Patents

Literature

50 results about "Water oil emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil in water emulsions are colloidal systems that have oil droplets dispersed throughout the water. Water in oil emulsions are colloidal systems having water droplets dispersed throughout the oil. Similarly, the dispersed phase of water in oil emulsions is water, while the dispersed phase of oil in water emulsions is oil.

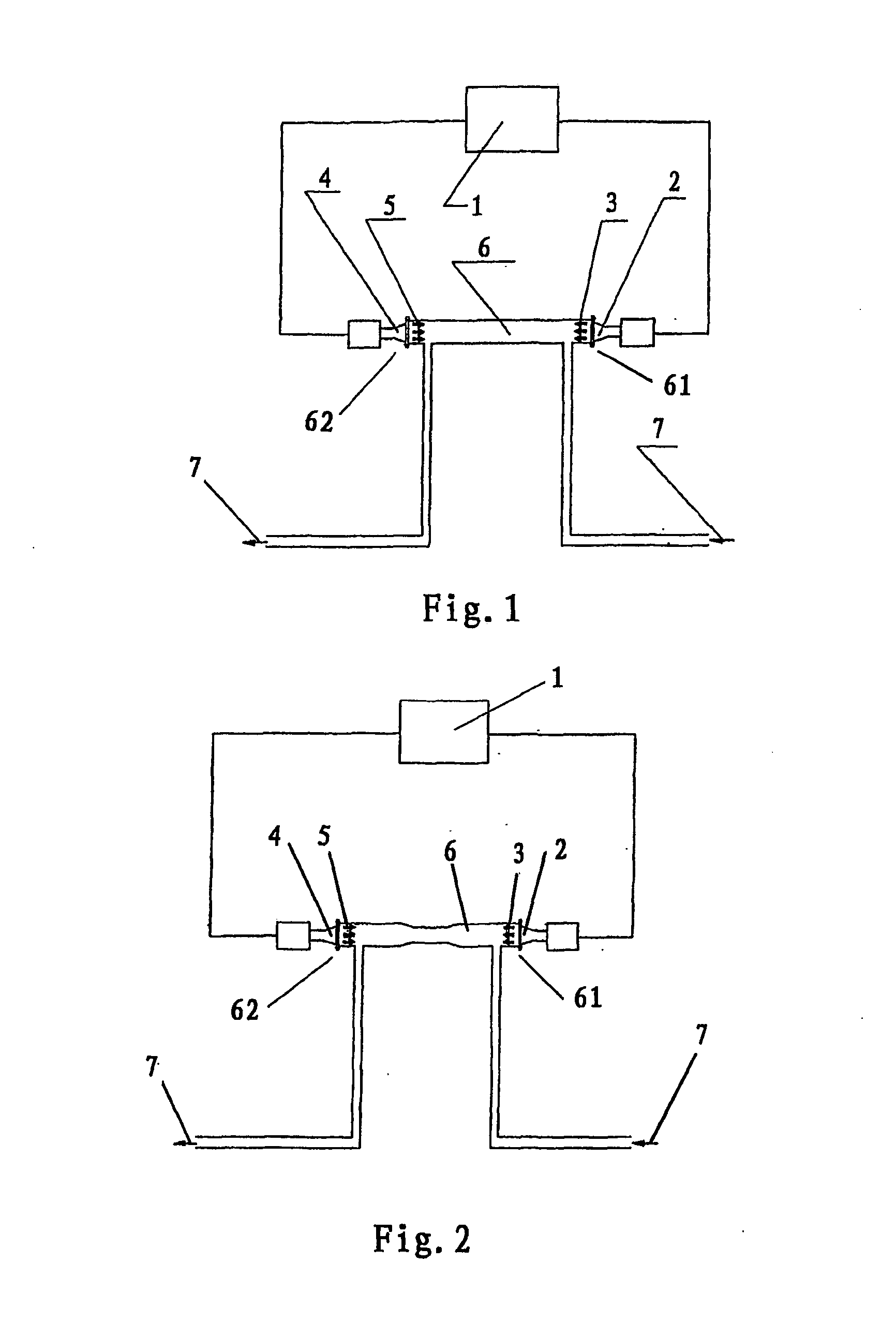

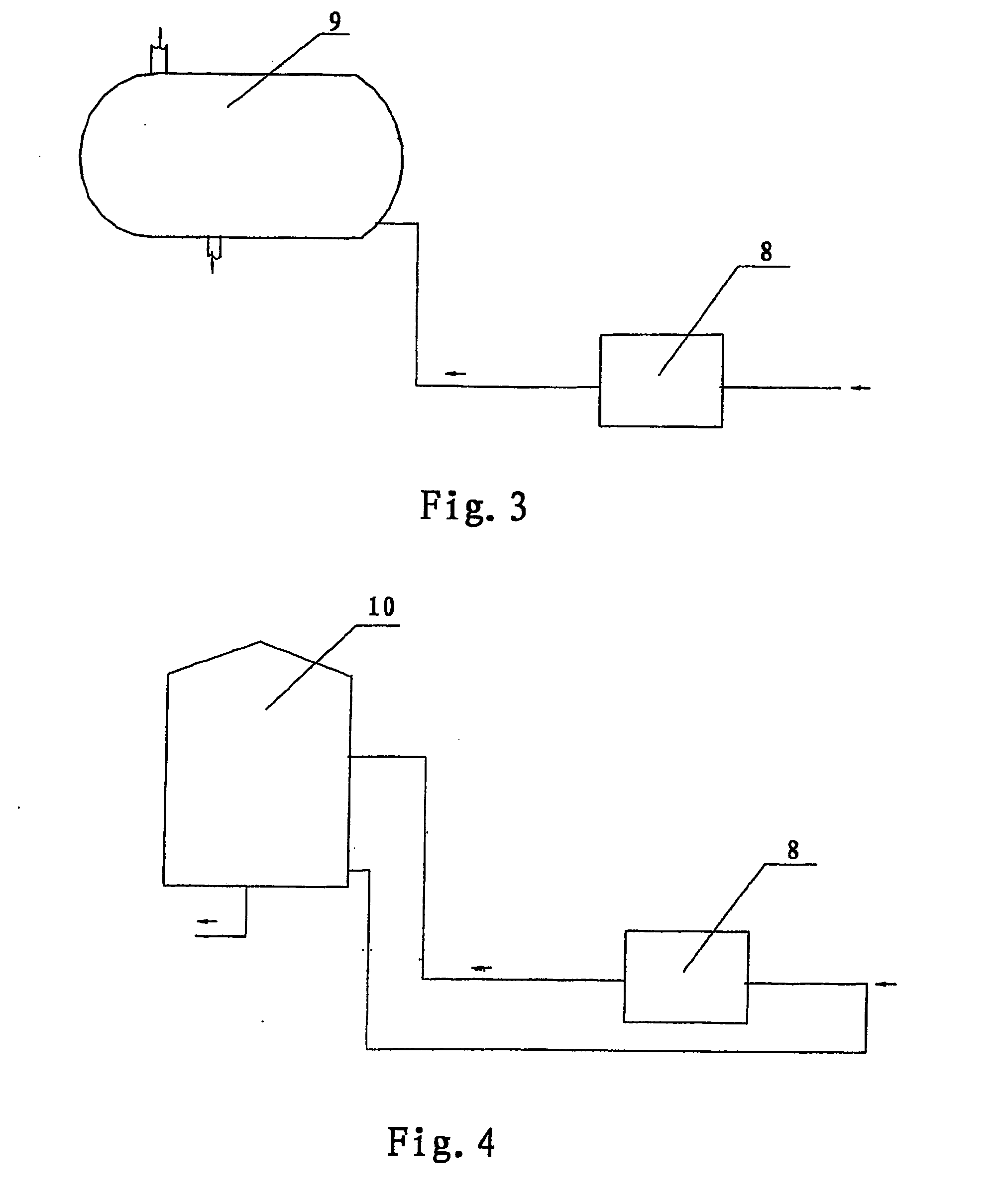

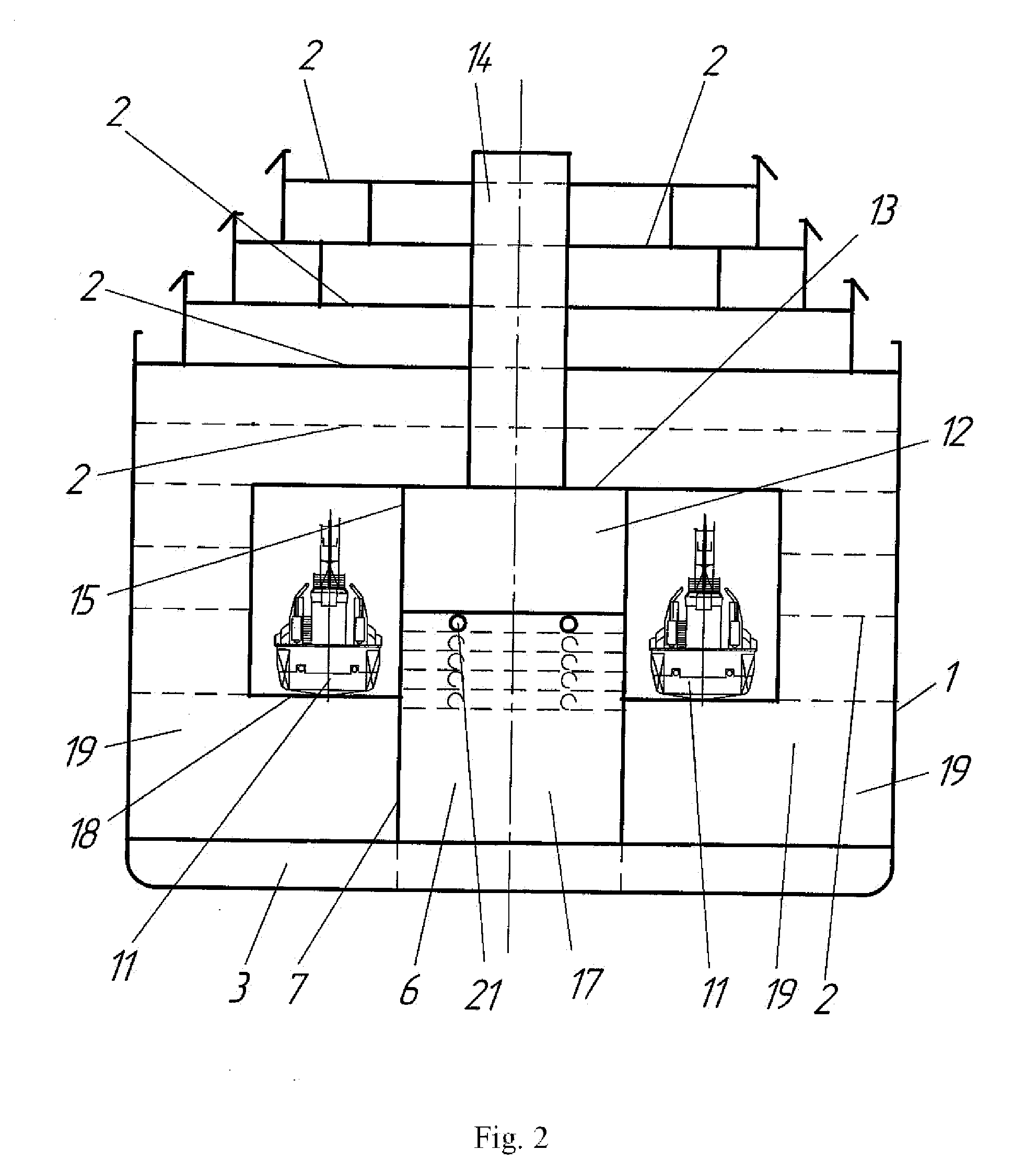

Method and Apparatus for Demulsifying an Oil-Water Emulsion Via Ultrasonic

ActiveUS20070272618A1Good effectExtension of timeDewatering/demulsification with mechanical meansLiquid separation by electricityUltrasound - actionOil water emulsion

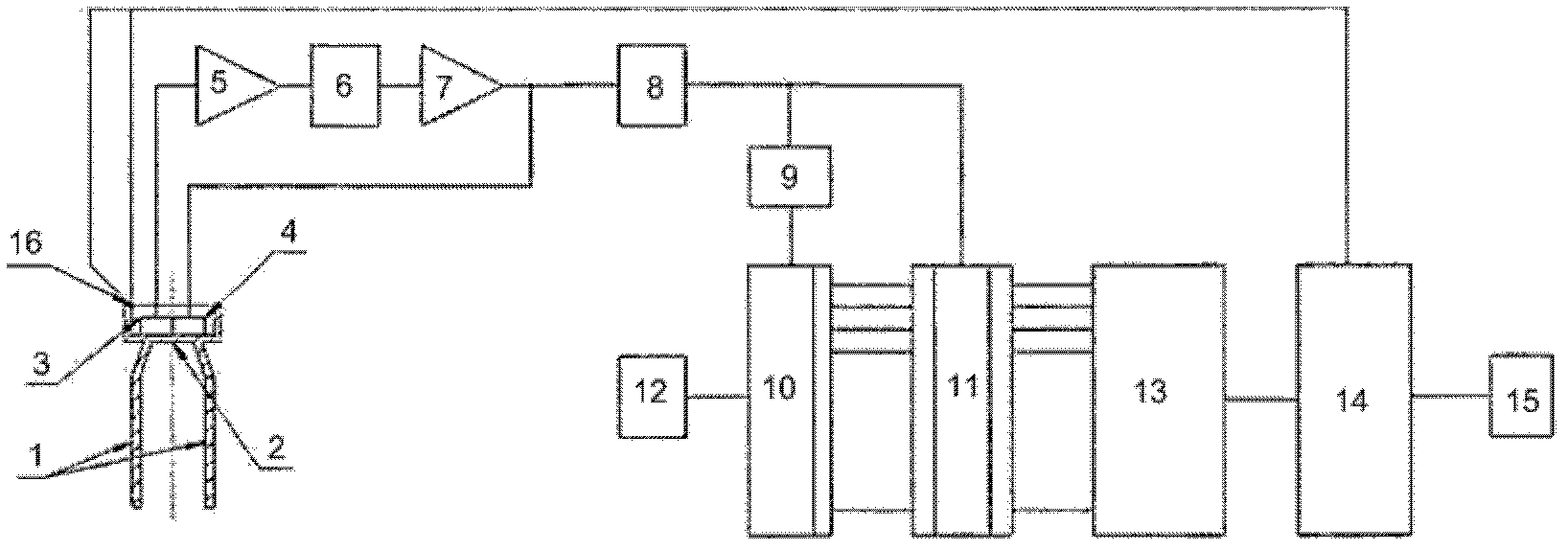

A method for demulsifying water-oil emulsions through ultrasonic action, comprises a step of making the water-oil emulsions flow through at least one ultrasonic acting region in a flow direction, wherein: within the ultrasonic acting region, a concurrent ultrasonic wave whose traveling direction is the same as the flow direction of the water-oil emulsions is generated by at least a one first ultrasonic transducer provided at the upstream end of the ultrasonic acting region, and at same time, a countercurrent ultrasonic wave whose traveling direction is opposite to the flow direction of the water-oil emulsions is generated by at least a one second ultrasonic transducer provided at the downstream end of the ultrasonic acting region; and the concurrent ultrasonic wave and the countercurrent ultrasonic wave act simultaneously on the water-oil emulsions which flow through the ultrasonic acting region, so as to demulsify the water-oil emulsions. After being demulsified, the water-oil emulsions gravity settle and separate, or settle and separate under an electric field, so as to be dewatered. The present invention can apply to various water-oil separating technologies in the procedures from mining to processing of crude oil.

Owner:CHINA PETROCHEMICAL CORP

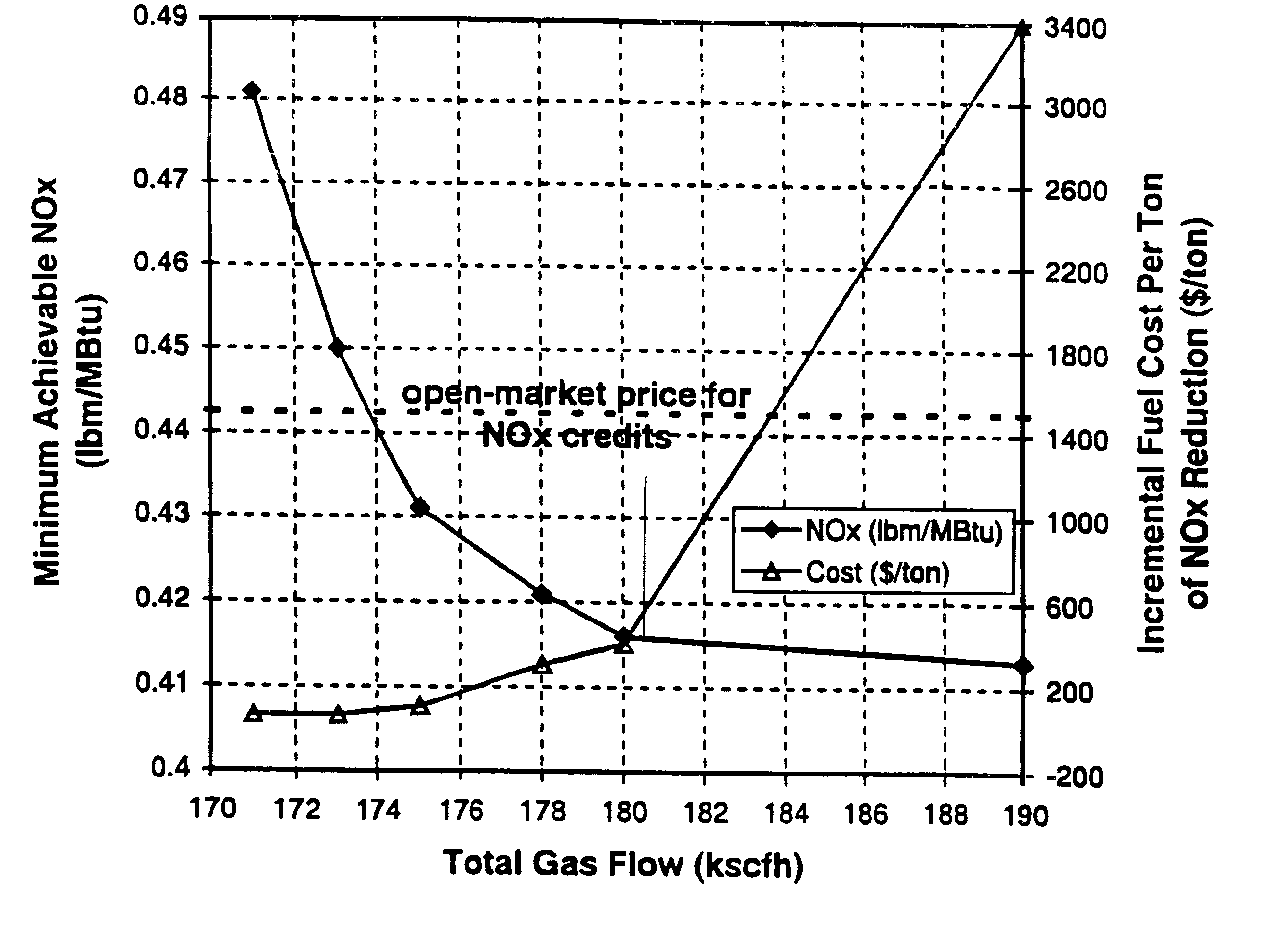

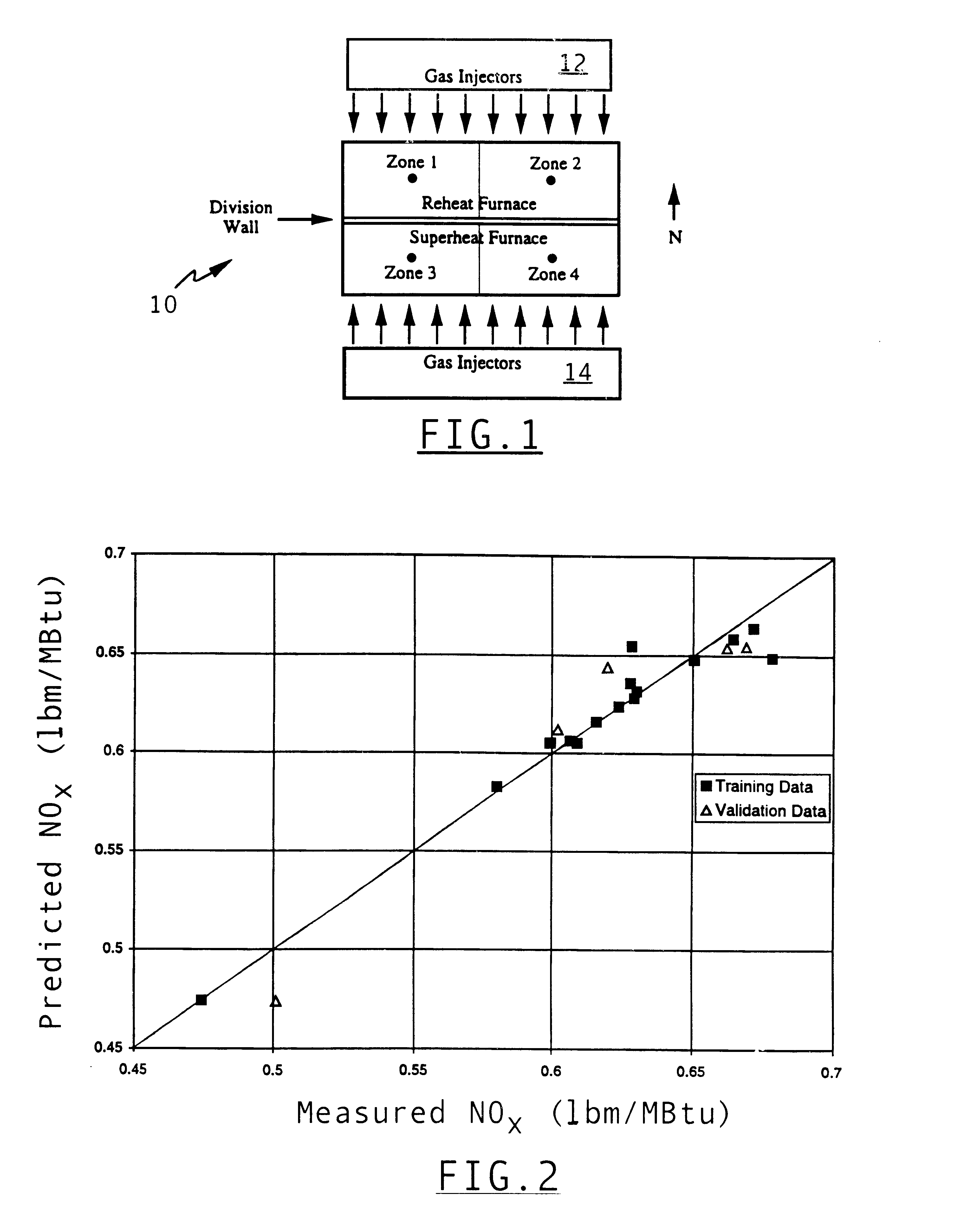

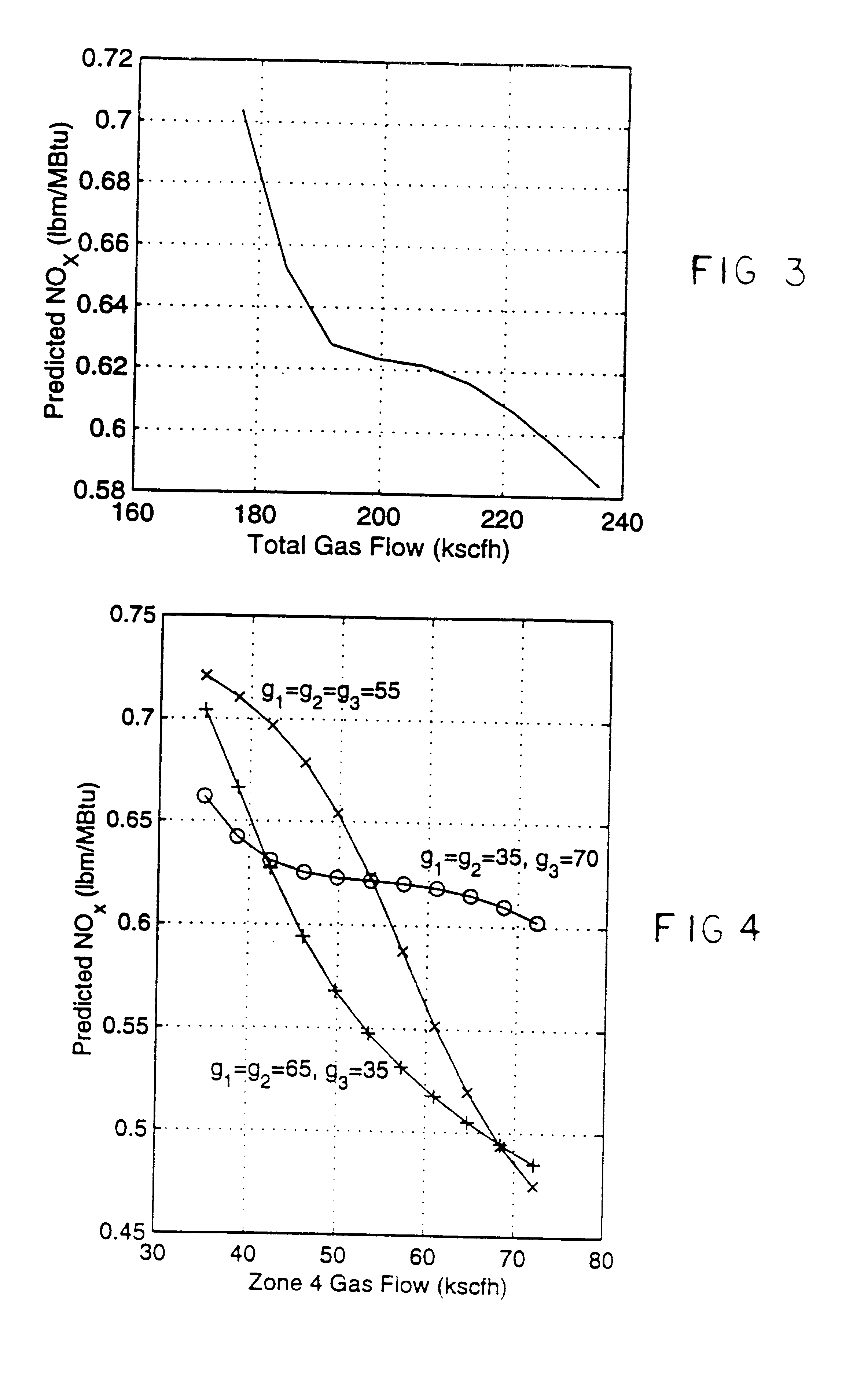

Intelligent emissions controller for substance injection in the post-primary combustion zone of fossil-fired boilers

InactiveUS6507774B1Emission reductionReduce pollutant emissionsSampled-variable control systemsCombustion signal processingWater oil emulsionU s economy

The control of emissions from fossil-fired boilers wherein an injection of substances above the primary combustion zone employs multi-layer feedforward artificial neural networks for modeling static nonlinear relationships between the distribution of injected substances into the upper region of the furnace and the emissions exiting the furnace. Multivariable nonlinear constrained optimization algorithms use the mathematical expressions from the artificial neural networks to provide the optimal substance distribution that minimizes emission levels for a given total substance injection rate. Based upon the optimal operating conditions from the optimization algorithms, the incremental substance cost per unit of emissions reduction, and the open-market price per unit of emissions reduction, the intelligent emissions controller allows for the determination of whether it is more cost-effective to achieve additional increments in emission reduction through the injection of additional substance or through the purchase of emission credits on the open market. This is of particular interest to fossil-fired electrical power plant operators. The intelligent emission controller is particularly adapted for determining the economical control of such pollutants as oxides of nitrogen (NOx) and carbon monoxide (CO) emitted by fossil-fired boilers by the selective introduction of multiple inputs of substances (such as natural gas, ammonia, oil, water-oil emulsion, coal-water slurry and / or urea, and combinations of these substances) above the primary combustion zone of fossil-fired boilers.

Owner:ENERGY SYST ASSOCD +1

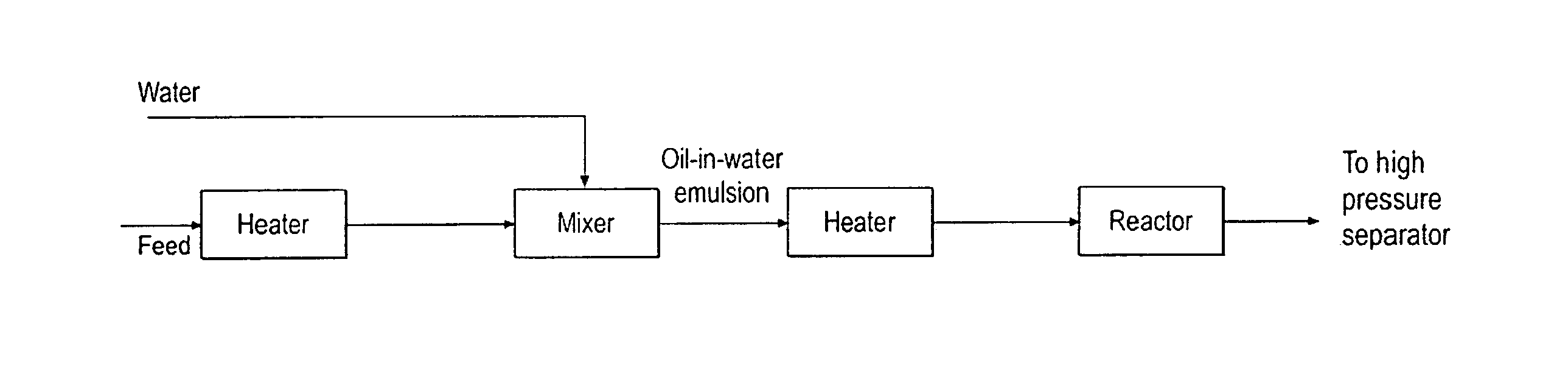

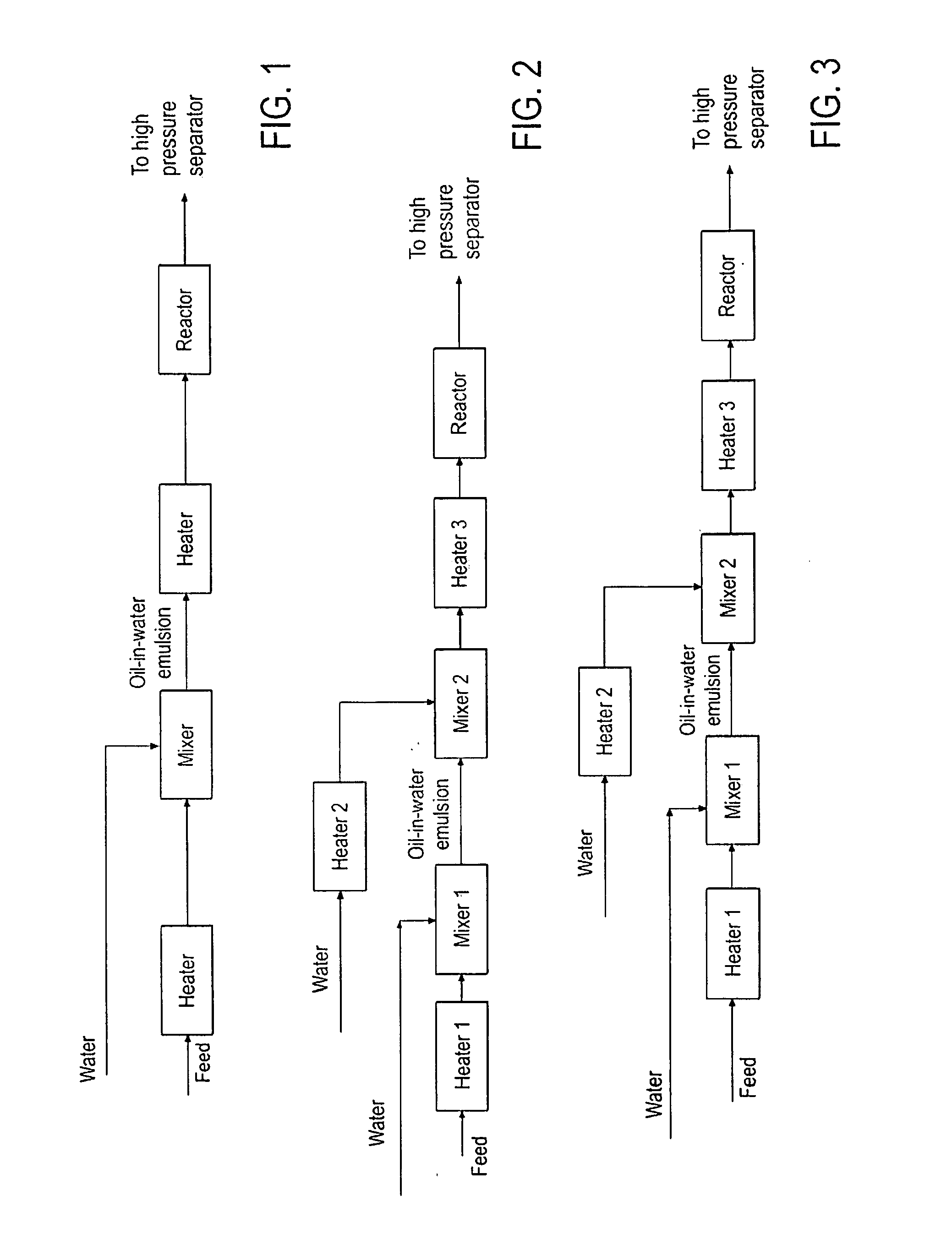

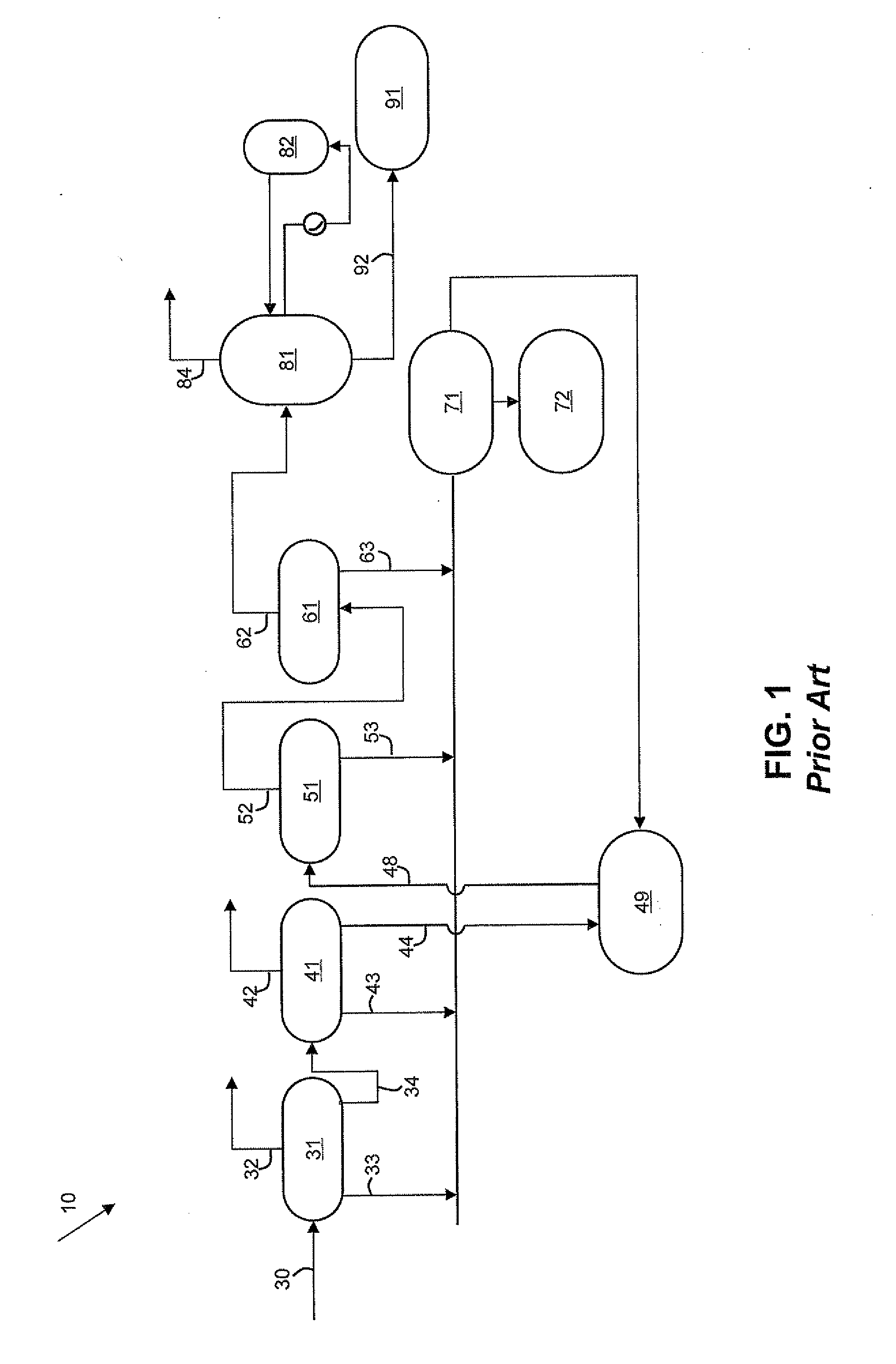

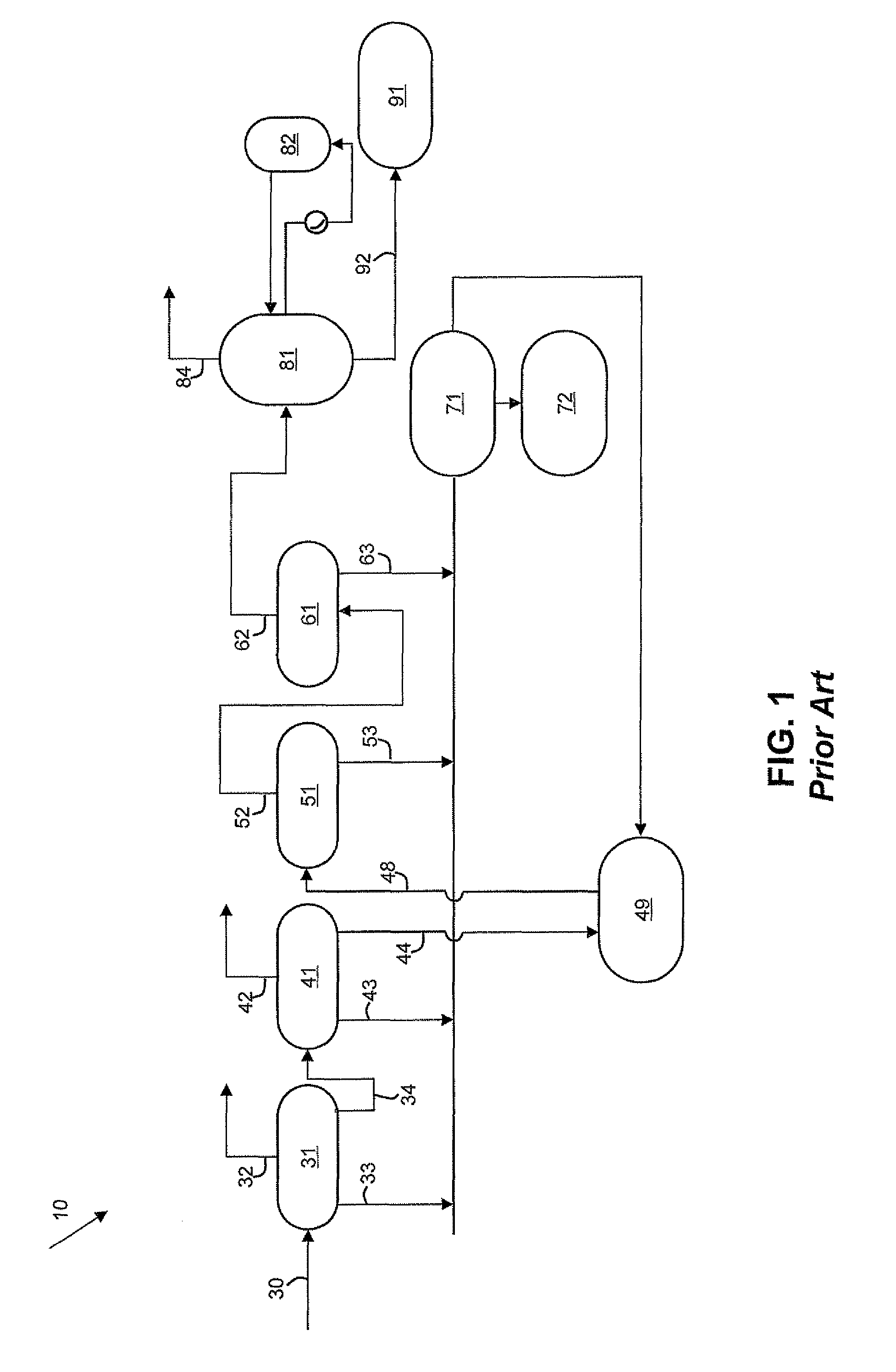

Upgrading heavy hydrocarbon oils

A process using supercritical water-oil emulsion to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts.

Owner:CHEVROU USA INC

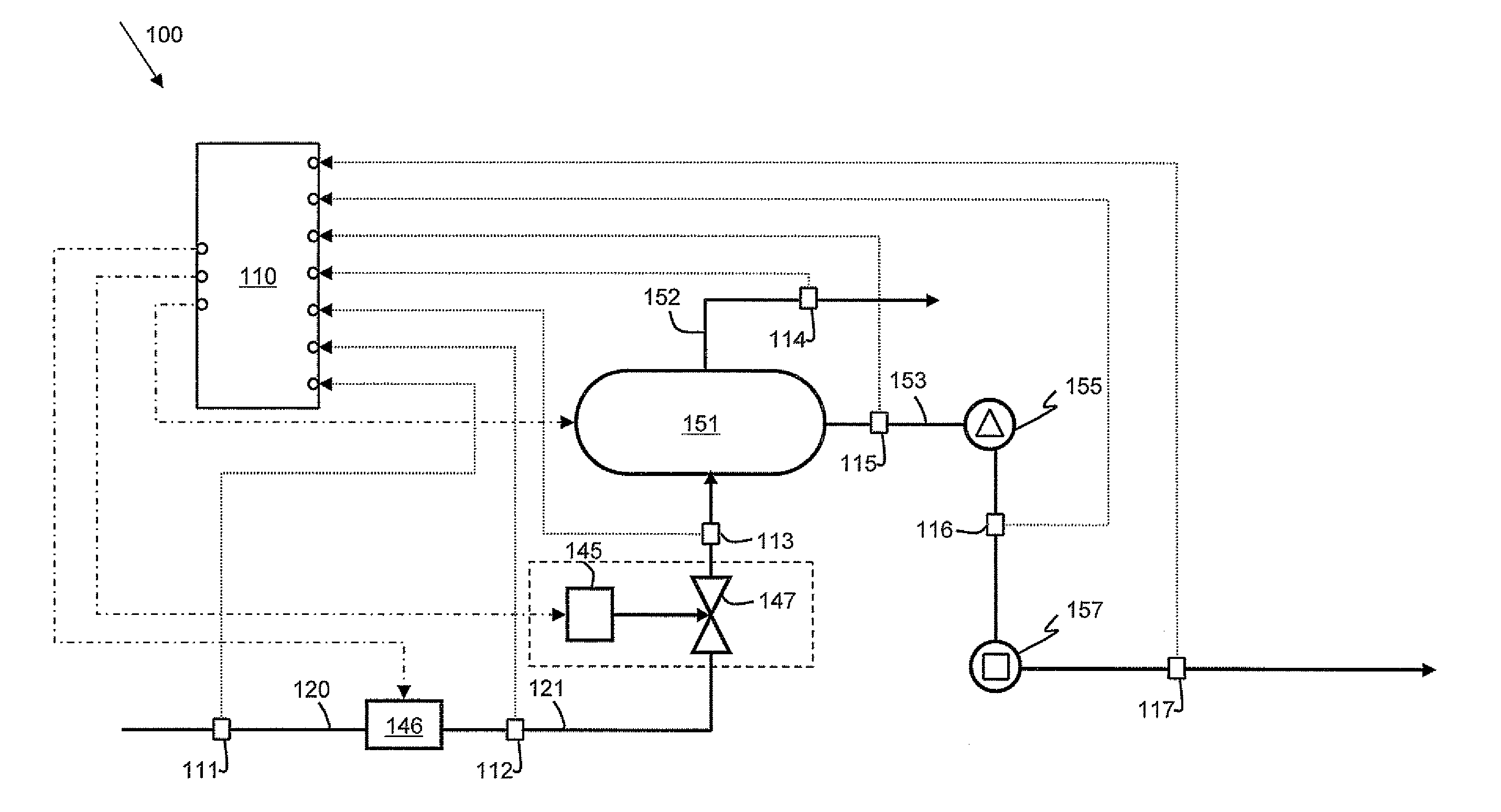

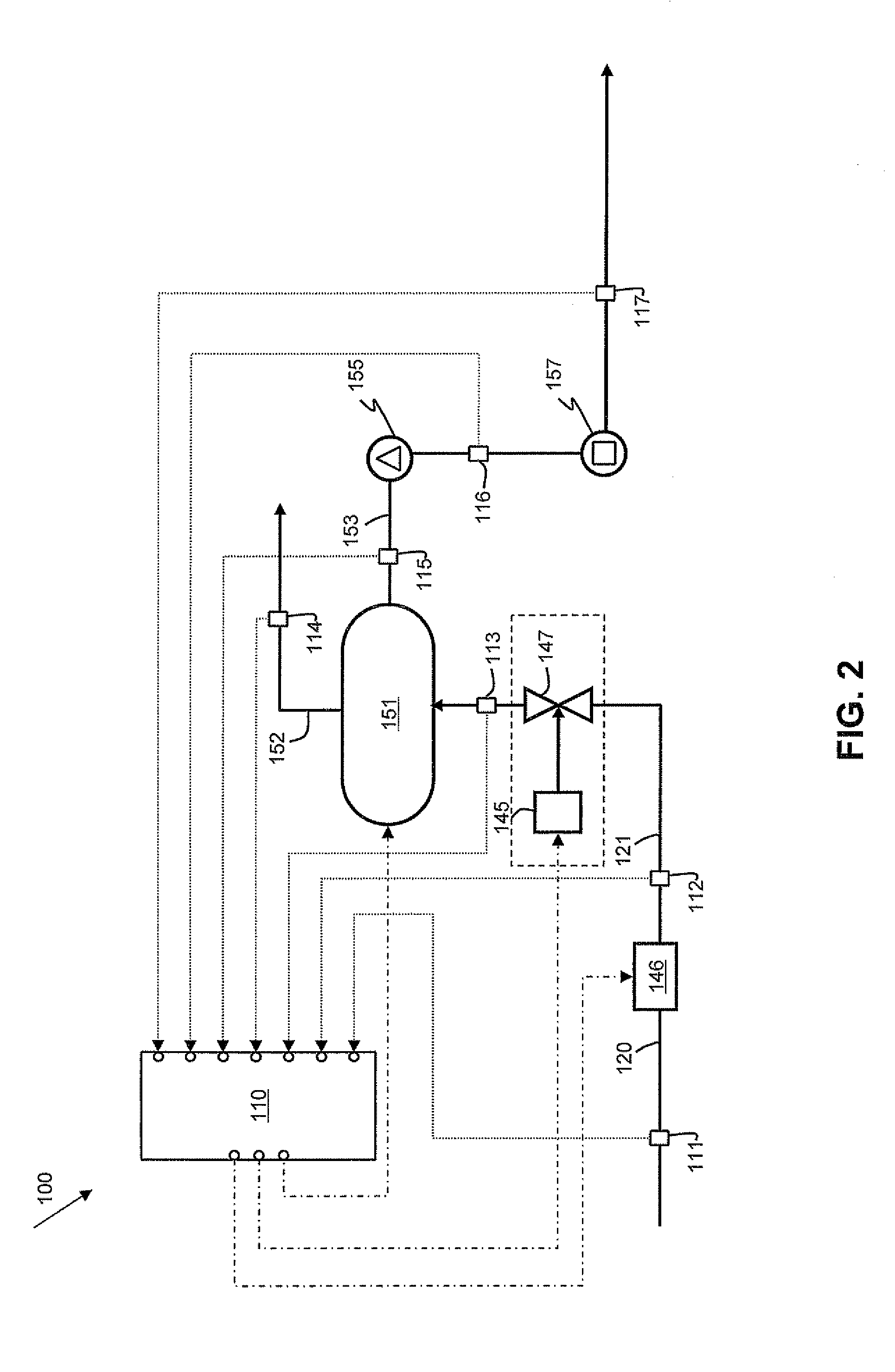

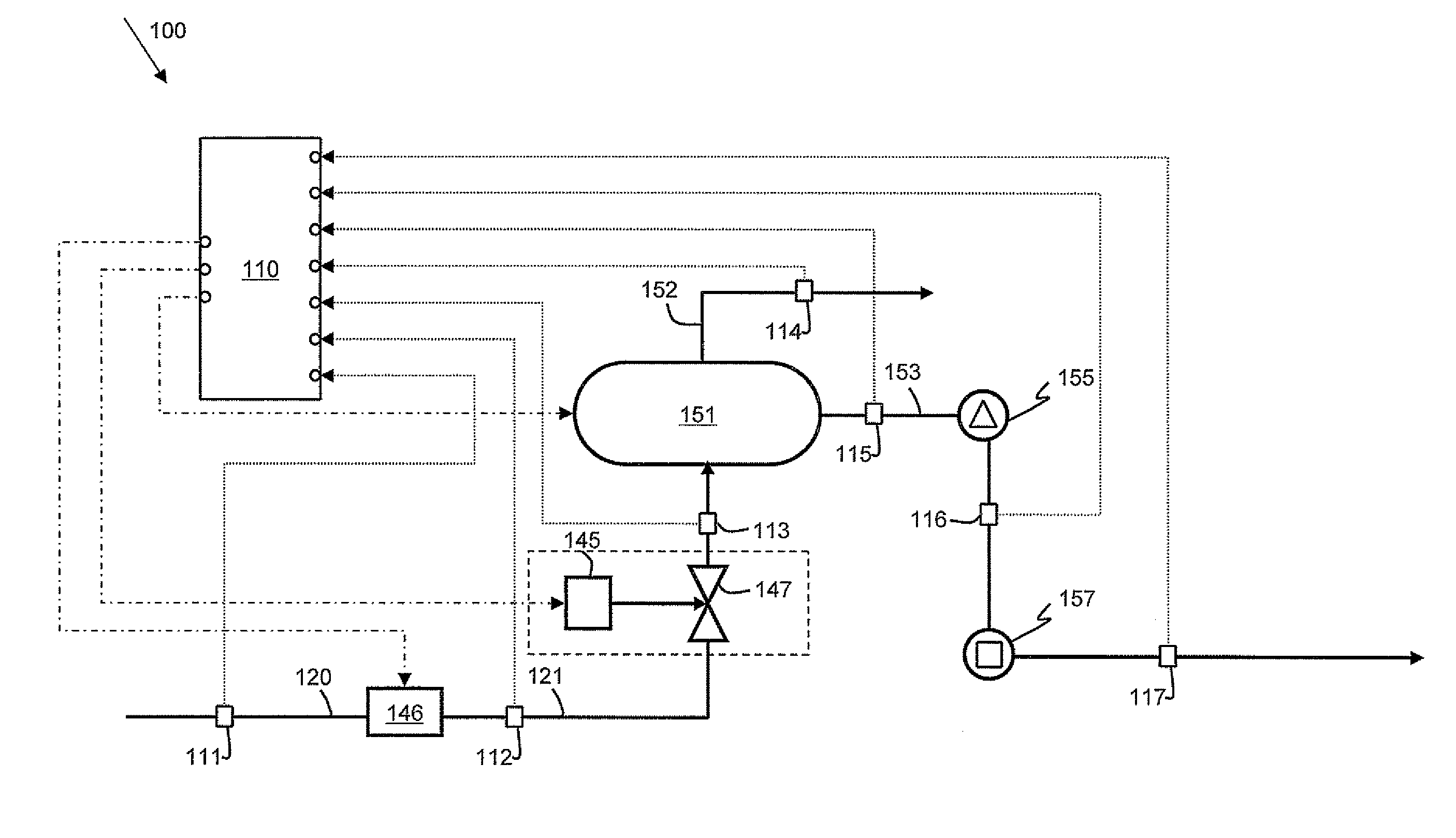

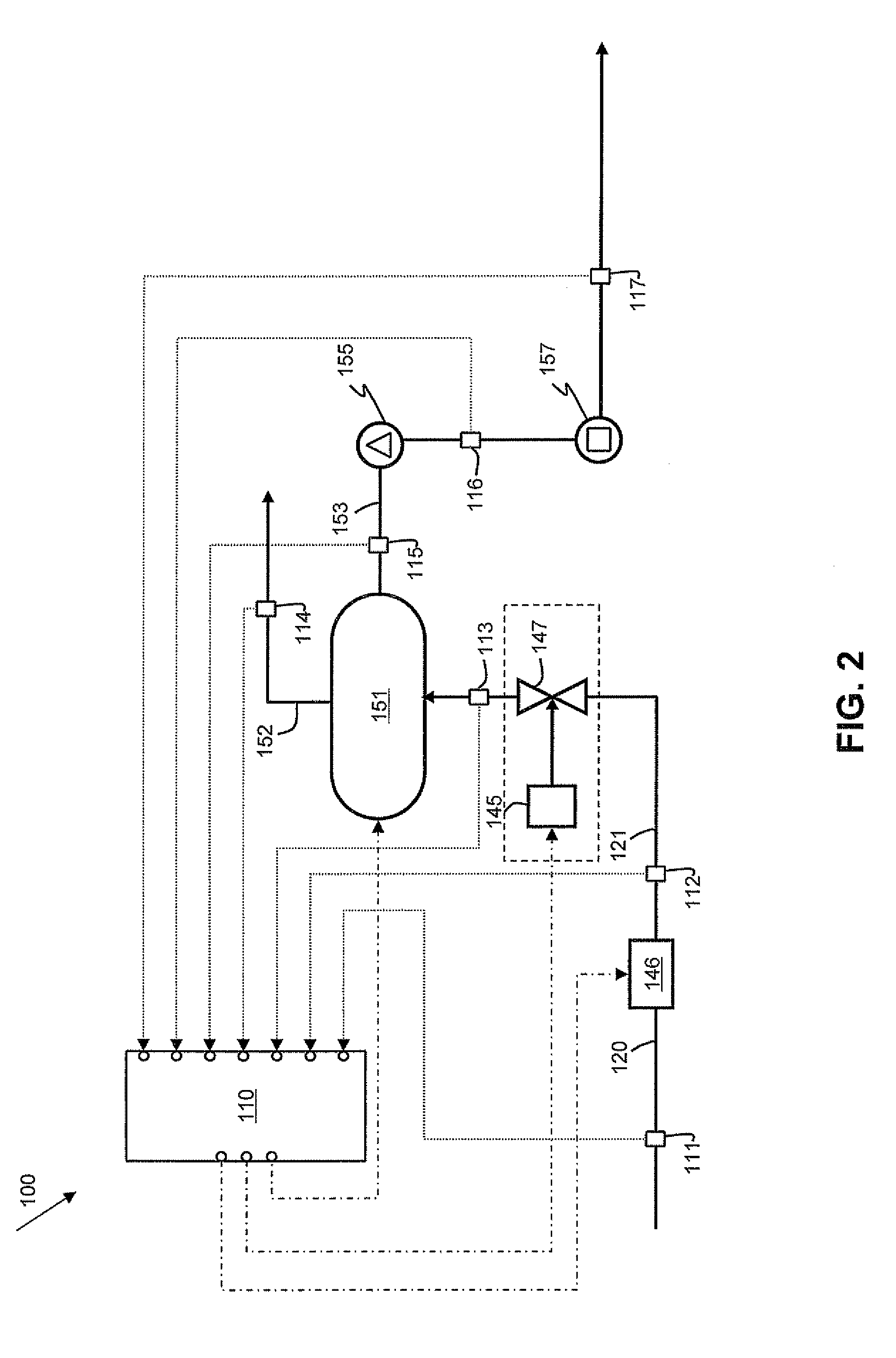

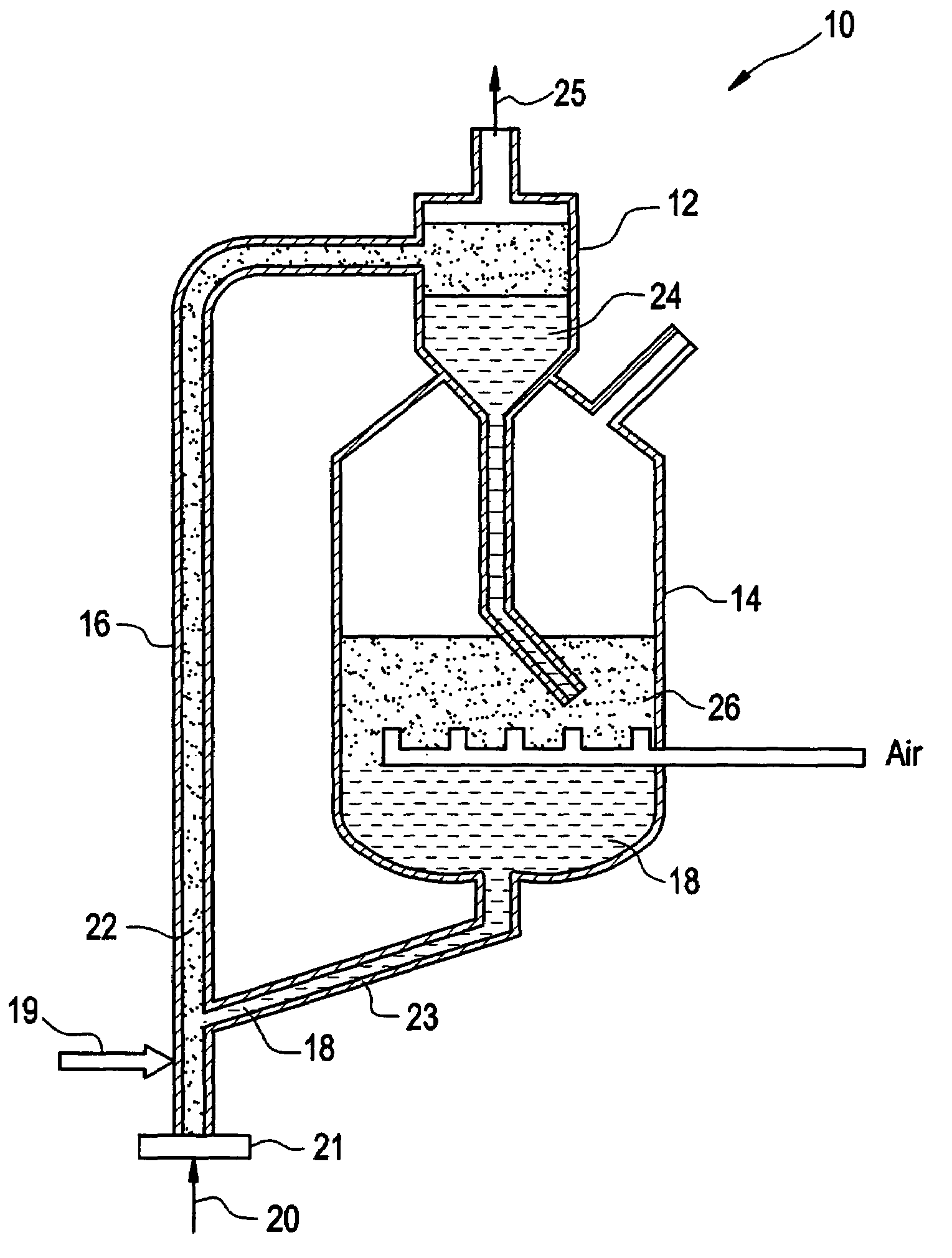

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS20130026082A1Low viscosityLiquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

Perfume oil emulsions

In a first aspect, the invention concerns oil-in-water emulsions comprising defined water-soluble emulsification polymers and having an oil phase comprising polar oils. In a second aspect, products, such as cosmetic products, are provided, comprising the emulsions. In a third aspect, a manufacturing method is provided for making the products.

Owner:THE PROCTER & GAMBLE COMPANY

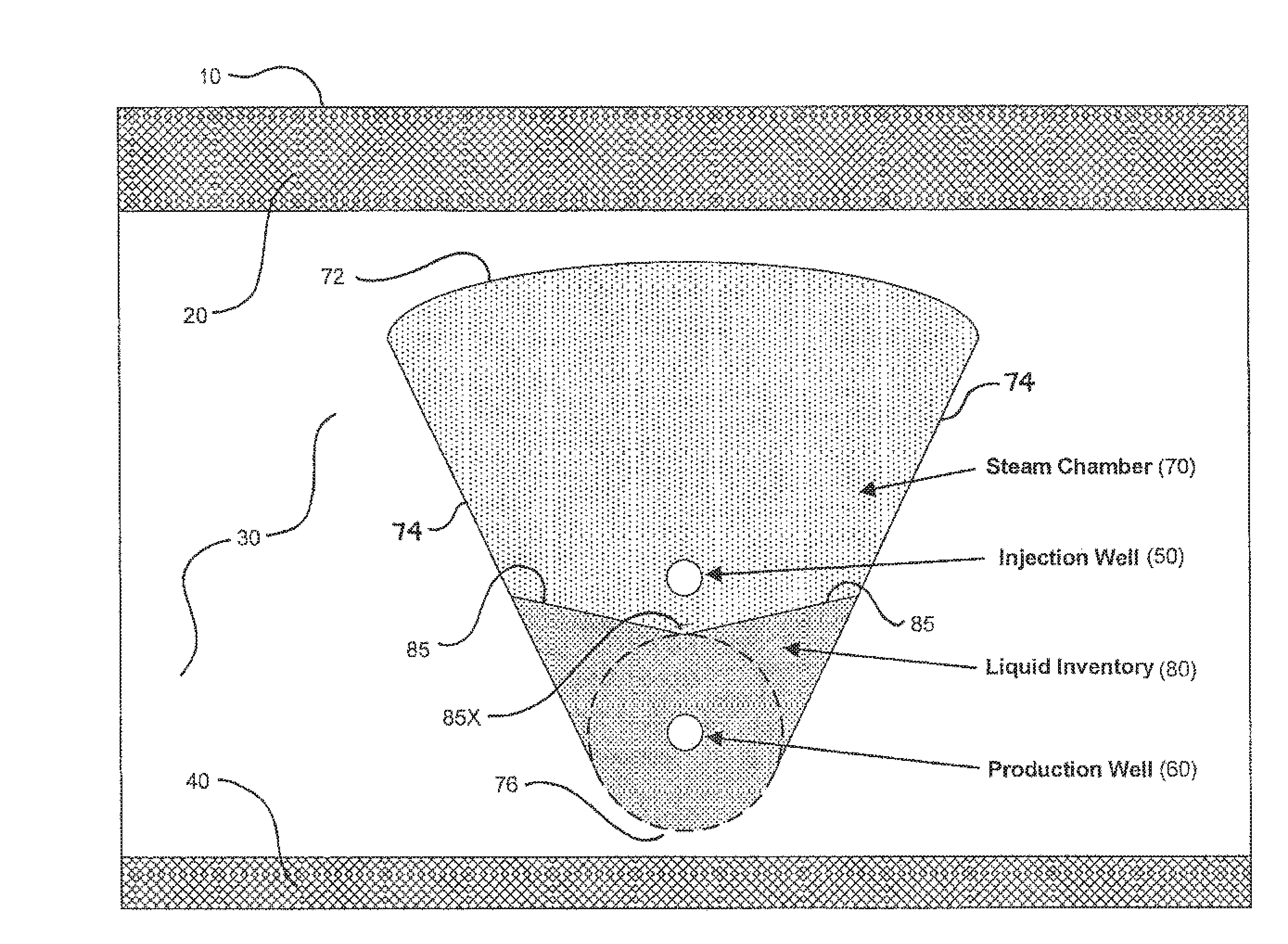

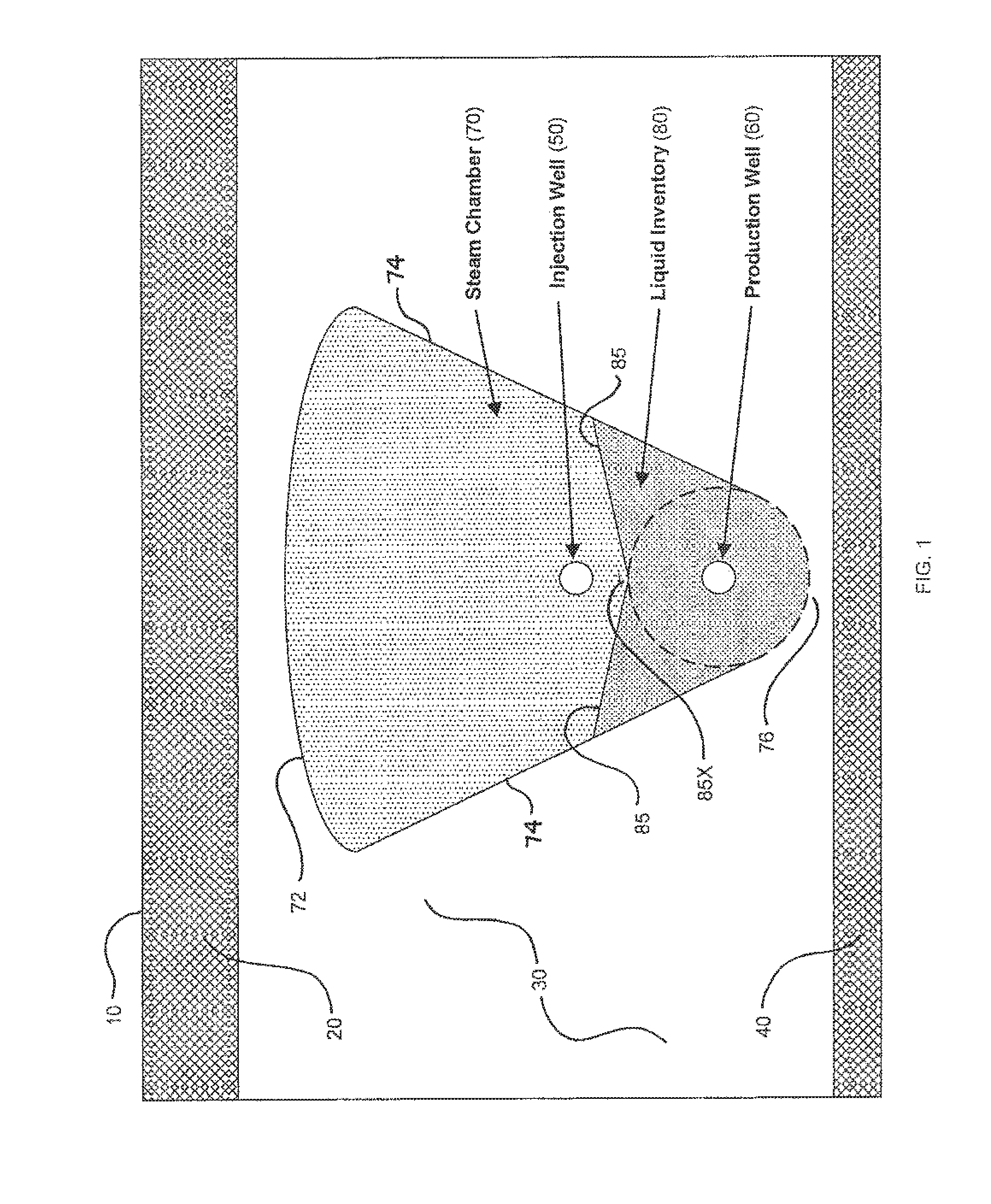

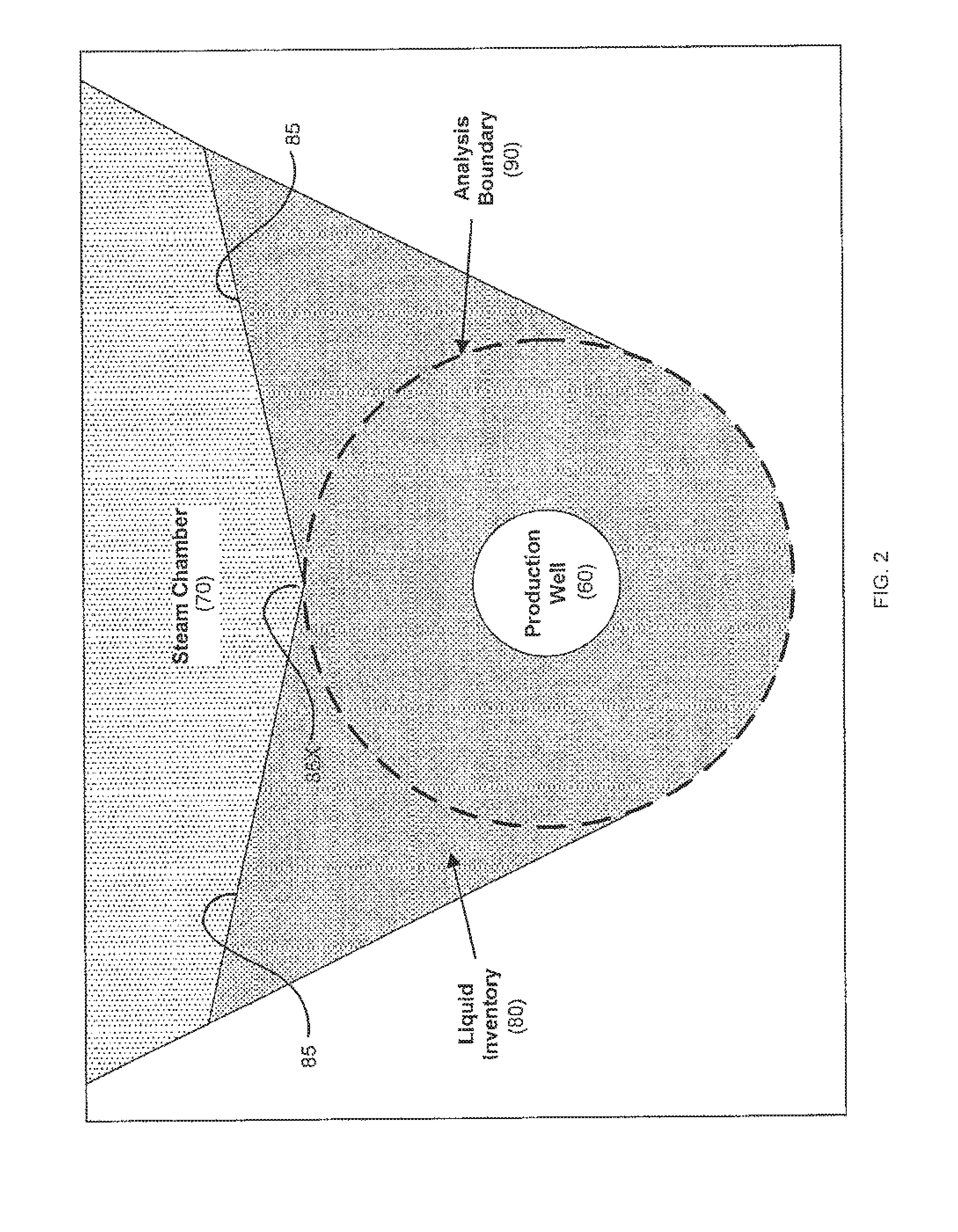

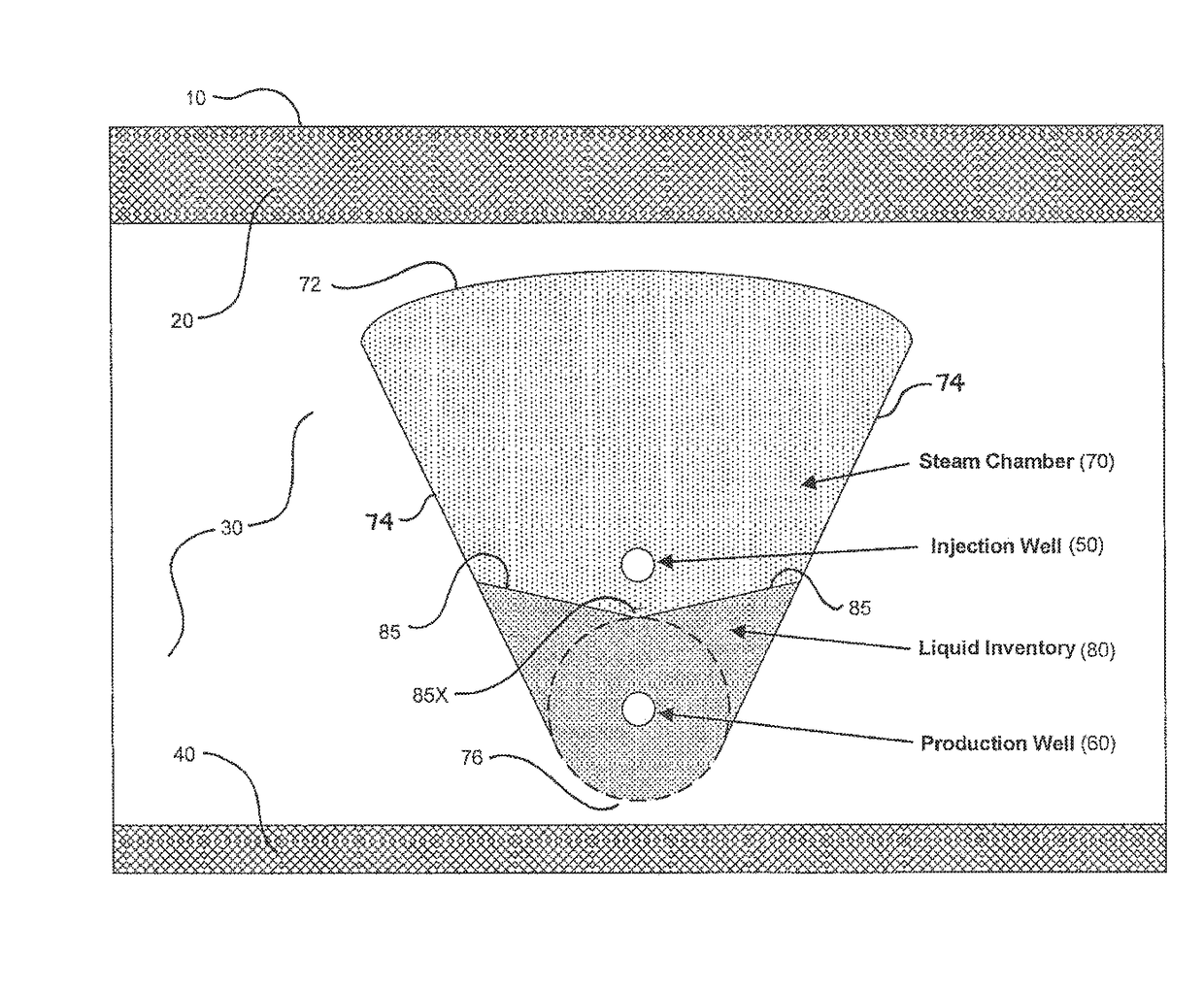

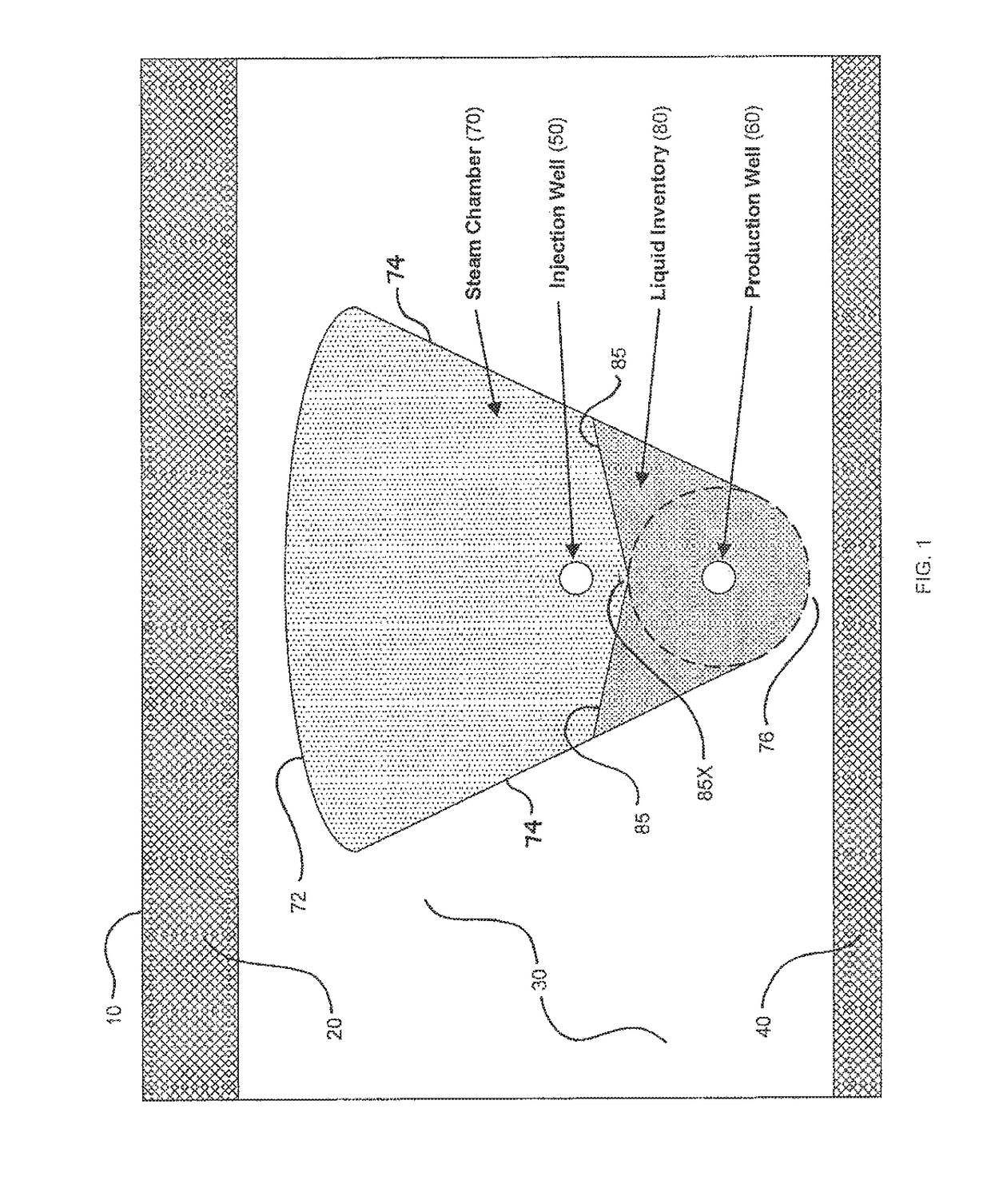

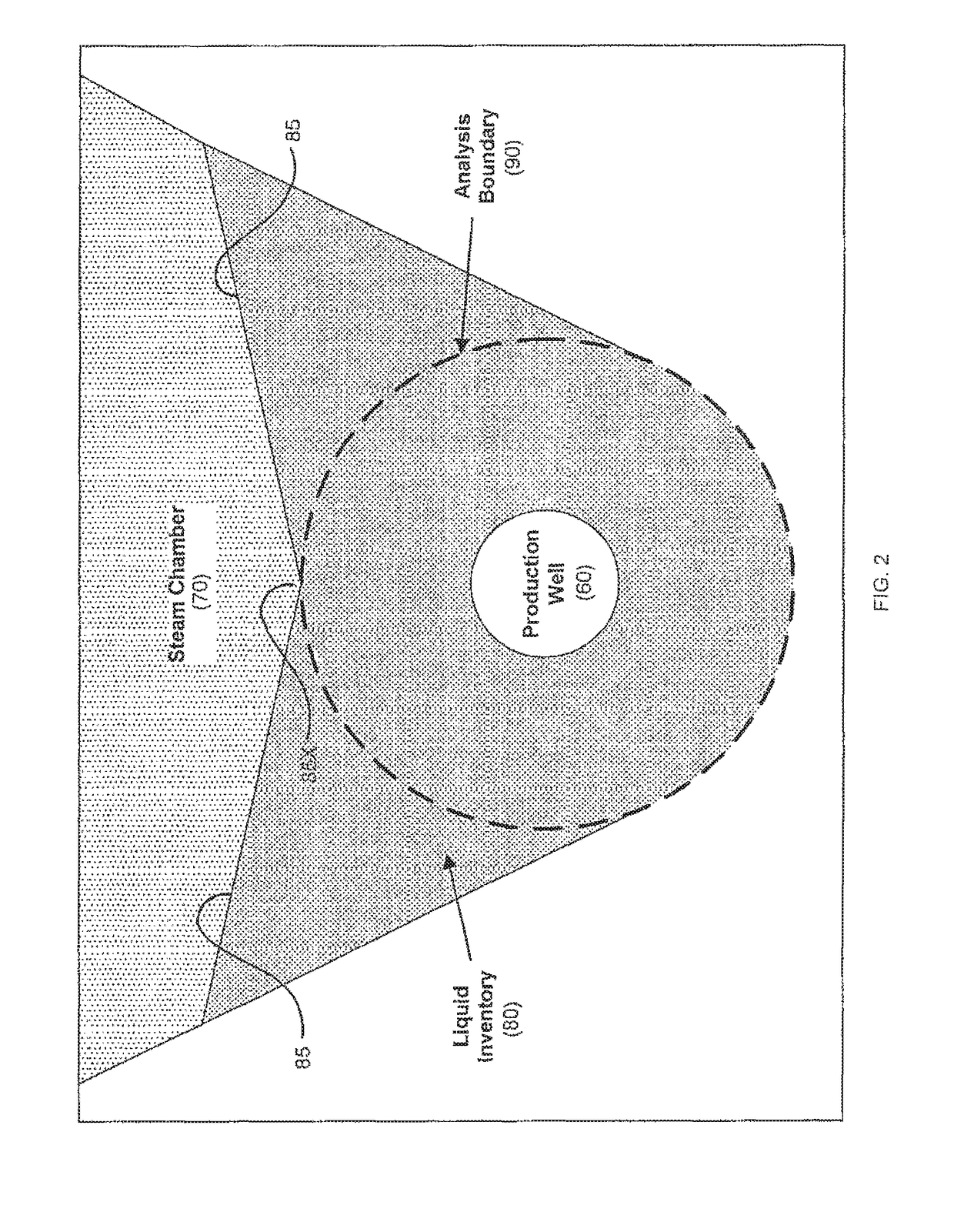

Method for controlling fluid interface level in gravity drainage oil recovery processes with crossflow

In a method for controlling the interface level between a liquid inventory and an overlying steam chamber in a subterranean petroleum-bearing formation, an inflow relationship is developed to predict the vertical position in a gravity field of the interface between two fluids with a density contrast (most commonly a water / oil emulsion and steam), relative to a horizontal producer well. The inflow relationship is applied to producer well completions by designing the completion to raise or lower sand face pressures over the horizontal length of the well. This pressure distribution will affect liquid levels according to the inflow relationship. Axial flow relationships for the liquid inventory may be developed to facilitate estimation of liquid levels at selected locations. Axial flow relationships for the steam chamber may also be developed to estimate the effect of the injector well completion on the steam chamber pressure and, in turn, the liquid level.

Owner:NOETIC TECH INC

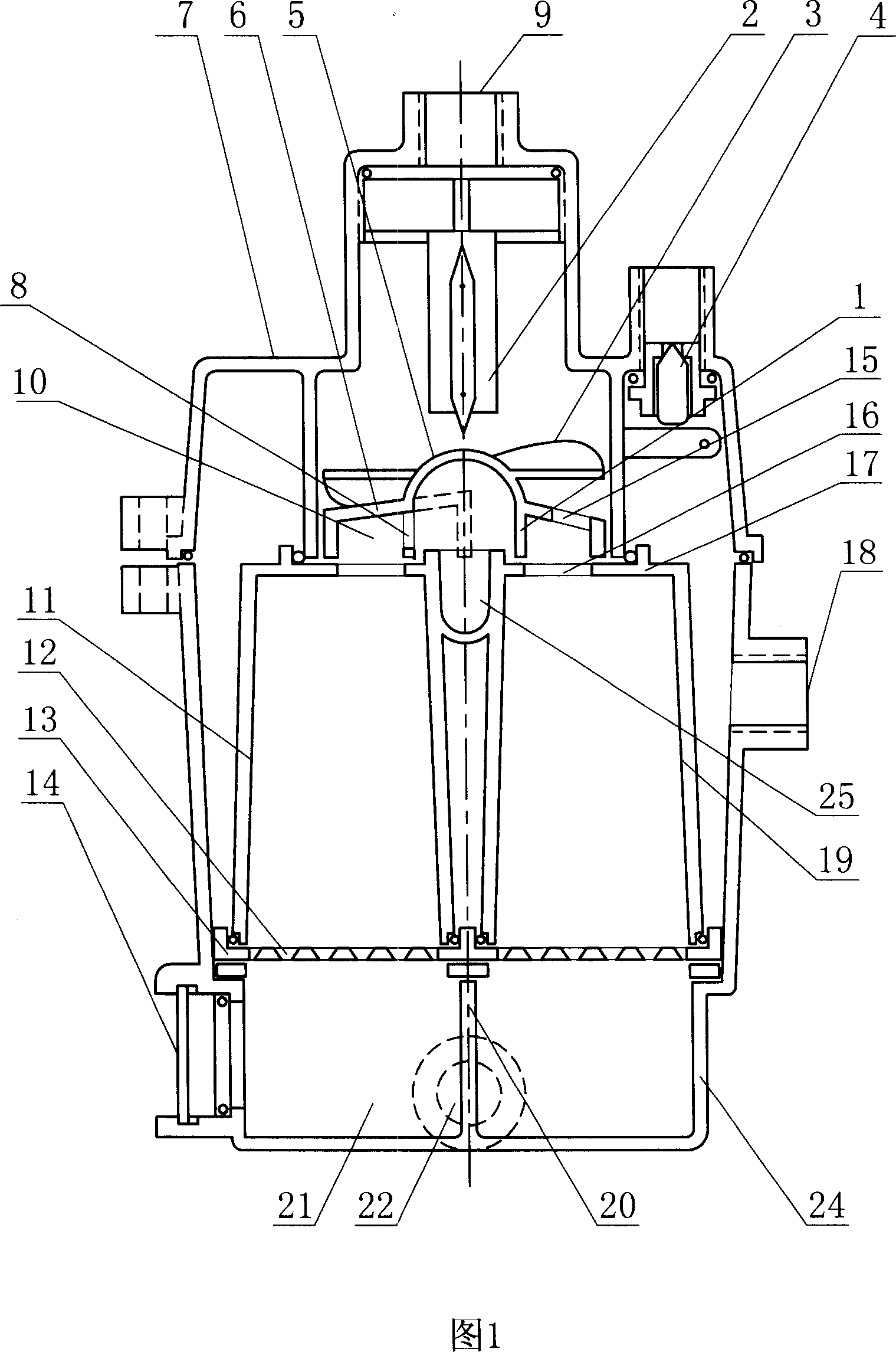

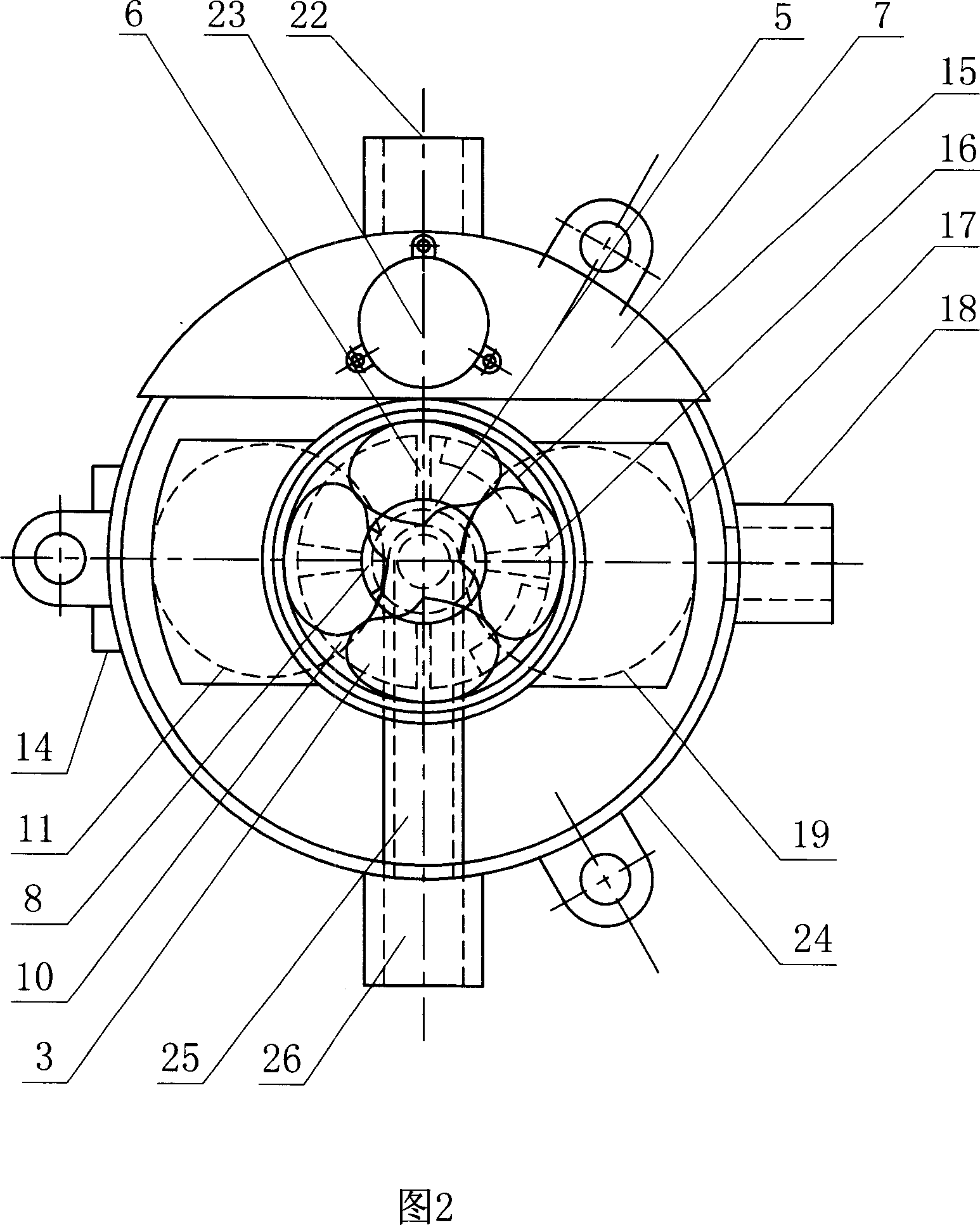

Automatic purifying energy-saving filter

InactiveCN101024130AReduce manufacturing costLow running costCombustion-air/fuel-air treatmentMachines/enginesParticulatesOil emulsion

The invention discloses a automatic energy-saving purification filter, its characteristics are that, at least two filter core, a change fluid set in the filter with roof of filter core constitute active cavity, through-hole on the roof of filter core, the active cavity through through-hole connect the cavity of filter core and through the back flow channel pass transferpump connect the enter fluid port. Based on no change of original tube and setting position, the invention used the spinning of the change fluid achieve fuel filtration and recoil washing function, which is a revolutionary improvement of the traditional electromechanical switch teams filter automatically filter with intermittent operation, the machine operator no more worry about removing filter core, fuel saving and environmental protection, science and simple structure, reducing the automatic filter manufacturing costs. The present invention can also make watered-oil emulsion, the use of emulsified oil in the middle operating condition saved about 5%, reducing harmful gases and soot particulate emissions above 30%, significant social and economic benefits.

Owner:瑞安市超声电器有限公司

Process for treatment of water/oil emulsions

InactiveUS20110186515A1Dewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansMicrowaveOil emulsion

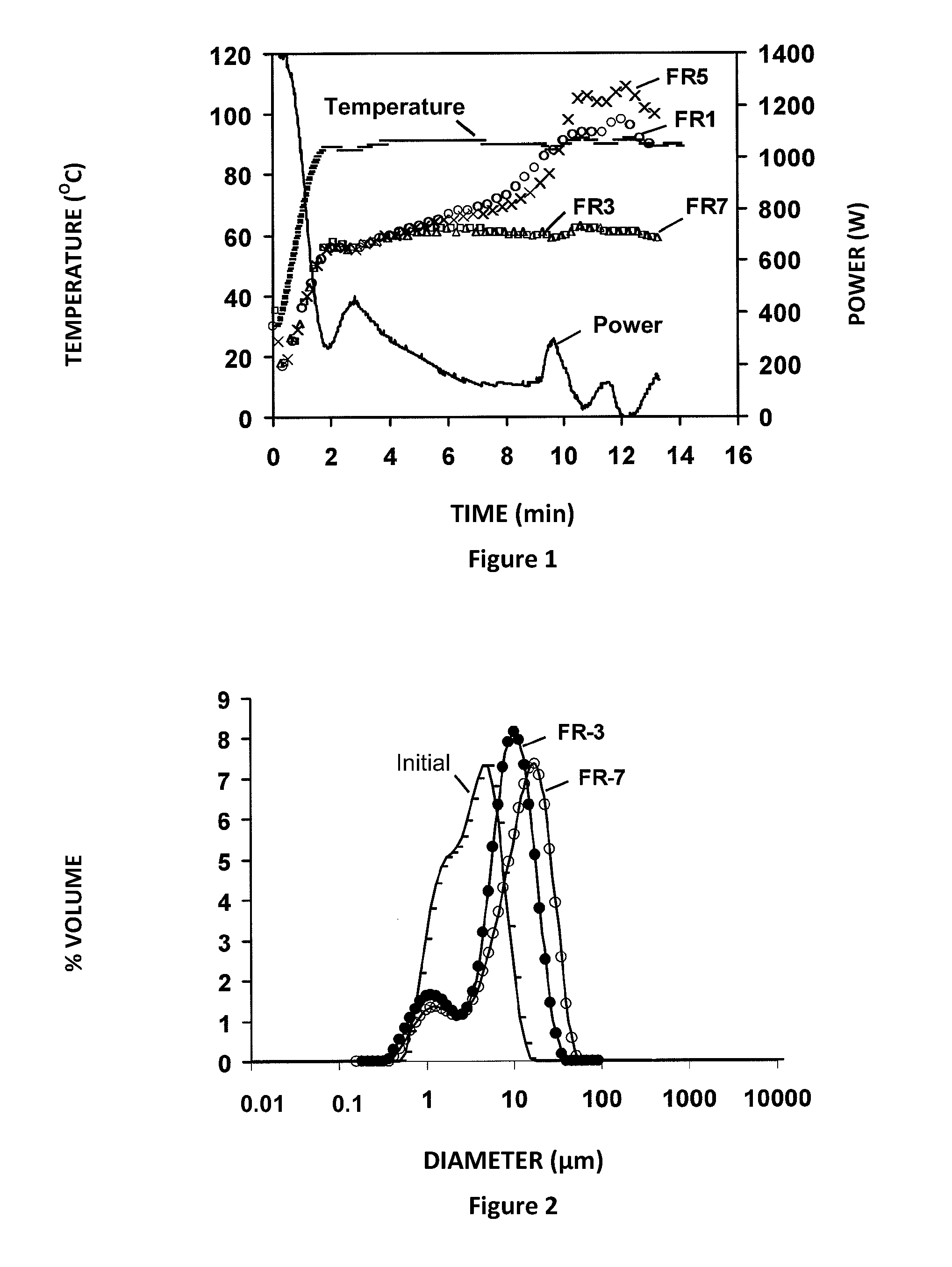

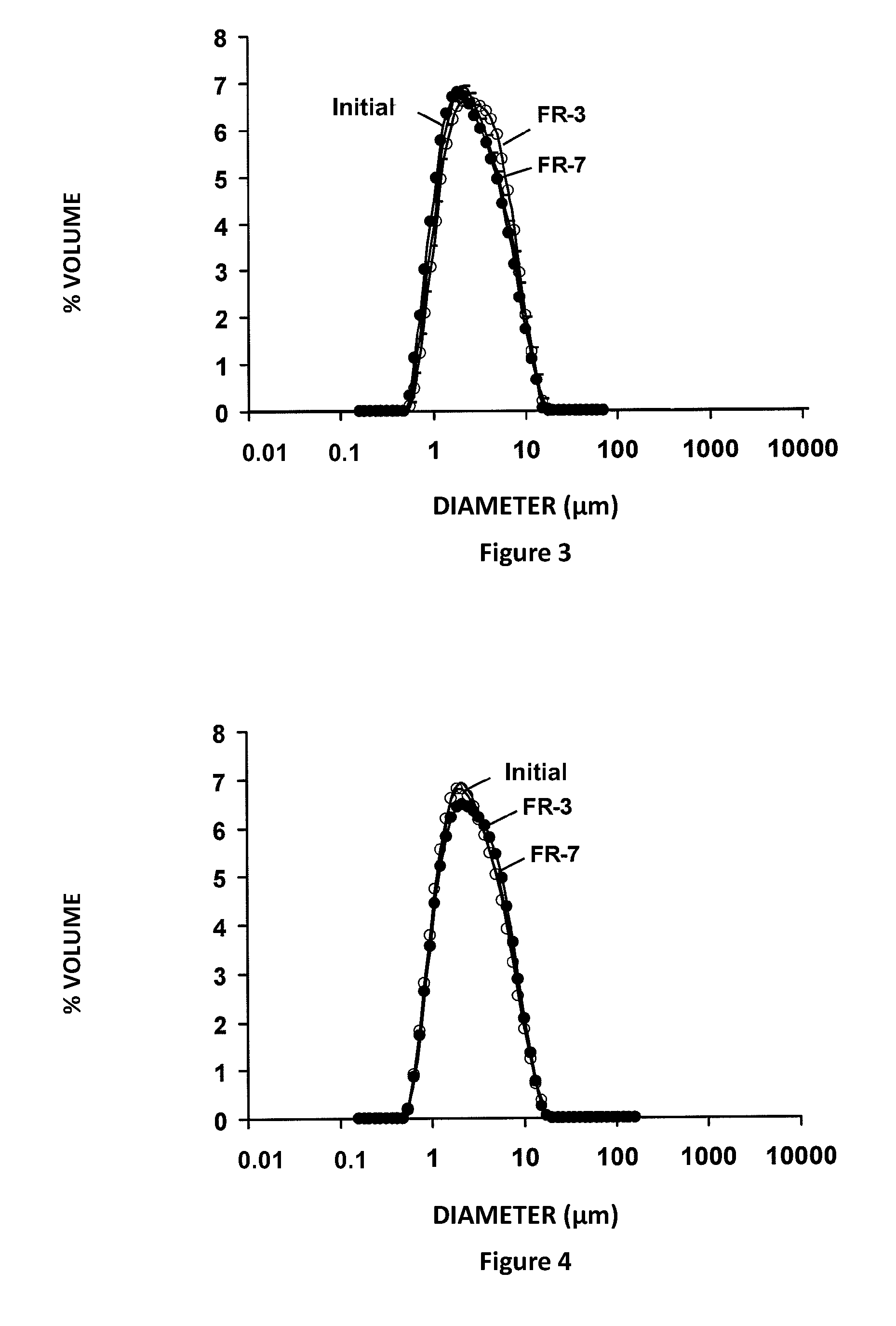

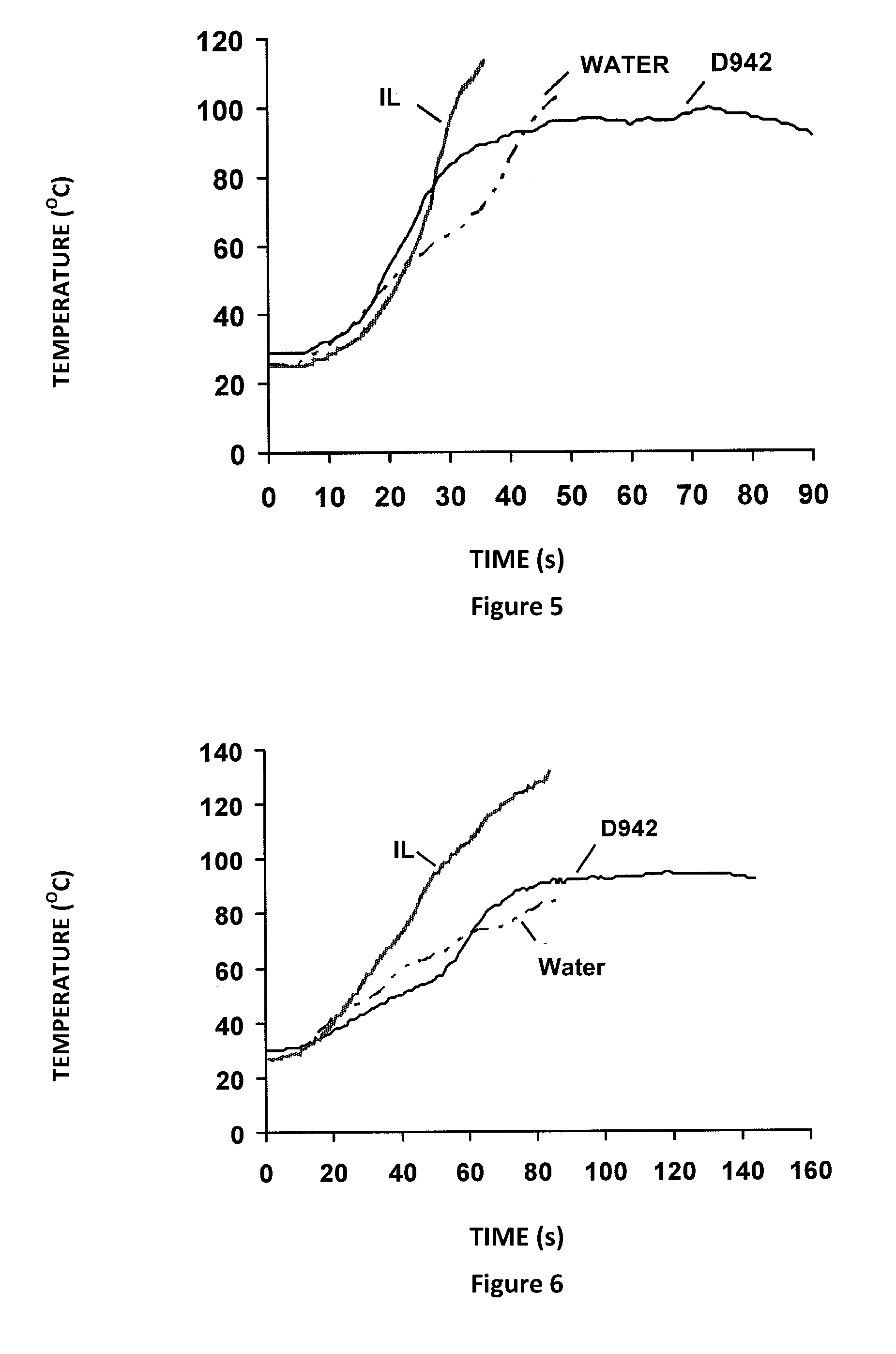

A process for the treatment of water / oil (W / O) emulsions is described which includes the addition of an ionic liquid, under heating, to a water / oil emulsion containing between 0.5% and 85% of water per volume as a dispersion phase, until the concentration of the ionic liquid in the emulsion remains within the range of 0.01 μL / g to 100 μL / g. The ionic liquid used is a salt of a general C+ A− formula in a liquid state at temperatures below 150° C., where A− is an anion and C+ is a cation, which has at least a hydrophobic alkyl chain connected to a cation group. The heating method includes conventional heating and heating via microwaves. In the heating via microwaves, the salts of the general C+ A− formula present synergic behavior in separation efficiency in relation to conventional heating.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method of making a temperature and scratch resistant anti-sticking coating

Owner:MIELE & CIE KG

Fluid density measurement device

A device for determining a density of a fluid is described. The devices comprises a mechanical resonator, a driver / receiver unit arranged to provide an actuation to the mechanical resonator, sense a response of the mechanical resonator to the actuation, and provide an output signal representing the response; and an evaluation unit. The evaluation unit of the device is arranged to i. determine an oscillation distribution from the output signal, ii. determine a resonance frequency estimate from the oscillation distribution, and iii. determine the density of the fluid based upon the resonance frequency estimate. The device according to the invention enables a more accurate determination of the fluid density for fluids comprising immiscible components (thus forming a heterogeneous mixture), like a water-oil emulsion, or a fluid with occluded gas.

Owner:安德雷·苏斯托夫

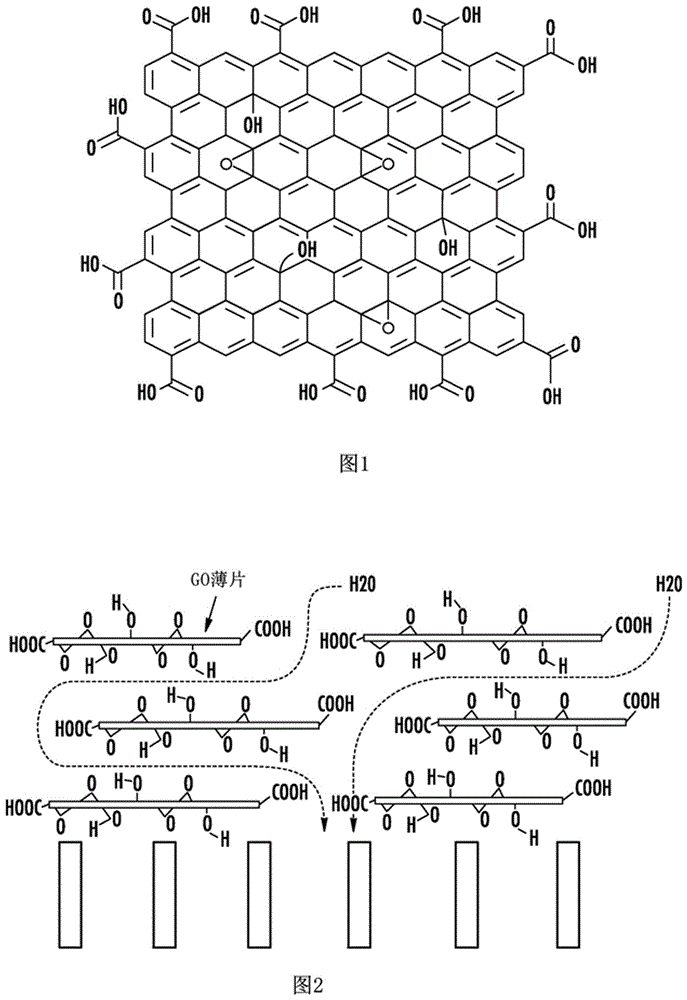

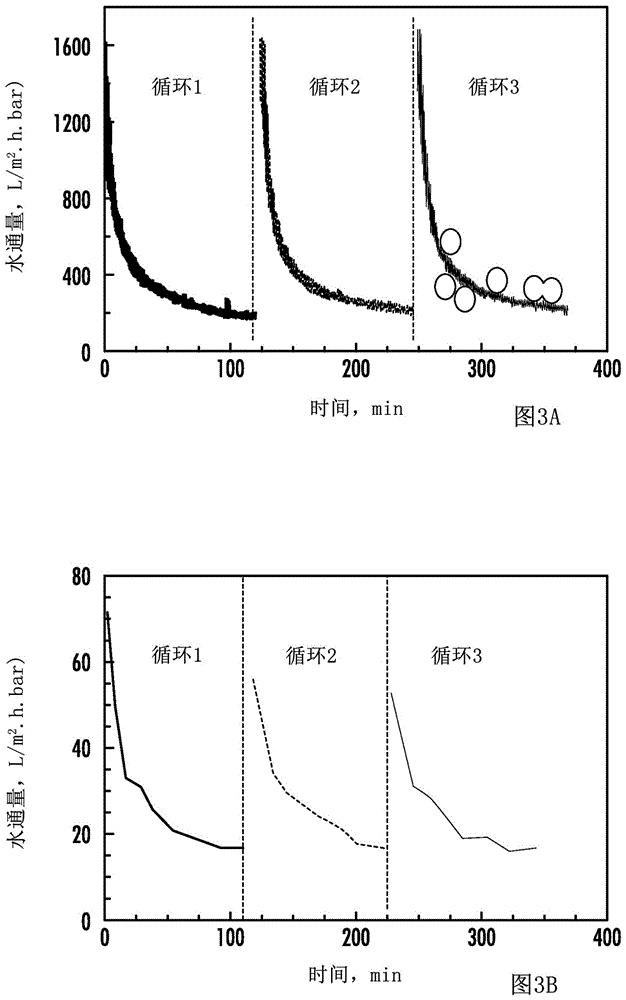

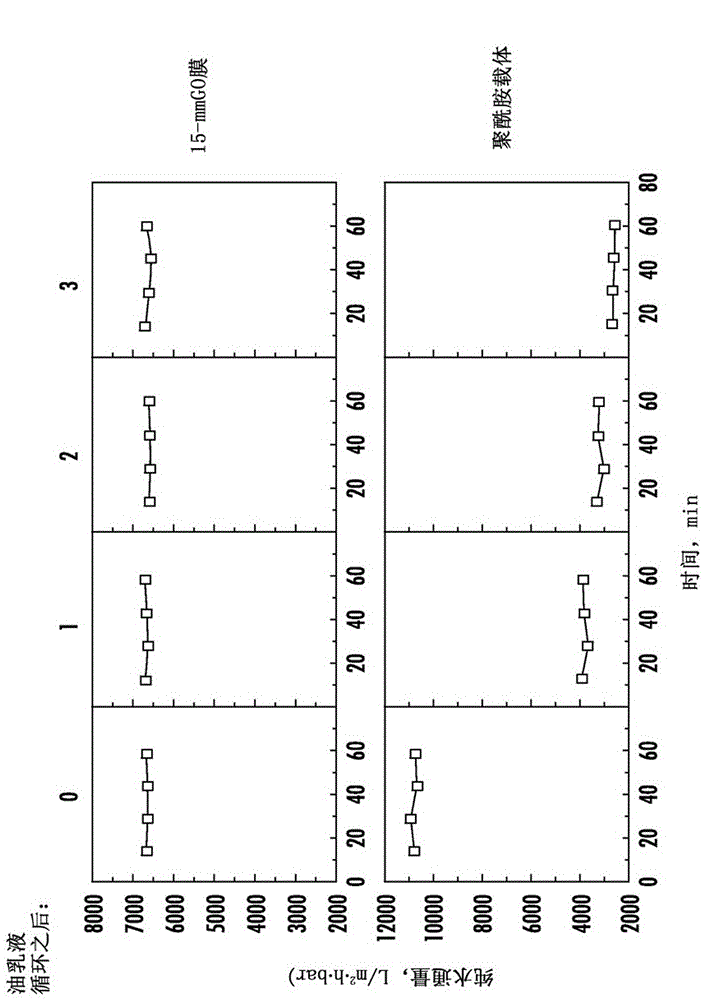

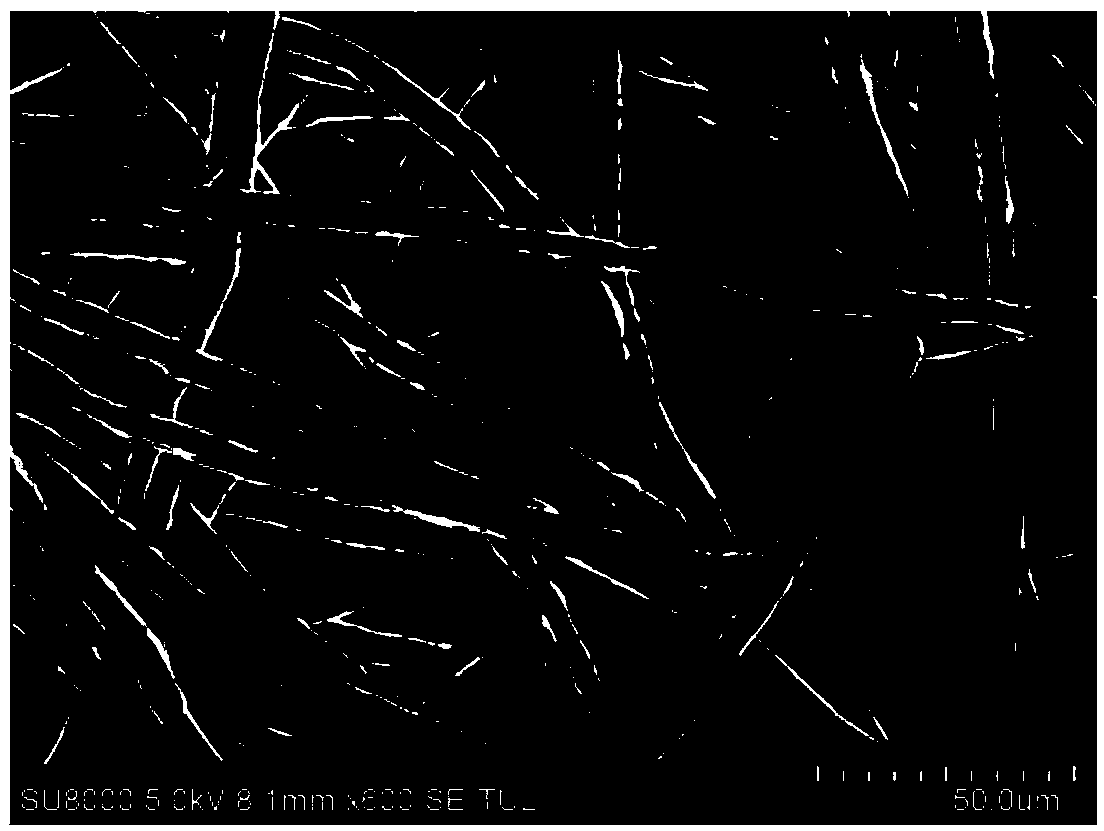

Ultrathin, graphene-based membranes for water treatment and methods of their formation and use

Methods are generally provided for forming a membrane. In one embodiment, the method includes: dispersing GO nanoparticles in a solvent; depositing the GO nanoparticles on a support to form a GO membrane; and reducing the GO membrane to form a rGO membrane. Also provided is the rGO membrane formed from such methods, along with a plurality of stacked rGO layers. Methods are also provided for separating water from a water / oil emulsion by, for example, passing water through the rGO membrane.

Owner:UNIVERSITY OF SOUTH CAROLINA

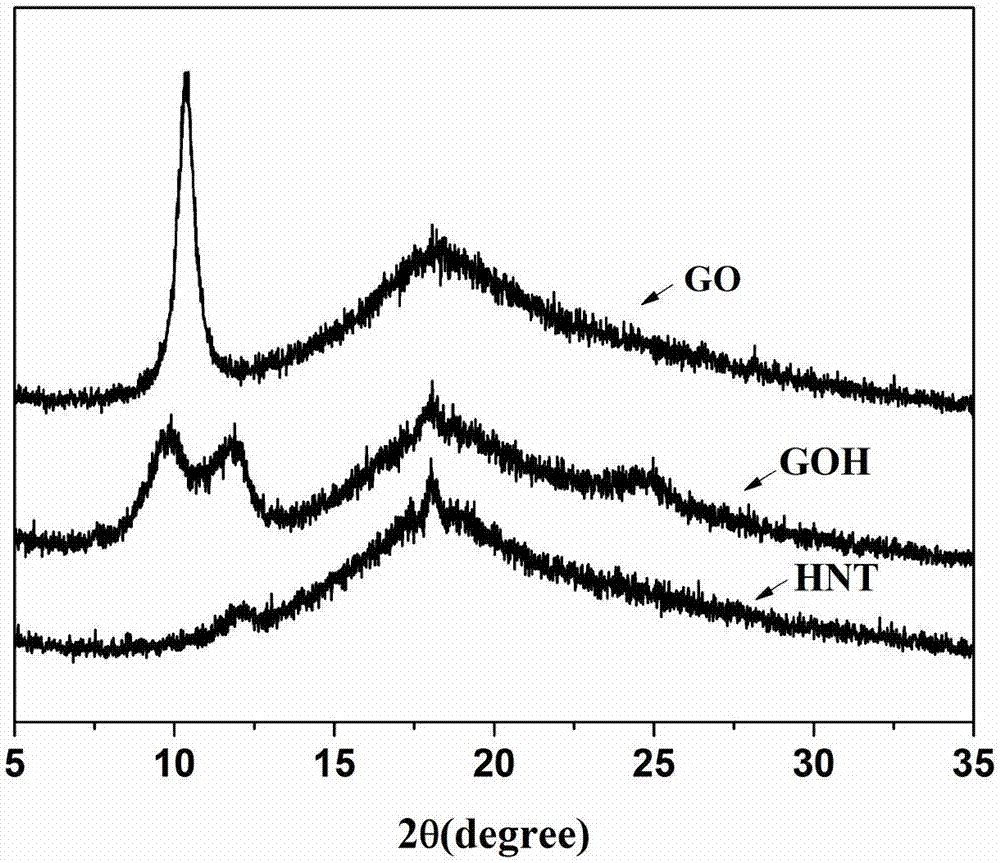

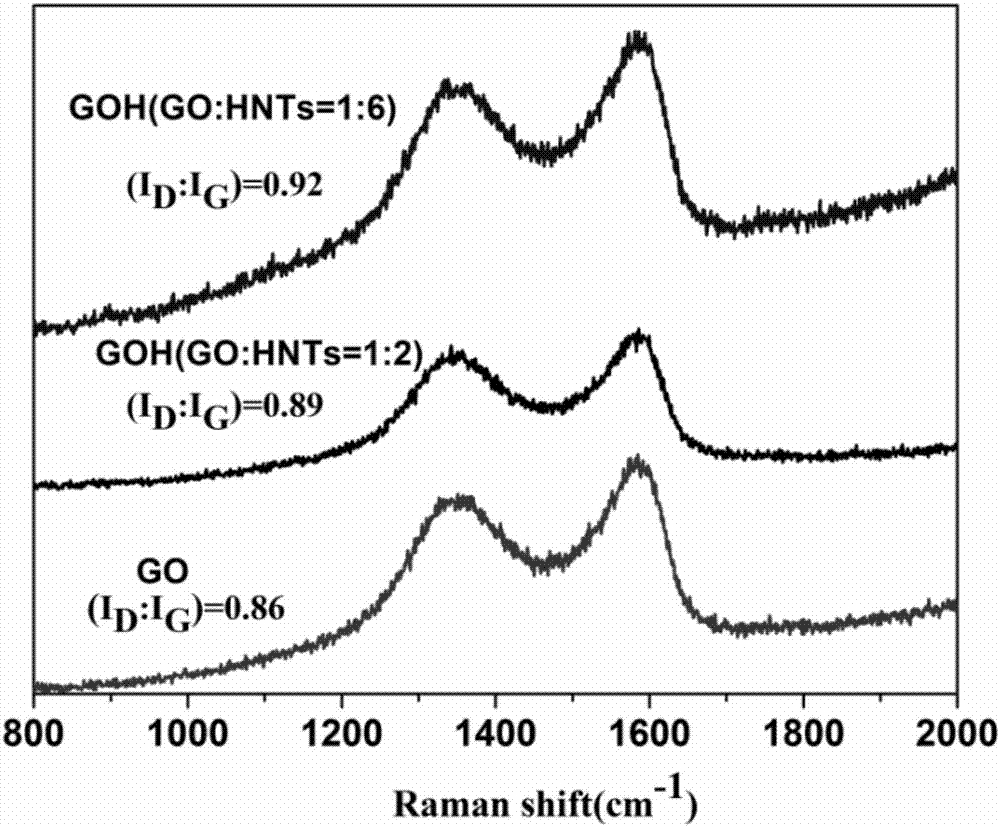

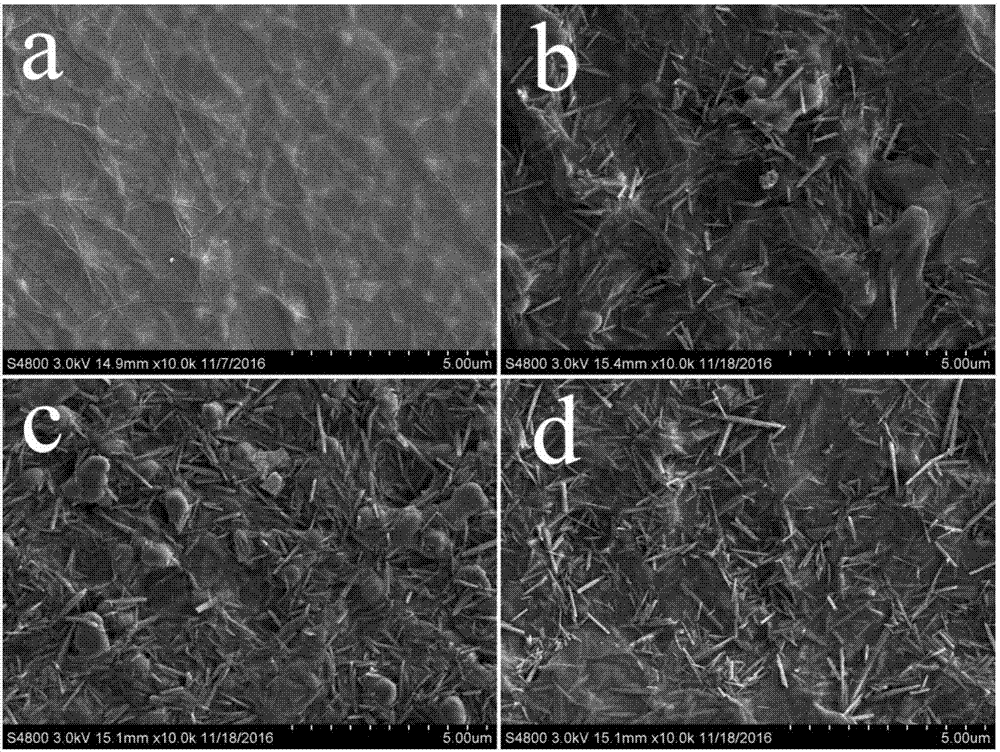

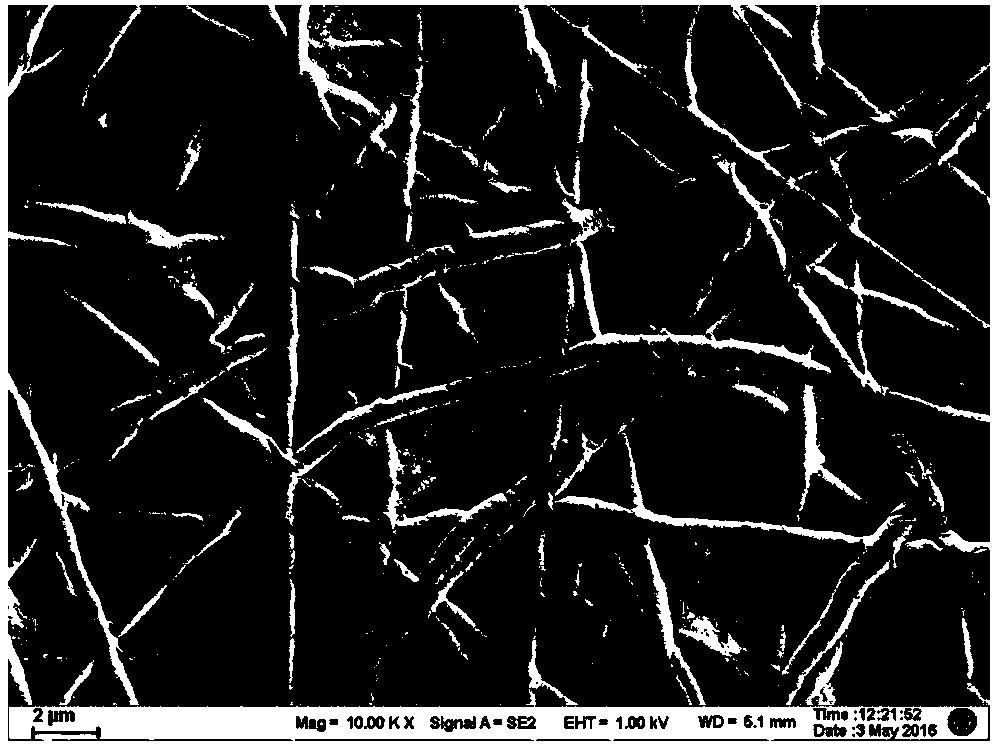

Preparing method of high-performance graphene oxide/halloysite nanotube composite water-oil separation film

InactiveCN107138048AHigh water fluxImprove antifouling performanceSemi-permeable membranesMembranesHalloysiteFiltration

The invention discloses a preparing method of high-performance graphene oxide / halloysite nanotube composite water-oil separation film. The preparing method is characterized by comprising the steps of firstly preparing lamella graphene oxide through an improved Hummer method, purifying a halloysite nanotube through acid treatment, then mixing the lamella graphene oxide and the halloysite nanotube into a composite solution, and then adopting a vacuum filtration method to make the composite solution into film through suction filtration to prepare the graphene oxide / halloysite nanotube composite water-oil separation film. In the prepared high-performance graphene oxide / halloysite nanotube composite water-oil separation film, the halloysite nanotube is introduced, the water flux can be greatly increased, and the anti-dirt performance is improved at the same time; meanwhile, the high-performance graphene oxide / halloysite nanotube composite water-oil separation film has a good separation effect on water-oil emulsion.

Owner:ANHUI UNIVERSITY

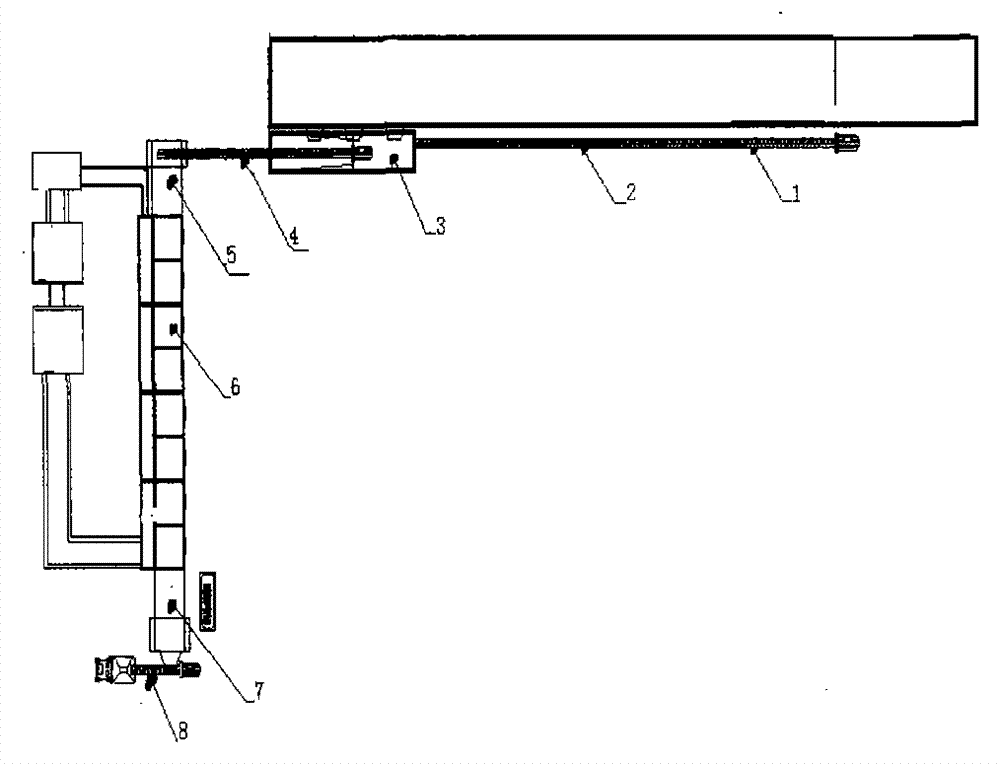

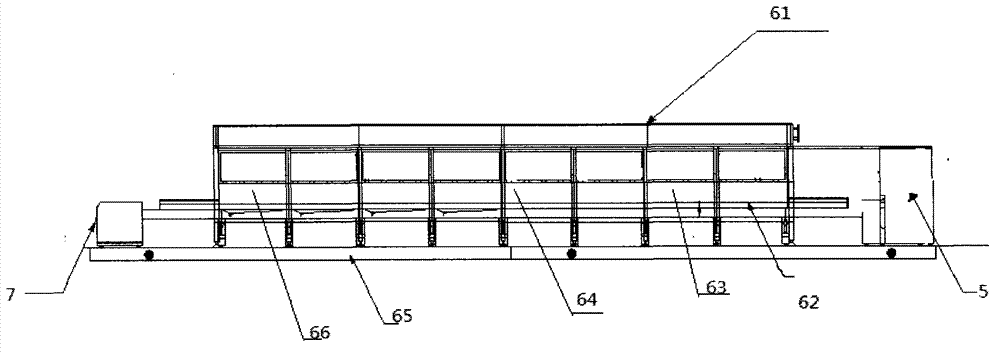

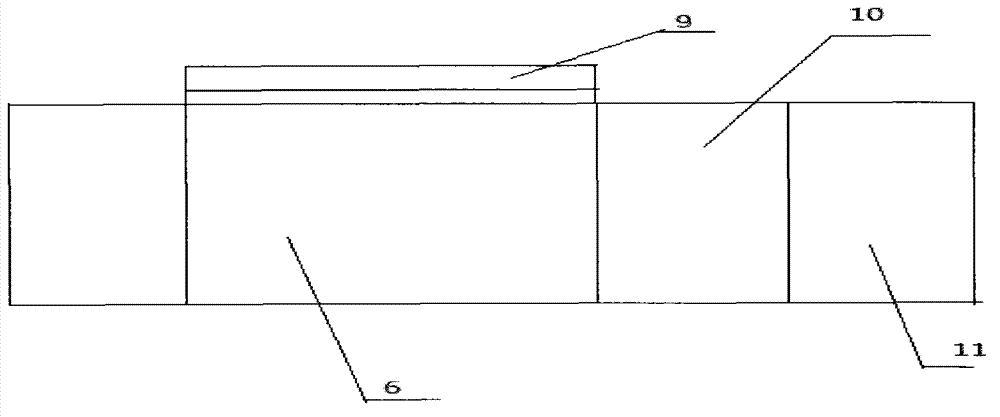

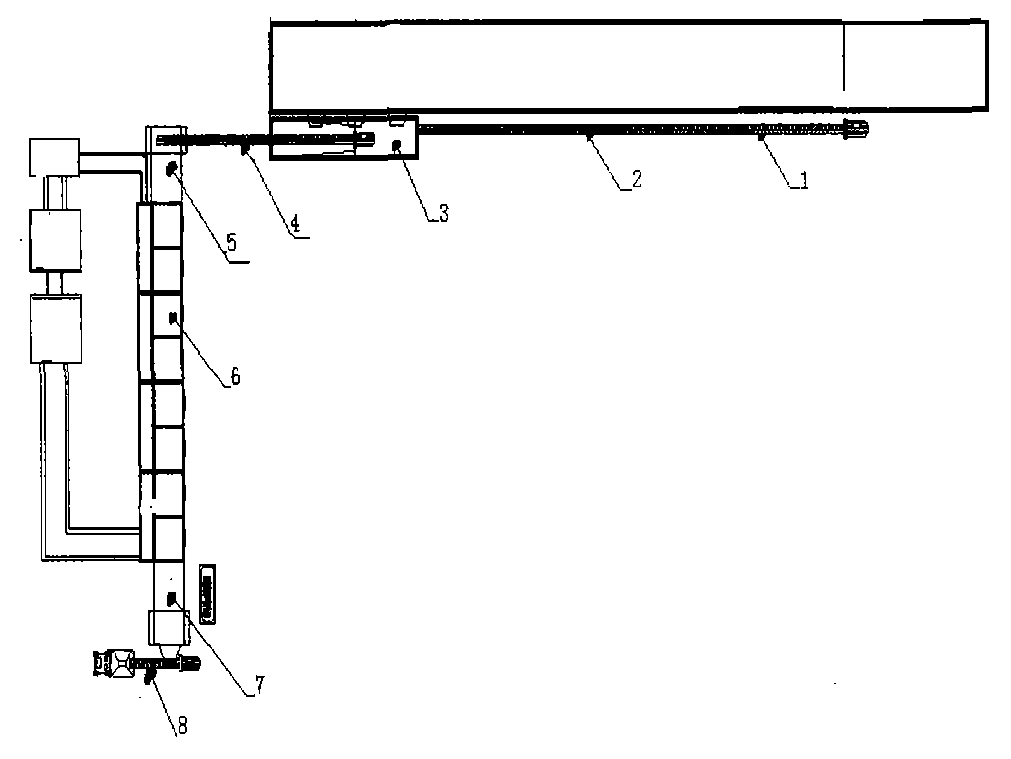

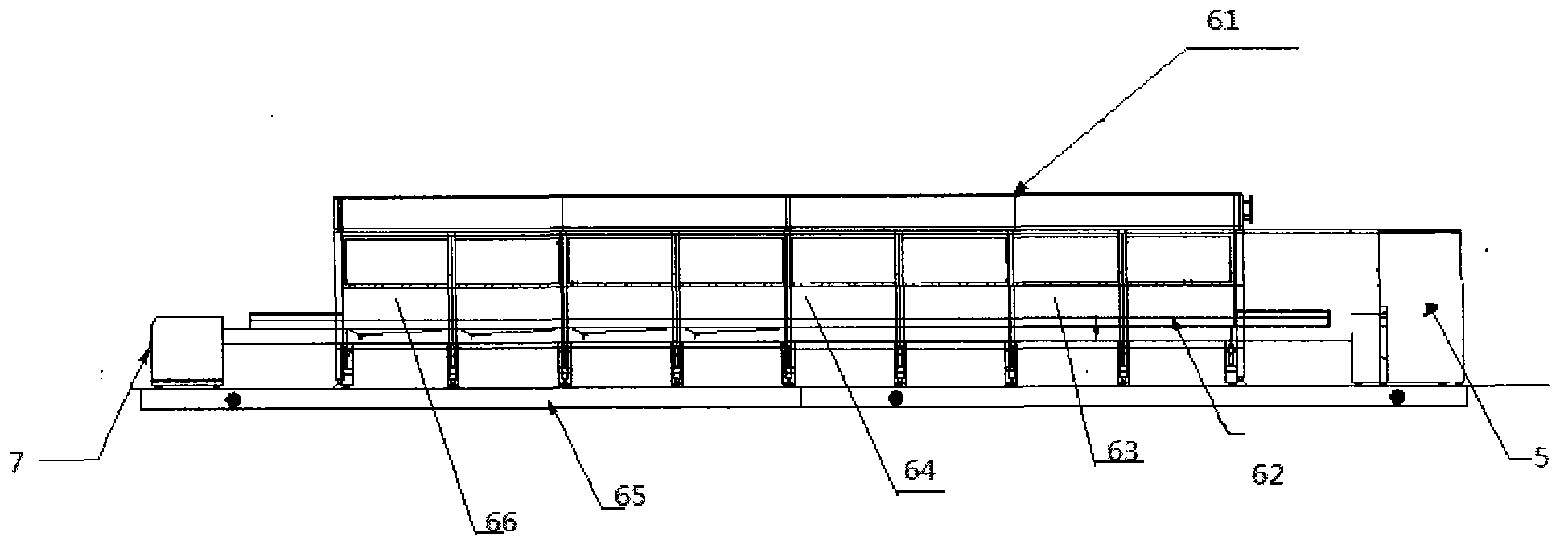

Electromagnetic treatment system and method for oil base drilling fluid waste

ActiveCN102826729AReasonable wayEasy to transportSludge treatment by de-watering/drying/thickeningSludgeResource utilization

The invention relates to a treatment system and a method for drilling fluid waste, in particular to an electromagnetic treatment system and a method for oil base drilling fluid waste. Comprehensive thermal effect of light wave, electromagnetic wave and microwave is utilized for demulsification separation of water-oil emulsion in oily sludge, drying, dewatering and vaporization of waste oil, and resource utilization of oil, water and residue can be realized. Oil contents in drilling cuttings and waste are decreased under two percent, and the national standards are reached. The pollution problem of oil base drilling fluid waste is elegantly resolved on the one hand, and the waste of oil base drilling fluid or synthetic base is reduced on the other.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

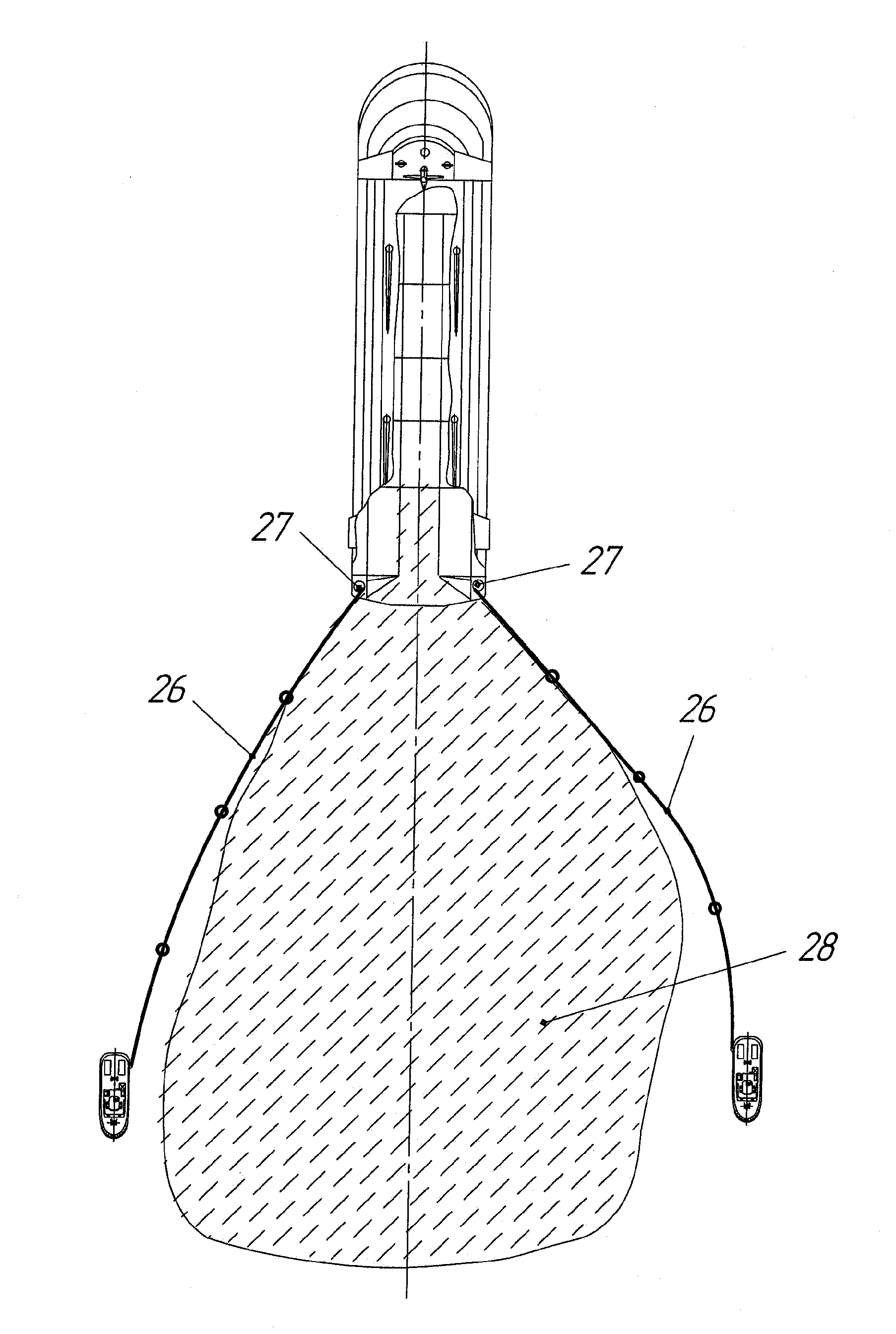

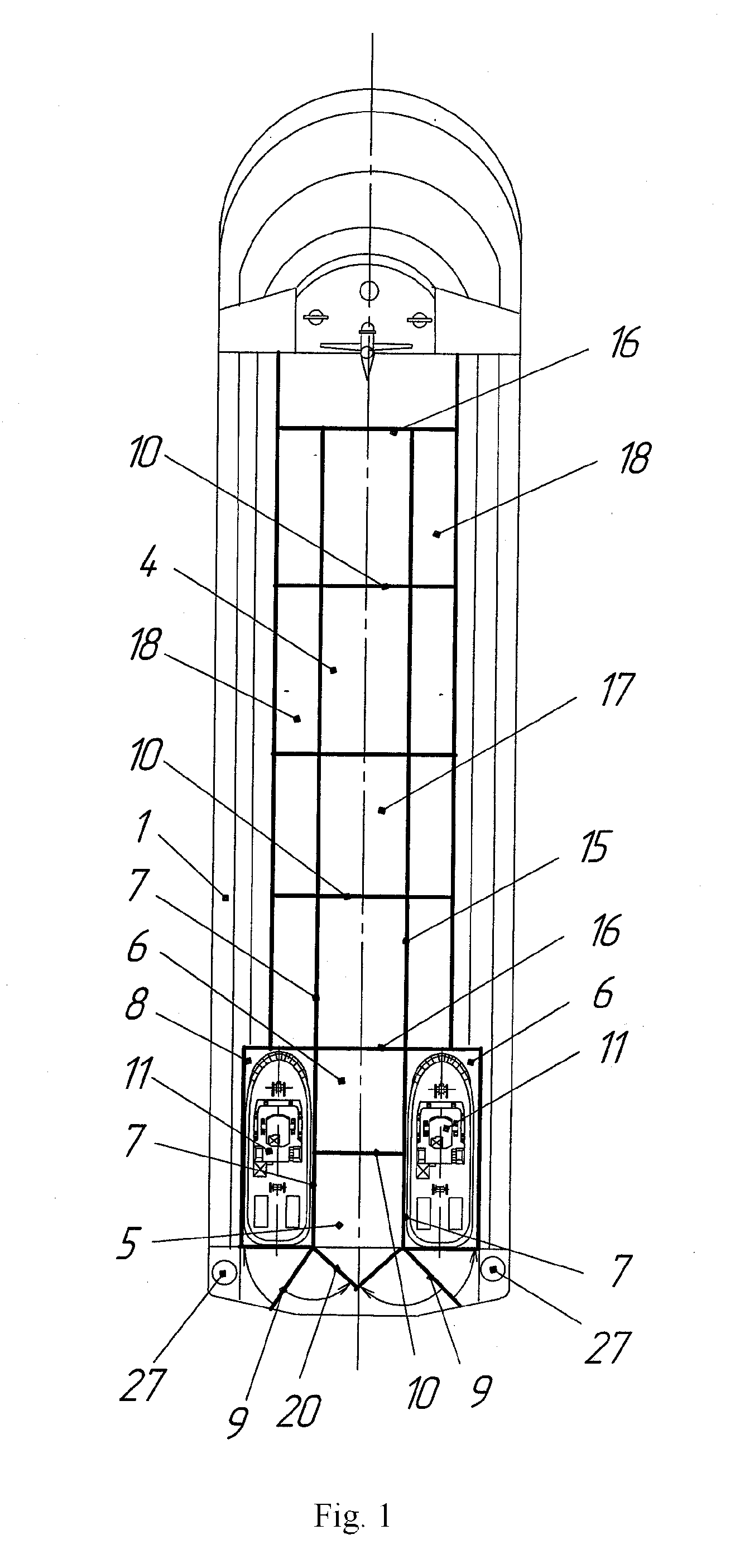

Device for skimming oil from the surface of water

InactiveUS20130313181A1Improve reliabilityImprove efficiencyWater cleaningWaterborne vesselsMarine engineeringWater oil emulsion

The dock vessel has the tow compartment for placement of tug-boats, and technological compartment. The technological compartment is made as a hangar at the bottom of which a central channel is located, along its upper boundaries, the rack-ledges with symmetrical location to the right and left, toward the hull, are placed on which the technological equipment for the water-oil emulsion treatment is placed. Between the dock-vessel hull walls and side walls of the central channel, the containers for collection of the emulsified oil are placed. The central channel of the technological compartment is equipped with, at least, two bulkheads in which, the hermetically pluggable openings located at different levels are made. The floating boom is made as the sectional net sleeve filled with elastic porous adsorbent and provided with positive buoyancy in the top edge of doubled net forming the net sleeve and negative buoyancy at its lower edge.

Owner:ZOTOV IGOR A +1

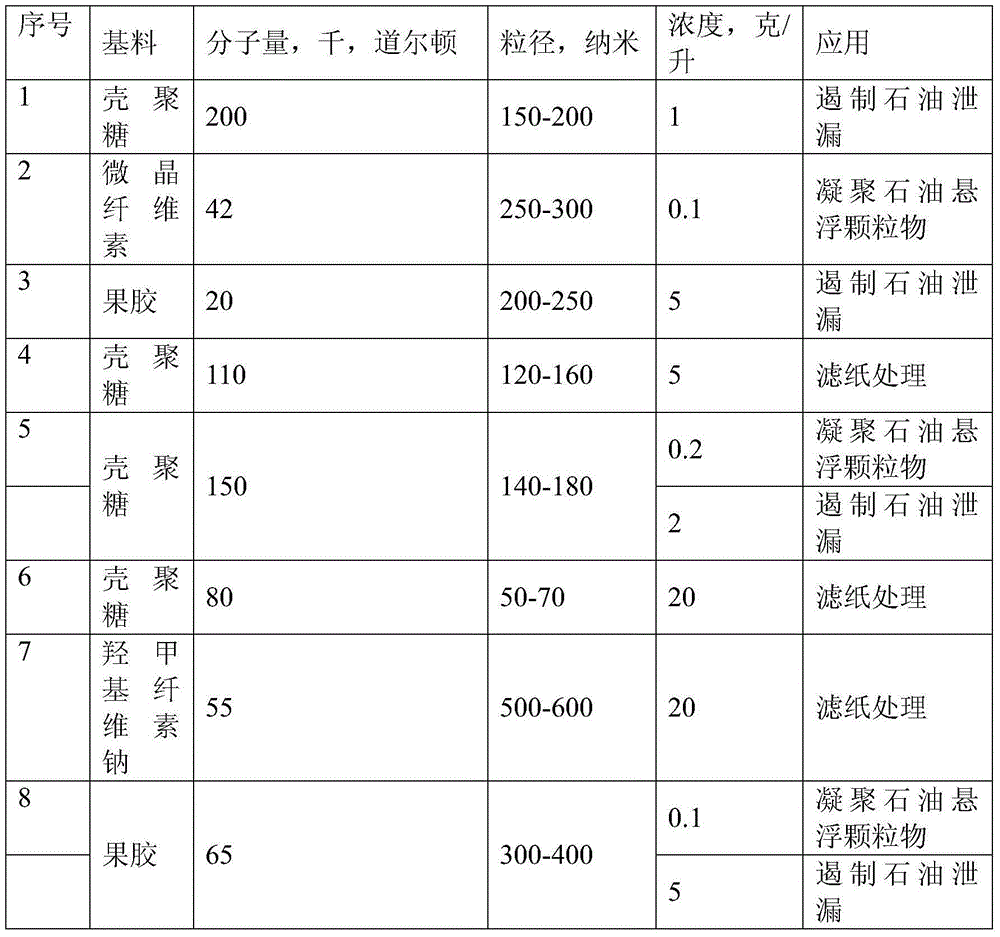

Polysaccharide microgels for cleaning water of petroleum and petroleum products and method for using same (variants)

ActiveCN104661969AImprove cleanlinessPrevent proliferationWaste water treatment from quariesGeneral water supply conservationSorbentPetroleum product

The group of inventions relates to the field of organic chemistry and can be used for cleaning water, industrial and domestic waste water or waste water sediment, and for the containment and recovery of petroleum and petroleum product spills in large bodies of water, rivers, lakes and seas. In the claimed group of inventions, aqueous solutions of polysaccharide microgels, having a molecular mass of 20000-200000 daltons and a particle size of 50-600 nm, are used as a substance for cleaning water of petroleum and petroleum products. Moreover, low concentrations of polysaccharide microgels in water, ranging from 0.1 to 20 g / l, are used. Said solutions are used as a surface modifier for a filter used in separating water-oil emulsions, as a sorbent for the containment and recovery of oil spills in an aqueous medium, and also as a coagulant for the cleaning of water polluted by petroleum and petroleum products. The technical result is in making it possible to recover a commercial product, recovered during the process of cleaning water of petroleum or petroleum products, and to recover the starting substance for the reuse thereof, while simultaneously simplifying the slurry utilization process.

Owner:尼波比奥米克罗格利有限责任公司

Method for controlling fluid interface level in gravity drainage oil recovery processes with crossflow

Owner:NOETIC TECH INC

Process, method, and system for removing heavy metals from fluids

InactiveUS8728303B2Waste water treatment from quariesWater contaminantsWater oil emulsionOxidizing agent

Trace element levels of heavy metals in crude oil are reduced by contacting the crude oil with an oxidizing agent, extracting heavy metals into a water phase for subsequent separation from the crude oil. The oxidizing agent is selected from the group of hydroperoxides, organic peroxides, inorganic peracids and salts thereof, organic peracids and salts thereof, and ozone. In one embodiment, the oxidizing agent converts heavy metals into the heavy metal cations in a water-oil emulsion, which can be subsequently separated from the crude oil, for a treated crude oil having reduced levels of heavy metals. In one embodiment, at least a complexing agent can be added to facilitate the removal by forming soluble heavy metal complexes in the water phase.

Owner:CHEVROU USA INC

Process, method, and system for removing heavy metals from fluids

InactiveUS20120125816A1Reduce heavy metal concentrationReduced heavy metal levelWaste water treatment from quariesWater contaminantsOil emulsionEnvironmental engineering

Trace element levels of heavy metals in crude oil are reduced by contacting the crude oil with an oxidizing agent, extracting heavy metals into a water phase for subsequent separation from the crude oil. The oxidizing agent is selected from the group of hydroperoxides, organic peroxides, inorganic peracids and salts thereof, organic peracids and salts thereof, and ozone. In one embodiment, the oxidizing agent converts heavy metals into the heavy metal cations in a water-oil emulsion, which can be subsequently separated from the crude oil, for a treated crude oil having reduced levels of heavy metals. In one embodiment, at least a complexing agent can be added to facilitate the removal by forming soluble heavy metal complexes in the water phase.

Owner:CHEVROU USA INC

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS9555345B2Liquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

Water-in-oil emulsions with anionic groups, compositions, and methods

Owner:SOLVENTUM INTELLECTUAL PROPERTIES CO

Oil-in-water emulsion having improved sensory properties

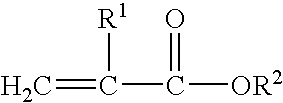

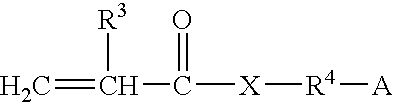

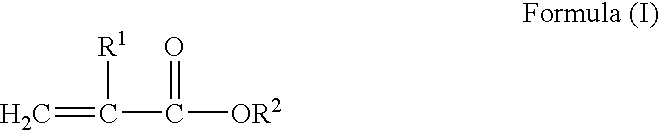

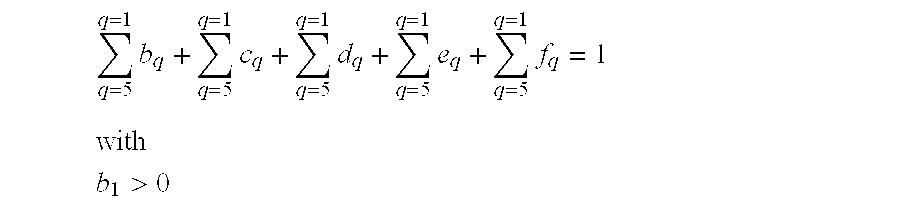

An oil-in-water emulsion includes, for 100 wt % thereof: a) 0.1 to 10 wt % of an emulsifying system including, for 100 wt % thereof: (i) 5 to 95 wt % of the mixture of the reaction products of a reducing sugar and 1,12-octadecanediol essentially consisting of hydroxyl-octadecyl polyglycosides of formula (I): HO—R—O-(G)n-H (I) and of polyglycosyl octadecyl polyglycosides of formula (II): H-(G)m-O—R—O-(G)p-H (II), where, in formulas (I) and (II), G is the remainder of the reducing sugar and R is the divalent radical octadecane-diyl-1,12, and where n, m and p, identical or different, each are, independently of each other, a decimal number between 1 and 5; (ii) 95 to 5 wt % of 1,12-octadecanediol; b) 0.01 to 5 wt % of at least one thickening and / or gelling agent; c) 10 to 50 wt % of an oil phase; and d) 89.89 to 35 wt % of an aqueous phase.

Owner:SOC DEXPLOITATION DE PROD POUR LES IND CHEM SEPPIC

Preparation method of submicron-grade scandium oxide

The invention provides a preparation method of submicron-grade scandium oxide. The preparation method comprises the steps that a first carboxylic acid extraction agent-organic solvent mixed solution and ammonia conduct a first saponification reaction, and thus first water-oil emulsion is obtained; a scandium ion-containing solution is subjected to extraction treatment through the first water-oil emulsion, and thus a scandium-loaded organic phase is obtained; a second carboxylic acid extraction agent-organic solvent mixed solution and a sodium hydroxide aqueous solution conduct a second saponification reaction, and thus second water-oil emulsion is obtained, wherein the dosage of the added sodium hydroxide aqueous solution is more than that of the second carboxylic acid extraction agent-organic solvent mixed solution; the scandium-loaded organic phase and the second water-oil emulsion conduct a precipitation reaction to obtain a scandium hydroxide precipitate; and the scandium hydroxideprecipitate is calcined, and thus the submicron-grade scandium oxide is obtained. According to the method, the size and shape of scandium hydroxide microparticles can be effectively controlled, and accordingly submicron-grade scandium oxide powder is obtained.

Owner:CHINA ENFI ENGINEERING CORPORATION

Water-in-oil emulsion comprising pigments in the water phase

ActiveUS20140178320A1High color intensityEvenly dispersed pigmentCosmetic preparationsHair cosmeticsOil emulsionDiol

Provided is a composition and especially a cosmetic composition comprising: A) an oily phase and B) an aqueous phase which comprises: a) water, b) a pigment, c) a modified phospholipid, and d) an alkyl substituted diol comprising 5 or more carbons; wherein the composition is in the form of an water-in-oil emulsion, and wherein the pigment essentially remains in the water phase. Also provide is a method of producing the composition which comprises: 1) obtaining a mixture of a modified phospholipid and an alkyl substituted diol comprising 5 or more carbons in the alkyl chain; 2) obtaining a mixture of water and a pigment; 3) combining the mixture of the modified phospholipids and the alkyl substituted diol with the mixture of the pigment and water; 4) obtaining an oil composition; and 5) combining the mixture from 3) with the oil composition of 4) to form an water-in-oil emulsion.

Owner:LOREAL SA

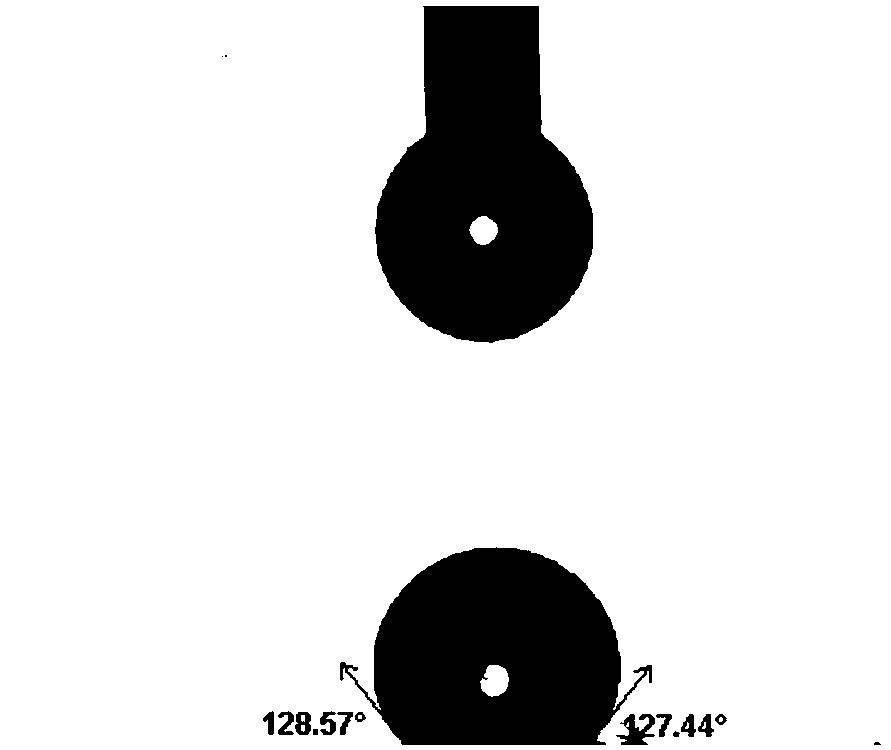

Coalescence material for emulsified water as well as preparation method and application of coalescence material

InactiveCN110743202AGood for coalescence and separationImprove separation efficiencyNon-miscible liquid separationPolymer scienceOil emulsion

The invention relates to a coalescence material for emulsified water as well as a preparation method and application of the coalescence material. The coalescence material for the emulsified water includes a substrate and a fluorine-containing polyurethane coating layer coating the surface of the substrate. The fluorine-containing polyurethane coating layer of the coalescence material contains a hydrophobic fluorine-containing chain segment and a hydrophilic chain segment, thereby having hydrophobic and lipophilic characteristics in the air; the contact angle between the fluorine-containing polyurethane coating layerandwater drops is 100-120 degrees, the contact angle between the fluorine-containing polyurethane coating layerandoil drops is 50-80 degrees, the contact angle of water under oil changes dynamically and decreases from 120-150 degrees to 50-80 degrees within 2 min, so that favorable conditions are provided for demulsification mixingof liquid drops in a water-oil emulsion, andcompared with other fluorocarbon materials in the prior art, the coalescence material provided by the invention has a significantly better coalescence and separation effect on the emulsified water; and the coalescence material is suitable for the separation of the water-oil emulsion containing different types and different concentrations of surfactants, and the water-oil separation efficiency isas high as 91-98%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

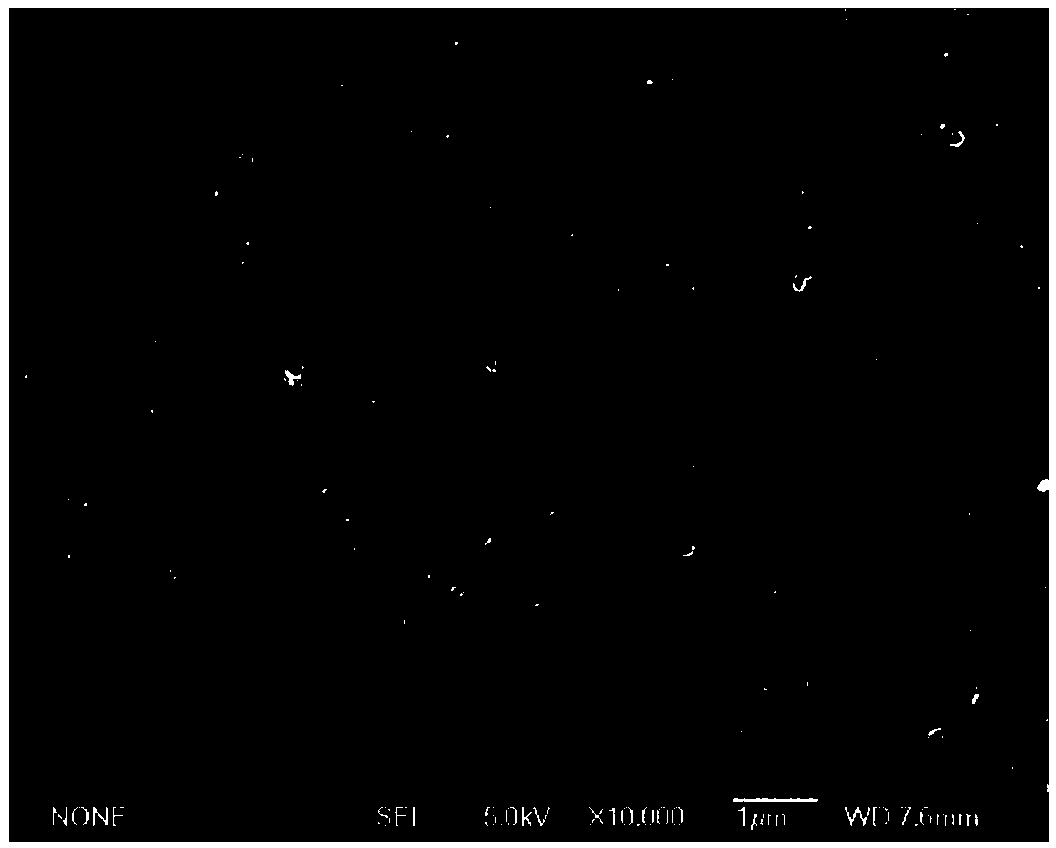

Nanofiber membrane for water-oil emulsion separation and preparing method thereof

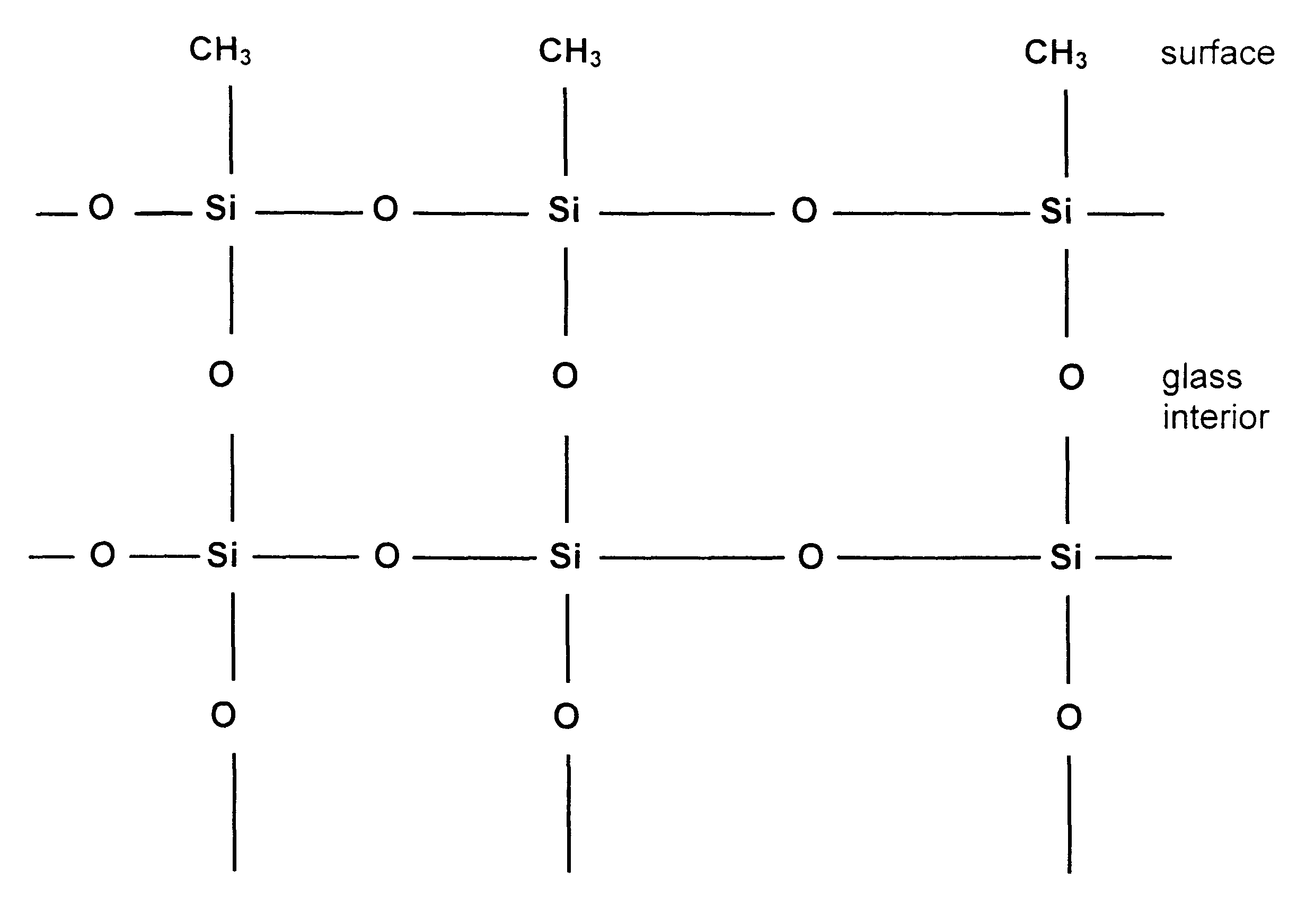

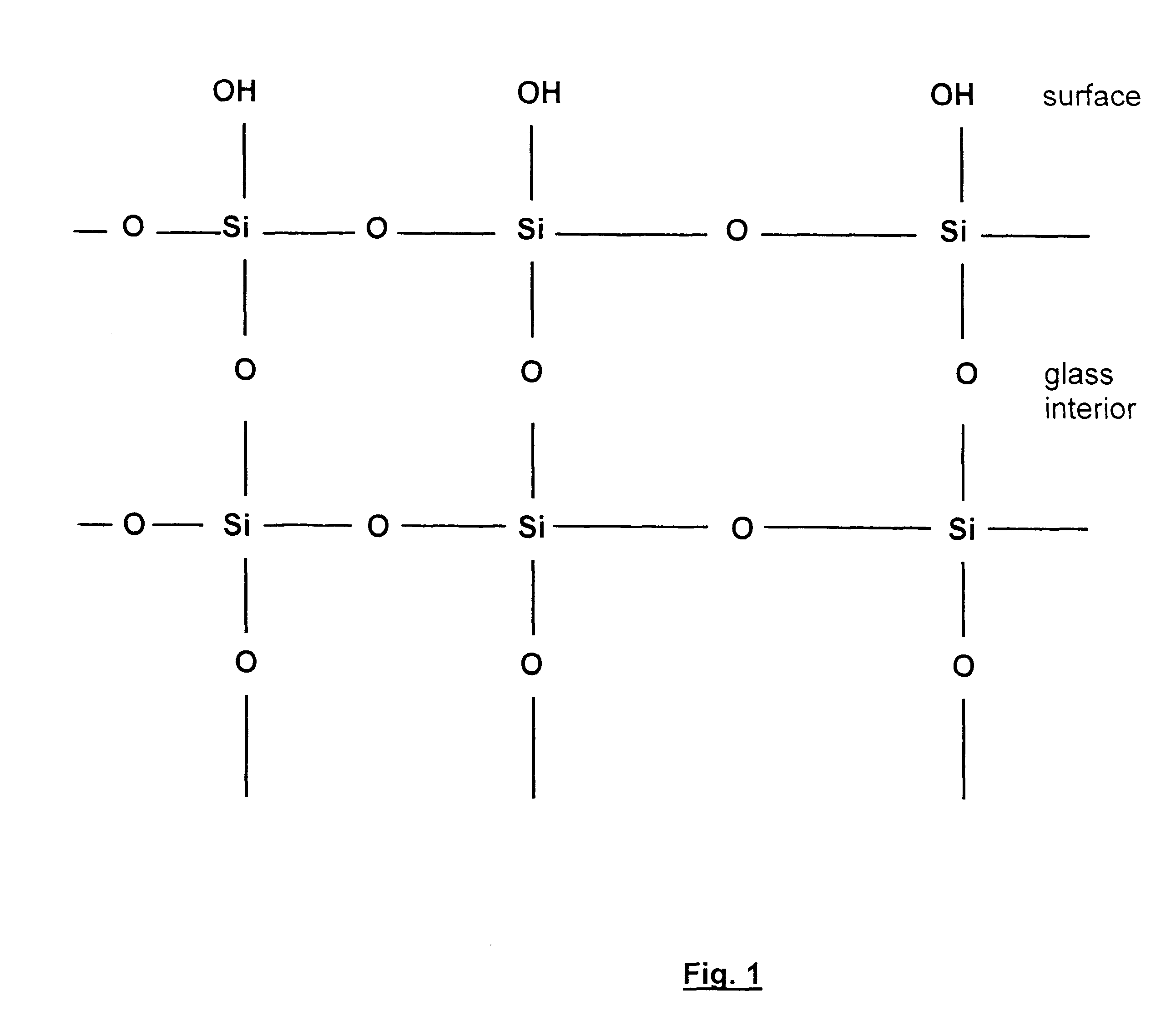

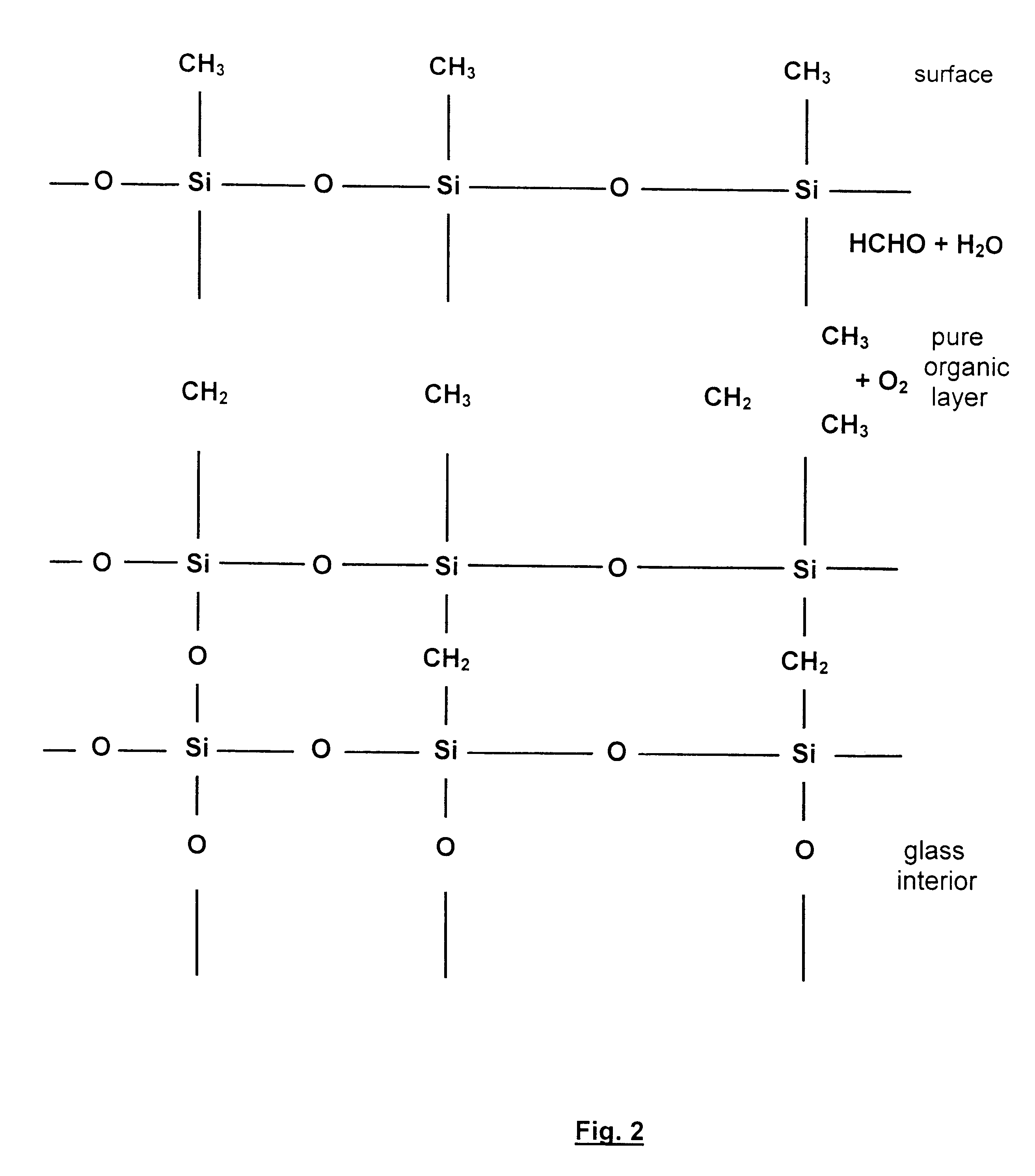

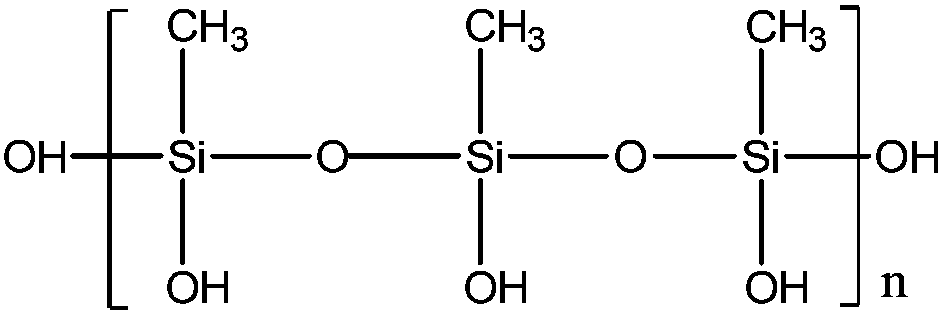

The invention discloses a nanofiber membrane coated with polymethylsilicate for water-oil emulsion separation and a preparing method thereof. The method includes the following steps of preparing a polymer solution, preparing a nanofiber membrane through static spinning, soaking the prepared nanofiber membrane in a potassium methyl silicate solution, adjusting the pH of the solution to be about 7 with acid under the ultrasonic condition, and conducting drying to prepare the nanofiber membrane coated with polymethylsilicate. The surface of the nanofiber membrane is coated with a layer of polymethylsilicate, so emulsified water-oil drops can be broken during water-oil filtering, and the water-oil separation efficiency and the repeated utilization rate are increased; on the other hand, the surfaces of nanofiber are coated with polymethylsilicate, so the use intensity of the filtering membrane is improved; the preparing method has the advantages of being easy to operate, low in cost, easy to control in the process and the like.

Owner:NANJING UNIV OF SCI & TECH

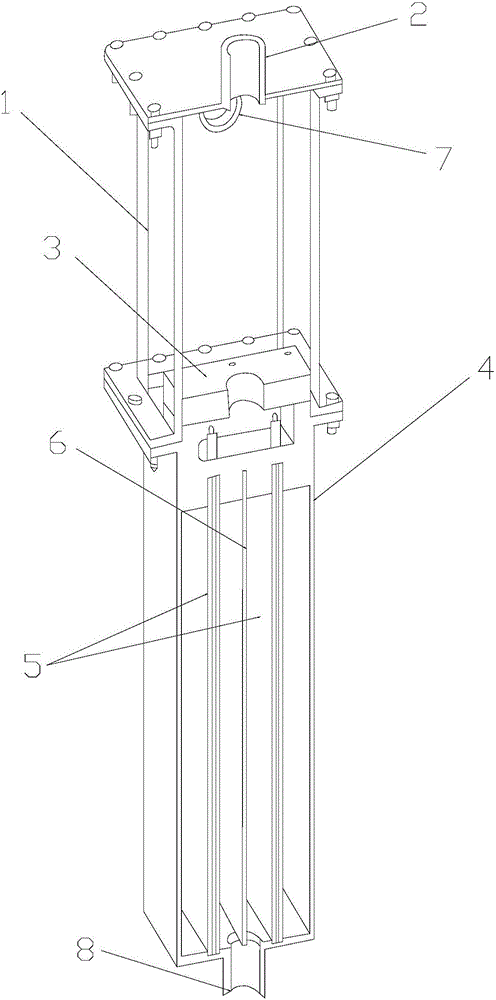

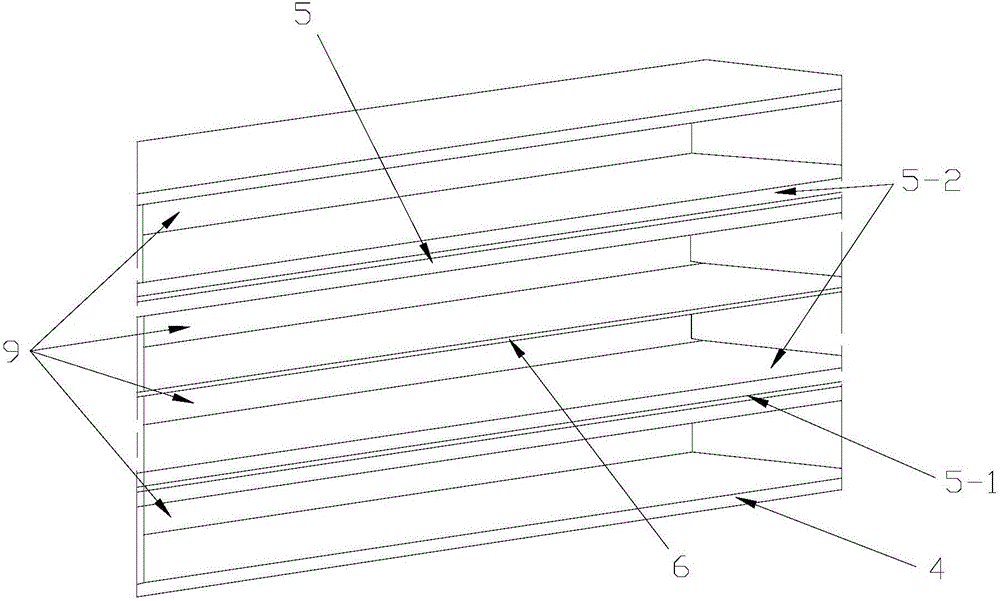

Plate electrode static coalescer

InactiveCN105802660AImprove separation efficiencyFast solutionLiquid separation by electricityDewatering/demulsification with electric/magnetic meansTransformerEngineering

The invention relates to the technical field of static coalescers, in particular to a plate electrode static coalescer.The late electrode static coalescer is characterized in that the upper portion of the coalescer is a high-voltage electricity input section, the lower portion of the coalescer is a coalescing section, the high-voltage electricity input section is provided with an observation chamber made of insulating organic glass, the upper end of the observation chamber is provided with a high-voltage insulating wire inlet, the bottom of the observation chamber is provided with an insulating wiring groove, a stainless steel shell is arranged below the observation chamber, the shell and an insulating electrode and a bare electrode which are located in the shell form the coalescing section, and the insulating electrode is connected with the high-voltage end of an external transformer through the insulating wiring groove and the high-voltage insulating wire inlet.The plate electrode static coalescer has the advantages that the speed of water-oil emulsion passing the coalescer becomes low, the staying time of the water-oil emulsion in an electric field becomes long, large electric field force effect is achieved, water drops in oil sufficiently collide and coalesce and are combined into large particles which are then settled, and oil-water separation efficiency is increased.

Owner:庄孟文

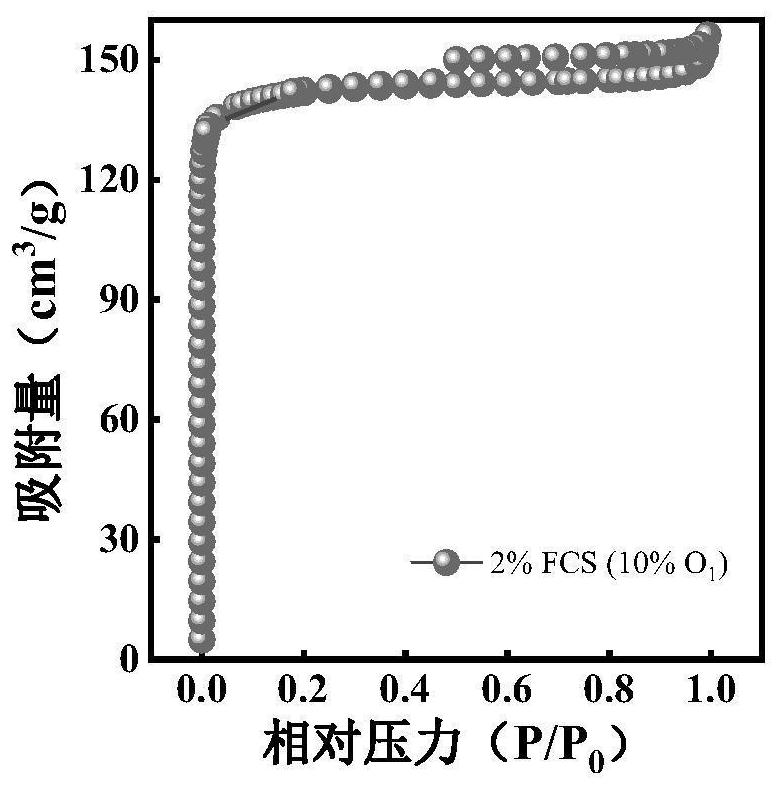

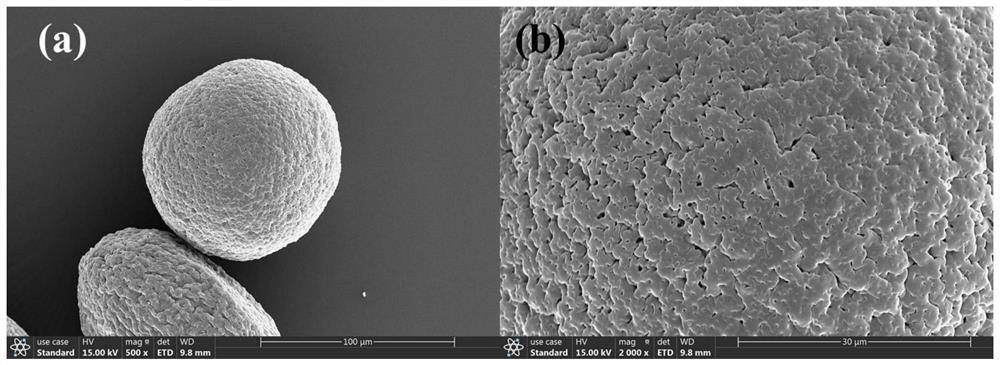

Microporous granular carbon and preparation method thereof

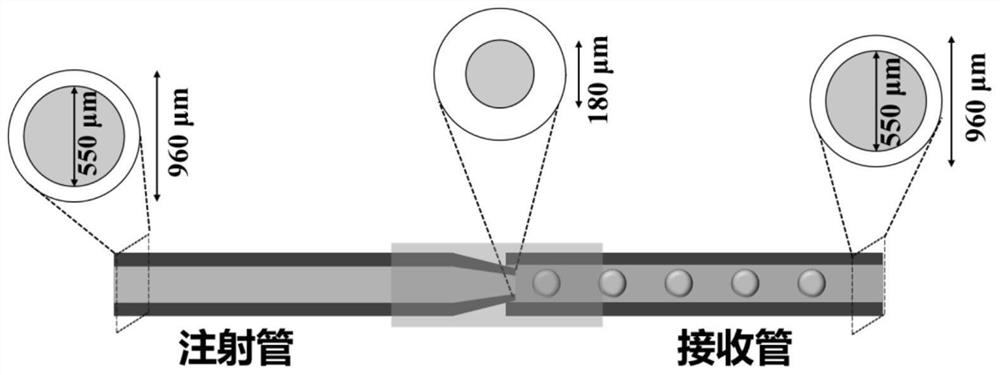

ActiveCN112169756AIncrease the content of basic functional groupsImprove adsorption capacityProductsGas treatmentOil emulsionPolyvinyl alcohol

The invention belongs to the field of environment-friendly materials, and particularly relates to microporous granular carbon and a preparation method thereof. The technical problem to be solved by the invention is to provide microporous granular carbon and the preparation method thereof. The preparation method comprises the following steps: A, emulsifying a chitosan solution or a polyvinyl alcohol solution, an oil-in-water emulsifier and an organic solvent to obtain an internal phase solution; mixing a water-in-oil emulsifier and an organic solvent to obtain an external phase solution; mixinga cross-linking agent and the external phase solution to obtain a curing bath; B, respectively injecting the internal phase solution and the external phase solution into an injection tube and a collection tube of a capillary micro-fluidic chip to form a monodisperse water-oil emulsion, and injecting the monodisperse water-oil emulsion into the curing bath to be subjected to a cross-linking reaction with the cross-linking agent to obtain particles; and C, washing, drying and carbonizing the particles to obtain the microporous granular carbon. The method can be used for obtaining the microporous granular carbon, and is simple, easy to operate and pollution-free.

Owner:SICHUAN UNIV

Electromagnetic treatment system and method for oil base drilling fluid waste

ActiveCN102826729BReasonable wayEasy to transportSludge treatment by de-watering/drying/thickeningSludgeResource utilization

The invention relates to a treatment system and a method for drilling fluid waste, in particular to an electromagnetic treatment system and a method for oil base drilling fluid waste. Comprehensive thermal effect of light wave, electromagnetic wave and microwave is utilized for demulsification separation of water-oil emulsion in oily sludge, drying, dewatering and vaporization of waste oil, and resource utilization of oil, water and residue can be realized. Oil contents in drilling cuttings and waste are decreased under two percent, and the national standards are reached. The pollution problem of oil base drilling fluid waste is elegantly resolved on the one hand, and the waste of oil base drilling fluid or synthetic base is reduced on the other.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

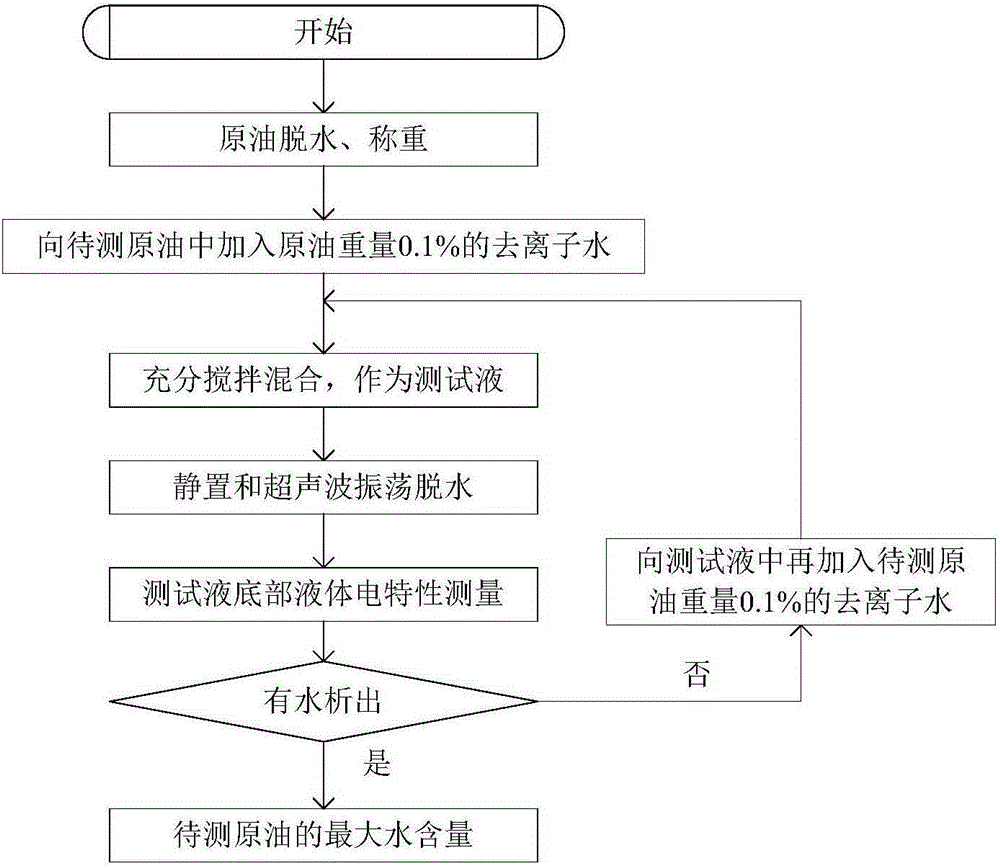

Test method for stability of water in crude oil

InactiveCN105223235ATest conditions are stableGood reproducibility of test resultsMaterial analysis by electric/magnetic meansMicroscopic observationWater oil emulsion

Relating to the technical field of crude oil corrosion prevention technologies, the invention discloses a test method for the stability of water in crude oil, and solves the problems of great difference between the test result and actual operating conditions, poor reproducibility and the like in existing oil film microscopic observation method for testing the water content of crude oil. The test method for the stability of water in crude oil specifically includes the steps of: employing a high speed centrifuge to dehydrate to-be-tested crude oil; weighing the dehydrated to-be-tested crude oil, and adding the dehydrated to-be-tested crude oil into a test bottle; adding deionized water into the to-be-tested crude oil to form an oil-water mixed solution; stirring the mixed solution for 24h by magnetic stirring to form a stable water-oil emulsion to serve as the test fluid; conducting standing for 24h, employing an ultrasonic oscillator to simulate crude oil storage and transport conditions, and carrying out dehydration operation on the test fluid; testing the electrical characteristics of a test bottle bottom solution by a test electrode, and judging whether water precipitates.

Owner:CHINA PETROLEUM & CHEM CORP +3

Spray atomization

InactiveUS7553878B2Improve atomization efficiencyThermal non-catalytic crackingCatalytic crackingWater vaporOil emulsion

The present invention provides a feedstock composition for increasing the efficiency of atomization in hydrocarbon processing that includes a water-in-hydrocarbon oil emulsion including a non-ionic surfactant capable of stabilizing the emulsion and having a hydrophilic-lipophilic balance of greater than about 12. The emulsion includes water droplets of about 5 to about 10 microns in diameter, the droplets being dispersed substantially uniformly in the hydrocarbon oil phase. These surfactants are capable of stabilizing the water-in-hydrocarbon oil emulsion under relevant temperature and pressure conditions for hydrocarbon processing. The inventive feedstock composition provides a metastable water-in-oil emulsion where expanding water vapor explodes under spray conditions where the system pressure is released, demolishing a larger oil droplet and producing smaller oil droplets.

Owner:BL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com