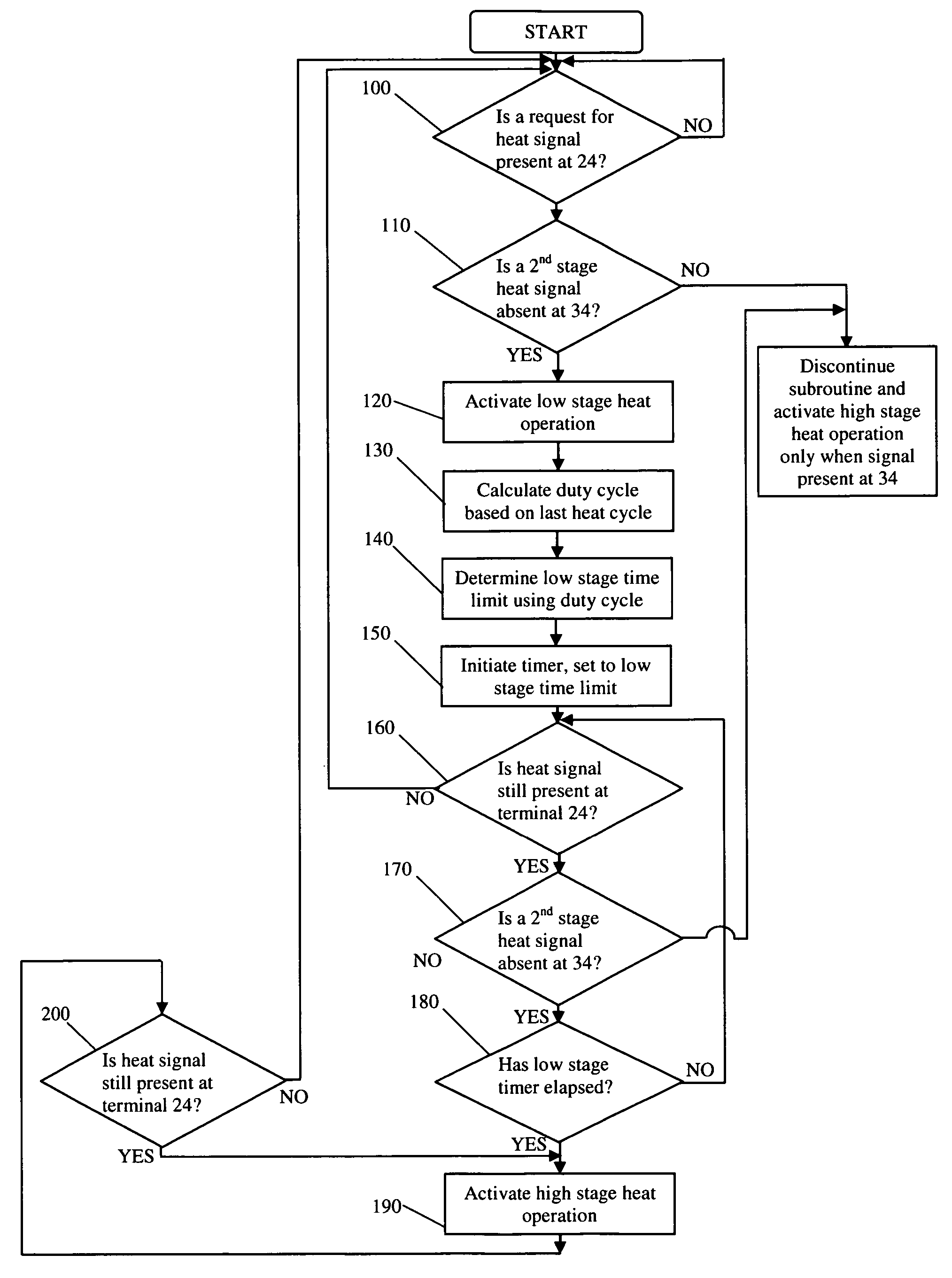

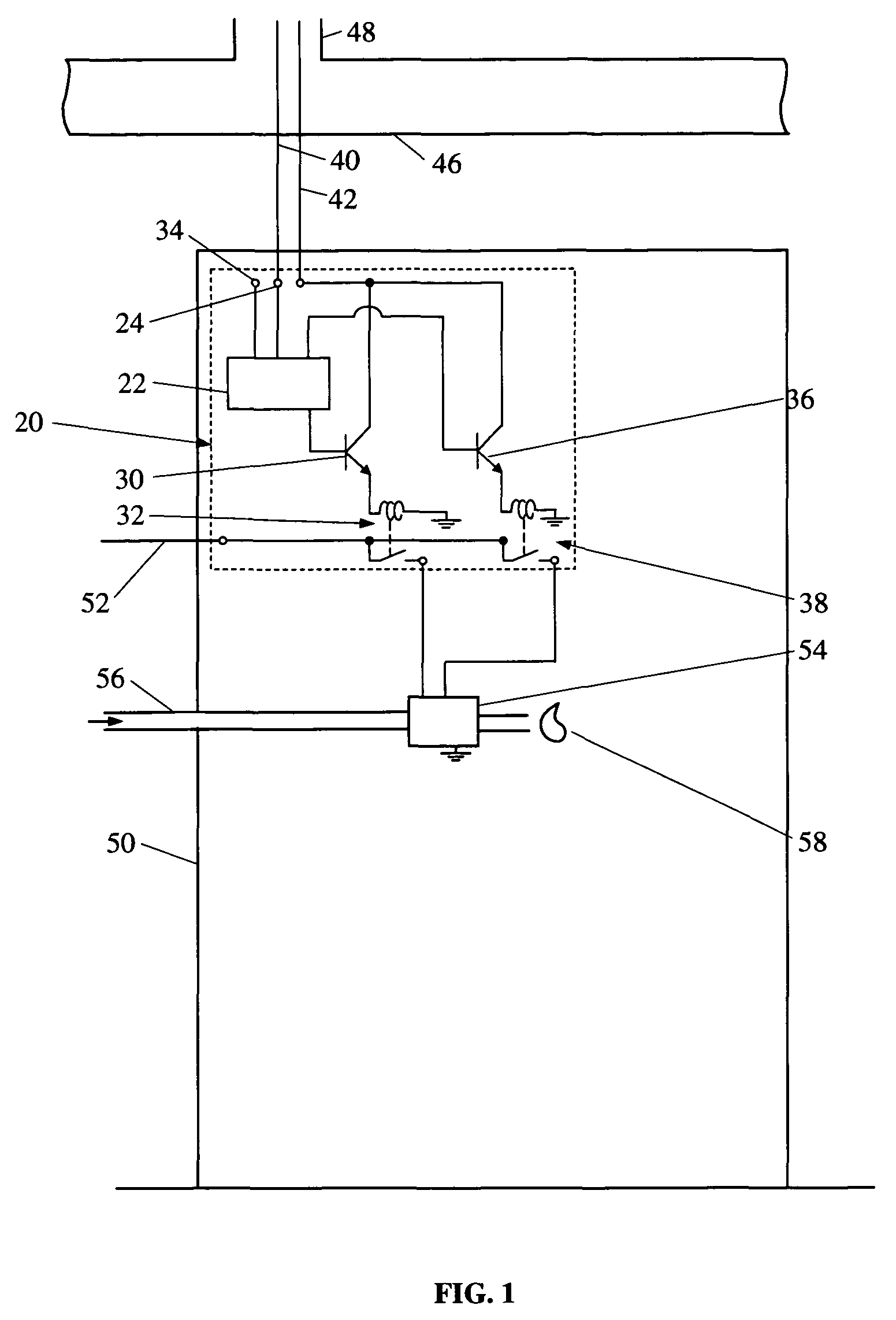

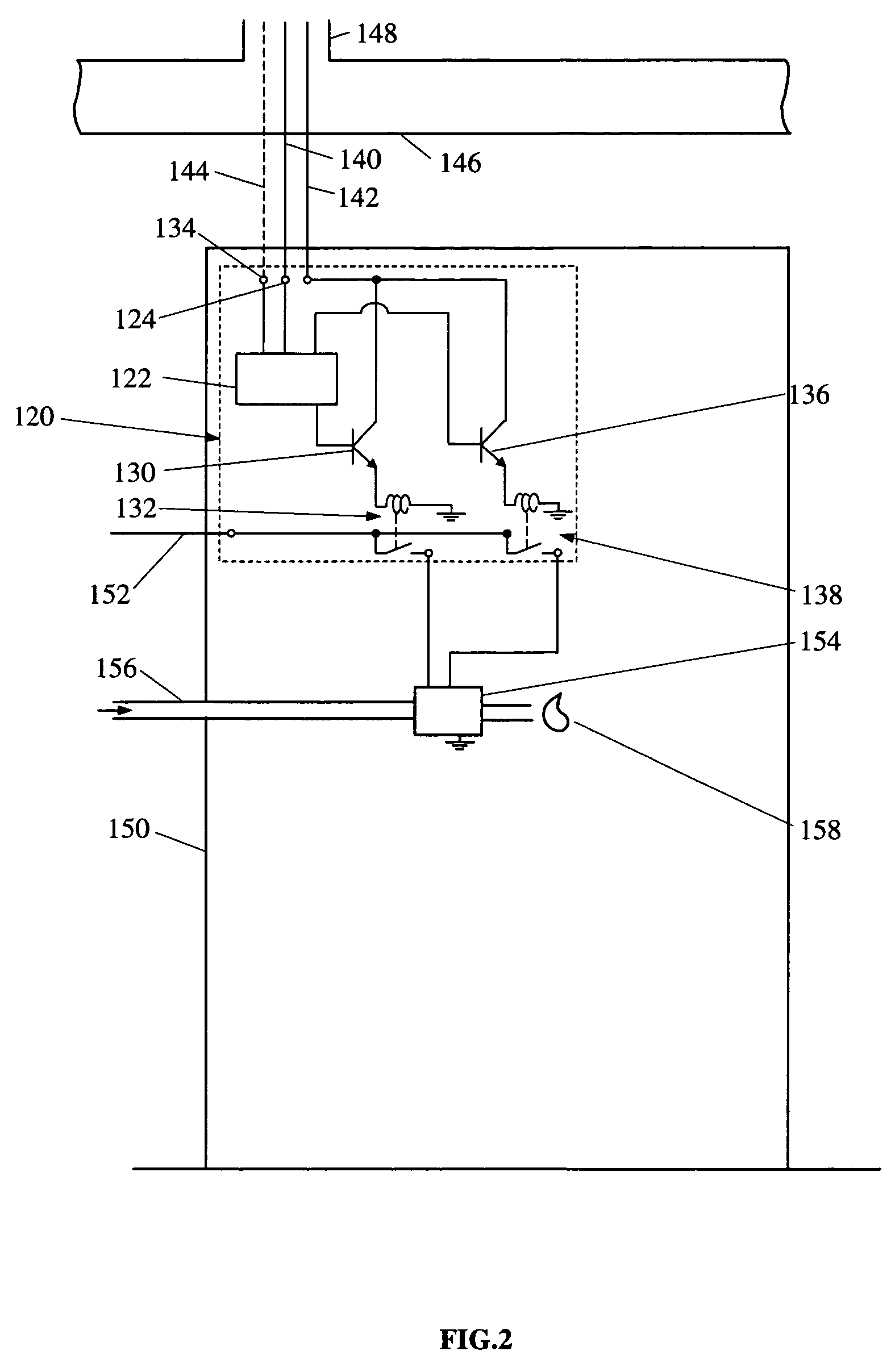

Controller for two-stage heat source usable with single and two stage thermostats

ActiveUS7731096B2Fluid heatersTemperature control without auxillary powerMicrocontrollerSingle stage

Owner:COPELAND COMFORT CONTROL LP

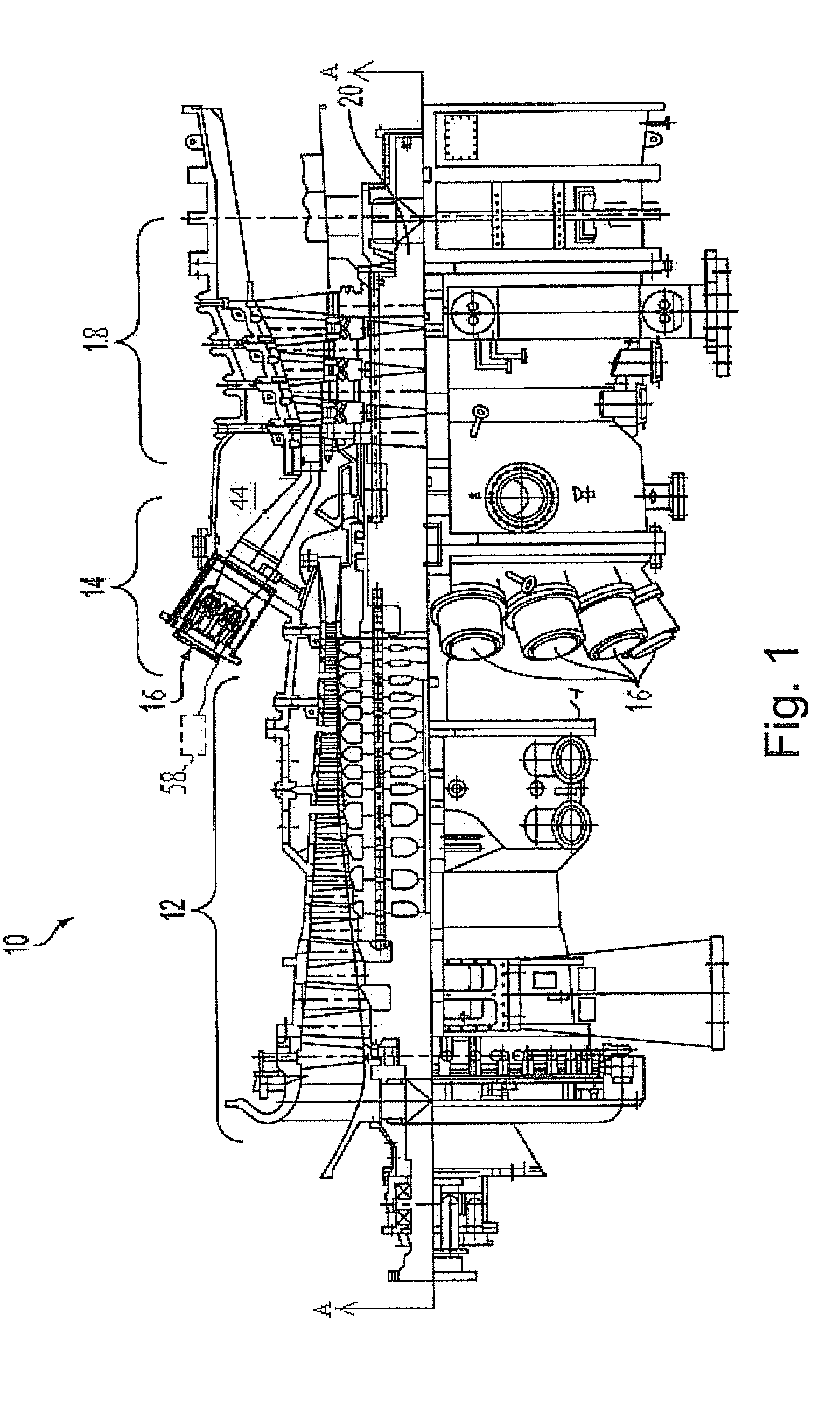

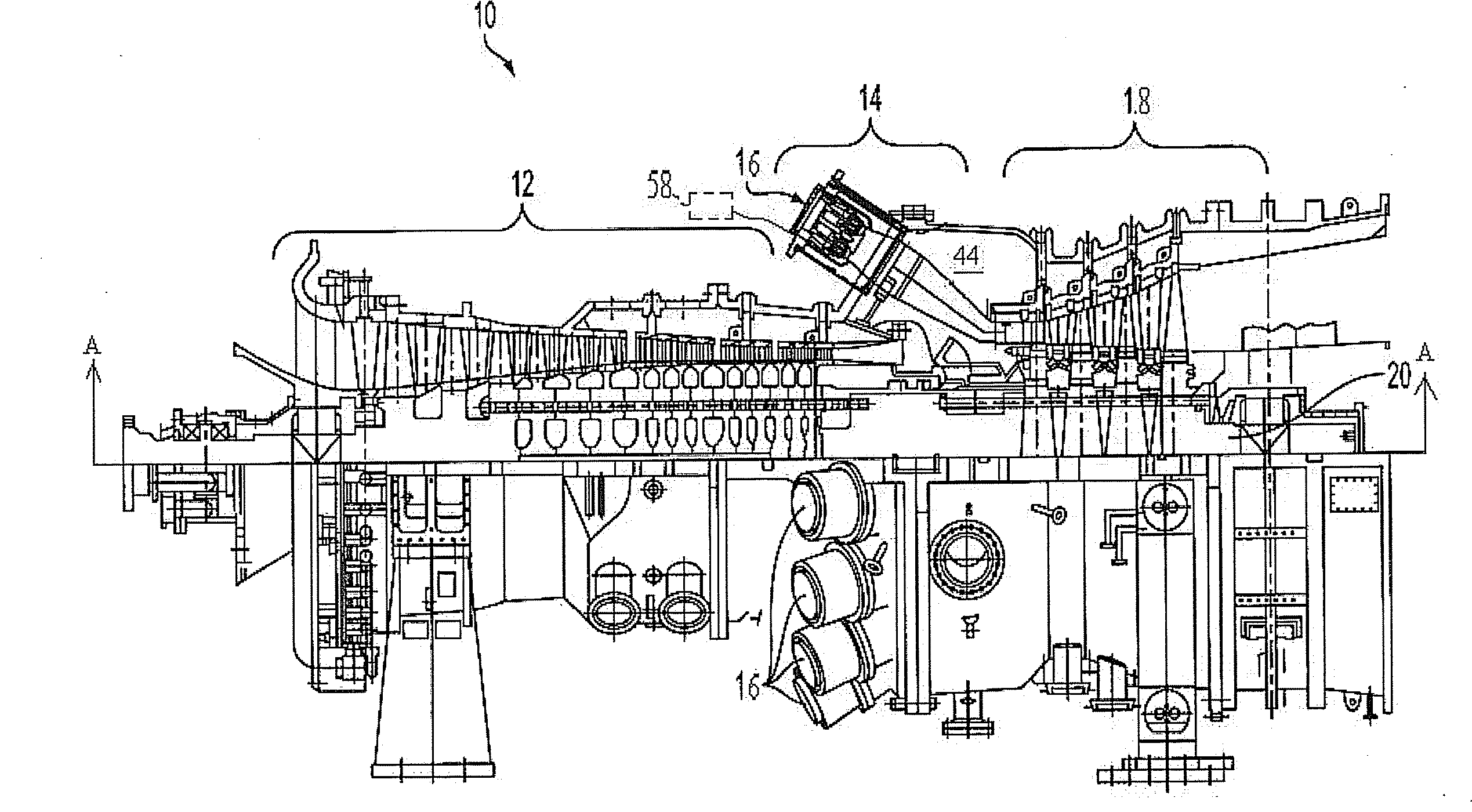

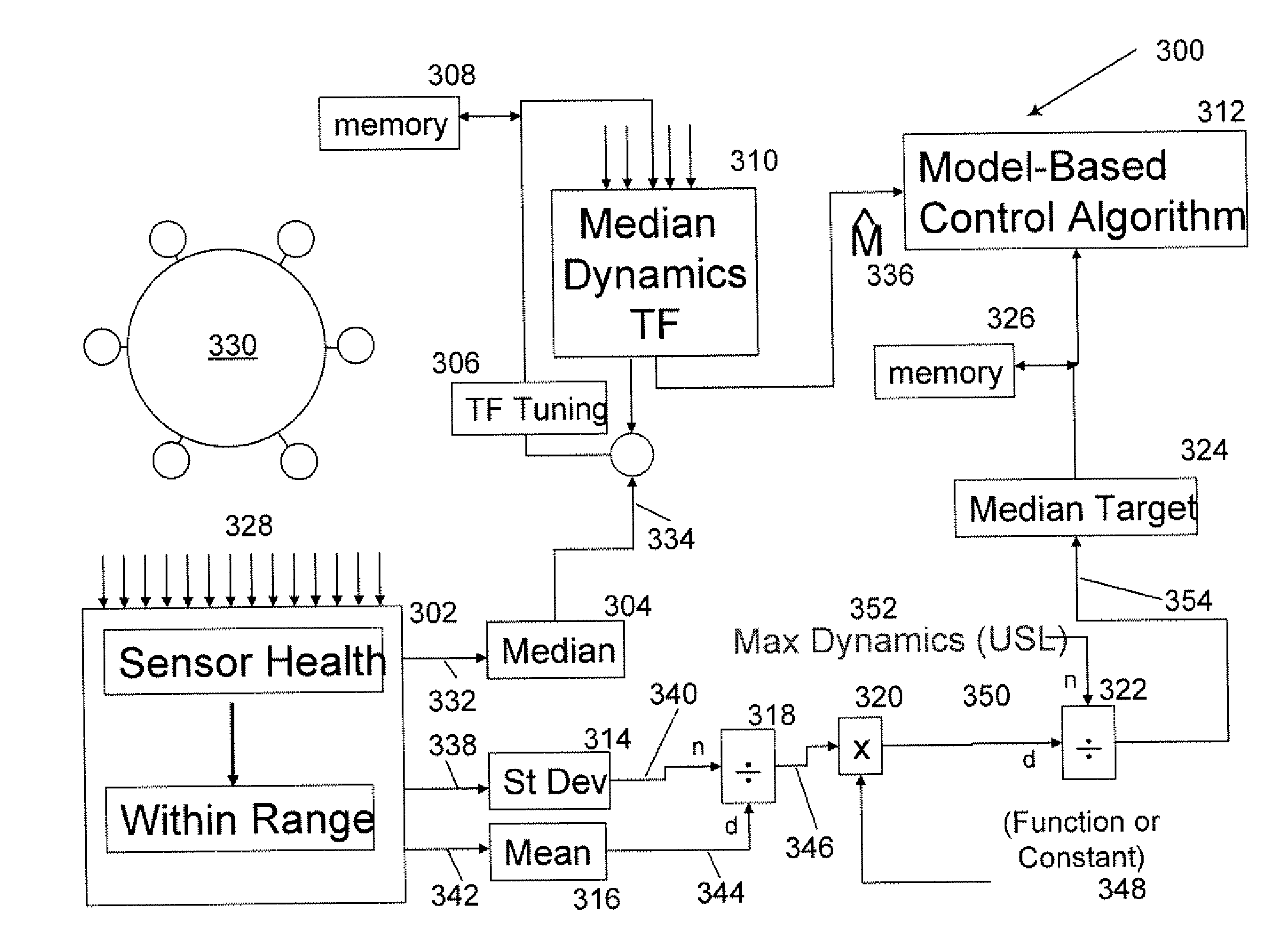

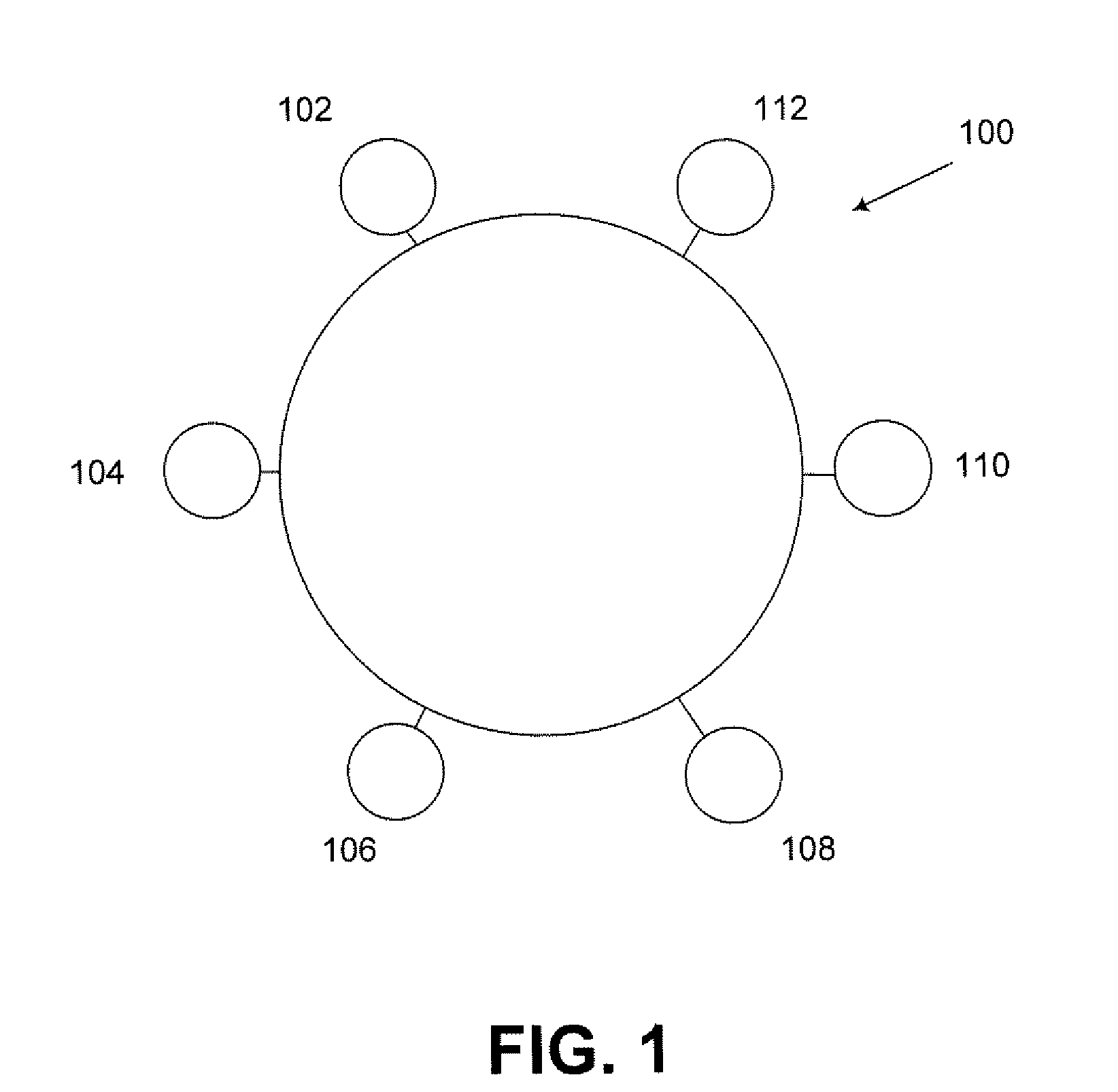

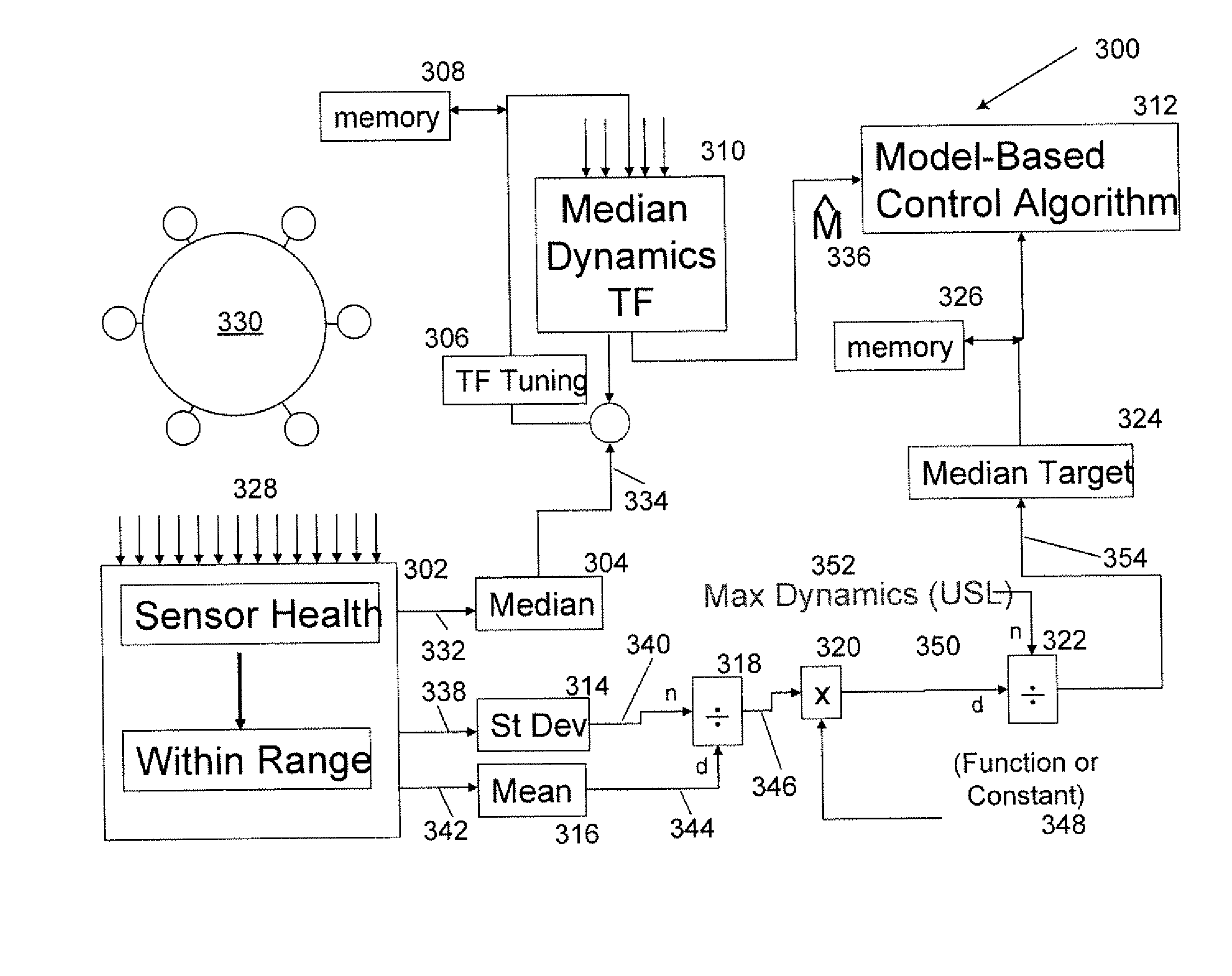

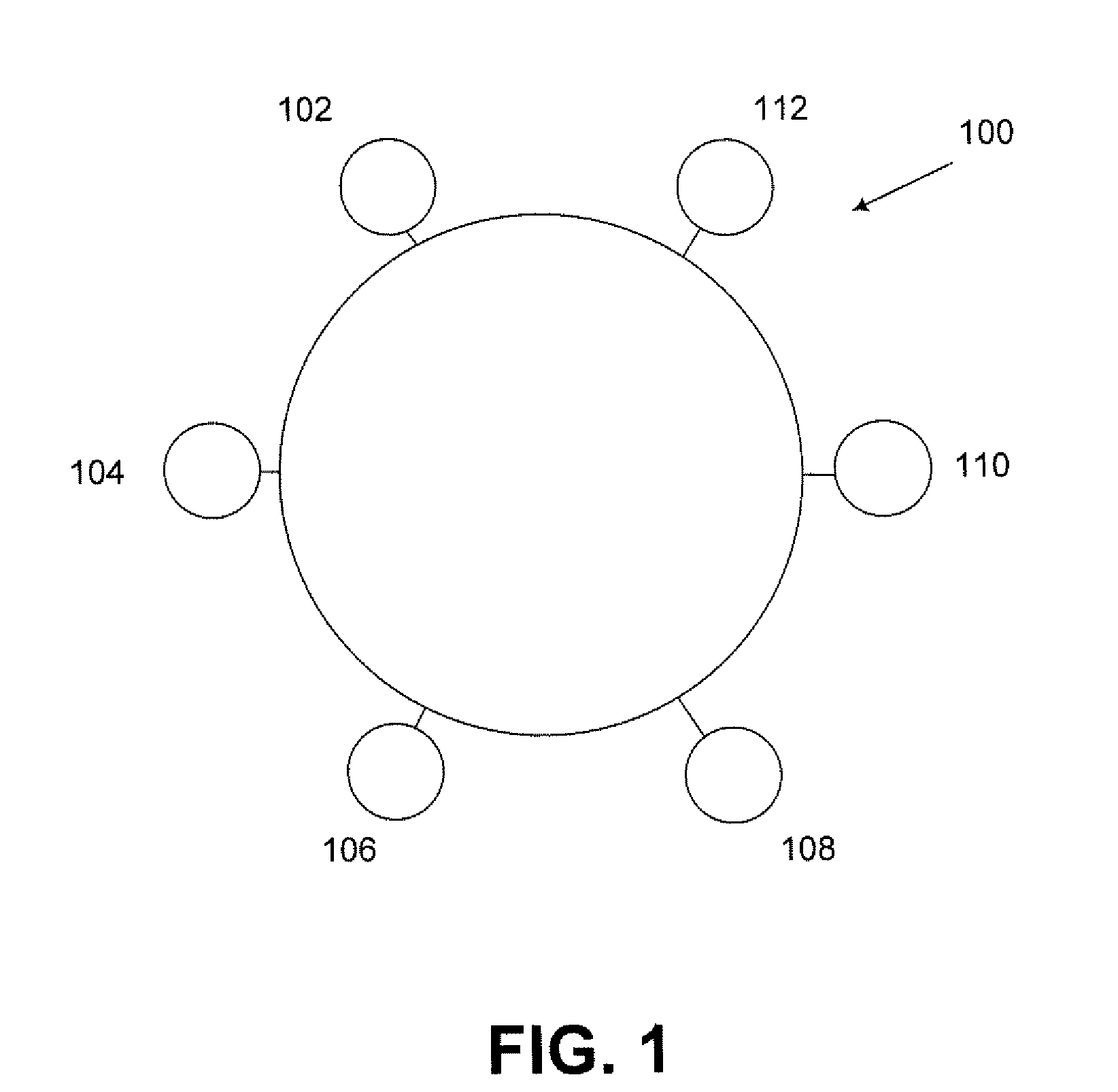

Systems and Methods for Using a Combustion Dynamics Tuning Algorithm with a Multi-Can Combustor

ActiveUS20090005952A1Analogue computers for vehiclesContinuous combustion chamberCombustorCombustion kinetics

Embodiments of the invention can provide systems and methods for using a combustion dynamics tuning algorithm with a multi-can combustor. According to one embodiment of the invention, a method for controlling a gas turbine engine with an engine model can be implemented for an engine comprising multiple cans. The method can include obtaining operating frequency information associated with multiple cans of the engine. In addition, the method can include determining variation between operating frequency information of at least two cans. Furthermore, the method can include determining a median value based at least in part on the variation. Moreover, the method can include determining whether the median value exceeds at least one operating threshold. The method can also include implementing at least one engine control action to modify at least one of the operating frequencies if at least one operating threshold is exceeded.

Owner:GENERAL ELECTRIC CO

Model based optimization of multiple power generating units

A method and apparatus for optimizing the operation of a single or multiple power generating units using advanced optimization, modeling, and control techniques. In one embodiment, a plurality of component optimization systems for optimizing power generating unit components are sequentially coordinated to allow optimized values determined by a first component optimization system to be fed forward for use as an input value to a subsequent component optimization system. A unit optimization system may be provided to determine goals and constraints for the plurality of component optimization systems in accordance with economic data. In one embodiment of the invention, a multi-unit optimization system is provided to determine goals and constraints for component optimization systems of different power generating units. Both steady state and dynamic models are used for optimization.

Owner:GE DIGITAL HLDG LLC

Graphical user interface system for a thermal comfort controller

InactiveUS20060027671A1Easily and intuitively programEasy programmingMechanical apparatusData processing applicationsGraphicsGraphical user interface

Owner:ADEMCO INC

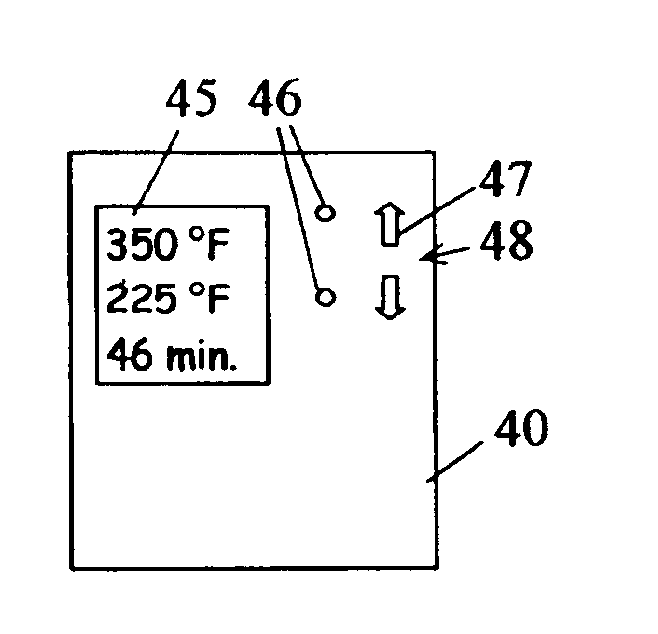

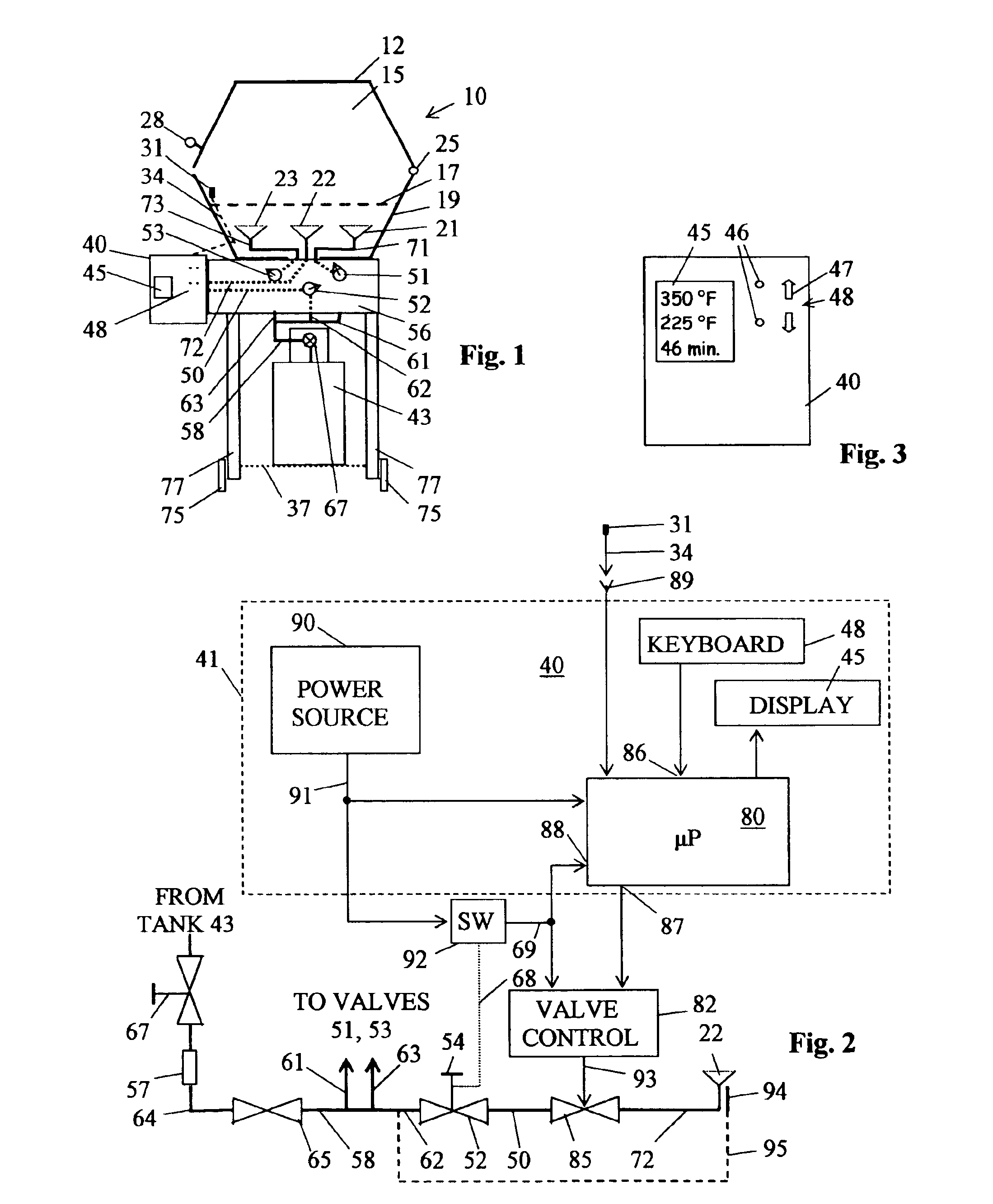

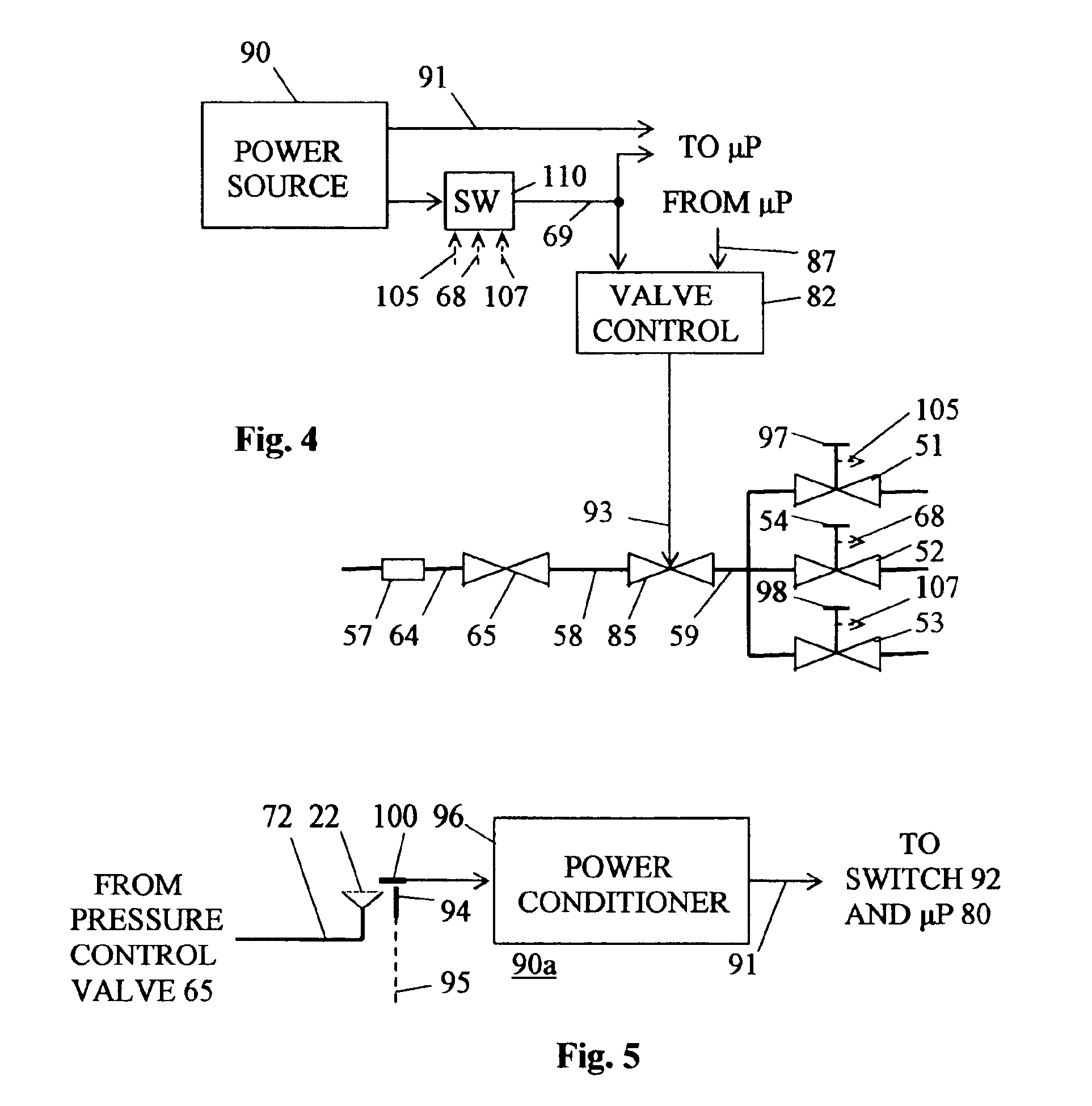

Temperature controlled burner apparatus

InactiveUS6881055B2Easy to controlMore powerTemperature control without auxillary powerSelf-cleaning stoves/rangesTemperature controlCombustor

A system for controlling temperature in an enclosure operates in a low heat or a high heat mode with flame always present. The presently intended use is for providing a cooking grill with a controlled temperature cooking space. An electrically controlled valve having high flow rate and low flow rate settings is interposed in the fuel line for at least one of the burners in the grill. A temperature sensor signals cooking space temperature to a controller that may be a microprocessor. The system includes a keyboard allowing the user to communicate a selected set point to the microprocessor and the microprocessor communicates status to a display. The microprocessor selects the setting of the electrically controlled valve. In a preferred embodiment, the electrically controlled valve is placed in series fuel flow with one of the manually adjustable valves commonly found on cooking grills.

Owner:ADEMCO INC

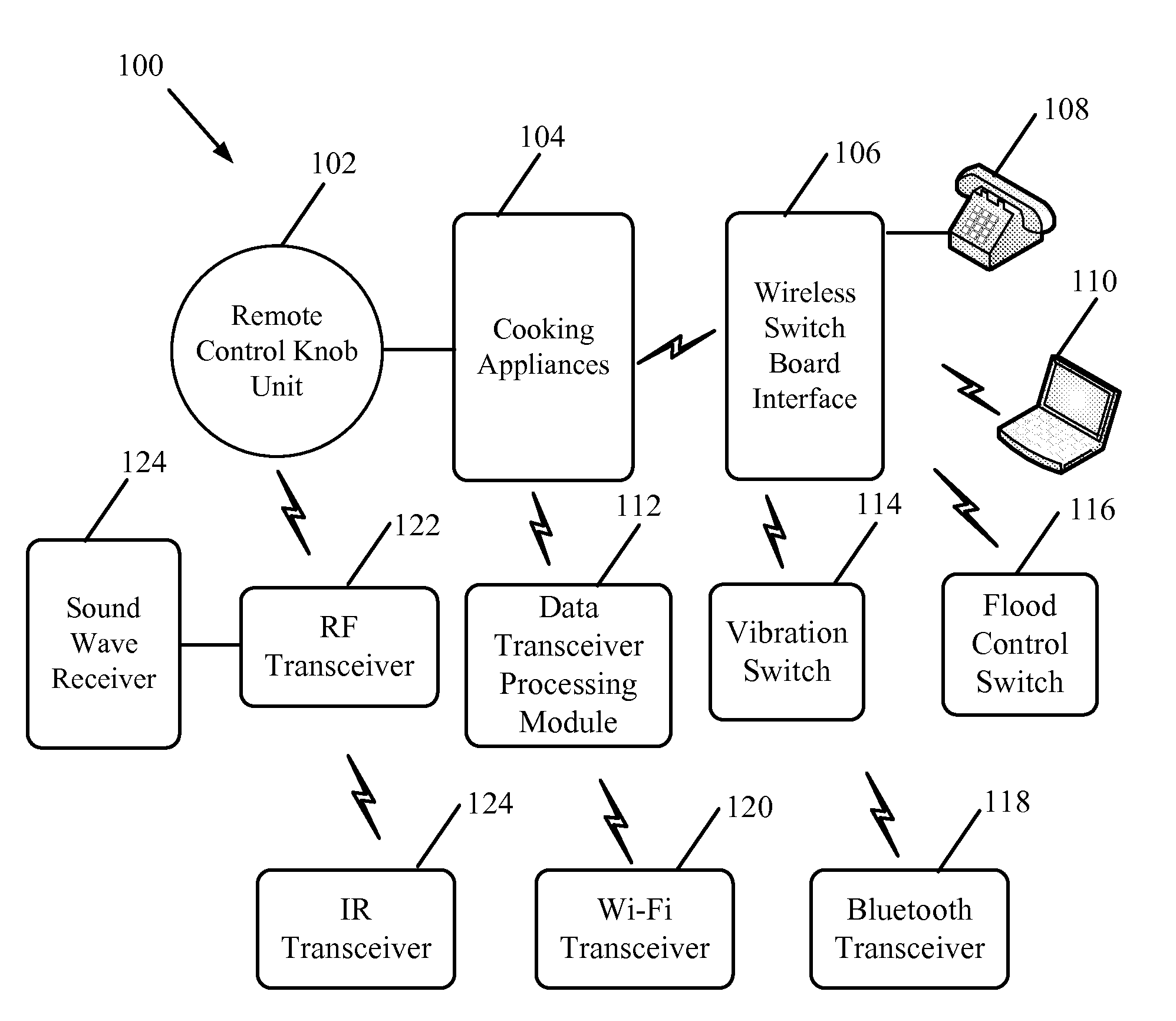

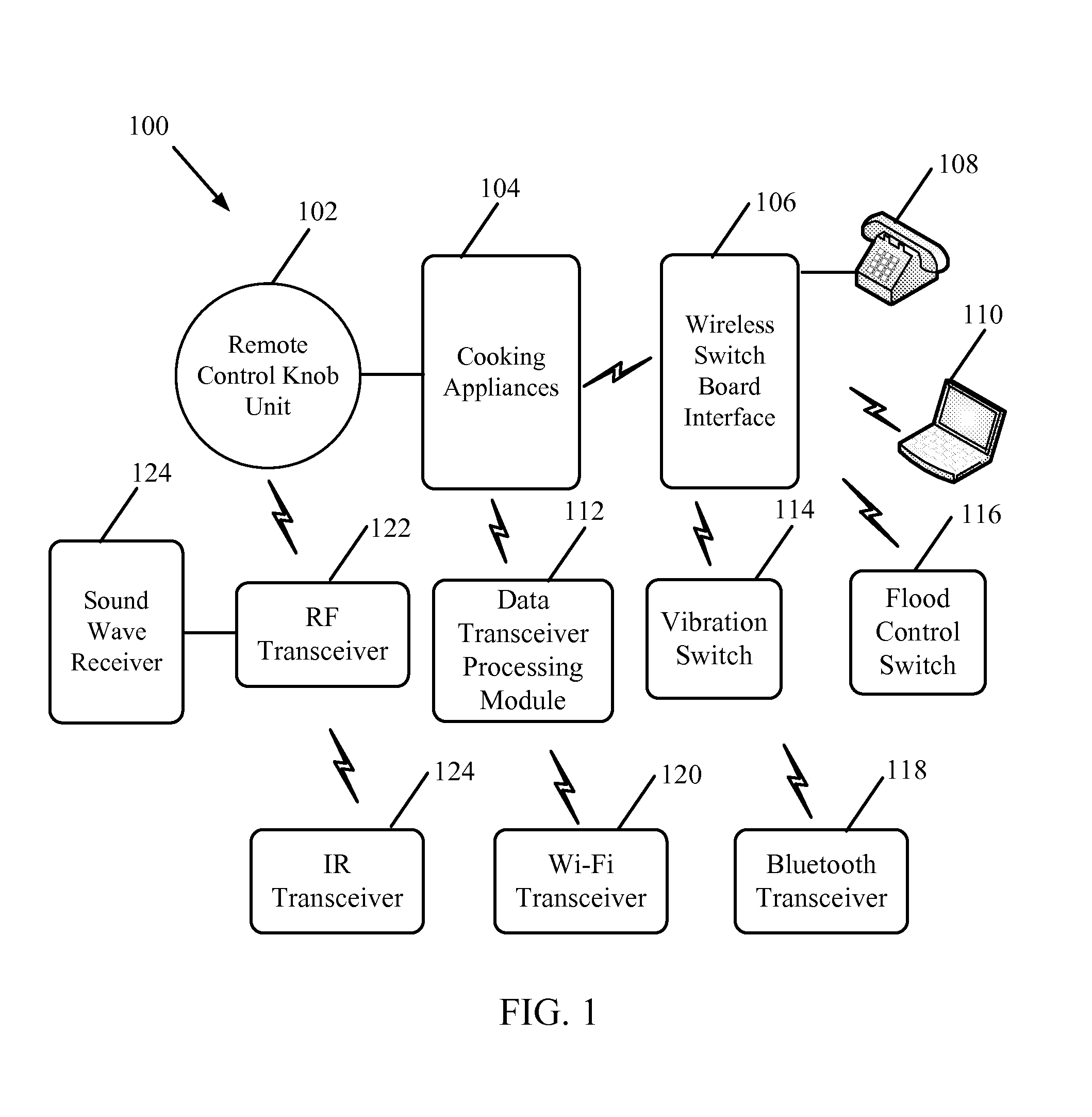

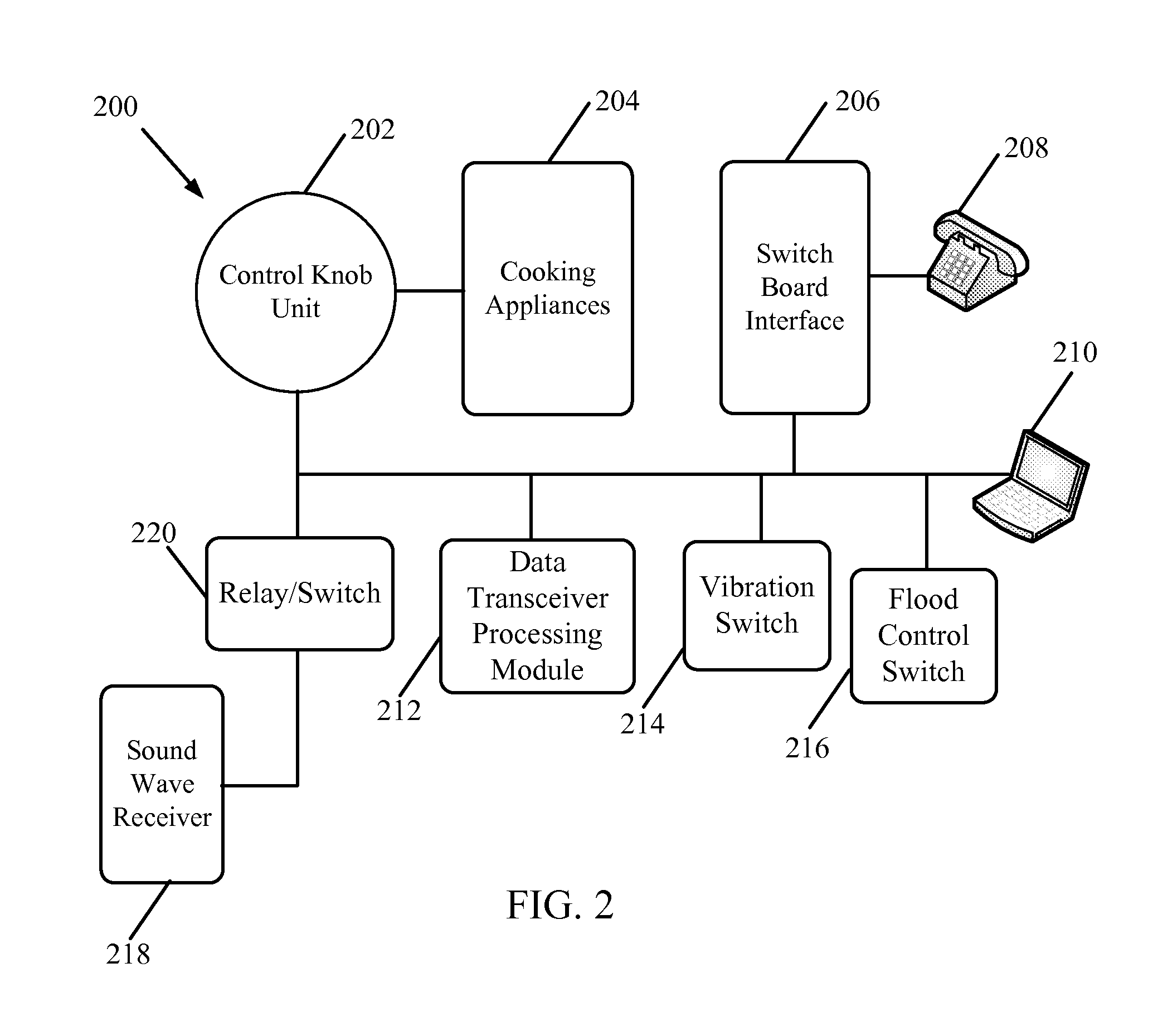

Systems and methods for automation of a control knob unit

InactiveUS20120325197A1Operating means/releasing devices for valvesDomestic stoves or rangesTransceiverProcess module

A system and method for automatically rotating a control knob unit on an appliance or other device to an Off position upon the occurrence of a safety event is provided. The control knob unit may be secured to and engaged with an operational shaft on the appliance which controls the flow of gas or power to the appliance. The system may include one or more detectors (or detector modules) that are configured to emit a signal upon an occurrence of the event, such as a fire, which may be an early indication of a developing emergency. The signal may be in the form of an audible alert, such as sound (or sound waves). A data transceiver processing module may receive a plurality of sound waves and analyze the plurality of sound waves for a variation in frequency (or Doppler Effect) to determine if any of the sound waves originate from the one or more detector modules.

Owner:LEGASPI FERDINAND VILLEGAS +2

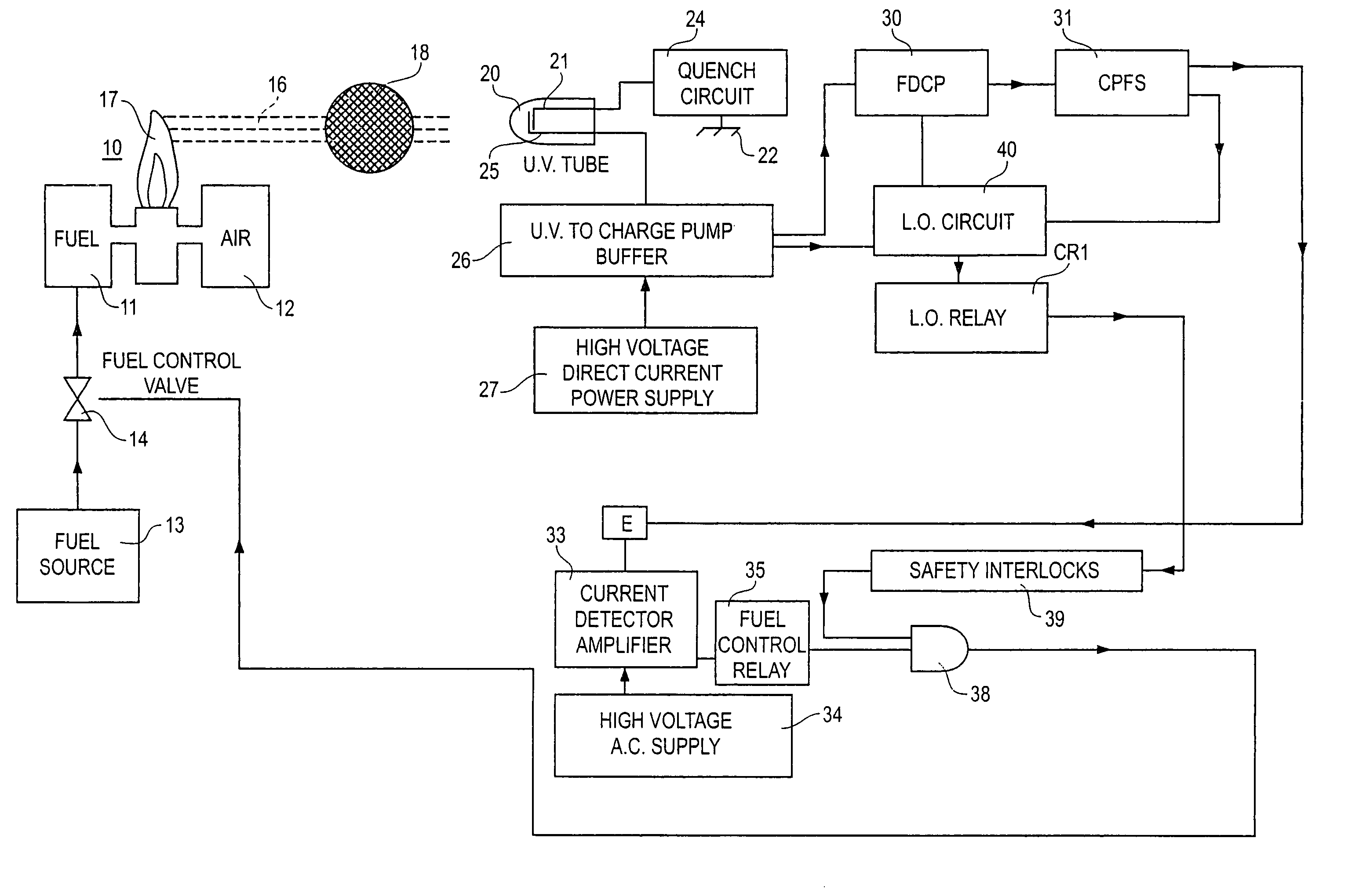

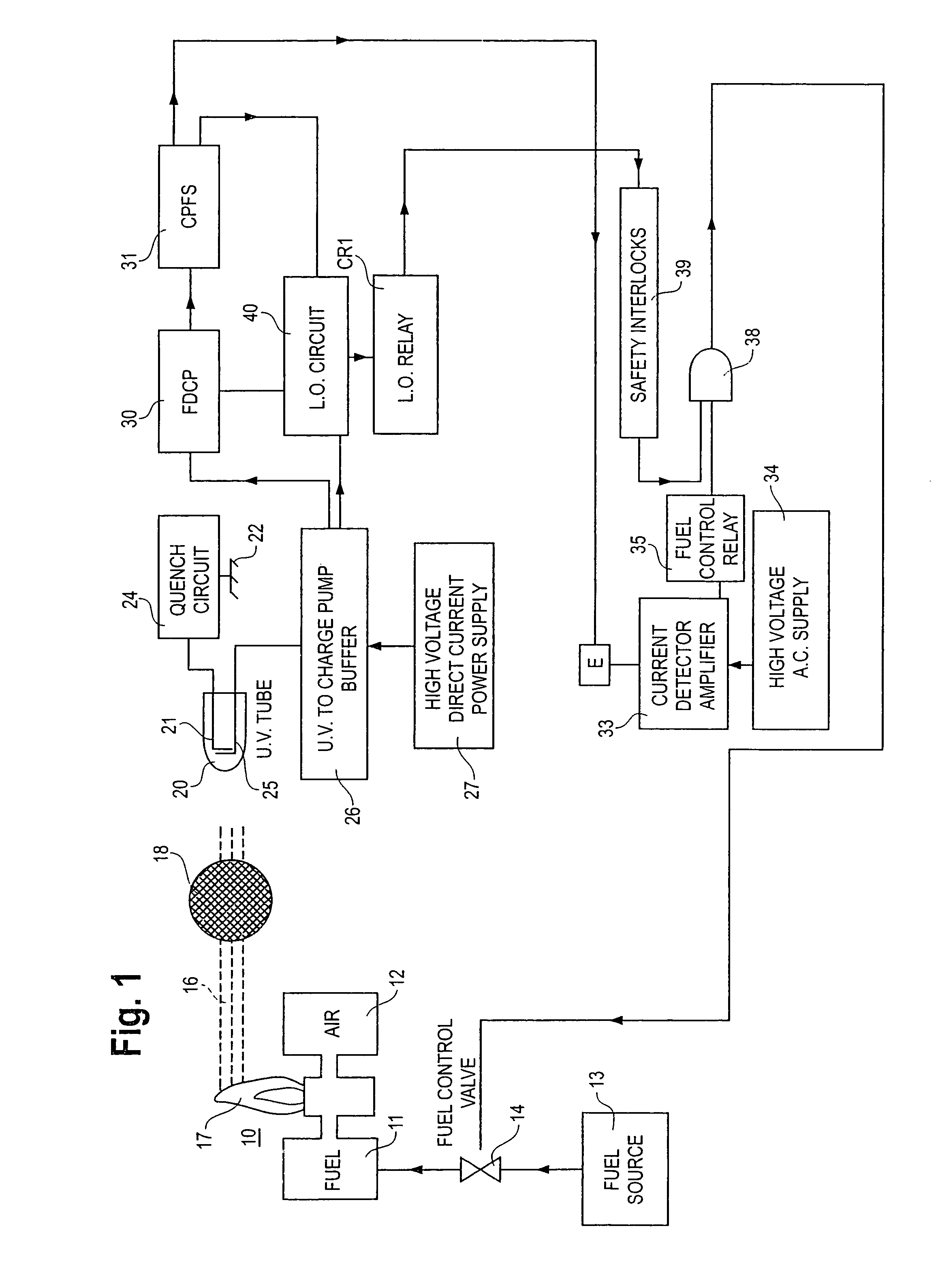

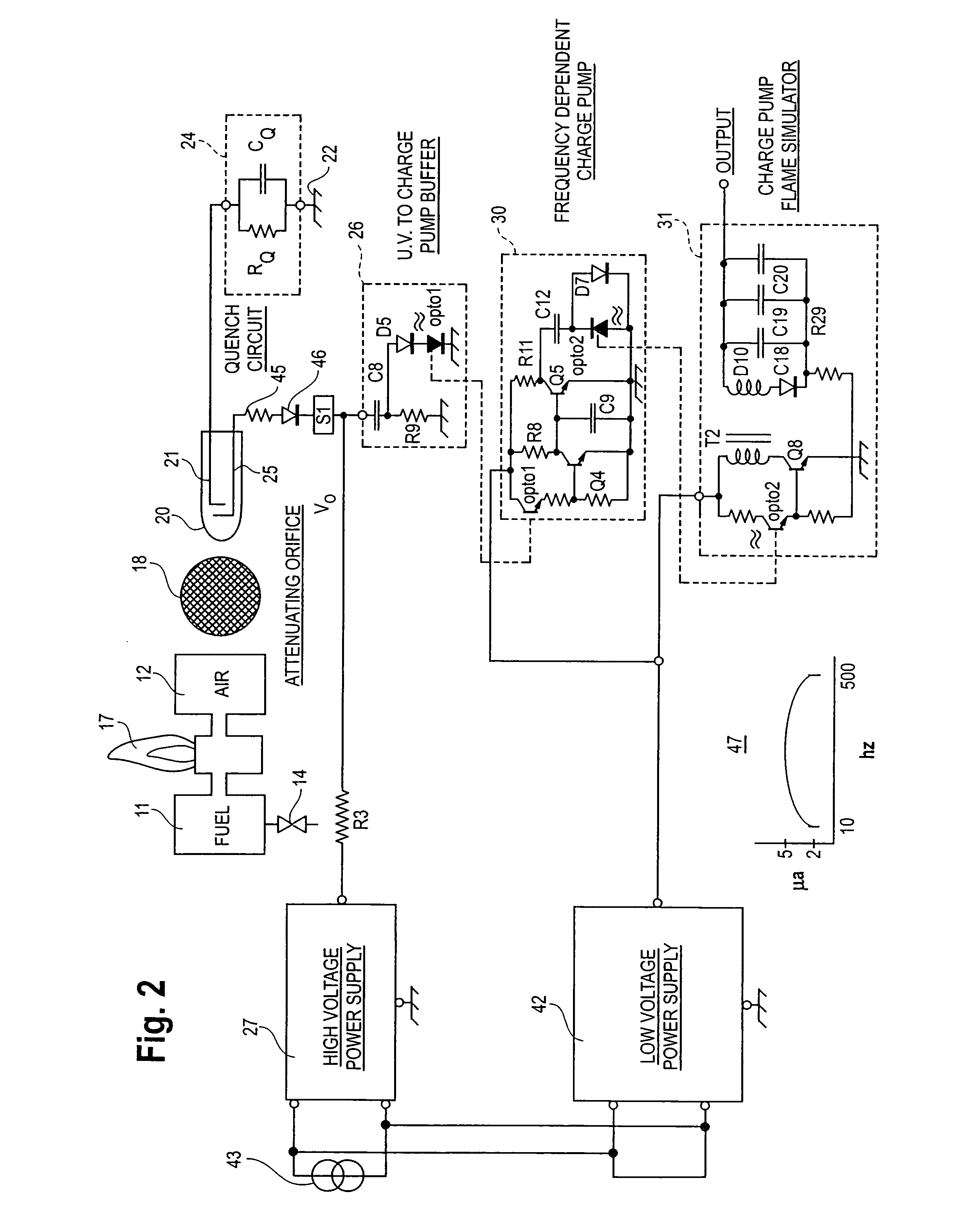

Flame detector, method and fuel valve control

InactiveUS7088253B2Material analysis by optical meansCombustion signal processingFrequency generationCold cathode

A flame detector and burner fuel valve control has an ultraviolet sensitive, cold cathode, gas discharge tube in a DC quench circuit. In the presence of a flame, the circuit generates a pulse signal at a frequency related to the intensity of radiation from the flame. The pulse signal from a contaminated tube is at a higher frequency. A frequency discriminator circuit distinguishes between a flame responsive signal and a contaminated tube signal and controls the burner fuel valve.

Owner:PROTECTION CONTROLS

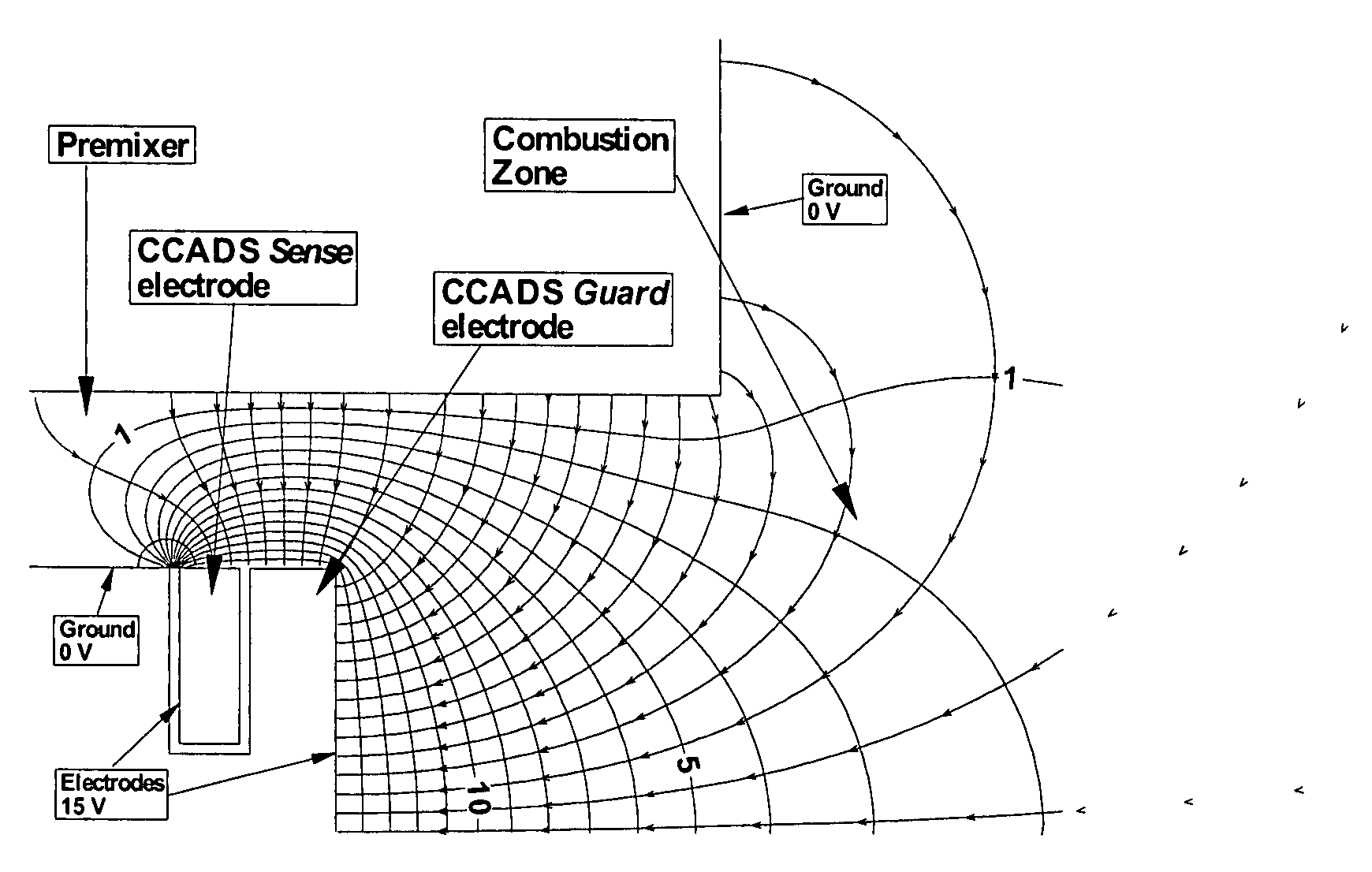

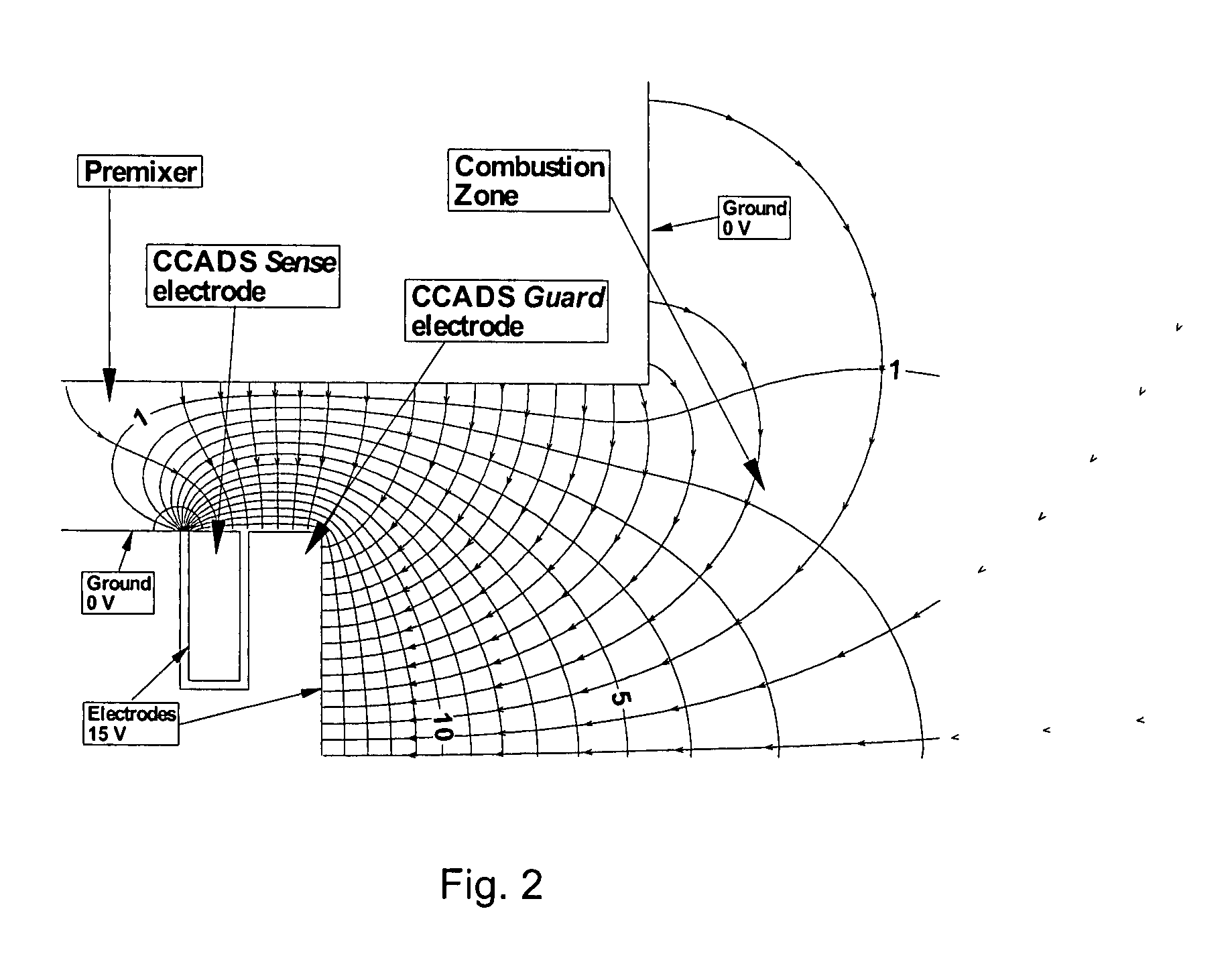

Time varying voltage combustion control and diagnostics sensor

InactiveUS7927095B1Reducing flame instabilityReduce pollutant emissionsSampled-variable control systemsFuel supply regulationCapacitanceCombustion system

A time-varying voltage is applied to an electrode, or a pair of electrodes, of a sensor installed in a fuel nozzle disposed adjacent the combustion zone of a continuous combustion system, such as of the gas turbine engine type. The time-varying voltage induces a time-varying current in the flame which is measured and used to determine flame capacitance using AC electrical circuit analysis. Flame capacitance is used to accurately determine the position of the flame from the sensor and the fuel / air ratio. The fuel and / or air flow rate (s) is / are then adjusted to provide reduced flame instability problems such as flashback, combustion dynamics and lean blowout, as well as reduced emissions. The time-varying voltage may be an alternating voltage and the time-varying current may be an alternating current.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

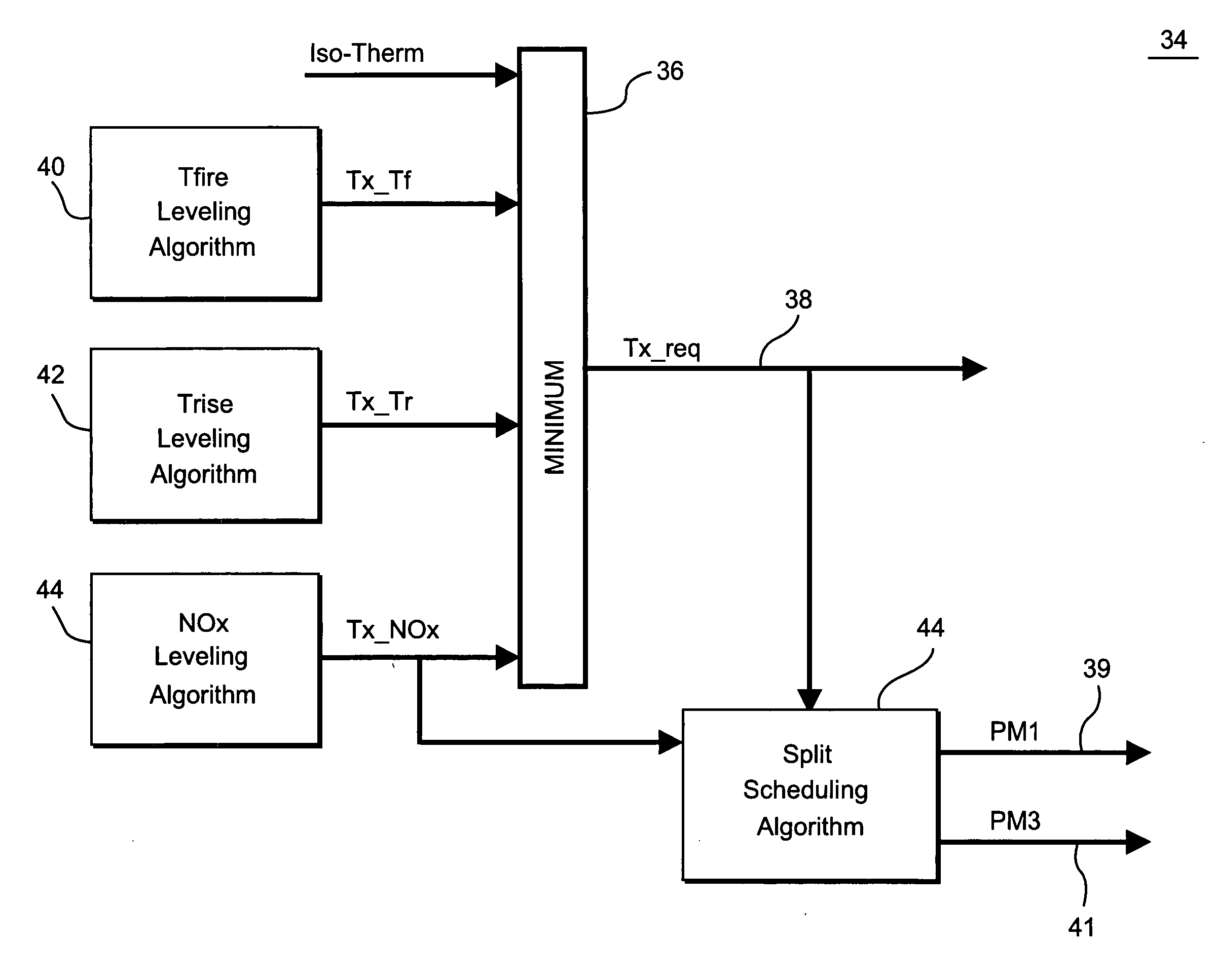

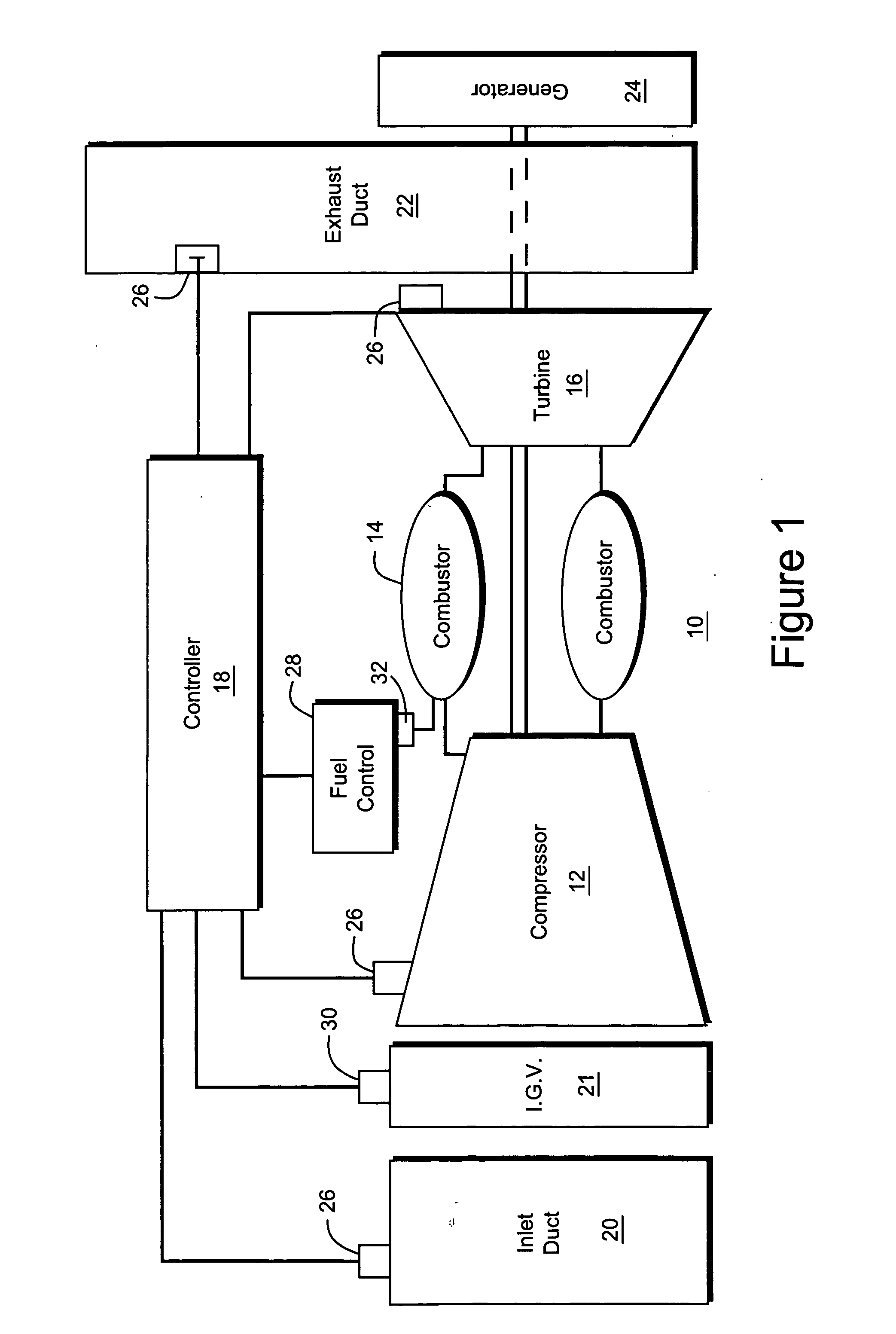

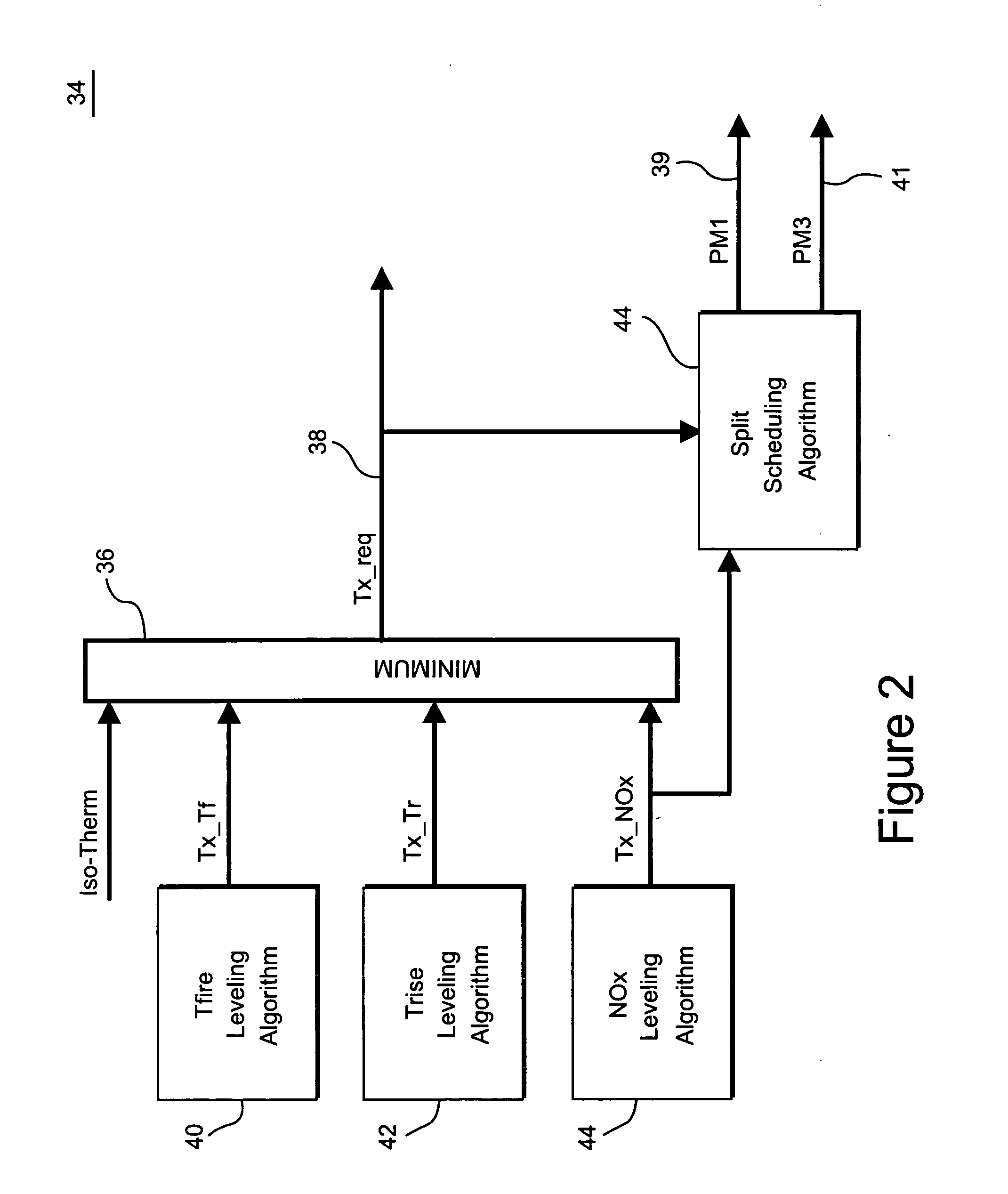

Method for controlling fuel splits to gas turbine combustor

A method for determining a target exhaust temperature for a gas turbine including: determining a target exhaust temperature based on a compressor pressure condition; determining a temperature adjustment to the target exhaust temperature based on at least one parameter of a group of parameters consisting of specific humidity, compressor inlet pressure loss and turbine exhaust back pressure; and adjusting the target exhaust temperature by applying the temperature adjustment.

Owner:GENERAL ELECTRIC CO

Graphical user interface system for a thermal comfort controller

InactiveUS20070194138A9Easily and intuitively programEasy programmingMechanical apparatusData processing applicationsGraphicsGraphical user interface

A graphical user interface system for a thermal comfort controller. The user interface system has a central processing unit coupled to a memory and a touch sensitive display unit. The memory stores a temperature schedule data structure and perhaps a temperature history data structure. The temperature schedule data structure is made up of at least one set-point. The temperature history data structure is made up of at least one Actual-Temperature-Point. The display presents the set-points and / or the Actual-Temperature-Points. One representation of the display is a graphical step-function. The user uses a finger or stylus to program the set-points by pointing and dragging a portion of the step-function.

Owner:ADEMCO INC

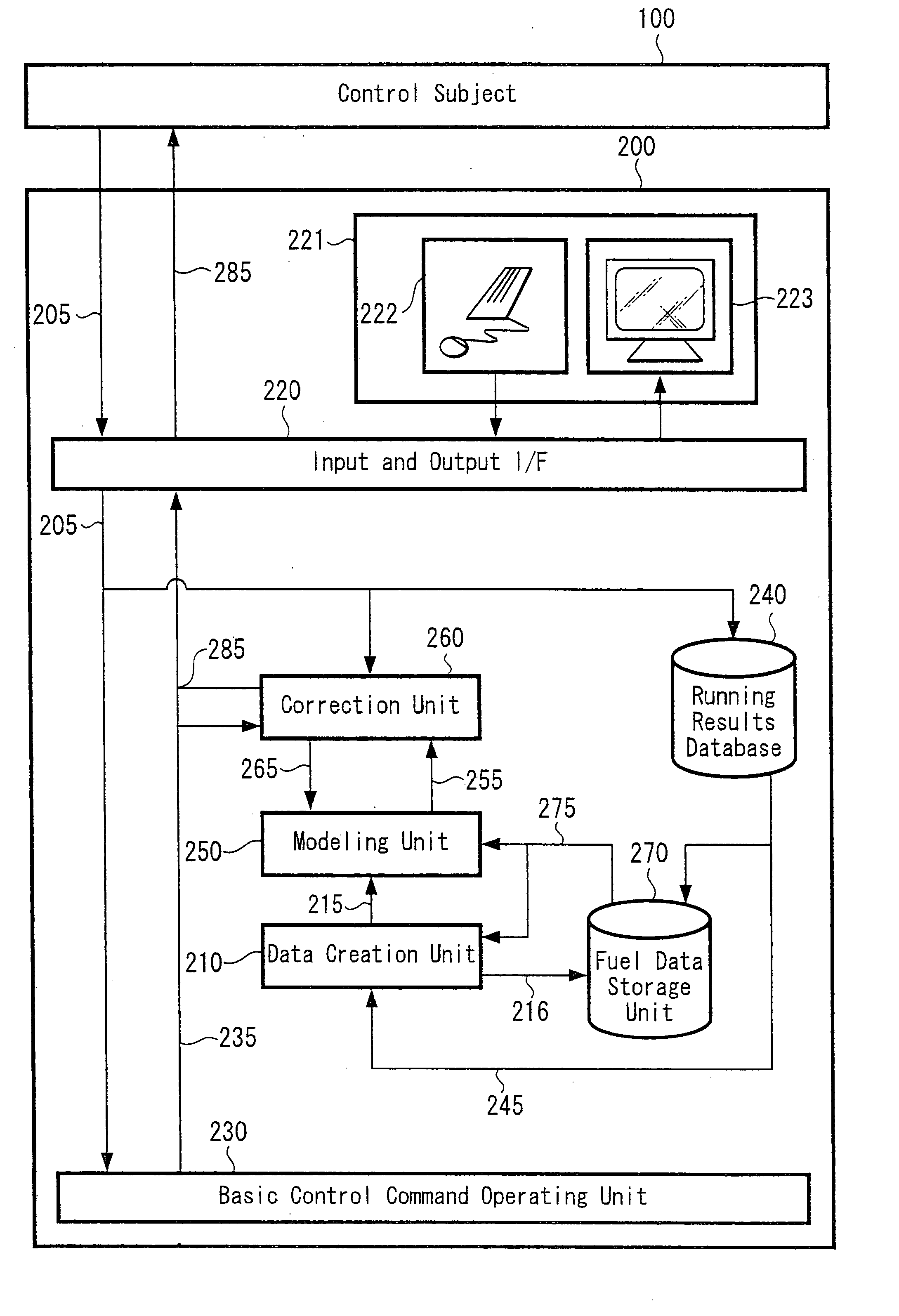

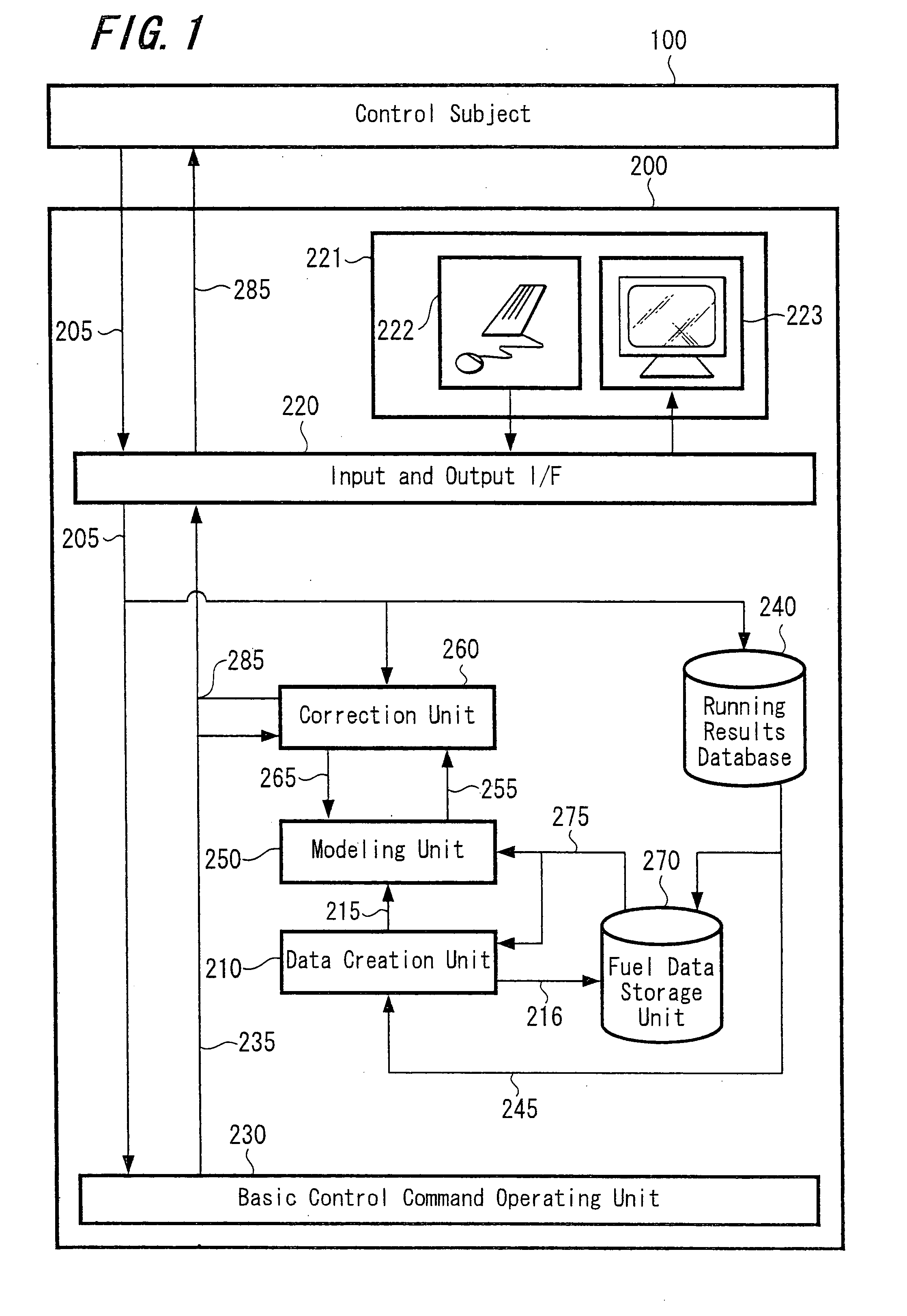

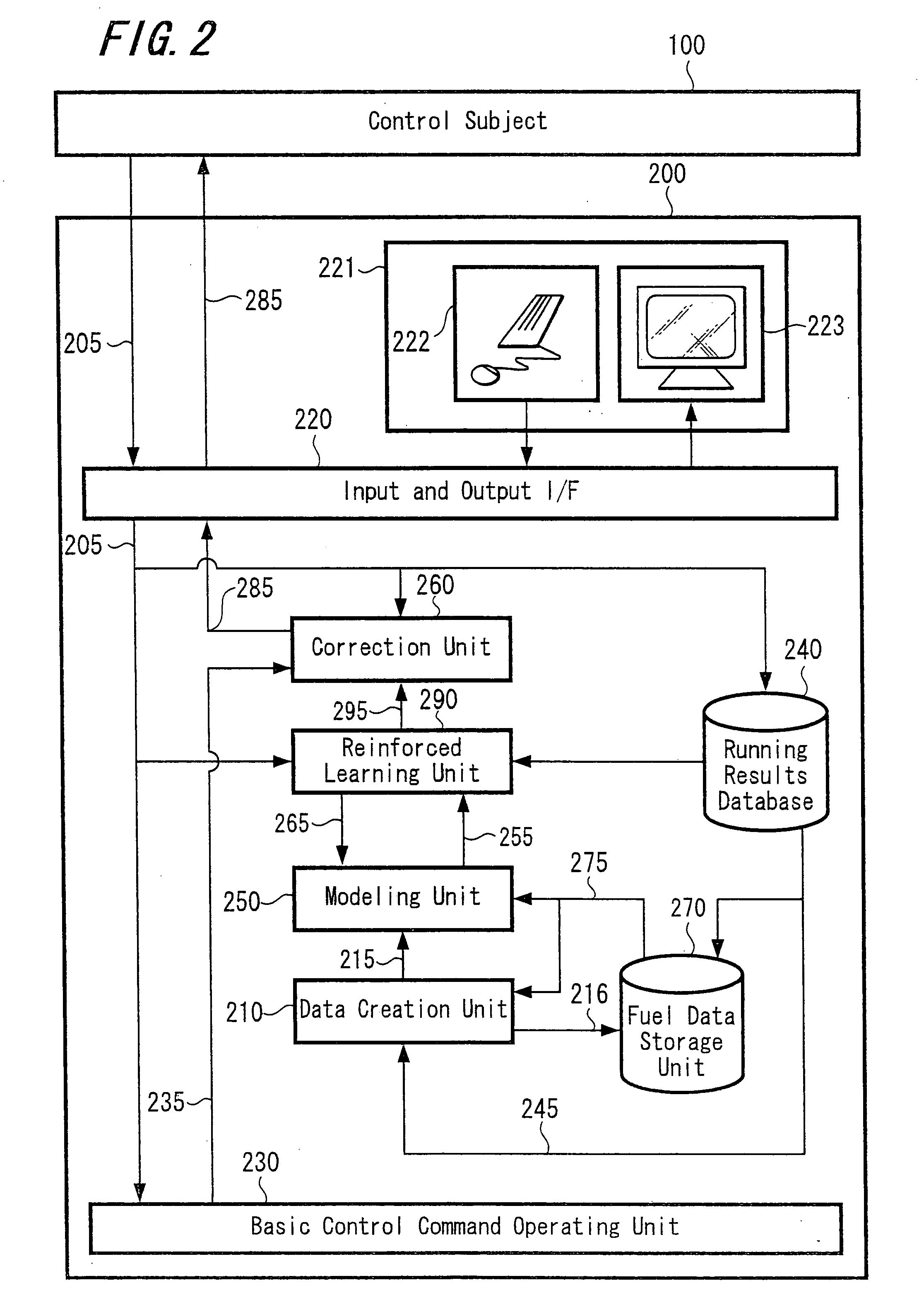

Control system for control subject having combustion unit and control system for plant having boiler

ActiveUS20070234781A1Reduce the amount requiredEasy to controlAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansControl subjectsCombustion

A control system includes a basic control command operating unit, a fuel data storage unit, a running results database for storing past running results values of a control subject, a data creating unit configured to calculate a distance between data of the past running results values and the data sets and determining data set in which a distance between data becomes minimum, a modeling unit configured to model a relationship between operation parameters of a combustion apparatus and components in combustion gas of the combustion apparatus by using the data set determined by the data creating unit and a correcting unit for calculating combustion apparatus operation parameters with which components having a better condition than that of the components in a current gas are provided by using a model of the modeling unit and correcting operation command values of the basic control command operating unit by calculated operation parameters.

Owner:HITACHI LTD

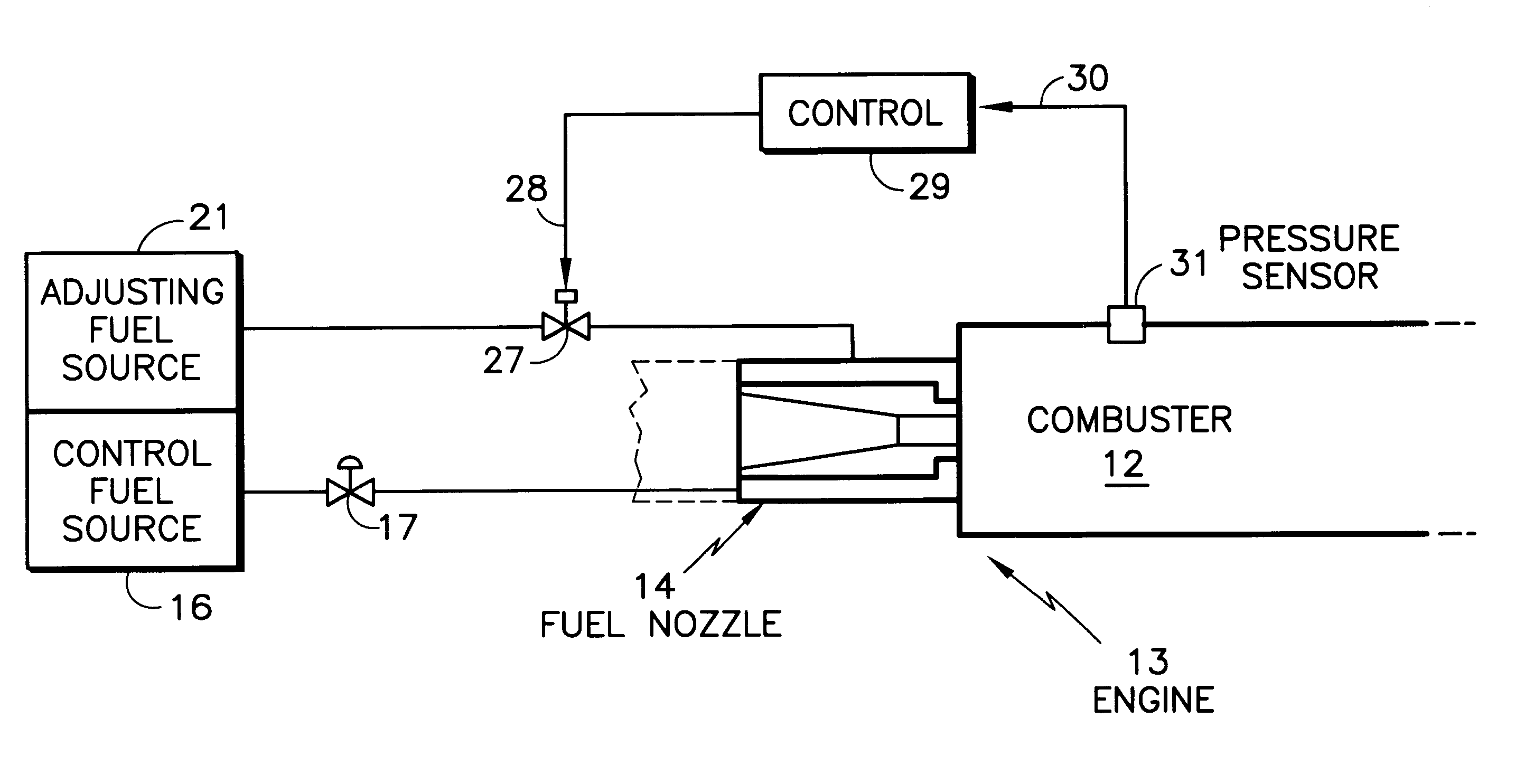

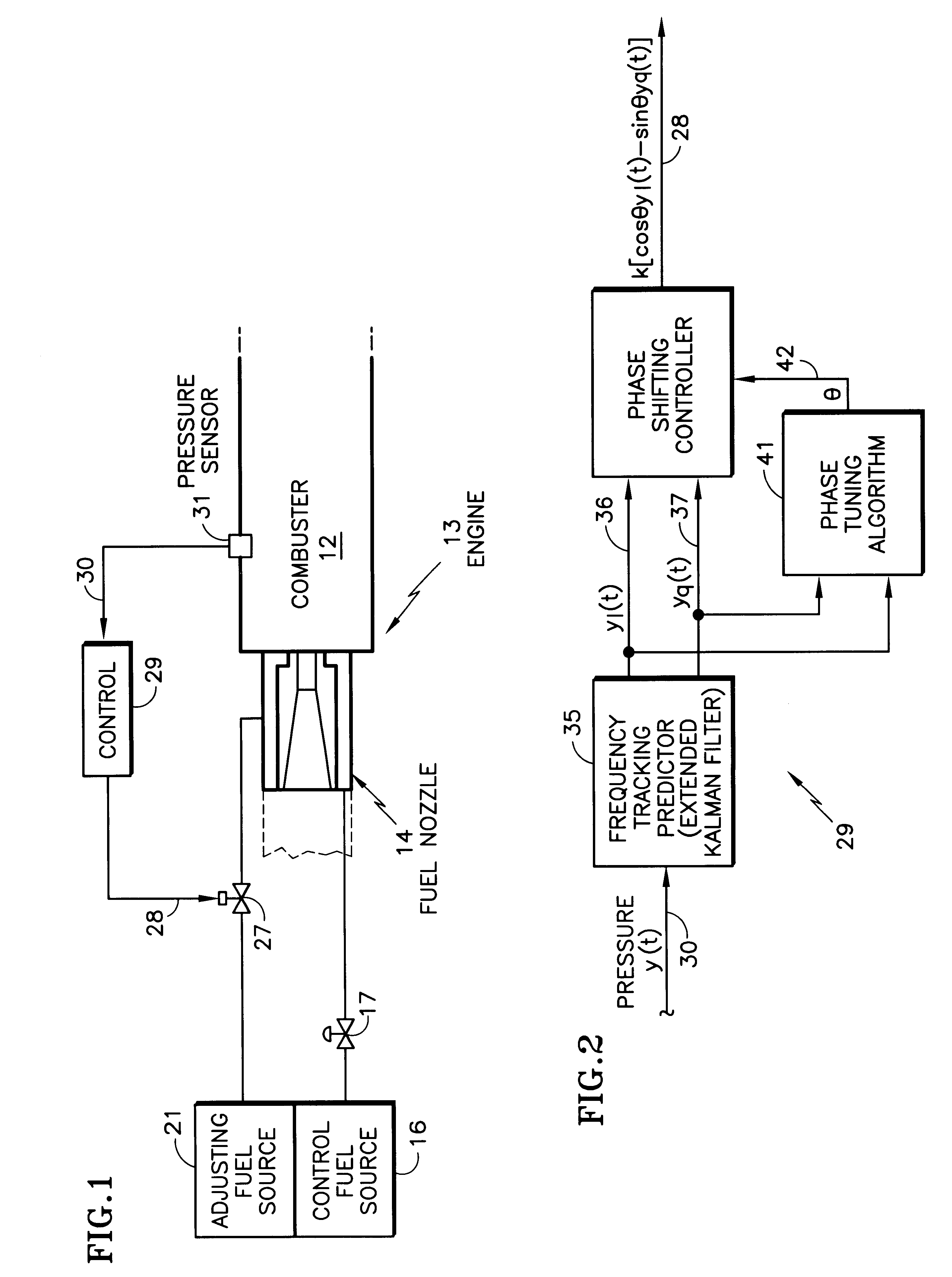

Suppressing oscillations in processes such as gas turbine combustion

A frequency tracking extended Kalman filter (35), responsive to combustor pressure (30), produces in-phase (36) and quadrature (37) components of the estimated magnitude of the undesirable combustor pressure variations, for which compensation is to be achieved; a bidirectional minimum-seeking algorithm (41) is used to select the phase (42) of a process adjusting input variable (28), such as fuel that is in addition to the main fuel flow used for power control purposes.

Owner:RAYTHEON TECH CORP

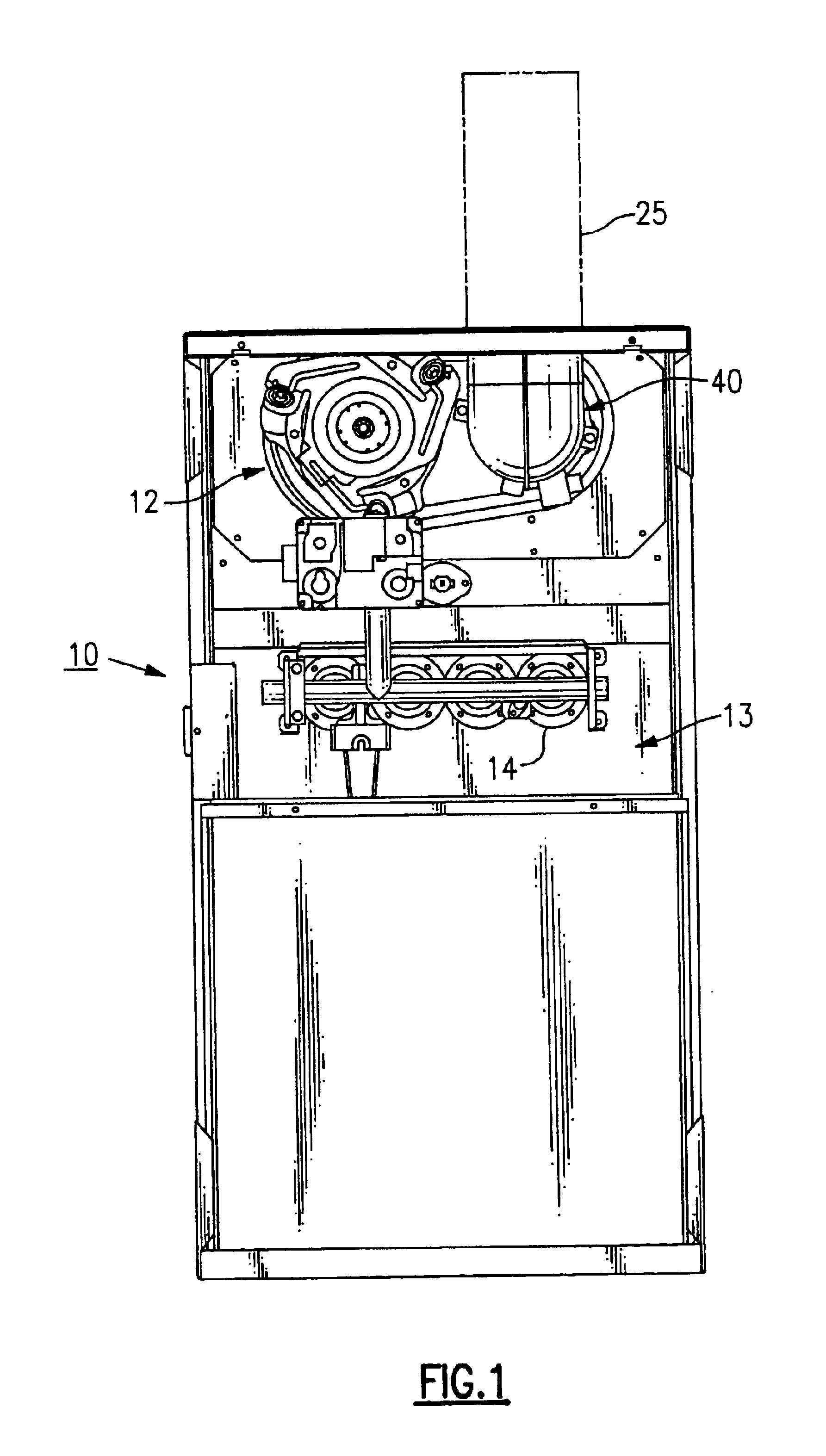

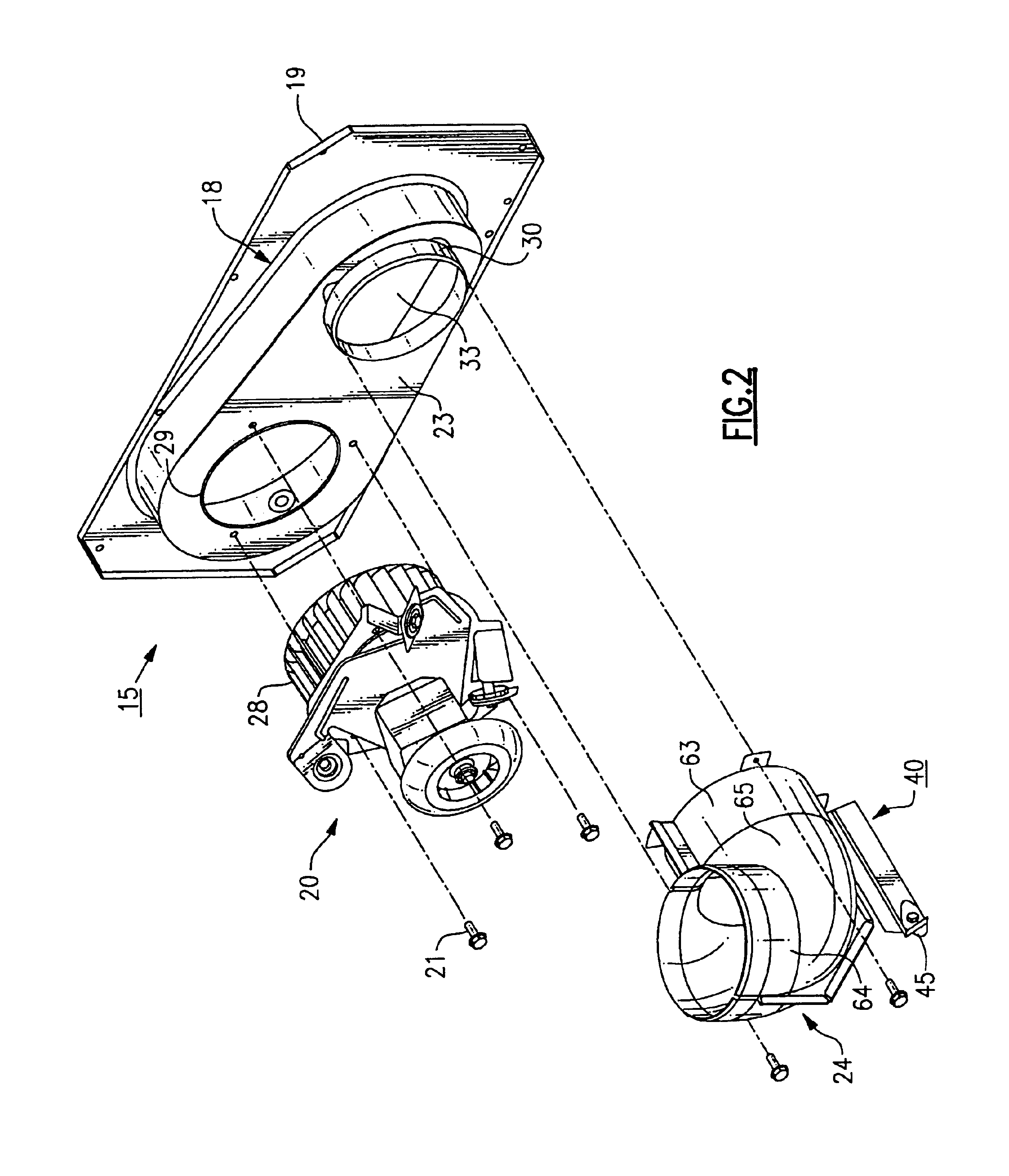

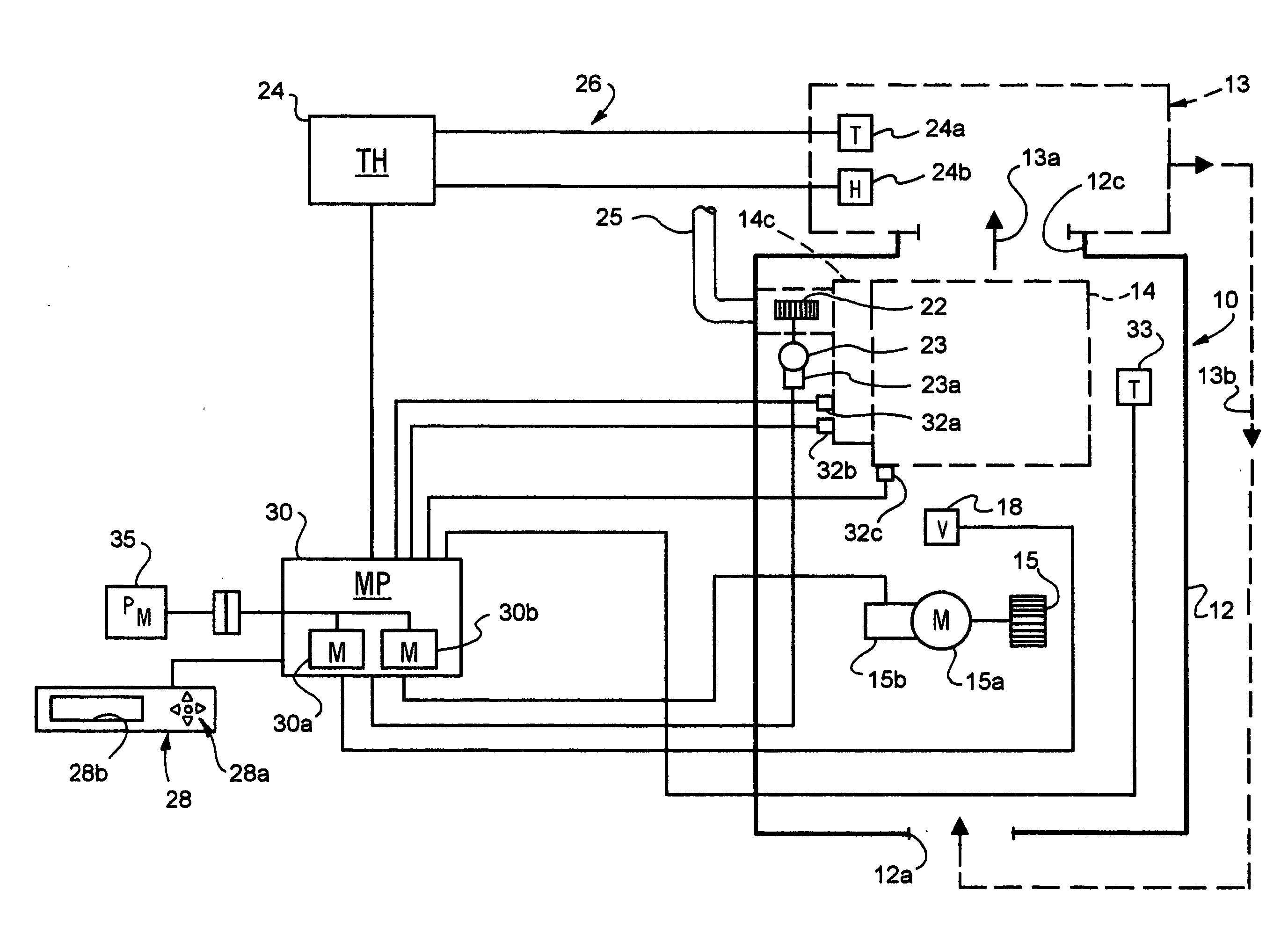

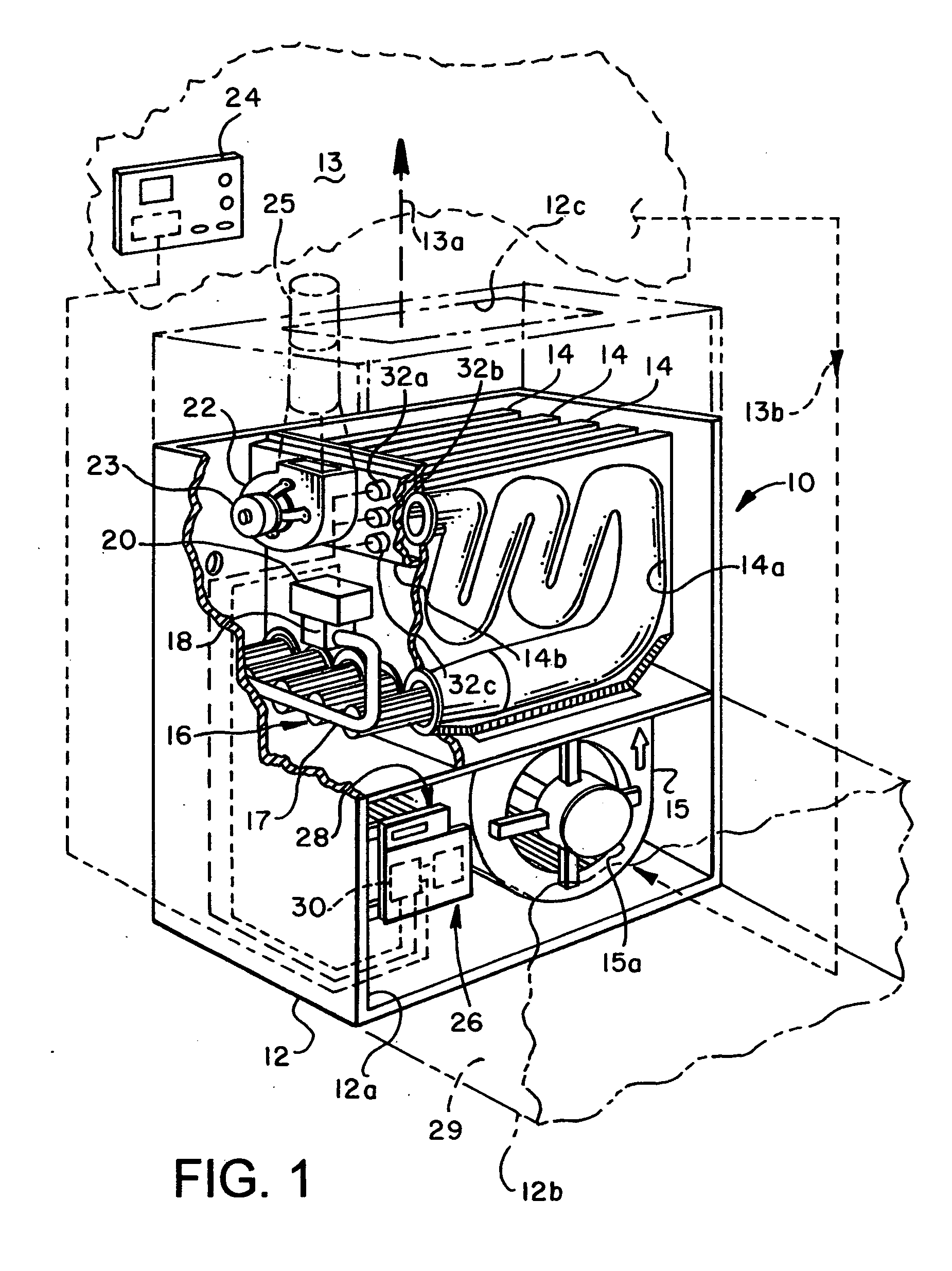

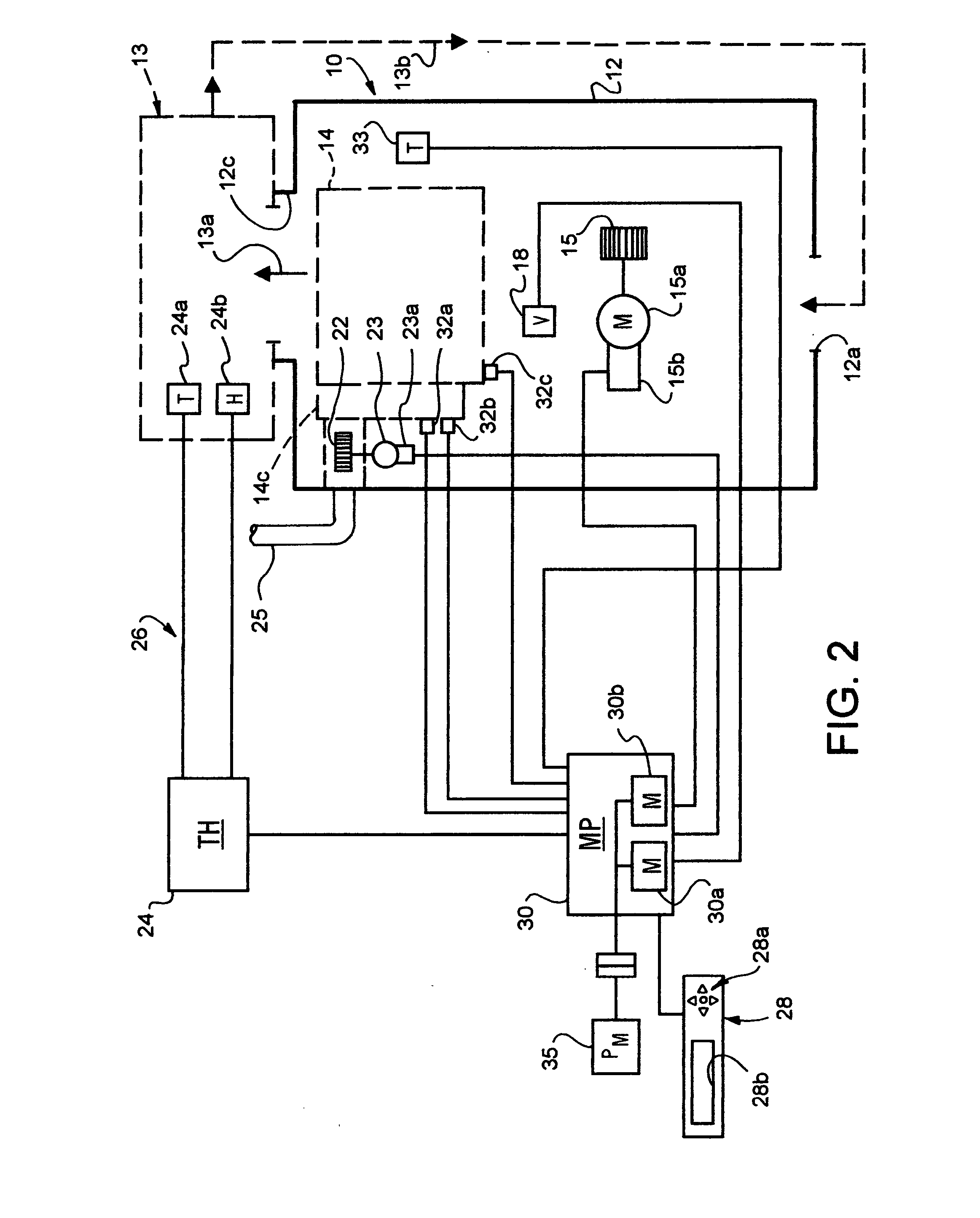

Inducer speed control method for combustion furnace

ActiveUS20090044794A1High fire ratingAccurate operationMechanical apparatusDC motor speed/torque controlMotor speedCombustion

In a multistage combustion furnace having a motor driven inducer blower and a pressure sensing device or set of switches for sensing pressure in the combustion gas flowpath through the furnace, a high firing rate blower speed and low firing rate blower speed are set based on the blower speed setting required for a medium firing rate. Each particular furnace, having its own pressures and combustion gas resistance to flow characteristics, may be provided with a database of inducer blower motor speeds required to achieve predetermined pressures in the combustion gas flowpath for a variety of combustion gas venting systems generating such resistance.

Owner:TRANE INT INC

Systems and methods for using a combustion dynamics tuning algorithm with a multi-can combustor

Embodiments of the invention can provide systems and methods for using a combustion dynamics tuning algorithm with a multi-can combustor. According to one embodiment of the invention, a method for controlling a gas turbine engine with an engine model can be implemented for an engine comprising multiple cans. The method can include obtaining operating frequency information associated with multiple cans of the engine. In addition, the method can include determining variation between operating frequency information of at least two cans. Furthermore, the method can include determining a median value based at least in part on the variation. Moreover, the method can include determining whether the median value exceeds at least one operating threshold. The method can also include implementing at least one engine control action to modify at least one of the operating frequencies if at least one operating threshold is exceeded.

Owner:GENERAL ELECTRIC CO

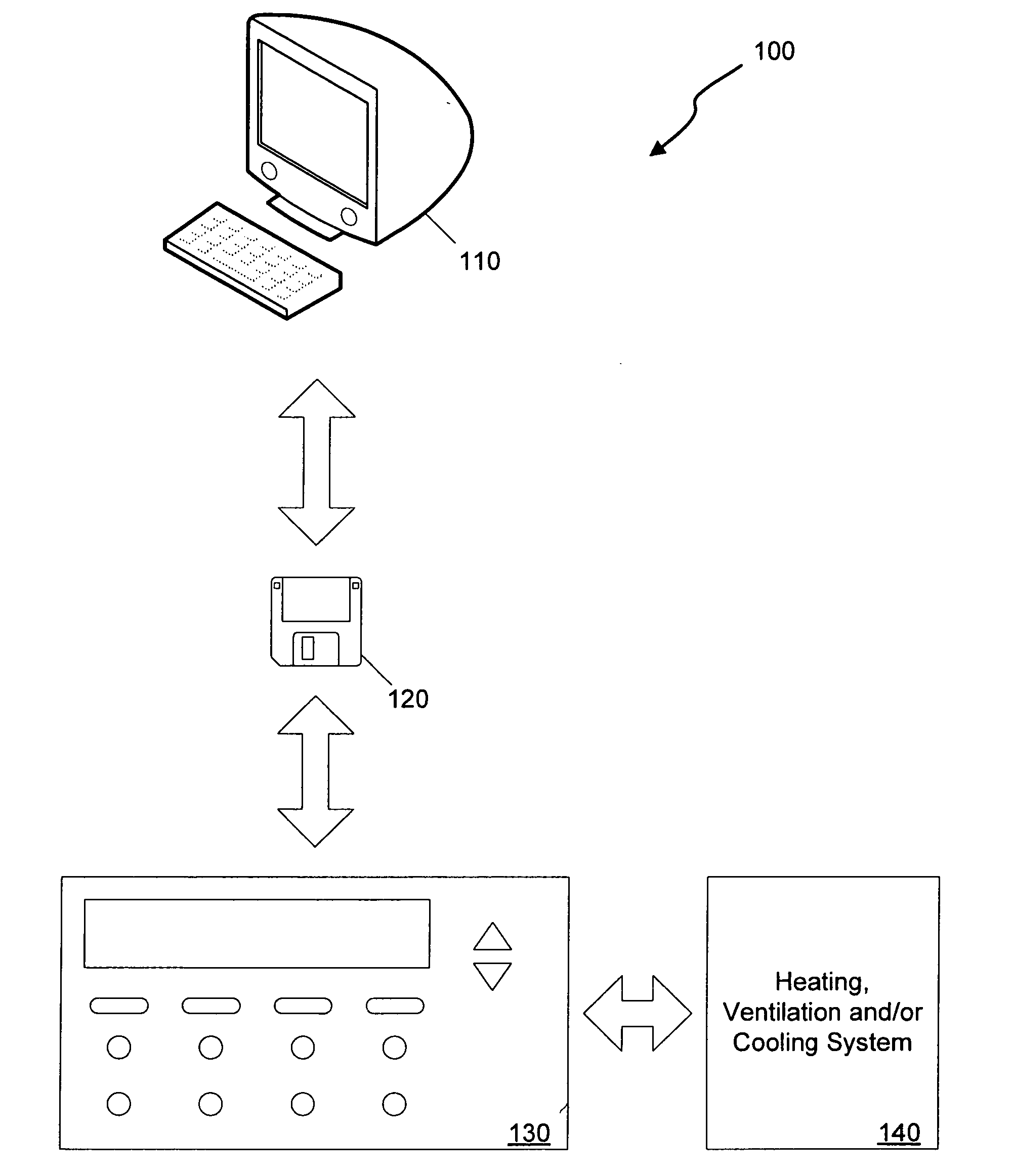

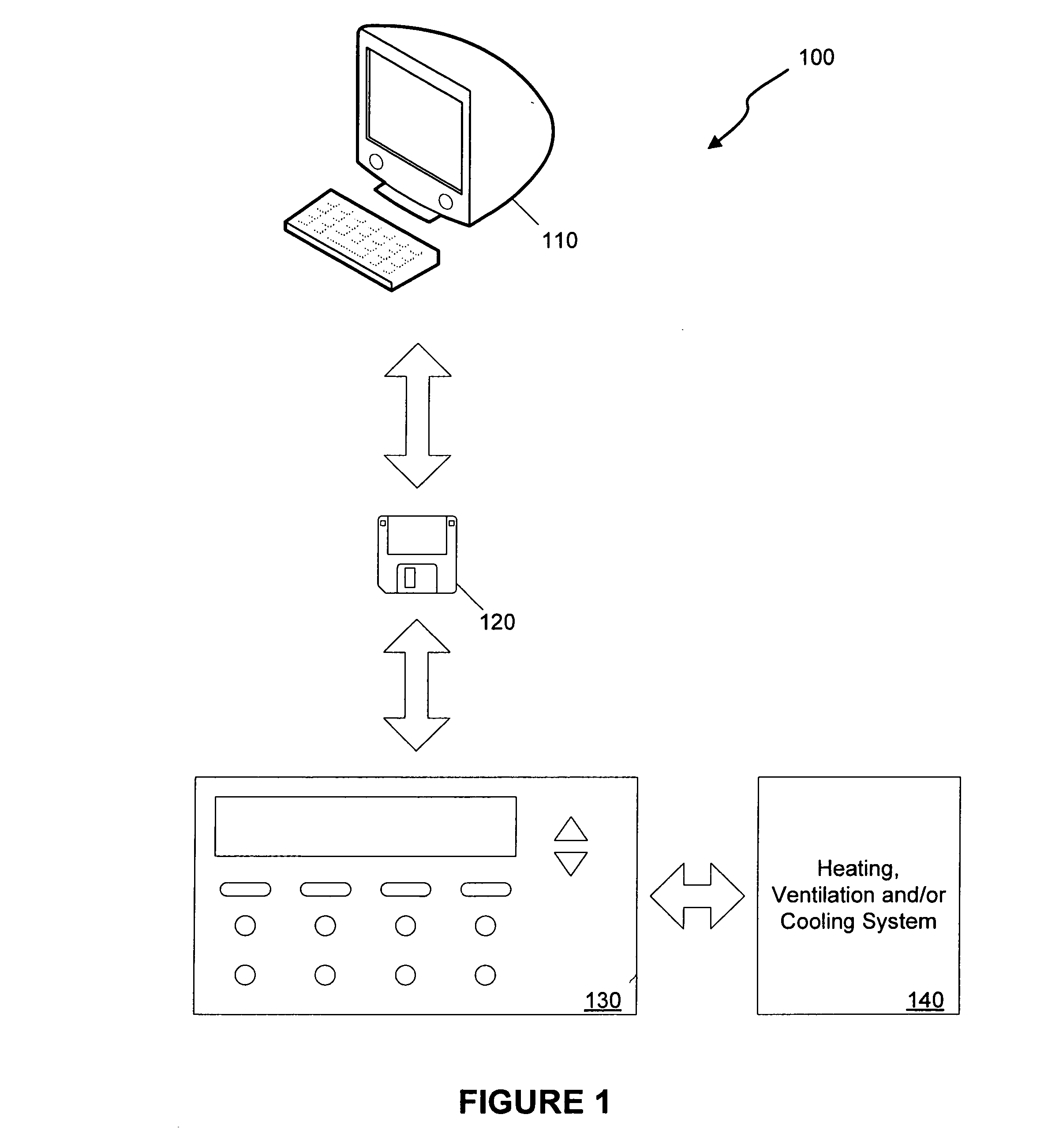

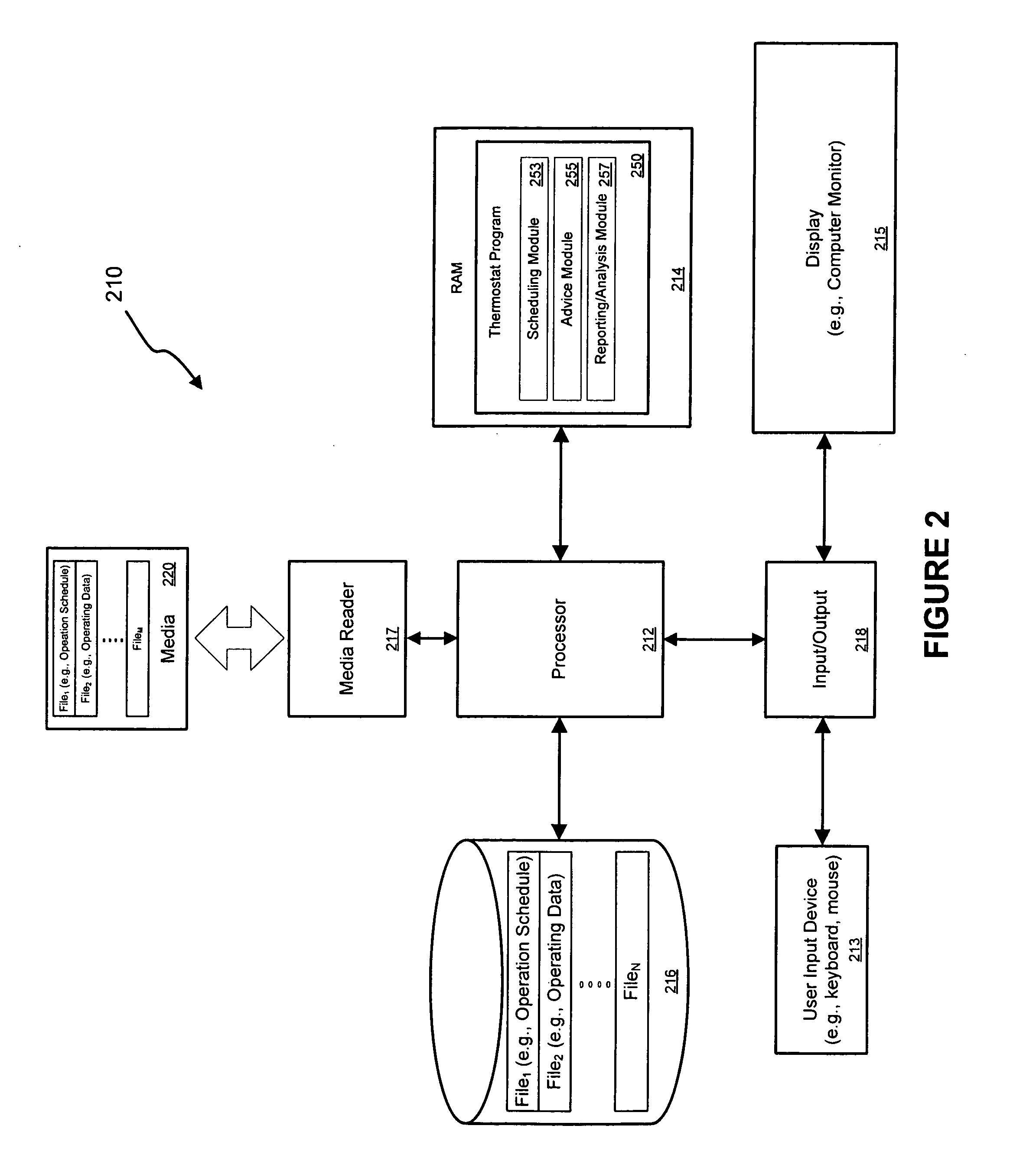

Programmable thermostat

InactiveUS20070210177A1Temperatue controlCombustion signal processingEngineeringProgrammable thermostat

A system and method for programming a thermostat is described. One embodiment includes a method for communicating a thermostat operation schedule to a media device that then communicates the thermostat operation schedule to a thermostat. An additional embodiment includes a computer readable medium encoded with executable instructions for establishing computer-readable code that effects operation of a thermostat. In yet another embodiment, a thermostat is included that operates upon computer-readable code to execute an operation schedule.

Owner:KARASEK JAN

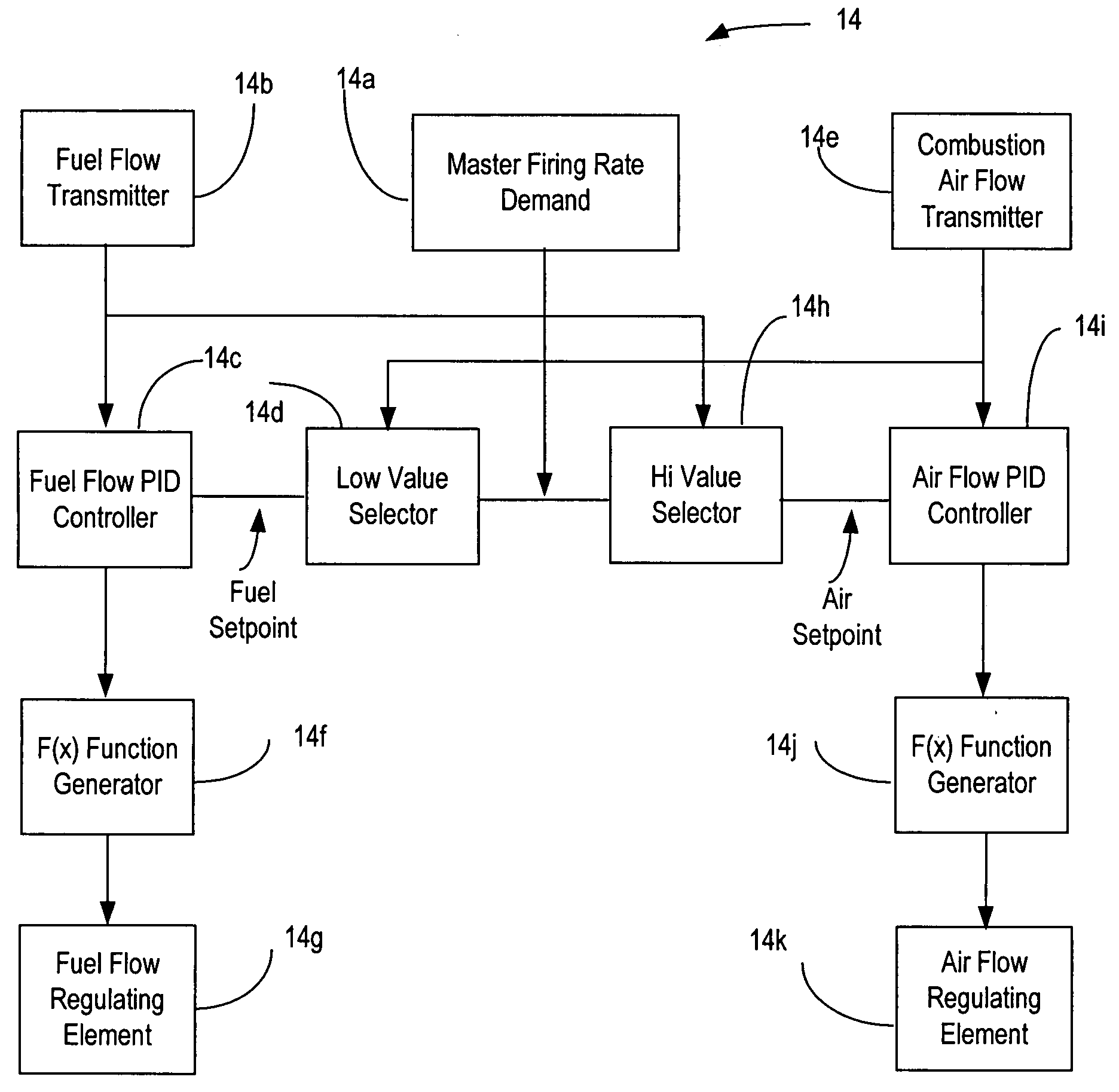

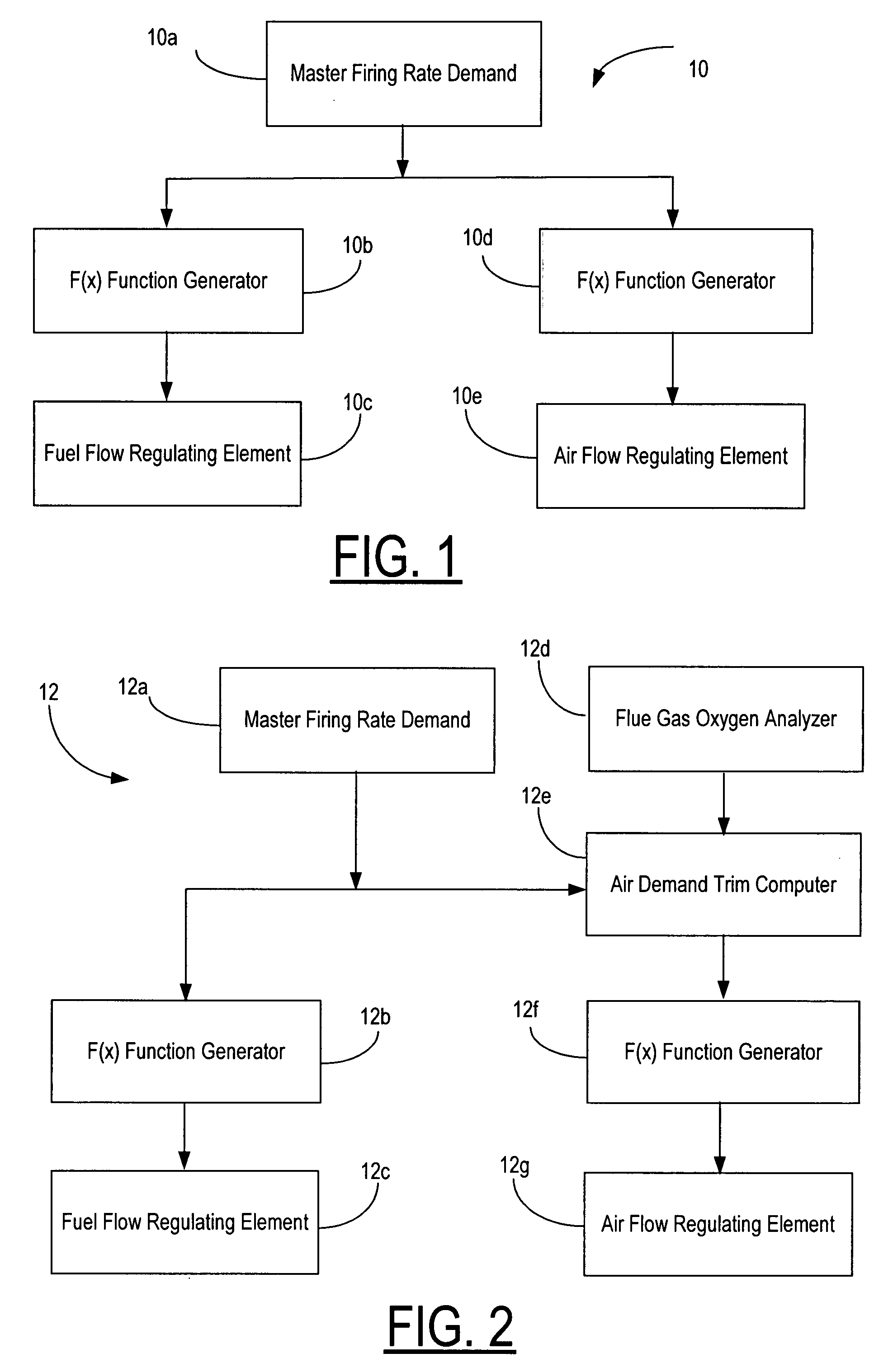

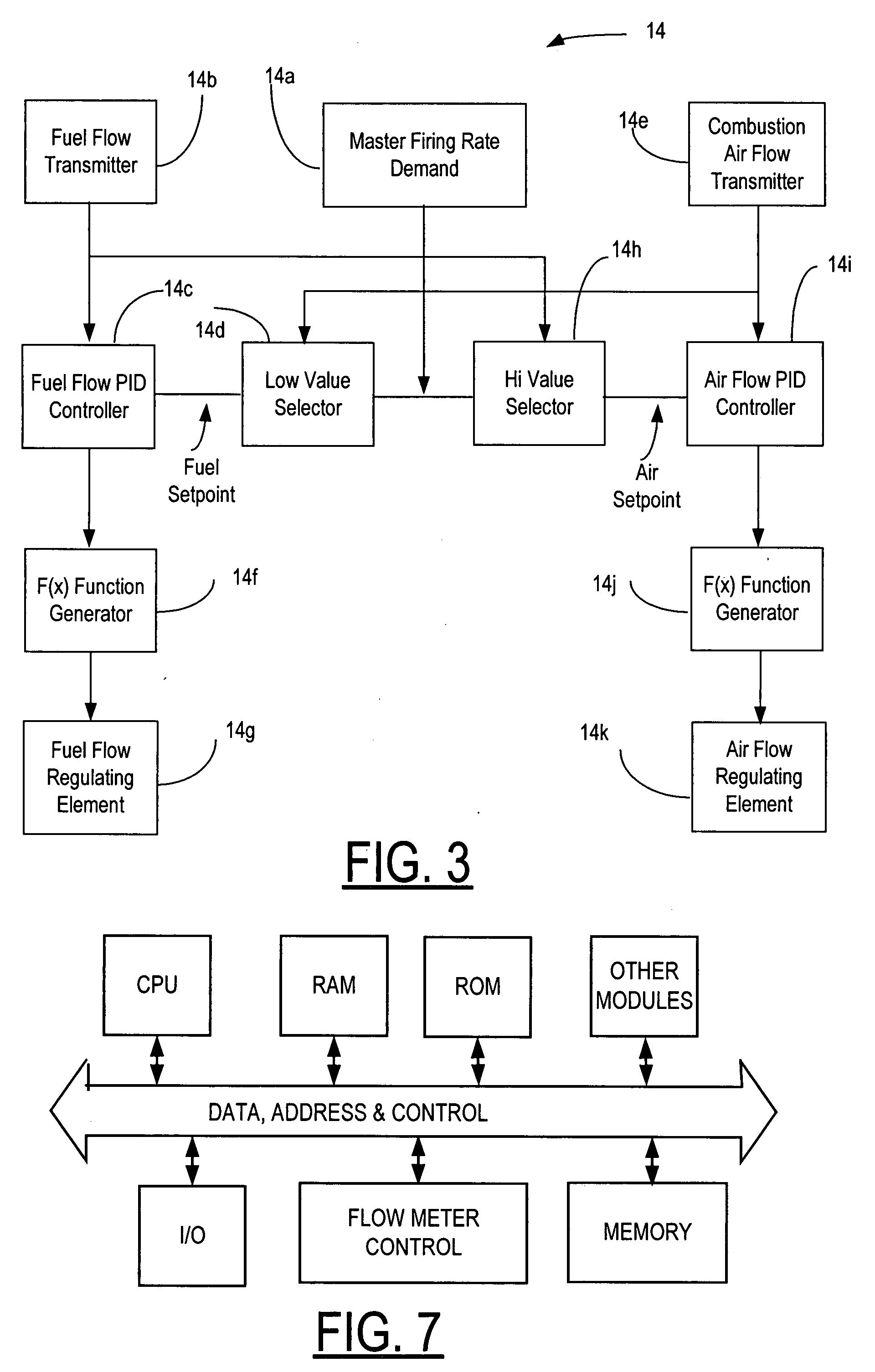

Metering combustion control

InactiveUS20090142717A1Sampled-variable control systemsFuel supply regulationCombustionControl theory

Metering combustion control in a fired equipment is disclosed in which both the fuel flow rate and the combustion air flow rate are metered in a desired ratio corresponding to a master firing rate demand, and the master firing rate demand combustion air flow directed to the combustion air regulating element is trimmed in response to an error based correction adjustment determined from the respective values of the fuel flow meter and combustion air flow meter input signals to drive the ratio between the fuel flow rate and the combustion air flow rate toward the desired ratio for controlling the combustion in accordance with the master firing rate demand.

Owner:PREFERRED UTILITIES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com