Automatic purifying energy-saving filter

An automatic purification and filter technology, which is applied in the direction of gravity filter, fixed filter element filter, filter separation, etc., can solve the problems of no backwash and unsatisfactory filtering effect, and achieve the effect of reducing manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

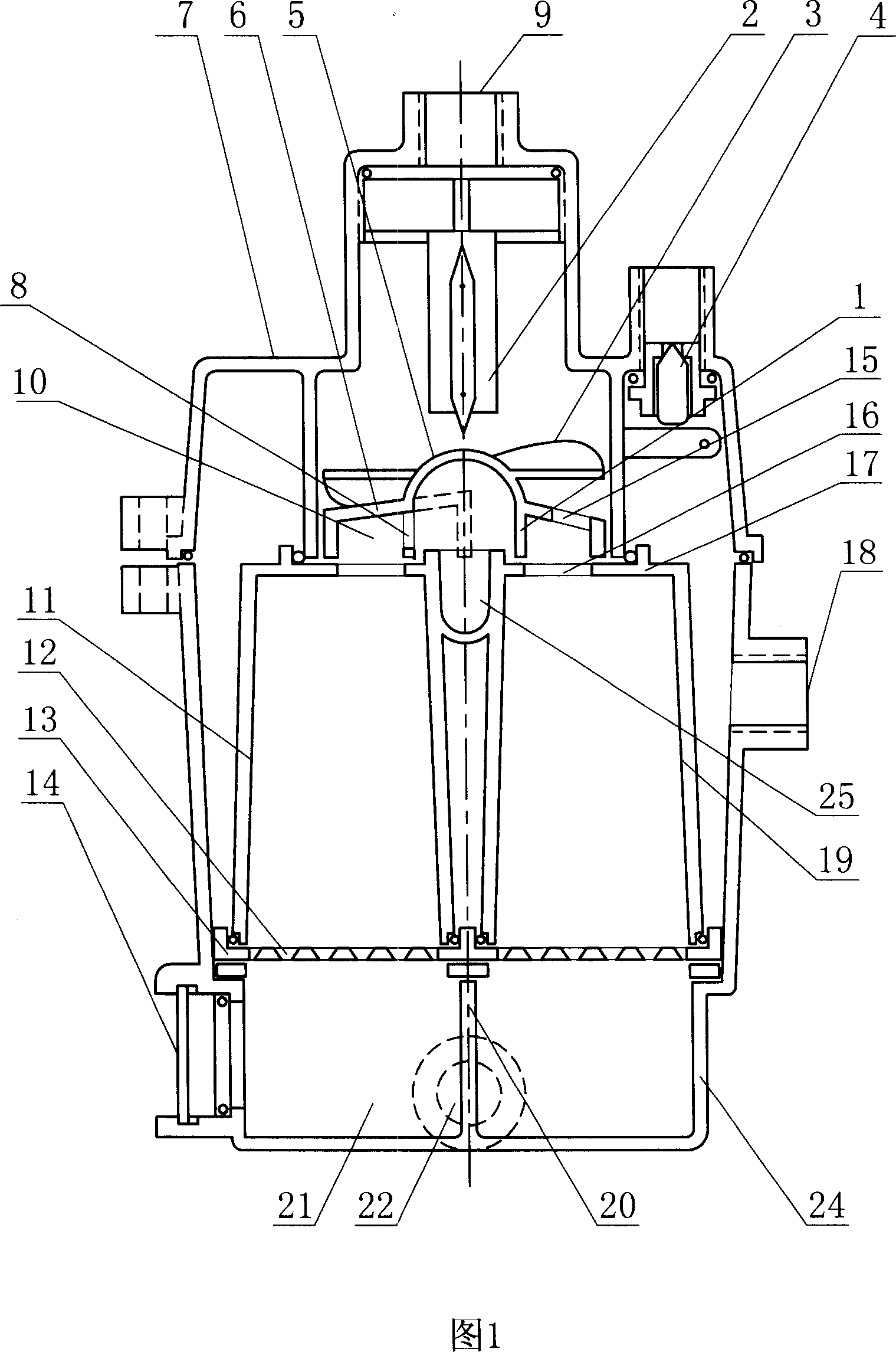

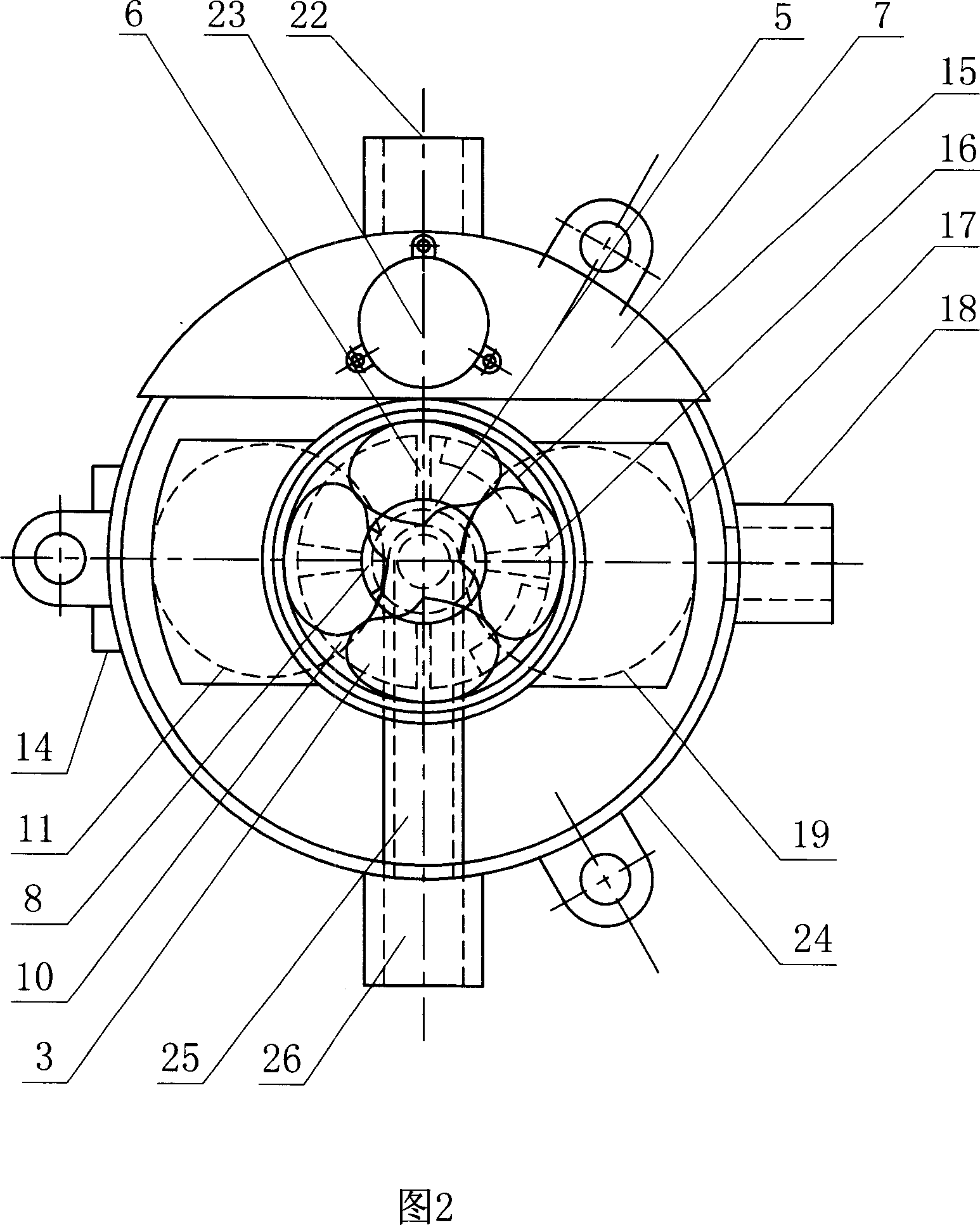

[0009] Referring to Figure 1 and Figure 2, taking diesel oil filtration as an example, the automatic purification energy-saving filter includes an upper casing 7, a lower casing 24, an oil inlet 9, an oil outlet 18, a return port 26, a filter element, and an exhaust valve 4 And the dirt sedimentation chamber 21, the oil inlet 9 and the exhaust valve 4 are located at the upper end of the housing, the dirt sedimentation chamber 21 is arranged below the housing, the ultrasonic generator 2 is installed at the oil inlet 9, and the oil outlet 18 The upper casing 7 and the lower casing 24 form a fuel chamber, and the fuel chamber 5 is provided with a replacement fluid 5, which has a fan-shaped paddle 3 and a circle with a downward opening. The cylinder body 1 and the baffle plate 6 are respectively provided with openings 8 and 15 on the cylinder body 1 and the baffle plate 6. The filter core has two left and right filter cores, which are made of a rigid thin-walled filter net. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com