Device for skimming oil from the surface of water

a technology for skimming oil and water surface, which is applied in the field of skimming oil from the surface of water, can solve the problems of oil garbage disposal vessels not loss of recovered oil, and only being able to operate such equipment in calm conditions, so as to improve reliability and efficiency, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

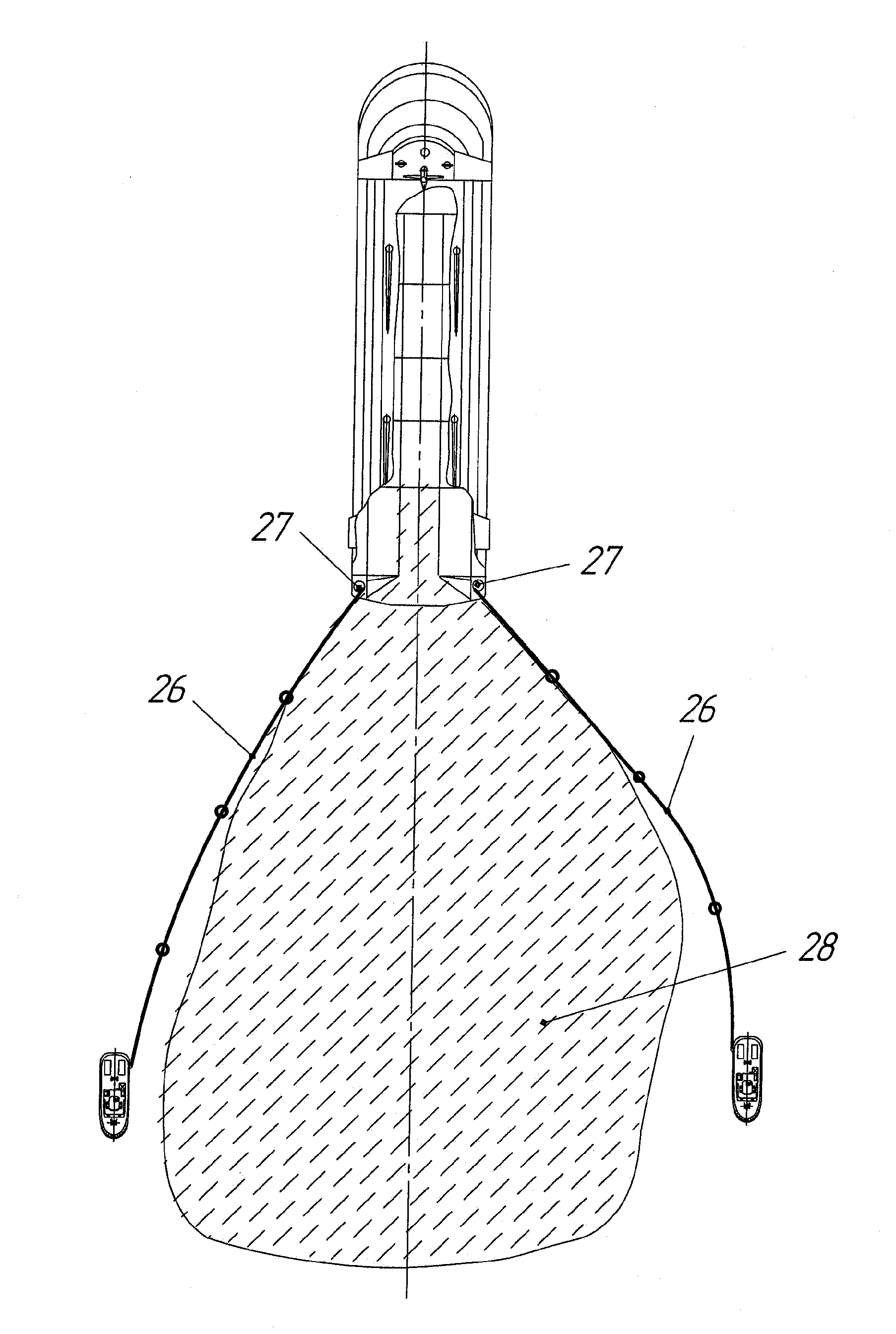

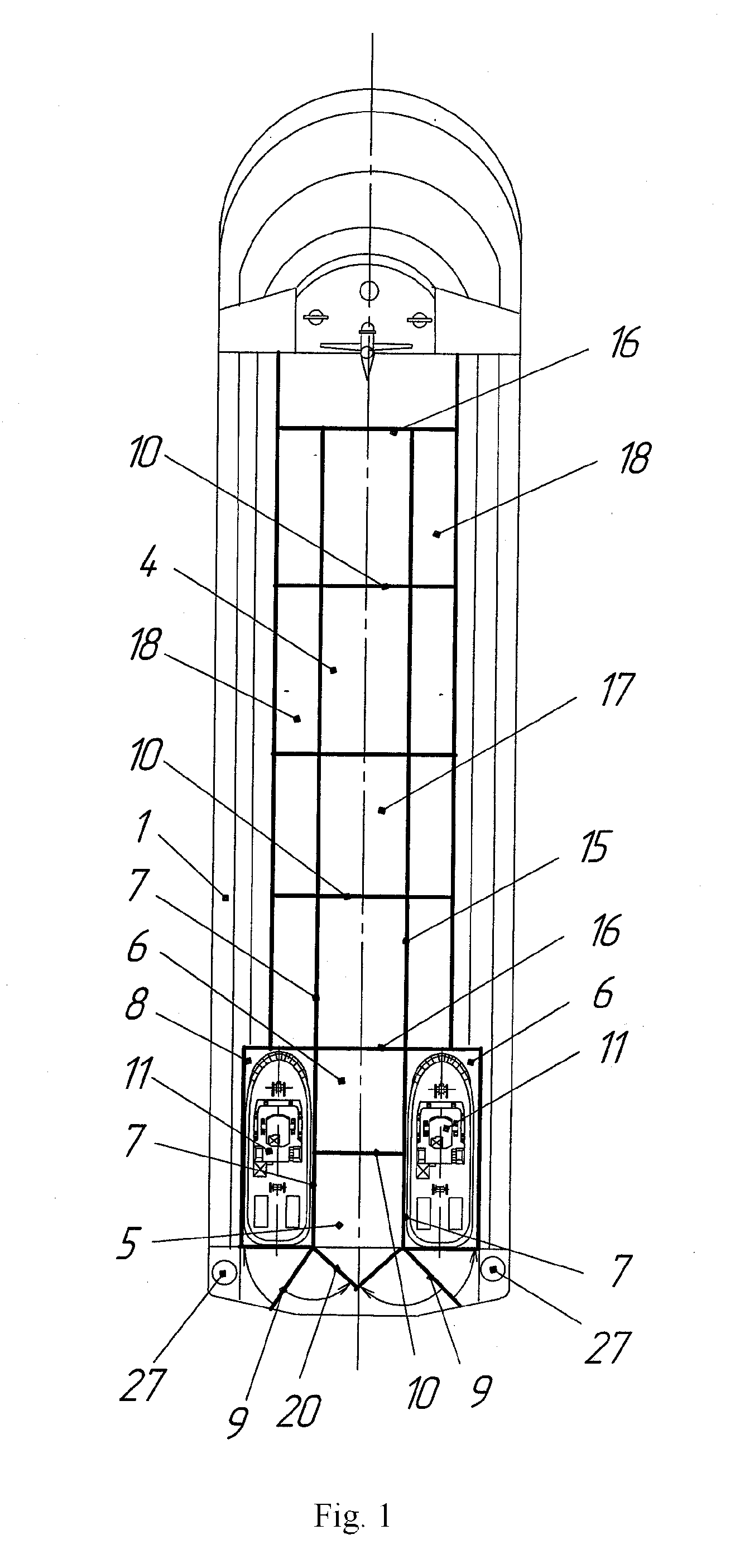

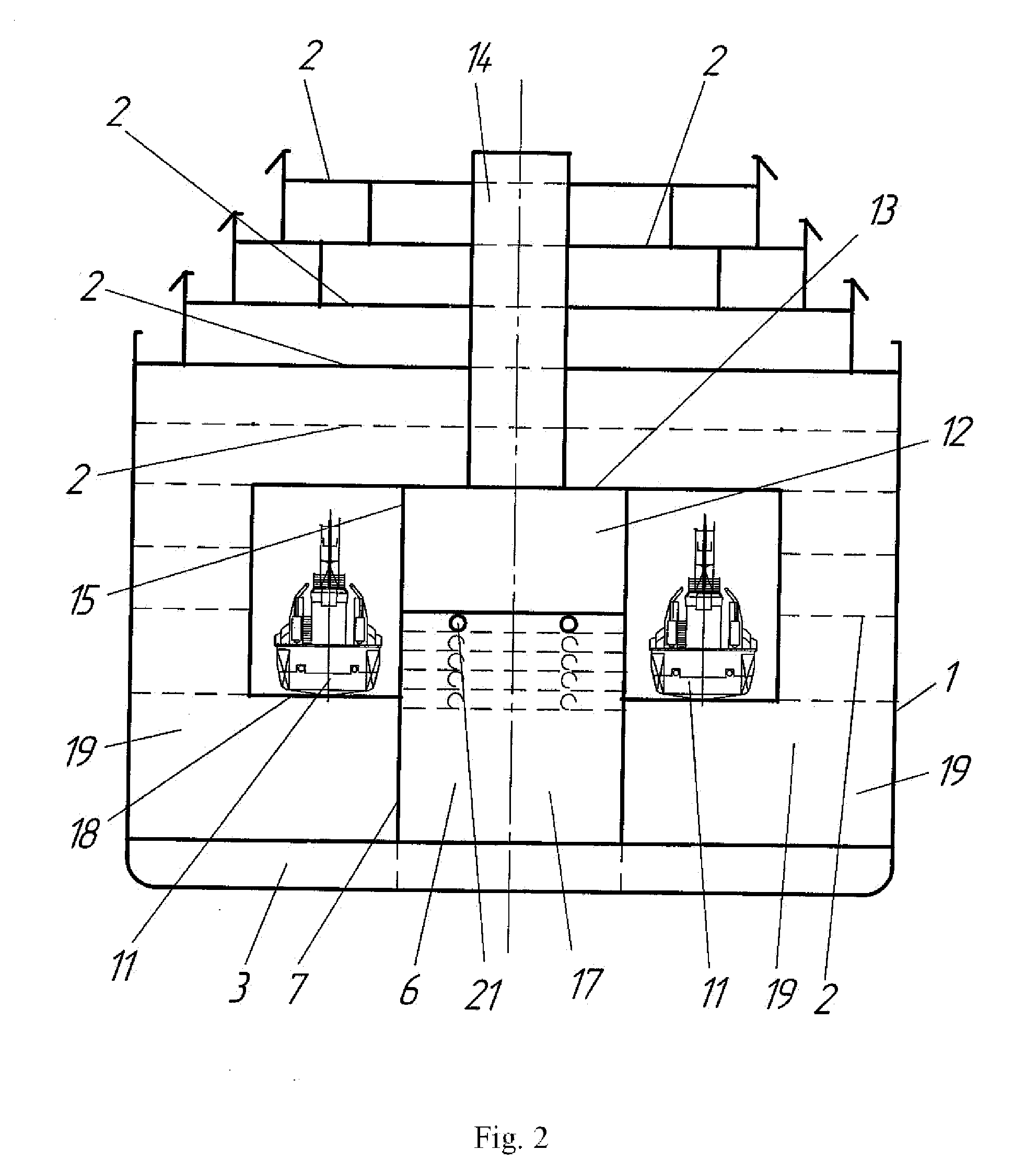

[0037]The device for skimming of oil on the sea is made as the dock vessel having a hull 1 with decks 2 and double bottom 3, the interior hull 1 is divided into two compartments: technological 4 and tow 5.

[0038]The tow 5 compartment is located in the after part of the hull 1 of dock vessel and made as a channel 6 framed by the walls 7 and two board 8 hangars equipped with separate 9 gates and bulkheads 10, at that, the width of the on-board hangar 8 is not less than that of the tug-boat 11 while the length is not less than that providing a placement of, at least, one tug-boat 11.

[0039]The technologic 4 compartment is made as a hangar 12 limited by a ceiling 13 fitted with ventilation shaft 14, side 15 and end 16 walls, at the bottom of a hangar 12, the central 17 channel is situated along the upper boundaries of the central 17 channel, the rack-ledges 18 with symmetrical location to the right and left, toward the hull, are placed on which the technological equipment (not shown in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com