Metering combustion control

a technology of combustion control and metering, applied in the direction of combustion regulation, fuel supply regulation, instruments, etc., can solve the problems of considerable skill in tuning and calibrating, current known and implemented and the current known and implemented metered cross-limited combustion control strategies are not entirely satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

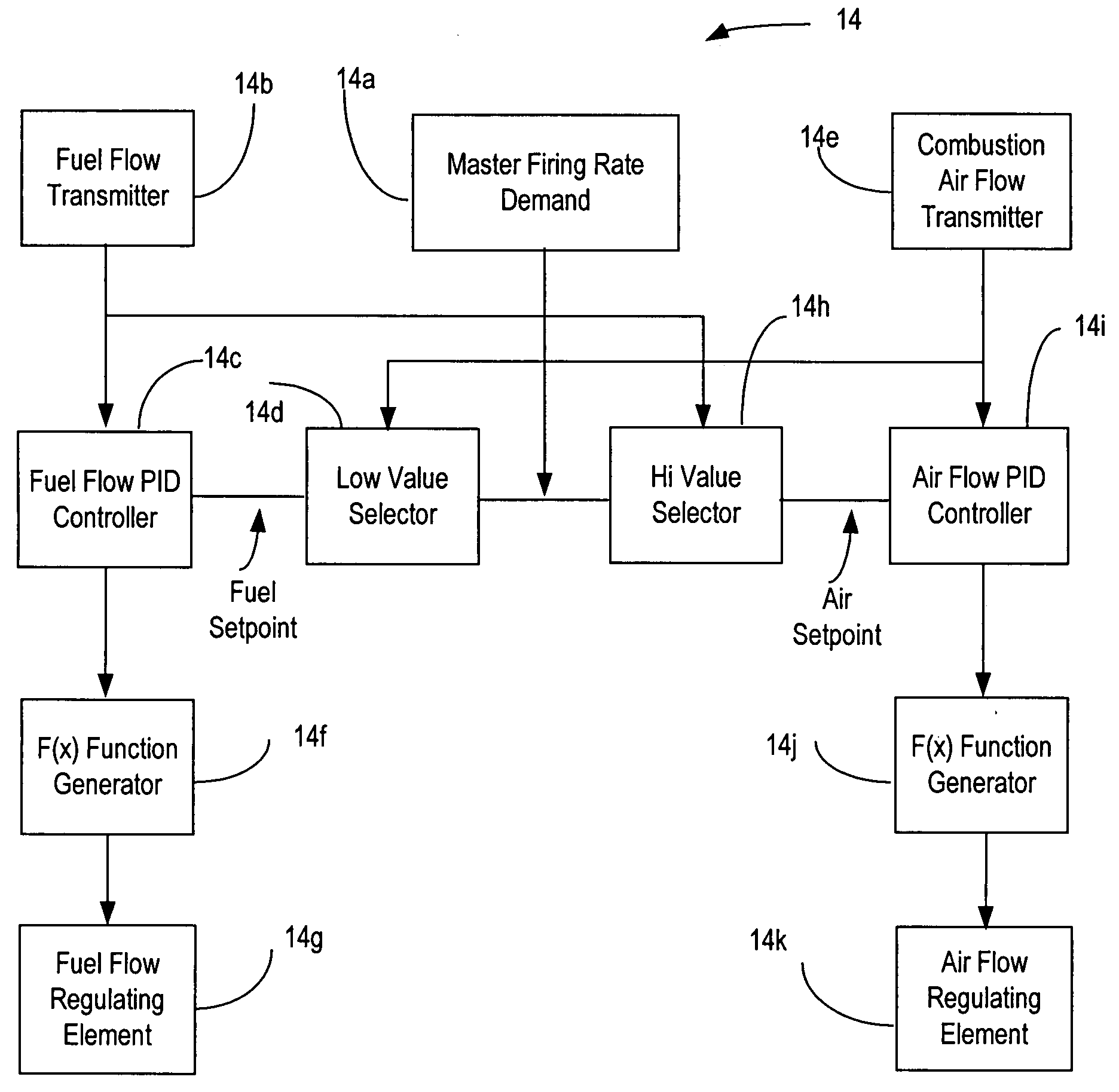

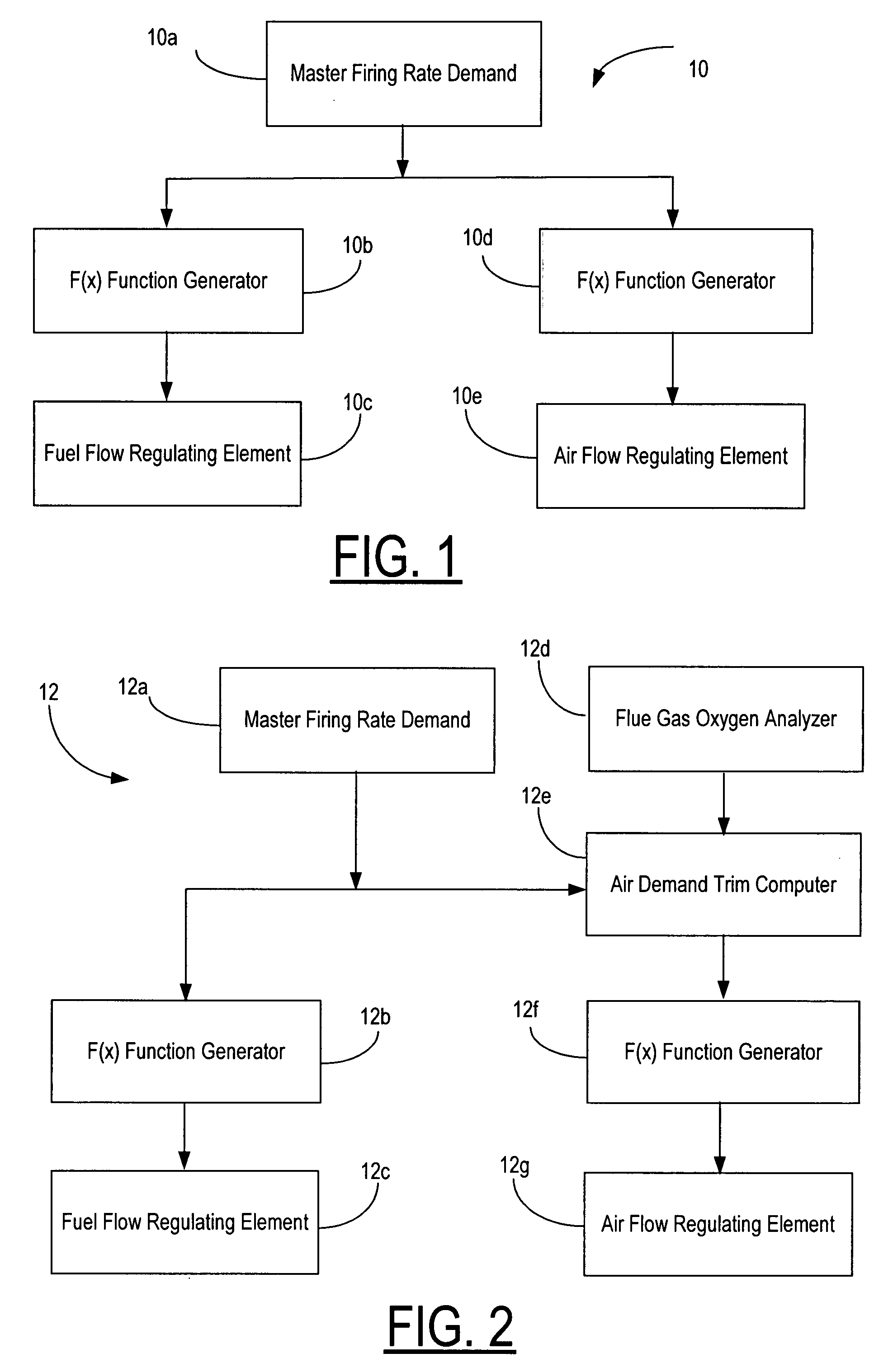

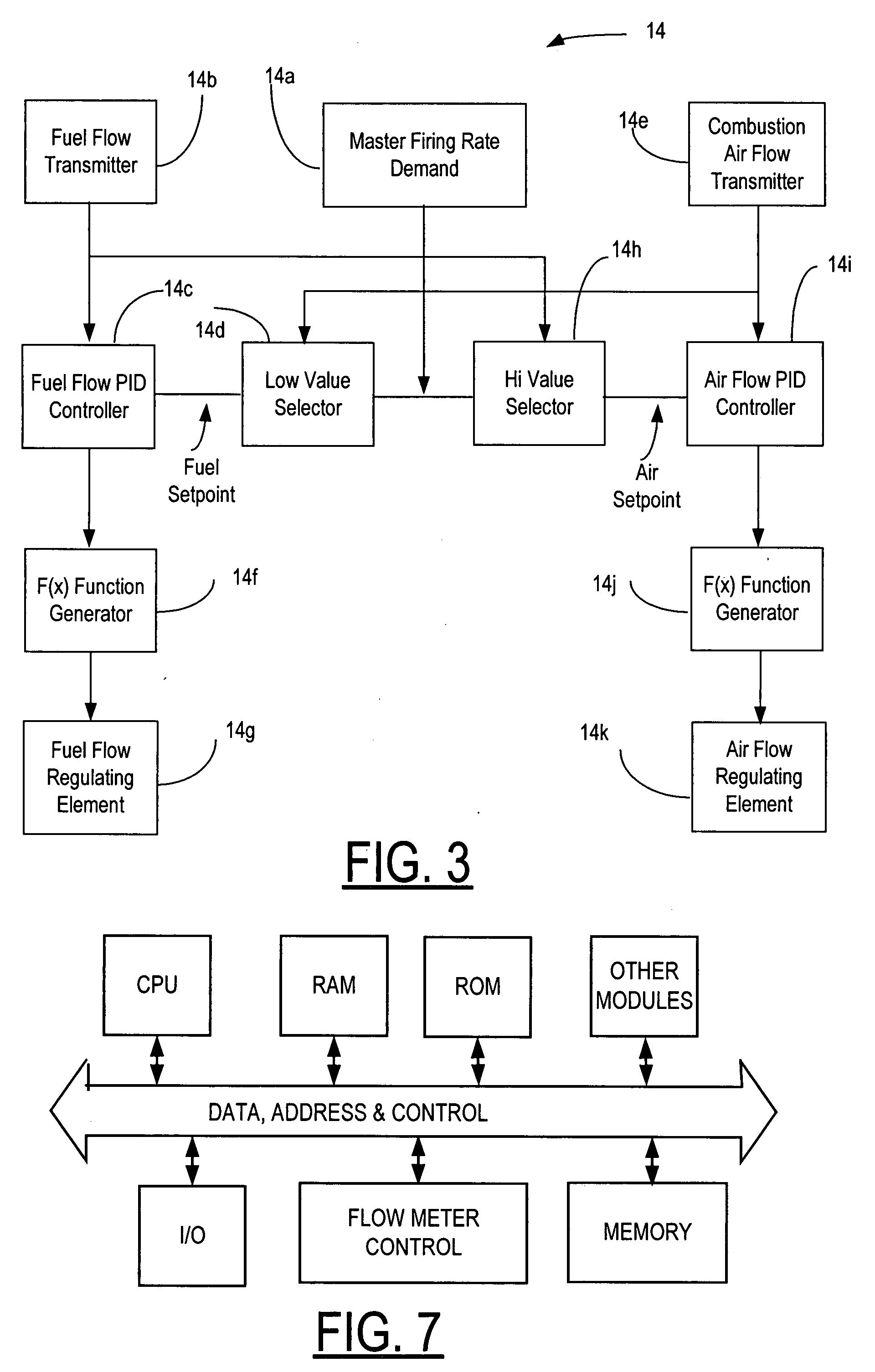

[0017]The basic purpose and intent of a combustion control strategy in a fired equipment is to maintain as stated above a process variable equal to a desired set-point by directing a firing rate demand signal to a fuel flow regulating element and a combustion air flow regulating element in the fired equipment. Such fired equipment may be for example, a steam generator, a hot water heater, a boiler, a chemical process heater, a heated manufacturing process, or other boiler combustion fired equipment although the invention is not limited to such fired equipment. For purposes of explanation and by way of example only, consider a steam generator. In this case the process variable is the steam pressure. Under the combustion control strategy, a reduction in the steam pressure relative to the set-point of the desired pressure results in an increase in the master firing rate demand signal with a coincidental call for an increase in the fuel input and combustion air input to the burner to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com